Patents

Literature

941results about "Charge composition/state" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

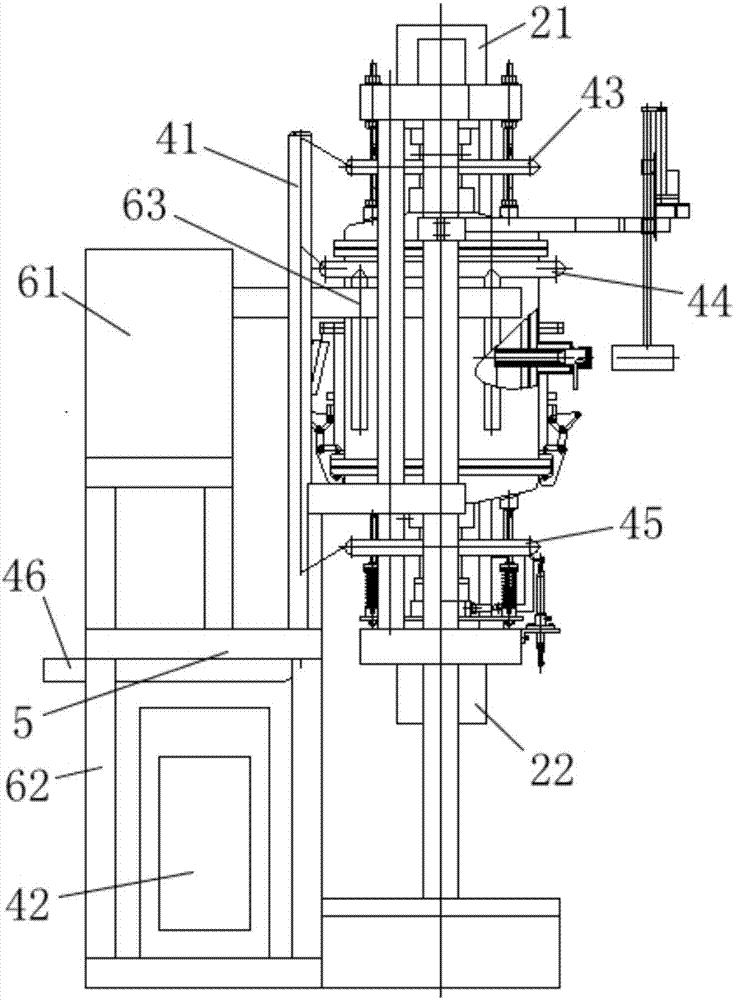

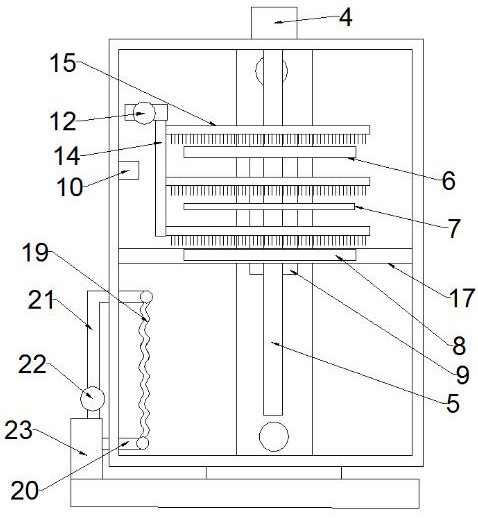

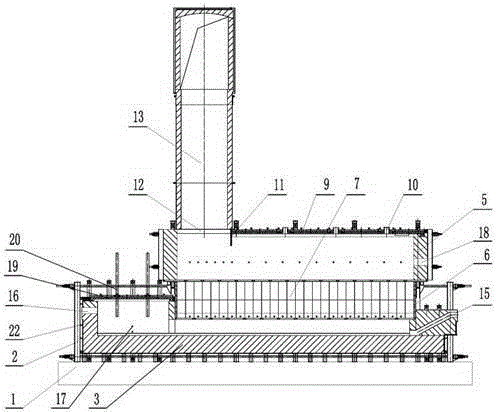

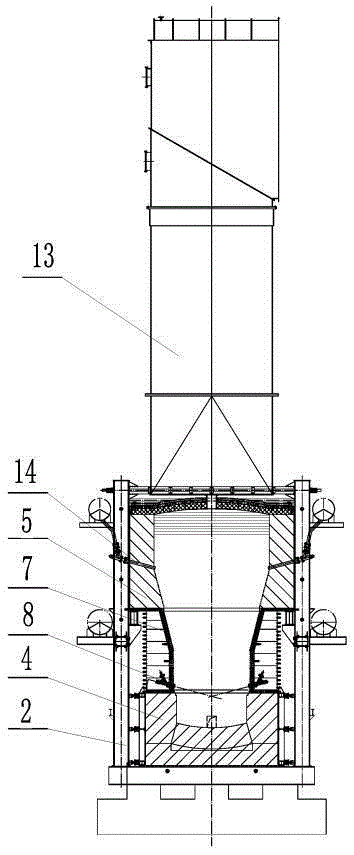

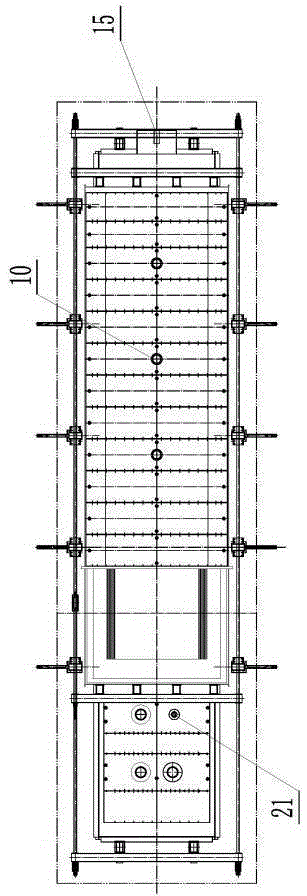

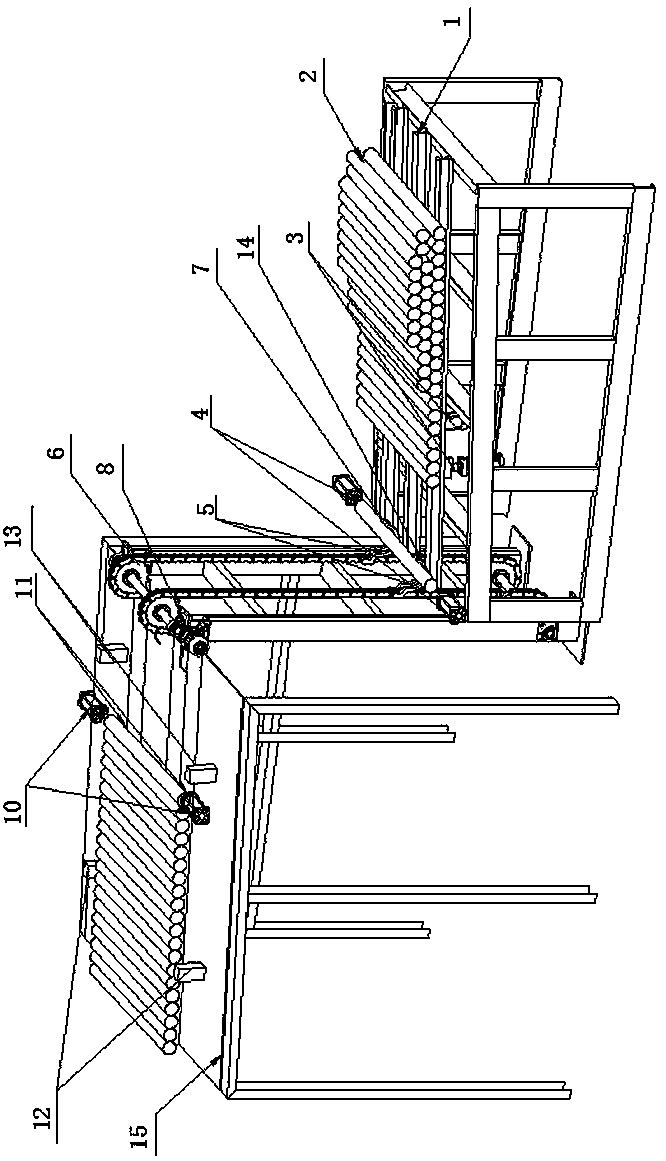

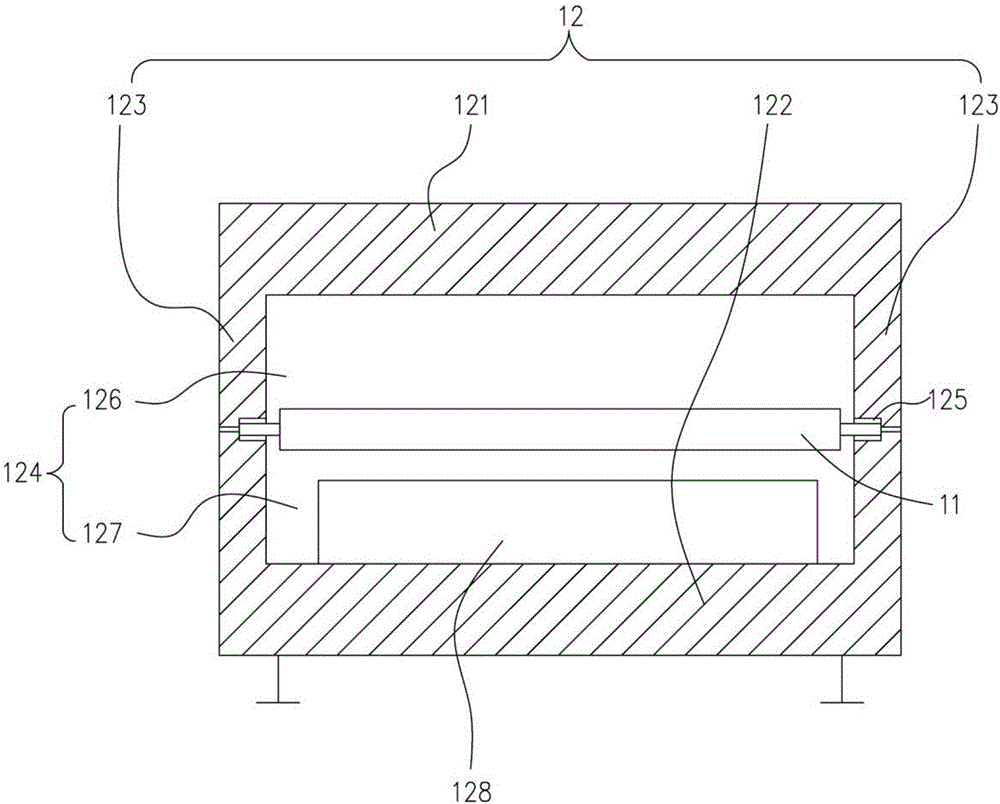

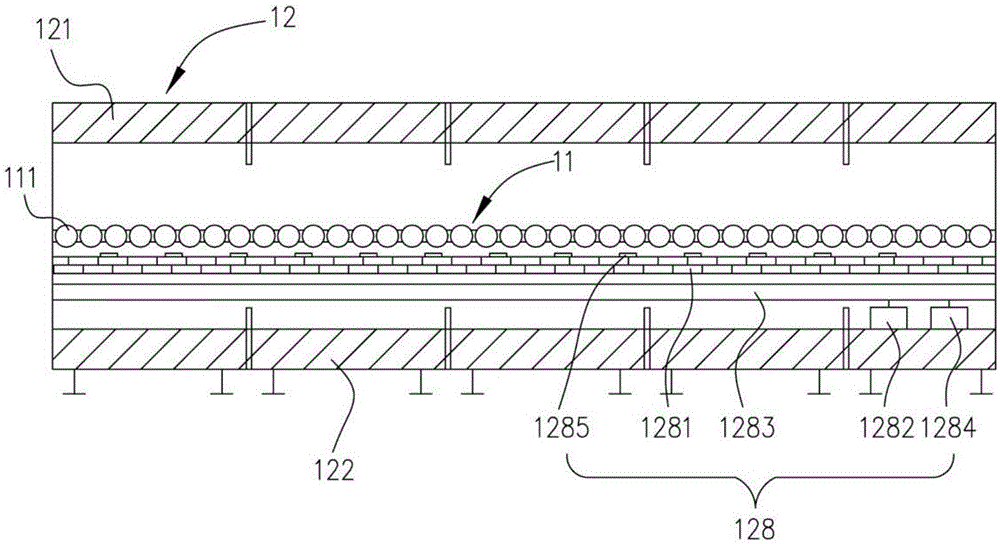

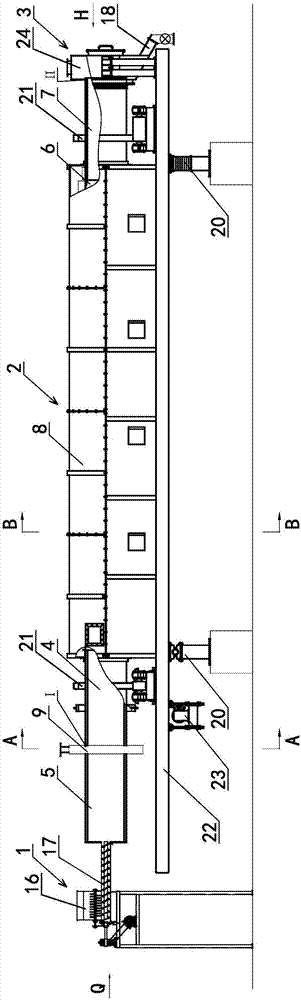

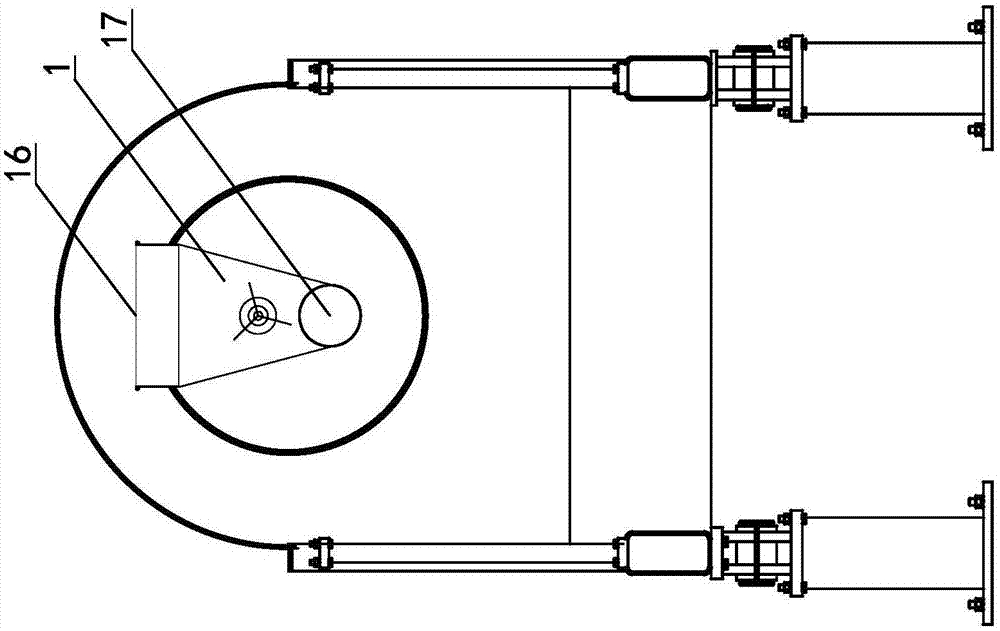

Oscillating hot press sintering furnace

InactiveCN107062891AUniform densityShort sintering timeMuffle furnacesCharge composition/stateVibration amplitudeMaterials preparation

Owner:ZHUZHOU XINRONGLI IND

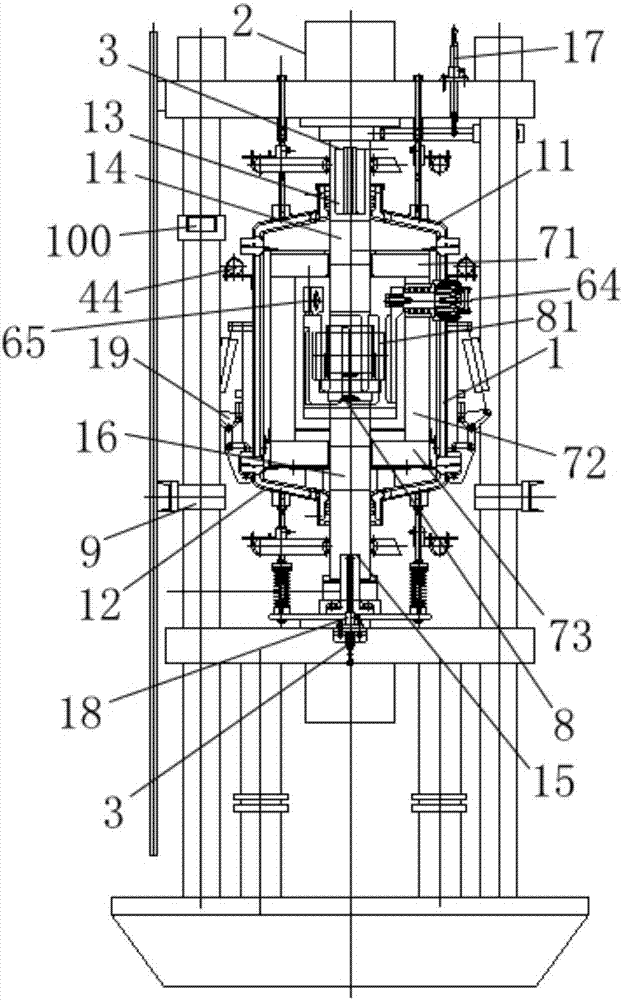

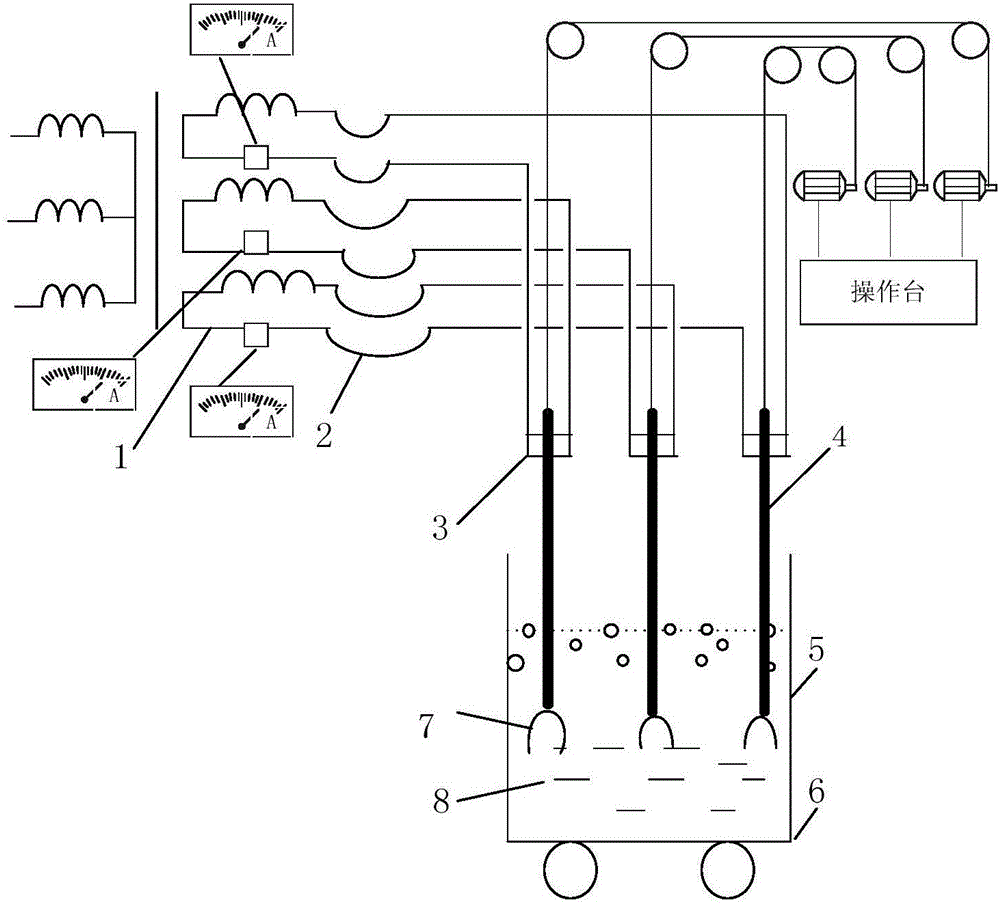

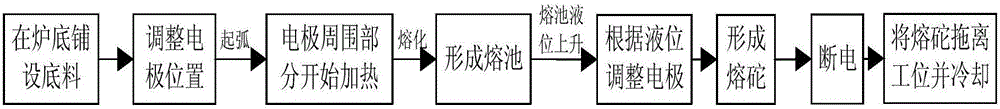

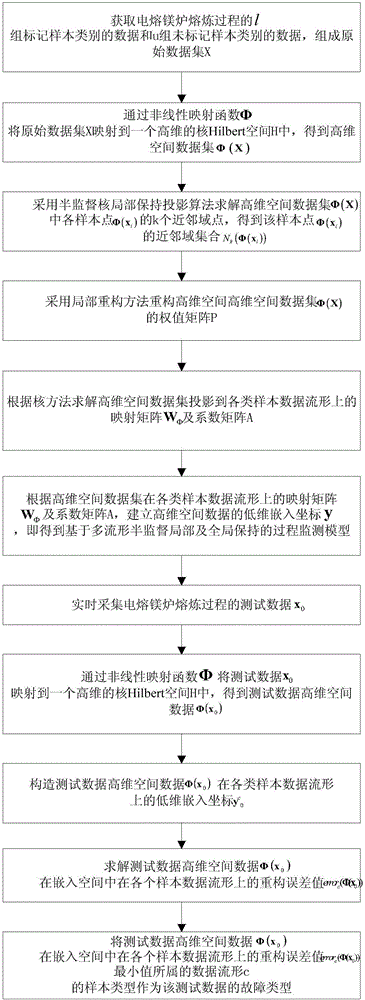

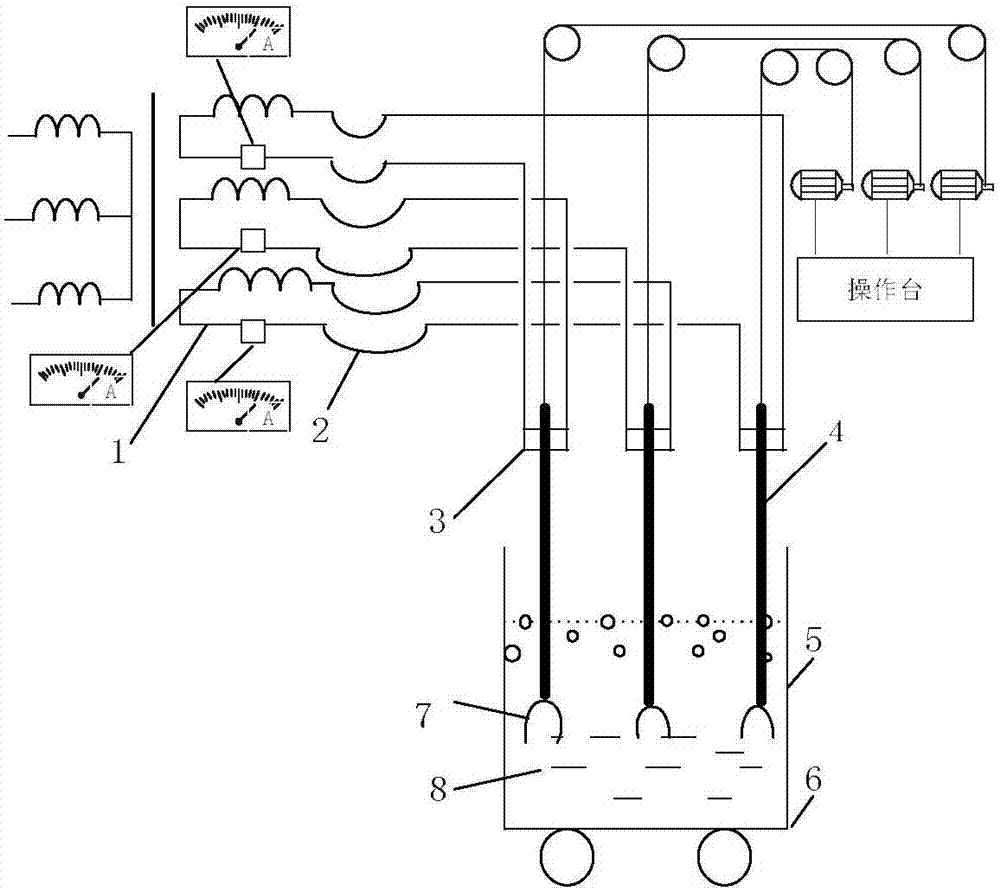

Electrical smelting furnace for magnesia fault monitoring method based on multi-manifold semi-supervised local-overall situation

ActiveCN106839769AReduce distanceIncrease distanceCharge composition/stateCharge treatment typeOriginal dataSmelting process

The invention provides a electrical smelting furnace for magnesia fault monitoring method based on a multi-manifold semi-supervised local-overall situation. The method comprises the steps of acquiring an original data set X during a smelting process of a electrical smelting furnace for magnesia, building a process monitoring model based on multi-manifold semi-supervised local-overall situation maintaining according to the original data set of the smelting process of the electrical smelting furnace for magnesia, acquiring test data x0 during the smelting process of the electrical smelting furnace for magnesia in real time, and carrying out fault type diagnosis on the test data x0 by adopting the process monitoring model based on multi-manifold semi-supervised local-overall situation maintaining. The method provided by the invention takes local and overall structures of data into consideration at the same time, and considers local diversity information among homogeneous data in order to prevent the occurrence of local overfitting, finally builds an optimal object function for multi-manifold semi-supervised fault diagnosis, and has a favorable monitoring effect.

