Patents

Literature

37results about How to "Bright glaze" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glaze material of high temperature fast firing crystal glaze archaized brick and preparation process thereof

The invention discloses a glaze material of a high temperature fast firing crystal glaze archaized brick and preparation process thereof. Raw material types of crystal glaze are few and wide in sources. A preparation method of the crystal glaze archaized brick is simple, traditional crystal glaze complex process and specific firing rules are broken through, the crystal glaze archaized brick can be obtained through once firing, operability is good, energy is saved, environment is protected, and firing cost is reduced. By adjusting proportion of glaze material components and colorants and the process method, crystal glaze with different colors and crystal flowers in different sizes are obtained through firing, glaze is light, a few needle holes exist occasionally, and firing yield reaches more than 92%.

Owner:FOSHAN DOWSTONG TECH

Metallic glaze and its preparation method

The invention discloses a metallic glaze. The metallic glaze comprises the following components: 5-25 parts by weight of feldspar, 10-30 parts by weight of albite, 25-40 parts by weight of quartz, 1-15 parts by weight of calcite, 5-20 parts by weight of kaolin, 15-40 parts by weight of frit powder, 0.1-5 parts by weight of titanium oxide, 0.5-5 parts by weight of vanadium pentoxide, 5-20 parts by weight of manganese dioxide, 0.1-5 parts by weight of copper oxide, 0.1-3 parts by weight of cobalt oxide and 0.1-5 parts by weight of nickel oxide, wherein the frit powder comprises potassium chloride, sodium chloride, silica, alumina, magnesia, boric acid and spodumene. The invention also discloses a preparation method for the metallic glaze. With the formula and preparation method for the metallic glaze, the prepared metallic glaze has excellent metallic luster and high glaze hardness and totally appears to be golden yellow.

Owner:湖南铜官海旭陶瓷有限公司

Light-emitting painted pottery glaze composition

The invention relates to a light-emitting painted pottery glaze composition which is characterized in that the glaze material is prepared from the components of, by weight, 45-55 parts of nano-silica, 25-35 parts of electronic-grade red lead, 0.4-0.6 part of graphene, 0.4-0.6 part of glyceryl behenate, 0.4-0.6 part of hydroxypropyl-beta-cyclodextrin, 0.4-0.6 part of modified corn starch, 4-6 parts of copper oxide, 1-2 parts of polyethylene wax, 0.1-0.3 part of iron oxide, 1-3 parts of potassium feldspar micro-powder, 0.4-0.6 part of silver nitrate, and 1-3 parts of sea mud. The painted pottery fired with the glaze composition has a crystal clear, bright and smooth glaze, and an excellent decorative effect. With the modified sea mud, the glaze never peels from a finished product, and the product can be preserved permanently.

