Patents

Literature

83 results about "Copper chromite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Copper chromite is an inorganic compound with the formula Cu₂Cr₂O₅ which is used to catalyze reactions in organic synthesis.

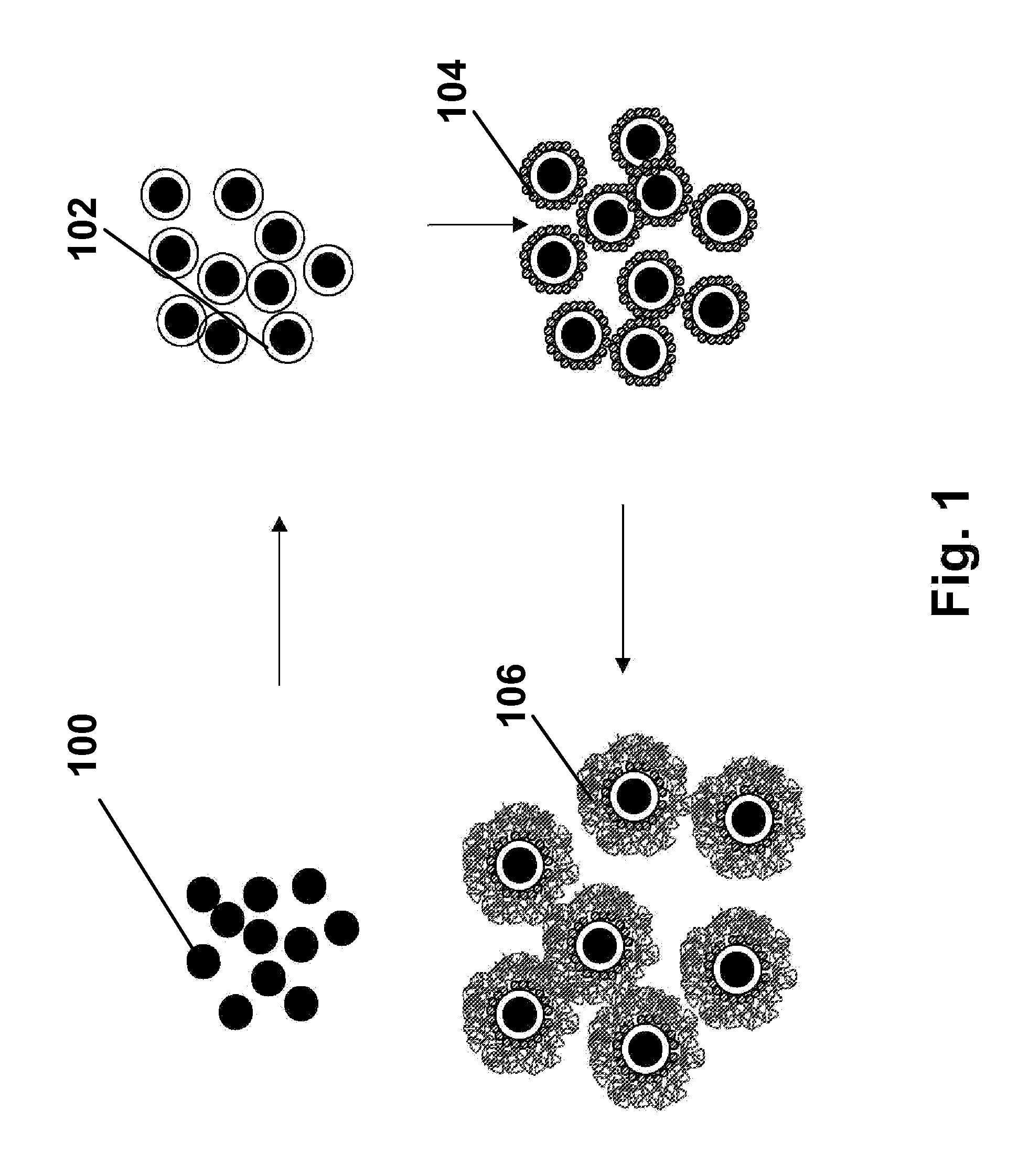

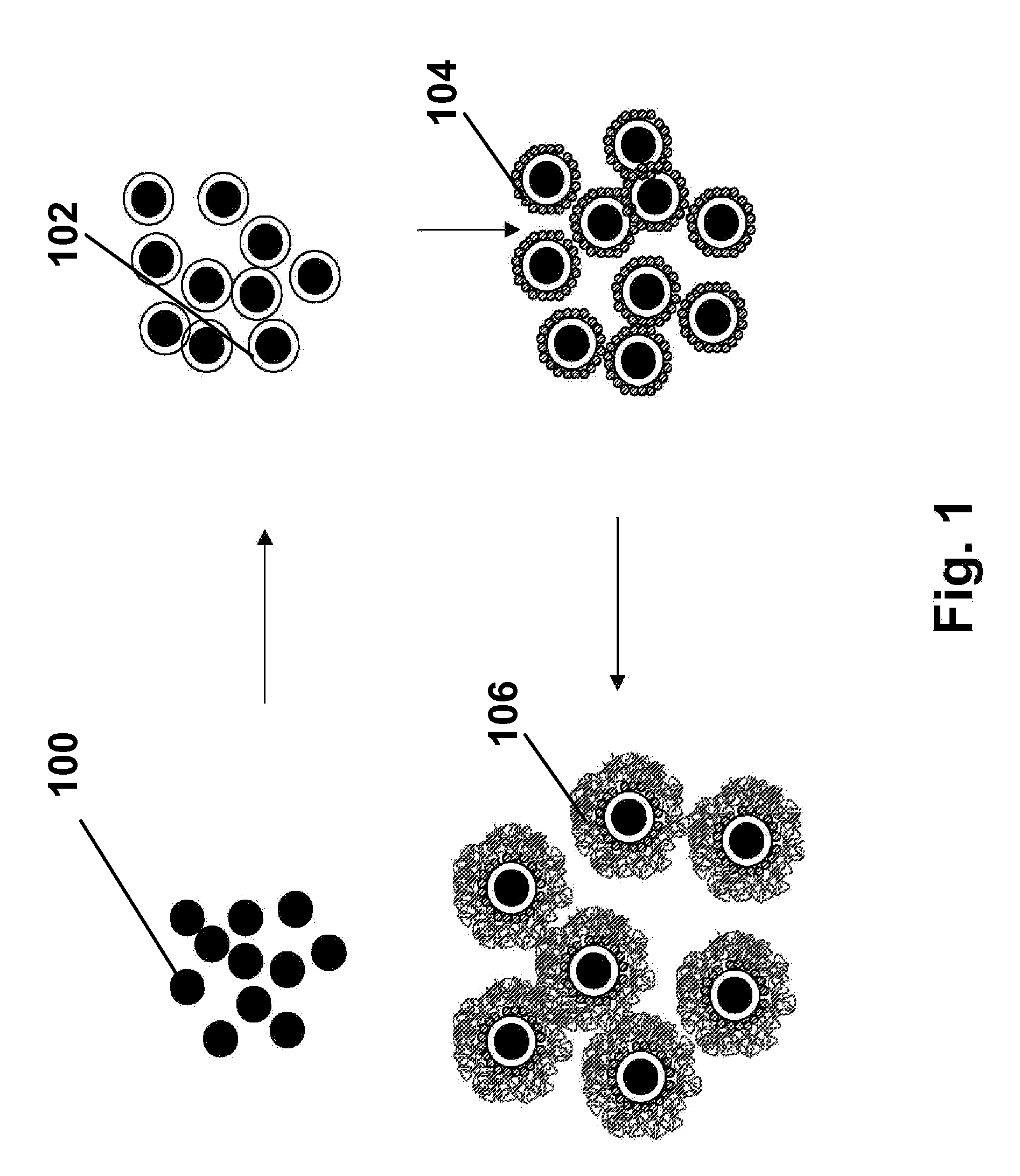

Electrophoretic particles, and processes for the production thereof

InactiveUS20050000813A1Volume/mass flow measurementFluid pressure measurement by electric/magnetic elementsElectrophoresisCopper chromite

Owner:E INK CORPORATION

Thermal protective coating

ActiveUS7105047B2Extended shelf lifeReduce weightAlkali metal silicate coatingsPretreated surfacesCalcium silicateSodium Bentonite

A coating, method of coating and substrates coated thereby, wherein the coating contains an inorganic adhesive such as an alkali / alkaline earth metal silicate such as sodium silicate, potassium silicate, calcium silicate, and magnesium silicate; a filler such as a metal oxide for example silicon dioxide, aluminum oxide, titanium dioxide, magnesium oxide, calcium oxide and boron oxide; and one or more emissivity agents such as silicon hexaboride, carbon tetraboride, silicon tetraboride, silicon carbide, molybdenum disilicide, tungsten disilicide, zirconium diboride, cupric chromite, or metallic oxides such as iron oxides, magnesium oxides, manganese oxides, chromium oxides and copper chromium oxides, and derivatives thereof. In a coating solution, an admixture of the coating contains water. A stabilizer such as bentonite, kaolin, magnesium alumina silicon clay, tabular alumina and stabilized zirconium oxide may be added.

Owner:WESSEX

Method for preparing nano-catalyst copper chromite and copper ferrite

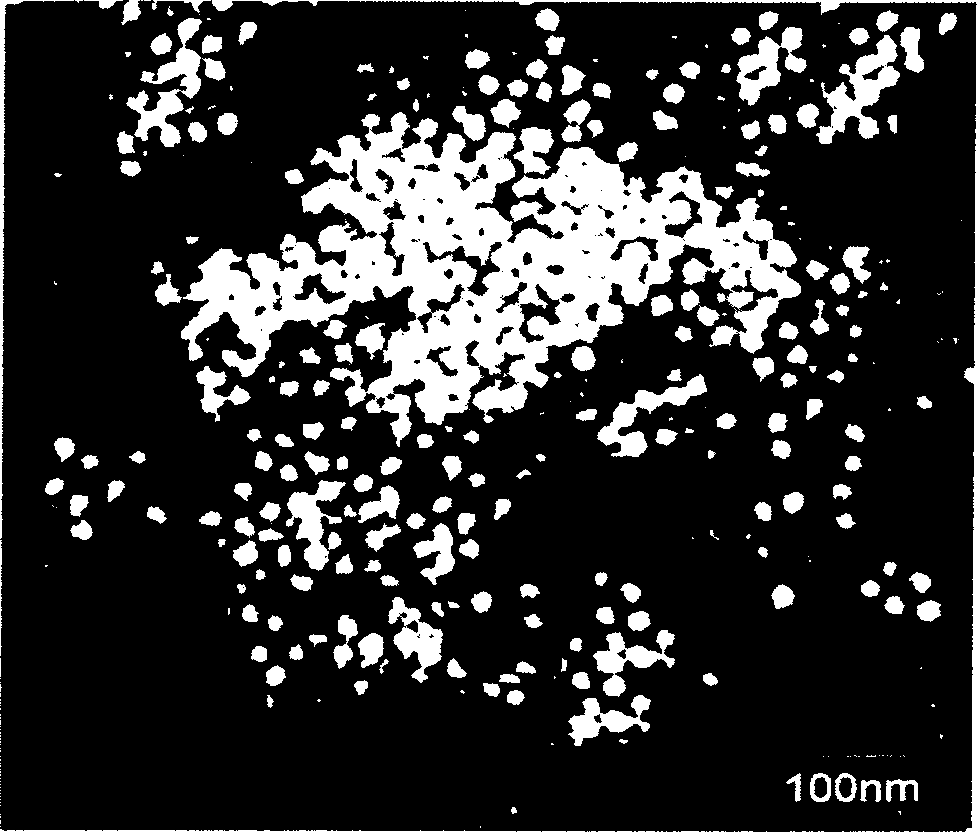

InactiveCN101367044AHigh puritySmall particle sizeMetal/metal-oxides/metal-hydroxide catalystsWater bathsNano catalyst

