Curve shaft rolling machine

The technology of a rolling machine and a curved shaft is applied in the field of curved shaft processing, which can solve the problems of affecting the roughness and rolling quality of cylindrical shafts, incapable of rolling processing of curved shafts of various diameters, and high manufacturing cost of a third rolling wheel. Achieve the effect of improving rotation flexibility, ensuring positioning, and convenient procurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

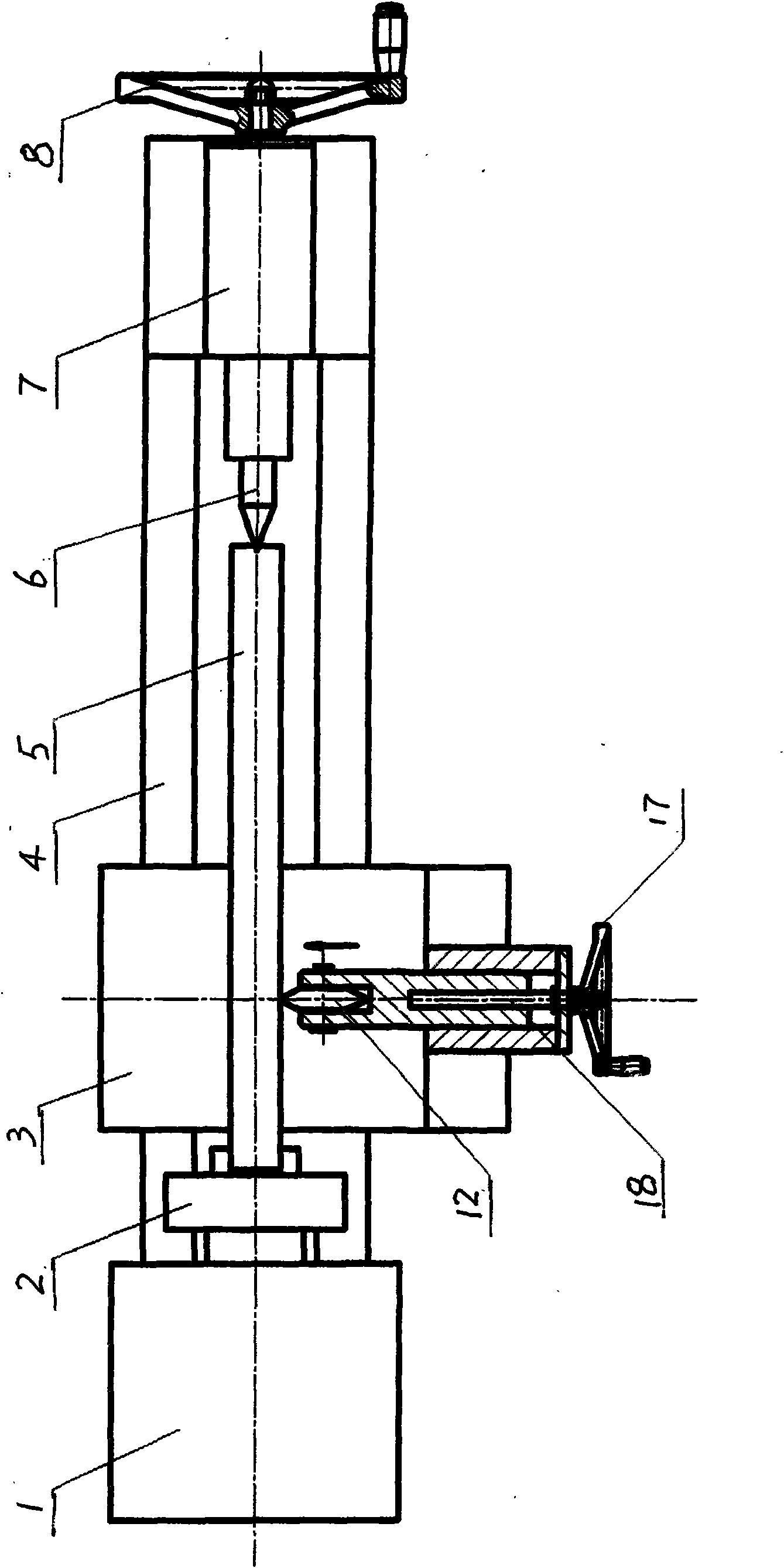

