Patents

Literature

704results about How to "Eliminate friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

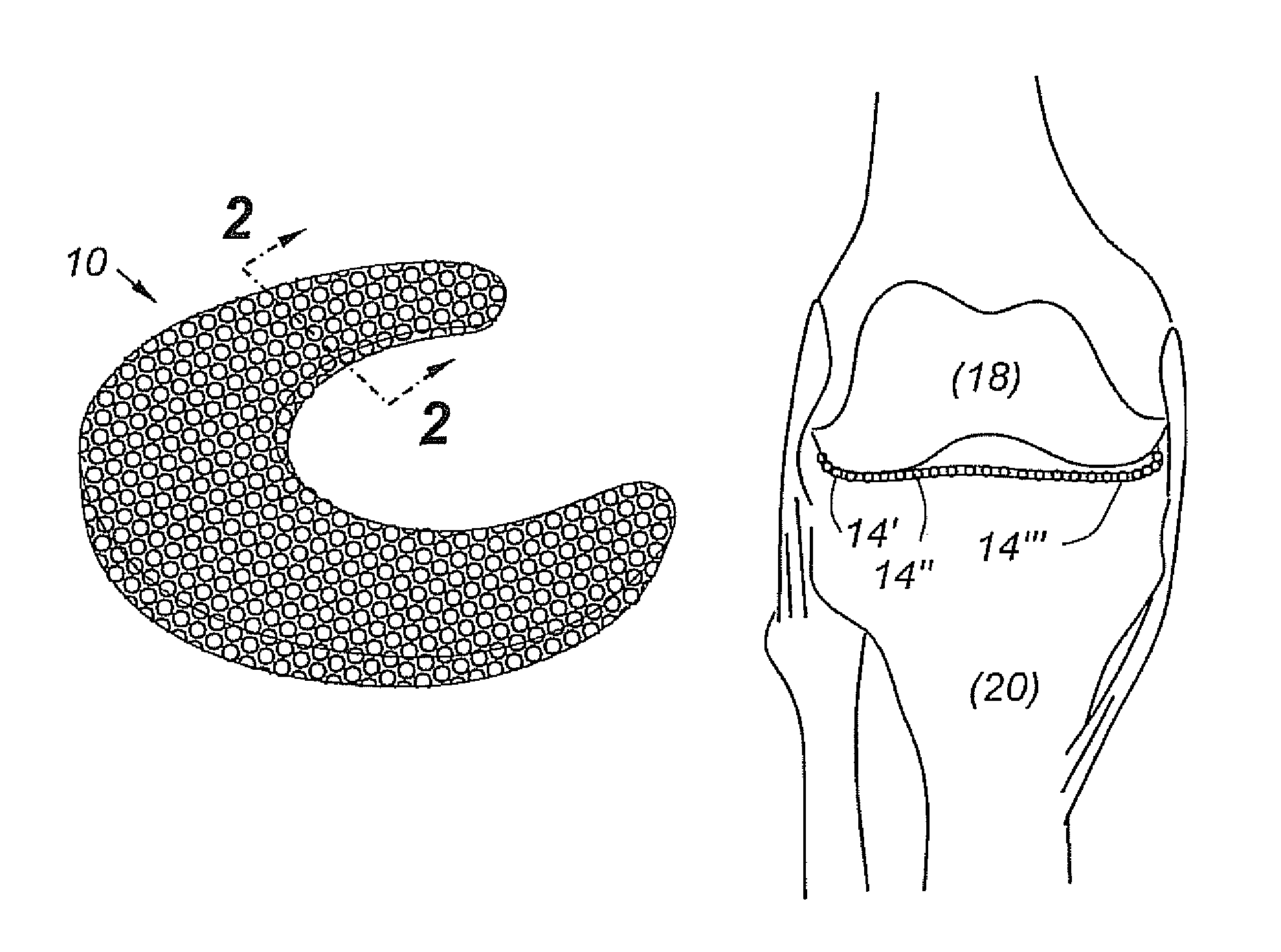

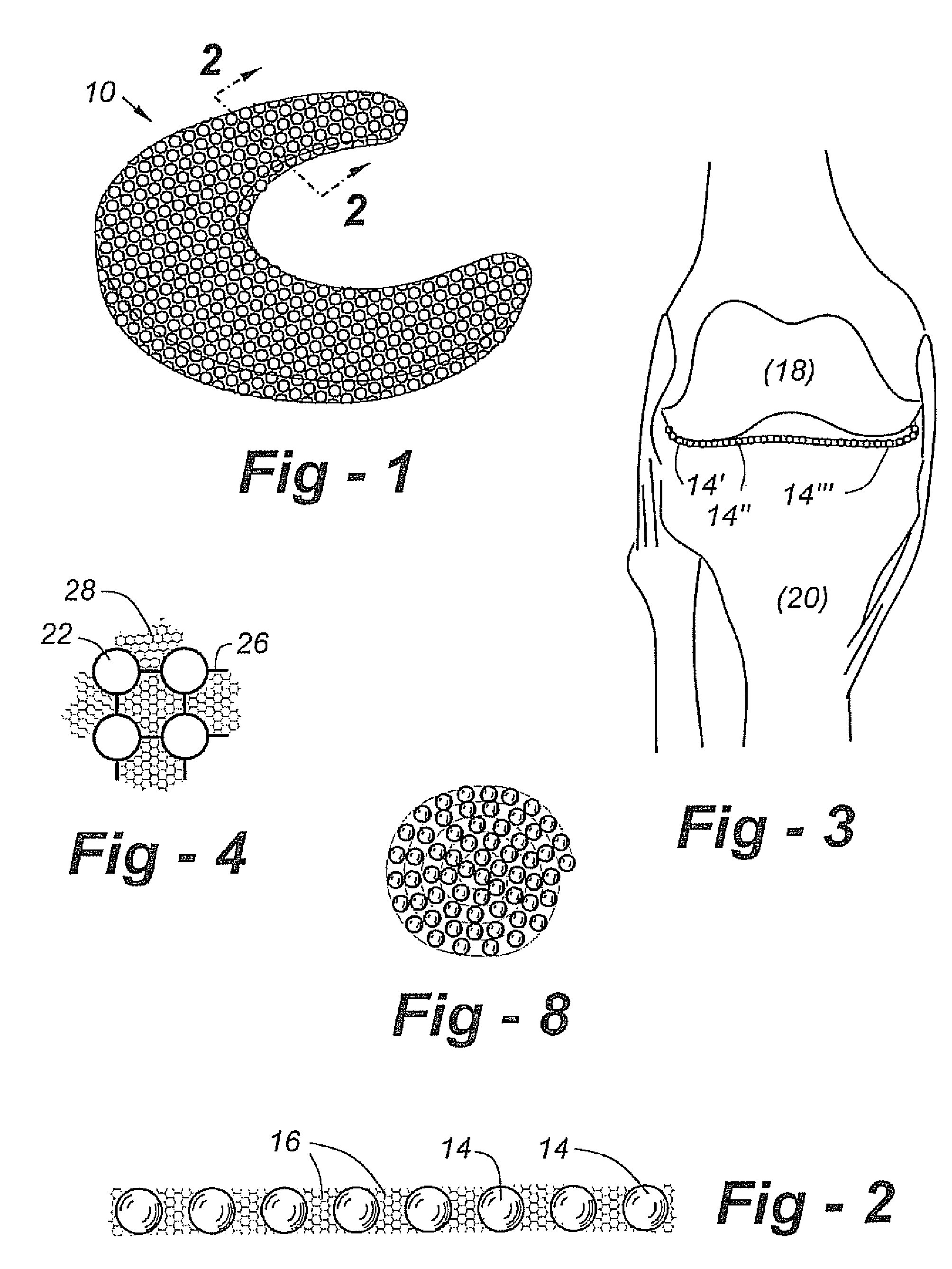

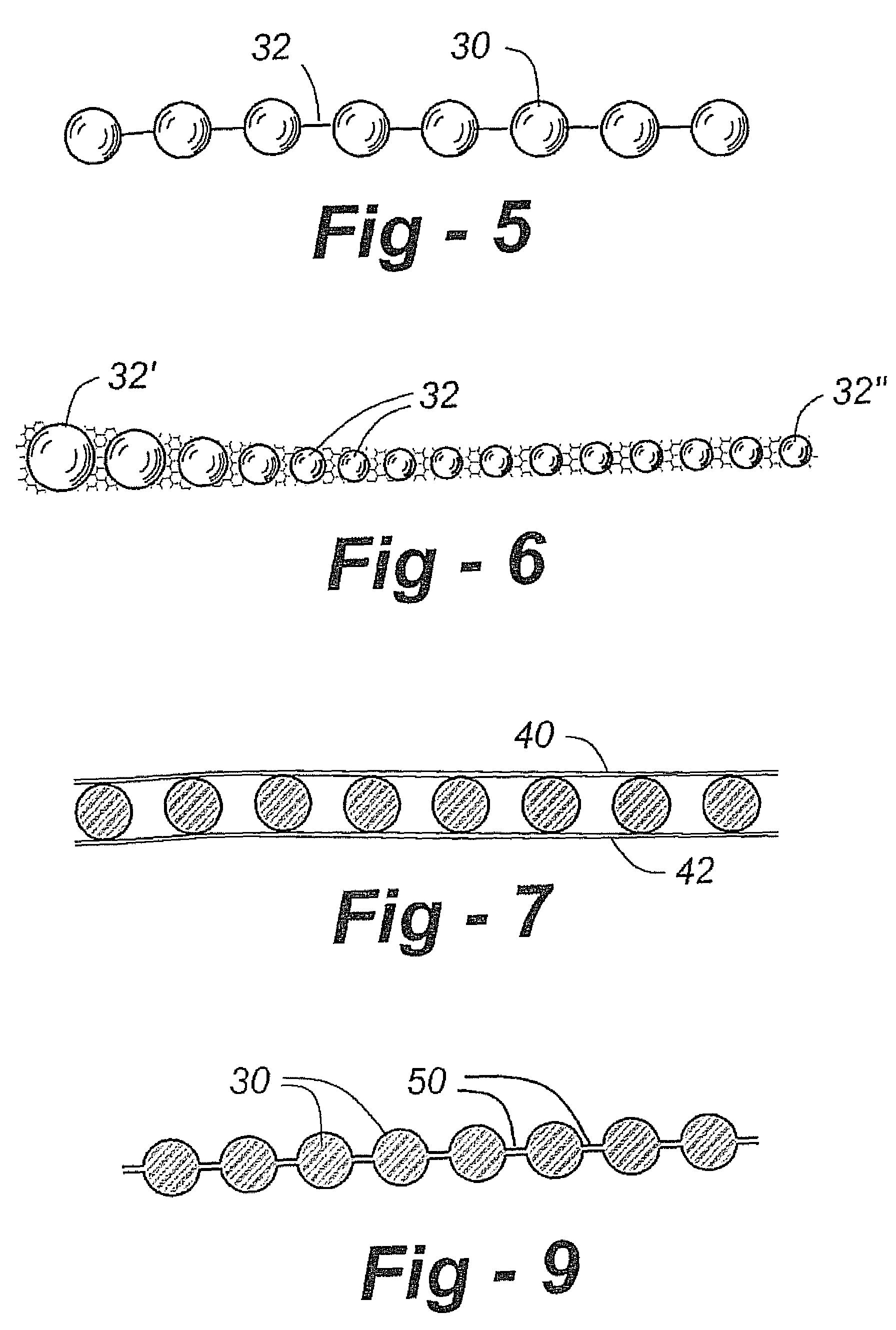

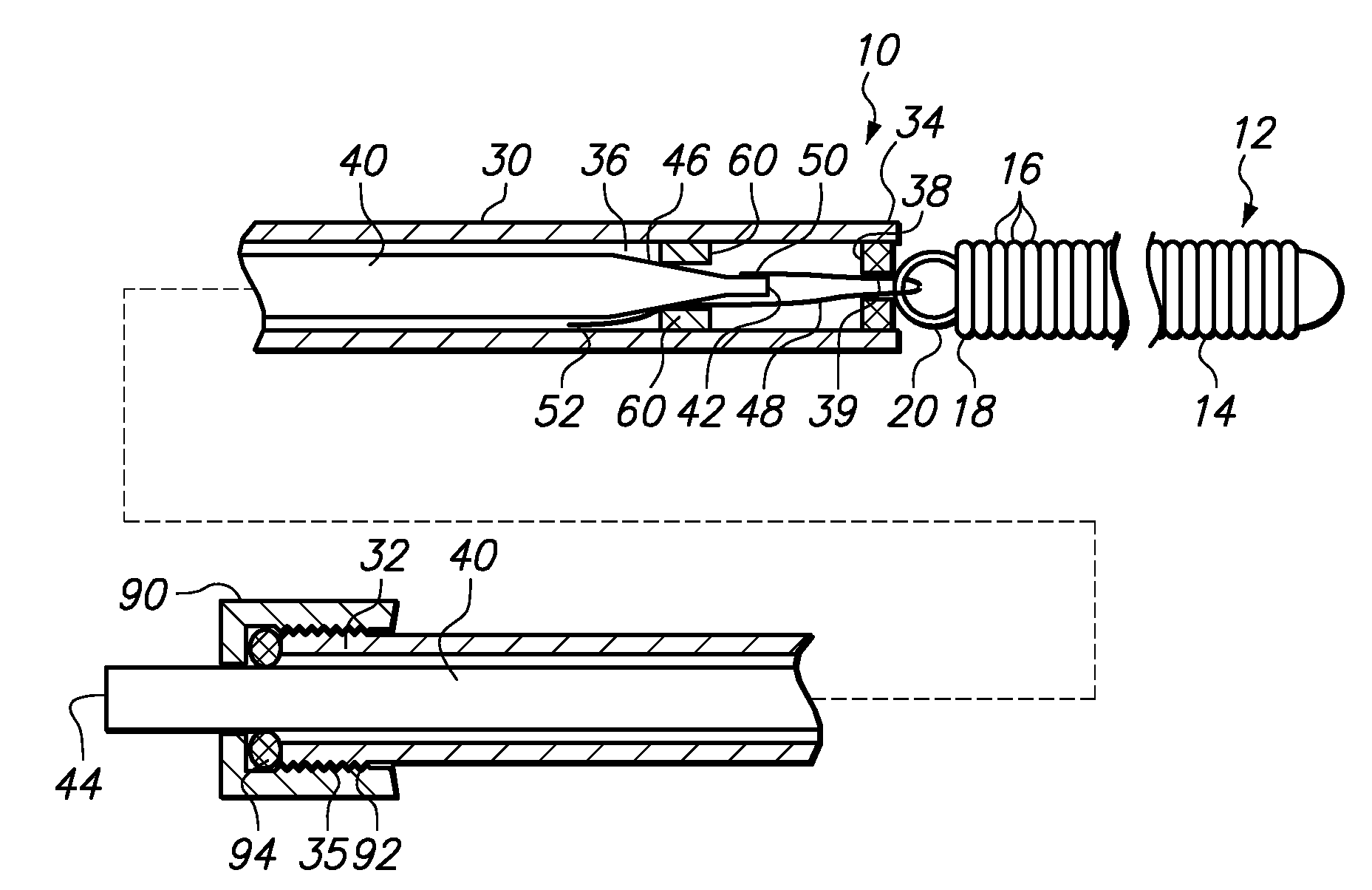

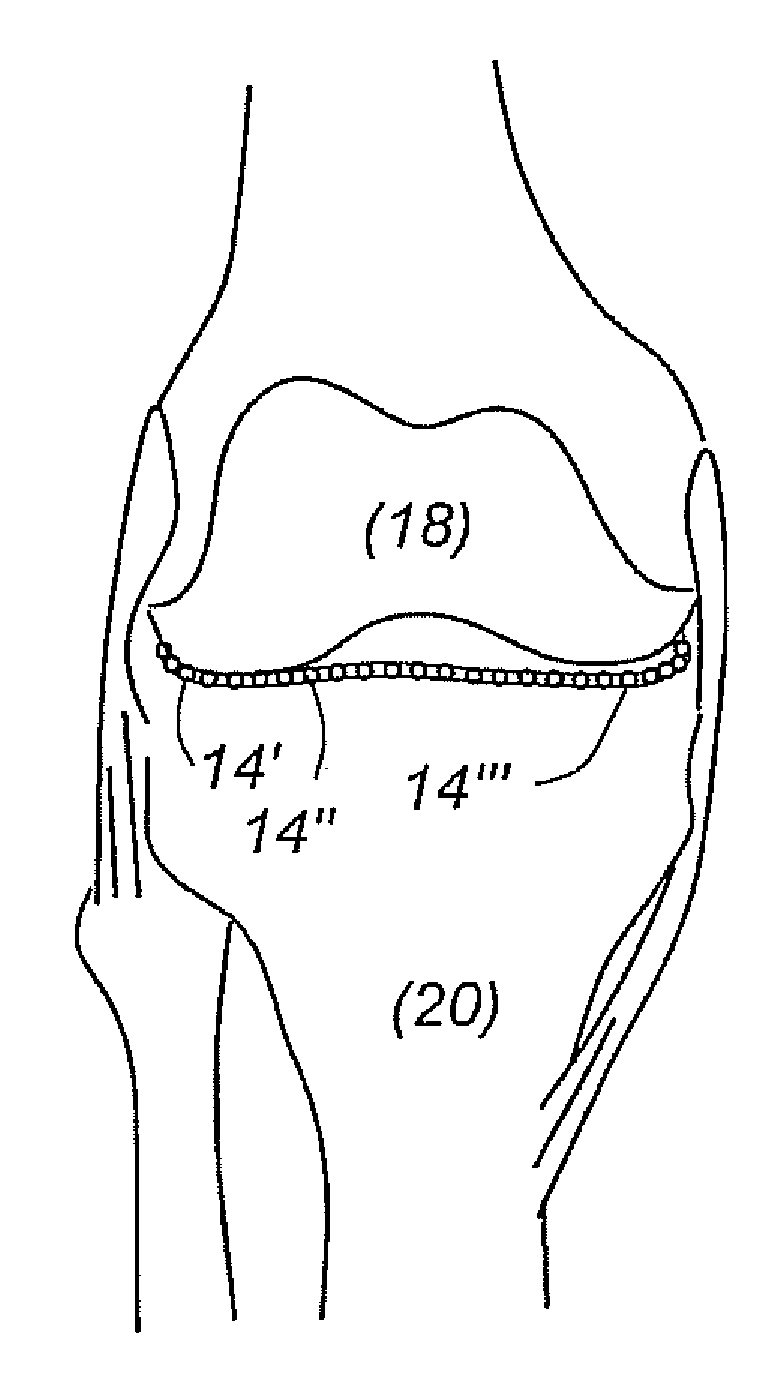

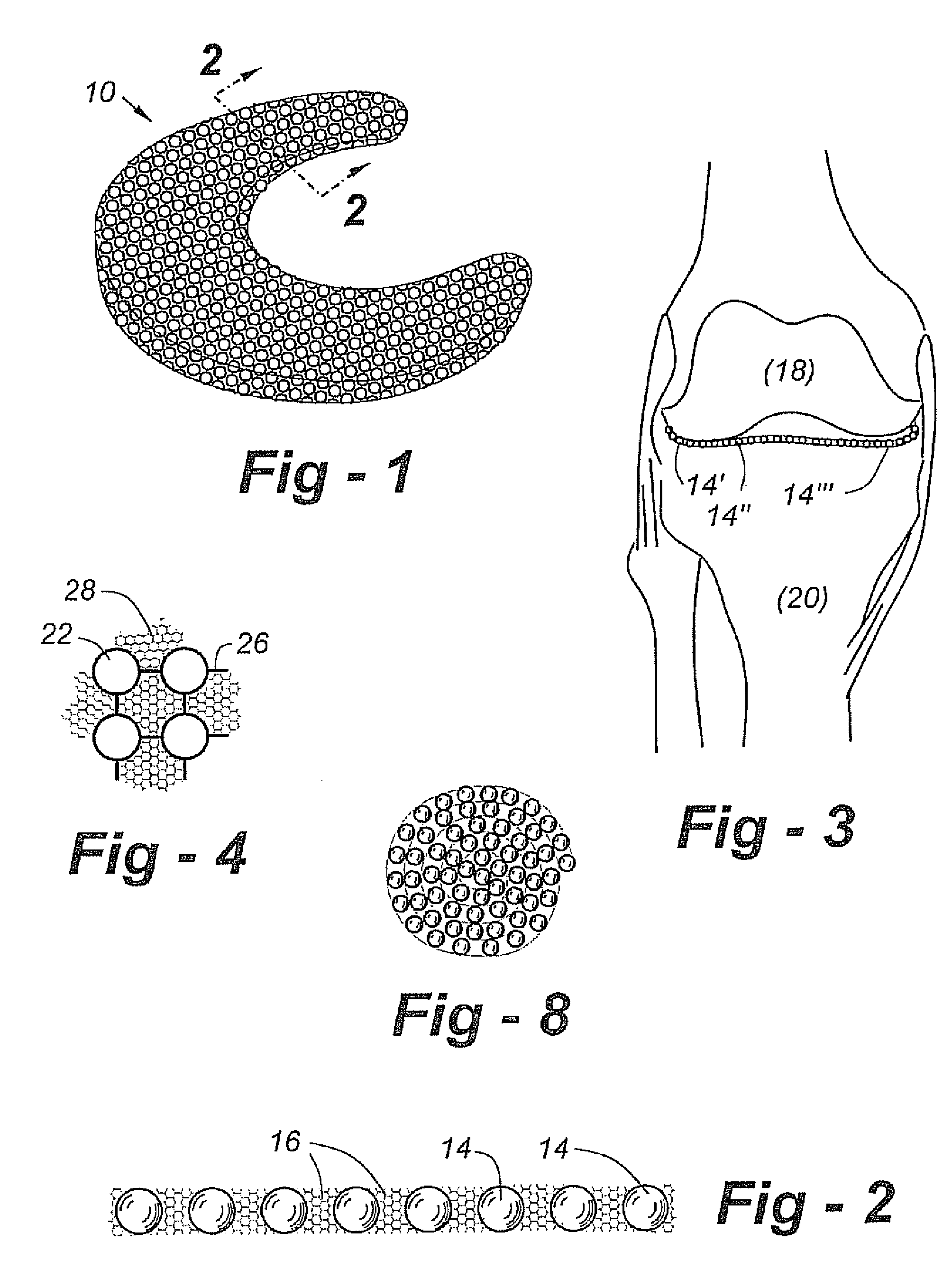

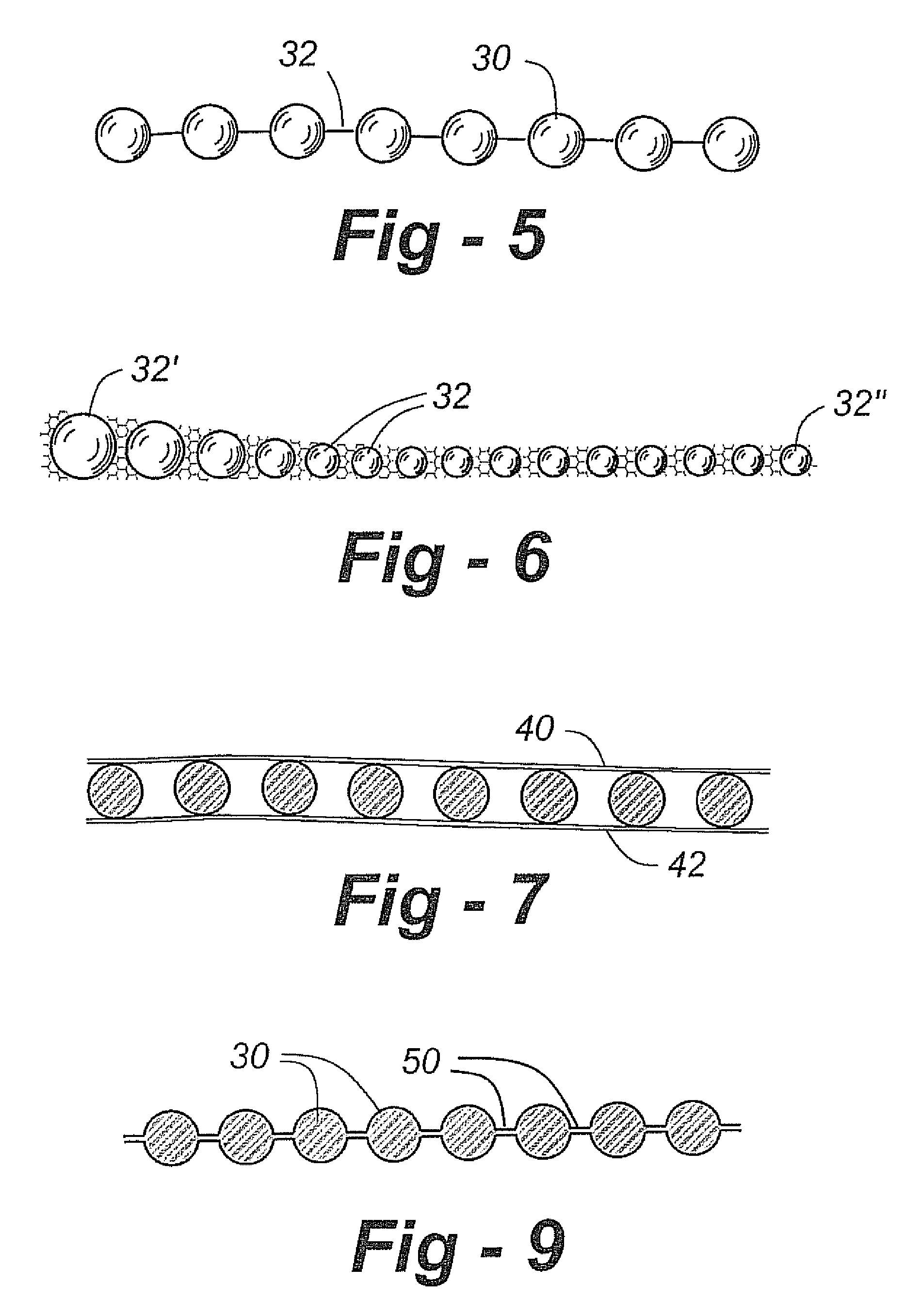

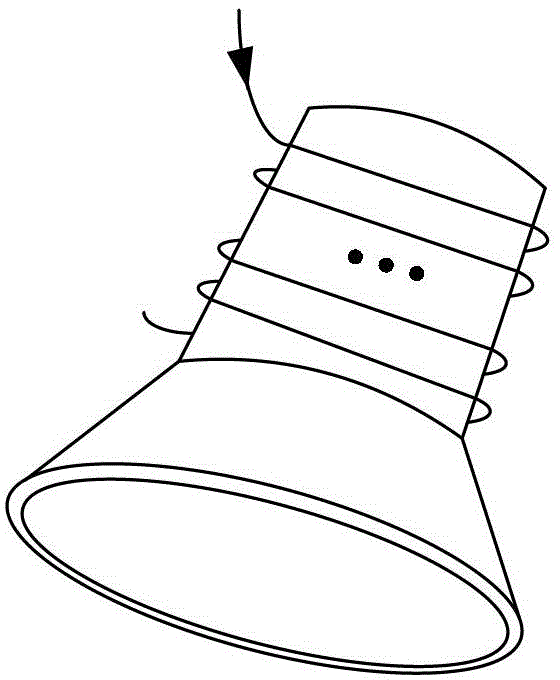

Prosthesis for replacement of cartilage

A cartilage replacement or repair prosthesis comprises a layer of streamlined elastomer elements, preferably in the form of spheres, supported in a matrix material so that the radially opposed surfaces of the spheres are positioned on opposite surfaces of the layer and make contact with the opposed surfaces of the femur and tibia and the forces exerted between these bones extend through the streamlined elements. The matrix material has a substantially lower resistance to deformation than the spheres to control the position of the spheres relative to one another without significantly restraining their load-responsive deformation under forces exerted between the femur and tibia. The layer, with its elastomeric inserts, is sufficiently thin and flexible to allow it to be rolled for arthroscopic insertion into a knee joint.

Owner:SUCCESSOR TRUSTEE OF THE EUGENE RIVIN LIVING TRUST +2

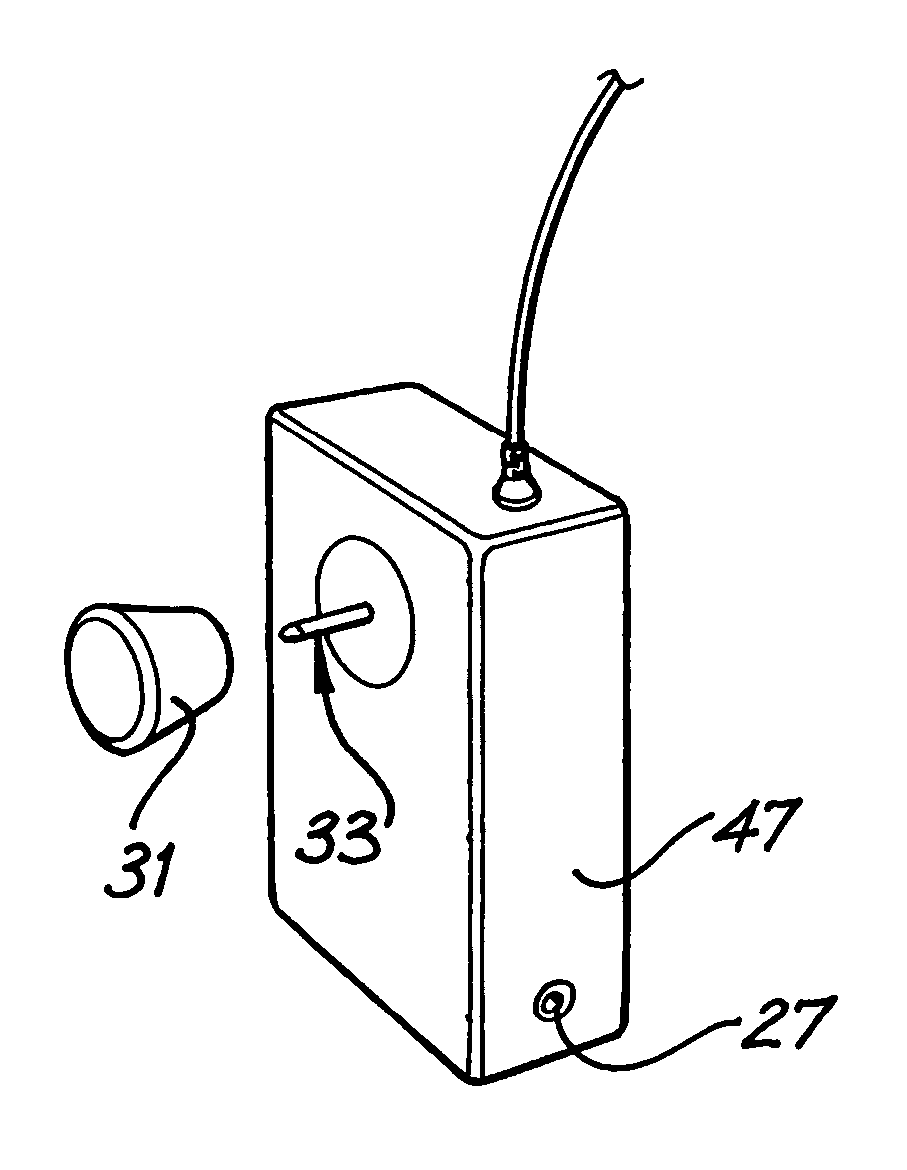

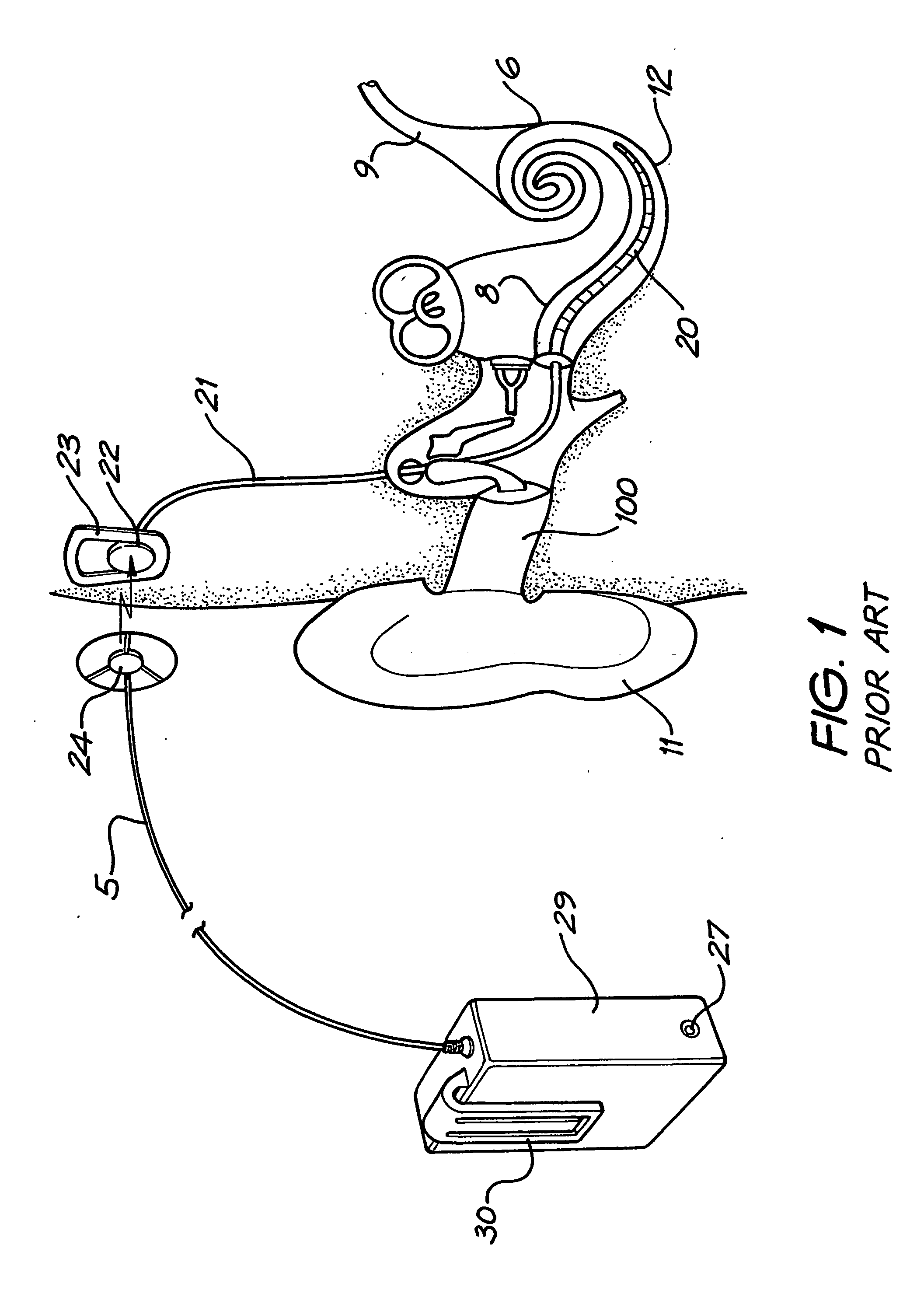

Mechanically detachable vaso-occlusive device

ActiveUS20080306504A1Eliminates frictional pinchingPrevent retractionDilatorsOcculdersBlood vesselGeneral surgery

Owner:BOSTON SCI SCIMED INC

Medical device

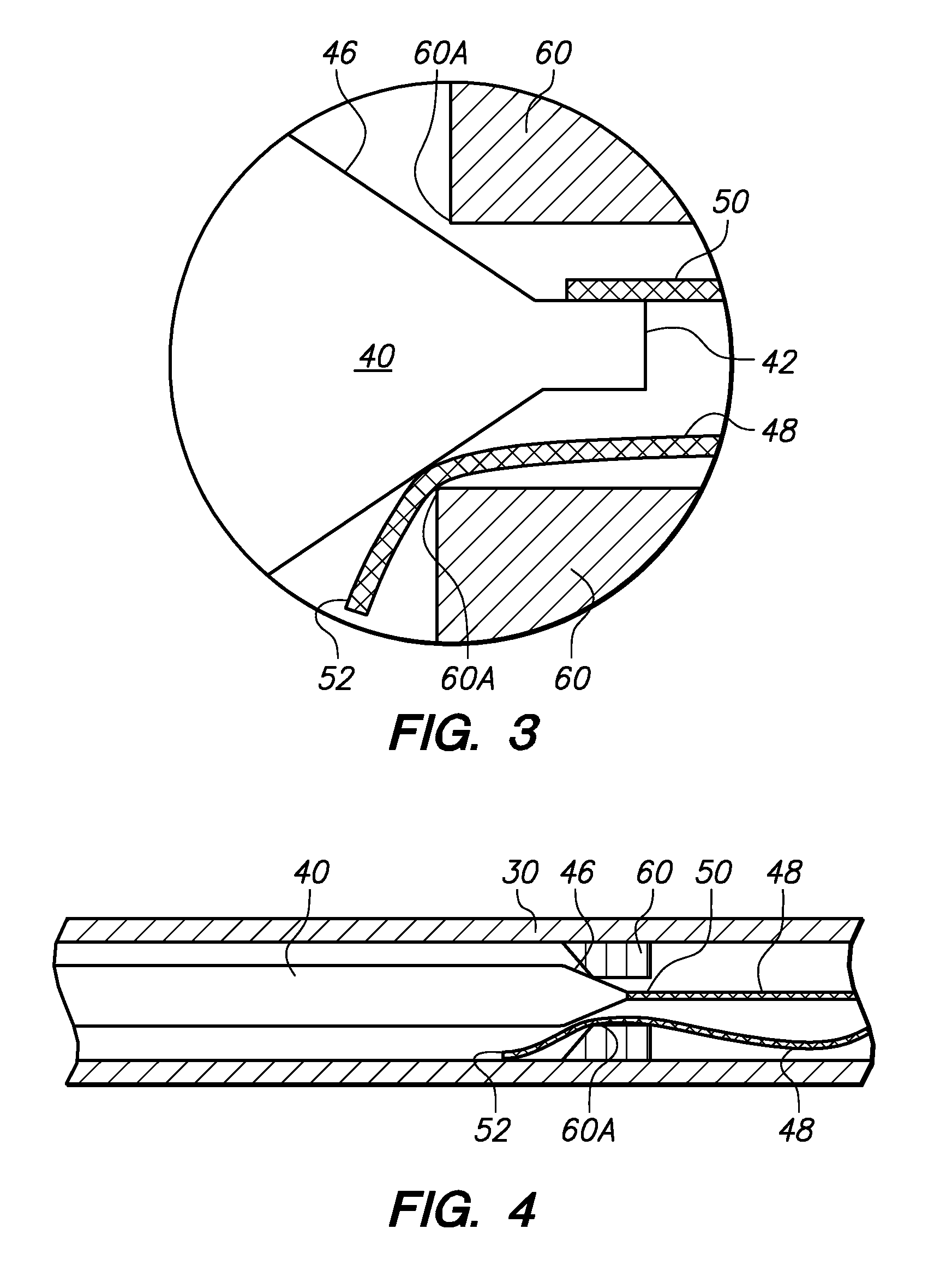

InactiveUS20050263549A1Remove frictional engagementIncrease the diameterElectrotherapyTravelling carriersSpeech ProcessorEngineering

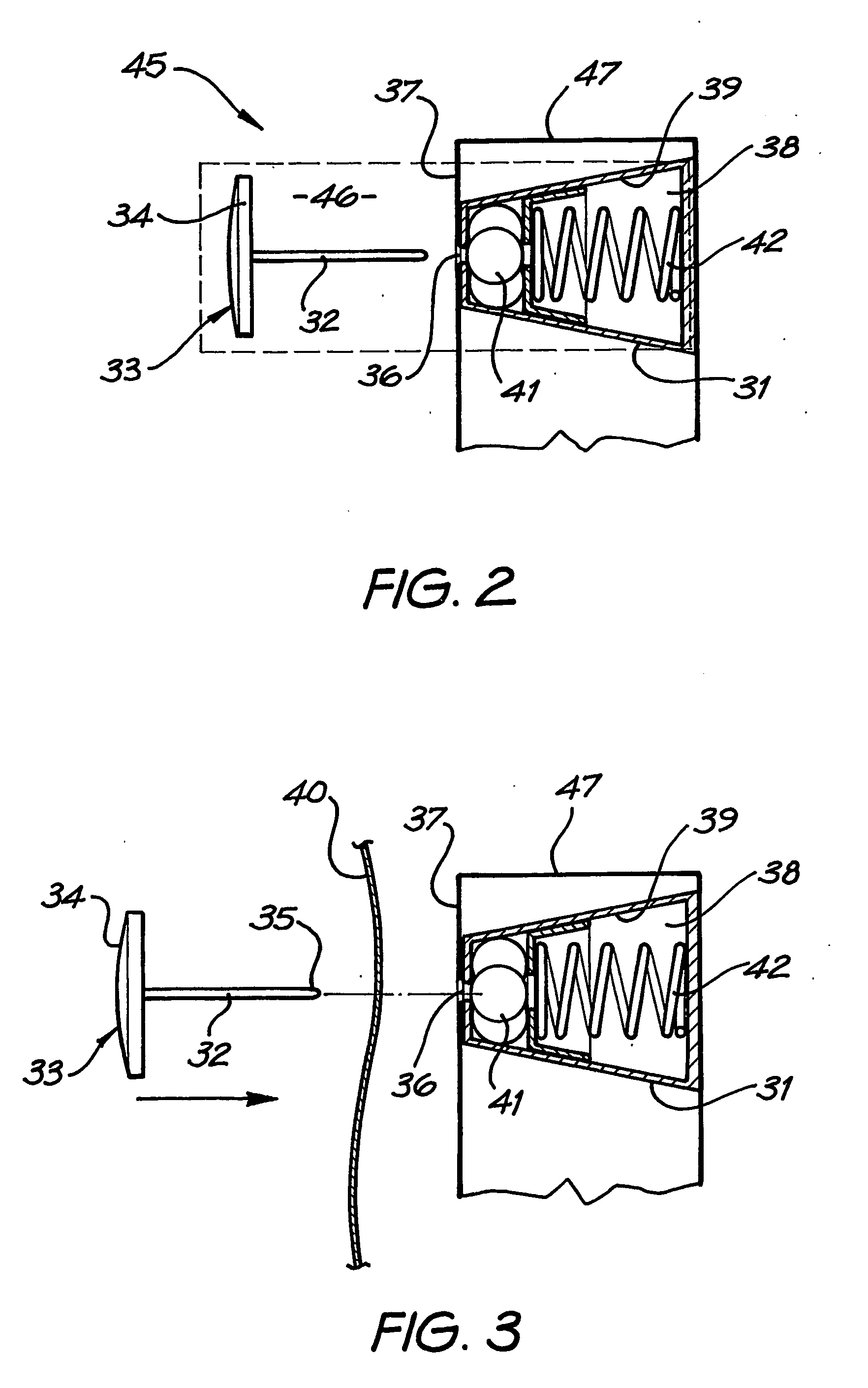

A mechanism for attaching a component, such as a speech processor unit (29) of a cochlear implant, to the clothing (40) of a user of that component. The attaching mechanism is operable by an unlocking device, such as a magnet (44), that can be held in the possession of a person other than the person wearing the clothing (40) to which the component is mounted. The attachment device can comprise an elongate pin member (33) that is adapted to pass through at least a portion of an item of clothing (40) and be received in a chamber (38) and held by frictional engagement therein.

