Power-driven lifting method for automobile glass

An automotive glass and electric technology, applied in the direction of power control mechanism, wing fan control mechanism, door/window accessories, etc., can solve the problem of unable to support the tightening of the transmission wire, and achieve simple design, reasonable design, and flexible operation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

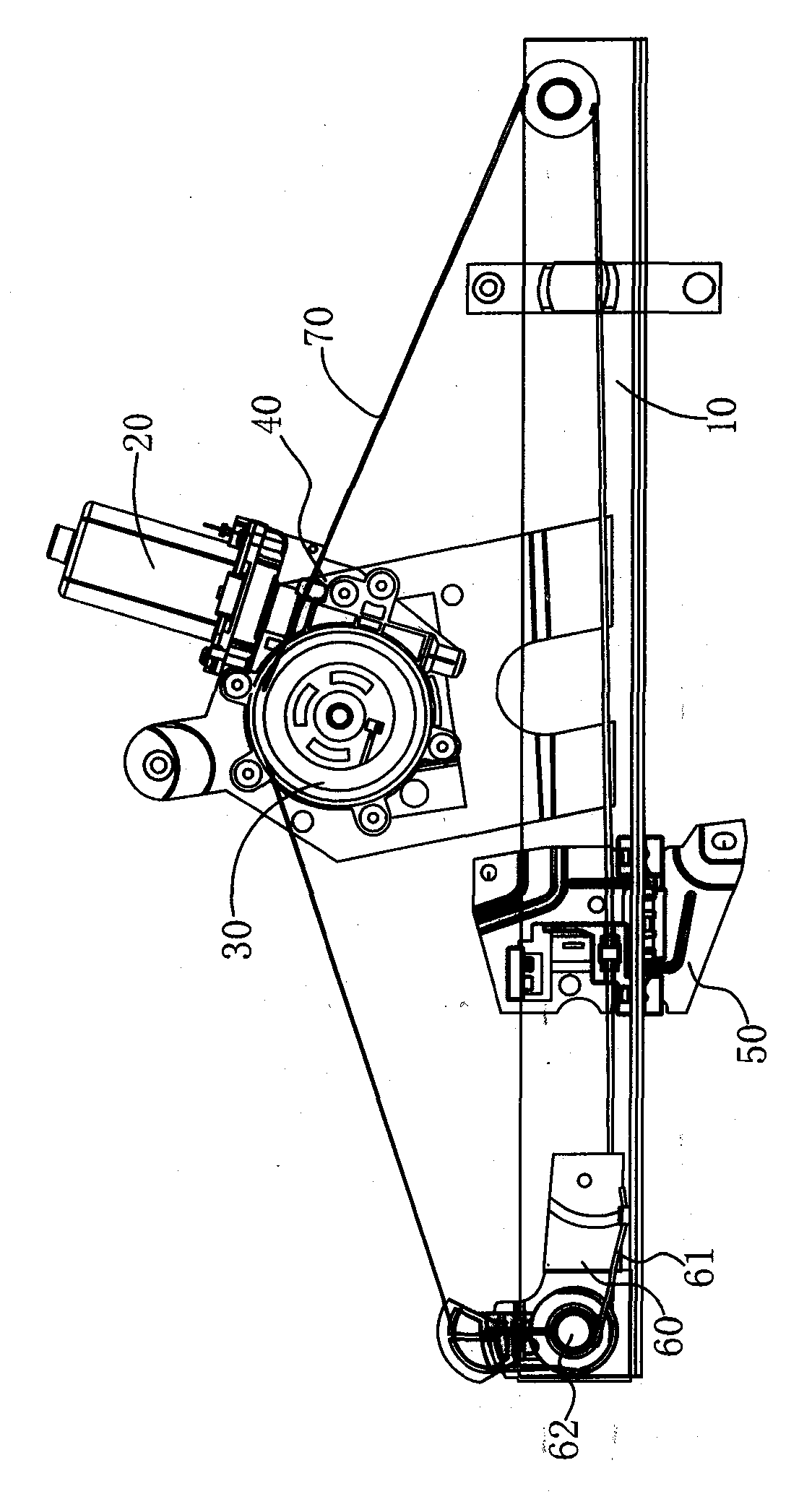

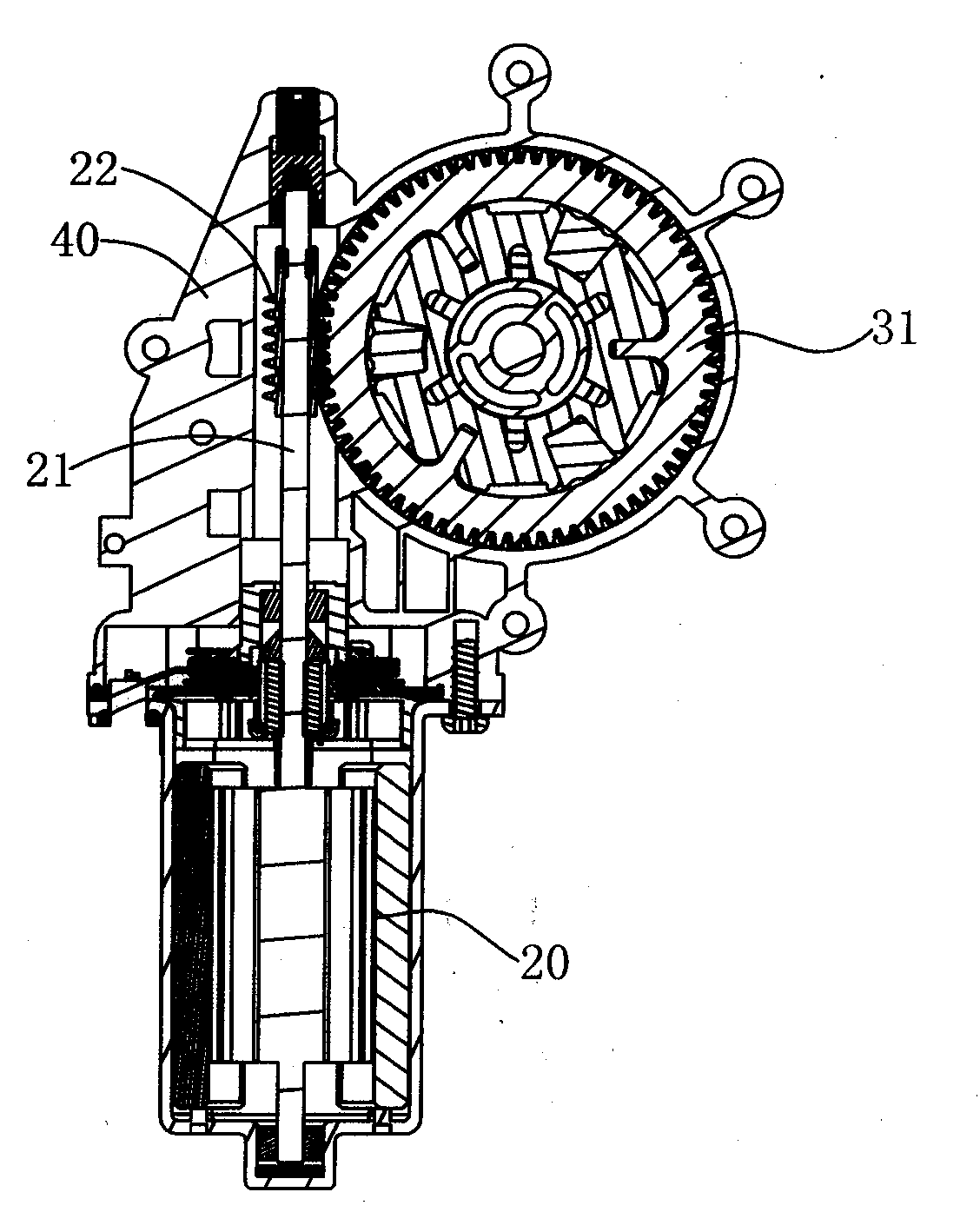

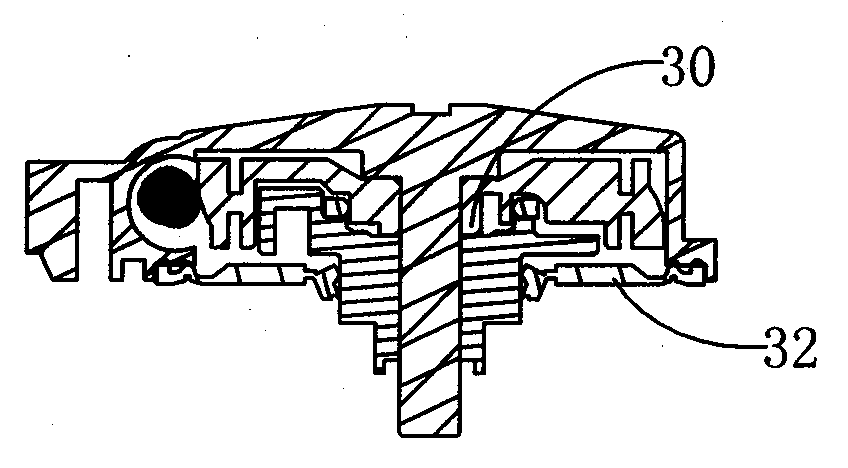

[0020] The electric lifting method of the automobile glass is used for the electric lifting control of the automobile glass, and the lifting method is completed by means of an electric lifting mechanism, such as figure 1 , figure 2 and image 3 As shown in the figure, the electric lifting method is specifically driven by the drive motor 20 to drive a transmission disc 31, and a transmission wire 70 is driven and sleeved on the transmission disc 31. The two ends of the transmission wire 70 are fixed on the glass pallet 50, and the transmission wire It is also set through a tensioning mechanism 60, and the transmission wire rope is always tensioned by the tensioning mechanism. The driving motor is mounted on a motor fixing base 40, a bearing is arranged on the motor fixing base, and one end of the rotor shaft 21 of the driving motor is assembled with the bearing. The drive motor drives a transmission disc connected to a reducer 30 in a worm manner, and the transmission disc d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com