Patents

Literature

175results about How to "Direct force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

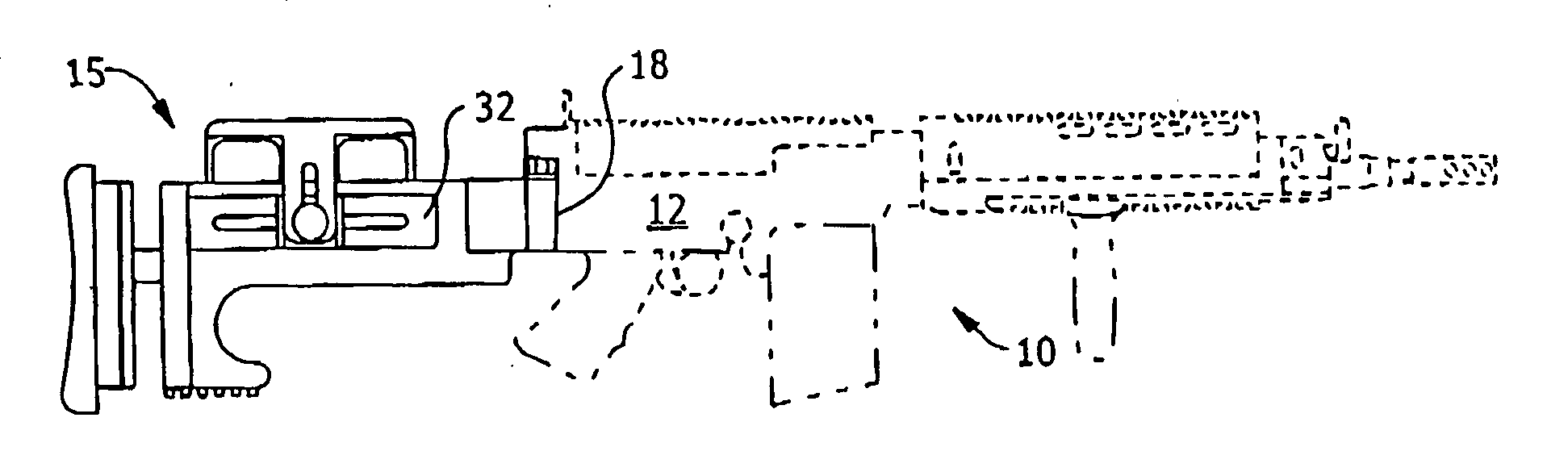

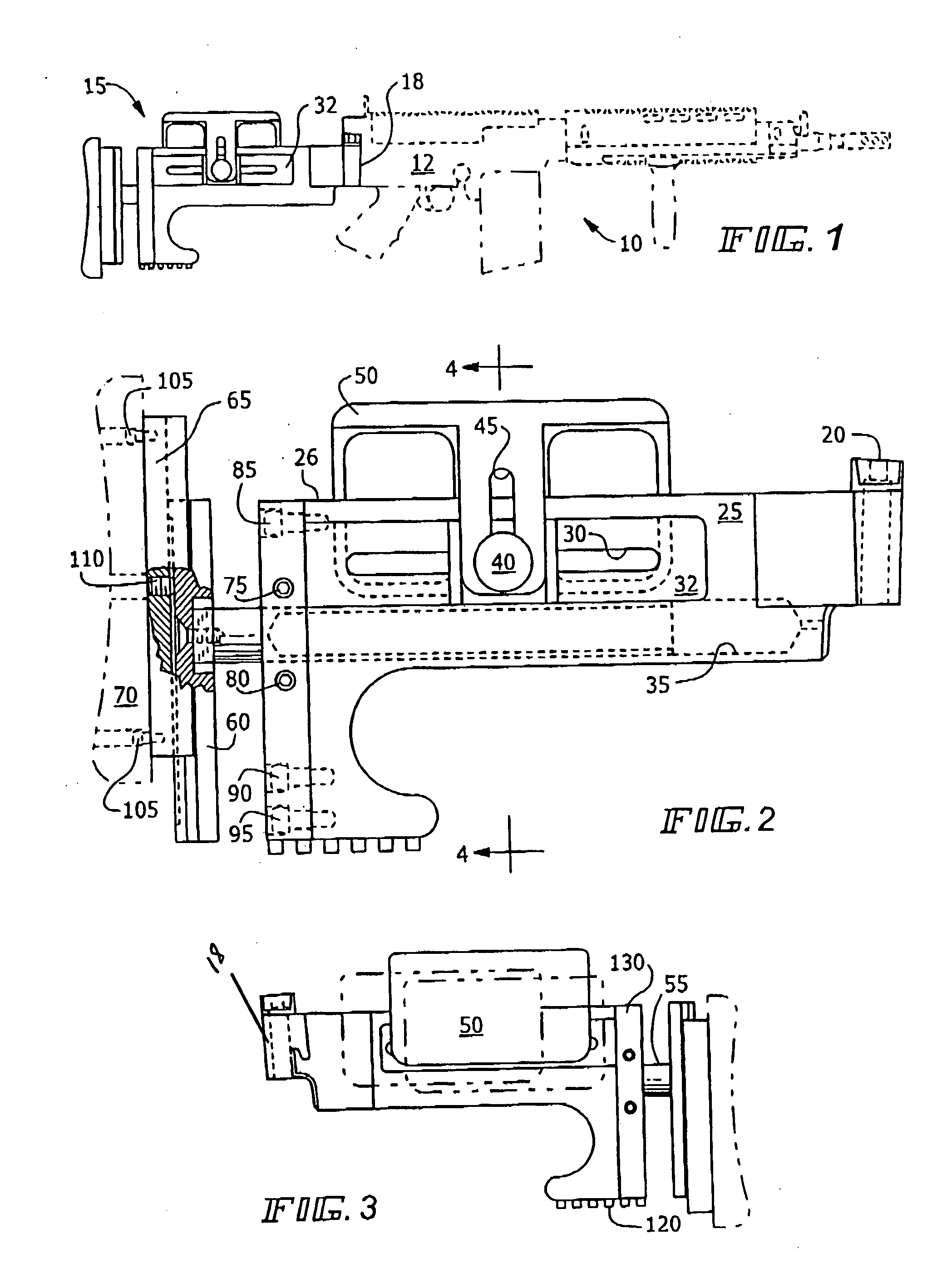

Adjustable butt stock

A butt stock for a shoulder held firearm with an horizontally and vertically adjustable cheek rest, reversibility of the cheek rest without loss of any of the other adjustments, a shoulder pad assembly to allow from 0 to 360 degrees of adjustment of the angle of the shoulder pad to the rest of the shoulder held firearm, an adjustable length of pull, and a butt stock body that could function as a cheek rest even if the adjustable cheek rest were to be disconnected.

Owner:ABRAHAM DICK +1

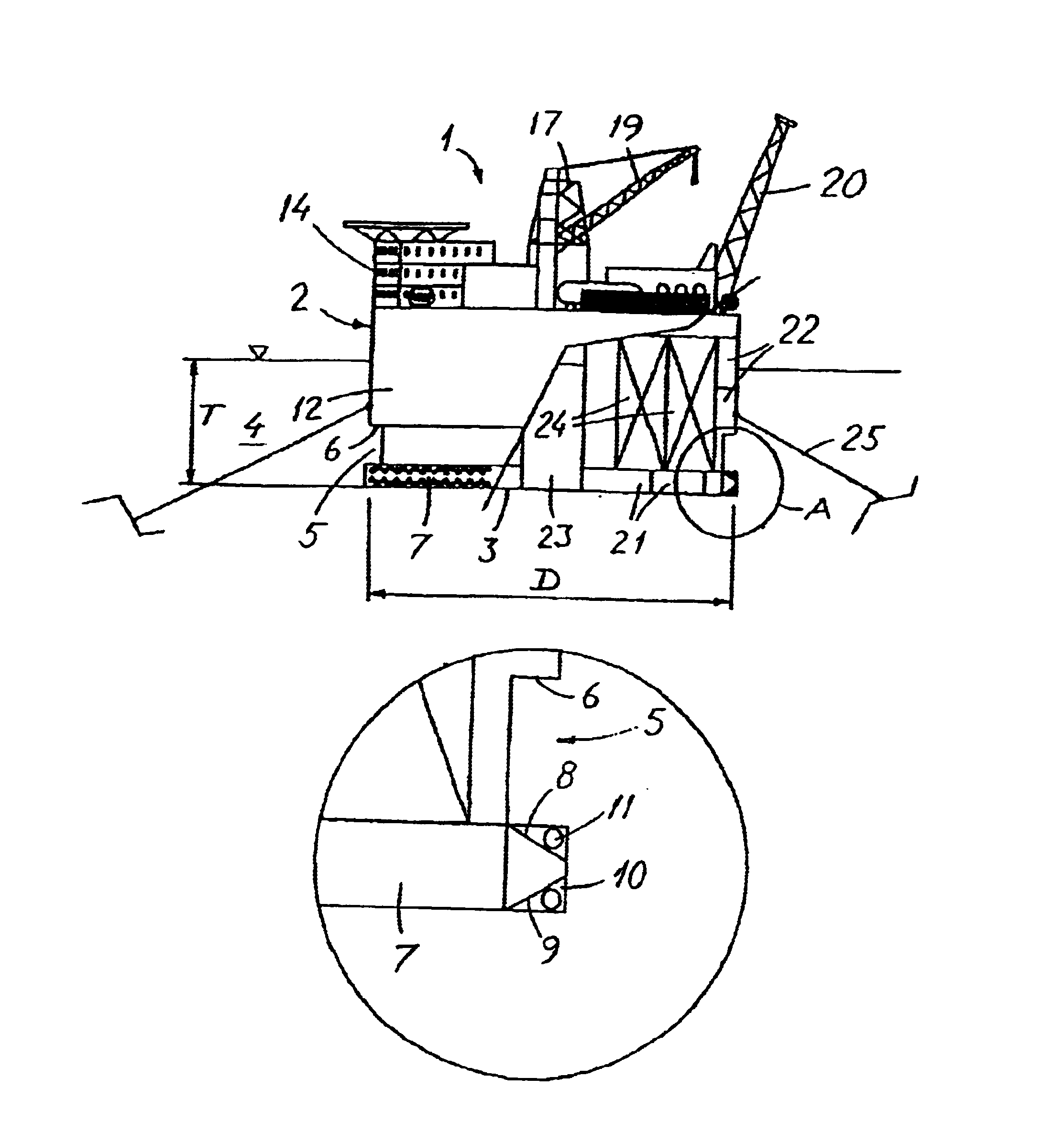

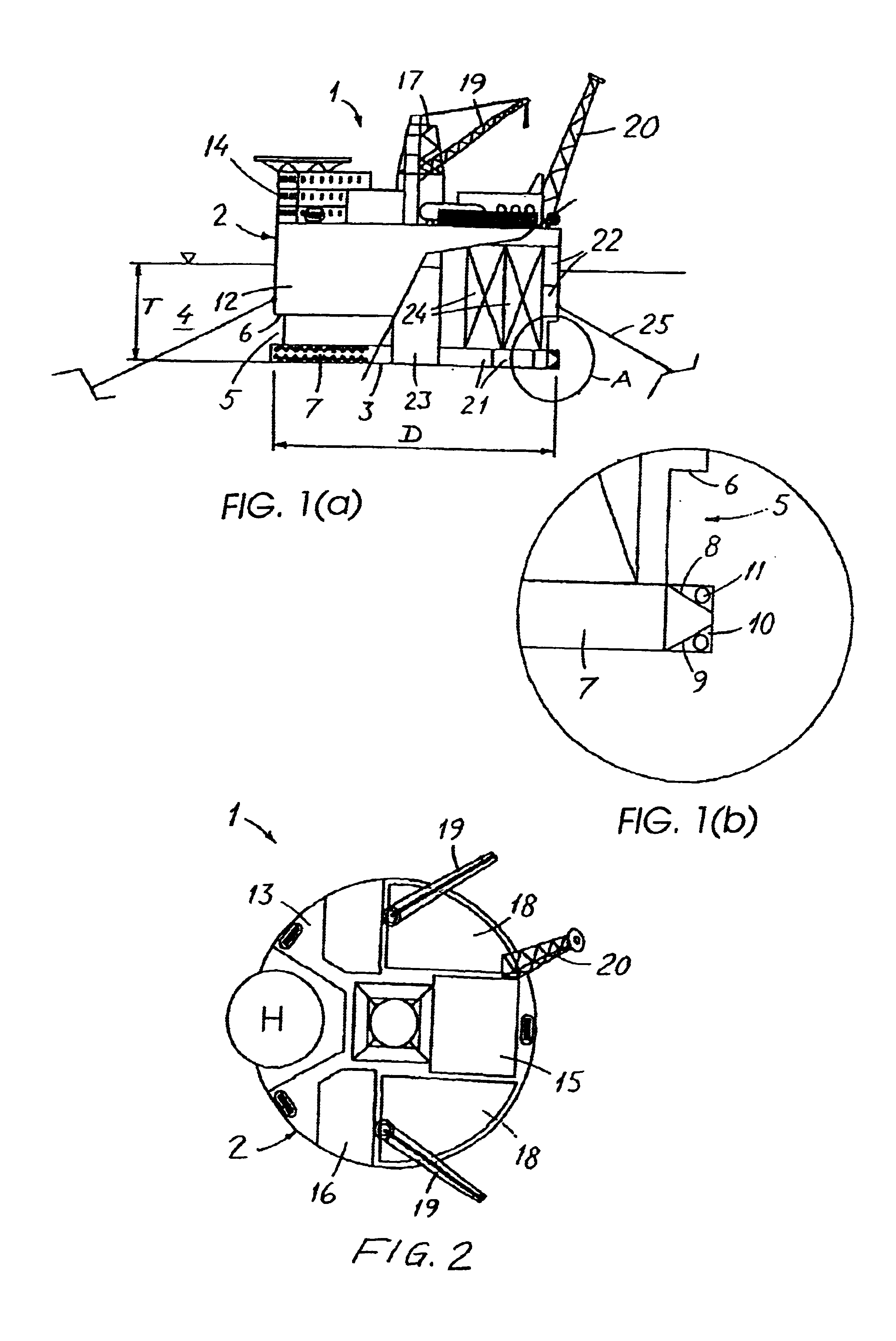

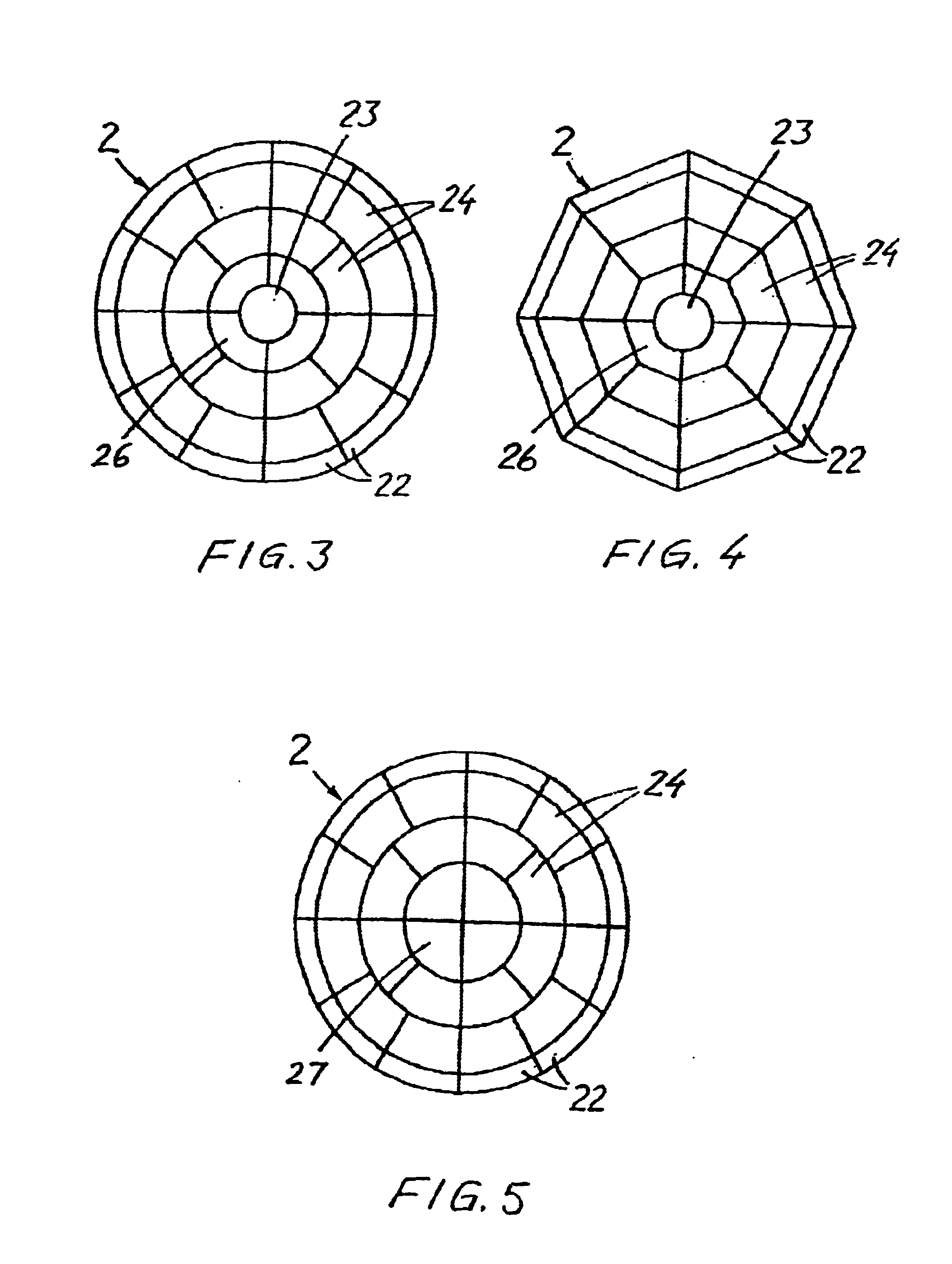

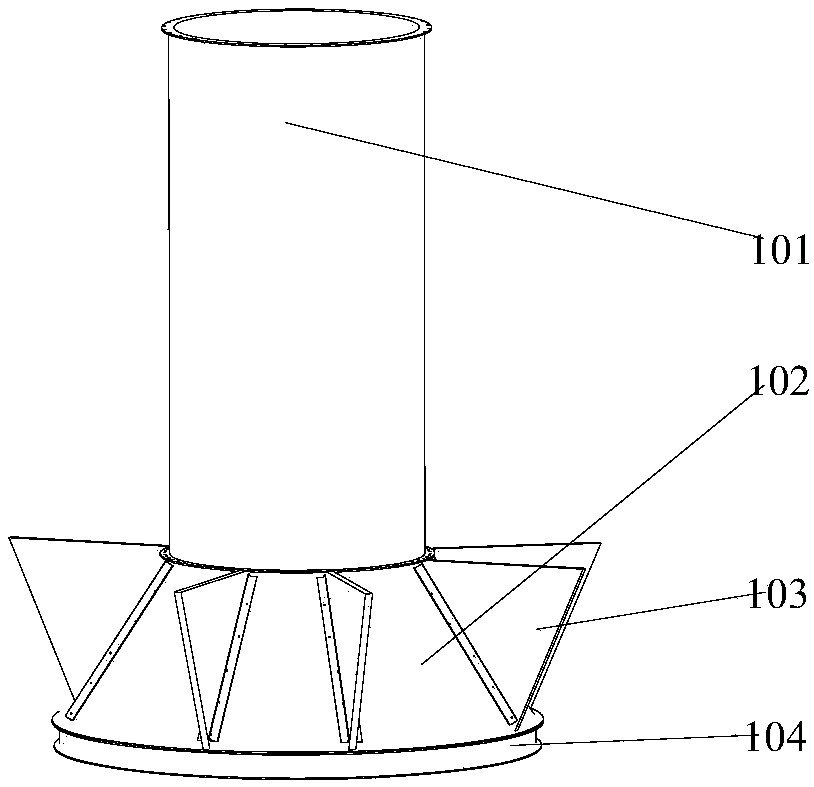

Offshore platform for drilling after or production of hydrocarbons

InactiveUS6945736B2Reduce forceReduce movementDrilling rodsDerricks/mastsWell drillingMarine engineering

Platform for drilling after or production of hydrocarbons at sea, consisting of a semi-submersible platform body which supports drilling and / or production equipment on its upper surface. The platform body is designed as a vertical mainly flat bottomed cylinder which is provided with at least one peripheral circular cut-out in the lower section of the cylinder since the centre of buoyancy for the submerged section of the platform is positioned lower than the centre of gravity of the platform.

Owner:SEMBCORP MARINE INTEGRATED YARD PTE LTD

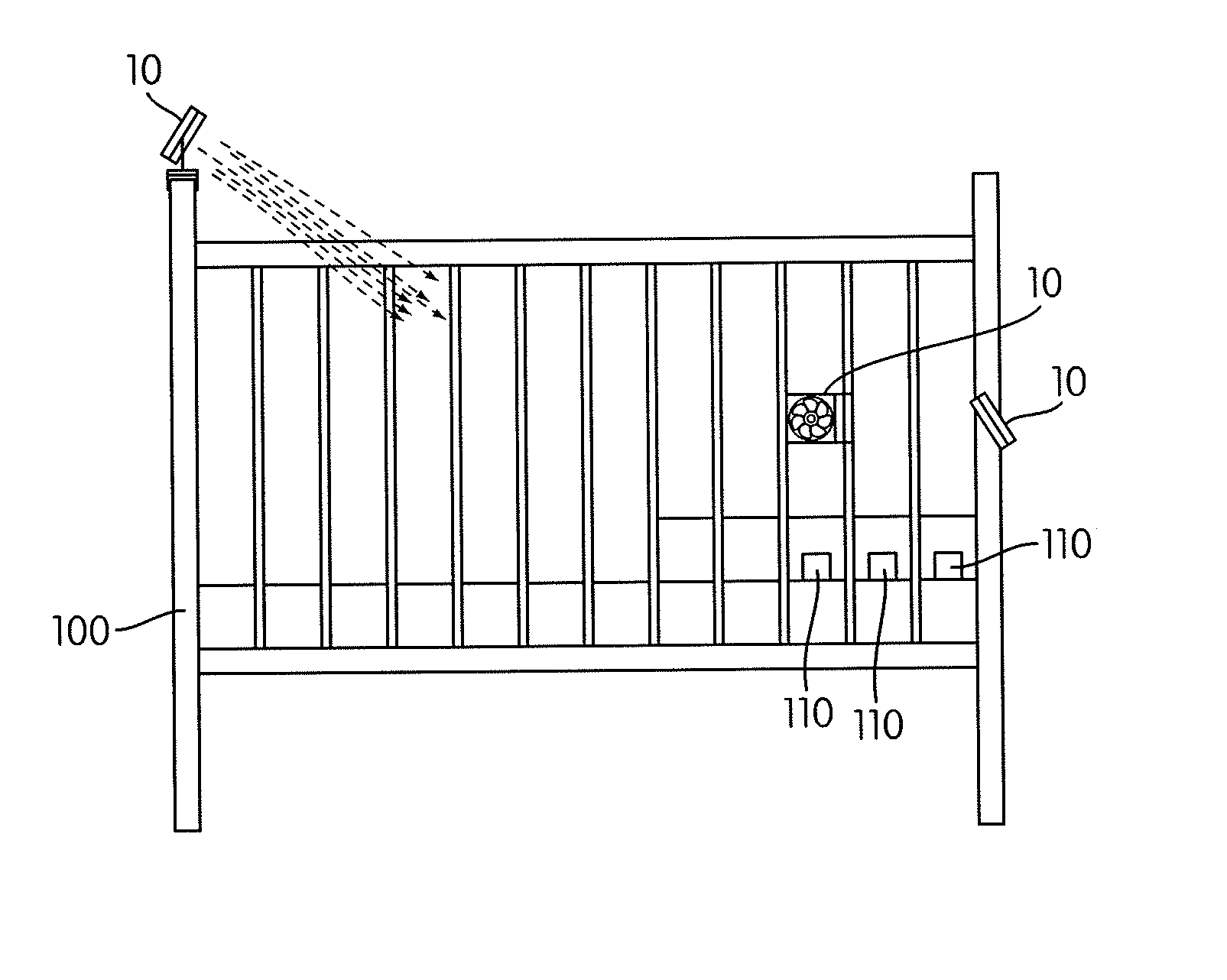

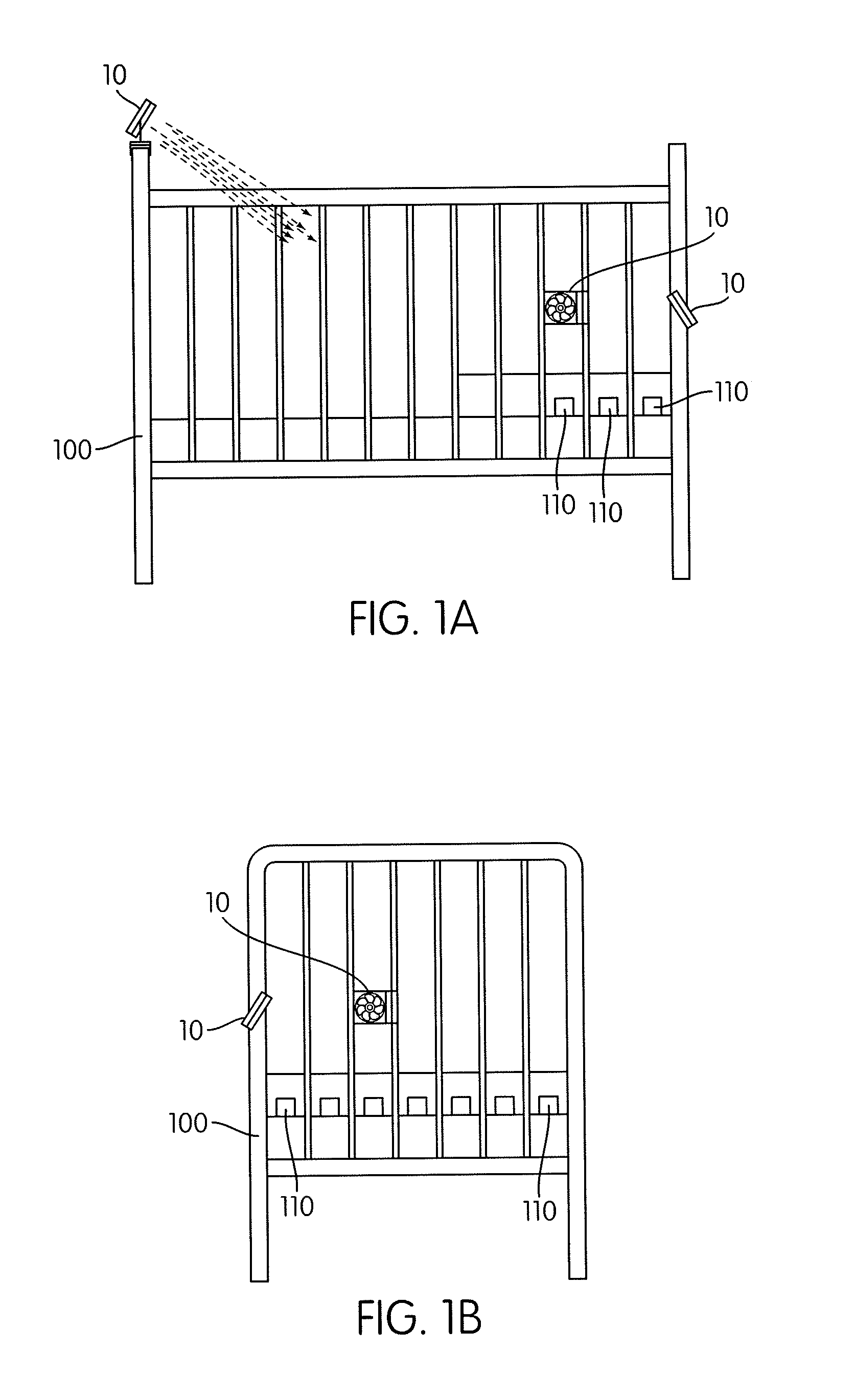

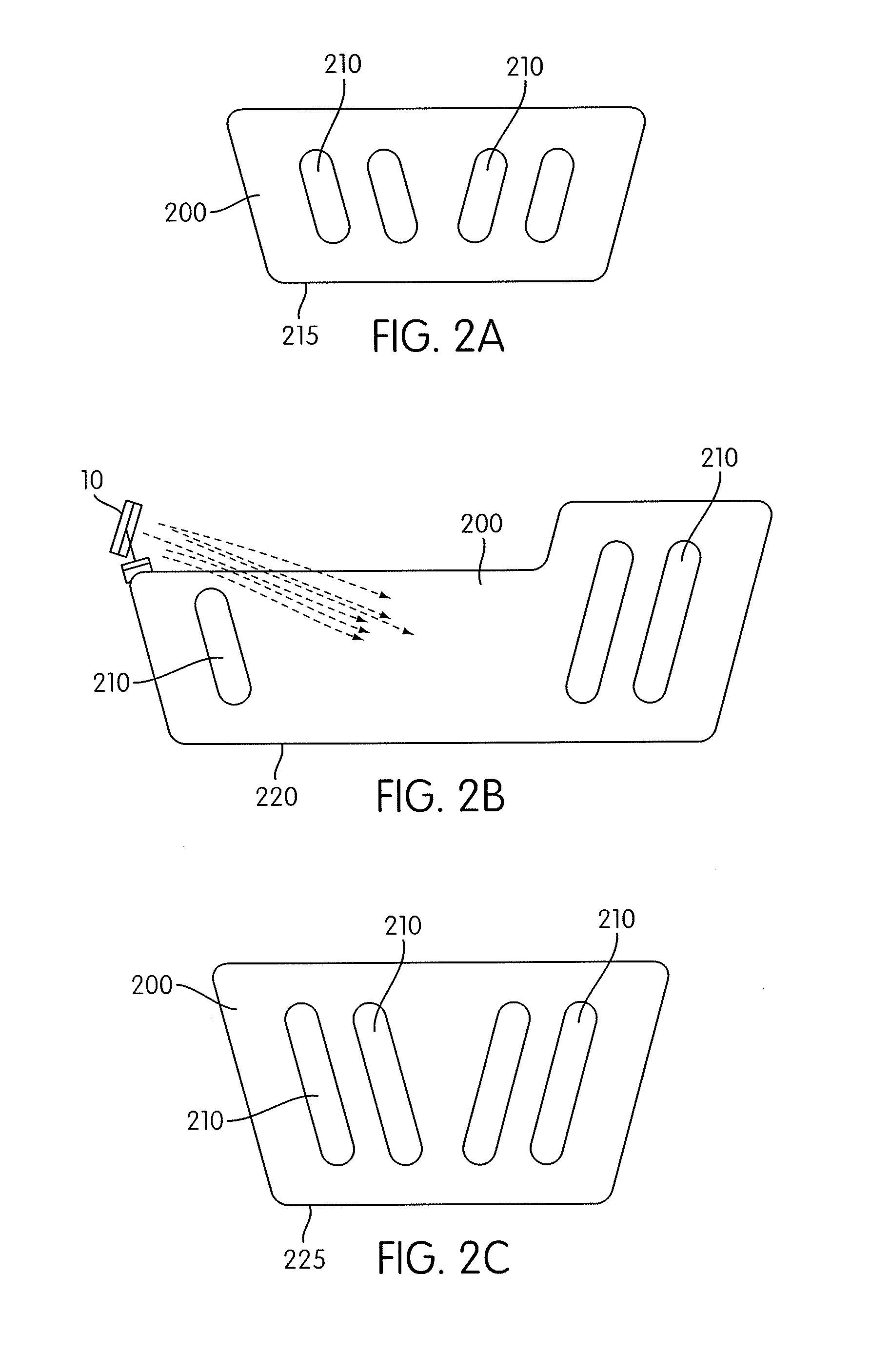

Infant Sleeping Area Ventilation System For the Prevention of Sudden Infant Death Syndrome

InactiveUS20100125949A1Increased oxygen levelsKeep sleeping areaVehicle seatsStuffed mattressesToxic gasSIDS - Sudden infant death syndrome

A ventilation system that includes a fan for providing fresh air within an infant's sleeping area. The fan may be mounted to the infant's sleeping device and may include fan guards surrounding the fan for increased safety. The ventilation system may include a sensing device for monitoring the conditions within the infant's sleeping area. The sensing device may monitor the oxygen level, the carbon dioxide level, and the presence of smoke. The sensing device may monitor for additional toxic gasses or hazardous conditions within the infant's sleeping area. The ventilation system may further include a remote receiver that receives signals from the sensing device if a hazardous condition exists within the infant's sleeping area. The ventilation system may further include local and remote alarms configured to provide notification of a hazardous condition within the infant's sleeping area.

Owner:REX ENTERPRISES

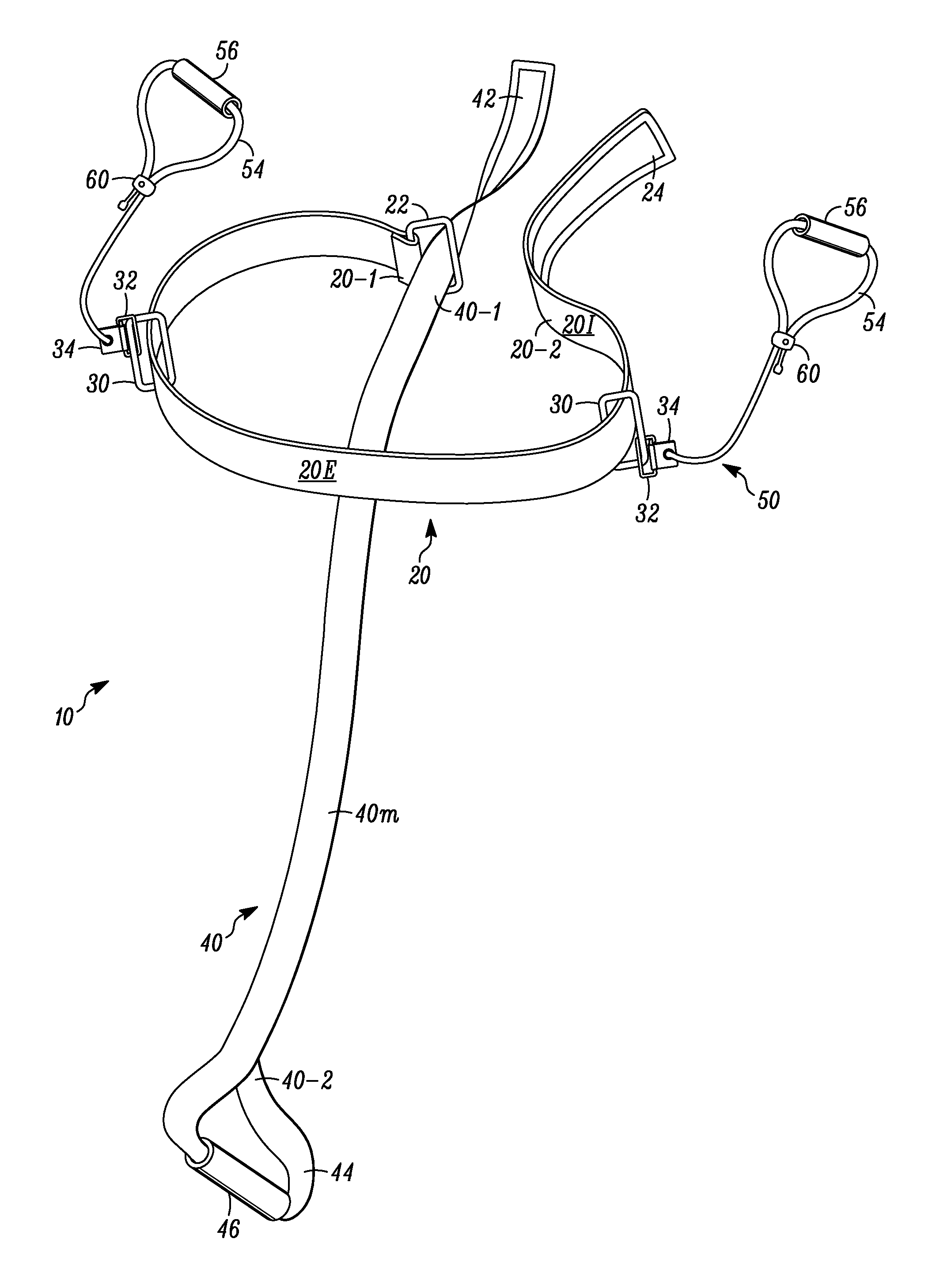

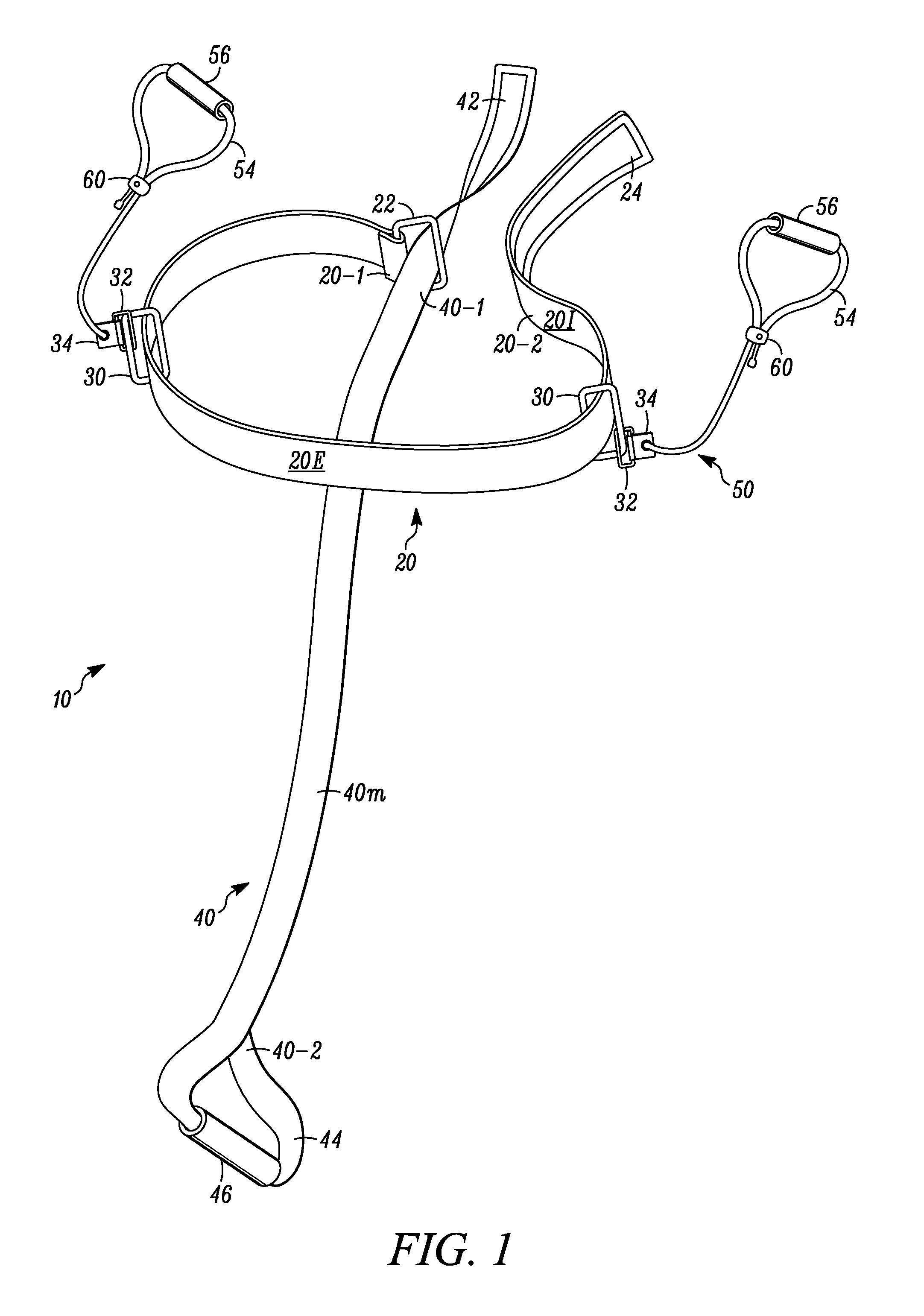

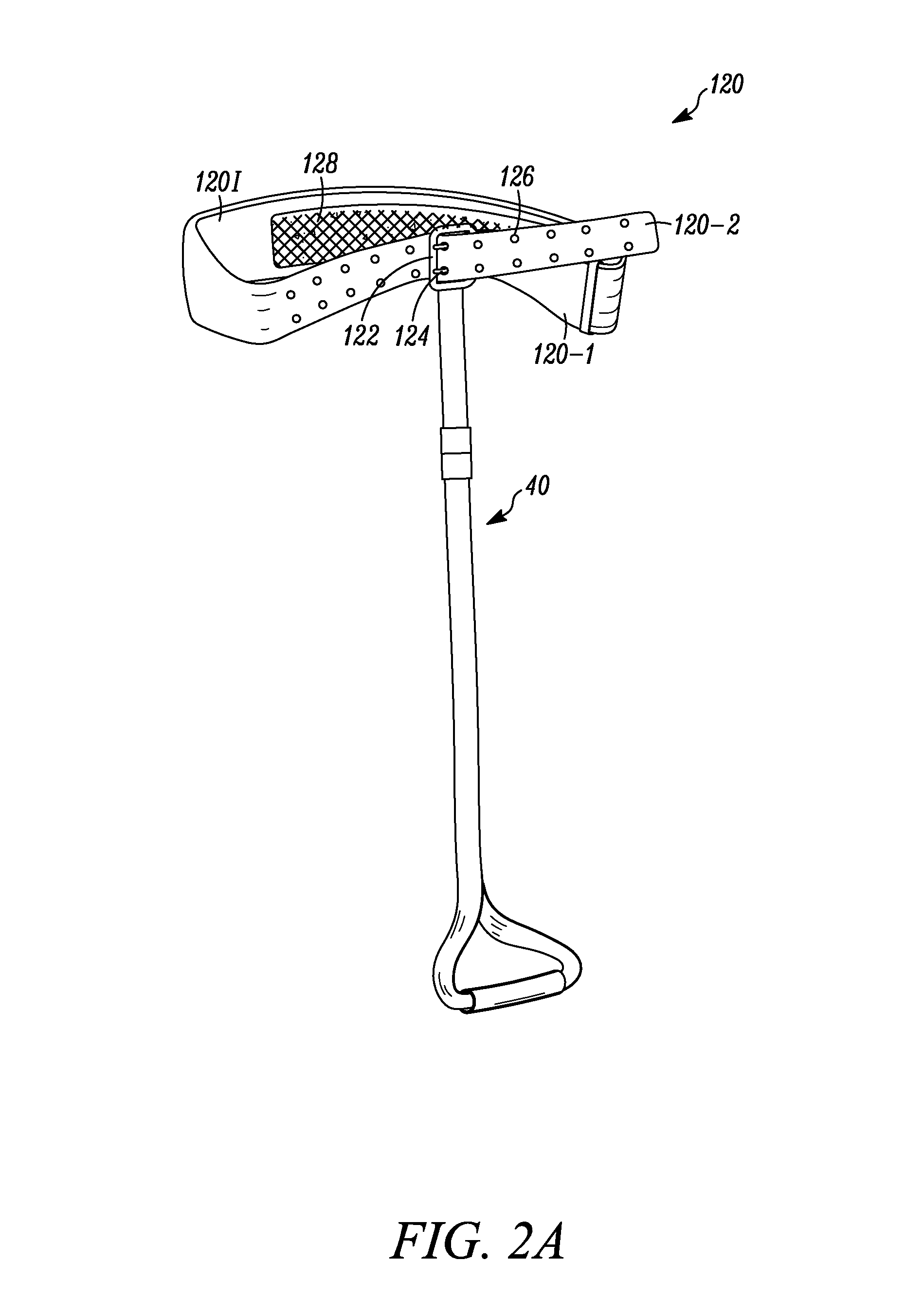

Spinal therapy device

ActiveUS20140200499A1Minimize shearLimited amountFreely-suspended gymnasticsChiropractic devicesAnesthesiaSacroiliac joint

The invention provides a spinal therapy device that can be used by an individual to self-apply overpressure, spinal decompression, spinal joint mobilization or a combination thereof to the spine, as well as methods for using a spinal therapy device to self apply overpressure, spinal decompression, spinal joint mobilization or a combination thereof.

