Patents

Literature

114results about How to "Uniform color distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

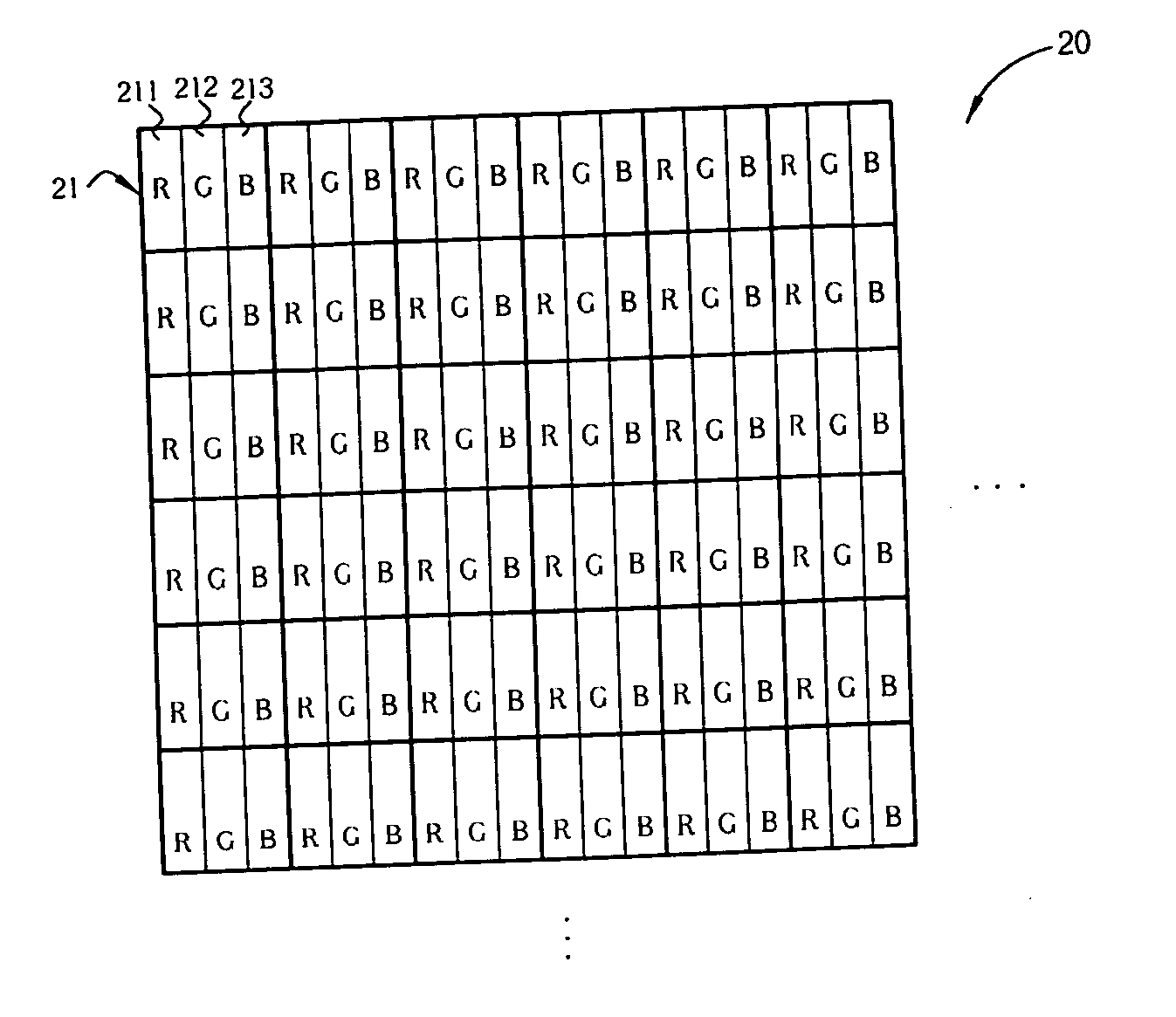

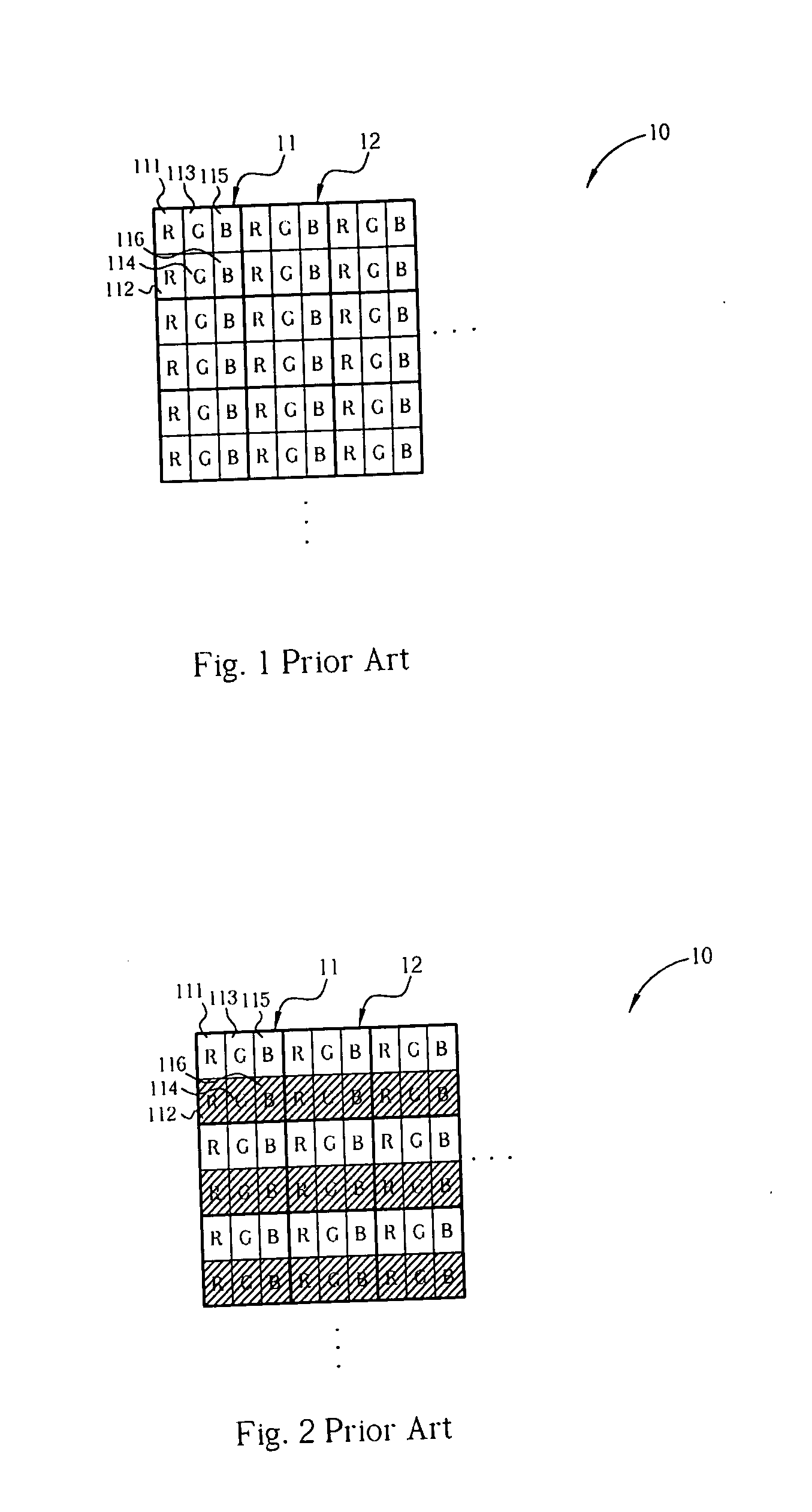

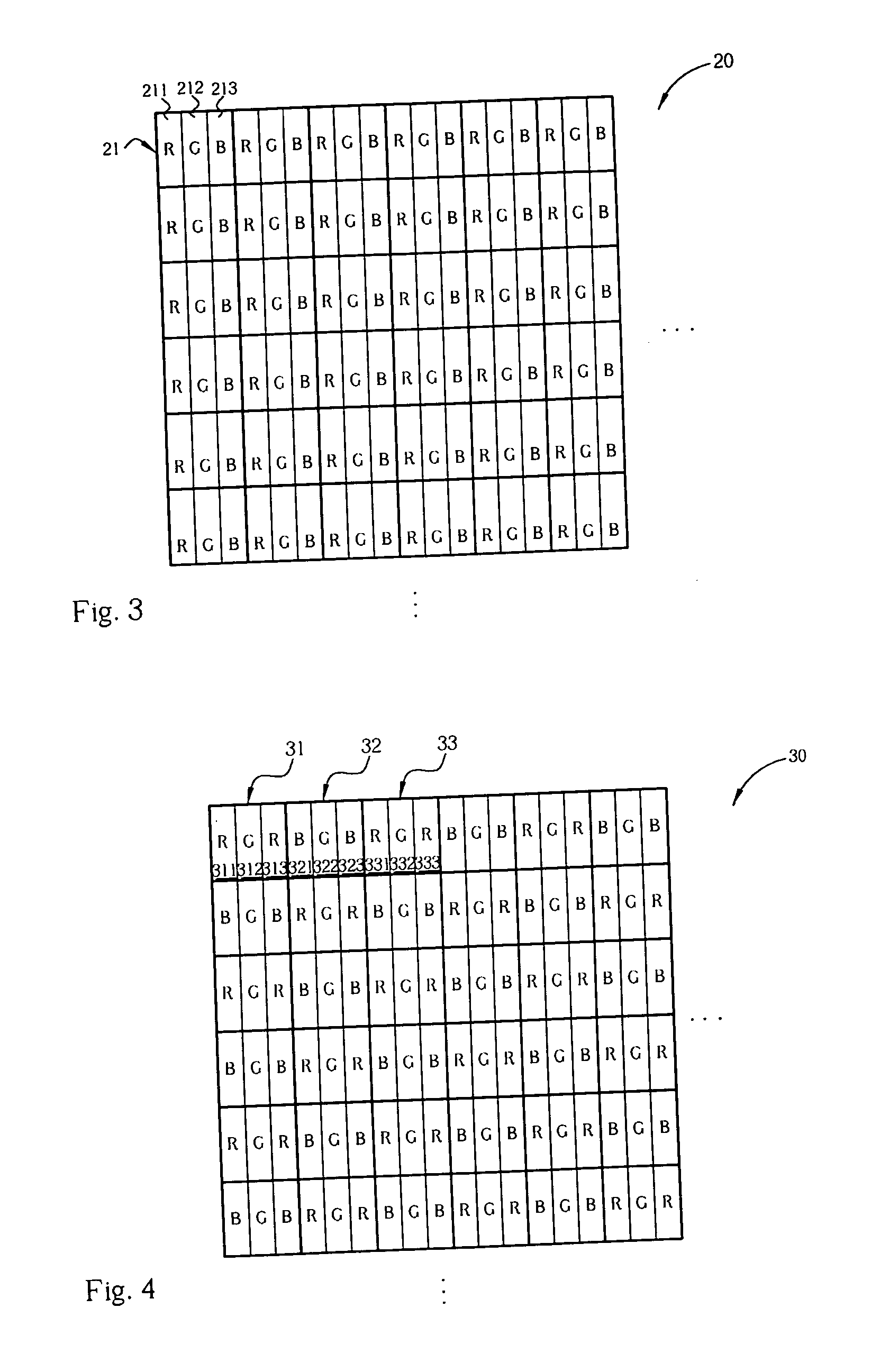

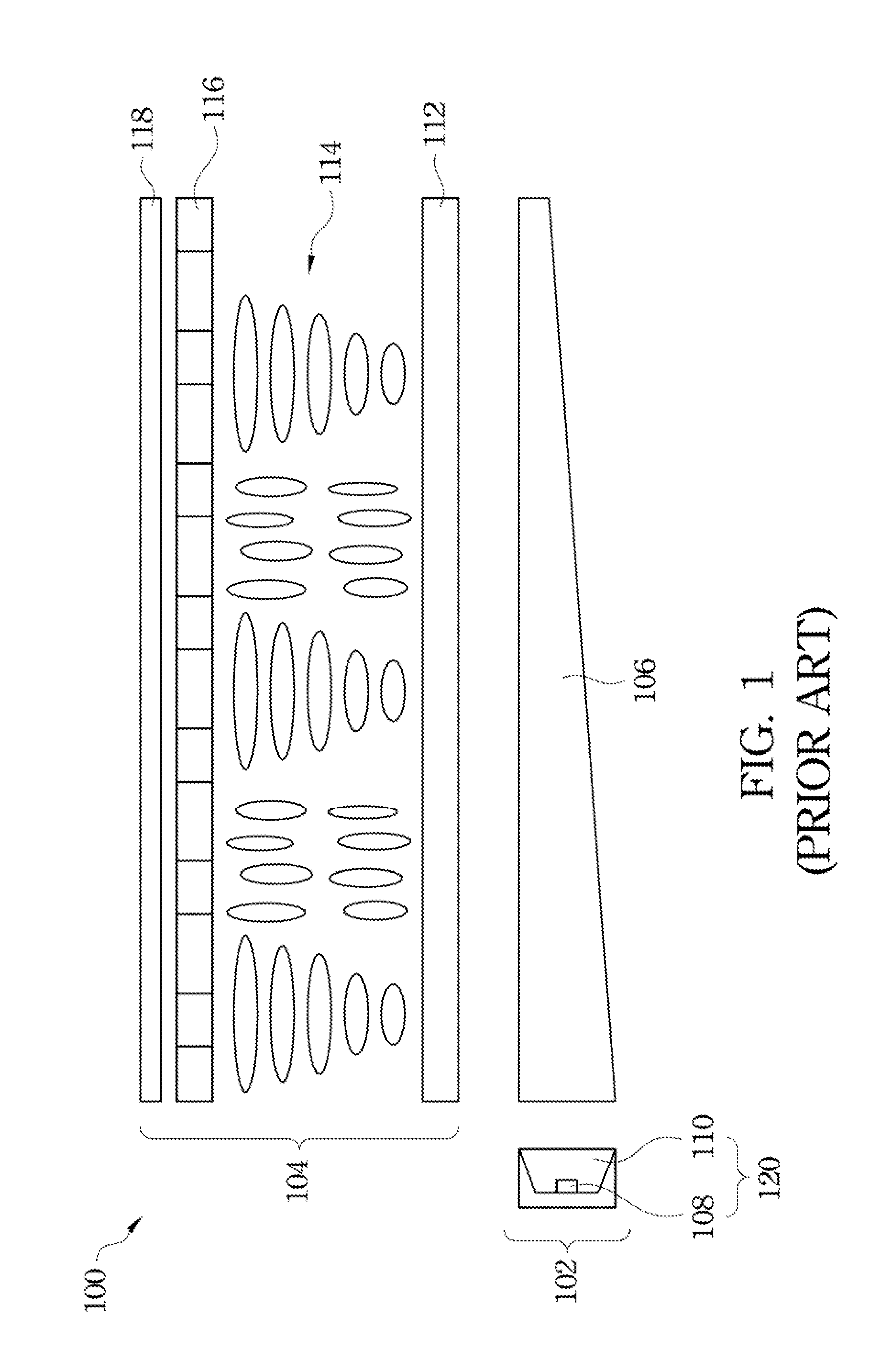

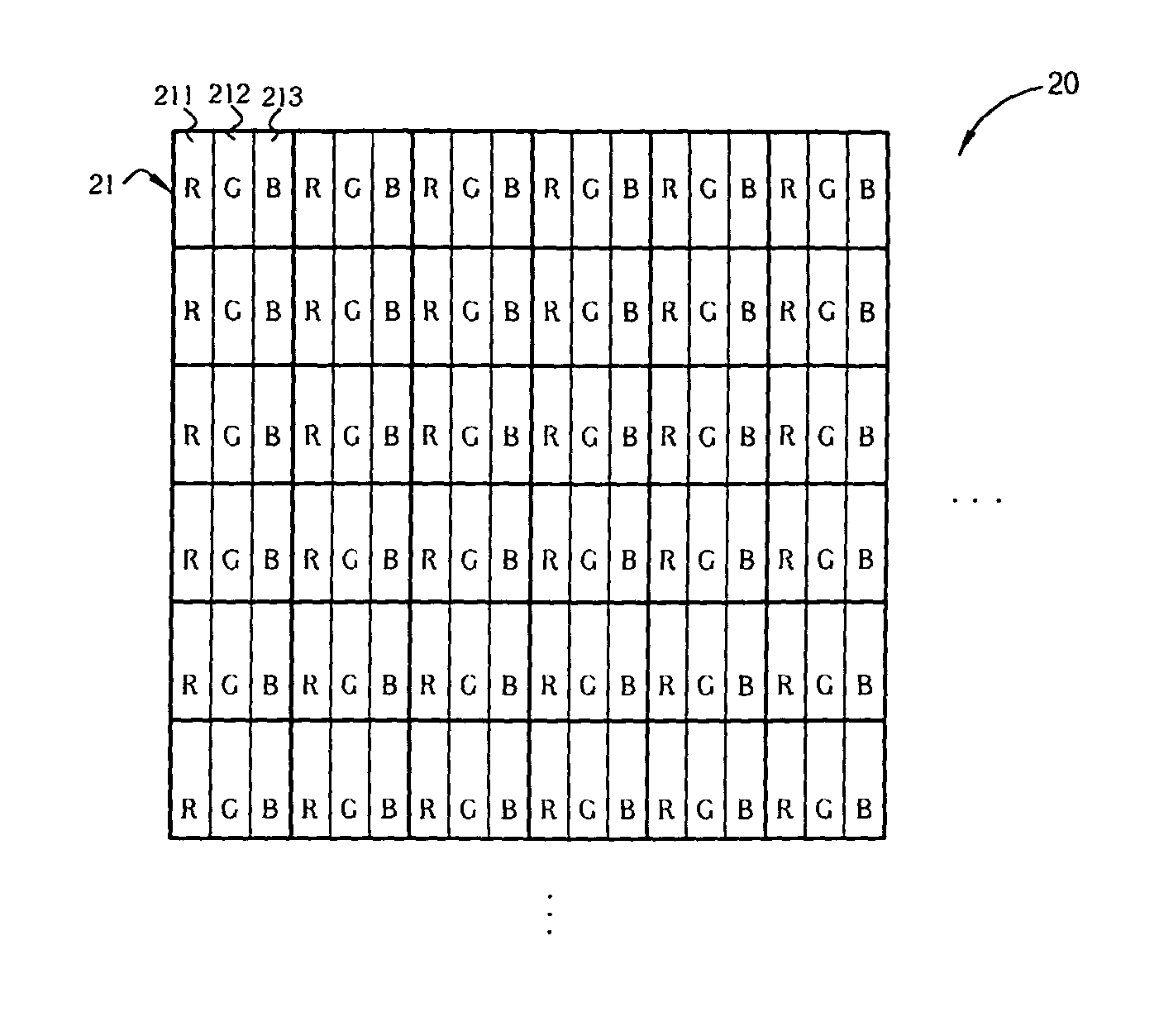

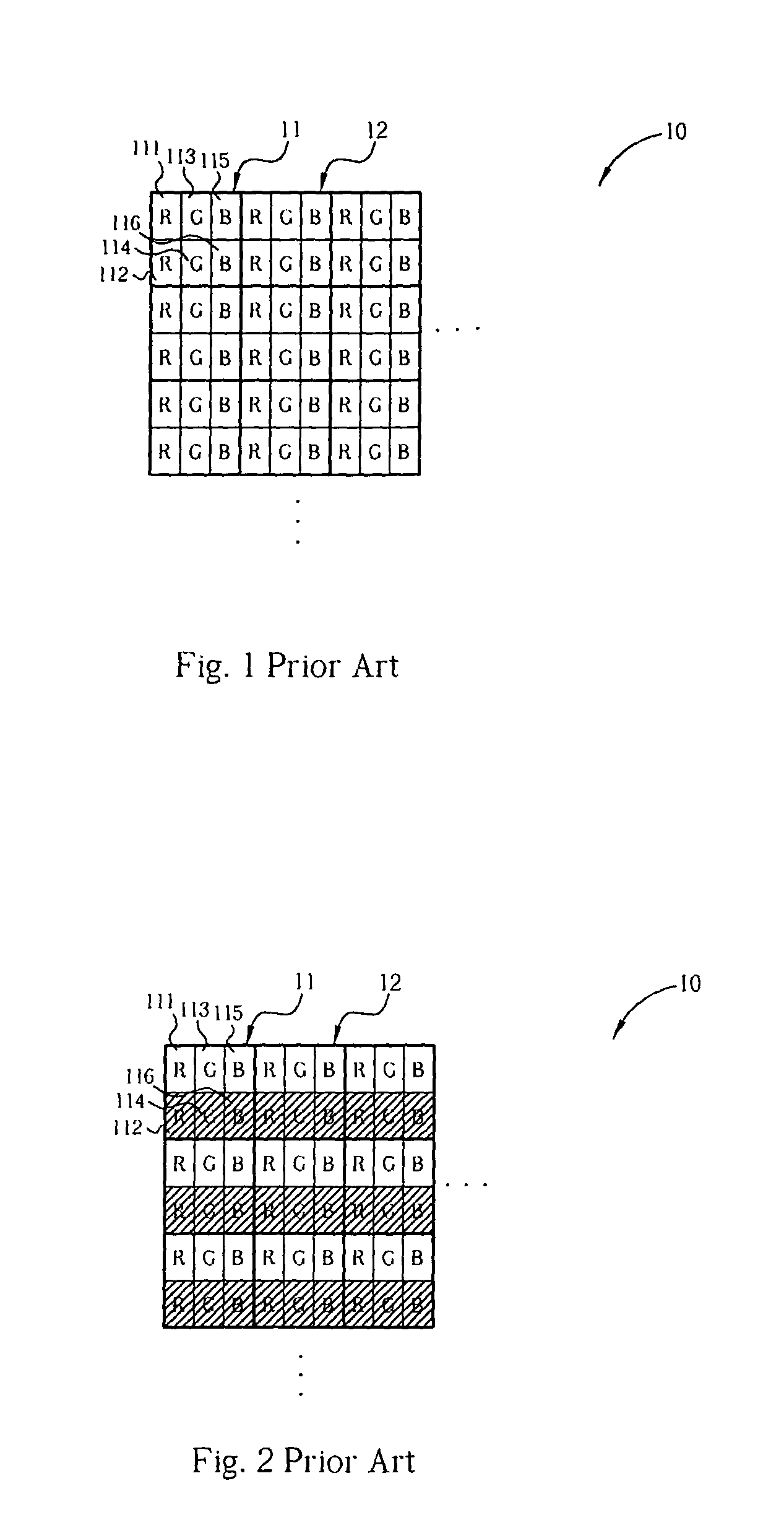

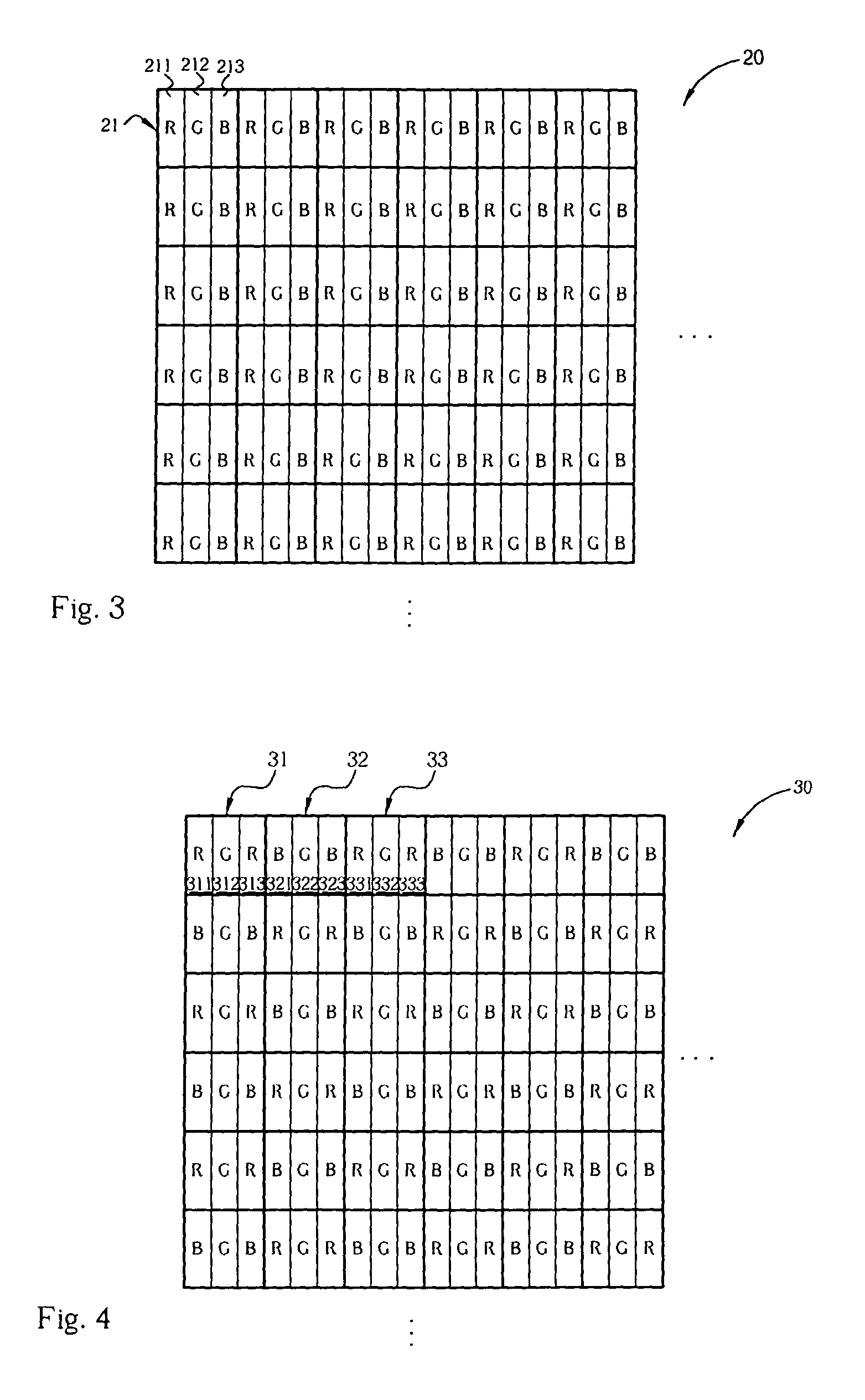

Displaying method and image display device

ActiveUS20060221030A1Reduce color castUniform color distributionCharacter and pattern recognitionCathode-ray tube indicatorsPattern recognitionColor shift

In a displaying method for use in an image display, an original gray scale is divided into a higher gray scale and a lower gray scale. Further, the color subpixels are divided into two groups corresponding to the higher and lower gray scales, respectively. The gray scale to be expressed by each subpixel is calibrated by weighing the original higher or lower gray scale for the pixel and the adjacent pixels and summing up the results. The color shift problem due to different visual angles can therefore be solved.

