Patents

Literature

146results about How to "Guaranteed movement accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

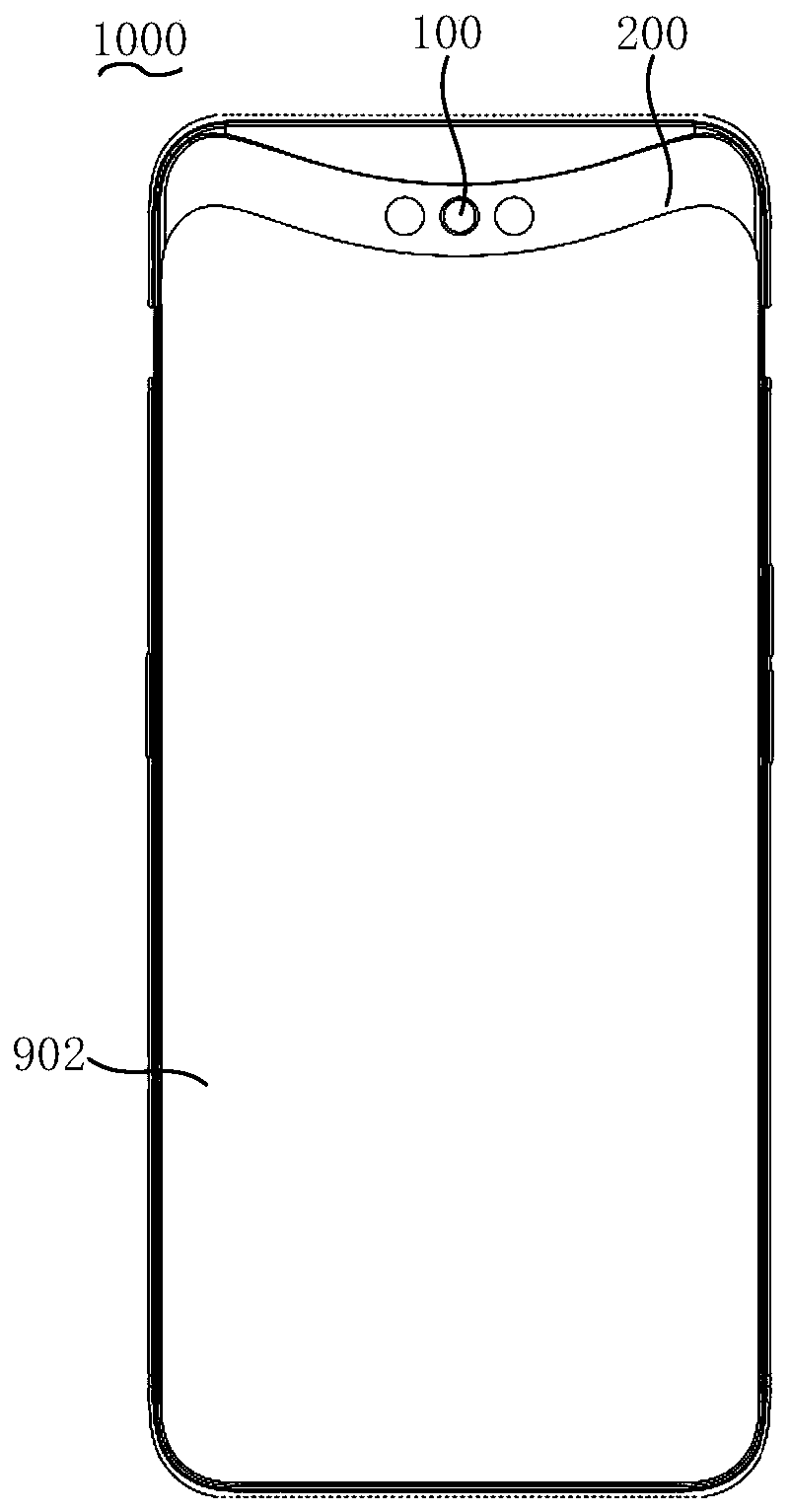

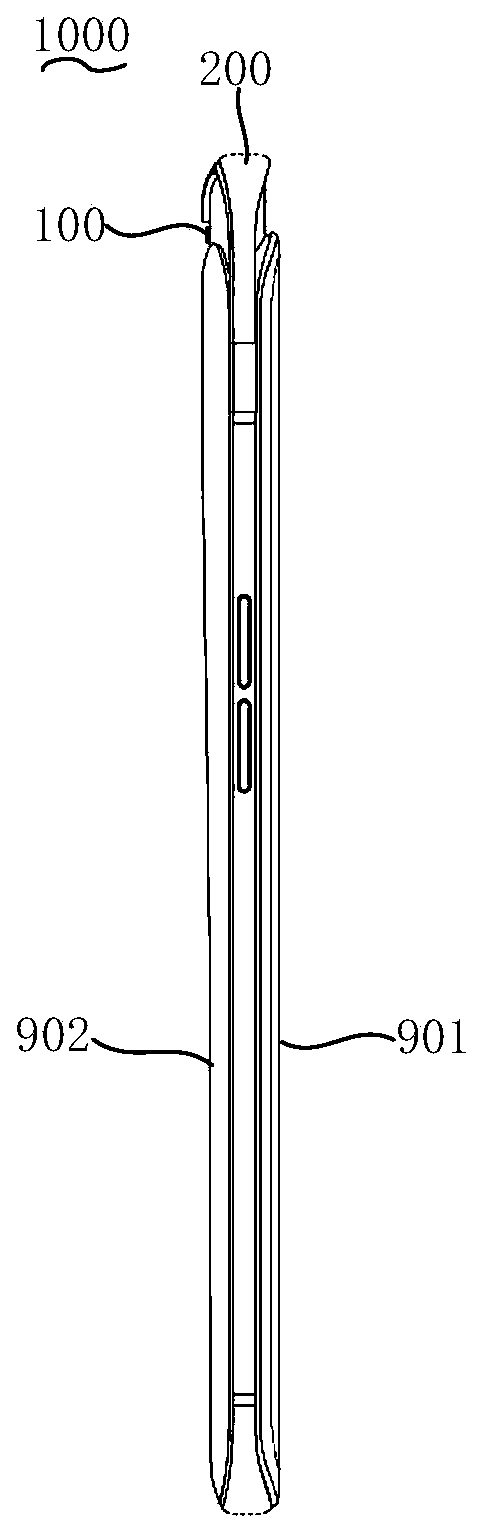

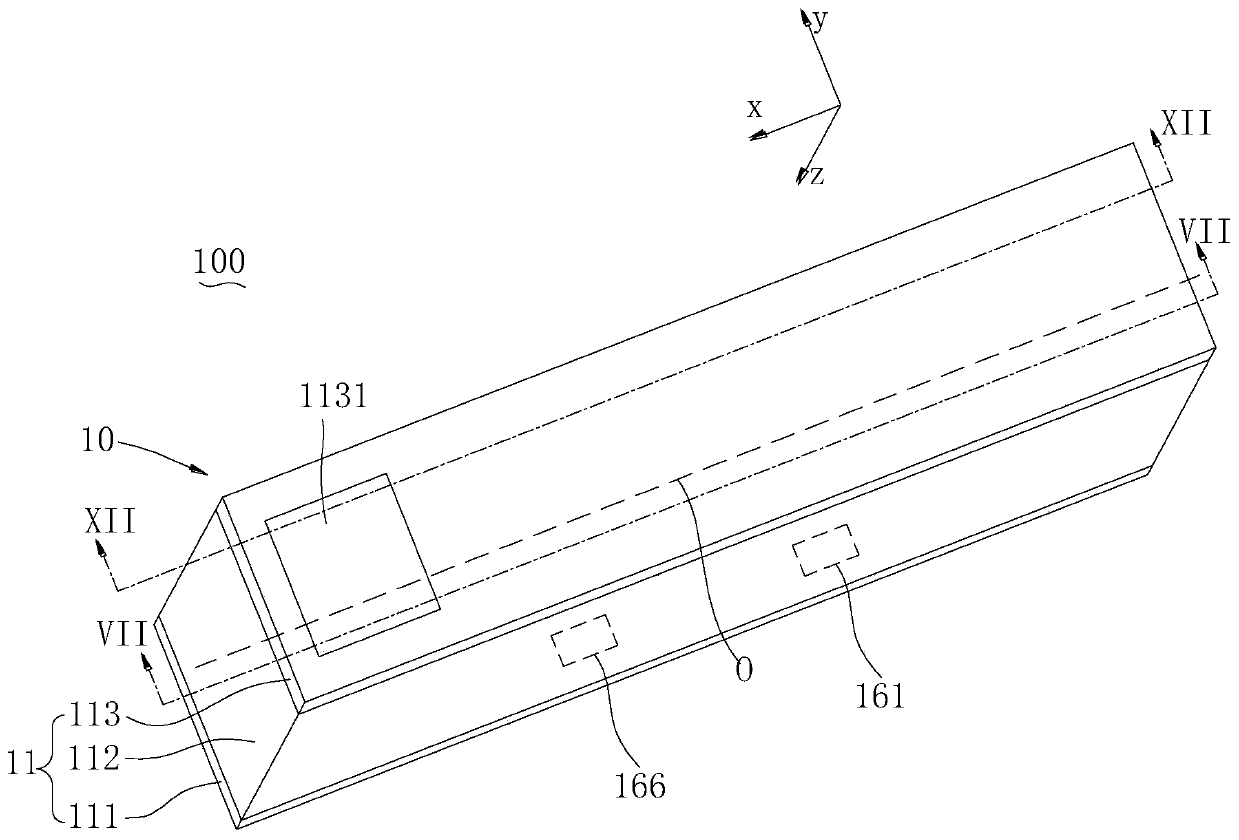

Zoom lens, camera module and electronic device

ActiveCN111158103ASmall effective control bitEffective control bitsProjector focusing arrangementCamera focusing arrangementOphthalmologyCamera module

The invention discloses a zoom lens, a camera module and an electronic device. The zoom lens comprises a shell, a first lens assembly, a second lens assembly, a third lens assembly and a first drivingchip. The first driving chip comprises a first control end, a second control end, a third control end and a fourth control end, and the first control end and the second control end respectively control the second lens assembly and the third lens assembly to move relative to the first lens assembly so as to realize zooming of the zoom lens; the third control end is used for controlling the third lens assembly to move relative to the first lens assembly under the first target focal length so as to realize focusing of the zoom lens; and the fourth control end is used for controlling the third lens assembly to move relative to the first lens assembly under the second target focal length so as to realize focusing of the zoom lens, and the first target focal length is different from the secondtarget focal length. According to the invention, under the condition that the effective control bits of the driving chip are few, focusing control is achieved through the independent control end of the zoom lens, and the focusing moving precision is guaranteed.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

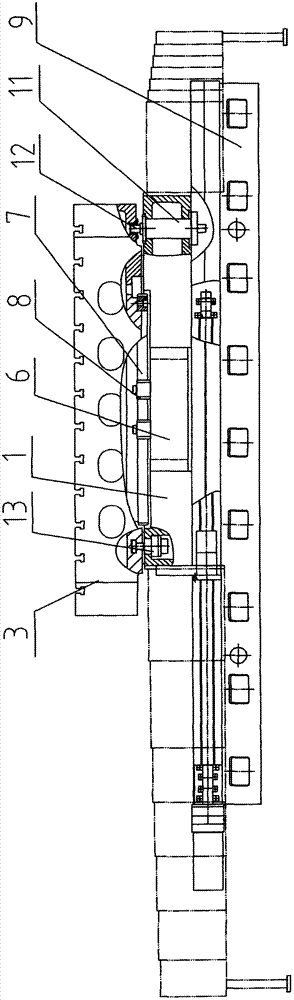

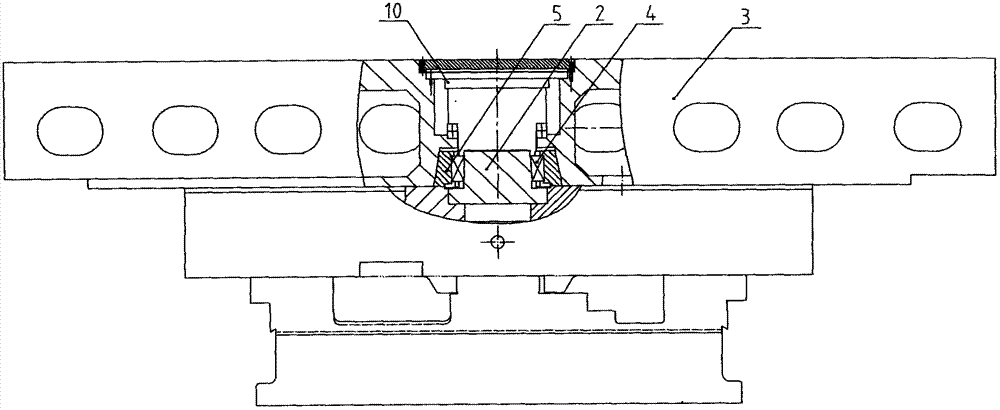

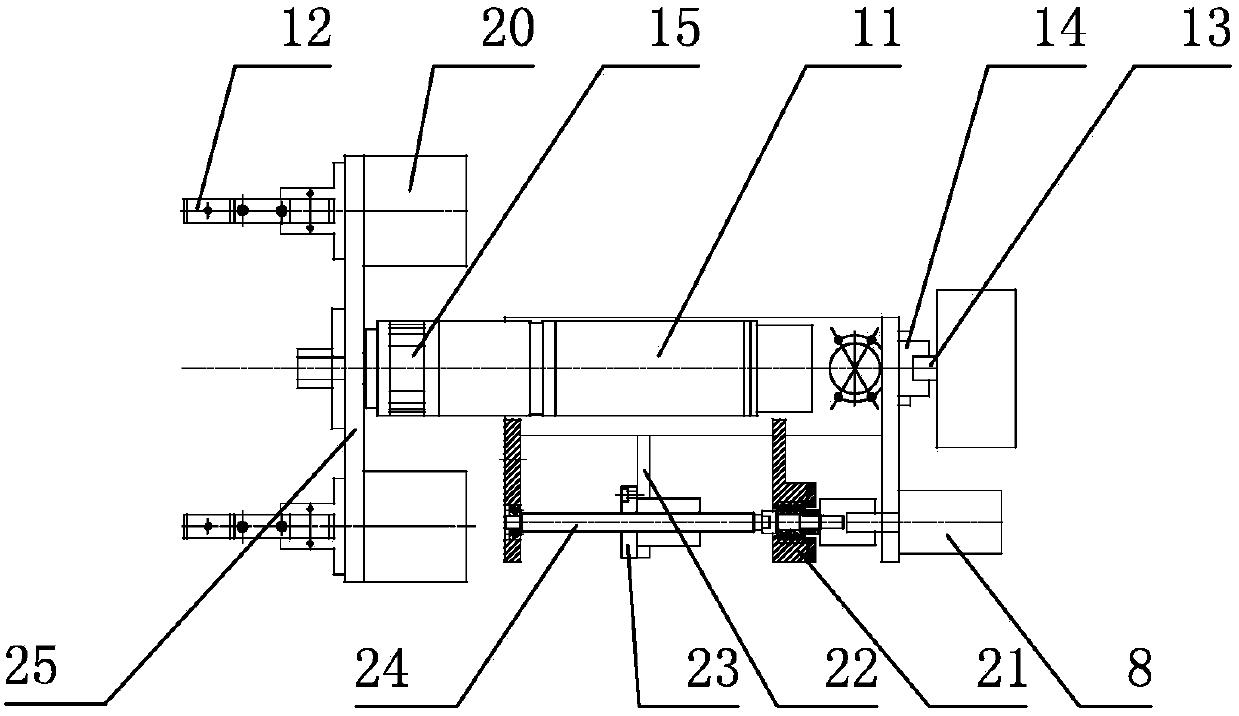

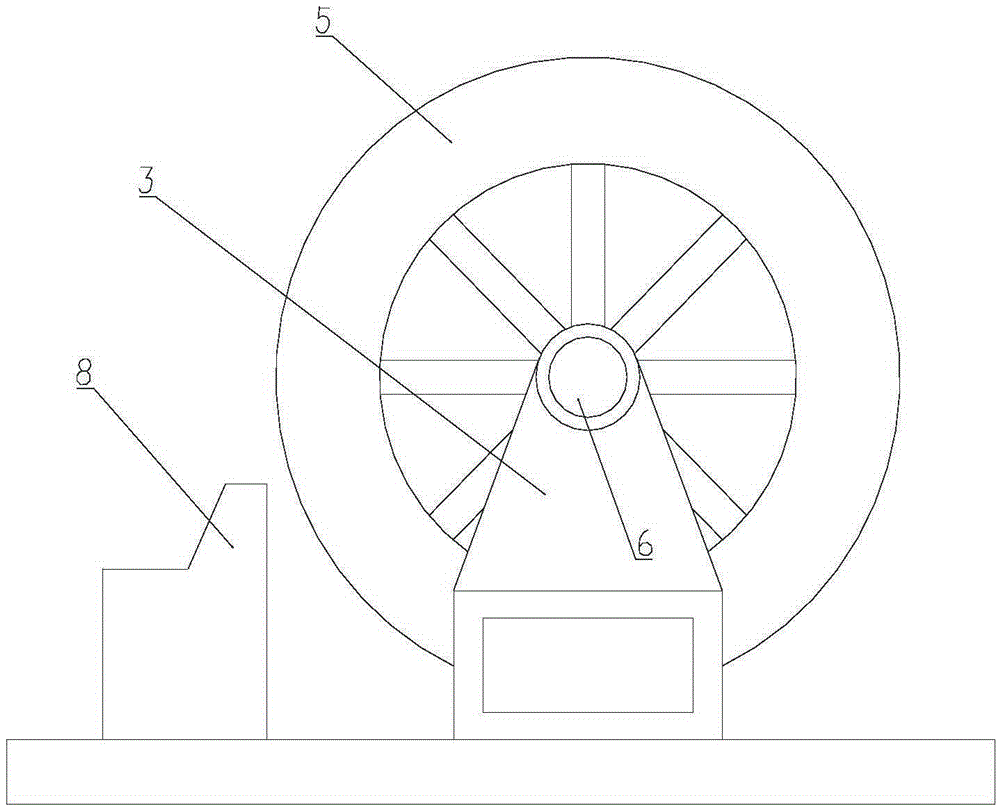

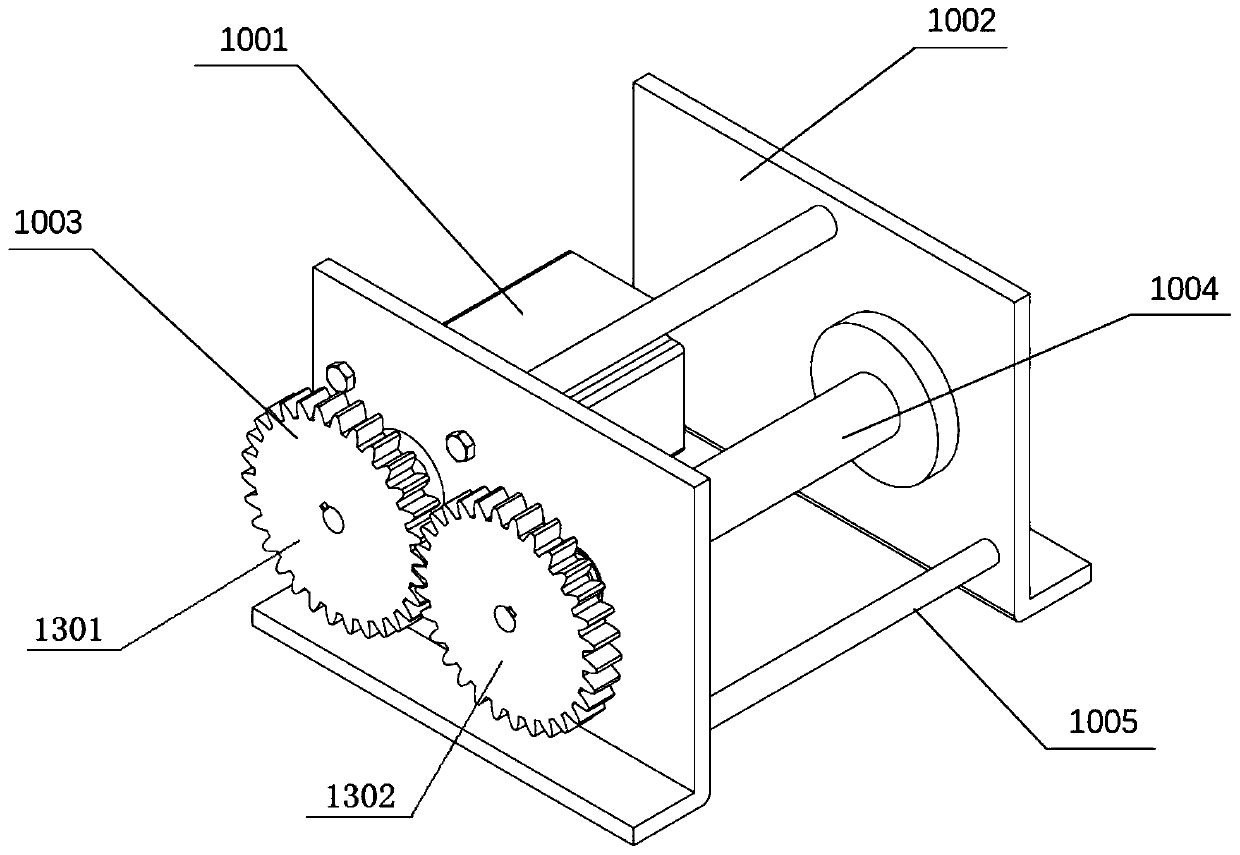

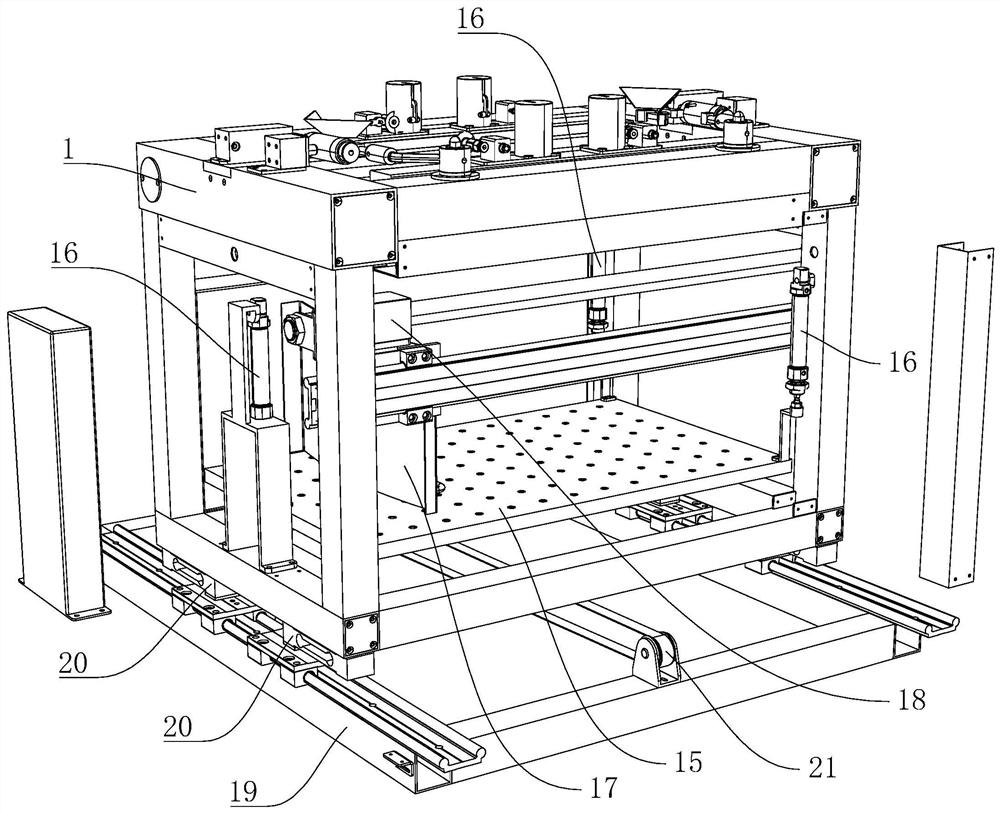

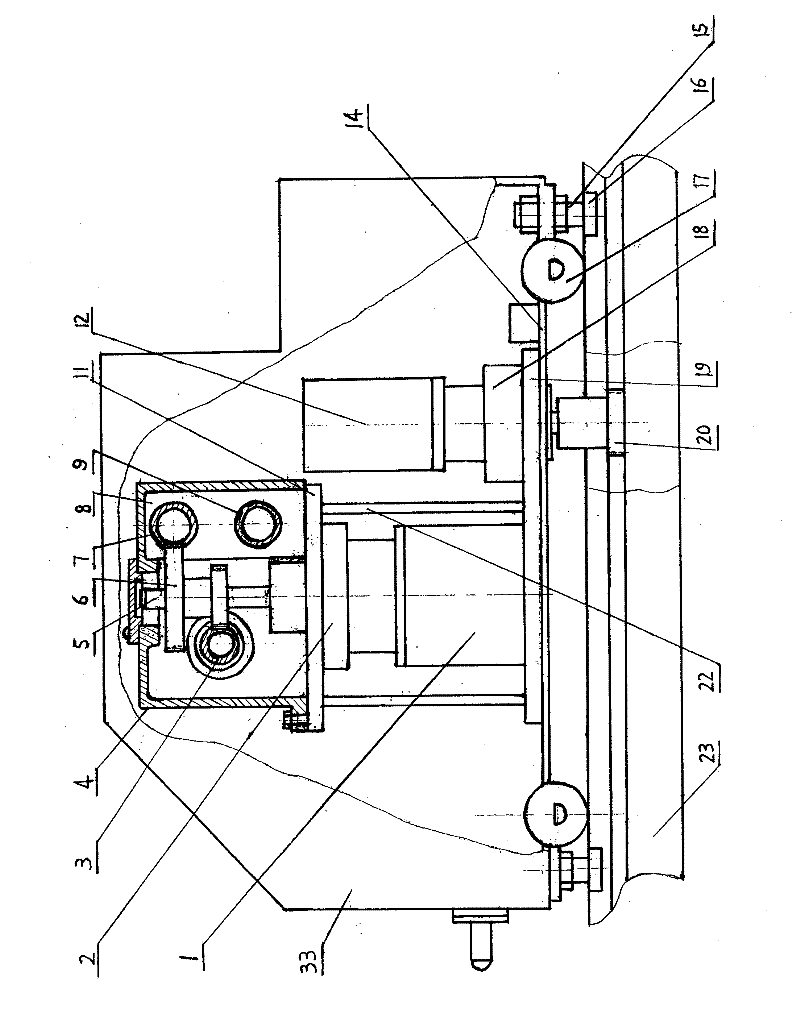

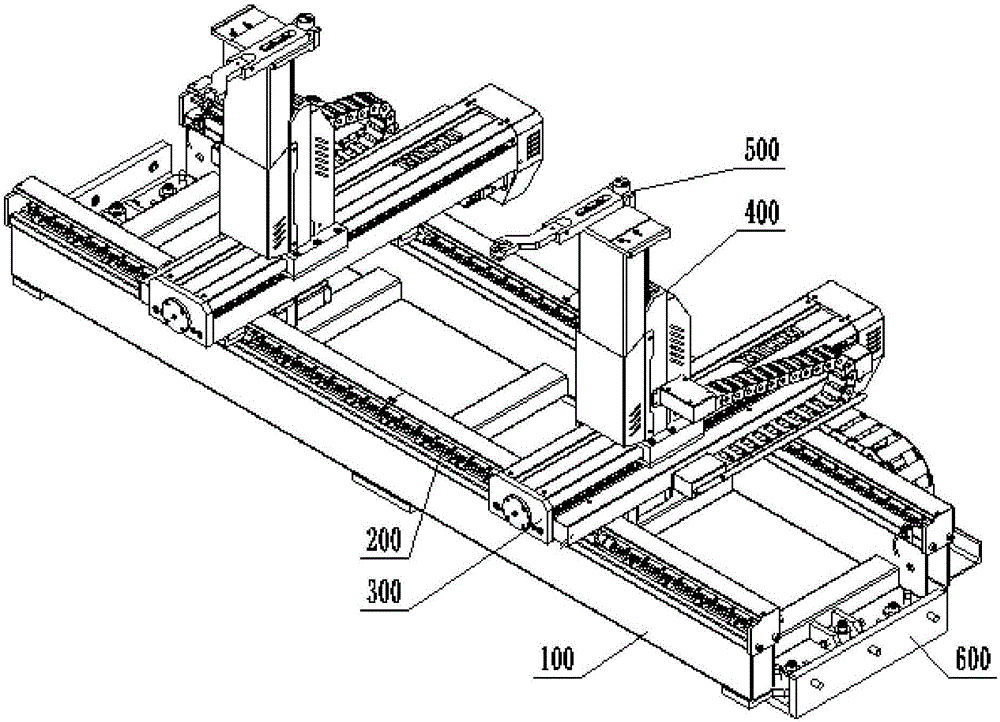

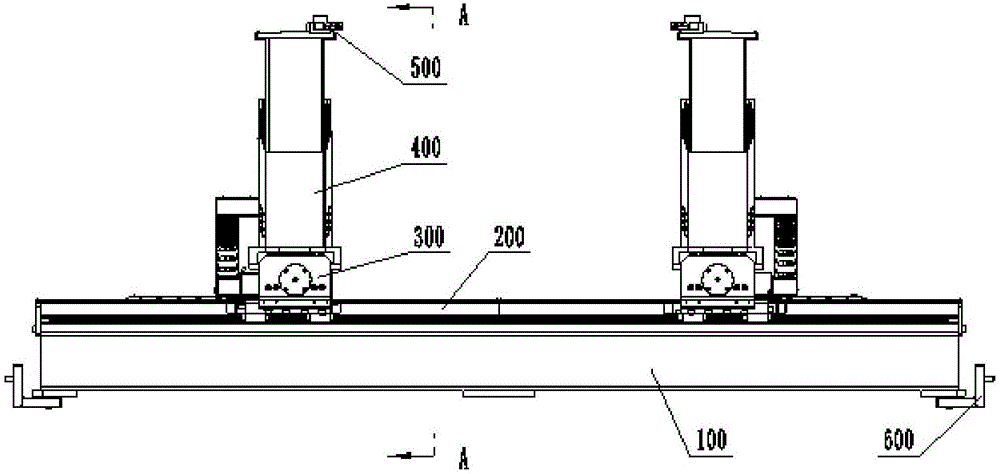

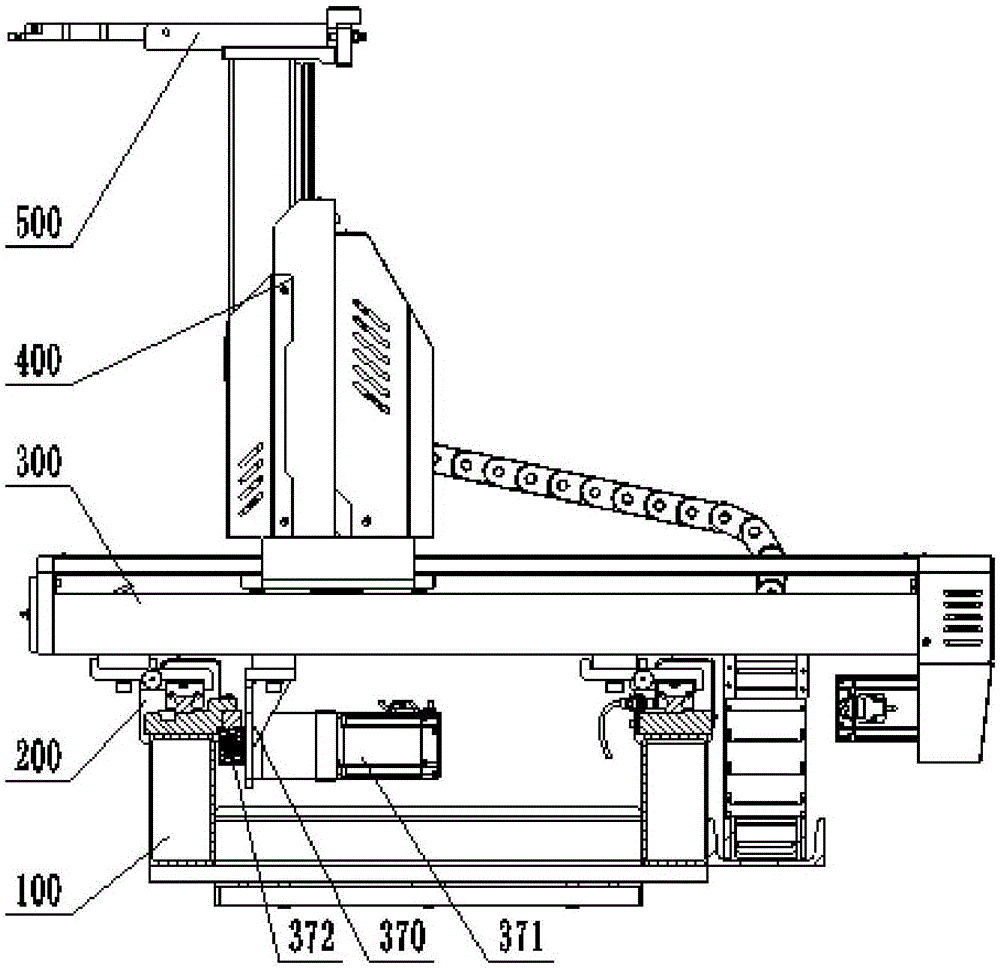

Rotary table for numerical control floor type boring miller

InactiveCN102773719AGuaranteed positioningGuaranteed positionLarge fixed membersNumerical controlGear wheel

The invention relates to a rotary table for a numerical control floor type boring miller. The rotary table comprises a rotary slide base, and a core shaft and a table top which are installed on the rotary slide base. The table top is installed on the rotary slide base through the core shaft; the rotary slide base is connected with a lead screw transmission mechanism used for driving the rotary slide base to move; a double-gear anti-backlash rotary mechanism is arranged between the rotary slide base and the table top, and is used for driving the table top to rotate; a rotary centering mechanism is arranged at the center of the table top, and comprises a two-line tapered roller bearing and a taper sleeve sheathed on the two-line tapered roller bearing; and the two-line tapered roller bearing is sheathed on the core shaft. The rotary table has the advantages that a backlash does not exist when the rotary slide base moves, so that the movement accuracy is high; and the backlash does not exist when the table top rotates, the rotary centering mechanism can guarantee the good centering performance of the rotary table when the load is large, the problem of rotary eccentricity is effectively solved, and the rotary table is positioned through a positioning air cylinder, so that the positioning performance of the table top is further guaranteed.

