Patents

Literature

1873 results about "Falsework" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Falsework consists of temporary structures used in construction to support a permanent structure until its construction is sufficiently advanced to support itself. For arches, this is specifically called centering. Falsework includes temporary support structures for formwork used to mold concrete in the construction of buildings, bridges, and elevated roadways.

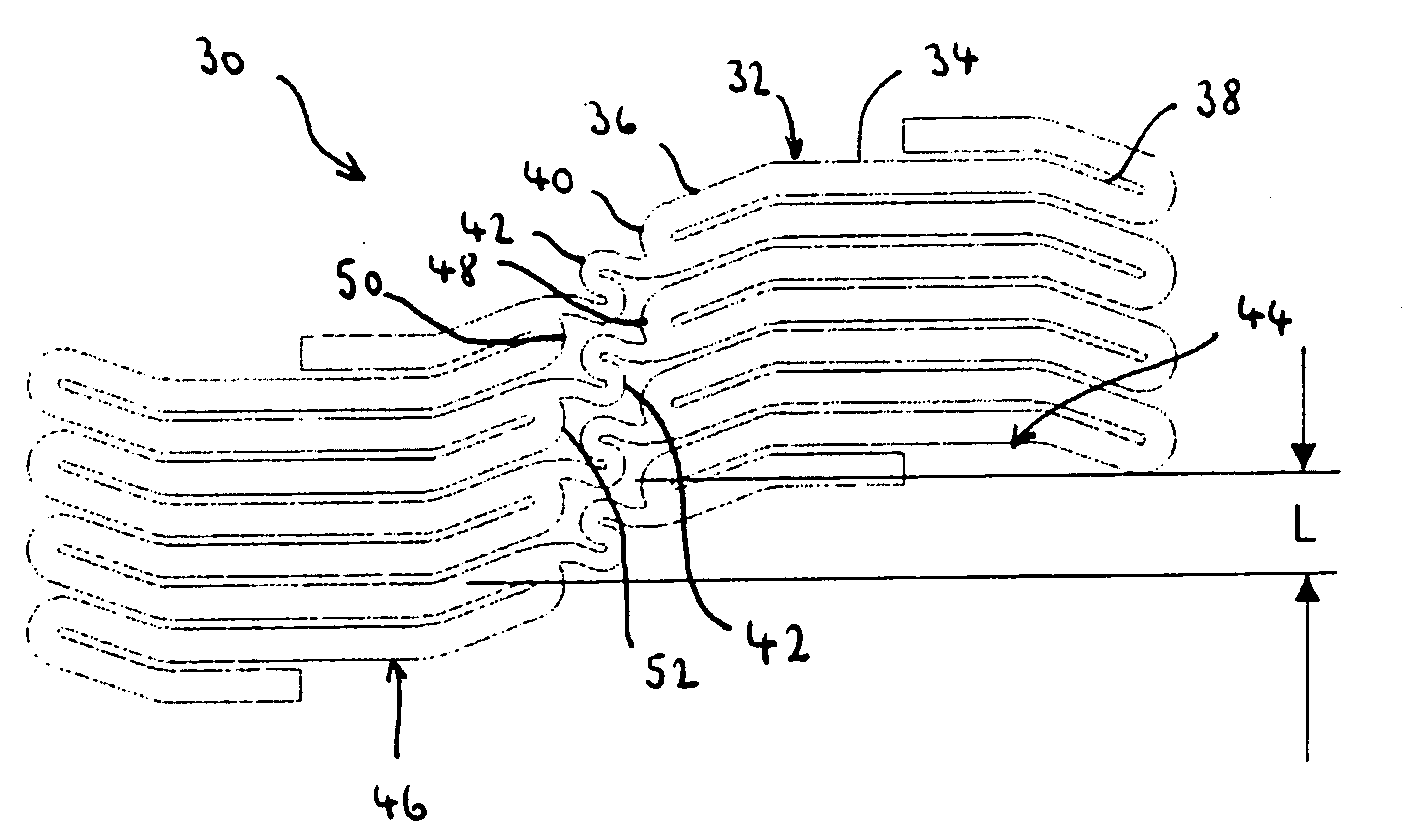

Resilient contact structures formed and then attached to a substrate

InactiveUS20020117330A1Simple technologyCoupling device connectionsSemiconductor/solid-state device testing/measurementEngineeringTopography

Owner:FORMFACTOR INC

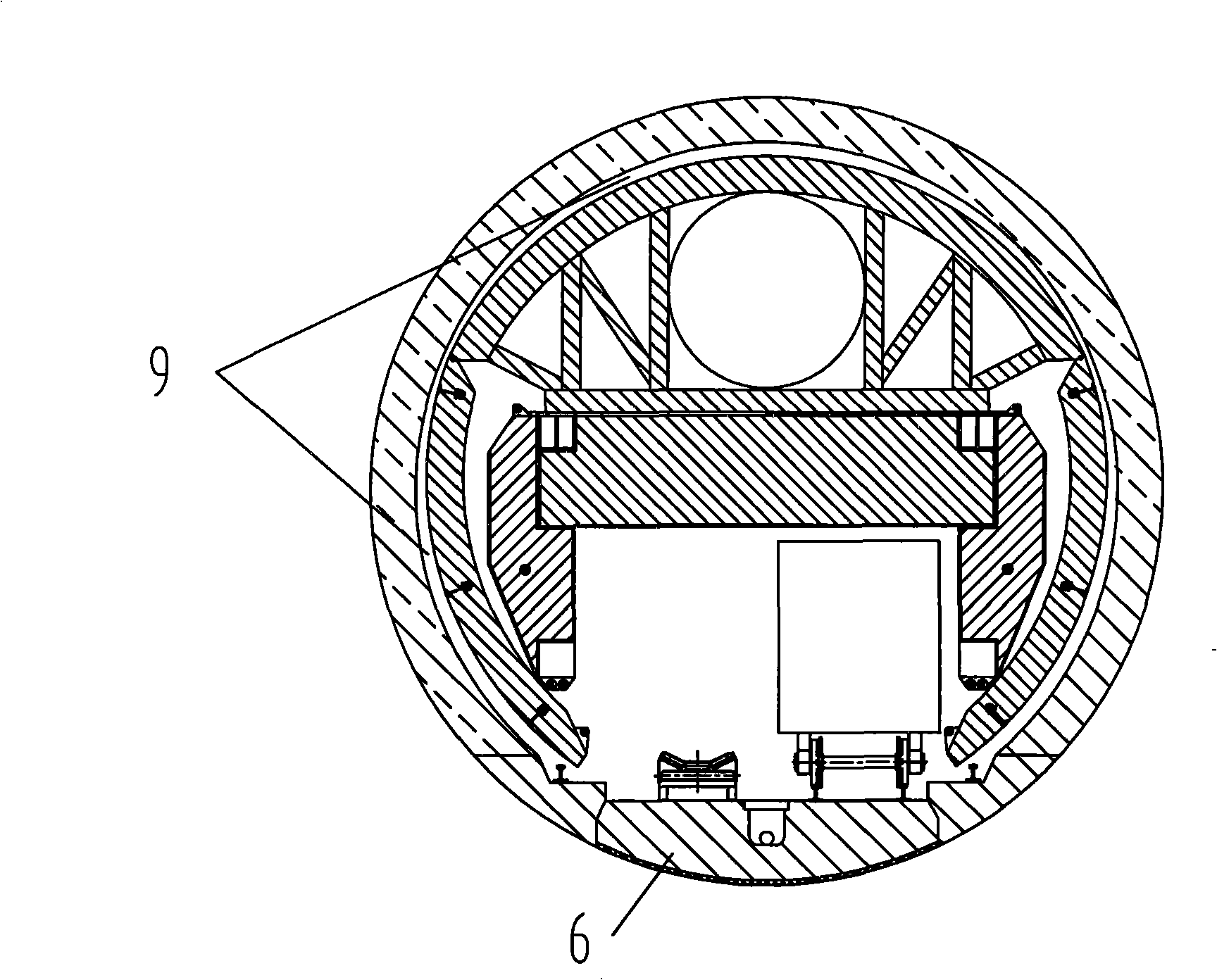

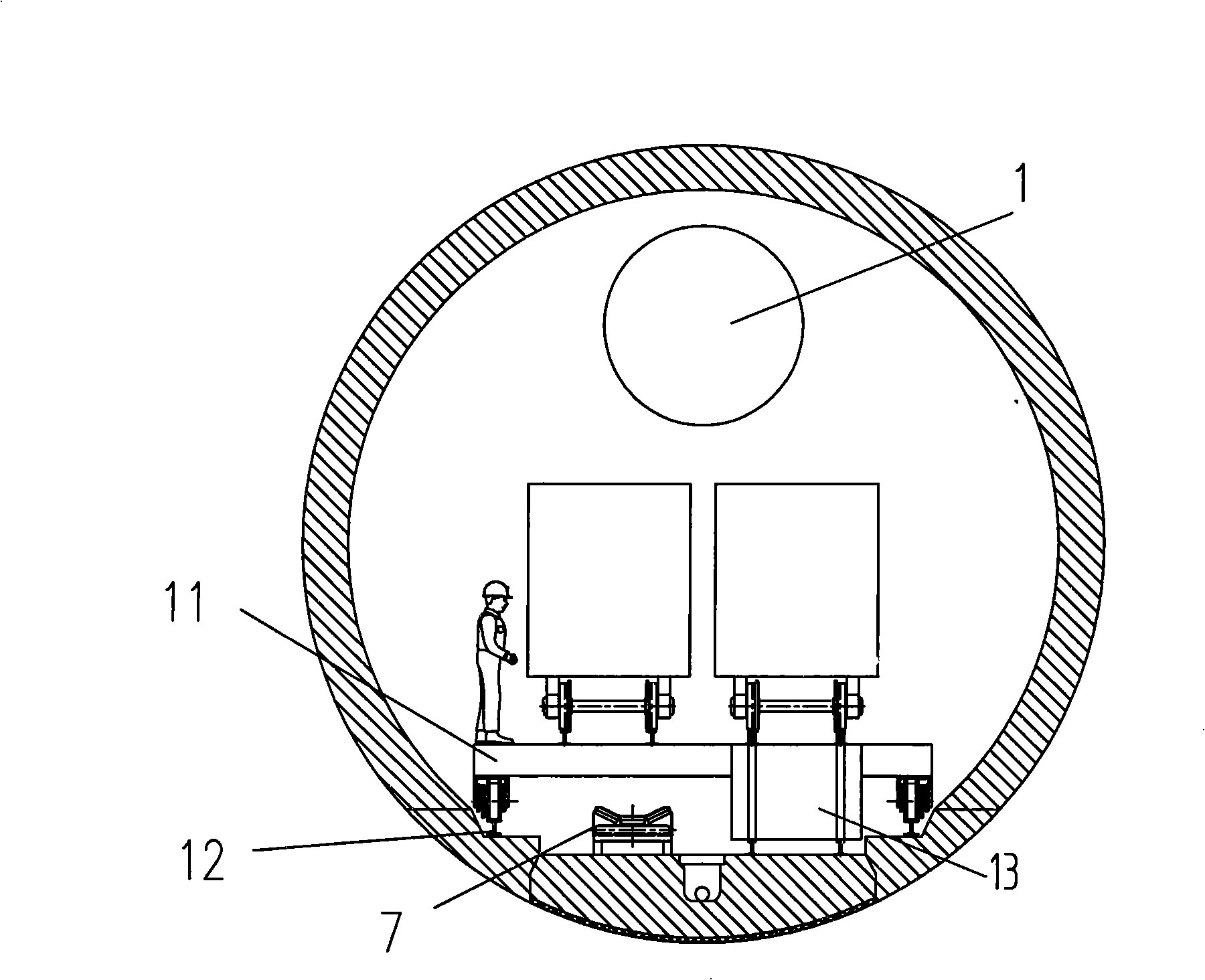

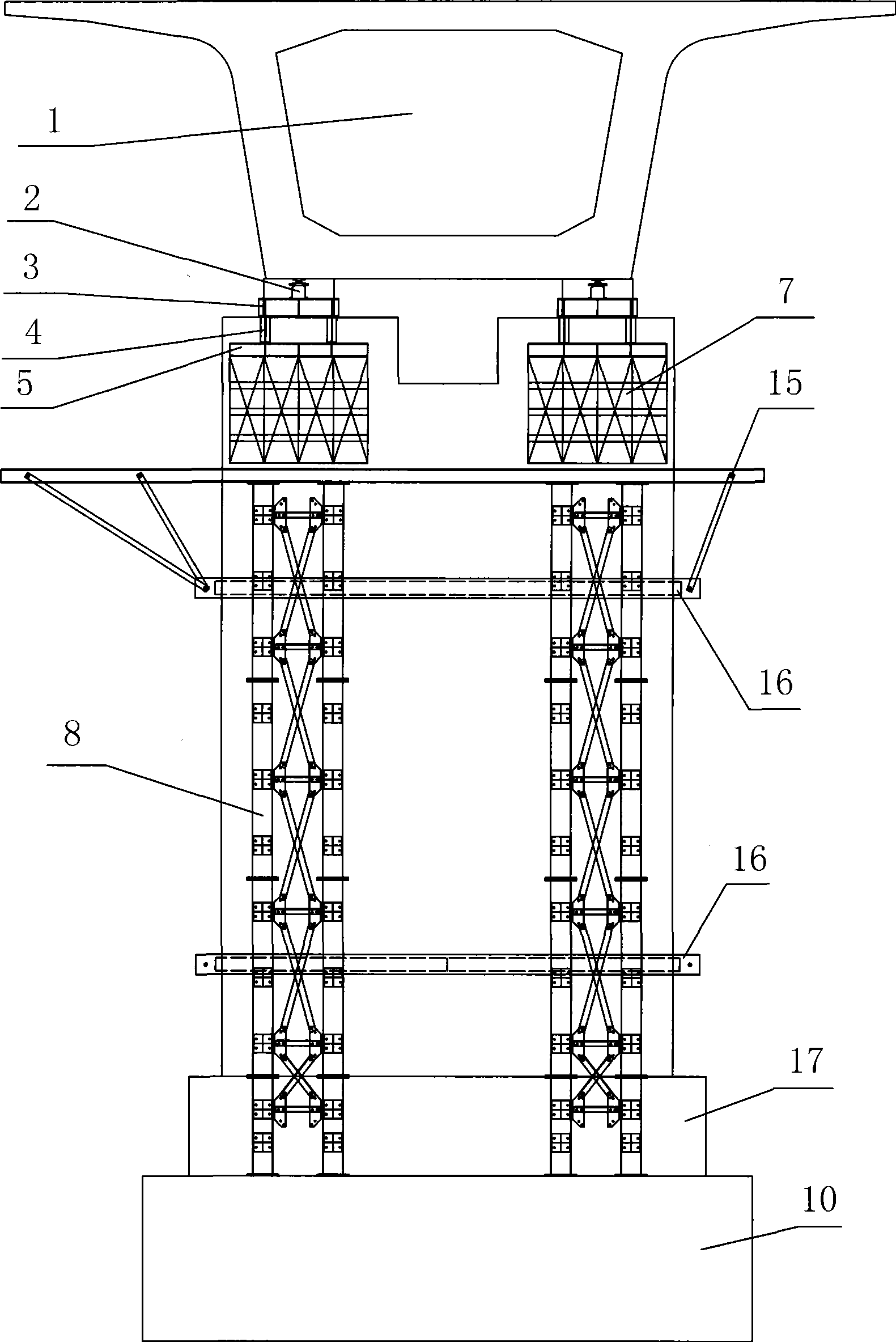

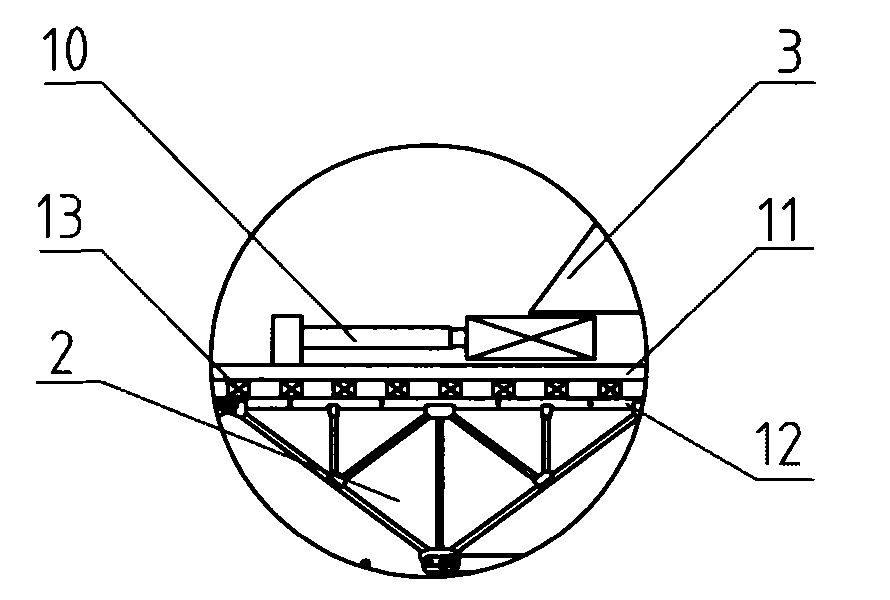

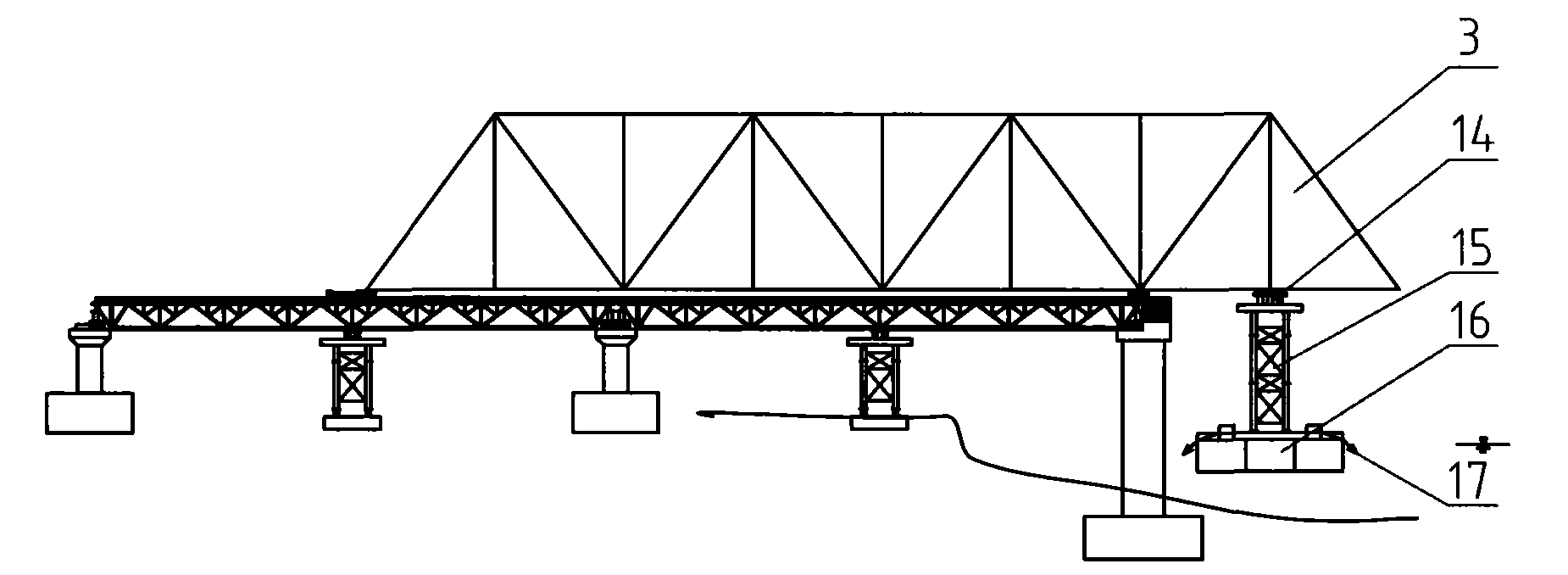

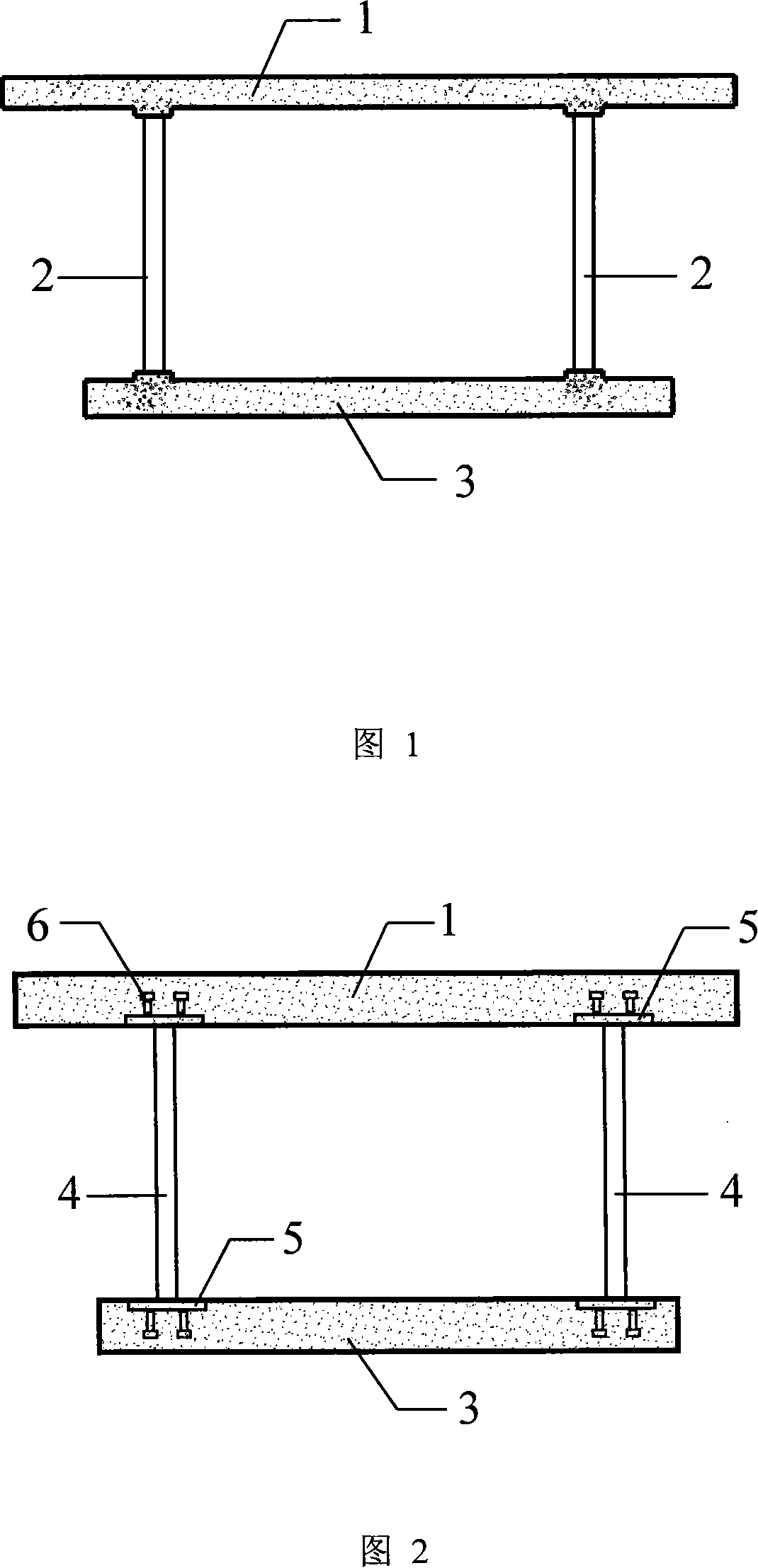

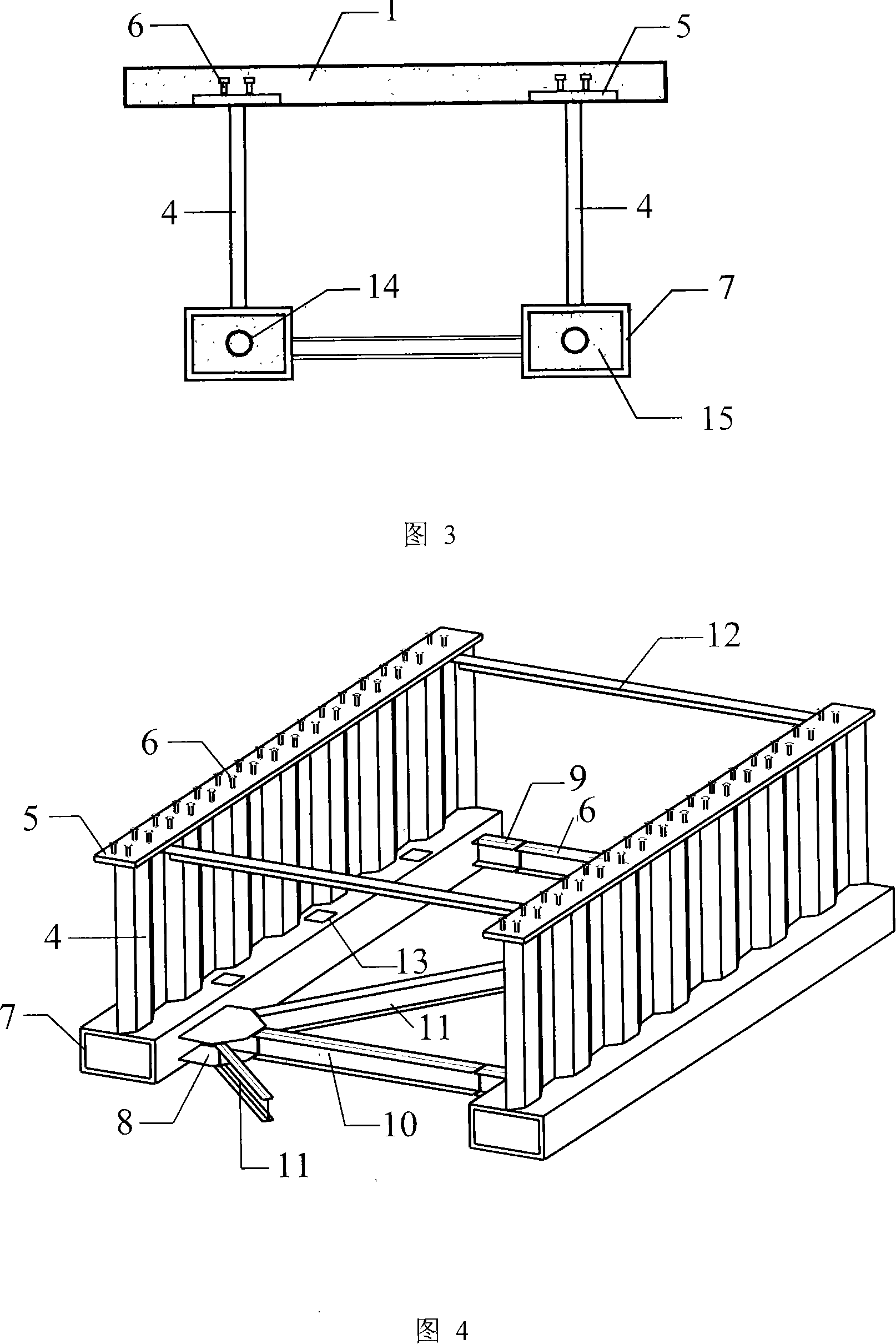

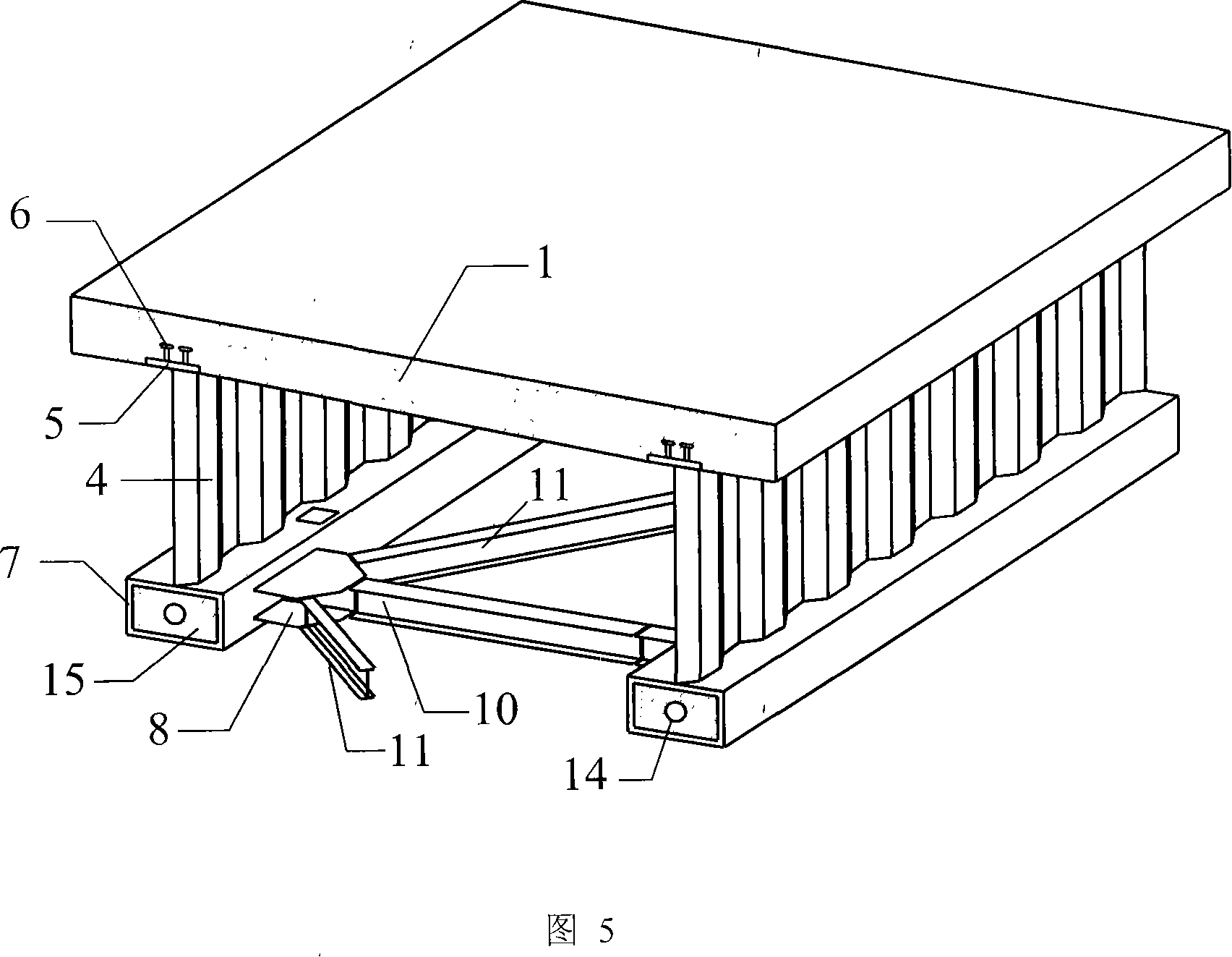

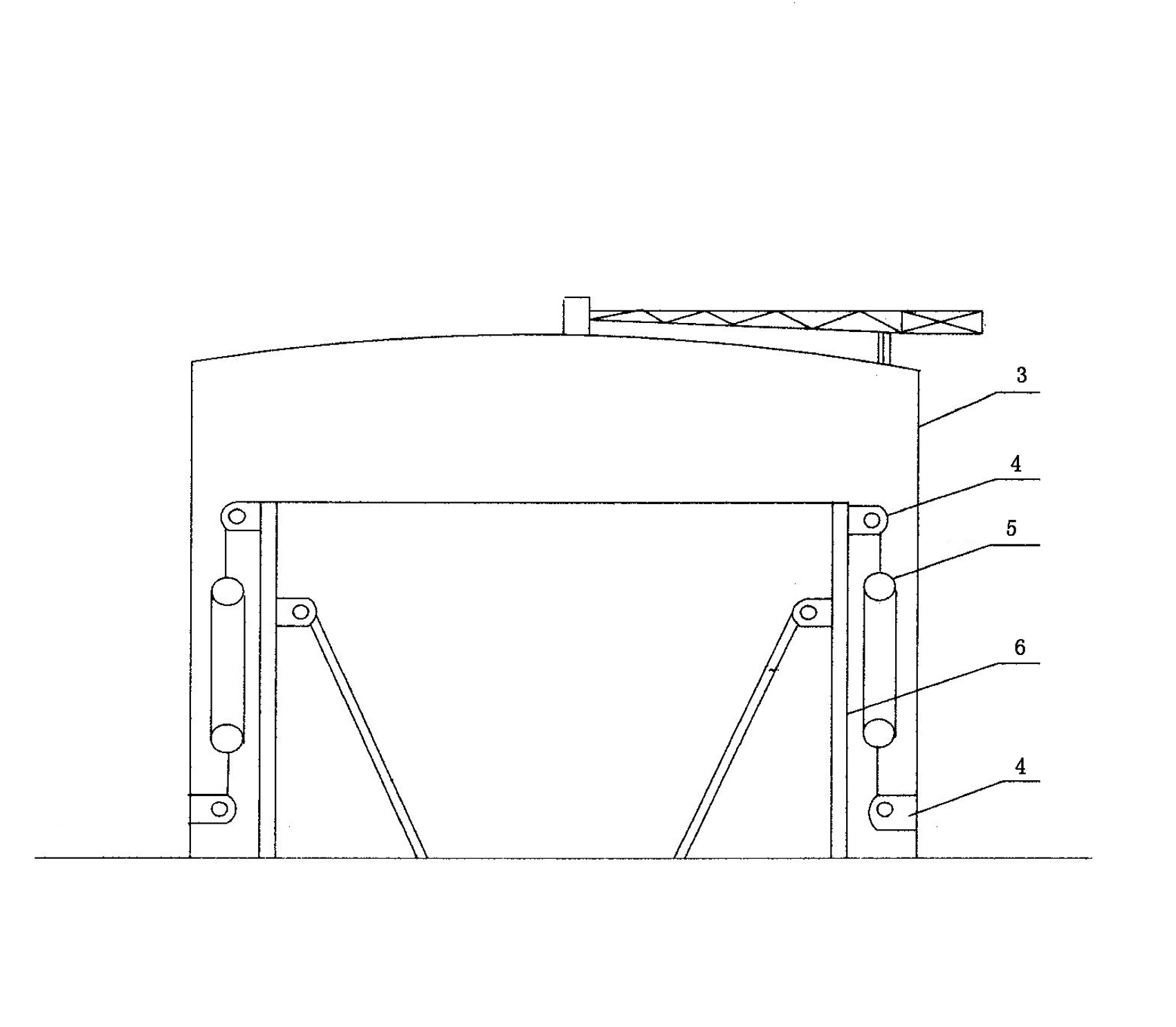

Construction method for tunnel continuous mucking, lining and excavation synchronization

ActiveCN101403305AImprove construction efficiencyShorten the construction periodUnderground chambersTunnel liningFalseworkTransport facility

