Patents

Literature

160results about How to "Low construction noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slope protection pile pouring and cable bolting construction method for deep foundation pit

InactiveCN102031784ASimplify construction stepsFacilitate construction quality controlDrill bitsExcavationsLine tubingRebar

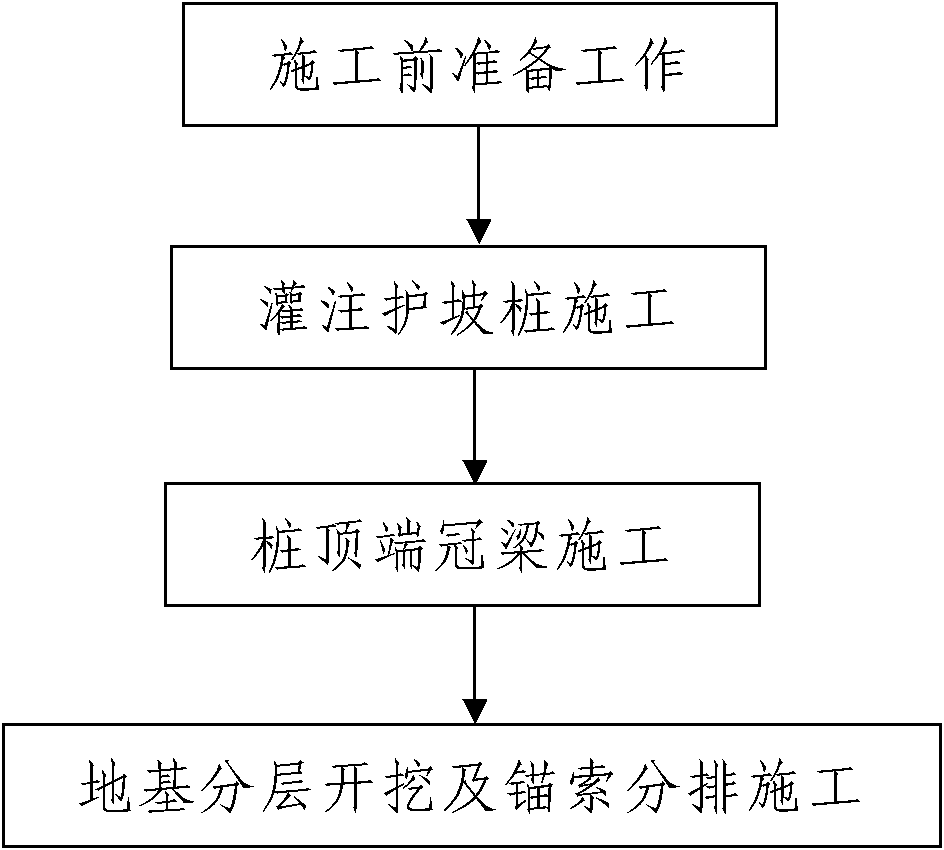

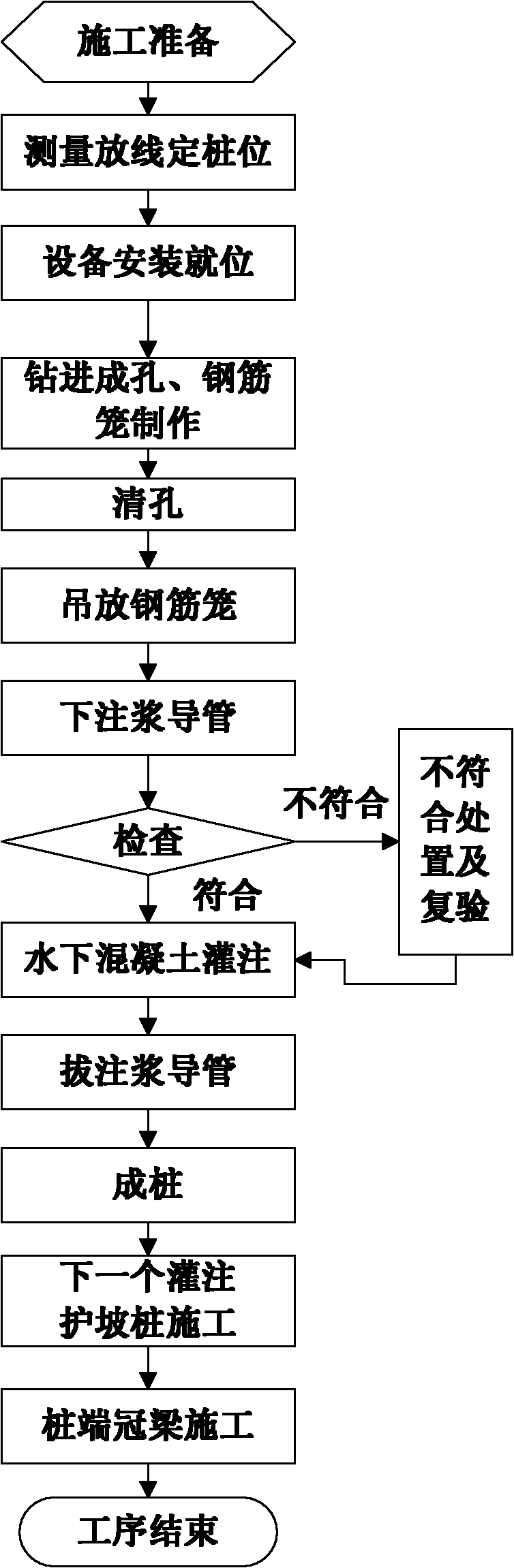

The invention discloses a slope protection pile pouring and cable bolting construction method for a deep foundation pit. The method comprises the following steps of: 1, making preparations before construction; 2, pouring a slope protection pile, namely measuring, paying off, molding and constructing the poured slope protection pile, punching holes on the poured slope protection pile, binding and hoisting a steel reinforcement cage for molding the slope protection pile, pouring concrete into the poured slope protection pile and constructing a crown beam at the top end of the pile; and 3, excavating a foundation in a layered form and constructing anchor ropes on different rows, namely excavating a first-layer foundation, arranging a first row of anchor ropes, arranging a steel waist rail, arranging anchor heads of the anchor ropes, tensioning the anchor ropes and finishing excavating processes of different layers of foundations and arranging different rows of anchor ropes. The method has a reasonable design, simple construction steps, low investment cost, large support depth and good using effect, and solves the problems of complicated construction steps, high construction cost, inconvenience in control, easy damage to surrounding pipelines, roads, buildings and the like, large construction space and the like existing in the conventional double-row pile supporting method can be solved.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

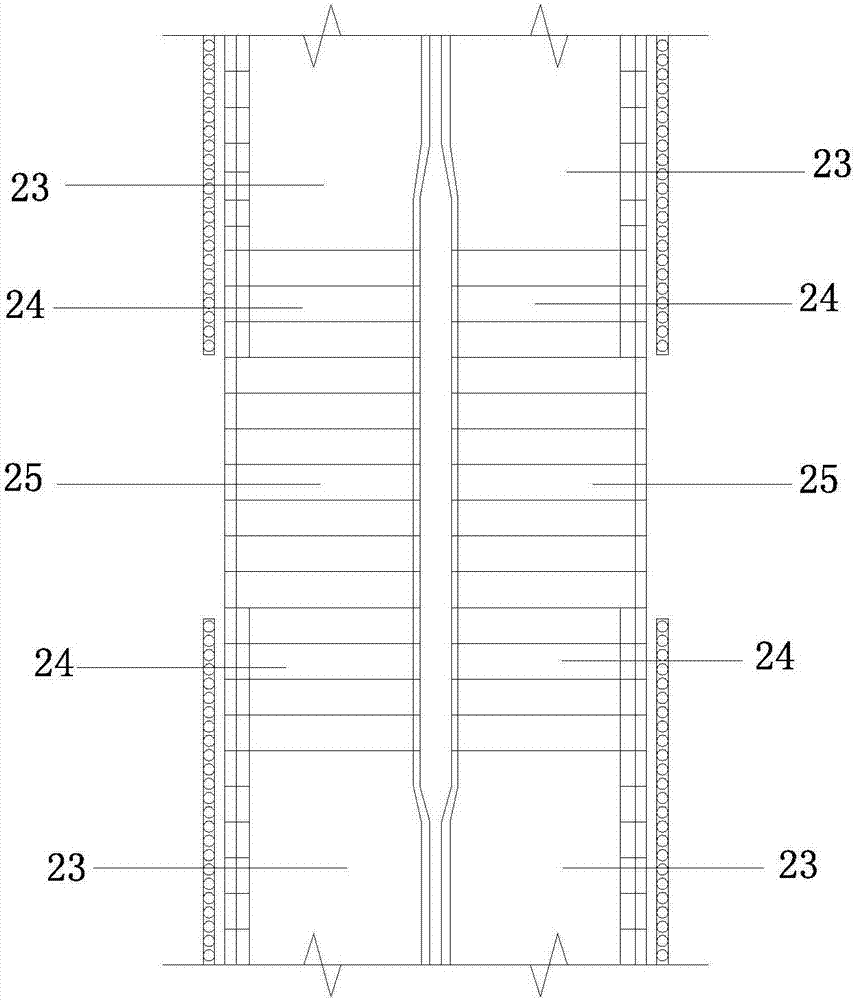

Construction method for supporting deep foundation pit through grouting after pile arrangement and anchor cable mounting

ActiveCN106320346AThe method steps are simpleReasonable designExcavationsBulkheads/pilesPre stressEngineering

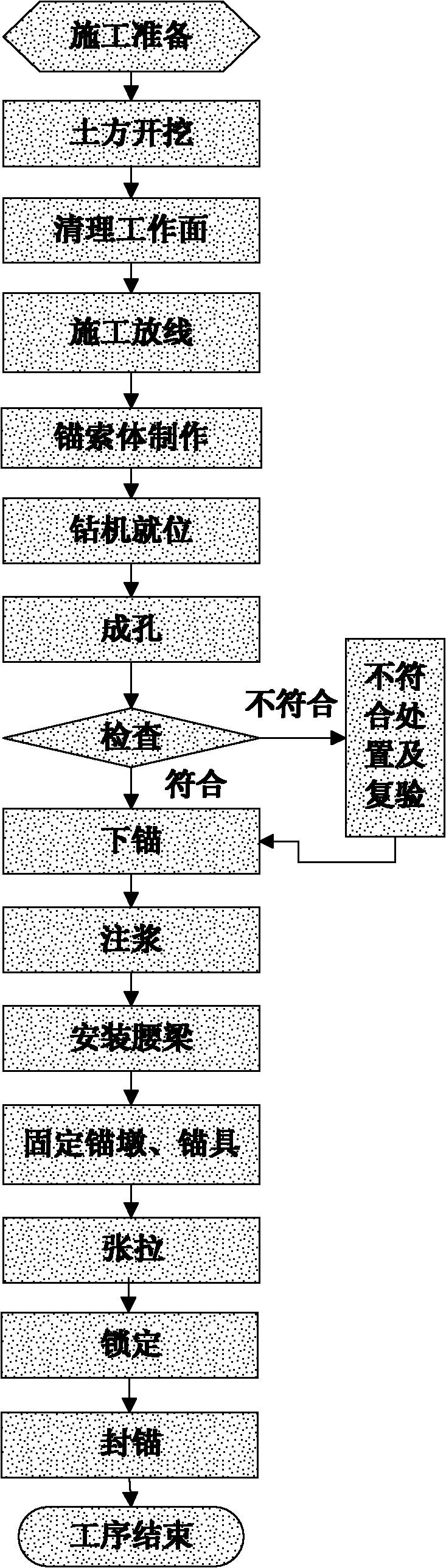

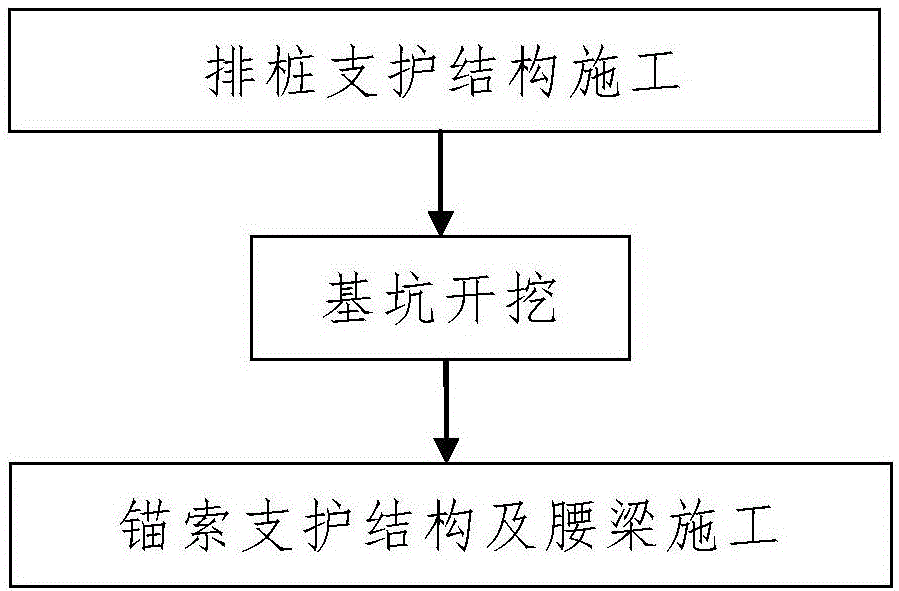

The invention discloses a construction method for supporting a deep foundation pit through grouting after pile arrangement and anchor cable mounting. The construction method comprises the steps that firstly, pile arrangement supporting structure construction is performed, wherein a pile arrangement supporting structure comprises multiple slope protection piles which are arranged along the peripheral edge line of the constructed foundation pit from front to rear and a crown beam connected to the upper portions of the slope protection piles; secondly, foundation pit excavation is performed, wherein the constructed foundation pit is excavated from top to bottom; and thirdly, anchor cable supporting structure and waist beam construction is performed, wherein during excavation of the constructed foundation pit, the constructed foundation pit is excavated to the anchoring position of an anchor cable supporting structure, and the anchor cable supporting structure is constructed; and the anchor cable supporting structure comprises multiple prestress anchor cables, each prestress anchor cable comprises an anchor cable body, a primary grouting pipe and a secondary grouting pipe, and each anchor cable body comprises multiple steel strands. The method has the beneficial effects that the steps are simple, the design is reasonable, construction is easy and convenient, the use effect is good, the deep foundation pit supporting construction process can be completely easily, conveniently and quickly, the cost of the adopted prestress anchor cables is low, the anchoring force is high, and the deep foundation pit can be supported effectively.