Owner:QINGDAO HUITENG MACHINERY EQUIP

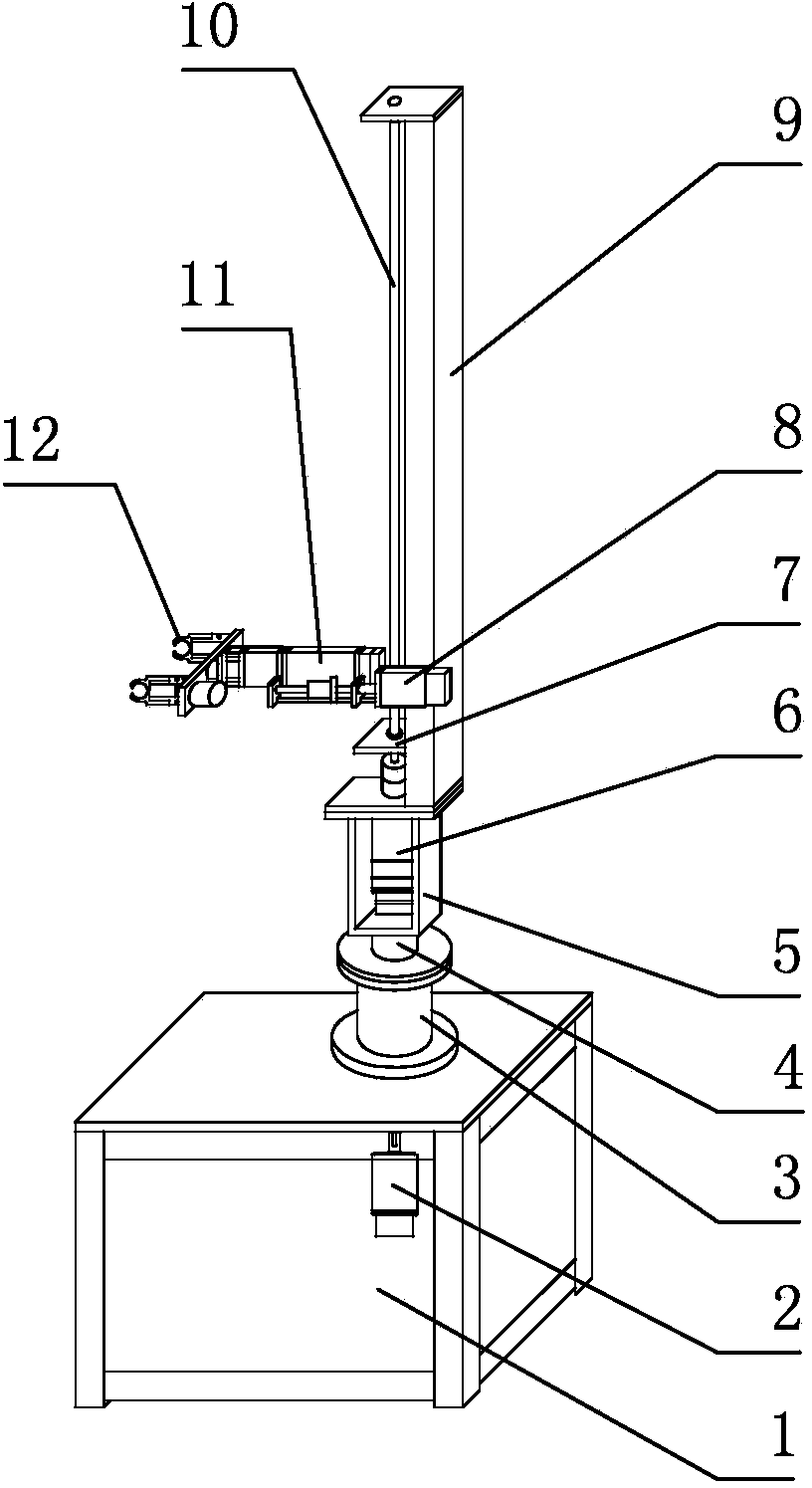

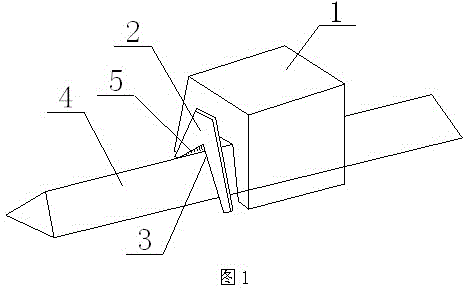

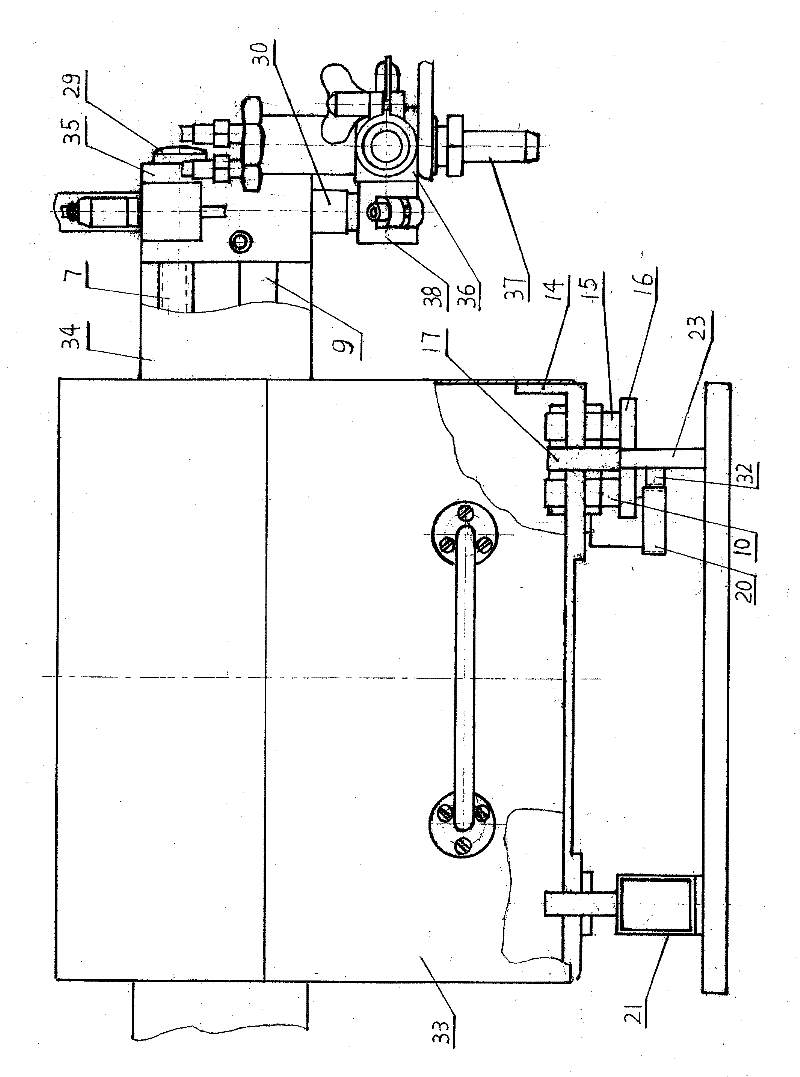

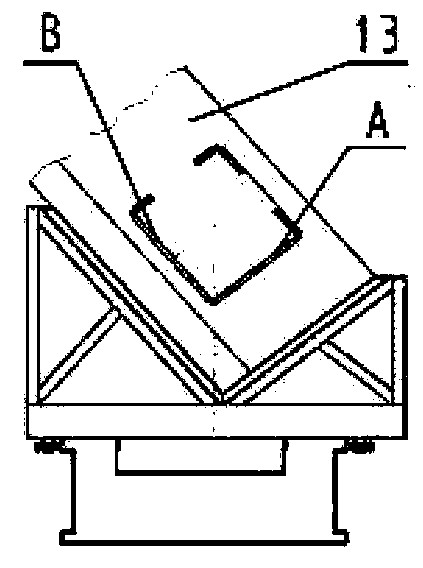

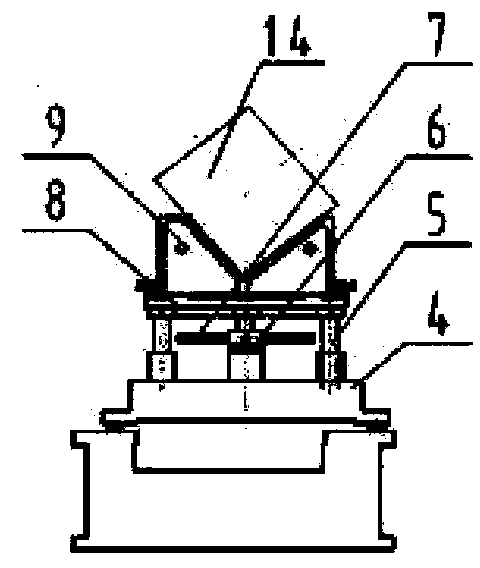

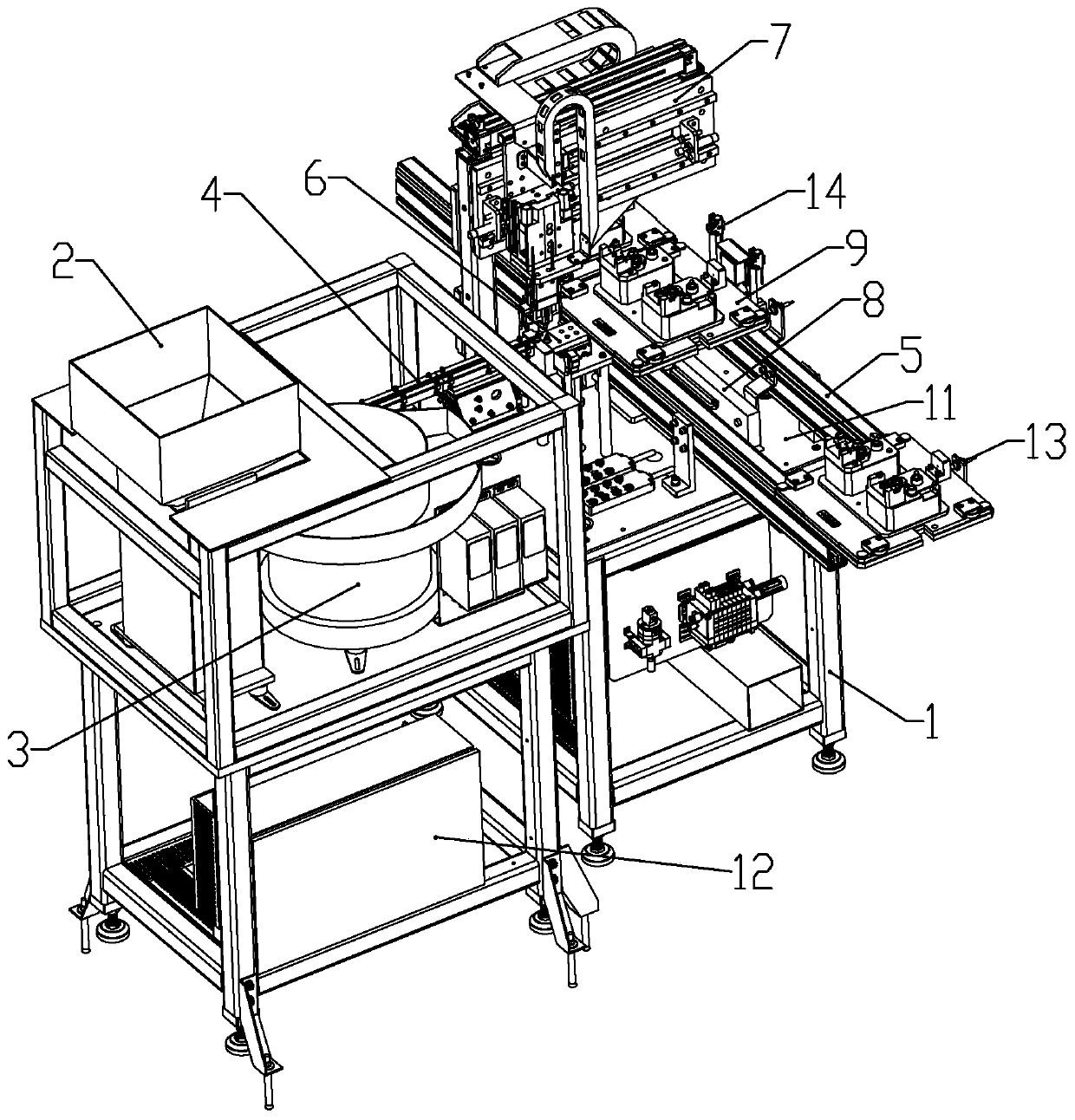

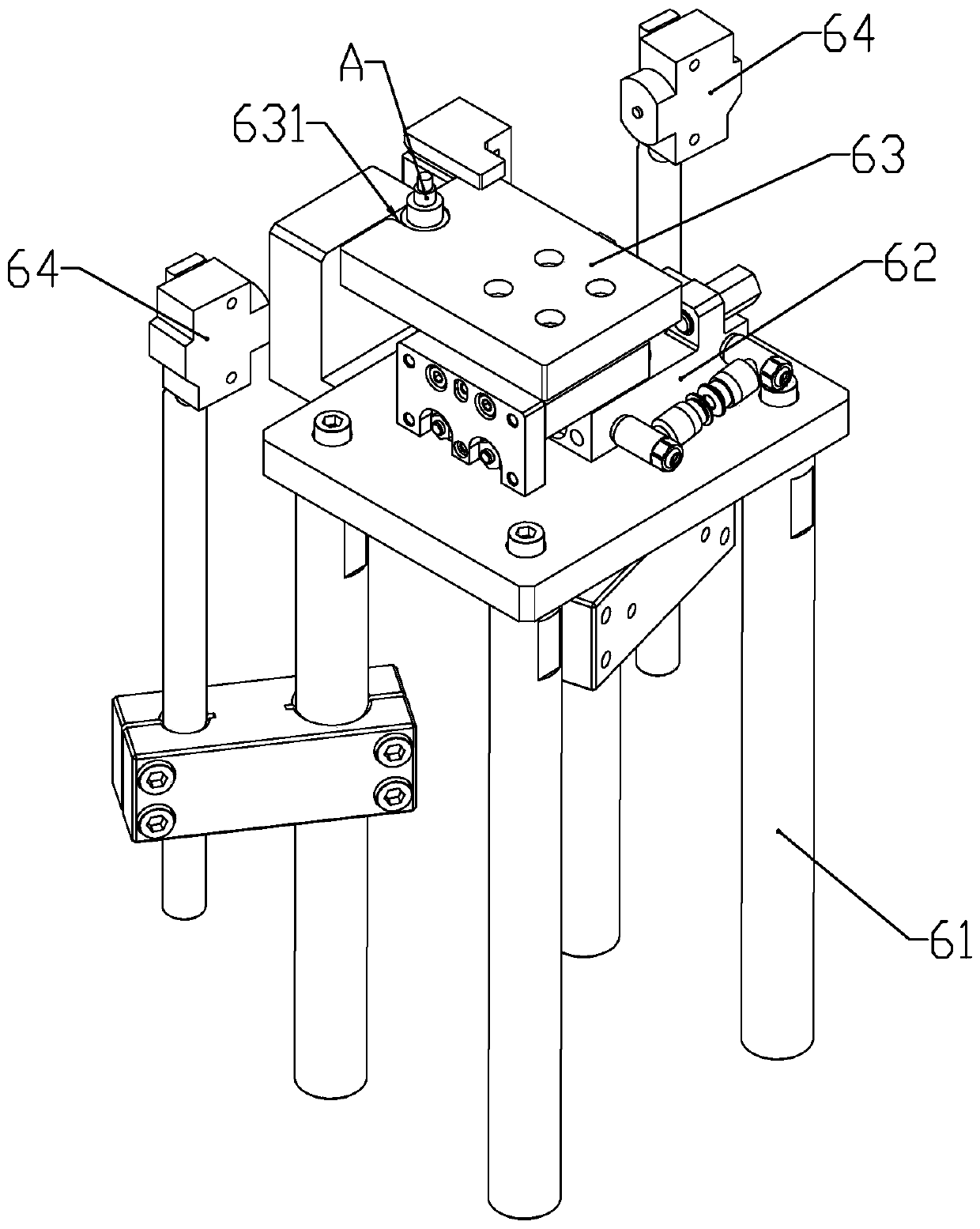

Automatic pipe insertion device

InactiveCN104176918AReduce labor intensitySmooth runningGlass reforming apparatusBottleUltimate tensile strength

The invention relates to an automatic pipe insertion device and in particular relates to an automatic pipe insertion device for matched pipe insertion of a glass pipe bottle making machine. The automatic pipe insertion device comprises a base box, a lifting rotary mechanism and a gripping mechanism, wherein the lifting rotary mechanism is mounted on the base box; the gripping mechanism is mounted on the lifting rotary mechanism and comprises a mechanical hand component and a forward pushing component; the mechanical hand component is connected with the lifting rotary mechanism through the forward pushing component. According to the automatic pipe insertion device, the pipe insertion operation of the bottle making machine can be automatically carried out, so that the working efficiency is improved, the labor intensity of workers is reduced, and the safety is high.

Owner:BOSHAN VACUUM EQUIP IND

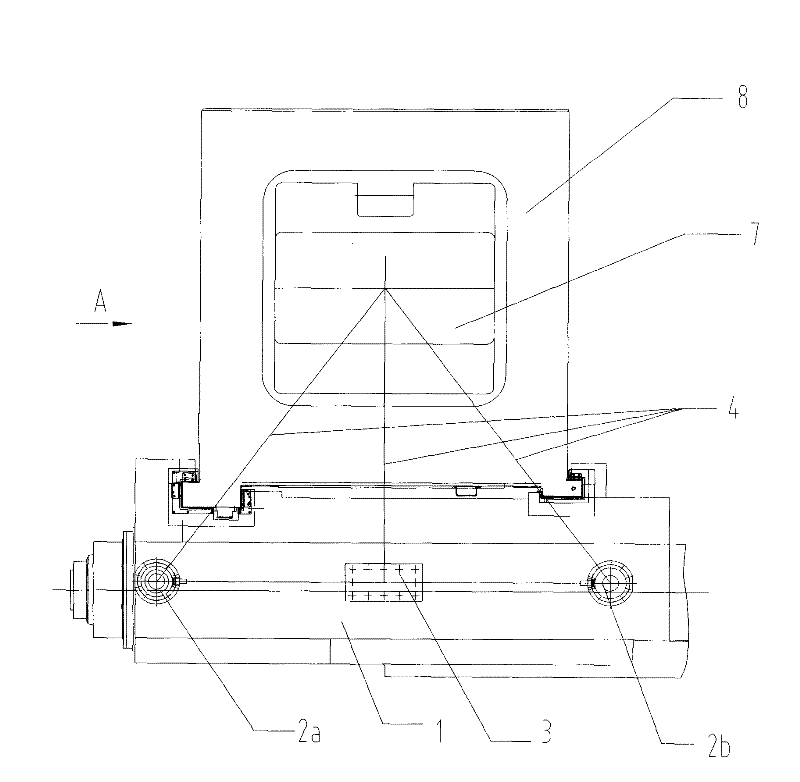

Balance compensation structure and mode for three hanging points of spindle box

ActiveCN102248183AControl outlet pressureGuaranteed levelOther manufacturing equipments/toolsBoring/drilling componentsElectro hydraulicEngineering

The invention belongs to a balance compensation structure and a balance compensation mode suitable for a spindle box of a numerical control milling and boring machine with a ram. The balance compensation structure mainly comprises a balance and tilt compensation unit and a spindle box three-hanging-point mechanism, wherein the spindle box is provided with front, middle and rear hanging points; the three hanging points are connected with the gravity center of a balance weight through a connecting rope and a pulley group; compensation oil cylinders are arranged at the front and rear hanging points; and an oil circuit control device consisting of an electro-hydraulic proportional valve, a hydraulic control one-way valve and an electromagnetic reversing valve is arranged in front of each compensation oil cylinder. The balance compensation mode is that: a numerical control system measures the working condition of the ram in real time, and oil pressure in each oil cylinder is controlled by the electro-hydraulic proportional valve. By the balance compensation structure and the balance compensation mode, the inclination of the spindle box can be corrected in real time, the structure, the process and control are simple, and the movement accuracy of the ram of the milling and boring machine and the machining accuracy of a workpiece are ensured.

