Patents

Literature

74results about How to "Power transmission is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

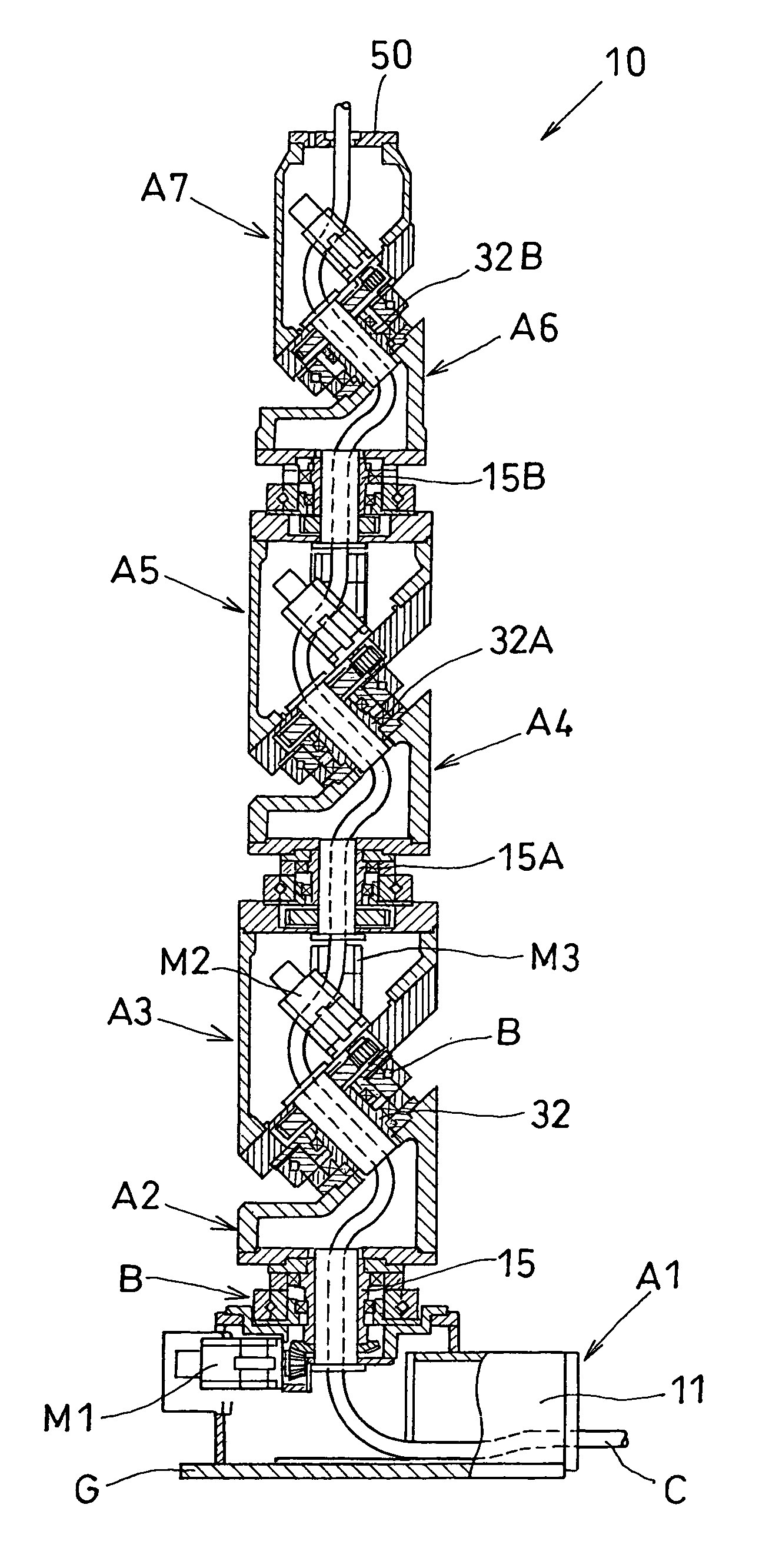

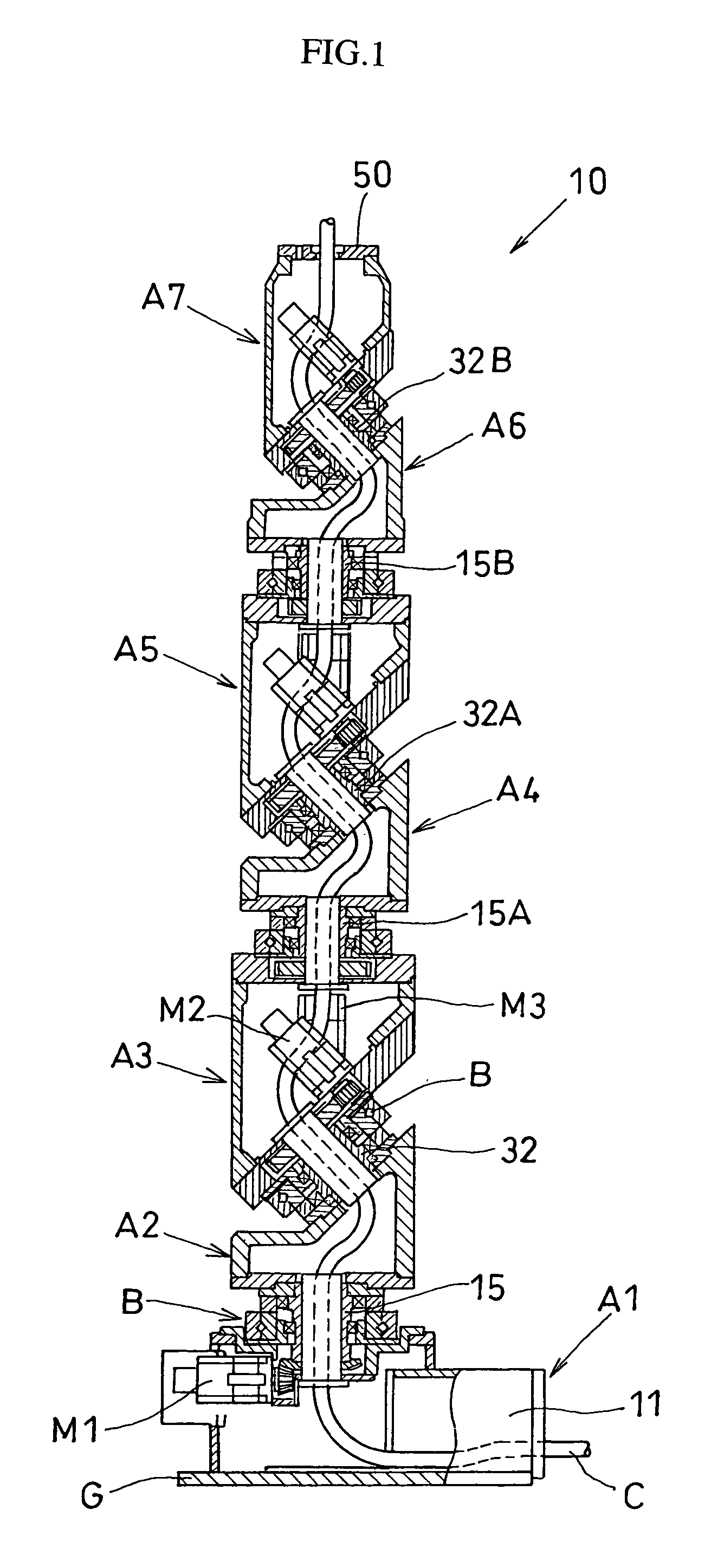

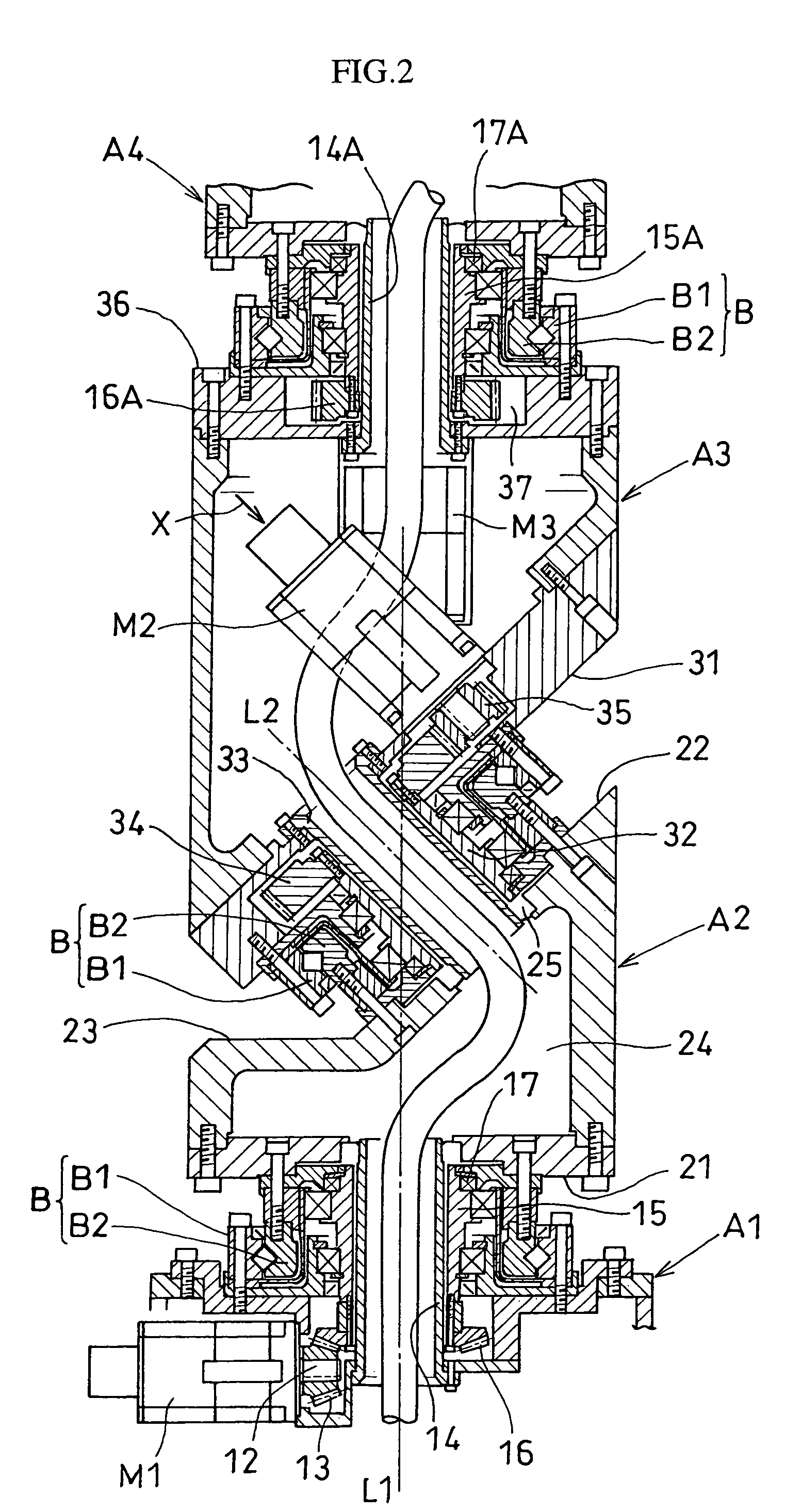

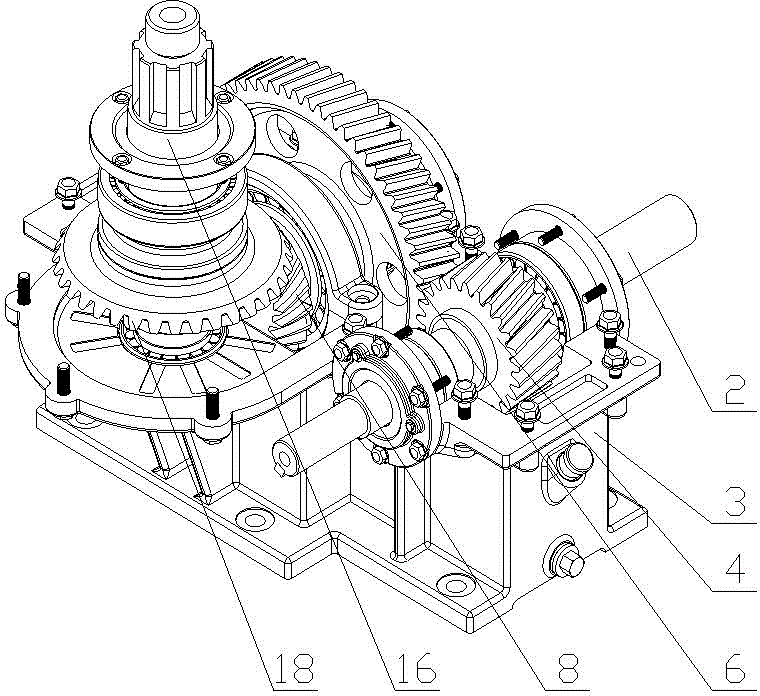

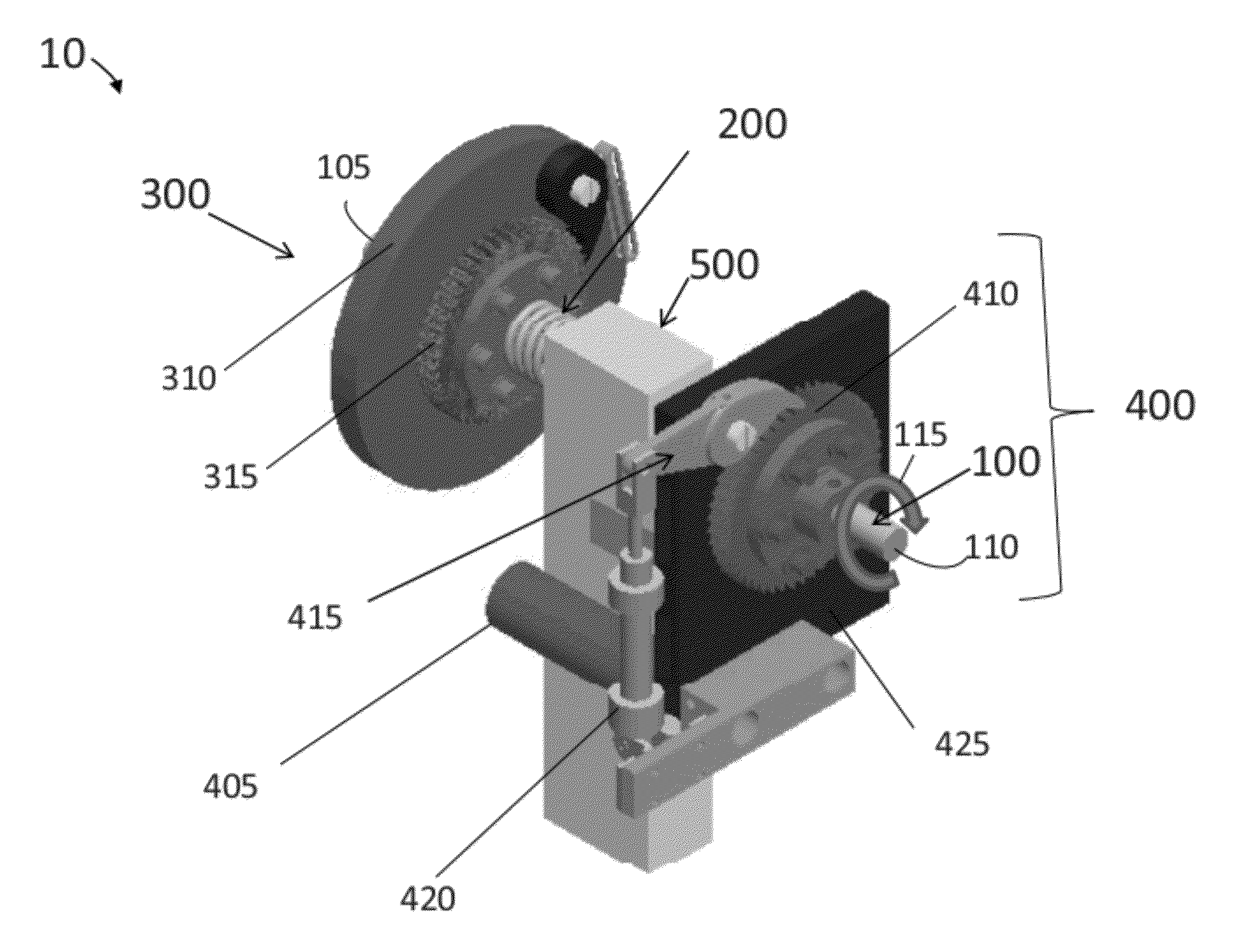

Articulated robot

ActiveUS7597025B2Reduce dead spaceWide areaProgramme-controlled manipulatorMechanical apparatusElectric power transmissionRotational axis

An articulated robot capable of reducing dead space while maintaining a wide operating area and simplifying a power transmission system necessary for moving each joint. A plurality of joint arms A1 to A7 are connected via first rotating shafts 15, 15A, and 15B as horizontal rotating shafts and via second rotating shafts 32, 32A, and 32B as inclined rotating shafts alternately. A motor M for driving the rotating shaft and a speed-reducing mechanism are provided for each rotating shaft.

