Fabricated joint capable of integrally connecting major and minor axes of I-shaped beam columns

A technology of I-shaped beams and I-shaped, which is applied in the direction of architecture and building structure, etc., to achieve the effect of solving the problem of low level of industrialization of buildings, easy construction and application, and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in further detail below in conjunction with accompanying drawing:

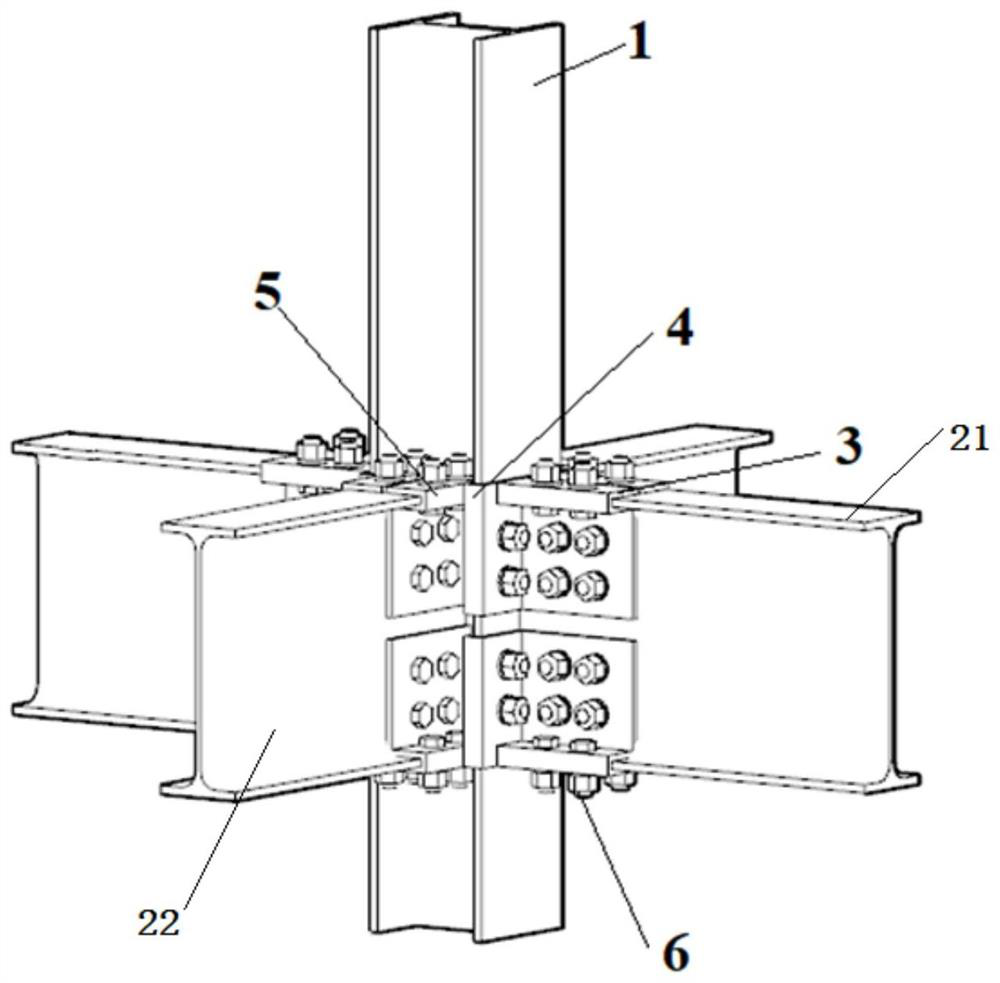

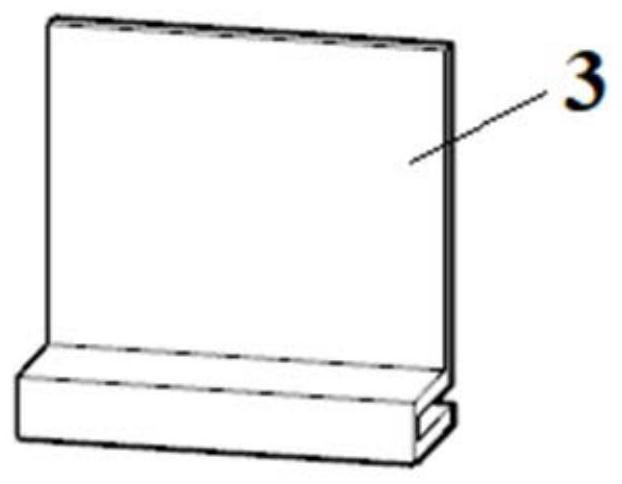

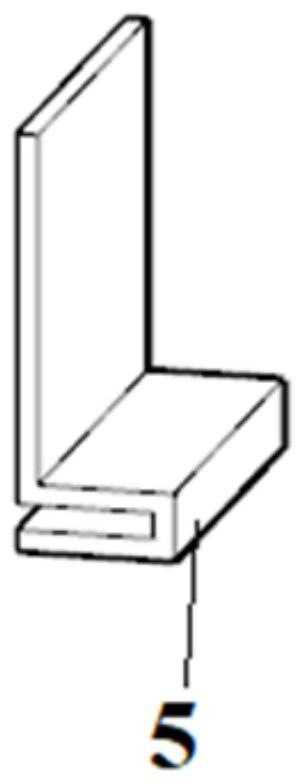

[0016] refer to figure 1 , figure 2 , image 3 and Figure 4 , the assembled joint of I-shaped beam-column strong and weak shaft integrally connected according to the present invention includes a first I-shaped beam 21, an I-shaped column 1, a second I-shaped beam 22, a weak axis gusset plate 5, and a column wing The edge gusset plate 4 and the strong shaft gusset plate 3; the first I-shaped beam 21 is facing the flange of the I-shaped column 1, the second I-shaped beam 22 is facing the web of the I-shaped column 1, and the weak The upper side of the shaft gusset plate 5 is buckled and fixed on one end of the second I-shaped beam 22, the lower side of the weak shaft gusset plate 5 is fixed on the web of the second I-shaped beam 22, and the column flange joint The plate part 4 is buckled and fixed on the flange of the I-shaped column 1, the upper side of the strong...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com