Patents

Literature

1092 results about "Poppet valve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A poppet valve (also called mushroom valve) is a valve typically used to control the timing and quantity of gas or vapour flow into an engine. It consists of a hole, usually round or oval, and a tapered plug, usually a disk shape on the end of a shaft also called a valve stem. The portion of the hole where the plug meets with it is called the "seat" or "valve seat". The shaft guides the plug portion by sliding through a valve guide. In exhaust applications a pressure differential helps to seal the valve and in intake valves a pressure differential helps open it. The poppet valve was most likely invented in 1833 by E.A.G. Young of the Newcastle and Frenchtown Railroad. Young patented his idea, but the Patent Office fire of 1836 destroyed all records of it.

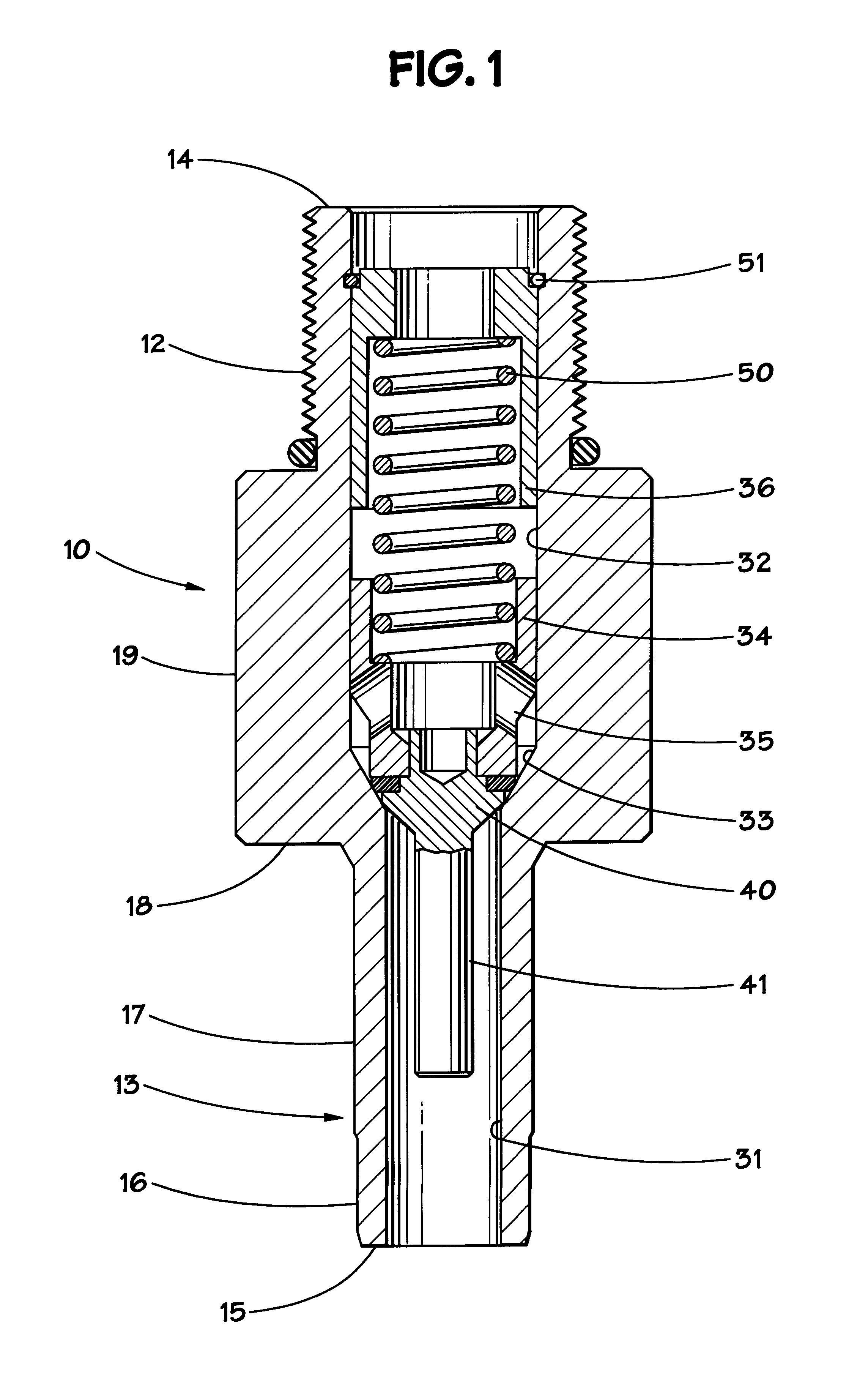

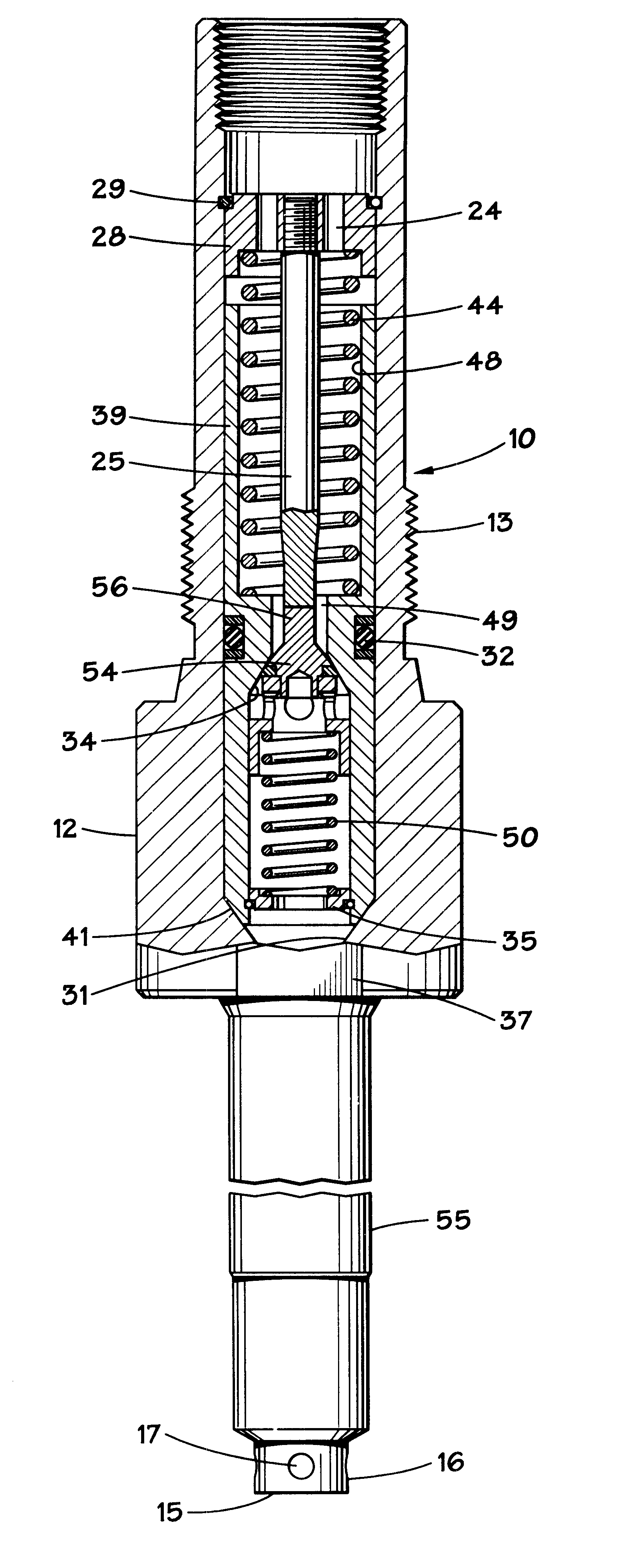

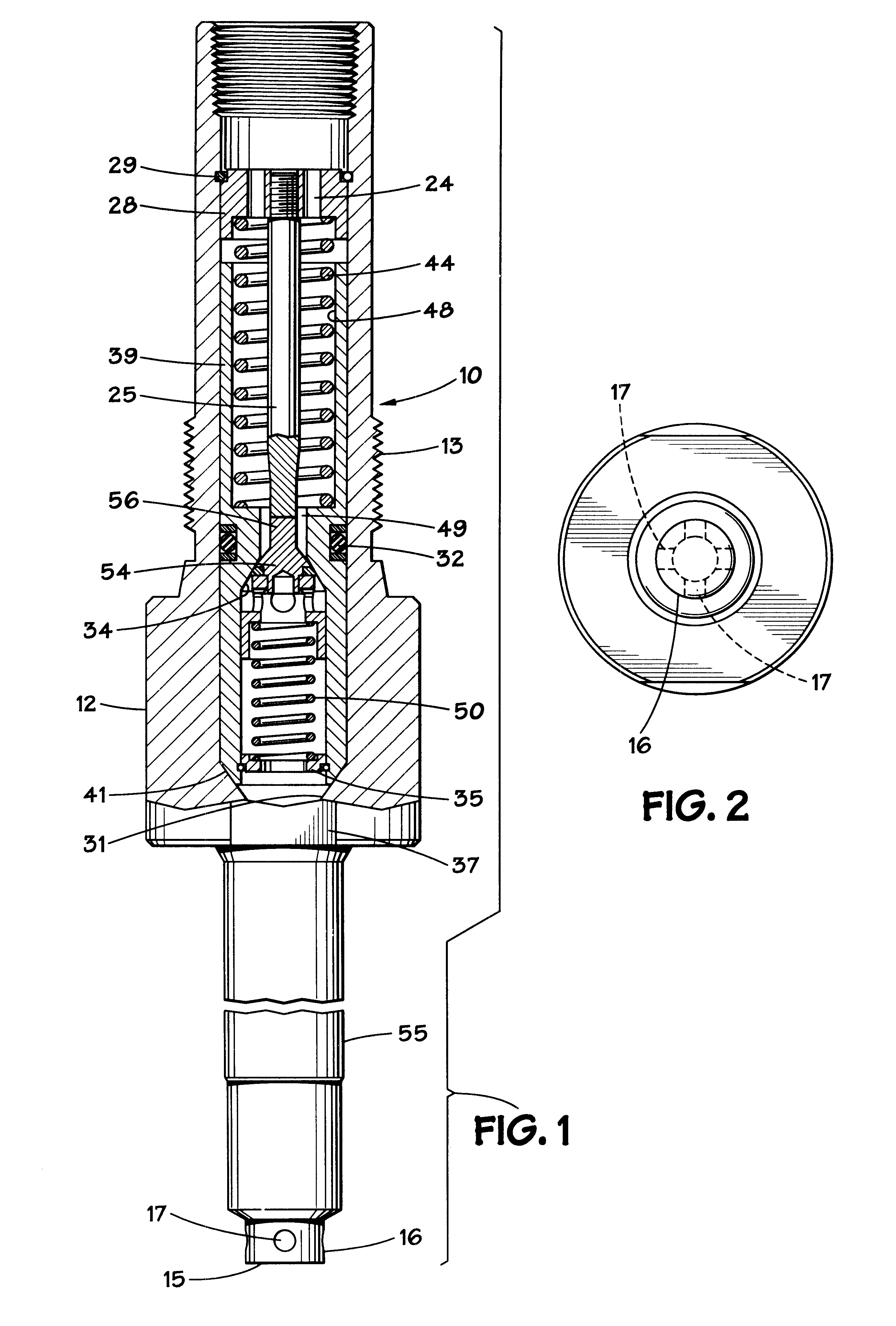

Poppet valve assembly, system, and apparatus for use in high speed compressor applications

InactiveUS20100090149A1Small diameterPositive displacement pump componentsCheck valvesMaximum diameterEngineering

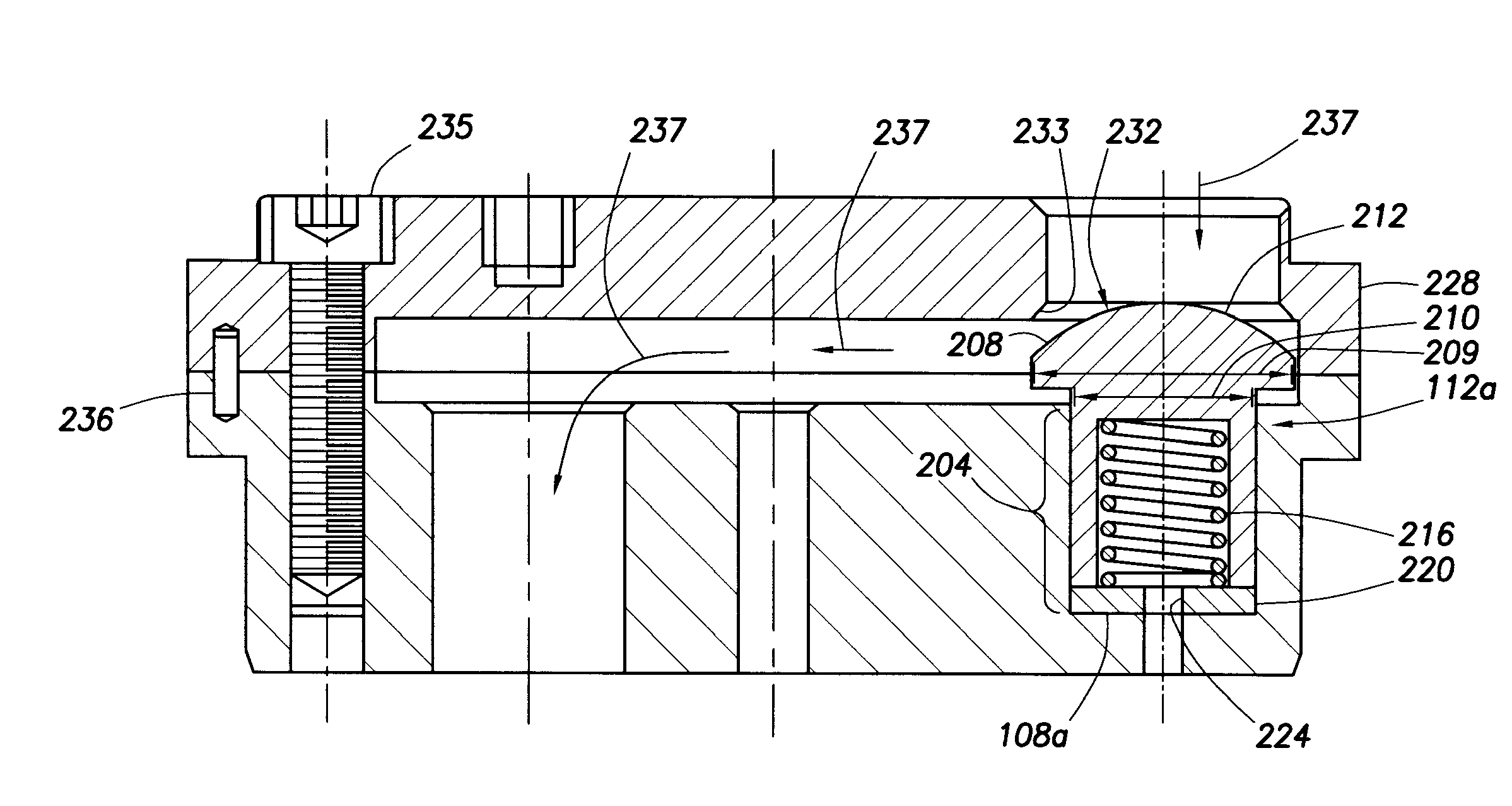

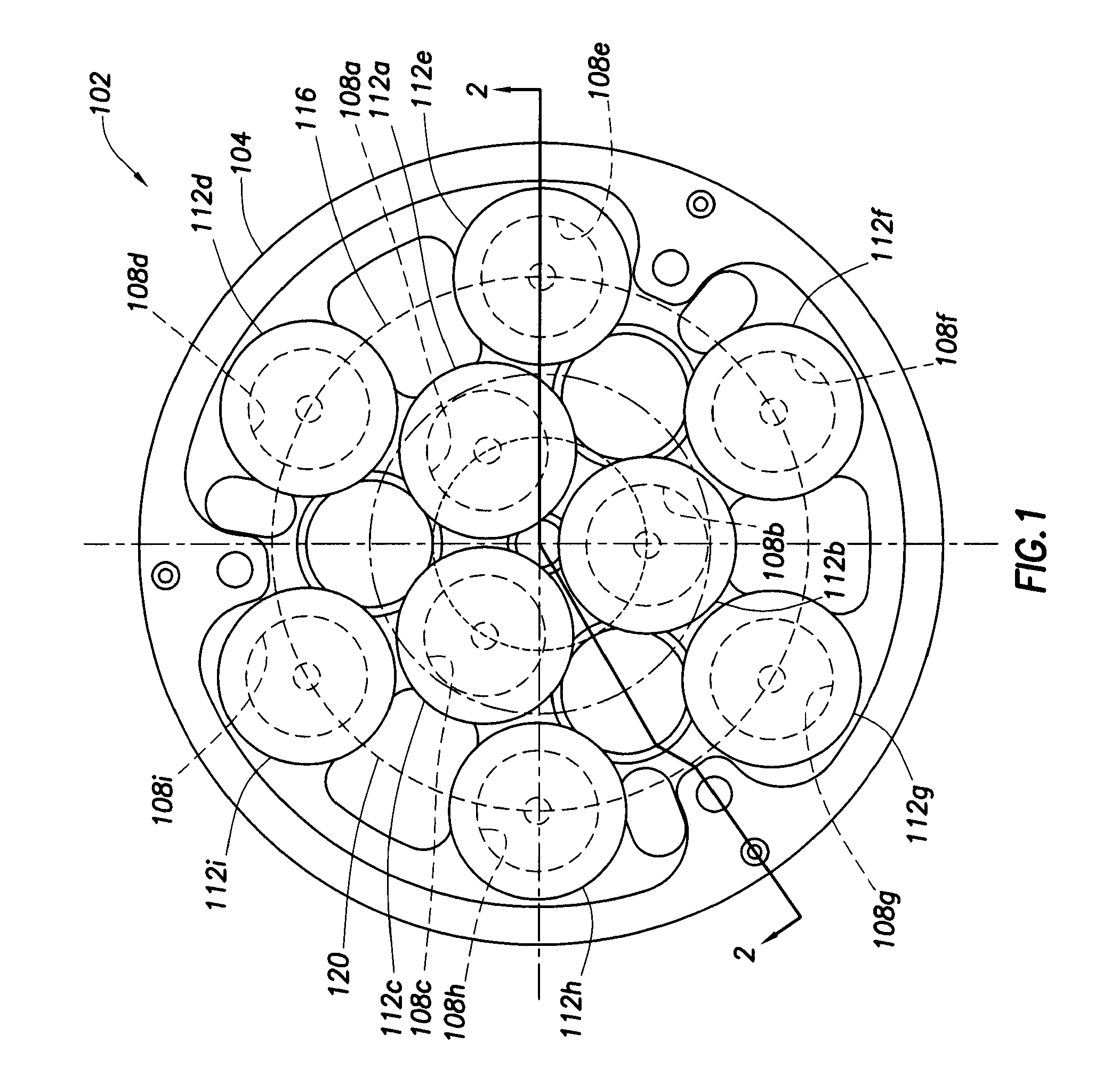

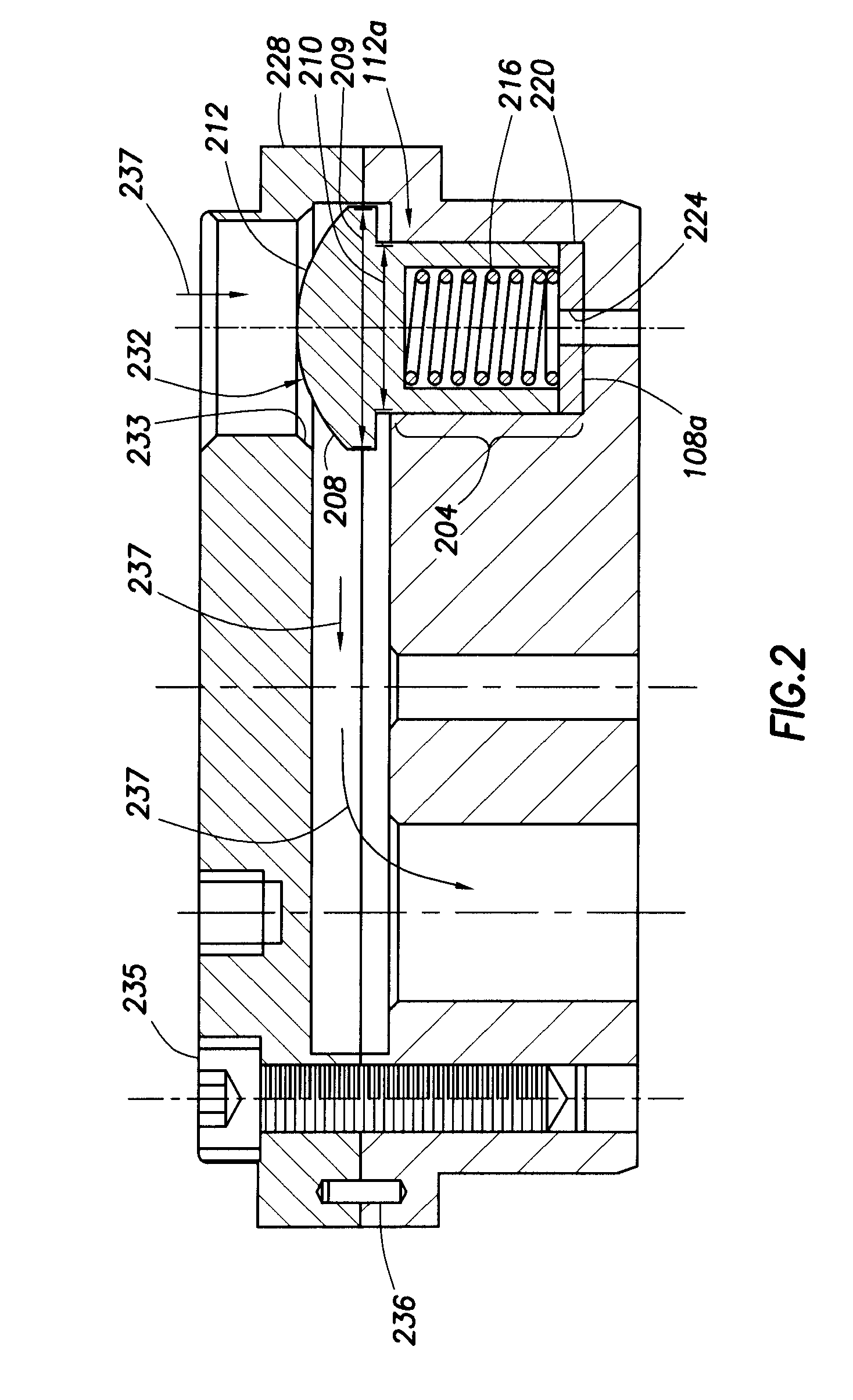

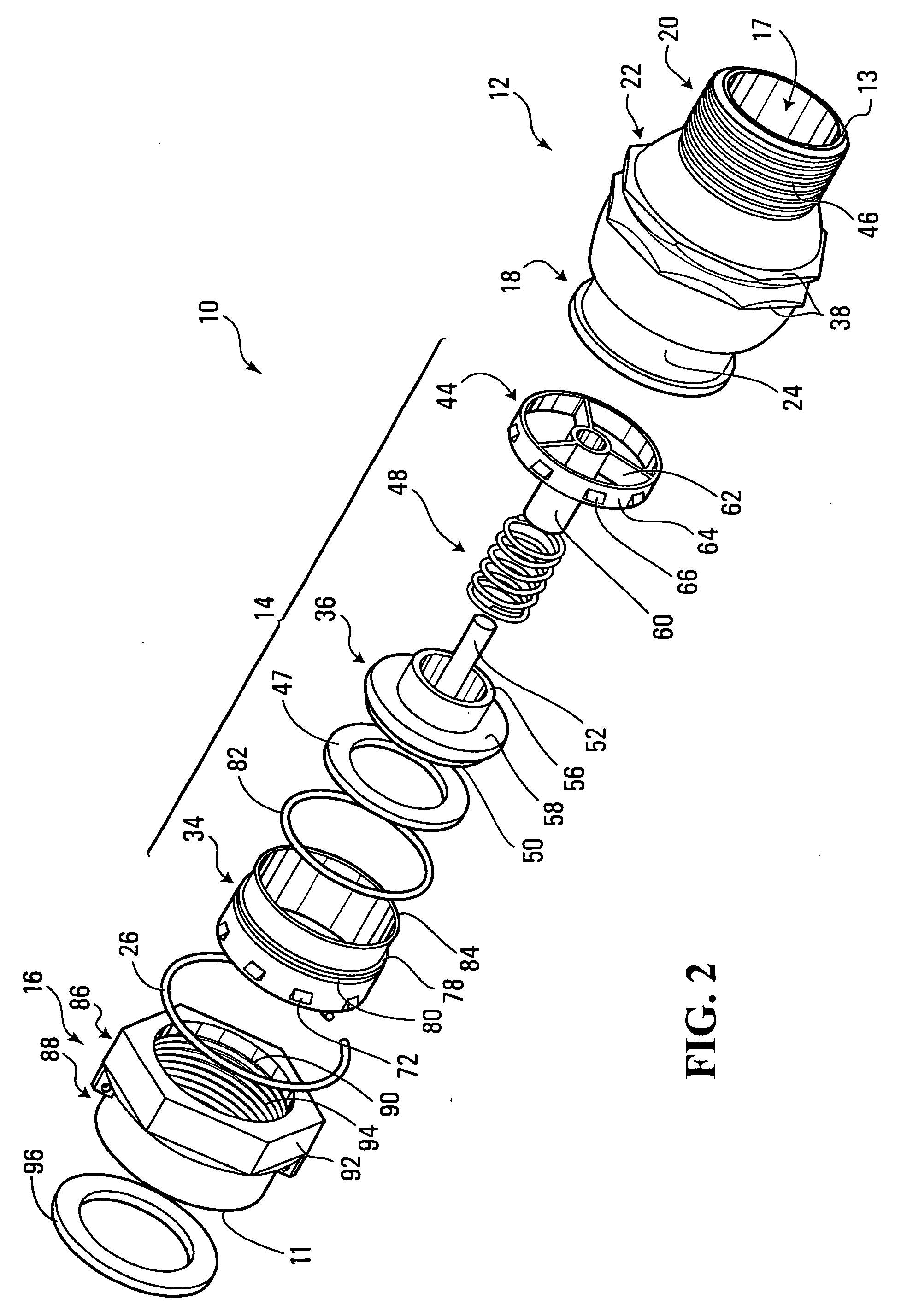

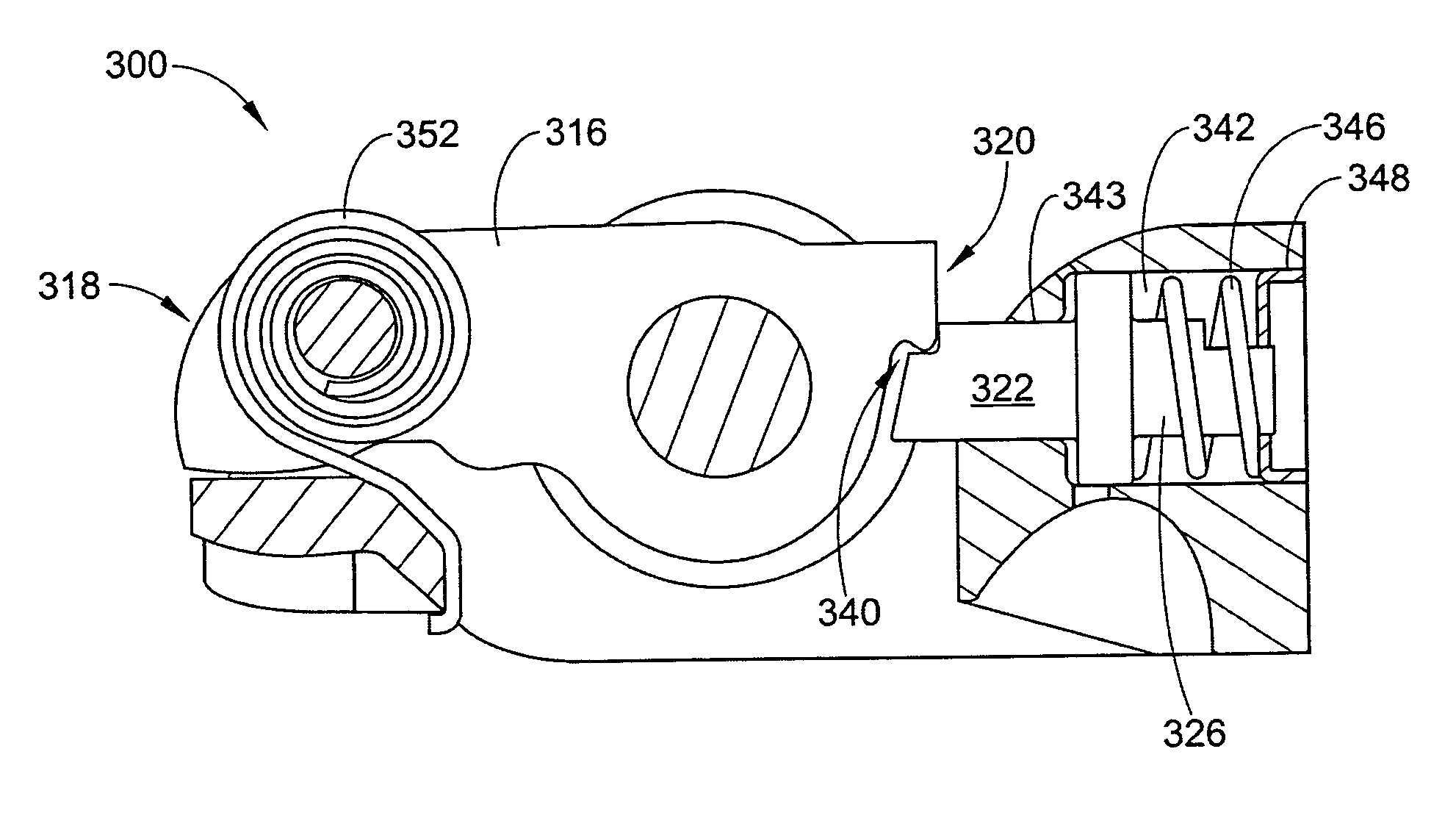

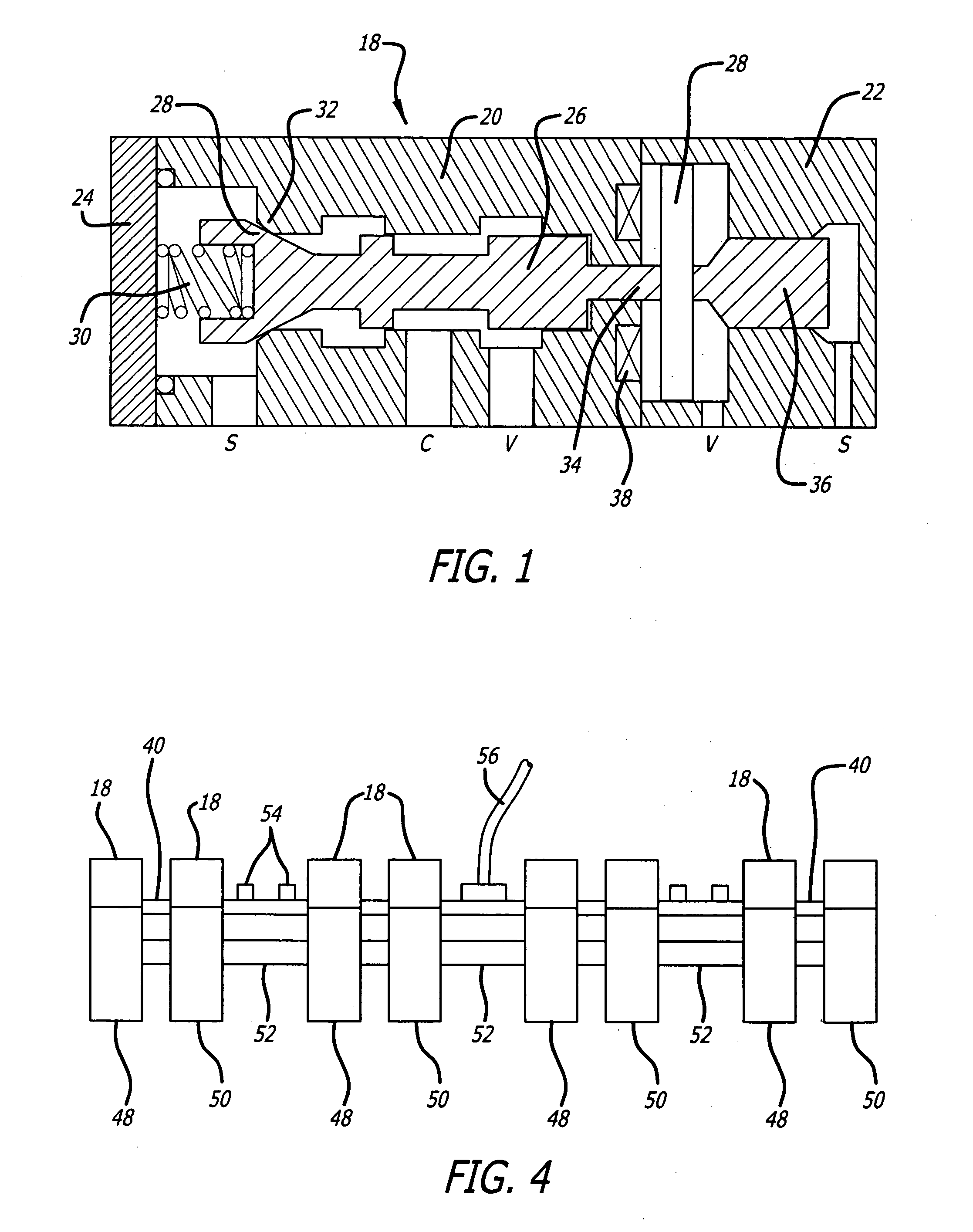

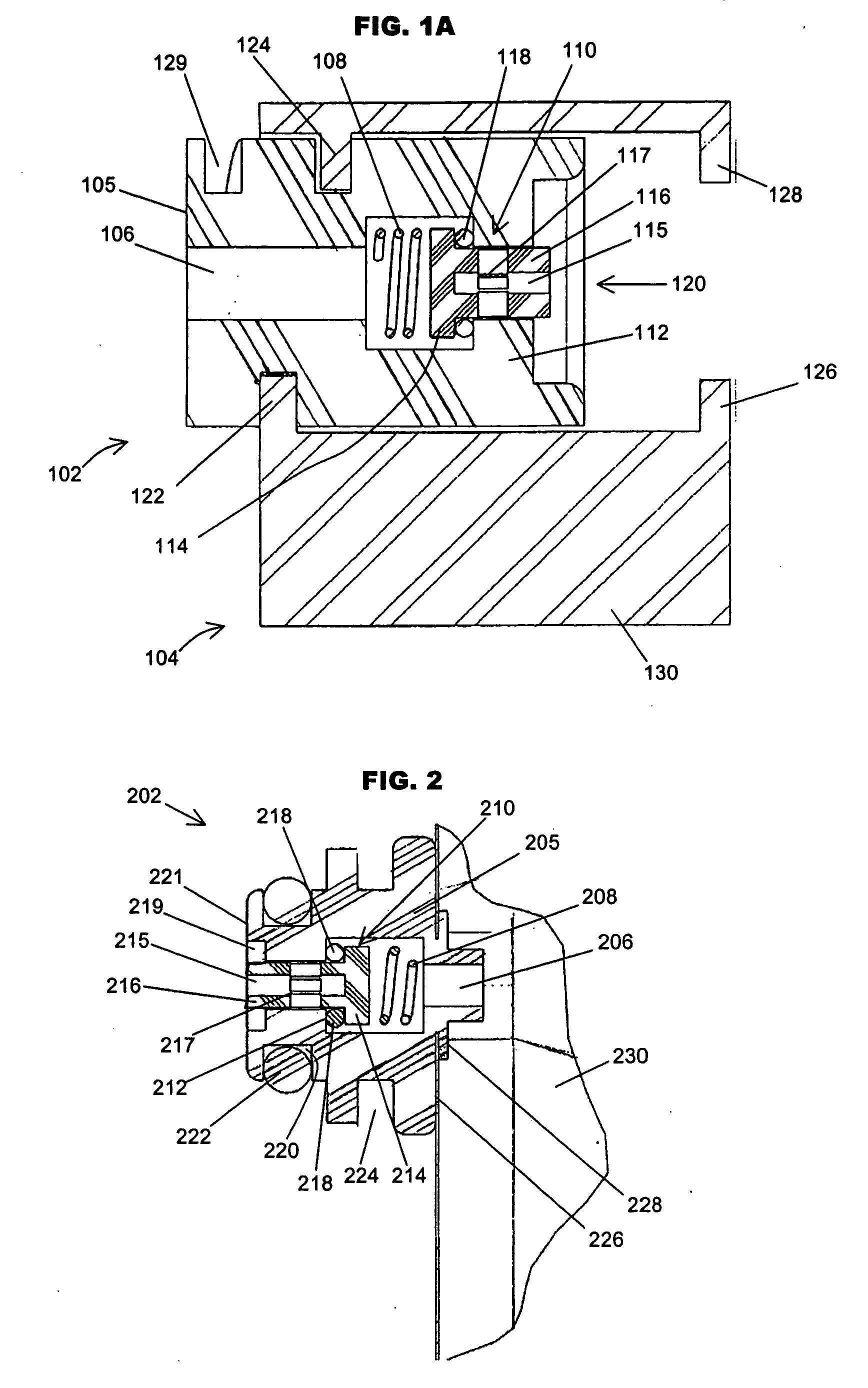

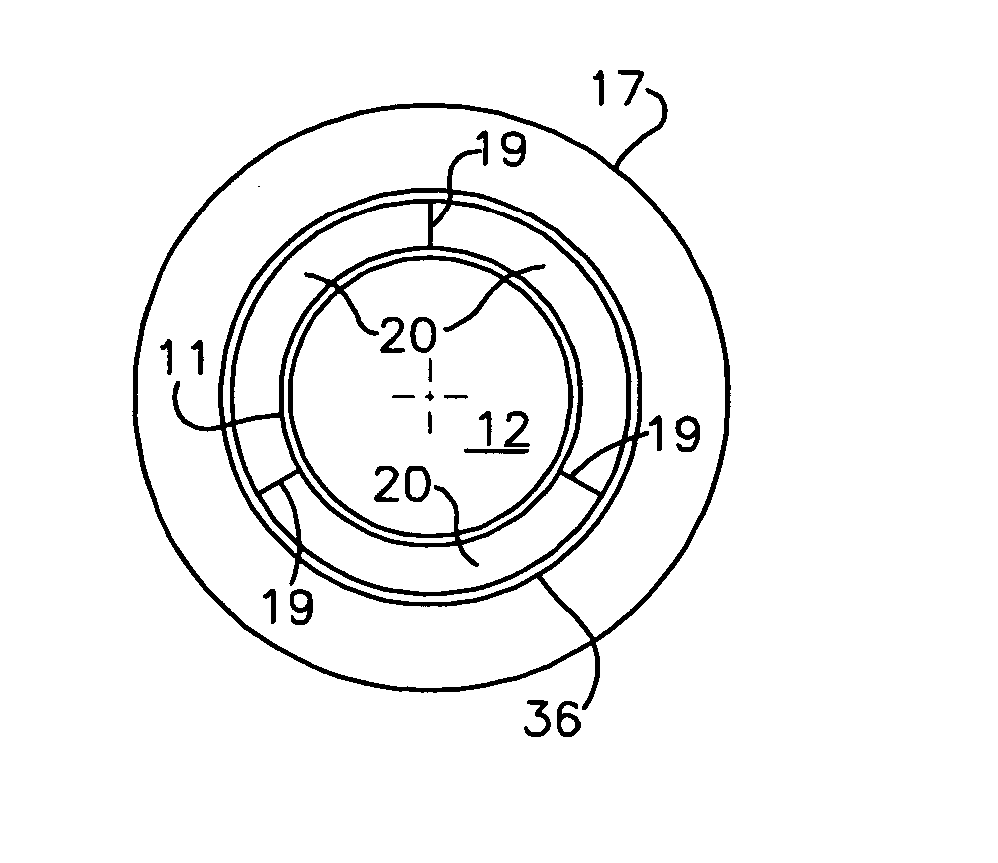

A poppet valve assembly for a high-speed compressor, the poppet valve assembly including a cage that includes a plurality of counter bores disposed therein. The poppet valve assembly further includes a plurality of poppets, each poppet having a stem and a head. The head of each poppet has a maximum diameter that is less than approximately 0.75 inches. The stem of the poppet is disposed in each of said counter bores. The poppet valve assembly also includes a seat plate overlying said cage, said seat plate including a plurality of through bores axially aligned with the counter bores of the cage. Each through bore is sized to have a smaller diameter than the maximum diameter of the head. A lift spacer is disposed in each of the counter bores.