Owner:INNOLUX CORP

Ink-jet recording material and preparation method thereof as well as method for preparing ink absorption layer coating liquid

ActiveCN102092209ALow priceIncrease polarityStarch dervative coatingsConjugated diene hydrocarbon coatingsPolymer scienceAdhesive

The invention provides an ink-jet recording material and a preparation method thereof as well as a method for preparing an ink absorption layer coating liquid, and relates to an ink-jet material and a preparation method thereof as well as a method for preparing an ink absorption layer coating liquid, so that the problems of poor ink absorption effect, nonuniform color distribution of printed images, unclear printed images and higher preparation cost of the existing ink-jet recording material can be solved. The ink-jet recording material is prepared from the ink-jet layer coating liquid which is prepared from PVC (polyvinyl chloride) serving as a base material, a 20-30% polyacrylic acid emulsion serving as a primer, an inorganic nano-pigment with the thickness of 10-100nm, a dispersing agent, acetic acid, deionized water and an adhesive aqueous solution. The prepared ink-jet recording material prepared through PVC material corona treatment, PVC substrate glue coating, drying, ink absorption layer coating and drying has the advantages that that the printed image is clear, the ink droplet does not diffuse, and the color is distributed uniformly; and the ink-jet recording material has excellent performances of color definition, color saturation, glossiness and the like. The raw material cost and the manufacture cost are low, so the ink-jet recording material is advantageous to industrial production, popularization and application.

Owner:HARBIN INST OF TECH

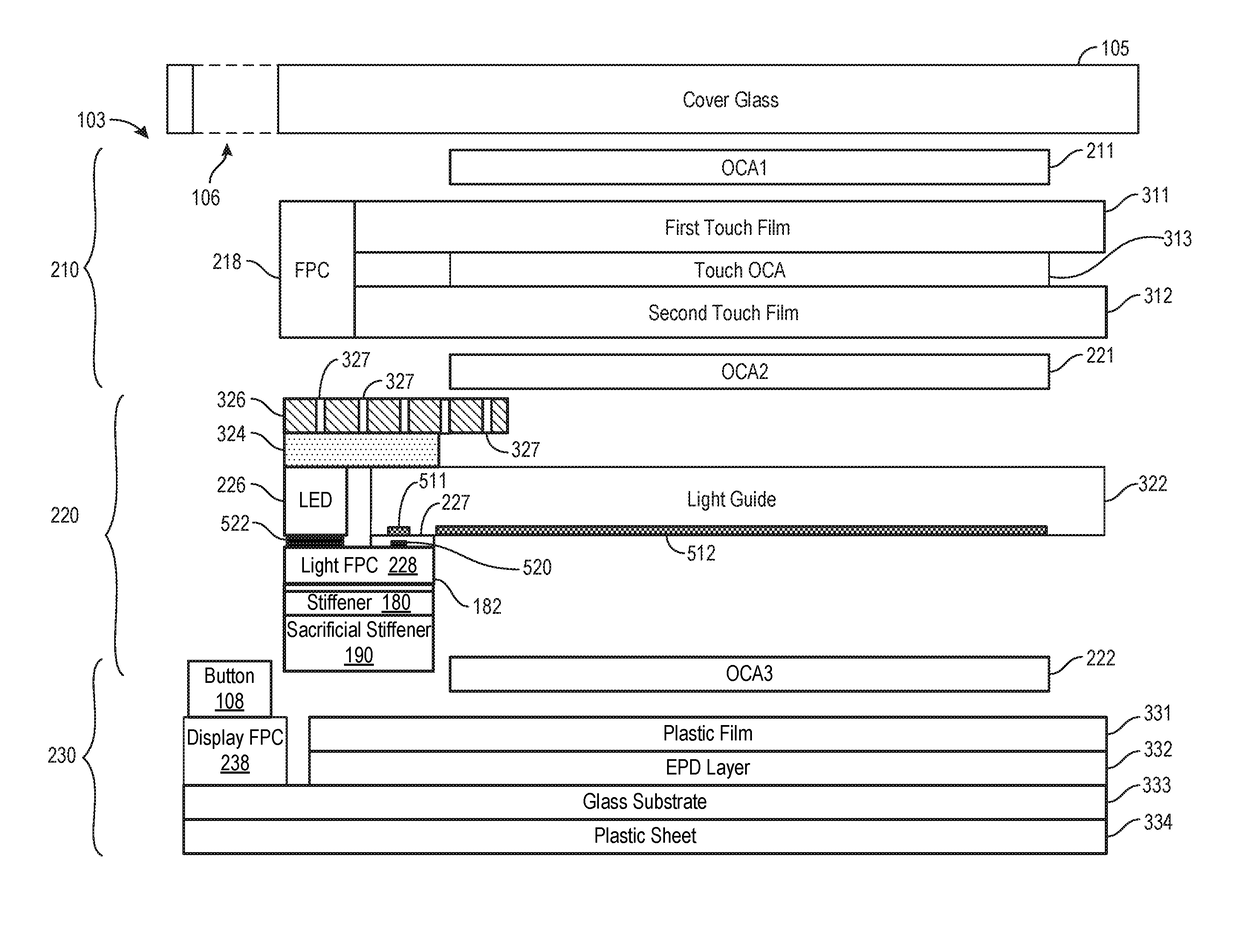

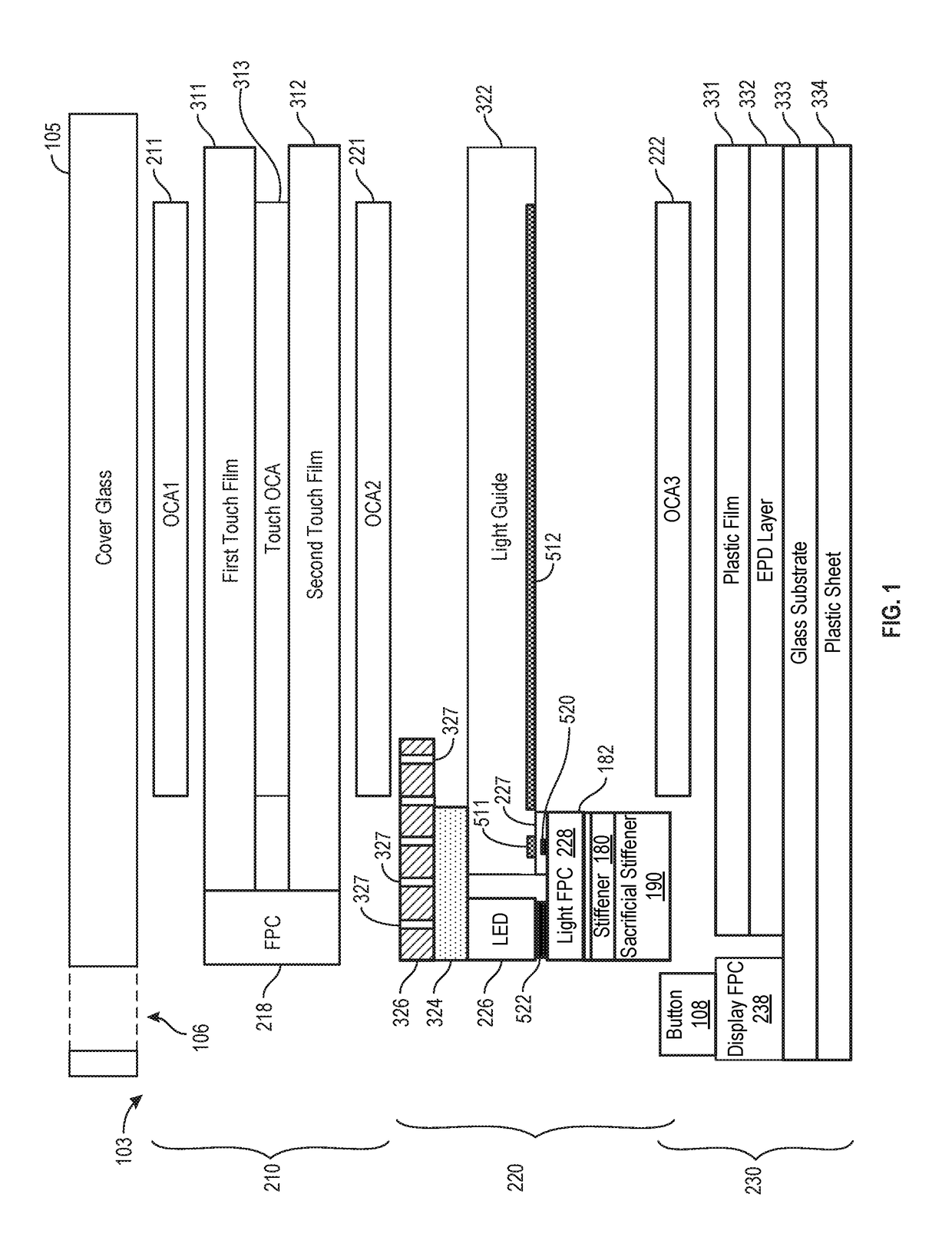

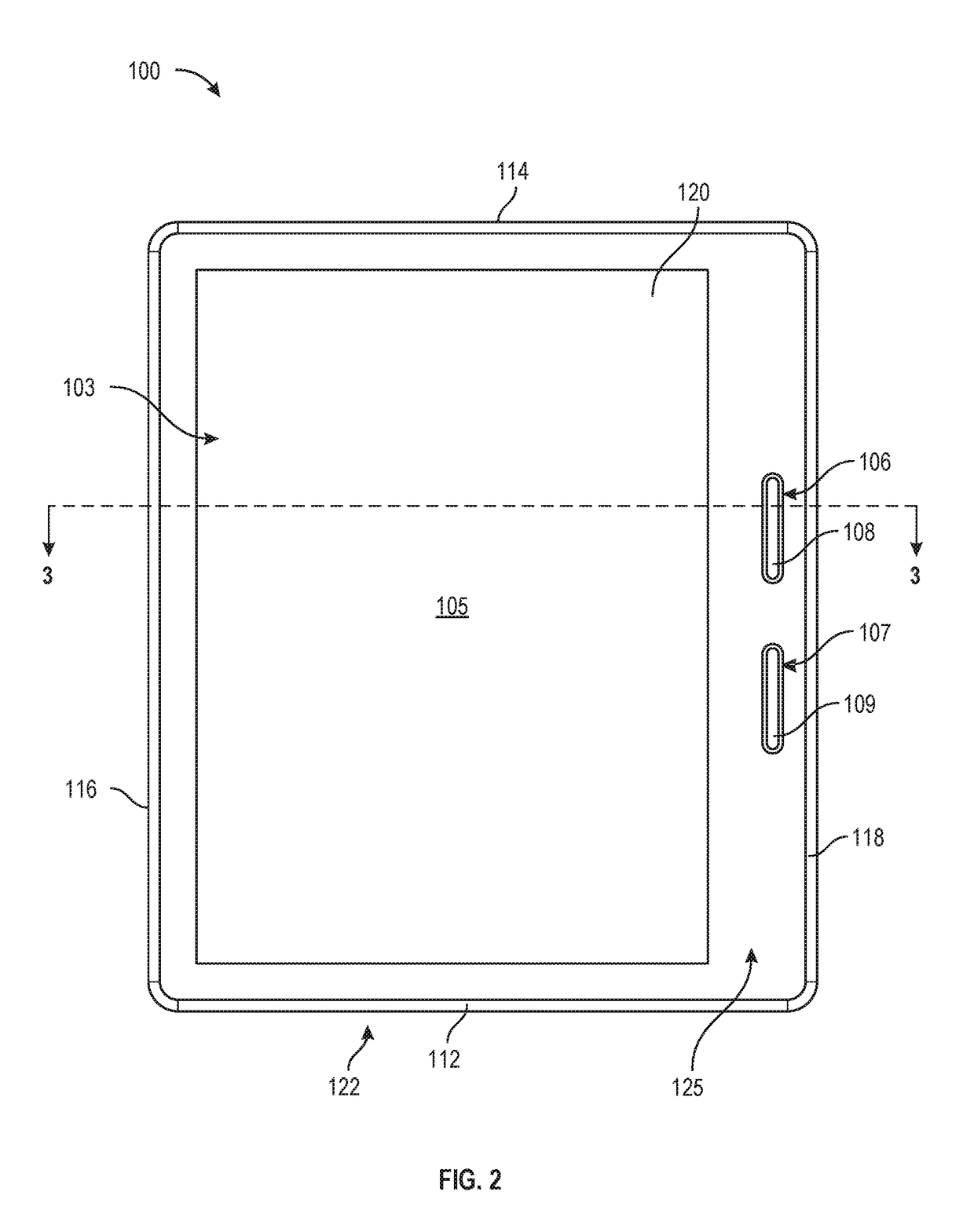

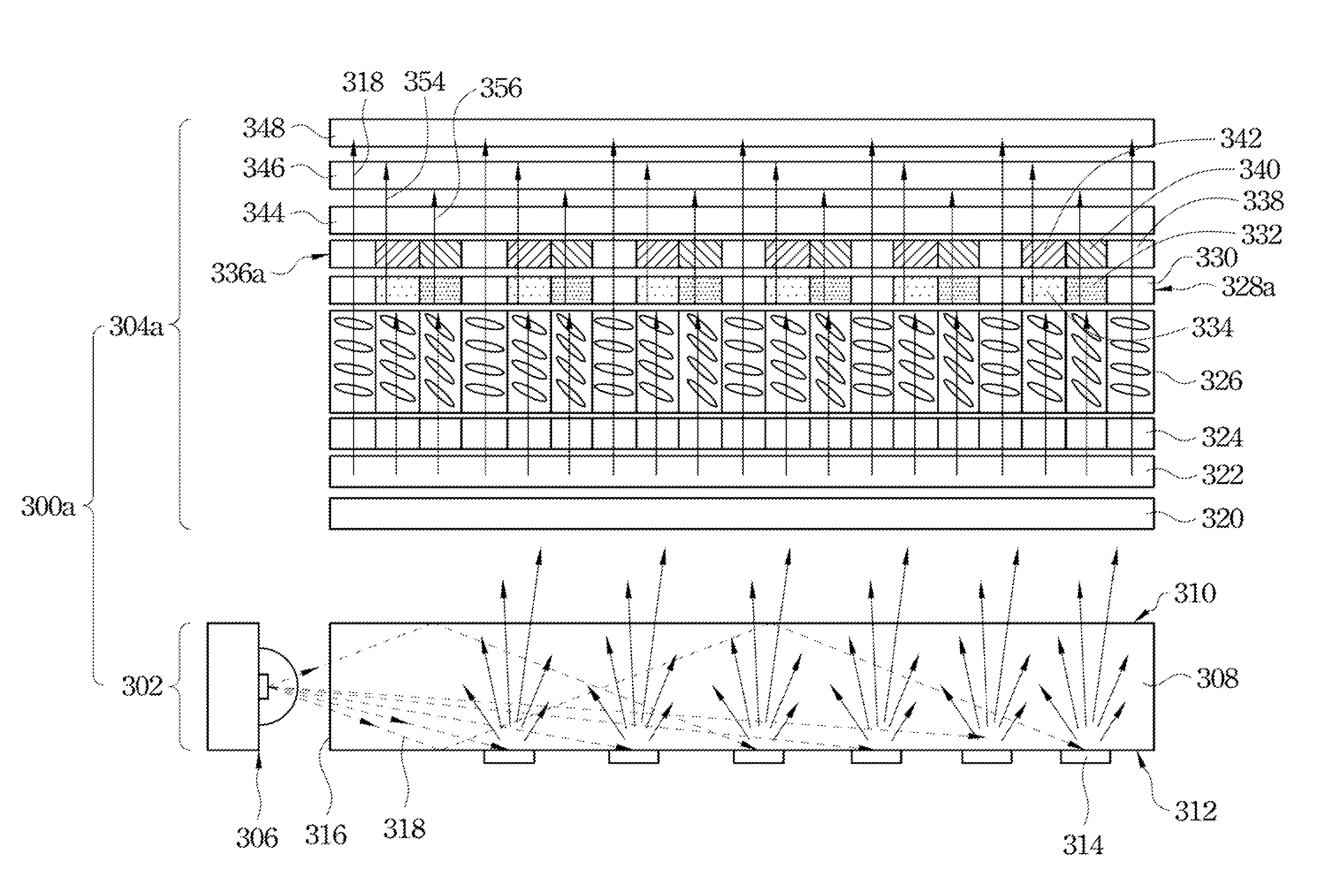

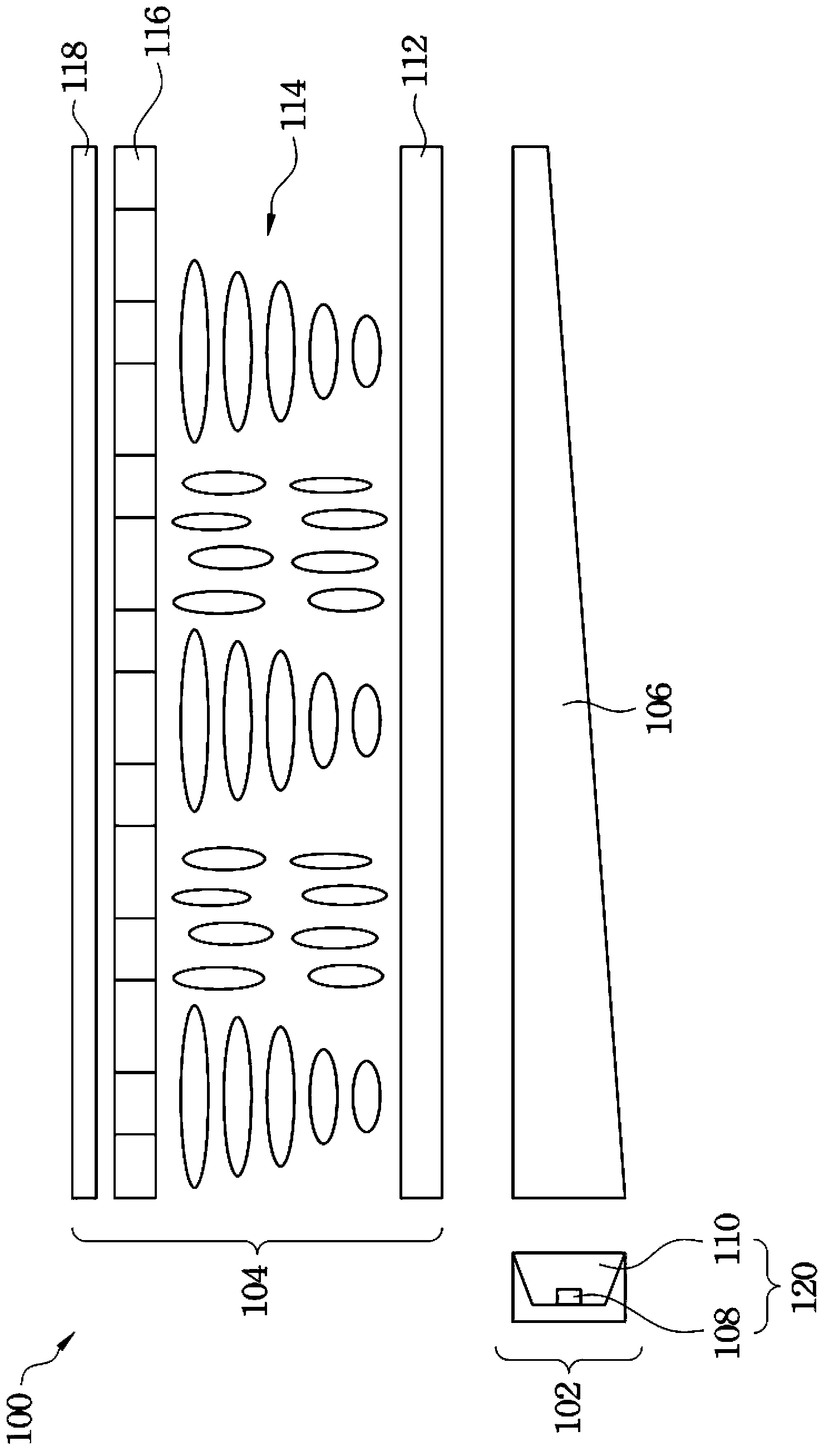

Electronic device stack assembly

ActiveUS20170176835A1Uniform color distributionSimple manufacturing processMechanical apparatusPlanar/plate-like light guidesLight guideTouch Senses

An electronic device includes a stack assembly and a cover glass. The stack assembly includes an electrophoretic display sub-assembly for rendering content, a front light sub-assembly comprising a light guide, a light FPC, and a plurality of light sources, and a capacitive touch sensing sub-assembly for detecting touch inputs. A yellow-pigmented tape is applied over the light sources and an edge of the light guide. A stiffener member is coupled to the light FPC opposite the yellow-pigmented tape.

Owner:AMAZON TECH INC

Copper-red transmutation glaze, copper-red transmutation glaze ceramic product prepared from same and preparation method

The invention relates to a copper-red transmutation glaze, a copper-red transmutation glaze ceramic product prepared from the same and a preparation method and belongs to the technical field of ceramics. The copper-red transmutation glaze comprises components in parts by weight as follows: a glaze type basic material including 34-35 parts of nepheline syenite, 20-22 parts of calcium carbonate, 3-4 parts of barium carbonate, 2-3 parts of zinc oxide, 1-2 parts of magnesium carbonate, 26-27 parts of kaolin and 9.5-10.5 parts of nano silicon oxide, and a chromogenic reagent including 1.8-2.5 parts of lithium carbonate, 2-4 parts of bone ash and 2-4 parts of copper carbonate. The ceramic product prepared from the copper-red transmutation glaze through firing has brighter red color, the glaze color is uniformly distributed, and the yield is high.