Owner:SCEGC NO 6 CONSTR ENG GRP CO LTD

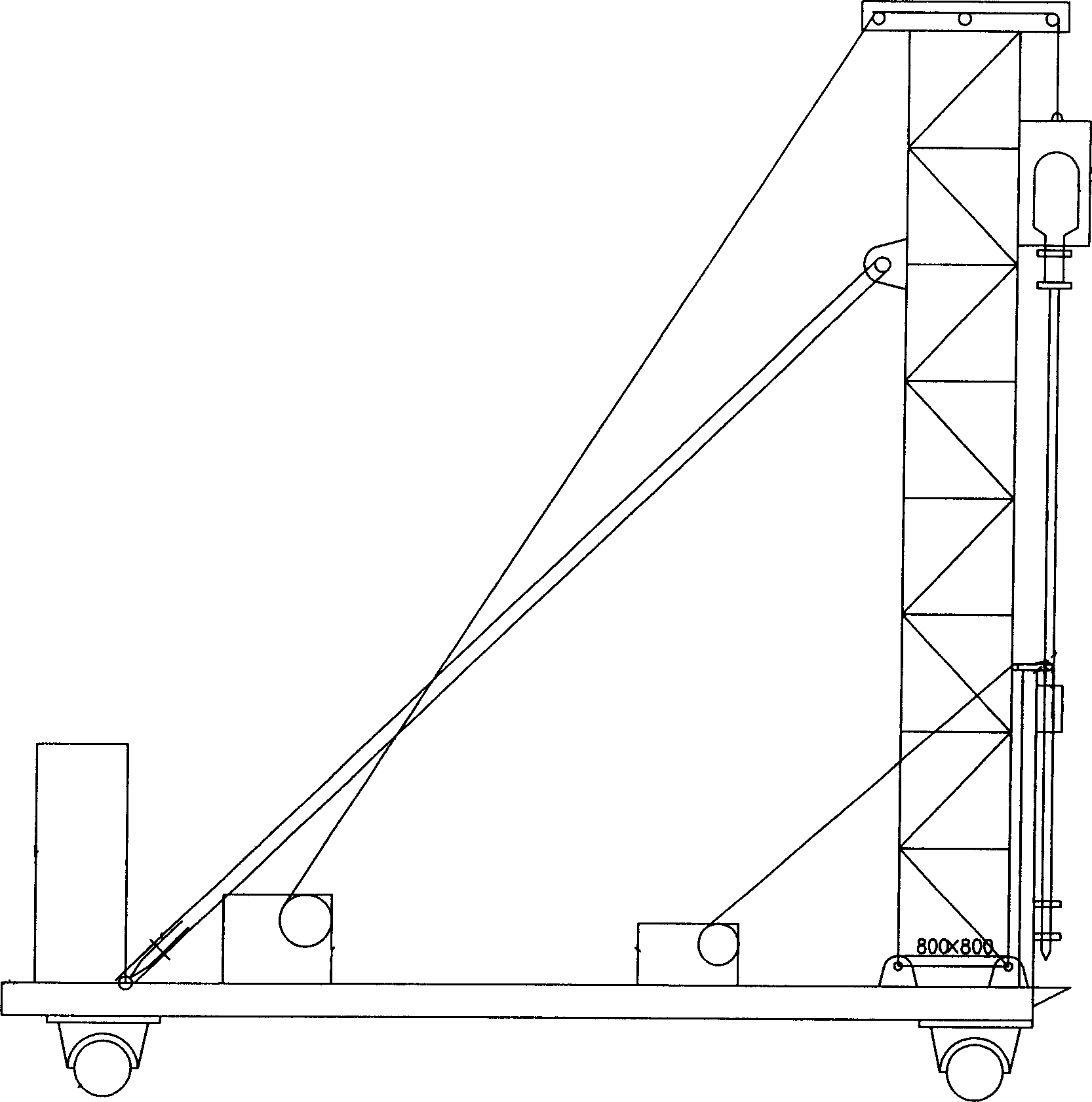

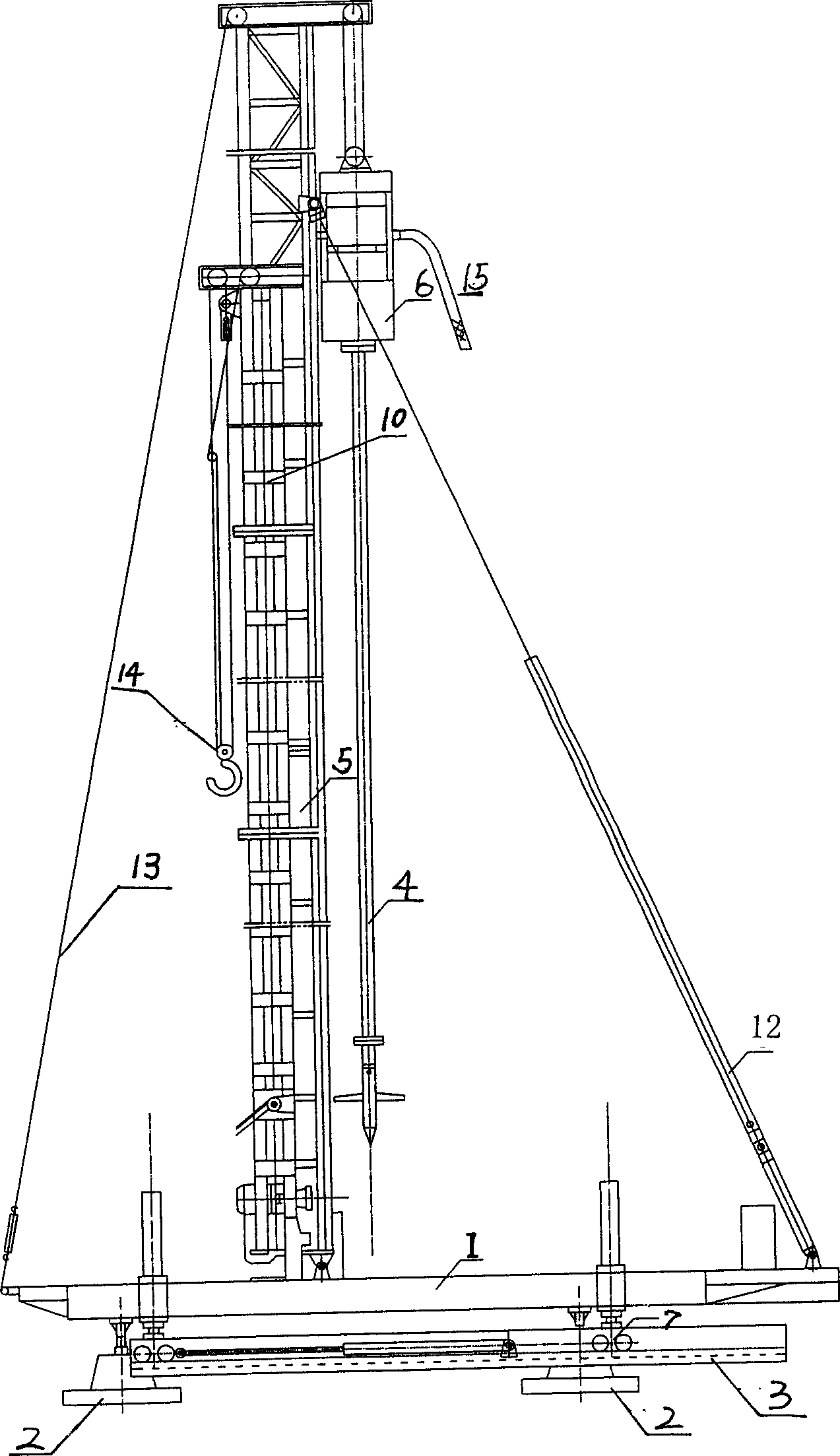

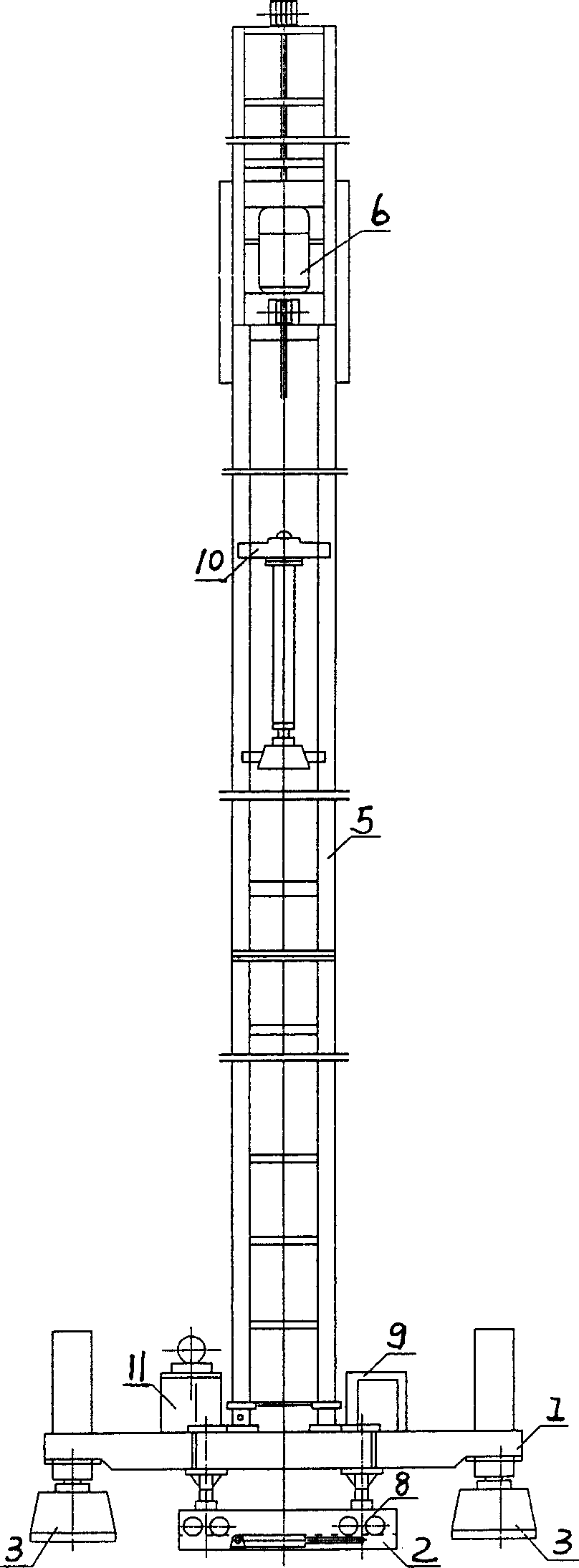

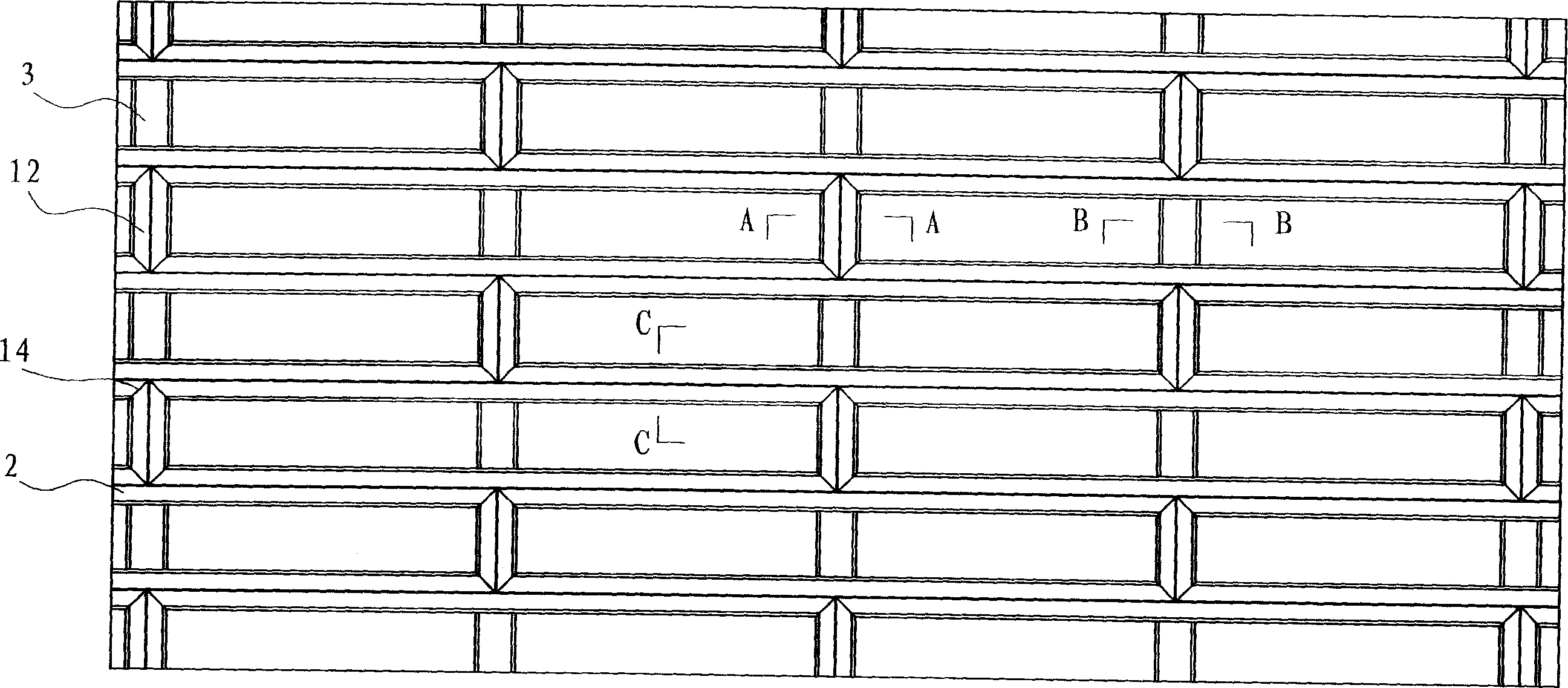

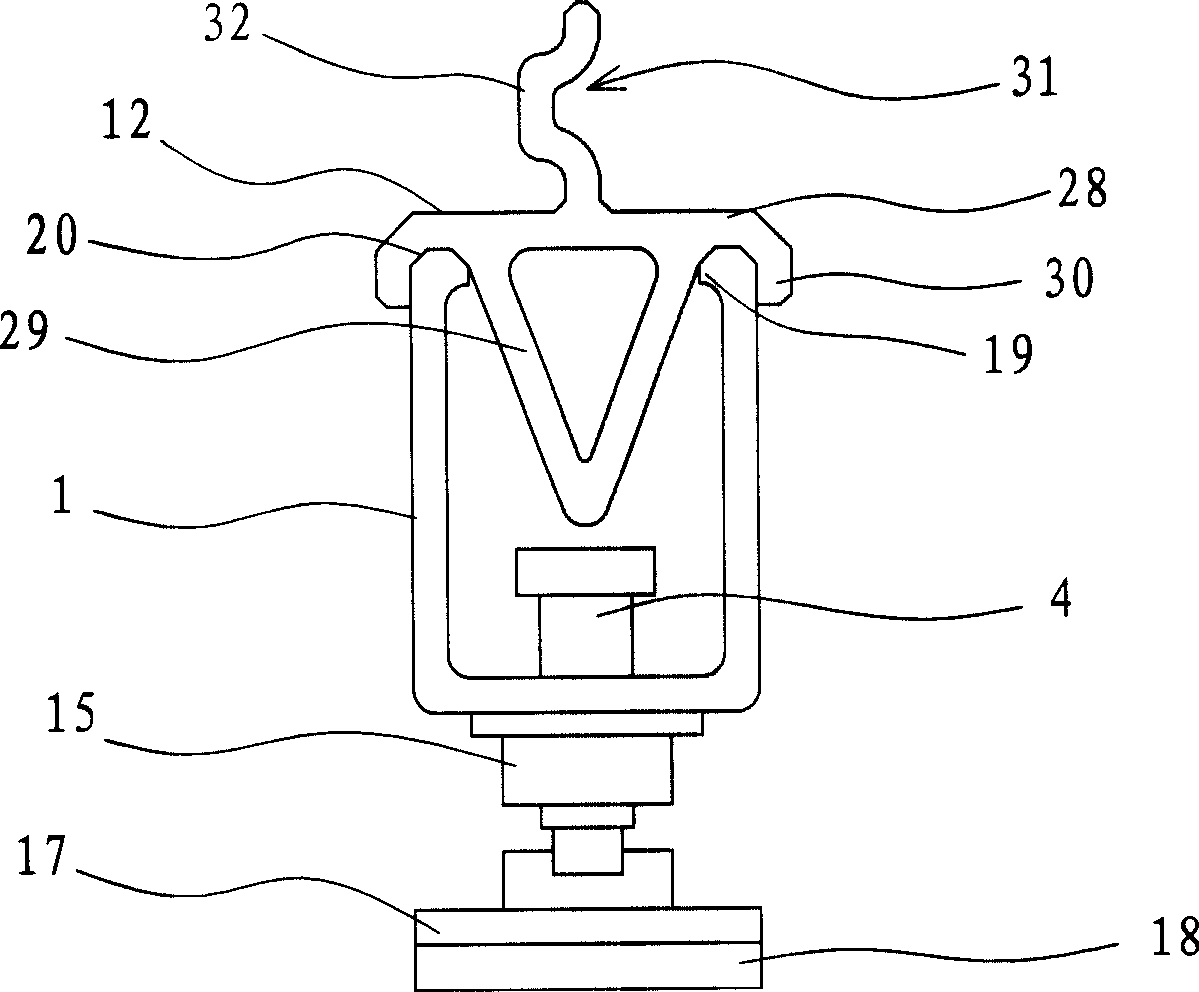

Concrete core cement soil stirring pile machine and its construction technological method

InactiveCN1718938AAvoid Weaknesses of Poor Fighting AbilityGuaranteed alignmentBulkheads/pilesHydraulic pumpArchitectural engineering

The present invention discloses a concrete core cement earth stirring pile machine and its construction process and method. The bottom portion of said pile machine is equipped with hydraulic walking system, including machine frame, base seat, hydraulic pump station, longitudinal and transverse moving beams, longitudinal and transverse roller supporting frames, guideway, deep stirring machine head, drilling machine, drill bit, slurry pump, distribution box and hydraulic pile-pressing system.

Owner:NANJING UNIV

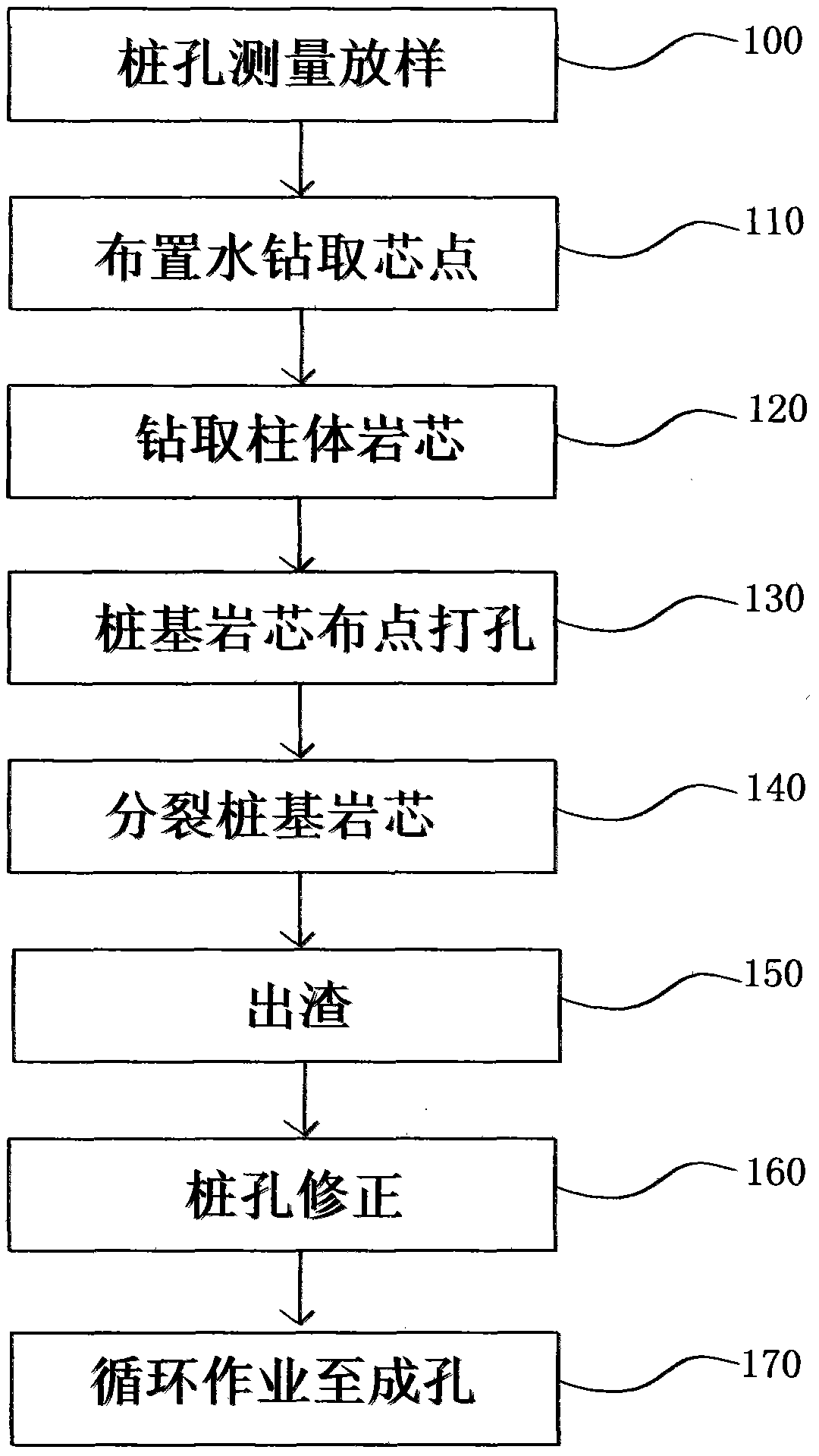

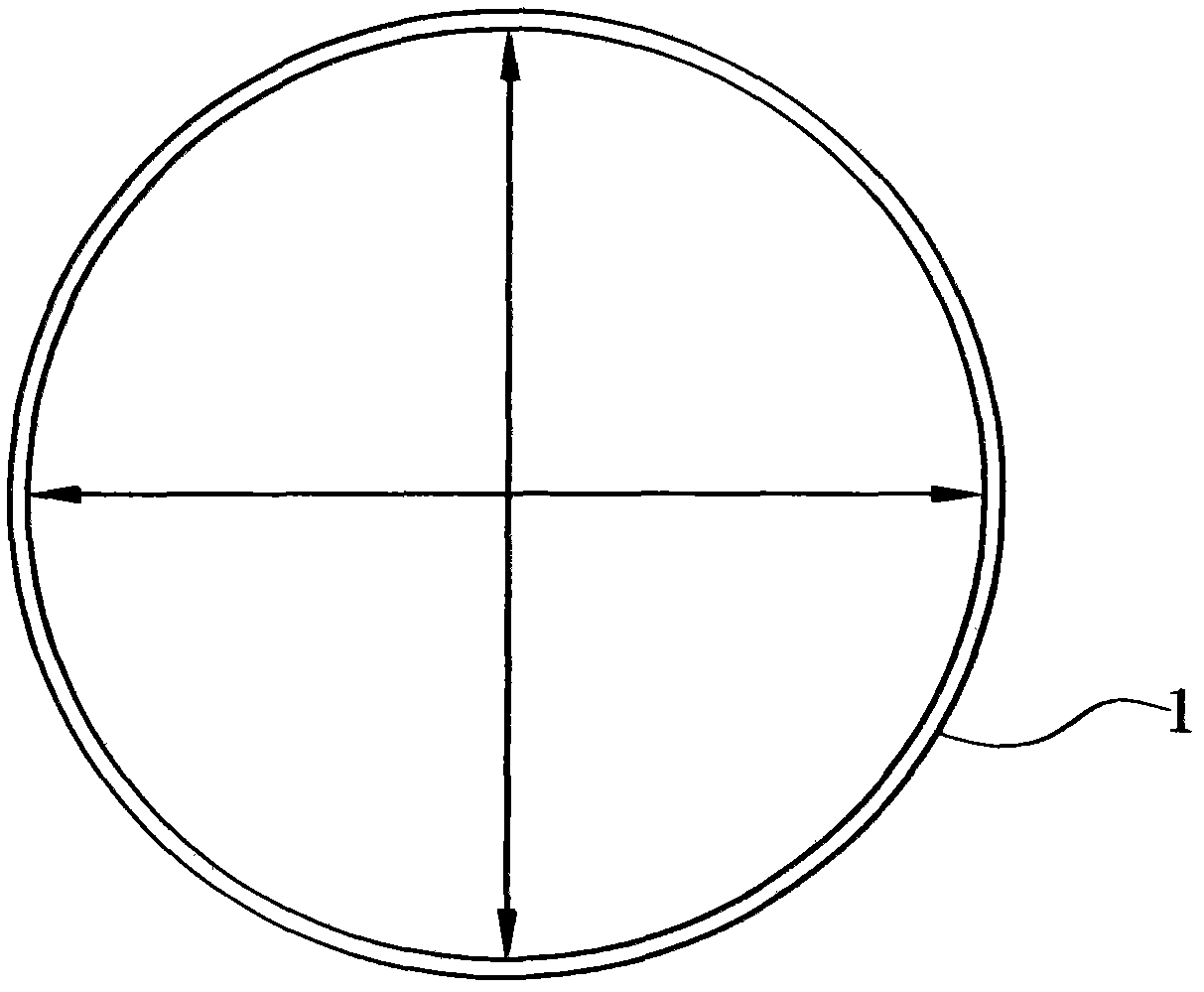

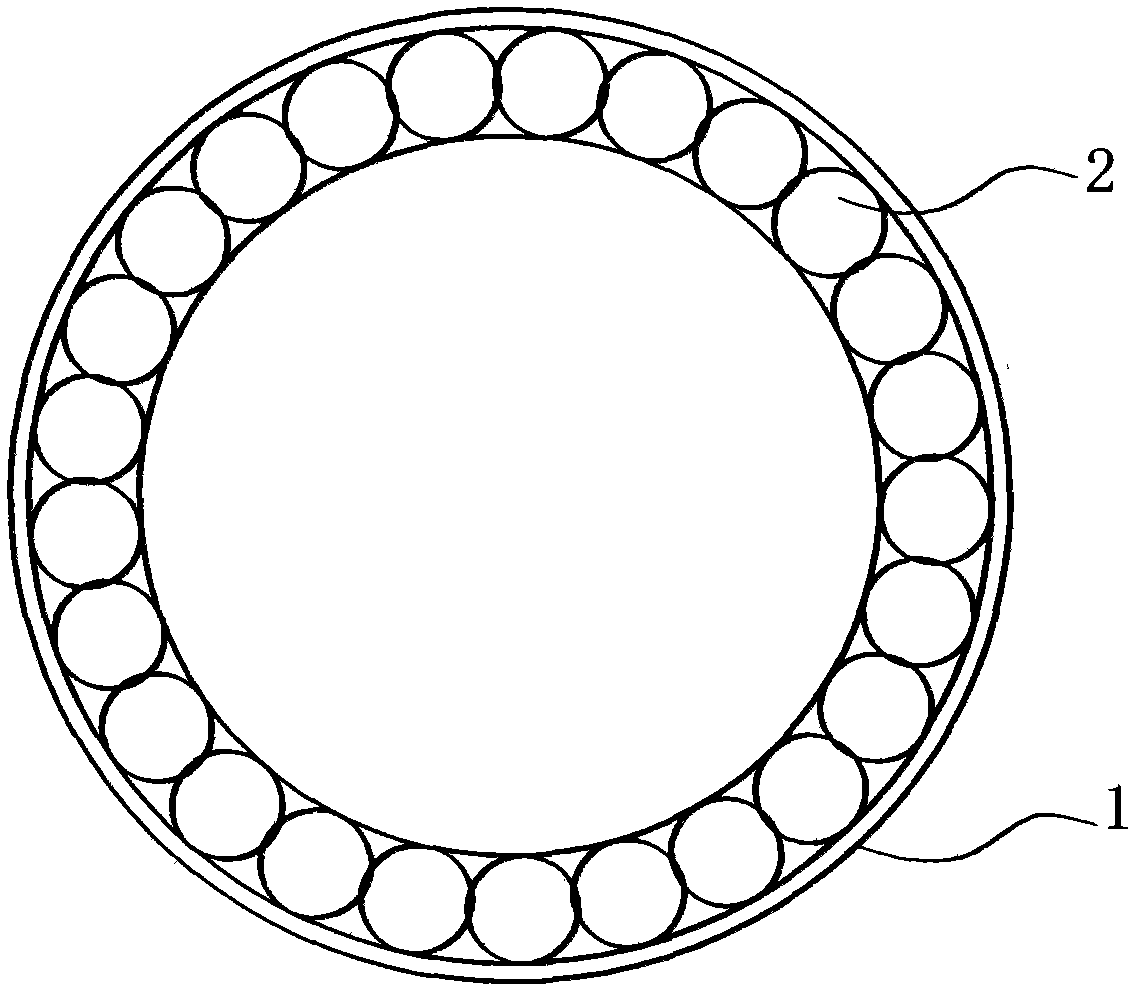

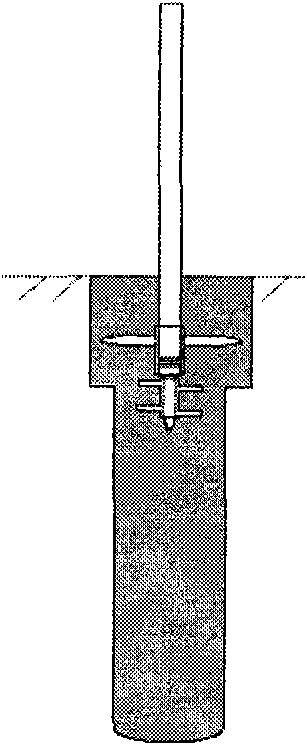

Water drill dug pile construction method

InactiveCN102071683AReduce disturbanceLow construction noiseBridge erection/assemblyBulkheads/pilesShear stressTension stress

The invention relates to a water drill dug pile construction method. In the method, layered construction is adopted, and a plurality of cylinder cores with certain height are drilled around the inner wall of a pile hole by a water drill when each layer is constructed, so that a pile foundation core is separated from the whole rock to form a free face; the pile foundation core is punched by an electric hand drill, and steel wedges are inserted into holes respectively; the steel wedges are hammered by a hammer, so that the steel wedges apply horizontal tension and shear stress to the pile foundation core; when the horizontal tension and the shear stress are larger than the limit tension stress and shear stress of the rock, the pile foundation core can be subjected to tension fracture and shear fracture to be split from the whole rock so as to clear fragmented rock away from the pile hole and correct the pile hole; and the next layer is constructed by the same processes and the processes are repeated until the pile hole is formed.

Owner:CCCC FOURTH HIGHWAY ENG

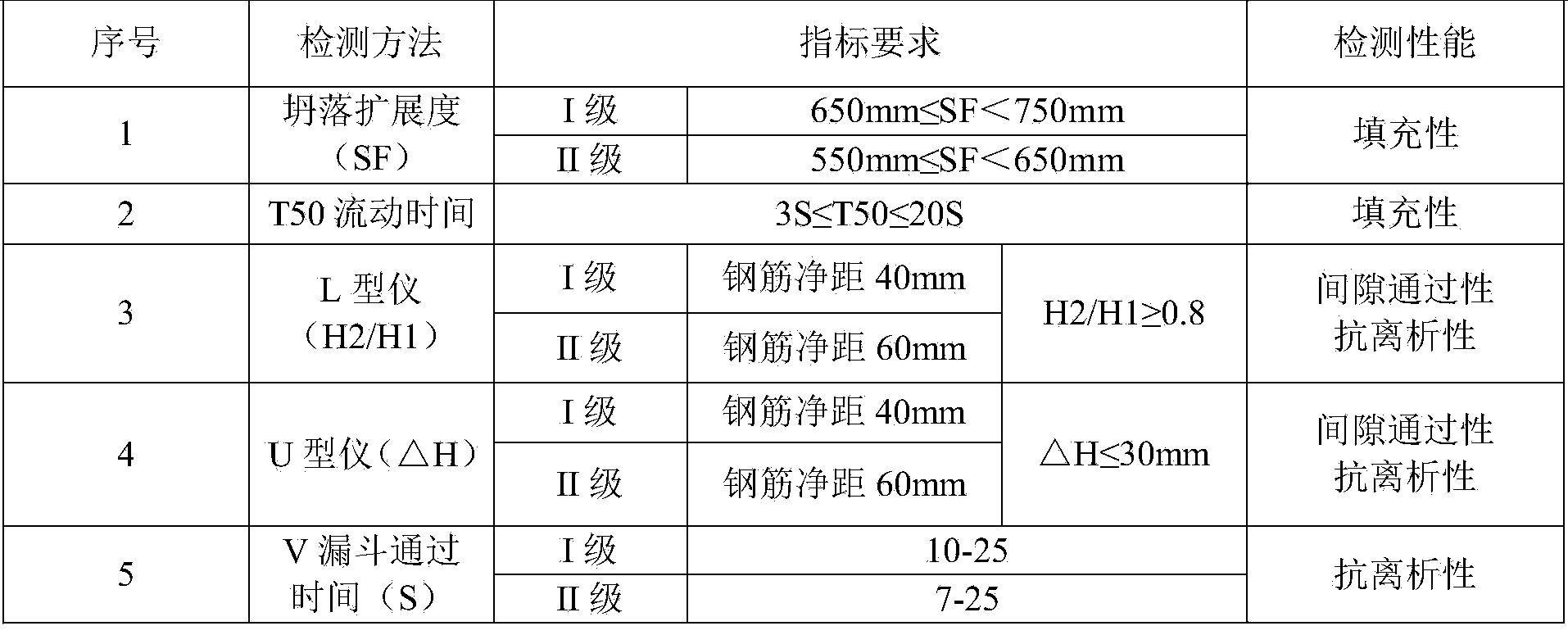

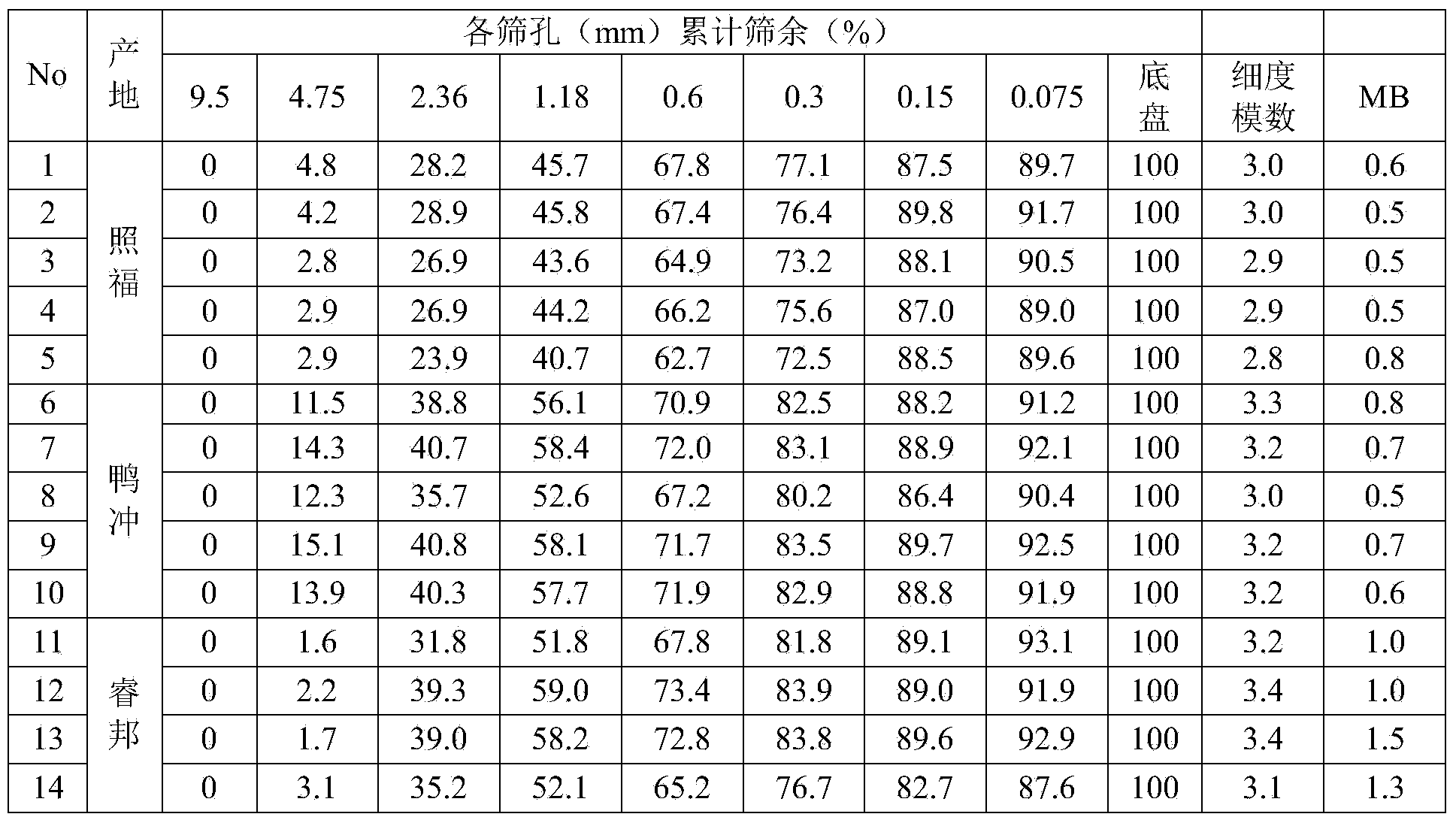

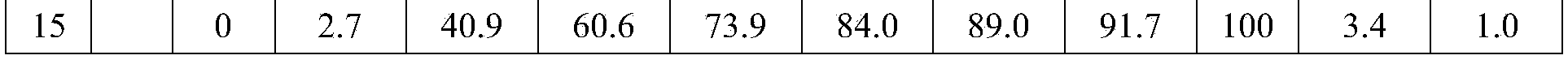

High-strength and vibration-free self-compacting concrete prepared from machine-made sand

InactiveCN104230223AImprove performanceImprove liquidityArchitectural engineeringStructural engineering

The invention discloses high-strength and vibration-free self-compacting concrete prepared from machine-made sand. The high-strength and vibration-free self-compacting concrete mainly comprises water, a cementing material, machine-made sand and gravels and is characterized in that the main technical parameters of the concrete are as follows: in the concrete, the water-binder ratio is 0.21-0.32, the water-powder ratio is 0.65-0.83, the sand ratio is 44-60%, and the unit paste volume dose is 0.45-0.53. The high-strength and vibration-free self-compacting concrete prepared from the machine-made sand, which is disclosed by the invention, has high flowability, non-segregation, uniformity and stability, flows relying on the self weight of the concrete in the process of pouring, and achieves a compacted effect without vibrating, so that the problem of cracking in section conversion in the process of construction is solved, and thus a series of purposes of reducing the amount of labor, accelerating the construction speed, reducing the construction noise, saving the construction cost, and the like are achieved.