Owner:TOYOTA JIDOSHA KK +1

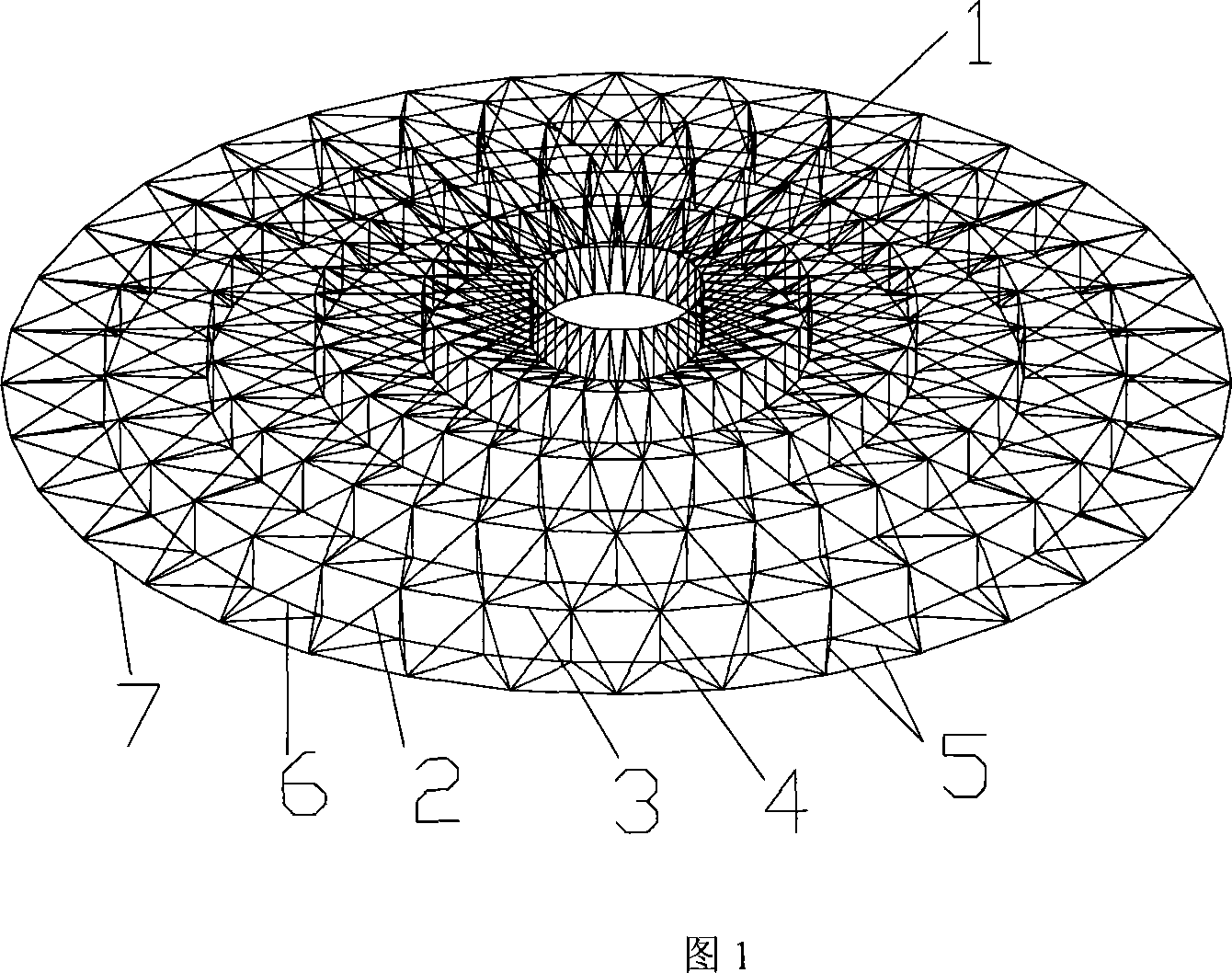

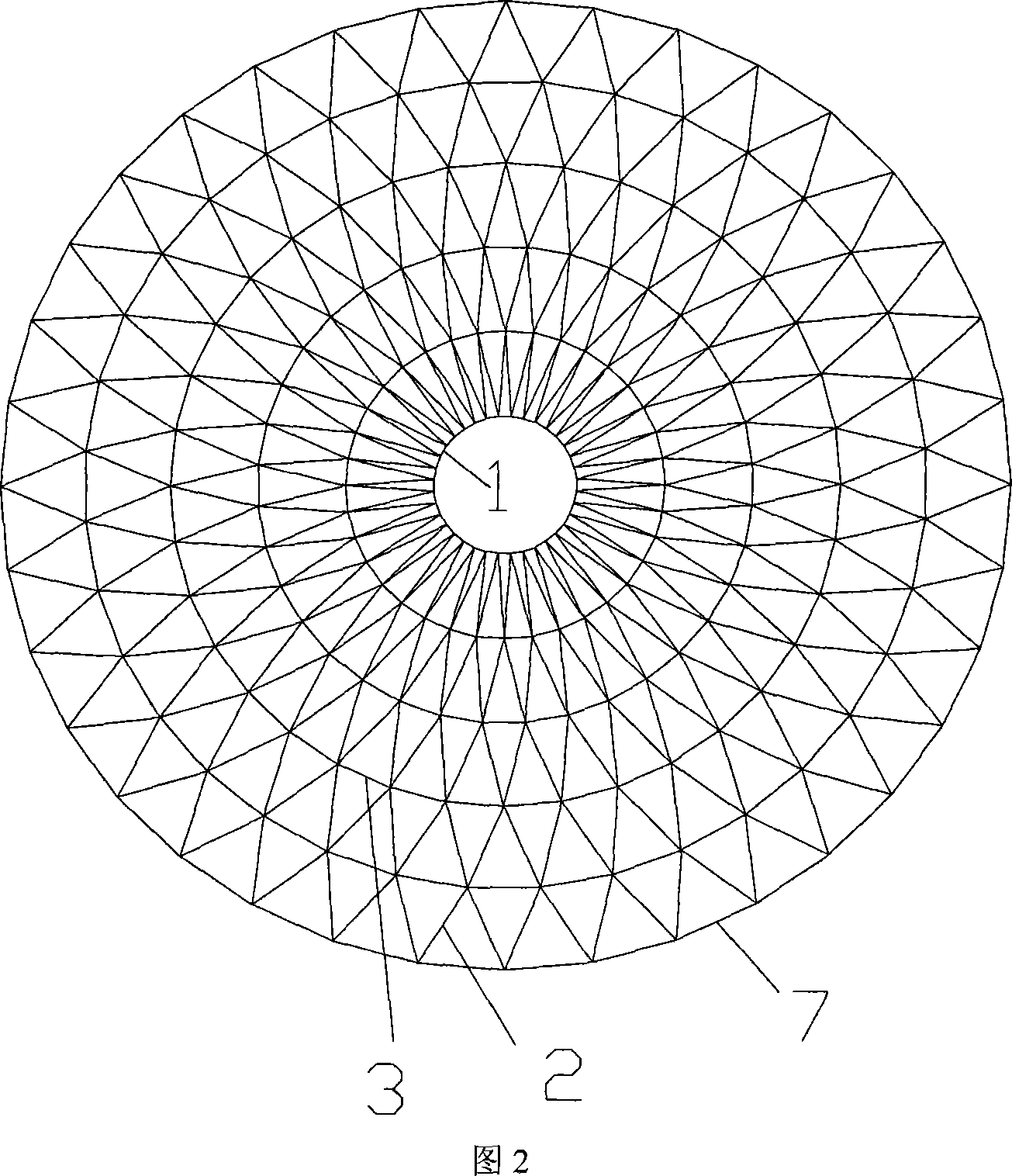

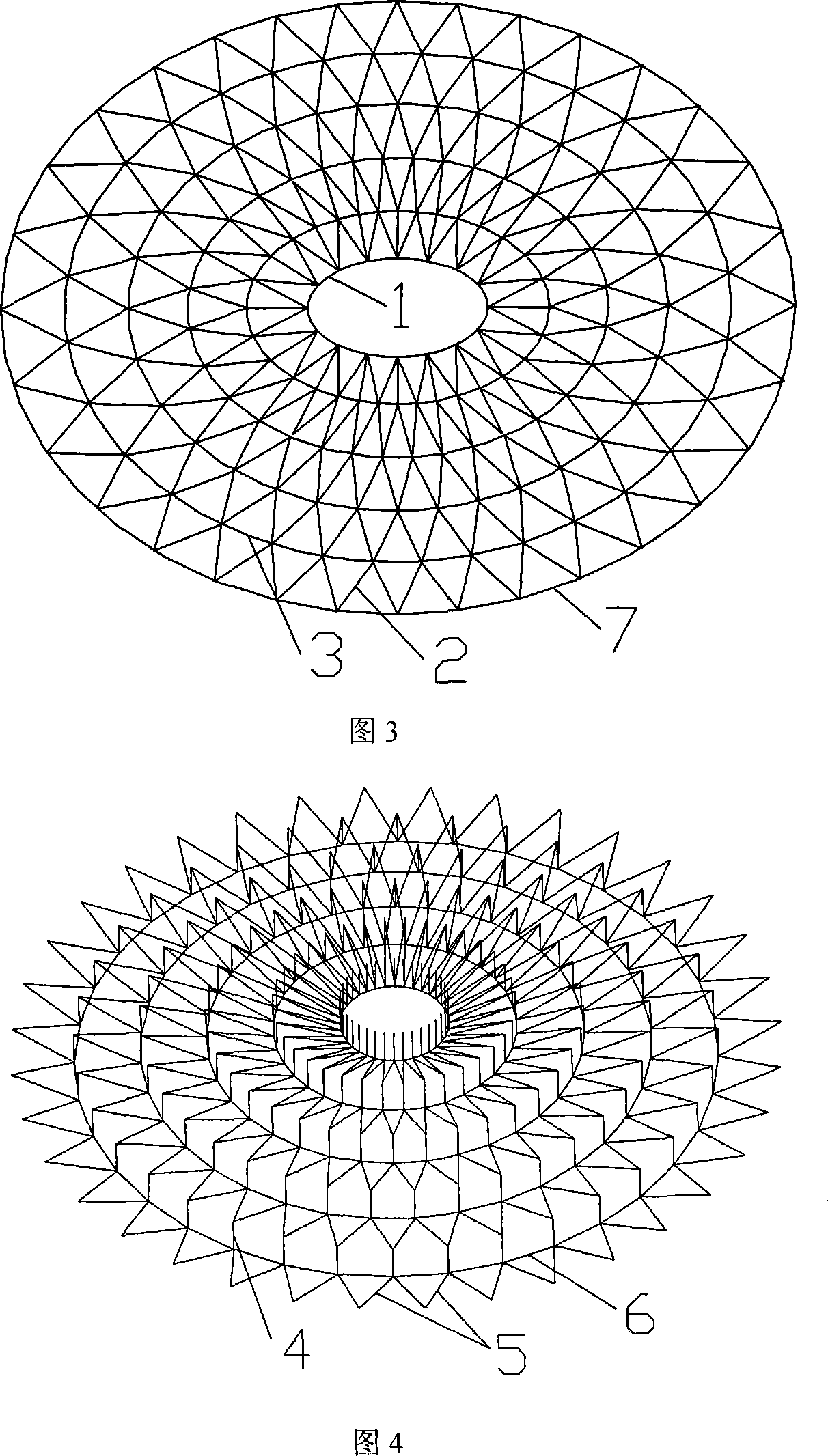

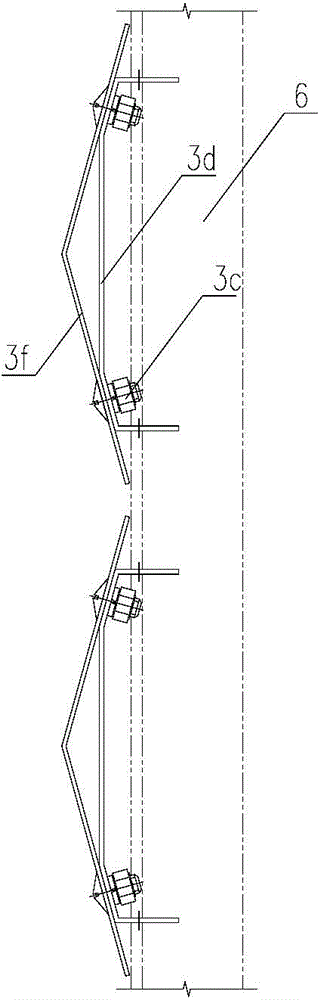

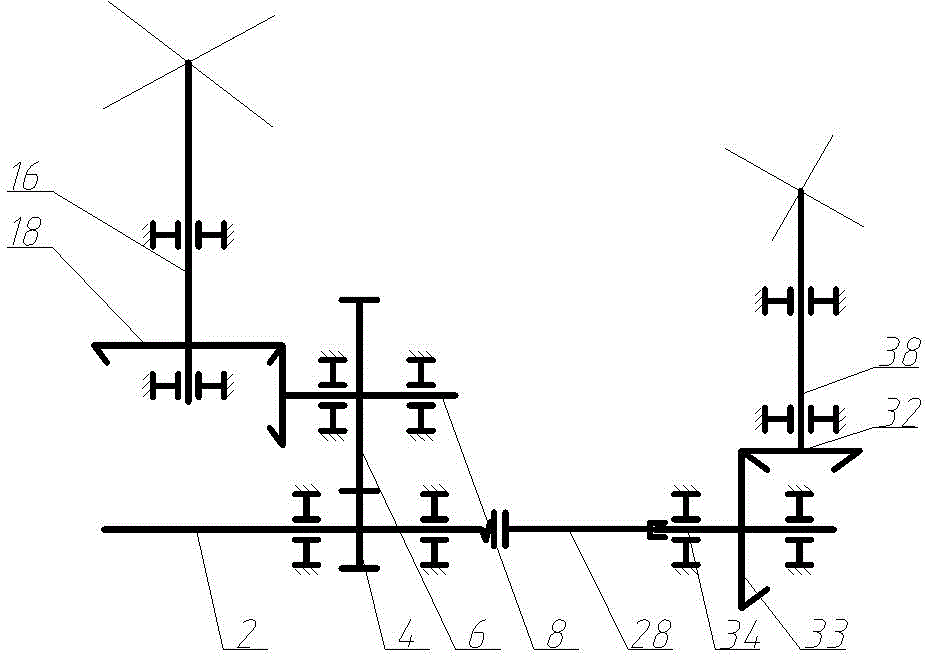

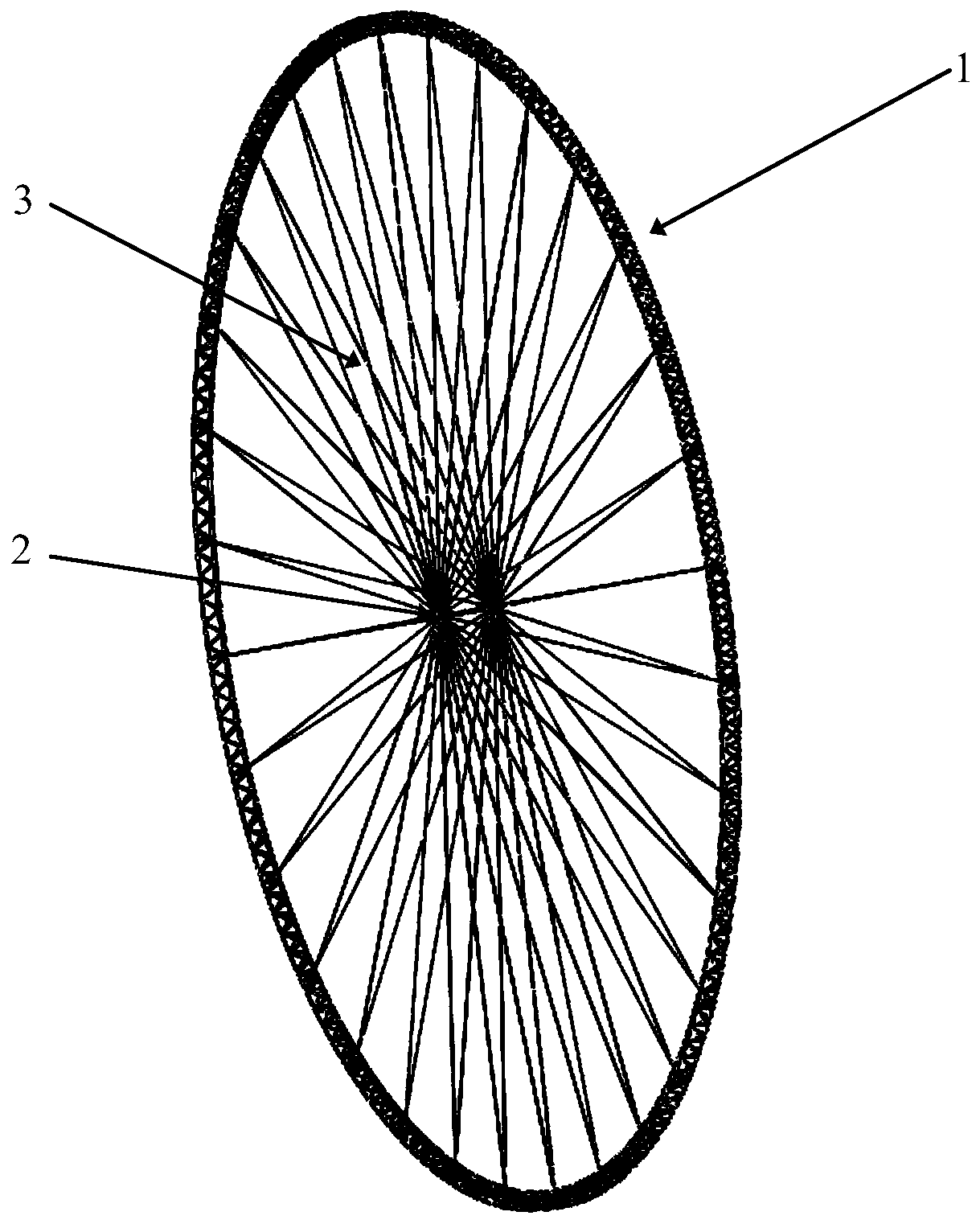

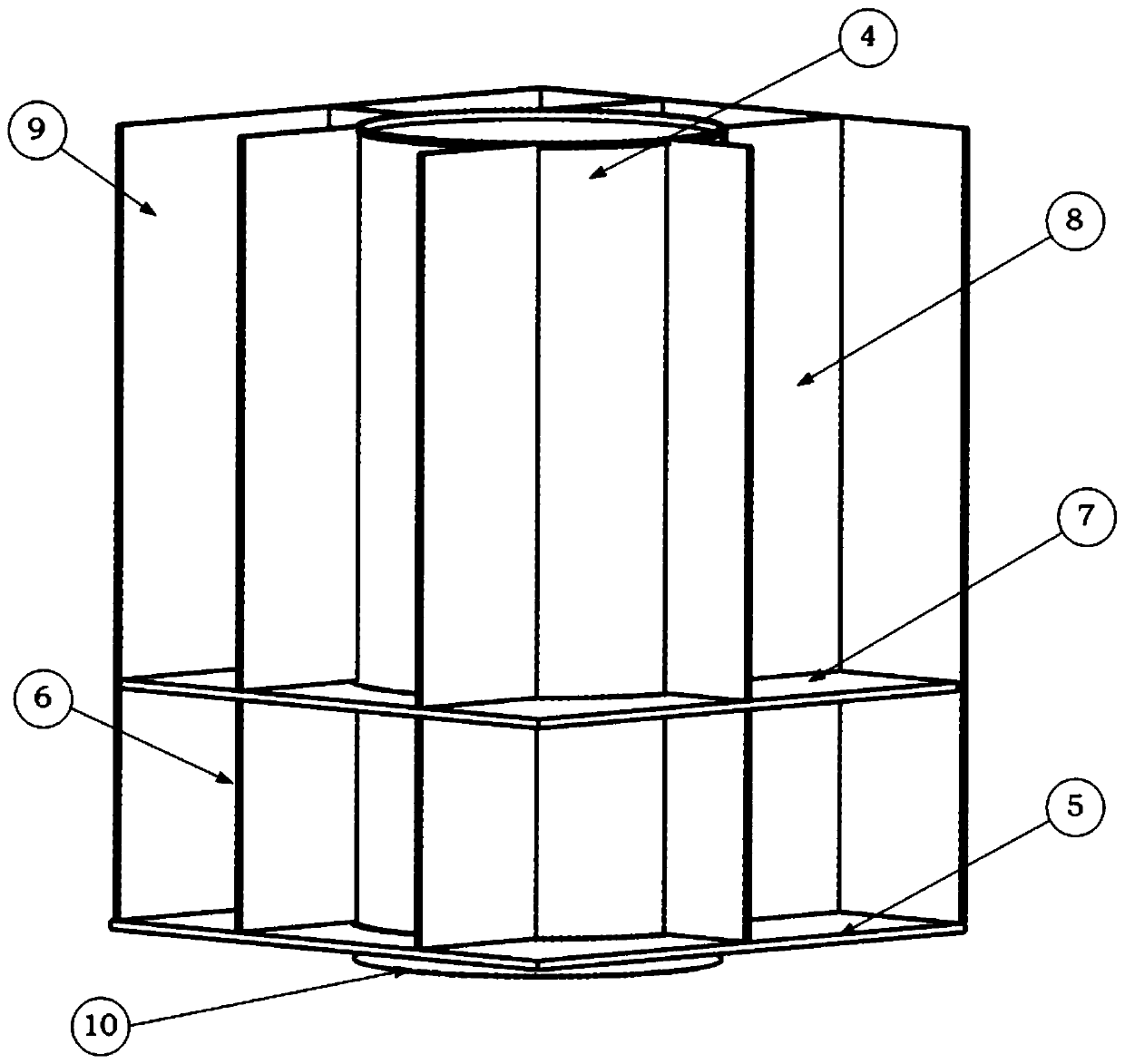

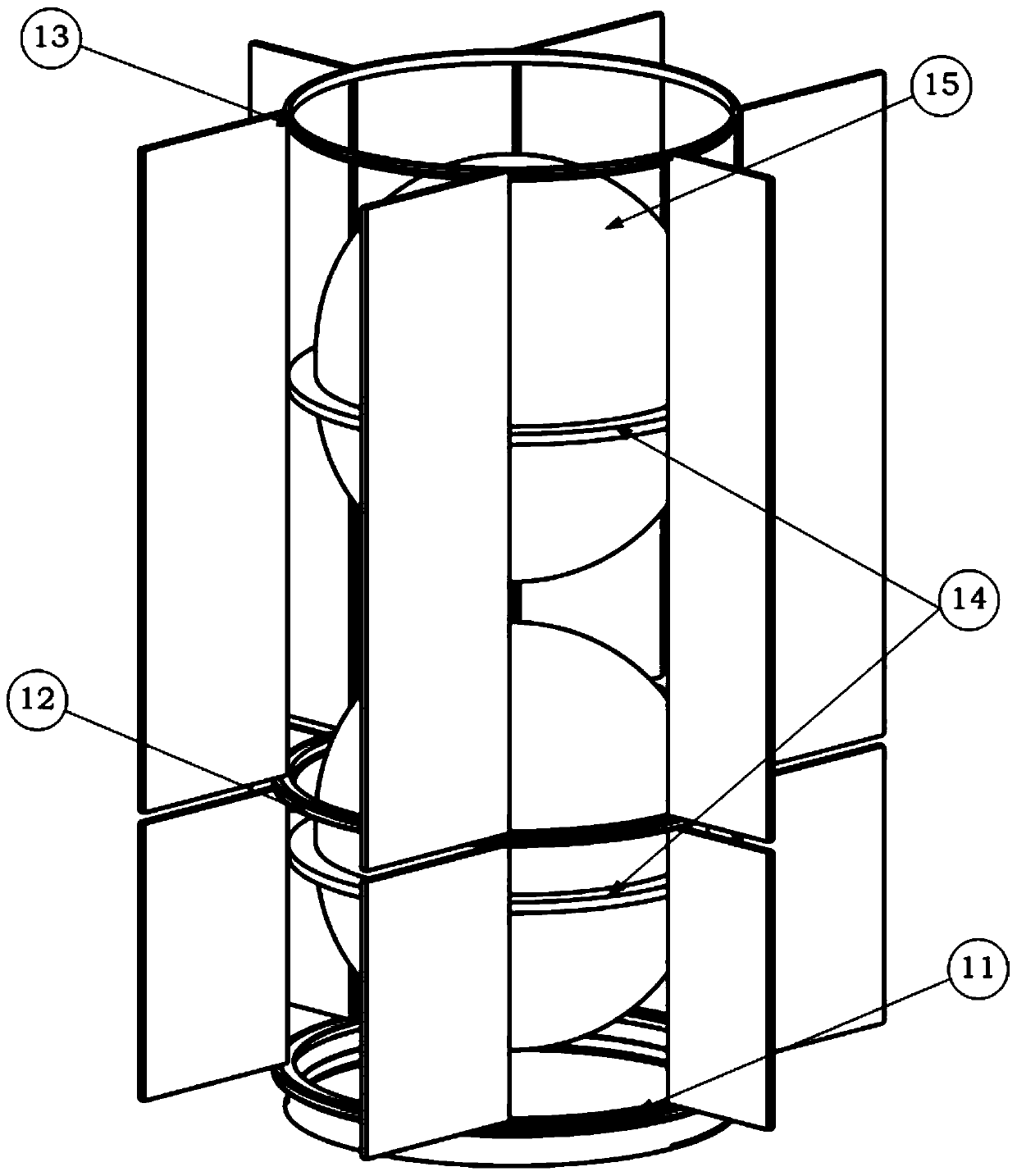

Suspended-dome multi-time prestressed construction method

InactiveCN101158195APower transmission is simpleReduce pressure peaksBuilding roofsInstabilityPre stress

The invention discloses a suspend dome structure multi-prestressed construction method used in construction field. The construction method is that: firstly, a central pressure ring, an upper radial bar and edge elements are arranged on an upper layer; secondly, a lower radial rope, a lower ring rope and a strut are arranged on a lower layer; thirdly, prestress is applied in the structure by stretching the lower ring rope or stretching the lower radial rope or adjusting the length of the strut; fourthly, a ring bar is arranged; fifthly, an external load is applied on the structure. Compared with the structure formed by a traditional method, the suspend dome structure formed by the invention reduces peak pressure of elements with concise force, even changes a part of elements from a pressure bar to a tension bar, avoids instability of elements, at the same time enhances the entire stability of the whole structure and enlarges the ultimate bearing capacity. Furthermore, the invention leads a more even distribution of internal force of the upper layer network shell bar elements, is helpful to the unity of the elements and convenient for design and construction, at the same time, the invention reduces the applied prestress value and reduces construction difficulty.

Owner:BEIJING UNIV OF TECH

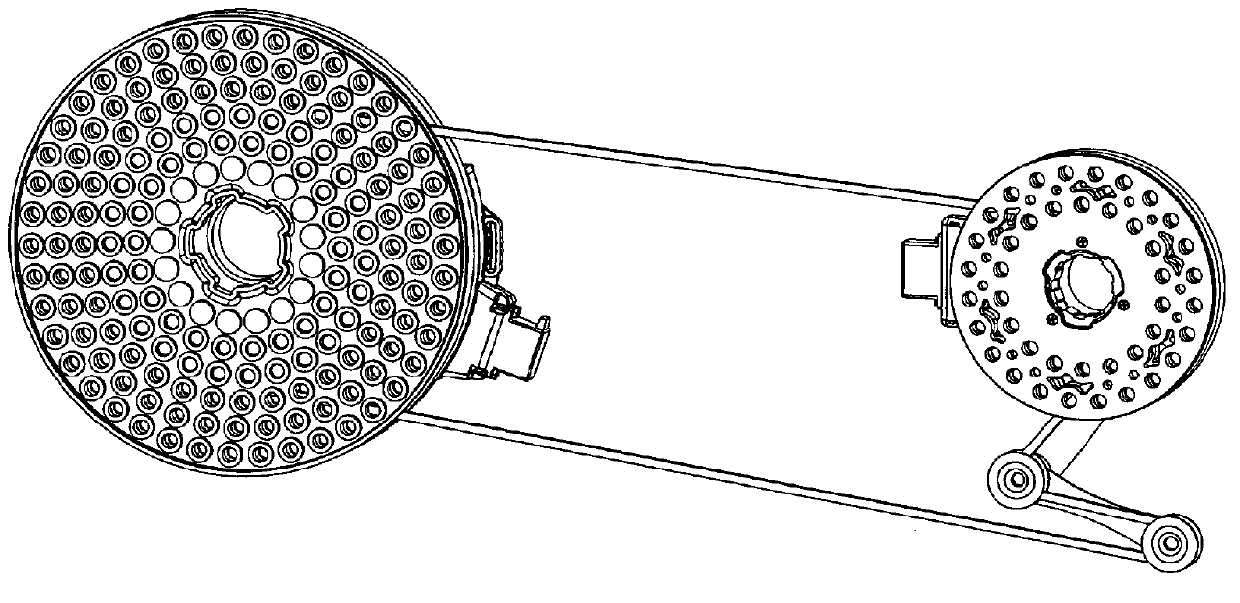

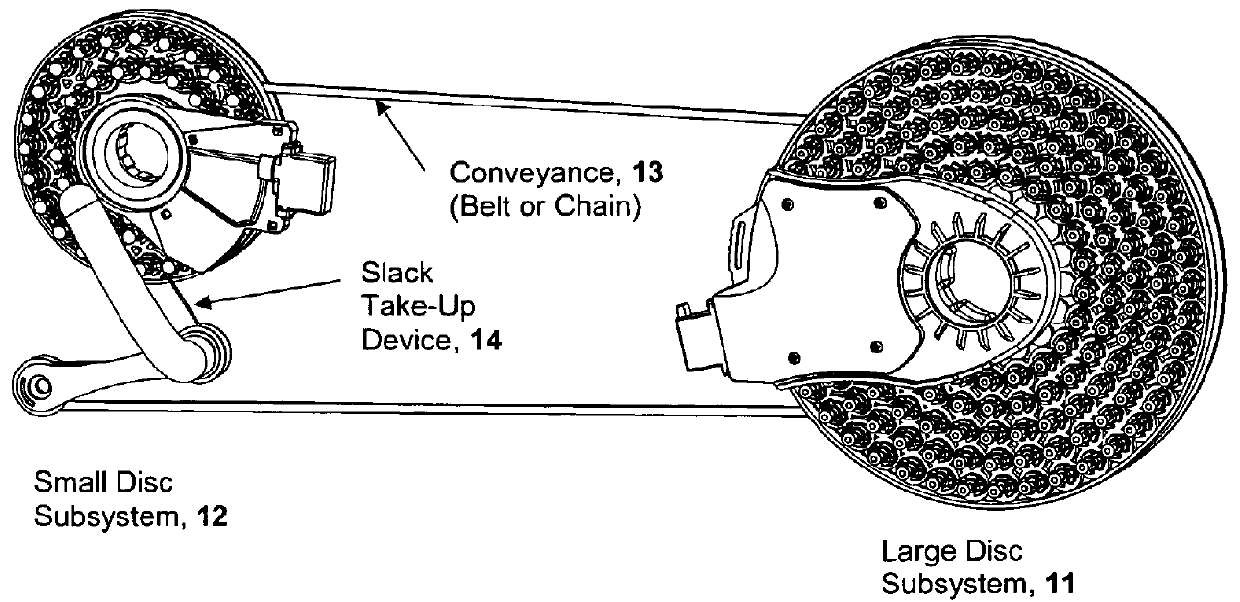

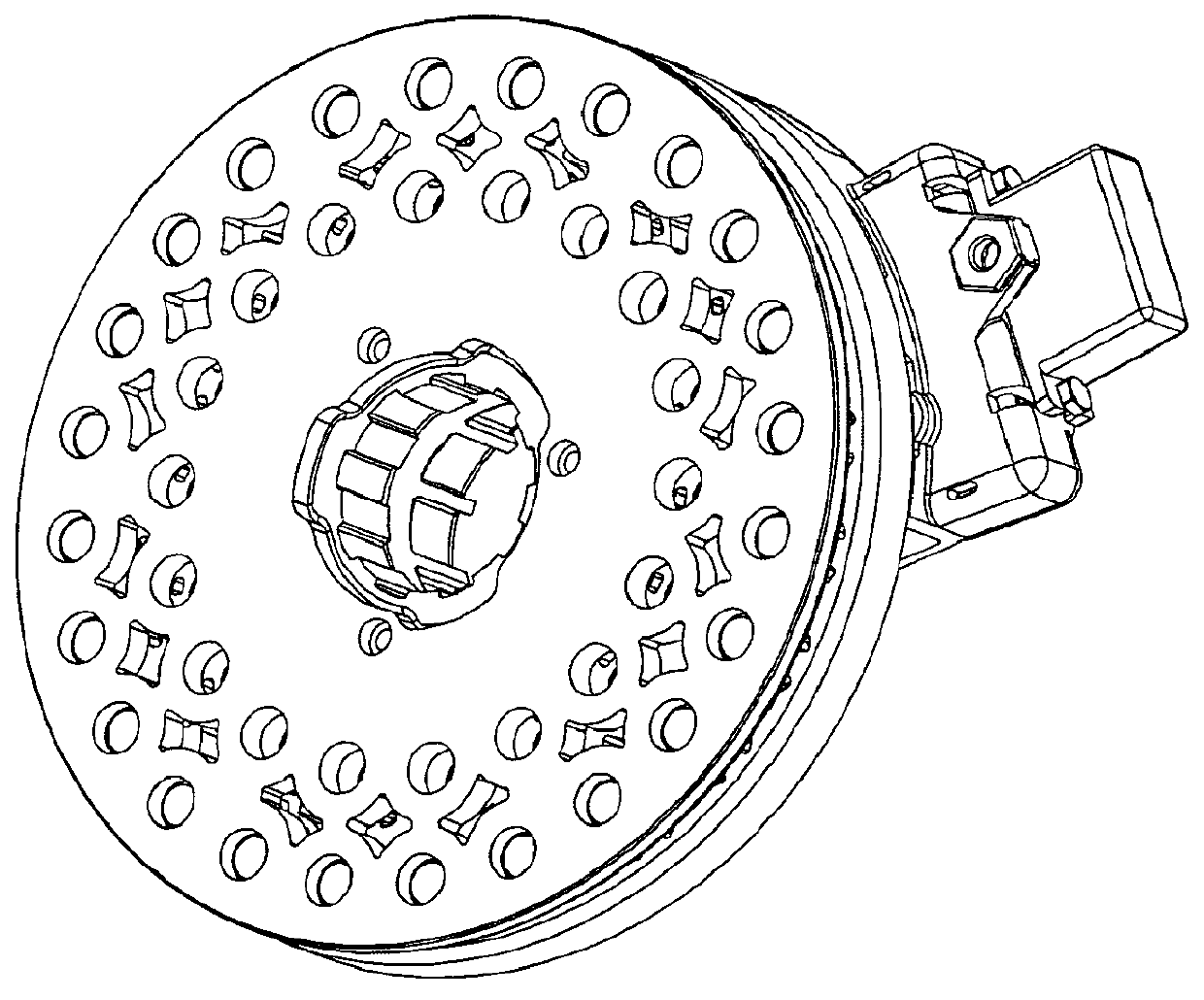

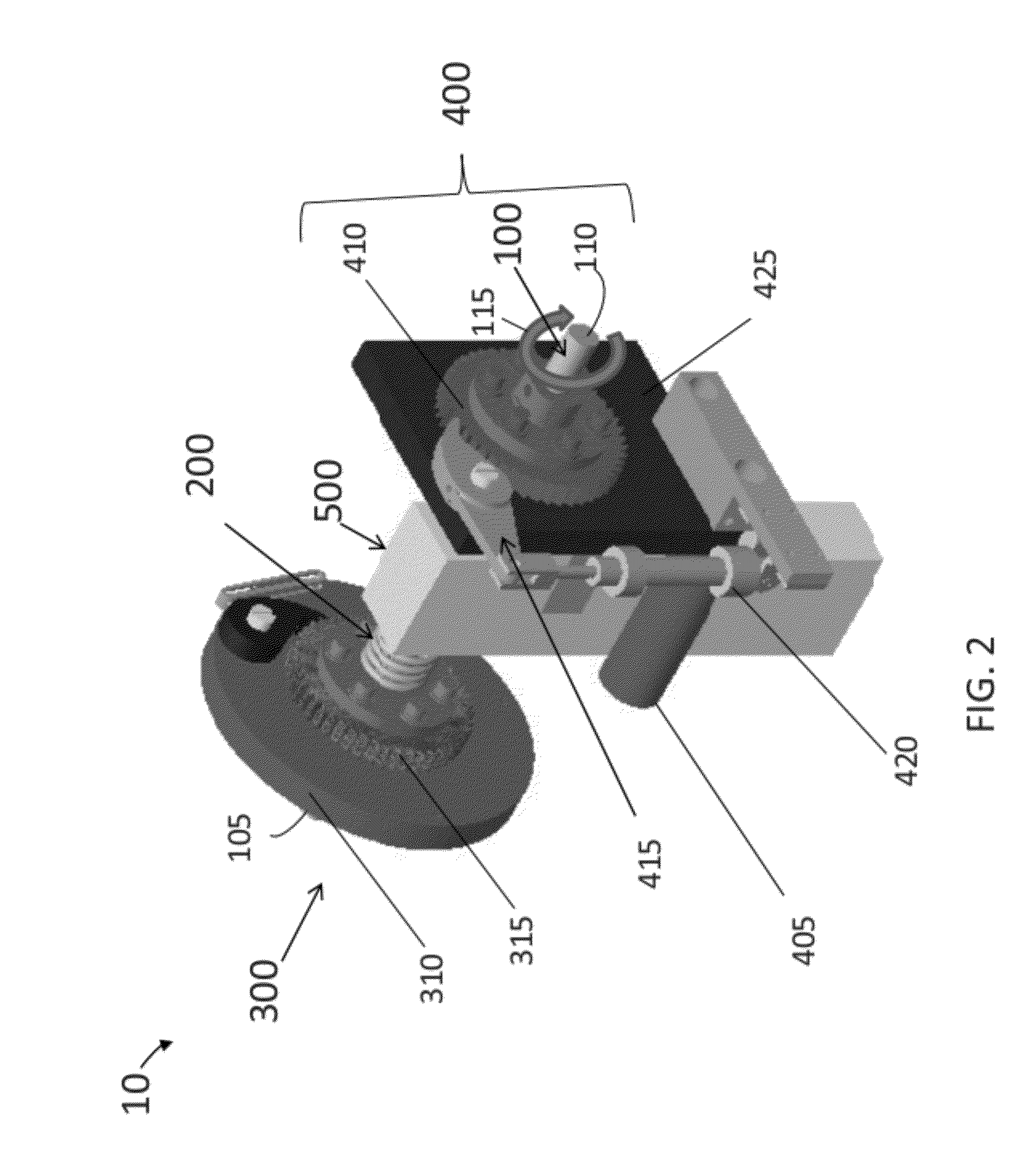

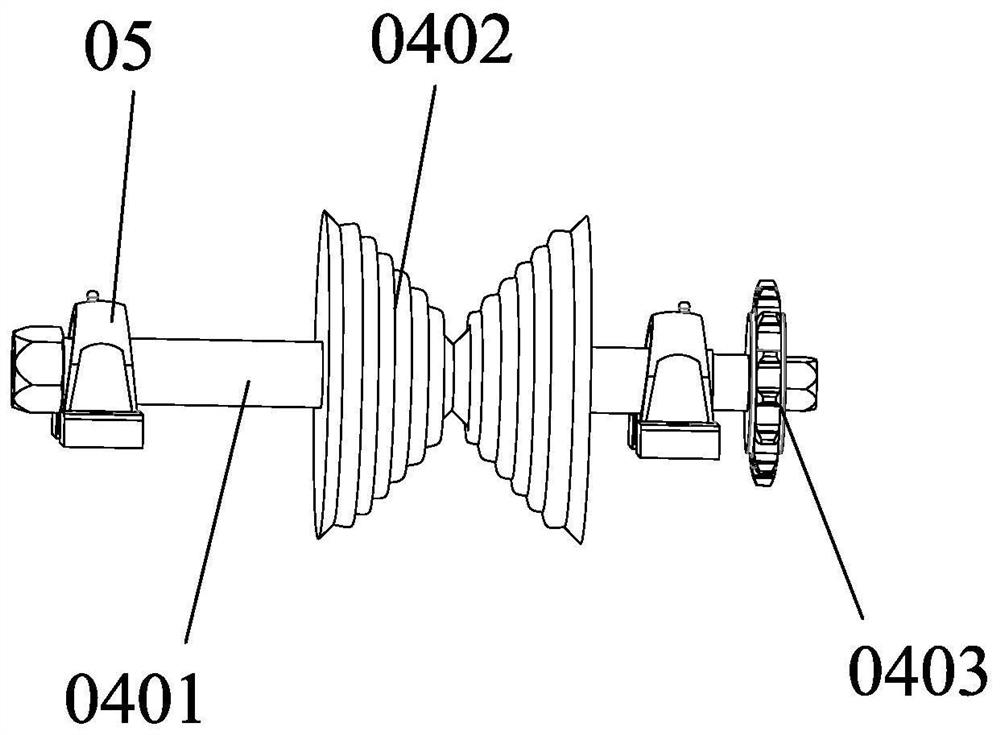

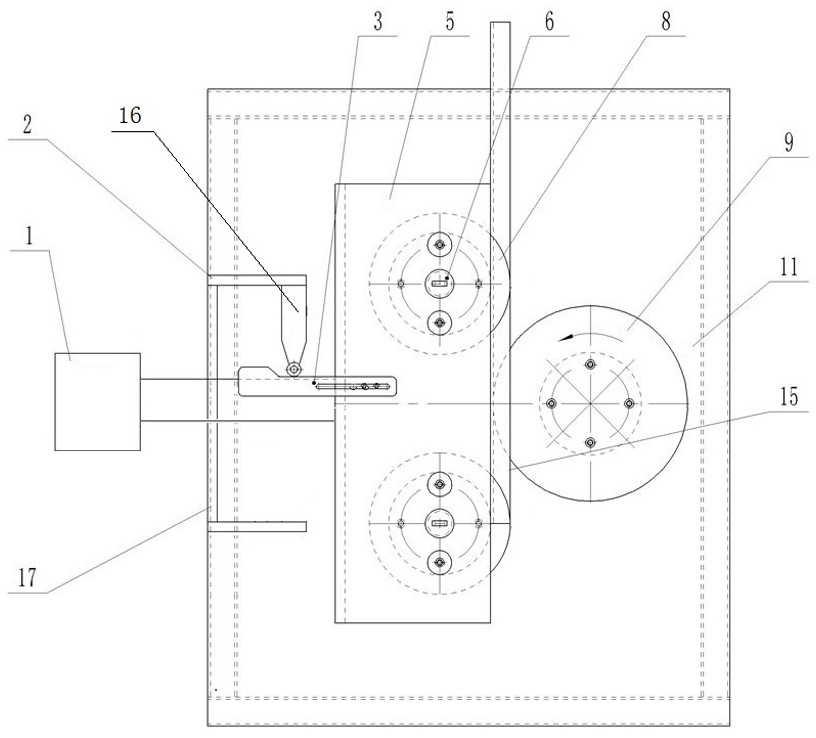

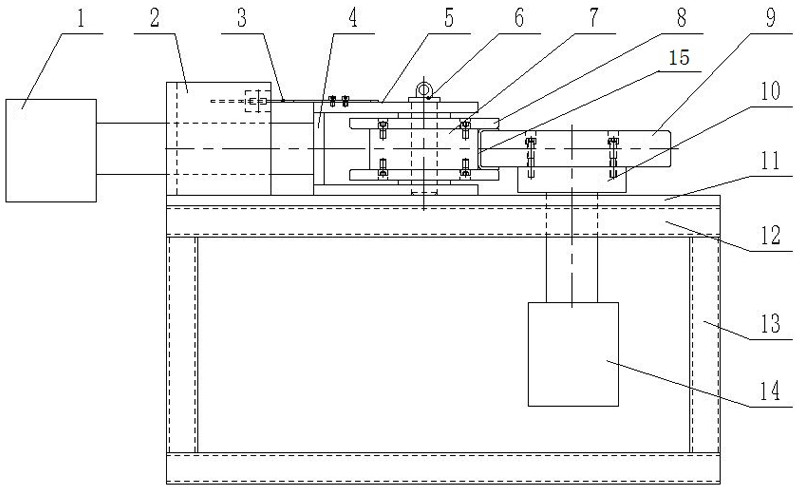

Versatile variable gear ratio transmission

InactiveUS8257209B1Easy constructionPower transmission is simpleChain/belt transmissionGearingConcentric ringGear ratio

A versatile, variable gear ratio mechanical transmission system is providing having similar first and second spaced Disc Subsystems connected by a belt or chain. Each subsystem of which comprises three primary components: (1) a Shift Actuation Structure located at one outermost side; (2) a Receiving Disc located at the opposite side; and, (3) a Retention Disc sandwiched between. The Retention and Receiving Discs accommodate concentric rings of proportionally spaced holes in which corresponding smooth, contoured or toothed Headed Pins are maintained, engaged, or retracted. When the pins are engaged, they span the slot between the Receiving Disc and Retention Disc and interface with the conveyance transferring load from Driving Disc Subassembly to the Driven Disc Subassembly.

