Patents

Literature

348results about How to "Ensure construction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Long screw extrusion-socketed cast-in-place pile construction method based on circulating slurry breast wall

ActiveCN106284313AReasonable structural designEasy to operateBulkheads/pilesDrilling machines and methodsUnderwaterHigh pressure

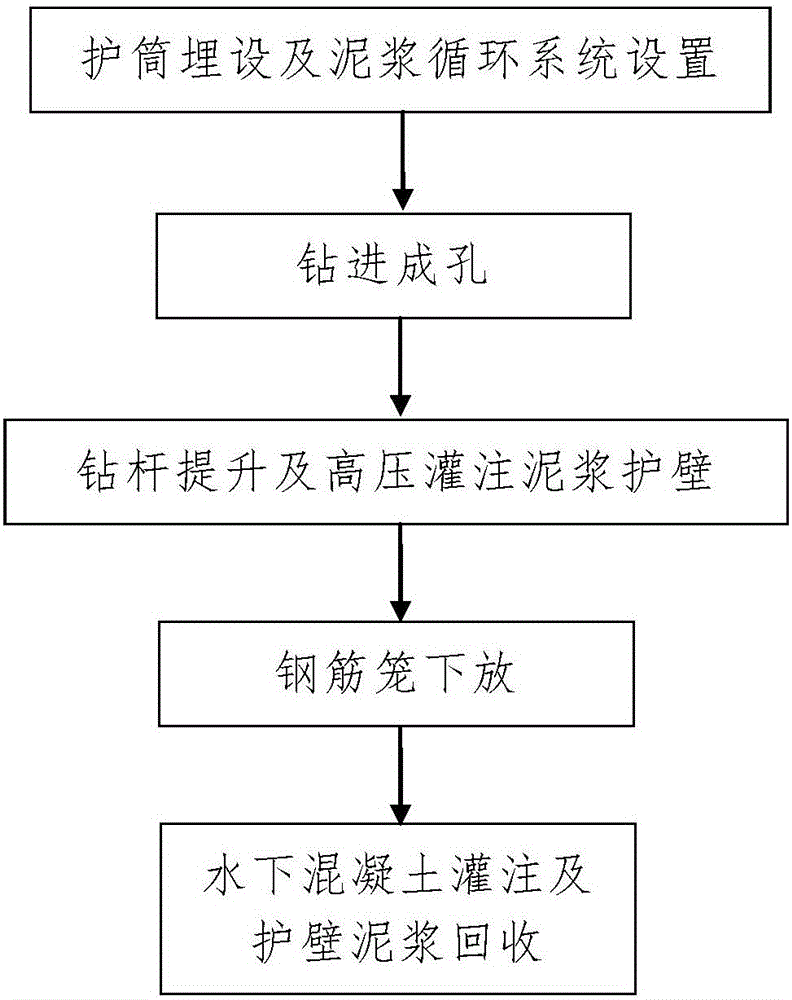

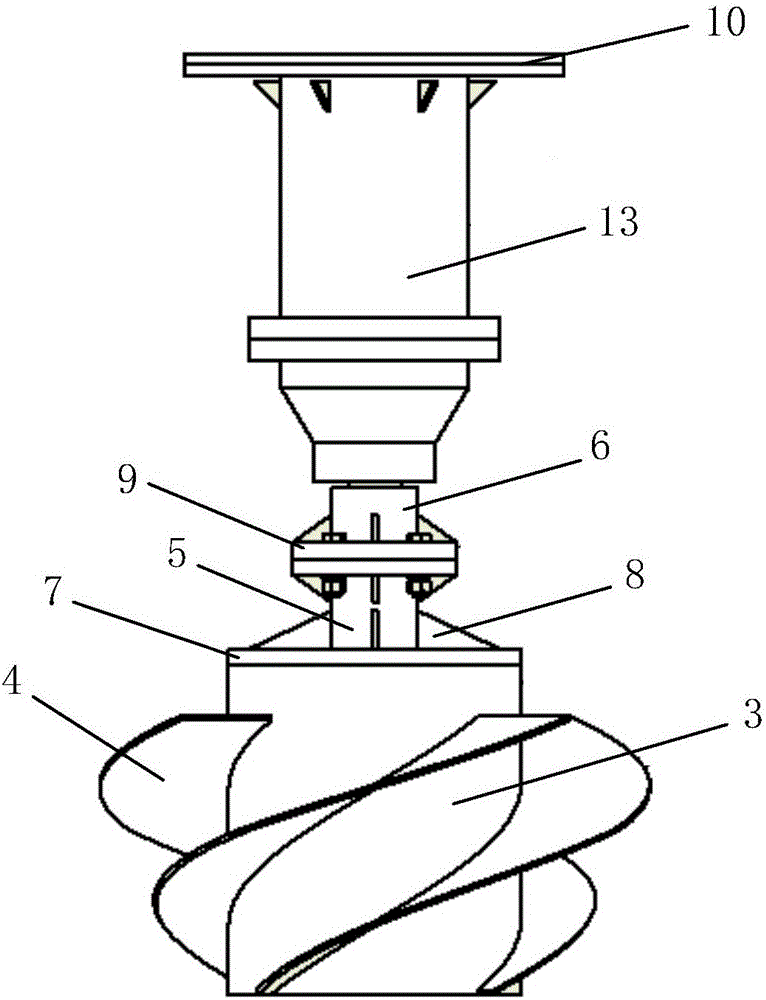

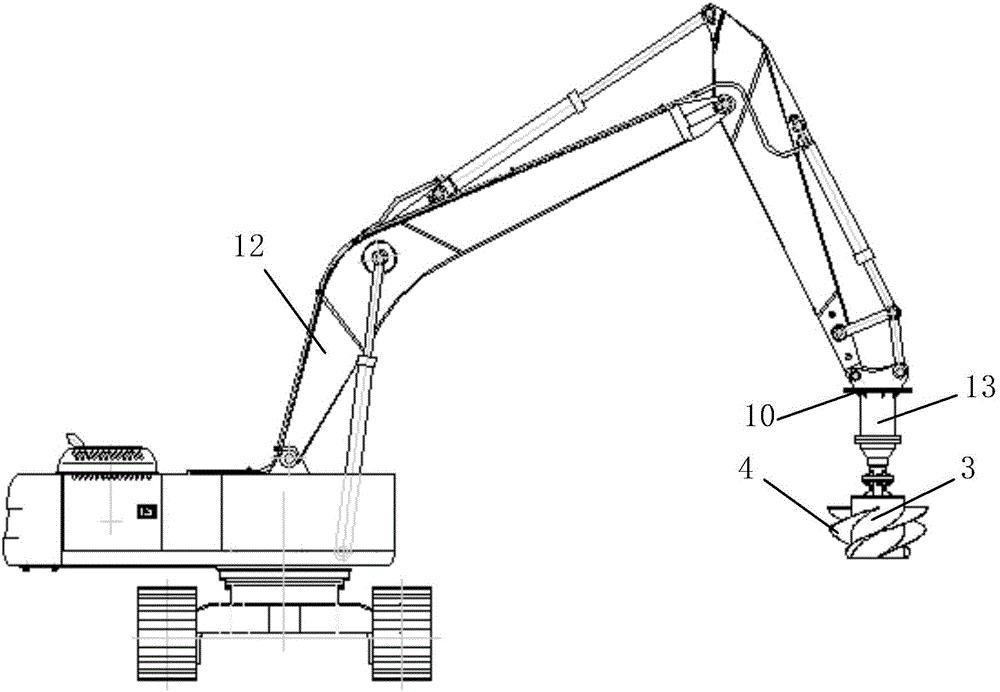

The invention discloses a long screw extrusion-socketed cast-in-place pile construction method based on circulating slurry breast wall, comprising the steps of first, burying a protective barrel and setting a slurry circulating system that comprises a slurry storage tank and a slurry pumping device, with the upper portion of the protective barrel provided with an overflow hole; second, drilling to form a borehole; third, lifting a drill pipe, and casting a slurry breast wall under high pressure: lifting up the drill pipe, and continuously casting wall supporting slurry from bottom to top from the borehole bottom through the drill pipe by using the slurry pumping device; fourth, lowering a reinforcement cage; fifth, casting concrete underwater and recycling the wall supporting slurry, and recycling the wall supporting slurry discharged through the overflow hole to the slurry storage tank for backup. The method has simple steps, is easy to implement, has high hole-forming quality and good construction effect, and enables the construction of a long screw extrusion-socketed cast-in-place pile to be finished simply and quickly, and by casting the wall supporting slurry from bottom to top from the borehole bottom in a high-pressure casting manner, it is possible to effectively protect the wall and keep the borehole bottom clean with no deposit; the wall supporting slurry is reusable.

Owner:SHAANXI ZHUANGXIN CONSTR ENG +4

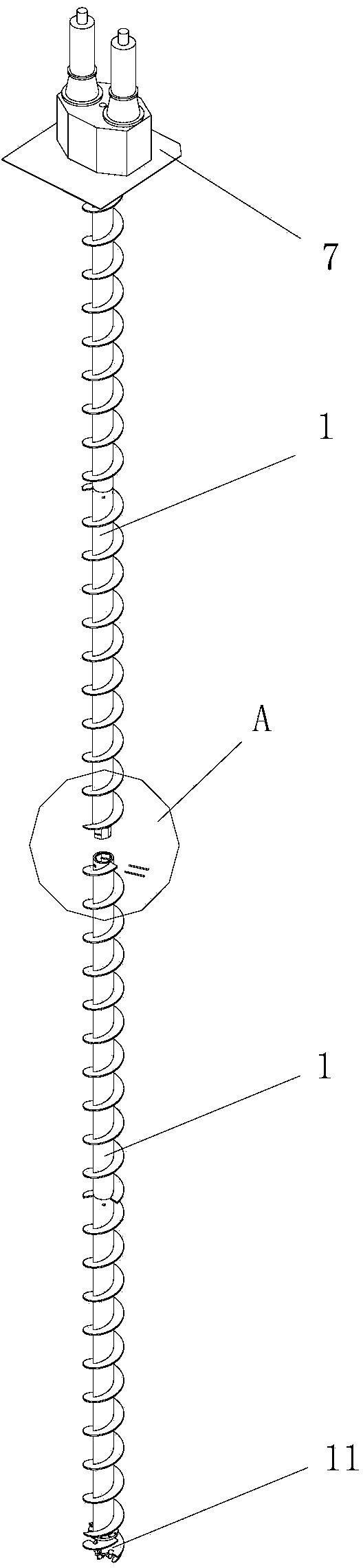

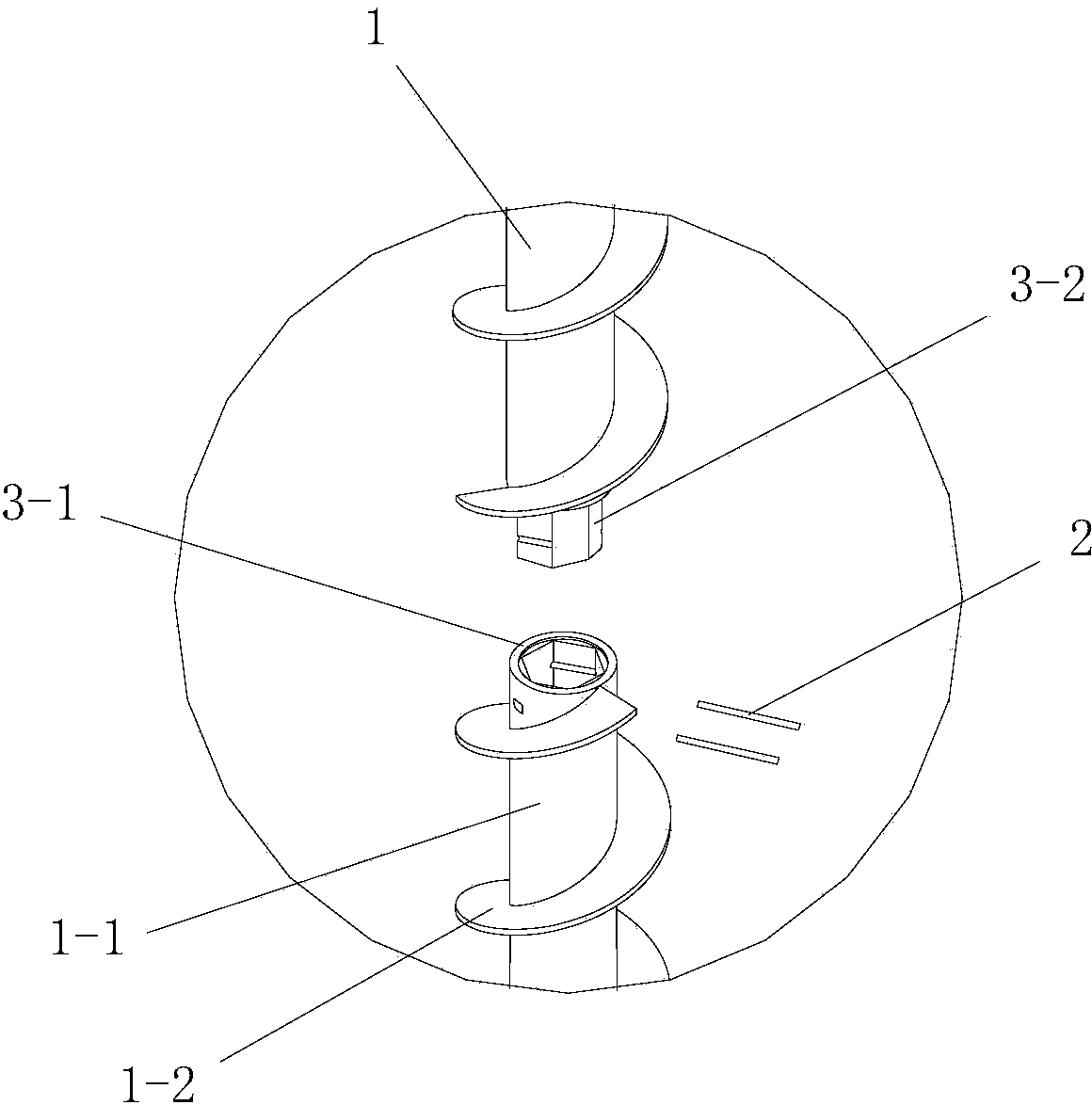

Construction technology for long-spiral cast-in-place pile extruded into rock

ActiveCN103850249AReasonable structural designEasy to operateDrilling rodsRotary drillingSlurryEngineering

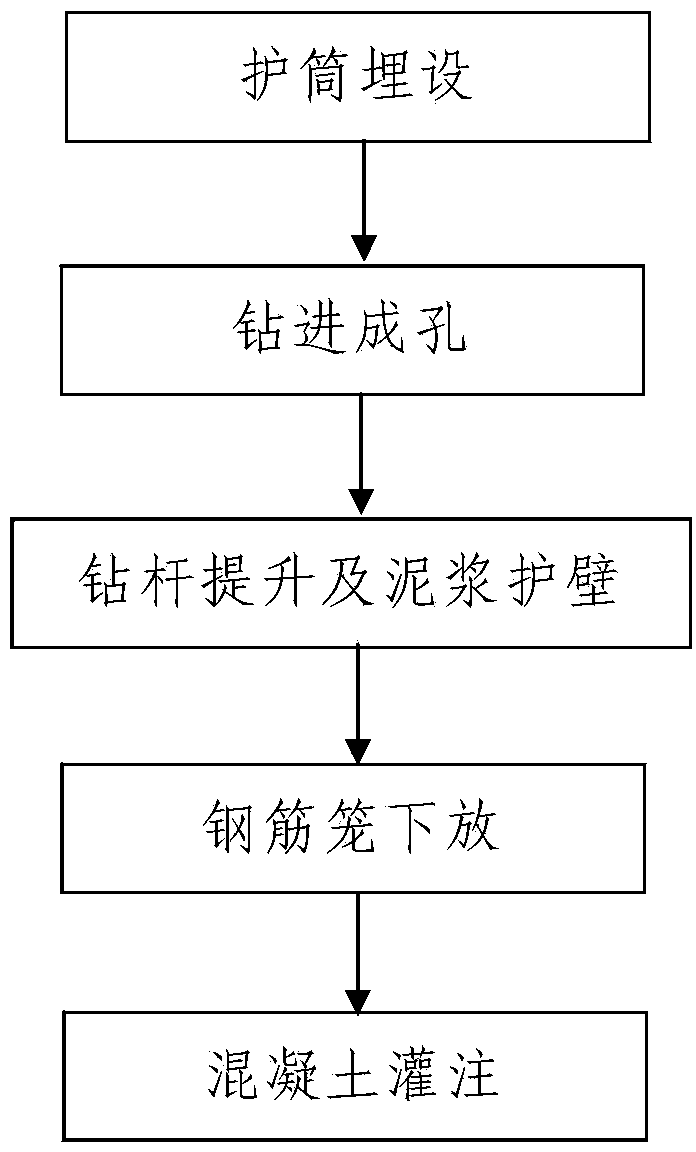

The invention discloses a construction technology for a long-spiral cast-in-place pile extruded into rock. The construction technology comprises the following steps: 1) embedding a pile casing: embedding the pile casing in a pile position acquired by surveying and setting out; 2) drilling a hole: downward drilling by a long-spiral pile machine and acquiring a constructed and formed hole after drilling in place; 3) lifting a drill rod and protecting a wall with slurry: upward lifting the drill rod after drilling in place till taking the drill rod out of the formed hole, adopting a grouting device and pumping the wall-protecting slurry through the drill rod during the process of upward lifting the drill rod, and protecting the wall with the slurry for the formed hole; 4) putting down a reinforced bar cage; 5) grouting concrete: performing concrete grouting construction on the constructed long-spiral cast-in-place pile extruded into rock through a concrete pumping device and a grouting guide tube. The construction technology provided by the invention has the advantages of simple steps, convenience in realization, high hole quality, good construction effect and capability of effectively solving the problems of the present construction for the long-spiral cast-in-place pile extruded into rock that the hole wall is easy to collapse, the hole is repeatedly cleaned, the construction efficiency is low, and the like.

Owner:SHAANXI ZHUANGXIN CONSTR ENG

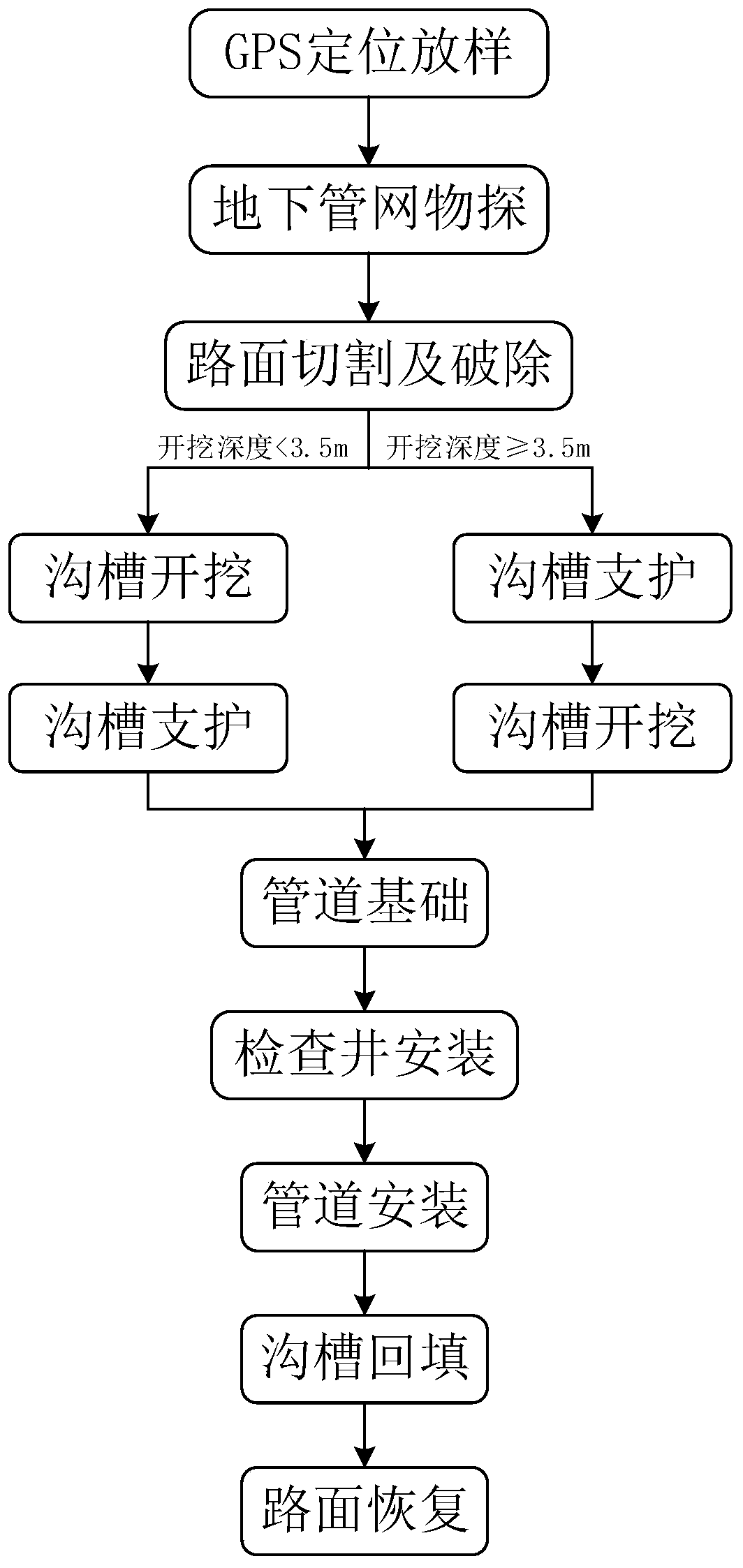

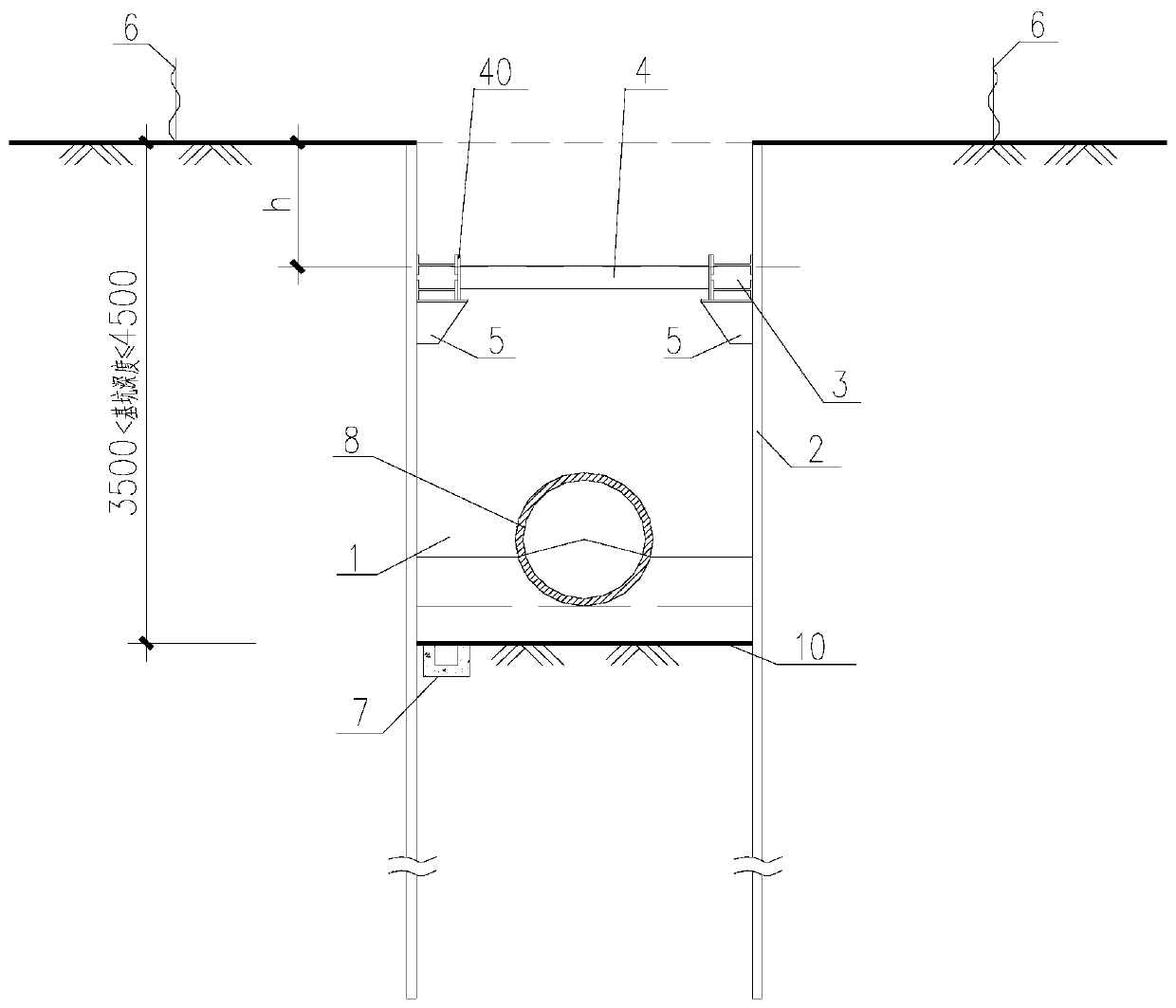

Construction method of sewage pipeline

ActiveCN110306616AReduce damageEnsure construction efficiencyArtificial islandsSoil-shifting machines/dredgersLine tubingRoad surface

The invention discloses a construction method of a sewage pipeline. The construction method comprises the following processes of GPS positioning and lofting, pavement cutting and breaking, pipeline groove supporting and excavation, pipeline foundation construction, inspection well mounting, pipeline mounting, pipeline groove backfilling, and pavement recovery. The pavement cutting and breaking process comprises the following steps of pipeline axis measuring and lofting, pavement cutting edge line marking, pavement cutting, and pavement breaking. When the pipeline groove supporting and excavation process is carried out, steel plate pile supporting is adopted when the depth is larger than 3.5 m. The pipeline foundation construction process comprises the following steps of foundation levelingand compacting, cushion layer paving, manual primary leveling, cushion layer compacting, and compactness detecting. The inspection well mounting process comprises the following steps of well bottom elevation rechecking, well bottom foundation checking, well chamber hoisting and splicing, and inspection well and pipeline connecting. The pipeline mounting process comprises the following steps of pipeline hoisting and manual mounting, pipeline axis positioning, pipeline joint cleaning, cutting, elevation and positioning retesting, and pipeline hot-melt welding or socket welding. According to theconstruction method, the construction period is greatly shortened, and the engineering efficiency is improved.