Owner:CHINA RAILWAY HI TECH IND CORP LTD

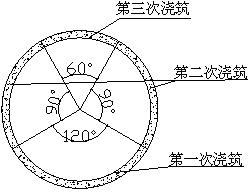

Pile-forming method for cement paste spraying multi-directional core entraining mixing pile

The invention provides a pile-forming method for a cement paste spraying multi-directional core entraining mixing pile, which is characterized in that (1) a mixing pile machine is in position and leveled, and a bit aims at a pile position; (2) a drill pipe downward stirs and cuts soil along a guide frame until the designed depth; (3) after the drill pipe reaches the predetermined design depth, concrete are locally and continuously sprayed and stirred at the tip of the pile for more than 10 to 30 seconds; (4) the drill pipe is lifted; (5) concrete spraying is carried out while stirring; the drill pipe is lifted to the surface of earth or the designed elevation to finish the construction of a signal multi-directional mixing pile; (6) the tip of the pile of a core pile passes through a central hole of a jacking pile platform and is inserted into the center of the finished multi-directional mixing pile; (7) after the core pile sinks by self-weight and is penetrated into a certain depth of the mixing pile, the core pile is collated along two directions and the verticality of the core pile is regulated; the core pile is continuously sunken without any unmistakable; and (8) the core pile is pressed by hydraulic static force until the designed appointed depth. The method can realize the synchronous implementation of the mixing pile and the core pile operation, has high working efficiency, convenient construction, and low construction noise; the stress of the pile body is more reasonable and the pile shaft has high strength.

Owner:武汉谦诚桩工科技股份有限公司

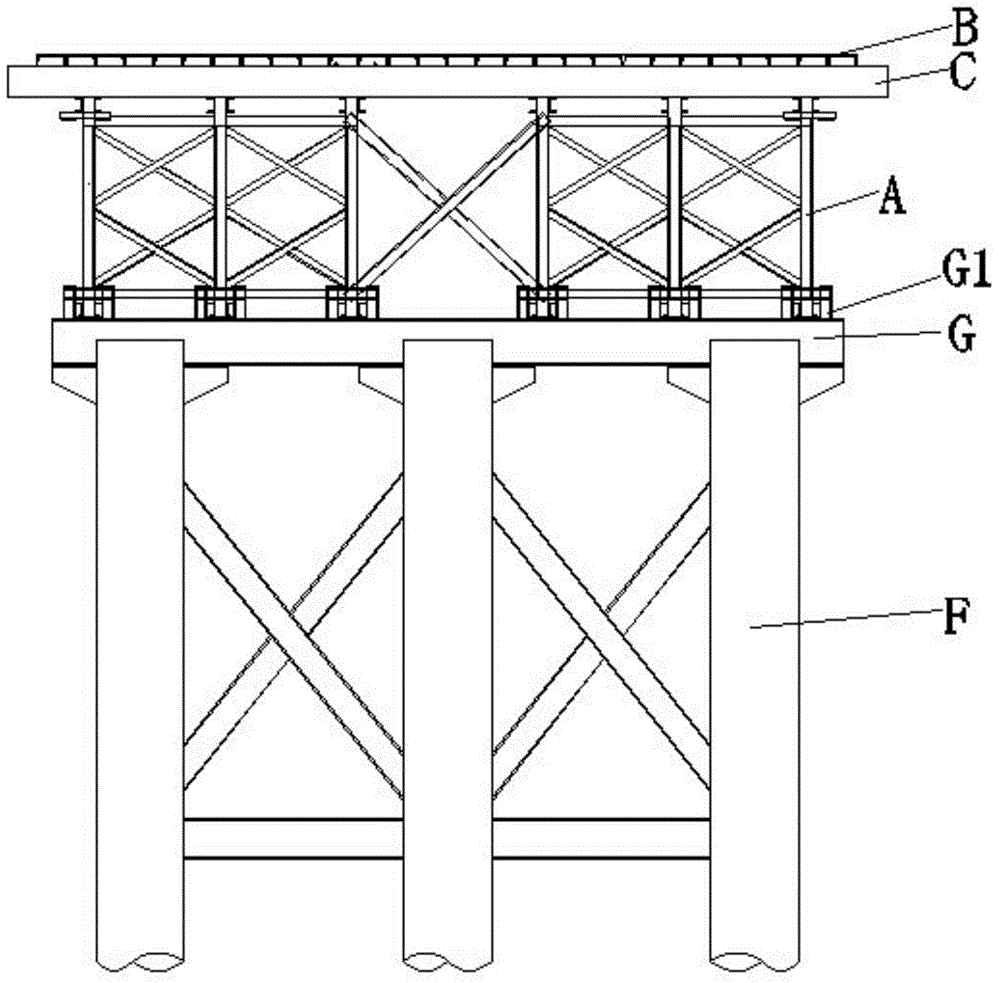

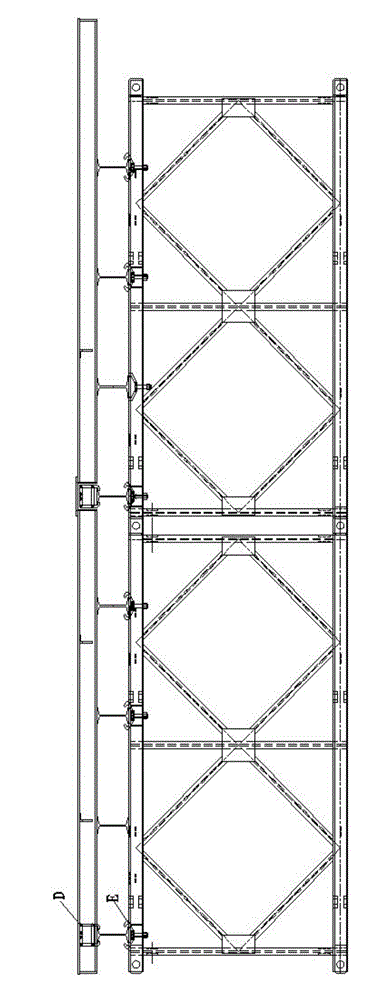

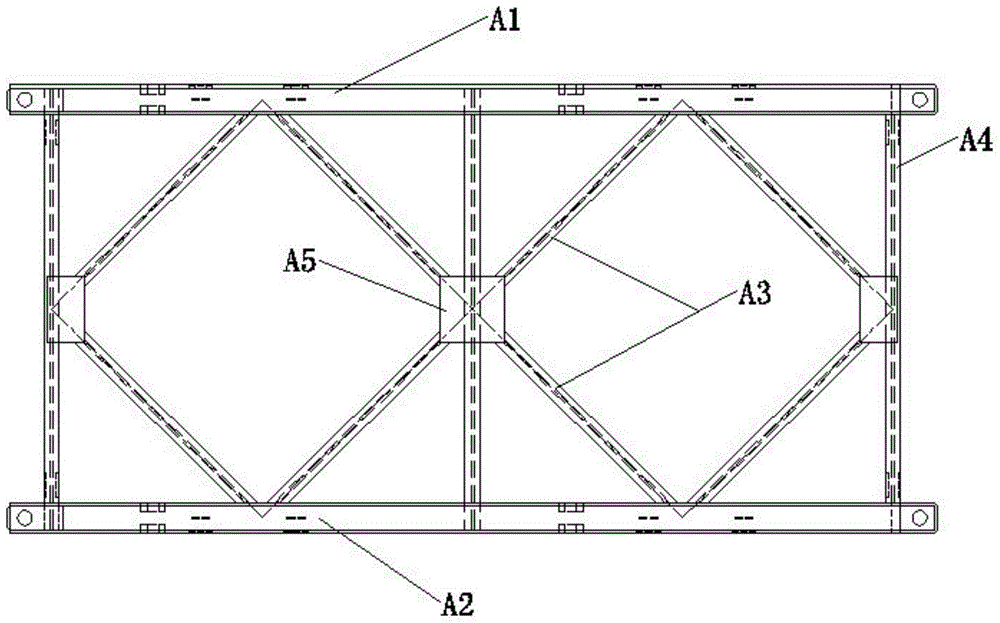

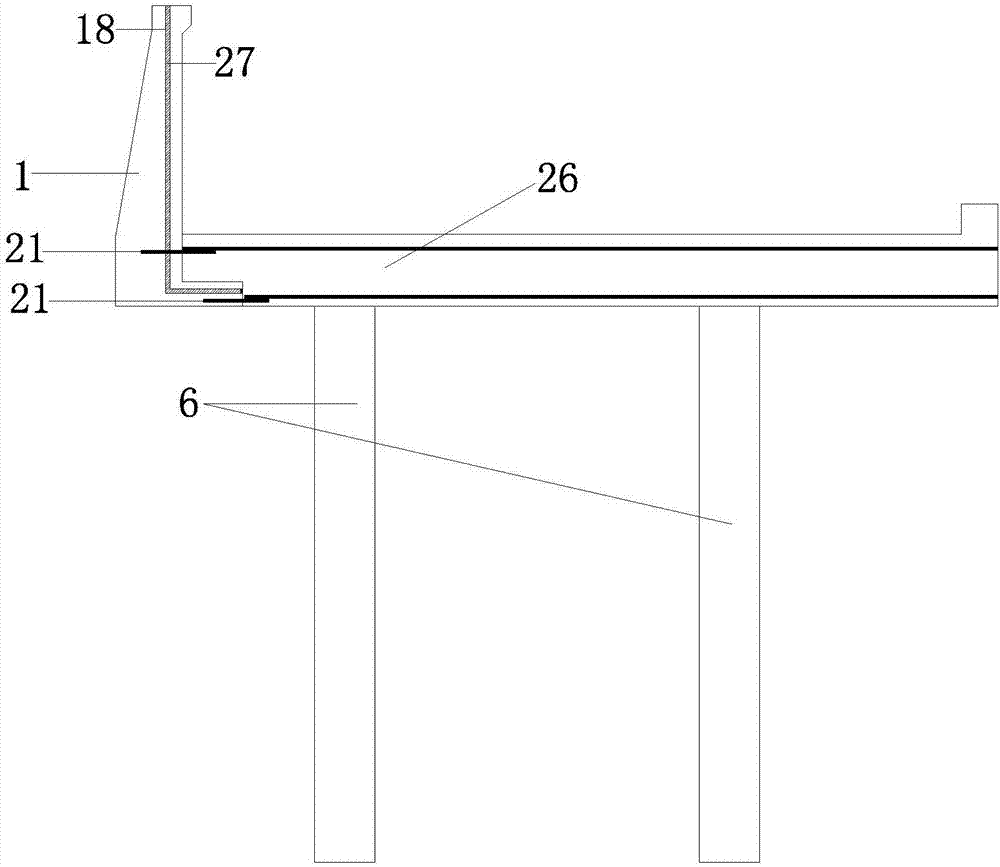

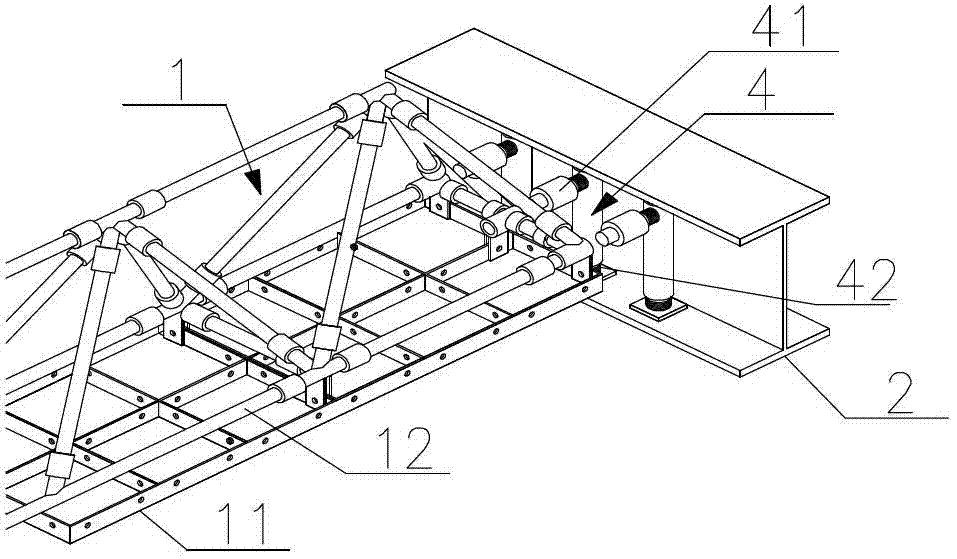

Assembly type steel bridge and building method thereof

ActiveCN104532735ALess componentsSimple structureBridge erection/assemblyBridge materialsBraced frameLocking mechanism

The invention relates to an assembly type steel bridge and a building method of the steel bridge. The assembly type steel bridge comprises supporting frames, a bridge deck slab, an H-shaped beam, bridge deck slab connecting parts and H-shaped beam locking mechanisms. The H-shaped beam is arranged on the supporting frames. The extension direction of the H-shaped beam is perpendicular to the extension direction of the supporting frames. The supporting frames support the H-shaped beam. The bridge deck slab is laid on the H-shaped beam. The supporting frames and the H-shaped beam are fixedly installed through the H-shaped beam locking mechanisms. The H-shaped beam and the bridge deck slab are fixedly installed through the bridge deck slab connecting parts. According to the steel bridge, the number of components is small, the structure is light and simple, erecting is fast, assembling, disassembling and replacing are convenient, the components can be purchased in batches according to the requirement of the construction progress in the construction and installation process, and installing and erecting are carried out while materials enter the site; in the disassembling process, disassembling is carried out while the materials are moved out of the site in batches, and the problem that due to stacking of the materials, construction of other special projects is influenced can be effectively solved.

Owner:ZHEJIANG XINGTU BRIDGE TEMPORARY STEEL STRUCTURE ENG

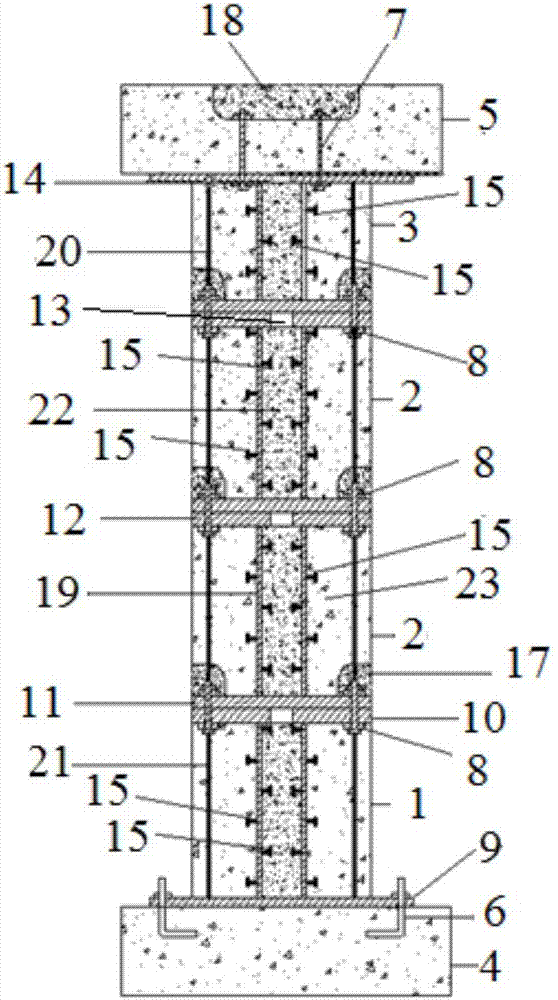

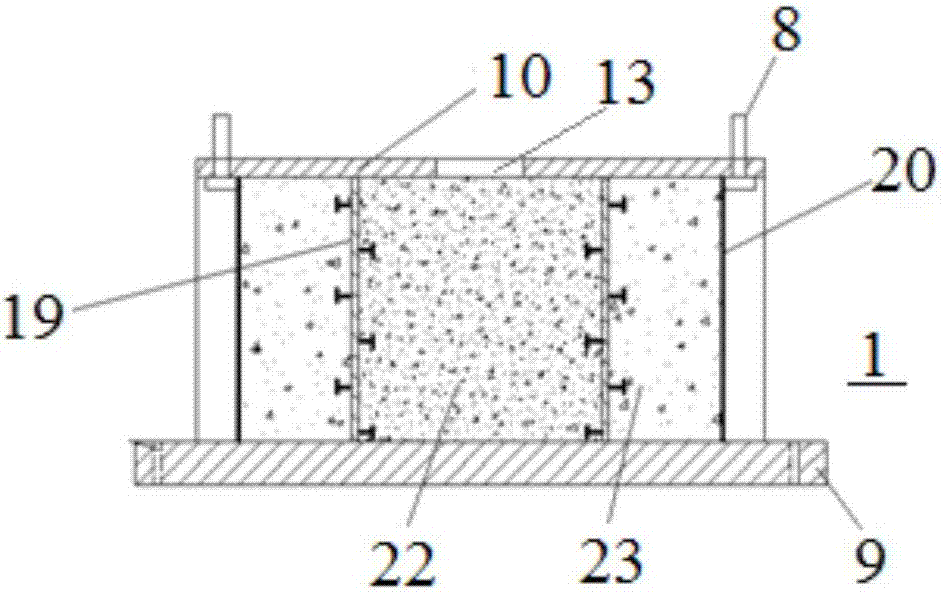

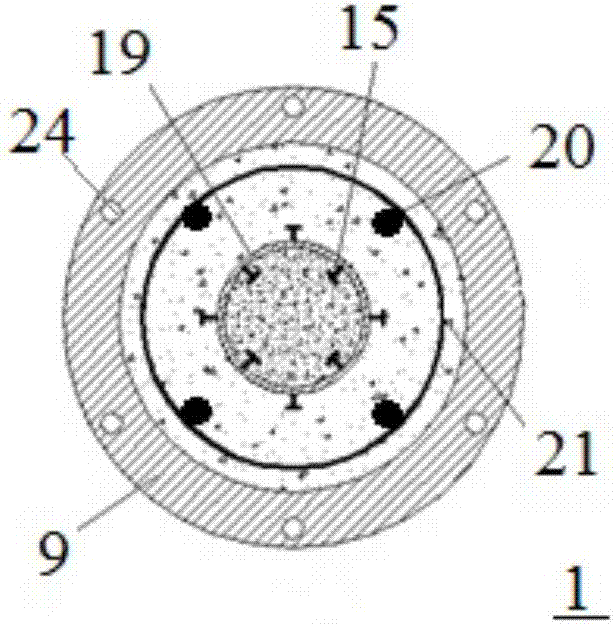

Precast steel pipe concrete laminated column

ActiveCN107268807AReduce section sizeImprove bearing capacityStrutsPillarsEnvironment effectSheet steel

The invention relates to a precast steel pipe concrete laminated column comprising a foundation and a plurality of steel pipe concrete segments. The steel pipe concrete segments comprise the bottom segment, the top segment and one or more intermediate segments. Each steel pipe concrete segment comprises a lower steel plate, a steel pipe concrete main body and an upper steel plate which are fixedly connected in sequence. The bottom segment and the corresponding intermediate segment are fixedly connected through connecting anchor bolts, and the corresponding intermediate segment and the top segment are fixedly connected through connecting anchor bolts. Bottom anchor bolts are arranged on the upper surface of the foundation. The bottom segment is fixed to the foundation by means of connection of the lower steel plate of the bottom segment and the bottom anchor bolt. The precast steel pipe concrete laminated column has the characteristics of high bearing capacity, good anti-seismic performance and excellent durability and can be precast and manufactured in a factory or a different place in advance, the defect of complex procedures of traditional cast-in-situ concrete construction is avoided, and the precast steel pipe concrete laminated column has the advantages that the construction speed is high, the influence on the environment is small, the construction period is short, construction noise is low, material stacking sites are few, and environmental protection is facilitated.

Owner:NORTHEASTERN UNIV

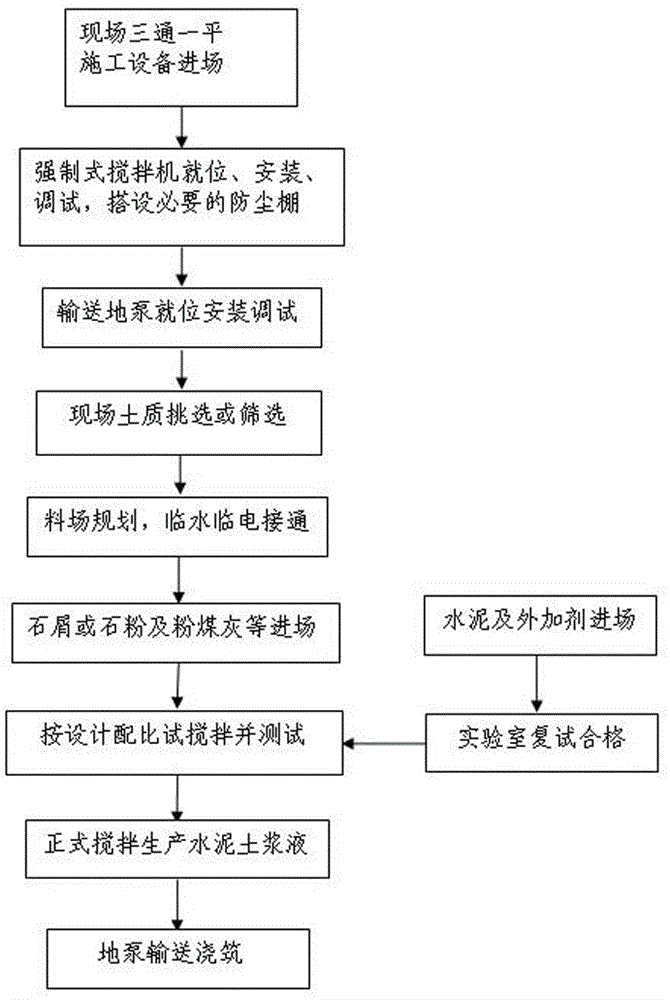

Self-compacting cement soil slurry for unbackfilled trench backfilling

InactiveCN106242422ALow construction noiseImprove the working environment of workersEmbankmentsScrapIndustrial waste

The invention relates to a self-compacting cement soil slurry for unbackfilled trench backfilling. The self-compacting cement soil slurry is characterized in that the basic formula is that the used materials in per stere comprise 100-400 kg of cement, 500-900 kg of local soil, 200-400 kg of stone chips or stone powder, 50-100 kg of fly ash, 1-3% of a quick-setting agent or early strength agent, and a right amount of water, the materials are uniformly stirring with a stirrer, and the stirred material is poured into a unbackfilled trench. According to the present invention, the vibrating pounding process is eliminated, the molding is achieved with the self-weight, the construction noise is reduced, the working environment of the workers and the living environment of the surrounding residents are improved, the problem that the vibrating pounding operation is not easily performed or cannot be performed is solved, the pouring speed is improved, the construction period is shortened, the labor intensity is reduced, the material cost is saved and the external conveying cost of the soil is reduced due to the local material taking, the industrial waste such as fly ash, stone chips and the like are utilized so as to provide the significant cost advantage compared to the concrete mortar, and the significant economic, social and environmental protection benefits are provided.