Owner:COMPRESSOR ENG CORP

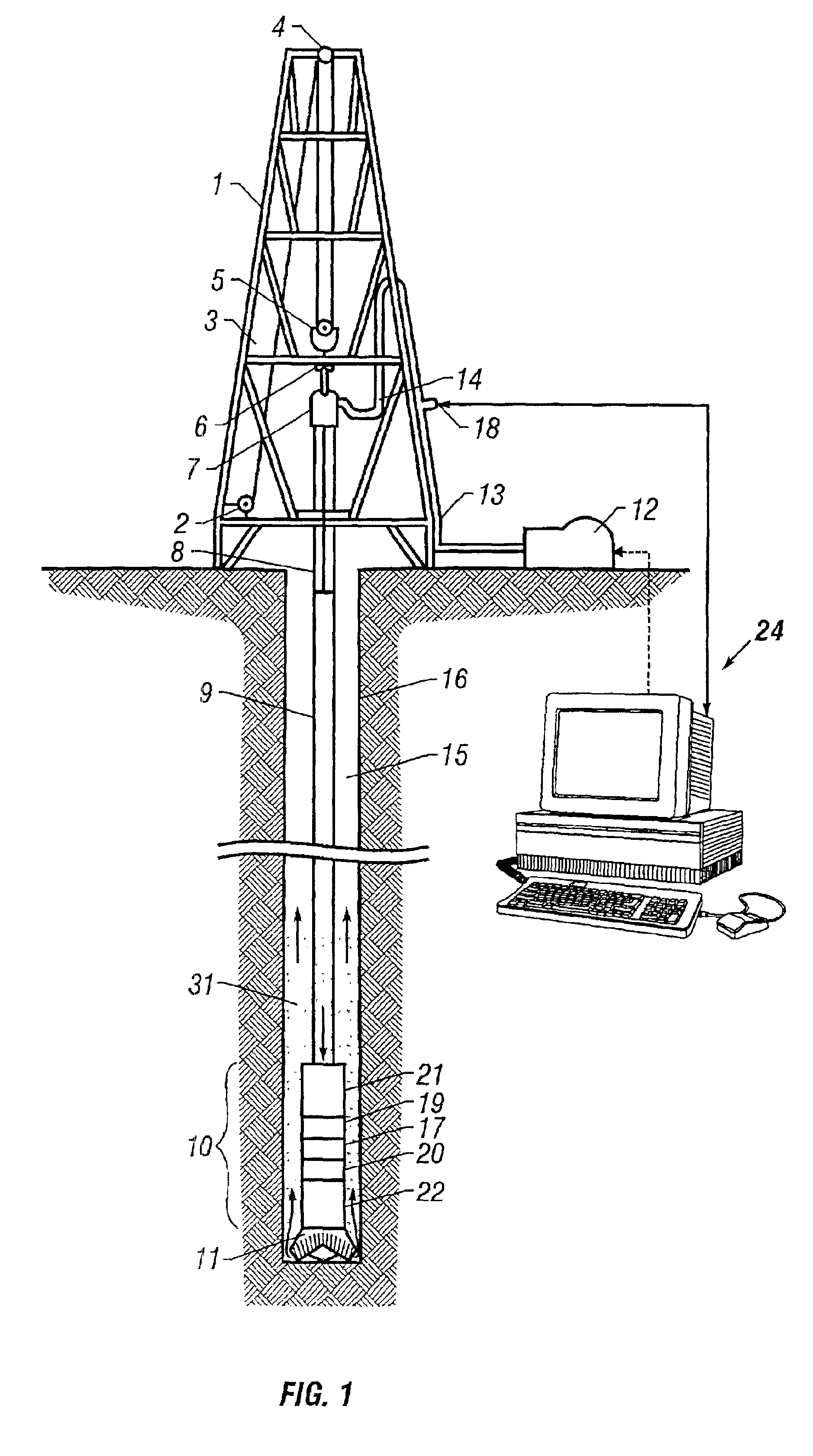

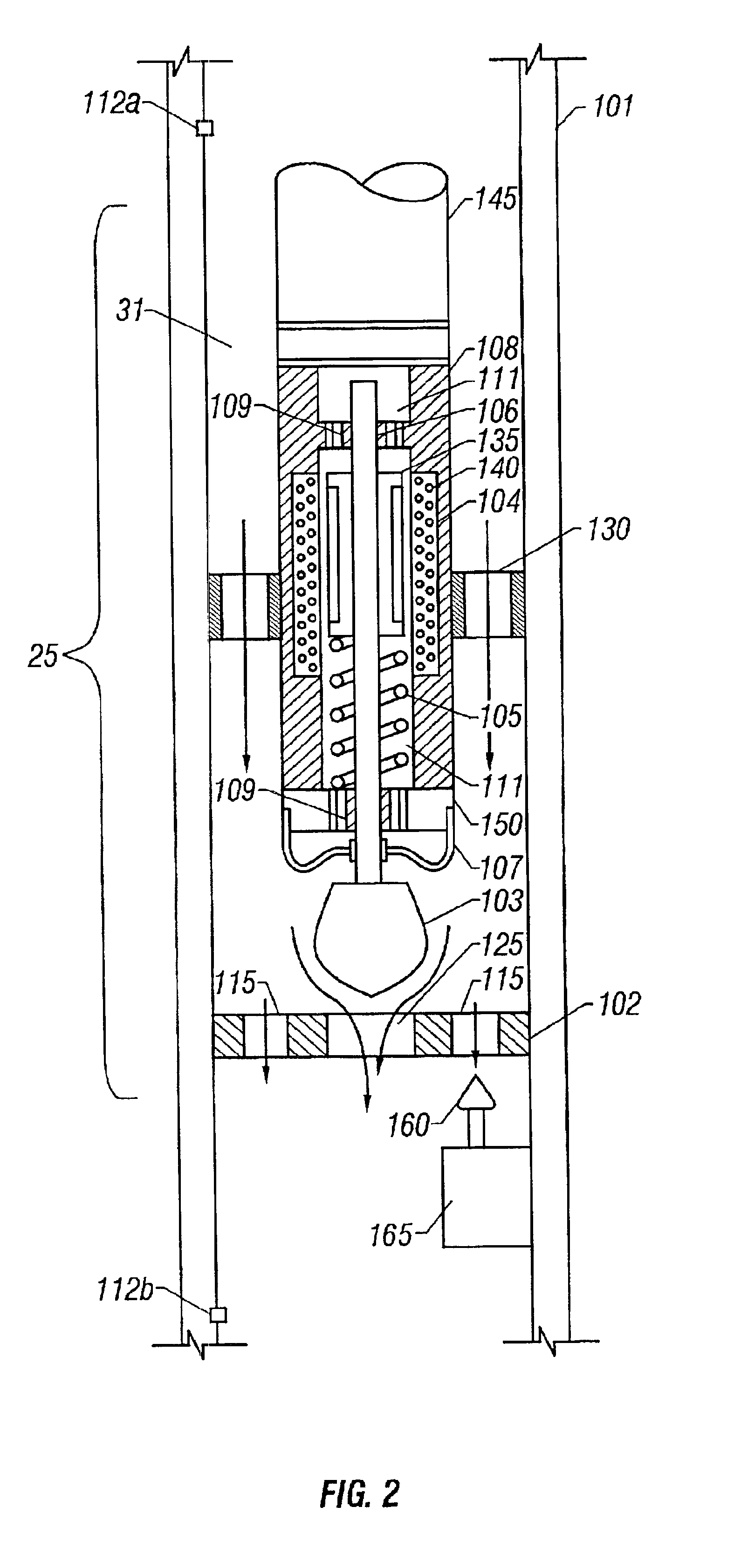

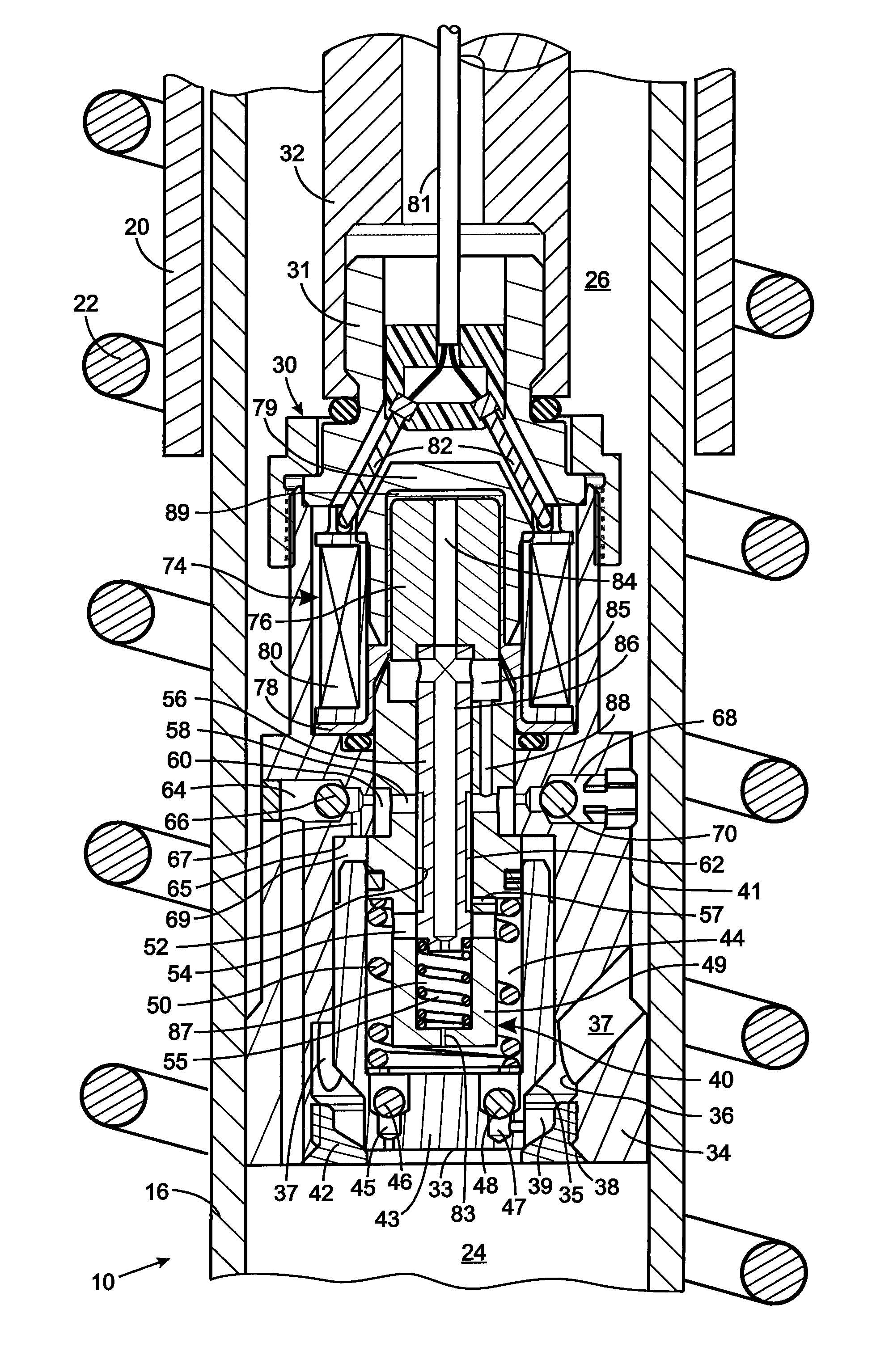

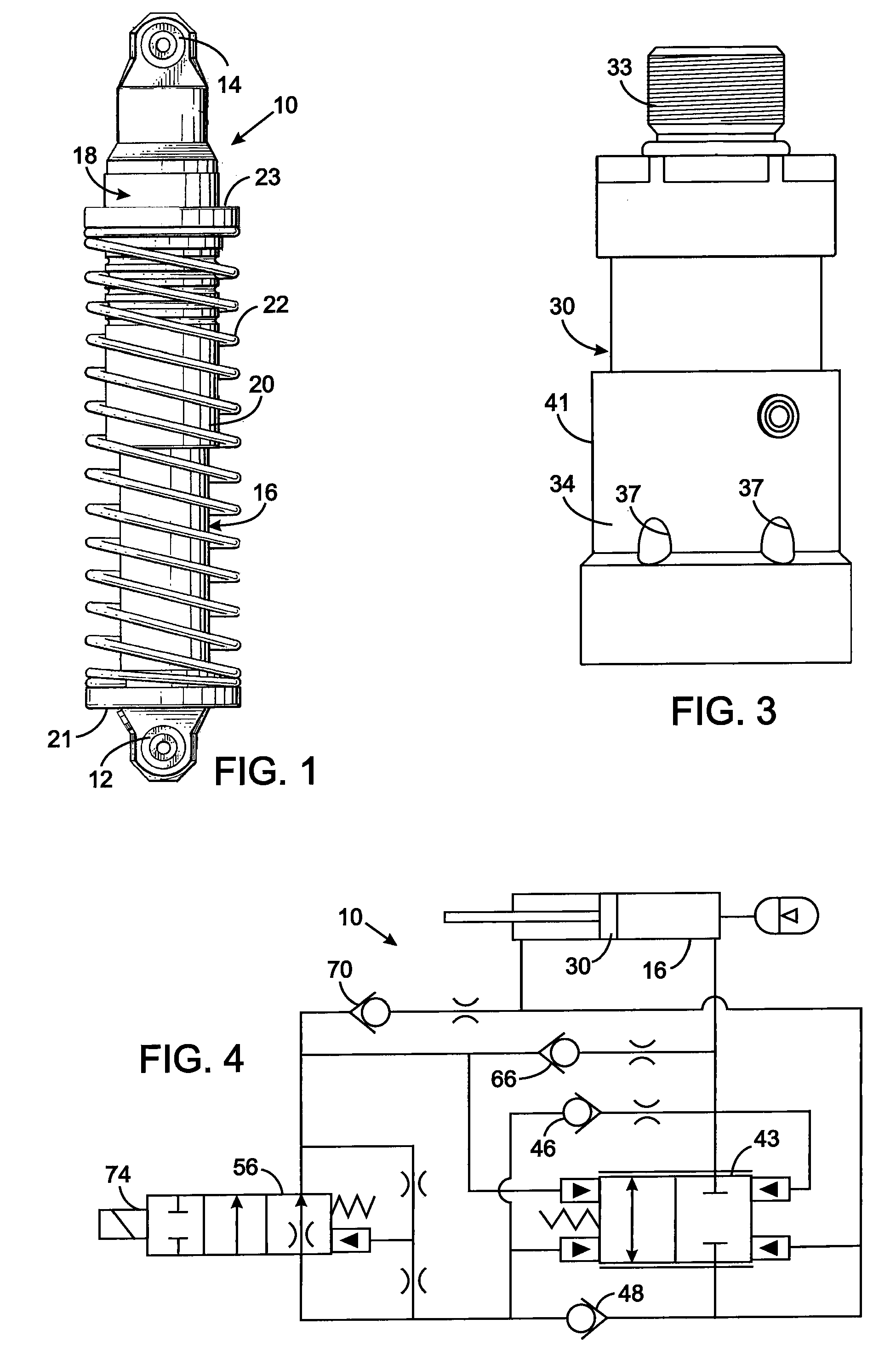

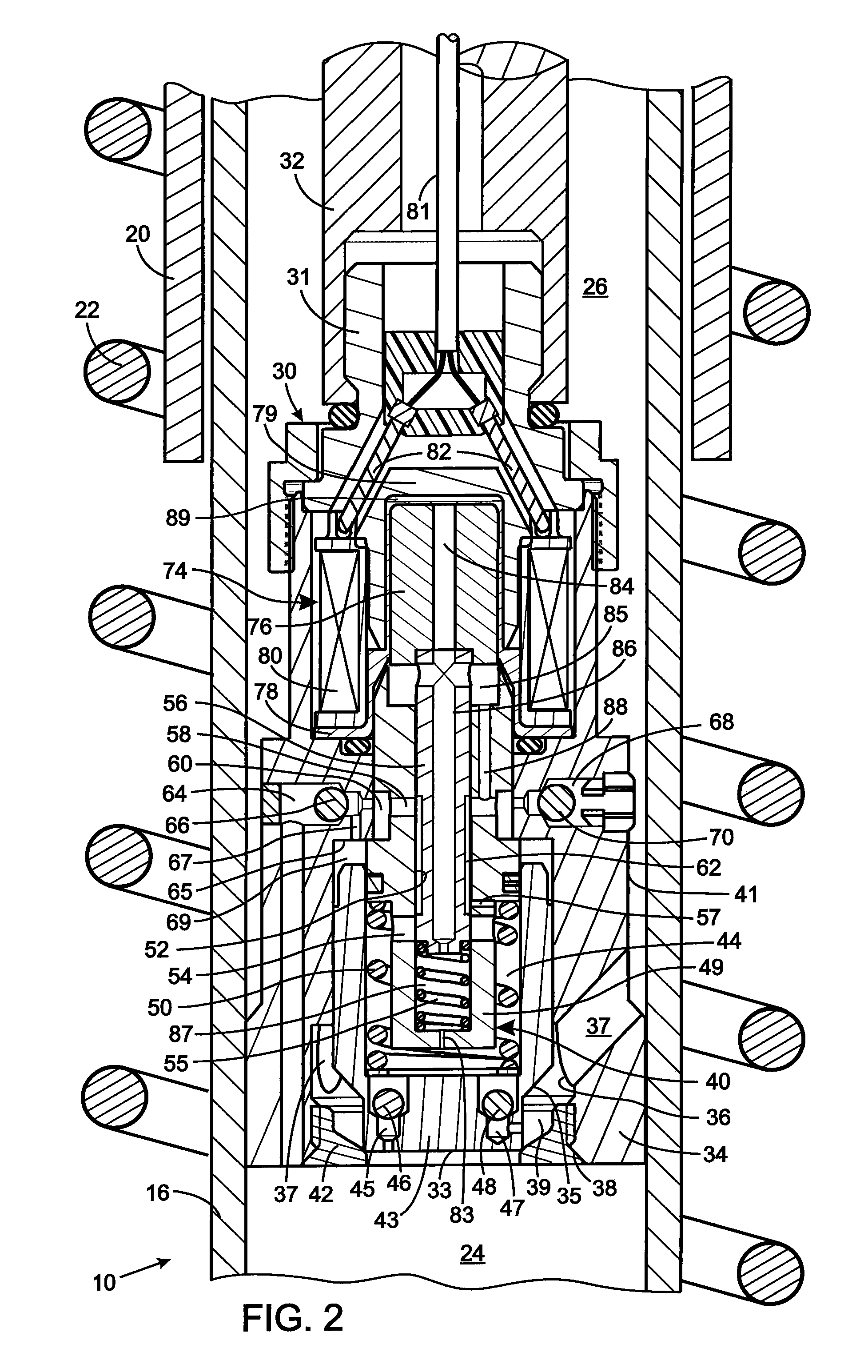

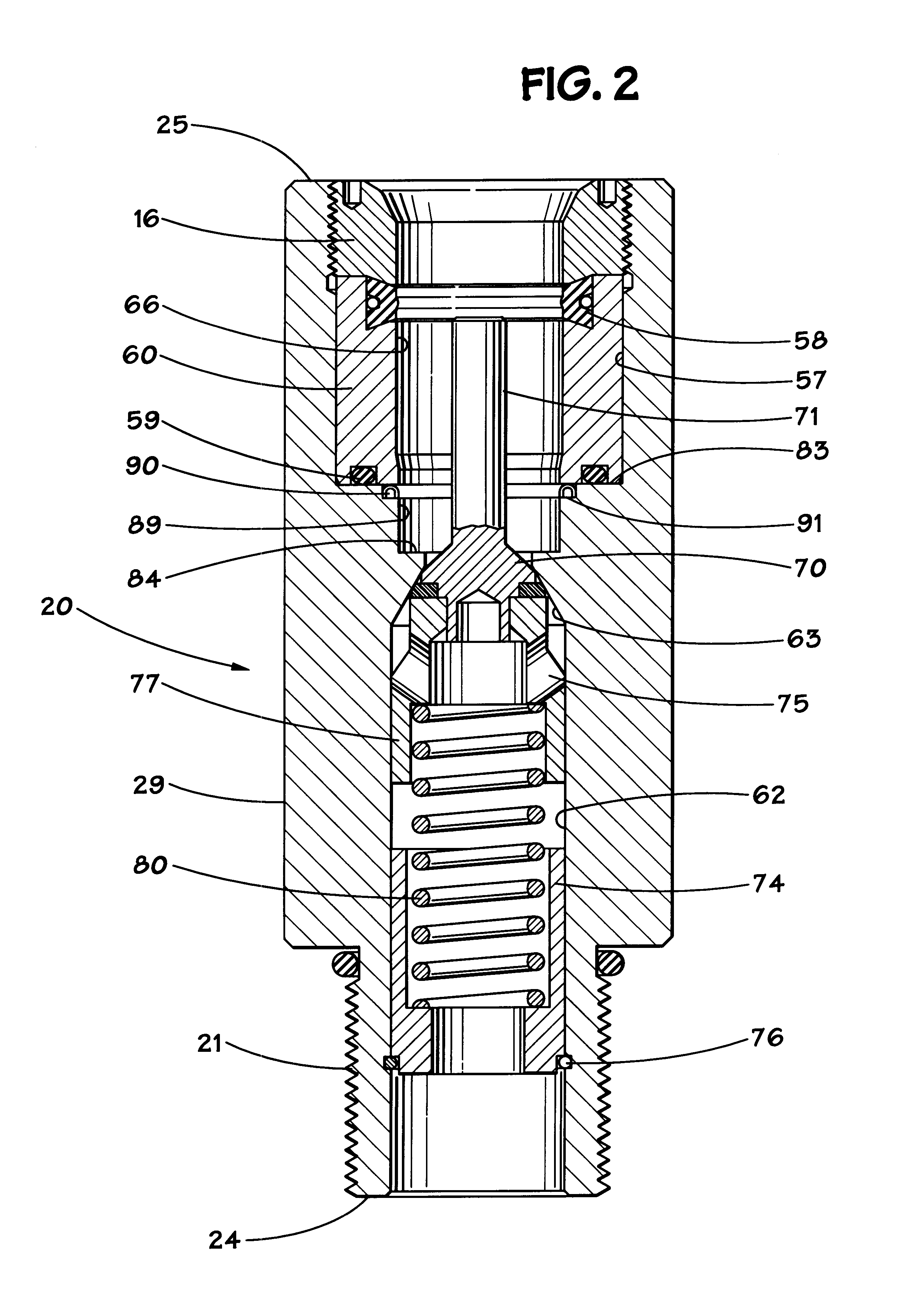

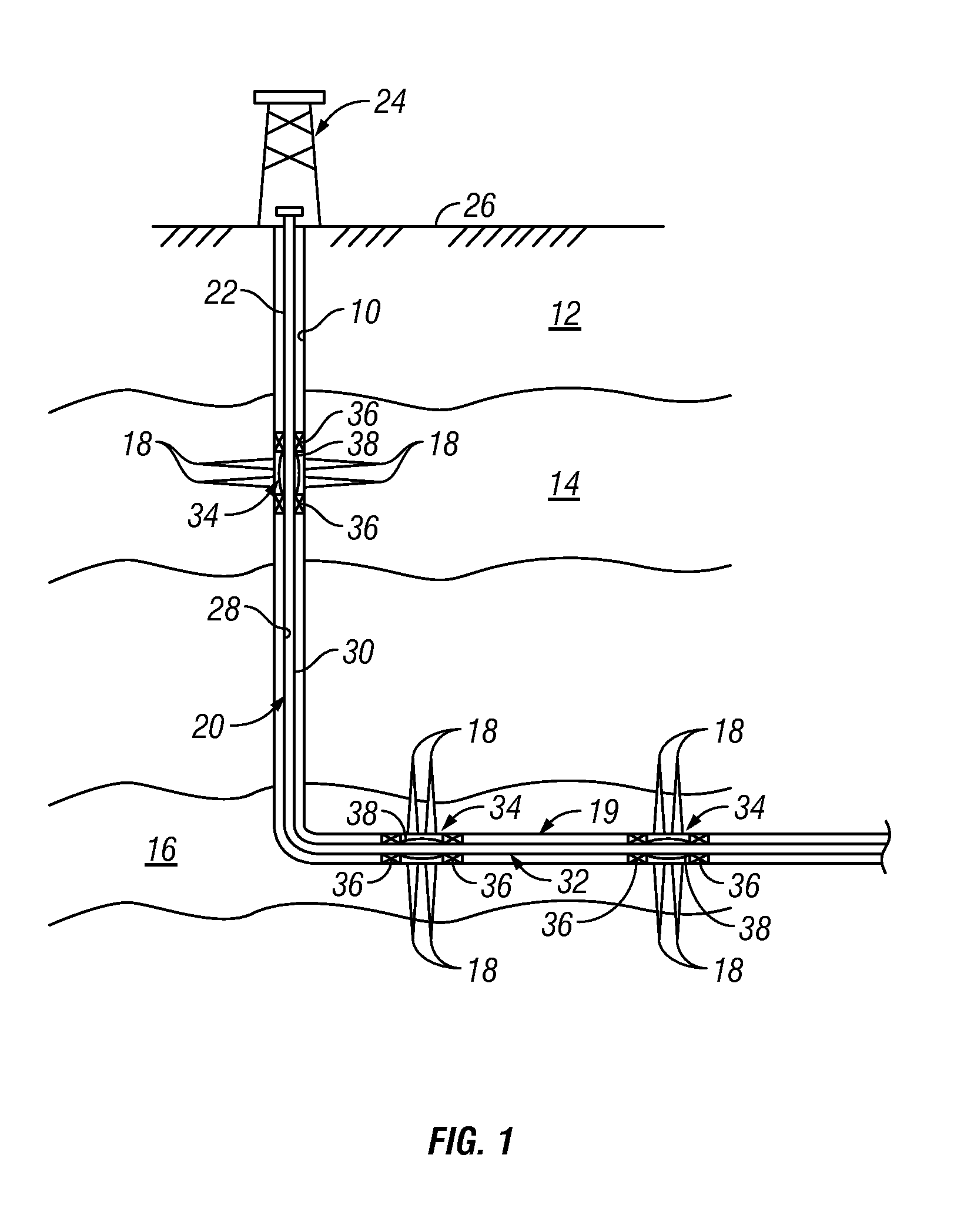

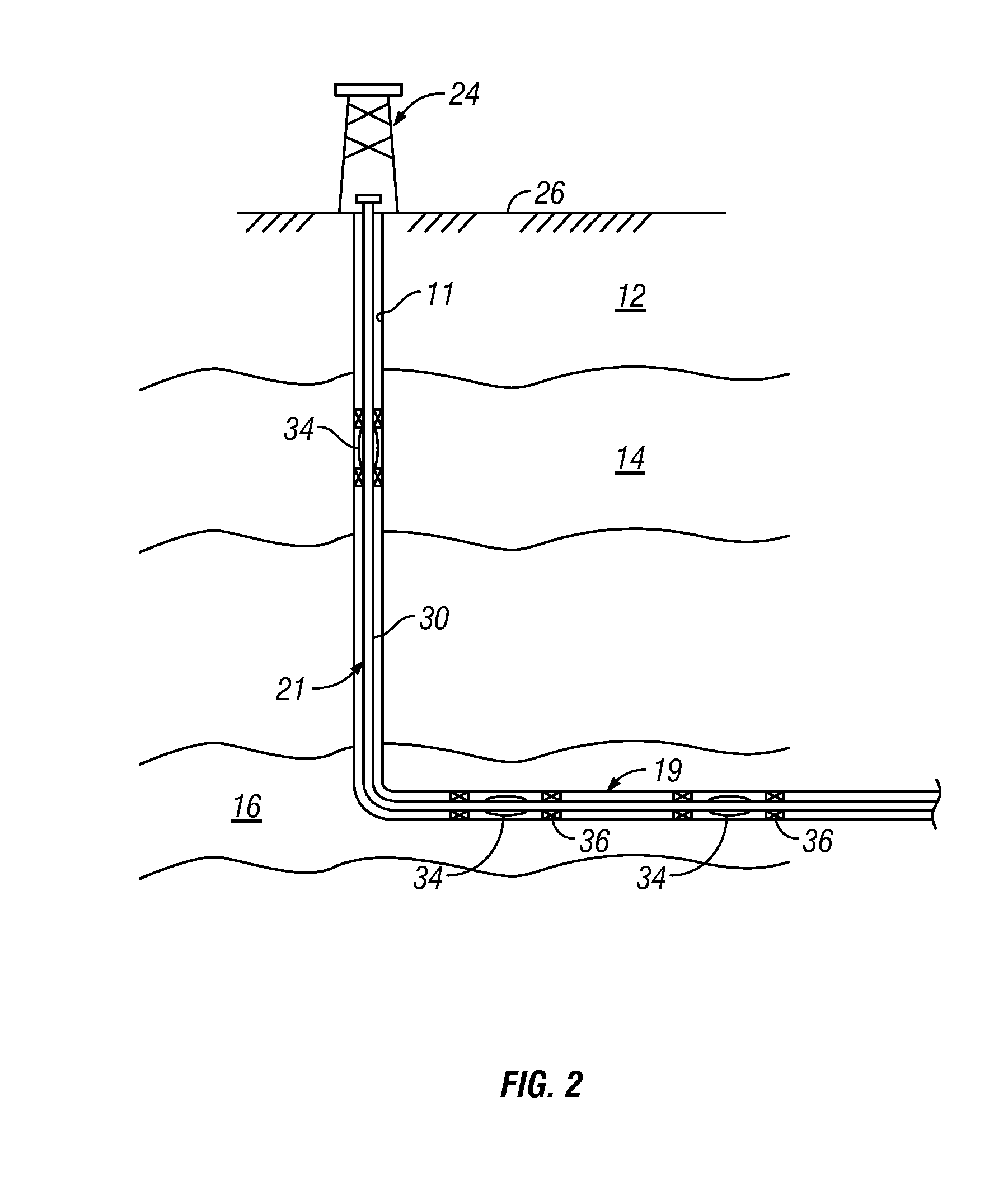

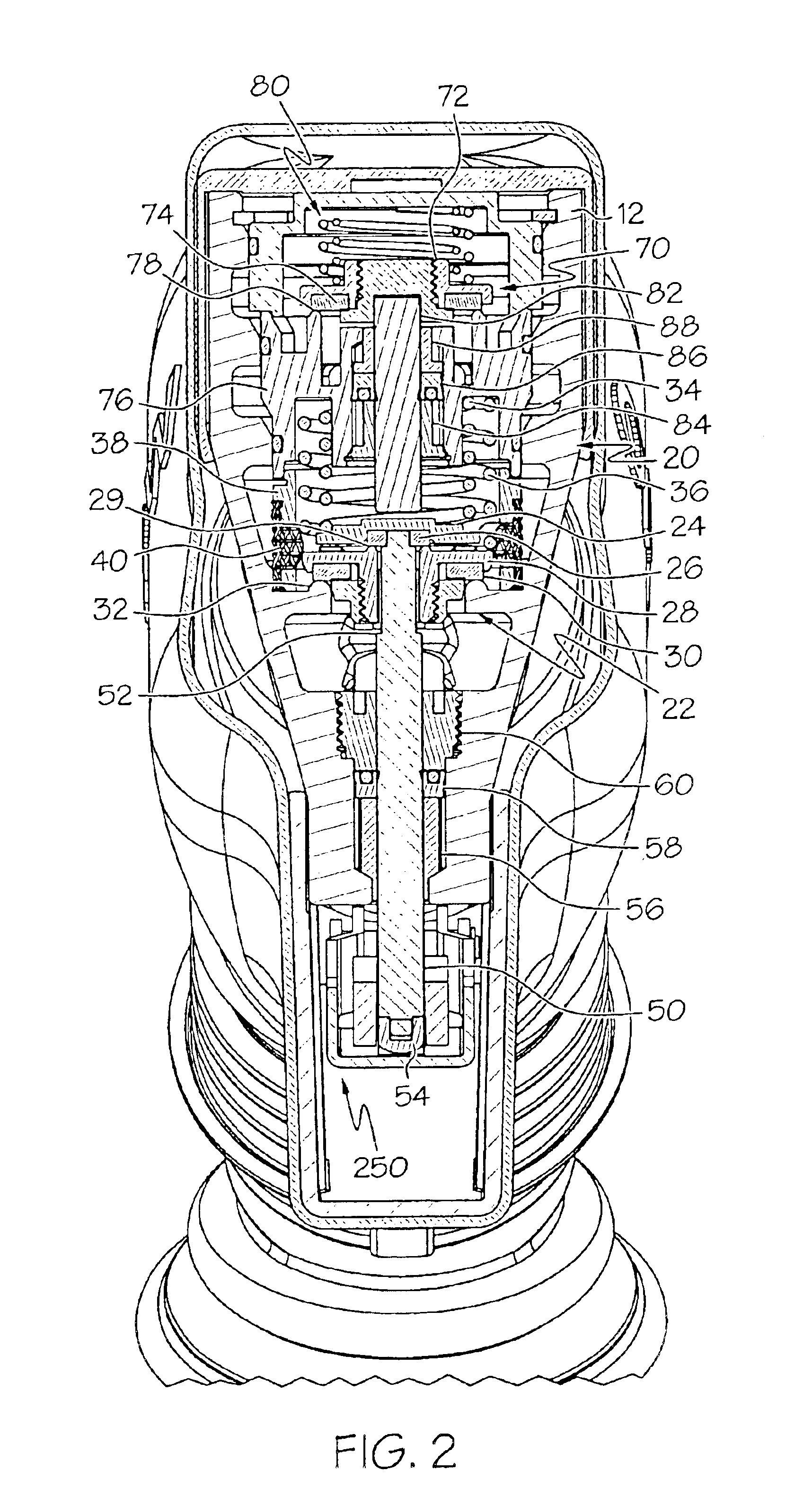

Hydraulically balanced reciprocating pulser valve for mud pulse telemetry

ActiveUS6898150B2Improve data transfer rateSurveyMultiple modulation transmitter/receiver arrangementsDifferential pressureReciprocating motion

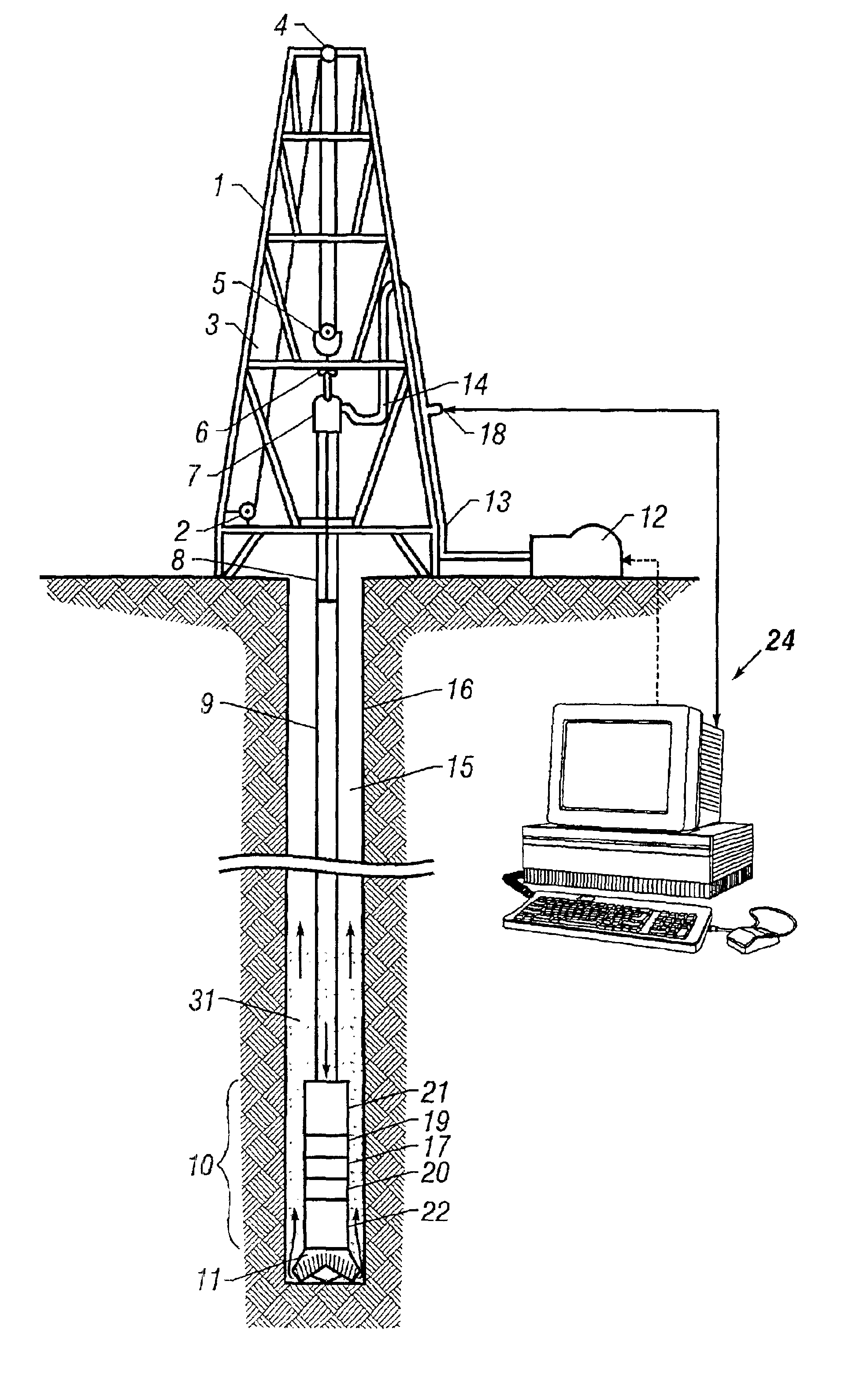

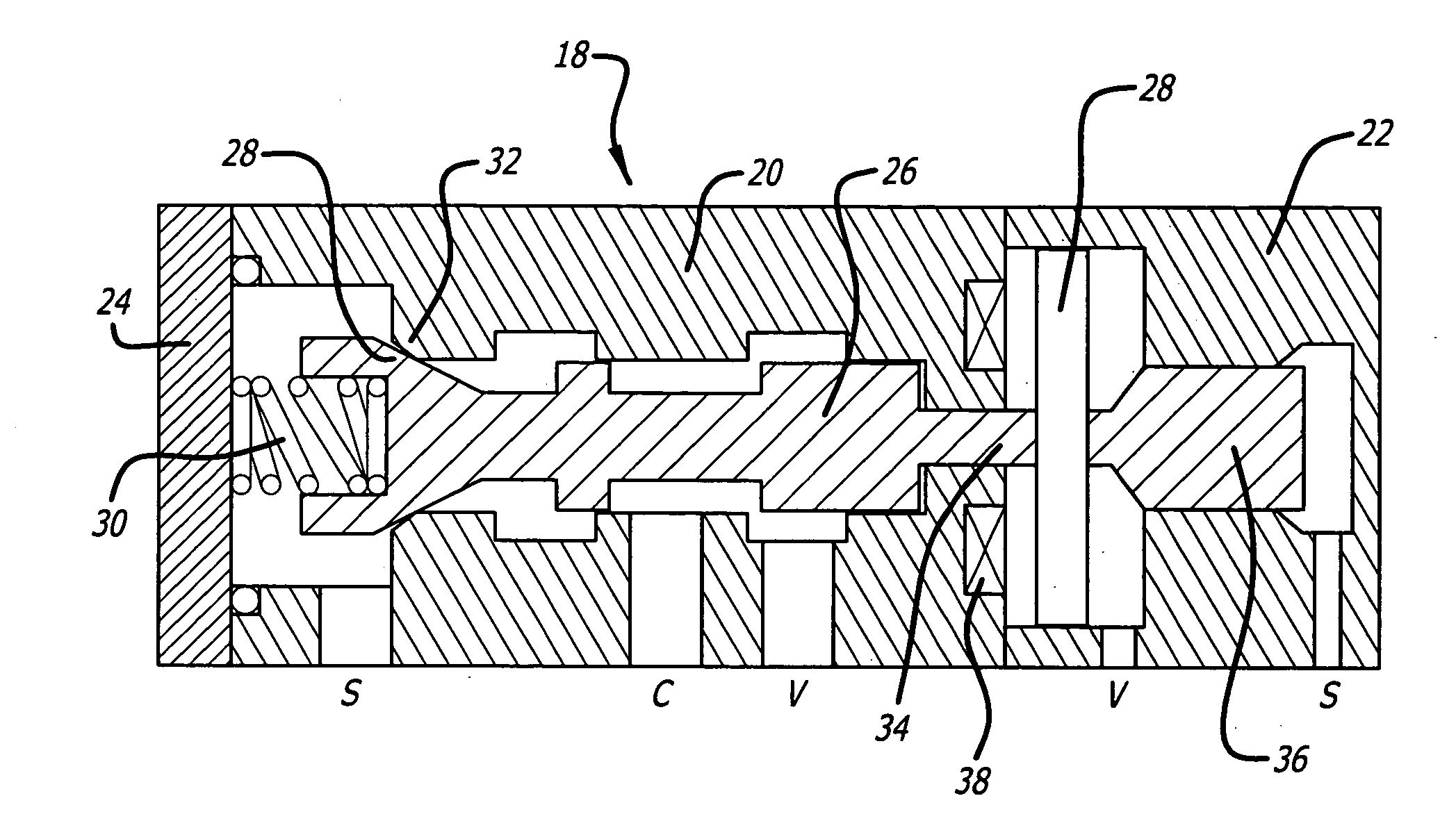

A reciprocating pulser system for generating pressure fluctuations in a flowing drilling fluid comprising a reciprocating poppet and a stationary valve assembly with axial flow passages. The poppet reciprocates in close proximity to the valve assembly, at least partially blocking the flow through the valve assembly and generating oscillating pressure pulses. The poppet passes through two zero speed positions during each cycle, enabling rapid changes in signal phase, frequency, and / or amplitude thereby facilitating enhanced data encoding. The poppet is driven by a linear electric motor disposed in a lubricant filled housing. In one embodiment, the housing to shaft seal is a flexible bellows. In one embodiment, a force balance spring is used to essentially offset the hydraulic flow forces on the poppet. In one embodiment, a bypass poppet is used to adjust the differential pressure across the valve assembly.

Owner:BAKER HUGHES INC

Breakaway hose coupling with a magnetic connection

ActiveUS7252112B1Simplifies reconnectionSimplifies recouplingValve arrangementsPipe elementsRare earthCoupling system

A breakaway coupling for a fuel supply hose includes a male valve body interfitting with a female valve body for defining a fuel passage, and the valve bodies enclose axially movable spring biased poppet valve members. The valve bodies are connected by a permanent magnetic coupling system which provides for moving the valve bodies from a connected position to a disconnected position in response to a substantial axial tension force on the valve bodies. In one embodiment, the coupling system includes an annular strike member surrounding the fuel passage and a mating annular magnet member supporting a plurality of circumferentially spaced permanent magnets of rare earth materials. In another embodiment, the valve bodies define a vapor return passage with a poppet valve member and disposed either radially outboard or inboard of the fuel passage. The magnetic coupling system also simplifies reconnecting the valve bodies.

Owner:GILBARCO

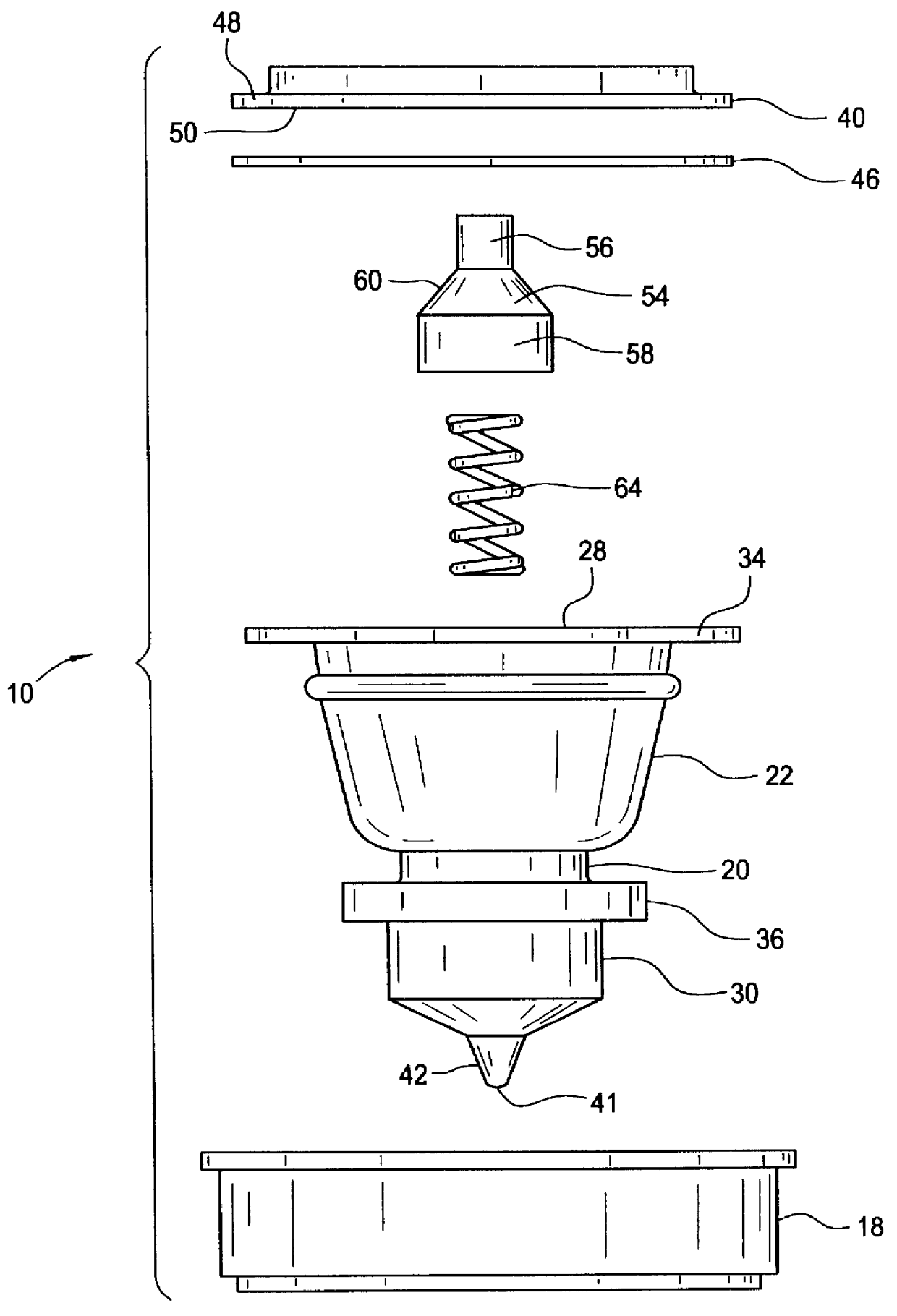

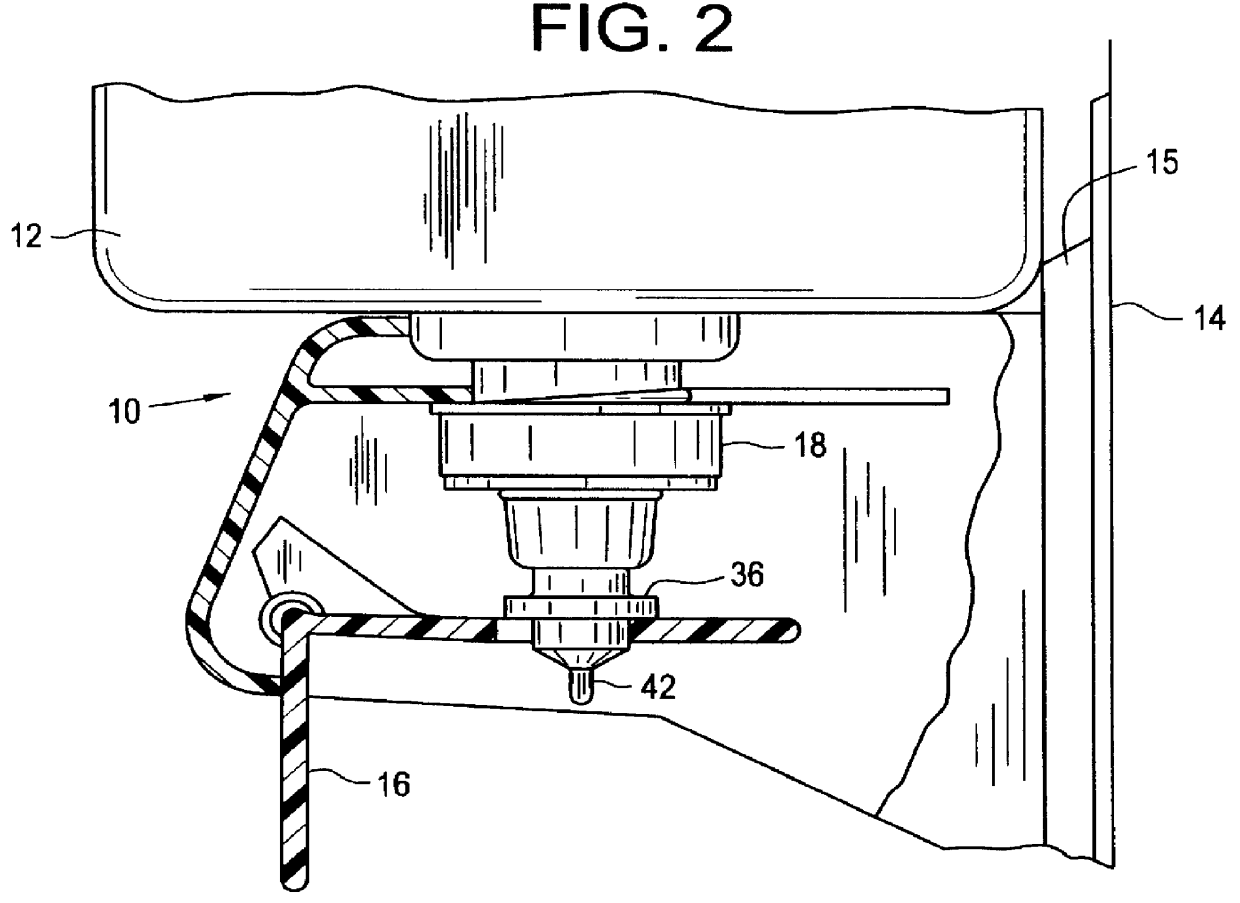

Fluid dispensing valve assembly

InactiveUS6053370AReduce manufacturing costEasy to useClosuresLiquid transferring devicesEngineeringCheck valve

A dispenser for dispensing charges of fluid from a container and applicable to a mouth of the container with the container in an inverted position and the mouth down. The dispenser includes a body formed of resilient elastomeric material having a hollow annular upper part having a flexible, resilient annular wall and an upper and lower end and constituting a bellows which is downwardly expansible and upwardly contractible by flexing of the annular wall. The body has integral with the bellows a lower part having a discharge port. The dispenser includes a first check valve at an entry end of the bellows operable for flow of fluid into the bellows on expansion thereof and operable to block flow of fluid from the pump member out of its upper end on contraction thereof. A second valve is operable for dispensing the charge of fluid from the bellows down into the outlet nozzle on contraction of the bellows and to block flow out of the bellows outlet on expansion of the bellows. The second check valve has a valve seat member at the intake of the bellows and outlet nozzle, has at least one outlet port below the valve and a spring biased to keep the poppet valve seated against the valve seat such that the fluid is expelled through the poppet valve, outlet nozzle, and outlet port on contraction of the pump member.