Owner:COCHLEAR LIMITED

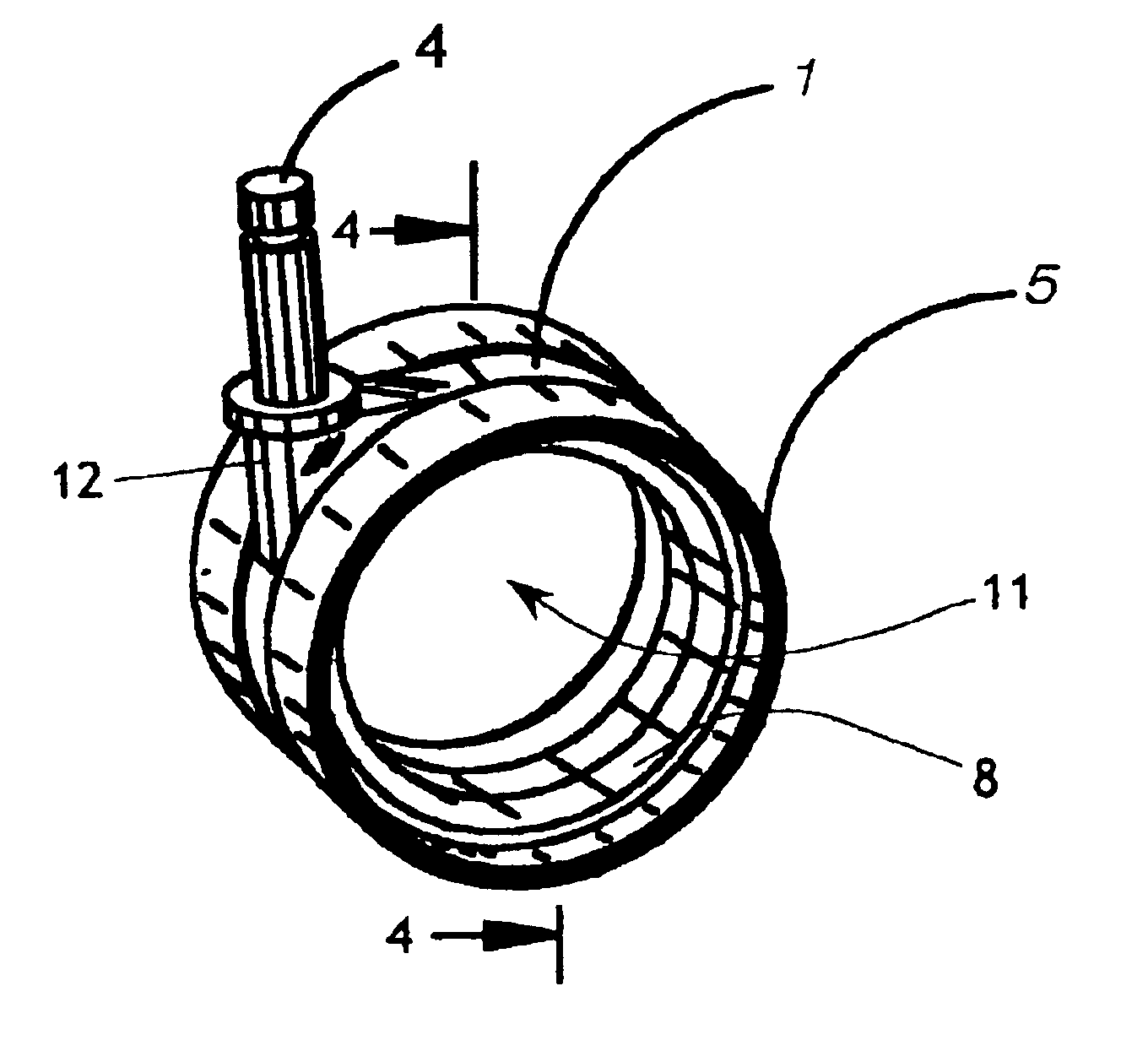

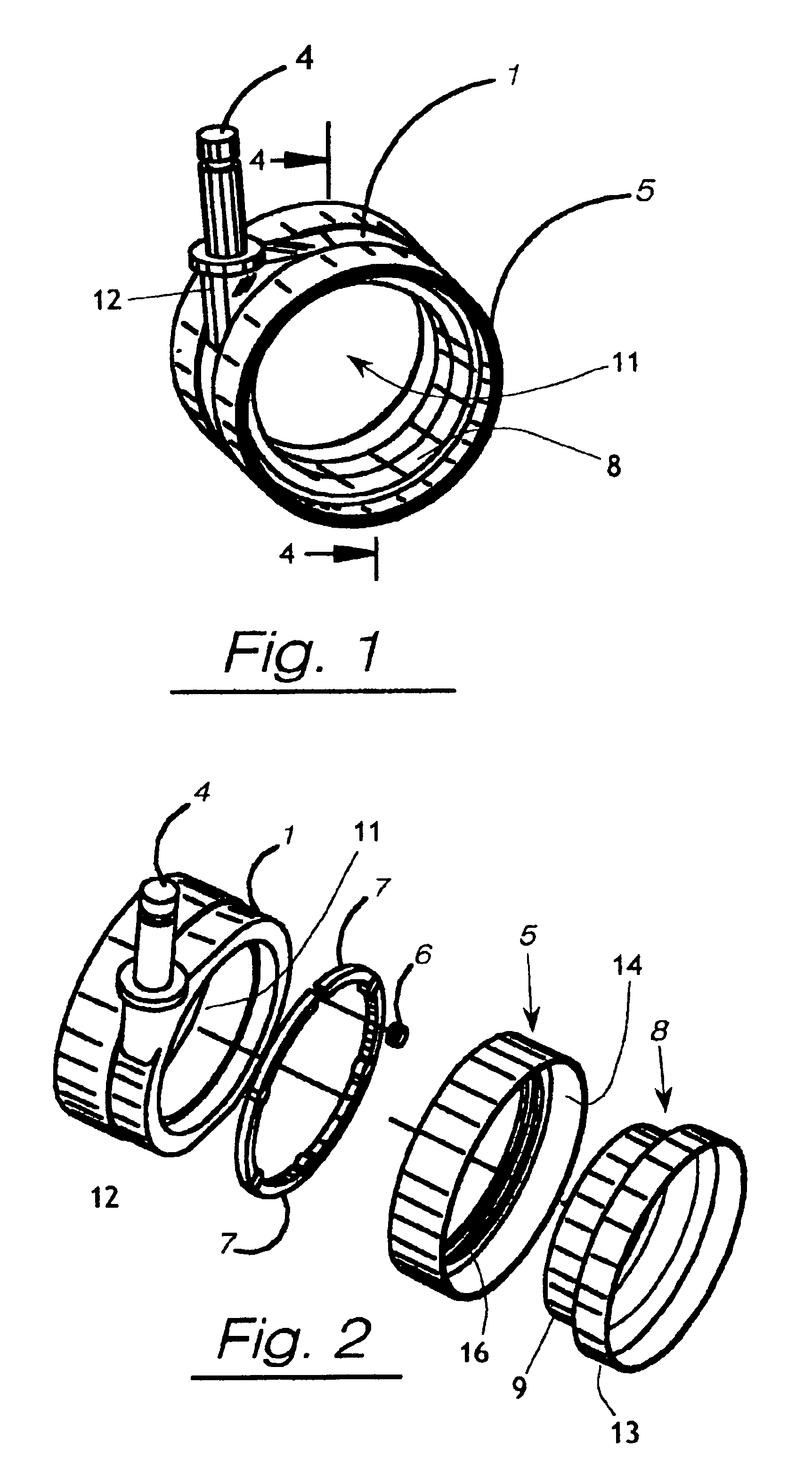

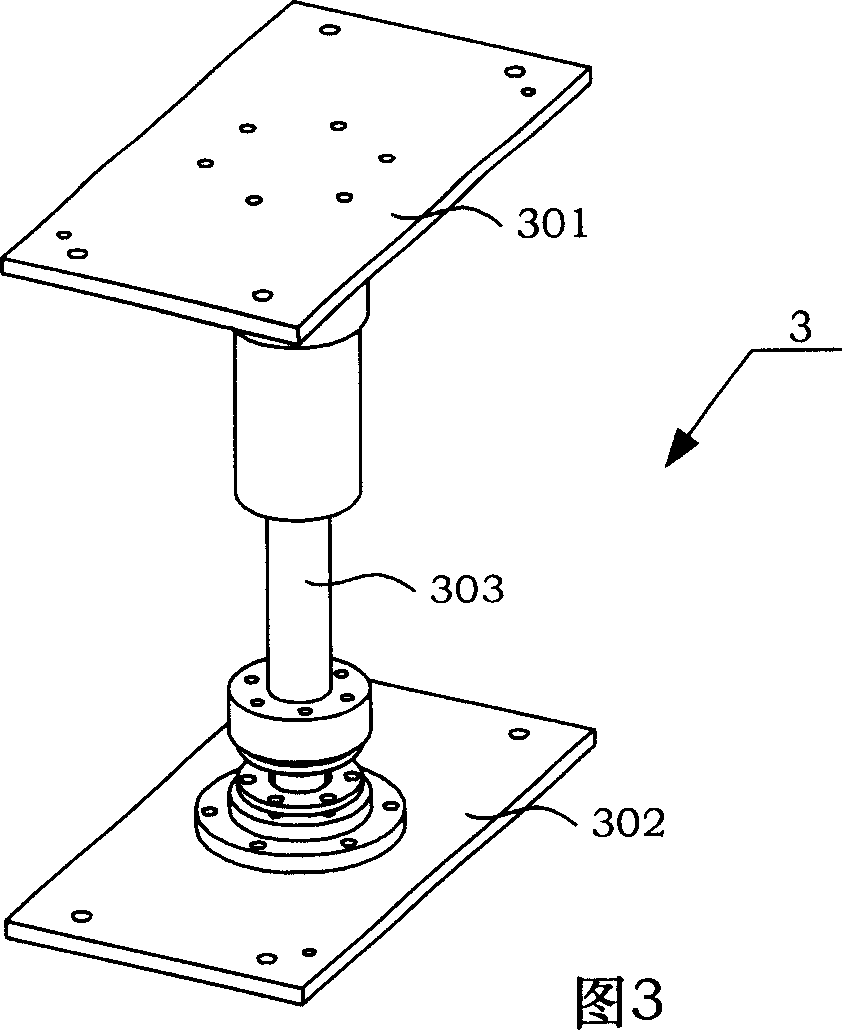

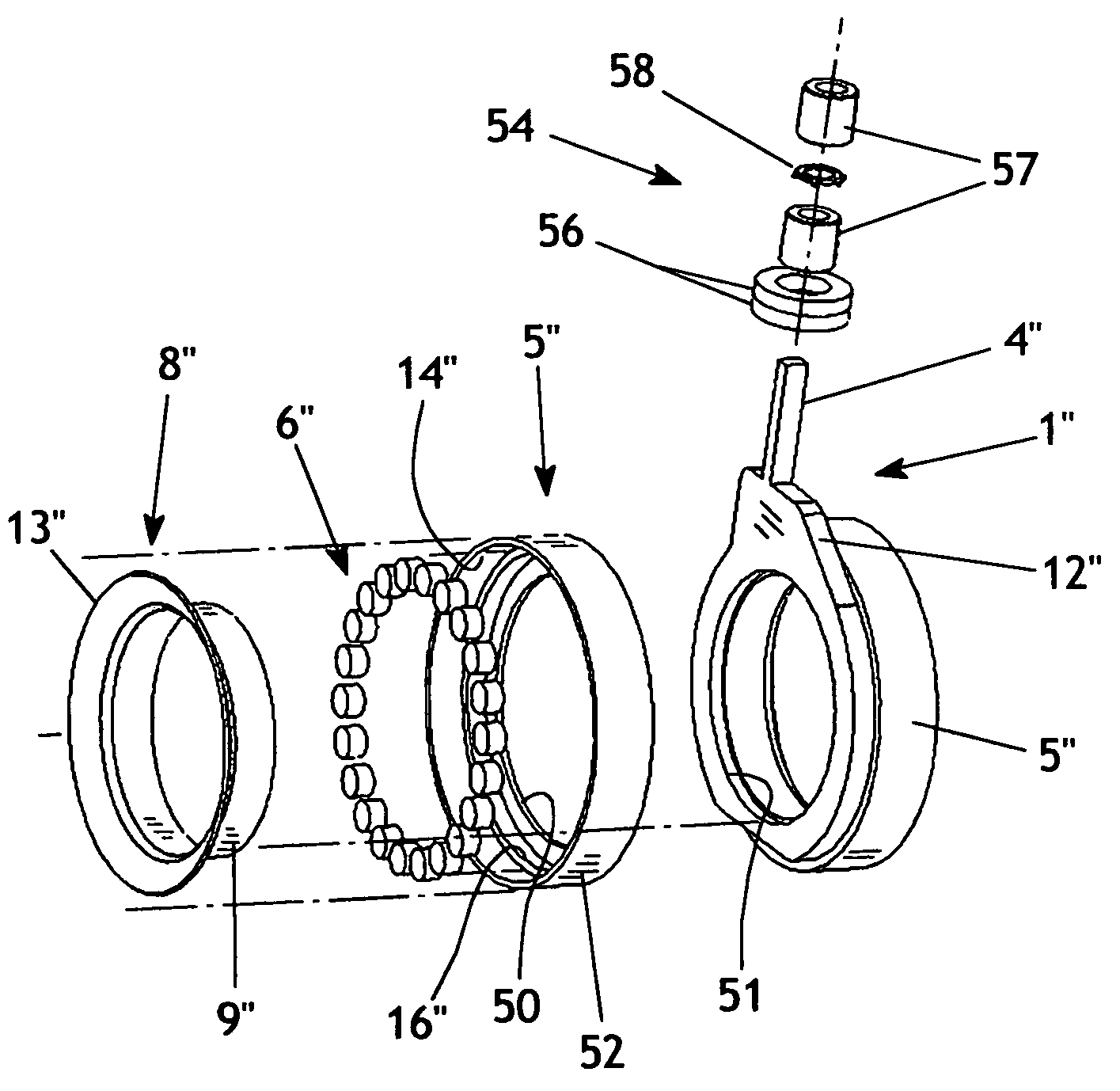

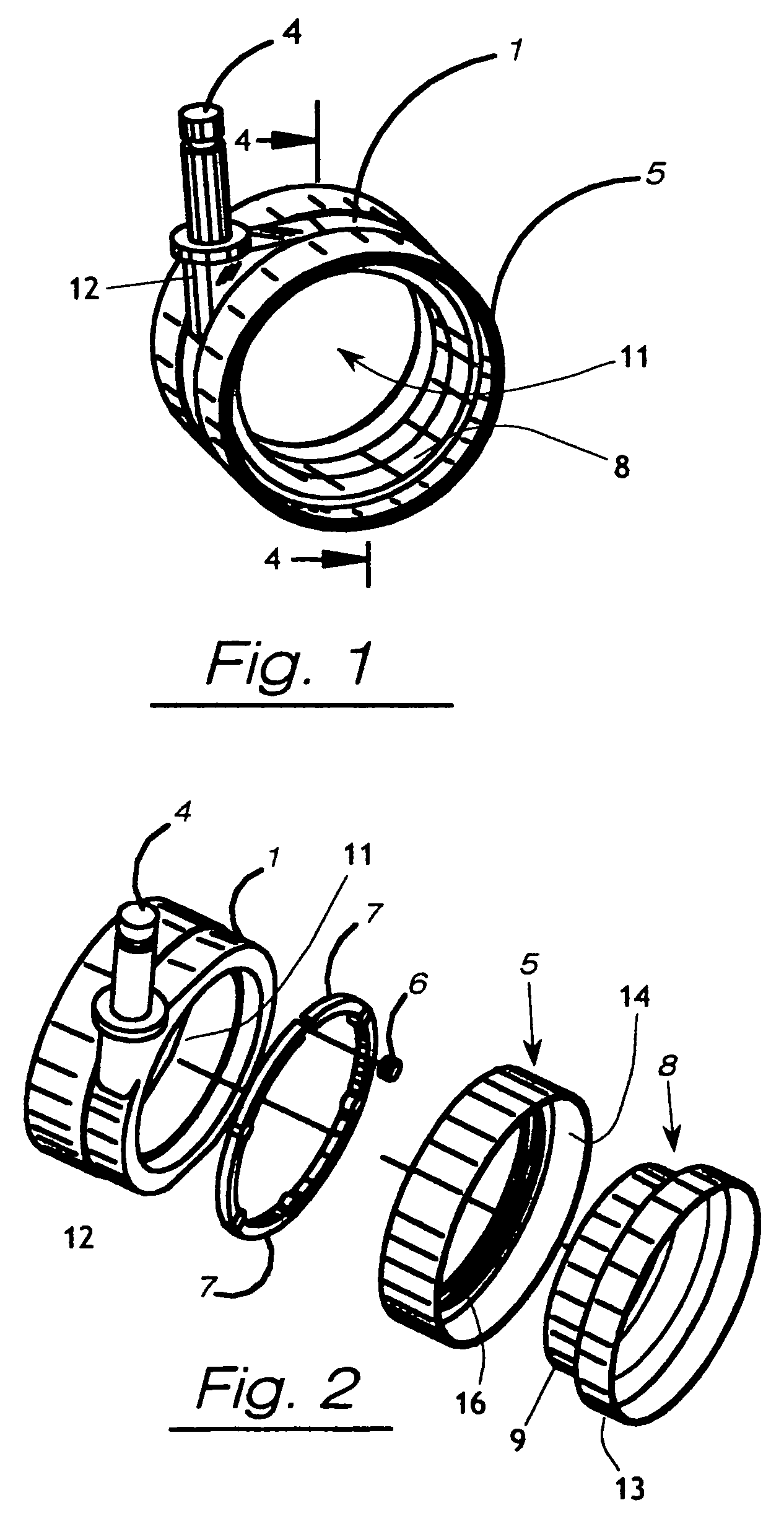

Hubless caster

InactiveUS6839939B2Alter visual appearanceReduce lever armSuction cleanersCastorsEngineeringFree rotation

A hubless caster assembly includes a caster body and at least one wheel, the wheel comprising a toroidal member having a bearing race, and a complementary bearing race supported by the caster body. Bearing elements in the races support the wheel in free rotation. The caster body may comprise a ring body having an axial opening, whereby the caster assembly has a large central aperture extending entirely therethrough. A centering ring may be secured in the axial opening with the complementary bearing race formed therein. A hub cap with visual treatment may be secured over the central aperture.

Owner:OCONOMOWOC MFG

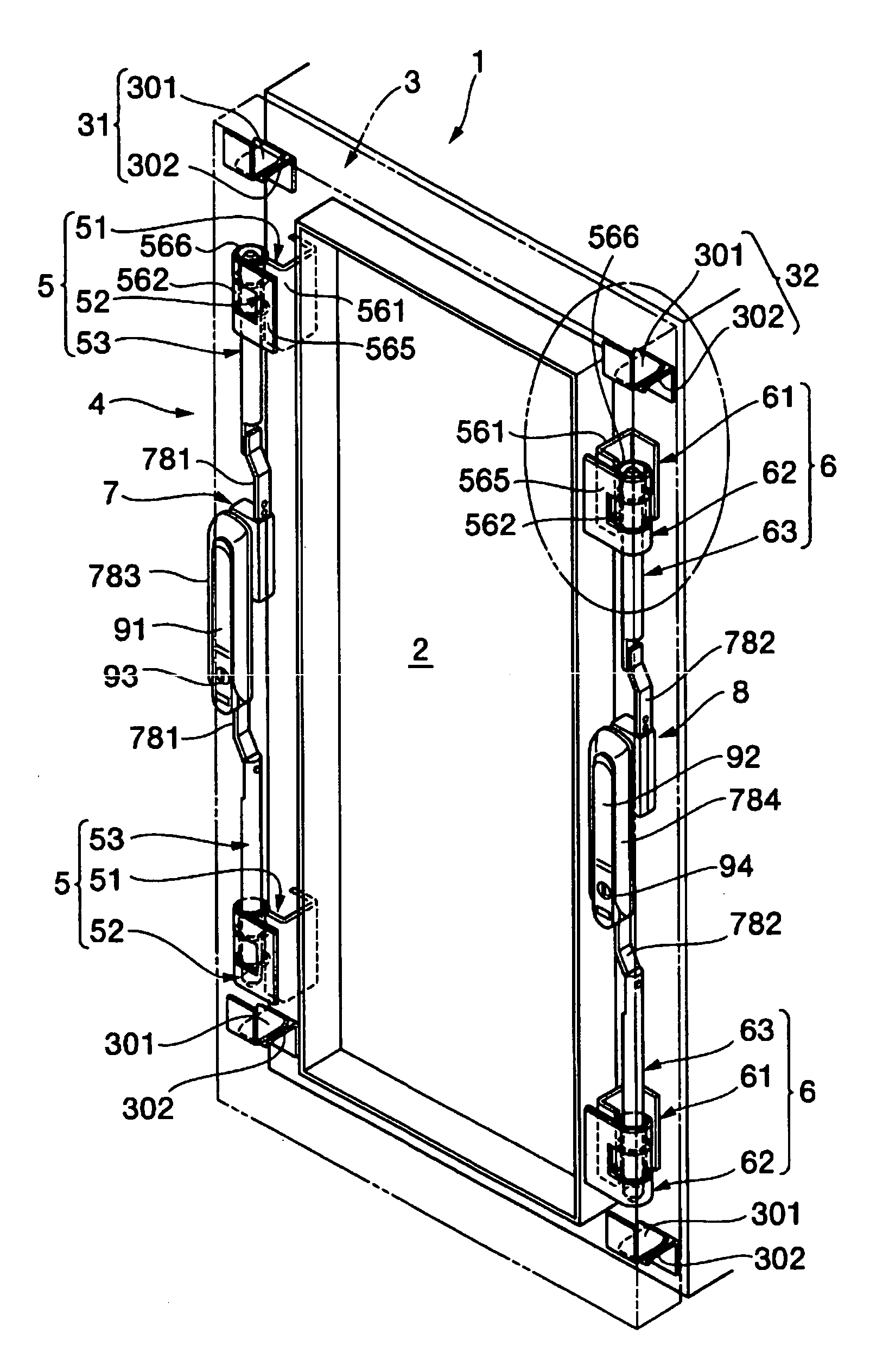

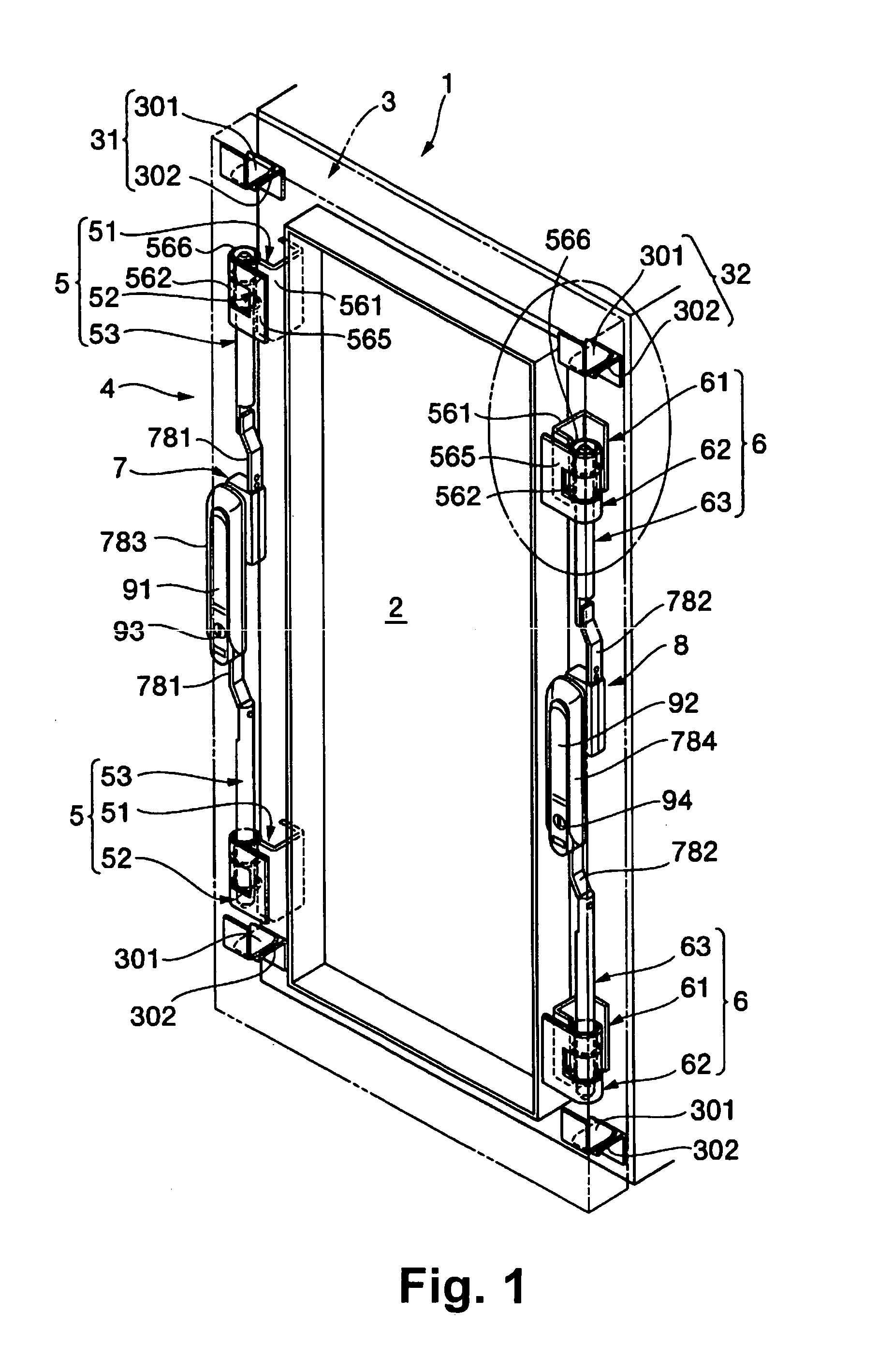

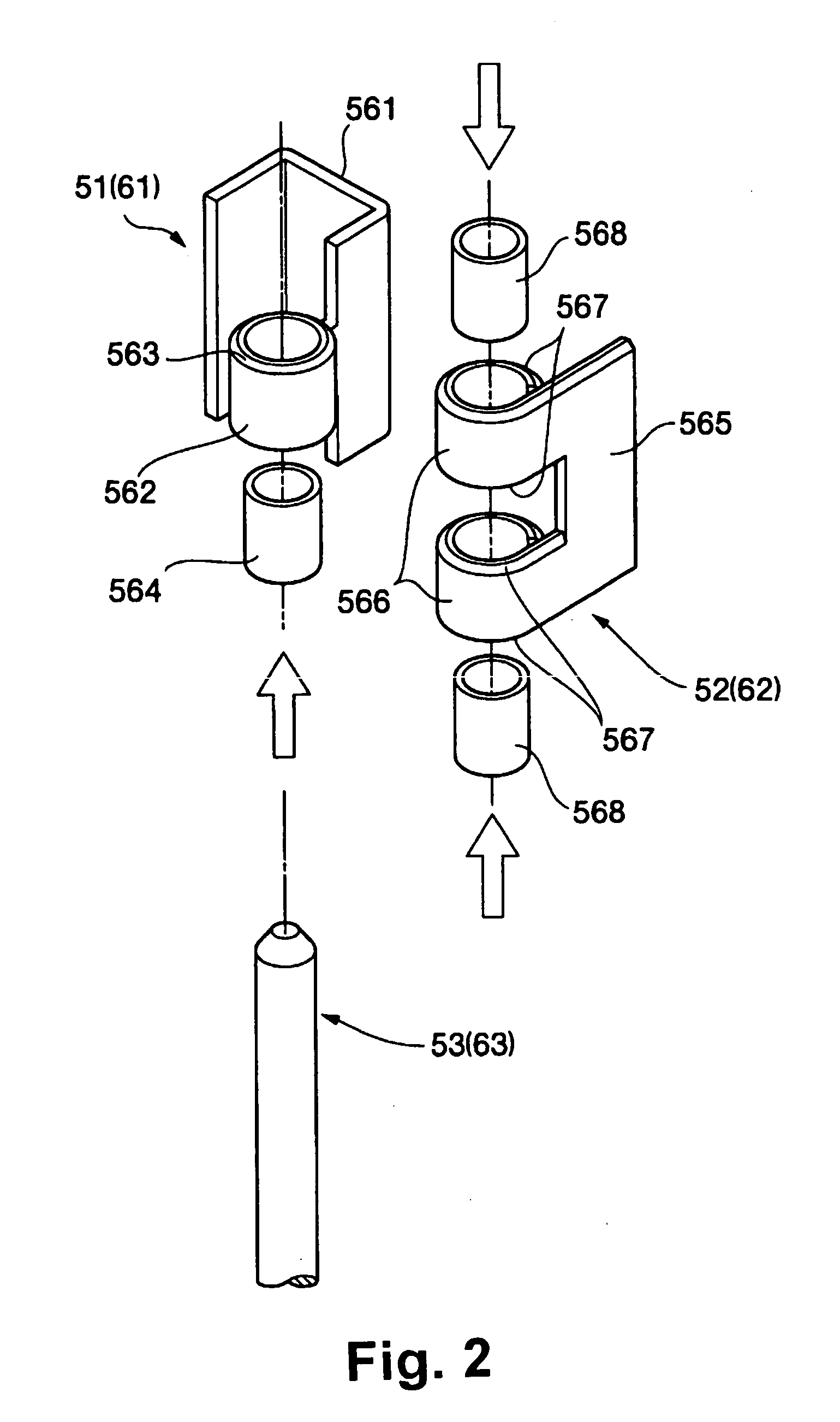

Dual-opening mechanism of door

InactiveUS7178292B2Eliminate frictionEasy extractionBuilding locksCasings/cabinets/drawers detailsEngineeringMechanical engineering

