Rotary table for numerical control floor type boring miller

A rotary table, boring and milling machine technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of poor centering accuracy, inconvenient installation, etc., to ensure position accuracy, ensure positioning, and solve the problem of rotation Eccentric effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

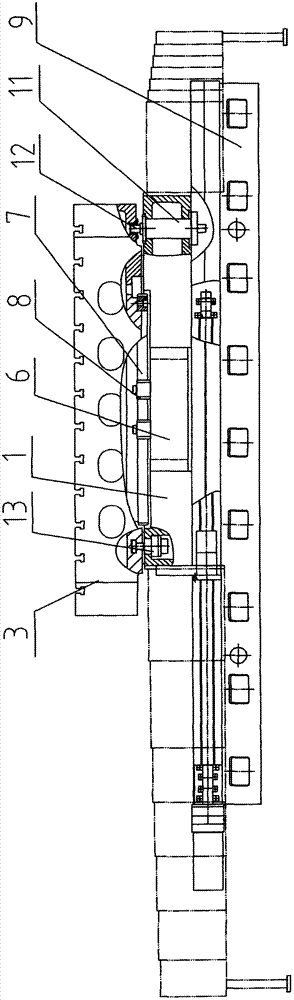

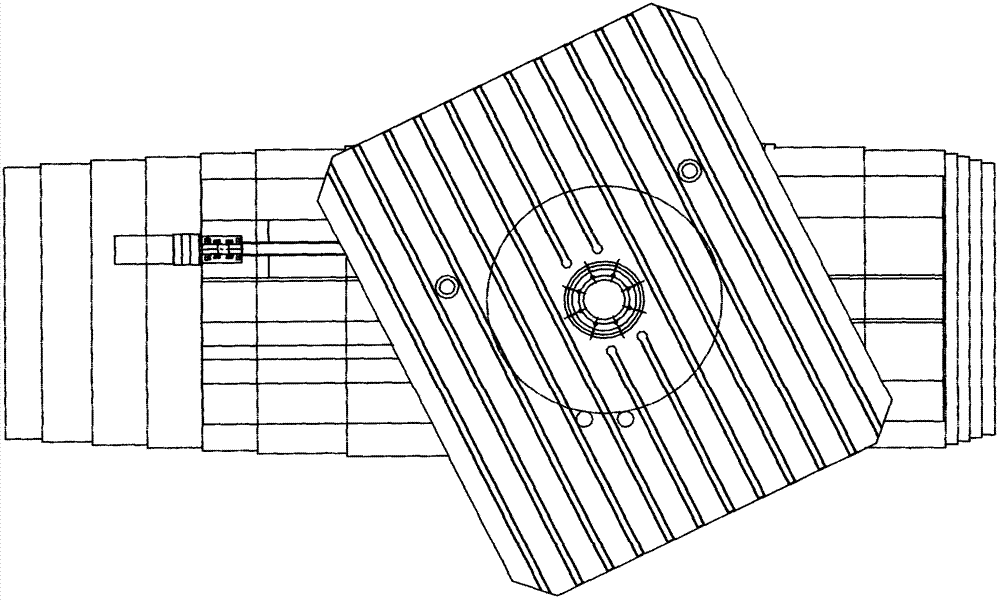

[0018] A rotary workbench for a CNC floor-type boring and milling machine, comprising a rotary slide 1, a mandrel 2 mounted on the rotary slide 1, and a working table 3, the worktable 3 is mounted on the rotary slide 1 through the mandrel 2.

[0019] The rotary slide 1 is connected with a screw transmission mechanism for driving the rotary slide 1 to move. The screw transmission mechanism includes a motor, a reducer and a double-nut anti-backlash pre-tightening ball screw. Tight ball screw connection, double nut anti-backlash pre-tightening ball screw and rotary slide 1 connection.

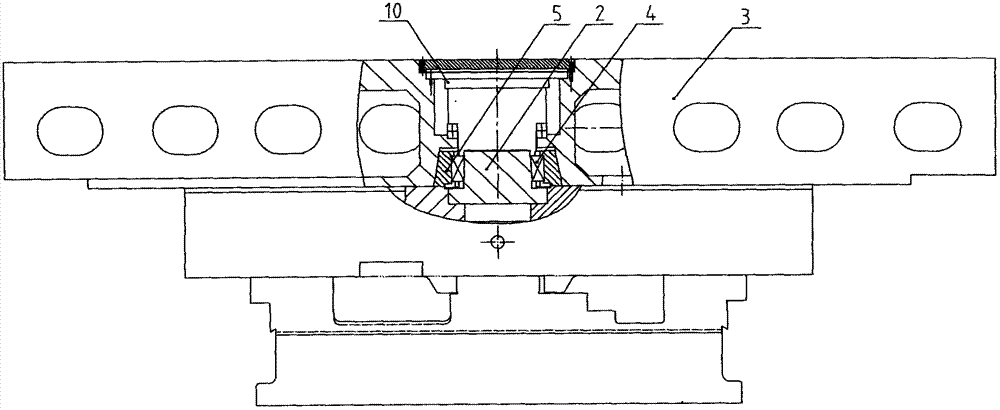

[0020] The center of the worktable 1 is provided with a rotary centering mechanism, which includes a double-row tapered roller bearing 4 with a tapered inner hole and a tapered sleeve 5 set on the double-row tapered roller bearing 4, and the double-row tapered roller bearing The roller bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com