Patents

Literature

34results about How to "Good inkjet printing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ink for ceramic ink-jet printing and method for preparing same

ActiveCN102964920AGood quality and stabilitySimple manufacturing methodInksAcrylate esterDefoaming Agents

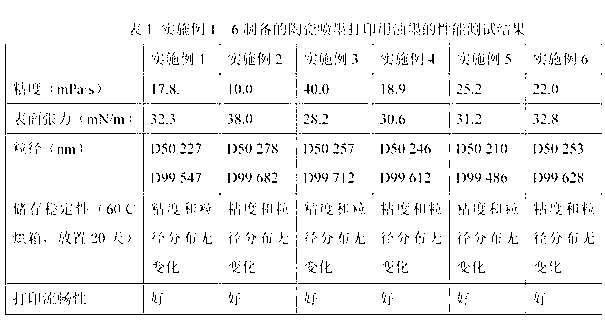

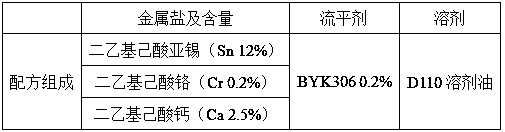

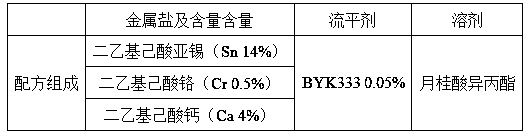

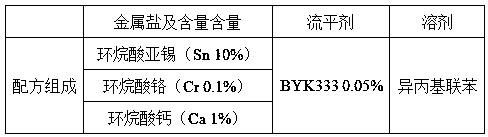

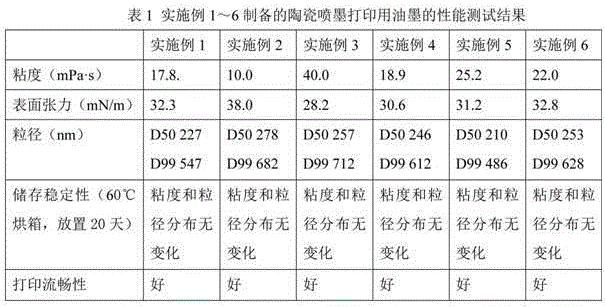

The invention discloses an ink for ceramic ink-jet printing and a method for preparing the same, wherein the ink comprises the following components by mass percent: 20-50% of ceramic pigment, 3-8% of resin, 2-10% of dispersant, 0.1-0.2% of flatting agent, 0.3-0.7% of defoamer, 0.08-0.12% of anti-settling agent and the balance of solvent; and the dispersant is a high-molecular-weight polyurethane type dispersant or a high-molecular-weight polyacrylate type dispersant. The ink for ceramic ink-jet printing provided by the invention is good in quality stability and thereby can be stored for a long time; the ink is excellent in ink-jet printing performance, low in ink viscosity and even in particle size distribution; the viscosity of the ink is between 10.0 and 40.0 mPa.s and is controllable; and the surface tension of the ink is 28-38 mN / m, while the average particle size is 200-300 nm and the maximum particle size is less than 800 nm. The method for preparing the ink for ceramic ink-jet printing provided by the invention is simple and efficient; and a one-step mill base grinding process and an ink performance regulation process are carried out, so that the production cost is greatly saved.

Owner:GUANGDONG DOWSTONE TECH

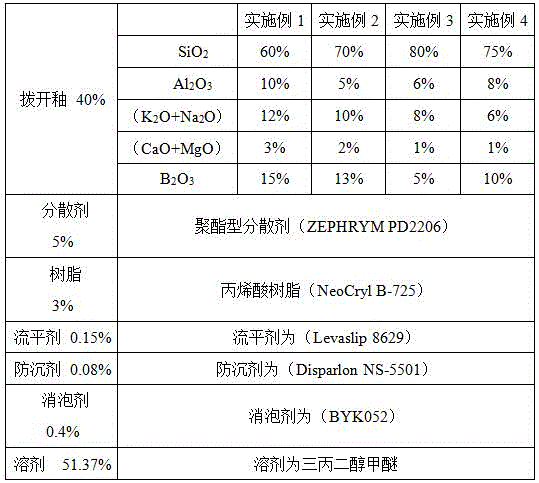

Matte glaze ink for ceramic jet printing and preparation method thereof

The present invention discloses a matte glaze ink for ceramic jet printing and preparation method thereof, wherein the ink comprises, based on the mass percentage, 30-50% of matte glaze, 3-8% of resin, 2-10% of dispersant, 0.1-0.2% of leveling agent, 0.3-0.6% of defoaming agent, 0.08-0.12% of anti-settling agent and the balance for the solvent, wherein the matte glaze includes raw materials of the following components of SiO2, Al2O3, K2O, Na2O, CaO, MgO, ZnO and BaO. Matte glaze ink prepared by the invention has low viscosity, uniform distribution of particle diameter with maximum particle diameter of less than 1Mum and good printing performance. Fired glaze owns gentle matte finish.

Owner:FOSHAN DOWSTONG TECH

Ceramic ink with sinking effect and preparation method thereof

The invention discloses ceramic ink with a sinking effect and a preparation method thereof. The ceramic ink comprises sinking glaze and an organic composition; the organic composition comprises resin, a disperse agent, a defoamer and a solvent; the sinking glaze comprises V2O5, Bi2O3, Ba2CO3, ZnO, SiO2, Al2O3, K2O and Na2O. The ceramic ink with the sinking effect is low in viscosity, controllable, uniform in particle size distribution and excellent in quality stability and ink-jet printing performance, and can show concave-convex vivid texture and strong third dimension of a ceramic tile in a more sufficient and visual manner when being matched with pigment ink for ceramic ink-jet printing to further improve the decorative effect and the added value of the ceramic tile. According to the ceramic ink with the sinking effect, the preparation method is simple and efficient, the controllability is excellent, and the industrial mass production is applicable.

Owner:FOSHAN DOWSTONG TECH

Peel glaze ink for ceramic ink-jet printing

The invention discloses peel glaze ink for ceramic ink-jet printing. The ink is prepared from a peel glaze, resin, a dispersing agent, a leveling agent, a defoaming agent, an anti-settling agent and a solvent. The peel glaze is prepared from SiO2, Al2O3, (K2O+Na2O), (CaO+MgO) and B2O3. The ink is good in quality stability, can be stored for a long time and has good ink-jet printing performance, the viscosity of the ink is 10.0-40.0 mPa.s and controllable, the surface tension is 26-40 mN / m, the average particle diameter is 300-500 nm, and the maximum particle diameter is smaller than 1mum. Ink printing products can fully and visually show exquisite texture and natural-transition color of stone bricks after sintered, can highly restore texture of natural stone and can be widely applied to the field of ceramic tiles and archaized bricks. When the peel glaze ink is matched with ceramic ink-jet printing pigment ink to be used, a decorative effect of tiles is further improved. Furthermore, material waste and labor cost are effectively reduced, and the peel glaze ink is also adaptable to digital development trend of ceramic ink jet.

Owner:GUANGDONG DOWSTONE TECH

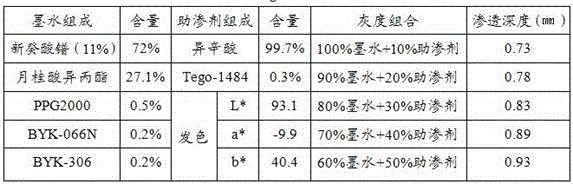

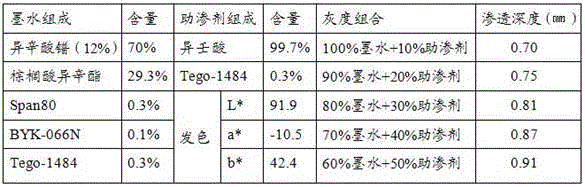

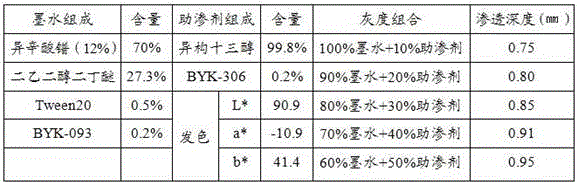

Praseodymium yellow ceramic jet-ink infiltrating ink and preparation method thereof

The invention discloses praseodymium yellow ceramic jet-ink infiltrating ink and a preparation method thereof. The praseodymium yellow ceramic jet-ink infiltrating ink comprises 65 to 75% of organic praseodymium salt, 25 to 35% of a solvent and 0.1 to 2% of an additive in percentage by mass; the organic praseodymium salt is carboxylic acid praseodymium. According to the invention, the organic praseodymium salt is used for preparing the praseodymium yellow ceramic infiltrating ink of which the penetration depth can be controlled within 0.1 to 1.5 millimeters, the infiltrating ink is bright-colored in chromogenic reaction and does not deteriorate within 8 months, the viscosity of the ink at the temperature of 40 DEG C is 20-25m Pa*s, the surface tension of the ink is 25-29mN / m, and the infiltrating ink has good ink-jet printing performance and can be used in a variety of mainstream nozzles.