Owner:NORTHEASTERN UNIV

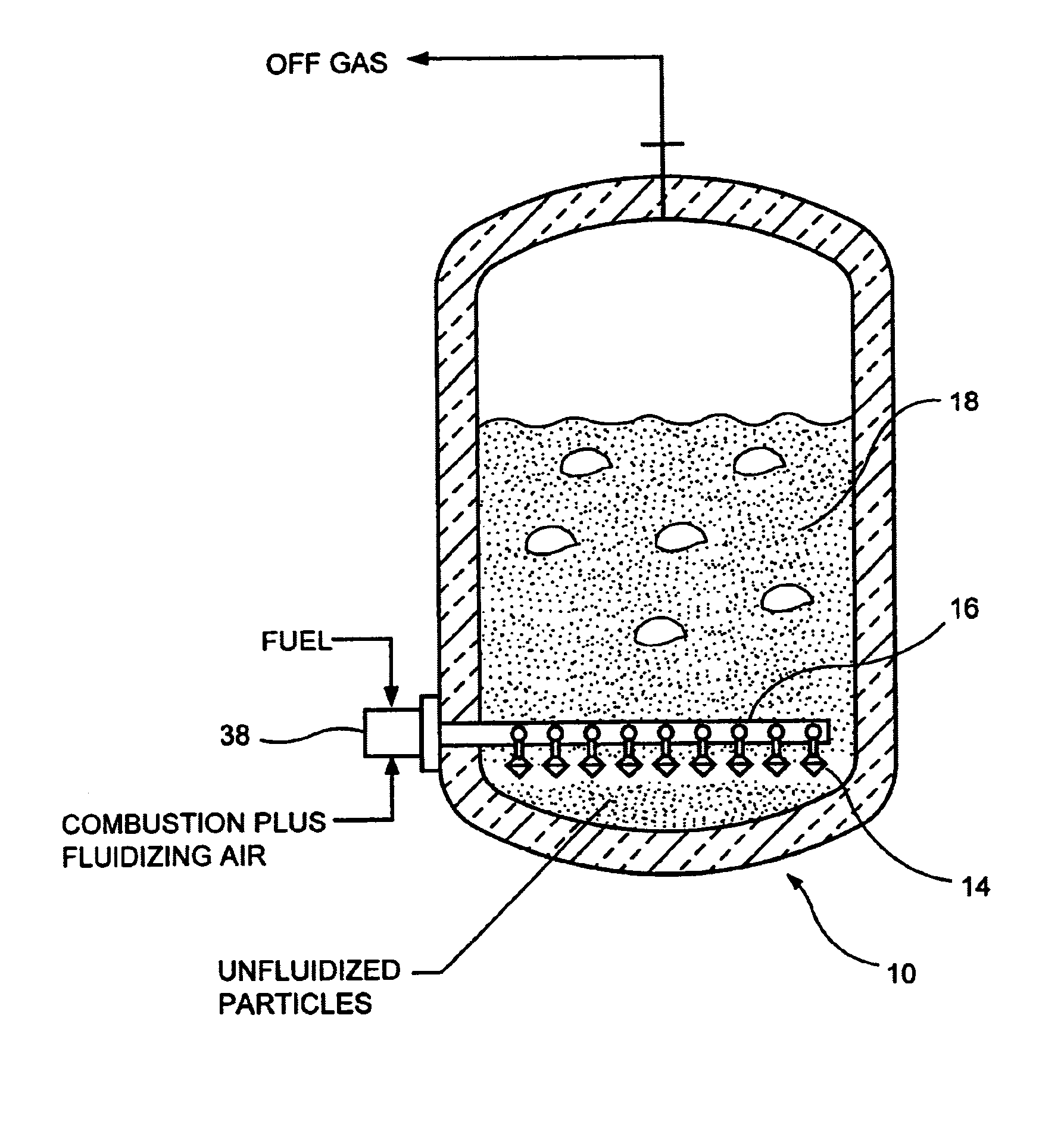

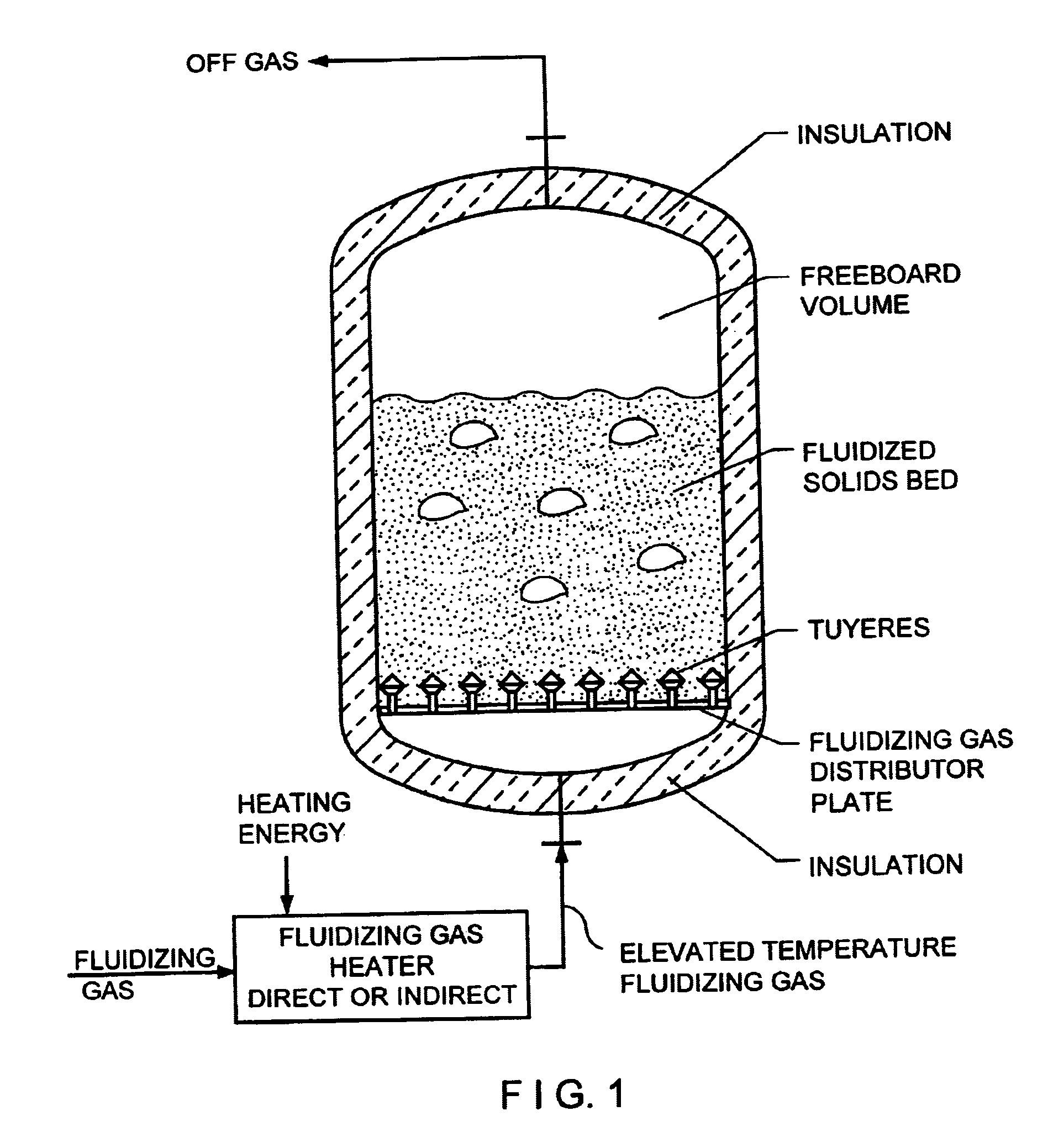

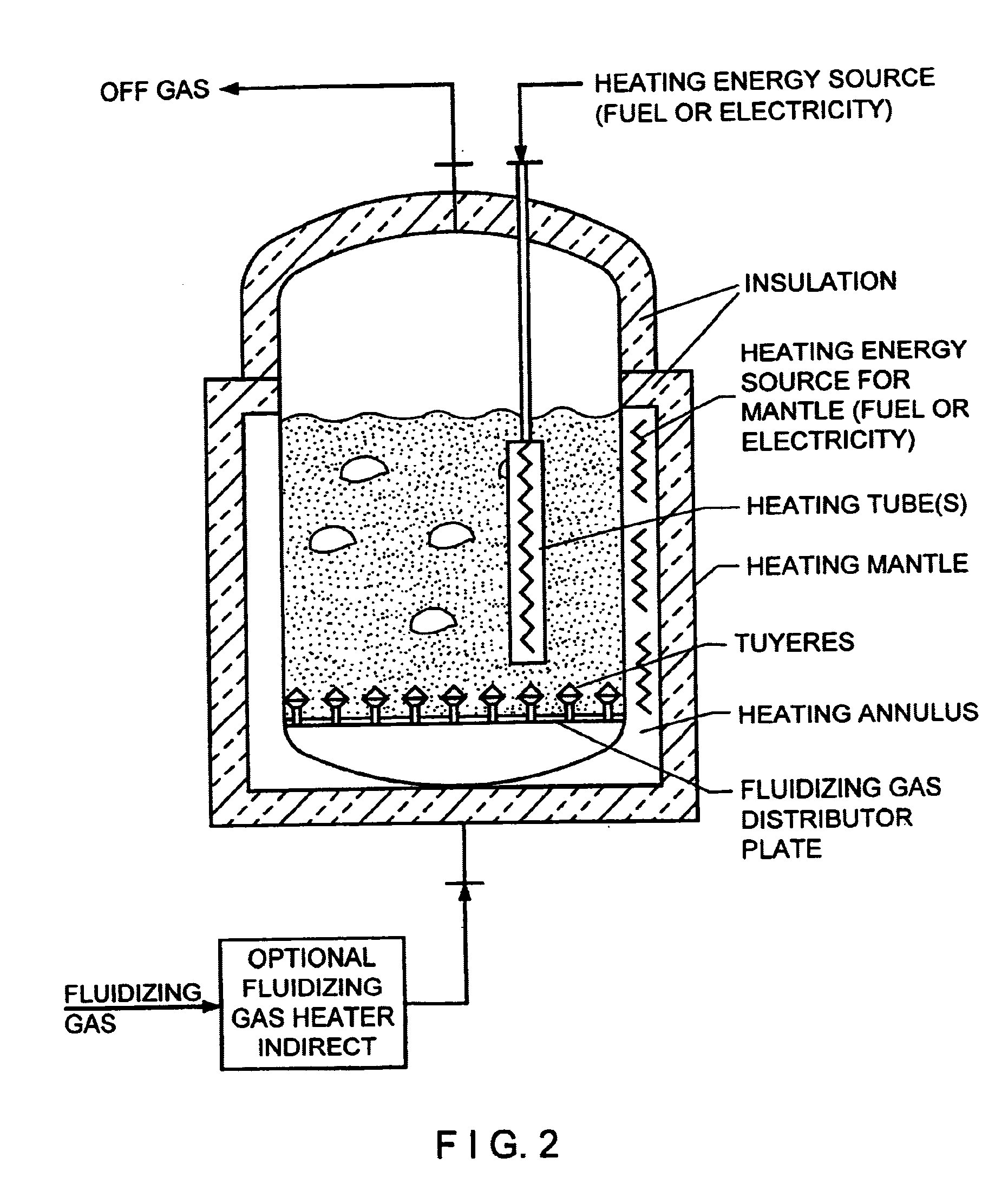

Fluidized bed gas distributor system for elevated temperature operation

InactiveUS6991767B1Favorable heat transfer behaviorMaximum heat transferFurnace doorsCharge composition/stateFluidized bedProcess engineering

A method and apparatus for the debonding and sand core removal of sand cores from cast parts, the heat treating of metal parts and the removal of organic contamination from metal parts, which is utilizing a fluid bed furnace having an improved fluidizing gas distributor which discharges fluidized gas in a downward direction away from the parts in the fluidized bed.

Owner:PROCEDYNE

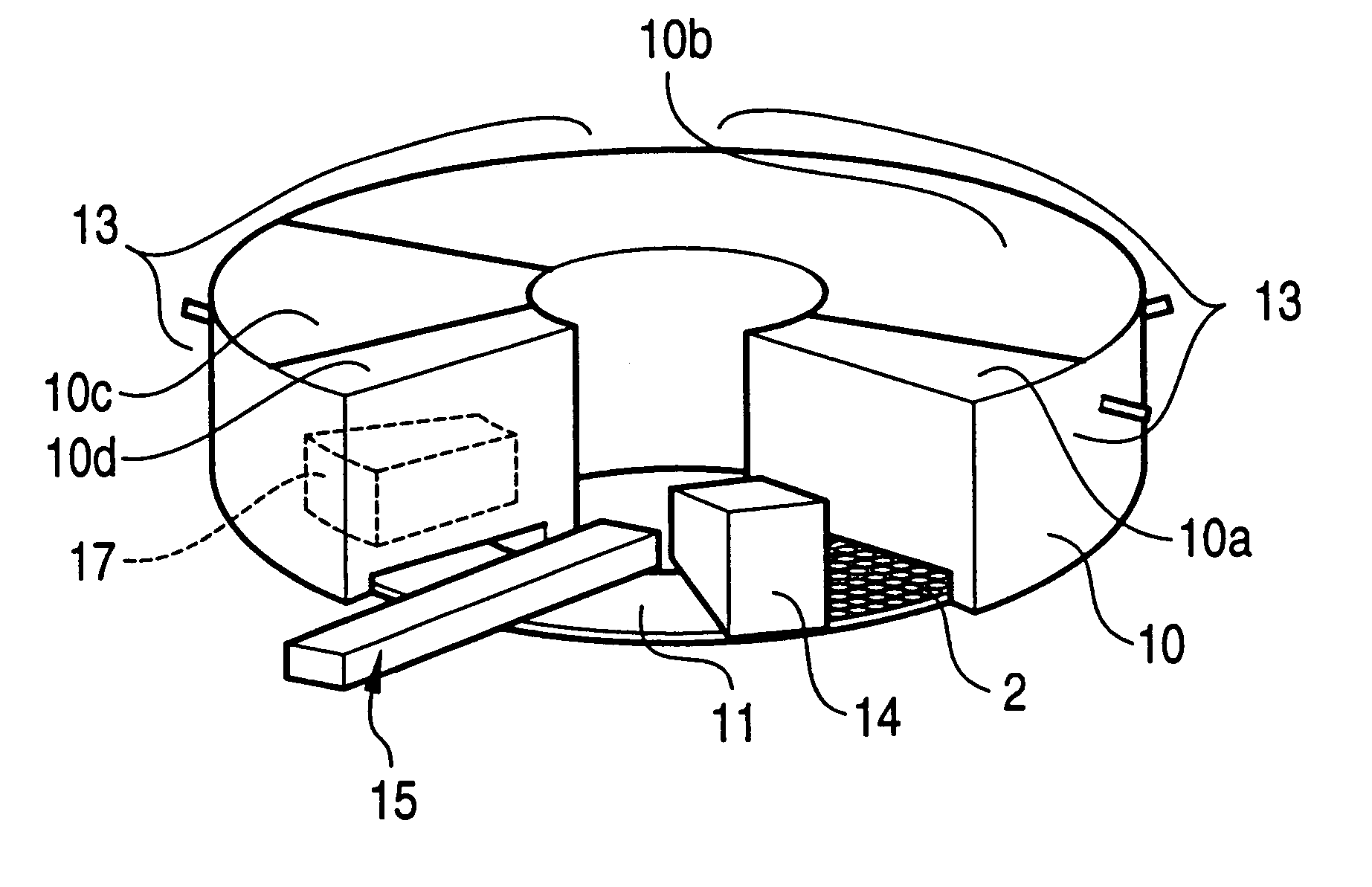

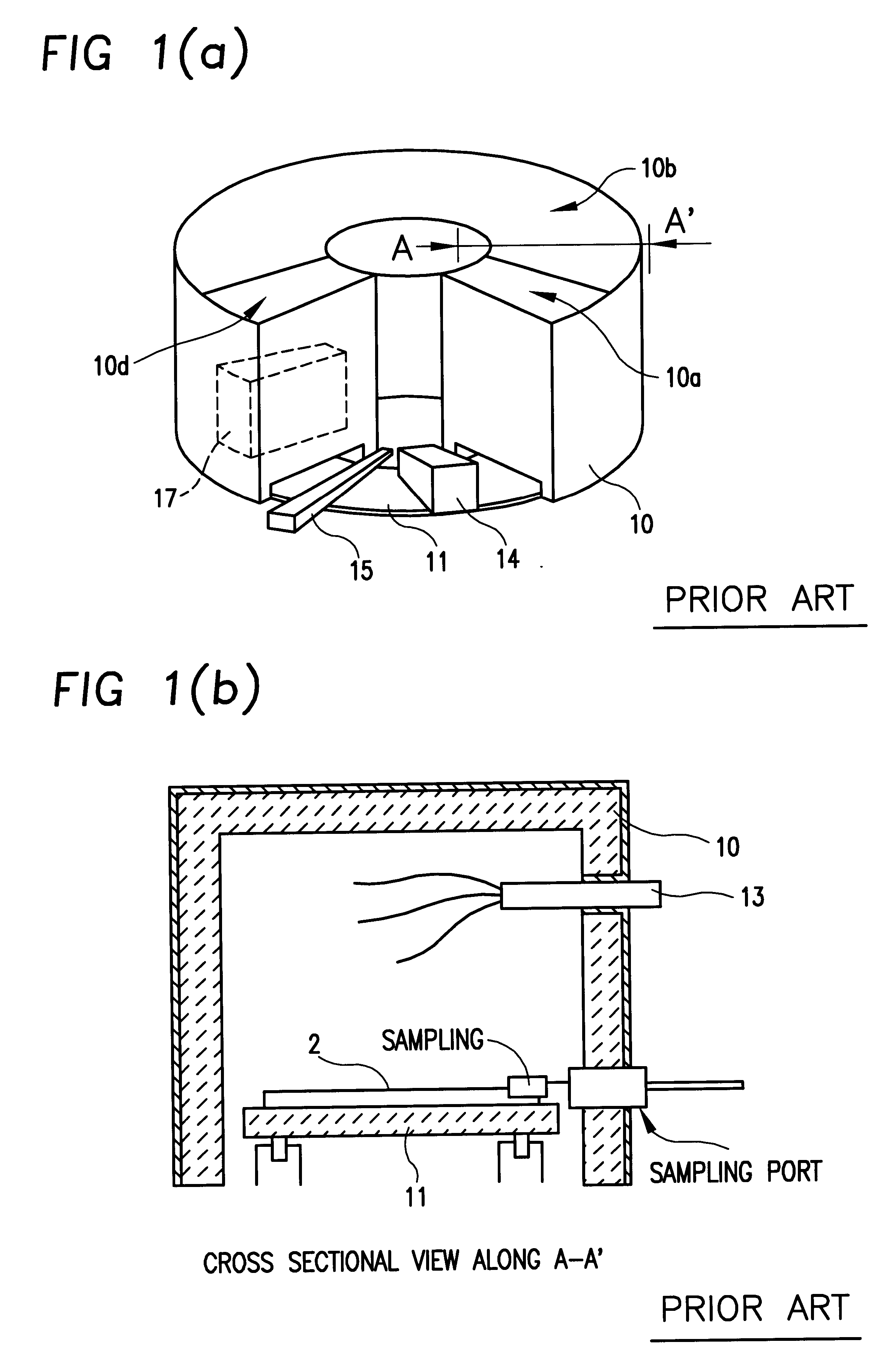

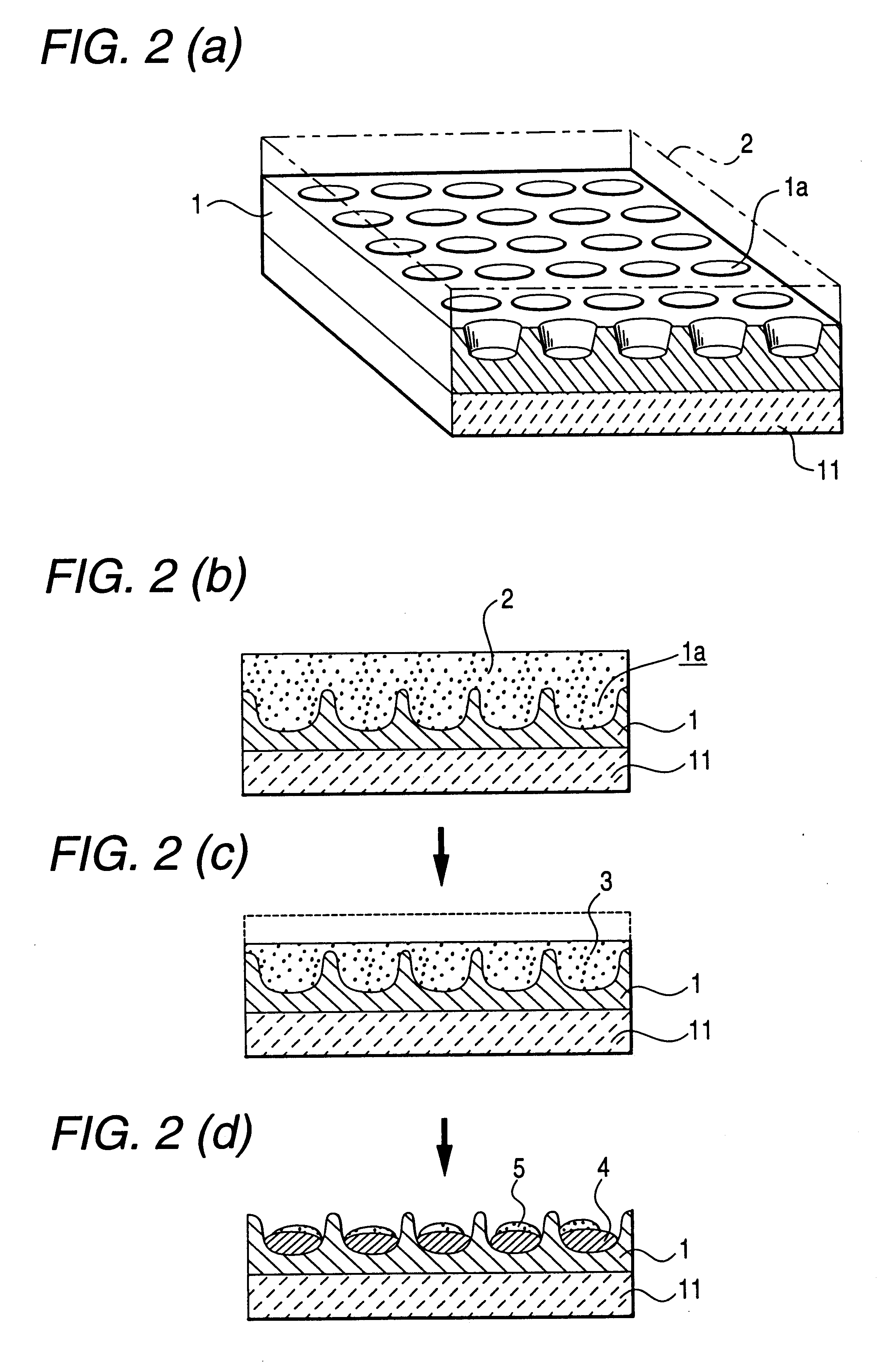

Apparatus for producing a reduced metal, and traveling hearth furnace for producing the same

InactiveUS6224820B1Low gangueLow ash contentRotary drum furnacesCharge composition/stateHearthFireplace

A traveling hearth for producing reduced metal by charging and stacking a raw material containing a metal-containing material and a solid-reducing material on a horizontally moving hearth, arranged for disposing a solid-reducing material layer on the hearth, forming concave portions at the solid-reducing material surface, stacking the raw material on the surface of the solid-reducing material layer, reducing the raw material by at least once heating and melting the material on the hearth to separate metal and gangue and ash ingredients, and discharging metal from the hearth.

Owner:KAWASAKI STEEL CORP

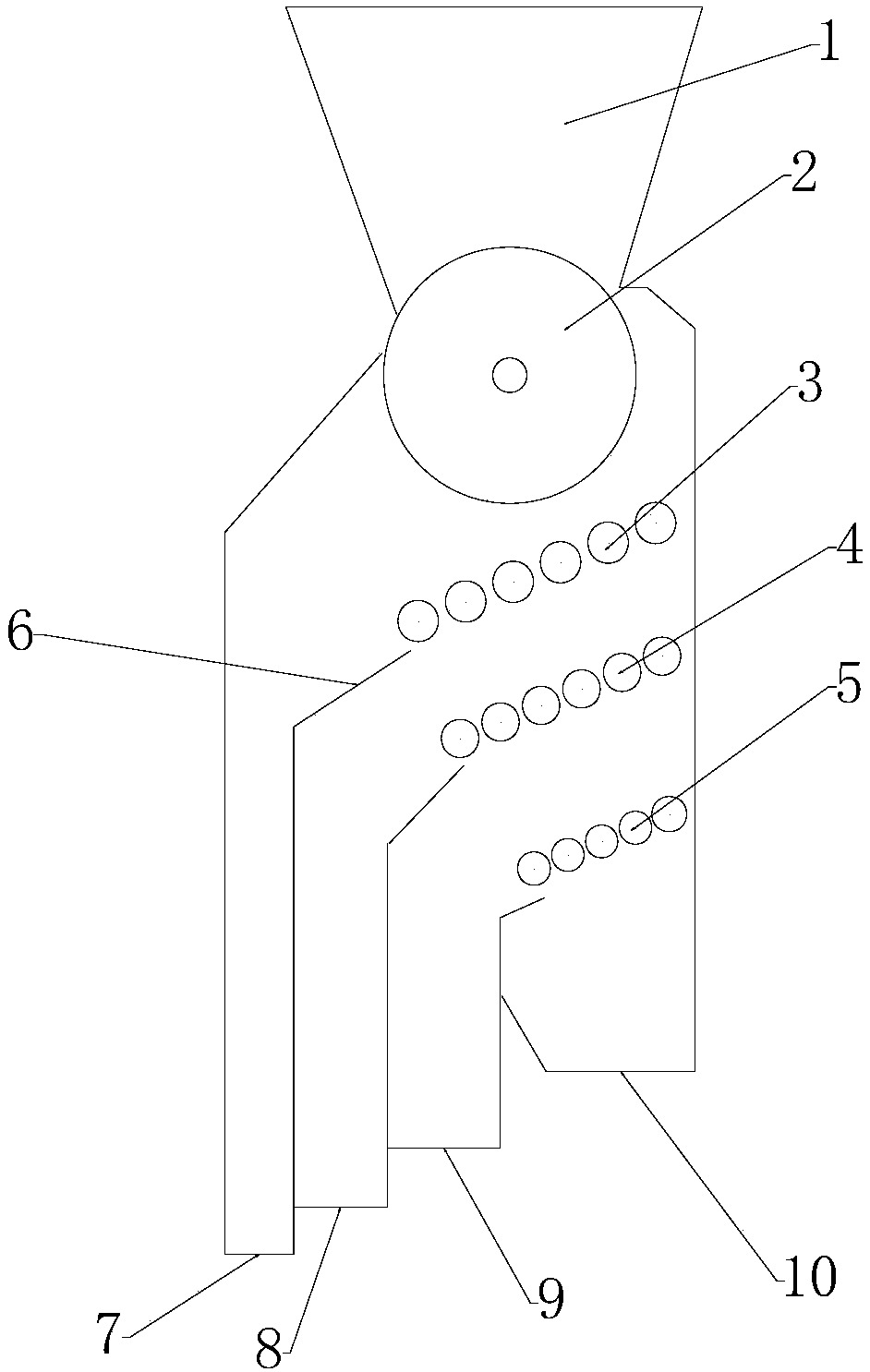

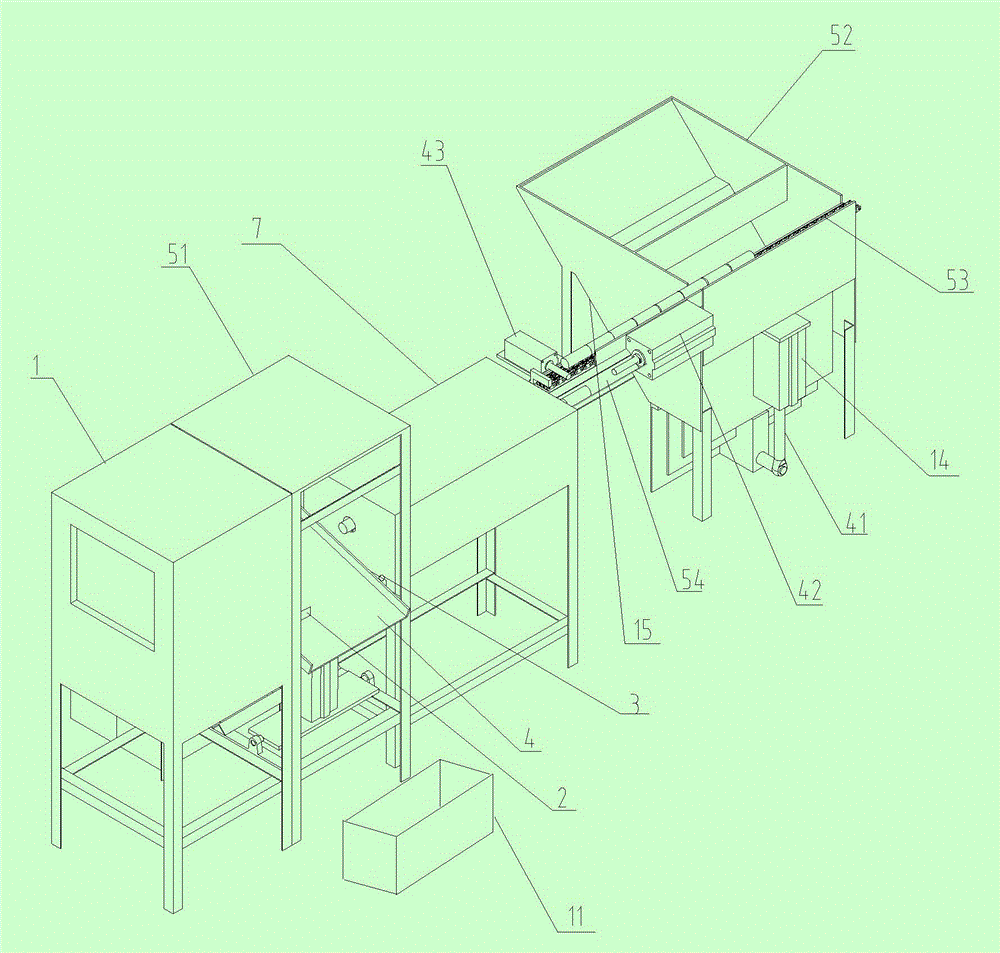

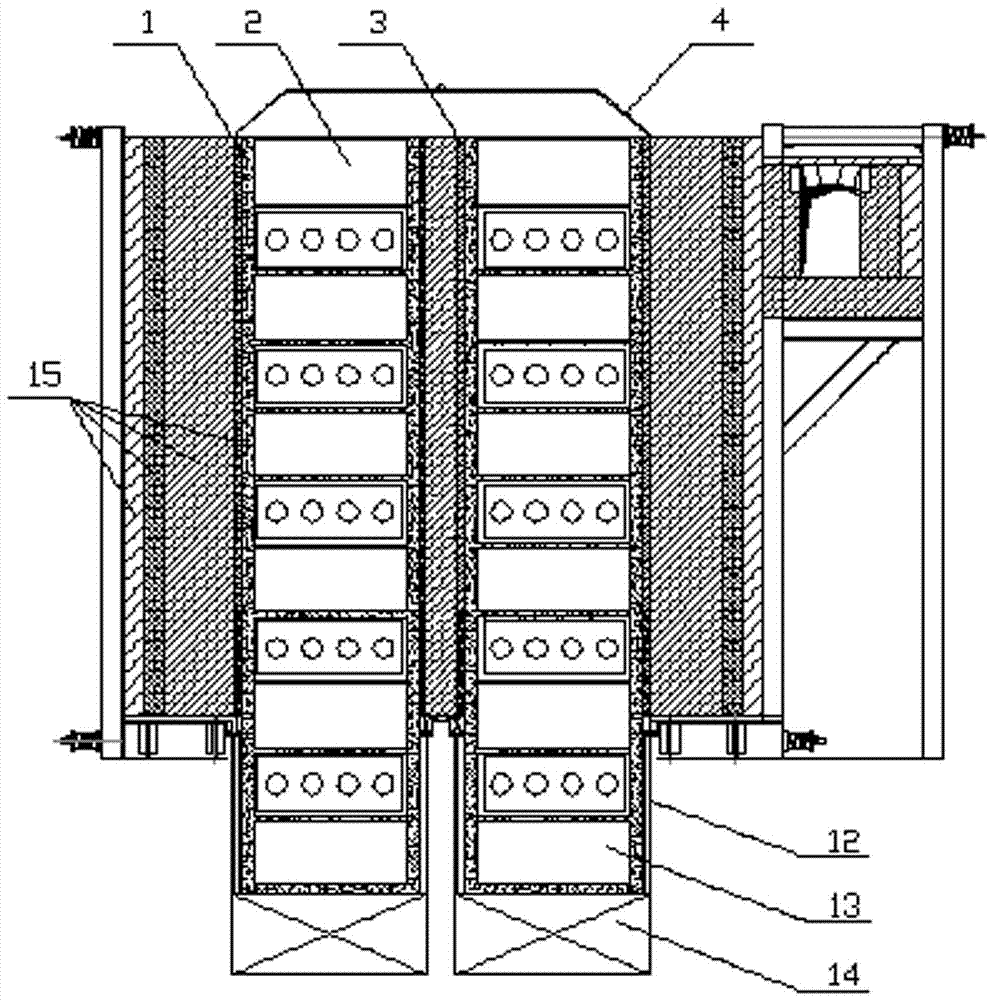

Sintered mixture preparation method, sintered mixture distribution apparatus and sintered mixture distribution method

