Hollow shear wall structure for cross diagonal reinforcing bar and construction method thereof

A shear wall and hollow technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of structural self-heavy, reduce shear wall stiffness, shear wall failure, etc., to improve seismic bearing capacity and structural ductility , Enhance the ability of emergence and expansion, and ensure the effect of bearing security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

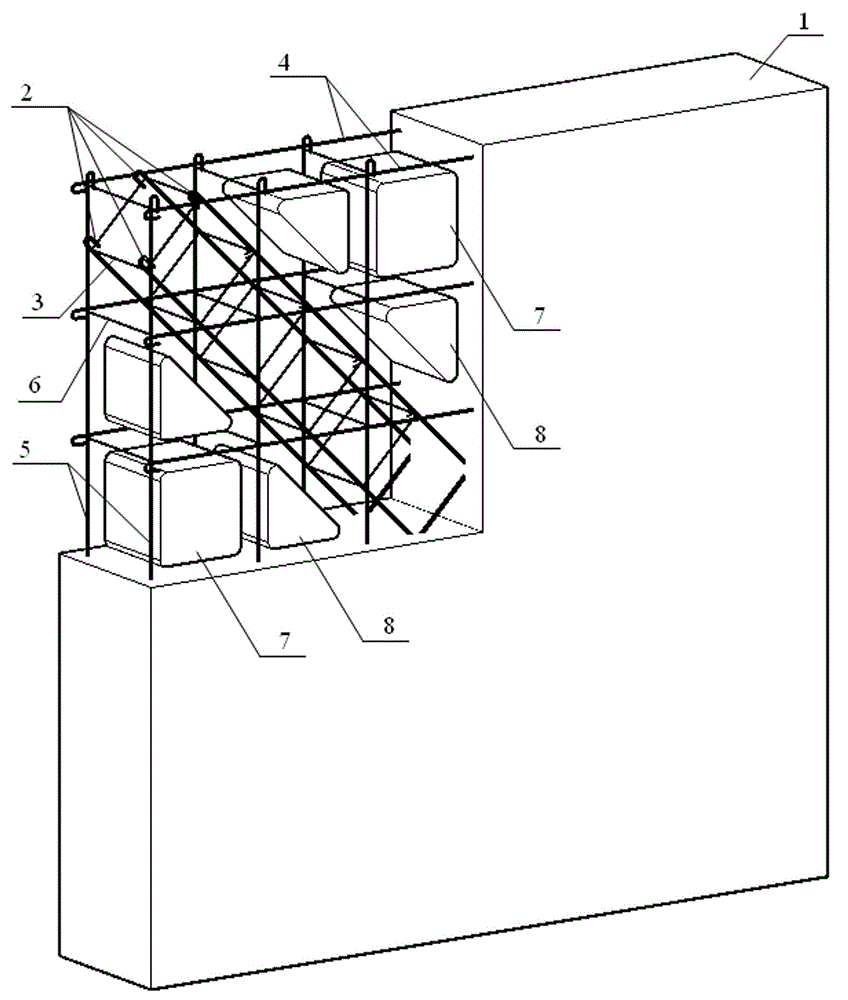

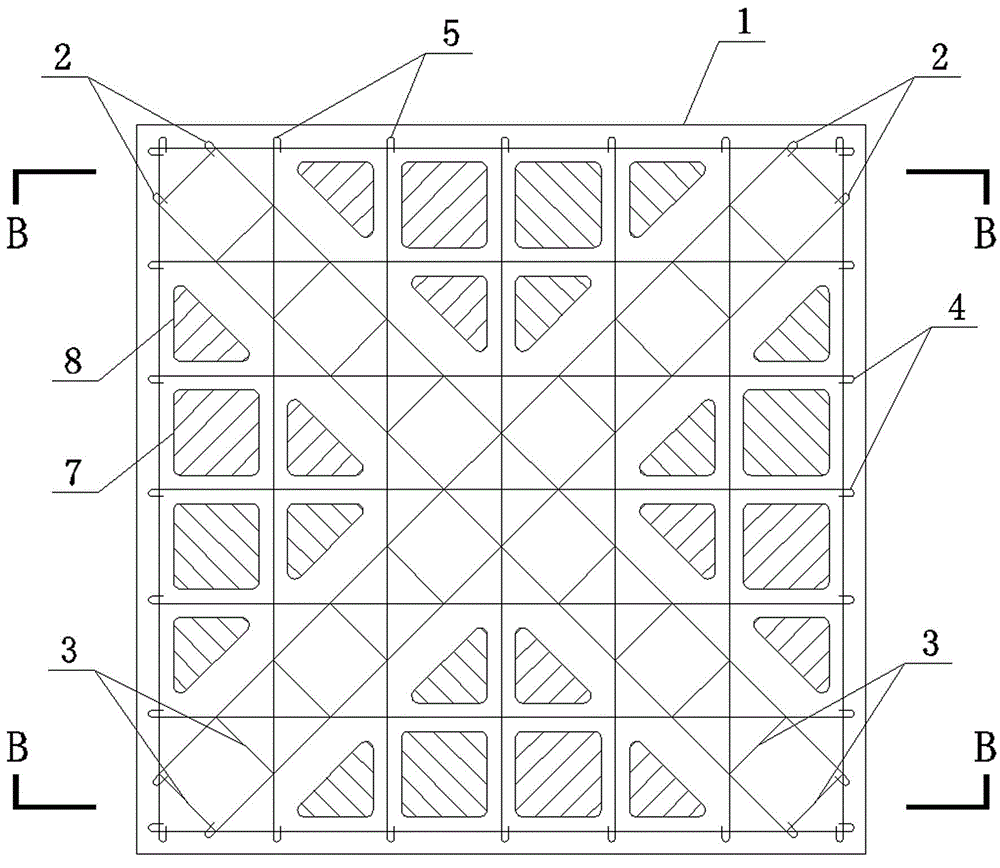

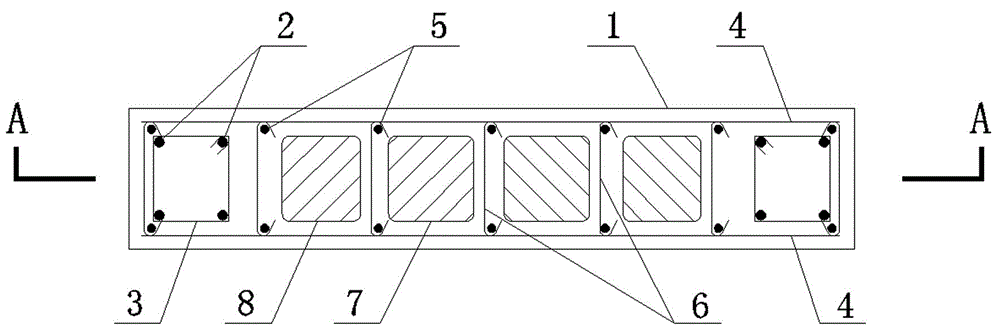

[0030] Example: such as Figure 1-3 As shown, a hollow shear wall structure with intersecting oblique reinforcement includes a shear wall body 1, and the shear wall body 1 is provided with a wall body horizontal direction steel bar 4, a wall body vertical direction steel bar 5 and a wall body Body tension 6, two sets of intersecting oblique reinforcement cages are respectively arranged along the diagonal direction of the shear wall body 1 plane and placed in the center along the thickness direction of the shear wall body 1, and the intersecting oblique reinforcement cages are parallel to the horizontal direction of the wall body The steel bar 4 is bound and connected with the vertical steel bar 5 of the wall, and each group of crossed oblique reinforcement cages includes at least four crossed oblique longitudinal bars 2 and crossed oblique stirrups 3 processed into a closed rectangle, and the intersected oblique longitudinal bars 2 and Cross oblique stirrups 3 are bound to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com