Vacuum microwave combined processing method for okra

A combined processing, vacuum microwave technology, applied in the direction of preservation of fruits/vegetables through dehydration, can solve the problems of unstable product quality and long time, and achieve the effects of easy instant control, improved production efficiency, and optimized drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Step 1, material selection: select fresh okra fruits that are free from diseases and insect pests and have uniform color as raw materials;

[0023] Step 2, cleaning: remove the root of the selected fresh okra fruit and wash away the surface impurities;

[0024] Step 3, draining: spread the washed fresh okra fruit on a bamboo sieve and drain until there are no water drops on the surface, and the draining time is 1 hour;

[0025] Step 4. Vacuum microwave drying: place the fresh okra fruit in a vacuum microwave drying chamber to dry under the conditions of microwave power 550W, vacuum degree 0.06Mpa, and drying time 13min.

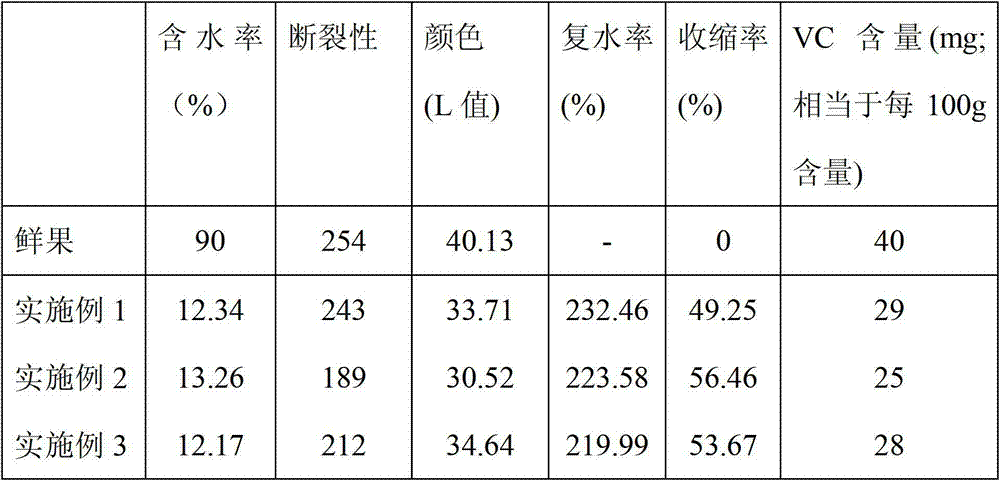

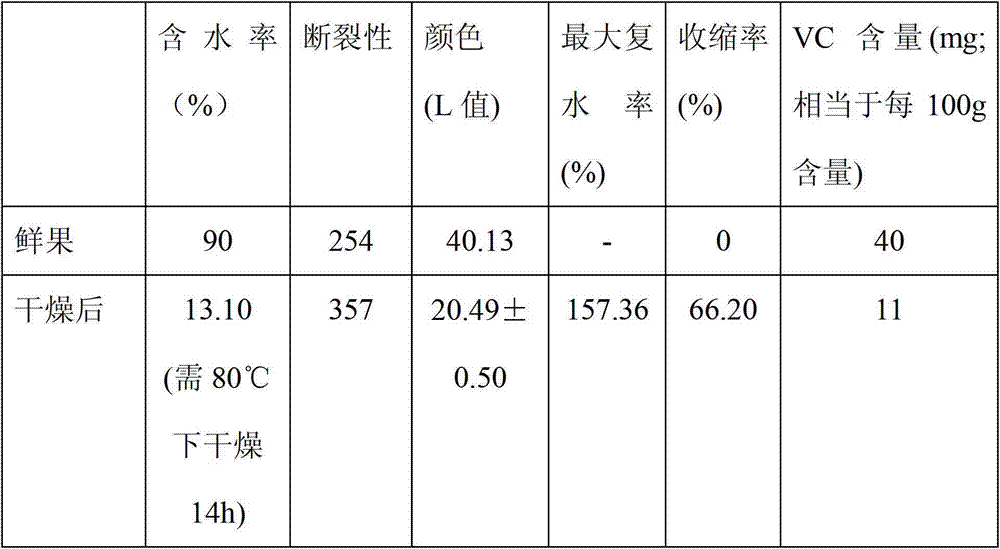

[0026] Determination of quality indicators: Determination of moisture content, color, fracture, rehydration rate, shrinkage rate and vitamin C content of dried okra fresh fruit;

[0027] Packing: After drying, the product is promptly packed into food-use plastic bags, one bag per 50g, and vacuum-sealed with a vacuum packaging machine.

Embodiment 2

[0029] Step 1, material selection: select fresh okra fruits that are free from diseases and insect pests and have uniform color as raw materials;

[0030] Step 2, cleaning: remove the fruit and root of the selected okra and wash away the surface impurities;

[0031] Step 3, draining: spread the washed fresh okra fruit on a bamboo sieve and drain until there are no water droplets on the surface, and the draining time is 1.5 hours;

[0032] Step 4. Vacuum microwave drying: put the fresh okra fruit in a vacuum microwave drying chamber, the drying conditions are: microwave power: 500W, vacuum degree 0.07Mpa, drying time 14min, and it is ready.

[0033] Determination of quality indicators: Determination of moisture content, color, fracture, rehydration rate, shrinkage rate and vitamin C content of dried okra fresh fruit;

[0034] Packing: After drying, the product is promptly packed into food-use plastic bags, one bag per 75g, and vacuum-sealed with a vacuum packaging machine.

Embodiment 3

[0036] Step 1, material selection: select fresh okra fruits that are free from diseases and insect pests and have uniform color as raw materials;

[0037] Step 2, cleaning: remove the root of the selected fresh okra fruit and wash away the surface impurities;

[0038] Step 3, draining: spread the washed fresh okra fruit on a bamboo sieve and drain until there are no water drops on the surface, and the draining time is 1 hour;

[0039] Step 4. Vacuum microwave drying: put the fresh okra fruit in a vacuum microwave drying chamber, the drying conditions are: microwave power: 600W, vacuum degree 0.08Mpa, drying time 12min, and it is ready.

[0040] Determination of quality indicators: Determination of moisture content, color, fracture, rehydration rate, shrinkage rate and vitamin C content of dried okra fresh fruit;

[0041] Packing: After drying, put the product in a food plastic bag in time, one bag per 100g, and vacuum seal it with a vacuum packaging machine.

[0042] Table 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com