Owner:FUJIAN DEHUA HUAMAO CERAMICS CO LTD

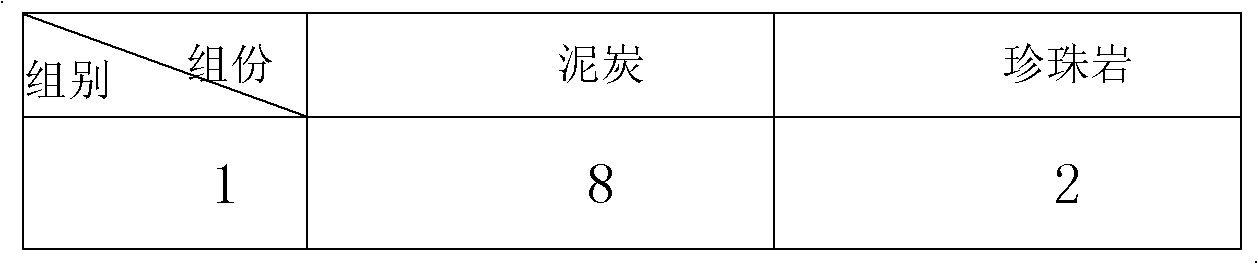

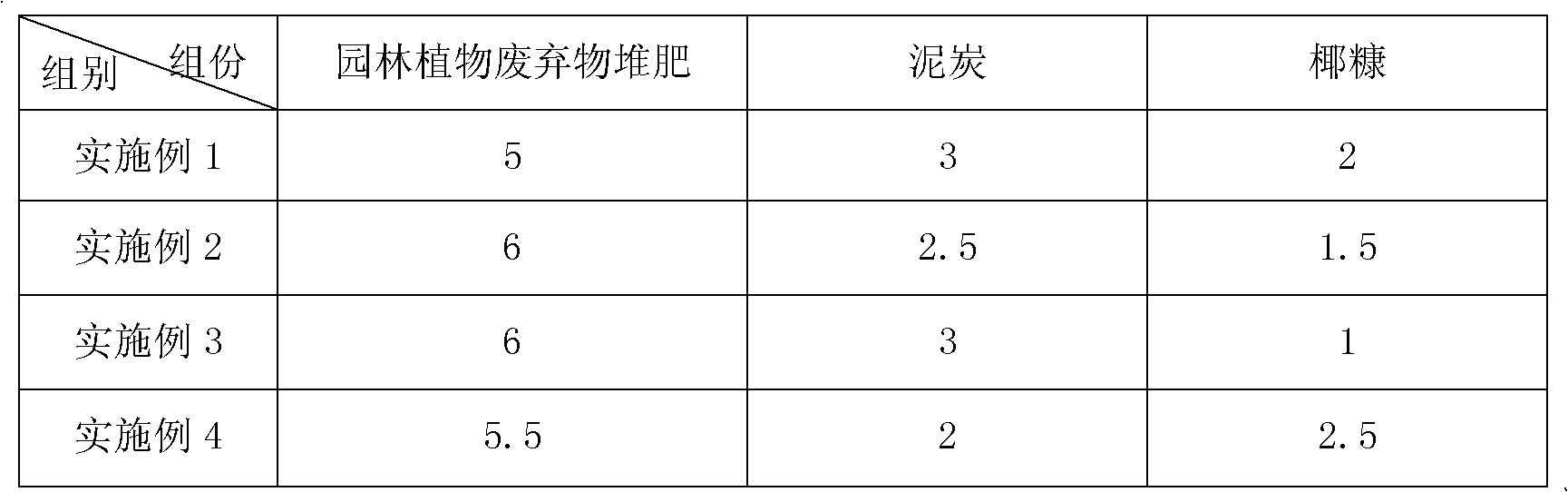

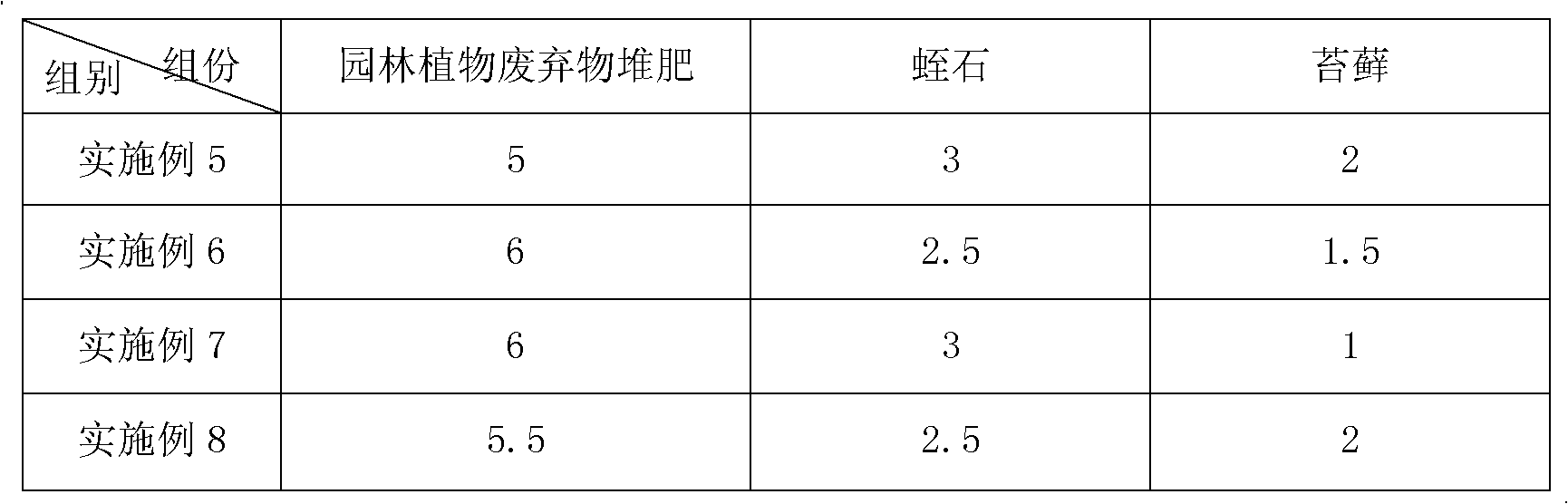

Scindapsus aureus cultivation medium and preparation method thereof

ActiveCN102976839AImprove survival rateMeet the requirements of cutting growth and developmentFertilizer mixturesSocial benefitsEnvironment of Albania

The invention discloses a scindapsus aureus cultivation medium and a preparation method thereof. The scindapsus aureus cultivation medium is prepared by mixing landscape plant waste compost and auxiliary materials according to a certain volume ratio. The landscape plant waste compost is prepared by cutting, crushing, urea and water addition, turning and fermentation. The scindapsus aureus cultivation medium improves physicochemical properties of the original medium, adopts raw materials which have wide sources, are convenient for acquisition and have low prices, utilizes a landscape plant waste compost part to replace non-renewable peat massively used in flower production, improves ornamental plant quality, reduces a production cost, is beneficial for landscape waste utilization and environmental protection, and has good environmental ecological, economic and social benefits.

Owner:SHENZHEN TECHAND ECOLOGY & ENVIRONMENT CO LTD

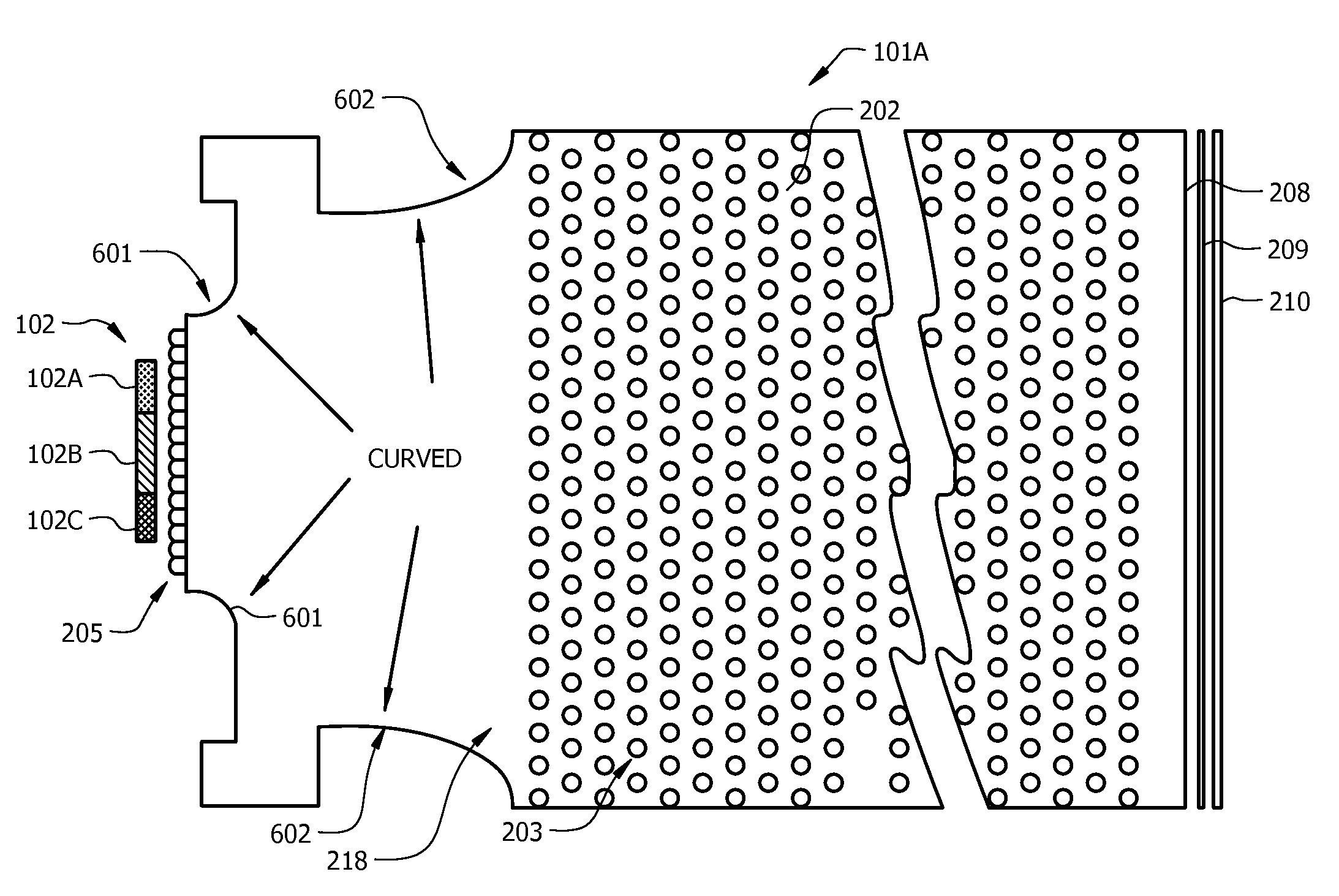

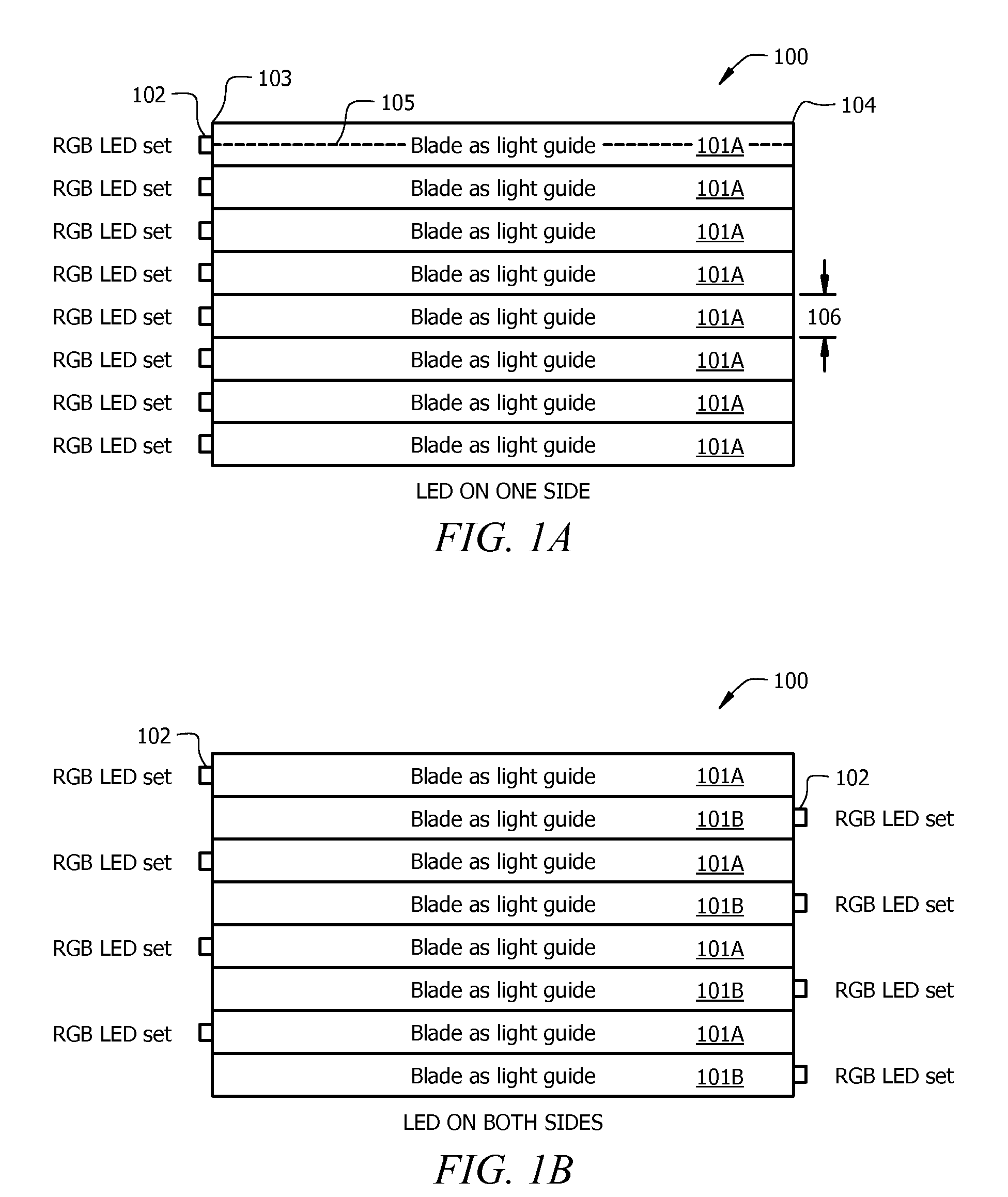

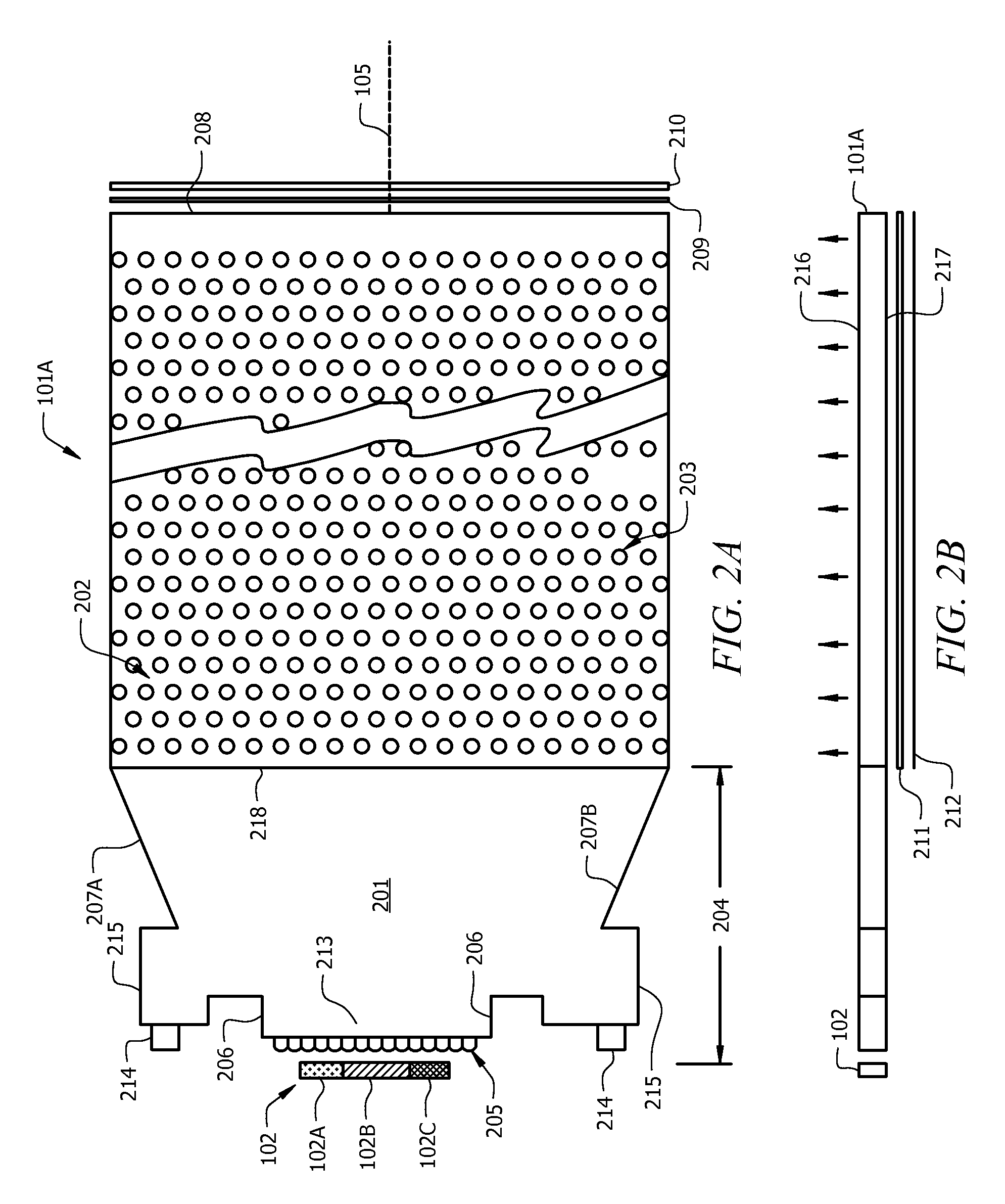

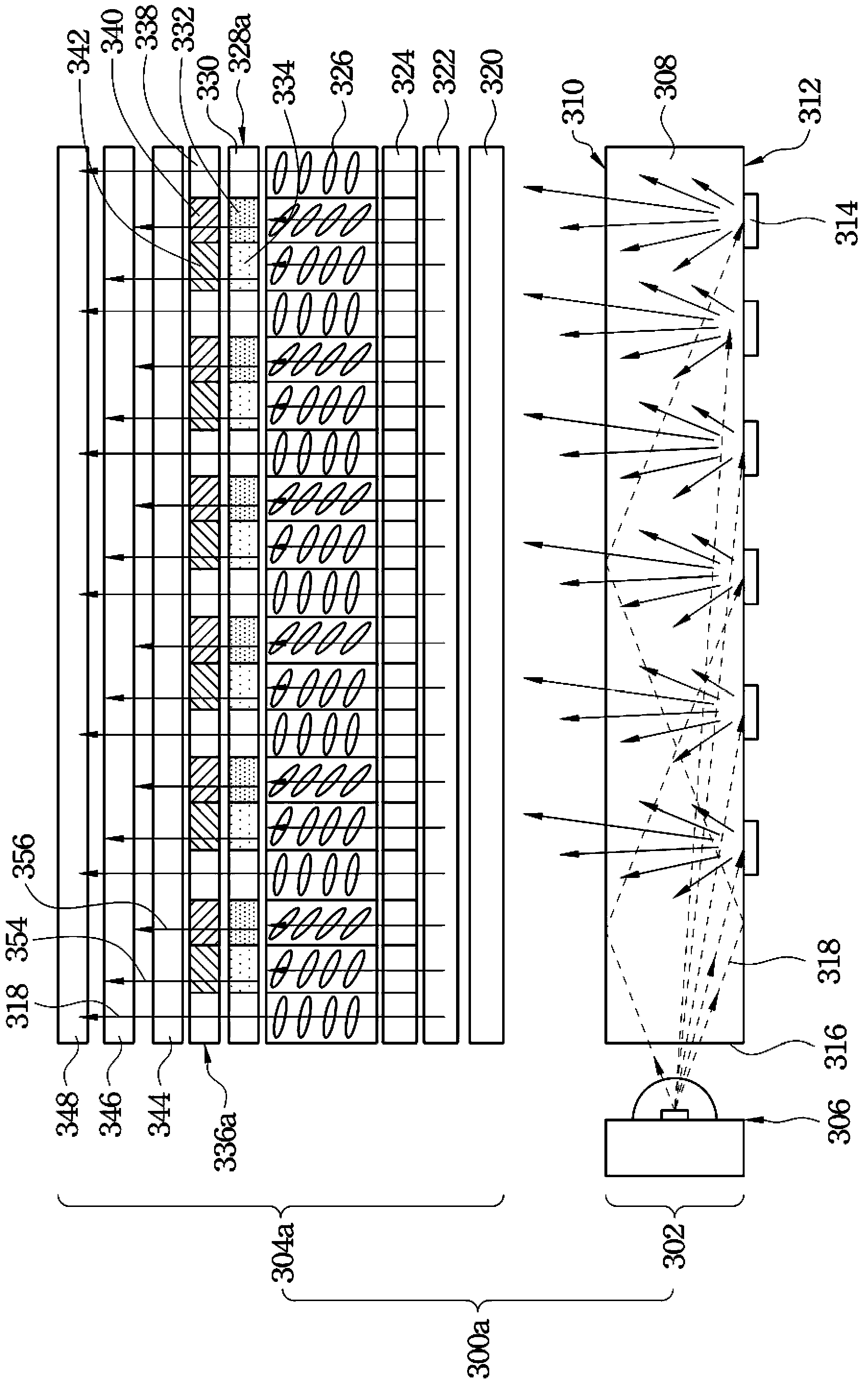

Light guide blade with color balancing structures and blue absorption compensation for large screen LED backlight unit

ActiveUS20090316077A1Improve efficiencyPrevent leakagePlanar/plate-like light guidesNon-linear opticsColor shiftProgressive scan

One or more embodiments of the present invention provide apparatuses, methods and systems to form a thin LED backlight unit for a large-screen flat-panel display. The backlight unit is able to achieve improved color mixing within a shorter mixing distance than the conventional art, while maintaining desired brightness uniformity, thereby allowing for a shorter bezel of a display device. One or more embodiments of the present invention include one or more light guides, which, by operating together, provide thin backlight units. High system efficiency is provided by introducing a recycling enhancement component, and uniform color distribution is achieved by incorporating color shift compensation. Multiple light guides are arranged adjacent to one another can offer a progressive scan illumination feature.

Owner:JABIL CIRCUIT INC

Colorful TPU (thermoplastic polyurethane) foaming material, method for preparing shoe material by colorful TPU foaming material and application

ActiveCN104262940AHigh degree of expansionPrevent interface migrationFootwearThermoplastic polyurethaneHardness

The invention discloses a colorful TPU (thermoplastic polyurethane) foaming material, a preparation method and an application. The colorful TPU foaming material comprises colorful foaming particles or colorful foaming sheets, pigment concentration of the colorful foaming particles or the colorful foaming sheets is 0.01%-5% by weight, pigments inside and outside the colorful TPU foaming material have the same concentration, the hardness of the colorful TPU foaming material is HA 5-65, the density is 0.05-0.5 g / cm<3>, and the average cell size is smaller than 100 mu m. The colorful TPU foaming material has the characteristics of good inside and outside uniformity, absence of wrinkles on the surface and the like.

Owner:JINJIANG GUOSHENG SHOE MATERIAL LTD

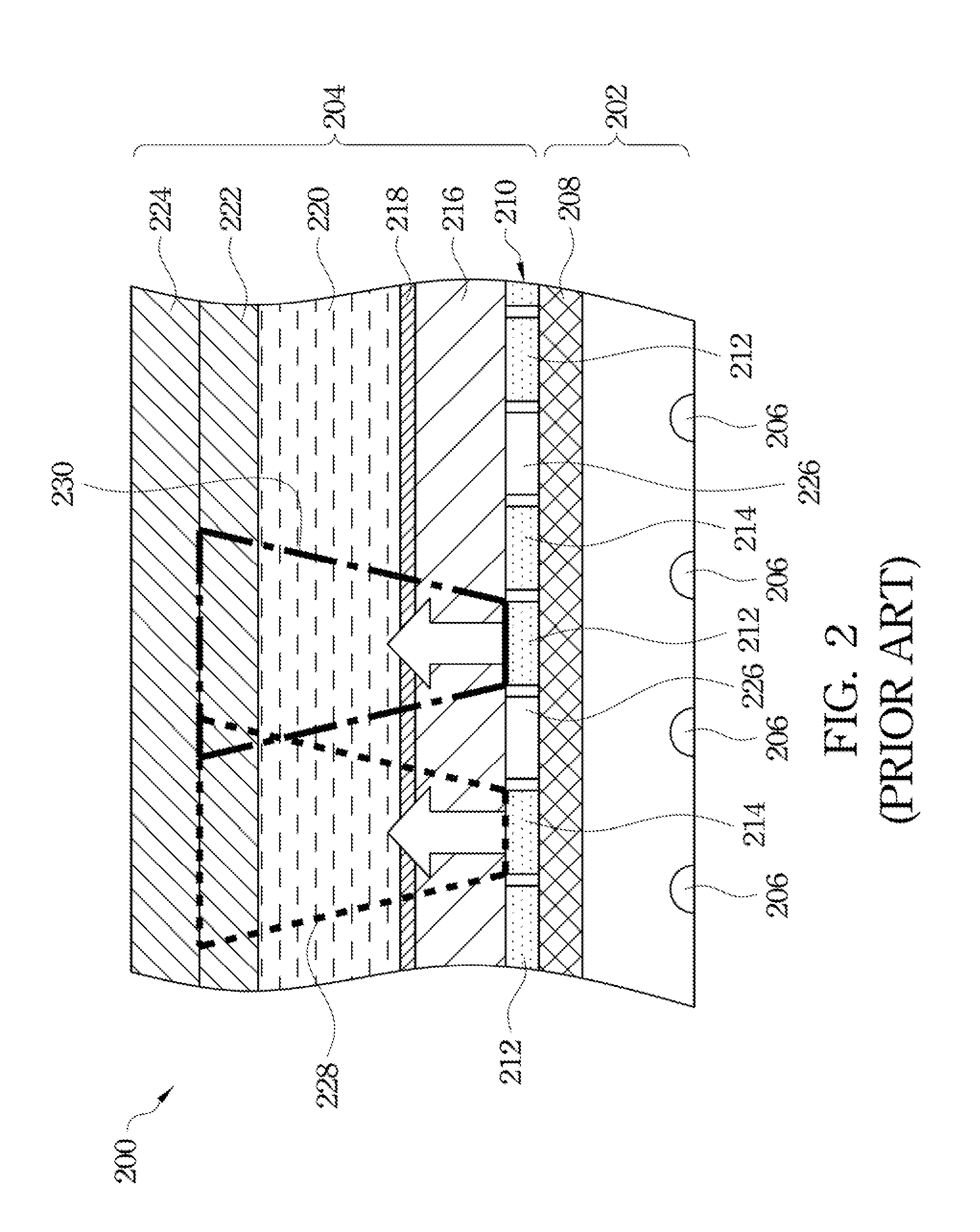

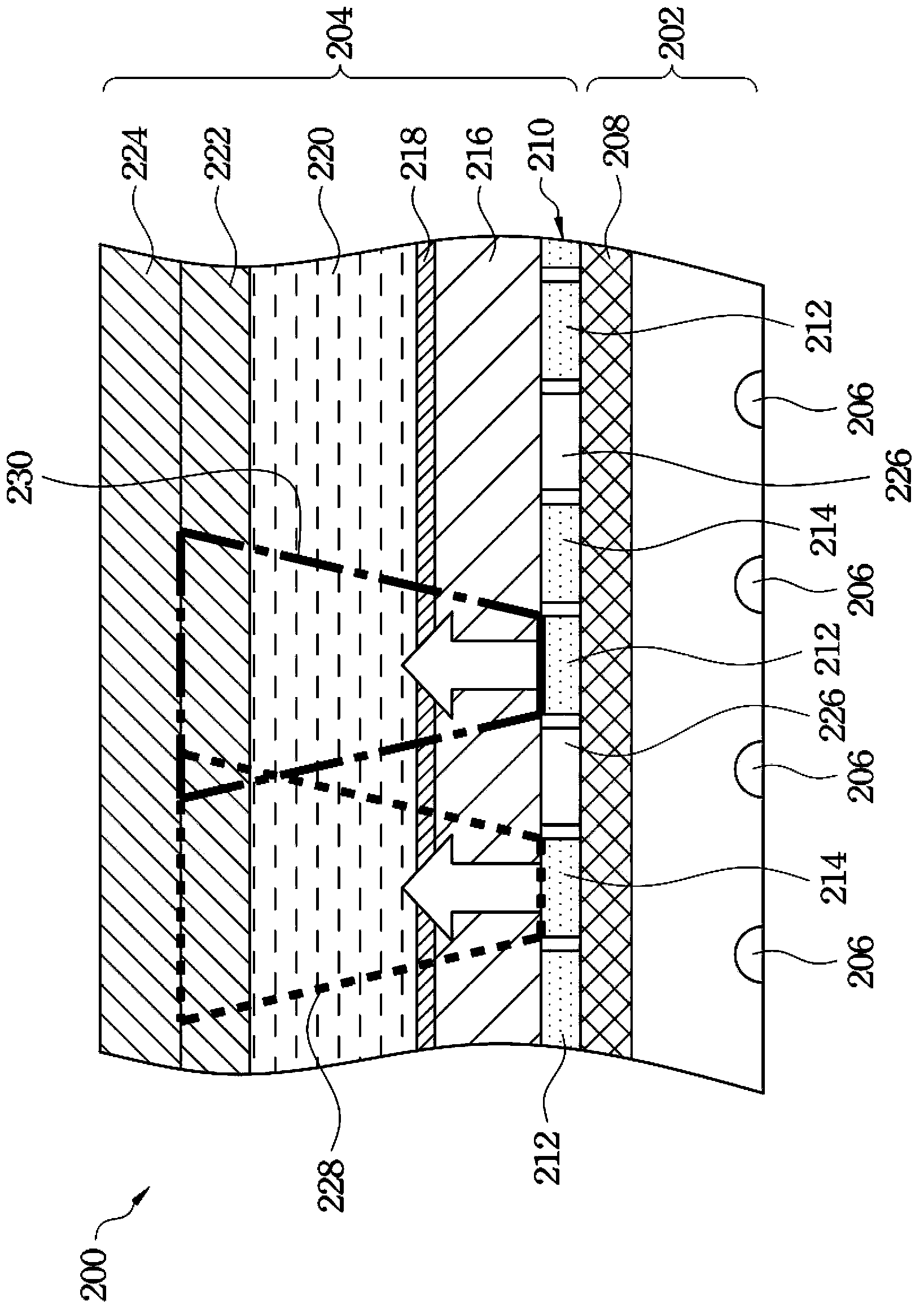

Liquid crystal display

InactiveUS20140168575A1Reduce manufacturing costYield lossNon-linear opticsLiquid-crystal displayFluorescence

A liquid crystal display is described, which includes a backlight module and a liquid crystal display panel. The backlight module includes a light guide plate and a plurality of blue light-emitting diodes adjacent to the light guide plate. The liquid crystal display panel is disposed above the backlight module. The liquid crystal display panel includes a first transparent substrate, a first electrode, a liquid crystal layer, a phosphor powder layer, a color filter, a second electrode and a second transparent substrate stacked above the light guide plate in sequence. The phosphor powder layer includes a plurality of green phosphor powder regions and red phosphor powder regions. The color filter is adjacent to the phosphor powder layer. The color filter includes a plurality of green color filter regions and red color filter regions respectively and correspondingly located, on the green phosphor powder regions and the red phosphor powder regions.