Owner:CCCC SHANGHAI DREDGING

Ultra-deep soft soil pile integral construction method based on high-precision information monitoring

ActiveCN105887811AGuaranteed verticalityGuaranteed accuracyFoundation testingBuilding constructionsNumerical controlInformation monitoring

The invention relates to an ultra-deep soft soil pile integral construction method based on high-precision information monitoring. The integral construction method mainly comprises the following construction steps of site hardening, steel pile splicing, stud connecting, steel casing arranging, rebar cage lowering, steel pile cage frame assembling, steel pile hoisting and lowering, steel pile position adjusting, steel pile perpendicularity adjusting and the like. According to the integral construction method, jacks for adjusting the horizontal position and the vertical position are separately arranged on the upper and lower ends of a steel pile cage frame, and the two kinds of jacks both adopt a numerical control mode; during the whole construction lowering process of a steel pile, the horizontal position and perpendicularity of the steel pile can be adjusted through the jacks; the jacks are all arranged on the steel pile cage frame which is provided with jack placement plates through welding, so that the jacks cannot move casually during the construction process, and construction efficiency and construction quality are ensured; the construction method is high in construction speed and good in construction quality; the position and perpendicularity of the steel pile can be correctly and conveniently adjusted; adjustment on the position of the steel pile in a reverse building method can be effectively controlled; construction is convenient; information monitoring construction can be realized; and the ultra-deep soft soil pile integral construction method has good application prospect.

Owner:SHENZHEN FUTIAN JIANAN CONSTR GRP

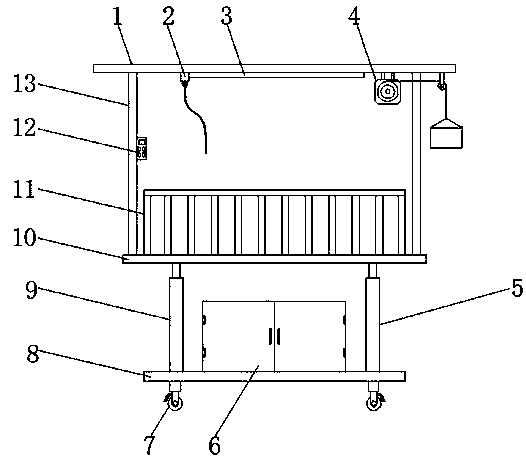

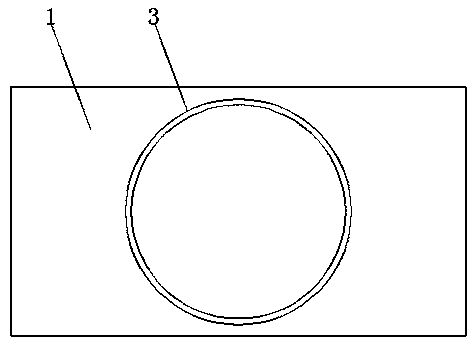

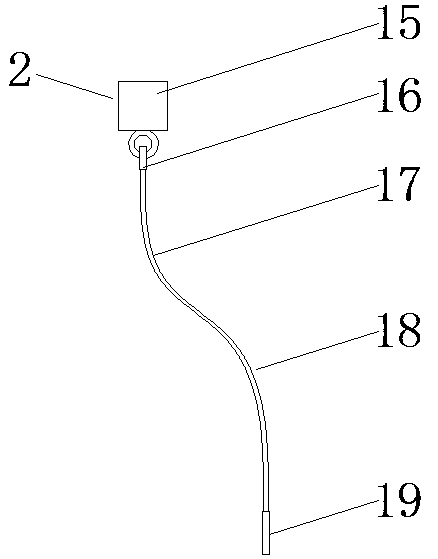

Lifting platform for municipal construction

PendingCN110078003AReasonable structureSimple designSafety devices for lifting equipmentsSafety beltsElectric machineryHanging basket

The invention discloses a lifting platform for municipal construction. The lifting platform comprises a protective guard, a safety rope, an operation platform, a switch and a motor, wherein the protective guard and the safety rope are arranged for protecting a constructor standing on the operation platform, a second lock catch is driven to move when the constructor walks on the operation platform,and therefore a slide block slides on a slide rail under the pulling of the safety rope, and the movement of the constructor on the operation platform is not influenced; when the constructor needs totake articles such as tools on the ground at high positions, the switch is used for controlling the motor to work, so that a lifting rope which winds a winding wheel is put into a long time, and a hanging basket moves downwards to the ground; and the ground constructor places the articles such as required tools into the hanging basket, the switch is further used for controlling the motor to work,and the winding wheel is enabled to roll up the lifting rope, so that the lifting basket is lifted, the constructor on the operation platform can conveniently collect the articles such as tools, thelifting operation platform is not needed, and the construction efficiency is guaranteed.

Owner:TIANJIN SHENGXING GARDEN LANDSCAPE ENG CO LTD

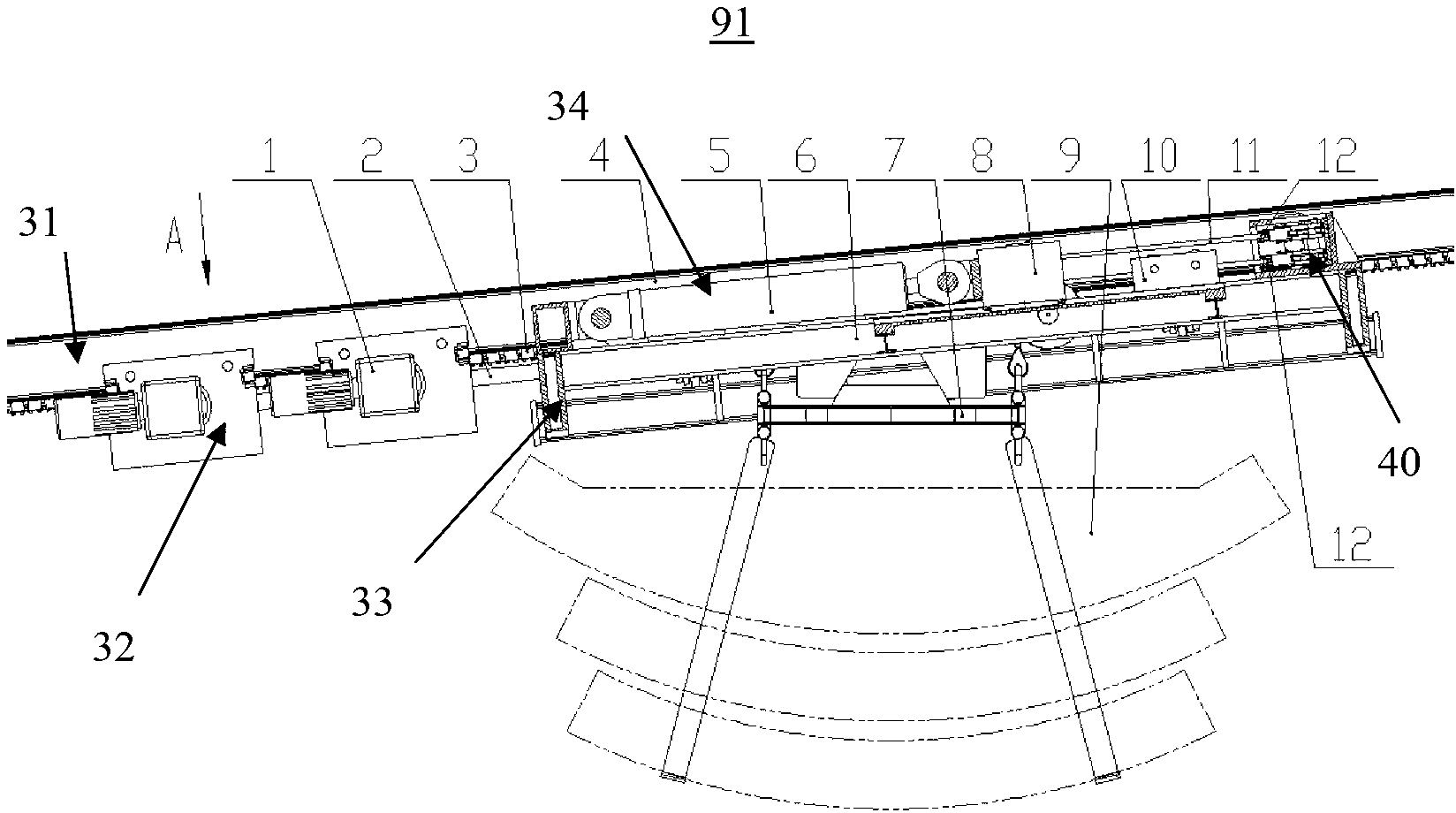

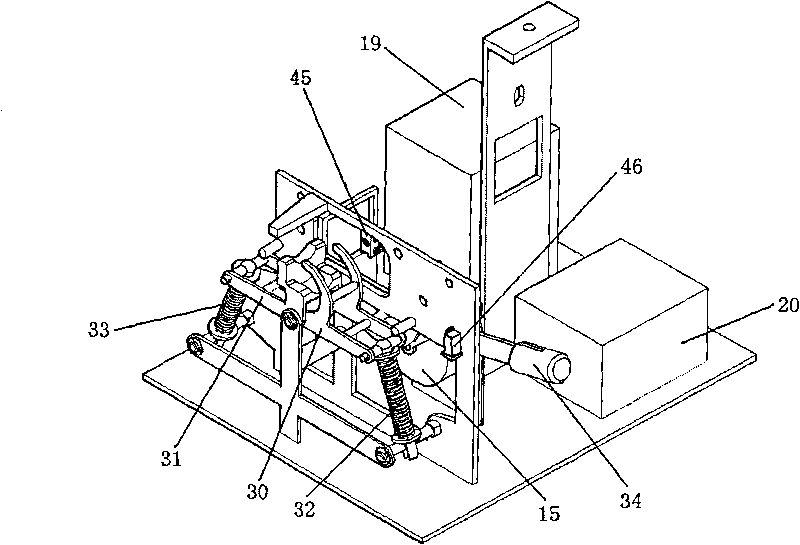

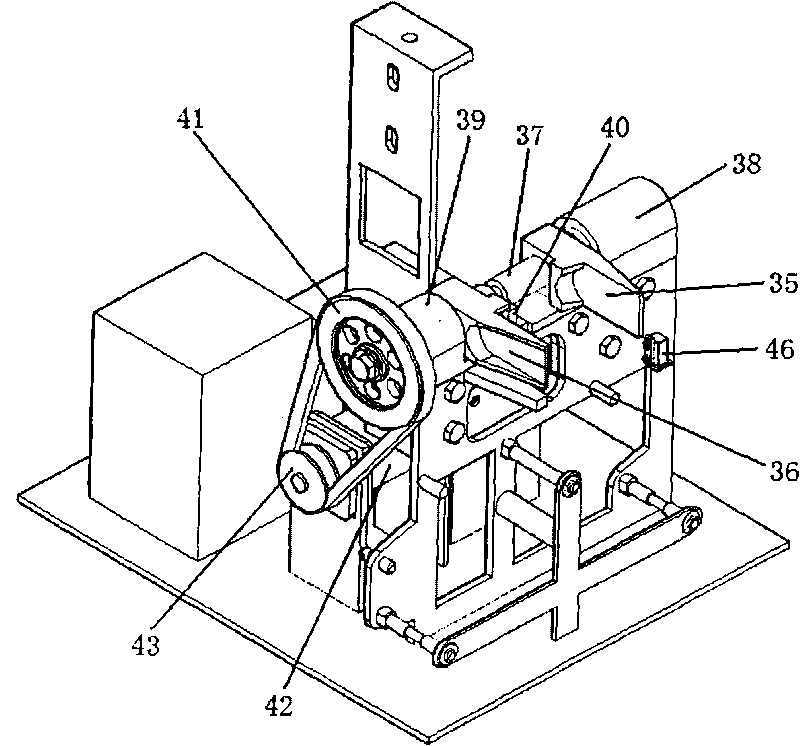

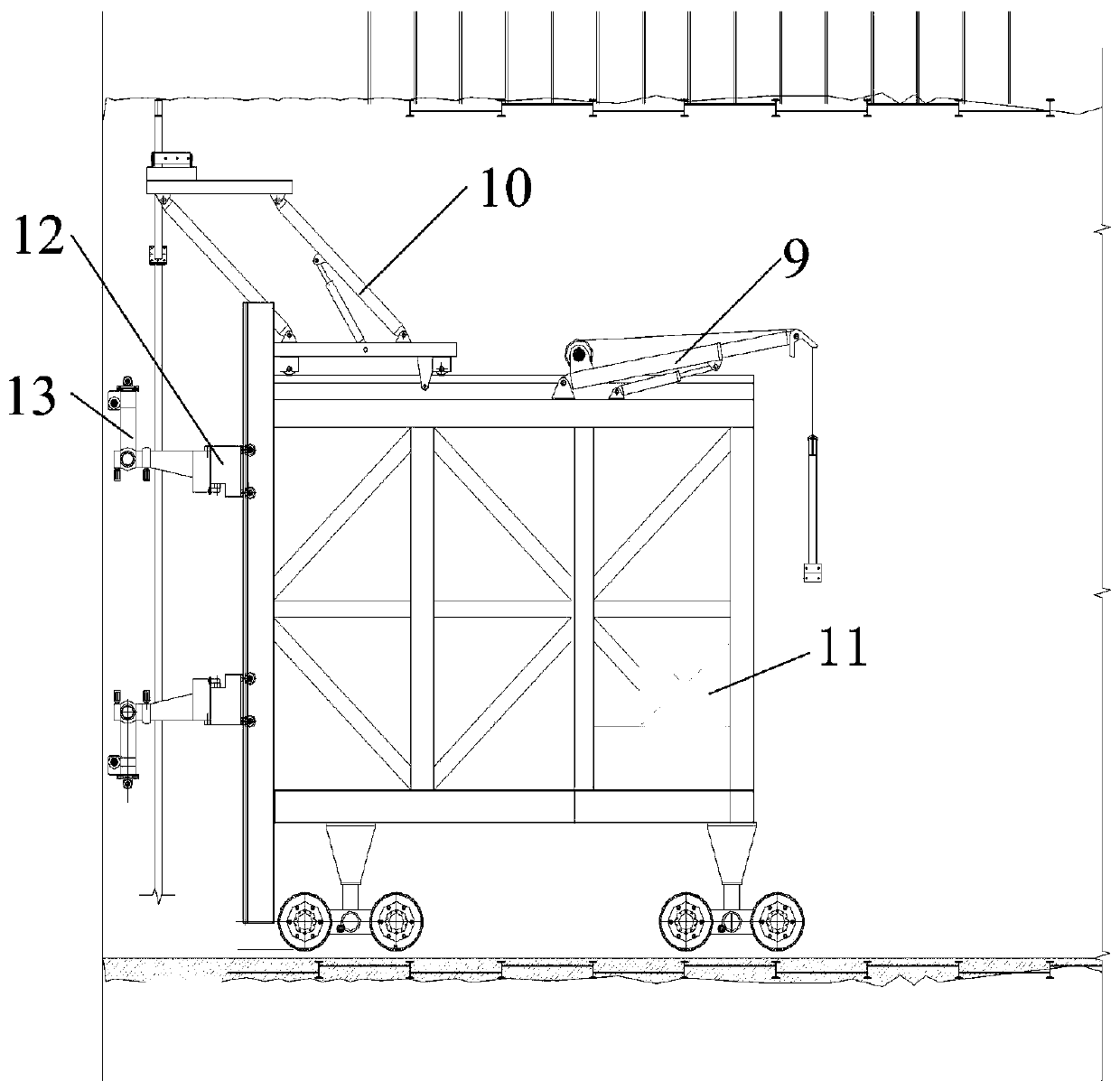

Material hoisting device for tunnel boring machine

ActiveCN103233752ASimple structureSmall footprintUnderground chambersTunnel liningTunnel boring machineEngineering

The invention relates to a material hoisting device for a tunnel boring machine. The material hoisting device for the tunnel boring machine comprises a guide rail mechanism, a power mechanism, a driven mechanism and a craning mechanism, wherein the guide rail mechanism comprises a guide rail and a first transmission part, the power mechanism comprises a power device and a connecting rod, the driven mechanism comprises a driven device and a driven machine frame, the craning mechanism comprises a balance frame, a hydraulic cylinder and a reverser. The reverser comprises a pulley wheel, a steel wire rope and a pulley wheel seat. Extension motion of the hydraulic cylinder is converted into lifting motion of the balance frame through the reversing of the steel wire rope and the pulley wheel, and accordingly material lifting is achieved. The power device and the first transmission part perform matched motion through the second transmission part to produce stable power, the stable power is acted on the driven mechanism through the connecting rod to enable the driven mechanism to drive the whole hoisting device to move together with the driven mechanism, and accordingly transportation of materials in the track direction is achieved. The material hoisting device for the tunnel boring machine has the advantages of being simple in structure, safe, reliable and high in efficiency, the problem that the materials and multiple tube pieces cannot be stably hoisted in a limited space at the same time is solved, and accordingly a construction schedule and the construction efficiency of the tunnel boring machine are guaranteed.

