Patents

Literature

214 results about "Copper carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

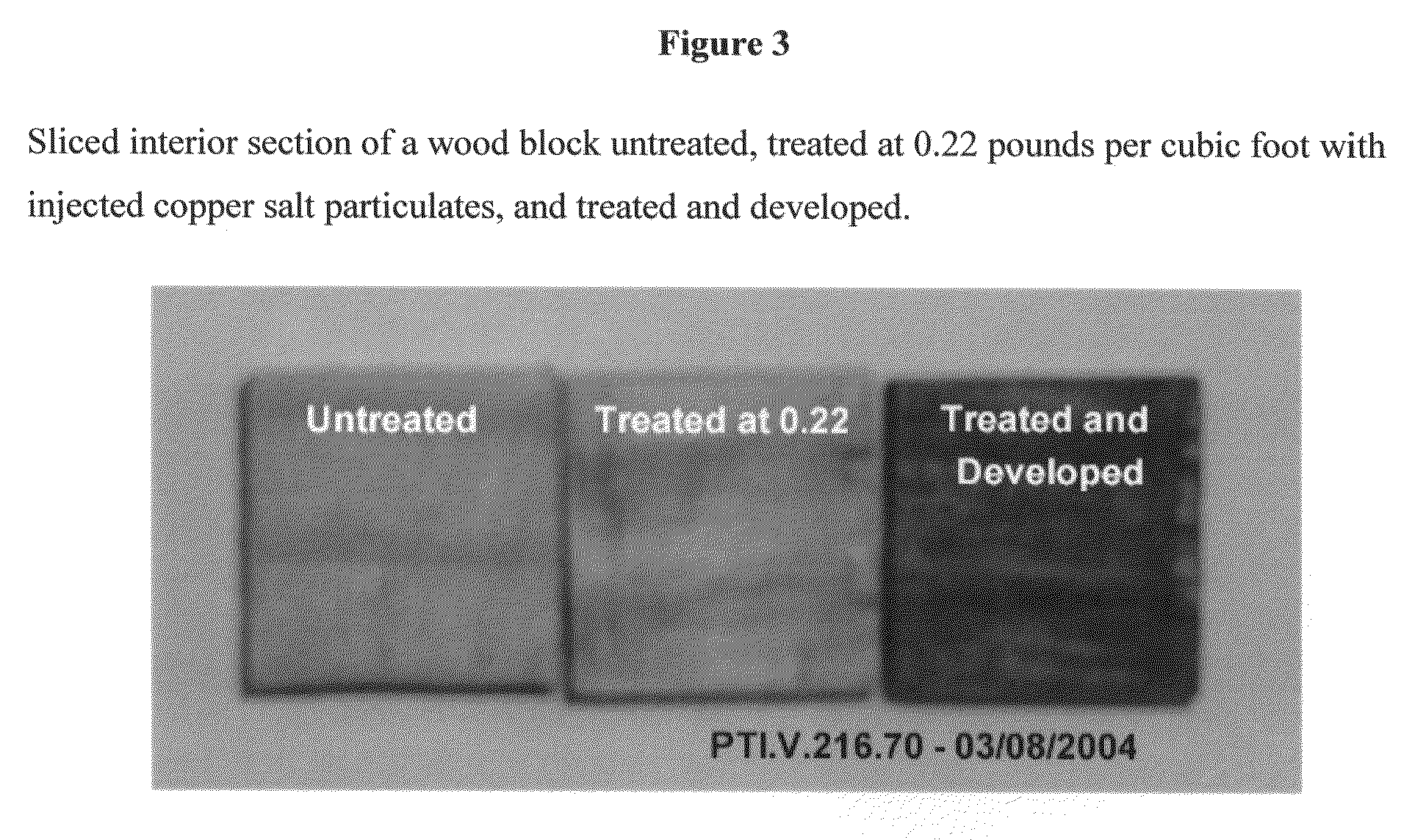

Particulate wood preservative and method for producing same

InactiveUS20050252408A1Reduce the amount requiredWide particle size distributionBiocideAntifouling/underwater paintsCopper(II) hydroxideBasic copper carbonate