Owner:TAKIGEN MFG CO LTD

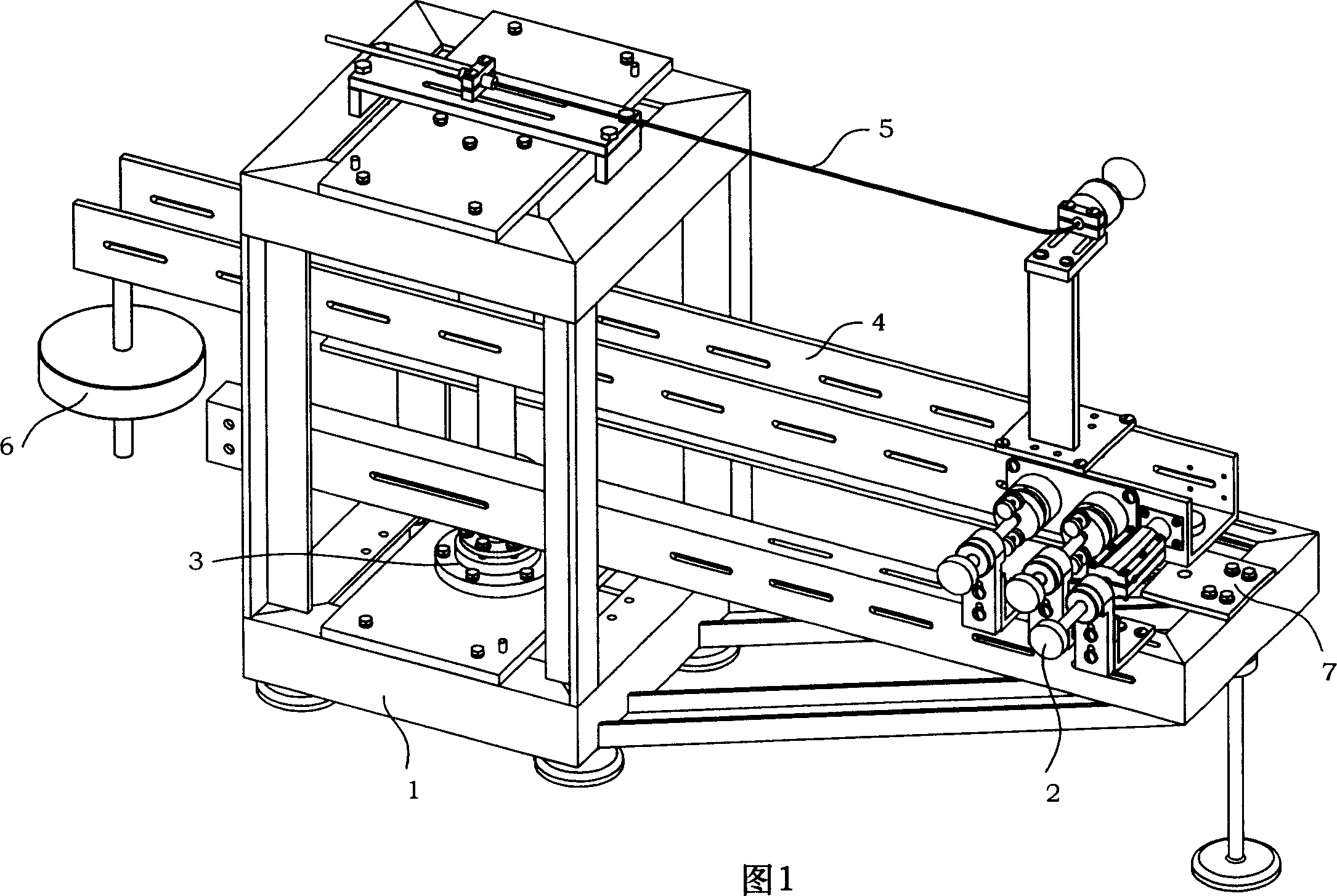

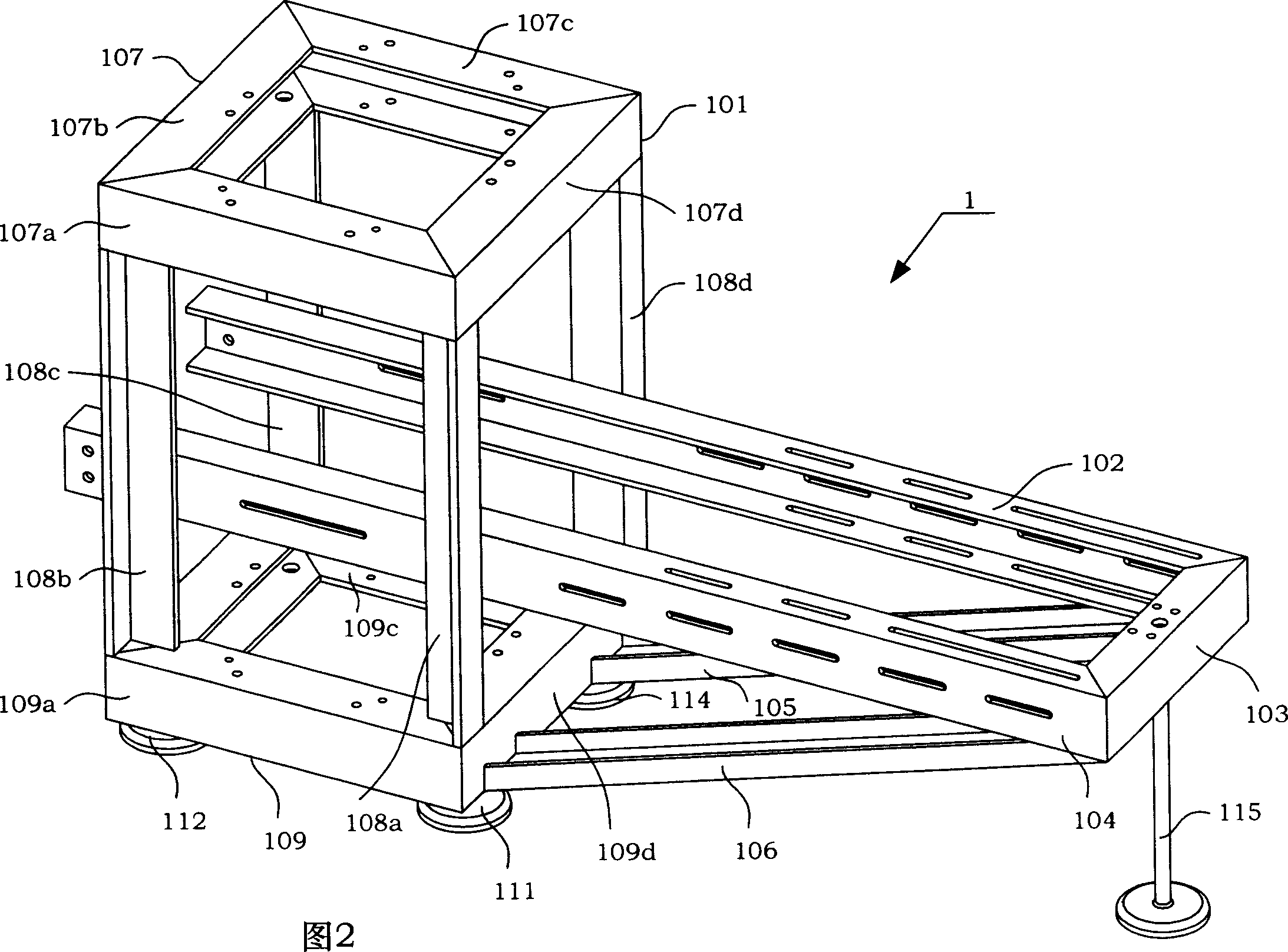

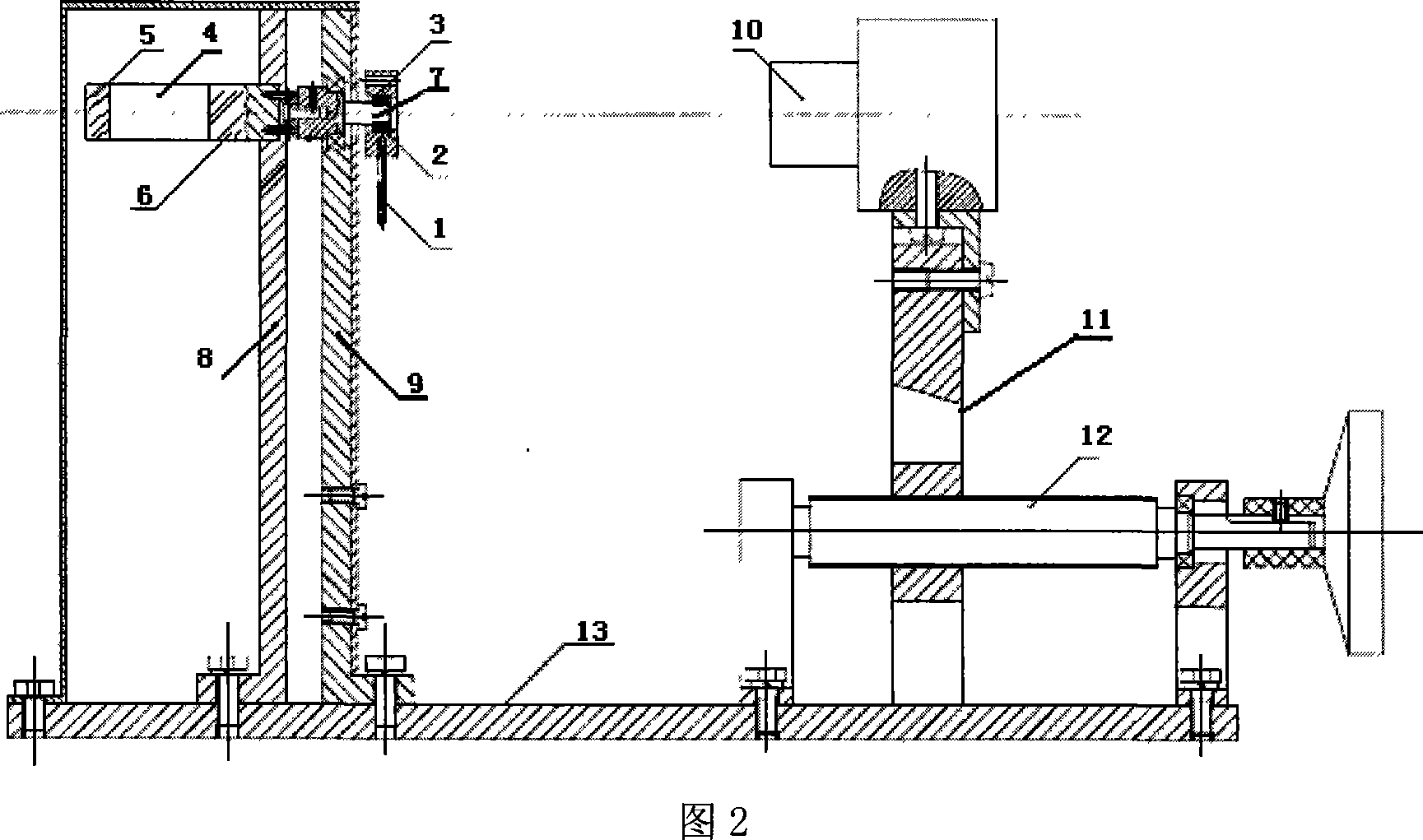

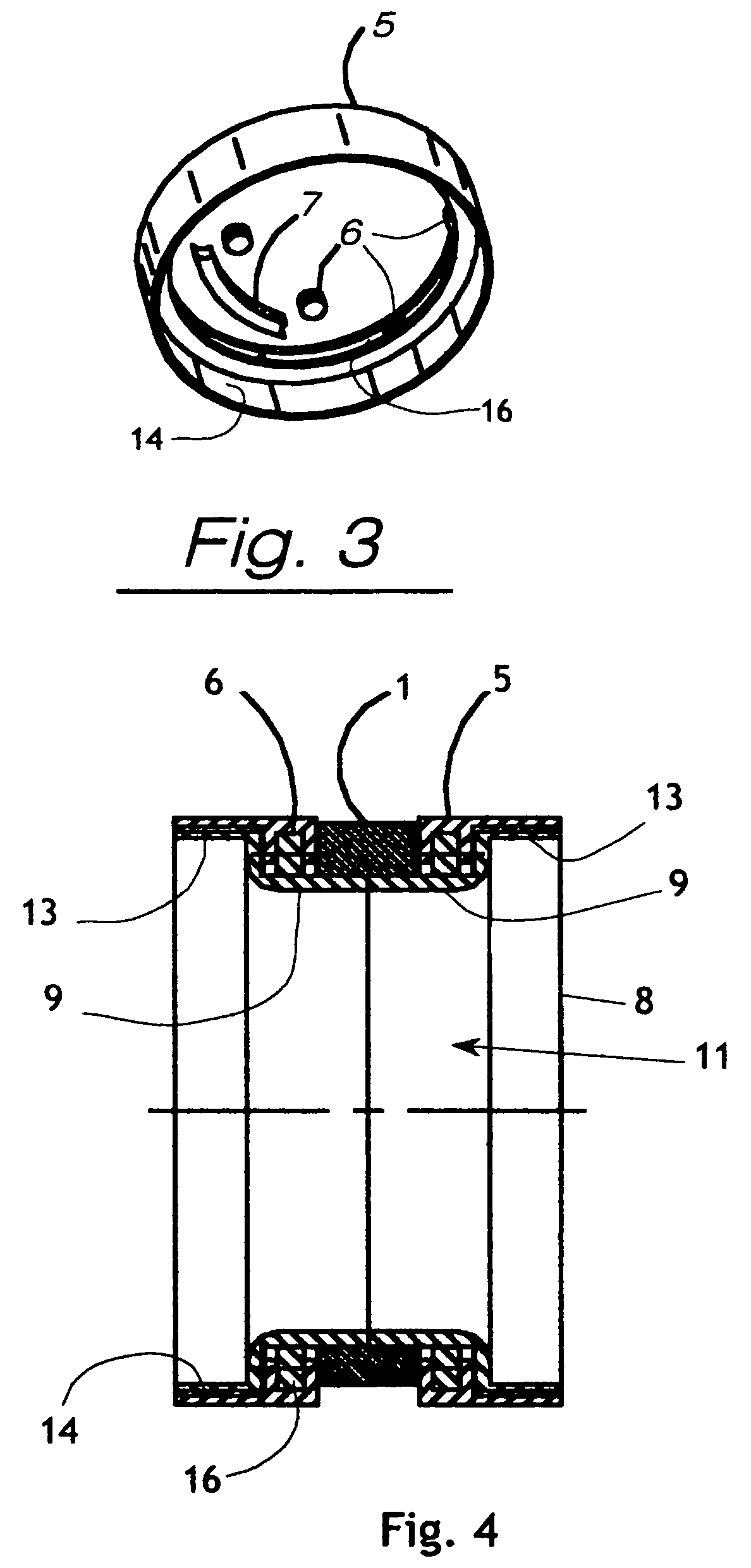

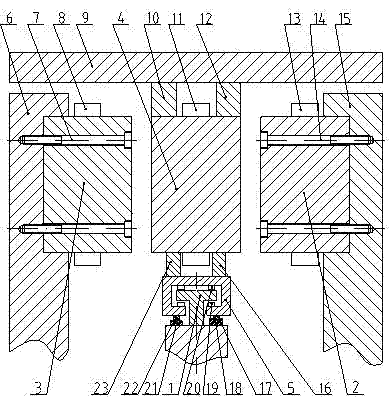

System for measuring thrust suitable to thrust engine with tiny space

InactiveCN1916580AEliminate frictionGuaranteed distanceEngine testingApparatus for force/torque/work measurementDriver circuitTransducer

A thrust measuring system of thrust engine used in small space comprises storage tank of thrust agent, engine, mechanical body, transducer, driving and controlling circuit. It is featured as setting transducer at external side of one end on working beam and balance weight block on another end; placing said driving and controlling circuit in horizontal trench of front and back support beams; arranging engine on connection piece; connecting one end of thrust agent tube to engine and another end to thrust agent storage tank; forming mechanical body by support frame, master shaft, working beam, thrust component and balance weight.

Owner:BEIHANG UNIV

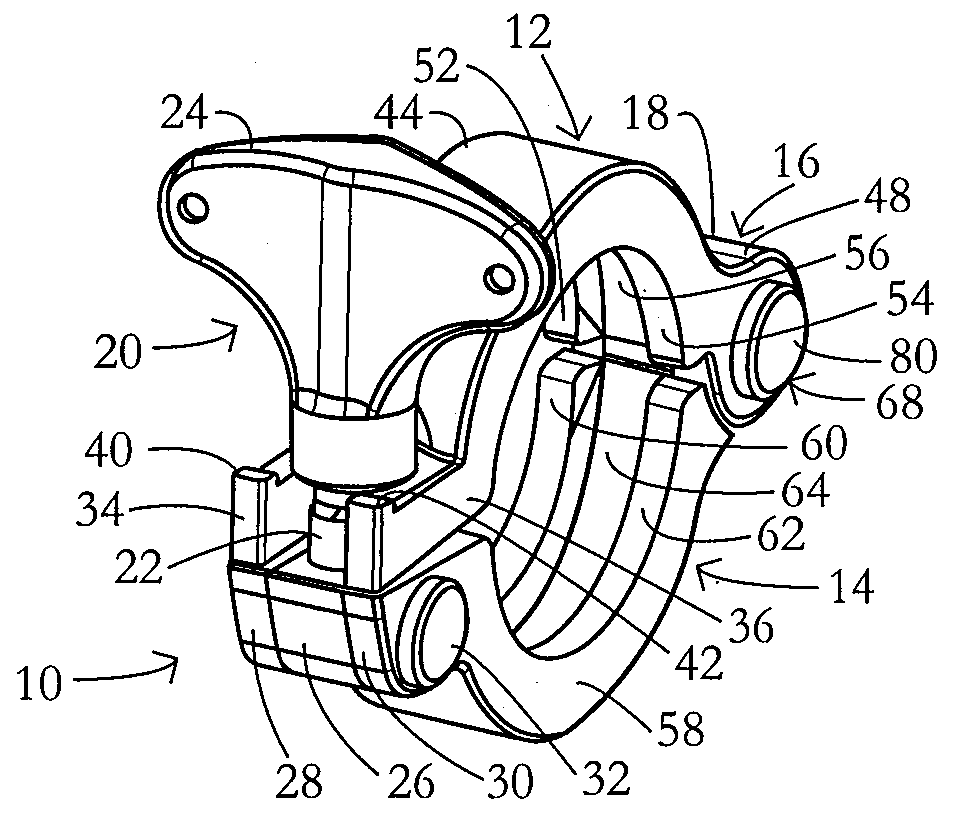

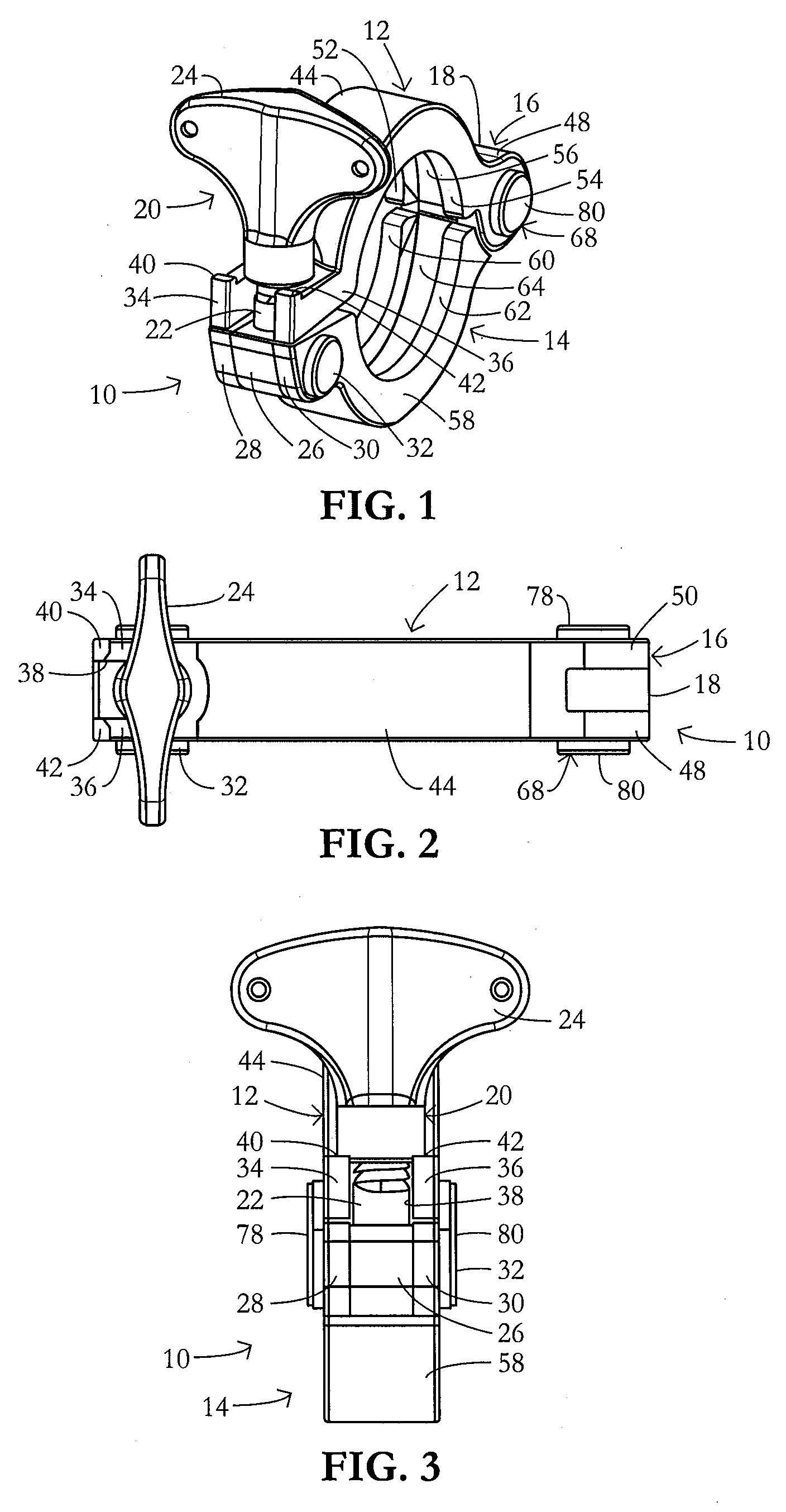

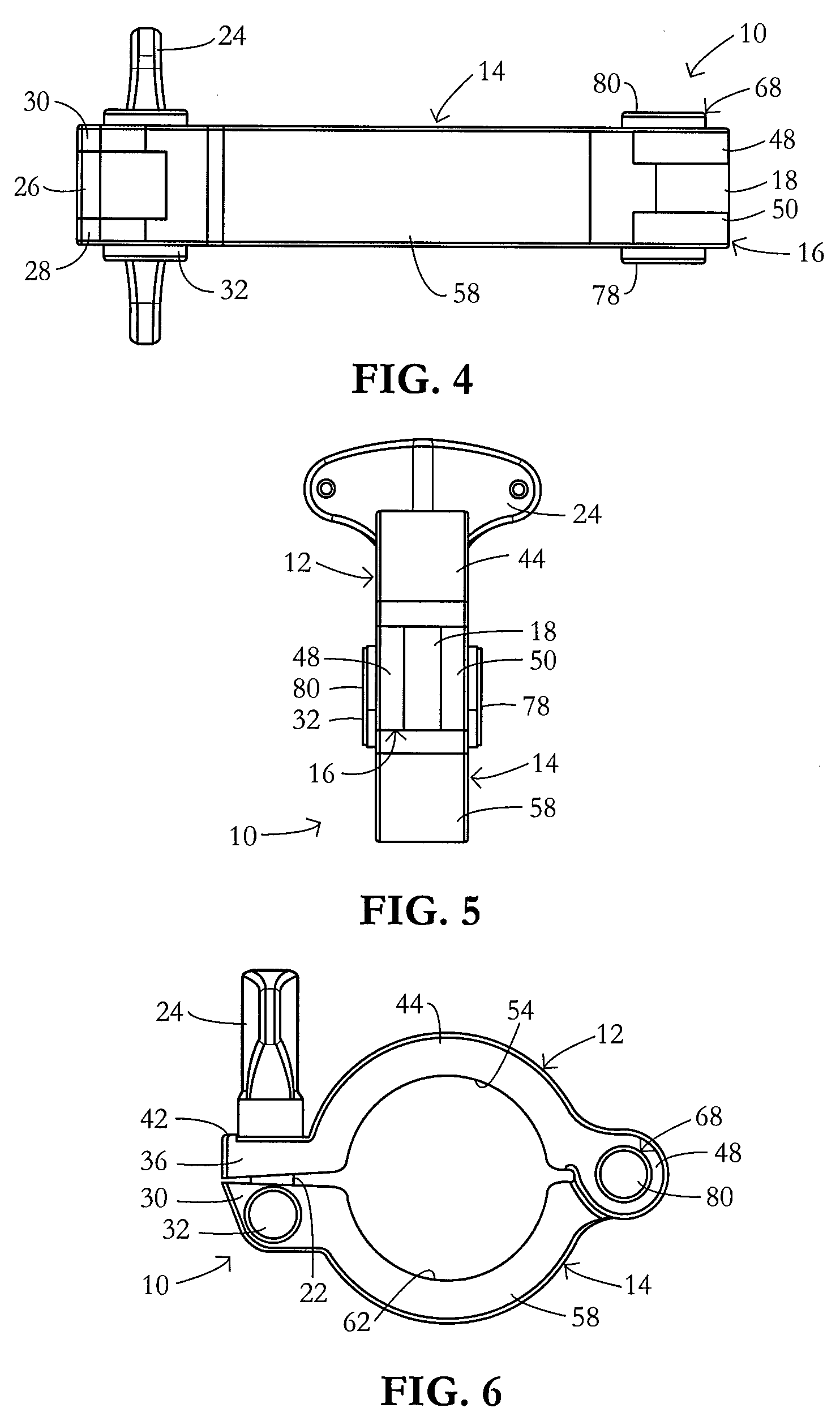

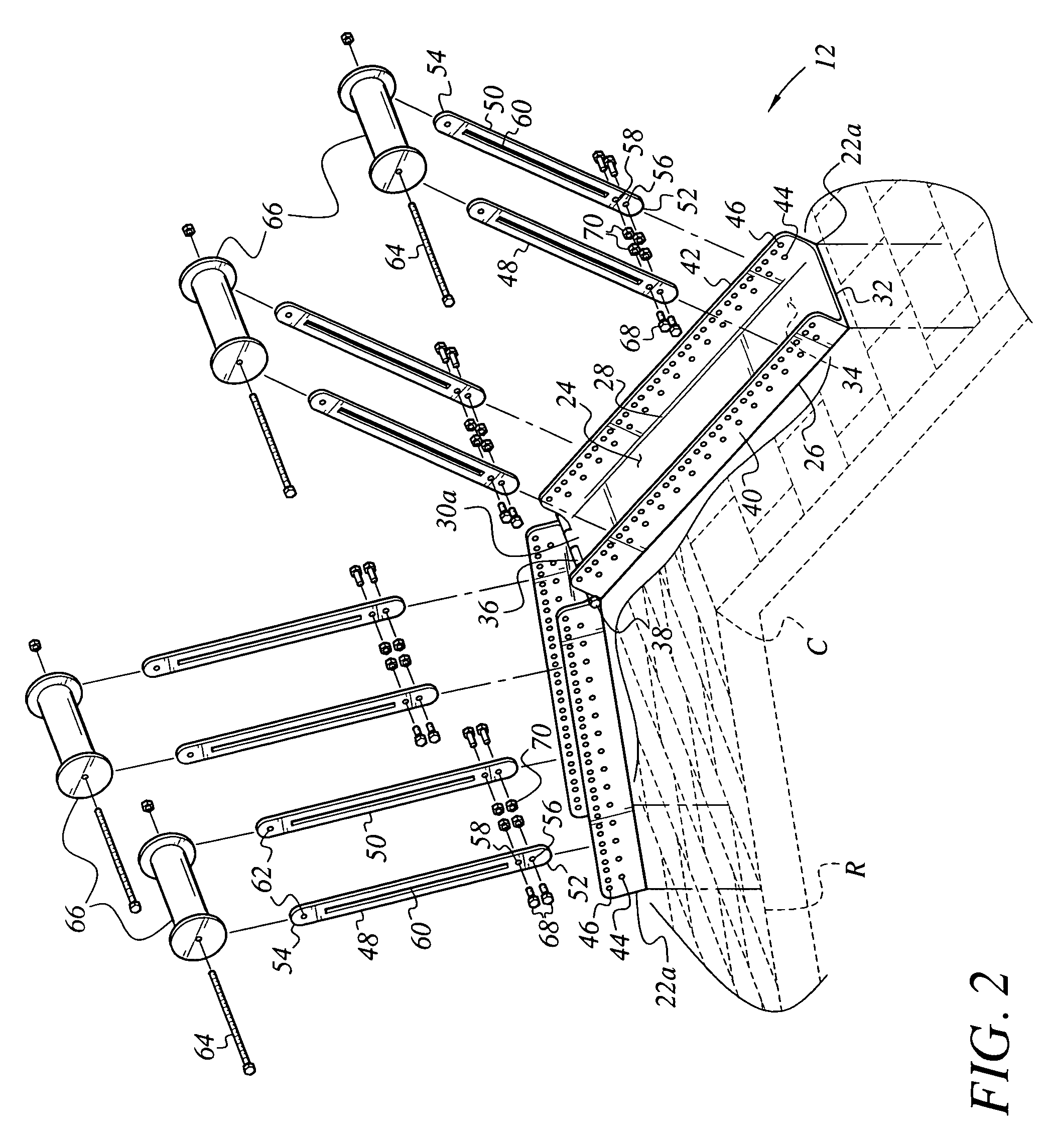

Tube or Pipe Clamp

A tube or pipe clamp has two clamp members that are pivotably connected to one another at respective hinge-forming ends thereof. The tube or pipe clamp has a locking device that includes a shaft and a locking element operatively attached to the shaft, the shaft being pivotably attached to one of the clamp members. The other clamp member has a pair of prongs defining a slot for receiving the shaft of the locking device, the locking element being engageable with the prongs to lock the clamp members to one another at ends thereof opposite the hinge-forming ends. The prongs each have at least one projection on a side facing away from the one clamp member. Each of the projections is disposed proximate the free end of the respective prong.

Owner:SANI TECH WEST INC

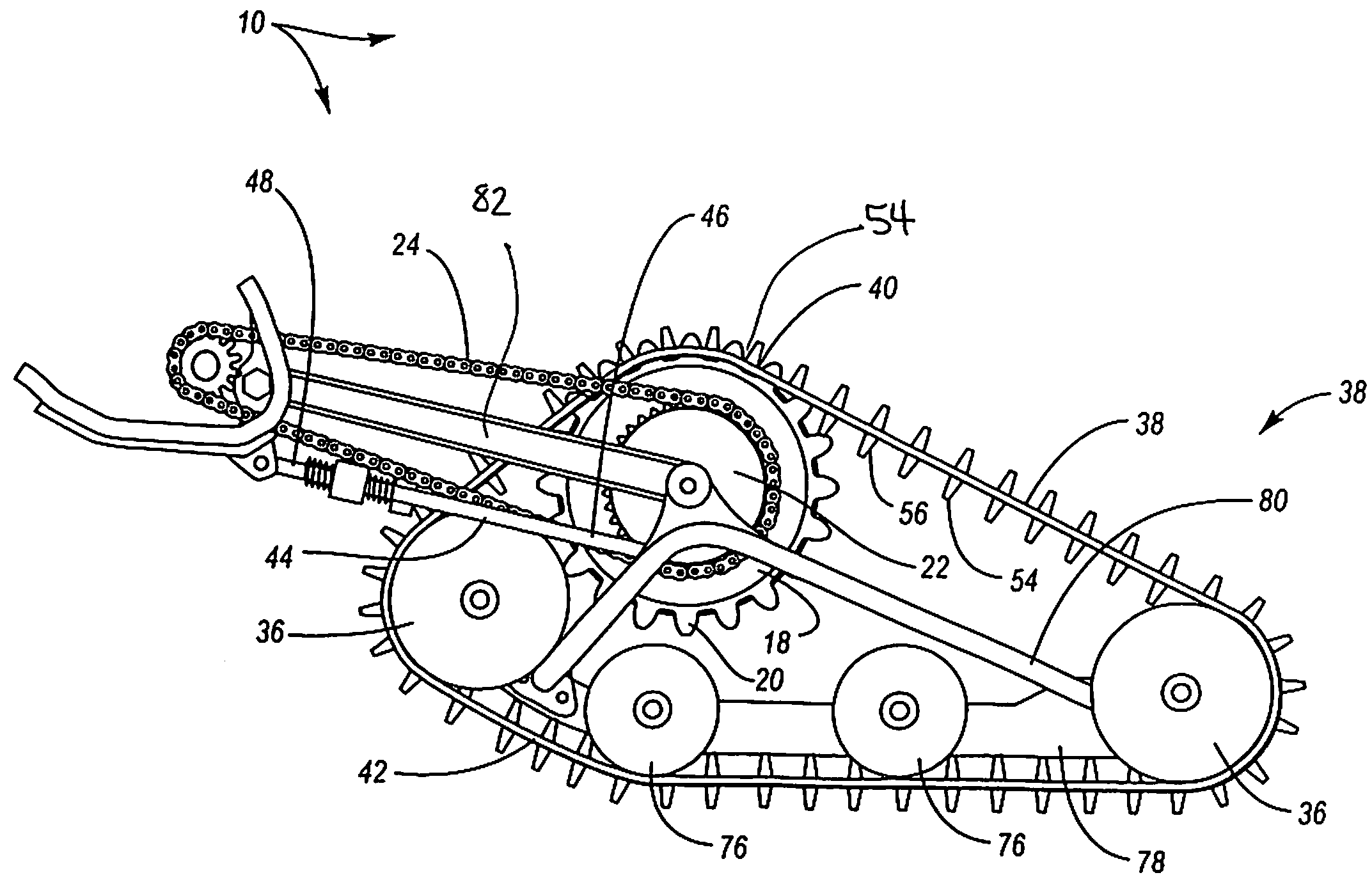

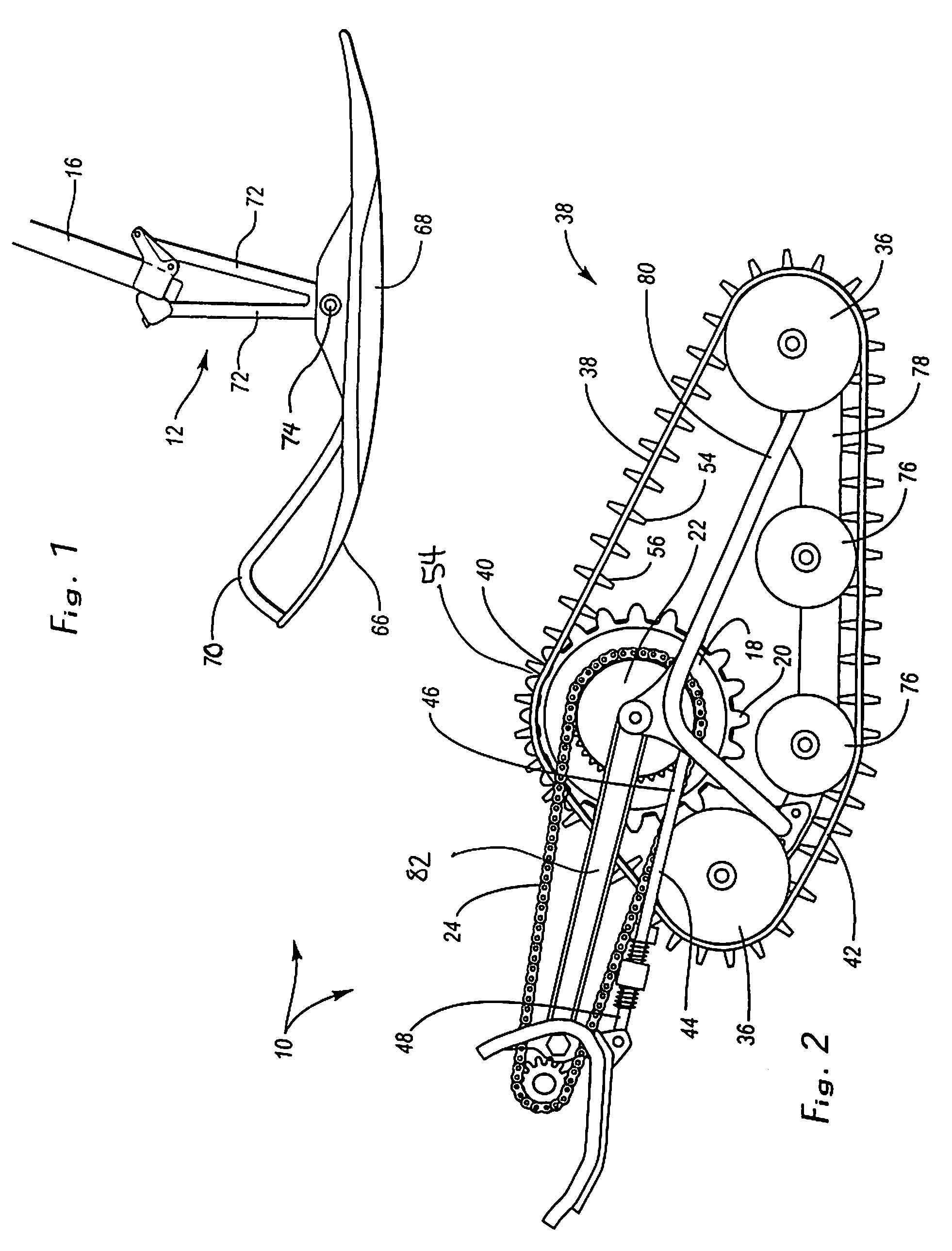

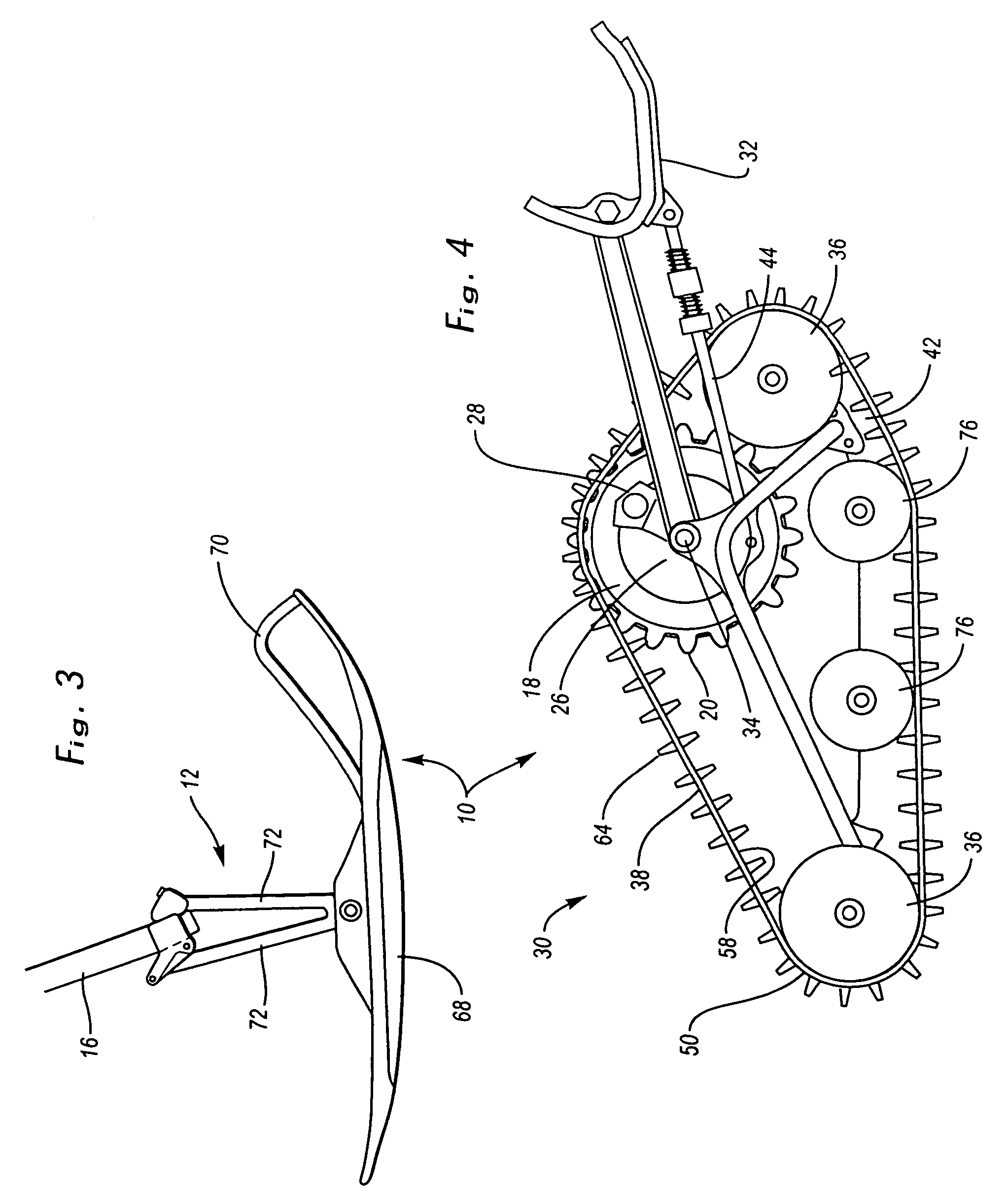

Kit for converting vehicle to tracked driven snow vehicle

InactiveUS7357201B2Eliminate frictionPrevent rotationConveyorsDriving beltsVehicle brakeVehicle braking

The invention is a conversion kit for converting a conventional two-wheeled vehicle, such as a bicycle or motorcycle, into a tracked vehicle for use on snow, mud and sand. The kit converts the vehicle without major modifications to the vehicle, and the vehicle may be converted back to two-wheeled use easily. The tracked version is powered by the original vehicle drive system, and uses the vehicles braking and suspension system.