Owner:柳培健

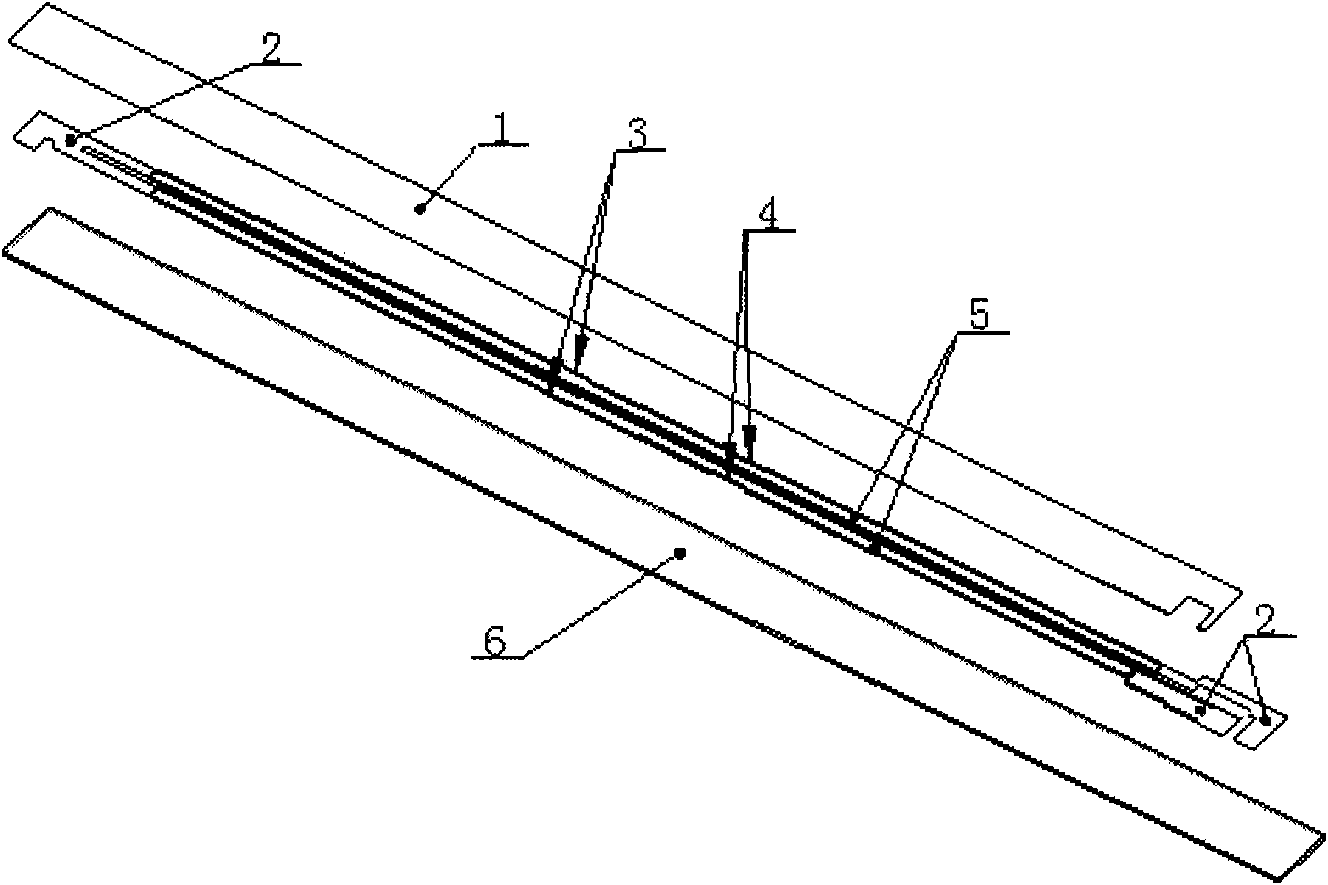

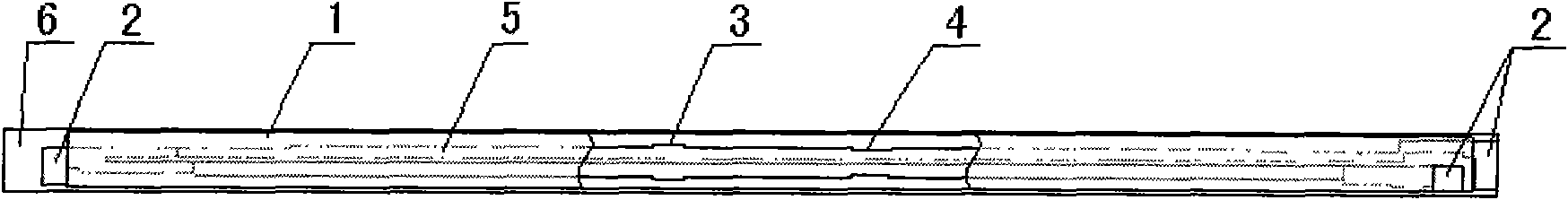

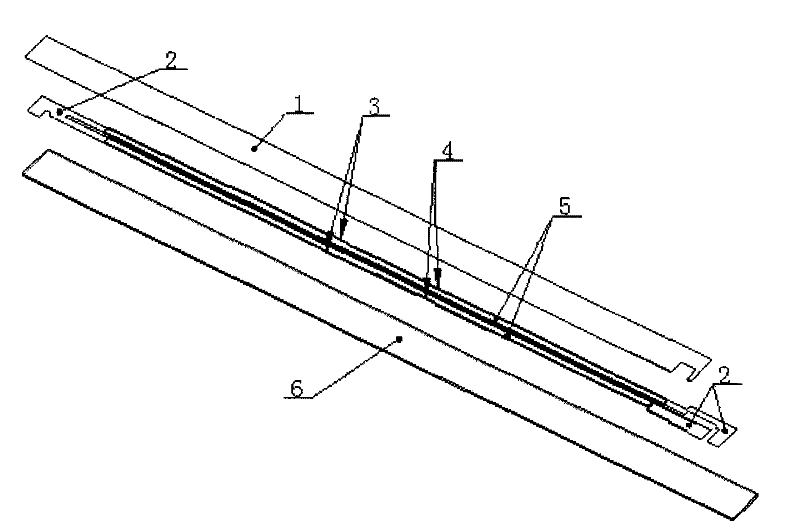

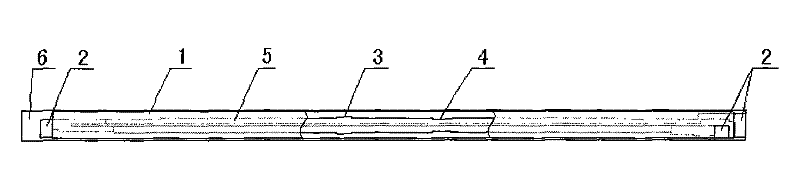

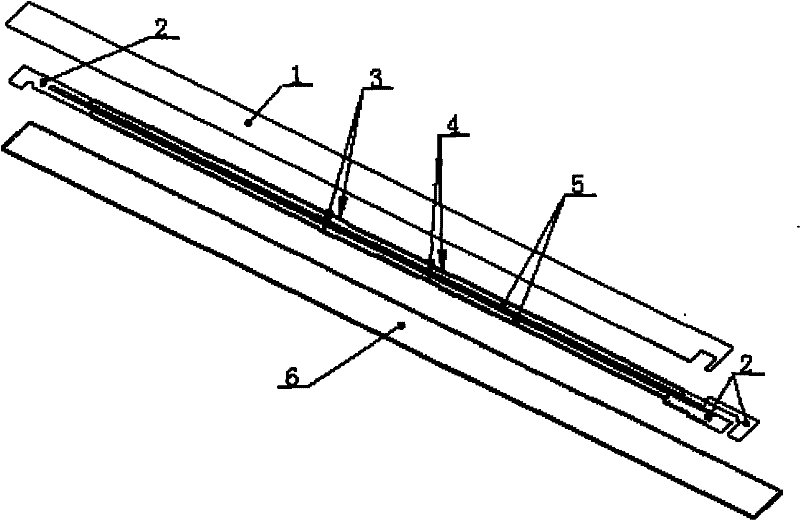

Ceramic heating piece for laser printer and manufacturing process thereof

ActiveCN101598924ALow priceImprove thermal conductivityElectrographic process apparatusHeating element materialsComputer printingThin membrane

The invention relates to a ceramic heating piece for a laser printer and a manufacturing process thereof, wherein a ceramic substrate is sintered with a film heating wire, two ends of the film heating wire are provided with extraction electrodes, a medium covering layer is arranged outside the film heating wire, the ceramic substrate is made from aluminum oxide, and the covering layer is made from glass glaze. The manufacturing process comprises the following steps: printing a conductive sizing agent on the substrate, performing high temperature sintering for the first time, printing a noble metal sizing agent, performing the high temperature sintering for the second time, printing a glass glaze sizing agent, and performing the high temperature sintering for the third time. The ceramic heating piece has the advantages of having low price, providing a convenient and practical objective condition for the regeneration of a damaged laser printer, and being advantageous for the development and the popularization of environmental protection and regeneration.

Owner:BEIJING LASER HI TECH CO LTD

Glaze material of high temperature fast firing crystal glaze archaized brick and preparation process thereof

Owner:FOSHAN DOWSTONG TECH

Process for producing in-glaze color bone china

The invention relates to a process for producing in-glaze color bone china. The surface of a green blank is applied with a layer of mixed glaze material in the general process, the green blank of which the surface is applied with the mixed glaze material is biscuited at a temperature of between 650 and 800 DEG C, then a pattern is drawn on the surface of a biscuit through high-temperature packagepigments, and then the processes such as high-temperature biscuiting and the like are carried out to generate the surface of the biscuit providing more convenience for drawing. The blank body has strong tinting strength and smudging force to achieve the effect of Chinese painting canvas, and tinting and chapped dyeing can be repeatedly carried out on the same position. Bone china finished products produced and processed by the process have the advantages of brilliant and full color, moist pictures, bright glaze surface and light and thin blank body.