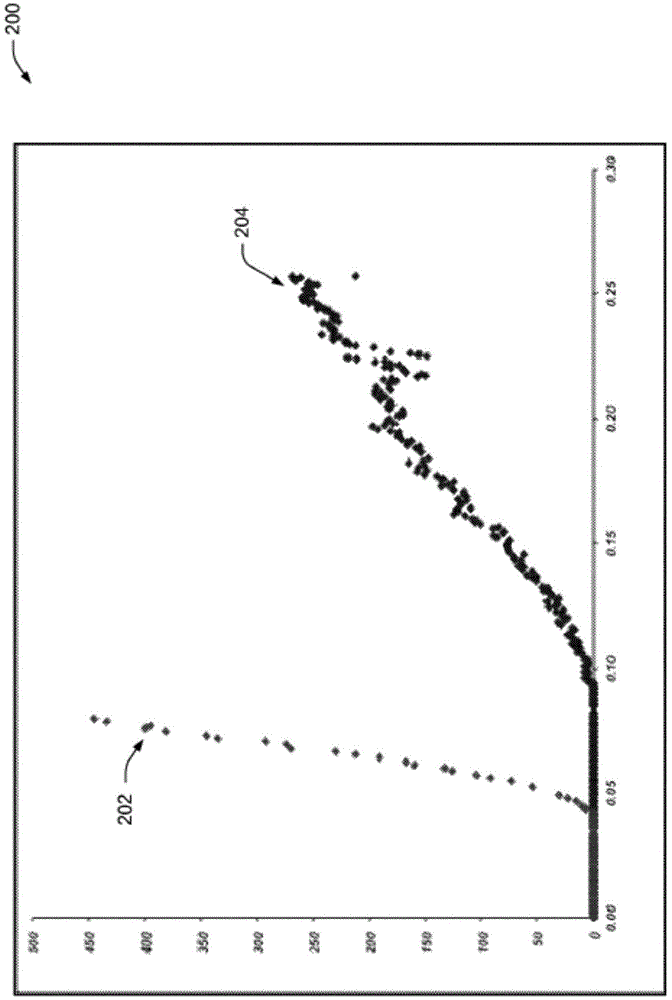

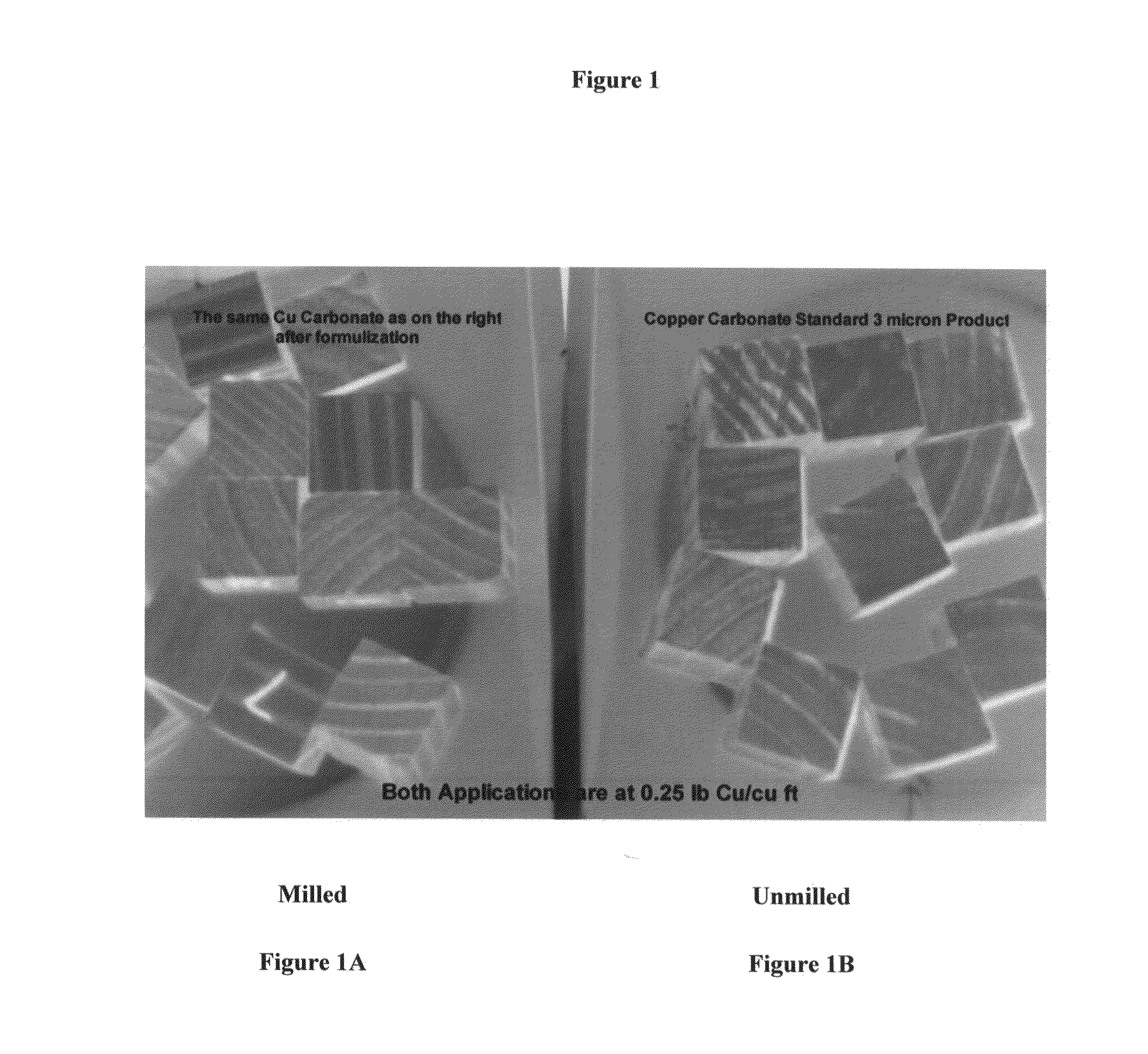

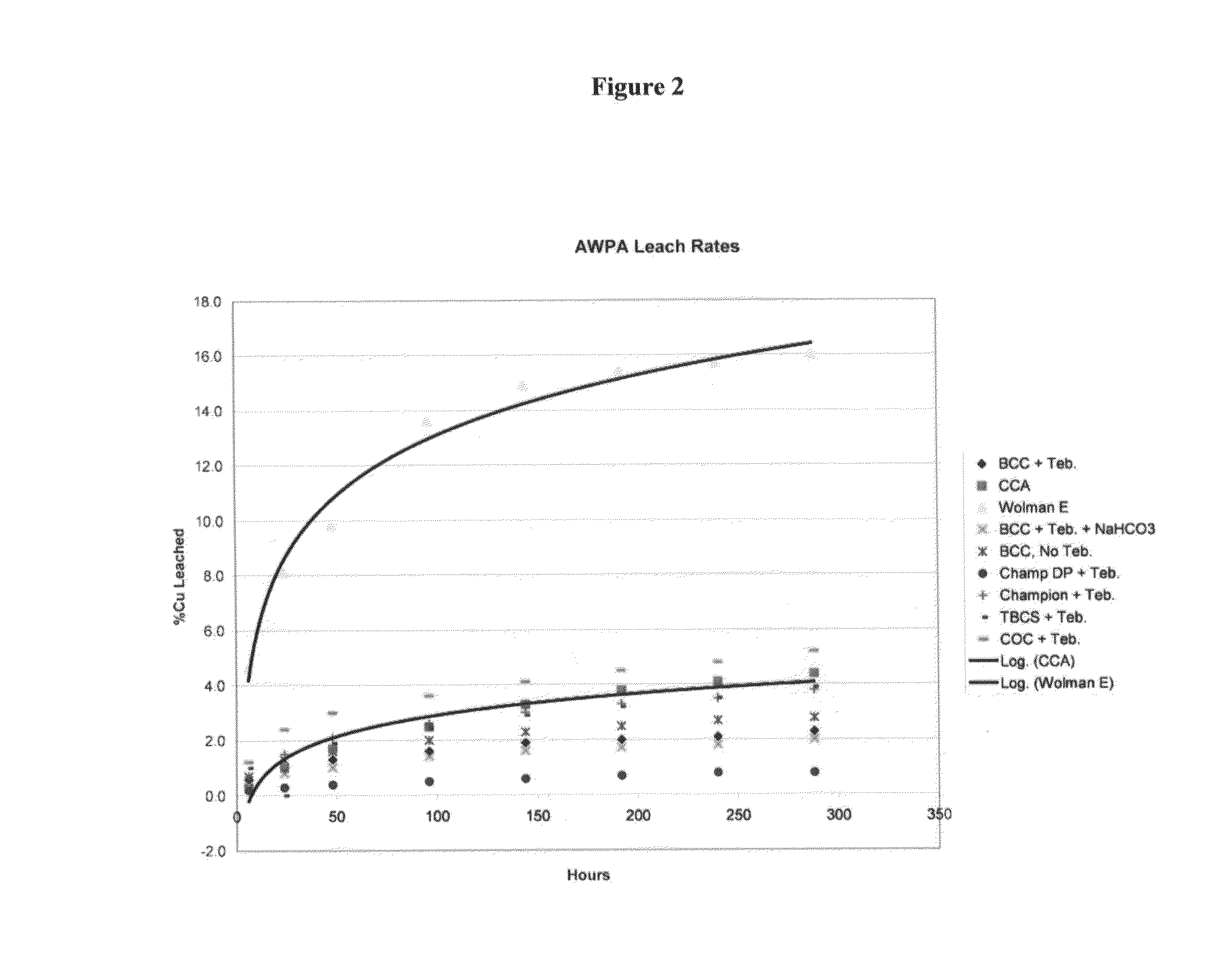

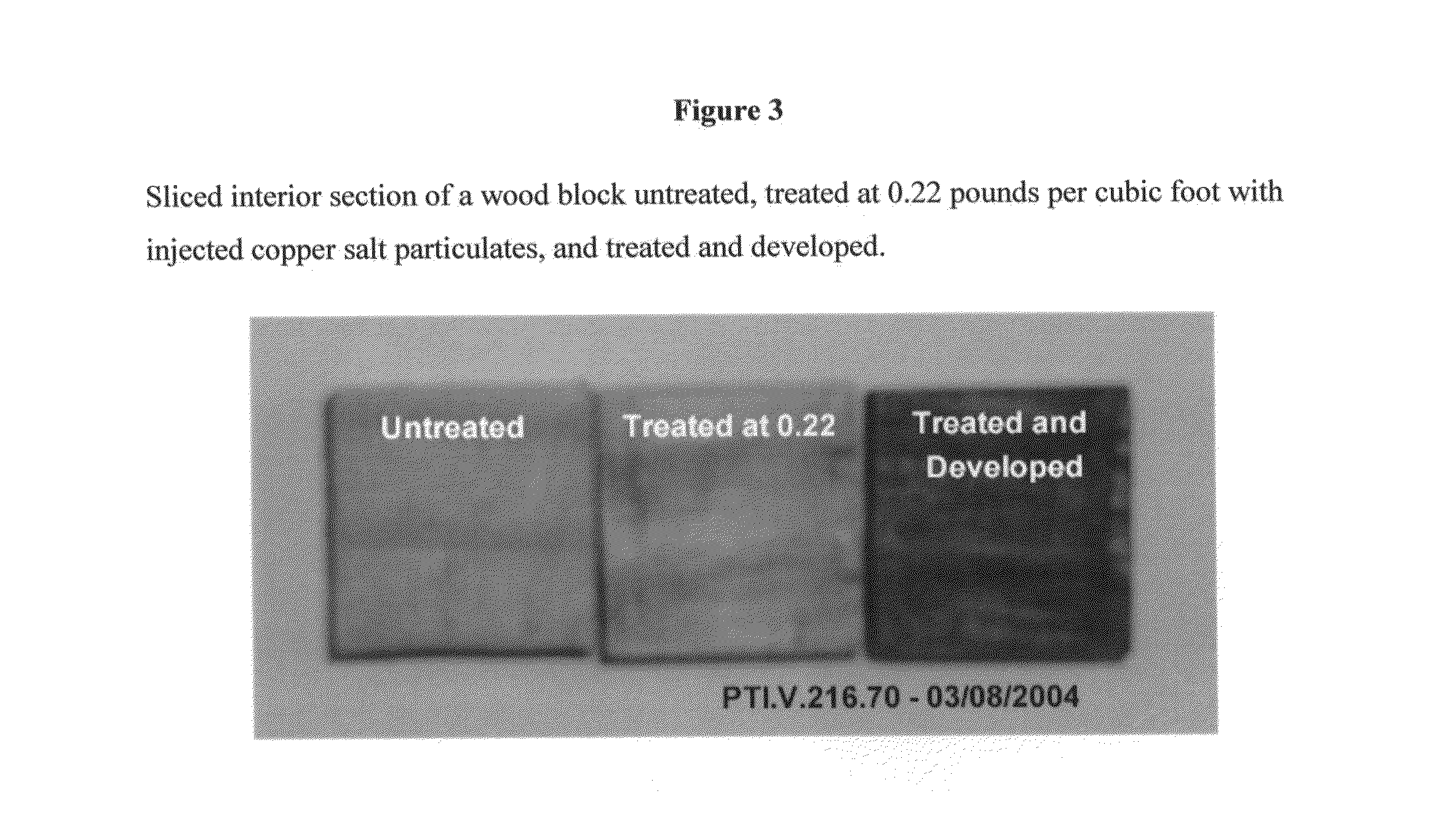

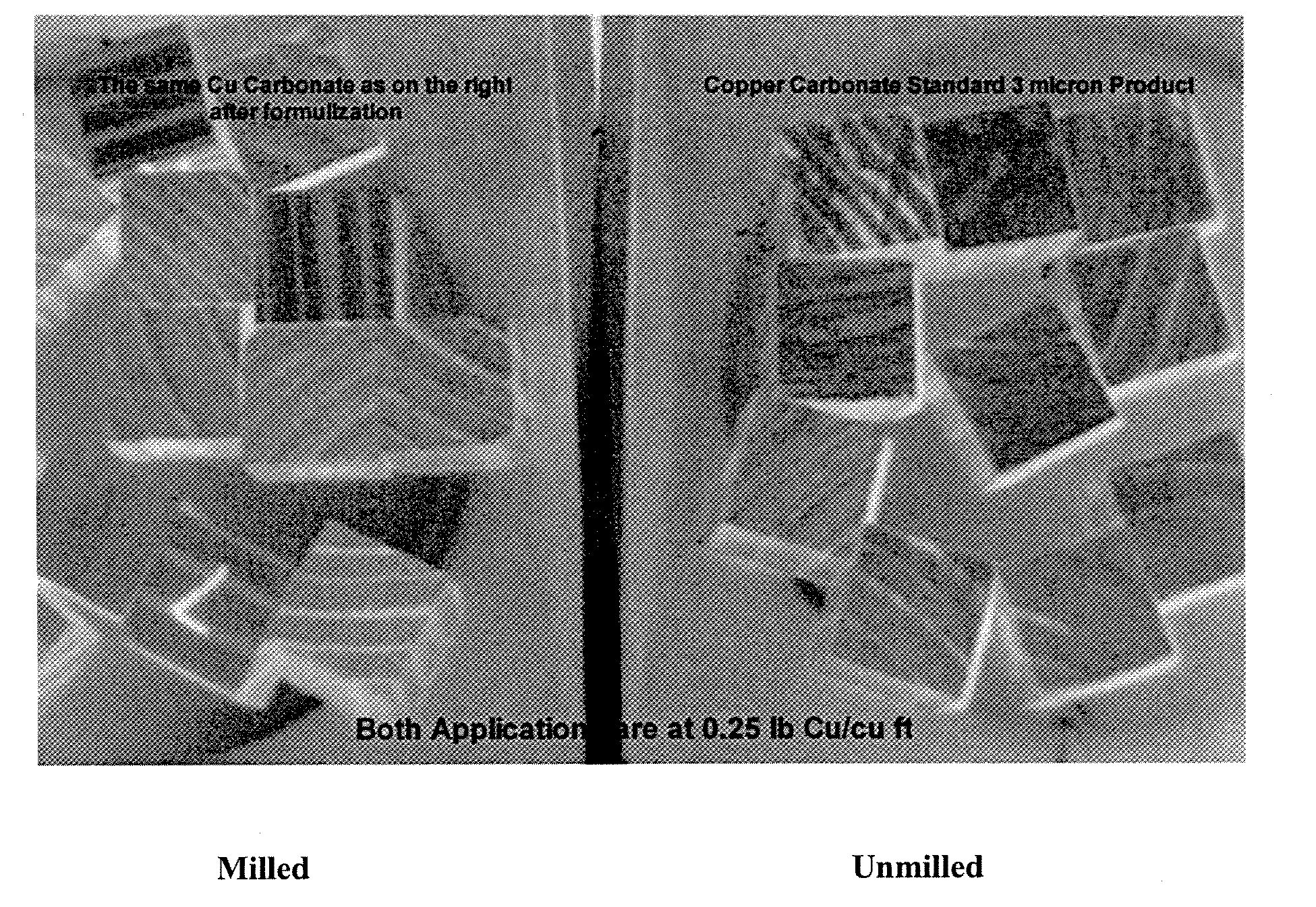

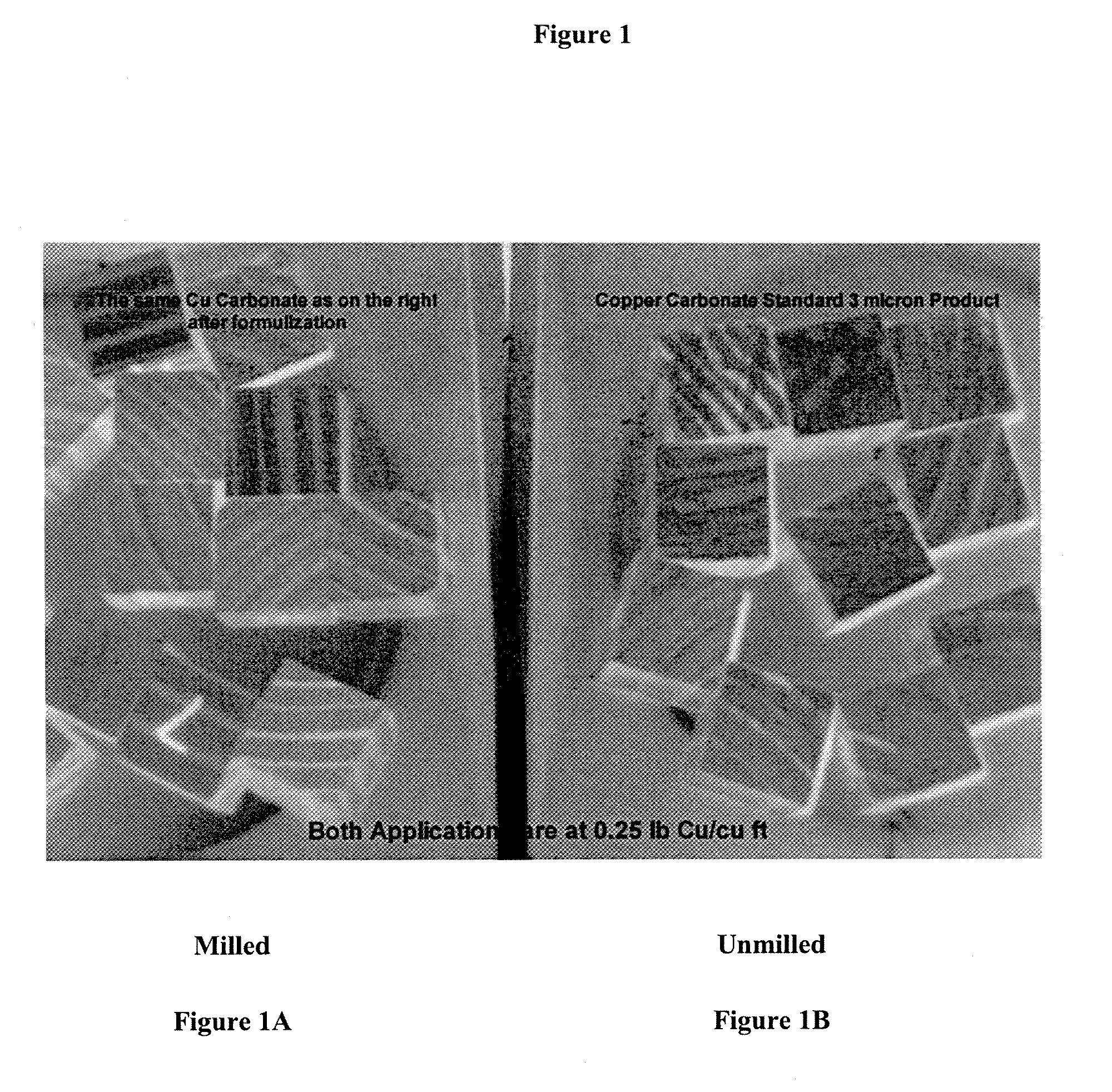

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper-based particles of the invention.

Owner:OSMOSE

Trace elements

The invention discloses a trace element solution, which comprises at least one metal selected from the group comprising selenium, copper, zinc, manganese and chromium and which comprises a concentration of the metal(s) of at least 60 mg / ml. The solution further comprises at least one compound selected from the group comprising iodine, potassium iodide, sodium iodide, iron, iron chloride, zinc oxide, manganese sulphate, sodium selenite, copper carbonate, sodium carbonate, anhydrous disodium EDTA and sodium hydroxide. The trace element solution is prepared by a method consisting essentially of the steps of preparing a MnCO3 mixture in a container; adding an EDTA / NaOH mixture to the container and subsequently adding at least one metal compound; and adding Na2SeO3 to the container to obtain the trace element solution. The method also comprises the step of adding CrCl3.6H2O to the trace element solution.

Owner:WARBURTON TECH

A kind of copper red glaze and its production method and the method for making ceramic product with it

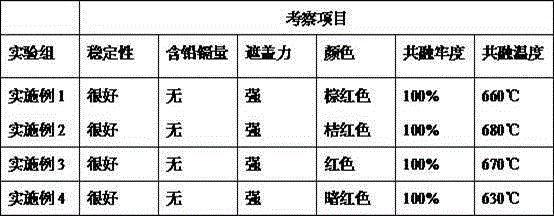

The invention discloses copper red glaze and a production method thereof, and a method for preparing a ceramic product therefrom. The copper red glaze is prepared from parent glaze, a coloring agent and a stabilizing agent, wherein the parent glaze is prepared from the following components in parts by weight: 26 to 32 parts of quartz, 24 to 30 parts of feldspar, 10 to 14 parts of limestone, 12 to16 parts of barium carbonate, 4 to 8 parts of clay, 0 to 4 parts of zinc oxide and 0 to 4 parts of sodium borate; the coloring agent is one or a mixture of a plurality of copper oxide, cuprous oxide and copper carbonate, and the adding amount of the coloring agent is 1 to 4 parts by weight; the stabilizing agent is one or a mixture of a plurality of stannic oxide, ferric oxide, lead oxide and silicon carbide, and the adding amount of the stabilizing agent is 3 to 6 parts by weight. According to the invention, the copper red glaze is bright crimson red, the ceramic product produced from the copper red glaze has high yield and low cost, and can be used for producing domestic ceramic and display art ceramic products.

