Patents

Literature

135results about How to "Driving force is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

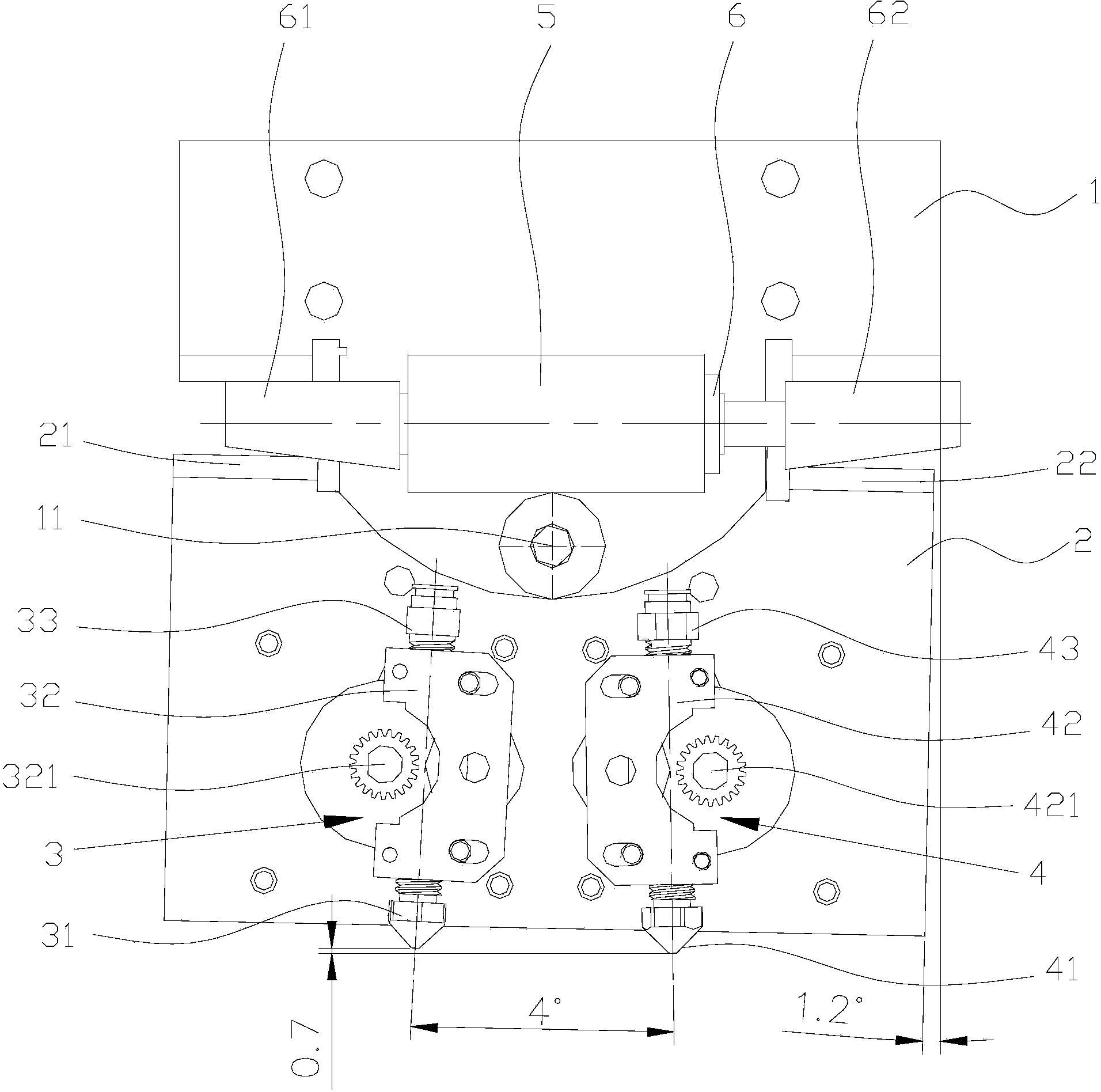

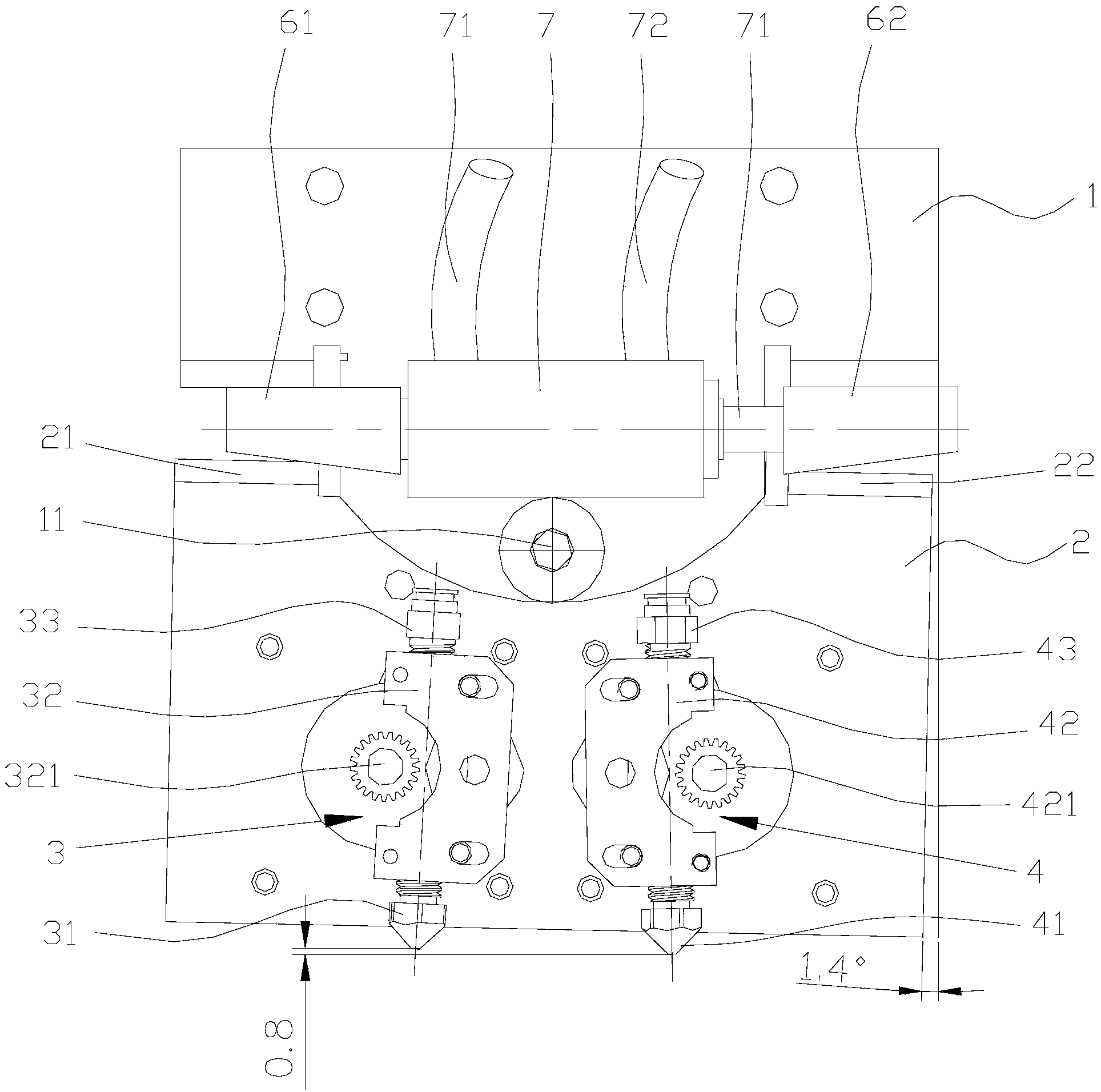

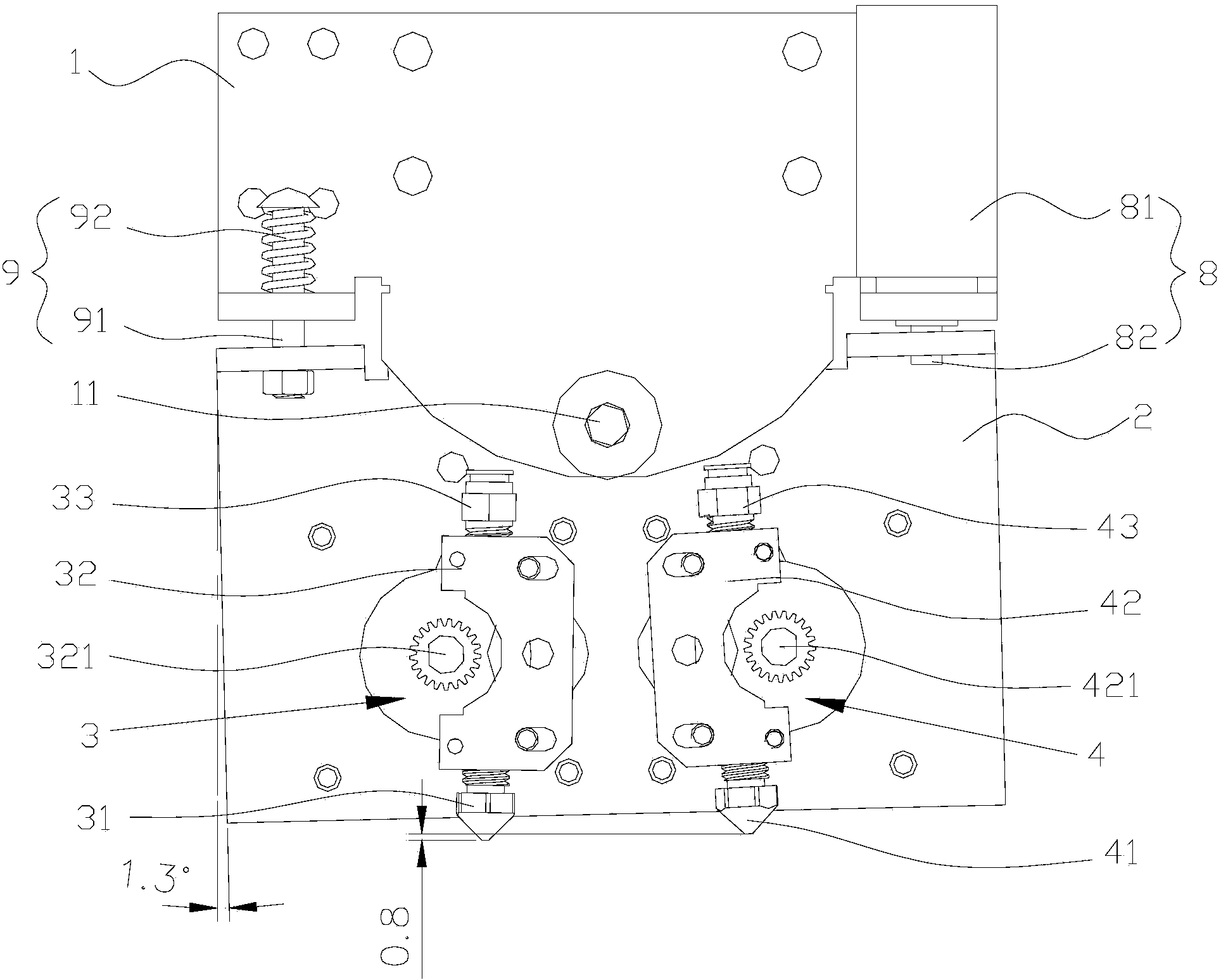