Owner:庄助民 +1

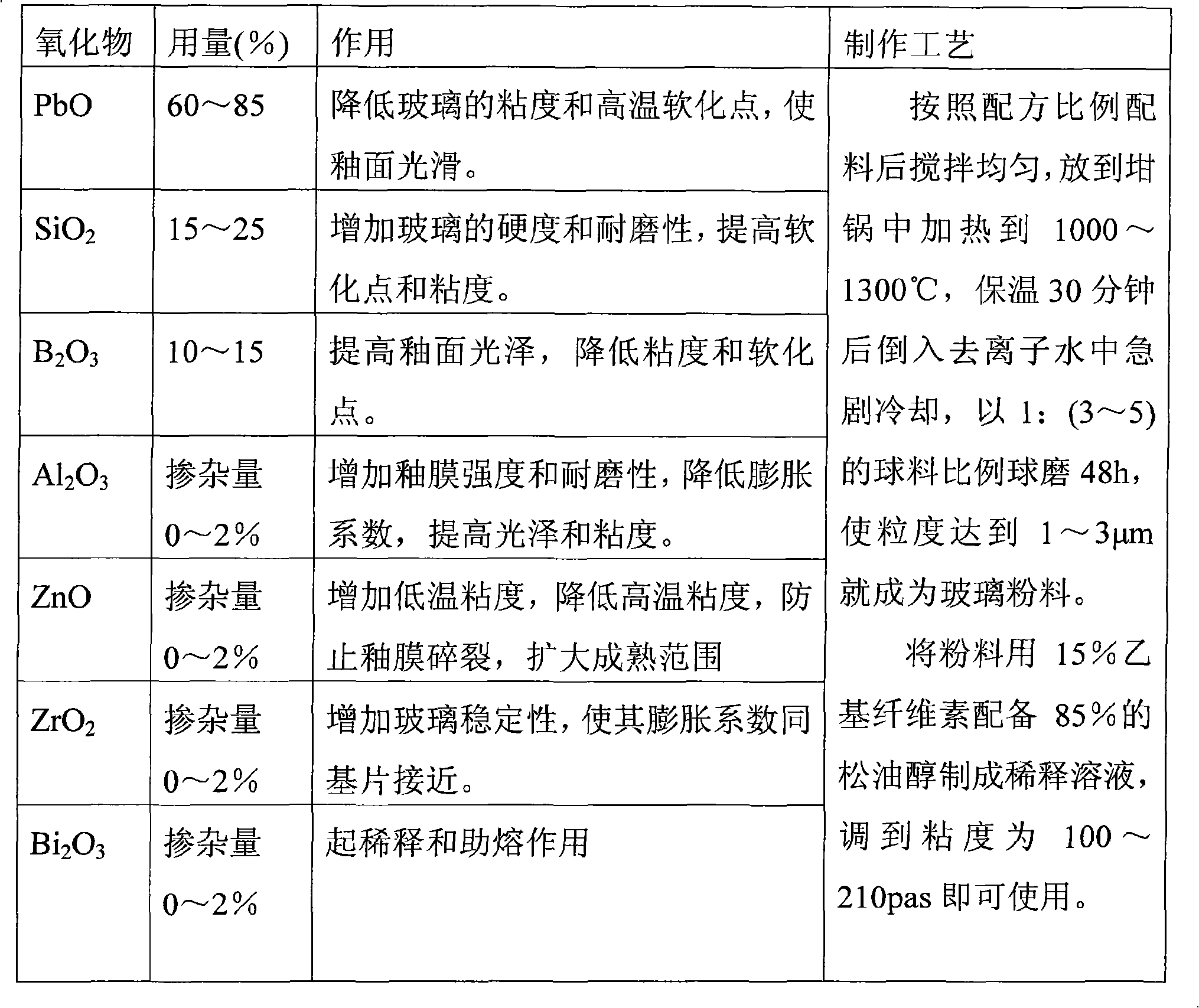

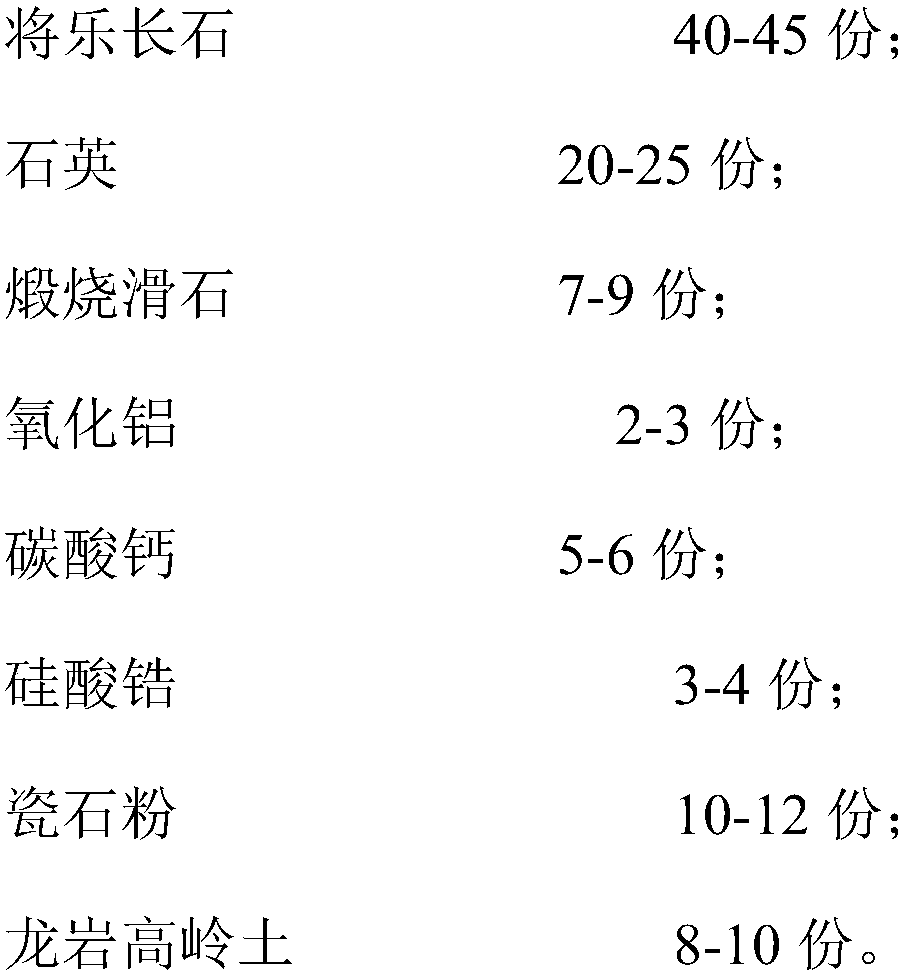

Glaze formula and preparation process thereof

The invention relates to a glaze formula and a preparation process thereof. According to the invention, feldspar, quartz, calcined talc, alumina, calcium carbonate, zirconium silicate, porcelain powder and kaolin of Longyan are ground and mixed, a glaze layer fired by the glaze formula has characteristics of bright glaze layer, uniform glaze thickness, wear resistance, and impact resistance, and can prevent the glaze from being damaged during the collision, and the firing qualification rate is more than 97%.

Owner:福州市陶瓷行业技术创新中心

Slip glaze and preparation method of domestic ceramic with the same

The invention discloses a slip glaze and a preparation method of domestic ceramic with the same. The slip glaze comprises the following raw materials by weight: 25-32 parts of red clay, 6-9 parts of red loam, 18-22 parts of feldspar, 20-26 parts of quartz, 2.5-3.5 parts of niobium disilicide, 3-5 parts of nano silicon dioxide, 1.5-2 parts of nano boron nitride, 5-8 parts of nano zinc oxide, 1.7-2.4 parts of nano magnesium oxide and 5-7 parts of calcium hydroxyphosphate. The slip glaze disclosed by the invention is used for domestic ceramics, and is low in cost, high in yield and energy-saving;the wear resistance of the prepared domestic ceramic is far better than that of common slip glaze domestic ceramics, and the wear resistance is good; the glossiness is much higher than that of commonslip glaze domestic ceramics; the thermal shock resistance is obviously superior to that of common slip glaze domestic ceramics, and the thermal shock resistance is good; and the glaze surface is bright, smooth and bright in color.

Owner:德化县嘉祥陶瓷有限公司

Low temperature metal color glaze material and application method thereof

The invention provides a low temperature metal color glaze material and an application method thereof. The low temperature metal color glaze material comprises a ground glaze and a cover glaze and is characterized in that the ground glaze is a mixture of 5 parts by weight of pigments P924, 2-3 parts by weight of pigments 22605, 4-6 parts by weight of pigments 56401, 1-3 parts by weight of flatting agents 3007 and 2-3 parts by weight of pigments 72503; the cover glaze is composed of a pigment SVSK-6068. According to the low temperature metal color glaze material and the application method thereof, obtained products have metallic luster.

Owner:东莞市高诚陶瓷制品有限公司

Special ceramic switch panel socket and manufacturing technology thereof

InactiveCN110436899AOvercoming the problem of easy shrinkageBright glazeContact member cases/bases manufactureCouplings bases/casesManufacturing technologyWear resistant

The invention belongs to the field of switch sockets, and concretely relates to a special ceramic switch panel socket and a manufacturing technology thereof. The special ceramic switch panel socket comprises a special ceramic switch panel, a plastic assembly and a copper contact, the special ceramic switch panel is made of a special ceramic, the special ceramic switch panel is provided with a plurality of openings and jacks, the plastic assembly comprises a fixing assembly, a protection door assembly and a switch assembly, the fixing assembly is snap-connected with the special ceramic switch panel, and the switch assembly is arranged in the openings of the special ceramic switch panel and is movably connected with the special ceramic switch panel. The switch panel made of the special ceramic is light and beautiful, and has a bright glazed surface and Chinese characteristics; the special ceramic adopts a carefully selected formula, solves the problems of easy shrinkage of common ceramics in the sintering process, is not prone to deform, and is solid and wear-resistant; and the manufacturing technology adopting automatic industrial production increases the production efficiency, reduces the production cost, and is suitable for industrial promotion.