Owner:山东国瓷康立泰新材料科技有限公司

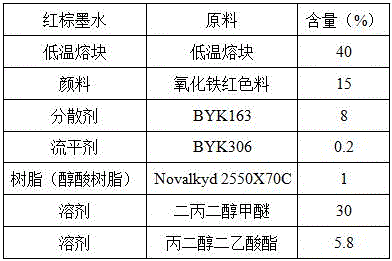

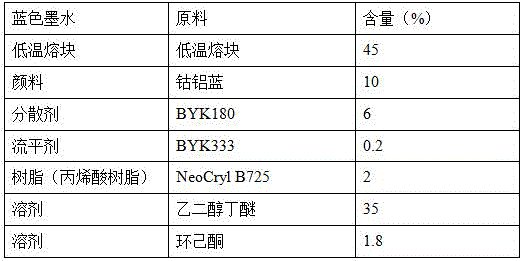

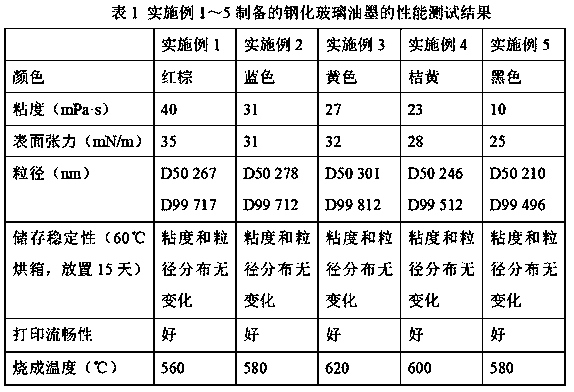

Tempered glass ink for ink-jet printing and preparation method thereof

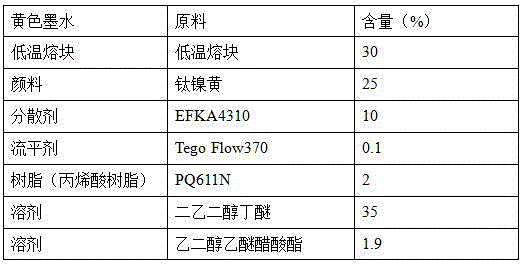

The invention discloses a tempered glass ink for ink-jet printing and a preparation method thereof. The ink is prepared from low-temperature frit, inorganic pigments, a dispersant, resin, a flatting agent and a solvent. The tempered glass ink for ink-jet printing has good stability, favorable ink-jet printing performance, low viscosity which ranges from 10.0 to 40.0mPa.s and can be regulated, uniform particle size distribution, the surface tension of 25 to 35mN / m, an average particle size of 200 to 400 nm and a maximum particle size of less than 1 micrometers, and can be stored for a long time. The ink prepared by the preparation method disclosed by the invention has low sintering temperature and can be well combined with glass. The sintered surface is strongly resistant to acid, alkaline and ultraviolet radiation.

Owner:广东道氏陶瓷材料有限公司

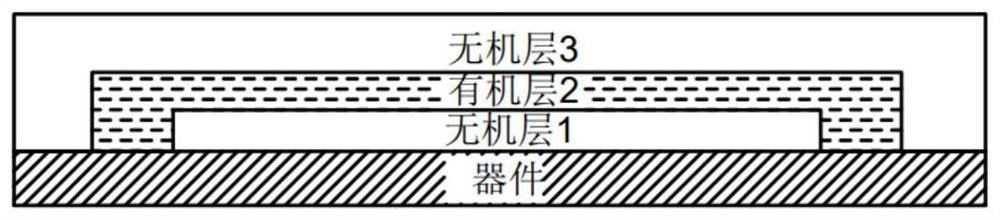

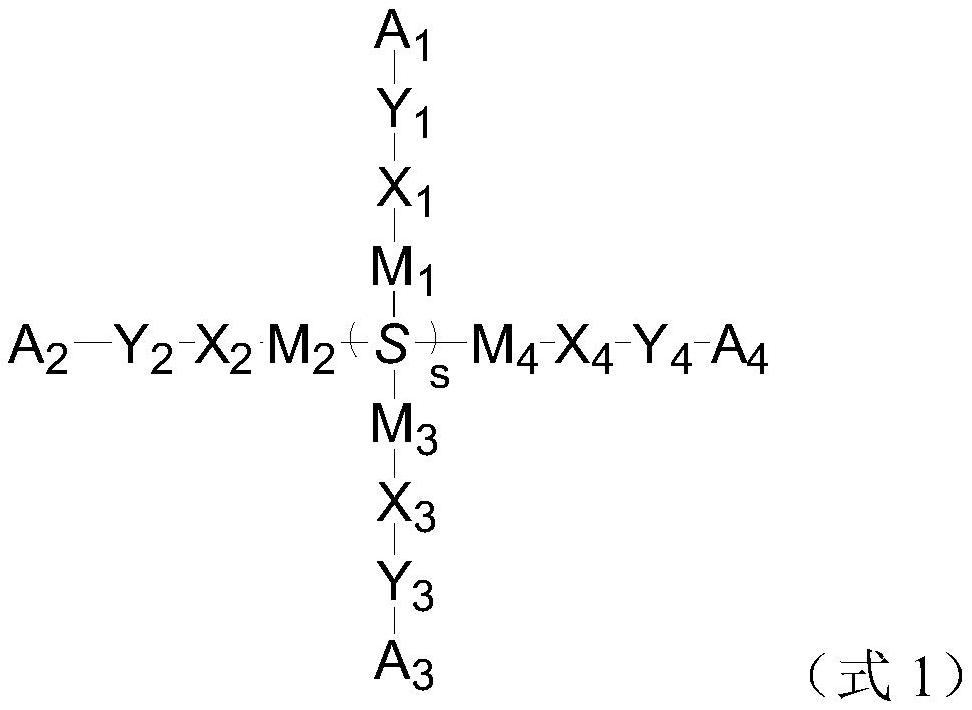

Composition for packaging optoelectronic device, packaging structure and optoelectronic device

ActiveCN111933823AImprove heat resistanceImprove featuresSolid-state devicesSemiconductor/solid-state device manufacturingThin membraneHydrophobe

The invention discloses a composition for packaging an optoelectronic device, a packaging structure and the optoelectronic device. The composition comprises 10%-70% of a photocurable monomer, 10%-70%of a monofunctional or trifunctional silicon-containing monomer; and 0.5%-10% of an initiator, using a silicon-containing monomer, on one hand, due to the fact that the deformation capacity of a Si-O-Si chain segment of the silicon-containing monomer is high, when the composition is impacted by force, the silicon-containing monomer can play a role in stress dispersion, internal stress is reduced,and the mechanical property of the organic packaging composition is improved; on the other hand, the thermal performance and the hydrophobic performance of the organic packaging composition can be effectively improved, and the service life of the device can be effectively prolonged when the organic packaging composition is used for thin film packaging of photoelectronic devices.