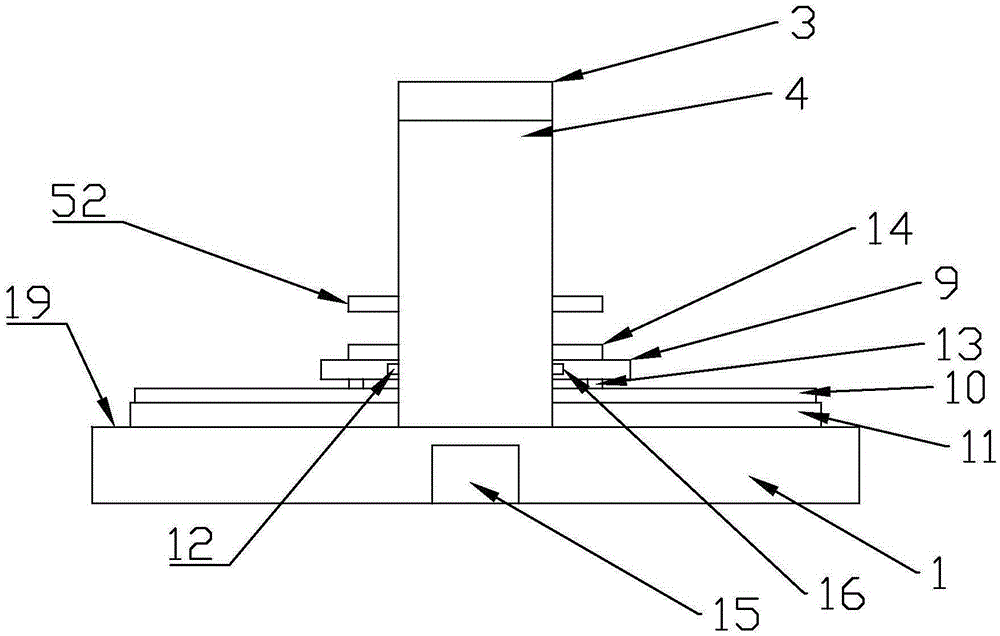

Dual-head 3D printer capable of rotatably switching printing heads

ActiveCN104228069AGuaranteed heightOvercoming problems with being at the same heightEngineering3d printer

