Automatic stokehold round steel bar feeding device for continuous heating furnace

A round steel and automatic technology, which is applied in the direction of furnace control devices, furnace materials, lighting and heating equipment, etc., can solve the problems of narrow working space on the heating furnace platform, increased manpower operation costs, and high labor intensity of employees, so as to save manpower operation costs , simple structure, and the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

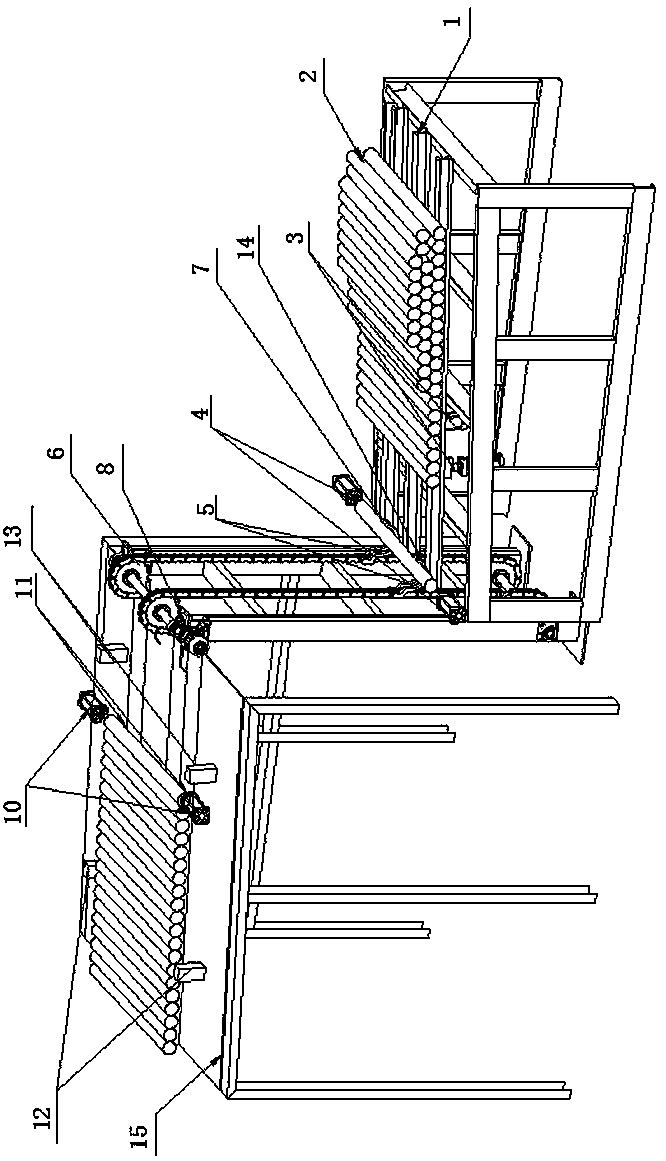

[0014] An automatic round steel feeding device in front of a continuous heating furnace, which is composed of a storage platform 15 in front of the furnace, a feeding platform 1, a chain hoist 6 and a control device. The height of the storage platform 15 in front of the furnace is the same as the furnace door of the continuous heating furnace Height matching, the height of the loading platform 1 is less than the height of the storage platform 15 in front of the furnace, the lower end of the chain hoist 6 is installed on the front end of the loading platform 2, and the upper end of the chain hoist 6 is installed behind the storage platform 15 in front of the furnace At the end, the chain hoists 6 are two arranged side by side and operate synchronously. The lifting hook 5 installed on the chain of the chain hoist 6 is installed on the feeding platform 1 with a top material 3 . Under the instruction of the control device, the raw material steel bar 2 on the feeding platform 1 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com