Owner:JORDAN TIM

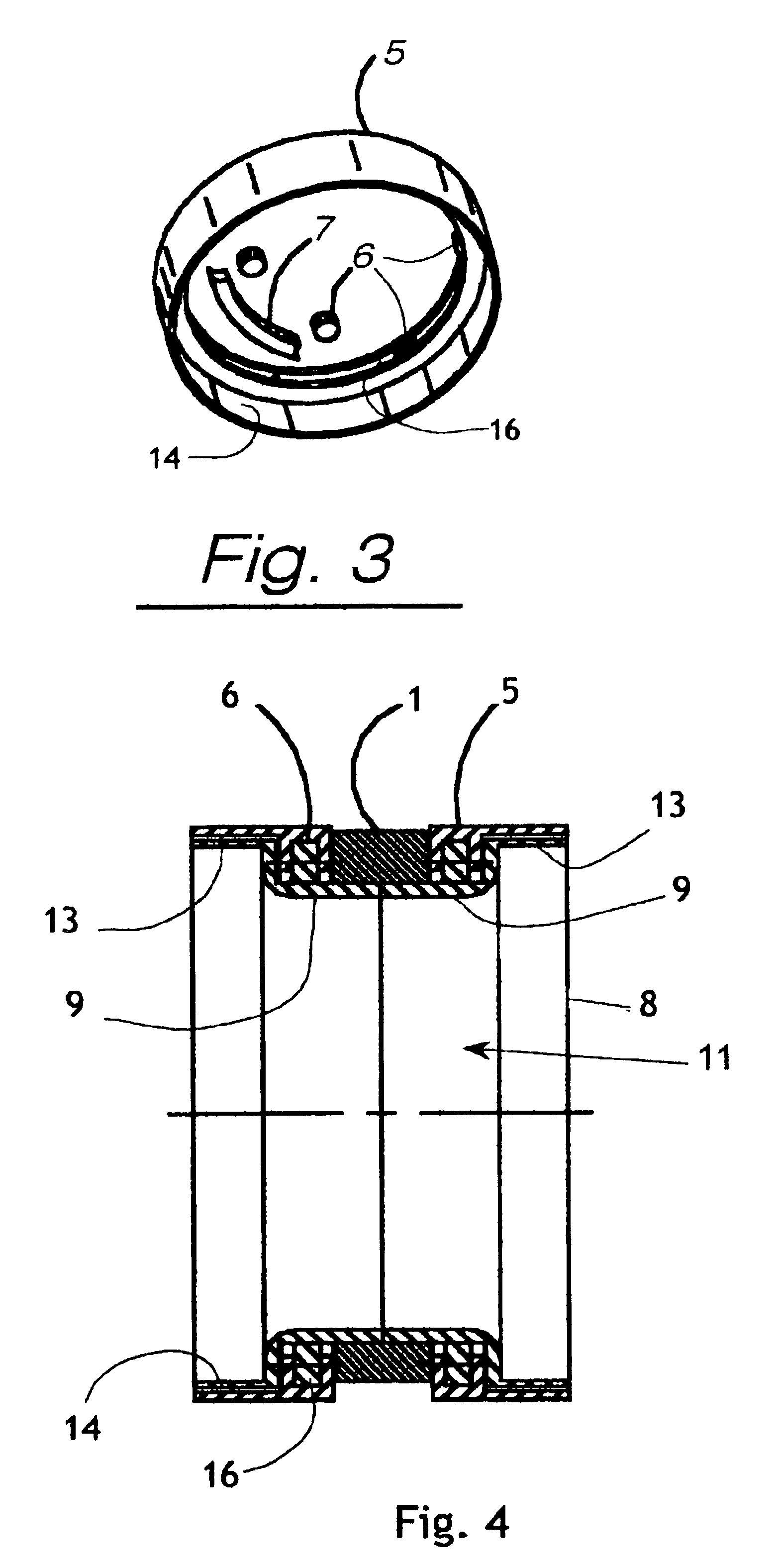

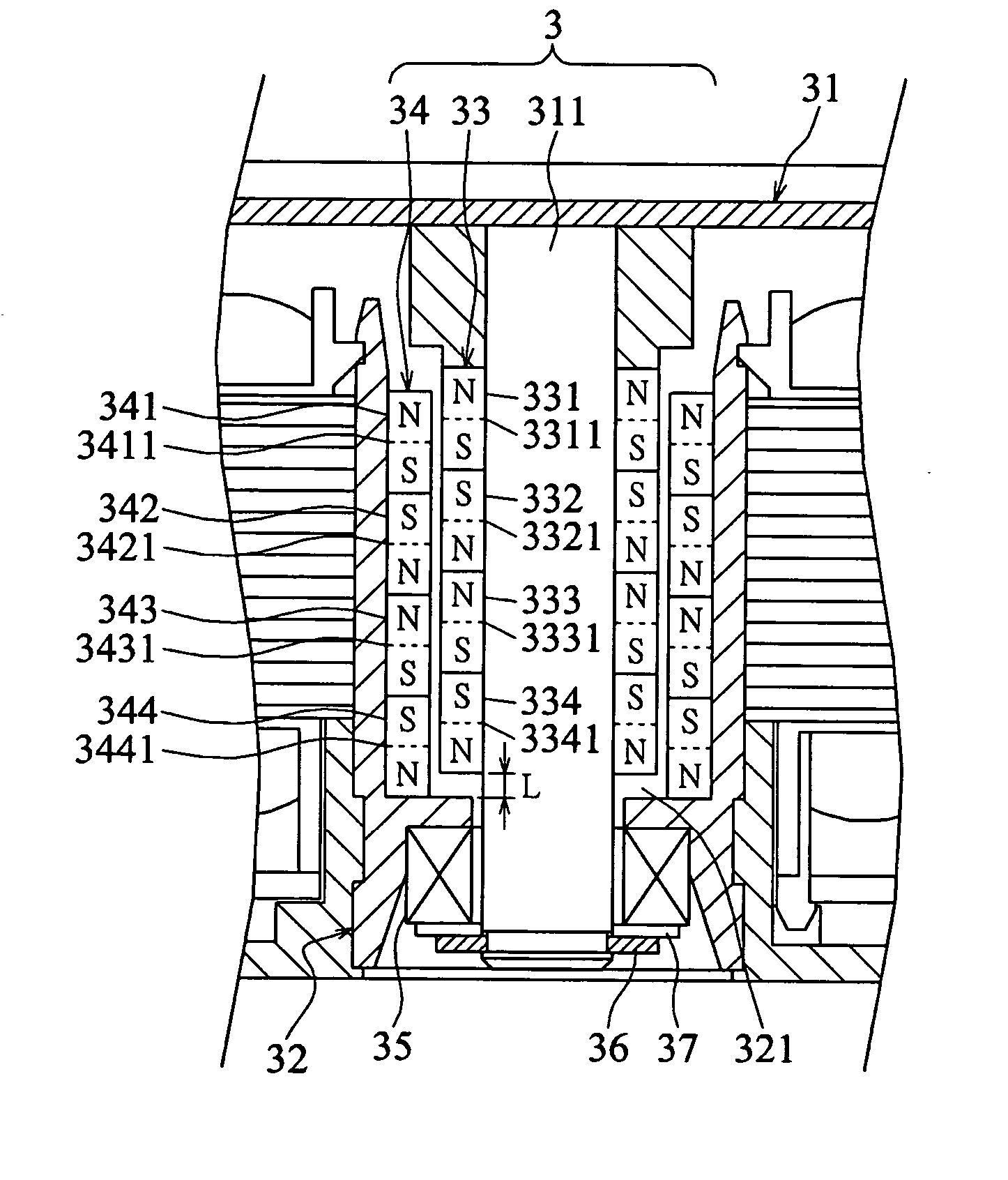

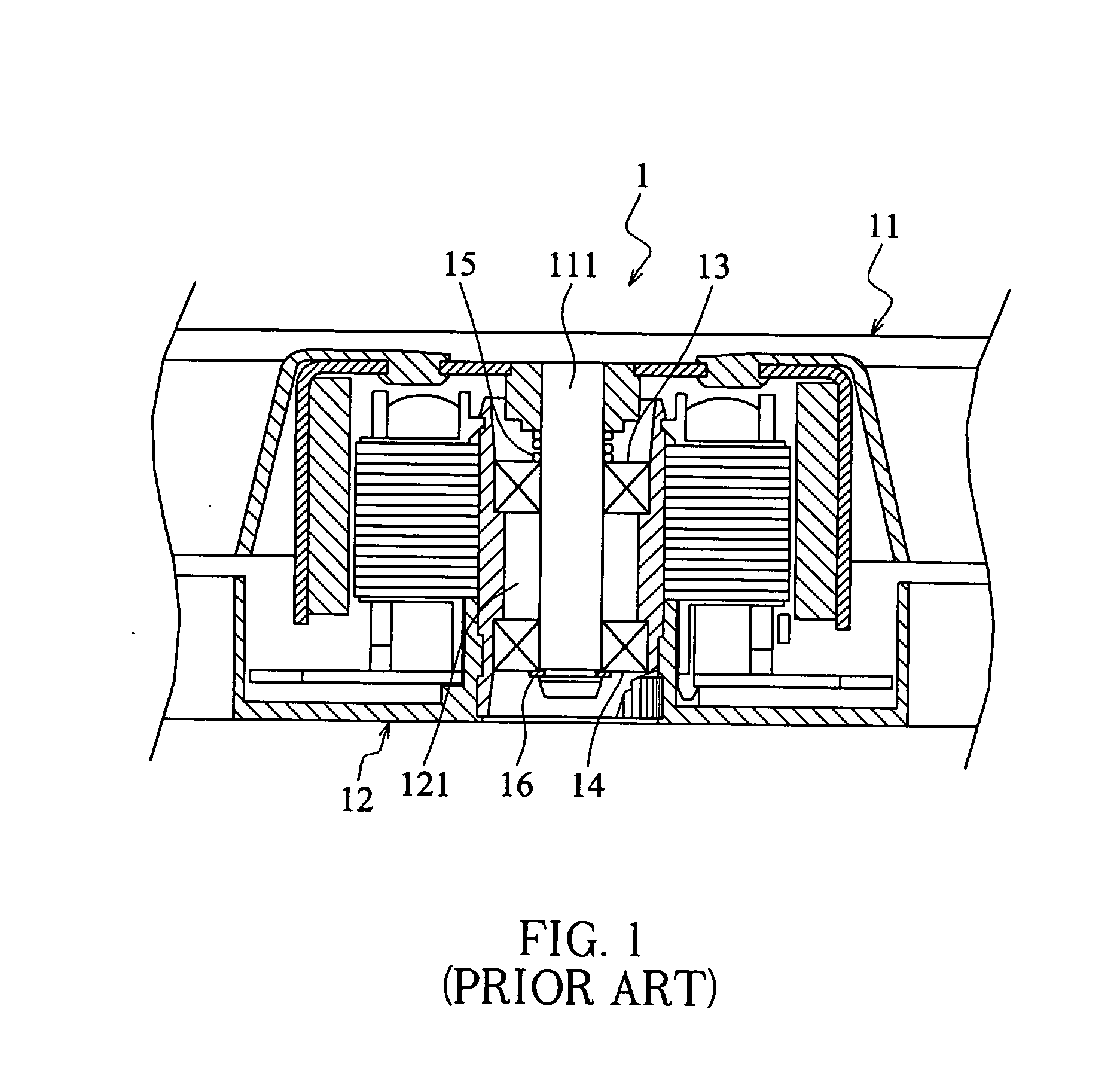

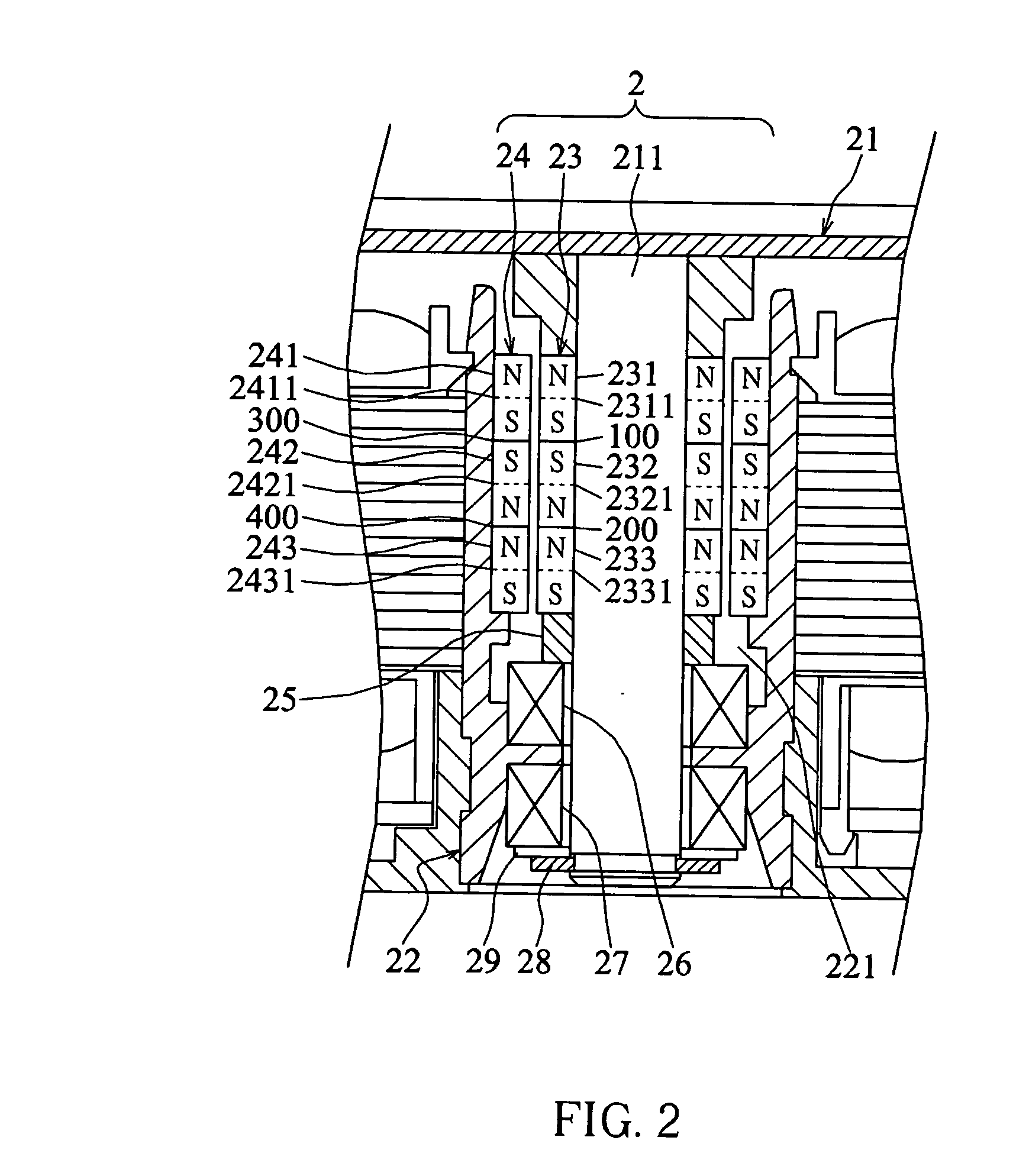

Magnetic bearing system

InactiveUS20050140228A1Easy to assembleEliminates radial large-area frictionRoller bearingsPump componentsMagnetic bearingEngineering

A magnetic bearing system for a rotating machine is disclosed. The magnetic bearing system provides a non-contacting radial rigid support for the rotating machine by employing two magnetic assemblies each being formed by stacked annular magnets. The magnetic assemblies are mounted separately on a shaft of the rotating machine and a shaft hole provided on the stator seat of the rotating machine for containing the shaft.

Owner:DELTA ELECTRONICS INC

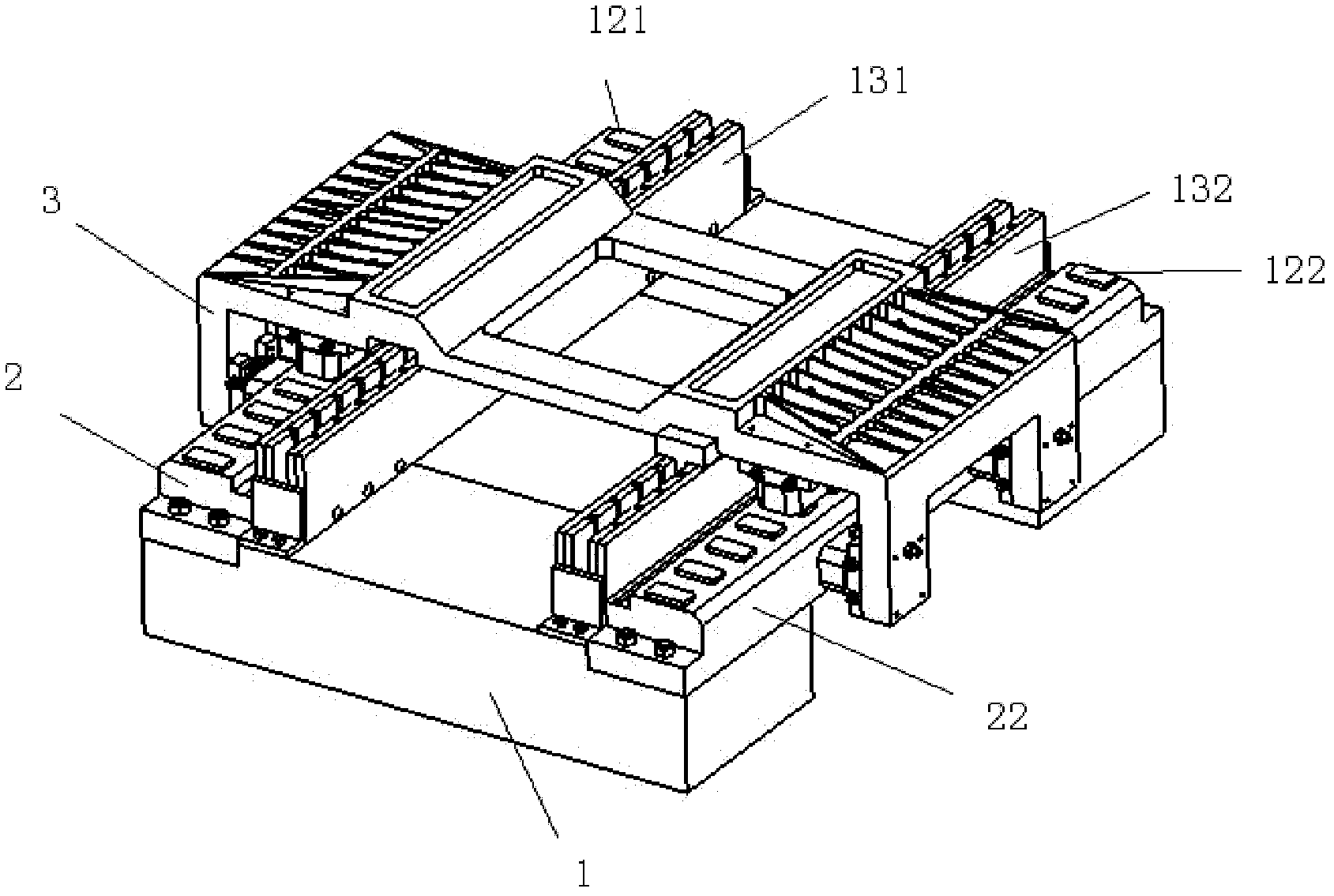

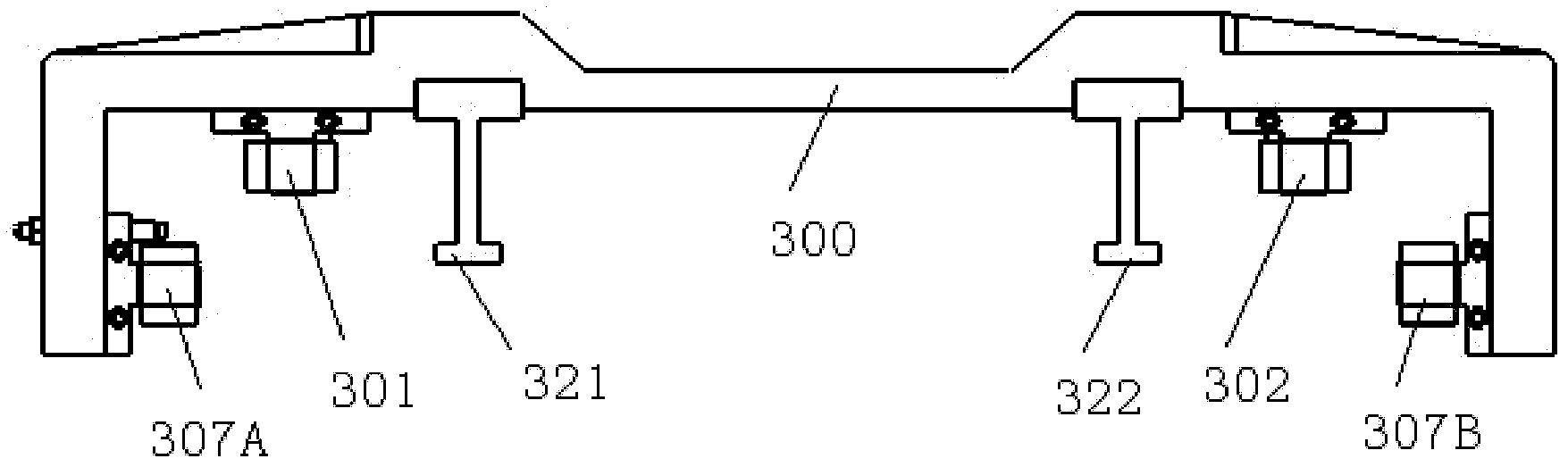

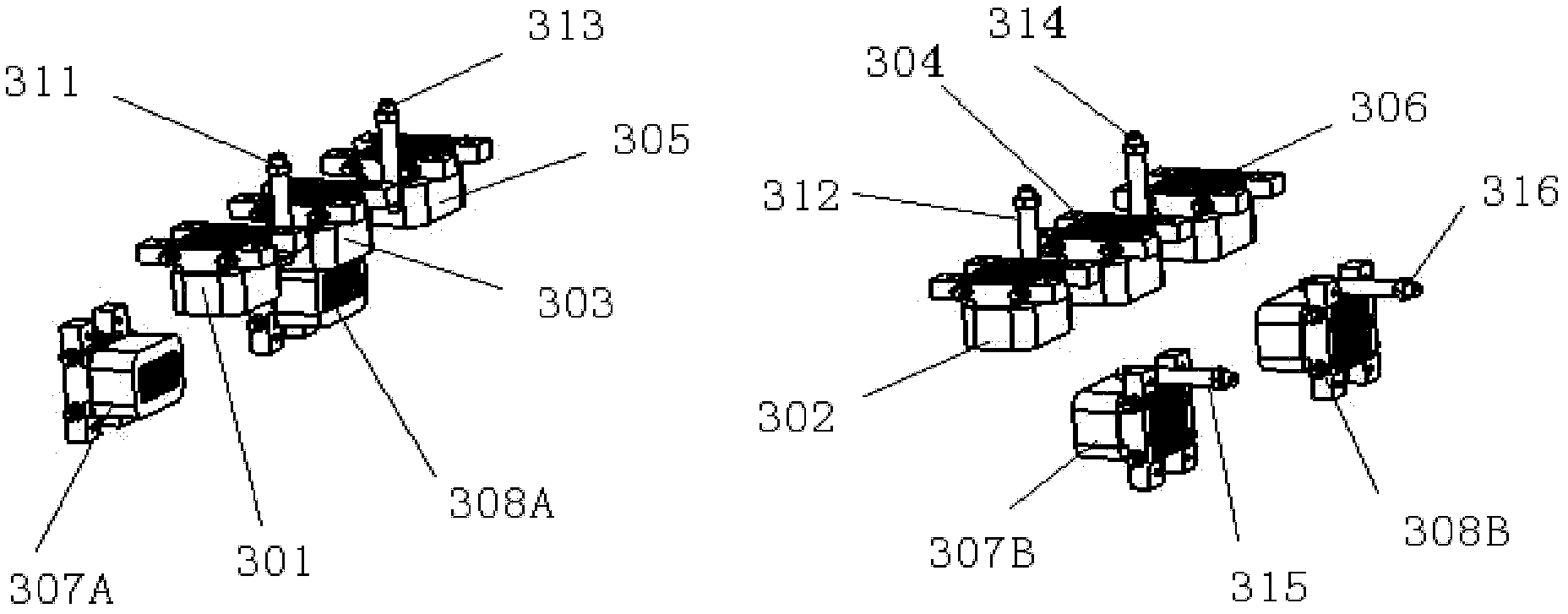

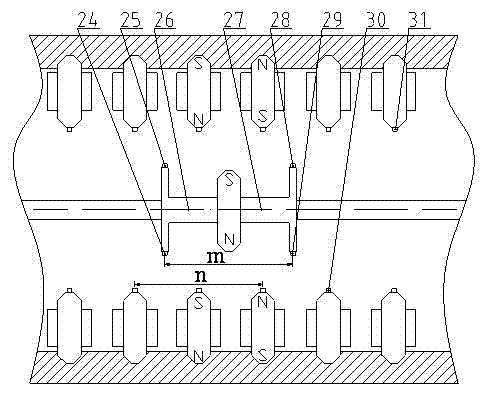

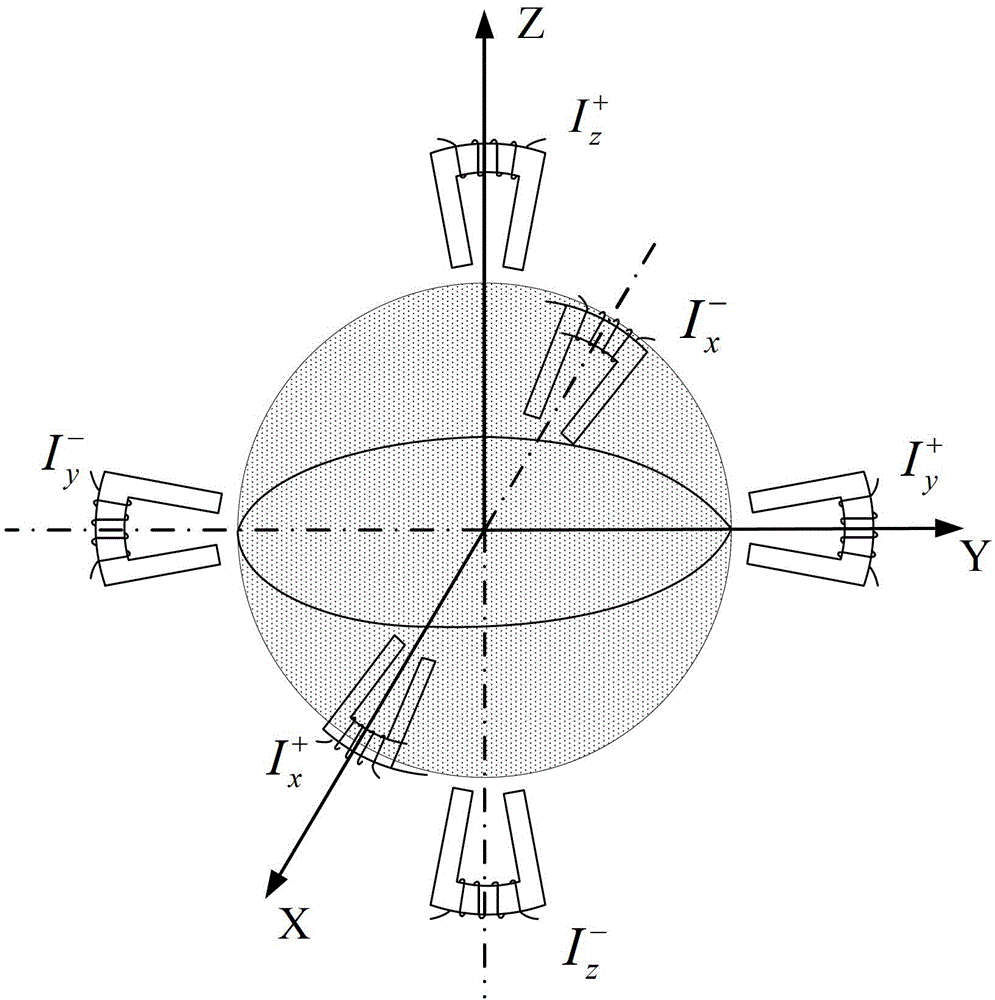

Magnetic suspension linear motion platform based on combination of permanent magnets and electromagnets

The invention discloses a magnetic suspension linear motion platform based on the combination of permanent magnets and electromagnets. The electromagnets are vertically installed in a suspensoid, array permanent magnets are arranged on the surface of a guide rail, the suspension of the suspensoid can be realized by utilizing the principle of holopolarity repulsion between the electromagnets and the permanent magnets; and meanwhile, an eddy current displacement sensor is combined to realize the stable suspension of the suspensoid above the guide rail; two pairs of electromagnets are horizontally installed in the suspensoid, which can provide guidance for the linear motion of the platform by combining with the eddy current displacement sensor; a linear motor stator is fixed on a base, a linear motor rotor is fixed on the suspensoid, a grating ruler is arranged on the surface of the guide rail, and the reading head of the grating ruler is installed on the suspensoid, thus the precise linear positioning motion of the suspensoid can be realized. The platform provided by the invention can realize the functions such as super cleaning, high speed, long stroke, precise positioning motion and the like, which can not be realized by the traditional scheme that a rotary servo motor is utilized to drive, a precise ball screw is utilized to transmit and a slide guide is utilized to support, and has the advantages of good load bearing characteristic and stable suspension performance.

Owner:CENT SOUTH UNIV

Prosthesis for replacement of cartilage

A cartilage replacement or repair prosthesis comprises a layer of streamlined elastomer elements, preferably in the form of spheres, supported in a matrix material so that the radially opposed surfaces of the spheres are positioned on opposite surfaces of the layer and make contact with the opposed surfaces of the femur and tibia and the forces exerted between these bones extend through the streamlined elements. The matrix material has a substantially lower resistance to deformation than the spheres to control the position of the spheres relative to one another without significantly restraining their load-responsive deformation under forces exerted between the femur and tibia. The layer, with its elastomeric inserts, is sufficiently thin and flexible to allow it to be rolled for arthroscopic insertion into a knee joint.

Owner:SUCCESSOR TRUSTEE OF THE EUGENE RIVIN LIVING TRUST +2

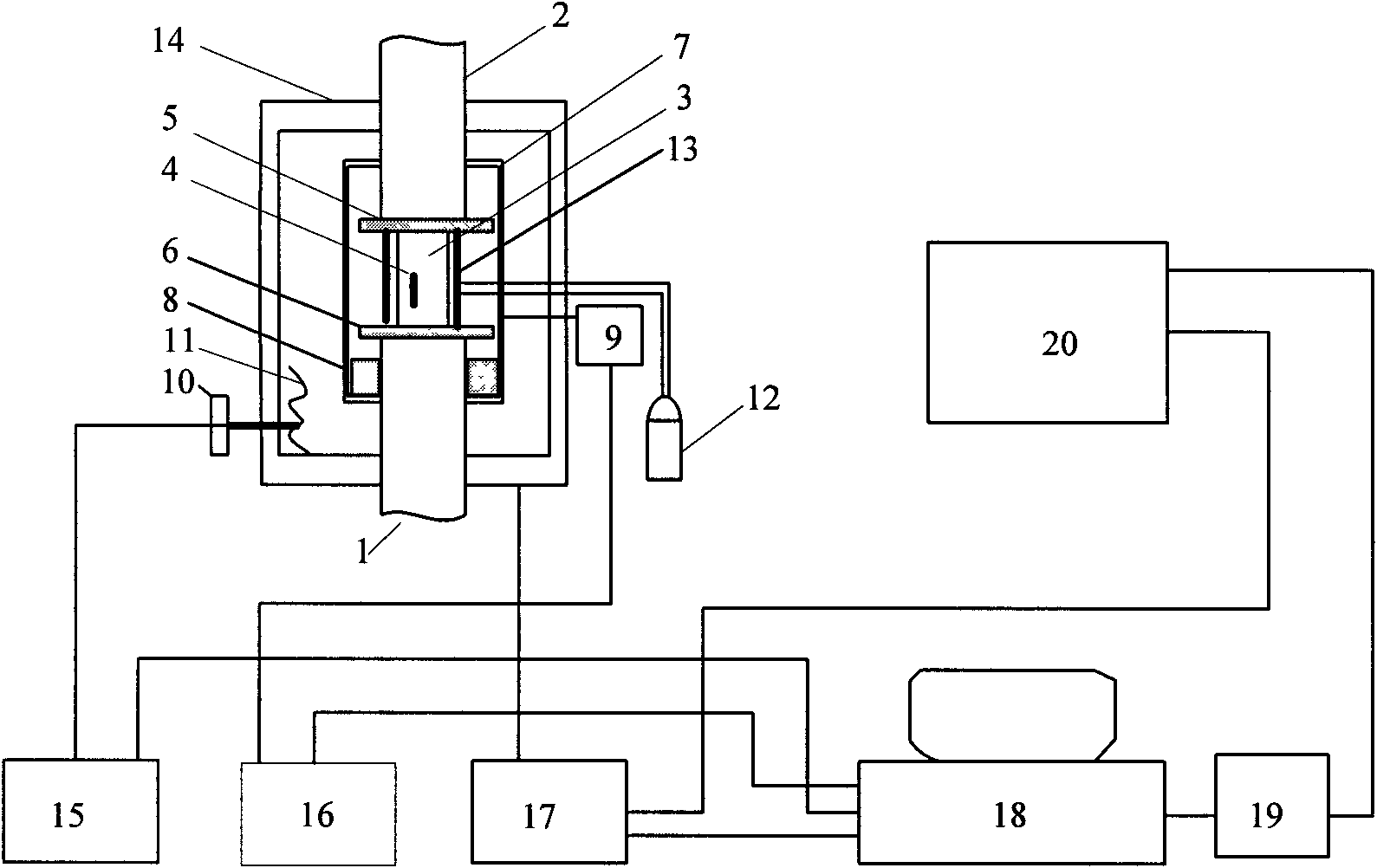

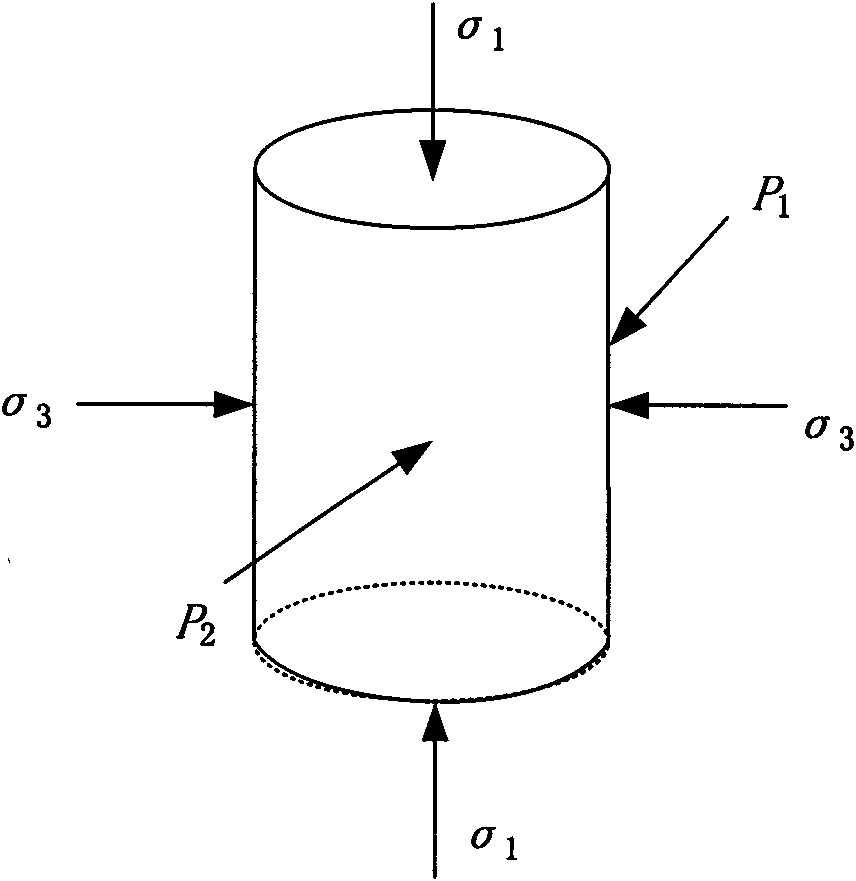

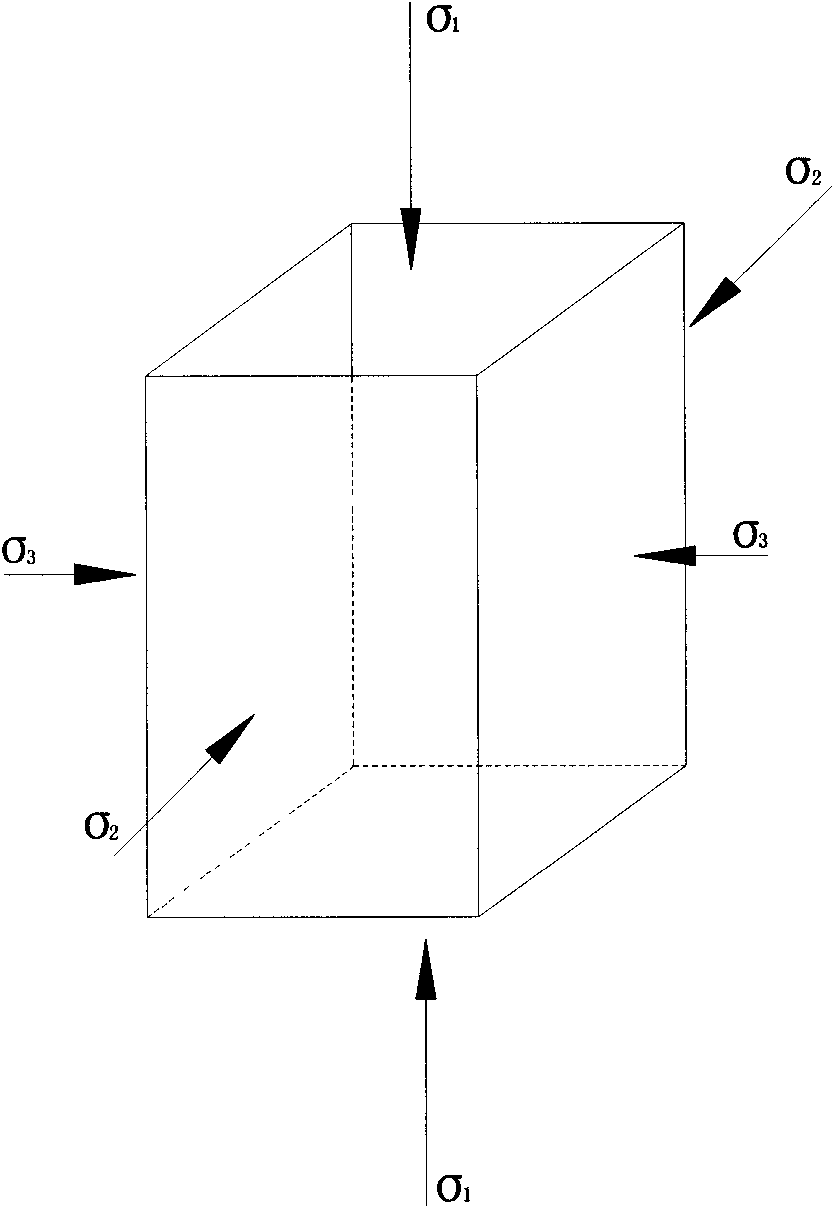

Triaxial compression rheological test system capable of simulating engineering geological environment

InactiveCN101886996AImplement rheological testsSolve the problem of uniform heatingInvestigating material ductilityLithologyMulti field

The invention provides a triaxial compression rheological test system capable of simulating an engineering geological environment, belonging to rock material compression experimental facilities. The remarkable characteristics of the invention are as follows: a test chamber in the triaxial compression rheological test system capable of simulating the engineering geological environment can depend on a normal rheological compression test device to realize the analogue simulation of the variations of a temperature field, a humidity field and a chemical field in the engineering geological environment by utilizing a humidifier, a heater and a fluid tank. The device fundamentally solves the problems of larger deviation of rock mechanics parameters obtained by a laboratory test and a field in-situ test and analogue simulation of a geotechnical wall-rock multi-field coupling environment. The test system has compact structure and low cost, is rather easy to install and dismount test pieces, detectors, pipelines and lead wires, and has stronger adaptability on the test pieces with different lithologies and sizes, thereby providing a set of complete technology and means for the study on the mechanical behavior of the wall-rock stability under a complex engineering geological condition.