Owner:WUHAN HEAVY MACHINE TOOL GRP

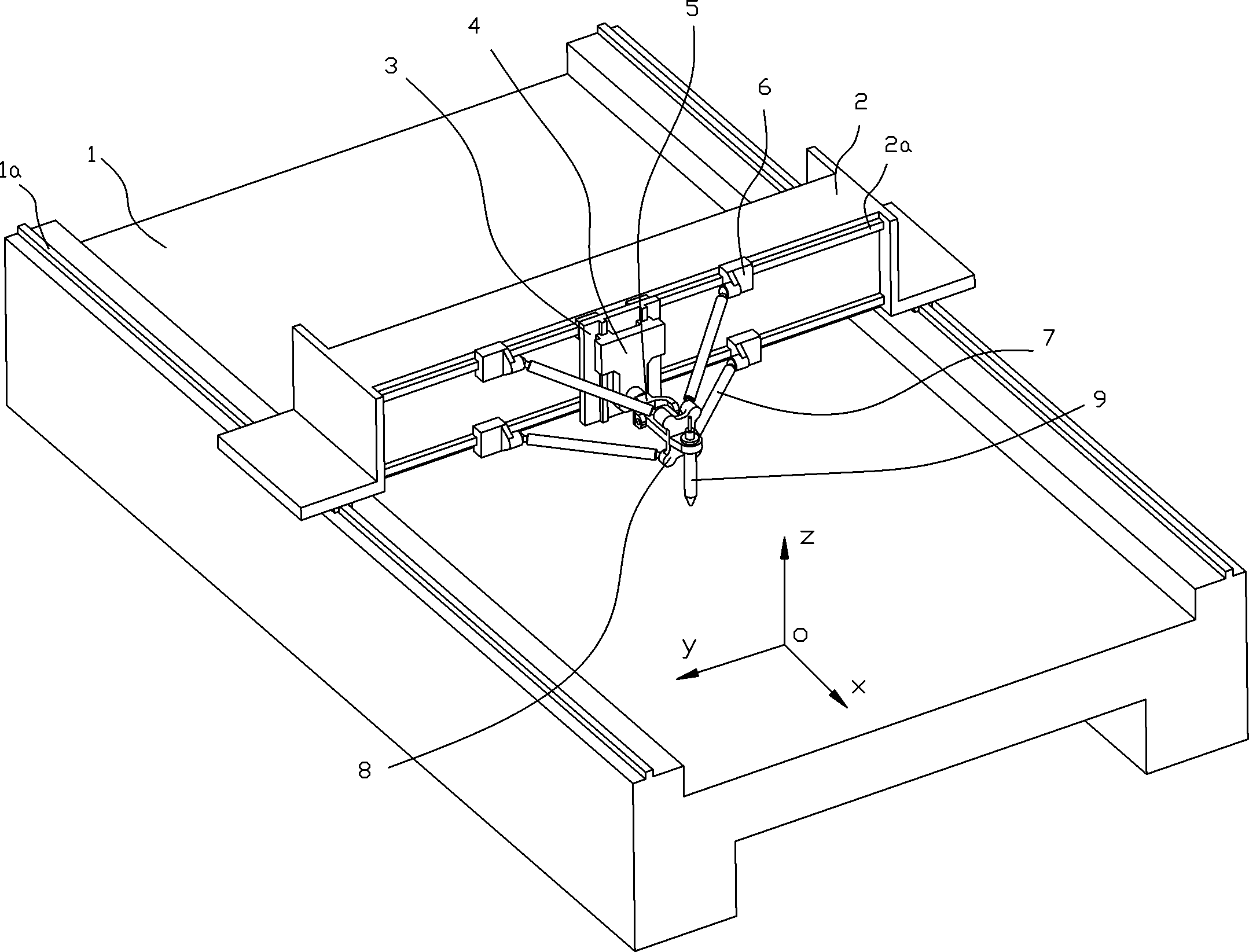

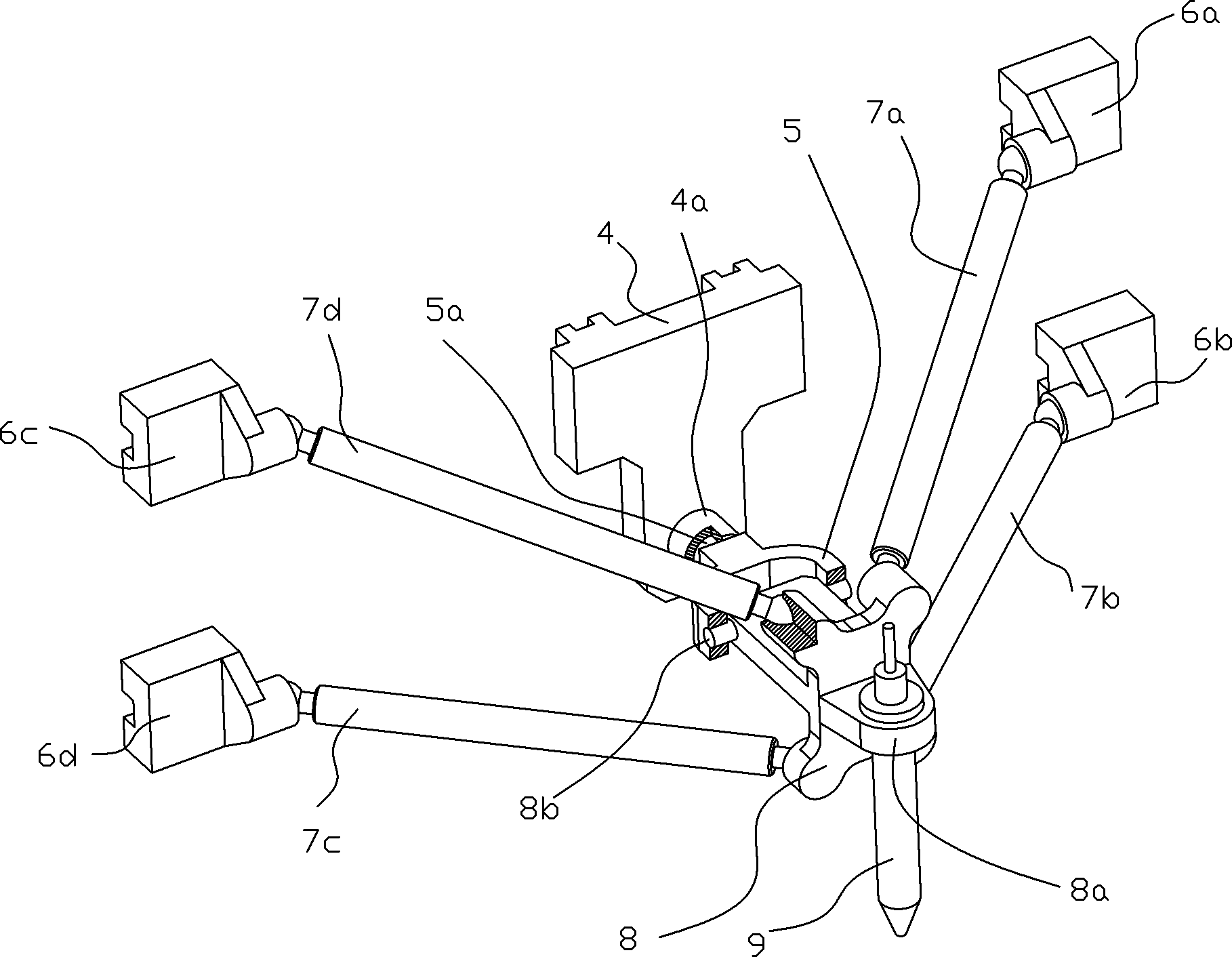

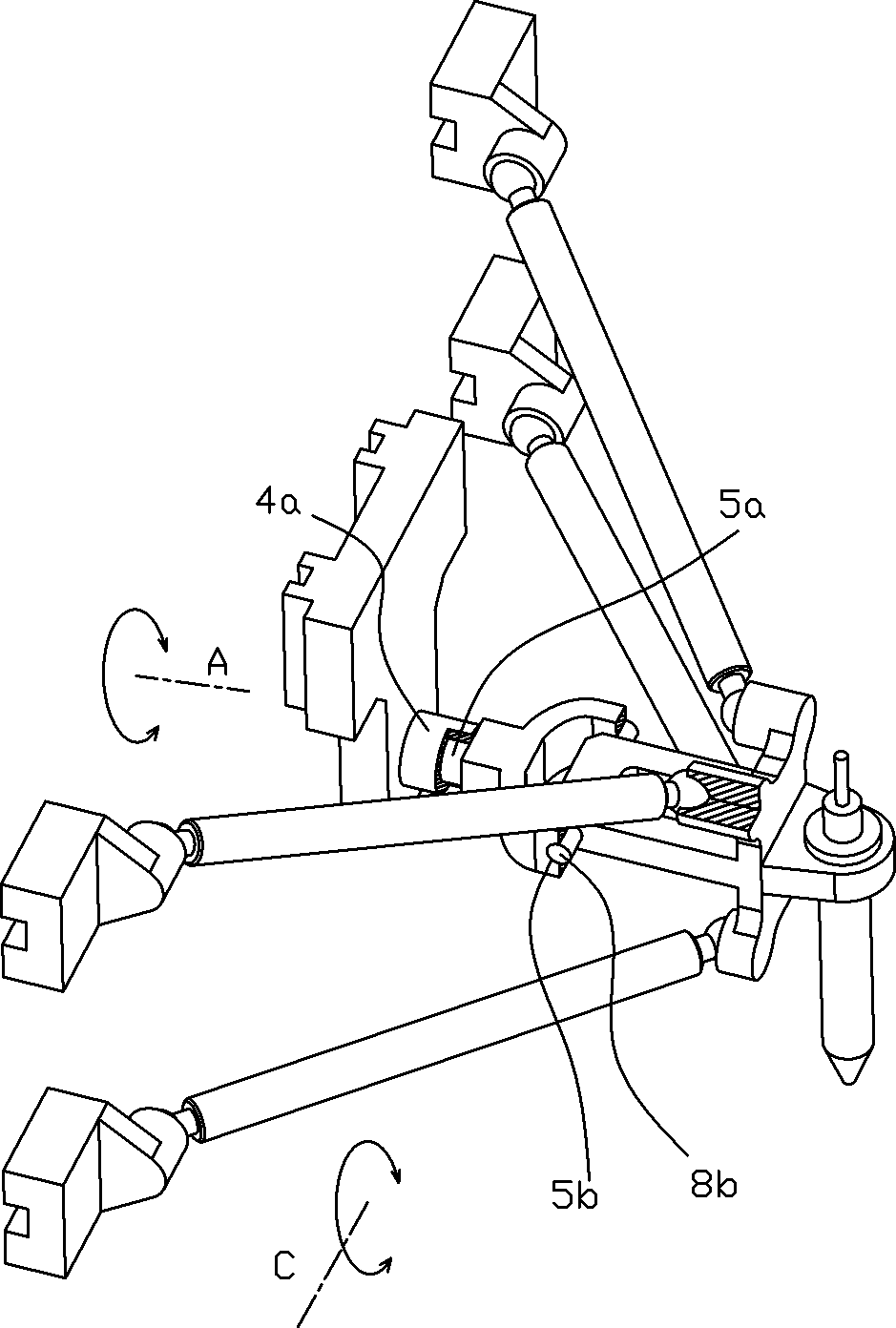

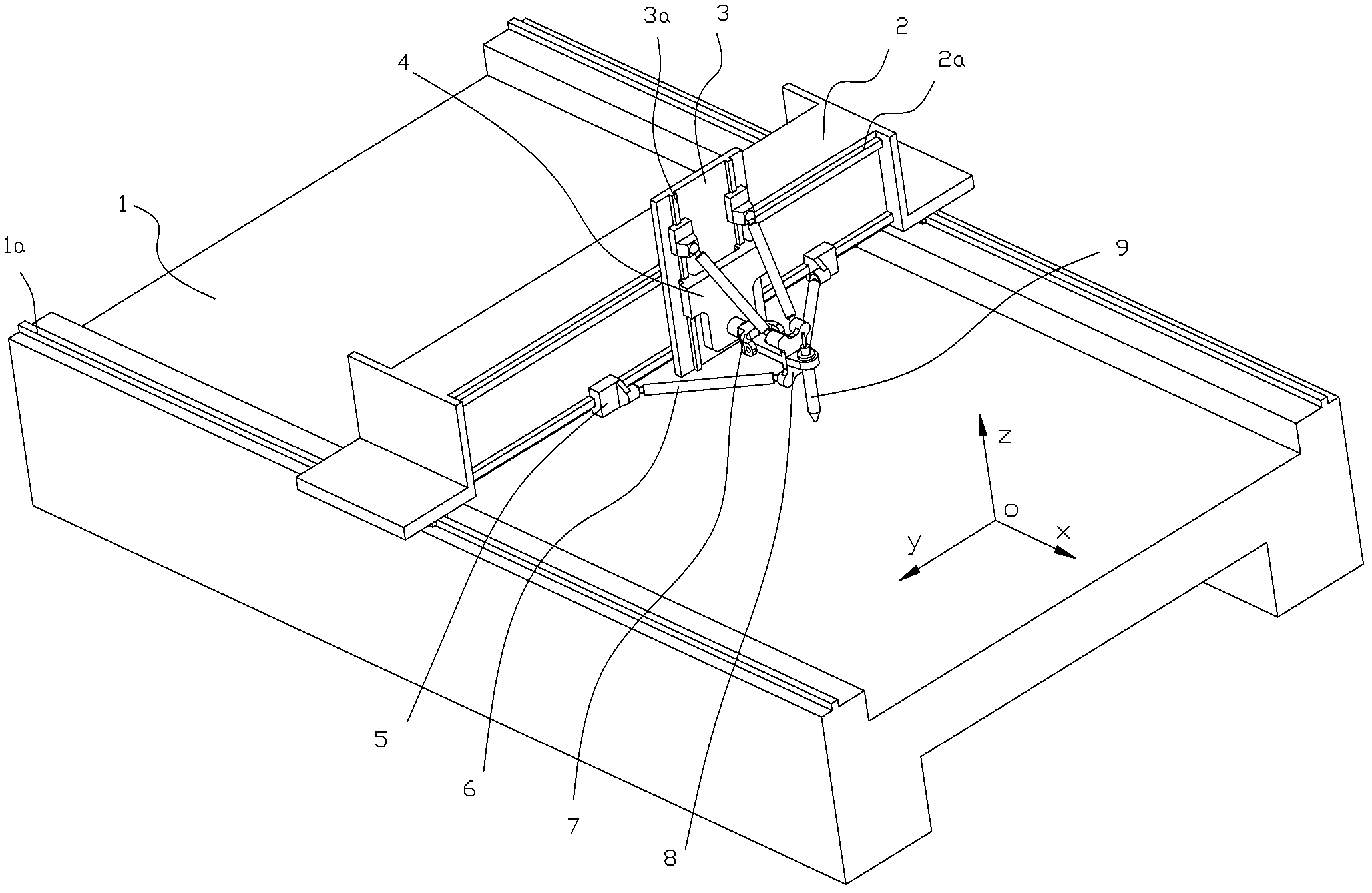

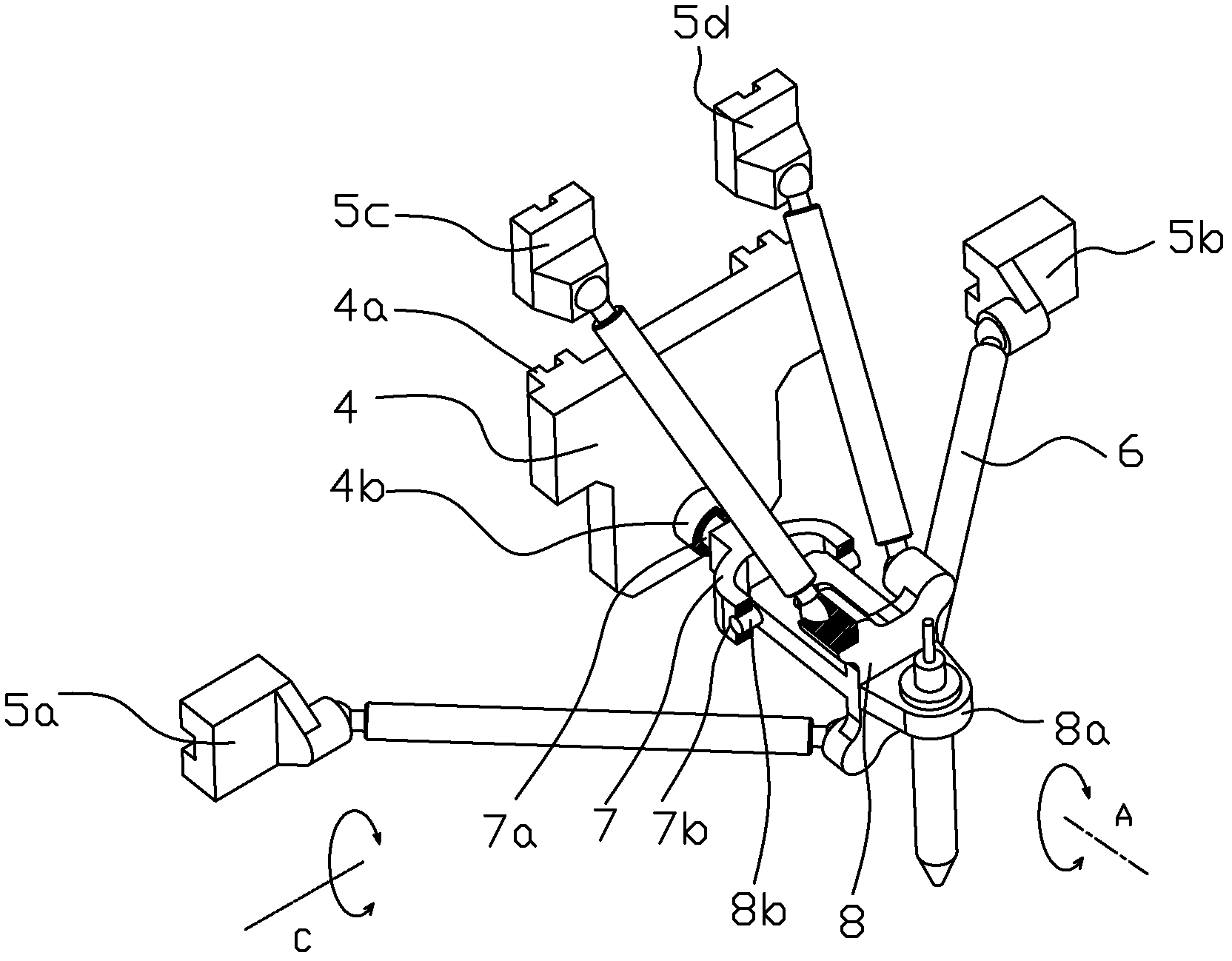

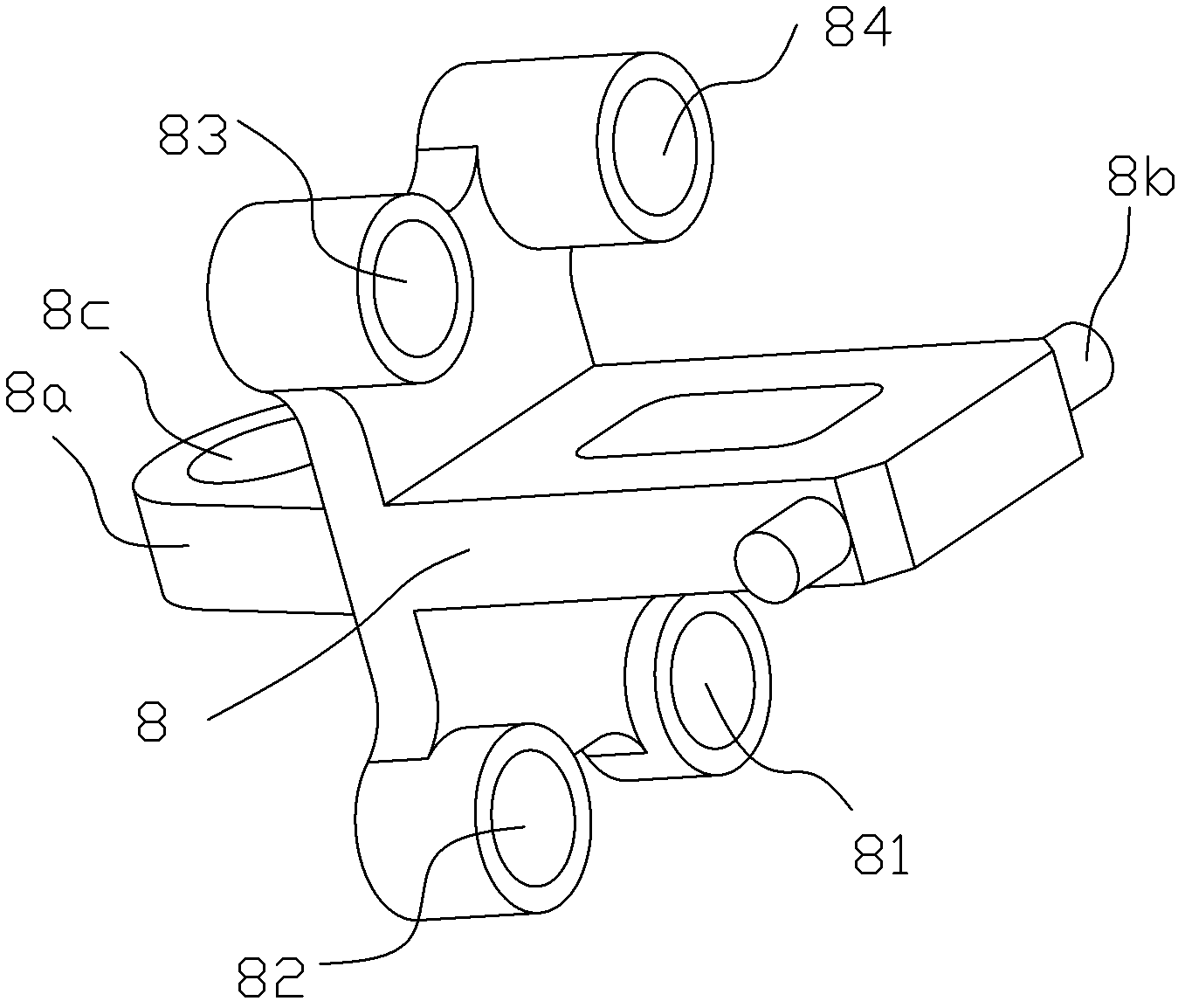

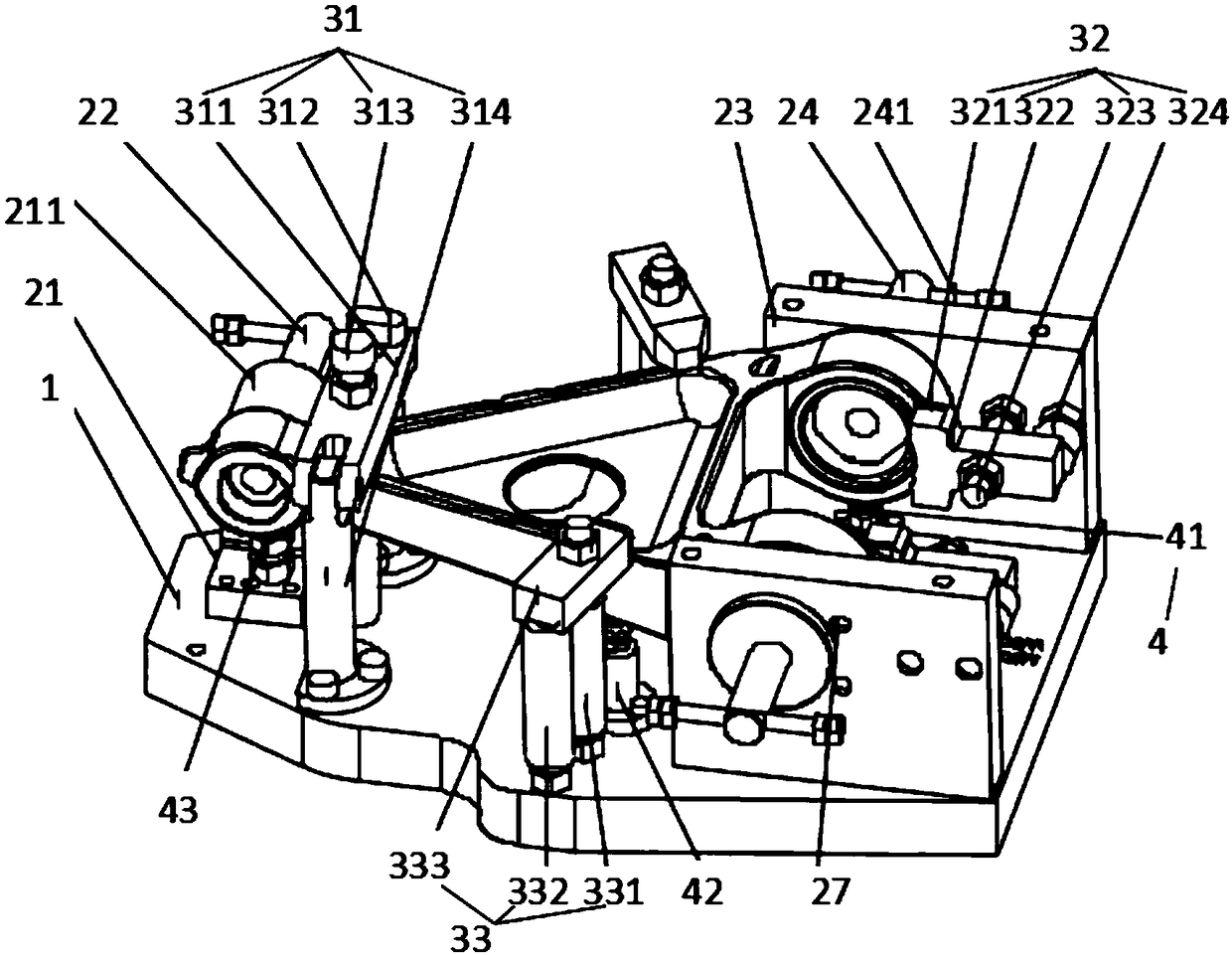

Imperfect degree-of-freedom parallel connection five-axis computerized numerical control laser cutting machine

ActiveCN102303186ARealize Joint MovementSmart structureLaser beam welding apparatusNumerical controlLaser cutting

The invention discloses an imperfect degree-of-freedom parallel connection five-axis computerized numerical control laser cutting machine, relating to a laser cutting machine with an imperfect degree-of-freedom parallel connection five- axis drive mechanism. The laser cutting machine comprises a machine body, an X-direction guide rail, a beam, a laser cutting heat and a controller, wherein the side surface of the beam is provided with a Y-direction guide rail, the laser cutting head is movably connected with the Y-direction guide rail through an imperfect degree-of-freedom parallel connectionmechanism; and the imperfect degree-of-freedom parallel connection mechanism comprises a Y-axis slide carriage device, a Z-axis slide carriage device, a cross, a laser head installing support, four equilong connecting rods and four linear driving devices. The invention realizes five-axis motion of the conventional laser cutting head through the imperfect degree-of-freedom parallel connection device, wherein the beam realizes basic X-direction motion relative to the motion of the machine body; four drive blocks respectively move and drive the laser heat installing support to make translation or rotation motion through respective connecting rods, mutual motion among the four drive blocks realizes combined motion of an Y axis, a Z axis, an A axis and a C axis; and the imperfect degree-of-freedom parallel connection five-axis computerized numerical control laser cutting machine has skilled structures of all parts, large rigidity and small inertia, so that the motion precision can be ensured.

Owner:江苏扬力数控机床有限公司

Three-dimensional five-axis computerized numerical control laser cutting machine

ActiveCN102303187AAvoid spatial symmetryImprove rigidityLaser beam welding apparatusNumerical controlLaser cutting

The invention discloses a three-dimensional five-axis computerized numerical control laser cutting machine, relating to a computerized numerical control laser cutting machine with a composite motion parallel connection five-axis drive mechanism, which comprises a machine body, an X-direction guide rail, a beam, a laser cutting head and a controller, wherein the side surface of the beam is provided with a Y-direction guide rail, and the laser cutting head is movably connected with the Y-direction guide rail on the side surface of the beam through a composite motion parallel connection mechanism. The invention realizes five-axis motion of the conventional laser cutting head through the composite motion parallel connection device, wherein the beam realizes basic X-direction motion relative to the motion of the machine body; and combined motion of an Y axis, a Z axis, an A axis and a C axis is realized through the composite motion parallel connection mechanism. The three-dimensional five-axis computerized numerical control laser cutting machine has an ingenious design, skilled structures of all parts, large rigidity and small inertia, so that the motion precision can be ensured. The three-dimensional five-axis computerized numerical control laser cutting machine integrates a lathe technology, a robot technology and a computerized numerical control technology, and has the advantages of simple structure and complex and accurate arithmetical operation in comparison with the traditional serial connection lathe. The three-dimensional five-axis computerized numerical control laser cutting machine has the remarkable advantages of large rigidity, rapid response speed, high precision, strong adaptability, high technical additional value and the like.

Owner:江苏扬力数控机床有限公司

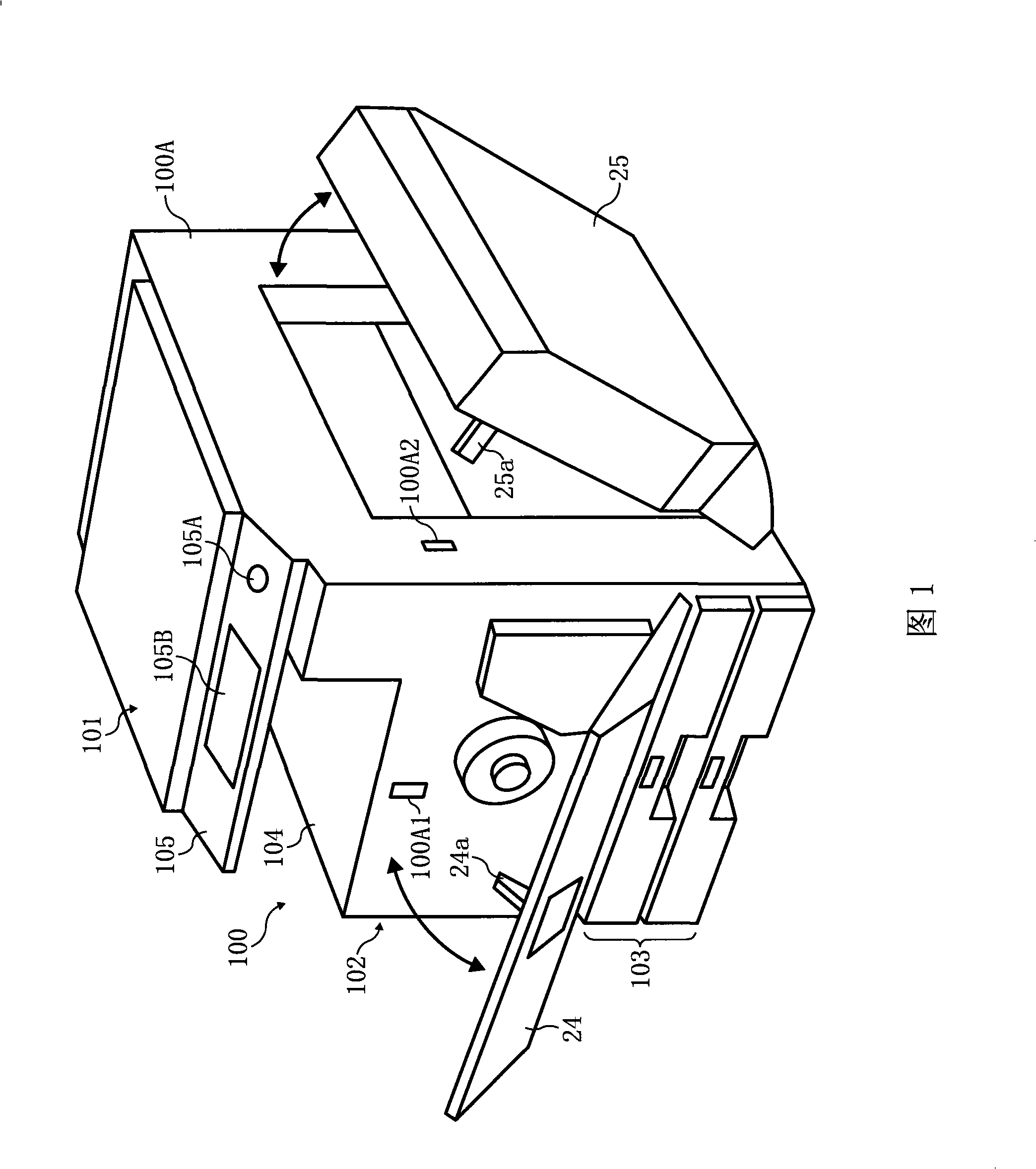

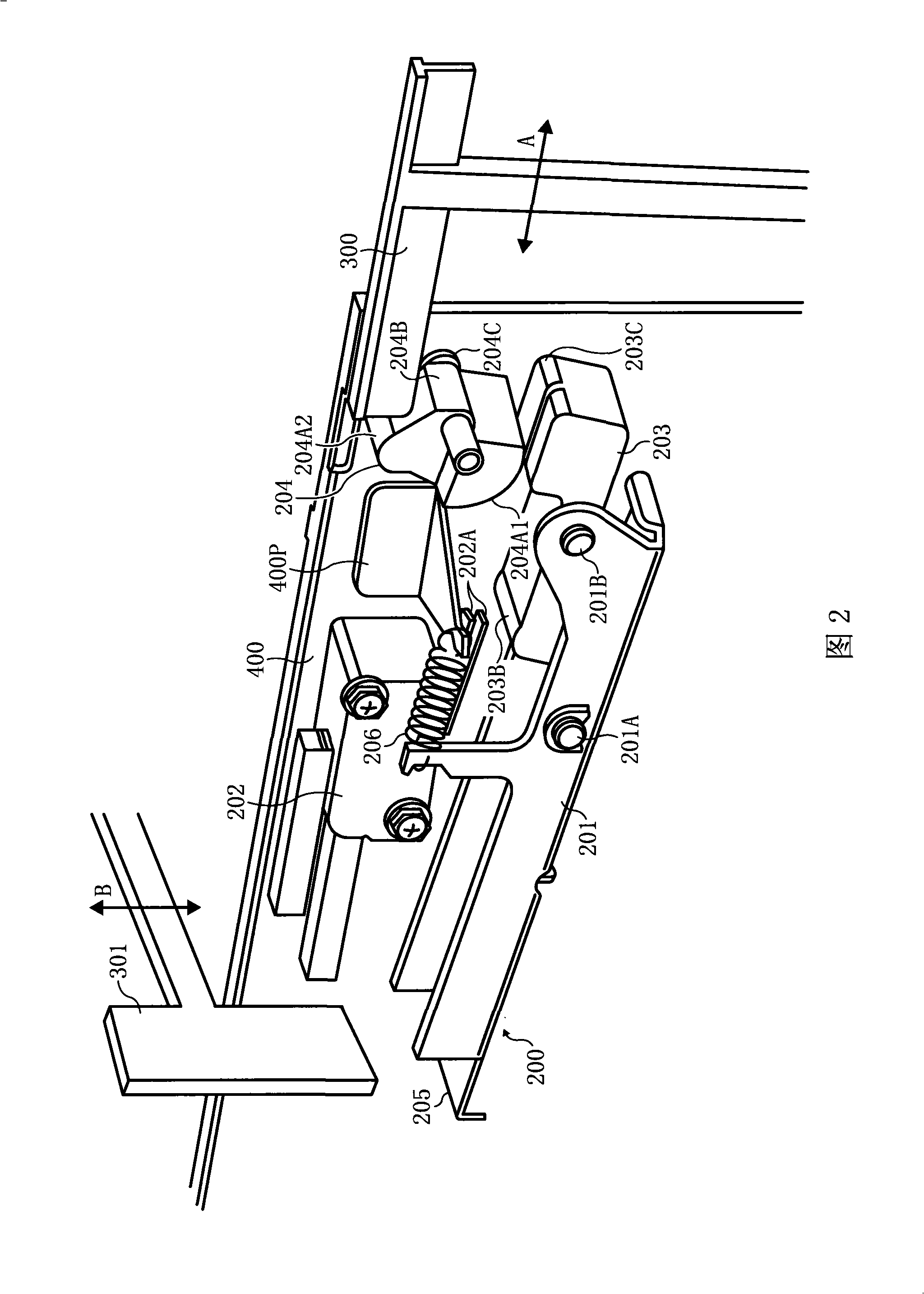

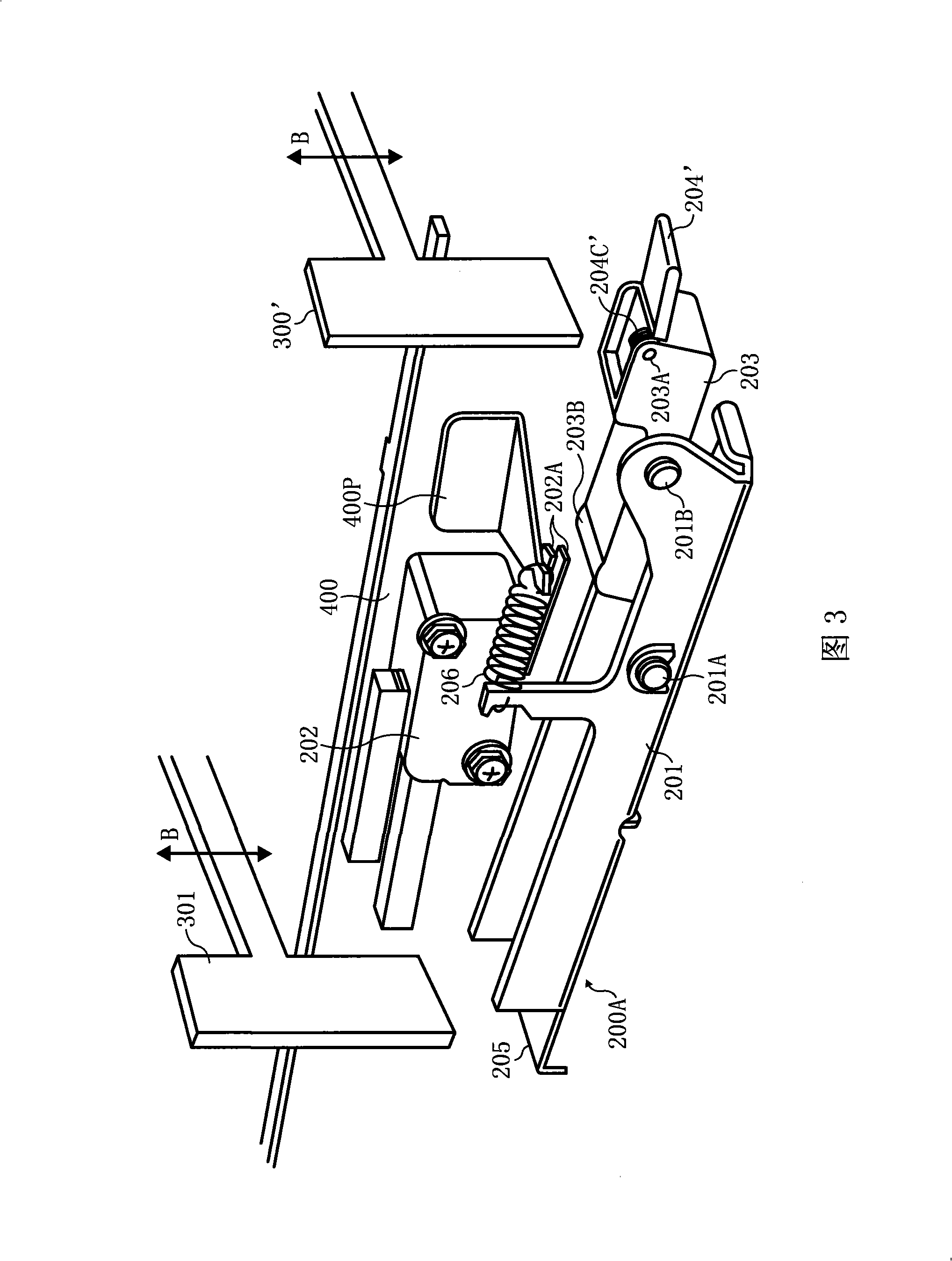

Switch actuation device, interlock mechanism, and image forming apparatus

InactiveCN101339383AIncrease contact areaSimple structureElectric switchesElectrographic process apparatusEngineeringCam

The invention is to provide switch actuation device with stable interlinking switch structure which can not result in upsizing for the device, a interlinking device for using the switch actuation device and a image forming device. The invention comprises a first lever member201 capable of rocking; a second lever member 203, rocking bi-directionally using fulcrum supported by the first lever member201 as pivot, a rocking end facing to switch actuation device; a first and a second actuation member 204, 205, selectively rocking the first or the second lever member 201, 203 pushed by moving body 300, 301. Because the first and the second actuation member 204, 205 pivots along moving direction of moving member of 300, 301, which reduces moving contact, and the first and second lever member 201, 203 are oppositely contacted with cam shape 204B, 205B, sensitivity can be maintained in rotation whether error of movement amount of moving member is big or not.

