Unilateral formwork erecting system of cast-in-site concrete arc outer wall body and construction method thereof

A single-side formwork and concrete technology, which is applied in the direction of formwork/formwork/work frame, connectors of formwork/formwork/work frame, and on-site preparation of building components, can solve problems such as difficult implementation and achieve saving Labor force, satisfying structural construction quality, and shortening the construction period

Inactive Publication Date: 2010-09-22

CHINA CONSTR SECOND ENG BUREAU LTD

View PDF3 Cites 37 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The invention provides a cast-in-situ concrete arc outer wall single-side formwork system and its construction method, which solves the technical problem that the traditional formwork method is difficult to implement when there is no construction work surface between the basement outer wall and the adjacent construction engineering outer wall

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

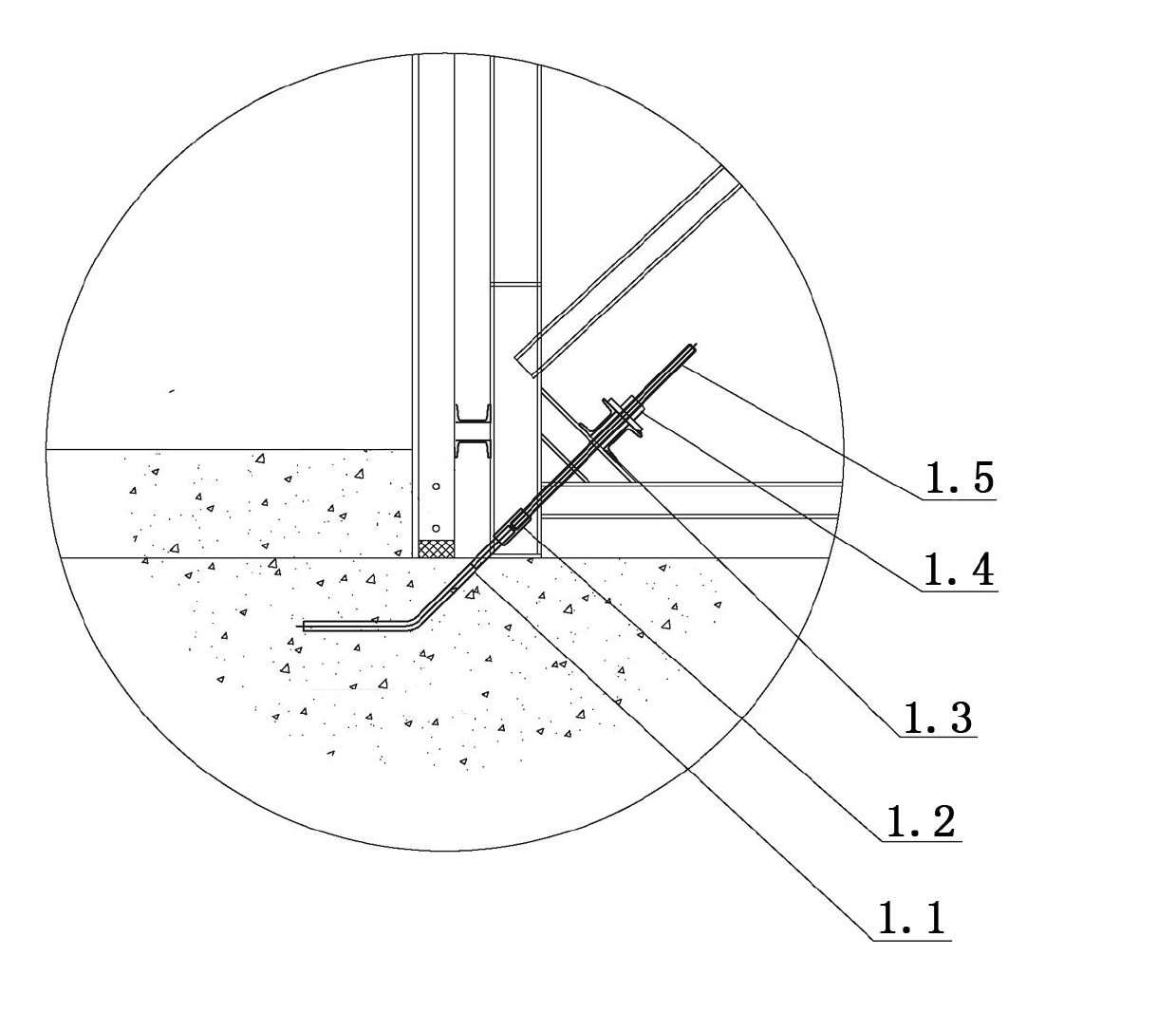

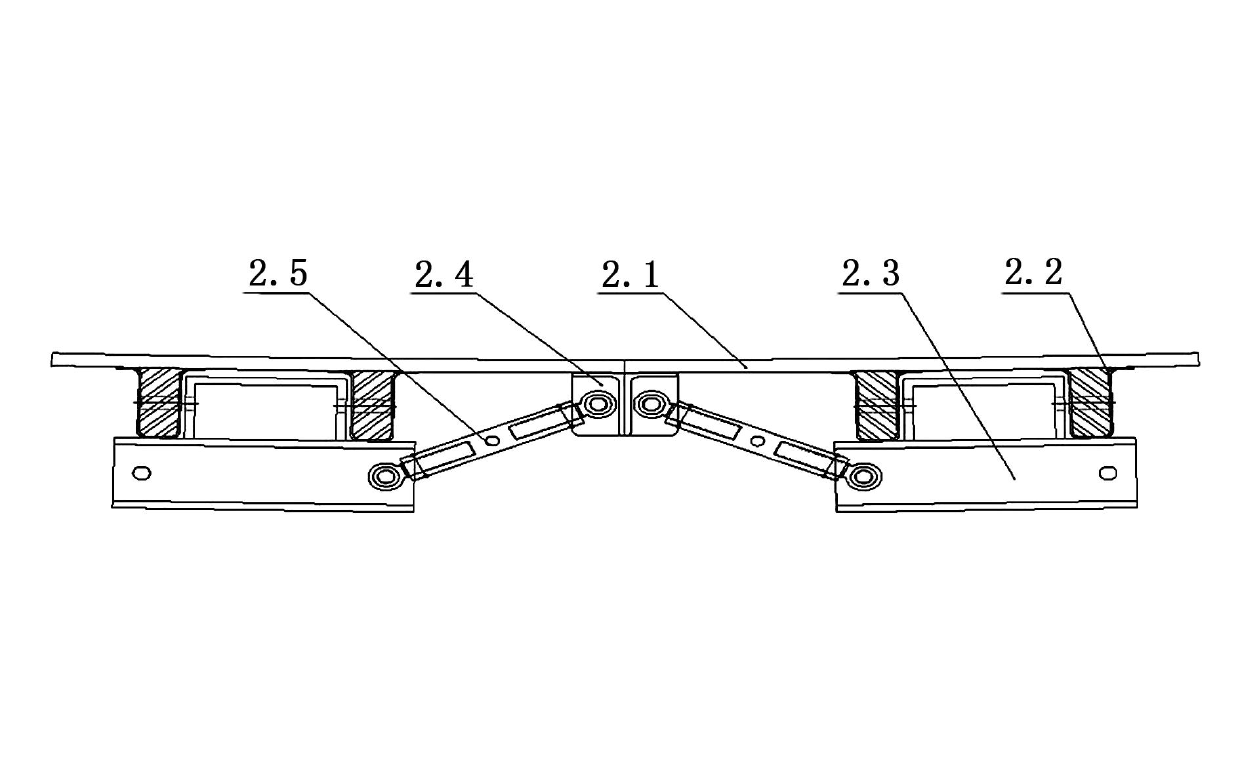

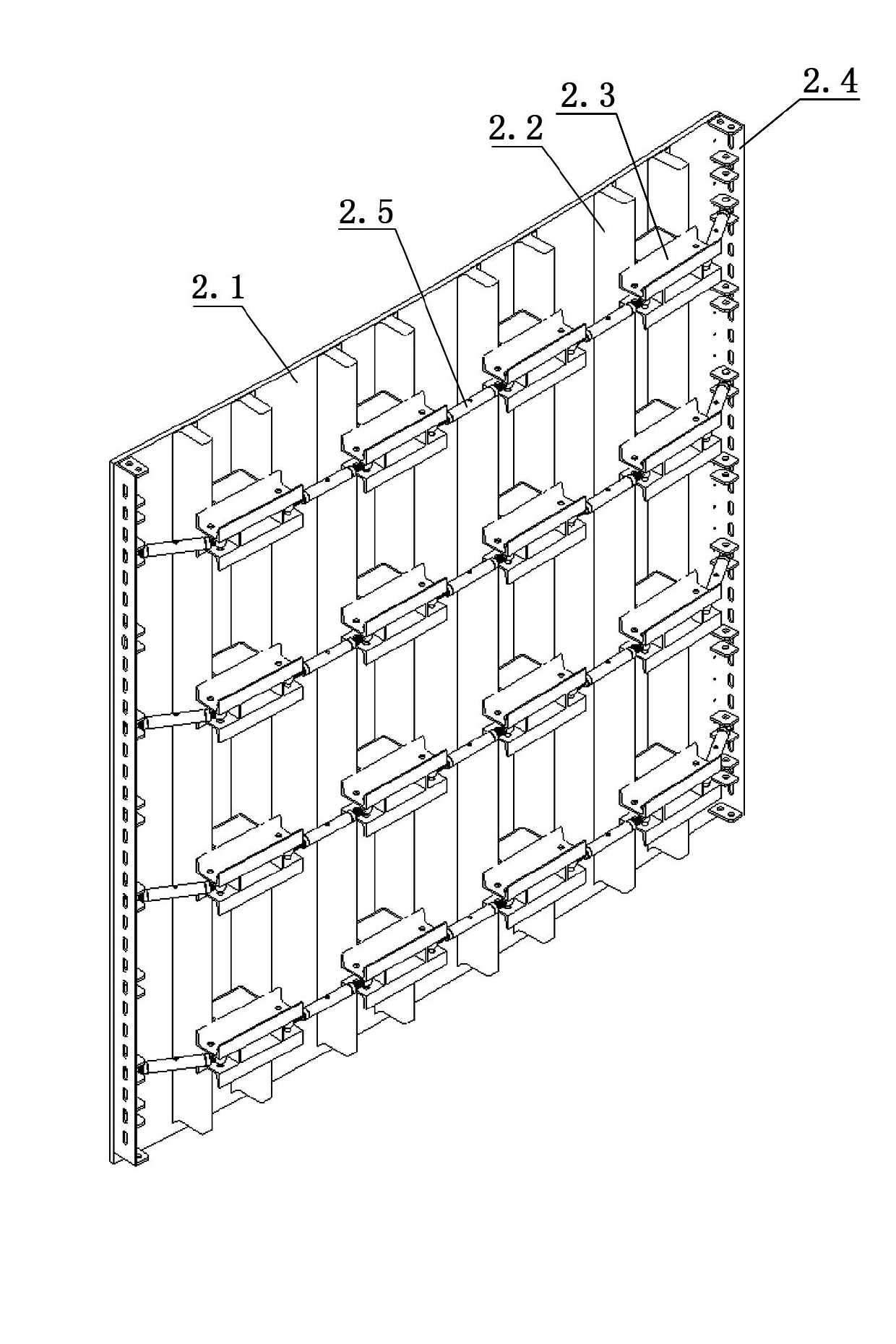