Owner:杨河龙

Preparation method of color-wiping chinaware with convex pattern

The invention discloses a preparation method of color-wiping chinaware with a convex pattern. The preparation method comprises the following steps: (1) preparing a color-wiping color material, namelytaking kaolin elutriated mud, chinastone, feldspar, cellulose and a coloring agent as raw materials of the color-wiping color material, mixing the kaolin elutriated mud, chinastone and feldspar, ball-milling, sieving, ageing for later use, mixing the aged raw materials with cellulose and a coloring agent, ball-milling, sieving, and blending to obtain the color-wiping material for later use; and (2) preparing the colore-wiping chinaware with the convex pattern: manufacturing a gypsum mold, forming a blank part, trimming theblank part, wiping with color, finishing the wiping-color pattern, dipping in glaze, and sintering. The product prepared in the invention has the following advantages: the wipe-coloring chinaware with the convex pattern has a unique style and a bright glaze surface, the convex pattern visible under a transparent glaze layer is clear, the color is uniform and bright, the thickness of the convex pattern is consistent, and the convex pattern surface presents strong stereoscopic impression and artistic style; and better aesthetic feeling is generated, and moreover, the product is regular in appearance and easy to clean.

Owner:潮州市三华陶瓷实业有限公司

Process for producing in-glaze color bone china

The invention relates to a process for producing in-glaze color bone china. The surface of a green blank is applied with a layer of mixed glaze material in the general process, the green blank of which the surface is applied with the mixed glaze material is biscuited at a temperature of between 650 and 800 DEG C, then a pattern is drawn on the surface of a biscuit through high-temperature packagepigments, and then the processes such as high-temperature biscuiting and the like are carried out to generate the surface of the biscuit providing more convenience for drawing. The blank body has strong tinting strength and smudging force to achieve the effect of Chinese painting canvas, and tinting and chapped dyeing can be repeatedly carried out on the same position. Bone china finished products produced and processed by the process have the advantages of brilliant and full color, moist pictures, bright glaze surface and light and thin blank body.