Owner:广东文化长城集团股份有限公司

Sterilization soil-improvement slow-release composite fertilizer and preparation method thereof

InactiveCN105347916ASolve the problem of insoluble in waterHas a bactericidal effectFertilizer mixturesSlagCopper carbonate

The invention discloses sterilization soil-improvement slow-release composite fertilizer. The sterilization soil-improvement slow-release composite fertilizer comprises, by weight, 20-25 parts of urea, 10-15 parts of ammonium biphosphate, 10-20 parts of potassium phosphate, 5-10 parts of potassium sulfate, 8-12 parts of sodium silicate, 4-6 parts of magnesium phosphate, 7-9 parts of calcium chloride, 0.2-0.4 parts of zinc ammonium phosphate, 0.1-0.3 parts of copper carbonate, 0.1-0.2 parts of manganese ammonium phosphate, 0.4-0.6 parts of potassium borate, 0.3-0.5 parts of ferric sulfate, 0.2-0.4 parts of sodium molybdate, 20-25 parts of sodium alginate, 35-45 parts of a coating material, 5-10 parts of cassava slag, 5-8 parts of furfural slag, 10-20 parts of chicken manure, 5-10 parts of carbonized rice husk, 10-15 parts of humic acid, 10-15 parts of straws, 5-8 parts of plant ash, 0.2-0.5 parts of biological fungi, 4-6 parts of thermopsine and 3-5 parts of Artemisia argyi powder. The invention also discloses a preparation method of the sterilization soil-improvement slow-release composite fertilizer.

Owner:全椒县琪悦家庭农场

Copper-red transmutation glaze, copper-red transmutation glaze ceramic product prepared from same and preparation method

The invention relates to a copper-red transmutation glaze, a copper-red transmutation glaze ceramic product prepared from the same and a preparation method and belongs to the technical field of ceramics. The copper-red transmutation glaze comprises components in parts by weight as follows: a glaze type basic material including 34-35 parts of nepheline syenite, 20-22 parts of calcium carbonate, 3-4 parts of barium carbonate, 2-3 parts of zinc oxide, 1-2 parts of magnesium carbonate, 26-27 parts of kaolin and 9.5-10.5 parts of nano silicon oxide, and a chromogenic reagent including 1.8-2.5 parts of lithium carbonate, 2-4 parts of bone ash and 2-4 parts of copper carbonate. The ceramic product prepared from the copper-red transmutation glaze through firing has brighter red color, the glaze color is uniformly distributed, and the yield is high.