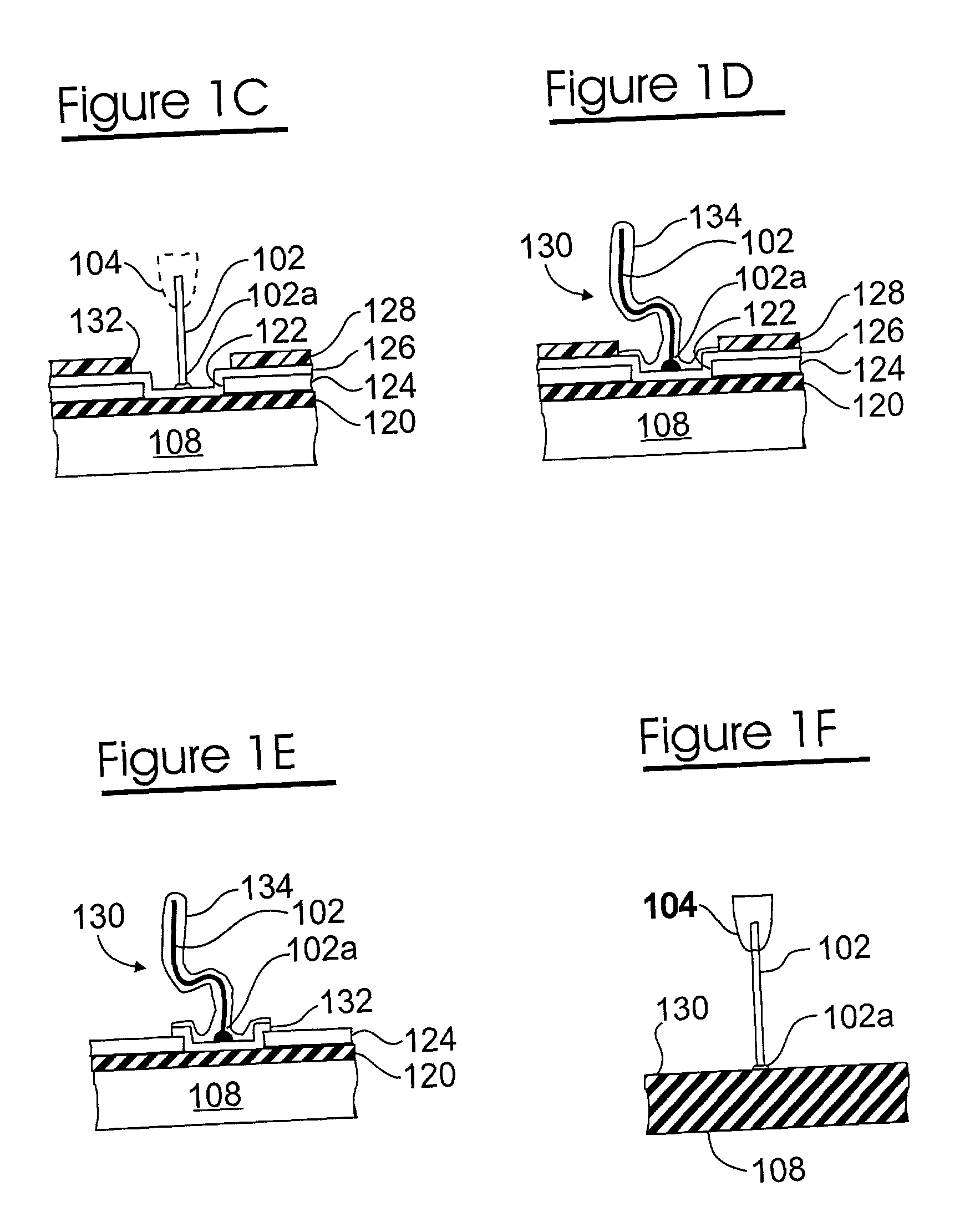

The invention provides a construction method for the continuous mucking, lining and excavation synchrony of tunnels (caves), which comprises the following steps: the front end of a belt conveyer is positioned in an excavation work area, the belt conveyer from the excavation work area to the lining area of a steel moulding plate trolley is positioned on an inverted arch precast block (6) or hung at the top of the tunnel; the belt conveyer in front of the steel moulding plate trolley causes a conveyer (7) to be positioned at one internal side of a moulding plate trolley gantry (4) when passing through the moulding plate trolley on the basis of being positioned on the inverted arch precast block or a cast-in-situ inverted arch; a falsework (14) is arranged in front of the moulding plate trolley (2) and positioned on a track (12) which is connected in front of the self-circulation of the steel moulding plate trolley; and the belt conveyer is positioned on the inverted arch precast block or hung at the top of the tunnel from a lining operating area to a tunnel entrance after passing through the steel moulding plate trolley. The construction method can realize the continuous mucking of the belt conveyer and the synchronous lining of the moulding plate trolley along with the excavation of the tunnel in tunnel construction and cause transport equipment such as cars or the track to transport facilities and other materials needed by tunnel construction.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

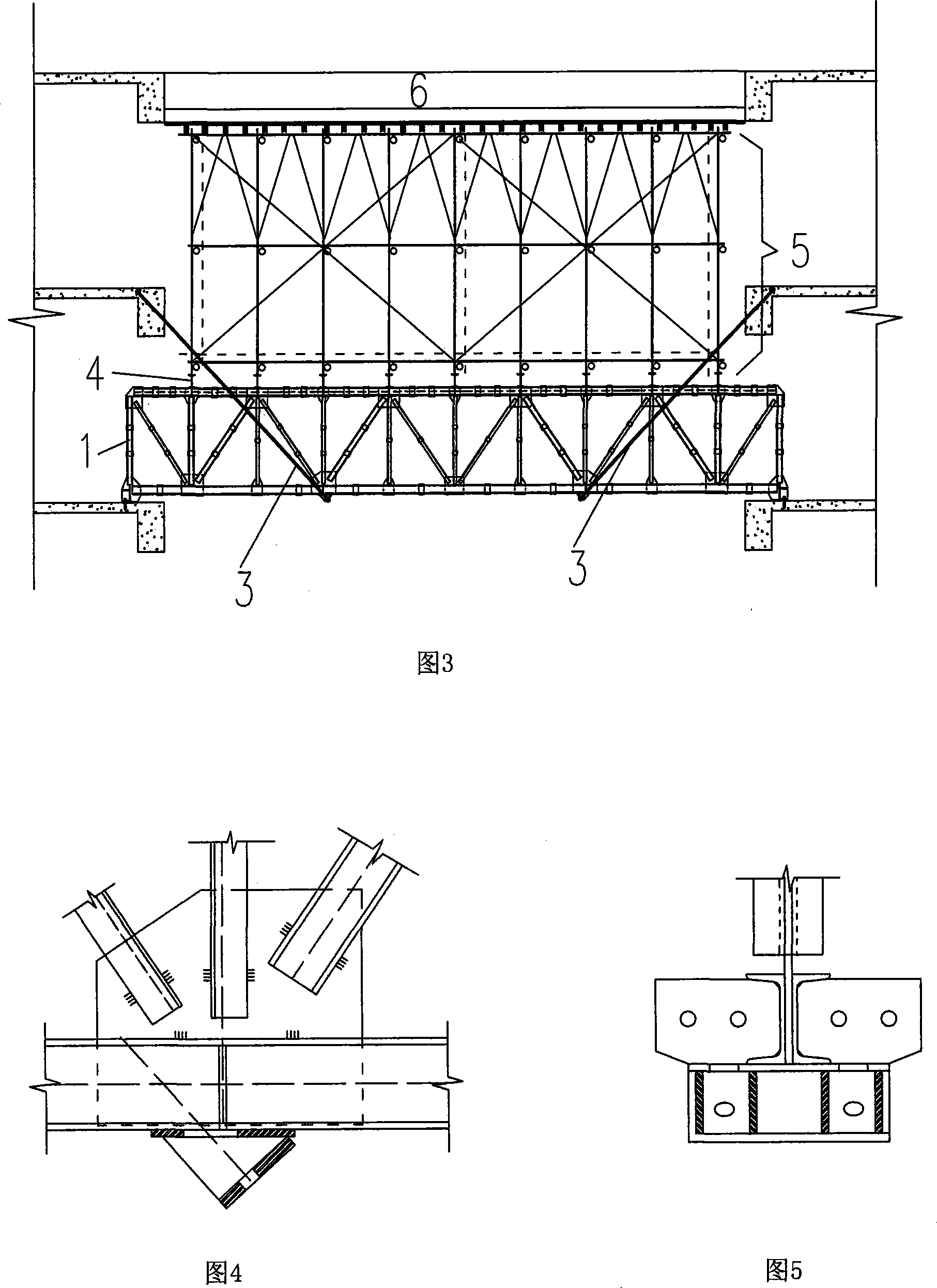

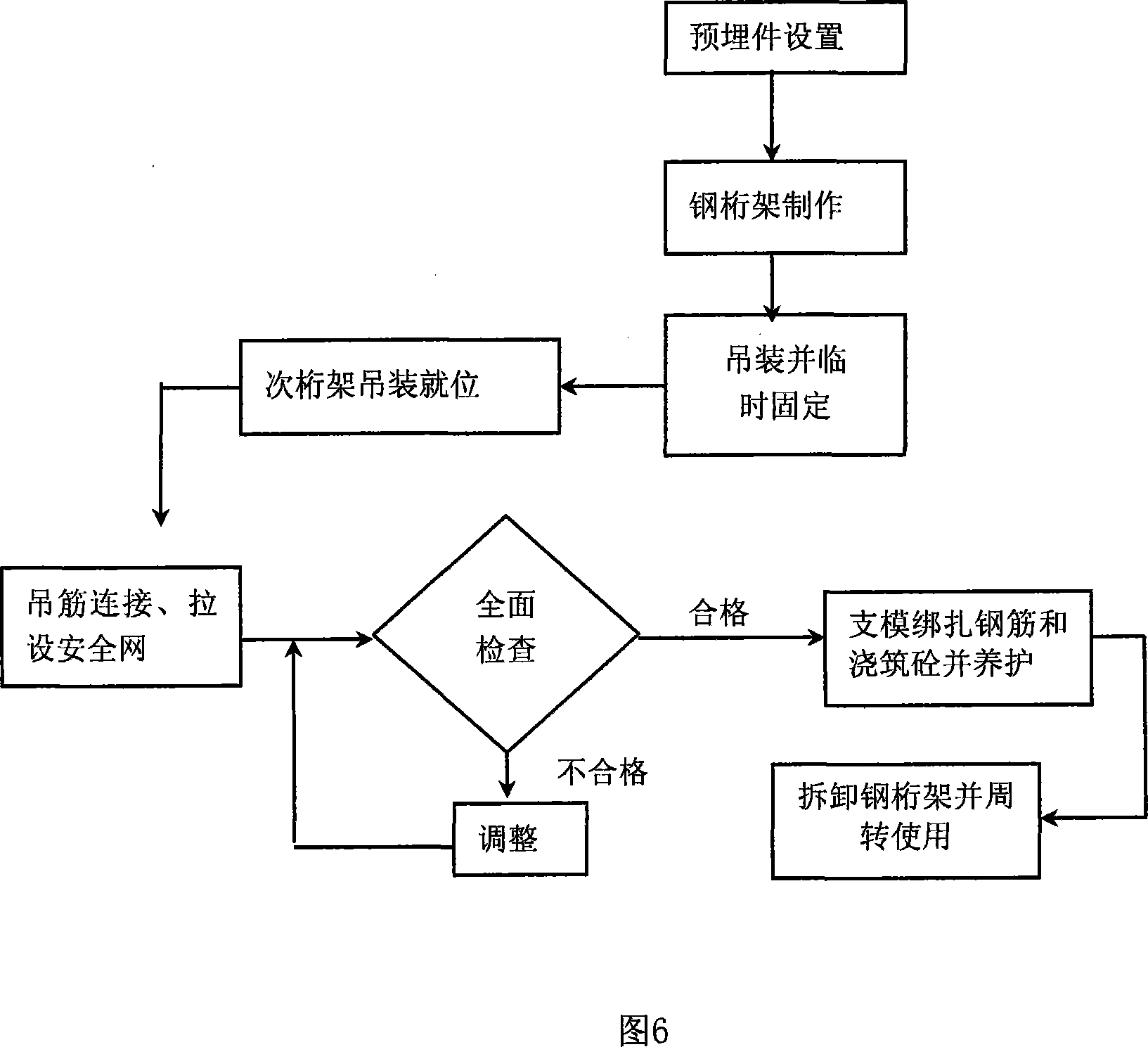

Method for high altitude installation of large span steel truss

InactiveCN101255768ASolve quality problemsSolve many disadvantages such as long construction periodBuilding material handlingSUSPENDING VEHICLEFalsework

The present invention relates to a method for installing a large span steel truss on high altitude. The method comprises the steps of arranging embedded part on the structure girder at two sides of the designed position of the steel truss, then installing extensible guide on the embedded part, and at last assembling a specialized steel structure tackle. Firstly, a large tonnage hoisting machine is used for hanging the steel truss which is wholly assembled underground to two tackles that are arranged on station. Afterwards, the steel trust is parallelly moved to the installation position through the synchronous slippage of two tackles on the extensible guide. Lastly, the two-end capitals of the designing position of the steel truss are installed with an independent holding pole, a chain block and a pulley assembly. These hoisting apparatuses are used for hanging the longeron from the tackle. The longeron of the lengthened part is cut and the steel truss is installed to the position according to the design requirement. Compared with the traditional high altitude dispersed splitting method for building whole surface of scaffold, the installing method provided by the invention subtly settles many abuses of difficulty for controlling the construction quality, long construction period and the like in the traditional method. The manpower and considerable material transportation are saved and the construction quality can be effectively guaranteed. Various requirements of the designing and constructing are excellently and rapidly satisfied.

Owner:NINGBO CONSTR +1

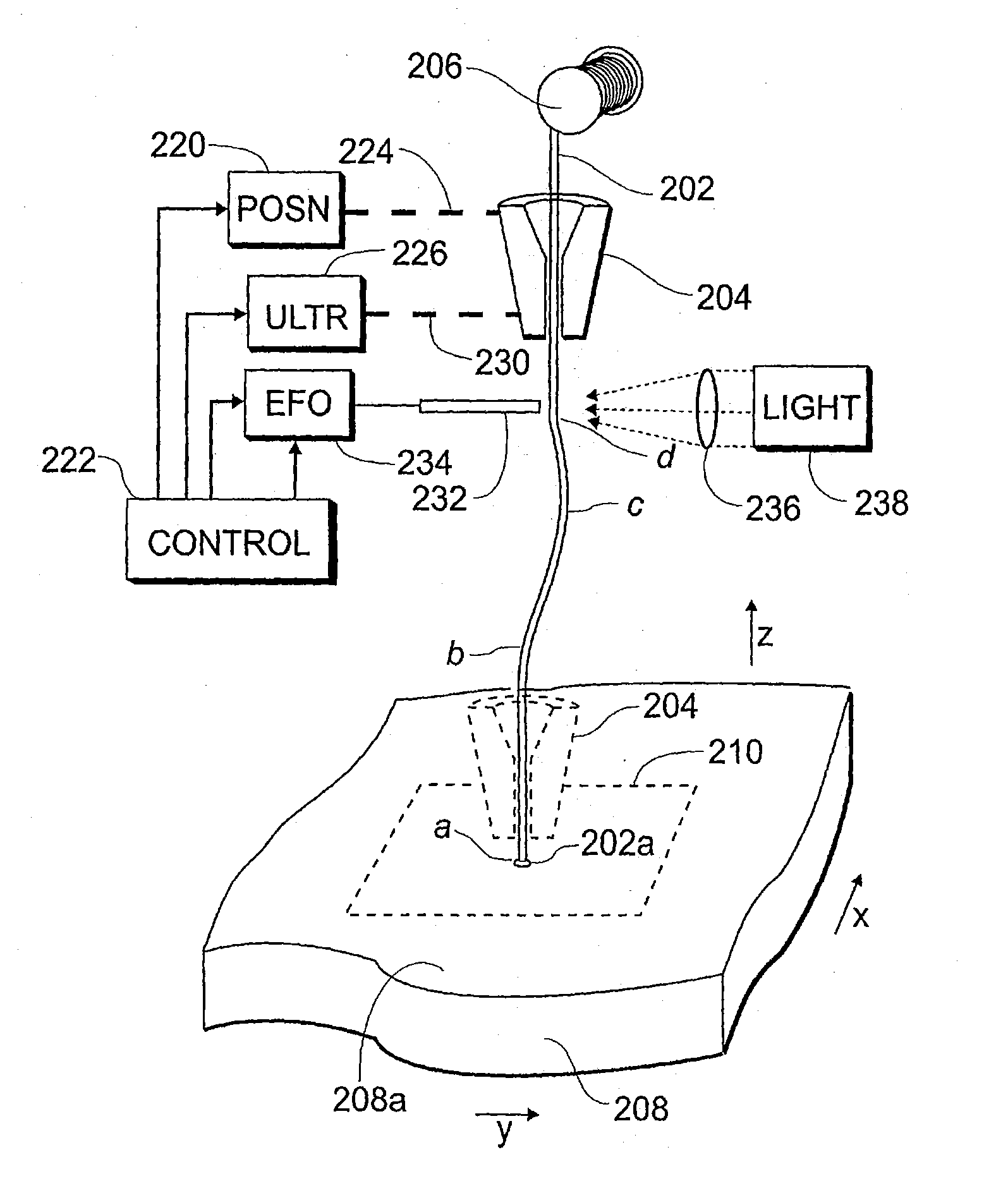

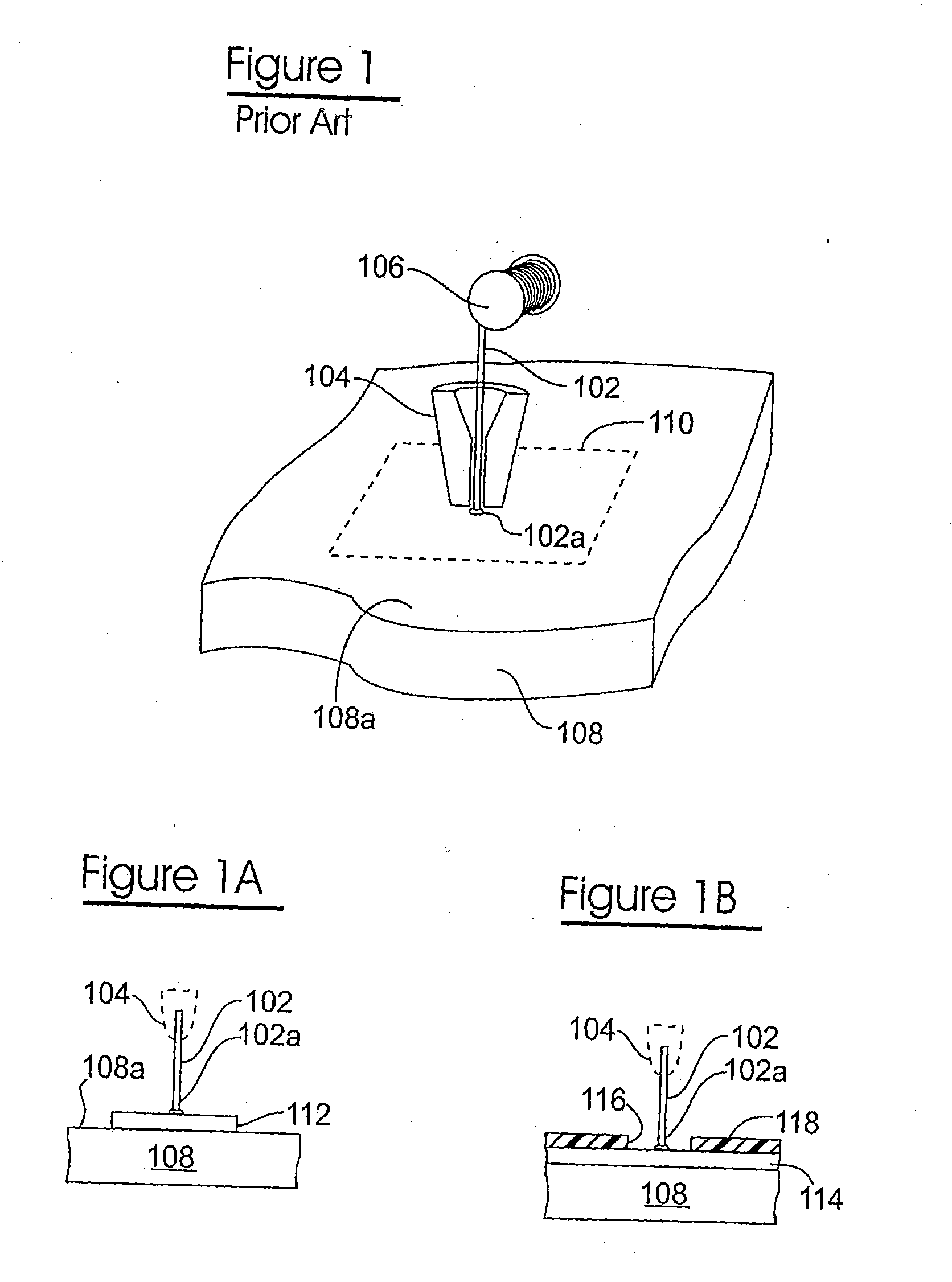

Method Of Wirebonding That Utilizes A Gas Flow Within A Capillary From Which A Wire Is Played Out

InactiveUS20070228110A1Simple technologyImprove bindingElectrical testingPrinted circuits structural associationsPrinted circuit boardTopography

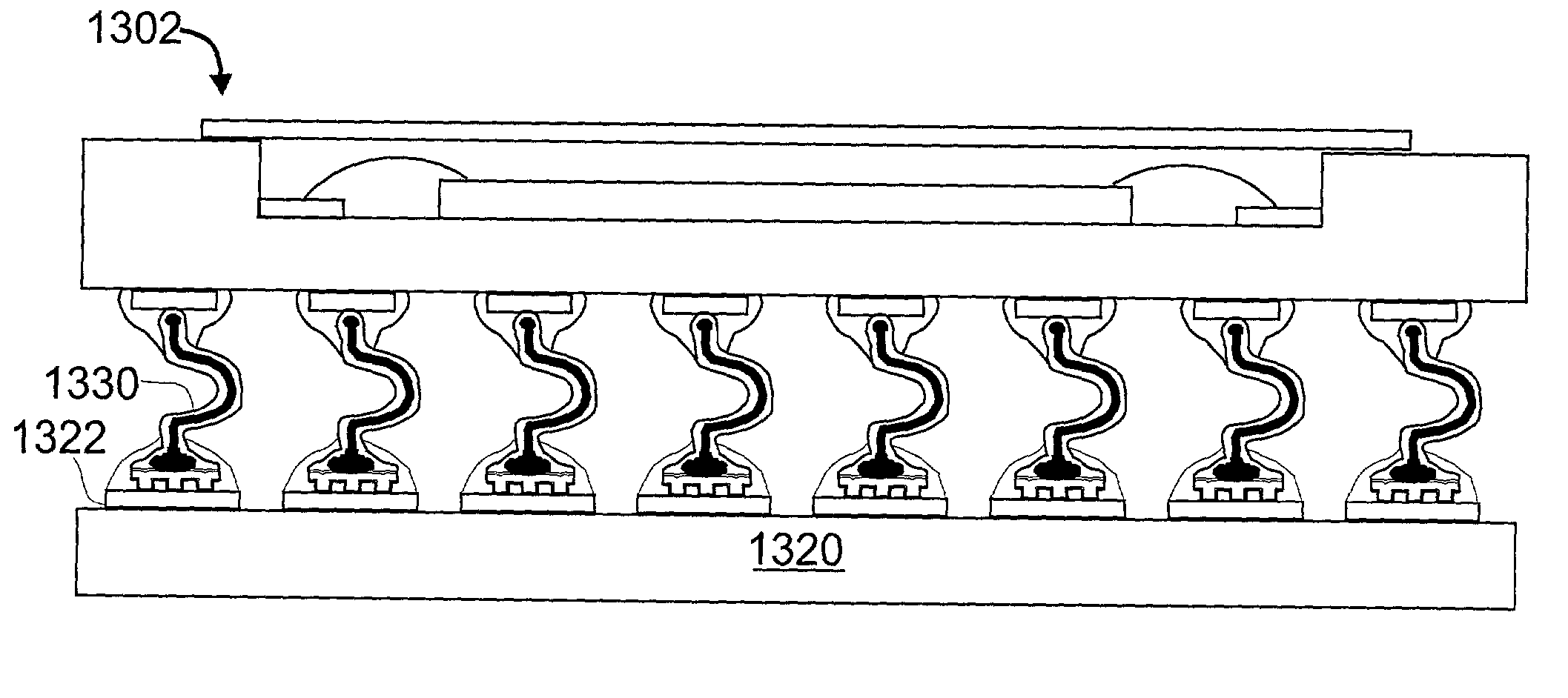

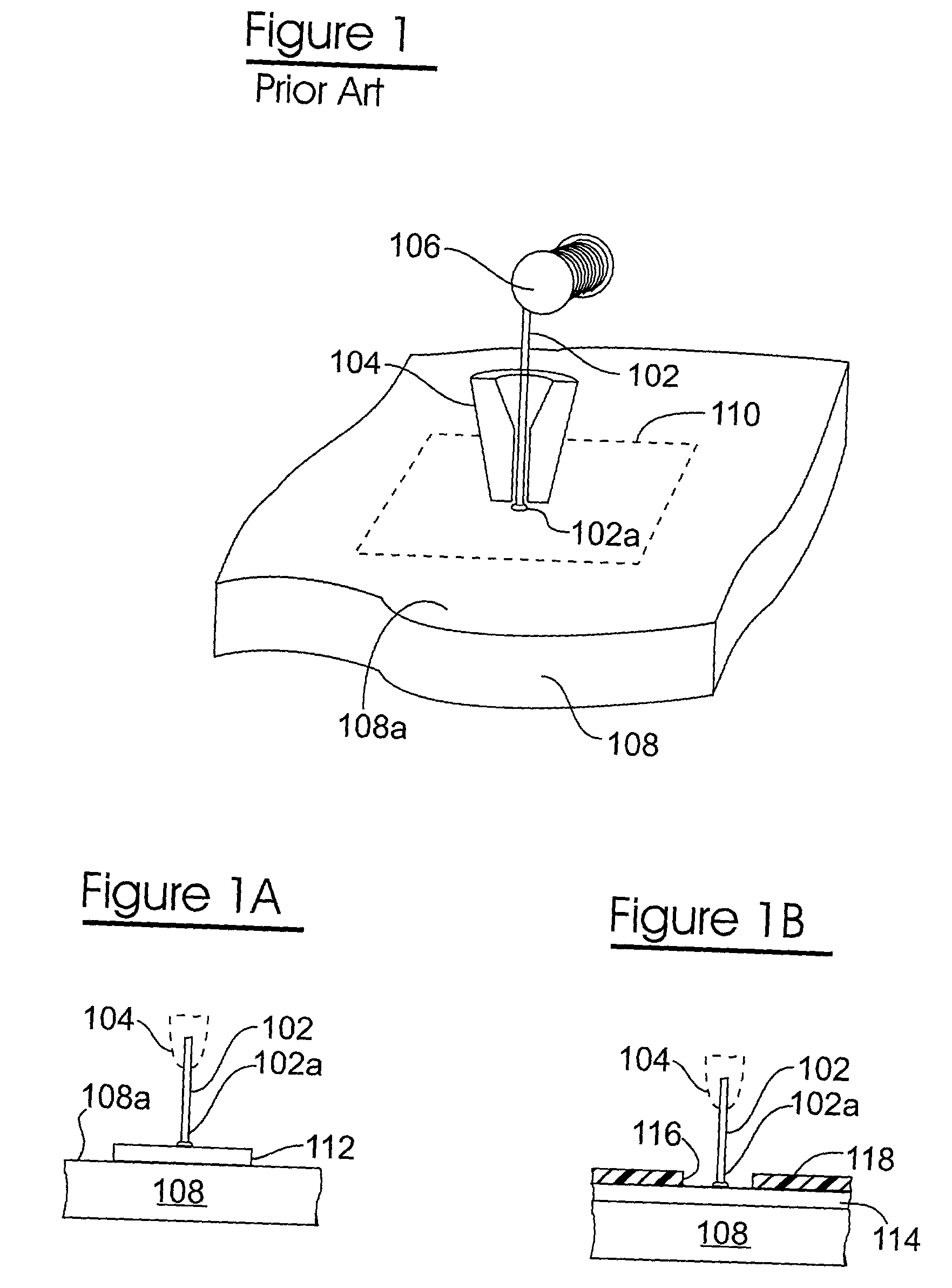

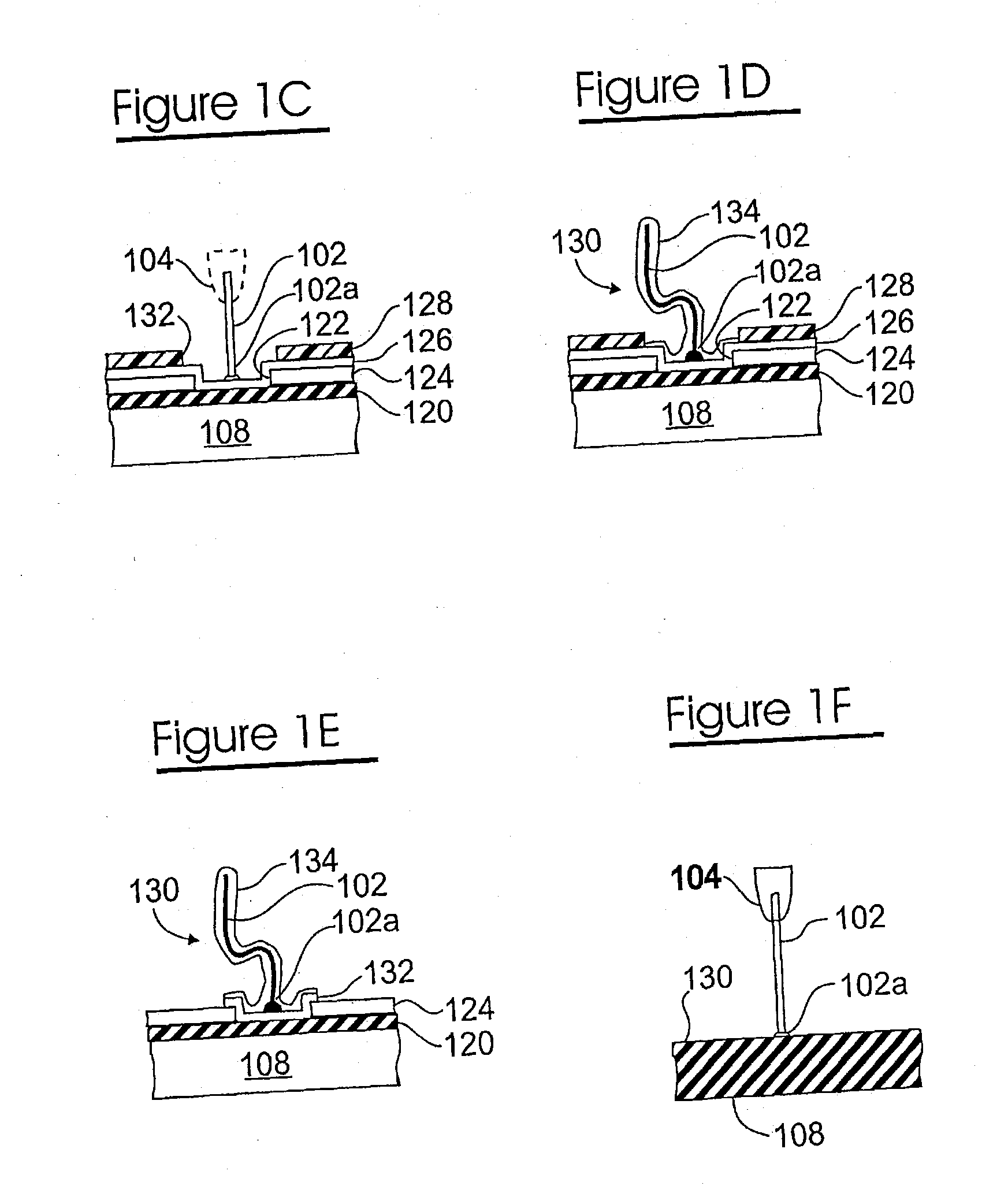

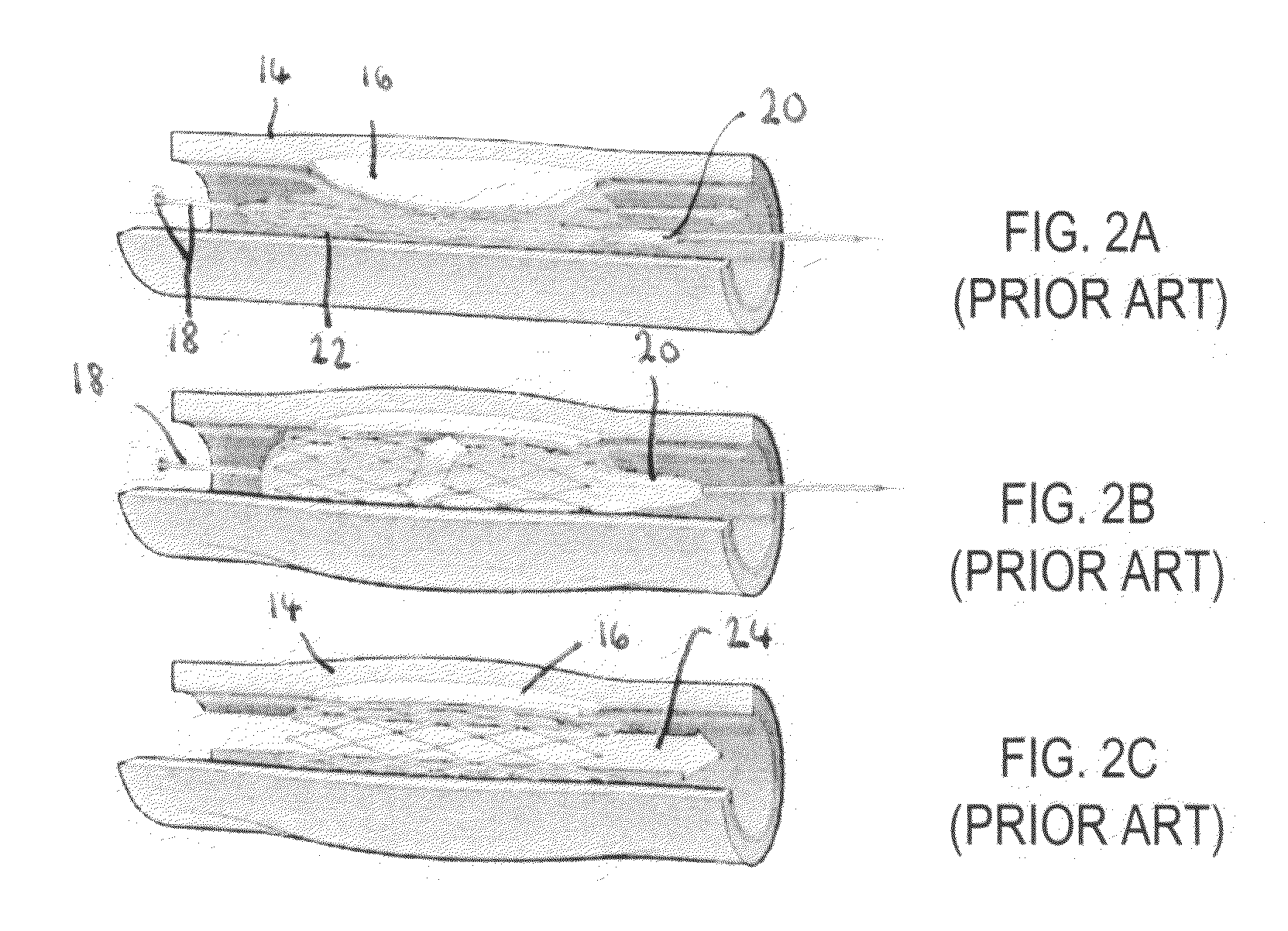

Contact structures exhibiting resilience or compliance for a variety of electronic components are formed by bonding a free end of a wire to a substrate, configuring the wire into a wire stem having a springable shape, severing the wire stem, and overcoating the wire stem with at least one layer of a material chosen primarily for its structural (resiliency, compliance) characteristics. A variety of techniques for configuring, severing, and overcoating the wire stem are disclosed. In an exemplary embodiment, a free end of a wire stem is bonded to a contact area on a substrate, the wire stem is configured to have a springable shape, the wire stem is severed to be free-standing by an electrical discharge, and the free-standing wire stem is overcoated by plating. A variety of materials for the wire stem (which serves as a falsework) and for the overcoat (which serves as a superstructure over the falsework) are disclosed. Various techniques are described for mounting the contact structures to a variety of electronic components (e.g., semiconductor wafers and dies, semiconductor packages, interposers, interconnect substrates, etc.), and various process sequences are described. The resilient contact structures described herein are ideal for making a “temporary” (probe) connections to an electronic component such as a semiconductor die, for burn-in and functional testing. The self-same resilient contact structures can be used for subsequent permanent mounting of the electronic component, such as by soldering to a printed circuit board (PCB). An irregular topography can be created on or imparted to the tip of the contact structure to enhance its ability to interconnect resiliently with another electronic component. Among the numerous advantages of the present invention is the great facility with which the tips of a plurality of contact structures can be made to be coplanar with one another. Other techniques and embodiments, such as wherein the falsework wirestem protrudes beyond an end of the superstructure, or is melted down, and wherein multiple free-standing resilient contact structures can be fabricated from loops, are described.