Owner:THE OAKFORD GRP LLC

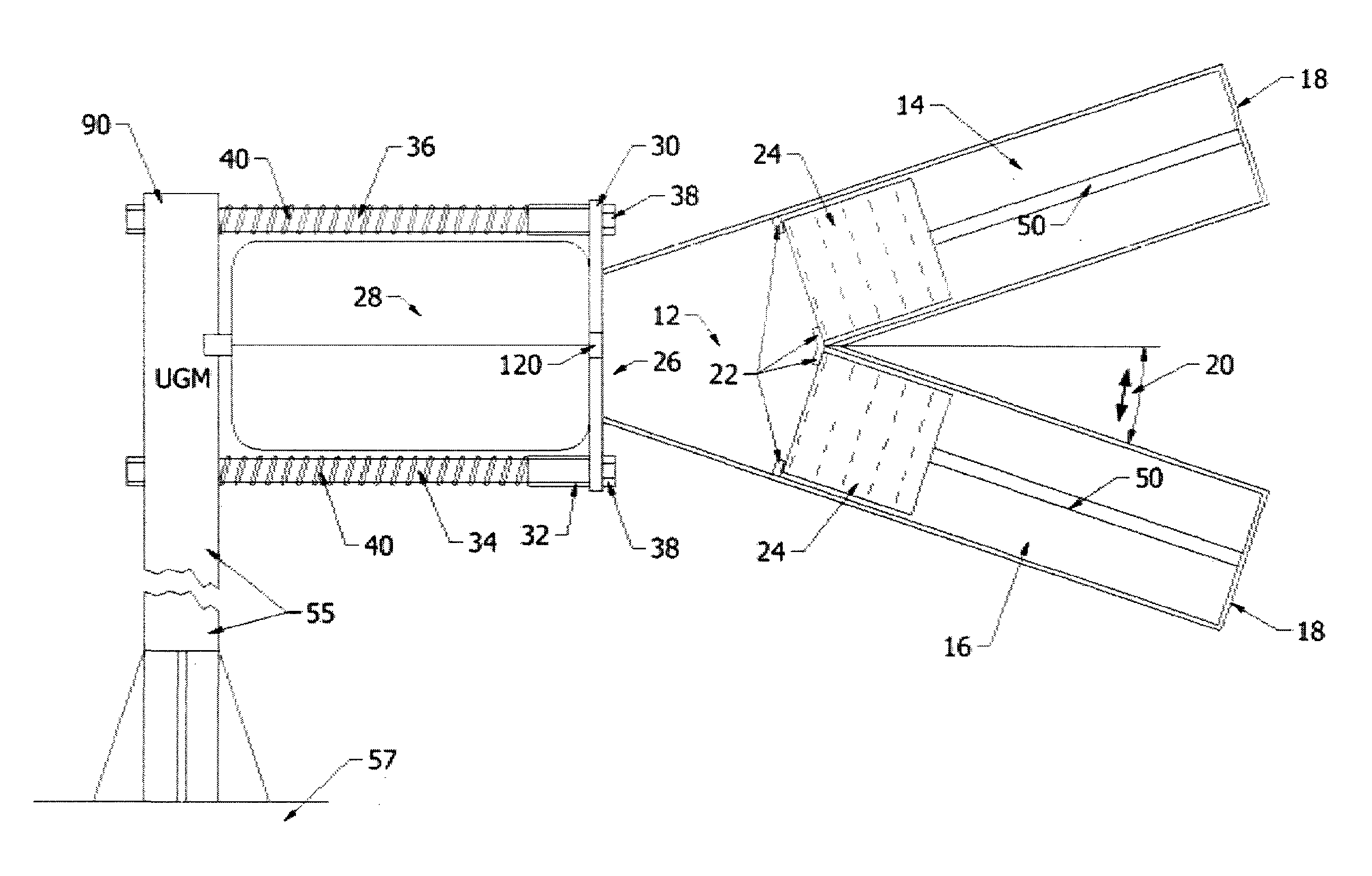

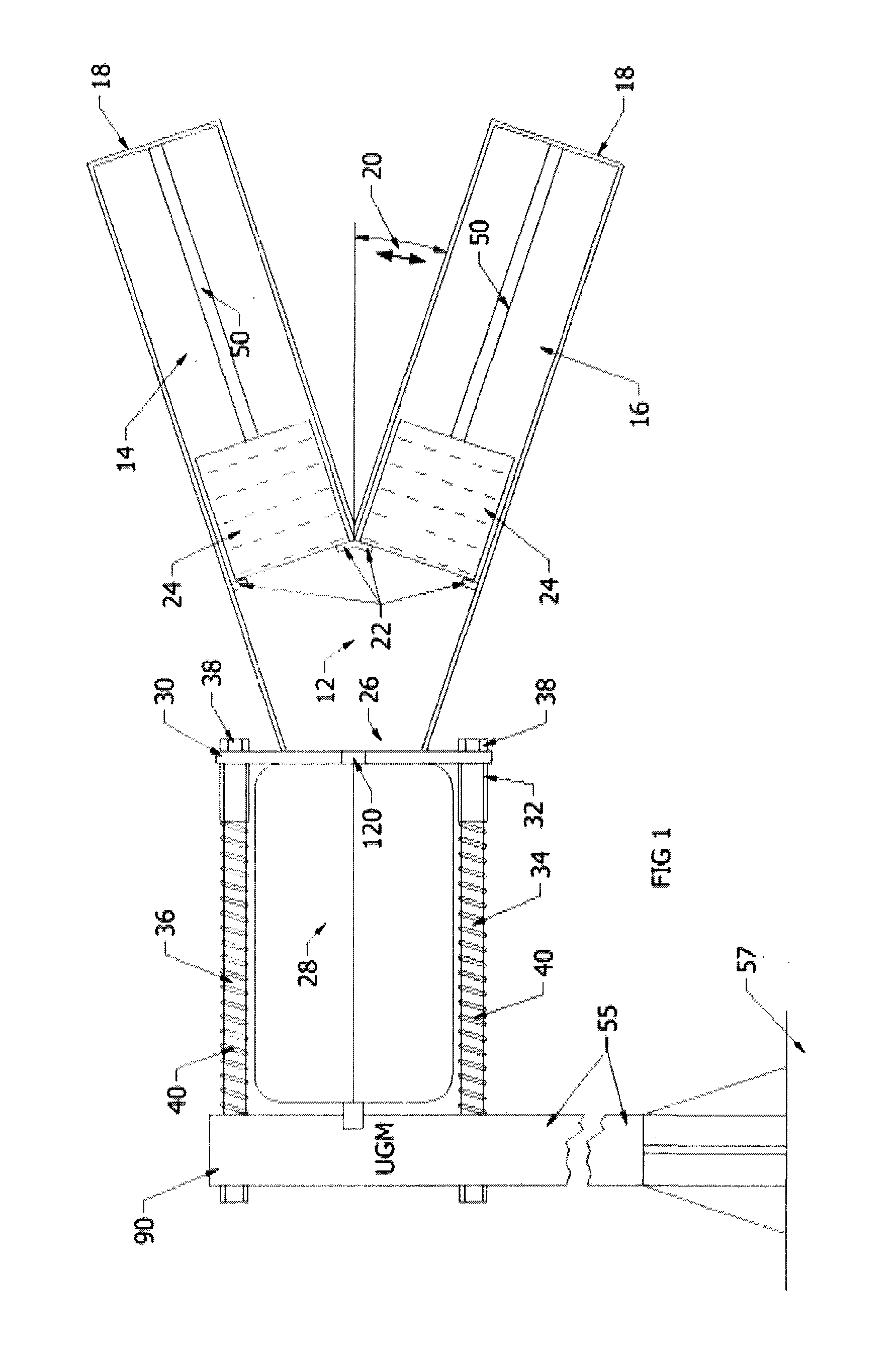

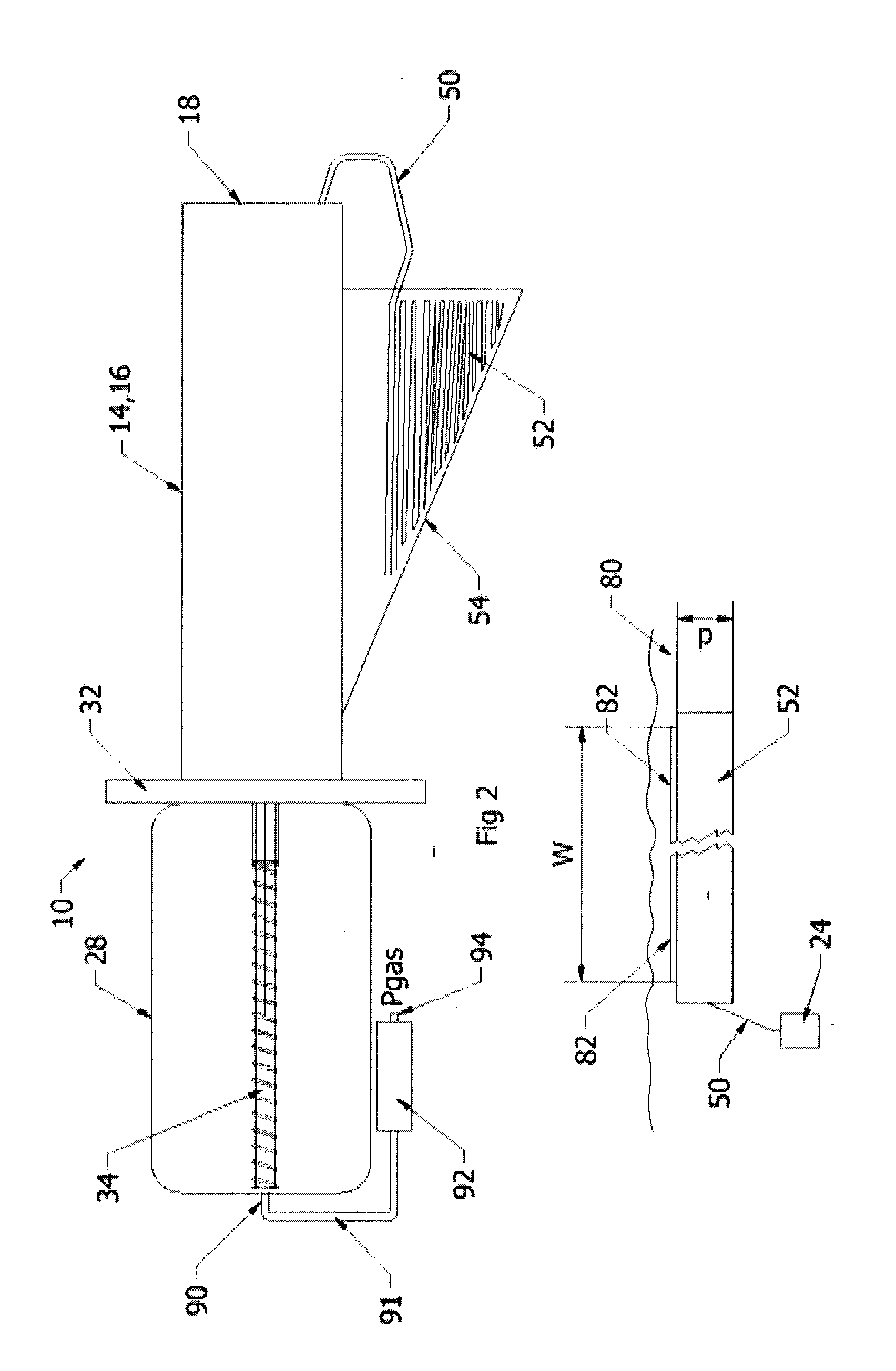

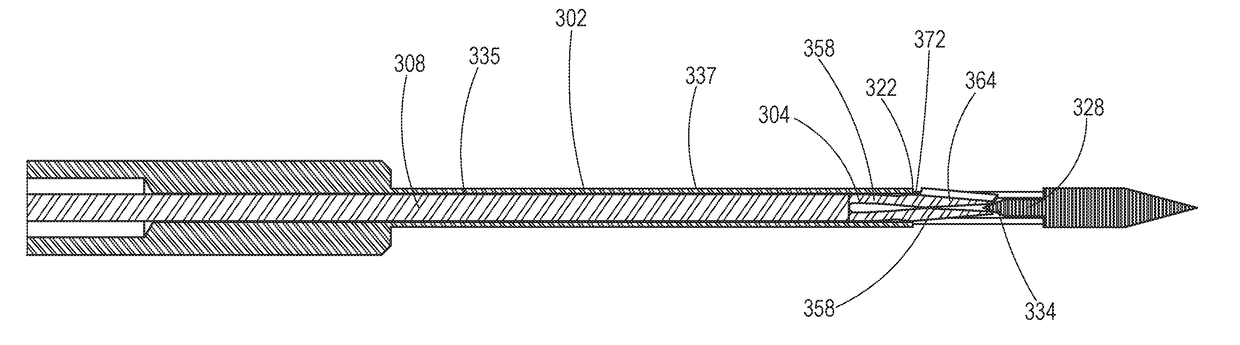

Air cannon and associated launch canister for a line-fouling system

ActiveUS20160161225A1Rapidly deployableDirect forceDefence devicesPeptide/protein ingredientsCouplingEqualization

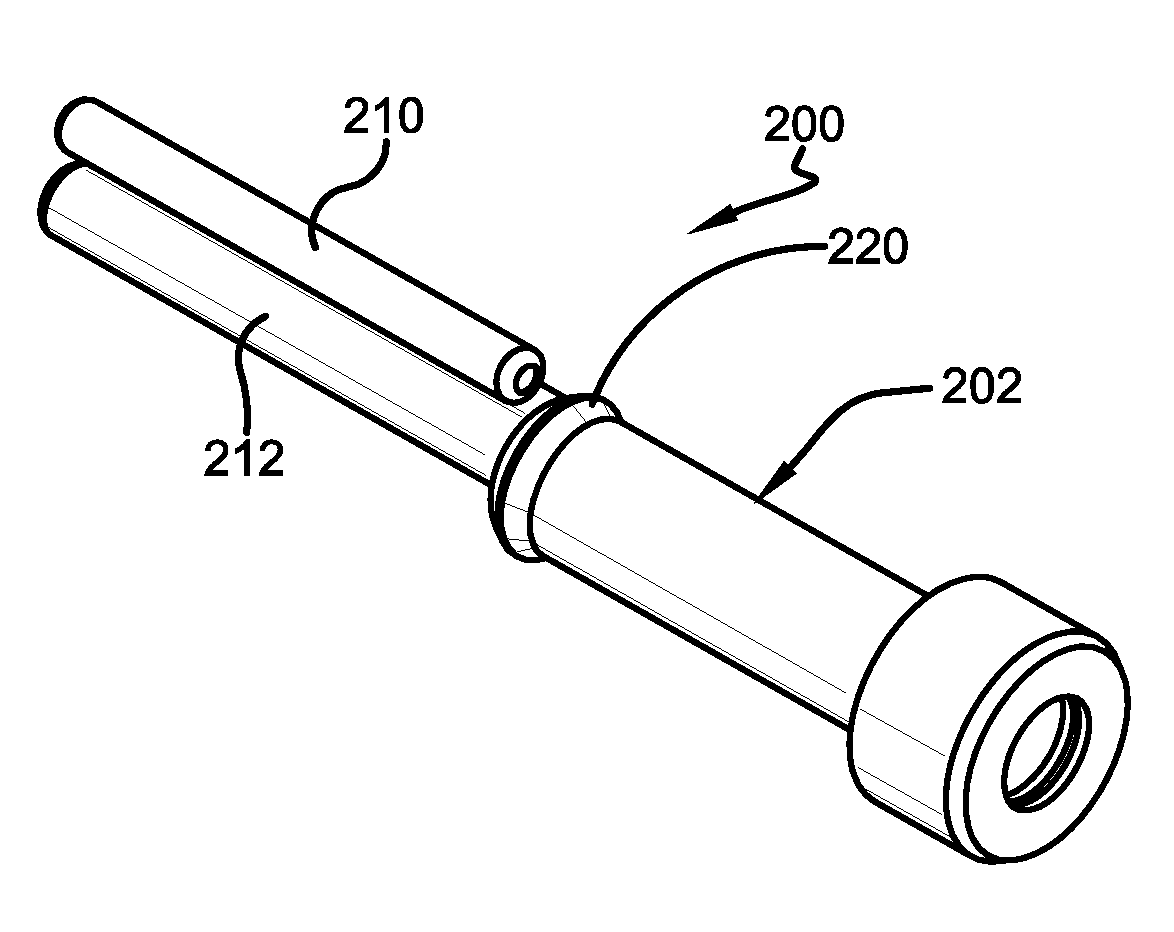

FIG. 7 shows an air cannon system loaded with a launch canister containing a prop-fouler. A pressure vessel (28) contains an inlet including a poppet valve (100) that, upon command, can be selectively placed in either a one-way flow position to permit charging of the pressure vessel or otherwise opened to trigger rapid discharge through pressure equalization with the ambient environment. The air cannon may include multiple splayed barrels or a single barrel (158). A launch canister (202), realized in the form of a tube, has a driving plate (350) that closes an end of the launch tube. The driving plate is the first point loaded into the barrel. Within the launch canister (202) a first portion of a floating prop-fouling line is stored. The prop-fouling line, such as made from Dyneema®, has at its ends two drogues that, upon entry into the water, fill with water to produce drag resistance to movement of the prop-fouling line. To avoid undue stress on canopy panels of each drogue and to avoid twisting of shroud lines (312) to the canopy, a rotating shackle (310a, 310b) acts as a coupling point between the shroud lines (312) and the prop-fouling line. Only one drogue (306), its associated coupling and a selected length prop-fouling line are loaded into the launch canister, with the other drogue and its rotating shackle (310b) loaded into a cradle (166). Upon firing, gas expansion causes the rapid acceleration and ejection of the launch tube (202) and generally straight line deployment of the prop-fouling line (302).

Owner:BCB INT

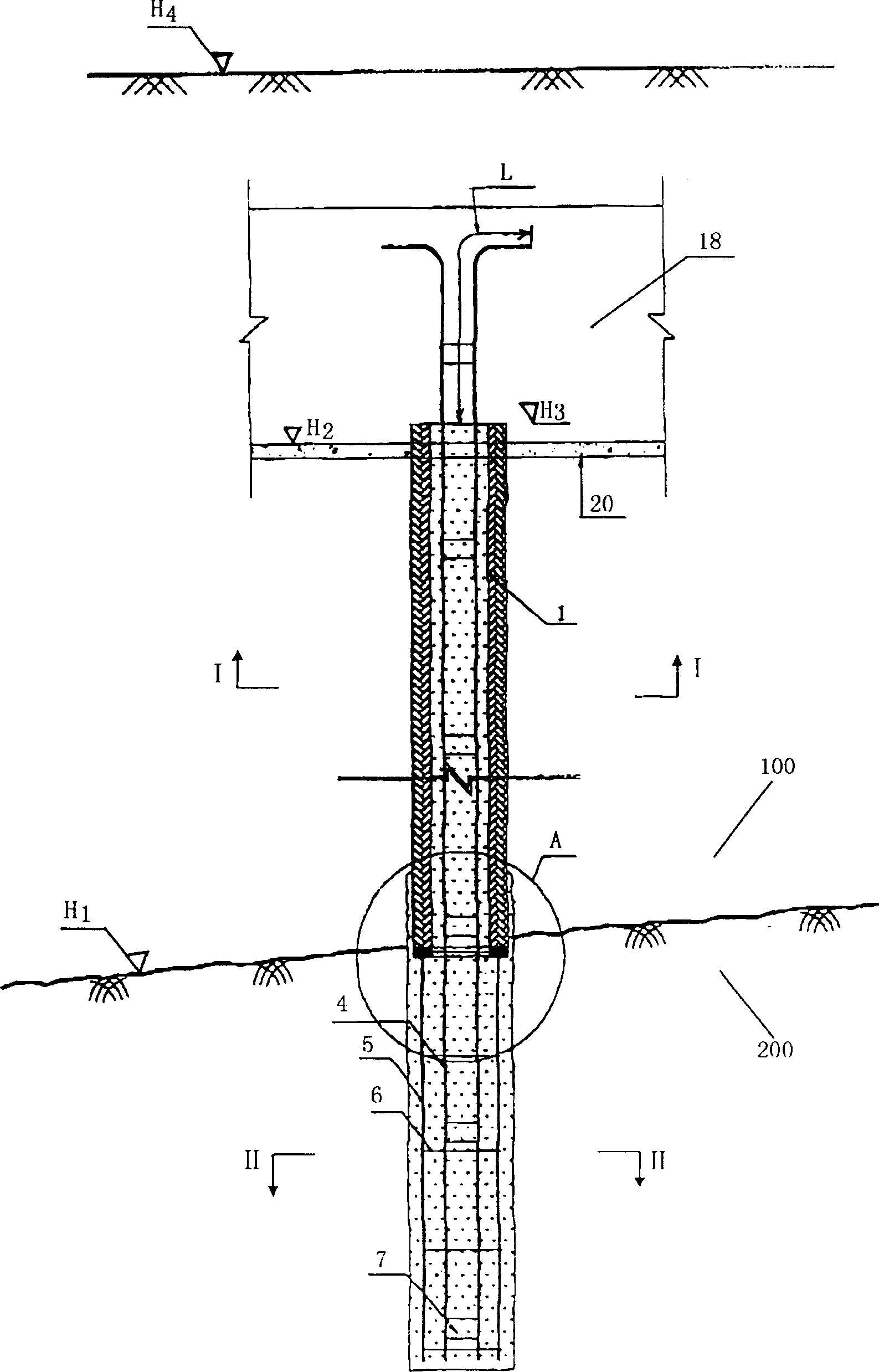

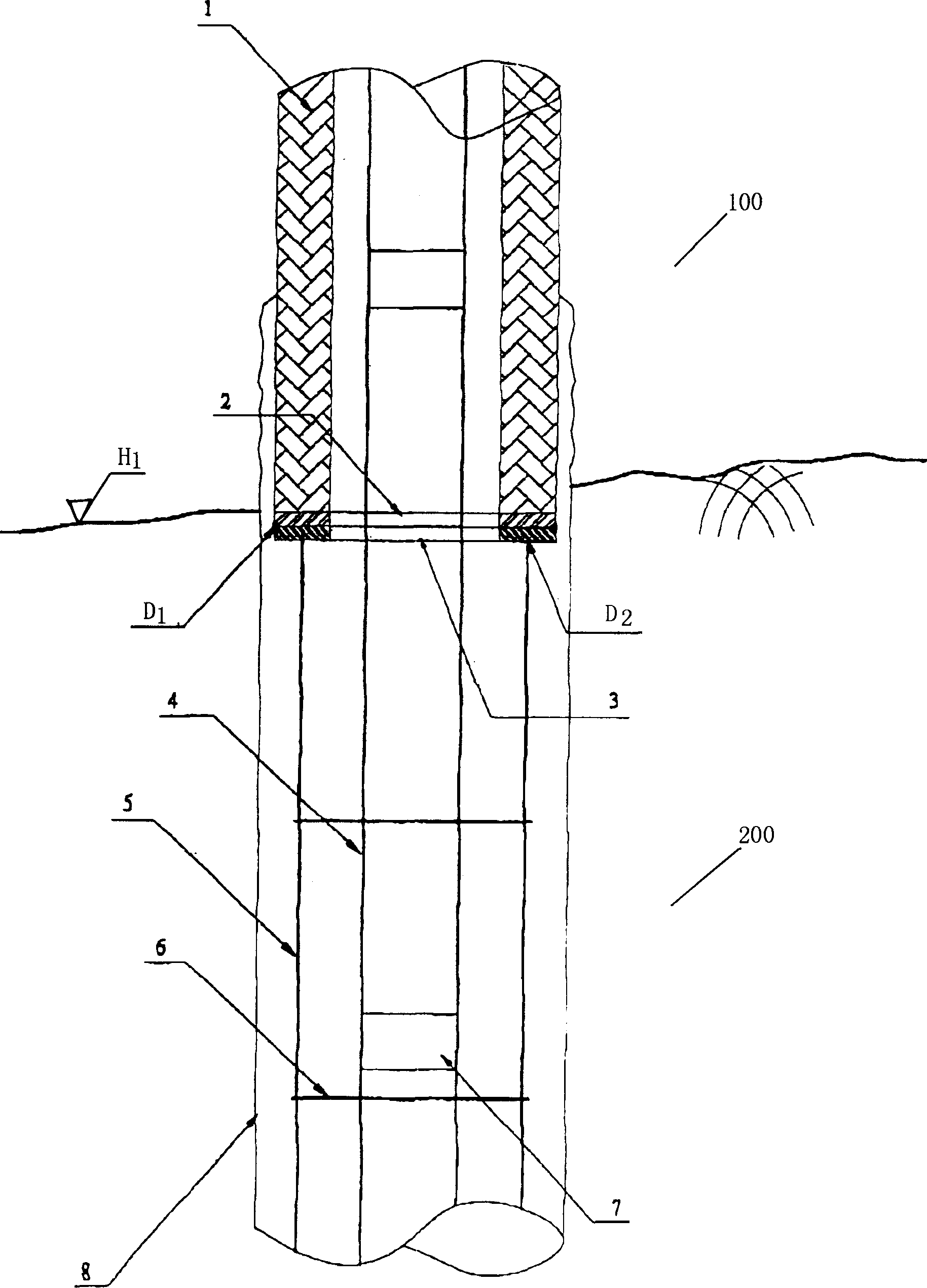

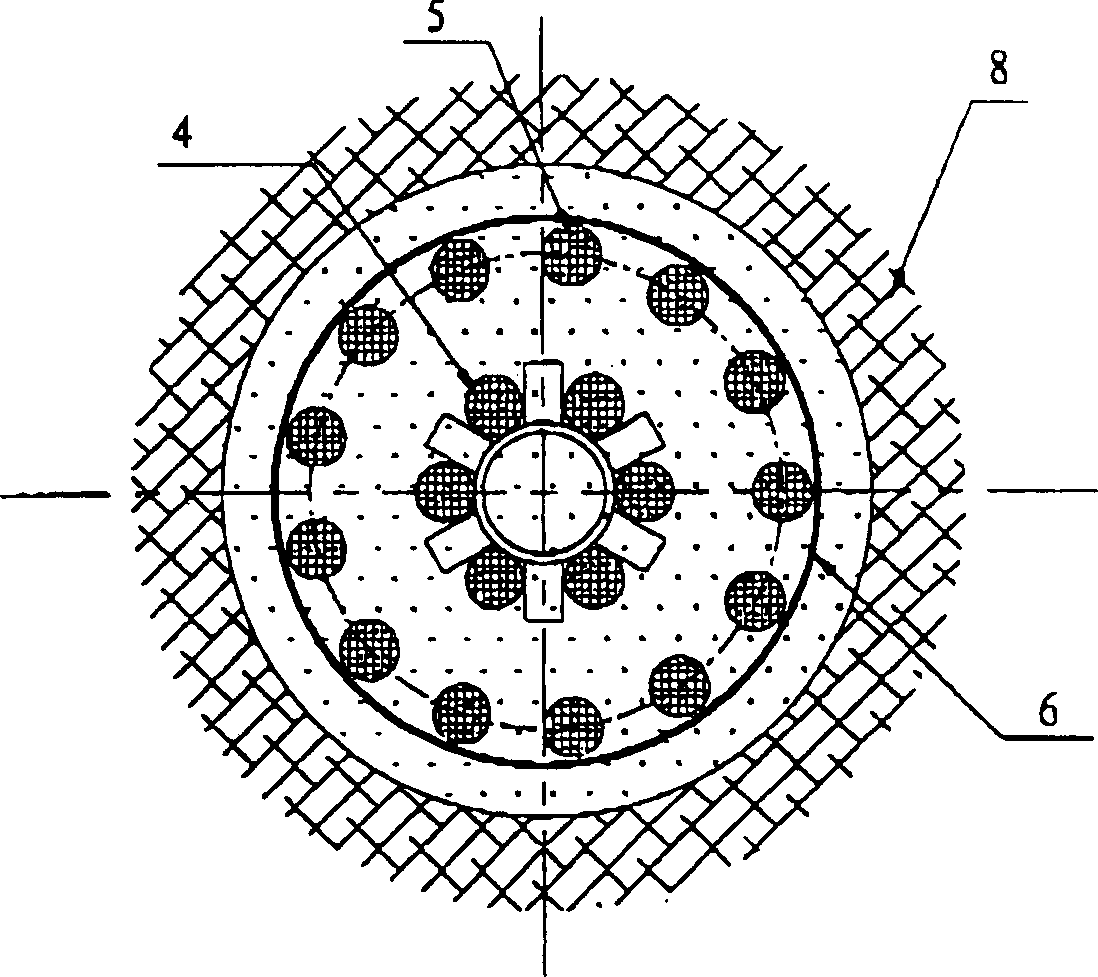

Combined rock-embedding pile and its construction method

A combined pile embedded in rock is constructed through prefabricating reinforced concrete pipe or other pile with reinforcing bars used as the load bearing member in soil layer, embedding the reinforced concrete member or steel member with reinforcing bars in the drilled hole in rock, and grouting in-situ. At least one group of reinforcing bars passes through said member and cast inside it for bearing pressure or pull and improving the integrity of whole pile. Its advantages are high load-bearing power, simple structure and low cost.

Owner:LIJI ENG

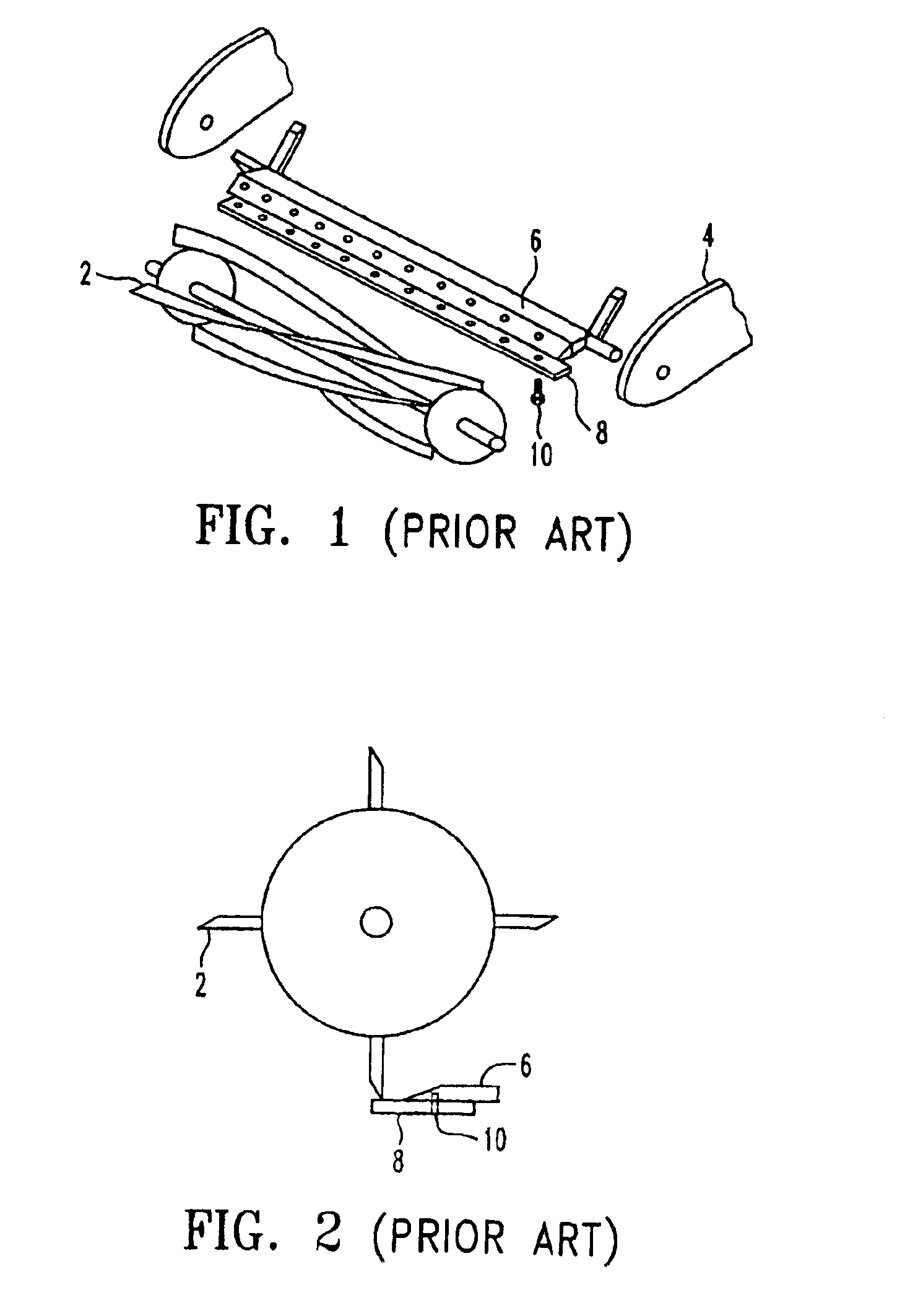

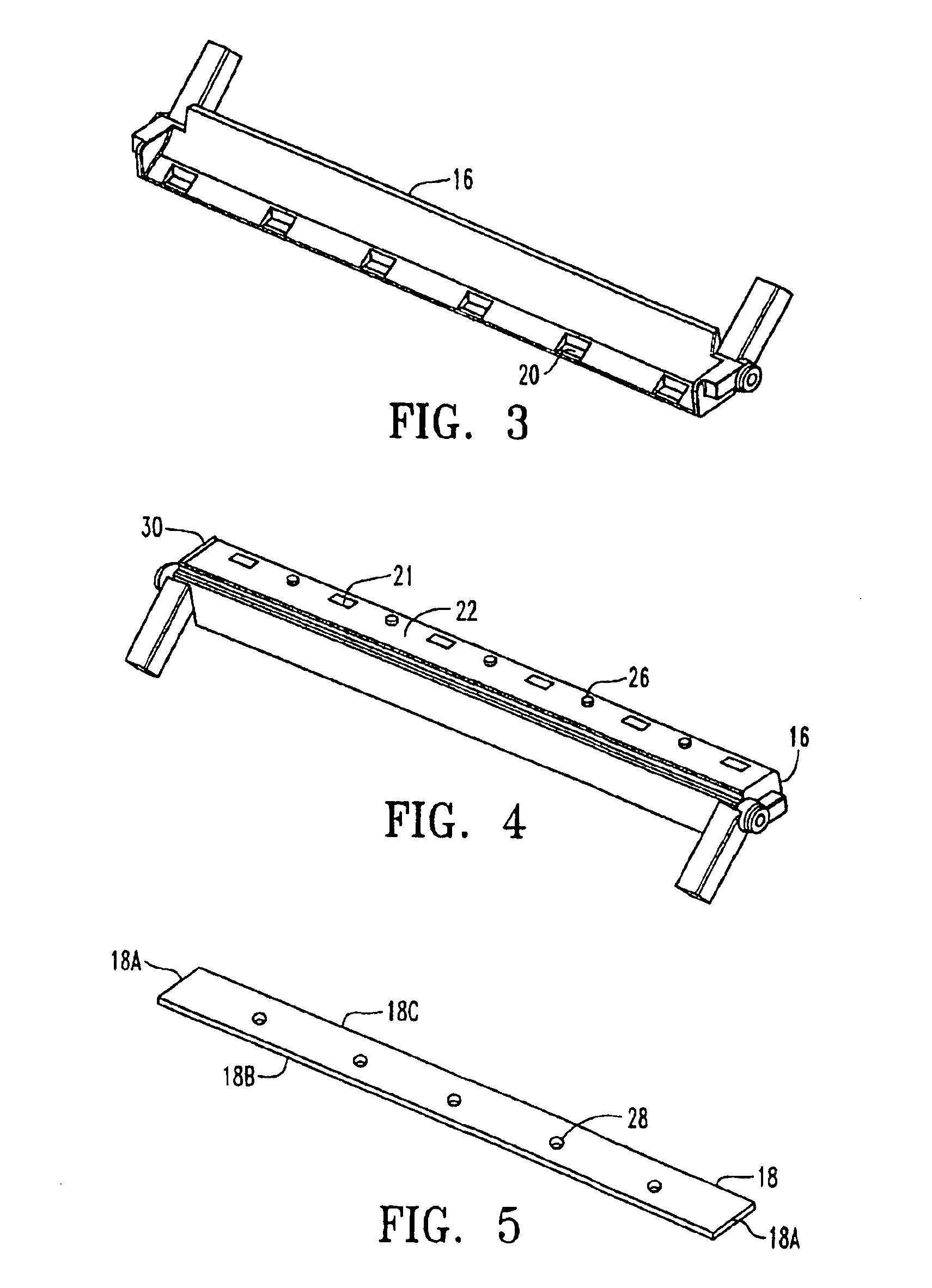

Magnetic attachment of a bed knife in a reel mower assembly

A reel mower assembly comprises a mower reel rotatably mounted to a frame, and a drive operative to rotate the reel about a reel axis. A plurality of magnets are mounted on the frame and a bed knife is magnetically held against the magnets in an operating position such that the bed knife is oriented in cutting relationship with the reel. When the bed knife is in an operating position, sliding movement of the bed knife with respect to the magnets while allowing the bed knife to move away from the magnets may be prevented, when a separating force is exerted on the bed knife in a direction away from the magnets that is greater than an attractive force exerted on the bed knife by the magnets.

