Construction method for support structure of coal tower template for tamping type coke oven

A formwork support and construction method technology, applied in the field of formwork/formwork/work frame, preparation of building components on site, building structure, etc., can solve the problems of high construction costs, potential safety hazards in supporting coal towers, and endangering life safety, etc. problems, to achieve the effect of safe and convenient operating conditions, high concrete structure strength, safe and reliable force bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with drawings and embodiments.

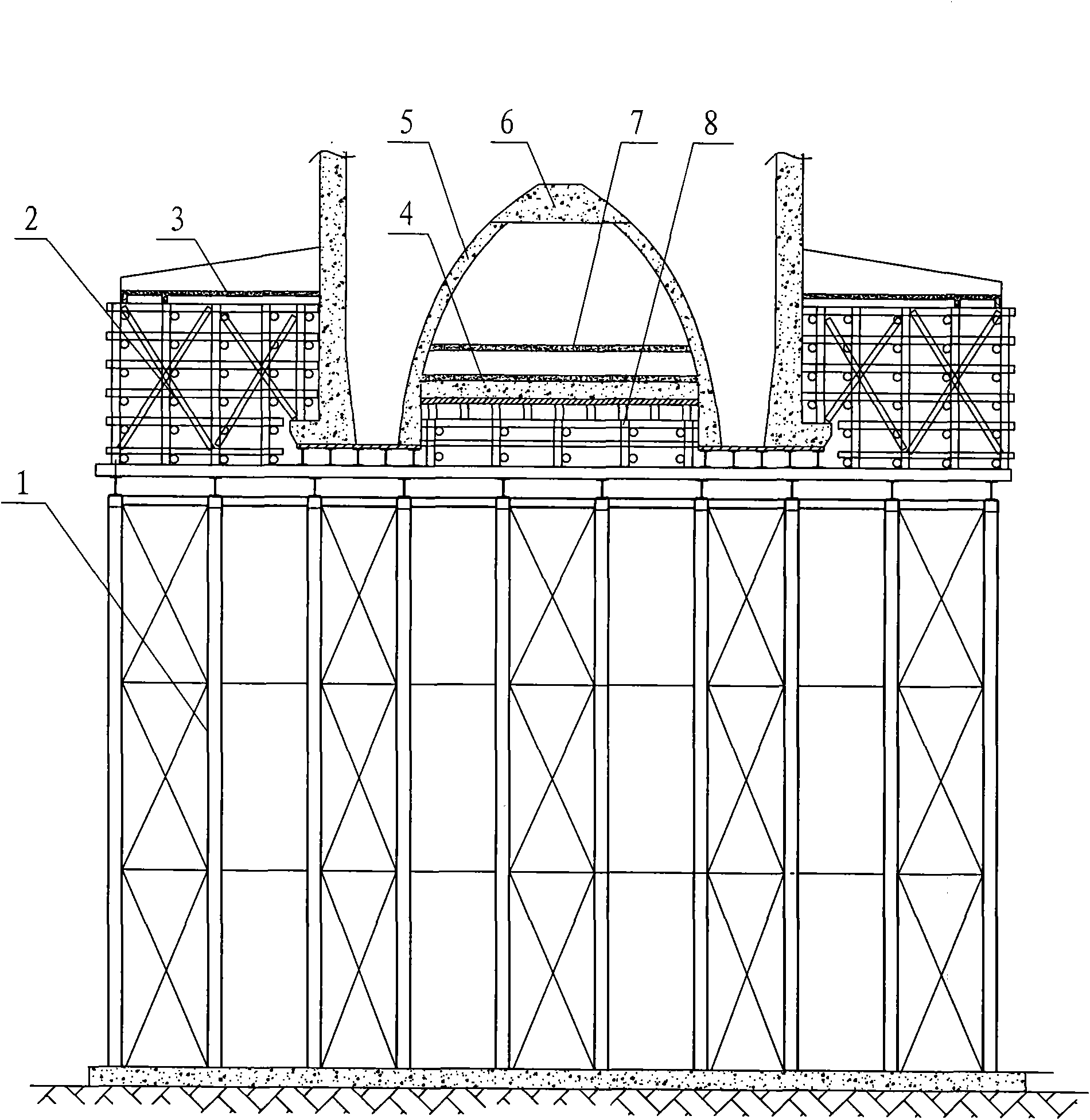

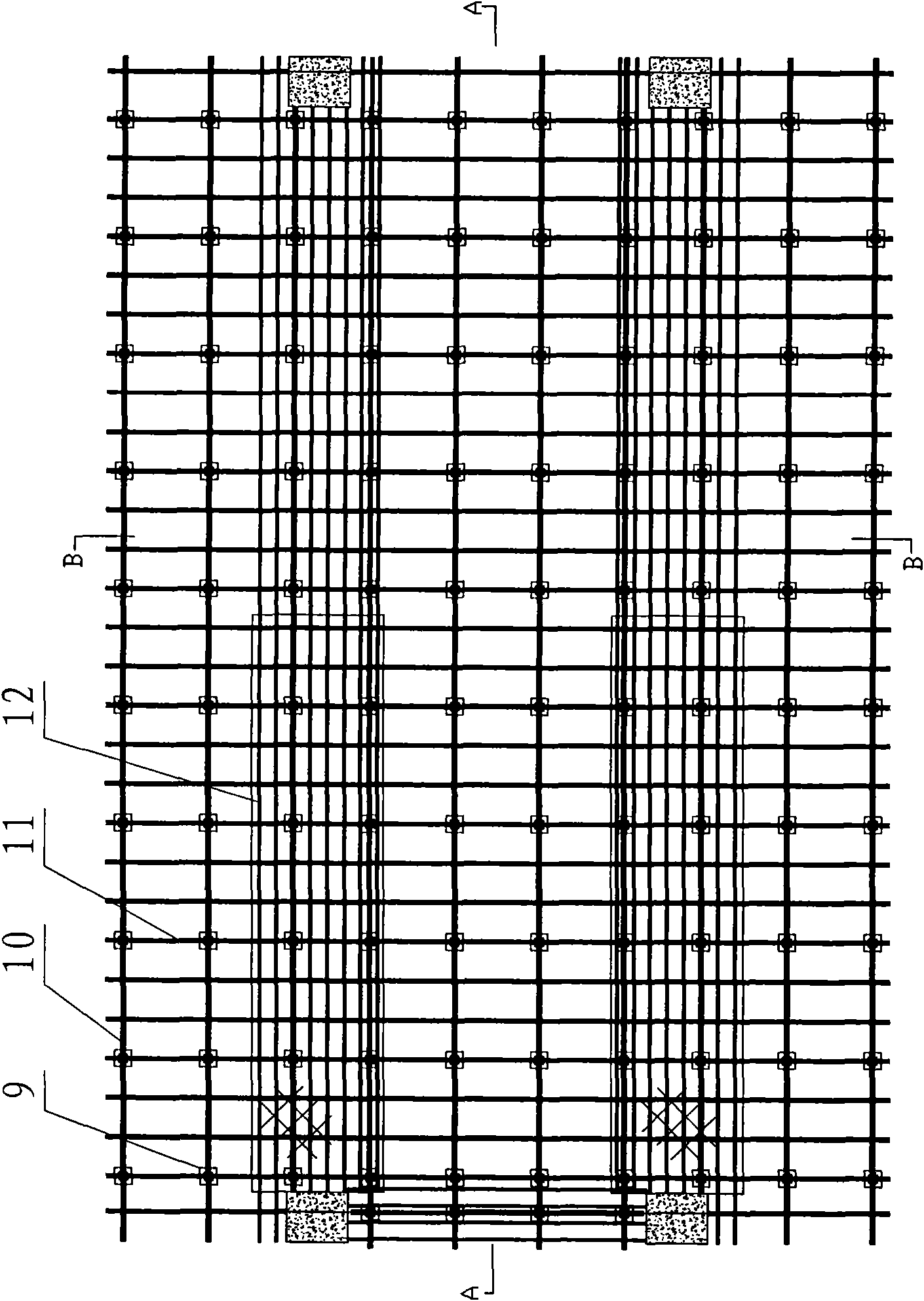

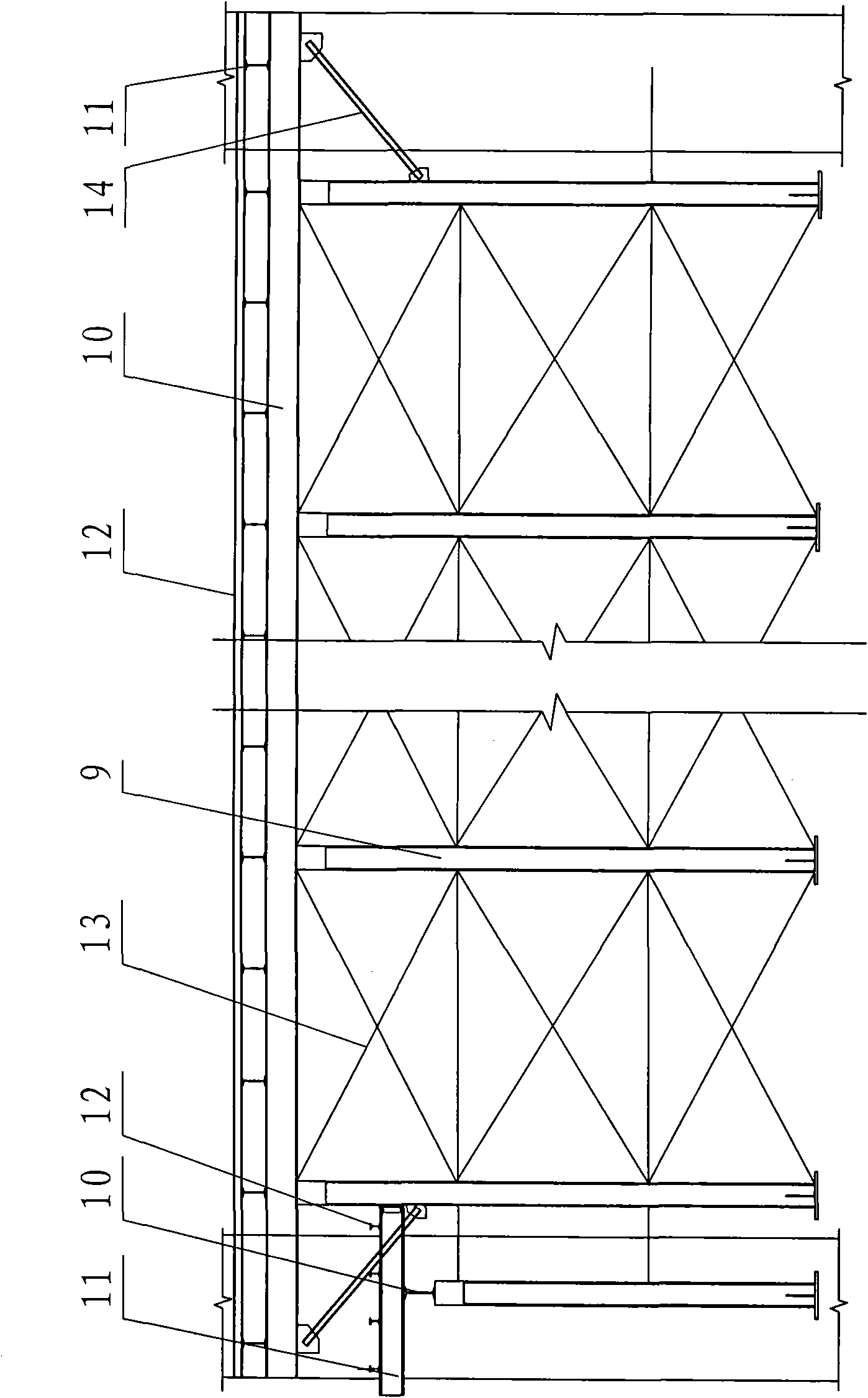

[0045] See attached Figure 1-6 , in the present embodiment, the construction method of the tamping-type coke oven coal tower large-span, high-branch, and heavy-duty formwork support structure, the support structure of this formwork includes a steel structure support platform 1 for supporting the formwork as a whole, and also includes Brackets for supporting the individual formworks, these include brackets for supporting Floor template 4, Floor template 7, Overhanging eave formwork 3, hyperbolic formwork 5 in the hyperbolic funnel formwork, formwork support frame of funnel main beam formwork 6.

[0046] Among them: the steel column 9 of the steel structure support platform 1 is made of H-shaped steel H250×250×14×14, which is welded with the anchor plate. The support between the steel columns 9 adopts L75×6 angle steel 13, and the gusset plate δ8. The steel beams...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com