The invention discloses a unilateral formwork erecting system of a cast-in-site concrete arc outer wall body and a construction method thereof. The construction method comprises the following construction steps: 1. setting an embedded part on a concrete floor slab below an arc wall body which is not cast; 2. pre-splicing an arc wall body formwork; 3. pre-splicing and mounting a unilateral support frame on site and fastening the unilateral support frame and the embedded part; 4. connecting the unilateral support frame and the arc wall body formwork; 5. setting up a scaffold required by the unilateral support frame; 6. adjusting, reinforcing and checking various parts; 7. casting arc wall body concrete between the arc wall body formwork and an arc outer wall body of an adjacent building; and 8. detaching the formwork after the concrete strength meets the specification requirement. The invention has the advantages of greatly shortening the construction period, saving labor force, reducing the construction cost and meeting the requirement of structural construction quality and is particularly applicable for wall body construction of automobile ramps, stadiums and other large-scale public buildings with arc structures.

Description

technical field The invention relates to an exterior wall formwork support system of a concrete building and a construction method thereof. Background technique In the construction of construction projects, the cast-in-place concrete exterior wall structure of underground projects has the characteristics of large wall thickness and high building floors. Single-sided arc walls are more common in underground garages. Due to site conditions, when there is no construction work surface between the exterior wall of the basement and the exterior wall of the adjacent construction project, the construction cannot be carried out according to the traditional double-sided formwork method, and the problems of lateral pressure and buoyancy of the formwork support system are difficult to solve. The traditional double-sided formwork not only requires a lot of turnover materials, but also has low efficiency and poor stability, which cannot meet the requirements of project quality and progr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04G11/10E04G17/04E04G17/14

Inventor 刘治国翟雷安凤杰杨凯明张辉张静涛张际永

Owner CHINA CONSTR SECOND ENG BUREAU LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com