Owner:付志亮

Mechanically detachable vaso-occlusive device

Owner:BOSTON SCI SCIMED INC

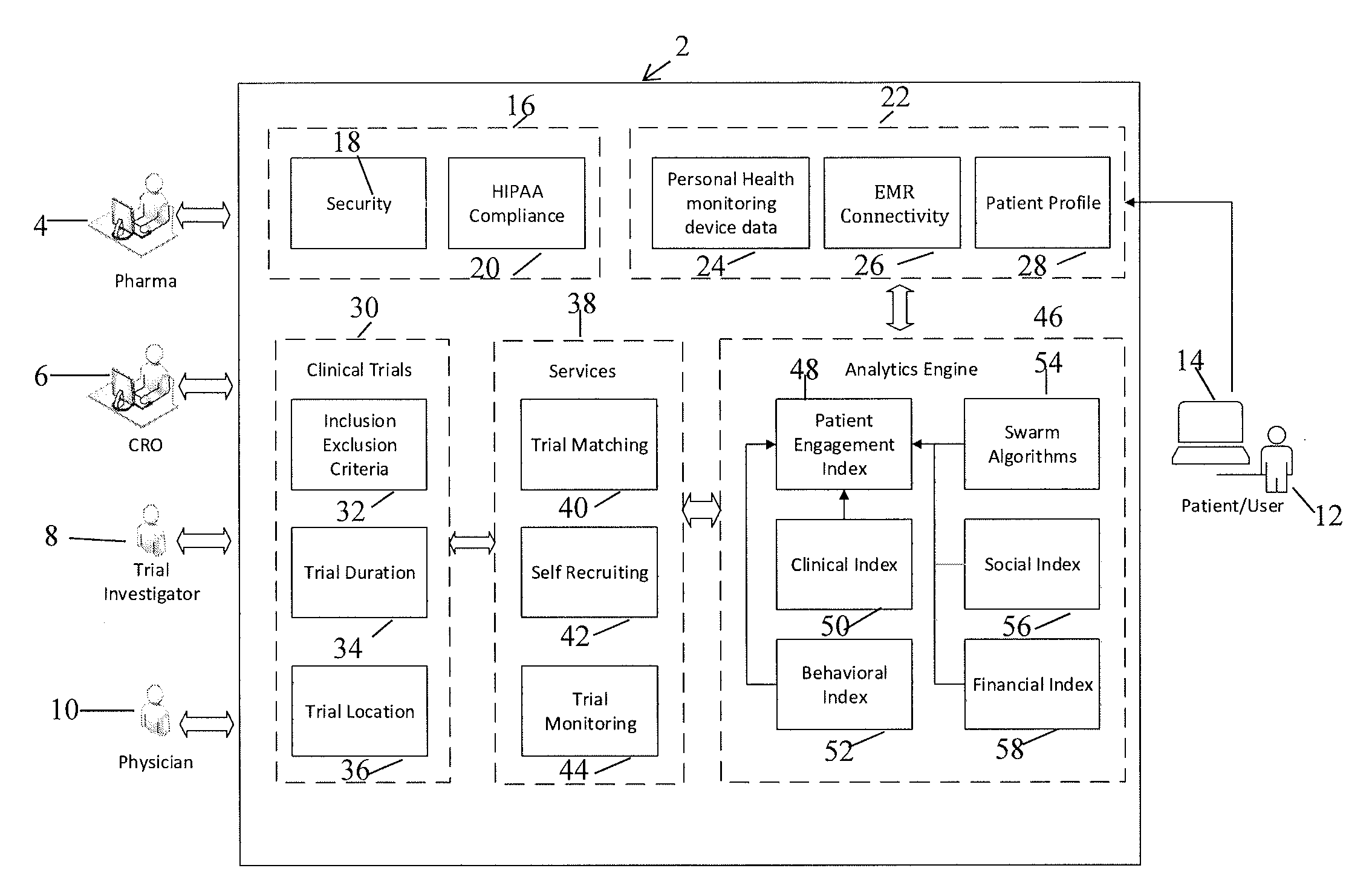

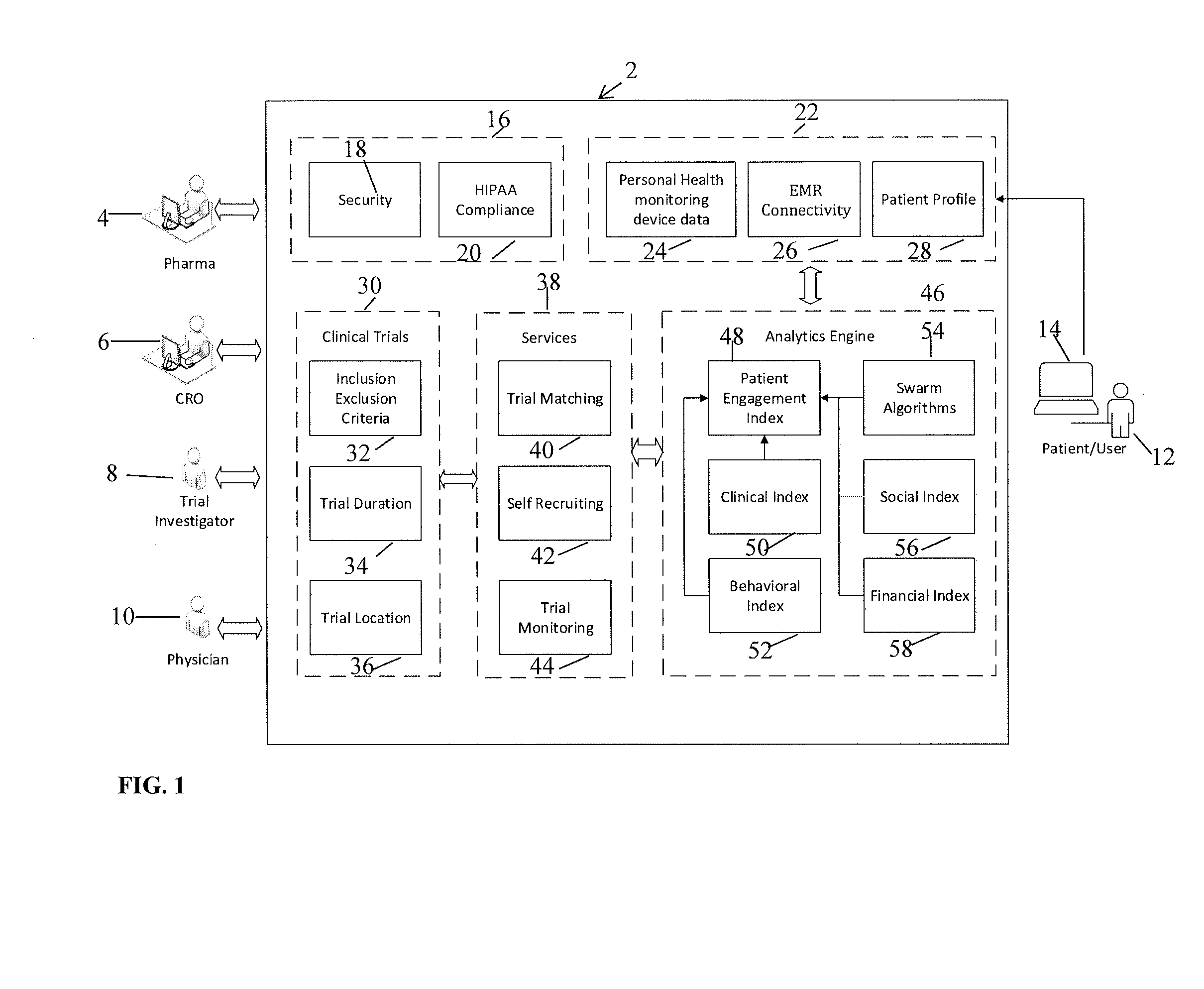

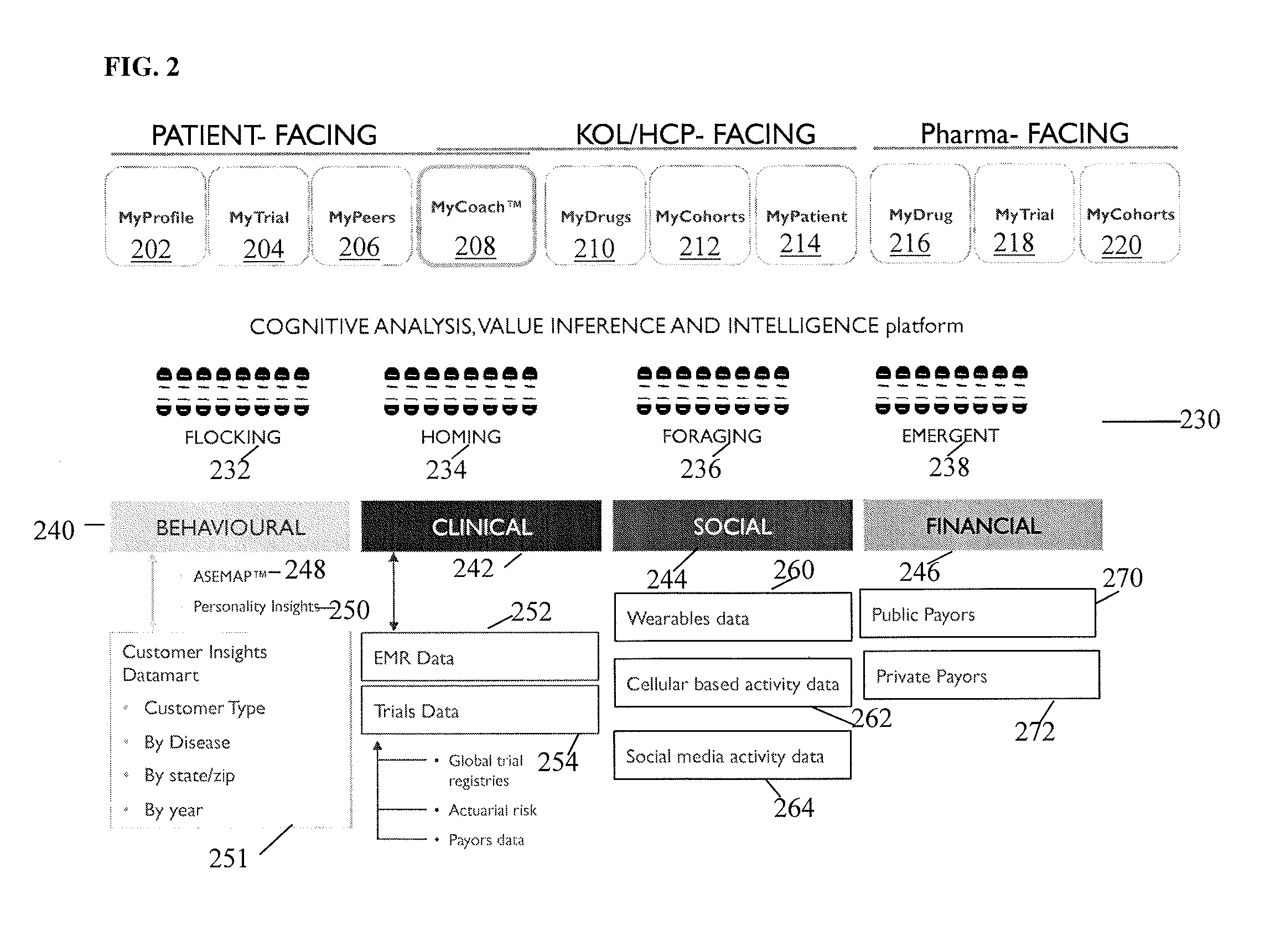

Method and apparatus for virtual clinical trial self-recruitment marketplace for patients based on behavioral stratification, patient engagement and patient management during clinical trials using behavioral analytics, gamification and cognitive techniques

InactiveUS20160357944A1Patient convenienceAvoid insufficient frictionFinanceComputer-assisted medical data acquisitionPatient managementApplication software

Method, Apparatus and non-transitory computer readable media that enhance patient-recruitment and participation in clinical trials preferably includes structure and / or steps whereby one or more APIs are used to interface at least one Cognitive Analytics Value Inference and Intelligence—Healthcare (CAVII-H) server with the patient(s), Pharma participant(s), Contract Research Organization(s), Trial Investigator(s), and Healthcare Providers (such as a physician). The at least one CAVII-H server preferably use at least one of stored trial data, user medical data, user behavioral date, user application collected data user registration data, healthcare professional data to guide patient participation. Preferably, information is obtained from the users through plural interactive algorithms designed to sharpen and perfect patient selection, preferably throughout the life of each trial. This creates a global clinical-trial patient engagement, recruitment and retention marketplace, which is open to patents and all trial stakeholders.

Owner:IYER GIRI +2

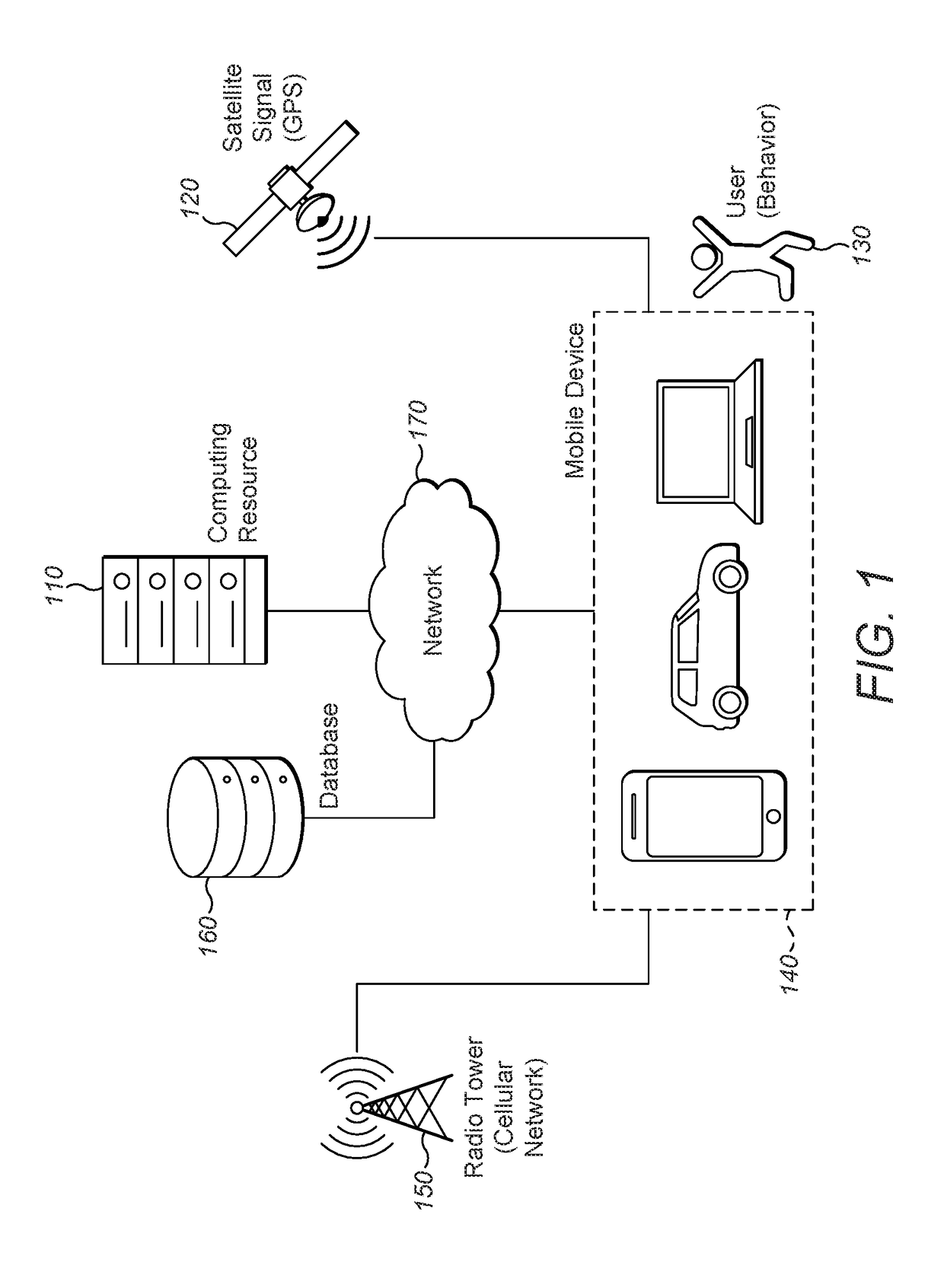

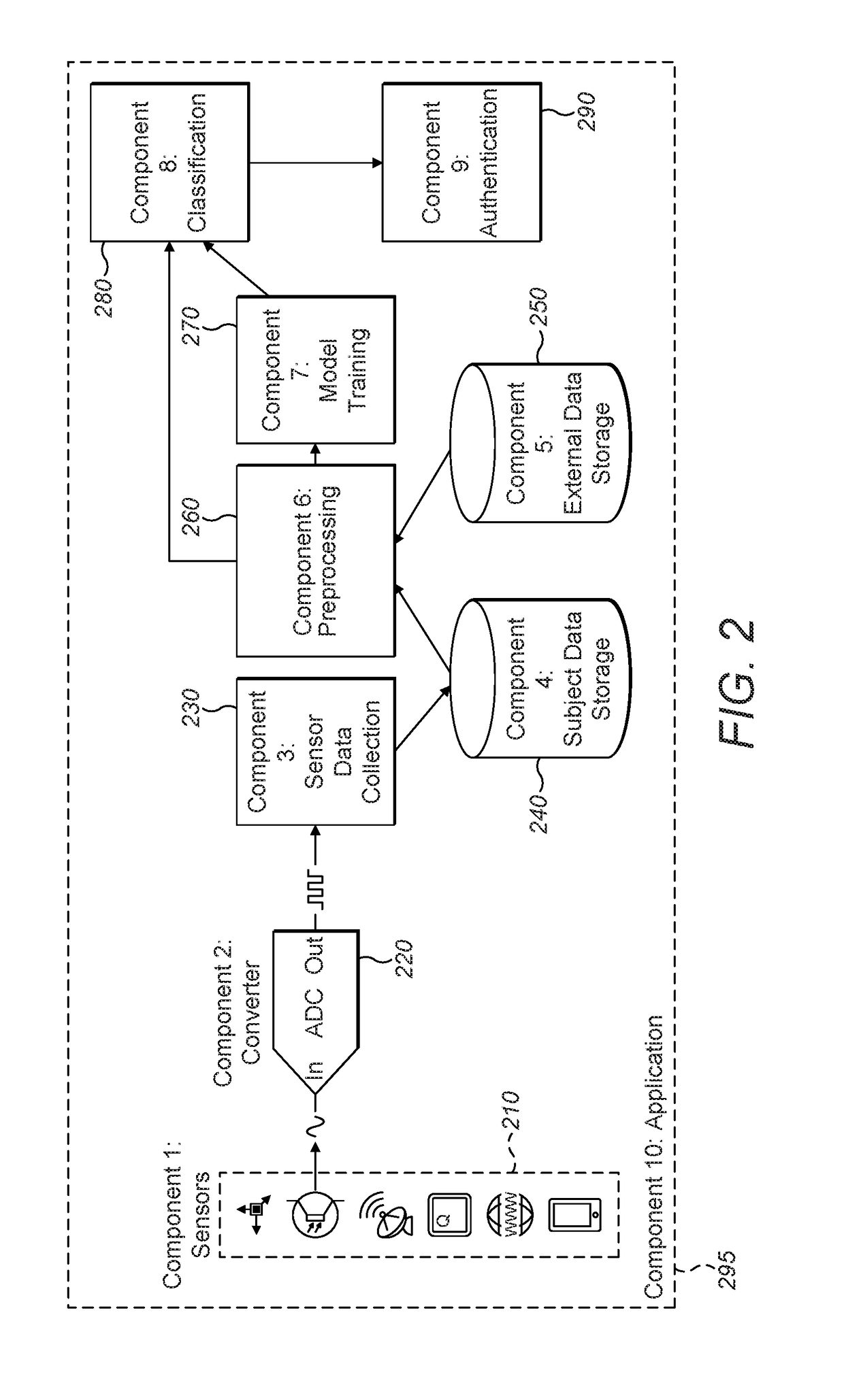

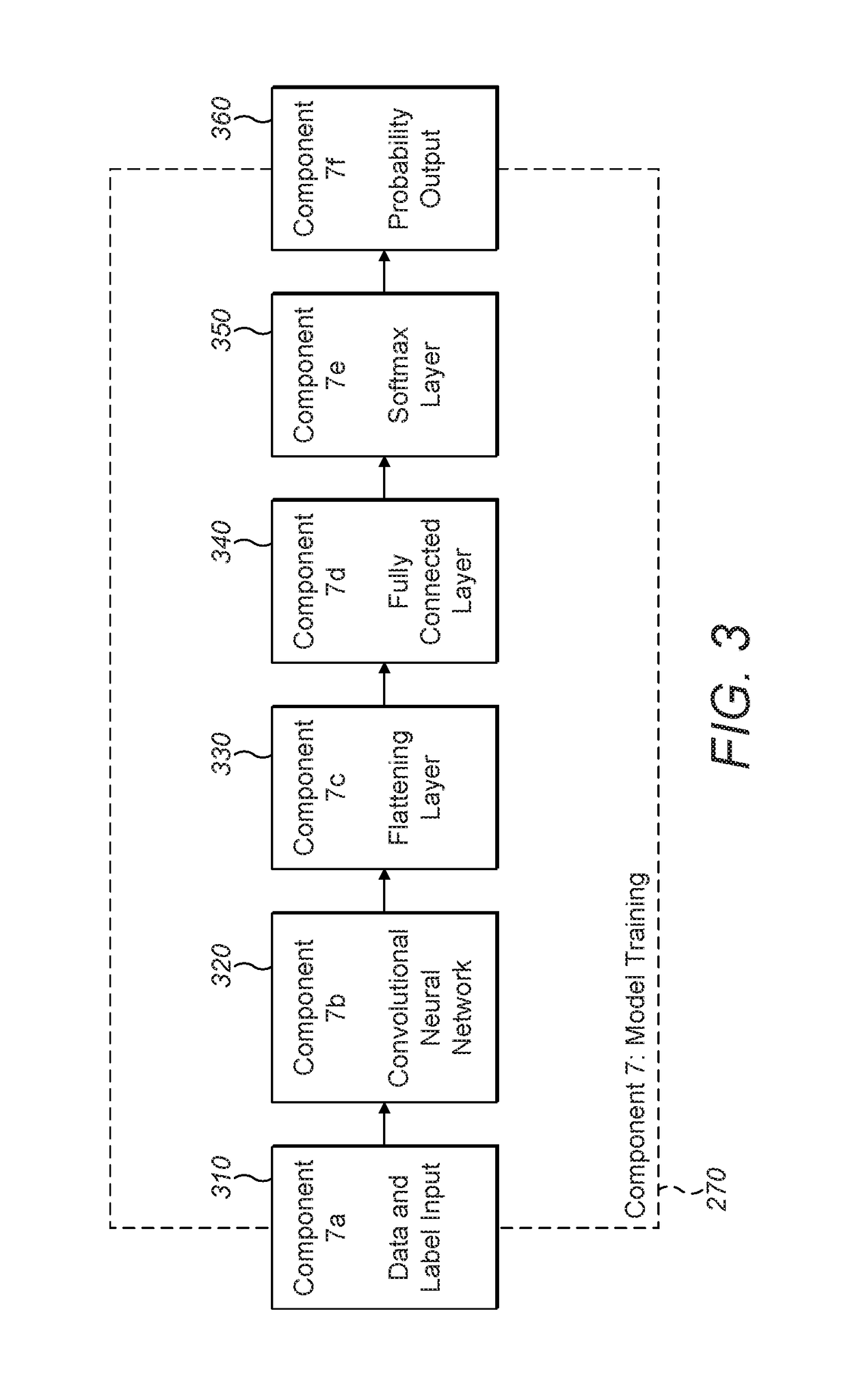

Deep Learning for Behavior-Based, Invisible Multi-Factor Authentication

InactiveUS20190044942A1Efficiently authenticatingOvercome obstaclesOther decoding techniquesDigital data authenticationUser deviceInternet privacy

Biometric behavior-based authentication may be enhanced by using convolutional deep neural networks to learn subject-specific features for each subject. The advantage is two-fold. First the need for a domain expert is eliminated, and the search space can be algorithmically explored. Second, the features that allow each subject to be differentiated from other subjects may be used. This allows the algorithm to learn the aspects of each subject that make them unique, rather than taking a set of fixed aspects and learning how those aspects are differentiated across subjects. The combined result is a far more effective authentication in terms of reduction of errors. Behavior-based, invisible multi-factor authentication (BIMFA) mays also automate the responses to authentication second and third factor requests (something you have and something you are). BIMFA leverages continuous, invisible behavioral biometrics on user devices to gain a continuous estimate of the authorization state of the user across multiple devices without requiring any explicit user interaction or input for authentication. As a result, BIMFA can demonstrate that a device is under the control of the authorized user without requiring any direct user interaction.

Owner:TWOSENSE INC

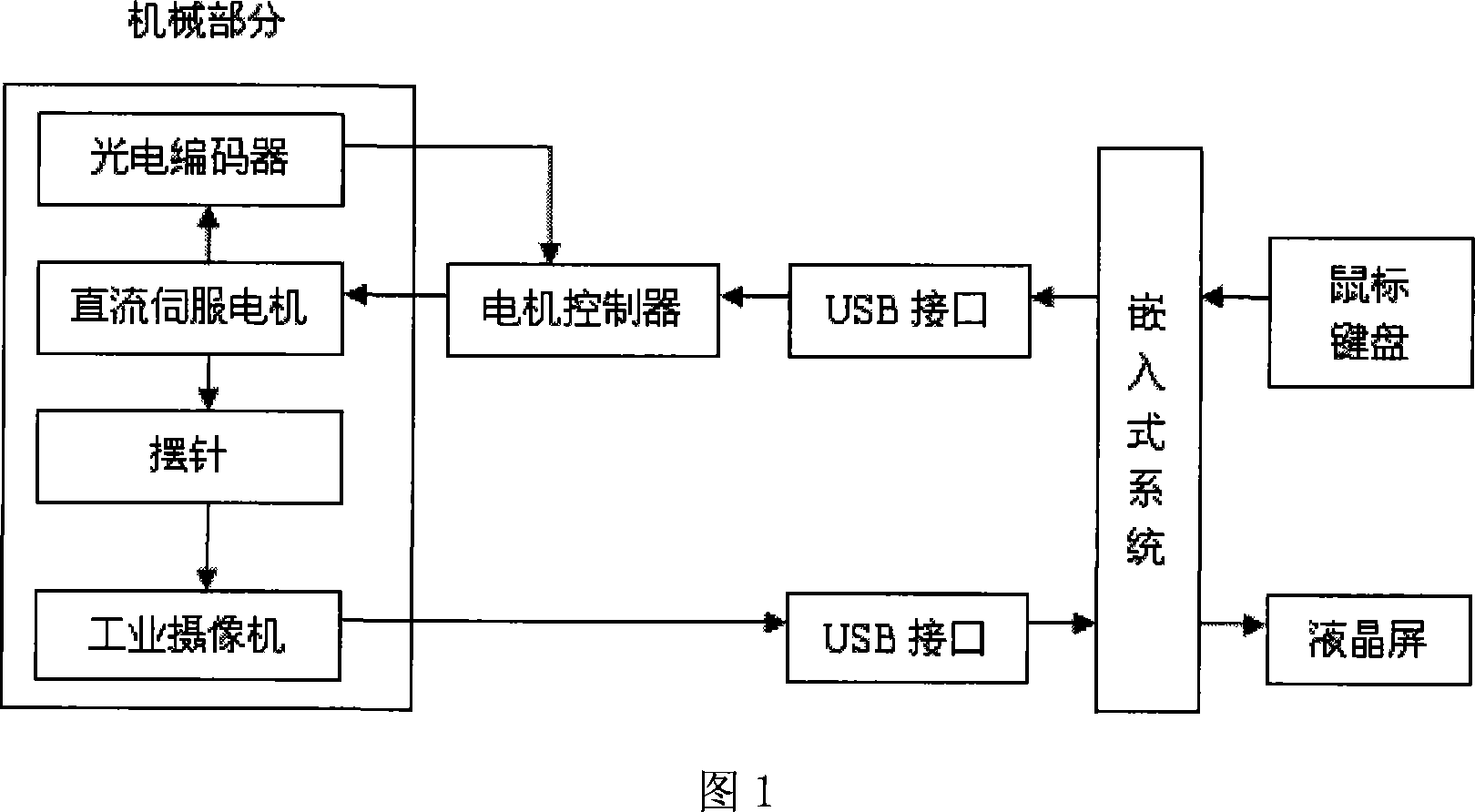

Micro-bearing friction torgue measuring instrument

InactiveCN101067578AEliminate frictionEliminate distractionsMachine bearings testingForce measurement using counterbalancing forcesEmbedded technologyFriction torque

The invention is a microtype bearing friction moment measurer, belonging to the field of measuring and control technique. And the invention comprises: mechanical part, electrical part and embedded system, where the mechanical part is connected with the input end of the electrical part through lead wires and USB interface, and the input and output ends of the electrical part are connected the input and output ends of the embedded system, respectively. And the invention adopts digital image processing technique, embedding technique and auto control technique to be able to accurately measure friction moment of a microtype bearing. And the measurer has simple structure, operating convenience and high measuring accuracy.

Owner:SHANGHAI JIAO TONG UNIV

Hubless caster

InactiveUS7150070B2Improve stabilityFunction increaseSuction cleanersCastorsFree rotationEngineering

A hubless caster assembly includes a caster body and at least one wheel, the wheel comprising a toroidal member having a bearing race, and a complementary bearing race supported by the caster body. Bearing elements in the races support the wheel in free rotation. The caster body may comprise a ring body having an axial opening, whereby the caster assembly has a large central aperture extending entirely therethrough. A centering ring may be secured in the axial opening with the complementary bearing race formed therein. A hub cap with visual treatment may be secured over the central aperture.

Owner:OCONOMOWOC MFG

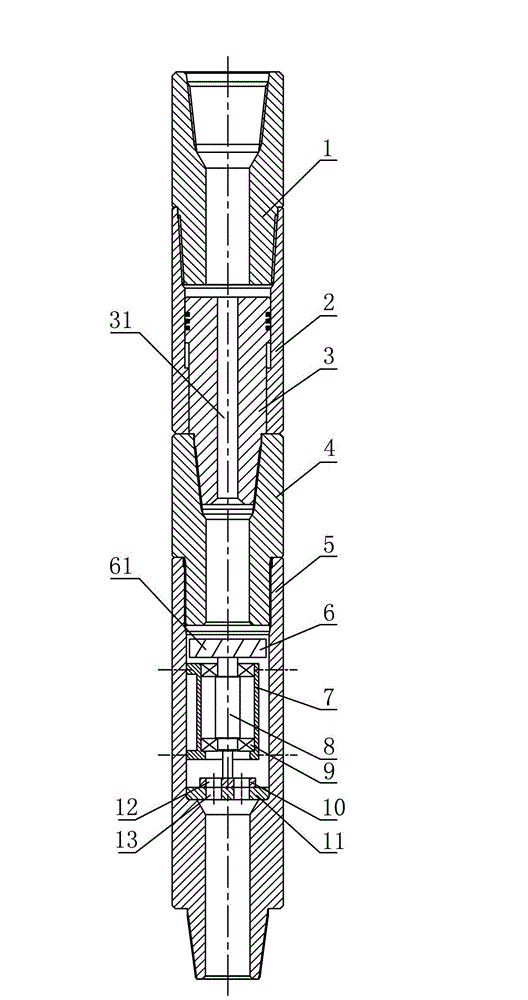

Drilling tool for stimulating vibration of drill column

The invention discloses a drilling tool for stimulating vibration of a drill column. The drilling tool comprises an upper shell, a lower shell and a poppet valve device, wherein an adapter is arranged at the upper end of the upper shell; a piston rod is arranged below the adapter in a sliding manner; a hollow piston rod runner is arranged on the piston rod; the upper end of the lower shell is fixedly connected with the lower end of the piston rod; a guide drive device is arranged inside the lower shell, and the poppet valve device is arranged below the guide drive device. When the drilling tool for stimulating vibration of the drill column is connected into the drill column to drill, a special valve system is driven by drilling fluid to generate hydraulic impact for driving the lower drill column to carry out periodic vibration in an axial direction, so that the phenomena of dragging and sticky slip generated in the drilling process of a high-friction torsional section can be eliminated, the contact state between the drill column and a well wall is improved, the upper drilling pressure and torque are effectively transmitted to a drill bit, and the penetration rate is increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

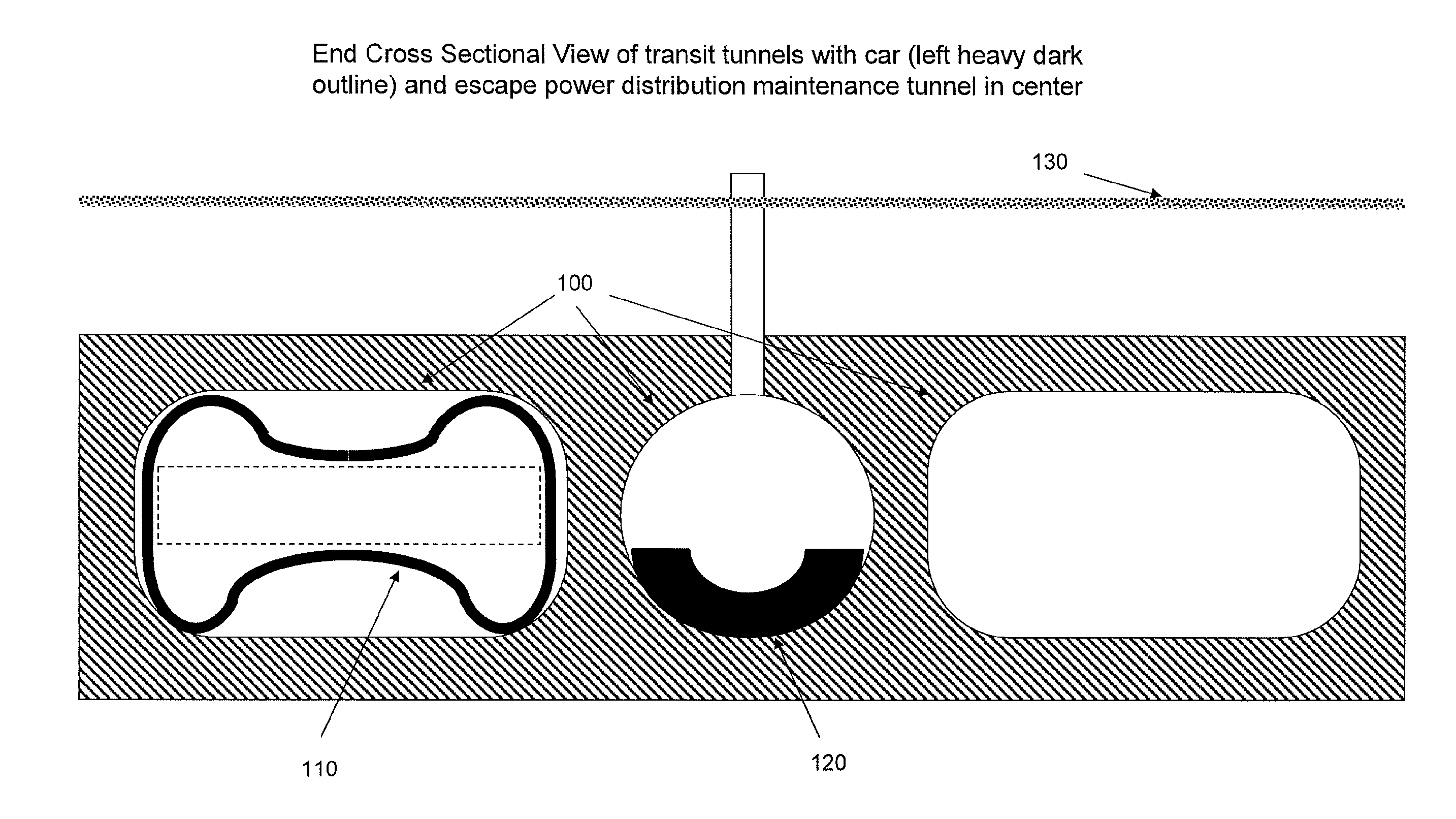

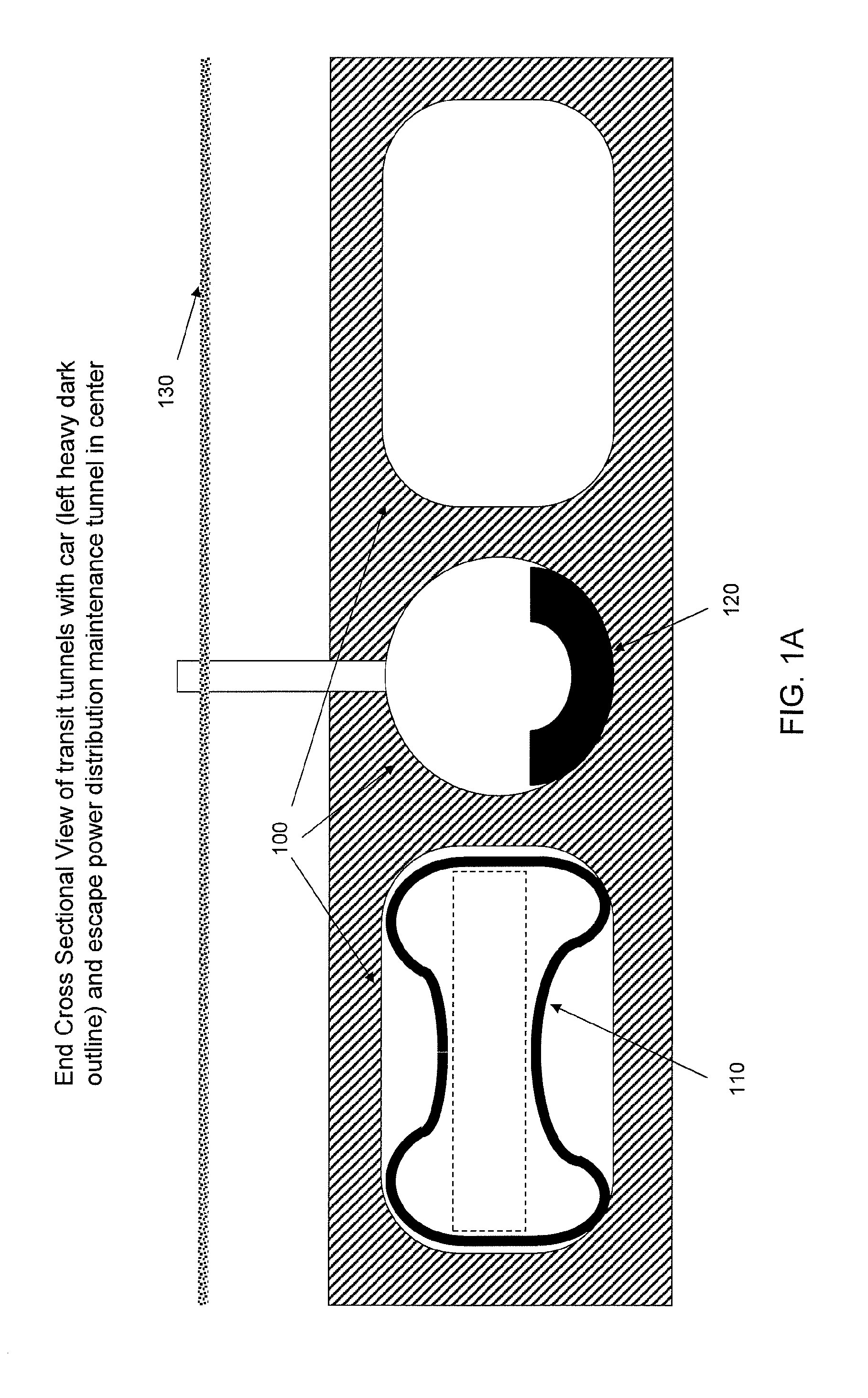

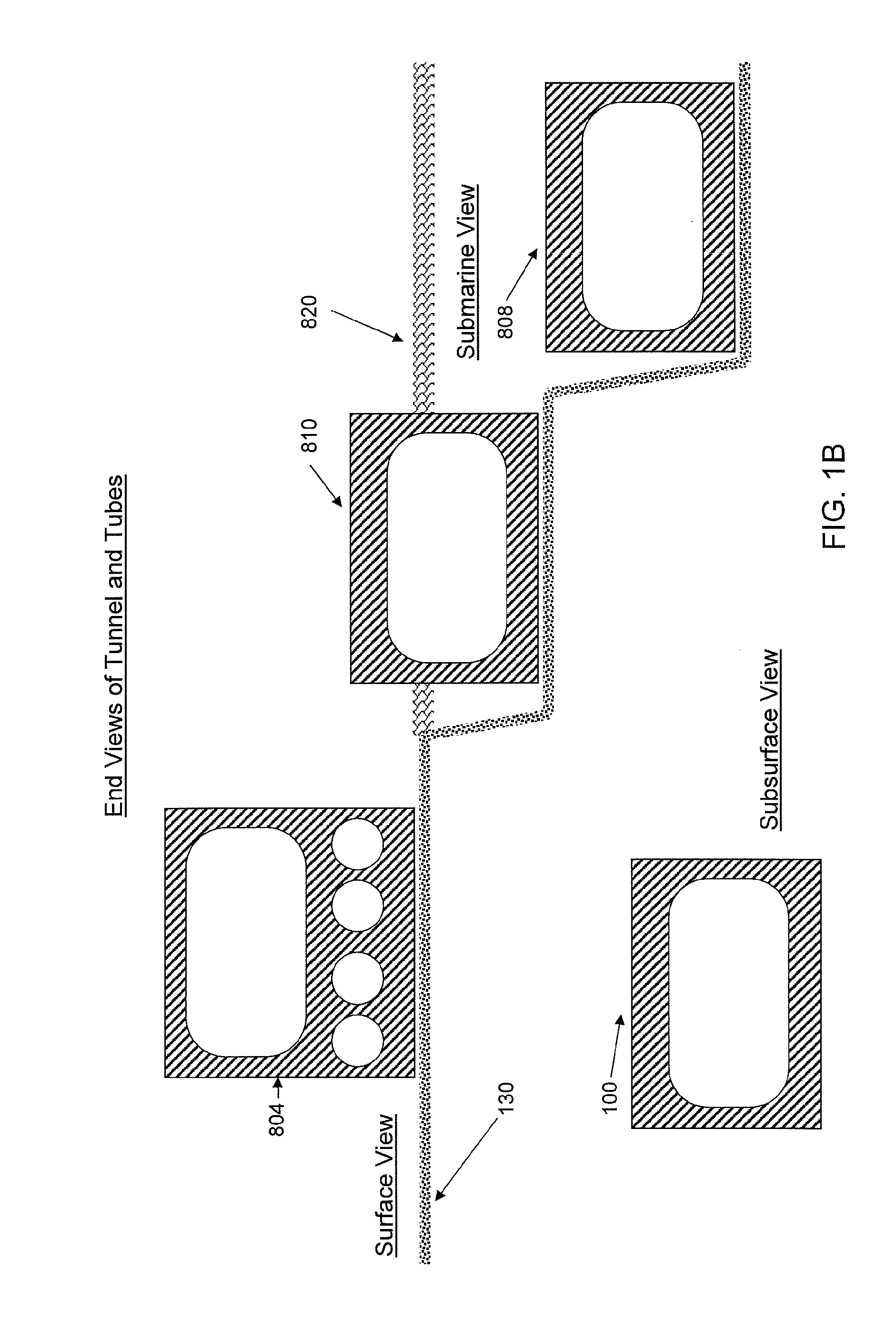

Superconducting Power and Transport System

InactiveUS20120089525A1Eliminate frictionEngine sealsData processing applicationsPower cableAbove ground

A transport and power system having a plurality of tubes or tunnels, a magnetic levitation and linear motor train, and a superconducting power cable. One of the tubes can be an escape, power distribution, and maintenance tunnel. These tubes can be above ground, below ground, at ground, or under water.