Owner:CHINA RAILWAY CONSTR HEAVY IND

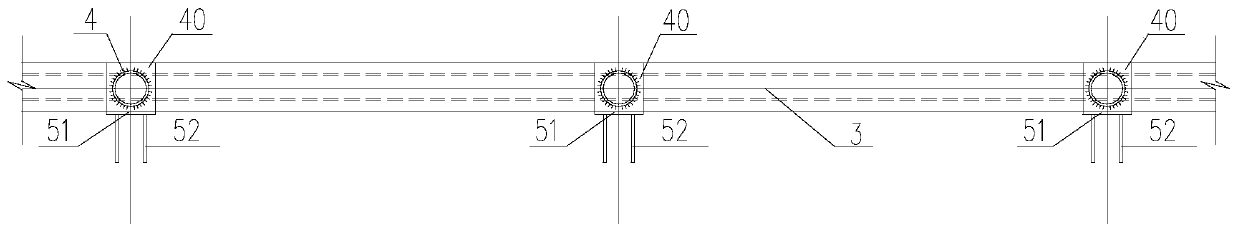

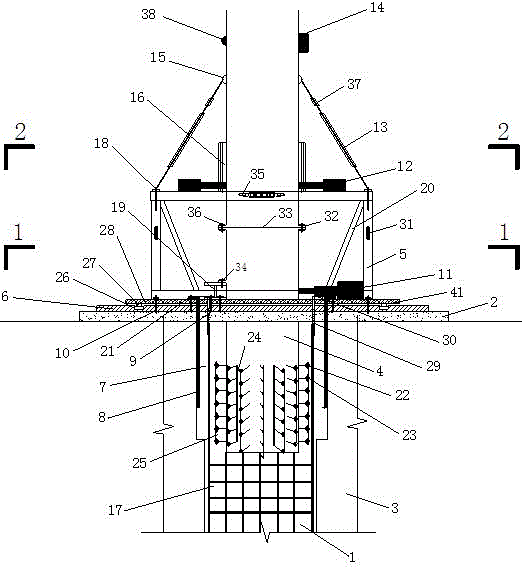

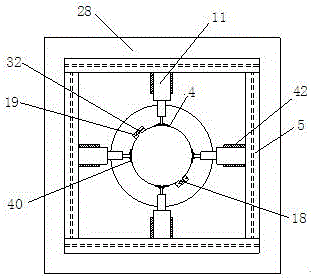

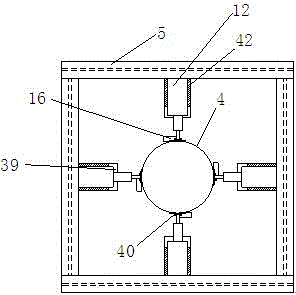

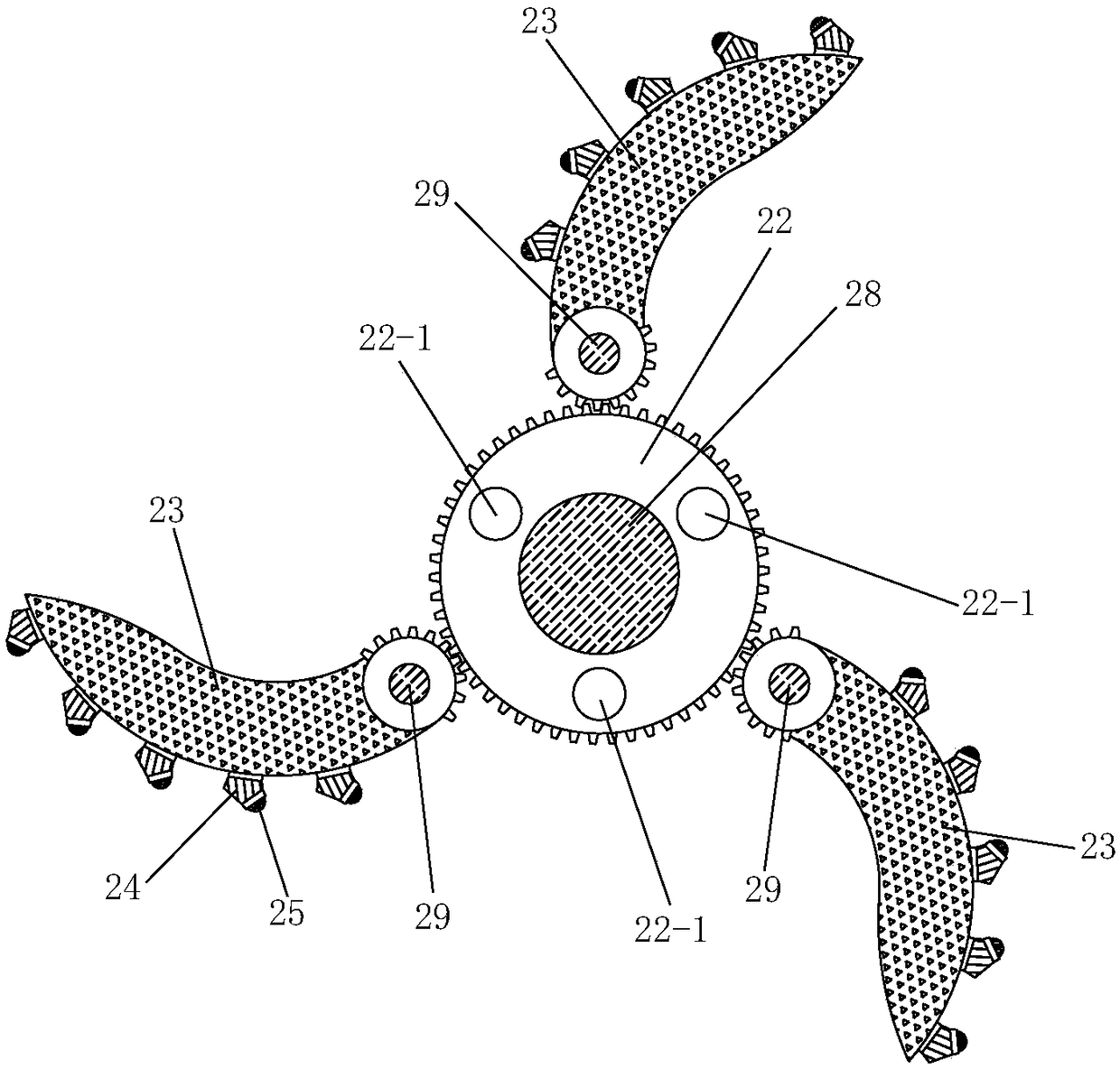

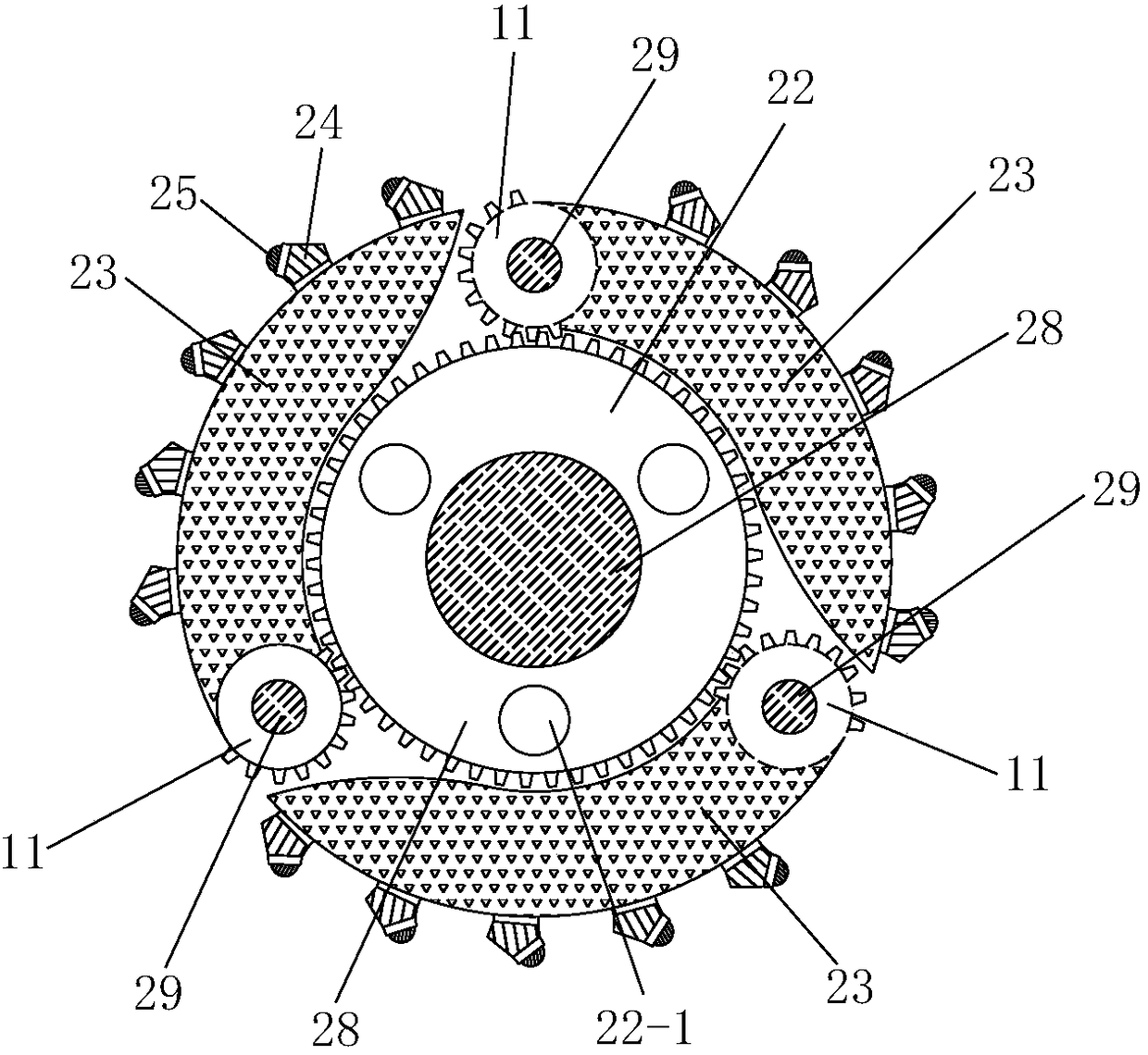

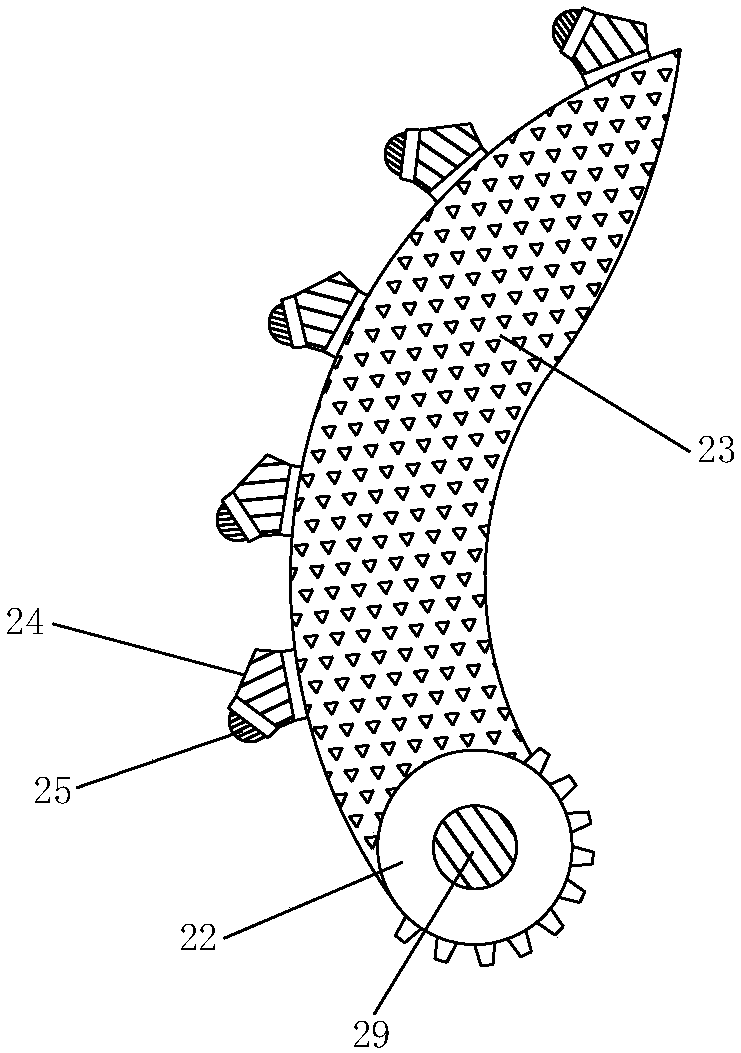

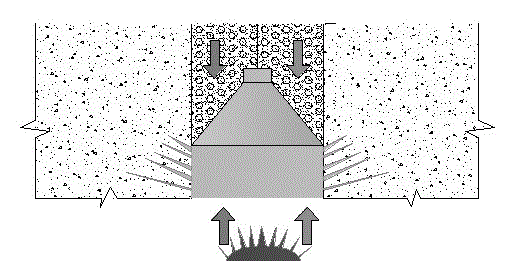

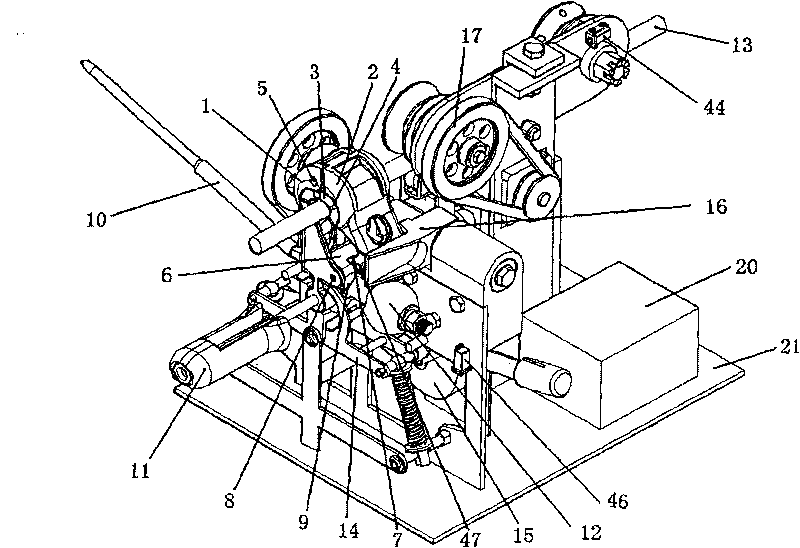

Coal mine gas extraction system and method for increasing concentration of gas extraction by reducing and pore broadening

InactiveCN108590742ANovel and reasonable designRealize the function of reamingDrill bitsFluid removalHydraulic cylinderEngineering

The invention discloses a coal mine gas extraction system and method for increasing the concentration of gas extraction by reducing and pore broadening. The coal mine gas extraction system comprises acoal mine drilling machine, a drill hole drill bit, a hole sealing mechanism, a grouting piping system, a gas extraction piping system and a reamer bit. The reamer bit comprises a power transmissionmechanism and three bit fins. The power transmission mechanism comprises a sun gear and three planetary gears, the sun gear is fixedly connected to a sun gear rotating shaft, the planetary gears are rotatably connected to a planetary gear rotating shaft, the three bit fins are separately and fixedly connected to the three planetary gears, and the bit fins are connected with cutting teeth through tooth bases. A hydraulic cylinder and an ejection rod are arranged in the sun gear rotating shaft, a spiral sliding groove is formed in the ejection rod, and a sliding block is arranged on the inner wall of the sun gear rotating shaft. The method comprises the steps that 1, hole drilling is performed; 2, pore broadening is performed; 3, hole flushing is performed; 4, grouting and hole sealing are performed; and 5, gas extraction is performed. The coal mine gas extraction system and method for increasing the concentration of gas extraction by reducing and pore broadening has novel and reasonabledesign, high strength of a reamer bit and simple reaming process, can improve hole sealing quality and the concentration of gas extraction, and is practical and effective and easy to popularize.

Owner:XIAN UNIV OF SCI & TECH

Superfine quick-setting self-compacting repair mortar and preparation method thereof

The invention relates to superfine quick-setting self-compacting repair mortar material and a preparation method thereof; the superfine quick-setting self-compacting repair mortar material is characterized by being prepared from, by total weight of the materials, 35.0-55.0% of quick-hardening early strength cement, 35.0-55.0% of fine aggregate, 3.0-10.0% of a mineral admixture, 2.5-5.0% of an excitant, 0.80-2.00% of redispersible latex powder, 0.25-0.50% of a water-reducing agent, 0.25-0.50% of a thickening time control agent, and 0.01-0.05% of a defoaming agent. The preparation method comprises: weighing the materials to a proportion, and mixing well in a mixing machine. The superfine quick-setting self-compacting repair mortar material has good constructability, is up to 330 mm in initial mobility, has initial setting time of < / =20 min and final setting time of < / =30 min, is up to 33.0 MPa and 50.0 MPa in 6 h compressive strength and 24 h compressive strength, has stably increasing late strength, is up to 4.0 MPa and 6.0 MPa in 1 d and 3 d interfacial flexural-tensile strength of concrete interface, has the advantages of micro-expansion effect and good construction operational simplicity, and is suitable for the quick repair of housing and roads, particularly for the repair of concrete fracture surfaces and damaged rail plates of high-speed railway ballastless tracks.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

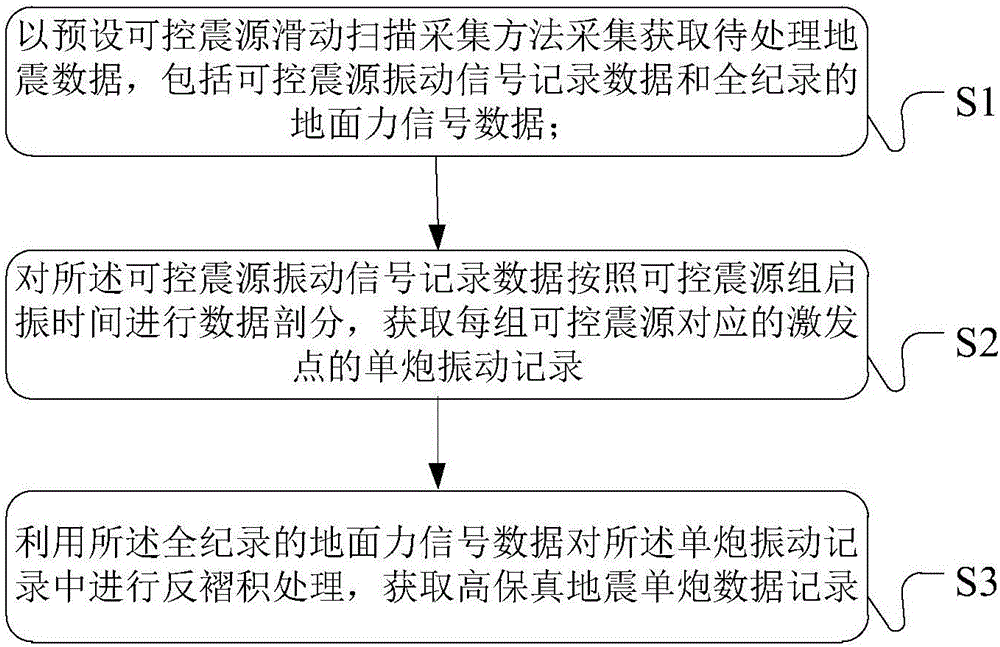

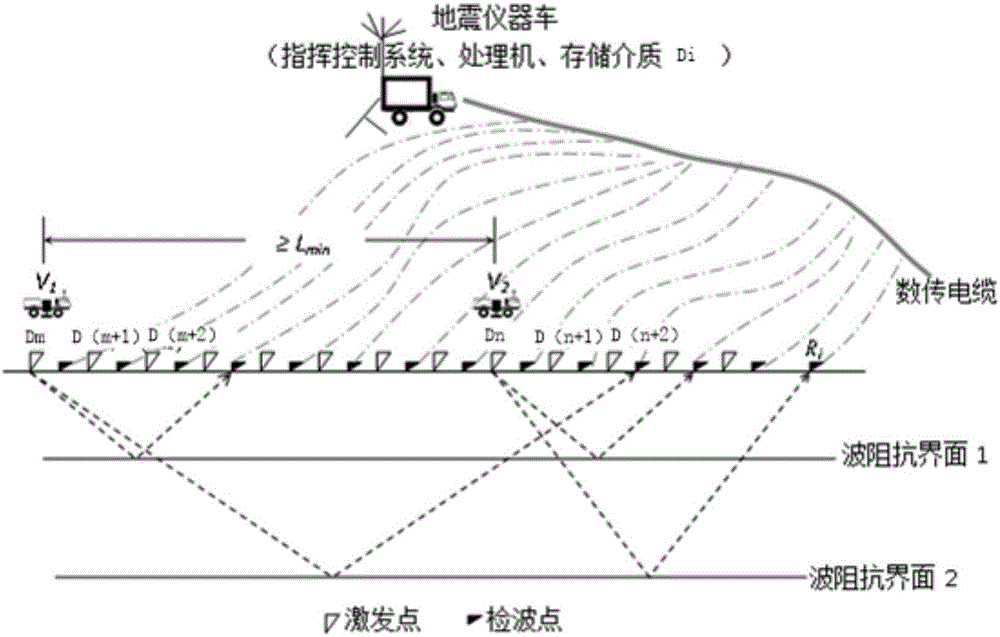

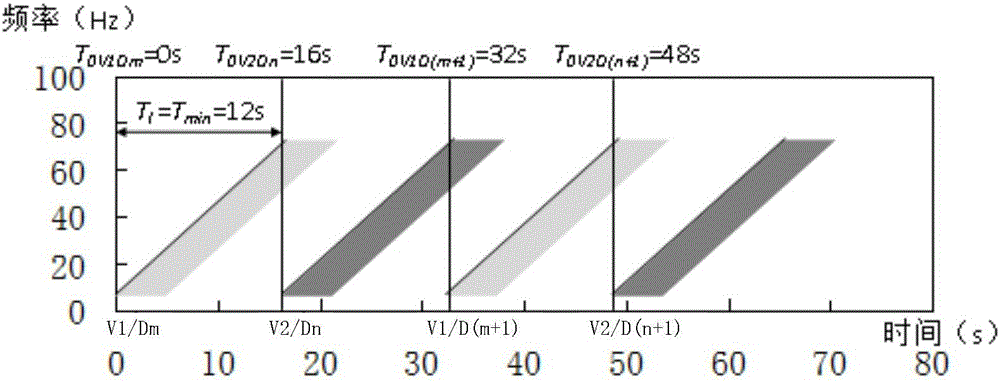

Vibroseis slip sweep data acquisition and processing method and device

InactiveCN106094024AGuaranteed fidelityEnsure construction efficiencySeismic signal transmissionSeismic signal processingGround forceTime parameter

The invention provides a vibroseis slip sweep data acquisition and processing method and device. The method comprises the steps that vibroseis vibration signal record data and all records of ground force signal data acquired based on predetermined sweep signal, the distance between vibroseis groups and slip time parameters are acquired by the preset vibroseis slip sweep acquisition method; data division is performed on the vibroseis vibration signal record data according to vibroseis group vibration starting time so that the single shot vibration record of the shot point corresponding to each vibroseis group is acquired; and deconvolution processing is performed on the single shot vibration record by using all records of ground force signal data so that the high-fidelity seismic single shot data record can be acquired. With application of the vibroseis slip sweep data acquisition and processing method and device, the problem that the high-fidelity seismic data cannot be acquired by the vibroseis seismic exploration correlation method slip sweep efficient acquisition technology can be solved so that the fidelity of the original seismic exploration data can be guaranteed and the construction efficiency of field production can also be guaranteed.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

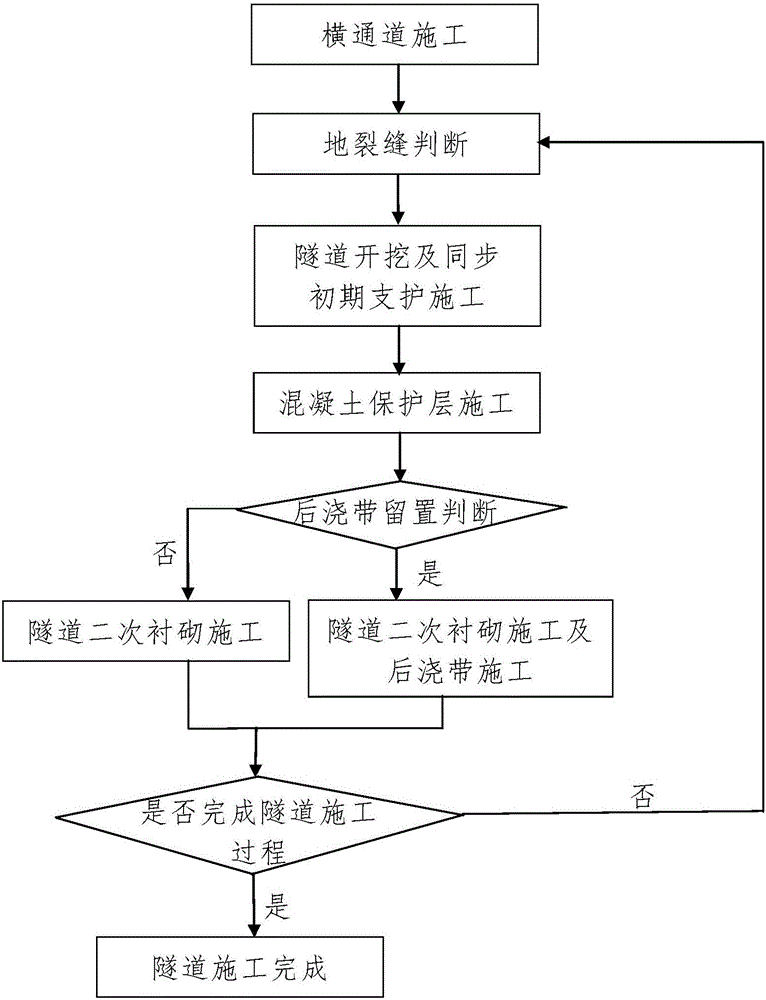

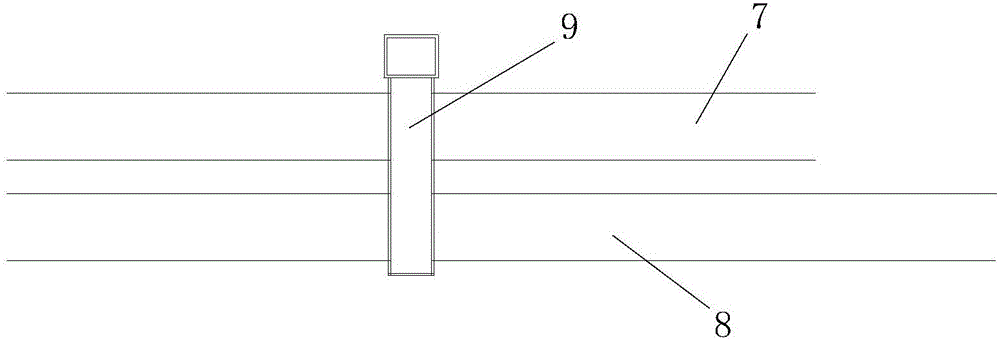

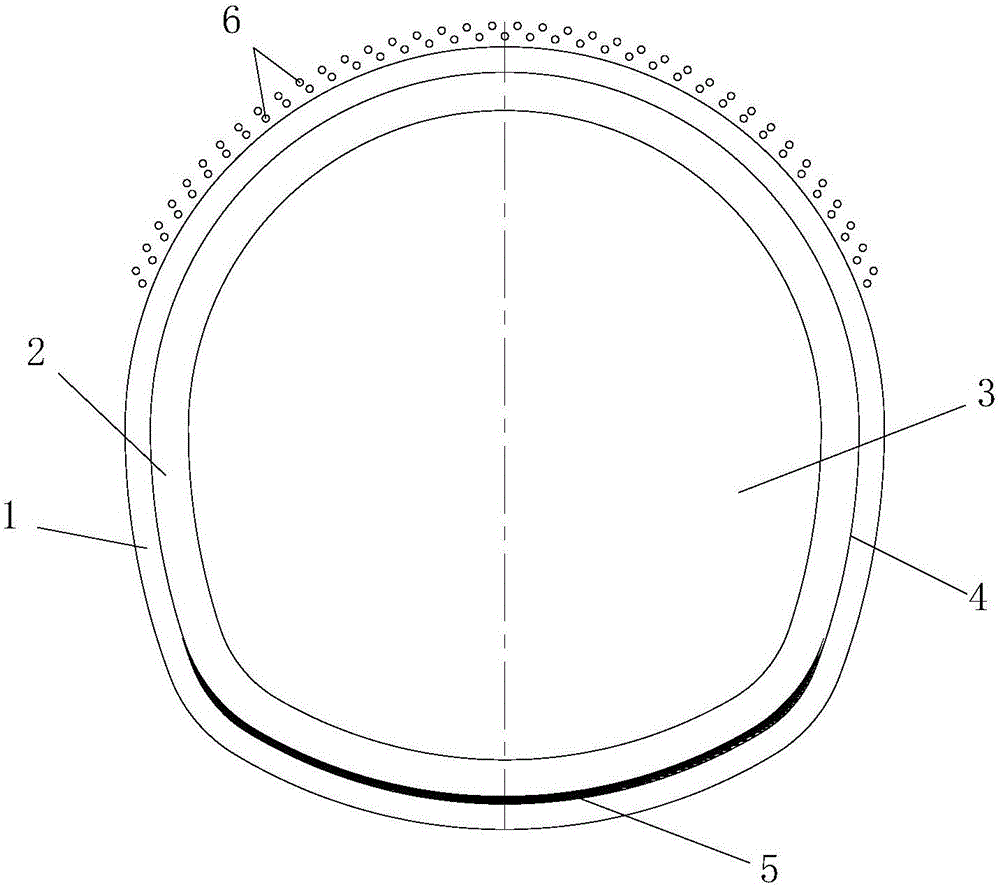

Ground fracture crushed zone passing construction method for shallow-buried tunnel excavation

ActiveCN106437726AThe method steps are simpleReasonable designUnderground chambersTunnel liningProtection layerTunnel construction

The invention discloses a ground fracture crushed zone passing construction method for shallow-buried tunnel excavation. A constructed shallow-buried excavation tunnel comprises a left line tunnel and a right line tunnel which are communicated through a transverse channel. During construction of the constructed shallow-buried excavation tunnel, the method comprises the steps that 1, transverse channel construction is performed; 2, tunnel construction is performed, wherein the two tunnel sections of the left line tunnel and the right line tunnel are constructed through the transverse channel, the construction is performed in the mode of multiple tunnel sections in the longitudinal extending direction of the tunnel from back to from during construction of any one tunnel section, and the construction of any one tunnel section includes the processes of ground fracture judgement, tunnel excavation and synchronous preliminary bracing construction, concrete protection layer construction, post-cast strip retention judgement, secondary tunnel lining construction and post-cast strip construction. The method includes simple steps and is reasonable in design, convenient to construct, good in construction effect, capable of simply and conveniently completing the shallow-buried tunnel excavation construction process of a ground fracture crushed zone and safe and reliable in construction process.