ActiveCN108396136AEnhanced granulationIncrease the ratio of reasonable granularityCharge composition/stateCharge manipulationMaterial distributionDistributor

The invention relates to a sintered mixture preparation method, a sintered mixture distribution apparatus and a sintered mixture distribution method, wherein the raw materials of the sintered mixturecomprise iron ore powder, coke powder, return ore, quicklime and limestone. The sintered mixture preparation method comprises: placing iron ore powder, quicklime, return ore with a particle size of less than 3 mm after wetting, coke powder with a particle size of less than 3 mm, limestone and water to a primary mixer, and uniformly mixing to obtain a primary mixture; and placing the primary mixture, return ore with a particle size of 3-5 mm after wetting, coke powder with a particle size of more than 3 mm, limestone with a particle size of greater than 3 mm and water to a secondary intensive mixer, and uniformly mixing to prepare the sintered mixture. The sintered mixture distribution method comprises: distributing the sintered mixture onto a sintering machine in layers through the sintered mixture distribution apparatus comprising three sets of multi-roller material distributors, wherein the particle sizes of the layers are sequentially reduced from bottom to top, the particle size ofthe first layer is more than 8 mm, the particle size of the second layer is 5-8 mm, the particle size of the third layer is 3-5 mm, and the particle size of the uppermost layer is less than 3 mm. According to the present invention, the particle size ratio of the sintered mixture is improved, the precise segregation multi-layer material distribution is achieved, and the gas permeability and the sintering utilization coefficient of the sintered mixture are improved.

Owner:ANGANG STEEL CO LTD

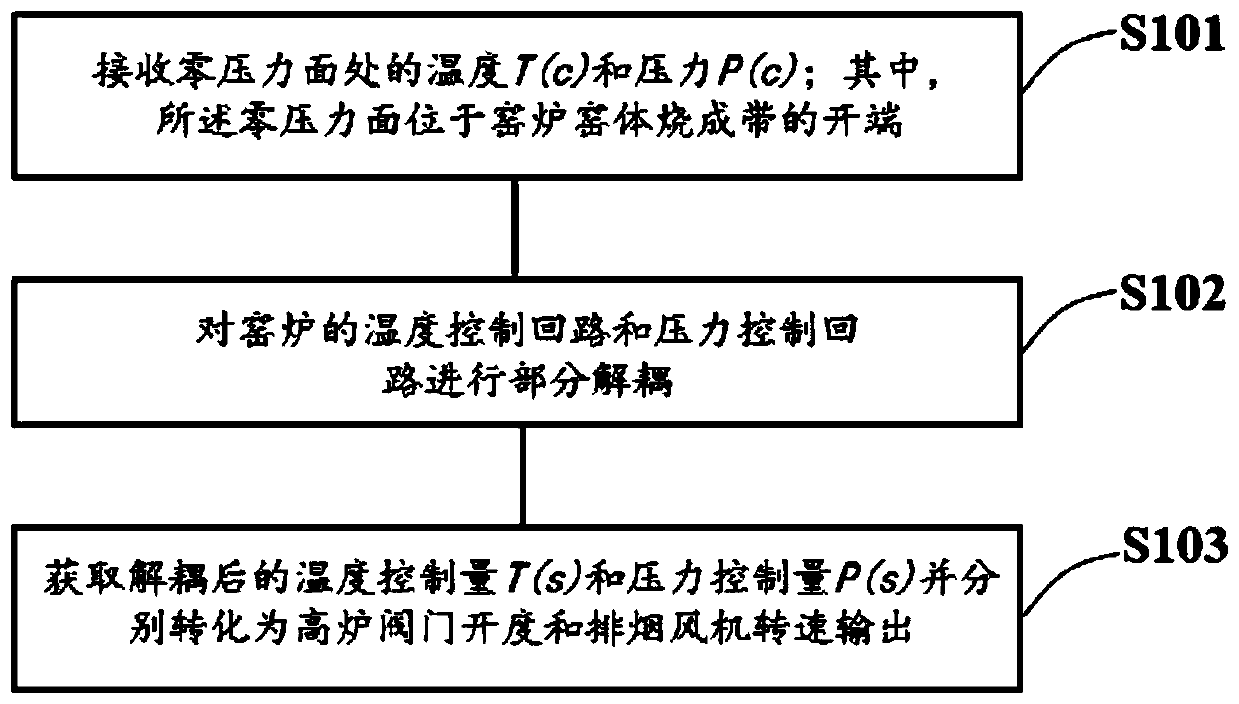

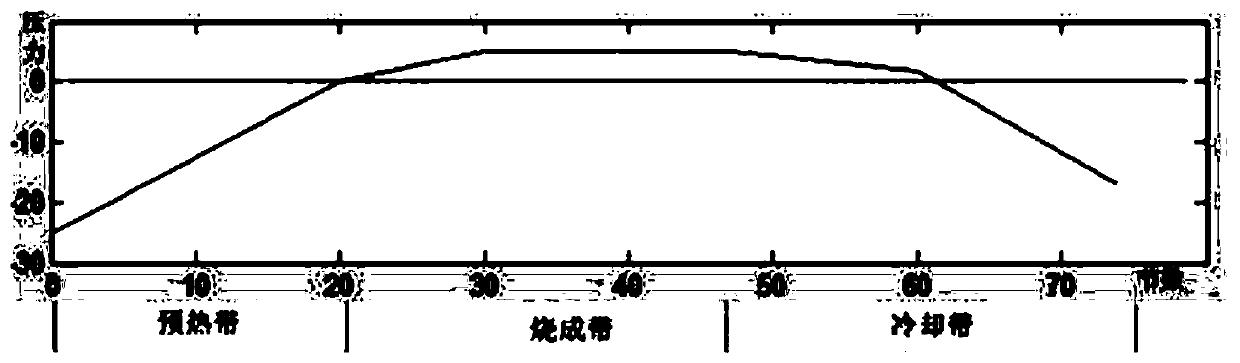

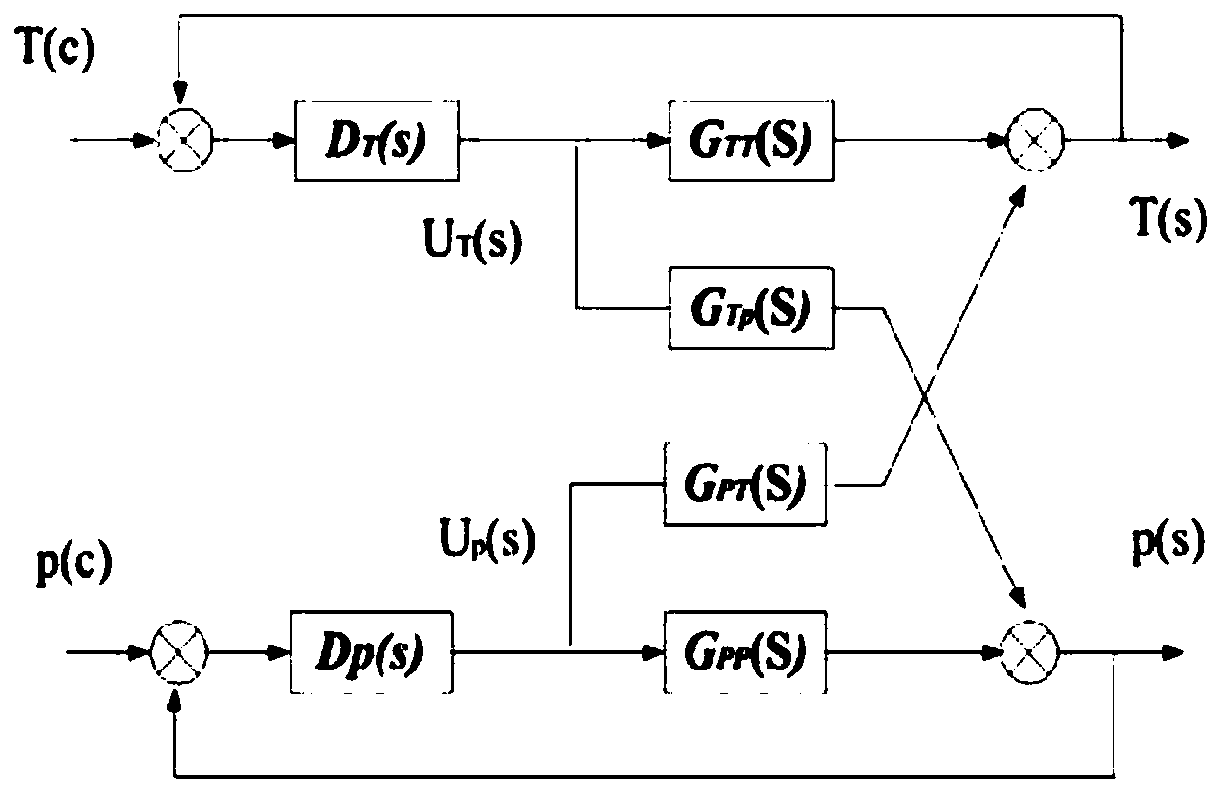

Kiln temperature-pressure decoupling control method, device, equipment and system

ActiveCN110108123AStable combustion air supplySmall temperature fluctuationsCharge composition/stateFurnace typesTemperature controlEngineering controls

The invention provides a kiln temperature-pressure decoupling control method, device, equipment and system, and relates to the technical field of engineering control. The method comprises the following steps: the temperature T(c) and the pressure P(c) on a zero-pressure surface are received, wherein the zero-pressure surface is positioned at an open end of a kiln body firing zone of a kiln; a temperature control loop and a pressure control loop of the kiln are partially decoupled; and a temperature control quantity T(c) and a pressure control quantity P(c) after decoupling are obtained, and are converted to the blast furnace valve openness and the smoke discharge fan rotating speed for outputting. Through use of the partial decoupling measure, the zero-pressure surface is positioned at thetail end of a preheating zone, so that the kiln internal temperature fluctuation is greatly reduced, the temperature and pressure control precision of the kiln body firing zone is improved, and the product quality is guaranteed.

Owner:厦门佳浴智能卫浴有限公司

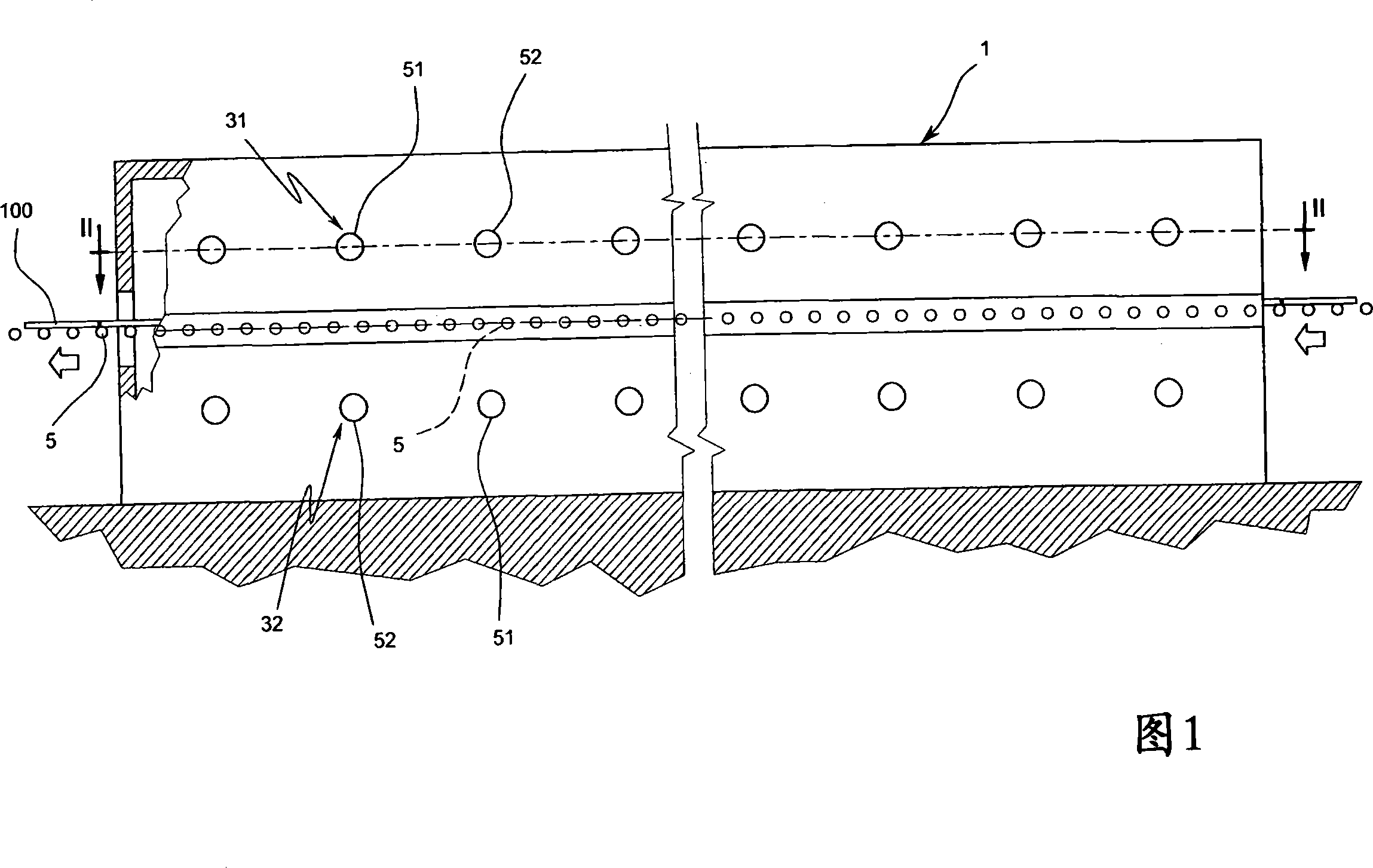

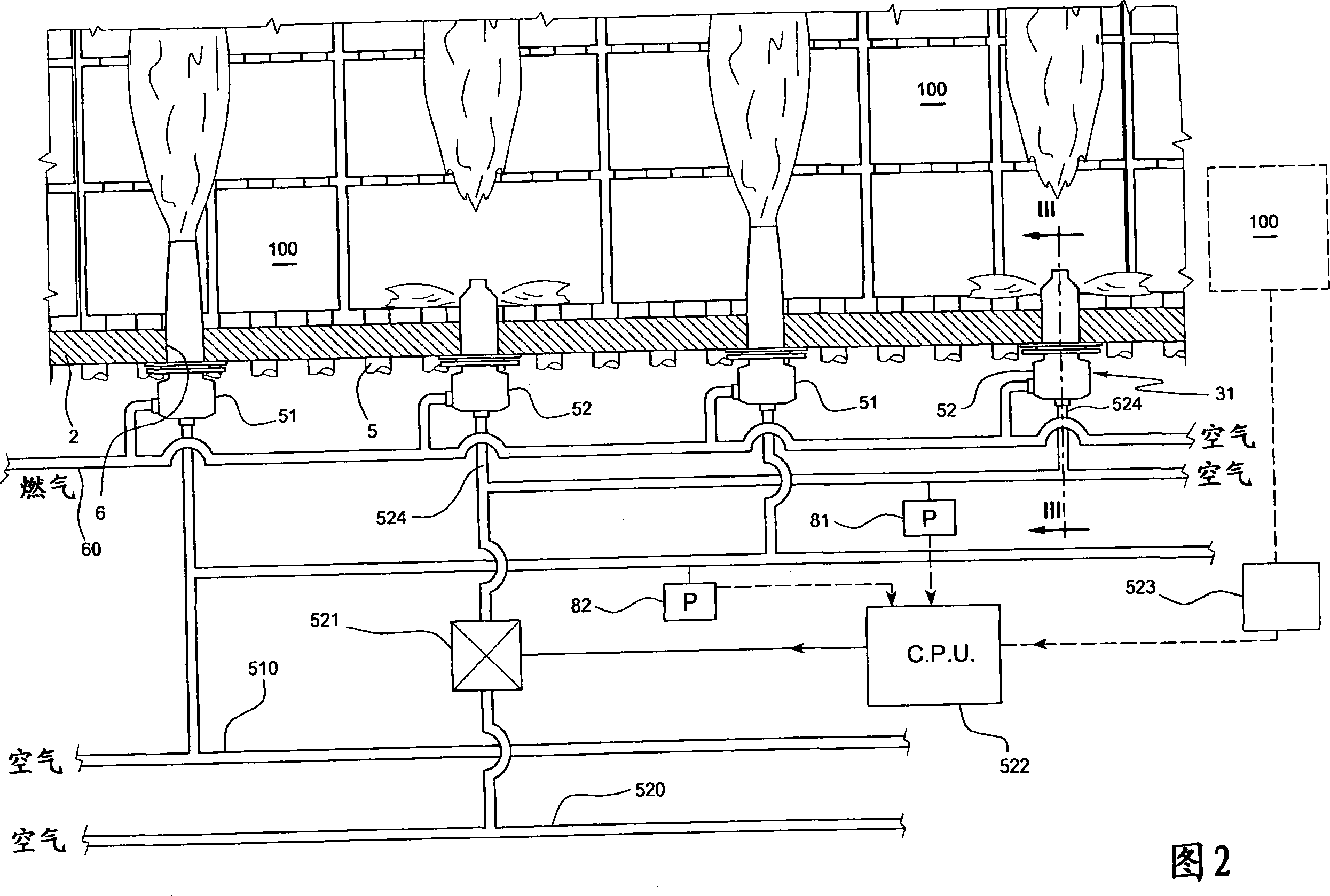

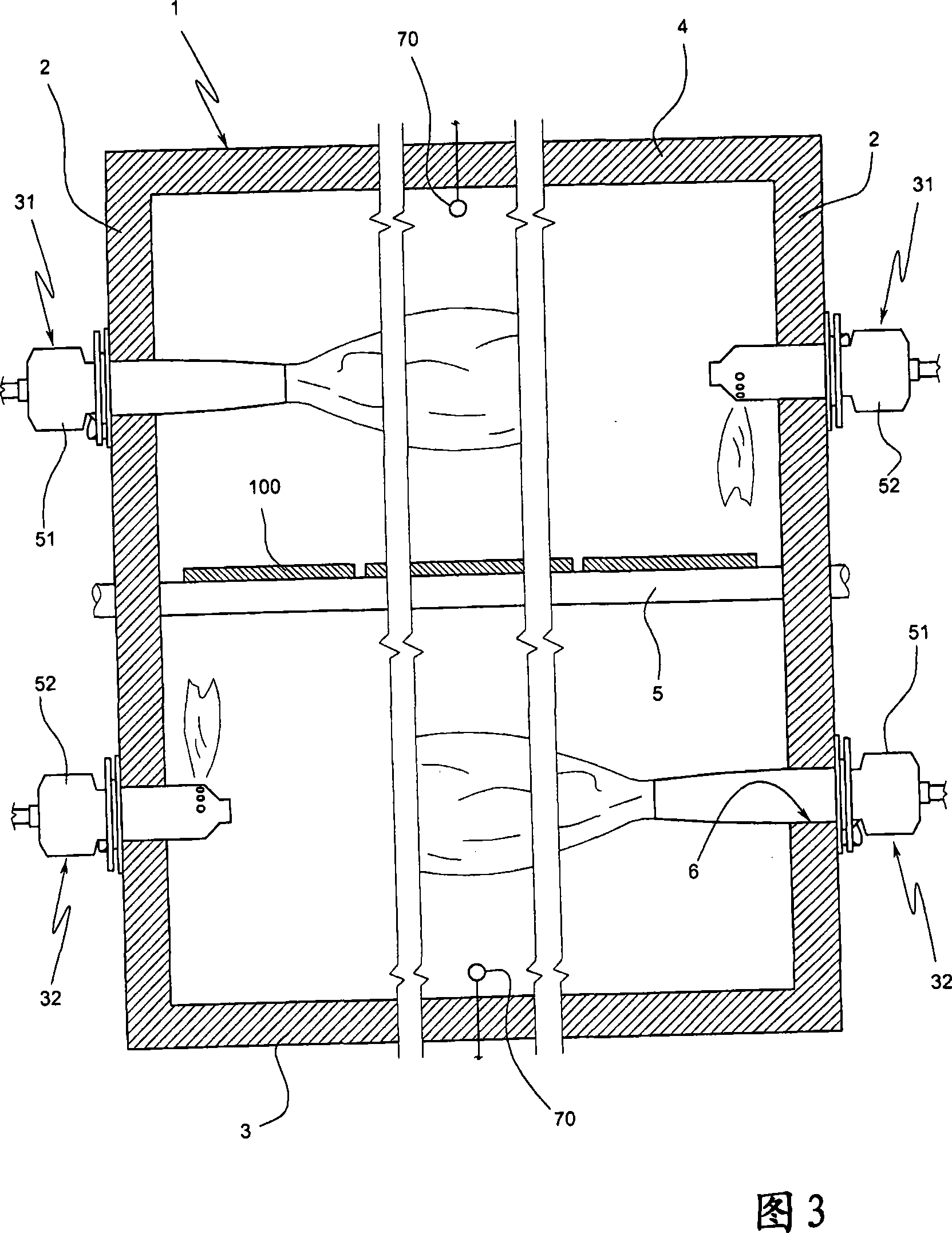

A tunnel kiln for ceramic products

InactiveCN101113873AAdvantageous embodimentFuel supply regulationAir supply regulationTunnel kilnCombustor

A tunnel kiln (1) for ceramic products comprising two opposite lateral walls (2), a horizontal roller conveyor (5) destined to support and advance a layer of tiles (100) internally of the kiln (1), a first series of burners (51) and a second series of burners (52) arranged aligned along the two lateral walls and facing towards the opposite wall, each burner (51) of the first series (51) being provided exclusively with an axial flame such as to heat a central zone of the tunnel while each burner (52) of the second series is provided with at least a radial-flame nozzle such as to beat a zone which is proximal to the lateral wall of the tunnel, each burner (51, 52) of the first and the second series being connected to a common conduit (60) of combustible gas and respectively to a first (510) and a second (520) conduit of a comburent, comprising: means (523) for detecting a dimensional out-of-size with respect to a design project specification for the products exiting the kiln (1); a control unit (522) for receiving data coming from the means (523) for detecting; means for regulating (521) a flow rate of the comburent to the burners (52) of the second series on the second conduit (520) of the comburent, the means for regulating (521) of the comburent flow rate being controlled by the control unit (522) which is programmed to command the means for regulating (521) according to the data received from the means for detecting (523).