Owner:RICOH KK

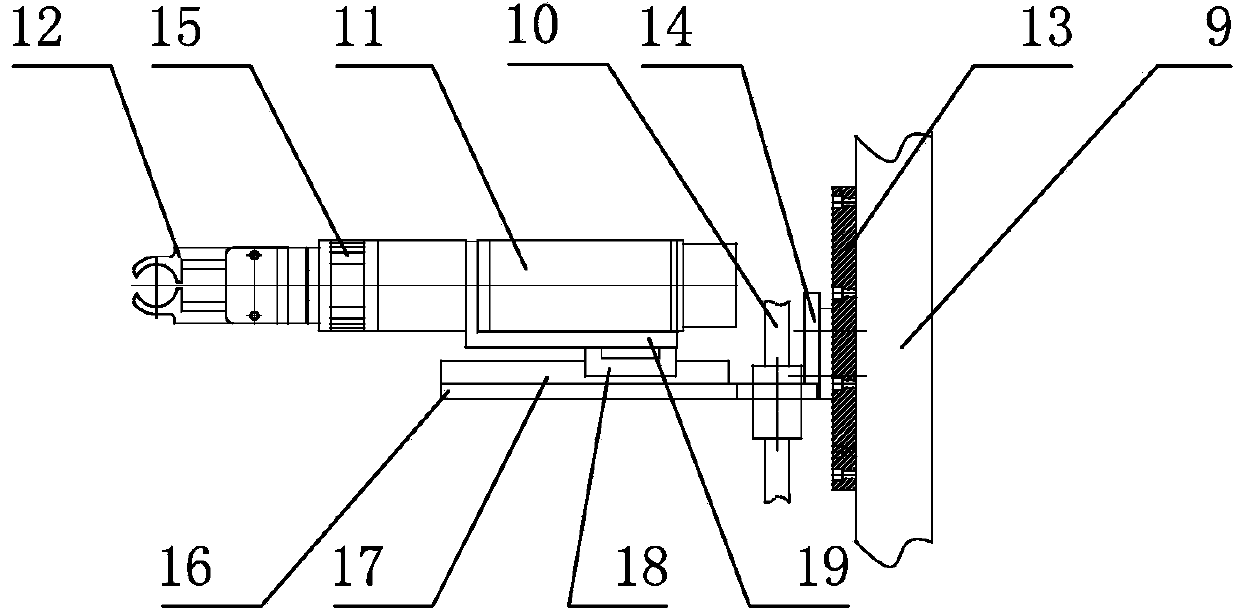

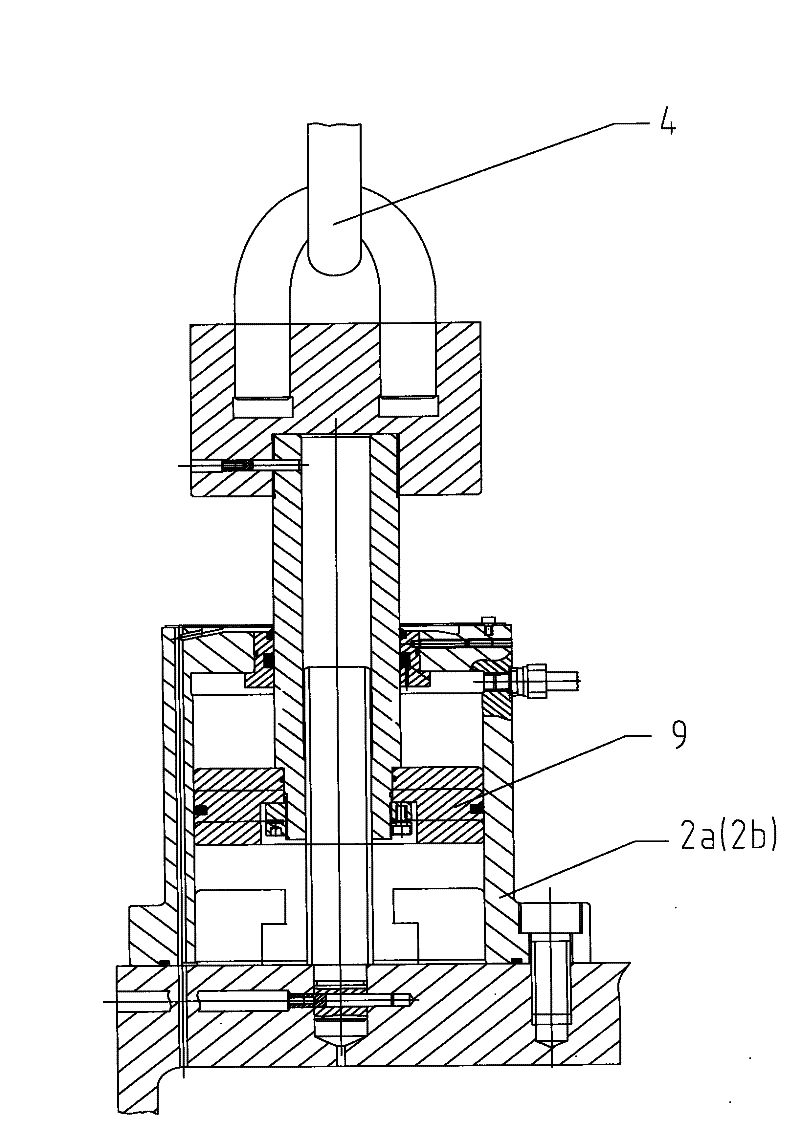

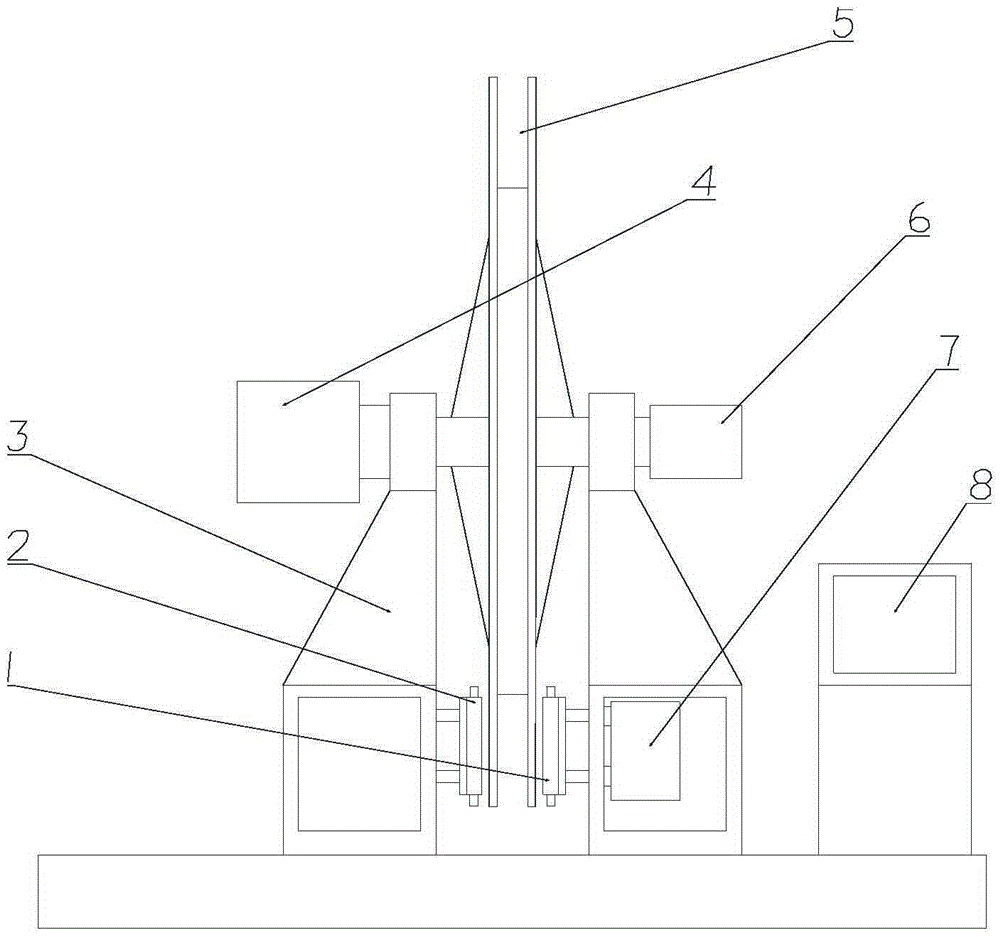

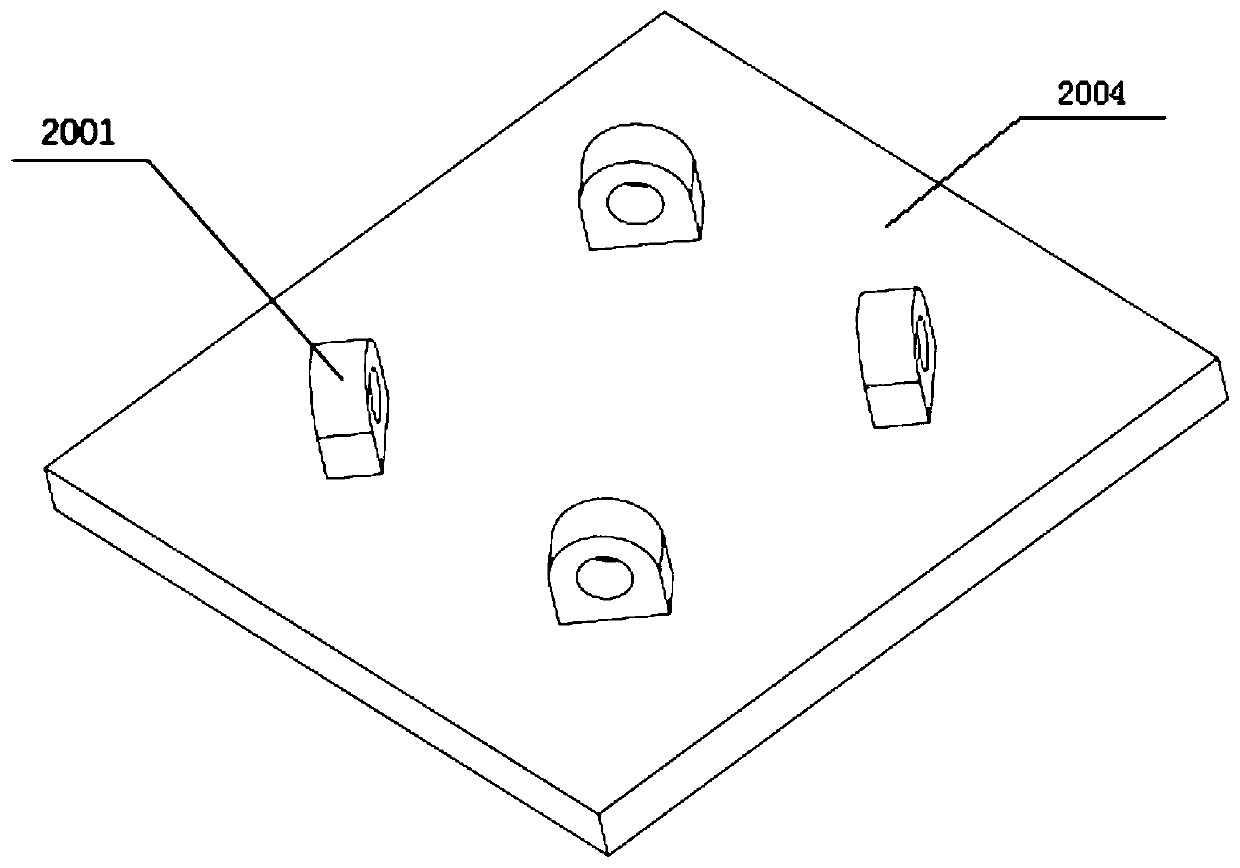

Integrated testing stand for linear motors

InactiveCN105425148AGuaranteed fixed effectGuaranteed installation accuracyDynamo-electric machine testingElectric machineLinear motor

The invention relates to an integrated testing stand for linear motors. The testing stand is characterized by comprising two linear motors arranged symmetrically, a composite rotor placed between the two linear rotors, a pair of supporting seats and a pair of servo mechanisms, wherein the two linear motors include a right motor and a left rotor; the composite rotor is arranged in the vertical direction and mounted on the supporting seats via a pin of the rotor; the right rotor and the left rotor are arranged symmetrically by taking the composite rotor as the center; the two servo mechanisms are also arranged symmetrically by taking the composite rotor as the center, and move simultaneously in the opposite directions, and the servo mechanisms are fixed to the linear motors respectively, so that the normal force of the right motor and that of the left motor are offset; and each servo mechanism includes a transverse sliding control and locking device, is mounted in the lower portion of the corresponding supporting seat, and is used to implement transverse movement and positioning on the corresponding linear motor. The integrated testing stand can be used to test and research the traction force, the normal force, the braking force, the driving power, the motor gap and the like of the linear motors, and can serve as a tester for the traction linear motors of automobile.

Owner:TONGJI UNIV

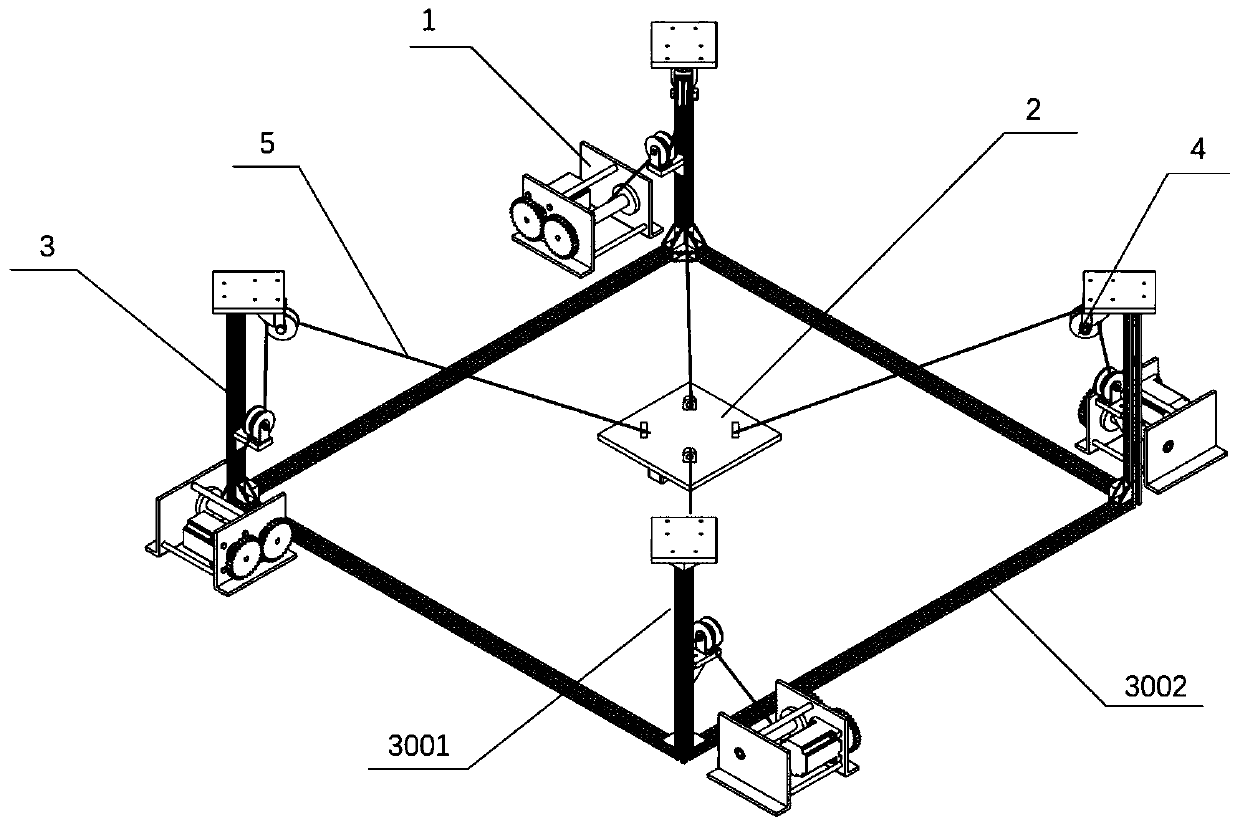

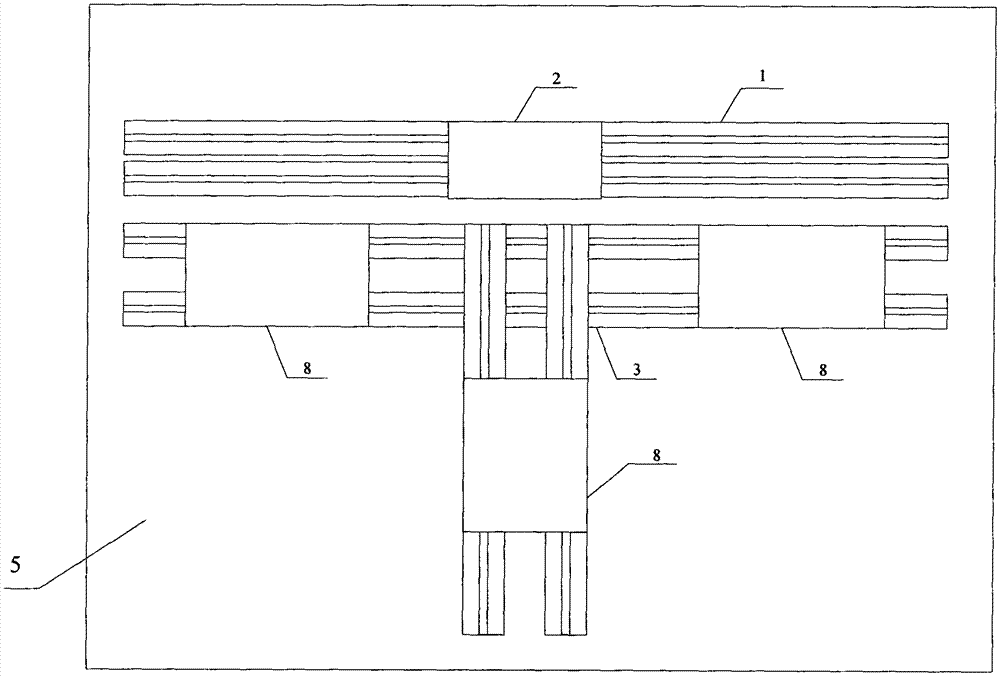

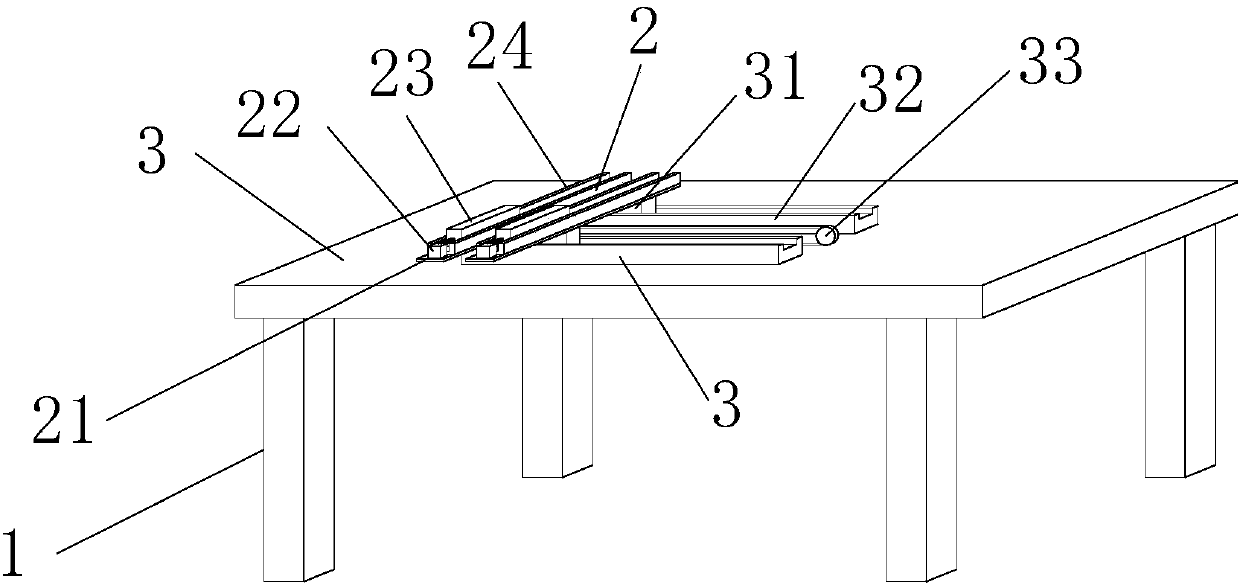

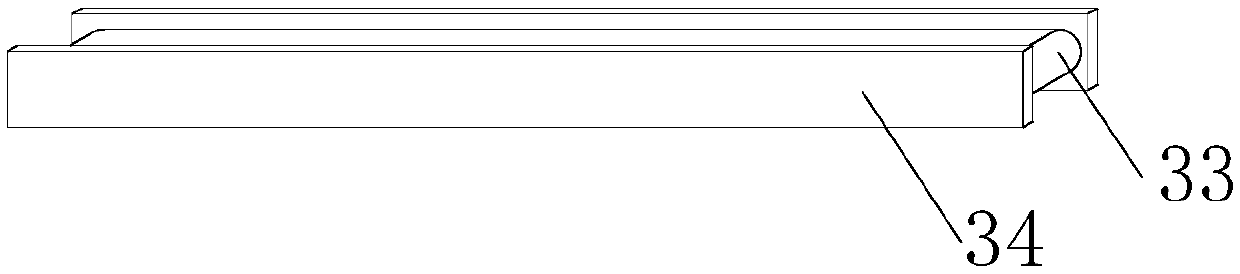

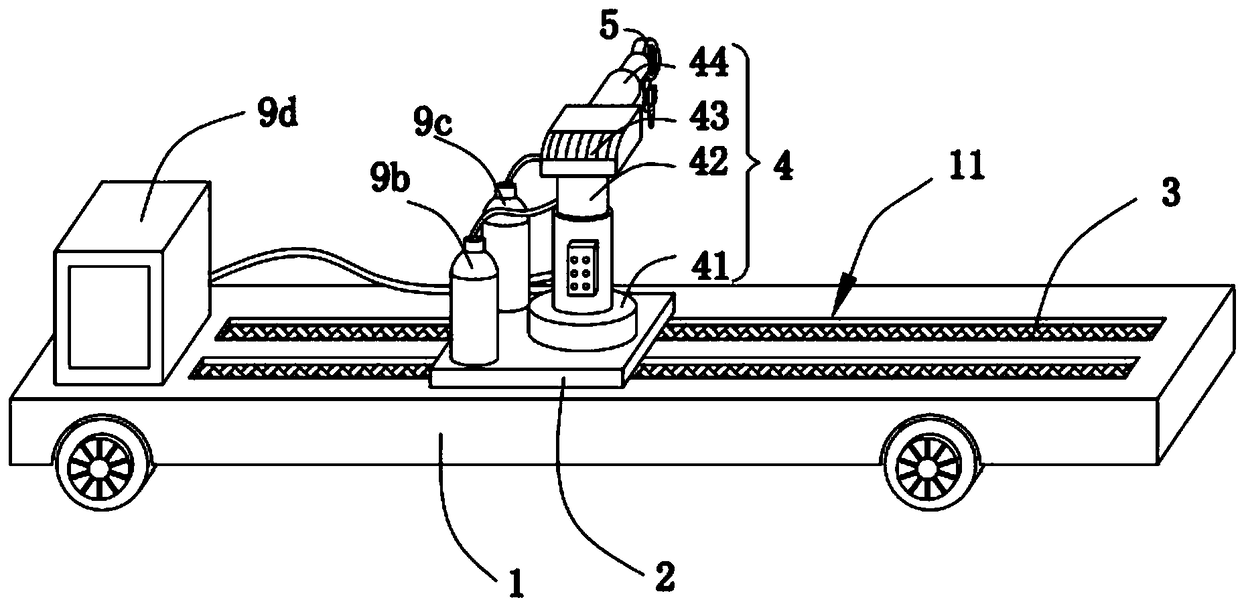

Wire driven parallel unmanned agricultural robot and control method thereof

ActiveCN111425733AImprove stabilityHigh precisionLifting framesStands/trestlesControl systemControl engineering

The invention discloses a wire driven parallel unmanned agricultural robot and a control method thereof. The unmanned agricultural robot comprises a mobile platform, a pillar system, a winding system,at least four wires, an ultrasonic module and a control system, wherein the mobile platform comprises a worktable and an automatic hook lock device, the pillar system comprises a rigid support and atleast four pulley blocks, and the winding system comprises at least four winding mechanisms that are located at four corners of the rigid support and respond to the at least four pulley blocks, respectively; the same ends of four wires are respectively fixed at four corners of the worktable, and the same other ends are wound on corresponding rollers; the ultrasonic module is used to generate ultrasonic wave, so as to collect space position information of agricultural equipment below the mobile space; and the control system is used to make the worktable move above the agricultural equipment through four wires, and hoist the agricultural equipment. The invention can improve the stability and accuracy of the agricultural robot with no need of manual guiding, so that automation of operationscan be greatly improved.