Owner:中铁二十局集团第五工程有限公司

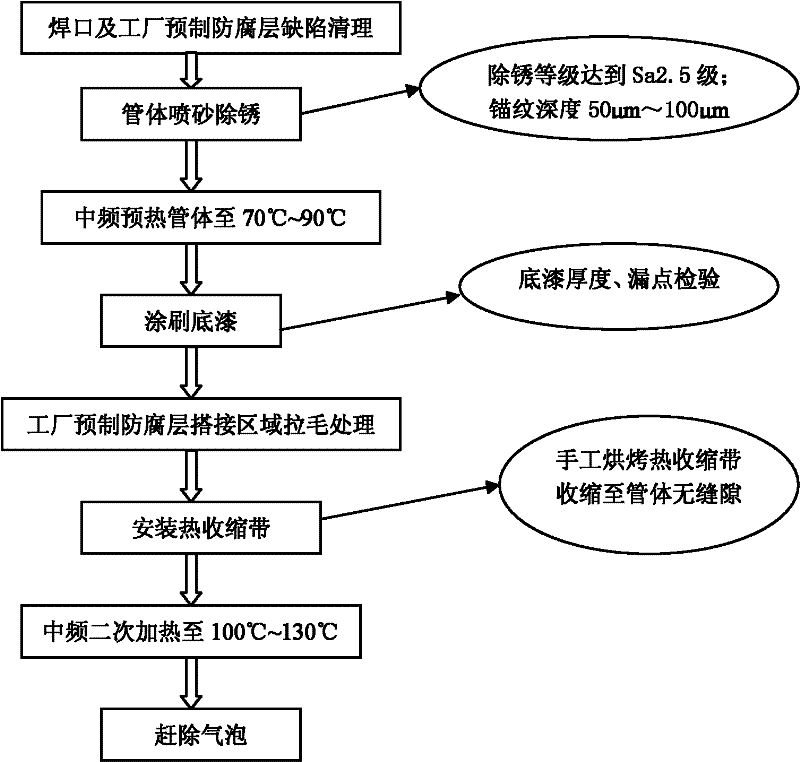

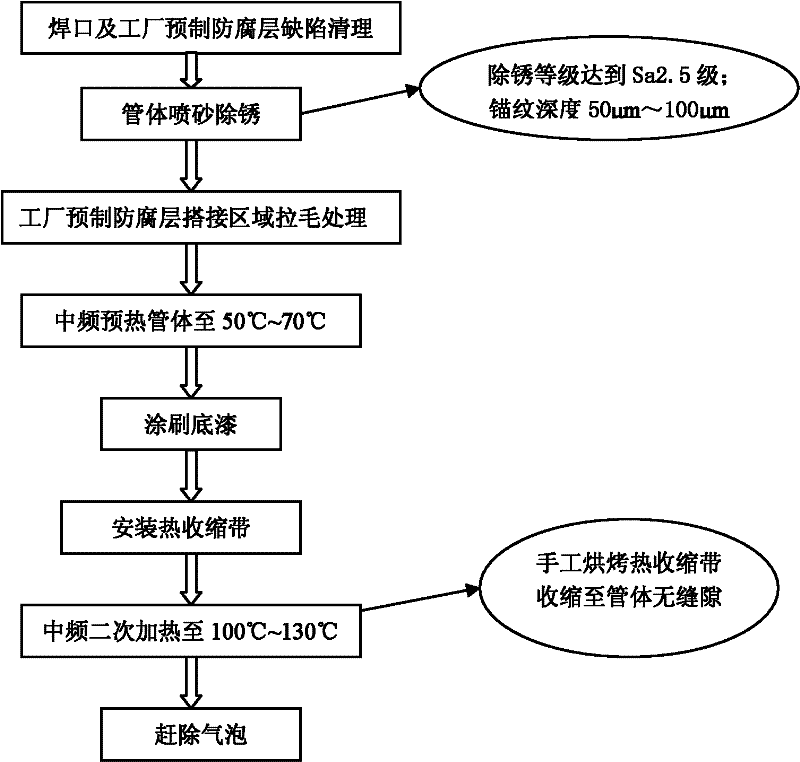

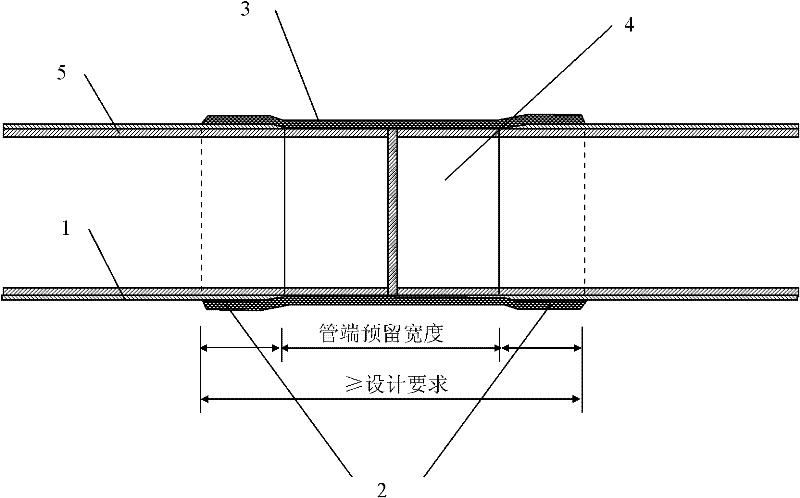

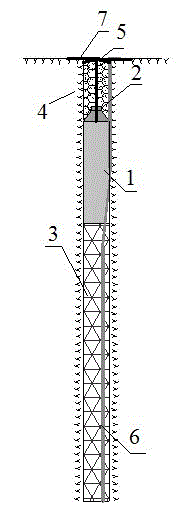

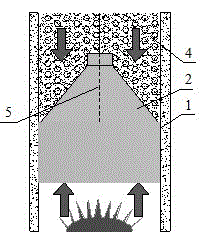

Intermediate-frequency heating repaired opening construction technology for thermal contraction band of buried steel pipeline

InactiveCN102679086ARealize flow operationAvoid secondary pollutionPipe elementsSand blastingIntermediate frequency

The invention relates to an intermediate-frequency heating repaired opening construction technology for a thermal contraction band of a buried steel pipeline. The construction technology comprises the following steps: 1) cleaning flaws of a welded junction and an anticorrosive layer prefabricated in a factory; 2) performing sand-blasting and de-rusting on a pipe body, wherein a de-rusting level is Sa2.5 level and an anchoring grain depth is 50 microns to 100 microns; 3) performing intermediate-frequency heating on the pipe body, wherein a preheating temperature is at 50-90 DEG C; 4) painting a primer, wherein the thickness of the primer is above 200 microns; 5) performing napping treatment on the surface of the anticorrosive layer prefabricated in the factory, in a flame manual steel wire brushing napping mode; 6) mounting the thermal contraction band: winding the thermal contraction band at the repaired opening, sticking a fixing sheet, and baking the surface till the thermal contraction band is completely and seamlessly covered on the pipe body; 7) secondarily intermediate-frequency heating under a secondary heating temperature at 100-130 DEG C, till fully melting a hot melt adhesive; and 8) removing air bubbles. According to the construction technology provided by the invention, the heating temperature is uniform, the influences of personal factors on construction quality are reduced and the efficiency and quality of repaired opening construction are greatly increased.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

De-noising and dust removal blast hole stemming method for drilling blasting of earth and stone in urban and rural areas

The invention discloses a de-noising and dust removal blast hole stemming method for drilling blasting of earth and stone in urban and rural areas. According to the method, a stemming section comprises a bottom water bag, a middle inverted funnel and a conventional stemming material, the water bag is tied down by a traction rope and is lifted into a hole, the other end of the traction rope is tied to a bearing bar of an orifice of a blast hole, and the edge of the inverted funnel is clamped on the wall of the blast hole to be fixed. Most of shock wave energy generated by explosion can be converted into internal energy required by water vaporization and atomization and kinetic energy of water jet so as to weaken noise; meanwhile, the blasting dust can be wrapped by dispersed water mist to reduce pollution; and in addition, after the water bag is broken, the lower part of the funnel is filled with water, so that the strength of shock waves is indirectly reduced, the stemming time is prolonged, and the stemming effect is enhanced. The method provided by the invention can also be used in rock blasting construction of mines, water and electricity, traffic and other fields.

Owner:WUHAN UNIV

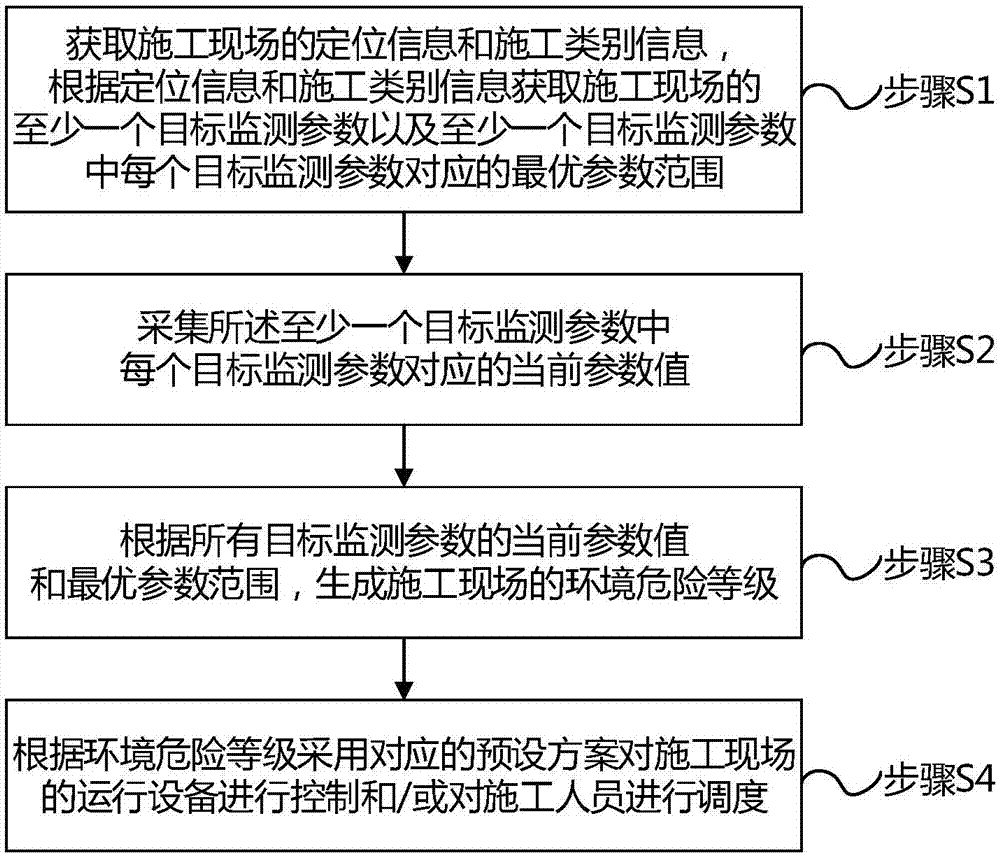

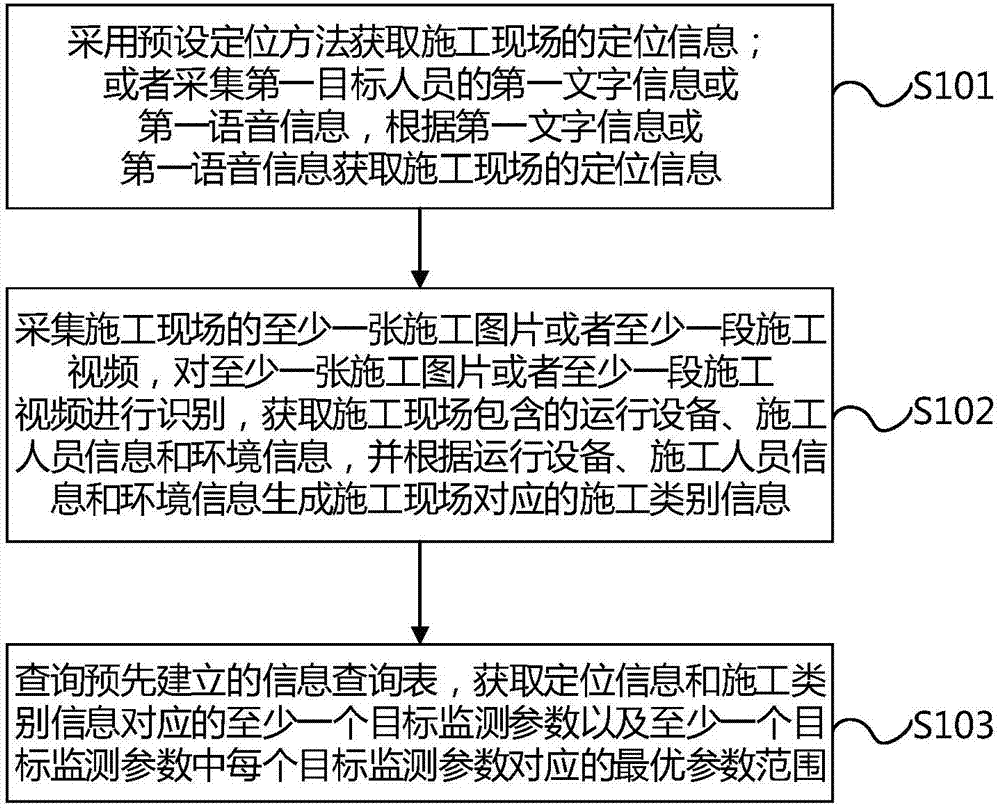

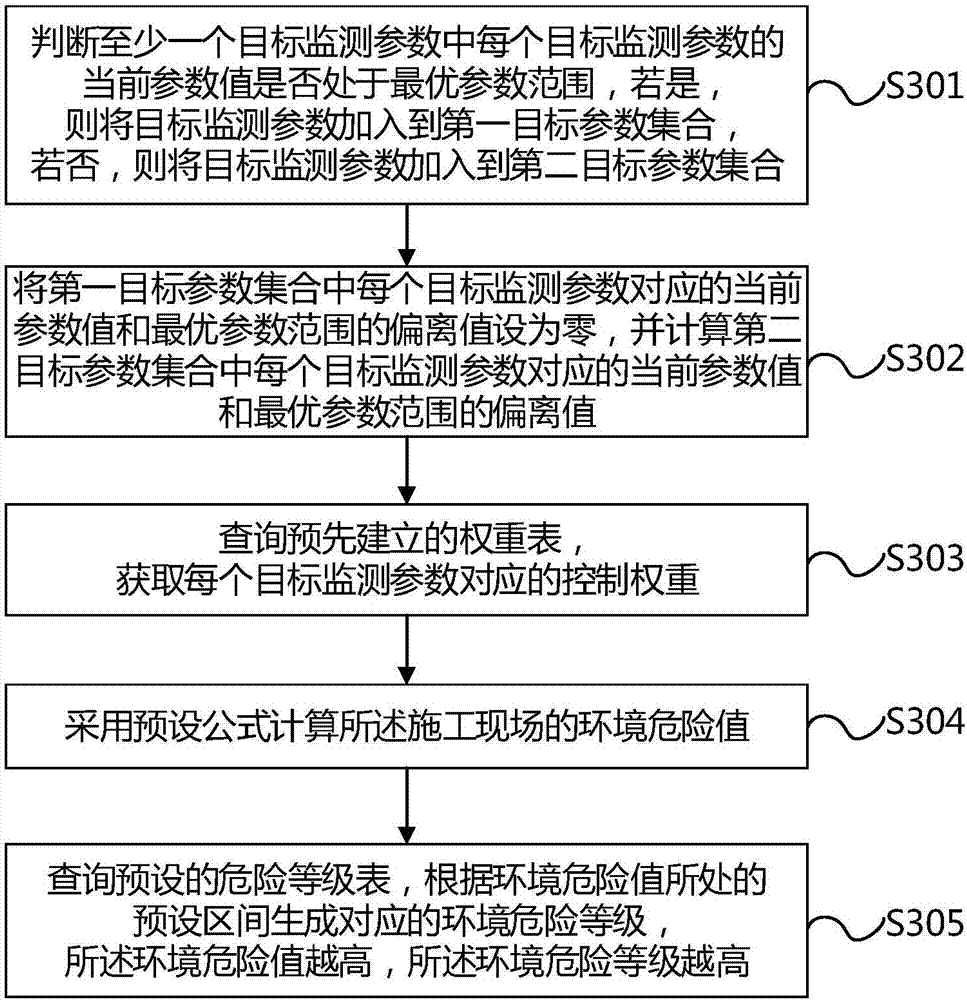

Safety management method and apparatus

InactiveCN107506903AEnsure personal safetyImprove safety management efficiencyResourcesTransmissionEconomic benefitsComputer science

The invention especially relates to a safety management method and apparatus. The method comprises the following steps: acquiring positioning information and construction type information of a construction site, and acquiring at least one target monitoring parameter and an optimal parameter range corresponding to each target monitoring parameter according to the positioning information and the construction type information; collecting a current parameter value corresponding to each target monitoring parameter; generating an environmental hazard level of the construction site according to the current parameter value and the optimal parameter range of each target monitoring parameter; and controlling operating equipment at the construction site and / or dispatching the construction staff by employing a corresponding preset plan according to the environmental hazard level. According to the invention, because different control solutions are used for different environmental hazard levels, the current parameter value of the monitoring parameter is adjusted to be in the optimal parameter range to guarantee the personal safety of the construction staff and reduce the influence on the construction efficiency, so that the construction capability of the enterprise is utilized fully and the economic benefit of the enterprise is increased.

Owner:SHENZHEN SHENGLU IOT COMM TECH CO LTD

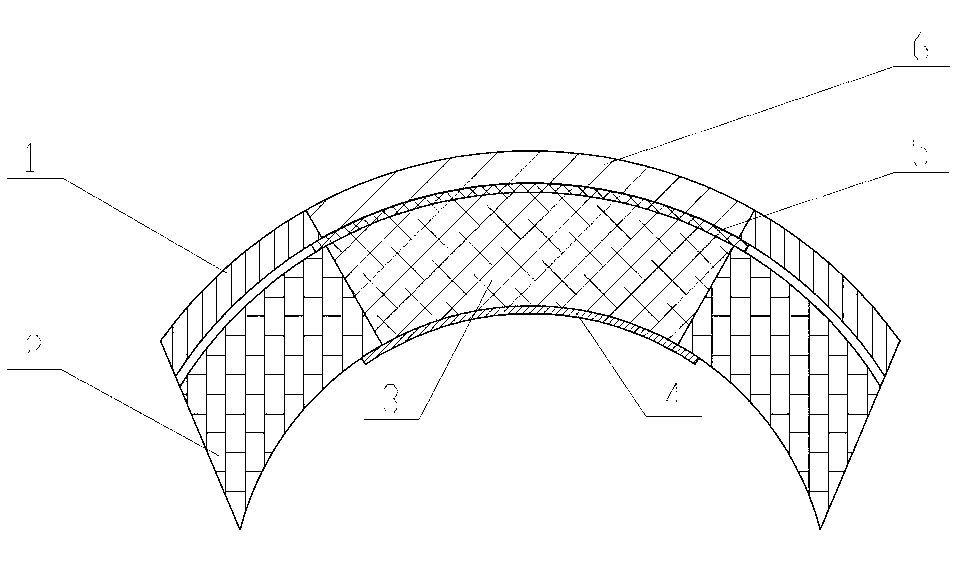

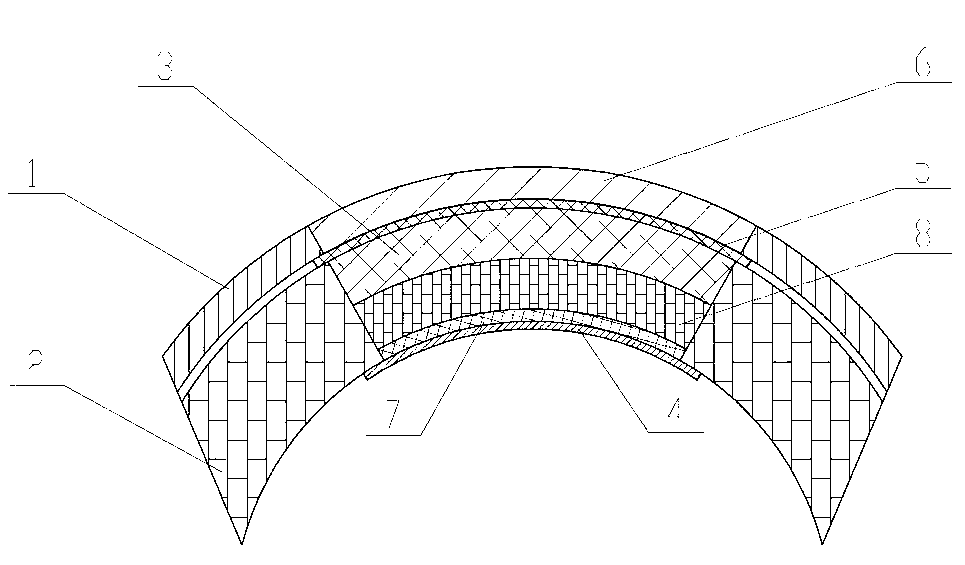

Maintenance method for air leakage from pipeline of hot-air system of blast furnace

ActiveCN103276130AShorten downtime for maintenanceImprove work efficiencyBlast furnace detailsHeating stovesHot blastSteel plates

The invention discloses a maintenance method for air leakage from a pipeline of a hot-air system of a blast furnace, and belongs to the treatment method of the air leakage from the pipeline. The method comprises the following steps of: firstly treating a position from which the air leaks; opening a notch on a fire-proofing tile; lifting a prepared steel plate at the notch along the inner wall of the fire-proofing tile; pouring a high-alumina castable along the steel plate, thereby forming a casting layer corresponding to the fire-proofing tile; shielding a machine-made fiberboard on the casting layer; and restoring a pipeline casing and grouting. According to the method, the damaged fire-proofing tile is repaired and treated outside the pipeline from which the air leaks, so that the time for wanting the furnace to be cooled is omitted. Thus, the maintenance time of the blast furnace in a shutdown manner is shortened greatly; the working efficiency is improved; and the economic loss caused by the furnace shutdown is reduced. For different damaging areas, the different treatment schemes are put forward, so that the construction safety and the construction efficiency of a worker are ensured. The method is also suitable for various pipelines and can be applied widely.