Owner:萨克米窑炉股份有限公司

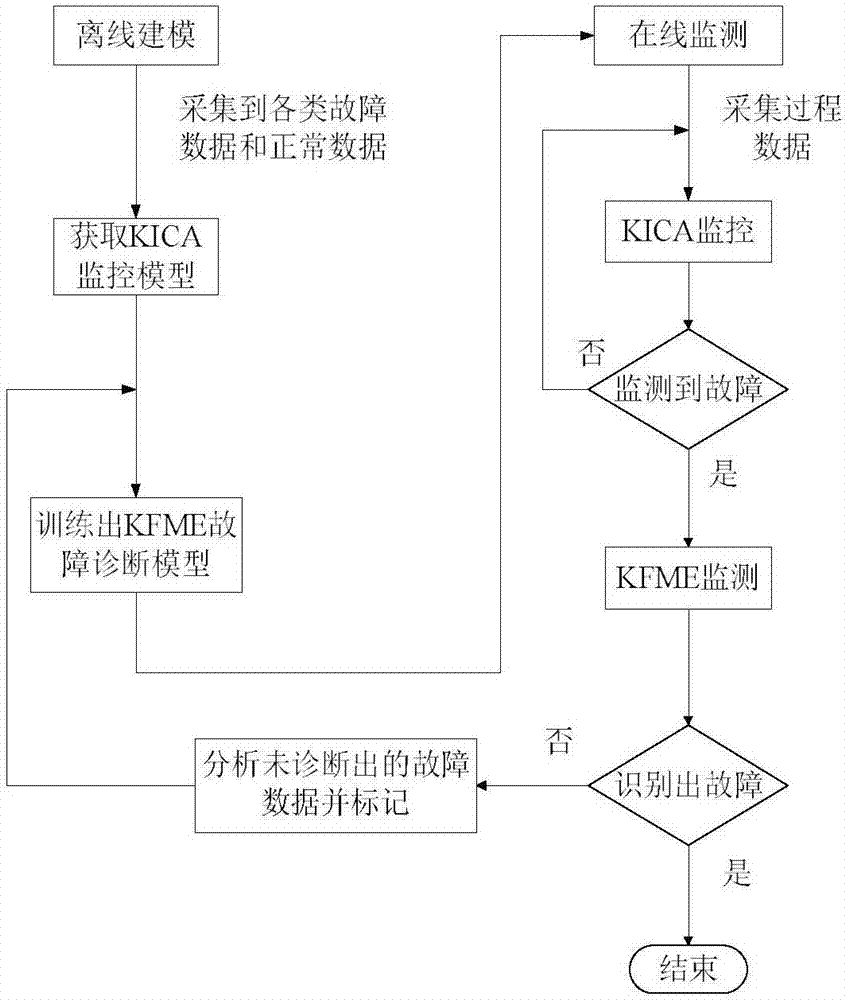

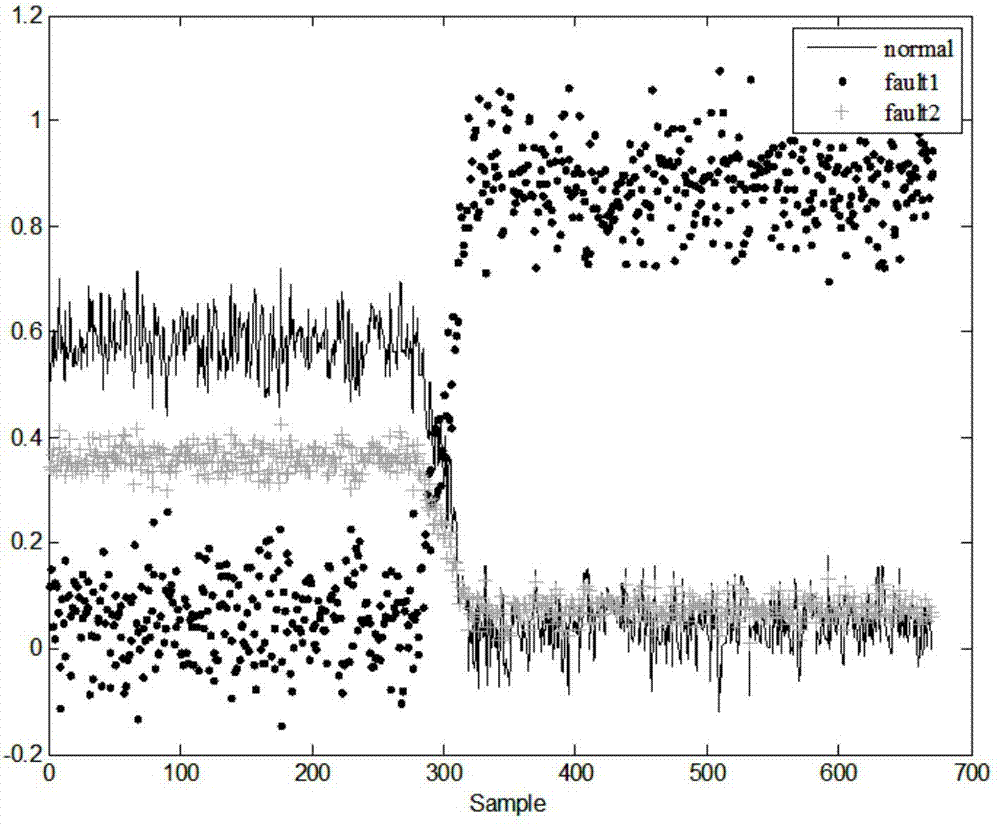

Nuclear flexible manifold embedding electric smelting magnesium furnace fault monitoring method

ActiveCN106907927AImprove monitoring effectReduce computing costCharge composition/stateCharge treatment typeElectricityOriginal data

The invention relates to a nuclear flexible manifold embedding electric smelting magnesium furnace fault monitoring method. The method comprises the steps that various kinds of fault data and normal data are collected; offline modeling is carried out, a KICA monitor model is acquired according to the collected data, and a KFME fault diagnosis model is trained; online monitoring is carried out, the KICA monitor model is utilized for carrying out real-time online monitoring, and process data are collected; if faults are monitored, a KFME monitor model is used for carrying out fault recognition; if faults are recognized, a one-time fault monitoring process is finished; and if no fault is recognized, non-diagnosed fault data are analyzed and marked, and the step of training the KFME fault diagnosis model is executed through jump. By means of the method, a small quantity of marked data and a large quantity of non-marked data are utilized for building a process monitoring model, the model is more accurate, data dimension reduction and original data information retention can be achieved well, the accuracy and antijamming capability of the fault diagnosis model are improved, and unknown faults are monitored.

Owner:NORTHEASTERN UNIV

Method and apparatus for recovering metal values from liquid slag and baghouse dust of an electric arc furnace

InactiveUS20010046251A1Reduce disposal costsLow cost of treatmentSolid waste disposalCharge composition/stateSteelmakingElectric arc furnace

An apparatus and method for processing liquid slag and baghouse dust from a steelmaking furnace such as an EAF to recover valuable metals from the slag and dust includes a treatment vessel having a movable lower shell portion for receiving liquid slag and an upper shell portion that couples with the movable lower shell portion during heat activation of the treatment vessel. The slag is combined with silicon dioxide, a reducing agent, baghouse dust, and an inert gas before being heated to between approximately 1400° C. and 3000° C. The heat treatment results in a molten reduced iron and manganese metallic material, a treated slag layer, and an off-gas containing lead, zinc, and carbon monoxide. The off-gas is combusted, cooled, and solidified, resulting in lead oxide and zinc oxide. The slag layer is tapped, cooled, and solidified. The metallic layer is tapped for recycle in the steel making process.

Owner:VALLOMY JOHN A

Temperature control sorting device used in pipe machining process

ActiveCN105674748AFully automatedThe phenomenon of realizing the flow to the subsequent processCharge composition/stateCharge manipulationTemperature controlIntermediate frequency

The invention relates to a temperature control sorting device used in the pipe machining process. The temperature control sorting device comprises an automatic feeding device, an intermediate frequency heating furnace, a sorting device and a control cabinet. The automatic feeding device is connected with a feeding inlet of the intermediate frequency heating furnace through a conveying mechanism. The sorting device is connected with a discharging outlet of the intermediate frequency heating furnace. The control cabinet is connected with the sorting device. The automatic feeding device is composed of a fixed plate and a plurality of ejector plates. A baffle with the two ends being connected with the two side faces of a hopper is fixedly arranged between each two ejector plates. The ejector surface of each ejector plate is tilted relative to a discharging outlet of the hopper. The ejector plates are driven by an ejector air cylinder to move up and down, and thus materials on the ejector surfaces inside the hopper are driven to cross the corresponding baffles under the effect of gravity to fall into the conveying mechanism in sequence. The sorting device comprises a temperature sensor. The control cabinet controls the sorting device by receiving a workpiece temperature detected by the temperature sensor so as to sort workpieces at the discharging outlet of the intermediate frequency heating furnace. The temperature control sorting device is simple in structure and capable of automatically achieving efficient and precise sorting.

Owner:湖南省亿利金属制品有限责任公司

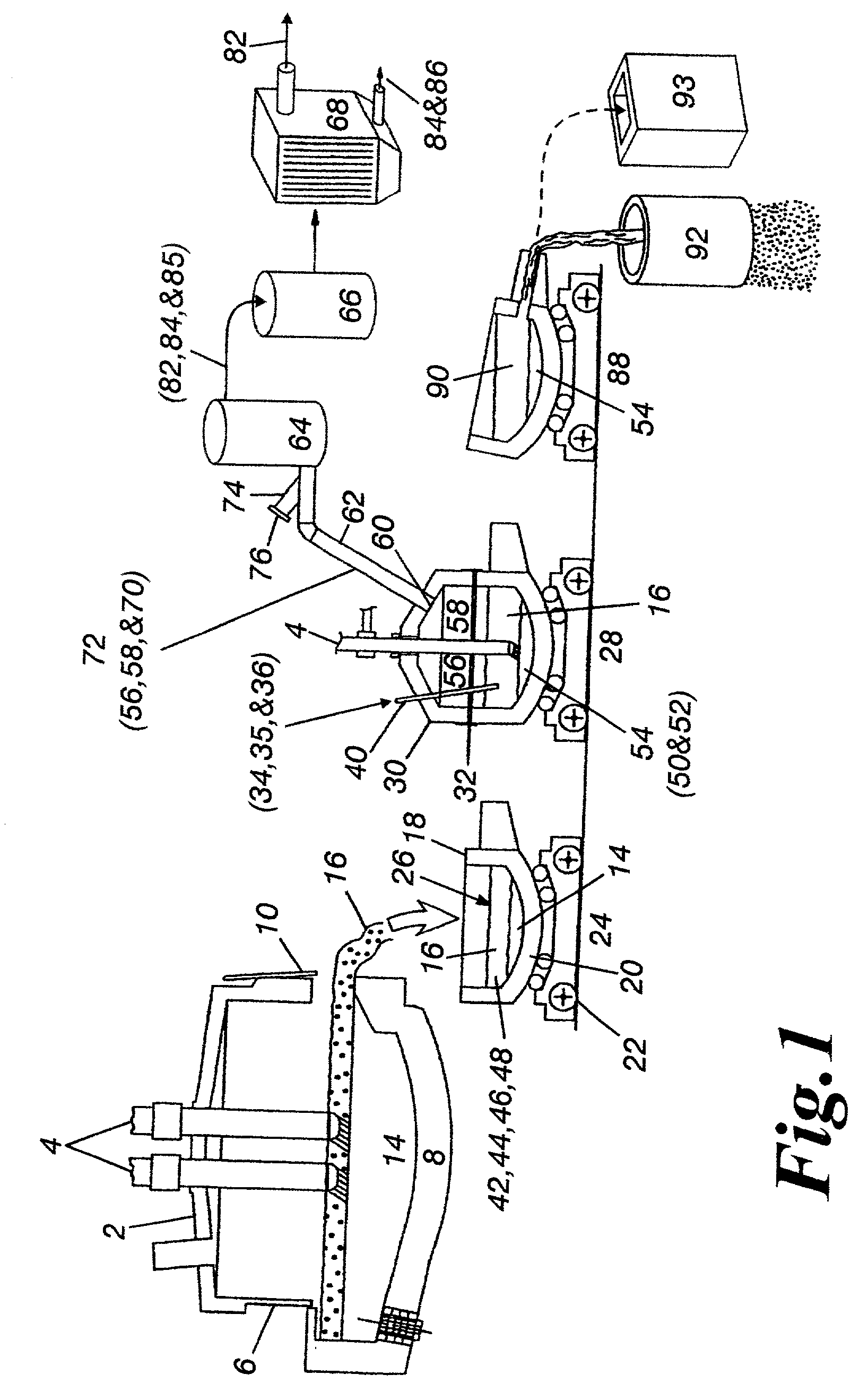

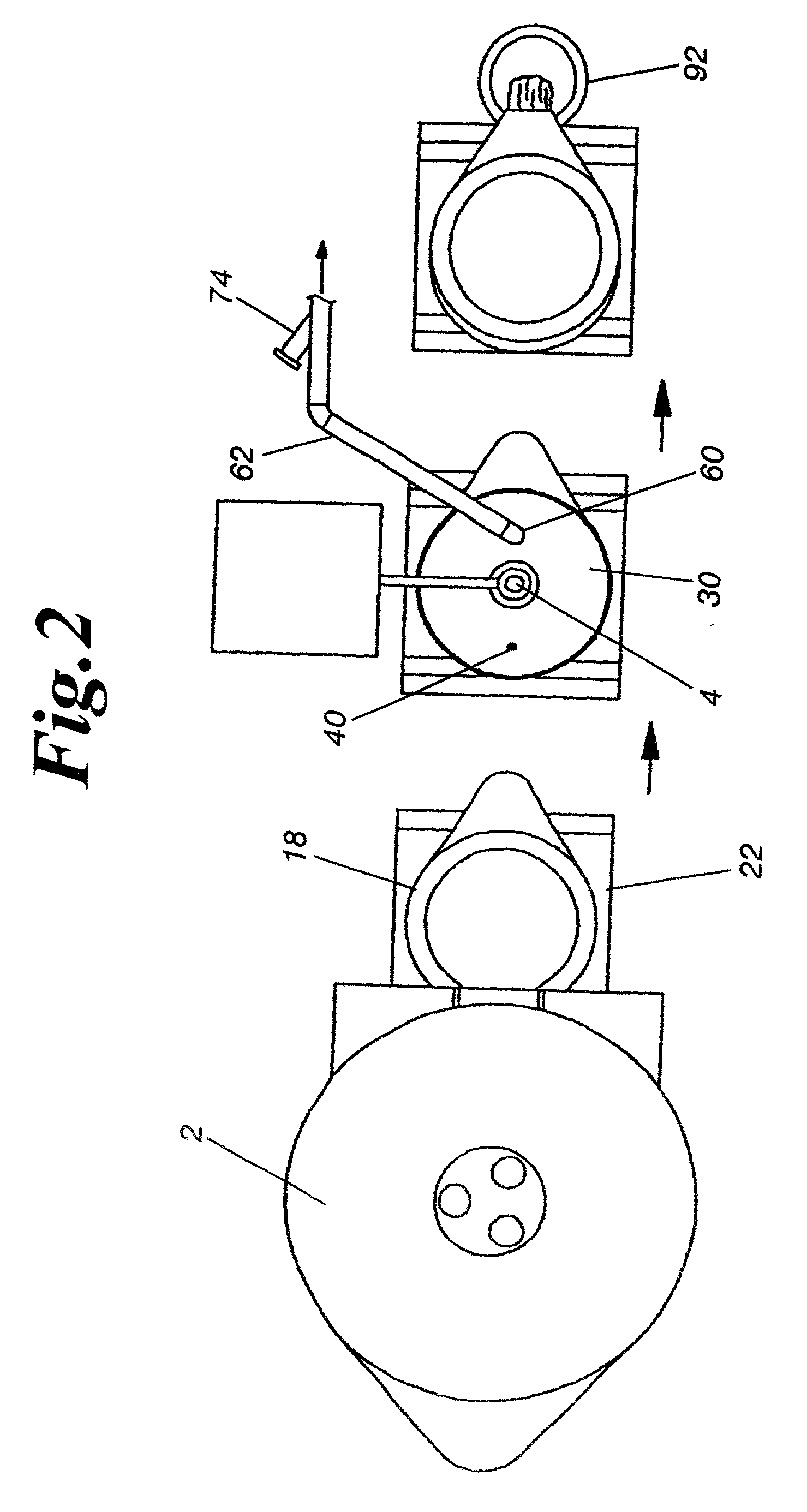

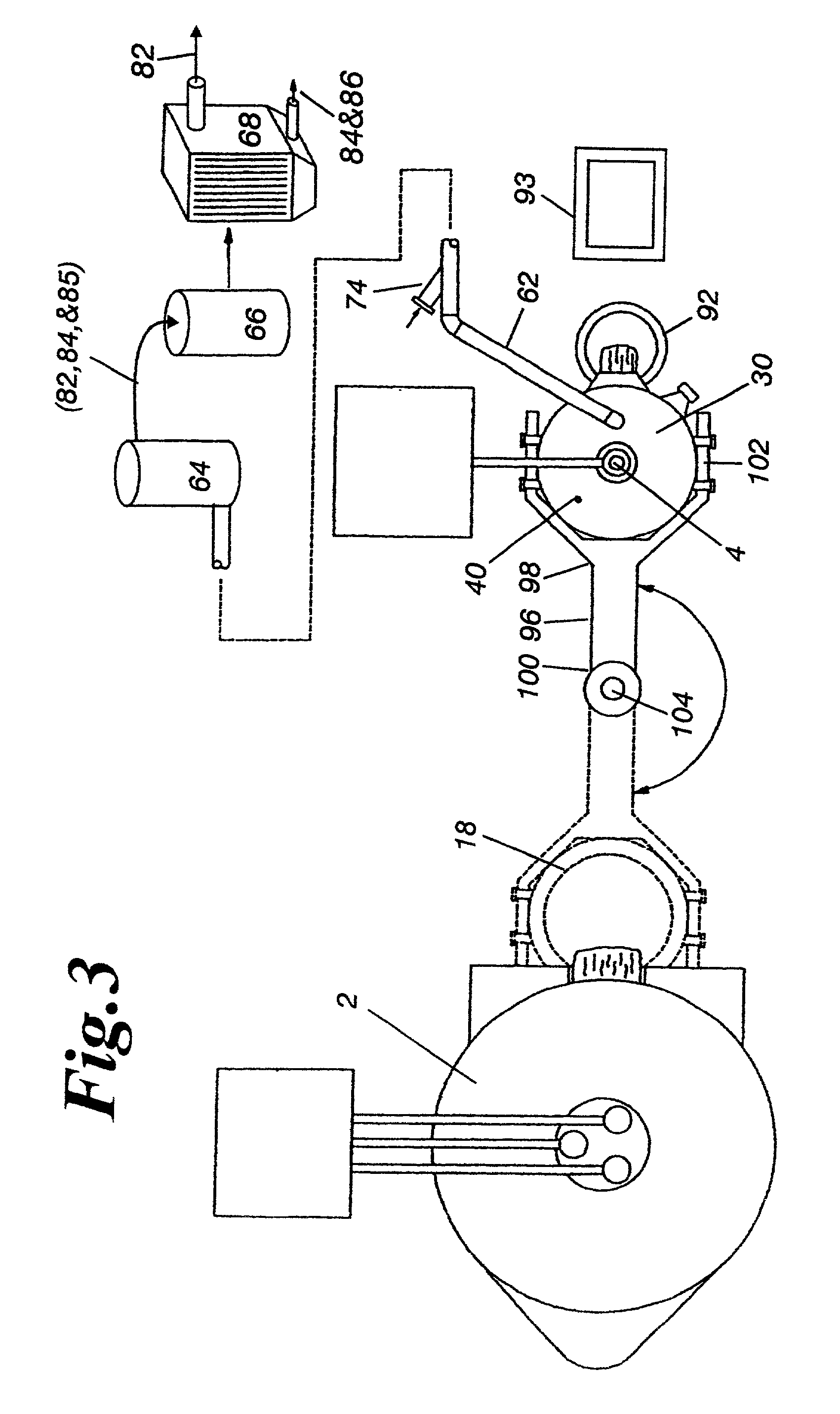

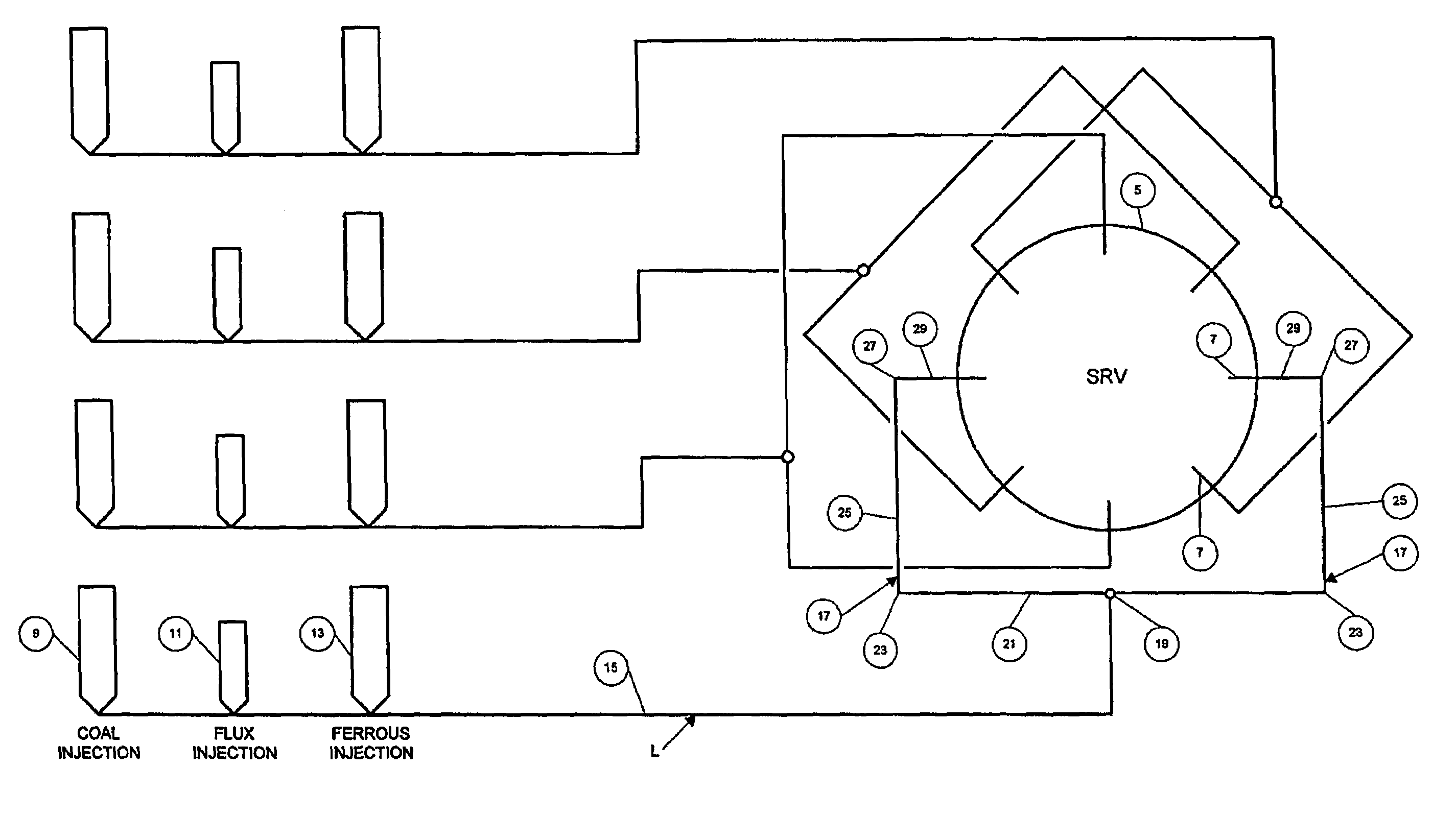

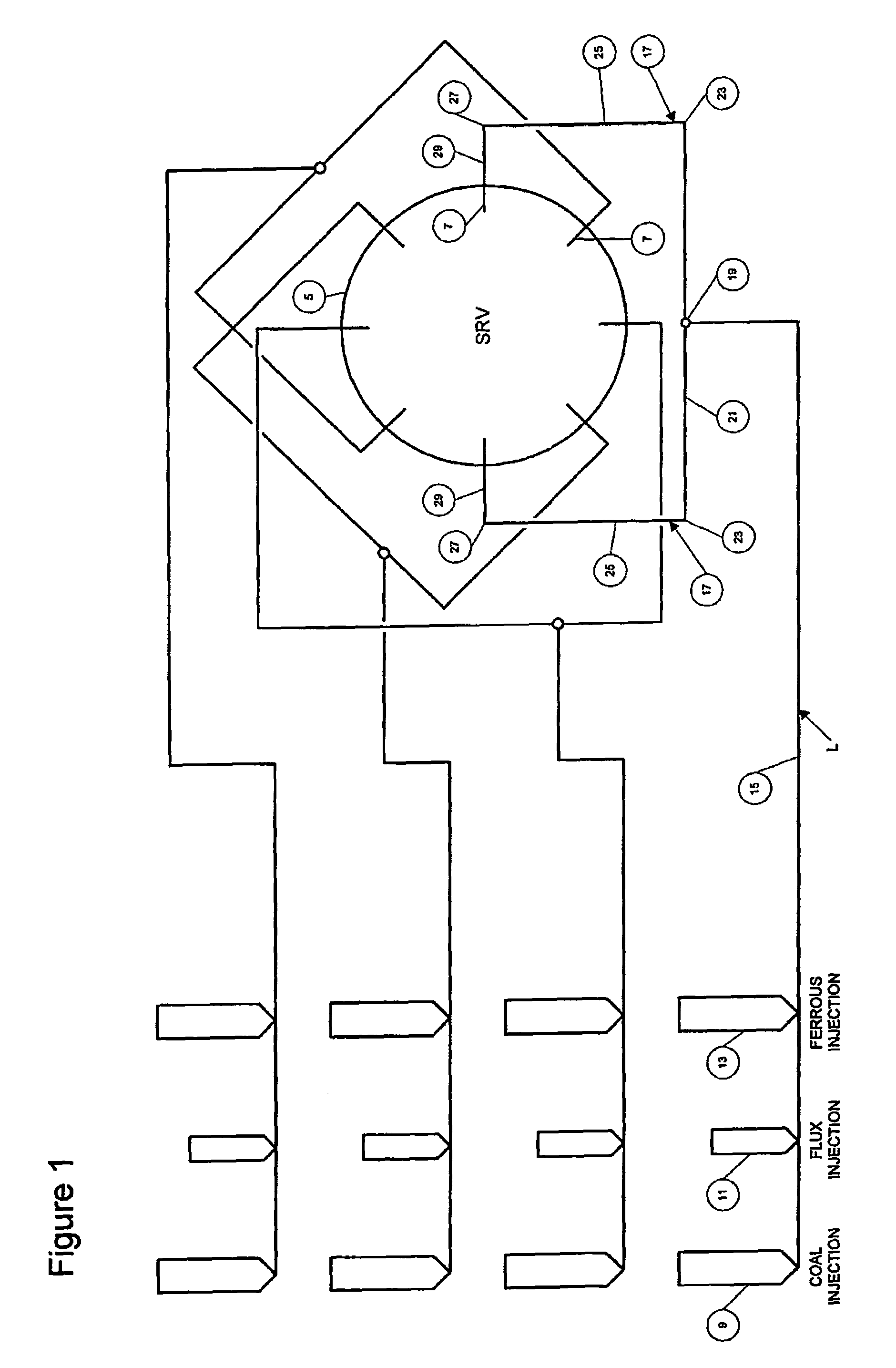

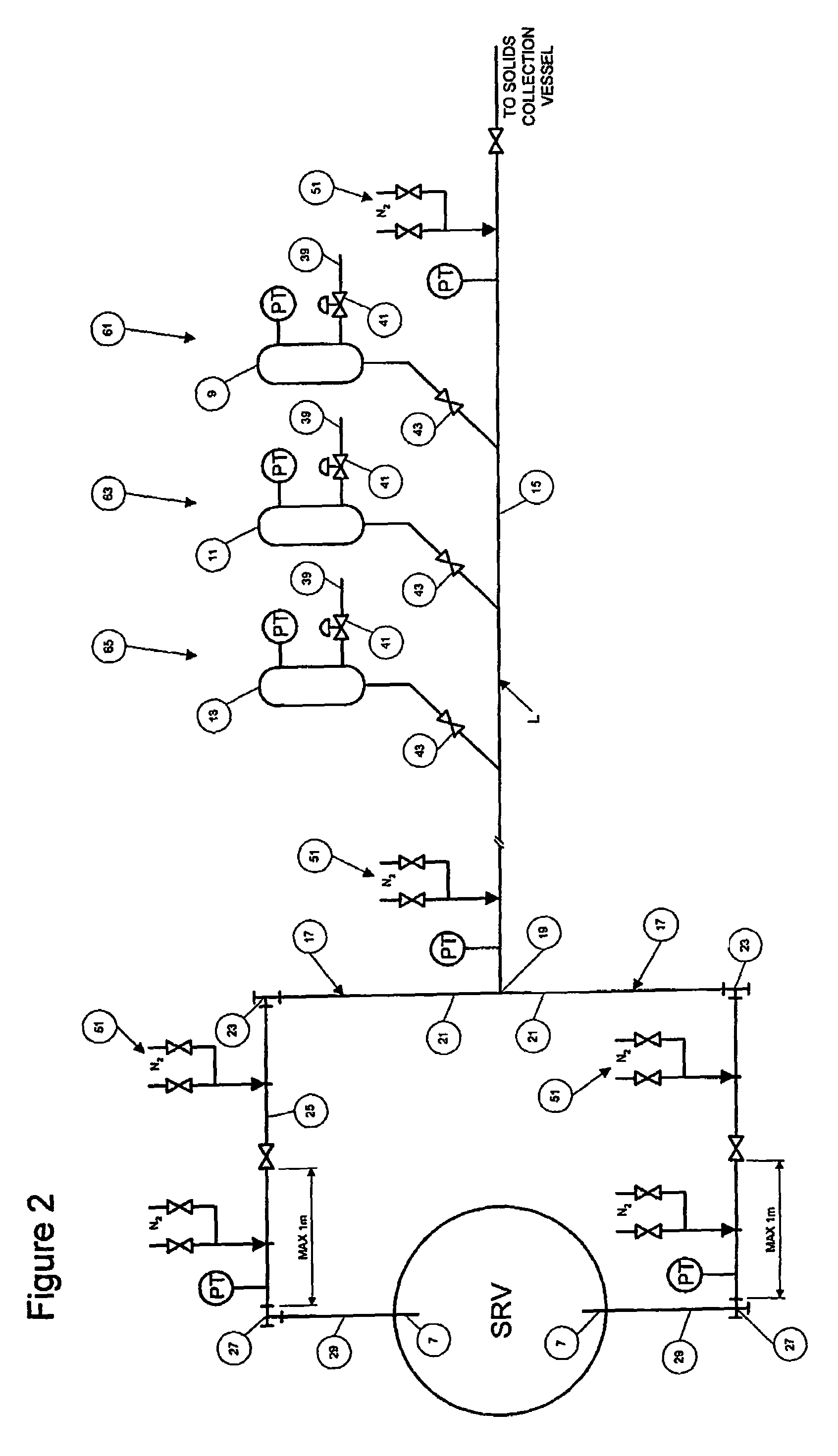

Supplying solid feed materials for a direct smelting process

InactiveUS7422622B2Effective and reliable processEffective and reliable and apparatusCharge composition/stateTuyeresSmelting processMaterial supply

A process and apparatus for supplying solid feed materials for a direct smelting process to solids injection lances of a direct smelting vessel is disclosed. The feed materials supply apparatus includes a supply line (L) for conveying iron-containing material and solid carbonaceous material under pressure to solids injection lances (7), and the supply line includes a main feeder line section (15) and a plurality of branch line sections (17) extending from the main feeder line section. Each branch line section is connected to one solids injection lance for supplying iron-containing material and carbonaceous material to that lance. The apparatus further includes an assembly for dispensing iron-containing material under pressure into the main feeder line section of the supply line and an assembly for dispensing carbonaceous material under pressure into the main feeder line section of the supply line.