Owner:LANE JOSEPH C +2

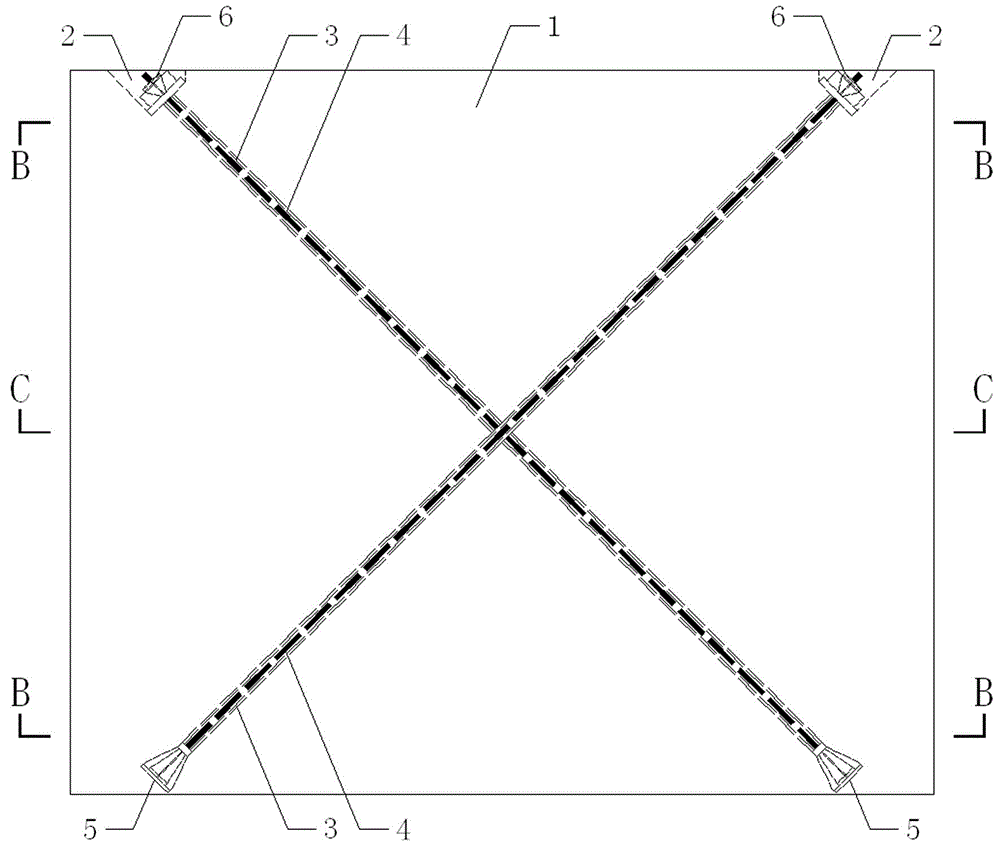

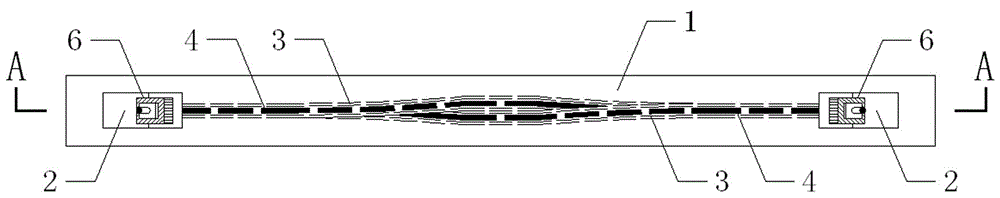

Shear wall structure configured with crossed slant internal prestress and construction method of shear wall structure

InactiveCN102979221ADirect forceReduces the likelihood of crossing oblique cracksWallsBuilding material handlingRebarPre stress

The invention relates to a shear wall structure configured with crossed slant internal prestress. The shear wall structure comprises a shear wall body, horizontal steel bars of the shear wall body and vertical steel bars of the shear wall body, wherein a shear wall tooth plate and a prestress tension end anchor tool are respectively arranged at the left upper corner and the right upper corner of the shear wall body, prestress anchoring end anchor tools are respectively arranged at the left lower corner and the right lower corner of the shear wall body, and a crossed slant prestress steel beam and a crossed slant prestress pipeline are arranged between the prestress anchoring end anchor tool and the prestress tension end anchor tool at the opposite corners. A construction method of the structure comprises steps of shear wall template erection and binding of ordinary steel beams of the wall body; crossed slant prestress pipeline arrangement and installation; prestress steel beam penetration and prestress anchor tool installation; shear wall concrete casting and maintenance; and prestress tension, pipeline grouting and end part anchor sealing. The shear wall structure greatly improves the anti-seismic performance of the shear wall.

Owner:ZHENGZHOU UNIV

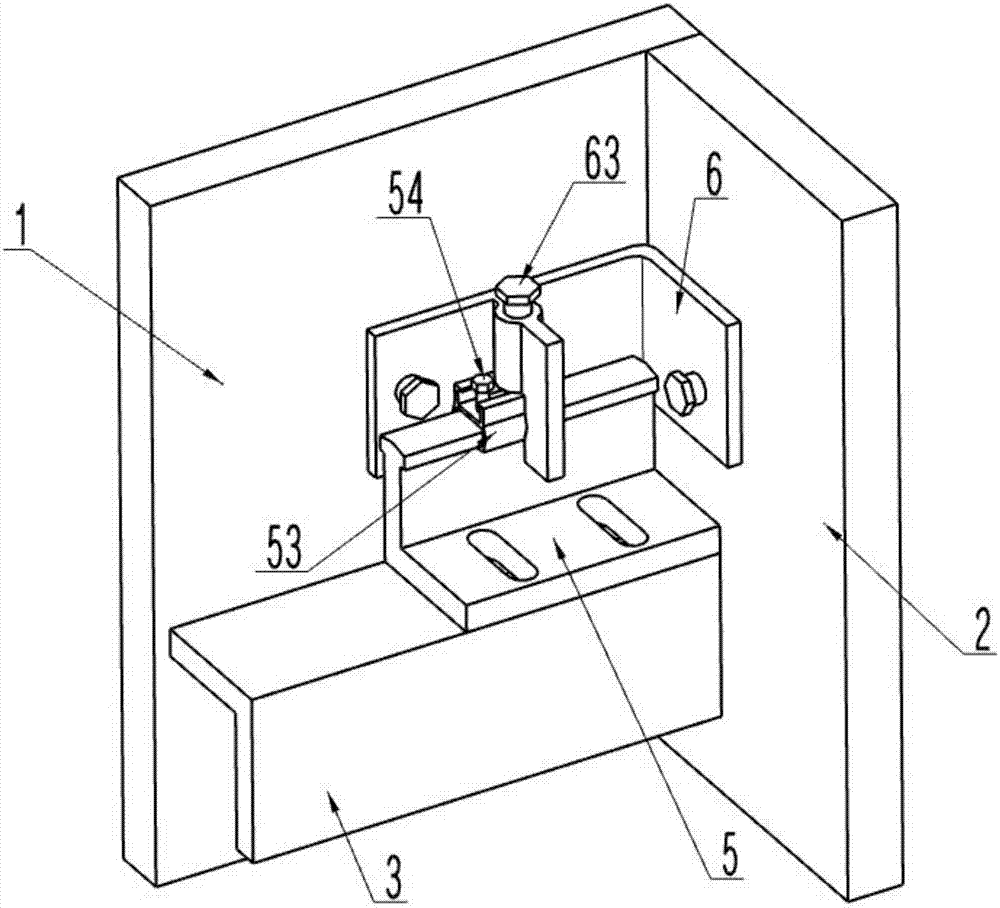

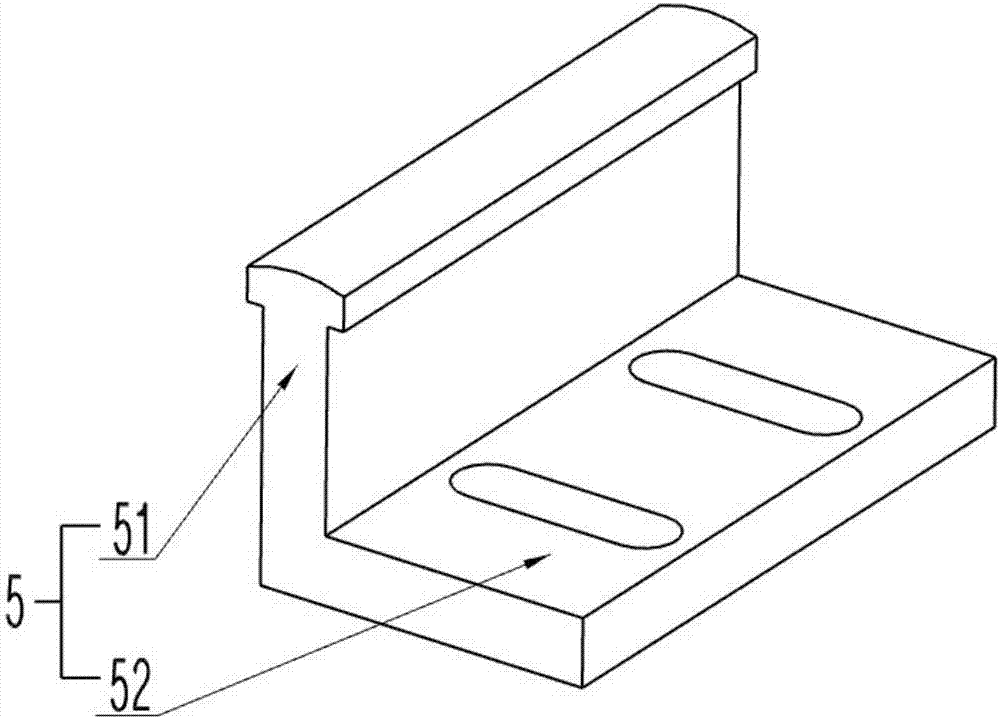

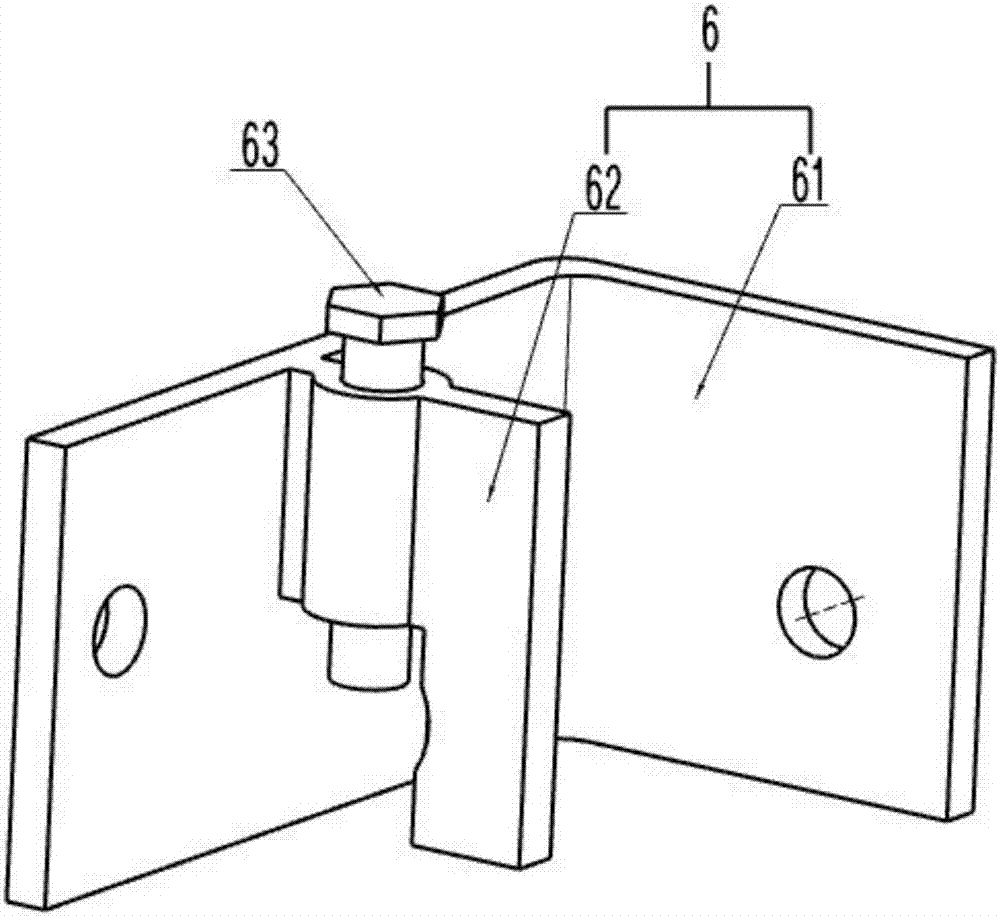

High altitude placing steel pole inner concrete operating platform frame

A high altitude pouring steel column internal concrete operating platform frame belongs to the technique field of the auxiliary equipment of the building structure construction. The platform frame comprises a tool falsework platform and is characterized in that a clamping bolt is provided. The tool falsework platform is laid on a steel girder which is used for facilitating to pour at least two concrete in the steel column. The clamping bolt is used for permanent connection between the tool falsework platform and the steel girder. The invention can simplify the high-difficult and high-dangerous high altitude operation to the ground. The use time of the tower crane is reduced and the ground is saved. The steel tube and buckle and the like are all common material in construction. The invention has the advantages of high recovery and use percentage, convenience to the constructor, alleviation to the labor intensity, increased construction efficiency, increased security, low cost and excellent economic property.

Owner:JIANGSU HUAJIAN CONSTR

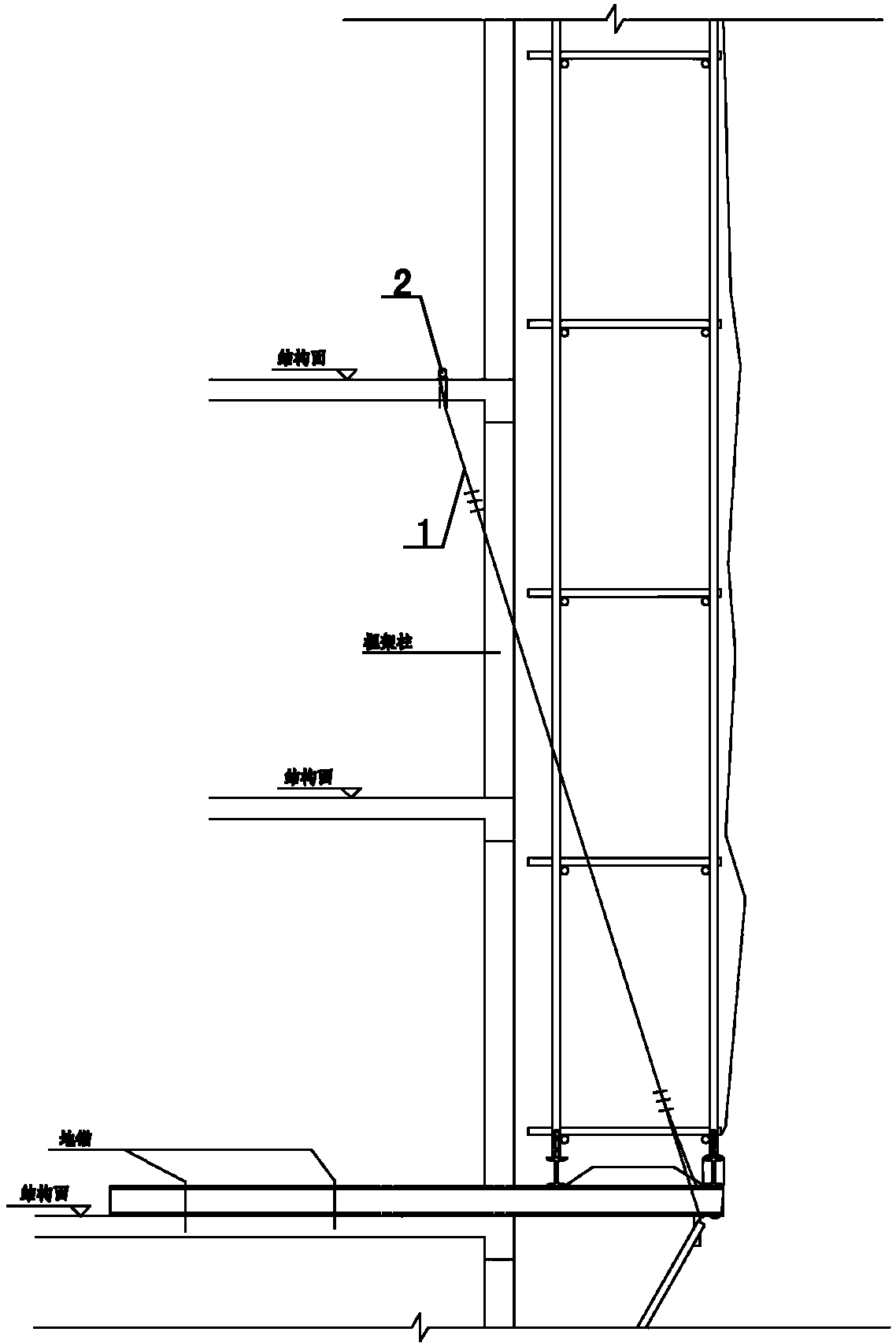

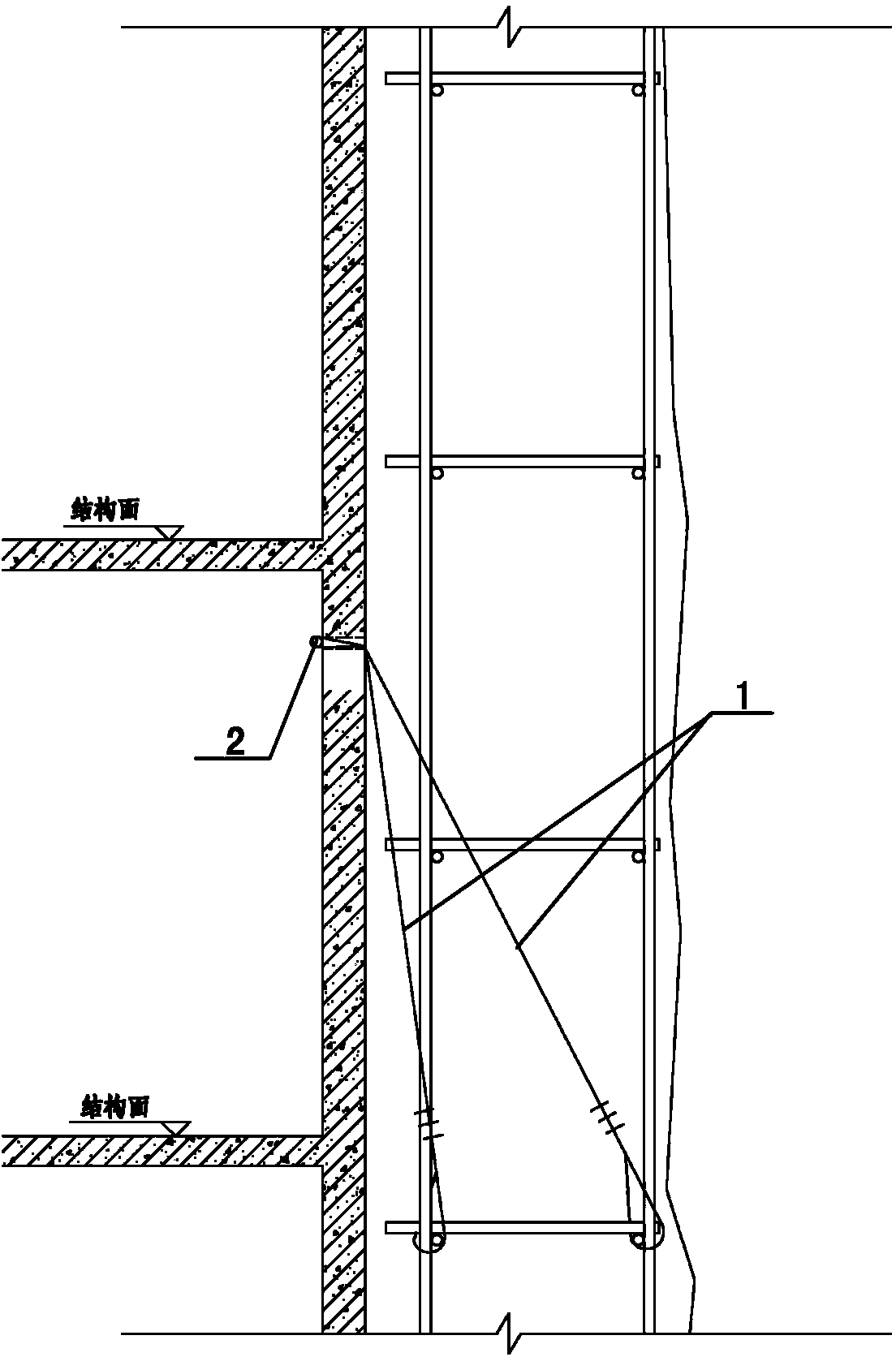

Scaffold unloading steel wire rope setting method

The invention relates to a scaffold unloading steel wire rope setting method. Unloading steel wire ropes are arranged on a whole scaffold or a local corner of the scaffold, wherein the bottom of the overhanging scaffold and the periphery of a middle layer of a scaffold body or the periphery of a floor frame body layer are provided with the steel wire ropes for unloading of the scaffold, the unloading steel wire ropes are fixedly connected with a structural main body through structural connection beam threading bolt holes or reserved penetration holes in a corresponding top plate or a corresponding wall body where the unloading steel wire ropes are located. Holes with a diameter of phi 28-phi 40 are reserved in the wall body or a floor, and the unloading steel wire ropes of the scaffold penetrate through the holes and are stuck to the inner sides of the holes by steel tubes with a diameter of phi 48. When the unloading steel wire ropes are stressed, the steel tubes are pulled to a structural face layer so that the steel tubes with the diameter of phi 48 are fixed to a structural face, and the situation that the steel tubes slip cannot occur. Compared with a traditional unloading mode that steel bar anchor rings are embedded in the wall body or the floor, the method is high in safety and easy to operate.

