Method for uniformly drying agaricus bisporus slices through variable-frequency ultrasound-assisted impregnation pretreatment and vacuum microwaves

A frequency conversion ultrasonic and vacuum microwave technology, applied in food preservation, fruit and vegetable preservation, food science, etc., can solve problems such as poor uniformity, achieve uniform shape, improve uniformity, and shorten drying time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

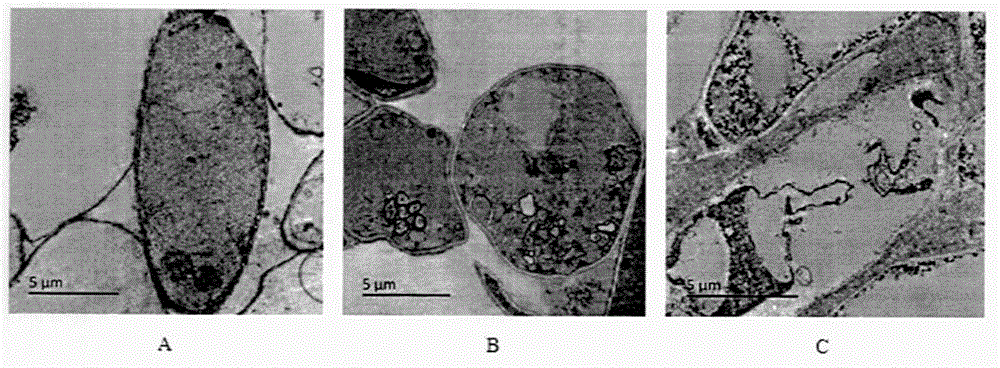

Image

Examples

Embodiment

[0026] 1. Choose a well-grown, no mechanical damage, no browning of Agaricus bisporus as raw material, after cleaning, use SA-300D semi-automatic slicer (Guangzhou Minhong Food Machinery Co., Ltd.) to slice, the slice thickness is 5-8mm;

[0027] 2. Quickly put the Agaricus bisporus slices in the color protection solution, which is a mixed solution of 0.2% vitamin C, 0.25% citric acid and 0.5% calcium chloride by weight, and the color protection time is 30 minutes;

[0028] 3. Take out the color-protected Agaricus bisporus slices and put them into the KQ-300GVDV ultrasonic cleaner (Kunshan Ultrasonic Instrument Co., Ltd.) for the first stage of ultrasonic treatment. The immersion liquid is clean water, the material-to-water ratio is 1:5, and the water temperature is set to 45. -50℃, ultrasonic frequency is 45KHz, ultrasonic power is 135W, processing time is 36min;

[0029] 4. Take out the bisporus mushroom slices after ultrasonic treatment, replace the dipping liquid with a mixture o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com