Owner:METADIGM L L C

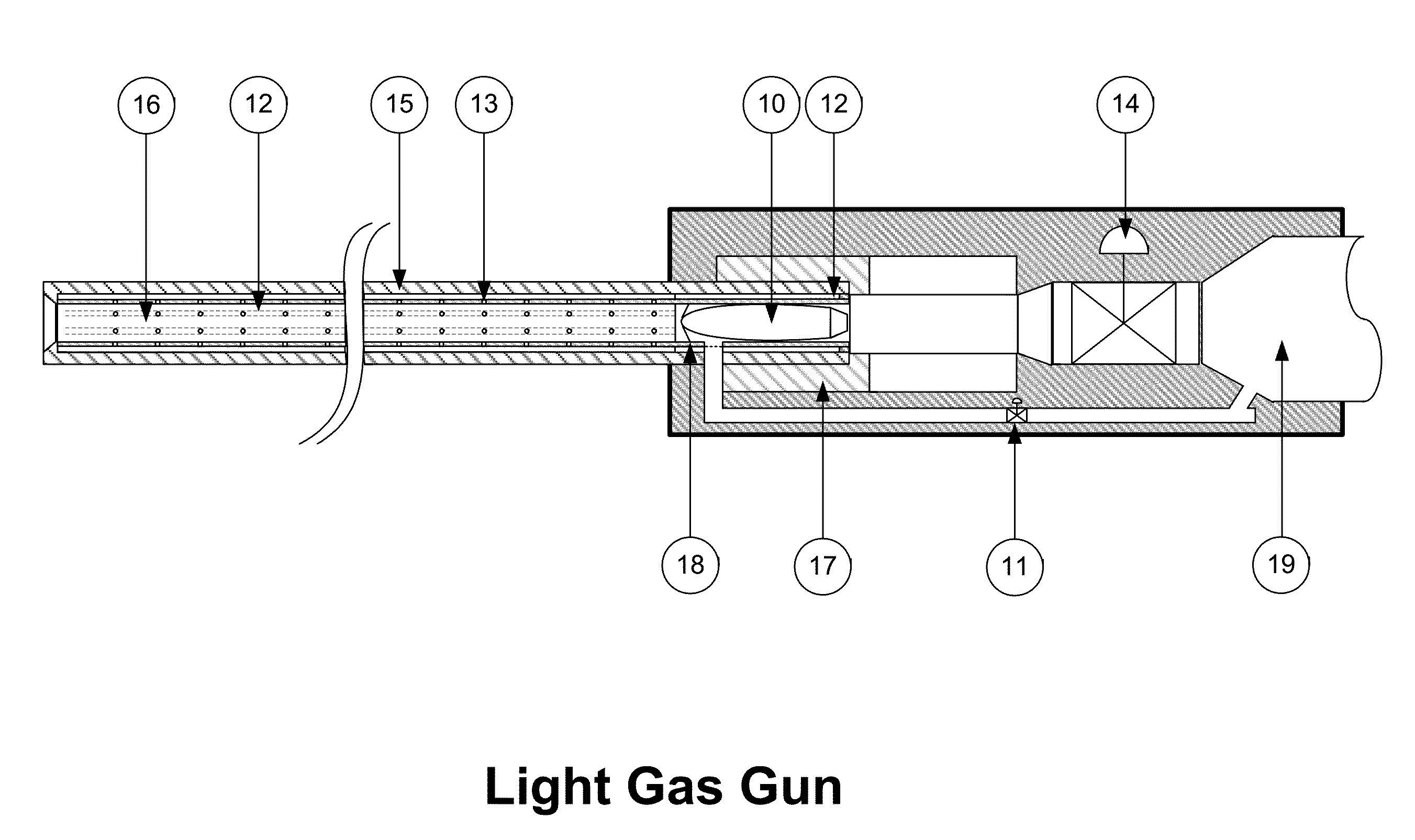

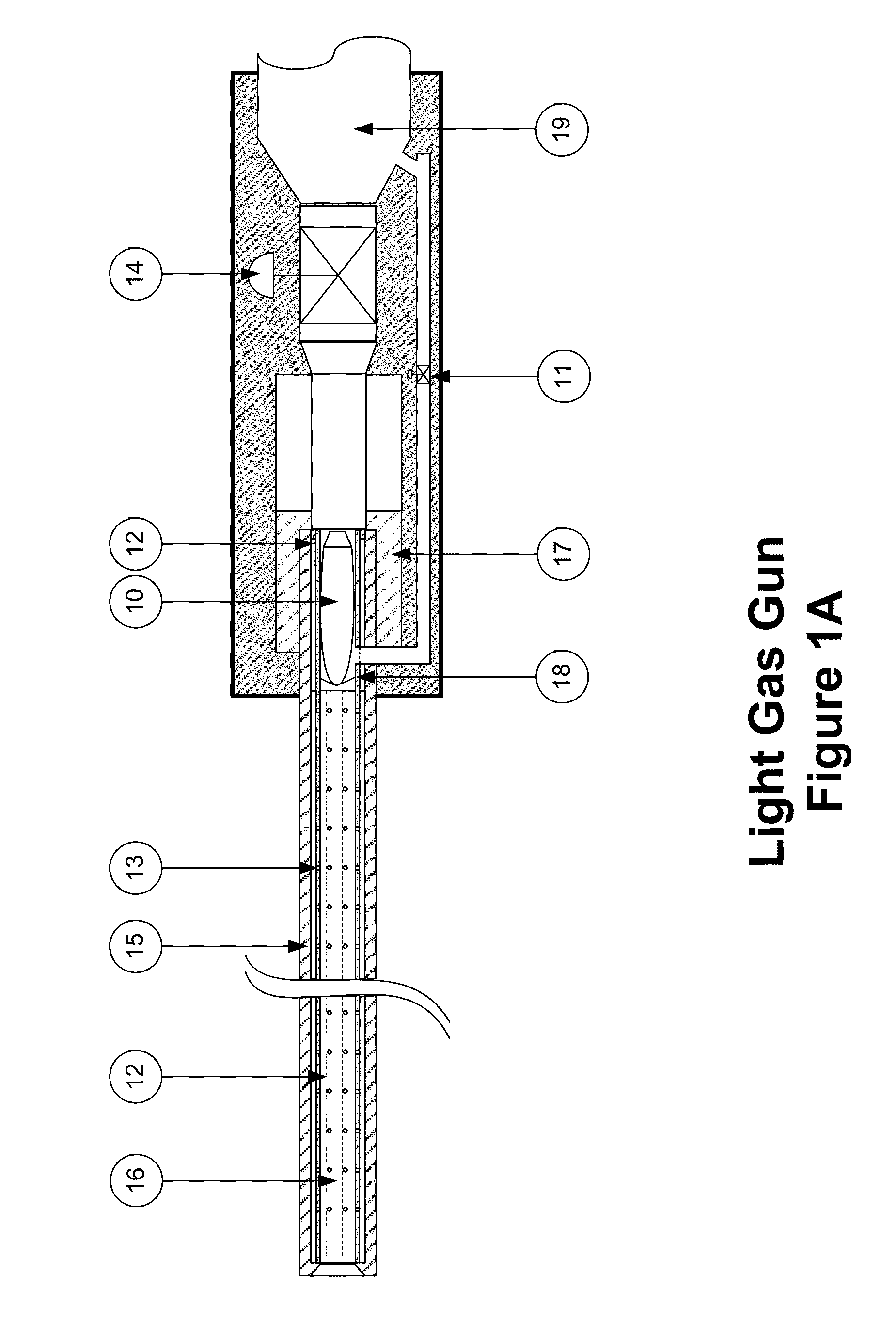

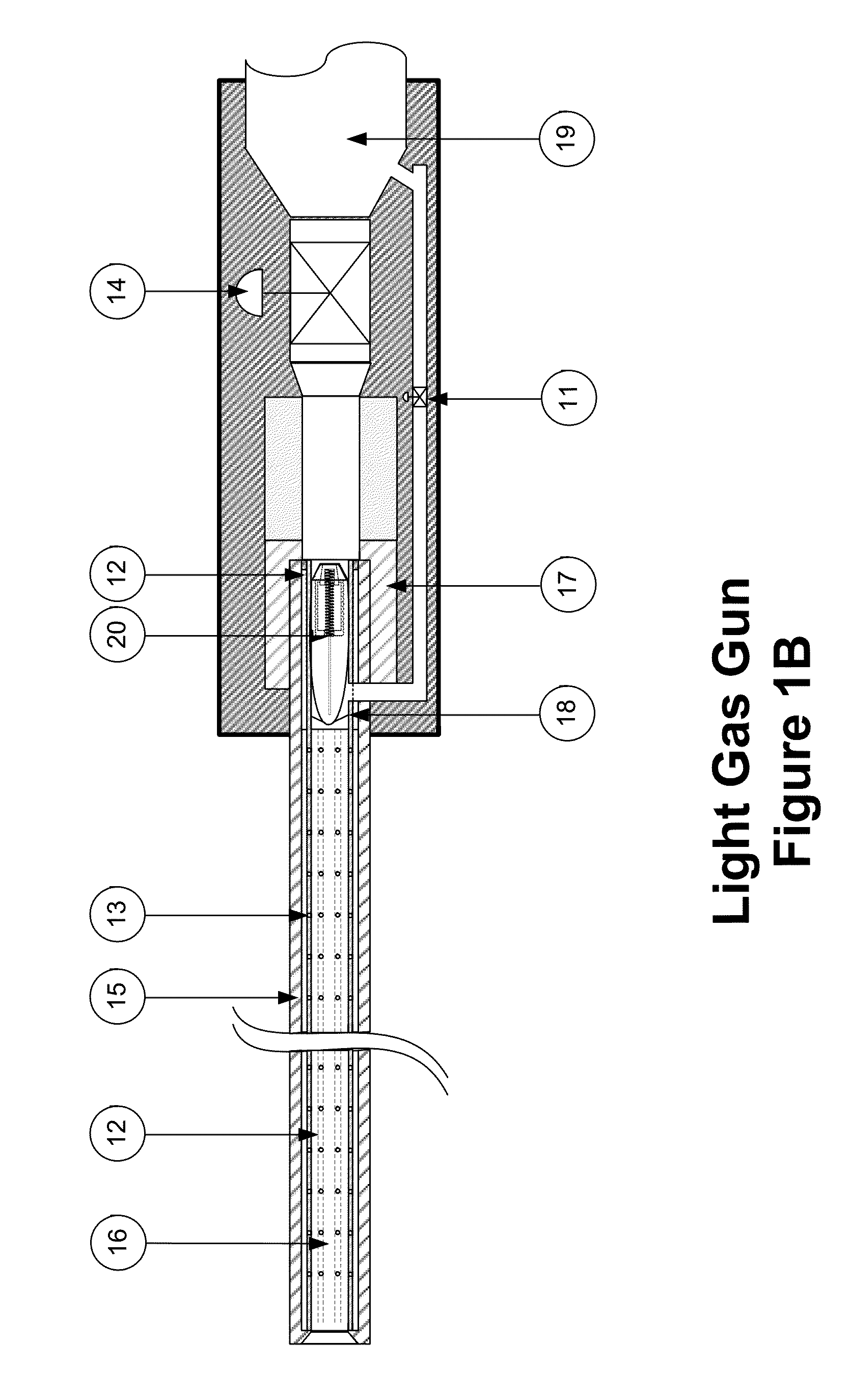

Light Gas Gun

ActiveUS20160161212A1Optimization rangeIncrease lethalityAmmunition projectilesMissile propulsionEngineeringAcoustic signature

An improved light gas gun launches a projectile in a light gas atmosphere as it travels through a frictionless barrel to achieve high muzzle velocities, decreased acoustic signatures, and increased ranges. The light gas atmosphere is introduced by a purge valve prior to firing or by a muzzle valve that holds a positive light gas pressure on the barrel and breech. The muzzle valve also routes the majority of propellant gases through a suppression canister, reducing the light gas gun's acoustic signature. The frictionless barrel uses light gas propellant routed through gas bearings to keep the projectile centered in the barrel and preclude the projectile from contacting the barrel walls, eliminating barrel wear. The system includes a projectile assembly that stores light gas from the firing and injects it into the boundary layer, reducing drag, increasing range and lethality, and decreasing acoustic signature of the projectile down range.

Owner:BERGERON DAVID WAYNE

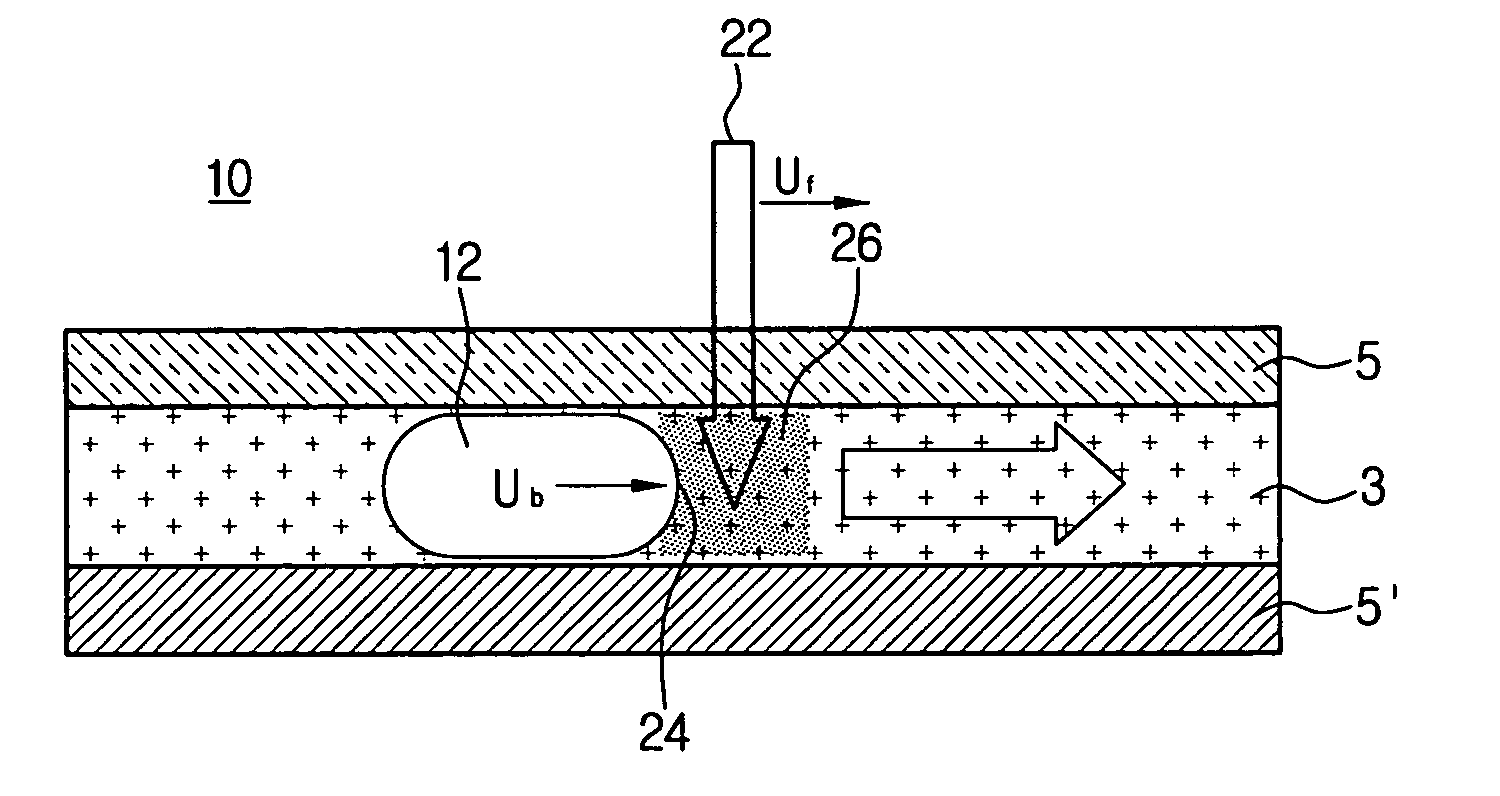

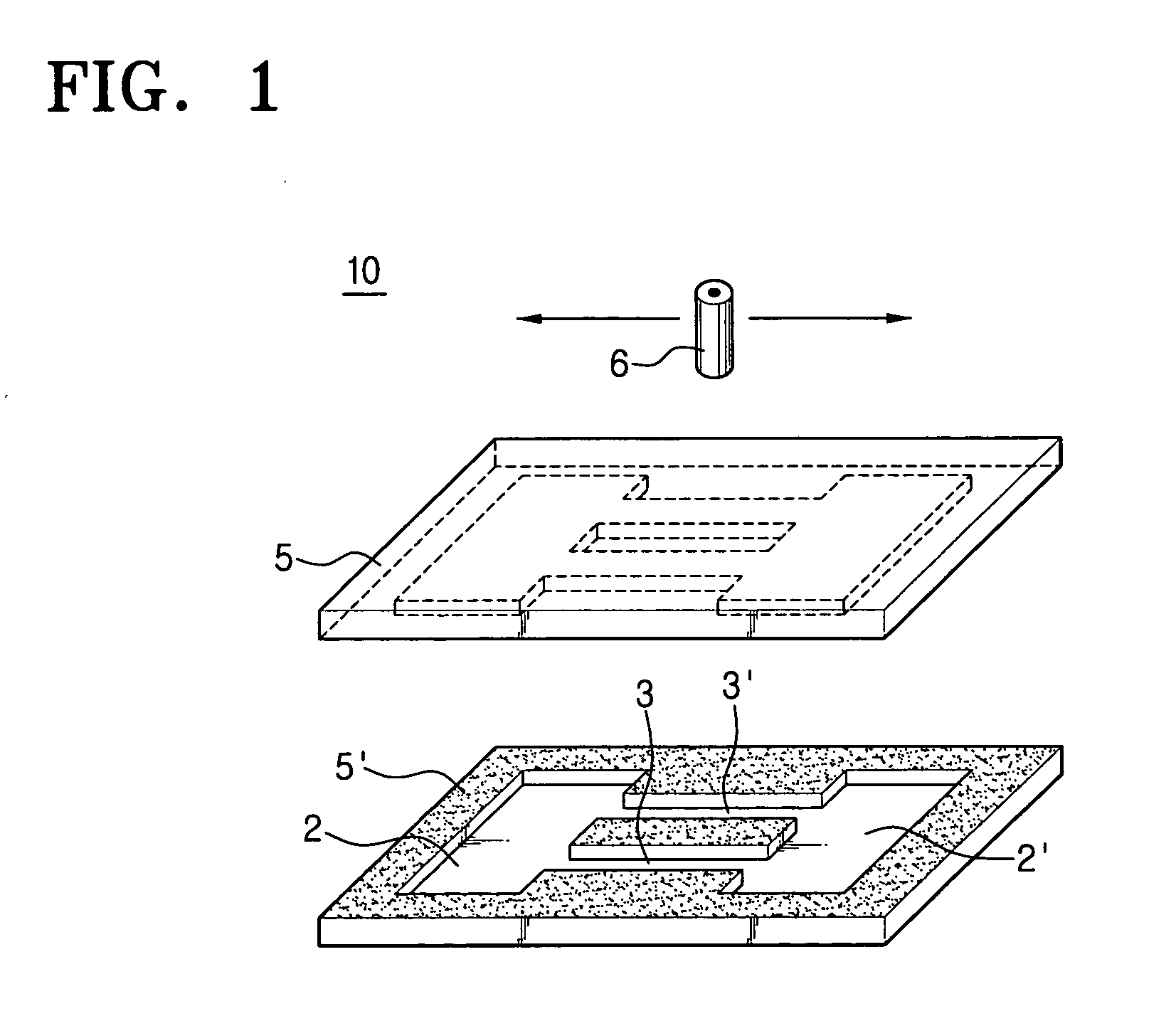

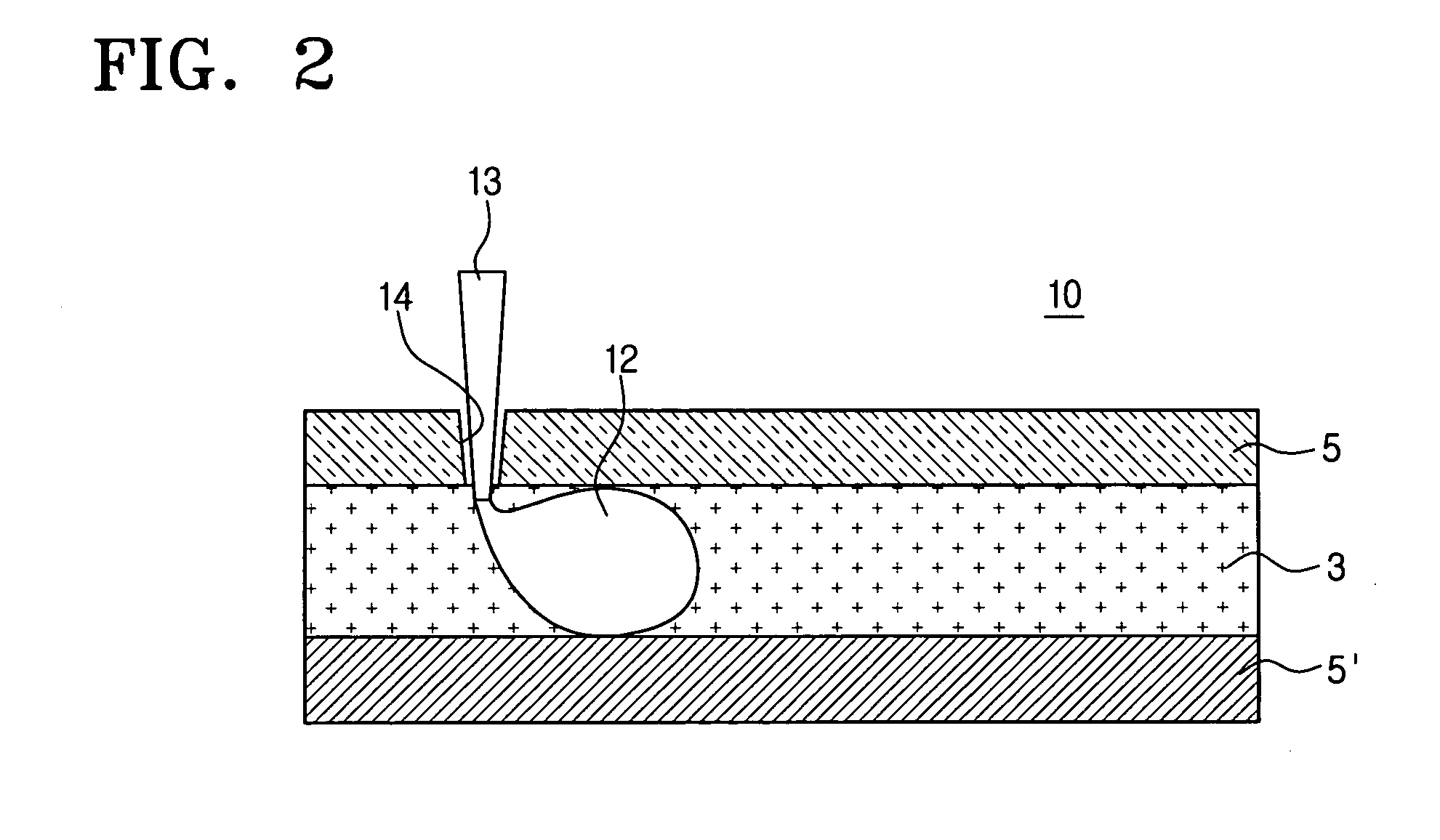

Device and method for pumping fluids employing the movement of gas bubbles in microscale

InactiveUS20050129529A1Eliminating solid frictionEliminate heat lossTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesLiquid temperatureLight beam

The present fluid pumping method for micro-fluidic devices uses gas bubbles to move fluid by light beams. The light beams are emitted to the fluid near the gas bubble through an optically transparent cover and correspondingly heat the fluid in the micro channels. The liquid temperature variation changes the surface tension of the gas bubble near the heated fluid side, therefore, a pressure gradient between the end portions of the gas bubble generates accordingly. By moving the light beams, the moved pressure difference will be achieved, which will drive the gas bubbles and pump the fluid. Such a fluid pumping can simplify the structure of a micro-fluidic device and eliminate heat loss because of using a controllable light beam.

