Inclined drawing steel truss high-supported formwork structure system and construction method thereof

A construction method and technology of steel trusses, which are applied to building structures, formwork/formwork/work frames, and on-site preparation of building components. The problem of complex force transmission of the steel pipe formwork support of the ground fasteners, etc., achieves the effect of reducing requirements and ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

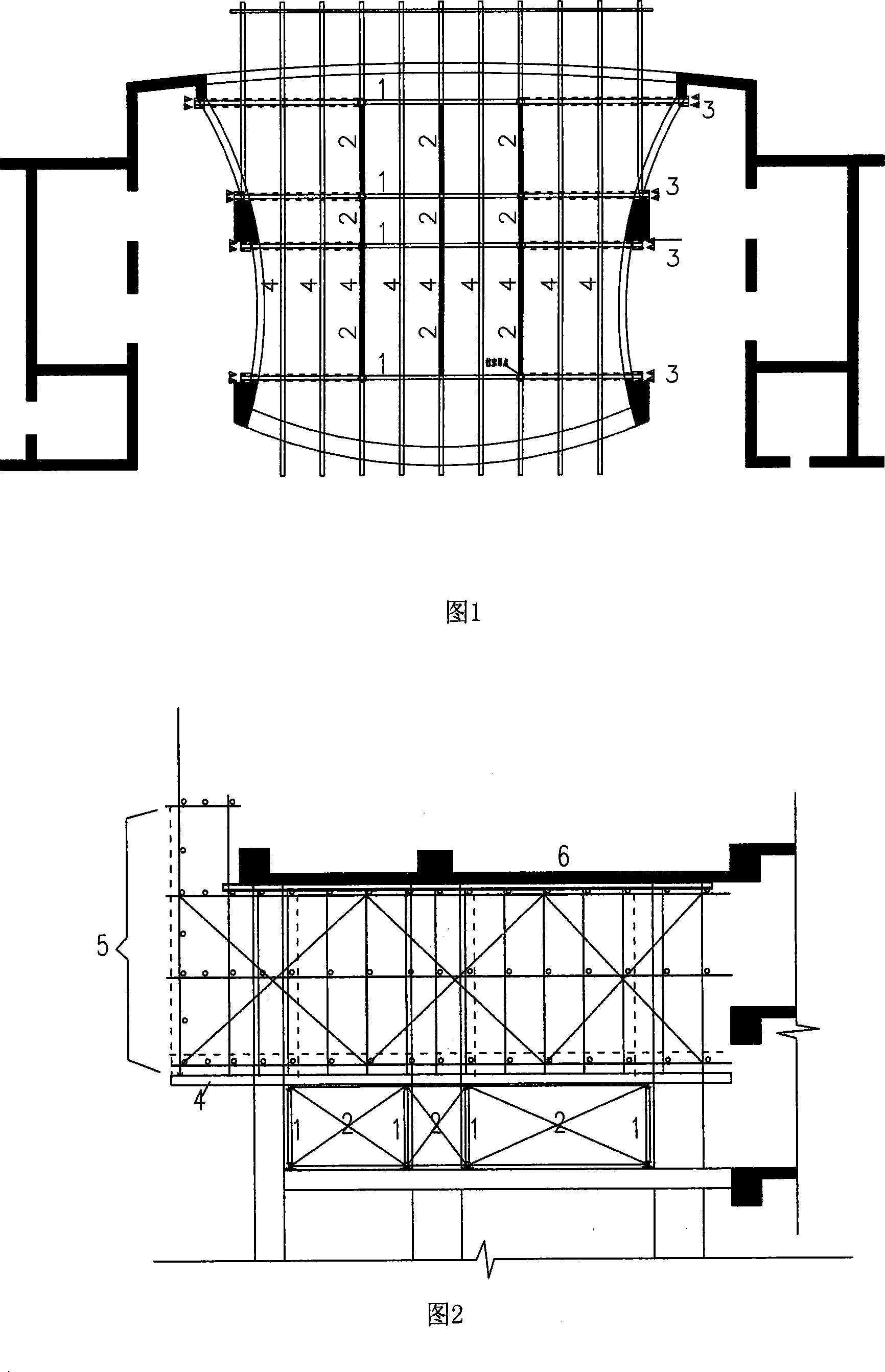

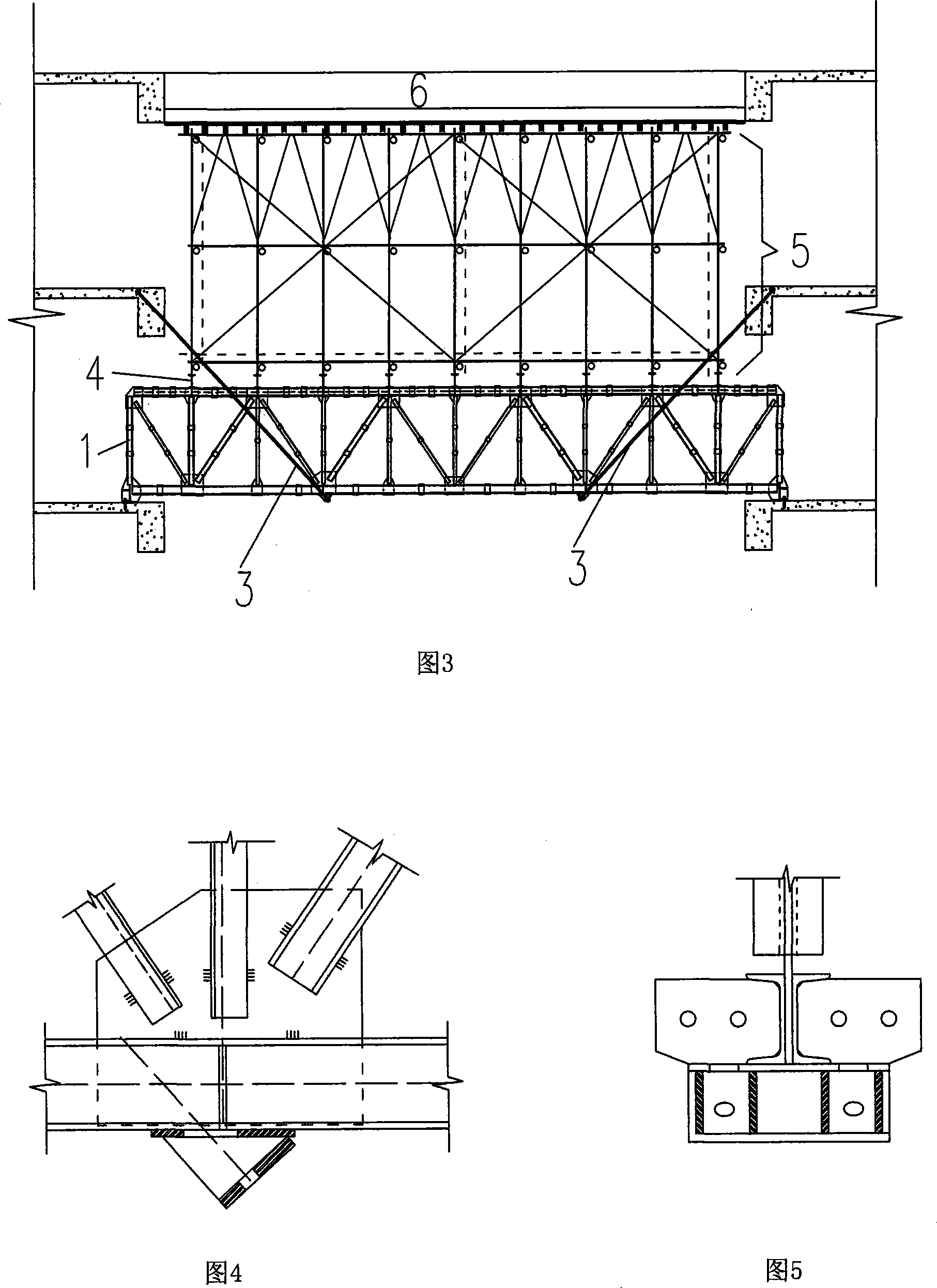