Owner:北京建工博海建设有限公司

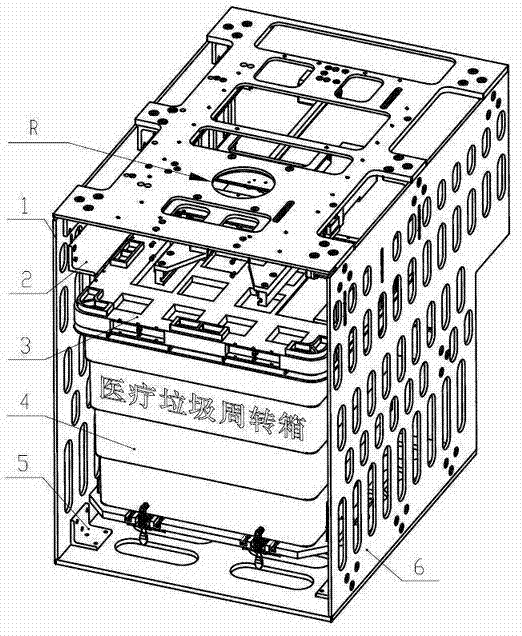

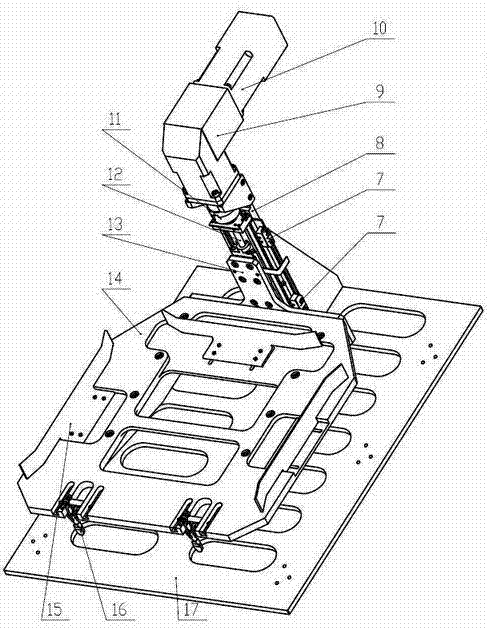

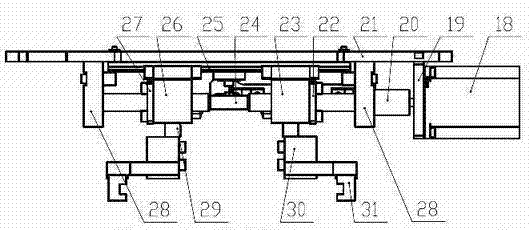

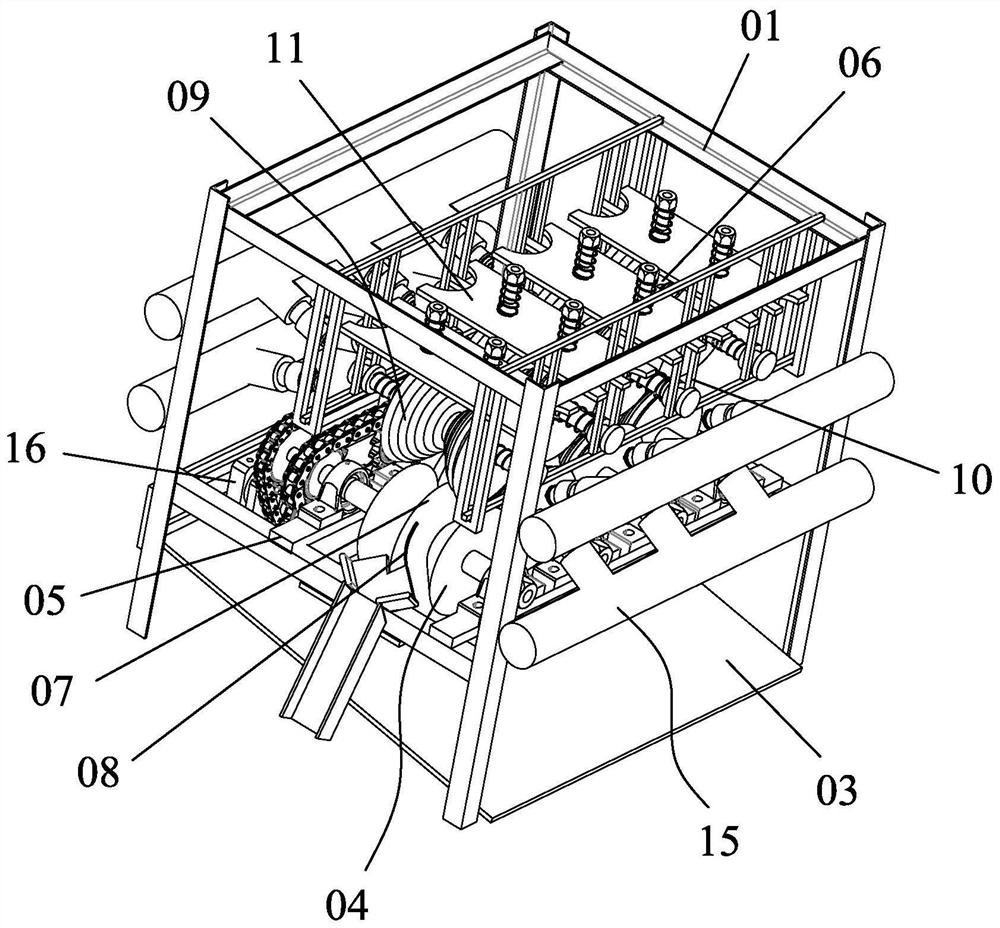

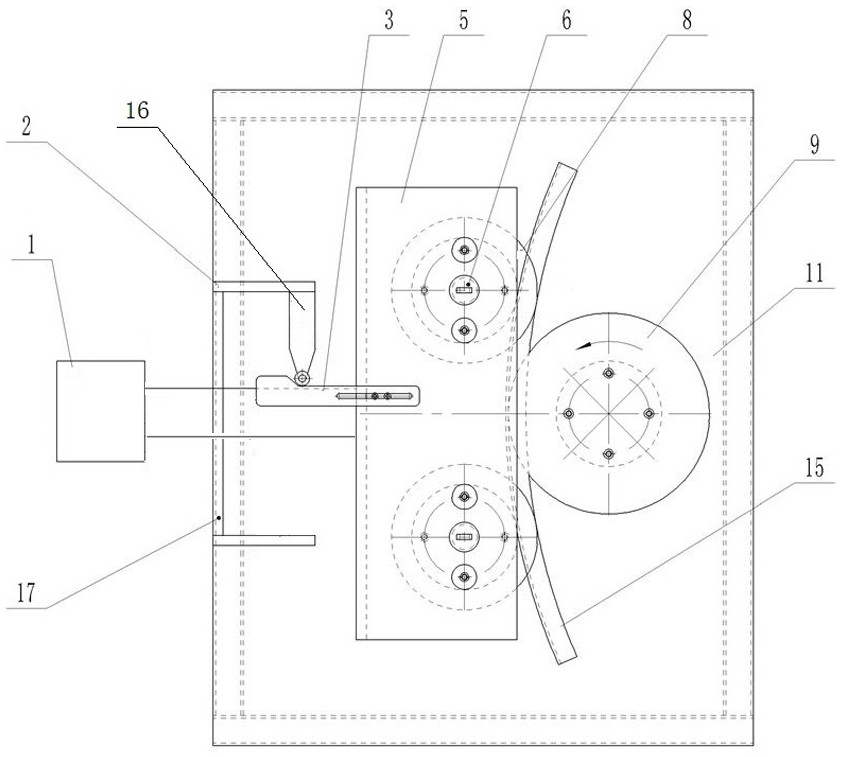

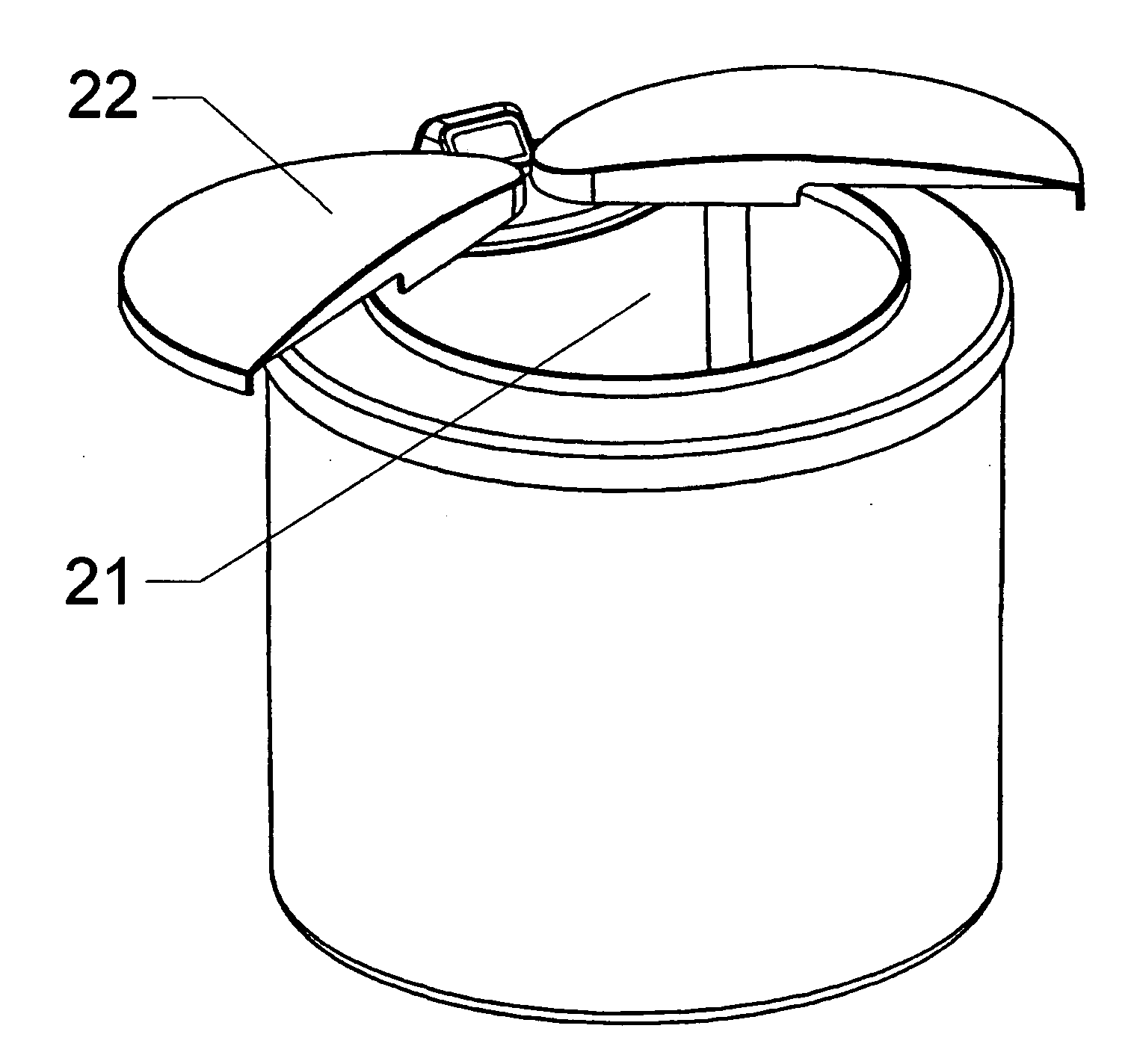

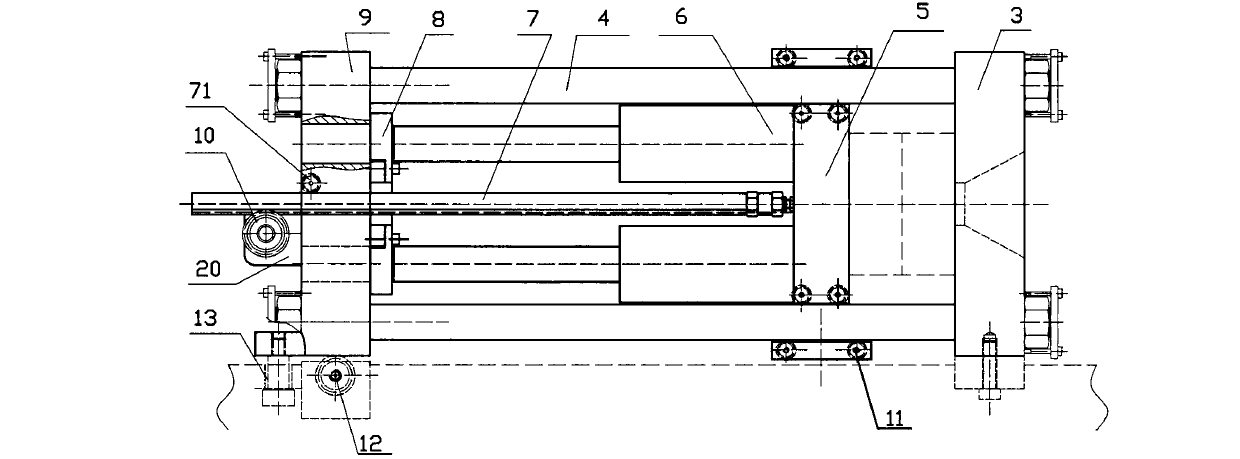

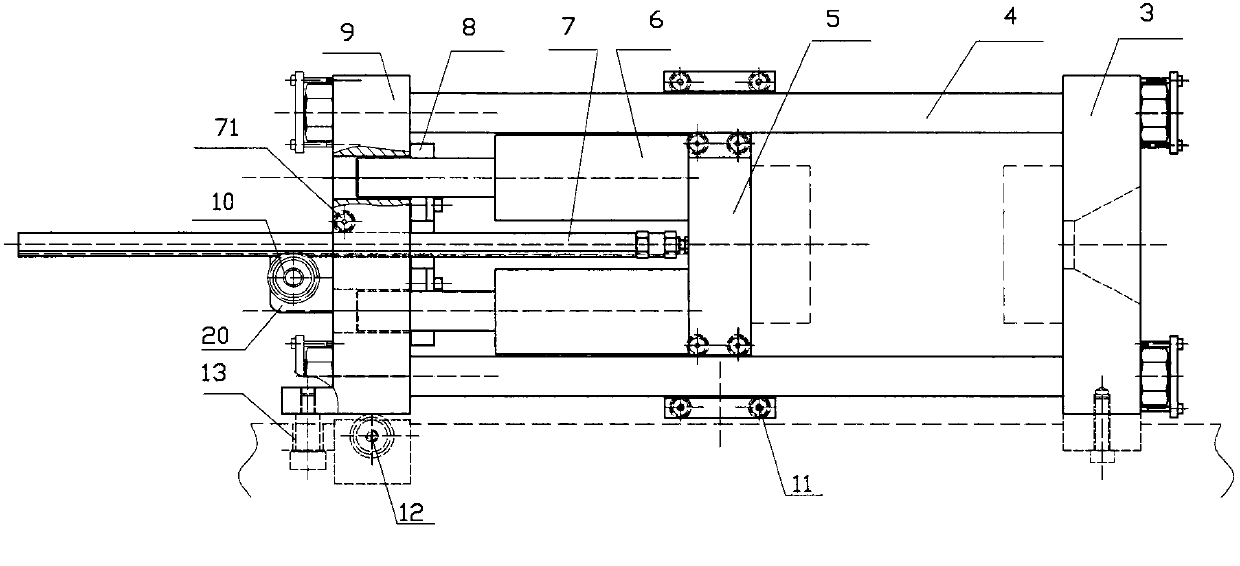

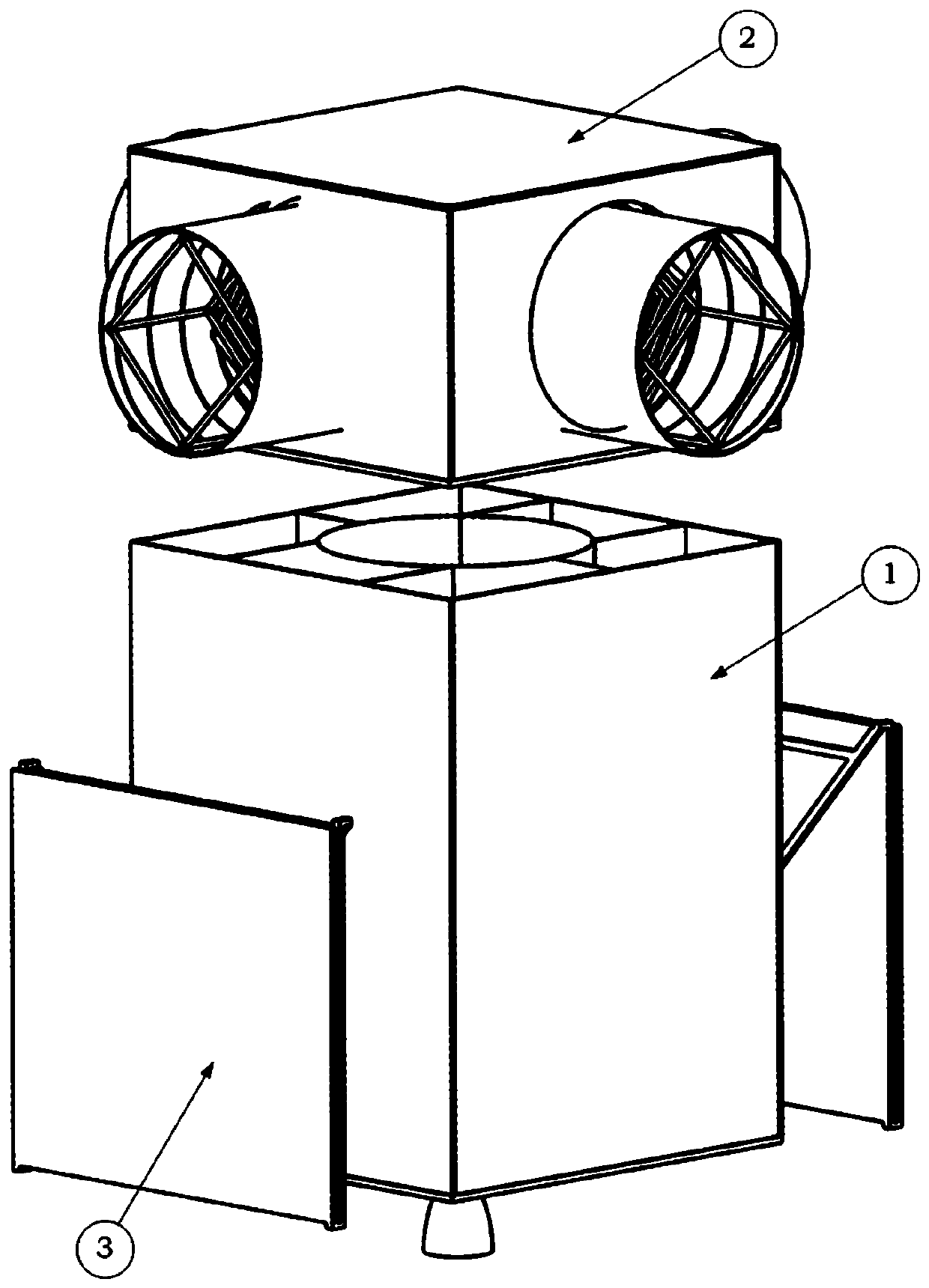

Automatic packaging system for medical waste

ActiveCN103569553AReasonable structurePower transmission is simpleRefuse receptaclesLinear actuatorLeft handed

The invention relates to an automatic packaging system for medical waste. The system comprises a case frame, a box lifting mechanism, a box cover grabbing mechanism, a box cover moving mechanism and a quick sealing mechanism, wherein a linear actuator is driven by a lifting motor of the box lifting mechanism to drive a bracket and a dustbin to rise and fall; a left-handed and right-handed trapezoidal screw is driven by a grabbing motor of the box cover grabbing mechanism to rotate to drive a left-handed trapezoidal nut and a right-handed trapezoidal nut to conduct opposite linear motions, so that actions of grabbing and releasing of a box cover are realized; a gear is driven by the box cover moving mechanism through a moving motor to rotate, so that forward and backward movement of the whole grabbing mechanism is realized; and a sealing gear is driven by a sealing motor of the quick sealing mechanism to rotate so as to drive a sealing rack and a rear sealing door to move, the rear sealing door moves along a sealing rail through a rolling wheel assembly, and a front sealing door moves in an opposite direction simultaneously, so that opening and closing of a waste inlet are realized. The system is reasonable in structure, simple and reliable in power transmission, high in operability and high in efficiency.

Owner:威海福瑞机器人有限公司

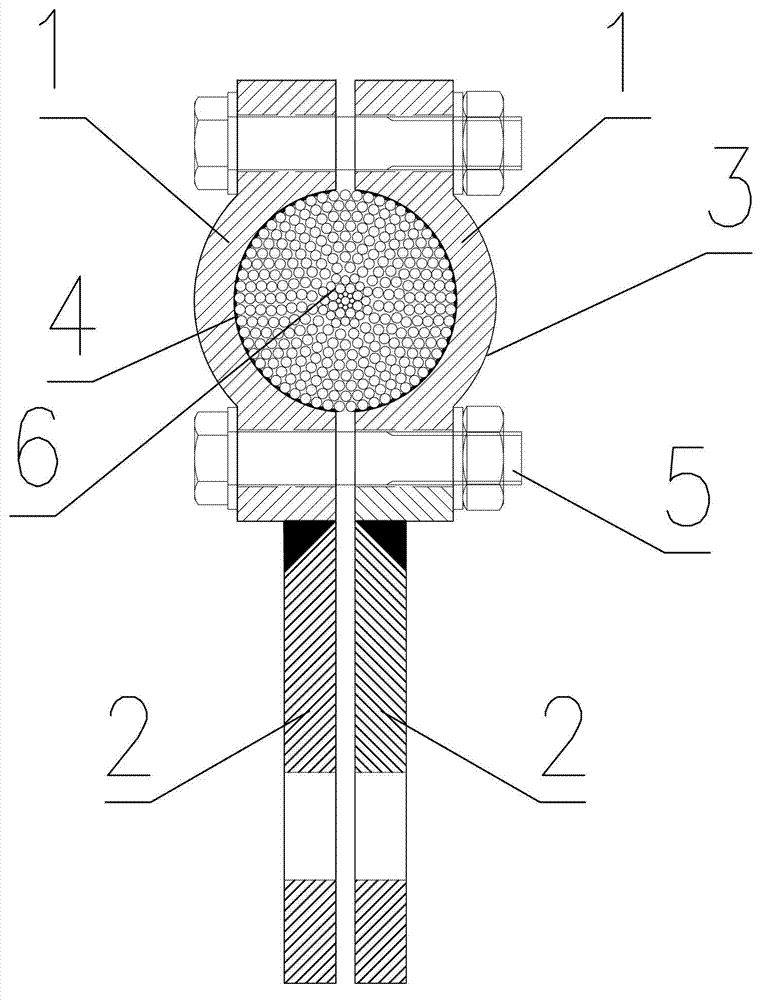

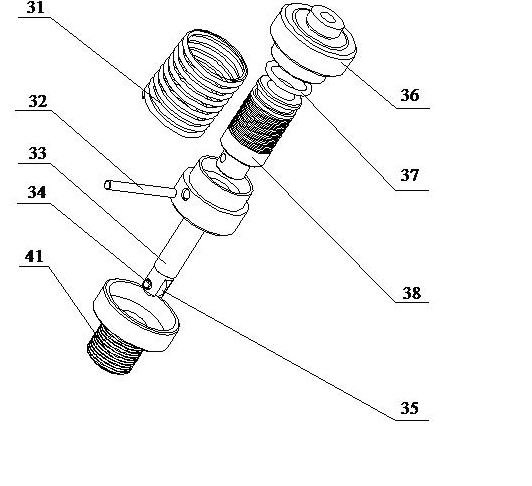

High-vanadium round wire tendon rope clamp as well as manufacturing process and design method thereof

ActiveCN102888896APower transmission is simpleReasonable forceBuilding constructionsPre stressingZinc

The invention discloses a high-vanadium round wire tendon rope clamp which comprises clamp bodies, connecting ear plates, an anticorrosion zinc layer, an anti-sliding metal layer and a high-strength bolt. According to the rope clamp, two rope clamp bodies which are symmetry in shape are integrally connected through the high-strength bolt so as to tightly clamp a high-vanadium round wire tendon rope body; the anti-sliding metal layer is filled at the contact part of the rope clamp bodies and the rope body; and the rope clamp bodies are subjected to hot galvanizing anticorrosion treatment. The invention also provides a manufacturing process of the rope bodies and a design method of shape and size. The rope bodies are machined by using high-strength steels, so that the problems of high manufacturing cost, quality defects and the like caused by the fact that cast steel joints are adopted are avoided. The rope clamp joint is simple in structure, convenient to manufacture and construct and economic and reasonable; the performance of the joint is verified through tests, so that the rope clamp joint is applicable to connection joints in a stretch-draw type rope rod beam pre-stress spatial structure. By adoption of the rope clamp, the force bearing performance of the high-vanadium rope body is effectively improved, the anticorrosion plated layer on the surface of the steel wire is protected, the anti-sliding ability of the rope clamp and the rope bodies is improved, so that the rope clamp is beneficial for the high-vanadium round wire tendon to be popularized and applied in China.

Owner:ZHEJIANG JINGGONG STEEL BUILDING GRP

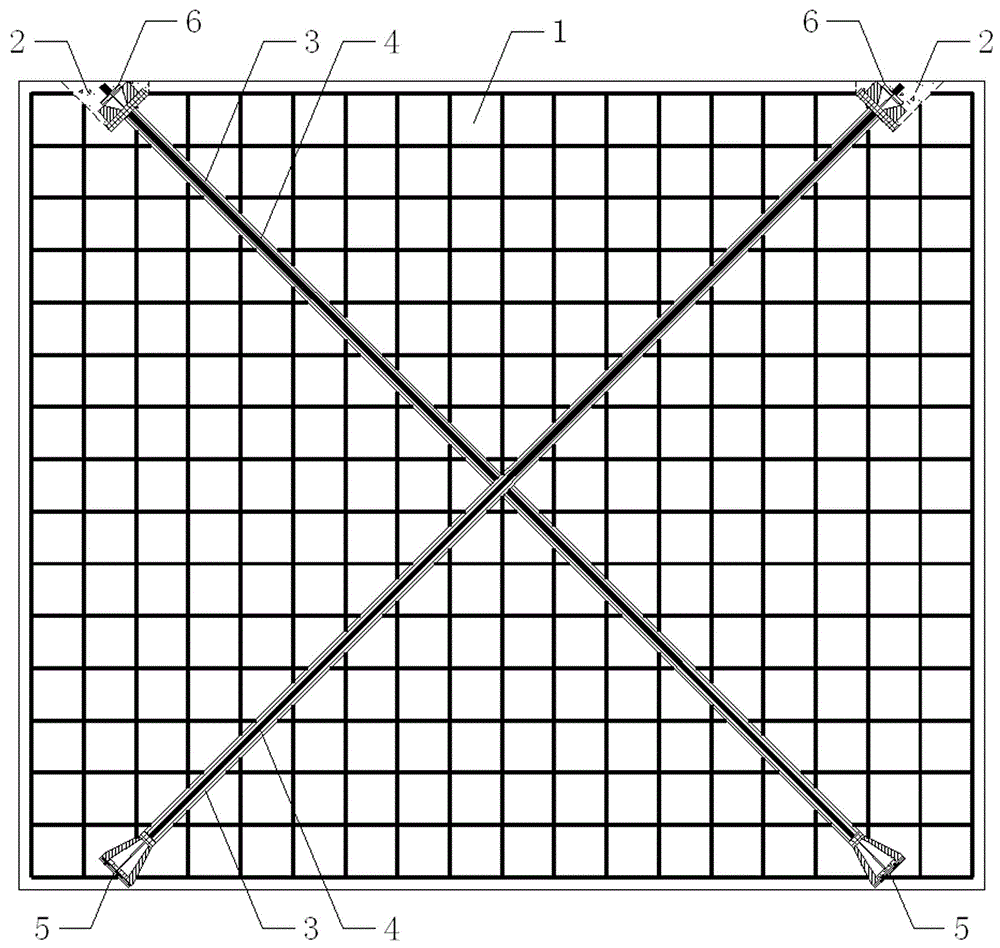

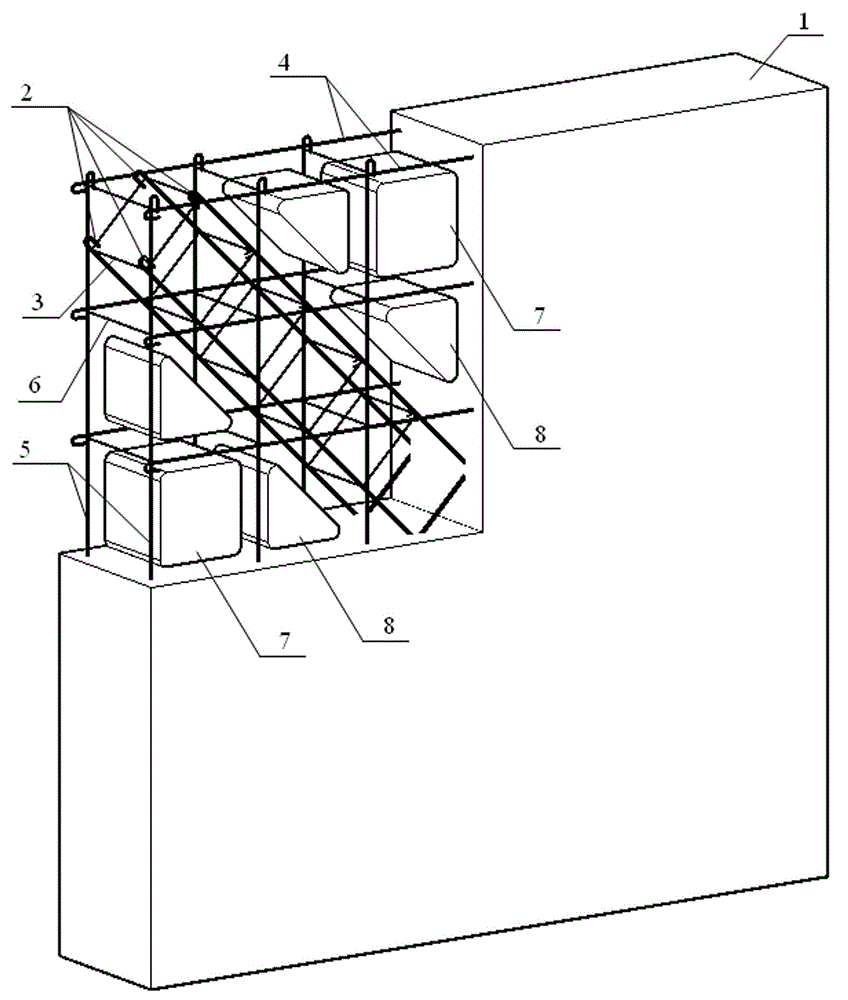

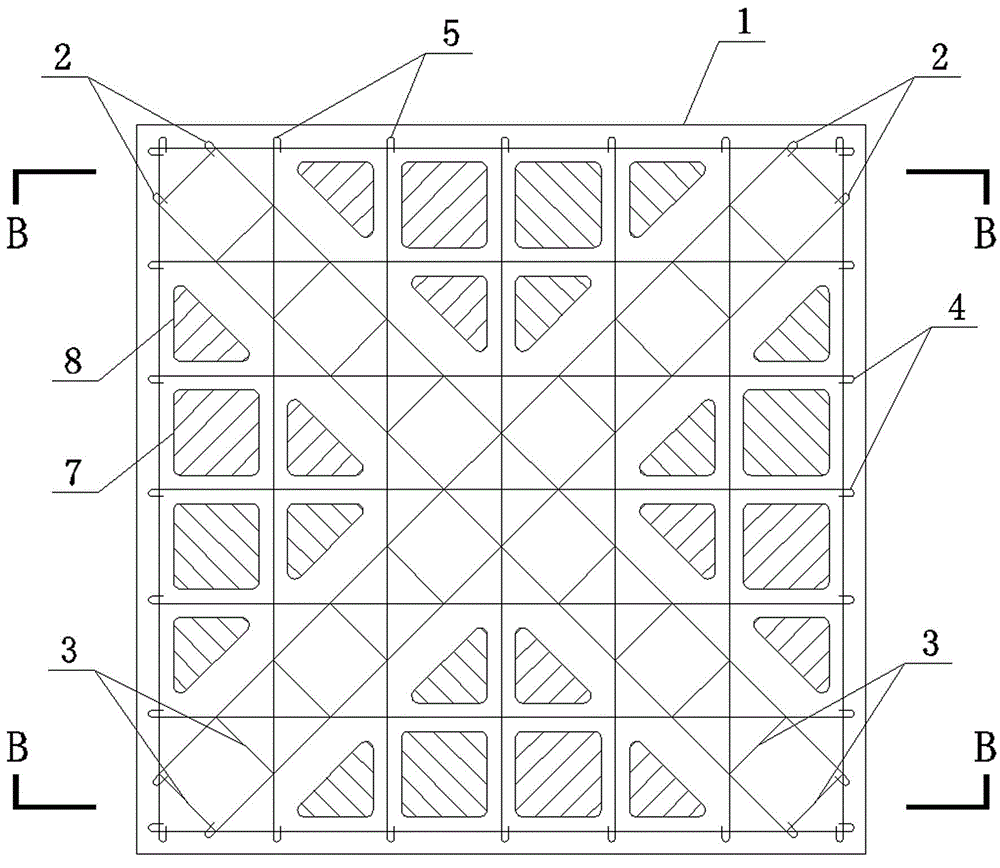

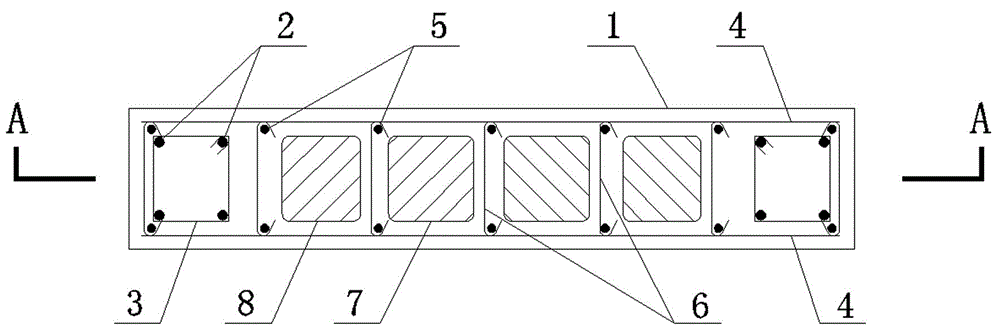

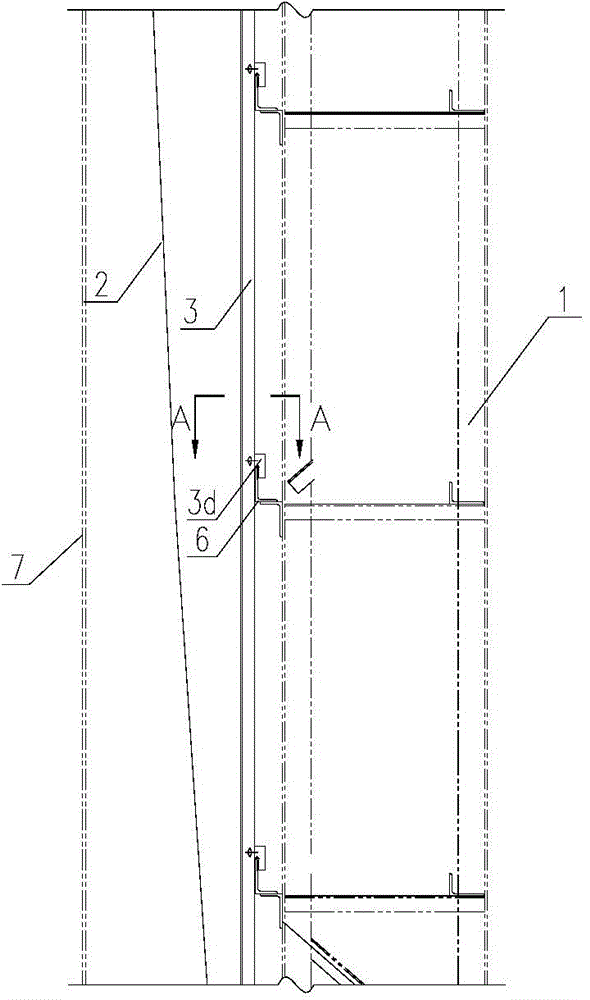

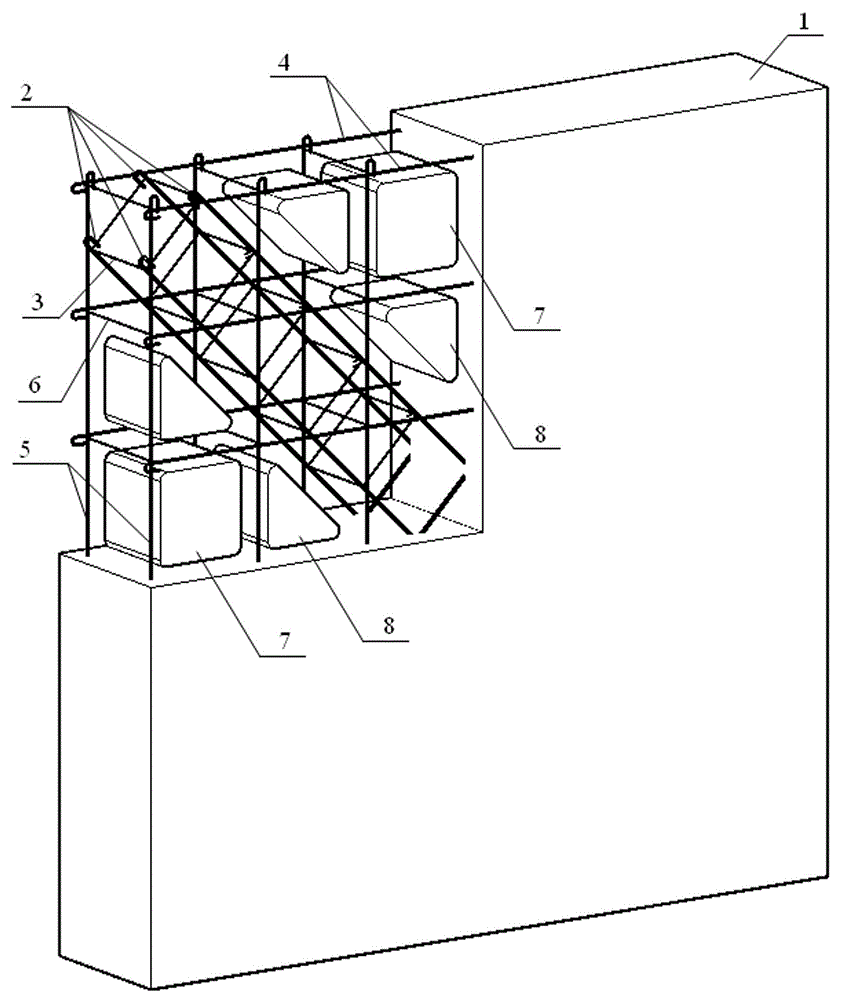

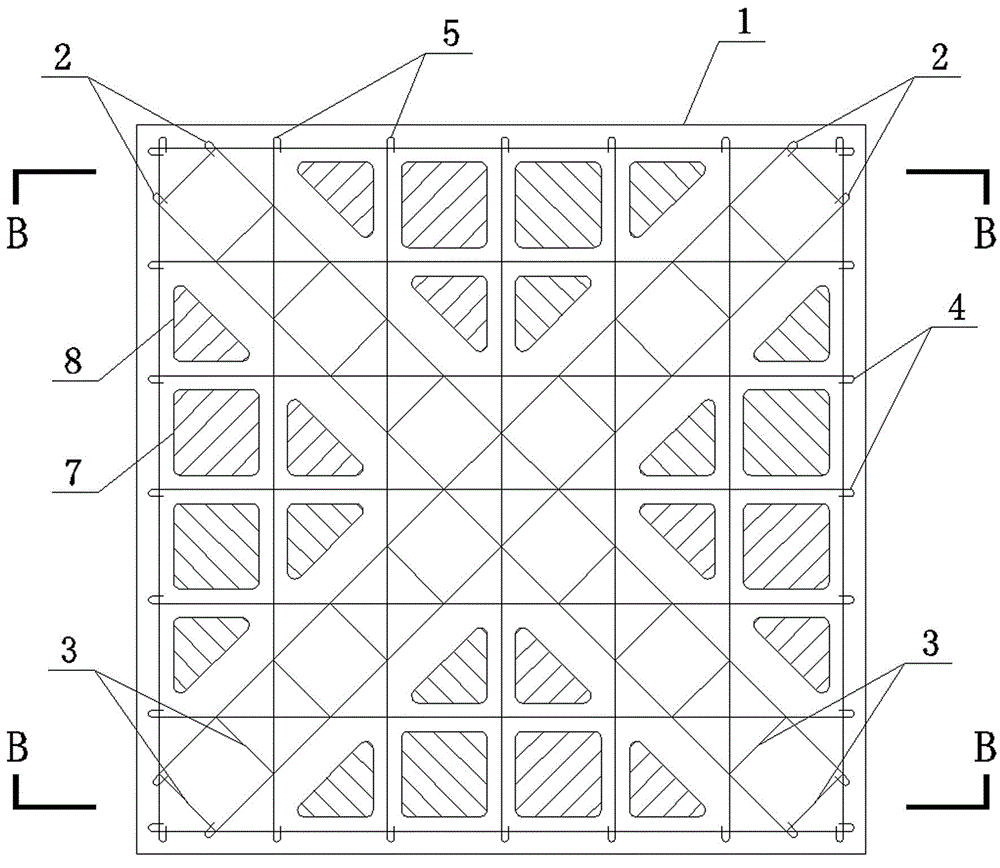

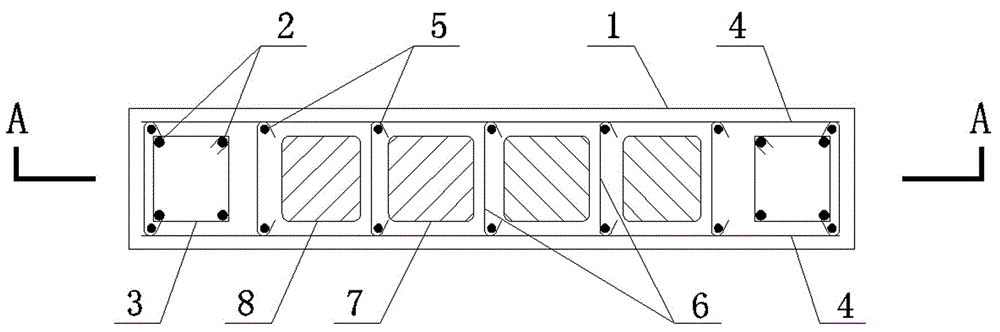

Hollow shear wall structure for cross diagonal reinforcing bar and construction method thereof

InactiveCN102979220AImprove the immunityImprove acceleration performanceWallsBuilding material handlingDiagonalEngineering

The invention discloses a hollow shear wall structure for a cross diagonal reinforcing bar. The hollow shear wall structure for the cross diagonal reinforcing bar comprises a shear wall body, wherein the inside of the shear wall body is provided with the horizontal-direction reinforcing bars of a wall body, the vertical-direction reinforcing bars of the wall body and wall body tie bars, wherein two groups of cross diagonal reinforcing bar cages are respectively arranged along the plane diagonal direction of the shear wall body; the cross diagonal reinforcing bar cages are bond and connected with the horizontal-direction reinforcing bars of the wall body and the vertical-direction reinforcing bars of the wall body; each group of cross diagonal reinforcing bar cage at least comprises four cross diagonal reinforcing bars and cross diagonal stirrups processed into a closed rectangle; the cross diagonal reinforcing bars and the cross diagonal stirrups are bond to form a rectangular strip-shaped cross diagonal reinforcing bar cage; and the inside of each space surrounded by the horizontal-direction reinforcing bars of a wall body, the vertical-direction reinforcing bars of the wall body, the wall body tie bars and the cross diagonal reinforcing bar cages is respectively embedded with a light internal die of a blocky foam plastic. The construction method for the hollow shear wall structure for the cross diagonal reinforcing bar comprises the following steps of: erecting a shear wall template; binding wall body reinforcing bar meshes; laying and binding the cross diagonal reinforcing bar cages; embedding the light internal die of the blocky foam plastic; and pouring and curing the shear wall concrete. According to the invention, materials are saved, the structural self weight is lightened, and the resistance to shock is good.