Owner:KOLLER ENTERPRISES +1

Piston With An Integral Electrically Operated Adjustment Valve For A Hydraulic Vibration Damper

A vibration damper includes a cylinder within which a piston is slidably received thereby defining compression and rebound chambers. The piston has a bore with a valve seat through which fluid flows between those chambers. A poppet selectively engages the valve seat and forms a pilot chamber an opposite side of the poppet from the valve seat. The greater pressure within the compression or rebound chambers is applied by a first logic arrangement to the pilot chamber and a pilot spool control a fluid flow between the pilot chamber and a pressure cavity in the piston body. A second logic arrangement connects the pressure cavity to either the compression and rebound chamber which has the lesser pressure. A solenoid that moves the pilot valve element to control pressure in the pilot chamber and thus the amount that the poppet moves to allow fluid flow through the piston.

Owner:HUSCO AUTOMOTIVE HLDG

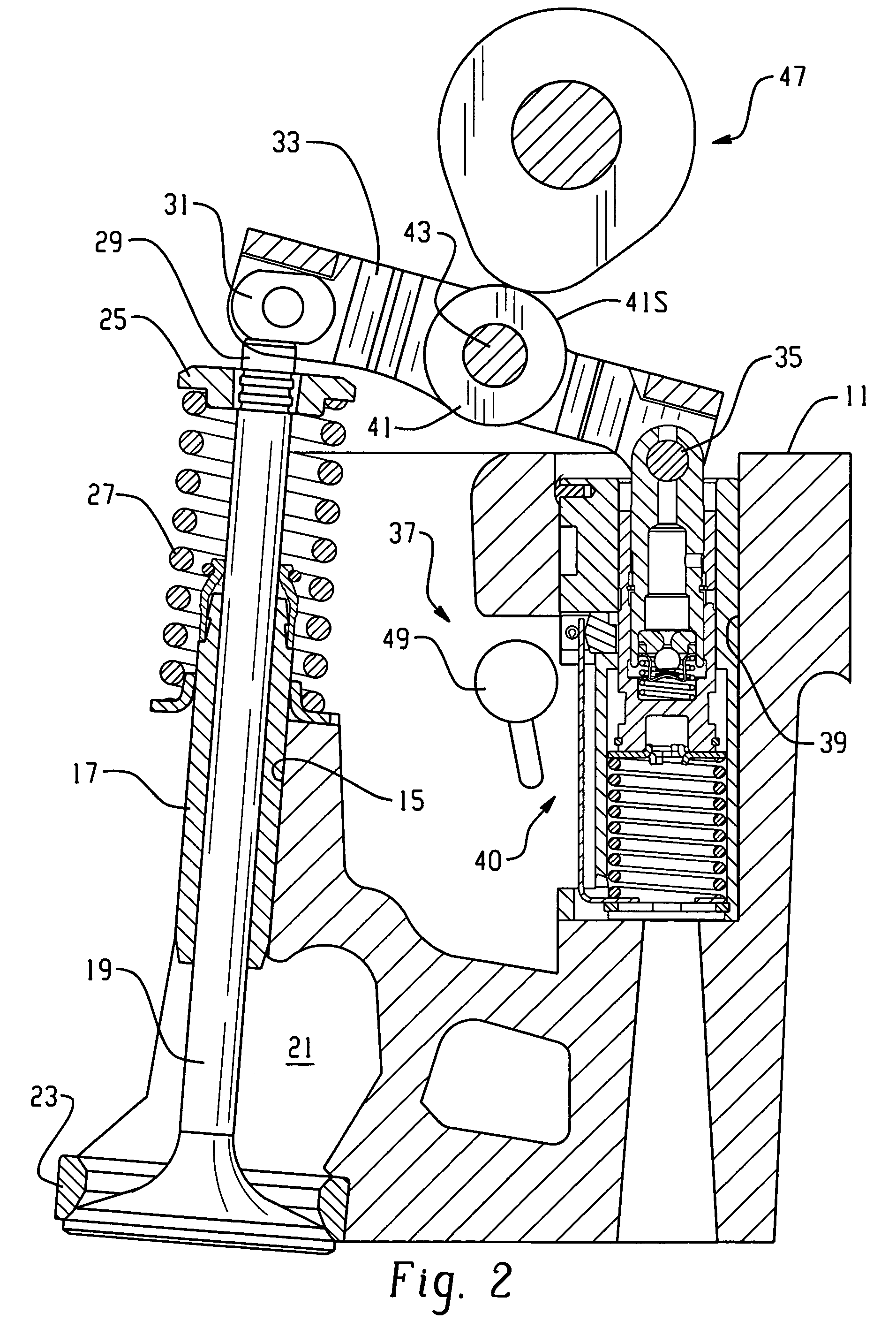

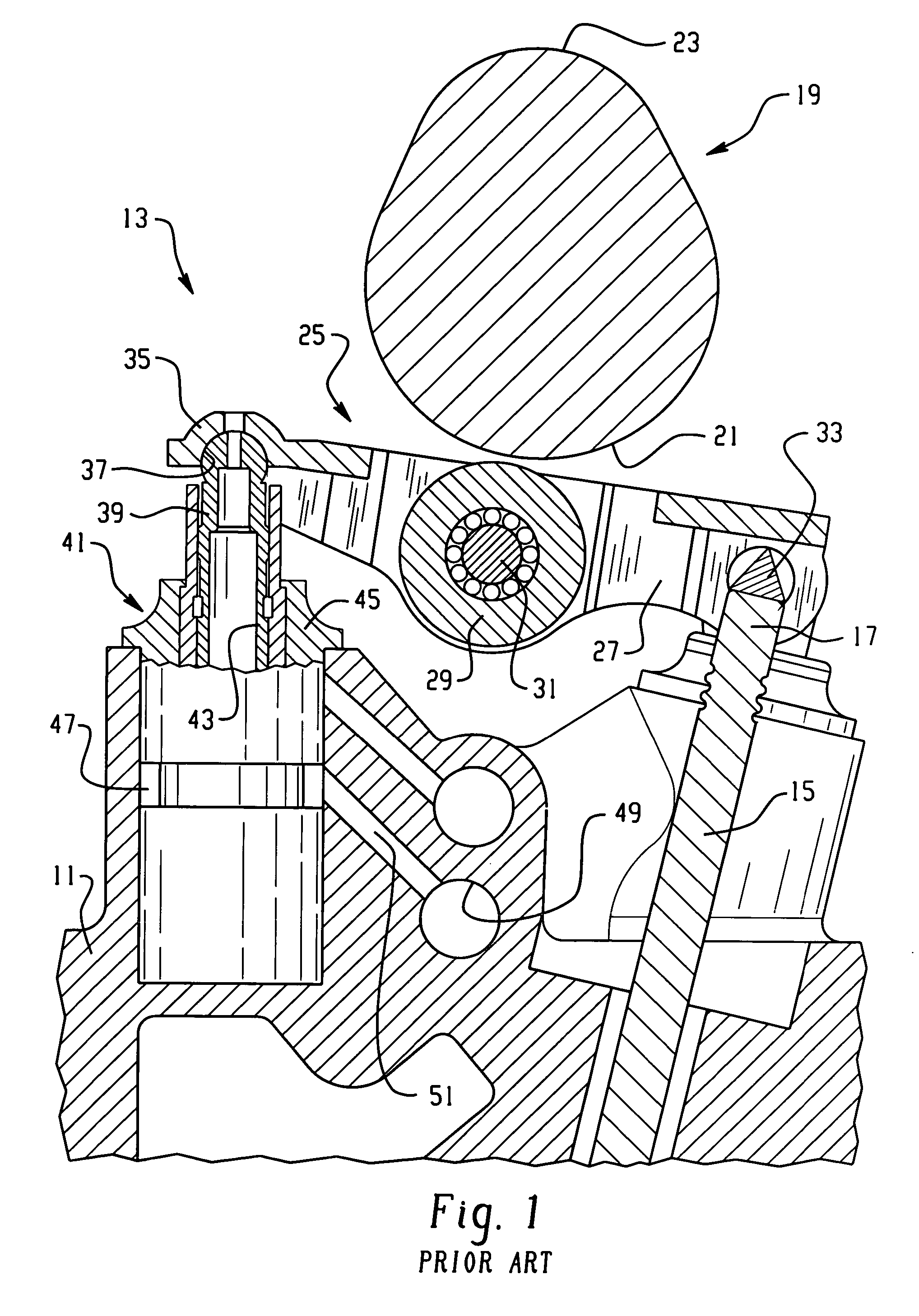

Deactivating roller finger follower

InactiveUS20070039573A1Prevent movementControlling membersValve arrangementsInternal combustion enginePiston

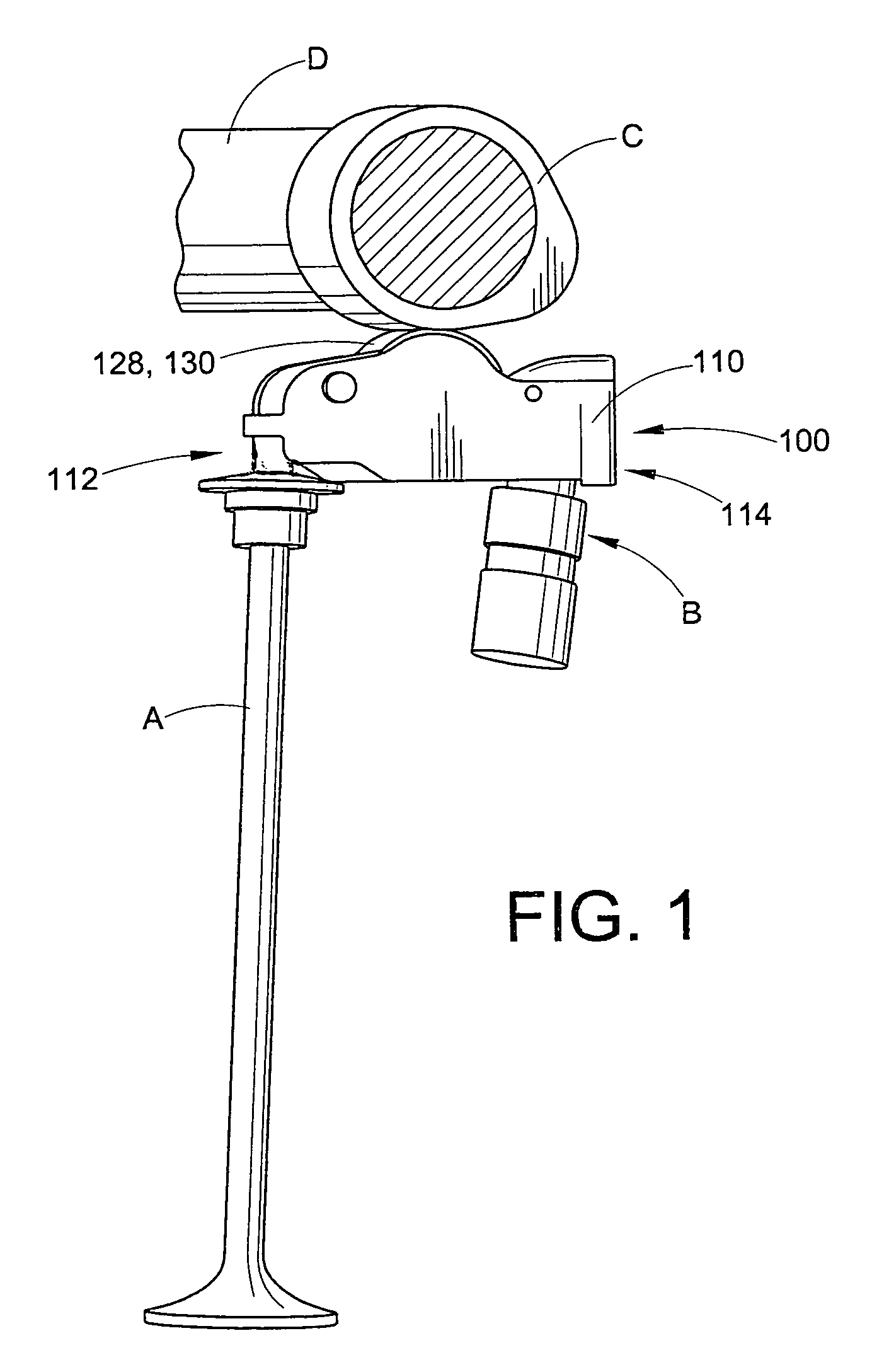

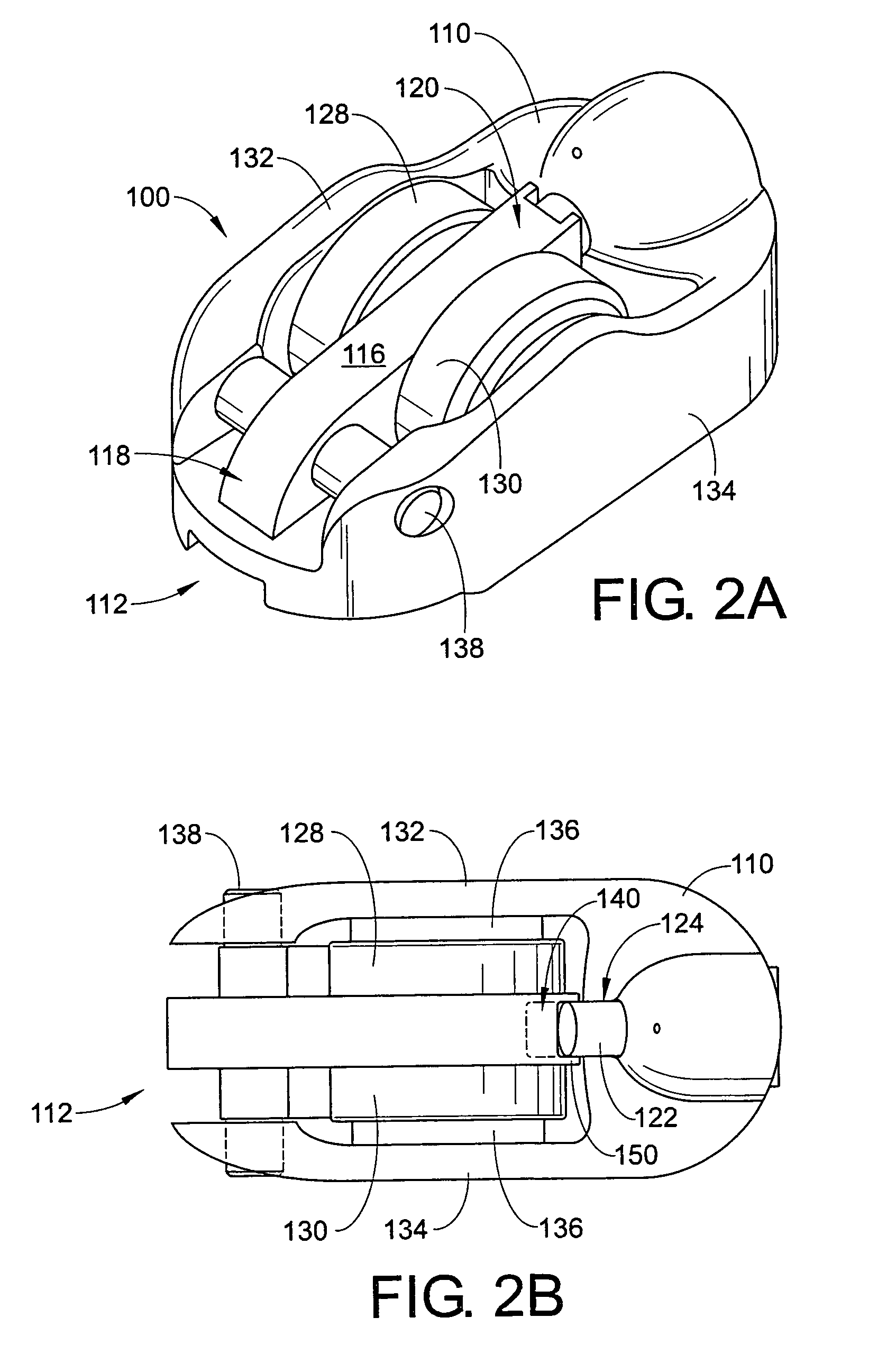

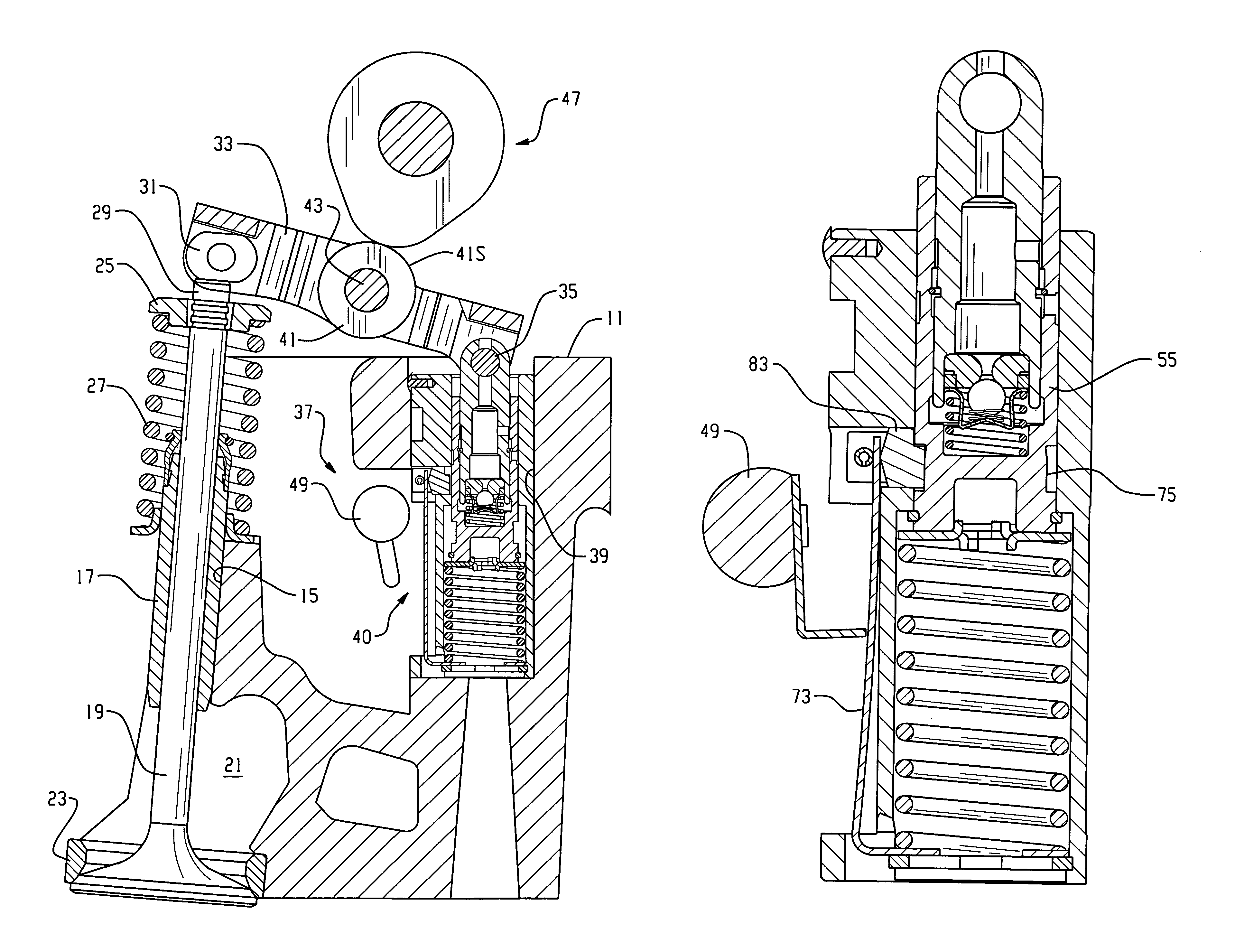

A deactivating roller follower assembly for deactivating an associated poppet valve for an internal combustion engine includes a body including a valve end, a pivot end, and a plunger bore. The valve end of the body is configured to contact the associated poppet valve and the pivot end of the body is configured to contact a pivot of the associated internal combustion engine. The assembly further includes a pivotable arm including a hinged end and a free end. The hinged end is rotatably mounted to the valve end of the body. The free end includes a curvilinear engaging surface for transmitting a force required to activate the associated poppet valve. In addition, the assembly includes a plunger including a latching end and a piston end. The plunger is disposed in the plunger bore in the pivot end of the body. The plunger moves between an extended position and a retracted position. The latching end of the plunger selectively engages the free end of the arm to place the arm in a latched state, whereby preventing the arm from moving relative to the body. And, the latching end of the plunger selectively disengages the free end of the arm to place the arm in an unlatched state, whereby permitting the arm to move relative to the body.

Owner:KOYO BEARINGS USA

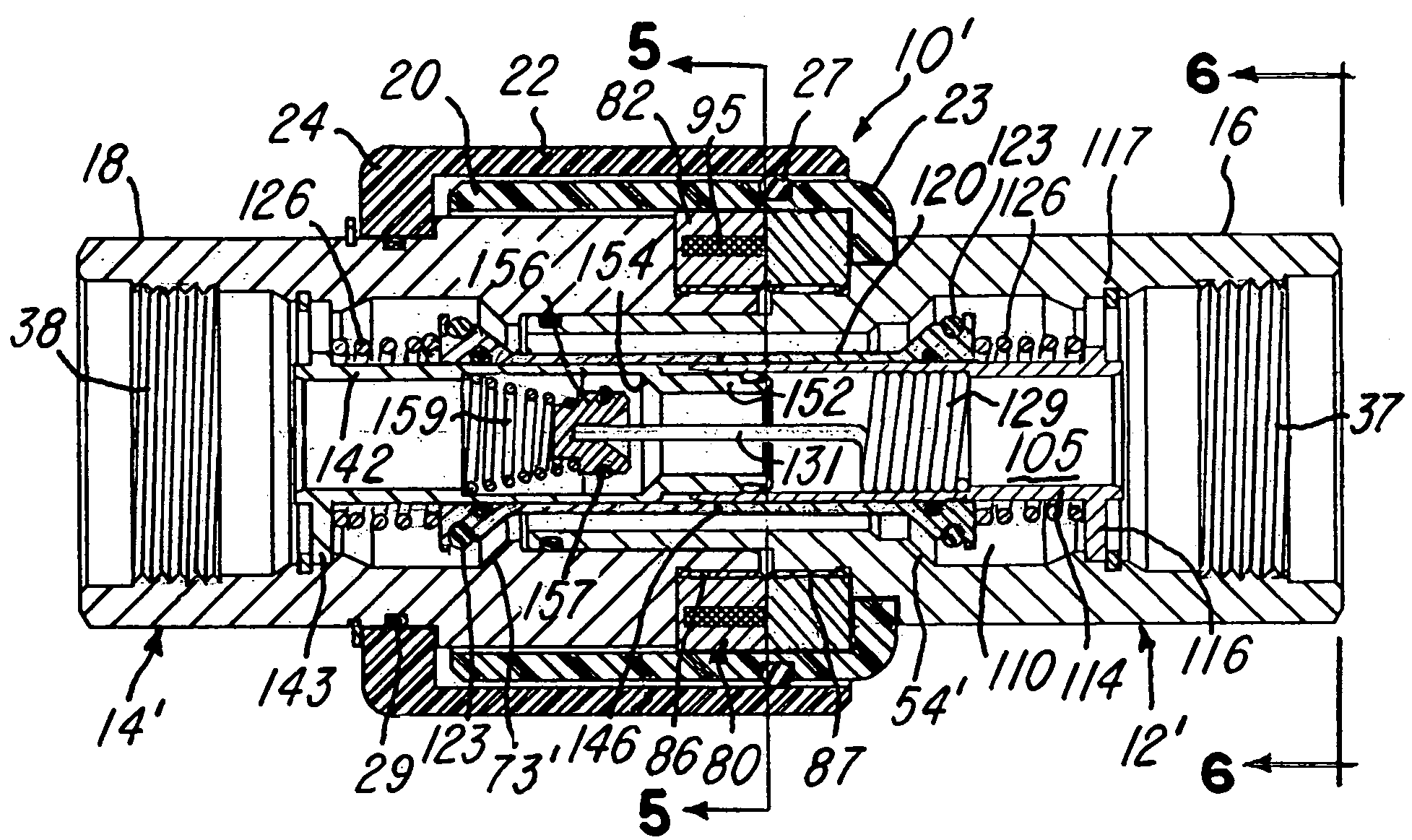

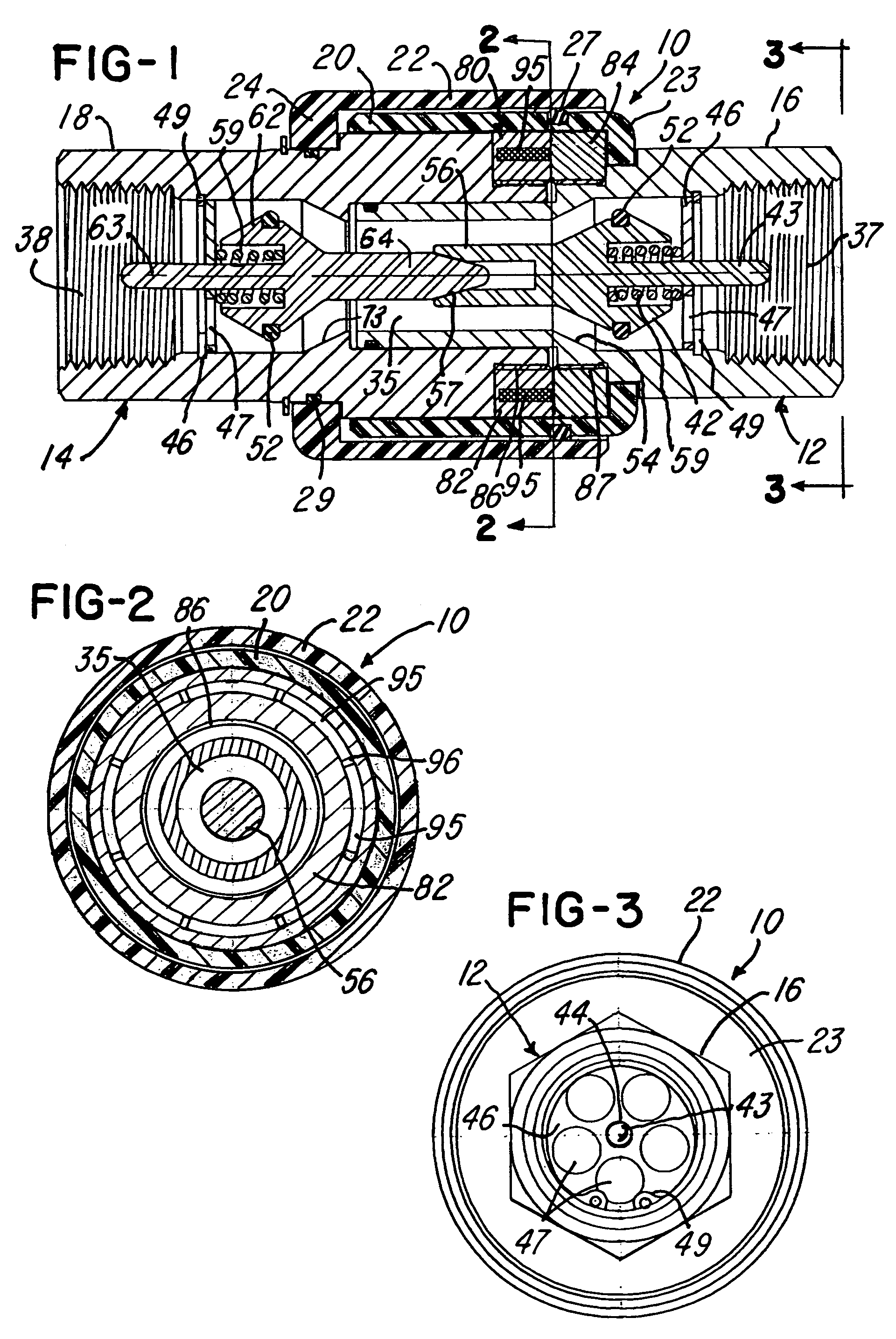

Check valve

A poppet-style check valve for allowing uni-directional flow in a fluid conducting system. The check valve comprises a valve body, and a poppet mounted therein for reciprocal axial movement between a first position in which the poppet is pressed against a valve seat restricting flow through the check valve, and a second position in which the poppet is spaced from the valve seat permitting flow through the check valve. An inner bore of the valve body is expanded in the area of the poppet to maximize flow through the check valve, and the external dimensions of the check valve are minimized by eliminating a conventional liner between the poppet and the valve body. Additionally, the elements of the valve mechanism are designed such that they lock in place within the valve body during assembly.

Owner:CAMBRIDGE BRASS

Pool vacuum

ActiveUS20080109972A1Impairs visibilityDrain fastCleaning filter meansSuction filtersImpellerEngineering

An improved pool vacuum includes a filter cone and poppet valve combination which enables quick drainage of water which has passed through and been cleaned by the cleaner's filter. A charging circuit is provided with isolation so that the pool vacuum can be used in an electrolytic environment without battery drainage. A combination charger and hang bracket enables the pool vacuum to be stored in a vertical position to both drain and charge simultaneously. An interstitial open exhaust gap between a rear body and nose-cone shaped front section provides a low pressure drop free exhaust area for an impeller. An optionally obstructed bottom gap portion helps to produce a net downward thrust to assist in using the vacuum in deep pools from a long pole structure.

Owner:WATERTECH

Deactivating roller finger follower

Owner:KOYO BEARINGS USA

Pressure balanced spool poppet valves with printed actuator coils

InactiveUS20070113906A1Operating means/releasing devices for valvesServomotor componentsSpool valveEngineering

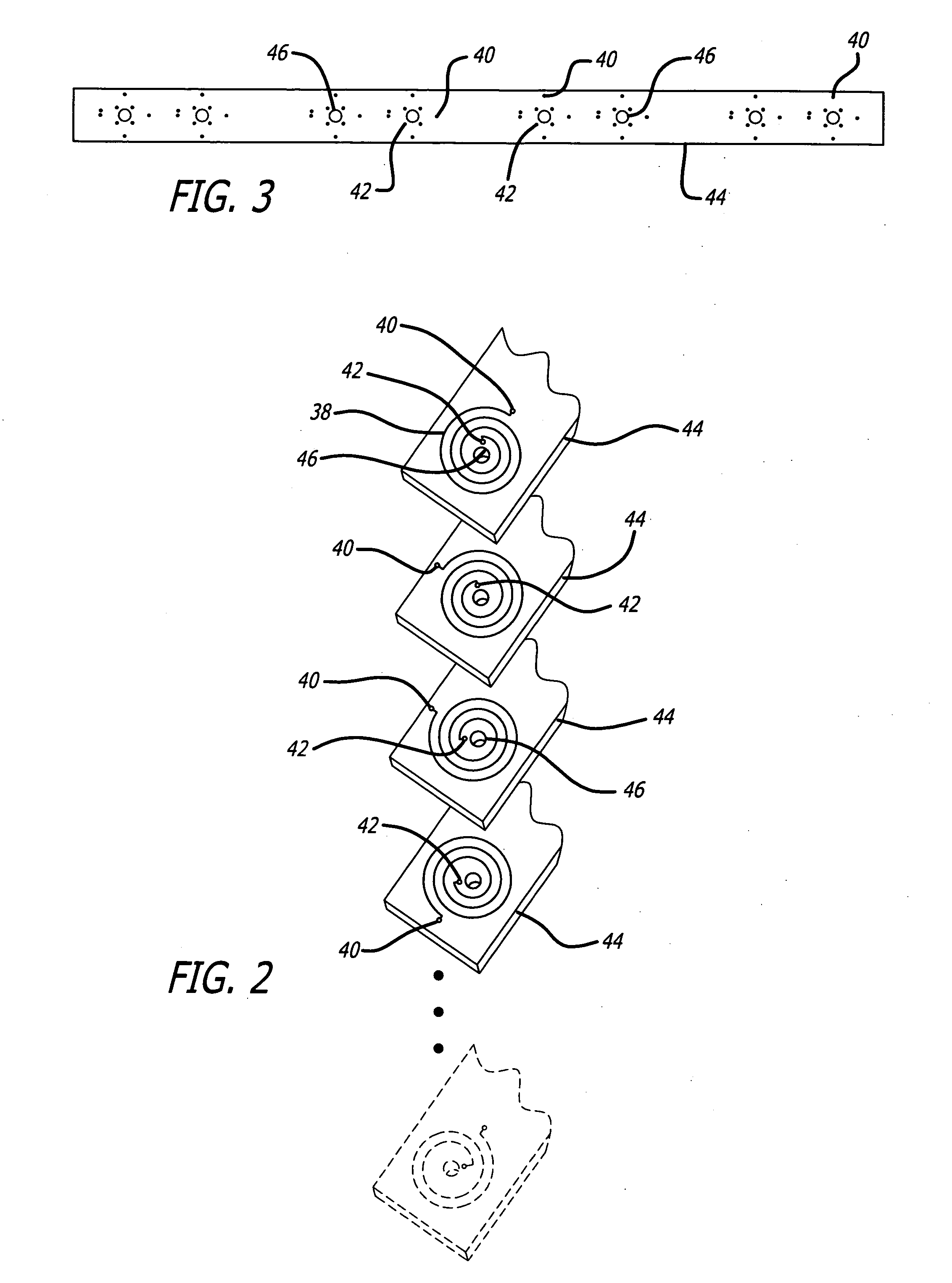

Pressure balanced spool poppet valves with printed actuator coils minimize valve leakage and facilitate efficient manufacturing and reliable operation. The spool poppet valves may be configured like a conventional spool valve, but further include a poppet valve at one end of the spool to proved much better sealing when the poppet valve is closed. Various features are disclosed, including pressure balancing for high pressure operation. The printed actuator coils for the spool poppet valves are formed by the interconnection of conductive coils on each of multiple layers of a multiple layer printed circuit board, which circuit board may have a hole there through for accommodation of mechanical and / or magnet requirements, and may include similar printed actuator coils for one or more additional spool poppet valves as well as electronic devices associated with the operation thereof. The spool poppet valves may be advantageously constructed without printed actuator coils, and the printed actuator coils may be advantageously used in actuators of other designs.

Owner:STURMAN DIGITAL SYST

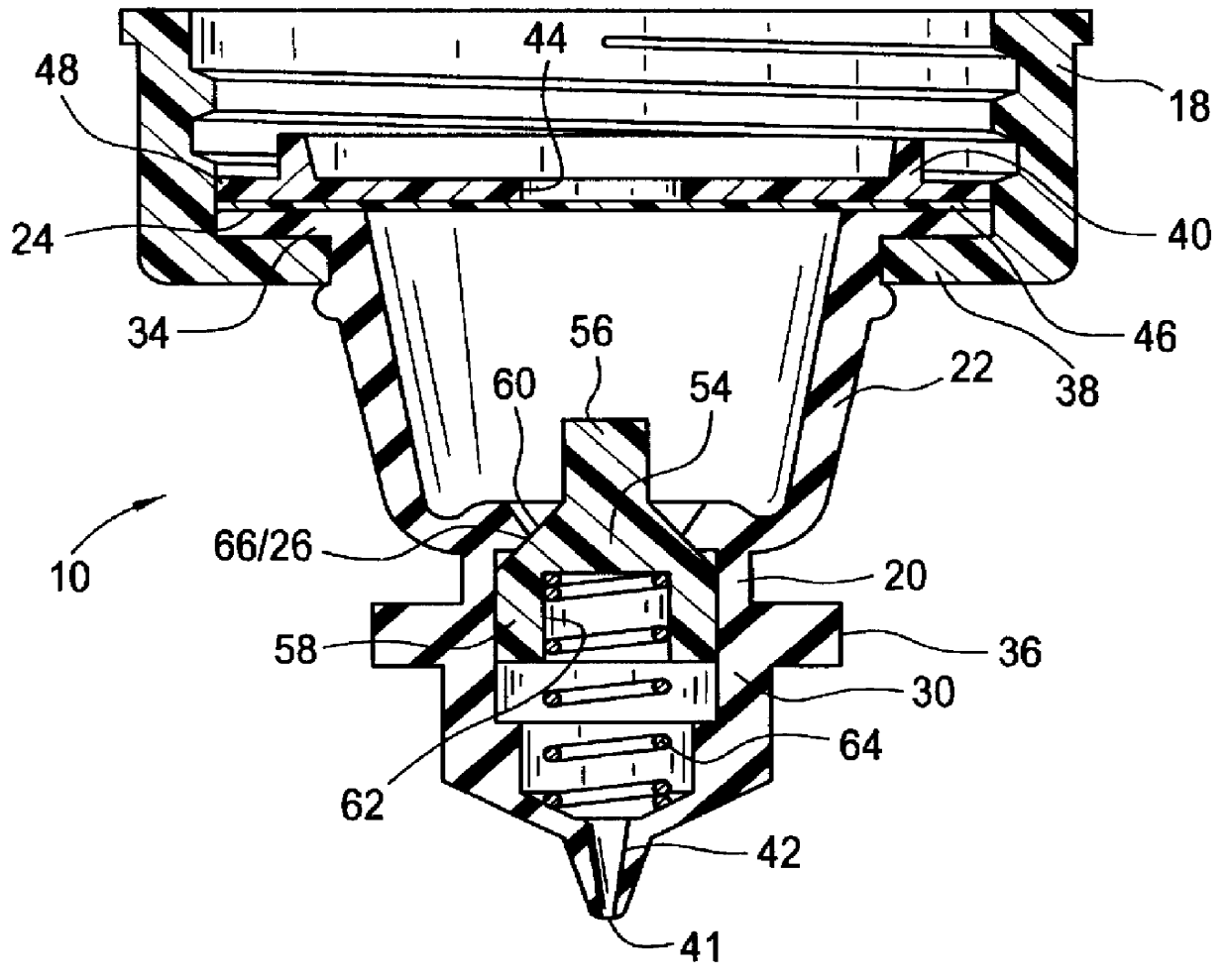

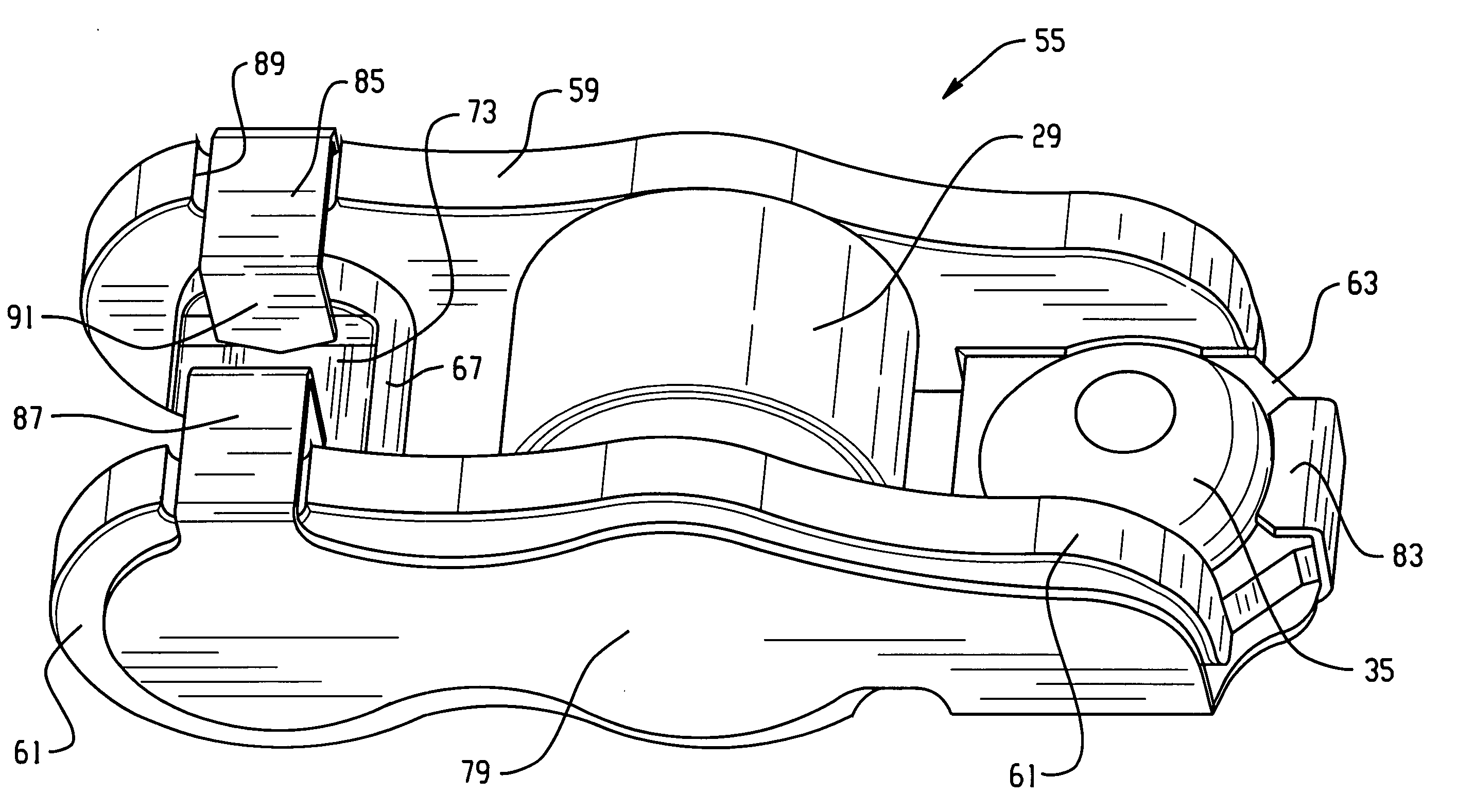

Valve deactivation system and improved latchable HLA therefor

ActiveUS7159551B2Improve performanceValve arrangementsInternal combustion piston enginesControl systemReciprocating motion