Owner:XINXING DUCTILE IRON PIPES CO LTD

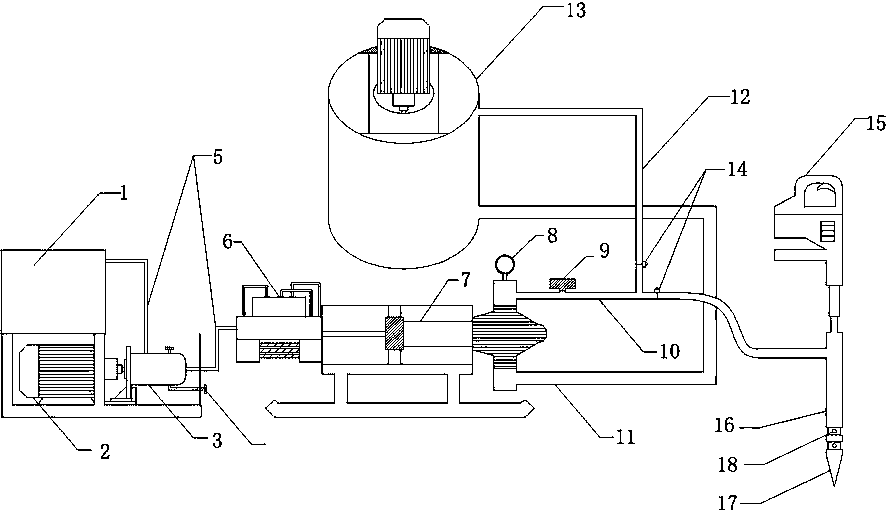

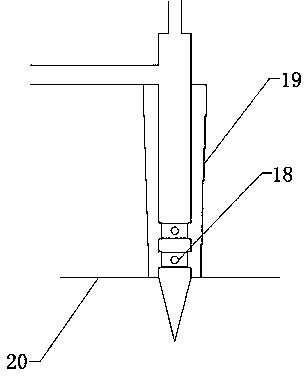

Portable intelligent high-pressure grouting system and grouting method of metamorphic concretes

ActiveCN104196030AReduce dosageEnsure construction efficiencyFoundation engineeringEngineeringHigh pressure

The invention discloses a portable intelligent high-pressure grouting system and a grouting method of metamorphic concretes. The portable intelligent high-pressure grouting system comprises a pulp feeding barrel, a pulp pump and a grouting bar which are connected though pipelines. A grouting head in a tapered shape is arranged on the grouting bar. Circular grooves are formed in the upper portion of the grouting head and internally provided with grouting holes. The tail end of the grouting bar is connected with an electric hammer. The grouting method includes the steps such as grouting and backflowing. The portable intelligent high-pressure grouting system and the grouting method are applied to automatic construction of the metamorphic concretes, construction efficiency is improved, construction workers are fewer, and grouting quantity of the metamorphic concretes is saved.

Owner:SINOHYDRO BUREAU 7 CO LTD +1

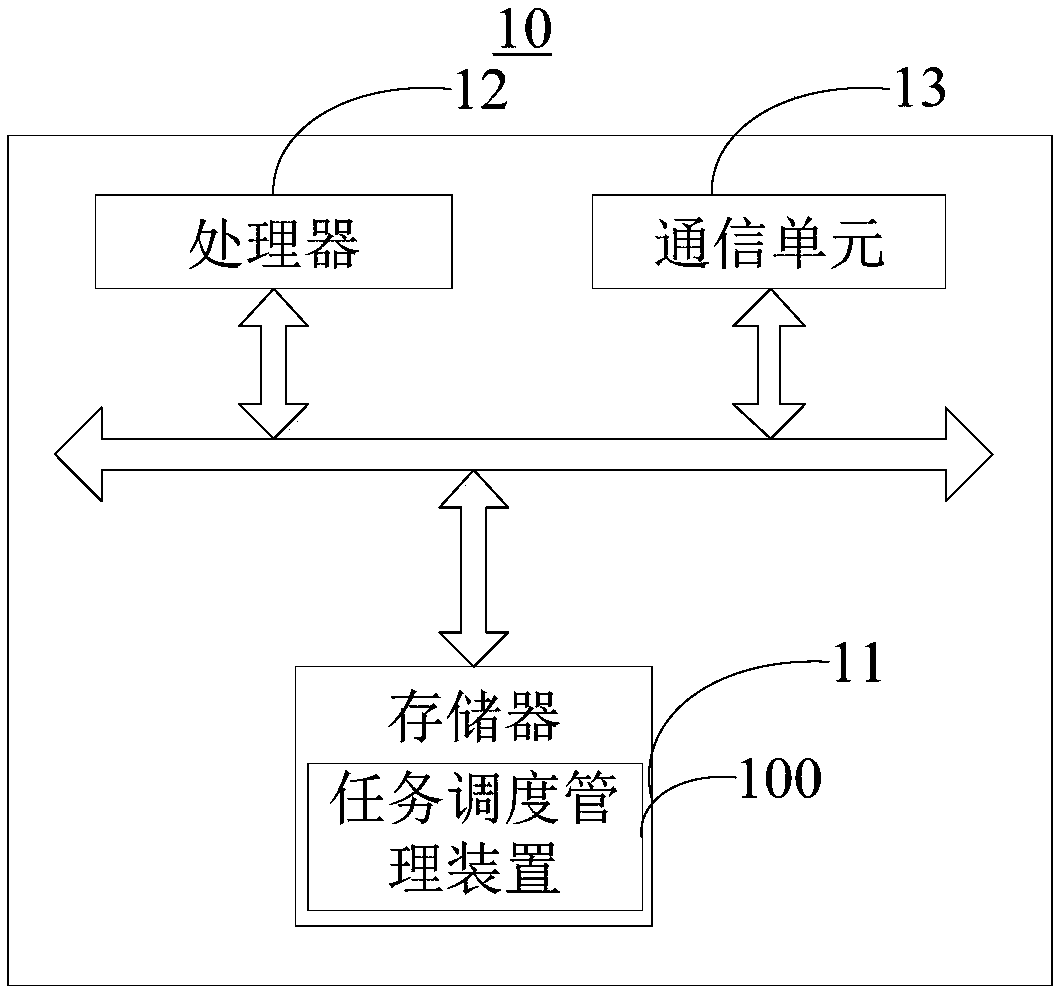

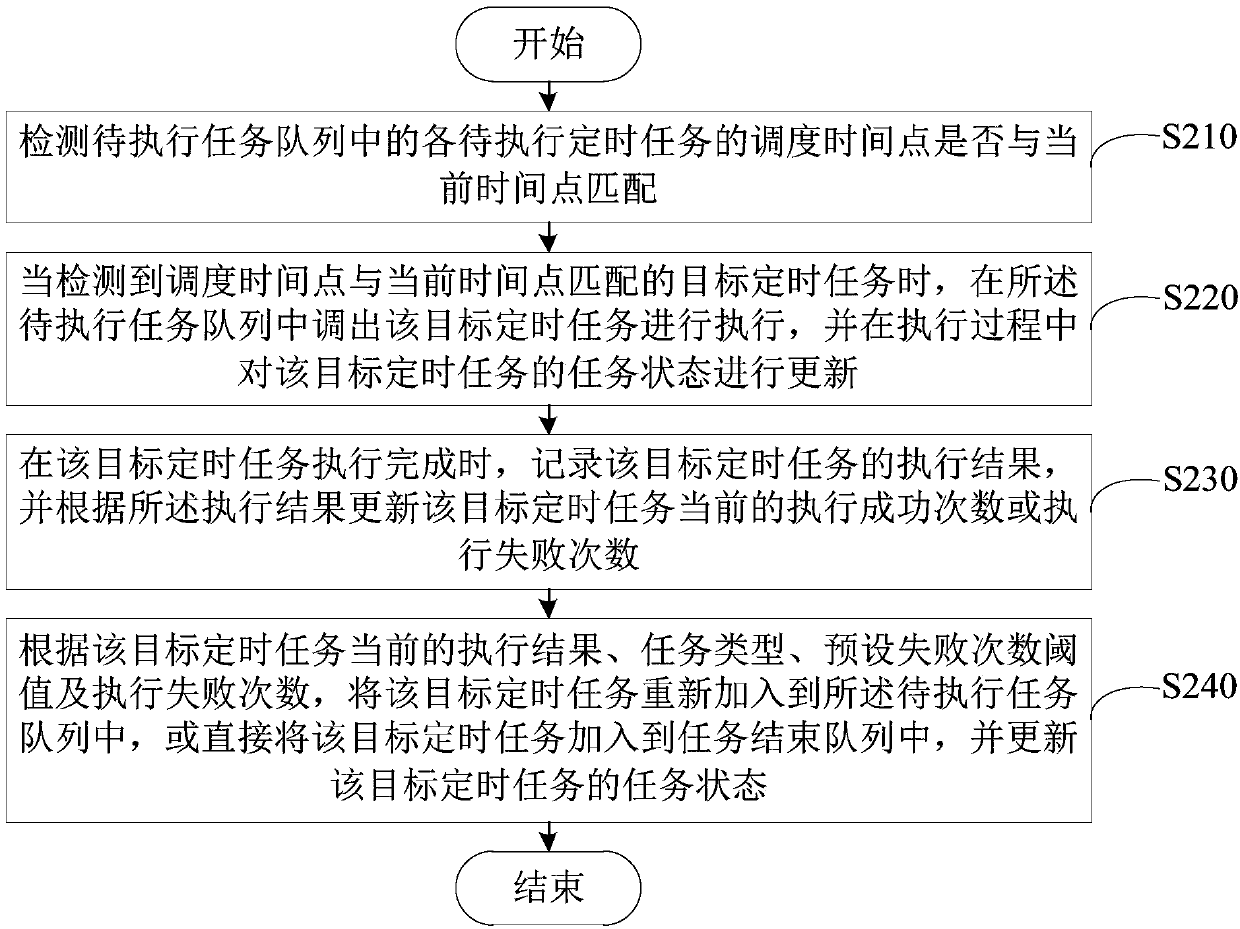

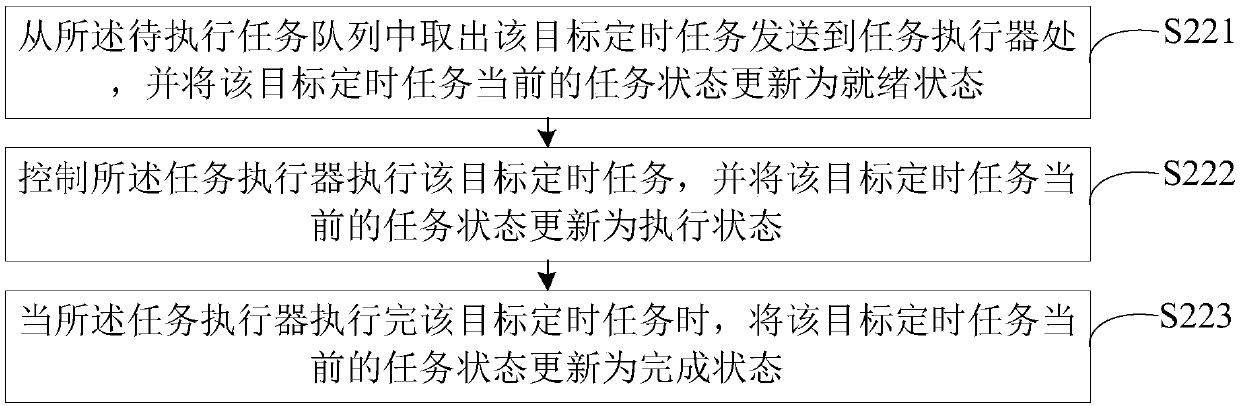

Task scheduling management method and device, and operation and maintenance management server

InactiveCN109634733AImprove construction efficiencyImprove operation and maintenance efficiencyProgram initiation/switchingMaintenance managementOperating system

The invention provides a task scheduling management method and device, and an operation and maintenance management server. The method comprises the steps of detecting whether a scheduling time point of each to-be-executed timing task in a to-be-executed task queue is matched with a current time point or not; When a target timing task of which the scheduling time point is matched with the current time point is detected, calling out the target timing task to execute the target timing task, and updating the task state of the target timing task in the execution process; When the target timing taskis completed, recording an execution result of the target timing task, and updating the current execution success frequency or execution failure frequency of the target timing task; And adding the target timing task into the to-be-executed task queue again, or directly adding the target timing task into the task ending queue, and updating the task state of the target timing task. According to themethod, the labor cost and the manual participation degree can be reduced, the construction efficiency and the operation and maintenance efficiency of the operation and maintenance platform are improved, and automatic management of the operation and maintenance platform is ensured.

Owner:CHENGDU SEFON SOFTWARE CO LTD

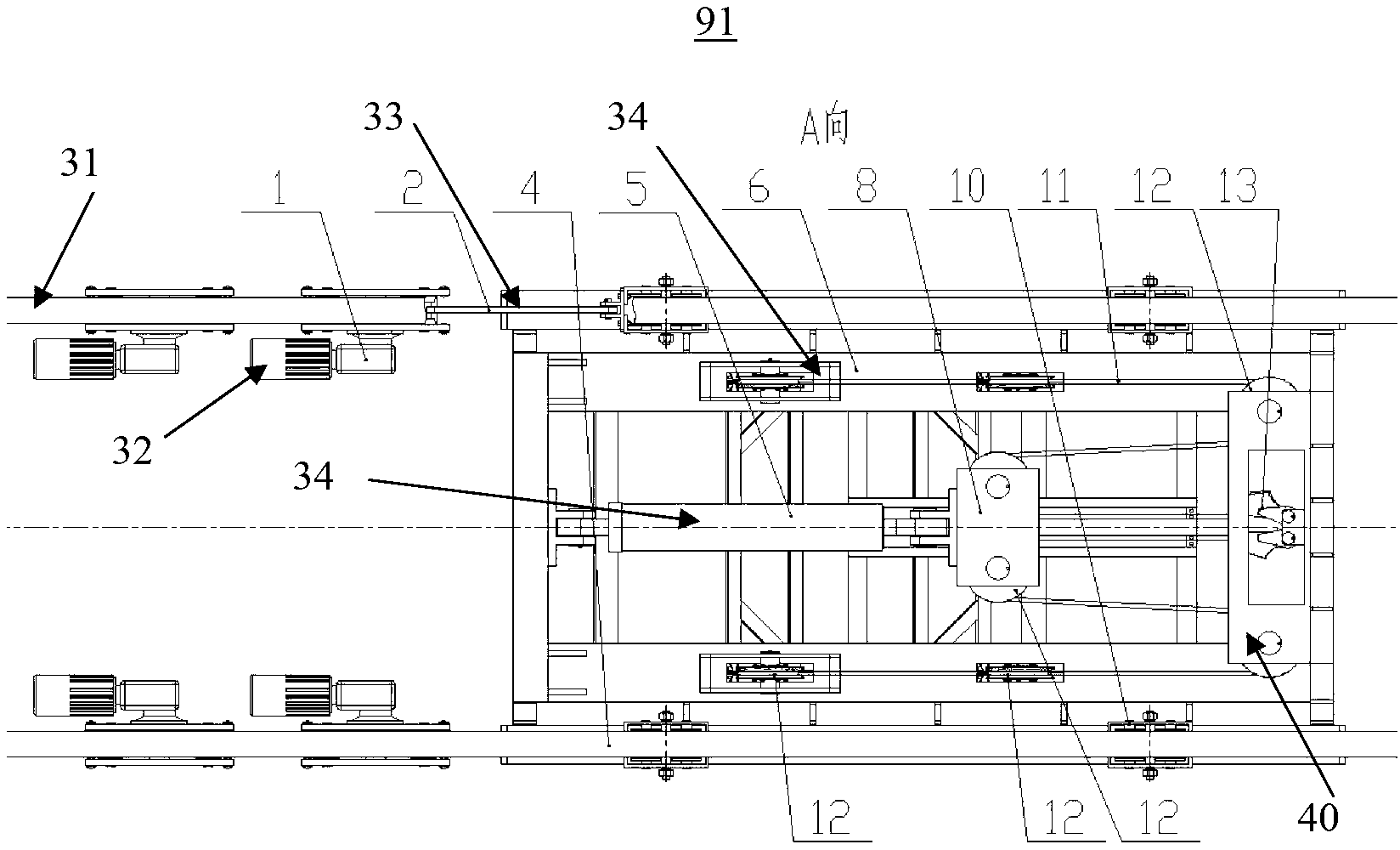

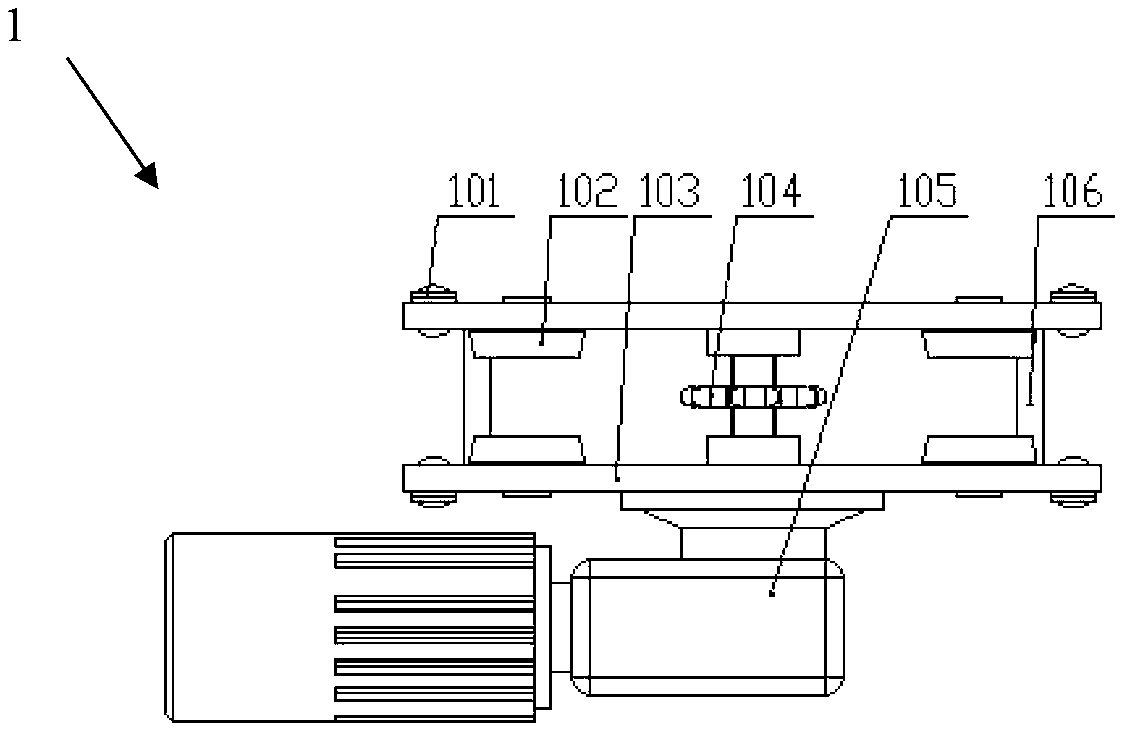

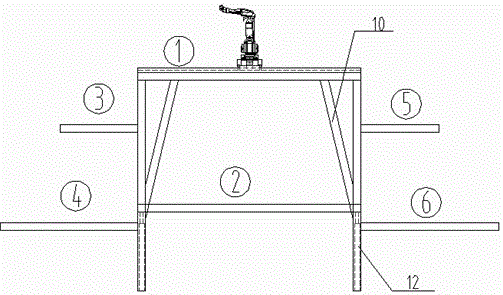

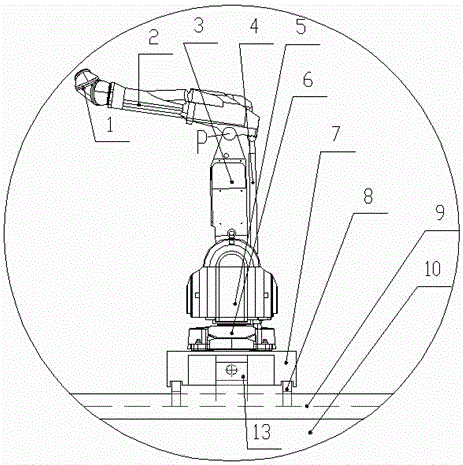

Automatic drill jumbo for tunnel and working method thereof

InactiveCN105113984ASimple structureEasy to implementDerricks/mastsDrilling machines and methodsEngineeringDrill bit

The invention discloses an automatic drill jumbo for a tunnel and a working method thereof. By means of the automatic drill jumbo for tunnel and the working method thereof, the problem that in the prior art, due to the fact that excavation is conducted through manpower, multiple defects exist is solved. The automatic drill jumbo for the tunnel comprises a jumbo frame structure which is provided with working platforms, and each working platform is provided with a mechanical arm system; each mechanical arm system comprises a rotary seat structure, a mechanical arm arranged on the rotary seat structure and a clamping device which is arranged at the tail end of the mechanical arm and used for being installed with a drill bit; each rotary seat structure can drive the corresponding mechanical arm to rotate along the cross section of the jumbo frame structure, and each mechanical arm can drive the corresponding clamping device to move upwards in the height direction of the jumbo frame structure; each working platform comprises a sliding rail system and a feeding system, each mechanical arm system is installed on the corresponding sliding rail system through the corresponding rotary seat structure and can move in the length direction of the jumbo frame structure through the corresponding sliding rail system, and each feeding system is used for providing power to make the corresponding mechanical arm system move on the corresponding sliding rail system.

Owner:TUNNEL TANG TECH

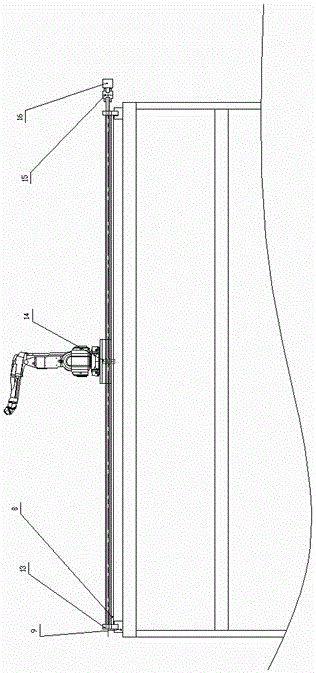

Fast fastening and lightning protection lightning rod and installation manipulator thereof

InactiveCN101741019AEasy to operateSimple and feasible constructionInstallation of lighting conductorsCorona dischargeManipulatorEngineering

The invention relates to a fast fastening and lightning protection lightning rod for an overhead power line, which can be fast fastened to an overhead ground wire, and a wireless control automatic installation manipulator. The fast fastening and lightning protection lightning rod comprises a wire clamp body, a cover plate, a damping conductive cushion, a conductive metal piece, a hinge axle, a lock tongue, a spring, a pin axle, a positive stop body, a lightning rod pole, a vibration prevention hammer and a balance-ball. In order to conveniently work in a charged way, the installation manipulator of the fast fastening and lightning protection lightning rod comprises a walking mechanism, a clamping mechanism used for clamping the lightning rod on the manipulator, a gripping mechanism used for gripping a wire clamp of the lightning rod on the ground wire, a controller, an execution mechanism and a detection mechanism. The controller carries out remote wireless control on the execution mechanism and the detection mechanism, an operator can send the lightning rod to an appointed position through a wireless remote controller, and the manipulator can automatically return after the lightning protection lightning rod is installed. By adopting the invention, charged work can be realized with the advantages of convenience, rapidness, safety and reliability.