Owner:苏州江南嘉捷光机电技术有限公司

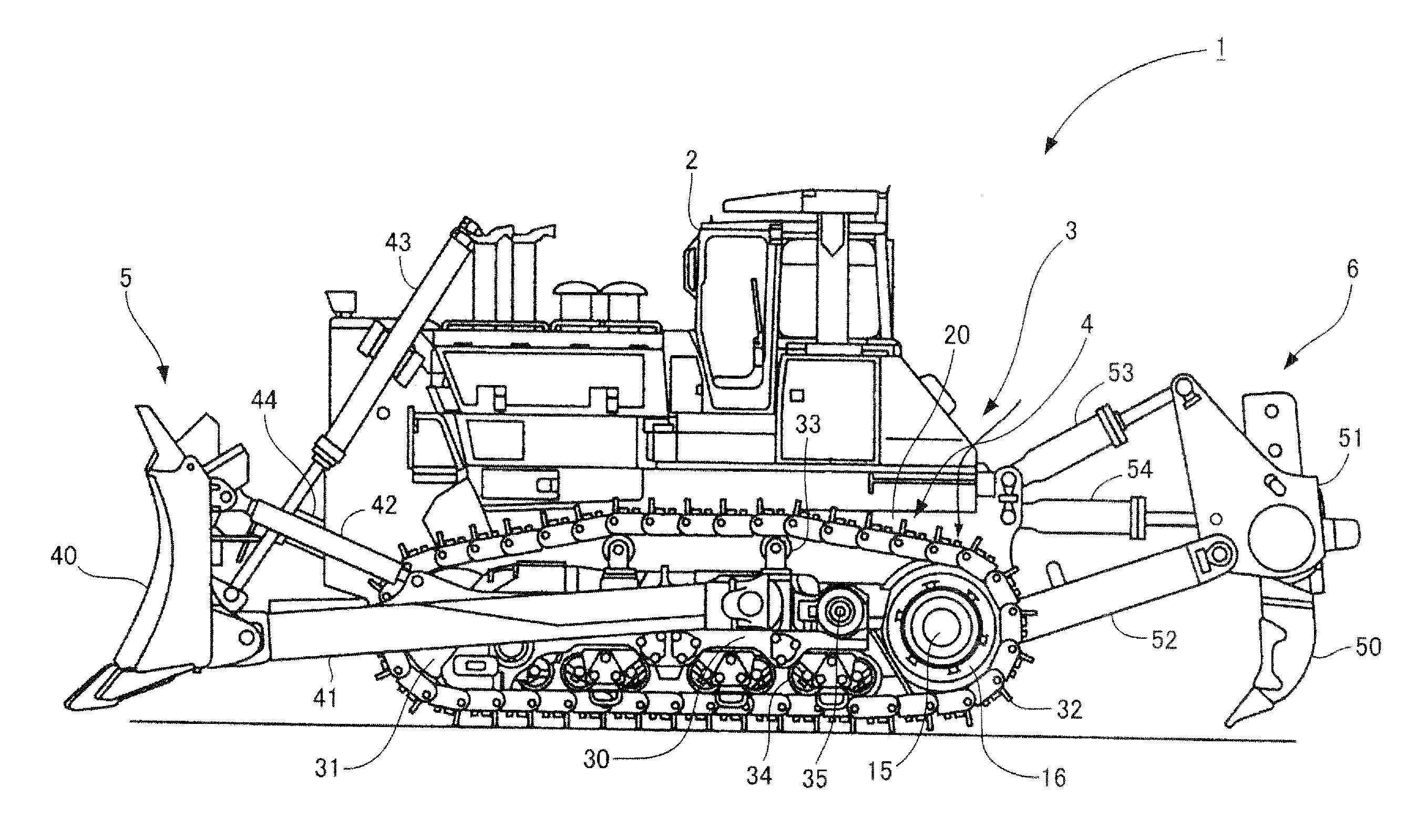

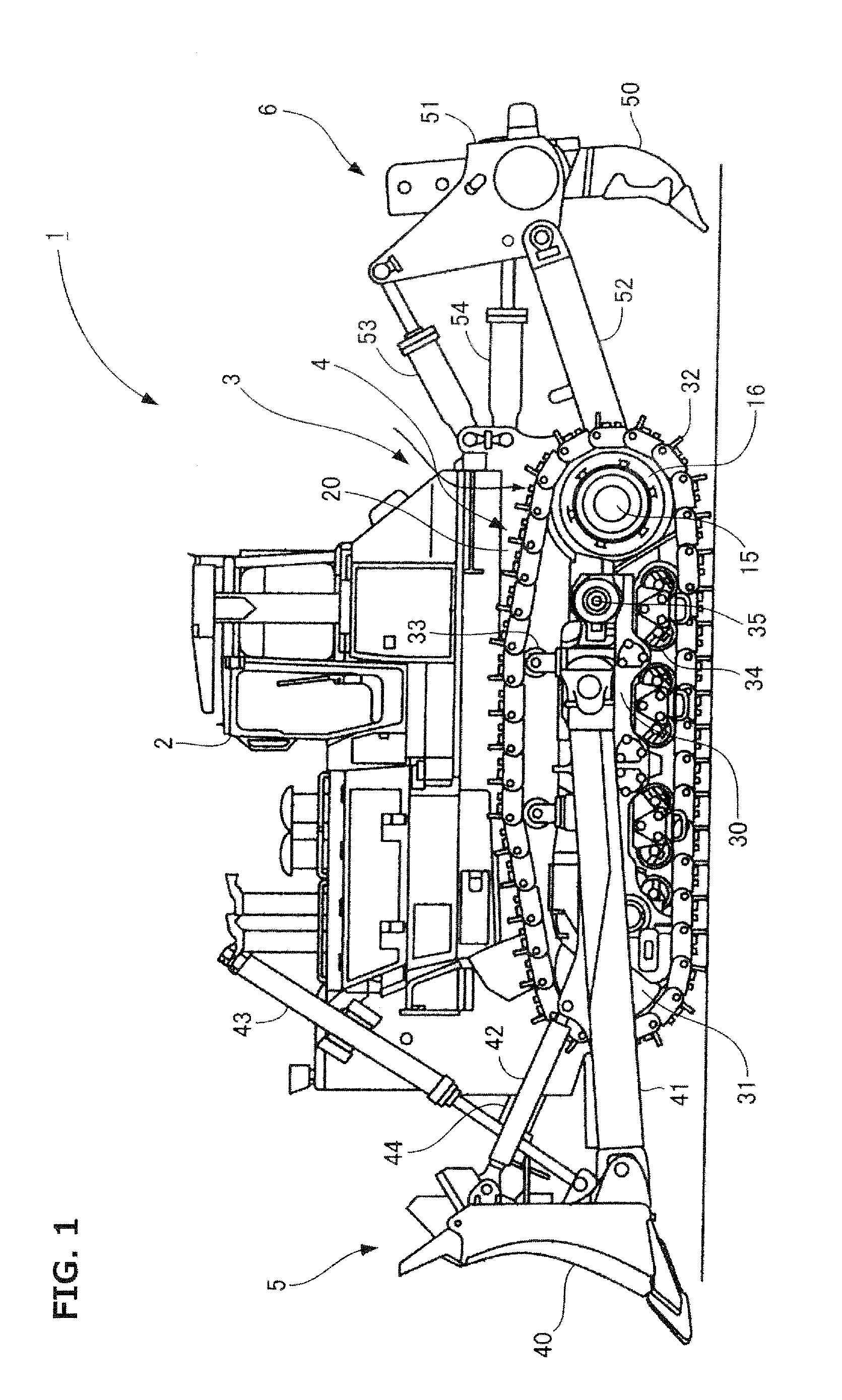

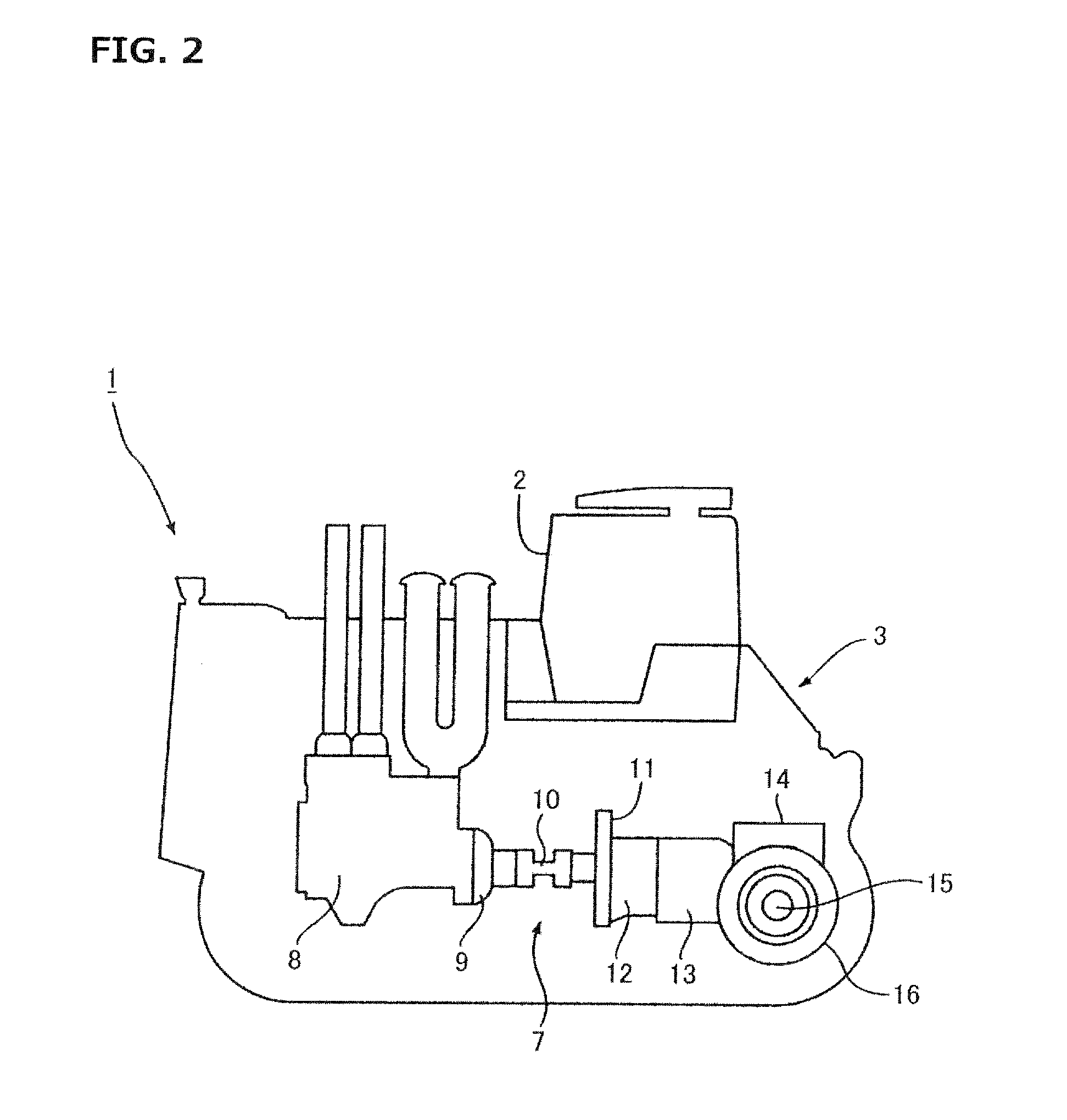

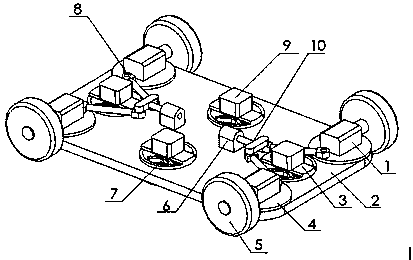

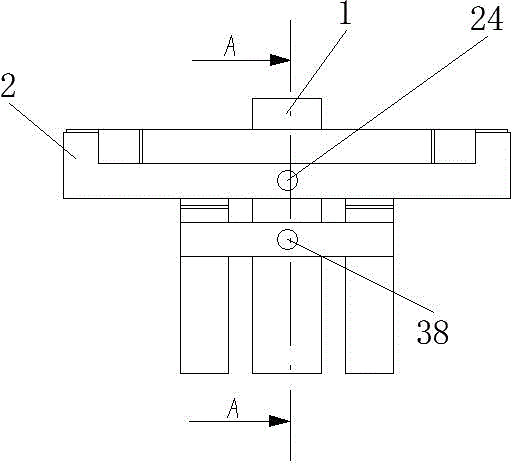

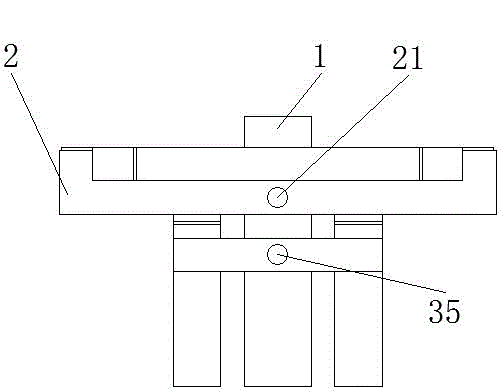

Suspension device for a work vehicle

InactiveUS20120073843A1Improve ride qualityDriving force is stableAgricultural machinesSoil-shifting machines/dredgersTerrainRide quality

A suspension device for a work vehicle is capable of not only providing improved ride quality during nonoperational traveling such as on-site movement over uneven terrain, but also ensuring stable driving power during operational traveling such as an excavation operation on uneven terrain. The suspension device 60 has an equalizer bar 61 for coupling undercarriages 4, 4′ provided on both sides, respectively, of a vehicle body 3, the equalizer bar 61 being provided in the vehicle body 3 so as to be freely swingable up and down. This suspension device 60 has pitch angle change cylinders 65 as maximum pitch angle changing mechanism for changing the maximum pitch angle of the equalizer bar 61.