Owner:TEXTRON INNOVATIONS +1

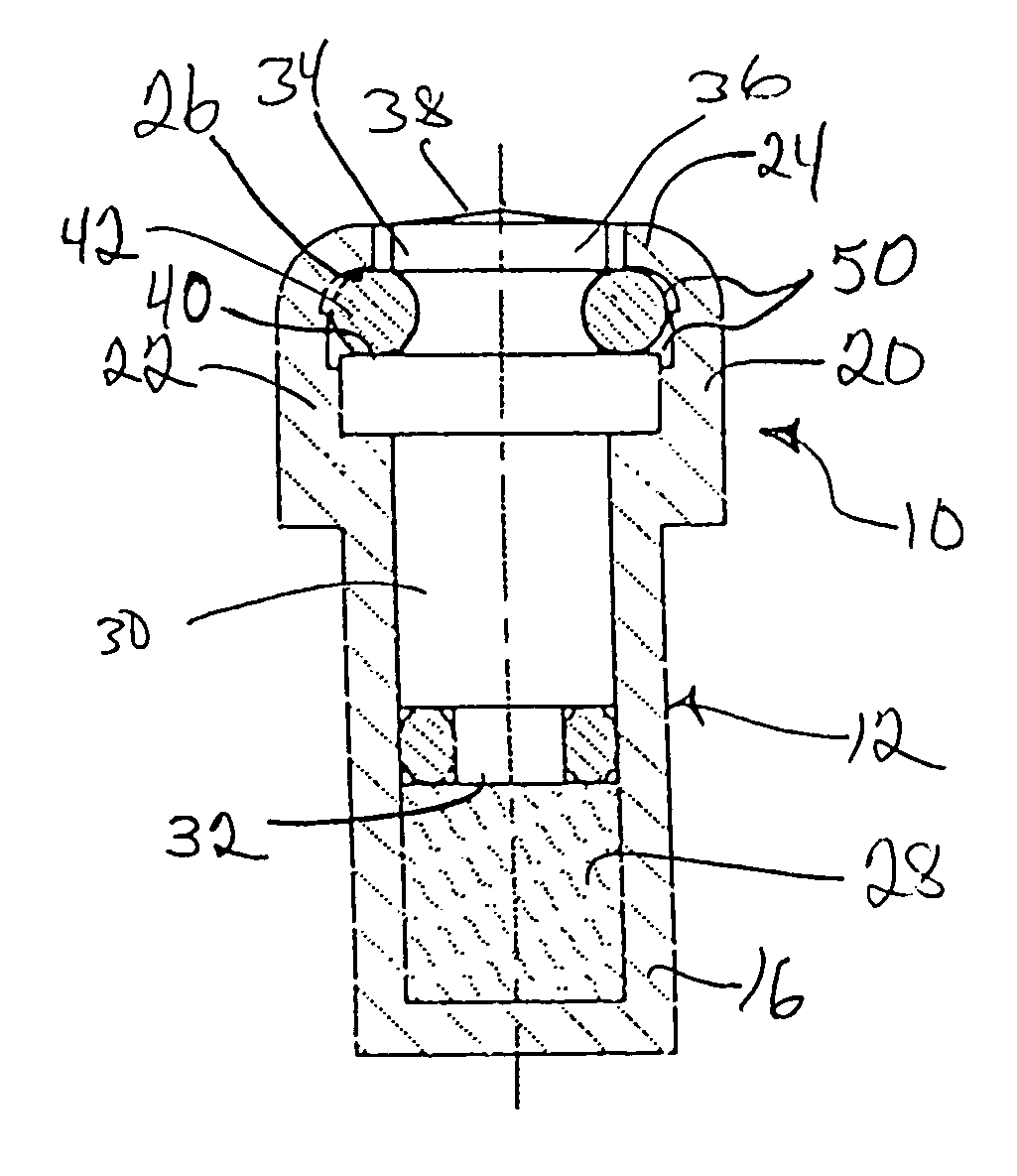

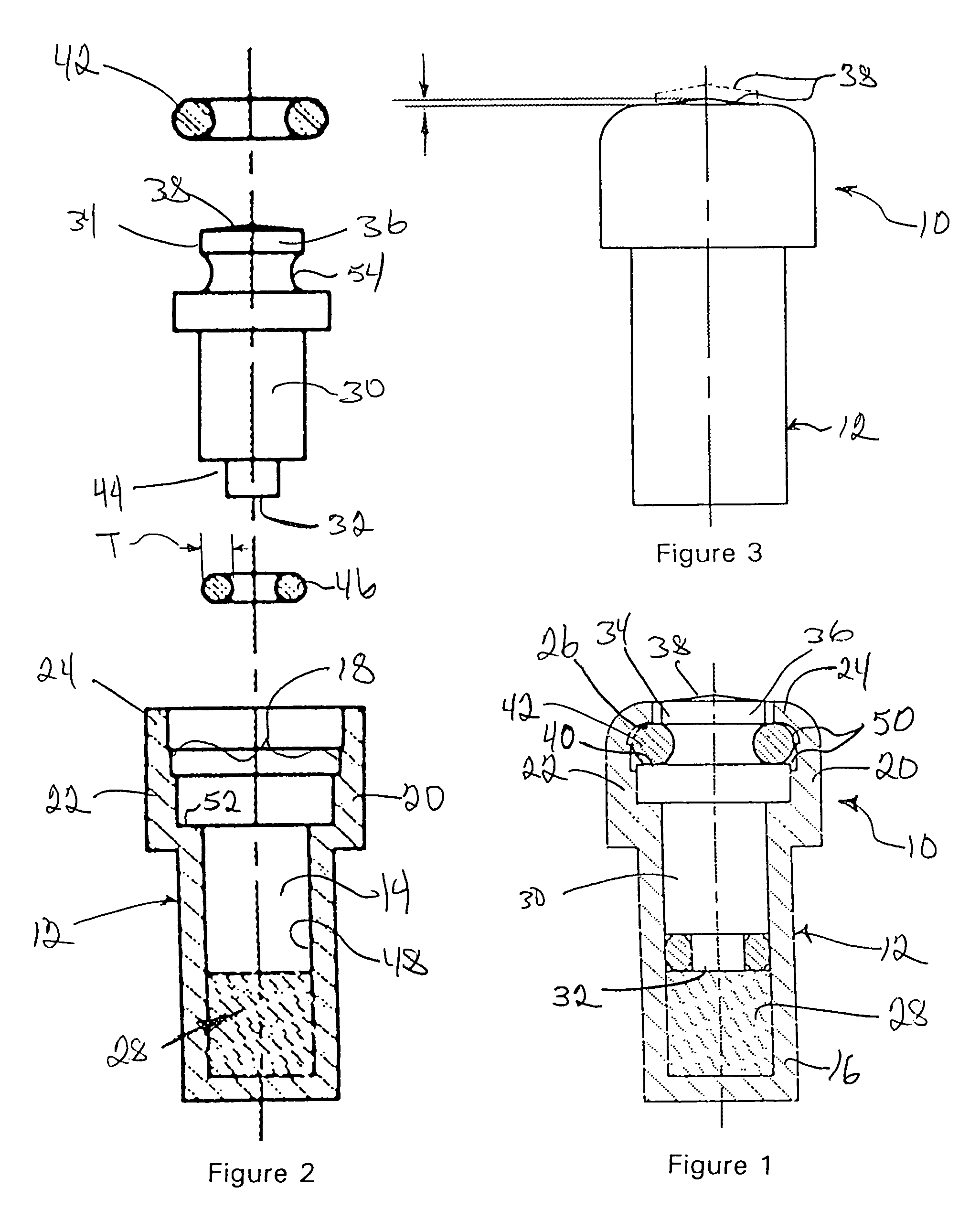

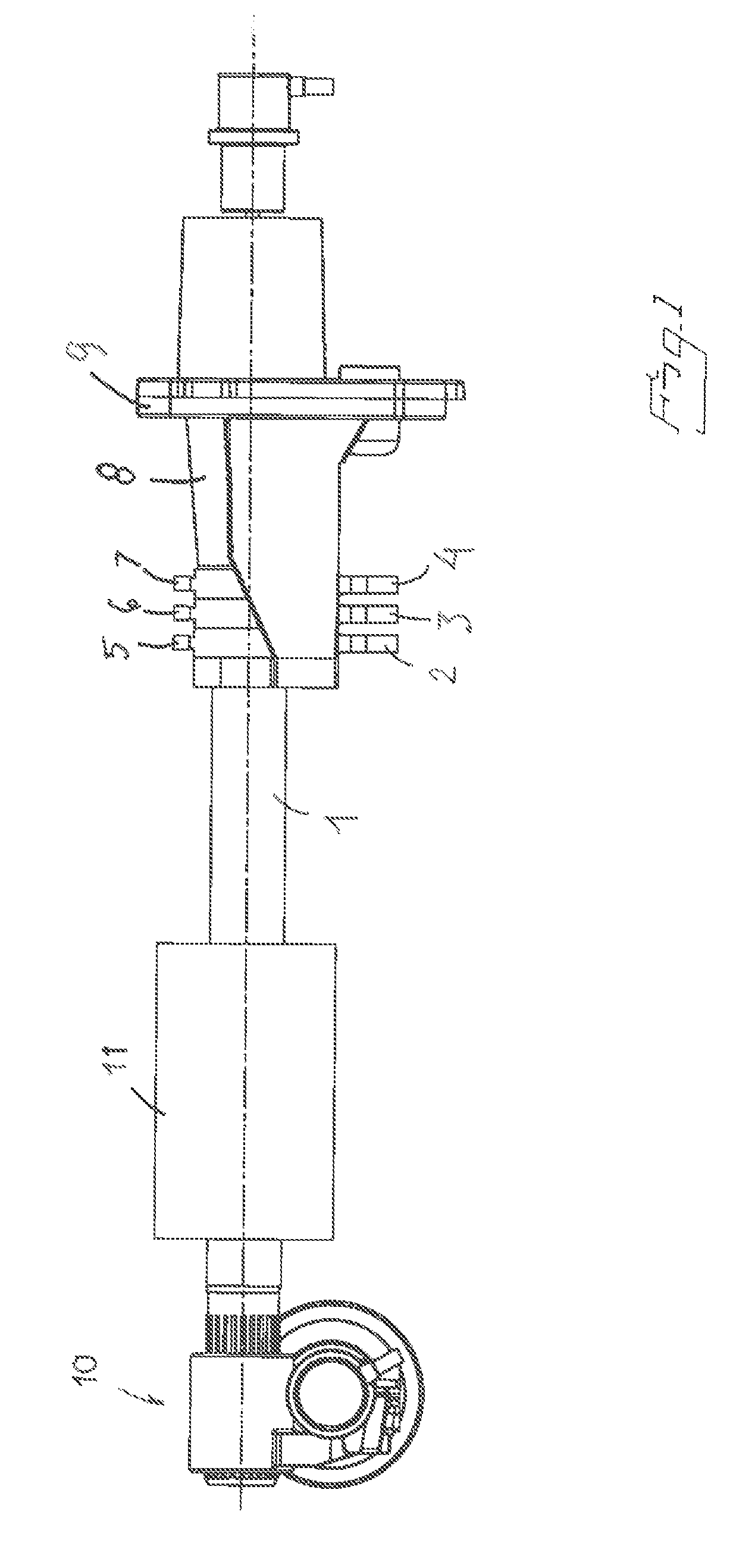

Self-contained thermal actuator

ActiveUS7469841B1Simple and durableImprove sealingTemperature control without auxillary powerOperating means/releasing devices for valvesPistonReciprocating motion

A self-contained thermal actuator positions the piston return member inside the actuator cup. The inventive configuration eliminates the guide and diaphragm seal that closed the open end of the wax filled cup in the typical thermal actuator configuration. The piston and an O-ring seal seated in an annular recess defined by the piston contain the thermally responsive wax. A return member within the cup and engaged between axially spaced, radially overlapping shoulders on the cup and piston biases the piston toward its pre-actuation position. The return member may be a spring or an elastomeric O-ring that also seals the thermal actuator against intrusion of contaminants from the use environment. The piston is closely received in the cup for guided axial reciprocation therein.

Owner:ROSTRA VERNATHERM

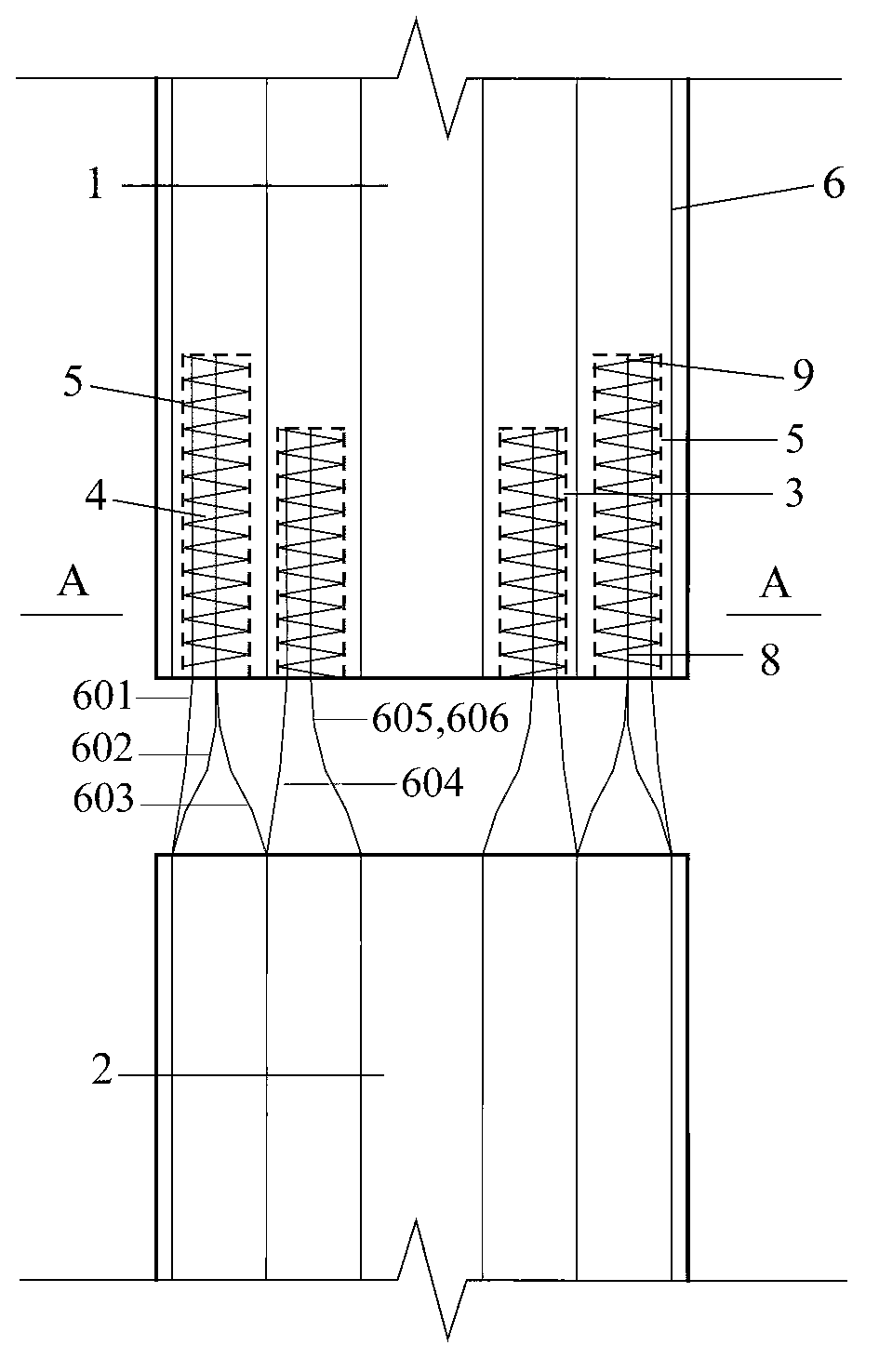

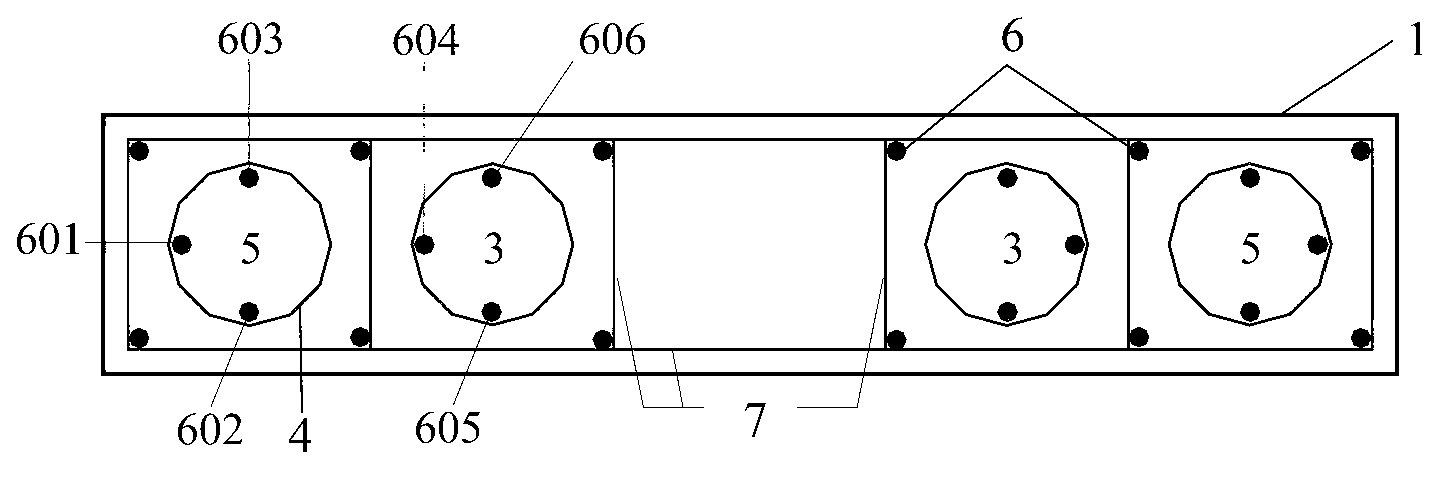

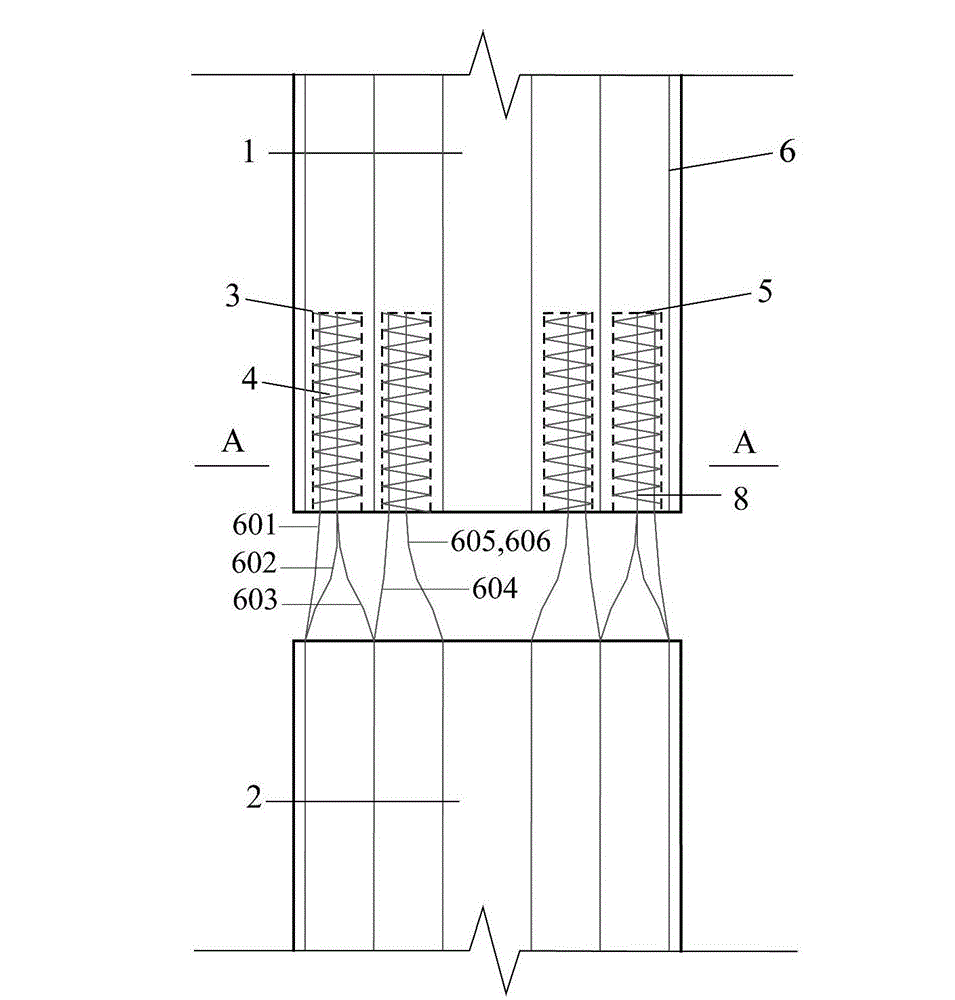

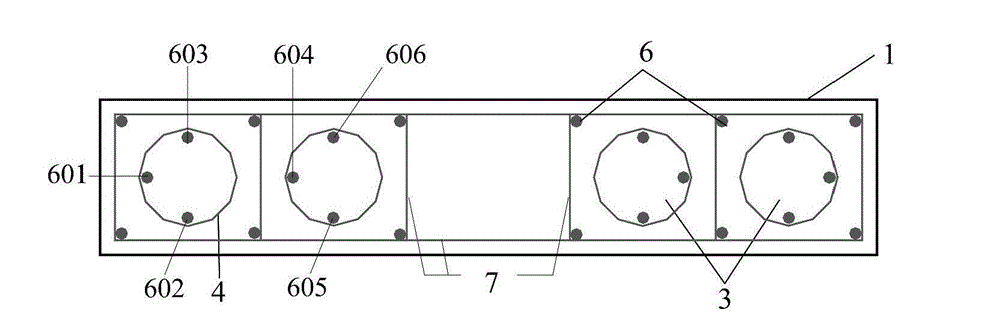

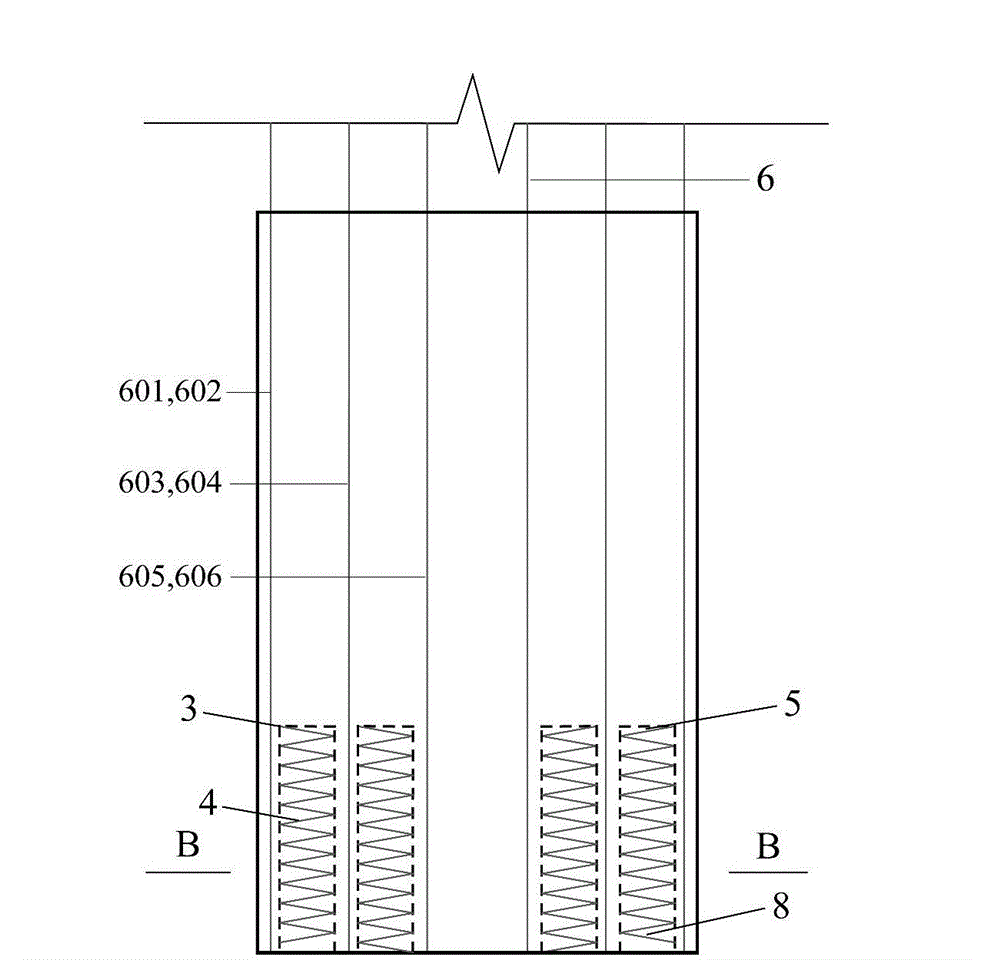

Prefabricated assembling whole type shear wall connected with staggered-height vertical steel bar

The invention provides a prefabricated assembling whole type shear wall connected with a staggered-height vertical steel bar, comprising an upper-layer wall body and a lower-layer wall body, wherein the two ends of the bottom of the upper-layer wall body are provided with a first reserved hole and a second reserved hole, which are vertical; the vertical height of the second reserved hole is 1.2-1.5 times as much as the vertical height of the first reserved hole; a spiral stirrup which is as high as the first reserved hole and the second reserved hole is respectively pre-buried in each one of the first reserved hole and the second reserved hole; vertical steel bars at the inner side of an edge member of the lower-layer wall body are bundled by groups; a plurality of combined steel bar bundles are respectively inserted into the first reserved hole and the second reserved hole; and concrete mortar materials are filled between the steel bar bundles and the first reserved hole, and between the steel bar bundles and the second reserved hole. According to the prefabricated assembling whole type shear wall, the concrete of a pressed region can be effectively restricted and the prefabricated assembling whole type shear wall can be used for overlapping the vertical steel bars in a prefabricated shear wall system.