Owner:FORMFACTOR INC

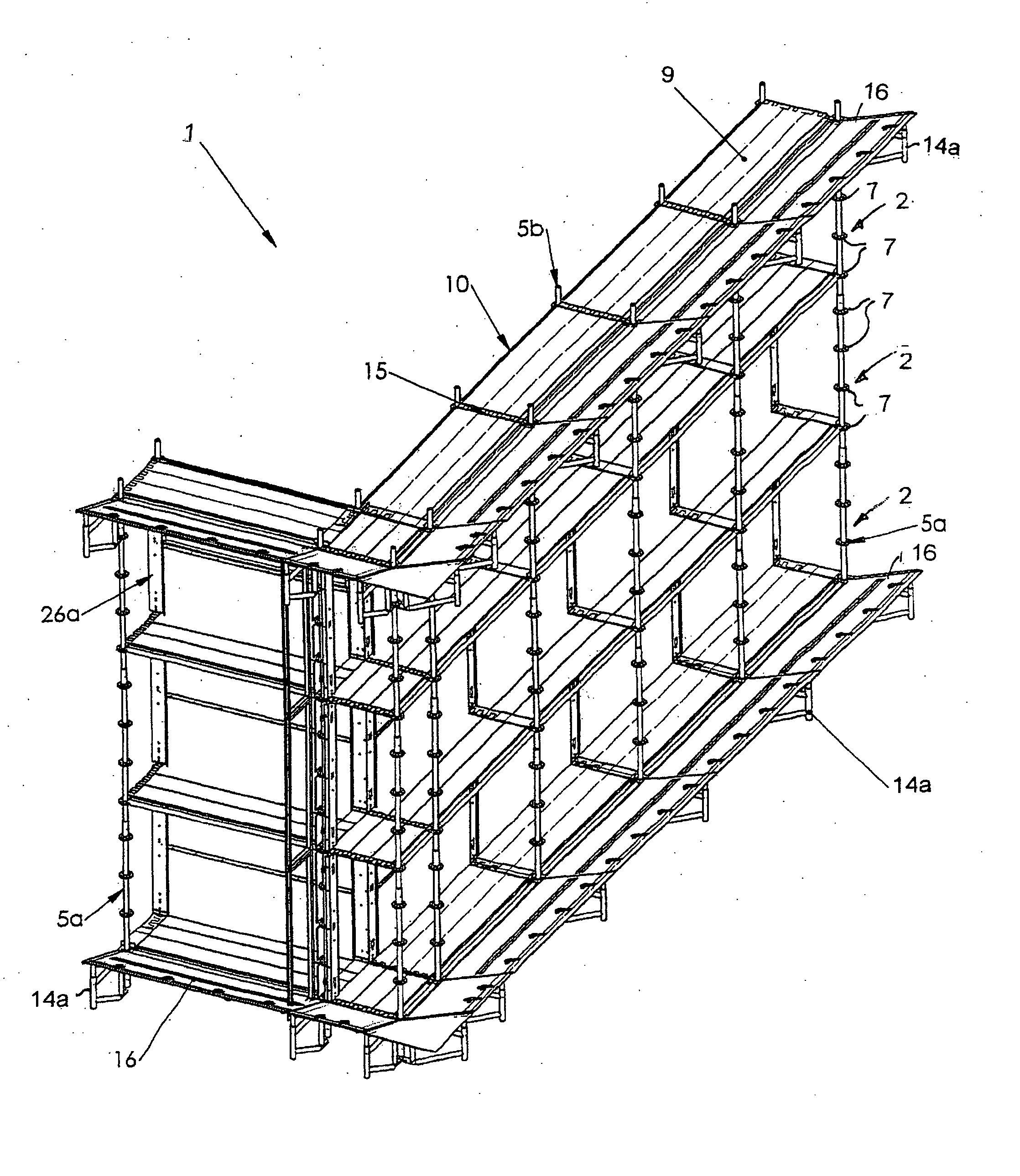

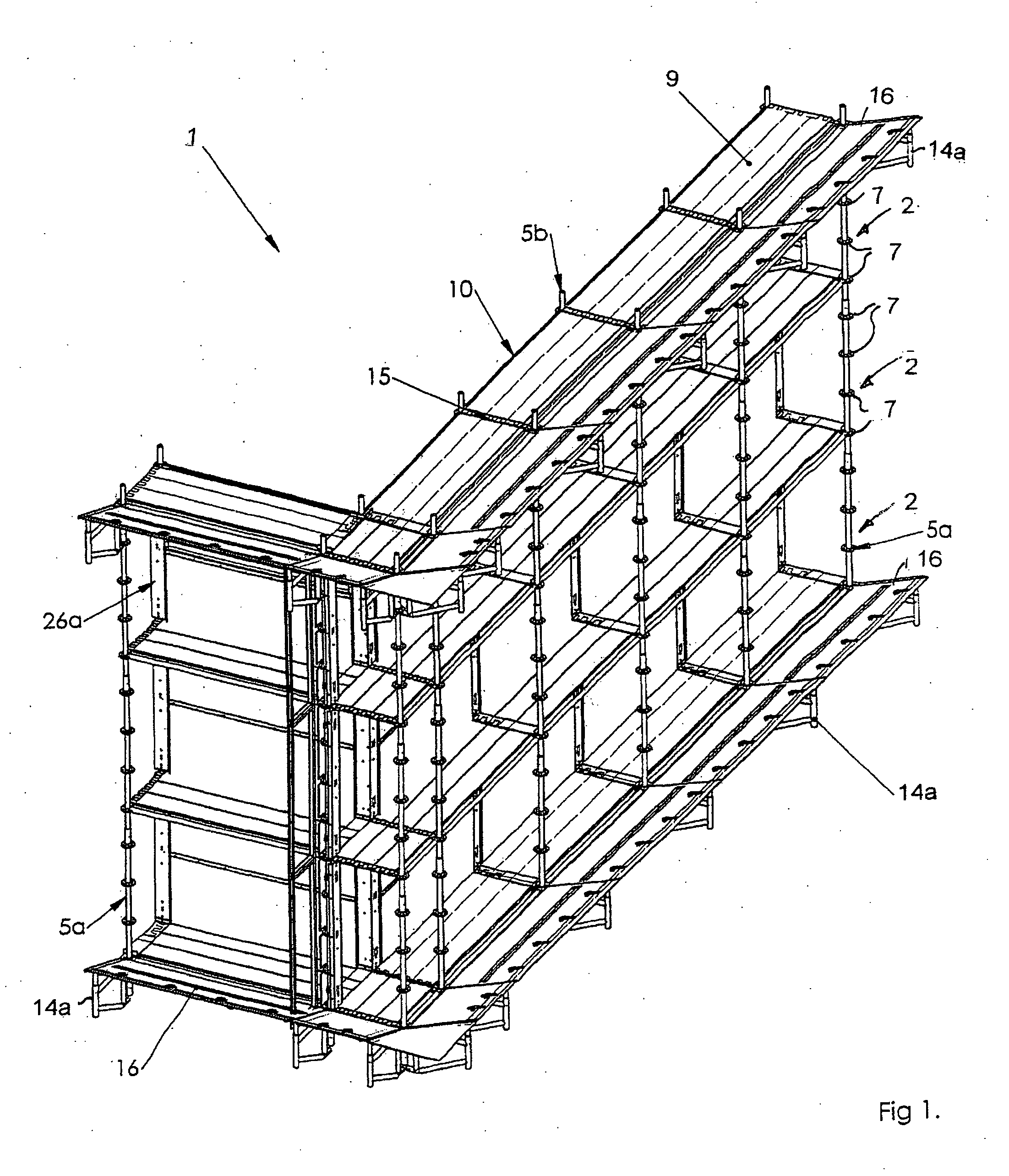

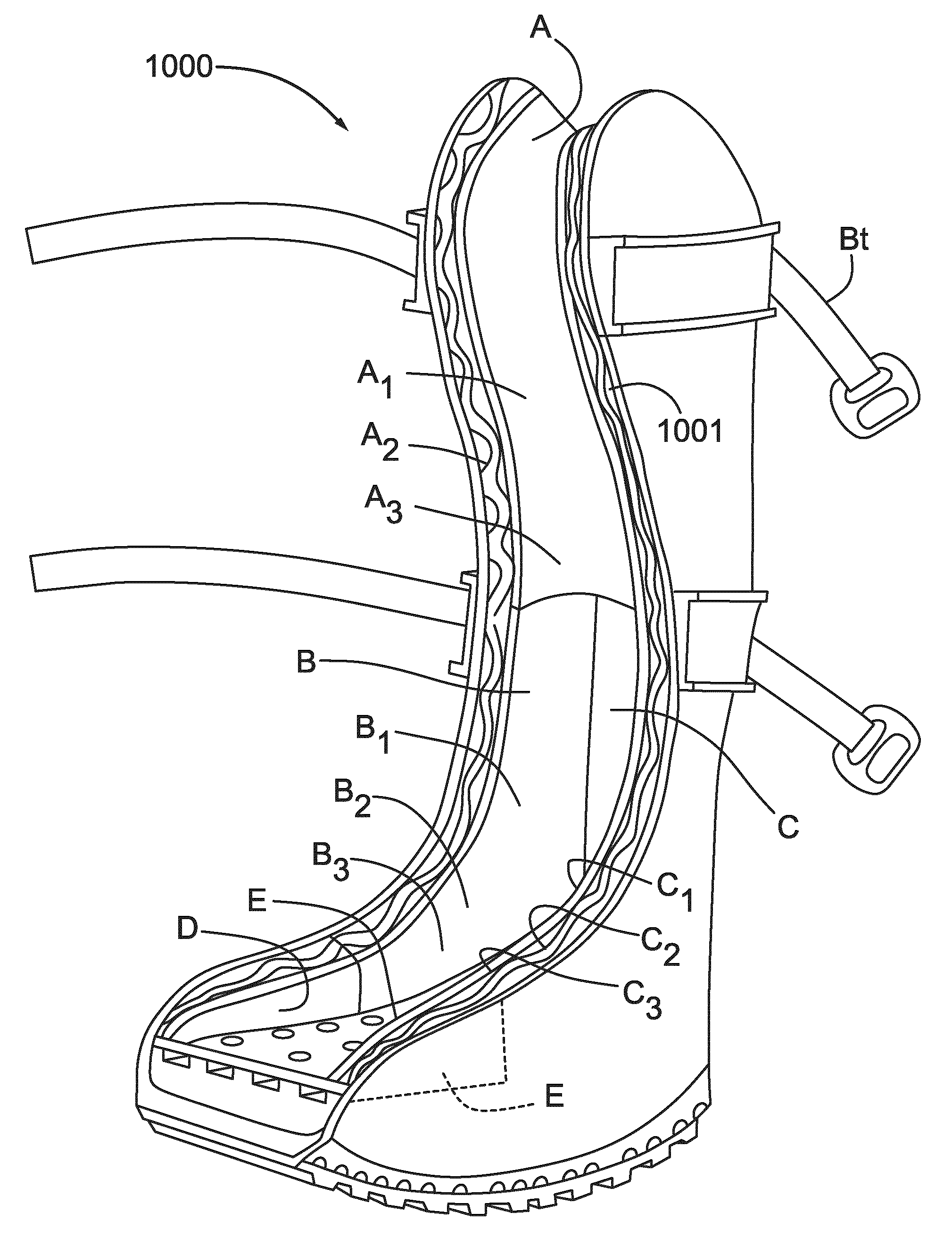

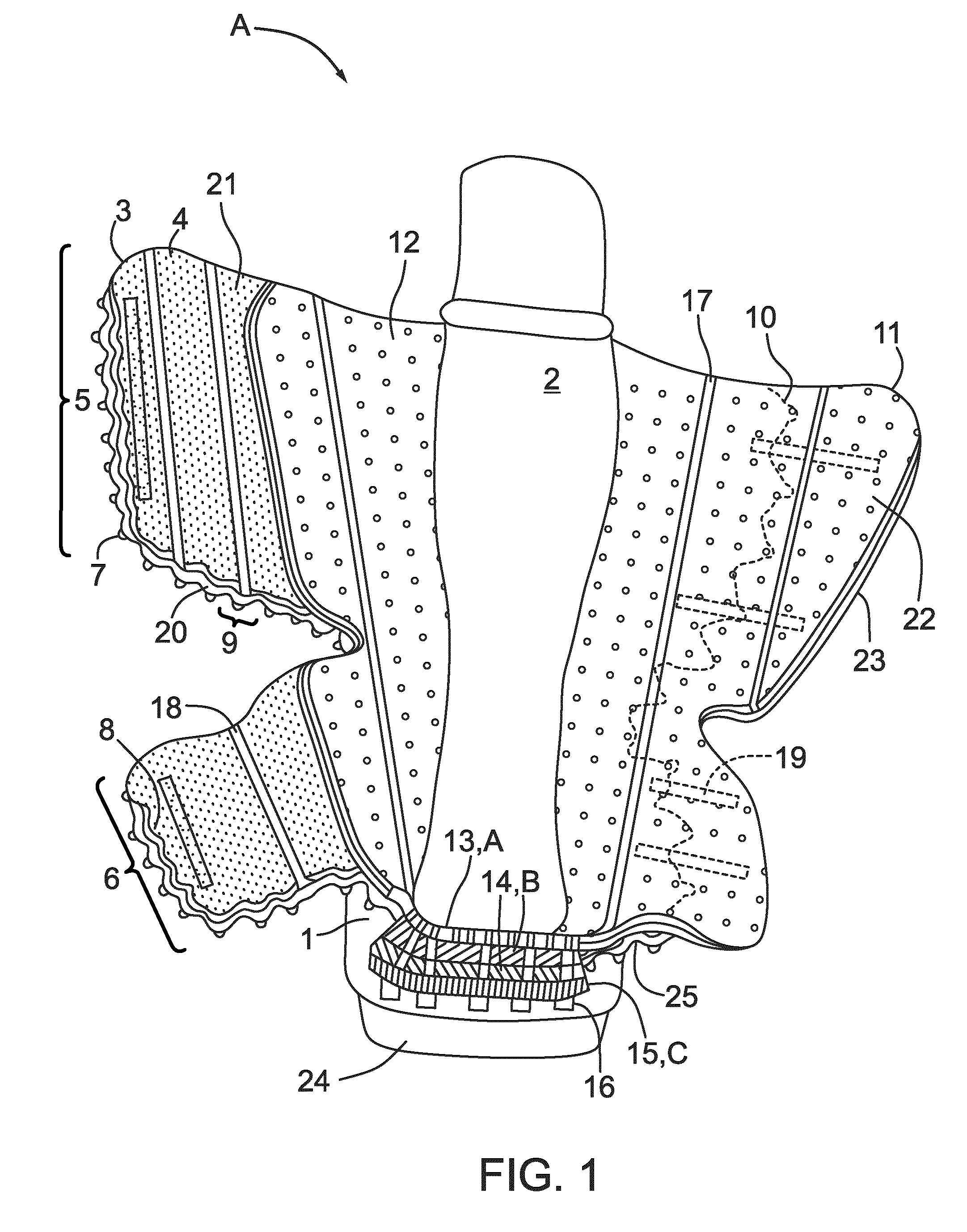

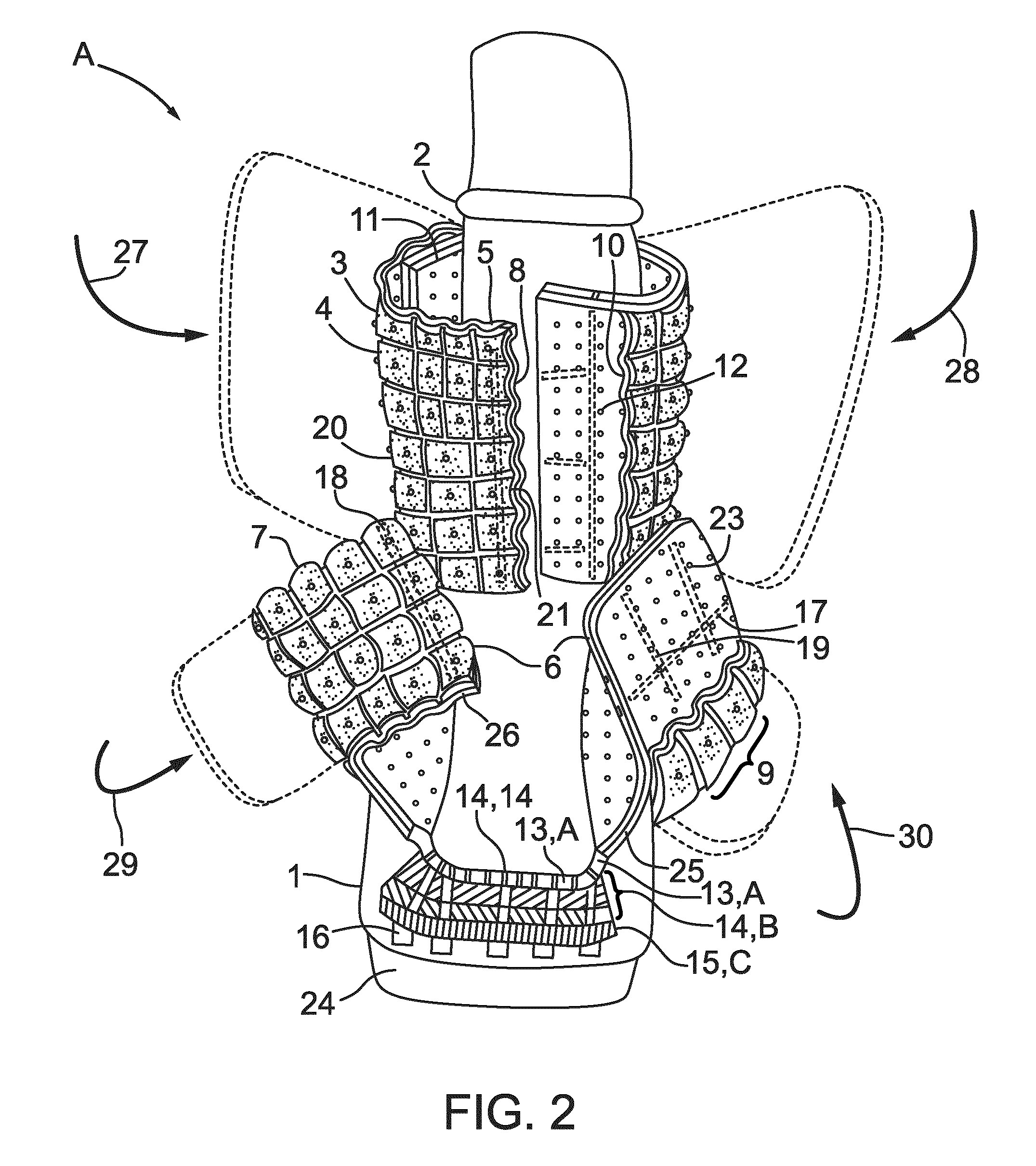

Constructing method for concrete cylinder of construction steel bar of high-rise steel structure

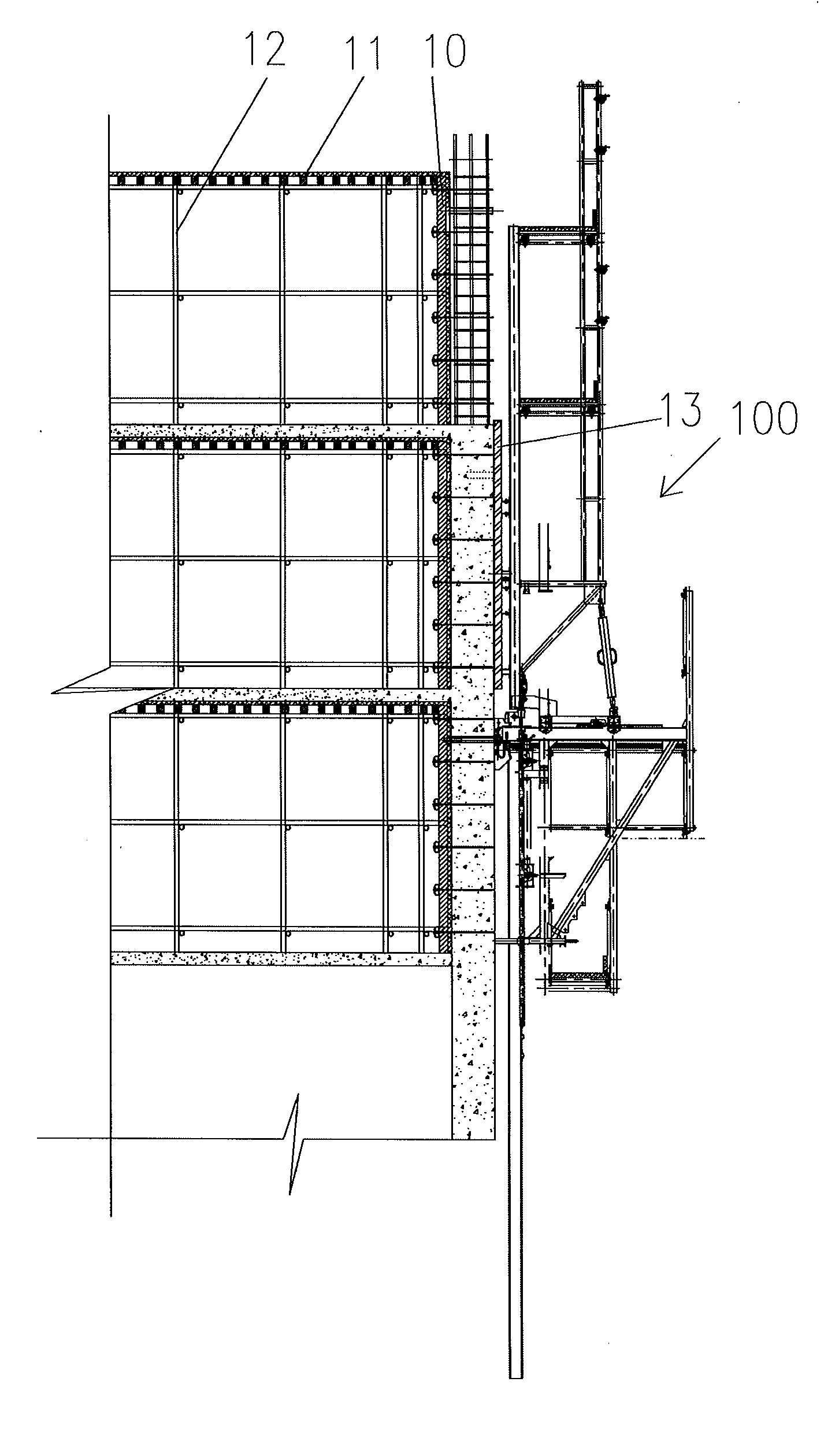

ActiveUS20140305070A1Construction safetyGood engineering qualityWallsBuilding repairsFalseworkReinforced concrete

A constructing method for a concrete cylinder of a construction steel bar of a high-rise steel structure adopts a constructing method of supporting inside and climbing outside. The outside of the cylinder adopts hydraulic mutual-climbing adhesive lifting scaffold creeping formwork system (100), and also has an outside wallboard mechanical formwork erection function and an outer frame protection function. For the inside of the cylinder, except that an appropriate structure is left for later processing according to a schedule requirement, beam walls all adopt a steel cylinder support to perform formwork erection, so as to greatly reduce the workload of repeatedly mounting / dismantling the scaffold and the formwork at a high place. The scaffold itself carries the formwork erection system, so formwork erection and formwork removal can be mechanized, thereby reducing the risk of formwork erection and formwork removal at a high place