Owner:北京建材地质工程有限公司 +2

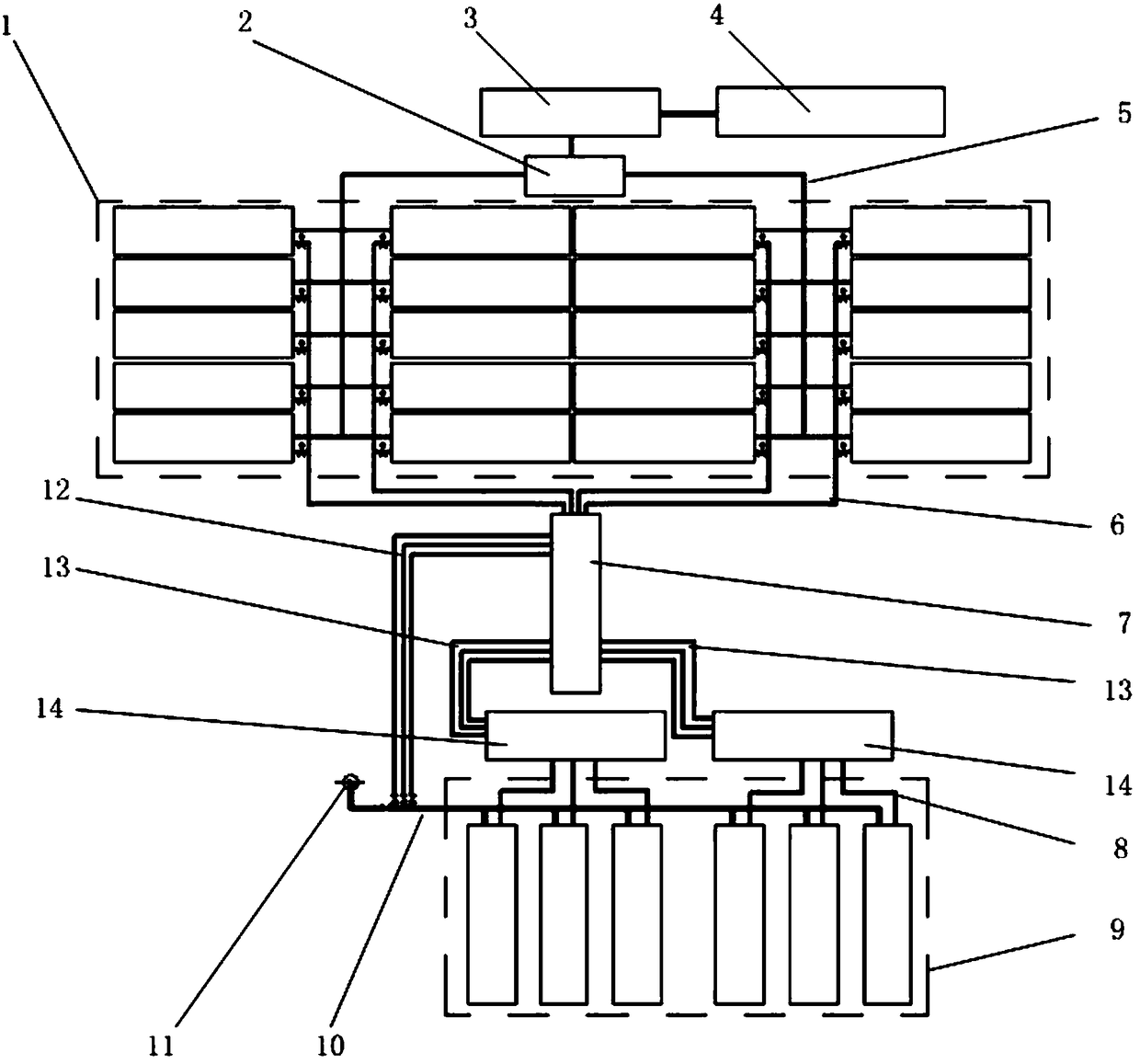

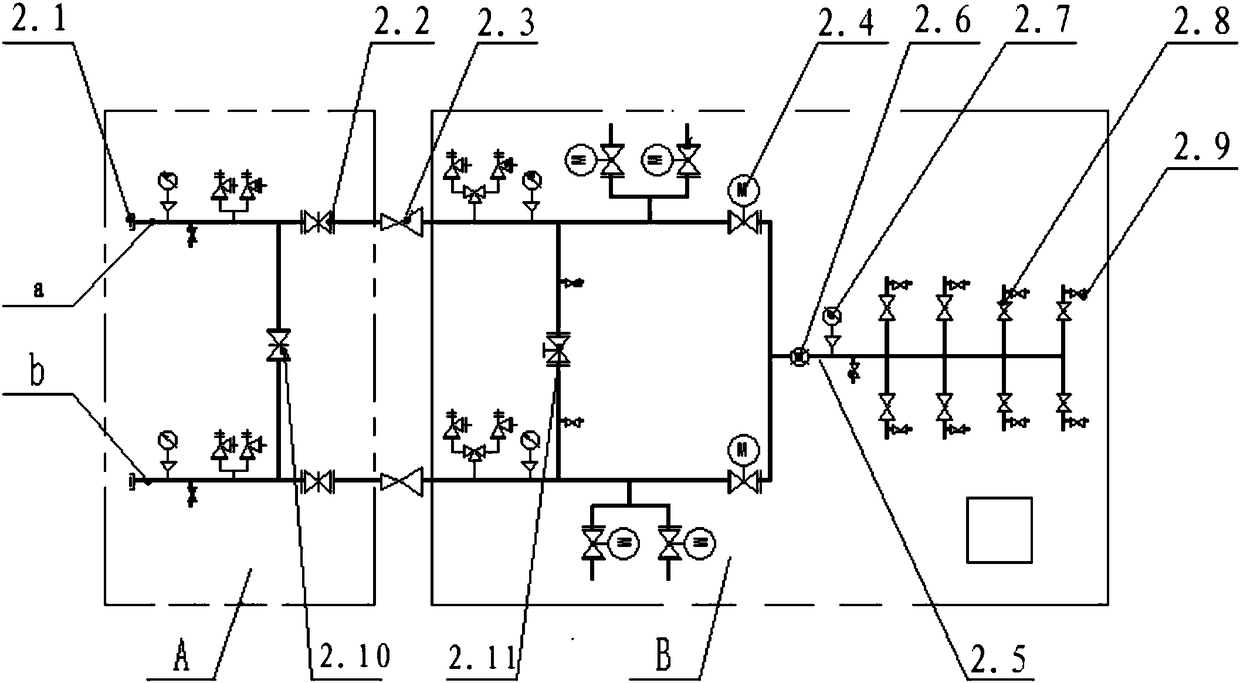

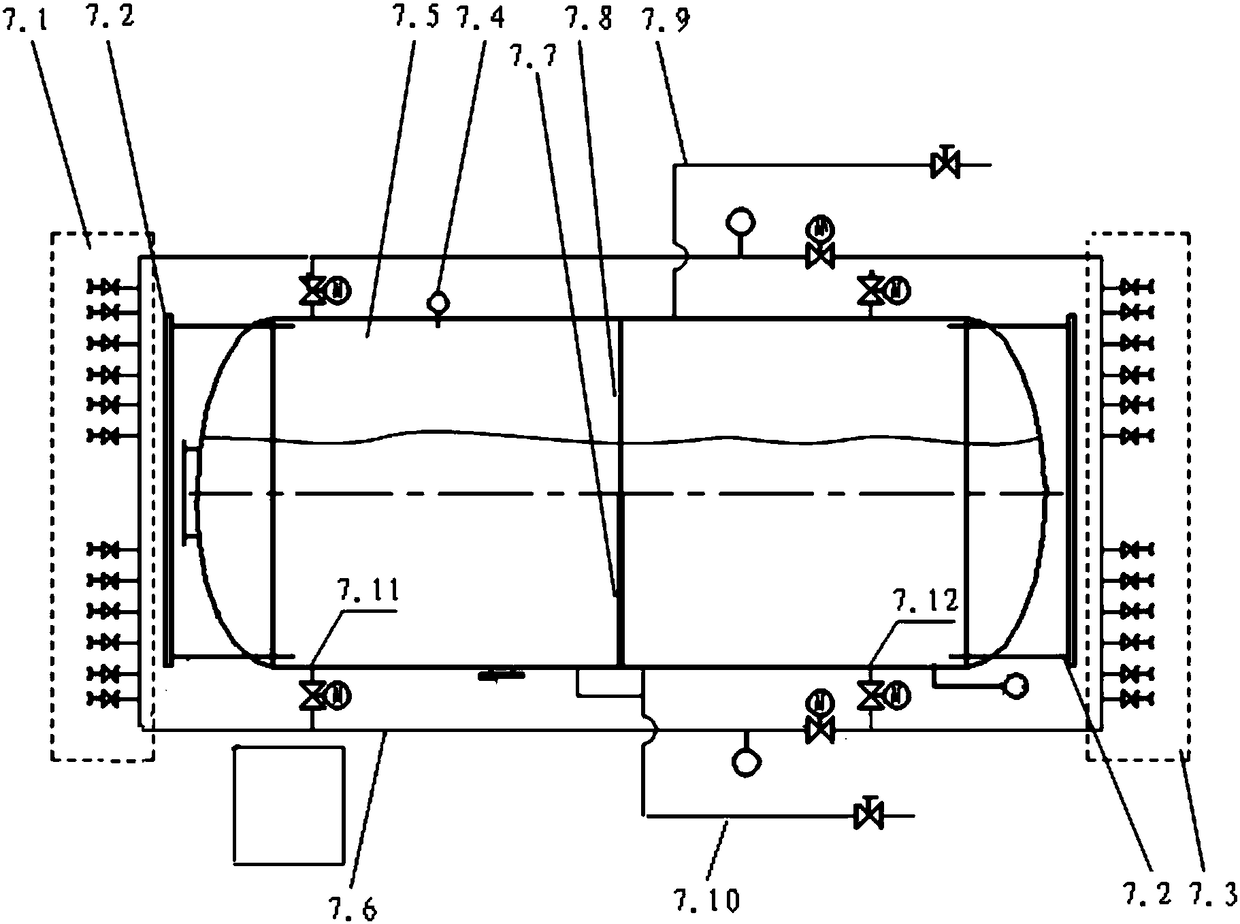

Liquid carbon dioxide dry-process sand fracturing system and technological process

PendingCN108374655ASolve the problem of insufficient construction displacementAchieve reuseOther gas emission reduction technologiesFluid removalFluid phaseTank truck

The invention discloses a liquid carbon dioxide dry-process sand fracturing system and a technological process. The liquid carbon dioxide dry-process sand fracturing system at least comprises a carbondioxide storage tank, a nitrogen pressurization device, a liquid nitrogen pump truck, a liquid nitrogen tank truck, a circulating cooling device, a fracturing truck and a sealed sand mixing device. The liquid nitrogen tank truck, the liquid nitrogen pump truck and the nitrogen pressurization device are sequentially connected through a pipeline. The nitrogen pressurization device is connected withthe carbon dioxide storage tank through a carbon dioxide storage tank gas-phase pipeline. The carbon dioxide storage tank is connected with the circulating cooling device through a carbon dioxide storage tank liquid-phase pipeline. The circulating cooling device is connected with the sealed sand mixing device through a sealed sand mixing device liquid inlet pipeline. The sealed sand mixing deviceis connected with the fracturing truck through a fracturing truck water feeding pipeline. The ground technological process can realize large discharge capacity construction, the concentrated emissionof gaseous carbon dioxide and the zero emission of gaseous carbon dioxide are realized in the pump cooling process of the fracturing truck, repeated use of carbon dioxide can be realized, and the construction cost is reduced.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

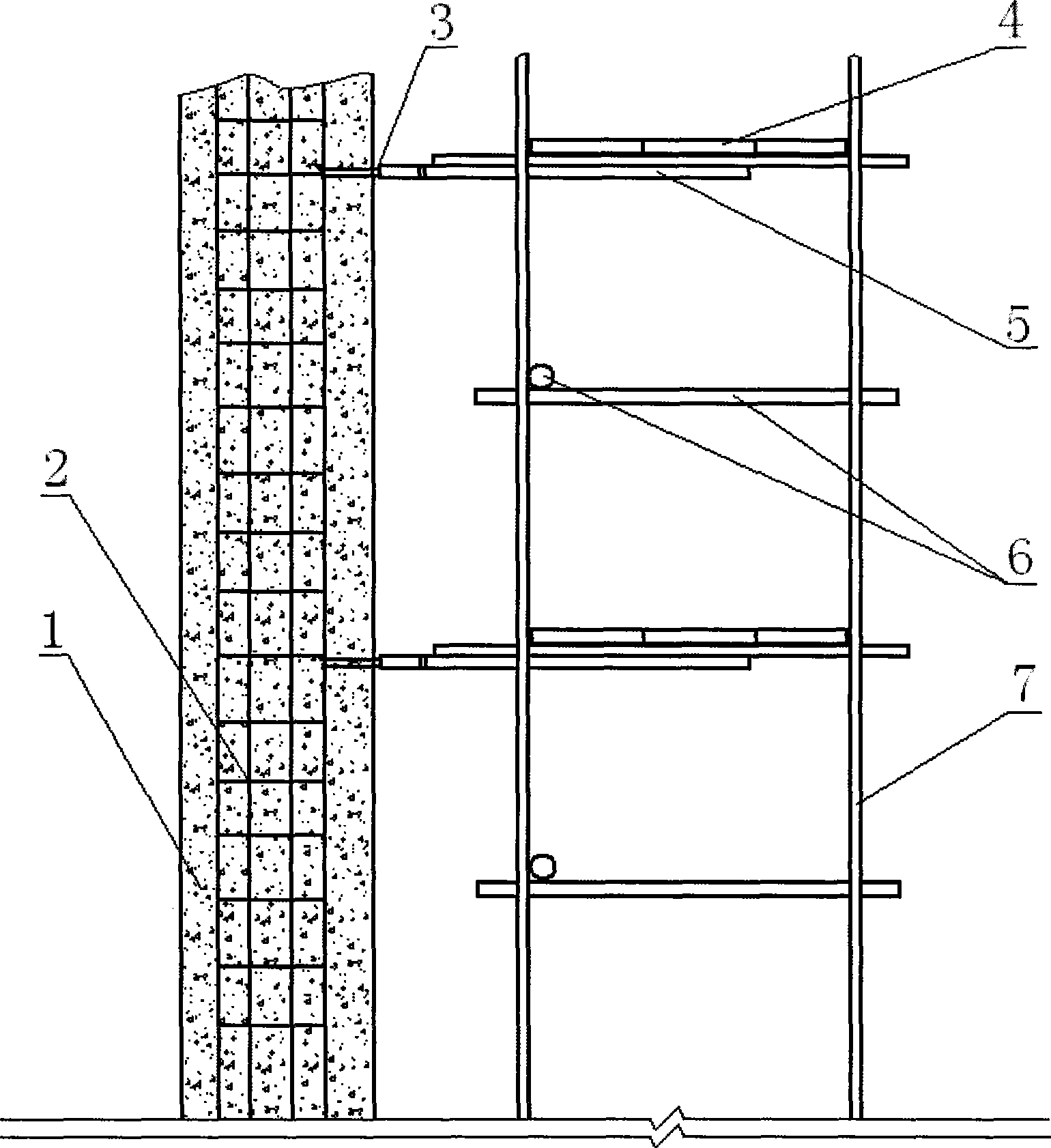

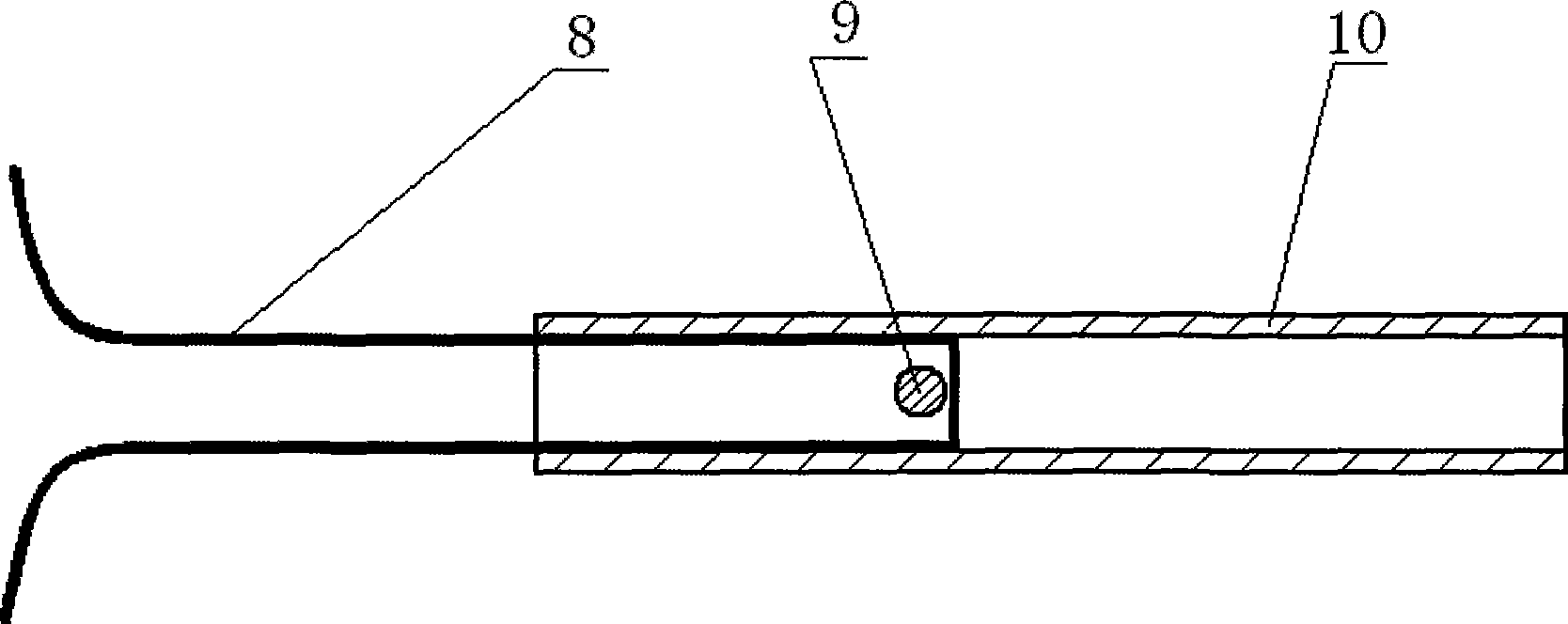

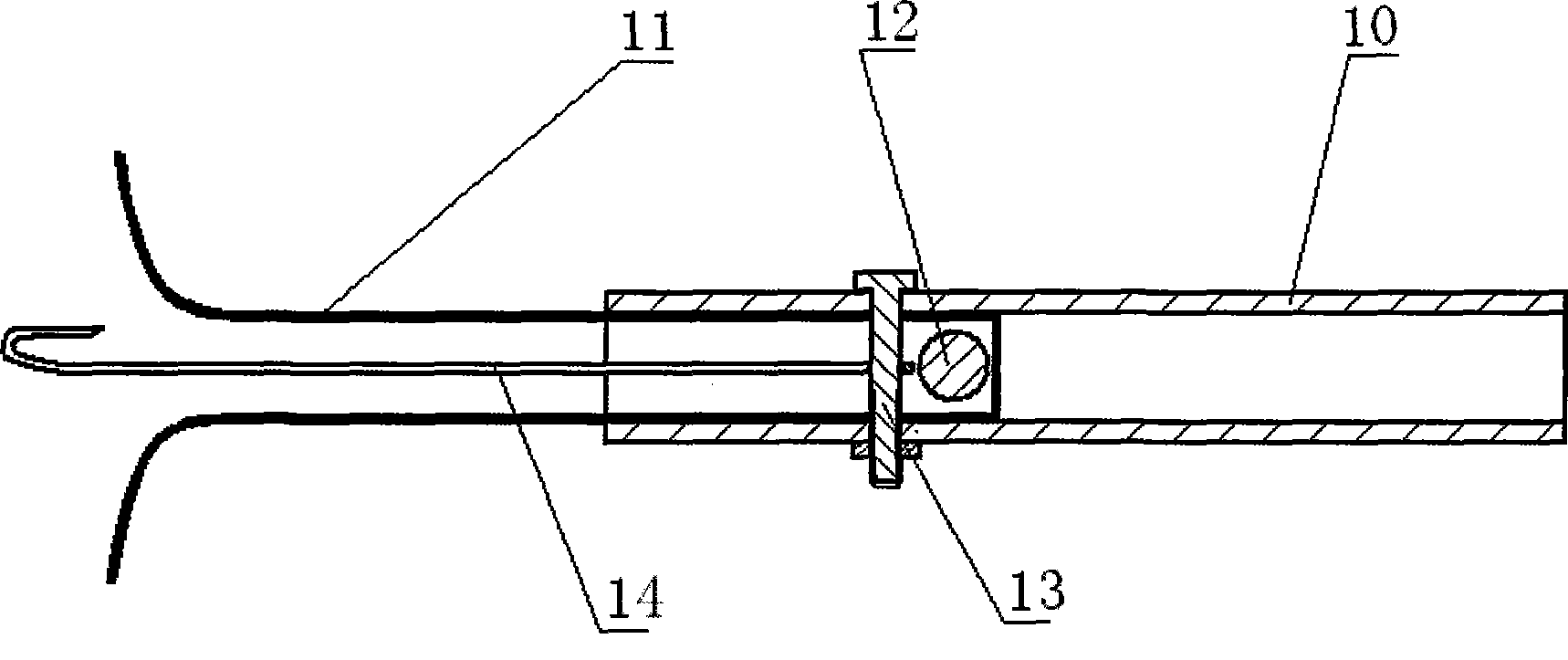

Wall connector of scaffold and its construction method of buckling member type steel pipe scaffold

InactiveCN101368442AGuaranteed integrityImprove penetration resistanceScaffold accessoriesSafety netRebar

The invention discloses a scaffold wall body connecting piece and a method for building a buckling tubular steel scaffold, including the following steps: 1), arranging the scaffold wall body connecting piece according to the standard space of three-step-two-span or three-step-three-span of the building; 2)building a sweeping pole, a vertical pole, a transverse pole and a connecting pole; and 3)building fencing guardrails, bridgings, a scaffold board, a safety net until the whole scaffold body develops into an integral sealed balanced system. The wall body connecting piece is composed of a connecting piece reinforcing steel bar which stretches into the building wall body, a connecting piece steel pipe outside the building wall body, and a detachable fixing piece which connects the connecting piece reinforcing steel bar and the connecting piece steel pipe. The U-shaped segment or rectangular segment of the connecting piece steel pipe outside the building wall body extends into the connecting piece steel pipe. Adopting such arrangement, the scaffold wall body connecting piece ensures the integrity of the building wall body, improves the impermeability of the building wall body, enhances the strength of the building wall body, reduces construction noises and shortens construction period.

Owner:CHINA CONSTR SEVENTH ENG BUREAU THE SECOND CO LTD

High-water-retaining-property shield construction premixed synchronous grout material

The invention discloses a high-water-retaining-property shield construction premixed synchronous grout material which comprises cement, coal ash, admixture, bentonite, fine sand, additives and water. The additives mainly comprise non-ionic cellulose ether, carbohydrate, polycarboxylic acid slump retaining agents, starch ether and magnetic hydrotalcite. The high-water-retaining-property shield construction premixed synchronous grout material has the advantages that the optimized admixture, the bentonite, the fine sand with the fineness modulus being 1.6 and the additives special for mortar are jointly used in the shield construction premixed synchronous grout material, the fluidity loss of the adjusted grout material is less than or equal to 30mm in 6 hours, bleeding rate is reduced to be lower than or equal to 3.0%, and sedimentation after a vibration test is less than or equal to 20mm; due to the fact that the magnetic hydrotalcite is added, the grout material can reduce construction noise during stirring and absorb heavy metal ions to prevent heavy metal in the mortar from causing secondary pollution on the basis that the original physical properties are kept.