Owner:TECHNOLOGICAL RESOURCES

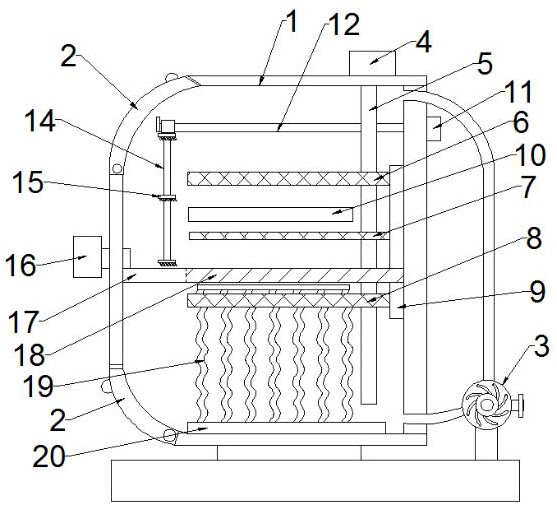

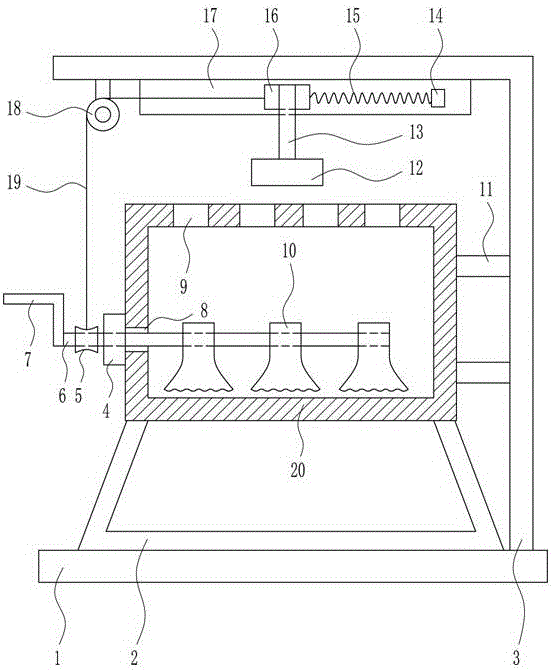

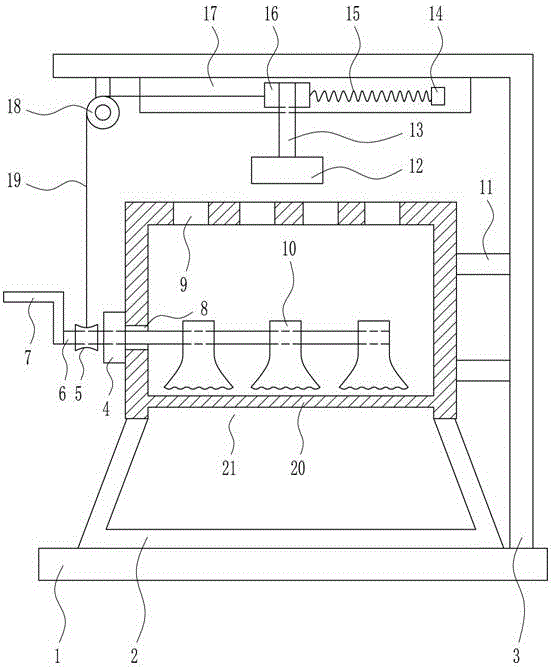

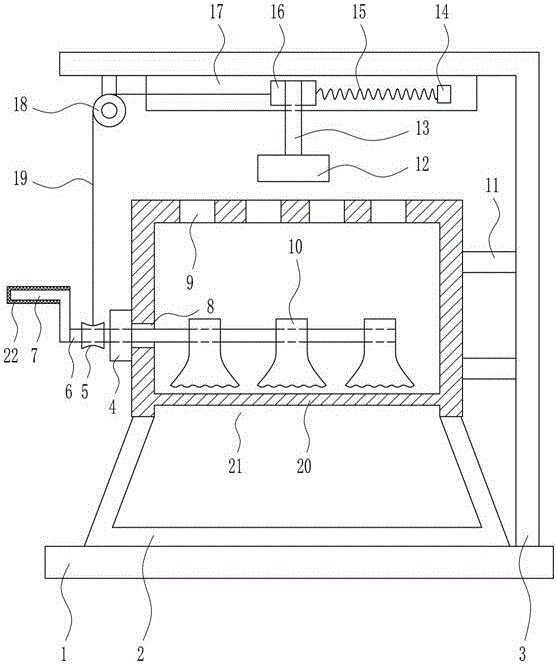

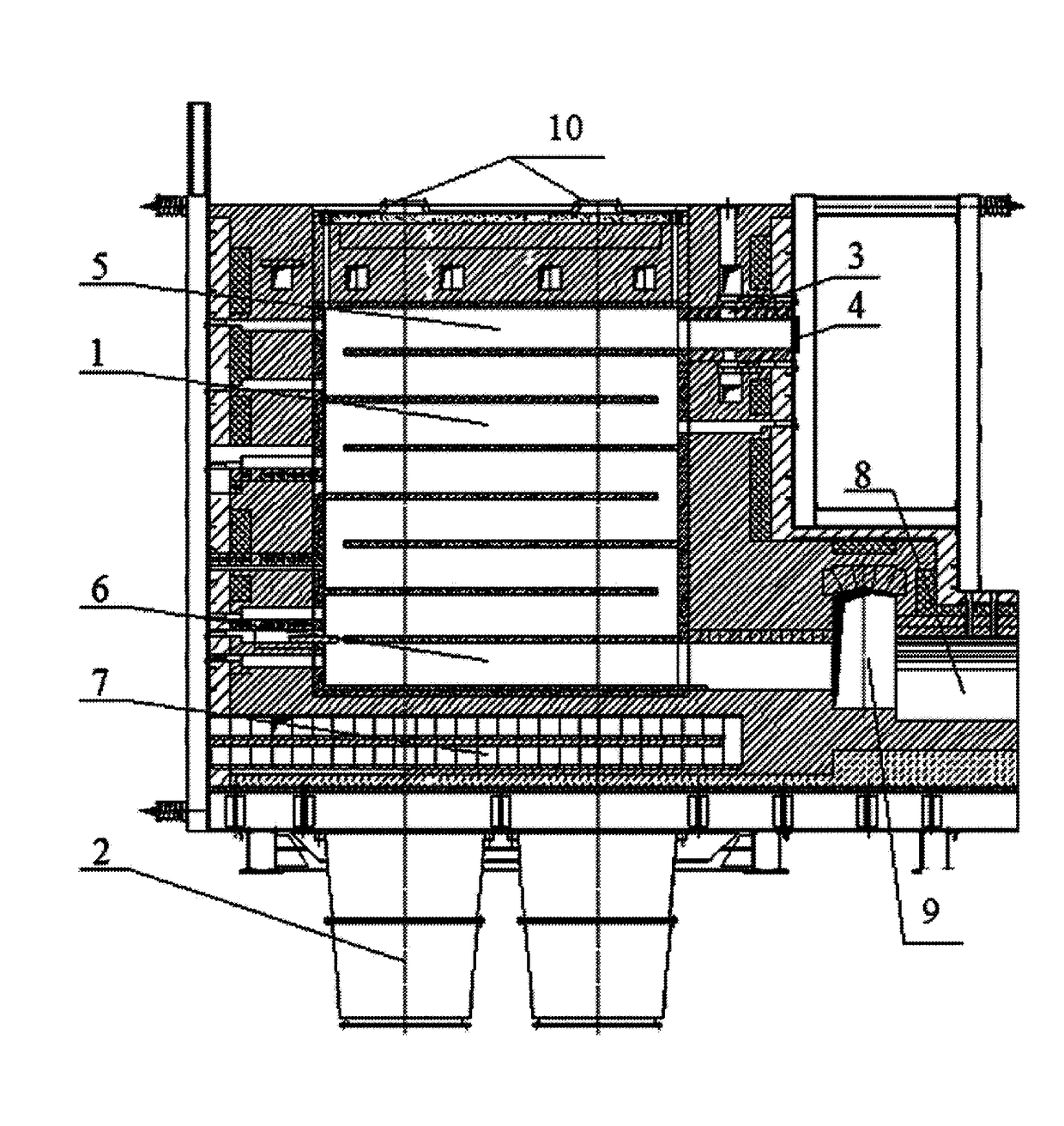

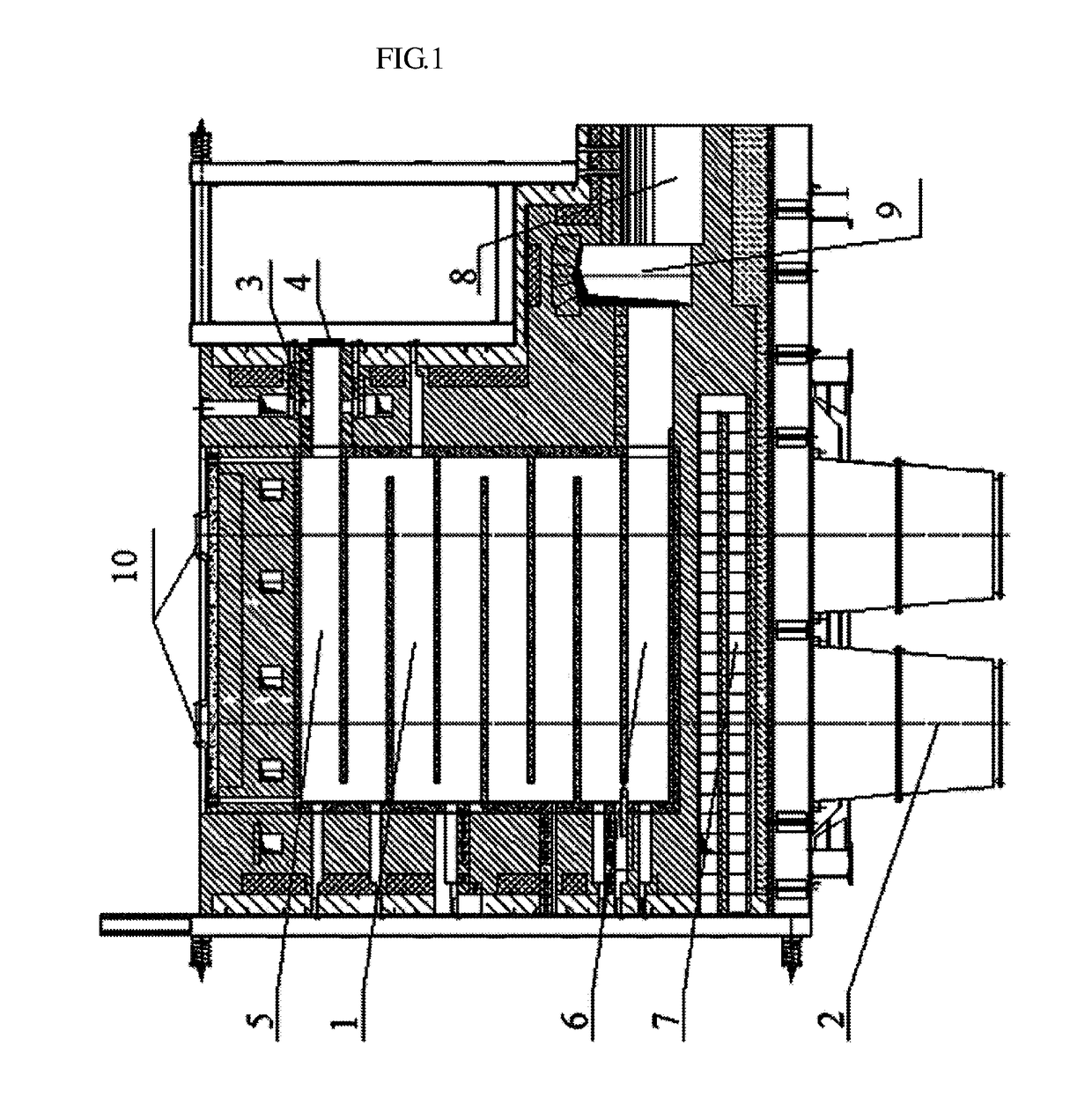

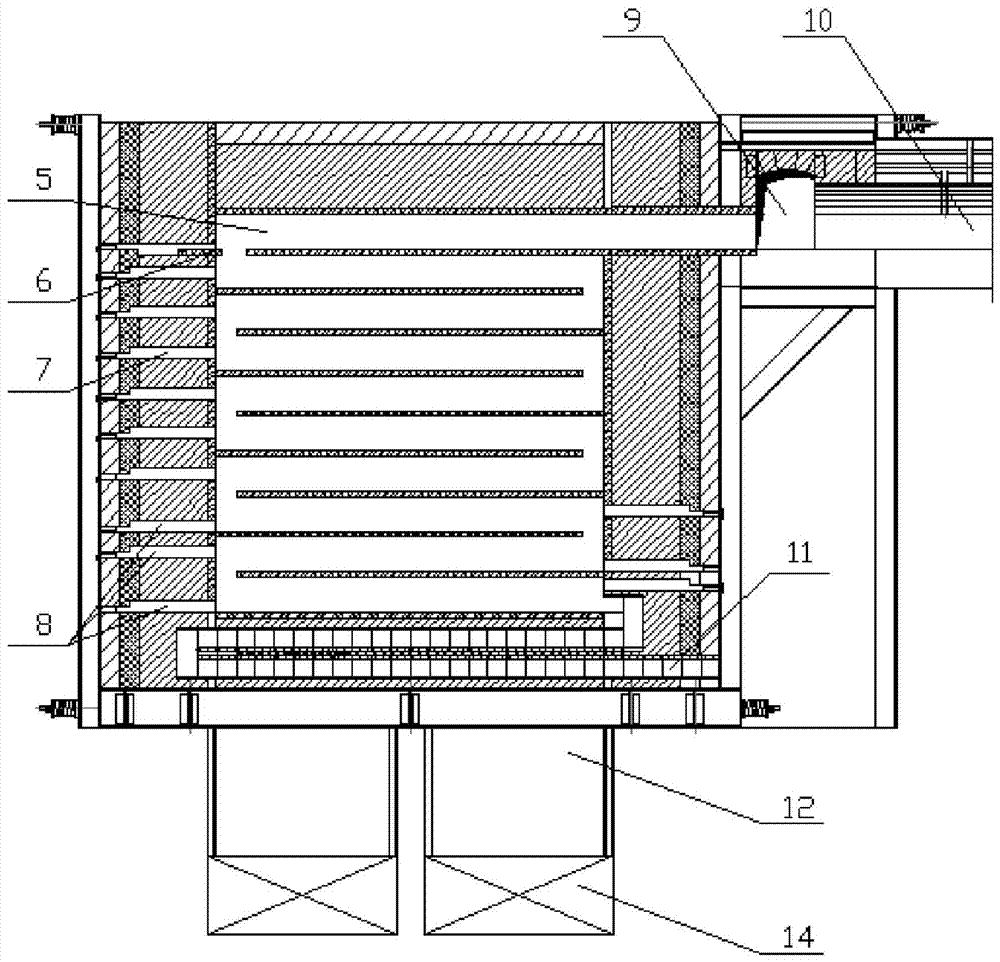

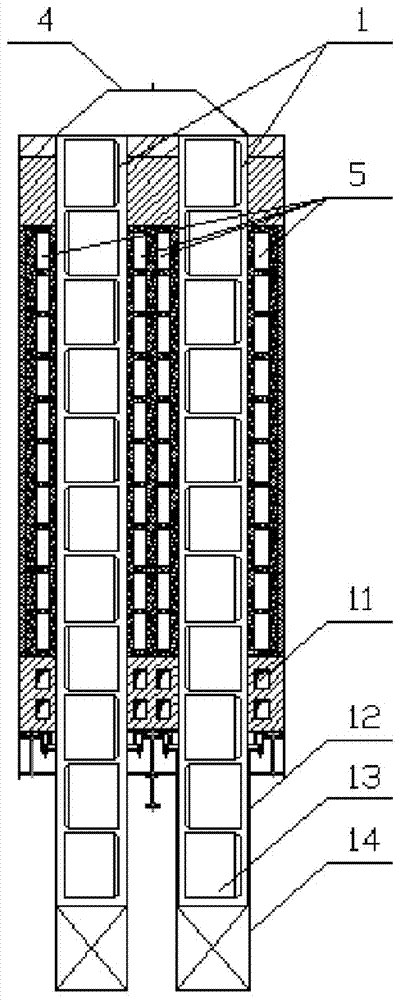

Neodymium iron boron vacuum sintering furnace

InactiveCN111795569AImprove work efficiencySave energyMuffle furnacesCharge composition/stateMetallurgyVacuum pump

The invention discloses a neodymium iron boron vacuum sintering furnace which comprises a furnace body, a vacuum pump, a sweeping device, a cooling device, a heating device and a containing device. Abaffle is transversely arranged in the furnace body and divides the interior of the furnace body into two spaces including a sintering cavity and a cooling cavity, the sweeping device and the heatingdevice are both arranged in the sintering cavity, the cooling device is arranged in the cooling cavity, the containing device is connected to the inner wall of the right side of the furnace body in sliding and clamped modes, a driving device is arranged on the containing device, the sintering cavity and the cooling cavity are each provided with a furnace cover, the furnace covers are connected tothe furnace body in a pivoted mode, and the vacuum pump is connected with the sintering cavity and the cooling cavity through air pipes. According to the neodymium iron boron vacuum sintering furnace,neodymium iron boron can be sintered in the sintering cavity and cooled in the cooling cavity, cooling and sintering are carried out separately, a large amount of energy is saved, the working efficiency of sintering and cooling procedures can be improved, neodymium iron boron residual substances in the sintering cavity can be automatically swept through the sweeping device, and a large amount oflabor cost is saved.

Owner:宁波元辰新材料有限公司

Efficient roasting device for rare earth waste

InactiveCN106482504AReasonable useEasy to passCharge composition/stateCharge treatment typeRare earthEngineering

The invention relates to a roasting device, in particular to an efficient roasting device for rare earth waste. The efficient roasting device for rare earth waste achieves the technical aims of being easy to operate, low in equipment cost and low in energy consumption and comprises a bottom plate, a roasting furnace, a support, a bearing pedestal, a reel, a rotating shaft, a rotating rod, shifting pieces, a first connecting rod, an exhaust fan, a second connecting rod, a baffle and the like; the top of the bottom plate is connected with the support in a welded manner, the support is located on the right of the roasting furnace, the upper portion and the lower portion of the right wall in the support are connected with the first connecting rod in a welded manner, and the left end of the first connecting rod is connected with a roasting box in a bolt connection manner. The effects of being rapid in heating, uniform in heating, low in energy consumption, simple in structure and capable of reasonably utilizing labor resources are achieved, and a groove is formed in the bottom of the roasting box.

Owner:明光智慧天顺技术转移服务有限公司

Vertical double-side-blowing smelting furnace

InactiveCN105423752AShort stayCharge composition/stateMaintainance of heating chambersSmelting processTuyere

The invention discloses a vertical double-side-blowing smelting furnace. The vertical double-side-blowing smelting furnace comprises a smelting reaction zone and an electric furnace zone. The smelting reaction zone comprises an upper section, a middle section and a lower section. Refractory bricks are laid in a steel shell of the upper section. Refractory brick side walls are provided with secondary air openings. The top faces of the four walls of the upper section are provided with furnace lids. The furnace lids are provided with a plurality of feeding holes. A smoke outlet is reserved in the end or the middle of the furnace top. Copper water jackets are adopted for all the four walls of the middle section, and the cooling water jackets of the side walls of the middle section are arranged in multiple layers. The lower section is formed by laying refractory bricks. A primary air supplying channel is formed in the lowest position of the bottommost layer of the water jackets and inclined downwards. According to the vertical double-side-blowing smelting furnace, the oxygen blowing positions closely abut against the upper plane of copper sulphate and incline downwards, and thus the thickness of a slag layer can be controlled to be about 600-800 mm. The time of produced smelted slag remaining in the furnace is much shorter than that of a deep molten bath method in the smelting process, and the slag layer is always in a stirred state, so that transverse partition films are not prone to forming in the smelting reaction zone.

Owner:黄艳玲 +2

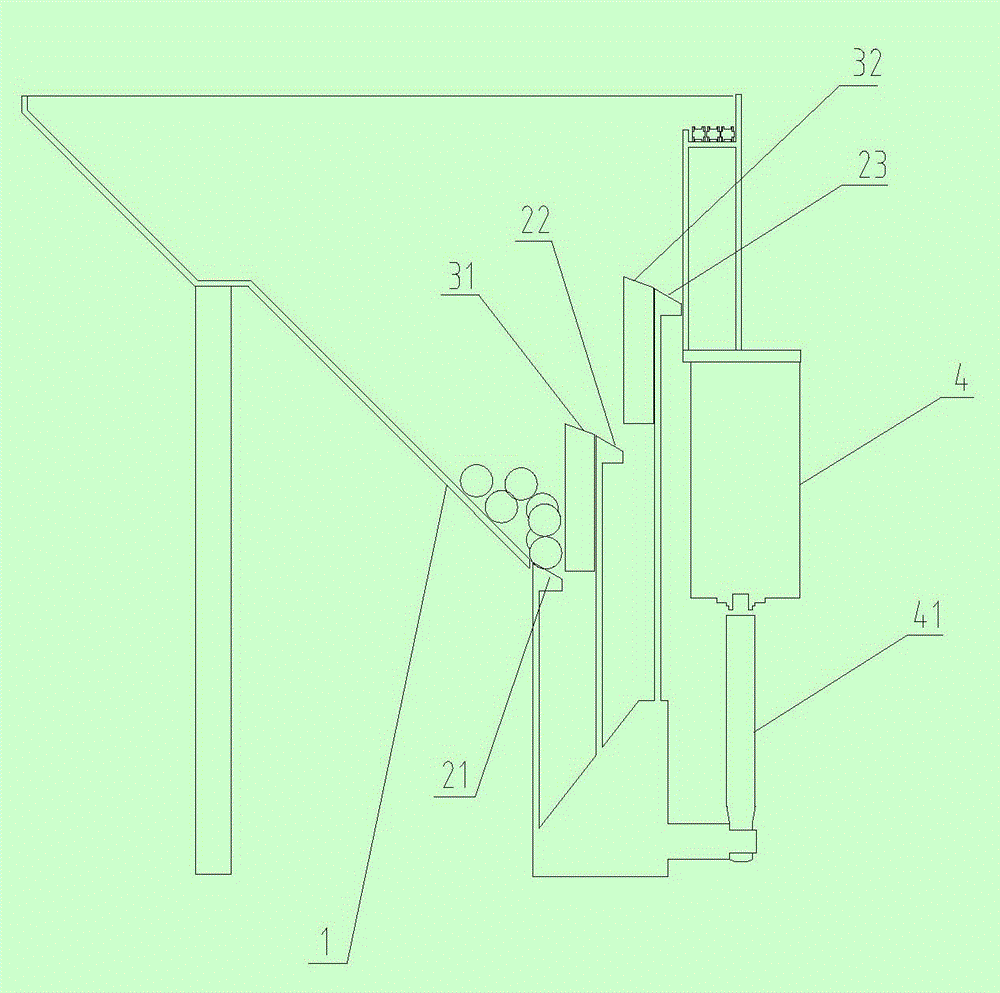

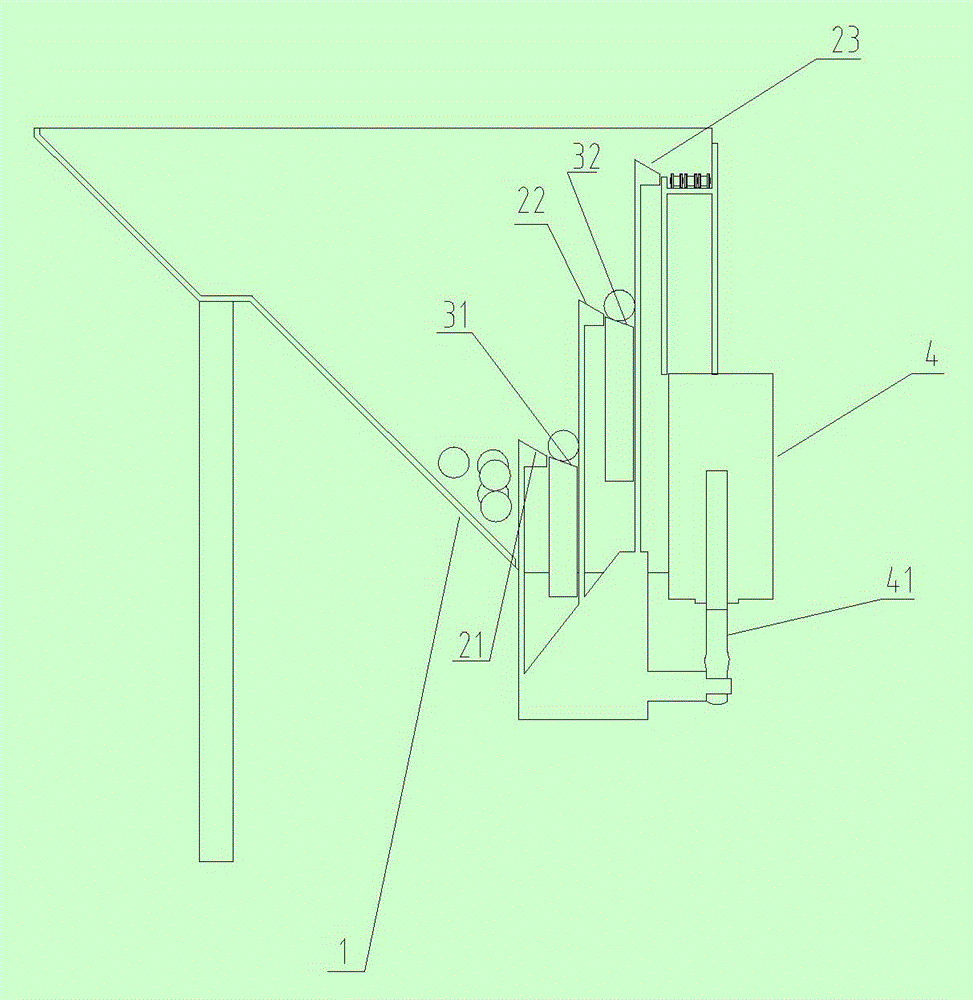

Automatic stokehold round steel bar feeding device for continuous heating furnace

InactiveCN108253798AEliminate potential safety hazardsSuitable for high volume useCharge composition/stateCharge manipulationLower limitEngineering

An automatic stokehold round steel bar feeding device for a continuous heating furnace is composed of a stokehold storage platform, a feeding platform, chain lifters and a control device. The height of the stokehold storage platform is matched with that of a furnace door of the continuous heating furnace, and the height of the feeding platform is smaller than that of the stokehold storage platform; the lower end of each chain lifter is installed at the front end of the feeding platform, the upper end of each chain lifter is installed at the rear end of the stokehold storage platform, and the two chain lifters are arranged in parallel and operate synchronously; lifting grabs are installed on chains of the chain lifters, and a jacking cylinder is installed on the feeding platform. Compared with the prior art, automatic correction feeding lifting of round steel bars can be carried out according to the tapping time of the continuous heating furnace, the round steel bars are arrayed in a line, feeding is automatically stopped after the round steel bars reach a set upper limit position, and bar lifting is automatically carried out after the round steel bars reach a lower limit position in the lowering process.