Owner:XIAN SMART MATERIALS CO LTD

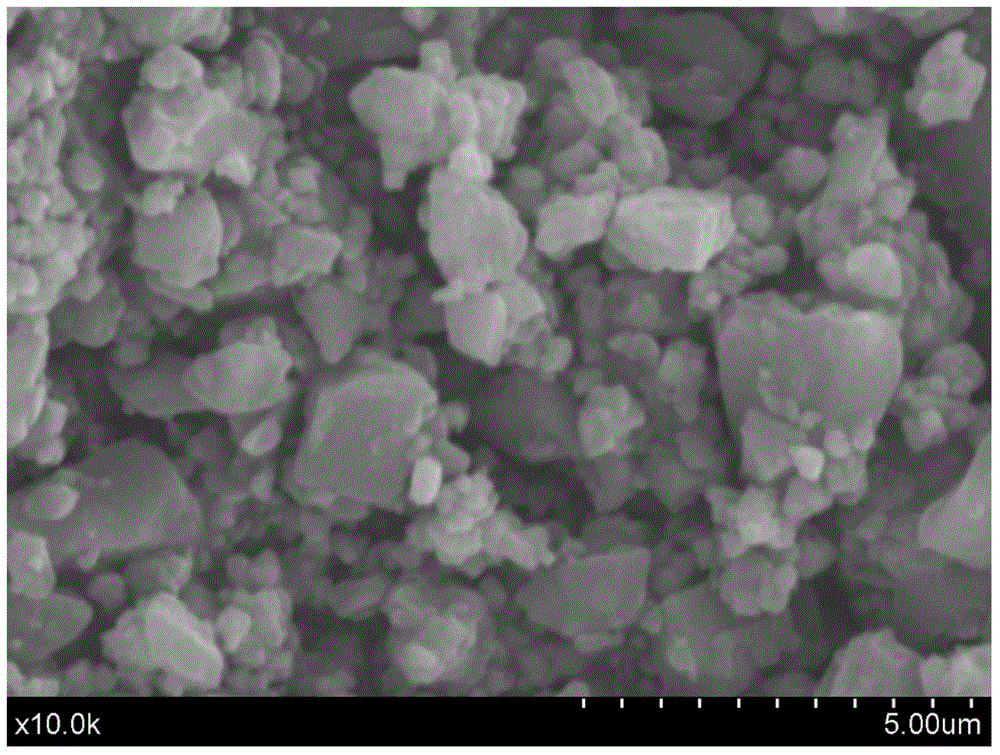

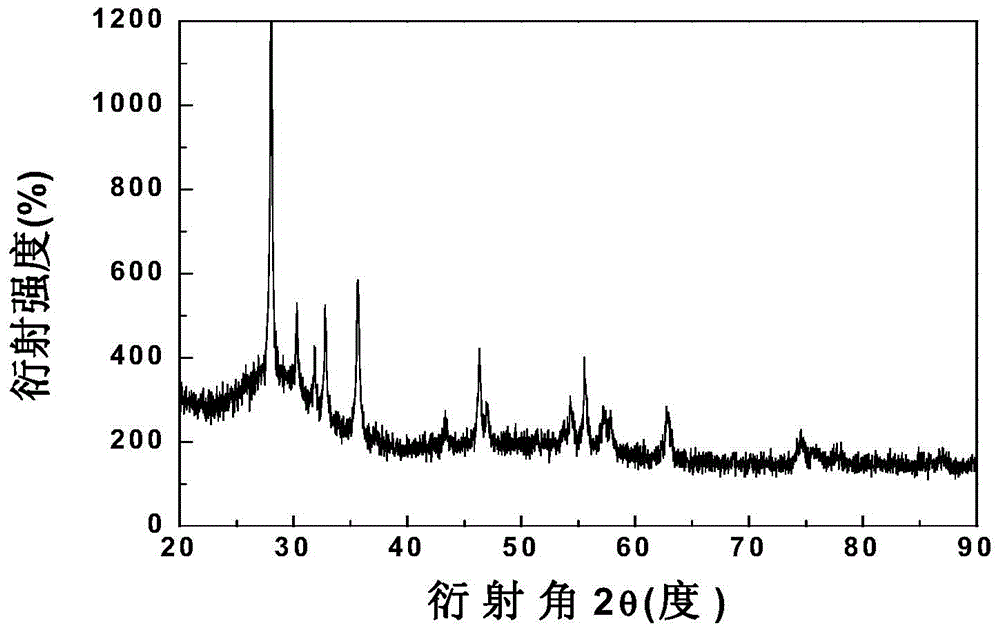

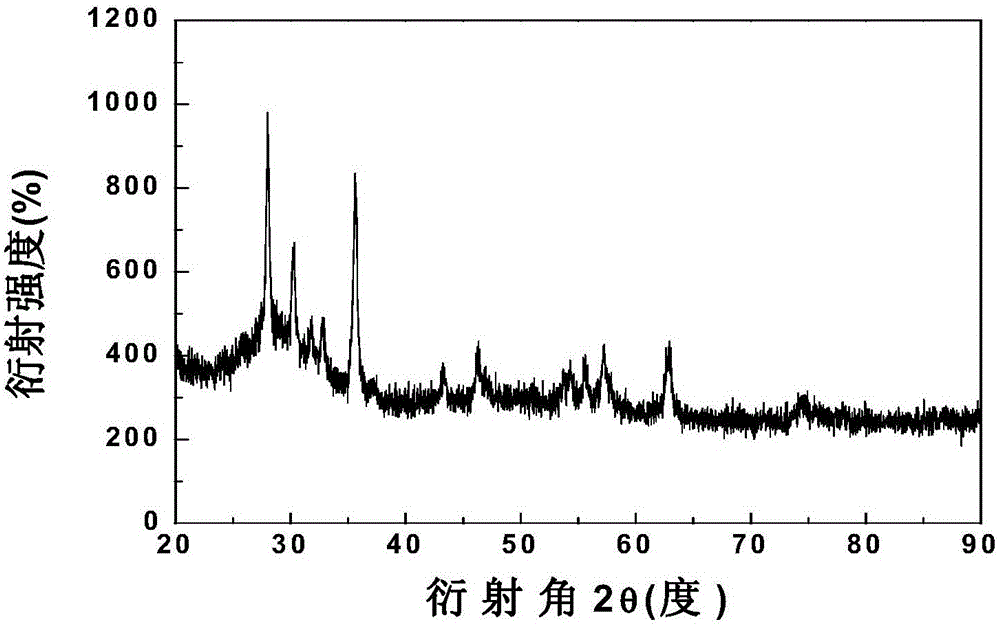

Bismuth-oxide-based black pigment used for glass digital inkjet printing and preparation method of bismuth-oxide-based black pigment

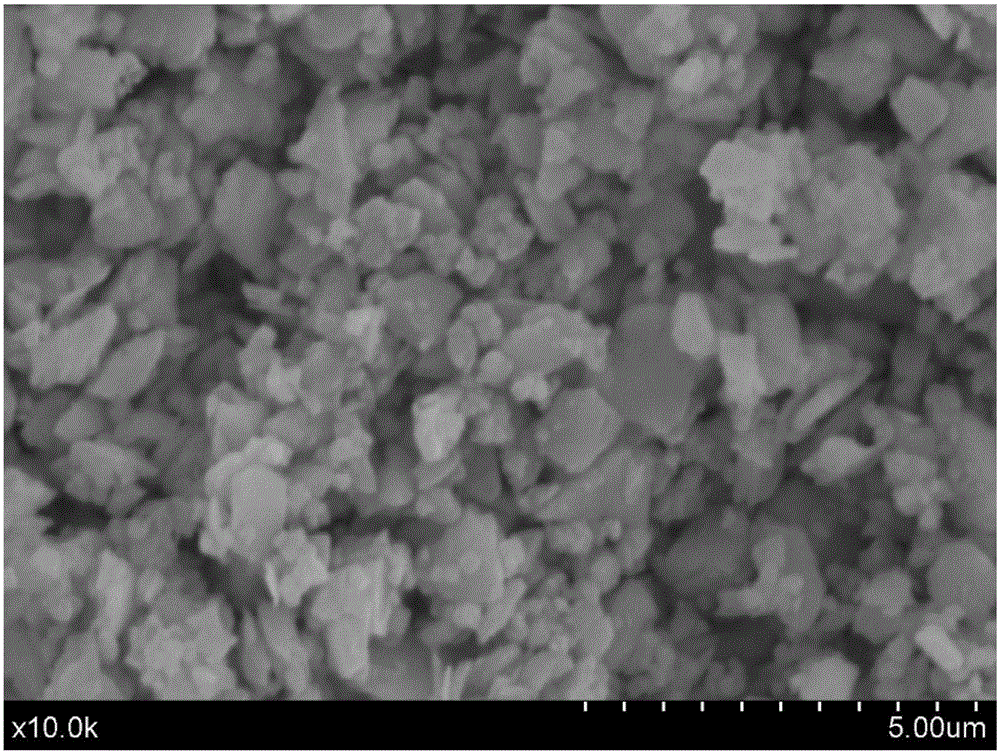

InactiveCN105062198AReduces inkjet head cloggingGood inkjet printing performanceInksLithium oxideSilicon oxide

The invention provides bismuth-oxide-based black pigment used for glass digital inkjet printing and a preparation method of the bismuth-oxide-based black pigment. The bismuth-oxide-based black pigment is characterized in that preparation raw materials of the bismuth-oxide-based black pigment include bismuth oxide (alpha type Bi2O3), amorphous state silicon oxide (SiO2), boron oxide (B2O3), lithium oxide (LiO2), aluminum oxide (Al2O3), zirconium oxide (ZrO2) and copper chromite black (common industrial coloring materials); the preparation method includes the steps of evenly mixing bismuth oxide (alpha type Bi2O3), amorphous state silicon oxide (SiO2), boron oxide (B2O3), lithium oxide (LiO2), aluminum oxide (Al2O3) and zirconium oxide (ZrO2), conducting high energy ball milling to make the mixture sufficiently and mechanically alloyed, and mixing the powder obtained through ball milling with copper chromite black in a ball milling mode. The maximum particle size of the bismuth-oxide-based black pigment is smaller than 2 micrometers, the sintering temperature on glass is between 600 DEG C and 700 DEG C, the bonding strength between the bismuth-oxide-based black pigment and the glass is high, and the bismuth-oxide-based black pigment has wide application prospects in the field of digital inkjet printing.

Owner:JIANGSU UNIV

Pink penetrating ink of ceramic inkjet

Owner:GUANGDONG DOWSTONE TECH

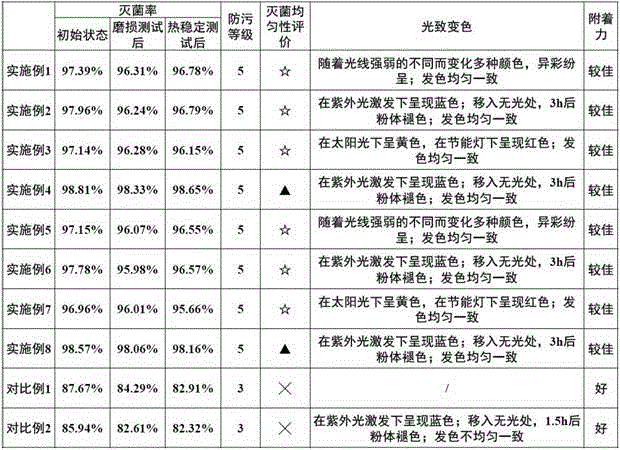

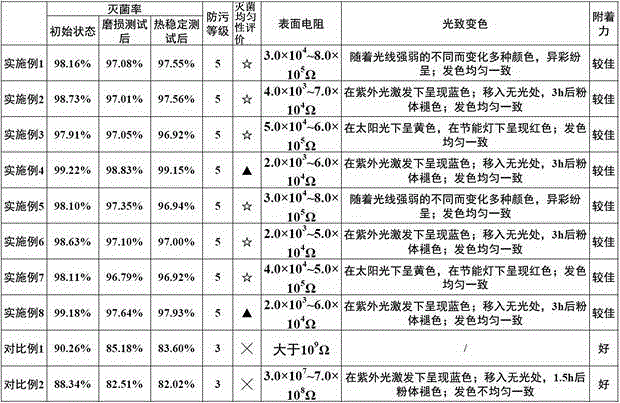

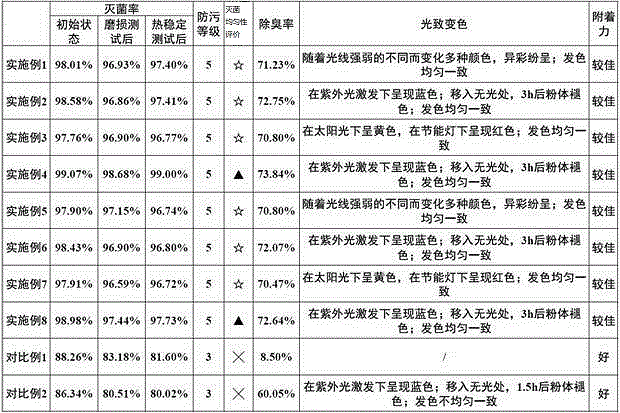

Photochromic ceramic ink capable of being sunken and used for ceramic ink jet and preparing method thereof