Owner:SAMSUNG ELECTRONICS CO LTD

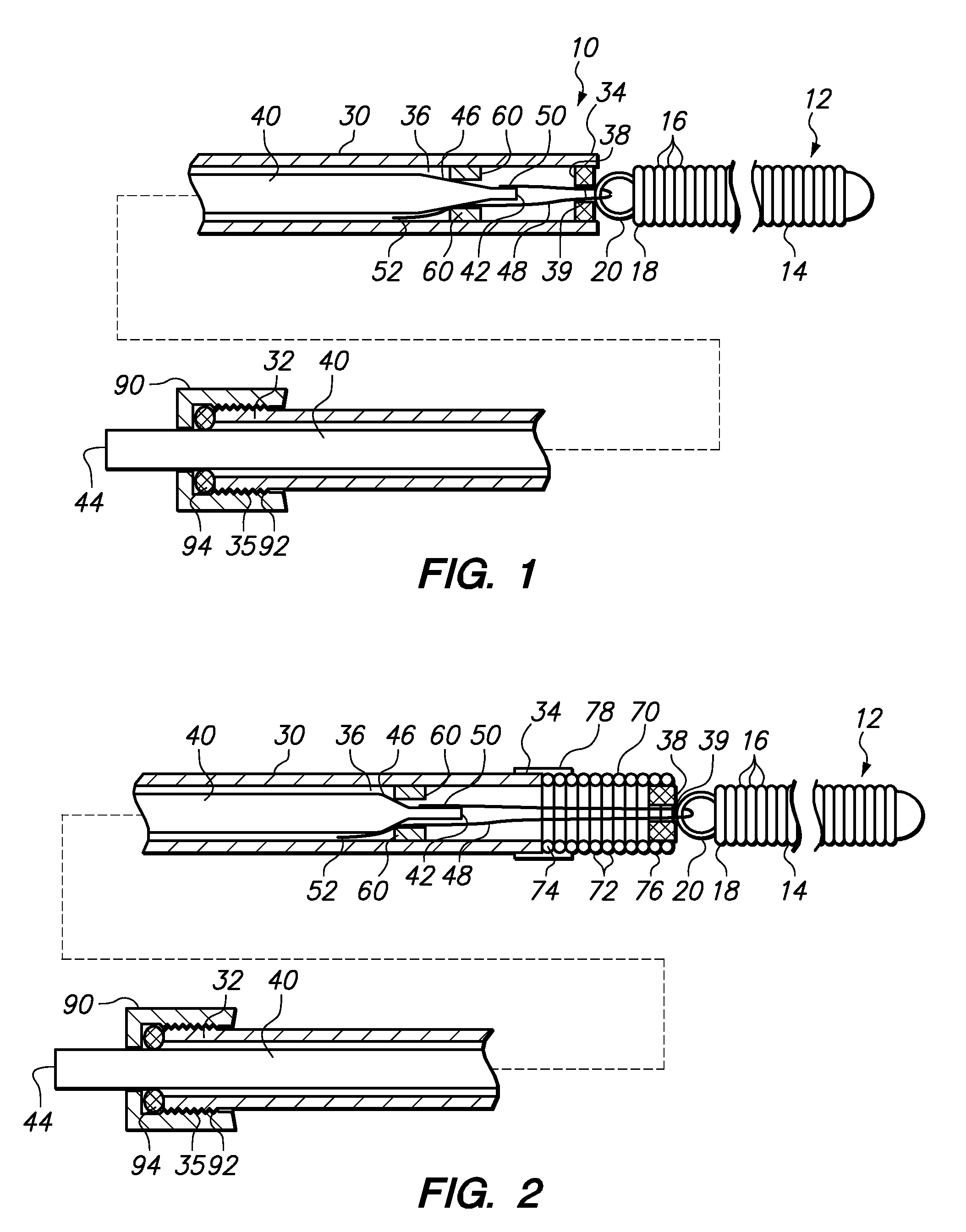

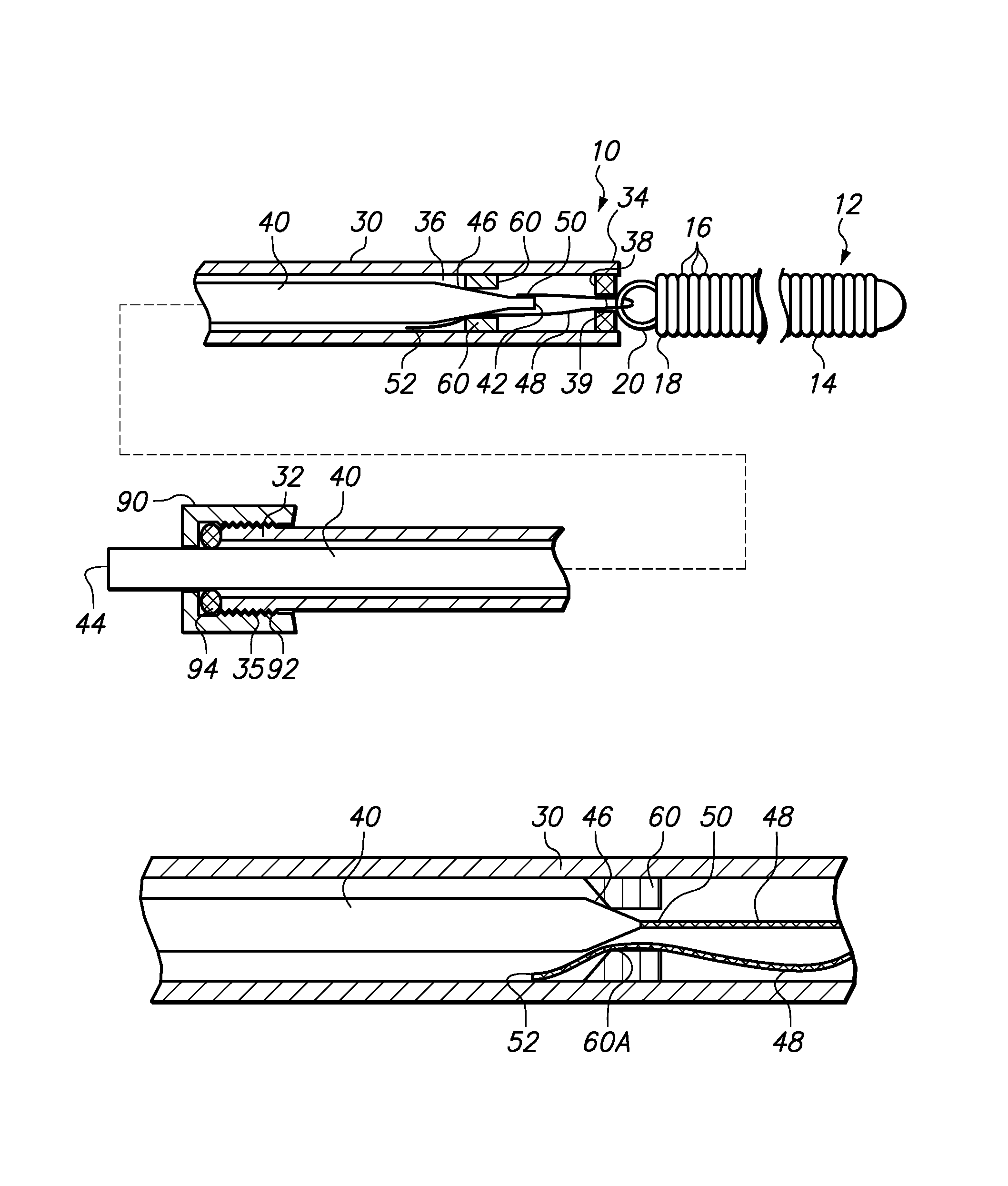

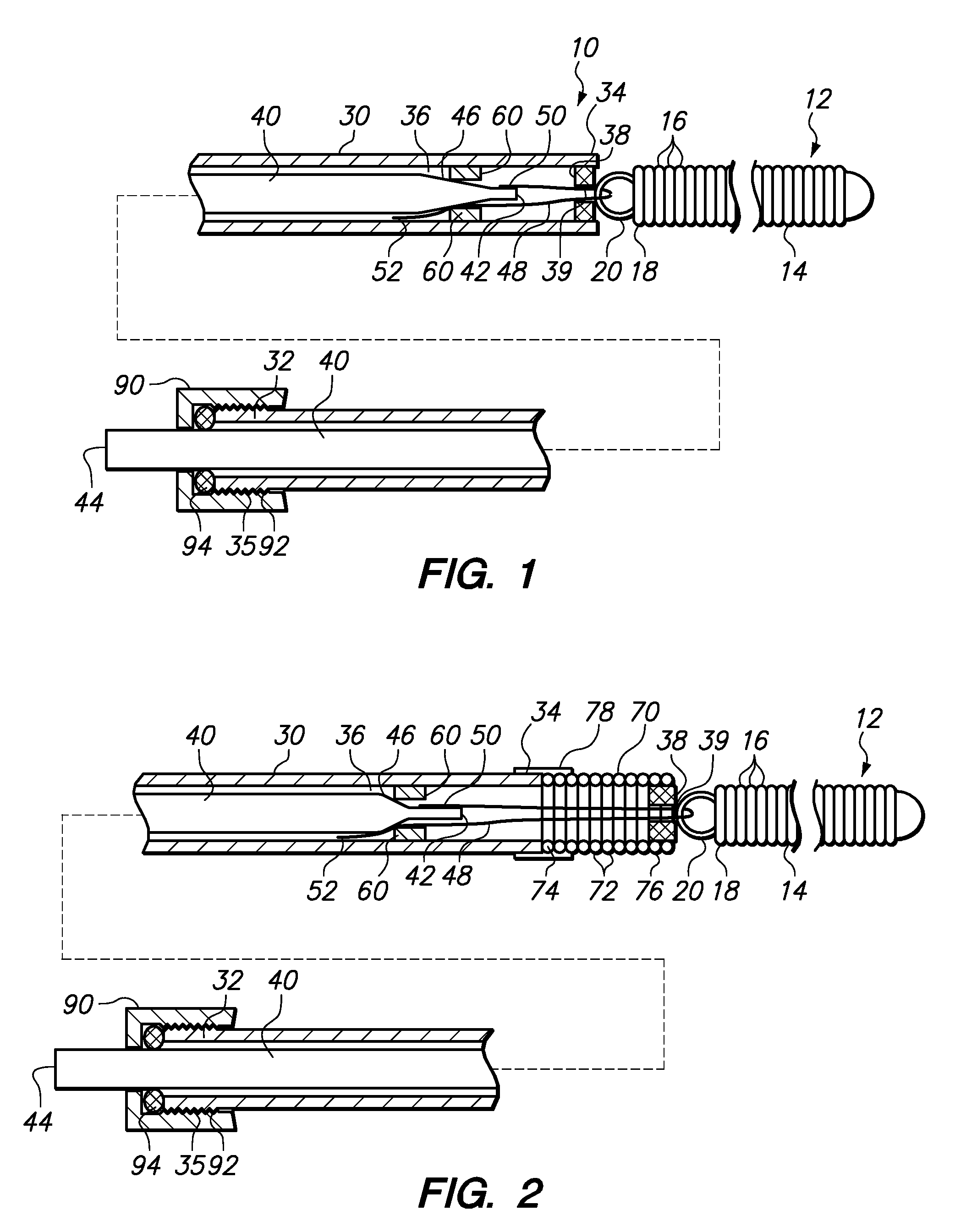

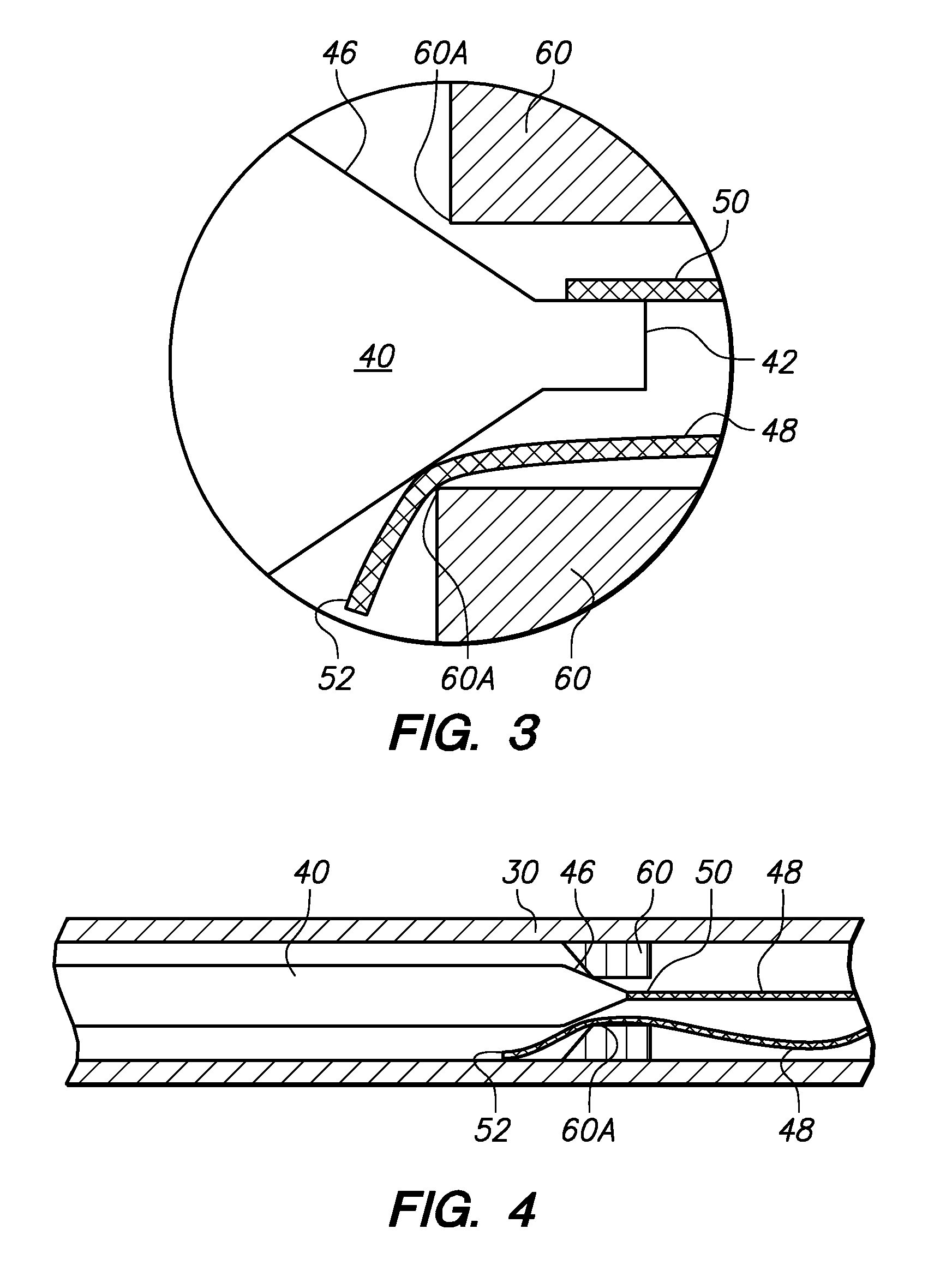

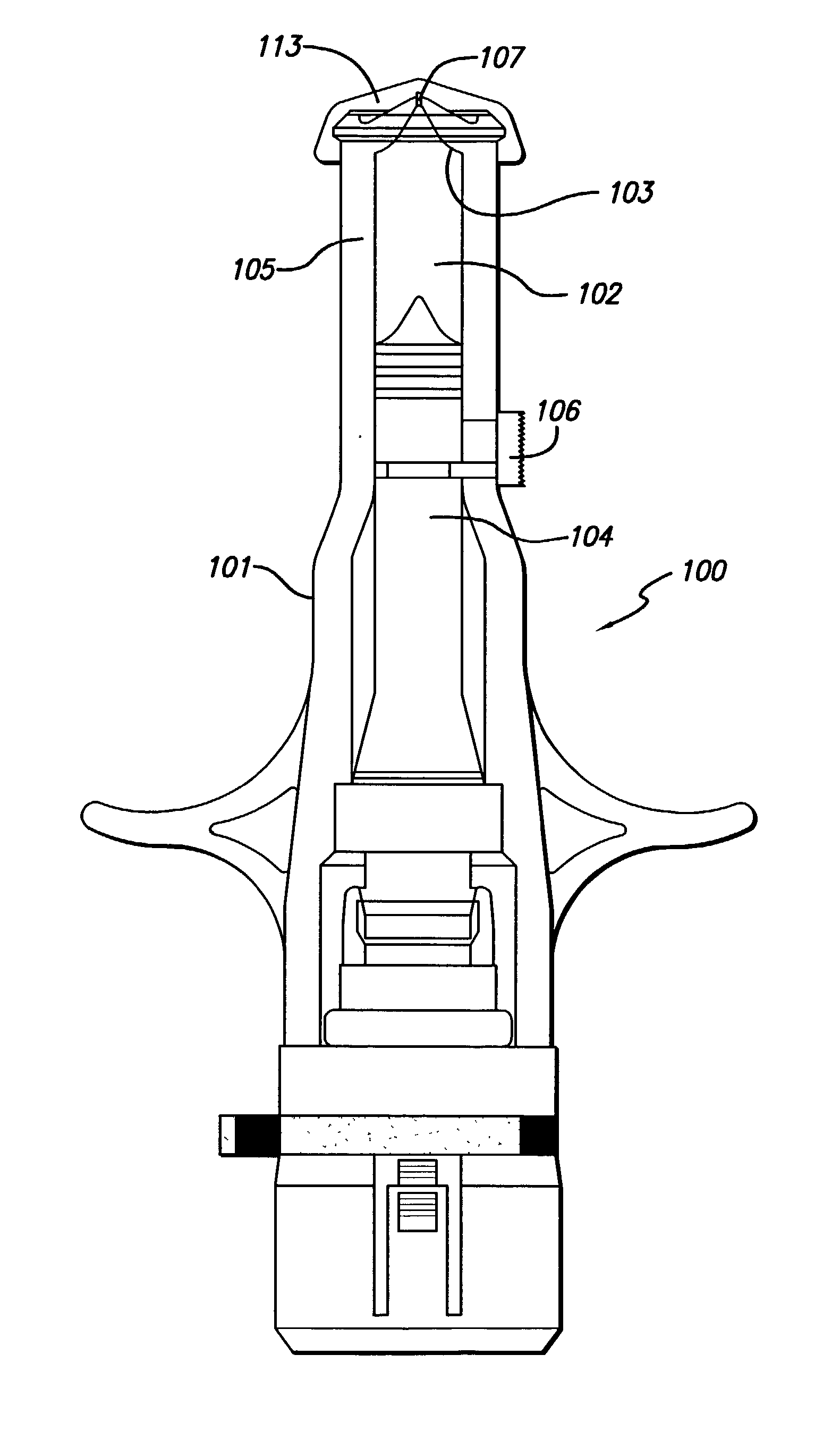

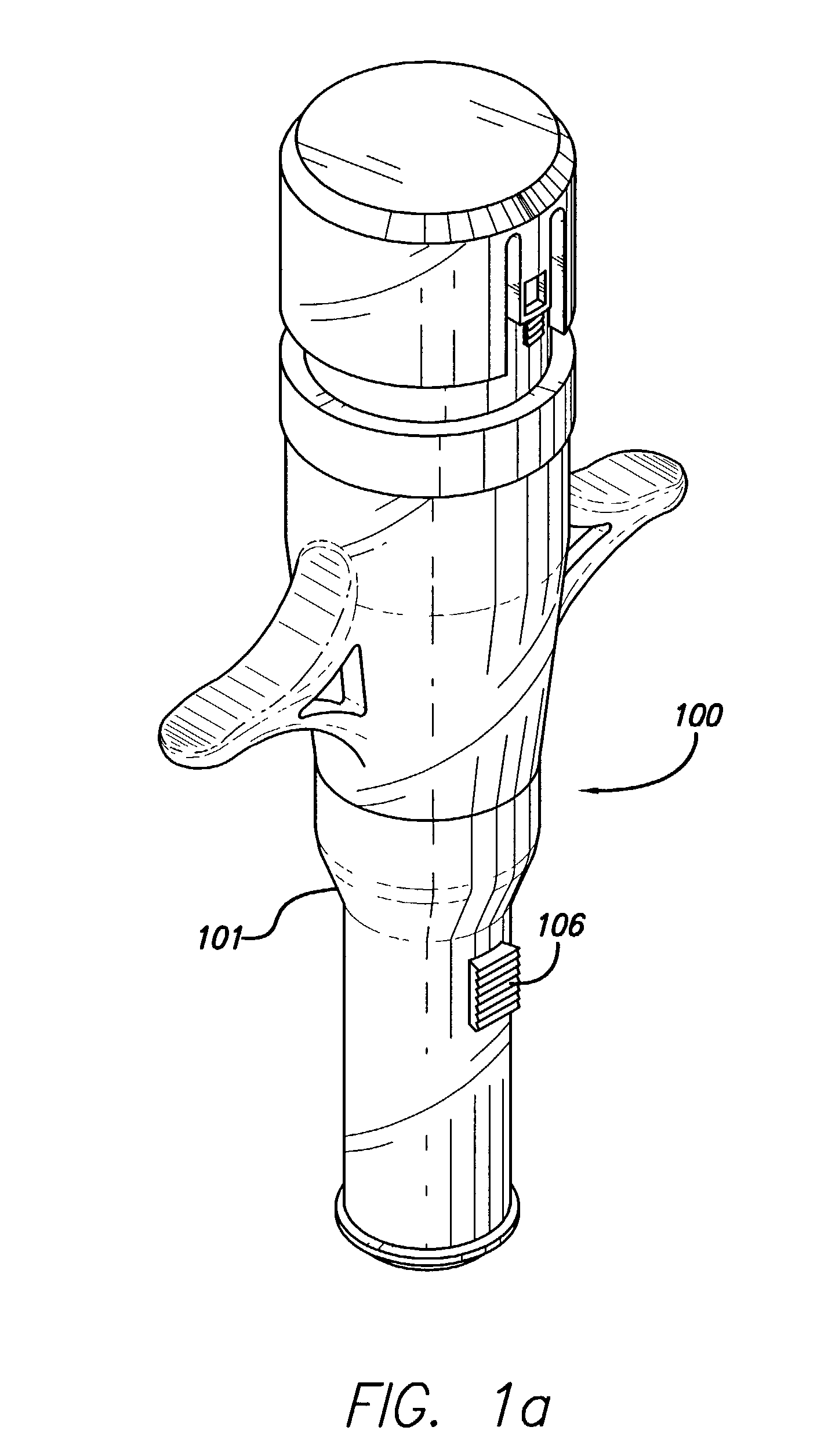

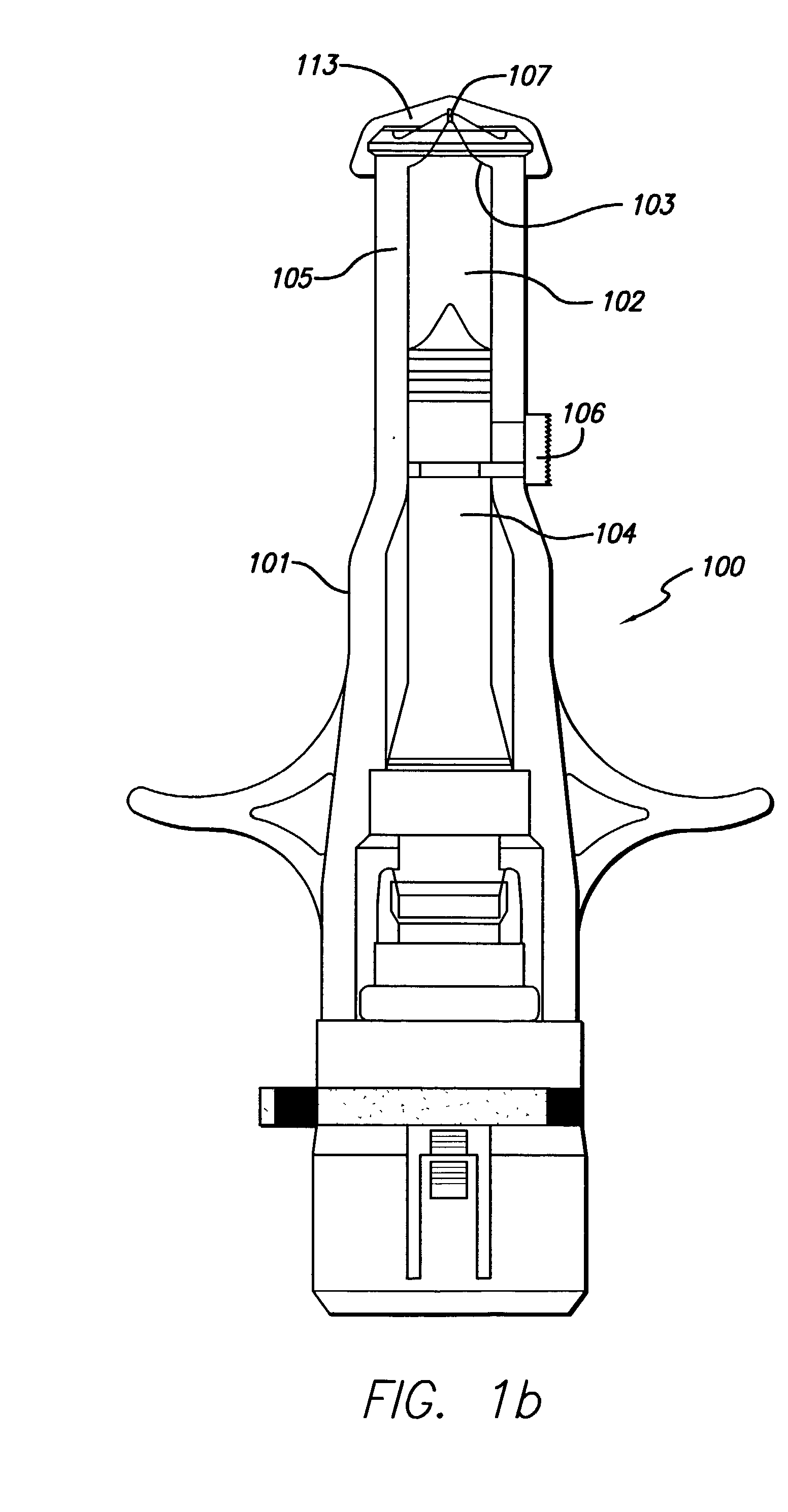

Method and apparatus for adjusting the contents of a needle-less injector

InactiveUS20040087896A1Lower the volumeMaintaining the sterility of the adjustment slotJet injection syringesMedical devicesNeedle Free InjectionEngineering

A method and apparatus for adjusting the contents of a needle-less injector that contains an injectable product are described. A needle-less injector includes an adjustment switch in mechanical contact with the driver of a needle-less injector. A user may displace the adjustment switch to expel air or gas contained in the product section of the needle-less injector prior to administration of a needle-less injection with the same. The adjustment switch may alternatively or additionally be used to expel at least a portion of the injectable product contained in the needle-less injector to reduce the volume of the product to be injected with the needle-less injector.

Owner:WISE ROGER R +1

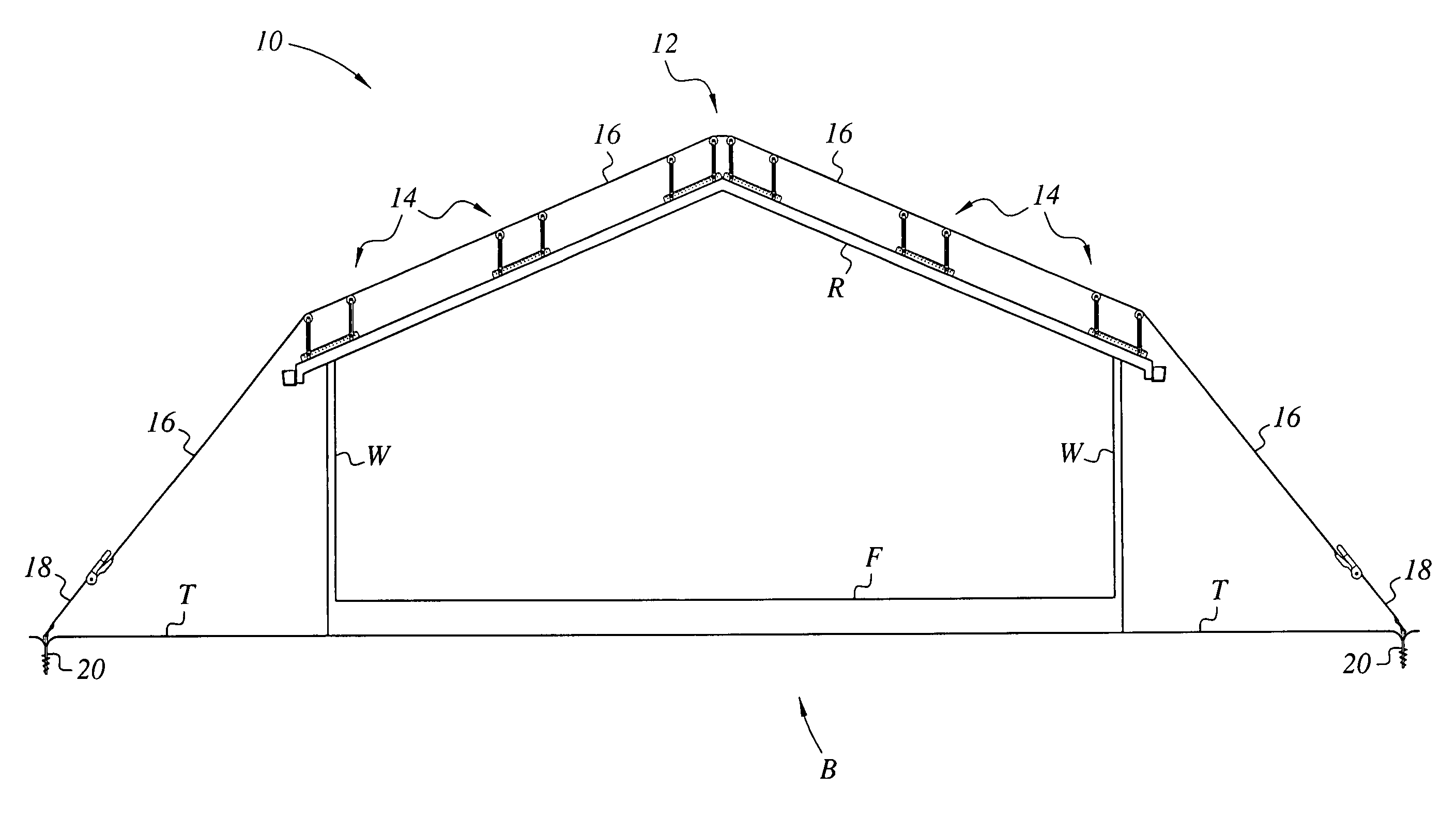

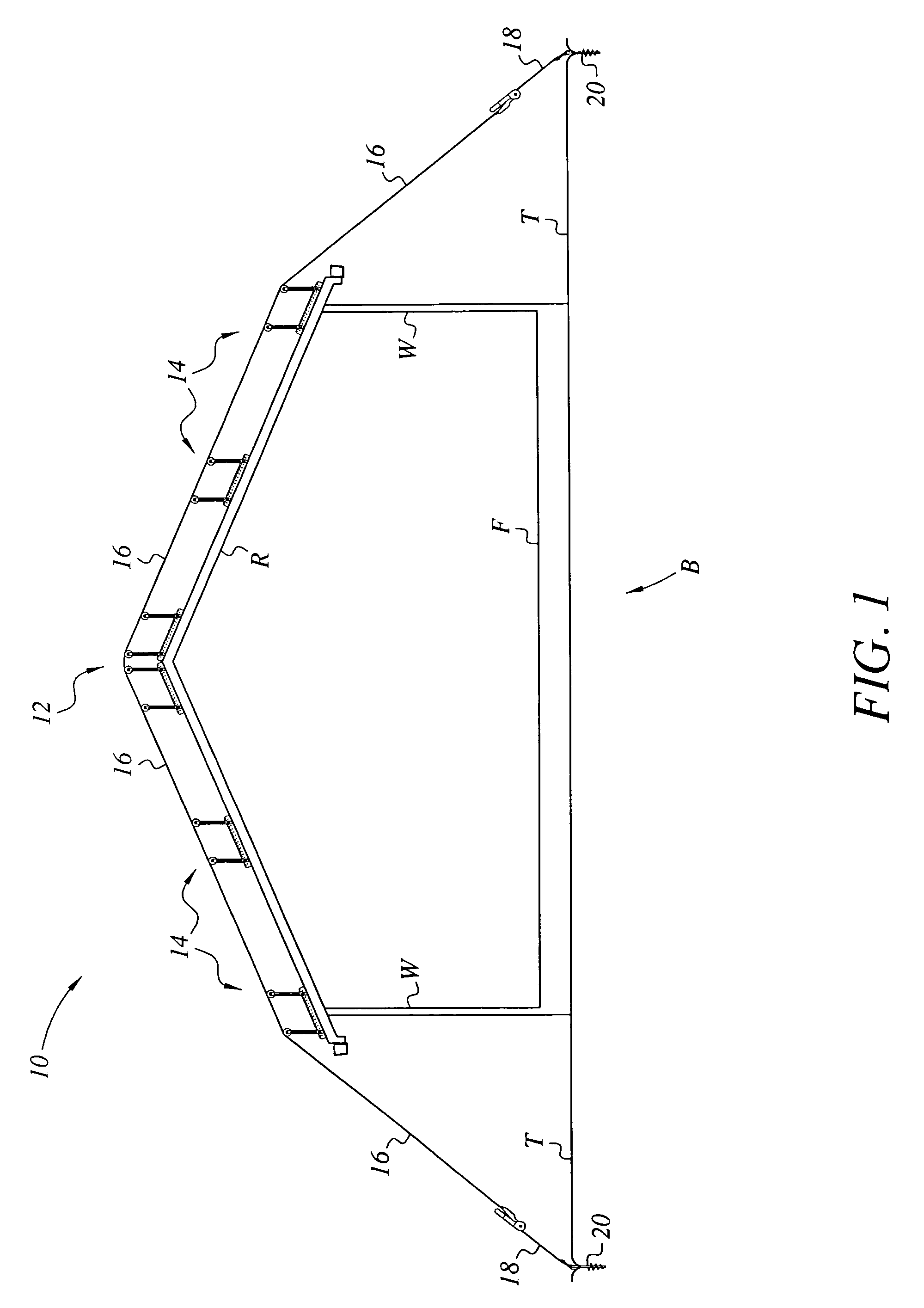

Wind cap for buildings

InactiveUS7310913B2Eliminate forceEliminate frictionHuman health protectionBuilding roofsTerrainEaves

A wind cap for buildings serves to anchor a building structure securely to the underlying terrain. The wind cap is a series of base plates which are temporarily and removably placed upon the roof of a structure, with a corresponding series of tiedown straps secured over the plates and attached to ground anchors on opposite sides of the structure. Two of the base plate components may be hinged together along their common edges for placement over the ridge line of the roof. Single plates are placed along the eaves and at intermediate points of the roof span. Each plate includes at least one pair of roller support arms adjustably extending upwardly therefrom, with a roller installed between each arm pair. The rollers eliminate the drag of the tiedown strap passing thereover, thereby eliminating asymmetrical loads on the underlying plates and roof as the straps are tightened.

Owner:PIERCE RILEY G

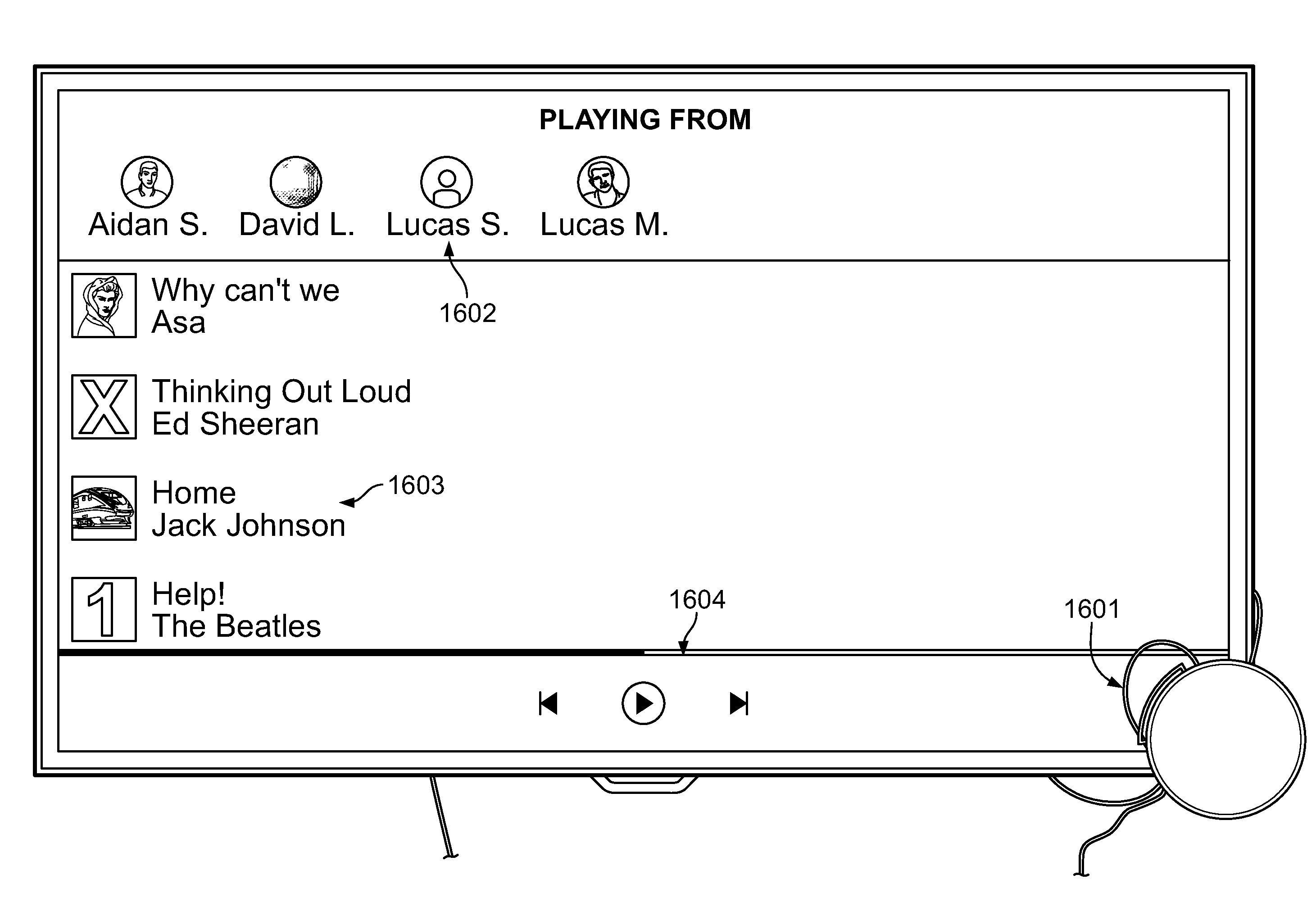

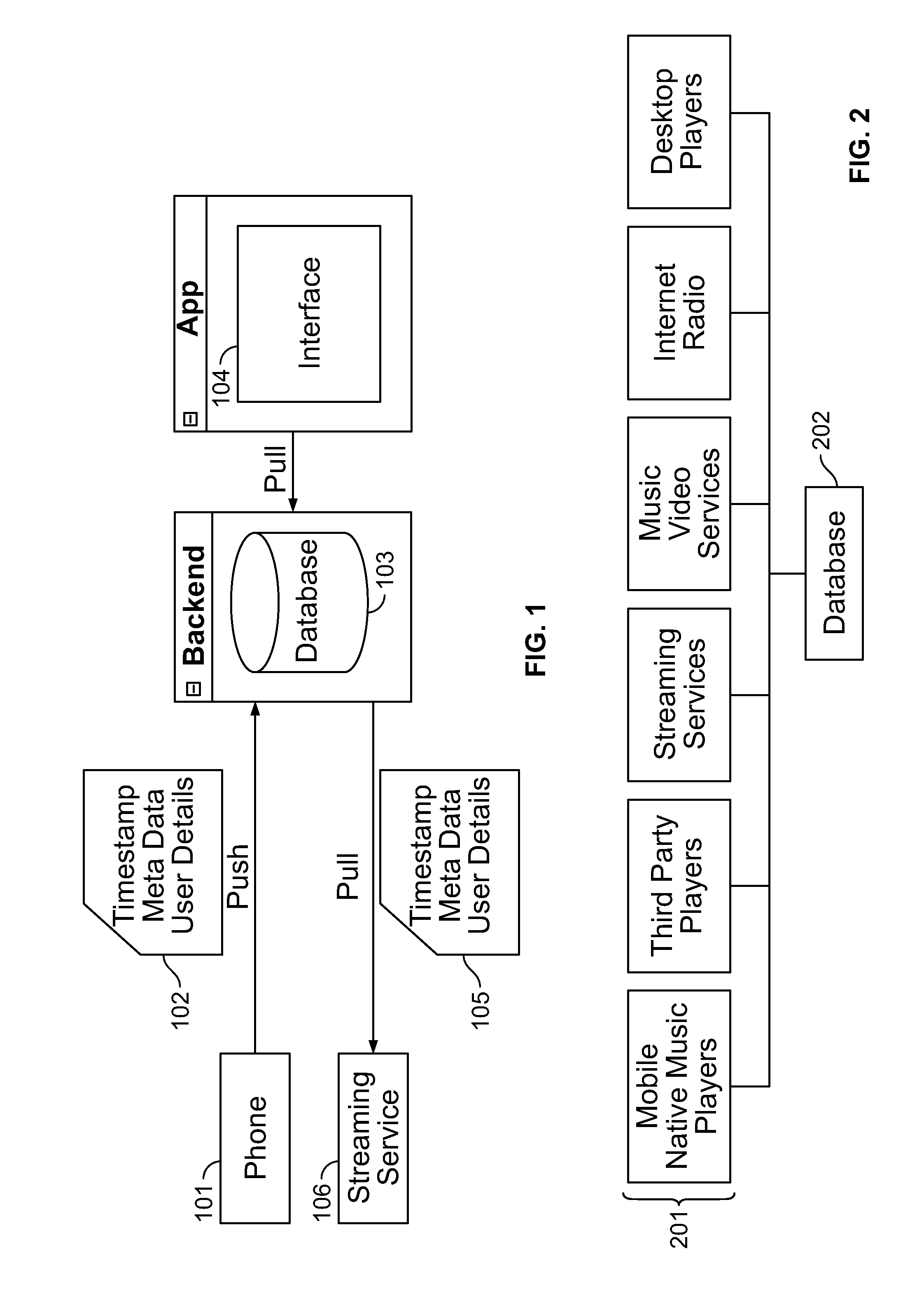

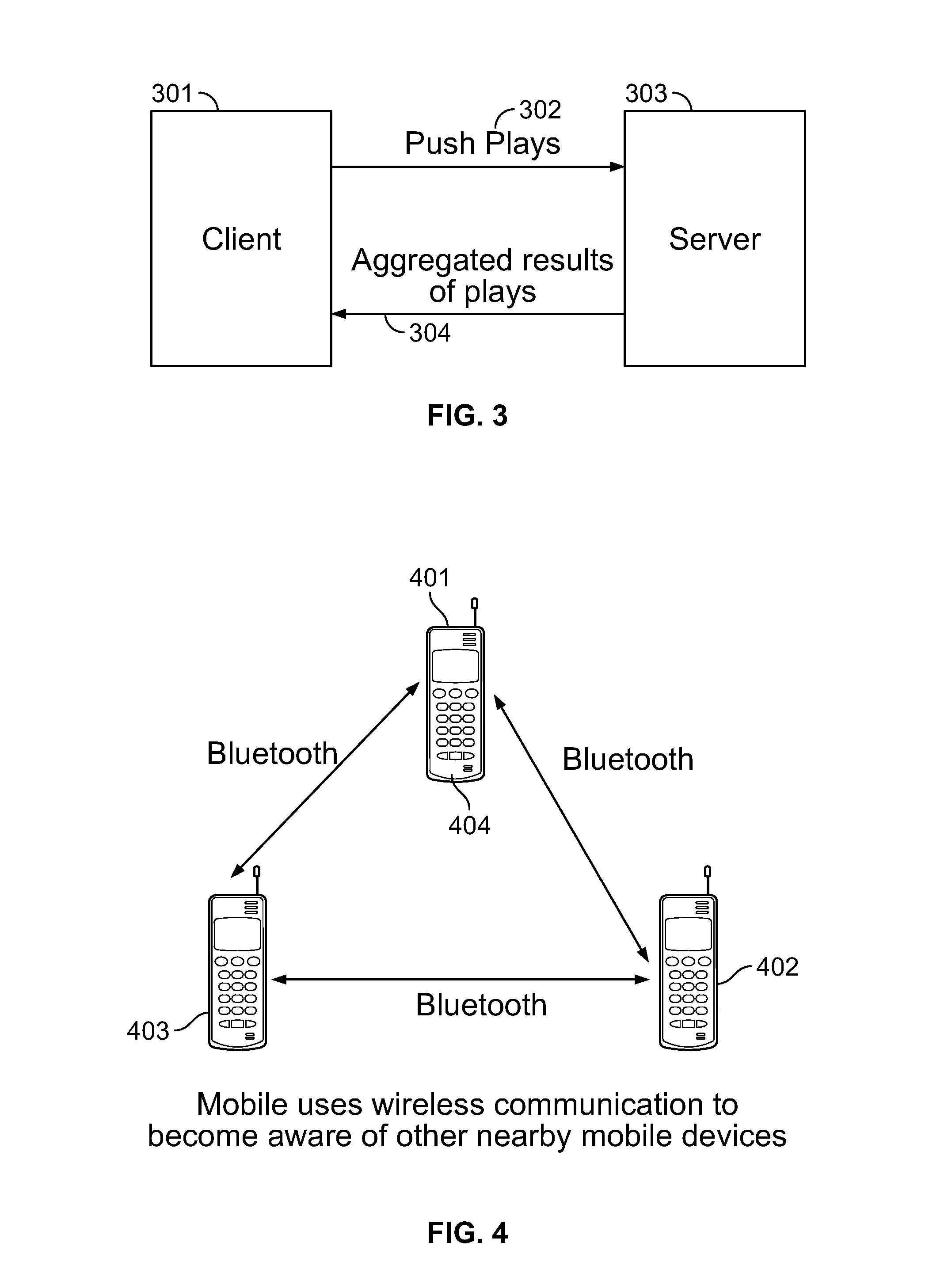

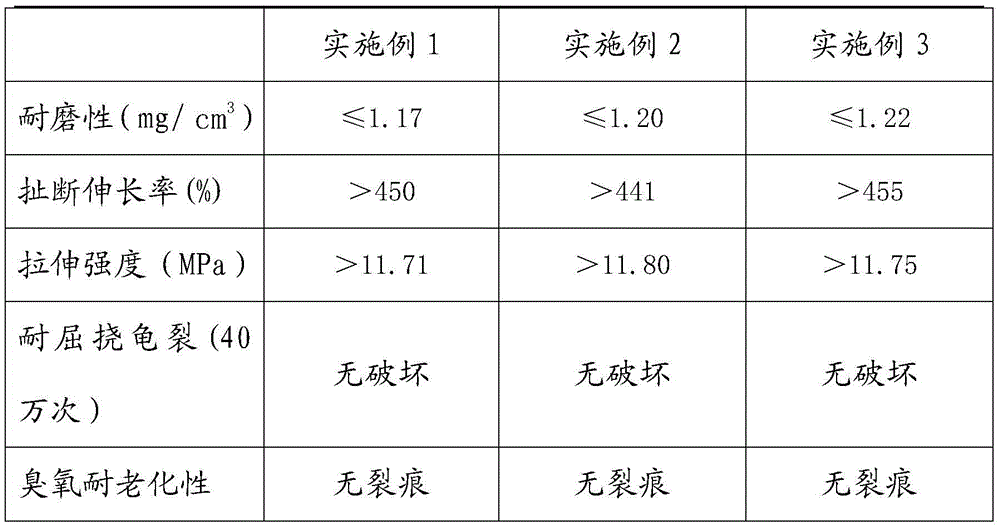

System and method for generating dynamic playlists utilising device co-presence proximity

InactiveUS20160294896A1Eliminate frictionEradicates the guesswork involvedPower managementMultimedia data retrievalCo presenceAcoustics

The invention provides a system and method for generating dynamic playlists utilising device co-presence proximity comprising the step of identifying of music preferences by analysing the listening history on a device of a user; and recognising what devices are co-present within a set proximity for the purposes of matching such devices.

Owner:SPOTIFY

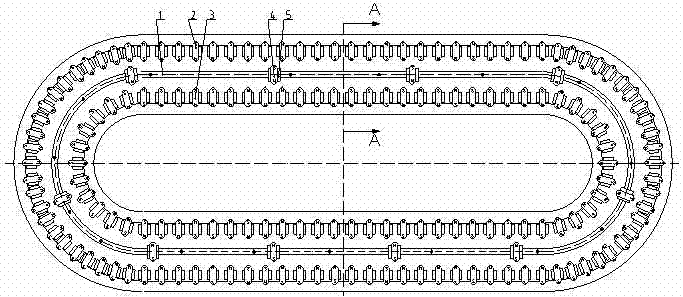

Pressure injection method for integral forming of non-pneumatic tire

The invention provides a pressure injection method for integral forming of a non-pneumatic tire. The method includes the following steps that firstly, configured raw materials for manufacturing the non-pneumatic tire are placed into a material storage box and are evenly stirred; secondly, the temperature of a pre-heating pressure injection machine is raised to 180-190 DEG C; thirdly, pressure of the pre-heating pressure injection machine is increased to 50-60 Pa; fourthly, the material inflow speed is adjusted to 10-20 m / s; fifthly, the pressure holding time is adjusted to 2-3 min; sixthly, the raw materials for manufacturing the non-pneumatic tire in the first step are injected into the pressure injection machine, and operation is started according to a preset mode; seventhly, after mold assembly, injection, hot melting, cooling and mold disassembly are sequentially performed, the non-pneumatic tire is obtained. The technology is simple, multi-time machining is not needed, one-time forming is achieved, operation is convenient, and cost is low; the obtained non-pneumatic tire is uniform and reasonable in structure and is not divided into an inner tire and an outer tire, friction force and resistance between the inner tire and the outer tire are eliminated, dynamic balance is good, and the non-pneumatic tire is resistant to abrasion and rolling and durable.

Owner:GUANGZHOU NEDONG INFORMATION TECH

Low-energy-consumption motor-less drive type conveying device

ActiveCN102969942ASuspension stabilityTimely control of power onStretchingMagnetic holding devicesElectricityElectric machine

The invention discloses a low-energy-consumption motor-less drive type conveying device. The low-energy-consumption motor-less drive type conveying device comprises supports, wherein static electricity magnets are uniformly arranged on the supports, a guide rail supporting seat is arranged in the center of two supports, a magnetic suspension guide rail pair is arranged on the guide rail supporting seat, a lower supporting block is arranged on the magnetic suspension guide rail pair, a dynamic electricity magnet is arranged on the lower supporting block, an upper supporting block is arranged on the dynamic electricity magnet, and a working platform is arranged on the upper supporting block; a coil is wound on each static electricity magnet and another coil is wound on each dynamic electricity magnet; and four corners of end faces in the vertical direction of each static electricity magnet and each dynamic electricity magnet are cut away, and the cut amounts and the cut angles of the four corners are consistent. With the adoption of the low-energy-consumption motor-less drive type conveying device, motor-less drive and automatic guide of a movable rail are realized, the energy consumption during conveying operation is greatly reduced, the friction during conveying operation is eliminated, and the accuracy during operation is improved.