Owner:孙渭清

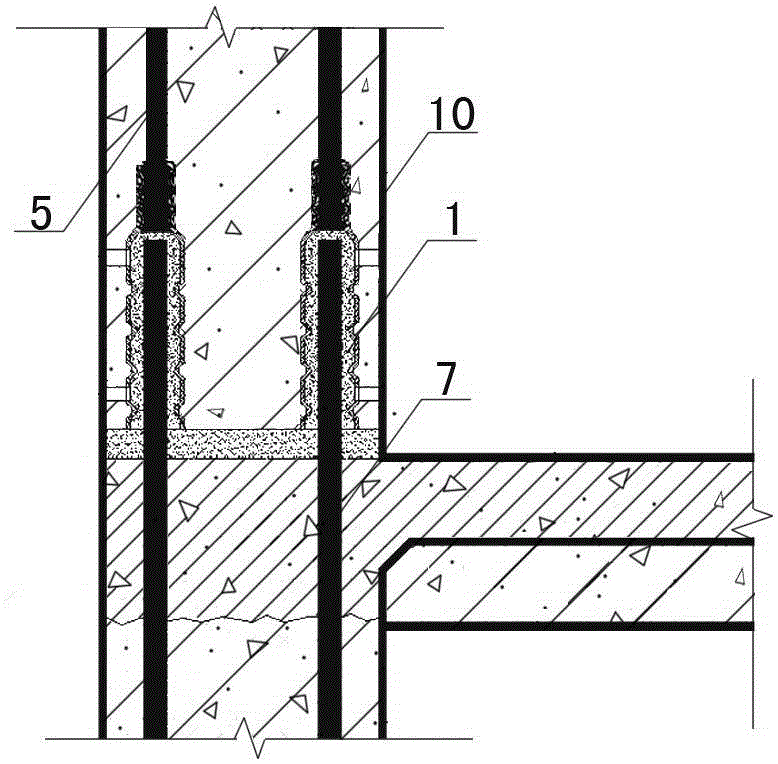

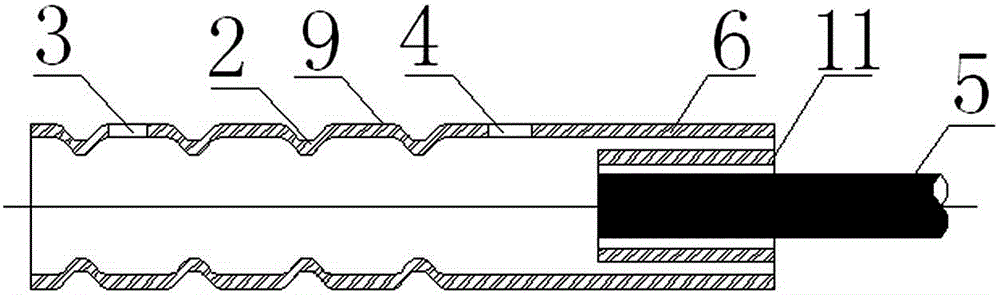

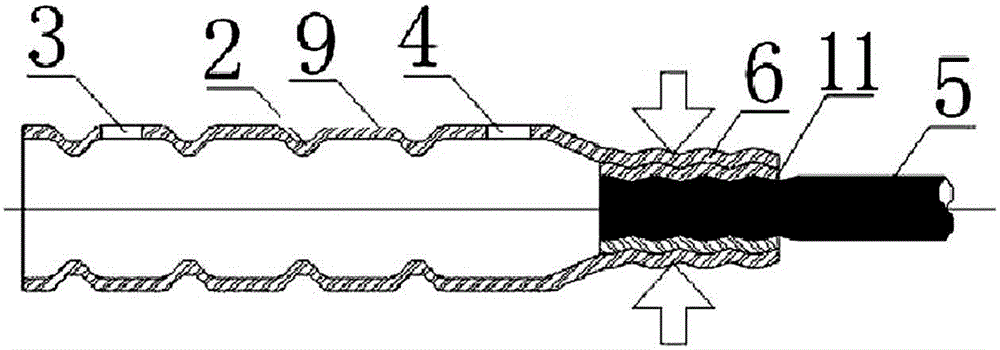

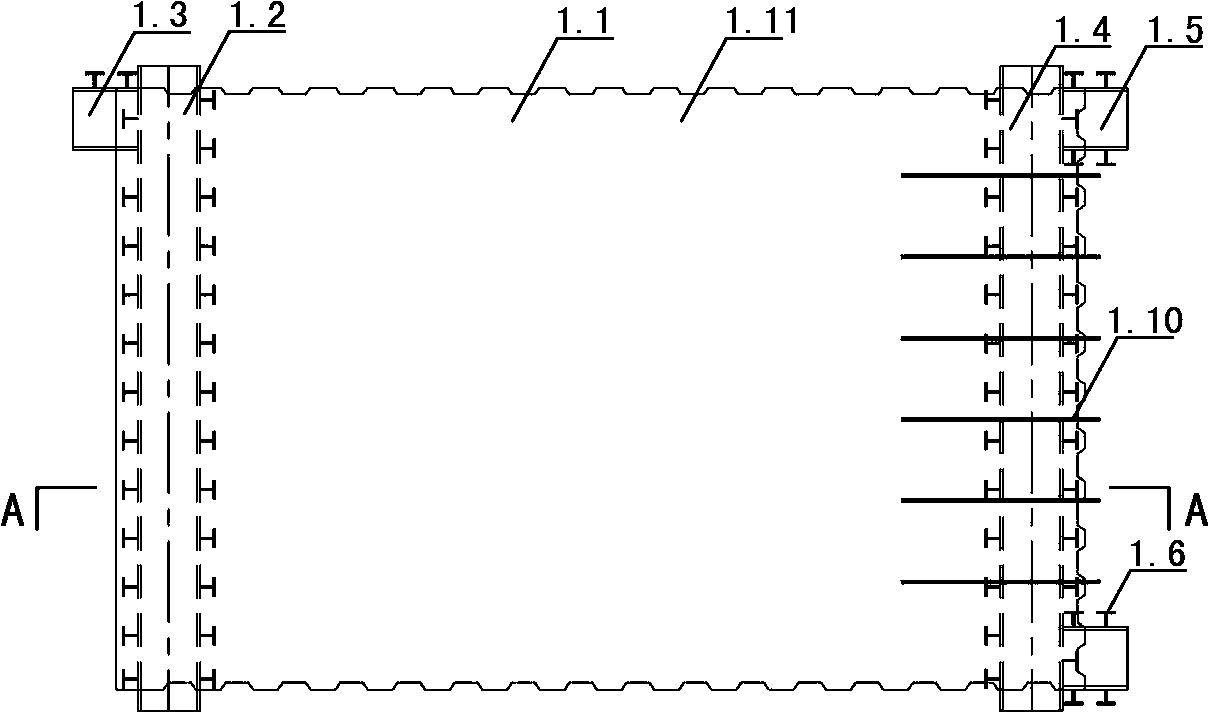

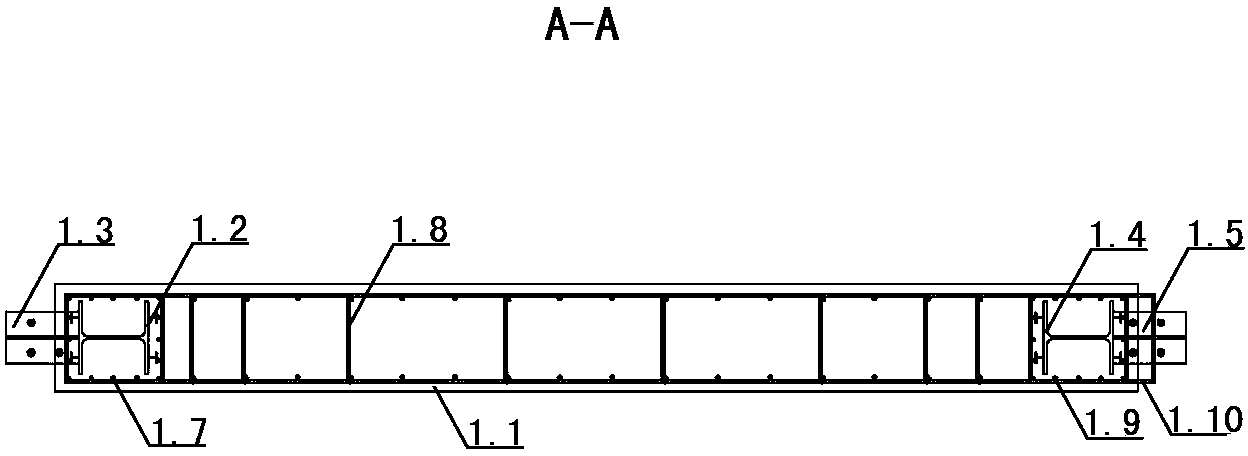

Extruded semi-grouting reinforced sleeve with built-in casing, connective structure, and construction method

InactiveCN105178516AReduce workloadImprove work efficiencyBuilding reinforcementsBuilding material handlingConcrete beamsEngineering

Disclosed are an extruded semi-grouting reinforced sleeve with a built-in casing, a connective structure, and a construction method. The sleeve is a hot-rolled seamless steel tube. The wall of the sleeve is provided with a grout inlet and a grout outlet. The sleeve is provided with circular inner projections. One end of the sleeve is an extruded end, and the rest is a grout-anchoring end. The built-in casing is arranged inside the extruded end. The inner diameter of the built-in casing is equal to the outer diameter of a rebar to be connected, and less than the inner diameter of the grout-anchoring end. All of the grout inlet, the grout outlet and the circular inner projections are located at the grout-anchoring end. By the use of the built-in casing, the deformation of the extruded end is lessened to avoid the extruded end being damaged during crimping; the sleeve is widely applicable to the rebar connection of prefabricated concrete columns in multi-storey and high-rise prefabricated assembled concrete frame structures, shear wall structures or frame shear wall structures, as well as the connection of horizontal rebars in prefabricated concrete beams, the connection of rebars in prefabricated concrete shear walls and the connection of rebars in existing reinforcement projects.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION +1

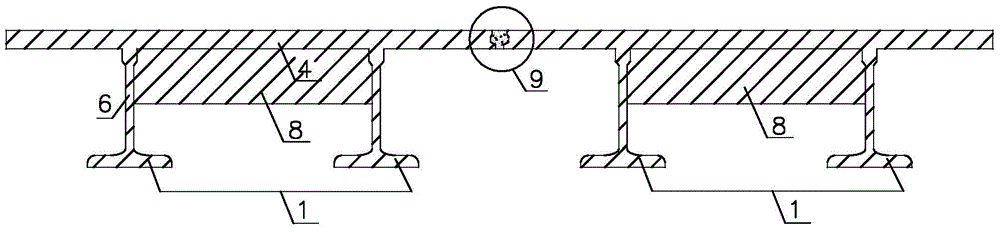

Integral hollow slab bridge structure based on ultra-high-performance concrete connection and construction method thereof

PendingCN107806008ASimple construction methodFast construction methodBridge structural detailsBridge erection/assemblyArchitectural engineeringRebar

The invention discloses an integral hollow slab bridge structure based on ultra-high-performance concrete connection and a construction method thereof. The bridge structure is formed by connecting atleast three prefabricated hollow slab bridges in the transverse direction of the bridges through at least two ultra-high-performance concrete joints and a plurality of ultra-high-performance concretetransverse stripes. Each ultra-high-performance concrete joint comprises a hinge joint between every two hollow slab bridges and ultra-high-performance concrete longitudinal stripes. The hinge joint forms a basic frame through two prefabricated hollow slab bridge web plates, embedded transverse connecting steel bars extending out of the web plates, longitudinal steel bars and hoop bars and is filled with ultra-high-performance concrete. The ultra-high-performance concrete longitudinal stripes include steel bar frameworks formed by prefabricated bridge top slab extending steel bars, longitudinal steel bars and transverse steel bars, and the ultra-high-performance concrete longitudinal stripes and the hinge joints are filled with ultra-high-performance concrete simultaneously. The integral hollow slab bridge structure is good in stress performance, good in durability and remarkable in full-life economical benefit, and construction steps can be executed by adopting a traditional construction device and process and are simple, quick and convenient.