Owner:ZHENGZHOU UNIV

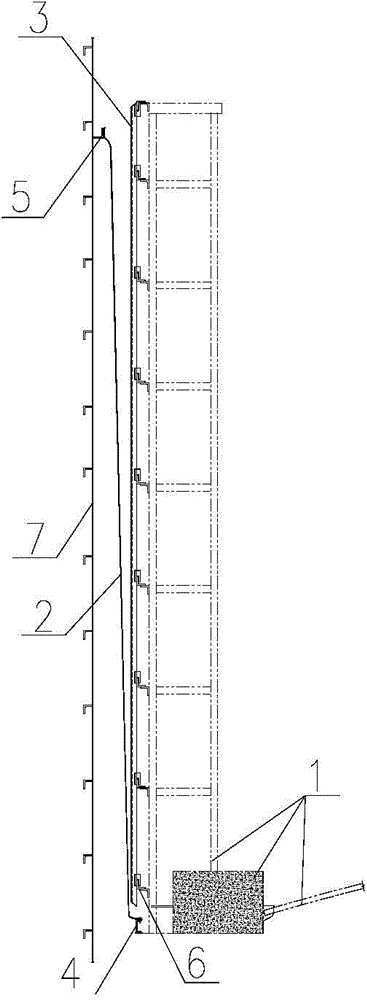

Sealing device for one-section type high-pressure rubber membrane sealing type gas holder

ActiveCN104864260AImprove operational safetyImprove applicabilityVariable capacity gas holdersRubber membraneMaterial consumption

The invention discloses a sealing device for a one-section type high-pressure rubber membrane sealing type gas holder, and the sealing device is designed mainly for providing a one-section type gas holder sealing device which is high in safety and bearing capacity. The sealing device for one-section type high-pressure rubber membrane sealing type gas holder comprises a sealing rubber membrane, sealing angle iron, sealing box iron and a corrugated plate device; the corrugated plate device comprises corrugated plates, connecting pieces with clamping grooves, fastening pieces and connecting bolts; the sealing angle iron is connected to the a gas holder side plate, the sealing box iron is connected to a piston base plate, and the sealing rubber membrane is connected to the sealing angle iron and the sealing box iron; the corrugated plates are connected through the connecting bolts; the corrugated plates are connected through the connecting pieces and the fastening piece to form a barrel-shaped integral structure which is hung on multiple layers of angle iron rings located on the outer edge of a piston baffle through the clamping grooves in the connecting pieces, and the sealing rubber membrane is closely attached to the corrugated plates due to the pressure in work. The sealing device for one-section type high-pressure rubber membrane sealing type gas holder is high in bearing capacity and little in material consumption and repair and maintenance workload.

Owner:HUATIAN ENG & TECH CORP MCC

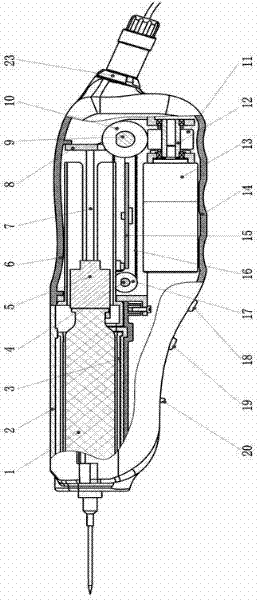

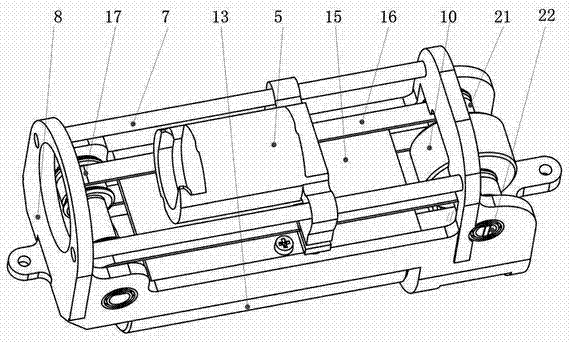

Hand-held medical liquid dispensing device

The invention relates to a hand-held medical liquid dispensing device. The hand-held medical liquid dispensing device comprises a shell, and a drive device and a main control circuit board which are positioned in the shell, wherein the drive device comprises a support frame, a direct current motor, a driving screw gear, a driven screw gear, synchronous belt wheels, synchronous belts, a push-pull head and a guide rod; the driving screw gear is mounted on a gear shaft connected with the direct current motor; the driven screw gear is mounted on a back rotation shaft; the driving screw gear and the driven screw gear are matched with each other; both sides of the driven screw gear on the back rotation shaft are respectively provided with one synchronous belt wheel; the two synchronous belts are mounted between the synchronous belt wheels; the lower part of the push-pull head is fixedly connected with the synchronous belts; and the rotating motion of the direct current motor is converted into the linear reciprocating motion of the push-pull head through the transmission of the screw gears and synchronous belts, thereby pushing / pulling a core rod of a syringe. The hand-held medical liquid dispensing device has the advantages of reasonable structure, small volume, light weight, convenient operation process and simple and reliable power transmission, and can be used with a common disposable syringe for medical liquid dispensing.

Owner:HARBIN INST OF TECH AT WEIHAI

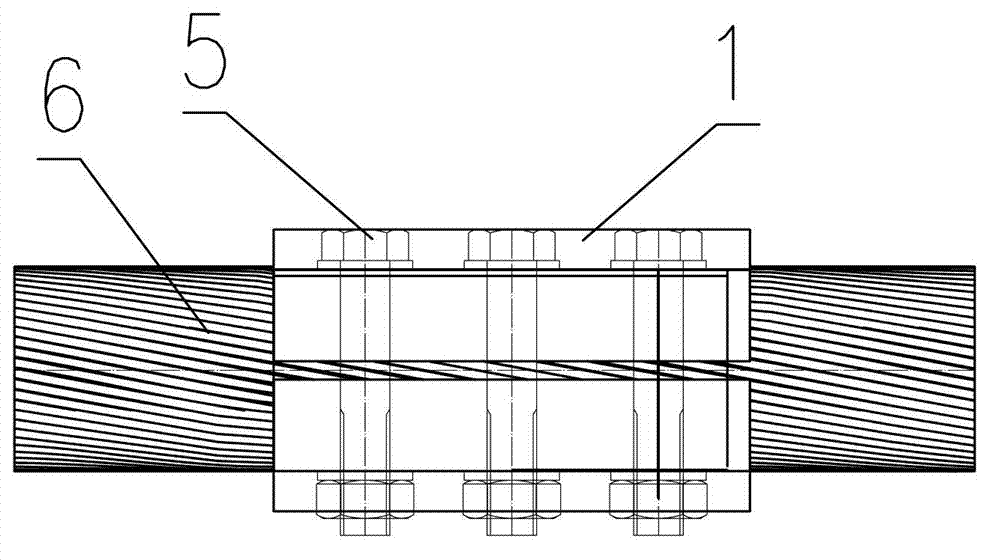

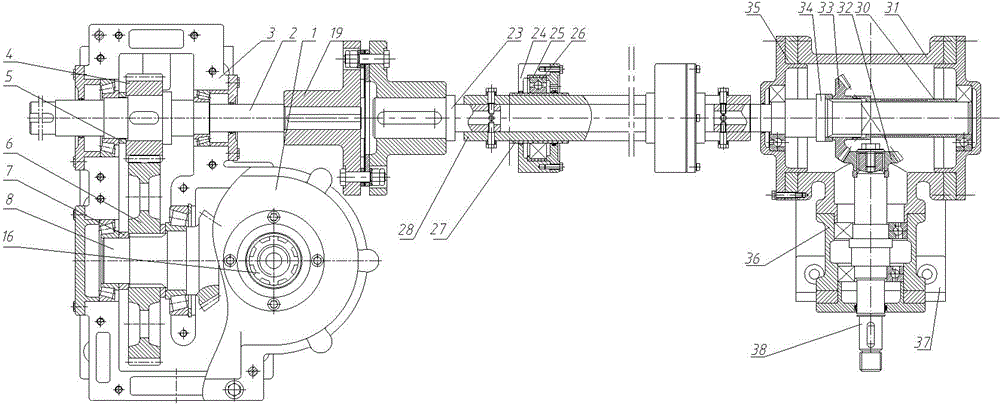

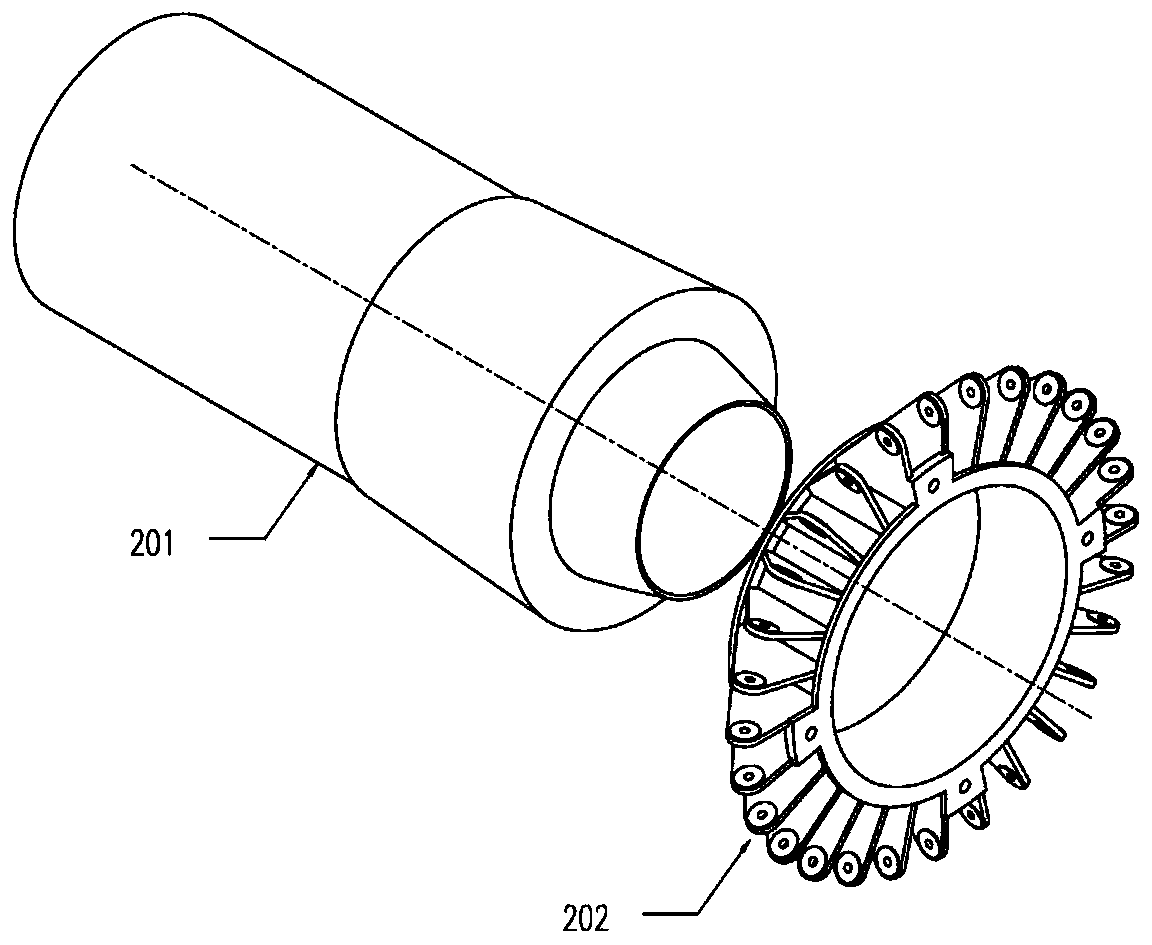

Transmission system device of light unmanned helicopter

ActiveCN104943868ASimple structureCompact structureAircraft power transmissionCouplingReduction drive

The invention relates to a transmission system of a light unmanned helicopter. The transmission system comprises a main speed reducer, a tail speed reducer and a middle transmission shaft system, wherein the main speed reducer comprises a high-speed shaft, an intermediate shaft and a rotor shaft; the high-speed shaft and the intermediate shaft are parallel with each other and are in meshed transmission through a pair of high-speed gears; the intermediate shaft and the rotor shaft are perpendicular to each other and are in meshed transmission through a pair of low-speed bevel gears; the tail speed reducer comprises a tail reducing input shaft and a tail rotor shaft which are perpendicular to each other and are in meshed transmission through a pair of bevel gears; the high-speed shaft and the tail reducing input shaft are connected through an intermediate transmission shaft system; the intermediate transmission shaft system comprises a coupling and a pipe shaft; the main speed reducer realizes power transfer and distribution, transfers the low speed to the rotor shaft through the pair of low-speed bevel gears and transfers the high speed to the tail rotor shaft through the intermediate transmission shaft system. The transmission system is simple and reasonable in structural design and convenient to mount and maintain and has the certain significance in design and improvement of transmission systems of military light unmanned helicopters.

Owner:HEFEI UNIV OF TECH

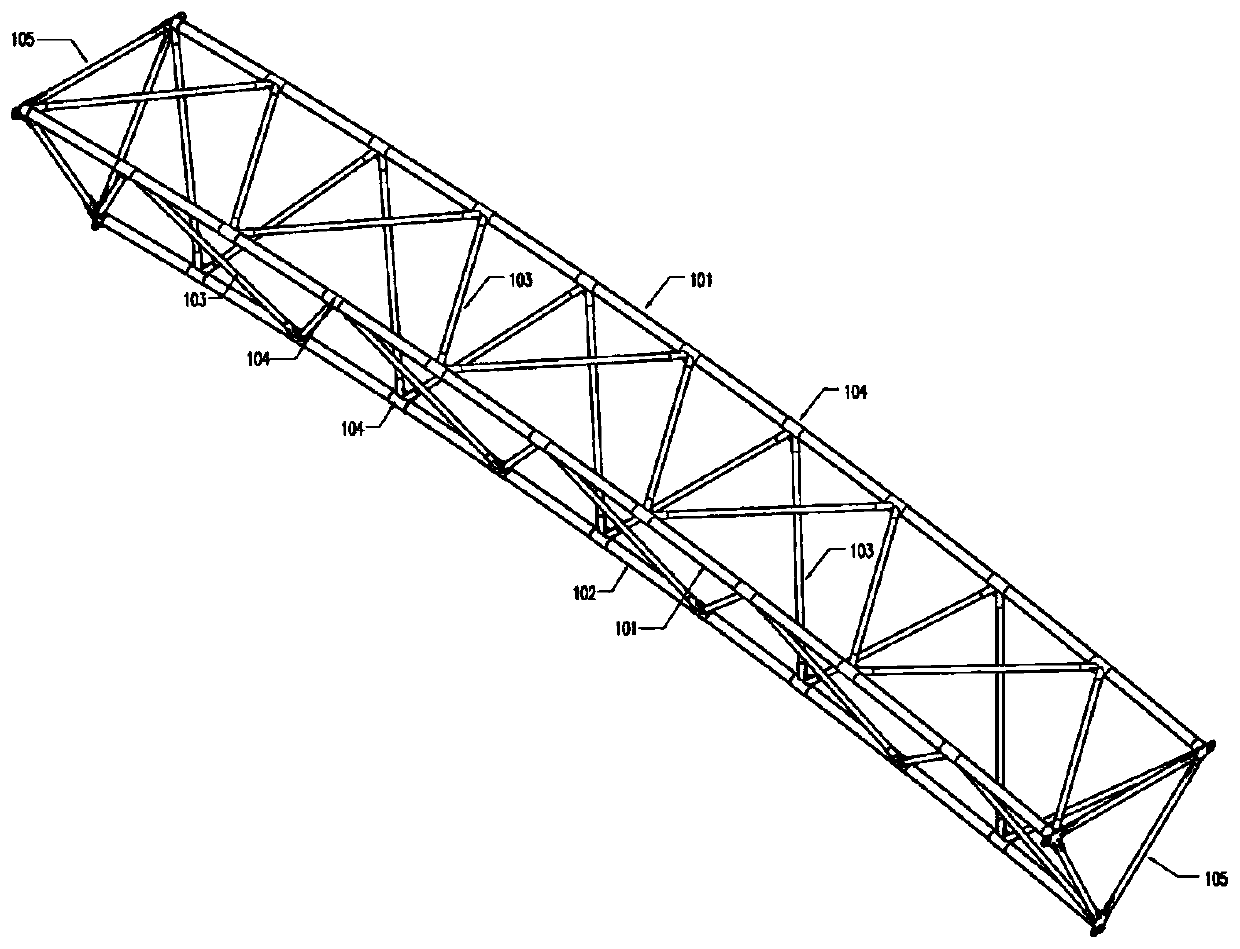

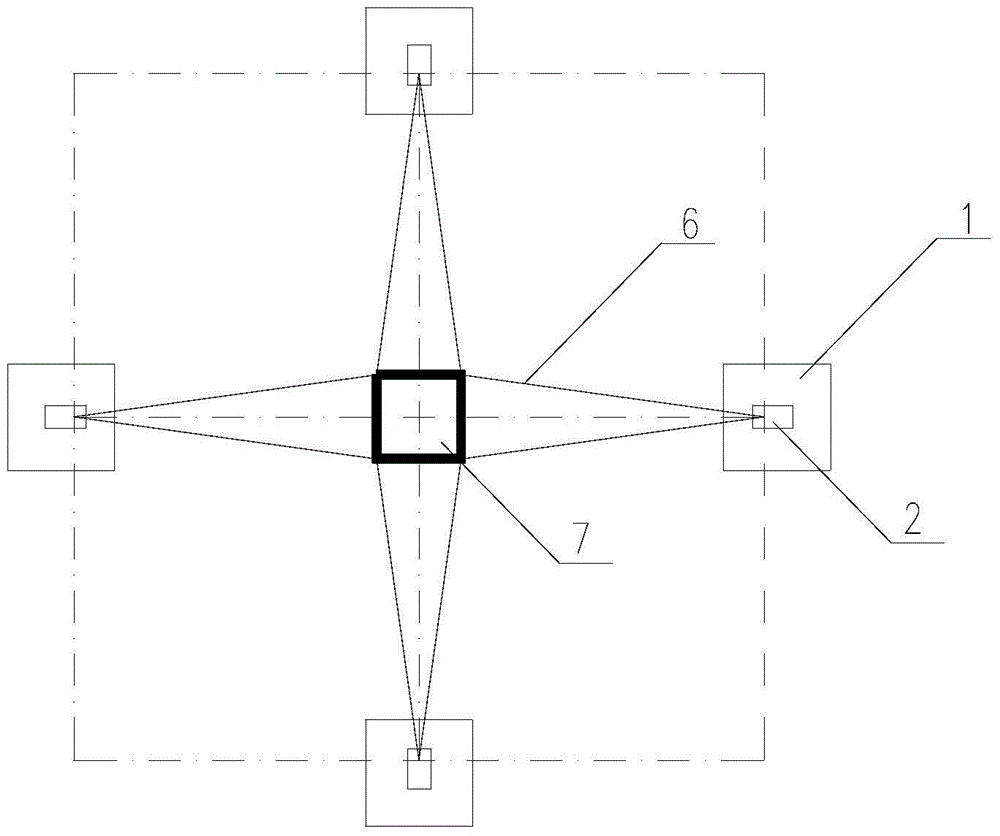

Large single-K node triangular truss stiffening ring and integrated tension application method

ActiveCN110395409AIncrease stiffnessImprove the ability to withstand load deformationFuselage framesCosmonautic vehiclesNODALEngineering

The invention discloses a large single-K node triangular truss stiffening ring. The stiffening ring is characterized by comprising a single K node triangular truss circular ring, an integrated centralhub and radial pull rods, wherein the single K node triangular truss circular ring is connected with the integrated central hub through the radial pull rods; the single-K node triangular truss circular ring is formed by splicing N standard sections, wherein each standard section comprises an outer chord tube, an inner chord tube, a web rod tube, a single K node and a reference triangular frame; the integrated central hub comprises a hub shaft tube and a hub plate node; and the 2 n radial pull rods are uniformly arranged around the integrated central hub in a spindle-shaped annular direction.The invention further provides an integrated tension application method of the large single-K node triangular truss stiffening ring. According to the stiffening ring and the method, the overall rigidity, the load deformation capability and the stability of a composite material truss can be improved, and the composite material truss can be applied to a large aircraft structure and an aerospace space assembly type platform.

Owner:SHANGHAI JIAO TONG UNIV +1

Energy storage and release system

ActiveUS20120125717A1Simple transmission and locking and release of energyReduce manufacturing costSpring motorMachines/enginesStored energyFree rotation

The technology is directed to an energy storage and release system that stores energy and enables a repeatable and accurately timed release of energy. A shaft member supports a drive assembly, a locking assembly and a lever member there between. The lever member and locking assembly are attached to the shaft. The drive assembly rotates freely about the shaft and loads energy into a torsion spring in communication with the lever member. The torsion spring connects at one end to the drive assembly and at the other end to the lever member without contacting the shaft member. The locking assembly provides a triggered release mechanism for selective release of stored energy from the torsion spring that accordingly rotates the lever member. The system can automatically reload the torsion spring once a signal is received from any number of events including, when the rotating lever member contacts a stop member or limit sensor that signals the end of travel for the lever member in either rotational directions.