Owner:RADIANT OPTO ELECTRONICS

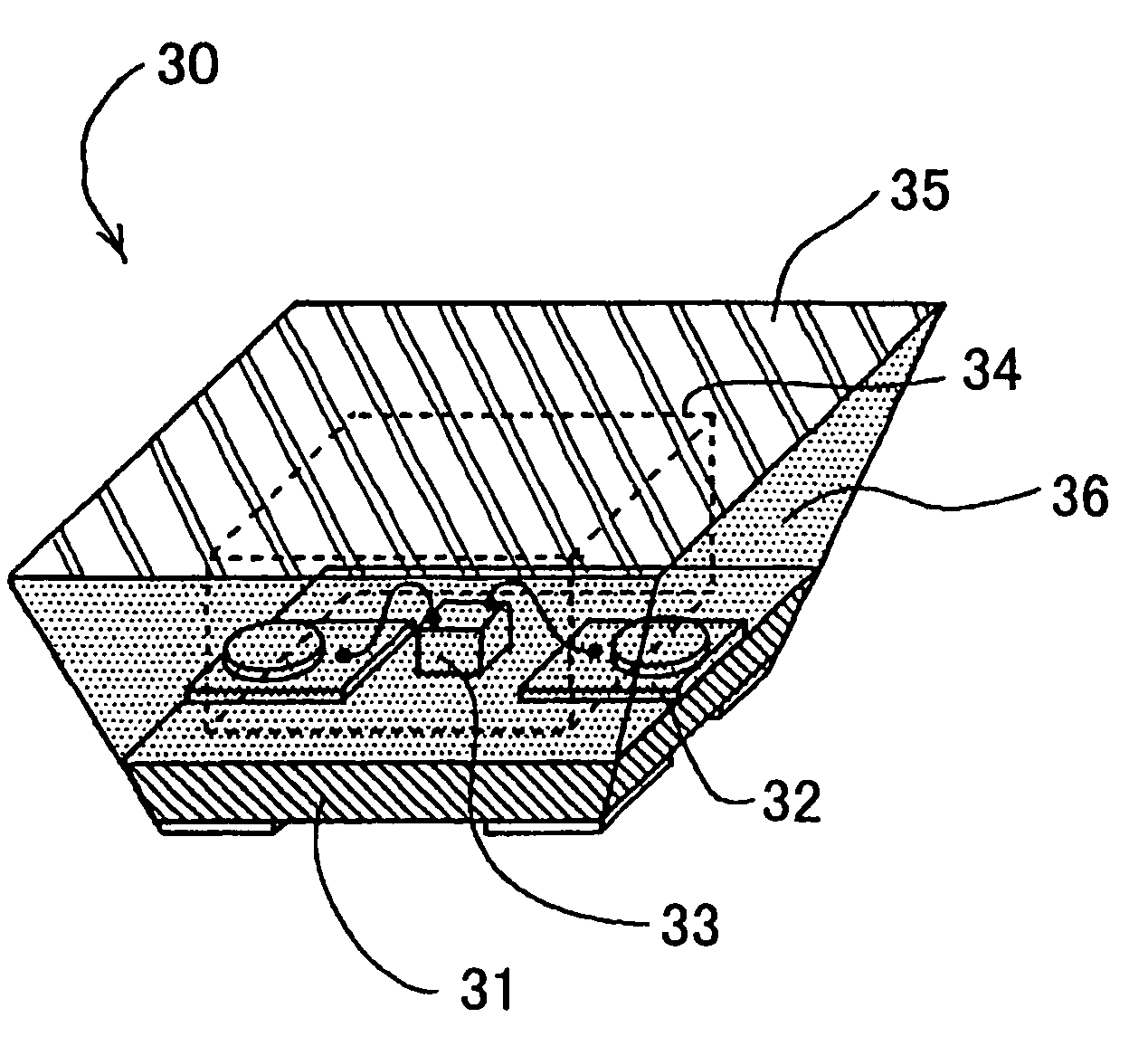

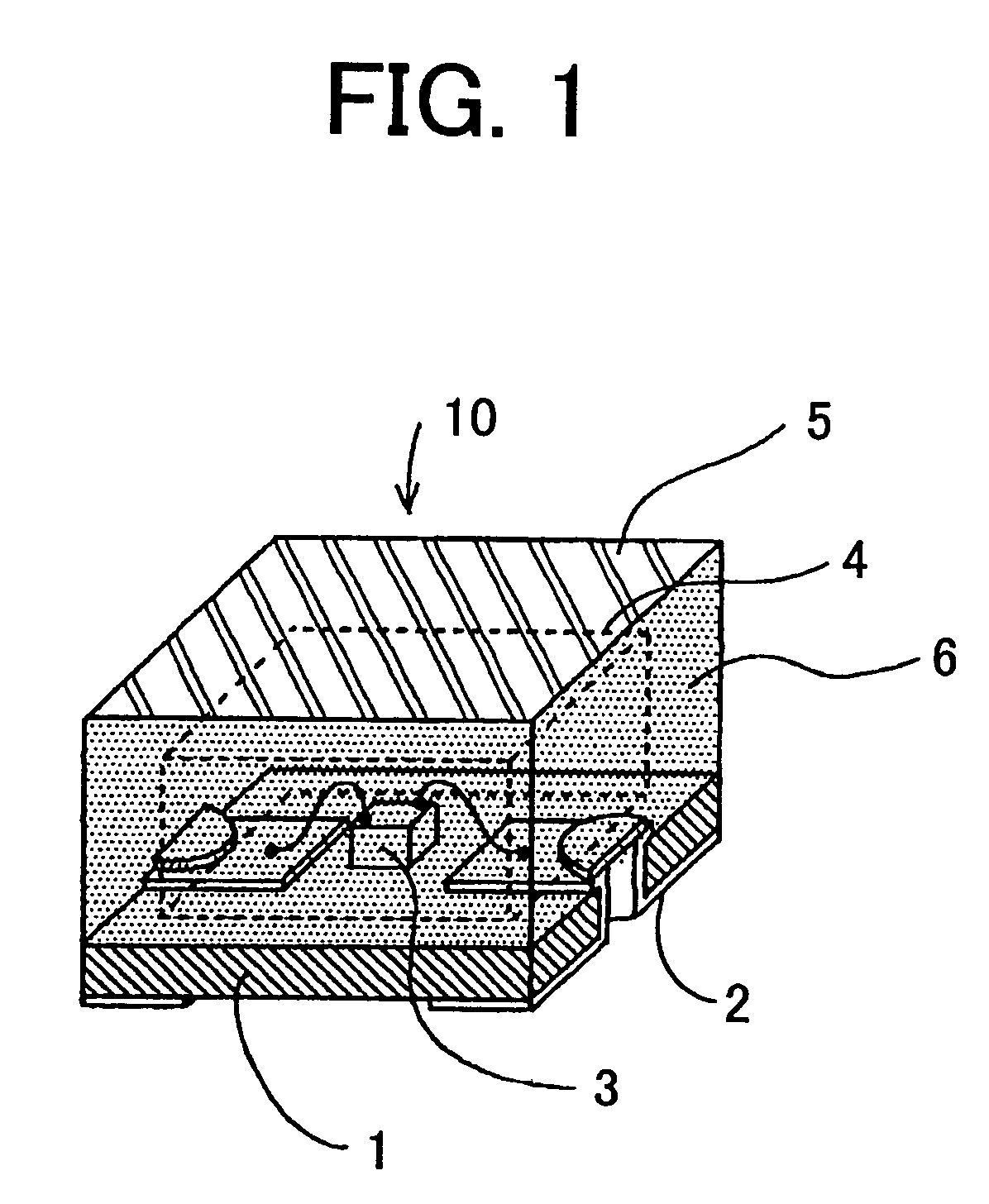

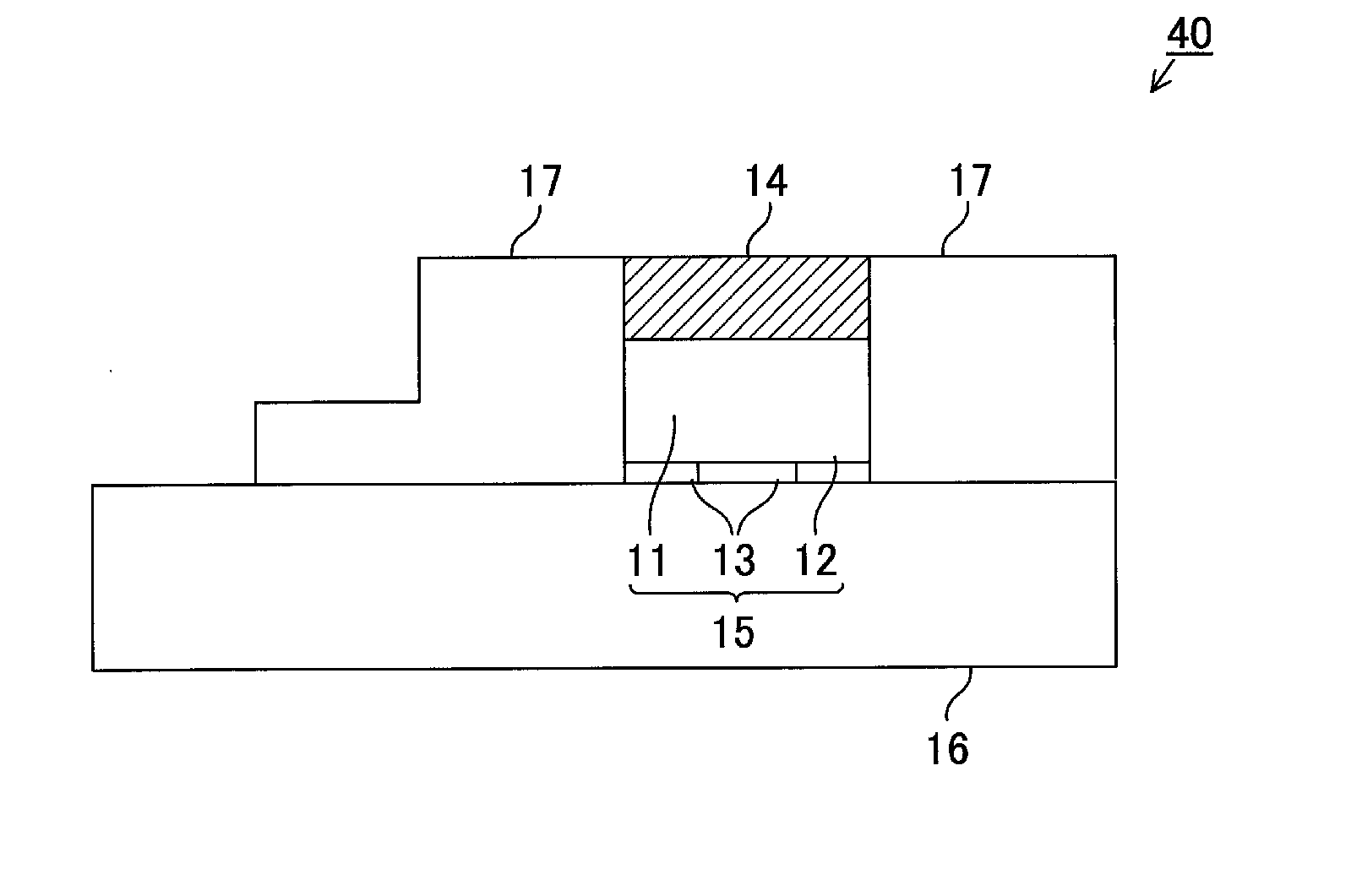

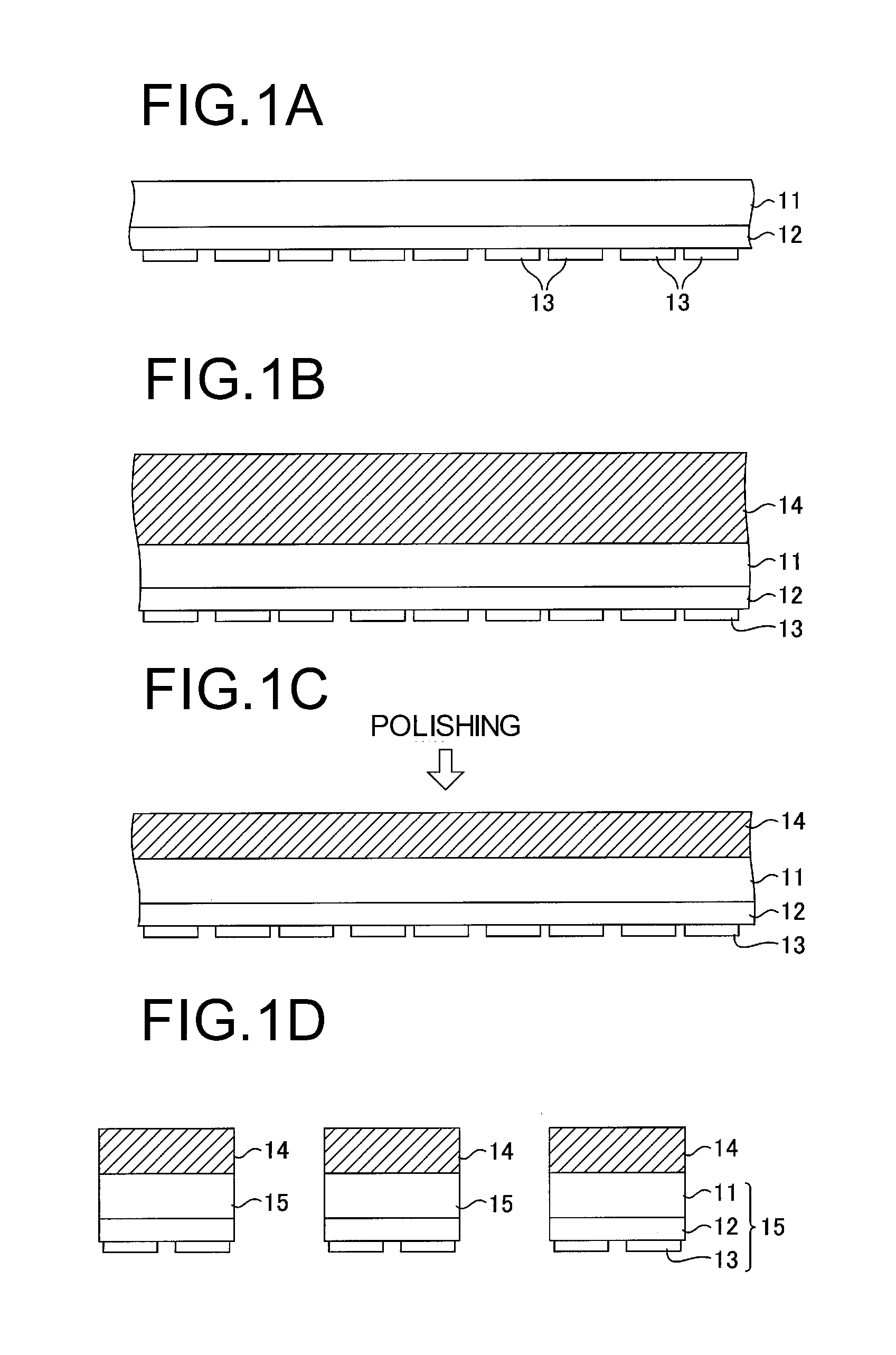

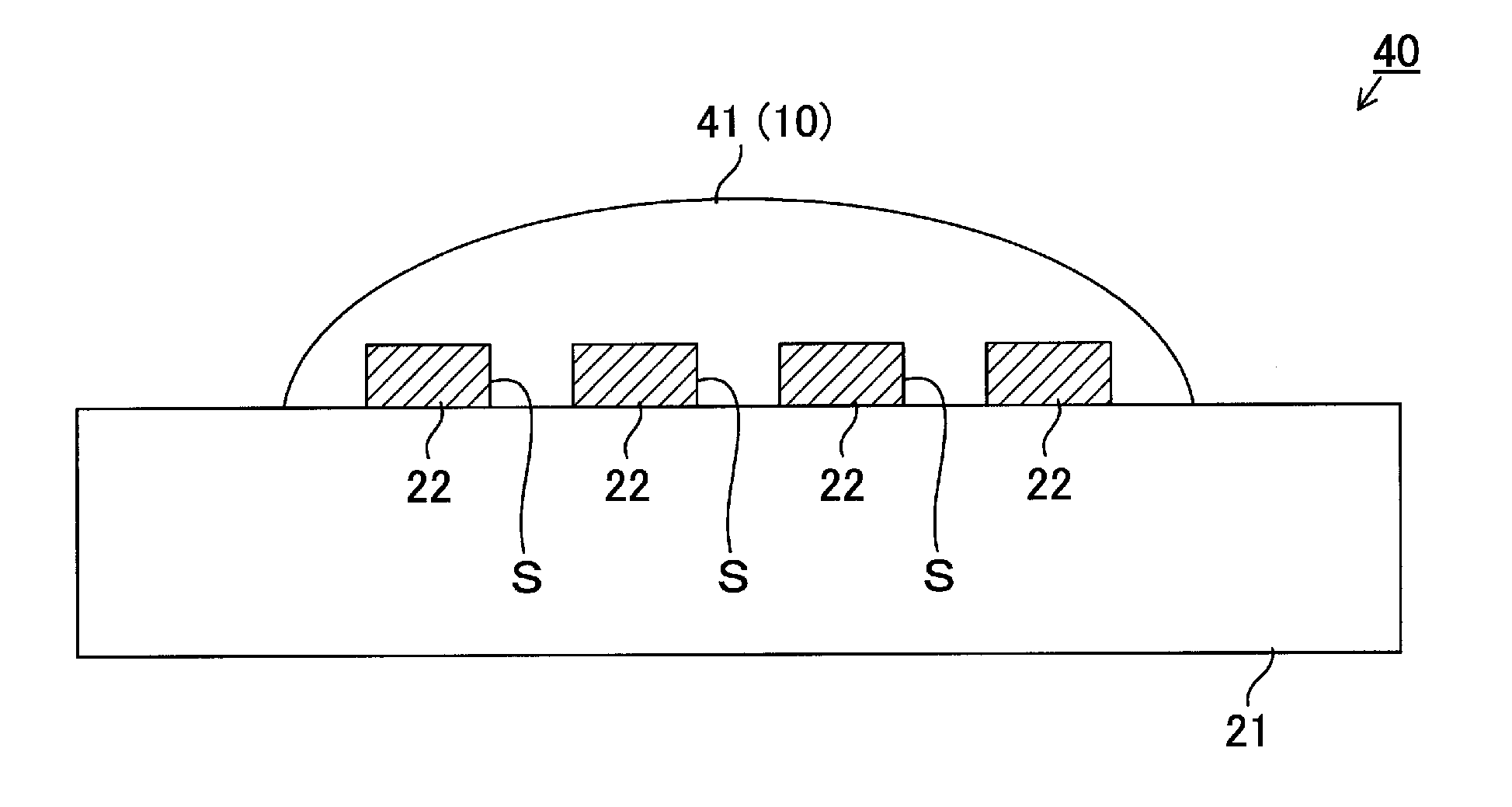

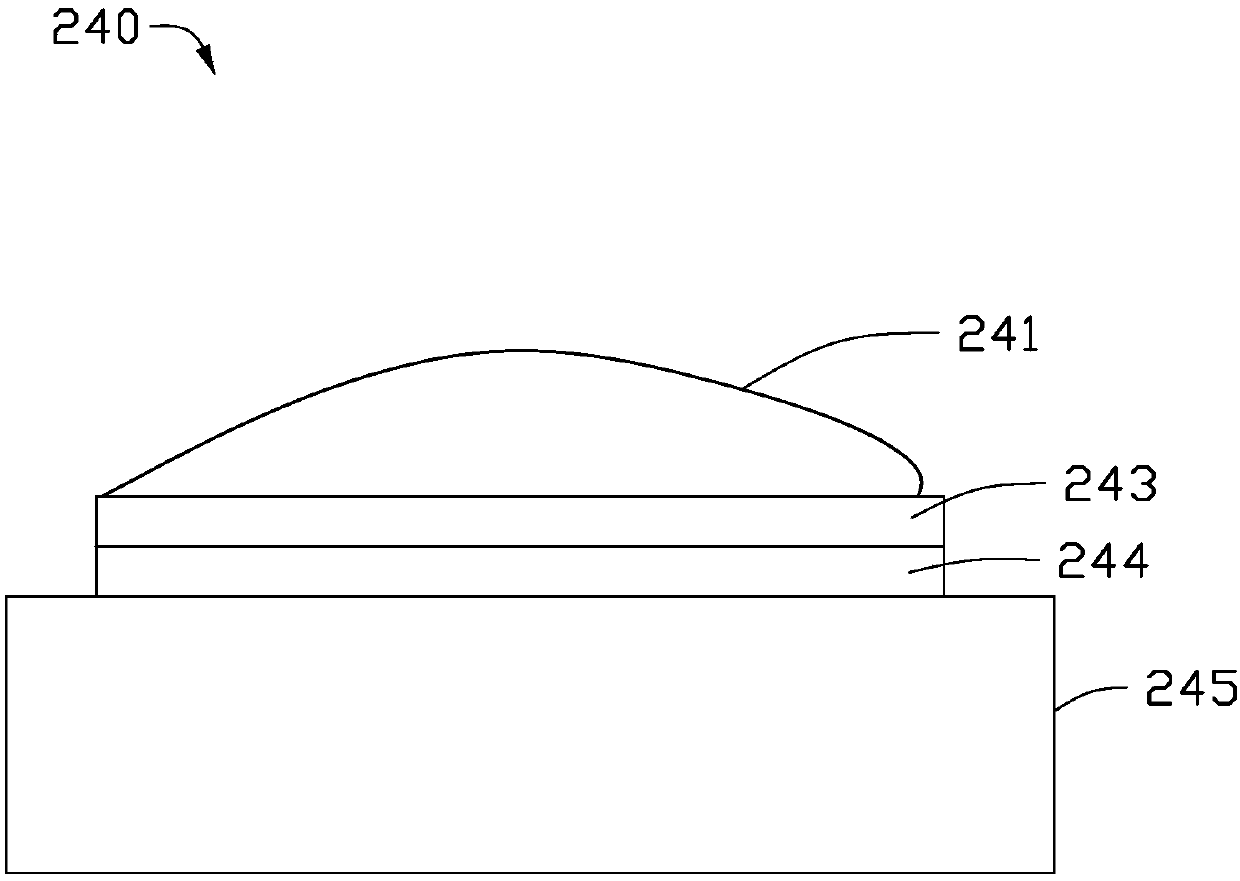

Light emitting device and manufacturing method thereof

InactiveUS7026661B2Uniform color distributionUniform luminance distributionDischarge tube luminescnet screensSemiconductor/solid-state device detailsLight emitting deviceFluorescent materials

A light emitting device has a substrate, an LED mounted on the substrate. A first transparent layer seals the LED, and a second transparent layer is provided around the first transparent layer. Particles of fluorescent material are included in the second transparent layer. A reflector layer is formed on outside walls except an upper side.