Owner:FUJIAN DEHUA HUAMAO CERAMICS CO LTD

Low-temperature fine desulfurizer and its preparation method

ActiveCN102512942AGuaranteed desulfurization efficiencyGuaranteed accuracyDispersed particle separationFlareCopper carbonate

The invention relates to a low-temperature fine desulfurizer and its preparation method. Raw materials for preparing the fine desulfurizer are consisting of, by weight, 40-60% of basic zinc carbonate, 15-25% of copper carbonate and at least one component selected from 0-10% of a pore forming agent, 0-10% of a binder and 5-10% of an extrusion aid. The fine desulfurizer is characterized by containing 20-30 wt% of a waste agent which can enhance catalyst strength and simplify the preparation technology. In addition, the preparation raw materials also contain 0-10 wt% of a lubricant which can raise binding performance of the materials. The method comprises the following steps of: uniformly mixing the above materials, adding 5-10 wt% of the extrusion aid, kneading for molding, and drying at 100-120 DEG C for 3-4 hours to obtain the fine desulfurizer used at low temperature. The low-temperature fine desulfurizer is applicable to fine desulphurization of industrial gases such as natural gas, oil-associated gas, refinery flares, coal gas and the like.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

Boiler coal combustion-improving denitrifying agent composition and preparation method thereof

The invention relates to an additive product suitable for coal-fired boilers in the petroleum, chemical and power industries and provides a boiler coal combustion-improving denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-8 parts of sodium carbonate, 3-7 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 6-15 parts of urea, 4-10 parts of ammonium carbonate, 4-10 parts of ammonium chloride, 3-9 parts of ferric oxide, 7-22 parts of potassium permanganate, 7-22 parts of potassium chlorate, 15-40 parts of activated attapulgite clay, 4-8 parts of chromium sesquioxide, 2-6 parts of manganese oxide, 4-8 parts of zinc oxide, 4-8 parts of copper chloride, 2-6 parts of copper oxide, 2-6 parts of copper carbonate, 3-7 parts of zinc sulfate, 2-5 parts of zinc nitrate, 0.5-1.5 parts of barium molybdate, 1-2 parts of titanium oxide, 0.5-1.5 parts of vanadium pentoxide, 0.2-0.5 part of copper sulfate, 0.2-0.5 part of cerium oxide, 1-3 parts of penetrating agent JFC and 0.1-0.2 part of lignosulphonate. The composition is efficient in combustion improving, has high coal saving rate and prolongs the service lives of the boilers.

Owner:GANSU HEIMA PETROCHEM ENG

Boiler coal combustion-improving desulfurizing agent composition and preparation method thereof

ActiveCN103194294AGood synergyHigh selectivitySolid fuelsFuel additivesActivated attapulgiteSodium acetate

The invention provides a boiler coal combustion-improving desulfurizing agent composition. The composition comprises the following components in parts by weight: 3-9 parts of sodium carbonate, 1-2 parts of sodium acetate, 3-9 parts of calcium carbonate, 4-9 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 3-10 parts of ferric oxide, 8-22 parts of potassium permanganate, 8-22 parts of potassium chlorate, 15-40 parts of activated attapulgite clay, 7-13 parts of manganese oxide, 4-8 parts of copper oxide, 4-8 parts of alumina, 3-8 parts of copper carbonate, 3-10 parts of zinc oxide, 3-10 parts of zinc nitrate, 4-11 parts of sodium dichromate, 0.5-1.5 parts of barium molybdate, 0.5-1.5 parts of vanadium pentoxide, 0.2-0.5 part of cerium oxide and 1-3 parts of dispersing agent JFC. The composition is an additive suitable for coal-fired boilers in the petroleum, chemical, power, thermoelectricity and metallurgy industries, can absorb and solidify sulfur dioxide generated in the combustion process, adsorbs dust and other harmful substances in quantity and simultaneously removes smoke dust scales and jelly adhering to the inner walls of combustors, thus inhibiting the concentration of flue gas emission.

Owner:GANSU HEIMA PETROCHEM ENG

Method of removing mercury from fluid stream using high capacity copper adsorbents

A method of removing mercury from a fluid stream comprises contacting the fluid stream with a sorbent comprising cupric sulfide. The cupric sulfide is formed from direct sulfidation of copper carbonate, without thermal decomposition of the copper carbonate to an oxide, at a temperature less than 150 DEG C.

Owner:UOP LLC

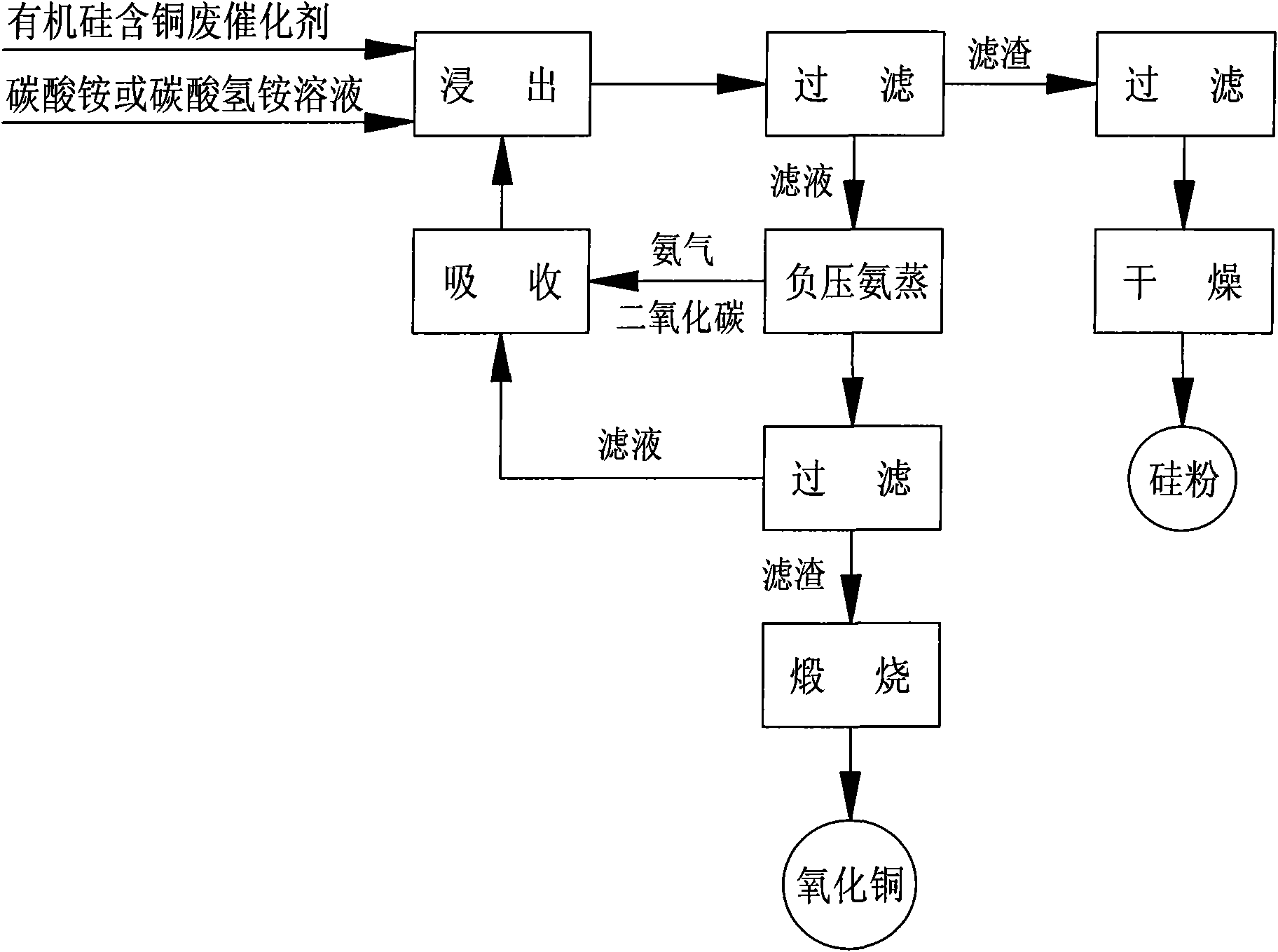

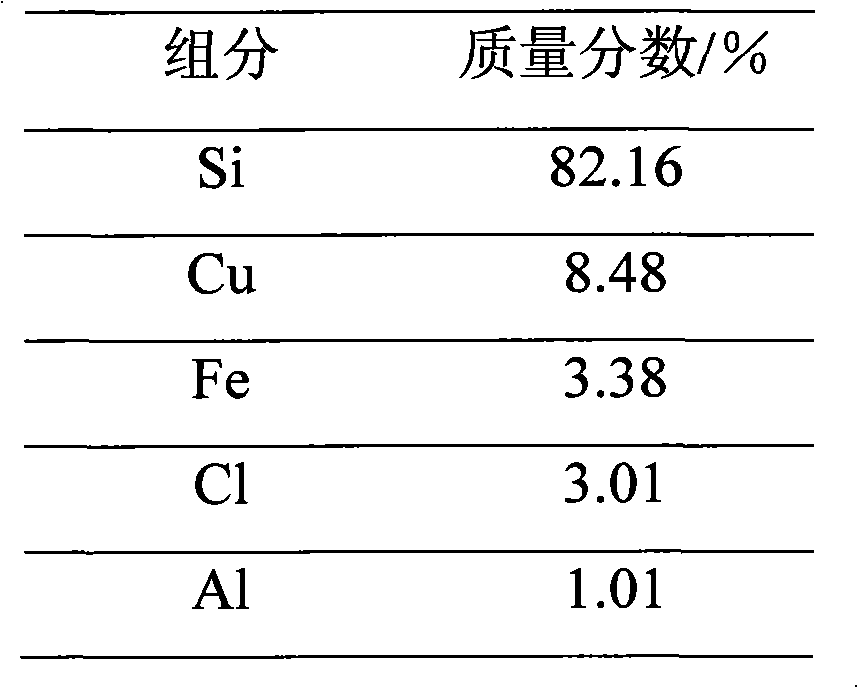

Disposal method of organic silicon copper-containing waste catalyst

InactiveCN102020307AHigh puritySolve pollutionSolid waste disposalCopper oxides/halidesCopper oxideCopper carbonate

The invention discloses a disposal method of an organic silicon copper-containing waste catalyst, which has the advantages of less investment, low cost and environment protection and is simple for operation. The disposal method comprises the following steps of: immersing the organic copper-containing waste catalyst into an ammonium carbonate or ammonium hydrogen carbonate solution with the concentration of 1.2-2.0 molar / liter according to the solid to liquid ratio of 1 to 4-6; stirring continuously; immersing for 4-8 hours at 40-60 DEG C; carrying out solid-liquid separation to the immersed liquid; cleaning and drying the separated solid phase to form a silicon-containing raw material; carrying out negative pressure ammonia still to the separated ammonium copper solution; recycling ammonia and carbon dioxide generated in the process of the negative pressure ammonia still; filtering the solution obtained by carrying out the negative pressure ammonia still; filtering to obtain filter residues containing alkali copper carbonate and copper oxide; and calcining the filter residues for 2-4 hours at 200-400 DEG C to obtain a raw material of copper oxide used as a main component. The disposal method is suitable for comprehensive utilization of devitalization waste catalyst in the process of producing organic silicon monomer by using a direct method and particles discharged from a fluidized bed during gas-solid separation.

