Praseodymium yellow ceramic jet-ink infiltrating ink and preparation method thereof

A technology of ceramic inkjet and praseodymium yellow, applied in ink, household utensils, applications, etc., can solve the problems of dim color and narrow color gamut of bleeding ink, and achieve the effect of bright color and good inkjet printing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

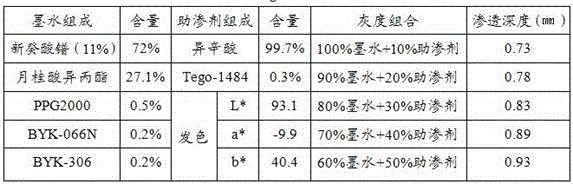

Embodiment 1

[0041] Example 1 (Penetration aid is isononanoic acid + Tego-1484):

[0042]

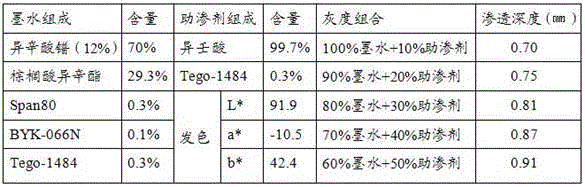

Embodiment 2

[0043] Example 2 (Penetration aid is isooctanoic acid + Tego-1484):

[0044]

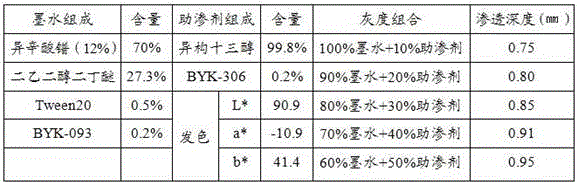

Embodiment 3

[0045] Example 3 (Penetration aid is isotridecyl alcohol + BYK-306):

[0046]

[0047] The application method of the above embodiment is performed according to the following steps:

[0048] 1. Color development test: The bleeding ink is printed on the ceramic tile body with color-generating fabric according to 100% gray scale, and then it is fired at 1210℃ to test the color of the ink.

[0049] 2. Ink penetration depth experiment: Put the ink and penetration aid into different channels of the inkjet machine respectively; according to the formulated gray-scale combination, simultaneously print the ink and penetration aid on the ceramic body with colored fabric; the printing is completed Afterwards, the green body was dried and calcined at 1210°C for 70 minutes. After cutting the product, the ink penetration depth was tested under an optical microscope.

[0050] The above two experimental conditions: the inkjet printer is a new Jingtai experimental inkjet machine, and the nozzle is Xaar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com