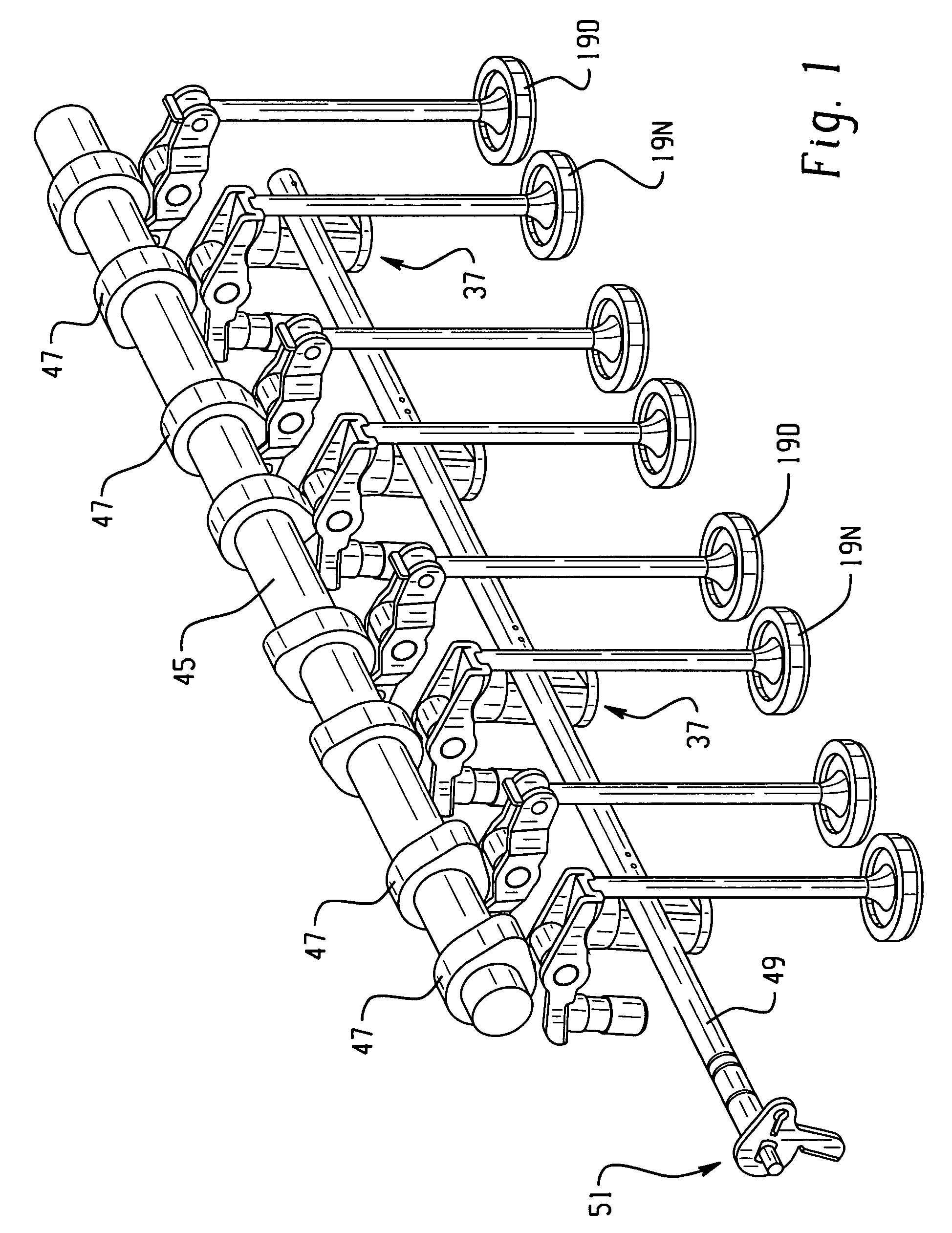

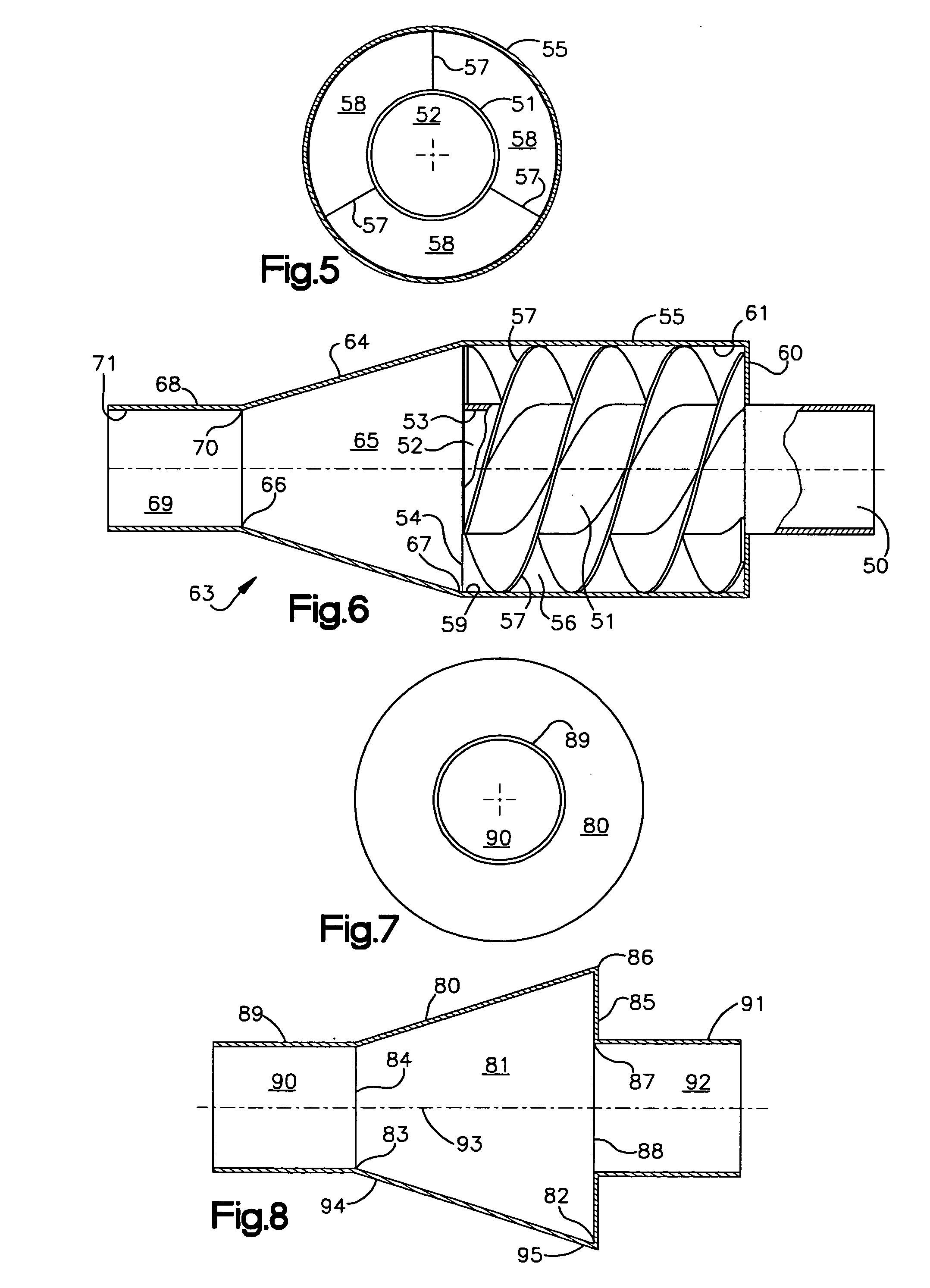

A deactivating valve control system for an internal combustion engine and, for each deactivating intake poppet valve (19D), there is provided a deactivating lash compensation device (37). Each of the devices (37) includes a latch member (83) biased toward an unlatched condition (FIG. 3) by a spring member 69, including a vertically-extending spring portion (73). In one embodiment (FIG. 1), the deactivation system includes an actuation rod (49) which is rotated to overcome the biasing force of the spring members (69) and move the latch members (83) into latching engagement (FIG. 5). In another embodiment (FIG. 7), an actuation wire (105) is reciprocated linearly to pivot a lever member (99) associated with each deactivating device (37), again to overcome the spring (69) and move the latch member (83) into latching engagement.

Owner:EATON INTELLIGENT POWER LTD

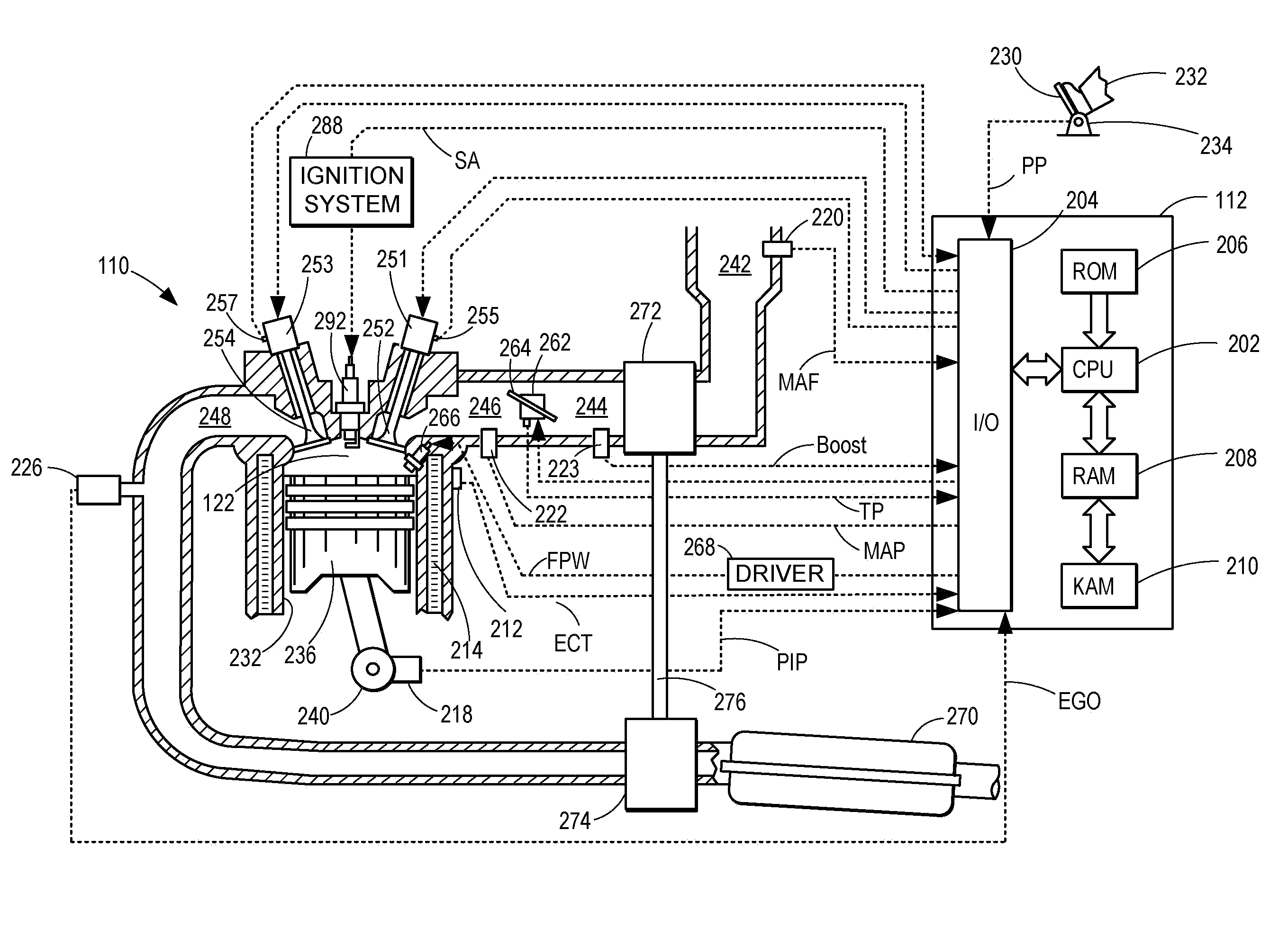

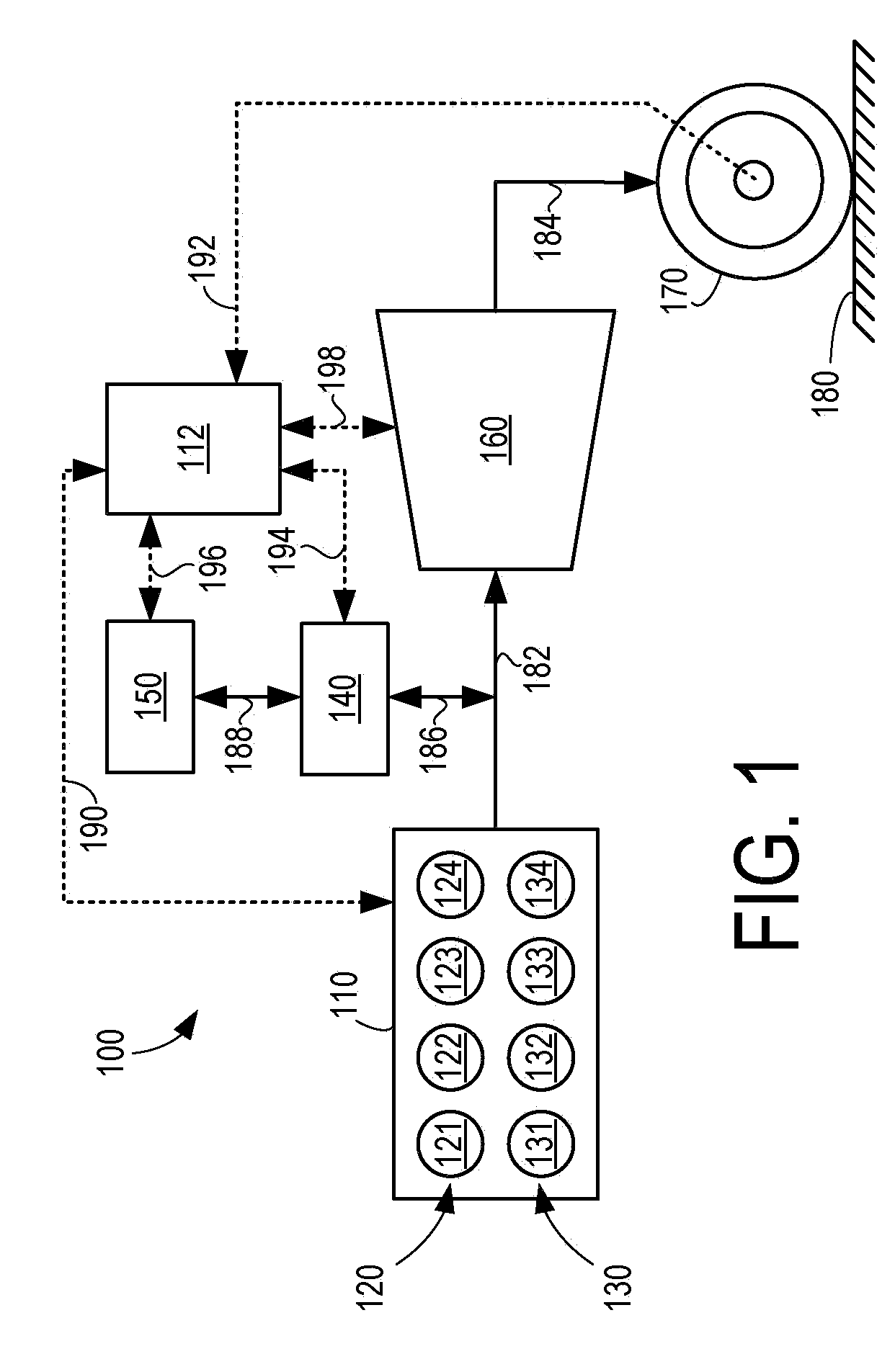

Control strategy for multi-stroke engine system

ActiveUS20090277434A1Improve engine efficiencyHigh outputElectrical controlInternal combustion piston enginesFour-stroke enginePoppet valve

An engine system and a method of operation are described. As one example, the method may include: during a first operating condition, operating a cylinder of the engine in a two stroke cycle to combust a first mixture of air and fuel, and adjusting an opening overlap between an intake poppet valve and an exhaust poppet valve of the cylinder to vary a composition of exhaust gases exhausted by the cylinder via the exhaust poppet valve; and during a second operating condition, operating a cylinder of the engine in a four stroke cycle to combust a second mixture of air and fuel, and adjusting a relative amount of fuel contained in the second mixture of air and fuel to vary the composition of exhaust gases exhausted by the cylinder via the exhaust poppet valve.

Owner:FORD GLOBAL TECH LLC

Extended stroke valve and diaphragm

ActiveUS7063304B2Extended service lifeHigh strengthDiaphragm valvesOperating means/releasing devices for valvesMaterial DesignEngineering

An extended stroke poppet valve particularly suited for handling caustic fluids and having features enabling an extended service life for the valve. The valve includes a two part primary diaphragm assembly with a wetted diaphragm made from highly fatigue resistant fluoropolymer material, and a diaphragm backer made from high strength fluoropolymer material designed to withstand the high stress loads imposed by an extended valve stroke. The combination of these two layers in a single primary diaphragm assembly yields a highly durable, caustic chemical resistant, diaphragm capable of use in a long stroke poppet valve and having a relatively long service life.

Owner:ENTEGRIS INC

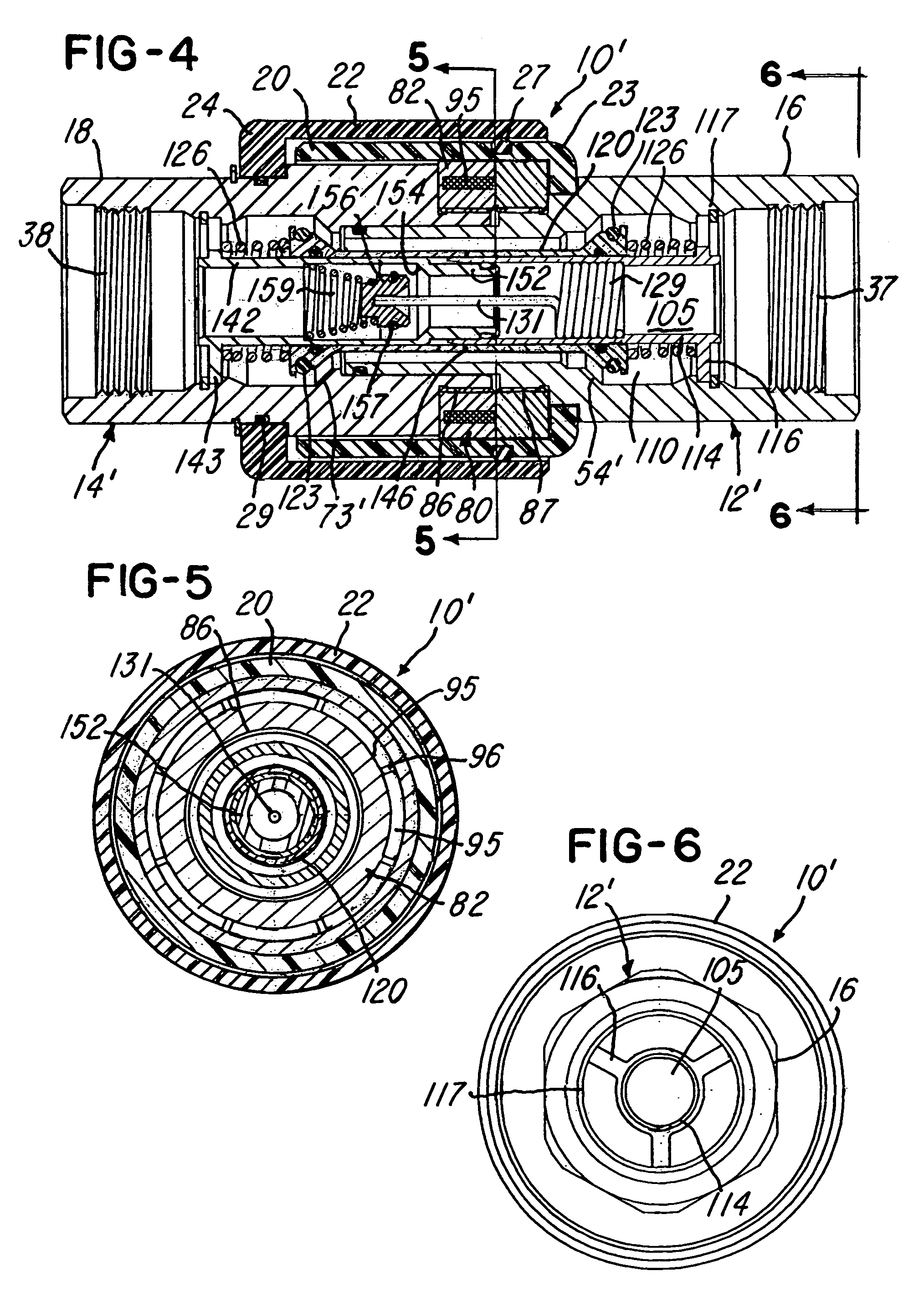

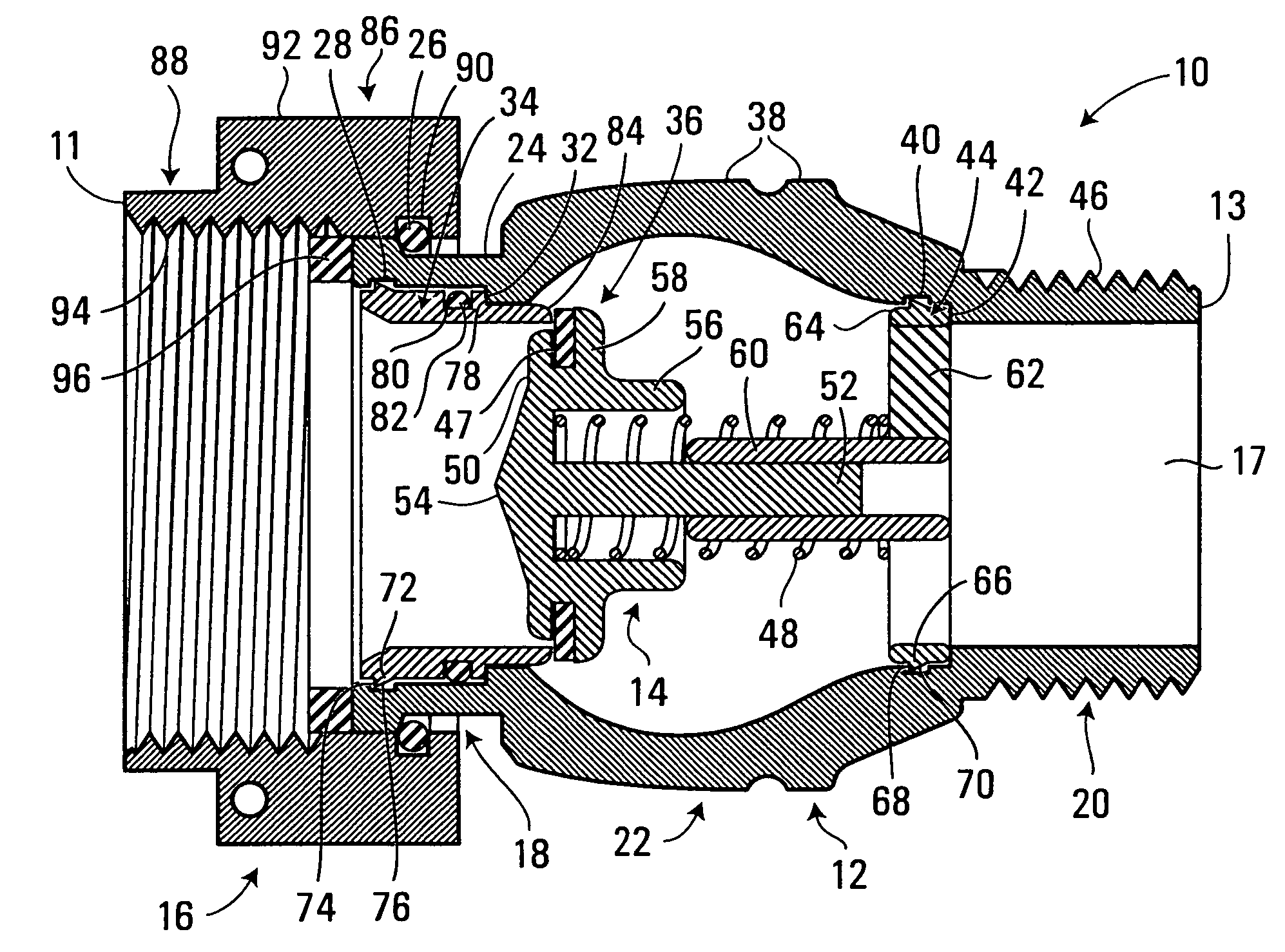

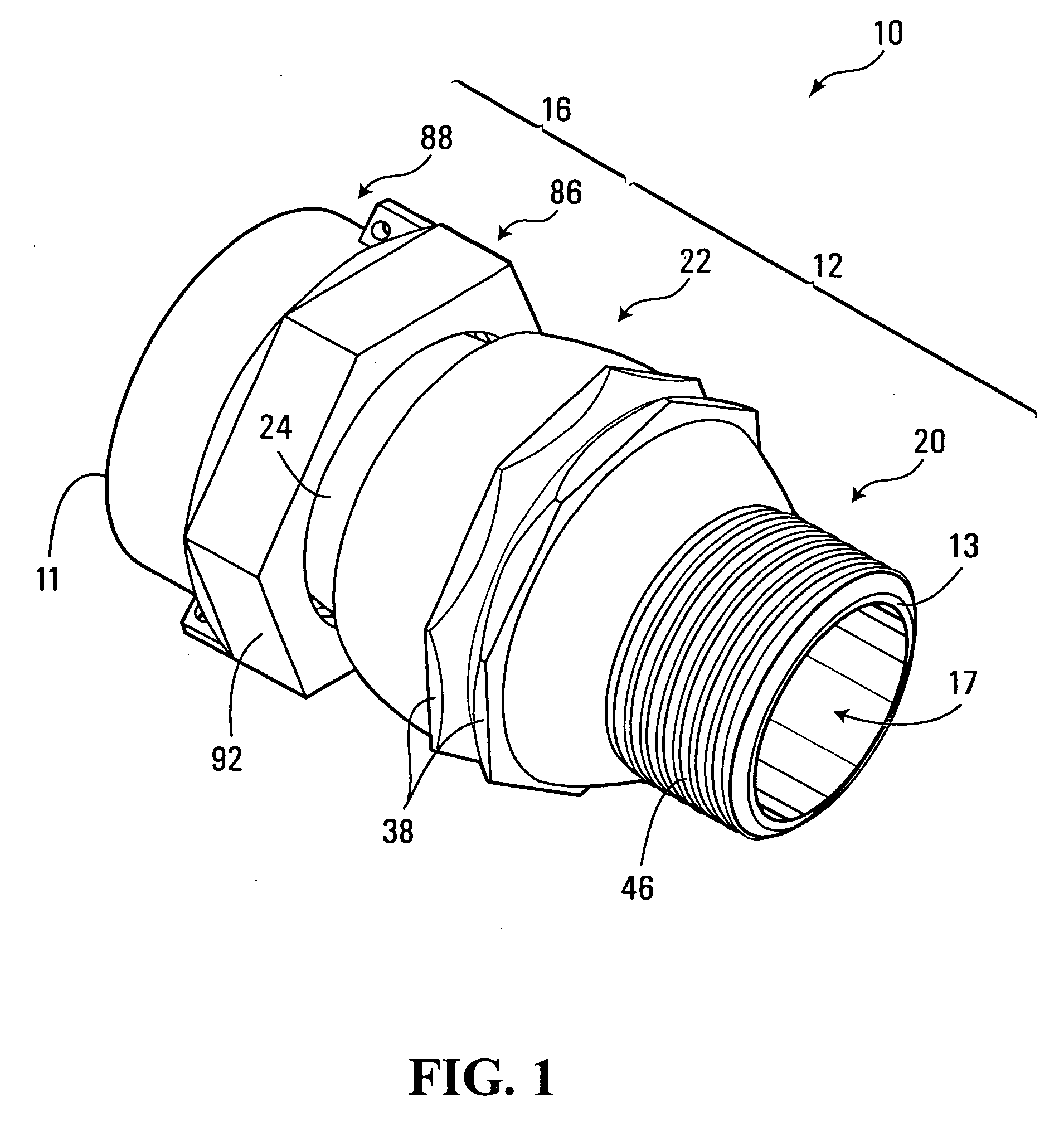

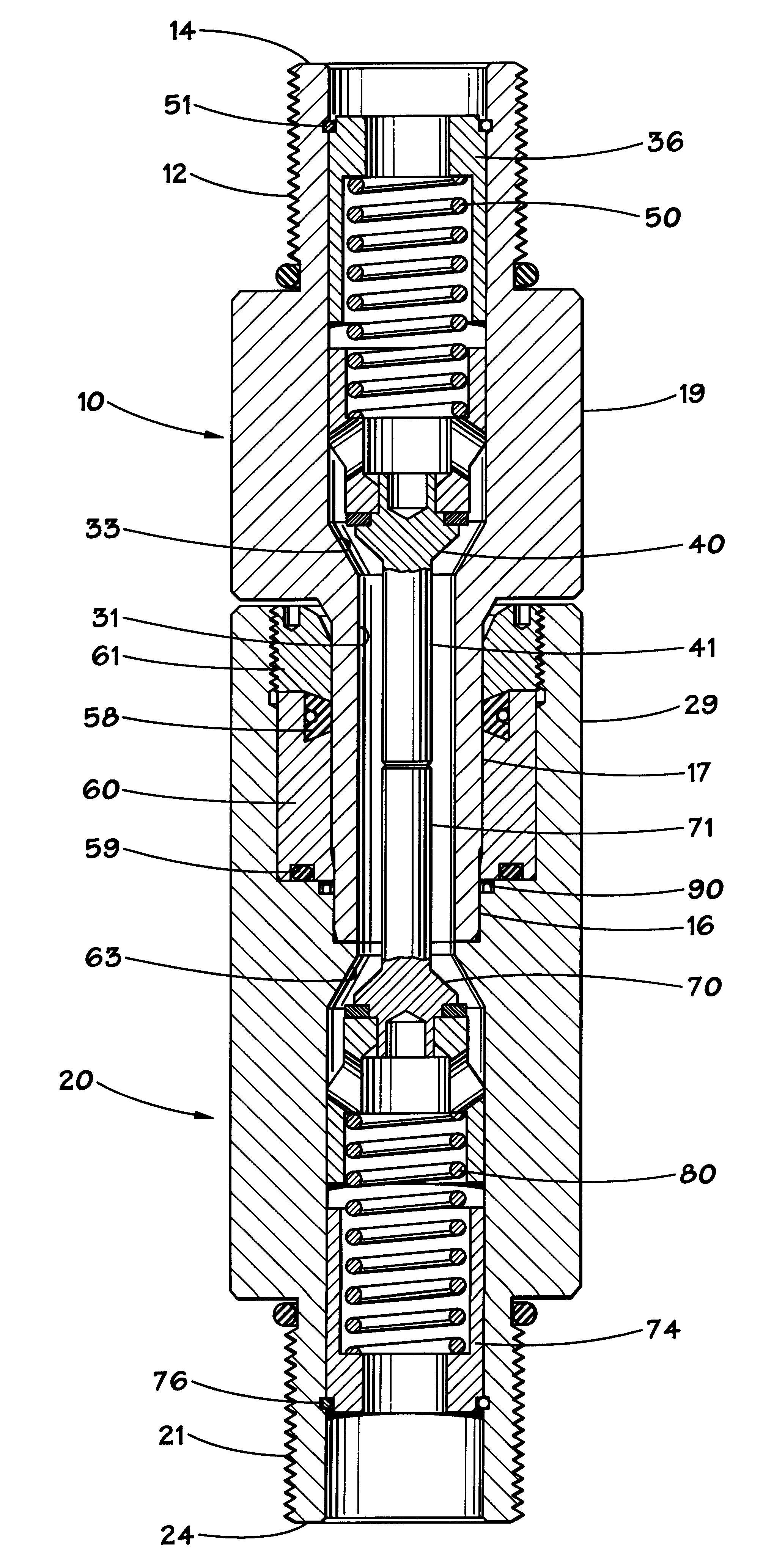

Undersea hydraulic coupling

An undersea hydraulic coupling having a stepped internal bore dimensioned to increase the flow rate through the coupling is disclosed. The coupling allows an increased flow rate without increasing the size or weight of the coupling, by positioning the poppet valve in the body section, rather than in the probe section, of the male coupling member.

