Pressure injection method for integral forming of non-pneumatic tire

A non-pneumatic tire, integral molding technology, applied in the field of tire production technology, can solve problems such as uneven tire pressure, uneven tire dynamic balance, shortened tire service life, etc. Yield and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

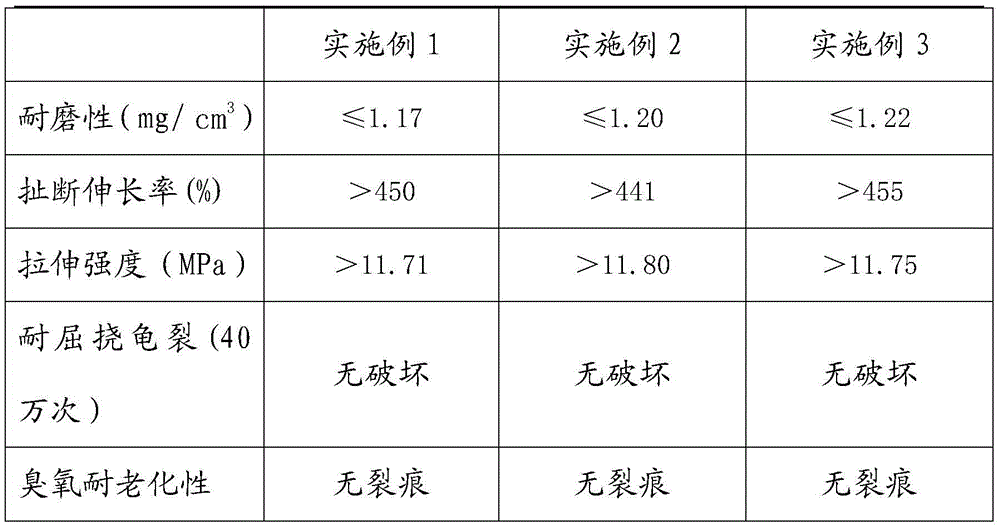

Embodiment 1

[0032] Put the prepared non-inflatable tire manufacturing raw materials into the funnel box, and use a stirring rod to stir evenly; preheat the injection machine to 180°C, so that the injection machine can fully dissolve the material, enhance the consistency of product density, and enhance the durability of the product. Aging performance, the aging resistance of the product is better at this temperature; increase the pressure of the injection machine to 50Pa to ensure that the injection machine has enough pressure to push the material into the mold; adjust the feeding speed to 10m / s to ensure that the material advances at a uniform speed , the softness and hardness of the product are uniform; adjust the holding time, the holding time is divided into three sections, each holding time is 42s, after these three sections of holding pressure, the tensile strength and elasticity of the product are greatly improved; the non-inflatable tire Manufacturing raw materials are injected into...

Embodiment 2

[0035] Put the prepared non-inflatable tire manufacturing raw materials into the funnel box, and use the stirring rod to stir evenly; preheat the injection machine to 185°C, so that the injection machine can fully dissolve the materials, ensure the consistency of product density, and enhance the durability of the product. Aging performance; increase the pressure of the injection machine to 55Pa, so that the injection machine has enough pressure to push the material into the mold; adjust the feeding speed to 15m / s to ensure that the material advances at a uniform speed, and ensure that the softness and hardness of the produced product are uniform state; adjust the holding time, the holding time is divided into three sections, each holding time is 42s, after these three sections, the tensile strength and elasticity of the product are greatly improved; the raw materials for non-inflatable tires are injected into the pressure injection Machine, adjust the injection machine to autom...

Embodiment 3

[0038] Put the prepared non-inflatable tire manufacturing raw materials into the funnel box, and use a stirring rod to stir evenly; preheat the injection machine to 190°C, so that the injection machine can fully dissolve the materials, ensure the consistency of the product density, and enhance the product Aging resistance; increase the pressure of the injection machine to 60Pa to ensure that the injection machine has enough pressure to push the material into the mold; adjust the feeding speed to 20m / s to ensure that the material advances at a uniform speed, so that the hardness of the product is uniform; adjust Pressure holding time, the pressure holding time is divided into three sections, each section of pressure holding time is 42s, after these three sections of pressure holding, the tensile strength and elasticity of the product are greatly improved; the raw materials for non-inflatable tires are injected into the injection machine, and the adjustment The injection machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com