Owner:HEFEI UNIV OF TECH

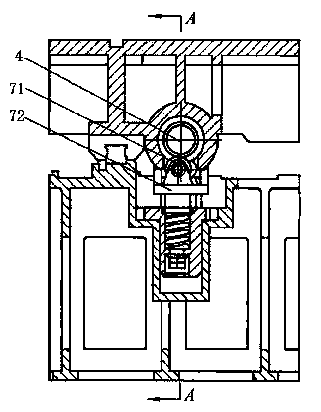

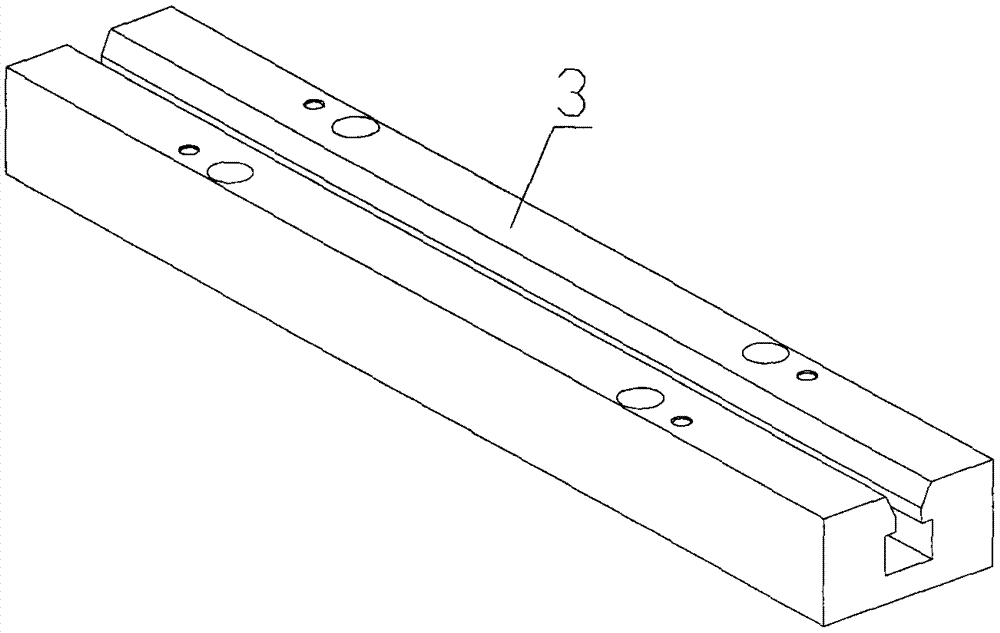

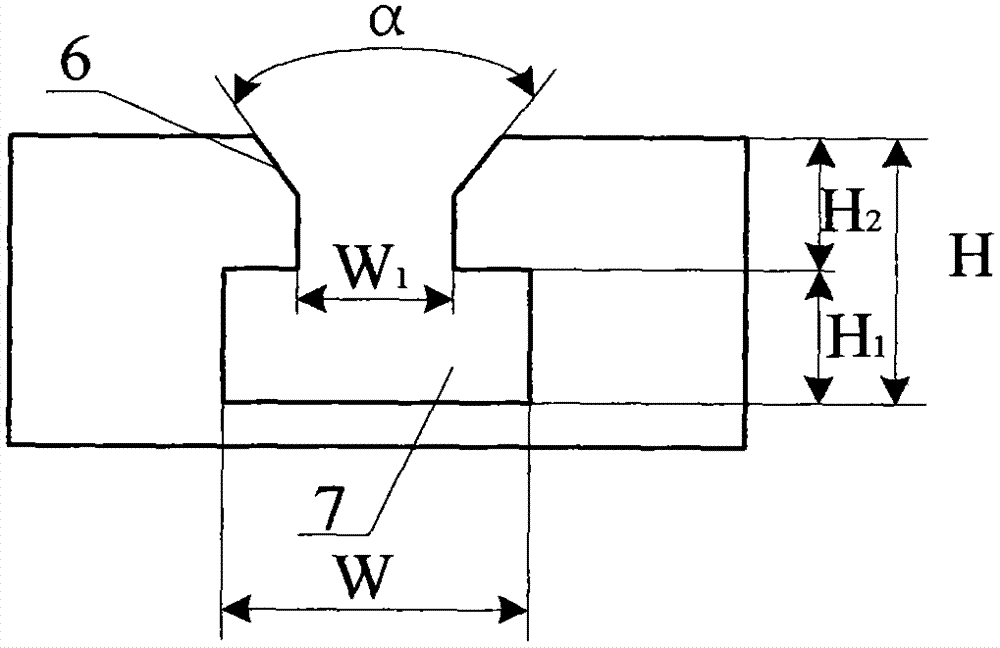

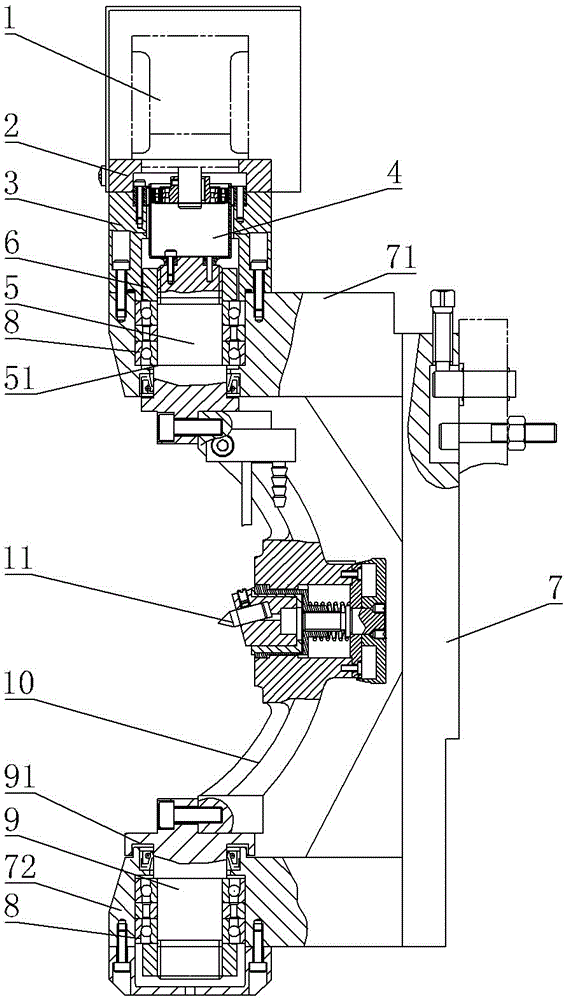

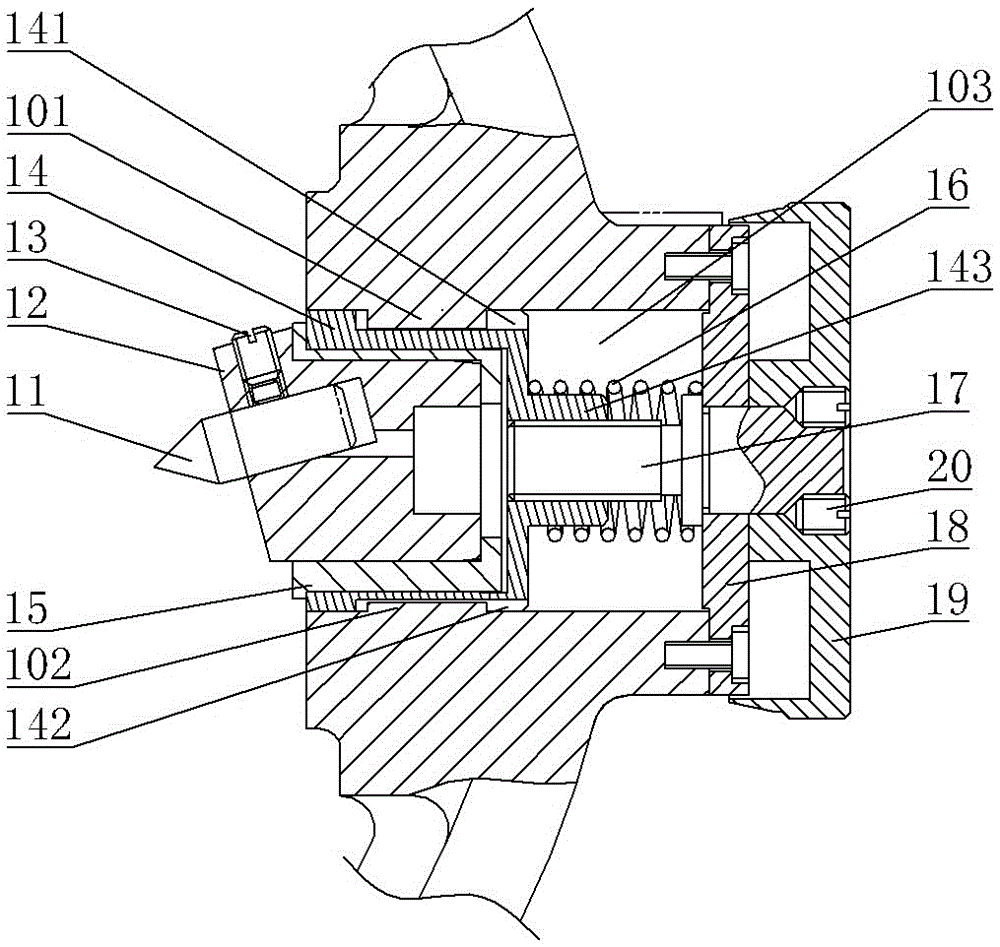

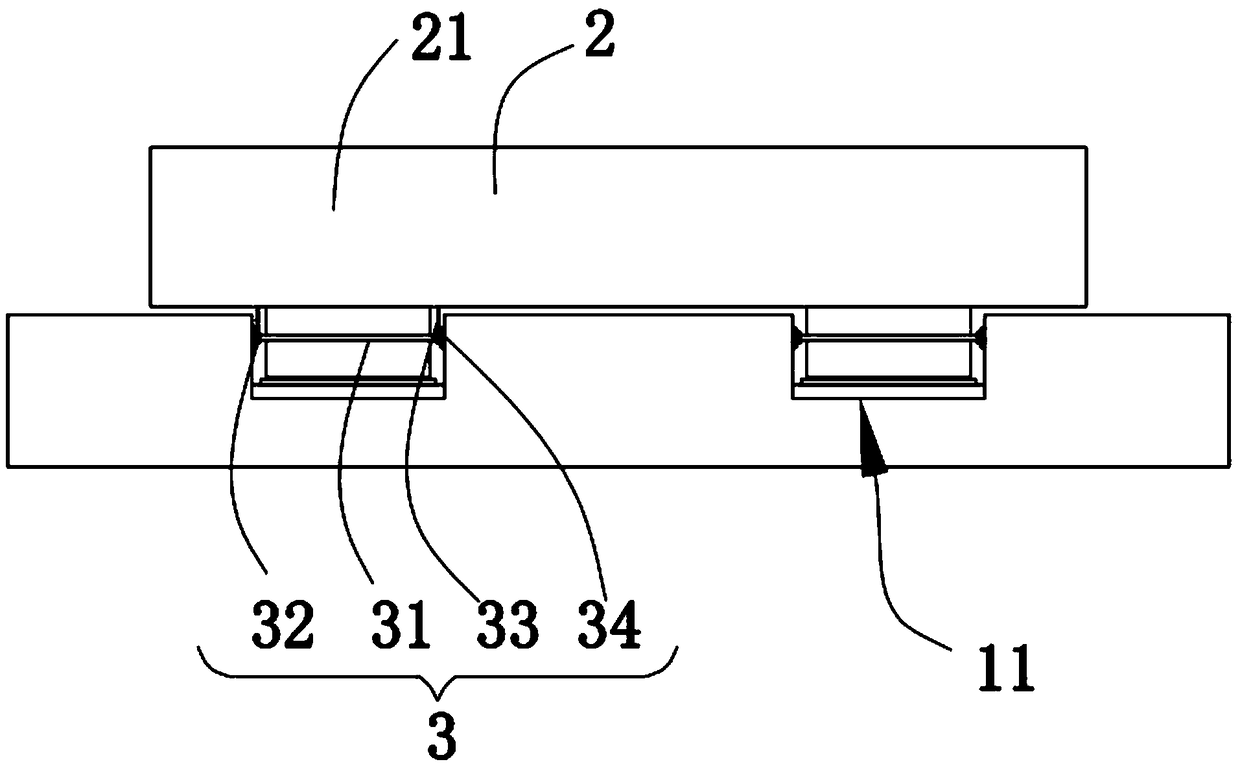

Ball screw support device

InactiveCN104325345ALess bendingReduce deflection deformationFeeding apparatusBall screwMaintainability

The invention discloses a ball screw support device. The ball screw support device comprises a support rod (72), a spring (76), an idler wheel (71), an upper inclined plate (73) and a lower inclined plate (75), wherein the spring (76) sleeves the support rod (72); the upper inclined plate (73) is arranged on an external workbench (3); the lower inclined plate (75) is arranged on the support rod (72); the idler wheel (71) is arranged on the top end of the support rod (72). According to the ball screw support device, the ball screw bending is reduced, the deflection deformation is reduced, and thus the movement precision of the workbench is guaranteed; the precision and the rigidity of a machine tool are improved. The ball screw support device is simple and reliable in structure, good in maintainability and low in cost.

Owner:南京金宇刀具制造有限公司

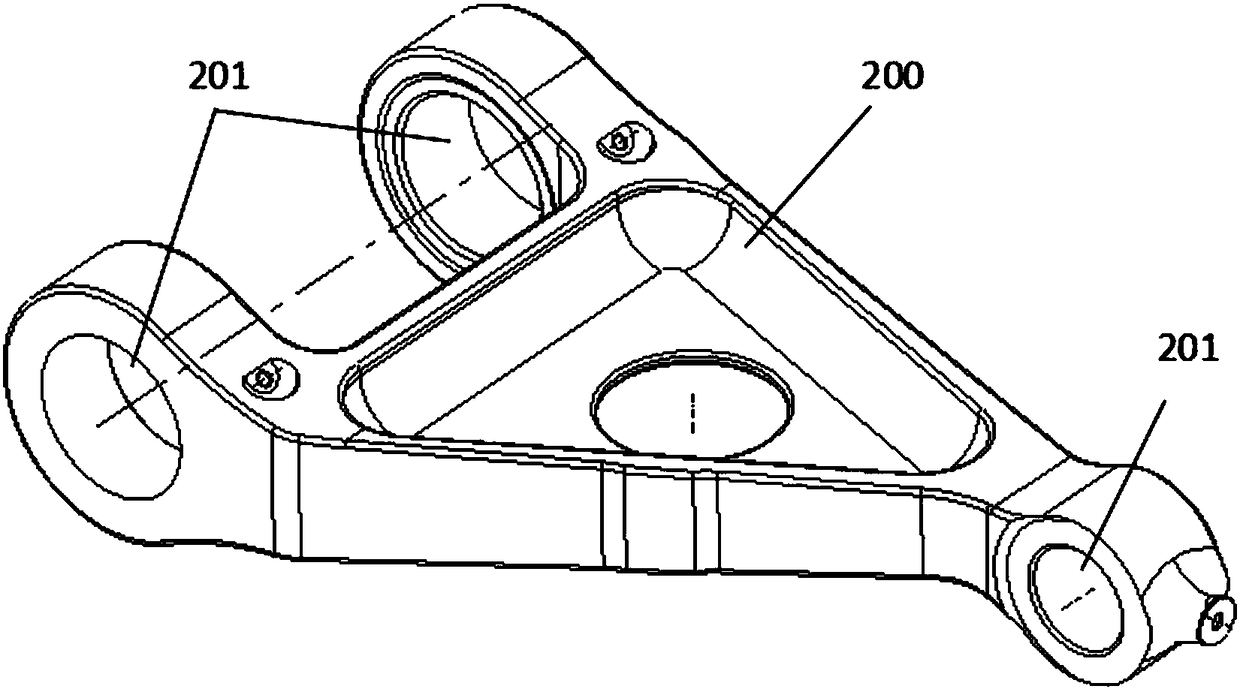

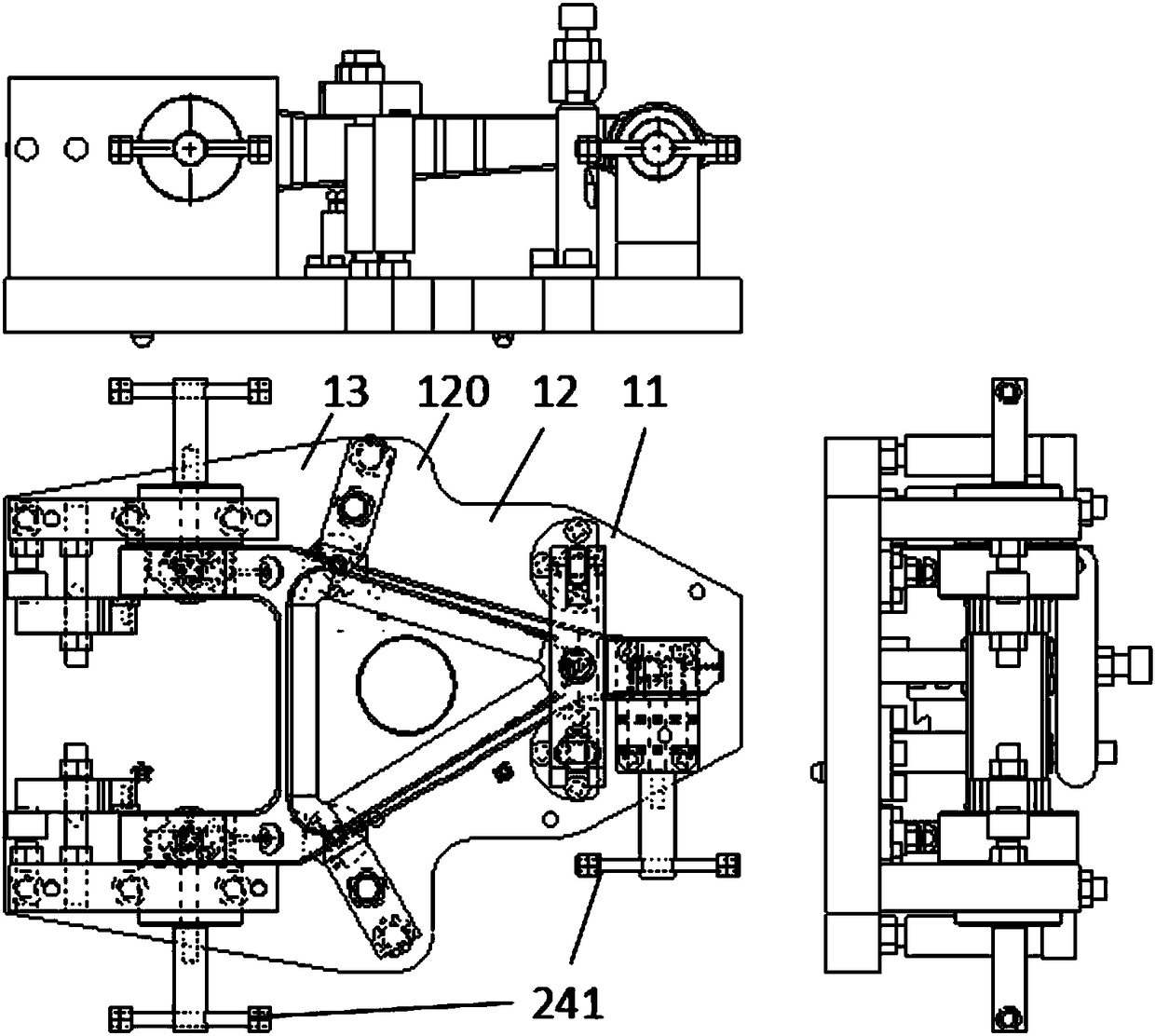

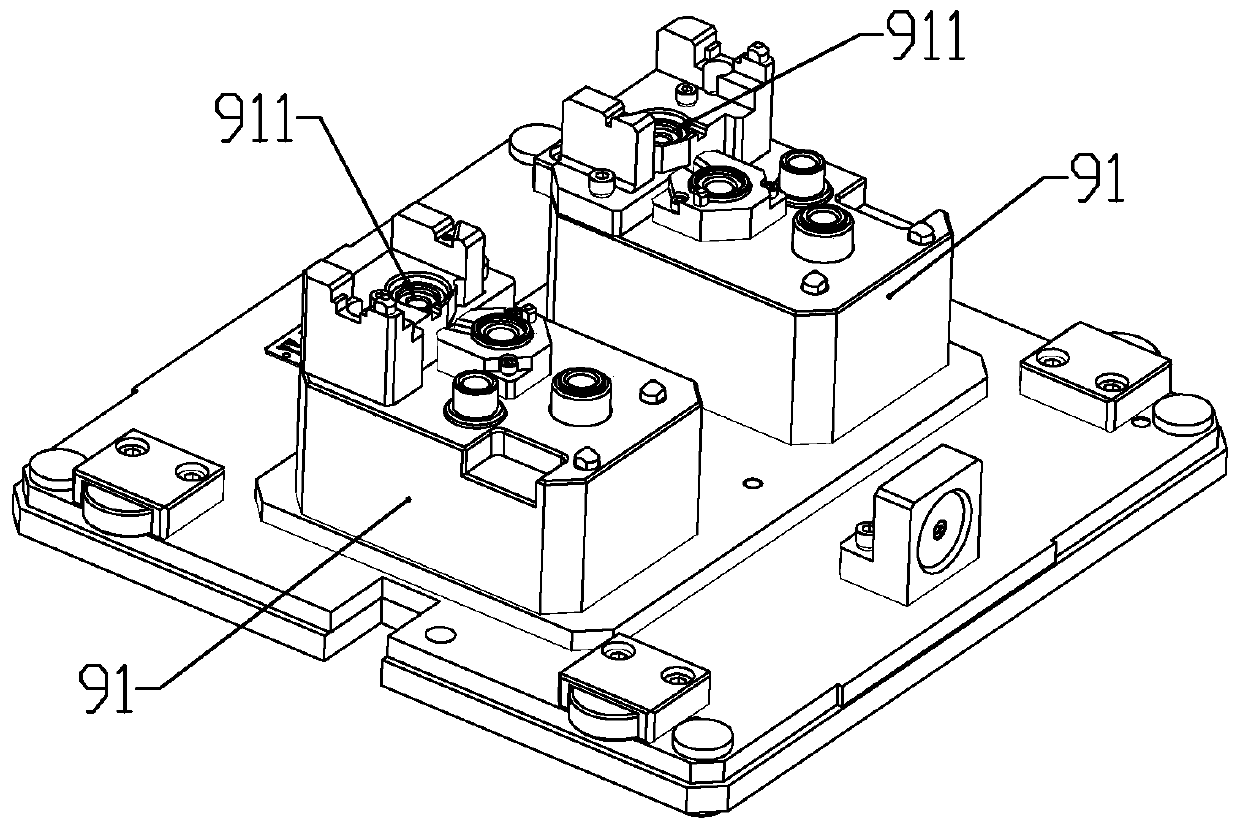

High-efficiency and high-precision fixture of aircraft undercarriage bracket and clamping method thereof

PendingCN108340173AClamp firmlyHigh positioning accuracyPositioning apparatusMetal-working holdersNeck partsSteel ball

The invention discloses a high-efficiency and high-precision fixture of an aircraft undercarriage bracket. The fixture comprises a fixture base plate, a fixing module, a pressing module and an auxiliary positioning piece; the fixture base plate comprises a front part, a neck part and a back part; the fixing module comprises a dovetail base, a dovetail positioning block, a positioning shaft, a positioning plate, an expansion mandrel, an expansion block, an expansion bolt and an endless bolt; the positioning plate is fixed at the back part; the expansion block and the expansion bolt respectivelycooperate with the external and the internal of the expansion mandrel; the pressing module comprises a front pressing module, a middle pressing module and a back pressing module for respectively pressing the front, middle and back parts of workpieces; and the auxiliary positioning piece comprises a movable steel ball positioning screw rod capable of adjusting the height and positioned below the workpieces, a positioning support column and a front movable screw rod. Through ordered cooperation of the fixing module, the pressing module and the auxiliary positioning piece, the clamping operationis clear, the errors are greatly reduced, and the positioning clamping precision and efficiency are improved.

Owner:SUZHOU CHANGXING MOLD MACHINERY

Dustproof device of improved machine tool guide rail

InactiveCN103551910AGuaranteed movement accuracyImprove dust removal effectMaintainance and safety accessoriesBristleEngineering

The invention relates to a dustproof device of an improved machine tool guide rail. Stop pieces are fixedly arranged on two side walls of a tool rest seat of a machine tool and are rubber stop pieces; tooth grooves matched with the side wall of the guide rail are formed in the lower ends of the stop pieces; the inner side walls of the tooth grooves are matched with the guide rail in a sliding manner; bristles are arranged on matched surfaces of the tooth grooves and the guide rail. According to the dustproof device, the bristles are additionally arranged on the matched surfaces of the tooth grooves and the guide rail, so that the dust removal effect is further enhanced, and the moving precision of the tool rest seat is ensured.

Owner:CHUZHOU YALI MOLD EQUIP

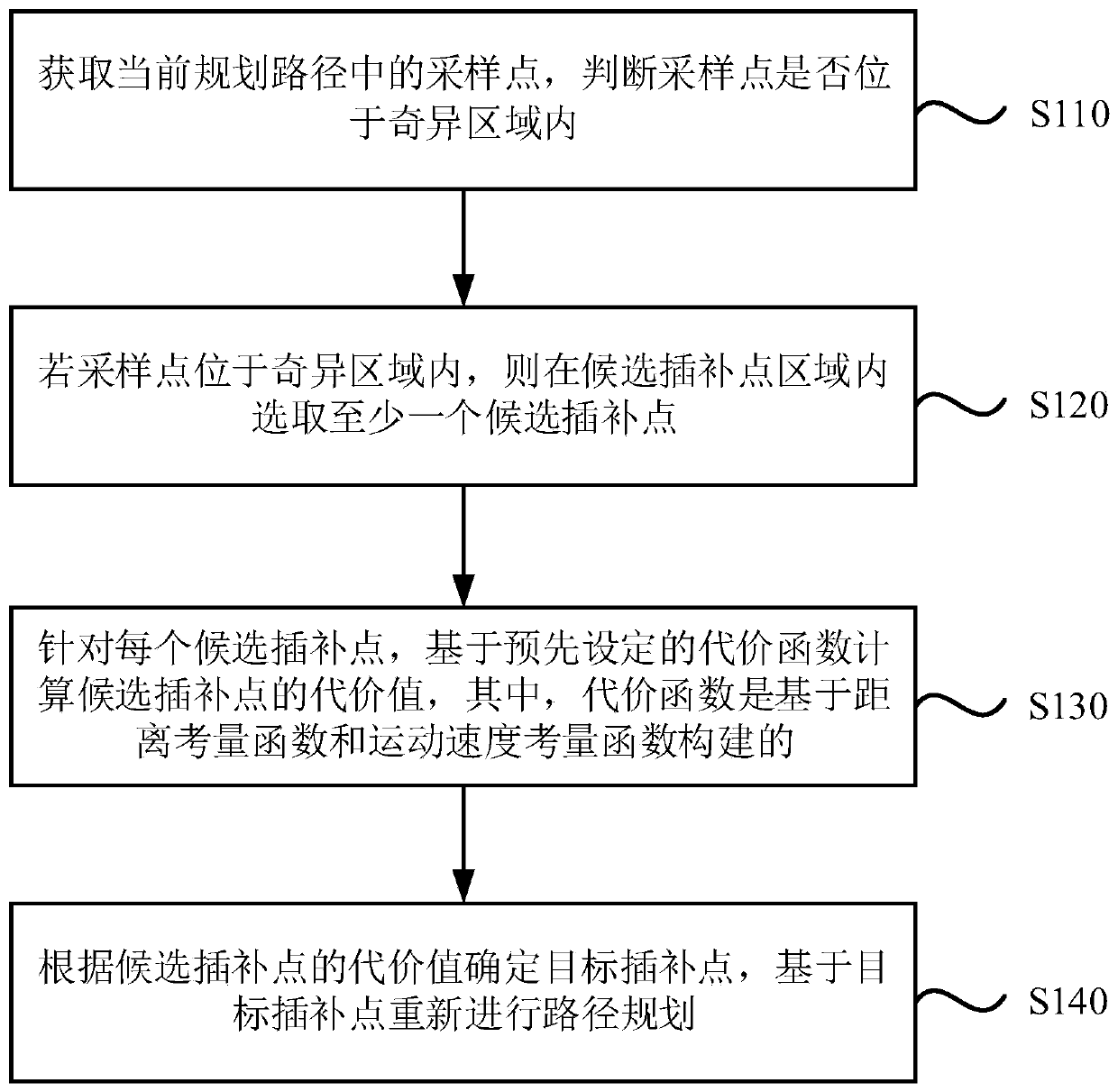

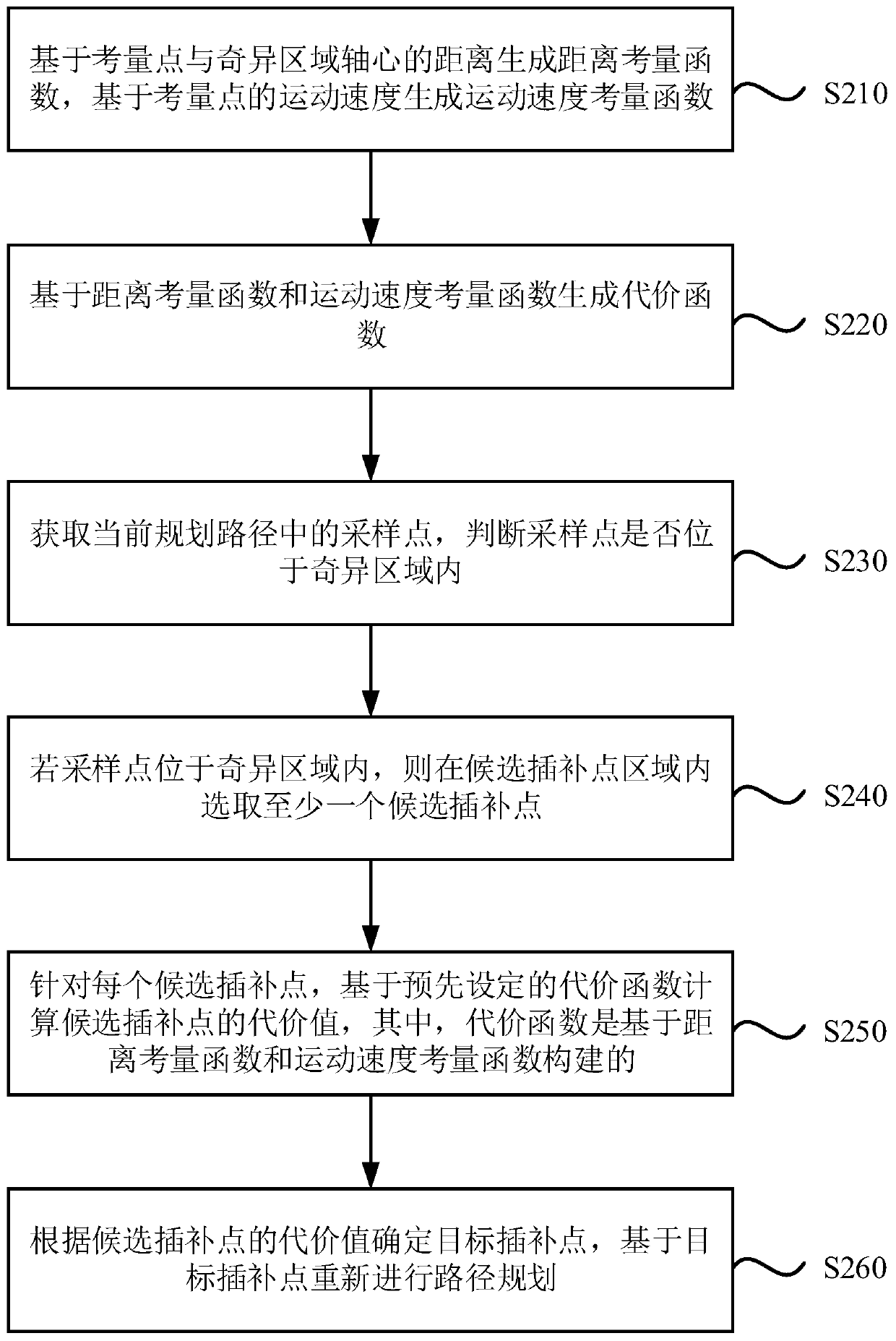

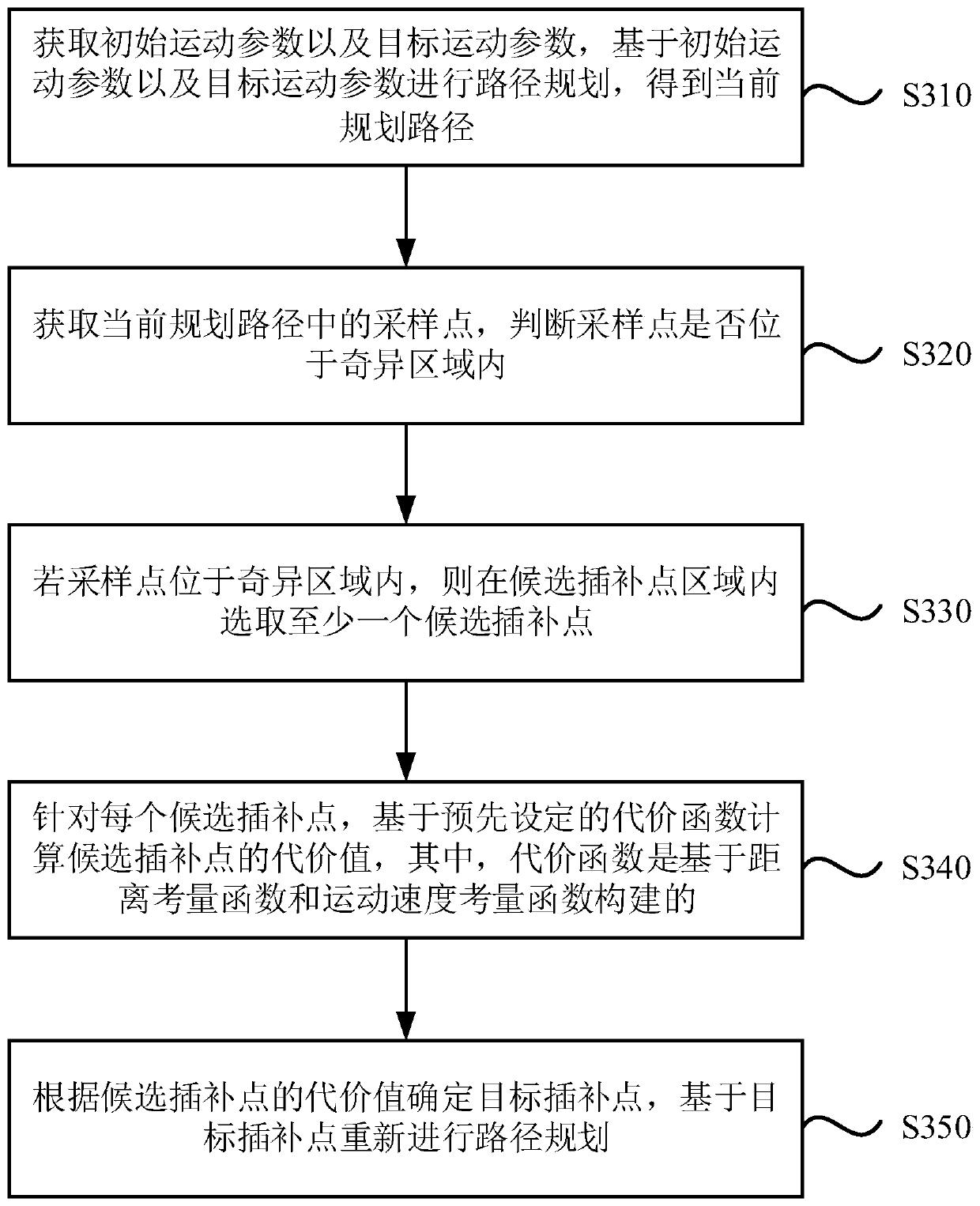

Singular point avoiding method and device, equipment and medium

ActiveCN110850807AAccurately determineSmooth and stable avoidanceNumerical controlAlgorithmControl theory

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

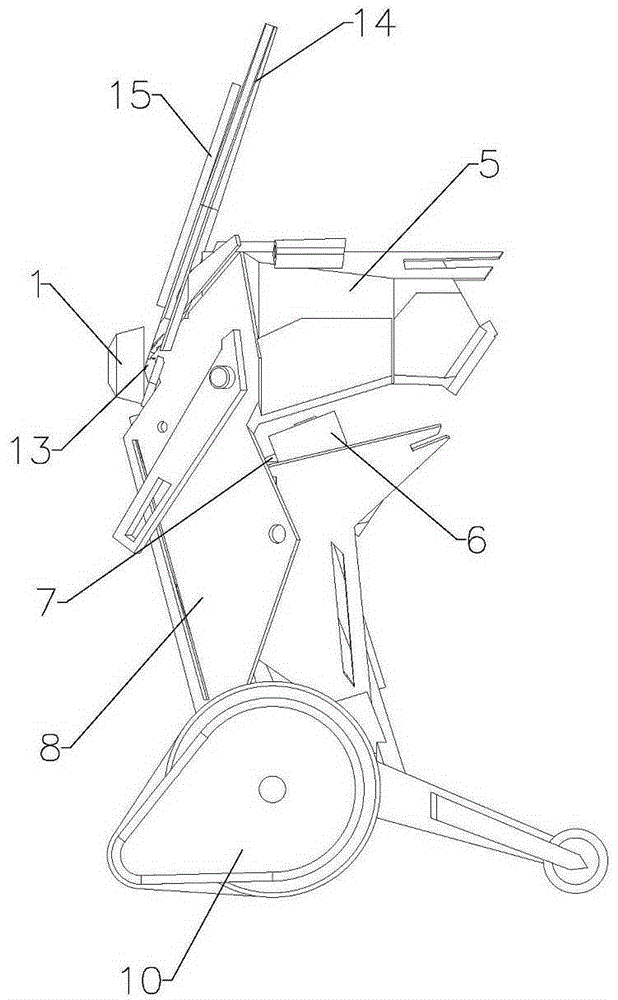

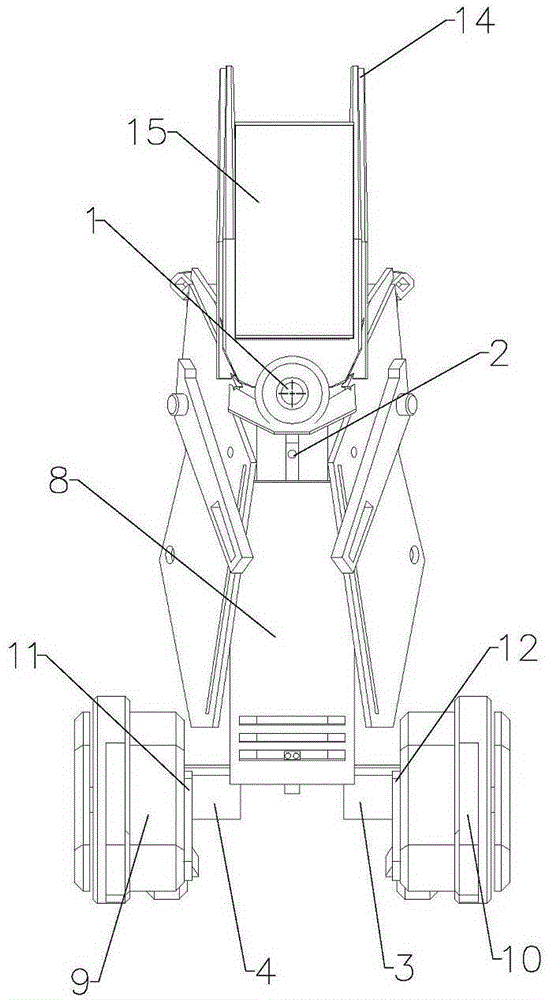

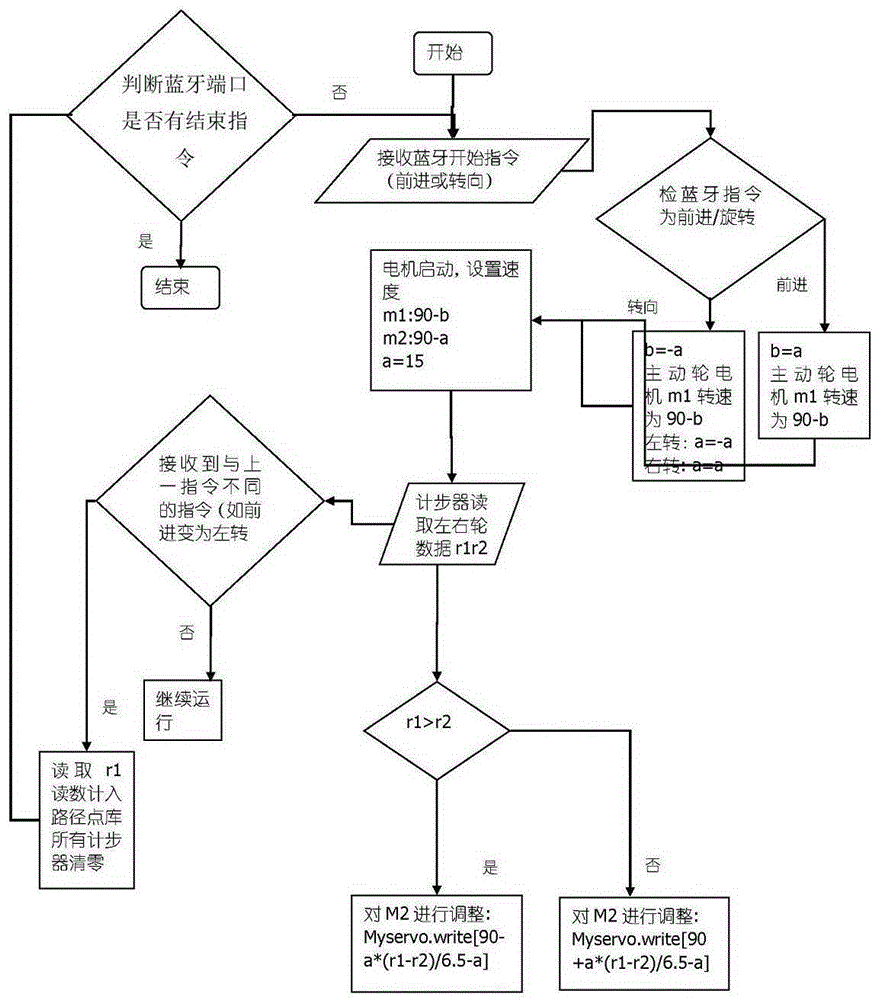

Control method of waypoint type walking robot

InactiveCN105215997AHigh movement accuracySave resourcesProgramme-controlled manipulatorTransmission systemsCrowdsComputer science

The invention discloses a control method of a waypoint type walking robot. The method comprises a waypoint forming step, a straight-line system walking step and an interaction step. A human body in front of the robot is found in time, an advertisement pushing manner is immediately transformed, different crowds can be identified, and targeted advertisement injecting is carried out, so that the advertisement communication efficiency and effectiveness are greatly improved; through a step calculation manner, information feedback is carried out, an algorithm is applied to correct the acceleration and deceleration of a motor, and therefore the higher stability is achieved, and errors are reduced; the robot can walk without assistance of black lines, and can precisely move according to the path; and the biased error of hundreds of meters in a straight line can be smaller than 5 degrees.