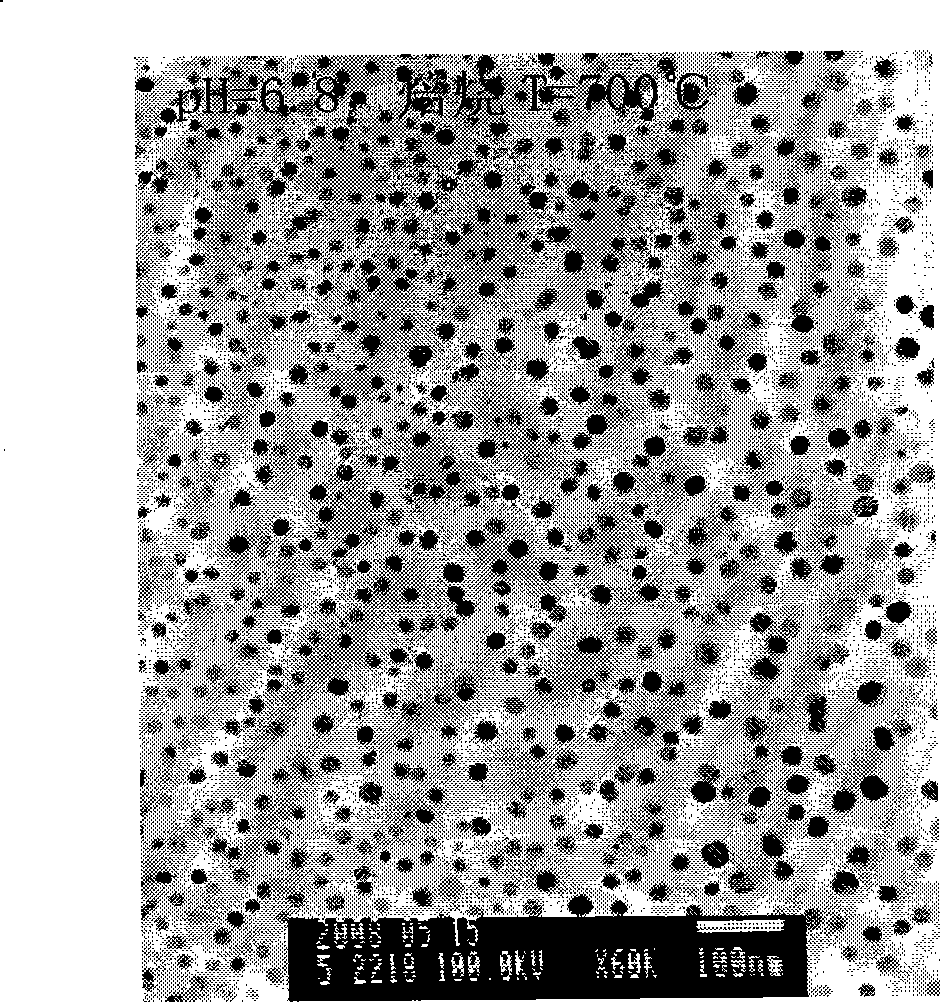

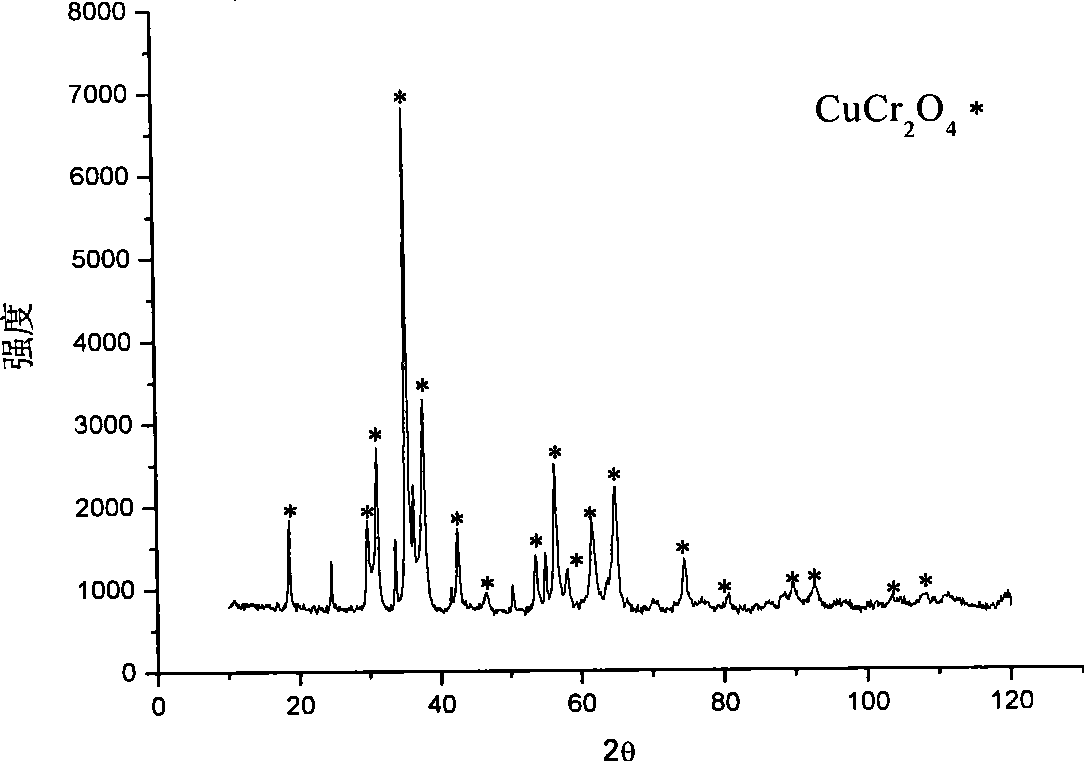

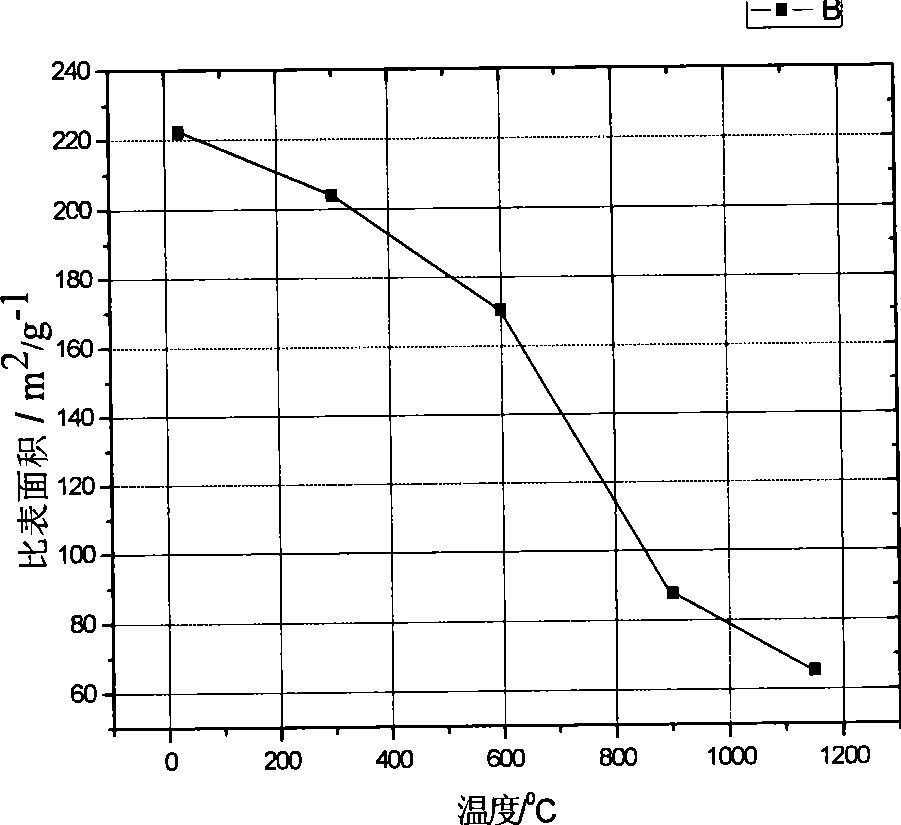

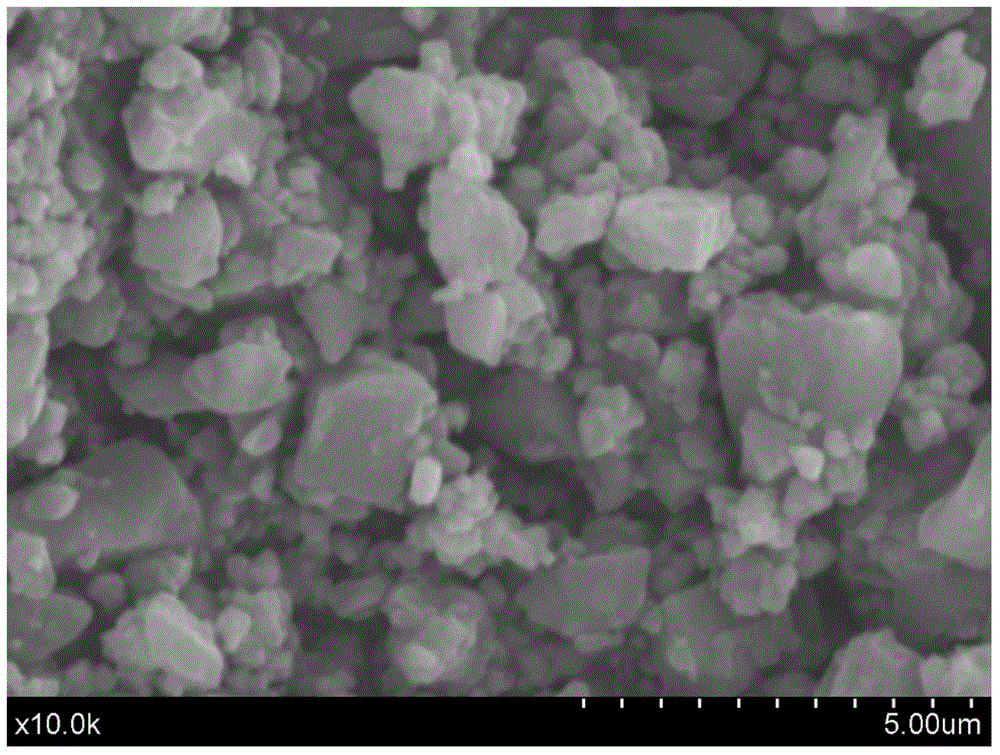

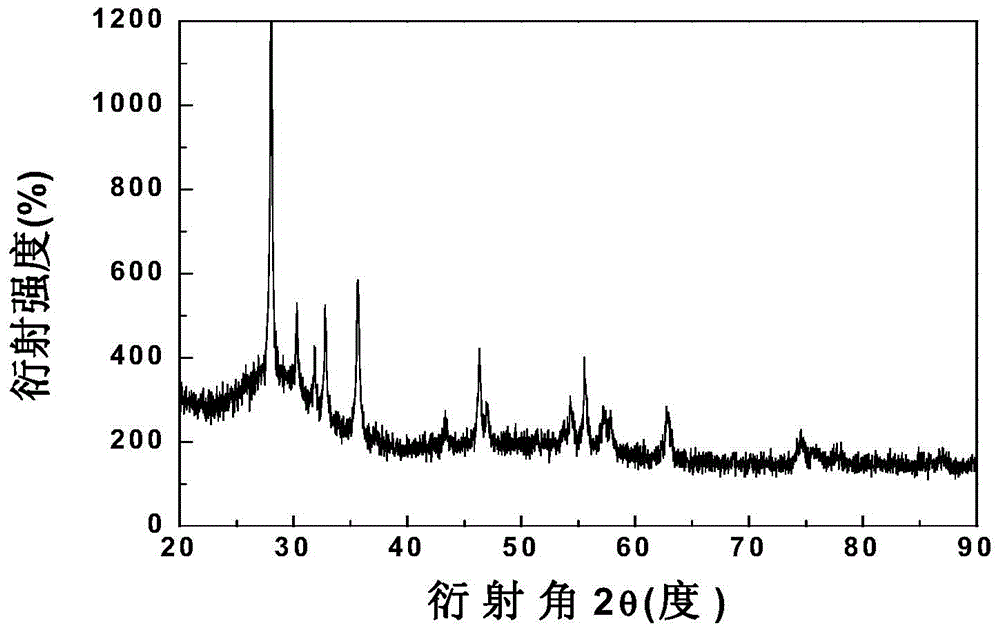

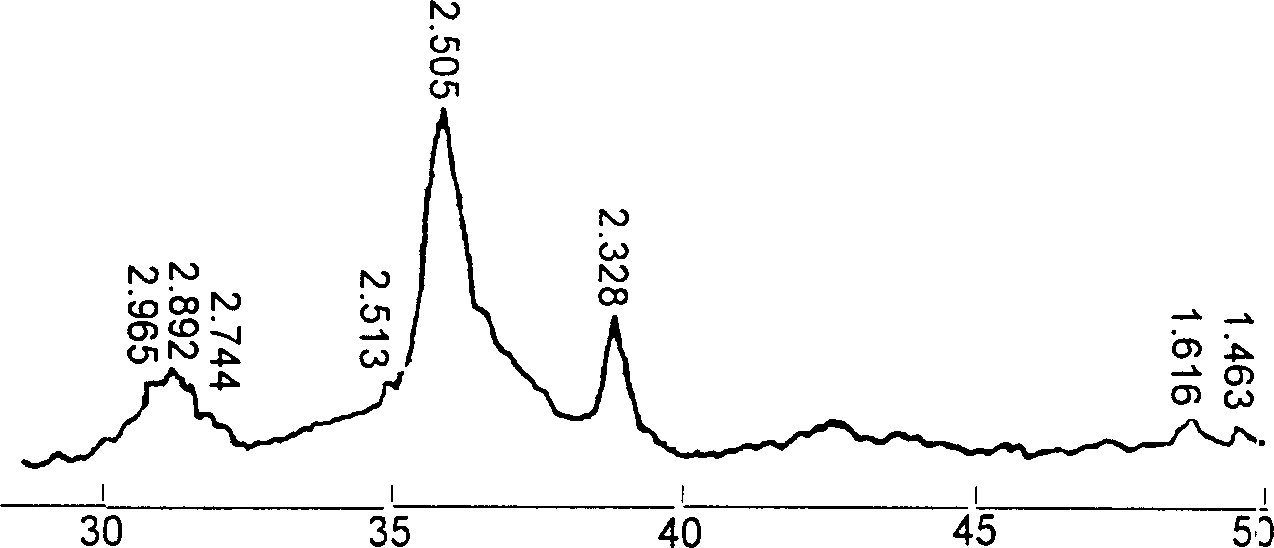

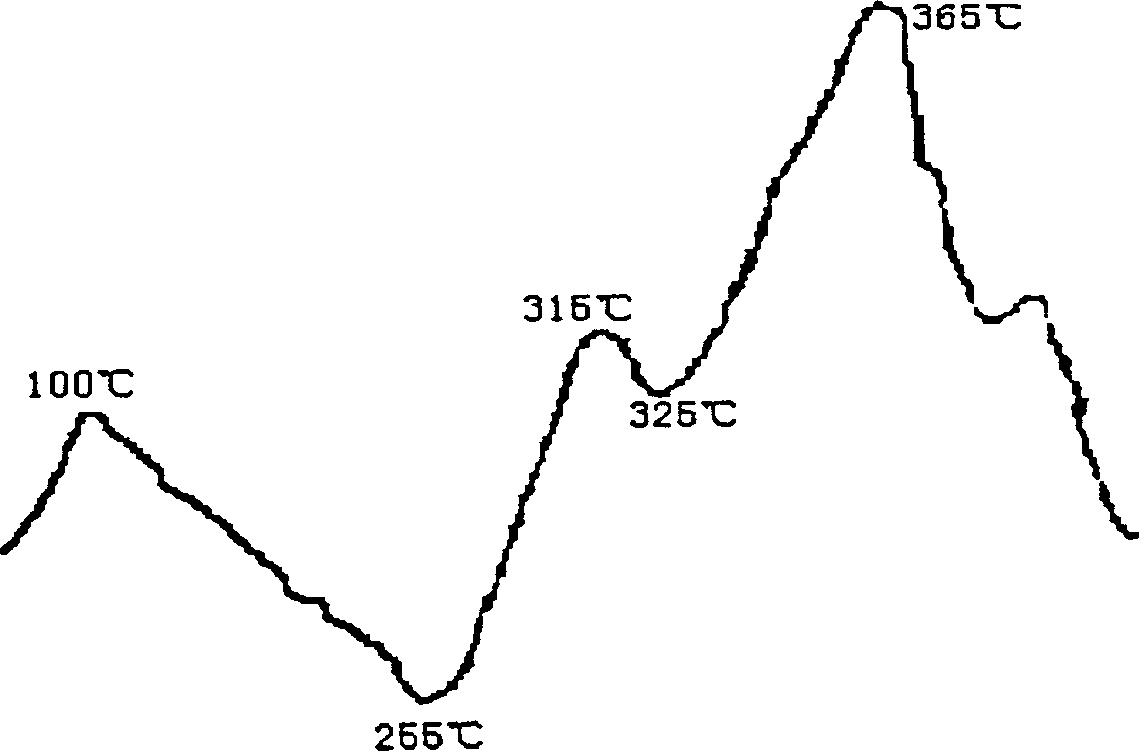

The invention discloses a method for preparing a nano-size catalyst of copper chromite and copper ferrite, and belongs to the technical field of nano-size catalyst preparation. The method of the invention comprises a sol-gel process and a vacuum freezing drying (VFD) process. Firstly, a mixed solution is prepared from a soluble copper salt and a soluble chromium salt or iron salt, added with a surface active agent, and mixed uniformly, and then the system is added with a precipitating agent to carry out precipitation reaction under the condition that the pH value is between 6.8 and 9.5, then is kept stand, aged, washed and melted in a water bath for 2 to 8 hours at