Owner:ZHEJIANG CONSTR ENG GRP CO LTD

Wall hanging scaffold

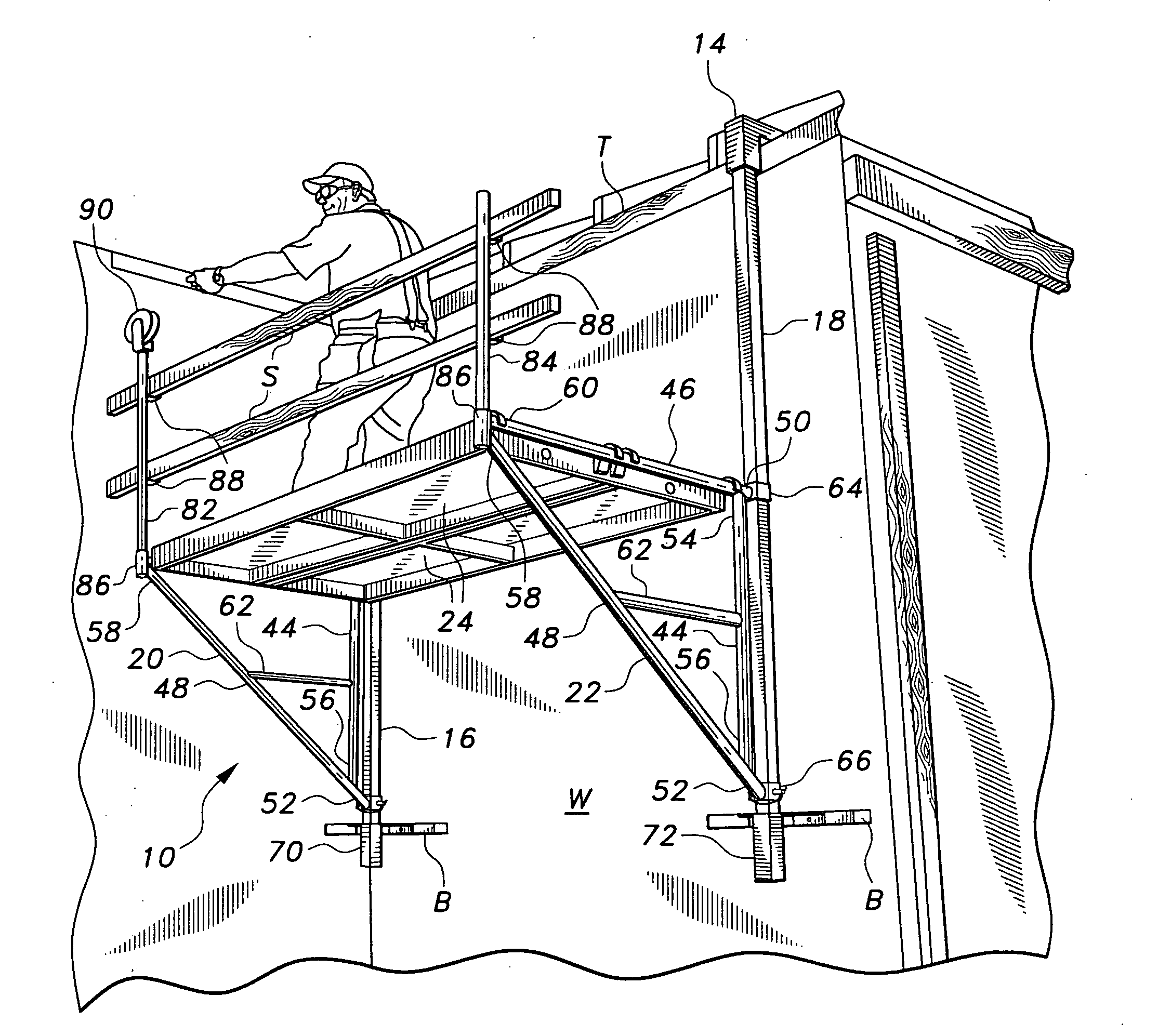

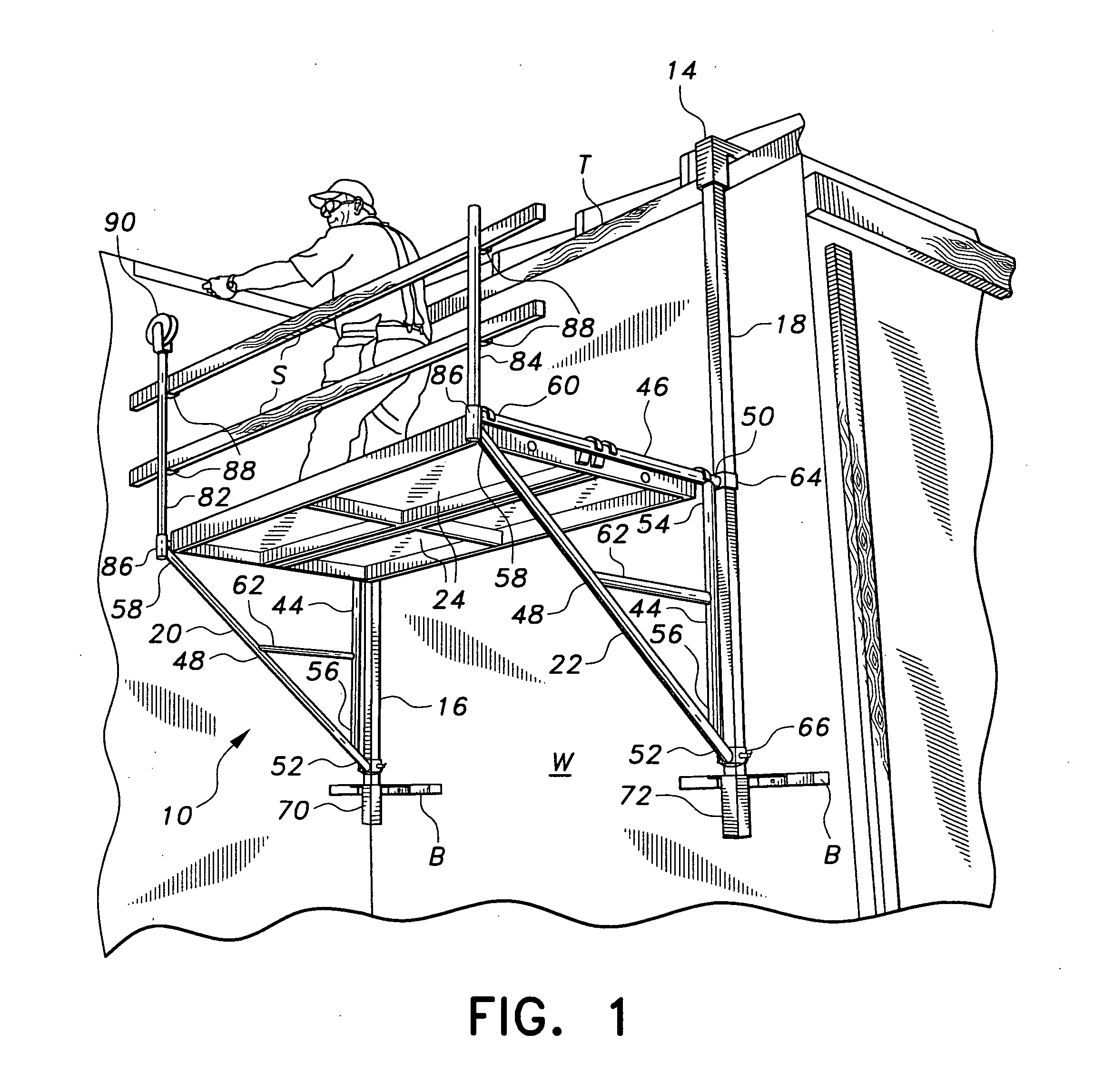

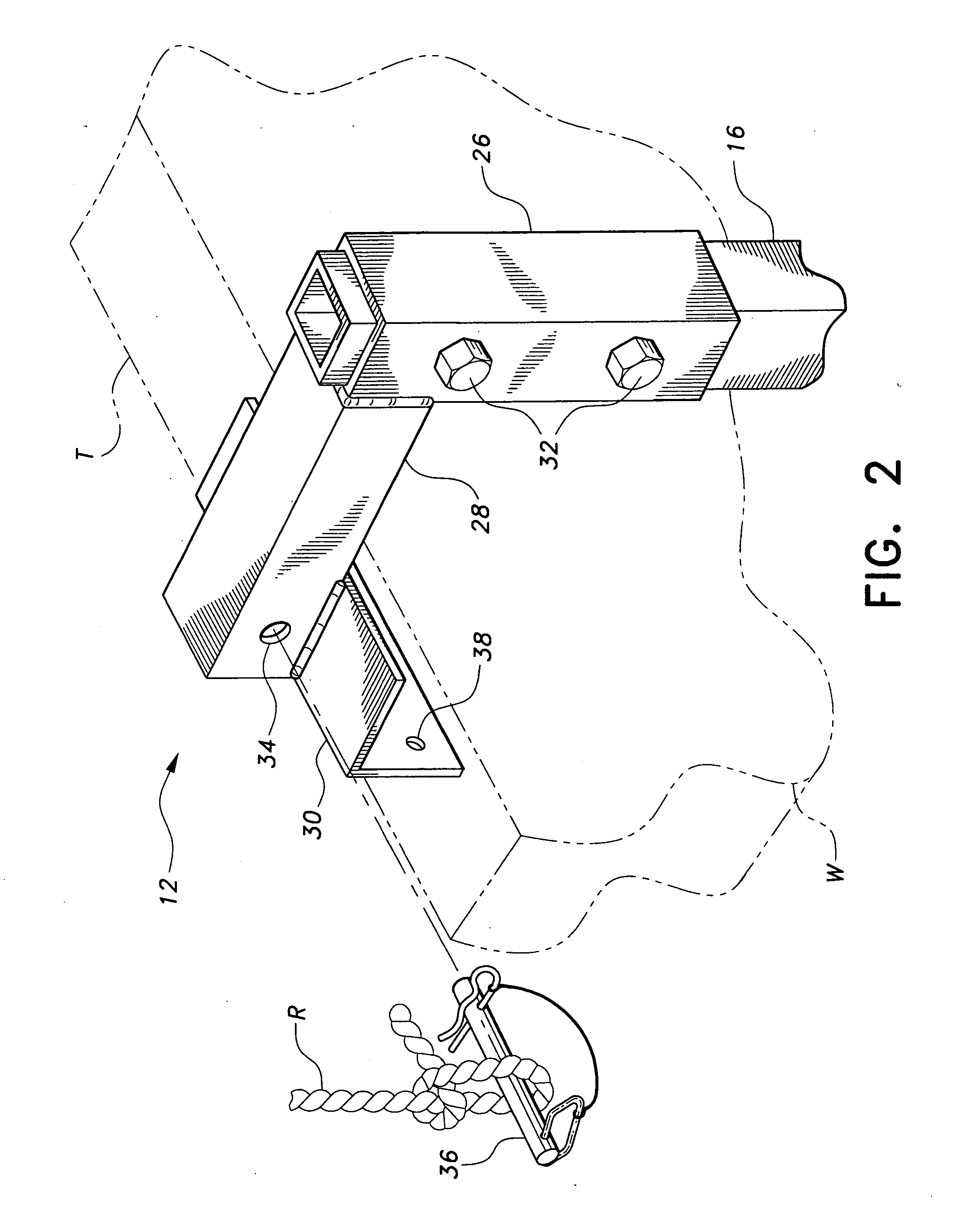

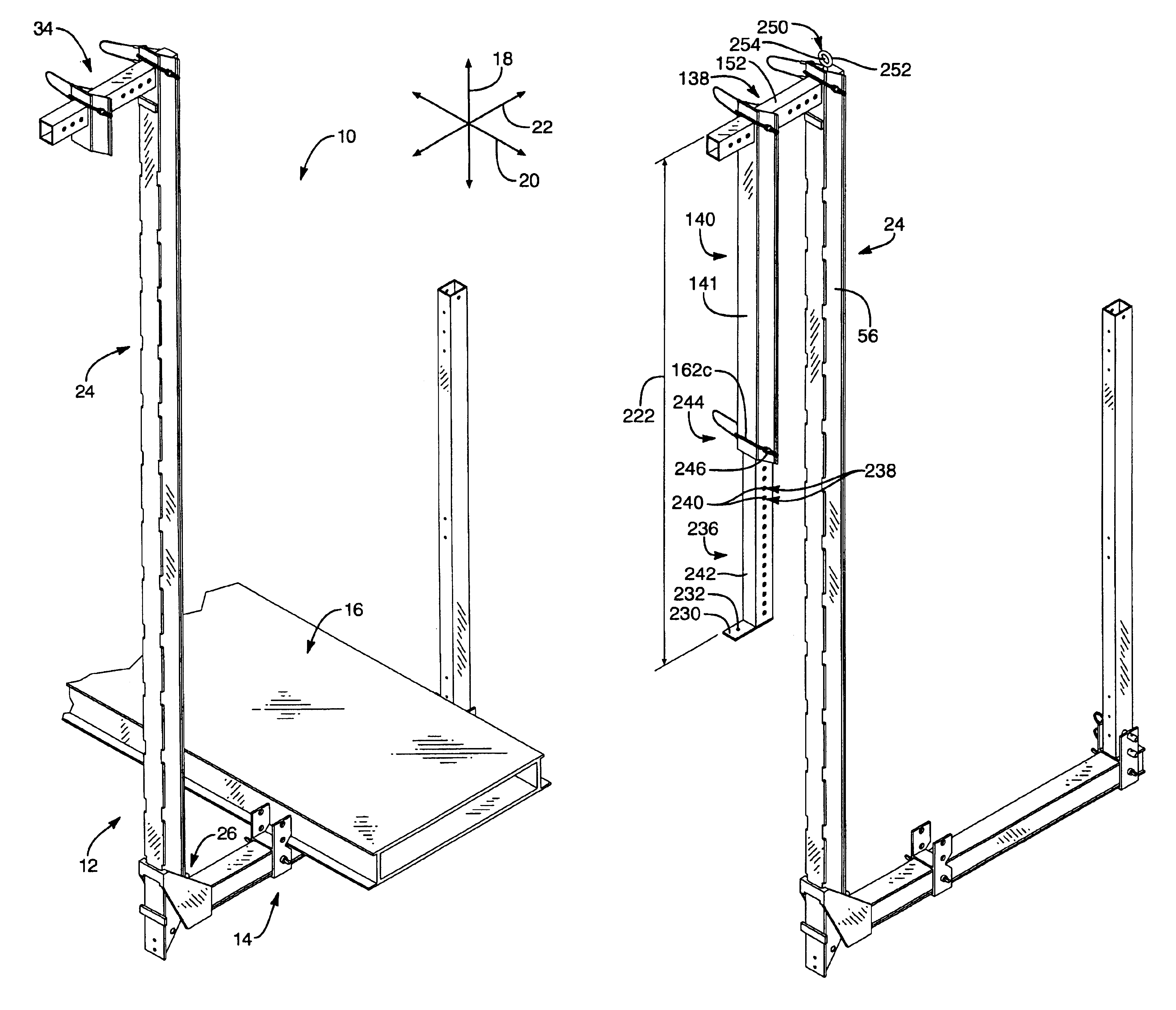

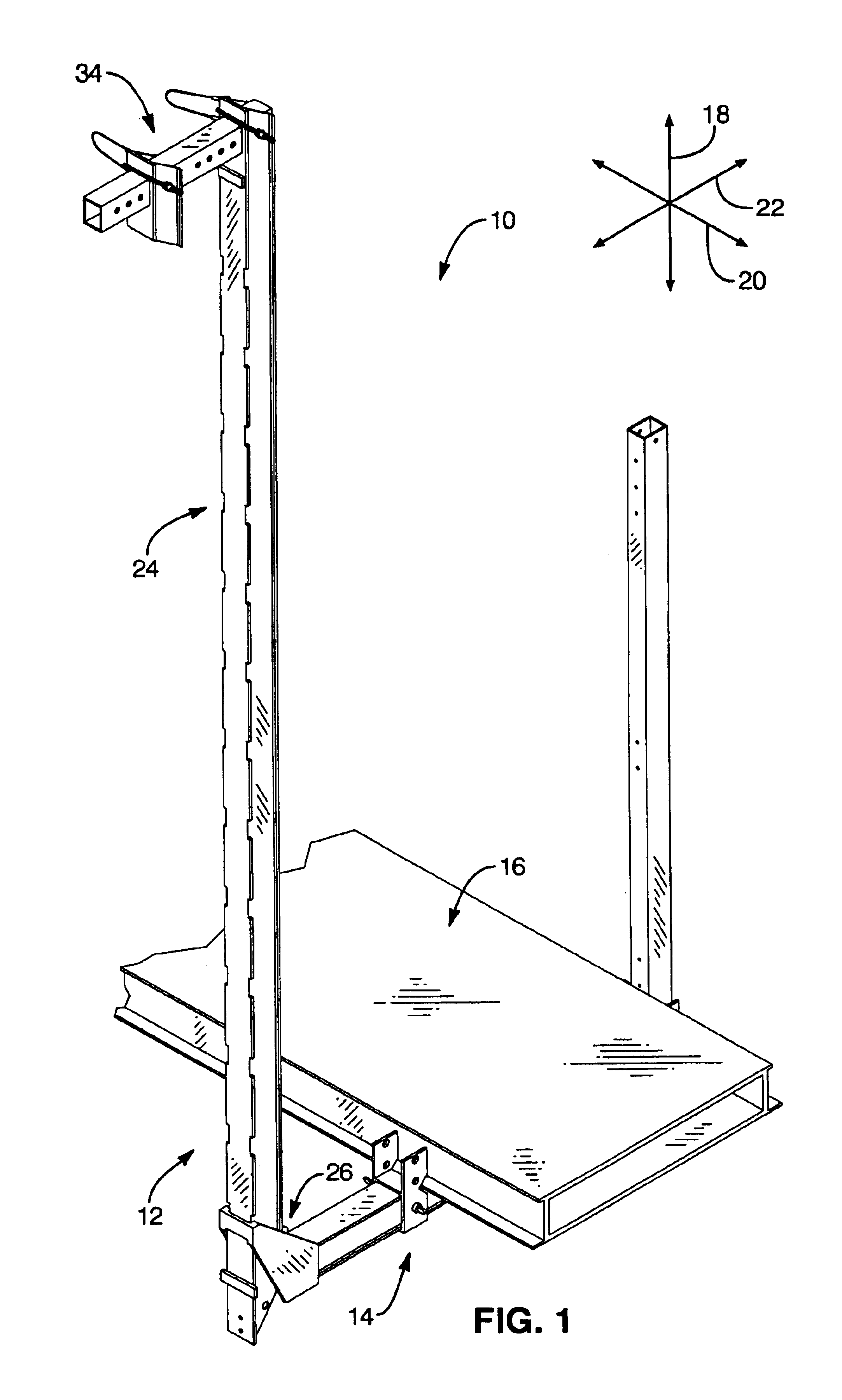

InactiveUS20060163001A1Easy to liftFacilitate raisingScaffold accessoriesBuilding support scaffoldsFalseworkEaves

The wall hanging scaffold includes a pair of vertical support poles, which hang from top plate attachment brackets along the wall of a building structure. Each pole has a rigid, monolithic, triangulated brace removably and vertically adjustably secured thereto, with a support platform extending across the braces. Additional safety structure, i.e., safety posts, may be installed in the outboard ends of the braces, with safety rails being installed across the safety posts. A pulley may also be placed in the upper end of a safety post for lifting material and equipment up to the scaffold from the underlying surface. A diagonal brace(s) may be secured to one or more of the upper top plate hanger brackets to relieve stress on the otherwise unbraced wall due to the scaffold resting thereon during construction. The scaffold may remain in place up to closure of the eaves and soffit of the structure.