Owner:RAYTHEON CO

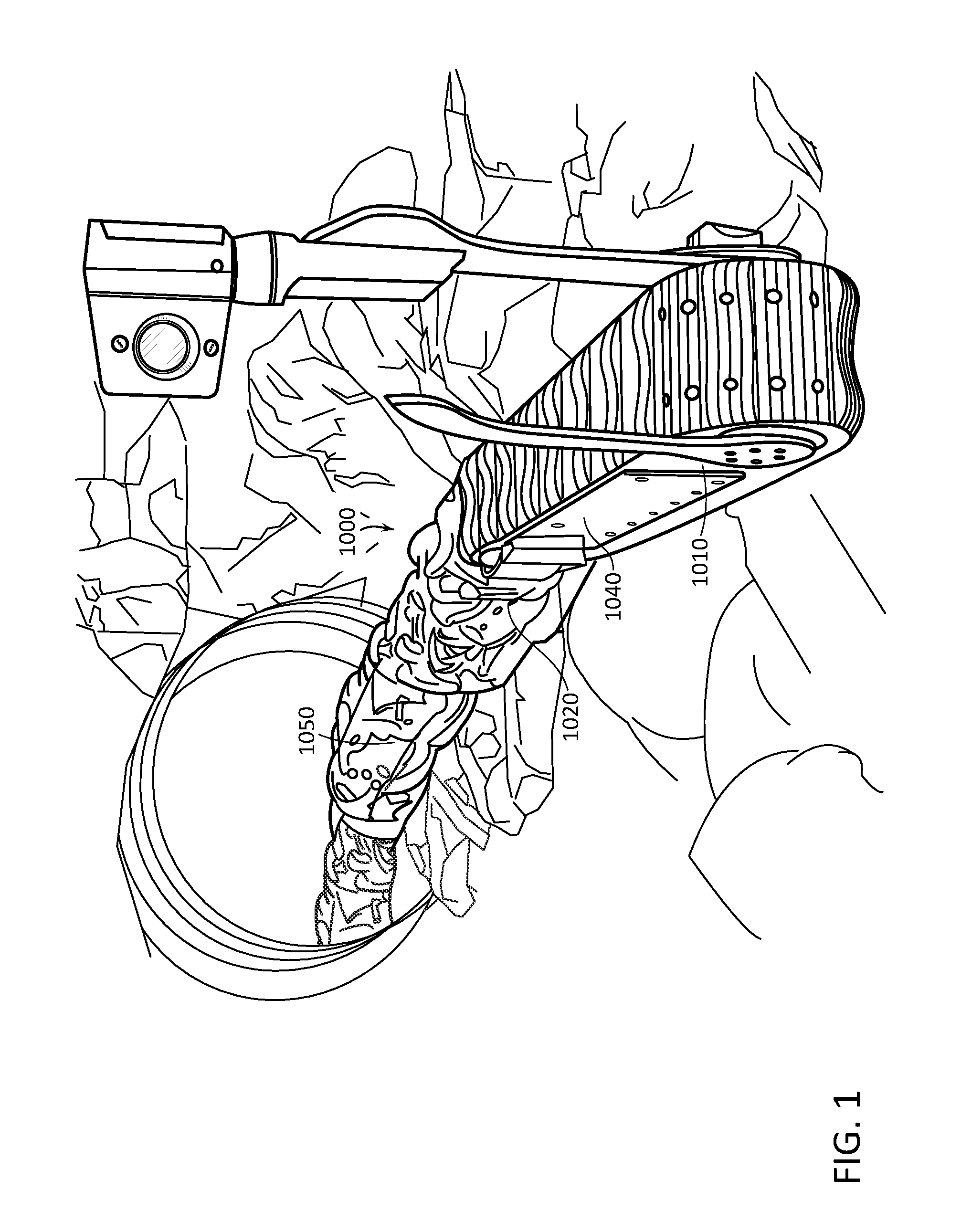

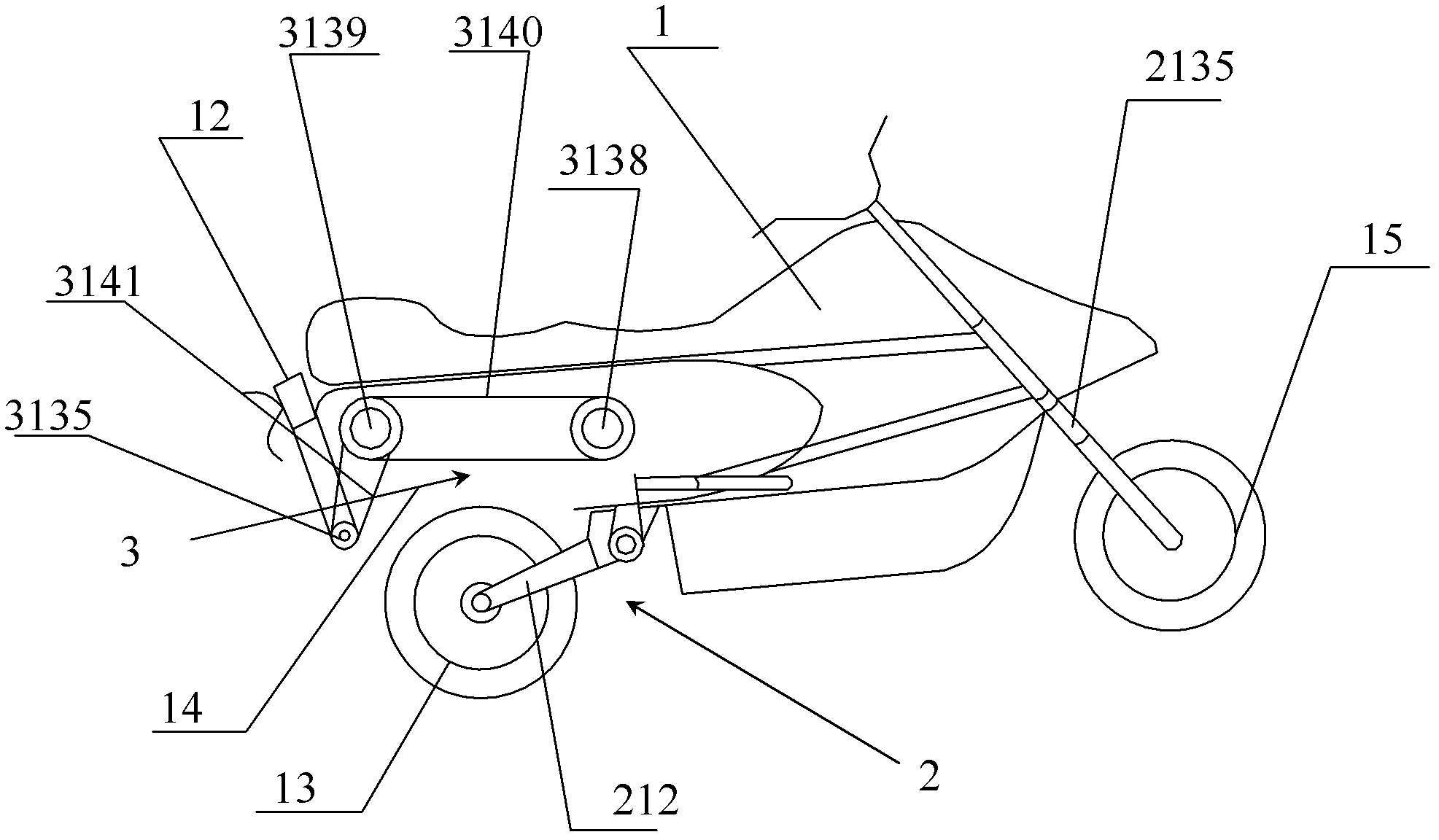

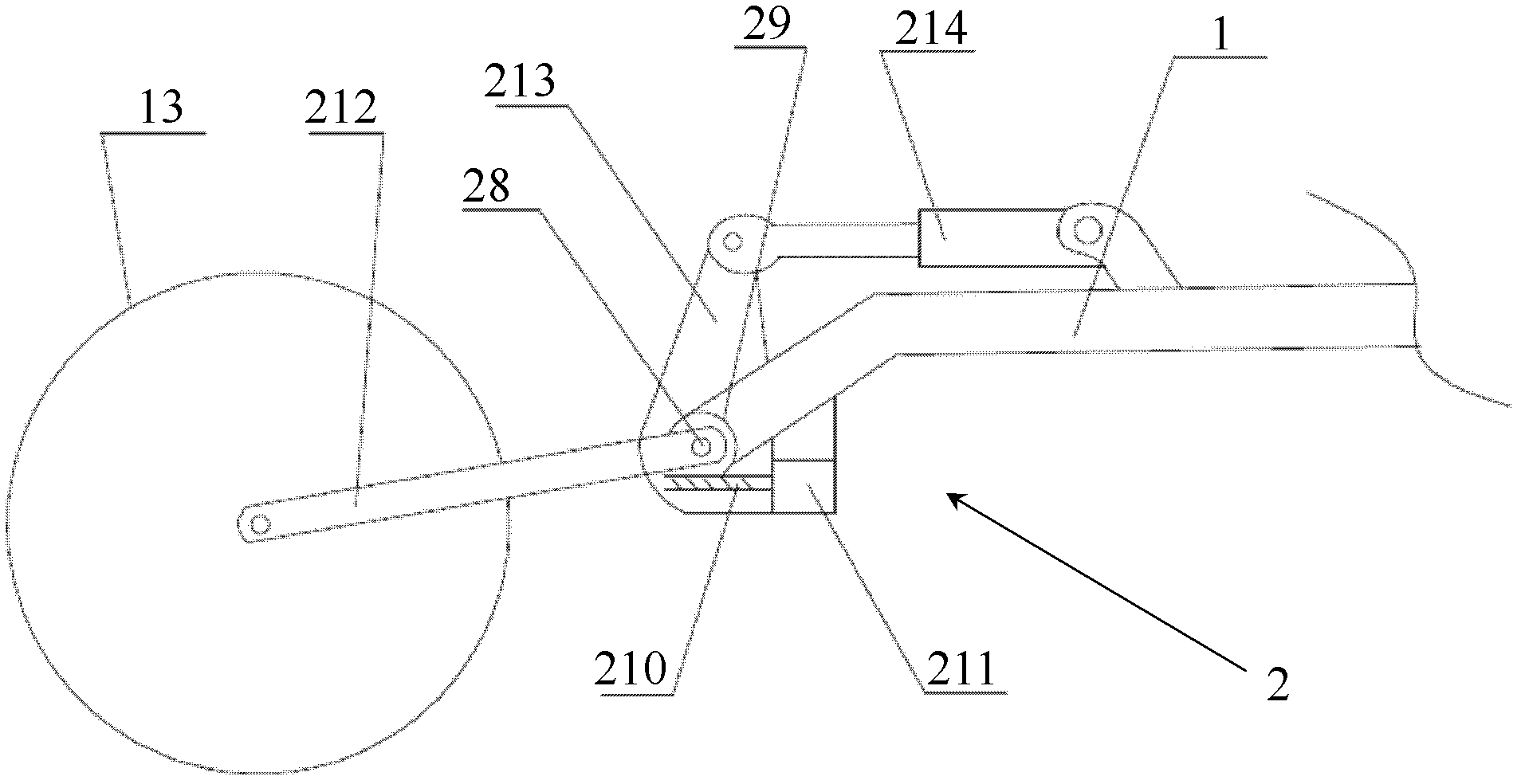

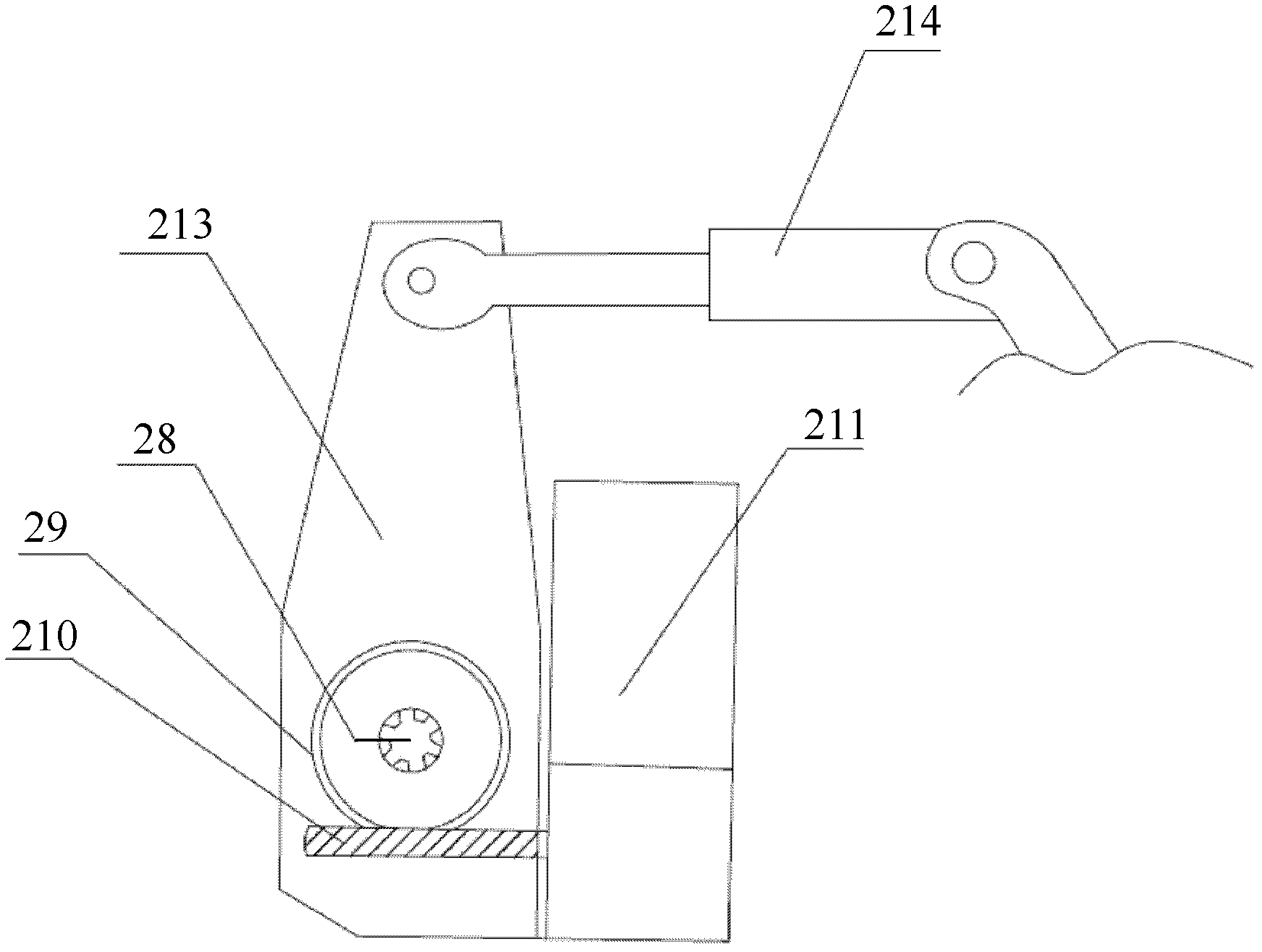

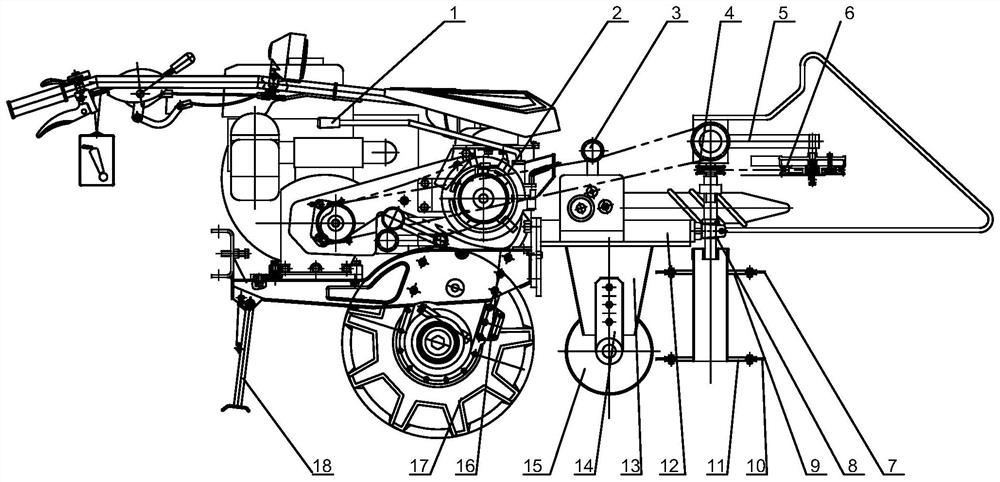

Amphibious motorcycle

The invention provides an amphibious motorcycle, which comprises a motorcycle body, a left pontoon and a right pontoon which are arranged on the left side and the right side of the motorcycle body respectively and pontoon collecting and releasing mechanisms for the left pontoon and the right pontoon respectively. The left pontoon and the right pontoon are respectively connected with the motorcycle body through the corresponding pontoon collecting and releasing mechanisms and move between a display position far away from the motorcycle body and a collecting position close to the motorcycle body through the corresponding pontoon collecting and releasing mechanisms. Influences on driving, volume and appearance of the motorcycle caused by existence of the pontoons are reduced, and the pontoons can be taken back towards the motorcycle body through the collecting and releasing mechanisms and a telescopic structure. When the amphibious motorcycle is operated on the land, the pontoons are tightly attached to the motorcycle body, volume of the pontoons is not large, and the pontoons can be arranged by using free space of the motorcycle body fully.

Owner:党远林

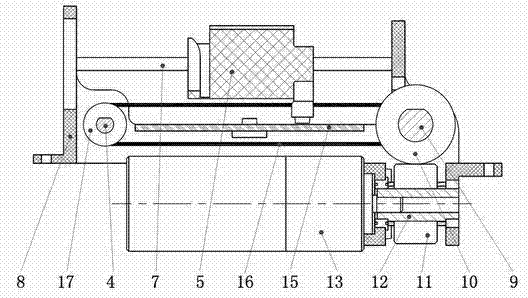

Corrugated pipe metering pump

InactiveCN101876304AImprove job stabilityChange the deformation strokeFlexible member pumpsPositive-displacement liquid enginesEngineeringCam

The invention relates to a corrugated pipe metering pump which comprises a bracket, an electromagnetic valve, a direct-current speed reducing motor, a cam and a corrugated pipe, wherein the upper part of the corrugated pipe is communicated with a liquid inlet and outlet pipeline of the electromagnetic valve through a corrugated pipe joint; a return spring is sleeved outside the corrugated pipe; the lower part of the closed corrugated pipe is connected with a transmission rod; the transmission rod passes through a nut; a bearing is installed at the bottom end of the transmission rod; the bearing is always in contact with the rim of the cam; the rotary cam drives the corrugated pipe through the transmission rod to extend and shrink to enable the corrugated pipe to suck and discharge liquid; the nut is matched with a corrugated pipe nut seat for supporting the corrugated pipe; and the deformation stroke of the corrugated pipe is adjusted by adjusting the screw-in depth of the nut in the corrugated pipe nut seat, thereby changing the liquid sucking amount and the liquid discharging amount of the corrugated pipe. The invention has the advantages of reasonable structure, simple and reliable power transmission, adjustable corrugated pipe displacement, no radial deformation, high repeated liquid feeding accuracy and adjustable pump displacement, and is suitable for occasions with the requirement of variable pump displacements.

Owner:HARBIN INST OF TECH AT WEIHAI

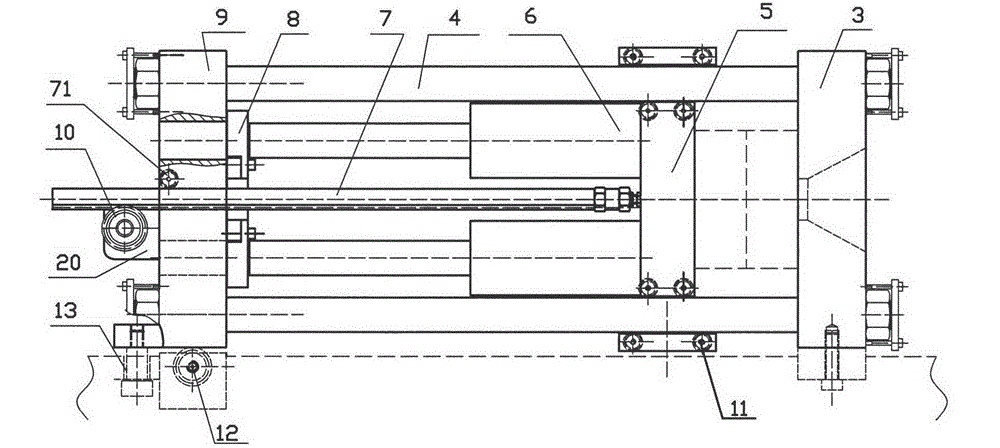

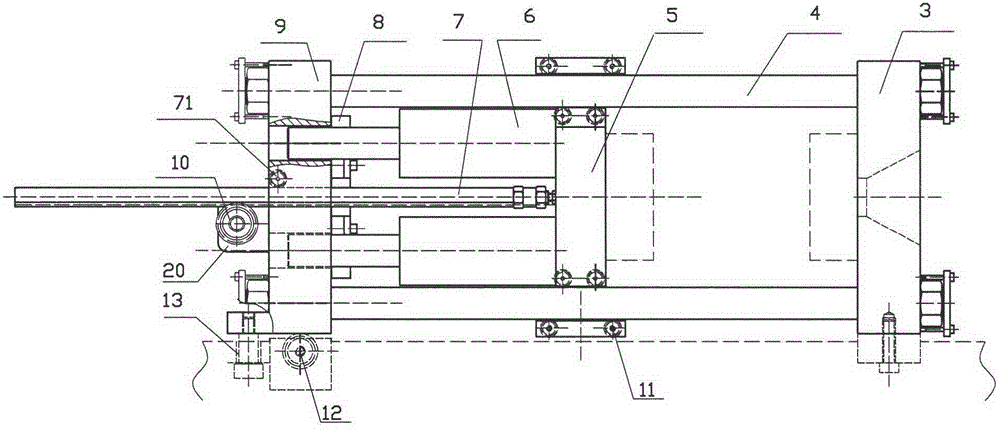

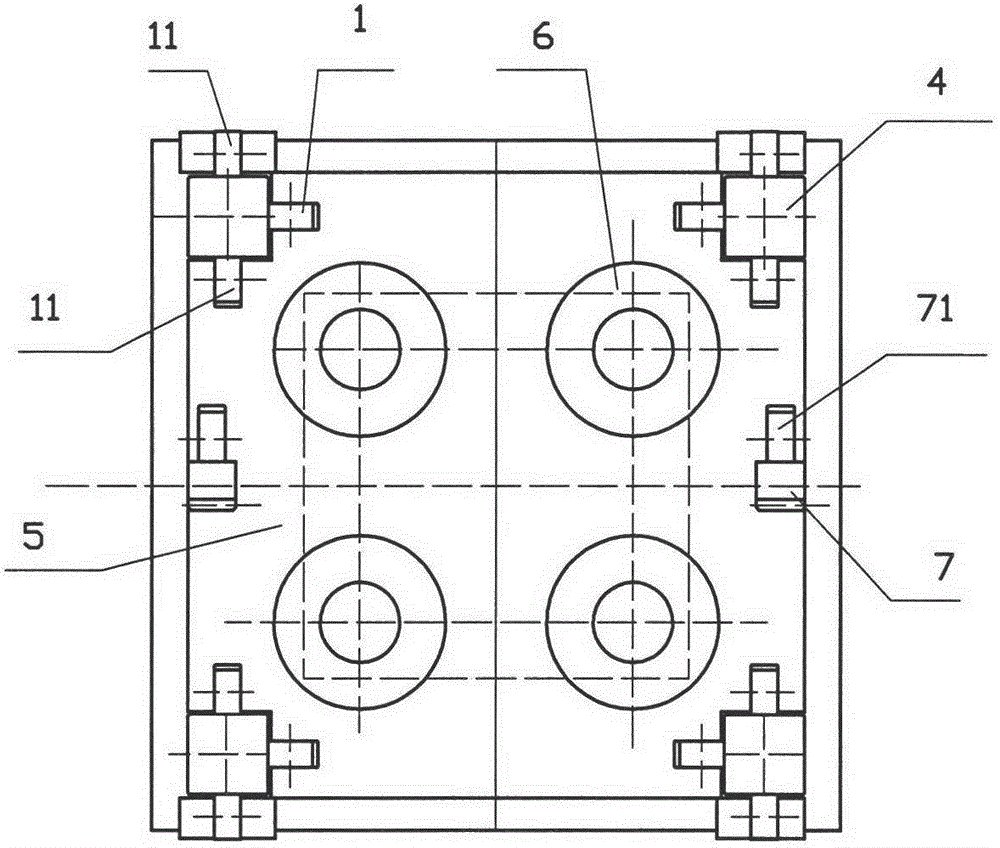

Precision injection molding machine clamping mechanism

InactiveCN103286928BImprove mechanical propertiesImprove efficiencyRolling resistanceInjection molding machine

Owner:上海云静企业发展有限公司

High-pressure washing type scaling and fish shearing machine

ActiveCN112535197AReduce labor intensitySimple mechanical structureFish washing/descalingMarine engineeringHigh pressure water

The invention belongs to the technical field of primary processing of fishes, and aims to provide a high-pressure washing type scaling and fish shearing machine. The scaling and fish shearing machinehas the characteristics of simple and light structure, low cost, good scaling effect and labor saving. According to the technical scheme, the high-pressure washing type scaling and fish shearing machine is characterized by comprising a rack, a conveying assembly, high-pressure water guns, a plurality of driving assemblies, a clamping assembly, an adjusting assembly, a belly dilator and belly flushing cleaners, wherein the conveying assembly is installed in the middle of the rack and conveys fishes from back to front; the high-pressure water guns are installed on the rack and located on the left side and the right side of the conveying assembly respectively so as to flush scales on the side faces of the fishes; the driving assemblies are used for driving the conveying assembly to move; theclamping assembly is arranged above the conveying assembly and matched with the conveying assembly so as to clamp the fishes in the left-right direction; the adjusting assembly is arranged above the clamping assembly to ensure that the clamping assembly clamps the fishes in the vertical direction; the belly dilator is arranged at a fish outlet of the conveying assembly to split the fish bellies; and the belly flushing cleaners are arranged on the left side and the right side of the lower part of the belly dilator respectively to flush scales on the fish bellies.

Owner:ZHEJIANG SCI-TECH UNIV

Arc rolling machine

PendingCN112139313AGuaranteed structural sizeAvoid actionVehicle componentsControl systemControl engineering

The invention provides an arc rolling machine. The arc rolling machine comprises a support, a workbench is arranged on the support, a power roller is rotationally installed on the workbench, and the axis of the power roller is perpendicular to the workbench; a power mechanism is in transmission connection with the power roller; an extrusion roller opposite to the power roller is arranged on the workbench, a machining channel allowing a workpiece to penetrate through is formed between the extrusion roller and the power roller, a position adjusting mechanism is fixedly arranged on the support, and the output end of the position adjusting mechanism is in transmission connection with the extrusion roller or the power roller so as to drive one of the extrusion roller and the power roller to move towards or away from the other one; and a limiting switch is arranged on the workbench in a relatively-fixed mode, a limiting piece is fixedly arranged relative to the output end of the position adjusting mechanism, the limiting switch can be triggered by the limiting piece, the limiting switch is in signal connection with a control system, and the control system is controllably connected to theposition adjusting mechanism and controls the position adjusting mechanism to stop acting when receiving a signal that the limiting switch is triggered. Therefore, the position adjusting mechanism isprevented from continuing to act, and the size precision of a formed product is guaranteed.

Owner:HENAN SENYUAN HEAVY IND

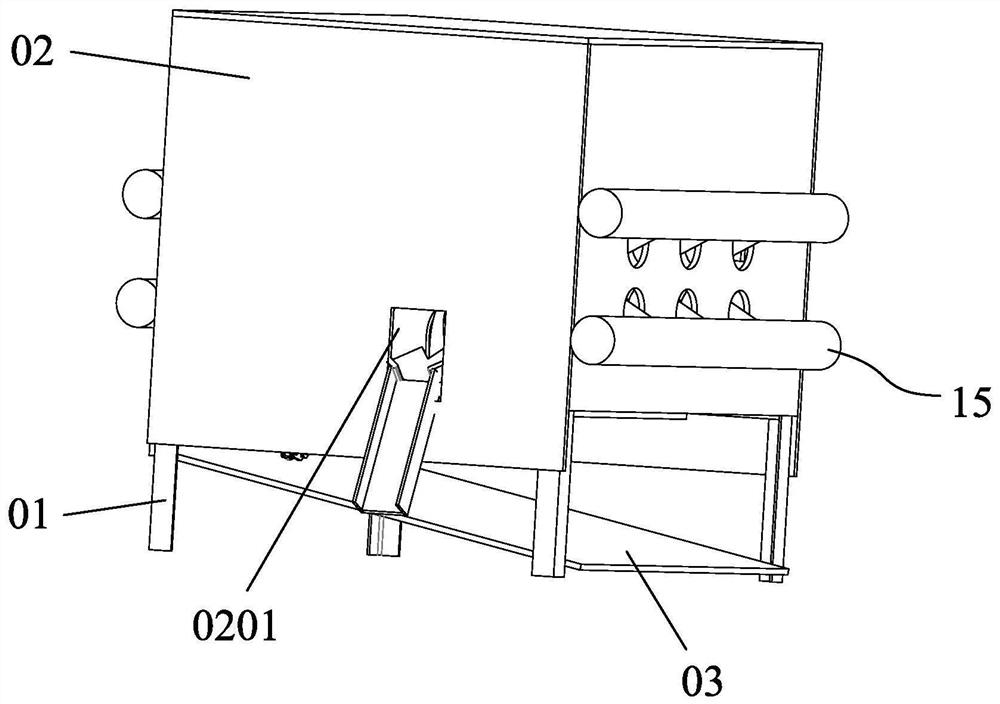

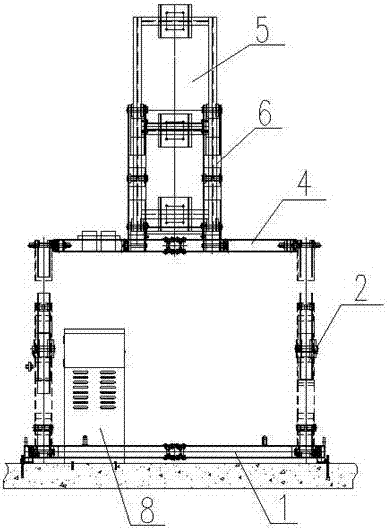

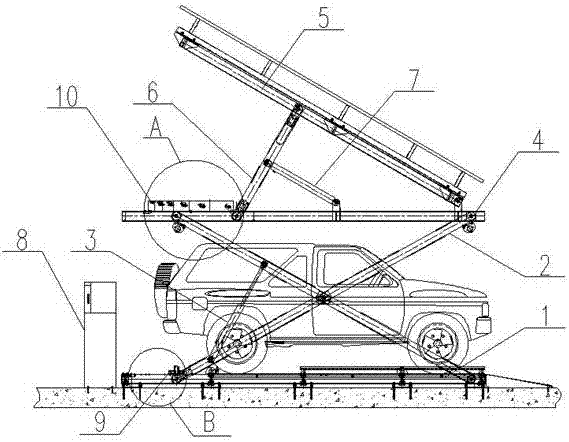

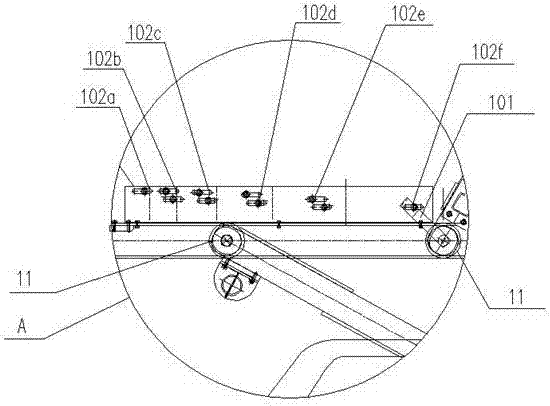

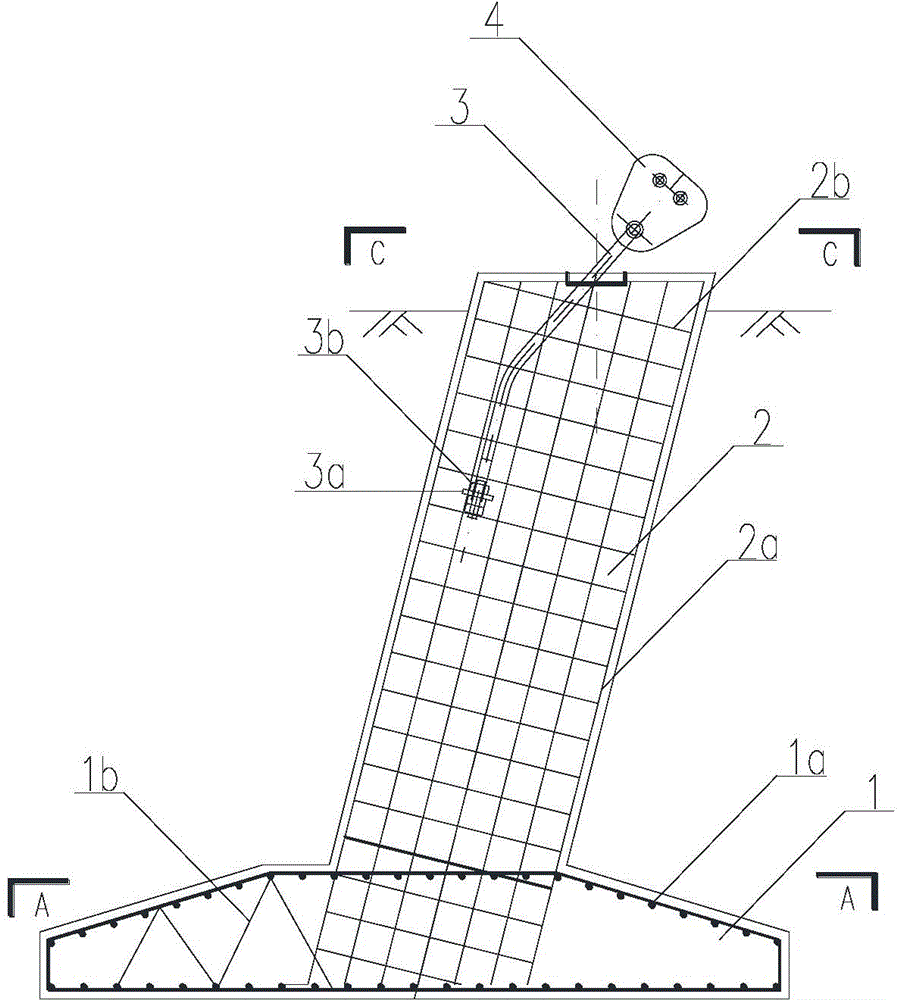

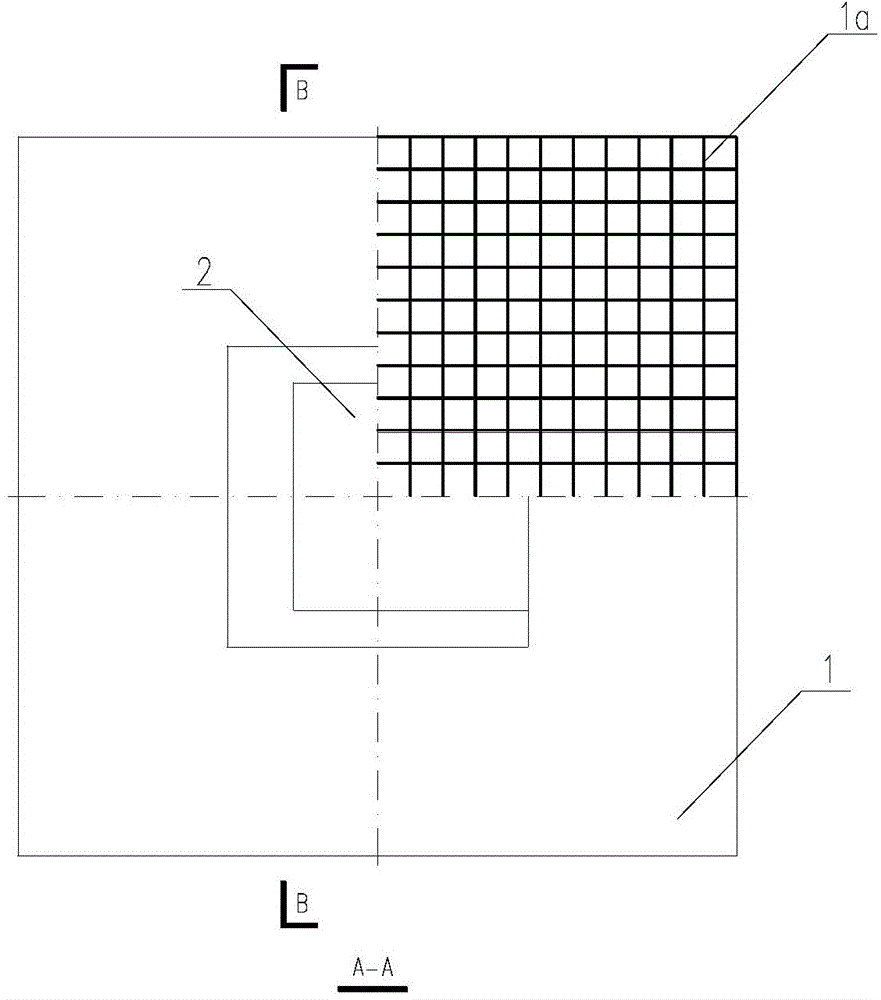

Pitching swing frame for installing and lifting solar photovoltaic panel

ActiveCN107253687AReduced installation effortEasy to transportPhotovoltaic supportsLifting framesMarine engineeringWorkload

The invention discloses an pitching swing frame for installing and lifting a solar photovoltaic panel. The inverted swing frame for installing and lifting the solar photovoltaic panel comprises a berth chassis, a lifting assembly, a lifting platform, a solar photovoltaic panel installing platform, an angle adjusting assembly, a lifting in-place detecting device and an pitching swing set angle in-place detecting device. The lifting platform is connected with the berth chassis through the lifting assembly. One end of the solar photovoltaic panel installing platform is movably connected with the lifting platform. The other end of the solar photovoltaic panel installing platform is connected with the lifting platform through the angle adjusting assembly. According to the pitching swing frame for installing and lifting the solar photovoltaic panel, delivering can be achieved in a complete machine mode, on-site tedious installation of equipment is not needed, the on-site installation workload is reduced dramatically, transport is convenient, and the moving capacity is high.