a temperature of between 70 and 95 DEG C, thus sol is obtained; then the sol is subjected to freezing drying in a vacuum freezing dryer to obtain dried gel which is a precursor of the catalyst; finally, the dried gel is roasted to obtain the nano-size catalyst of copper chromite (CuCr2O4) or copper ferrite (CuFe2O4). The catalyst prepared by the method has the advantages of high purity, small grain diameter, good dispersivity, high catalytic activity, and the like.

Owner:TSINGHUA UNIV

Composition for laser marking

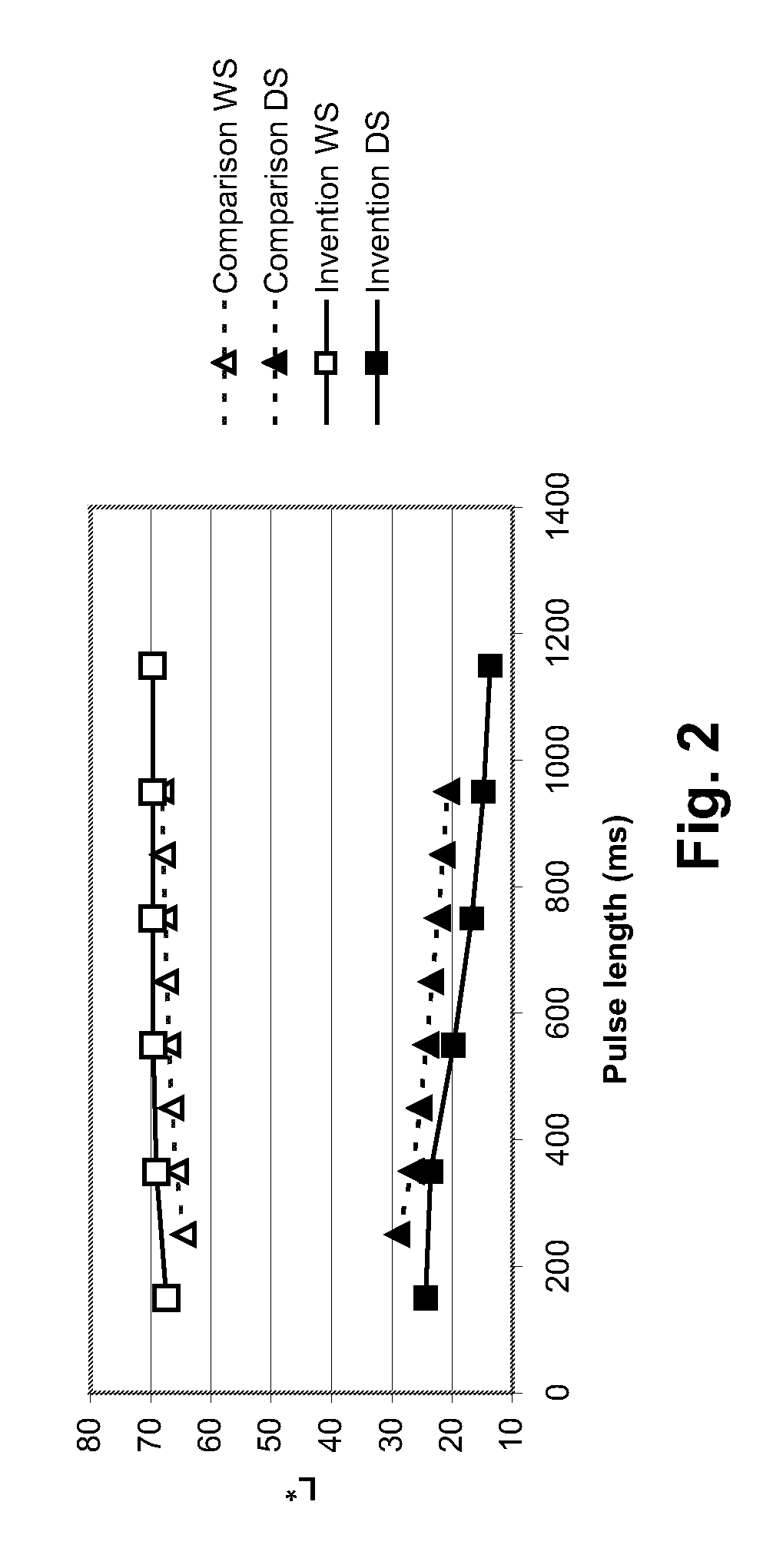

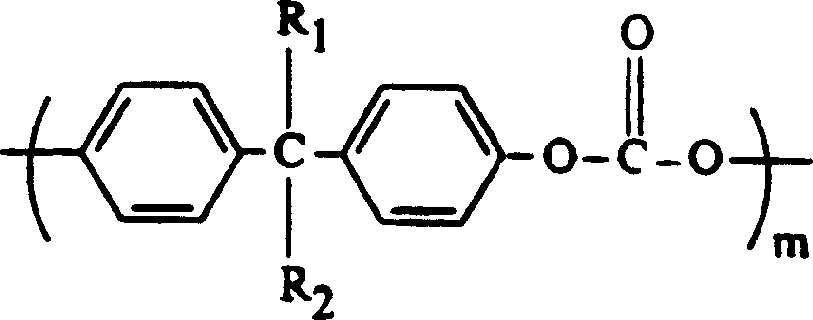

A resin composition having laser marking properties comprising a polycarbonate resin, an effective amount of a copper chromite having a spinel structure and up to 0.05% by weight of the total composition of carbon black, wherein said polycarbonate resin foams in laser struck areas to form light colored markings in the laser struck areas on a dark background.

