Wastewater treatment method and device based on hydrodynamic cavitation

A technology for hydraulic cavitation and wastewater treatment, which is applied in water/sewage treatment, special compound water treatment, oxidized water/sewage treatment, etc. Efficiency and safety improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

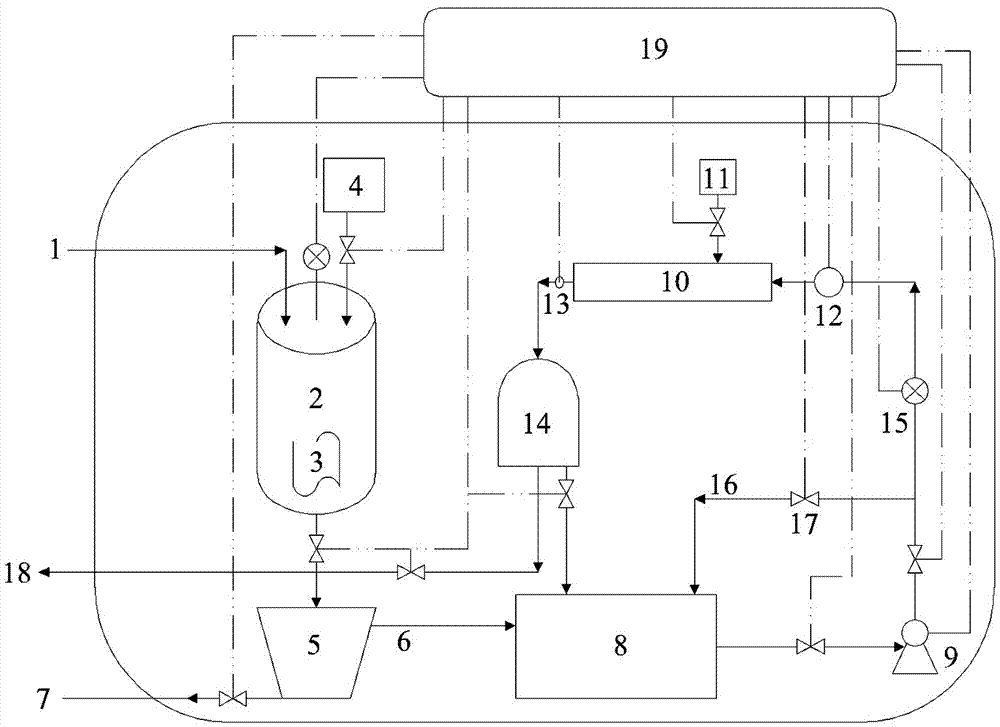

[0039] The structure of the integrated hydraulic cavitation device for wastewater treatment is as follows: figure 1 As shown, it consists of wastewater pretreatment system, water supply system, hydraulic cavitation system and control system.

[0040] The wastewater pretreatment system includes a wastewater coagulation tank 2 with a stirring device 3 for pretreatment of wastewater, and the wastewater coagulation tank is externally connected to the wastewater inlet 1; A coagulant dispensing tank 4 for adding coagulant to the wastewater coagulation tank; a sedimentation tank 5 located below the wastewater coagulation tank, connected to the wastewater coagulation tank 2 by a valve 17 and a pipeline, below the sedimentation tank 5 A sludge discharge port 7 for discharging sludge is provided, and a pretreated waste water outlet 6 is provided above to connect to the water supply system. The waste water and coagulant are pretreated in the waste water coagulation tank 2, and the waste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com