Owner:CITIZEN ELECTRONICS CO LTD

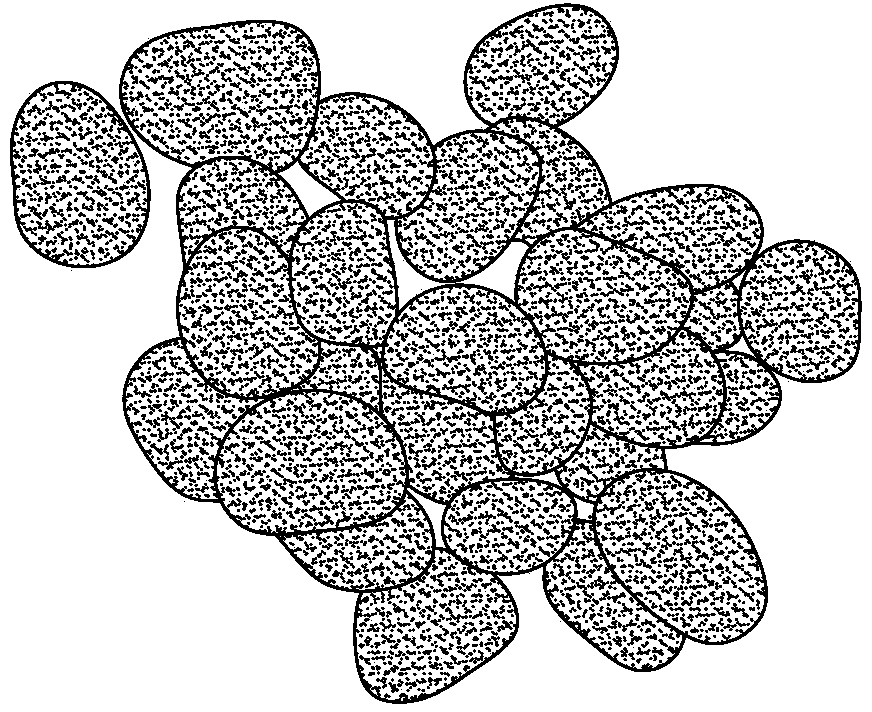

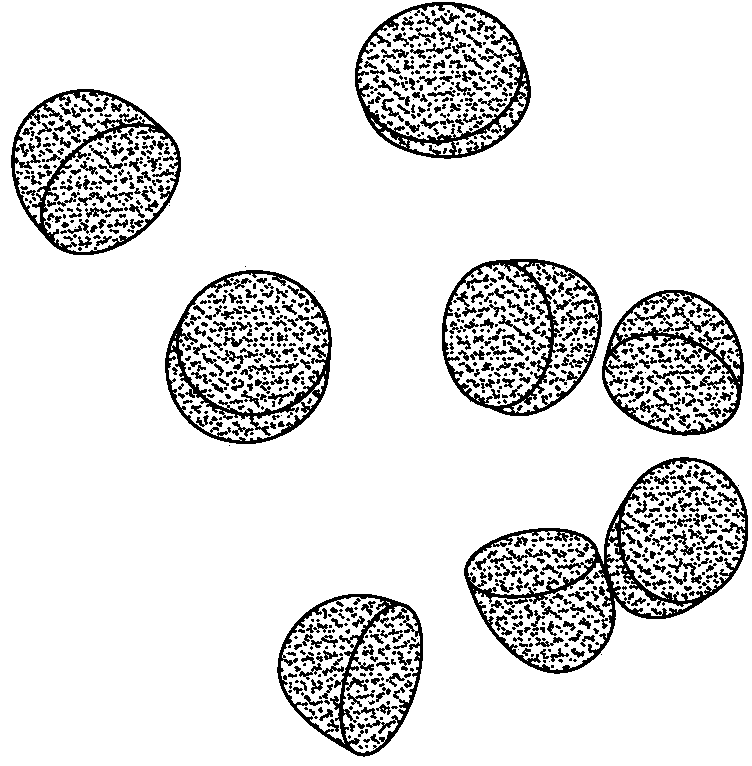

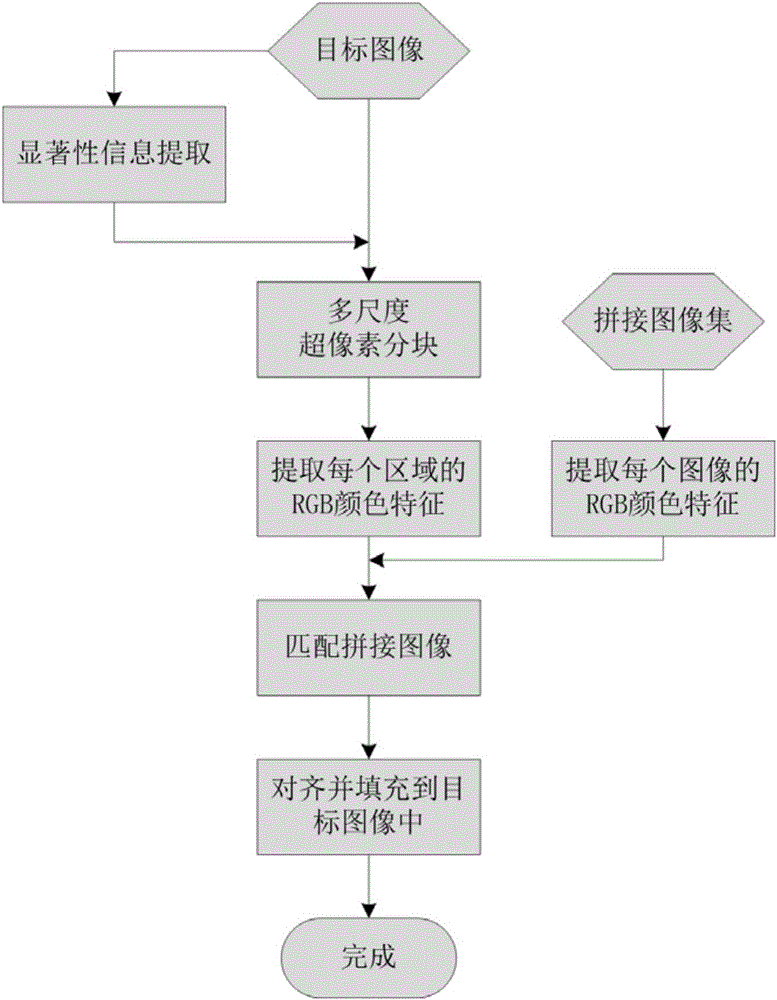

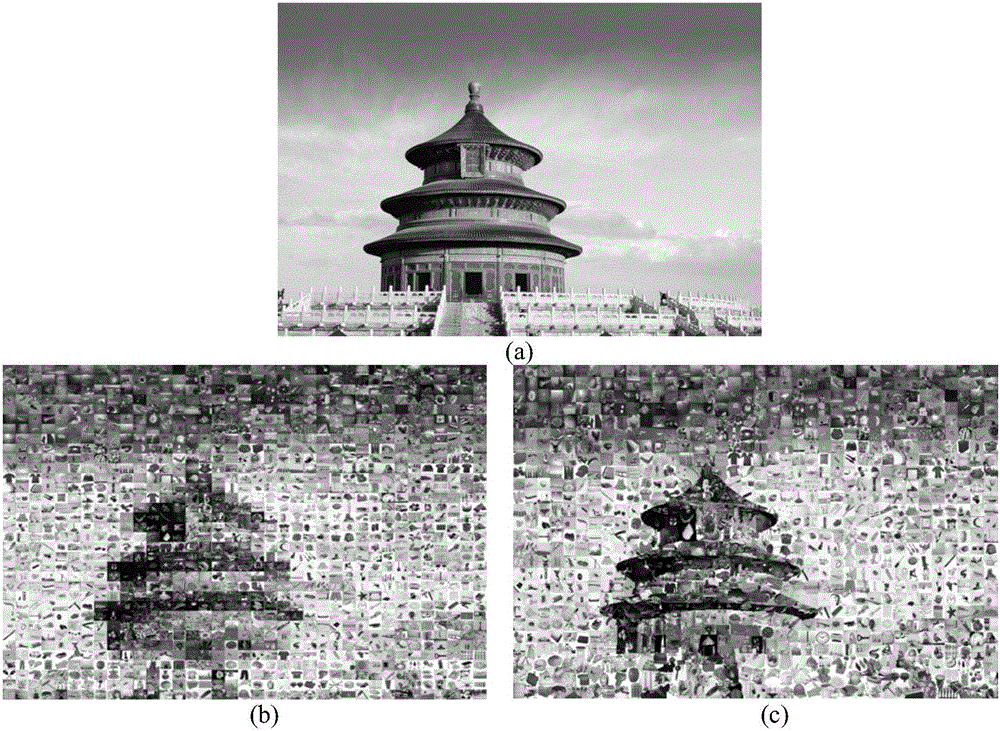

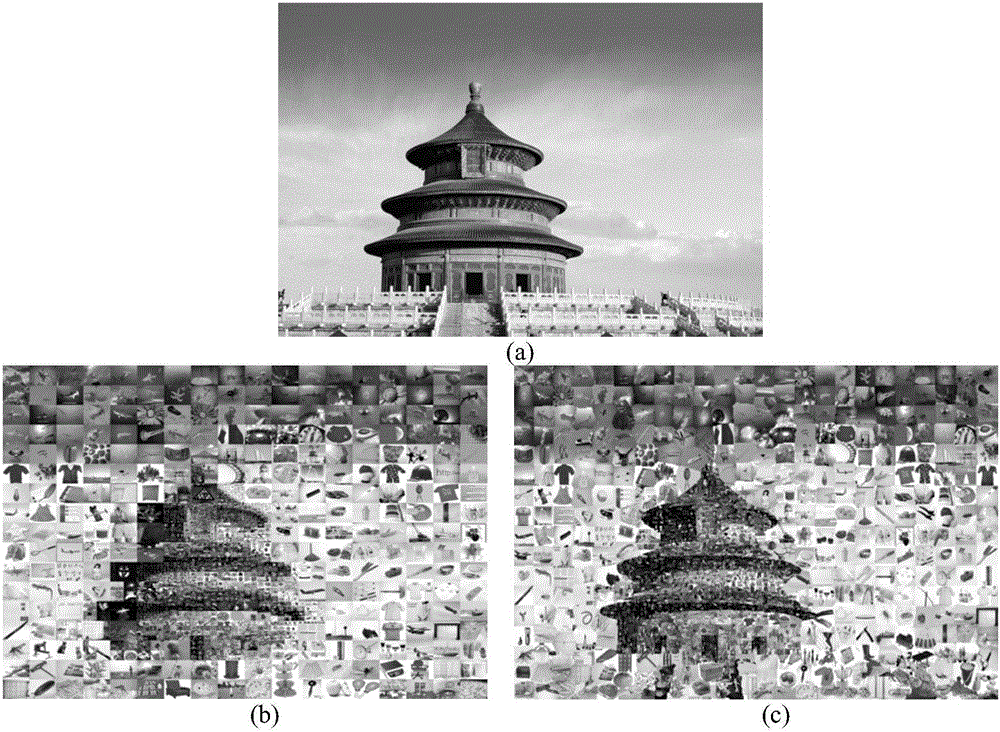

Salient information guided image irregular mosaic splicing method

ActiveCN105931180ARealization reservationInhibition lossImage enhancementImage analysisInformation hidingComputer vision

The invention discloses a salient information guided image irregular mosaic splicing method. The main objective of the invention is to solve the problems of large number of jagged structures at the boundary of a target and the lack of detailed information in the prior art. The implementation process of the method includes the following steps that: 1, a target image is inputted, and the salient region of the image is extracted; 2, the target image is segmented into grid images with different densities according to saliency levels; 3, the color mean value characteristics of the images of a splicing image set and the grid regions of the target image are extracted; 4, splicing images of which the color characteristics are most similar to the color characteristics of the grid regions are selected for the grid regions; and 5, the width and height information of the grid regions are extracted, and corresponding splicing images are shrunk and expanded according to the width and height information of the grid regions, and the splicing images are aligned with the grid regions and are trimmed, and the trimmed splicing images are filled in corresponding grids, and mosaic filling of the whole image is completed. With the method of the invention adopted, the ornamental value of a mosaic spliced image can be kept, and the detailed information of the target image can be enhanced. The method of the invention can be applied to image transmission, image security, image information hiding and advertisement design.

Owner:XIDIAN UNIV

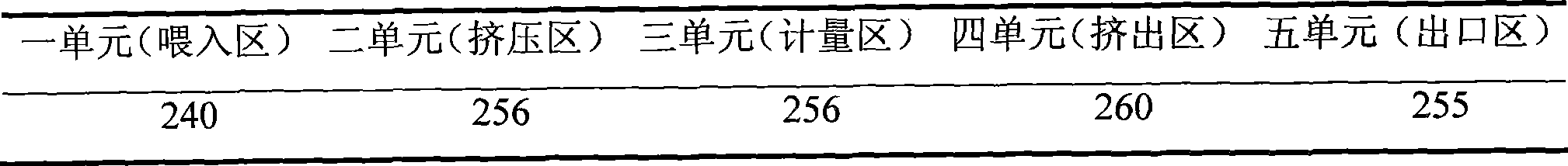

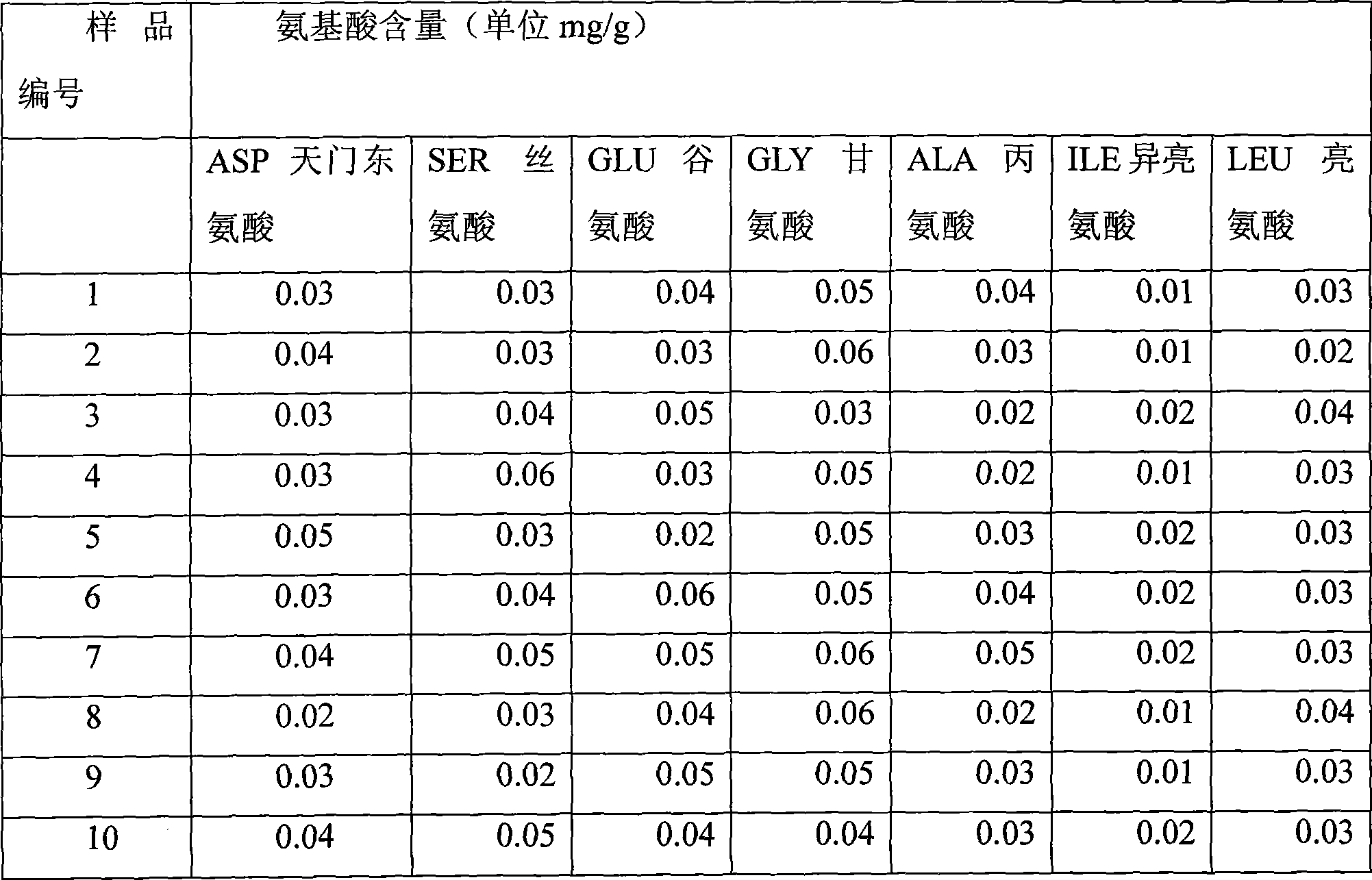

Method for preparing nano-pearl colored polyester fiber

InactiveCN101519808ASmall fluctuationInhibit unstable factorsHollow filament manufactureFilament/thread formingPolyesterFiber

The invention relates to a method for preparing nano-pearl colored polyester fiber, which comprises the following steps that: (1) pearls are sheared and ground to obtain crude pearl powder, then the crude pearl powder is mixed with water, a water dispersion of the pearl powder with a grain diameter of between 50 and 100 nm is obtained through high-pressure crushing, a thermal stabilizer, an antioxidant and an emulsifying agent are added into the water dispersion of the pearl powder, and the drying treatment is performed; (2) the obtained product is mixed evenly with a compatilizer at normal temperature, then the mixture is added into polyester chips, and granulation is performed on the mixture by a double screw extruder; and (3) nano-pearl polyester chips, the polyester chips and color master batch are blended for spinning. The method can be finished on the prior spinning equipment, tows are even and have evenly distributed color and luster; fabric is smooth, and has the characteristic of soft luster; the method is widely applied in the fields of apparel, decoration and industry; and at the same time, the blended color master batch can be used for preparing fibers with various lusters, and the prepared fibers have good nutrition and health care effects on human bodies.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD

Method for preparing nano silicon dioxide modified polyester fibers

InactiveCN102330188AInhibit unstable factorsEvenlyFilament/thread formingMonocomponent polyesters artificial filamentPolyesterFiber

The invention relates to a method for preparing nano silicon dioxide modified polyester fibers, which comprises the steps of preparing a nano silicon dioxide modified polyester slices and spinning by a blending FDY (Fully Drawn Yarn) technology. The method disclosed by the invention can be completed on conventional spinning equipment. Tows have good evenness. Glossy distribution is uniform. A textile fabric is smooth and flat. The nano silicon dioxide modified polyester fibers have the characteristic of soft gloss, can be widely applied to the clothing field, the decoration field and the industry field.

Owner:JIANGSU YINGXIANG FIBER

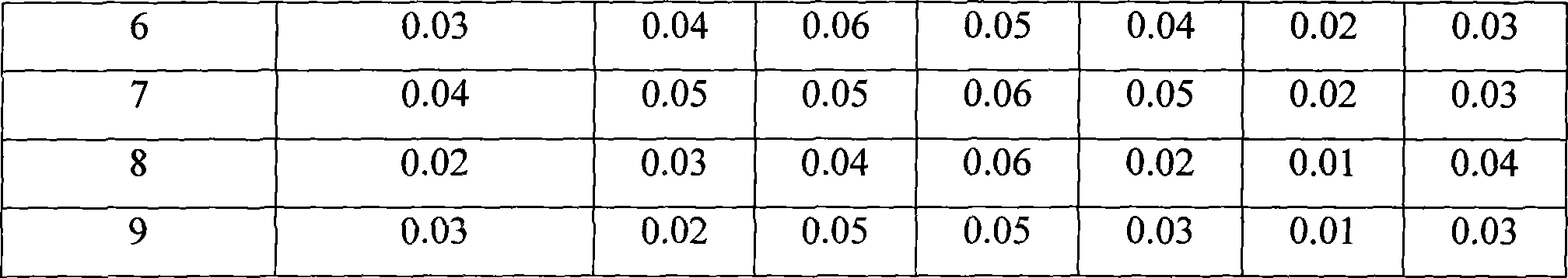

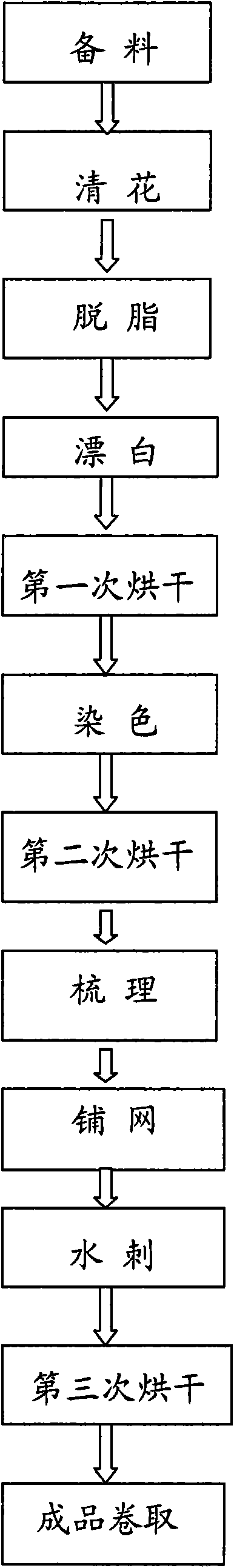

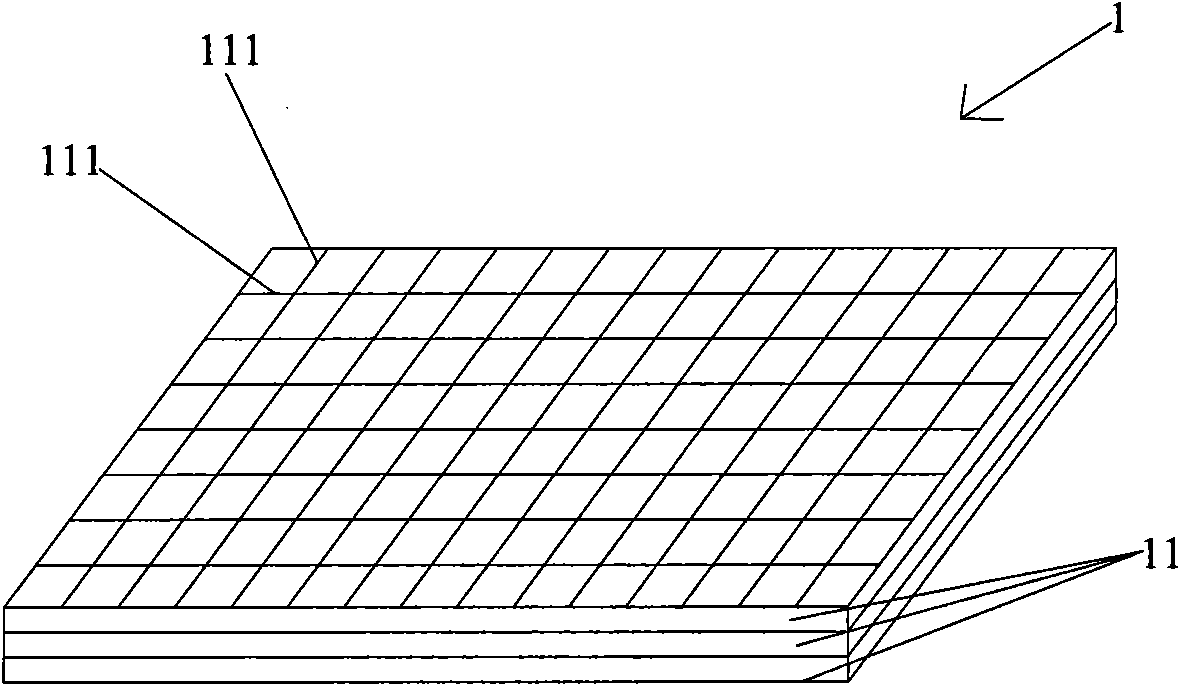

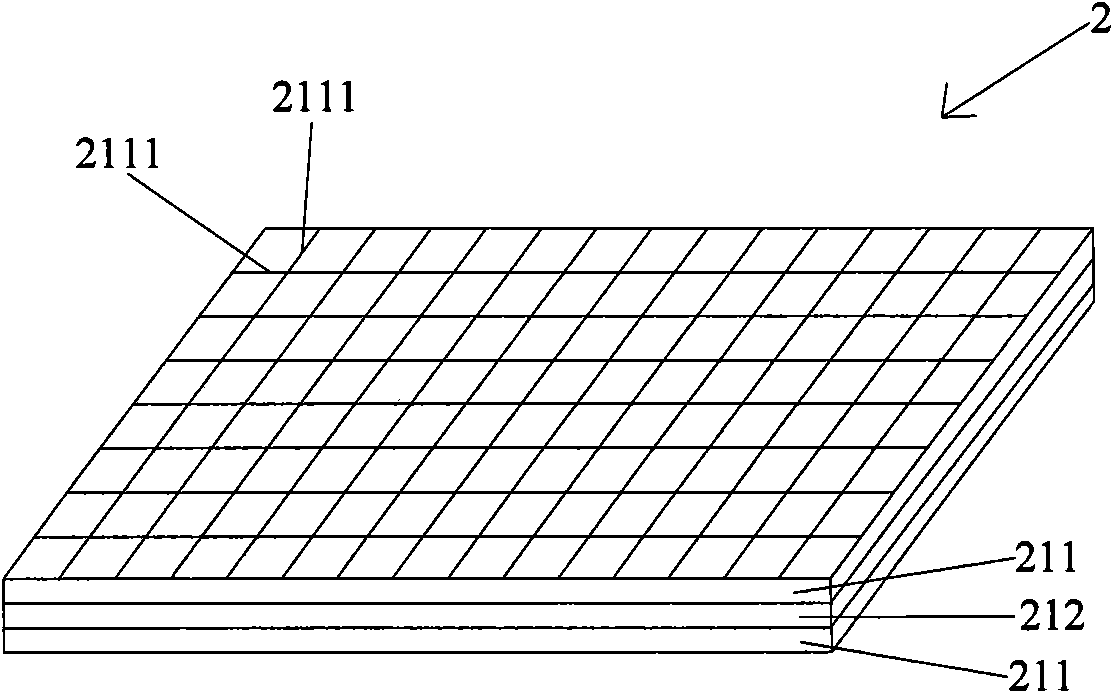

Dyed cotton spun-laced production process and product

InactiveCN102051765AUniform color distributionImprove dyeing effectNon-woven fabricsCardingPulp and paper industry

The invention is applied in the field of non-woven fabrics, and provides a dyed cotton spun-laced production process and a dyed cotton spun-laced product. The process comprises the following steps of: blowing, degreasing, bleaching, dyeing, primary drying, carding, lapping, spinning-lacing, secondary drying and finished product coiling. The dyed cotton spun-laced product obtained by the process has multiplayer dyed cotton fibers, and the dyed cotton fiber of each layer contains multiple colors and can also contain one color. Spinning-lacing and dyeing in the traditional dyed cotton spun-laced production process are changed into dyeing and spinning-lacing, only partial cotton fibers before spinning-lacing are dyed, then un-dyed cotton fibers and the dyed fibers are blended in different modes, and finally the cotton fibers of different colors are fully entwisted by the spinning-lacing treatment and the colors are distributed uniformly, so that the dyed cotton spun-laced products of different styles can be obtained, and meanwhile, the purpose of obtaining good dyeing effect with little dye is also fulfilled; and compared with the traditional process, the production cost is saved.