Owner:SABIC GLOBAL TECH BV

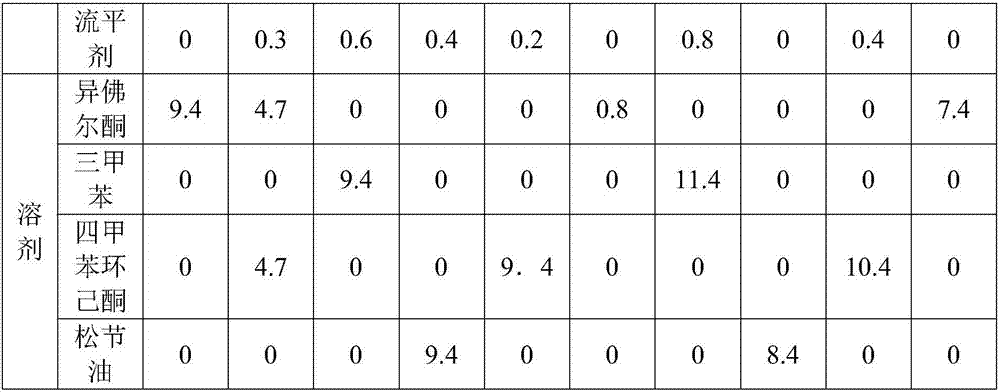

High-temperature sintering heating conductive ink and preparation method of high-temperature sintering heating conductive ink

InactiveCN107502067AImprove thermal efficiencyFast heatingChemical industryInksCopper chromiteMass ratio

The invention belongs to the technical field of conductive inks, and particularly relates to a high-temperature sintering heating conductive ink and a preparation method of the high-temperature sintering heating conductive ink. The ink comprises the following components of graphene, copper chromite black, a tourmaline powder, a glass powder, a resin, an auxiliary and a solvent at the mass ratio of (23-33):(1.5-5.5):(1.5-5.5):(30-40):(15-25):(0.2-0.8):(7.4-11.4). The preparation method comprises the following steps: adding the graphene, the copper chromite black, the tourmaline powder, the glass powder, the resin and the auxiliary into the solvent according to the composition and the proportion of the formula, fully stirring, conducting ultrasonic dispersion, grinding, and filtering to obtain the high-temperature sintering heating conductive ink. The efficiency of transforming electric energy into heat of the conductive ink is high, the heating is fast, the controllable range of the resistance is wide, the controllable temperature range of heating is wide, the conductive ink has the far infrared function, the application process in the later period is simple, the scope of application is wide, and the conductive ink has a broad market prospect.

Owner:王雨生

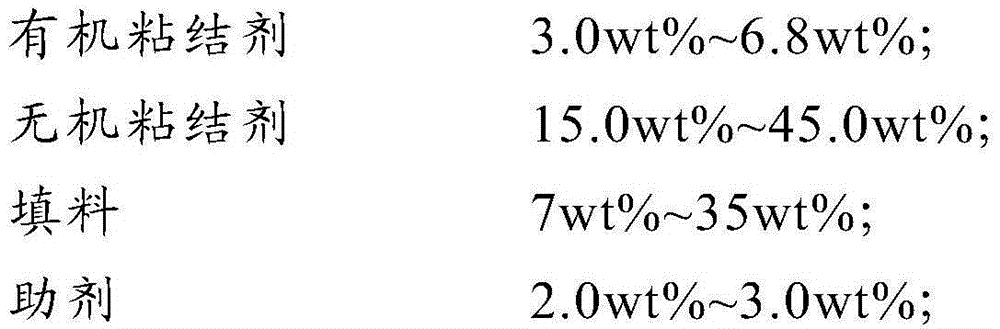

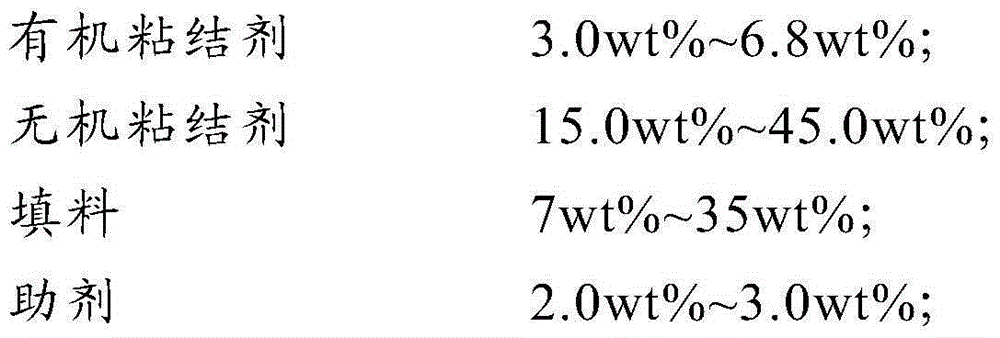

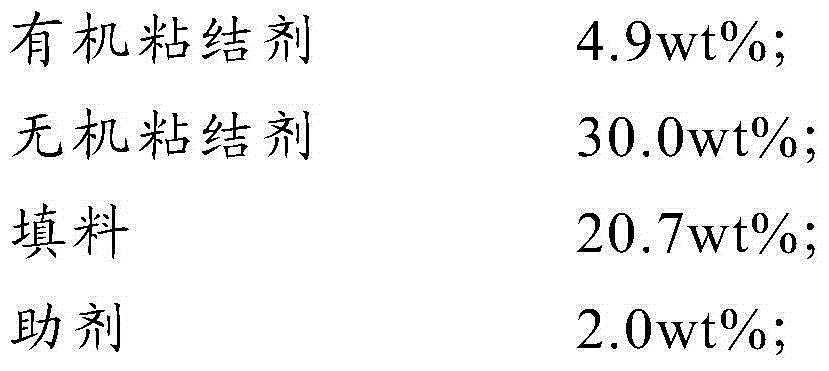

Ceramic paint and application thereof

The invention provides ceramic paint. The ceramic paint comprises 3.0wt%-6.8wt% of organic binders, 15.0wt%-45.0wt% of inorganic binders, 7wt%-35wt% of packing, 2.0wt%-3.0wt% of auxiliaries and the balance water. The organic binders are made of silicone emulsion, the inorganic binders are made of sodium water glass, and the packing comprises rare-earth oxide, graphite, mica, kaolin, copper chromite black, zirconia and chromium oxide. The invention further provides application of the ceramic paint to industrial furnaces. The ceramic paint and the application have the advantages that mutual synergistic effects can be realized by components in the ceramic paint, and accordingly the ceramic paint is excellent in comprehensive performance when used as a ceramic coating.

Owner:铜陵兆山科技有限公司

Catalyst used for preparing hydroxy acetone by glycerol dewatering, preparation and application thereof

InactiveCN101698151AHigh activityHigh yieldCarbonyl compound preparation by oxidationMetal/metal-oxides/metal-hydroxide catalystsCopper chromiteGlycerol

The invention relates to a catalyst used for preparing hydroxy acetone by glycerol dewatering, preparation and an application thereof. The main component of the catalyst is copper chromite. A metal auxiliary agent is respectively one of the components of zinc, aluminum, magnesium, zirconium, titanium and the like and is prepared by a dipping method. The auxiliary agent metal is in the catalyst in an oxide form of the auxiliary agent metal. The catalyst is suitable for preparing the hydroxy acetone by crude glycerine dewatering. The catalyst has simple preparation process, and the introduction of the metal auxiliary agent can enhance the activity of the catalyst, lower the reaction temperature obviously, enhance the yield of the hydroxy acetone and prolong the service life of the catalyst.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Copper-chrome black pigment and preparation method thereof

ActiveCN109054452AImprove stabilityUniform particlesChromates/bichromatesPigment physical treatmentCopper chromitePhysical chemistry

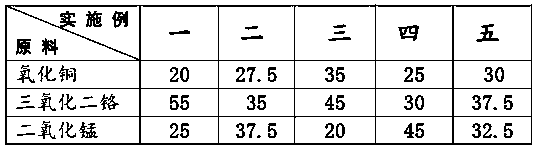

The invention discloses a copper-chrome black pigment and a preparation method thereof. The copper-chrome black pigment is prepared from the following raw materials in percentage by weight: 20-35 percent of copper oxide, 35-55 percent of chromium oxide, and 20-45 percent manganese dioxide. The particle diameter D50 of copper oxide, chromium oxide and manganese dioxide is less than or equal to 2 microns. The copper-chrome black pigment prepared by the method has the advantages of fine particles, uniform particle distribution, and complete copper chromite crystal, so that the copper-chrome blackpigment has strong coloring power, high stability and low product cost, and can satisfy the requirements on the copper-chrome black pigment in various fields.

Owner:中山市华山高新陶瓷材料有限公司

Method for preparing gamma-valerolactone by levulinic acid ester without solvents

InactiveCN104844542AImprove reaction efficiencySimplify separation and purification stepsOrganic chemistryPropanoic acidAlcohol

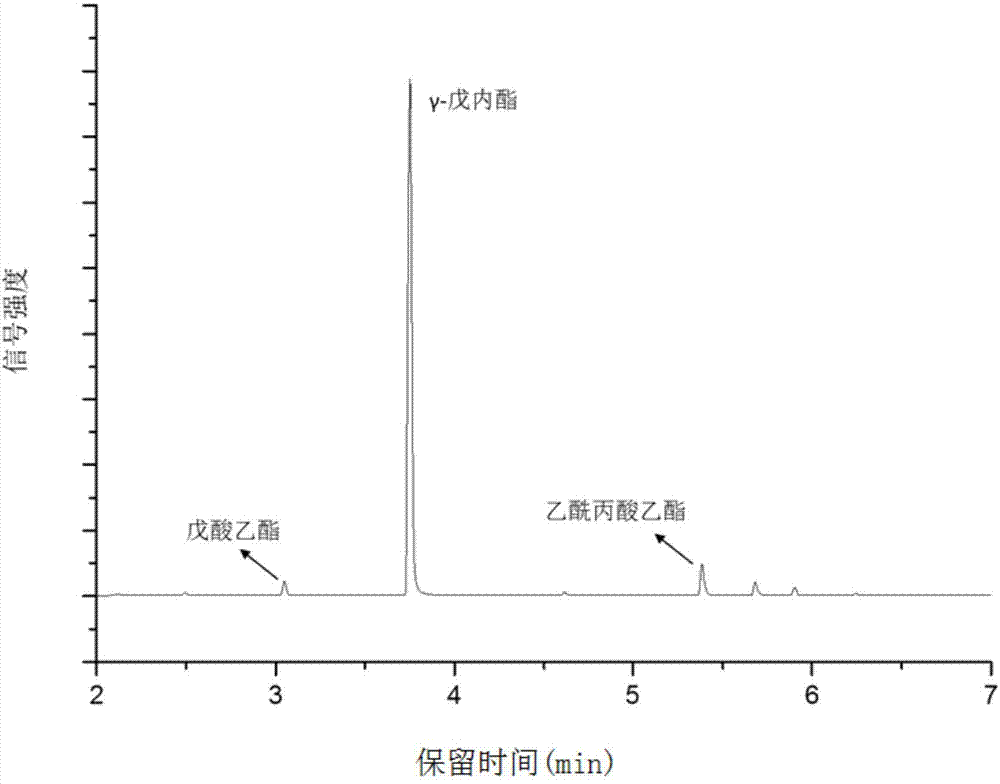

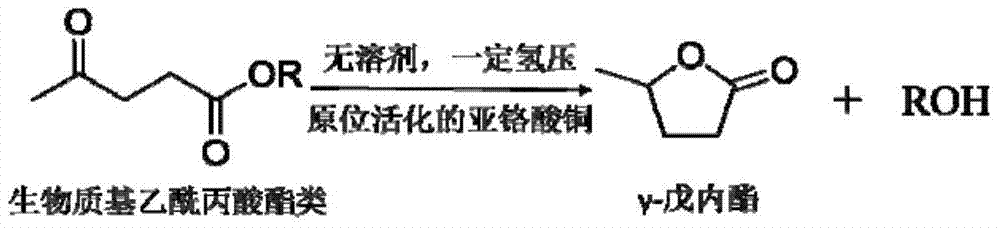

The invention discloses a method for preparing gamma-valerolactone by levulinic acid ester without solvents, and relates to gamma-valerolactone. A copper chromite catalyst is added into the levulinic acid ester and reacts in hydrogen atmosphere to obtain solid-liquid mixture, pressure is reduced, suction filtration is performed to obtain binary liquid mixture containing gamma-valerolactone and corresponding alcohols, and the alcohols are recovered by distillation to obtain the gamma-valerolactone. Cheap and easily separated copper chromite serving as the catalyst is added into the levulinic acid ester from biomass, and the gamma-valerolactone is prepared at one step in a solvent-free system. The copper chromite catalyst is activated in situ in the system, so that a traditional catalyst pre-hydrogenation step is omitted. The method is simple and efficient, and an effective way is provided for large-scale preparation of biomass-based gamma-valerolactone.