Owner:KOMATSU LTD

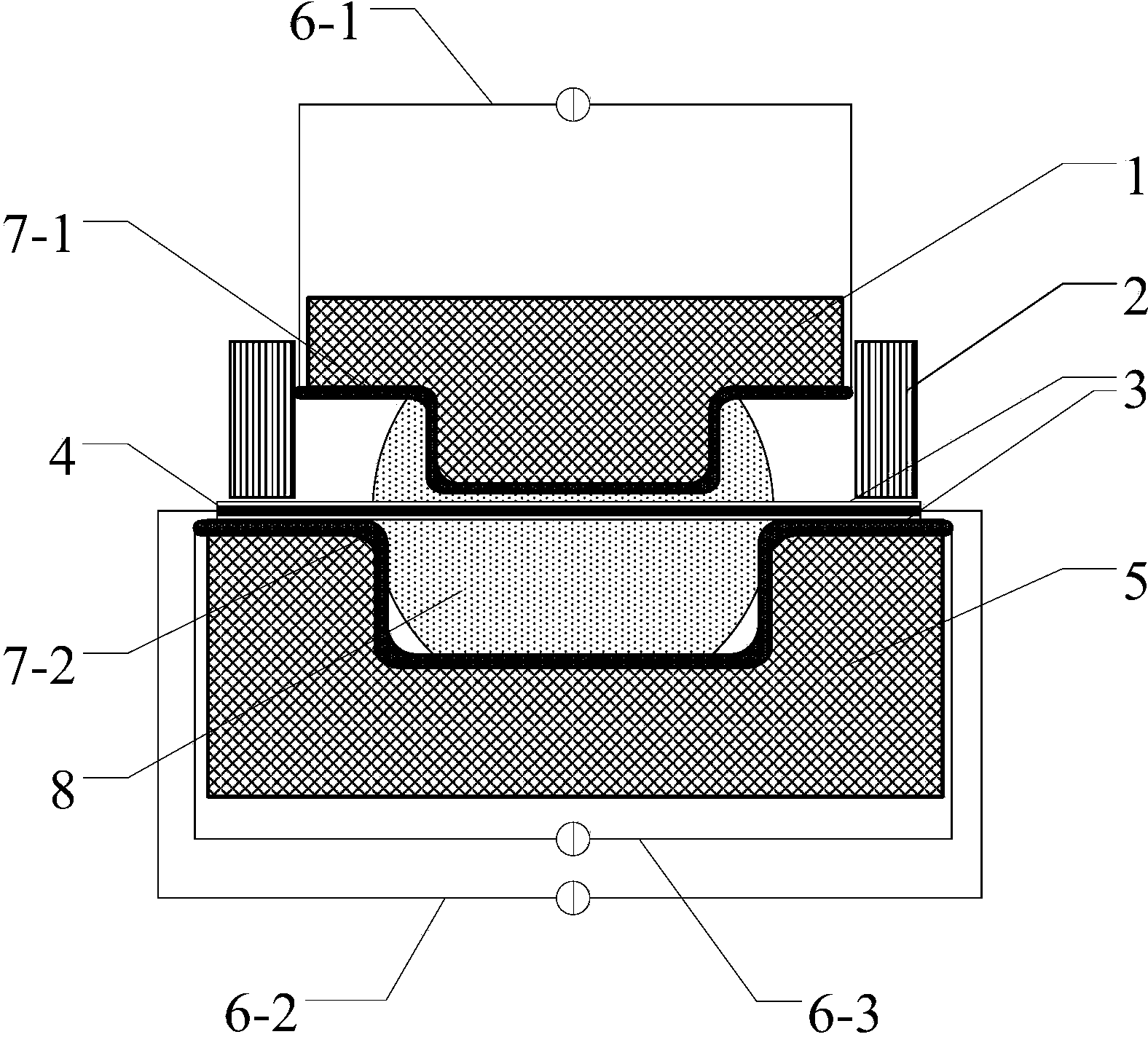

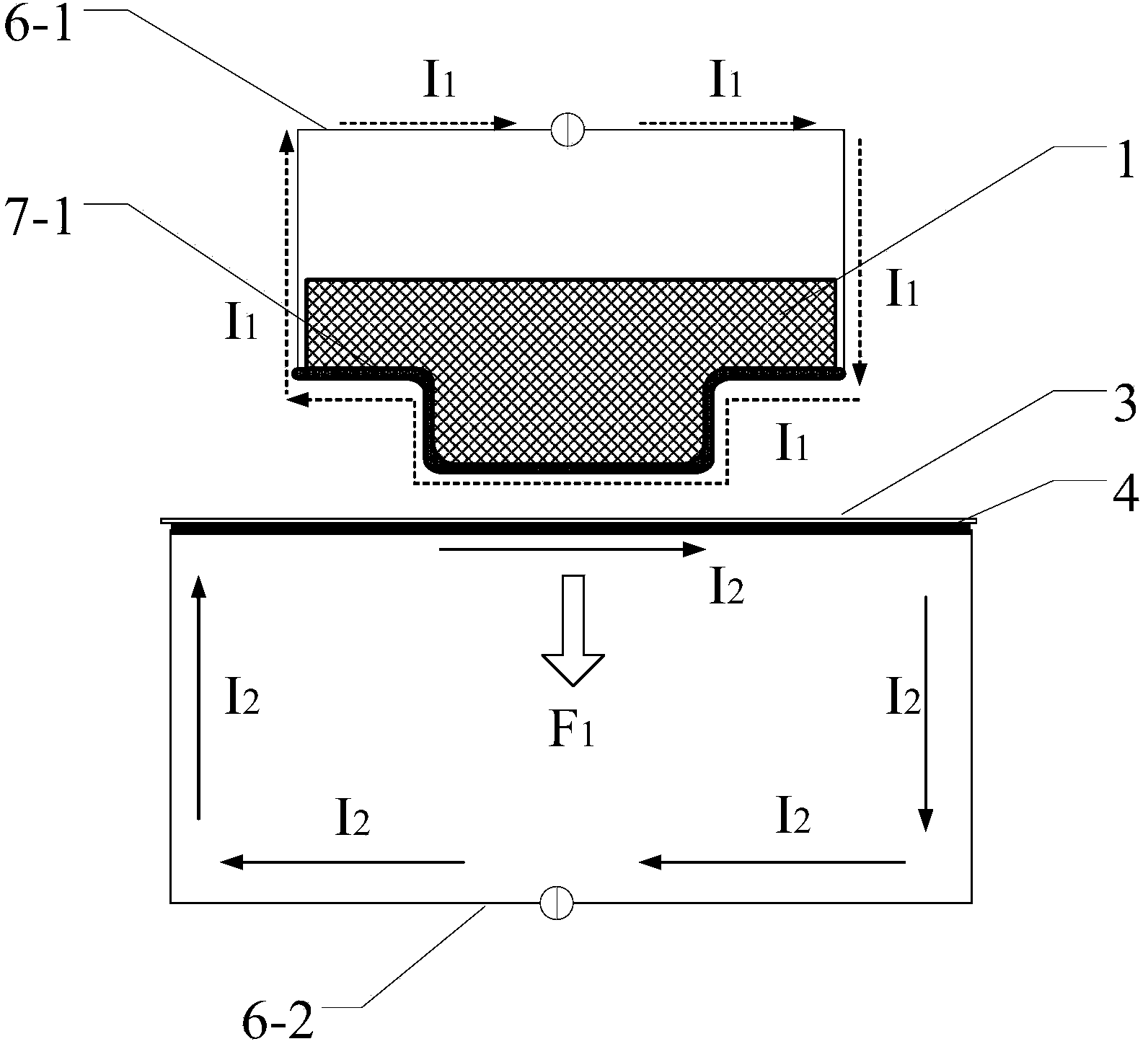

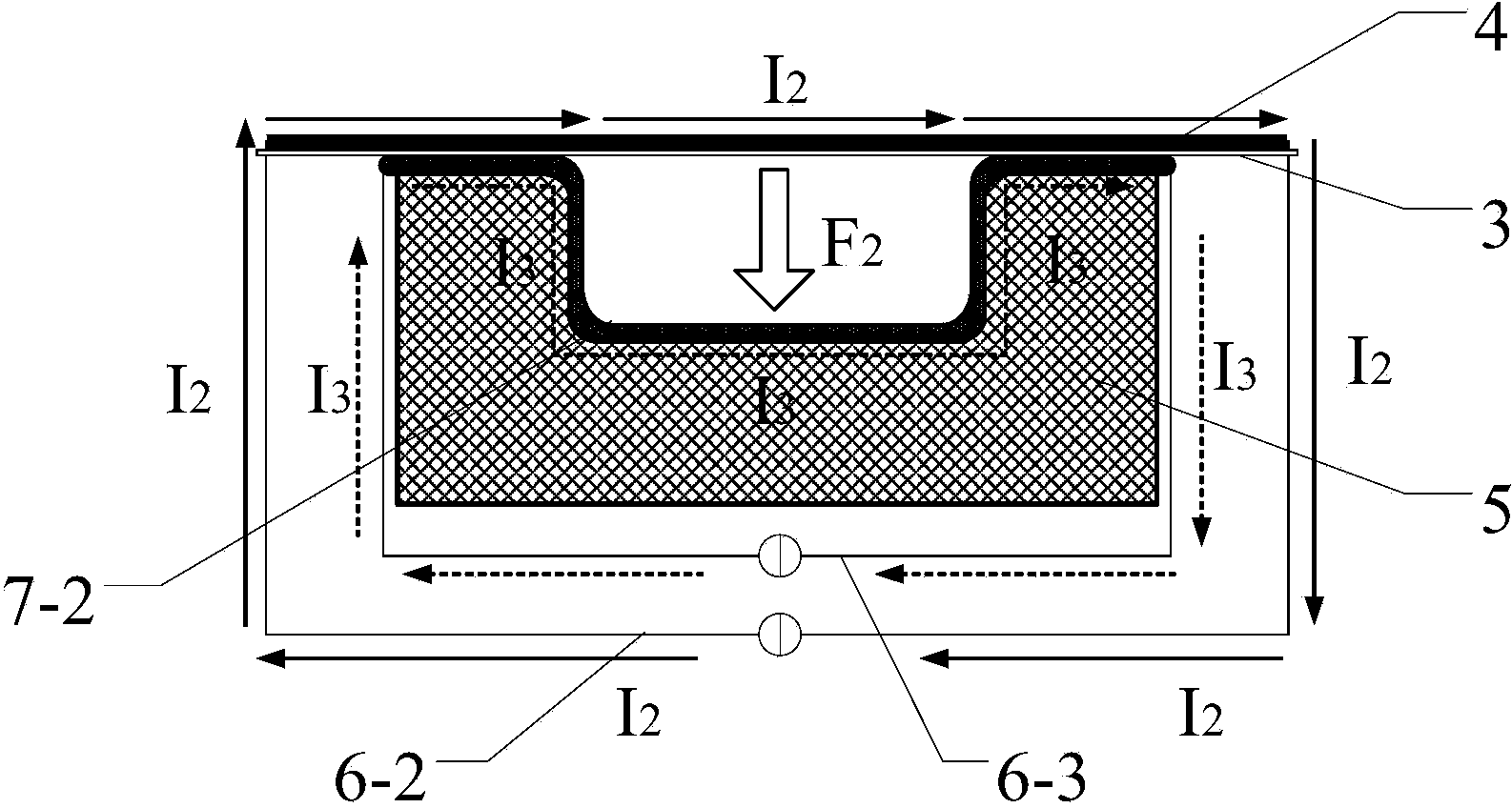

Metal material plastic forming method through electromagnetic force driving

ActiveCN103962437ADriving force is stableThe electromagnetic force is stable and continuousShaping toolsMetallic materialsElectromagnetic interference

The invention discloses a metal material plastic forming method through electromagnetic force driving. The metal material plastic forming method through electromagnetic force driving comprises the following steps that after insulating coatings are sprayed on the upper surface and the lower surface of a metal blank, the metal blank is arranged on a lower mould and is pressed through an edge pressing mould, and a certain interval is kept between an upper mould and the upper surface of the metal blank; current is applied to the metal blank, current opposite to the current of the metal blank in direction is applied to the upper mould, or / and current in the same direction as the current of the metal blank is applied to the lower mould, and downward electromagnetic force generated by mutual action of the current drives the metal blank to deform; the metal blank is attached to the upper surface of a groove of the lower mould after free expansion, mould attaching and other deformation stages under the driving of electromagnetic force, and the metal blank plastically deforms until formation. The invention further discloses a corresponding forming device. By means of the metal material plastic forming method through electromagnetic force driving, stable and continuous electromagnetic force is generated through the current, obviously improves deformation efficiency, increases the plasticity of materials, saves energy, and is suitable for the plastic formation of various metal plates.