Owner:河北三楷展创建材有限公司

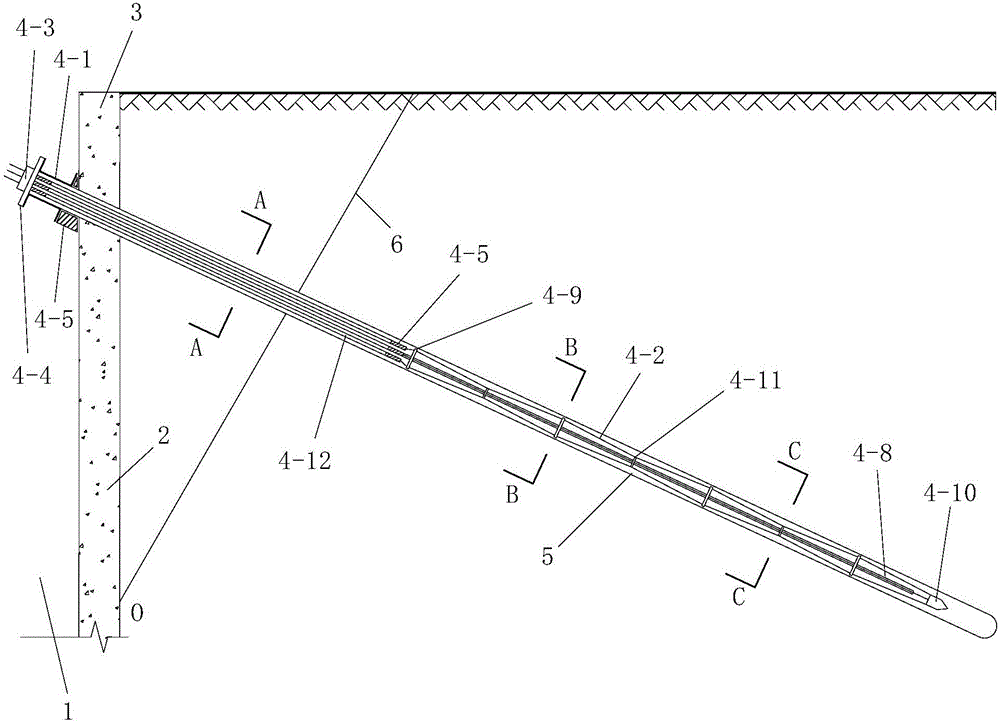

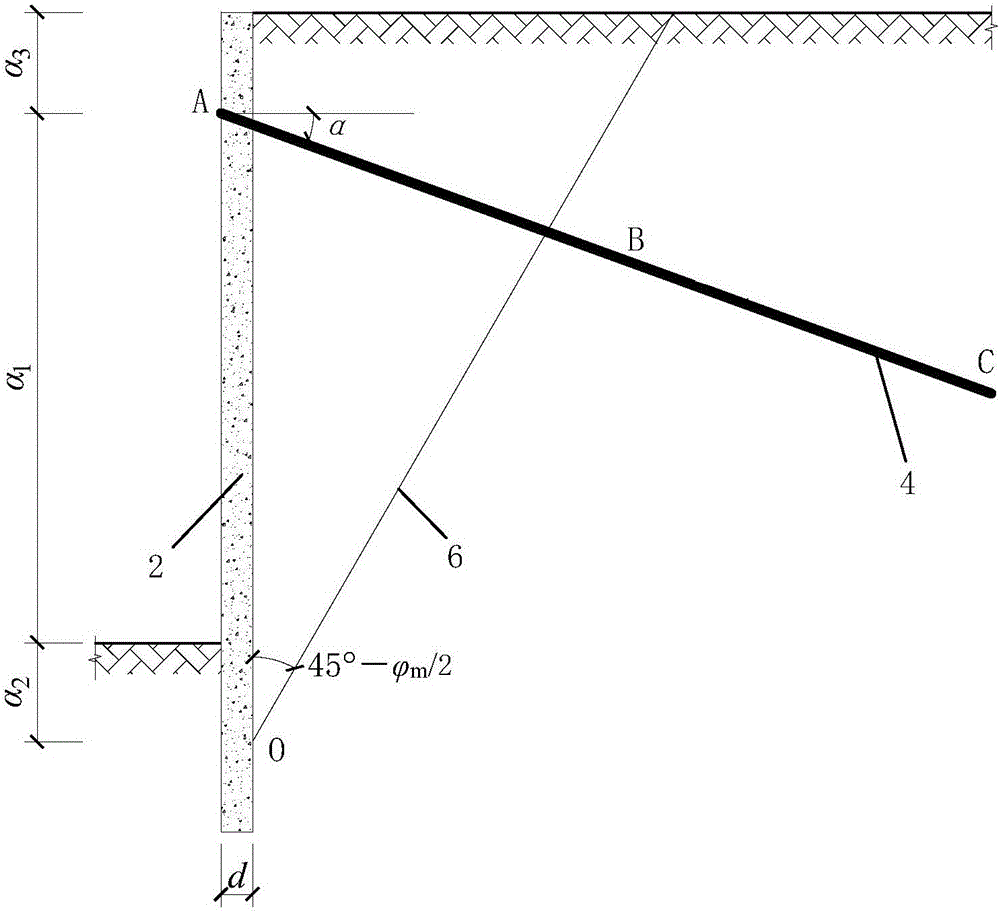

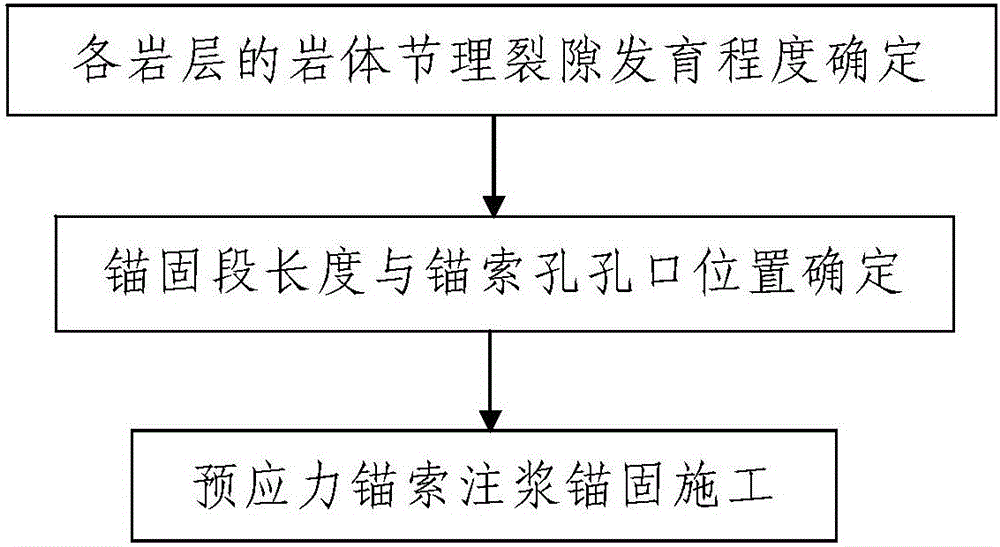

Fissure-contained rock soil stratum prestressed anchor cable grouting and anchoring construction method

ActiveCN106522243AThe method steps are simpleReasonable designExcavationsBulkheads/pilesPre stressHigh pressure

The invention discloses a fissure-contained rock soil stratum prestressed anchor cable grouting and anchoring construction method. Multiple prestressed anchor cables uniformly distributed on the same one plane are adopted to reinforce a slope to be reinforced; the method comprises the following steps: (1) the rock mass joint fissure development degree of each rock stratum is determined; (2) the lengths of anchoring sections and the hole port positions of anchor cable holes are determined; the prestressed anchor cables include anchor cable bodies, primary grouting pipes and secondary grouting pipes; anchoring tools are mounted at the back ends of the anchor cable bodies; and the anchor cable bodies include multiple steel strands; and (3) the prestressed anchor cables are grouted and anchored: when any one prestressed anchor cable is grouted and anchored, the construction includes the steps of drilling, placement of the anchor cables, normal-pressure grouting, high-pressure grouting, tensioning of the anchor cables and anchor sealing. The method is simple in steps, reasonable in design, convenient to construct, high in construction efficiency and excellent in use effect, and can conveniently and quickly finish the reinforcing process of the slope to be reinforced; and the adopted prestressed anchor cables are low in cost and higher in anchoring force, and can effectively reinforce the slope to be reinforced.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

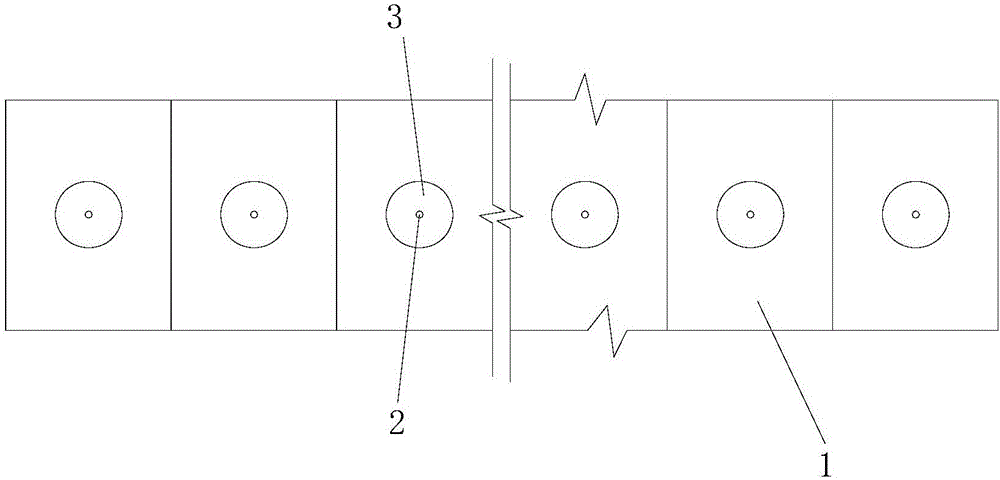

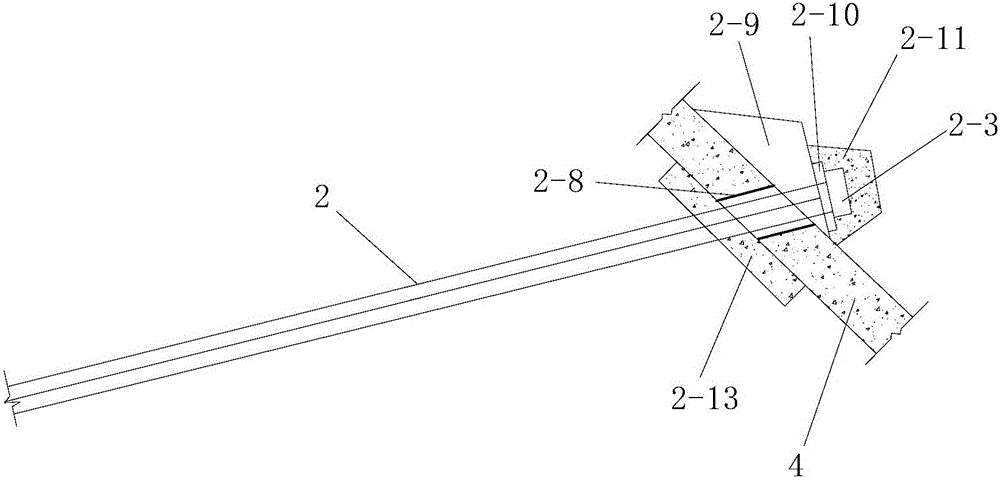

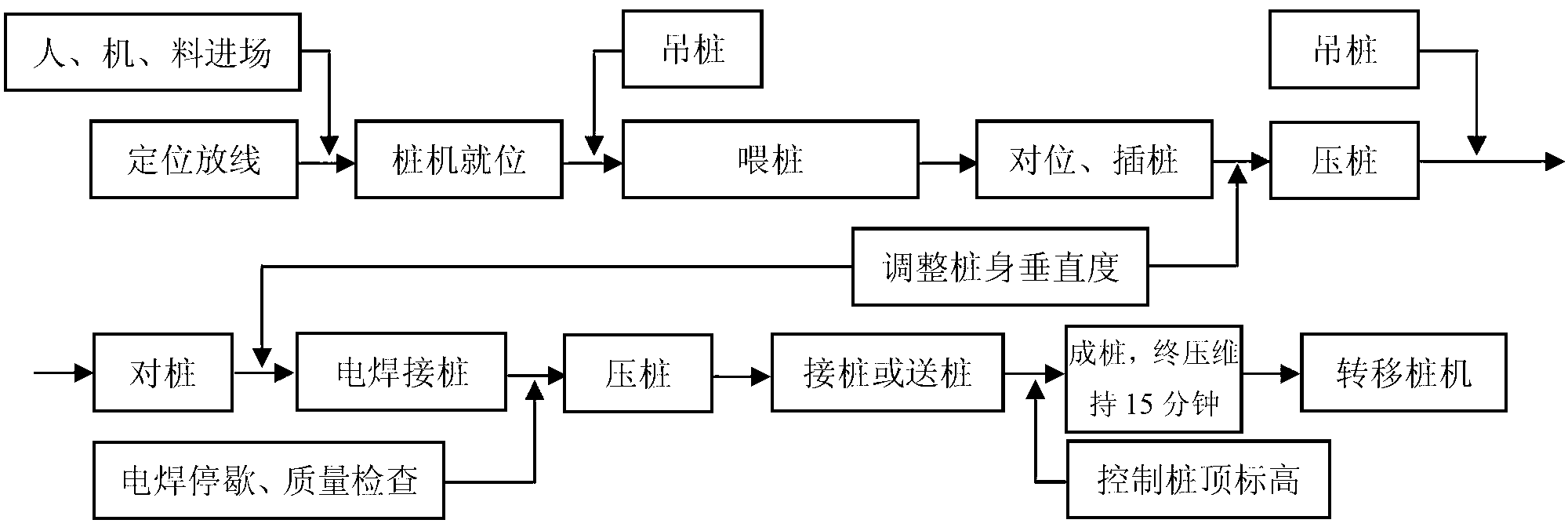

Construction method for preventing static-pressure precast tubular piles from floating

InactiveCN103290846AImprove carrying capacityReduce dosageProtective foundationBulkheads/pilesEconomic benefitsBearing capacity

The invention discloses a construction method for preventing static-pressure precast tubular piles from floating. The method mainly comprises the steps of conducting positioning and paying off, taking a pile machine in place, pitching the piles, pressing the piles, splicing the piles, feeding or cutting the piles and forming the piles. The method can prevent the piles from rebounding and moving up to the maximum extent after the piles are pressed, bearing capacity of the piles is improved, the practical quantity of the piles is reduced, and therefore a pile arrangement coefficient is reduced. According to actual measurement of a project, the bearing capacity of a single pile can be improved by 15 percent to 20 percent, construction cost of the tubular piles is saved by 15 percent, and economic benefits are quite obvious.

Owner:ZHEJIANG UNIV CITY COLLEGE +2

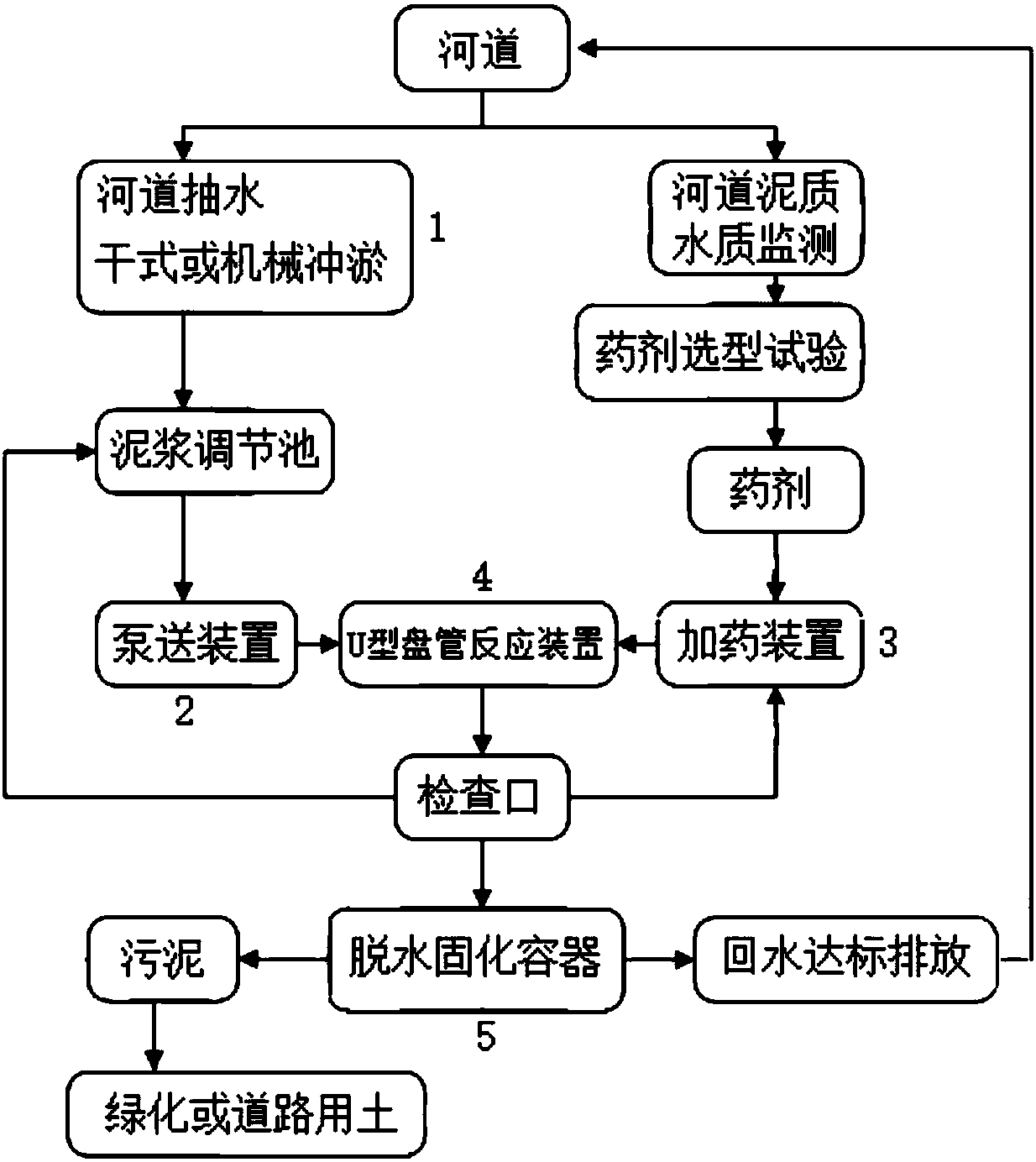

City and town medium-and-small river sludge ecological treatment system

InactiveCN107915392AAvoid secondary pollutionSecondary pollution is not easy to causeSludge treatment by de-watering/drying/thickeningMechanical machines/dredgersSludgeEngineering

The invention discloses a city and town medium-and-small river sludge ecological treatment system. The system comprises five subsidiary modules of a river dredging subsidiary module, a slurry pumpingsubsidiary module, an agent adding device subsidiary module, a reaction device subsidiary module and a slurry dehydration and solidification subsidiary module; the city and town medium-and-small riverdredging subsidiary module is connected with the slurry pumping subsidiary module and the agent adding device subsidiary module, macromolecular flocculation agent for water treatment is selected according to analysis of river sediment properties, the agent is put into the slurry pumping subsidiary module through the agent adding device subsidiary module, slurry is fully reacted with the agent inthe reaction device subsidiary module, and finally solidification is conducted in a dehydration container of the slurry dehydration and solidification subsidiary module to achieve slurry-water separation. The sludge is subjected to reduction, stabilization, hazard-free treatment and resourceful treatment; the construction noise is low, secondary pollution is not easily caused, the treatment and volume reduction effect of the wastewater and the slurry is good, the treatment and volume reduction efficiency of the wastewater and the slurry is high, the size of the sludge can basically be reducedby 50% or above within one month, a fixed plant is not needed, the treatment cost is low, the treatment capability can be flexibly adjusted, and the application range is wide.

Owner:上海市水利工程集团有限公司

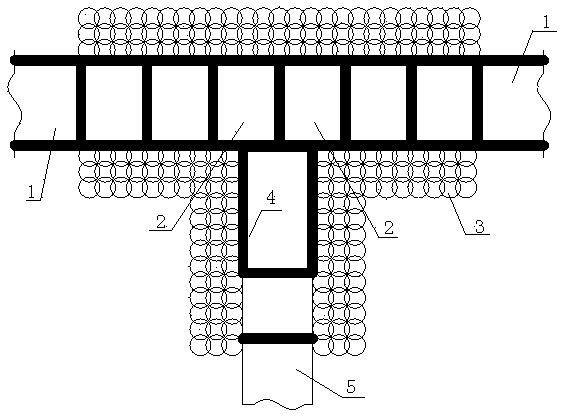

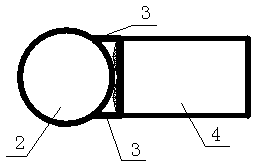

Construction method of reinforced concrete jacked pipe underground T-shaped butt joint

ActiveCN103807504AAchieving Conservation GoalsLow construction noisePipe laying and repairReinforced concreteButt joint

The invention relates to a construction method of the reinforced concrete jacked pipe underground T-shaped butt joint. The construction method is characterized by including the steps of (1) numbering longitudinal jacked pipes, (2) using steel pipes as pipe bodies at the butt joint position, (3) jacking the pipes through a pipe jacking machine, (4) replacing the reinforced concrete pipes with the steel pipes when the pipes are jacked to the butt joint position, (5) jacking transverse reinforced concrete pipes through the pipe jacking machine, (6) carrying out high-pressure jet grouting pile reinforcing on the periphery of the butt joint pipe section, (7) disassembling the pipe jacking machine, and retaining tool pipes, (8) carrying out welding on the tool pipes and the steel pipes at the butt joint position, (9) carrying out cutting to enable the T-shaped butt joint position to be completely through, and (10) carrying out concrete pouring on pipe sections of the whole T-shaped butt joint position. According to the construction method, roads are not damaged, the construction noise is low, influences on the roads, traffic and the surrounding environment are small, the construction period is short, and the aim of protecting the environment is truly achieved.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +1

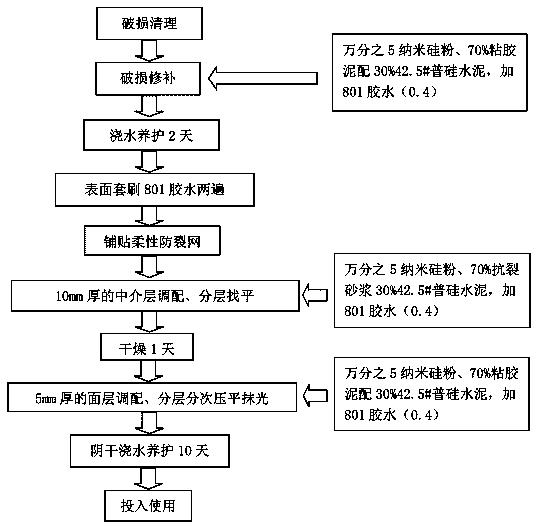

Damage repairing construction method for cement flooring

ActiveCN103953181ALow technical requirements for constructionSimple construction processFlooringSurface layerEmulsion

The invention discloses a damage repairing construction method for cement flooring. The damage repairing construction method for the cement flooring comprises the following steps: cleaning a damage; repairing the damage and curing; brushing glue; paving an anti-crack mesh; leveling an intermediate layer; surviving a surface layer; performing secondary curing, wherein the material used for repairing comprises the following components in percentage by weight: 0.05 percent of 200-nm nano- silica fume, 55 to 85 percent of viscous cement, and 45 to 15 percent of 42.5# ordinary Portland cement and 801-glue with the glue-to-cement ratio of 0.4; the material used for the intermediate layer comprises the following components in percentage by weight: 0.05 percent of 200-nm nano-silica fume, 15.9 to 75.1 percent of emulsion compound emulsion anti-crack mortar, 85.1 to 24.9 percent of 42.5# ordinary silicone salt cement and 801-glue with the glue-to-cement ratio of 0.4. A paste slurry material prepared by the 200-nm nano-silica fume, and the viscous cement and the 801-glue in a certain ratio is used for repairing holes and depressions, and the 801-glue serves as an interface for adhering the flexible anti-crack mesh, so that the crack resistance of the flooring is improved, the flooring can be prevented from cracking, and the service life of the flooring is greatly prolonged.

Owner:UNIJES GRP

Modular prefabricated spliced undercrossing tunnel and splicing structure thereof

PendingCN107989065AFast constructionShort time on the roadArtificial islandsUnderwater structuresTerrainMarine engineering

The invention discloses a modular prefabricated spliced undercrossing tunnel. The modular prefabricated spliced undercrossing tunnel comprises tunnel shallow ship chute sections located at the two ends of the tunnel, a tunnel frame section located at the middle portion of the tunnel, and tunnel deep ship chute sections which are located on the two sides of the tunnel and connect the tunnel frame section with the tunnel shallow ship chute sections. Each tunnel shallow ship chute section comprises a plurality of shallow ship chute section prefabricated side plates which are arranged in the length direction of the tunnel and can be connected into a whole through a cast-in-place bottom plate. Each tunnel deep ship chute section comprises a plurality of deep ship chute section splicing units which are arranged in the length direction of the tunnel and can be connected into a whole through a cast-in-place bottom plate. The tunnel frame section comprises a plurality of frame section splicingunits which are arranged in the length direction of the tunnel and can be connected into a whole through a cast-in-place bottom plate. Through modular design of prefabricated plates of the shallow ship chute sections, the deep ship chute sections and the frame section, the chute sections are constructed and spliced into a whole; and splicing of tunnels which are located in different terrains and are different in length is facilitated, and field rapid splicing construction is achieved.

Owner:CCCC SECOND HARBOR ENG

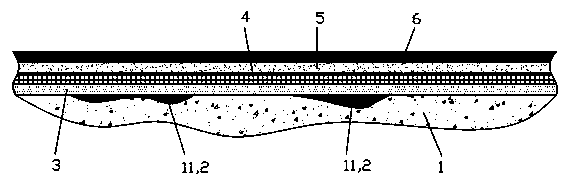

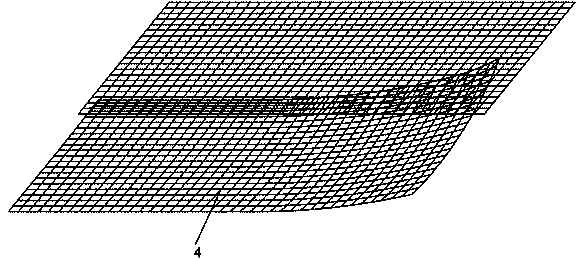

Flow construction method for forming cast-in-place bored pile for gravel-decomposed rock stratum in double-machine combined mode

InactiveCN106677166AAvoid pollutionOvercome pollution and other deficienciesRotary drillingRotary-drilling machinesEngineeringRebar

The invention discloses a flow construction method for forming a cast-in-place bored pile for a gravel-decomposed rock stratum in a double-machine combined mode. The flow construction method comprises the steps that a high-power hydraulic spiral drilling machine is adopted to conduct drilling; drilling is conducted to the design pile bottom elevation; the requirements of a design and related specifications for the length of the pile and a bearing course at the pile end are met; pore-forming is finished; a drilling rod is lifted out; residue soil produced by pore-forming with the high-power hydraulic spiral drilling machine is layered again and poured in a pile hole through equipment such as an excavator, the speed rate of backfill is controlled, and the filling quality of backfill soil to the pile hole is guaranteed; after a pile position is rechecked and set out again, a long spiral drilling machine is adopted to conduct drilling again on the backfill hole position and pile body concrete is pumped into the pile hole through the end of a drilling rod of the long spiral drilling machine; the pouring top face of the pile body concrete is 0.5-1 m higher than the design pile top elevation; after pumping is finished, a reinforcement cage is lowered to the design elevation trough the method that after vibrating, the reinforcement cage is inserted into the pile body concrete; and the steps are repeated, so that pile-forming flow construction is realized through the combination of the high-power hydraulic spiral drilling machine and the long spiral drilling machine.