Owner:XIAMEN UNIV

High-emissivity high-temperature ceramic coating

InactiveCN103788733AHigh emissivityAnti-staining and slaggingAntifouling/underwater paintsPaints with biocidesCeramic coatingRare earth

The invention relates to a high-emissivity high-temperature ceramic coating and aims at providing a high-emissivity high-temperature ceramic coating capable of being resistant to 1350 DEG C high temperature, fouling and slagging, high-temperature corrosion and abrasion, high in emissivity, not prone to falling off and bulging, made of carbon steel and long in service life. The high-emissivity high-temperature ceramic coating comprises, by weight, water 30.5-45.1 parts, bactericide AM7287 0.3-0.5 part, CF-10 dispersing agent 0.3-0.5 part, DF-104 defoaming agent 0.3-0.5 part, silica solution 25-30 parts, organic silicone emulsion 4-5 parts, calcined kaolin with more than 2000 meshes 4-5 parts, aluminum oxide with more than 600 meshes 4-5 parts, copper chromite black with more than 600 meshes 4-5 parts and rare earth cerium oxide powder with more than 500 meshes 2-3 parts.

Owner:北京远科宏大石油技术开发有限公司

Water-based ink thermal transfer ribbon and preparation method thereof

InactiveCN106085019ASmall finenessImprove transfer effectFireproof paintsInk ribbonsWater basedEpoxy

The invention discloses a water-based ink thermal transfer ribbon which comprises a base, a release layer, an ink layer and a heat resistant coating, wherein one side of the base is coated with the release layer, the outer side of the release layer is coated with the ink layer, and the other side of the base is coated with the heat resistant coating; the ink layer is prepared from the following raw materials in parts by weight: 14-17 parts of waterborne polyurethane resin, 10-15 parts of epoxy resin, 18-23 parts of acrylic resin, 15-20 parts of carbon black, 8-12 parts of copper chromite black, 22-26 parts of kaolin, 9-13 parts of quartz powder, 2-5 parts of diatomite, 5-8 parts of polyethylene wax, 0.7-1.5 parts of polysiloxane defoaming agents and 0.5-1.0 part of chitosan. The invention further discloses a preparation method of the water-based ink thermal transfer ribbon. The prepared thermal transfer ribbon is free from toxic solvents such as methylbenzene and butanone, operating environments can be favorably improved, health of workers is ensured, and environmental protection requirements are met.

Owner:POMA IND SHANGHAI

Laser carving powder applied to laser marking and preparation process thereof

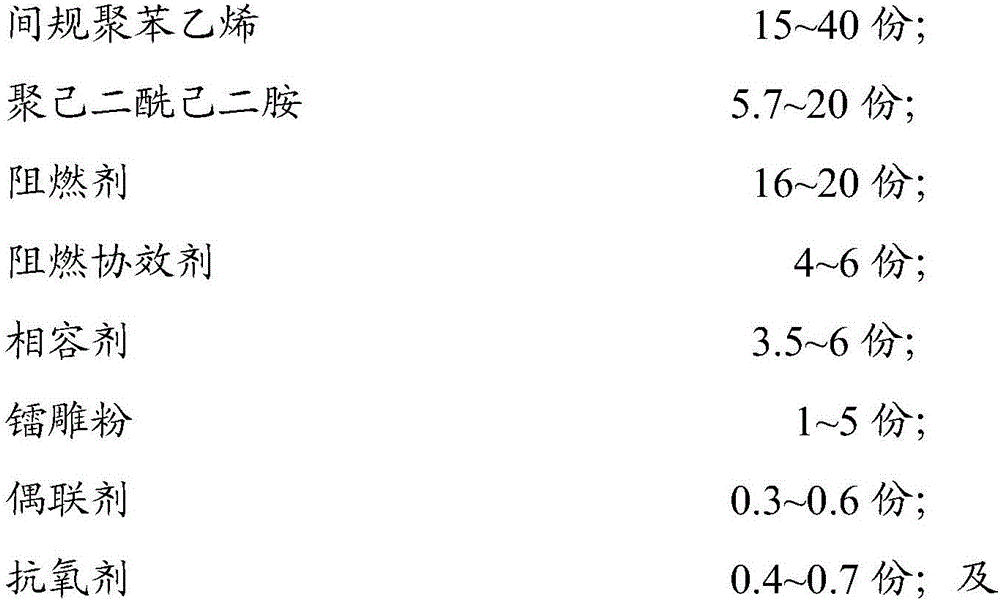

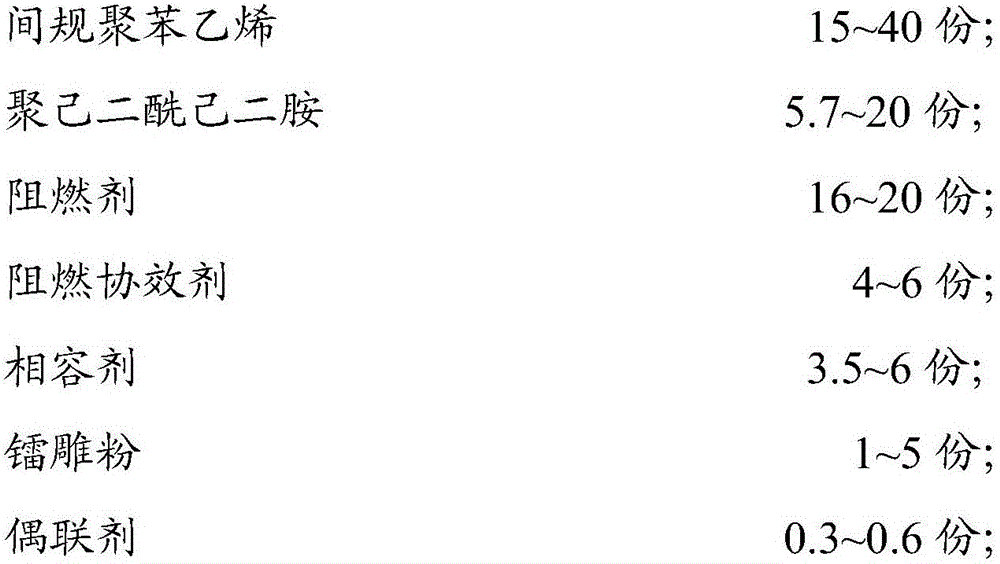

The invention discloses laser carving powder applied to laser marking. The laser carving powder comprises the following raw materials in parts by weight: polypropylene resin, C5 petroleum resin, barium sulfate, a nucleating agent, an antioxidant, toner, a lubricant, silicon oxide, titanium dioxide, zinc sulfide, chromium sesquioxide, neodymium oxide, bismuth oxide, tin oxide, zinc molybdate, ammonium molybdate, basic copper phosphate, copper oxide, copper chromite black, copper carbonate, copper sulfate, copper chloride, copper chromite, copper thiocyanate, spinel, tin dioxide, tin ash, sodiumstannate, potassium stannate, zinc sulfate, antimony trioxide, antimony pentoxide, sodium antimonate, potassium carbonate, syndiotactic polystyrene and polyhexamethylene adipamide; according to the preparation process of the laser carving powder applied to laser marking, the laser carving powder applied to laser marking is prepared, and the preparation process comprises the following steps: S1, grinding; S2, performing crushing; S3, performing mixing; S4, adding a chemical agent; S5, drying; and S6, crushing.

Owner:东莞市烁康新材料科技有限公司

Process for preparing neopentyl glycol by cracking high boilers occuring in the production process

ActiveUS20110184212A1Organic compound preparationPreparation by oxygen reductionPolymer scienceBoiling point

The present invention relates to a process for obtaining neopentyl glycol by hydrogenating cracking of high-boilers occurring in the production process in the presence of copper-chromite catalysts. The hydrogenating cracking proceeds in the absence of solvent at a temperature of 140 to 220° C. and at pressures of 7 to 28 MPa.