Owner:WEIFANG YUANTONG CENTURY IND & TRADE

Moving mechanism

ActiveCN103776606AVarious formsGuaranteed movement accuracyVibration testingSheet steelPre embedding

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

Grinding wheel dresser for grinding machine

InactiveCN106346366AQuick trimEasy to trimAbrasive surface conditioning devicesSteel ballEngineering

The invention provides a grinding wheel dresser for a grinding machine, which aims at solving the technical problems of poor universality and waste of processing time and labor in the existing grinding wheel dresser. The grinding wheel dresser comprises a diamond pen base, a swing rod, a machine base and a driving device, wherein a diamond pen is arranged on the diamond pen base; both ends of the swing rod are rotationally supported at both ends of the machine base; the driving device is used for driving the swing rod to rotate. The grinding wheel dresser is characterized in that a shaft hole is formed in the swing rod, a slide sleeve is arranged in the shaft hole, and the diamond pen base is inserted into the slide sleeve; slide blocks are arranged at both radial ends of the inner side of the shaft hole and extend in the axial direction, both radial ends of the slide sleeve are provided with slide grooves which are matched with the slide blocks, the two sides of each of the slide blocks and the slide grooves are provided with arc-shaped grooves, and steel balls fill the opposite arc-shaped grooves; a thread sleeve is arranged at the tail part of the slide sleeve, and is connected with an adjusting rod through threads, the adjusting rod is parallel with the axis of the shaft hole, an end cover is covered at the tail part of the shaft hole, the adjusting rod penetrates through the end cover and is vertically and fixedly connected with a dial, a spring is sheathed on the thread sleeve, and both ends of the spring are respectively abutted against the slide sleeve and the end cover.

Owner:WUXI MACHINETOOL

Double-headed asynchronous cutting machine

PendingCN107717247AGuaranteed movement accuracyLaser beam welding apparatusControl engineeringStructural engineering

The invention relates to a double-headed asynchronous cutting machine which comprises supporting legs, a workbench, a seat body, second sliding rails, a single belt conveyor, a crossbeam, a driving assembly, a laser seat and a first sliding rail. The supporting legs are arranged on the lower end face of the workbench, the two second sliding rails are symmetrically arranged on the upper end face ofthe workbench, the second sliding rails are slidably connected with the seat body, the single belt conveyor is arranged between the two second sliding rails through a mounting plate, the crossbeam isfixedly disposed on the seat body, the first sliding rail is fixedly arranged on the crossbeam, the driving assembly is arranged on the front side of the first sliding rail, the laser seat is slidably connected to the first sliding rail, and the design ensures movement precision of X-axis twin beams.

Owner:DONGGUAN SHENGUANG LASER TECH CO LTD

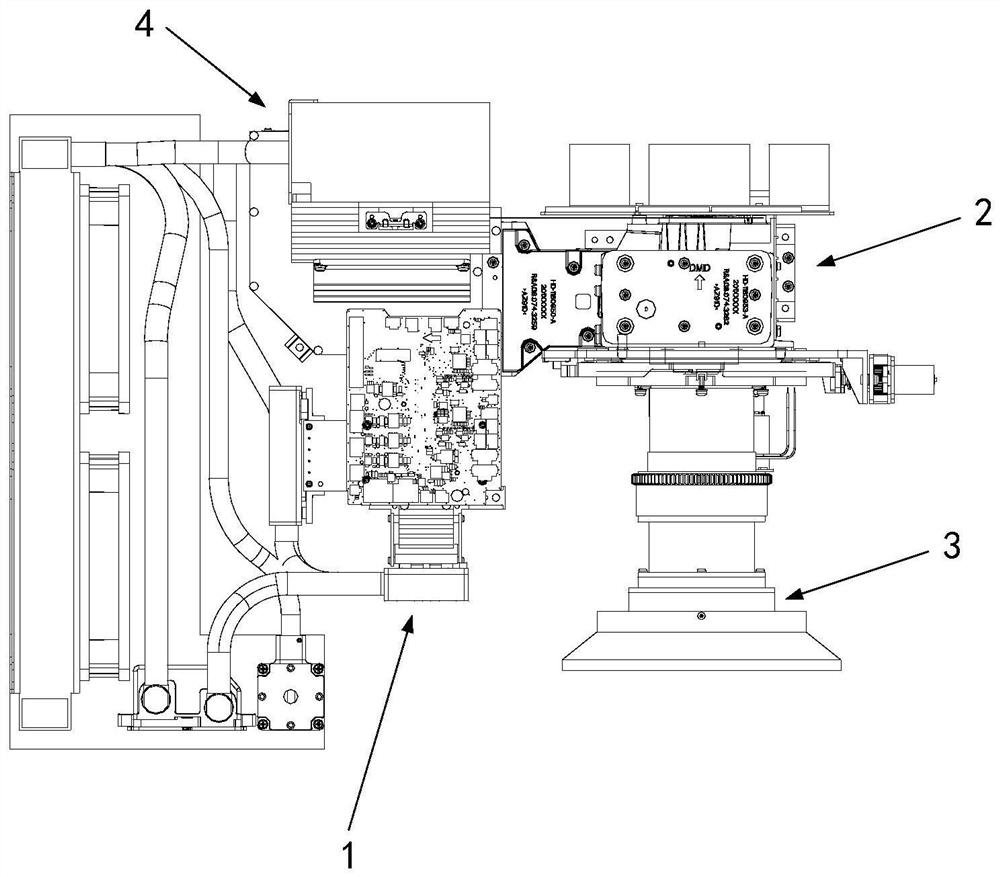

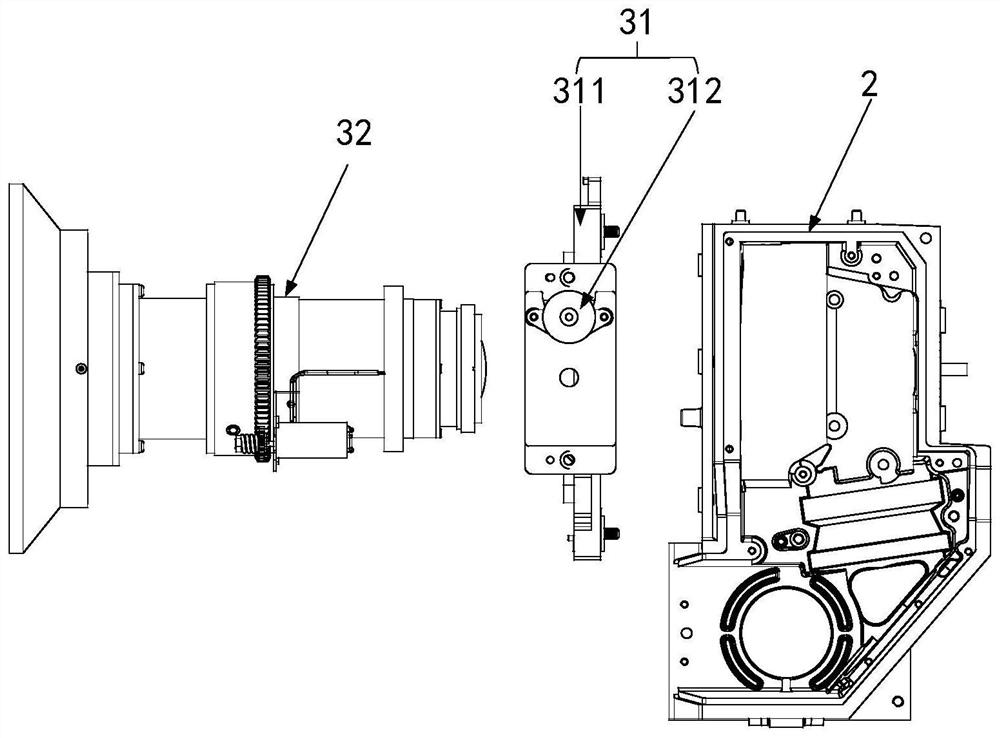

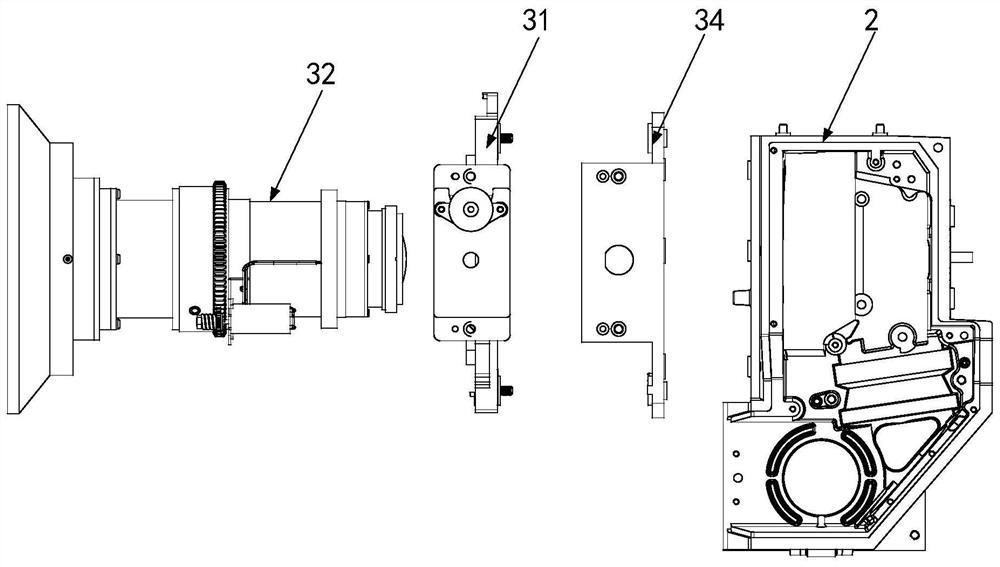

Projection host

The embodiment of the invention discloses a projection host, and belongs to the technical field of projection. The projection host comprises a light source system used for emitting a light beam; an optical-mechanical system, located on the light emitting side of the light source system, and the optical-mechanical system being used for receiving the light beam and emitting a modulated light beam after modulation; and a lens, comprising a first moving assembly and a lens barrel. The first moving assembly comprises a first moving bearing shell and a first control assembly, the first moving bearing shell is slidably connected to the light emitting side of the optical-mechanical system, and the first control assembly is fixed to the light emitting side of the optical-mechanical system and is in transmission connection with the first moving bearing shell; the lens barrel is connected with the first movable bearing shell, and the first movable bearing shell is provided with a first light hole. According to the embodiment of the invention, the first control assembly drives the lens barrel to move, so that the movement precision of the lens barrel is ensured, the position accuracy of the lens projection area after movement is ensured, and the projection effect of the projection host is improved.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

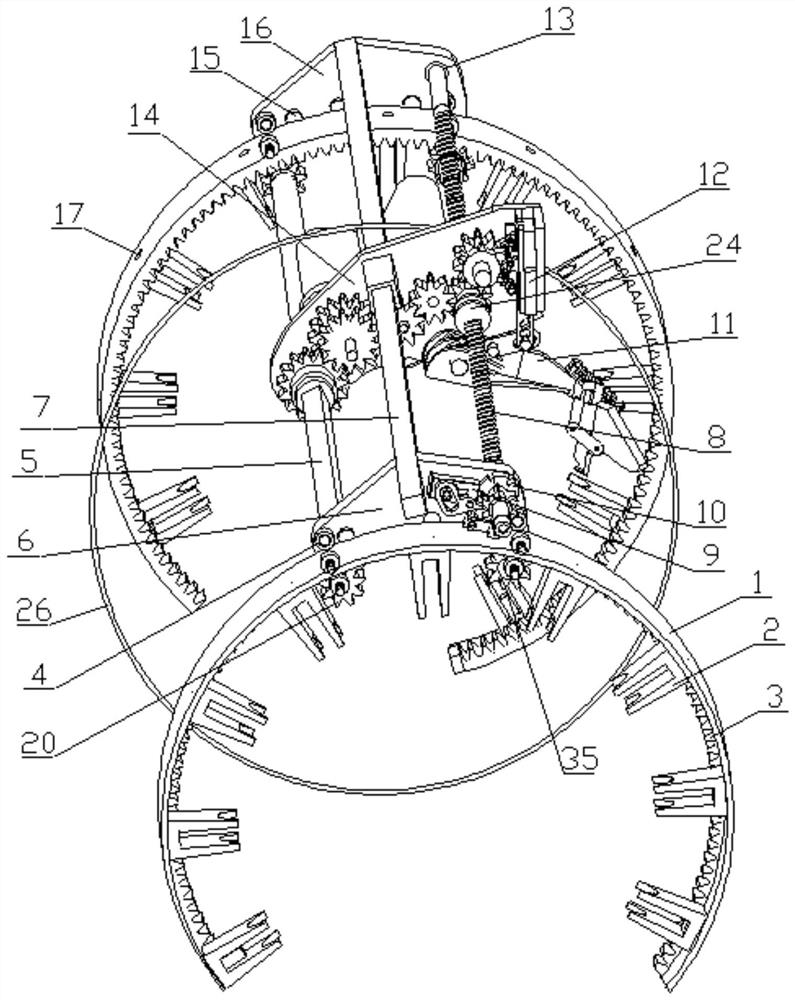

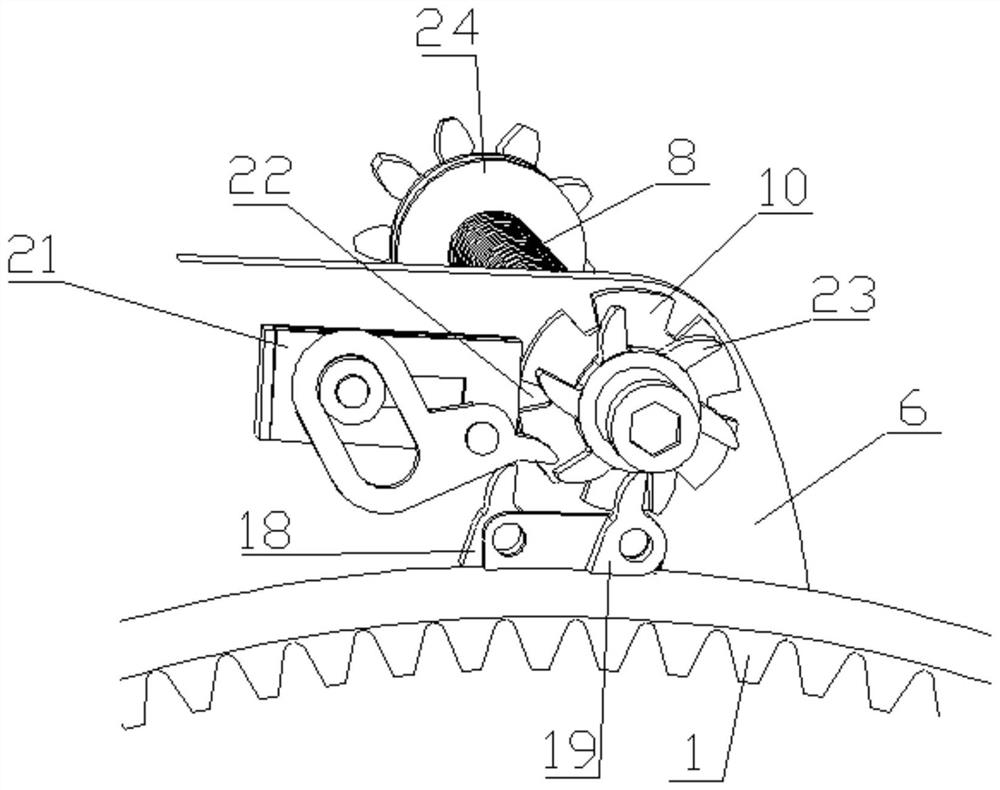

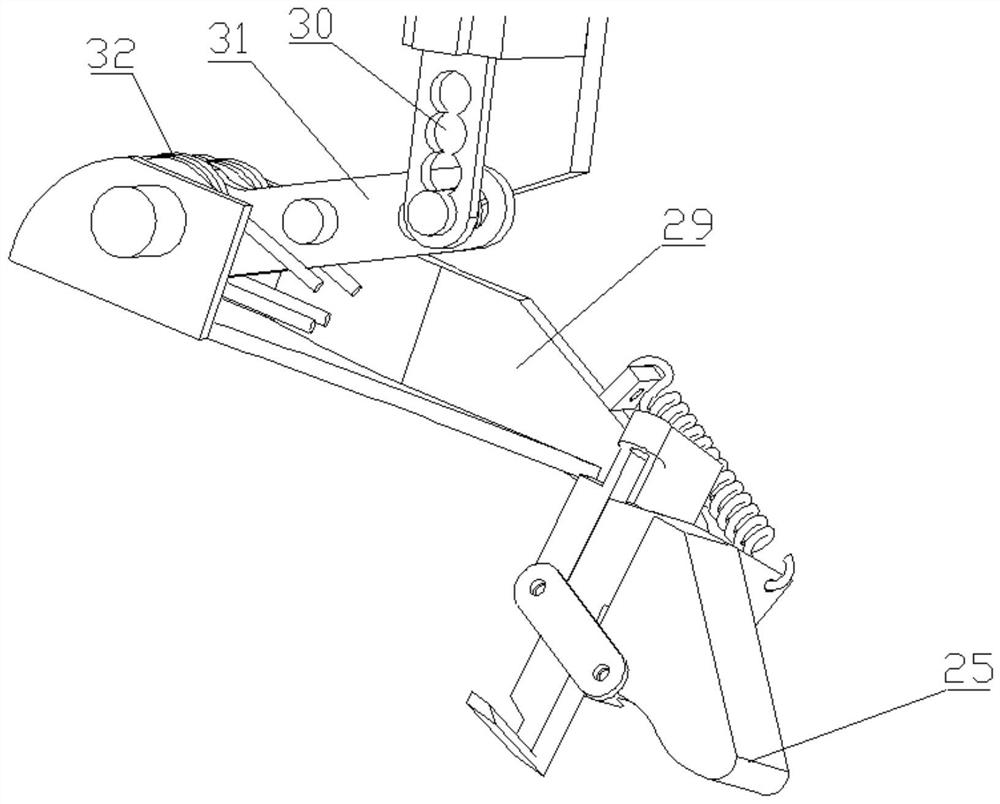

Rubber tapping machine used for cutting bark of rubber tree

The invention discloses a rubber tapping machine used for cutting bark of a rubber tree. The rubber tapping machine is composed of a rubber tapping track control mechanism, a cutter control mechanism, a fixed descending stroke control mechanism and a rubber tapping machine tree leaving alarm, a rotating square bar for controlling a rubber tapping track and a lead screw are simultaneously connected with a unique power source motor of the novel rubber tapping machine through a change gear, a driving walking gear on the rotating square bar meshes with teeth on the inner wall of an inner gear ring, the cutter control mechanism is composed of a linkage ratchet gear connected with a motor gear and a sliding block mechanism, the fixed descending stroke control mechanism is composed of pawls which are fixed to the inner gear ring, a clamping pin, a linkage lead screw ratchet wheel which is fixed to the lead screw and a lock groove disc, and the rubber tapping machine tree leaving alarm is composed of a tree surrounding wire and a power failure alarm. According to the novel rubber tapping machine disclosed by the invention, parts including a power source are reduced through structural optimization design, the cost and the failure rate are reduced, and meanwhile, the control precision is improved.