Owner:POZELL CHARLES A

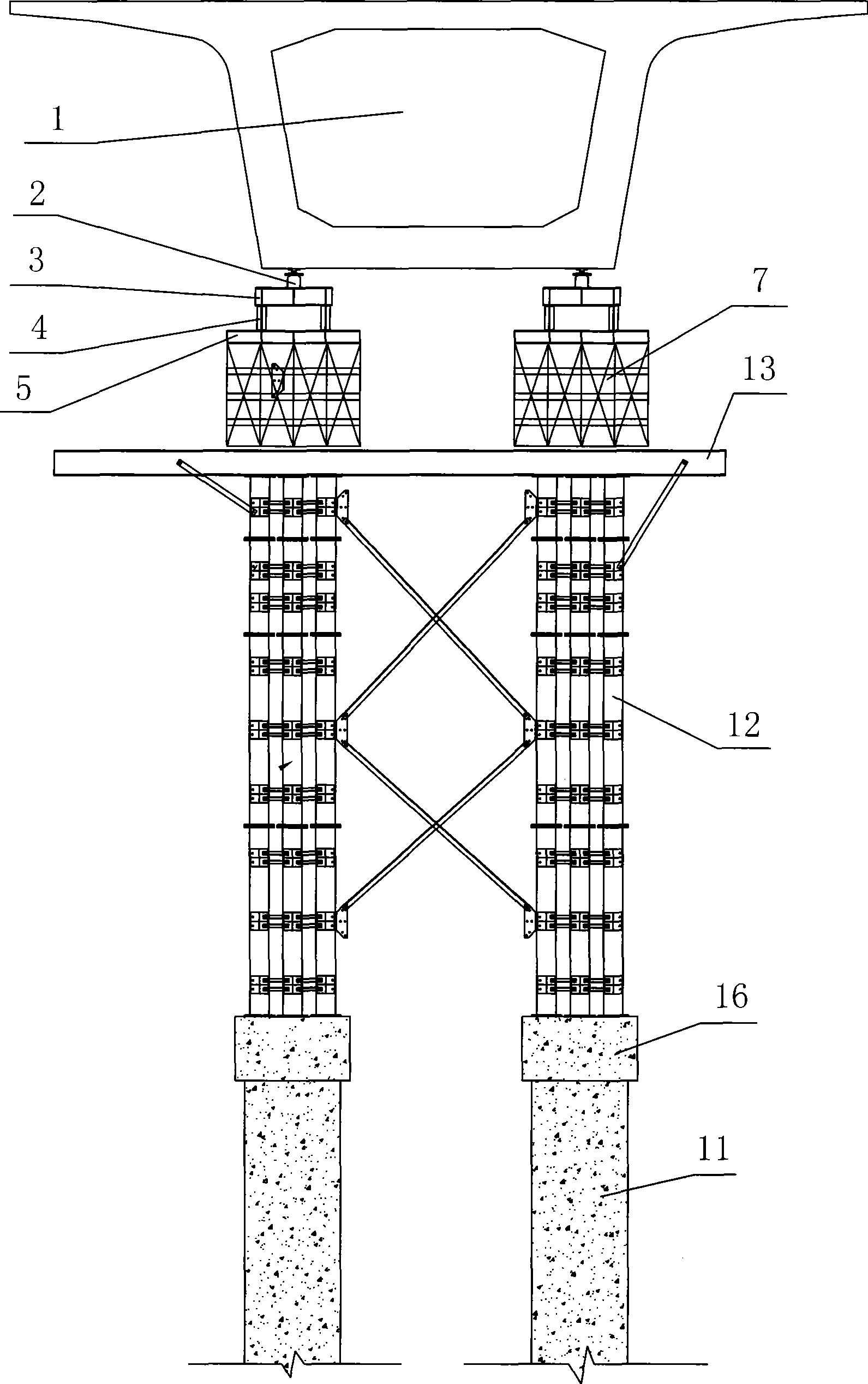

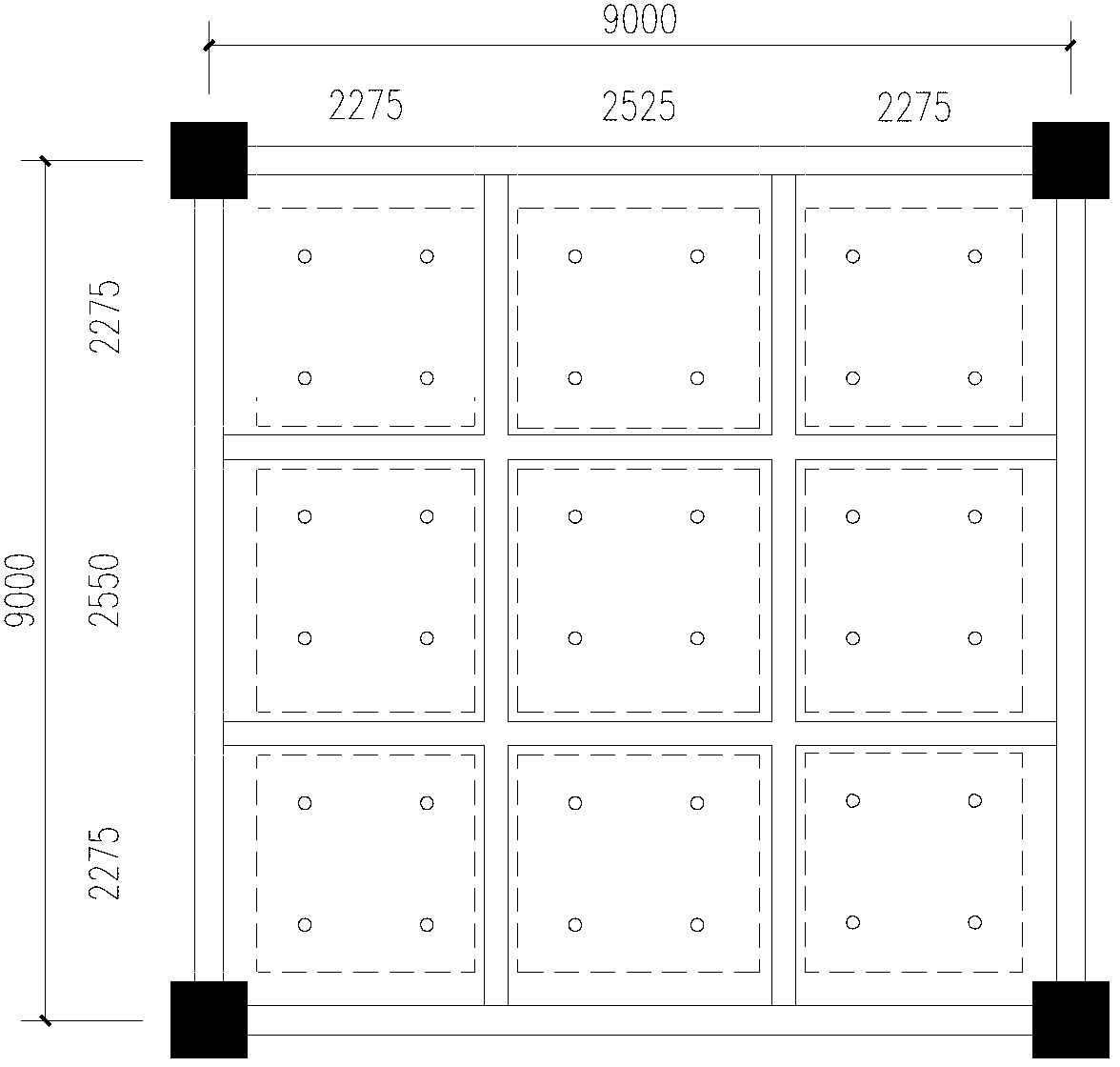

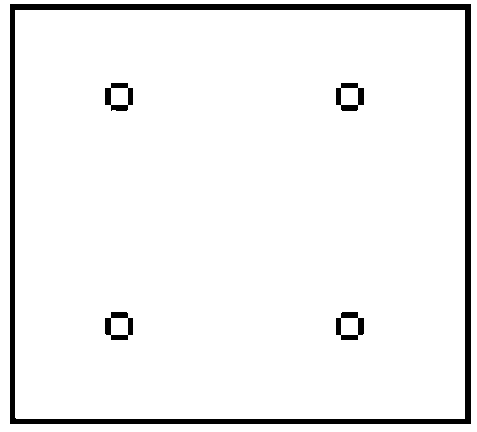

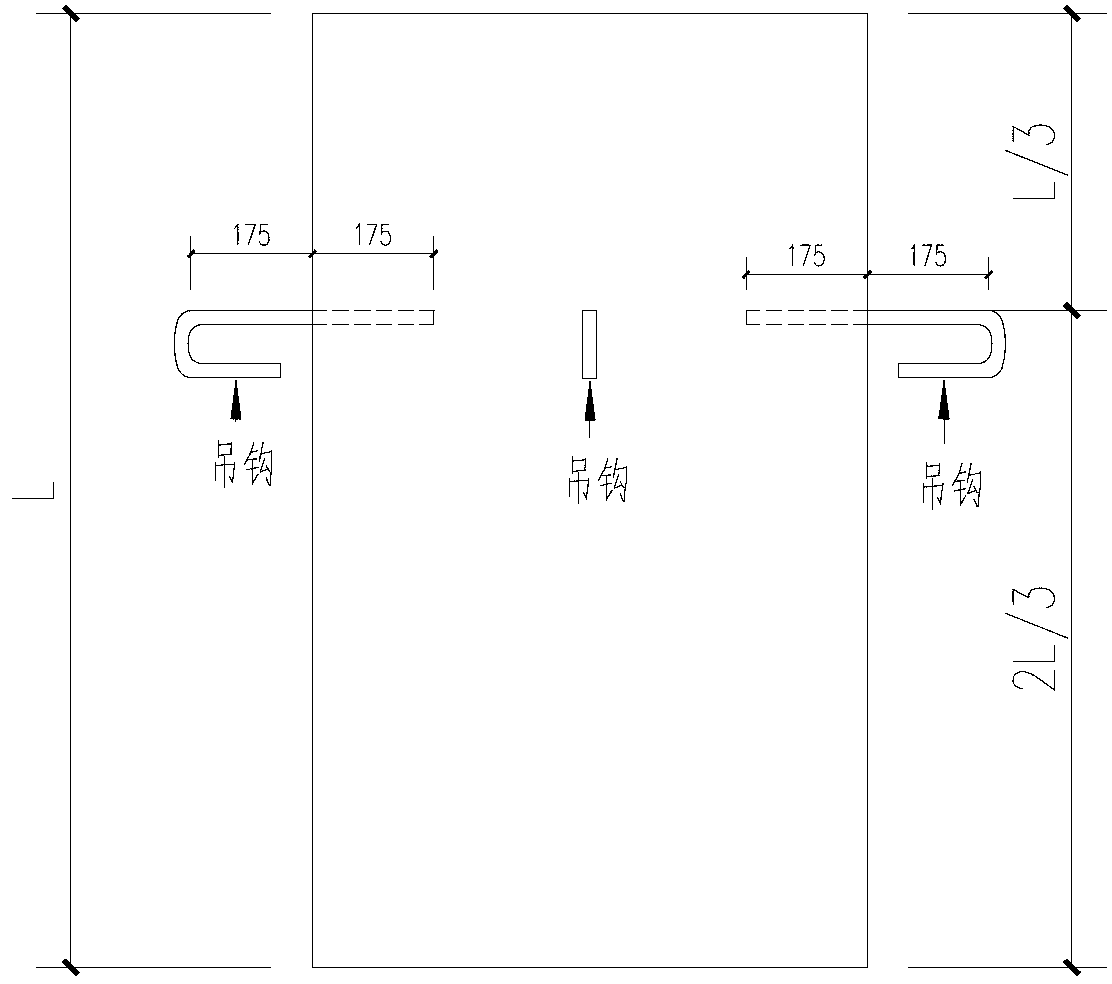

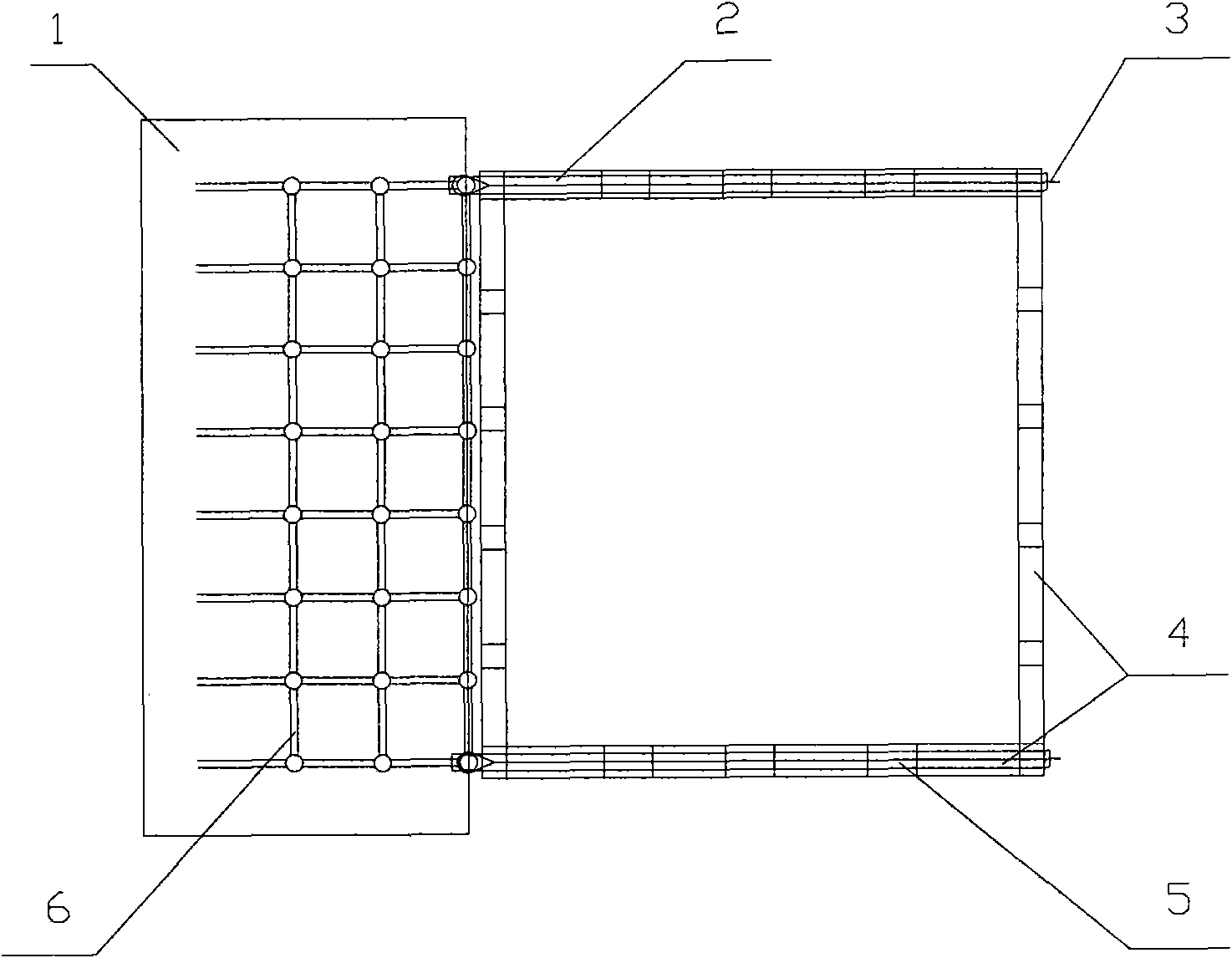

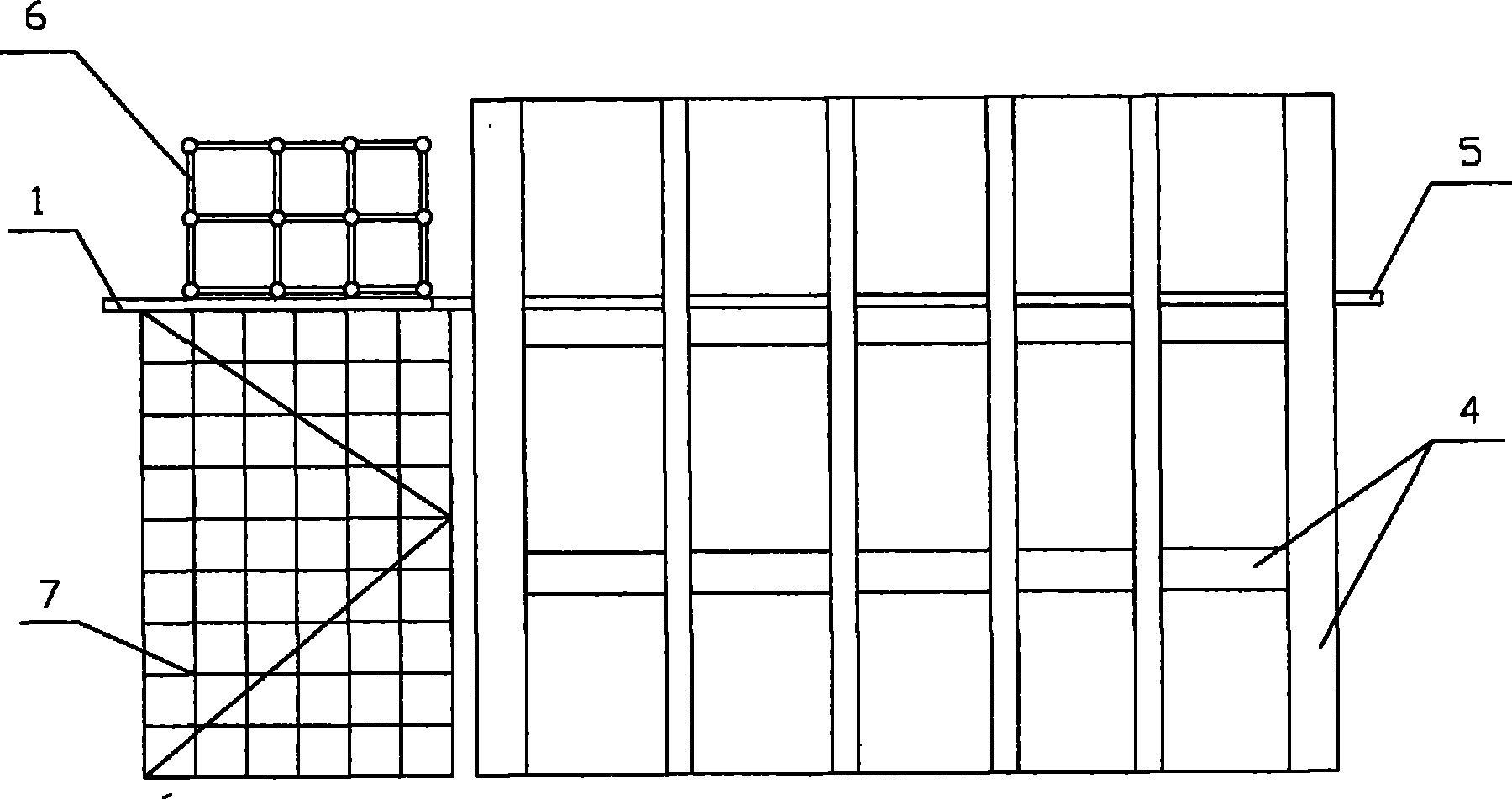

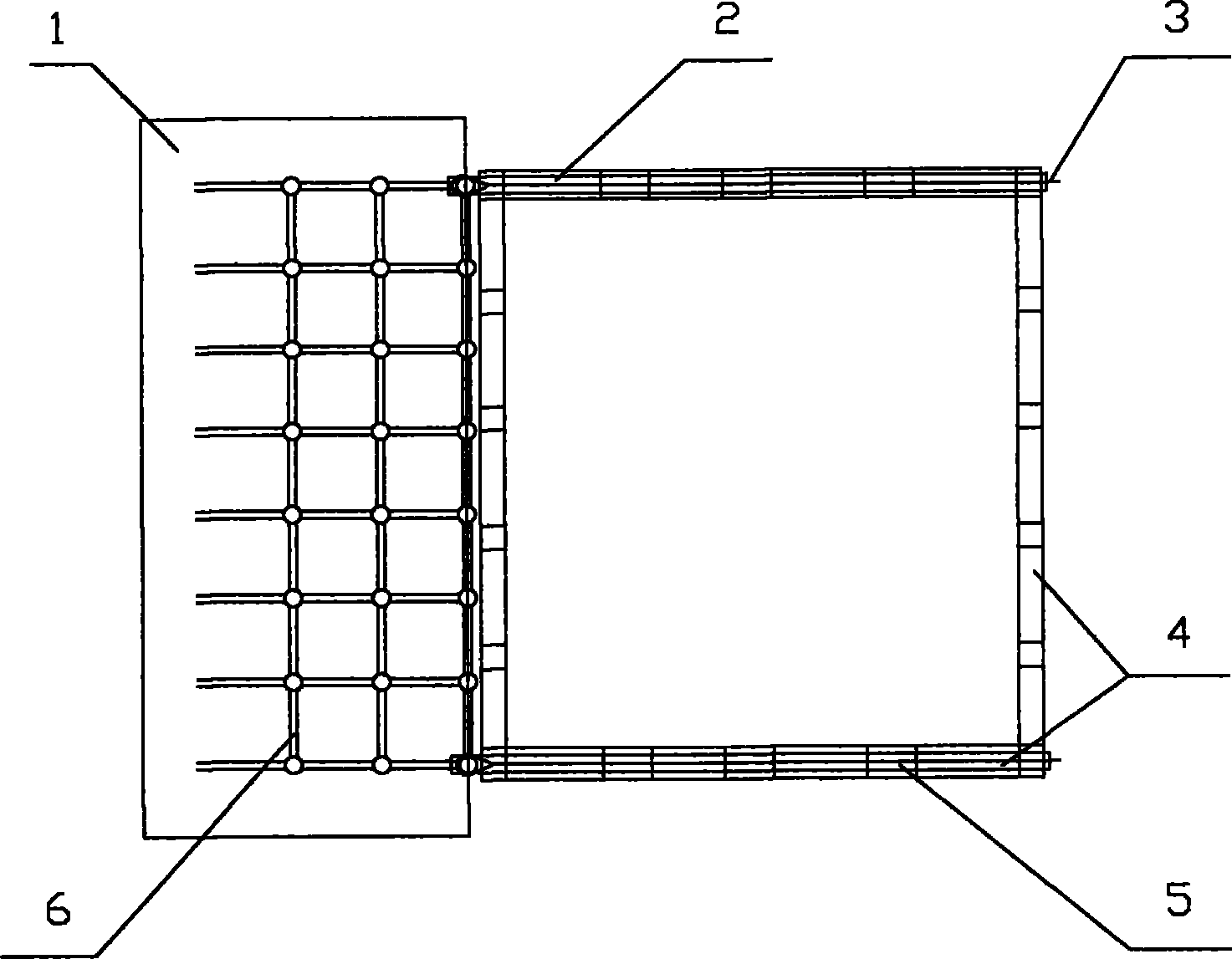

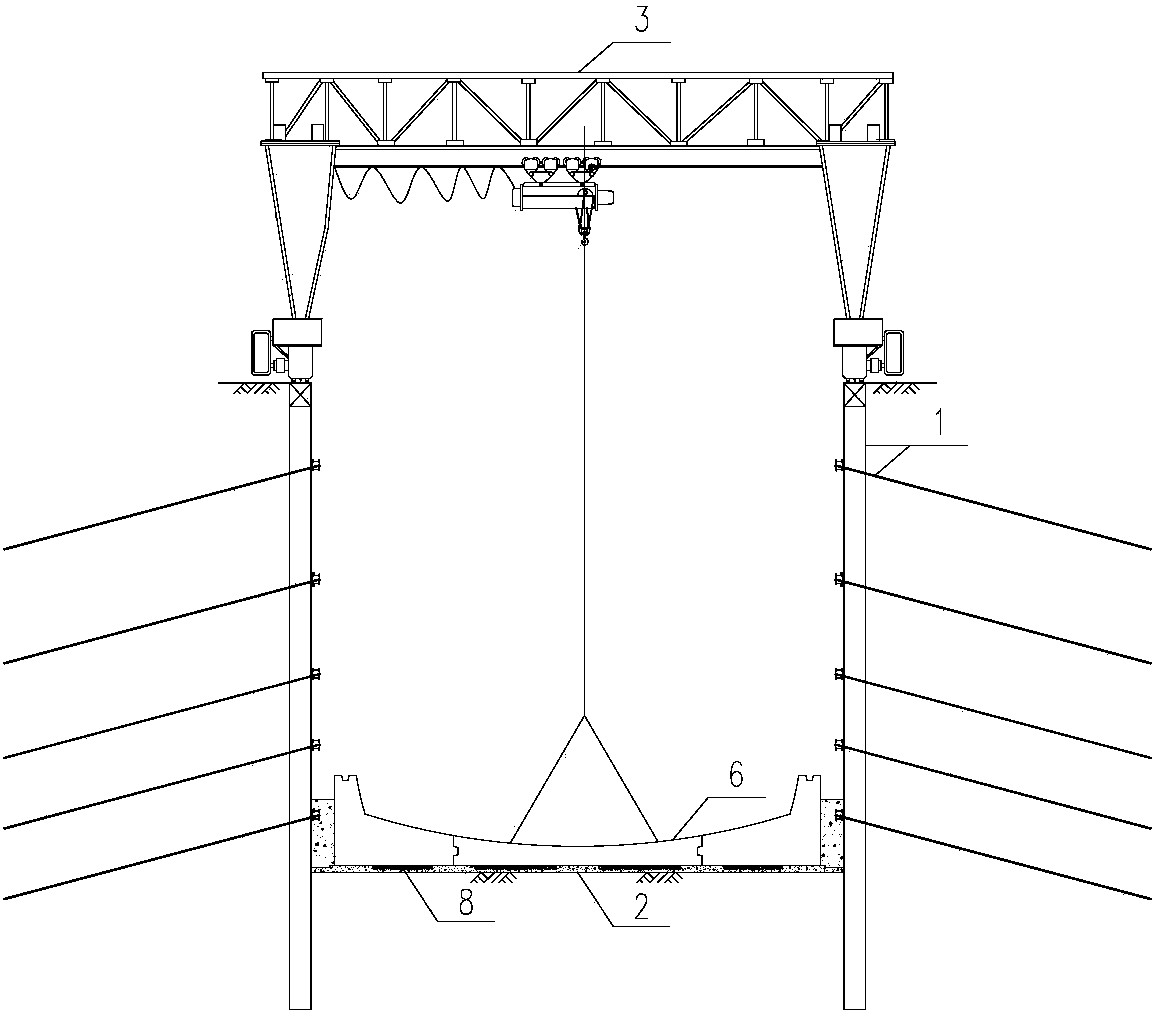

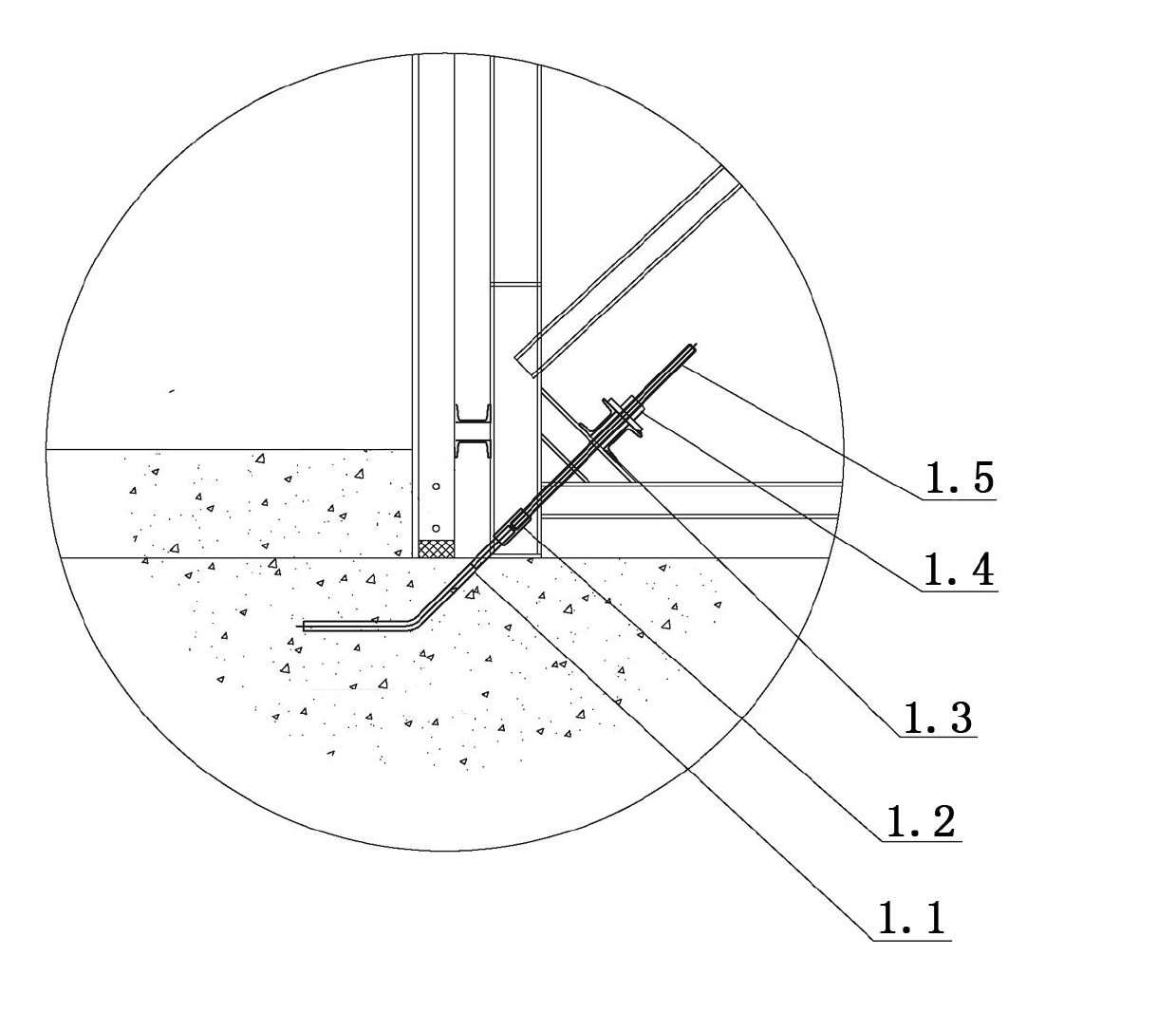

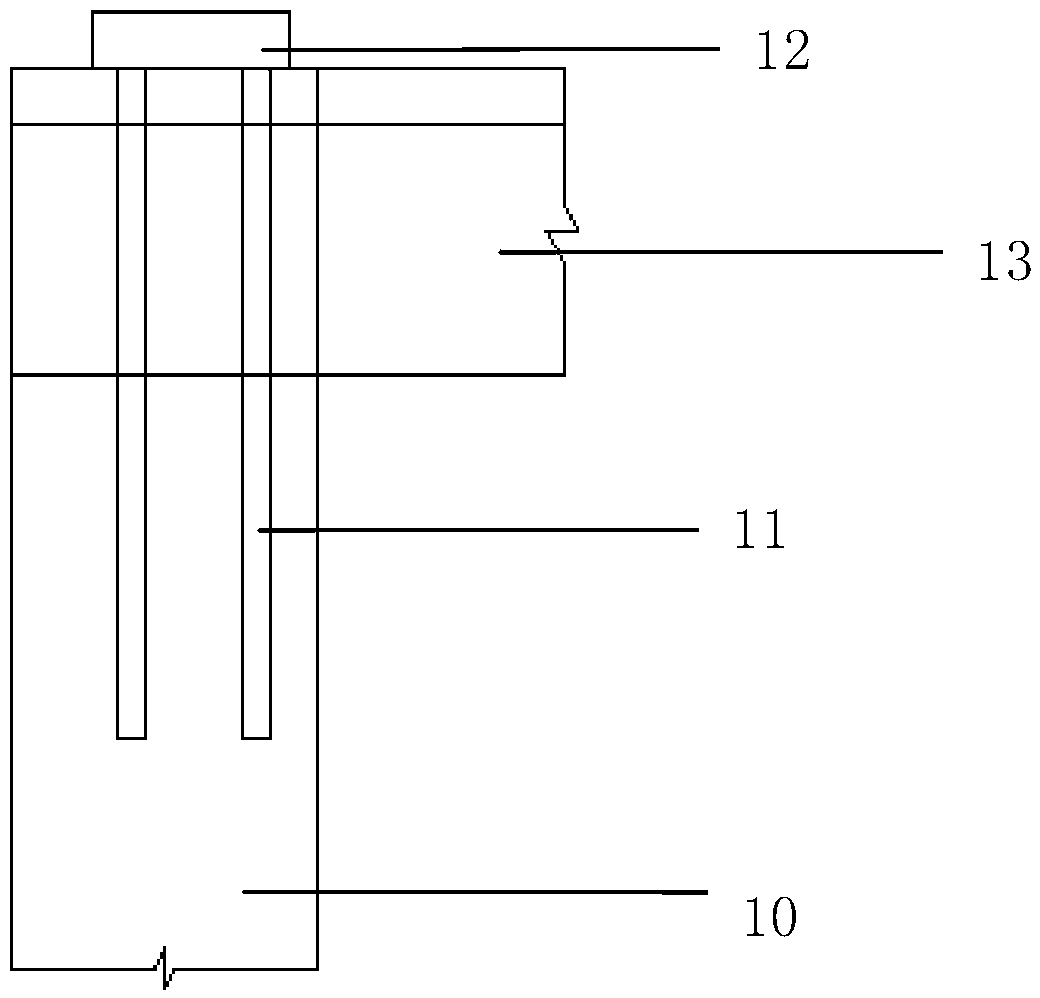

Segment-assembling simply supported box girder movable falsework construction method

The invention discloses a segment assembled simple box girder movable trestle construction method. The required construction simple box girder has single hole or multiple holes, and is assembled by a plurality of longitudinal (i.e. along bridge direction) segment box grinders; the method comprises the following steps: prefabricating all the segment box girders for assembling the simple box girder in concentration; assembling and erecting the first hole grinder, which comprises the steps of: assembling and erecting the trestle (i.e. assembling platform), hanging the segments on to the assembling platform according to the assembling sequence and adjusting the arch degree, line style and position accurately, constructing the segments on the assembling platform by segment assembling construction technology until complete the whole hole grinder construction, and dismounting the trestle and moving to the next hole grinder; and performing the subsequent hole grinders in order according to the construction steps of the first hole grinder. the invention achieves the advantages of simple steps, low construction difficulty, short construction cycle and low onetime fund investment; can solves the practical problems existing in the segment assembling construction process of current large-span bridge fabrication machine.

Owner:CHINA RAILWAY FIRST GRP CO LTD

Concrete static force cutting dismantling construction method

InactiveCN103291085ANo vibration loadStructure has no effectBuilding repairsFalseworkReinforced concrete

The invention discloses a concrete static force cutting dismantling construction method which mainly comprises the steps of construction equipment selection, cutting unit division, supporting scaffold erection, hoisting auxiliary facility installation, cutting construction, component hoisting and site cleaning. The concrete static force cutting dismantling construction method has the obvious advantages that the effect on the surrounding structures is small in the process of constructing, the constructing speed, the constructing precision and the safety are high, and components which are cut through the static force are convenient to clean. The concrete static force cutting dismantling construction method is suitable for dismantling various reinforced concrete members, and especially for dismantling the part structures with the high demand for dismantling and with the small effect on an original structure. Time and production cost are greatly saved, and the construction period is effectively shortened.

Owner:恒中达建筑有限公司 +1

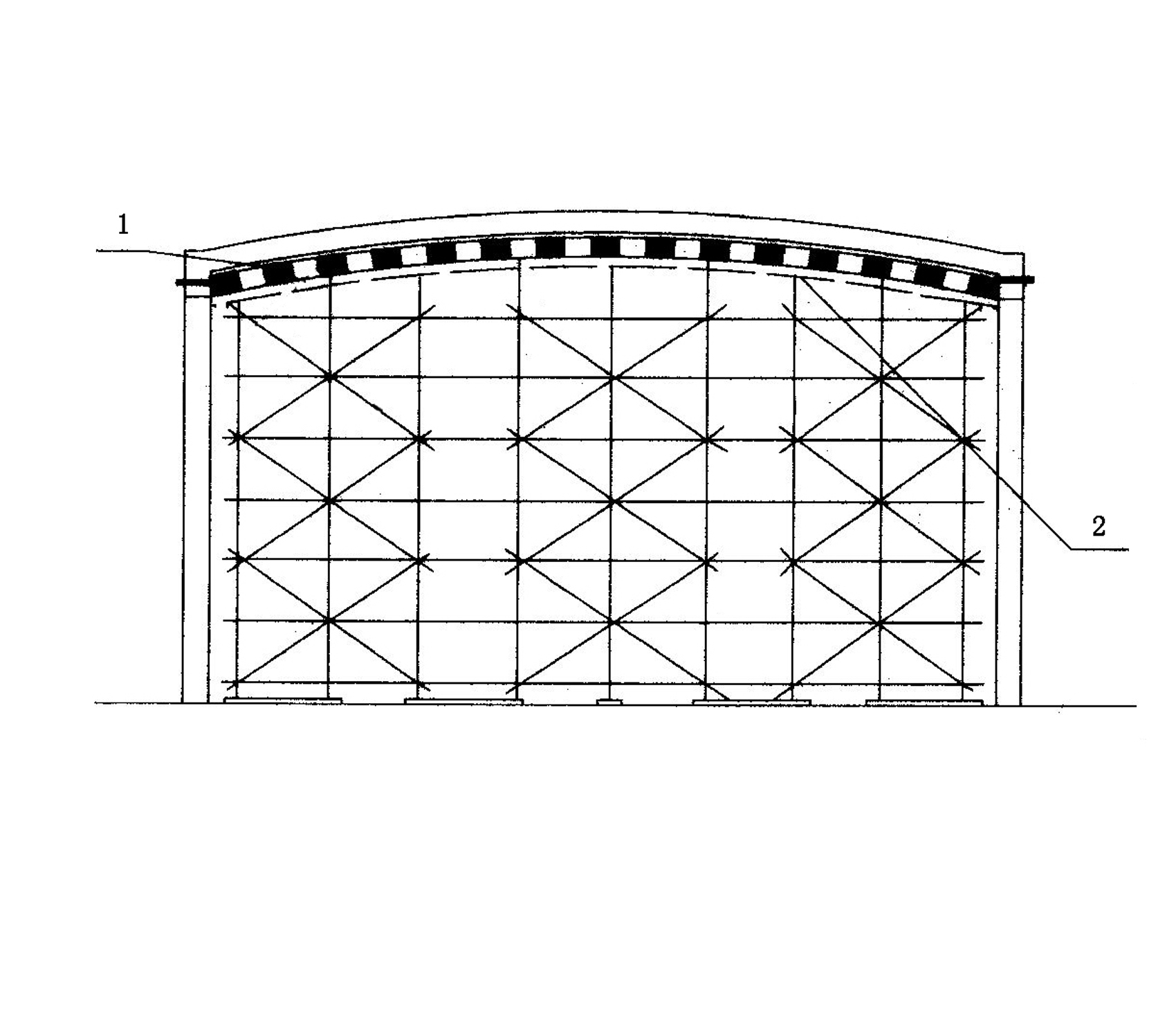

Space truss structure aerial pairing integral slide installation method

InactiveCN101775907AStructural solutionQuick pairBuilding material handlingFalseworkBuilding construction

The invention relates to a space truss structure aerial pairing integral slide installation method, which belongs to the installation technical field of an aerial steel structure. The invention relates to an aerial space truss steel structure installation method. Scaffolds are arranged outside a house to pair a platform, after each pairing, the pair of platforms slide into the house, the splicing continues until all platforms slide in place, and slide rails are disassembled after supports are installed. The method has the advantages that the difficulty that the span of the space truss is large and no large-sized hoisting device exists on the spot can be solved; during the construction period of the roof space truss, the lower part of the civil work can be alternatively carried out; the expense for establishing the spliced platform is saved by 60 percent or more compared to an all-round scaffold aerial scattered installation method; and moreover, the peripheral land occupation of the building is less, and only one construction field is required.

Owner:BEIJING SHOUGANG CONSTR GROUP

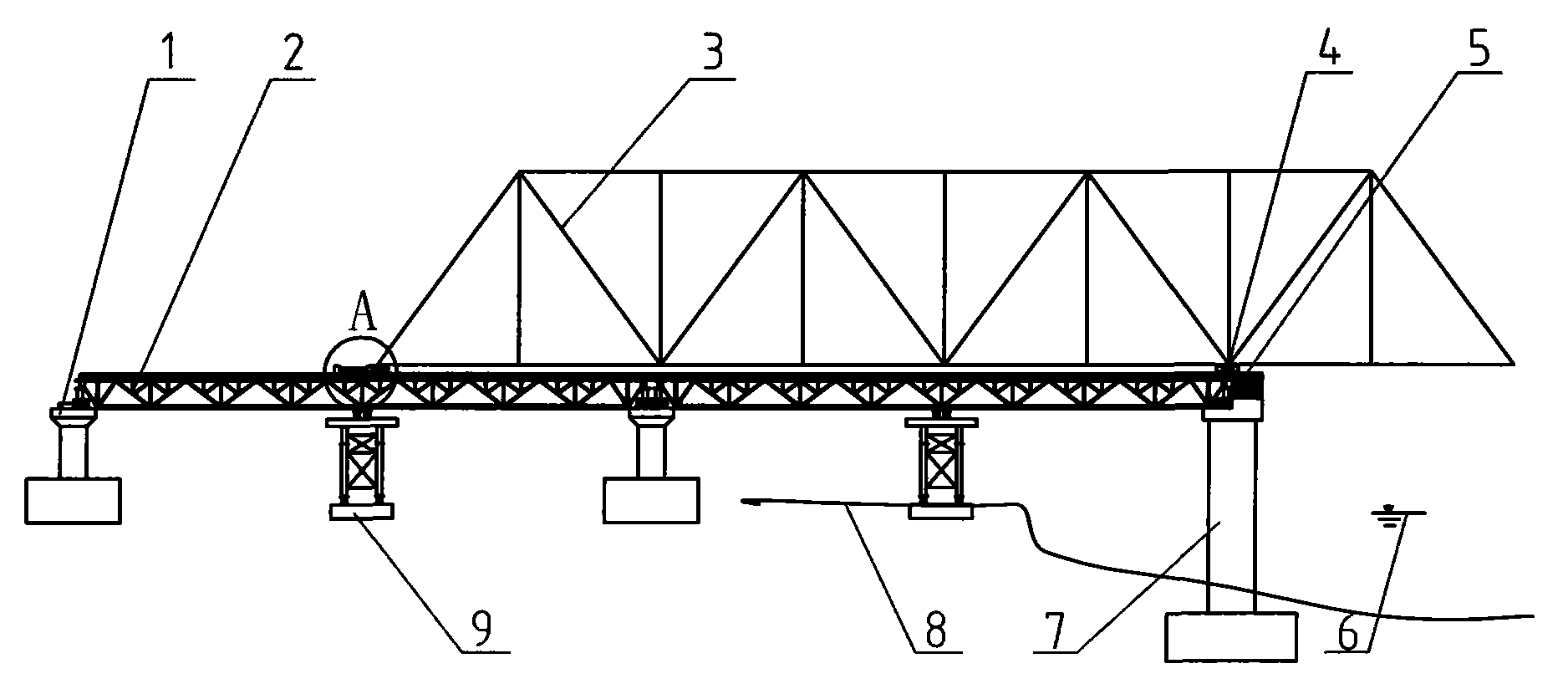

Construction method for erecting steel truss girder on uplift pushing tow

The invention discloses a construction method for erecting a steel truss girder. In the technical proposal of the invention, a buoyancy tank group serves as a carrier for levitation support; buoyancy tanks in the central part thereof are used to fill or drain water to ballast water to adjust elevation in a convenient manner; in addition, the proposal of using pushing tow construction is adopted, so that the steel truss girder can be assembled on a falsework on the spot in a convenient manner, hoisting of members is convenient and construction safety is high; the invention provides a construction method for erecting steel truss girder on uplift pushing tow, which features short construction cycle, convenient operation, short navigation closure period and low cost of erecting the steel truss girder and solves the problems that in the construction of the pushing tow, deflection of the steel truss girder is overlarge and internal stress of the steel truss girder is also overlarge.

Owner:RAILWAY NO 10 ENG GRP CO LTD

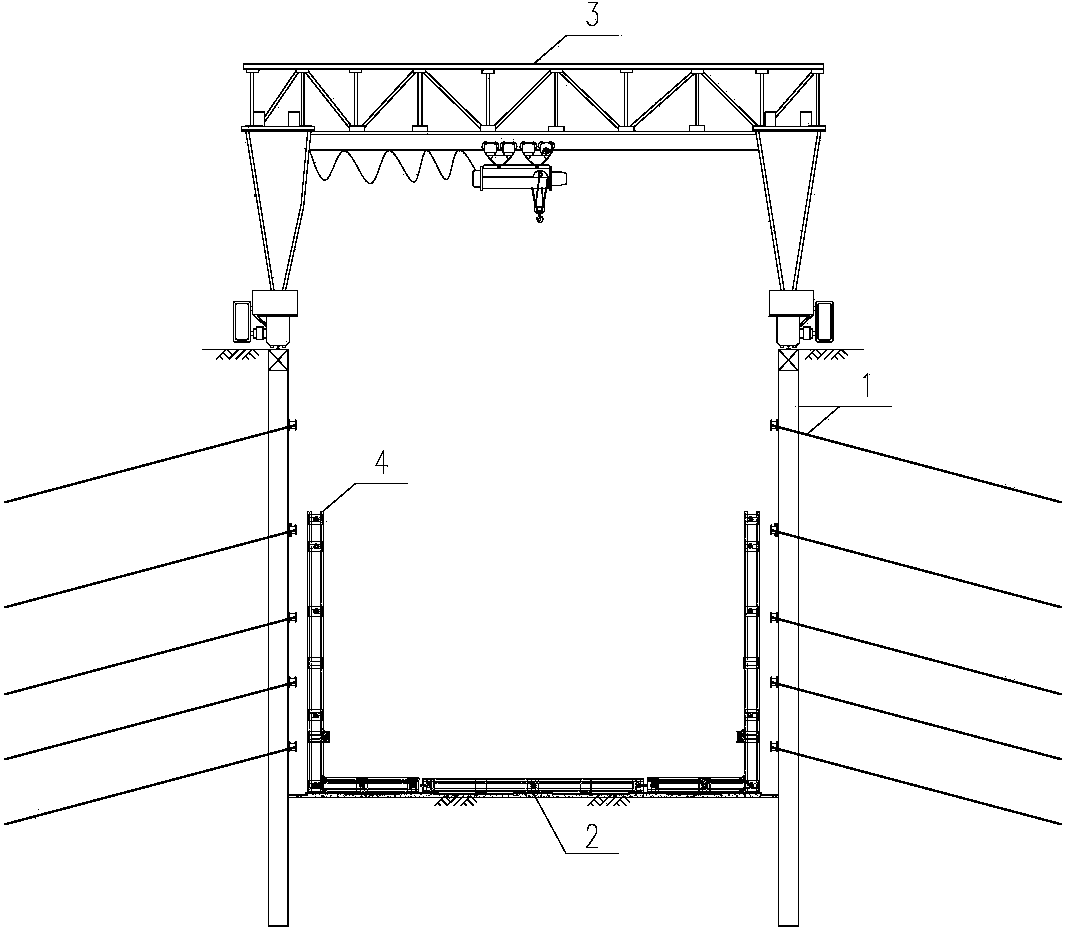

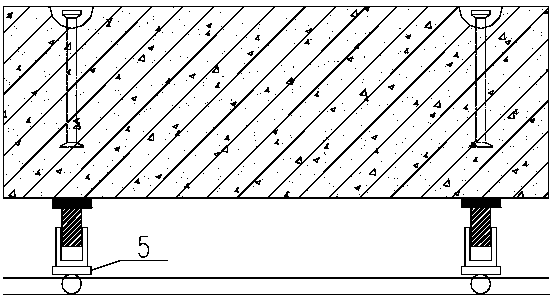

Construction method of open excavation prefabricated underground structure

ActiveCN103912010AReduce in quantityImprove construction qualityArtificial islandsUnderwater structuresFalseworkResource consumption

A construction method of an open excavation prefabricated underground structure includes the steps: 1, leveling a ground to serve as a foundation pit supporting structure and a base cushion layer; 2, mounting a fixing support at an assembly initial end; 3, hoisting prefabricated components to assemble a structural base plate; 4, assembling a special assembly trolley on the structural base plate; 5, assembling side walls and top plates of the prefabricated components; 6, backfilling upper portions of the top plates and outer portions of structural side walls to complete assembly of the underground structure. The construction method has the advantages that construction mechanical level is improved; operating personnel amount is greatly decreased, operating efficiency is improved, engineering construction quality is improved, resource consumption is reduced, environmental influences are lowered, and construction period can be greatly shortened; amount of mould plates in cast-in-situ concrete structures, peripheral shields, scaffolds and wastes is greatly decreased to relieve field operation intensity and reduce construction input; construction in chilly winter is realized, engineering construction quality is improved, and potential safety hazards such as fire hazards and the like in construction of traditional cast-in-situ concrete structures in winter can be avoided.

Owner:BEIJING URBAN CONSTR DESIGN & DEV GRP CO +2

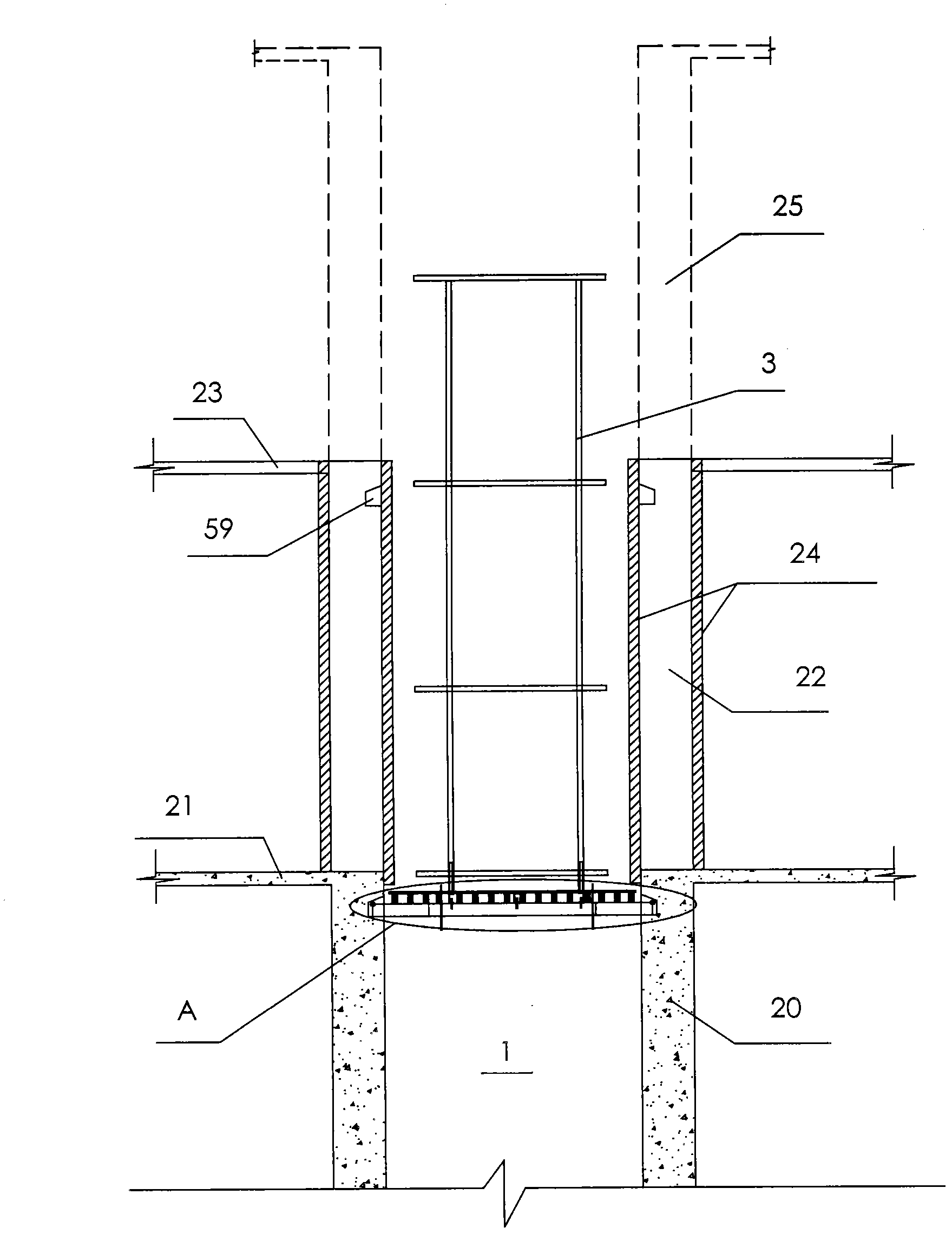

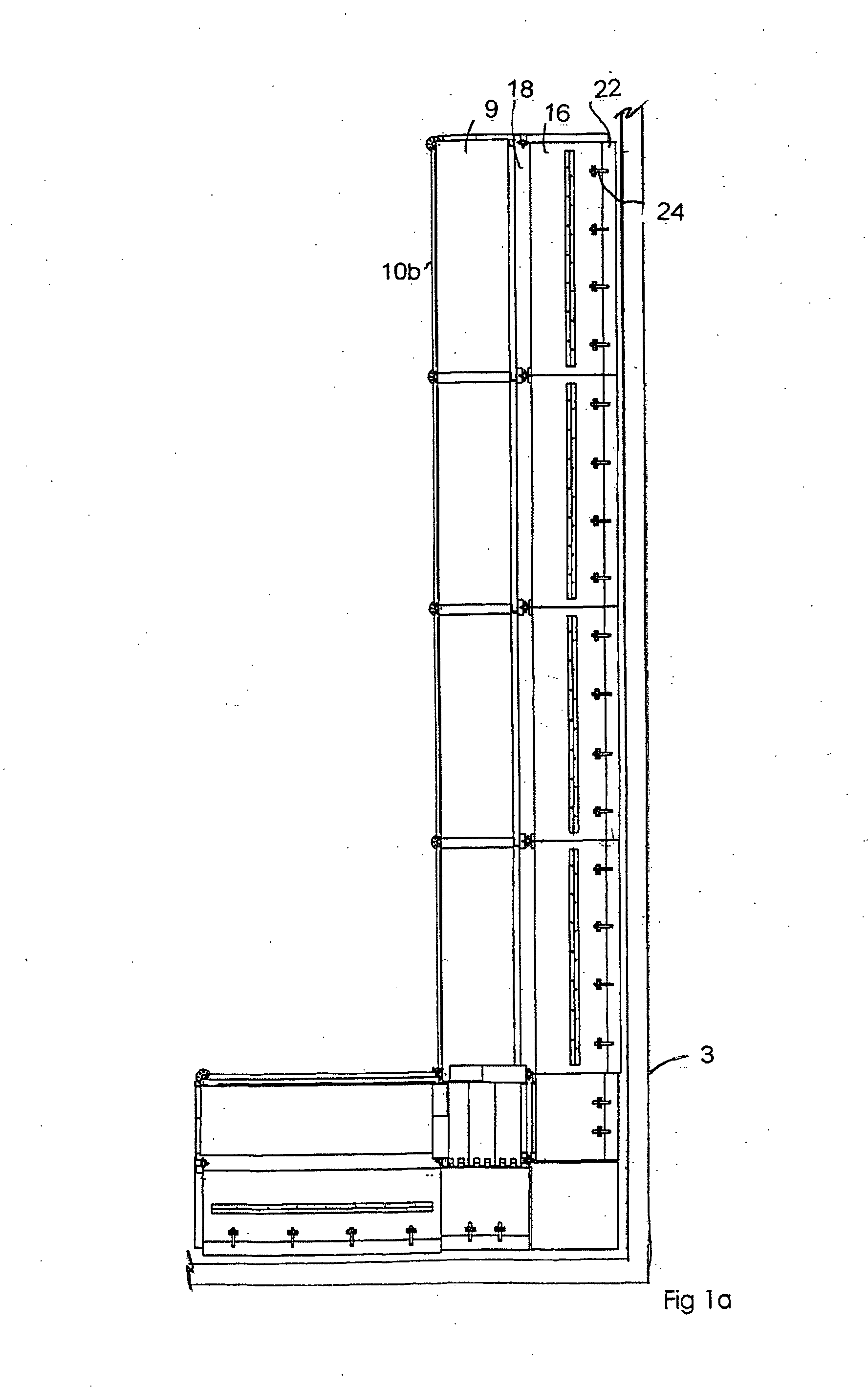

Elevator shaft construction scaffolding device capable of being elevated along with construction layer of building main body structure and method for setting same

InactiveCN102322135AEasy to installEasy to foldBuilding material handlingScaffold accessoriesFalseworkSurface layer

The invention relates to an elevator shaft construction scaffolding device capable of being elevated along with construction layer of building main body structure and a method for setting the same. The device comprises a scaffold made by setting up steel tubes, hoisting rings, a platform steel frame, support climbing feet, a plurality of wood joists and a template surface layer, wherein the platform steel frame consists of two steel joist main beams and a plurality of secondary beams; the support climbing feet are hinged with the end edges at two ends of the steel joist main beams; the hoisting rings are fixedly connected on the main beams; the plurality of wood joists are arranged above the main beams at a certain interval in the same direction as that of the secondary beams; the template surface layer is fixed above the wood joists through iron nails; the hoisting rings and the connecting short heads of the platform steel frame penetrate through the template surface layer; and the scaffold made by setting up the steel tubes is fixedly connected with the connecting short heads of the platform steel frame penetrate. The device and the method provided by the invention have the following advantages that: the mounting, the positioning, the hoisting and the repositioning of the whole elevator shaft construction scaffolding device are very simple and fast; and the whole system including wall templates can be once finished hoisting within about five minutes.