Owner:江苏省岩土工程公司

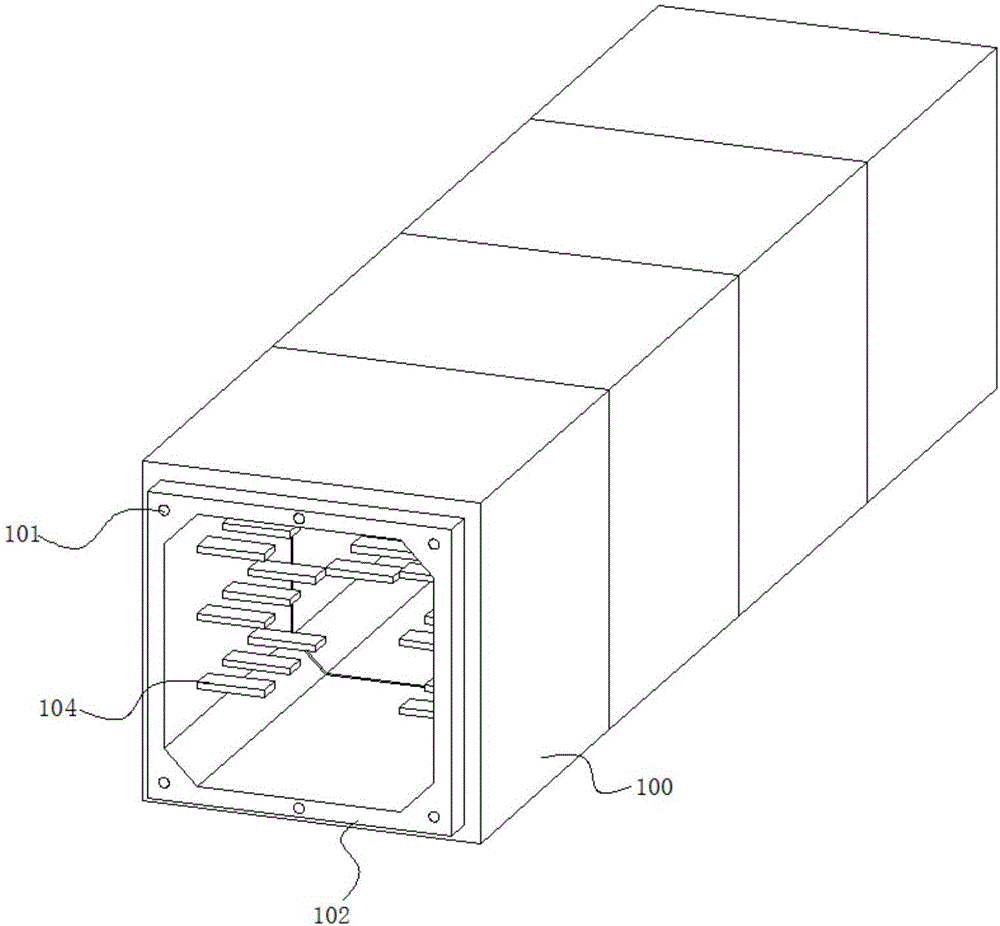

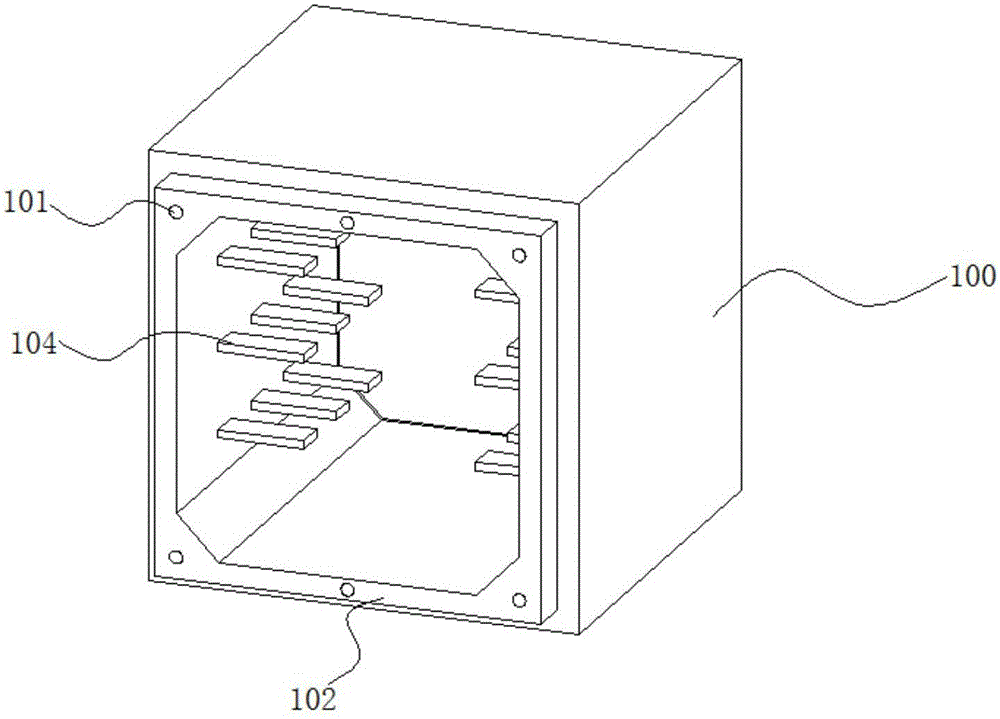

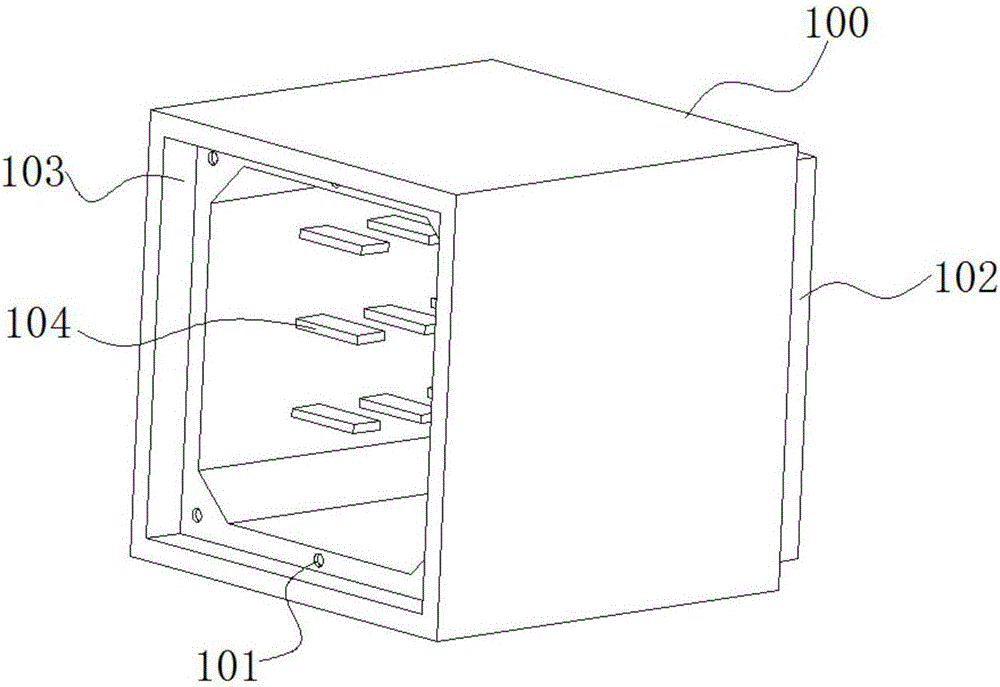

Intelligent comprehensive pre-fabricating pipe gallery and construction technique thereof

InactiveCN106677209APrevent leakageImprove the construction environmentArtificial islandsUnderwater structuresArchitectural engineeringEngineering

The invention provides an intelligent comprehensive pre-fabricating pipe gallery and a construction technique thereof and relates to the technical field of municipal infrastructure building. The intelligent comprehensive pre-fabricating pipe gallery comprises a plurality of pipe-shaped pre-fabricating square culverts; connecting holes are formed in the inner walls of the pre-fabricating square culverts in the axial directions of the pre-fabricating square culverts, the multiple pre-fabricating square culverts are sequentially connected and correspond to the connecting holes one to one; and connecting pieces are installed in the connecting holes in a penetrating mode, and the multiple pre-fabricating square culverts are tightly attached in sequence through the connecting pieces. The technical problem that through a cast-in-place type pipe gallery, the construction quality is difficult to control due to limiting of the conditions such as the construction on-site environment and climate is solved, and the technical effects that rainwater leakage is effectively avoided, the construction quality is guaranteed, the construction environment is improved, the construction period is shortened, the influences of construction on city transportation and surrounding resident lives are reduced are achieved.

Owner:HENAN GUOLONG IND

High-efficiency honeycomb type pile head breaking construction process

The invention discloses a high-efficiency honeycomb type pile head breaking construction process. The construction process comprises the steps that in the process of processing and manufacturing a reinforcement cage, each main reinforcement and each sounding pipe of the reinforcement cage are each sleeved with an isolation sleeve; after completion of processing of the reinforcement cage, the reinforcement cage is put into a drill hole, concrete is poured into the drill hole to form a cast-in-place pile; a pit is excavated in seven days after pouring, steel wedge blocks are symmetrically and horizontally inserted and driven in the annular tangent positions until a pile head is separated from a pile body, and then the pile head is removed. According to the high-efficiency honeycomb type pilehead breaking construction process, the main reinforcements are sleeved with the isolation sleeves, and damage to the main reinforcements in the treatment process of the pile head is effectively avoided. Moreover, the operating process is simple, and the construction efficiency is high. Input of construction equipment is reduced. Construction noise is greatly lowered. Dust flying is prevented. The construction environment is improved. Health of construction staff is effectively protected.