Owner:SOUTHEAST UNIV

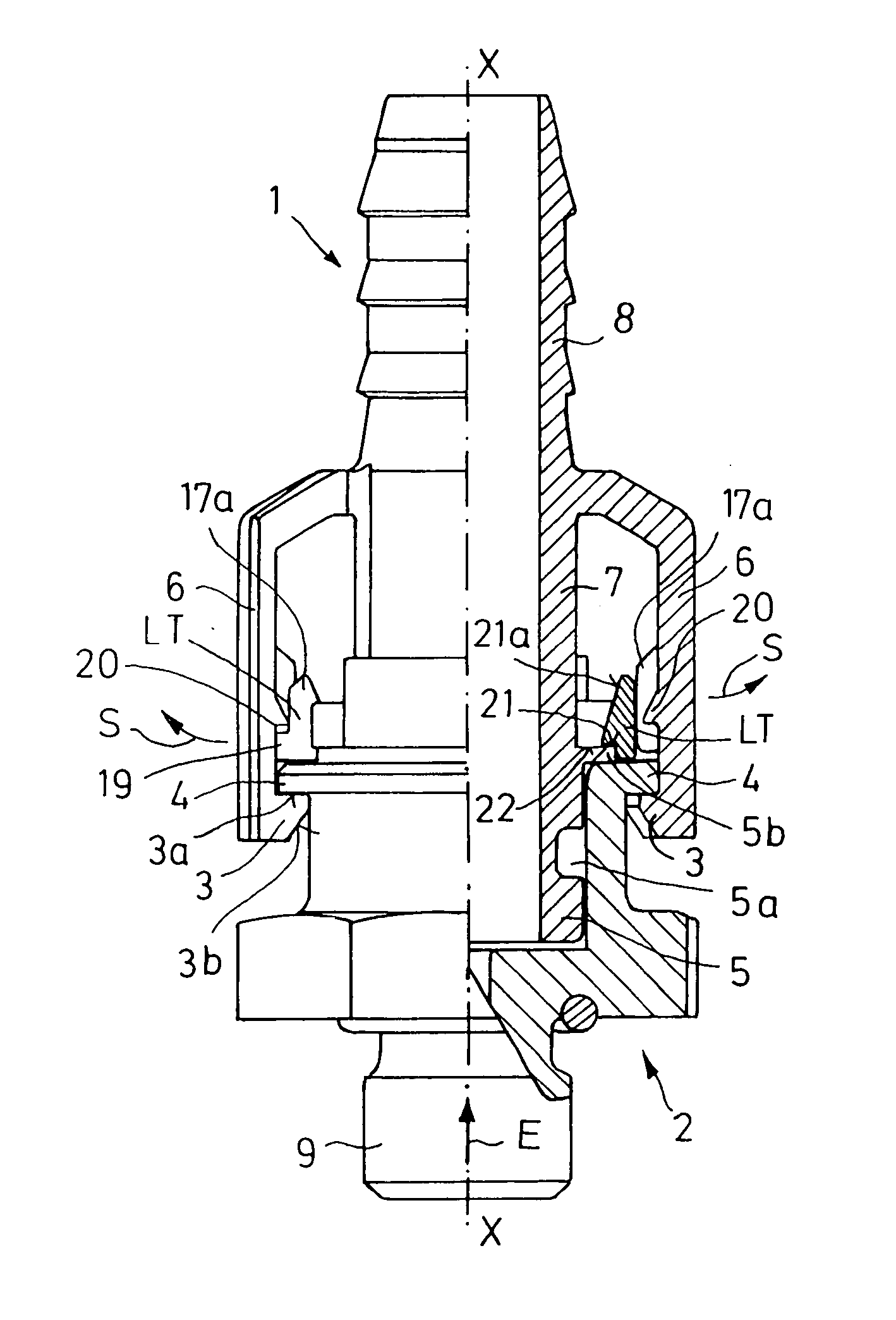

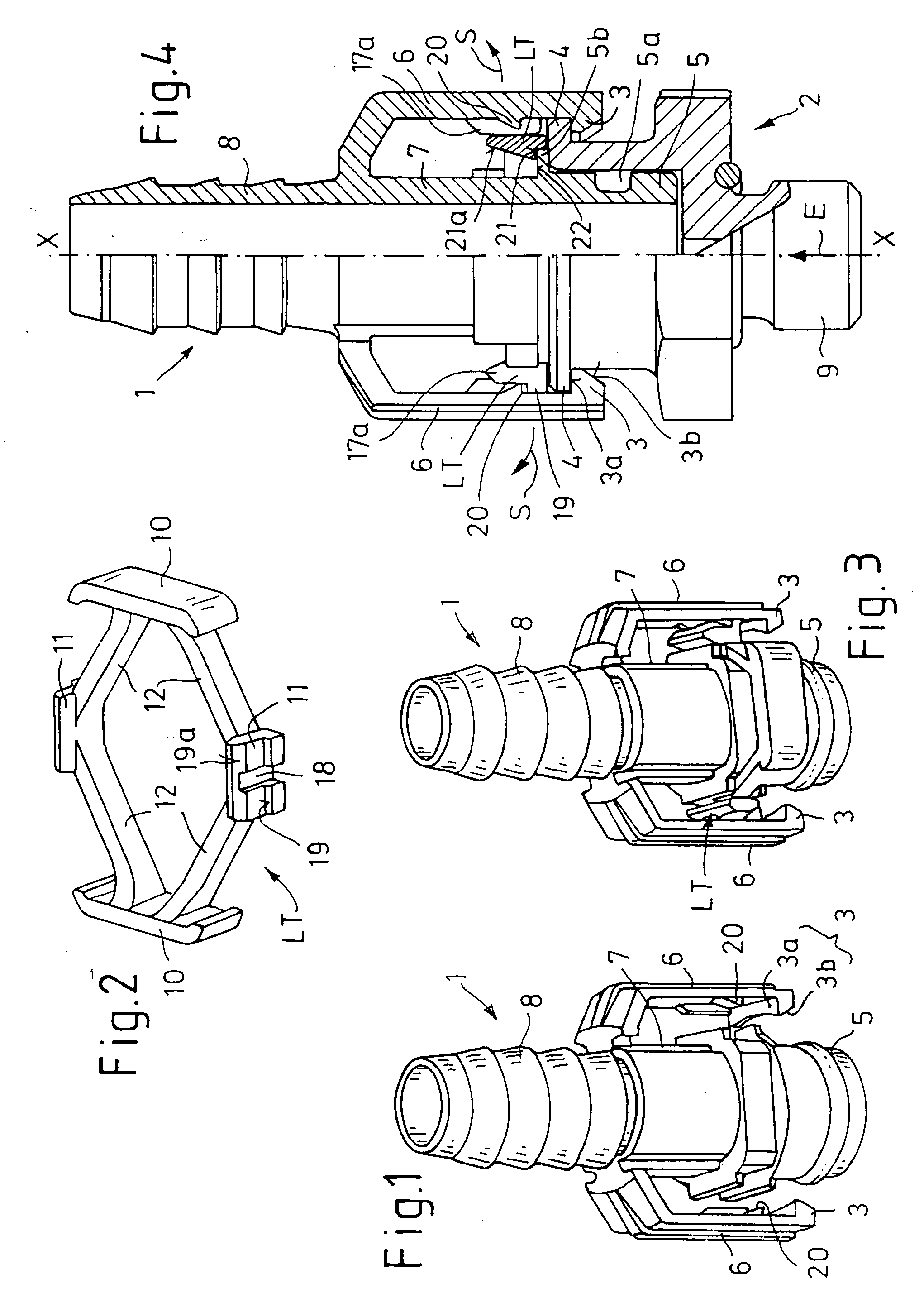

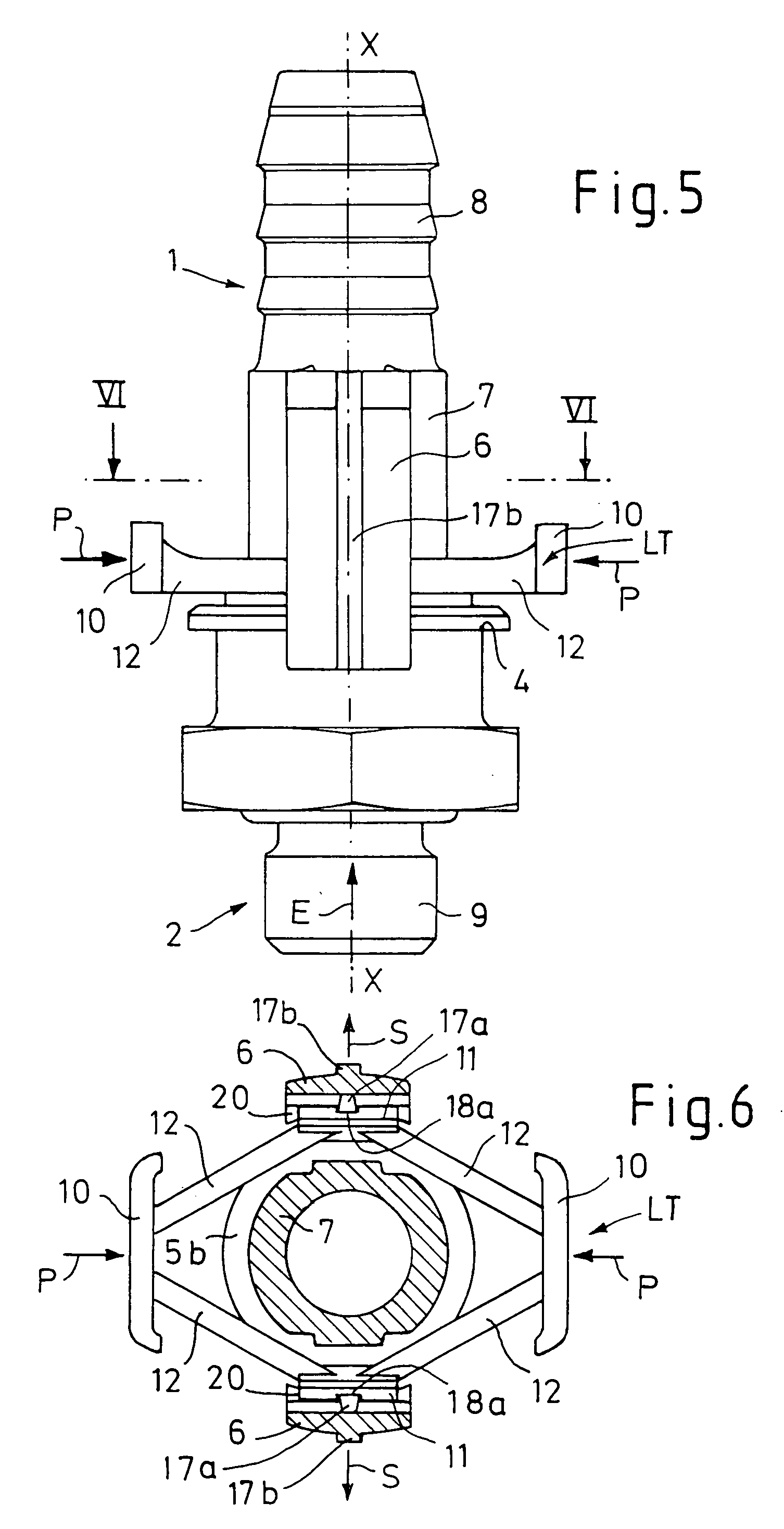

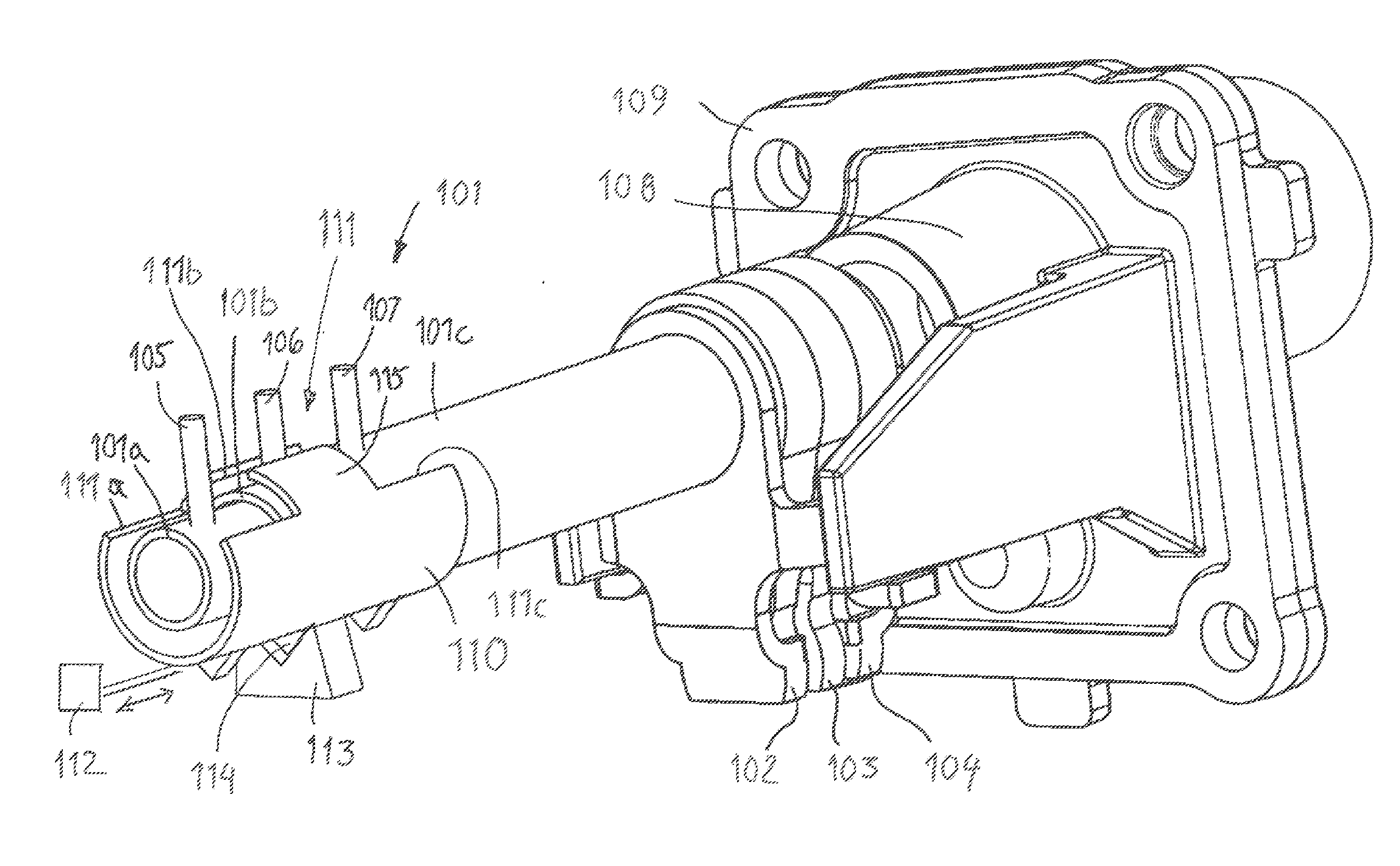

Plug-in coupling for fluid systems

The invention relates to a plug-in coupling for fluid systems having two coupling parts connectable to one another, which each have coordinated catches for connecting them together, one of the coupling parts having an end union section, by means of which it can be plugged into the other coupling part, and one of the coupling parts having at least one end retaining section carrying its catches, by means of which section it grips over an outer peripheral contour of the other coupling part, on which the coordinated complementary catches are formed. In order to achieve a simplified means of detachment whilst ensuring ease of assembly and a highly stable connection of such a plug-in coupling, it is proposed to provide a separate release part, which in the assembled state is held on the first coupling part and / or the second coupling part and which serves for separating the locking connection between the catches of the first coupling part and the catches of the second coupling part.

Owner:VOSS AUTOMOTIVE

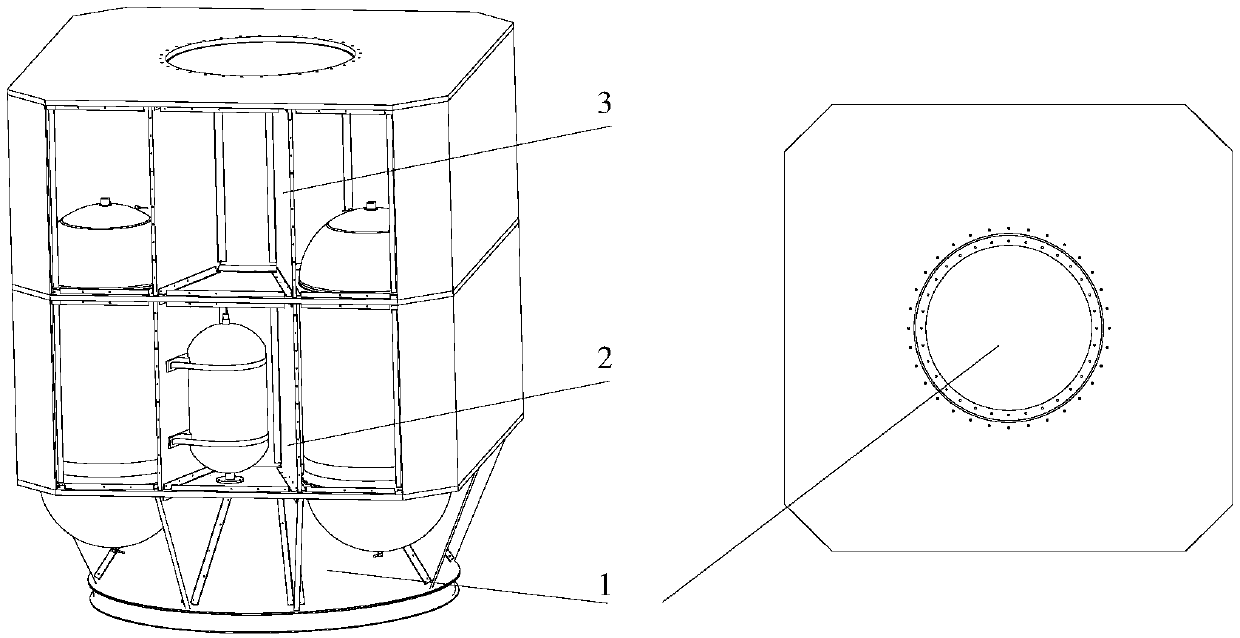

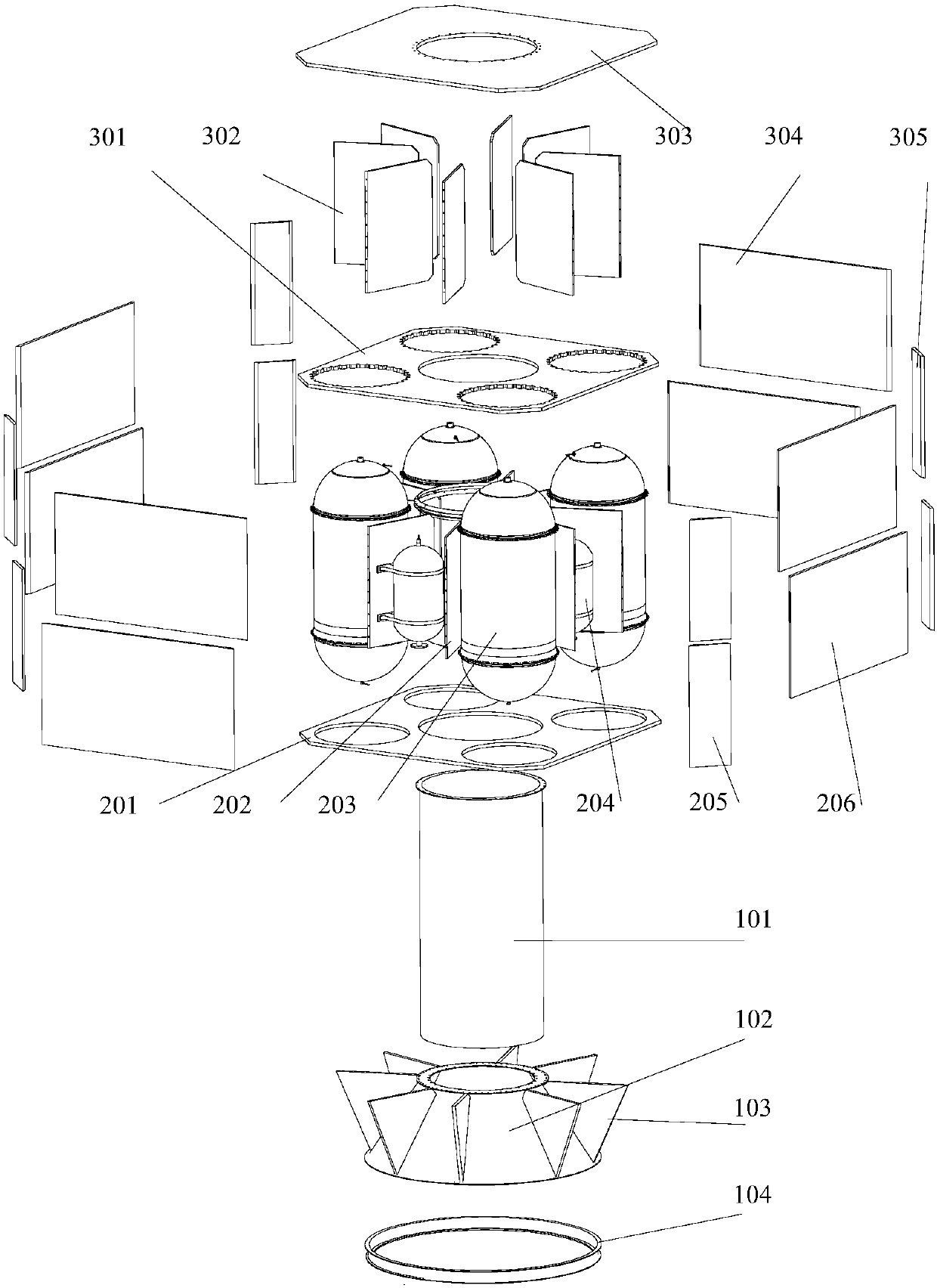

Hollow high-bearing high-maneuverability spacecraft configuration

InactiveCN107651221AReduce the overall heightReduce the lateral deviation of the center of massCosmonautic vehiclesCosmonautic propulsion system apparatusLarge sizeInstrumentation

The invention provides a hollow high-bearing high-maneuverability spacecraft configuration. The hollow high-bearing high-maneuverability spacecraft configuration includes a payload cabin, a propulsioncabin and an instrument cabin. The payload cabin is located at the central axis of a spacecraft. The payload cabin passes through the central axes of the propulsion cabin and the instrument cabin. The interior of the payload cabin is a cylindrical space which is open at the front and back, and the payload cabin runs through the whole of the spacecraft, and is used for carrying a large space loadwhich needs to be arranged in the middle of the spacecraft. The propulsion cabin is located at the exterior of the payload cabin. The instrument cabin is positioned above the propulsion cabin. According to the hollow high-bearing high-maneuverability spacecraft configuration, the large space is reserved in the central axis of the spacecraft and used for installing a large-size and high-mass load system with a slender shape, the overall height and centroid height of the spacecraft can be effectively reduced, centroid lateral deviation of the spacecraft is reduced, and a better mechanical environment is provided for both the load and the spacecraft.

Owner:SHANGHAI AEROSPACE SYST ENG INST

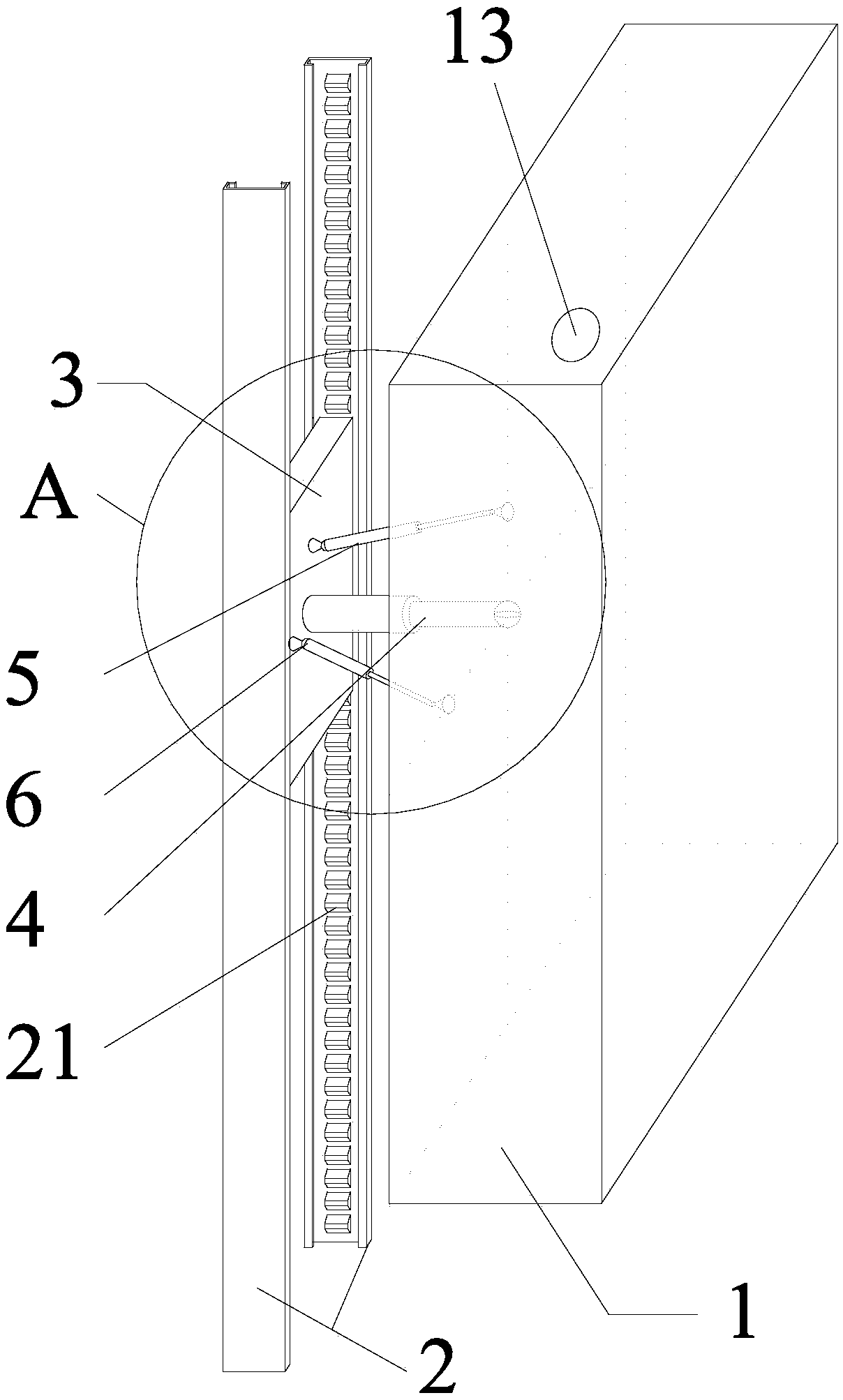

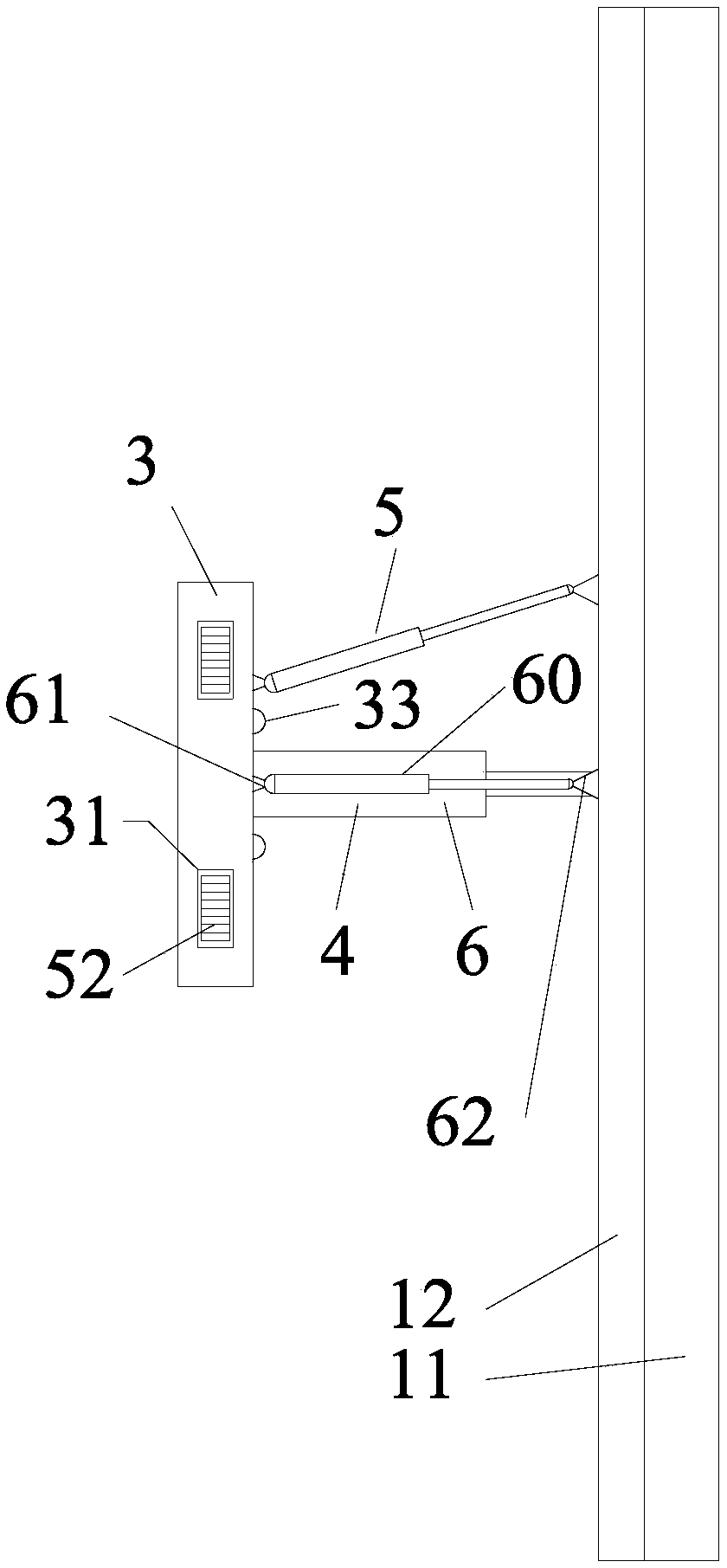

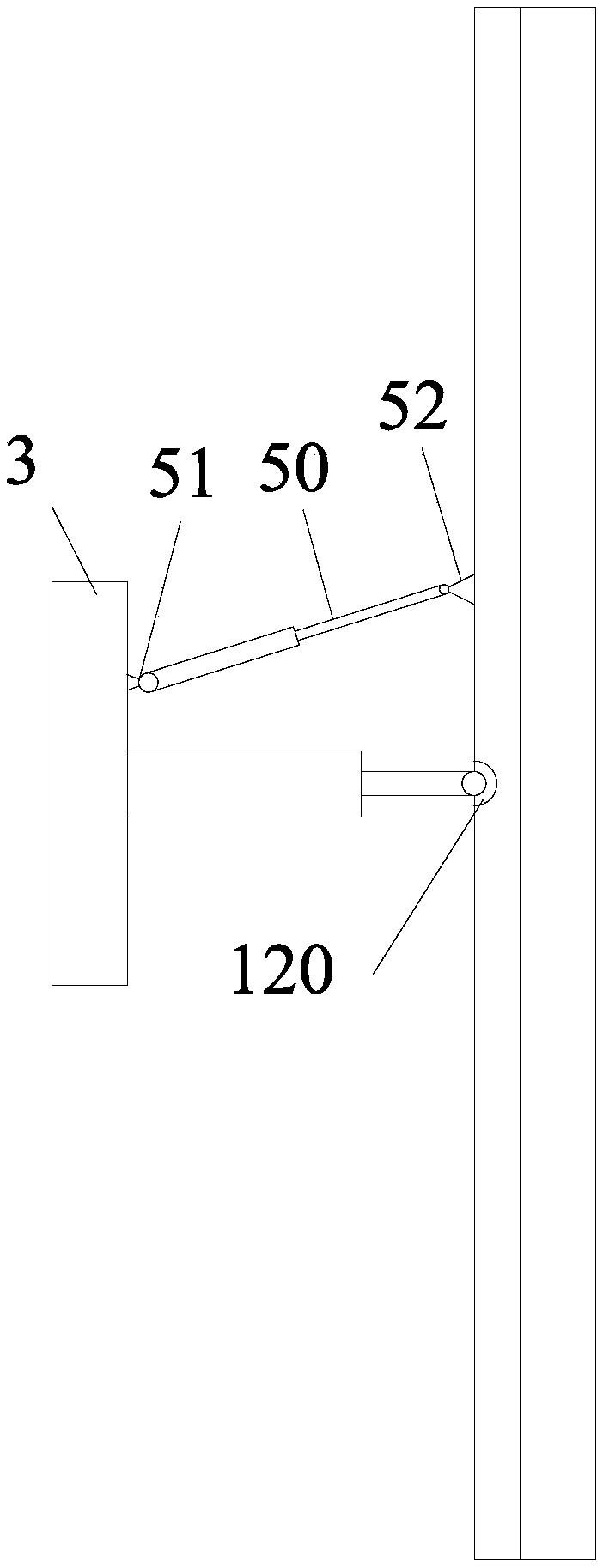

Vehicle-mounted LCD intelligent display screen capable of being adjusted in multiple dimensions

ActiveCN109159744AAdjust distanceRealize multi-dimensional adjustmentOptical viewingIdentification meansEngineeringAutomation

The invention discloses a vehicle-mounted LCD intelligent display screen capable of being adjusted in multiple dimensions. The LCD intelligent display screen is arranged on the center console or the seat back, includes a display screen body and a backplane, Vertical guide assembly, sliding support plate, an automatic telescopic device and a drive assembly hinged between the sliding support plate and the back plate for rotationally adjusting about the X axis and a drive assembly for rotationally adjusting about the Y axis, the sliding support plate can make lifting and lowering adjustment between the vertical guide rails, The automatic telescopic assembly can adjust the distance of the vehicle-mounted LCD intelligent display screen, and the automatic telescopic device is connected with theback plate through a ball hinge, and can realize the adjustment of any angle of the LCD intelligent display screen in cooperation with the driving assembly rotated and adjusted around the X axis and the driving assembly rotated and adjusted around the Y axis. The invention can automatically adjust the viewing angle to the best according to the needs of users, and has the advantages of good viewingeffect and high automation degree.