Owner:WINNER MEDICAL CO LTD

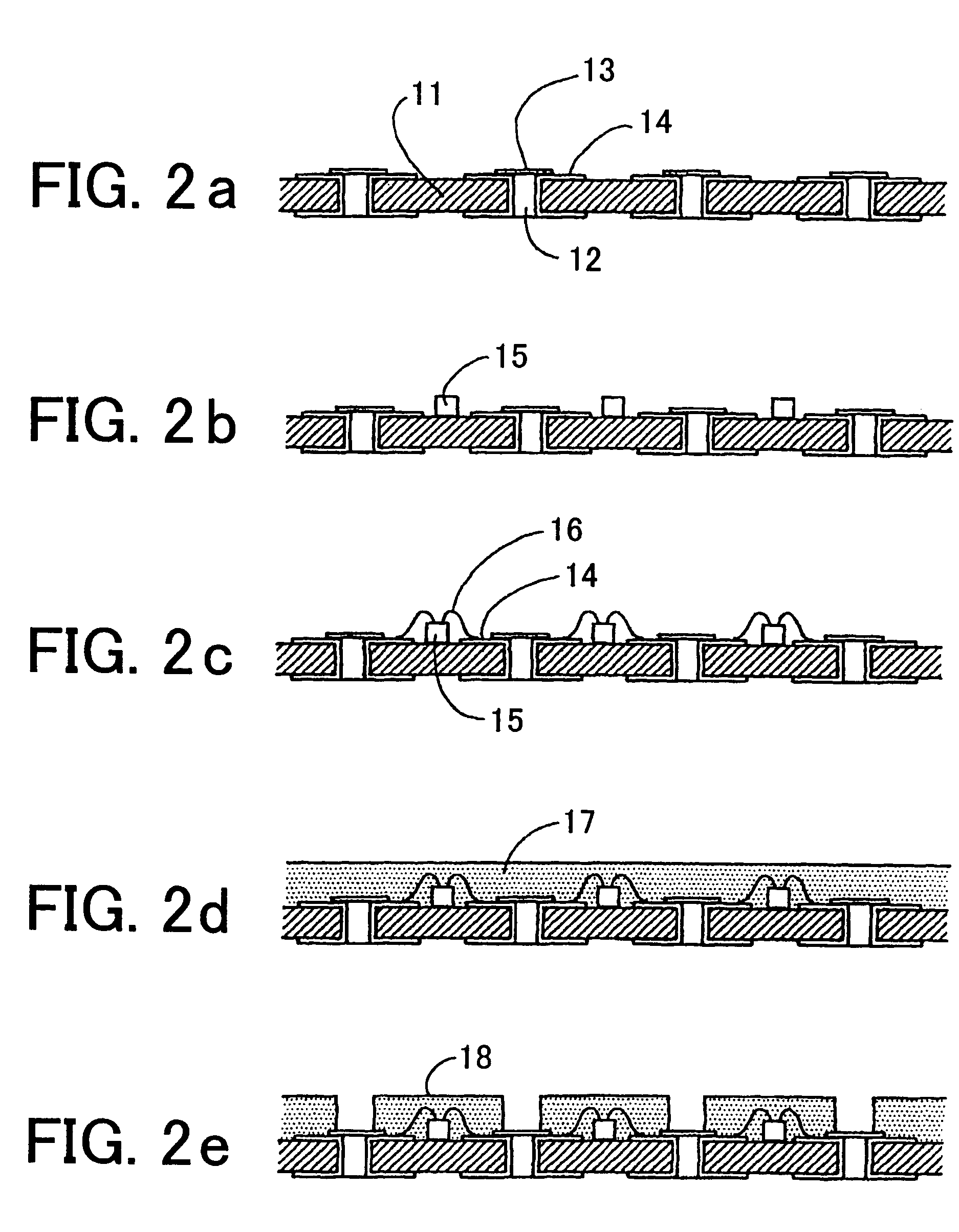

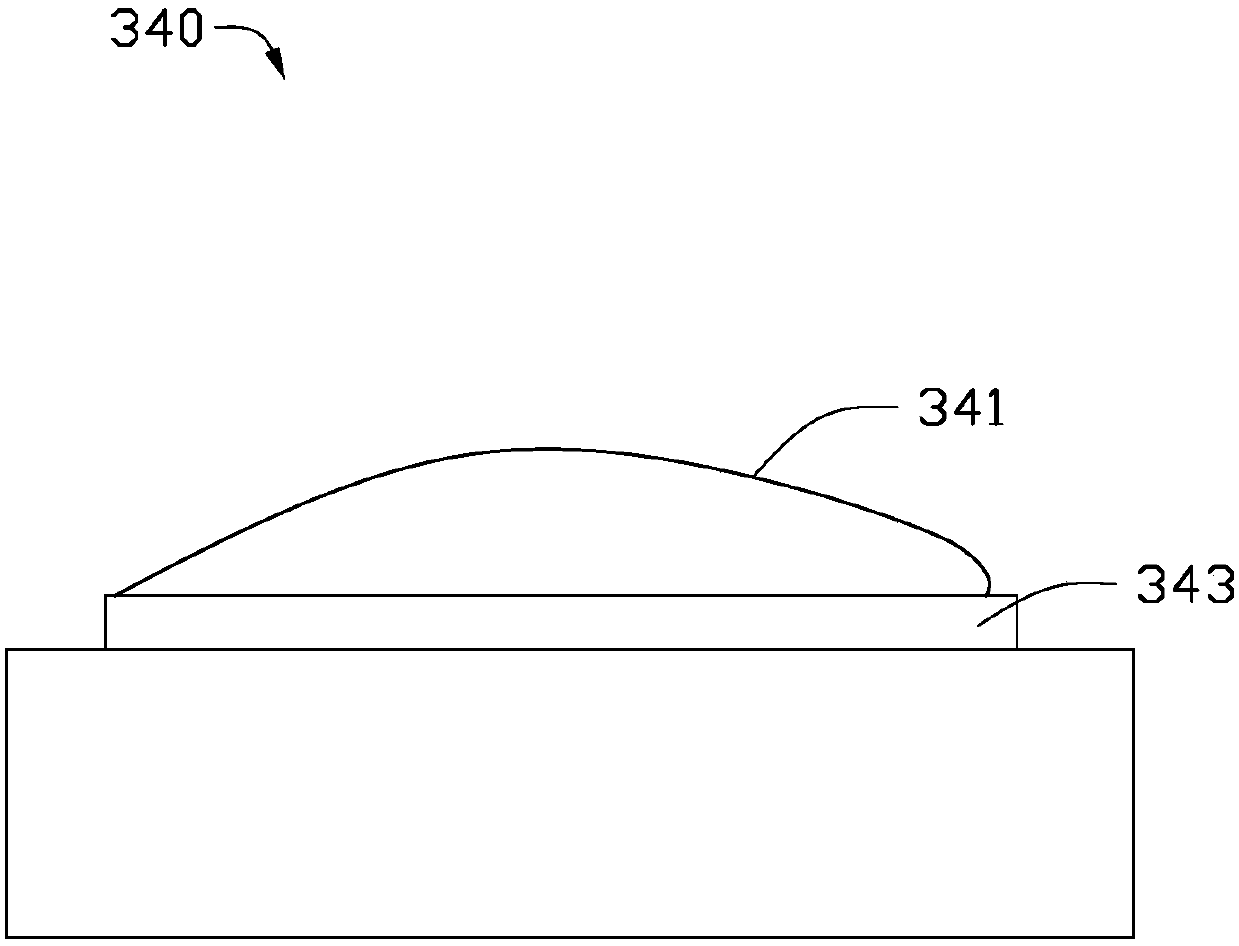

Method of manufacturing light emitting device

ActiveUS20150280081A1Avoid damageEfficiently dissipatedSemiconductor/solid-state device manufacturingSemiconductor devicesPhosphorLight emitting device

In a method of manufacturing a light emitting device, a luminescent color conversion member made of a translucent material including phosphors is directly fixed to light emitting surface side of light emitting elements in a light emitting element group, and a stack of the light emitting element group and the luminescent color conversion member is divided into a plurality of chips. In each of the light emitting elements, a piece of the luminescent color conversion member is directly fixed to the light emitting surface of the light emitting element.

Owner:TOYODA GOSEI CO LTD

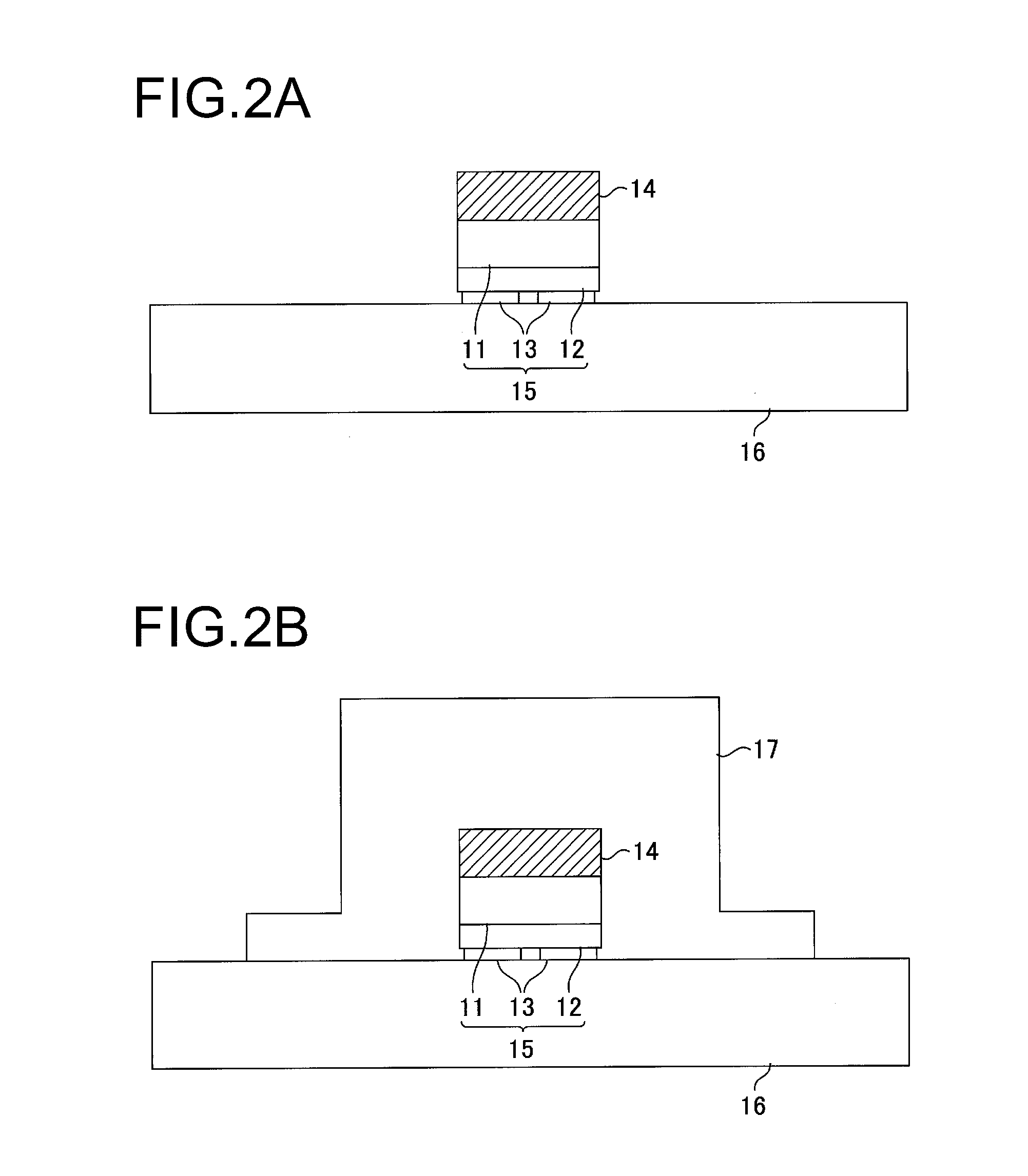

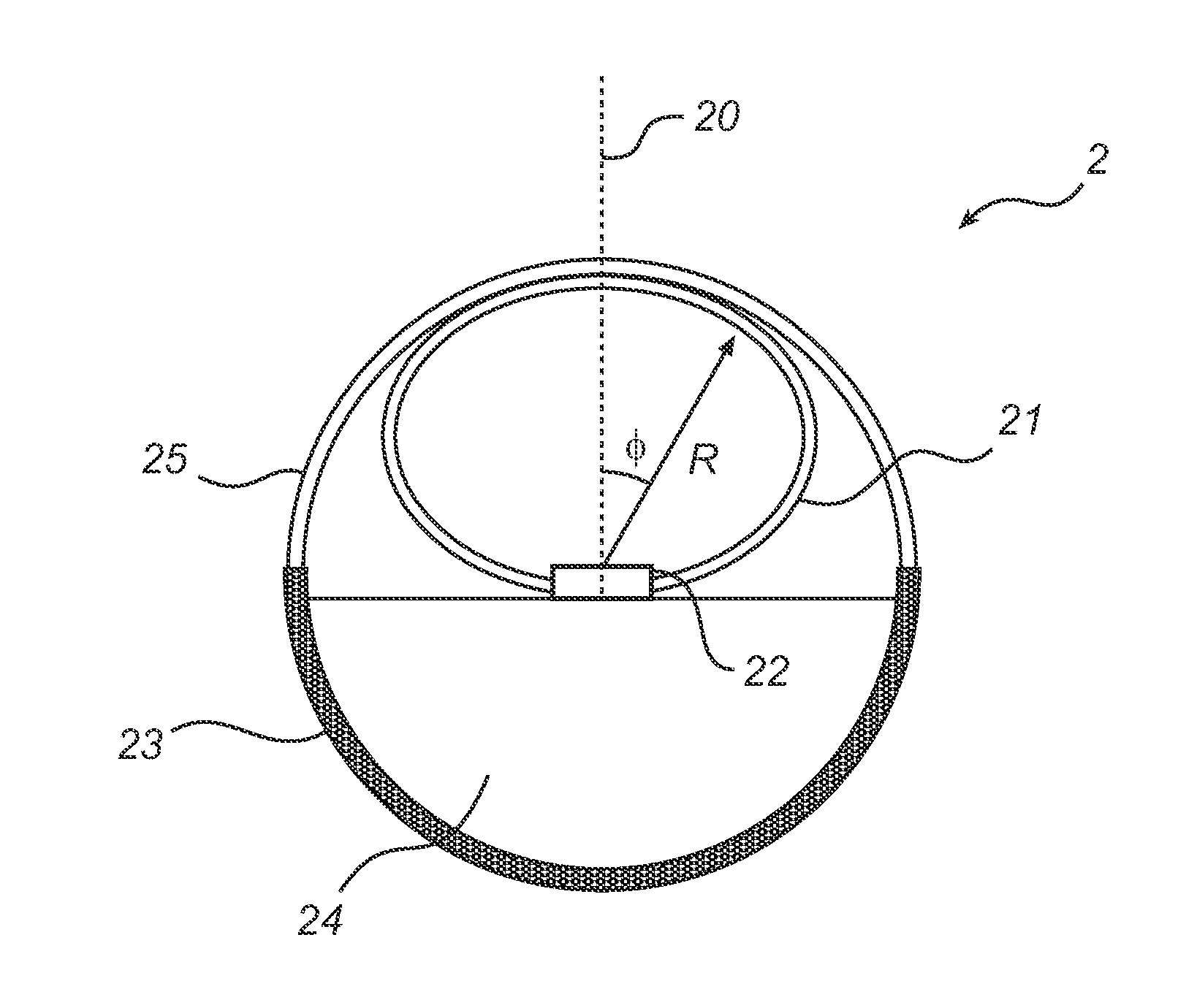

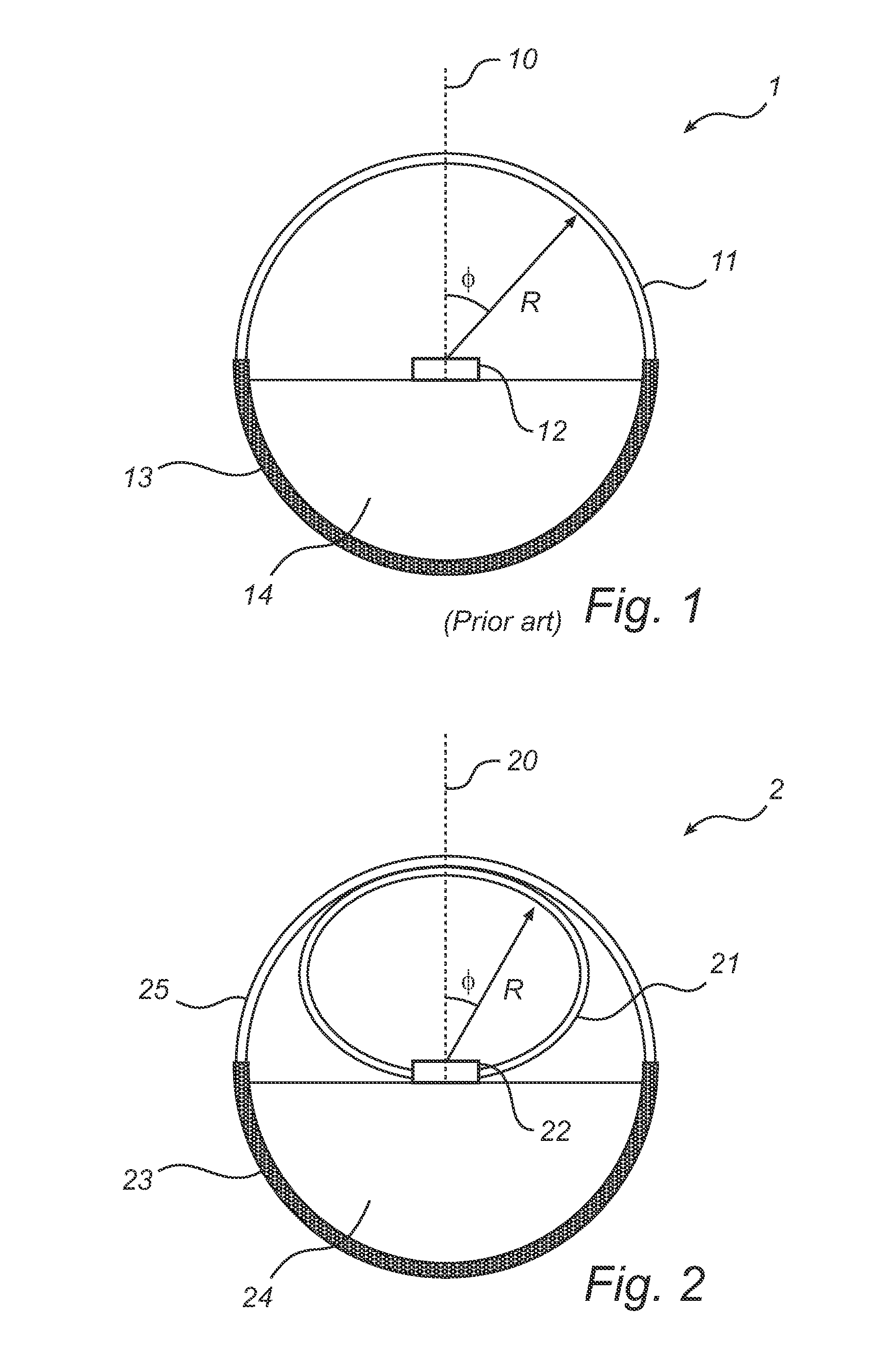

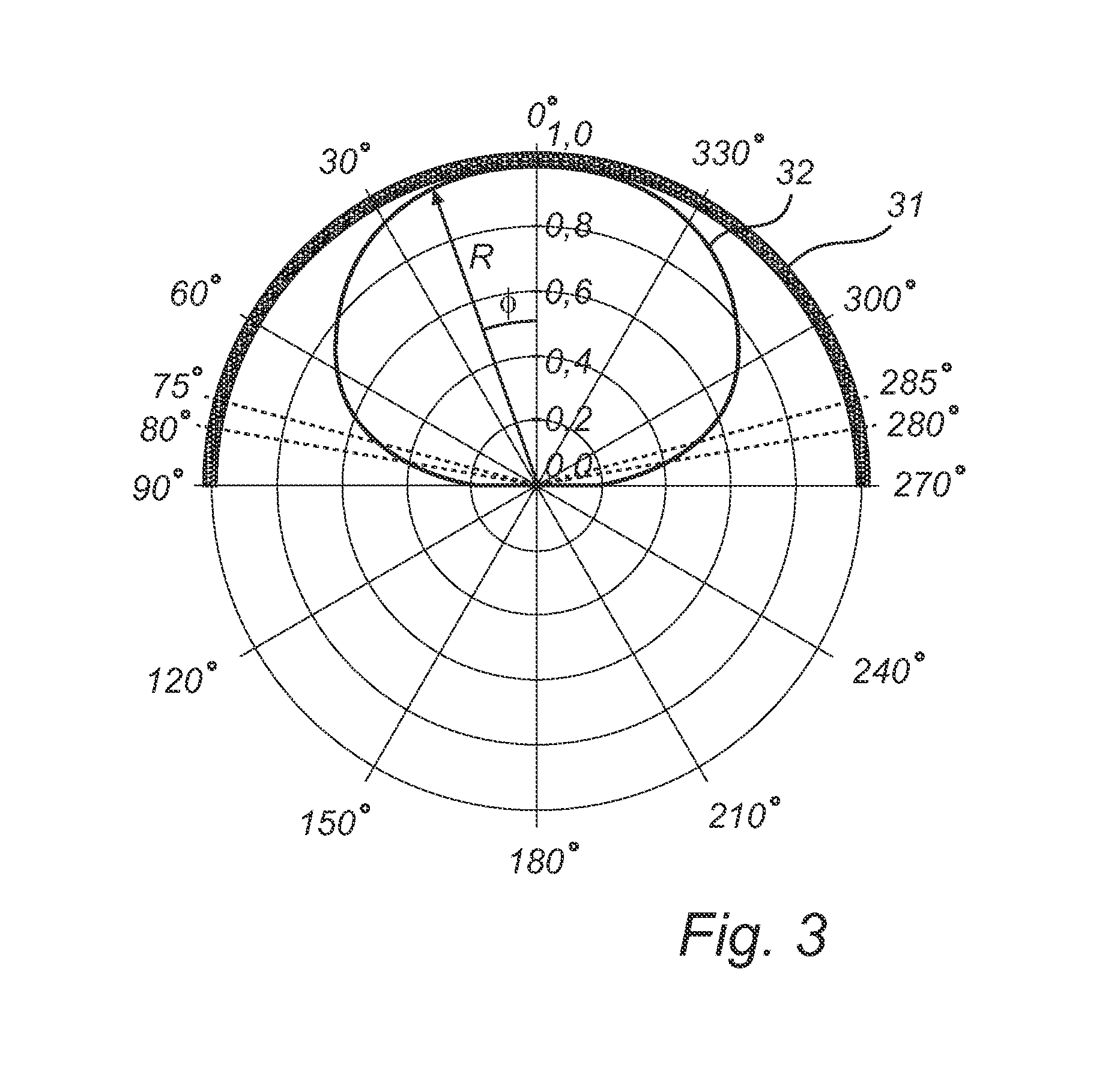

Lighting device having a remote wavelength converting layer

ActiveUS20150146407A1Reducing optical contactOptical contactElongate light sourcesLighting heating/cooling arrangementsLuminous intensityCurve shape

According to an aspect of the present invention, a lighting device (2) is provided. The lighting device (2) comprises a wavelength converting layer (21) having a curved shape and a light source (22) arranged to emit light towards the wavelength converting layer (21). The wavelength converting layer (21) intersects a plane extending through the light source (22) and being parallel with the optical axis of the light source (22), at a curve given, in a polar coordinate system centered at the light source (22), by the equation: R(φ)=k·I(φ)1 / 2±D, wherein k is a constant, 0 is an angle with respect to said optical axis, / (φ) is a function defining a luminous intensity profile of the light source and D is a deviation ranging from zero to 20% of the maximum value of said curve, Rmax. The present invention is advantageous in that the lighting device (2) has a more uniform color distribution of emitted light across the wavelength converting layer (21) and the risk of color gradients and artifacts is reduced.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Copper-red glaze and preparation method thereof

The invention relates to copper-red glaze and a preparation method thereof. The copper-red glaze comprises, by weight, 5-10 parts of kaolin, 18-35 parts of quartz, 10-16 parts of calcium phosphate, 15-22 parts of albite, 15-24 parts of potassium feldspar, 2-9 parts of talcum, 1-2 parts of cupric oxalate, 0.5-1.5 parts of tin oxide, 8-16 parts of calcite, 0.5-1.5 parts of zinc oxide and 10-13 parts of borax. The copper-red glaze has the advantages that the glaze is even in color and good in glossiness, and porcelain processed by the copper-red glaze is even in color and thick in glaze, has an unique artistic effect, gives an impression of depth, steadiness, dignity and elegance to people, has a bright red color and is even in glaze color distribution and high in yield.