Owner:广州公路工程集团有限公司

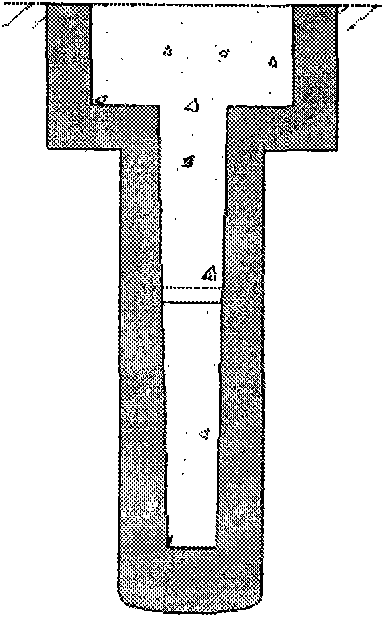

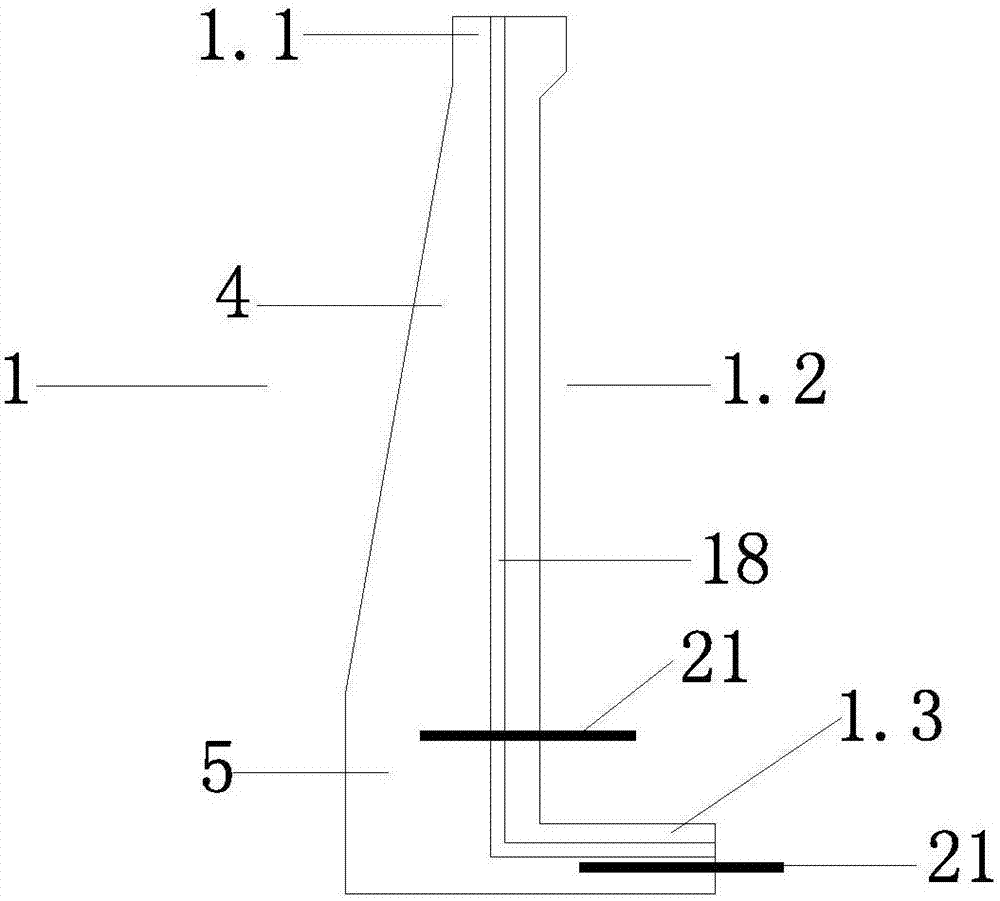

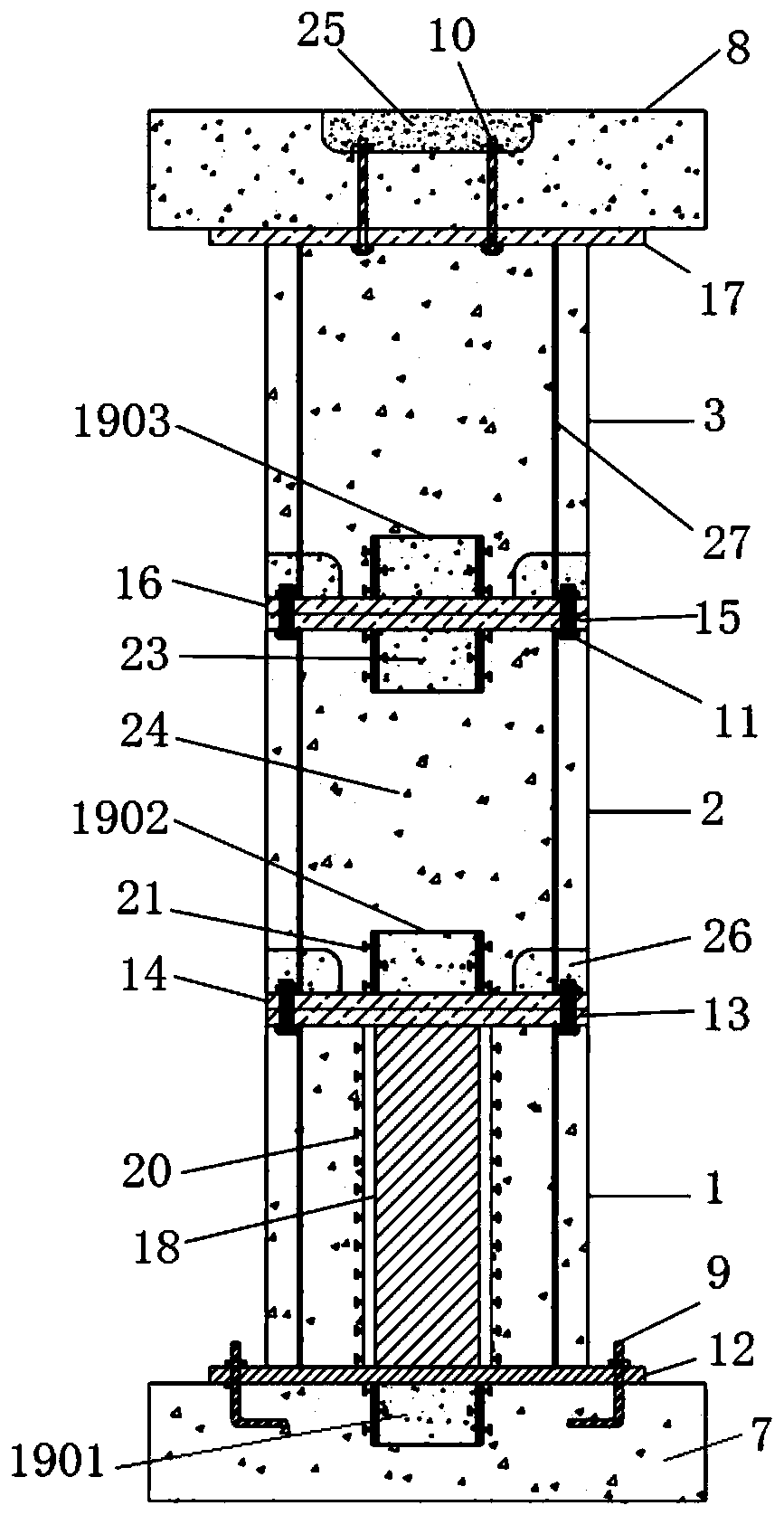

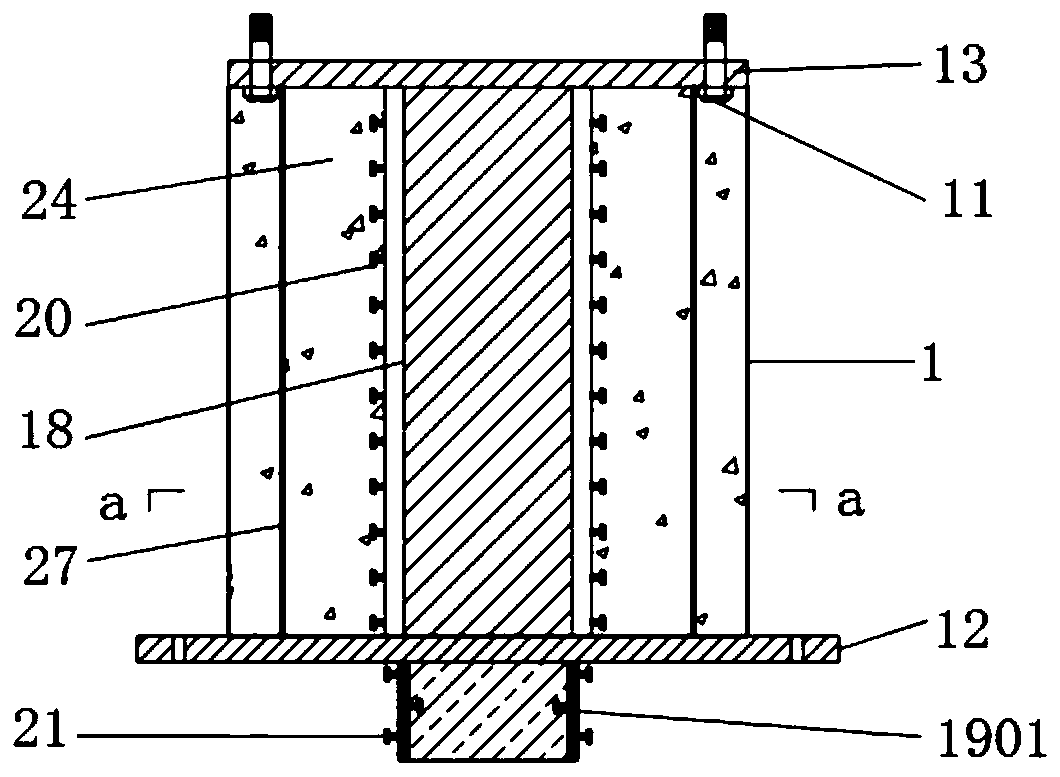

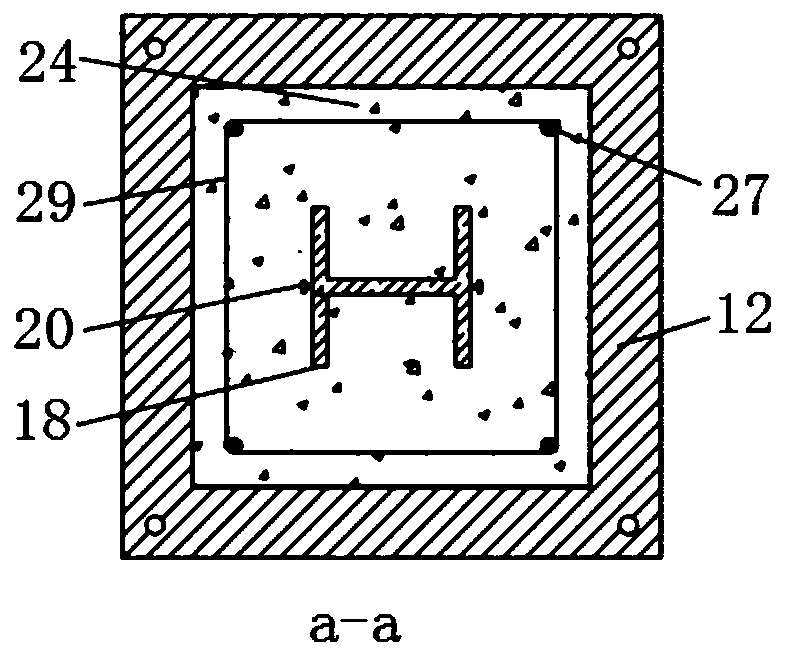

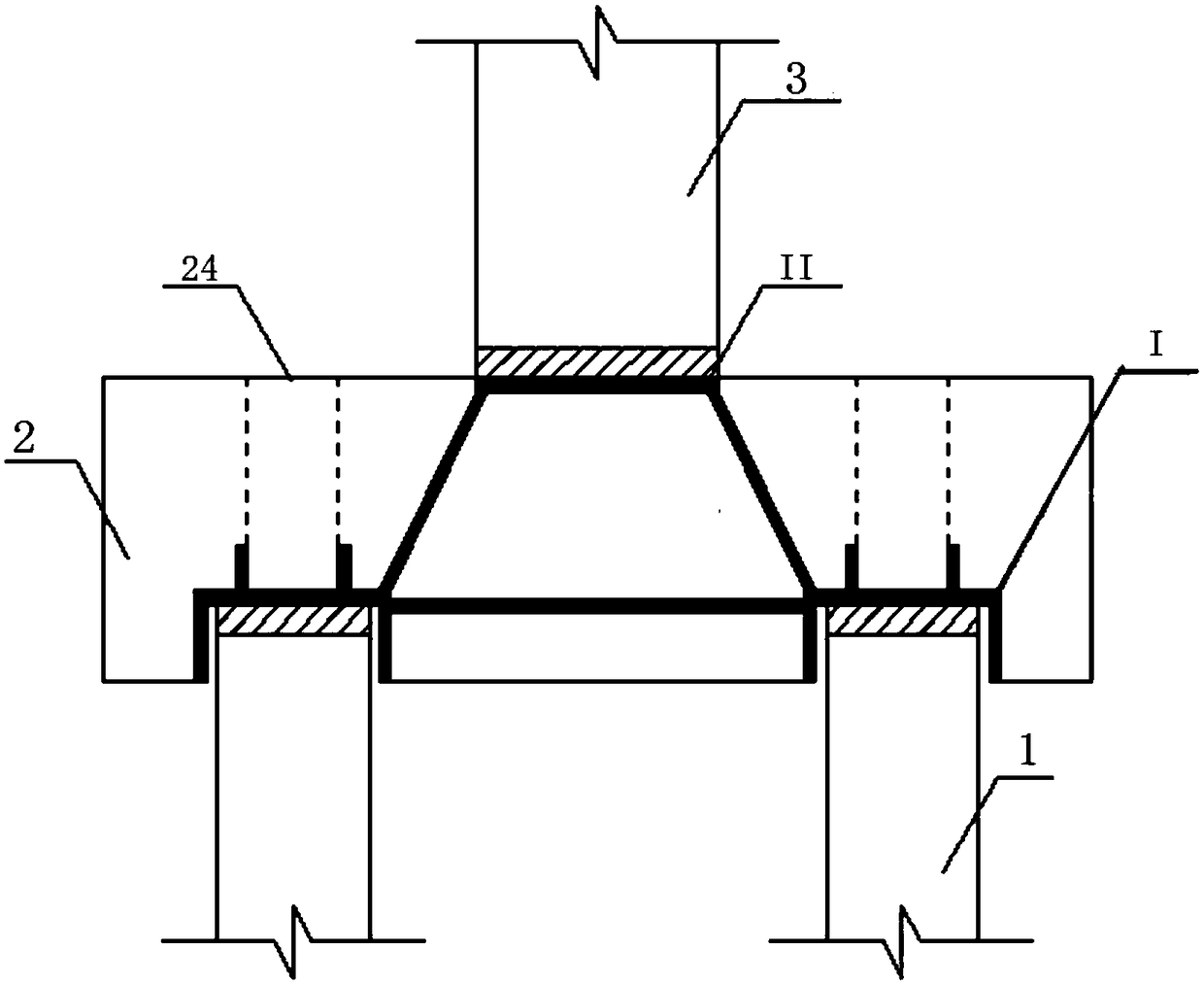

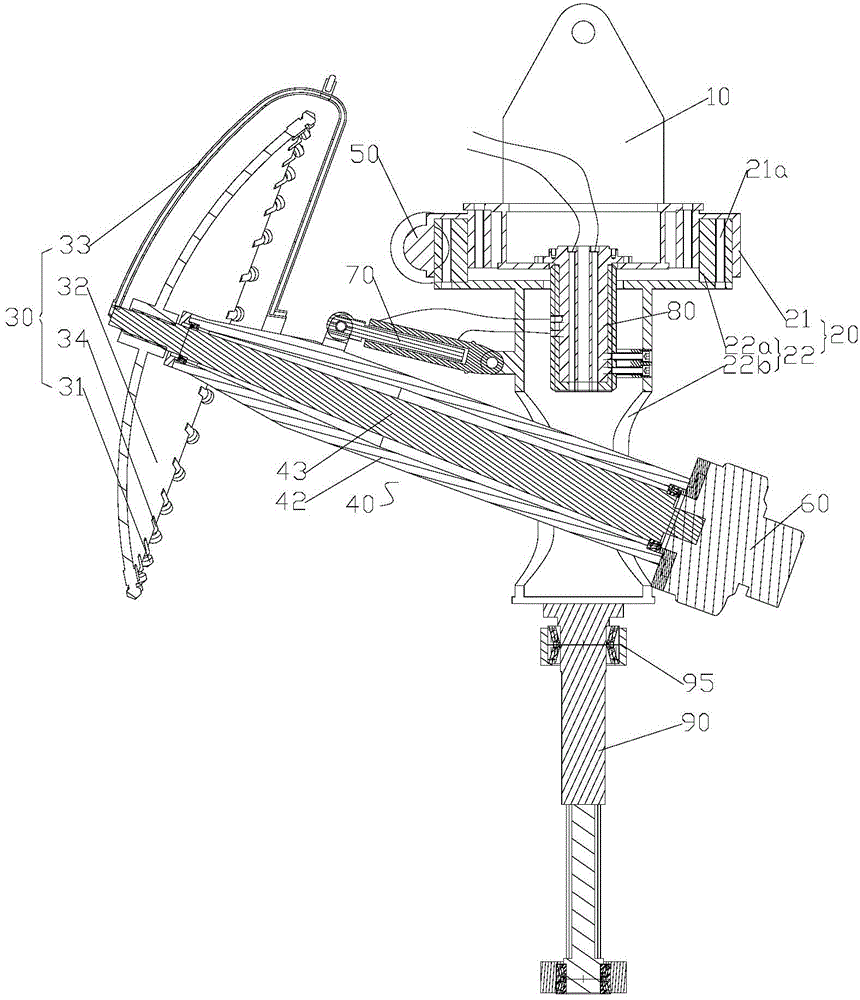

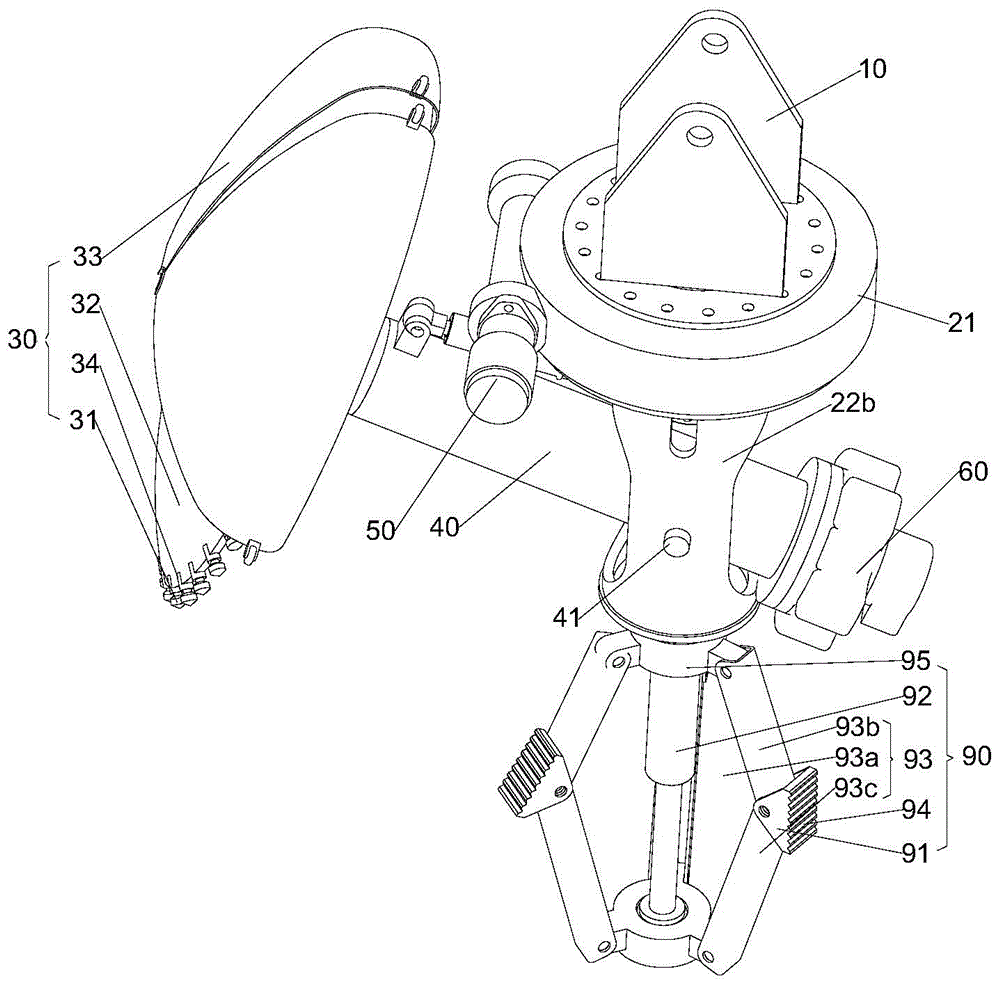

Prefabricated steel reinforced concrete and reinforced concrete assembled pier and construction process

ActiveCN110952440AFast constructionLow construction noiseBridge structural detailsBridge erection/assemblyReinforced concreteArchitectural engineering

Prefabricated steel reinforced concrete and reinforced concrete assembled bridge piers are provided with two connecting modes including bolt connection and connector connection, and each assembled bridge pier connected through bolts comprises a foundation, a first bottom section, a first middle section, a first top section and a bent cap. The assembled pier connected through the connectors comprises a foundation, a second bottom section, a second middle section, a second top section and a bent cap. The construction process of the prefabricated steel reinforced concrete and reinforced concreteassembled pier comprises the following steps that 1, components are manufactured, specifically, the first bottom section, the first middle section, the first top section and the bent cap are prefabricated, or the second bottom section, the second middle section, the second top section and the bent cap are prefabricated; 2, the components are mounted. The designed connection technology of the prefabricated sections and the foundation, the connection technology of the prefabricated sections and the connection technology of the prefabricated sections and the bent cap can guarantee that all the prefabricated parts are connected into a whole, and the structure is jointly stressed and deformed harmoniously.

Owner:NORTHEASTERN UNIV

Precast assembled pile foundation pier and construction method thereof

PendingCN109267472AConducive to the realization of prefabricated assembly construction of the whole bridgeRealize the prefabricated assembly construction of the whole bridgeBridge structural detailsFoundation engineeringShear capacityDuctility

The invention relates to a prefabricated pile foundation pier and a construction method thereof, comprising a prefabricated pile, a prefabricated bearing cap and a prefabricated pier column, wherein the pile foundation pier is integrally connected by a first connection structure for connecting the prefabricated pile and the prefabricated bearing cap and a second connection structure for connectingthe prefabricated pier column and the prefabricated bearing cap; the first connection structure connects the precast pile and the bearing cap into a whole, which ensures the reliability of the connection between the pile and the bearing cap, and at the same time satisfies the sufficient compression, bending and shearing capacity and certain tensile capacity at the pile top. The second connectionstructure connects the precast pier column with the cap, and ensures that the bottom of the pier has sufficient compression, bending, shear and ductility seismic capacity. Compared with the prior art,the invention is conducive to realizing the whole bridge segment assembly construction of the concrete bridge, improving the construction quality, greatly accelerating the construction process, shortening the construction period, reducing the adverse impact on the environment, reducing the construction noise and the like.

Owner:TONGJI UNIV +1

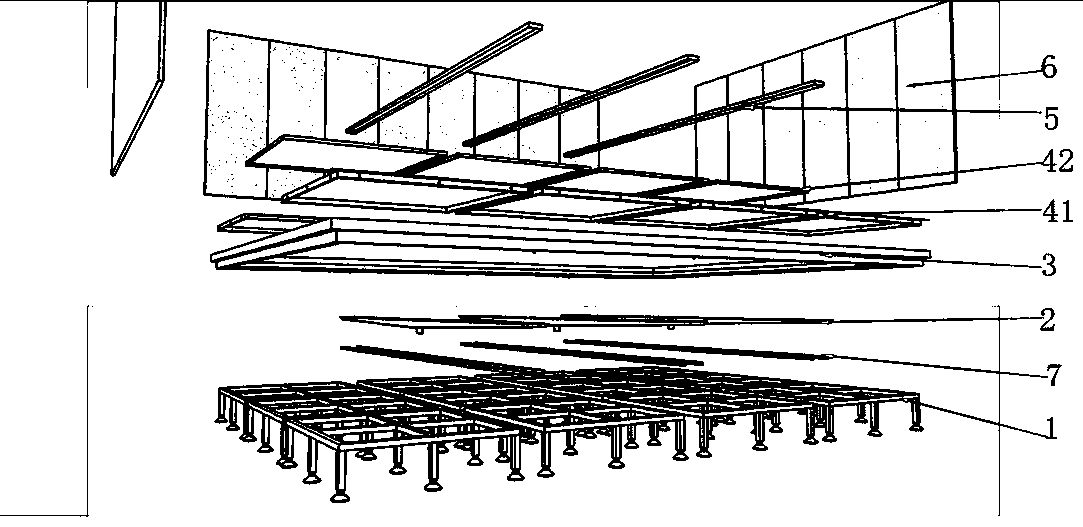

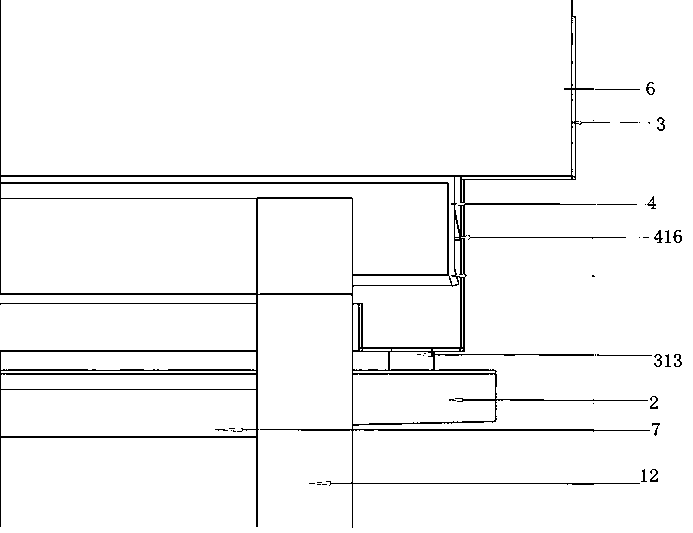

Fast and high-efficiency integrated ground

PendingCN109958258AShorten the construction periodLow construction noiseFalse floorsSewer pipelinesEngineeringGround level

The invention discloses a fast and high-efficiency integrated ground. The fast and high-efficiency integrated ground comprises one or more groups of ground bases, a drainage tank, a wall side special-shaped water guiding groove, floors, a water tank cover plate and wall panels, the drainage tank is fixed between the two ground bases through a drainage tank fixing frame, the wall side special-shaped water guiding groove is formed in the position above the ground bases, the water tank cover plate is installed at the gap, above the drainage tank, between the floors, the wall panels are installedon the peripheries of the ground bases, and arranged in a frame body of the wall side special-shaped water guiding groove. According to the fast and high-efficiency integrated ground, the constructionperiod can be shortened, the construction noise is lowered, the construction environment is improved, meanwhile, the ground is elevated, integrated and modularized, waterproofing treatment is changedfrom the traditional containment type to the drainage type, repairing can be conducted in time when the seepage is found, and the recyclability is achieved.

Owner:SUZHOU QIXINTIAN F & B

Steel pipe pile assembly, foundation pit retaining structure and construction method of foundation pit retaining structure

PendingCN110644472AHigh strengthIncrease stiffnessExcavationsBulkheads/pilesArchitectural engineeringPipe

The invention provides a steel pipe pile assembly and a foundation pit retaining structure. The steel pipe pile assembly comprises at least two steel pipe piles arranged in parallel and lock hook pairs matched with the steel pipe piles, wherein two lock hooks in each lock hook pair are distributed in axial symmetry relative to the matched steel pipe piles; the lock hooks of the two adjacent steelpipe piles are bitten for sealing, so that the two steel pipe piles are integrally connected and the gap between the two steel pipe piles is sealed. Foundation pit retaining is implemented through theabove steel pipe pile assembly to form the integrated steel pipe pile enclosure system integrating soil retaining and permeability resistance properties based on the good properties of high strength,high stiffness and high stability of the steel pipe pile assembly. In the pile sinking process, the steel pipe piles have the advantages of thin-wall driving and not obvious soil compaction effect. Moreover, the construction procedures are simple, and the construction efficiency is high. The steel pipe piles can be connected through the lock hooks. There is no need to arrange a waterproof curtainon the outside of a pit. The construction noise and construction waste are reduced. The steel pipe pile, the foundation pit retaining structure and the construction method of the foundation pit retaining structure are consistent with green construction.

Owner:SHANGHAI NO 4 CONSTR

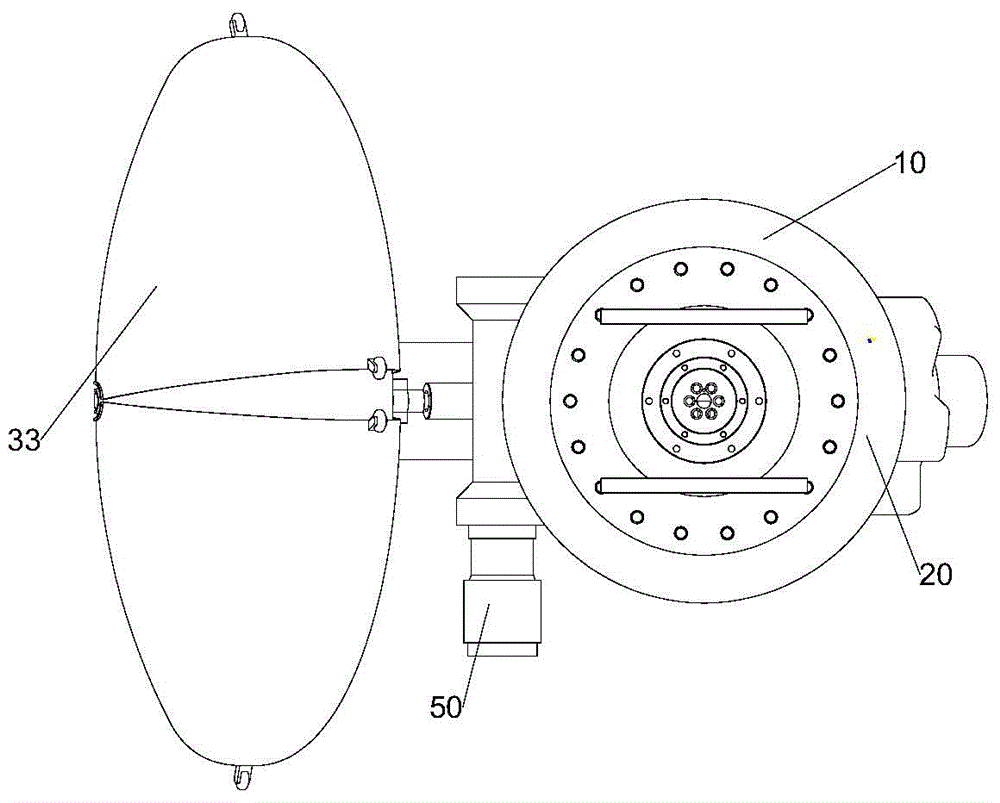

Pavement repairing device

ActiveCN104594170AEasy to operateReduce manufacturing costRoads maintainenceReinforced concreteEngineering

The invention provides a pavement repairing device. The pavement repairing device comprises a fixed part, a rotating part which is pivotally connected with the fixed part and circumferentially rotated about the fixed pat, and a cutter part which is connected with the rotating part; the cutter part comprises a cutter; a cutting edge of the cutter extends toward one side of a pavement. When being used, the pavement repairing device is mounted at a working position through the fixed part, the rotating part rotates about an axis of a wellhead, and the cutter of the cutter part cuts pavement asphalt; the cutter part continuously cuts the pavement asphalt along with the rotating part so as to mill and treat the pavement surrounding the wellhead, and therefore, workers can repair a reinforced concrete structure of an inspection shaft. With the adoption of the pavement repairing device, the pavement surrounding the wellhead can be cut without manual assistance, so that the labor intensity of the workers can be reduced, the working efficiency can be improved, and the time of occupying a road in construction can be reduced.

Owner:中机恒通环境科技有限公司

Manufacture method for concrete irregular fender post

InactiveCN102626946AAdvantages of preparation methodImprove compactnessShaping reinforcementsEngineeringParallelogram

The invention provides a manufacture method for a concrete irregular fender post, which belongs to the field of building and particularly relates to a fender post used for retaining soil and water and applied to a deep base pit project. The novel concrete irregular fender post is provided with a reserved hole. The cross section of a novel concrete maintaining post is approximately in a shape of a parallelogram, two semi-circular grooves are arranged on one inclined side, and two semi-circular protruding ribs are arranged on the other inclined side. The novel concrete irregular fender post is a prefabricated post, is good in compaction, anti-permeability and lateral pressure resisting capacity, and does not need repairing. The novel concrete irregular fender post is simple in construction method, connection between posts is compact, time is saved, labor is saved, a construction cycle is short, and a water retaining and soil retaining effect is better.

Owner:ZHEJIANG ZHONGJI PILE IND

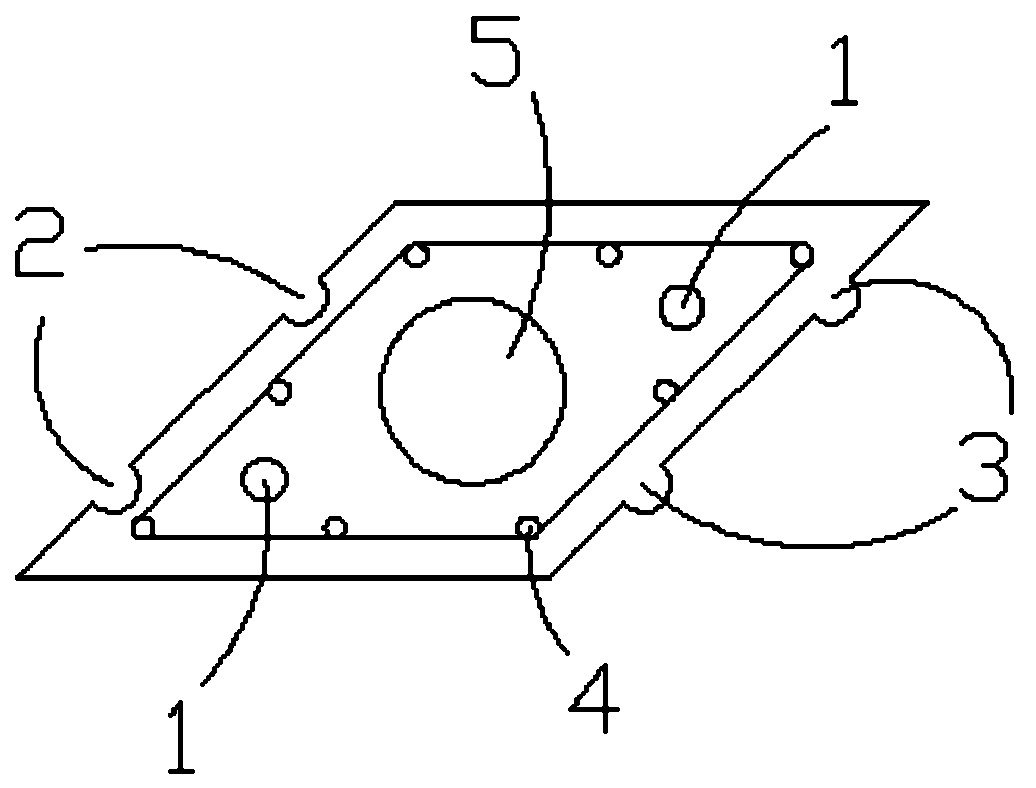

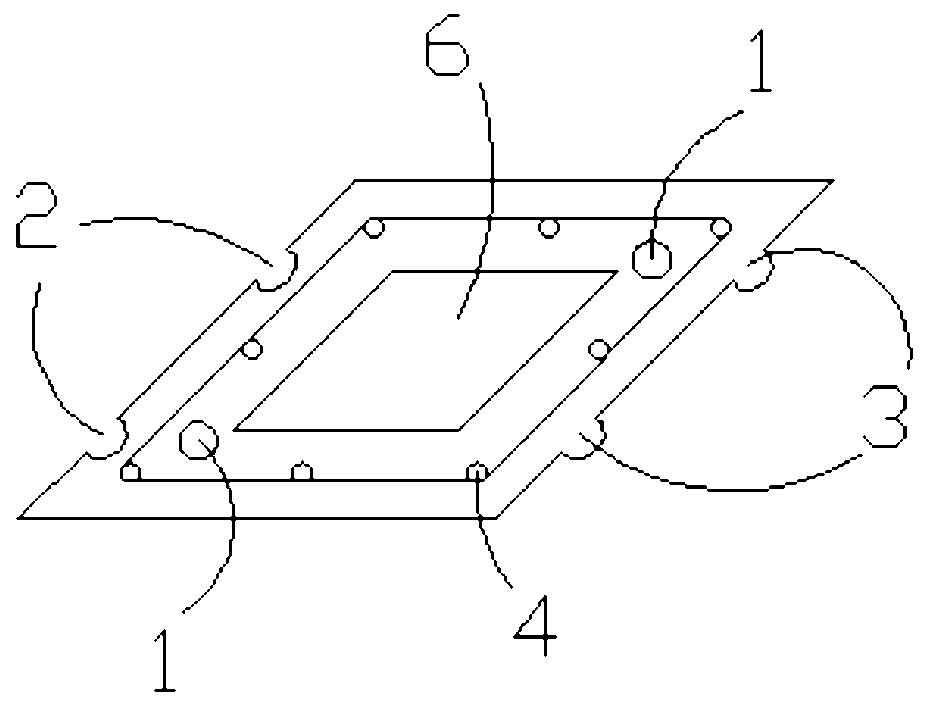

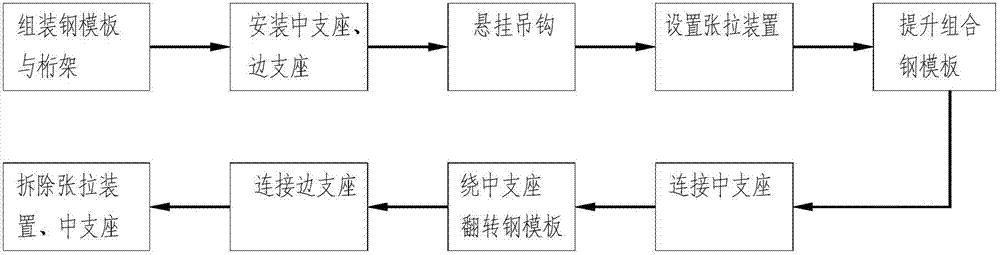

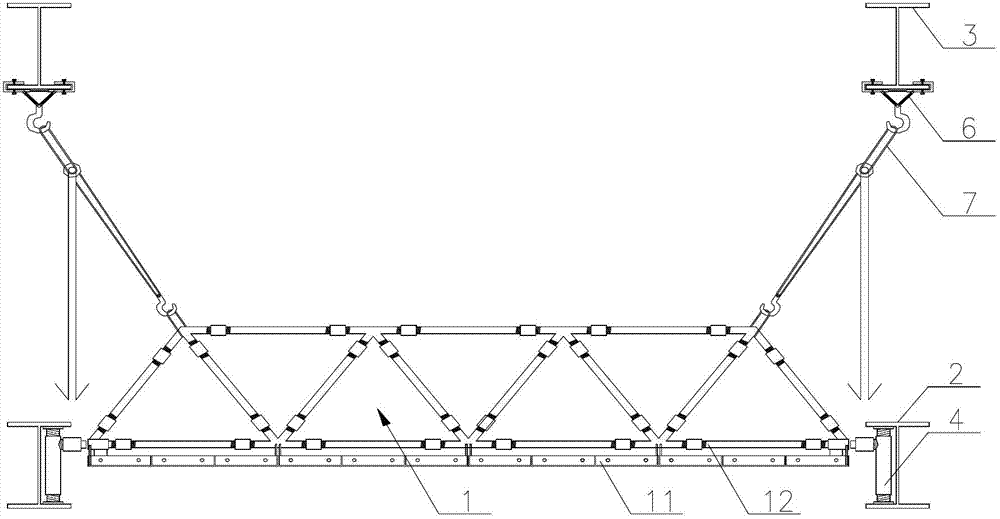

Self-supporting combined steel template construction method

ActiveCN102787717AReduce construction costsFast constructionForms/shuttering/falseworksFalseworkSystem construction

The invention relates to a multi-story and high-rise mixed structure building system construction technology, and aims to provide a self-supporting combined steel template construction method. The method comprises the following steps of: integrally and inversely assembling a self-supporting combined steel template on the ground surface or a platform, and lifting the inverse self-supporting combined steel template to a specified position through a tensioning device; connecting the inverse self-supporting combined steel template with a middle supporting seat though a horizontal connecting rod, and integrally overturning the inverse self-supporting combined steel template into place around a middle supporting seat horizontal connecting rod under the action of self-gravity; realizing connection through a side supporting seat horizontal connecting rod; and during construction of a self-supporting combined steel template of a next independent unit, circularly performing the construction steps. Compared with a construction method for erecting full framing scaffolding, the method has the advantages that the template construction cost is lowered greatly, the construction speed is increased greatly, and the site construction environment is improved remarkably.