Owner:庄助民 +1

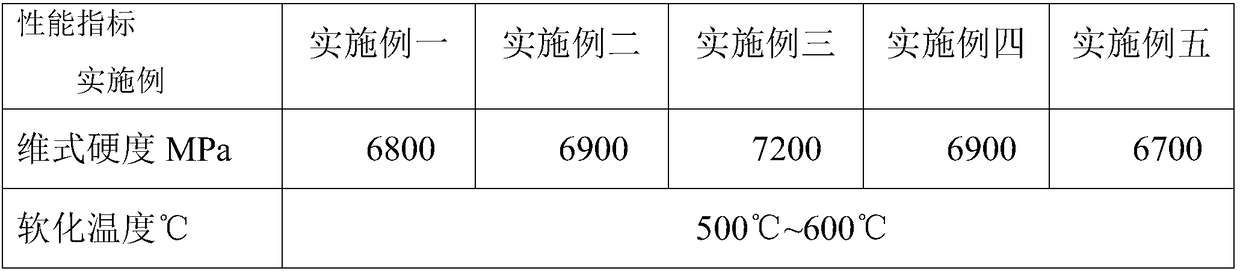

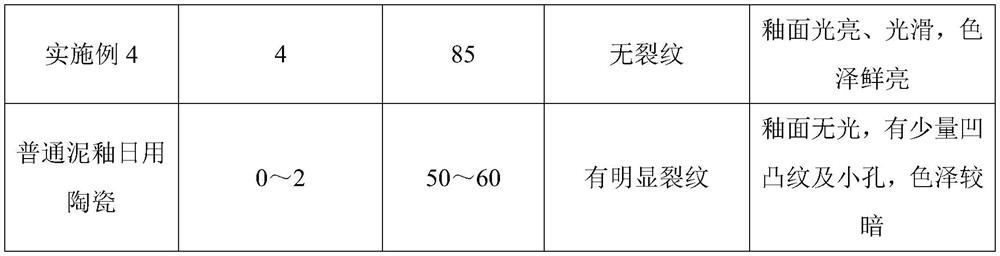

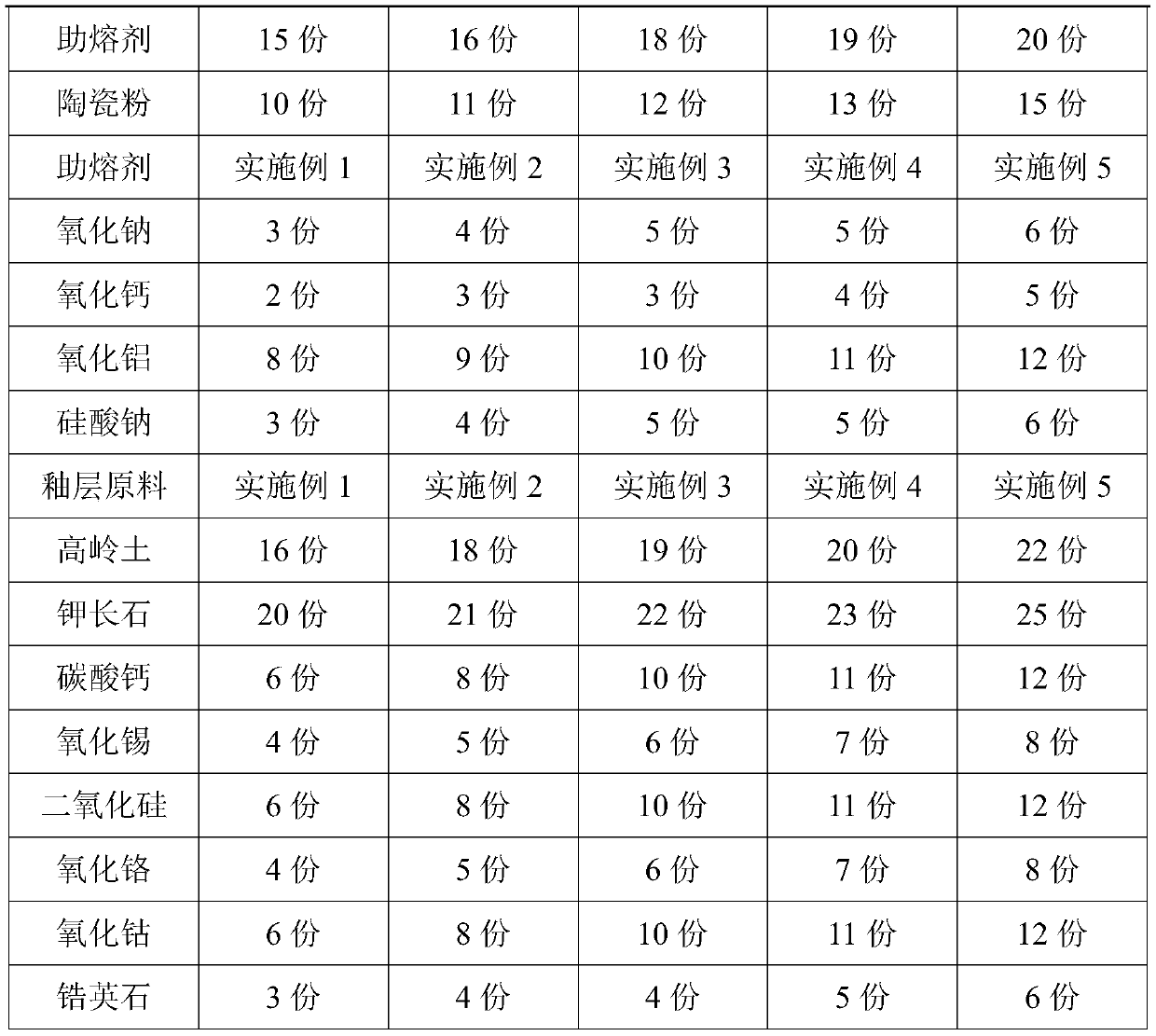

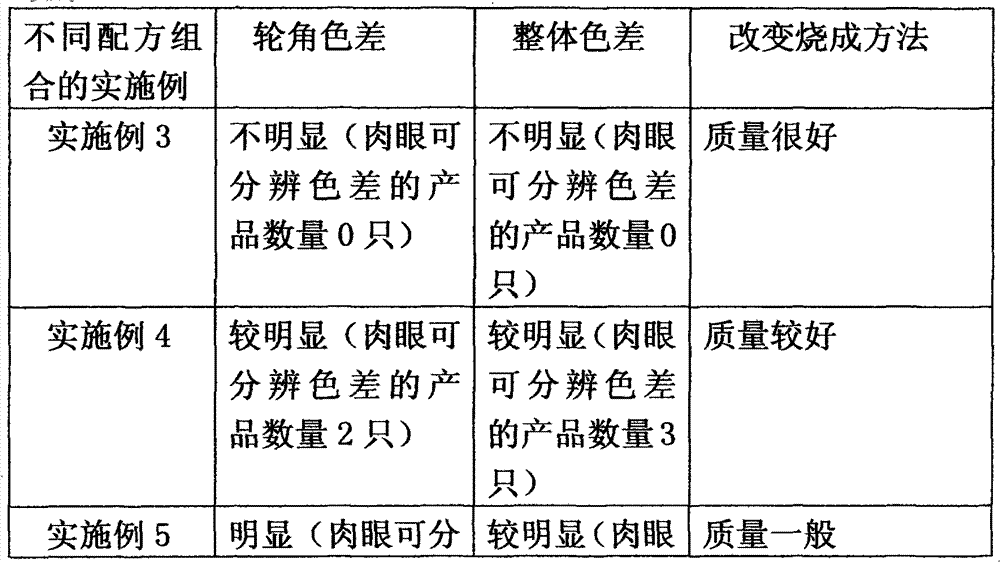

High-strength red glaze daily ceramic and preparation method thereof

The invention relates to high-strength red glaze daily ceramic and a preparation method thereof, and belongs to the technical field of ceramics. The ceramic product comprises a blank body and a glazelayer, wherein the blank body comprises the following components in parts by mass: 30-35 parts by weight of kaolin, 20-25 parts by weight of quartz, 15-20 parts by weight of a fluxing agent and 10-15parts by weight of ceramic micropowder; and the glaze layer comprises the following components in parts by mass: 16-22 parts of kaolin, 20-25 parts of potassium feldspar, 6-12 parts of calcium carbonate, 4-8 parts of tin oxide, 6-12 parts of silicon dioxide, 4-8 parts of chromium oxide, 6-12 parts of cobalt oxide and 3-6 parts of zircon. The preparation method comprises raw material preparation, blank body preparation, glaze water preparation and glazing and firing. The ceramic product prepared by the invention has bright glaze, beautiful agate red or red grape color, soft luster and fine porcelain quality, and also has the characteristics of high strength, firmness, durability, easy cleaning and non-friability.

Owner:福建省德化县合和陶瓷技术开发有限公司

Persimmon red ceramic glaze and preparation method and glazing method thereof

InactiveCN108585505AStable molecular structureQuality improvementClaywaresOxalateManganese(II) carbonate

The invention provides a persimmon red ceramic glaze and a preparation method and glazing method thereof. The persimmon red ceramic glaze is prepared from, by weight, 15-20 parts of melilite, 22-25 parts of quartz, 18-24 parts of kaolinite, 8-12 parts of red mud, 6-8 parts of iron oxide red powder, 10-15 parts of ferrous oxalate, 5-8 parts of soapstone, 5-10 parts of white feldspar, 3-5 parts of bone meal, 1.2-1.8 parts of potassium oxide, 0.6-1.2 parts of lanthanum oxide, 0.5-0.8 parts of zinc oxide and 0.3-0.5 parts of manganese carbonate, wherein the ferrous oxalate, the red mud, the iron oxide red powder and the melilite are selected to be a color developing agent of the glaze, the mutual cooperation and synergistic effect of the ferrous oxalate, red mud, iron oxide red powder and melilite make the color of the glaze to be persimmon red, the prepared glaze has a stable molecular structure, and the persimmon red ceramic glaze with shining glaze, conspicuous color and lustre and stable quality is formed.

Owner:德化县如瓷生活文化有限公司

Ceramic glaze

The invention relates to the technical field of enamel, in particular to ceramic glaze. The ceramic glaze is prepared from the following ingredients in parts by weight: 25-40 parts of albite, 10-15 parts of quartz, 4-8 parts of titanium dioxide, 4-8 parts of wollastonite, 4-8 parts of kaolin, 15-20 parts of zinc oxide, 15-20 parts of lithium carbonate, 1-4 parts of boracic acid, 15-25 parts of zirconia, 1-4 parts of aluminium hydroxide, 2-5 parts of POE (Polyolefin Elastomer) and 3-6 parts of modified starch. According to the ceramic glaze, glaze components and process methods are regulated to burn glaze layers of different specifications, a glaze surface is bright, the thickness of the glaze layer is even, the glaze layer is wearproof and has anti-impact performance, damage and glaze falling in a collision process can be avoided, and a sintering percent of pass reaches 95% or more.

Owner:四川金辉卫浴洁具有限公司

Grain-yellow glaze for ceramics and preparation method thereof

The invention discloses a valley yellow glaze for ceramics, which is composed of 44-47 parts of feldspar, 15-18 parts of quartz, 14-16 parts of calcite, 4-5 parts of material soil and 3-4 parts of manganese carbonate according to weight parts. 1.5-2.0 parts of wrought iron, 3-4 parts of barium carbonate, and 8-10 parts of frit. The specific method is a. Accurately weigh the above components by weight, and mix them uniformly to form a mixed solid raw material, which is calculated into the ball mill according to the ratio of ball stone: mixed solid raw material: water=2:1-1.1:0.8-0.85 Mix and ball mill to form a slurry; b. Ball mill for 11-13 hours. After the ball-milled glaze passes through a 160-mesh sieve, put it in a crucible and burn it at a temperature of 1000-1150°C. Put the burnt glaze frit into crushed machine pulverization; c, the pulverized glaze: ball stone: water = 1: 1.5: 0.5, wet ball milling for 7-9 hours, after testing the fineness of the glaze, the finished product of Guhuang glaze is obtained. The preparation and operation of the invention are simple, and the glaze surface of the prepared glutinous yellow glaze ceramic handicraft is moist and bright, and has the advantages of easy dispersion, strong tinting power, bright color, high brightness, uniform color and luster, and the like.