Owner:南通大学技术转移中心有限公司

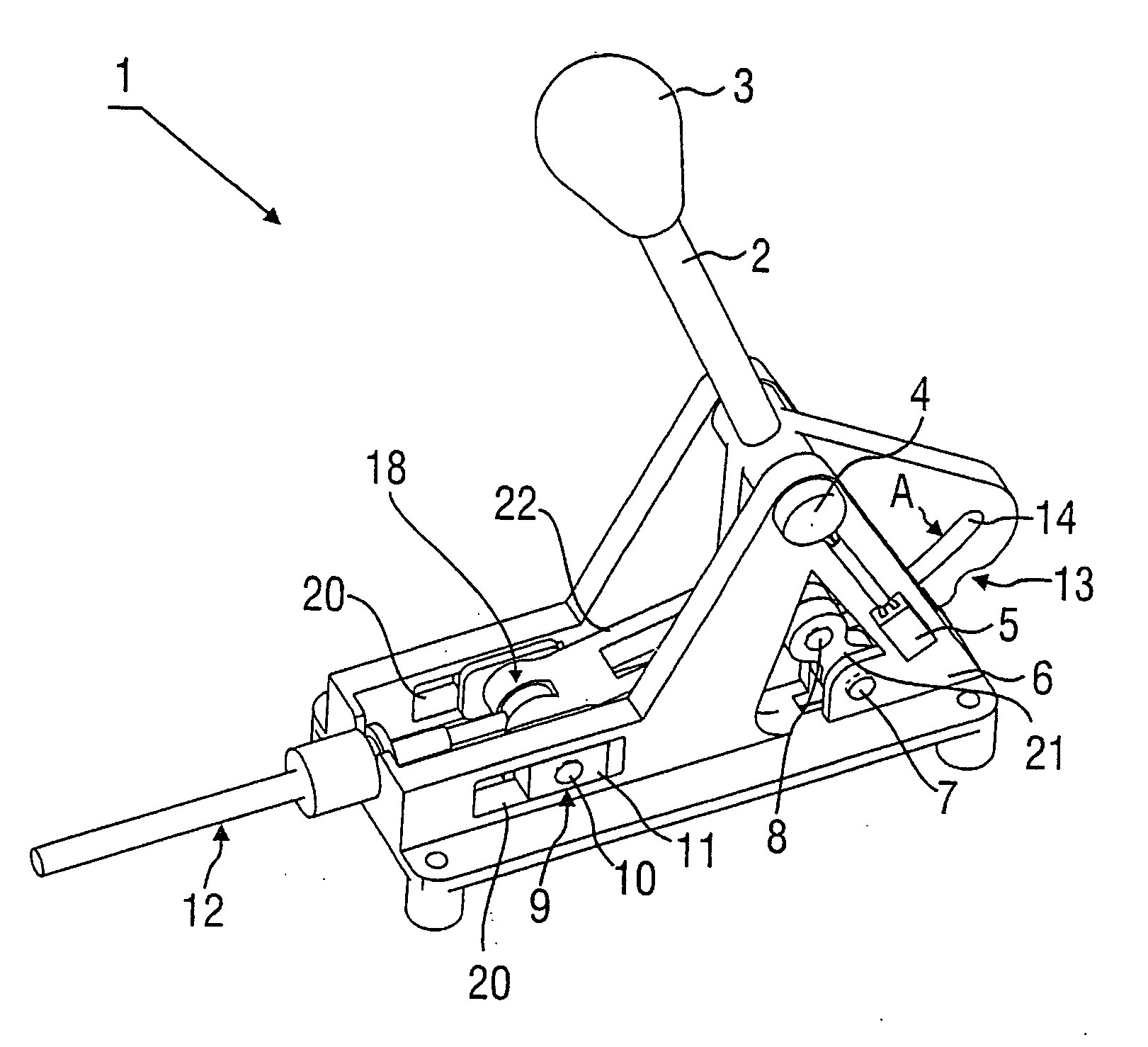

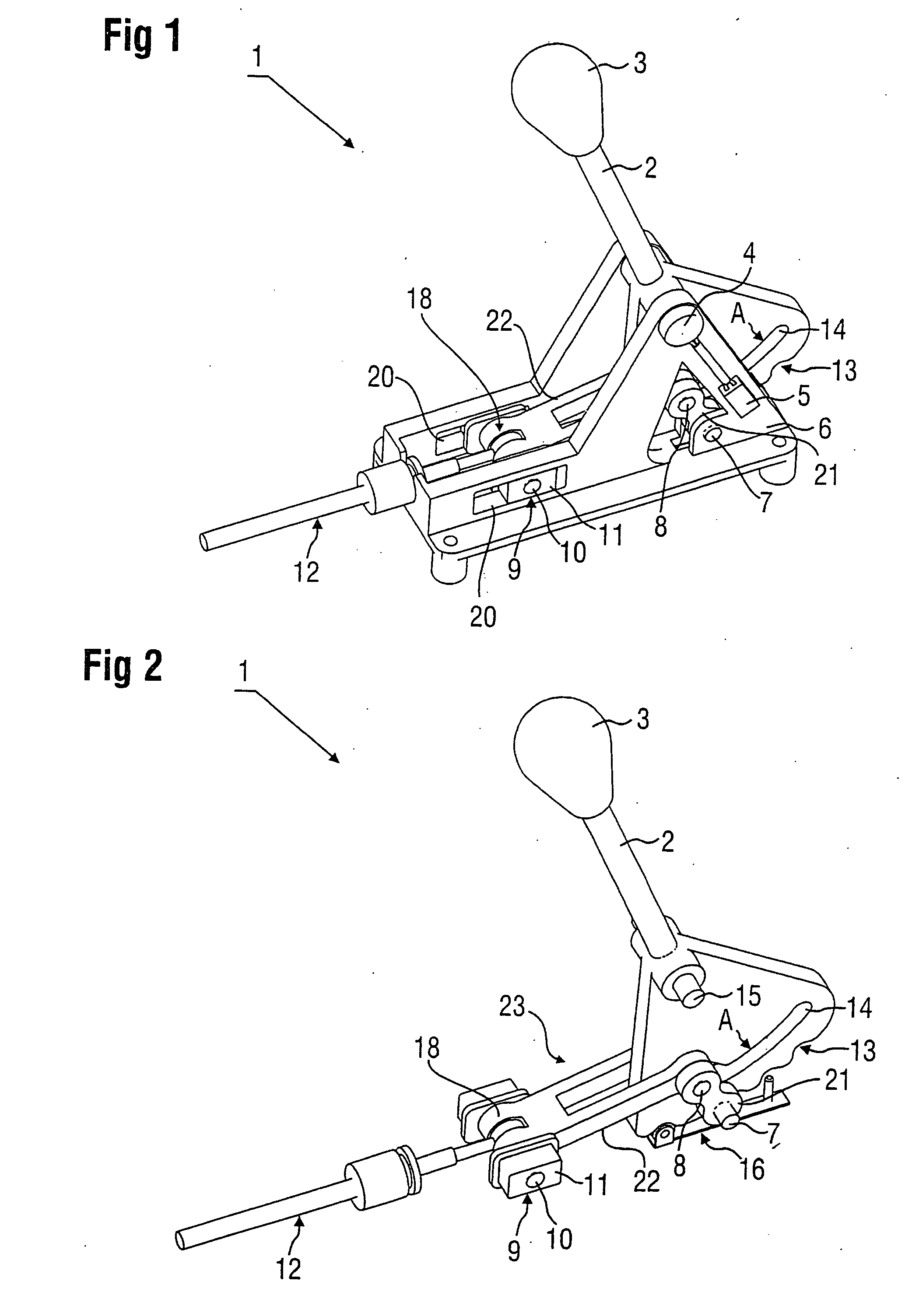

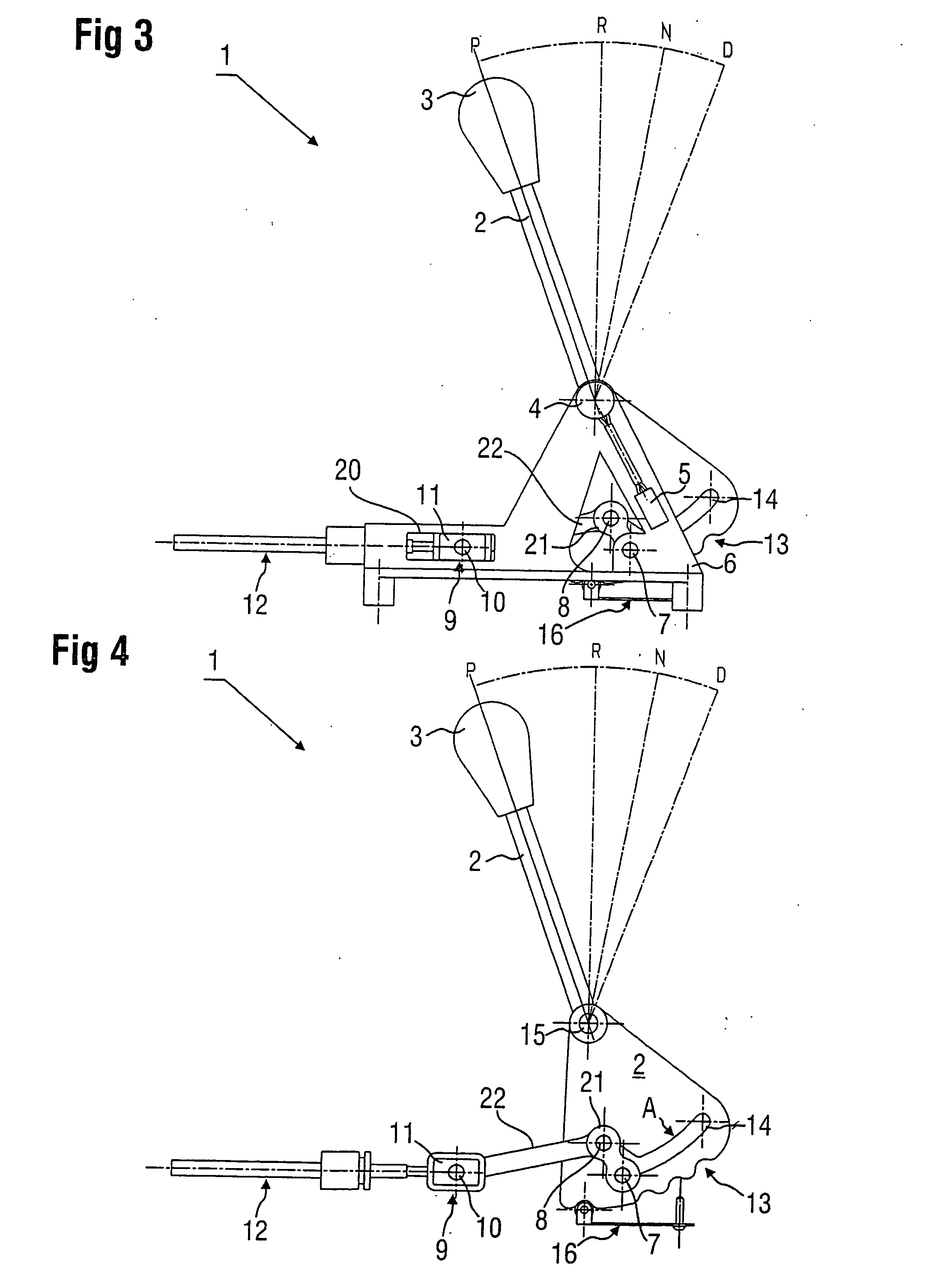

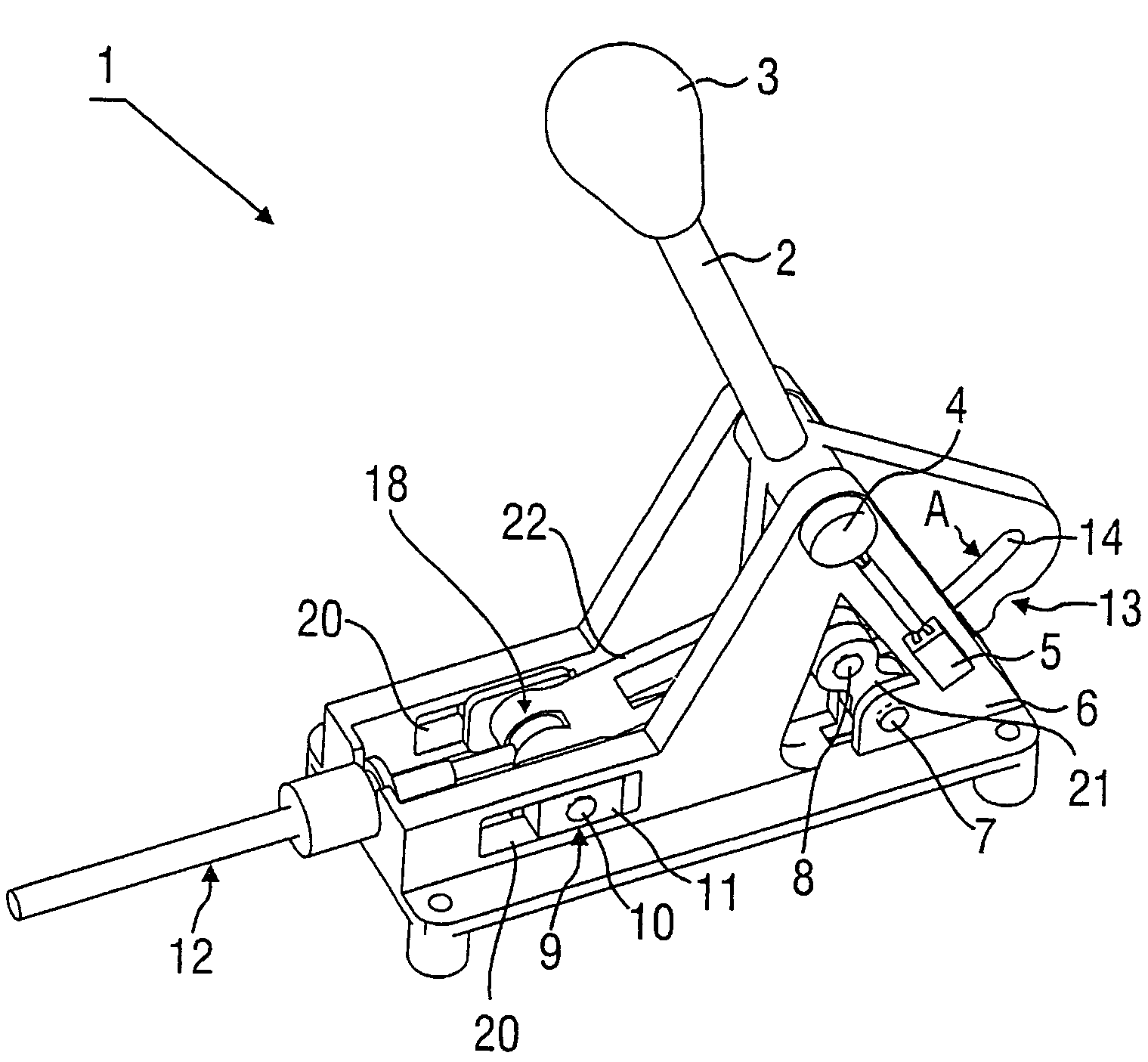

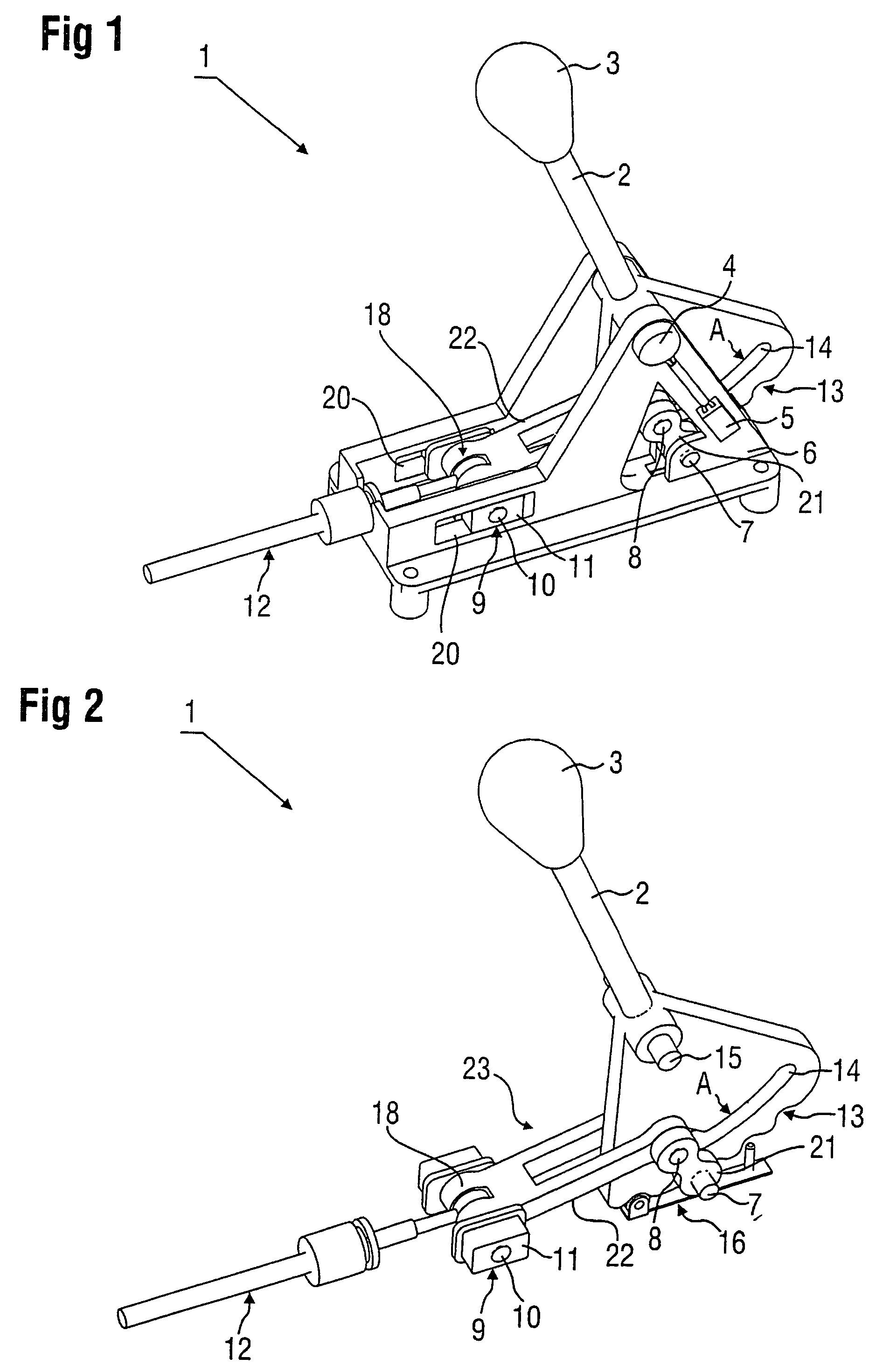

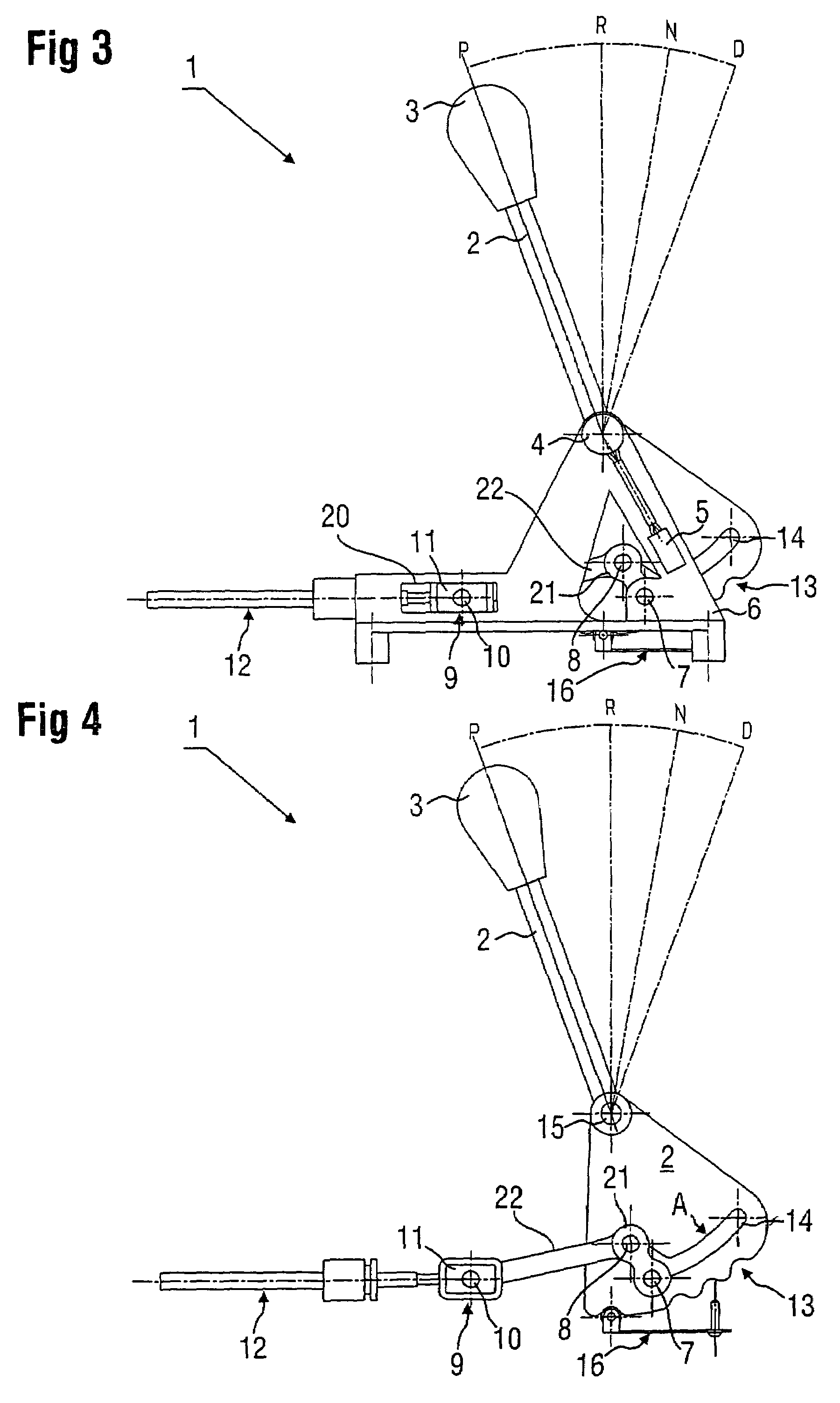

Shifting device for the mechanical coupling-free transmission of shift commands to the automatic transmission of a motor vehicle

InactiveUS20050239596A1Simple actionReliably engage and disengage the parking brakeManual control with multiple controlled membersGas pressure propulsion mountingMobile vehicleAutomatic transmission

A shifting device (1) is provided for the mechanical coupling-free transmission of shift commands to an automatic transmission of a motor vehicle (shift-by-wire shifting), with at least one housing and / or one frame and one selector lever for the manual selection of shift commands for the vehicle transmission in at least one shift gate. The selector lever can be moved manually into at least four positions (P, R, N, D), pivotable about at least one shift axis. A transmission device(s) is provided for transmitting the shift commands without mechanical coupling with the vehicle transmission (shift bay wire). A parking brake, engaged in the P position, locks at least a transmission output shaft. A mechanical coupling (16) is provided between the selector lever (2) and the transmission of the vehicle. This mechanical coupling (16) activates the parking brake exclusively and automatically when the selector lever (2) is engaged in the P position and is automatically uncoupled from the selector lever when the selector lever (2) is pivoted out beyond the adjacent position.

Owner:ZF FRIEDRICHSHAFEN AG

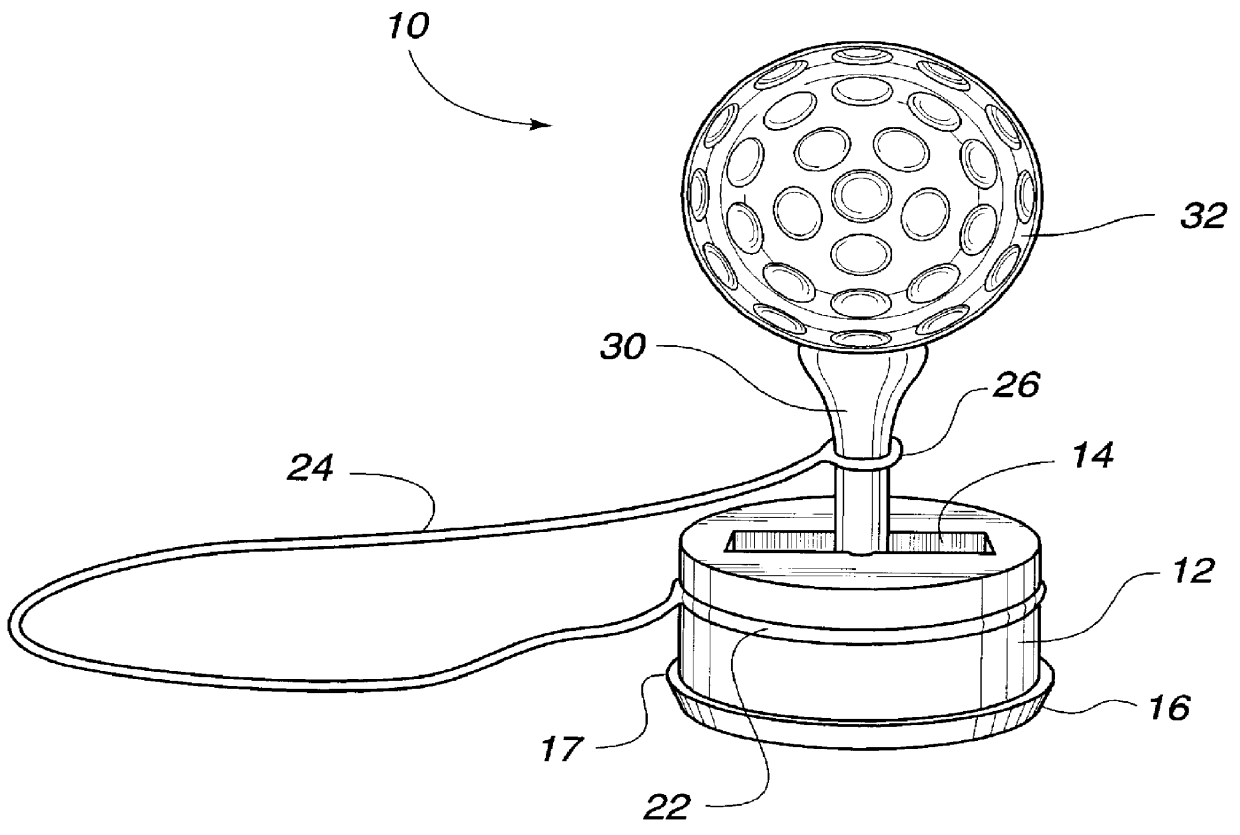

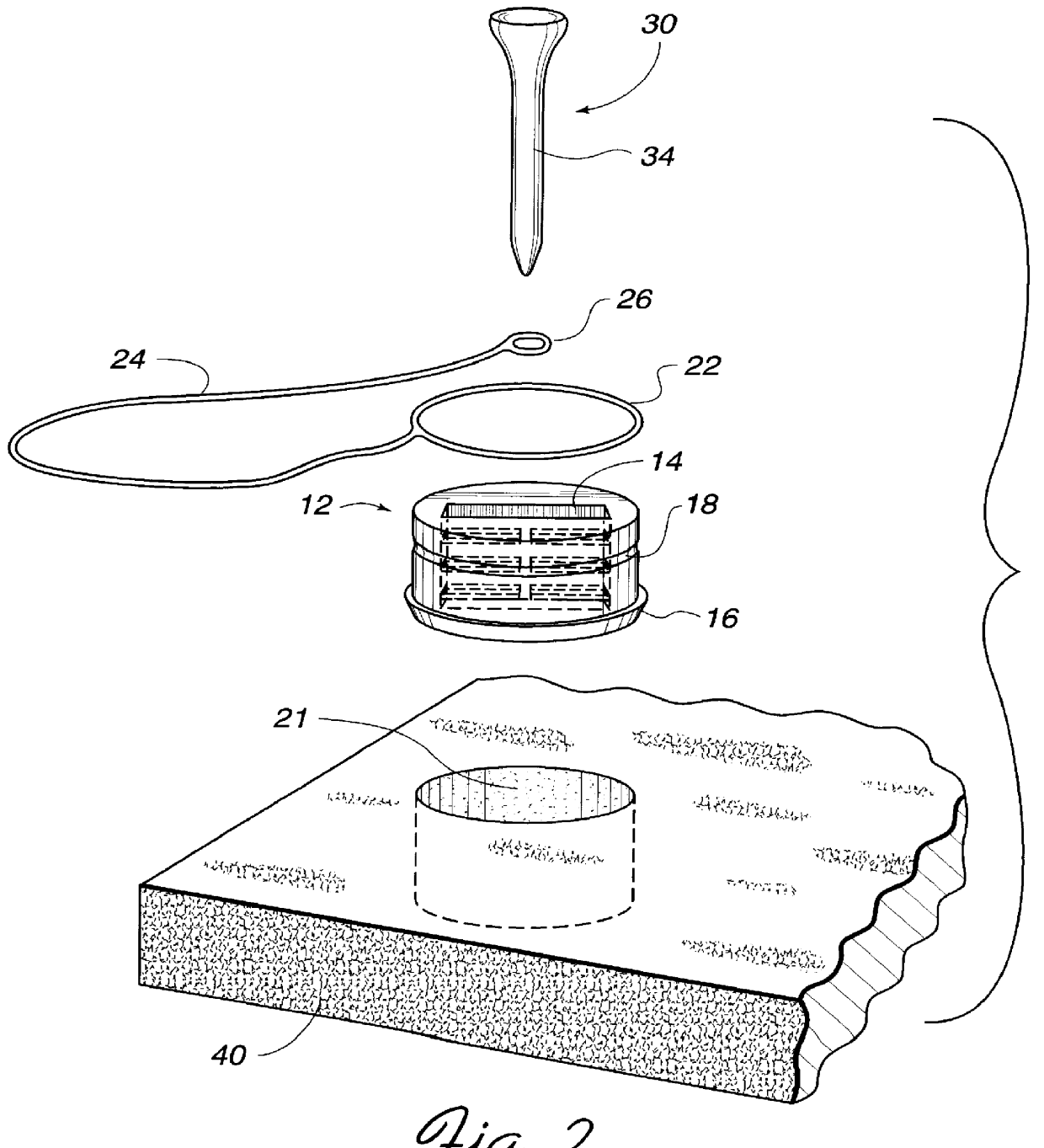

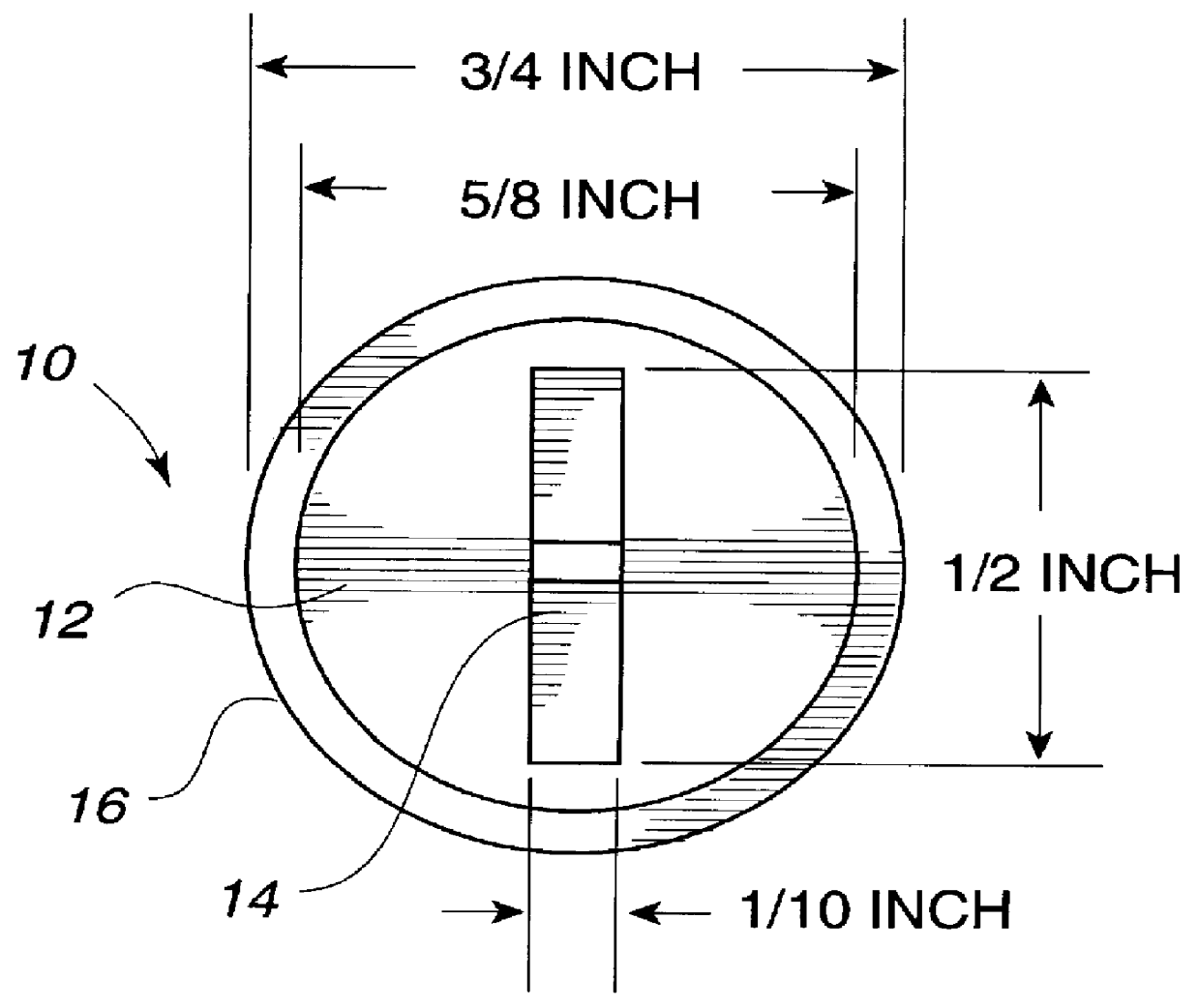

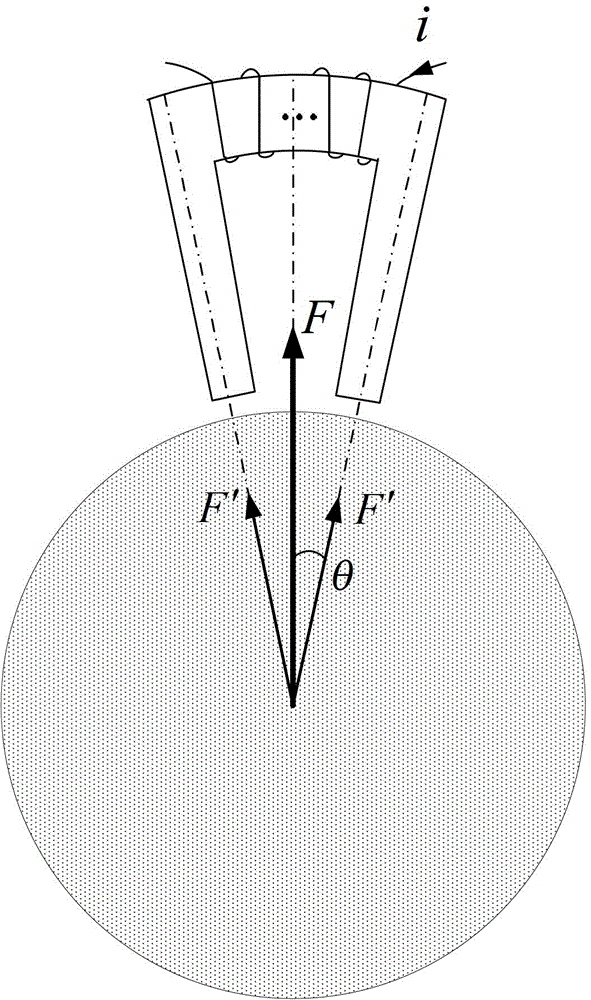

Golf tee setting apparatus

A golf tee setter according to the present invention allows golfers to use a real tee on a practice mat to practice their swing in golf driving ranges as if they are actually practicing on real ground. The golf tee setter is configured to be placed in the rubber tee hole of the practice mat and has a slit formed in a tee holder to hold the tee in substantially vertical position in relation to the practice mat to place a golf ball on the tee. The slit has a plurality of flaps extending from front and rear inner walls of the slit. The flaps are made of a flexible material to absorb any tilting force of the golf tee and prevents the golf tee from ejecting from the golf tee setter. The golf tee setter includes a base portion which has a slightly larger diameter than the body of the tee holder to enable the tee holder to be inserted into the practice mat from the top surface instead of from the bottom surface. In addition, a cord tethers the golf tee and the golf tee setter for repeated use of the golf tee.

Owner:CHUN WON HO

Magnetic suspension universal momentum sphere device and realizing method thereof

ActiveCN102975868AZero frictionZero resistanceSpacecraft guiding apparatusMagnetic tension forceMomentum

The invention discloses a magnetic suspension universal momentum sphere device and a realizing method thereof. The magnetic suspension universal momentum sphere device comprises a momentum sphere, a position control electromagnetic system, a rotation control electromagnetic system, a sphere body state detection system and a central control system, wherein the momentum sphere is used for rotation, the position control electromagnetic system is used for generating a magnetic force in any direction for the momentum sphere, the rotation control electromagnetic system is used for generating a rotating torque capable of rotating towards any direction for the momentum sphere, the sphere body state detection system is used for detecting the operation state of the momentum sphere and the central control system is used for controlling the electromagnetic system and the sphere body state detection system and receiving operation state data of the momentum sphere, detected by the sphere body state detection system. The momentum sphere is adopted for replacing a momentum wheel, therefore the magnetic suspension universal momentum sphere device is capable of realizing rotation in any direction; the rotating torque enabling the sphere body to rotate is generated through a rotating magnetic field, therefore, the magnetic suspension universal momentum sphere device realizes non-contact, non-resistance and accurate rotation control; and the sphere body is magnetically suspended through the magnetic force, therefore the friction force is thoroughly eliminated.

Owner:张珩 +1

Shifting device for the mechanical coupling-free transmission of shift commands to the automatic transmission of a motor vehicle

InactiveUS7322457B2Reliably engage and disengage the parking brakeSimple actionManual control with multiple controlled membersGas pressure propulsion mountingMobile vehicleAutomatic transmission

A shifting device (1) for the mechanical coupling-free transmission of shift commands to an automatic transmission of a motor vehicle (shift-by-wire shifting), with at least one housing and / or one frame and one selector lever for the manual selection of shift commands for the vehicle transmission in at least one shift gate. The selector lever can be moved manually into at least four positions (P, R, N, D), pivotable about at least one shift axis. A transmission device(s) transmits the shift commands without mechanical coupling with the vehicle transmission (shift by wire). A mechanical coupling (16) is provided between the selector lever (2) and the transmission of the vehicle. This mechanical coupling (16) activates the parking brake exclusively and automatically when the selector lever (2) is engaged in the P position and is automatically uncoupled from the selector lever when the selector lever (2) is pivoted out beyond the adjacent position.

Owner:ZF FRIEDRICHSHAFEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com