Owner:HUAZHONG UNIV OF SCI & TECH

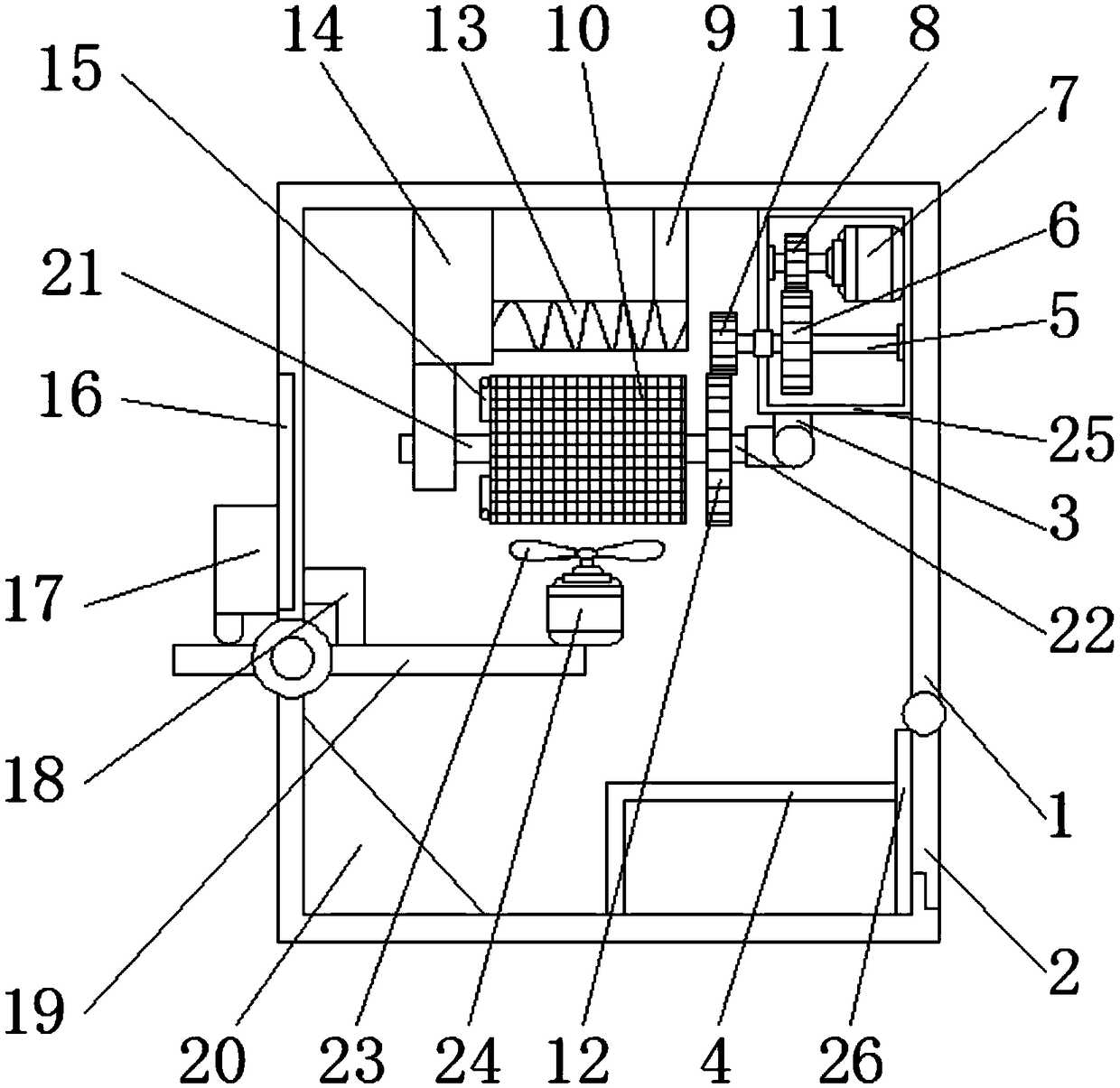

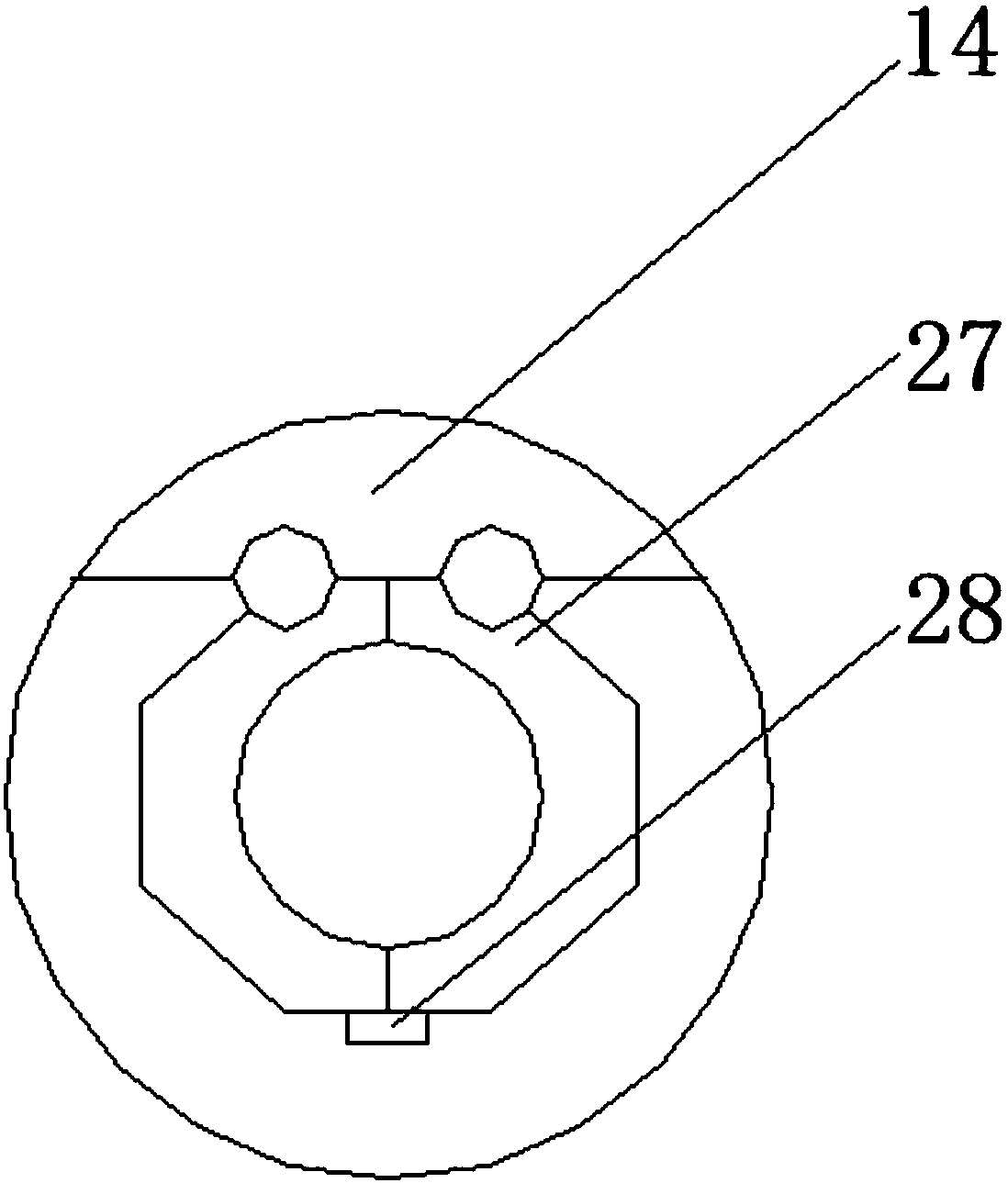

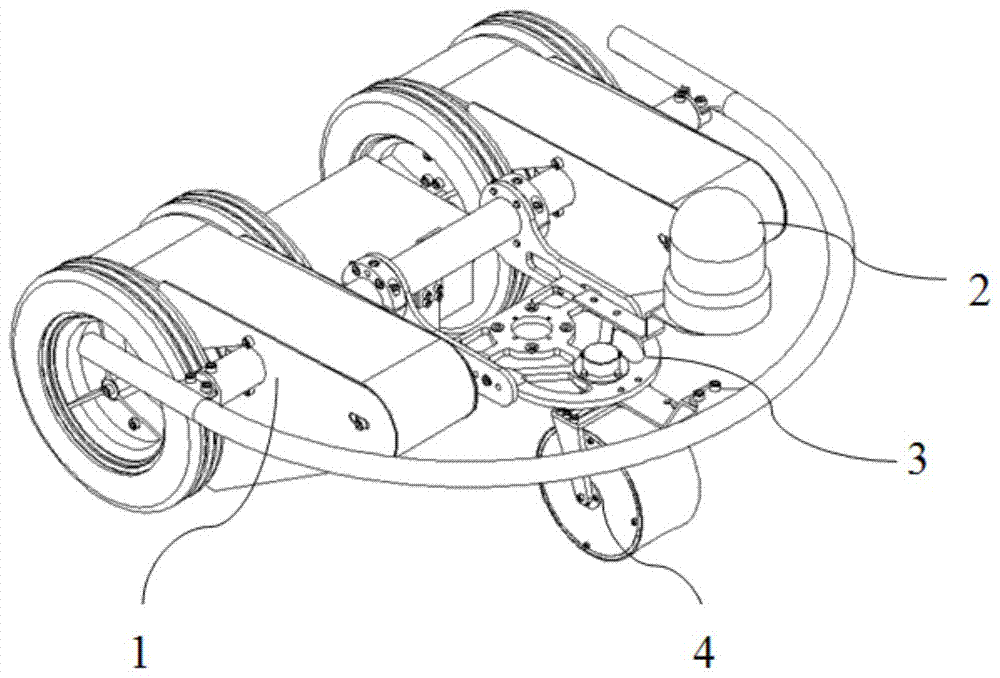

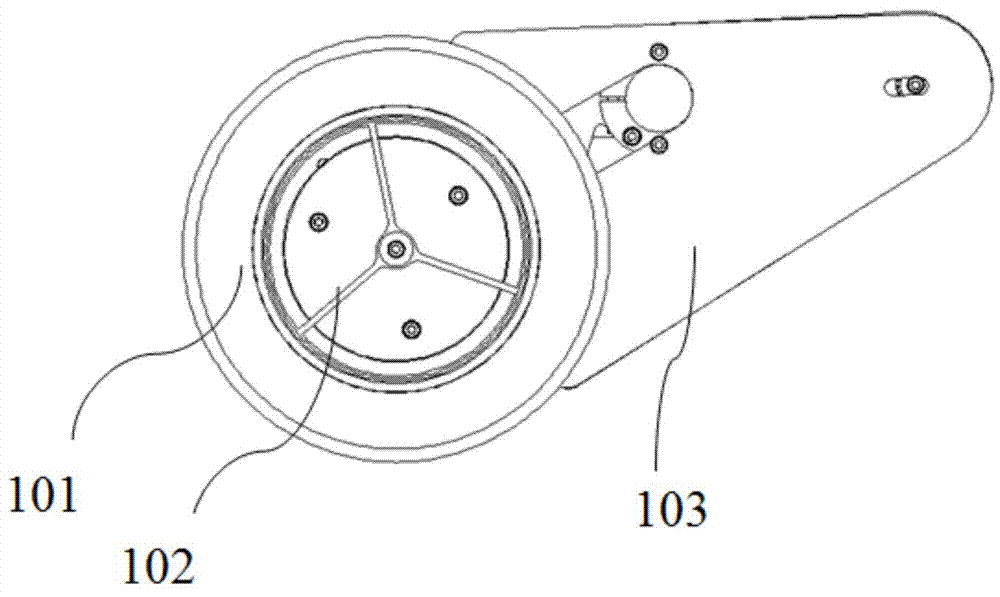

Multi-cavity crab-type negative-pressure wall-climbing robot

InactiveCN103802905AGood continuity of motionImprove reliability and adaptabilityVehiclesWall climbingClimbing robots

The invention discloses a wall-climbing robot which comprises a power system, an adsorption system and a control system. The power system comprises a wheel, a driving motor, a rotating disc, a linear motor, a pushing rod and a connecting rod. The adsorption system comprises a high-speed motor, a fan, labyrinth cavities and a vacuum air supplement valve device. Due to the multi-cavity structure, reliability and adaptability of the wall-climbing robot in the working process are improved. Meanwhile, due to the vacuum air supplement valve device, the walking driving force of the wall-climbing robot is more stable, and adaptability of the wall-climbing robot to different wall faces is improved. The wall-climbing robot can be used for conducting crack inspection on a nuclear waste liquid tank and a reactor pressure tank, conducting thickness measurement and weld joint flaw detection, conducting coating on large wall faces, cleaning the glass wall faces, installing ceramic tiles, conducting bridge flaw detection and conducting inspection, measurement and maintenance on the inner wall face and the outer wall face of a large circular tank or a spherical tank, and can also be used for conducting rust removal, spray coating and the like on a ship.