Owner:邯郸久诺知识产权服务有限公司

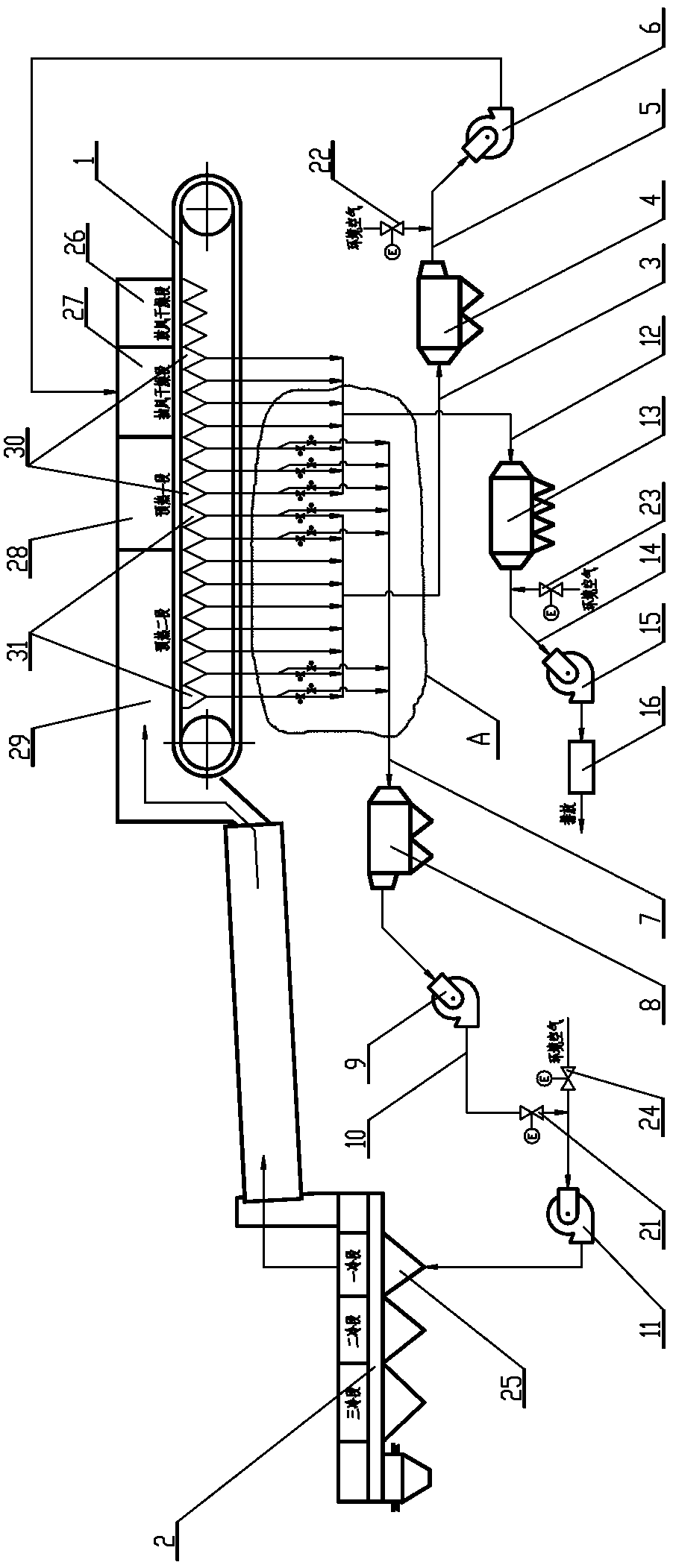

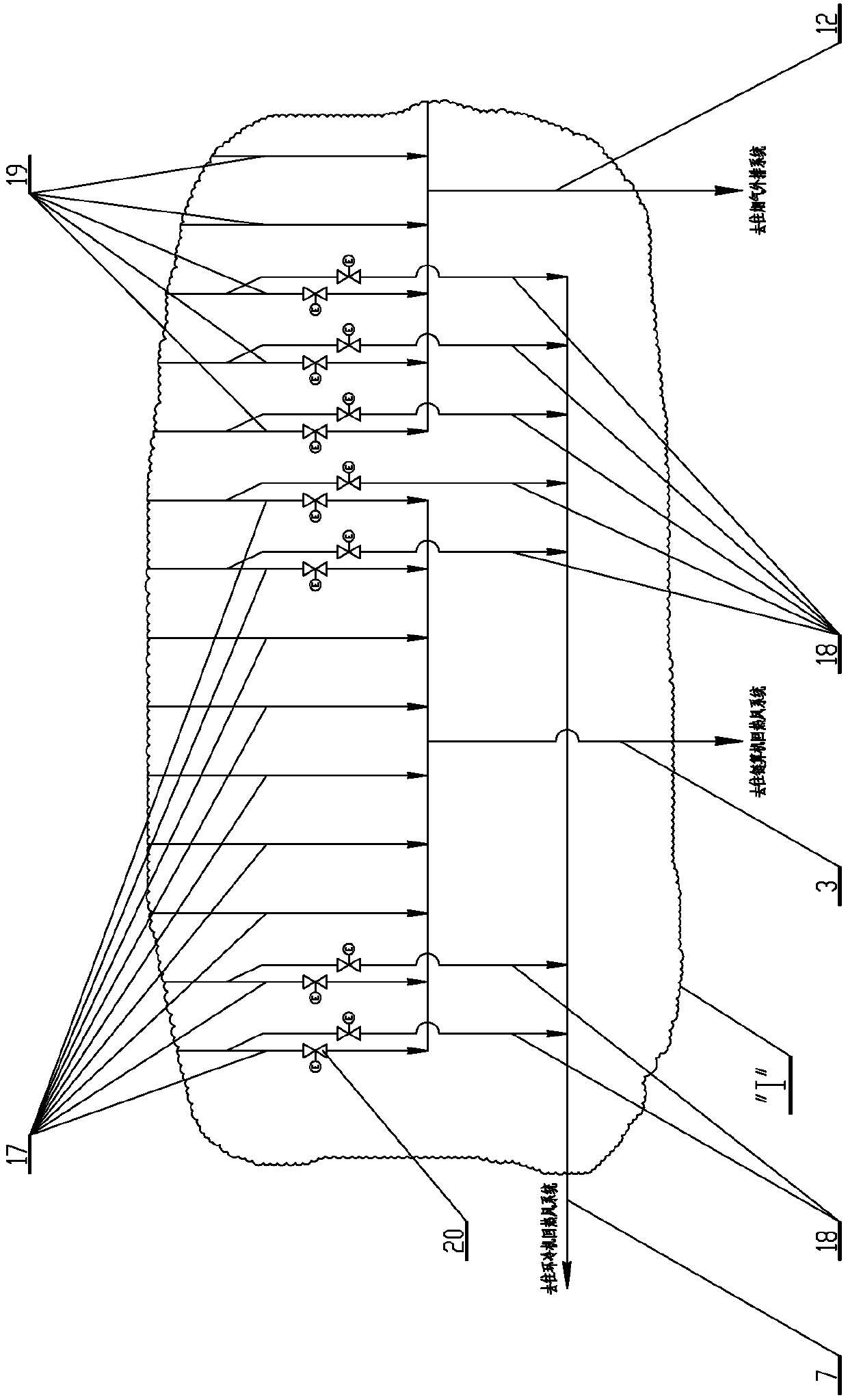

Chain grate machine exhausting drying section and preheating section flue gas recycling and exhausting system

PendingCN110068224AAdjustable temperatureConvenient temperature controlCharge composition/stateFurnace typesFlue gasEngineering

The invention relates to a chain grate machine exhausting drying section and preheating section flue gas recycling and exhausting system which comprises a chain grate machine, a chain grate upper cover, a chain grate machine air tank, a ring cold machine, a ring cold machine upper cover, a ring cold machine air tank, a chain grate machine hot air return system, a ring cold machine hot air return system and a flue gas exhausting treatment system; and the chain grate machine upper cover is divided into a forced air drying section, an exhausting drying section, a first preheating section and a second preheating section. The chain grate machine exhausting drying section and preheating section flue gas recycling and exhausting system is characterized in that the chain grate machine air tank isdivided into three groups, an air tank I corresponds to the forced air drying section, an air tank II corresponds to the exhausting drying section and the front half section of the first preheating section, and an air tank III corresponds to the rear half section of the first preheating section and the second preheating section; and the air tank II and the air tank III are connected with the chaingrate machine hot air return system, the ring cold machine hot air return system and the flue gas exhausting system through flue gas branch pipes respectively. The chain grate machine exhausting drying section and preheating section flue gas recycling and exhausting system has the advantages that a temperature of return air of the chain grate machine can be adjusted; and a part of flue gas of each preheating section is used as cooling air for recycling, so that the quantity of the exhausted flue gas is lowered, and conditions are created for accurate control, energy conservation and emissionreduction of the pellet production process.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

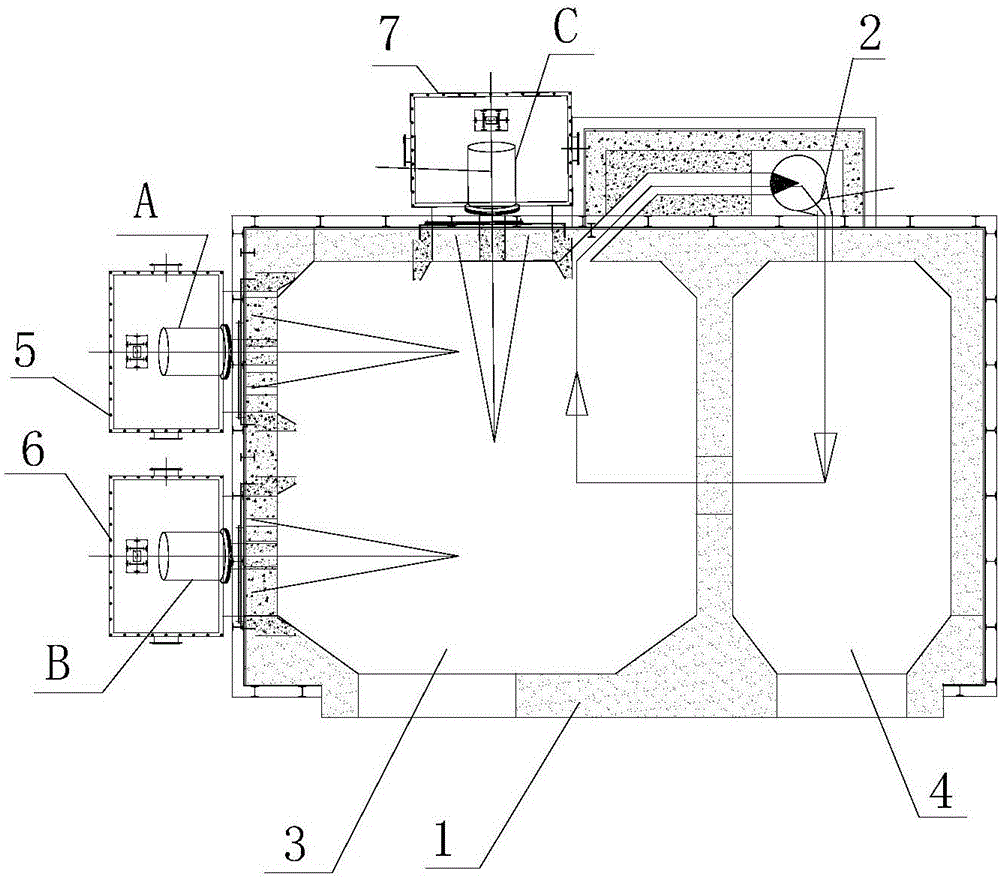

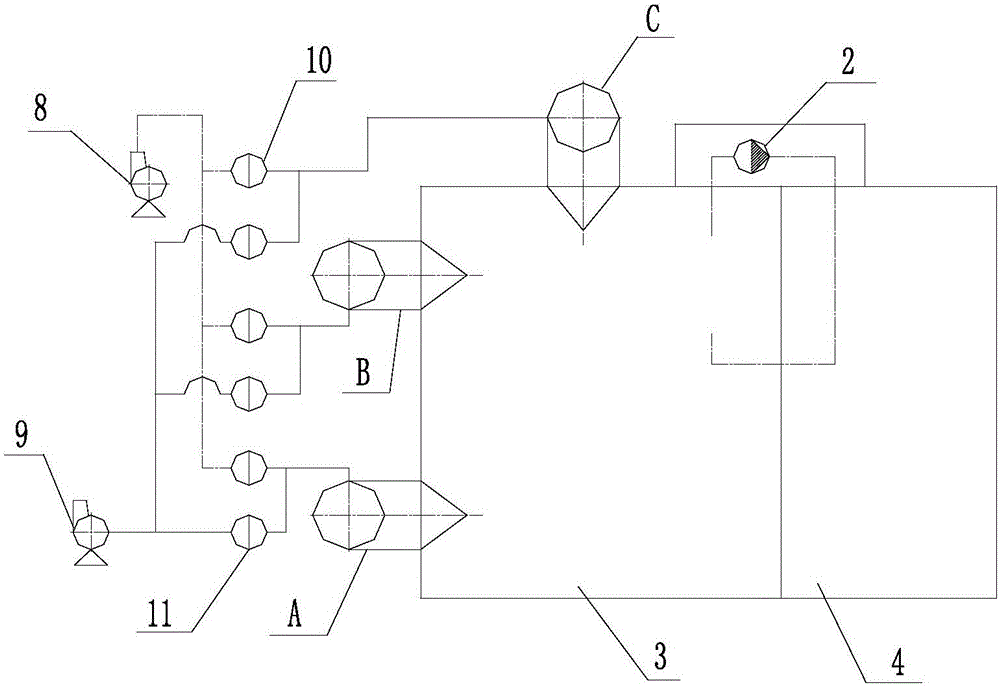

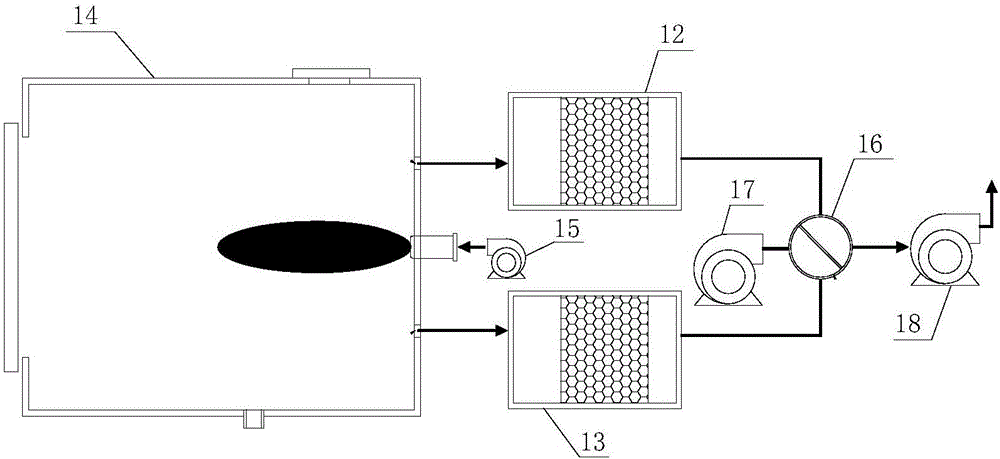

Novel burning and circulating system for aluminum smelting furnace

InactiveCN106766890AReduce burning lossFull recoveryCharge composition/stateCharge treatment typeFlue gasTorch

The invention discloses a novel burning and circulating system for an aluminum smelting furnace. The novel burning and circulating system comprises a mother furnace body, a melting chamber, a feeding chamber, a heat storage system and an aluminum water circulating pump. The mother furnace body is internally provided with the melting chamber and the feeding chamber, the melting chamber and the feeding chamber are separated, the bottom of the melting chamber communicates with the bottom of the feeding chamber, and the upper portions of the melting chamber and the feeding chamber are partitioned by liquid. The heat storage system comprises three heat storage chambers arranged on the mother furnace body and corresponding heat storage burning torches and burners. The novel burning and circulating system further comprises a combustion air pipeline, a combustion fan, a flue gas emission pipeline, an exhaust gas fan and a PLC system. The combustion air pipeline and the flue gas emission pipeline are each internally provided with a plurality of two-way valves which are connected in parallel. The combustion fan communicates with the corresponding heat storage type burning torches and burners through the combustion air pipeline, and the exhaust gas fan communicates with the corresponding heat storage type burning torches and burners through the smoke emission pipeline. By means of the novel burning and circulating system, the burning efficiency is greatly improved, the heat is recycled completely, the gas consumption per unit is reduced, the number of times of ash beating is increased, the melting efficiency is improved, and the burning loss is reduced.

Owner:HUANGSHI FUXING ALUMINUM

Pot Furnace for Calcining Petroleum Coke at Low Temperature

ActiveUS20170261262A1Reduce the amount requiredReduce corrosionCoke ovensCharge composition/stateFlue gasWater jacket

A pot furnace for calcining petroleum coke at low temperature may include a pot, and a cooling water jacket and a flame path below the pot. The flame path may include eight layers. An inlet of a first flame path layer may be in communication with a volatile channel in the front wall, and is provided with a first flame path layer flashboard. An eighth flame path layer may be in communication with a communication flue. Flue gas may be discharged out of the furnace body through a main flue. A furnace bottom cooling channel may be provided below the eighth flame path layer.

Owner:CHINA ALUMINUM INT ENG CORP

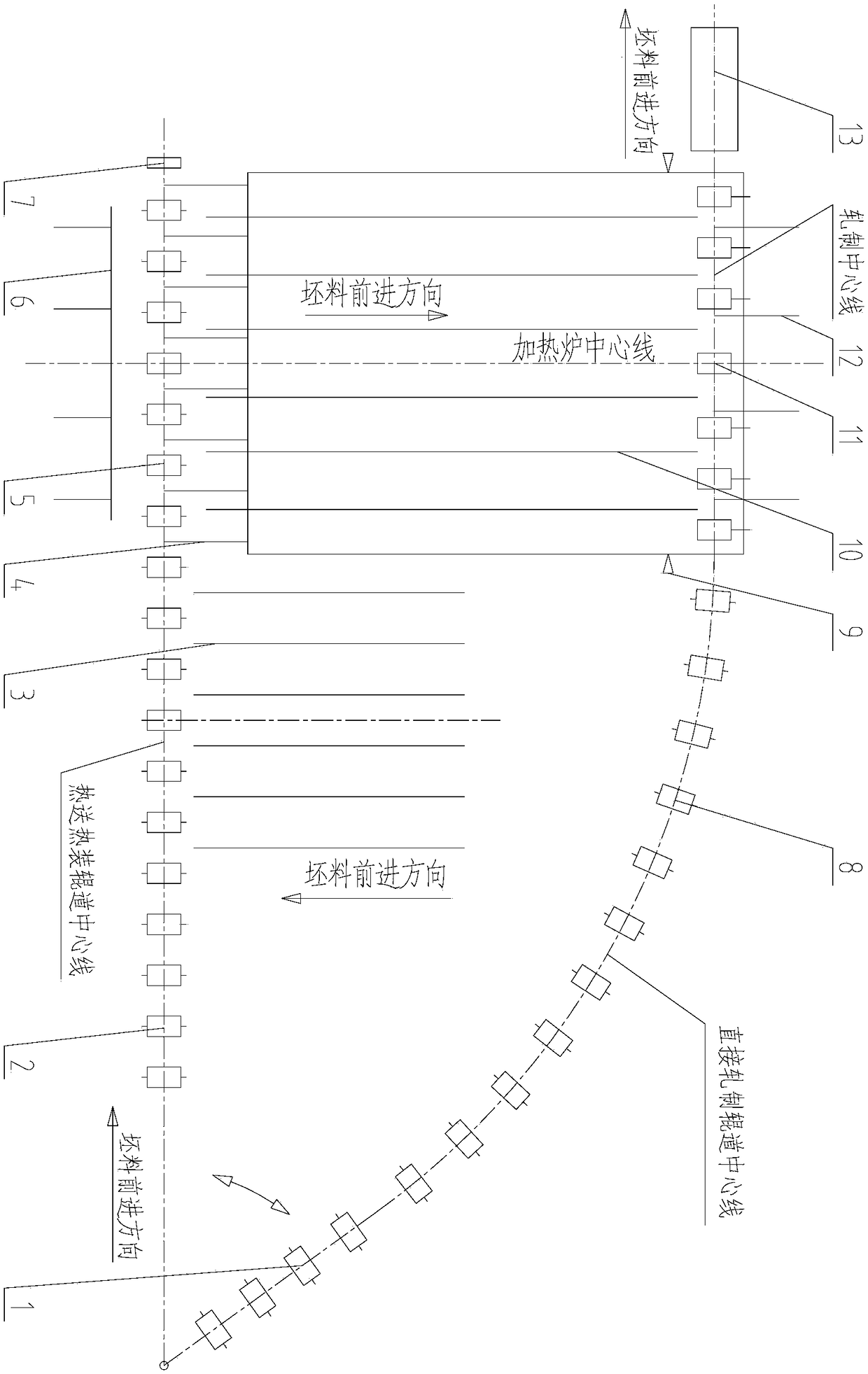

Pusher-type heating furnace for rod and wire production line hot transporting and hot charging and direct rolling

ActiveCN108151538AGuaranteed uptimeReduce equipment typesCharge composition/stateCharge manipulationEngineeringHeating furnace

The invention discloses a pusher-type heating furnace for rod and wire production line hot transporting and hot charging and direct rolling, and belongs to the technical field of industrial furnaces.The pusher-type heating furnace comprises a swinging roller way, a hot transporting roller way, a cold blank rack, a transition rack, a furnace-front roller way, a pusher, a buffering baffle, an arc-shaped heat preservation roller way and the like; the swinging roller way is connected with the hot transporting roller way and the arc-shaped heat preservation roller way; the furnace-front roller wayand a furnace bottom beam are connected through the transition rack; the buffering baffle is located at the tail end of the furnace-front roller way; the arc-shaped heat preservation roller way is connected with the swinging roller way and a discharging cantilever roller way in the pusher-type heating furnace; and the discharging cantilever roller way is connected with the arc-shaped heat preservation roller way. The pusher-type heating furnace has three working modes including a direct rolling mode, a hot transporting and hot charging mode and a cold blank charging mode. The pusher-type heating furnace has the advantages that stabilization, coordination, high efficiency and continuity of overall running of the production process are promoted, and the energy conservation and emission reduction potential abilities of a continuous casting blank hot transporting and hot charging and direct rolling technology are fully achieved.

Owner:BEIJING SHOUGANG INT ENG TECH

Roller kiln

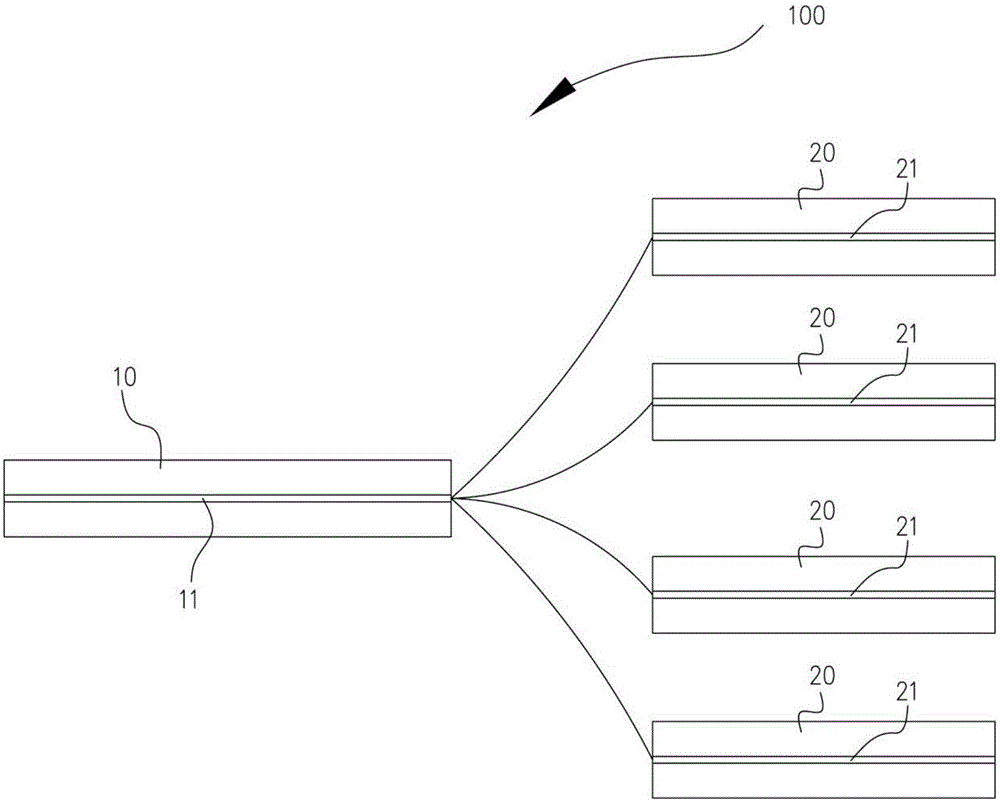

PendingCN107525398AImprove annealing efficiencyIncrease productivityCharge composition/stateCharge manipulationKilnRaw material

The invention discloses a roller kiln. The roller kiln comprises a heating area and multiple annealing areas; the heating area is provided with a heating rail; each annealing area is provided with an annealing rail connected with the heating rail; the heating rail is used for placing ceramic raw materials; and the ceramic raw materials are respectively transmitted to the multiple annealing rails after heating in the heating area, and are respectively cooled in the multiple annealing areas. The multiple annealing rails transmit the ceramic raw materials of the heating roller at the same time, that is, the multiple annealing rails are used for annealing the ceramic raw materials at the same time, so that the annealing efficiency is improved, and the production efficiency is improved.