Owner:CHINA RAILWAY CONSTR ENG GROUP

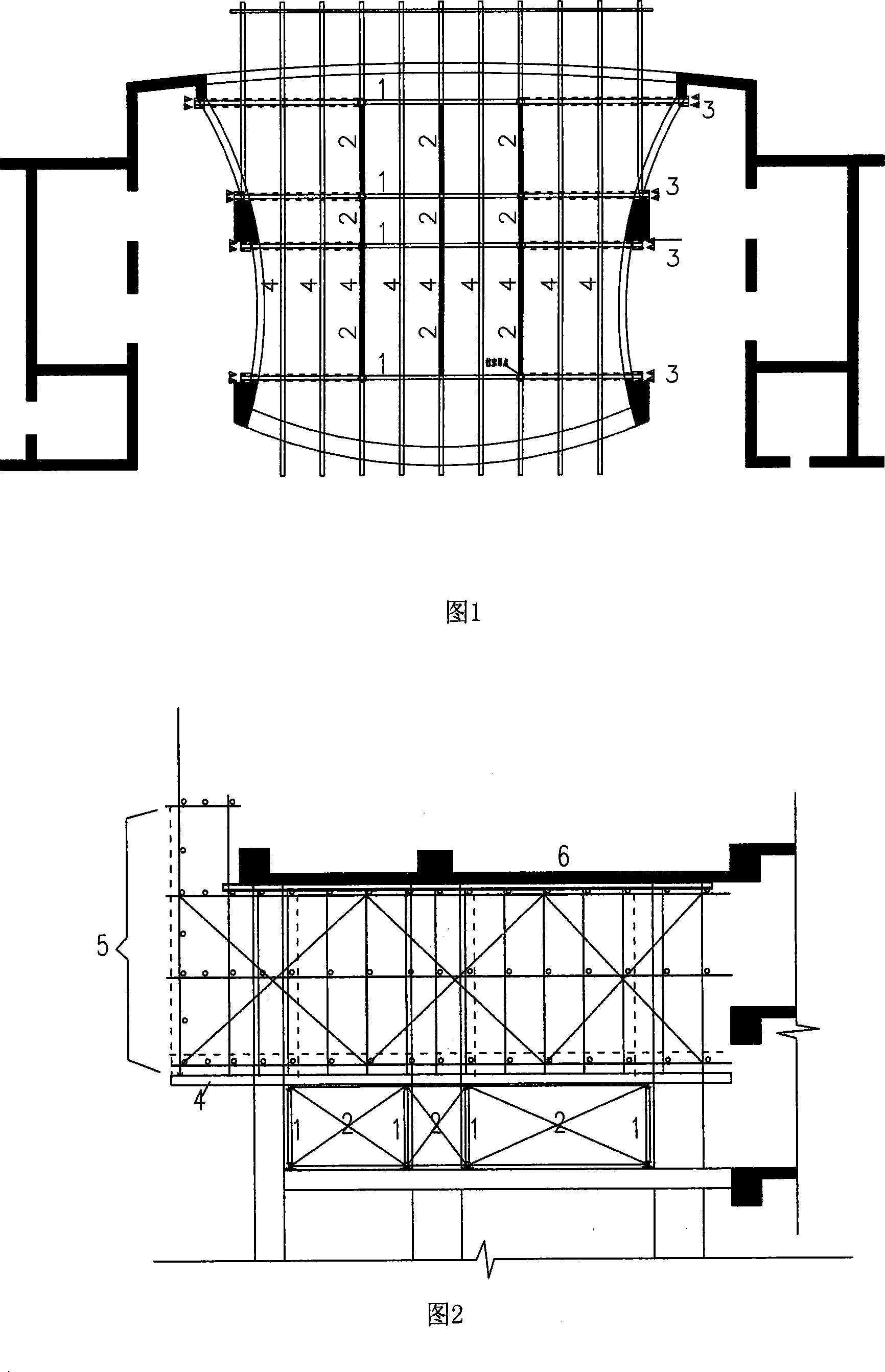

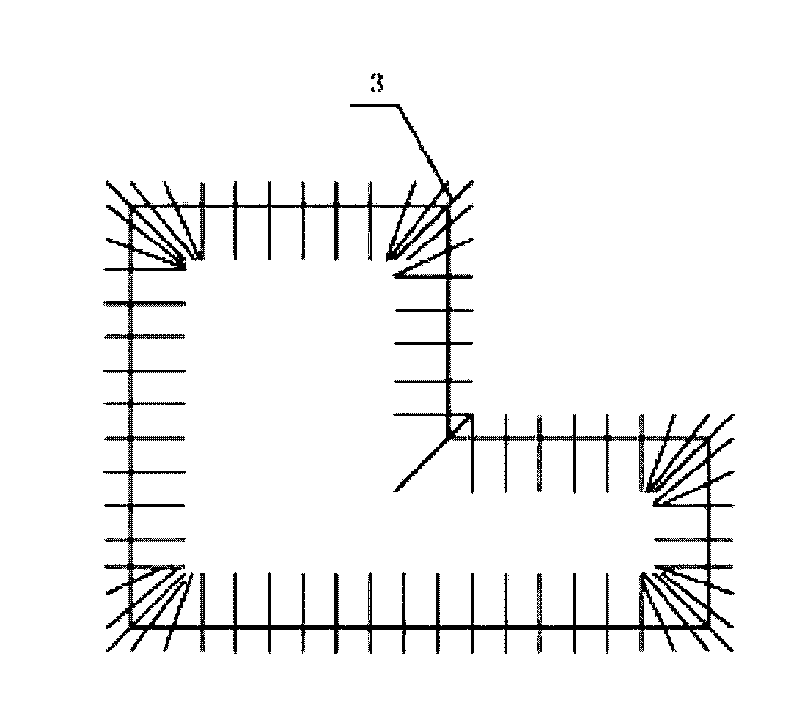

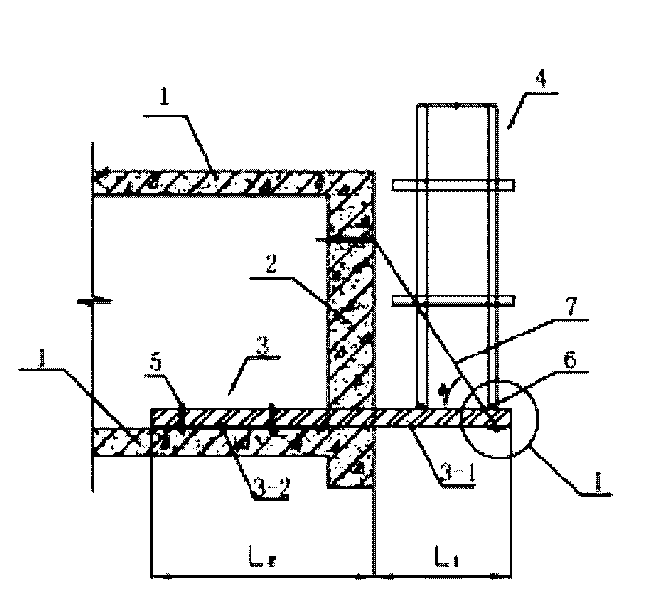

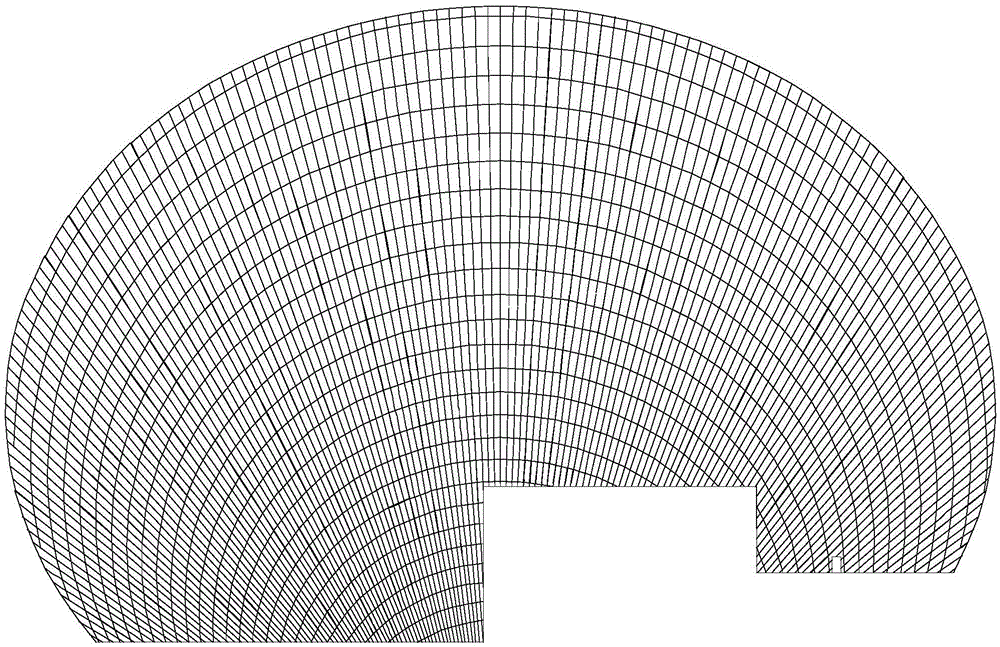

Unilateral formwork erecting system of cast-in-site concrete arc outer wall body and construction method thereof

InactiveCN101839061AWon't breakGuaranteed reliabilityForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksFalseworkFloor slab

The invention discloses a unilateral formwork erecting system of a cast-in-site concrete arc outer wall body and a construction method thereof. The construction method comprises the following construction steps: 1. setting an embedded part on a concrete floor slab below an arc wall body which is not cast; 2. pre-splicing an arc wall body formwork; 3. pre-splicing and mounting a unilateral support frame on site and fastening the unilateral support frame and the embedded part; 4. connecting the unilateral support frame and the arc wall body formwork; 5. setting up a scaffold required by the unilateral support frame; 6. adjusting, reinforcing and checking various parts; 7. casting arc wall body concrete between the arc wall body formwork and an arc outer wall body of an adjacent building; and 8. detaching the formwork after the concrete strength meets the specification requirement. The invention has the advantages of greatly shortening the construction period, saving labor force, reducing the construction cost and meeting the requirement of structural construction quality and is particularly applicable for wall body construction of automobile ramps, stadiums and other large-scale public buildings with arc structures.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

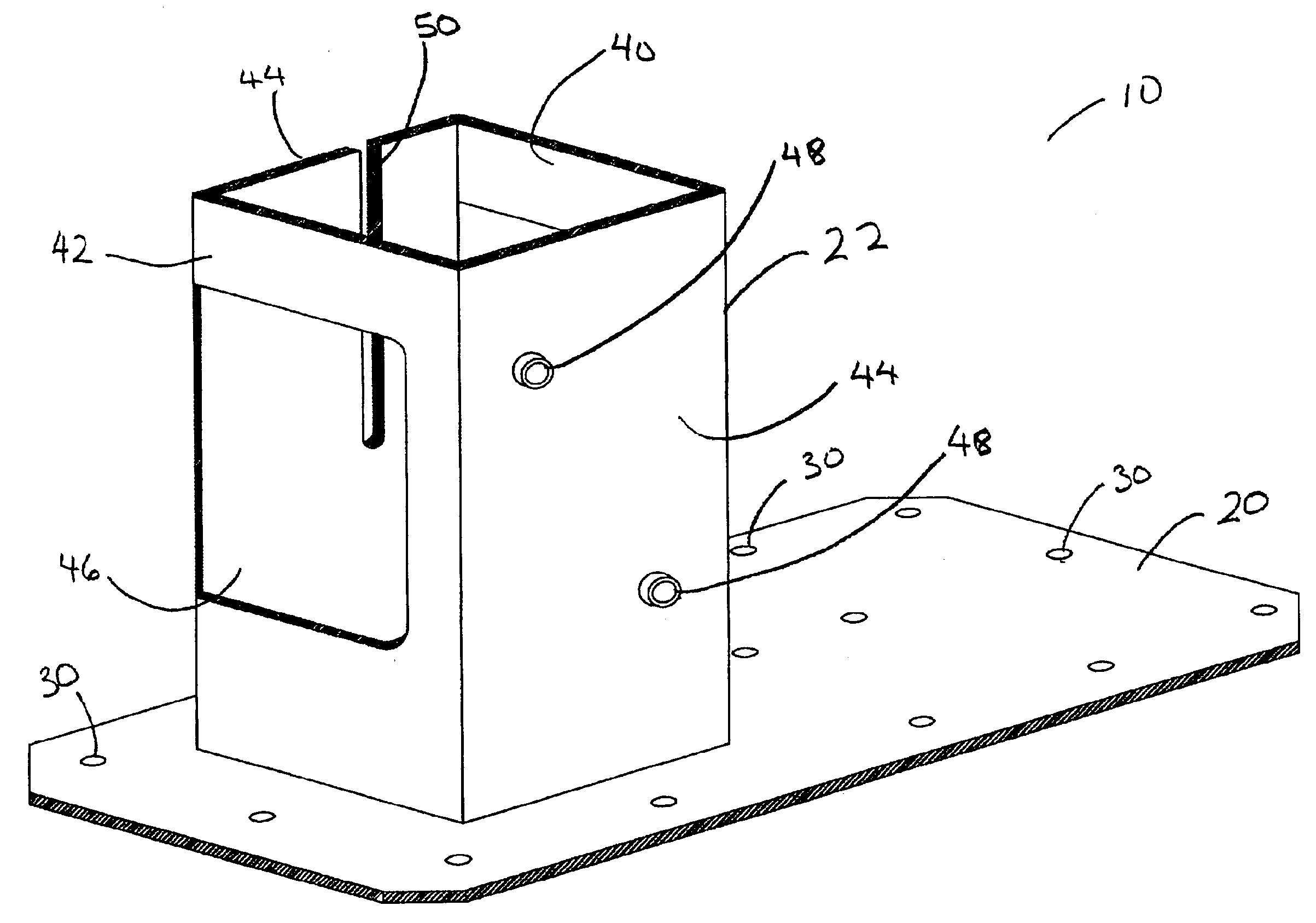

Temporary structure bracket

Owner:FUOCO MAURIZIO

Construction method for spherical curved surface stainless steel curtain wall

ActiveCN102535844ARealize spherical hyperboloid modelingAccurate spatial positioningWallsBuilding material handlingSurface finishFalsework

The invention relates to a construction method for a spherical curved surface stainless steel curtain wall. The method comprises the following steps of: performing construction setting-out, erecting an operating scaffold, installing steel supports, steel keels and backing galvanized iron sheets, constructing fireproof layers and thermal insulation layers, installing waterproof aluminum plates, aluminum alloy keel supports and double curved surface stainless steel panels, injecting glue, performing a spray test, constructing sound absorbing layers, and the like on the outer side of the finished spherical building structure, so that a spherical mirror surface stainless steel plate curtain wall which has strong metal texture and high surface finish and is convenient to clean is formed on the surface. The fireproof layers and the thermal insulation layers are constructed in a spraying mode, so that a reinforcement measure in the conventional mode for the fireproof layers and the thermal insulation layers is eliminated, and engineering cost is saved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

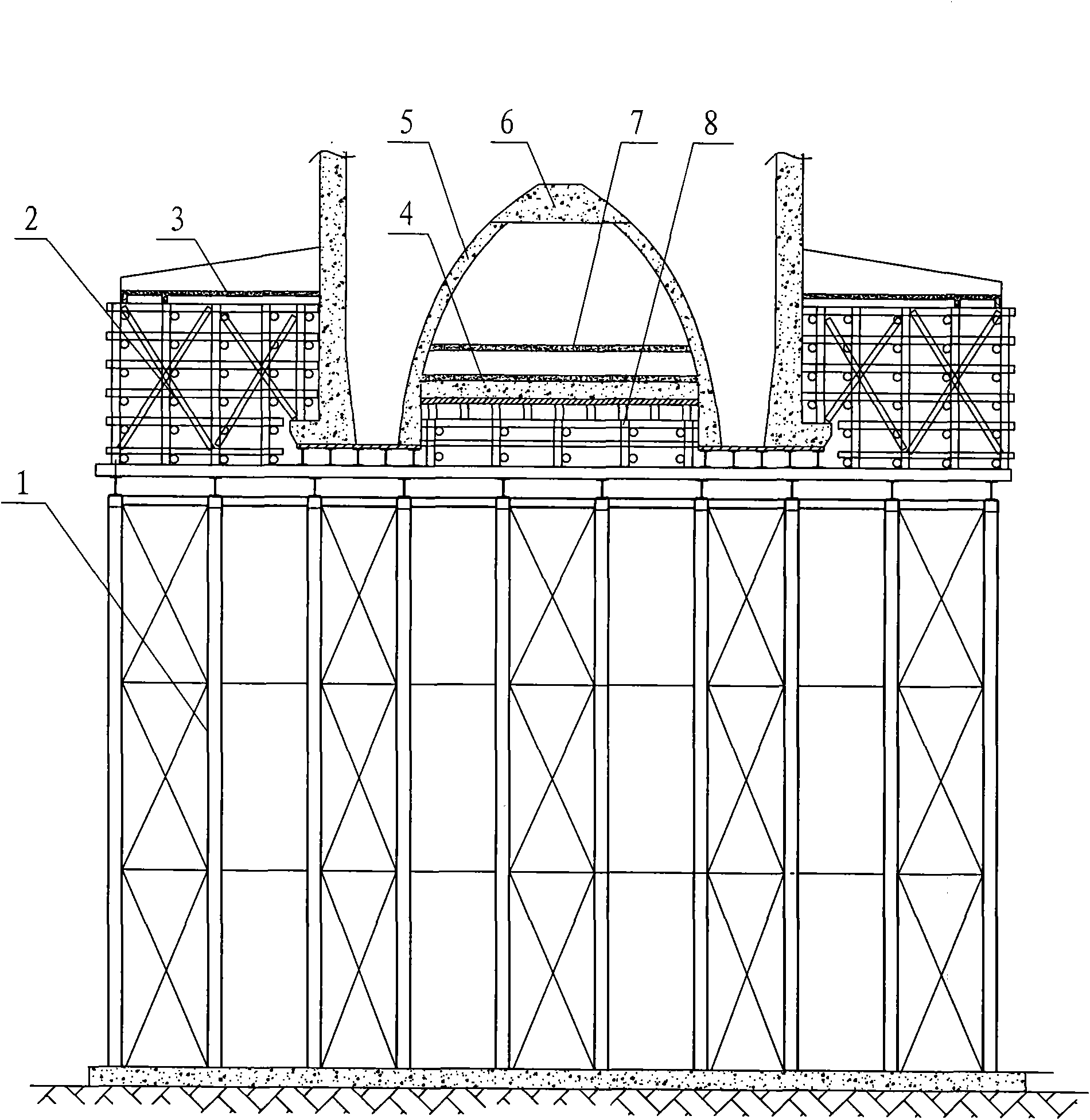

Construction method for support structure of coal tower template for tamping type coke oven

The invention relates to a construction method for a support structure of a coal tower template for a tamping type coke oven, which comprises the following steps of 1, treating a base of a steel structure supporting platform; 2, manufacturing and installing the steel structure supporting platform; 3, prepressing the steel structure supporting platform: the prepressing materials are a resistance wall for the coke oven and a precast slab for a basement, the steel structure supporting platform is overloaded and prepressed according to 110% design load, an observing point is arranged, and the prepressing time is seven days, and the observation is carried out once a day; 4, installing each falsework of the template; and 5, removing the falsework and the steel structure supporting platform. The construction method can realize effective monitoring by well design of a large-span, high-support and heavy-load template support system, particularly is the first in the country in coal towers with a span of 34.045 meters but the beam does not have cracks, solves the difficult problem of construction of a large-span, high-support and heavy-load structure, adapts to the coking technique to be developed in large size and tamping type coke ovens, and has the advantages of short construction period, revolving material saving, safety, reliability, easy quality control and high concrete strength.

Owner:CHINA 22MCC GROUP CORP

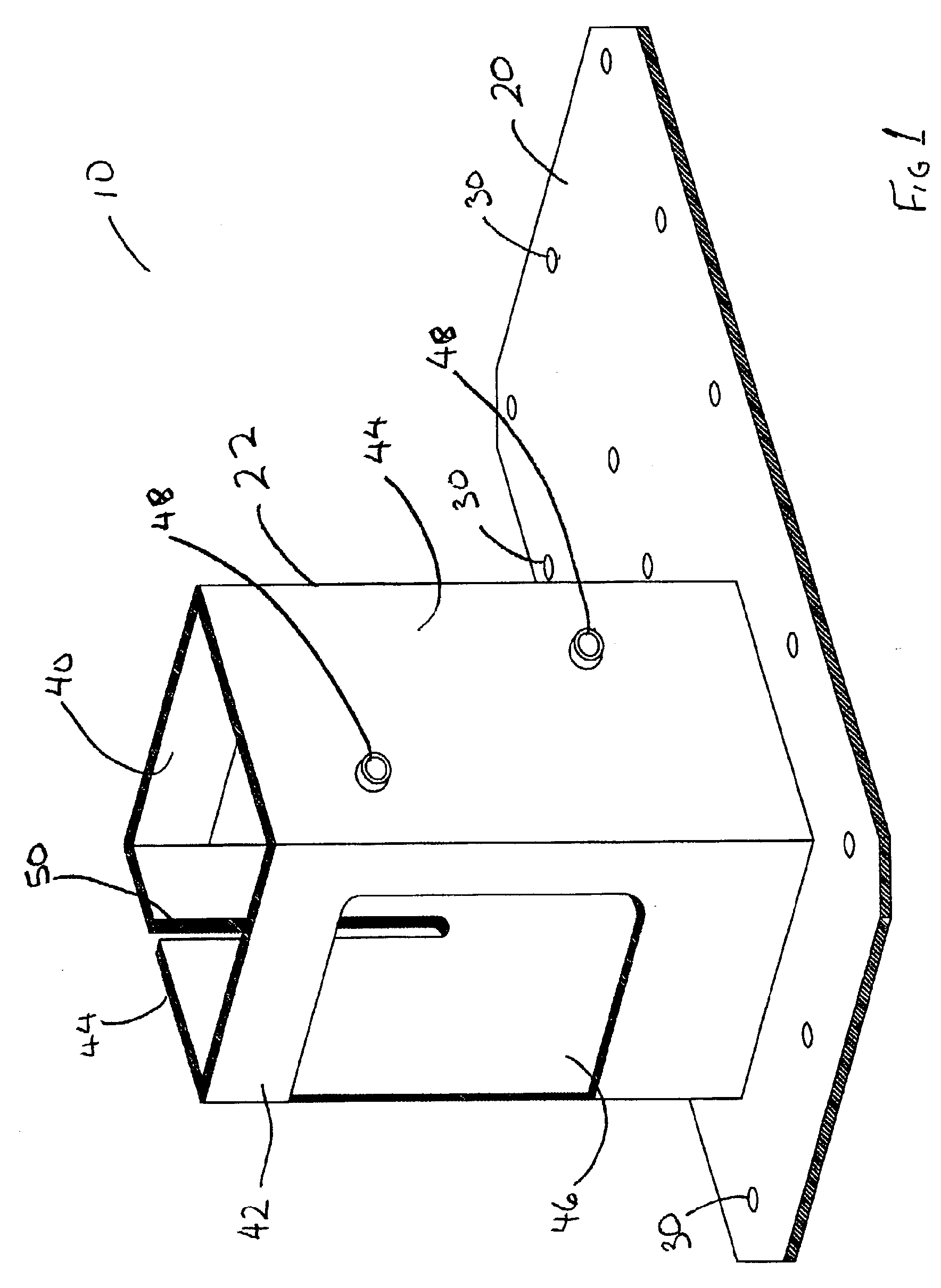

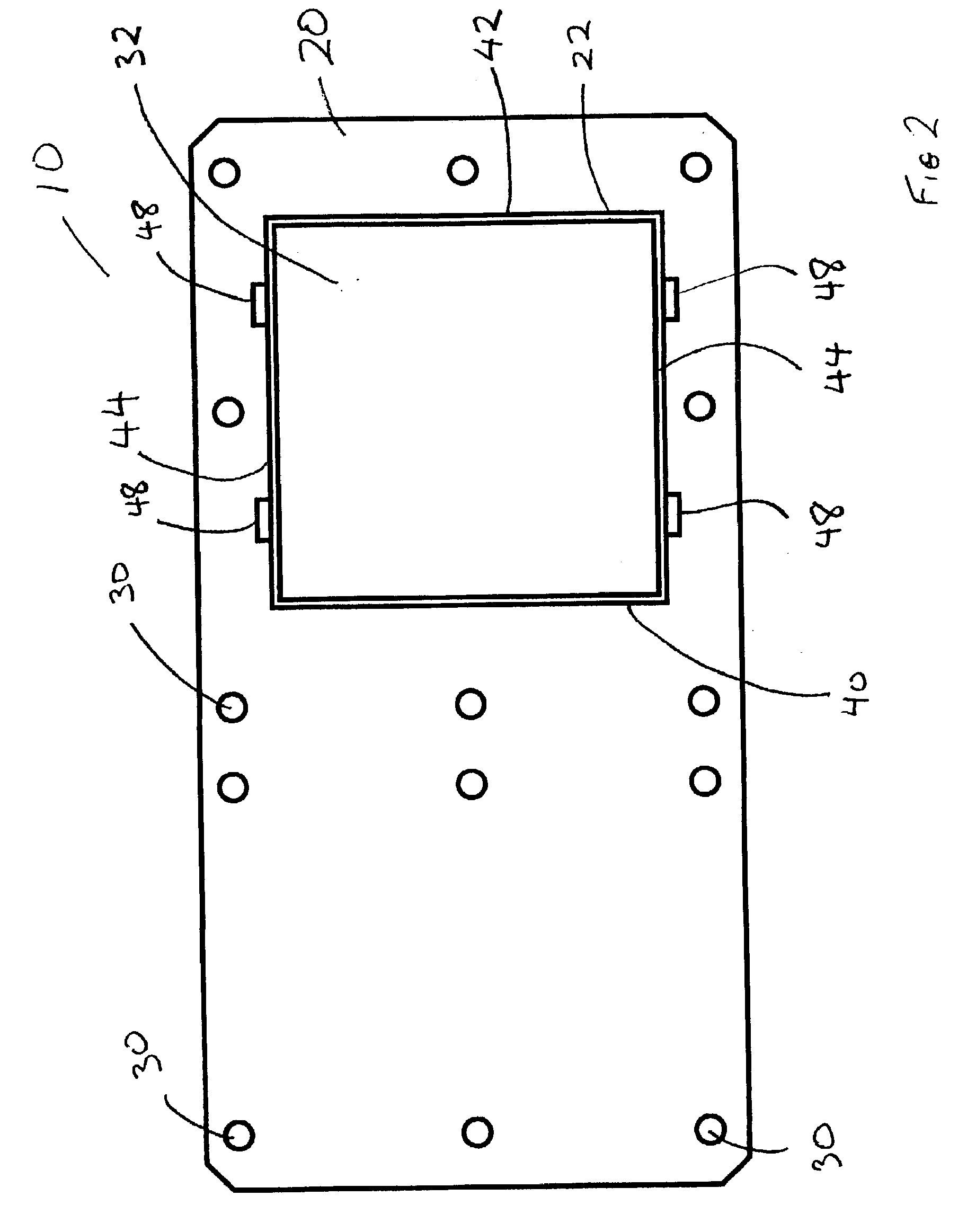

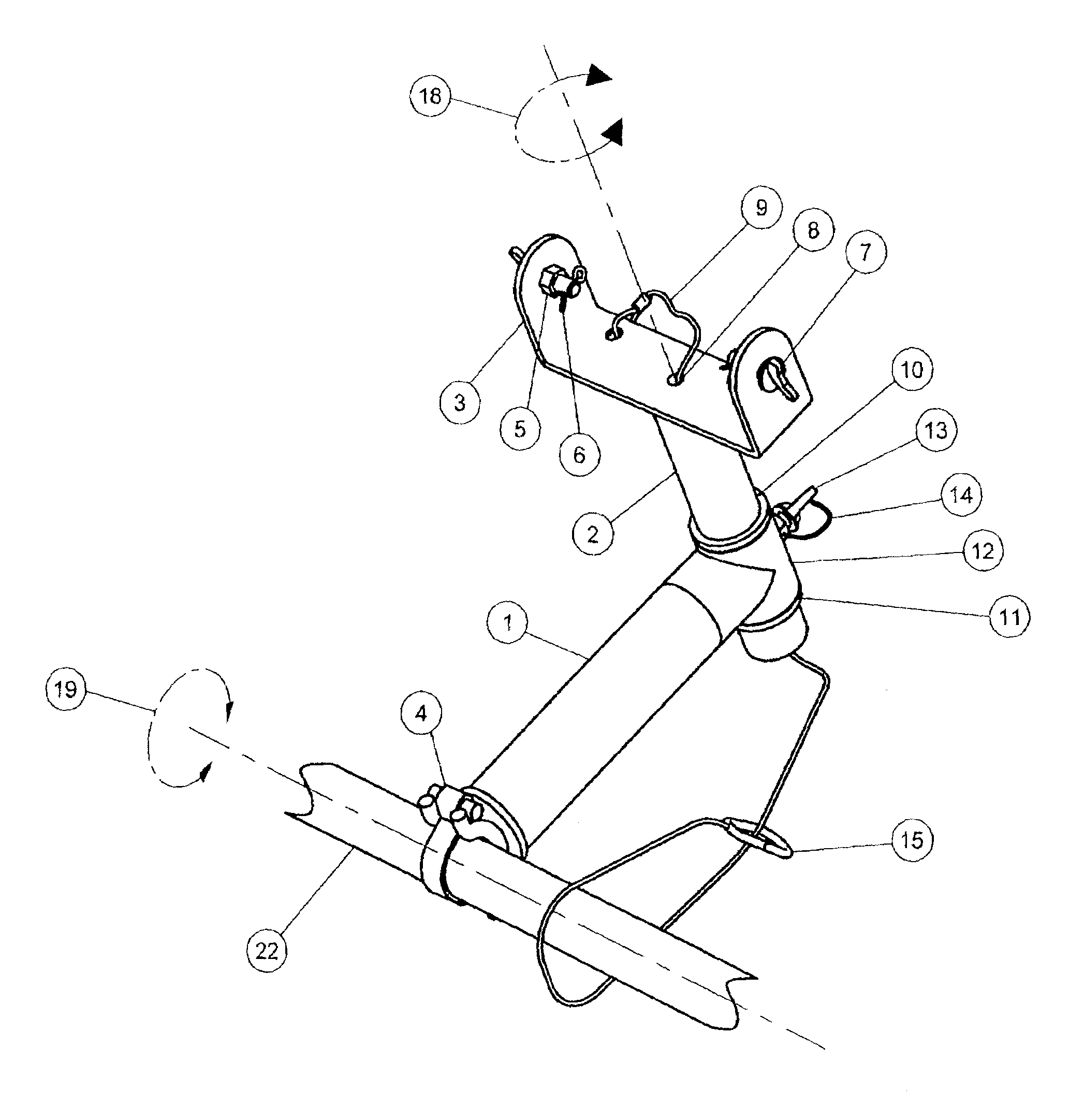

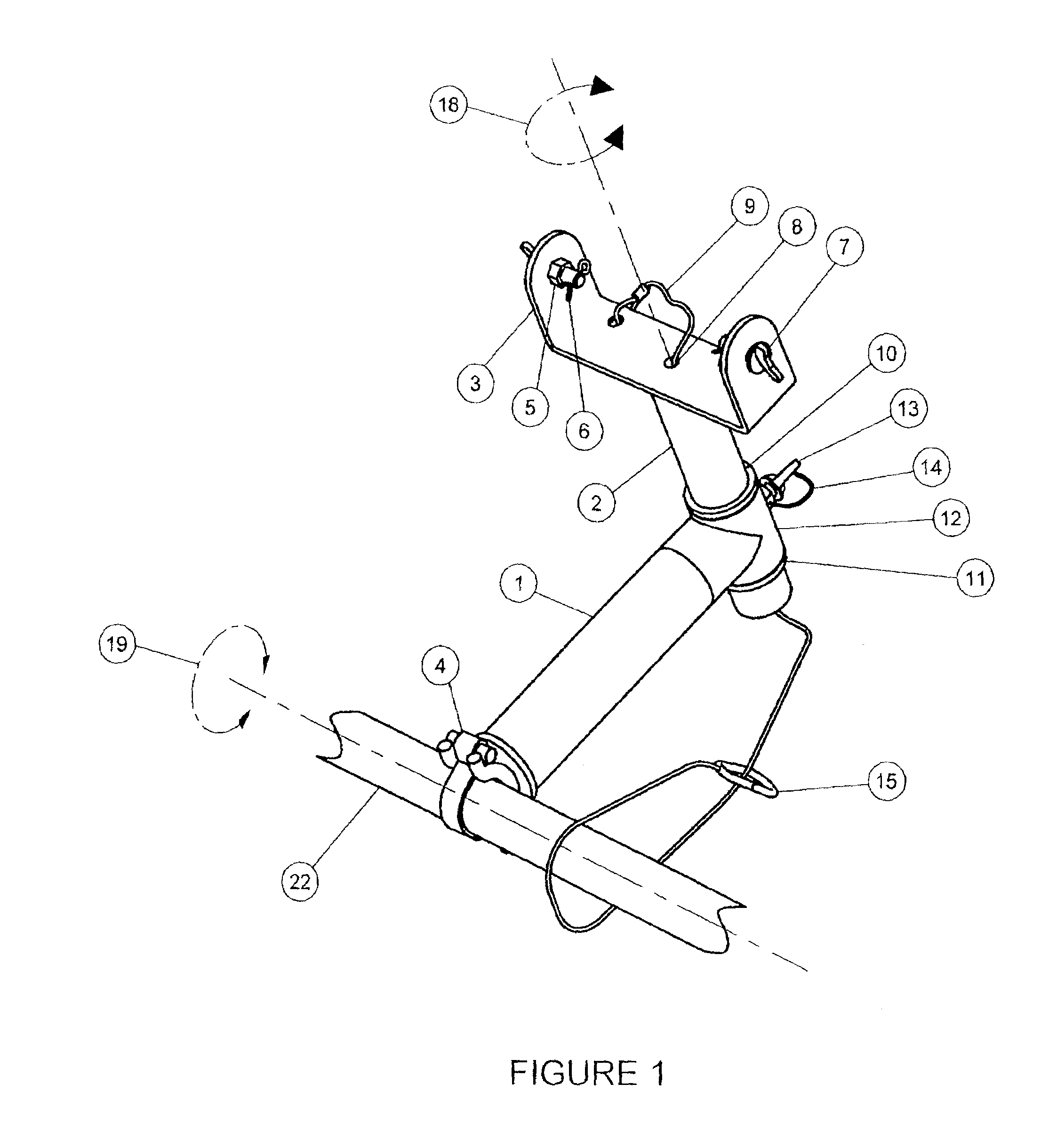

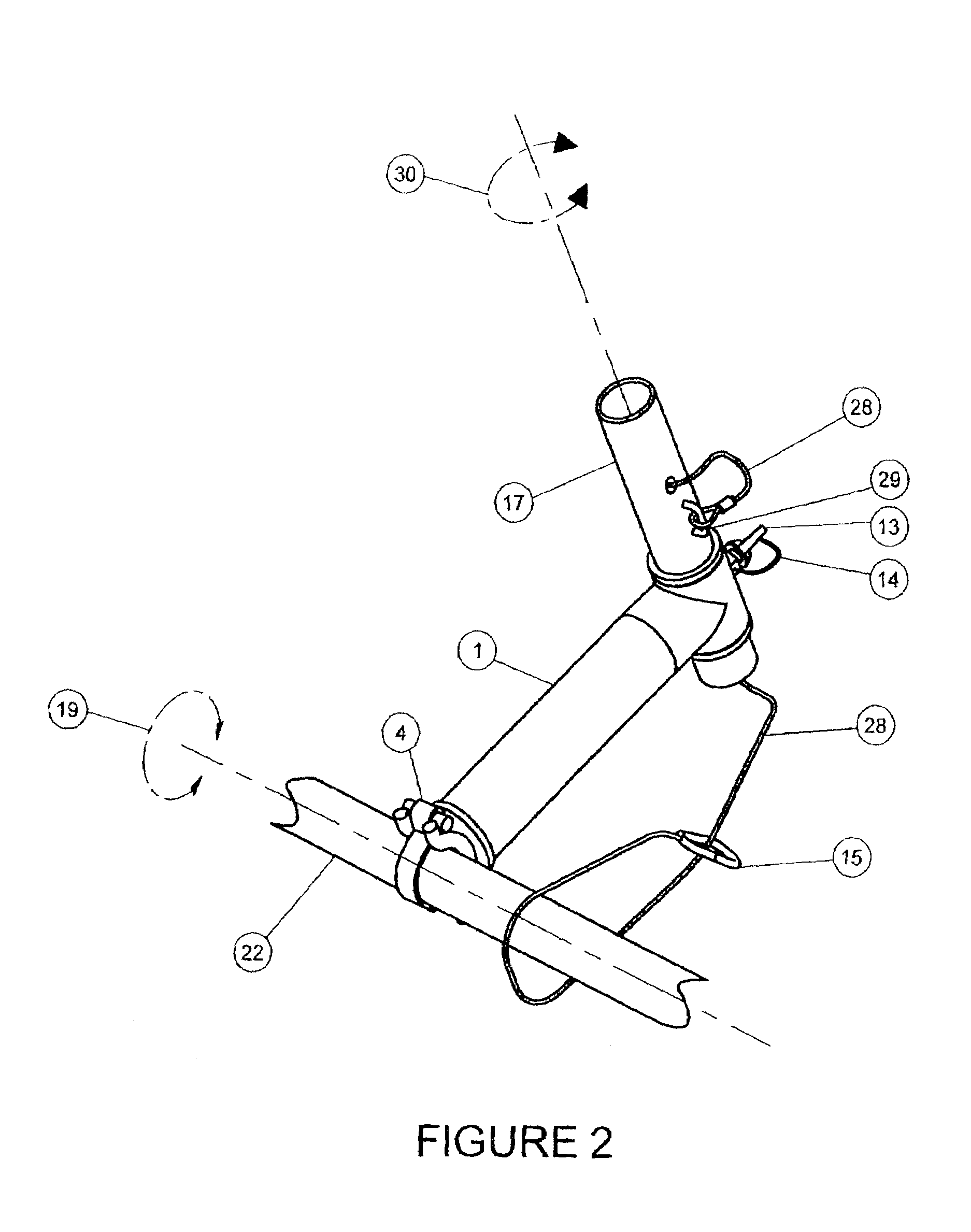

Temporary lighting support assembly for scaffolding systems

ActiveUS7566151B2Fast wayEasy to implementNon-electric lightingMechanical apparatusFalseworkEffect light

The present invention is concerned with providing a support for temporary lighting for use with scaffolding systems. The support assembly comprises of two main components and the required fastening systems to affix lighting fixtures and mast light fixtures embodied in two configurations. The support consists of a thin walled pipe with a tube half clamp welded to one end and a thin walled tee welded to the opposite end. The clamp and tee are orientated to provide the support with a precise mounting position. A second thin walled pipe is positioned concentrically through the tee to create framework that has an angled appearance. The second pipe is maintained annular and concentric to the first pipe by means of two washer type collars welded above and below the tee that constrains both pipes to each other. A small space between the collar and tee provides the second pipe with unconstrained rotational movement. Lanyards incorporated in the support are fixed directly to the scaffold for job site safety concerns. Another aspect of the invention is the tube half clamp, which can provide quick assembly and infinite positional placement on a horizontal or vertical pipe member of a scaffolding system.

Owner:WHELAN BRENDAN

Inclined drawing steel truss high-supported formwork structure system and construction method thereof

This is a cable stayed steel truss module structure and its construction method. At least two steel trusses are installed to support a high building to be grouted with connecting steel held in between. At least four truss cables are stayed between the building and the steel truss. Beam is installed on the top of the truss with falsework module fixed to the beam.

Owner:LONGXIN CONSTR GRP

Enclosed scaffolding assembly

A scaffolding assembly includes a plurality of sound attenuating sheets, detachably mounted on a frame erectable substantially adjacent to a structure. The frame includes sheet supporting members. The sheet supporting members and the plurality of sound attenuating sheets when mounted on the sheet supporting members define an enclosed working area adjacent the structure, so as to affect a seal to substantially contain air pollution and other detritus, and noise pollution within the enclosed scaffolding assembly when erected adjacent to the structure. An inclined catchment ramp is mounted along the length of at least one of the scaffold working decks so as to sandwich each ramp between the working deck and the adjacent wall of the structure.