Owner:高忠文

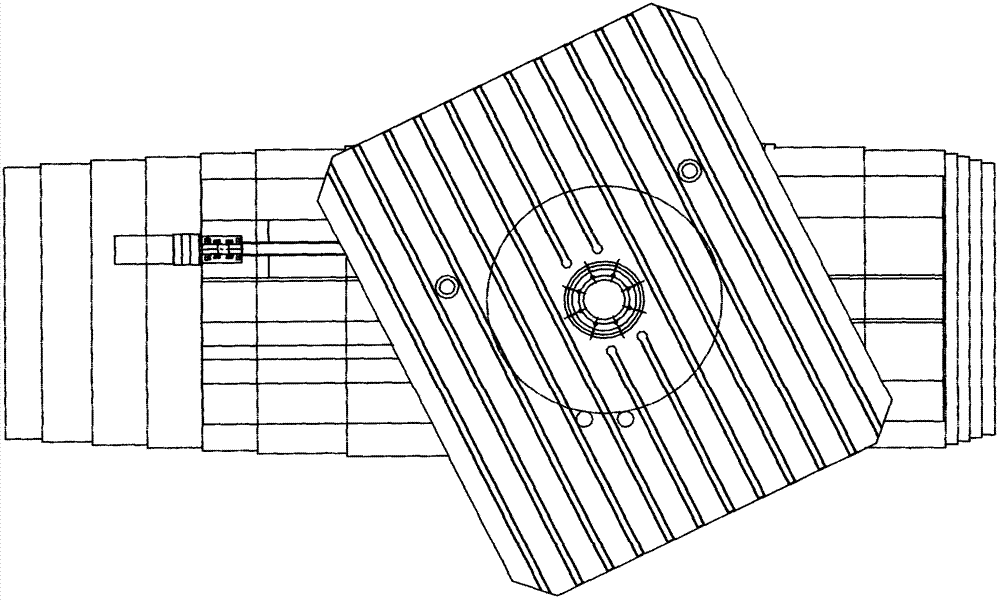

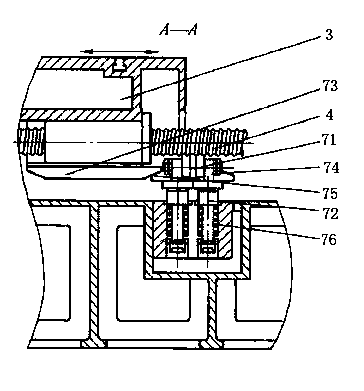

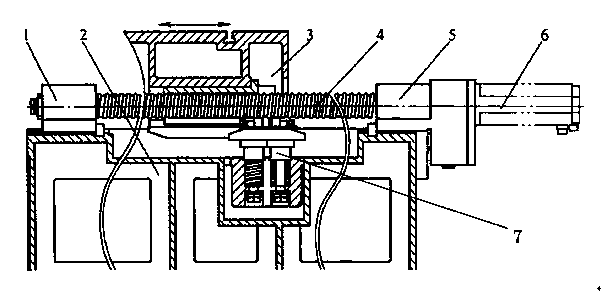

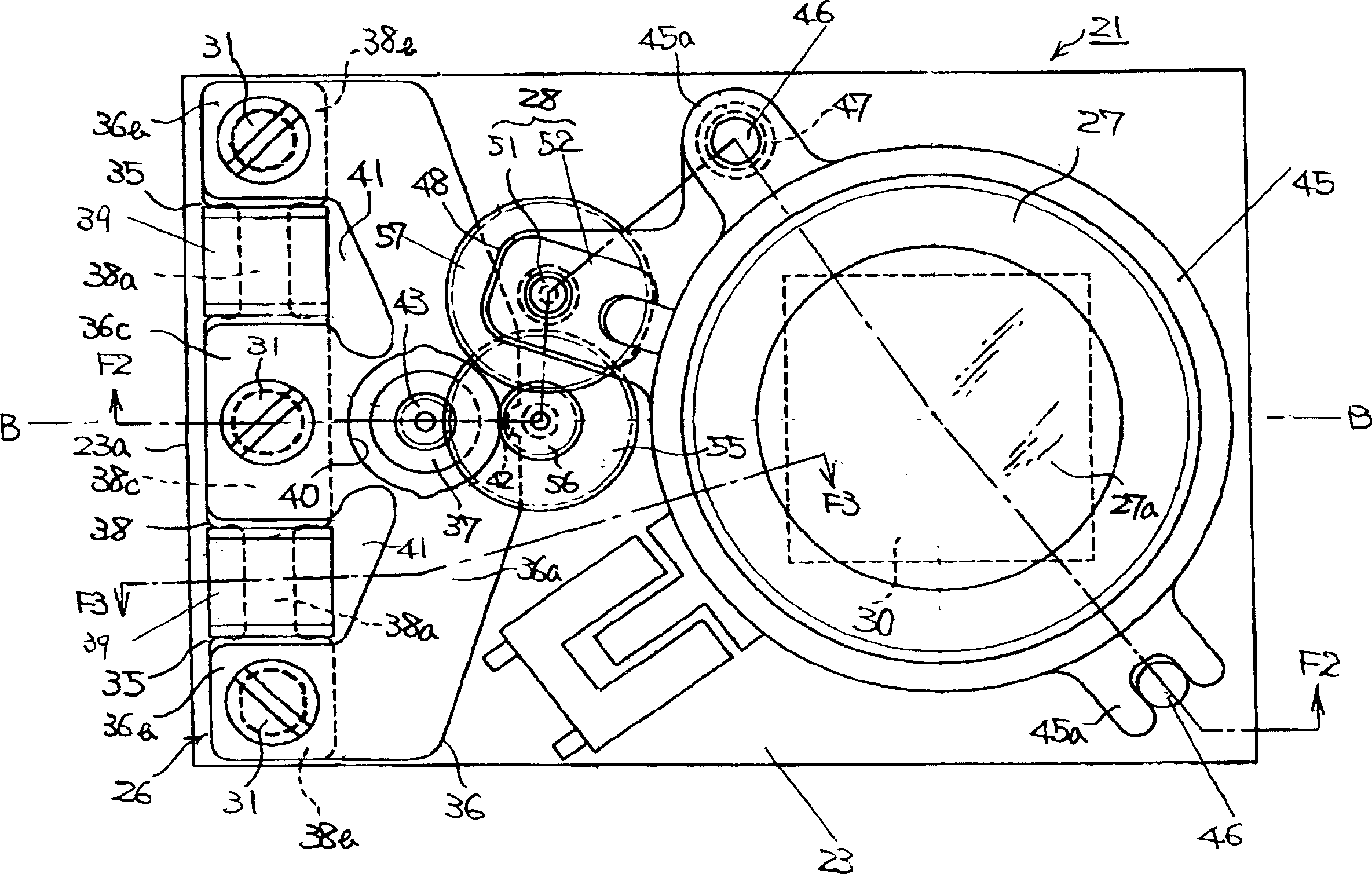

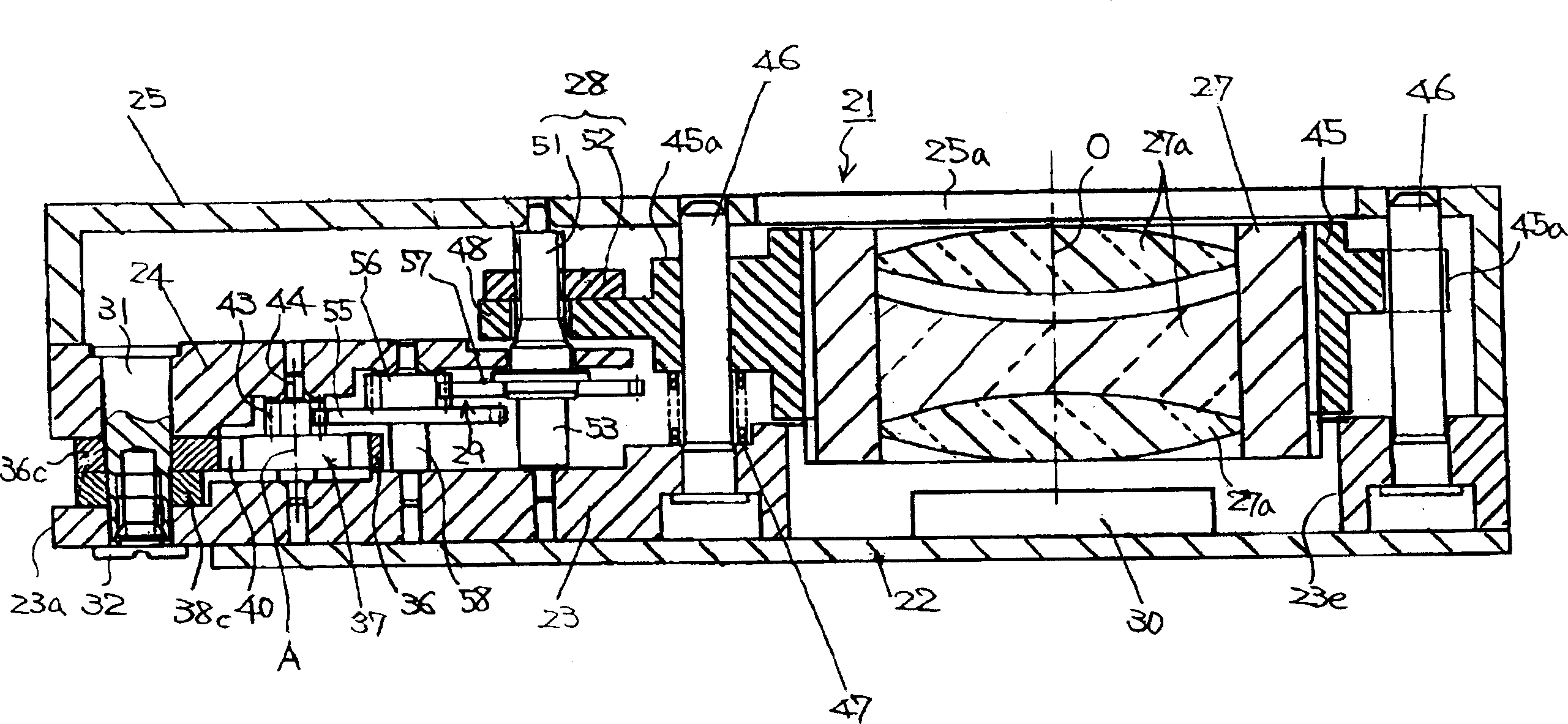

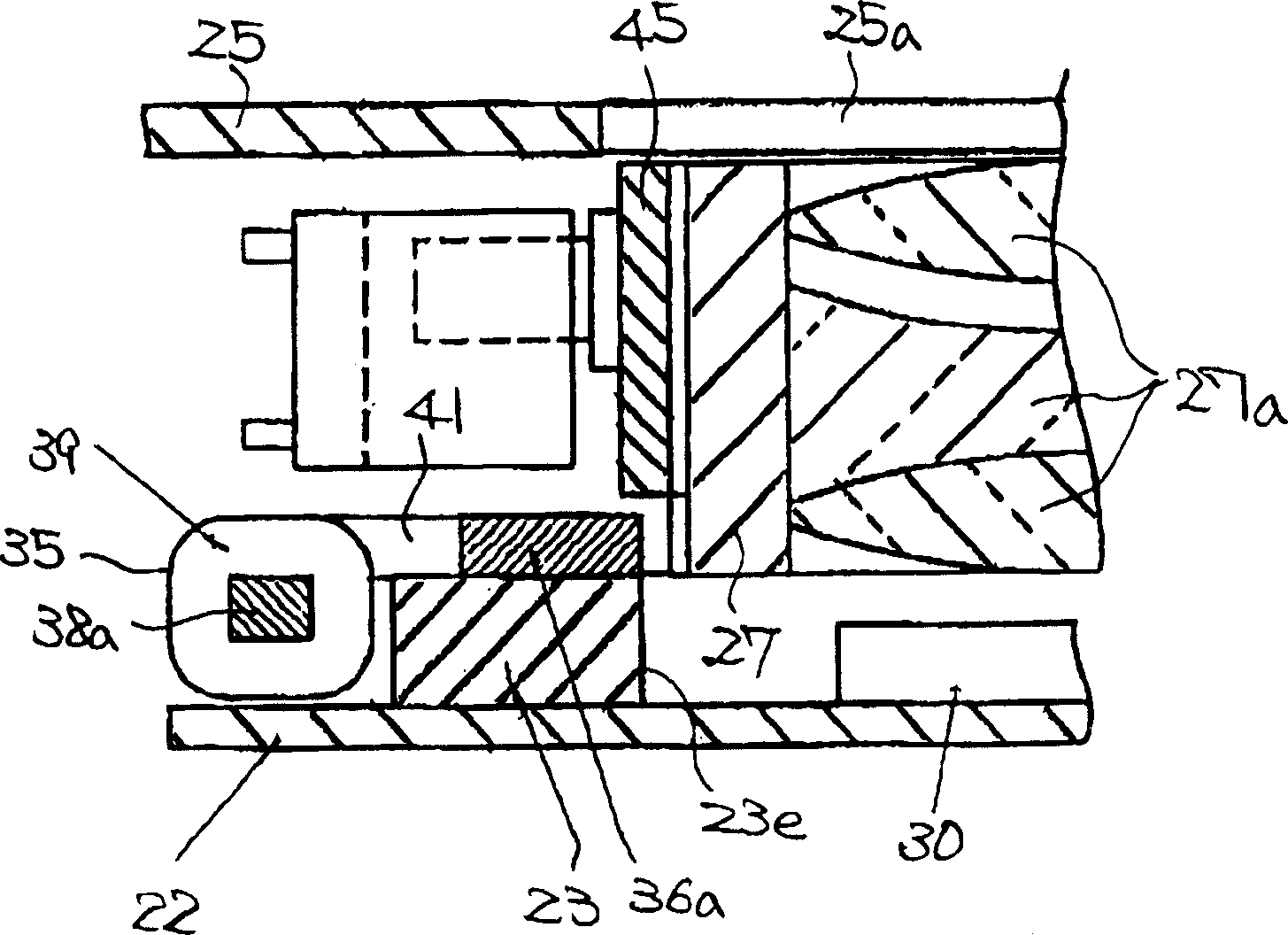

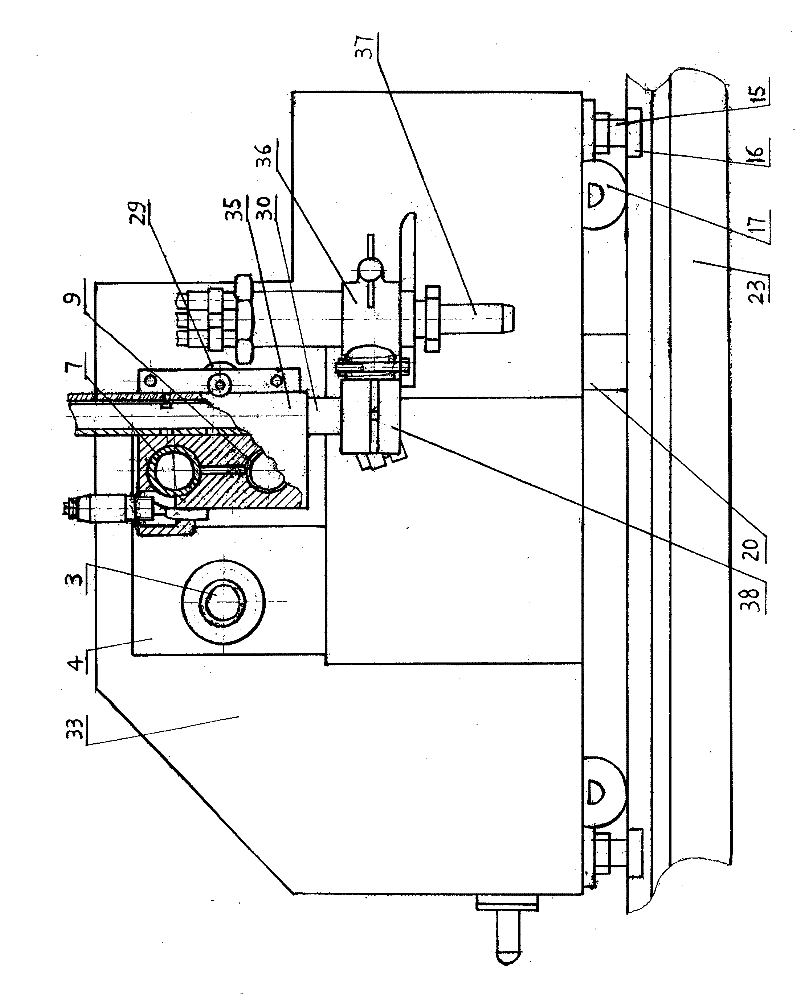

Optical module and camera module

InactiveCN1661410AGuaranteed movement accuracySuppress power lossProjector focusing arrangementCamera focusing arrangementOptical ModuleOptical axis

Provided is an optical module that is thin, allows freedom of design in configuration, and assures the accuracy of movement of an optical part while suppressing power loss. A stepping motor 26 and a lens barrel 27 that is moved by moving means 28 are positioned offset from each other along a base plate 23 , and the optical axis of the lens barrel 27 and the axis of a rotor 37 provided in the stepping motor 26 are arranged in parallel with each other on one surface of the base plate 23 . Further, a reduction gear train 29 , which operatively couples the rotor 37 and the moving means 28 together, is arranged on the one surface. The stepping motor 26 consists of a flat-shaped motor equipped with: coil blocks 35 each having an excitation coil 39 horizontally mounted along the base plate 23 ; a yoke 36 whose magnetic path portion 36 a excluding end portions 36 b and 36 c connected with the coil blocks 35 is provided so as not to overlap the coil blocks 35 ; and the rotor 37 arranged within a rotor pass-through hole 40 of the yoke 36.

Owner:SEIKO INSTR INC

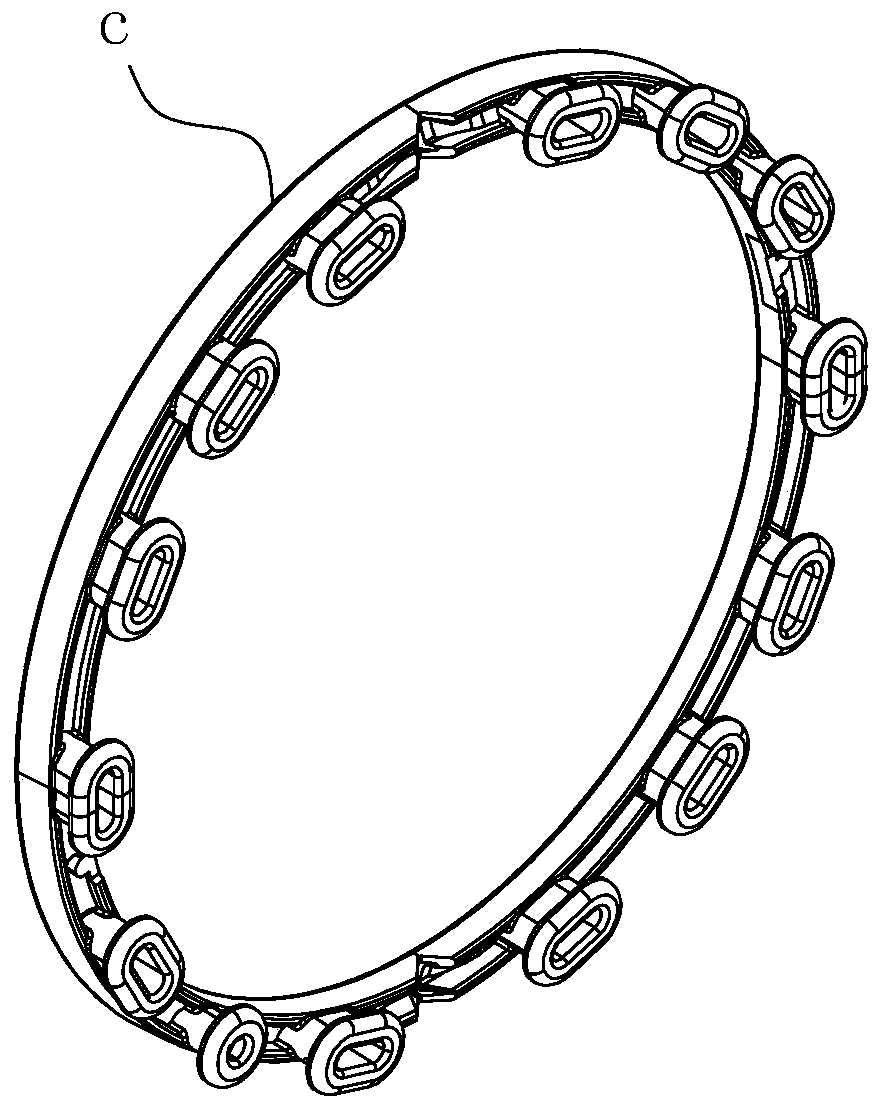

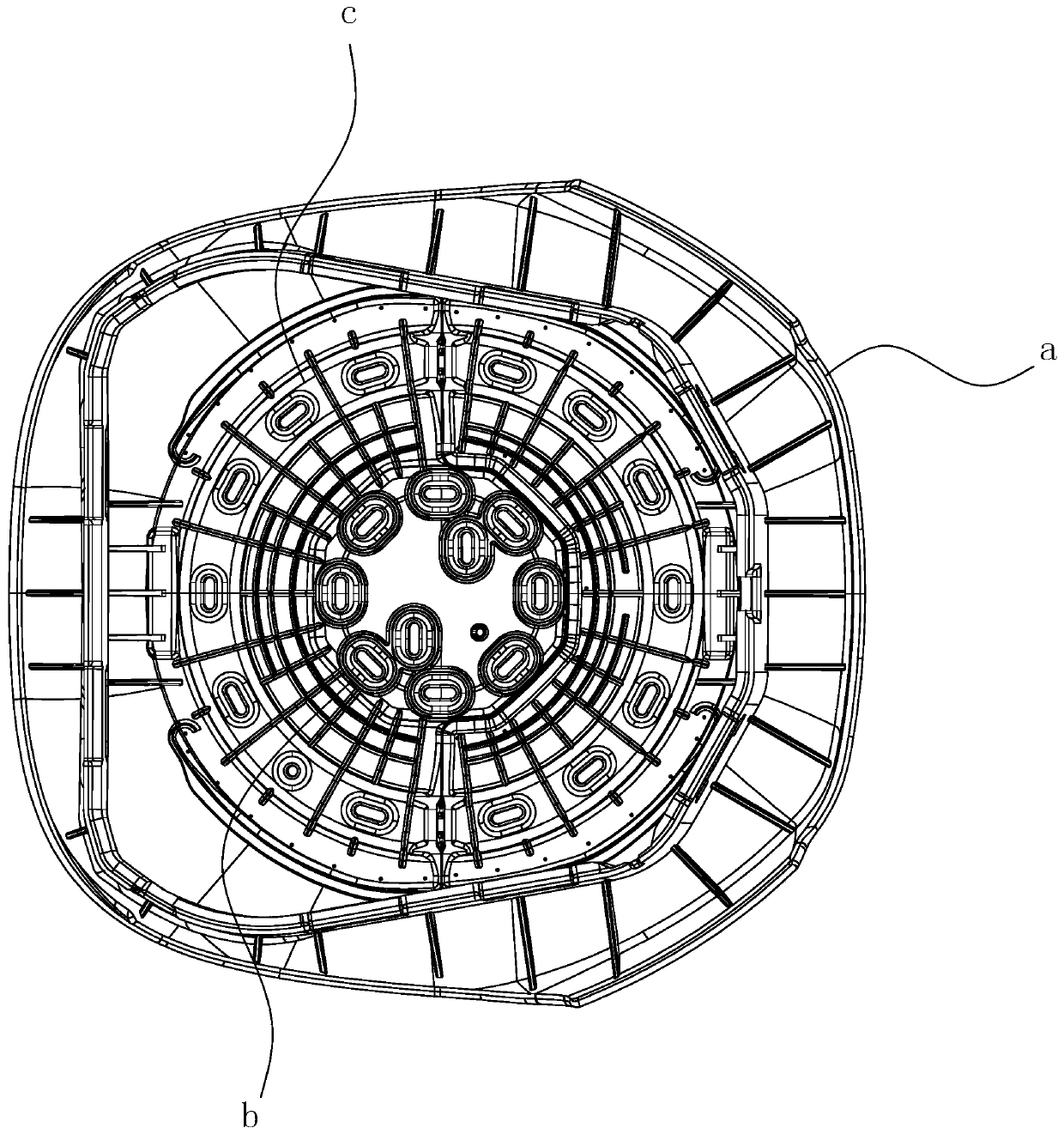

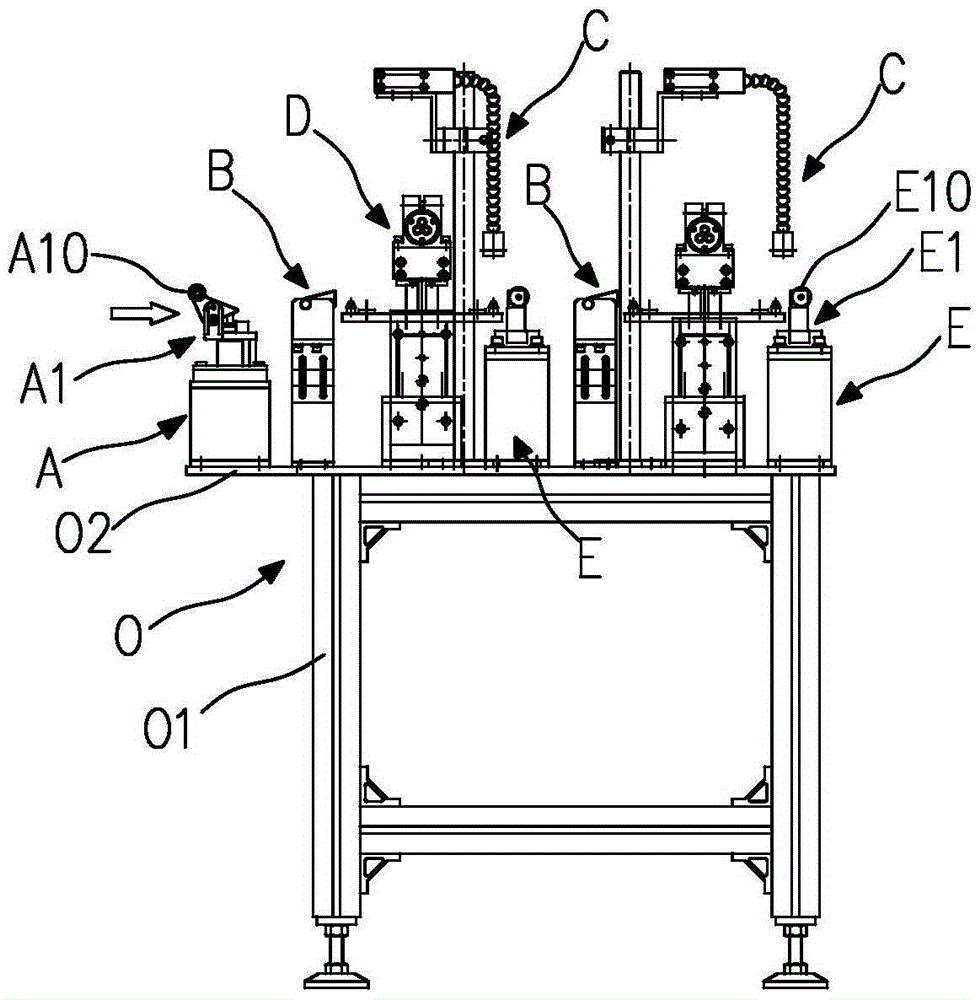

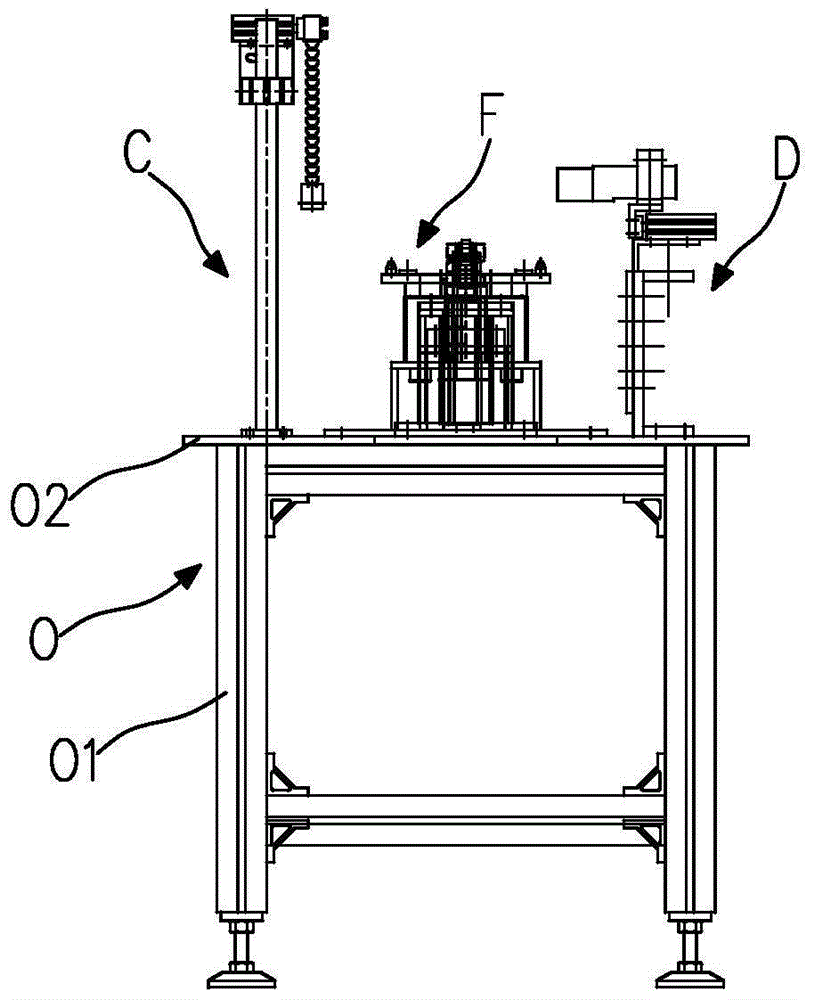

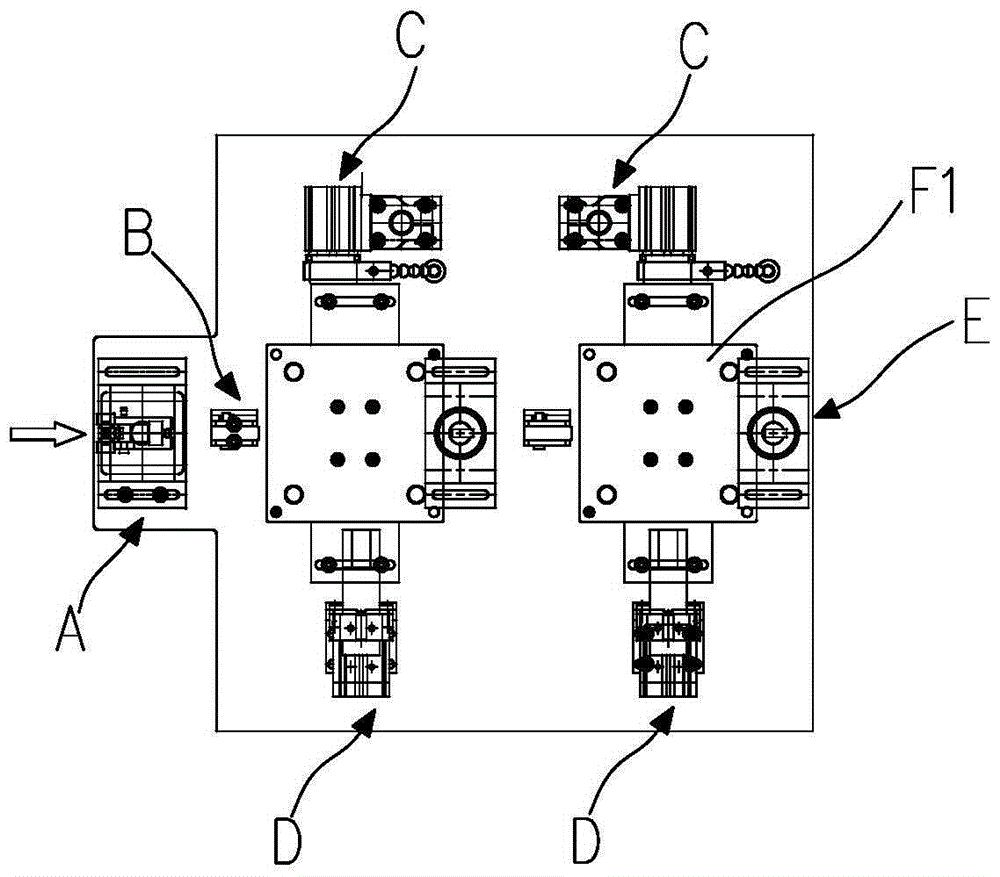

Four-station turntable type hot air welding machine and welding method thereof

The invention belongs to the technical field of automobile part processing, and particularly relates to a four-station turntable type hot air welding machine and a welding method thereof. The four-station turntable type hot air welding machine comprises a machine frame with a working table board, and a turntable assembly, a hot air assembly and a riveting assembly which are arranged at the side ofthe turntable assembly are arranged at the machine frame. The four-station turntable type hot air welding machine has the advantages that automatic welding operation of a company mark and a company mark ring at a safety air bag cover can be realized, and the operation threshold is low, time and labor are saved in the welding process, and no harm is caused to workers in the welding process, and the welding quality of the company mark and the company mark ring can be effectively guaranteed. The welding method applying the four-station turntable type hot air welding machine comprises the following steps of 1) a pre-processing process; 2) a code scanning process; 3) a hot air process; 4) a riveting process; and 5) a shooting and discharging process. The welding method has the advantages thatthat the actual processing efficiency of the welding process is systematically improved.

Owner:明光利拓智能科技有限公司

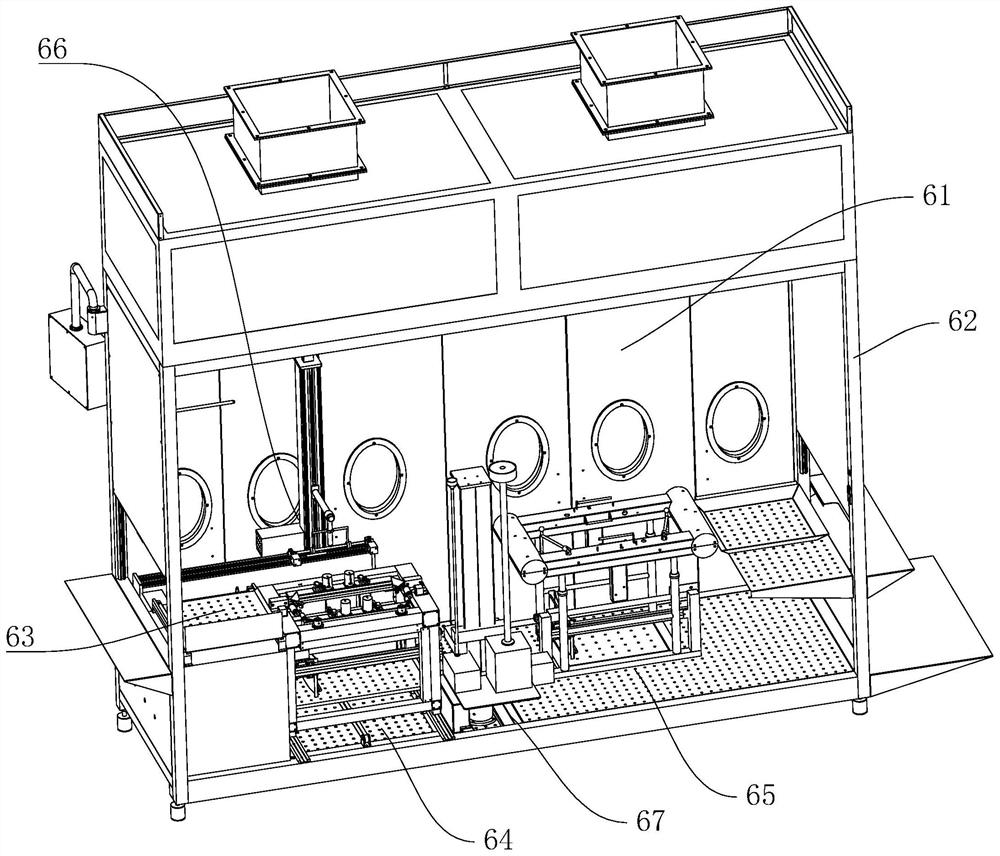

Full-automatic double-bag packaging ORABS system for sterile inner bags

ActiveCN112591208AGuaranteed working environmentGuaranteed movement accuracyPackage sterilisationWrapper twisting/gatheringProcess engineeringMechanical engineering

The invention discloses a full-automatic double-bag packaging ORABS system for sterile inner bags. The full-automatic double-bag packaging ORABS system comprises a machine shell with a sterile packaging cavity, a bag placing area, an inner bag sealing machine and an outer bag sealing machine are arranged in the sterile packaging cavity, and a bag grabbing and transferring device for conveying bagson the bag placing area into the inner bag sealing machine is arranged in the sterile packaging cavity. An inner bag lifting and transferring device for conveying the bags packaged by the inner bag sealing machine into the outer bag sealing machine is arranged in the sterile packaging cavity. The automatic double-bag packaging ORABS system for the sterile inner bags has the following advantages and effects that a mechanical mode is used for replacing manual work to complete the double-packaging process of inner and outer double bags, automation of the packaging process is achieved, and long-term development of enterprises is met. An ORABS system is adopted in the sterile packaging cavity, a barrier is formed through aeromechanics of the micro-positive pressure effect, and the protective effect on the sterile packaging cavity is achieved. The circulation speed is controllable, so that the air can be continuously circulated and updated. Particles existing in an operation room can be removed, pollution from the outside is prevented, and the A-level requirement of a clean area of a new edition of GMP is met.