Owner:ZHANGJIAGANG KAINA INFORMATION TECH

Red glaze and preparation process thereof

The present invention discloses a red glaze, which is characterized by comprising, by mass, 44 parts of potassium feldspar, 20 parts of quartz, 20 parts of calcium carbonate, 10 parts of kaolin, 7 parts of zinc oxide, 5 parts of dolomite, 10 parts of talc, 2 parts of zirconium silicate, 5 parts of high boron frit, 2 parts of tin oxide, and 1.5 parts of copper carbonate. According to the present invention, the red glaze can be obtained, has a bright color, and can meet more creative and decorative needs.

Owner:陈能谟

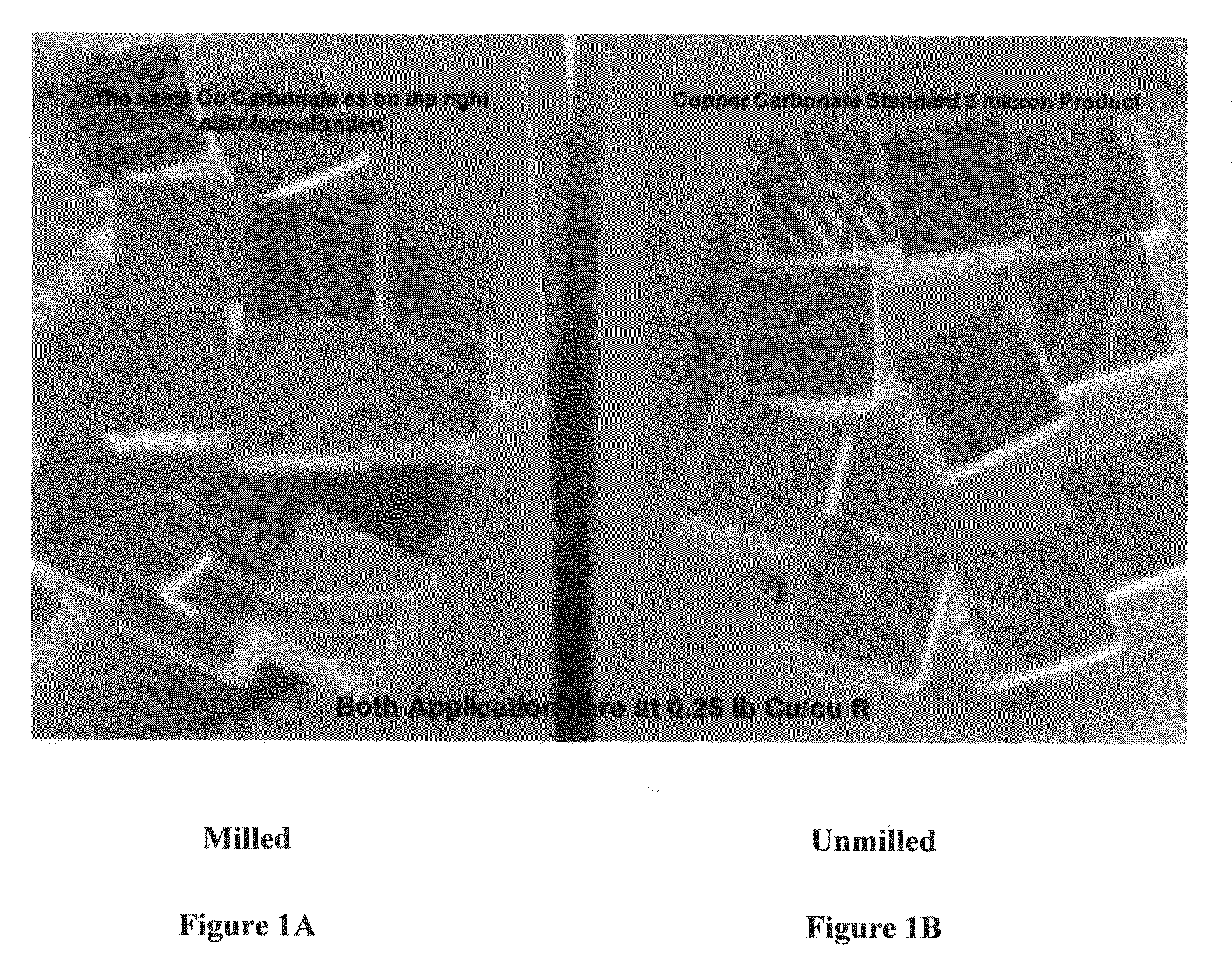

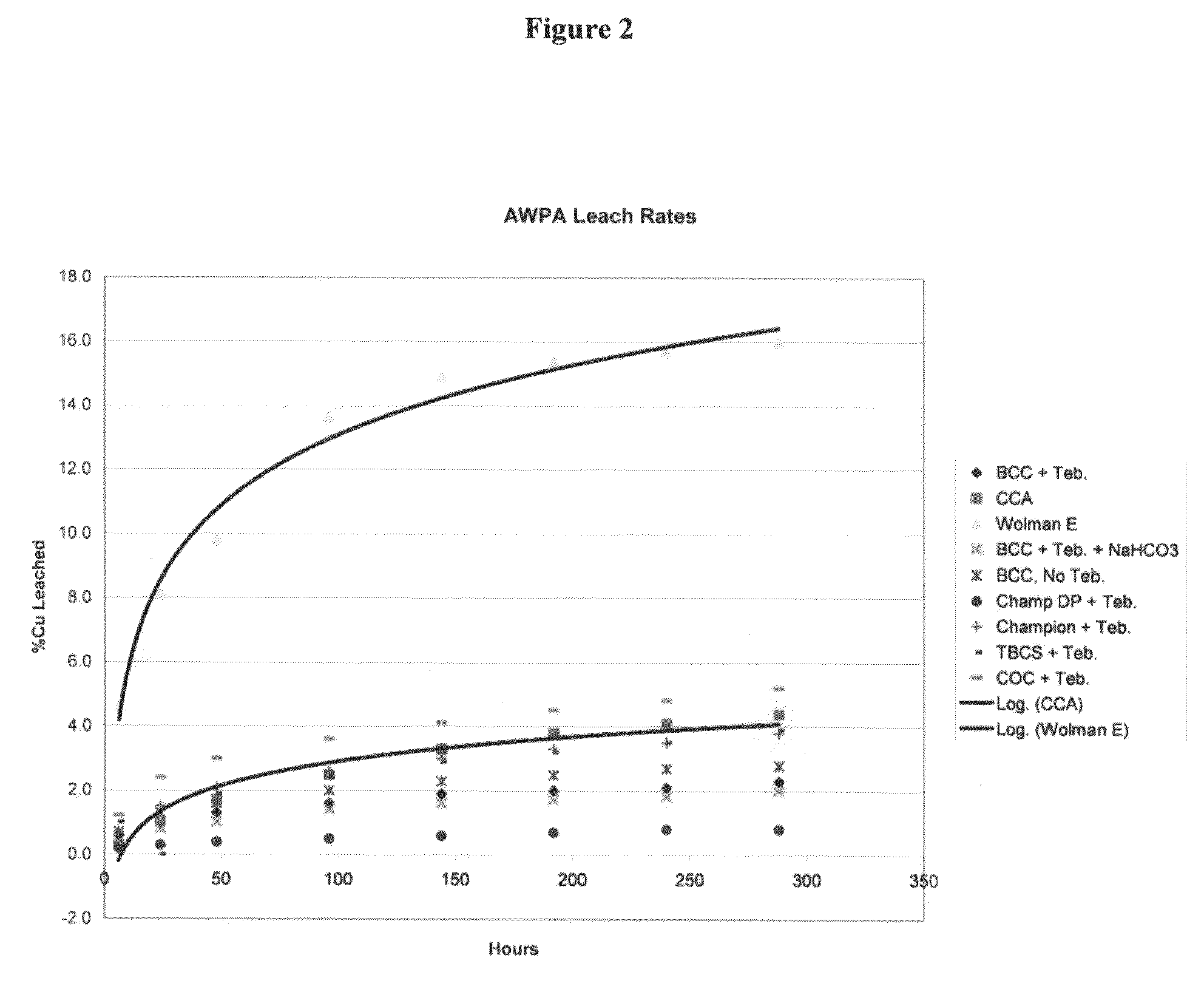

Particulate wood preservative and method for producing the same

ActiveUS8409627B2Effective, long-lasting, environmentally responsible, non-staining/coloringLow dissolution ratePowder deliveryBiocideCopper(II) hydroxideCopper nitrate

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper based particles of the invention.

