Triplet vertical component construction device, combination body and method

A technology of vertical components and construction devices, which is applied in infrastructure engineering, construction, sheet pile walls, etc., can solve the problems of large on-site work volume of bored piles, uneconomical, small diameter of pipe piles and square piles, etc. The effect of high construction efficiency, low construction noise and large single pile section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

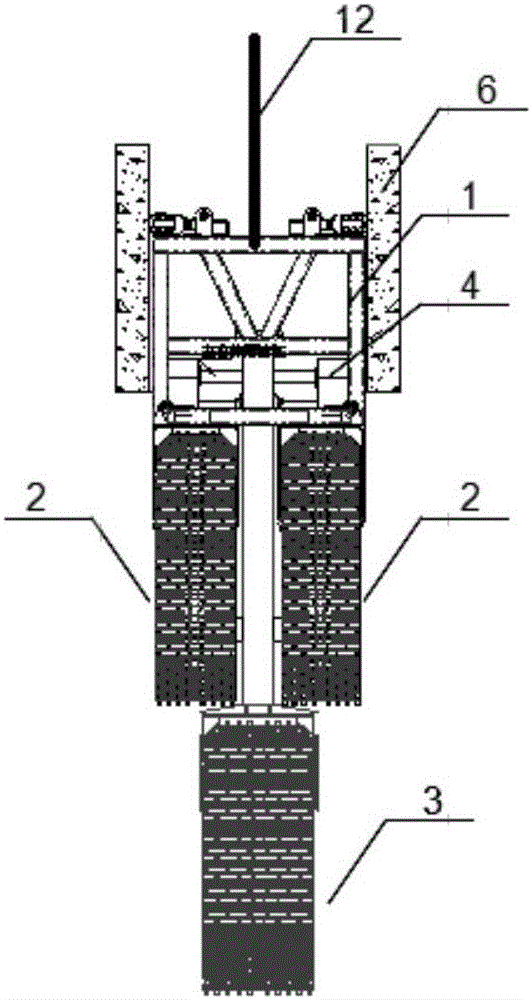

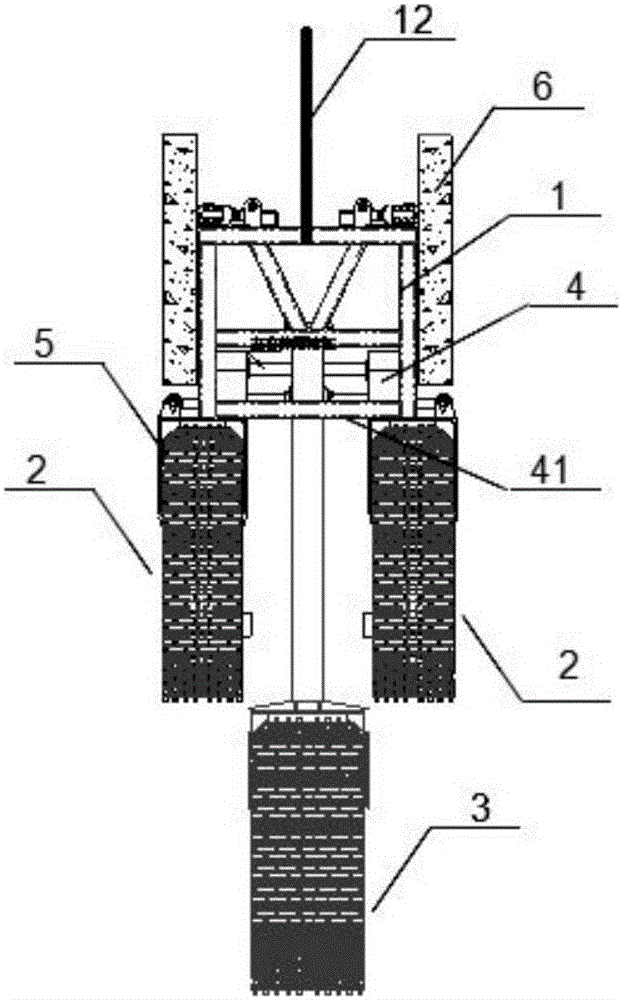

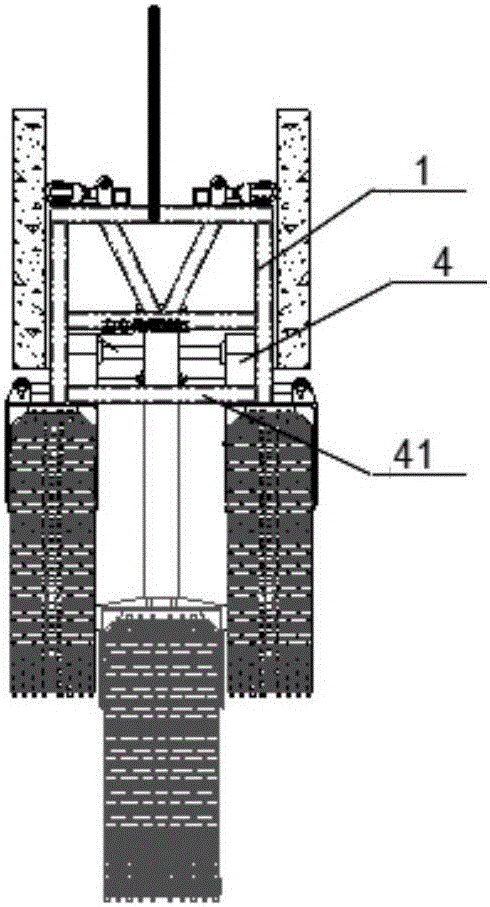

[0030] The embodiment of the triplex vertical member construction device of the present invention includes a positioning frame 1 and three stirring heads arranged on the positioning frame 1 in the shape of a "product" or an inverted "product", and the stirring heads can be placed on the positioning frame 1. Expansion and contraction in the horizontal direction, wherein the two first stirring heads 2 are installed side by side, and can be moved and positioned horizontally and vertically, and the remaining second stirring head 3 is arranged staggered with the two first stirring heads 2 in height. The heads move horizontally and longitudinally to the outside and expand horizontally and transversely, and the sum of the projected surfaces of the three stirring heads can cover the cross section of the vertical member 6 . T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com