Owner:长沙市望城区铜官官山陶瓷有限公司

Golden black glaze for jun-porcelain and preparation method of golden black glaze

The invention provides a golden black glaze for jun-porcelain and a preparation method of the golden black glaze. The golden black glaze for jun-porcelain comprises the following components in parts by weight: 40 to 50 parts of melilite, 15 to 25 parts of quartz, 10 to 20 parts of calcite, 5 to 10 parts of copper ore, 5 to 10 parts of white feldspar, 5 to 10 parts of Benyao, 5 to 10 parts of ironore, 2 to 4 parts of manganese powder, 2 to 5 parts of plant ash and 2 to 5 parts of copper oxide. The components are accurately weighed in parts by weight and mixed uniformly to form a mixed solid raw material; according to the ratio of mixed solid ball stone, a raw material and water are respectively added into a ball mill according to the ratio of 2:(1.2-1.5):(0.9-1.5) for mixing and ball milling to form slurry; the slurry fineness is detected after the ball milling is performed for 12.5 to 14 hours; and the fineness-qualified slurry is sieved to remove iron, and the golden black glaze is obtained. Compared with the prior art, the preparation process provided by the invention is simple, and a prepared golden black glaze jun-porcelain handicraft is moist and bright in glaze, and has theadvantages of easy dispersibility, strong tinting strength, bright color, high brightness, uniform color and the like.

Owner:杨鹏飞

Preparation Technology of Underglaze Red Nixing Pottery

The invention provides a preparation process of underglaze red nixing pottery. The preparation process comprises the steps of blank preparing, blank forming, blank drying, blank decorating and blank burning, wherein, in the blank decorating, a layer of clear glaze is applied on a dry blank body after describing patterns by using an underglaze red pigment and / or writing characters; the underglaze red pigment is prepared from the following raw materials in parts by weight: 12 to 15 parts of copper oxide, 58 to 65 parts of hydrophite, 19 to 25 parts of glass powder and 6 to 9 parts of diabase; the clear glaze comprises the following raw materials in parts by weight: 79 to 81 parts of glaze stone, 21 to 23 parts of glaze ash and 5 to 8 parts of fluorite. According to the invention, the underglaze red pigment can be directly applied on the blank of the nixing pottery without need of ground glaze, the process is simplified, the finished products are bright-colored, and the glaze is bright.

Owner:QINZHOU UNIV

Dazzling china used for decorating bone china

The invention relates to technology for firing dazzling china for decorating bone china and formula composition of the dazzling china. According to the technology, a product of the dazzling china of the invention meets the requirements by changing the conventional process, making use of colors prepared by modern high technology, applying a particular process means and adopting a multi-firing method. The process flow of the technology comprises the following steps of: stock preparing, slurry casting or mechanically pressing and forming (preparing by using a die), drying, fettling, water replenishing, finished green body inspecting, low-temperature biscuit firing, biscuit inspecting, dusting agent painting, color spraying, inspecting, loading, high-temperature biscuit firing, unloading, inspecting, polishing, cleaning, drying, glaze spraying, glazing and firing, glaze firing, deglazing and firing, inspecting and selecting, semi-finished product warehousing, decaling, enamel firing, footrim milling, enamel selecting, packaging and finished product warehousing. The dazzling china for decorating the bone china has the advantages that: the dazzling china provided by the invention is obtained by decorating the bone china by using traditional bright red and golden yellow, and the product has pure and brilliant colors and bright glaze and is rich and elegant.

Owner:SHENZHEN BRIGHT FUTURE IND CO LTD

Green glaze for ceramics and preparation method thereof

The invention discloses a green glaze for ceramics and a preparation method thereof. According to parts by weight, the composition is: 10-15 parts of albite, 50-65 parts of glass powder, 8-10 parts of kaolin, 3.5-5 parts of copper oxide, apple 8‑12 servings of green ingredients. a. Accurately weigh each component in the above parts by weight and mix them uniformly to form mixed solid raw materials; b. According to the ratio of mixed solid ball stone: raw material: water = 2: 1-1.1: 0.8-0.9, they are respectively included in the ball mill and mixed Ball milling to form a slurry; c. After ball milling for 14-16 hours, detect the fineness of the slurry; d. Sieve the qualified slurry to obtain a green glaze. Compared with the prior art, the preparation and operation of the present invention are simple, and the prepared green-glazed ceramic handicraft has a moist and bright glaze surface, and has the advantages of easy dispersion, strong tinting power, bright color, high brightness, uniform color and luster.

Owner:长沙市峰云陶艺有限公司

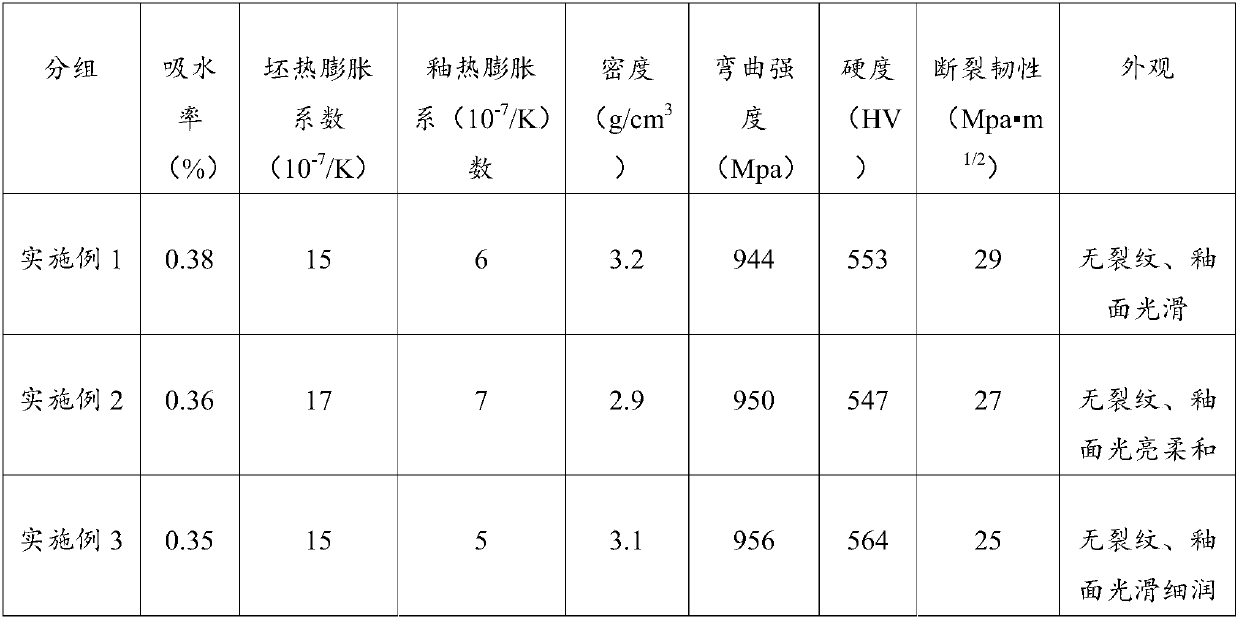

Method for producing fine ceramic by using waste ceramic as main material

InactiveCN109553391AHigh densityHigh strengthCeramic materials productionClaywaresUltimate tensile strengthGreen body

The invention belongs to the technical field of ceramic manufacturing, and specifically discloses a method for producing fine ceramic by using waste ceramic as a main material. The method comprises the following concrete operation steps: a, crushing; b, purification; c, additive addition; d, drying; e, molding; f, processing of a green body; g, glazing; and h, glaze firing. The method for producing the fine ceramic by using the waste ceramic as the main material provided by the invention has the following advantage: the ceramic prepared by using the method provided by the invention has good appearance, high compression resistance and bending strength and excellent fracture toughness.