Owner:JIANGSU PARKTEC PARKING EQUIP

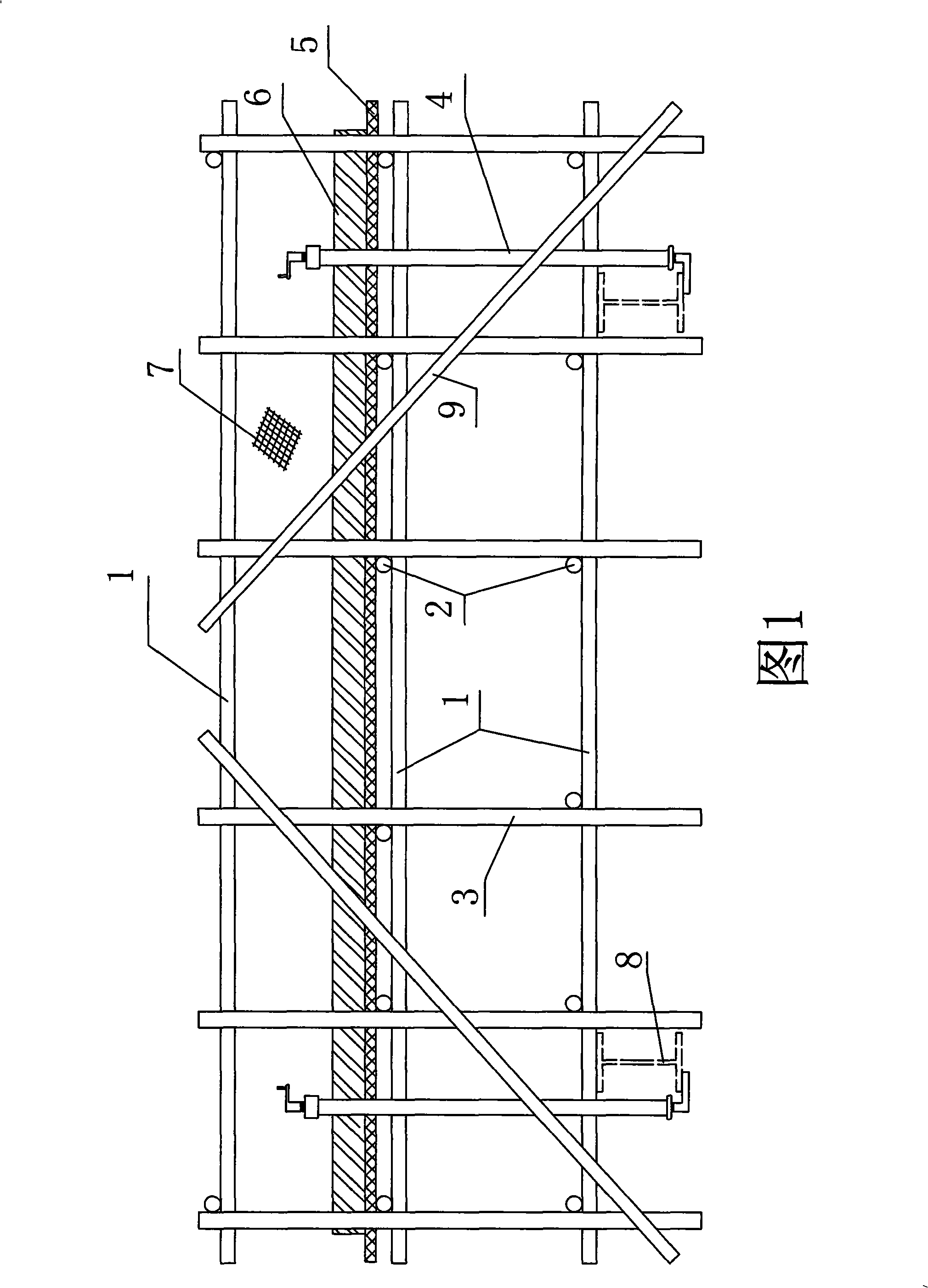

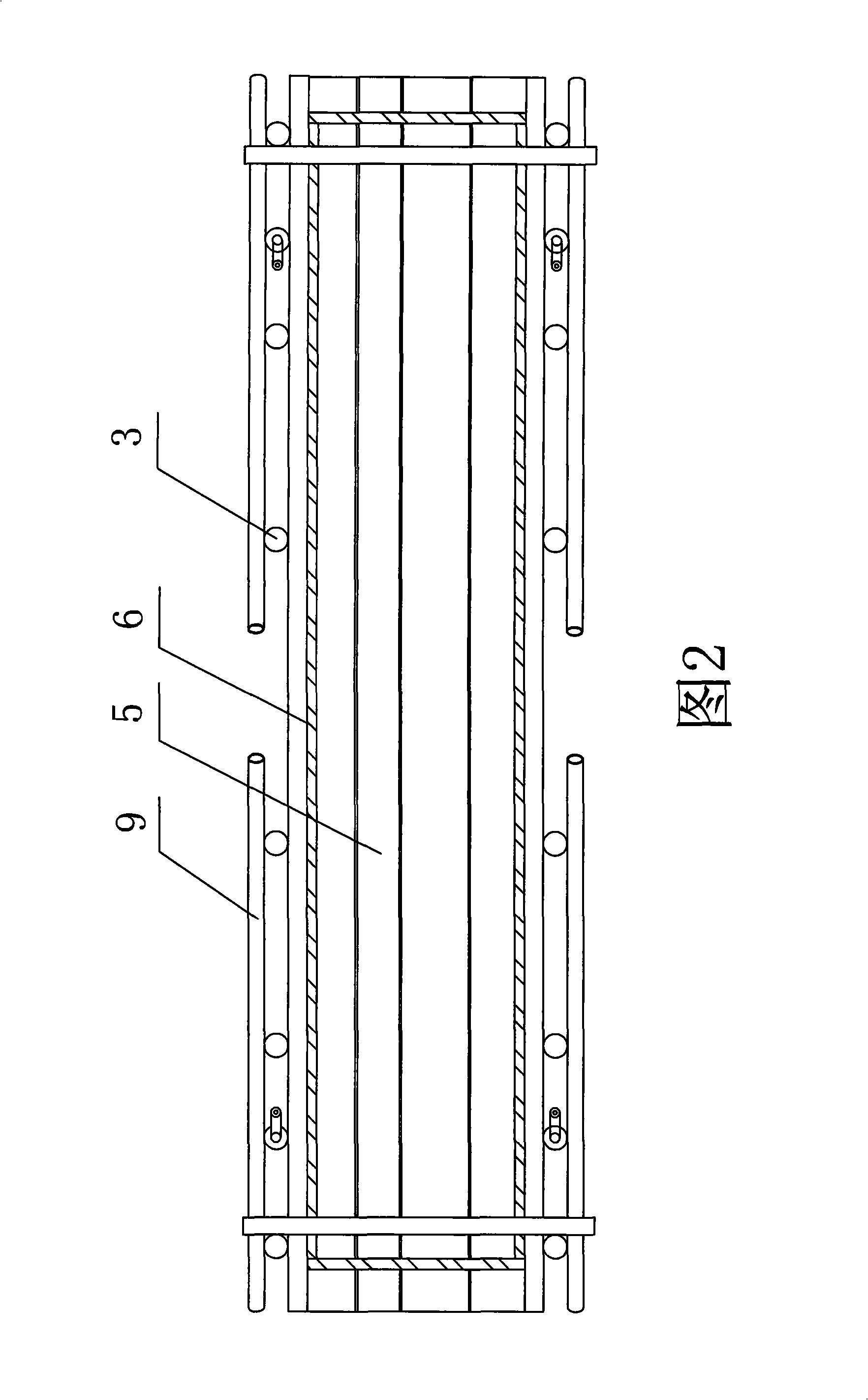

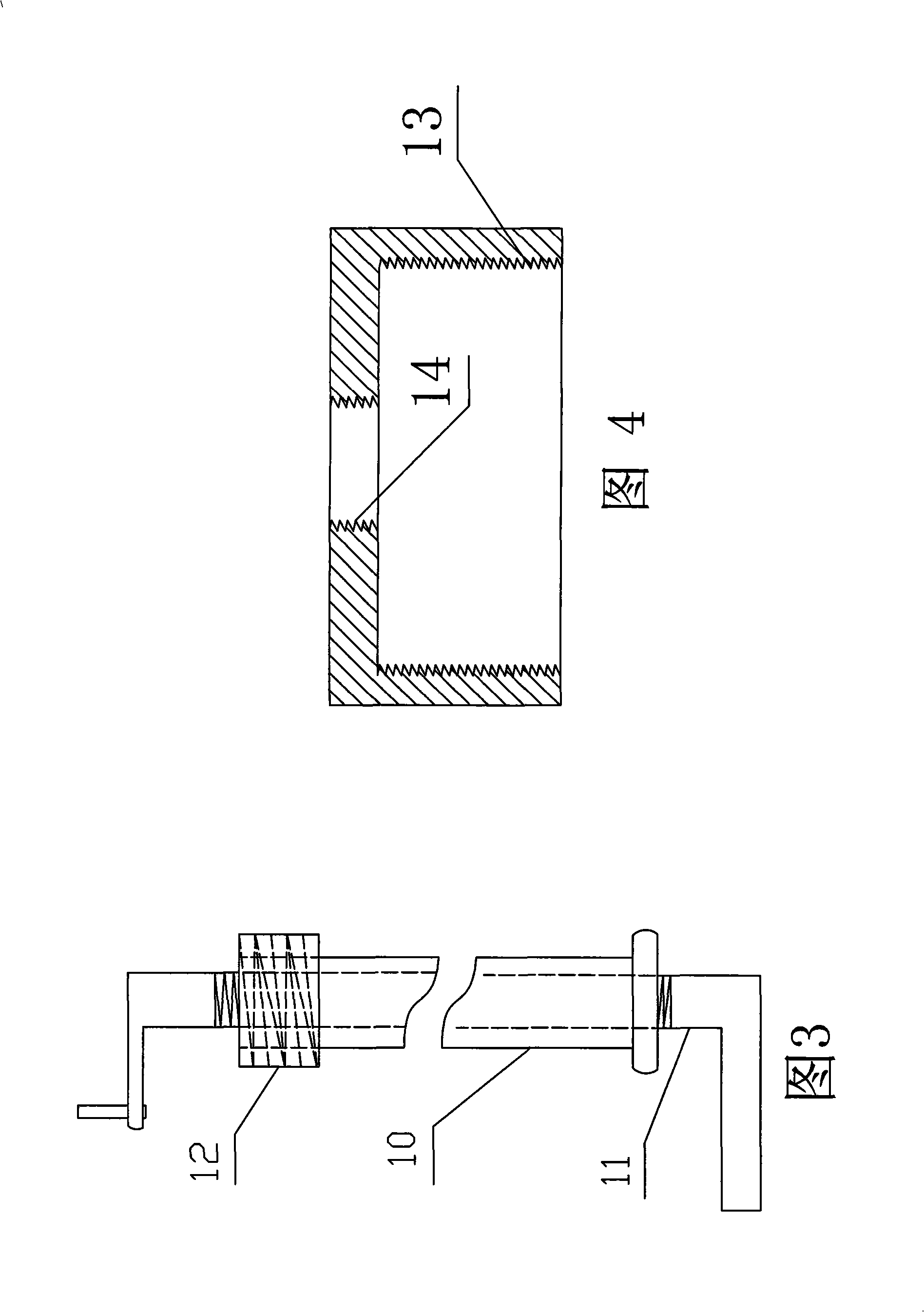

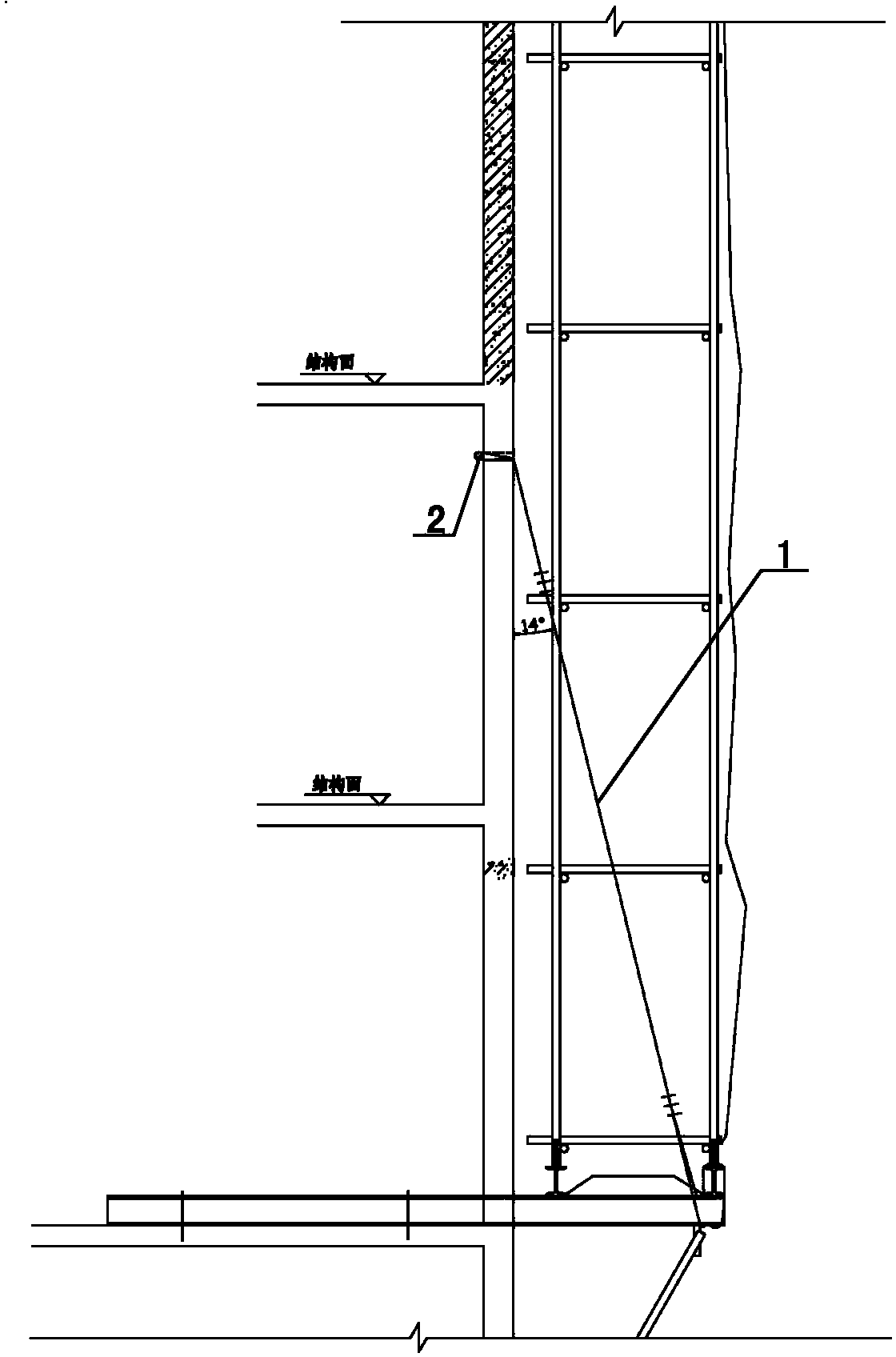

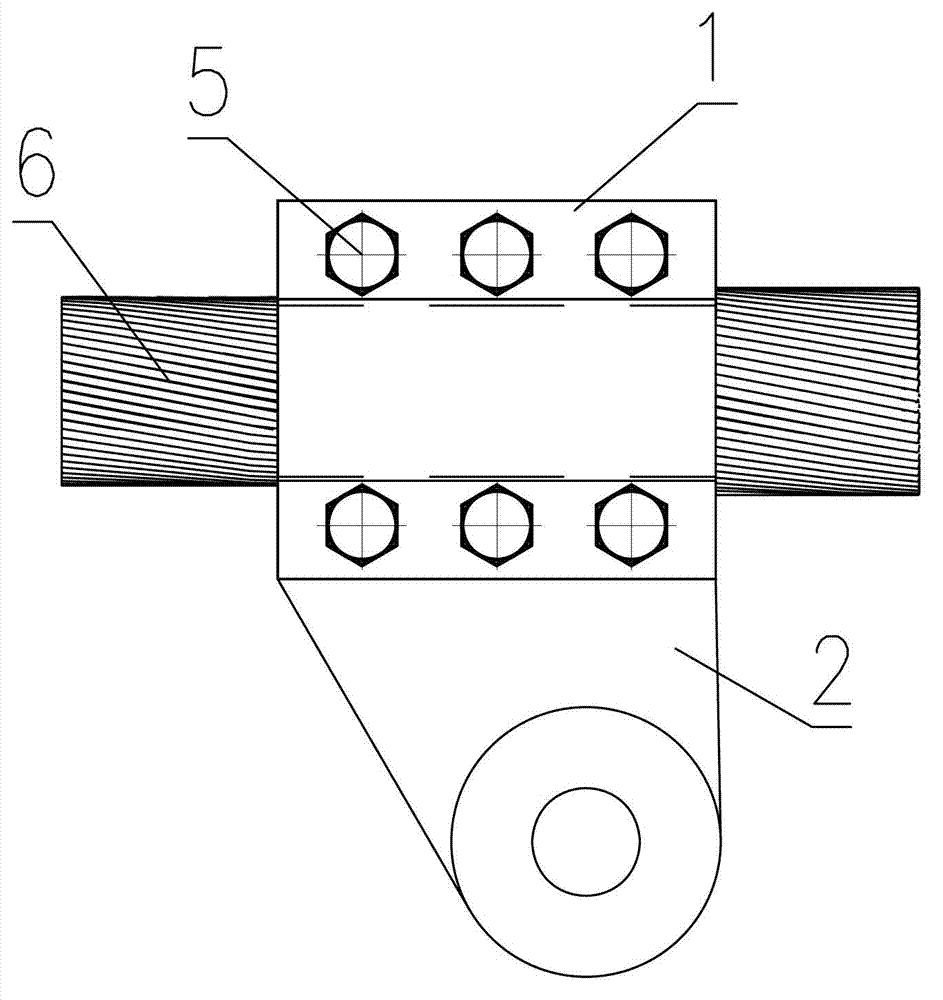

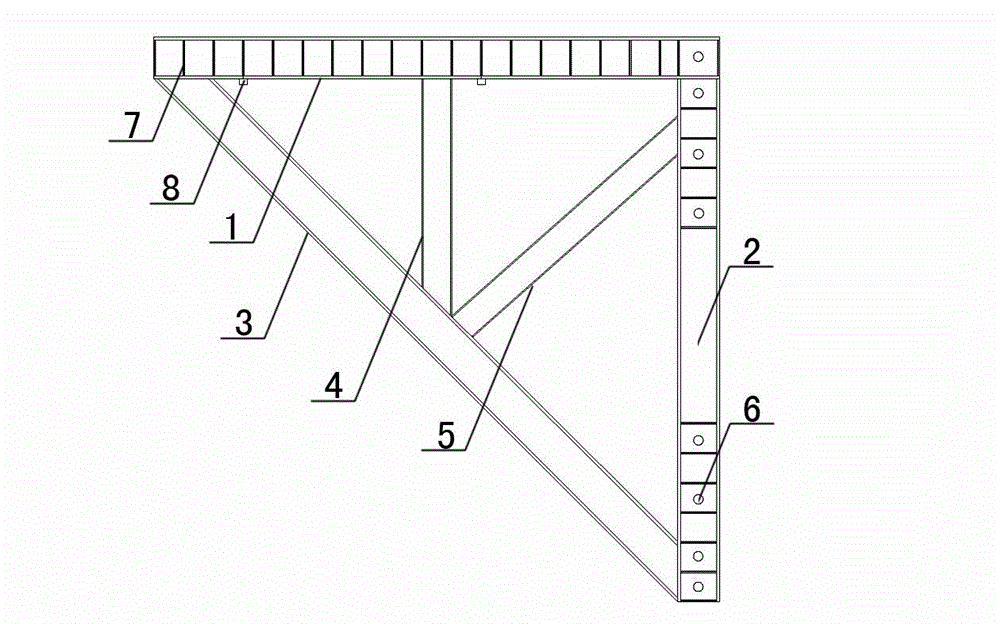

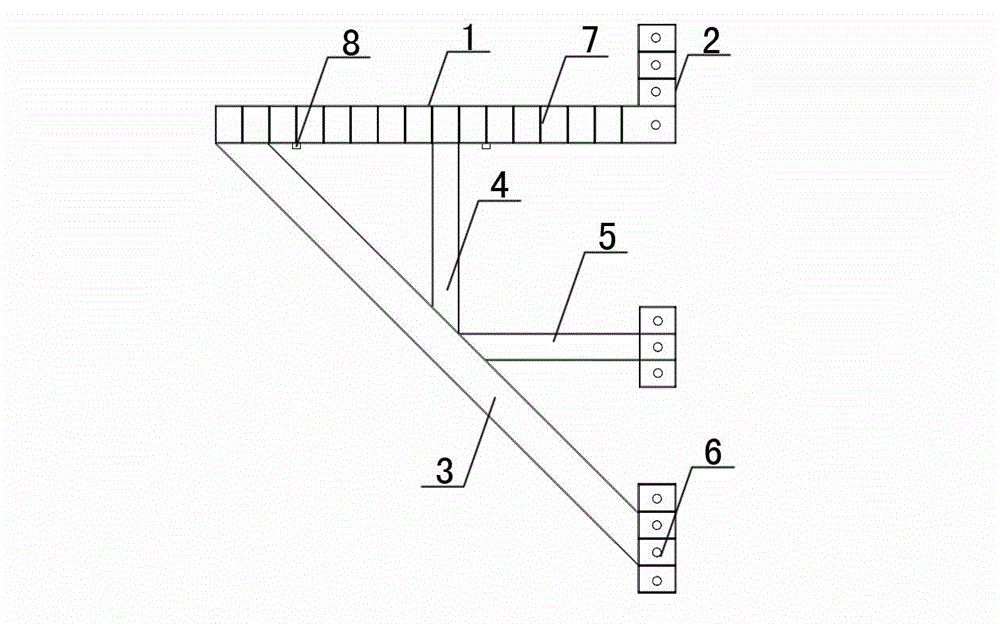

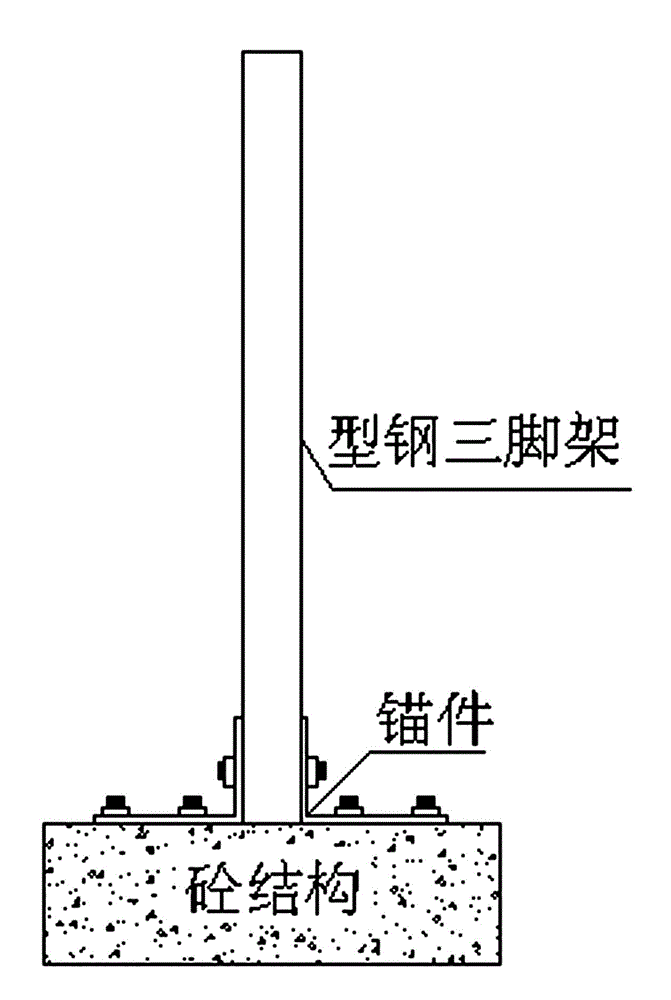

Section steel tripod for cantilevered scaffold and scaffold system

ActiveCN103334580AClear forcePower transmission is simpleScaffold accessoriesBuilding support scaffoldsFloor slabEngineering

The invention relates to a section steel tripod for a cantilevered scaffold. The section steel tripod comprises a beam, a vertical strut and an inclined strut, wherein the beam, the vertical strut and the inclined strut form a triangular structure; a small vertical strut is arranged between the beam and the inclined strut; a small cross strut is arranged between the vertical strut and the inclined strut; strong-strength bolt preformed holes are formed in the vertical strut; the vertical strut is connected with a structural column or a wall body through the preformed holes by anchor parts to realize the mounting of the section steel tripod; 14# I-steel is adopted for the beam and the vertical strut; 10# I-steel is adopted for the small vertical strut and the small cross strut; the beam is provided with stiffening rib plates; and limiting reinforcement heads are arranged below the beam. For a local core tube part (such as an elevator room position and a staggered floor of steel cantilever beams) without a floor slab, steel beams of an ordinary cantilevered scaffold cannot be normally arranged, and is fixedly arranged on a main body structure through the section steel tripod, and stress on the cantilevered scaffold is transmitted to a structural wall body through anchoring bolts by the tripod, so that the tripod is clear in stress and simple in stress transmission, and can be recycled, the construction safety and operability are ensured, a requirement on a construction period is met, and the efficiency is improved.

