Construction method for anti-uprush of ultra-deep foundation pit

A construction method and deep foundation pit technology, which can be used in infrastructure engineering, excavation, construction, etc., can solve problems such as hidden dangers of pressurized water inrush, so as to avoid pressurized water inrush, solve hidden dangers of pressurized water inrush, Guarantee the effect of construction quality and construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

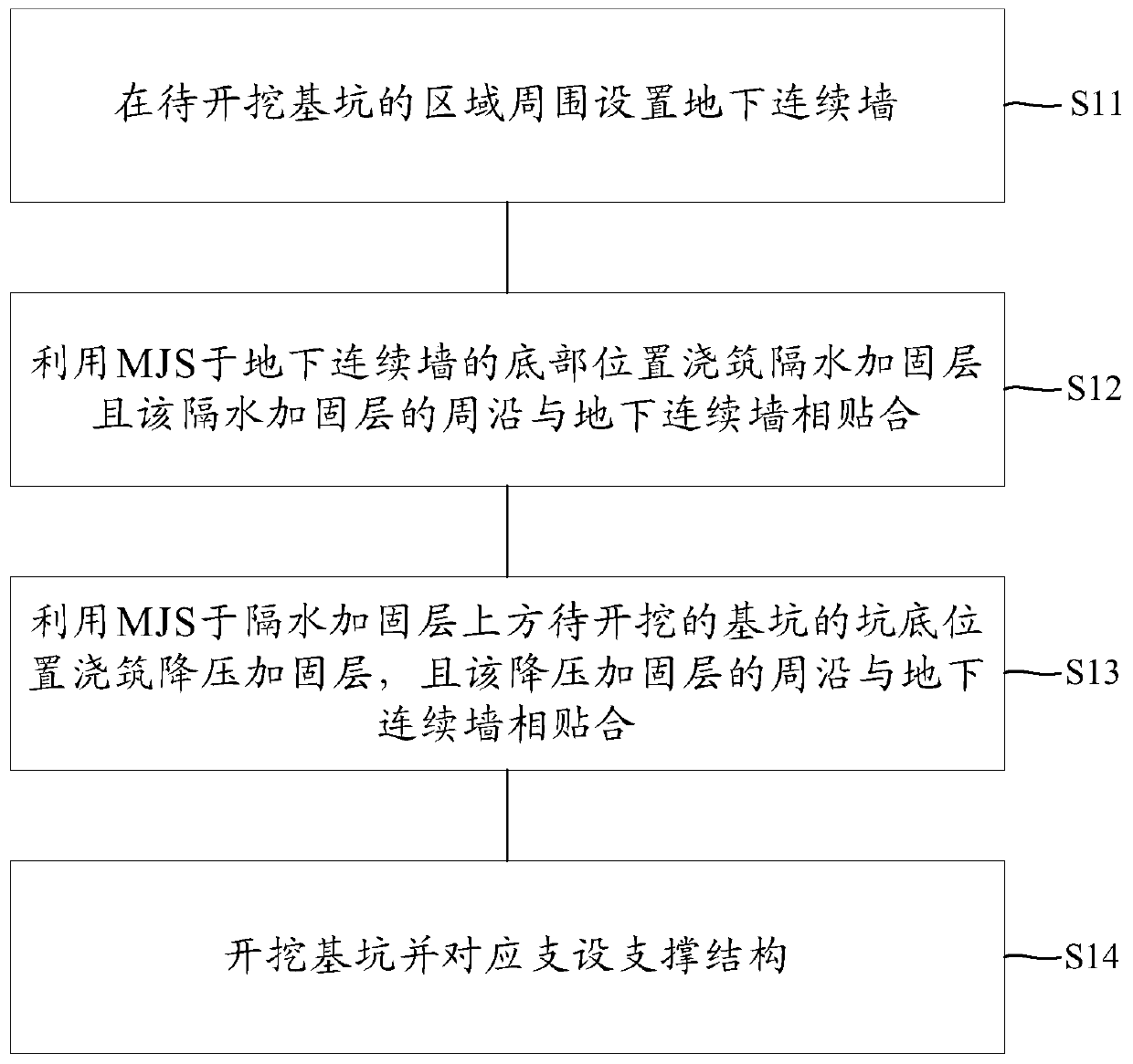

Method used

Image

Examples

specific Embodiment approach