Owner:NAT COUPLING

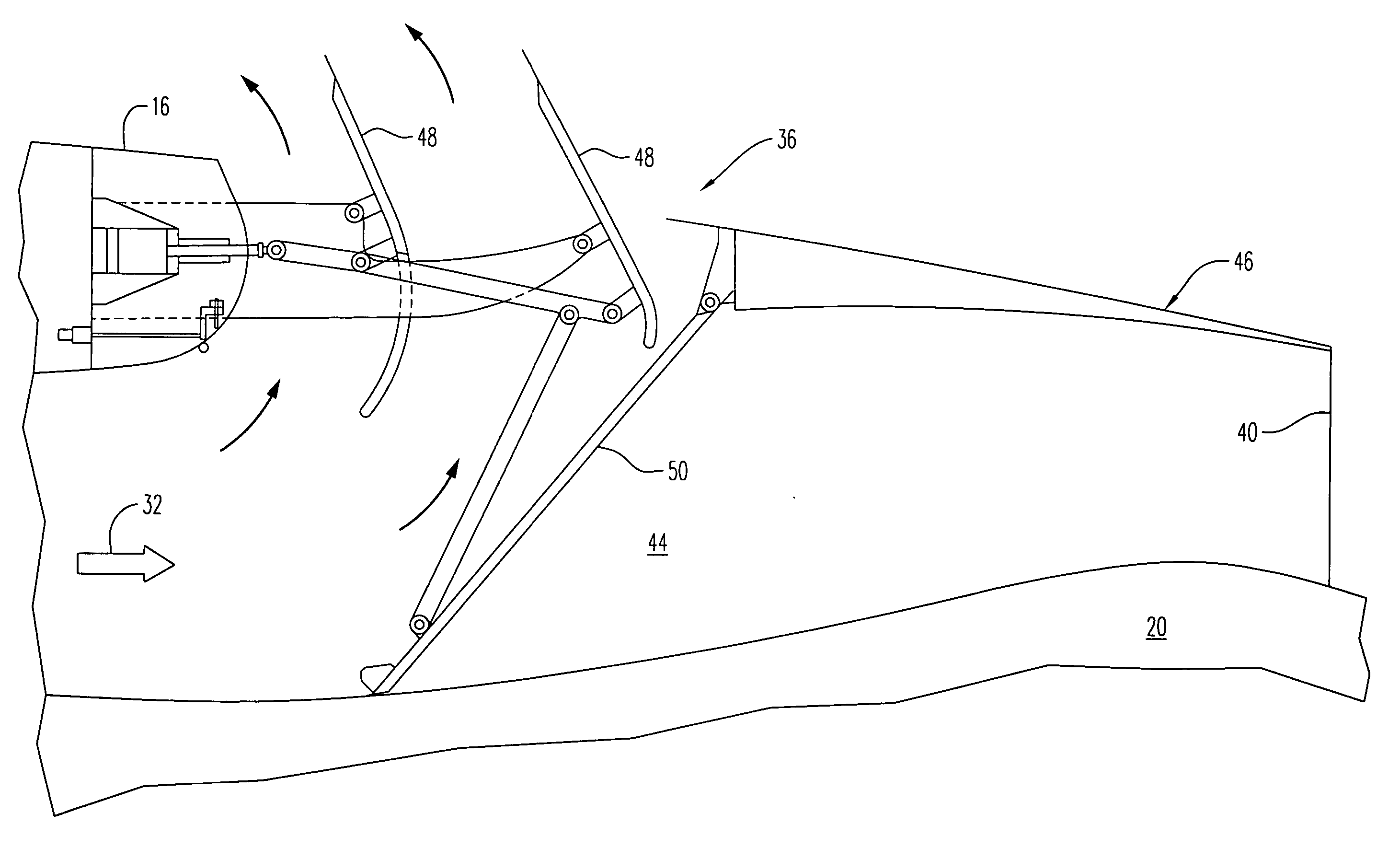

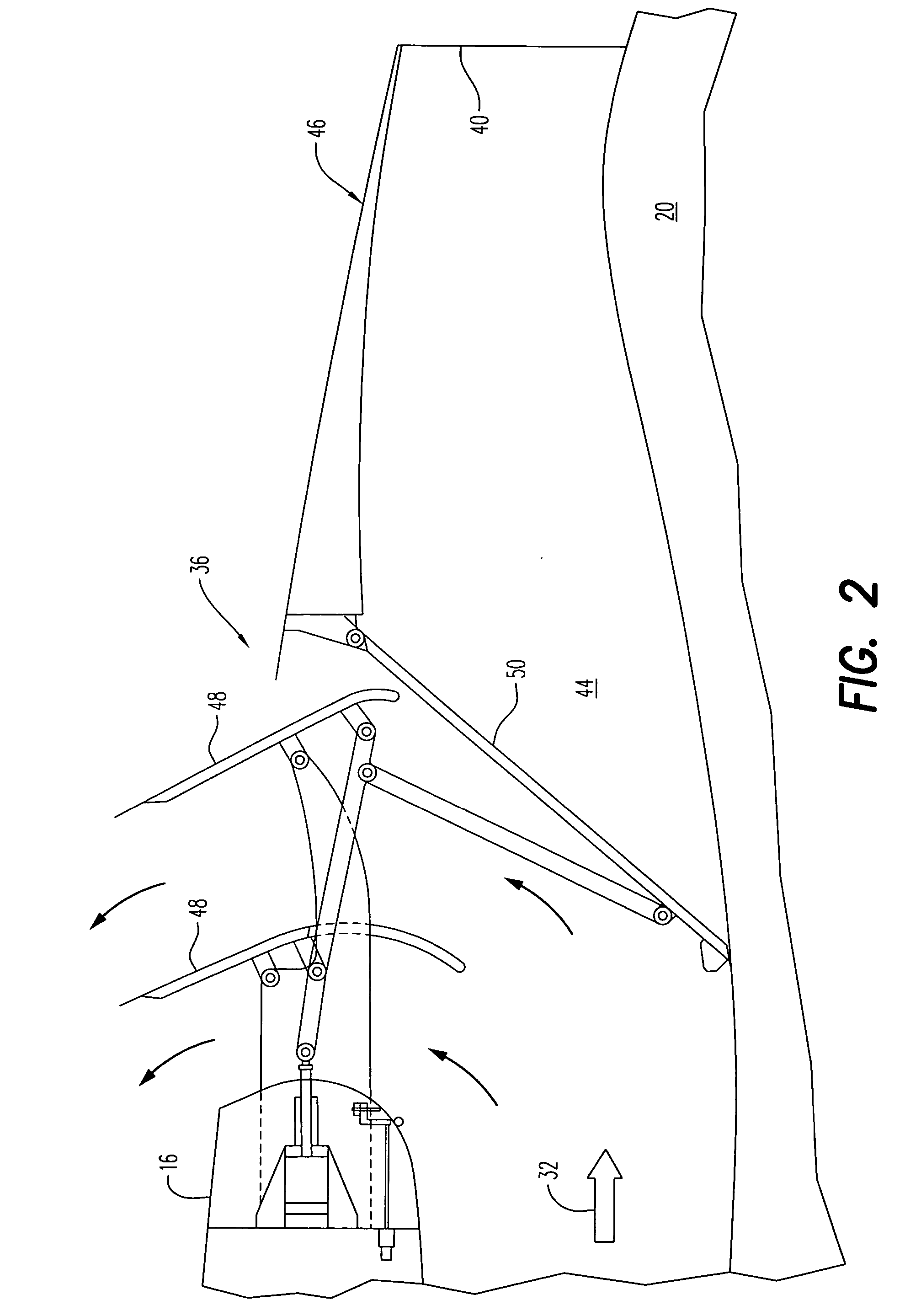

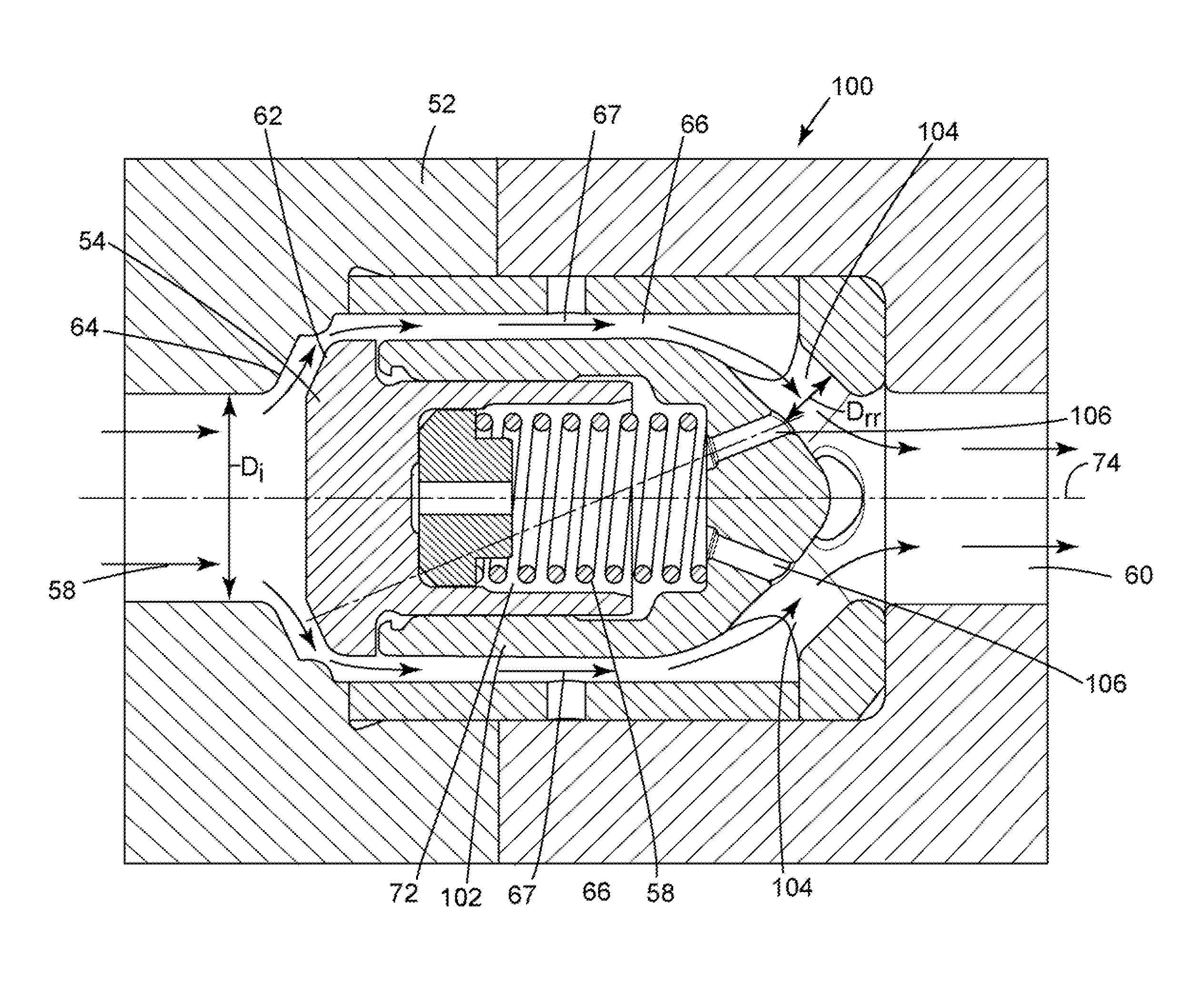

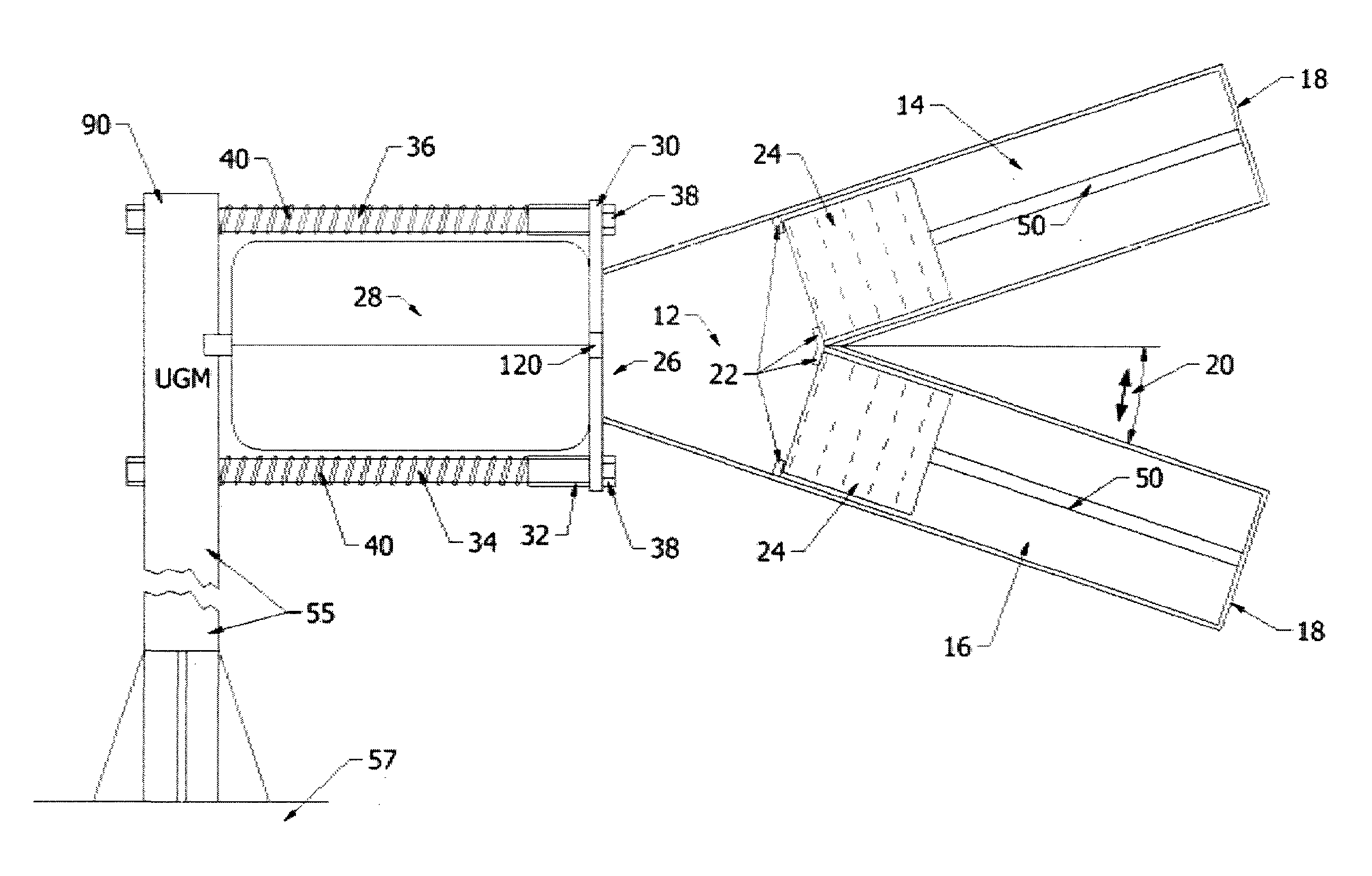

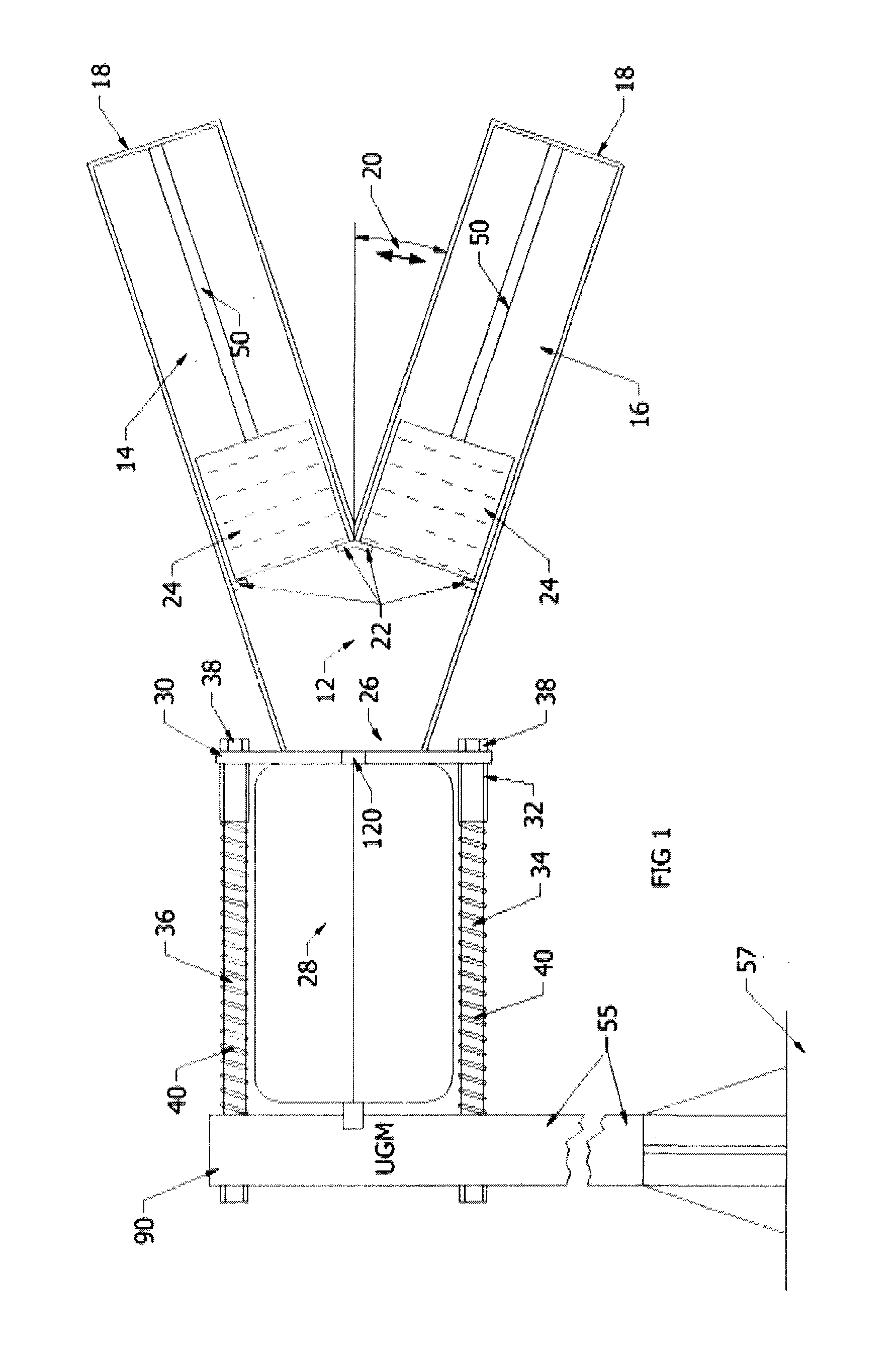

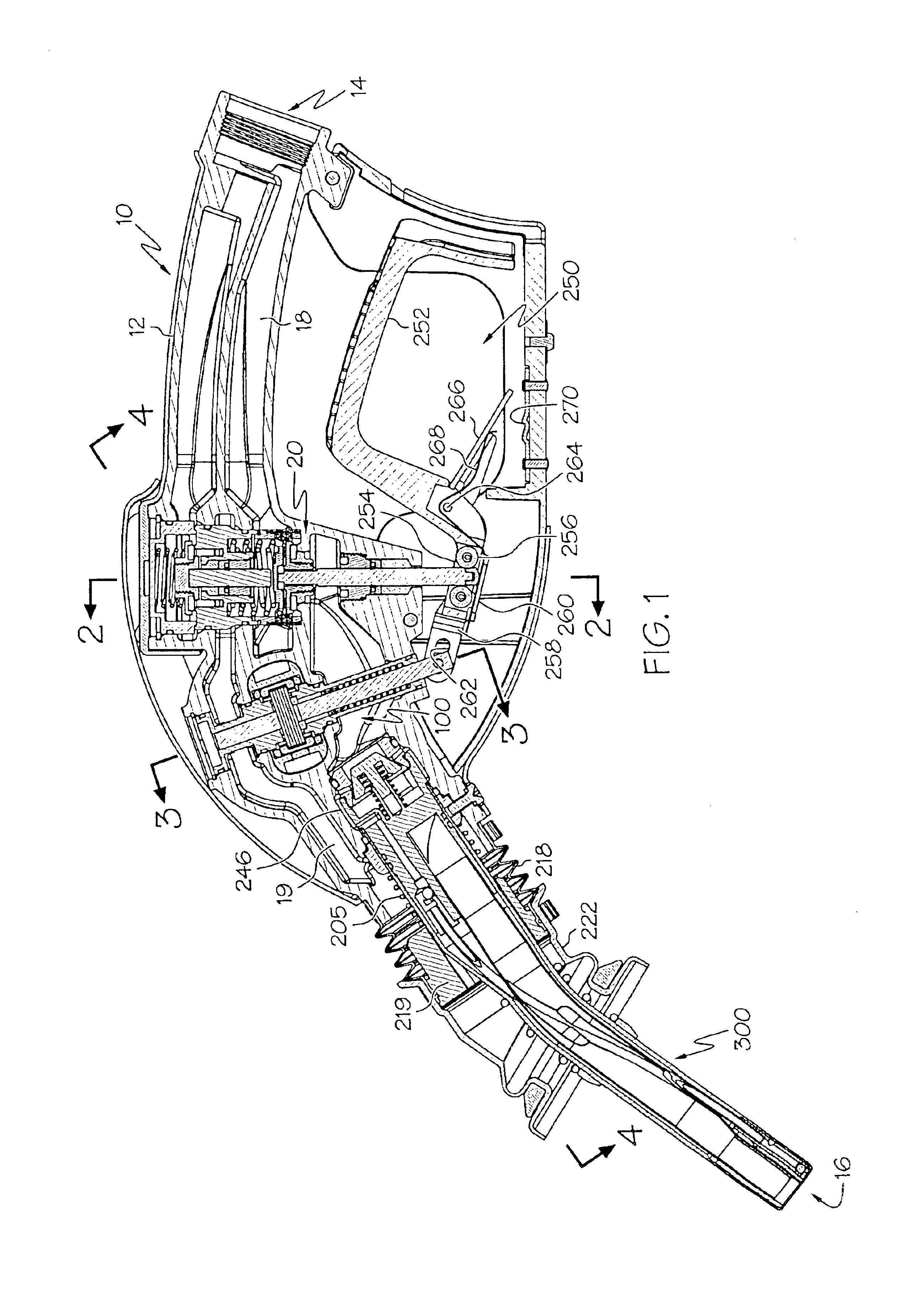

Turbofan core thrust spoiler

A turbofan engine includes a fan driven by a core engine. A surrounding fan nacelle includes a thrust reverser and fan nozzle disposed aft therefrom. A core cowl surrounds the core engine and includes a core nozzle extending aft therefrom. A row of poppet valves extends through the core cowl between the core nozzle and fan nozzle for selectively spoiling thrust from the core nozzle when the reverser is deployed.

Owner:AERONAUTICAL CONCEPT OF EXHAUST

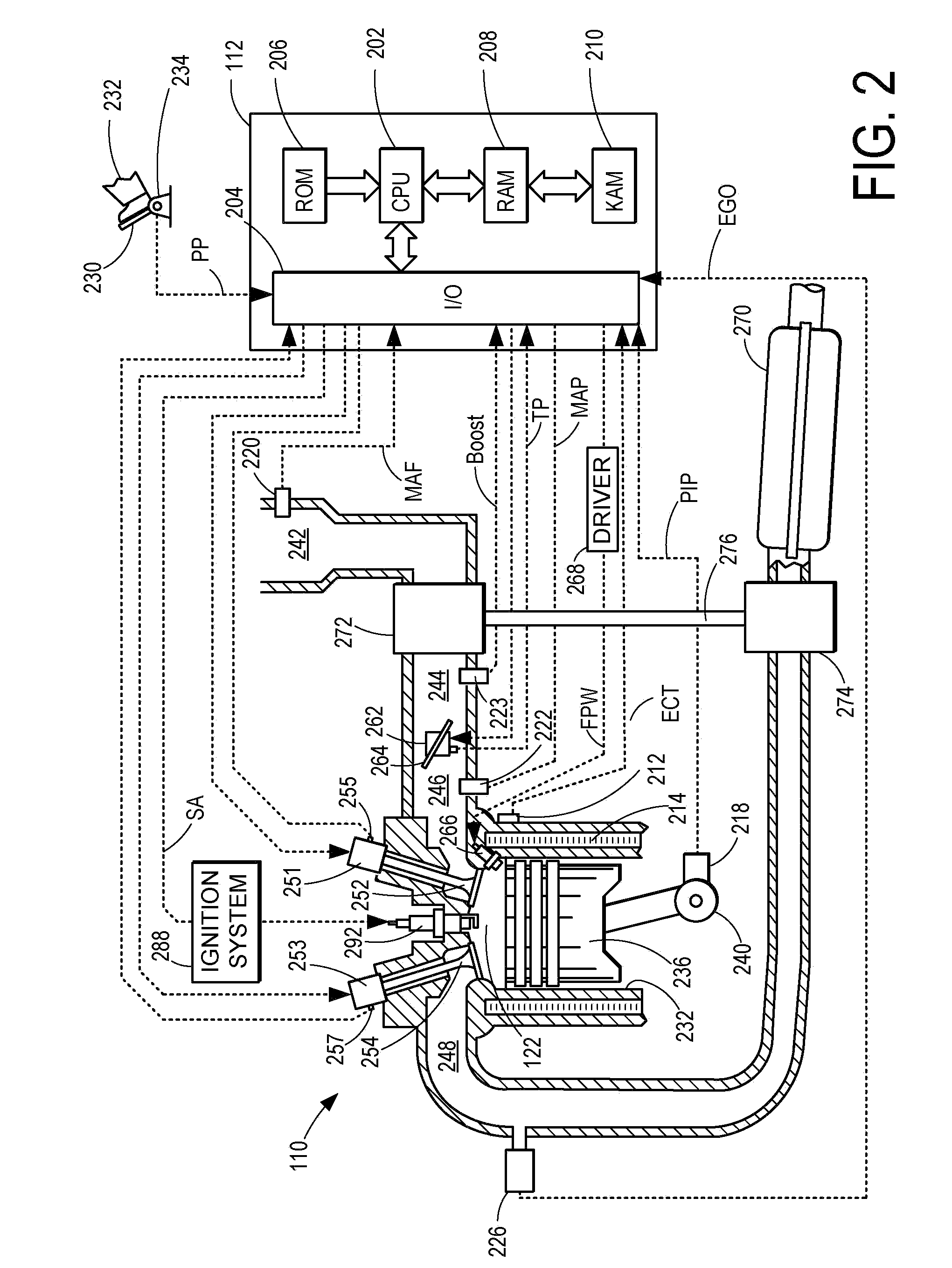

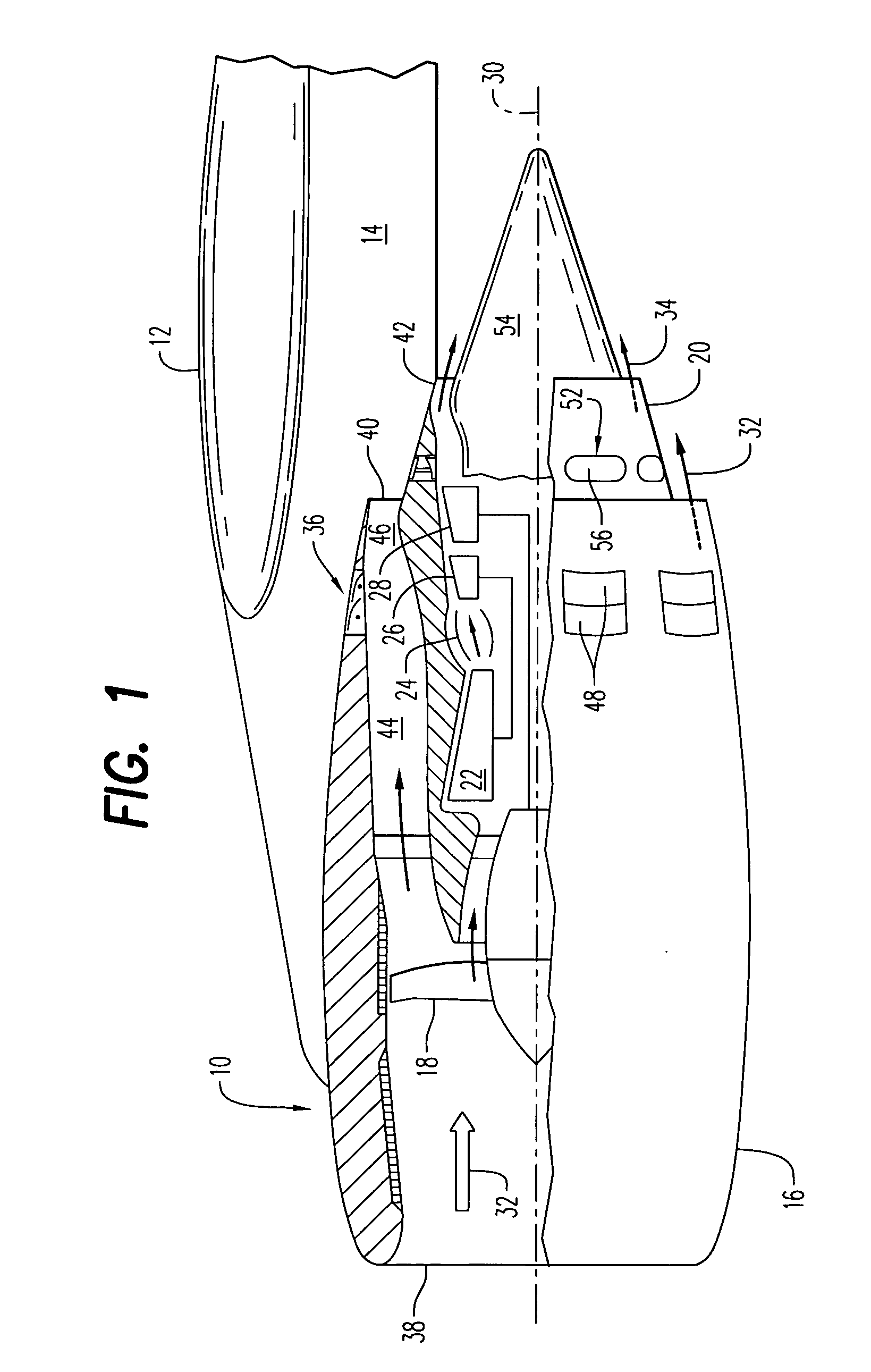

System for variable valvetrain actuation

InactiveUS20070125329A1Simple taskReduce in quantityValve drivesMachines/enginesCylinder headGasoline

An electromechanical VVA system for controlling the poppet valves in the cylinder head of an internal combustion engine. The system varies valve lift, duration, and phasing in a dependent manner for one or more banks of engine valves. A rocker subassembly for each valve or valve pair is pivotably disposed on a control shaft between the camshaft and the roller finger follower. The control shaft may be displaced about a pivot axis outside the control shaft to change the angular relationship of the rocker subassembly to the camshaft, thus changing the valve opening, closing, and lift. A plurality of control shafts for controlling all valvetrains in an engine bank defines a control shaft assembly. The angular positions of the individual control shafts may be tuned to optimize the valve timing of each cylinder. The system is applicable to the intake and exhaust camshafts of diesel and gasoline engines.

Owner:DELPHI TECH IP LTD

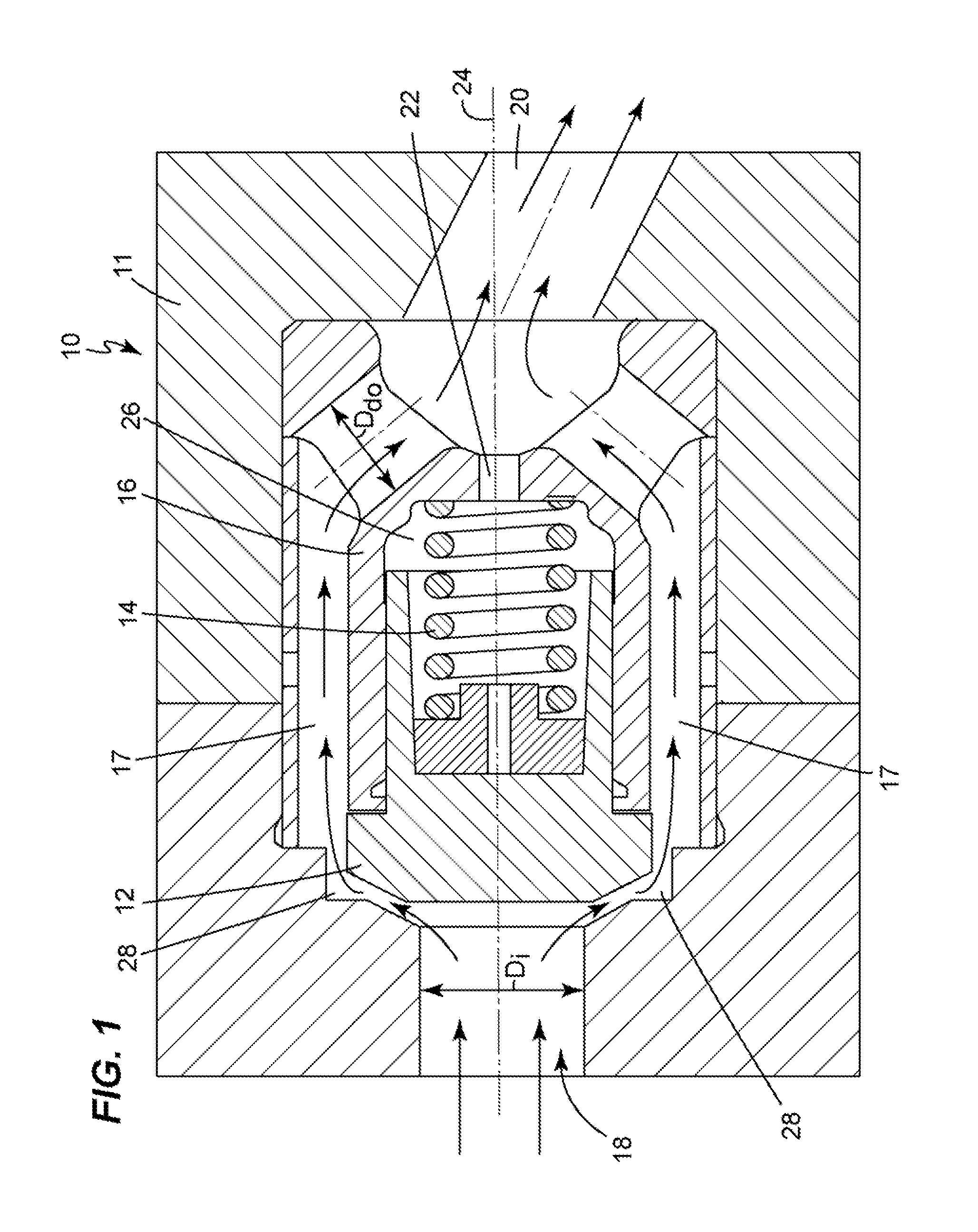

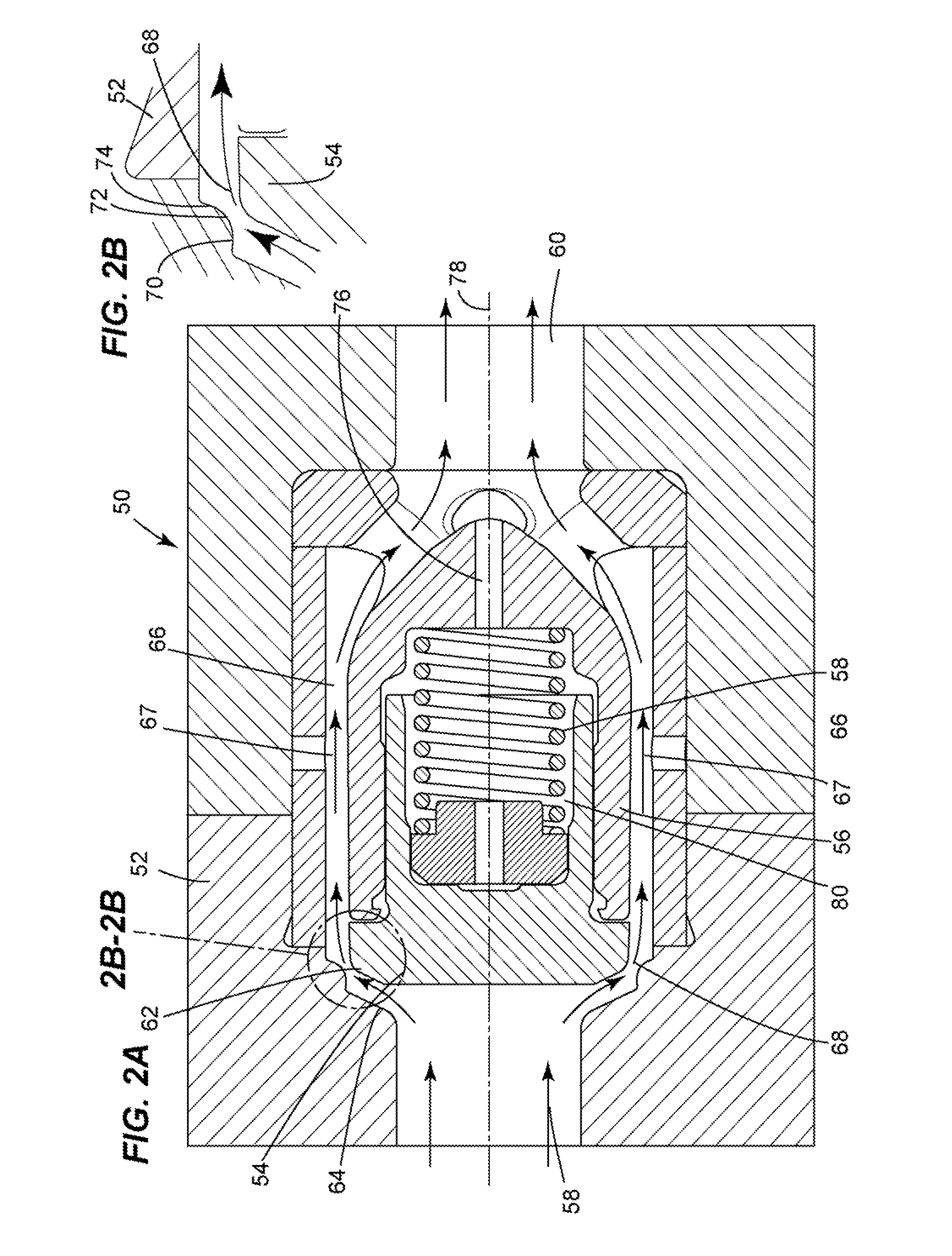

Poppet valve with diverging-converging flow passage and method to reduce total pressure loss

ActiveUS20100024891A1Stabilizing dynamic openingImprove performanceCheck valvesValve members for absorbing fluid energyEngineeringMechanical engineering

A poppet valve is disclosed that include a valve body, a poppet guide disposed inside the valve body so as to form a a flow passage from a flow inlet to a flow outlet of the valve, a poppet shutter disposed inside the poppet guide, and a converging-diverging flow passage formed by a portion of an outer surface of the poppet shutter and a corresponding portion of an inner surface of valve body. A method for reducing a closing pressure force acting on a poppet shutter of a poppet valve is also disclosed.

Owner:NUOVO PIGNONE TECH SRL

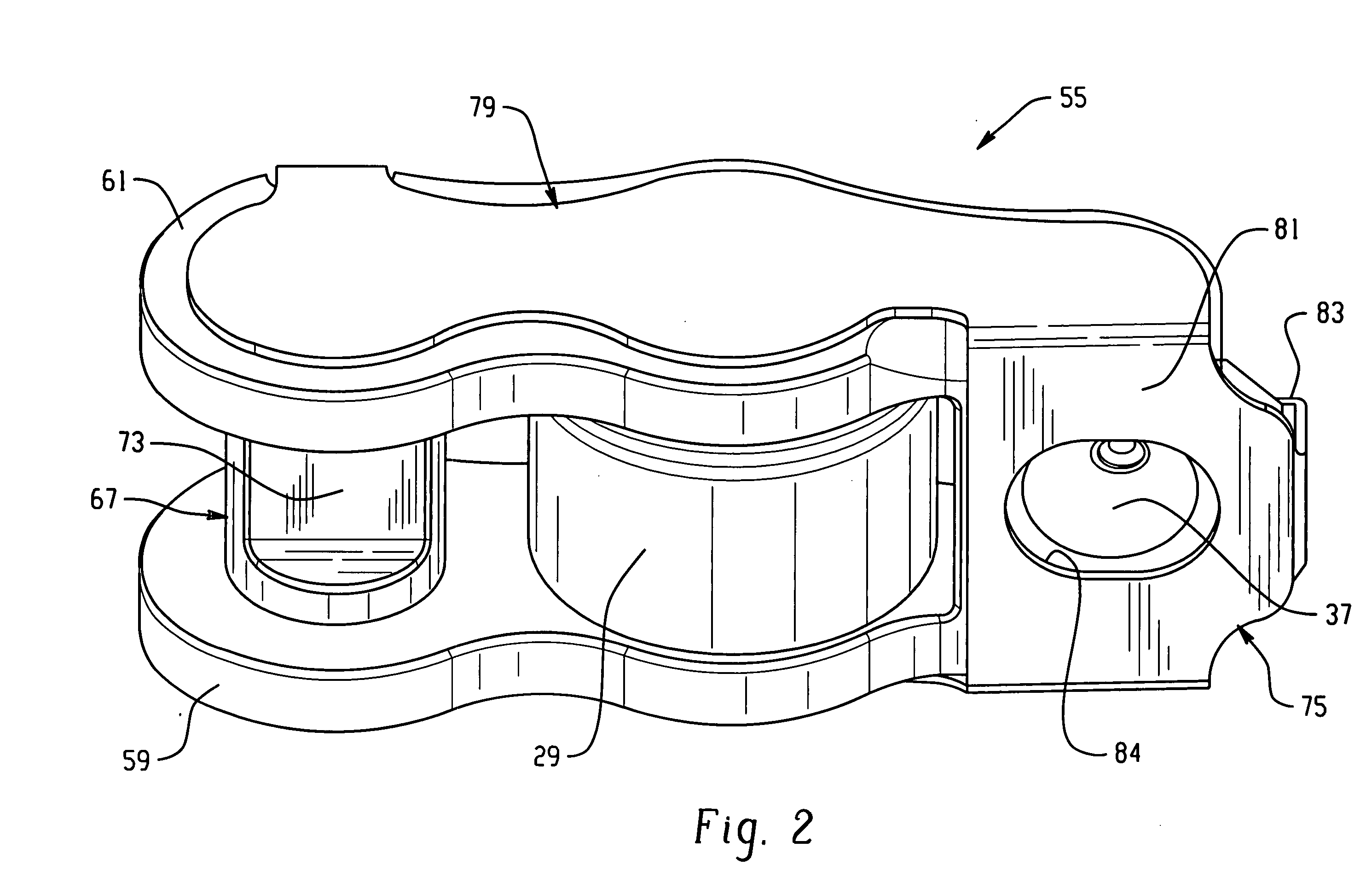

Valve guide for rocker arm assembly

ActiveUS20050016480A1Shorten assembly timeLow costValve arrangementsCam-followersControl systemCylinder head

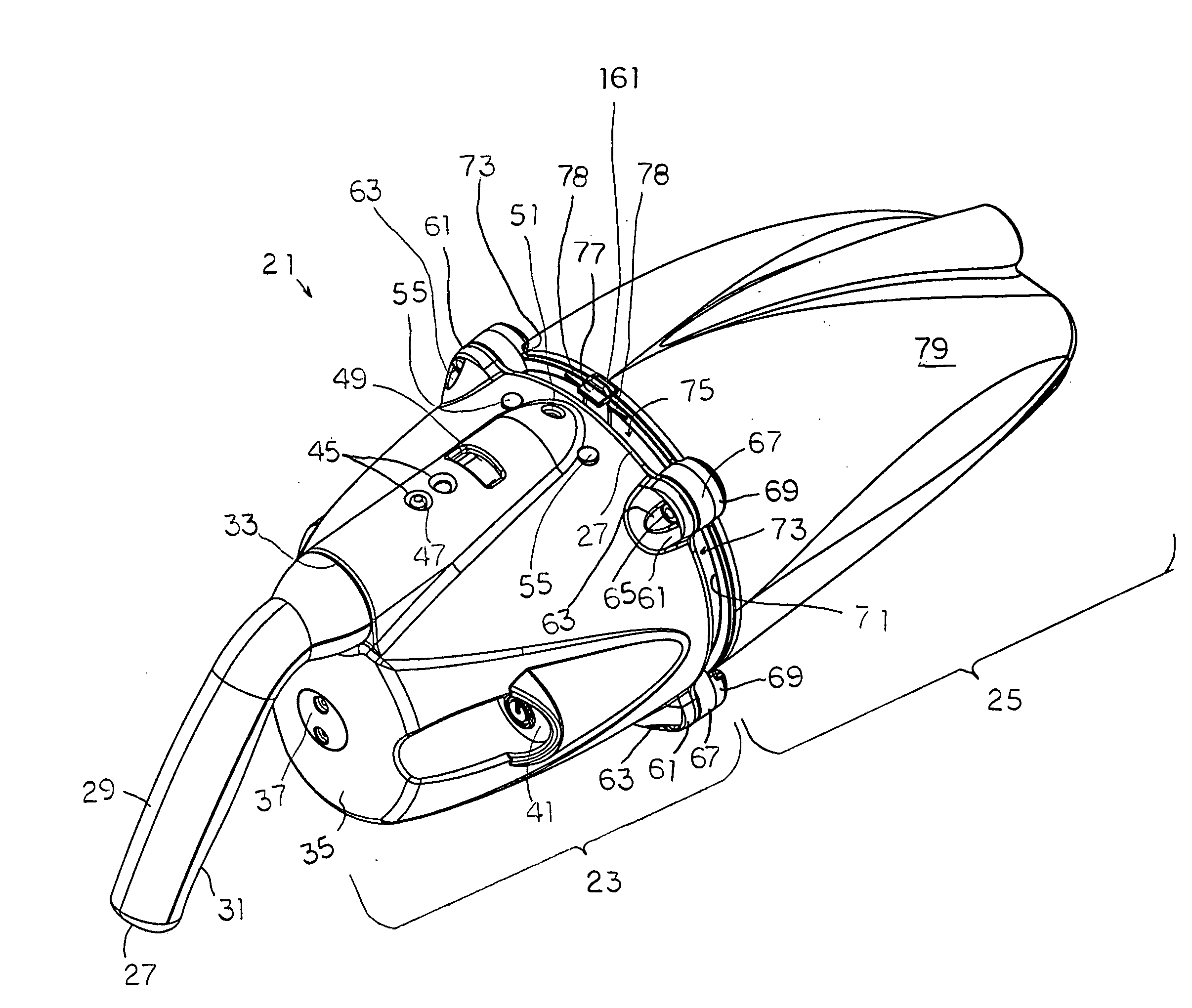

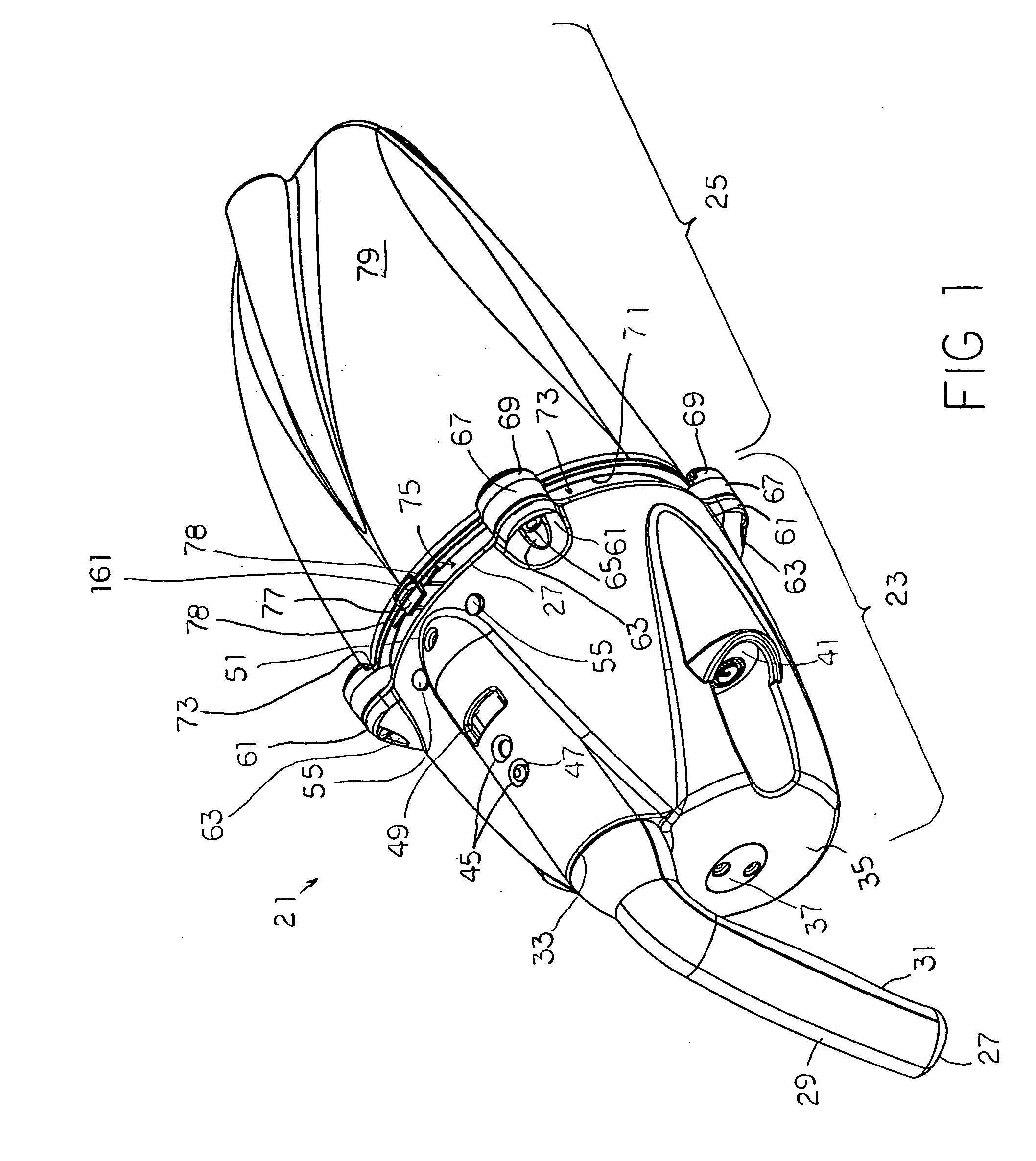

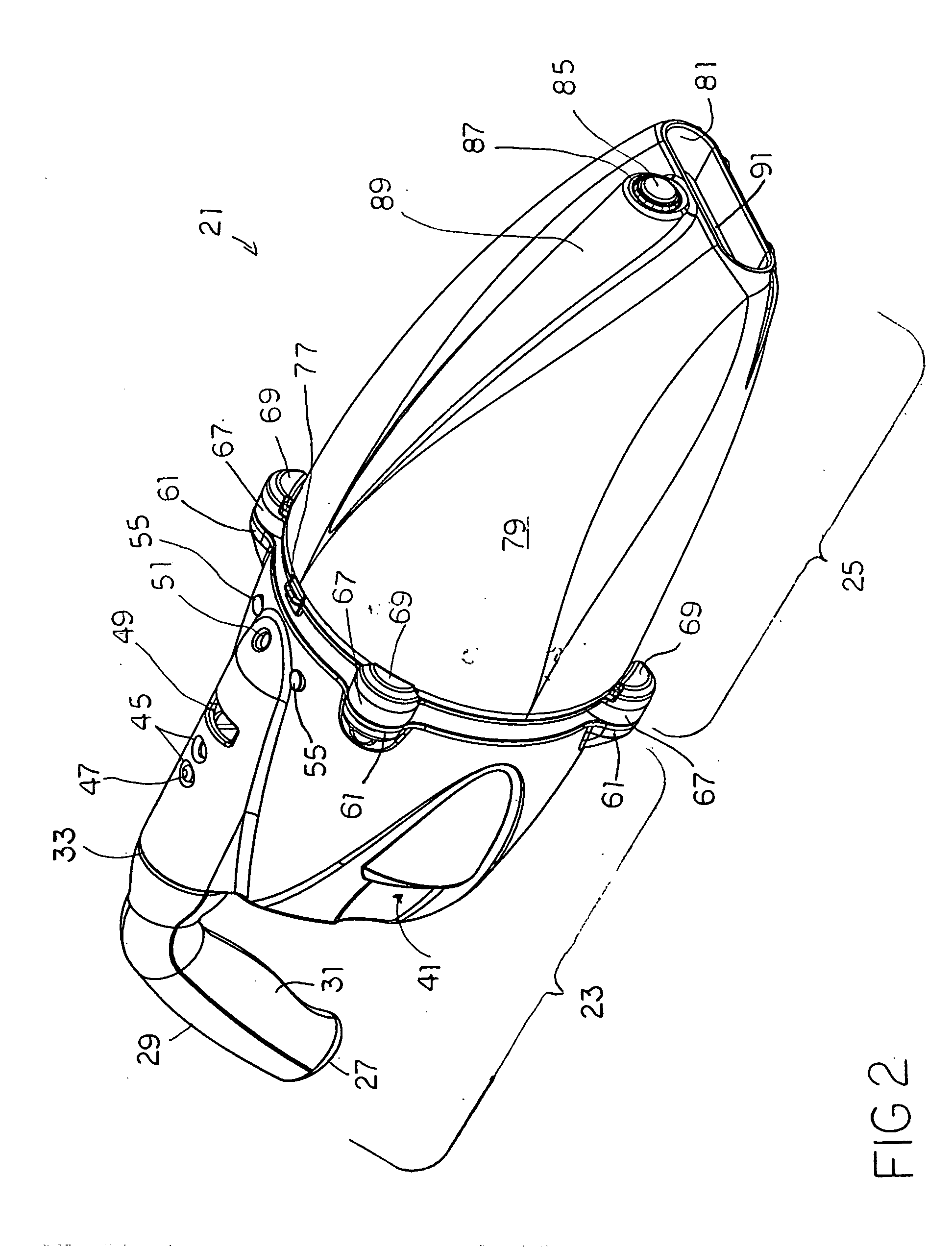

A rocker arm assembly (55) for a valve control system in an internal combustion engine including a cylinder head (11), and a poppet valve (15). The valve control system comprises an HLA (41) having a ball plunger portion (39). The assembly (55) comprises a rocker arm (57) including axially spaced apart side walls (59,61) and a portion (63) for engagement with the ball plunger (39). The rocker arm assembly (55) further comprises a cam follower (29) disposed about a mounting shaft (31) extending into shaft openings (65) defined by the side walls (59,61), and a pin member (67) defining a valve pad for engagement with a stem tip portion (17), the pin member extending into pin openings (71) defined by the side walls. The assembly (55) includes a clip member (75) including spaced apart clip side walls (77,79) disposed on the outside of the side walls of the rocker arm (57). A connection portion (81) interconnects the clip side walls to restrain axial movement of the mounting shaft (31) and of the pin member (67). The clip side walls (77,79) include retention portions (85,87) engaging the adjacent side walls (59,61) of the rocker arm and extending therebetween and include terminal portions (91) adjacent the pin member (67) to limit rotation of the pin member about its axis, relative to said rocker arm (57).