Owner:北京建工博海建设有限公司

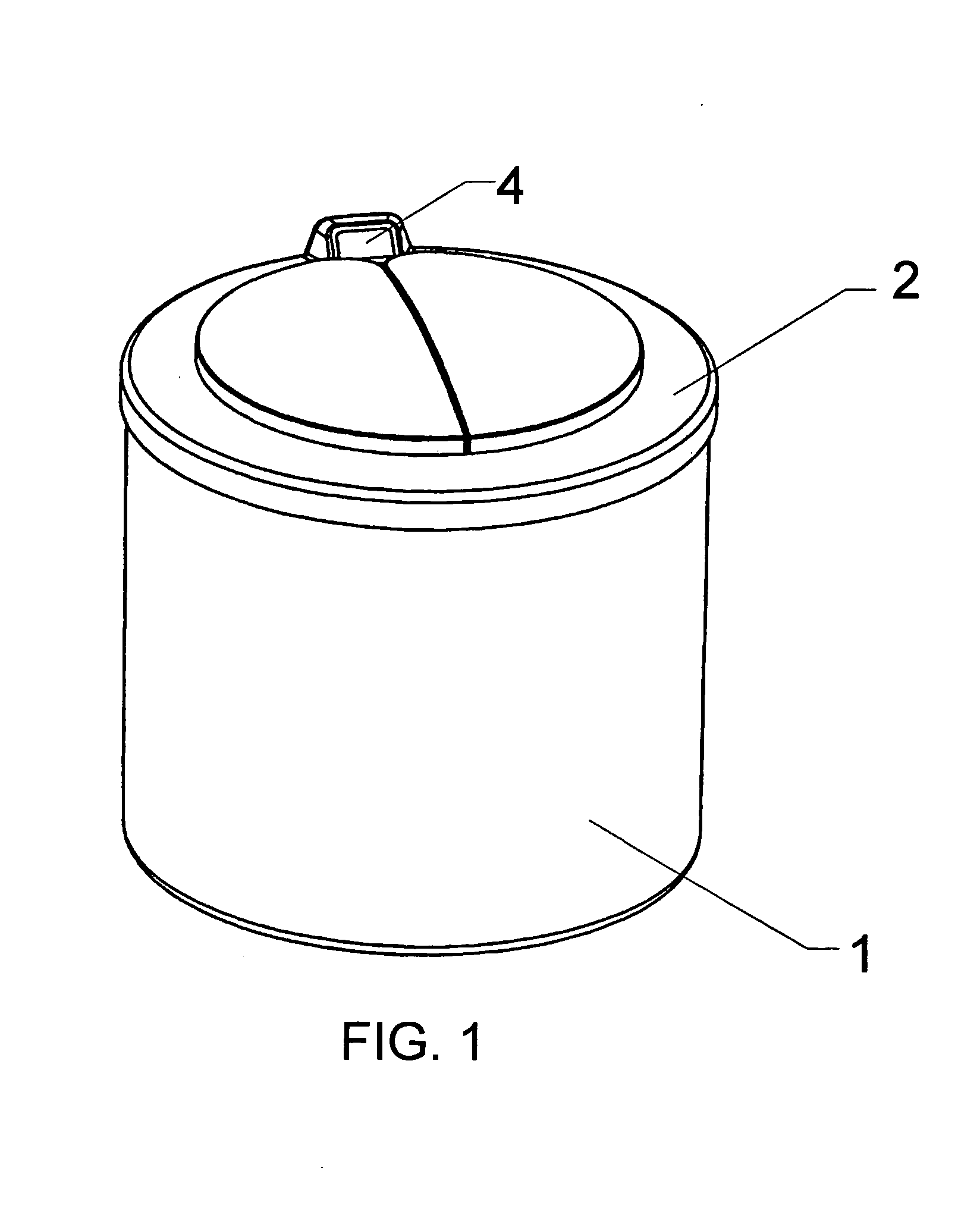

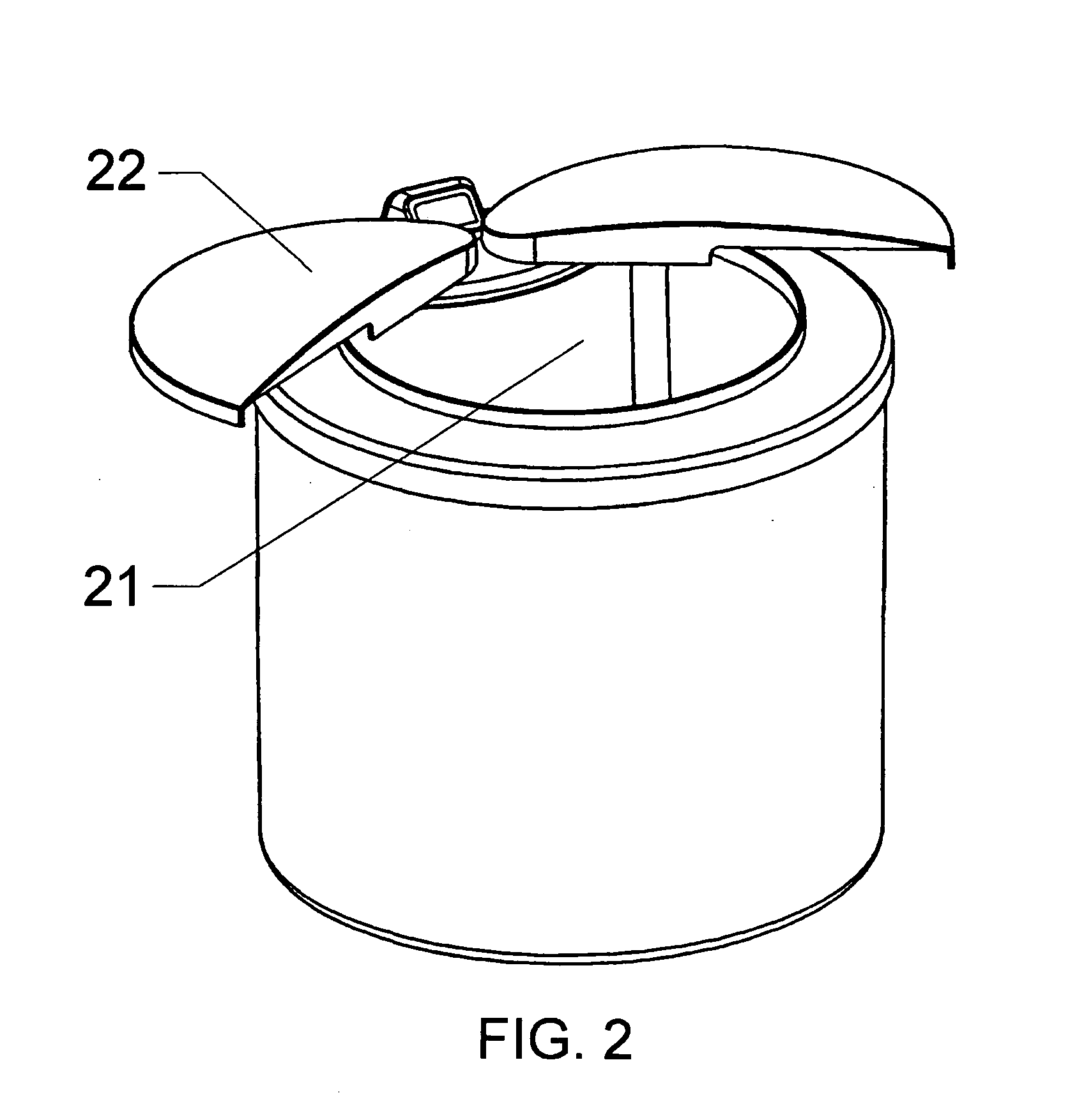

Horizontal open inducting garbage bin

Owner:NINE STARS GRP U S A INC

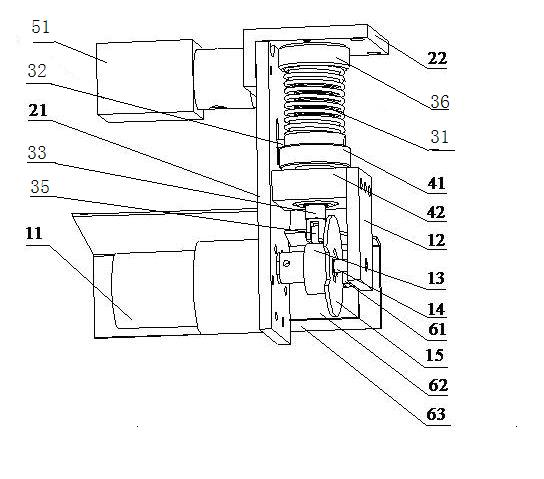

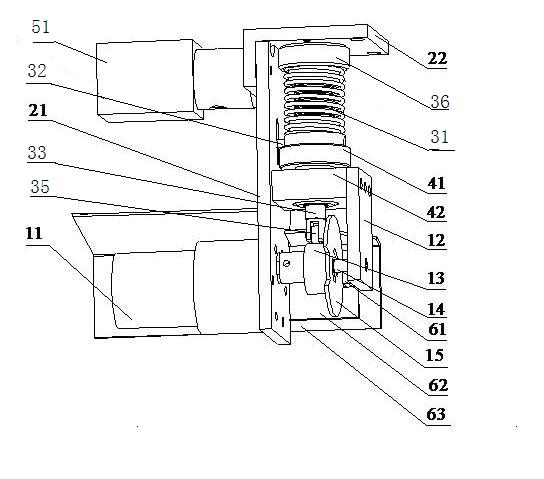

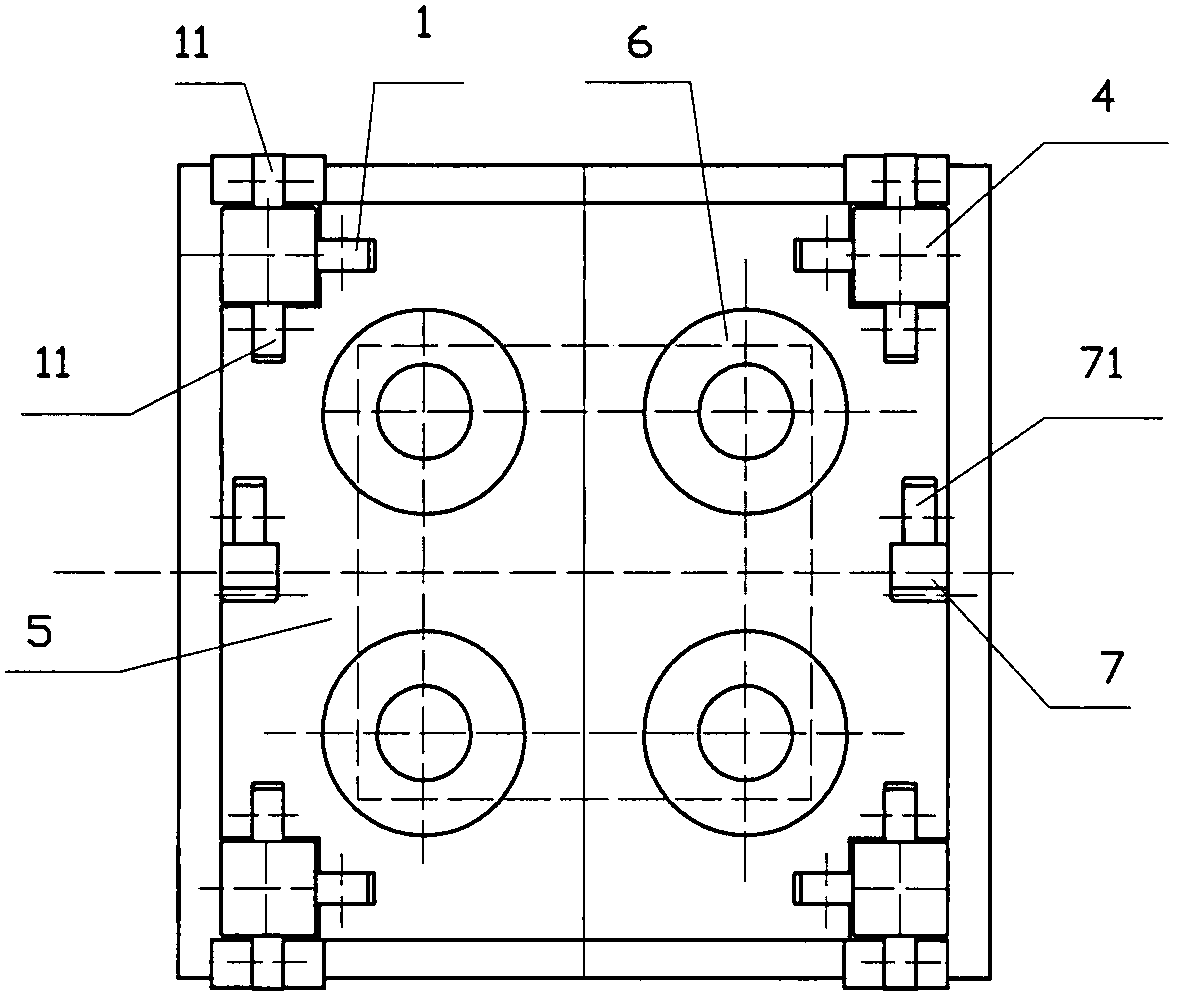

Clamping mechanism for precision injection molding machine

The invention relates to a clamping mechanism for a precision injection molding machine. The clamping mechanism comprises a structure frame composed of a fixed die plate, a movable die plate, a rear die plate and a guide column, a movable die plate fast moving mechanism and a clamping cylinder structure; the section of the guide column on the structure frame is rectangular, four corner parts of the movable die plate are provided with rollers on the upper column surface, the lower column surface and the inner side of the guide column; the movable die plate fast moving mechanism is composed of a motor reduction gear, a pair of engaged gears and rack and a guide wheel; the clamping cylinder structure is composed of four cylinders, a clamping support plate and a transmission mechanism, and the rear die plate has a through hole through which a cylinder piston rod is capable of passing. The clamping mechanism provided by the invention has the advantages that the friction between the movable die plate and the guide column is changed as the rolling friction from the sliding friction, the fit clearance is adjustable, the movement precision is improved, the movement resistance is decreased, and the energy consumption is reduced; through the rotation of the clamping support plate, the length of the guide column required for die closing is greatly shortened through the support or discharging provided for the cylinder piston rod, the whole machine body is reduced, and the control is simplified.

Owner:上海云静企业发展有限公司

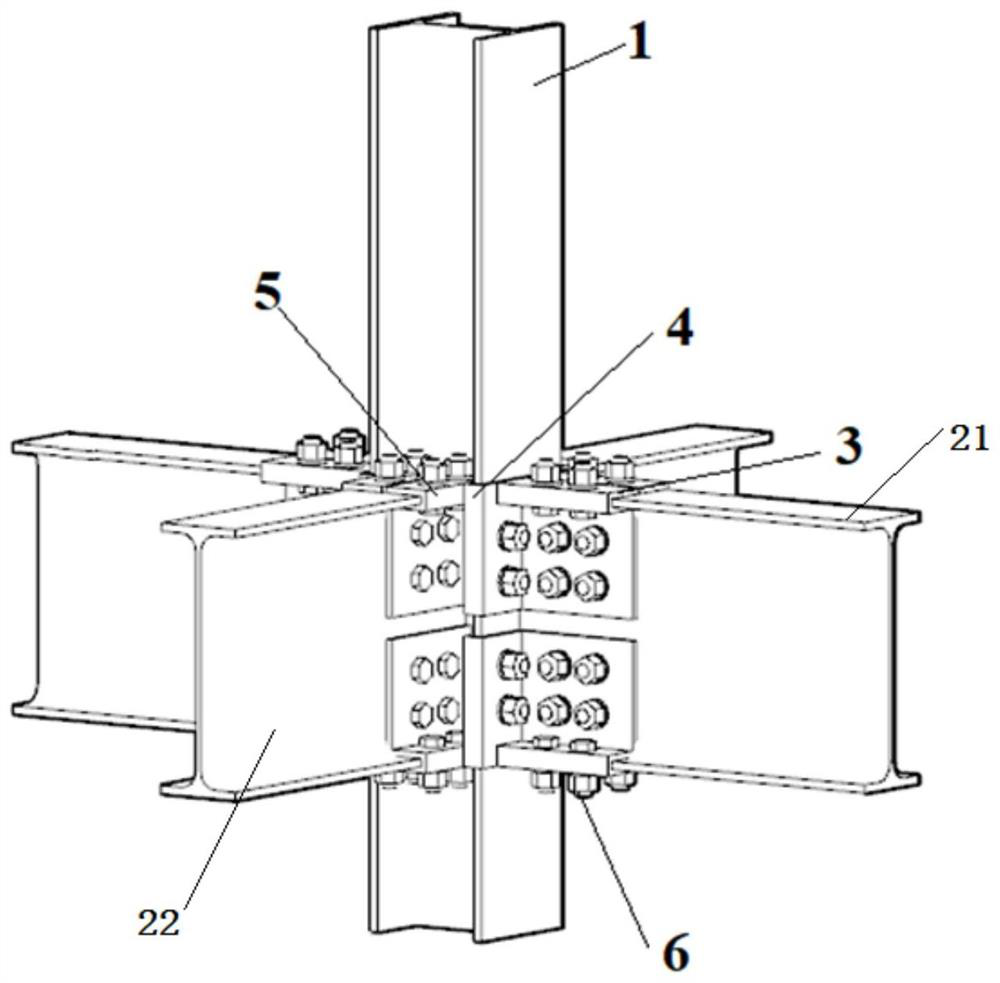

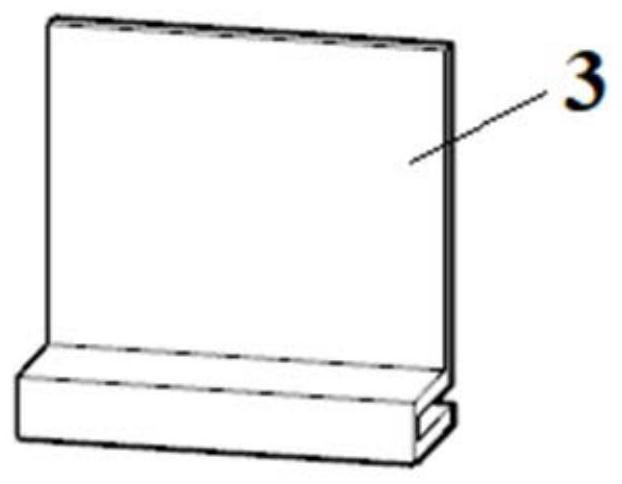

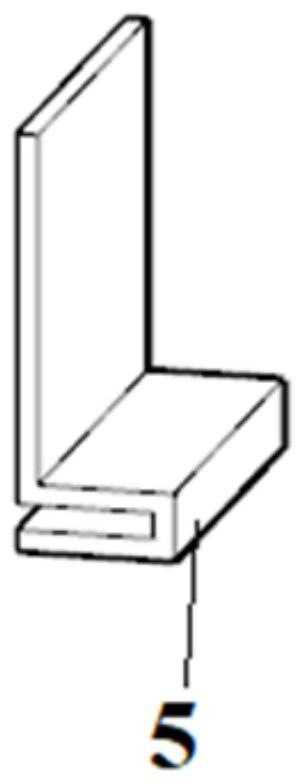

Fabricated joint capable of integrally connecting major and minor axes of I-shaped beam columns

PendingCN111962671AAchieving an all-in-one connection designEasy to assembleBuilding constructionsGusset plateShaped beam

The invention discloses a fabricated joint capable of integrally connecting major and minor axes of I-shaped beam columns. A first I-shaped beam directly faces a flange of an I-shaped column; a secondI-shaped beam directly faces a web plate of the I-shaped column; the upper side of a minor axis gusset plate is buckled and fixed at one end of the second I-shaped beam; the lower side of the minor axis gusset plate is fixed on a web plate of the second I-shaped beam; a column flange gusset plate is buckled and fixed on the flange of the I-shaped column; the upper side of a major axis gusset plate is buckled and fixed on the flange of the first I-shaped beam; the lower side of the major axis gusset plate is fixed to a web of the first I-shaped beam, the end part of the major axis gusset plateis fixed to one side of the column flange gusset plate, the end part of the upper side of the minor axis gusset plate is fixed to the other side of the column flange gusset plate, and the joint can achieve integrated connection of a major axis and a minor axis.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Basic structure for extra-high-voltage single-column guyed tower V-shaped stayguys

ActiveCN104358272AEasy downward force transferAvoid eccentric forceFoundation engineeringPolygonal lineEngineering

The invention discloses a basic structure for extra-high-voltage single-column guyed tower V-shaped stayguys. The basic structure comprises stayguys, a tower column connected by the stayguys, and a plurality of basic structure main bodies, wherein each basic structure main body comprises a base plate, an inclined main column fixed on the top surface of the base plate, a U-shaped stayguy rod of which one end is embedded into the inclined main column and the other end is exposed out of the top surface of the inclined main column, and a triangular connecting plate fixed on the exposed end of the U-shaped stayguy rod, the stayguys are fixed on the triangular connecting plate, two stayguys are arranged between each basic structure main body and the tower column in a V shape, the U-shaped stayguy rod is bent in the inclined main column, a bending line of the lower section is parallel to a geometric center line of the inclined main column, and a bending line of the upper section is parallel to a plane on which the two stayguys on the basic structure main body are positioned. The basic structure can be preferably matched with a V-shaped stayguy arrangement structure, the bearing requirement of an extra-high-voltage guyed tower can be satisfied, the quantity of foundations is reduced, the form is simple, and the basic structure is easy to realize.

Owner:NORTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP

Satellite platform configuration with extensible truss node cabin

ActiveCN111409871AIncrease profitSmall outer envelopeCosmonautic vehiclesCosmonautic power supply systemsStructural engineeringSolar cell

The invention provides a satellite platform configuration with an extensible truss node cabin, which comprises a configuration body and a solar cell array. The solar cell array is arranged on the south and north side surfaces of the configuration body. The configuration body comprises a service cabin and a node cabin, and the node cabin is installed on the upper portion of the service cabin. According to the node cabin, the four extensible truss systems are fixed through the cuboid frame structure, the node cabin can be connected with other sub-platforms in four horizontal directions at the same time, a plurality of satellite sub-platforms are connected into a whole, and an ultra-large platform is constructed for complex tasks. The fixing frame is connected with a force bearing cylinder ofthe service cabin through a node cabin bottom plate in the longitudinal direction, and a cross-shaped and central circular combined reinforcing frame is pre-buried in the node cabin bottom plate, sothat the whole satellite platform has high rigidity.

Owner:SHANGHAI SATELLITE ENG INST

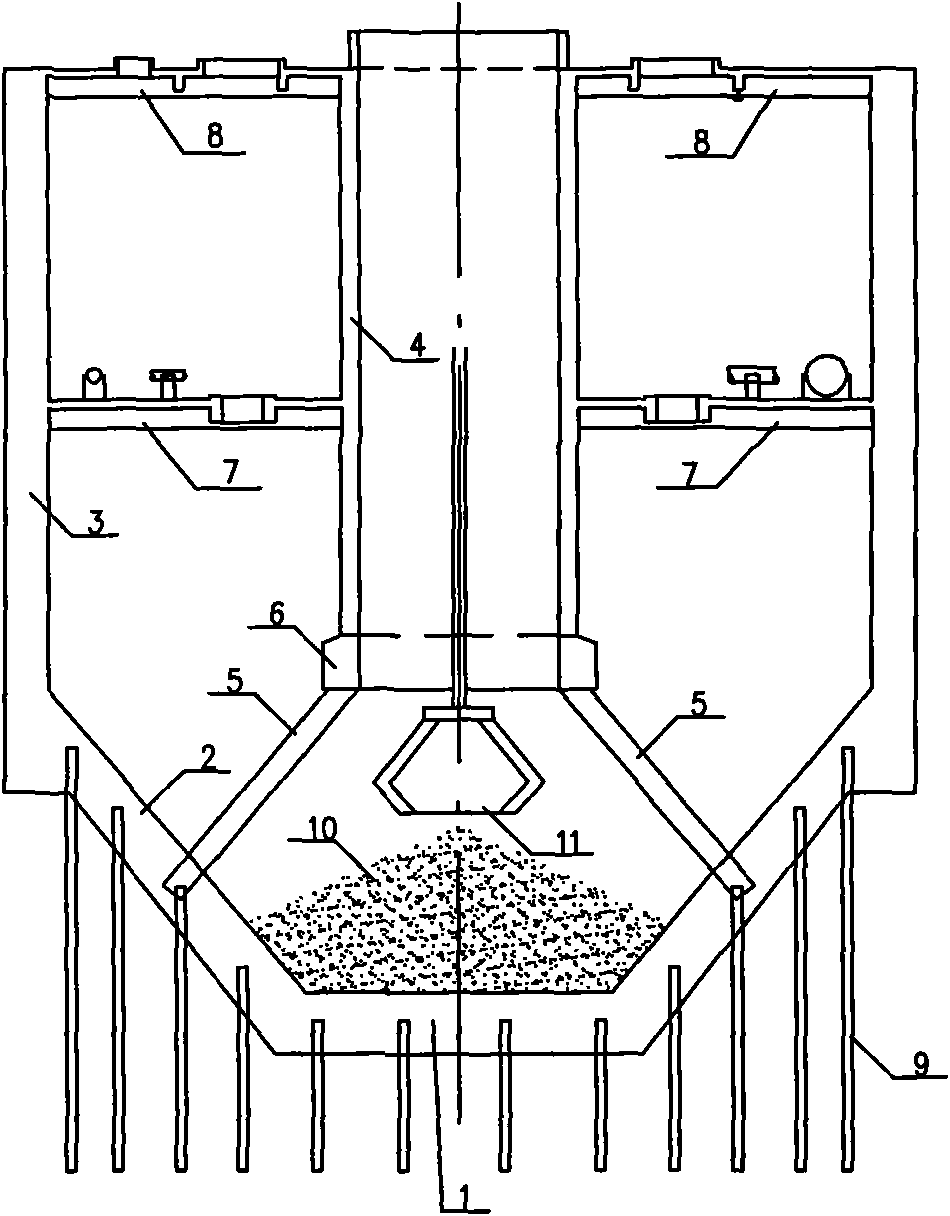

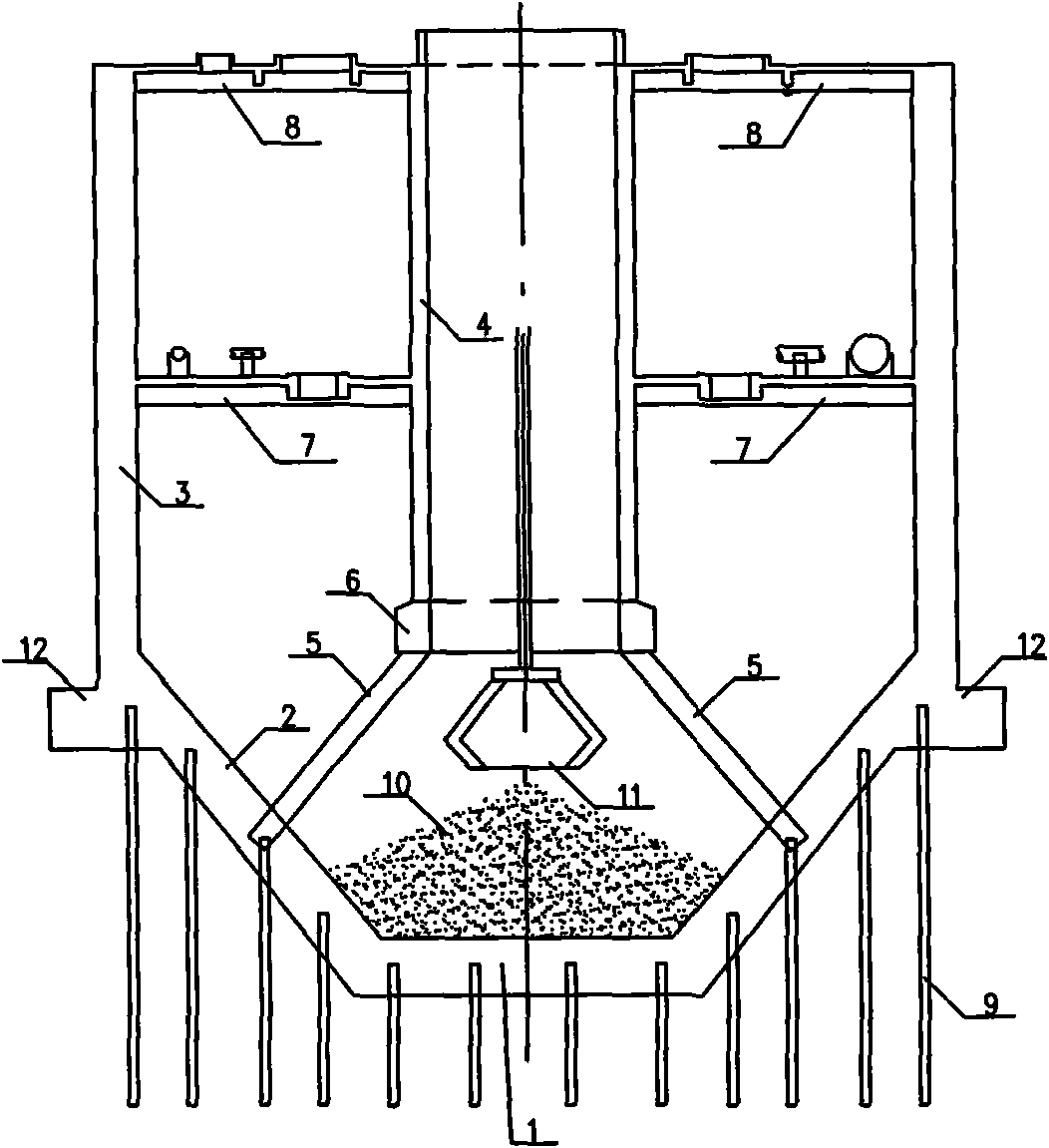

Whirlwind tank

The invention relates to a whirlwind tank, comprising a bottom plate (1), an oblique cone (2), an outer barrel (3), an inner barrel (4) and a support (5), wherein the support (5) is an oblique support. The whirlwind tank causes grab bucket working performance to be high, and floating resistant capability of the whirlwind tank is strong.

Owner:CISDI ENG CO LTD

Corner stone connecting component

Owner:姚长付

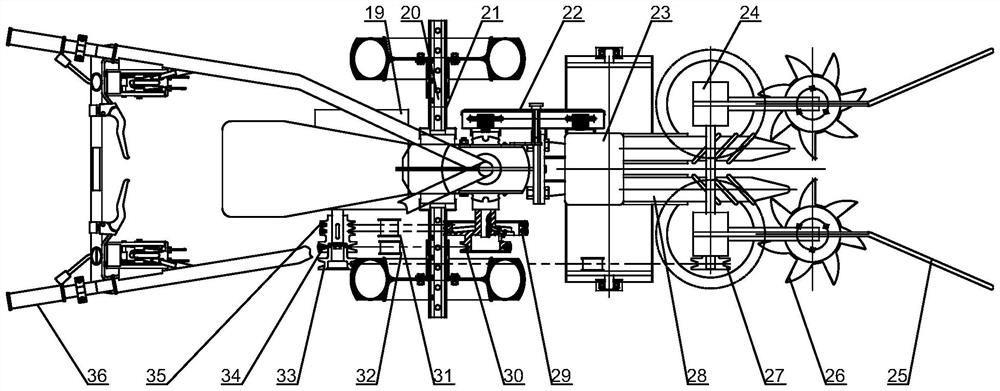

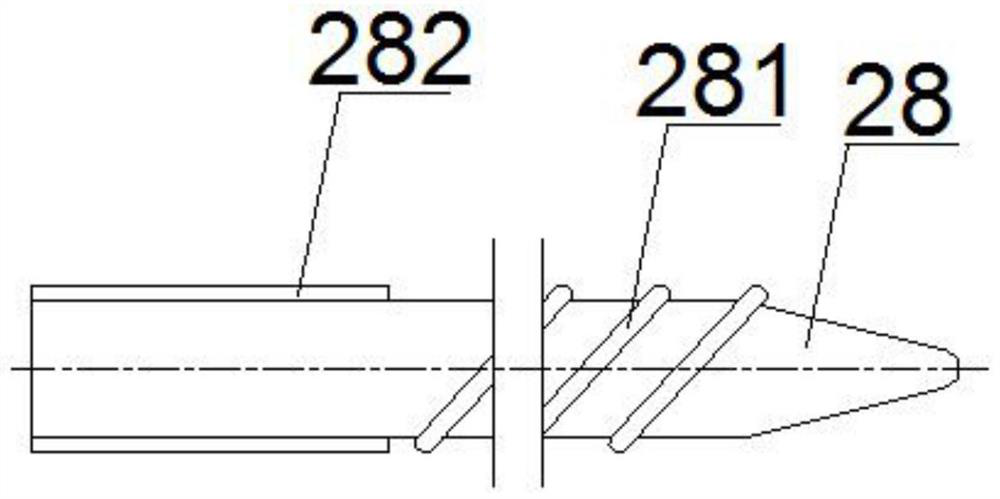

Male parent cutting machine for hybrid rape seed production field

PendingCN114223388AMeet the needs of different speedsLow input speedCrop conditionersMowersAgricultural engineeringMechanical engineering

The invention discloses a male parent cutting machine for a hybrid rape seed production field. The male parent cutting machine comprises a rack which is provided with a handle, an engine, a gear shifting handle, a walking gearbox, a spiral conveying roller gearbox, two cutter gearboxes, two reel mechanisms and two dividing plate assemblies. A first output shaft on the engine is in transmission connection with an input shaft of the walking gearbox through a first transmission mechanism, an input shaft of the cutter gearbox is in transmission connection with an input shaft of the walking gearbox through a second transmission mechanism, and the reel mechanism is in transmission connection with an output shaft of the cutter gearbox. A second output shaft on the engine is in transmission connection with an input shaft of the spiral conveying roller gearbox through a power output transmission box, a pair of spiral conveying rollers is arranged on an output shaft of the spiral conveying roller gearbox, and a double-layer cutting knife is arranged on an output shaft of the cutting knife gearbox. According to the cutting machine, the cutting efficiency and effect of the rape male parents are greatly improved, time and labor are saved, and the labor cost is reduced.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI +1

Hollow shear wall structure for cross diagonal reinforcing bar and construction method thereof

InactiveCN102979220BImprove the immunityImprove acceleration performanceWallsBuilding material handlingDiagonalRebar

The invention discloses a hollow shear wall structure for a cross diagonal reinforcing bar. The hollow shear wall structure for the cross diagonal reinforcing bar comprises a shear wall body, wherein the inside of the shear wall body is provided with the horizontal-direction reinforcing bars of a wall body, the vertical-direction reinforcing bars of the wall body and wall body tie bars, wherein two groups of cross diagonal reinforcing bar cages are respectively arranged along the plane diagonal direction of the shear wall body; the cross diagonal reinforcing bar cages are bond and connected with the horizontal-direction reinforcing bars of the wall body and the vertical-direction reinforcing bars of the wall body; each group of cross diagonal reinforcing bar cage at least comprises four cross diagonal reinforcing bars and cross diagonal stirrups processed into a closed rectangle; the cross diagonal reinforcing bars and the cross diagonal stirrups are bond to form a rectangular strip-shaped cross diagonal reinforcing bar cage; and the inside of each space surrounded by the horizontal-direction reinforcing bars of a wall body, the vertical-direction reinforcing bars of the wall body, the wall body tie bars and the cross diagonal reinforcing bar cages is respectively embedded with a light internal die of a blocky foam plastic. The construction method for the hollow shear wall structure for the cross diagonal reinforcing bar comprises the following steps of: erecting a shear wall template; binding wall body reinforcing bar meshes; laying and binding the cross diagonal reinforcing bar cages; embedding the light internal die of the blocky foam plastic; and pouring and curing the shear wall concrete. According to the invention, materials are saved, the structural self weight is lightened, and the resistance to shock is good.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com