Owner:GUANGDONG KITO CERAMICS GROUP CO LTD

Roasting furnace and roasting method

InactiveCN107238295AChange the disadvantages of periodic heat storageHigh thermal efficiencyCharge composition/stateIncreasing energy efficiencyChinese charactersFlue gas

The invention relates to a roasting furnace and a roasting method. The roasting furnace is composed of one or more units. Each unit is provided with four workbins and four flues, wherein the four workbins are distributed in the shape of a Chinese character 'tian' which means 'fields', the two sides of every two vertical workbins of the four workbins are provided with two flues, and each unit is provided with the four flues. The roasting furnace and the roasting method have the following advantages that the thermal efficiency of the roasting furnace is improved, the energy consumption level of the roasting process is lowered, and the production cost of the roasting process is lowered; the service life of a furnace body is greatly prolonged; the utilization efficiency of a refractory material of the furnace body is improved, and the investment cost of the roasting furnace is lowered; products in the workbins and high-temperature flue gas in the flues operate in a countercurrent mode, and high-temperature zones and low-temperature zones of the flues and the workbins have the same variation trend; and furthermore, through control of temperature thermocouples and negative pressure in the flues, it can be guaranteed that good temperature distribution in the flues is achieved, the products in the workbins can have controllable heating rates, and the product quality is guaranteed.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Calcining technology and calcining device for producing high-brightness and low-hardness talc by utilizing black talc

PendingCN107140655AAvoid it happening againFully oxidative combustionMagnesium silicatesCharge composition/stateCombustorPhysical chemistry

Disclosed are a calcining technology and a calcining device for producing high-brightness and low-hardness talc by utilizing black talc. The calcining technology comprises the following steps: smashing and milling to enable grain fineness of a black talc raw material to be 150 to 8000 meshes; feeding the milled black talc raw material into the calcining device for calcining, wherein calcining temperature is 200 to 850 DEG C, and calcining time is 2 to 8h; and introducing high-concentration and high-pressure oxygen in a calcining process to form an oxidizing atmosphere, wherein oxygen concentration is 30 to 80 percent, and oxygen pressure is 0.05 to 0.7 MPa. The calcining device comprises a feeding mechanism, a rotary kiln and a discharging mechanism; a rotary cylinder of the rotary kiln is horizontally arranged rotatably, and comprises a feeding section, a heating section and a discharging section; the feeding section and the feeding mechanism are connected, and the discharging section and the discharging mechanism are connected; the rotary kiln comprises a combustor and also comprises an oxygen support ring, wherein the combustor is used for heating to calcine the powdery black talc raw material in the heating section, and the oxygen supply ring sheathes the feeding section, and is provided with an oxygen inlet and an oxygen chamber; a plurality of oxygen supply hoods are arranged in the rotary cylinder; and an oxygen hole is formed in each oxygen supply hood, and is in gas communication with the oxygen supply ring. According to the calcining technology and the calcining device disclosed by the invention, lower temperature calcination is performed under the oxidizing atmosphere, so that the talc does not produce phase change and is high in brightness.

Owner:苏州中材非金属矿工业设计研究院有限公司

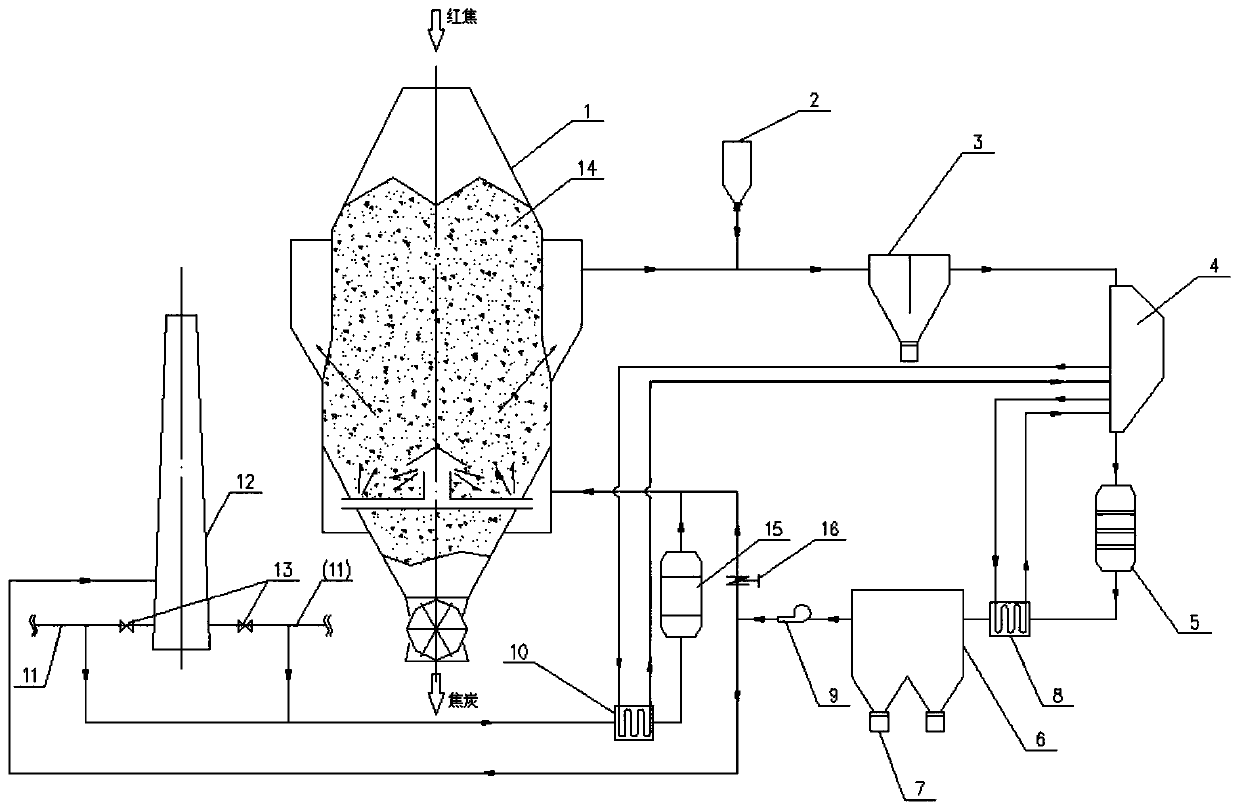

Waste gas waste heat recovery and purification process of coke oven gas heating system

InactiveCN110813006AImprove the heat quality of waste heat recoveryRealize desulfurization and denitrification purification treatmentCombination devicesCoke quenchingFlue gasExhaust fumes

The invention relates to a waste gas waste heat recovery and purification process of a coke oven gas heating system, and the method comprises the following steps: carrying out heat exchange cooling and dehydration treatment on coke oven waste flue gas generated in the coke oven heating process, and feeding into a dry quenching furnace for cooling high-temperature coke; allowing high-temperature waste flue gas discharged from the dry quenching furnace to enter a primary dust remover for dust removal, and meanwhile, spraying a desulfurizing agent into the primary dust remover to desulfurize thewaste flue gas; allowing the desulfurized high-temperature waste flue gas to enter a waste heat boiler for recovery of the heat of the high-temperature waste flue gas by the waste heat boiler, and controlling the outlet temperature of the waste flue gas by the waste heat boiler to allow the waste flue gas discharged after heat exchange to directly enter an SCR denitration device for denitration; and after heat exchange cooling and secondary dust removal are carried out on the denitrated waste flue gas, conveying one part of the denitrated waste flue gas to a chimney to be discharged, and conveying the other part of the denitrated waste flue gas to a waste flue gas pipeline on the upstream of the dry quenching furnace for recycling. According to the invention, the red coke waste heat and the coke oven waste flue gas waste heat are recycled, and meanwhile, the coke oven waste flue gas is purified, so that the flue gas emission meets the national standard, and the atmospheric pollution isreduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

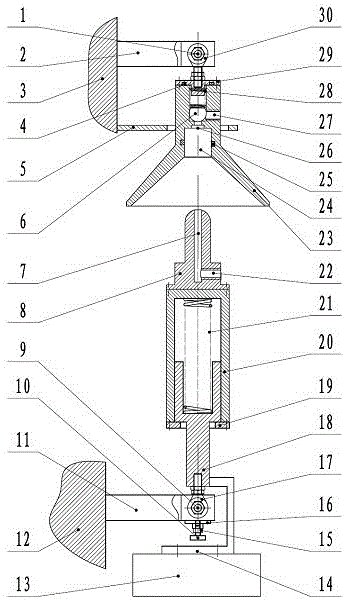

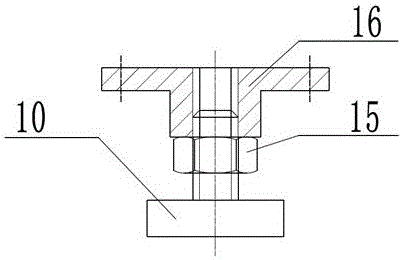

Spring buffer type automatic argon blowing connector

ActiveCN106834611AImprove air tightnessImprove reliabilityMelt-holding vesselsCharge composition/stateButt jointEngineering

The invention discloses a spring buffer type automatic argon blowing connector. The spring buffer type automatic argon blowing connector comprises an argon sending mechanism, an argon receiving mechanism, an automatic axis calibrating and hanging mechanism and a deflection range restricting mechanism. The spring buffer type automatic argon blowing connector has the advantages that due to design of an argon sending mechanism guiding head, a loudspeaker guiding opening and a dual-sealing structure composed of butt joint soft sealing and butt joint hard sealing, butt joint and coordination are smooth, and airtightness of a transportation channel is good; due to design of the automatic axis calibrating and hanging mechanism and the deflection range restricting mechanism, argon blowing connection can be implemented and completed in a larger deviation range, center positioning accuracy requirement when a steel ladle settles down is greatly reduced, and operation of a crane driver is much easier; and due to design of a buffer device, collision and damage accidents of equipment can be reduced, and reliability is high.

Owner:WUHAN UNIV OF SCI & TECH

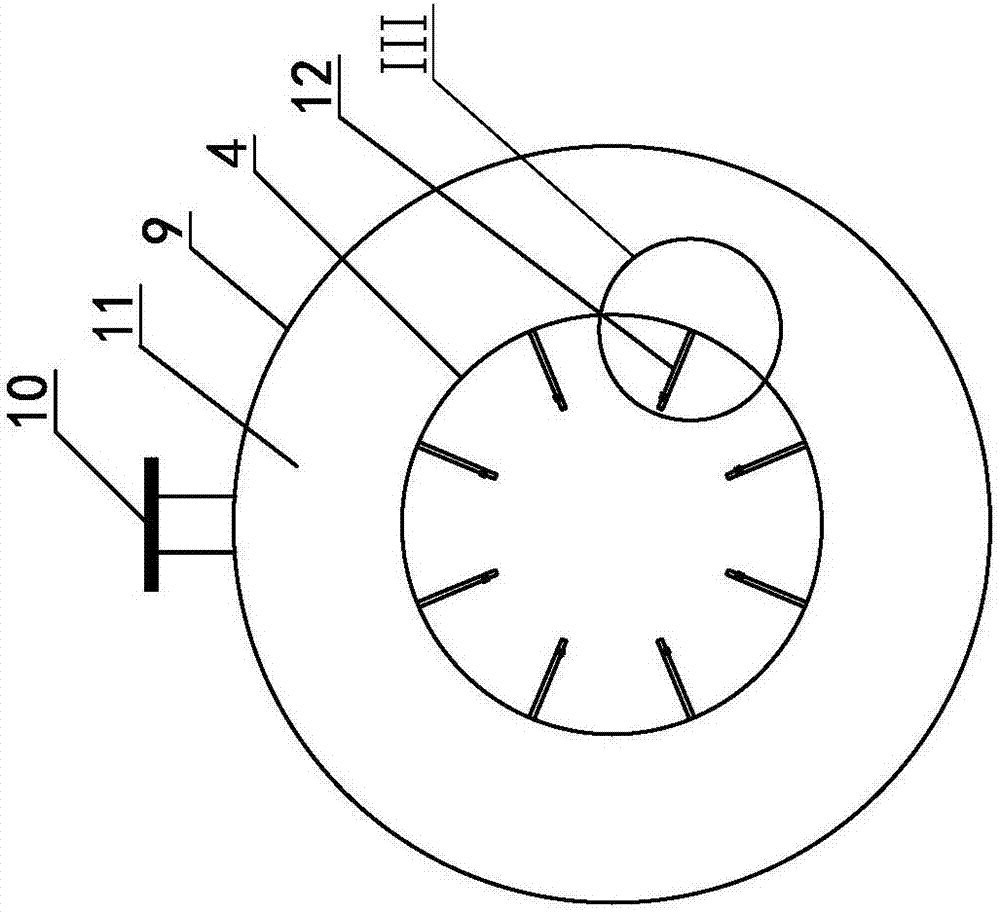

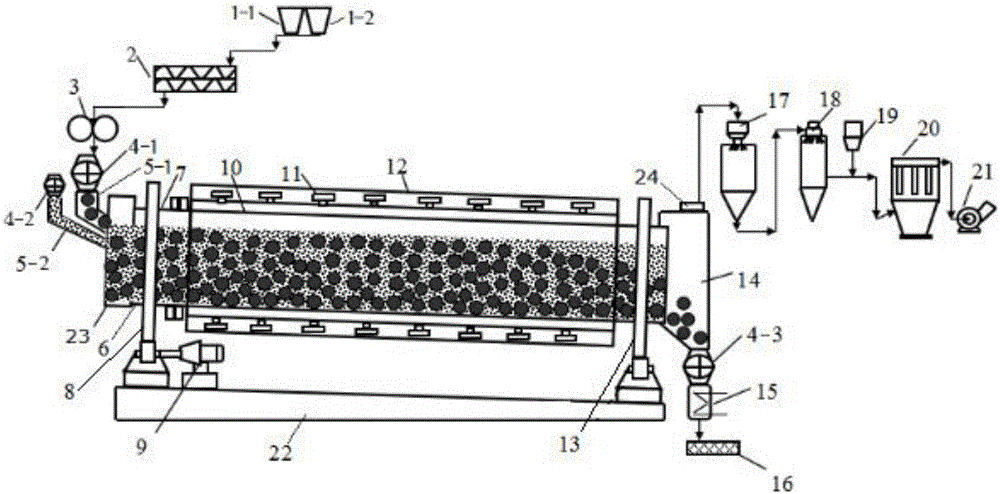

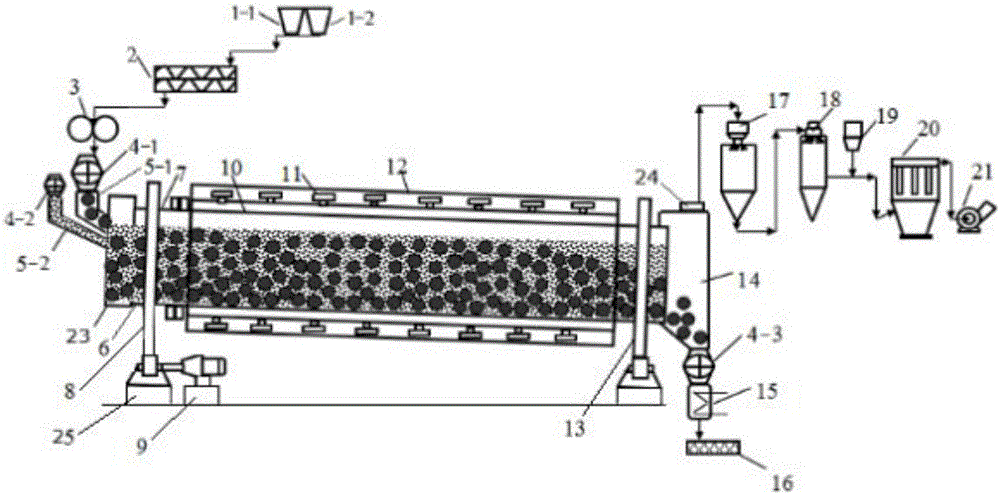

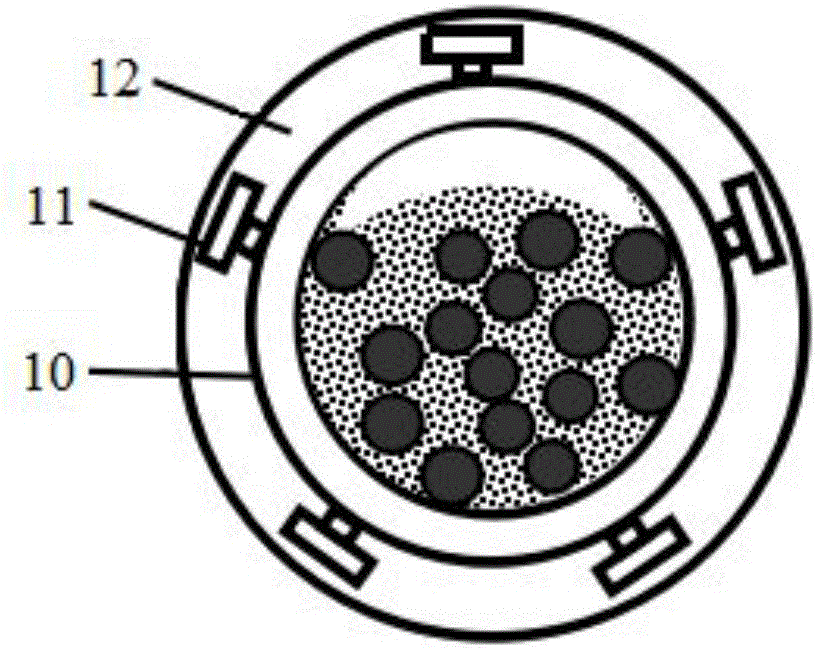

Device for microwave sintering of ceramic particles by rotary garbage incineration fly ash and operation method

ActiveCN106466881AImprove sintering efficiencyIncrease profitCharge composition/stateRotary drum furnacesSlagExpanded clay aggregate

The invention discloses a device for microwave sintering of ceramic particles by rotary garbage incineration fly ash and an operation method. The garbage incineration fly ash is mixed with pyrite sintering slag for pelletizing to enter a rotary furnace body with microwave coupling agent powder for microwave sintering; a rotary reaction furnace is inclined, so that the ceramic particles are heated by microwaves in rolling mixing; the sintered ceramic particle clinkers are separated from a microwave coupling agent; the separated microwave coupling agent serves as a raw material for recycling; the innovation increases the utilization rate of the microwave coupling agent; meanwhile, the device is simple in preparation process and full in energy utilization, solves the problem of generating a lot of harmful smoke needing to be purified in a traditional sintering technology, promotes the industrial process of incineration fly ash microwave sintering, and in particular, is suitable for the fly ash harmless treatment with sintering of the ceramic particles by the incineration fly ash as the purpose.

Owner:TIANJIN CHENGJIAN UNIV

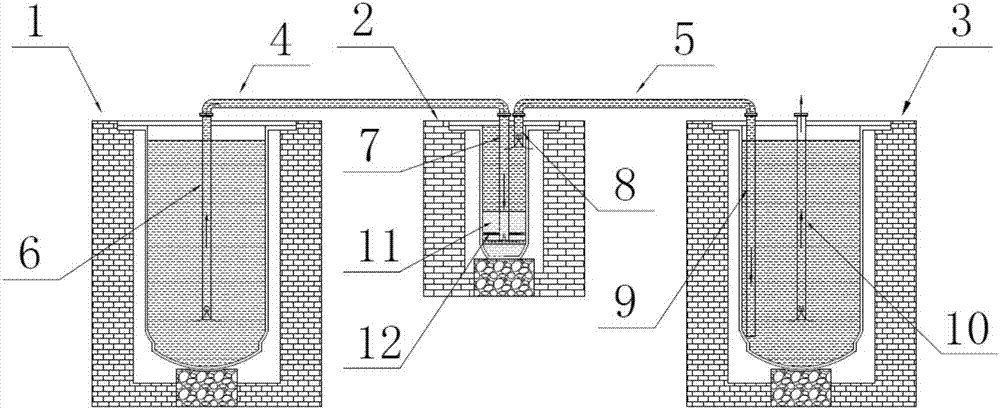

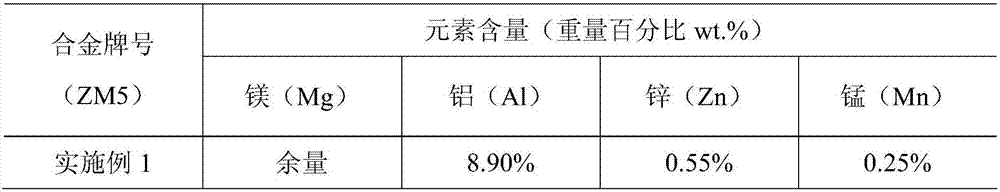

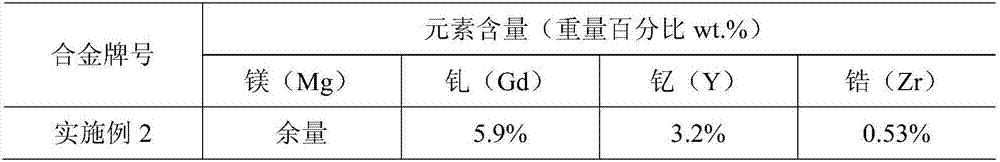

Multi-furnace combined type fusion casting equipment and technology for producing high-cleanness magnesium or magnesium alloy

ActiveCN107289782AReduce pollutionEasy work for workersCharge composition/stateCharge treatment typeCrucibleMaterials science

The invention discloses multi-furnace combined type fusion casting equipment and a technology for producing high-cleanness magnesium or a high-cleanness magnesium alloy, and belongs to the technical field of metal smelting. The equipment adopts a plurality of smelting furnaces and mating crucibles for combined operation, and the smelting furnaces consist of a melting furnace, a purifying furnace and a heat preservation holding furnace; the melting furnace and the crucible of the melting furnace are used for melting magnesium or the magnesium alloy; a magnesium melt or a magnesium alloy melt is transferred to the purifying furnace and the crucible of the purifying furnace through an insulating pipeline, and penetrates through a screen mesh structure submerged in a molten flux and a flux layer, and occluded foreign substances in the magnesium melt or the magnesium alloy melt are removed cleanly; and the purified melt is transferred to the heat preservation holding furnace and the crucible of the heat preservation holding furnace through an insulating pipeline for subsequent operation. The magnesium melt or the magnesium alloy melt is purified thoroughly, the operation difficulty of an operation worker is lowered, continuous automatic production can be realized, the production efficiency is high, and the technology has lower pollution to the environment than a traditional technology.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

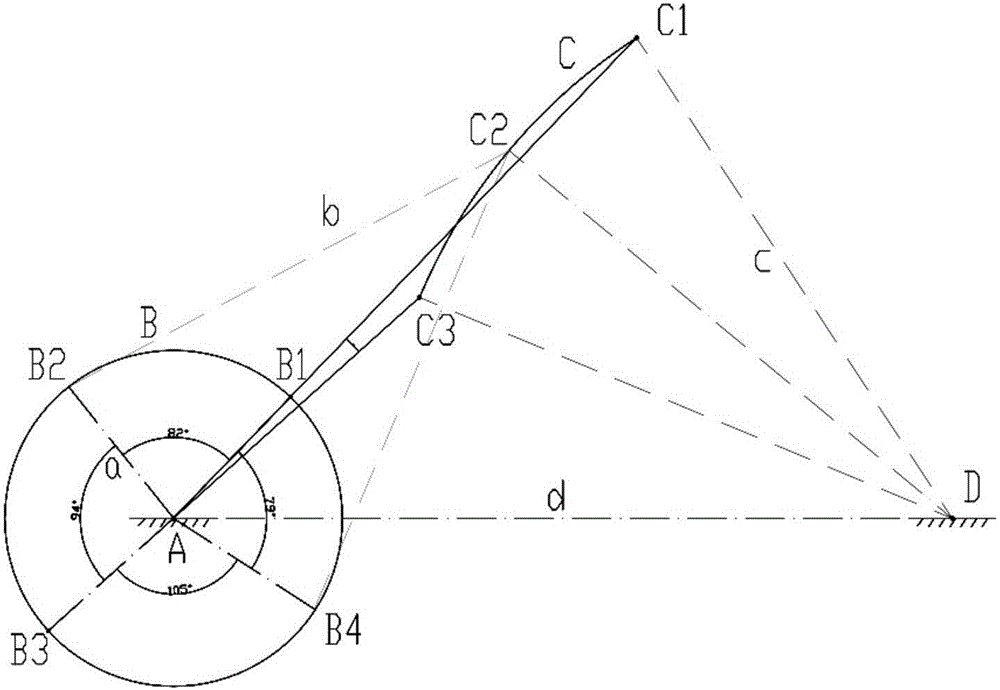

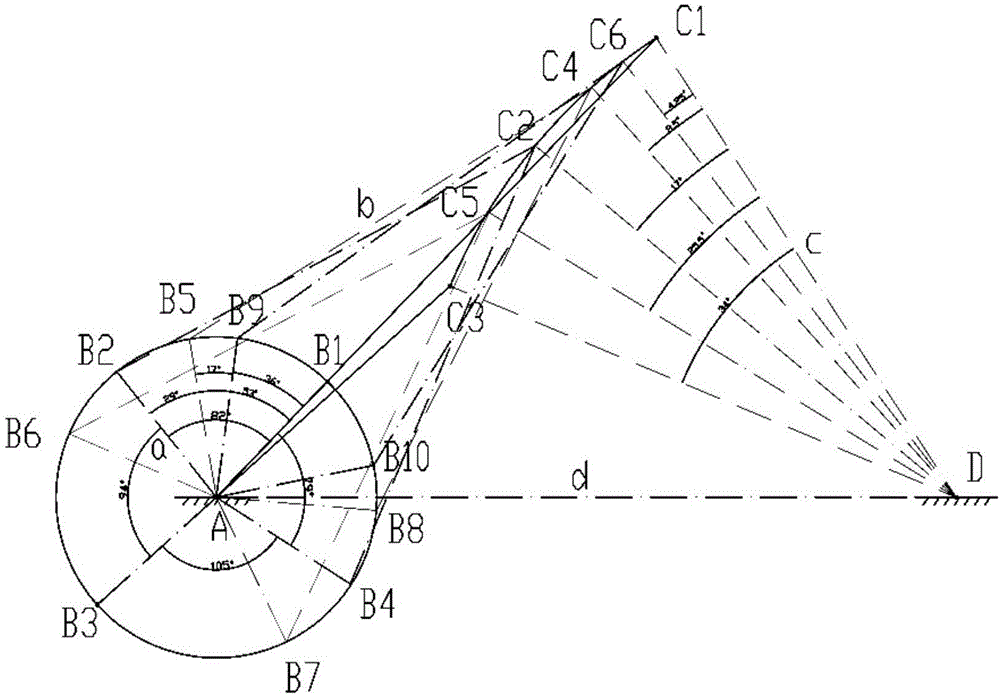

Intelligent pellet distribution control system and method

ActiveCN106086395AContinuous detectionHigh-precision detectionCharge composition/stateCharge manipulationDistribution controlAirflow