Owner:EATON INTELLIGENT POWER LIMITED

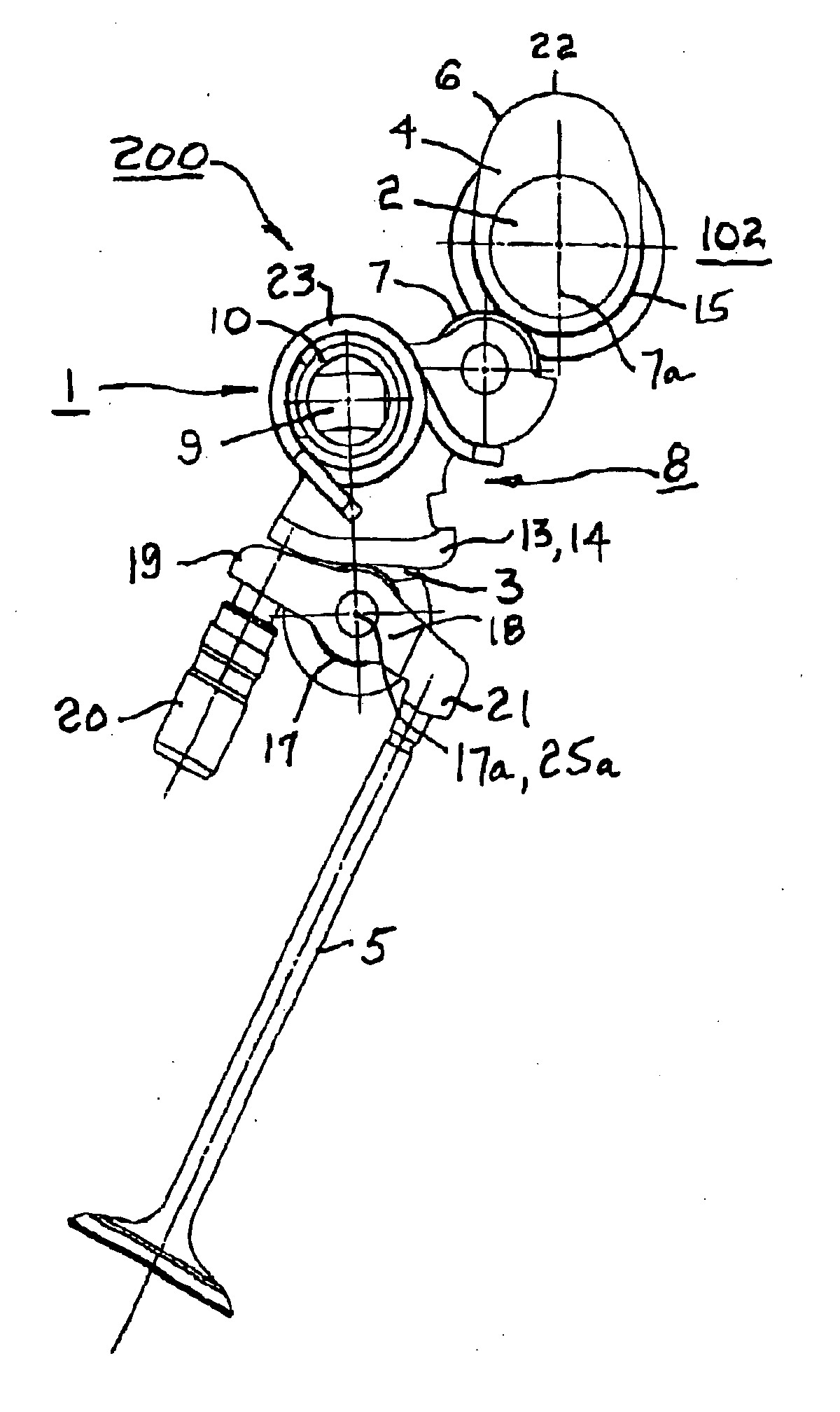

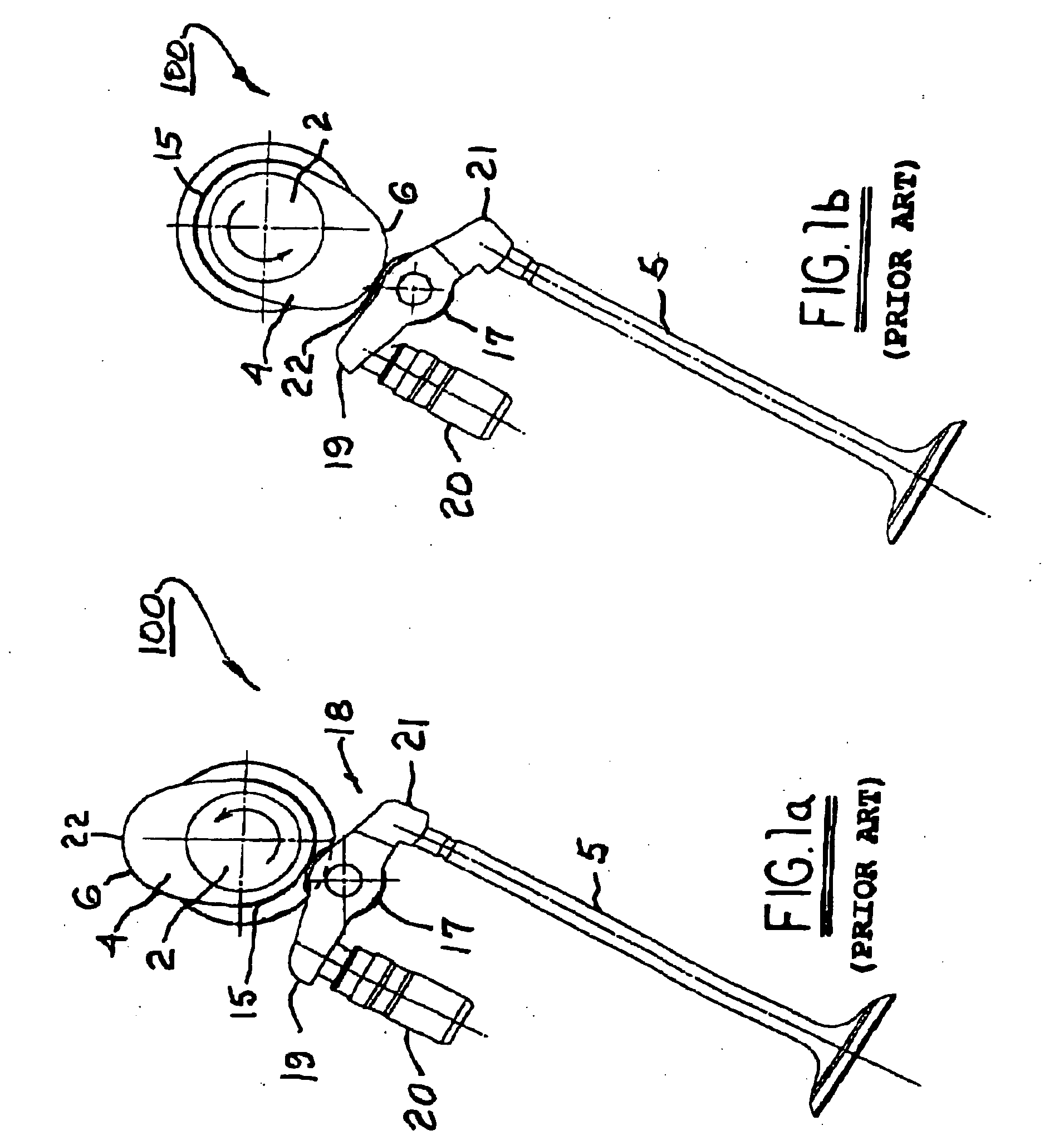

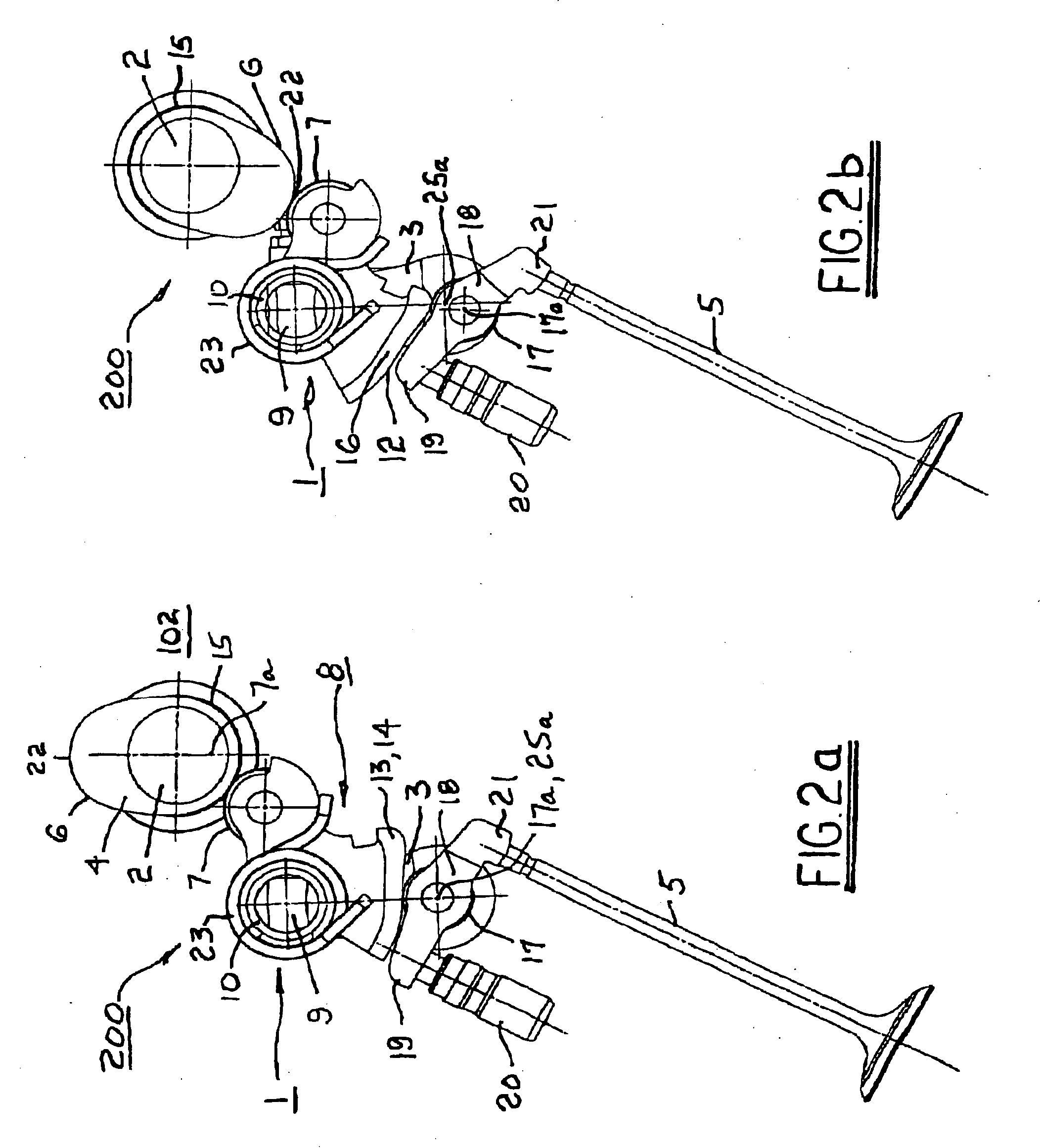

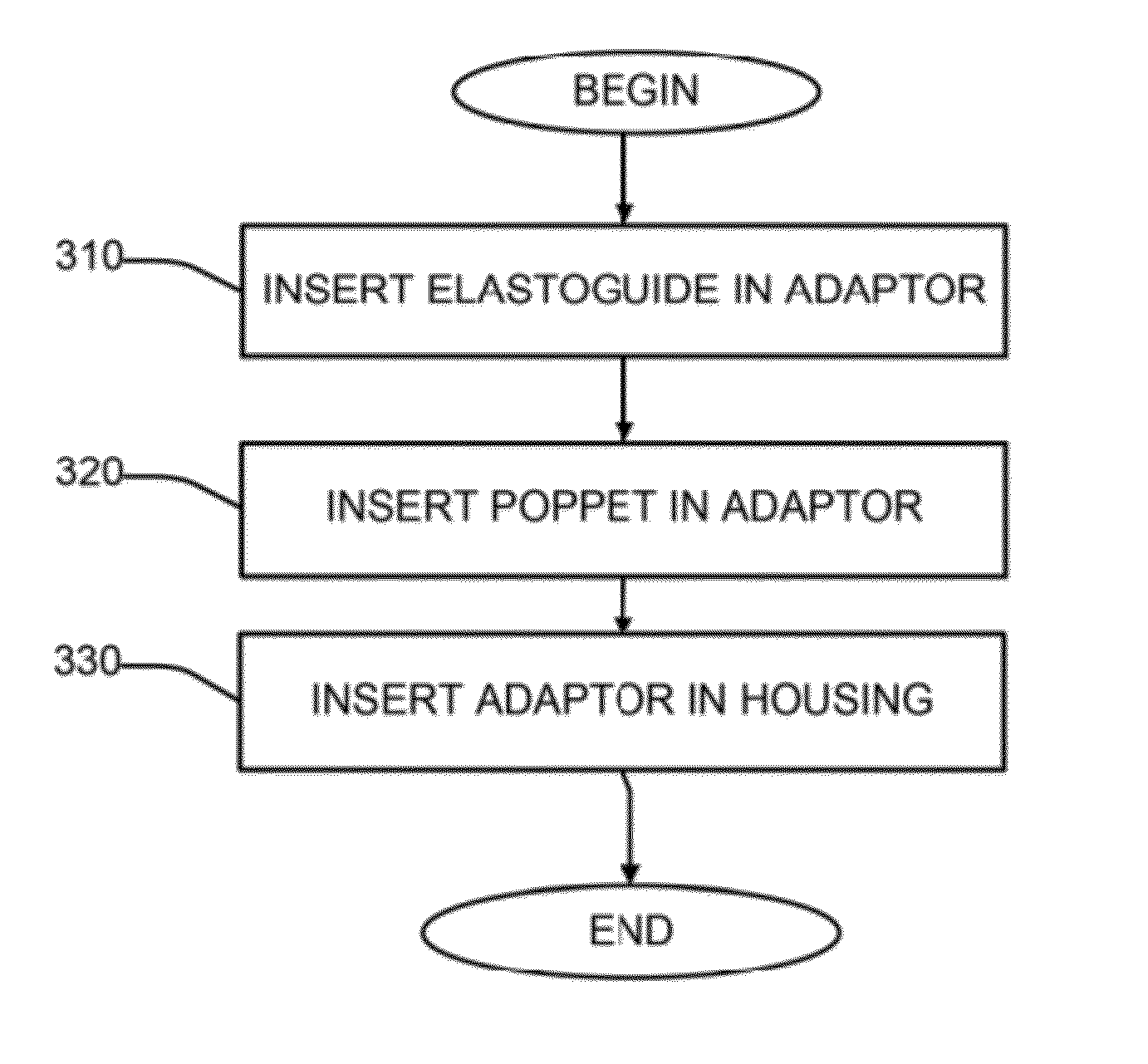

Luer access valve

InactiveUS20120153201A1Operating means/releasing devices for valvesIntravenous devicesEngineeringMechanical engineering

A valve system that comprises a housing having an opening for receiving or ejecting a fluid, a poppet that controls a flow of the fluid through the opening, an elastoguide that drives the poppet to a closed position, and an adaptor that receives and holds the poppet and the elastoguide.

Owner:AMSINO INT

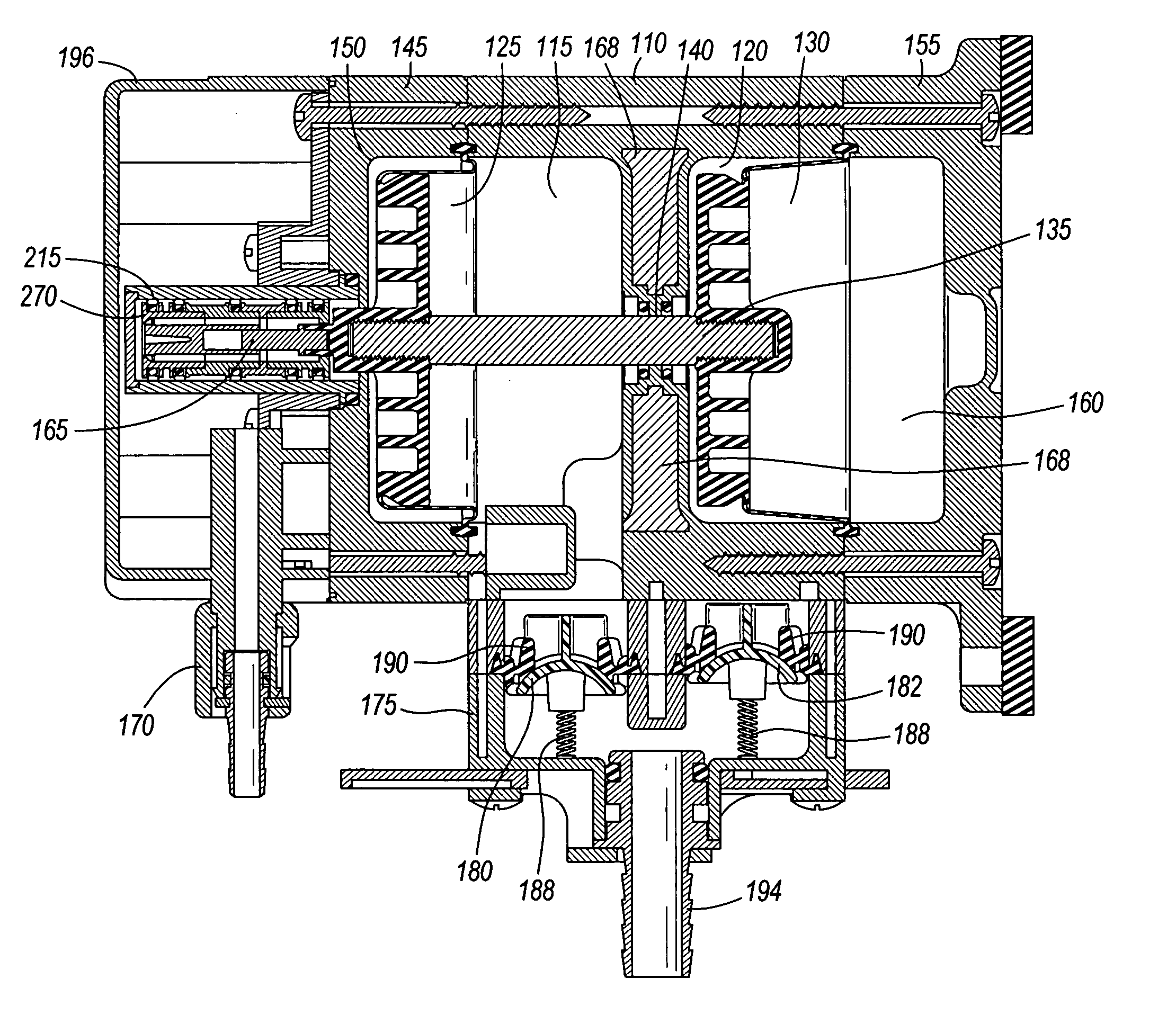

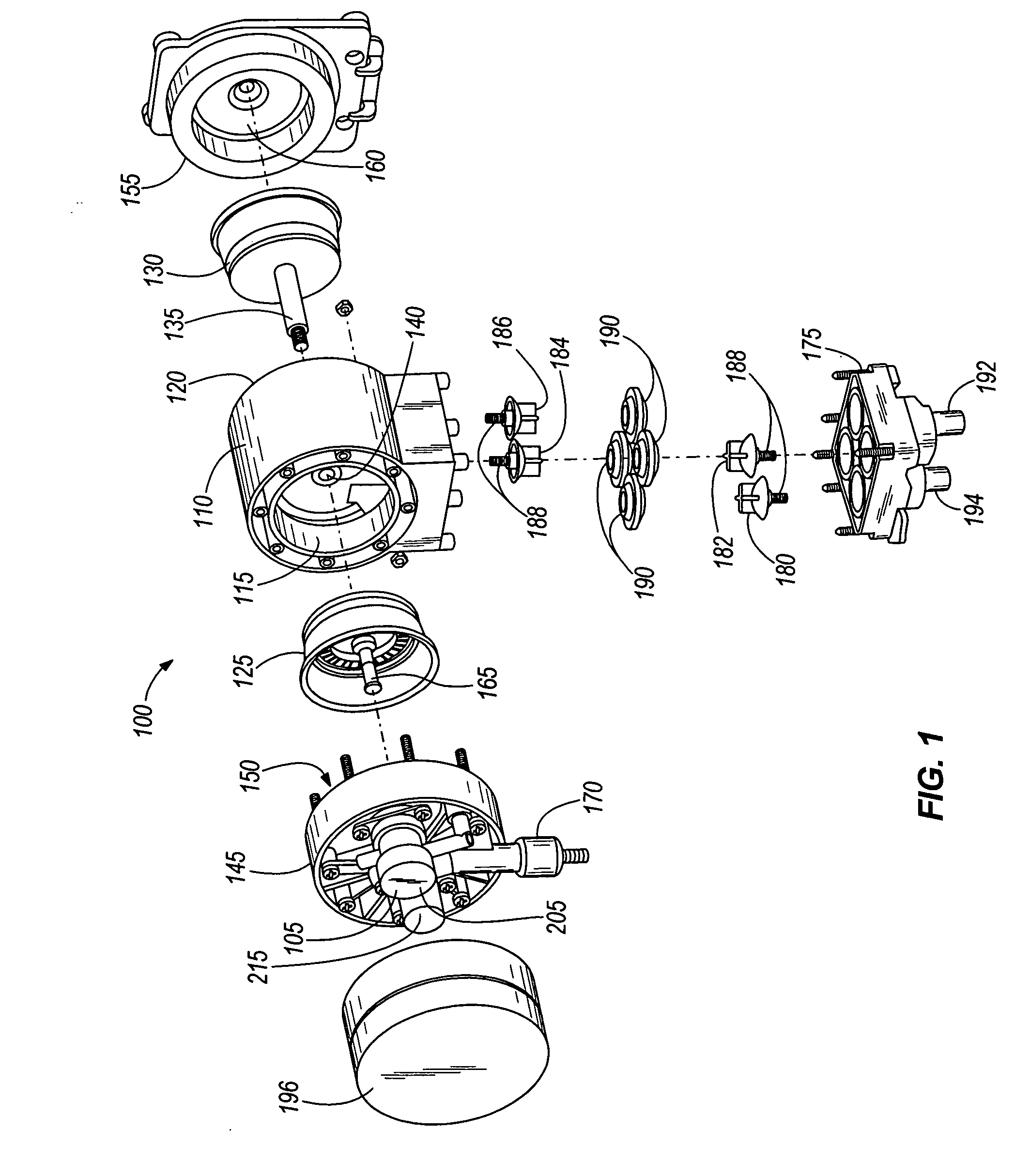

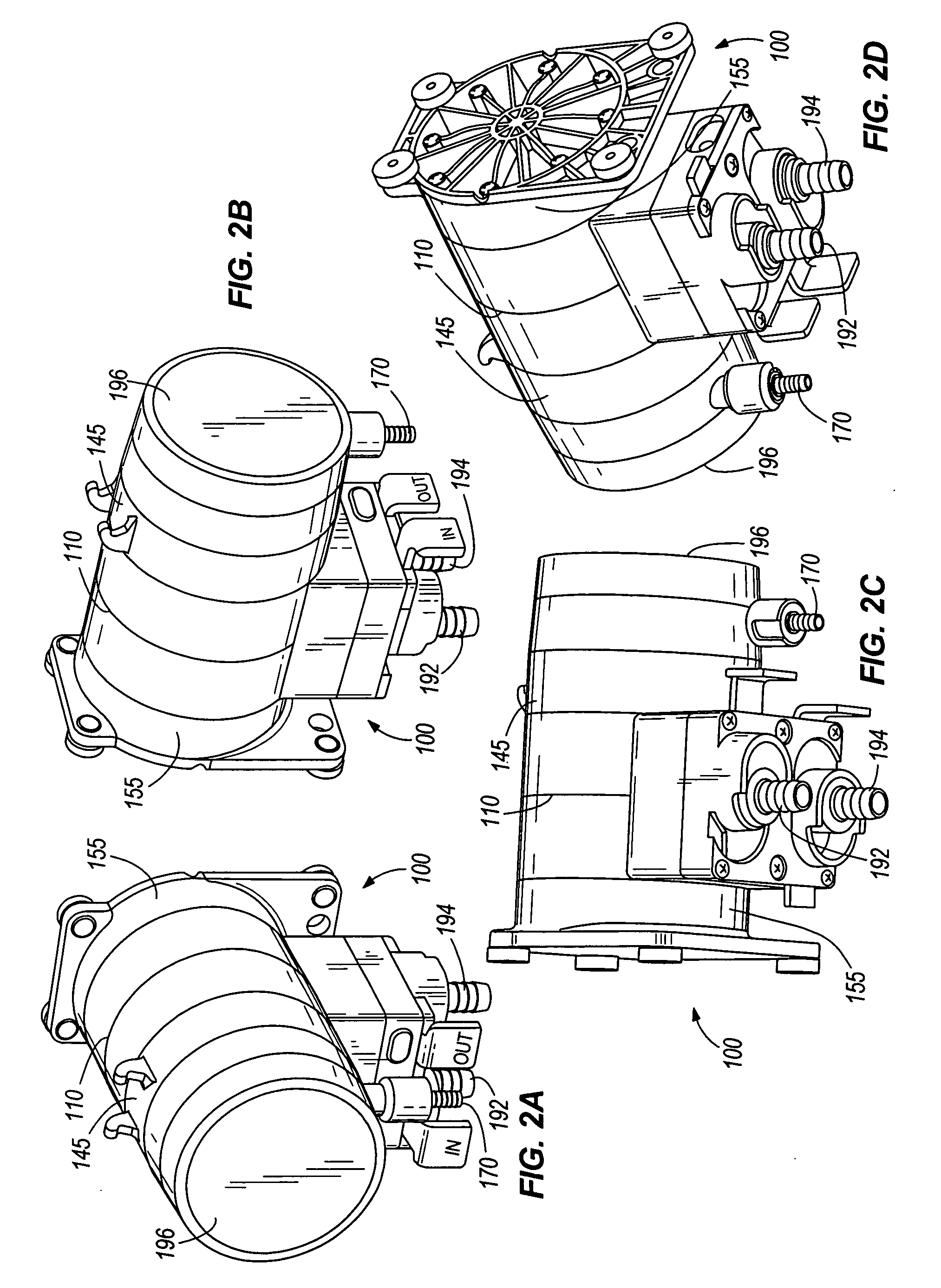

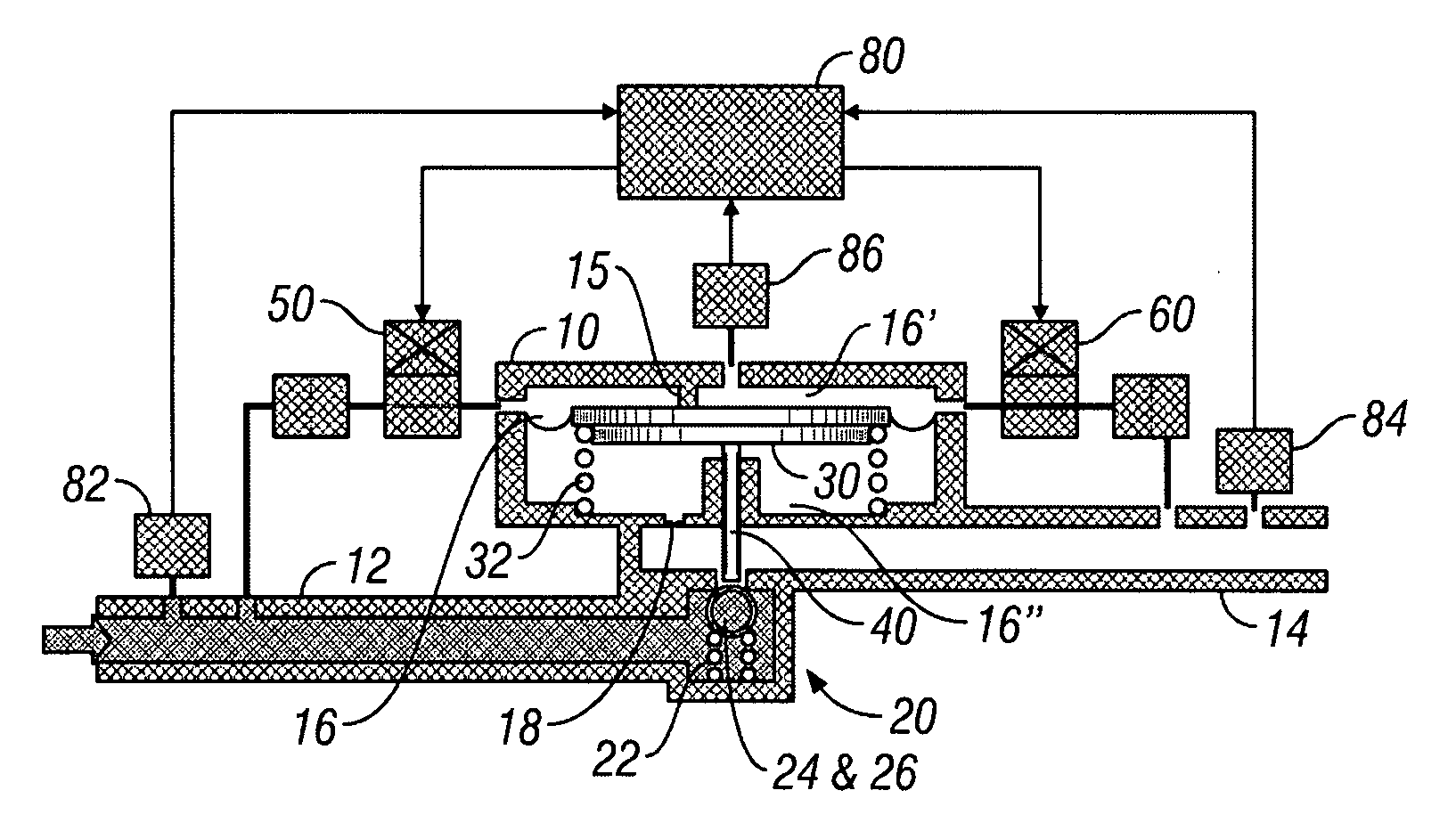

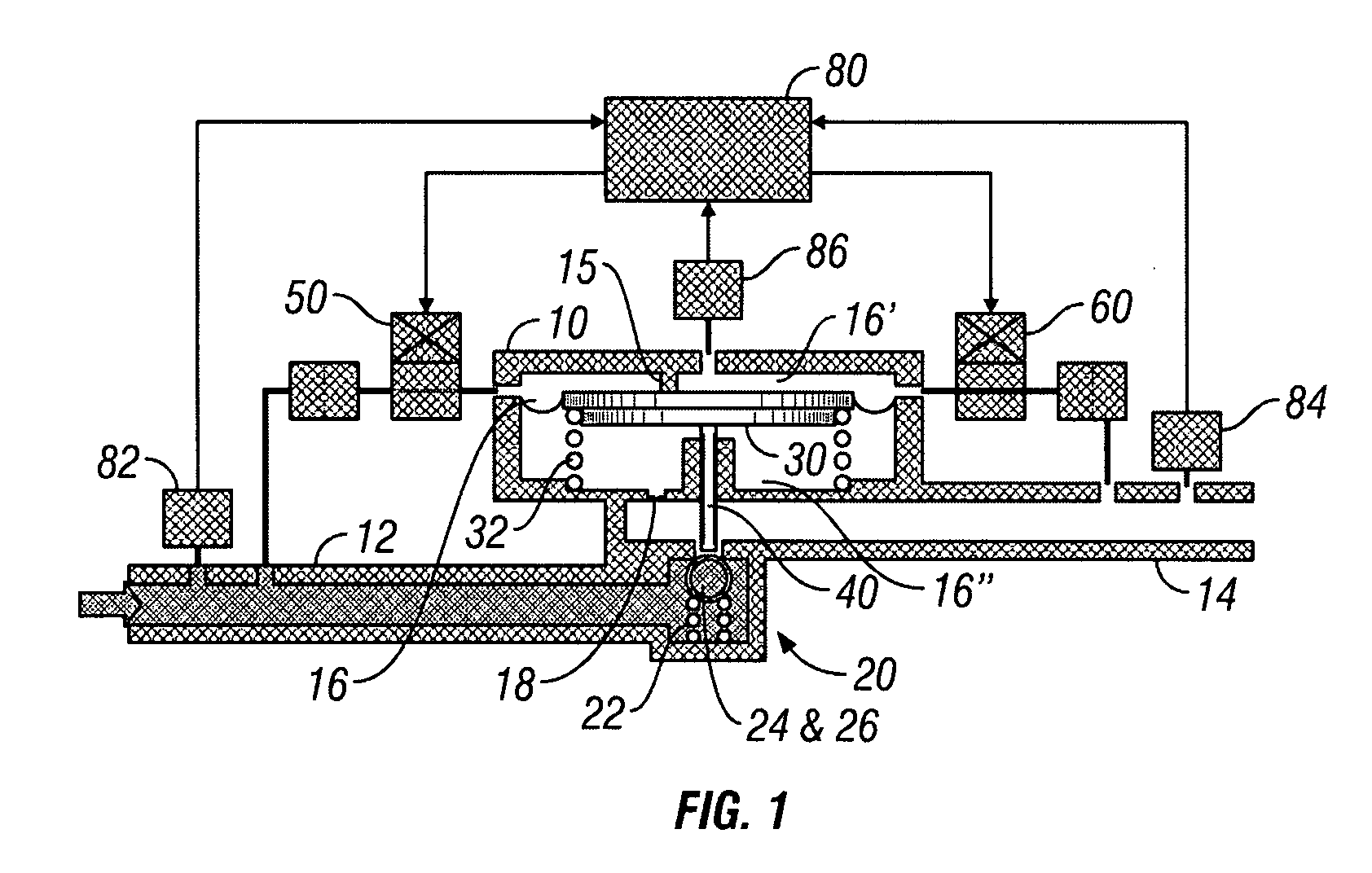

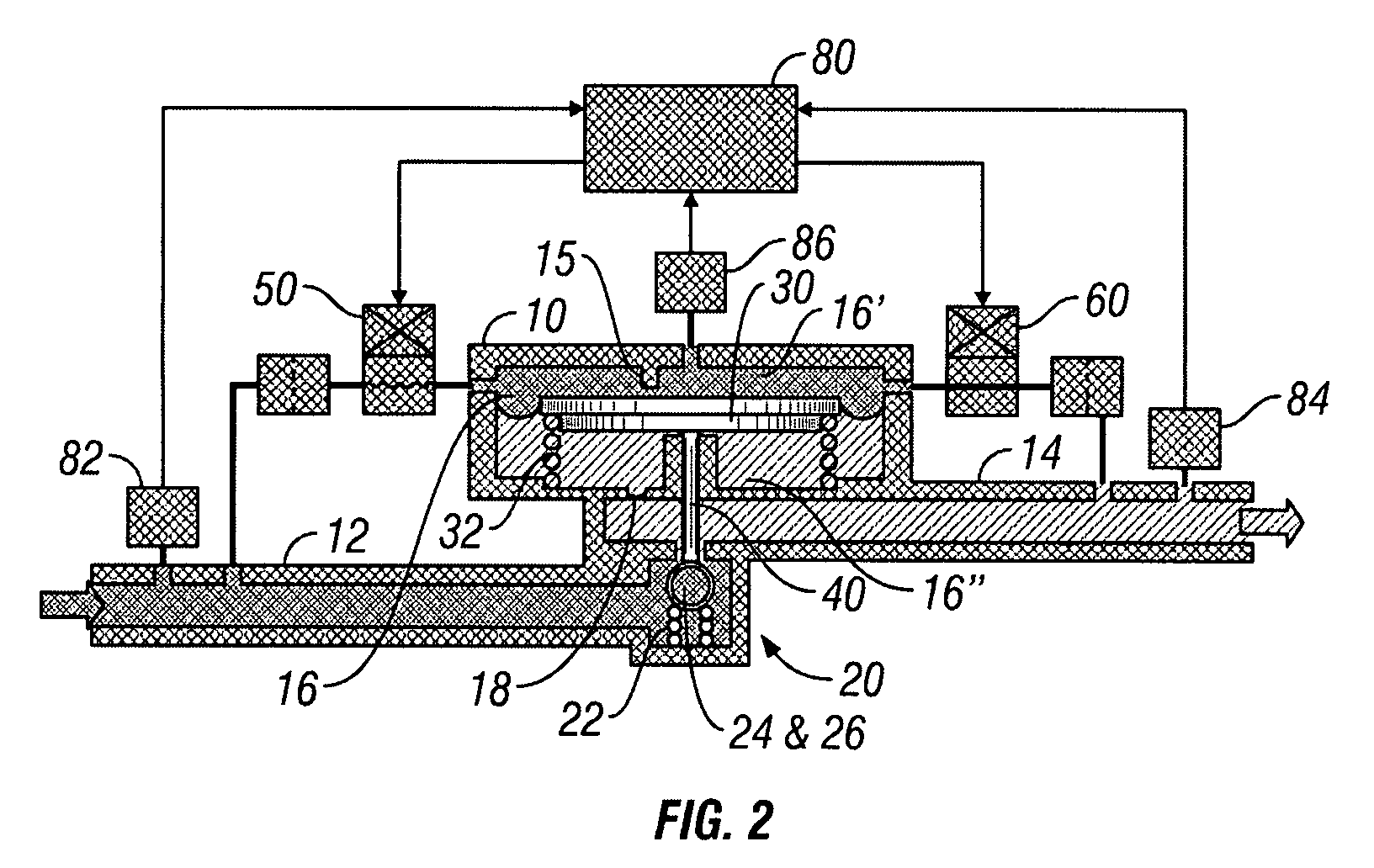

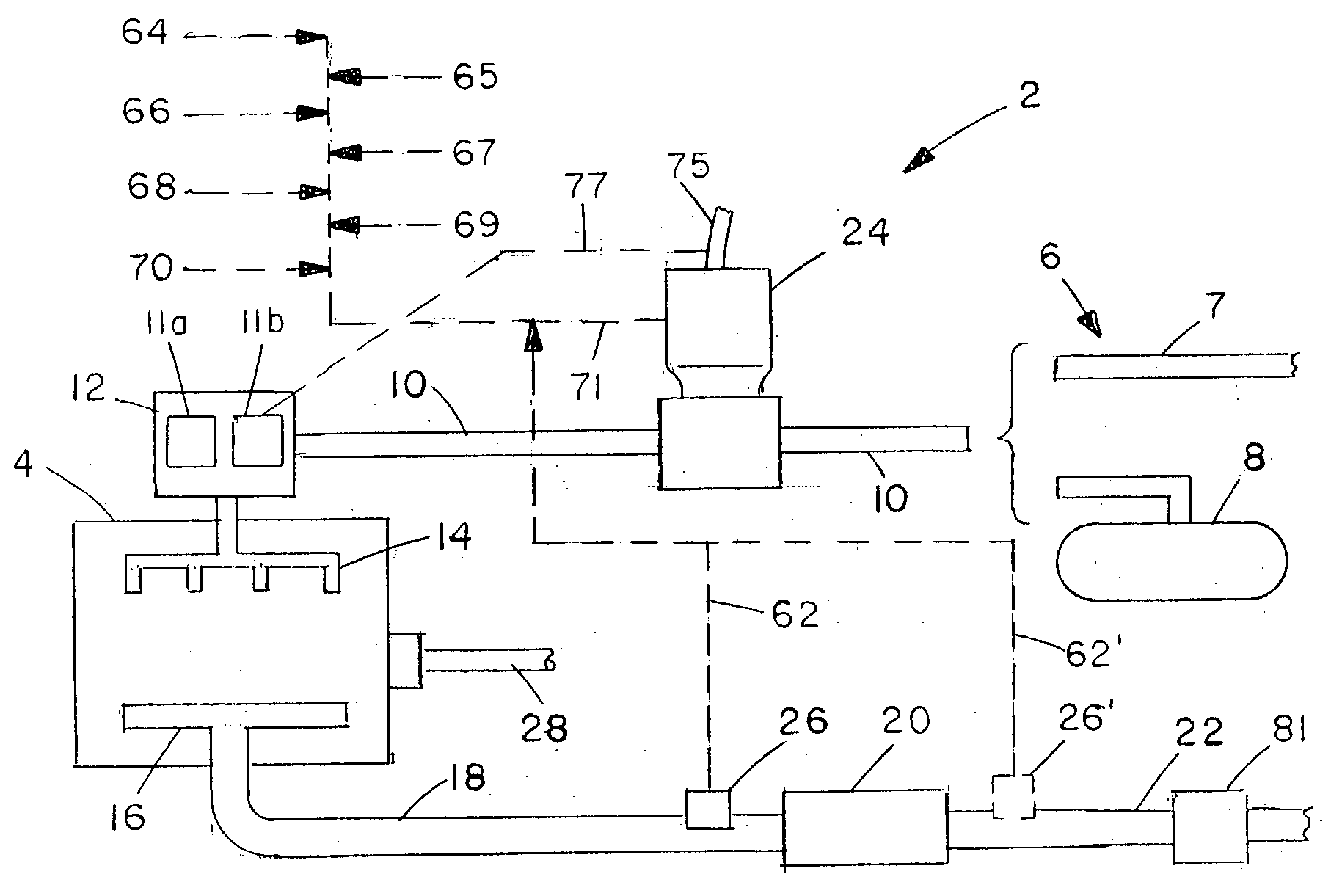

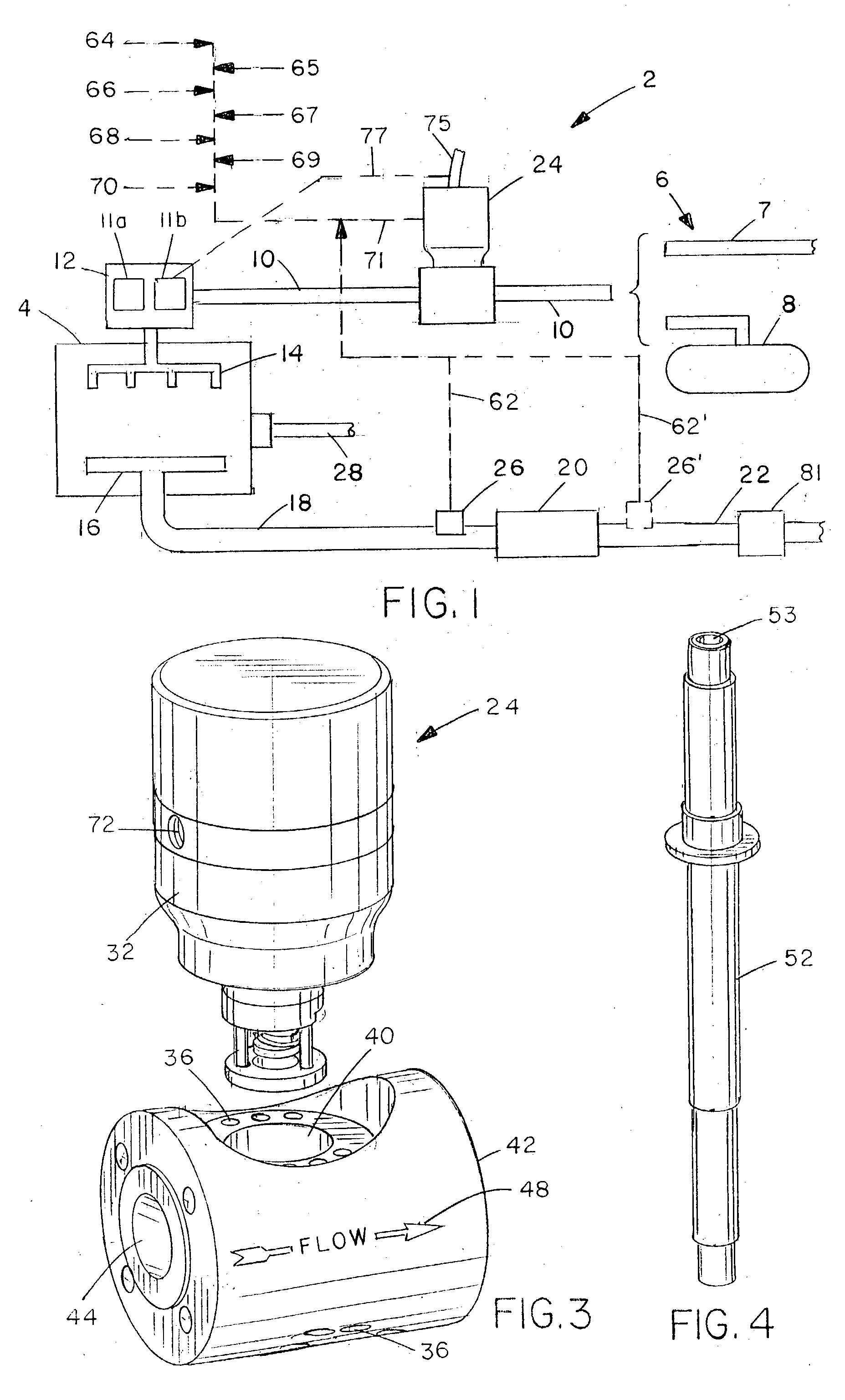

Pump and valve actuator system and method

InactiveUS20070092385A1Positive displacement pump componentsFlexible member pumpsSpool valveDiaphragm pump

A double diaphragm pump including a dual spool valve actuator. A set of piston / diaphragm assemblies can be coupled to a pilot spool valve, which can direct air flow to a main spool valve. The main spool valve can direct air flow to pump chambers. Components of the pump can be manufactured by injection molding and press-fit together. The pump can include lens-shaped ports and positive-return poppet valves.