Owner:HANGZHOU HENGDA STEEL STRUCTURE

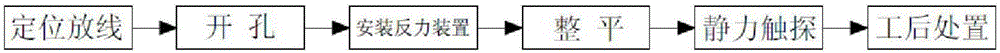

Static sounding construction technology for pavement of urban road

ActiveCN105714752AReduce human and material resources inputSmall damage to the road surfaceIn situ soil foundationRoad surfaceMaterial resources

The invention belongs to the technical field of road exploitation and particularly relates to a static sounding construction technology for the pavement of an urban road. The static sounding construction technology for the pavement of the urban road specifically includes the steps of paying off in a positioned mode, tapping, installation of a counter-force device, leveling, static sounding and treatment after construction, wherein in the process of installation of the counter-force device, the corresponding ground position of the counter-force device is drilled with a hole through an electric drill, the hole diameter is matched with the diameter of an expansion bolt, the depth of the hole needs to be 5-10 cm larger than the length of the expansion bolt, and the counter-force device is mounted after drilling. Compared with the prior art, the static sounding construction technology for the pavement of the urban road can complete the static sounding construction operation of the pavement of the urban road quickly on the premise of not affecting normal traffic, primary data are provided for design of a next procedure, input of manpower and material resources is greatly lowered, and social influence is reduced. Therefore, the static sounding construction technology for the pavement of the urban road has the following characteristics that the range of damage to the pavement is small, the pavement is likely to recover, construction noise is low, and environmental protection and cleanliness are achieved.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

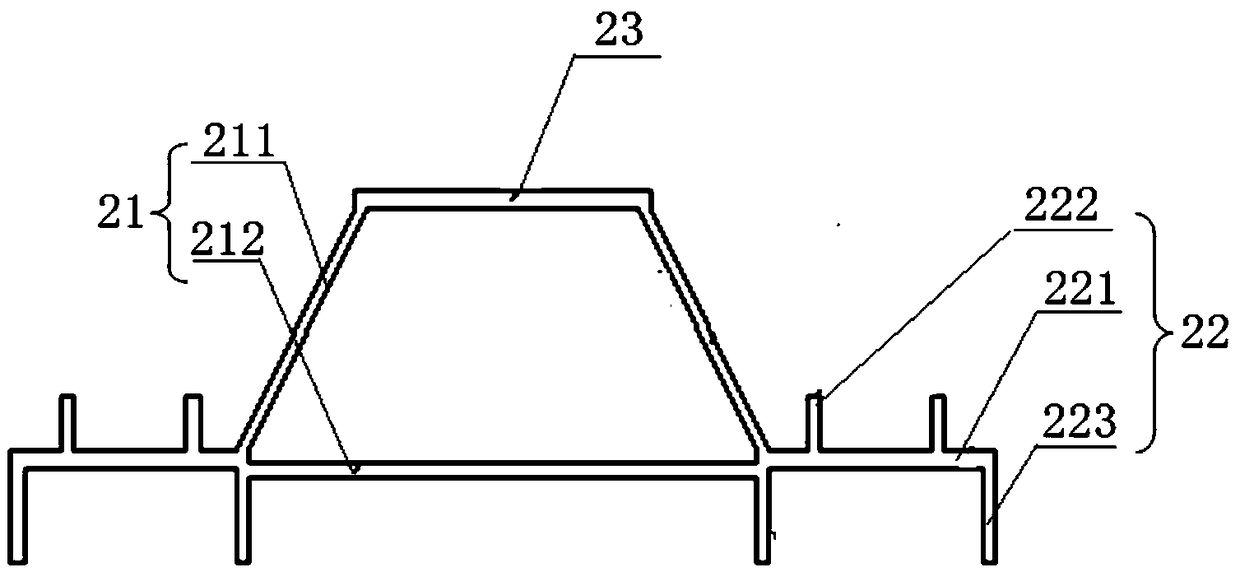

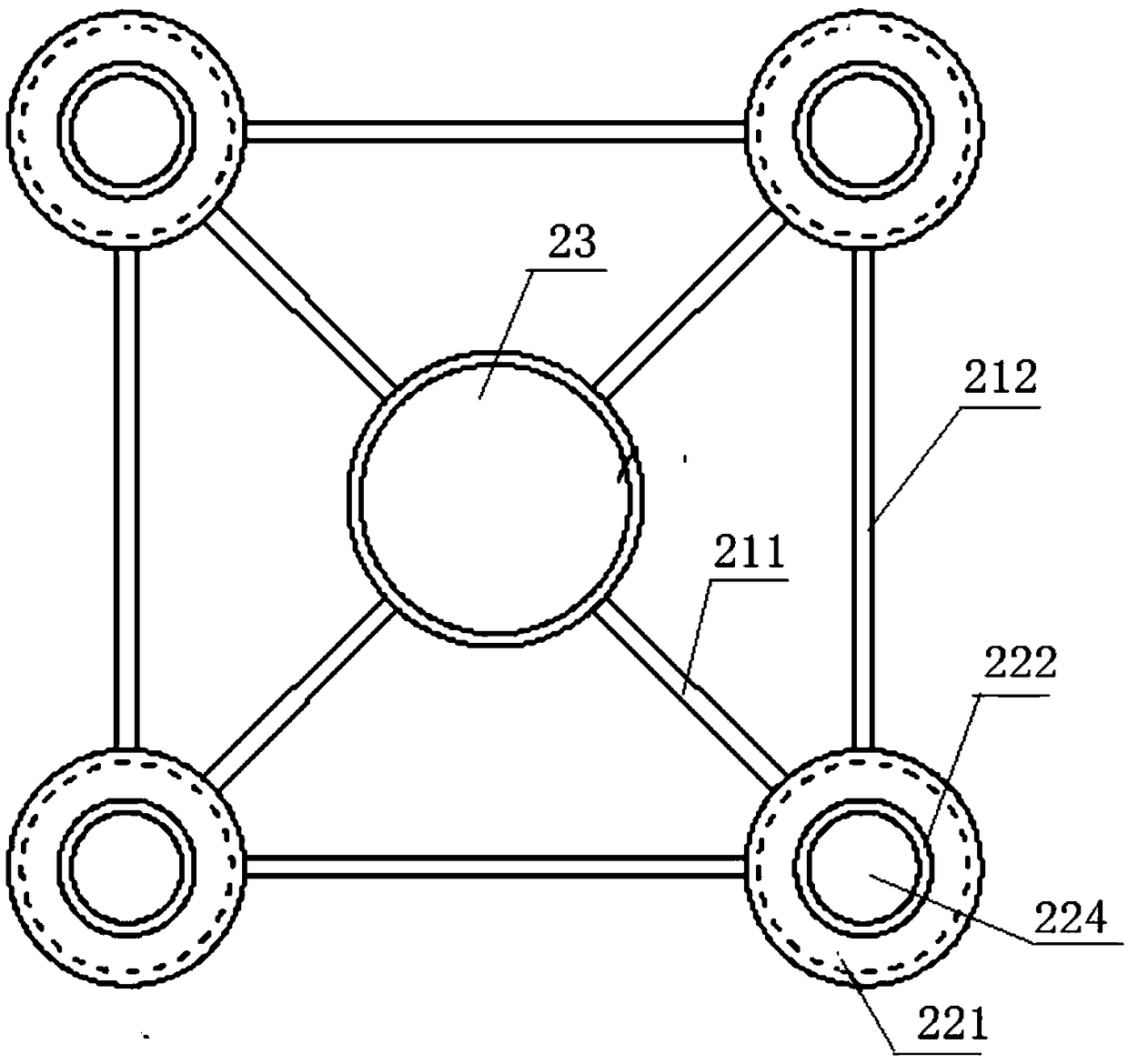

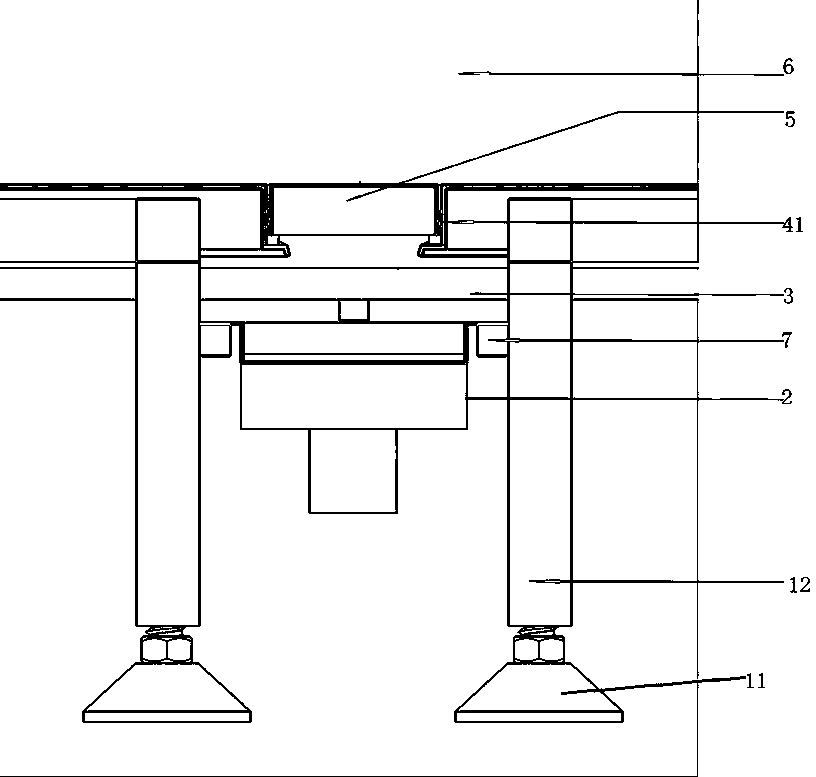

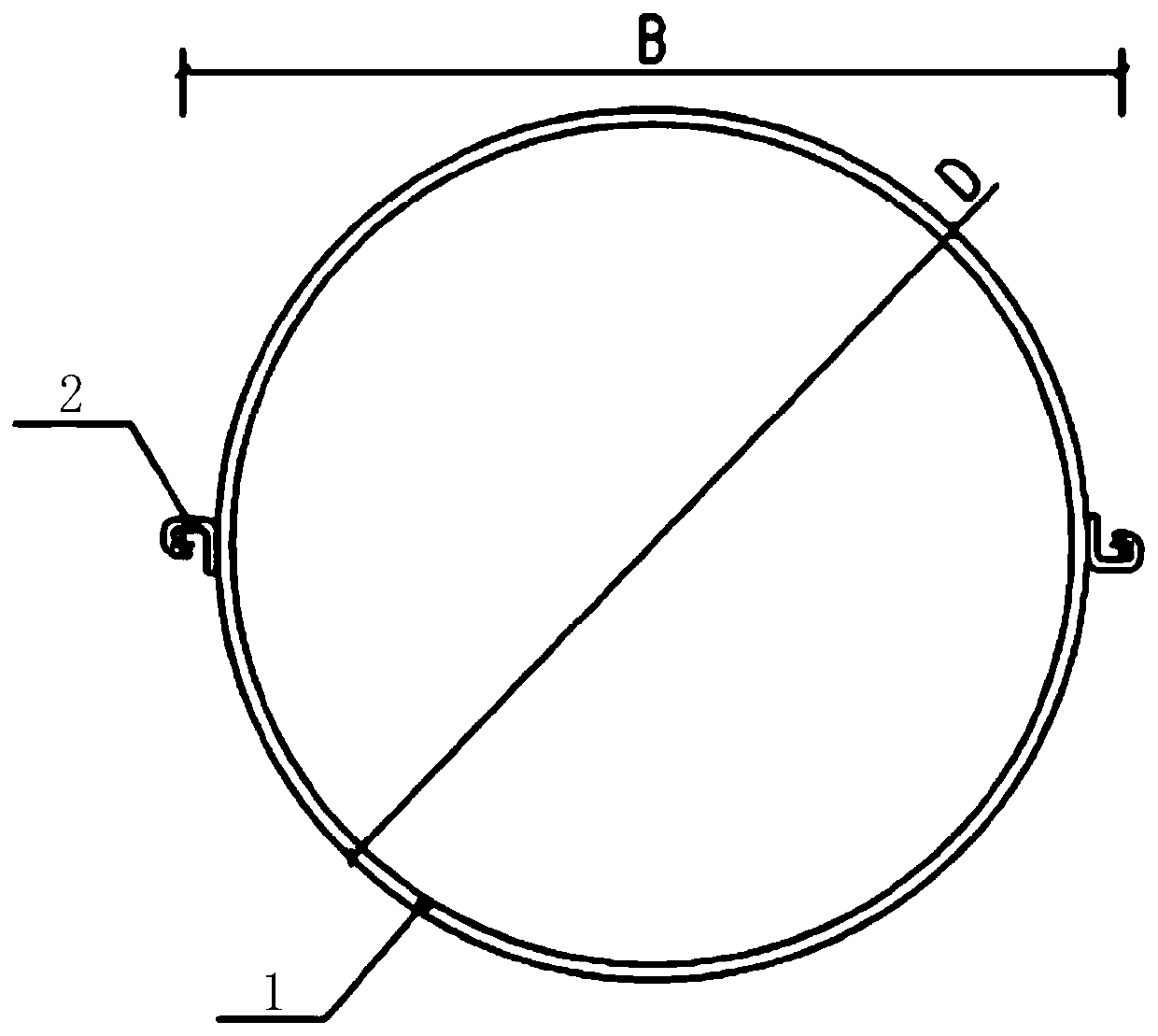

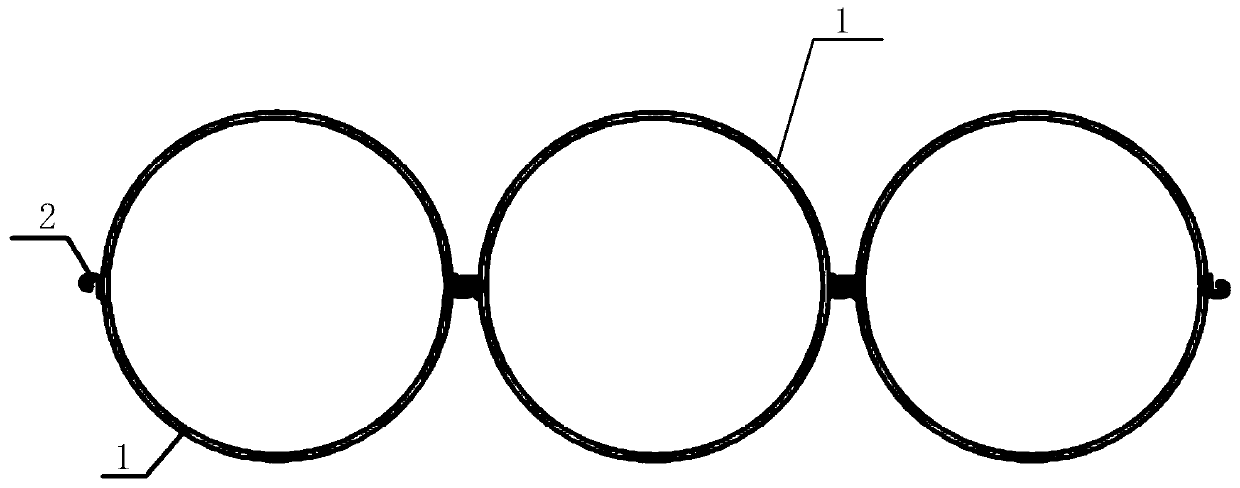

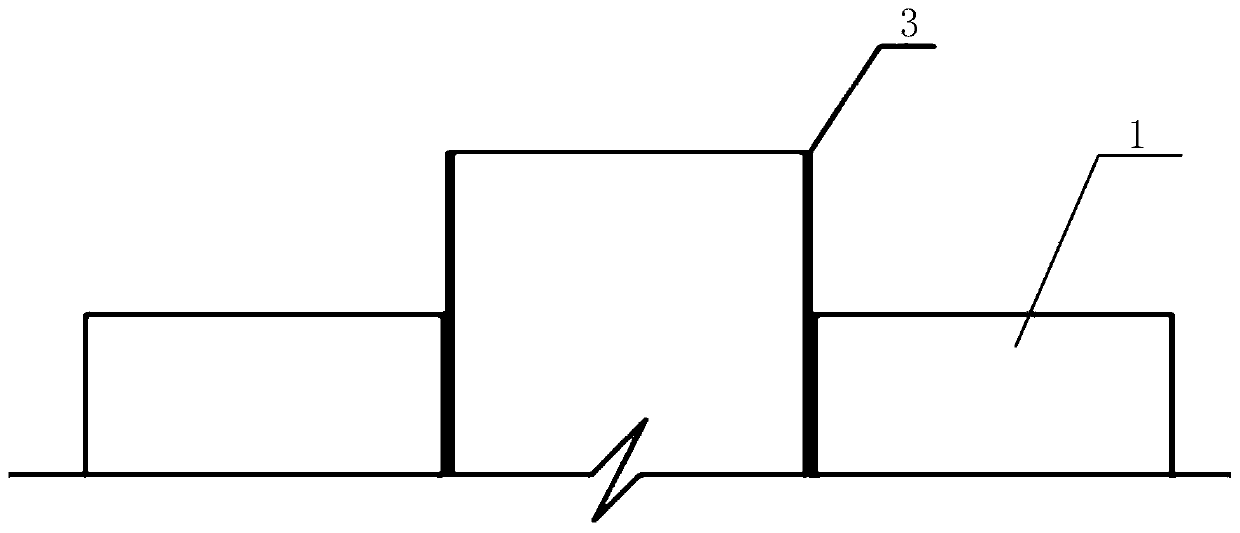

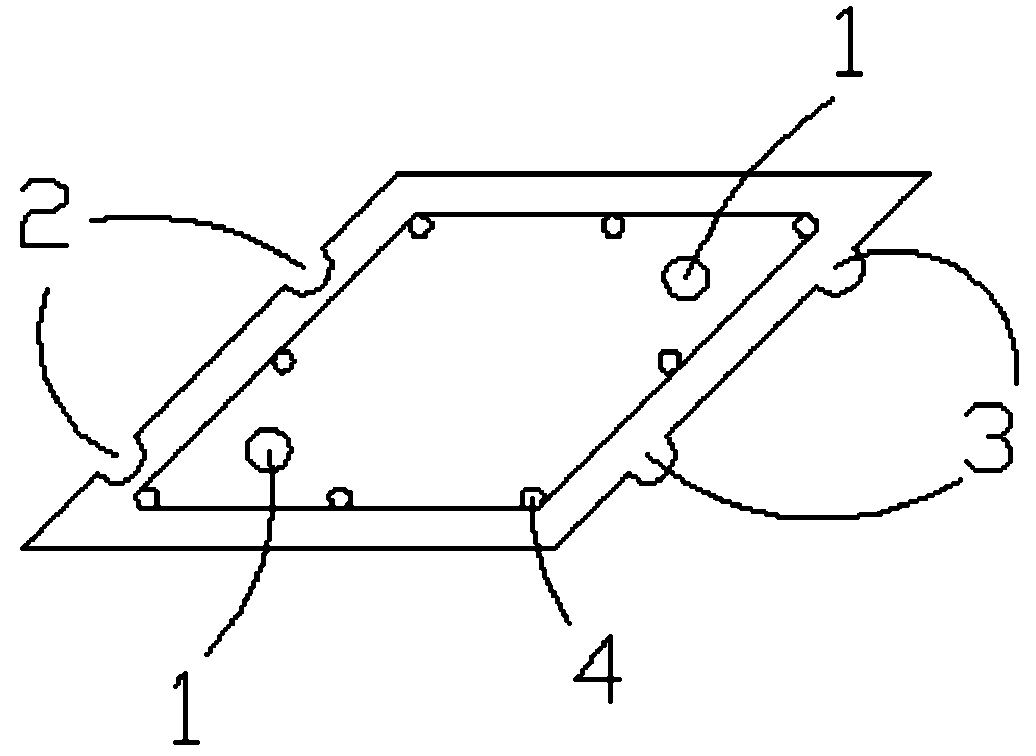

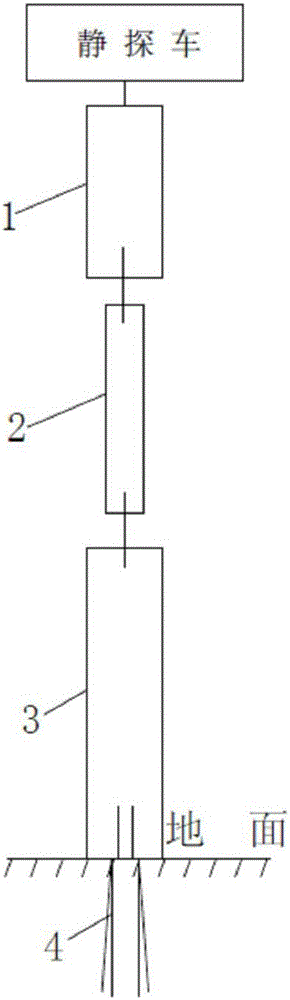

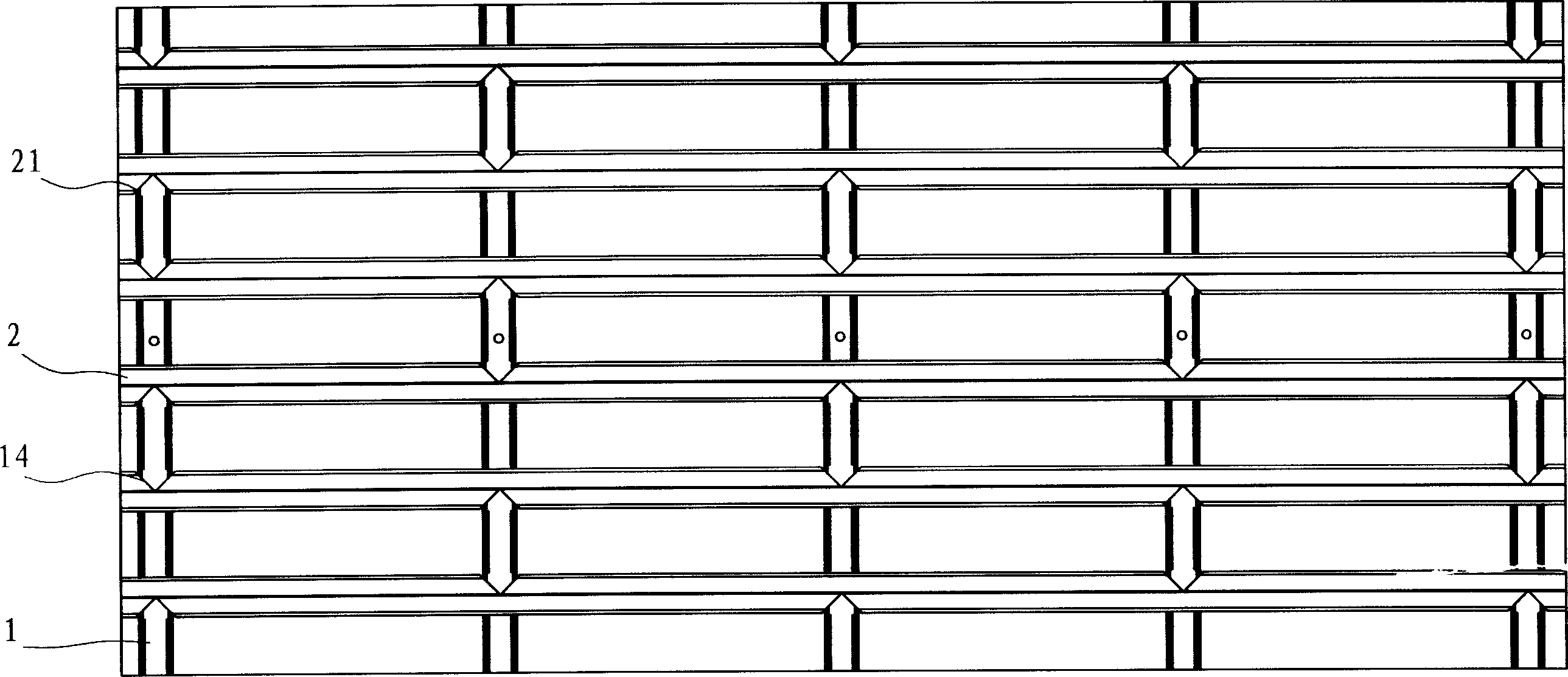

Joist frame for laying floor

The invention relates to a keel support used to lay floor, which comprises dual longitudinal main keels. Wherein, it is characterized in that: it comprises dual transverse keels that spanning each main keel; the distance between nearby transverse keels is the width of 1-4 blocks of floor, to form the frame with longitudinal main keel; the main keel is the section bar with upward opening, whose bottom is fixed with dual foots; the foot comprises base and horizontal adjuster; the adjusting element of horizontal adjuster, via the opening at the bottom of main keel, extends into the main keel; said transverse keel comprises horizontal support, strength bar at the bottom and the separate column protruded at the top; the clamp part of transverse keel to the main keel has clamp groove matched with the side wall of main keel; tow sides of separate column are arranged with the wedges of nearby two floors or the concave-convex structure. The invention can improve the laying quality and speed.

Owner:陈杰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com