Owner:江苏亚楠电子科技有限公司

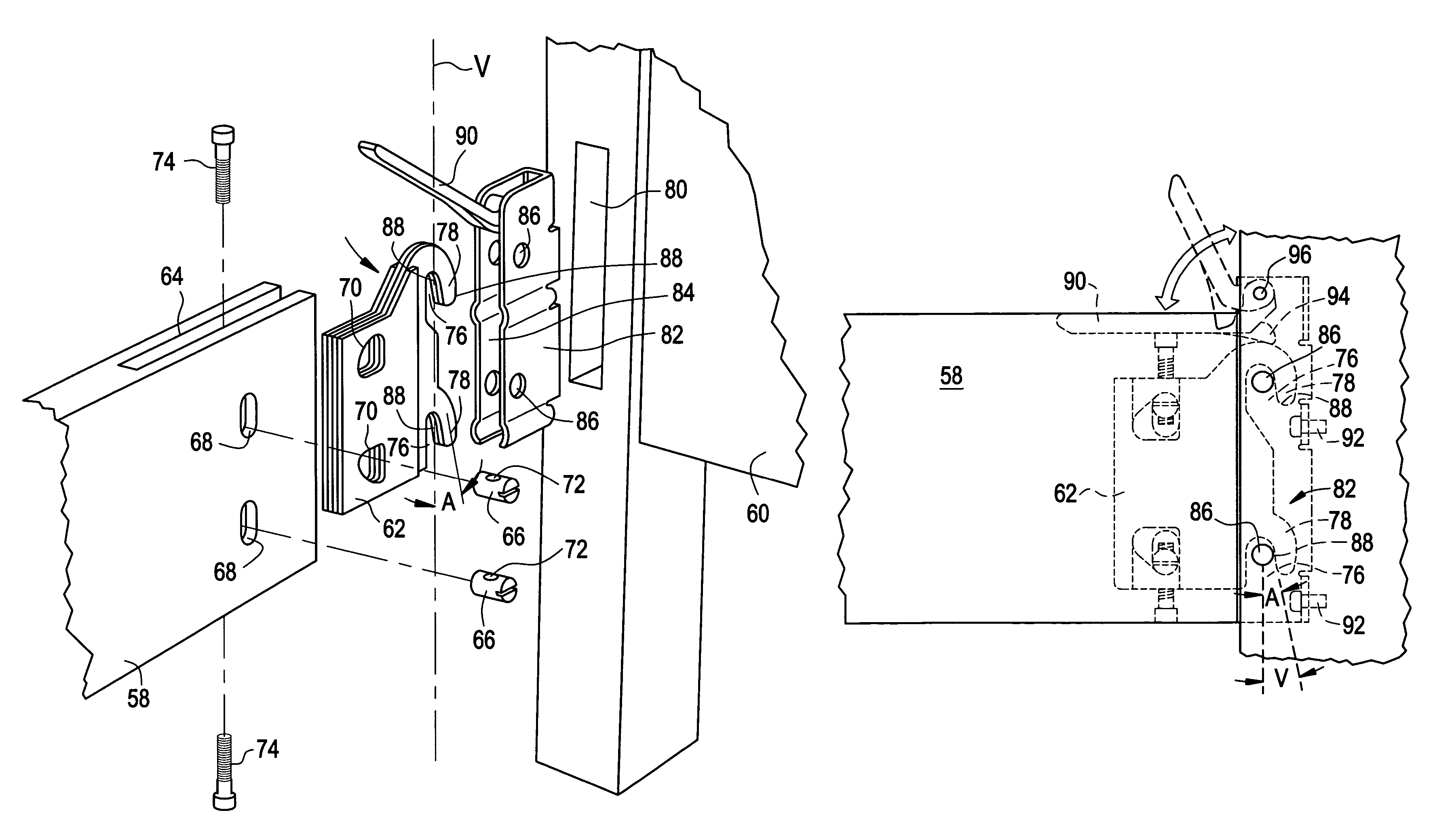

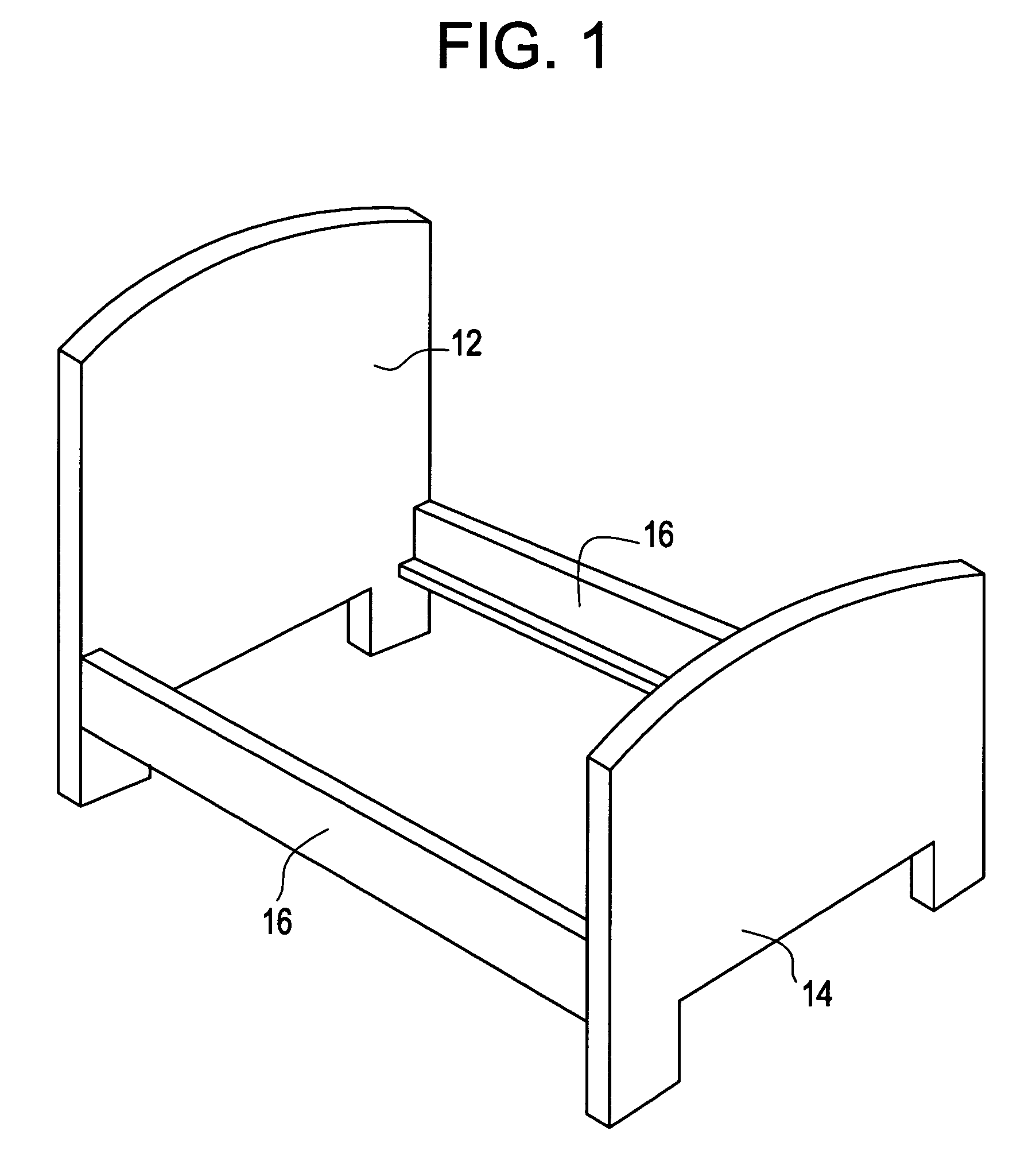

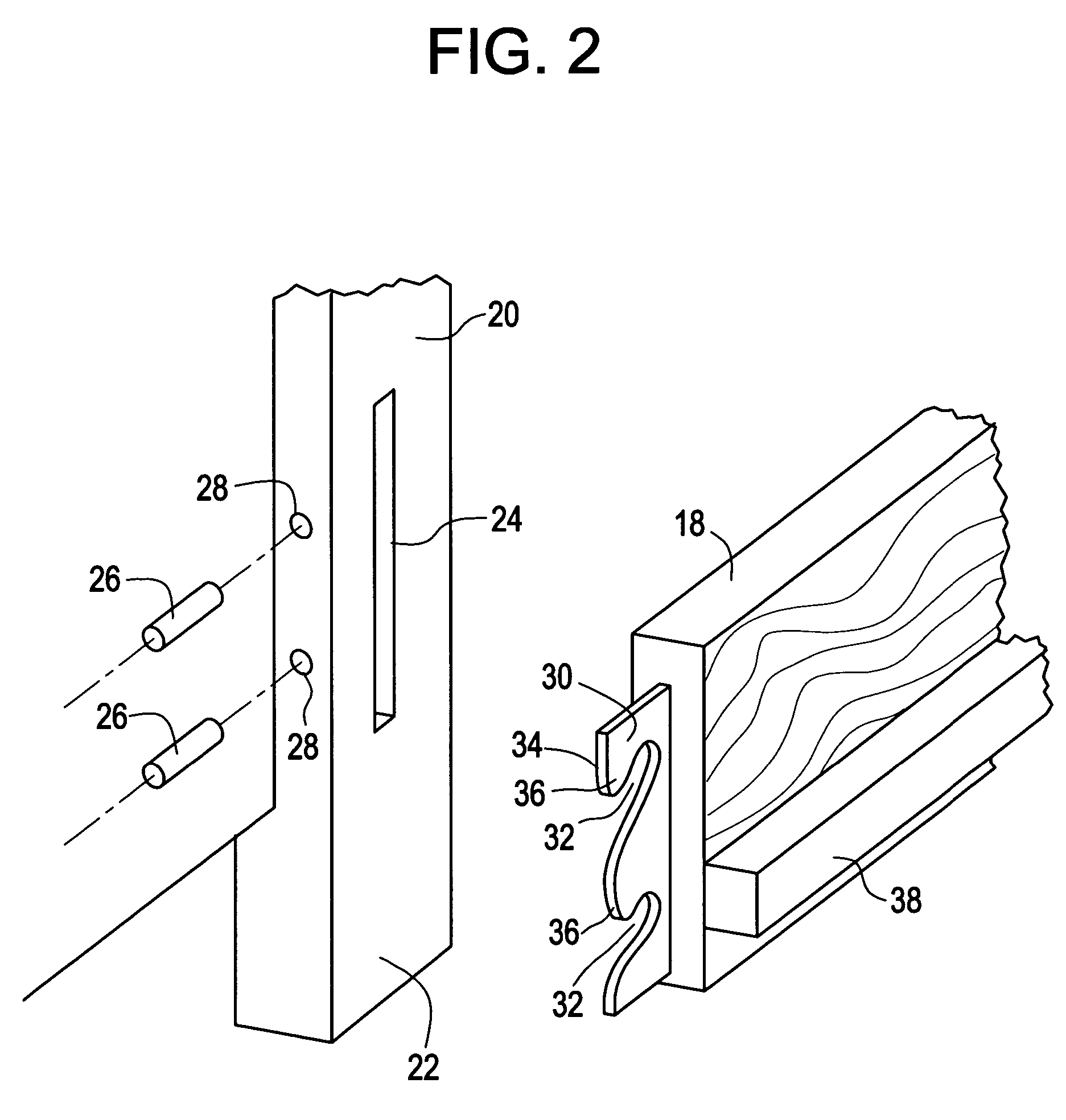

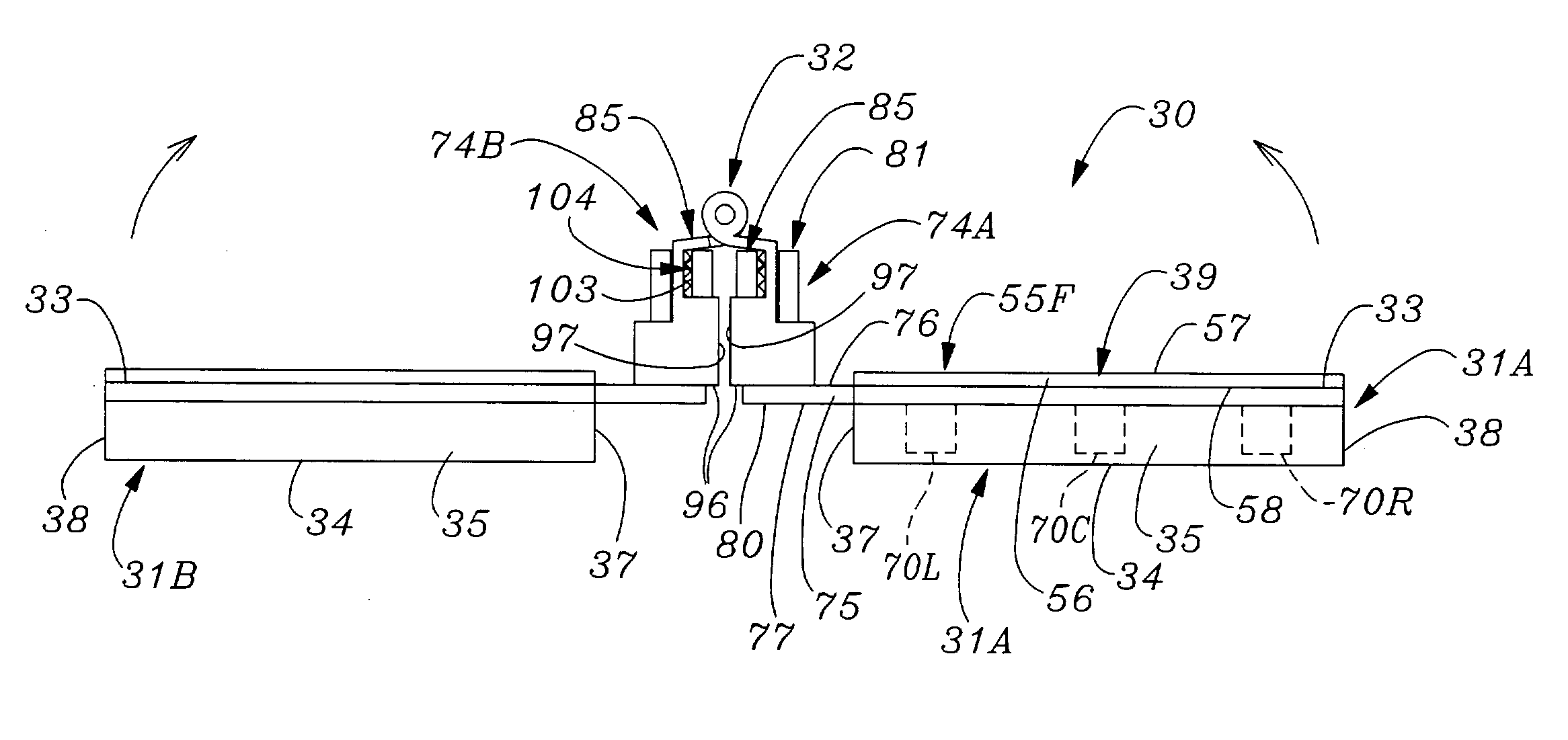

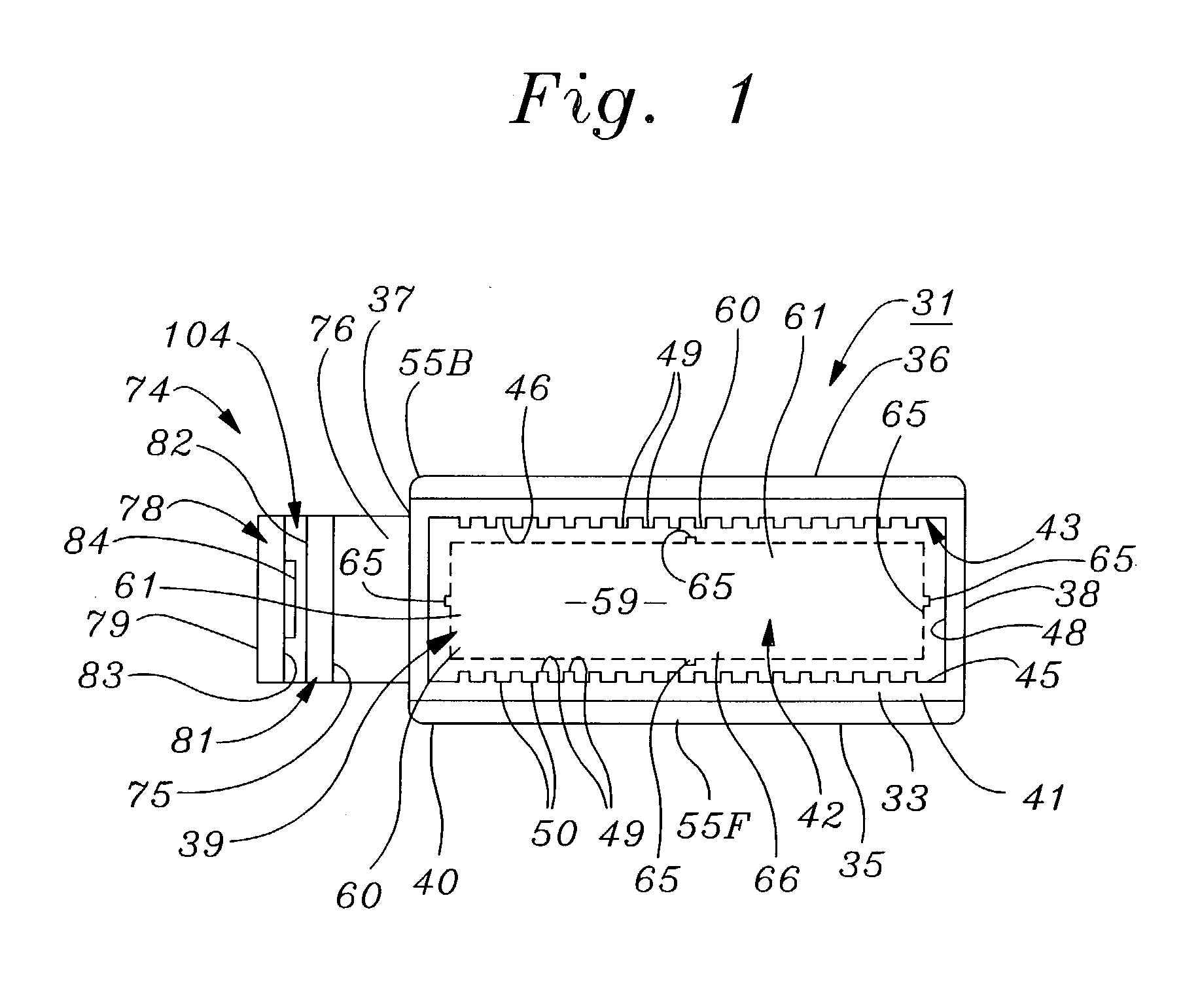

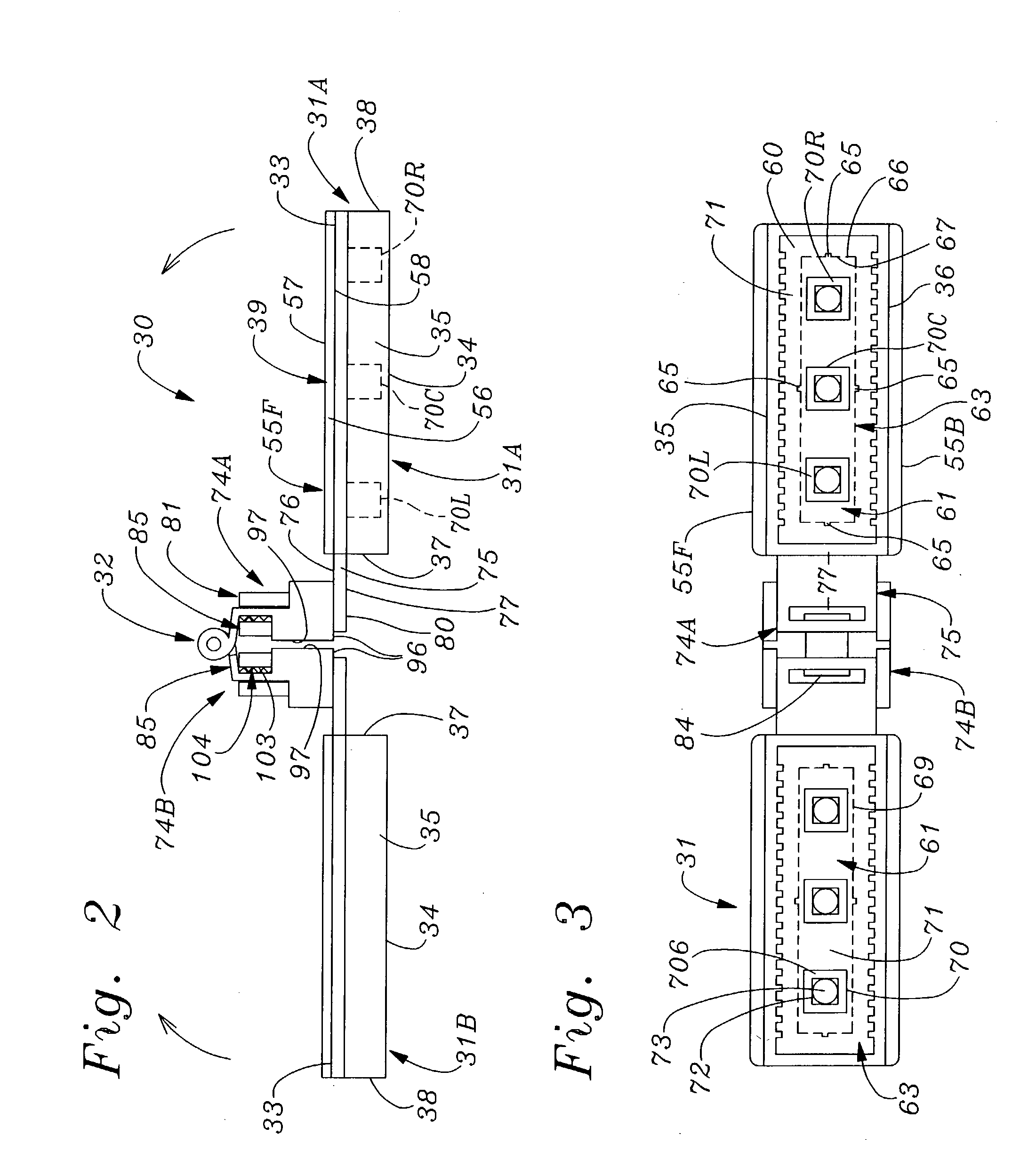

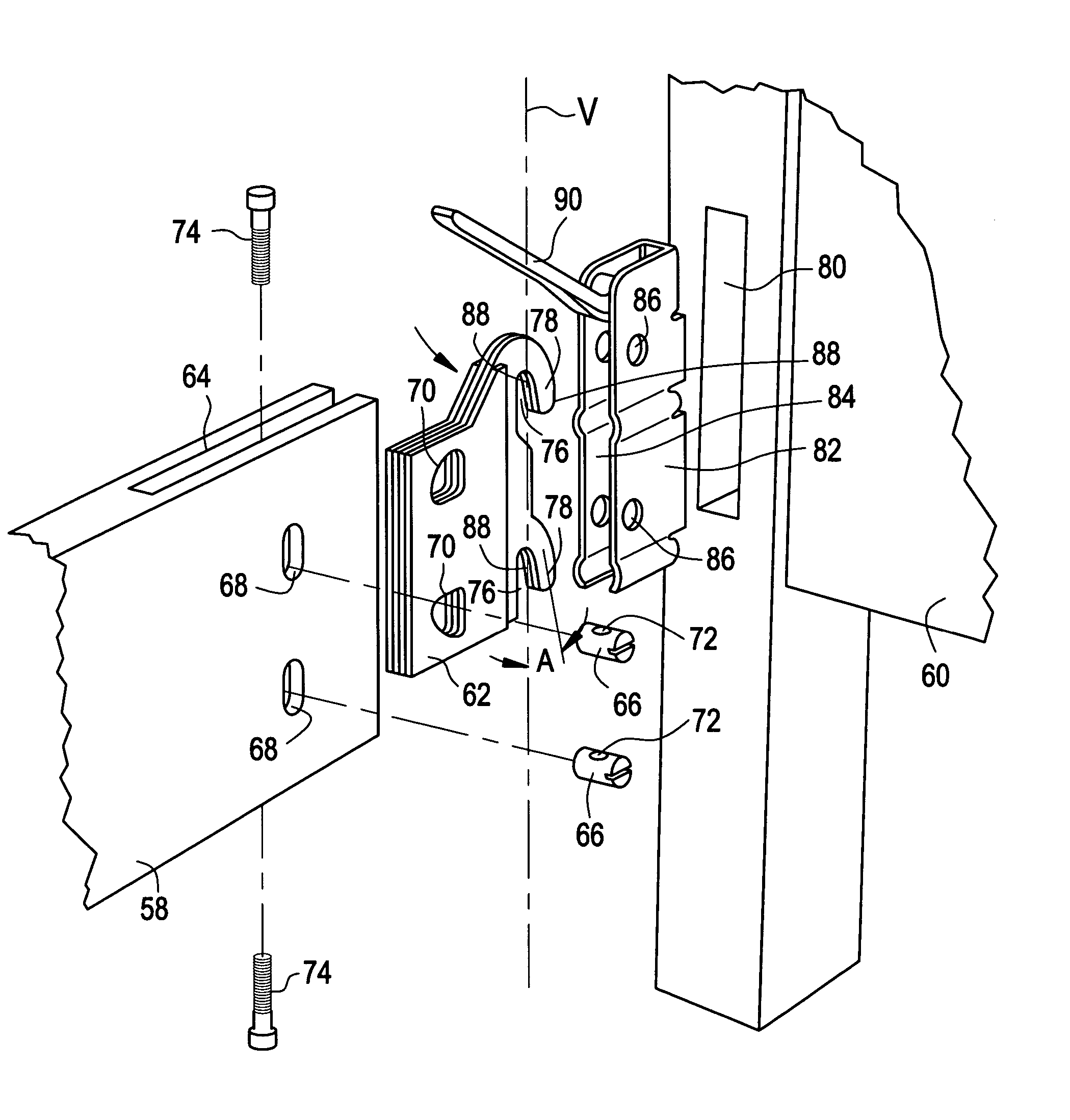

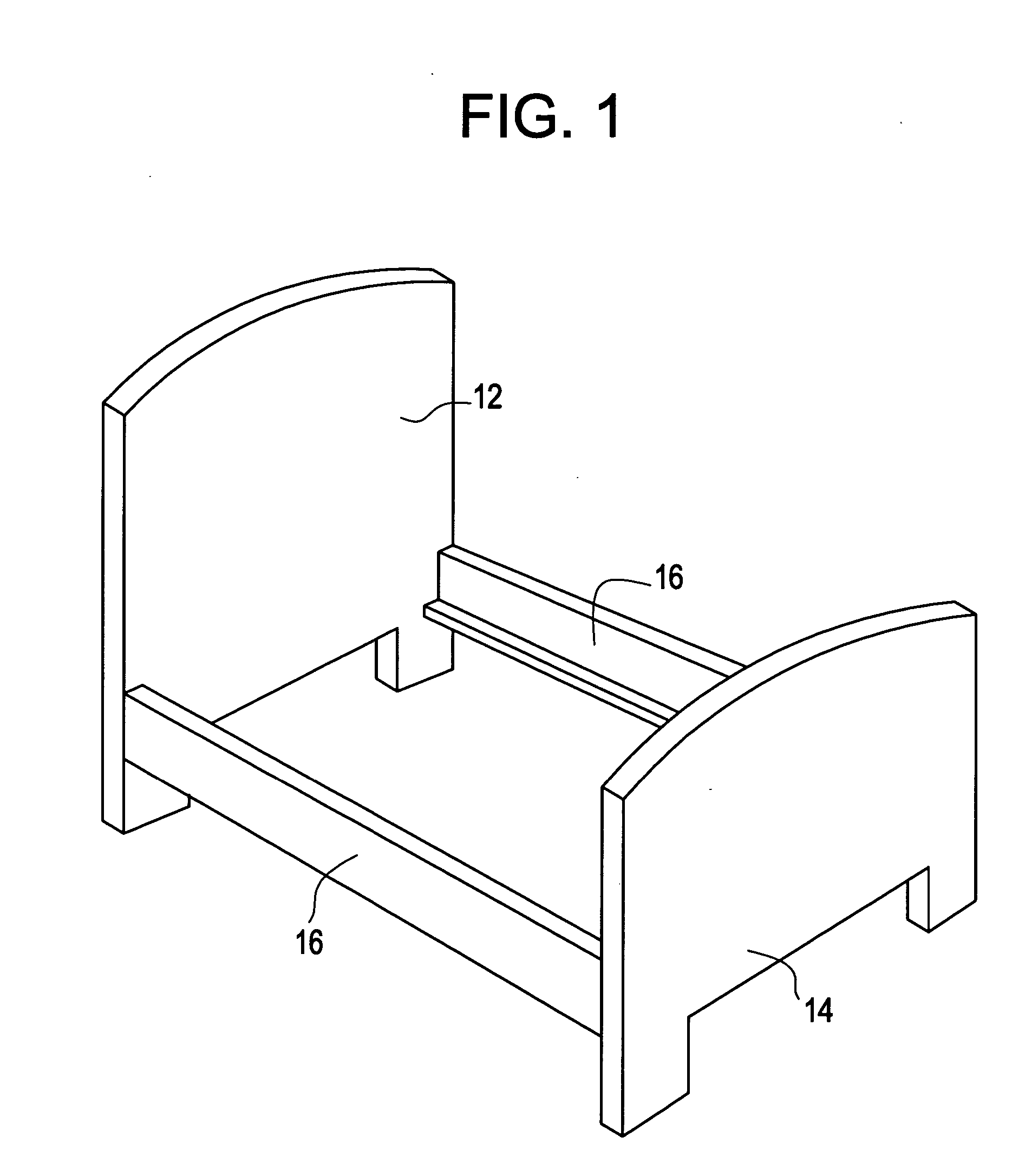

Side rail end connection system for bed frame

A system for connecting side rails of a bed frame with a headboard and / or footboard. A hook plate is affixed to the side rails and has a pair of hooks extending outwardly from the ends of the side rails. The hooks form slots in the hook plates and the slots have forward edges formed at a predetermined angle with respect to the vertical. A receiver housing is affixed to the headboard and / or footboard and has a vertical opening with a pair of transverse pins that span that opening. The side rails are affixed to the headboard and / or footboard by inserting the hooks into the vertical opening to engage the pins. A lever arm, pivotally affixed to the receiver housing, can be pivoted to force the hook plate downwardly to forcefully engage and lock the forward edge of the slots with the pins.

Owner:FINGER LAKES INTPROP

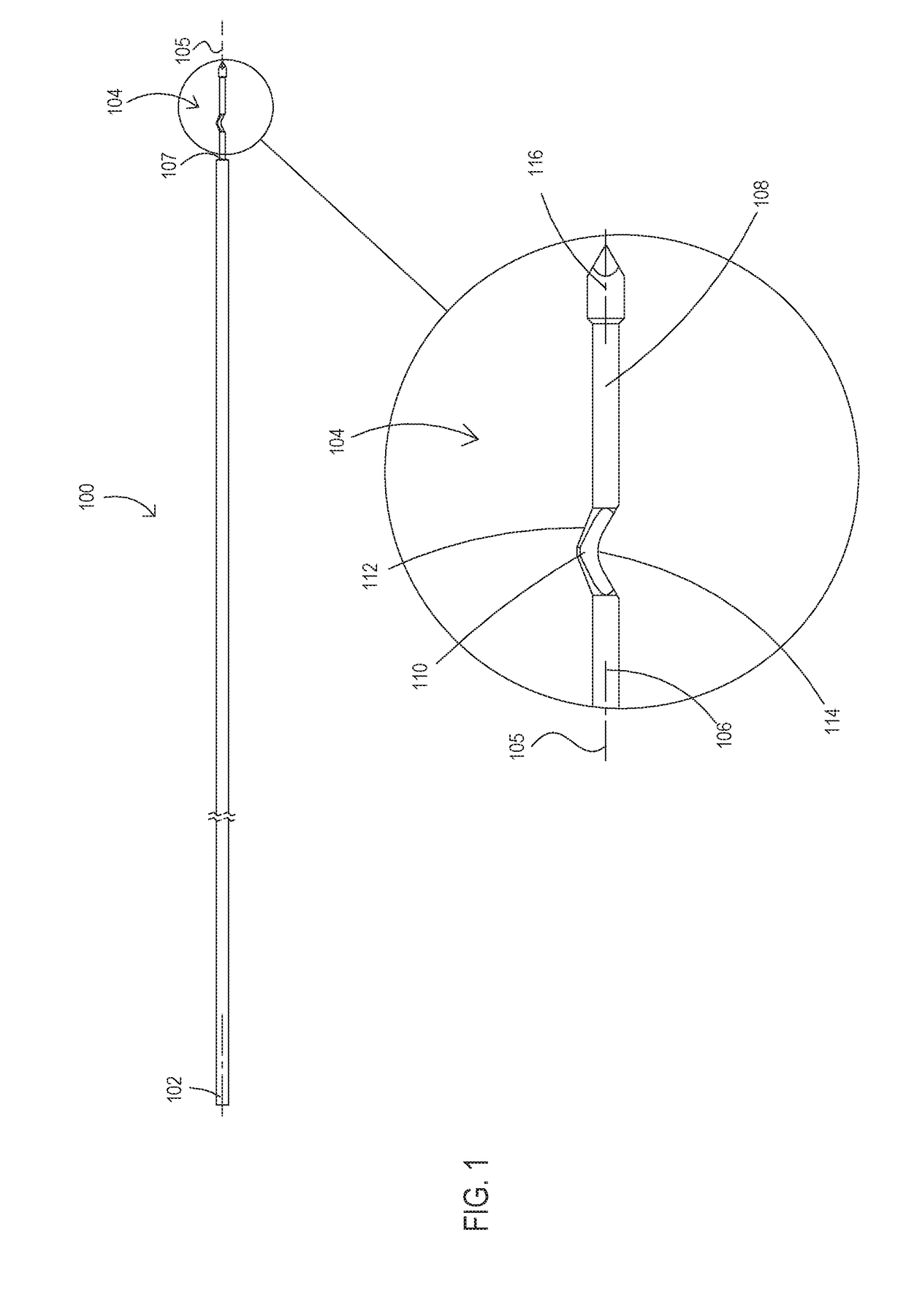

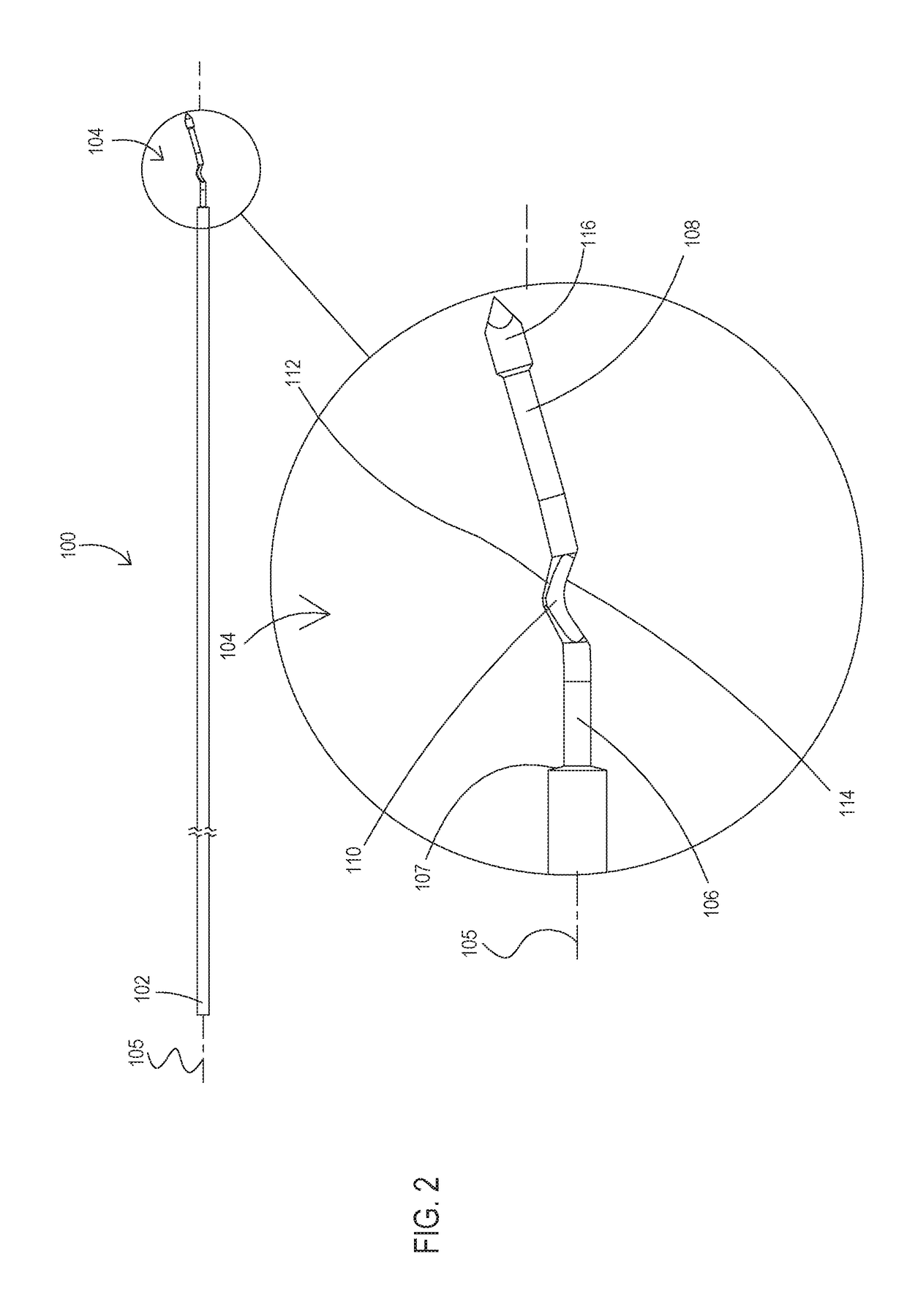

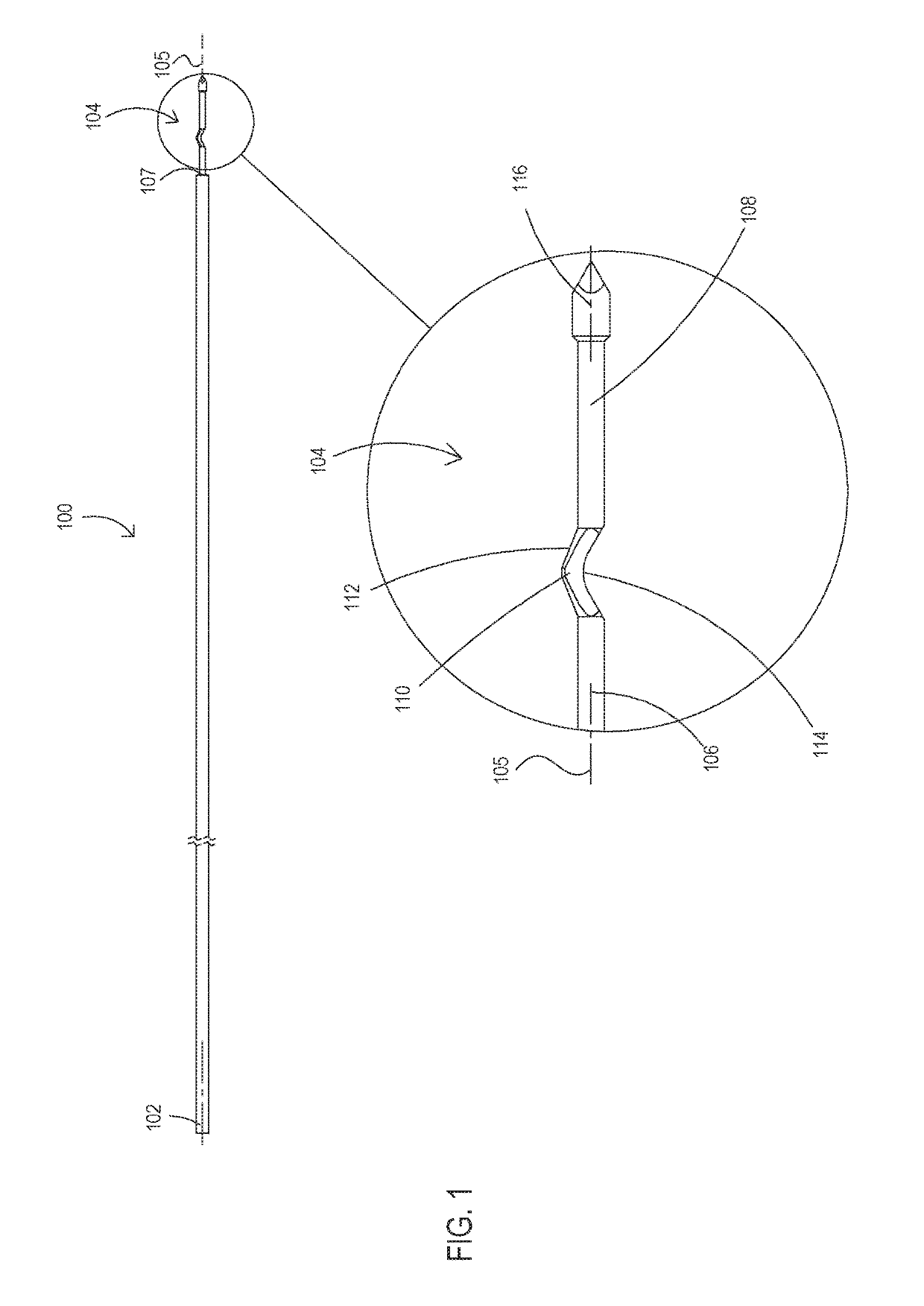

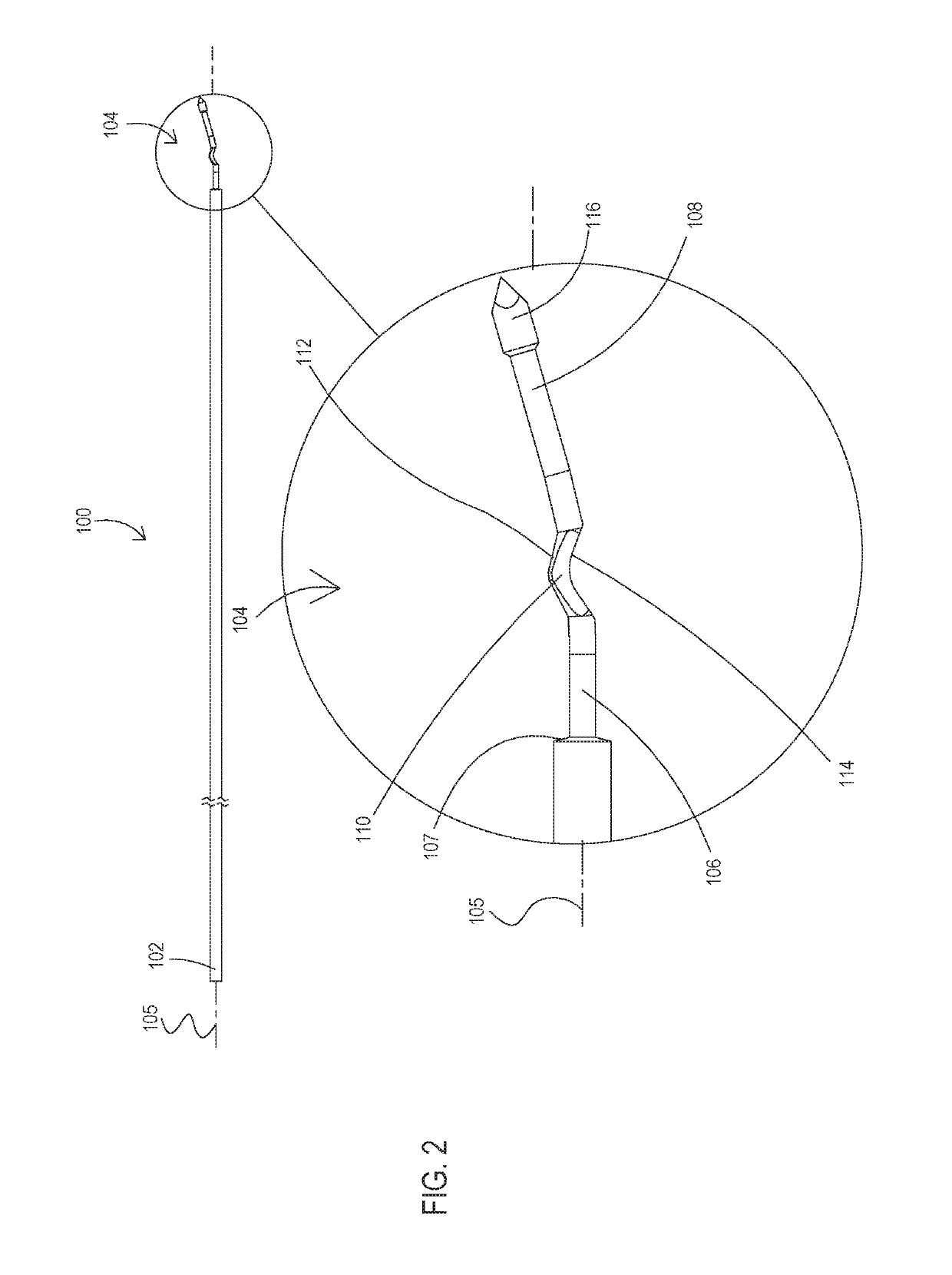

Bone material removal device and a method for use thereof

A bone material removal device including a cannula, a bone drilling forward tip and a bore widening element including a bone carving portion that slides axially relative to the cannula and extends in a circumferential direction and wherein the axial movement of the bore widening element relative to the cannula brings a carving portions to travel and extend radially in a circumferential direction beyond a surface of the cannula and carve bone from a wall of a bore.

Owner:T MEDICAL DEVICES AGRI COOP

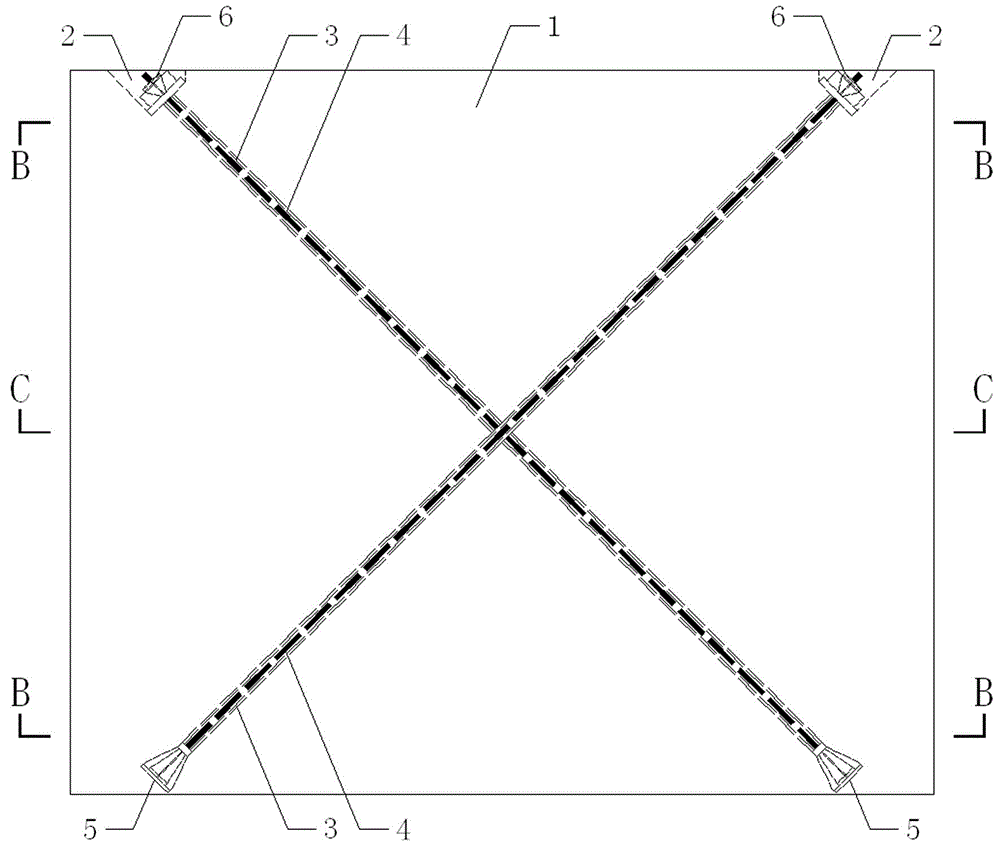

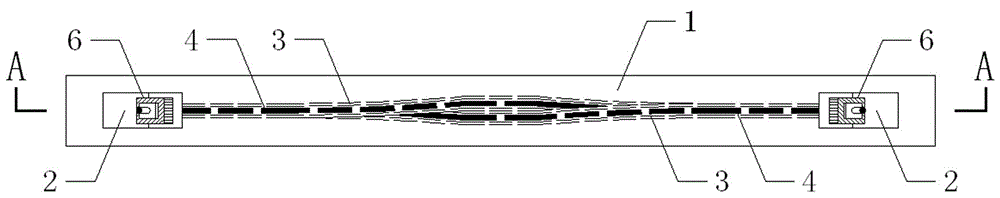

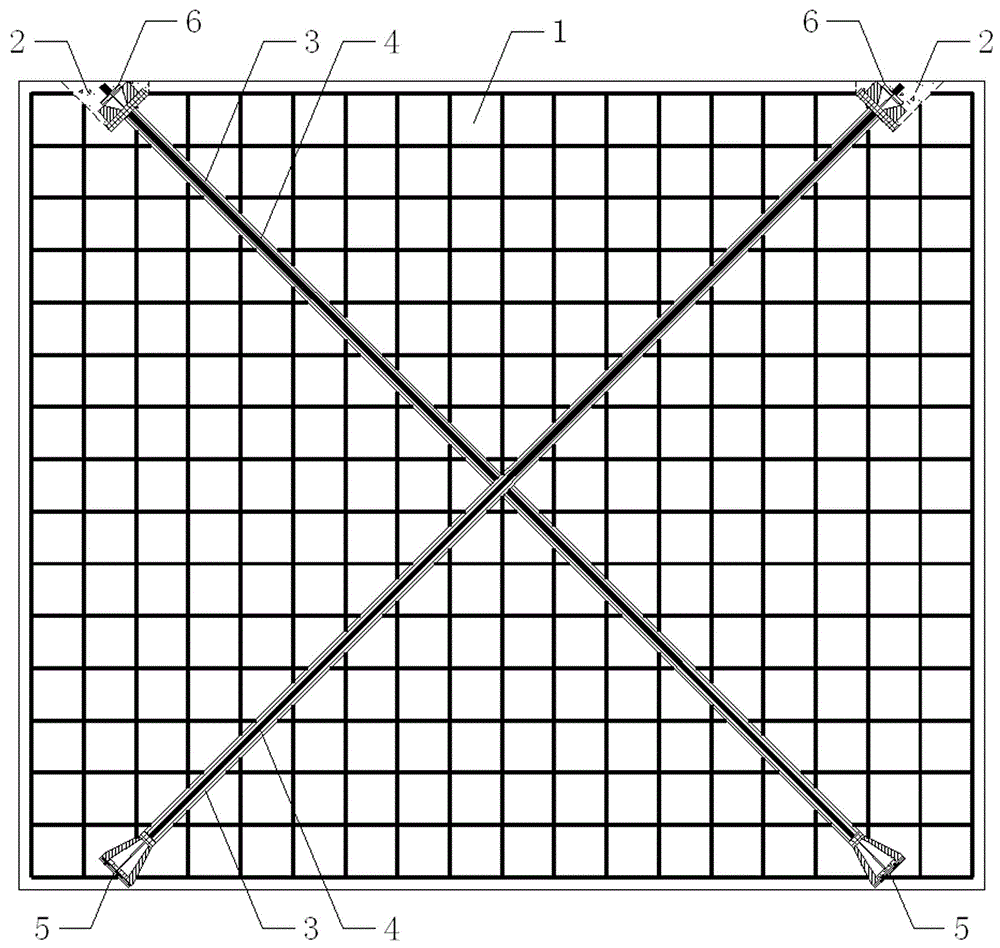

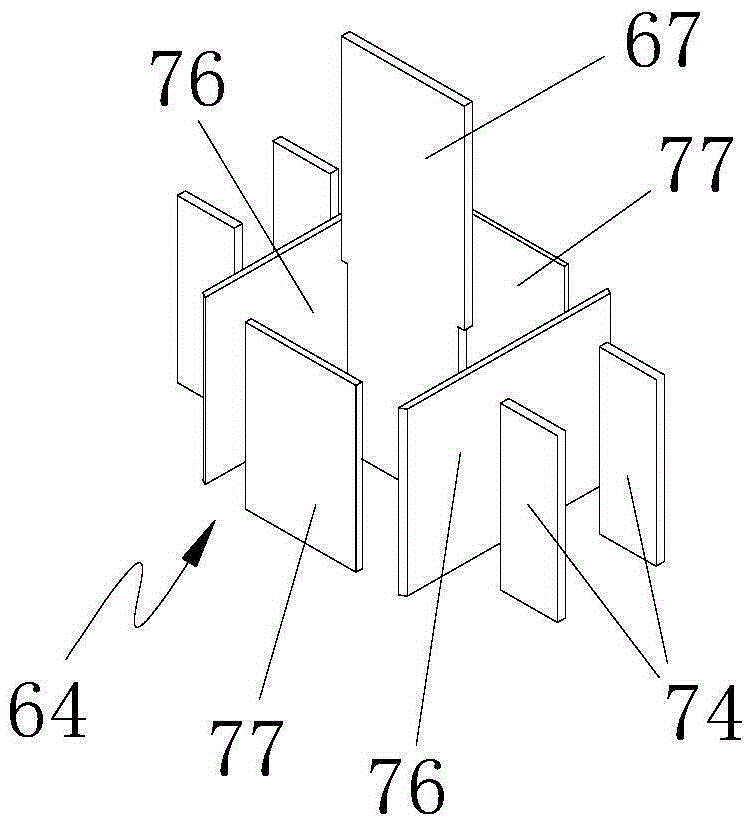

Shear wall structure configured with crossed slant internal prestress and construction method of shear wall structure

InactiveCN102979221ADirect forceReduces the likelihood of crossing oblique cracksWallsBuilding material handlingRebarPre stress

The invention relates to a shear wall structure configured with crossed slant internal prestress. The shear wall structure comprises a shear wall body, horizontal steel bars of the shear wall body and vertical steel bars of the shear wall body, wherein a shear wall tooth plate and a prestress tension end anchor tool are respectively arranged at the left upper corner and the right upper corner of the shear wall body, prestress anchoring end anchor tools are respectively arranged at the left lower corner and the right lower corner of the shear wall body, and a crossed slant prestress steel beam and a crossed slant prestress pipeline are arranged between the prestress anchoring end anchor tool and the prestress tension end anchor tool at the opposite corners. A construction method of the structure comprises steps of shear wall template erection and binding of ordinary steel beams of the wall body; crossed slant prestress pipeline arrangement and installation; prestress steel beam penetration and prestress anchor tool installation; shear wall concrete casting and maintenance; and prestress tension, pipeline grouting and end part anchor sealing. The shear wall structure greatly improves the anti-seismic performance of the shear wall.