The invention discloses a photochromic ceramic ink capable of being sunken and used for ceramic ink jet and a preparing method thereof. The preparing method comprises the steps of A, preparing a subsidence glaze; B, measuring the subsidence glaze, a dispersing agent, a surface additive, an antifoaming agent, a binding agent and the balance solvent according to a ratio, and grinding the mixture to obtain an ink semi-finished product; C, filtering the ink semi-finished product to obtain an ink finished product. Compared with a prior ceramic ink capable of being sunken, the photochromic ceramic ink capable of being sunken is used cooperatively with a pigment ink, which can show concavo-convex and lifelike textures of ceramic tiles more fully and vividly, have a better third dimension, further improve ornamental effects of the ceramic tiles, create colorful patterns, and can be widely applied to fields of ceramic chips, archaized bricks and the like; meanwhile through reasonable matching of photochromic compounds and antibiosis composite materials with the ceramic ink, the ceramic ink has excellent antibacterial, antifouling and photochromic characters, which further broadens applied range of the ceramic ink capable of being sunken.

Owner:FOSHAN GAOMING HAIDI CERAMIC RAW MATERIAL CO LTD

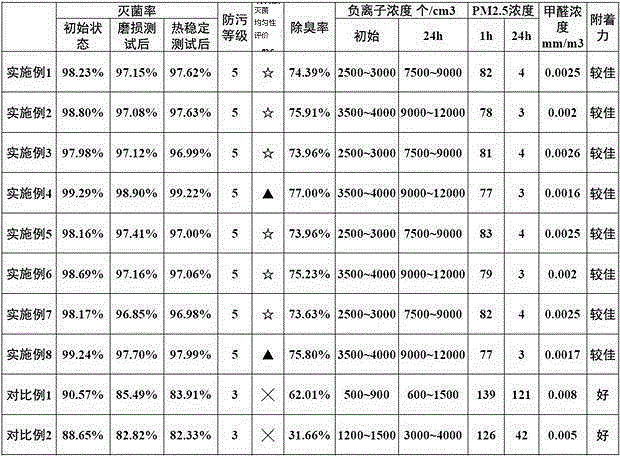

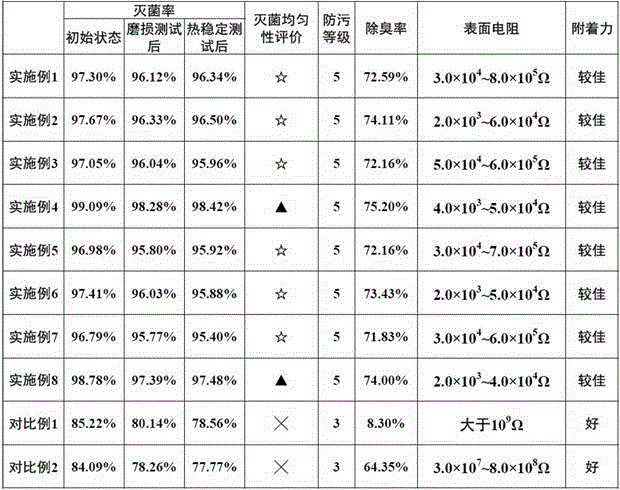

Antibacterial ceramic inkjet ink with marble crack effect and method for preparing antibacterial ceramic inkjet ink

The invention discloses antibacterial ceramic inkjet ink with a marble crack effect and a method for preparing the antibacterial ceramic inkjet ink. The method includes steps of A, mixing and stirring solvents, hyper-dispersants, regulators, defoaming agents and anti-diffusion agents with one another to obtain mixed solution, adding 0.1-5% antibacterial compounds into the mixed solution and uniformly stirring the antibacterial compounds and the mixed solution; B, adding permeating powder and photochromic compounds into the mixed solution, grinding the permeating powder, the photochromic compounds and the mixed solution, then adding solvents and anion compounds into the mixed solution and grinding the solvents, the anion compounds and the mixed solution to obtain semi-finished ink products; C, filtering the semi-finished ink products to obtain finished ink products. The antibacterial ceramic inkjet ink and the method have the advantages that as compared with existing ceramic ink, the antibacterial ceramic inkjet ink manufactured by the aid of the method contains scientific ingredients, is stable in performance and has grains, colors and textures of natural marble, decoration effects of ceramic tiles further can be improved, and the antibacterial ceramic inkjet ink further can be widely applied to the fields of ceramic chips, antique bricks and the like; the photochromic compounds, the anion compounds and antibacterial composite materials are reasonably matched with one another, accordingly, the antibacterial ceramic inkjet ink is excellent in antibacterial performance, air purification and photochromic characteristic, and the application range of the antibacterial ceramic inkjet ink further can be broadened.

Owner:FOSHAN GAOMING HAIDI CERAMIC RAW MATERIAL CO LTD

Anti-static ceramic ink having dermatoglyph effect and preparation method thereof

The invention discloses an anti-static ceramic ink having a dermatoglyph effect and a preparation method thereof. The preparation method comprises the following steps: a step A of preparing dermatoglyph glaze; a step B of weighing the dermatoglyph glaze, a dispersing agent, a surface additive, an antifoaming agent, a binding agent and the balance solvent, and performing grinding to obtain semi-finished ink; and a step C of performing filtration to obtain finished ink. Compared with existing ceramic ink having a dermatoglyph effect, the anti-static ceramic ink is scientific in ingredient, is prepared reasonably and is good in quality stability; the anti-static ceramic ink is matched with pigment ink for ceramic ink-jet printing to be used, convave-convex lifelike grains of a dermatoglyph tile can be embodied more fully visually, the stereoscopic impression is high, the decorating effect of the tile is further improved, and the anti-static ceramic ink can be widely applied in the fields of tiles and archaized bricks. Through reasonable matching of conductive filler, a photochromic compound and an antibacterial composite material, the ceramic ink has excellent antibacterial and antifouling, photochromic and antistatic functions, and the application range of the sunken ceramic ink is further expanded.