Owner:崔松伟

Method for uniformly drying agaricus bisporus slices through variable-frequency ultrasound-assisted impregnation pretreatment and vacuum microwaves

ActiveCN104304426AImprove uniformity of vacuum microwave dryingUniform colorFruits/vegetable preservation by dehydrationDielectricAgaricus

The invention relates to a method for uniformly drying agaricus bisporus slices through variable-frequency ultrasound-assisted impregnation pretreatment and vacuum microwaves, and belongs to the field of deep processing of agricultural products. The method comprises the following steps: cleaning agaricus bisporus and cutting into 5-8mm thick slices, protecting color by using a mixed solution of vitamin C, citric acid and calcium chloride, and carrying out variable-frequency staged ultrasound impregnation treatment on the color-protected agaricus bisporus slices: a first stage: putting the agaricus bisporus slices in clear water according to a ratio of agaricus bisporus slice to water of 1:5, and setting the water temperature to 45-50 DEG C, the ultrasonic frequency to 45KHz, the ultrasonic power to 120-150W, and the treatment time to 30-40min; a second stage: taking out the agaricus bisporus slices and putting into a mixed solution of 50-60% by mass fraction of sucrose and 5% by mass fraction of salt according to a ratio of agaricus bisporus slice to mixed solution of 1:10, and setting the water temperature to 35-40 DEG C, the ultrasonic frequency to 100KHz, the ultrasonic power to 210-240W and the treatment time to 40-50min; finally, carrying out vacuum microwave drying, and setting the microwave transmitting power to 15-20W / g, the degree of vacuum to 70-80kPa and the drying time to 15-25min. The agaricus bisporus slices subjected to variable-frequency ultrasound-assisted impregnation treatment has uniformly distributed dielectrics; when the vacuum microwave drying is carried out, a material is uniformly heated in a microwave field, and moisture is rapidly evaporated, so that the dried agaricus bisporus slice is uniformly distributed in color and luster, and is uniform in shape and better in rehydration.

Owner:JIANGSU ACAD OF AGRI SCI

Liquid crystal display

InactiveCN103885242AReduce manufacturing costImprove availabilityNon-linear opticsPhosphorLight guide

A liquid crystal display is described, which includes a backlight module and a liquid crystal display panel. The backlight module includes a light guide plate and a plurality of blue light-emitting diodes adjacent to the light guide plate. The liquid crystal display panel is disposed above the backlight module. The liquid crystal display panel includes a first transparent substrate, a first electrode, a liquid crystal layer, a phosphor powder layer, a color filter, a second electrode and a second transparent substrate stacked above the light guide plate in sequence. The phosphor powder layer includes a plurality of green phosphor powder regions and red phosphor powder regions. The color filter is adjacent to the phosphor powder layer. The color filter includes a plurality of green color filter regions and red color filter regions respectively and correspondingly located, on the green phosphor powder regions and the red phosphor powder regions.

Owner:RADIANT OPTO ELECTRONICS

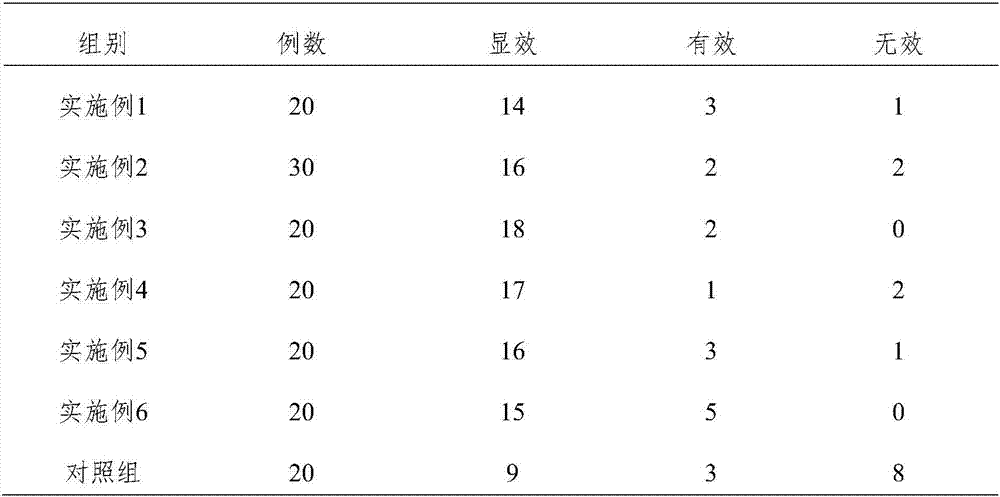

Rhizoma bletillae toothpaste and a preparing method thereof

InactiveCN106943327AIncrease profitUniform color distributionCosmetic preparationsToilet preparationsBletilla striataOral ulcers

The invention relates to the technical field of traditional Chinese medicines, and particularly relates to rhizoma bletillae toothpaste and a preparing method thereof. Rhizoma bletillae, a toothpaste matrix and a traditional Chinese medicine composition are adopted as raw materials and prepared into the toothpaste according to a proper ratio in combination with preparing process parameter adjustment. The toothpaste has a daily tooth cleaning function, and also has sterilizing and anti-inflammatory effects. After long-term using of the toothpaste, teeth are made white, clean and bright, and oral ulcer, periodontitis, and other diseases can be prevented and treated.

Owner:ZHENYUAN DAOYITANG BIOTECH CO LTD

Preparation method of nano silver oxide modified polyester fiber

InactiveCN102345178AInhibit unstable factorsImprove the bactericidal effectMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention relates to a preparation method of nano silver oxide modified polyester fiber, which comprises a process of preparing nano silver oxide modified terelyene slices and a process of blending FDY for spinning. The method of the invention can be finished on the routine spinning equipment, the tow has the characteristics of dry and uniform strips, uniform color distribution, flat fabric, luster and softness, and can be widely used in the clothing field, the decoration field and the industry field.

Owner:JIANGSU YINGXIANG FIBER

Method for preparing normal-temperature normal-pressure dyeable polyester pearl fiber

ActiveCN101519807ASmall fluctuationInhibit unstable factorsHollow filament manufactureFilament/thread formingPolyesterFiber

The invention relates to a method for preparing normal-temperature normal-pressure dyeable polyester pearl fiber, which comprises the following steps: (1) shearing and grinding pearls to obtain crude pearl powder, then mixing the crude pearl powder and water according to the weight ratio of 1: 10-100, crushing the mixture to obtain a water dispersion of the pearl powder, adding a thermal stabilizer, an antioxidant and an emulsifying agent into the water dispersion of the pearl powder, and performing drying treatment; (2) mixing the obtained product evenly with a compatilizer at normal temperature according to the weight ratio of 1: 0.1-0.5, then adding the mixture into normal-temperature normal-pressure dyeable polyester chips, performing granulation on the mixture by a double screw extruder, and obtaining nano-pearl polyester chips, wherein the weight content of the mixture in the normal-temperature normal-pressure dyeable polyester chips is between 10 and 30 percent; and (3) blending the nano-pearl polyester chips and the normal-temperature normal-pressure dyeable polyester chips for spinning. The method can be finished on the prior spinning equipment, tows are irregular, and have evenly distributed color and luster after the dying; fabric is smooth, and has the characteristic of soft luster; and the method can be widely applied in the fields of apparel, decoration and industry.

Owner:ZHEJIANG JINXIA NEW MATERIAL TECH CO LTD

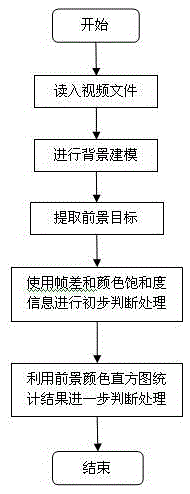

Video smoke event detection method based on bionic color sensing model

ActiveCN105528581AMove with easeDesaturationCharacter and pattern recognitionComputer visionSpecific time

The present invention provides a video smoke event intelligent detection method based on a bionic color sensing model. According to the method, a user selects a source video and uses a video smoke event intelligent detection method based on a bionic color sensing model to carry out smoke detection on the video, the alarming is carried out when smoke is detected and the frame of picture of the video is stored into a specified path, at the same time the specific time point of detecting the smoke is recorded in the video, and the recording information is stored in a text file format after the detection is completed. The method is different from a traditional sensor fire alarming method and is not limited by space height, thermal barrier, explosion, toxicity and other environmental conditions, the timely alarming can be carried out in a short time that the smoke appears in the video, and the method is suitable for multiple outdoor video scenes of forests, fields and the like.

Owner:SOUTH CHINA UNIV OF TECH

Displaying method and image display device

ActiveUS7893904B2Low color shift (LCS) display modeAvoid brightnessCharacter and pattern recognitionCathode-ray tube indicatorsPattern recognitionColor shift

In a displaying method for use in an image display, an original gray scale is divided into a higher gray scale and a lower gray scale. Further, the color subpixels are divided into two groups corresponding to the higher and lower gray scales, respectively. The gray scale to be expressed by each subpixel is calibrated by weighing the original higher or lower gray scale for the pixel and the adjacent pixels and summing up the results. The color shift problem due to different visual angles can therefore be solved.

Owner:INNOLUX CORP

Preparation method of nanometer calcium carbonate modified polyester fiber

InactiveCN102330169APearly lusterClear fire and detoxifyMonocomponent polyesters artificial filamentArtifical filament manufactureYarnPolyester

The invention relates to a preparation method of a nanometer calcium carbonate modified polyester fiber. The preparation method comprises the preparation of a nanometer calcium carbonate modified polyester chip and a process of spinning with a blended FDY (fully drawn yarn) technology. The method of the invention which can be completed with routine spinning equipment allows uniform yarn evenness, uniform color distribution, and smoothness of the fabric to be realized and has the characteristic of soft luster, so the method can be widely applied to the clothing field, the decoration field and the industrial field.

Owner:JIANGSU YINGXIANG FIBER

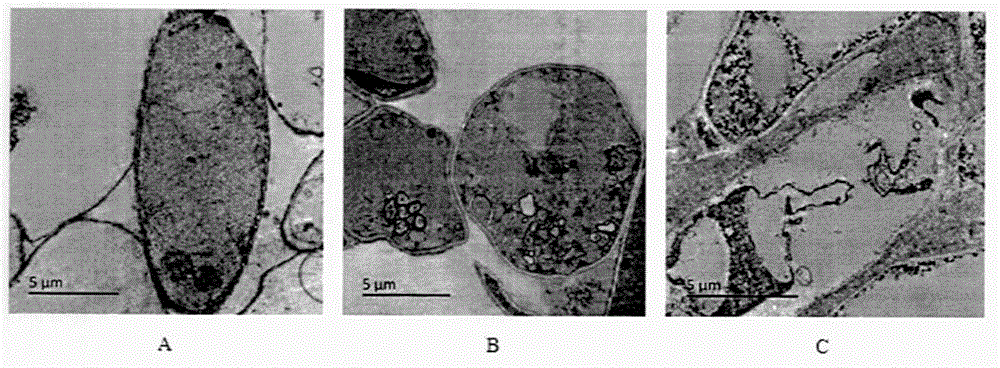

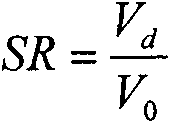

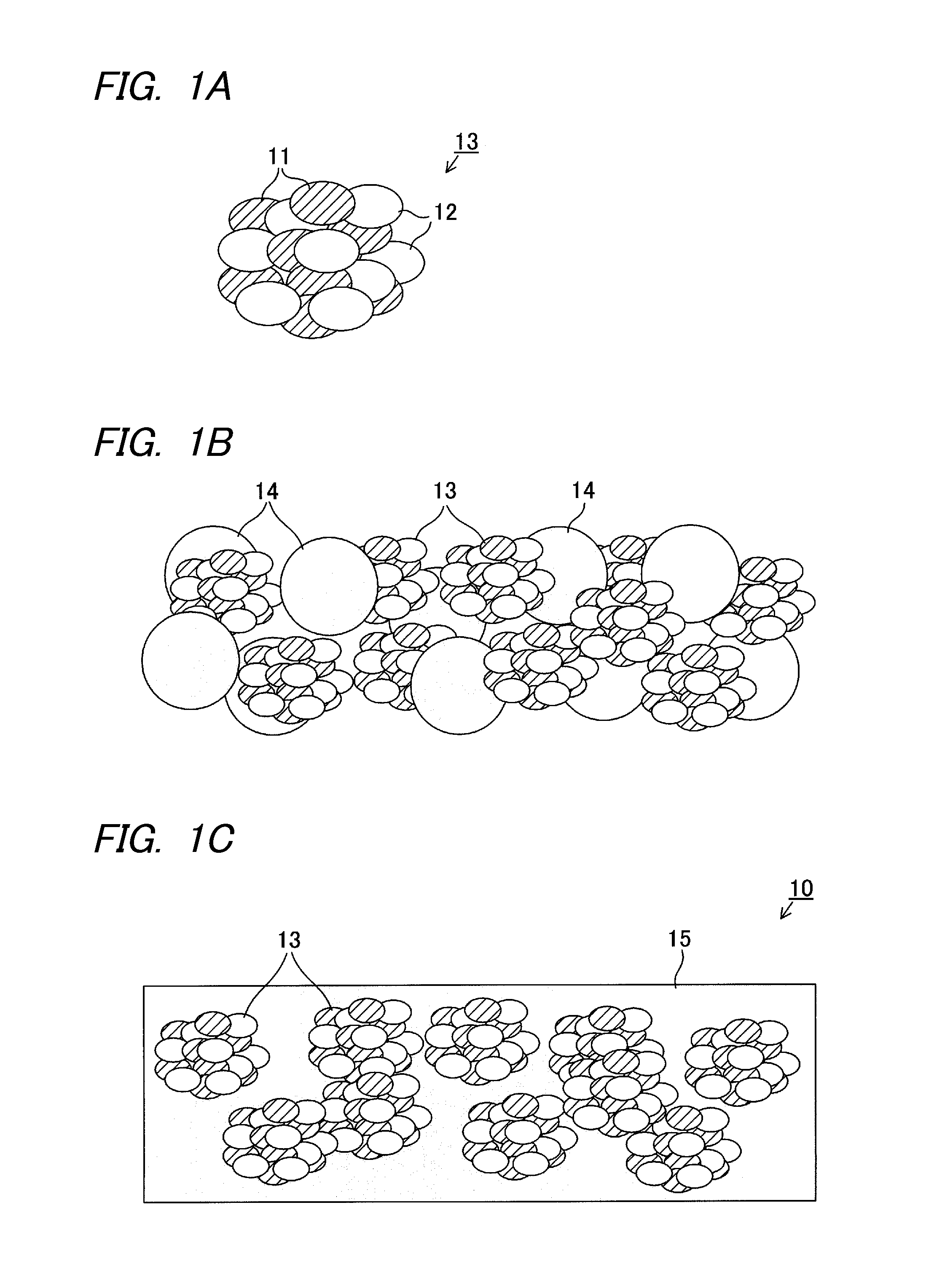

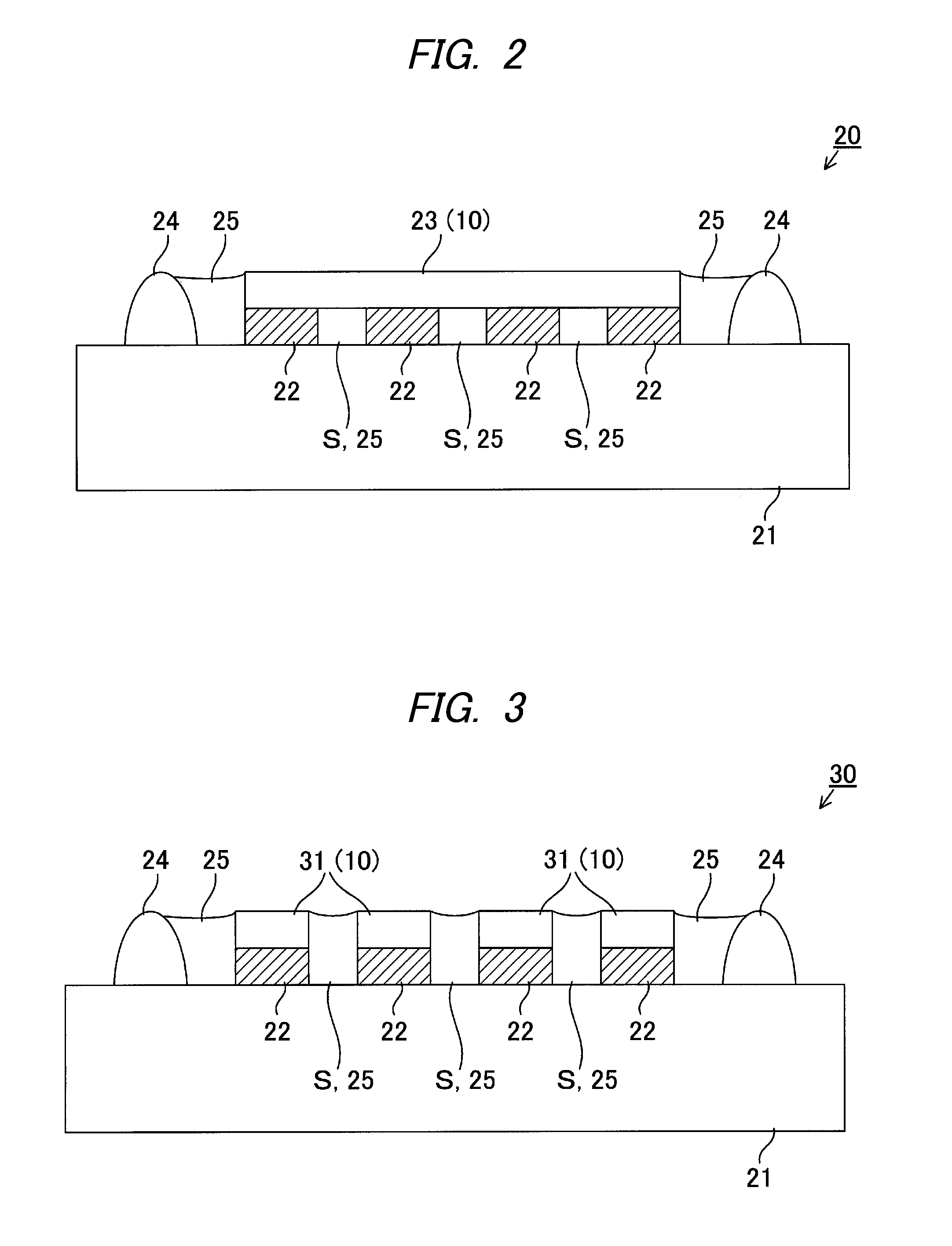

Luminescent color conversion member and light emitting device

ActiveUS20150275073A1Uniform color distributionSmall particle sizeSolid-state devicesLuminescent compositionsPhosphorGlass particle

A luminescent color conversion member of a light emitting device includes a glass and integrated particles dispersed inside the glass, each of the integrated particles being a mixture of phosphors and a dispersively binding material that are bonded to each other. The luminescent color conversion member is configured as a sintered body of a mixture of the integrated particles and glass particles. The dispersively binding material is a non-glass material having transparency and bondability to the phosphors.

Owner:TOYODA GOSEI CO LTD

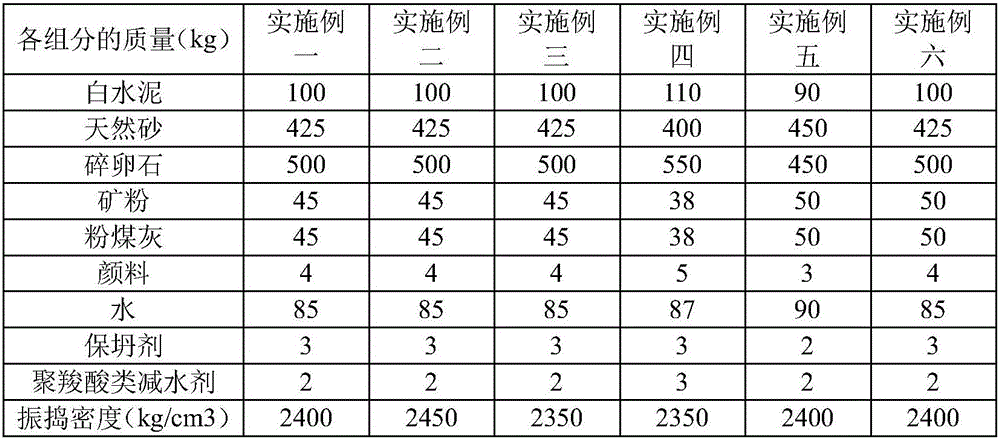

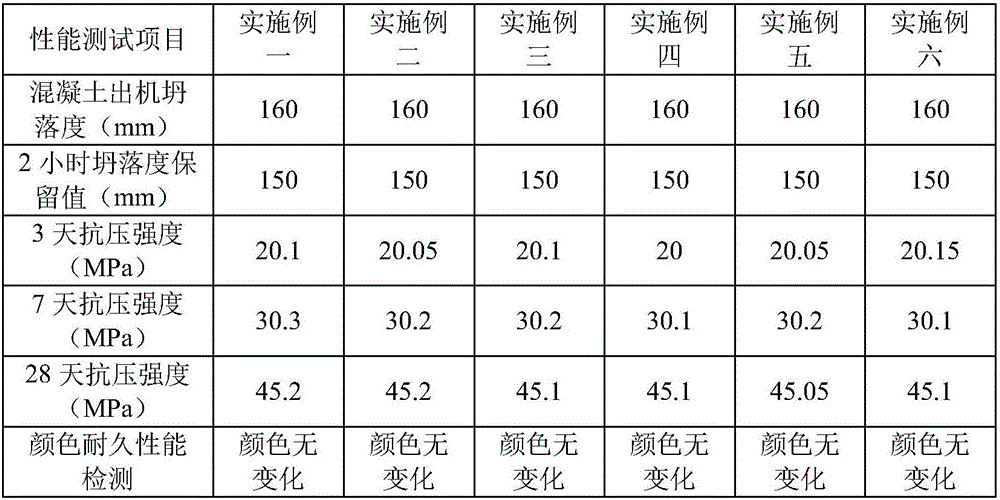

Colored concrete as well as preparation method and application method thereof

The invention discloses colored concrete which comprises the following components in parts by weight: 180-220 parts of white cement, 150-200 parts of a mineral admixture, 800-900 parts of fine aggregate, 900-1100 parts of coarse aggregate, 6-10 parts of pigments, 8-12 parts of additives and 170-180 parts of water. A preparation method of the colored concrete comprises the following steps: adding different components into respective raw material cabins, pre-homogenizing, performing continuous blending according to a weight ratio, stirring the blended white cement, the material admixture, the pigments and the fine aggregate for 0.5-1 minute in a compulsive stirring machine, adding water and the additives, and stirring for 0.5-1 minute. An application method of the colored concrete comprises the following steps: casting the colored concrete, vibrating the colored concrete till the density is 2350-2450kg / cm<3>, and coating the surface of the colored concrete with a protection agent. The colored concrete is not liable to fade, and the overall durability can be improved.

