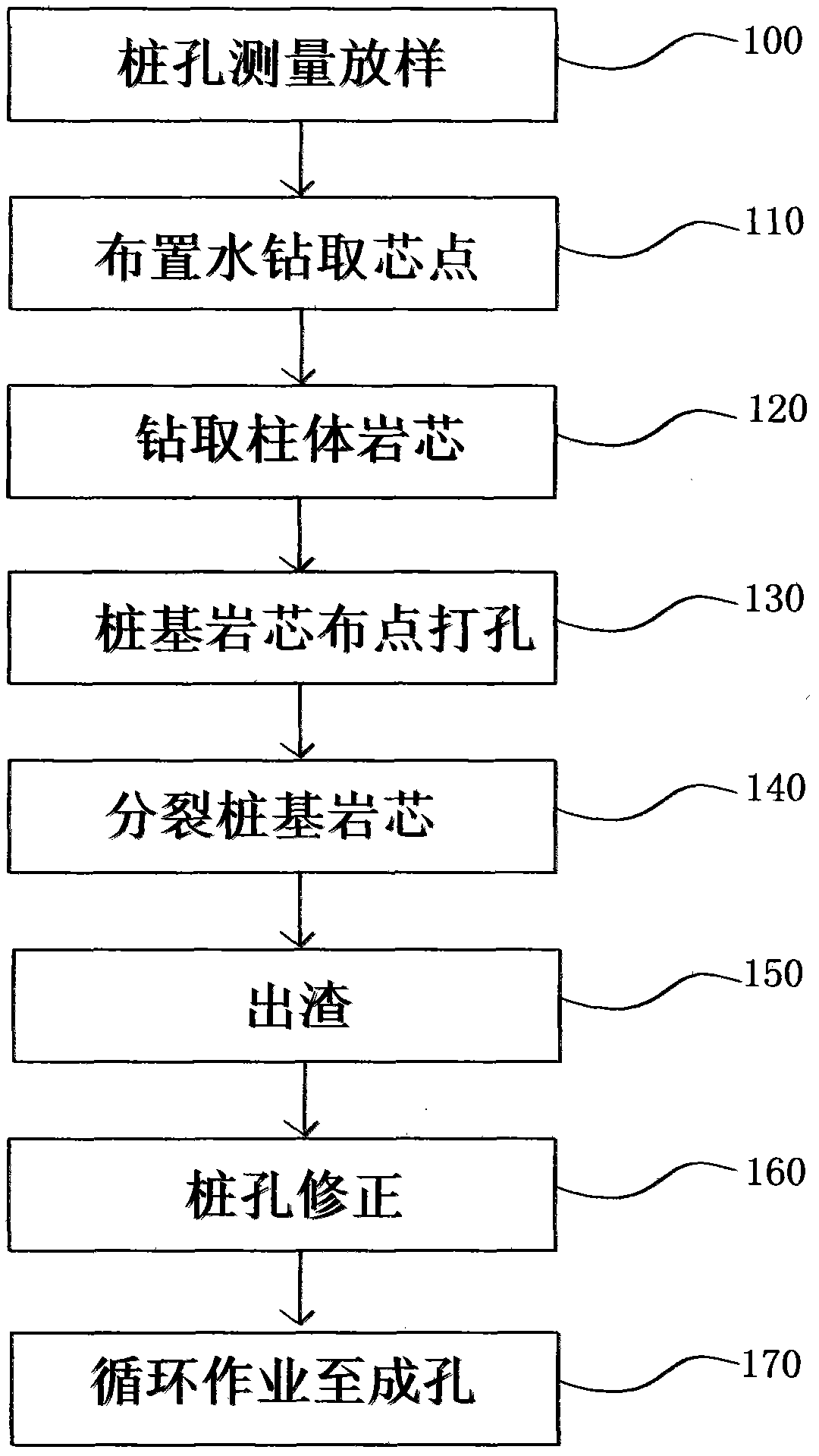

Water drill dug pile construction method

A construction method and technology of digging piles, which are applied in sheet pile walls, foundation structure engineering, erection/assembly of bridges, etc., to achieve the effects of fast construction progress, slow solution progress, and reduced labor cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