Owner:OQ CHEM GMBH

Copper chromite black pigment, and preparation method and application thereof

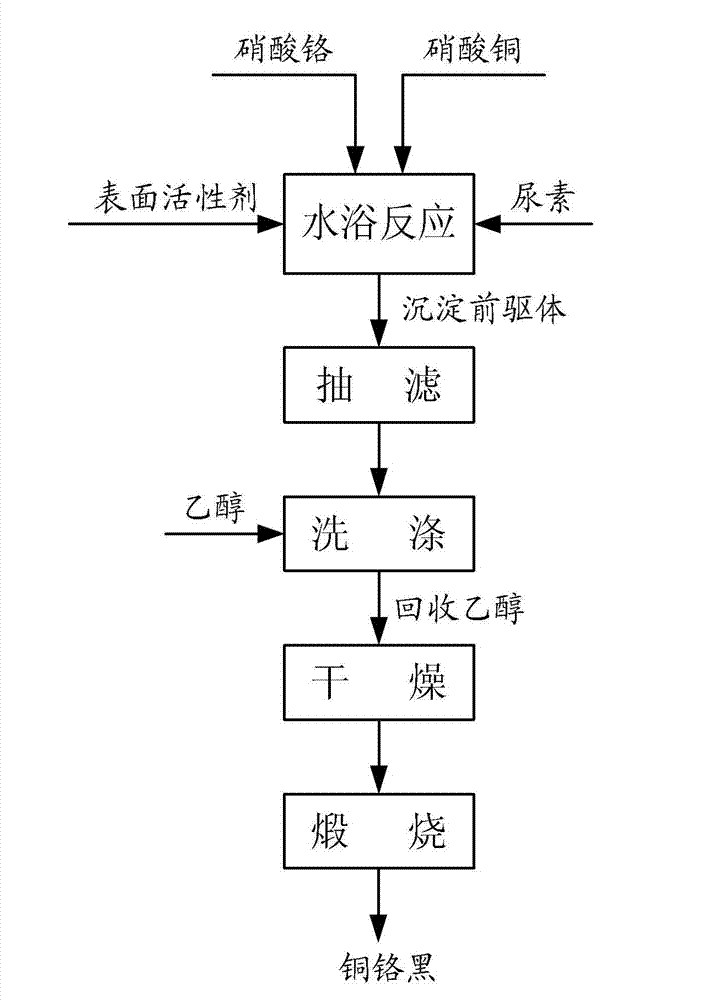

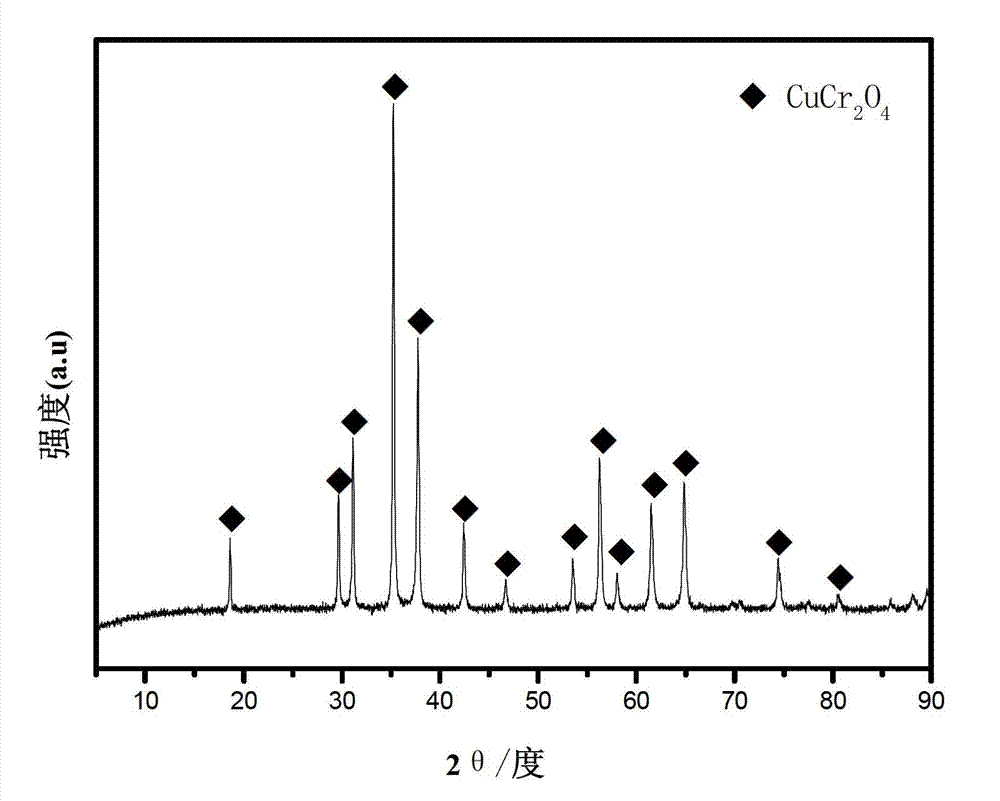

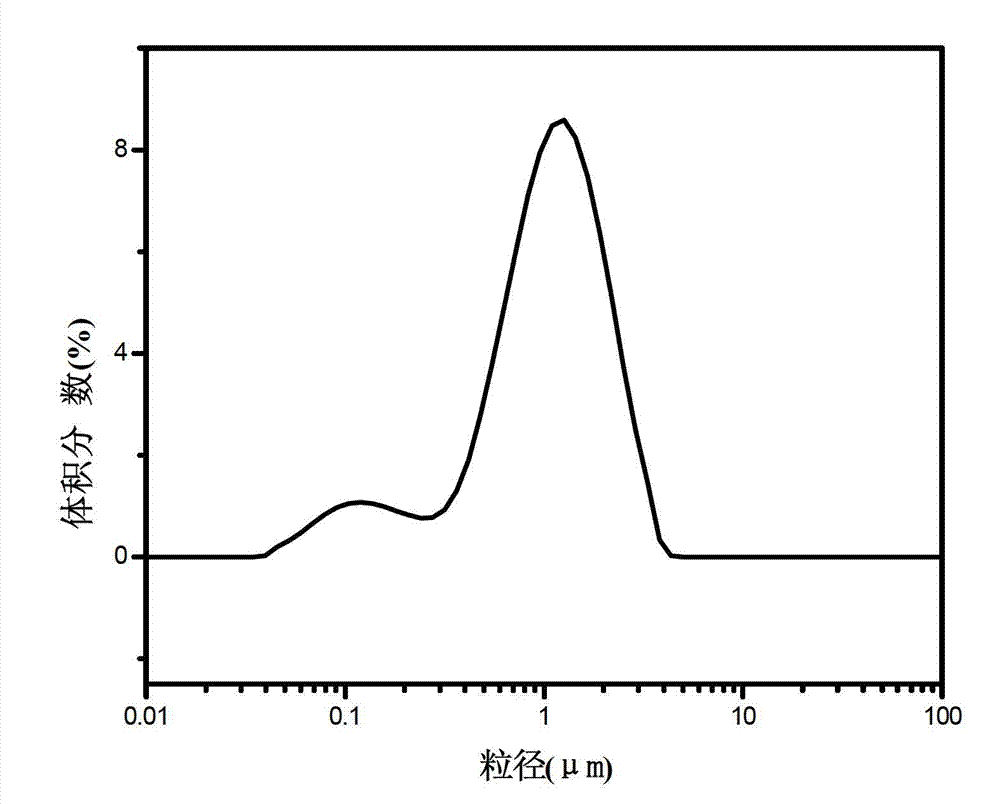

ActiveCN103708555ASmall particle sizeEvenly distributedChromium oxides/hydratesAlcoholCopper chromite

The invention relates to a preparation method of a copper chromite black pigment. The method comprises the steps of adding a urea solution into a mixed solution of a divalent copper salt and a trivalent chromic salt to generate a copper chromite black precipitate in an environment in presence of a surfactant; washing the precipitate with alcohol; and drying the precipitate to obtain the copper chromite black precipitate. The preparation method of the copper chromite black is high in reactive activity; a sintering temperature is reduced by about 200 DEG C than that of a solid phase method; the obtained copper chromite black powder is very fluffy; and the copper chromite black pigment with small particle size and uniform distribution can be obtained without any grinding or ball-milling process.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Dehydrogenation of alkylene glycol ethers to ether detones and aldehydes

InactiveCN1474798AOrganic compound preparationPreparation by dehydrogenationWater basedCopper chromite

A catalytic dehydrogenation of alkylene glycol ether to ether ketone or aldehyde is disclosed. The dehydrogenation is performed with copper chromite catalyst and at least 5 wt % of water based on alkylene glycol ether. It has been found that the selectively to formation of ether ketone or aldehyde increases with increasing the amount of water in the alkylene glycol ether.

Owner:ARCO CHEM TECH INC

Bismuth-oxide-based black pigment used for glass digital inkjet printing and preparation method of bismuth-oxide-based black pigment

InactiveCN105062198AReduces inkjet head cloggingGood inkjet printing performanceInksLithium oxideSilicon oxide

The invention provides bismuth-oxide-based black pigment used for glass digital inkjet printing and a preparation method of the bismuth-oxide-based black pigment. The bismuth-oxide-based black pigment is characterized in that preparation raw materials of the bismuth-oxide-based black pigment include bismuth oxide (alpha type Bi2O3), amorphous state silicon oxide (SiO2), boron oxide (B2O3), lithium oxide (LiO2), aluminum oxide (Al2O3), zirconium oxide (ZrO2) and copper chromite black (common industrial coloring materials); the preparation method includes the steps of evenly mixing bismuth oxide (alpha type Bi2O3), amorphous state silicon oxide (SiO2), boron oxide (B2O3), lithium oxide (LiO2), aluminum oxide (Al2O3) and zirconium oxide (ZrO2), conducting high energy ball milling to make the mixture sufficiently and mechanically alloyed, and mixing the powder obtained through ball milling with copper chromite black in a ball milling mode. The maximum particle size of the bismuth-oxide-based black pigment is smaller than 2 micrometers, the sintering temperature on glass is between 600 DEG C and 700 DEG C, the bonding strength between the bismuth-oxide-based black pigment and the glass is high, and the bismuth-oxide-based black pigment has wide application prospects in the field of digital inkjet printing.

Owner:JIANGSU UNIV

Preparation of nano copper chromite using microemulsion method

InactiveCN1426965AImprove catalytic performanceChromates/bichromatesColloidal chemistry detailsPotassiumCopper sulfate

A process for preparing nanometre-class copper chromite by the microemulsion method includes such steps as mixing toluene, water and emulsifier, ultrasonic emulsifying to form microemulsion, dropping the ammonia solution of potassium bichromate and the solution of copper sulfate to generate colloid deposit, distilling to remove toluene and water, washing with absolute alcohol, then with water and finally with acetone, drying at 55-65 deg.C and calcining.

Owner:RUNJI SCI & TECH DEV SHANGHAI

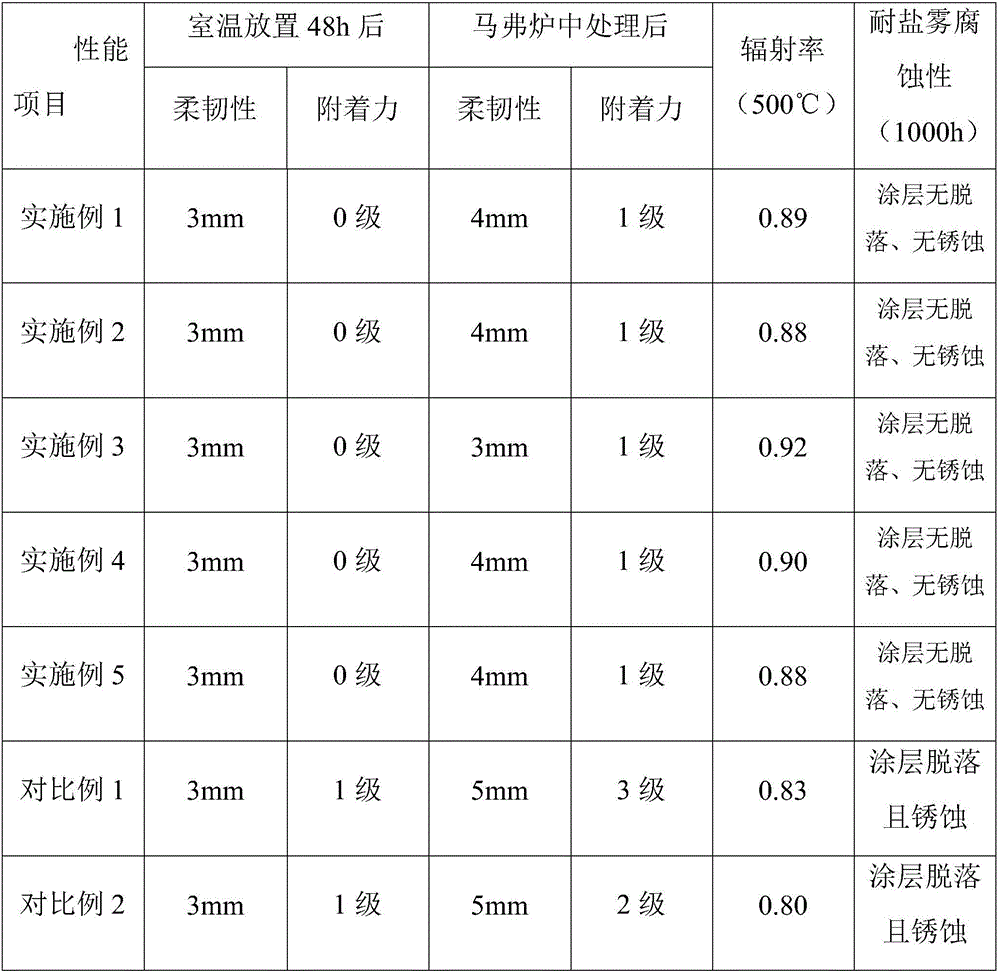

High-temperature resistant anticorrosion paint with high irradiation rate and preparation method thereof

ActiveCN106700917AGood flexibilityGood adhesionFireproof paintsAnti-corrosive paintsMaterials scienceManganese ferrite

The invention discloses a high-temperature resistant anticorrosion paint with high irradiation rate and a preparation method thereof. The high-temperature resistant anticorrosion coating with high irradiation rate is prepared from the following raw material ingredients in parts by weight: 20-25 parts of methoxyphenyl organosilicon, 10-15 parts of methyl organosilicon, 0.5-1.0 part of tetrabutyl titanate, 0.5-1.0 part of tetramethyl guanidine, 2-4 parts of zinc powder, 4-6 parts of aluminum powder, 8-10 parts of manganese ferrite black spinel and 2-4 parts of copper chromite black spinel. A coating obtained by the paint has the advantages of high temperature resistance, anti-corrosion property and high irradiation rate.