Owner:ZHENGZHOU UNIV

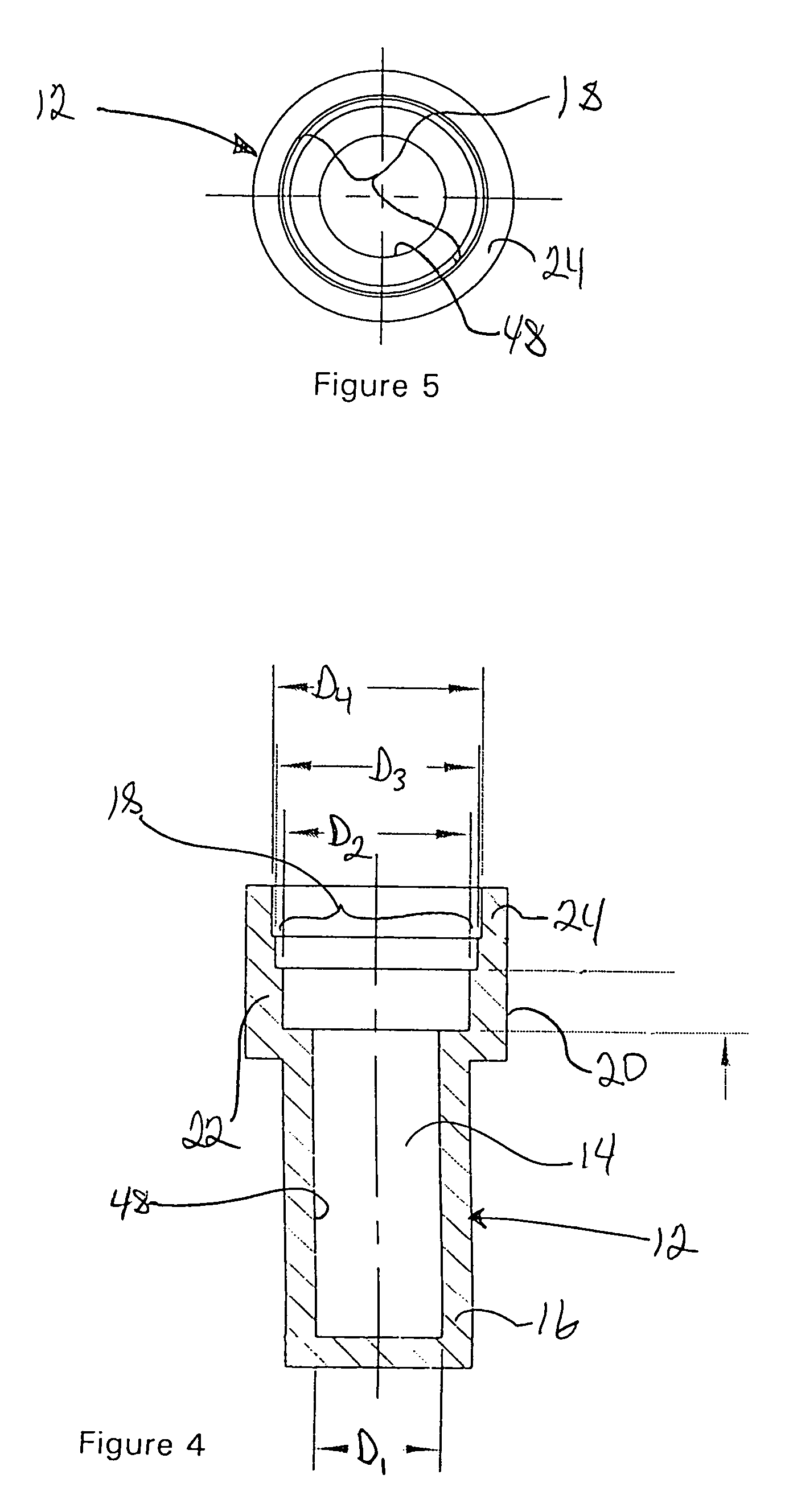

Pin tray dental prostheses modeling system with re-usable tray

InactiveUS20040166466A1Quickly and easily removedEasy to installImpression capsDental articulatorsDenturesEngineering

A dental prostheses modeling system includes a re-usable tray having in an upper part thereof a trough for receiving a semi-liquid casting material such as plaster of Paris or die stone, the trough having opposed vertical walls in which are formed alternating vertically disposed ribs and grooves for molding complementary shaped grooves and ribs in opposed sides of the base of a dental model casting molded in said tray. The trough has a base frame which overlies an upwardly concave lower cavity for receiving liquid die stone after the casting base has solidified, hardened and been removed. The base frame has therethrough an elongated aperture joining the upper trough to the lower cavity. A resilient insert is removably lodged in the base frame aperture to form therewith a liquid-tight seal, whereupon liquid die stone is poured into the upper trough to form the base of a dental model casting. After the casting has hardened, the insert is removed, and pins are fitted into selected portions of the cast base. The tray is then inverted to receive liquid die stone which hardens to form a stone base matrix for insertably receiving pins protruding from the casting base. The casting is then severed into segments which are releasably re-engageable along with adjacent portions of the casting within the tray, proper registration between segments of the casting being effected by insertable receipt of pins within holes formed in the matrix during hardening thereof, and engagement between ribs and grooves of the casting segment bases with complementarily-shaped grooves and ribs in the inner side walls of the upper tray trough.

Owner:HONSTEIN JERRY P

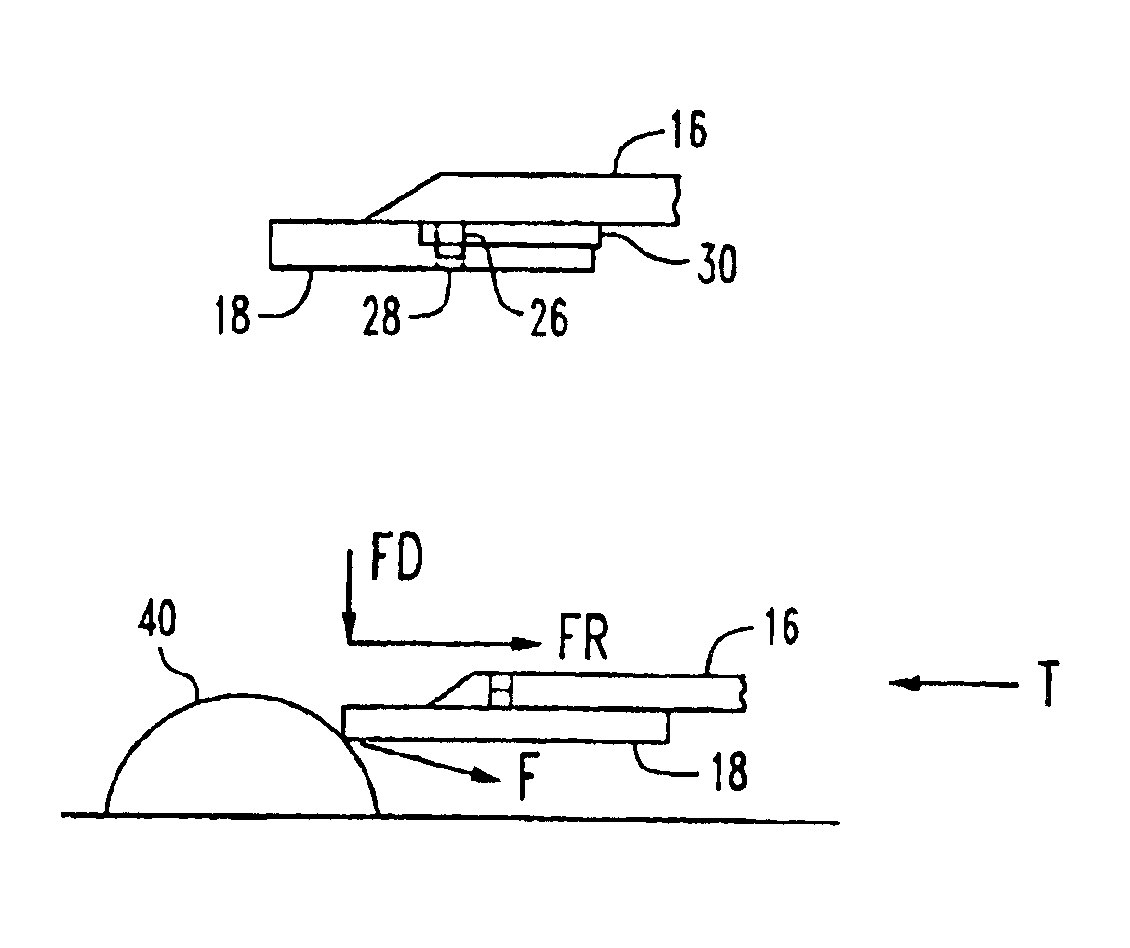

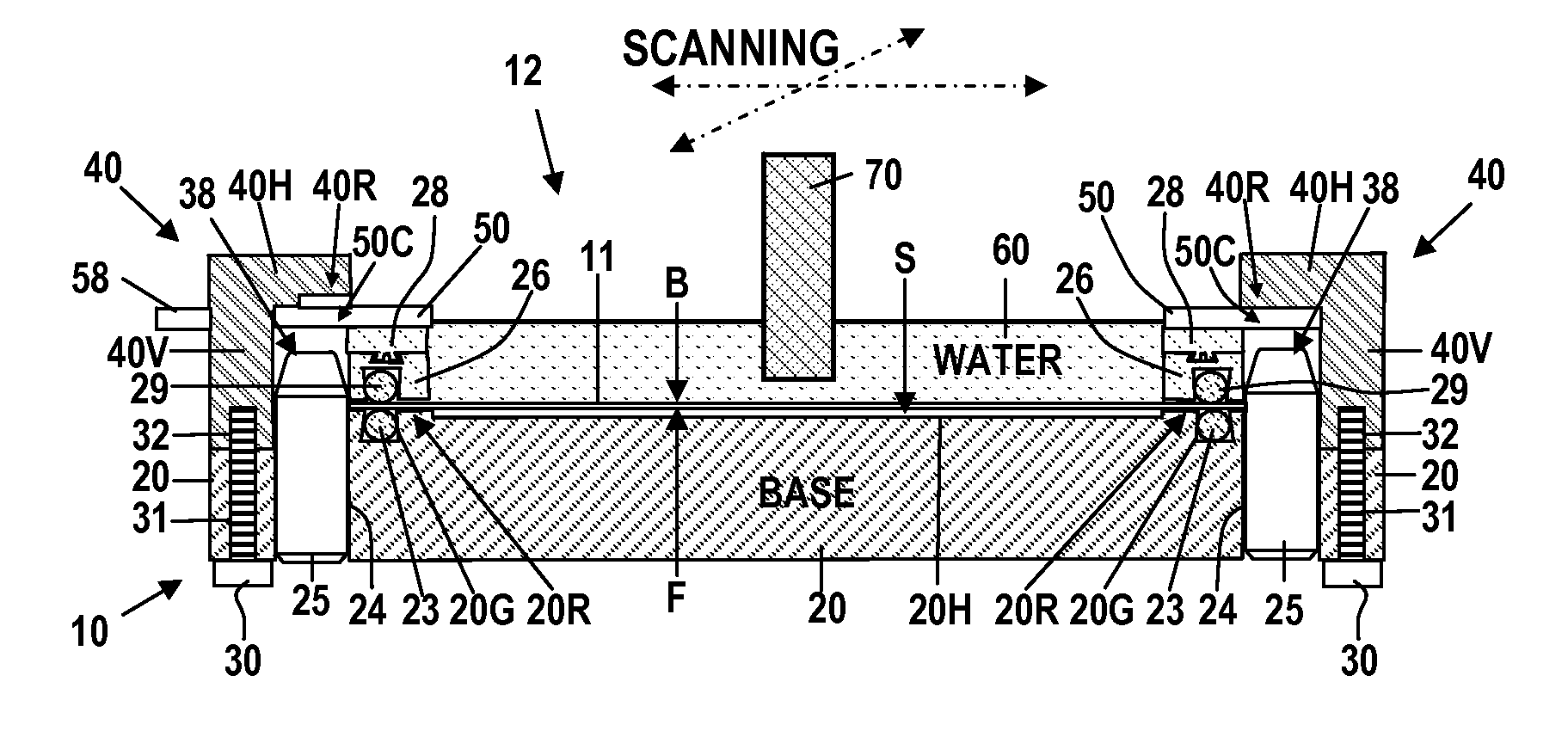

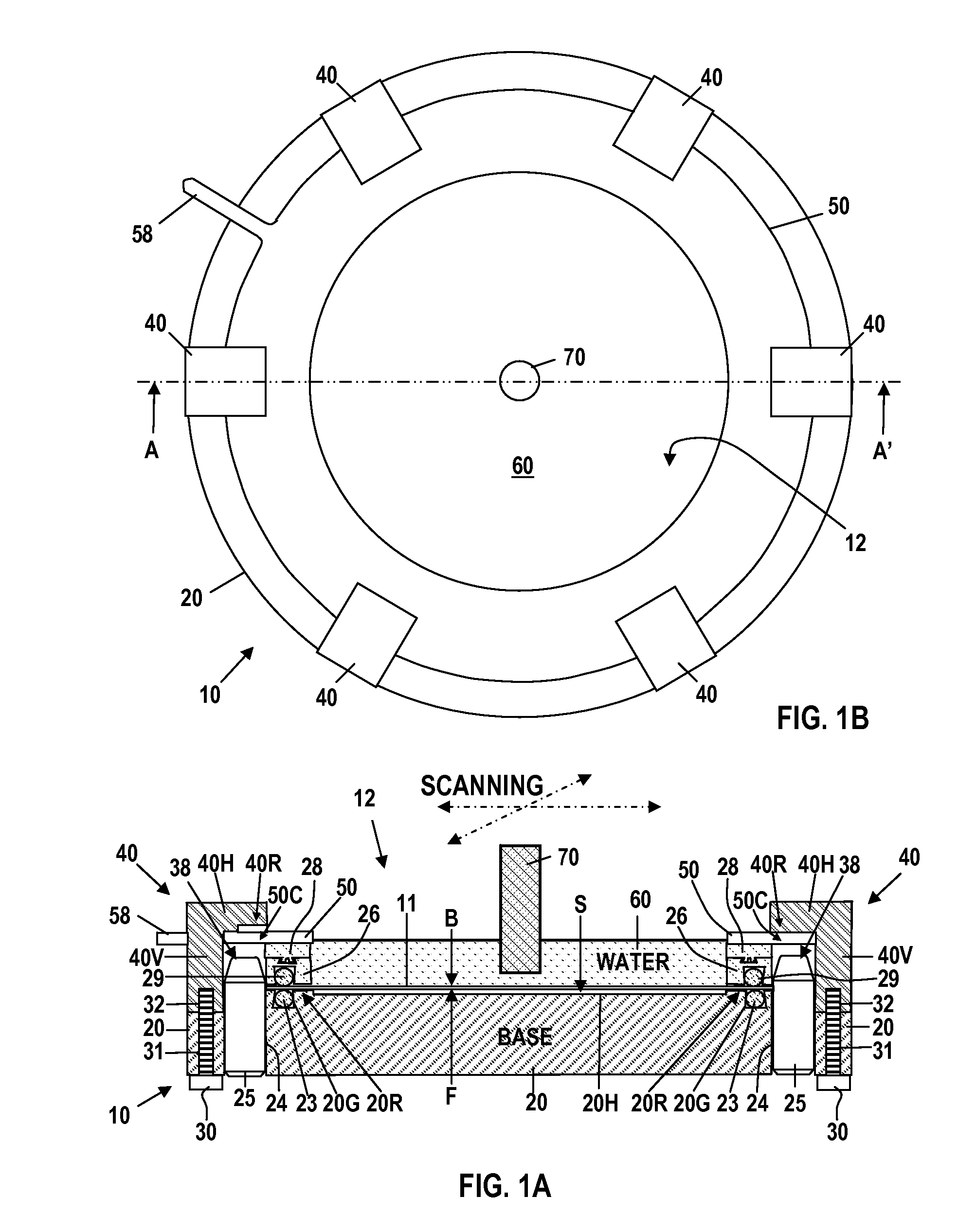

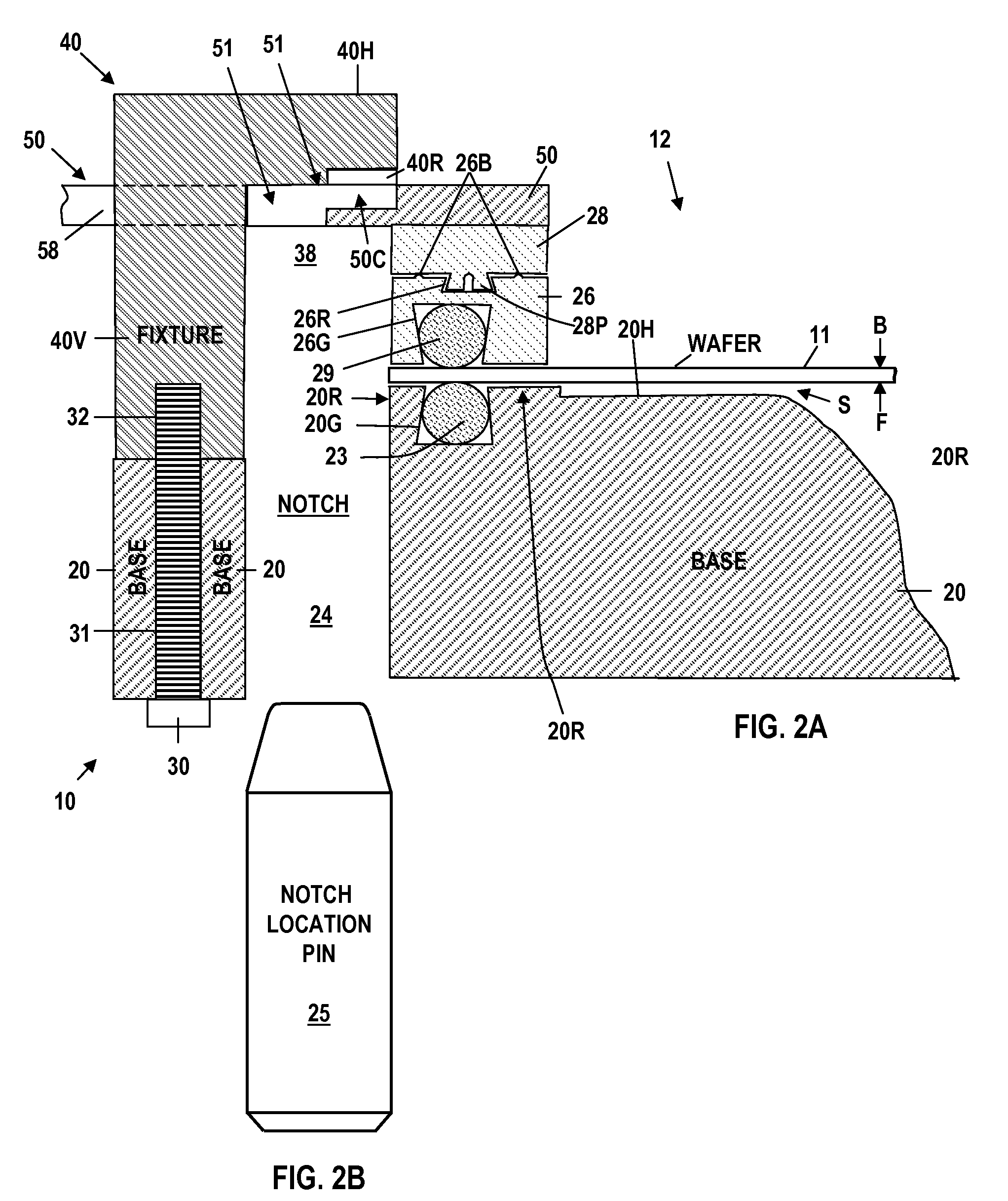

Slip ring positive z force liquid isolation fixture permitting zero net force on workpiece

InactiveUS20090084183A1Direct forceWide operating zoneAnalysing solids using sonic/ultrasonic/infrasonic wavesMagnetic property measurementsAcoustic transmissionNet force

Apparatus for Scanning Acoustic Microscopy (SAM) of a semiconductor device including a substrate with an acoustic probe, The substrate has upper and lower surfaces. A sealed lower space provides an environment surrounding the lower surface. An upper ring structure formed above the upper surface includes an upper sealing ring in contact with the upper surface, with the upper sealing structure and the seal forming a dam for retaining the acoustic transmission fluid above the upper surface. A fixture base retains a lower sealing ring in contact with the lower surface surrounding the lower surface. An acoustic scanning probe positioned confronting the upper surface of the semiconductor device extending into the acoustic transmission fluid retained in contact with the upper surface.

Owner:GLOBALFOUNDRIES INC

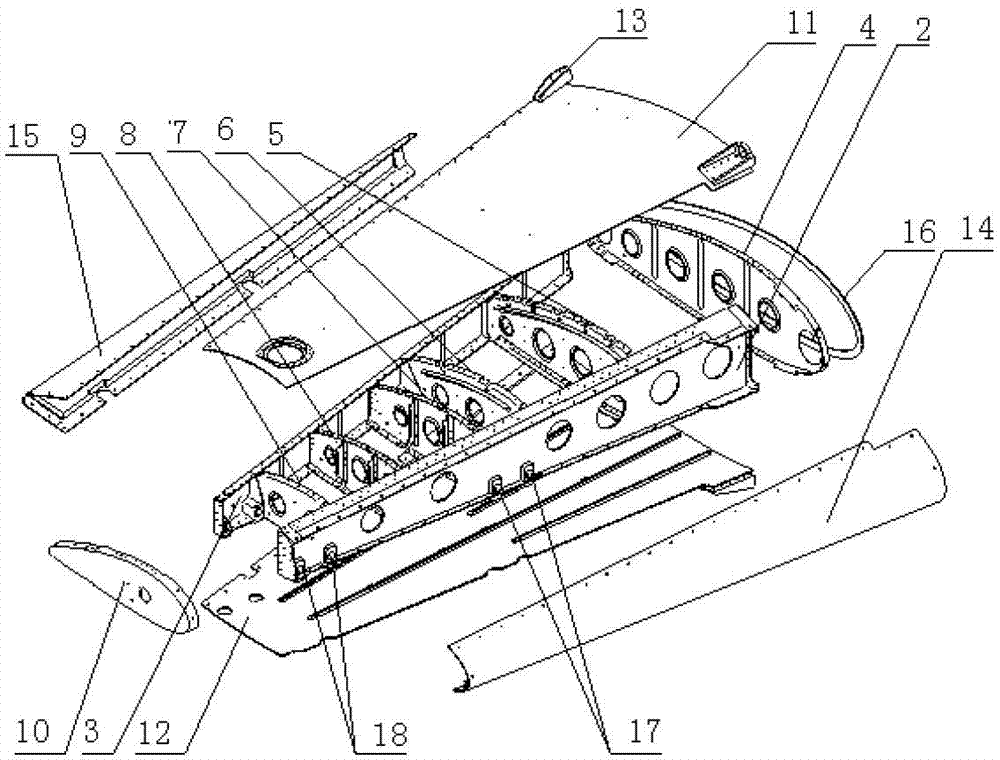

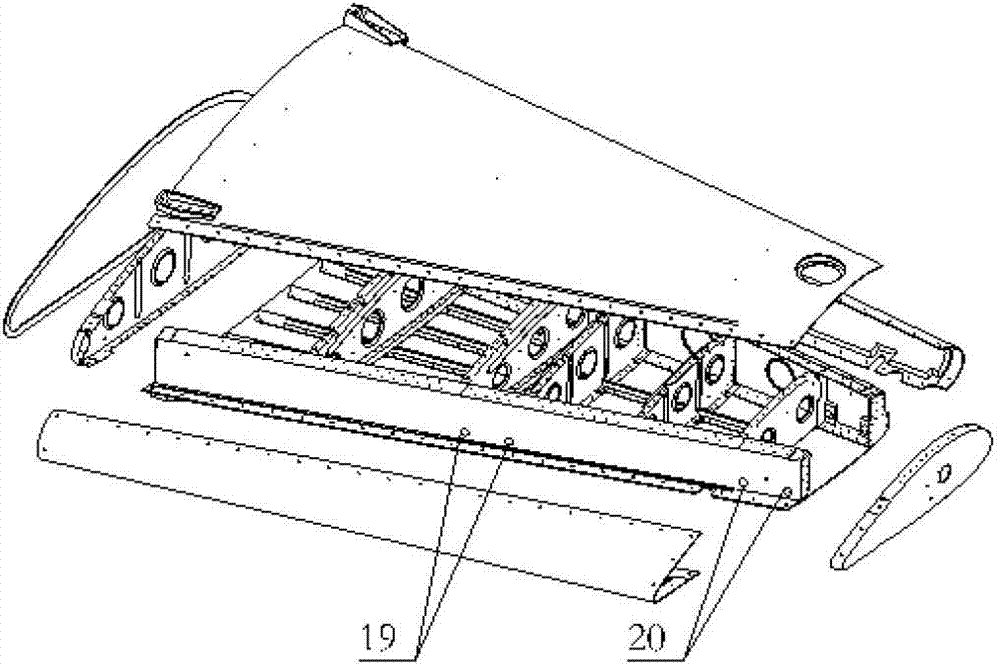

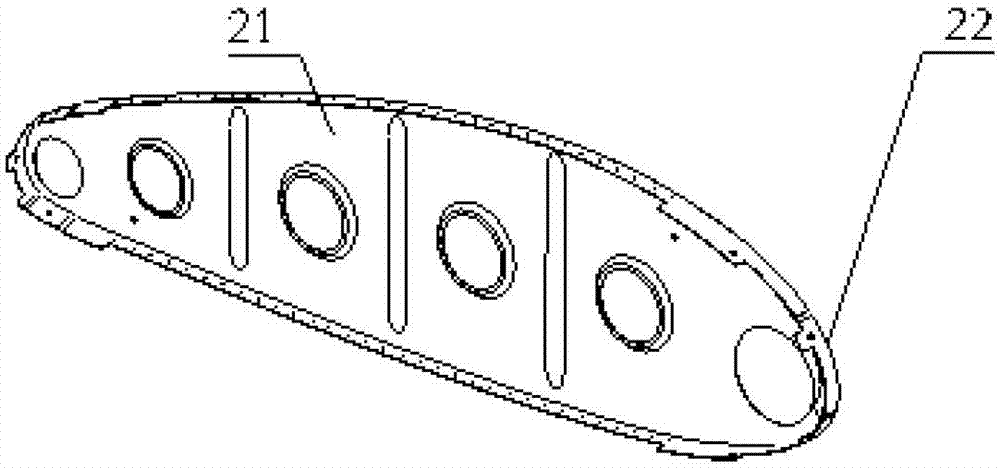

Multi-purpose plug-in device for helicopter

InactiveCN103204236AImprove interchangeabilityIncrease loading capacityAircraft componentsEngineeringDesign technology

The invention belongs to the technical field of structural designs of helicopters, and relates to a multi-purpose plug-in device for a helicopter. The multi-purpose plug-in device for the helicopter provided by the invention is fixed at the left side and right side of the helicopter through bolts, so that simplicity and convenience in dismounting and strong interchange property can be realized; two mount points are arranged at the single side, so that the mount capacity of the helicopter is greatly improved; the multi-purpose plug-in device has a specific structural manner, so that not only can good rigidity be realized, but also the entire aerodynamic performances of the helicopter can be improved, the structural weight of a helicopter body is reduced, and the advantages of convenience in dismounting, benefits on interchange and maintenance and the like can be realized. The multi-purpose plug-in device for the helicopter provided by the invention uses an interchange design manner, is in a double-beam type structure manner, and forms a sealed box section with upper and lower skin assemblies and a beam rib assembly, so that the entire structure has the advantages of direct transmission, light weight, large rigidity and the like; the mount capacity is improved, and four hooks can be mounted on the left side and the right side; the multi-purpose plug-in device for the helicopter uses the interchange design and is beneficial to maintain; and the aerodynamic performance of the helicopter can be improved.

Owner:HARBIN

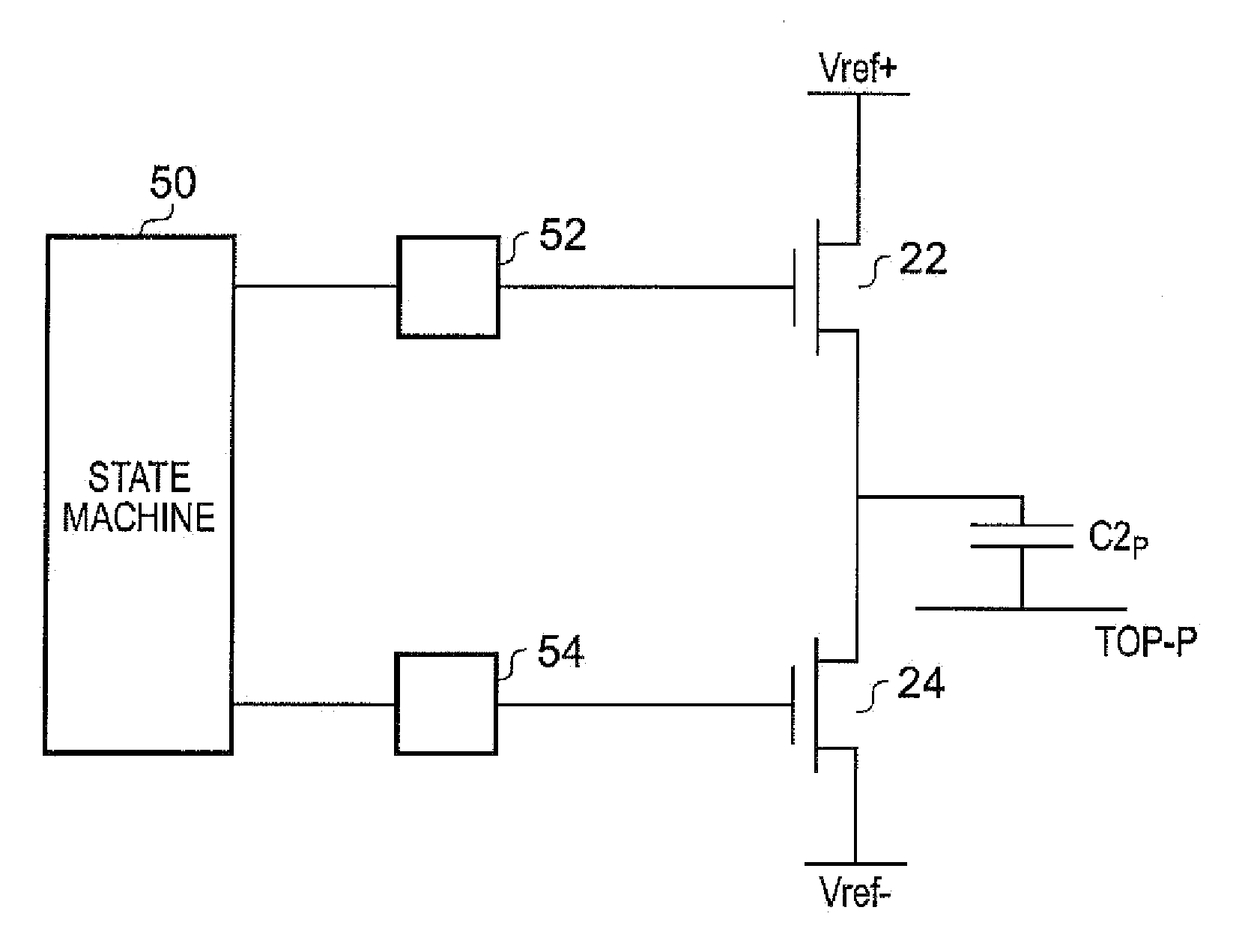

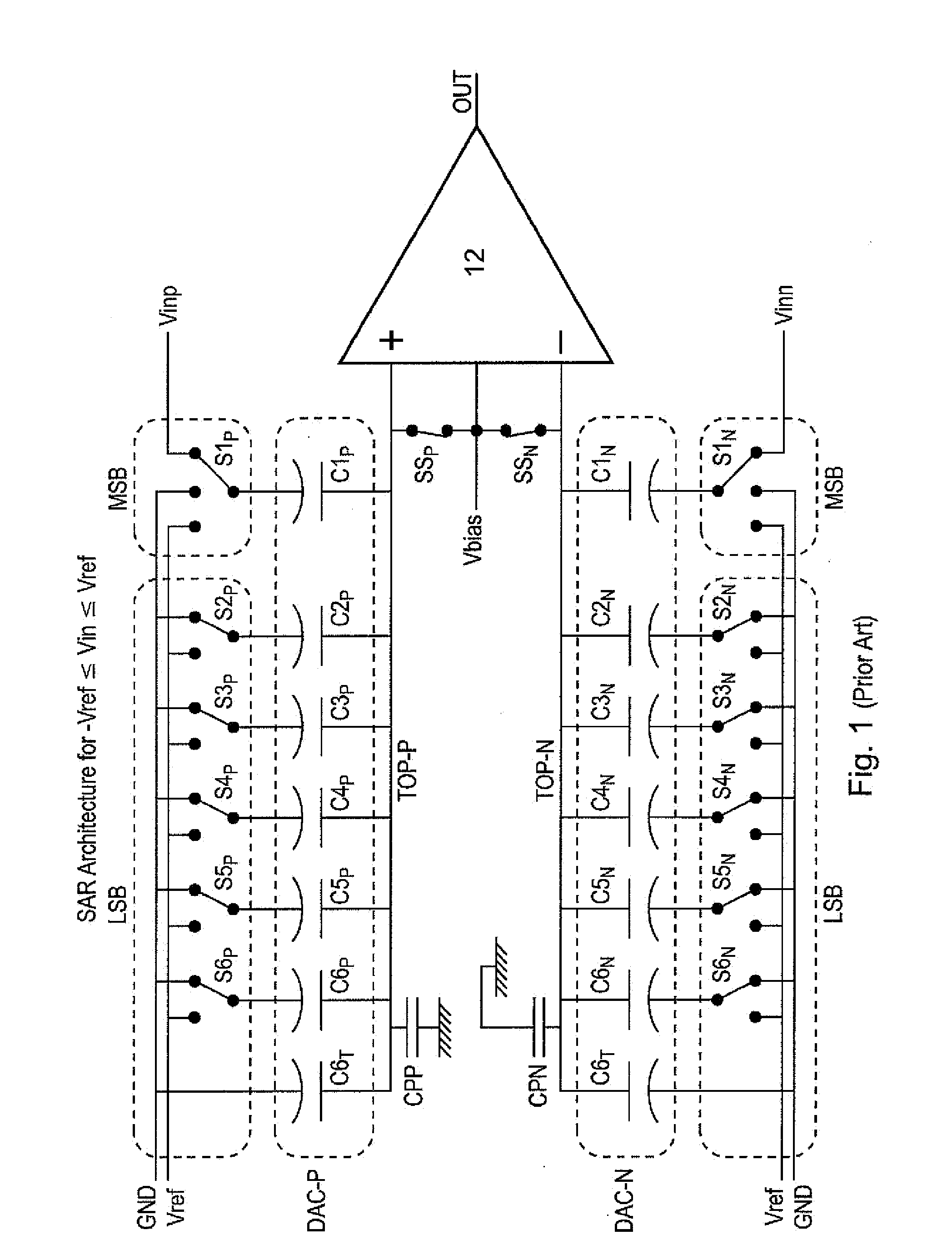

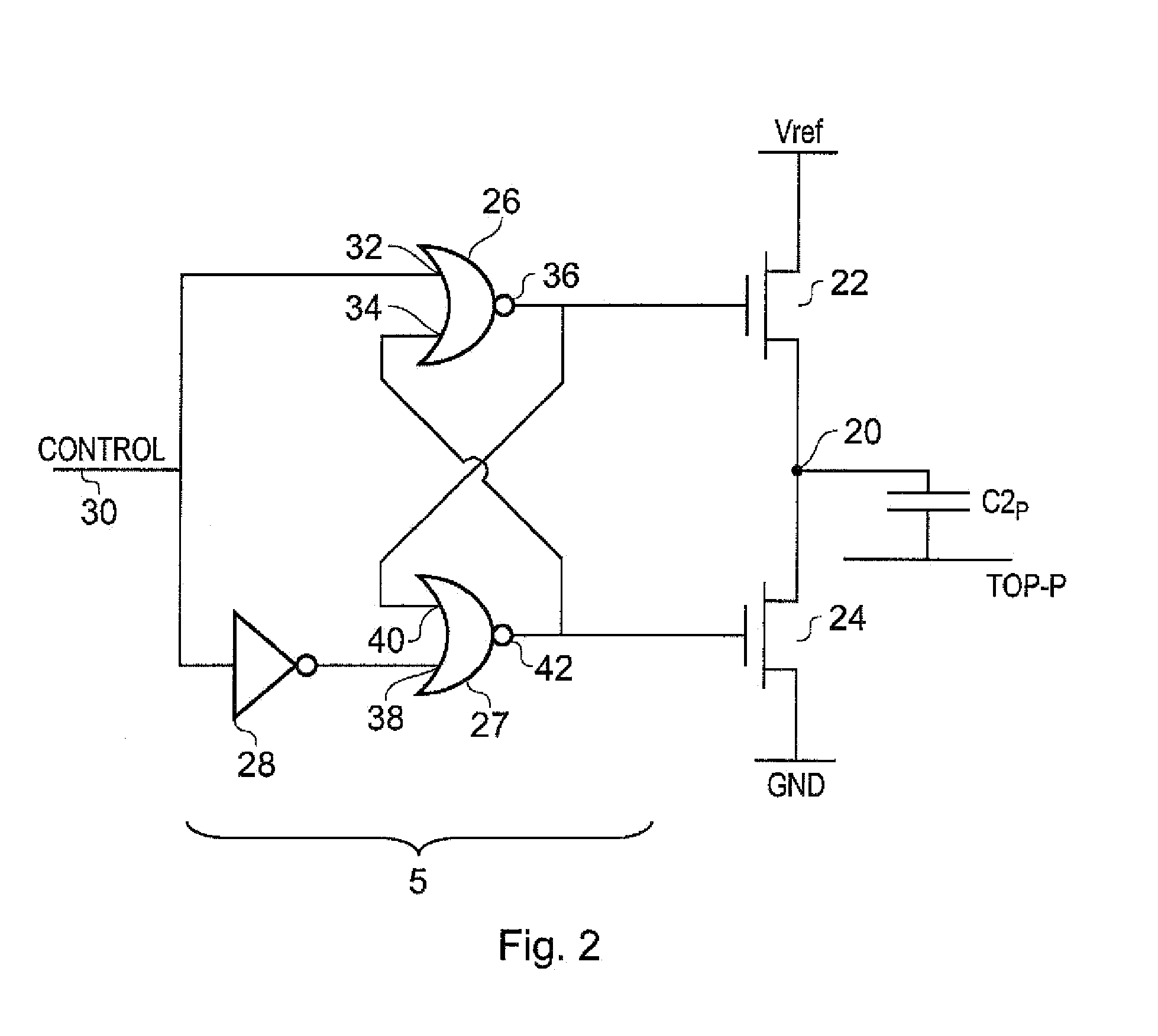

Successive approximation analog to digital converter

ActiveUS7589659B2Improve throughputQuick switchPower reduction in field effect transistorsTransistorA d converterEngineering

A successive approximation analog to digital converter comprising a plurality of capacitors which during a successive approximation conversion are selectively connectable to a first reference or a second reference under the command of a controller. During a conversion step where the connections of a given capacitor may be varied, the switches to the given capacitor are both placed in a high impedance state during a decision period of a comparator.