Owner:FOSHAN GAOMING HAIDI CERAMIC RAW MATERIAL CO LTD

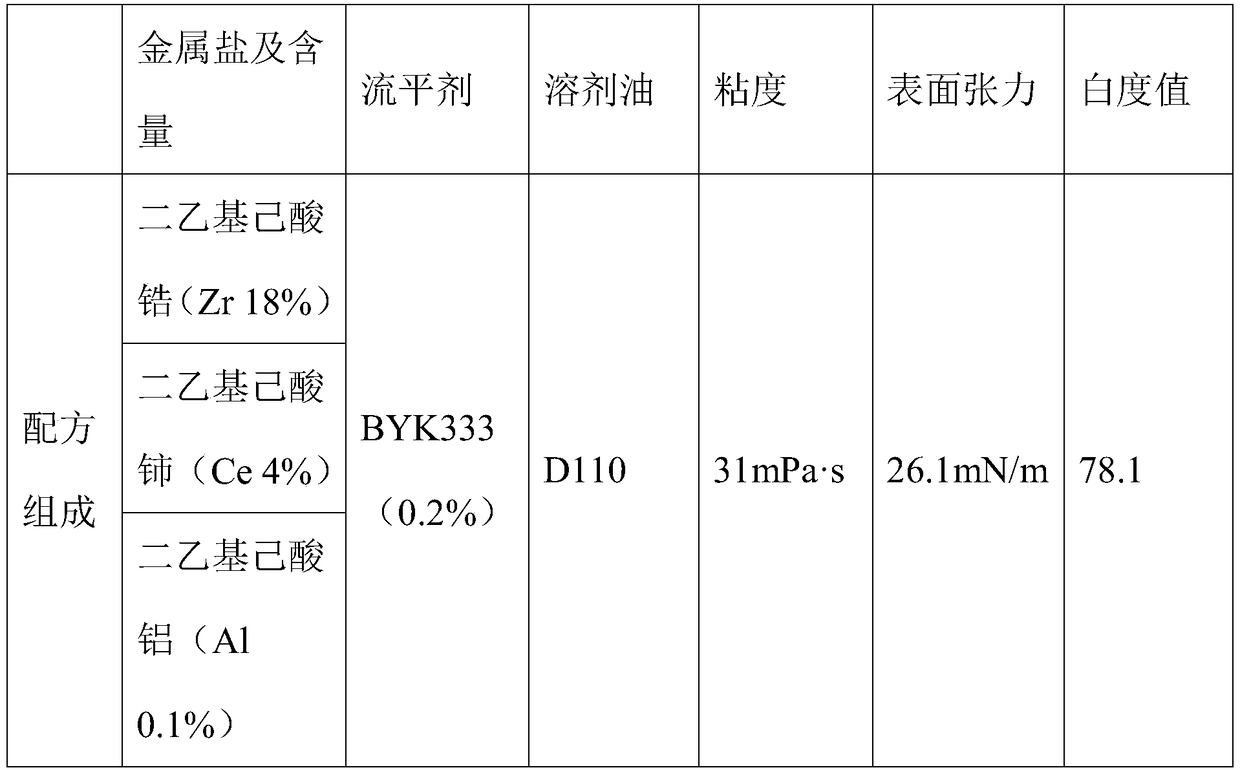

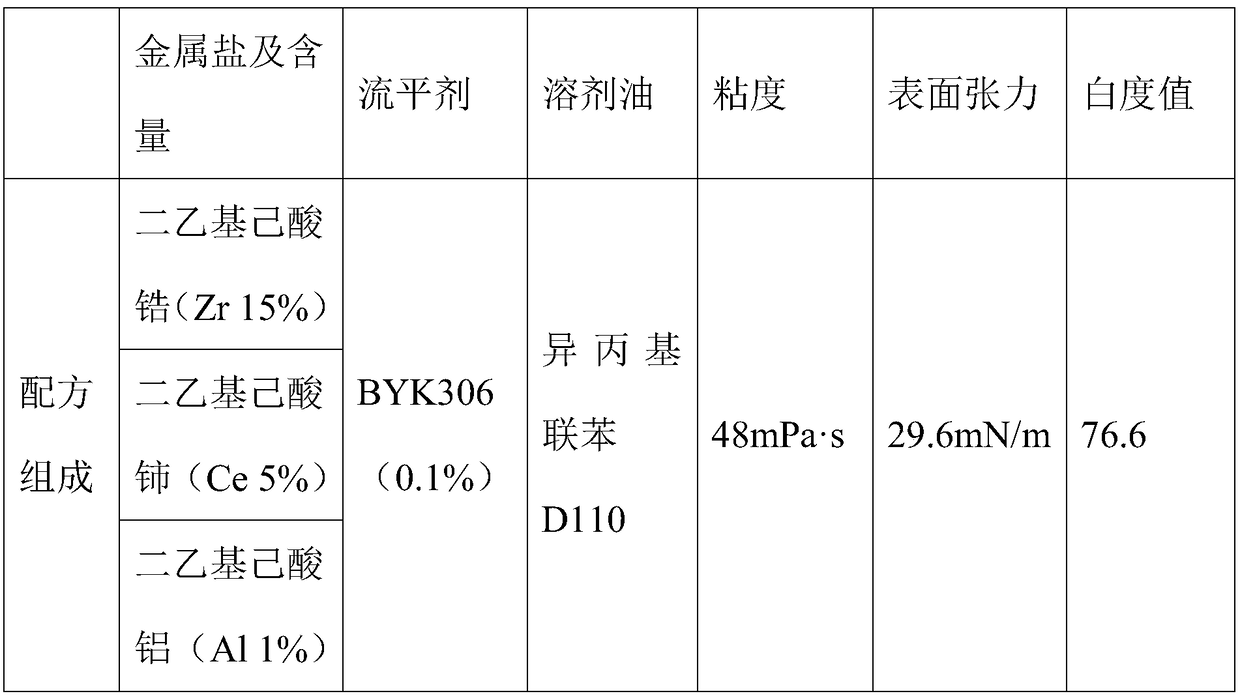

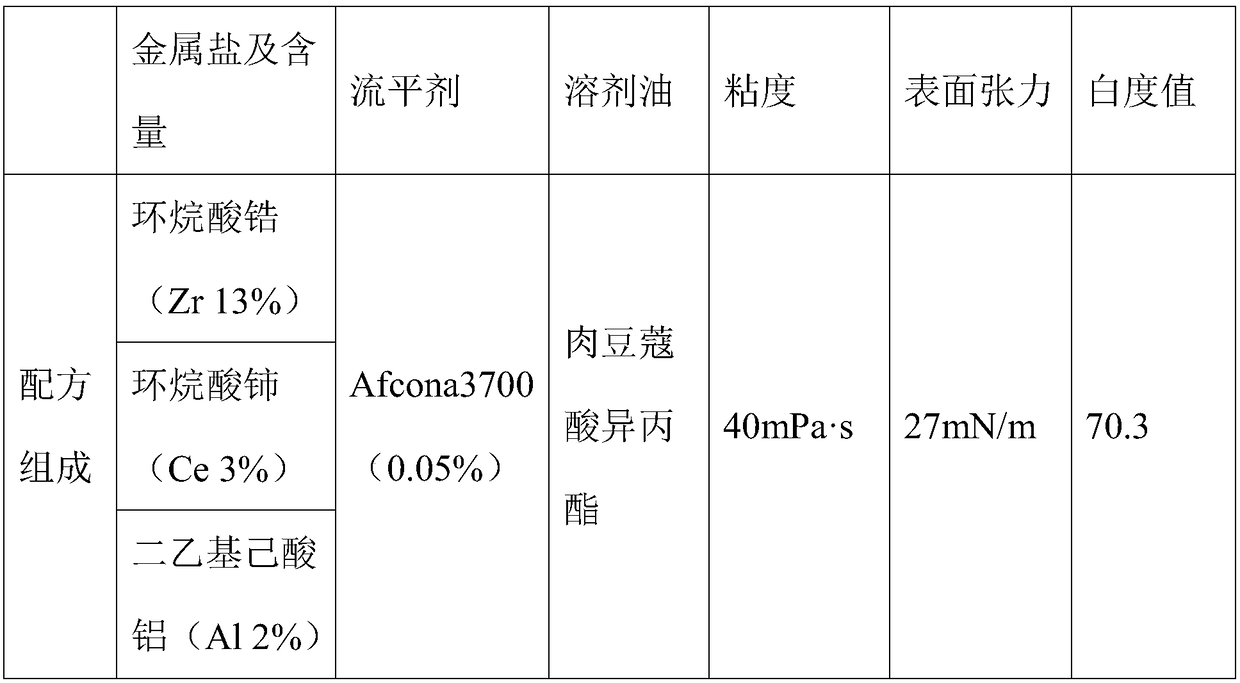

White stain-bleeding printing ink for ceramic ink-jet printing and preparation method thereof

The invention discloses a white stain-bleeding printing ink for ceramic ink-jet printing and a preparation method thereof. The printing ink is composed of following components in percentage by weight:0.05 to 0.2 wt.% of a leveling agent, 20 to 25 wt.% of chromophoric organic metal salts (by the weight of metal ions), and the balance being a solvent; wherein the chromophoric organic metal salts are mixed metal salts of organic cerium, organic zirconium, and organic aluminum. The printing ink has a white decorative effect, the species of ceramic stain-bleeding printing inks are enriched, and the decorative effect of ink-jet bleeding-stained bricks is further enhanced.

Owner:FOSHAN UNIVERSITY

Solvent of bismuth-oxide-base ink for glass digital inkjet printing

The invention relates to a solvent of a bismuth-oxide-base ink for glass digital inkjet printing, which is characterized by comprising the following components in percentage by mass: 65-85% of main solvent, 8-22% of dispersing agent, 6-11% of surfactant and 0.1-2% of light stabilizer, totaling 100%. The main solvent is one or mixture of any of 1-(2-methoxy-1-methylethoxy)isopropanol, 1-ethoxy-2-propanol, 1-methoxy-2-propanol and cyclohexanone. The dispersing agent is diethylene glycol butyl ether. The surfactant is 1,2-propylene-glycol diacetate. The light stabilizer is HS-508. The surface tension of the solvent is 28-32 mN / m. The solvent has the advantages of favorable dispersity for bismuth-oxide-base inorganic powder pigments, high volatilization speed and favorable inkjet printing properties. The preparation method is simple and efficient, has the advantages of favorable controllability and low cost, is suitable for industrialized large-scale production, and has wide application prospects in the field of glass digital inkjet printing.