Owner:BEIJING TAIPINGYANG CEMENT PROD CO LTD

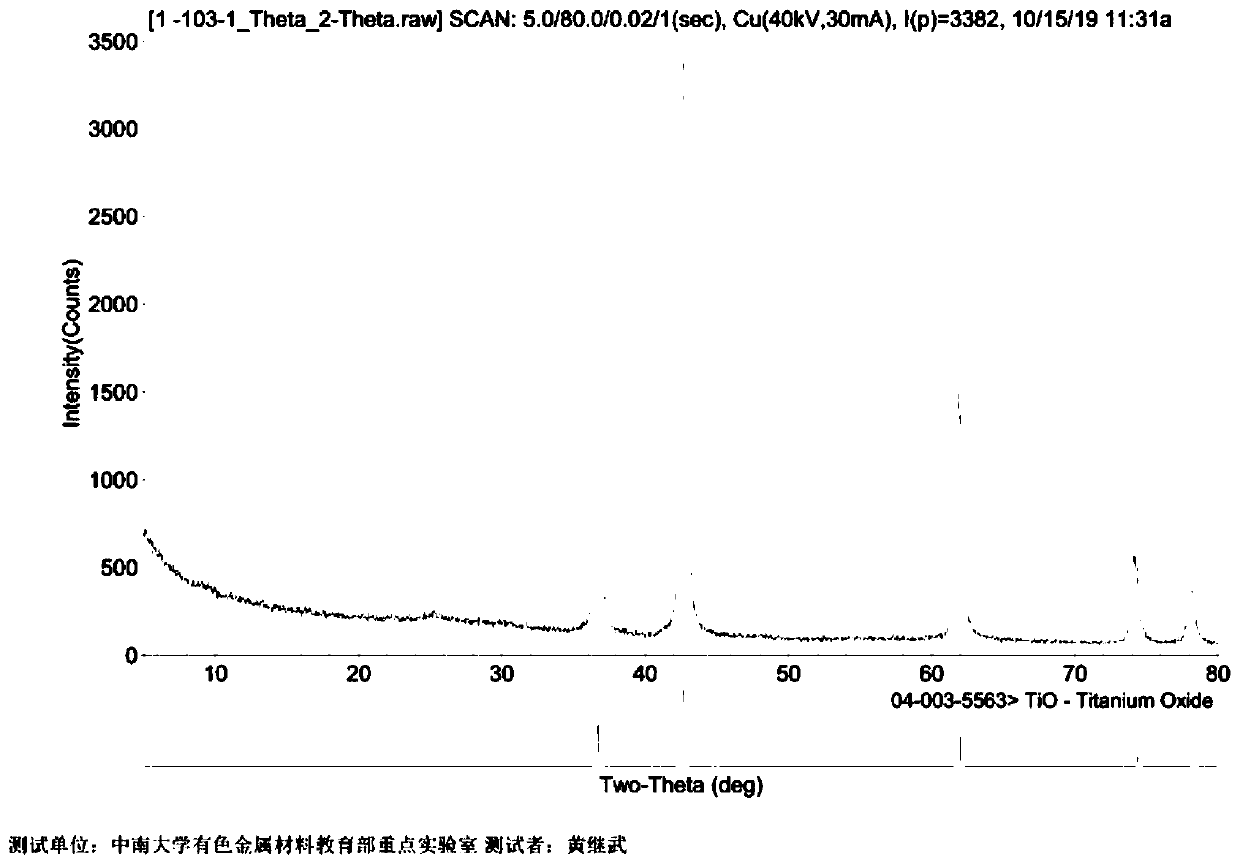

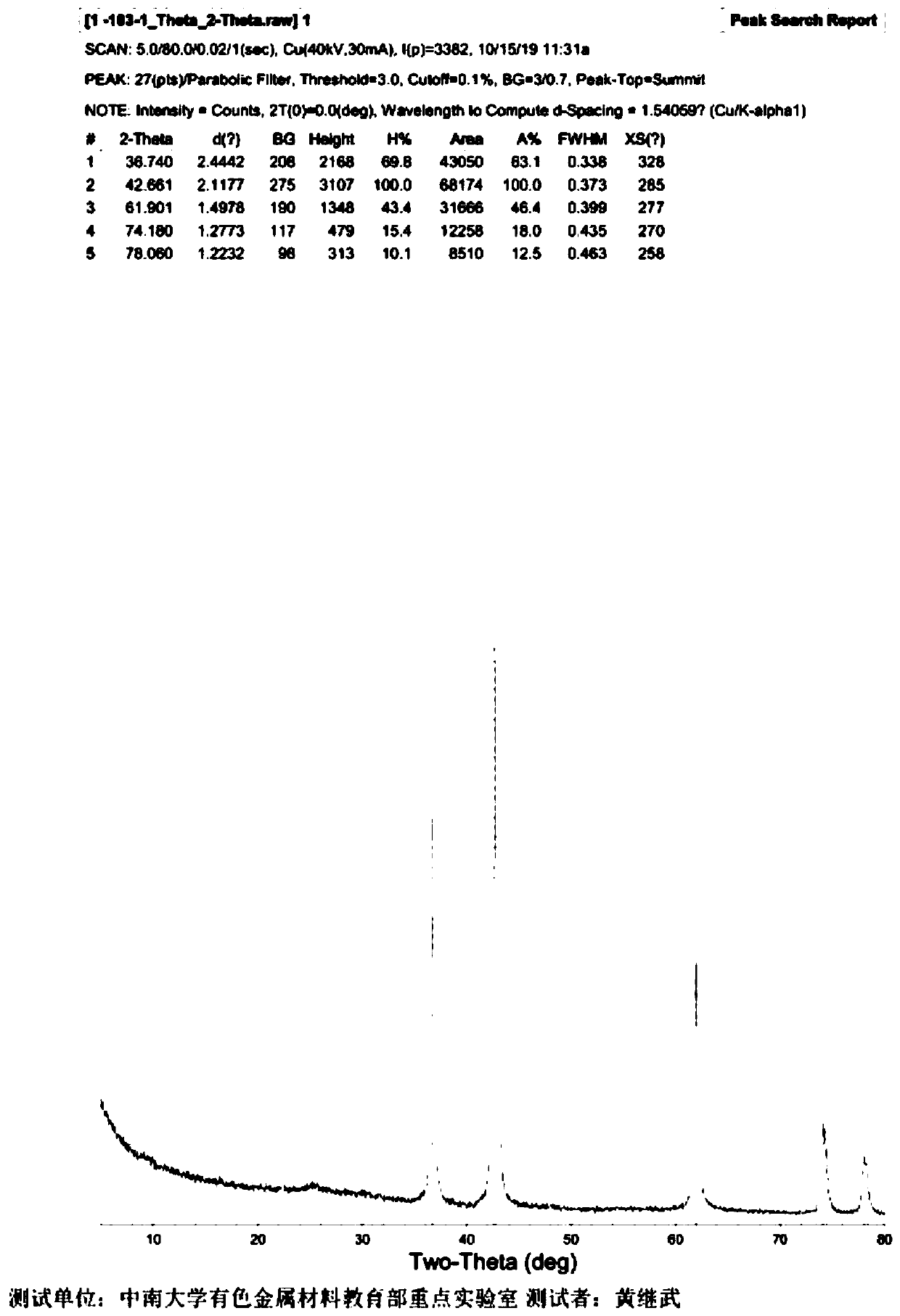

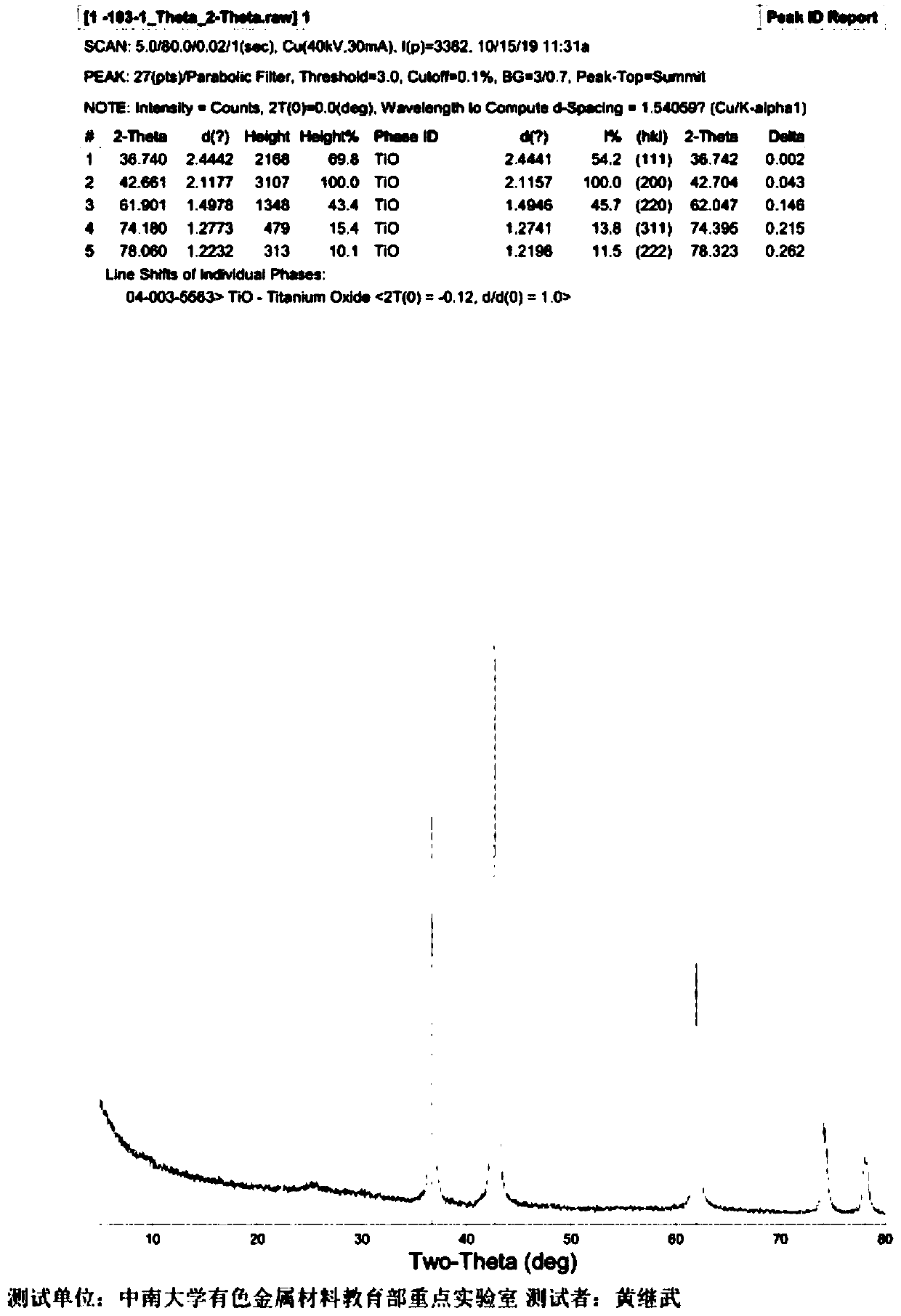

Preparation method of black titanium dioxide powder

InactiveCN110790305AUniform color distributionPoor repeatabilityMaterial nanotechnologyTitanium dioxideMetallurgyNitrogen atmosphere

The invention discloses a preparation method of black titanium dioxide powder. The preparation method comprises the following steps that ascorbic acid powder and titanium dioxide powder are taken formixing and grinding to obtain mixed powder; the mixed powder is sintered in a nitrogen atmosphere to obtain a sintering body; the obtained sintering body is naturally cooled to 50-55 DEG C, then fullywashed, and the washed sintering body is obtained; and the obtained washed sintering body is dried to obtain the black titanium dioxide powder. By using the preparation method, the bright black titanium dioxide powder is successfully prepared; the black titanium dioxide powder is uniform in color distribution, higher in product brightness, good in high temperature and chemical stability, and hasno possibility of color dilution in use; the black titanium dioxide powder is simple in process method, high in practicality, low in production cost, low in requirements for equipment, high in production efficiency, short in time consuming, complete in reaction, high in quality, and is conducive to large-scale production; and the used raw materials are environment friendly and safe without safetyand environmental problems, and the energy consumption is low.

Owner:湖南科莱新材料有限公司

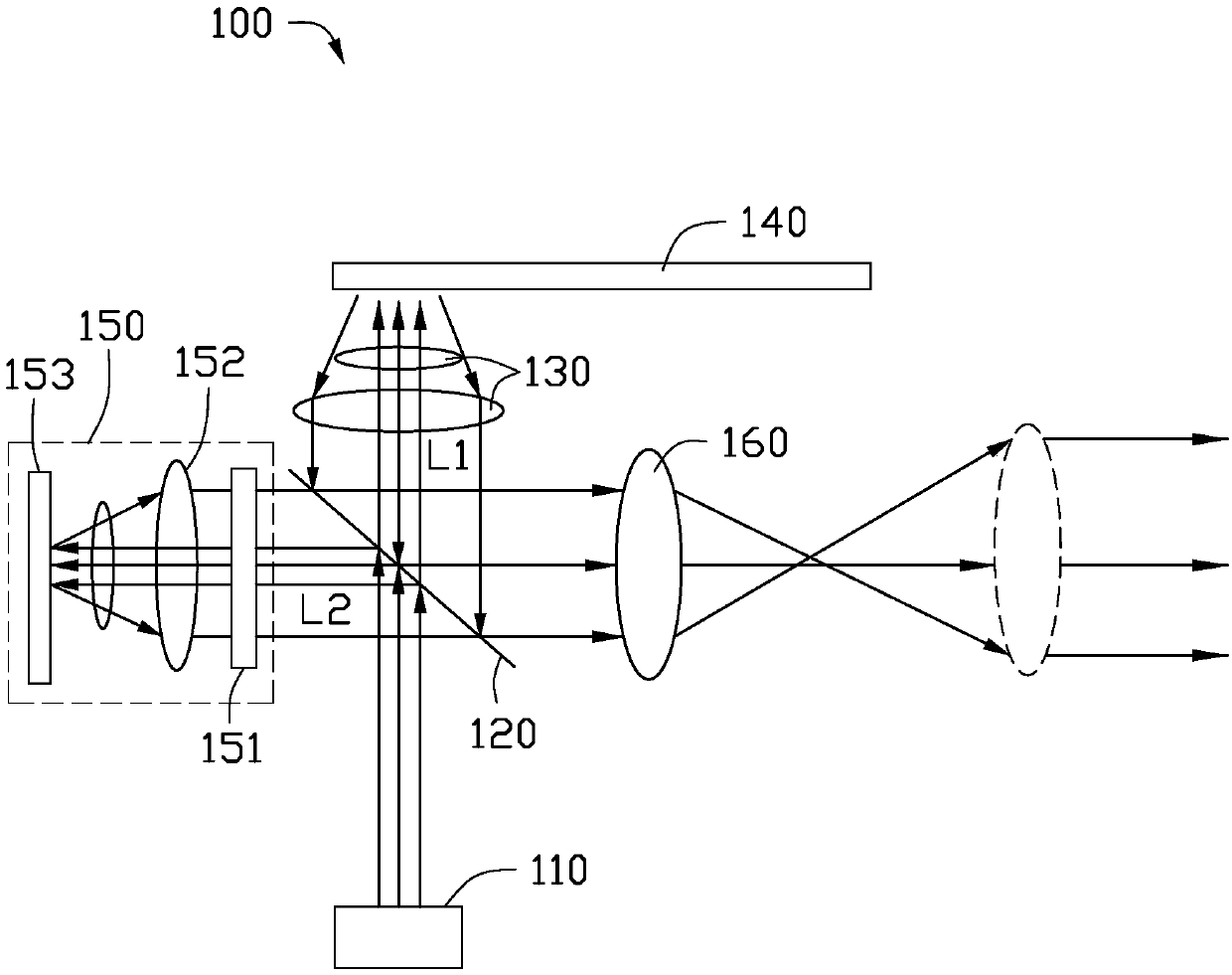

Light source system and illumination equipment

PendingCN109681790ALuminous intensity distribution is approximately the sameSame luminous intensity distributionLighting applicationsMechanical apparatusLuminous intensityLight spot

The invention provides a light source system and illumination equipment. The light source system comprises a light emitting module, a wavelength conversion device and a compensation device, wherein the light emitting module is used for emitting first light along a first light path and second light along a second light path; the wavelength conversion device is used for receiving the first light andemitting stimulated light with the color which is different from that of the first light; the compensation device is used for guiding the second light and adjusting the light emitting strength distribution of the second light; the second light emitted by the compensation device is roughly the same as the light emitting strength distribution of the stimulated light; and the stimulated light and the second light emitted by the compensation device are compounded to generate third light emitted by the light source system. The light emitting strength distribution of the first light and the secondlight in the third light is roughly the same and the colors of illumination light spots are uniform.

Owner:YLX INC

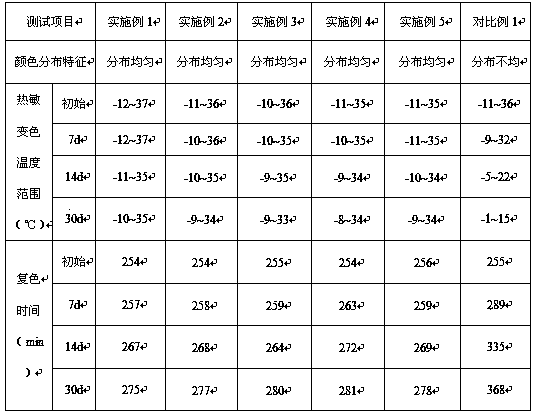

Color-changable architectural decorative diatomite dry powder coating and preparation method thereof

InactiveCN108864776AFast coloringHigh chromaPowdery paintsThermosensitive paintsEmulsionColor changes

The invention discloses a color-changable architectural decorative diatomite dry powder coating and a preparation method thereof. The diatomite dry powder coating is prepared by the following steps: a, mixing crystal violet lactone, bisphenol A, with higher fatty alcohol to obtain a complex color developing agent; b, adding an emulsifier into the complex color developing agent, homogenizing, and shearing, to obtain a complex emulsion; c, adding the precursor liquid of hydroxypropyl-beta-cyclodextrin capsule and a dispersing agent into the complex emulsion to prepare a transparent microcapsulewrapped with the color developing agent; and d, uniformly mixing the transparent microcapsule with diatomite, inorganic fillers, rubber powders and auxiliary agents, to prepare color-changable architectural decorative diatomite dry powder coating. The method has the following advantages: through adopting hydroxypropyl-beta-cyclodextrin to wrap the complex color developing agent to prepare the transparent microcapsule, the coating formed by construction is uniform in color distribution. The transparent microcapsule is used to wrap and protect the developing agent, without affecting color development, and the color-changable architectural decorative diatomite dry powder coating effectively prolongs the service life of the color developing agent, has a wide temperature range of thermosensitive color change, and has a good decorative effect at the same time.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

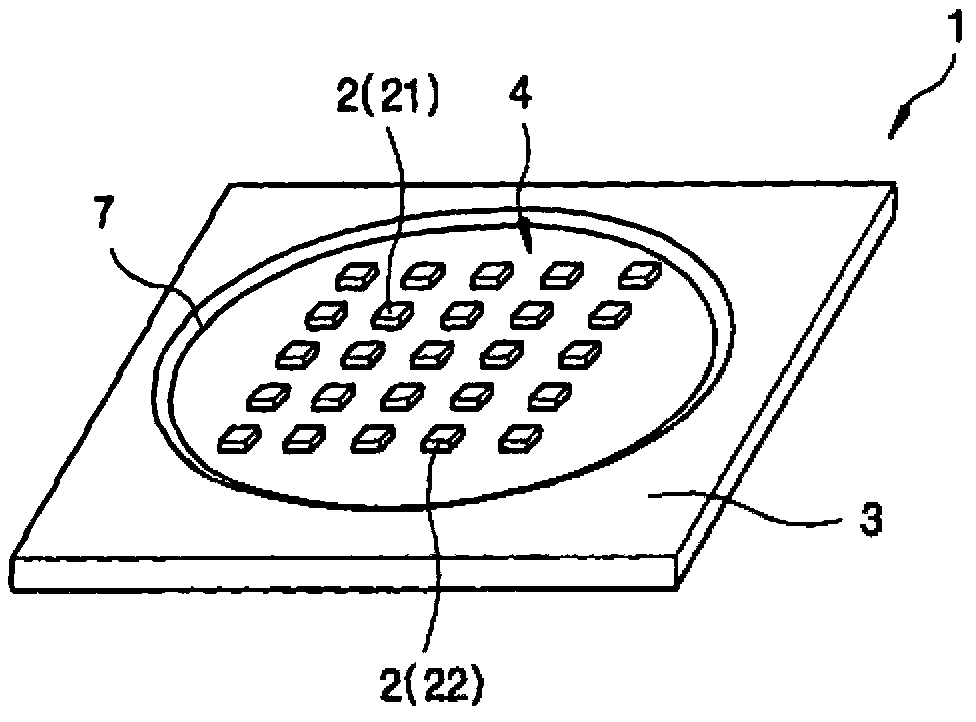

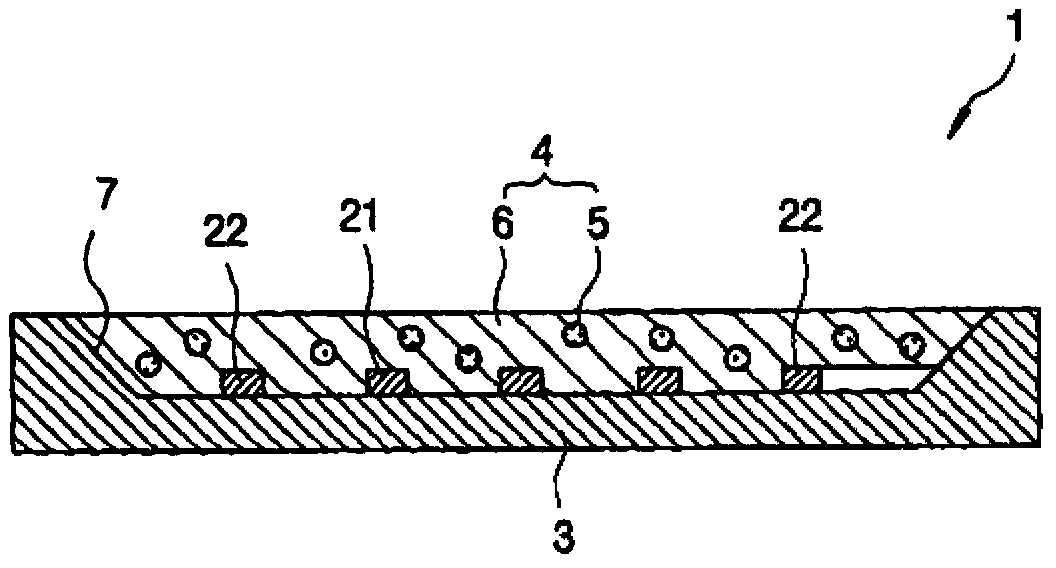

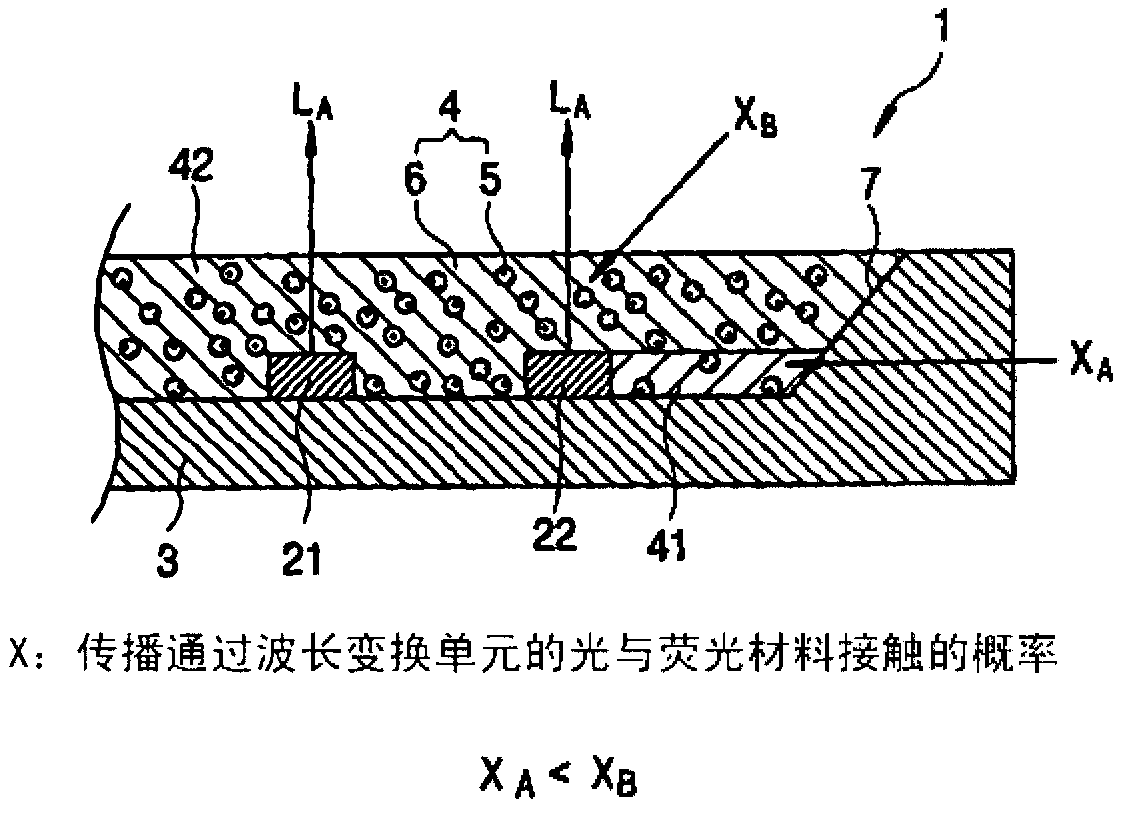

Light emitting device and illumination apparatus including same

InactiveCN102832208AUniform color distributionUniform radiation patternPoint-like light sourceSolid-state devicesLight equipmentLength wave

A light emitting device includes a plurality of solid-state light emitting elements mounted on a substrate, and a wavelength converting unit covering the solid-state light emitting elements, the wavelength converting unit containing fluorescent materials. The solid-state light emitting elements include inner solid-state light emitting elements arranged in a central position of the substrate and outer solid-state light emitting elements arranged outwardly of the inner solid-state light emitting elements, and the wavelength converting unit is configured such that a probability that light propagating through the wavelength converting unit is brought into contact with the fluorescent materials in a portion of the wavelength converting unit covering the outer solid-state light emitting elements is lower than a probability that light propagating through the wavelength converting unit is brought into contact with the fluorescent materials in other portions.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com