Owner:ANALOG DEVICES INC

Prefabricated integral type shear wall

The invention discloses a prefabricated integral type shear wall. The prefabricated integral type shear wall comprises an upper wall body and a lower wall body; cylindrical reserved holes are vertically formed in two ends of the bottom of the upper wall body; vertical spiral stirrups with same heights are arranged in the reserved holes; exhaust vents which are communicated with the outside are formed in the top ends of the reserved holes; grouting holes which are communicated with the outside are formed in the lower parts of the reserved holes; vertical steel bars at the inner sides in edge constructional elements in the lower wall body extend out of the top of the lower wall body and then are bundled in groups, and the multiple grouped steel bar bunches are respectively inserted into the corresponding reserved holes till to be up to the tops of the reserved holes; and concrete mortar is filed between each steel bar bunch and each reserved hole. The prefabricated integral type shear wall has the advantages of being capable of reducing the construction difficulty of overlapping joint of the steel bar bunches, effectively restricting concrete in a compressive zone and being used for the overlapping joint among the vertical steel bars in a prefabricated integral type concrete shear wall system.

Owner:SOUTHEAST UNIV

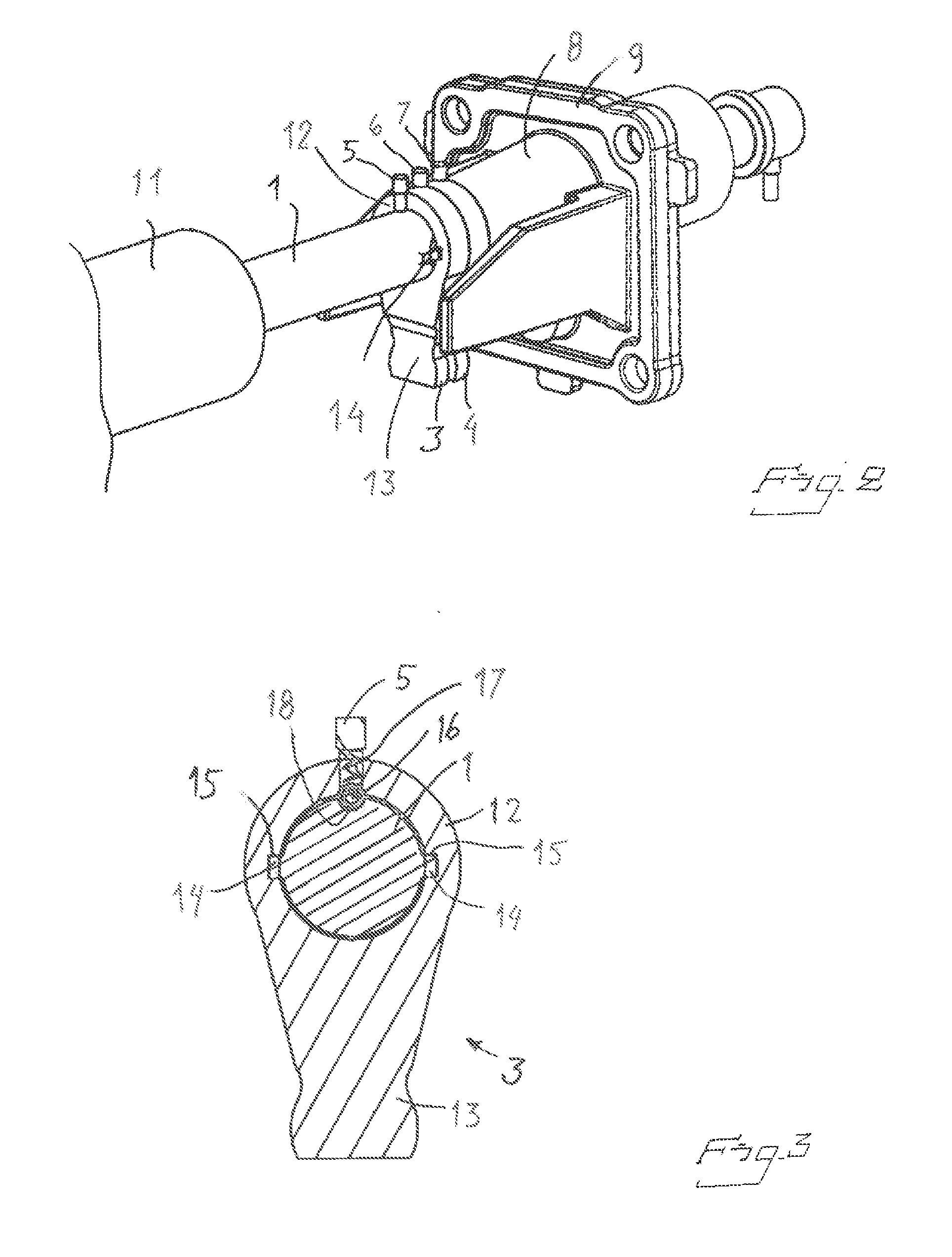

Device for the automatic operation of a manual gear box

InactiveUS20120090421A1Easy to operateGood precisionGearing controlControl devicesGear wheelAutomatic train operation

Owner:SCANIA CV AB

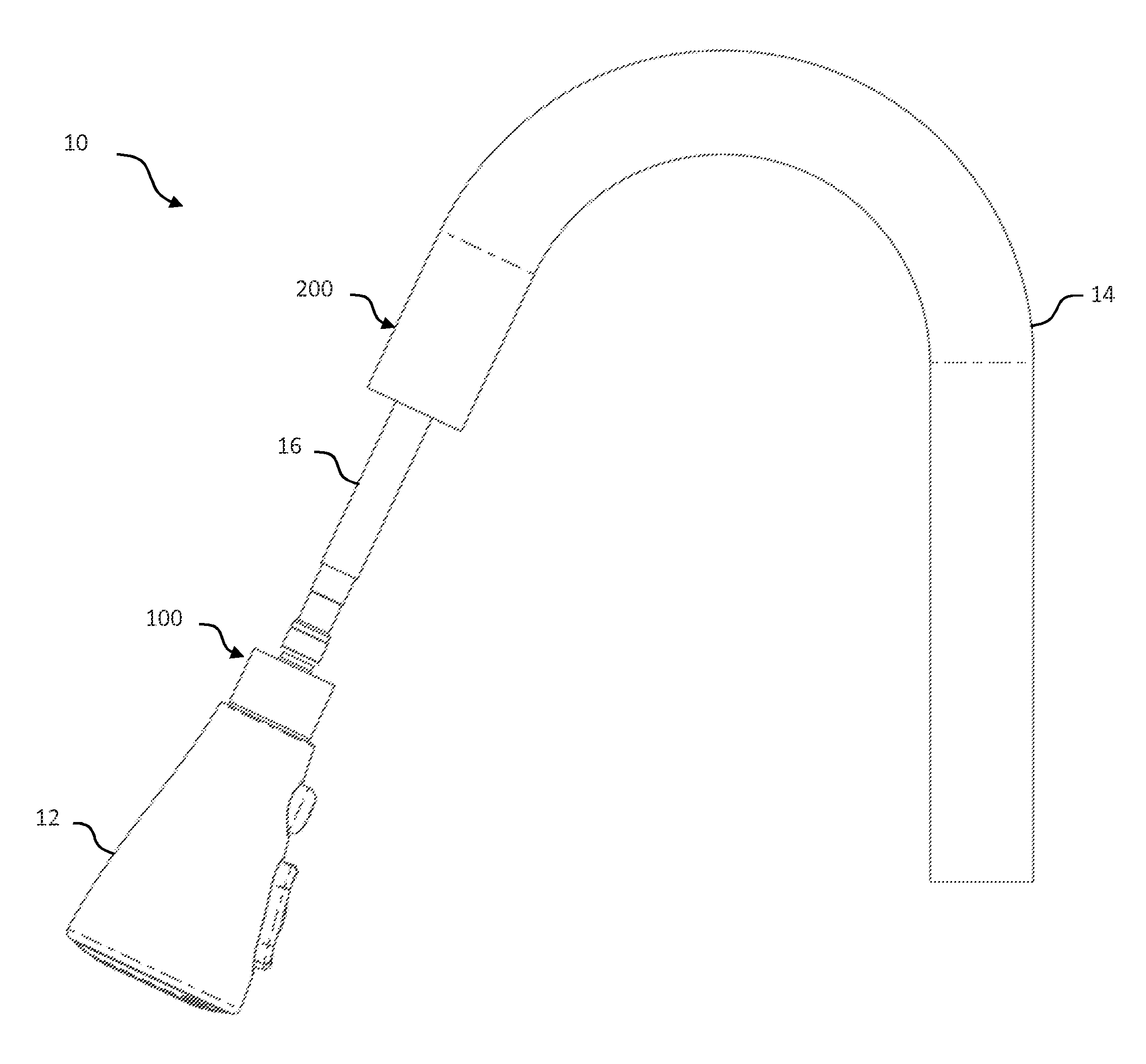

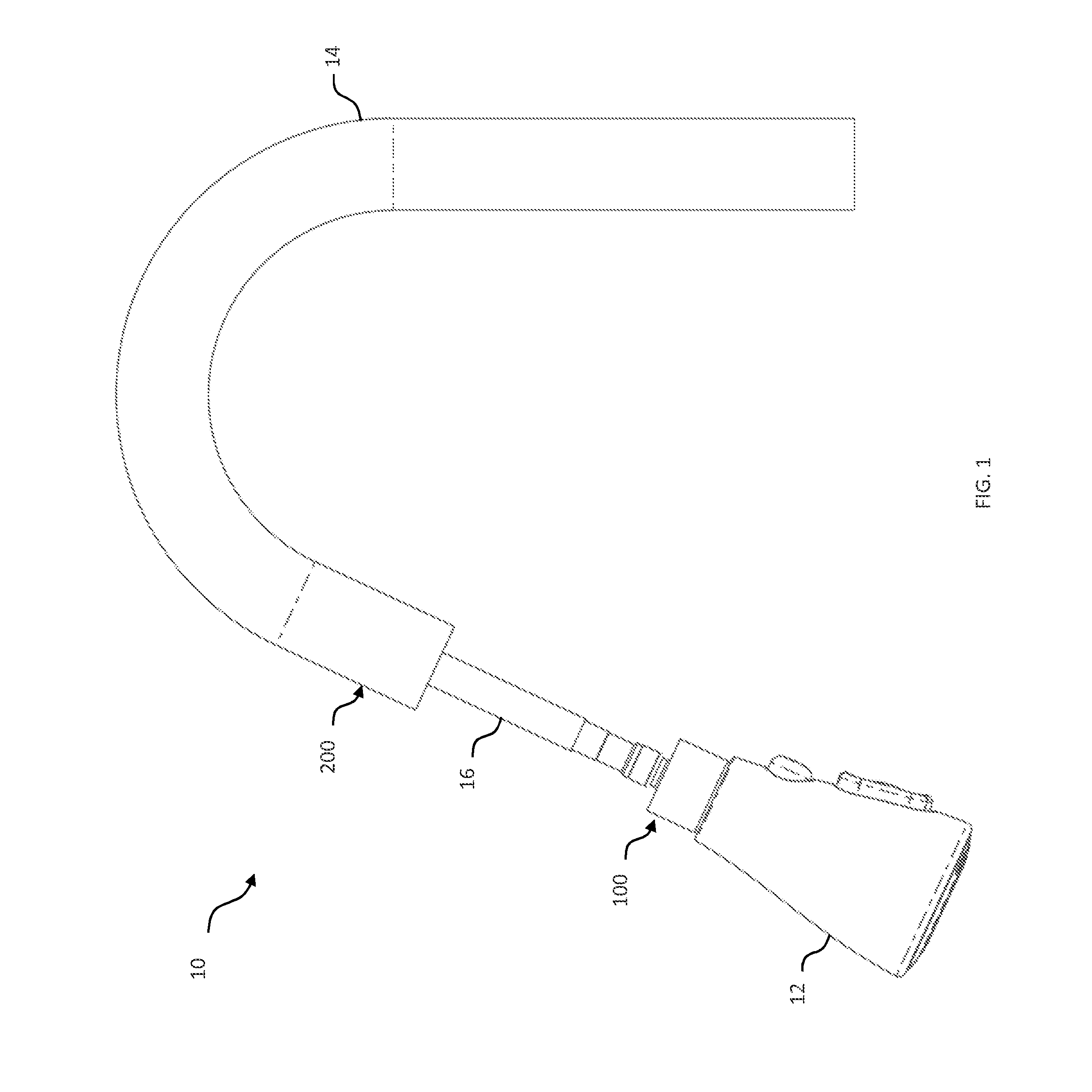

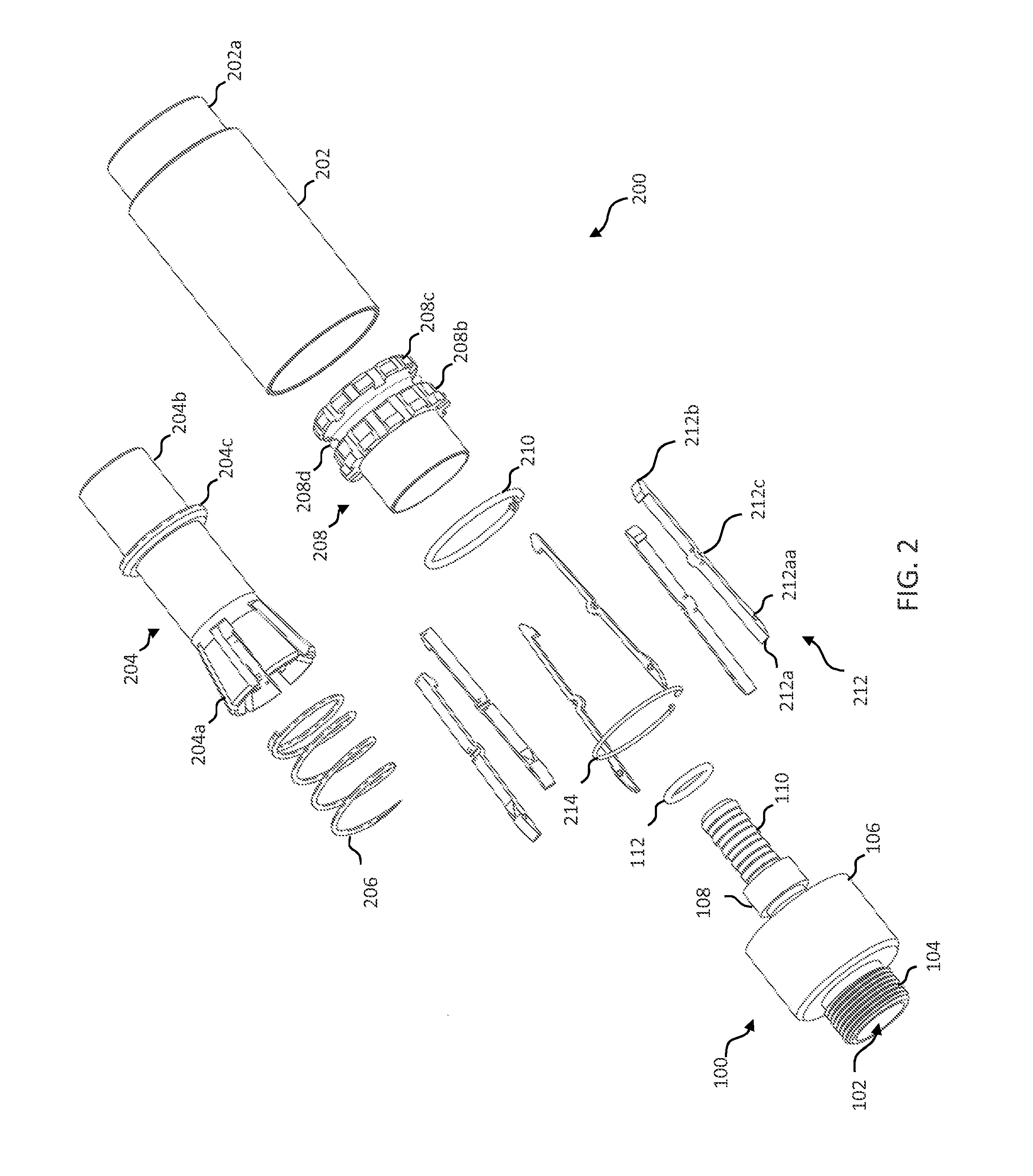

Auto-retracting mechanism for faucet spray head

ActiveUS20160083942A1Avoid disadvantagesEasy to installDomestic plumbingFire rescueMechanical engineeringEngineering

An auto-retracting faucet spray head has an auto-retract mechanism, which includes a docking assembly provided at the end of the faucet body to facilitate automatic retraction and docking of the spray head. The docking assembly includes a spring-loaded mechanism that automatically docks the spray head to the faucet body when an adapter coupled to the spray head engages the docking assembly.

Owner:AS AMERICA

Side rail end connection system for bed frame

ActiveUS20050217027A1Easy to useHigh compression forceSpring mattressesSofasMechanical engineeringHook plate

A system for connecting side rails of a bed frame with a headboard and / or footboard. A hook plate is affixed to the side rails and has a pair of hooks extending outwardly from the ends of the side rails. The hooks form slots in the hook plates and the slots have forward edges formed at a predetermined angle with respect to the vertical. A receiver housing is affixed to the headboard and / or footboard and has a vertical opening with a pair of transverse pins that span that opening. The side rails are affixed to the headboard and / or footboard by inserting the hooks into the vertical opening to engage the pins. A lever arm, pivotally affixed to the receiver housing, can be pivoted to force the hook plate downwardly to forcefully engage and lock the forward edge of the slots with the pins.

Owner:FINGER LAKES INTPROP

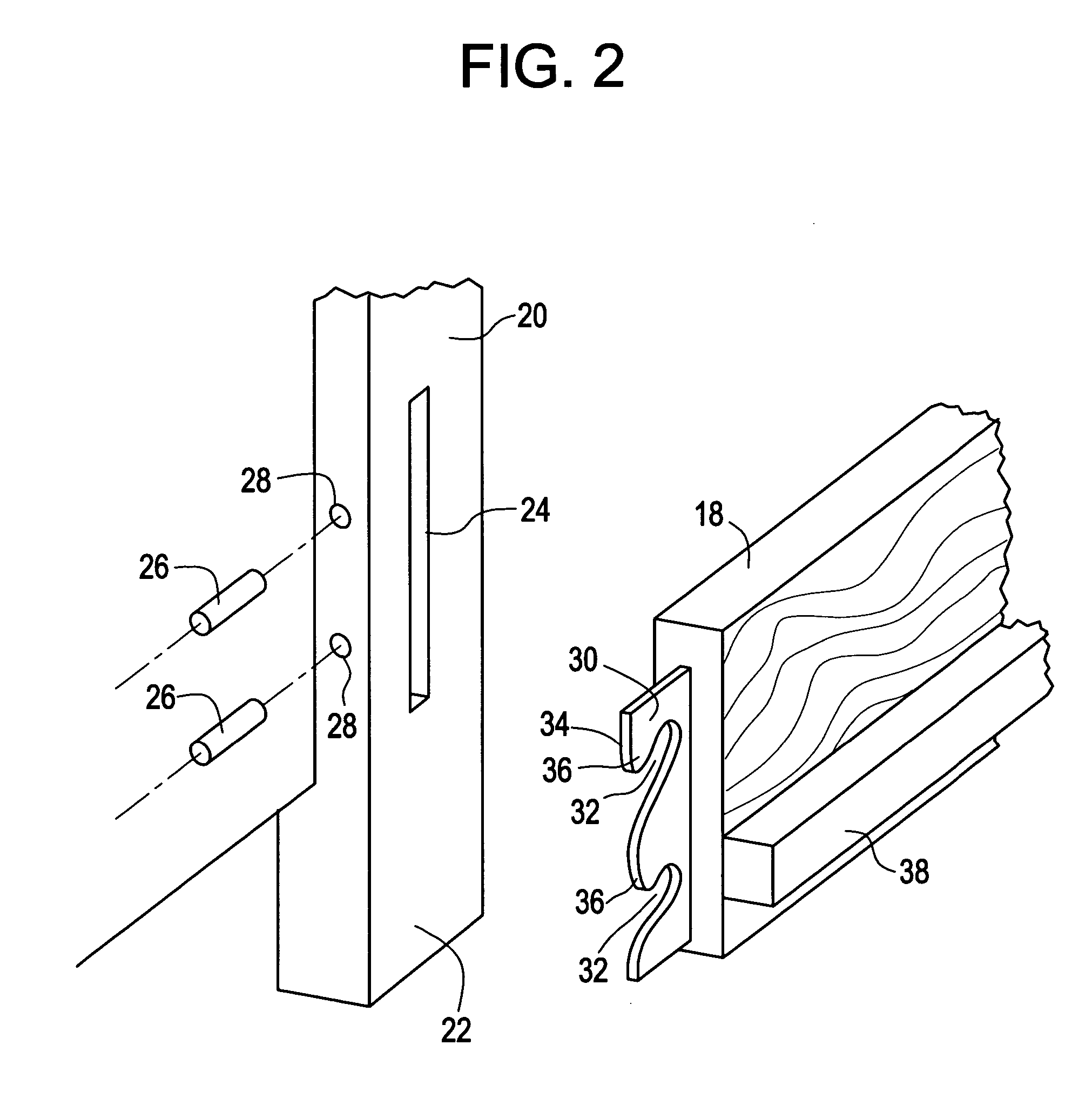

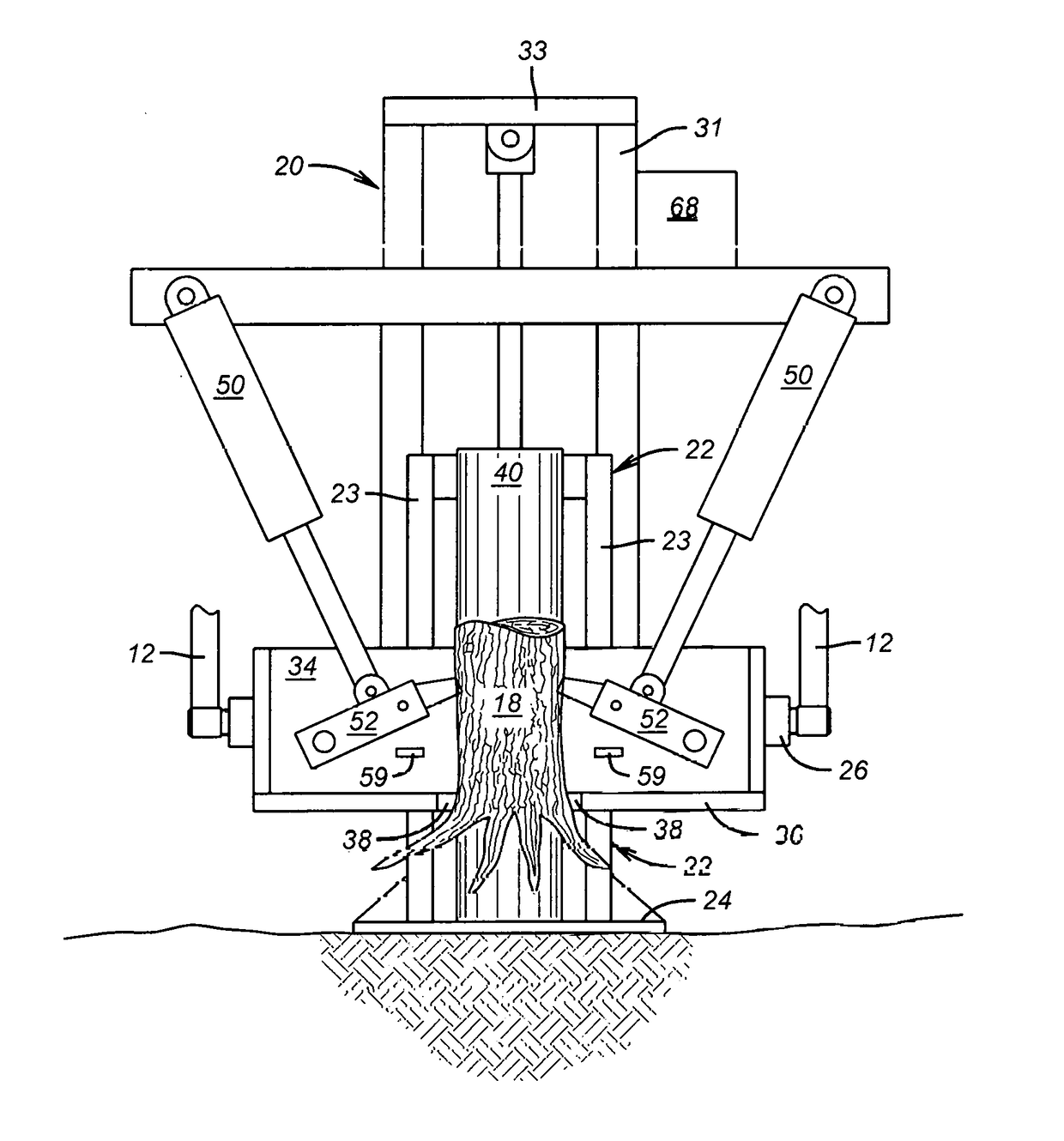

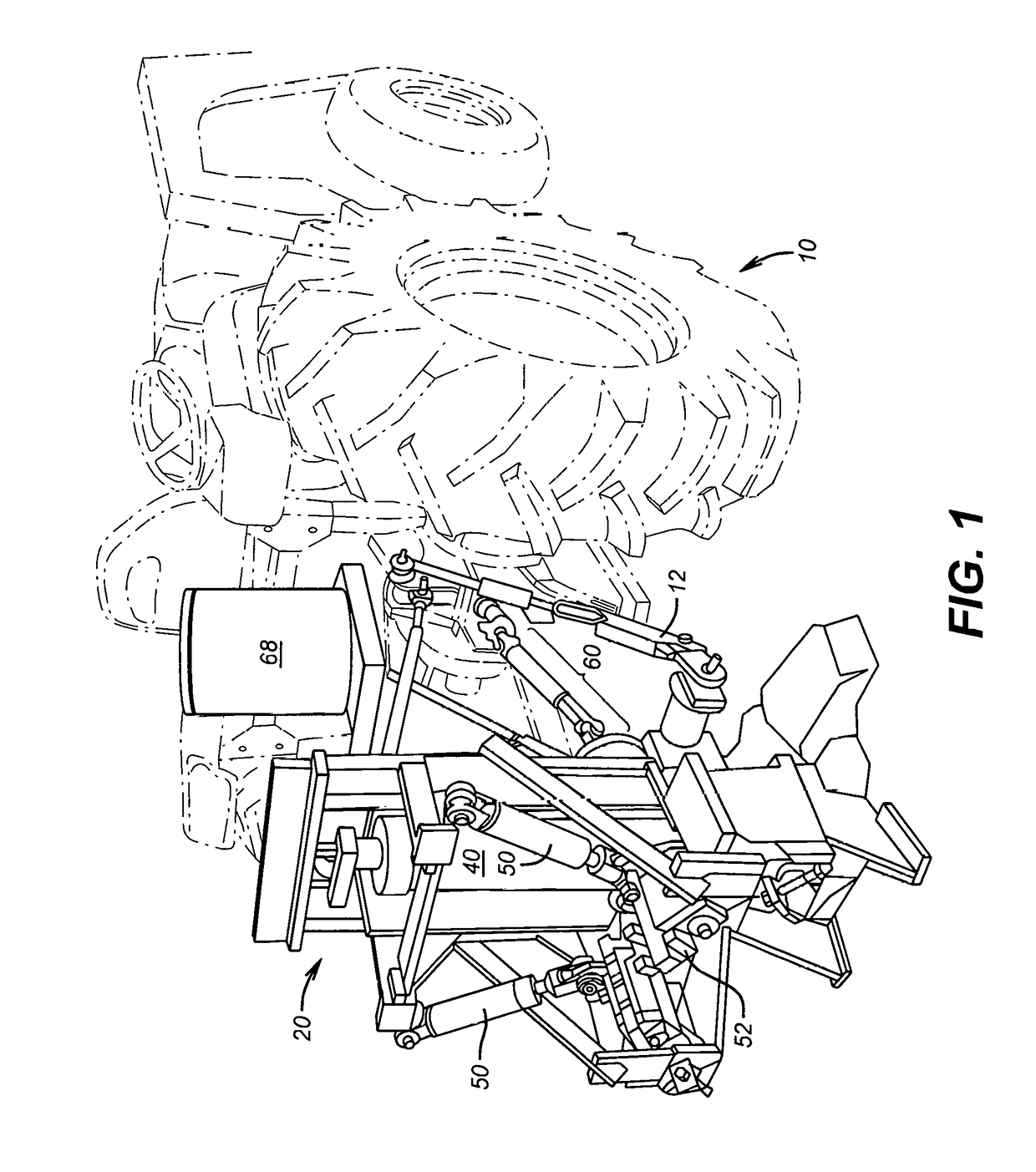

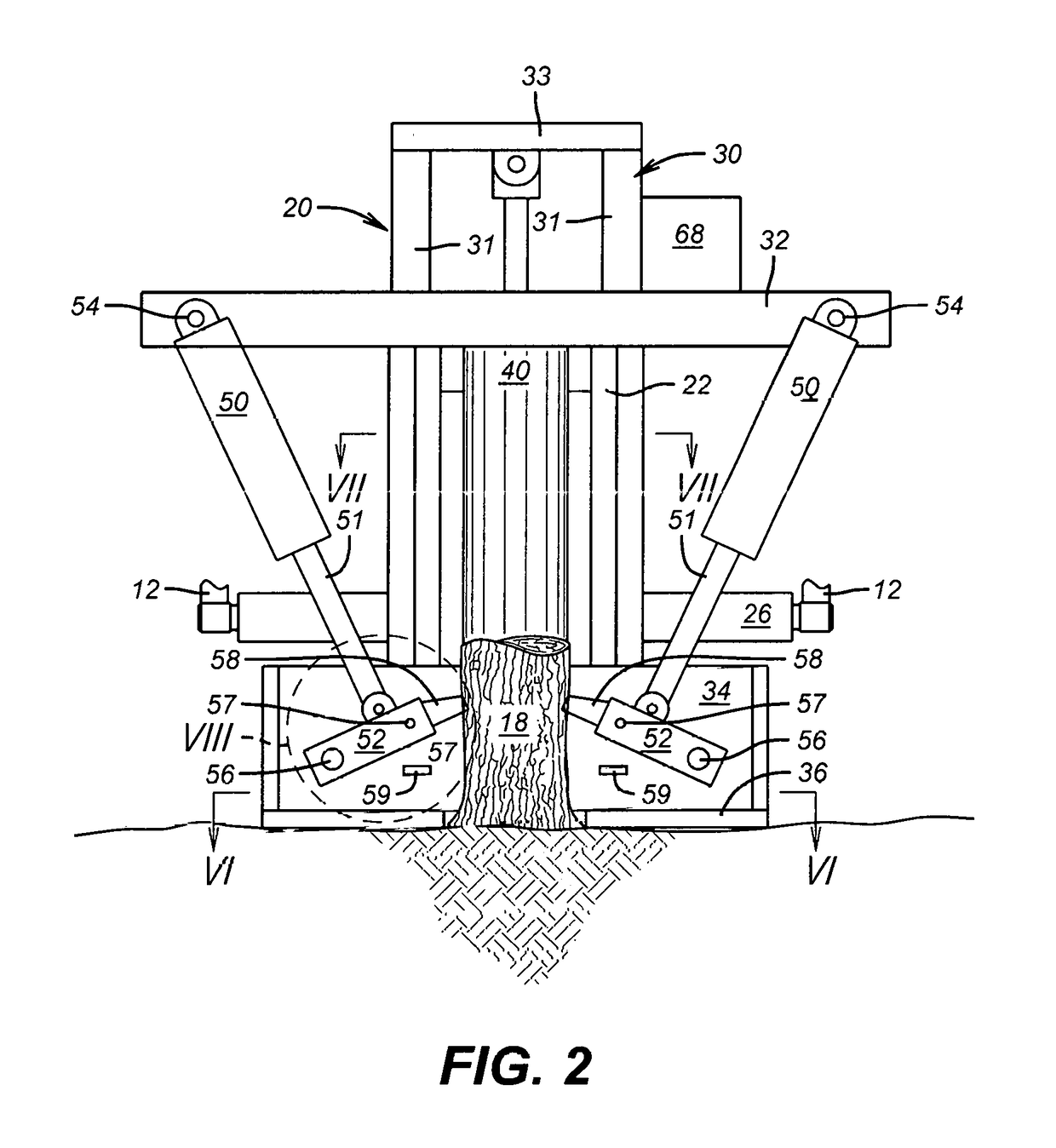

Tree, stump and post puller

ActiveUS20180049377A1Constant pressure maintenancePrevent slight movementForestryEngineeringLinear motor

An apparatus for extracting trees, stumps, posts and similar structures from the ground is attached to a 3-point hitch tractor accessory. The apparatus comprises a base frame and a lifting frame. The base frame includes a pair of vertical guides for confining a corresponding pair of vertical rails on the lift frame. A piston / cylinder type of linear motor is connected between the base frame and lifting frame to translate the lifting frame relative to the base frame. A pair of independently controlled gripping cylinders that are connected to respective gripping cams are mounted on the lifting frame. A tree is extracted by engaging the gripping cams against the tree and translating the lifting frame.