Owner:JIANGSU FANHUA GLASS CO LTD

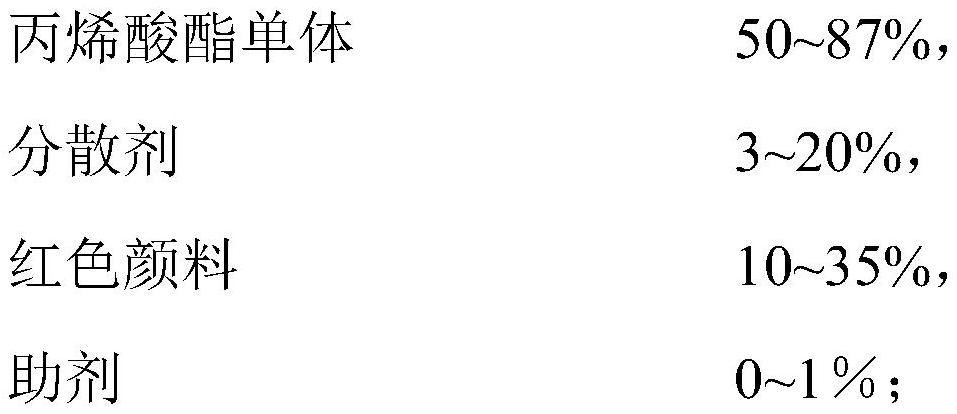

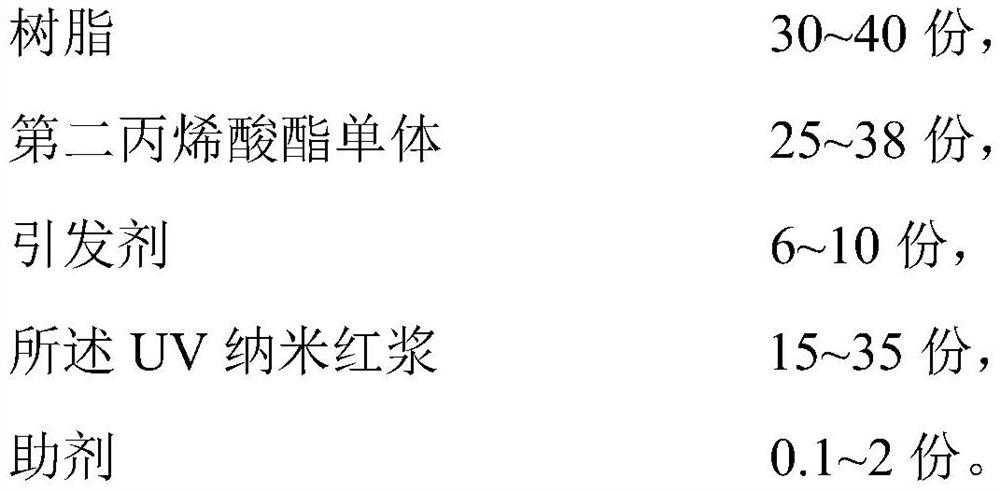

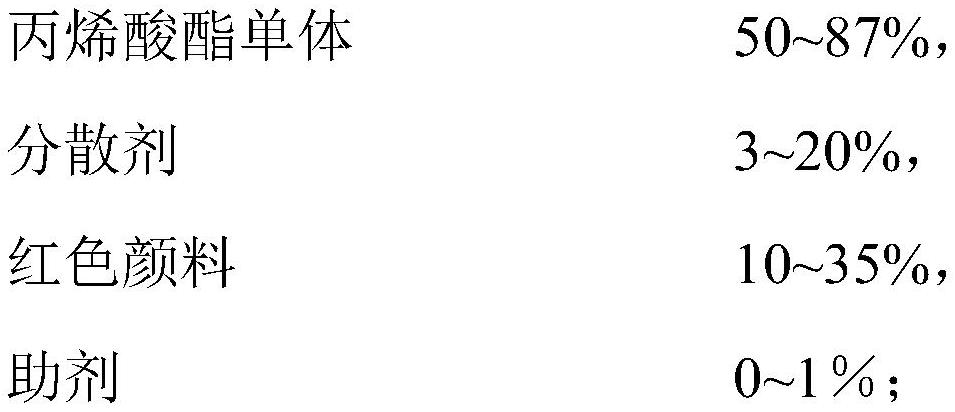

UV nano red paste and preparation method thereof and UV ink

InactiveCN112300636AGood inkjet printing performanceImprove bindingInksPigment pastesPolymer scienceAcrylate ester

The invention belongs to the technical field of UV color paste, and particularly relates to UV nano red paste and a preparation method thereof and UV ink. The UV nano red paste is prepared from the following raw material components in percentage by mass: 50-87% of acrylate monomer, 3-20% of dispersing agent, 10-35% of red pigment and 0-1% of auxiliary agent, wherein the auxiliary agent comprises an oxygen polymerization inhibitor. In the UV nano red paste, the red pigment has sufficient wettability, good dispersion stability and proper viscosity and leveling property in each monomer, can be directly applied to a UV ink formula, has excellent fluency, stability and color performance in UV ink, and can be applied to soft ink, medium ink and hard ink. When the UV color paste is applied to UVink, the UV ink has good ink-jet printing performance, the bonding performance of the ink and a matrix is good, and excellent wet fastness is provided for soft and neutral ink.

Owner:深圳市墨库图文技术有限公司

Photochromic ceramic ink with leather effect and preparation method thereof

The invention discloses photochromic ceramic ink with a leather effect and a preparation method thereof. The preparation method comprises the following steps that 1, leather glaze is prepared; 2, the leather glaze, a dispersion agent, a surface additive, an antifoaming agent and a binding agent are weighed in proportion, the balance is a solvent, and grinding is carried out to obtain a semi-finished product; 3, filtering is carried out to obtain the finished ink. Compared with ceramic ink with the leather effect in the prior art, the accessories are scientific, preparation is reasonable, the quality stability is good, the ink is used in cooperation with ceramic ink-jet printing pigment ink, the concave-convex vivid texture of a leather ceramic tile can be shown more fully and visually, the stereoscopic sense is high, the decoration effect of the ceramic tile is further improved, and the ink can also be widely applied to the fields of ceramic tiles, archaized bricks and the like. A photochromic compound, a deodorant and an antibacterial composite are reasonably matched, so that the ceramic ink has excellent bacterium resisting and antifouling functions, an excellent air purifying function and an excellent photochromic function, and the application range of the ceramic ink capable of sinking is widened.

Owner:FOSHAN GAOMING HAIDI CERAMIC RAW MATERIAL CO LTD

Air-purifying ceramic ink with dermatoglyphs effect and preparation method thereof

The invention discloses an air-purifying ceramic ink with dermatoglyphs effect and preparation method thereof. The preparation method includes the following steps: step A. preparing dermatoglyph glaze ; step B. weighing by proportion dermatoglyph glaze, dispersant, surface additive, defoamer, bonding agent, the rest is solvent, grinding to obtain the ink semi-product; step C. filtering to obtain the ink finished product. Compared with current ceramic ink with dermatoglyphs effect, the present invention has scientific ingredients, reasonable preparation, and good stable quality. Used in connection with the color ink of ceramic ink-jet printing, the vivid concave-convex lines are more fully visualized and revealed for dermatoglyph ceramics. The 3-D effect is strong, further enhancing the decorative effect of ceramics. The present invention can also be widely applied in such fields as tiles and archaized brick, meanwhile through reasonably combining negative ion compound with deodorant and antibacterial compound material, the ceramic ink has superior antibacterial, antifouling, air-purifying function, further broadening the application scope of sinkable ceramic ink.

Owner:FOSHAN GAOMING HAIDI CERAMIC RAW MATERIAL CO LTD

A kind of ceramic ink with sinking effect and preparation method thereof

Owner:FOSHAN DOWSTONG TECH

Sinkable negative ion ceramic ink for ceramic ink jetting and preparation method thereof

The invention discloses sinkable negative ion ceramic ink for ceramic ink jetting and a preparation method thereof. The preparation method comprises the following steps that 1, sinking glaze is prepared; 2, the sinking glaze, a dispersing agent, a surface additive, a defoaming agent and a bonding agent are weighed in proportion, the balance solvent is added, and the materials are ground into a semi-finished ink product; 3, filtering is conducted to obtain a finished ink product. Compared with existing sinkable ceramic ink, the sinkable negative ion ceramic ink has the advantages that the ceramic ink is used by cooperating with pigment ink, the concave-convex vivid textures of tiles can be shown more fully and visually, the stereoscopic impression is high, then the decorative effect of the tiles is improved, patterns in varied colorful splendor are created, and the ceramic ink also can be widely applied to the fields of ceramic chips, archaized bricks and the like; meanwhile, a negative ion composite, conductive filler and an antibacterial composite material are reasonably matched and achieve the synergistic effect, so that the ceramic ink has the excellent characteristics of resisting bacteria, preventing fouling and purifying air and an anti-static function and further widens the application range of the sinkable ceramic ink.

Owner:FOSHAN GAOMING HAIDI CERAMIC RAW MATERIAL CO LTD

Antibacterial ceramic ink with depression effects for ceramic inkjet and preparation method thereof

The invention discloses antibacterial ceramic ink with depression effects for ceramic inkjet and a preparation method thereof. The preparation method comprises the following steps: a step A, preparation of glaze with depression effects; a step B, glaze with depression effects, a dispersant, a surface additive, an antifoaming agent, a binder, and the balance being a solvent are weighed according to a proportion, and an ink semi-finished product is grinded; a step C, an ink finished product is filtered. Compared with prior ceramic ink with depression effects, the ceramic and pigment ink are matched for usage, in order to fully and visually present accidented and vivid texture of the tiles with good stereo perception, further the decorative effects of the tiles are improved, patterns with extraordinary splendor are created, and the ink can be widely applied to ceramics and antique bricks and other fields. At the same time, a negative ion compound, a deodorant and an antibacterial composite material are reasonably matched, the three materials are synergetic, so that the ceramic ink has excellent antibacterial, antifouling and air purifying characteristics, further application ranges of the ceramic ink with depression effects are widened.

Owner:FOSHAN GAOMING HAIDI CERAMIC RAW MATERIAL CO LTD

Bismuth oxide based green pigment for glass digital jet printing and preparation method thereof

InactiveCN105131714AUniform particle size distributionReduces inkjet head cloggingInksLithium oxideHigh energy

The invention discloses a bismuth oxide based green pigment for glass digital jet printing and a preparation method thereof. The bismuth oxide based green pigment is characterized by being prepared from bismuth oxide (alpha-type Bi2O3), amorphous silicon oxide (SiO2), boric oxide (B2O3), lithium oxide (Li2O), aluminum oxide (Al2O3), zirconium oxide (ZrO2) and cobalt green. The preparation method comprises the steps that firstly, the bismuth oxide (alpha-type Bi2O3), the amorphous silicon oxide (SiO2), the boric oxide (B2O3), the lithium oxide (Li2O), the aluminum oxide (Al2O3) and the zirconium oxide (ZrO2) are evenly mixed to conduct high-energy ball milling for sufficient mechanical alloying, and then powder obtained through ball milling is mixed with cobalt green in a ball-milling mode. The maximum particle size of the bismuth oxide based green pigment for glass digital jet printing is smaller than 2 micrometers, the sintering temperature on glass is 600-700 DEG C, the binding force between sintered bismuth oxide based green pigment and glass is high, and the bismuth oxide based green pigment has the wide application prospect in the field of digital jet printing.