Owner:SHANXI PROVINCIAL RES INST OF COMM

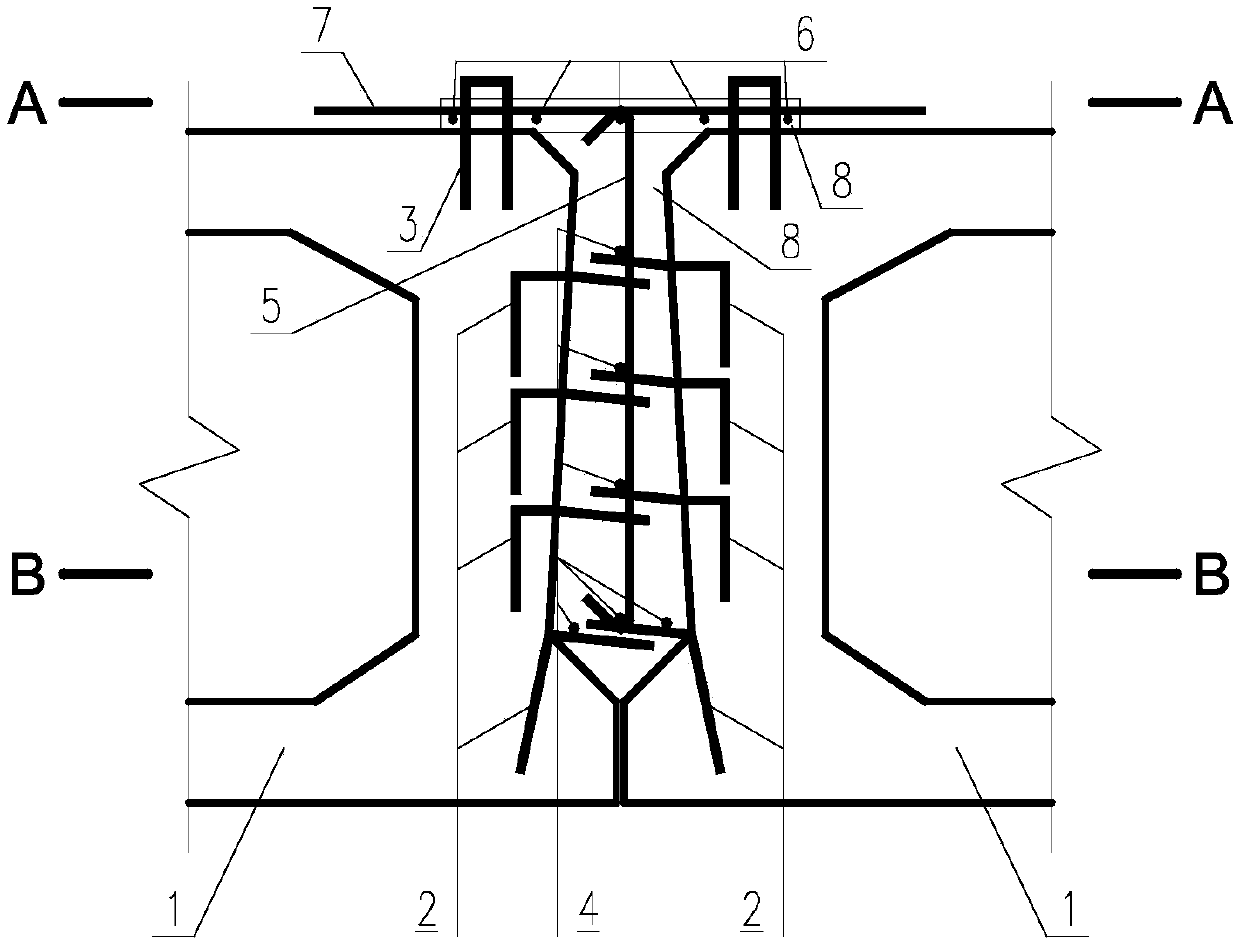

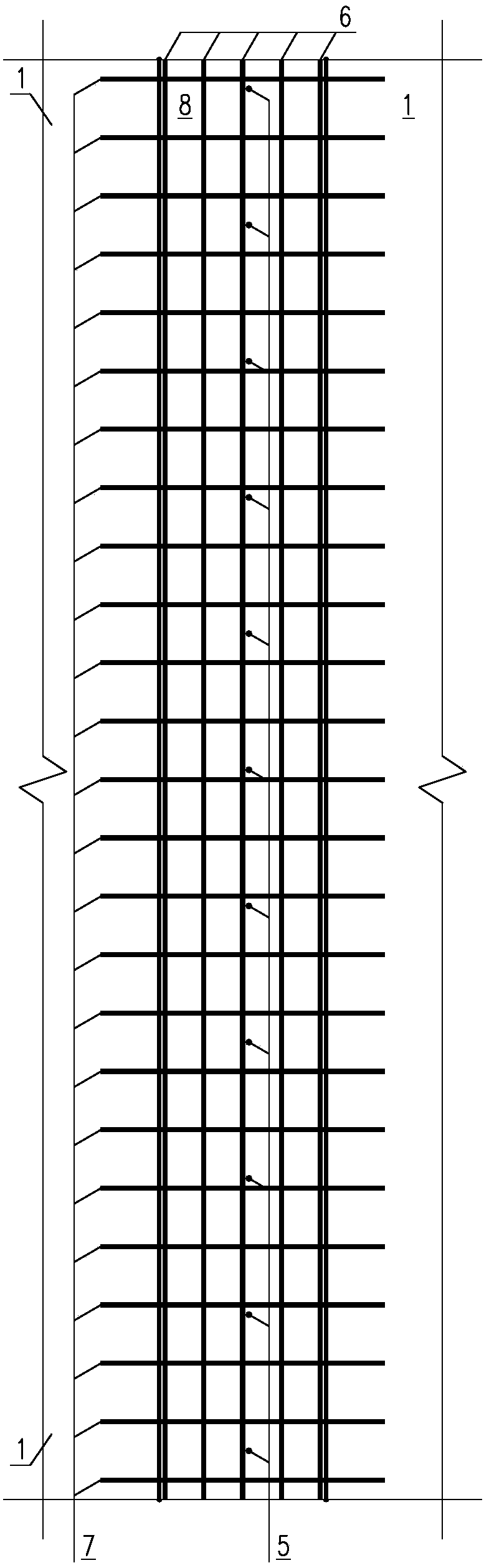

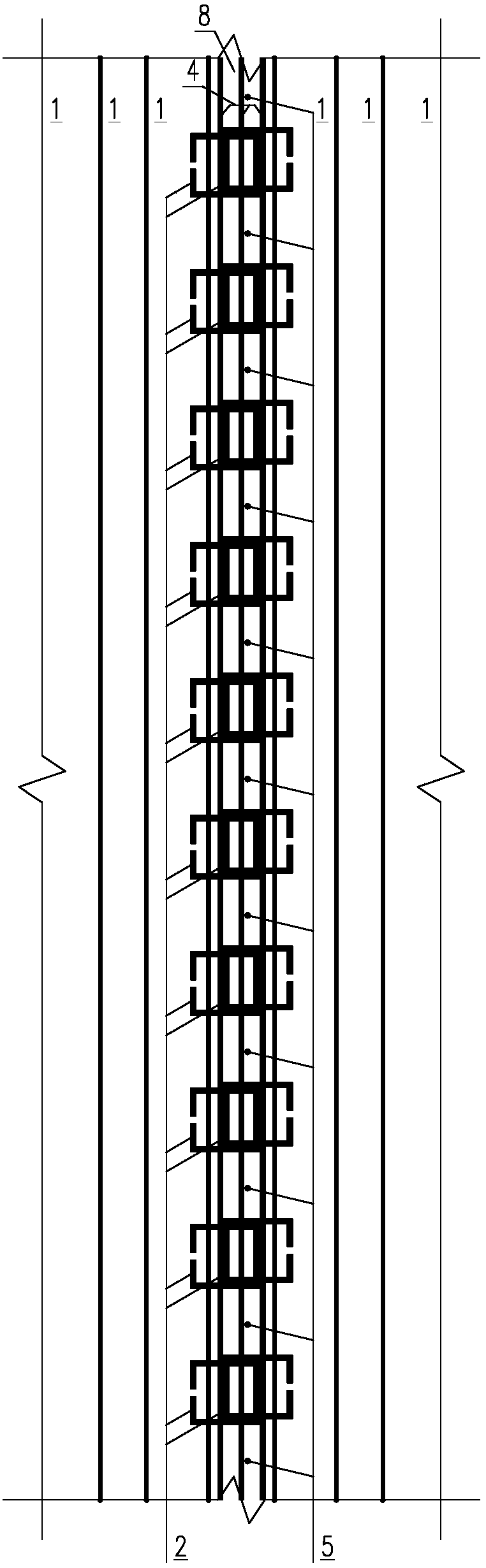

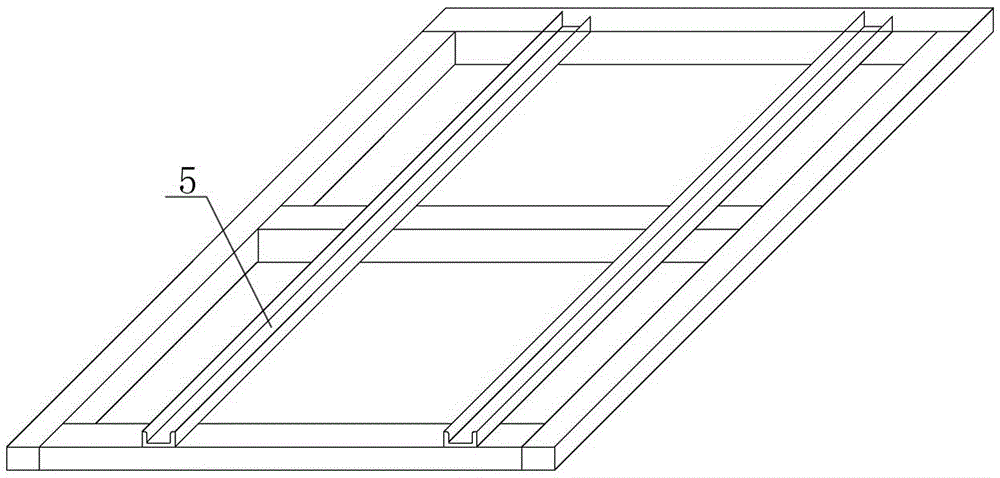

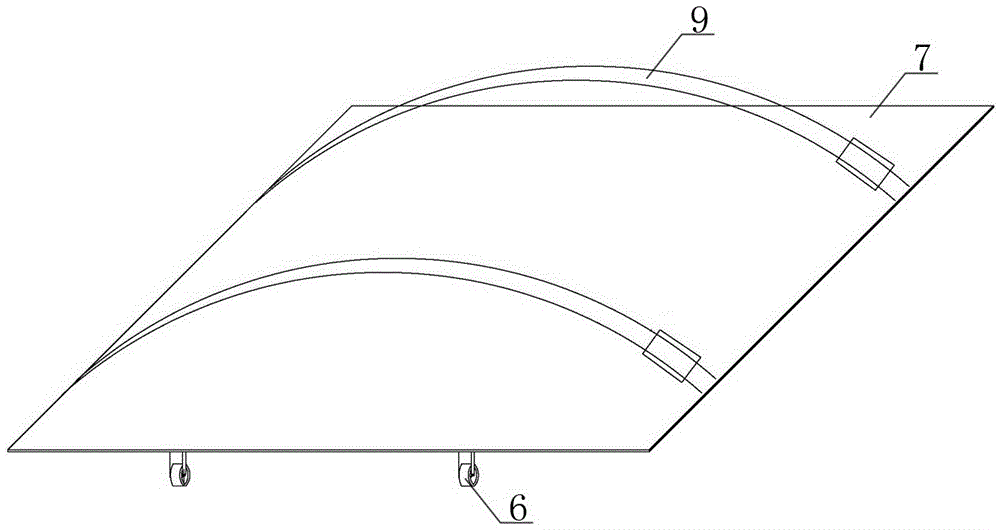

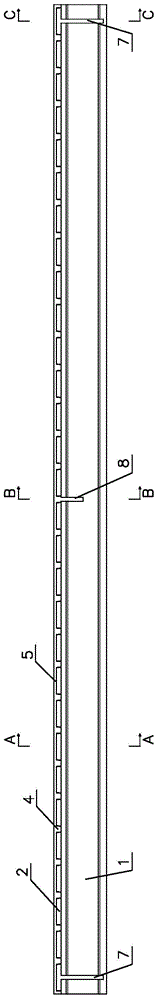

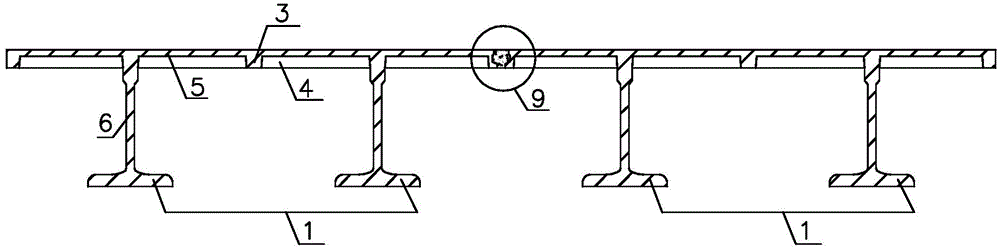

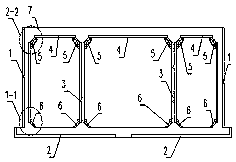

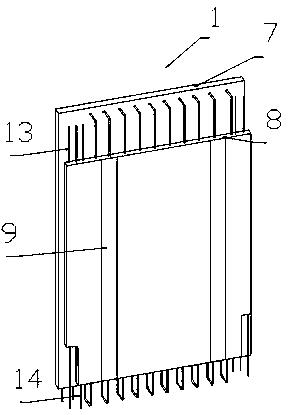

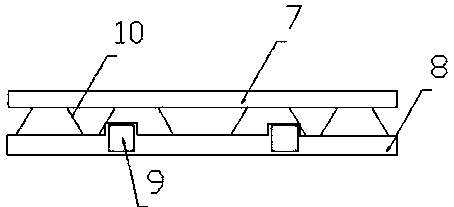

Automatic vibration device

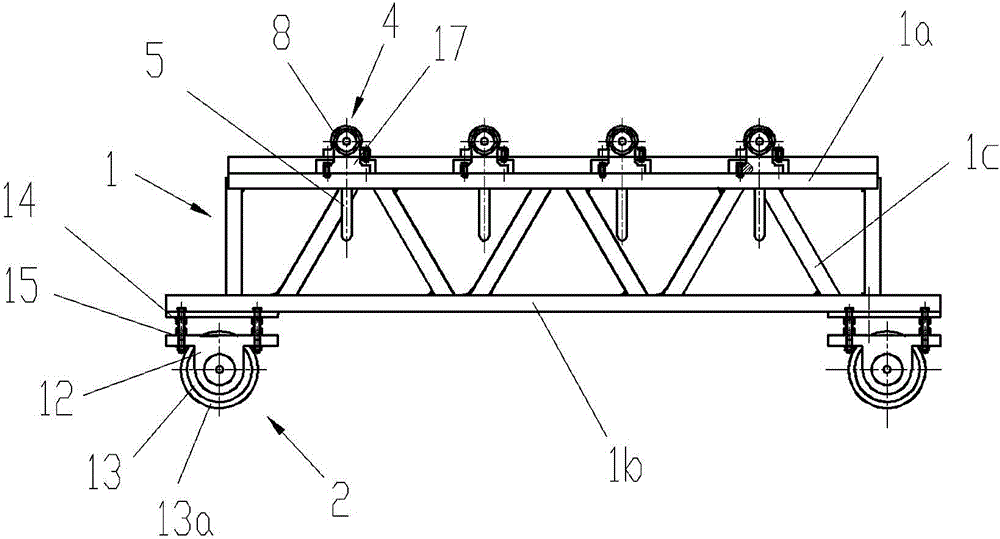

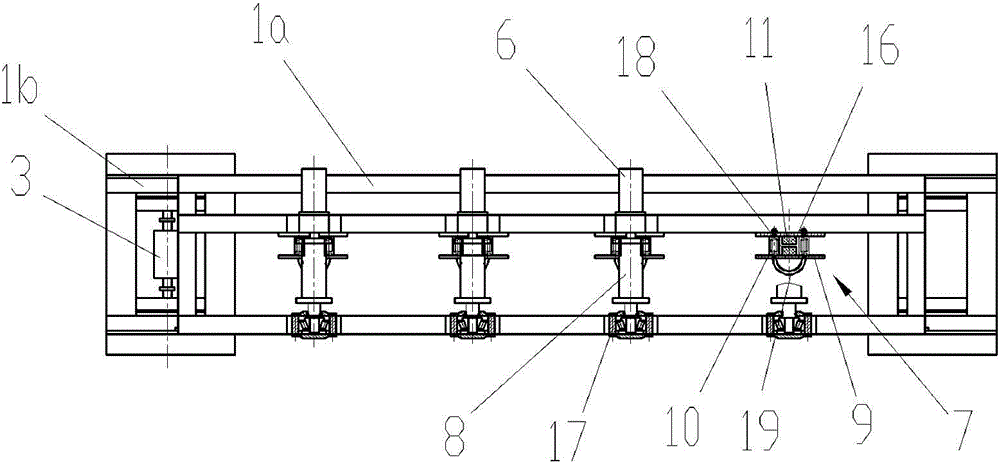

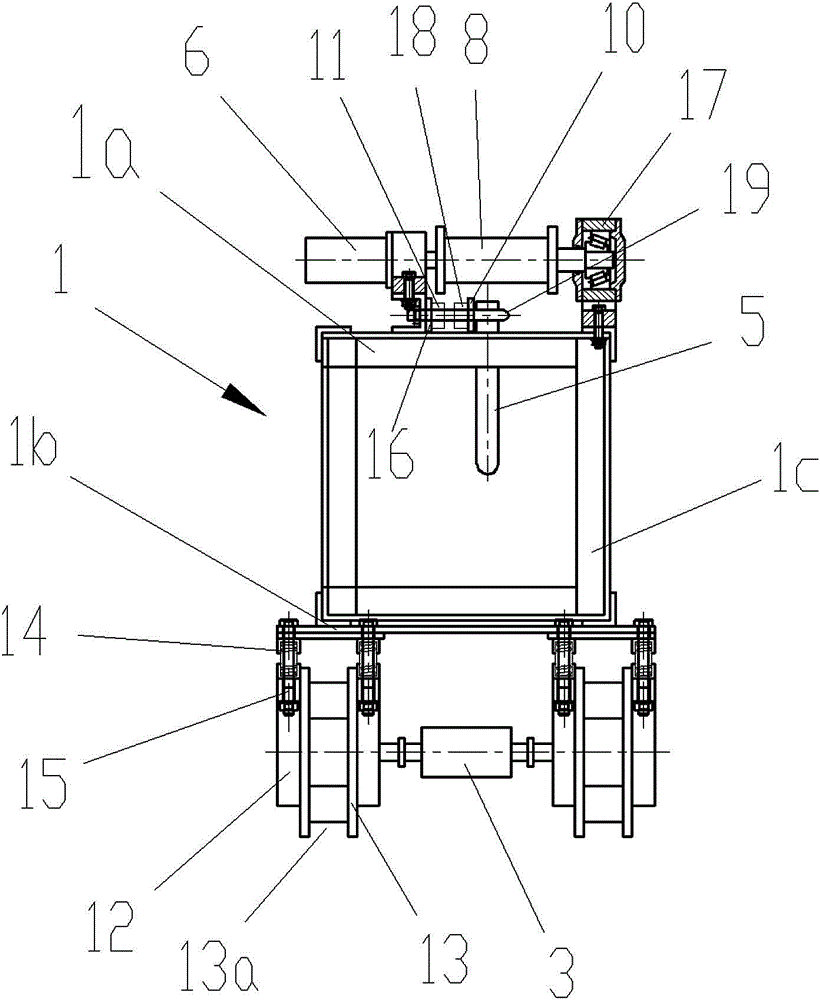

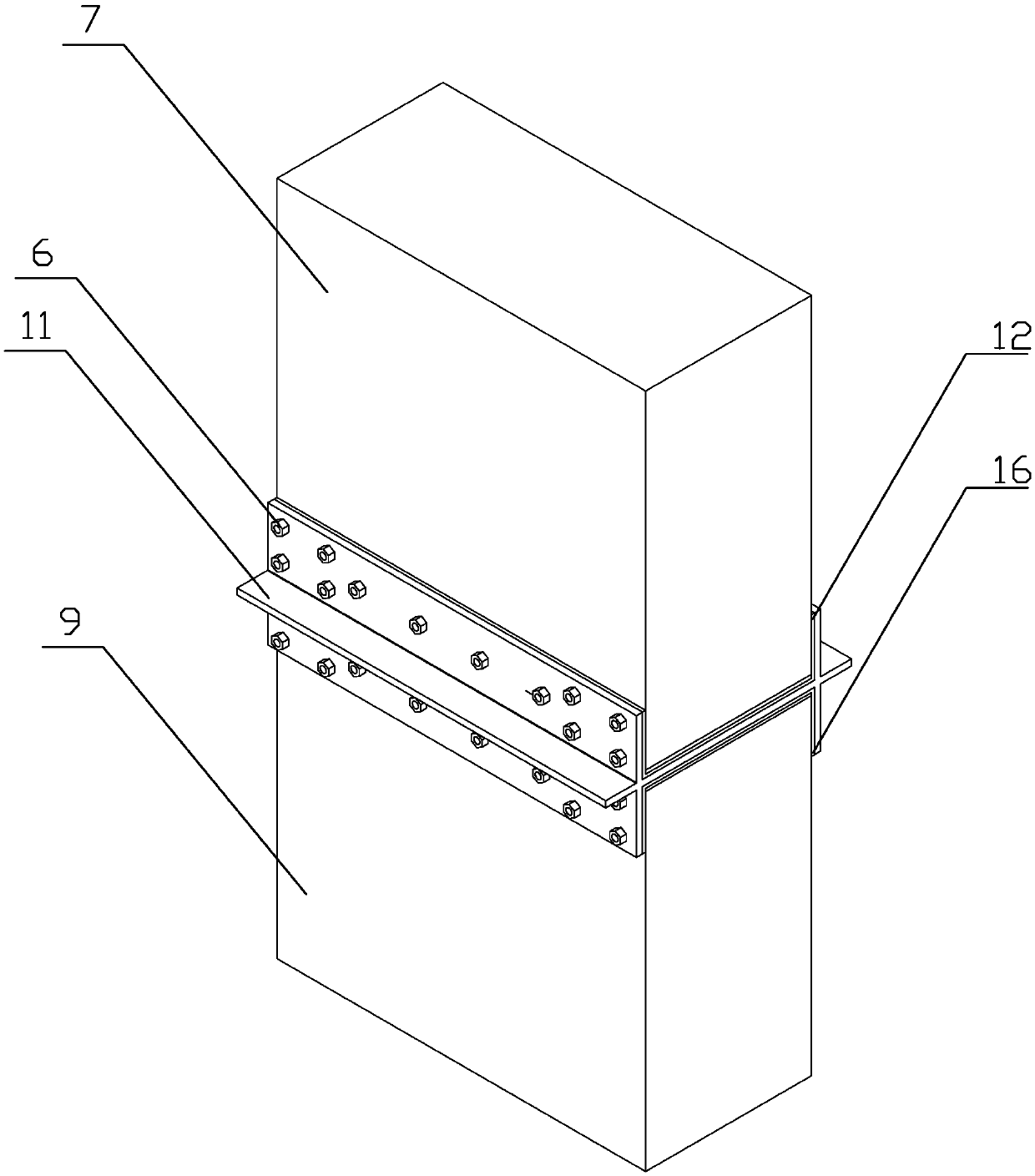

ActiveCN105178606ASimple structureEasy to moveBuilding material handlingAutomatic controlConcrete beams

The invention relates to an automatic vibration device. The automatic vibration device is characterized by comprising a truss (1), wherein a set of wheels (2) is arranged at the lower side of the truss (1); at least one of the wheels (2) is connected with a walking motor (3); the truss (1) is at least connected with a wire winding device (4); each wire winding device (4) is connected with a vibration rod (5); the wire winding device (4) comprises a wire winding motor (6); and the wire winding motor (6) is connected with a winding shaft (8). The automatic vibration device has the following advantages: the device is simple in structure, is suitable for vibrating a concrete beam in the beam construction, is convenient for movement and disassembly, can guarantee the construction quality and the construction efficiency, realizes automatic control, guarantees the equipment working stability, can adjust the size to adapt to the requirements of different working conditions within a certain extent, and reduces the noise pollution and the hazard index to a certain extent.

Owner:BENGBU FUYUAN ELECTRONICS TECH

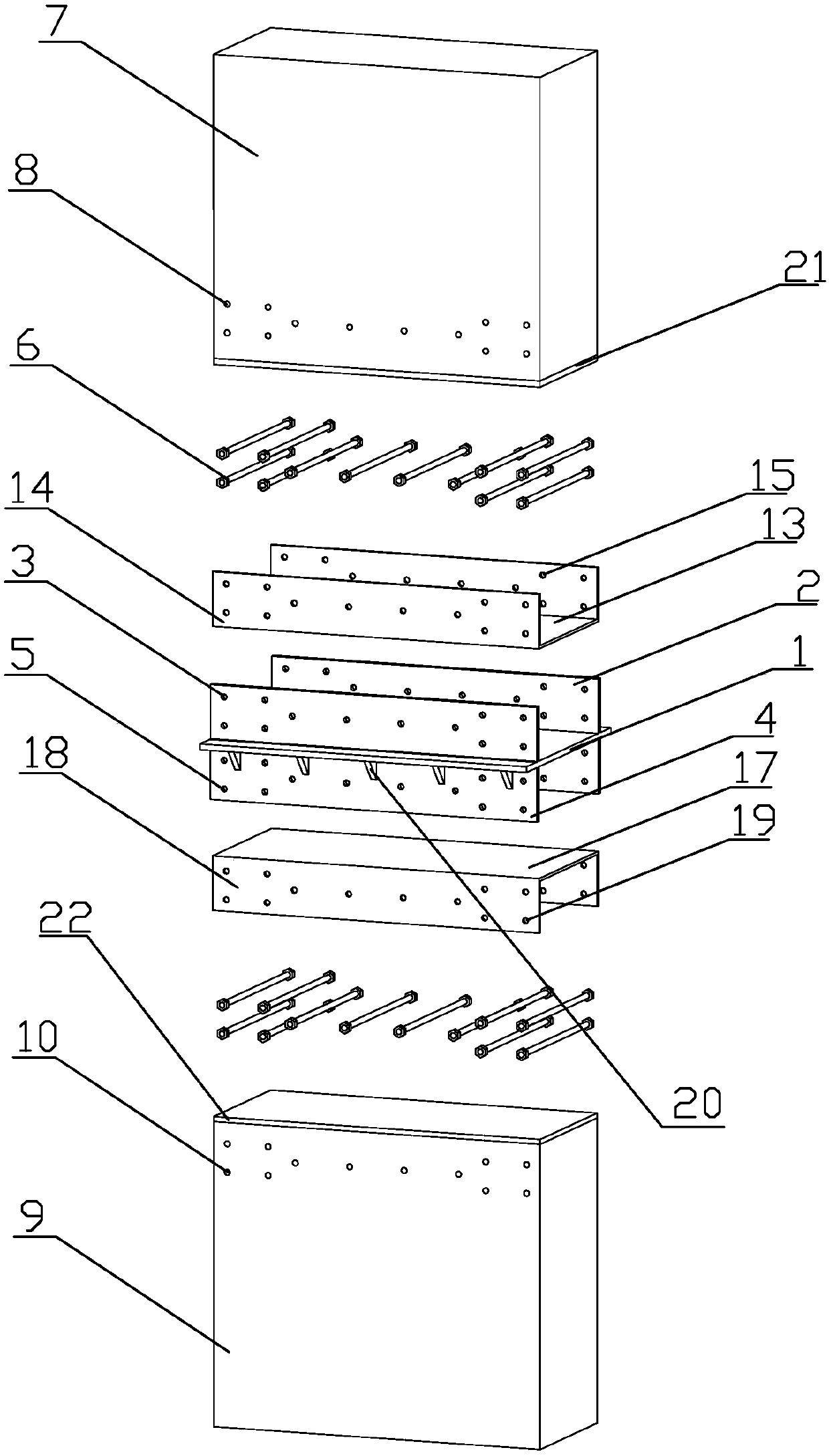

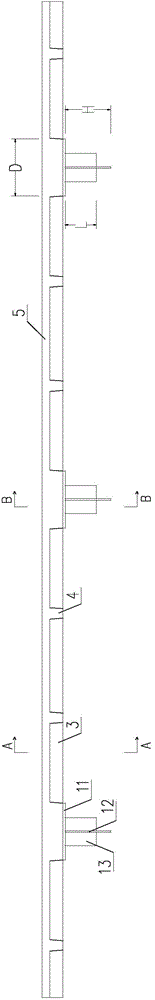

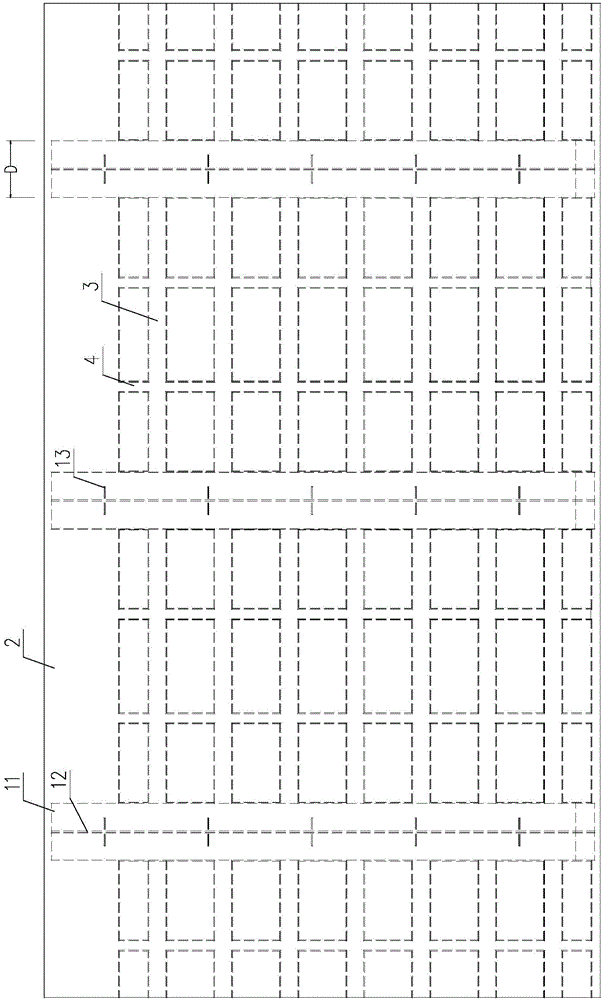

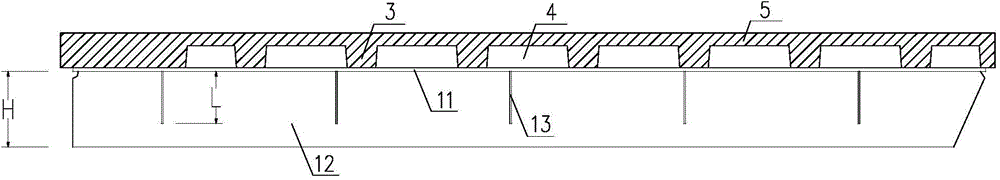

Fabricated shear wall horizontal connection structure and construction method

The invention relates to the technical field of building engineering, in particular to a fabricated shear wall horizontal connection structure and a construction method. The fabricated shear wall horizontal connection structure comprises a horizontal plate, two first connection plates in opposite arrangement are arranged on the upper portion of the horizontal plate, a plurality of bolt holes are formed in each first connection plate, two second connection plates in opposite arrangement are arranged on the lower portion of the horizontal plate, a plurality of second bolt holes are formed in each second connection plate, and a bolt is connected in each of the first bolt holes and the second bolt holes; an upper shear wall is arranged between the first connection plates, third bolt holes corresponding to the first bolt holes are formed in the upper shear wall, a lower shear wall opposite to the upper shear wall is arranged between the second connection plates, and fourth bolt holes corresponding to the second bolt holes are formed in the lower shear wall. The fabricated shear wall horizontal connection structure has the advantages that the shear walls are connected together quickly and firmly through a connector and a horizontal plate, so that construction efficiency is ensured, and integral performance and anti-seismic performance of a building are enhanced; high-strength bolts are utilized for connection, so that horizontal connection reliability of the shear walls is further improved.

Owner:谢建林

Bridge deck unit without transverse surface tensioned joints, bridge structure without transverse surface tensioned joints and construction method of bridge structure

ActiveCN104562931ASimple construction methodFast construction methodBridge structural detailsBridge erection/assemblyBridge deckRebar

The invention discloses a bridge deck unit without transverse surface tensioned joints. The bridge deck unit is mainly formed by integral prefabrication of diaphragm plates and a bridge deck slab. Upper flanges of the diaphragm plates are pre-embedded in the bridge deck slab, and the upper sides of the upper flanges are free of the transverse surface tensioned joints; a latticed thin plate provided with longitudinal ribs and transverse ribs is selected as the bridge deck slab, and two sides of the bridge deck slab are set to be connection portions and extend outwardly to form connection rebars. At least two bridge deck units, lower webs and longitudinal bridge steel beams are connected to from a bridge structure without the transverse surface tensioned joints, wherein the lower webs and the longitudinal bridge steel beams are positioned on the lower portions of the bridge deck units, and cast-in-situ joints are arranged on the upper sides of upper flanges of the longitudinal bridge steel beams; the connection rebars of every two adjacent bridge deck units are bound at the cast-in-situ joints. A construction method includes welding longitudinal bridge steel beam segments, welding shearing-force nails, erecting prefabricated bridge deck slab construction formworks, prefabricating the bridge deck units through casting, lifting the bridge deck units to the steel beam segments, welding the diaphragm plates and finally, casting the joints in situ to complete construction. The bridge deck unit has the advantages of light dead weight, high durability, good stress performance, low cost and the like.

Owner:湖南中路华程桥梁科技股份有限公司

Assembly-type T-shaped mixed coupled wall and construction method thereof

Disclosed are an assembly-type T-shaped mixed coupled wall and a construction method thereof. The assembly-type T-shaped mixed coupled wall comprises a first wall unit and a second wall unit which are connected together perpendicularly and form a T shape. Both the first wall unit and the second wall unit are prefabricated parts, and the first wall unit and the second wall unit are connected through a joint post-pouring belt. According to the assembly-type T-shaped mixed coupled wall, steel beams are used for replacing concrete beams and section steel columns are used for replacing edge constraint reinforced concrete embedded columns, so that the mixed coupled wall has better energy-dissipating capacity and progressive-collapse-resistant capacity than a traditional coupled wall; prefabrication and on-site installation are conducted at the same time, therefore, the problems that the quantity of wet construction on a construction site is large and a lot of construction waste is generated are solved, building operating requirements can be met conveniently, and assembly procedures can be simplified conveniently; after butt welding is conducted on joint short beams, high rigidity is formed between the wall units, therefore, the stability of wall bodies in the construction process is facilitated, the procedure that a shear wall is prefabricated to be used as a temporary support is omitted and the construction efficiency is guaranteed. The construction method can be widely applied to construction of mixed coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

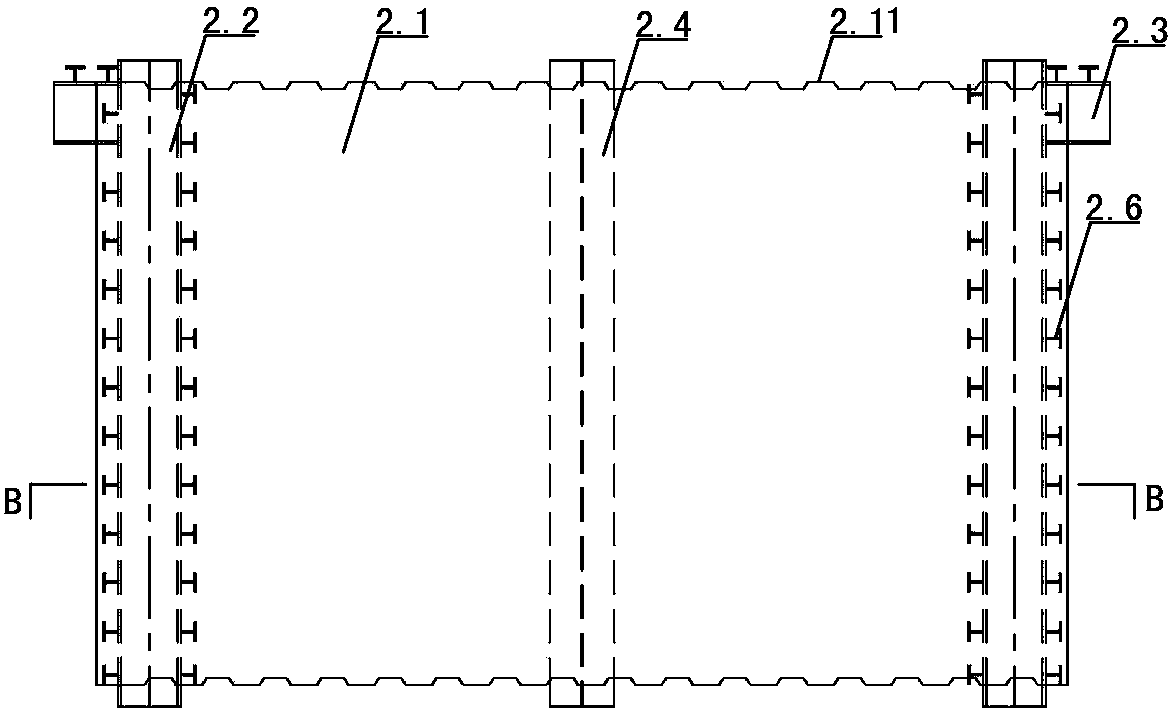

Spray plastering technology

ActiveCN106256970AImprove plaster qualityEnsure construction efficiencyCovering/liningsSlurryStructural engineering

The invention provides a spray plastering technology. The spray plastering technology comprises the steps of base layer treating; slurry throwing and mesh laying, wherein steel wire meshes are laid at the boundaries of different material substrates, and an interface agent is painted in a to-be-plastered area; rib arranging on the wall surface, wherein ribs are arranged on the wall surface; form block installing, wherein form blocks are arranged at the positions, forming exposed corners, of the wall surfaces, each form block is closely attached to one side wall surface of the corresponding exposed corner of the wall surface, corrected and then fixed, one end of each form block protrudes towards the side where the other side wall surface of the exposed corner is located, the protruding thickness is the plastering thickness of the other side face of the exposed corner; layering plastering treating, wherein the perpendicularity, the flatness and the plastering thickness of wall surface plastering are controlled by taking the ribs and the form blocks as a standard; form removal treating. According to the spray plastering technology, the plastering quality and the plastering efficiency can be guaranteed, and the skill requirements on plasterers can be lowered.