Owner:JINGDEZHEN UNIV

A kind of high-brightness colorful ceramic product and its preparation method

The invention provides a high-brightness and colorful ceramic product and a preparation method thereof. The high-brightness and colorful ceramic product includes a green body and a glaze applied on the surface of the green body, and the green body includes the following components in parts by weight: kaolin 20-45 parts, 8-15 parts of albite, 15-25 parts of quartz sand, 5-10 parts of high-permeable silica powder and 4-8 parts of cordierite; the glaze includes the following components by weight: lead oxide 8‑15 parts, 5‑8 parts of zinc sulfide, 6‑10 parts of copper oxide and 4‑6 parts of cobalt oxide. The glaze of the present invention is composed of specific components, which can not only obtain colorful and colorful ceramic products, but also stimulate a certain amount of fluorescence. The glaze is glazed on the green body of the present invention, and high-permeable silicon micropowder and Viola The transparent refraction of bluestone can produce high-brightness and colorful ceramic products. The glaze color is shiny and bright, and it has a glass texture, which is pleasing to the eye.

Owner:福建省德化县优扬工艺品有限公司

Jun porcelain and preparation method thereof

The invention discloses a manufacturing method for jun porcelain. The method comprises the following steps: step 1, putting a qualified blank body subjected to ash removal treatment into a baking ovenat a temperature of 35-40 DEG C for baking for 3-4 hours; step 2, carrying out glazing; step 3, carrying out glaze firing, wherein the glaze firing comprises pre-firing, firing in an oxidizing atmosphere, and firing in a reducing atmosphere. The temperature in the furnace is increased at a constant speed from 1000-1050 DEGC to 1400-1500 DEG C; then fresh air is stopped from being conveyed into akiln; and nitrogen is conveyed into the kiln, wherein in 0-3 hours, the conveying amount of the nitrogen is 0.002-0.003 m<3> / s, in 3-7 hours, the conveying amount of the nitrogen is 0.0005-0.001 m<3> / s, and in 7-9 hours, the conveying amount of the nitrogen is 0.003-0.004 m<3> / s. The invention also discloses jun porcelain manufactured by the manufacturing method for jun porcelain. The preparationmethod provided by the invention has the advantage of low rejection rate, high precious product rate, simple operation and the like.

Owner:XUCHANG UNIV

Sapphire green glaze for faience

The invention provides a turquoise glaze for colored pottery products. The turquoise glaze is characterized by being prepared from the following components in parts by weight: 50-70 parts of electronic-grade red lead, 10-30 parts of silicon dioxide, 4-6 parts of Soochow clay, 4-6 parts of copper oxide, 4-6 parts of modified sea mud, 0.1-0.3 part of graphite, 0.1-0.3 part of barium stearate, 0.1-0.3 part of cordierite powder, 1-3 parts of borax, 0.4-0.6 part of morganite, 2-4 parts of aluminum silicate, 0.4-0.6 part of selenium powder, 1-2 parts of cyanite, 0.4-0.6 part of zirconium silicate, 0.2-0.4 part of zinc oxide, 0.1-0.3 part of cobalt powder and 0.2-0.4 part of shell powder. The prepared and fired turquoise glaze is glittering and translucent, bright and smooth in glaze color, and is as shine as the turquoise, and therefore, when the turquoise glaze is applied to colored pottery artworks, an excellent decoration effect can be achieved; the modified sea mud is added so that the finished product can be protected from peeling permanently and can be preserved permanently.

Owner:界首市王京胜彩陶艺术有限公司

Preparation method of ceramic shadow carving artwork

ActiveCN103587340BPorcelain with strong light transmittanceSoft shadow carving two-dimensional stereoscopic effectSpecial ornamental structuresRegular patternTransmittance

The invention relates to ceramic stone-shadow carving artwork and a preparation method thereof. The ceramic stone-shadow carving artwork comprises a ceramic body, wherein the thickness of the ceramic body is smaller than 5mm, the outer surface of the ceramic body is fluctuated to form regular patterns, and the inner side of the ceramic body is provided with a light source. The ceramic stone-shadow carving artwork is produced through the procedures such as production of a map, production of a gypsum board, carving, duplication of a process template and production technology. The artwork has the porcelain quality which is thin as a piece of paper and transparent as silk, the light transmittance is strong, the thickness of the thinnest concave part is not more than 1mm, the thickness of the convex part is not more than 3mm, the entire work has a soft, bright and transparent stone-shadow carving three-dimensional effect under the effect of the light source, and the porcelain is transparent and warm as silk and jade through the warm light; the production process and the rich culture connotation included by the image integrates the advantages of the two-dimensional ceramic process and can completely reflect the perfect combination of modern technology and art, and the product is strong in three-dimensional attractiveness, is a masterpiece of the modern ceramics and has high collection value.