Owner:JIANGSU UNIV

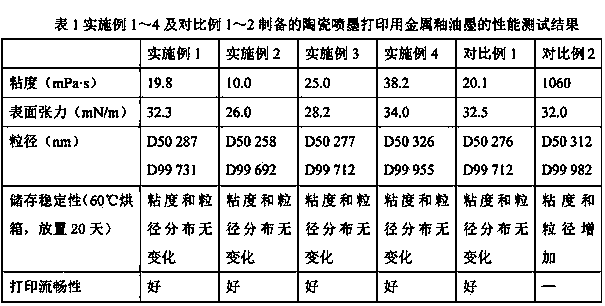

A kind of metallic glaze ink for ceramic inkjet printing and preparation method thereof

ActiveCN103224724BGood quality and stabilityGood inkjet printing performanceInksPrinting inkDefoaming Agents

The invention discloses a metal glaze printing ink for ceramic ink-jet printing and preparation method thereof, wherein the printing ink comprises, based on the mass percentage: 40-60% of metal glaze, 2- 5% of resin, 4 - 8% of dispersant, 0.1-0.2% of flatting agent, 0.2 - 0.5% of defoamer, 0.08 - 0.12% of anti-settling agent, and the balance for solvent; wherein the metal glaze contains the following components of SiO2, Al2O3, K2O, Na2O, CaO, MgO style, Fe2O3, P2O5, ZnO. The metal glaze printing ink for ceramic ink-jet printing is provided with advantages of good quality stability, long preservation, and good performance of ink-jet printing. The metal glaze printing ink prepared by the invention has low viscosity, even particle size distribution, simple and efficient preparation. The metal glaze printing ink prepared by the invention can be used with pigment printing ink for ceramic ink-jet printing, and can further improve the decoration effect of the ceramic tiles.

Owner:FOSHAN DOWSTONG TECH

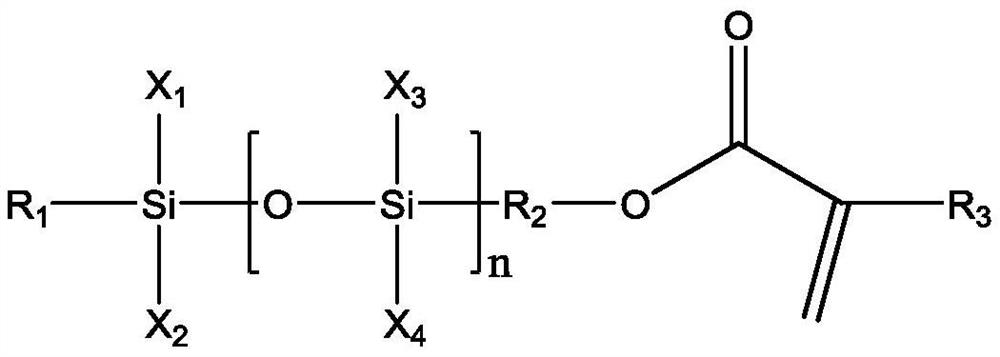

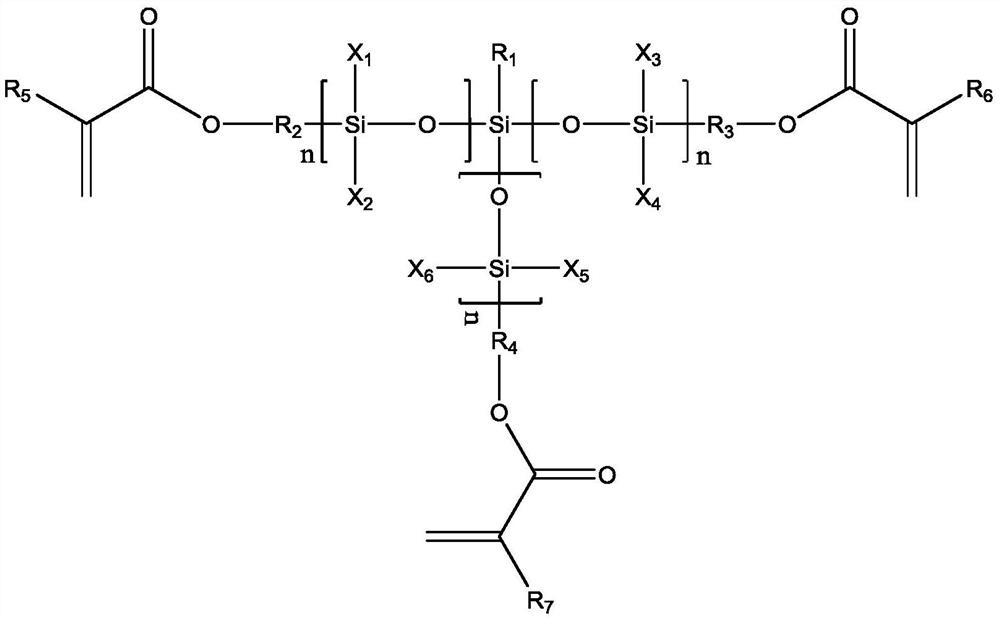

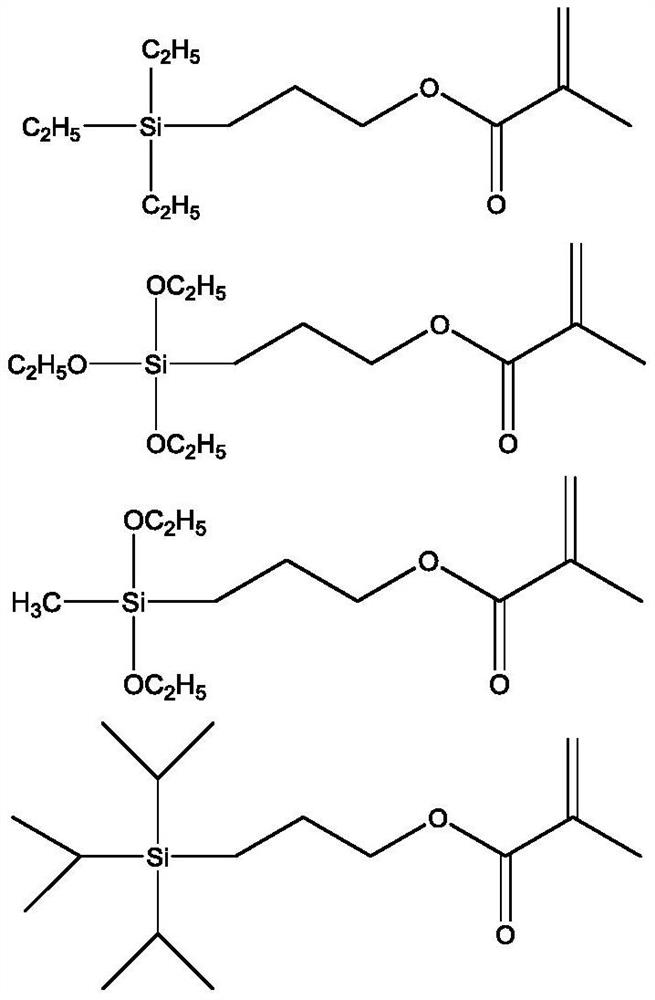

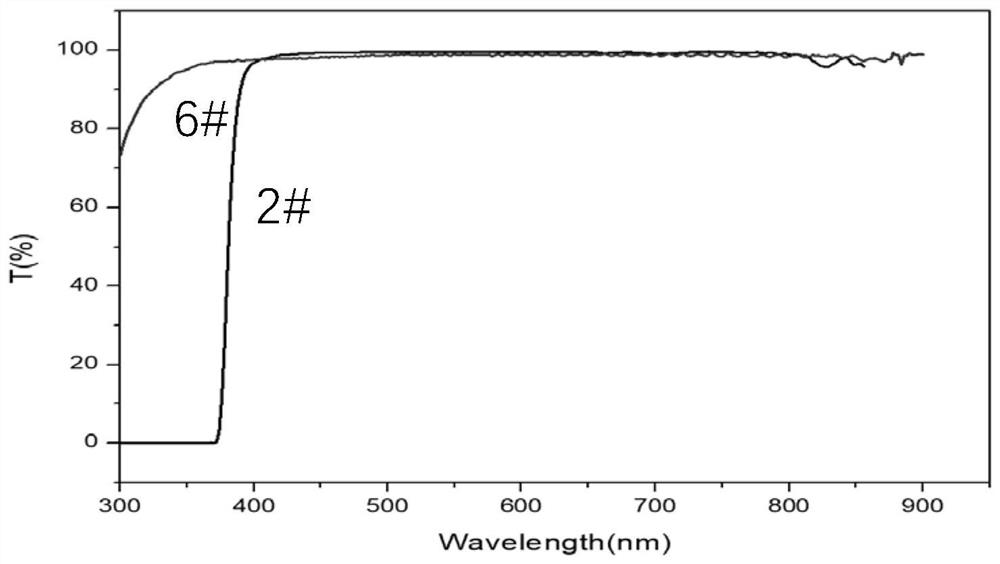

Composition for packaging optoelectronic device and packaging structure formed by composition

PendingCN113549401AImprove curing rateImprove solubilitySolid-state devicesSemiconductor/solid-state device manufacturingArylAdhesive

The invention discloses a composition for packaging a photoelectronic device. The composition comprises the following components in percentage by mass: 49-91% of a multi-component acrylate monomer; 6%-50% of a monofunctional group acrylate monomer; and 0.5%-5% of a photoinitiator. A packaging adhesive formed by using the silicon-containing acrylate component has the advantages that on one hand, the stress dispersion effect can be achieved, the internal stress is reduced, and the mechanical property of the organic packaging composition is improved; and on the other hand, the thermal performance and hydrophobic performance of the organic packaging composition can be effectively improved, and the service life of a device can be effectively prolonged when the organic packaging composition is used for film packaging of an optoelectronic device. In addition, due to the introduced aryl or heteroaryl and derivative units thereof, conjugation in molecules is enhanced, and the absorption effect of the packaging layer on ultraviolet rays is improved.