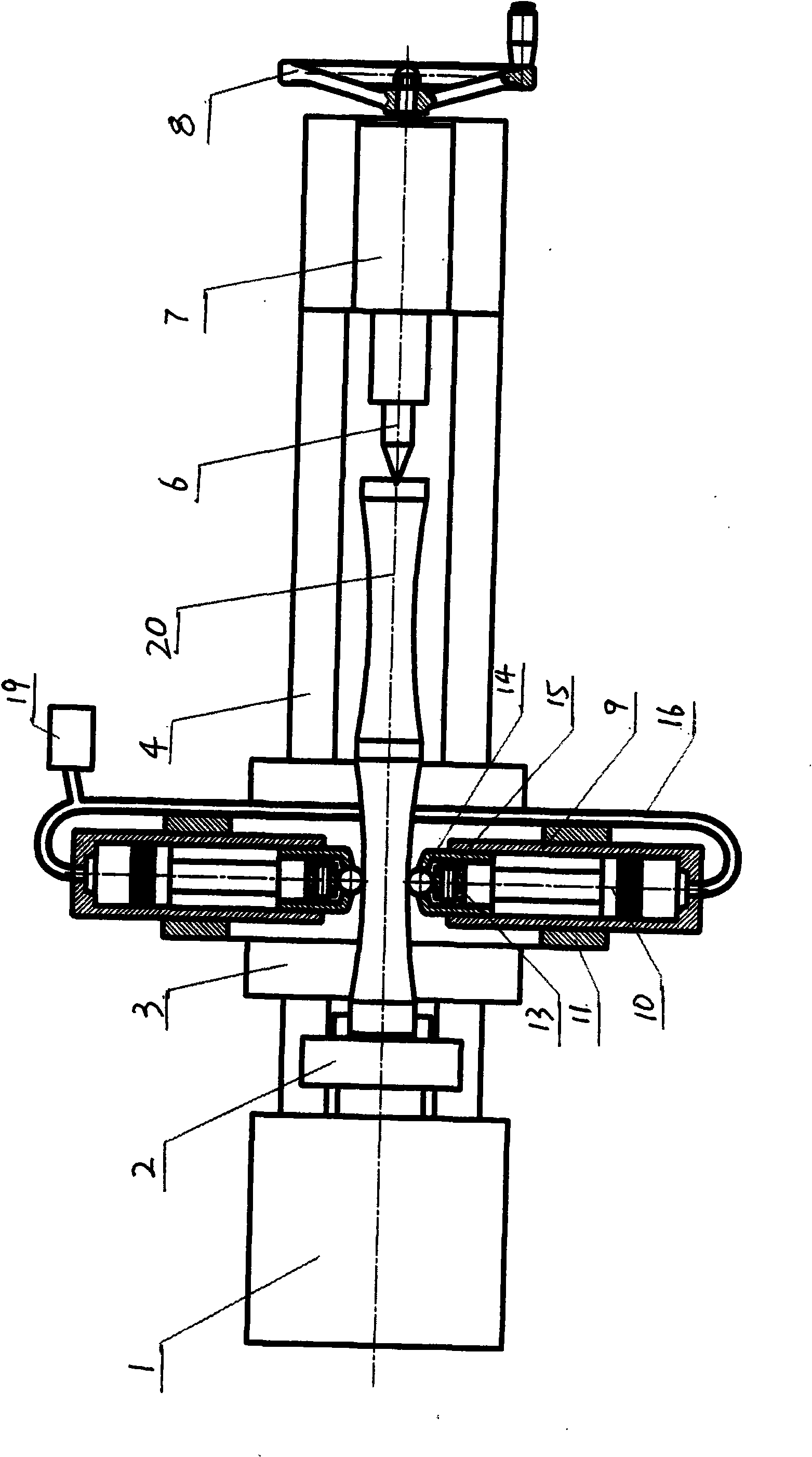

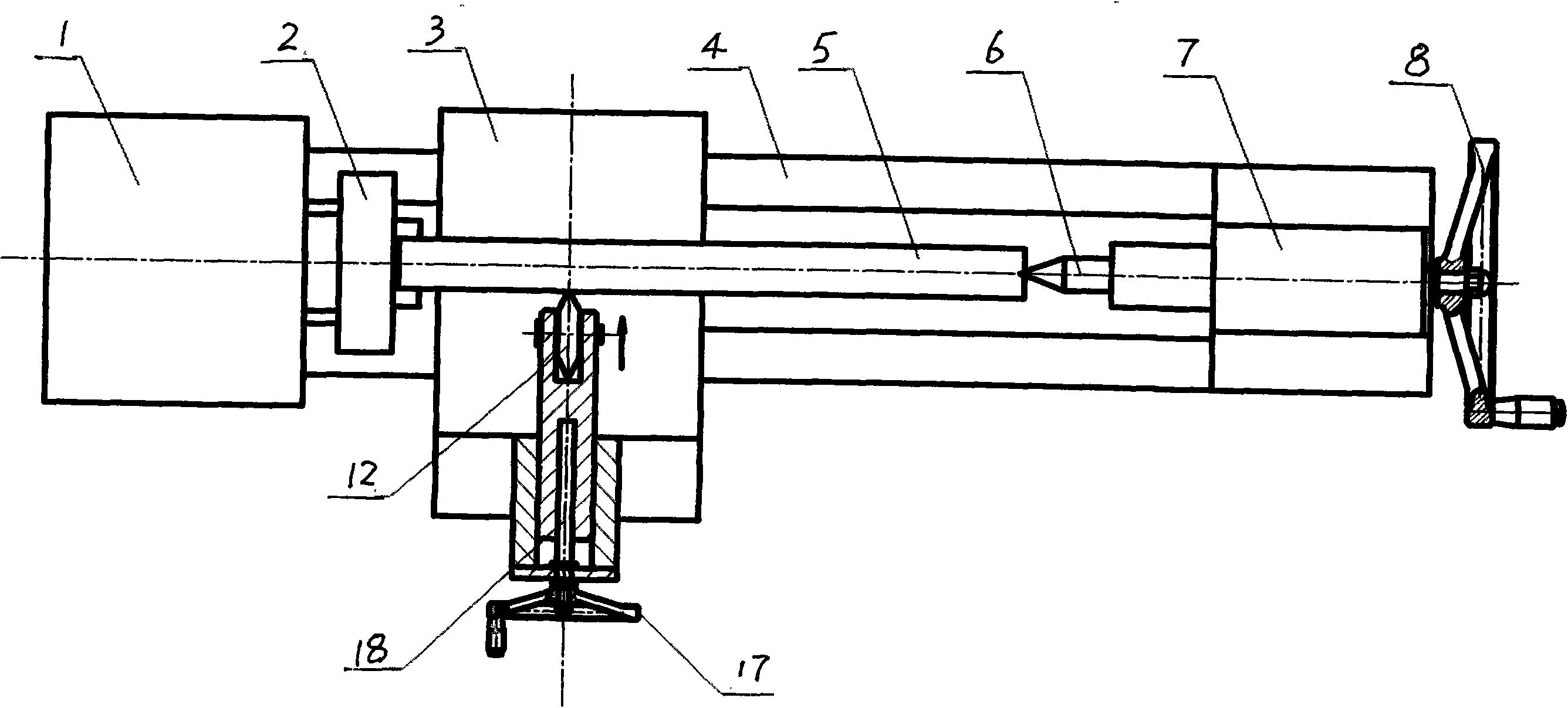

[0010] The structure of the traditional shaft rolling machine is as follows figure 1 shown. It is composed of power box 1, chuck 2, sliding table 3, guide rail 4, top 6, tailstock 7, hand wheel 8, hand wheel 17, screw 18, rolling wheel 12, power box 1 and chuck 2 form a rotating Power mechanism, the top 6 tailstock 7 handwheel 8 constitute the workpiece tightening mechanism, and the slide table 3 guide rail 4 constitutes the horizontal movement mechanism. Working process: First, clamp one end of the cylindrical shaft 5 to be rolled on the chuck, turn the hand wheel 8 to make the tip 6 protrude and tighten the other end of the cylindrical shaft 5; start the power box 1 to make the chuck 2 drive the cylindrical shaft 5 to rotate; The hand wheel 17 drives the screw 19 to rotate to move the rolling wheel 12 to the cylindrical shaft 5 until it is pressed against the cylindrical shaft 5. The rolling wheel 12 rotates with the cylindrical shaft 5 and rolls, and the operator starts th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com