Owner:SHURFLO

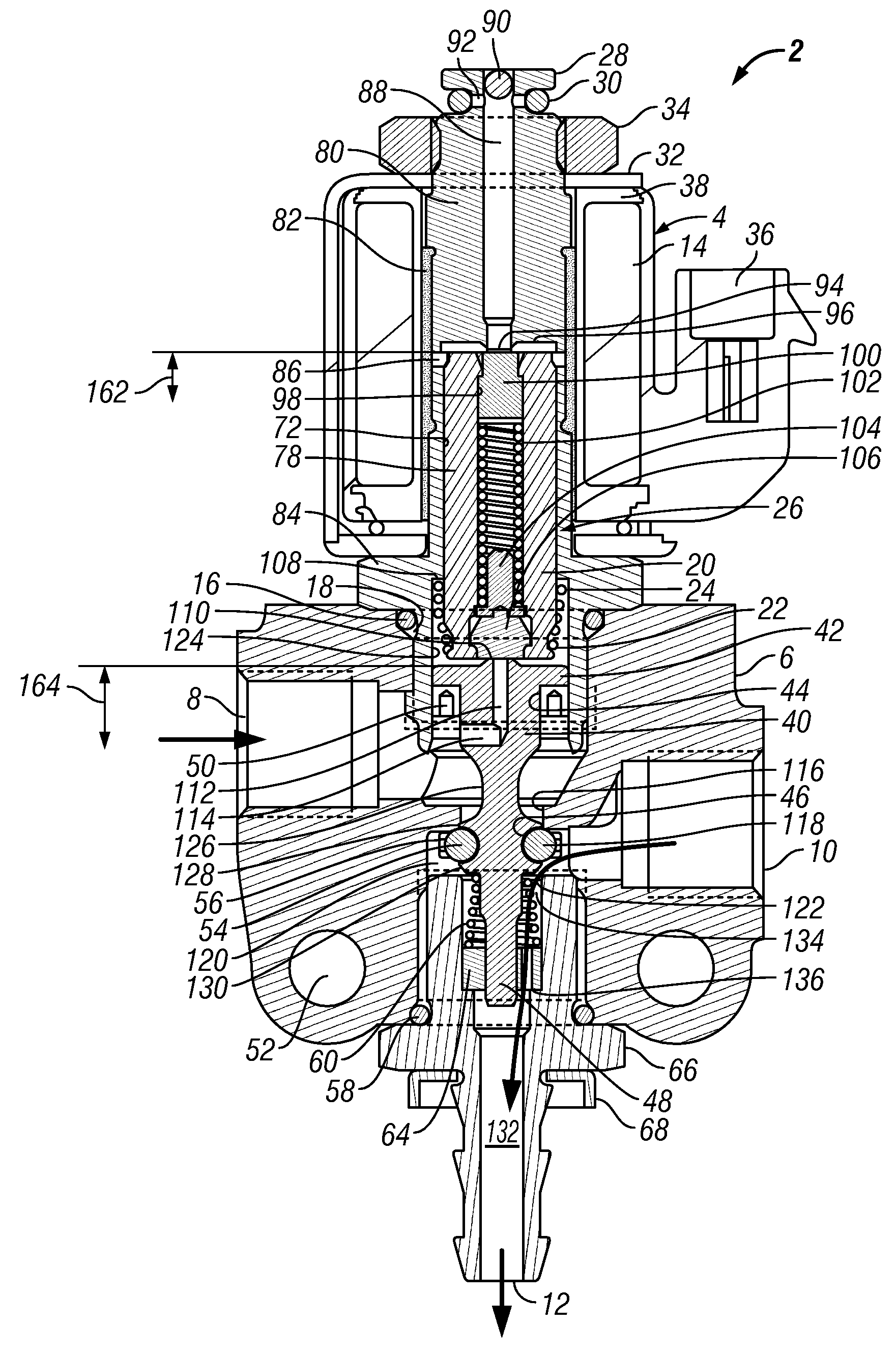

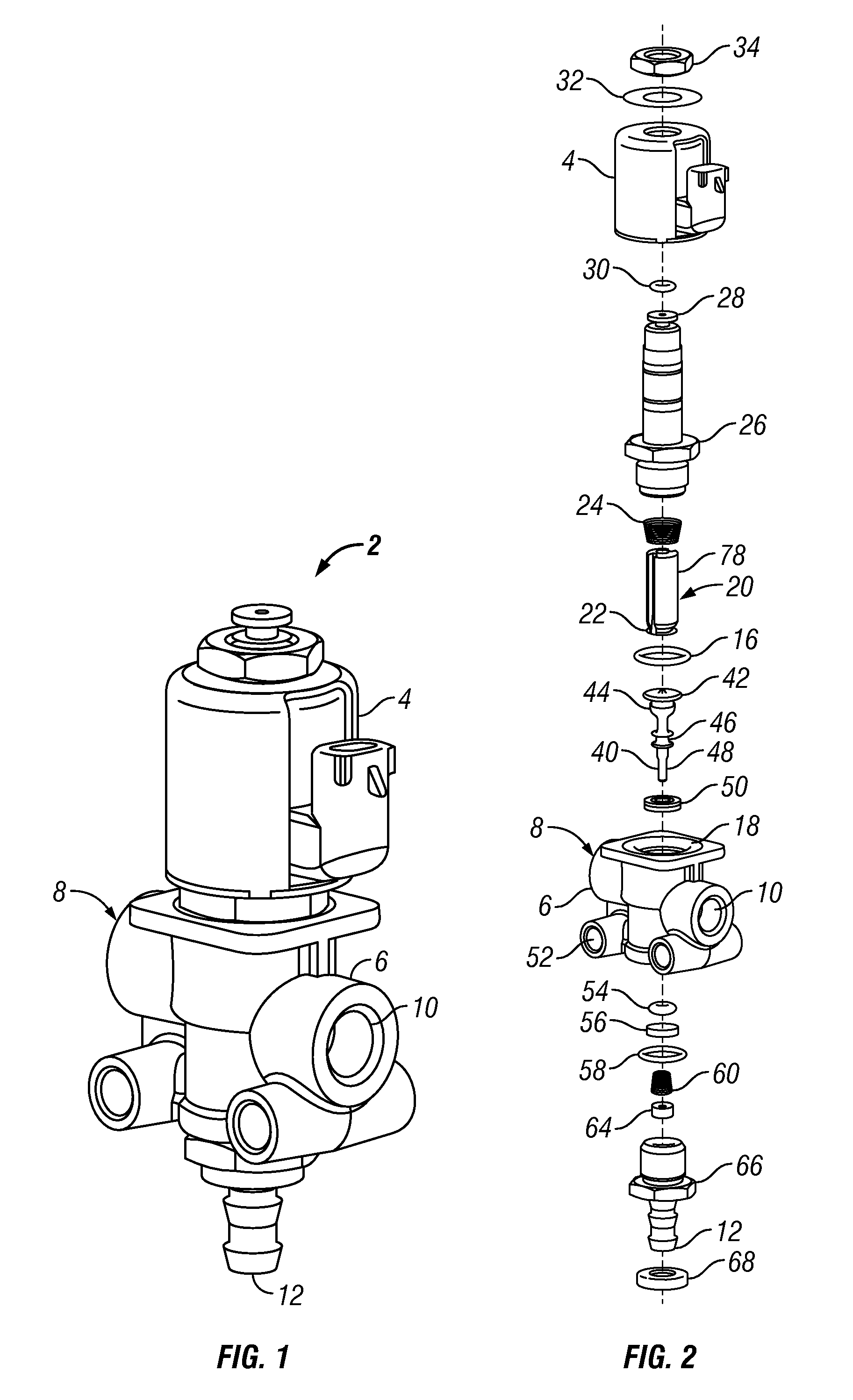

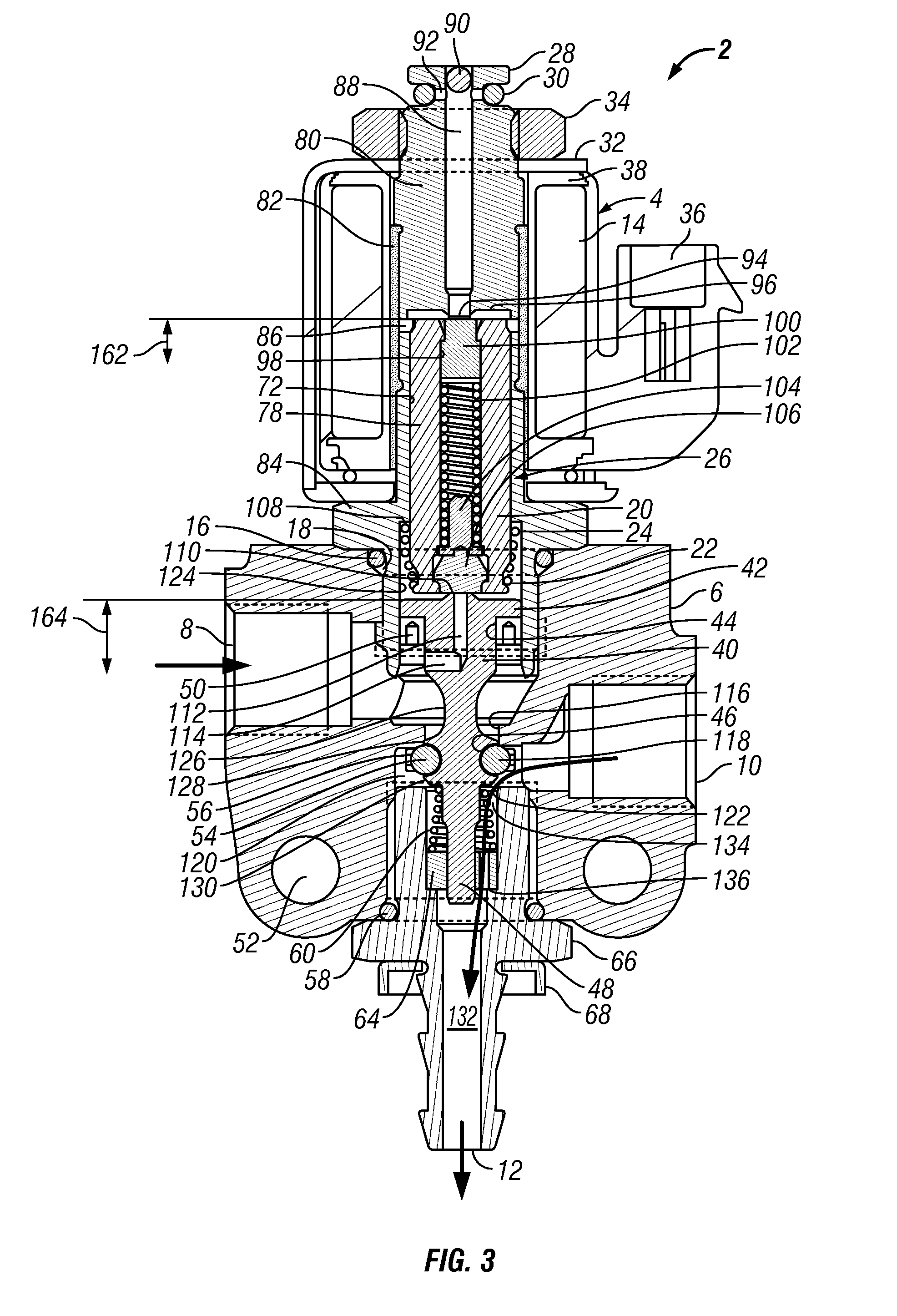

Three-way direct pilot valve

InactiveUS20070164243A1High strengthMore compactOperating means/releasing devices for valvesMultiple way valvesEngineeringPilot valve

The present disclosure provides a method, apparatus, and system of an inline direct acting solenoid pilot valve. The valve has a solenoid assembly with a longitudinally moveable core assembly that shifts alternatively between sealing engagement on a lower first end of the core assembly with a pilot port formed in a poppet and sealing engagement on an opposite upper end with a stationary pilot exhaust port in the solenoid assembly. The core assembly can move in the same or opposite direction than the poppet and thus is independently moveable from the poppet to effect the various modes of operation. Because the movement is independent, the core assembly can advantageously operate within the solenoid with a shorter stroke to produce a higher overall force per length relative to a conventional core assembly stroke that is longer than the poppet stroke. The overall design allows a more compact and simplified design.

Owner:ASCO CONTROLS LP

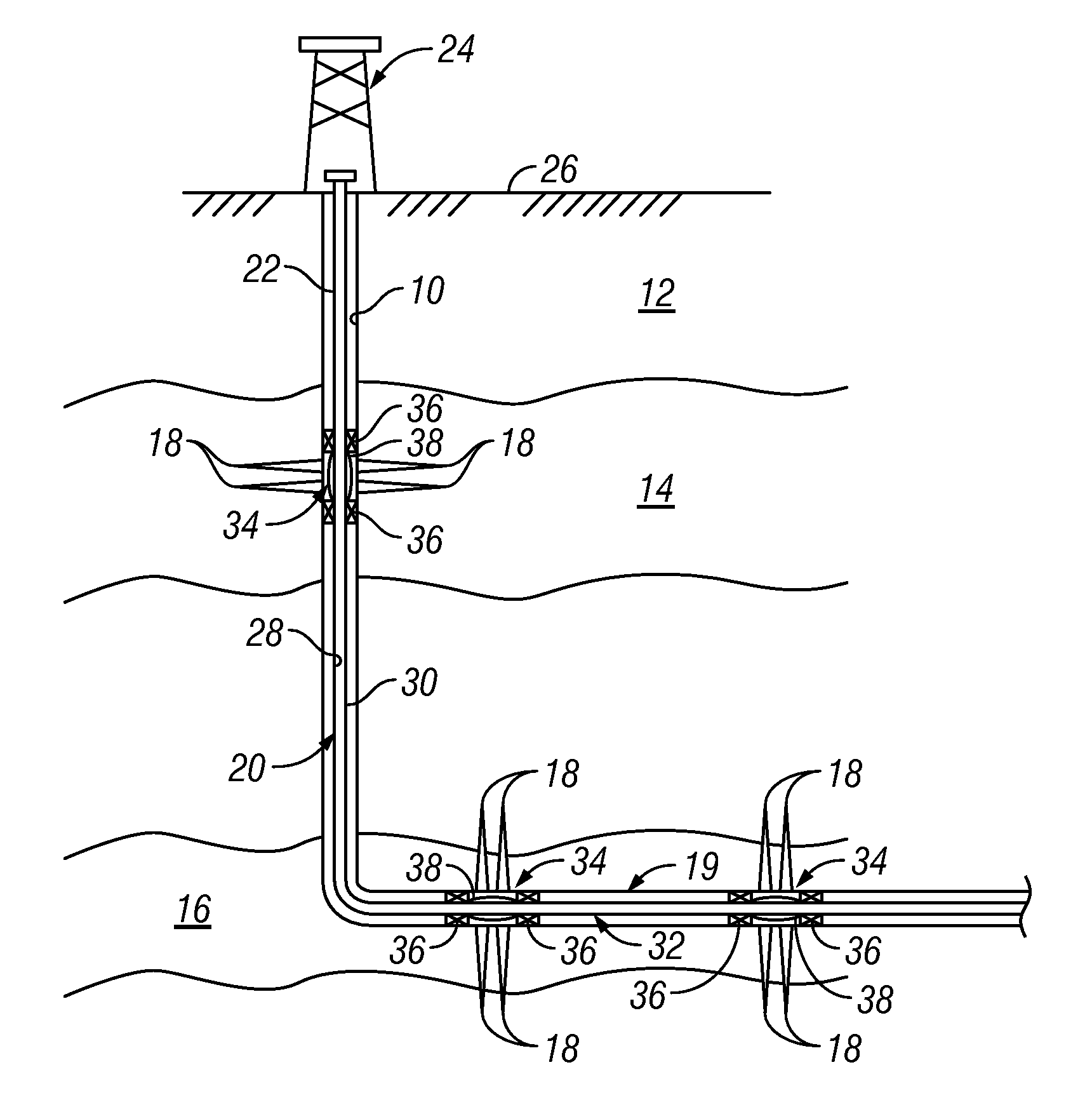

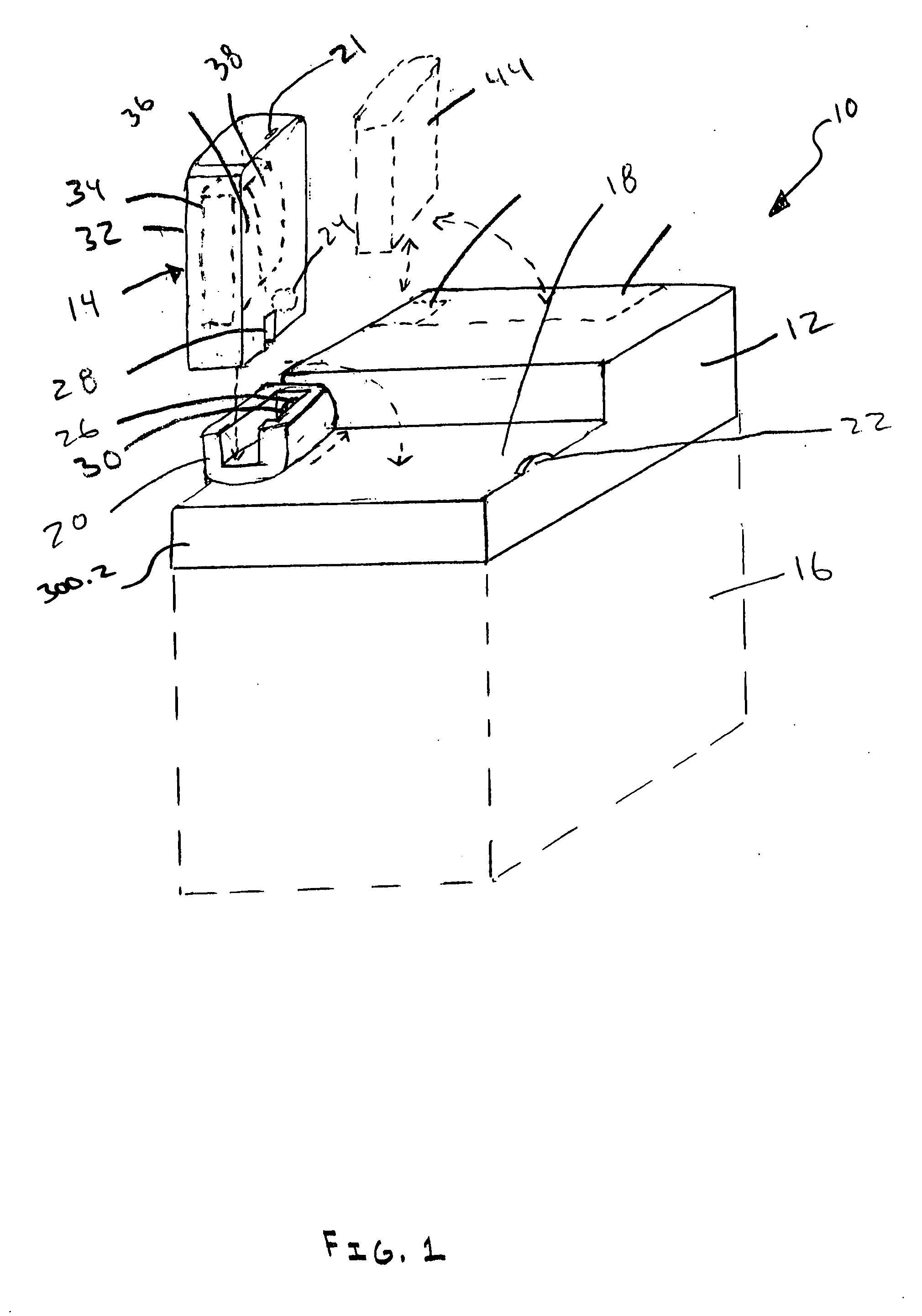

Water sensitive variable counterweight device driven by osmosis

InactiveUS20090236102A1Fluid removalWell/borehole valve arrangementsControl flowHydrocotyle bowlesioides

A method for producing fluid from a subterranean formation includes configuring a body to at least partially fill with a selected fluid; and actuating a flow restriction element using the body. The selected fluid may be water. An apparatus for controlling flow of a fluid into a wellbore tubular may include a selectively buoyant body, and a flow restriction element responsive to a movement of the selectively buoyant body. The selectively buoyant body includes a membrane configured to block a flow of hydrocarbons into the selectively buoyant body. The flow restriction element may include a flapper, a sliding sleeve, and a poppet valve. The body may be at least partially filled with a permeable material, which includes, but is not limited to, open-cell foam, reticulated metal foam, shaped sintered powder and capillary tubes.

Owner:BAKER HUGHES INC

Connector assembly for fluid transfer

InactiveUS20050147864A1Quick connectionReduce liquid leakageReactant parameters controlPipeline systemsFuel cellsCoupling

A fuel cell system has an improved connector assembly to provide for the quick connection of a fuel cartridge and the fuel cell. Two leak resistant connector members with an easy to engage coupling mechanism that stably grips the two connector members to provide for flow between the members. The first connector member is adapted to engage the second connector member to form a unitary structure, which can establish fluid communication between the connector members. Generally, both the first connector member and the second connector member comprise a fluid flow path that can be each sealed / unsealed by a poppet valve or other suitable valve members. In some embodiments, the connector members can be engaged / disengaged by rotating an element of the coupling mechanism. The connector assemblies can be particularly useful for the connection of a fuel cell with a fuel cartridge.

Owner:ENTEGRIS INC

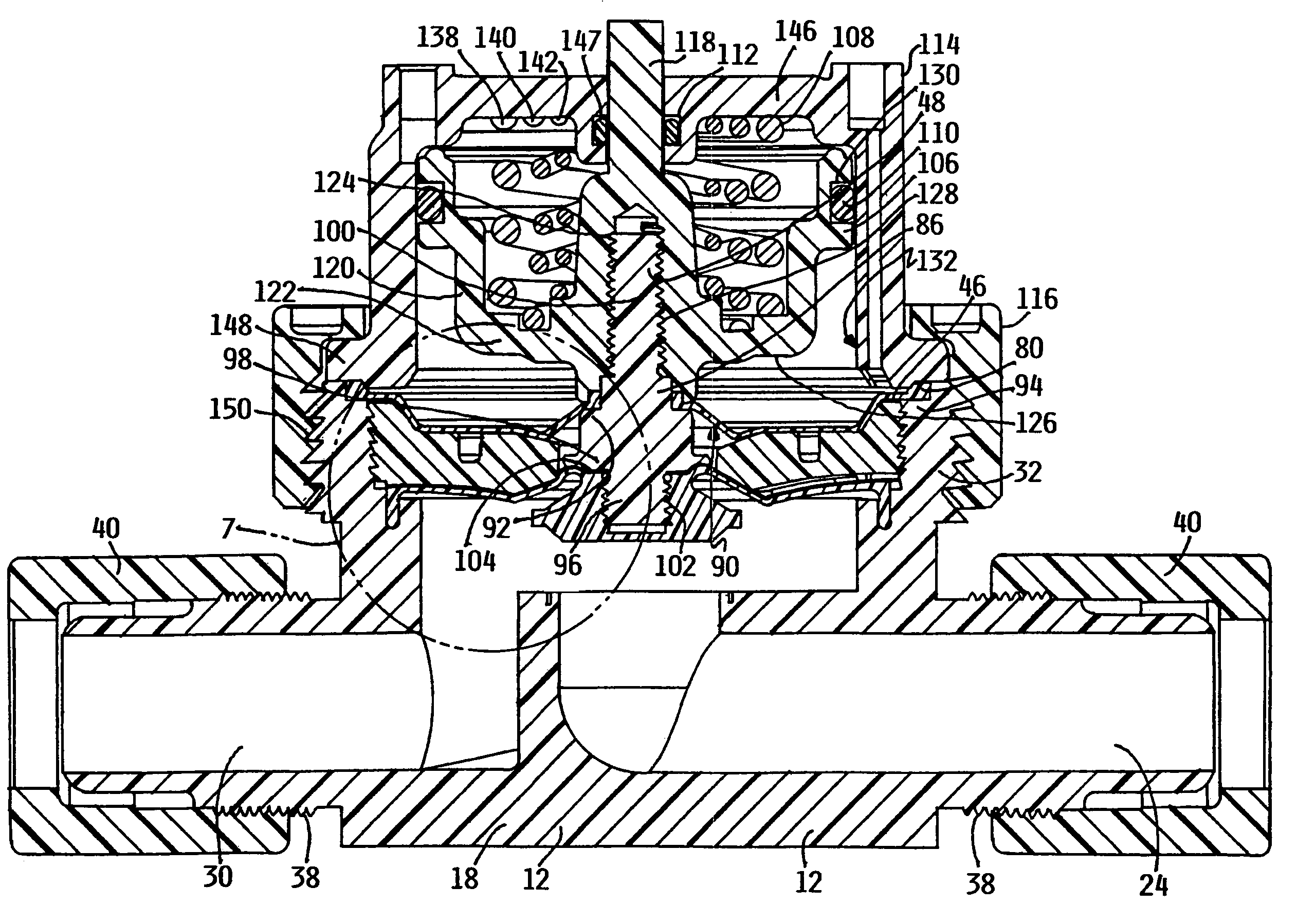

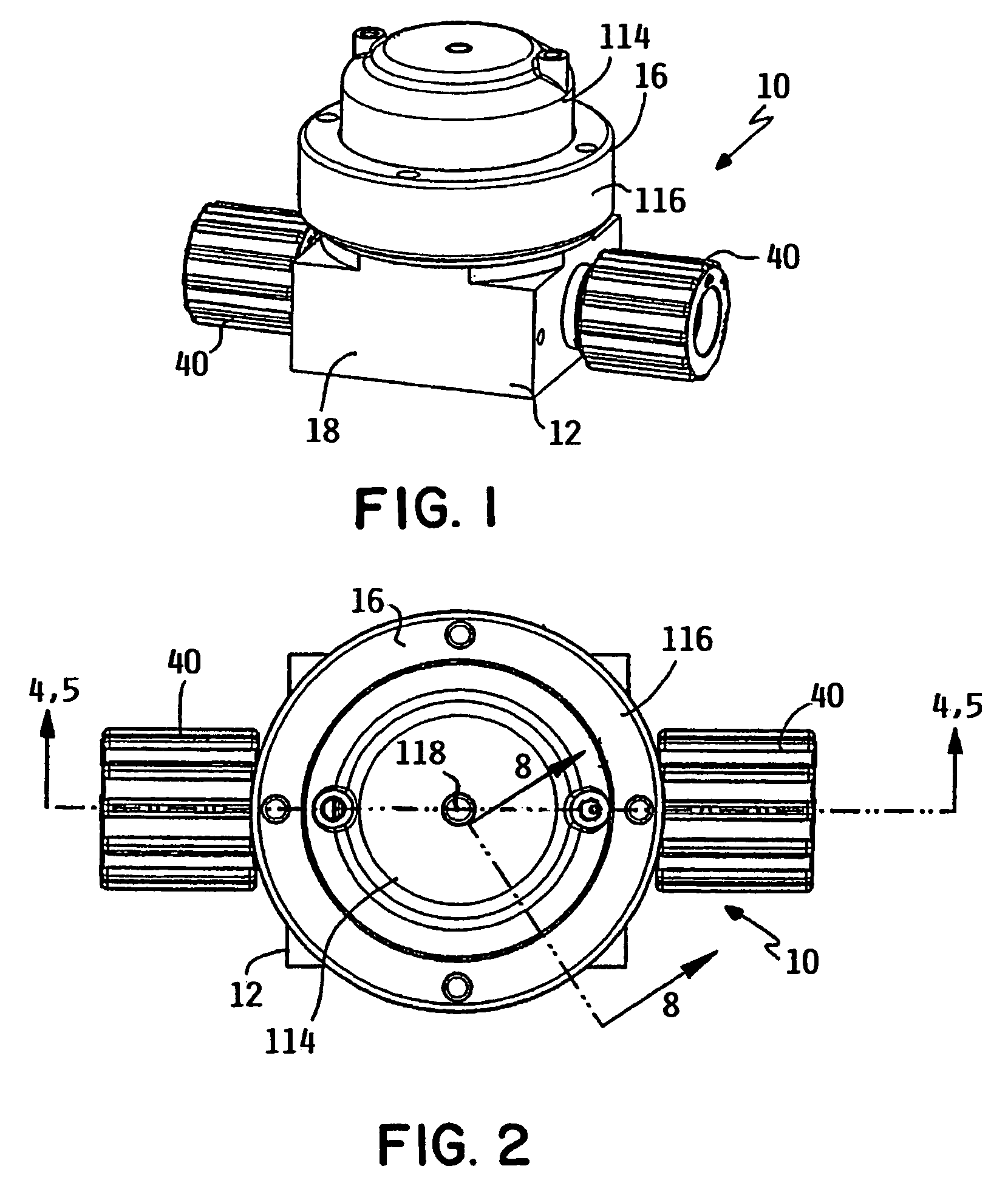

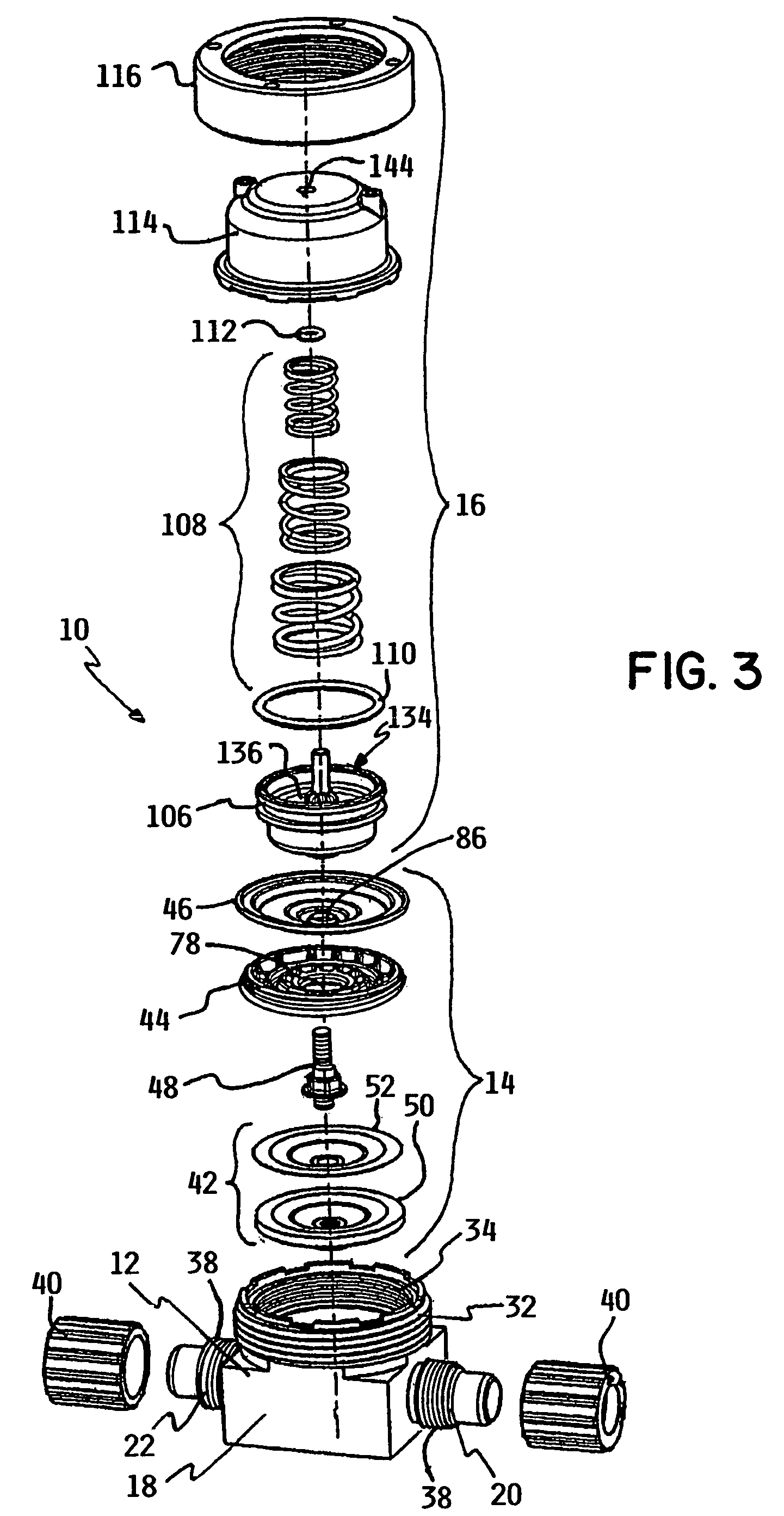

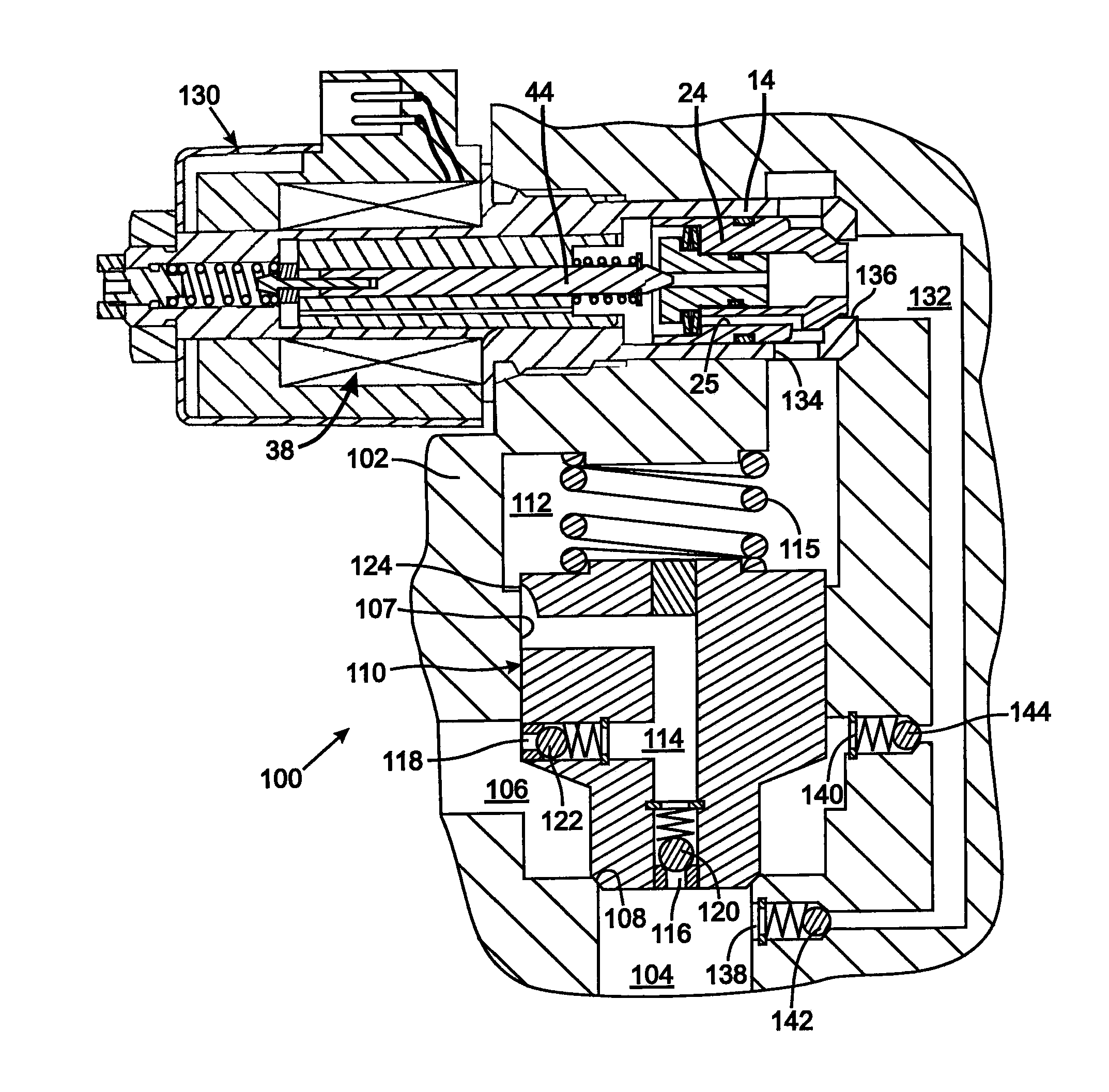

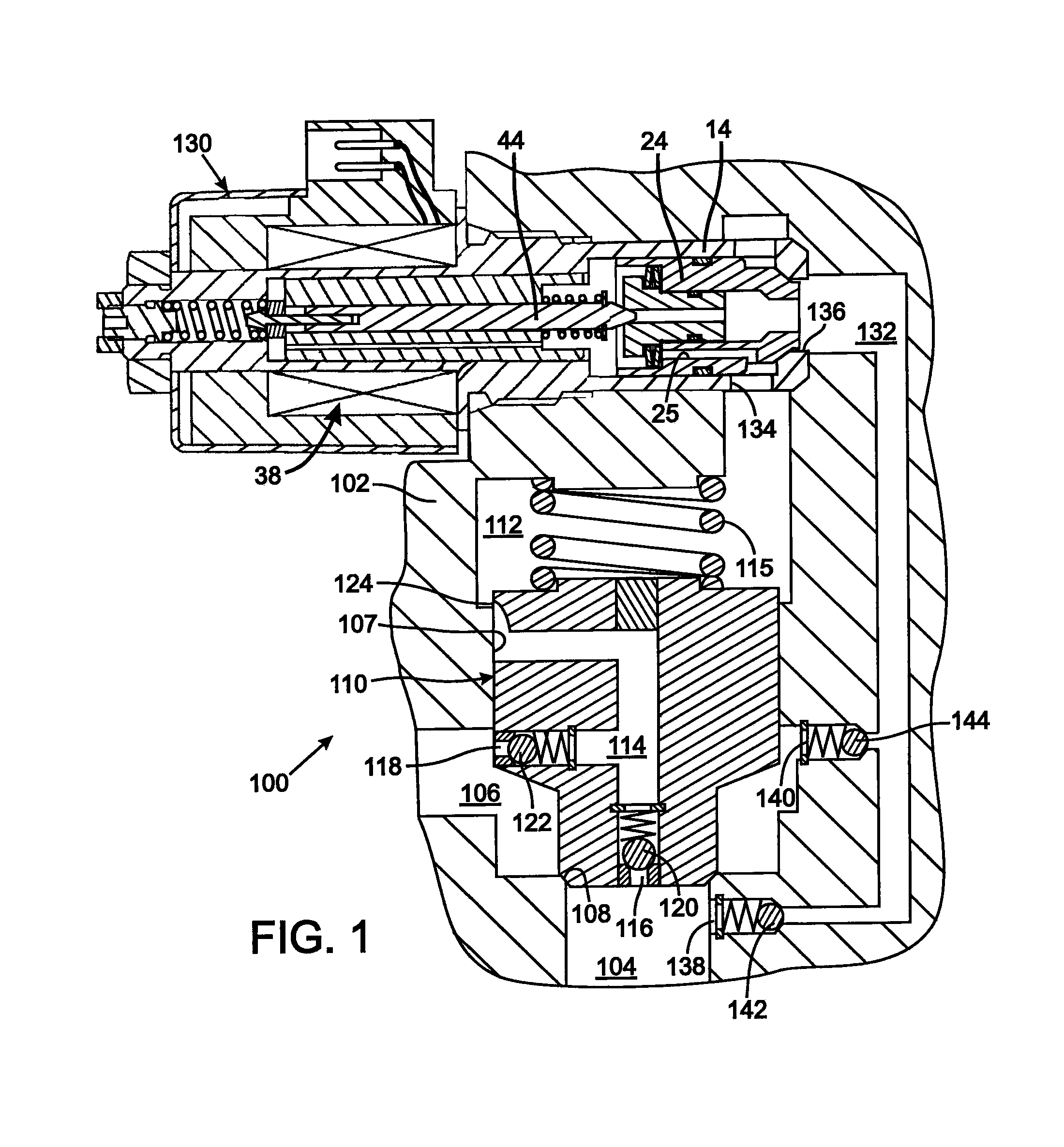

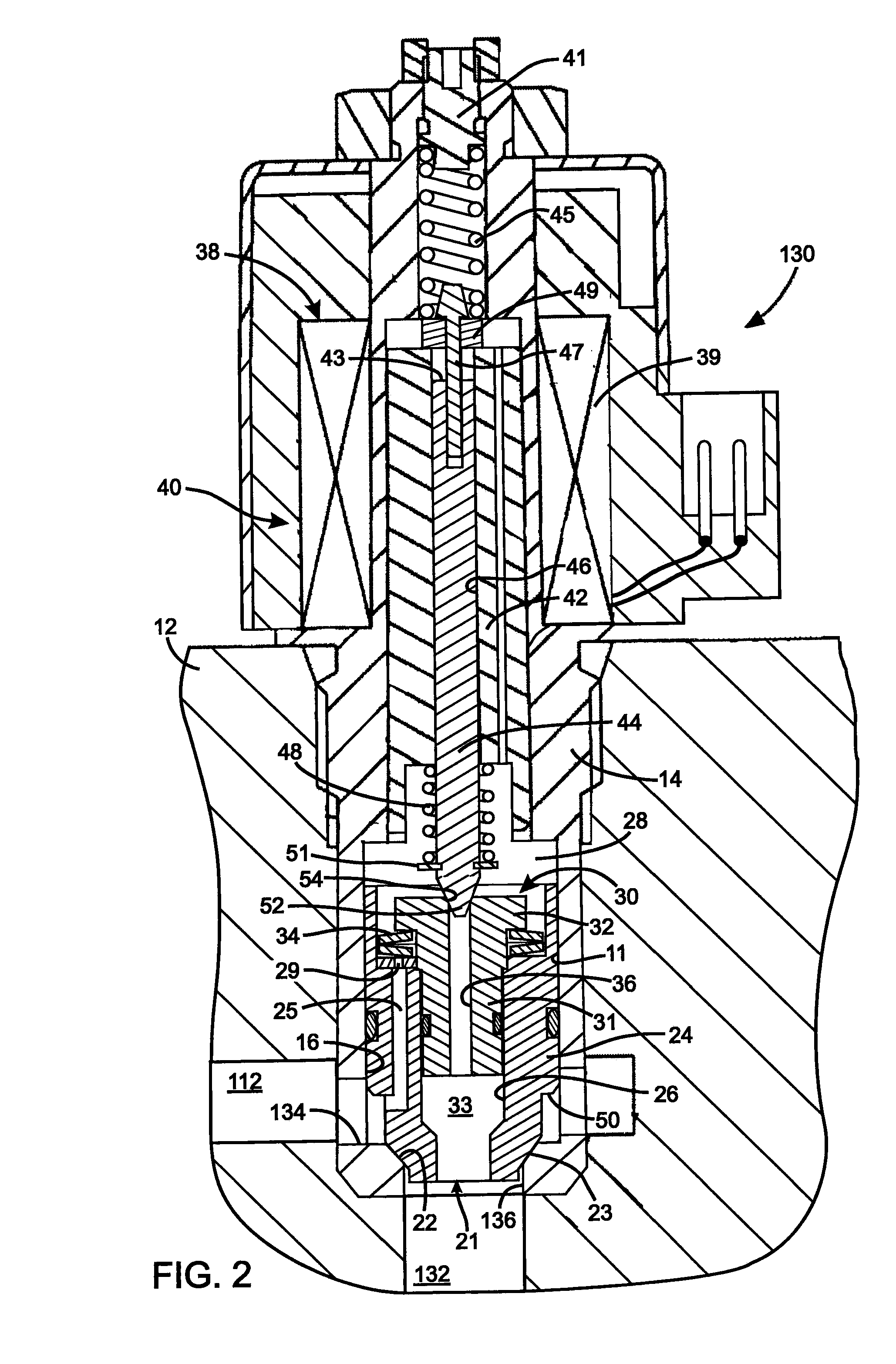

Multi-functional regulator

InactiveUS20080023662A1Reduce number and sizeReduce complexityOperating means/releasing devices for valvesCheck valvesDifferential pressureInlet pressure

A multifunctional regulator provides a housing having an inlet passage joined with an outlet passage through a poppet valve. The housing has a control diaphragm separating the control chamber into a first volume and a second volume and depending on the differential pressure between the two volumes, the diaphragm will push open the poppet valve. Pressurizing and depressurizing valves join the first volume with the inlet and outlet passages, whereby, with an inlet pressure level within the inlet passage greater than an outlet pressure level within the outlet passage, and with the pressurizing valve admitting the inlet pressure level to the first volume, the diaphragm is displaced into the second volume thereby forcing the poppet valve to open and thereby raising the outlet pressure toward the inlet pressure with fluid flow from the inlet to outlet passages.