Owner:KOPPERS PERFORMANCE CHEM

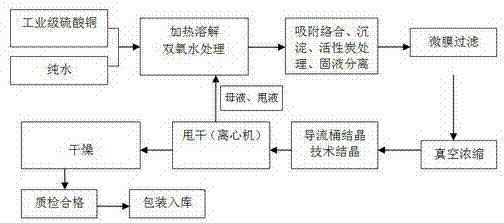

Production method of high-purity copper sulphate

InactiveCN102826584ASimple and fast operationImprove product qualityCopper sulfatesFiltrationTechnical grade

The invention discloses a production method of high-purity copper sulphate. The production method of high-purity copper sulphate comprises the following steps of: dissolving industrial grade copper sulphate into ultrapure water, heating to the temperature of 40-70 DEG C, dropwise adding sulphuric acid to regulate pH to be 1.0-2.0, stirring and dissolving, and then adding hydrogen peroxide; mixing polymeric ferric sulphate with basic copper carbonate in a mass ratio of 1: (2.5-4.5) to prepare a precipitation complexing agent, adding the precipitation complexing agent the weight of which is 0.5-2.5wt% of weight of the solution into the insulated solution, then adding activated carbon the weight of which is 0.5-2.5wt% of the weight of the solution, stirring for 3-7 hours, cooling to room temperature, and standing overnight; and carrying out rough filtration on the solution, then filtering with a microporous membrane with the size of 0.2mu m, and concentrating and crystallizing filtrate to obtain high-purity copper sulphate.

Owner:XILONG SCI CO LTD

Inhibition of calcium and magnesium precipitation from wood preservatives

InactiveUS7252706B2Prevent precipitationPrevents the deposition of scaleFireproof paintsBiocideEthylene diaminePreservative

A wood preservative that contains a copper salt complex and a precipitation inhibitor is provided. The wood preservative may contain copper carbonate, an alkanolamine such as monoethanolamine and precipitation inhibitor such as a phosphonate or ethylene diamine compound. Also provided is a method of using the wood preservative.

Owner:OSMOSE

Desulfurizer

InactiveCN101961594AHigh precisionHigh sulfur capacityDispersed particle separationBASIC CUPRIC CARBONATEDecomposition

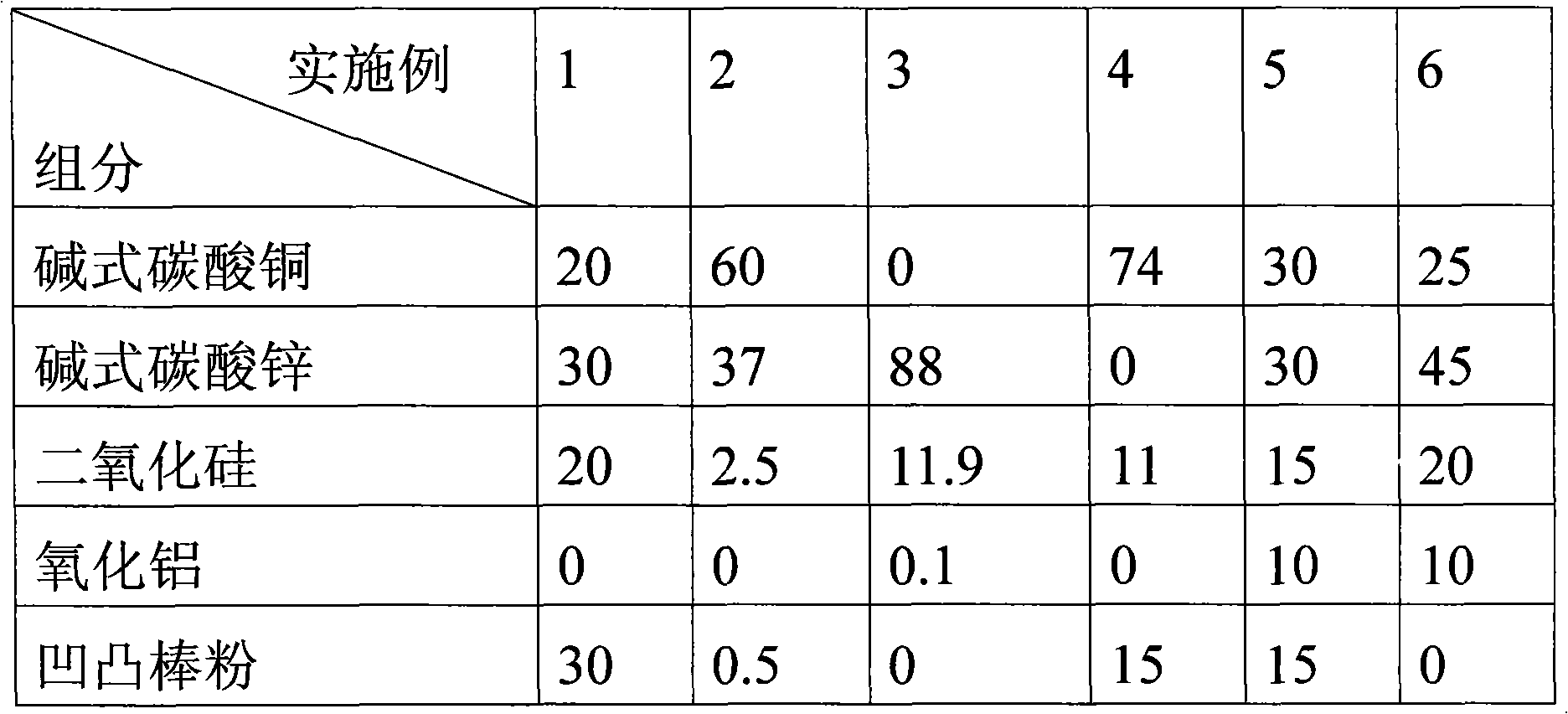

The invention discloses a desulfurizer which is composed of subcarbonate, silica and accessory ingredient. Based on the total weight of the desulfurizer, the desulfurizer comprises, in percentage by weight, 50-97 wt% of subcarbonate, 2.5-20 wt% of silica and 0.1-30 wt% of accessory ingredient, wherein the subcarbonate is at least one of basic cupric carbonate and basic zinc carbonate, and the accessory ingredient is at least one of alumina and attapulgite powder. The desulfurization (H2S) precision of the desulfurizer can be less than 0.05mg / M3, and sulphur content is about 20% (Wt / Wt). Because the raw material does not need high-temperature decomposition, energy consumption can be greatly lowered by more than 50%, thus obtaining the purpose of energy saving and emission reduction.

Owner:昆山市精细化工研究所有限公司

Particulate wood preservative and method for producing the same

ActiveUS20090280185A1Low dissolution rateEasy to characterizePowder deliveryBiocideCopper nitrateTribasic copper sulfate

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper based particles of the invention.

Owner:KOPPERS PERFORMANCE CHEM

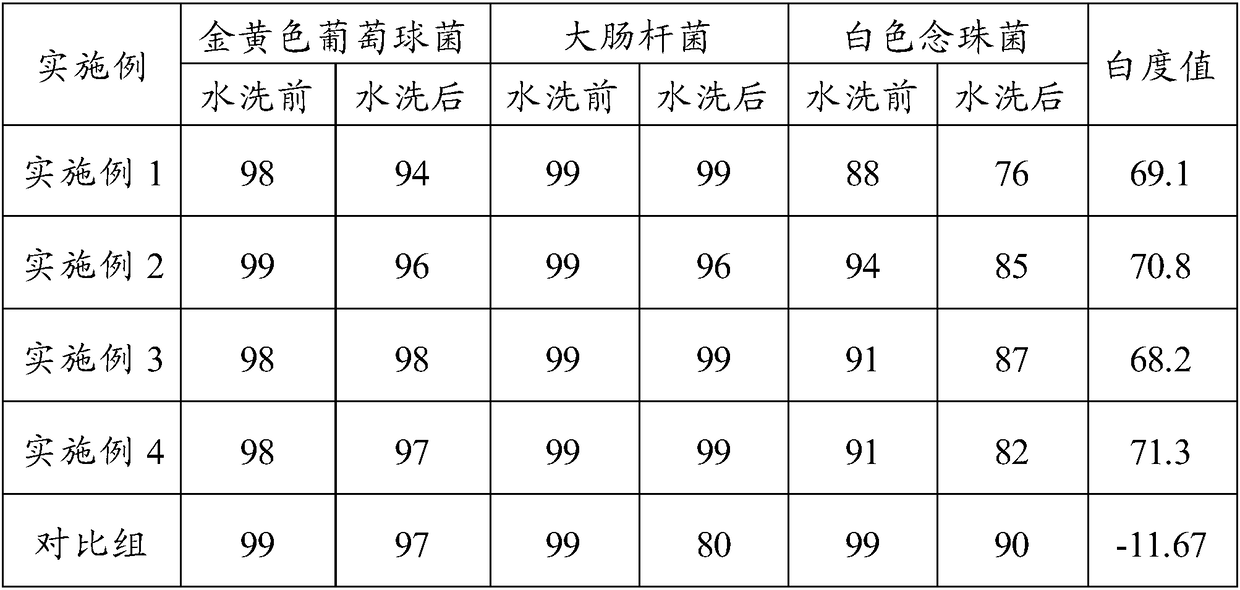

Preparation method for durable antibacterial cellulose fibres

ActiveCN109440450AImprove antibacterial propertiesHigh whiteness valueBiochemical fibre treatmentVegetal fibresSodium bicarbonateZinc hydroxide

The invention provides a preparation method for durable antibacterial cellulose fibres. The preparation method comprises the following steps: S1, removing impurities from cellulose fibres in a physical mechanical mode to obtain impurity-removed fibres; S2, performing pre-treatment on the impurity-removed fibres, and dewatering to obtain dewatered fibres, wherein the pre-treatment comprises a cleaning process and / or a refining and bleaching process; S3, performing antibacterial finishing on the dewatered fibres with an antibacterial working liquid to obtain durable antibacterial cellulose fibres, wherein the antibacterial working liquid comprises an antibacterial agent, an alkaline auxiliary agent and a penetrating agent; the antibacterial agent is one or more of magnesium carbonate, coppernitrate, copper chloride, copper hydroxide, copper carbonate, basic cupric carbonate, zinc chloride, zinc sulphate, zinc hydroxide and zinc carbonate; and the alkaline auxiliary agent is one or moreof sodium hydroxide, potassium hydroxide, sodium bicarbonate, ammonium carbonate, ammonia water, sodium phosphate and sodium carbonate. The prepared cellulose fibres have a durable antibacterial effect; and the whiteness value of the fibres is high.