Owner:MAXWELL CHRISTIAN LANE

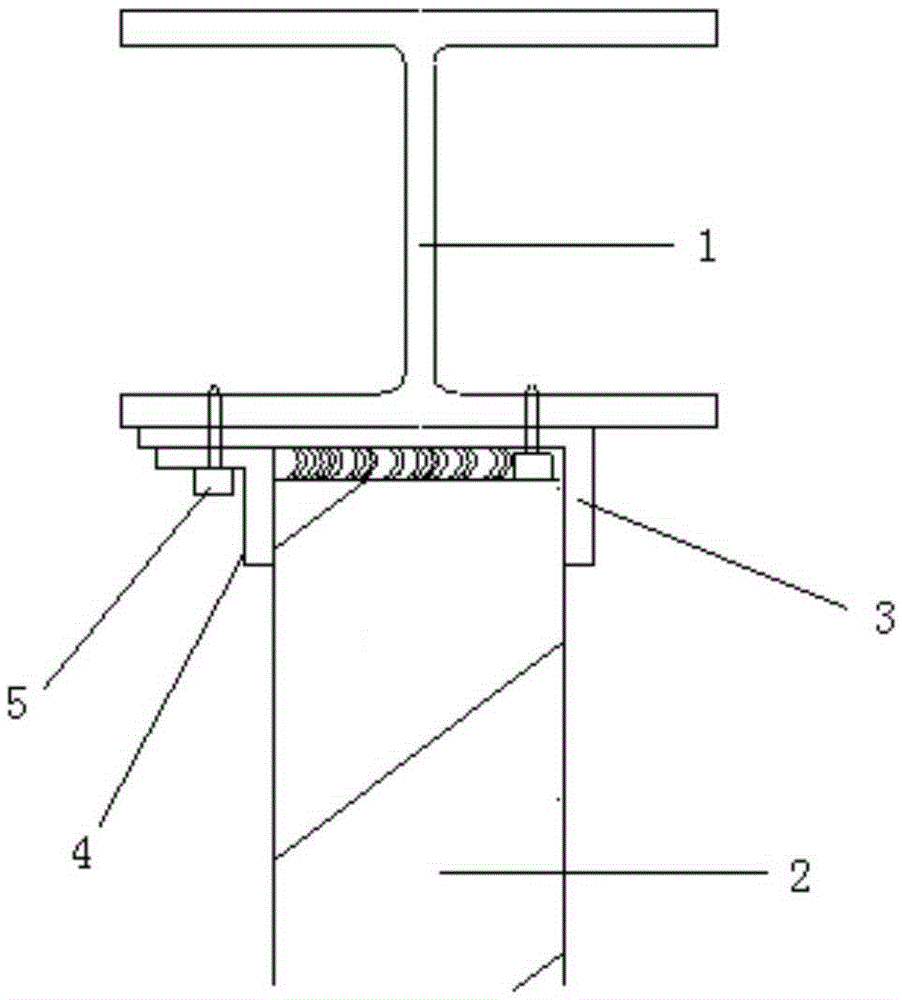

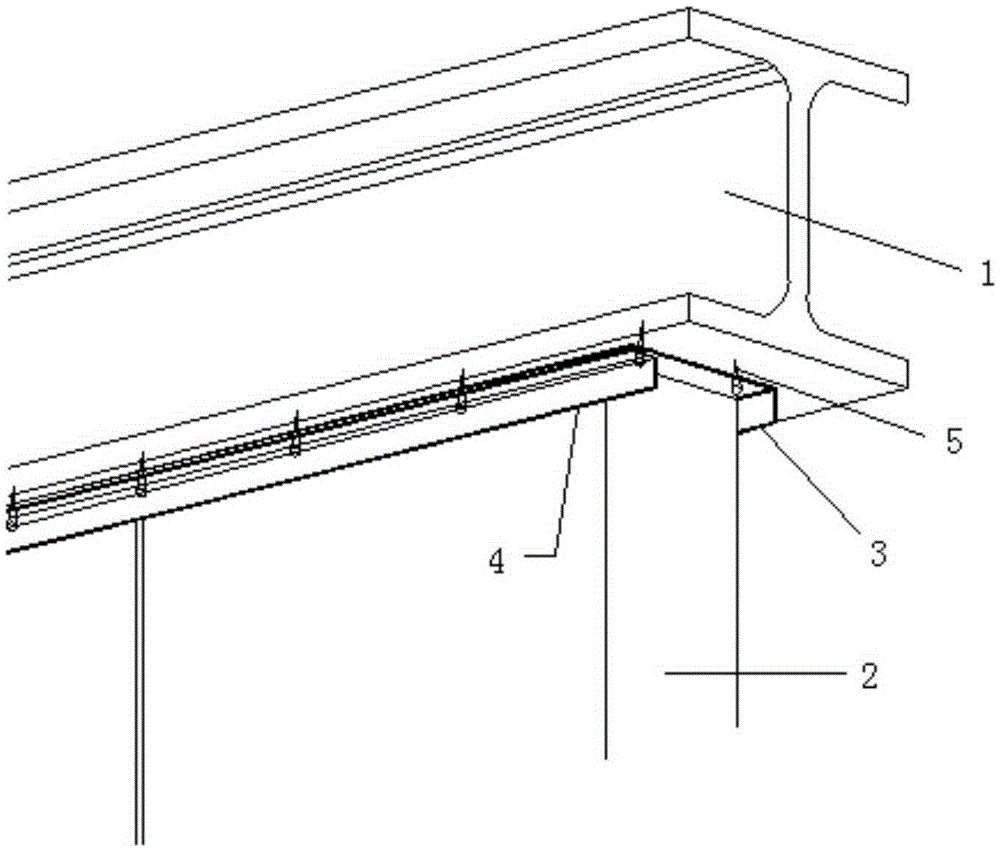

Light inner wall and steel beam connection structure with self-tapping screws

The invention discloses a light inner wall and steel beam connection structure with self-tapping screws. The connection structure comprises a steel beam, an L-shaped clamping set and the self-tapping screws. The L-shaped clamping set comprises a first L-shaped clamp and a second L-shaped clamp. One end of the long edge of the first L-shaped clamp is connected with the steel beam through one self-tapping screw, the other end of the long edge of the first L-shaped clamp and the long edge of the second L-shaped clamp are connected with the steel beam through the remaining self-tapping screws, and a space is formed between the short edge of the first L-shaped clamp and the short edge of the second L-shaped clamp and used for containing a light inner wall board. Construction is convenient and fast, on-site assembly is easy and convenient, wet construction and pollution are avoided, and constructing site positioning is accurate; the connection structure can be directly completed in a factory, on-site workloads are reduced, construction efficiency is greatly improved, and industrial production can be easily achieved; connection is firmer, a lower flange of the steel beam looks more attractive, and the light inner wall and steel beam connection structure is suitable installing light inner walls and body structures of a multi-rise and high-rise steel structure building and is wide in adaptability.

Owner:SHENYANG JIANZHU UNIVERSITY

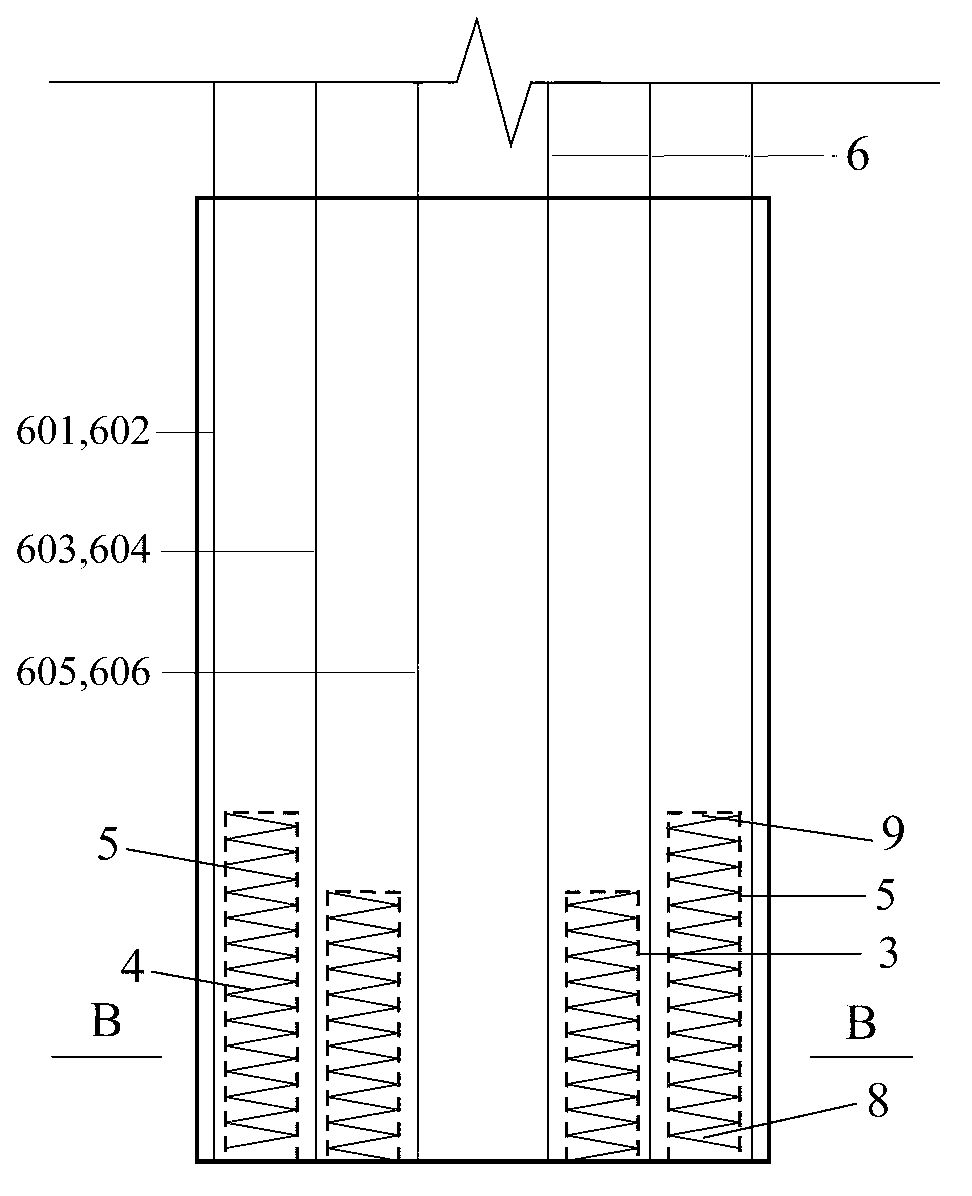

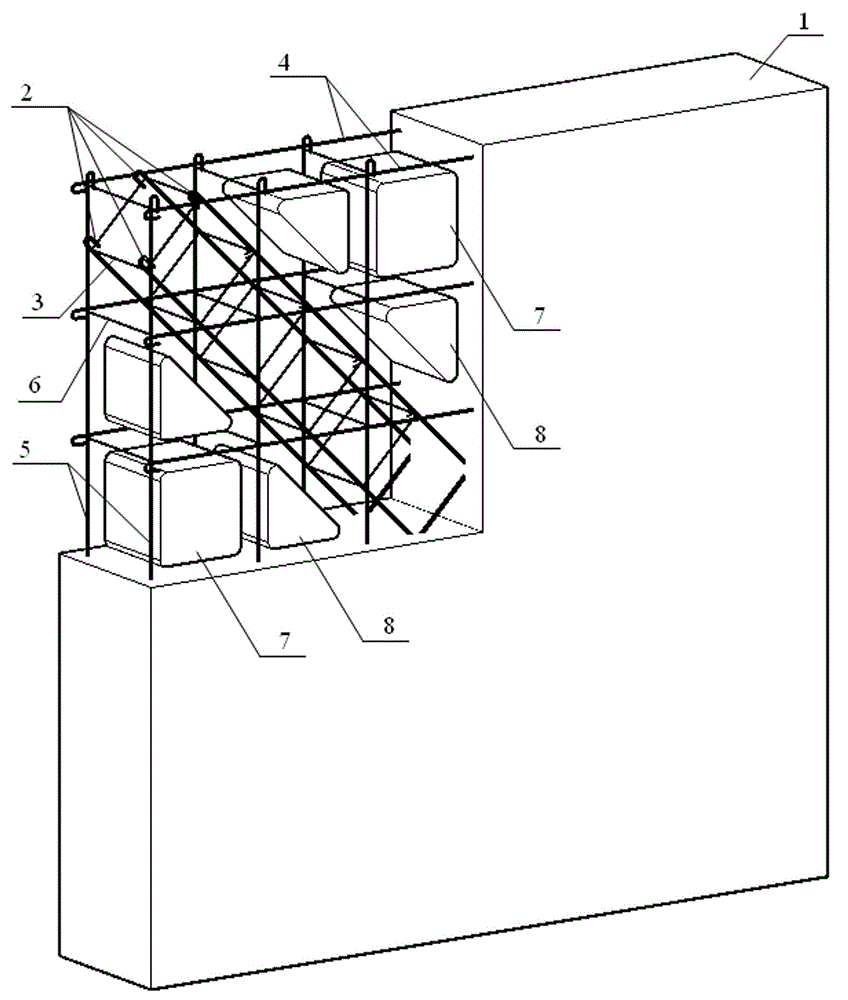

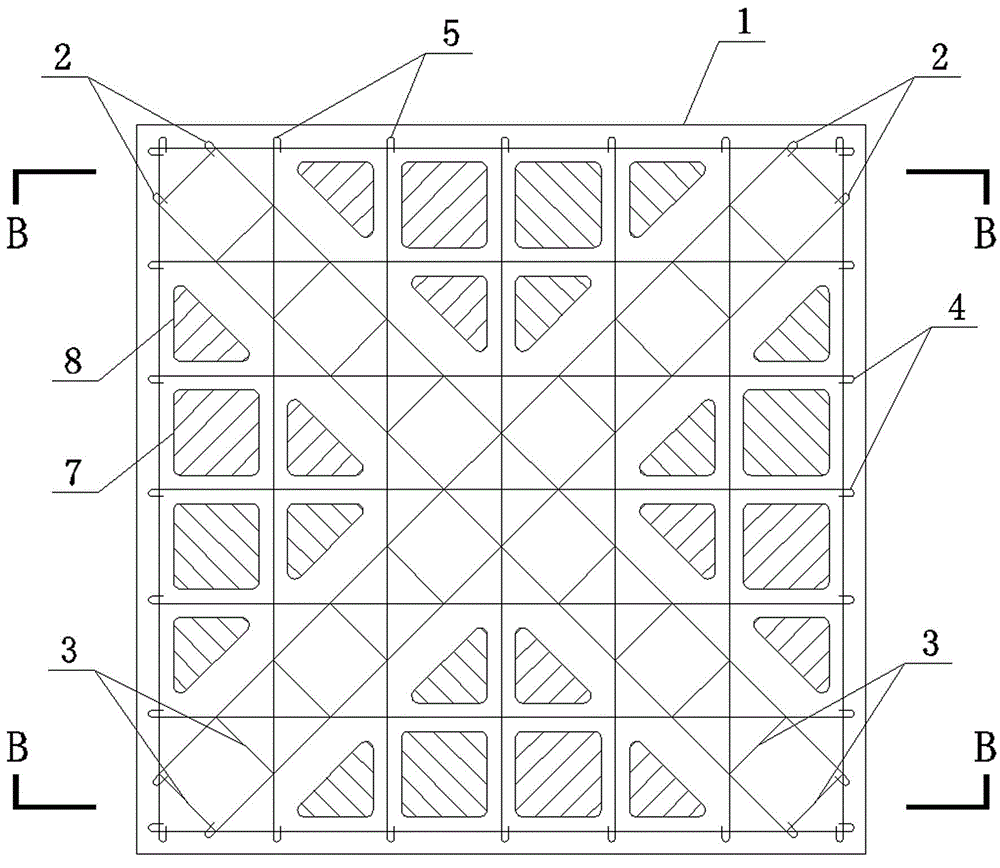

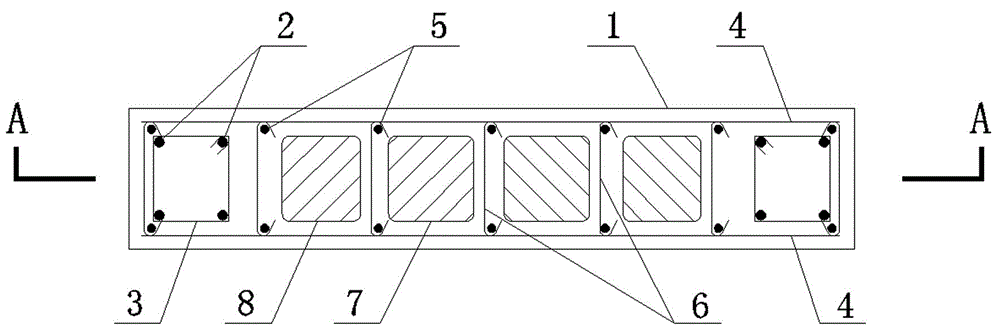

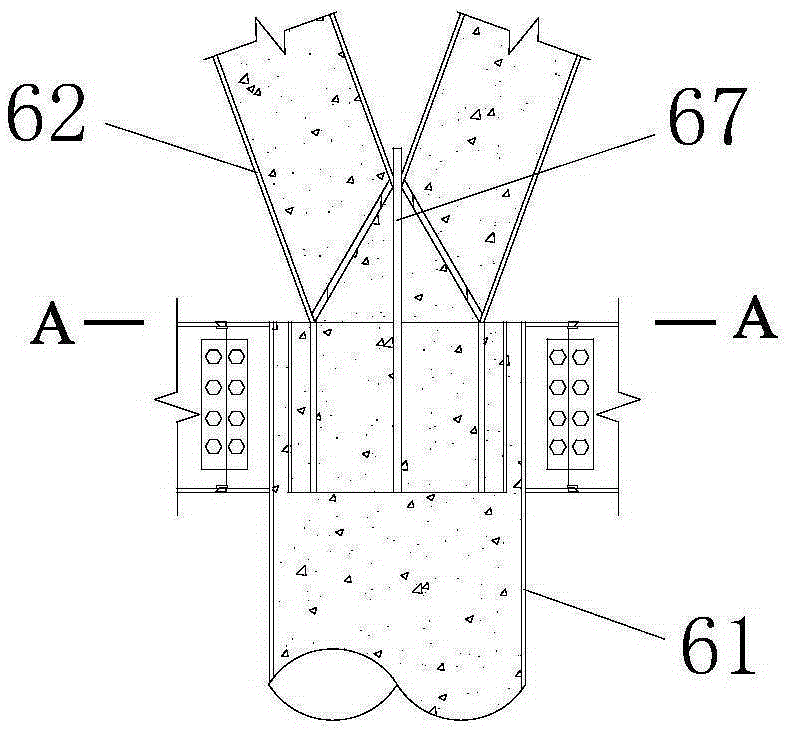

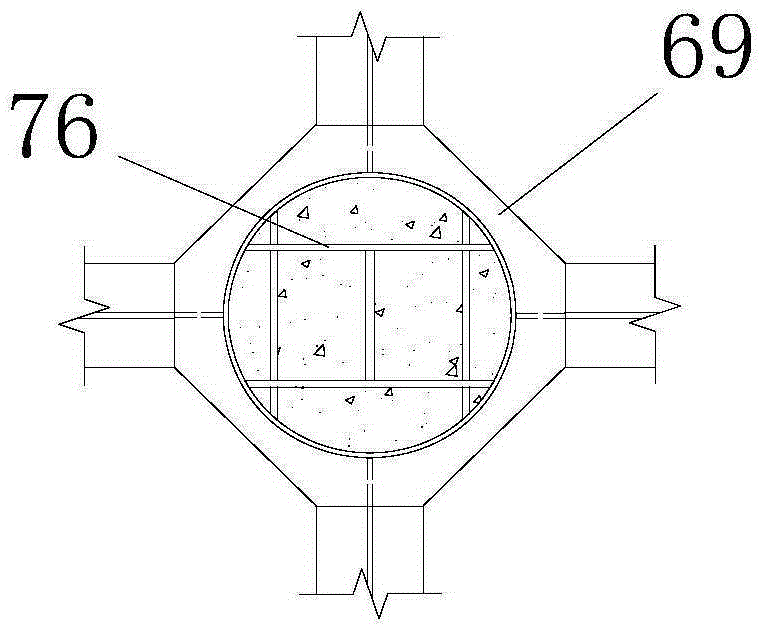

Hollow shear wall structure for cross diagonal reinforcing bar and construction method thereof

InactiveCN102979220AImprove the immunityImprove acceleration performanceWallsBuilding material handlingDiagonalEngineering

The invention discloses a hollow shear wall structure for a cross diagonal reinforcing bar. The hollow shear wall structure for the cross diagonal reinforcing bar comprises a shear wall body, wherein the inside of the shear wall body is provided with the horizontal-direction reinforcing bars of a wall body, the vertical-direction reinforcing bars of the wall body and wall body tie bars, wherein two groups of cross diagonal reinforcing bar cages are respectively arranged along the plane diagonal direction of the shear wall body; the cross diagonal reinforcing bar cages are bond and connected with the horizontal-direction reinforcing bars of the wall body and the vertical-direction reinforcing bars of the wall body; each group of cross diagonal reinforcing bar cage at least comprises four cross diagonal reinforcing bars and cross diagonal stirrups processed into a closed rectangle; the cross diagonal reinforcing bars and the cross diagonal stirrups are bond to form a rectangular strip-shaped cross diagonal reinforcing bar cage; and the inside of each space surrounded by the horizontal-direction reinforcing bars of a wall body, the vertical-direction reinforcing bars of the wall body, the wall body tie bars and the cross diagonal reinforcing bar cages is respectively embedded with a light internal die of a blocky foam plastic. The construction method for the hollow shear wall structure for the cross diagonal reinforcing bar comprises the following steps of: erecting a shear wall template; binding wall body reinforcing bar meshes; laying and binding the cross diagonal reinforcing bar cages; embedding the light internal die of the blocky foam plastic; and pouring and curing the shear wall concrete. According to the invention, materials are saved, the structural self weight is lightened, and the resistance to shock is good.

Owner:ZHENGZHOU UNIV

Bone material removal device and a method for use thereof

Owner:T MEDICAL DEVICES AGRI COOP

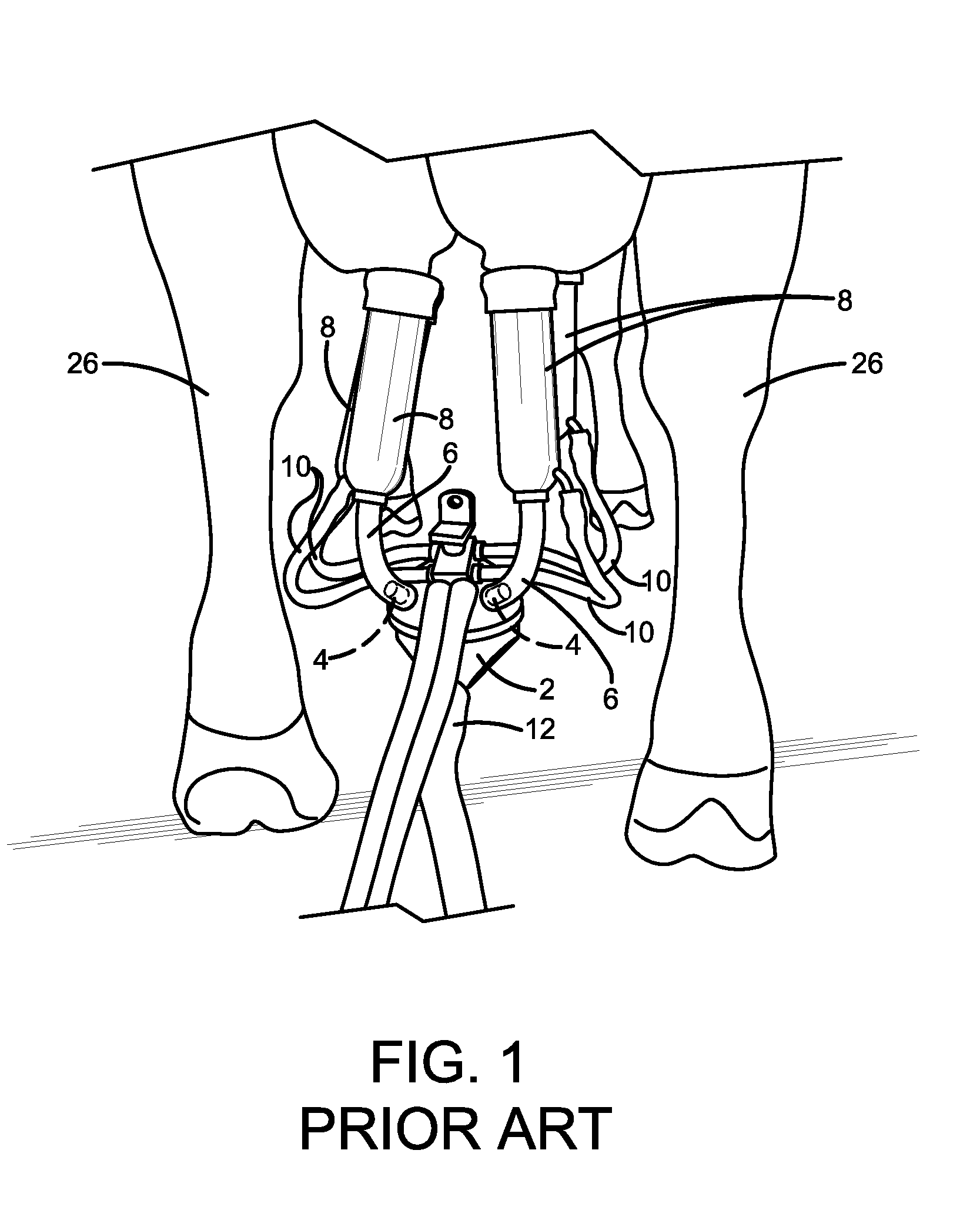

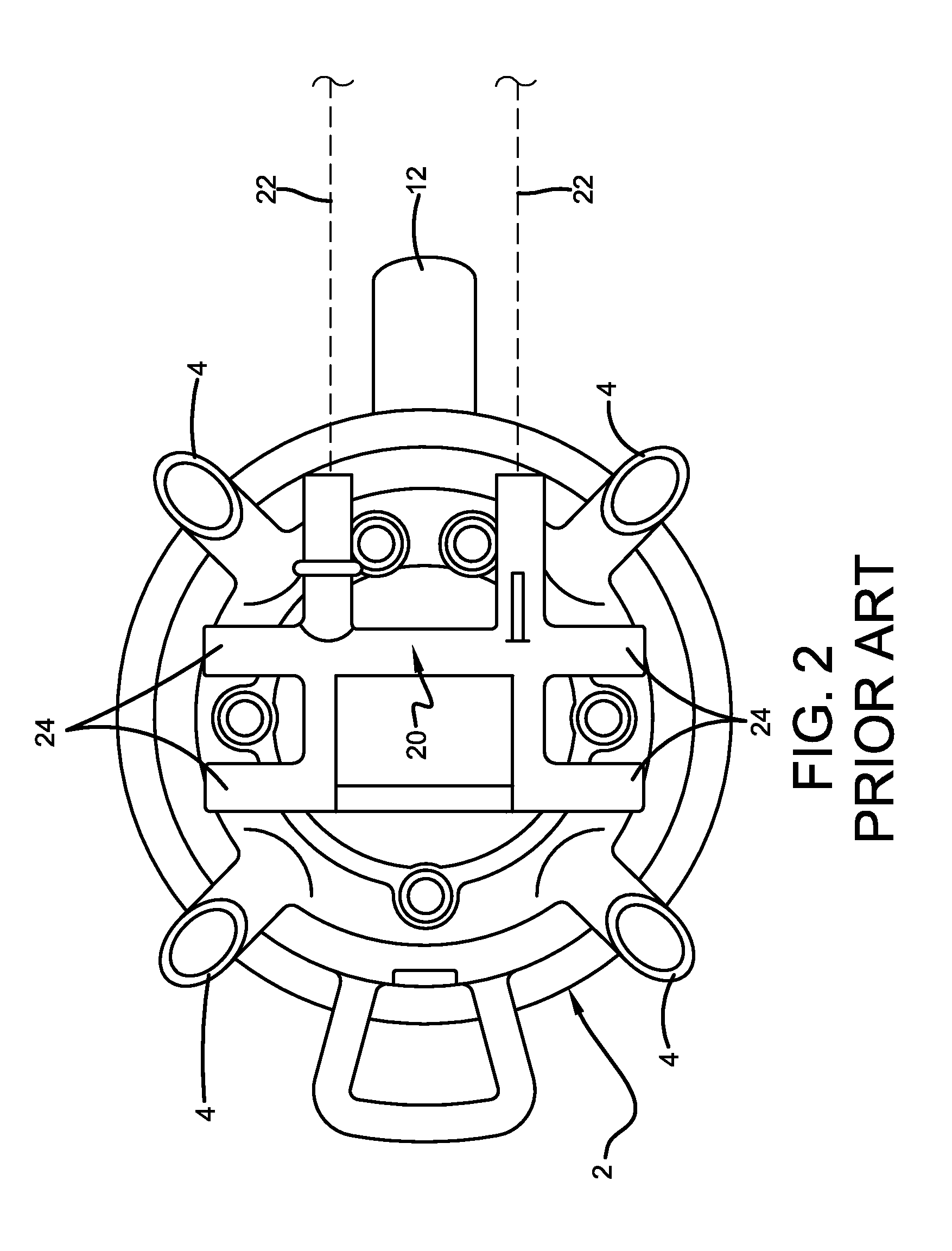

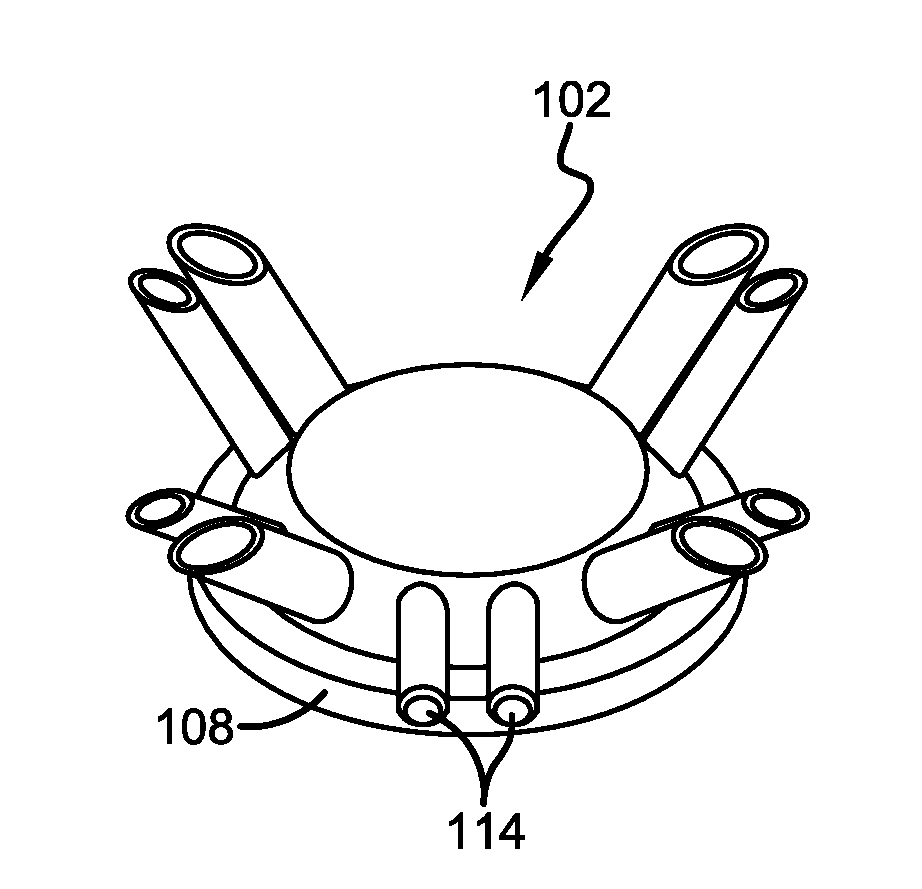

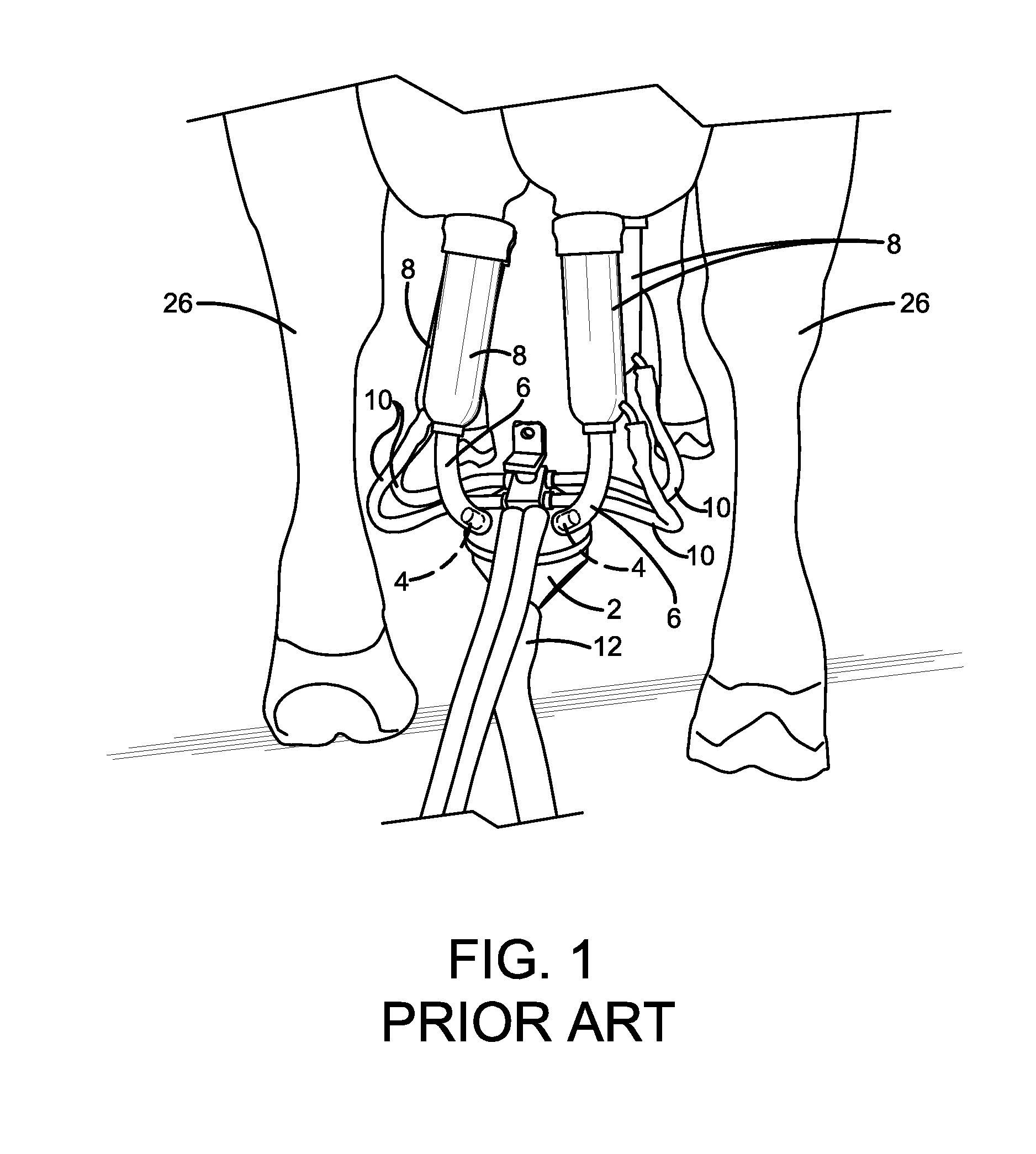

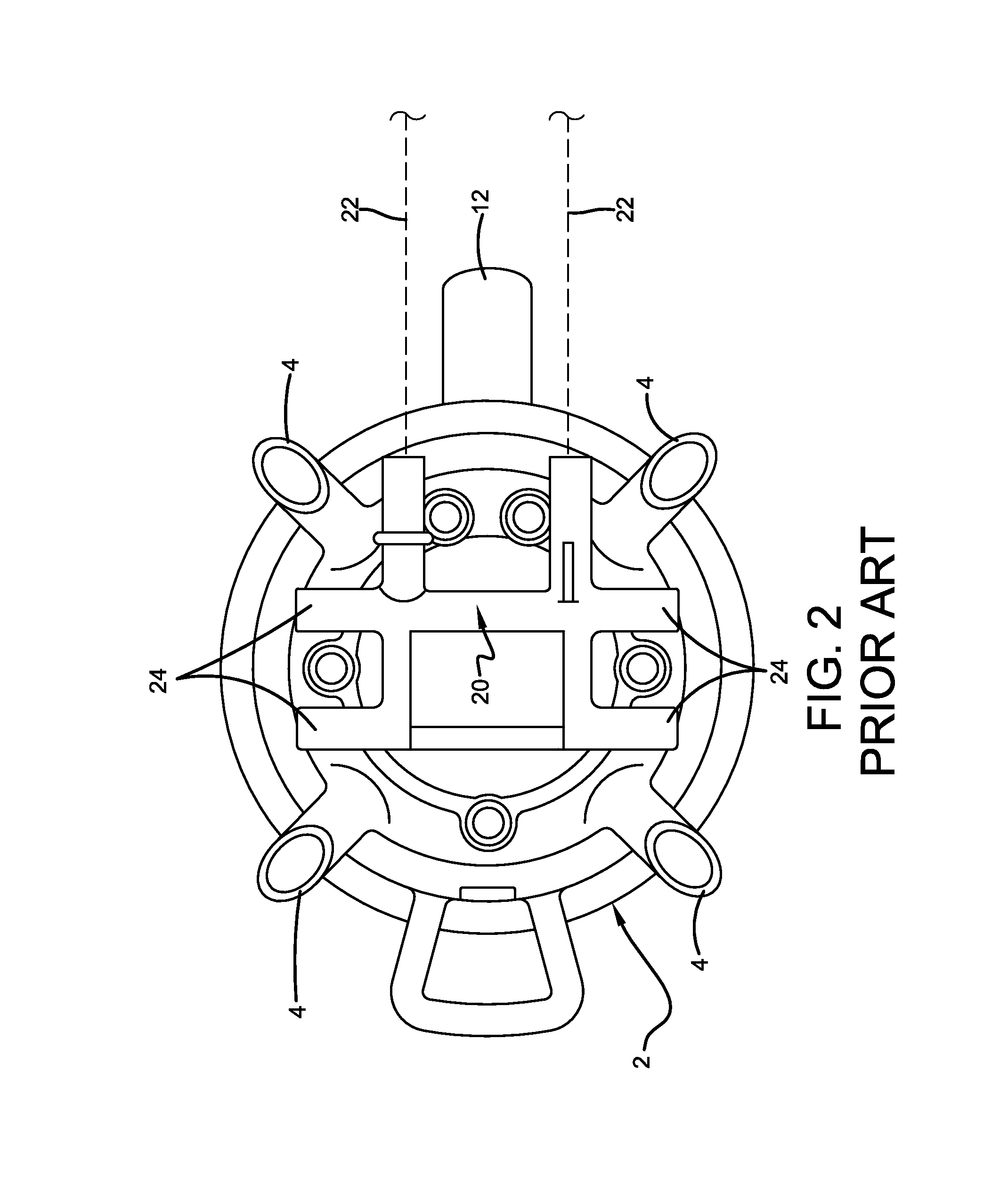

Dairy milking devices and methods

A milking liner includes an integrated short air tube and short milk tube. In one configuration, the pulsation air is delivered through the bead of the milking liner directly inside the shell when the liner is connected to the shell. In another configuration, the integrated short air tube has an outlet outside the shell. The disclosure also provides aligned nipple pairs on the claw top. One configuration is provided wherein the pulsation nipples and air fork are integrated with the claw that has the liner nipples. Another configuration is provided wherein the air fork is separate from the claw. A method of readily supplying pulsation air to a shell includes the step of integrated the step of connecting the short air tube and the shell with the step of connecting the shell to the milking liner.

Owner:LAUREN AGRISYST

Dairy milking devices and methods

Owner:LAUREN AGRISYST

Concrete filled steel tube transfer joint structure and construction method thereof

The invention discloses a concrete filled steel tube transfer joint structure and a construction method thereof. The concrete filled steel tube transfer joint structure comprises a strut, a batter post and a socket frame; the batter post is fixedly connected to the socket frame; the socket frame is fixedly arranged inside the strut and located at a top end of the strut; the socket frame comprises a vertical inner ribbed plate; the batter post is provided with a section including a cross section; a shape of the vertical rib ribbed plate corresponds to a shape of the cross section and a connecting ribbed plate extends out of the vertical inner ribbed plate; the connecting ribbed plate extending out is fixedly connected to an inner wall of the strut; the batter post is fixed on the vertical inner ribbed plate through the section. The concrete filled steel tube transfer joint structure is integrated with the advantages of a concrete-filled steel tube and a battery post transfer structure, and has the advantages of direct force transfer, high bearing capacity, small sectional dimension of the component, good utilization of building space, no need for support formwork, small field welding workload, guaranteed construction quality and the like. Two batter posts and a beam system form a triangular force transfer mode, and meanwhile, excellent side force resisting capability is realized.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com