Owner:苏州合创电子科技有限公司

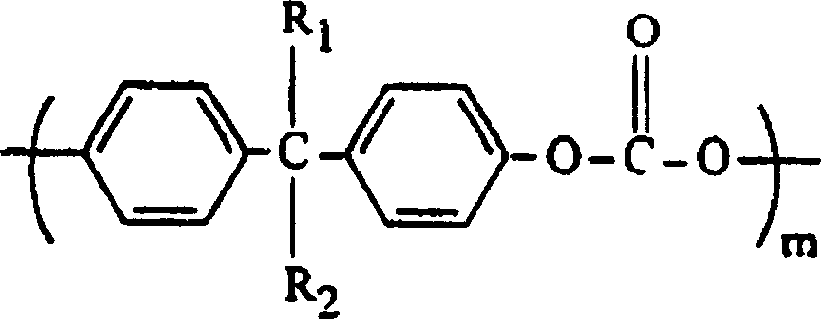

Two-component paint with high temperature resistance and preparation method

InactiveCN106280986AImproves tarnish resistanceImproved cold and heat resistance and convenient performanceAnti-corrosive paintsZinc phosphateAlcohol

The invention relates to paint with high temperature resistance and a preparation method, in particular to two-component paint with high temperature resistance and a preparation method. The two-component paint with high temperature resistance is prepared from a first component and a second component, wherein the first component is prepared from phenyl methyl silicone resin, a wetting dispersant, a copper chromite black pigment, mica powder, barium phosphonate, zinc phosphate, glass powder and n-butyl acetate in proportion; the second component is prepared from gamma-aminopropyltriethoxysilane and absolute ethyl alcohol in equal proportion through mixing, the two components in a ratio being (100:1)-(105:1) in parts by weight are mixed, and the two-component paint with high temperature resistance is obtained. The temperature resistance, the discoloration resistance and the alternate cooling and heating resistance of the two-component paint with high temperature resistance are greatly improved, and adhesive force and corrosion resistance of the two-component paint with high temperature resistance are excellent.

Owner:SHANDONG DIGAO PAINT IND CO LTD

Resin composition with laser marking performace, moulding product thereof and marking method

Owner:SABIC GLOBAL TECH BV

High-temperature corrosion resistant ceramic coating

The invention discloses a high-temperature corrosion resistant ceramic coating. The high-temperature corrosion resistant ceramic coating is characterized by comprising the following substances in parts by weight: 1-32 parts of silica sol, 5-17 parts of rare earth cerium oxide powder, 10-32.5 parts of silica sol, 15-48 parts of talcum powder, 21-39 parts of petalite, 11-40 parts of carbon fiber, 7.8-19.5 parts of tetramethyl ammonium hydroxide, 3-12 parts of silica sand, 4-18 parts of zinc borate, 9-27 parts of ethyl silanol sodium, 21-56 parts of copper chromite black, 3-18 parts of aluminium oxide, 1-14 parts of silicon carbide, 2-14 parts of water-soluble resin emulsion and 30-71 parts of water. The high-temperature corrosion resistant ceramic coating can be high-temperature resistant, high in emissivity, fouling and slagging resistant, high-temperature corrosion resistant, anti-abrasive, and free of falling or bulking, and is made of carbon steel, so that the service life is long.

Owner:QINGDAO XIANGHAI ELECTRONICS

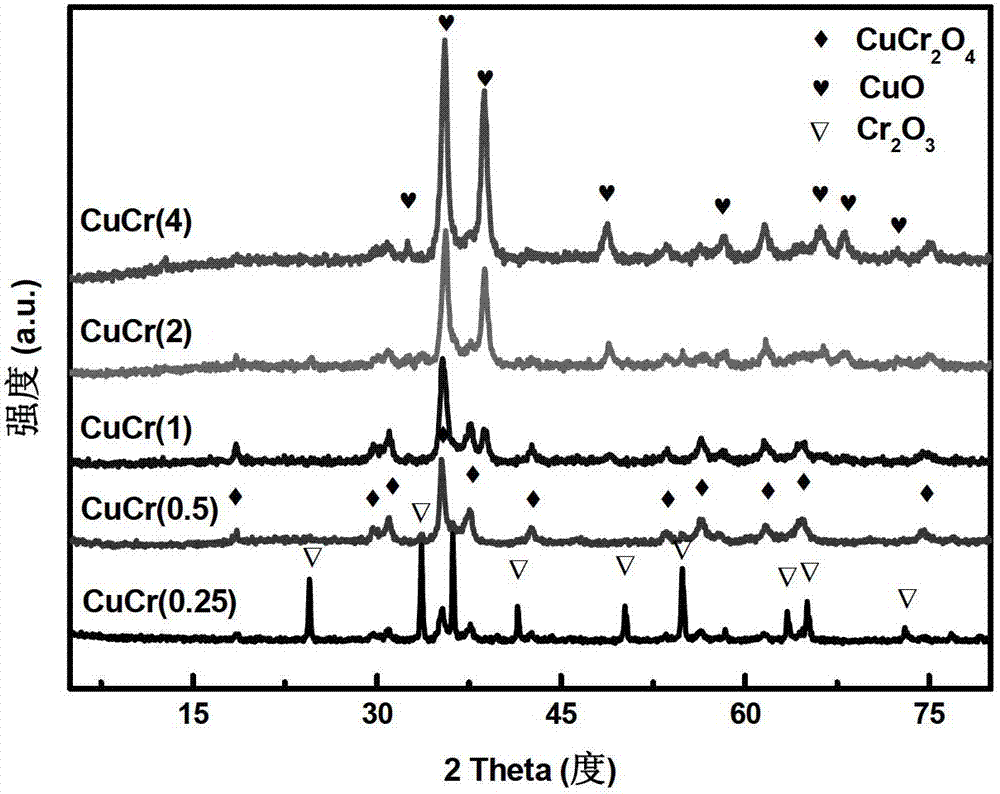

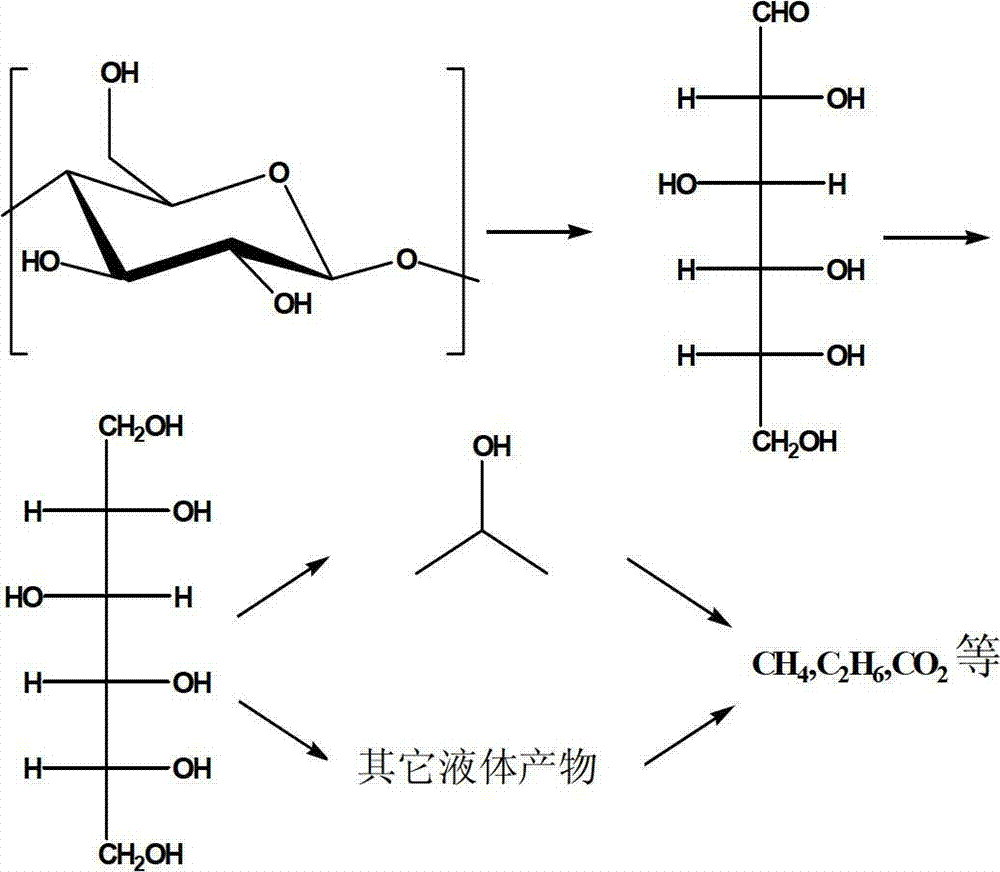

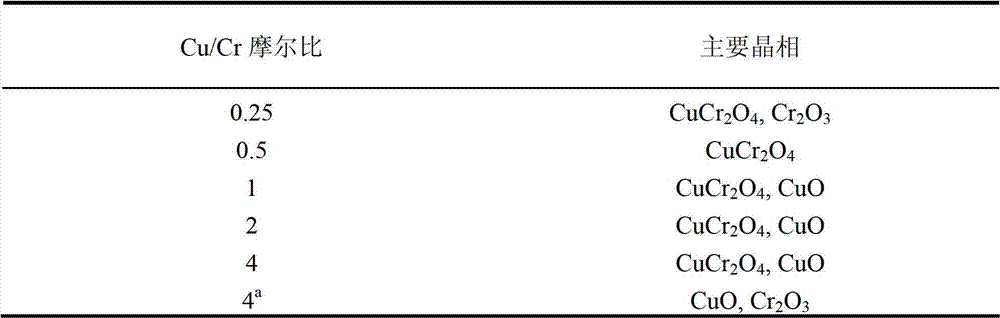

Method of preparing isopropanol by catalytic conversion of cellulose

ActiveCN102757310AExcellent isopropanol selectivityHigh yieldOrganic compound preparationCatalyst activation/preparationCelluloseCopper chromite

The invention relates to a method of preparing isopropanol by cellulose. The method is characterized in that the catalytic reaction is carried out on cellulose in the presence of a copper chromite catalyst so that the cellulose is converted into isopropanol, wherein the copper chromite catalyst comprises a CuCr2O4 active phase or an active phase of a group formed by CuO and Cr2O3, the mass ratio of the cellulose to water is below 15 wt%, and the temperature of the catalytic reaction is 200-270 DEG C.