Owner:山东欣悦健康科技有限公司 +1

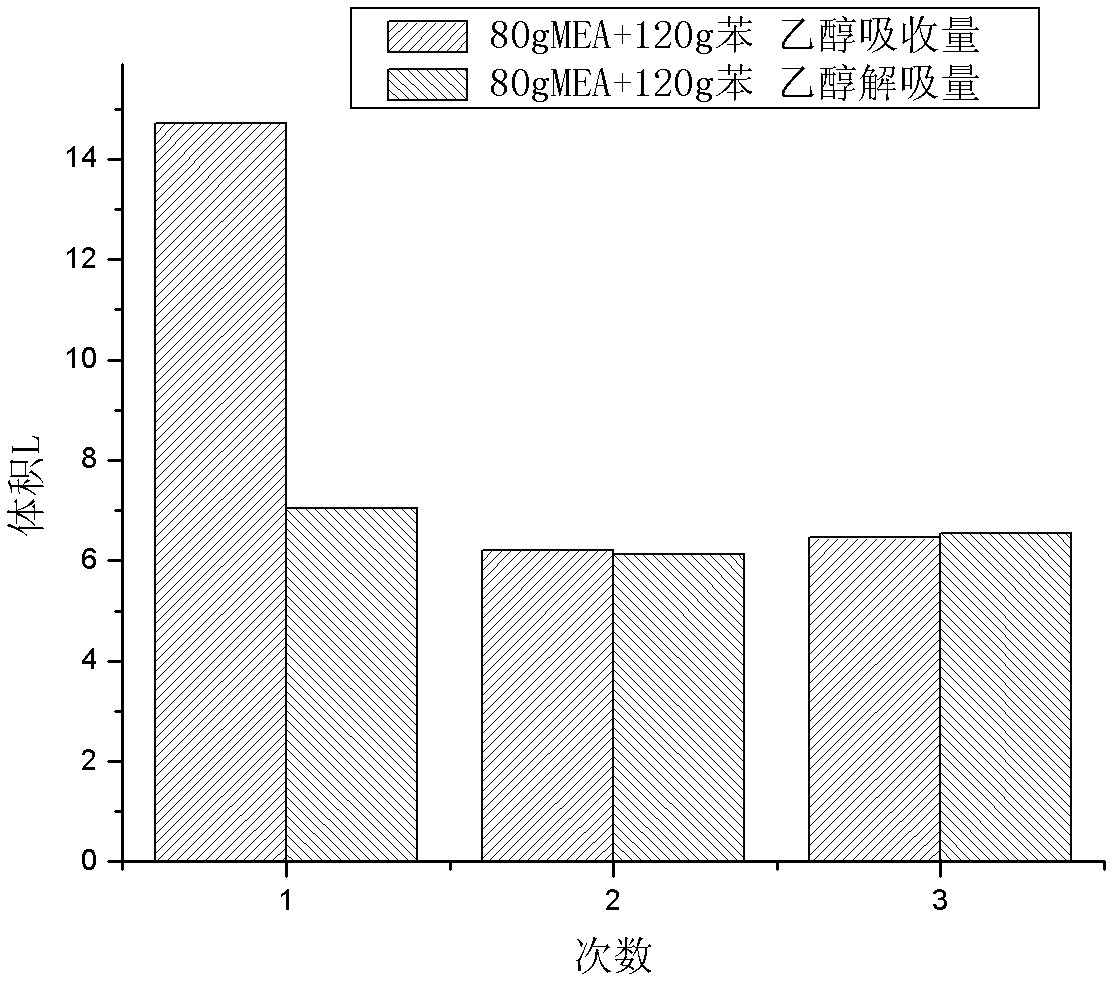

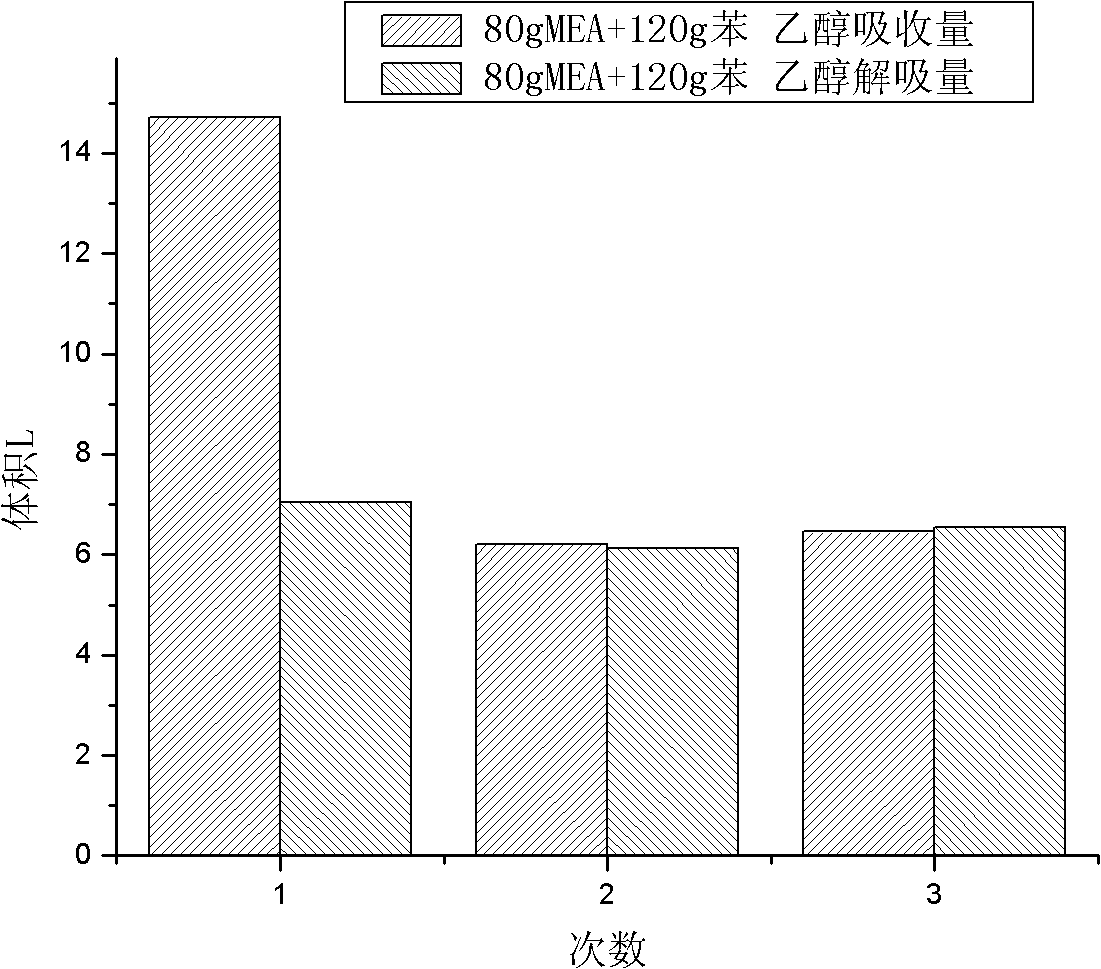

A method for capturing carbon dioxide in mixed gas with composite decarburization solution

InactiveCN102284227APromote absorptionIncrease desorptionCarbon compoundsDispersed particle separationAbsorption capacityChemical reaction

The invention relates to a composite decarburization solution for capturing carbon dioxide in mixed gas, belonging to the technical field of carbon dioxide gas capture. It relates to a composite decarburization solution, which is composed of solvent benzyl alcohol, phenyl alcohol, N-methylpyrrolidone or a mixture thereof, main absorption component MEA, auxiliary absorption components EDA, DETA and TETA, active components PZ and 2, 3-butanedione, the corrosion inhibitor is sodium chromate, and the antioxidant is sodium metavanadate and copper carbonate. Since the composite decarburization liquid uses a mixed solvent, it not only improves the absorption capacity, purification degree and desorption rate of carbon dioxide, expands the reaction temperature range, but also reduces the volume of the desorption tower, greatly reduces regeneration energy consumption, and reduces equipment investment and operating costs. The invention is mainly used for capturing carbon dioxide in various chemical reaction tail gas, ore decomposition gas, combustion flue gas, natural gas, city gas and biogas, and has broad application prospects.

Owner:DALIAN UNIV OF TECH

Modified de-arsenic catalyst and preparation method thereof

ActiveCN101591556ALow costIncrease contentRefining with metal oxidesMetal/metal-oxides/metal-hydroxide catalystsCopper oxideFilter press

The invention relates to a modified de-arsenic catalyst, comprising the following materials by weight: 15-30wt% of copper oxide, 15-30wt% of zinc oxide, 20-28wt% of VIII group metal oxides, 5-10wt% of aluminum oxide and the balance of inactive substances. The preparation method comprises the following steps: a) preparing copper carbonate suspension, adding zinc oxide and / or a zinc oxide precursorand aluminium oxide and / or an aluminium oxide precursor to form mixed suspension, then filter-pressing and baking the mixed suspension to obtain a mixture which contains copper, zinc and aluminium, wherein, the substance ratio of the respective compound of copper, zinc and aluminium in the mixture is 3-6:3-6:1-5; and b) mixing the mixture which is obtained in step a) and contains copper, zinc andaluminium with the material which contains VIII group metal compounds, also with additive and water, kneading to obtain a moulding material, finally drying and baking to obtain the finished products of modified de-arsenic catalyst. The modified de-arsenic catalyst in the invention has the advantages of low cost and simple manufacturing process.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Acid-resistant poisonous gas immersing active carbon and producing method thereof

ActiveCN1583559AImprove adsorption capacityWide range of applicationsOther chemical processesUnsymmetrical dimethylhydrazinePhosgene

A dipped activated carbon for preventing acidic toxic gas is prepared through proportionally mixing the solution of copper ammonium carbonate with carbonate of alkali metal, silver nitrate and ammonia water to obtain a liquid mixture, dipping activated carbon in it, and drying.