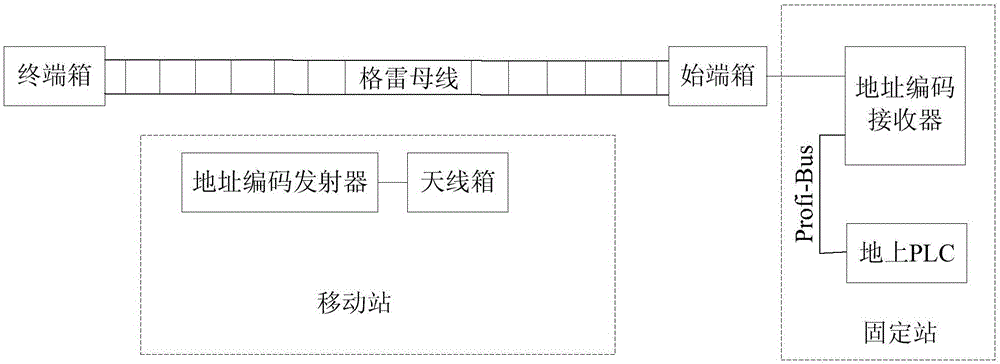

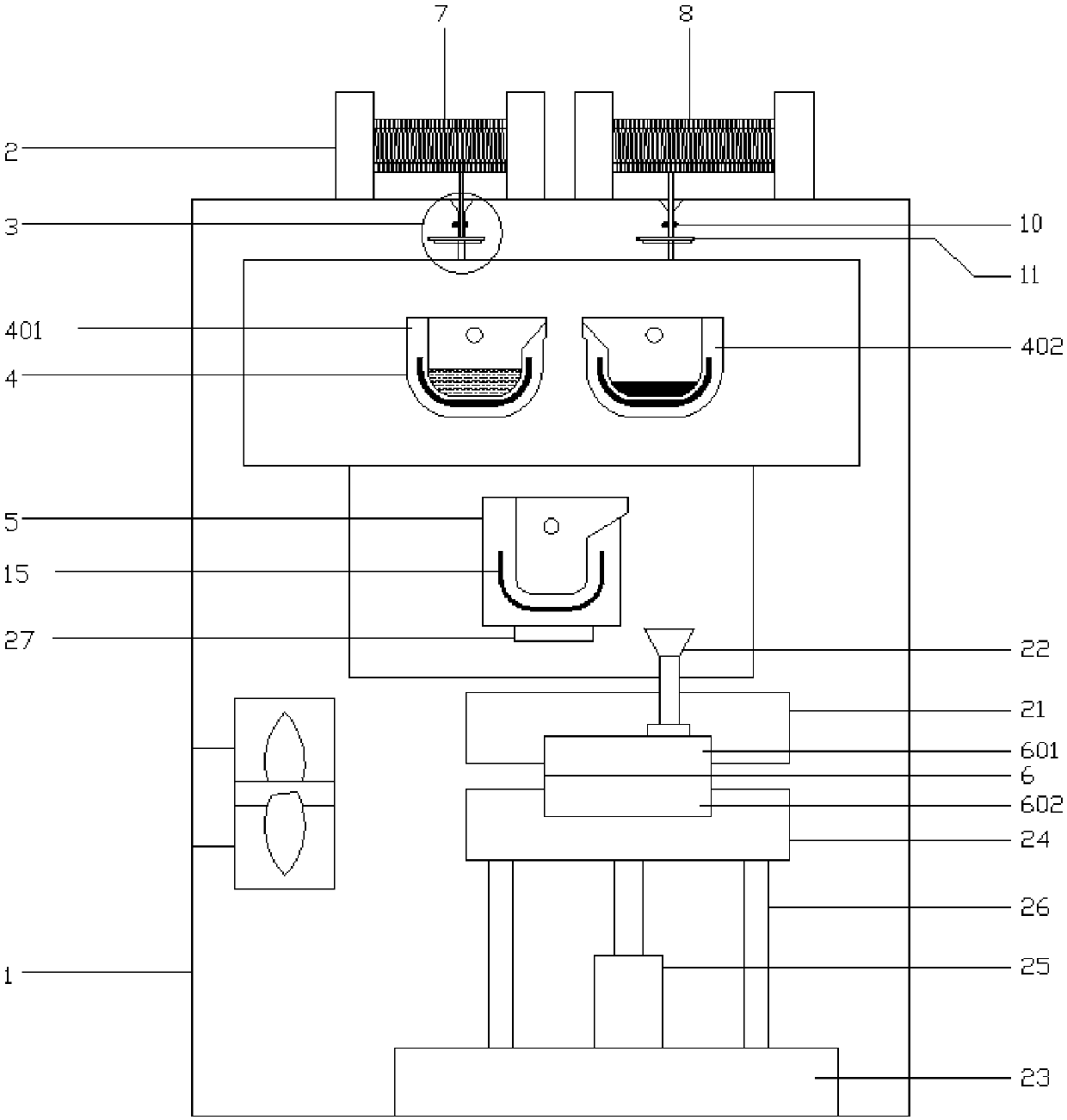

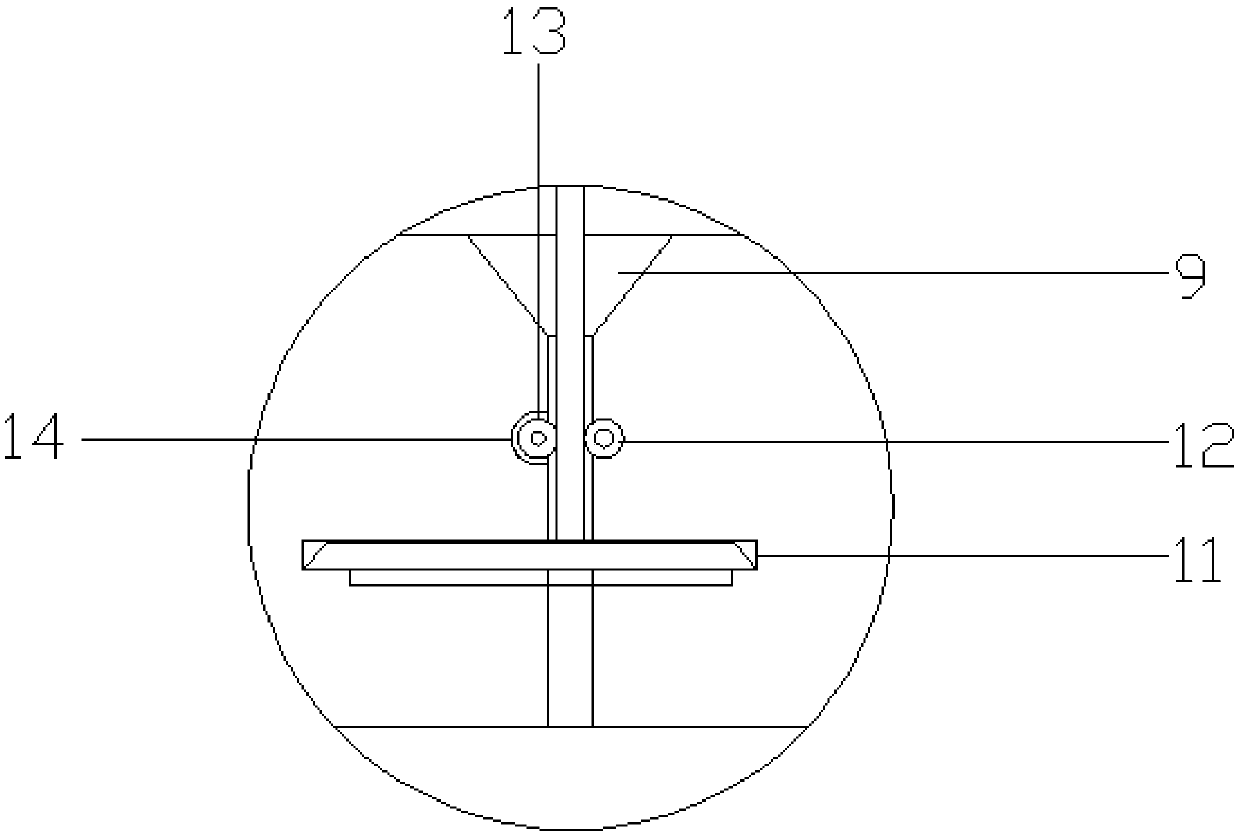

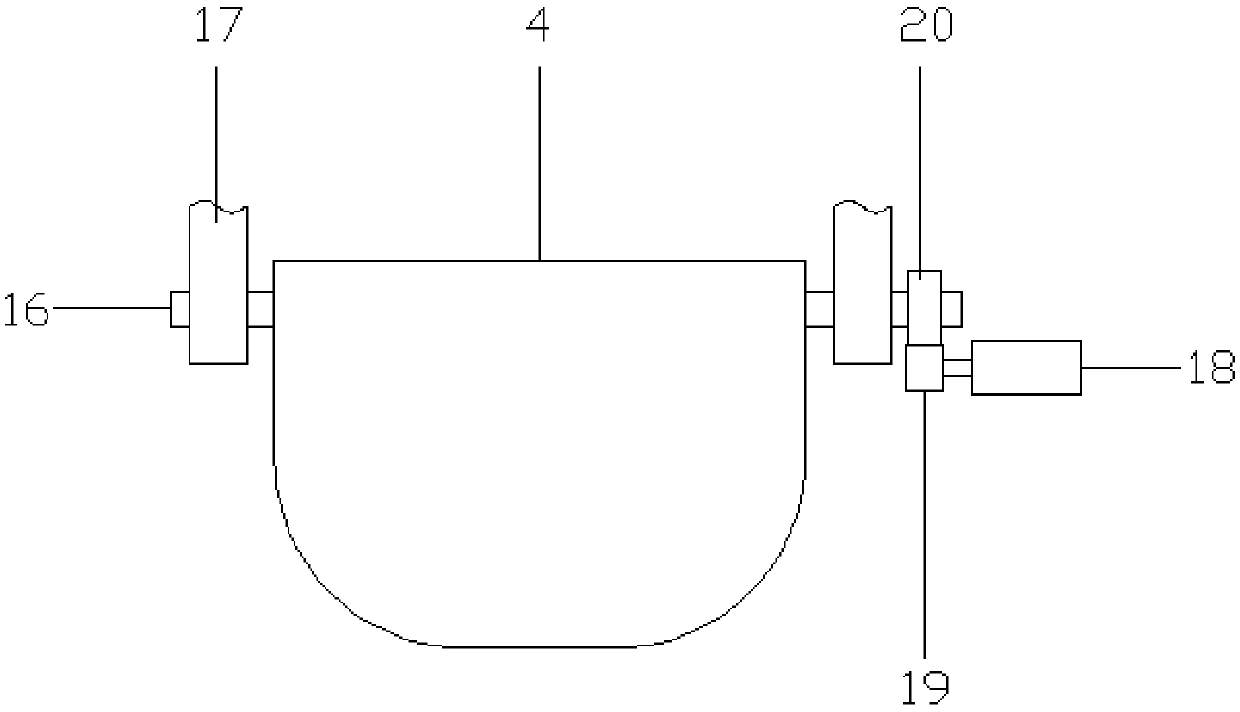

The invention provides an intelligent pellet distribution control system and method and belongs to the technical field of pellet distribution. The system comprises a swinging adhesive tape machine, a rotating disc, a crank-rocker conveying mechanism, a moving station, a Gray bus and a fixed station. The system can thoroughly solve or greatly reduce the problems that distribution on a grate bed of a chain grate machine is asymmetrical left and right, back and forth feeding is not uniform and the edge effect is caused, and distribution on the grate bed of the chain grate machine can be uniform. The system fundamentally solves the problem that due to the fact that distribution of the chain grate machine is not uniform, in the production process, raw pellet preheating is not uniform, hot air flow in a hot air pipeline cannot be utilized effectively, a grate plate of the chain grate machine is damaged frequently, the two ends of a small shaft are heated unevenly, bending of different degrees is generated, deviation of the grate bed is caused, falling of the grate plate and a side plate of the chain grate machine is caused easily, a material shoveling plate is lifted up, raw pellet exploding occurs, rings are formed on a rotary kiln, the dry pellet strength is poor, and rejected products are formed easily. The yield of produced products is increased, the quality is improved, energy consumption is reduced, environmental pollution is reduced, and the service life of equipment is prolonged.

Owner:中冶北方(大连)工程技术有限公司

Device for producing iron and aluminum composite material

InactiveCN109093077AGood choiceInnovative designCharge composition/stateFoundry mouldsAluminum compositesRaw material

The invention discloses a device for producing iron and aluminum composite materials. The device comprises a device body, wherein the device body comprises raw material rolls, feed devices, a high-temperature melting furnace, a high-temperature rabbling furnace and a mold from top to bottom sequentially; the raw material rolls are wound with an iron wire and an aluminum wire which are connected with the feed devices; the feed devices comprise feed holes connected with the iron wire and the aluminum wire as well as drive devices and shear devices arranged at the feed holes; the iron wire and the aluminum wire are melted respectively by the high-temperature melting furnace, poured into the high-temperature rabbling furnace, rabbled by the high-temperature rabbling furnace and injected into the mold, and the iron composite materials are molded. The iron composite materials with different composition and different proportions can be produced by the device and used for research, and the optimal iron composite material can be selected.

Owner:KUNSHAN JIANJIN IND DESIGN

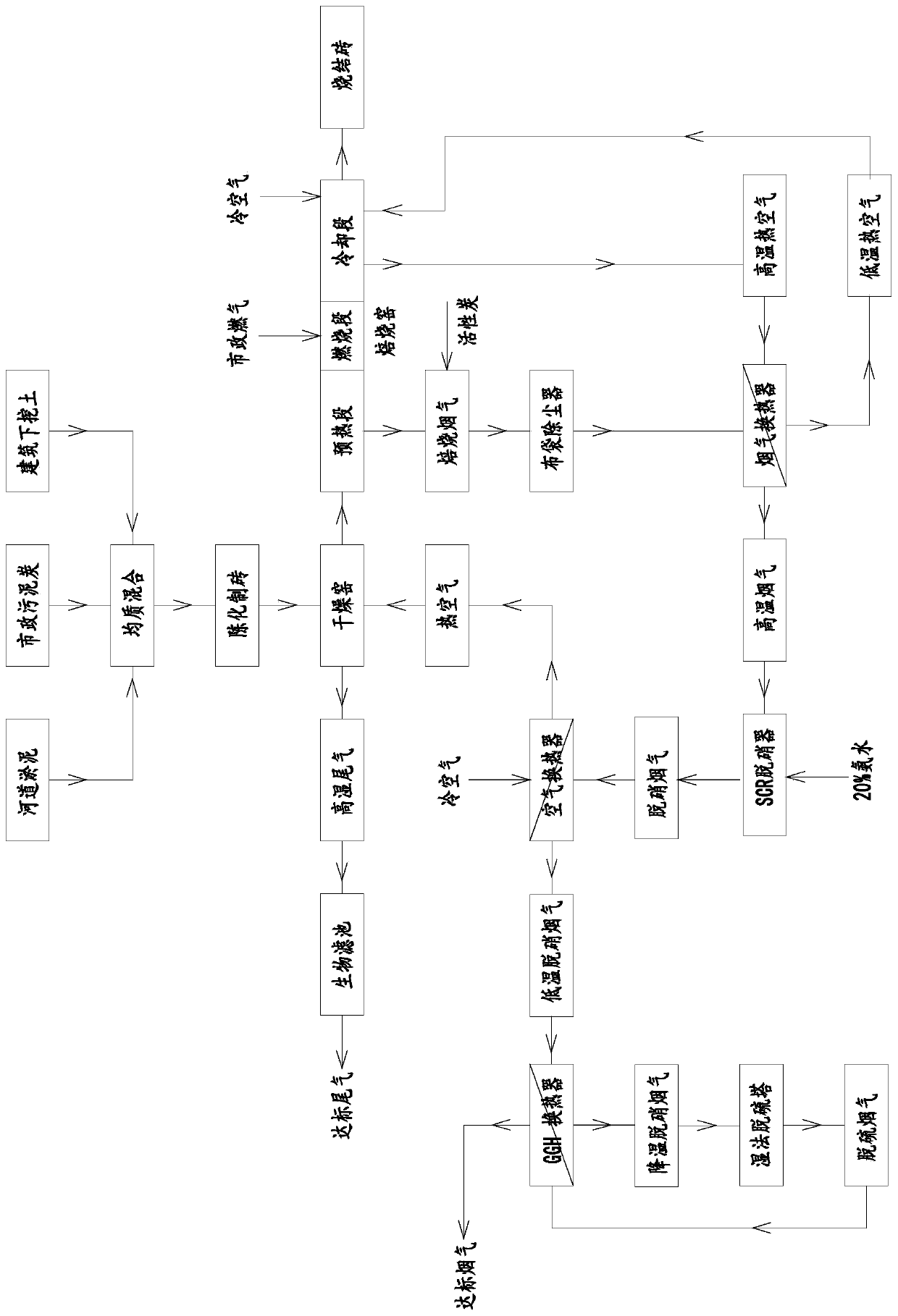

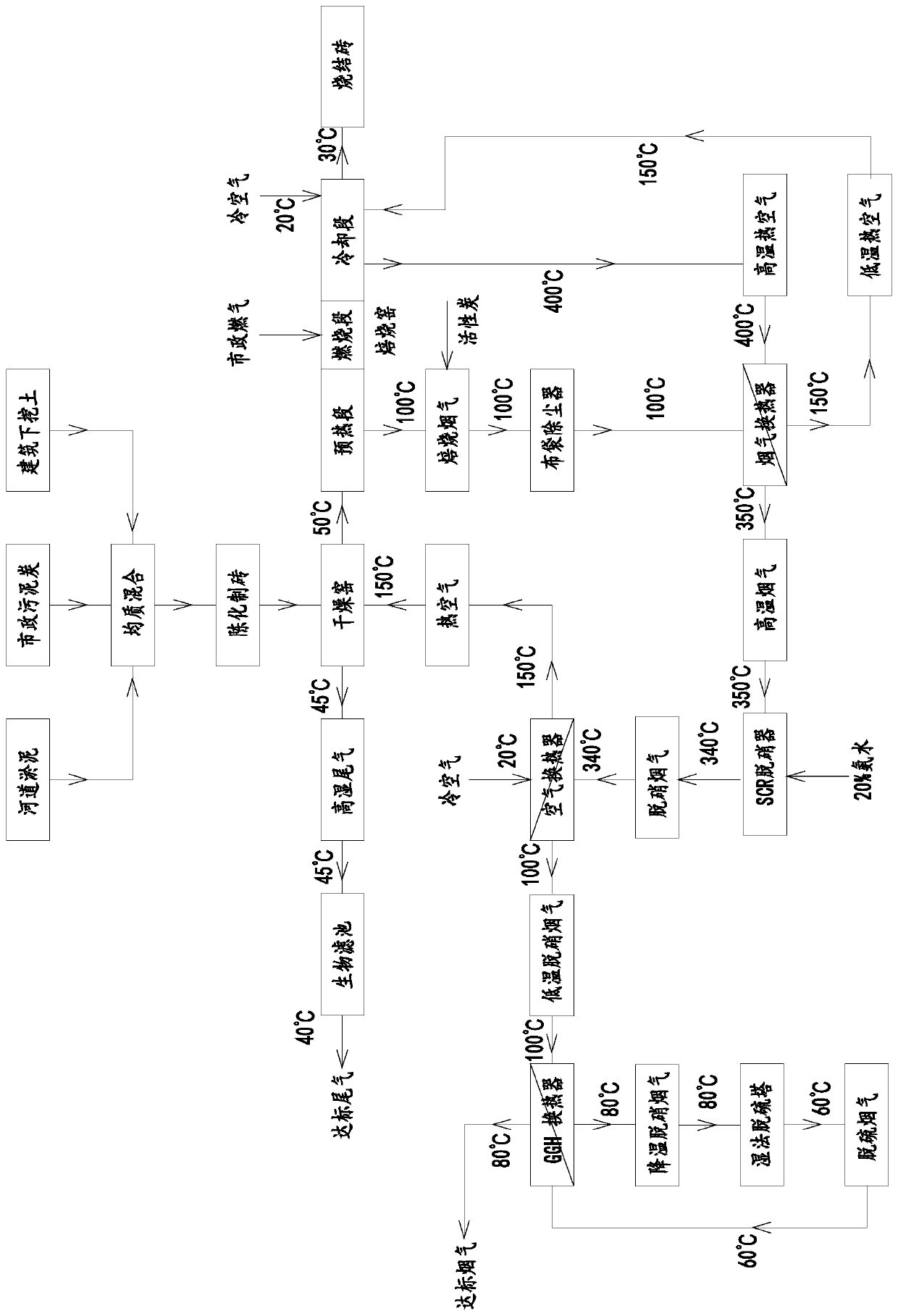

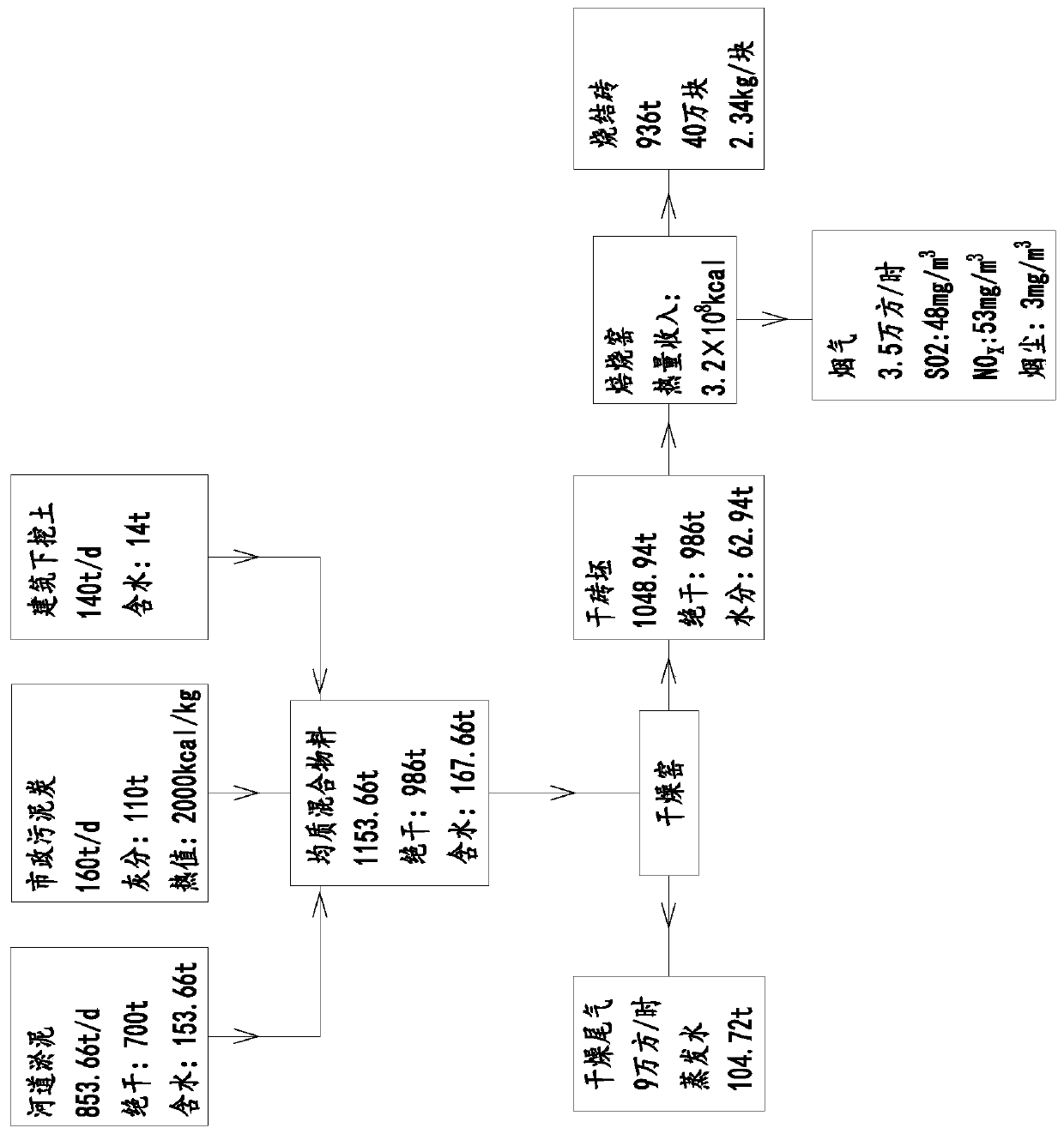

Sintered brick made from watercourse sludge and peat, sintering and waste gas purifying system, and sintering and waste gas purifying method

ActiveCN110317038AHigh calorific valueEasy landingCharge composition/stateDrying gas arrangementsBrickSludge

The invention discloses a sintered brick from watercourse sludge and peat, a sintering and waste gas purifying system, and a sintering and waste gas purifying method. The water content of a green bodyof the sintered brick is 12-18%. Based on dry basis, the green body comprises, by weight, 60-75% of the watercourse sludge, 8-20% of earth under buildings and 15-22% of the municipal peat. The systemcomprises a drying kiln, a dry flue gas purifying device, a calcining kiln and a calcined flue gas purifying device. The drying kiln is connected with the dry flue gas purifying device and the calcining kiln, and the calcined flue gas purifying device is connected with the calcining kiln. The method includes a purification step for calcining kiln flue gases and a purification step for drying kilnflue gases. Solid waste including the watercourse sludge and the municipal peat is fully utilized for producing building materials, the municipal peat is used as sintering fuel, and accordingly, energy conservation and environmental protection are achieved; the sintered brick has low cost and high quality, and treated waste gases meet the national emission standards.

Owner:广东鸿发环境投资有限公司

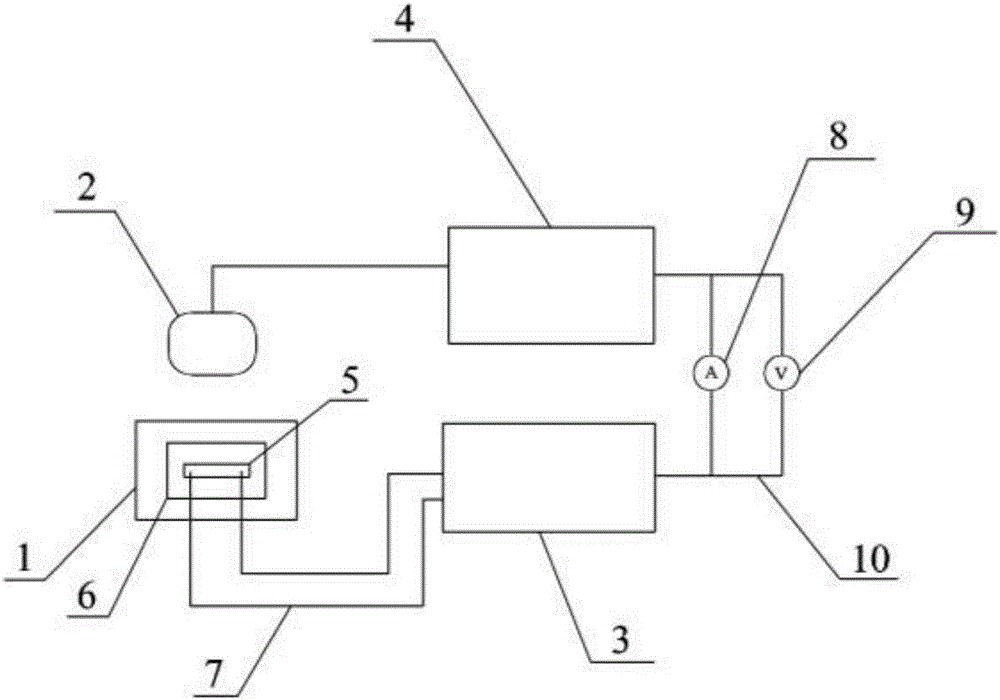

Electric-field-assisted ceramic low temperature rapid sintering device

ActiveCN106116559AFast sinteringSimple structureCharge composition/stateCharge treatment typeLinear contractionData acquisition

The invention discloses an electric-field-assisted ceramic low temperature rapid sintering device. The rapid sintering device comprises a heating plate, a direct current power supply, an infrared camera and a data acquisition device, wherein the heating plate is used for placing and heating a sample, the two ends of the sample are respectively connected with an anode and a cathode of the direct current power supply; the infrared camera is arranged at a corresponding position of the heating plate, and the infrared camera is connected with the data acquisition device. The rapid sintering device disclosed by the invention has the advantages that heat energy is supplied to ceramic by virtue of the heating plate, and low temperature rapid sintering of a ceramic material is realized under the assistant action of a direct current electric field; and in-situ observation of temperature variation and linear contraction of the sample in each stage during flash sintering can be realized by virtue of the infrared camera and the data acquisition device, and energy consumption and requirement on equipment are effectively reduced.

Owner:SOUTHWEST JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com