Sealing device for one-section type high-pressure rubber membrane sealing type gas holder

A sealing device, rubber membrane technology, applied in the direction of adjustable capacity air storage tank, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problem of increasing material consumption, overhaul, maintenance workload, increasing piston baffle The problems such as the outer edge angle steel ring and the larger gap of the local corrugated plate can reduce the time and cost of installation and maintenance, increase the operation safety and reduce the load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

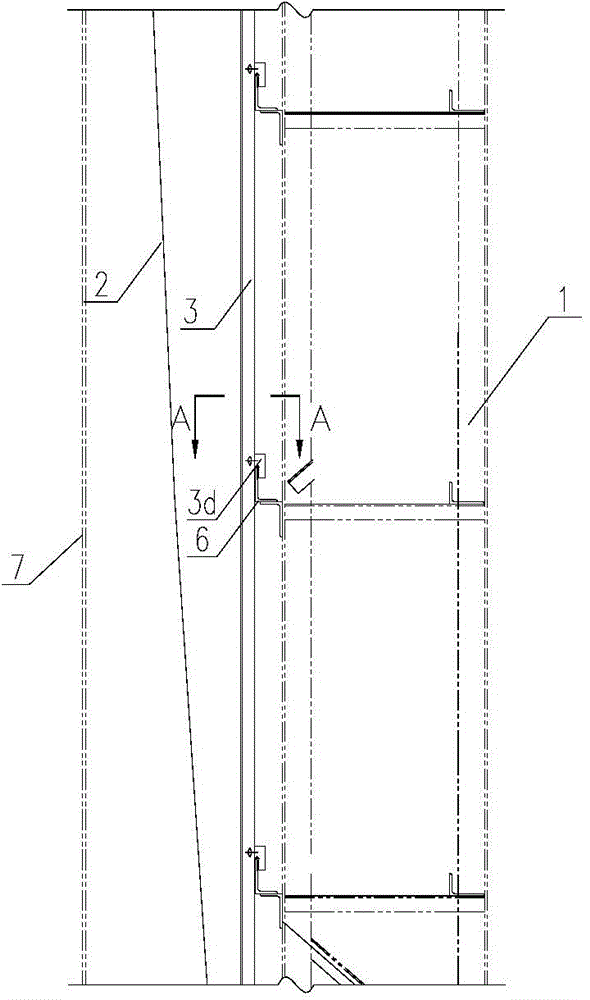

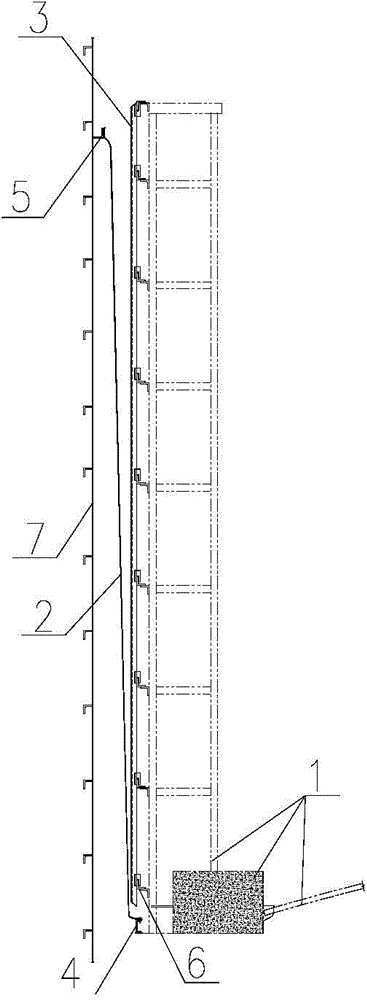

[0027] like image 3 As shown, in this embodiment, the one-stage high-pressure rubber membrane sealing type gas cabinet sealing device, the sealing channel steel 4 is welded on the bottom plate of the piston 1, and the sealing rubber membrane 2 is connected and sealed with the sealing channel steel 4 through bolts and pressure plates and other components. The angle steel 5 and the side plate 7 of the gas cabinet are connected and sealed by welding seams, and the sealing angle steel 5 is connected and sealed with the sealing rubber membrane 2 through bolts and pressure plates, and the sealing rubber membrane 2 is tightly attached to the corrugated plate device 3 when the gas tank is inflated. Up, it stretches as the piston 1 rises and falls. The above connection forms a one-stage high-pressure rubber membrane-sealed gas cabinet sealing device, which is simple and reliable.

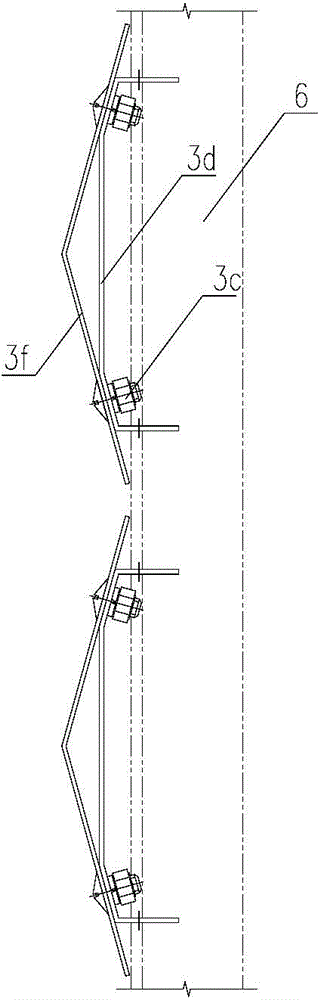

[0028] like Figure 4~5 As shown, the one-stage high-pressure rubber membrane-sealed gas cabinet seali...

Embodiment 2

[0030] like Figures 3 to 4 As shown in , 6, the one-stage high-pressure rubber film sealing type gas cabinet sealing device of this embodiment, the sealing channel steel 4 is welded on the bottom plate of the piston 1, and the sealing rubber film 2 is connected and sealed with the sealing channel steel 4 through bolts, pressure plates and other components. , the sealing angle steel 5 and the side plate 7 of the gas tank are connected and sealed by welding, and the sealing angle steel 5 is connected and sealed with the sealing rubber membrane 2 through bolts and pressure plates, and the sealing rubber membrane 2 is tightly attached to the corrugated plate when the gas tank is inflated On the device 3, it stretches along with the lifting of the piston 1. The above connection forms a one-stage high-pressure rubber membrane-sealed gas cabinet sealing device, which is simple and reliable.

[0031] like Figure 4~5As shown, the one-stage high-pressure rubber membrane-sealed gas c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com