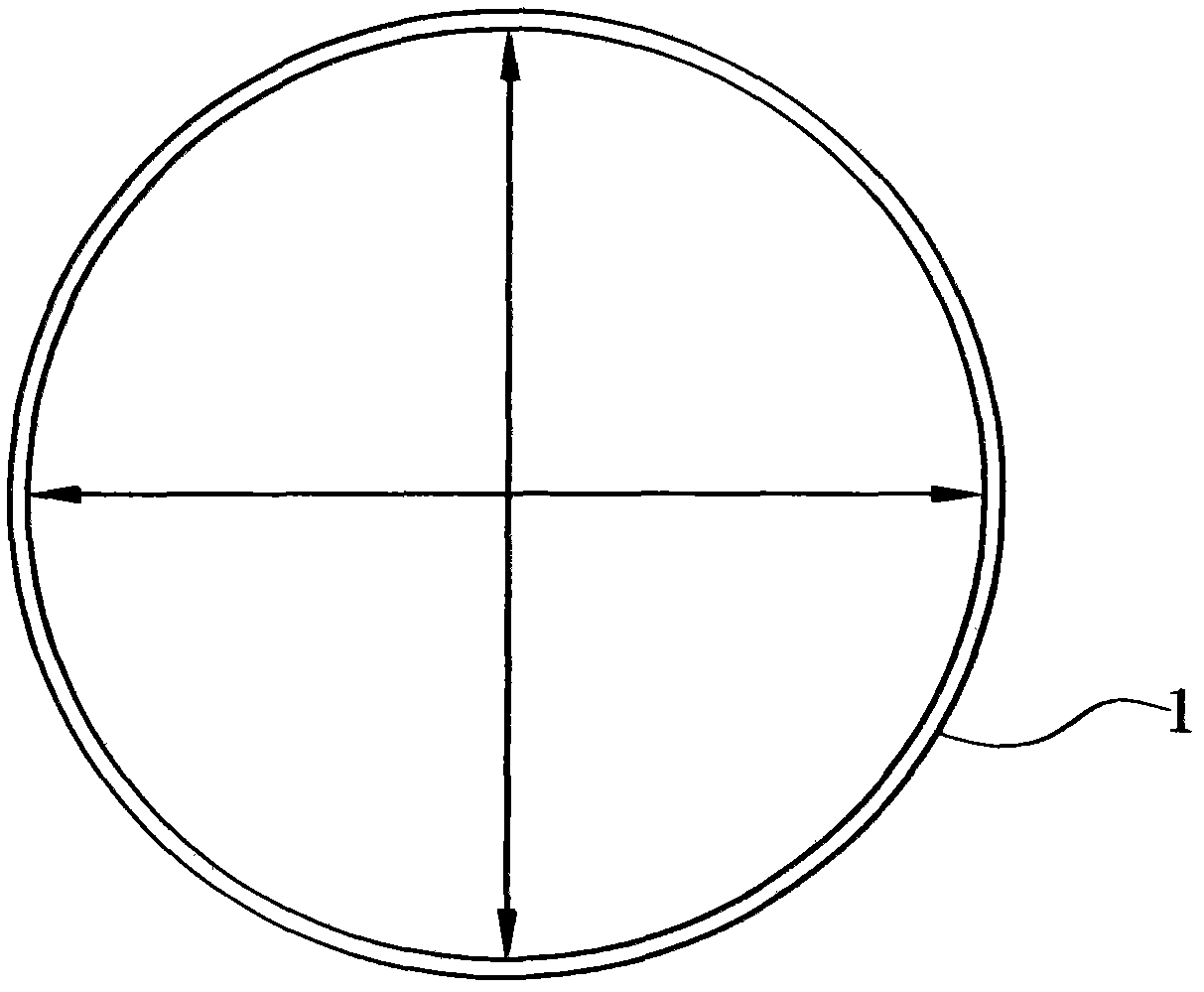

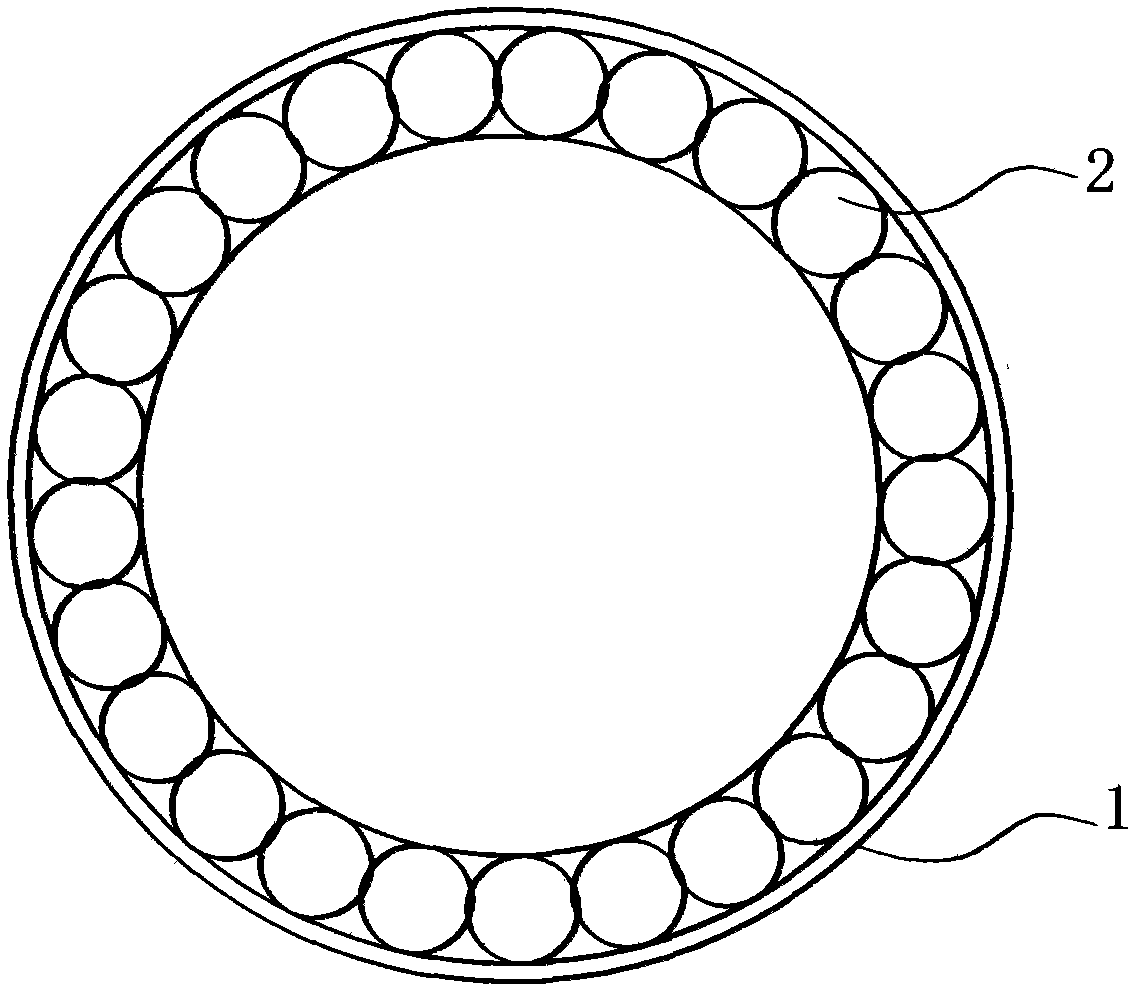

[0033] The construction method of the water drilling excavation pile proposed by the present invention adopts layered construction. When constructing each layer, first utilize the water drilling to drill some column cores of a certain height around the inner wall of the pile hole, so that the pile foundation core and the whole rock Separate to form a free surface, then use a hand drill to drill holes in the pile foundation core, insert steel wedges in the holes, and then hammer the steel wedges with a hammer, the steel wedges will give the pile foundation core a horizontal tension and shear force. Shear stress, when the horizontal tensile force and shear stress are greater than the ultimate tensile and shear stress of the rock, the core of the pile foundation will be cracked and sheared, split with the whole rock, and the broken rock will be cleared out of the pile hole , Correct the pile hole, and then proceed to the next layer of construction according to the same process, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com