Prefabricated integral type shear wall

A prefabricated assembly and shear wall technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of increased on-site construction volume, additional vertical reinforcement, high on-site operation and construction accuracy requirements, etc., to reduce construction difficulty. , On-site construction is convenient, and the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, and with reference to accompanying drawing, the present invention will be further described:

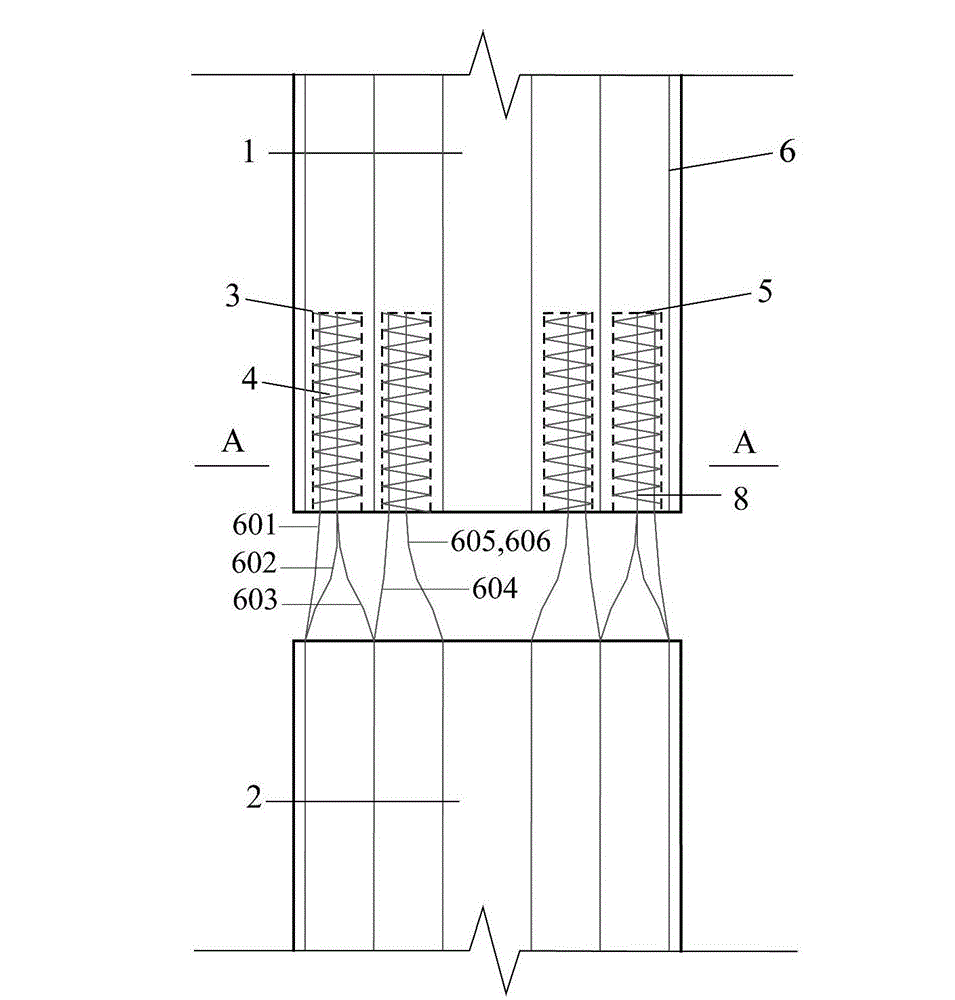

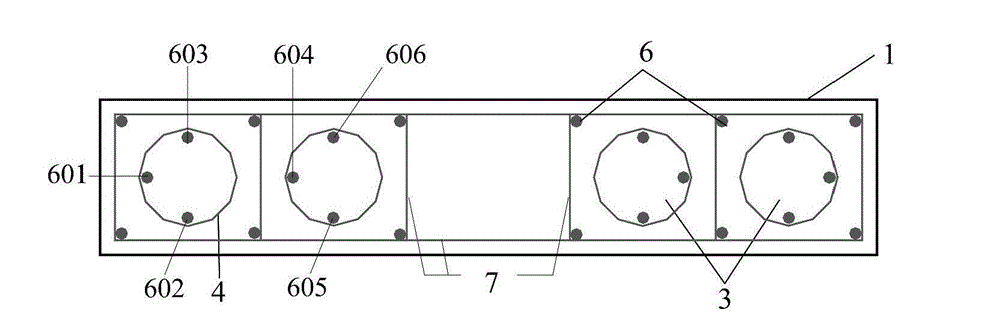

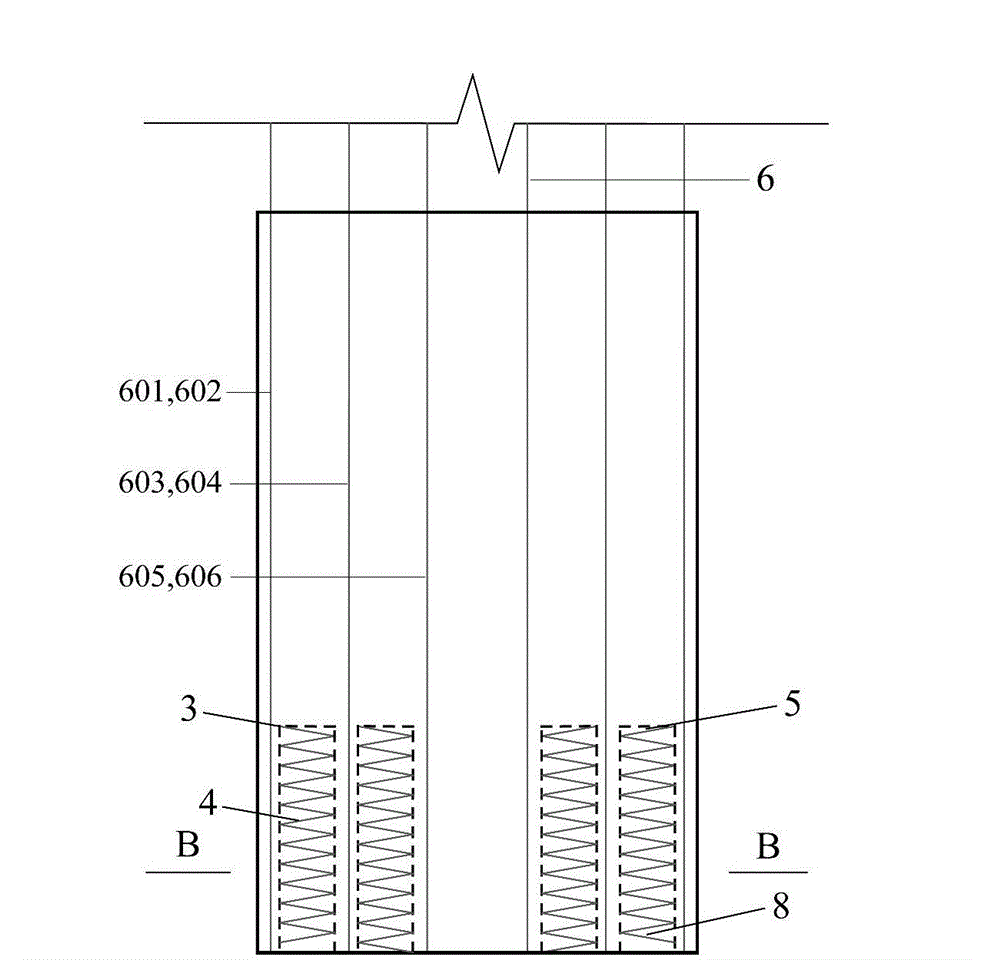

[0022] figure 1 It is a schematic diagram of the vertical reinforcement connection between the upper wall body 1 and the lower wall body 2 of the prefabricated integral shear wall of the present invention, and figure 2 corresponding figure 1 A-A sectional view of the upper wall body 1 of the medium shear wall. Such as figure 1 , figure 2 As shown, a prefabricated integral shear wall, its main components include: the upper wall 1 of the shear wall structure, the lower wall 2, the reserved hole 3, the spiral stirrup 4, and the vertical reinforcement 6. The vertical stressed steel bars 6 protruding from the top of the lower wall 2 are clustered in groups, and then respectively extend into a reserved hole 3 preset at the bottom of the upper wall 1, wherein the inner wall of the reserved hole 3 is pre-buried vertically With the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com