Owner:FUJIAN JIAMEI GRP

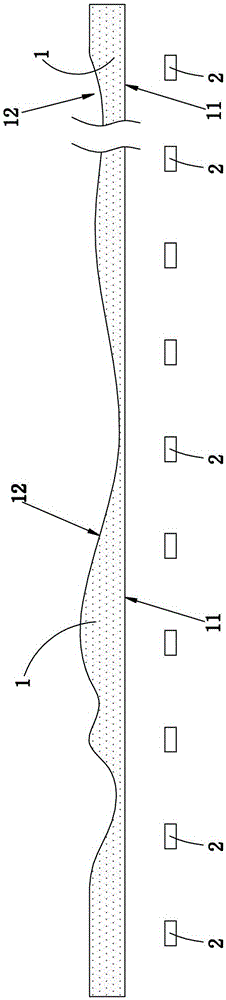

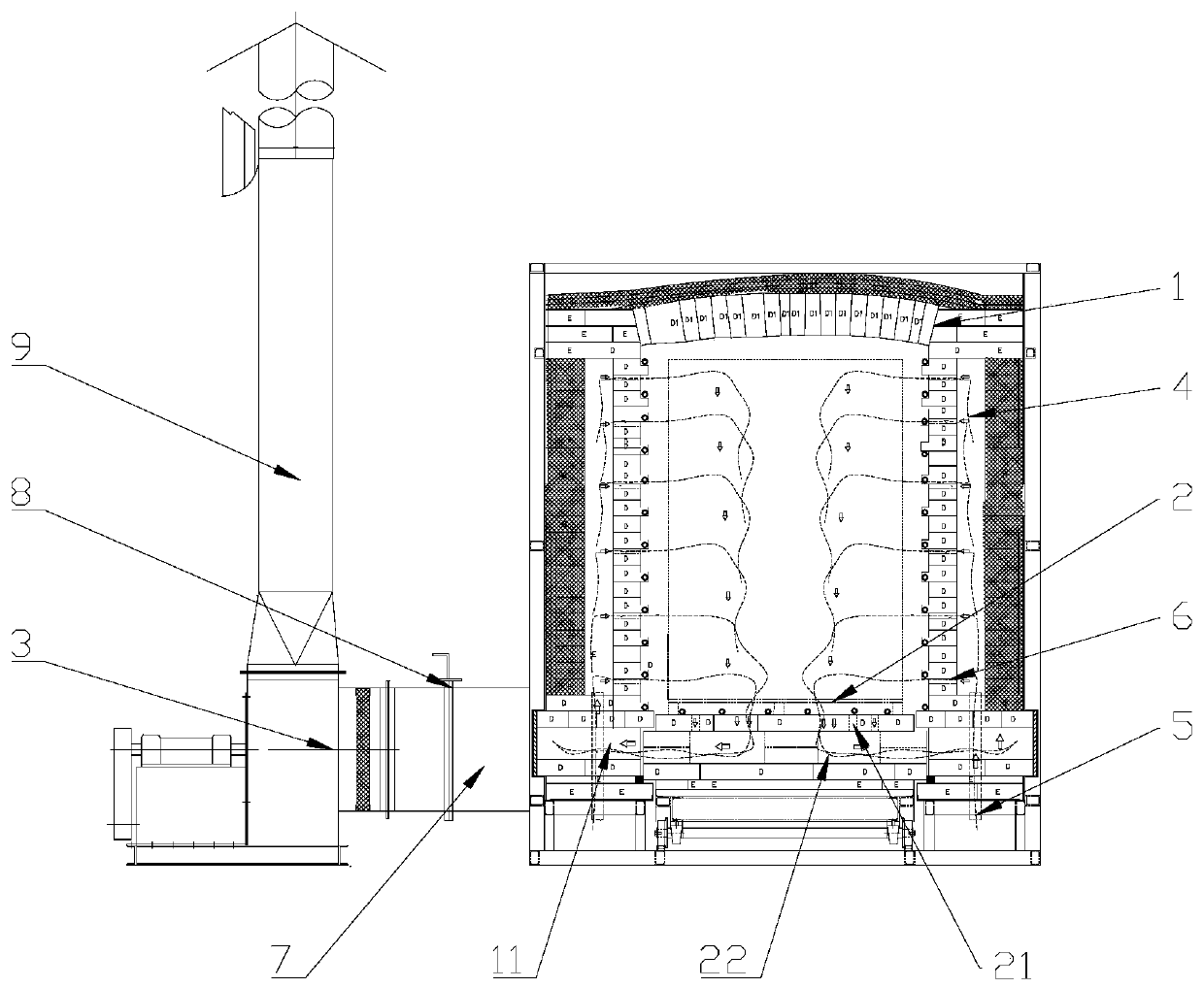

Equipment with automatic novel cooling mode for low-temperature glaze firing product

InactiveCN110440601ABright glazeUniform brightnessCharge composition/stateCharge treatment typeEngineeringCooling methods

The invention discloses equipment with an automatic novel cooling mode for a low-temperature glaze firing product. The equipment with the automatic novel cooling mode for the low-temperature glaze firing product comprises a shuttle-type electric cubic kiln, a kiln car and a heat extraction windmill, wherein a cooling air chamber is arranged in the side wall of the shuttle-type electric cubic kiln;a cooling air inlet is formed in the bottom part of the cooling air chamber; a wall air inlet pipe is arranged on the inner side wall of the cooling air chamber; an air outlet and a hot air channel are arranged on the bottom part of the kiln car; a hot air channel of the shuttle-type electric cubic kiln communicates with the hot air channel of the kiln car; and a hot air pipeline of a windmill isarranged between the shuttle-type electric cubic kiln and the heat extraction windmill so as to be used for connecting the shuttle-type electric cubic kiln and the heat extraction windmill. After theshuttle-type electric cubic kiln is cooled to reach the preset temperature below 1200 DEG C, a cooling system is started, and cooling air enters the kiln through an optimized channel through a reasonable design of an inner structure of a kiln furnace, so that automatic cooling is realized without the need for opening a kiln door. The cooling time is 220 minutes in the whole process, and the speedis faster than before, so that the aim of quickly cooling is achieved, slags cannot fall, and the glaze brightness is bright and uniform.

Owner:广东派陶科技有限公司

Ceramic heating piece for laser printer and manufacturing process thereof

ActiveCN101598924BLow priceImprove thermal conductivityElectrographic process apparatusHeating element materialsSizingCeramic substrate

The invention relates to a ceramic heating piece for a laser printer and a manufacturing process thereof, wherein a ceramic substrate is sintered with a film heating wire, two ends of the film heating wire are provided with extraction electrodes, a medium covering layer is arranged outside the film heating wire, the ceramic substrate is made from aluminum oxide, and the covering layer is made from glass glaze. The manufacturing process comprises the following steps: printing a conductive sizing agent on the substrate, performing high temperature sintering for the first time, printing a noble metal sizing agent, performing the high temperature sintering for the second time, printing a glass glaze sizing agent, and performing the high temperature sintering for the third time. The ceramic heating piece has the advantages of having low price, providing a convenient and practical objective condition for the regeneration of a damaged laser printer, and being advantageous for the developmentand the popularization of environmental protection and regeneration.

Owner:BEIJING LASER HI TECH CO LTD

Preparation method of red ceramic glaze

The invention discloses a preparation method of red ceramic glaze. The preparation of the high-grade red glaze is realized by increasing the use amount of the iron oxide red pigment and a double-layer glaze process. The red ceramic glaze prepared by the invention is bright in color, bright in glaze surface, high in thermal shock resistance and low in price. The usage amount of the iron oxide red is more than 12%, preferably 16-30%, preferably 20-25%, and especially more than 40%.

Owner:武汉甄美颜料有限公司

Huge vase with dragon, and its making method

The invention discloses a huge vase with dragon, and its making method, and relates to the technical filed of ceramic. The huge vase with dragon comprises 12-18wt% of quartz, 15-25wt% of porcelain stone, 10-20wt% of feldspar powder, 22-35wt% of hard clay, 10-25wt% of loess powder, 1-4wt% of silicon micro-powder and 2-5wt% of feldspar submicron powder. The making method comprises the following steps: 1, making a large die; 2, making a green bottle body; and 3, sculpturing dragon on the outer side of the bottle by a sculpturer. The vase made in the invention has characteristics of hard porcelain, bright glaze, thickness reaching 0.35, a maximum waist diameter reaching 2.3m, a height reaching 6m and a high yield of 60%. The disadvantages of no bearing of the green body weight and cracking of present ceramic vases are overcome, and the phenomena of no corresponding connection between modules, collapsing and shedding are improved.

Owner:牛继伟

Huacai base glaze and Huacai glaze Jun porcelain and preparation method thereof

InactiveCN110092638AControl surface tensionUniform particlesCeramic materials productionClaywaresGlazeKaolinite

The invention relates to Huacai base glaze and Huacai glaze Jun porcelain. The Jun porcelain includes 8-12 parts of boron trioxide, 15-25 parts of silicon dioxide, 12-20 parts of kaolin, 20-28 parts of calcite, 20-35 parts of felspar, 10-15 parts of limbra stone, and 5-10 parts of plant ash; the outer surface of the Jun porcelain is coated with Huacai base glaze and Huacai glaze; the Huacai base glaze consists of 10-20 parts of boron oxide, 12-18 parts of potassium oxide, 4-7 parts of kaolinite, 5-12 parts of aluminum oxide, 8-15 parts of titanium oxide, 8-15 parts of copper oxide, 10-16 partsof zirconia, and 5-12 parts of silicon dioxide; and the Huacai glaze consists of 4-8 parts of boron oxide, 6-10 parts of the potassium oxide, 4-7 parts of iron oxide, 3-6 parts of the aluminum oxide,5-12 parts of the titanium oxide, 5-10 parts of the copper oxide, 10-16 parts of the zirconia, and 5-12 parts of the plant ash. The Jun porcelain has advantages of being environment-friendly, green,nontoxic and beautiful.

Owner:大宋官窑股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com