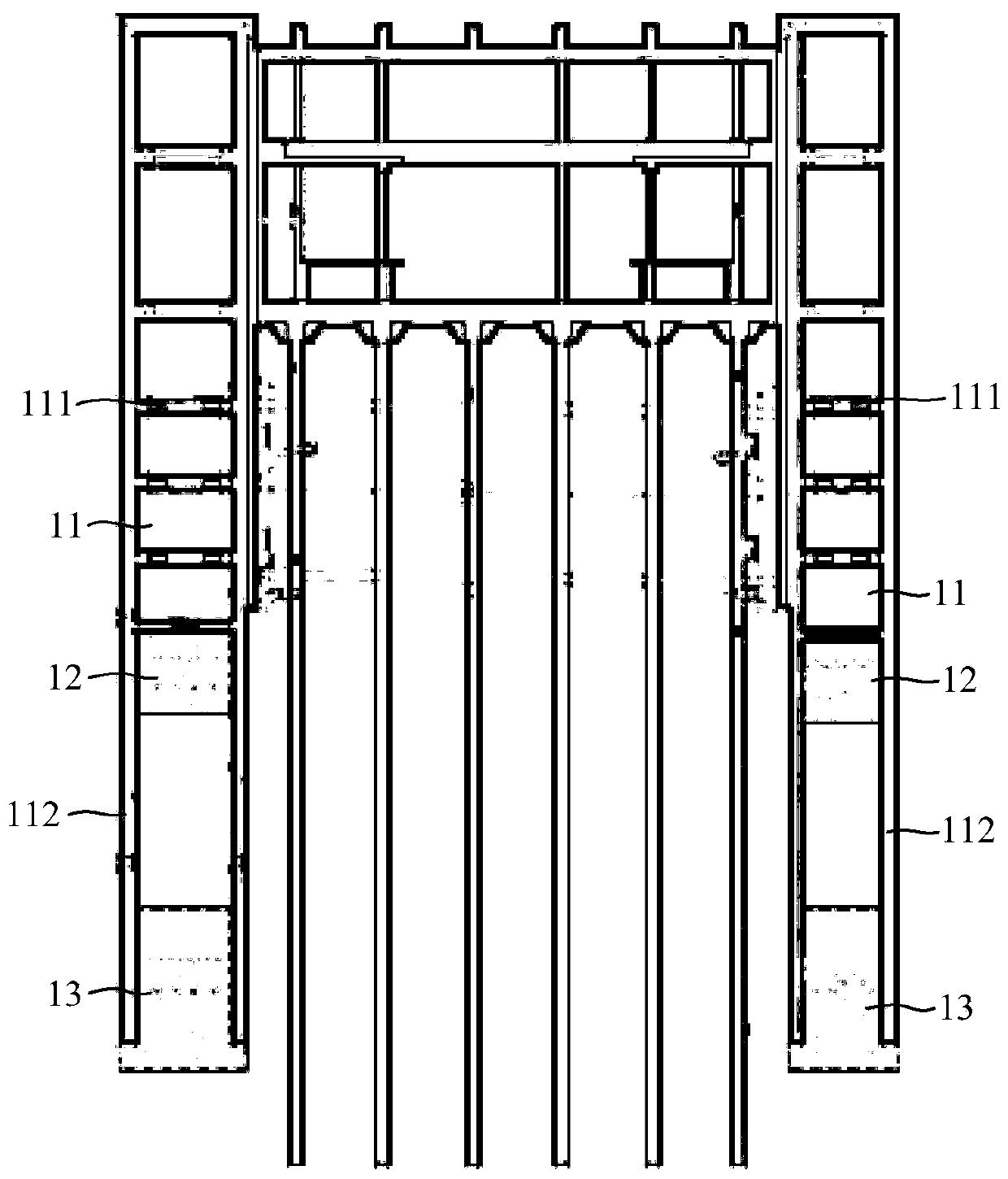

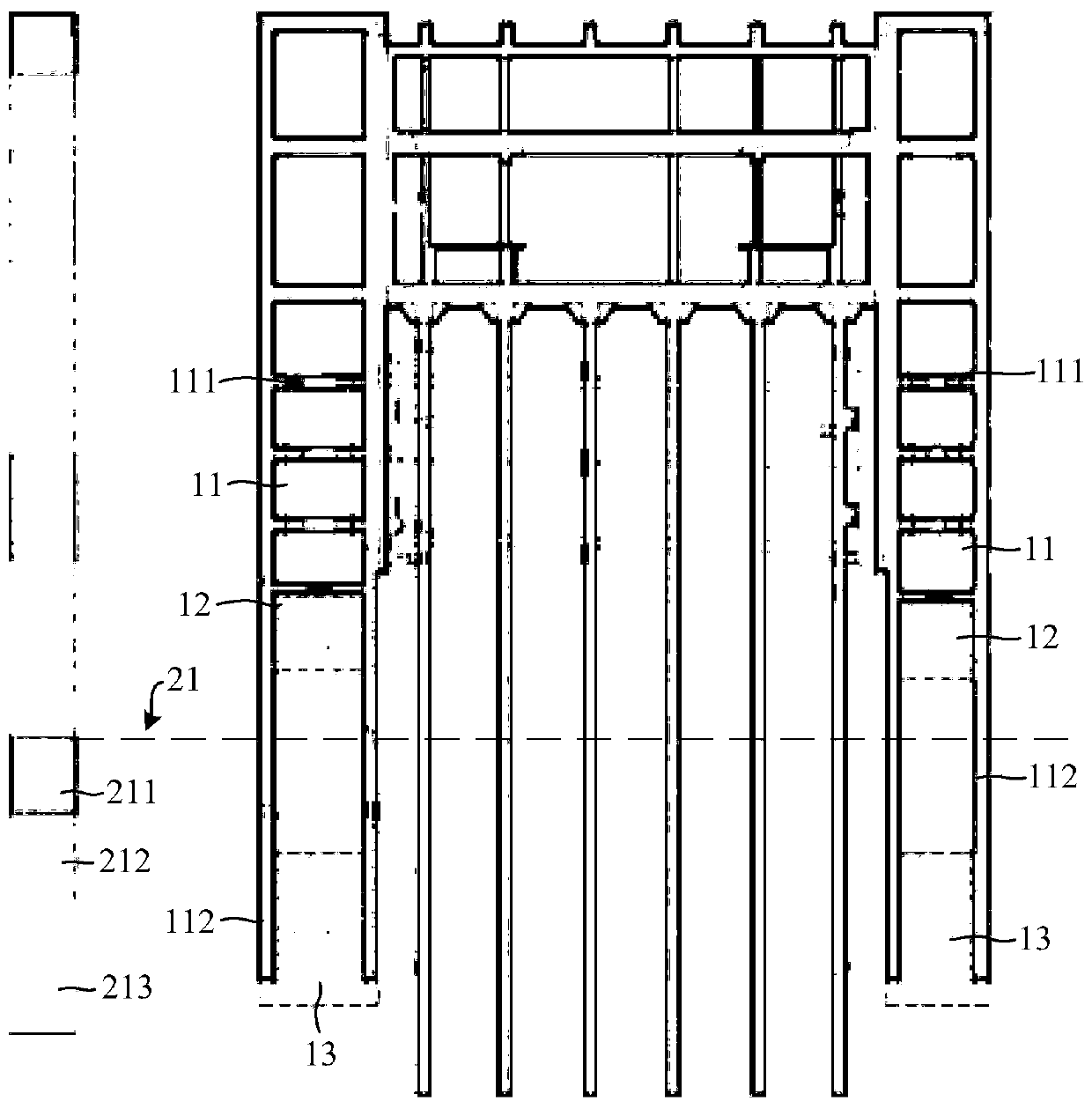

[0086] Taking the barrier-clearing wells on both sides of the rail transit station as an example, the foundation pit to be constructed is a barrier-clearing well. Since the surrounding buildings of the foundation pit are stations, the requirements for ground settlement are extremely high, and the settlement range should not be greater than 2mm, and should not be greater than 5mm , the elevation of the top surface of the confined water layer in the construction area is -23.92~-26.31m, and the deepest excavation of the foundation pit is 23.6m very close to the confined water layer. According to the site geological survey data and water survey feedback, the confined water depth needs to be Only when the height of 13.6m can meet the safety requirements of foundation pit excavation, four foundation pits need to be excavated for this project;

[0087] According to ∑h·γs≥Fs·γw·H, the bottom elevation of the reinforced layer of the aquifer is calculated, the thickness of the reinforced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com