Owner:SHANXI XINHUA CHEM

Direct synthesis of copper carbonate

ActiveUS20070269362A1High purityEasy to convertGroup 1/11 element organic compoundsCopper ammonia complexesOxygenCopper carbonate

A basic copper salt selected from basic copper carbonate, basic copper sulfate, basic copper acetate, basic copper citrate, and basic copper nitrate is manufactured by contacting copper metal with an aqueous solution having ammonia; an acid selected from carbonic acid, sulfuric acid, acetic acid, nitric acid, or citric acid; and oxygen, under conditions where the copper metal is converted to the basic copper salt; and then recovering the basic copper salt. The most economical embodiment is where the ammonia is present in the aqueous solution is in an amount between about 6.7 g / l and about 15 g / l calculated as NH3, and the pH of the composition is between 8 and 10, and the temperature of the composition is between 25° C. and 100° C. The method is particularly useful if the basic copper salt is basic copper carbonate. The basic copper carbonate produced has the formula: (CuCO3)x(Cu(OH2)y, where y is 1 and x is between 0.1 to less than 1; or where y is 1 and x is 1, or where y is 1 and x is between 0.5 to less than about 0.95, or where y is 1 and x greater than 1.

Owner:KOPPERS PERFORMANCE CHEM

Particulate Wood Preservative and Method for Producing Same

ActiveUS20090123505A1Reduce the amount requiredWide particle size distributionBiocideLiquid surface applicatorsCopper nitrateTribasic copper sulfate

A wood preservative includes injectable particles comprising one or more sparingly soluble copper salts. The copper-based particles are sufficiently insoluble so as to not be easily removed by leaching but are sufficiently soluble to exhibit toxicity to primary organisms primarily responsible for the decay of the wood. Exemplary particles contain for example copper hydroxide, basic copper carbonate, copper carbonate, basic copper sulfates including particularly tribasic copper sulfate, basic copper nitrates, copper oxychlorides, copper borates, basic copper borates, and mixtures thereof. The particles typically have a size distribution in which at least 50% of particles have a diameter smaller than 0.25 μm, 0.2 μm, or 0.15 μm. At least about 20% and even more than 75% of the weight of the particles may be composed of the substantially crystalline copper salt. Wood or a wood product may be impregnated with copper-based particles of the invention.

Owner:KOPPERS PERFORMANCE CHEM

A formulation of semiconductor surface electrothermal coat and making method thereof

A formula of semiconductor surface electric heating coating an preparation method thereof, which is composed of (by weight) 60-70 % of tin tetrachloride, 10-15 % of copper carbonate, 10-15 % of graphite, 5-8 % boric acid, 2-3 % of antimonous chloride etc, the preparation contains 1, mixing above mentioned compositions and pulverizing into powder, added with absolute ethyl alcohol and terpineol, agitating into uniform emulsify slurry, 2, pretreating insulation base unit component and drying, 3, spraying slurry to surface of insulation base unit surface, solidifying in furnace at 400-600 degree centigrade, insulation for 15-20 minute, then cooling in furnace.

Owner:杨葆华 +1

Preparation method of nickel coated copper composite powder

The invention relates to a preparation method of nickel coated copper composite powder. The preparation method comprises the following process steps that copper salt and oxalate or carbonate take reaction to generate cupric oxalate or copper carbonate sediments, the filtering is carried out, pure water is used for flushing to be in a neutral state, and solution with the concentration being 10 to 80g / L is prepared; and nickel salt solution and the required oxalate or carbonate solution are prepared according to a proportion that the copper nickel weight ratio is 2:1 to 1:2 and are added into the cupric oxalate or copper carbonate solution for reaction to generate nickel coated copper resultants. The preparation method has the advantages that firstly, nickel salts are used for coating copper salts, then, the thermal decomposition is carried out, nickel coated copper powder is obtained, the production process is simple, the operation is easy, the production cost is low, and the industrial production can be realized. The nickel coated copper powder or alloy prepared by the method has the morphology in a spherical shape, a near-spherical shape, an irregular shape or a tree branch shape, and has the advantages that the powder dispersion is uniform, no segregation is generated, the coating effect is good, the coating is compact, the particle size is controllable, and the like. The nickel coated copper powder or alloy can be used for electromagnetic shielding materials and powder metallurgy prealloyed powder. The preparation method can be used for preparing nickel-copper alloy powder.

Owner:NAT ENG RES CENT FOR SPECIAL METAL MATERIALS OF TANTALUM & NIOBIUM

Environment-friendly copper ruby glass glaze, preparation method of environment-friendly copper ruby glass glaze and method for preparing copper ruby glass glaze surface from environment-friendly copper ruby glass glaze

The invention discloses environment-friendly copper ruby glass glaze for float-process flat glass surface decoration, a production method of the environment-friendly copper ruby glass glaze and a method for preparing a copper ruby glass glaze surface from the environment-friendly copper ruby glass glaze. The glass glaze disclosed by the invention is prepared from parent glaze and a colorant, wherein the parent glaze is prepared from the following components: 30-75% of SiO2, 5-20% of B2O3, 5-19% of ZnO, 1-15% of Al2O3, 3-5% of Bi2O3 and 4-25% of R2O (R comprises Li, Na or K) or 3-30% of RO (R comprises Mg, Ca, Ba or Sr). The colorant is one or a mixture of copper oxide, cuprous oxide and copper carbonate. The copper ruby glass glaze disclosed by the invention is free of lead and cadmium, is capable of avoiding injuring a human body or damaging the environment and is specially used for manufacturing a float-process flat glass surface. The copper ruby glass glaze can be regulated to different red colors as required, is suitable for common float-process flat glass and can be tempered and sintered.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

Direct synthesis of copper carbonate

ActiveUS7411080B2High purityEasy to convertNitrogen-metal/silicon/boron binary compoundsCopper organic compoundsCopper nitrateOxygen

A basic copper salt selected from basic copper carbonate, basic copper sulfate, basic copper acetate, basic copper citrate, and basic copper nitrate is manufactured by contacting copper metal with an aqueous solution having ammonia; an acid selected from carbonic acid, sulfuric acid, acetic acid, nitric acid, or citric acid; and oxygen, under conditions where the copper metal is converted to the basic copper salt; and then recovering the basic copper salt. The most economical embodiment is where the ammonia is present in the aqueous solution is in an amount between about 6.7 g / l and about 15 g / l calculated as NH3, and the pH of the composition is between 8 and 10, and the temperature of the composition is between 25° C. and 100° C. The method is particularly useful if the basic copper salt is basic copper carbonate. The basic copper carbonate produced has the formula: (CuCO3)x(Cu(OH2)y, where y is 1 and x is between 0.1 to less than 1; or where y is 1 and x is 1, or where y is 1 and x is between 0.5 to less than about 0.95, or where y is 1 and x greater than 1.

Owner:KOPPERS PERFORMANCE CHEM

Inhibition of calcium and magnesium precipitation from wood preservaties

InactiveUS20060162611A1Prevent precipitationMore inhibitorFireproof paintsBiocideCopper carbonateEnvironmental chemistry

A wood preservative that contains a copper salt complex and a precipitation inhibitor is provided. The wood preservative may contain copper carbonate, an alkanolamine such as monoethanolamine and precipitation inhibitor such as a phosphonate or ethylene diamine compound. Also provided is a method of using the wood preservative.

Owner:OSMOSE

Trace elements

The invention discloses a trace element solution, which comprises at least one metal selected from the group comprising selenium, copper, zinc, manganese and chromium and which comprises a concentration of the metal(s) of at least 60 mg / ml. The solution further comprises at least one compound selected from the group comprising iodine, potassium iodide, sodium iodide, iron, iron chloride, zinc oxide, manganese sulphate, sodium selenite, copper carbonate, sodium carbonate, anhydrous disodium EDTA and sodium hydroxide. The trace element solution is prepared by a method consisting essentially of the steps of preparing a MnCO3 mixture in a container; adding an EDTA / NaOH mixture to the container and subsequently adding at least one metal compound; and adding Na2SeO3 to the container to obtain the trace element solution. The method also comprises the step of adding CrCl3.6H2O to the trace element solution.

Owner:WARBURTON TECH

Laser carving powder applied to laser marking and preparation process thereof

The invention discloses laser carving powder applied to laser marking. The laser carving powder comprises the following raw materials in parts by weight: polypropylene resin, C5 petroleum resin, barium sulfate, a nucleating agent, an antioxidant, toner, a lubricant, silicon oxide, titanium dioxide, zinc sulfide, chromium sesquioxide, neodymium oxide, bismuth oxide, tin oxide, zinc molybdate, ammonium molybdate, basic copper phosphate, copper oxide, copper chromite black, copper carbonate, copper sulfate, copper chloride, copper chromite, copper thiocyanate, spinel, tin dioxide, tin ash, sodiumstannate, potassium stannate, zinc sulfate, antimony trioxide, antimony pentoxide, sodium antimonate, potassium carbonate, syndiotactic polystyrene and polyhexamethylene adipamide; according to the preparation process of the laser carving powder applied to laser marking, the laser carving powder applied to laser marking is prepared, and the preparation process comprises the following steps: S1, grinding; S2, performing crushing; S3, performing mixing; S4, adding a chemical agent; S5, drying; and S6, crushing.

Owner:东莞市烁康新材料科技有限公司

Production method of EDTA complex metal salt

InactiveCN1426998ATo achieve the purpose of removing inorganic saltsRaise the reaction temperatureOrganic compound preparationAmino-carboxyl compound preparationComplexonsIron sulfate

A process for preparing high-purity complexed metal salt of complexon used for trace-element fertilizer includes such steps as adding complexon and sodium hydroxide to water, stirring while reaction to obtain sodium salt of complexant, adding metal salt which is one of FeCl3, iron sulfate, manganese carbonate, alkaline copper carbonate, zinc oxide, etc., and reaction at 70-150 deg.C.

Owner:钟林 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com