Owner:ECO ENVIRONMENTAL ENERGY RES INST +1

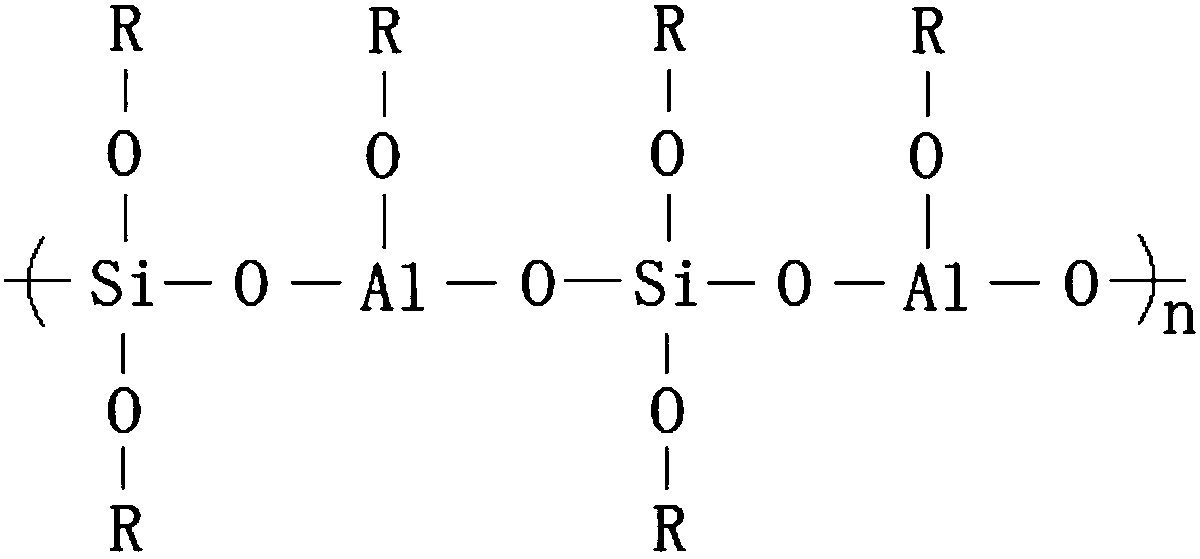

Geopolymer coating and preparation method and application thereof

The invention discloses geopolymer coating and a preparation method and an application thereof which belong to the field of high temperature resistant coating. The geopolymer coating is prepared from,by weight, the following components: 100 parts of copper chromite black, 1-200 parts of a thermal conductive filler, 100-500 parts of a silicate binder, 10-150 parts of metakaolin, and 100-1000 partsof water. A geopolymer is formed through a reaction of the copper chromite black, the metakaolin and the silicate binder; the geopolymer coating provided by embodiments of the invention employs the advantages of high strength in geopolymer, good chemical corrosion resistance, high temperature resistance and durability; and therefore, the coating can be firmly adhered to the surface of a metal material without cracking or falling off due to expansion of metal, thereby prolonging the service life of the coating, and the thermal efficiency of a kiln is improved for a long time.

Owner:PETROCHINA CO LTD

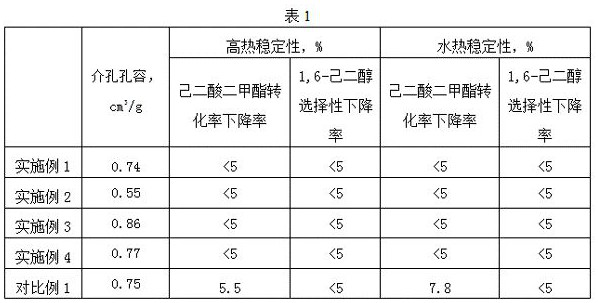

Catalyst for preparing 1, 6-hexanediol by hydrogenating dimethyl adipate, and preparation method and application thereof

ActiveCN111659375AIncrease loading capacityGood dispersionOrganic compound preparationHydroxy compound preparationIridiumPtru catalyst

The invention discloses a catalyst for preparing 1, 6-hexanediol through hydrogenating dimethyl adipate. The catalyst is composed of a carrier and an active component dispersedly loaded on the carrier, wherein the active component is composed of a first active component and a second active component, the first active component is ruthenium and / or iridium, and the second active component is copperchromite; the carrier is a lanthanum doped SiO2 / ZrO2 carrier; and the carrier is of a mesoporous structure, and the pore size of the carrier is 10-50 nm. The catalyst provided by the invention not only has the advantages of high dimethyl adipate conversion rate and strong 1, 6-hexanediol selectivity, but also has the excellent performances of large specific surface area, high active component loading capacity, stable performance and long service life. The invention further discloses a preparation method and application of the catalyst for preparing 1, 6-hexanediol through hydrogenating dimethyl adipate.

Owner:TANGSHAN ZHONGRONG TECH CO LTD

High-emissivity ceramic paint

InactiveCN104178030AHigh emissivityAnti-staining and slaggingCoatingsCeramic coatingTemperature resistance

The invention discloses high-emissivity ceramic paint. The high-emissivity ceramic paint is characterized by comprising the following substances in parts by weight: 31-56 parts of copper chromite black, 3.8-4.4 parts of dispersing agent, 11.7-15 parts of silica sol, 3.4-5.9 parts of rear earth cerium oxide powder, 1-5 parts of silica sol, 25-30 parts of talcum powder, 1-3 parts of zinc borate, 3.5-14.7 parts of sodium silicate, 5-12.7 parts of polyethylene methyl ether methacrylate, 3-8 parts of tri-isotripolyisocyanate, 11-18 parts of sulfonated melamine formaldehyde condensation compound, 0-15 parts of sodium ethyl siliconate, 15.4-30.7 parts of aluminum oxide, 5.1-10.7 parts of defoaming agent, 1-14 parts of silicon carbide, 1.5-13 parts of water-soluble resin emulsion and 40.5-60 parts of water. The high-emissivity ceramic pain has the beneficial effects of high temperature resistance, high emissivity, fouling and slagging resistance, high temperature corrosion resistance, wear resistance, no dropping and bulging phenomena, capacity of being applied to carbon steel, and long service life.

Owner:QINGDAO XIANGHAI ELECTRONICS

Syndiotactic polystyrene flame-retardant composite material

The invention relates to a syndiotactic polystyrene flame-retardant composite material. The syndiotactic polystyrene flame-retardant composite material comprises the following components in parts by weight: 15-40 parts of syndiotactic polystyrene, 5.7-20 parts of polyhexamethylene adipamide, 16-20 parts of flame retardant, 4-6 parts of flame-retardant synergistic agent, 3.5-6 parts of compatilizer, 1-5 parts of laser etching powder, 0.3-0.6 part of coupling agent, 0.4-0.7 part of antioxidant and 10-50 parts of glass fiber, wherein the laser etching powder is selected from at least one of silicon dioxide, titanium dioxide, zinc sulfide, chromic oxide, neodymium oxide, bismuth oxide, tin oxide, zinc molybdate, ammonium molybdate, basic cupric phosphate, copper oxide, copper chromite black, copper carbonate, copper sulfate, copper chloride, copper chromite and carbon black. The syndiotactic polystyrene flame-retardant composite material is simple to machine, and has favorable mechanical property, flame retardancy and heat resistance.

Owner:古道尔工程塑胶(深圳)有限公司

Method for the Production of Neopentyl Glycol

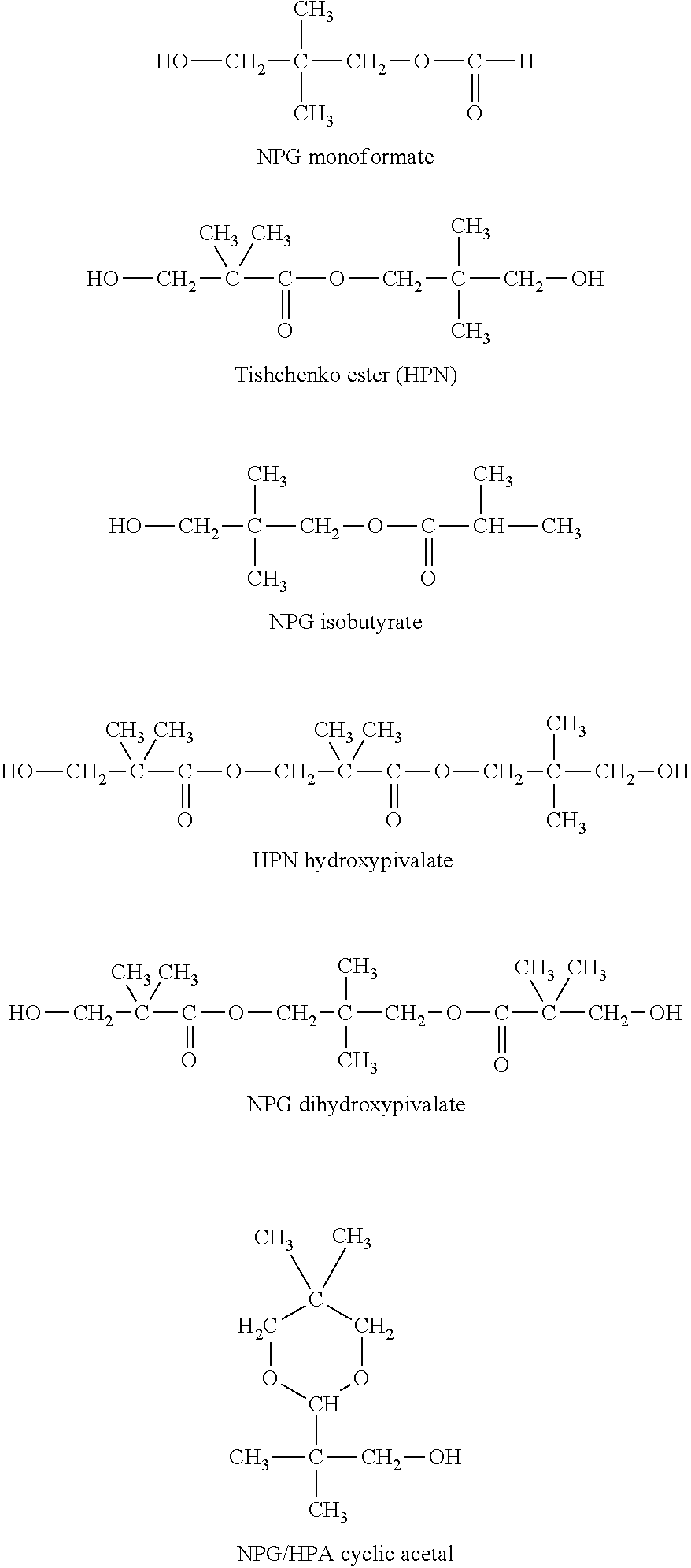

ActiveUS20150239809A1High selectivityIncreased space-time yieldOrganic compound preparationHeterogenous catalyst chemical elementsCopper chromiteManganese

A method for preparing neopentyl glycol by addition of isobutyraldehyde and formaldehyde in the presence of a tertiary alkylamine as catalyst to give hydroxypivalaldehyde with subsequent hydrogenation at a temperature of 80 to 140° C. and at a pressure of 2 to 18 MPa in the liquid phase, is characterized in that the hydrogenation is carried out in the presence of a copper chromite catalyst comprising the activators barium and manganese.

Owner:OQ CHEM GMBH

High-performance corrosion-resistant ceramic coating

InactiveCN104151956AHigh emissivityAnti-staining and slaggingAnti-corrosive paintsWear resistantPolyvinyl alcohol

The invention discloses a high-performance corrosion-resistant ceramic coating which is characterized by comprising the following substances in parts by weight: 55-80 parts of copper chromite black, 1-10 parts of dispersing agent, 10-30 parts of plaster, 5-17 parts of coal cinder powder, 6-14 parts of potassium oxide, 3-5 parts of sericite, 1.5-4.2 parts of magnesium oxide, 17-28 parts of apatite, 3-20 parts of zirconite, 15-34 parts of dolomite, 13-40 parts of zirconium silicate, 20-40 parts of polyvinyl alcohol, 11-20 parts of expanded perlite powder, 11-30 parts of synthetic rubber, 50-69 parts of mullite, 3.4-5.9 parts of rare earth cerium oxide powder, 1-8 parts of silicon carbide and 50-90 parts of water. The high-performance corrosion-resistant ceramic coating is high-temperature-resistant, high in emissive power, anti-fouling and anti-scaling, high-temperature corrosion-resistant, wear-resistant and incapable of falling off and bulking; the service life of the carbon steel is long.

Owner:QINGDAO XIANGHAI ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com