Owner:FERLIN KEITH A +1

Lower edge open truss style corrugated steel web combination beam

InactiveCN101139812AImprove crack resistanceIncreased durabilityLoad-supporting elementsBridge materialsFalseworkCrack resistance

A truss-type corrugated steel web composite beam with an open bottom chord belongs to a bridge support member. The bottom chord opened and truss-type corrugated steel web composite beam comprises an upper wing edge concrete slab, a corrugated steel web and a bottom chord opened truss-type rectanglar steel tube concrete member. Compared with steel truss-type web composite corss section, the invention adopts the corrugated steel web with rather high shear strength to replace a steel web member, so as to guarantee quite high shear bearing capacity. The opened truss-type bottom chord is composed of two parallel-arranged rectanglar steel tubes arranged in parallel and internally cast concrete, as well as horizontal braces and batter braces between the rectanglar steel tubes. Moreover, the bottom chord adopts the steel tube concrete member to overcome the problem of rather high work volume that, in traditional composite cross section of corrugated steel web box beams and steel truss-type webs, such execution measures as scaffolding, formwork-support, concrete casting and etc. should be taken for lower wing edge concrete slabs. Meanwhie, the invention can effectively improve structure crack resistance, avoid crackage exposure and etc, and considerably increase structure durability. The bottom chord is a brace-connected open-type structure with advantages of simple structure and fast, smooth and convenient execution.

Owner:TSINGHUA UNIV

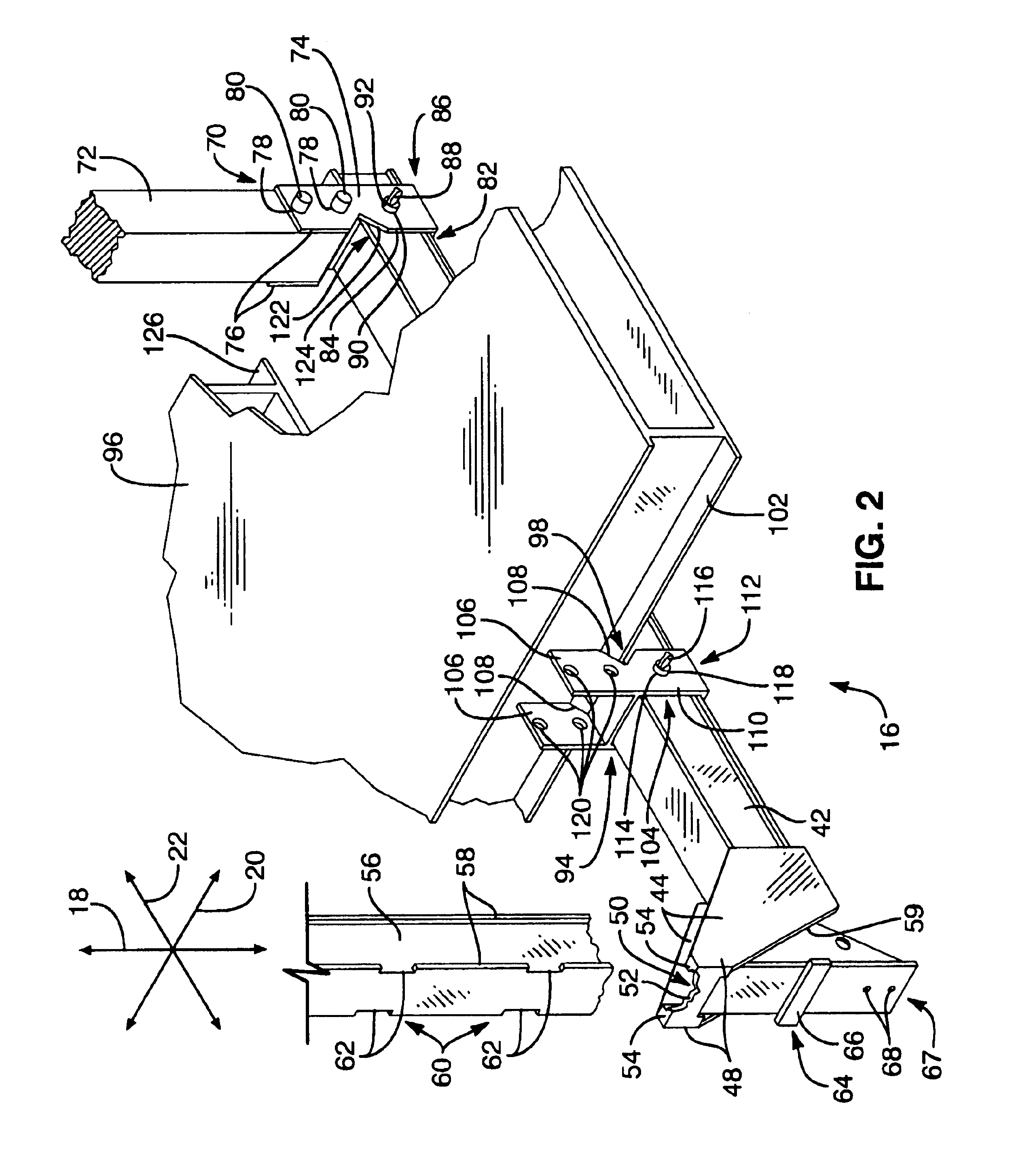

Hanging scaffold support

InactiveUS6886662B2Inhibition releaseEasy to insertStands/trestlesKitchen equipmentSupporting systemFalsework

A scaffold support system having an adjustable-width hanger. A vertical leg may support a foot upon which rests a deck, providing a working surface during building construction or modification. A lateral beam rests on a support structure forming part of the wall of a building with the vertical leg securing to the lateral beam at a plurality of points. A stop secured to the lateral beam to capture a support structure between itself and the vertical leg. The stop may be adjustable along the lateral beam to accommodate support structures of varying widths. An operator may insert the hanger from inside a building and pass the coupler through a gap between a frieze block and a top plate, presenting the coupler for securement to the vertical leg. A catch may slide along the foot into and out of engagement with an edge of the deck to prevent rotation of the deck.

Owner:JDPR INVESTMENTS LLC

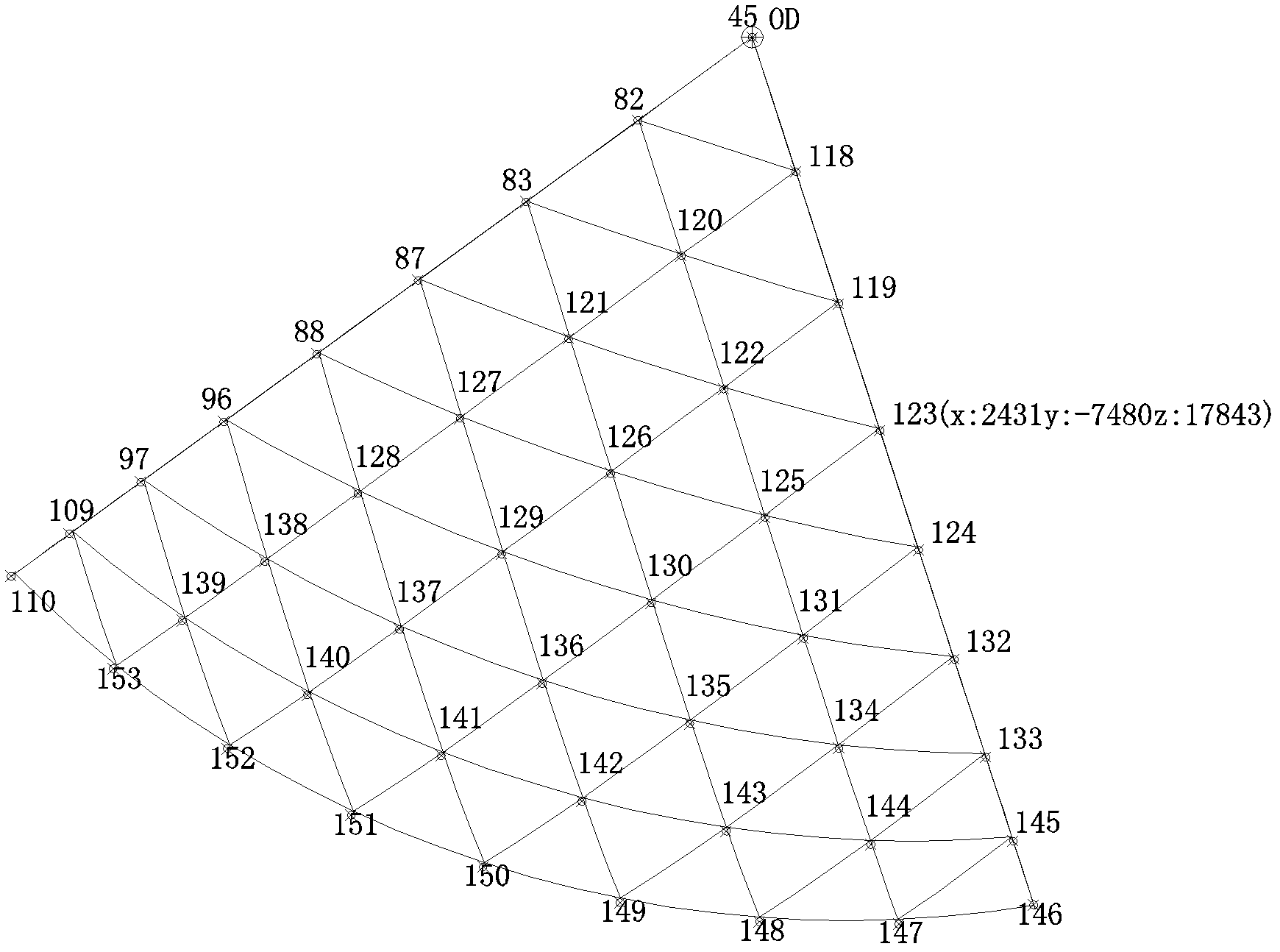

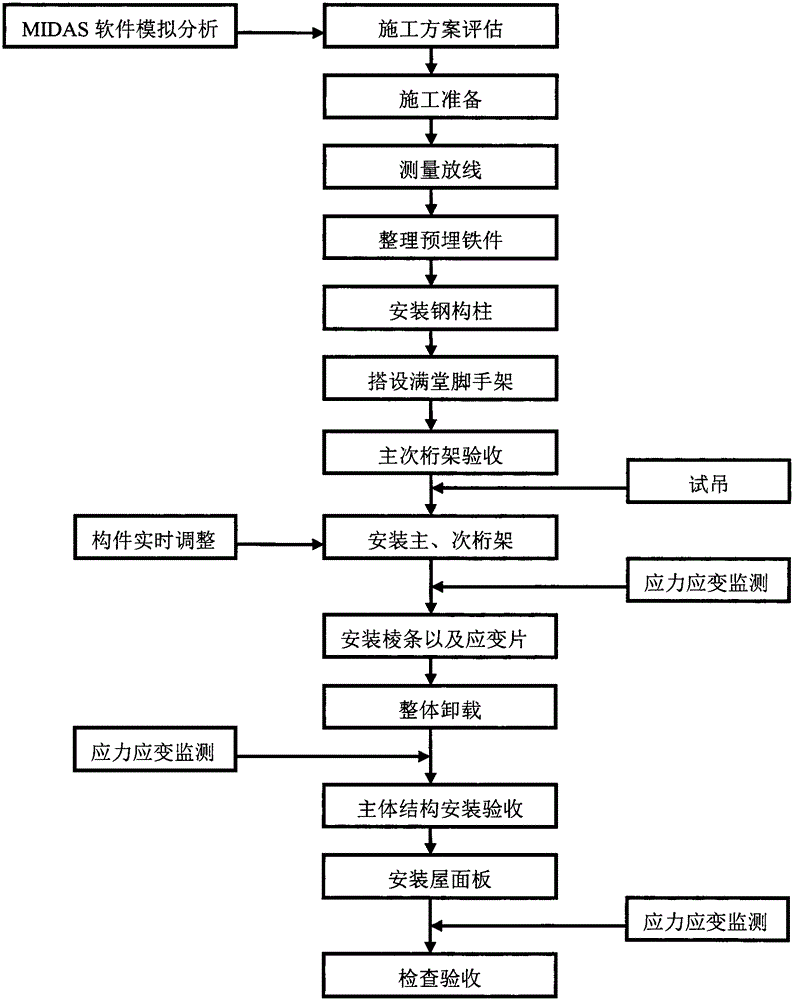

Spatial curved surface steel structure pipe truss roof installation construction method

InactiveCN105133841AClose up smoothlyImprove construction accuracyGirdersJoistsFalseworkElement model

A spatial curved surface steel structure pipe truss roof installation construction method relates to the technical field of a building construction method. The construction method comprises the following steps of elevating a scheme, making preparation for the construction, measuring and setting out, tidying a pre-buried iron member, setting up an all-around scaffold, checking and accepting a main and secondary trusses, installing the main and secondary trusses, installation ridges and stress sheets, detaching the whole, checking and accepting after main body installation, installing a roof panel plate and checking and accepting the whole. Finite element modeling for a non-linear construction phase can be achieved; construction scheme safety is evaluated according to stimulation check of component stress and strain during the construction, so practical construction can be guided; strain displacement can be monitored during the construction; real-time adjustments can be conducted to components, so construction precision can be improved and building cost can be reduced.

Owner:五洋建设集团股份有限公司

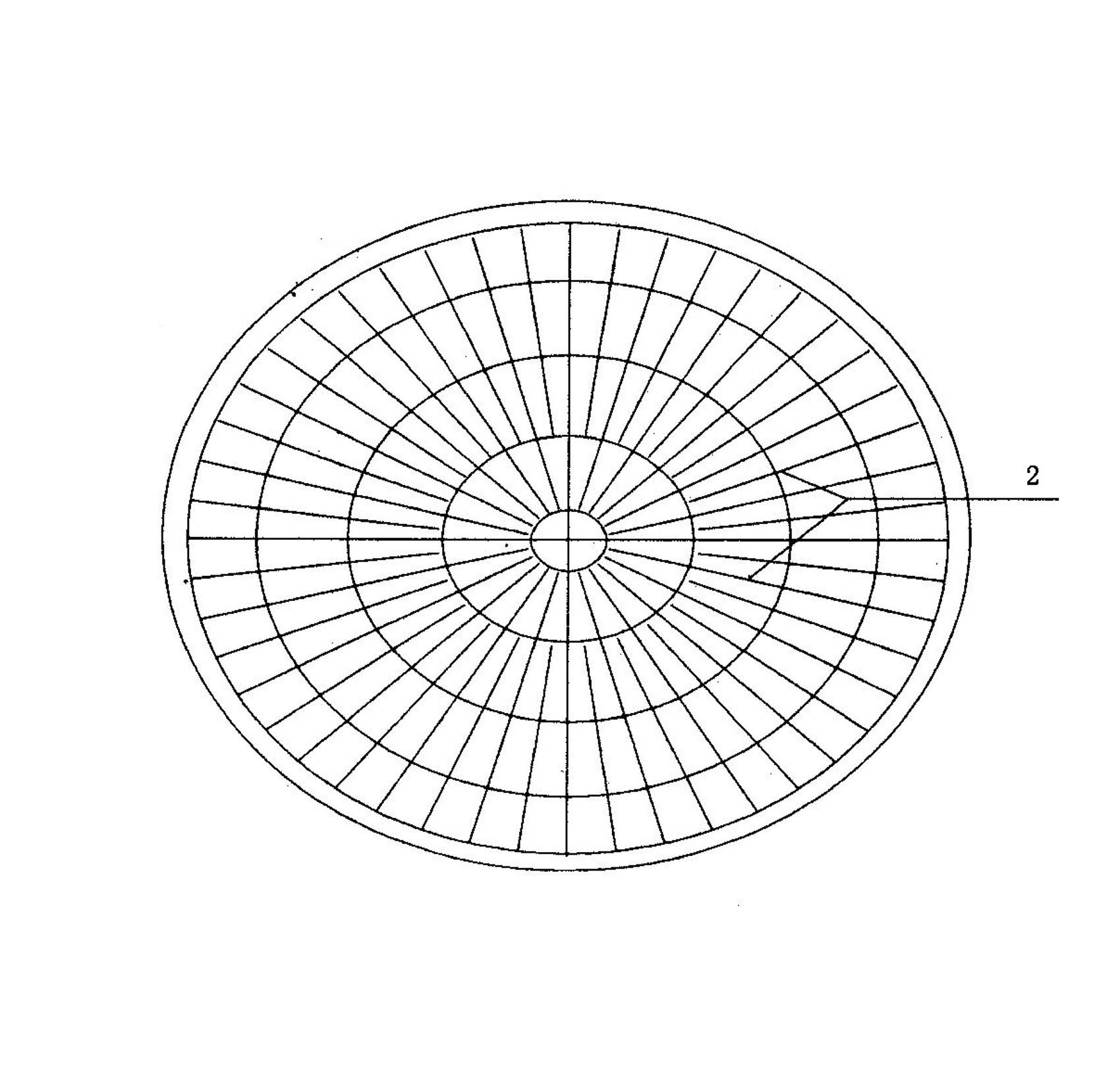

Construction method of soil covering tank

ActiveCN101852031AReduce construction intensityEmission reductionArtificial islandsUnderwater structuresRebarDust emission

The invention relates to a construction method of a soil covering tank for storing product oil and the like, which comprises the following steps of: (A) building a tank chamber of a soil covering tank: firstly, carrying out earth excavation with a method combining a back-acting shovel and manual excavation; then, manufacturing a ring beam, precasting concrete blocks on the spot according to the radian of the ring beam, and building the concrete blocks; carrying out the engineering of steel bars: welding steel bars by machining, and manually binding the steel bars on the spot; carrying out the engineering of templates and scaffolds: taking a bamboo plywood as a top plate template of a concrete thin shell of the tank chamber, designing a camber at the middle part, and taking scaffold tubes as bottom template brackets of the thin shell of the tank; then, carrying out concrete engineering and asphalt sand construction; and finally, carrying out waterproof engineering, thereby completing the construction of the tank chamber of the soil covering tank; and (B) installing a storage tank body of the soil covering tank: firstly, precasting the storage tank body; then, installing a tank bottom plate; installing the tank body, and welding the storage tank; and finally, testing and inspecting to complete the whole construction process of the soil covering tank after the construction is qualified. The invention reduces the occurrence of accidents, increases the benefit and reduces the dust emission.

Owner:中国化学工程第四建设有限公司

Flexible stent with elevated scaffolding properties

InactiveUS20080294239A1Provide flexibilityDegree of improvementStentsBlood vesselsFalseworkInsertion stent

The present invention concerns a stent that generates an elevated degree of scaffolding to a bodily vessel while retaining a highly flexible structure. In one embodiment, a stent according to the present invention includes an essentially tubular body formed by a web structure that is configured to expand from a contracted delivery configuration to an expanded deployed configuration and that is composed of a plurality of longitudinally adjacent web rings. Those web rings are formed by a plurality of web elements disposed circumferentially around the longitudinal axis of the stent and adjoined one to the other with a junction bend. Each junction bend in a first web ring is coupled to another junction bend in a neighboring ring with a S-shaped connector, and the coupled junction bends are not longitudinally aligned but are instead laterally offset.