Owner:STANDFORD MU

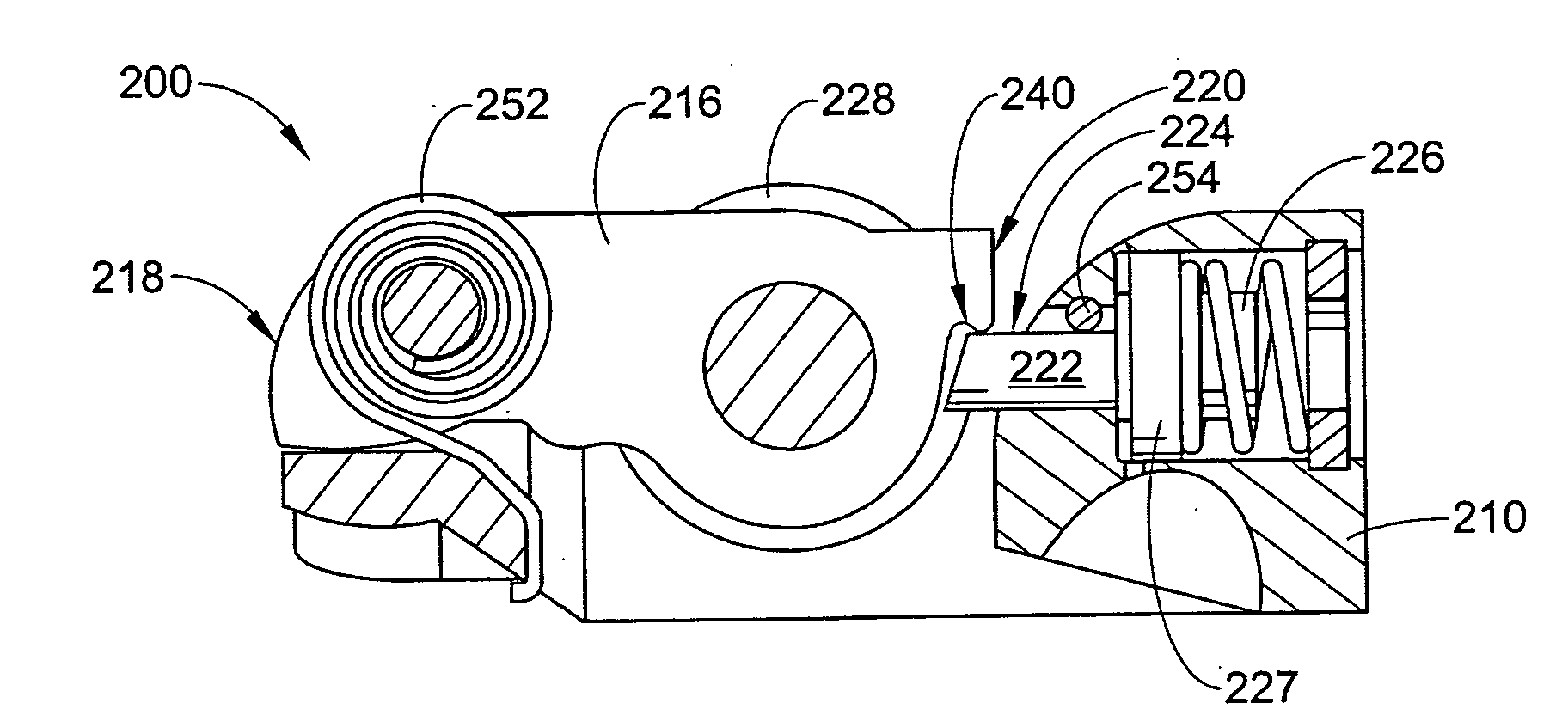

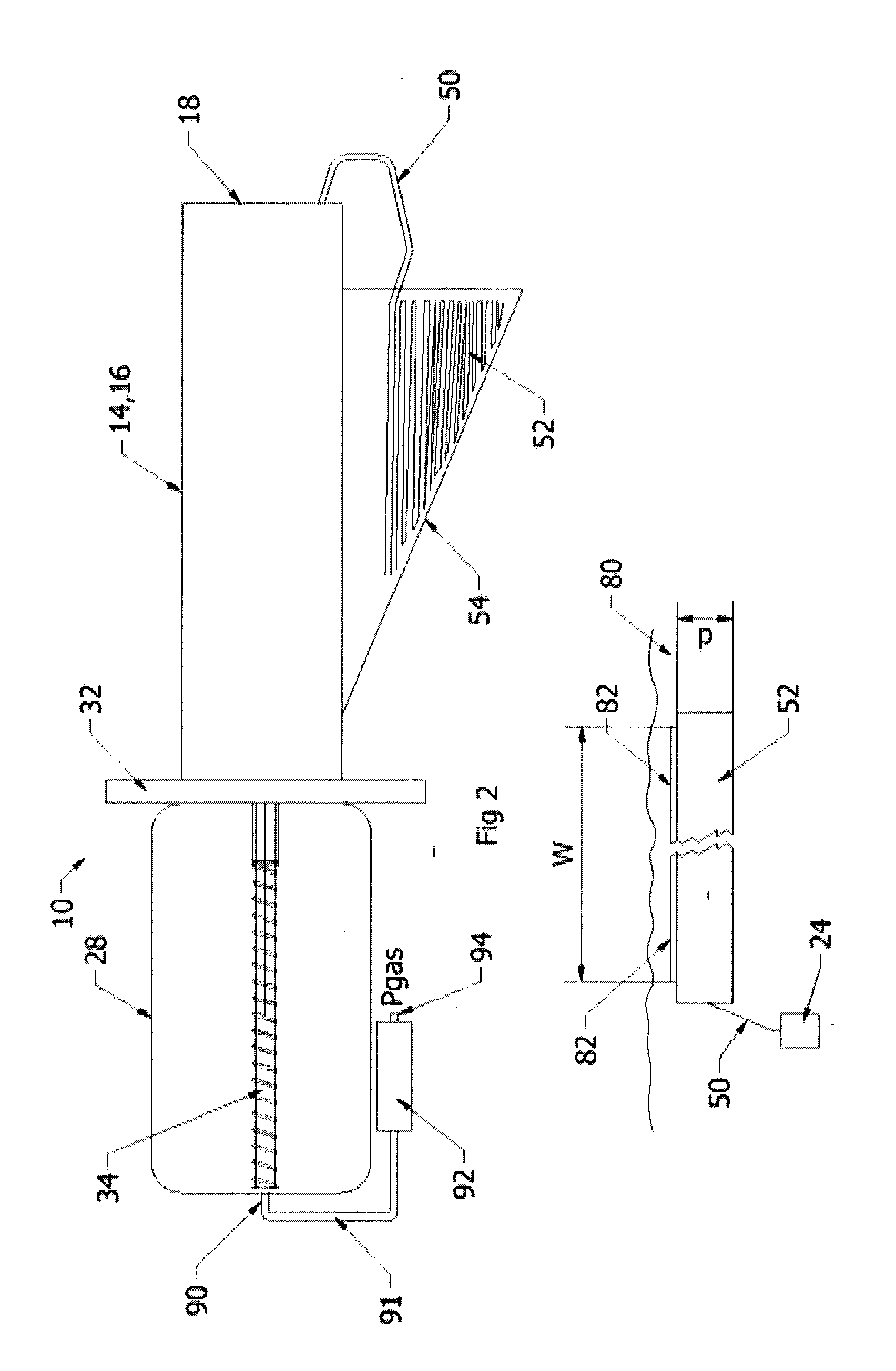

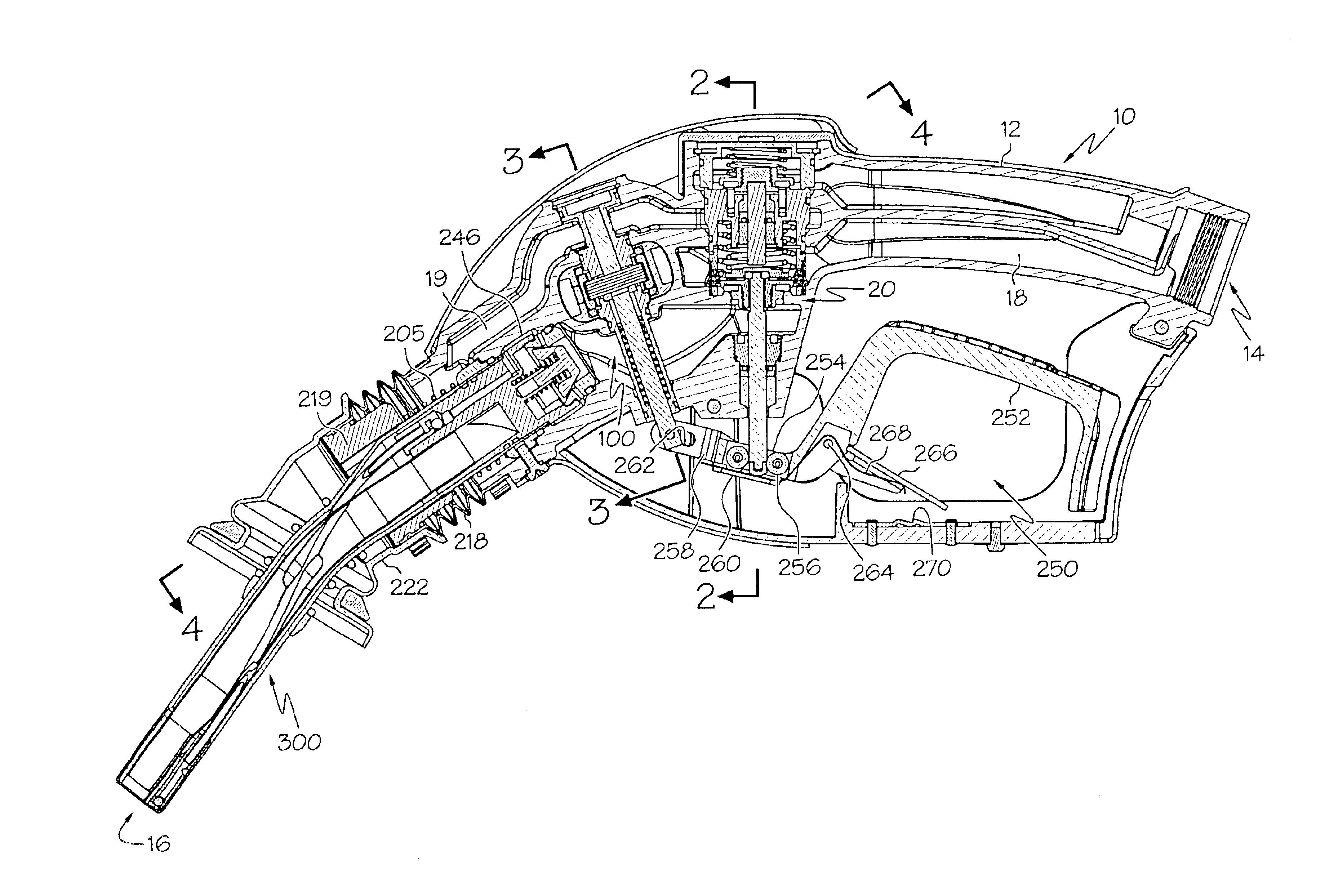

Air cannon and associated launch canister for a line-fouling system

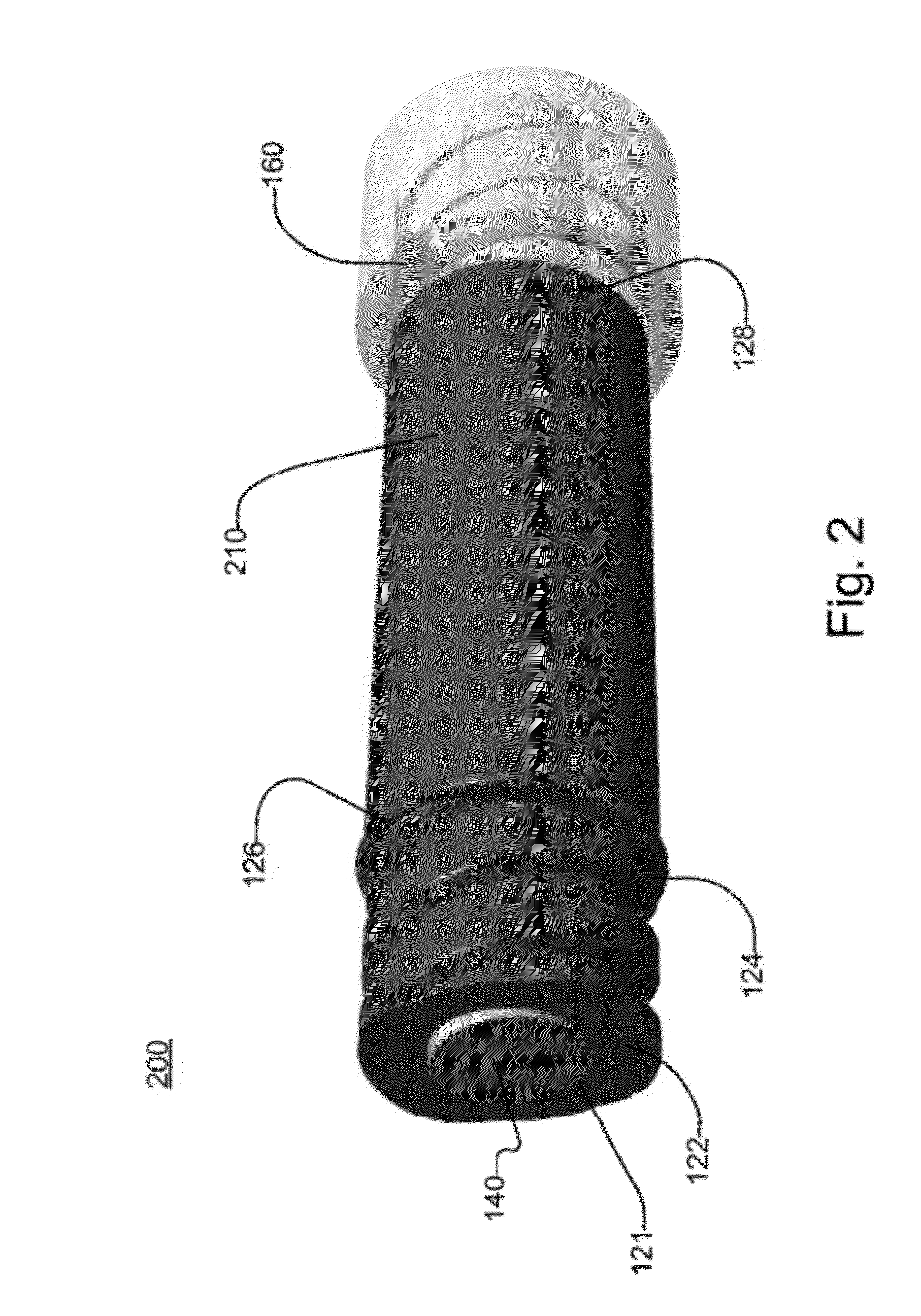

ActiveUS20160161225A1Rapidly deployableDirect forceDefence devicesPeptide/protein ingredientsCouplingEqualization

FIG. 7 shows an air cannon system loaded with a launch canister containing a prop-fouler. A pressure vessel (28) contains an inlet including a poppet valve (100) that, upon command, can be selectively placed in either a one-way flow position to permit charging of the pressure vessel or otherwise opened to trigger rapid discharge through pressure equalization with the ambient environment. The air cannon may include multiple splayed barrels or a single barrel (158). A launch canister (202), realized in the form of a tube, has a driving plate (350) that closes an end of the launch tube. The driving plate is the first point loaded into the barrel. Within the launch canister (202) a first portion of a floating prop-fouling line is stored. The prop-fouling line, such as made from Dyneema®, has at its ends two drogues that, upon entry into the water, fill with water to produce drag resistance to movement of the prop-fouling line. To avoid undue stress on canopy panels of each drogue and to avoid twisting of shroud lines (312) to the canopy, a rotating shackle (310a, 310b) acts as a coupling point between the shroud lines (312) and the prop-fouling line. Only one drogue (306), its associated coupling and a selected length prop-fouling line are loaded into the launch canister, with the other drogue and its rotating shackle (310b) loaded into a cradle (166). Upon firing, gas expansion causes the rapid acceleration and ejection of the launch tube (202) and generally straight line deployment of the prop-fouling line (302).

Owner:BCB INT

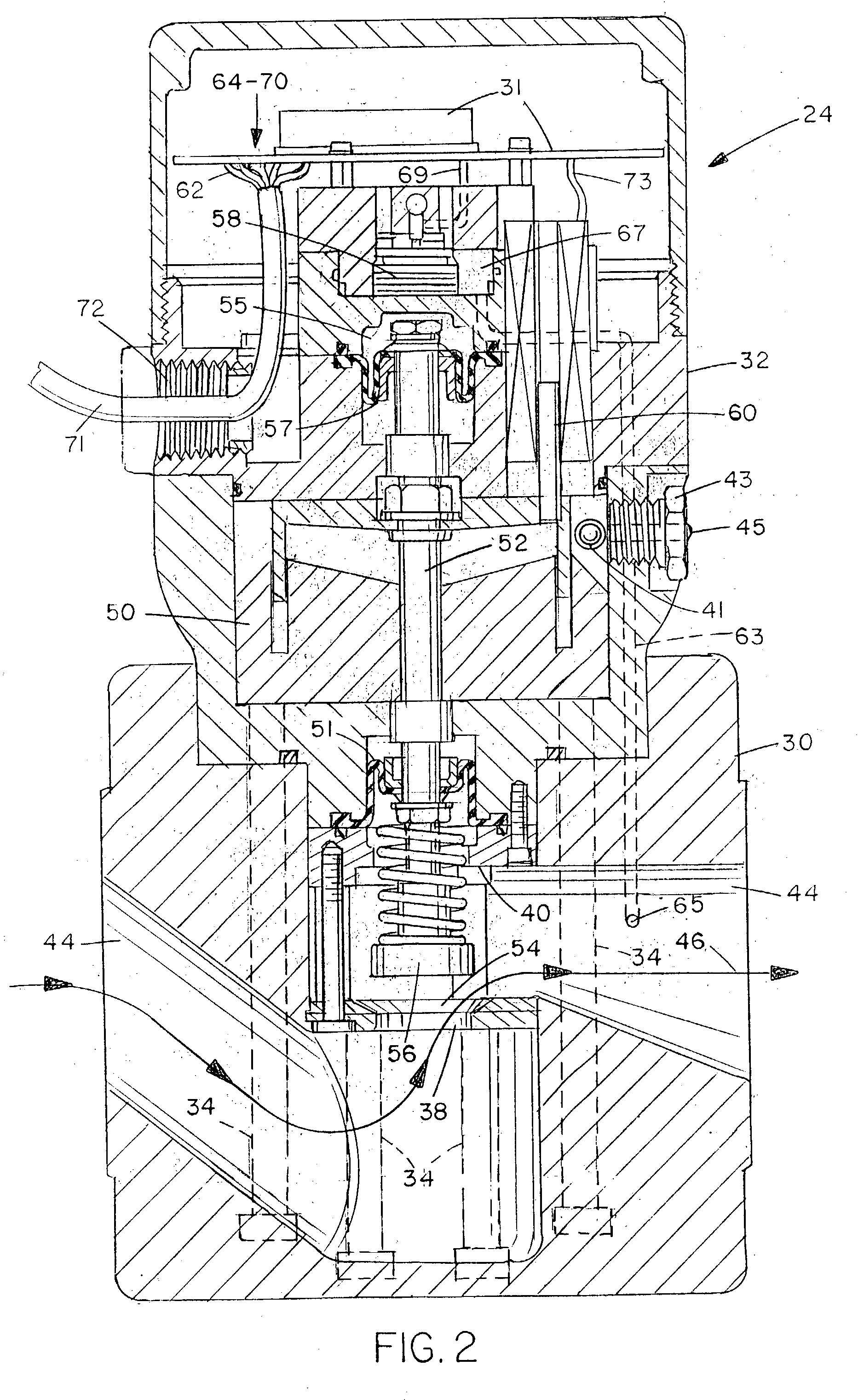

Emission control valve for gas-fueled engines

InactiveUS20040139951A1Electrical controlOperating means/releasing devices for valvesActuatorInternal combustion engine

An emission control device for use with stationary or mobile gas-fueled internal combustion engines is described, which is placed in the fuel supply line and operates with full fuel authority. An oxygen sensor measures exhaust oxygen content. The valve internally houses a programmable microprocessor, a pressure transducer and a fuel flow conduit throttled by a balanced poppet valve. Signals to the microprocessor from the oxygen sensor, the pressure transducer indicating outflow gas pressure cause the microprocessor to motivate an actuator to move the valve within the gas stream and thus regulate the outlet pressure and also the gas flow rate to maintain a desired air / fuel ratio to the engine and keep exhaust emissions at an optimum level consistent with the engine operating load requirements and characteristics. Finite incremental control of valve position, preferably assisted by an internal position transducer, permits close control of the exhaust emissions.

Owner:CONTINENTAL CONTROLS CORP

Undersea hydraulic coupling member

An undersea hydraulic coupling member is disclosed having a bleed valve which opens to allow hydraulic fluid trapped in the coupling member to escape until the pressure is below a predetermined amount. The coupling member employs a poppet valve within a sleeve.

Owner:NAT COUPLING

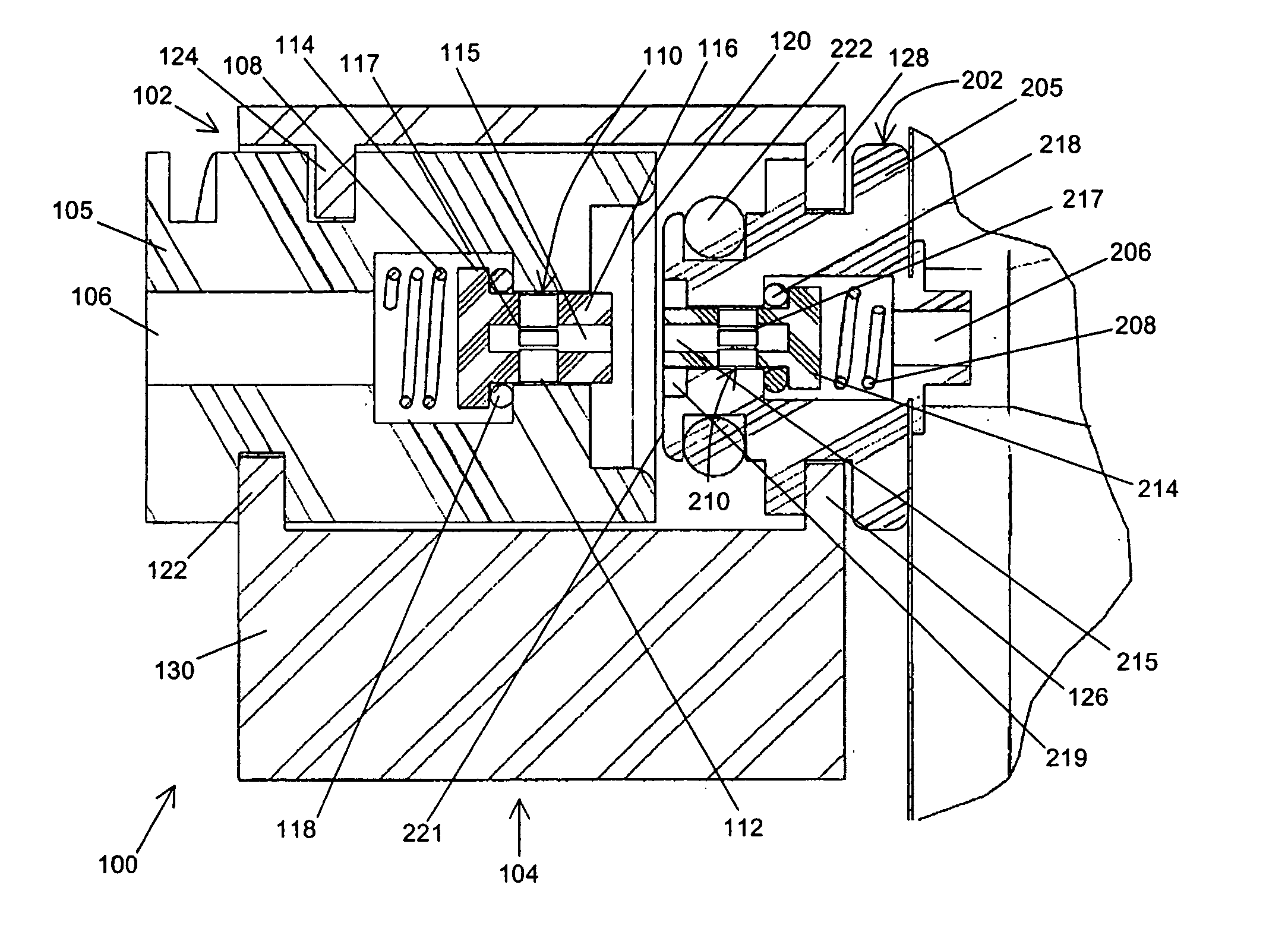

Poppet valve operated by an electrohydraulic poppet pilot valve

ActiveUS20100155633A1Operating means/releasing devices for valvesServomotor componentsControl roomEngineering

A control valve includes a main poppet that moves in response to pressure in a primary control chamber and thereby controls the flow of fluid through a valve seat between first and second ports. A passageway extends between the second port and the primary control chamber and includes a variable flow restriction that decreases as the main poppet moves away from the valve seat. An electrohydraulic pilot valve has a pilot poppet which controls fluid flow from the primary control chamber to the first port in response to pressure in a pilot control chamber. A sub-pilot valve selectively releases pressure in the pilot control chamber to operate the pilot poppet to open and close a path between the inlet and the outlet. Using an electrohydraulic pilot valve enables the main poppet to operate quickly in controlling large fluid flow rates. Unidirectional and bidirectional versions of the control valve are described.

Owner:HUSCO INT INC

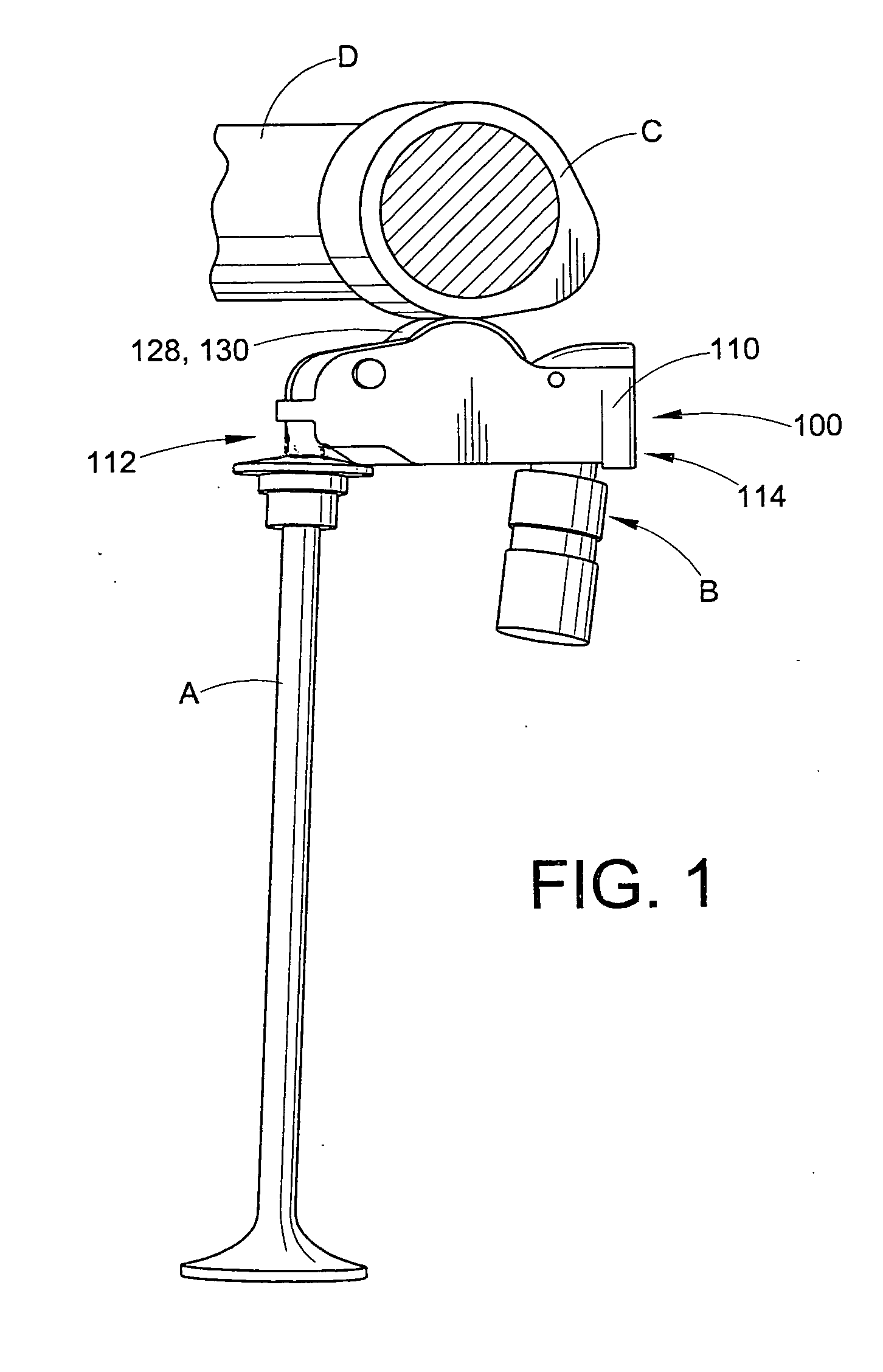

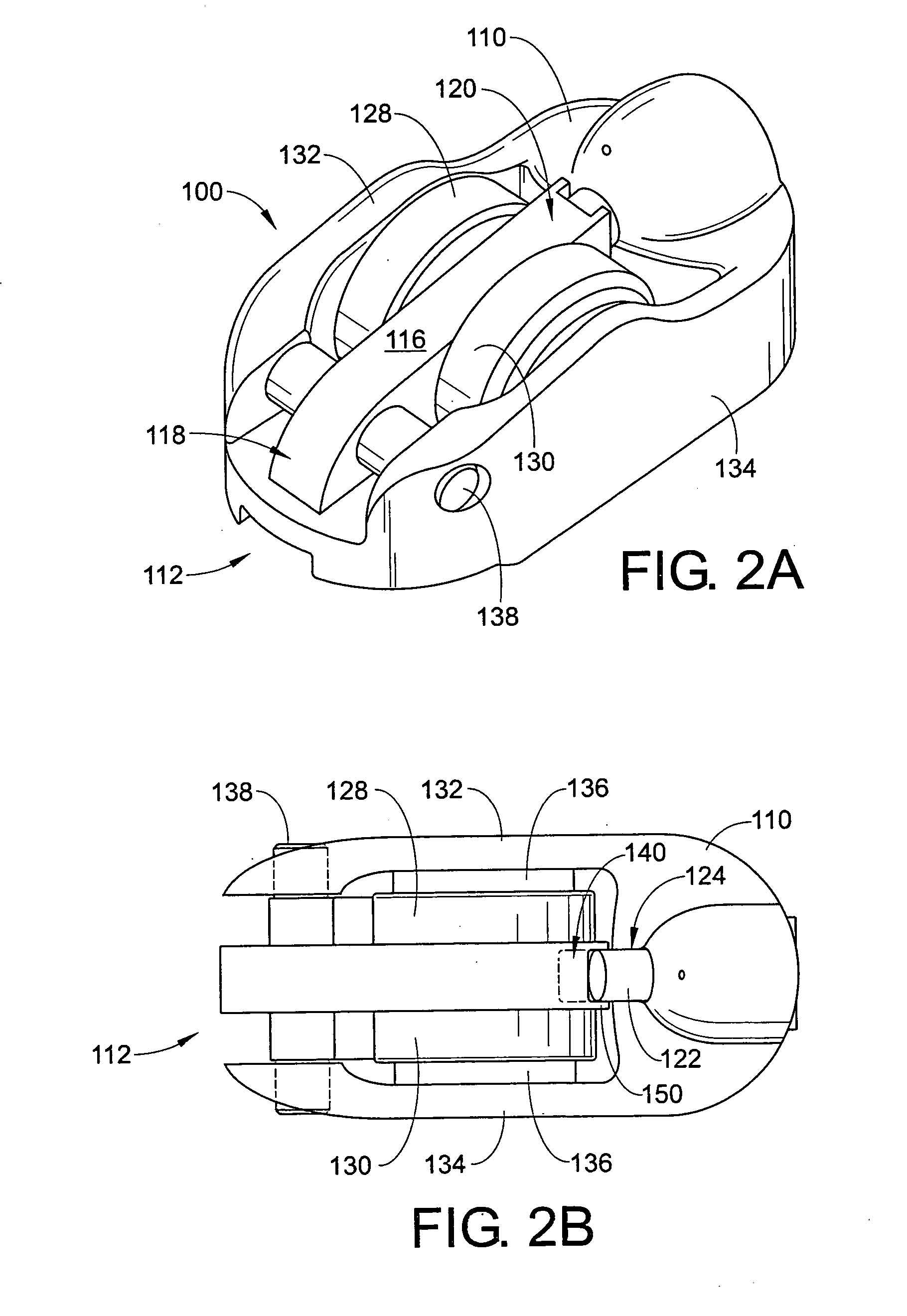

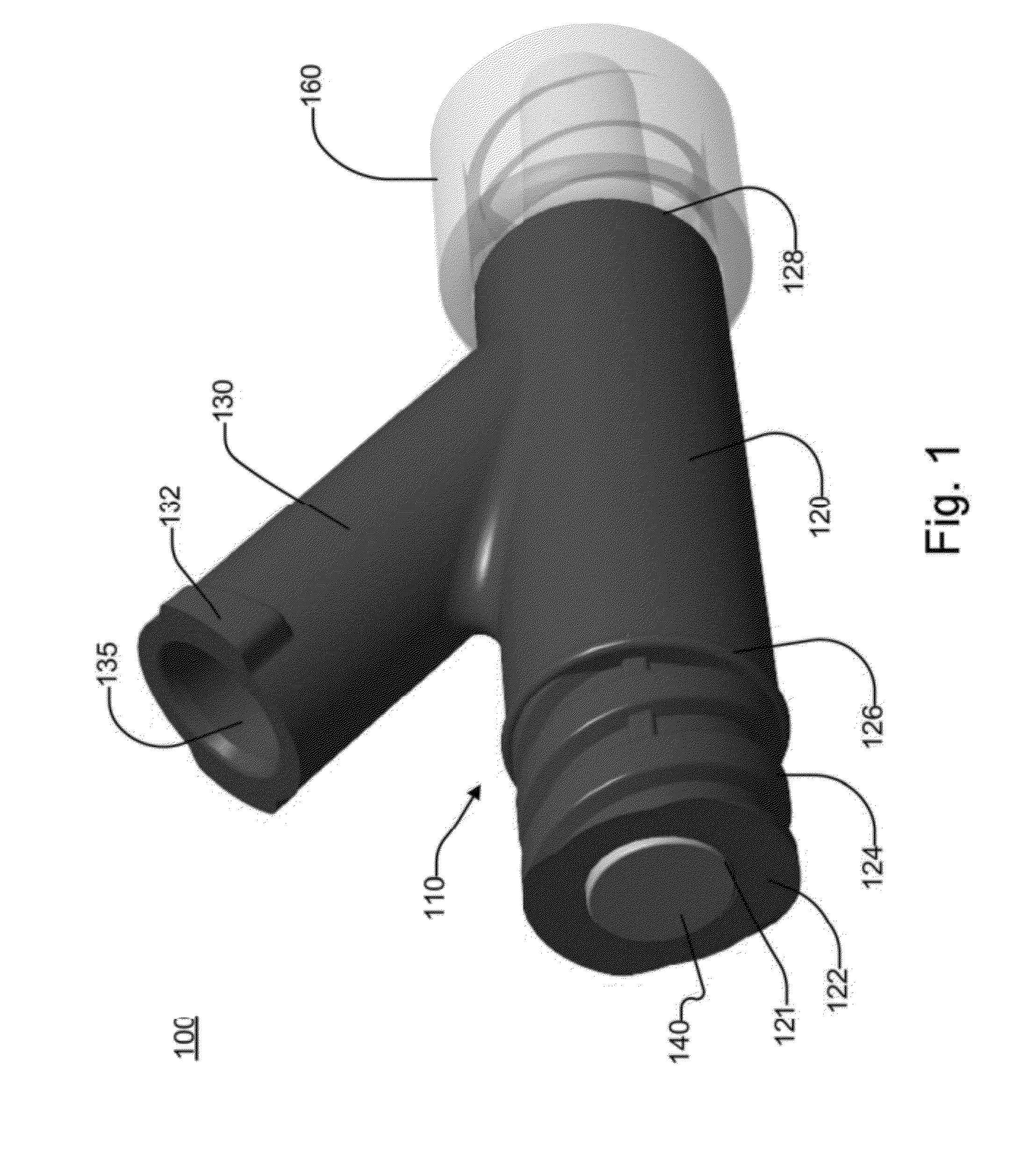

Nozzle including first and second lever portions

A nozzle is provided for dispensing liquid into a container. The nozzle includes a nozzle body, having an inlet for receiving liquid, an outlet for dispensing liquid, and a liquid passage extending between the inlet and the outlet. A poppet valve assembly including a poppet valve stem, wherein the poppet valve assembly is adapted to selectively control the flow of liquid through the liquid passage. A latch stem is provided that is slidable to and from an operative position. A retention pin attached to the latch stem and at least one first rotatable member is disposed to contact the retention pin. A first lever portion includes at least one second rotatable member disposed to contact the poppet valve stem and a second lever portion. The second lever portion has a first end pivotally attached to the first lever portion and a second end that engages at least one of the retention pin and first rotatable member.

Owner:OPW FUELING COMPONENTS LLC

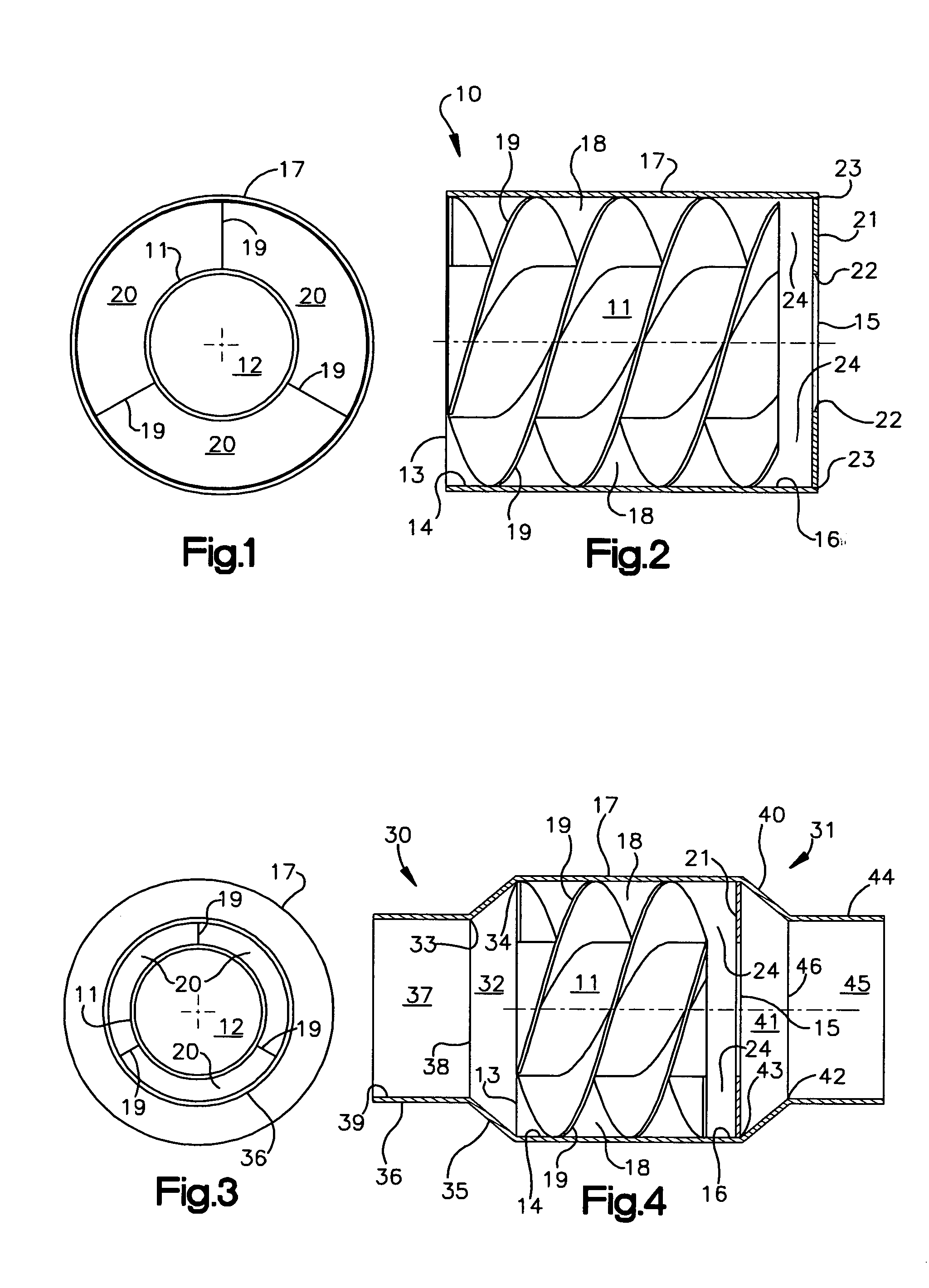

Devices for regulating pressure and flow pulses

Devices are provided for regulating the pressure pulses and flow pulses that are emitted in the exhausts of apparatus and equipment such as internal combustion engines, compressors and poppet valves. The pressure pulses are reflected from a reflecting member to their source as expansion waves that create a reduced pressure zone that allows subsequently emitted flow pulses to be more easily emitted, thereby enhancing the operational efficiency of the apparatus and equipment. Flow pulses that contain exhaust products such as the products of combustion from an internal combustion engine are regulated so that the exhaust flow they generate is not unduly restricted within the device and an undesirable back pressure that resists the emission of flow pulses from their source created. In regulating the pressure and flow pulses, the devices attenuate the noise generated by the pressure and flow pulses.

Owner:DADD PAUL M

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com