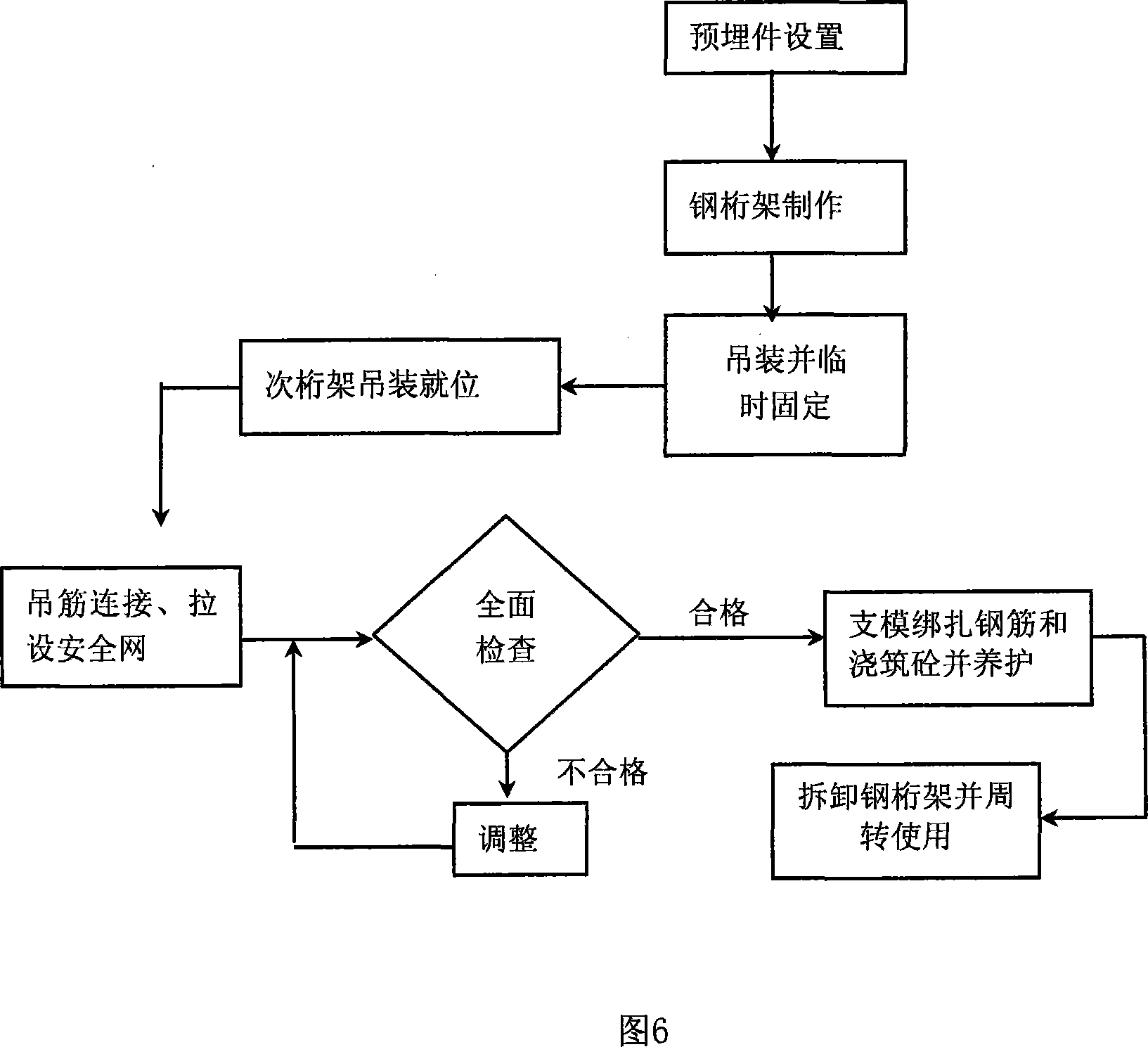

[0038] As shown in Figures 1-3, a cable-stayed steel truss high formwork structure system according to the present invention includes a main load-bearing steel truss 1, a connecting steel support 2, a truss cable-stayed hanging bar 3, and a beam 4 And steel pipe scaffold formwork support 5, four steel trusses 1 are set on the structure of the completed building under the high-altitude and long-span reinforced concrete floor to be poured in the form of two-end support, and the steel trusses 1 of each group are connected by setting steel supports 2 To increase the plane stability of the steel truss, the four truss cable-stayed hanging bars 3 are symmetrically suspended between the steel truss 1 and the main structure of the completed building on both sides; The formwork support 5 is built on the beam 4, and the tall atrium floor 6 is poured on the basis of the steel pipe scaffold formwork support 5. The steel truss 1 can be a finished Bailey frame or a military truss beam, or a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com