Owner:ABBOTT LAB VASCULAR ENTERPRISE

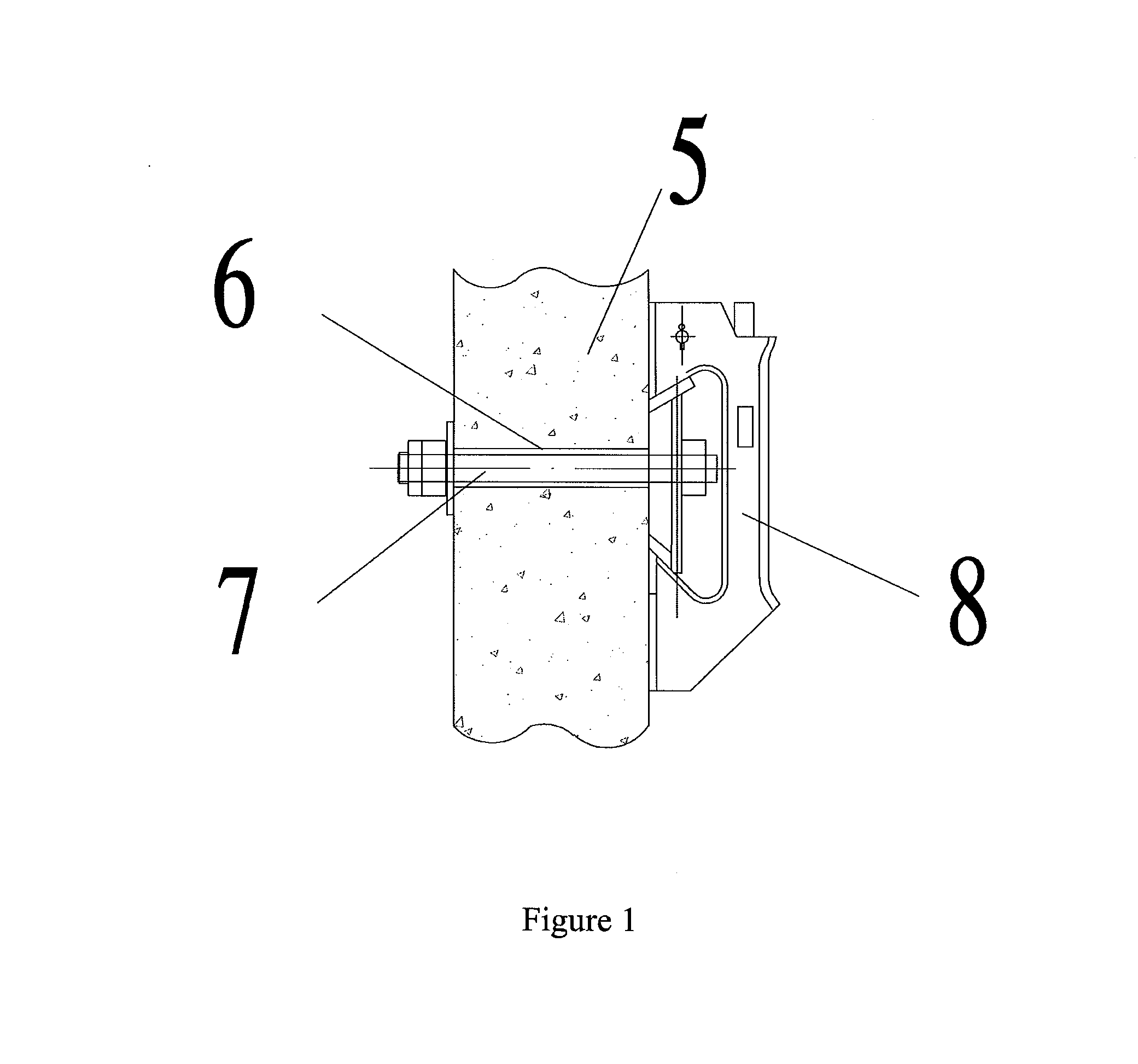

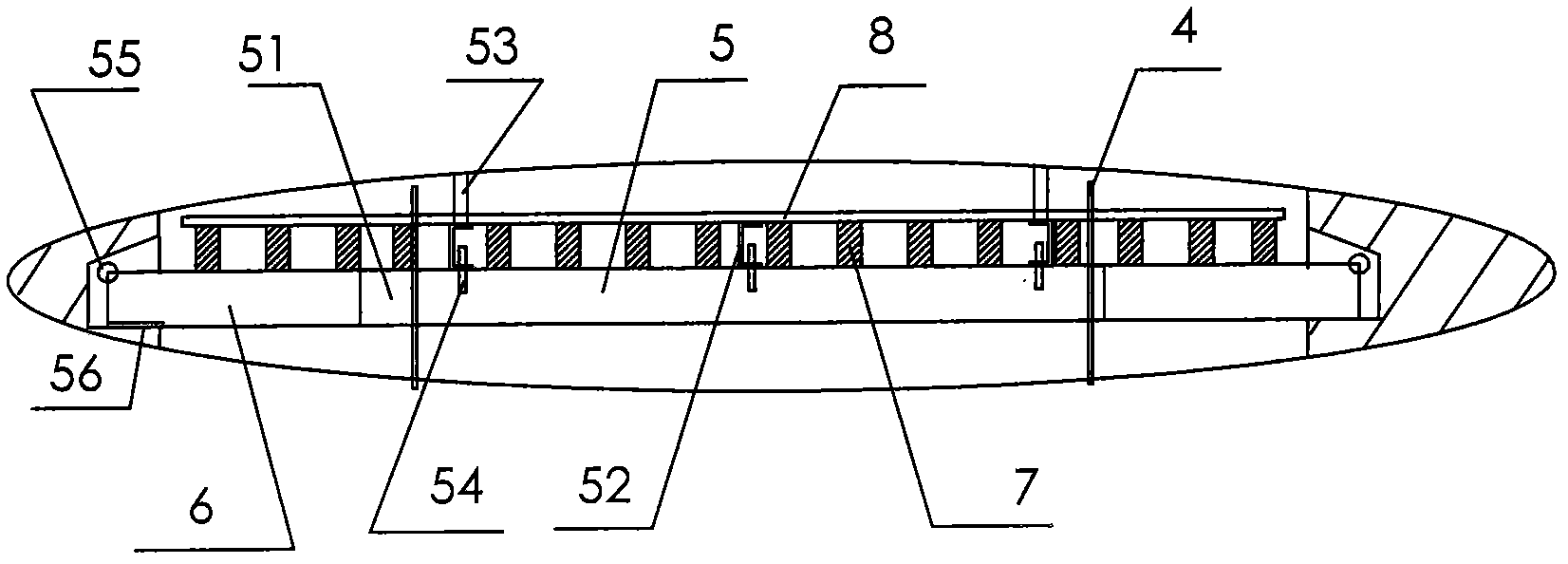

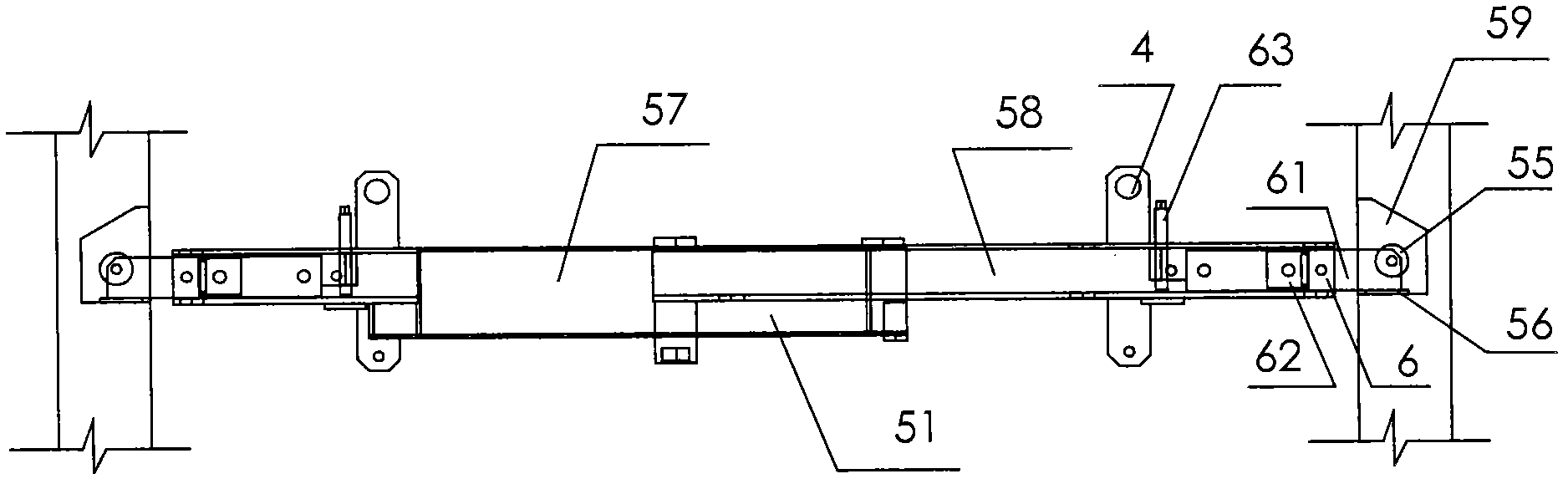

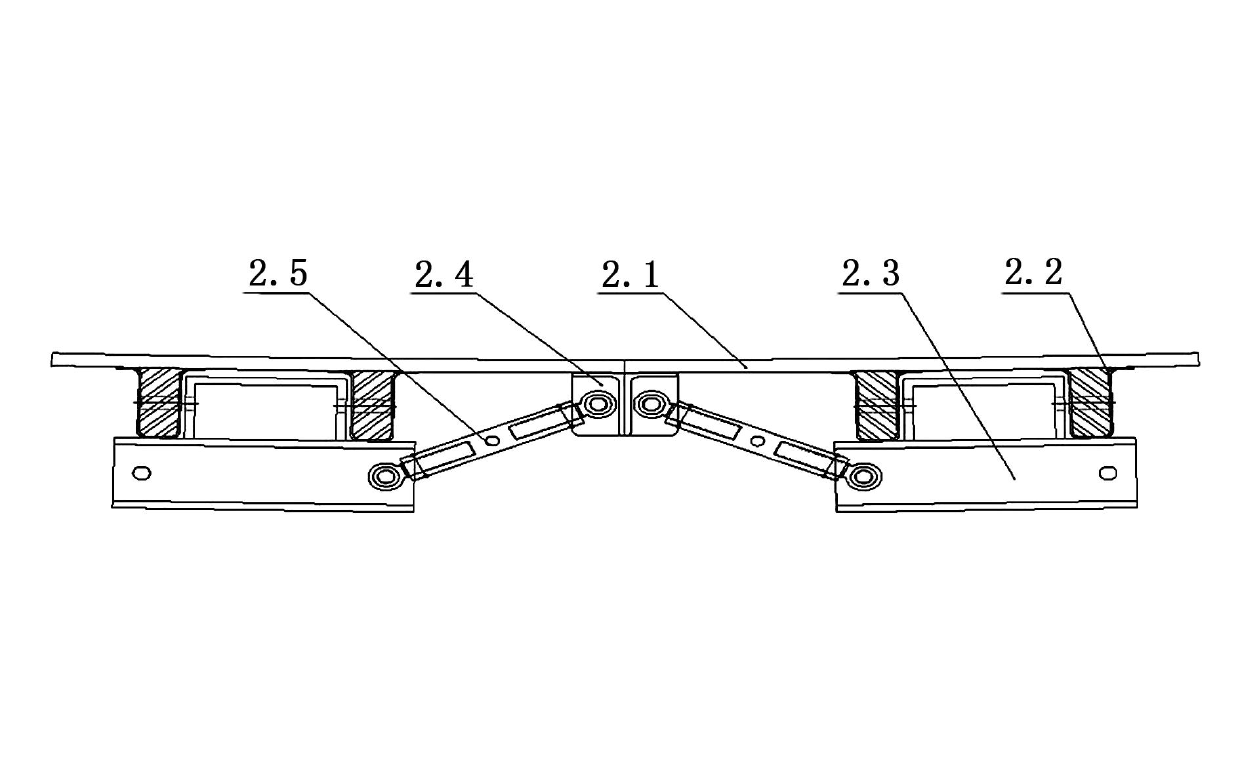

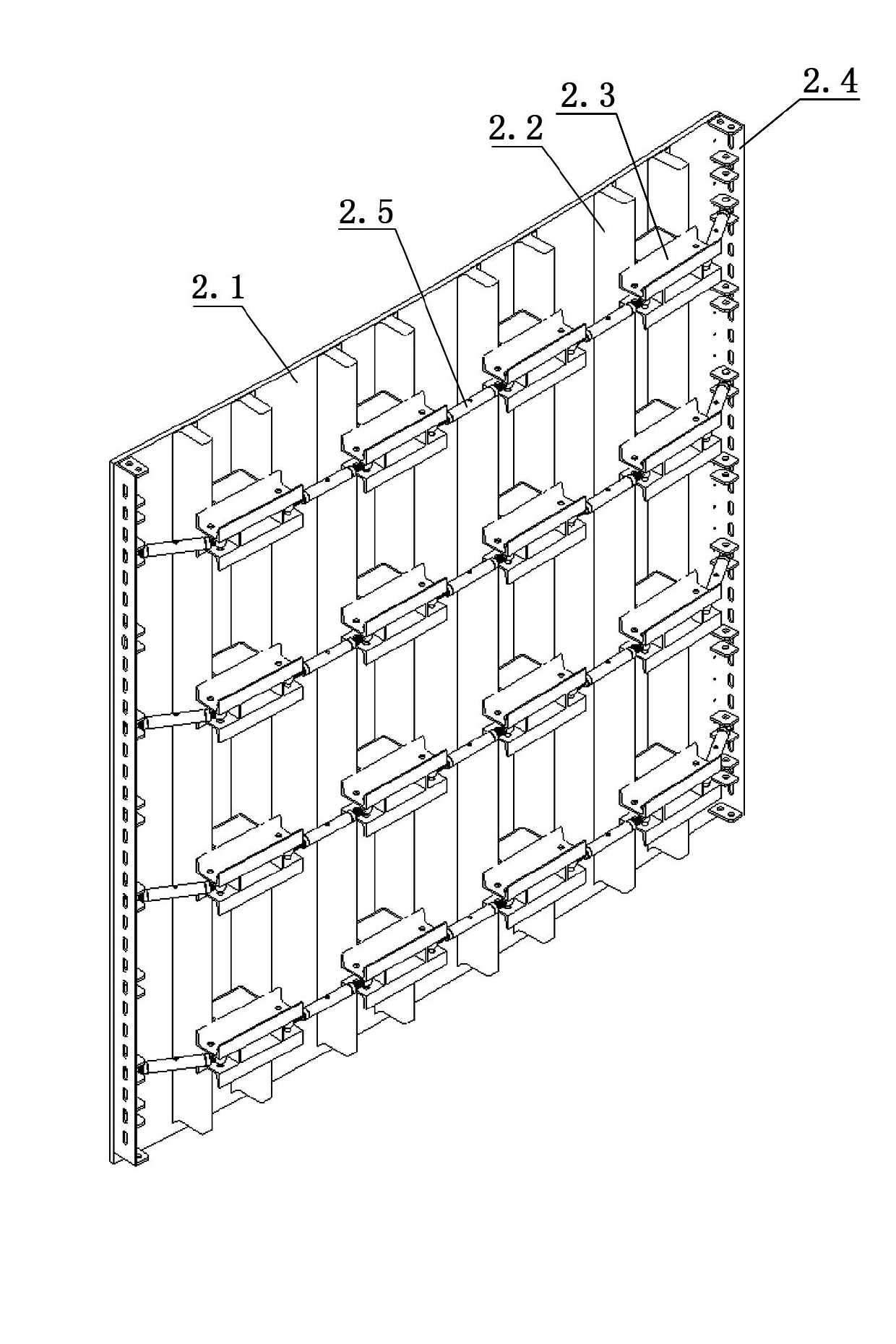

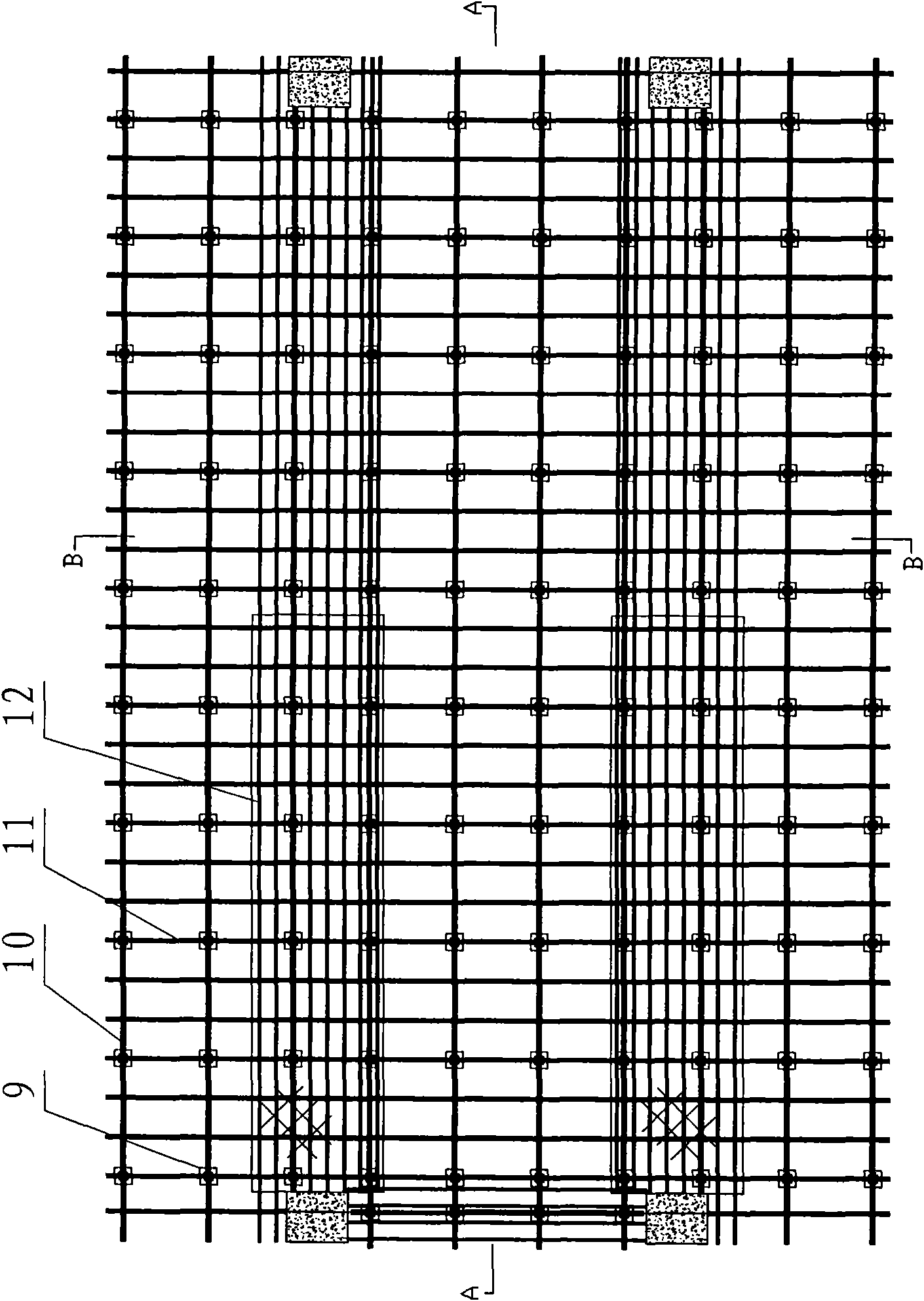

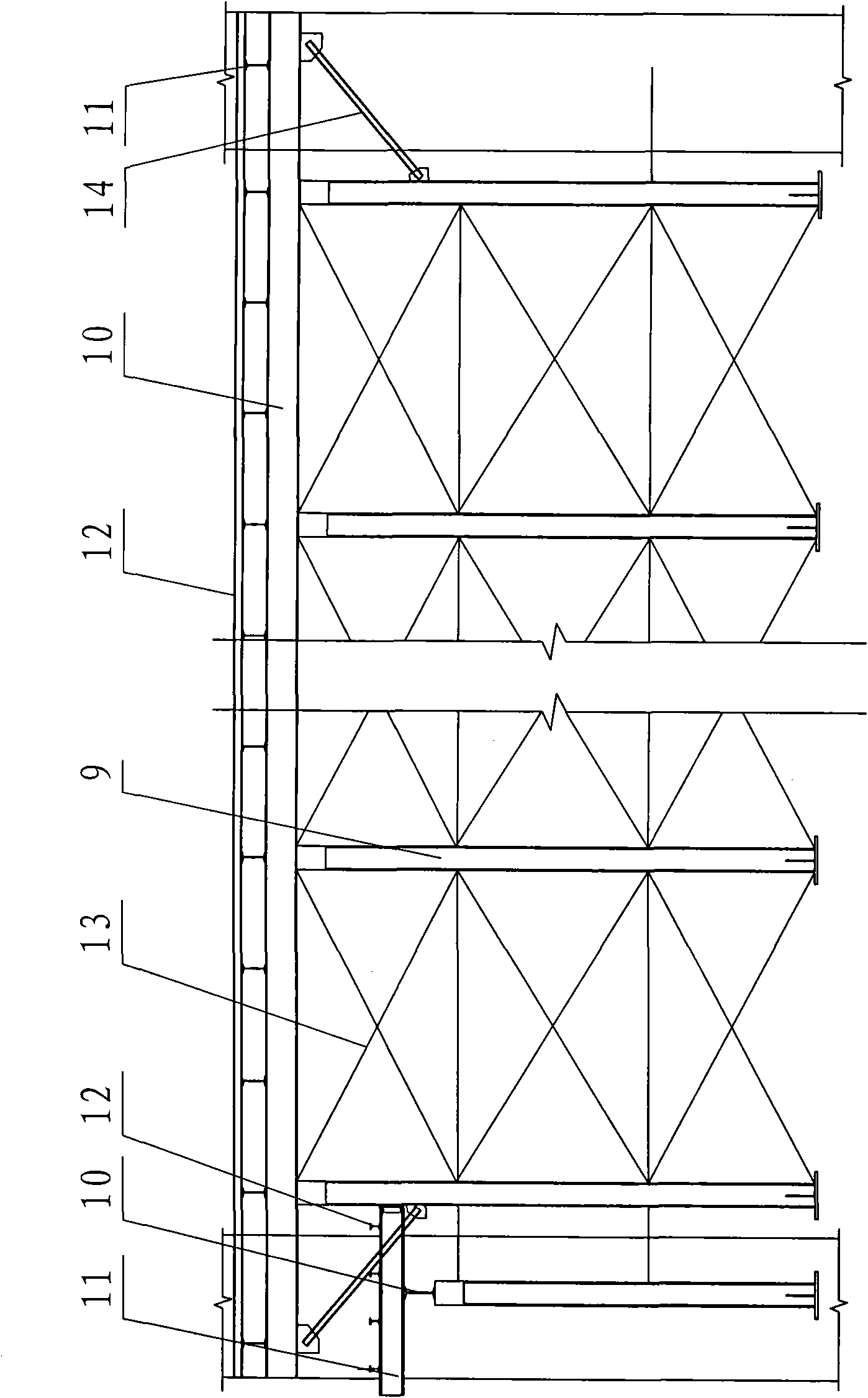

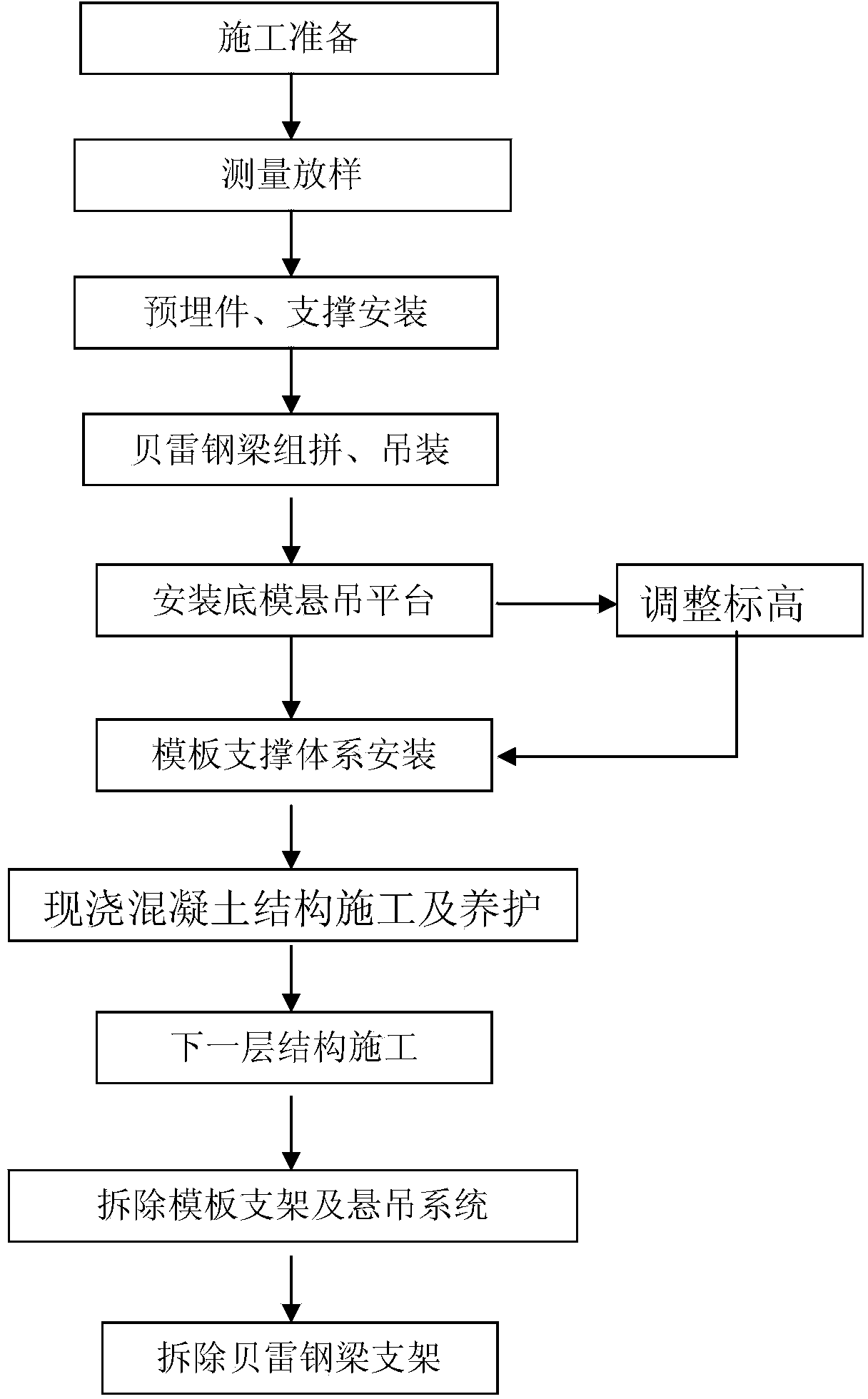

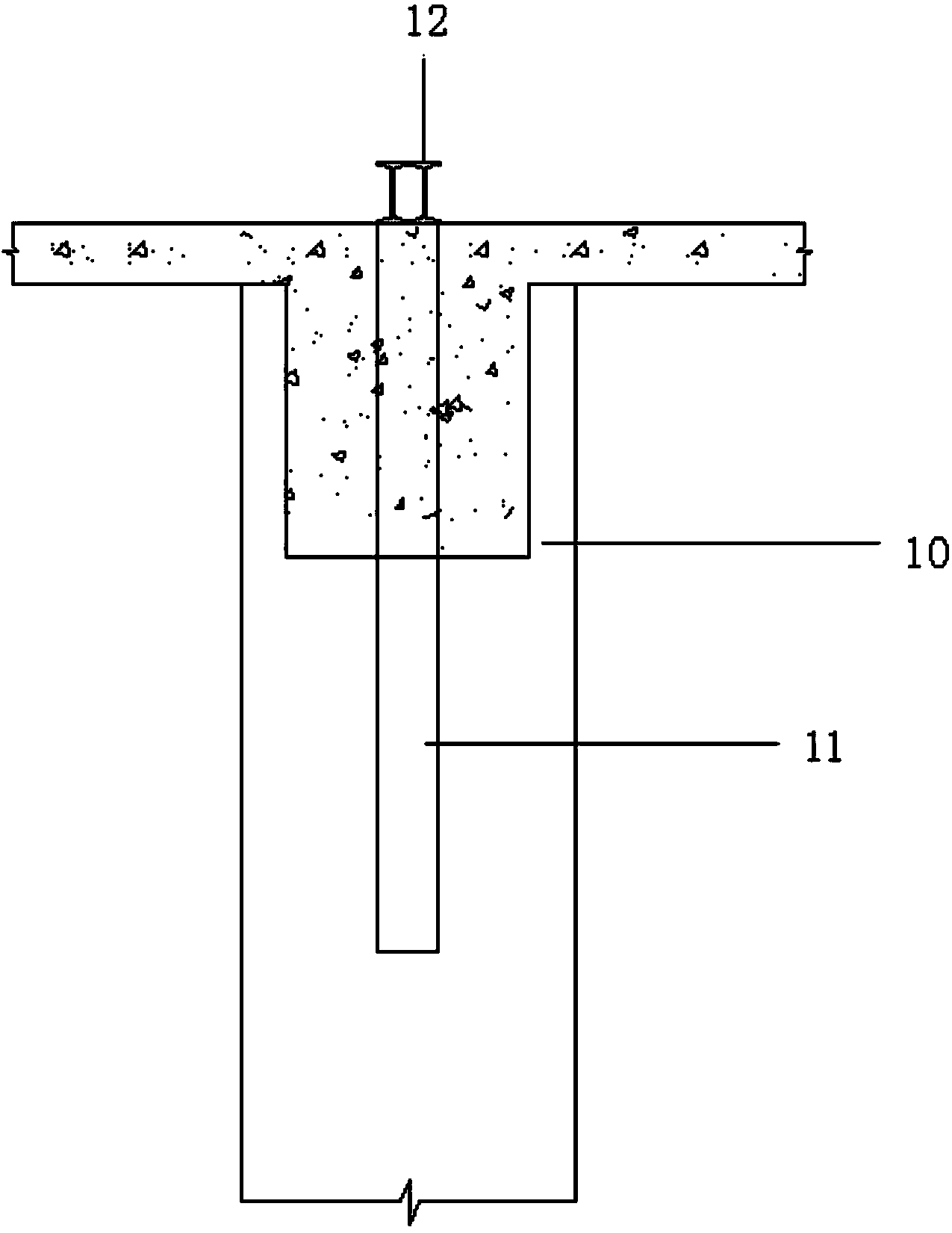

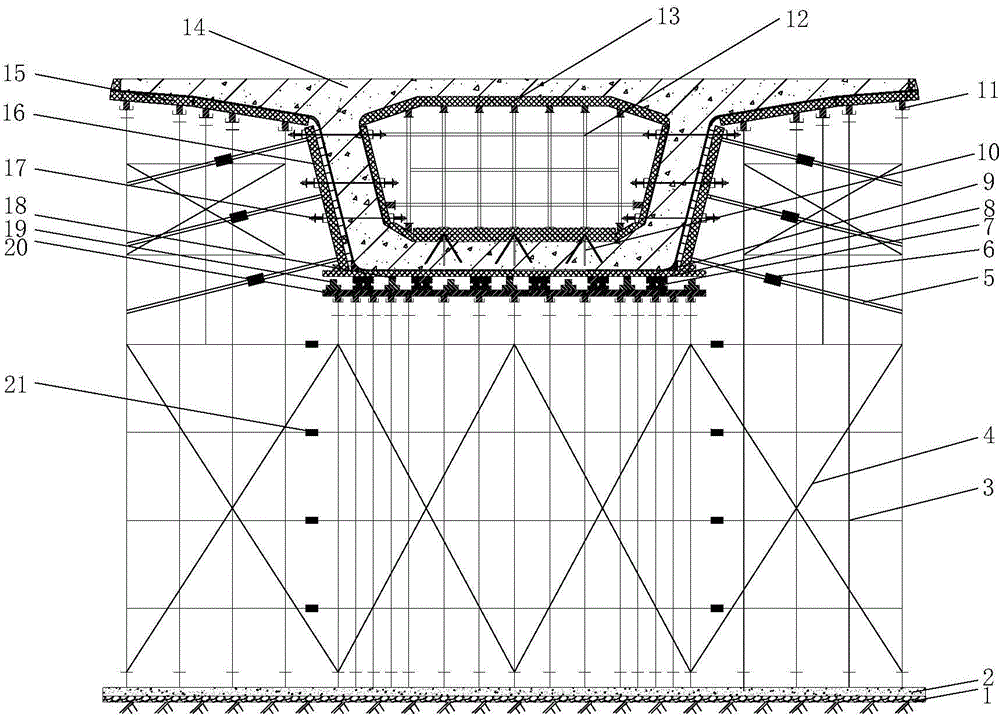

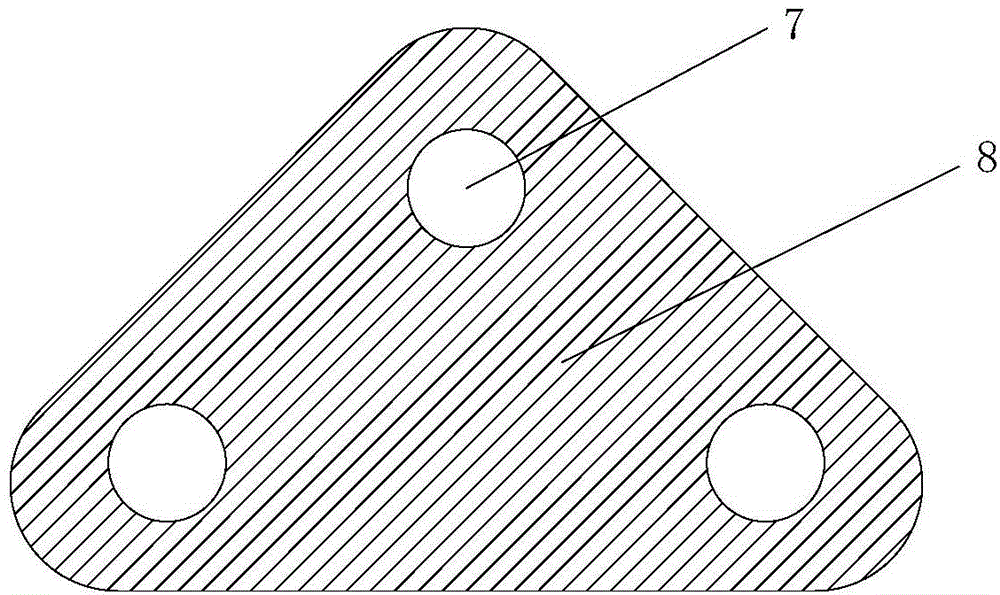

Bailey beam suspension formwork supporting system and construction method thereof

ActiveCN104141383ASimple structureEasy to transportForms/shuttering/falseworksBuilding material handlingFalseworkSupporting system

The invention discloses a bailey beam suspension formwork supporting system and a construction method thereof. The bailey beam suspension formwork supporting system comprises longitudinal and transverse stress trusses (2) consisting of bailey beams (1); suspenders (5) are arranged on transverse bailey beams (3) and the suspenders penetrate through a concrete layer structure bottom formwork (6) for suspending a bidirectional I-shaped steel load-bearing platform (7); a steel pipe scaffolding formwork supporting system (8) is arranged above the platform, the transverse bailey beams are perpendicularly arranged above the longitudinal bailey beams (9) according to spacing, and the longitudinal bailey beams (9) are supported on a framework structure or temporary supports (10). The construction method of the bailey beam suspension formwork supporting system comprises the following steps: erecting a bailey beam formwork supporting system suspension system at the upper part of an additionally constructed layer in advance, and laying a formwork support operating platform below. The bailey beam suspension formwork supporting system and the construction method thereof have the advantages that the construction site is not occupied, the system and the method are suitable for cast-in-situ concrete construction of aerial connecting corridors, high and large muntin and transfer layer engineering of reinforced concrete or section steel combined structures, are particularly suitable for additionally constructed engineering which does not have a stress relationship with original structures, and have unique advantages.

Owner:北京万兴建筑集团有限公司

Mold supporting structure for variable cross-section cast-in-place box girder at section combining horizontal and longitudinal curves, and construction method of the mold supporting structure

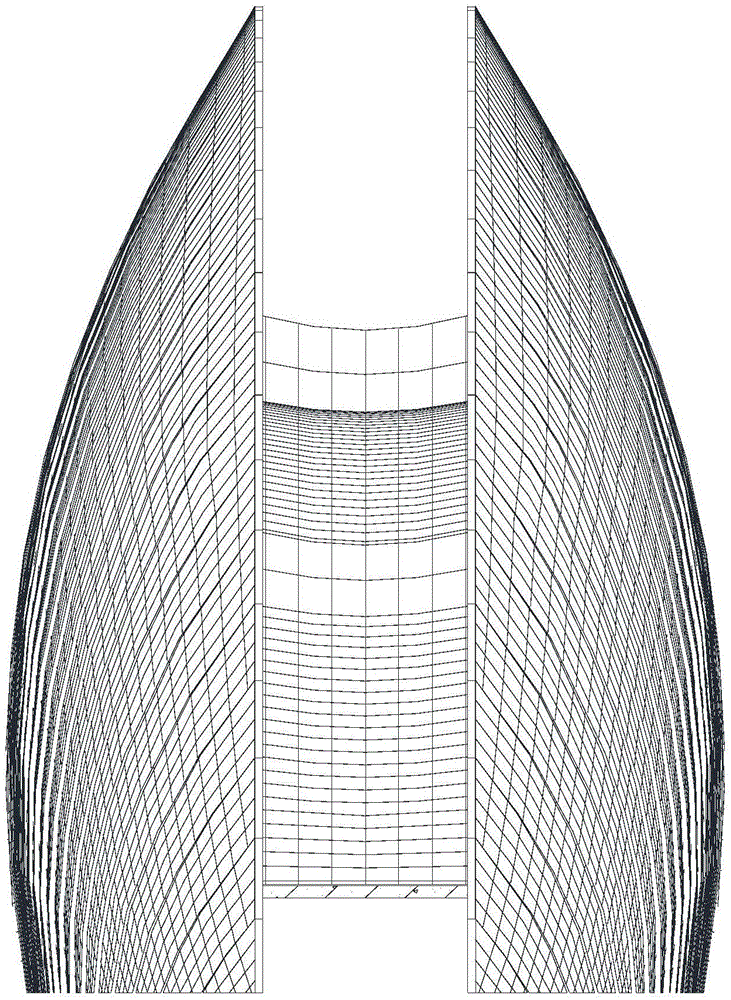

ActiveCN104963290ARealize three-way stereo controlMonitor stress changesBridge erection/assemblyFalseworkBox girder

The invention relates to a mold supporting structure for a variable cross-section cast-in-place box girder at a section combining horizontal and longitudinal curves. The mold supporting structure mainly comprises an all-round scaffold, adjustable inclined supports, synchronous hydraulic jacks, composite moulds and adjustable supporting bases, wherein the all-round scaffold is formed by the overlapping connection of scaffold sets; the synchronous hydraulic jacks and the adjustable supporting bases are uniformly arranged at the joints of longitudinal supporting beams and transverse supporting beams at the top; the synchronous hydraulic jacks and the adjustable supporting bases are used as an upper part supporting body system, and a bottom mold is mounted on the top surface; the mounting angle of each lateral mold is adjusted through the adjustable inclined supports, and the lateral molds are fixedly connected with the bottom mold and an inner mold; custom-made steel templates are arranged at chamfers and circular-arc parts of the variable cross-section cast-in-place box girder; a core mold of the variable cross-section cast-in-place box girder is supported by an internal scaffold, and is fixed to the lateral molds through opposite-pull screw rods. Through the adoption of the mold supporting structure disclosed by the invention, the three-dimensional control for the moulds of the cast-in-place box girder at the section combining horizontal and longitudinal curves is realized, and besides, the uniform stress for the scaffold during concrete pouring can be guaranteed. The invention further provides a construction method of the mold supporting structure for the variable cross-section cast-in-place box girder at the section combining horizontal and longitudinal curves.

Owner:CITIC GUOAN CONSTR GRP CO LTD

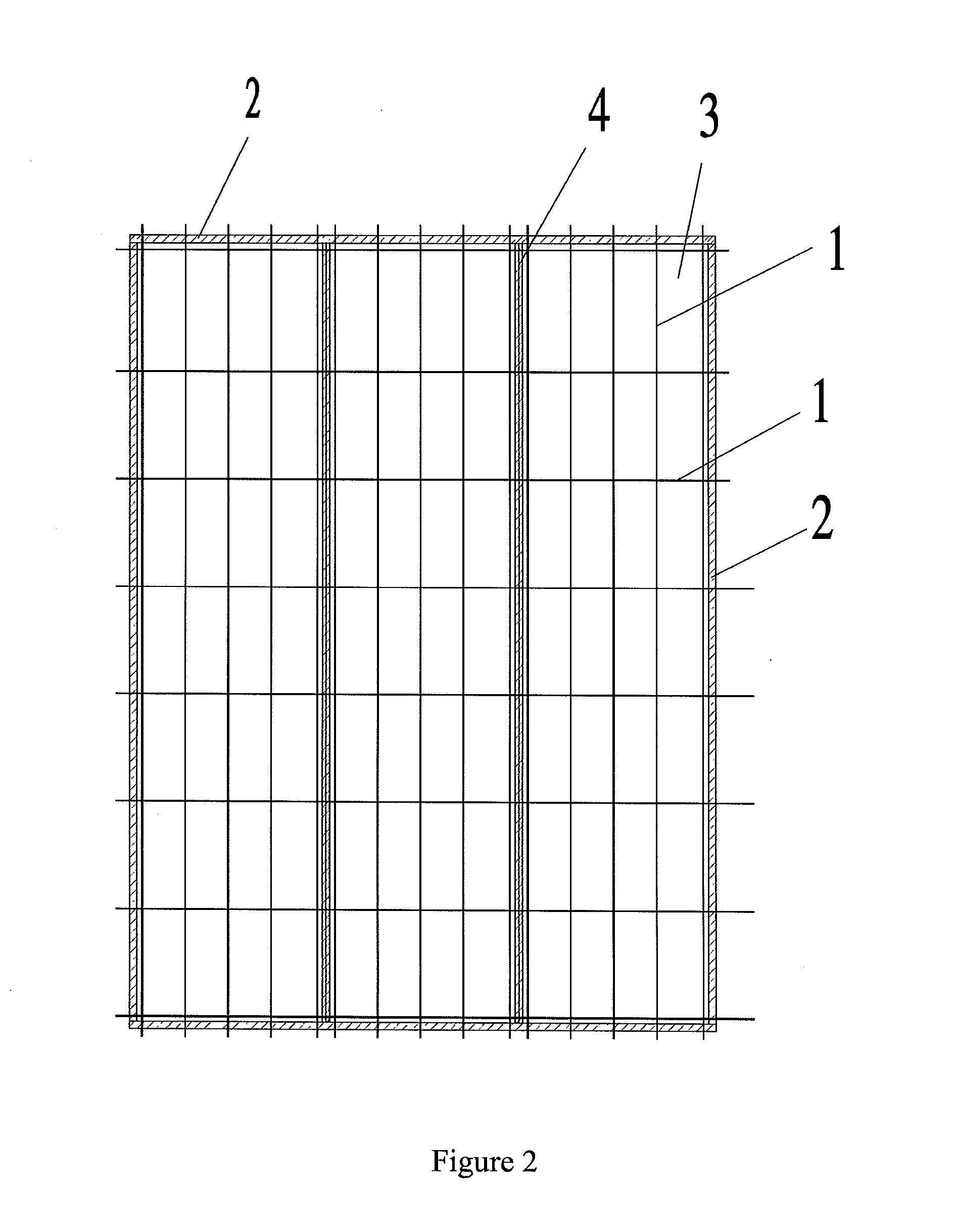

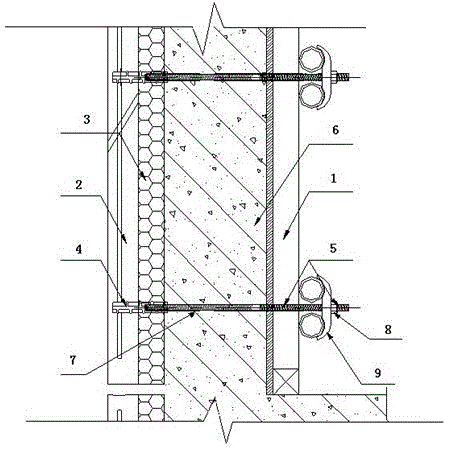

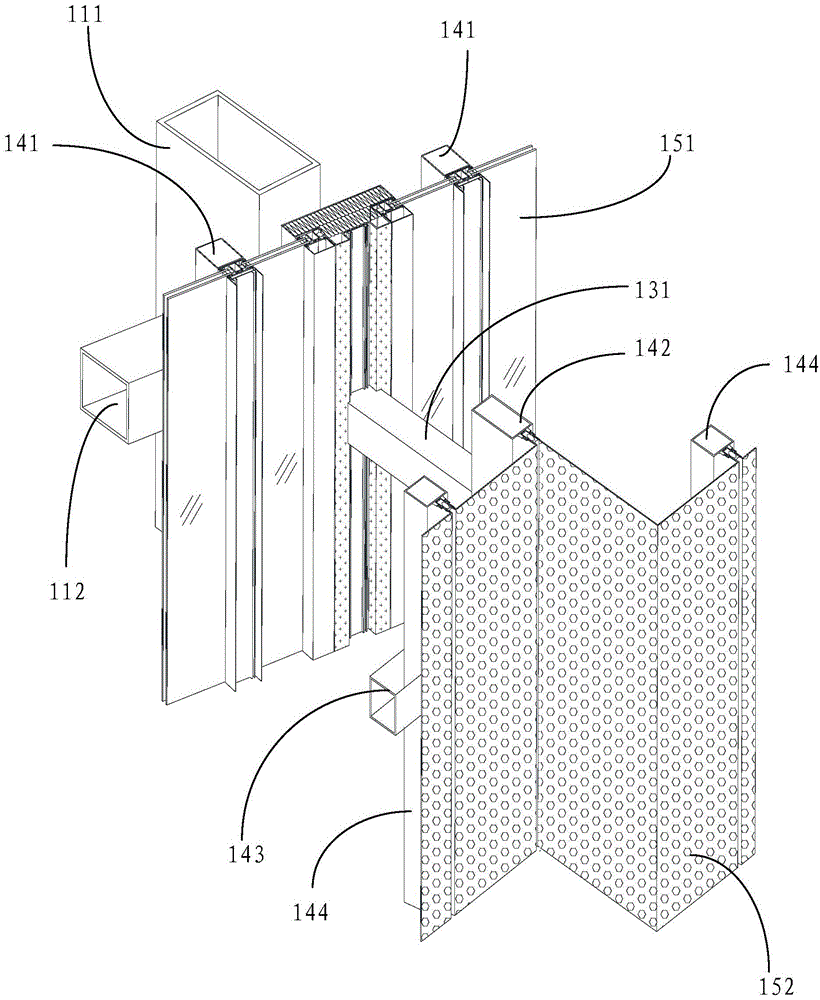

Prefabricated external wall template structure system with heat insulation function, and construction method thereof

InactiveCN105019573AReduce secondary constructionImprove insulation effectWallsFalseworkInsulation layer

The invention discloses a prefabricated external wall template structure system with a heat insulation function, and a construction method thereof. The prefabricated external wall template structure system with the heat insulation function comprises a prefabricated concrete external wall template. A heat insulation layer is fixed at inside of the prefabricated concrete external wall template. A cast-in-situ shear wall is poured at inside of the heat insulation layer. The cast-in-situ shear wall is obtained through field pouring in a manner that the prefabricated concrete external wall template and an inner template which is vertically arranged at inside of the prefabricated concrete external wall template are used as supports; and wall body reinforcing bars are bond in the cast-in-situ shear wall. Compared with the prior art, the prefabricated external wall template structure system and the construction method are advantageous in that the heat insulation layer is combined with the prefabricated concrete external wall template, thereby saving secondary construction of the heat insulation layer; the heat insulation layer is arranged at inside part of the prefabricated concrete external wall template, so that the service life of the heat insulation layer is same with that of the body structure, thereby improving durability of the heat insulation layer, improving heat insulation performance of a building wall and improving construction quality. According to the prefabricated external wall template structure system, a construction external template and an external scaffold can be saved, thereby improving construction efficiency.

Owner:NANJING YANGTZE RIVER URBAN AGCHITECTURAL DESIGN

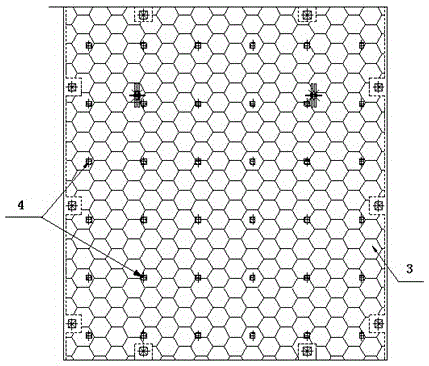

Porous orthopedic or prosthetic support having removable cushioning and scaffolding layers

An orthopedic or prosthetic support including at least three layers that allows for aeration and cushioning of the enclosed area is described herein. The orthopedic or prosthetic support includes an inner cushioning layer which is compressed against the skin in use. An intermediate scaffolding layer is situated substantially parallel to the inner cushioning layer and is maintained in spaced apart relationship with the inner cushioning layer by spacer members. An exterior layer overlays the intermediate scaffolding layer and may be either a flexible breathable fabric such as velvet or a thermoplastic with a plurality of perforations. The inner cushioning layer and the intermediate scaffolding layer include a plurality of perforations providing air pathways through the two layers. The grid-like arrangement of spacer members also define air passages between the inner and intermediate layers which further enhance circulation of exterior air to the skin covered by the orthopedic or prosthetic support.

Owner:BARBERIO ALESSANDRO

Overhanging type scaffold supporting system

ActiveCN101736893AImprove construction efficiencyImprove securityBuilding support scaffoldsSupporting systemFalsework

The invention provides an overhanging type scaffold supporting system capable of solving the problems that an overhanging type scaffold can not be supported and has potential safety hazards in the prior art. The overhanging type scaffold supporting system comprises a floor plate and an outer wall body of a building, and a plurality of overhanging beams passing through the outer wall body, wherein each overhanging beam is divided into a cantilever part extending out of the outer wall body and a fixed part fixed on the floor plate, the scaffold is arranged on the cantilever parts, and the length of each fixed part is at least 1.5 times of that of each cantilever part. The invention provides a normalized and standardized overhanging type scaffold supporting system which can be adapt to the construction of the overhanging type scaffold for the outer walls of various high-rise buildings, has the characteristics of factory and standardized fabrication, flexible use, high construction efficiency, reliable installation quality and high safety, and effectively ensures the quality of the construction technology of the overhanging type scaffold for the high-rise buildings.

Owner:QINGDAO TONGGUANG CONSTR ENG GROUP

Construction method of large conchoidal hyperbolic curtain wall

The invention discloses a construction method of a large conchoidal hyperbolic curtain wall. The construction method comprises the following steps of mounting a scaffold support and a wall connecting piece on a conchoidal hyperbolic main structure; mounting a scaffold on the scaffold support and the wall connecting piece; mounting a bracket structure on the conchoidal hyperbolic main structure; mounting a first cambered keel frame on one side, which is close to the conchoidal hyperbolic main structure, of the bracket structure; mounting a second cambered keel frame on the other side, which is far away from the conchoidal hyperbolic main structure, of the bracket structure; mounting a first cambered curtain wall on the first cambered keel frame; and mounting a second cambered curtain wall on the second cambered keel frame. The scaffold is mounted by the scaffold support arranged on the conchoidal hyperbolic main structure, and can be supported by the conchoidal hyperbolic main structure, and connection between the scaffold and the conchoidal hyperbolic main structure is improved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com