Owner:XIAN SMART MATERIALS CO LTD

Royal blue ceramic jet printing ink

The invention discloses royal blue ceramic jet printing ink which is characterized by comprising an inorganic metal salt and a solvent, wherein the inorganic metal salt is a mixture of inorganic cobalt salt, inorganic nickel salt and inorganic copper salt. The ink disclosed by the invention has royal blue decorative effect, and can enrich the color range of ceramic ink, so that an ink jet printingpolished tile has richer colors and brighter colors. The ink provided by the invention can be stored for a long time, has no possibility of precipitation or nozzle blockage, and has good ink-jet printing performance.

Owner:SHANGHAI INST OF TECH

A kind of toughened glass ink for inkjet printing and preparation method thereof

The invention discloses a tempered glass ink for ink-jet printing and a preparation method thereof. The ink is prepared from low-temperature frit, inorganic pigments, a dispersant, resin, a flatting agent and a solvent. The tempered glass ink for ink-jet printing has good stability, favorable ink-jet printing performance, low viscosity which ranges from 10.0 to 40.0mPa.s and can be regulated, uniform particle size distribution, the surface tension of 25 to 35mN / m, an average particle size of 200 to 400 nm and a maximum particle size of less than 1 micrometers, and can be stored for a long time. The ink prepared by the preparation method disclosed by the invention has low sintering temperature and can be well combined with glass. The sintered surface is strongly resistant to acid, alkaline and ultraviolet radiation.

Owner:广东道氏陶瓷材料有限公司

Anti-static ceramic jet ink with marble crack effects and preparation method thereof

The invention discloses an anti-static ceramic jet ink with marble crack effects and preparation method thereof. The method comprises the steps of A, mixing and stirring the combination of solvent, super dispersants, modifiers, defoamers and anti-dispersants into the mixed solution, adding the antimicrobial compound and stirring envenly; B, adding the permeating powder and the conducting filler, grinding, adding the solution and deordorant, grinding again to obtain the semi product of the ink; C, filtering to acquire the end product of the ink. Compared with the current ceramic ink, the present invention has a more scientific formula of ingredients with stable properties and a natural marble vines, colors and texture which enhances the decorative effects of the ink and can be widely used in the fields such as the ceramic tiles and archaic bricks. With the proper coordination of deordorant, conducting filler and anti-microbial compounds the ceramic ink is provided with more significant antimicrobial, air purification and anti-static characteristics which broadens the application even further.

Owner:FOSHAN GAOMING HAIDI CERAMIC RAW MATERIAL CO LTD

Anti-radiation ceramics ink-jet ink with marble crack effect and preparing method thereof

The invention discloses an anti-radiation ceramics ink-jet ink with marble crack effect and a preparing method thereof. The preparing method comprises the following steps: A, mixing a solvent, hyperdispersant, modifier, an antifoaming agent and a nonproliferation agent to be prepared into a mixing solution; and then adding an antimicrobial composite to be uniformly stirred;B, adding permeation powder and a negative ion compound, after being grinded, adding the solvent and an anti-radiation composite into the mixture, after being grinded, obtaining the semi-finished product of ink; step C, filtering and obtaining finished product of the ink. Compared with the current ceramics ink,the ceramics ink provided in the invention has scientific burdening and stable performance.With marble line, color and texture, the decoration effect of the tile is improved further; the ceramics ink can be widely applied in the fields of tiles,archaized brick, etc. By burdening the anti-radiation composite, negative ion composite and antimicrobial composite rationally, the ceramics ink has features of excellent bacterial resistance, air purifying and radiation resistance; and the application range is further widened.

Owner:FOSHAN GAOMING HAIDI CERAMIC RAW MATERIAL CO LTD

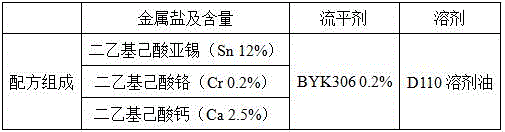

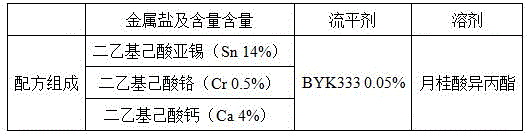

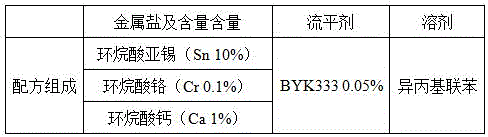

A pink ceramic inkjet bleeding ink

The invention discloses pink penetrating ink of ceramic inkjet. The pink penetrating ink comprises a leveling agent, a colored organic metal salt and a solvent, wherein the colored organic metal salt is dissolved in the solvent and can be converted into pink metal oxide at high temperature. The organic metal salt is a mixed salt of organic tin, organic chromium and organic calcium. The ink disclosed by the invention has the pink decorative effect, and can enrich the color gamut of ceramic penetrating ink, so that an ink jet polishing brick is richer and brighter in color.

Owner:GUANGDONG DOWSTONE TECH

Ink for ceramic ink-jet printing and method for preparing same

ActiveCN102964920BGood quality and stabilitySimple manufacturing methodInksAcrylate esterDefoaming Agents

Owner:GUANGDONG DOWSTONE TECH

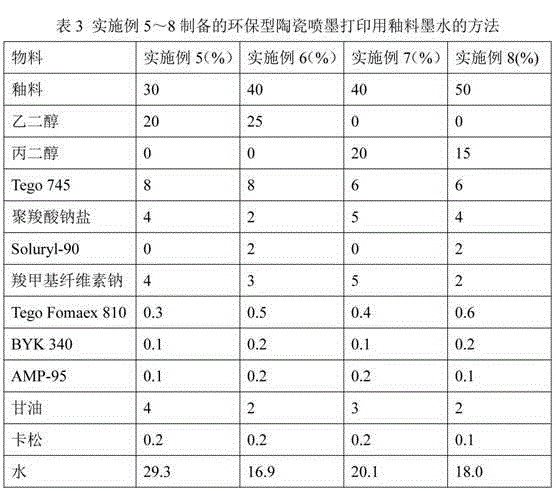

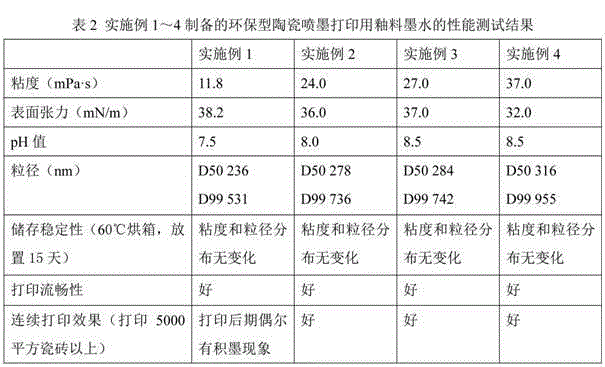

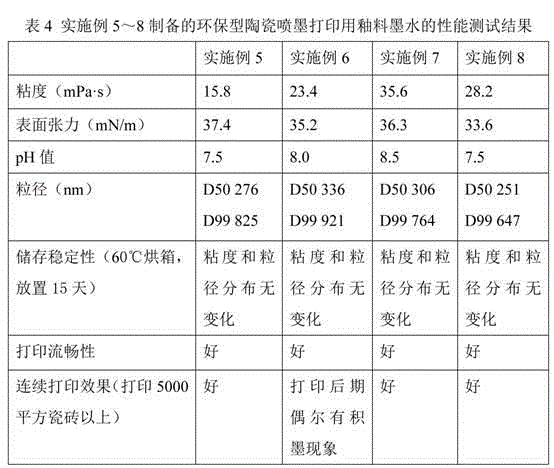

Eco-friendly glaze ink for ceramic jet printing and preparation method thereof

ActiveCN103224727BGood quality and stabilityGood inkjet printing performanceInksOrganic solventPreservative

The present invention discloses an eco-friendly glaze ink for ceramic jet printing and preparation method thereof, the ink comprises, based on the mass percentage, 30-50% of ceramic glaze, 15-25% of organic solvent, 4-10% of dispersant, 2-5% of water reducing agent, 2-5% of resin, 0.3-0.6% of defoaming agent, 0.1-0.2% of leveling agent, 0.1-0.2% of pH modulators, 2-5% of viscosity regulator, 0.1-0.3% of preservative and the balance for water. The eco-friendly glaze ink for ceramic jet printing provided by the invention has good stability for long-term storage and good performance for ink-jet printing, with low ink viscosity and uniform distribution of particle diameter, wherein the regulable viscosity is between 10 and 40.0mPa.s, and the surface tension is between 32 and 40mN / m, and the pH value is between 7.5 and 8.5, and the average particle diameter is between 200 and 400nm, and the maximum particle diameter is less than 1 Mum.

Owner:FOSHAN DOWSTONG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com