Fast fastening and lightning protection lightning rod and installation manipulator thereof

A lightning rod and anti-shielding technology, applied in the fields of electric power equipment, circuit equipment and hardware, can solve the problems of imperfect anti-vibration and installation performance, difficulty in live operation and automatic installation, easy damage to ground wires and lightning rods, etc. Convenient one-handed operation, safe and reliable performance, simple and feasible construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

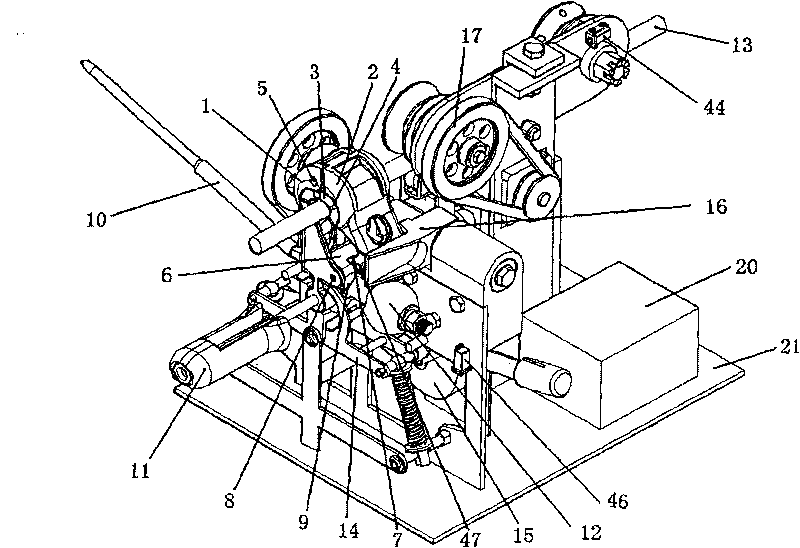

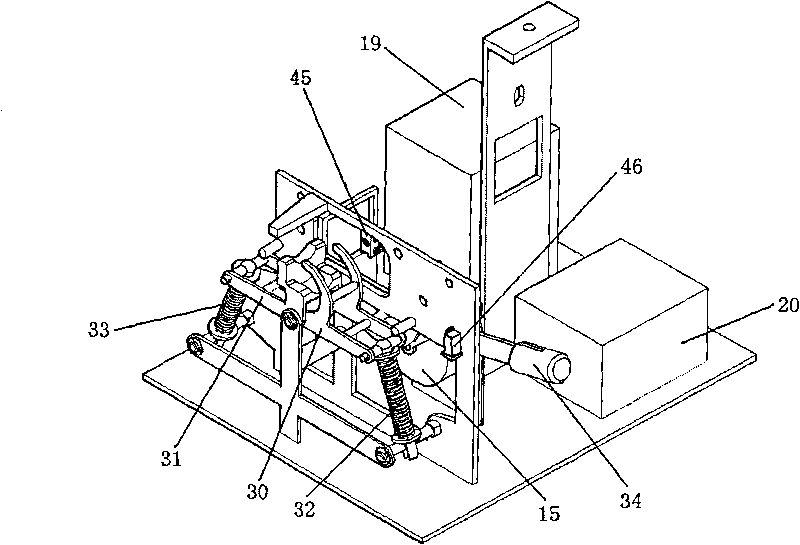

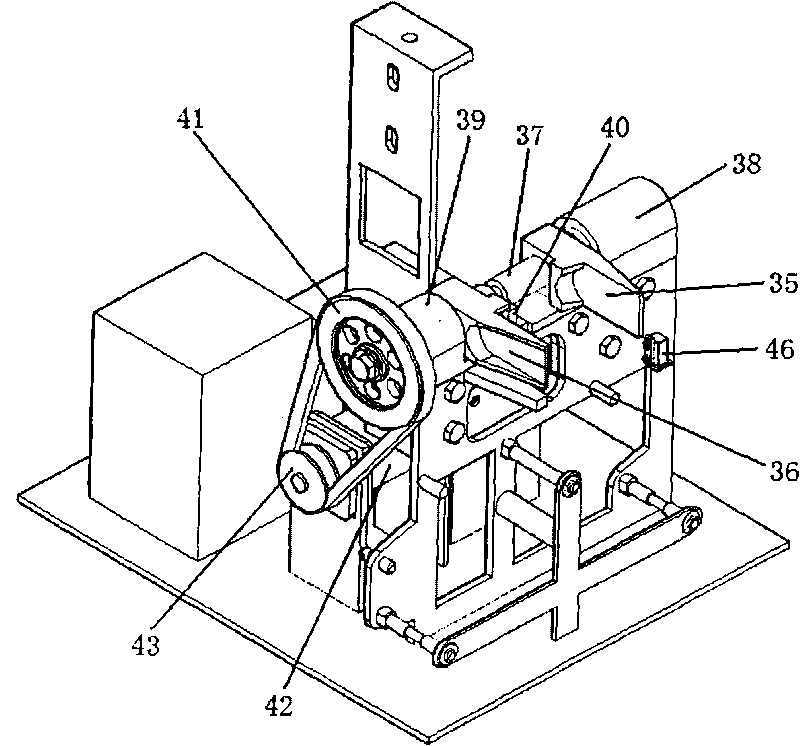

[0029] A fast locking anti-shielding lightning rod, which mainly includes a clamp body 1, a cover plate 2, a damping conductive rubber pad 3, a conductive metal sheet 4, a hinge shaft 5, a locking tongue 6, a locking spring 7, a pin shaft 8, Limiting body 9, lightning rod rod 10, anti-vibration hammer 11 and balance ball 12, lightning rod rod 10 and anti-vibration hammer 11 are connected with wire clamp body 1, balance ball 12 is installed on the symmetrical position of lightning rod rod 10, and wire clamp body 1 passes through The damping conductive rubber pad 3 and the conductive metal sheet 4 are connected to the ground wire 13, and are quickly locked on the ground wire 13 through the lock tongue 6, the spring 7, and the limiter 9; A damping conductive rubber pad 3 and a conductive metal sheet 4 are inlaid respectively; the pin holes of the hinge sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com