Owner:湖南瑞吉达科技有限公司

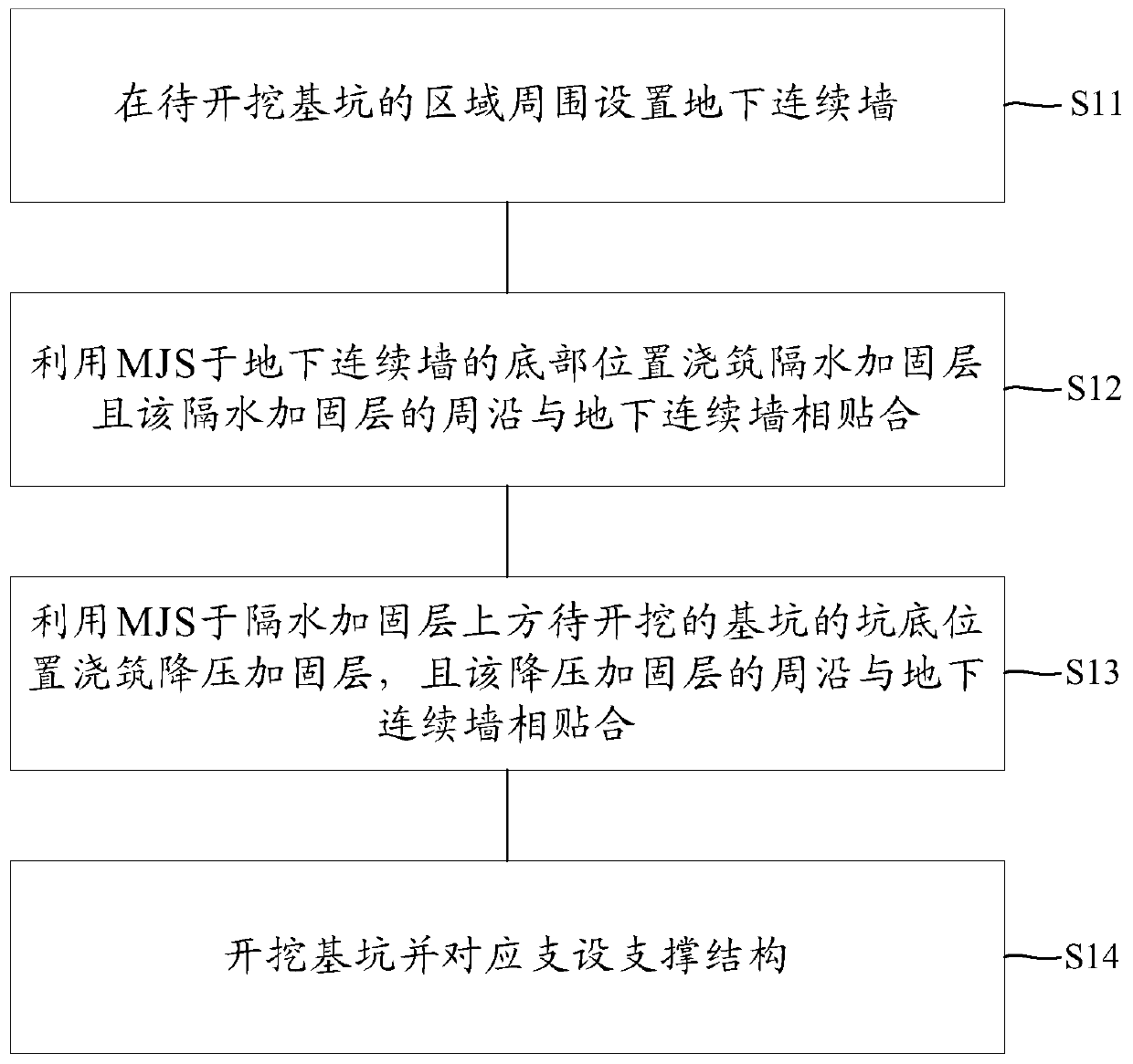

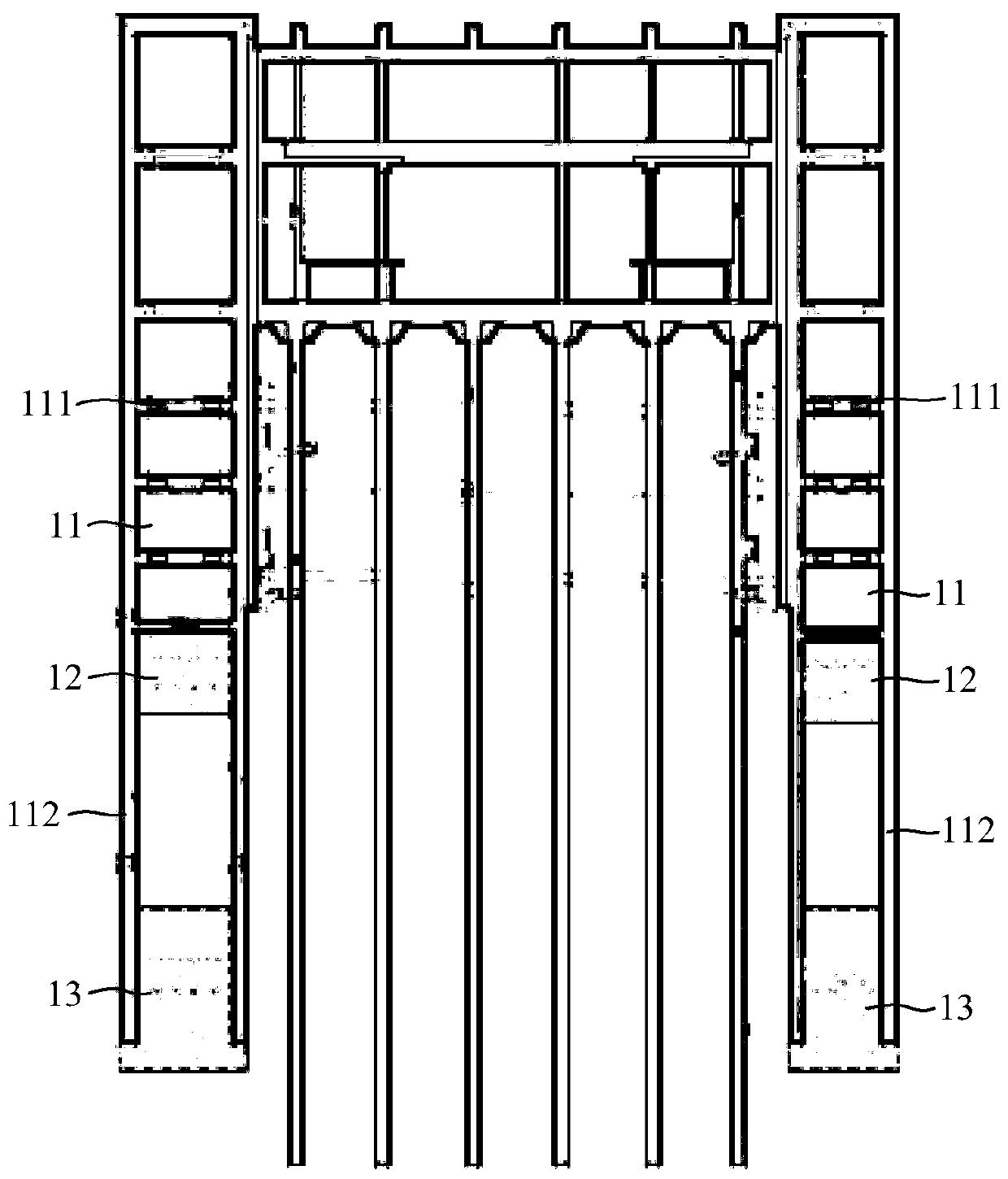

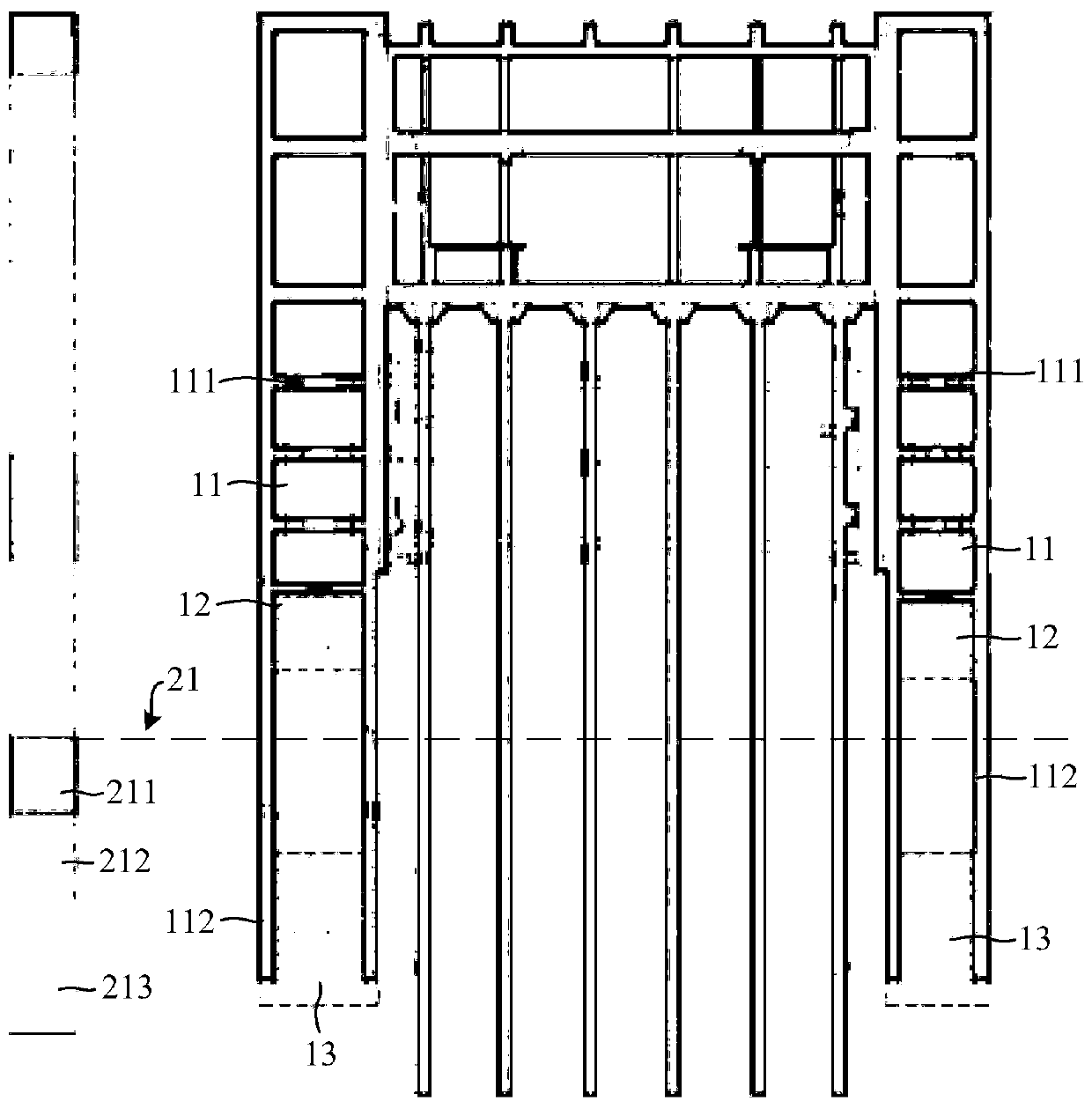

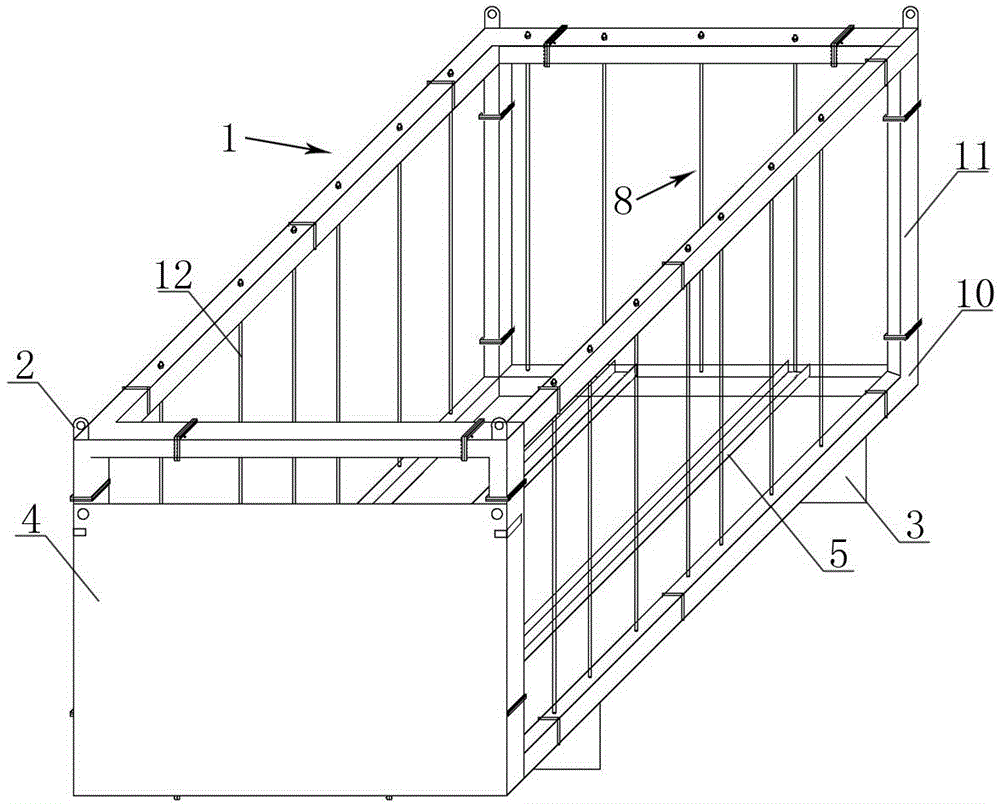

Construction method for anti-uprush of ultra-deep foundation pit

ActiveCN110387884ASolve the hidden danger of pressurized water inrushWill not cause subsidenceExcavationsSlurry wallEngineering

The invention relates to a construction method for anti-uprush of an ultra-deep foundation pit. The bottom of the foundation pit to be excavated is close to a confined aquifer, and the construction method comprises the steps of setting a underground diaphragm wall around the area of the foundation pit is to be excavated; pouring a water-retaining reinforcement layer at the bottom position of the underground diaphragm wall through using MJS, and the periphery of the water-retaining reinforcement layer is adhered to the underground diaphragm wall; pouring a depressurization reinforcement layer at the bottom position of the foundation pit to be excavated above the water-retaining reinforcement layer by using MJS, and the periphery of the depressurization reinforcement layer is adhered to theunderground diaphragm wall; and excavating the foundation pit and supporting a support structure correspondingly. The construction method provided by the invention effectively solves the problem of uprush hidden danger of the confined aquifer when excavating the ultra-deep foundation pit, and has little influence on the surrounding environment during construction, does not cause settlement of surrounding buildings, and can ensure construction quality and construction efficiency.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

Size adjustable type material lifting device and construction method of size adjustable type material lifting device

InactiveCN105672675AStrong and stable structureIncreased durabilityBuilding material handlingEngineeringSelf locking

The invention provides a size adjustable type material lifting device. The size adjustable type material lifting device comprises a frame body and a lifting lug connected onto the frame body, wherein the frame body is a three-dimensional framework formed by eight adapter coupling nodes and at least eight connection segment rods, which are mutually combined; the adapter coupling nodes are located at eight corner positions of the frame body and comprise three node heads which are vertical to one another; the connection segment rods are respectively connected between among the adjacent node heads respectively. The size adjustable type material lifting device adopts the frame body made of a metal material, and is simple in structure and convenient to manufacture; the flexibility and the adaptability are improved; the frame body is firstly assembled and materials are put on a conveying platform and are bound and fixed by a binding belt; then the materials are hoisted to an appointed building position and then a fixed turning plate is overturned outwards, so that the materials arefixed turning plate is overlapped on a building; the materials slip out of the frame body through a self-locking trundle and can be transported to a proper position; thea whole process is simple and feasible, the design of all links is reliable, and the safety and practicability are guaranteed; furthermore, the construction efficiency and the construction quality are guaranteed. The size adjustable type material lifting device can be widely applied to material transportation.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

Prefabricated ultra-high-performance concrete pi-shaped beam unit, bridge structure and construction method thereof

ActiveCN104389261ASimple construction methodFast construction methodBridge structural detailsBridge erection/assemblyShaped beamButt joint

The invention discloses a prefabricated ultra-high-performance concrete pi-shaped beam unit applicable to bridge construction. The prefabricated ultra-high-performance concrete pi-shaped beam unit is formed by integrally prefabricating a T-shaped double-main beam and bridge deck slabs, wherein the T-shaped double-main beam comprises two main beam webs which are arranged in parallel; a gridded thin slab piece is adopted as each bridge deck slab, and longitudinal ribs and transverse ribs are arranged at the lower part of each gridded thin slab piece; one or two sides of each bridge deck slab is / are set as a connection part(s); a connecting steel bar which is connected with another adjacent pi-shaped beam unit extends out of each connecting part. The pi-shaped beam unit is spliced along the transverse direction of a bridge, a cast-in-situ seam is formed in a butt joint, the connecting steel bar is bound at the cast-in-situ seam, and a longitudinal steel bar is configured at the cast-in-situ seam. A construction method of a pi-shaped bridge structure comprises the following steps of firstly, prefabricating the ultra-high-performance concrete pi-shaped beam unit; secondly, transversely splicing the unit on a construction site; thirdly, binding the connecting steel bar at a longitudinal seam, and casting ultra-high-performance concrete in situ; finally, performing maintenance to complete construction. The prefabricated ultra-high-performance concrete pi-shaped beam unit has the advantages of being light in dead weight, high in durability, capable of effectively reducing the cracking risk of a beam body and the like.

Owner:HUNAN UNIV

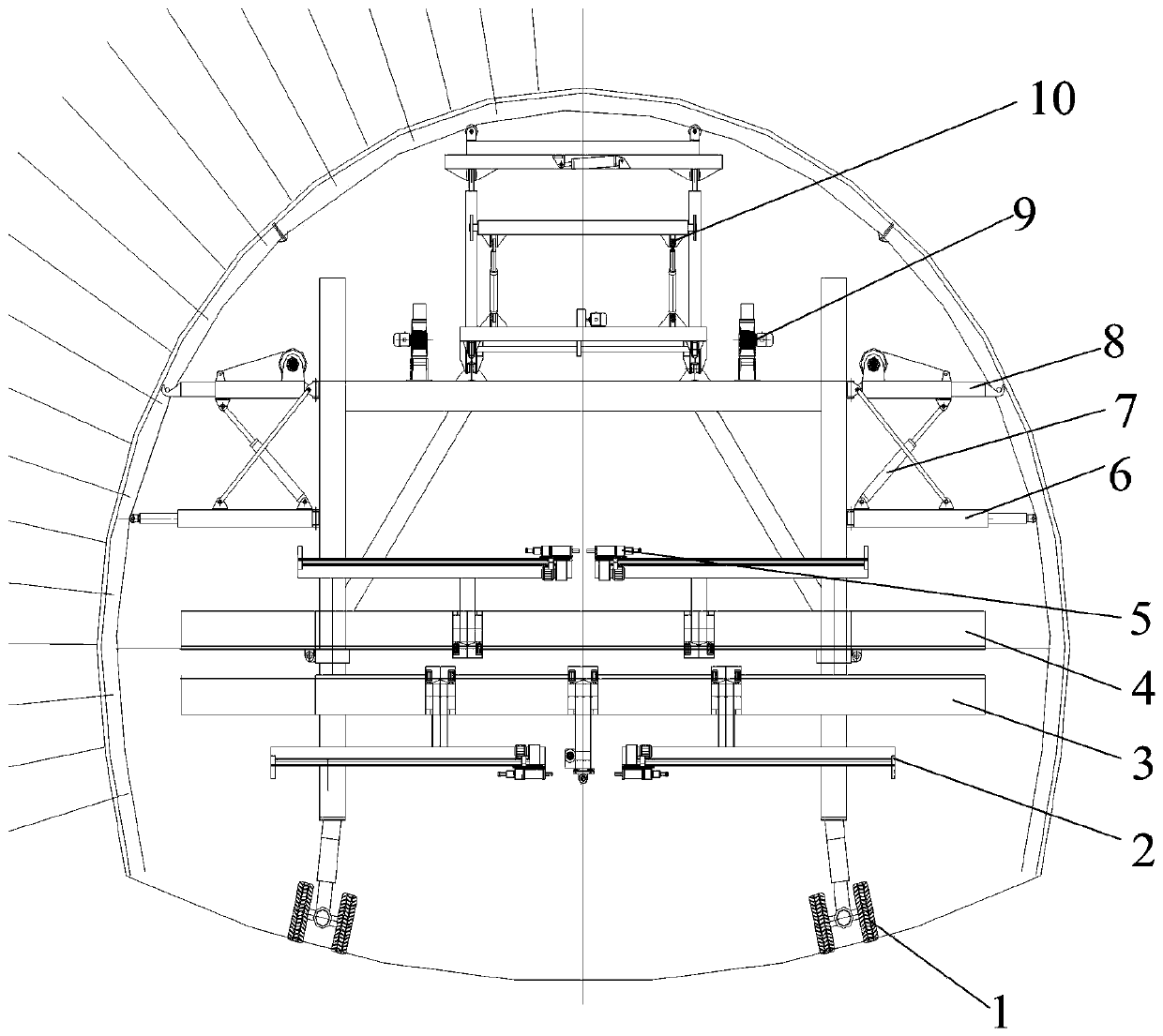

Trolley for tunnel full-face excavation, drilling and steel arch installation

PendingCN109931005AEnsure construction efficiencyStable controlUnderground chambersDerricks/mastsDrilling systemTunnel construction

The invention discloses a trolley for tunnel full-face excavation, drilling and steel arch installation. The trolley for tunnel full-face excavation, drilling and steel arch installation comprises shifting rollers, telescopic cross beams, a bottom lifting support beam, a top lifting support beam, a drilling system, support hydraulic telescopic arms, hydraulic rods, propped hydraulic telescopic arms, telescopic lazy arms, a steel arch small trolley and a hydraulic system. Compared with the prior art, the trolley for tunnel full-face excavation, drilling and steel arch installation, disclosed bythe invention, has the advantages that 1) drilling at any angle in the longitudinal and radial directions of a tunnel can be realized; 2) the positions of the bottom lifting support beam and the toplifting support beam can be adjusted, so that different tunnel construction requirements can be adapted to; 3) the moving small trolley is additionally installed, so that the hoisting, adjustment andfixation of a steel arch can be realized; 4) the hydraulic system drives and controls hydraulic parts of the whole device, and ensures stable control, concentrated control and convenient operation; and 5) a plurality of types of work can coordinate and work simultaneously, and the construction efficiency is ensured.

Owner:CHINA FIRST HIGHWAY ENG +2

Full-fracture surface supporting-free overlapped fabricated type comprehensive pipe gallery structure and construction method

ActiveCN108708394ASolve the problem of interfering constructionReduce handlingArtificial islandsUnderwater structuresRebarWall plate

The invention relates to a full-fracture surface supporting-free overlapped fabricated type comprehensive pipe gallery structure and a construction method. The structure comprises a fabricated overlapped top plate, a fabricated overlapped base plate, a fabricated side wall plate and a fabricated inner wall plate; the side wall plate is formed by a side wall inner sheet plate and a side wall outersheet plate, and steel tie bars are arranged between the side wall inner sheet plate and the side wall outer sheet plate; and the upper and lower ends of the side wall inner sheet plate are provided with reserved extending-out reinforcing steel bars, the lower end of the side wall outer sheet plate is provided with reserved extending-out reinforcing steel bars, and the inner wall plate is formed by overlapping two wall plates. A vertical-support-free method for assembling an overall concrete pipe gallery is provided for solving the problems that an existing technology for assembling the overall comprehensive pipe gallery has the problems that a vertical support has interference in construction, axillary corner construction is difficult, and the installing field slope limitation exists; andaccording to the method, a self-designed stiffened axillary corner pouring formwork is mainly adopted, and the formwork capable of achieving supporting-free installation and capable of solving the problem about axillary corner pouring is achieved in cooperation with wallboard structure construction adjustment.

Owner:GUANGDONG JIAN YUAN CONSTR ASSEMBLY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com