Owner:浙江亚光科技股份有限公司

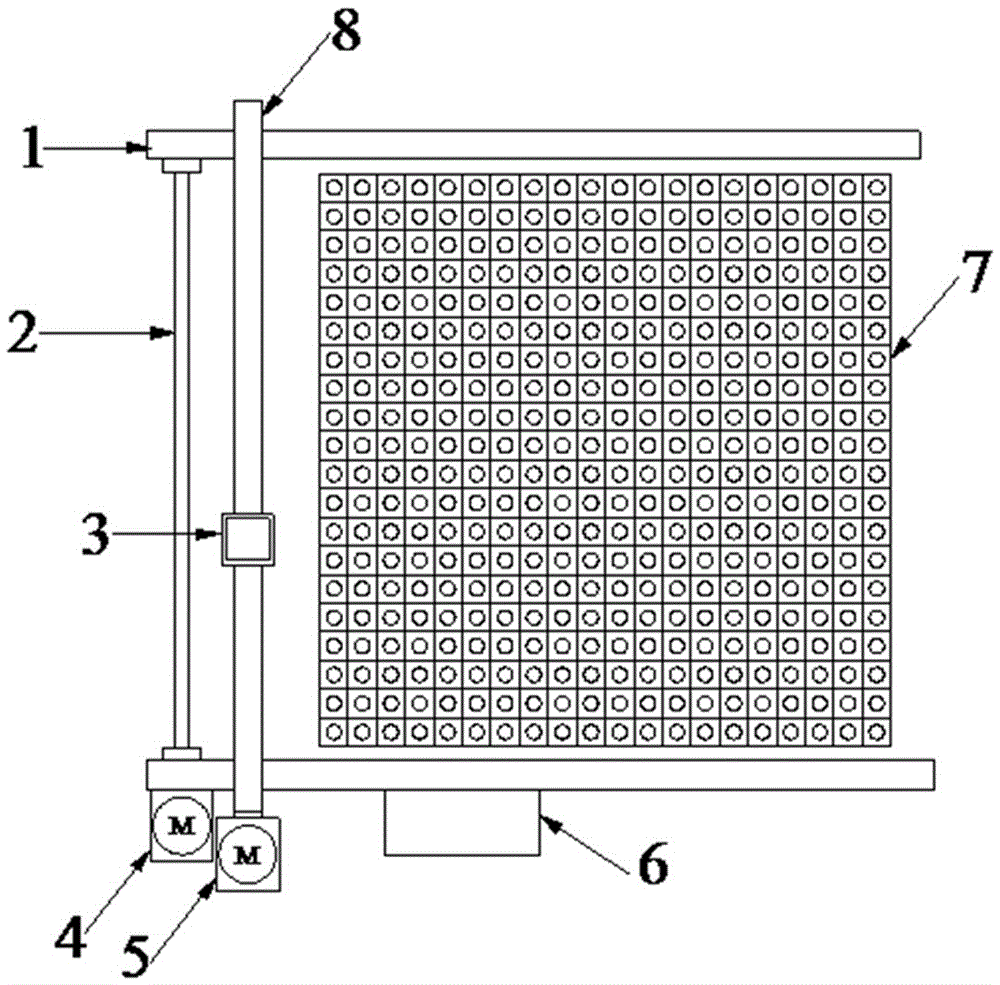

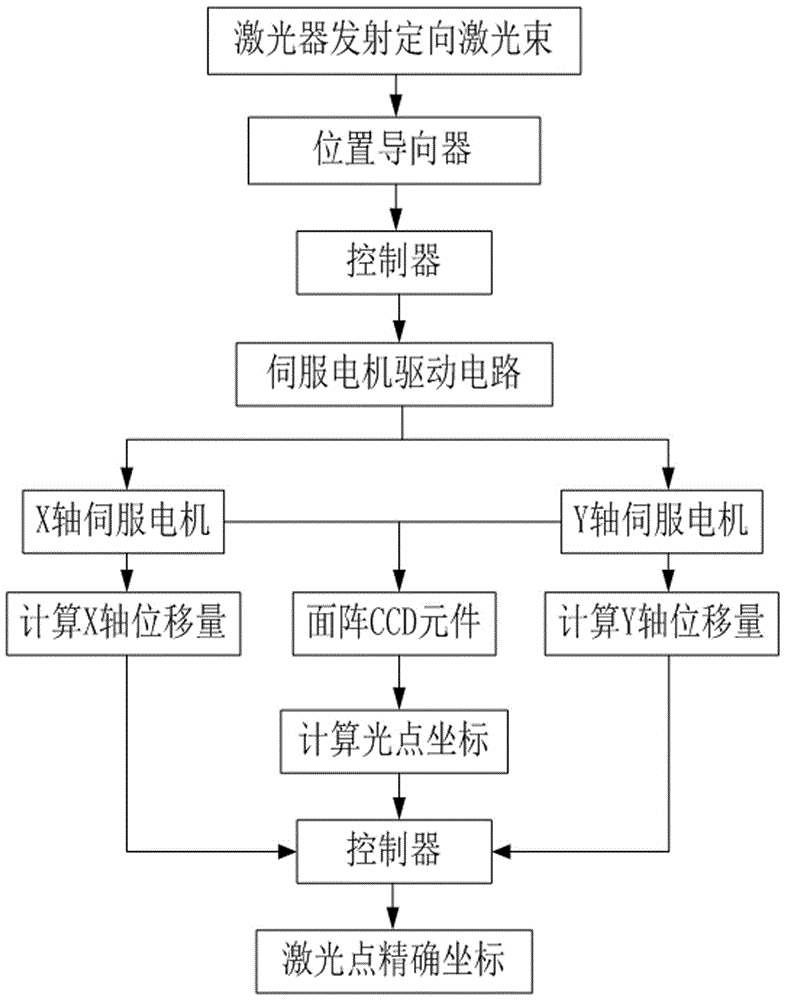

Method and device for accurate measurement of large-range displacement and application

InactiveCN106500600ALarge measuring rangeLarge rangeHeight/levelling measurementUsing optical meansMeasurement precisionLarge range

The invention relates to the technical field of accurate measurement of displacement, particularly to the technical field of settlement observation, and discloses a method and device for accurate measurement of large-range displacement and application. Through cooperative use of an area array CCD and a position guider, and through combination of two-stage displacement measurement, a distance measurement range is greatly expanded. The device provided by the invention is high in automation degree, the measurement accuracy reaches up to a micron grade, and the device has the characteristics of accuracy, rapidness and wide displacement measurement range. The device can be widely applied to a measurement process of large-range displacement offset, such as high-speed railroad subgrade settlement monitoring and tunnel deformation measurement.

Owner:SHIJIAZHUANG TIEDAO UNIV

Portable cantilever-type numerical control cutter

ActiveCN102528215AImprove balanceGuaranteed movement accuracyGas flame welding apparatusNumerical controlMotor drive

A portable cantilever-type numerical control cutter is characterized in that a transverse stepping motor drives a duplicate gear through a planetary gear reducer, an upper gear and a lower gear of the duplicate gear are engaged with a transverse moving rack rod and a balance rack rod respectively, a cutting torch support is fixedly mounted at the front ends of the transverse moving rack rod and a transverse guide rod, a lifting rack rod is arranged on the cutting torch support, a bevel gear on a lifting motor is engaged with the lifting rack rod, and a cutting torch is mounted on a fixed support at the lower end of the lifting rack rod. A longitudinal stepping motor drives the planetary gear reducer, a longitudinal gear on the reducer is engaged with a rack on a guide rail, a guide wheel shaft and an eccentric guide wheel shaft which are distributed on two sides of the guide rail are fixed to two ends of the bottom edge of a trolley, and guide wheels close to the guide rail are mounted on the wheel shafts. The portable cantilever-type numerical control cutter is high in moving precision and fine in transverse movement stability, longitudinal movement is pure rolling with gapless guide so that the portable cantilever-type numerical control cutter is excellent in cutting precision and comparable to a gantry-type numerical control cutter, and the portable cantilever-type numerical control cutter is easy in mounting and carrying and long in service life.

Owner:赵拥军 +1

Improved track-type welding robot control system

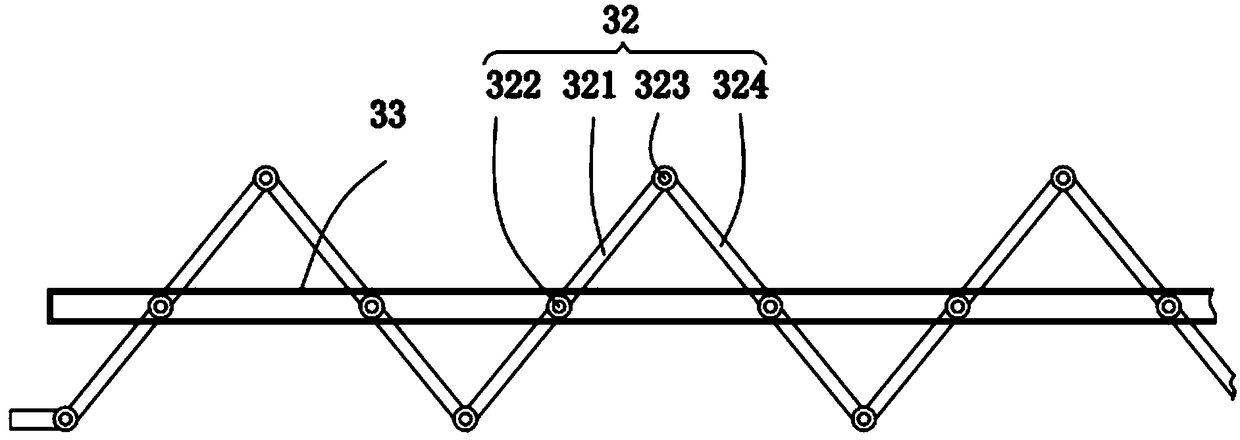

InactiveCN109158725AHigh movement accuracyGuaranteed movement accuracyGas flame welding apparatusOxygenBottle

The invention discloses an improved track-type welding robot control system. The improved track-type welding robot control system comprises a transport cart, sliding grooves, a moving car, wheels, sealing mechanisms, sealing flexible boards, shear-type racks, first supporting rods, first rotation shafts, second rotation shafts, second supporting rods, guide rails, a supporting mechanism, a rotating chassis, a first hydraulic rod, a fixing base, a second hydraulic rod, a rotating and adjusting mechanism, a rotating wheel, a fixing frame, a rotating motor, a connecting column, a fixing base, limiting rotary knobs, a welding mechanism, an air source connector, a stud, an air injection welding pipe, a flue gas treatment mechanism, a connector, a draft fan, an activated carbon adsorption board,a smoke exhaust pipe, a protective cover, a smoke exhaust connector, an oxygen bottle, an acetylene bottle and a machine case. According to the welding robot, sealing protection on the sliding grooves can be achieved, the tops of the sliding grooves are completely covered, outside dust and smudge entering is avoided, the moving precision of the moving car is guaranteed, and then the welding precision is improved; and produced flue gas and heat can be quickly extracted out.

Owner:江苏派远软件开发有限公司

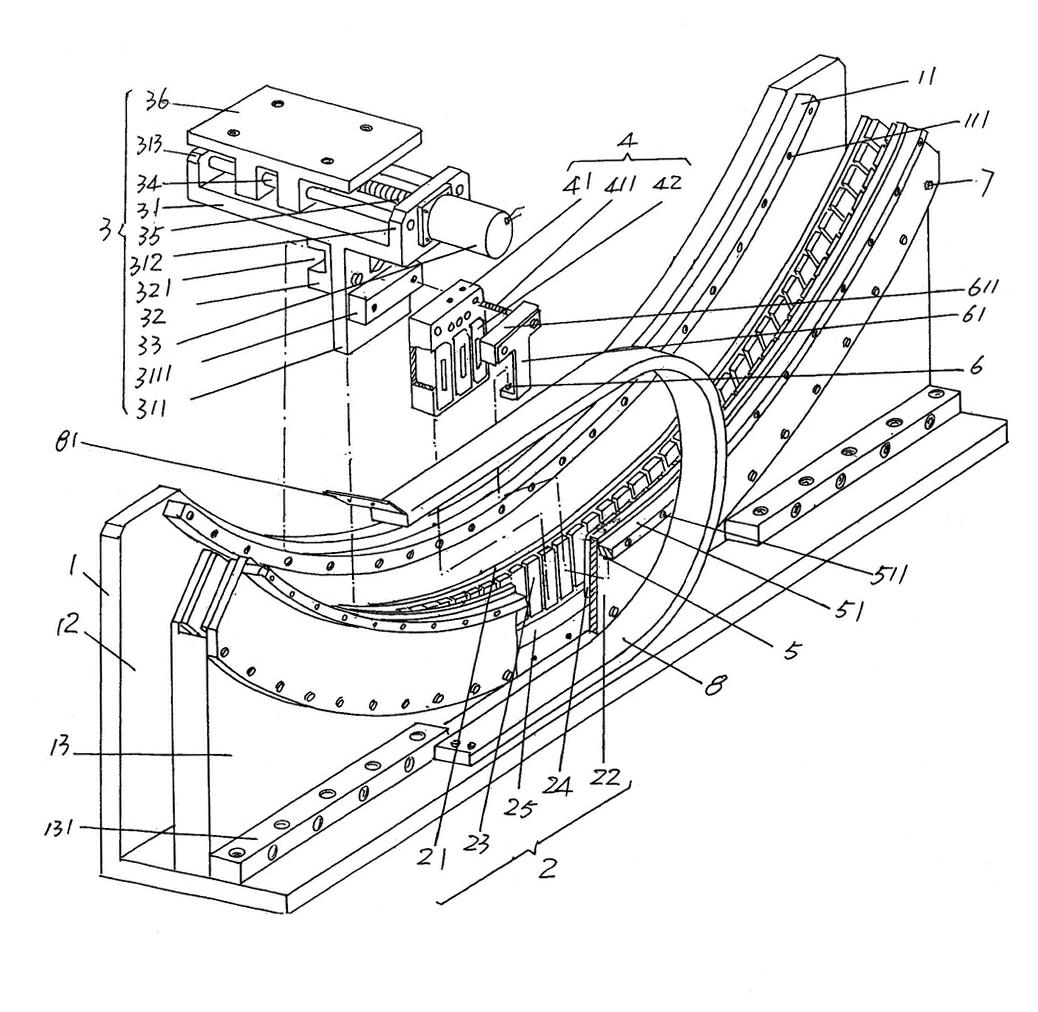

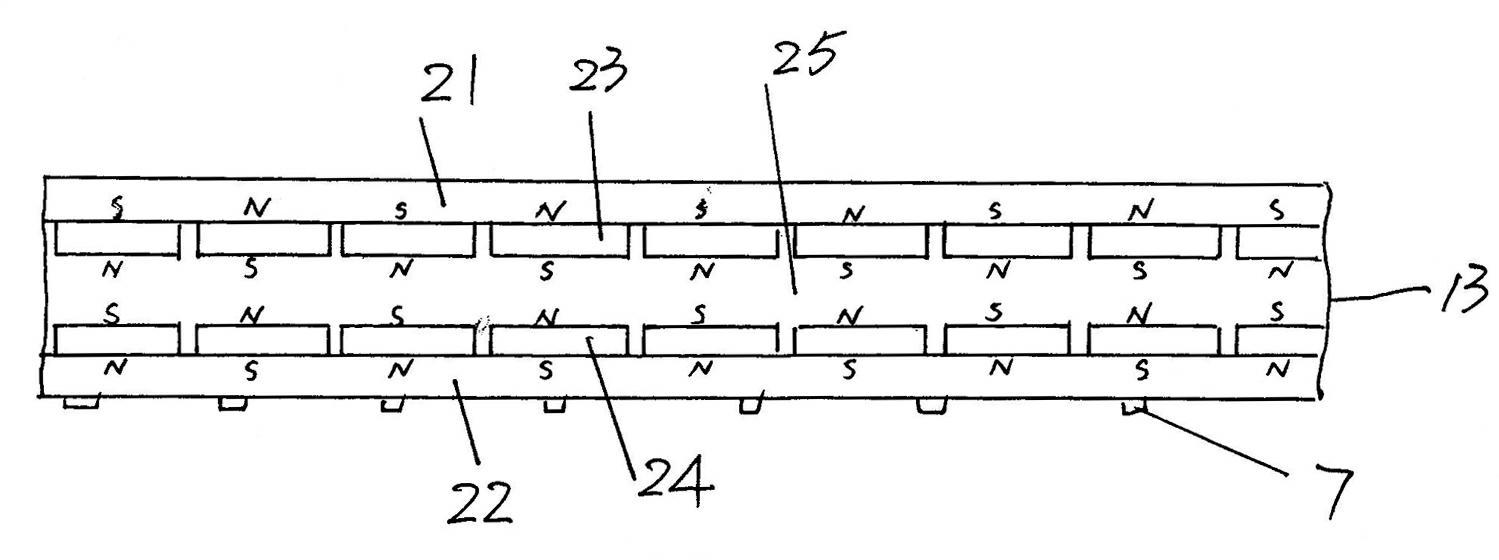

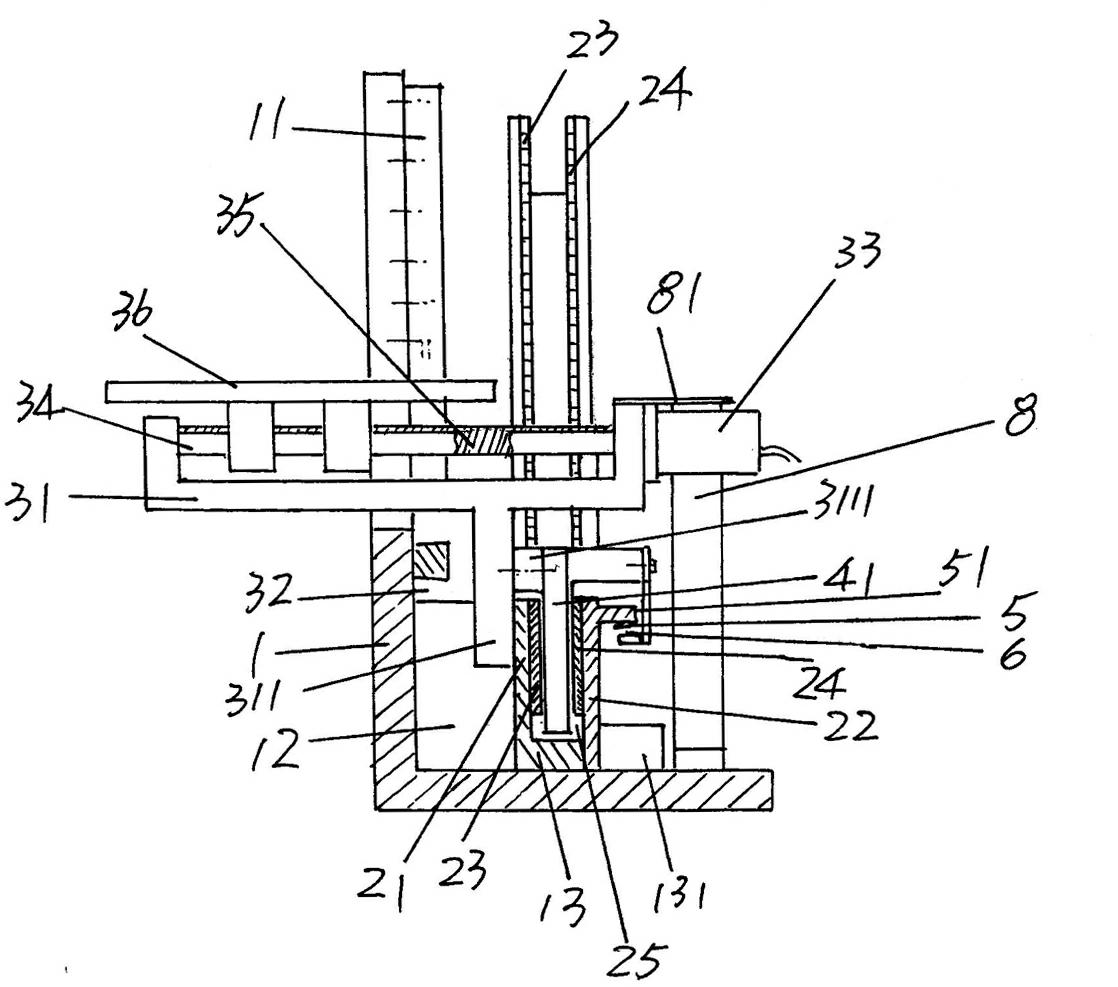

Direct-drive circular arc movement platform structure

InactiveCN102490165AGuaranteed movement accuracyEnsure movement stabilityWork benchesGratingControl engineering

The invention discloses a direct-drive circular arc movement platform structure, belonging to the technical field of measurement and automation control devices. The direct-drive circular arc movement platform structure comprises a substrate, a stator mechanism, a circular arc movement platform, a mover mechanism, a grating scale and a grating head, wherein the top of the substrate in the length direction takes the shape of a circular arc, the stator mechanism is fixed on the substrate and corresponding to the length direction side of the substrate, the circular arc movement platform is arranged on the substrate, the mover mechanism is fixed on the circular arc movement platform and matched with the stator mechanism, the grating scale is arranged on the stator mechanism, and the grating head is fixed on the mover mechanism and matched with the grating scale. The direct-drive circular arc movement platform structure has the advantages that: the movement precision and movement stability of the circular arc movement platform can be ensured, and the reliability in transverse movement of the circular arc movement platform can also be ensured; the whole structure is simple and compact thus being conducive to manufacture and assembly; a subsequent control algorithm can be simplified due to the cooperation of the grating head and the grating scale so as to satisfy operating requirements on precise detection, precise manufacture and automation control occasion.

Owner:SUZHOU PUSI AUTOMATION TECH

Integrated and interchangeable rear material-blocking device of bending machine

ActiveCN107520294ARealize fully automatic controlGuaranteed uptimeMetal-working feeding devicesPositioning devicesEngineeringStructural engineering

The invention discloses an integrated and interchangeable rear material-blocking device of a bending machine and belongs to the technical field of bending machines. The integrated and interchangeable rear material-blocking device of the bending machine comprises a pair of beams, X-axis components, Y-axis components, Z-axis components, finger-blocking components and a balance adjusting component, wherein the beams are used for installing the X-axis components, the X-axis components are used for driving the Y-axis components to move in the X-axis direction, the Y-axis components are used for driving the Z-axis components to move in the Y-axis direction, and the Z-axis components are used for driving the finger-blocking components to move in the Z-axis direction. The balance adjusting component comprises an adjusting plate connected with the beams and a supporting plate connected with the bending machine; adjusting screw nails at two ends of the adjusting plate penetrate through the adjusting plate and props against the supporting plate; adjusting holes in two ends of the adjusting plate are internally provided with fastening screw nails which are used for connecting the adjustment plate with the supporting plate; and two sides of a hole in the middle of the adjusting plate is provided with a pair of blocking plates, a positioning column penetrates through the hole and is connected to the supporting plate, and the blocking plates are provided with locking screw nails which are used for pressing the positioning column tightly. According to the integrated and interchangeable rear material-blocking device of the bending machine, the material-blocking position is adjustable, and the integrated and interchangeable rear material-blocking device of the bending machine is of better universality, interchangeability and impact resistance, and the problem that the positioning of the material-blocking position is inaccurate due to machining and assembly errors is eliminated.

Owner:ANHUI JACO NC MACHINE MFG

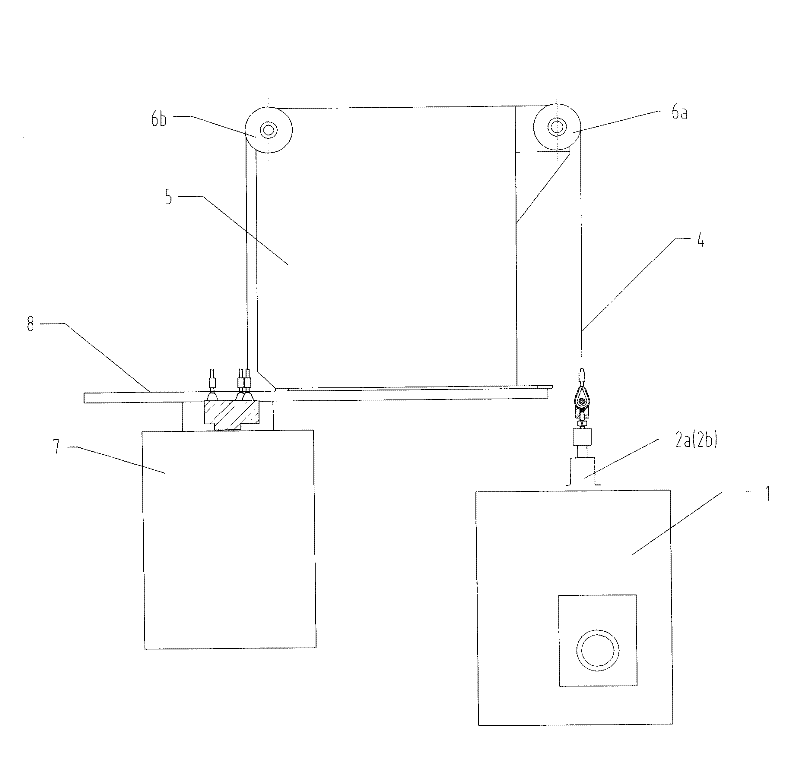

Assembling and scraping method of spindle box square hole assembling and scraping device

The invention discloses an assembling and scraping method of a spindle box square hole assembling and scraping device. The process is as follows: a moving seat is pushed, so that a ram part moves stably on a precision linear guide track to a position near the front end of a spindle box; a handle on a ram support adjusting mechanism is rotated, and a center of the ram part and a square hole center of the spindle box are enabled to be equal in height by the aid of a lead screw nut adjusting mechanism; a traction cable is connected with two ends of the ram part, bypasses a fixed pulley on a traction pulley support, and is connected with a lifting hook of a travelling crane; the ram part is pushed into a square hole of the spindle box; and the ram part is pulled forward and backward through the movement of the lifting hook on the travelling crane, and assembling and scraping are performed. With the adoption of the technical scheme, the production efficiency is improved, a potential danger that the ram part collides into the spindle box, so that a workpiece is bumped or damaged is eliminated, the manufacturing accuracy of a product is improved, the product quality is greatly improved, and human power and material resources are saved.

Owner:WUHU HENGSHENG HEAVY MACHINE TOOL

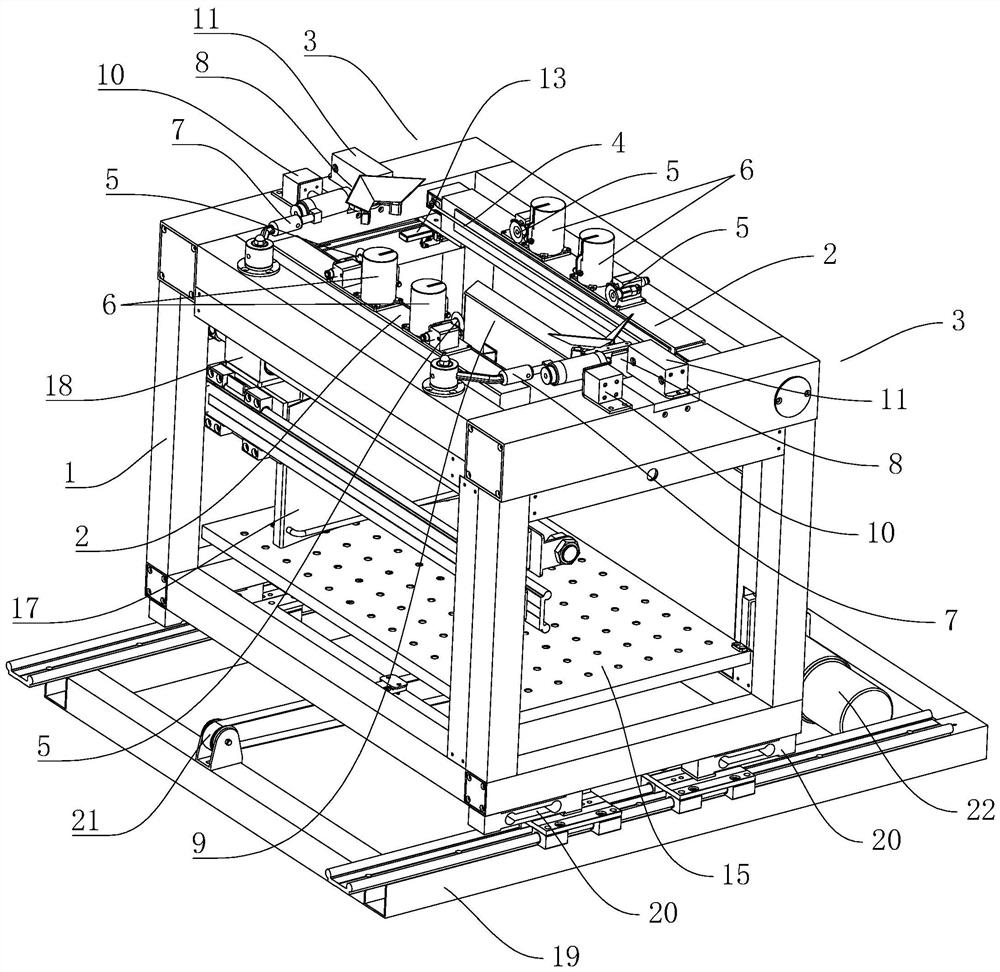

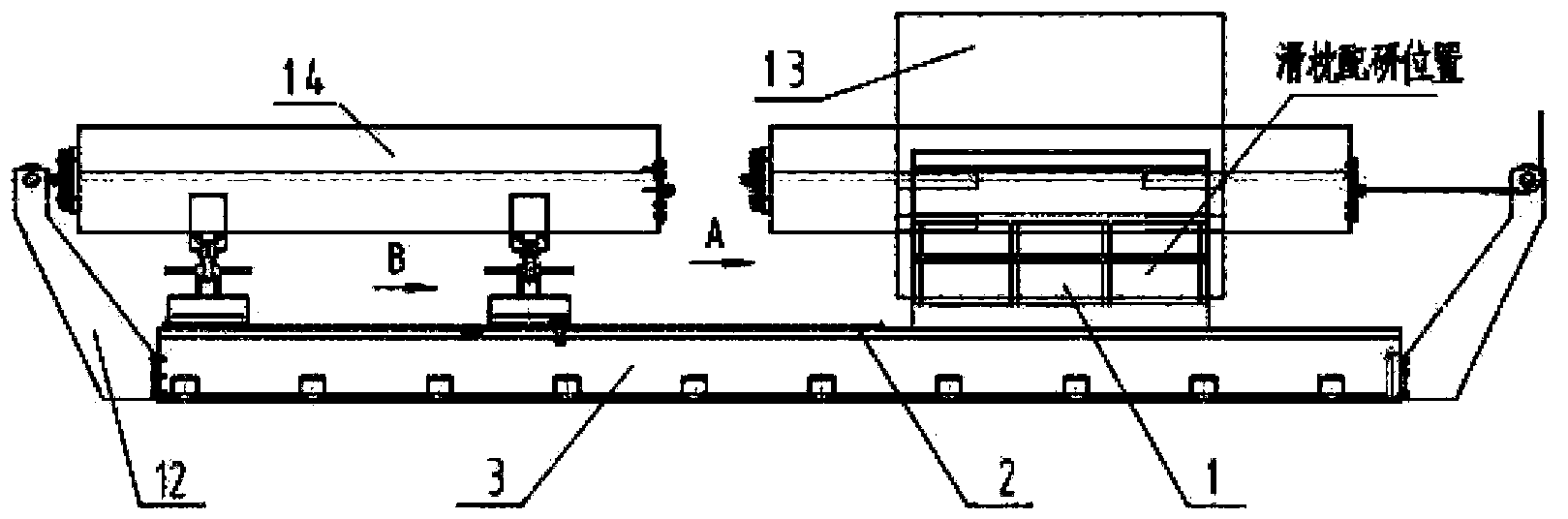

Automatic feeding equipment for symmetrical positions of paired workpieces

ActiveCN110902303AEasy to moveGuaranteed movement accuracyControl devices for conveyorsMechanical conveyorsAssembly lineClassical mechanics

The invention belongs to the field of machining and particularly relates to automatic feeding equipment for symmetrical positions of paired workpieces. The equipment comprises a bottom frame, a hopper, a vibrating disk, a conveying rail which is mounted at an outlet of the vibrating disk and used for conveying parts, and an assembly line mounted on the bottom frame, wherein a carrier is arranged on the assembly line, a mounting plate is fixedly connected with the bottom frame, the mounting plate is provided with a material receiving part, a transplanting mechanism used for mounting parts ontothe carrier from the material receiving part and a positioning mechanism used for positioning the carrier, the transplanting mechanism has no displacement in the direction of the assembly line, and the movement tracks of the transplanting mechanism are the same all the time. The equipment is advantaged in that the positioning mechanism is arranged so that two part mounting holes in the carrier move to the same mounting position by several times, moving tracks of the transplanting mechanism are the same, and moving precision of a pneumatic clamping jaw during part clamping is kept, through a structural form, moving precision of the positioning mechanism driving the carrier to move can be kept consistent, and errors are reduced.

Owner:SUZHOU ZHIRUI PHOTOELECTRIC MATERIAL TECH CO LTD

Refrigerator compressor performance test equipment

ActiveCN105201811APrevent reboundSmooth power-on performance test processPump testingPositive-displacement liquid enginesRefrigerated temperatureTest equipment

The invention discloses refrigerator compressor performance test equipment. The equipment comprises a mounting base, a first retaining device and multiple test units, wherein the first retaining device and the multiple test units are sequentially fixed on the mounting base; each test unit comprises a non-return device, a venting device, an energizing device and a second retaining device which are sequentially fixed on the mounting base; the first retaining device, the non-return devices and the second retaining devices are sequentially fixed along a refrigerator compressor conveying line, and the venting devices and the energizing devices are fixed on two sides of a detection station on the refrigerator compressor conveying line respectively. Jacking devices are further arranged on the refrigerator compressor detection station between the venting devices and the energizing devices and drive positioning tooling plates through double guide bar cylinders to ascend so as to lift refrigerator compressors, and the refrigerator compressors are separated from the conveying line. The equipment is compact in structure, high in adjusting speed and high in universality, is applicable to different types of refrigerator compressors and guarantees accuracy and reliability of tests.

Owner:HEFEI GENERAL MACHINERY RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com