Owner:王也

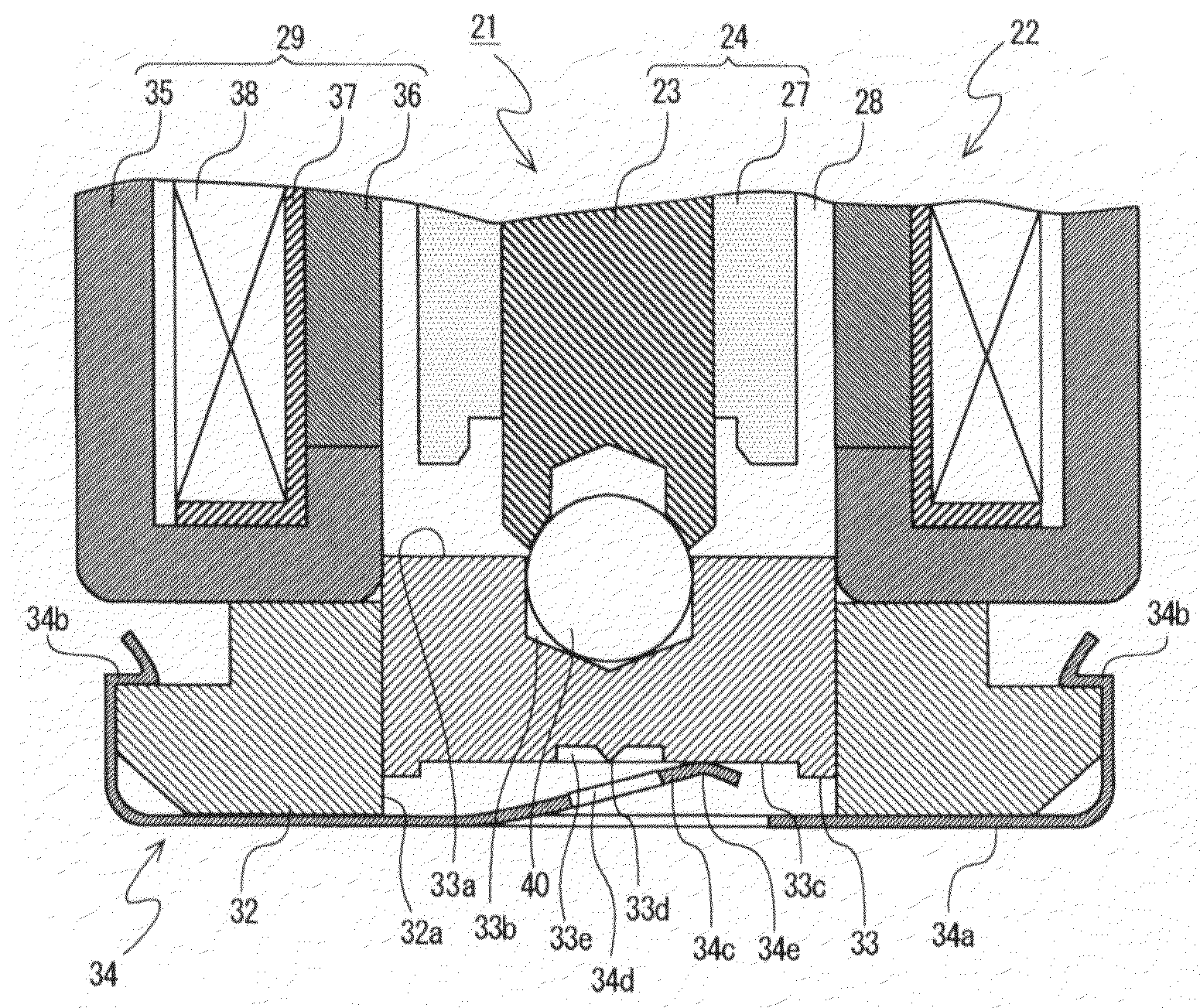

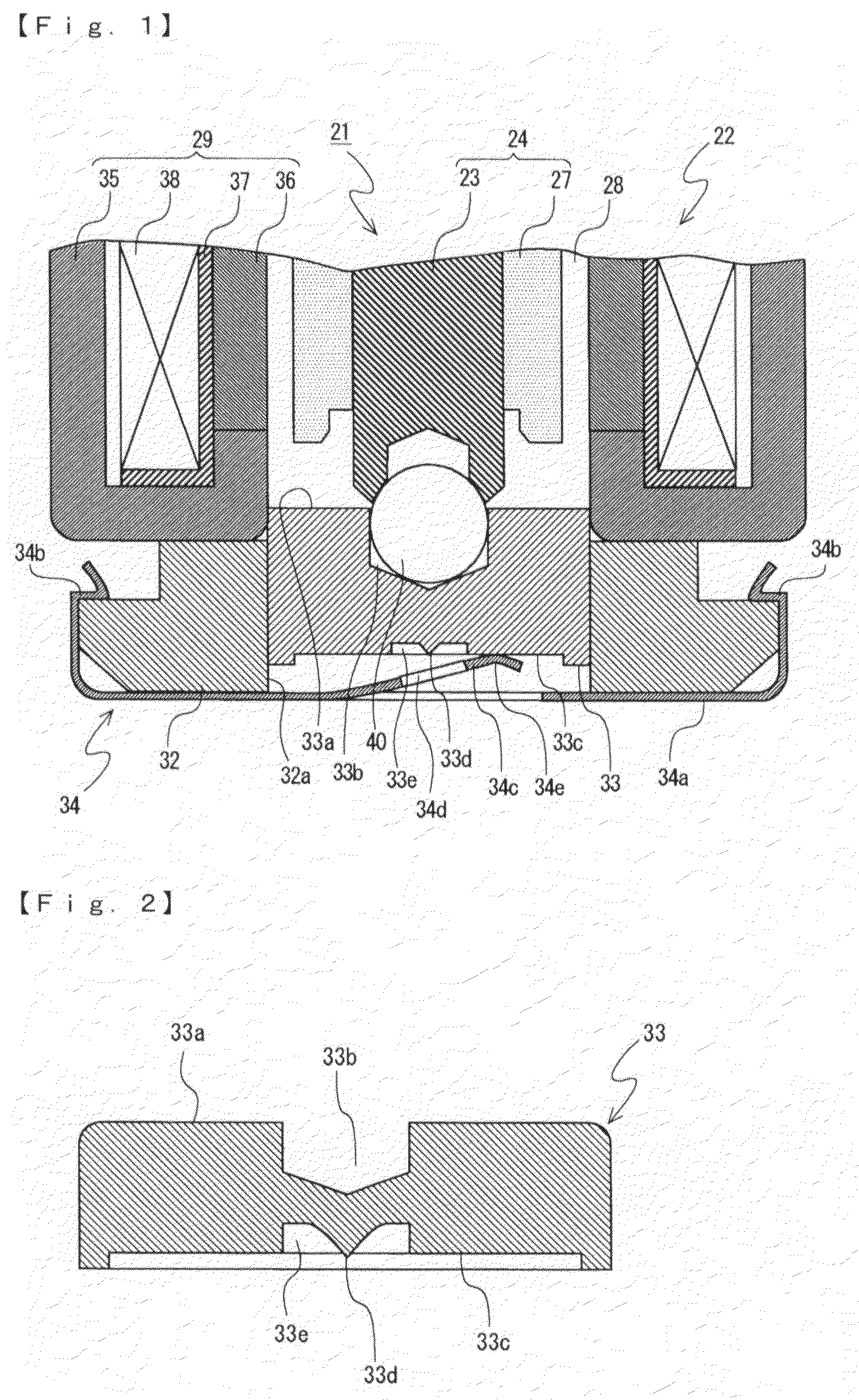

Motor

InactiveUS20070222313A1Simple moldingLarge abuttingShaftsMagnetic circuit stationary partsEngineeringMetal

A motor may include a bearing made of resin for rotatably supporting one end part of the rotor shaft, and an urging member attached to a bearing holder and abutted with a pressurization face of the bearing to urge the bearing toward a side of the rotor shaft. A molding material injection gate trace (projection) which has been used when the bearing is resin-molded is positioned at a center portion of the pressurization face. The molding material injection gate trace may be positioned in a recessed part which is formed at a roughly center portion of the pressurization face of the bearing. Further, the urging member may include an urging piece which is formed by cutting a center portion of a metal plate in a ring shape and an opening part is formed in the urging piece.

Owner:SANKYO SEIKI MFG CO LTD

Gecko robot

InactiveCN103832500AGood continuity of motionOvercoming adaptation problemsVehiclesControl systemLiquid tank

The invention discloses a gecko robot. The gecko robot comprises a power system, an absorption system and a control system. The power system comprises wheels, a drive motor, a rotary disc, a linear motor, a push rod and a connecting rod. The absorption system comprises a high-speed motor, a fan, labyrinth-type cavities and a vacuum air supplement device. Due to the multi-cavity structure, the reliability and adaptability of the robot in the working process are improved. By the vacuum air supplement device, walking drive force of the robot is more stable, and the capacity of the robot of adapting to different walls is enhanced. The gecko robot can be used for detecting cracks, measuring thicknesses and detecting cracks of weld joints of nuclear waste liquid tanks and reactor pressure tanks, for spraying giant walls, cleaning glass walls, installing tiles, detecting cracks of bridges, and detecting, measuring and maintaining inner walls and outer walls of circular large tanks or spherical tanks, and can also be used for rust removing, spraying and the like of ships.

Owner:上海市闵行区知识产权保护协会 +1

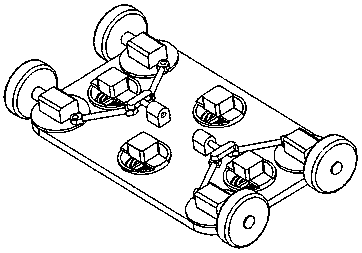

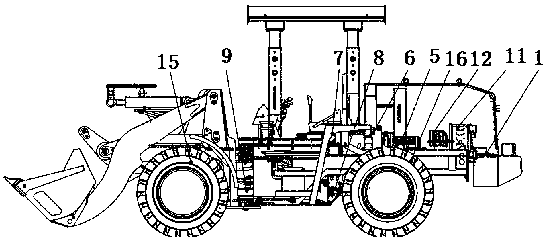

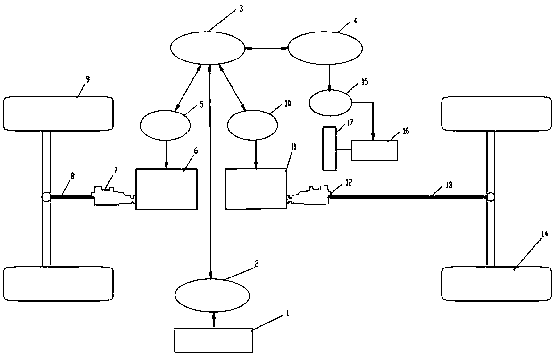

Drive control system for pure electric loader

PendingCN109457744AReduce use costReduce noiseMechanical machines/dredgersHydraulic motorTransfer case

The invention discloses a drive control system for a pure electric loader and belongs to the technical field of shoveling-transferring engineering mechanical vehicles. A traveling system is connectedto the lower side of a machine body. The machine body is provided with a hydraulic system and further provided with a hydraulic motor and a traveling motor. The hydraulic motor is connected with a hydraulic pump. The hydraulic pump supplies power to the hydraulic system. The traveling motor is connected with a traveling system through a transmission system. The transmission system comprises a fully-automatic speed changing box connected with the hydraulic motor. The output end of the fully-automatic speed changing box is connected with a transfer case. The transfer case is connected with the traveling system and supplies power to the traveling system. According to the drive control system, the traveling system is driven by the traveling motor, and the hydraulic system is driven by the hydraulic motor; compared with mechanical transmission adopted in the prior art, the traveling system is high in transmission efficiency, electrodeless speed changing can be achieved, and gear shifting isachieved easily; the power is great; the hydraulic system can provide stable and efficient powerful driving force; the drive control system is great in universality and convenient to maintain; and defects of an existing loader are overcome.

Owner:XCMG CONSTR MACHINERY

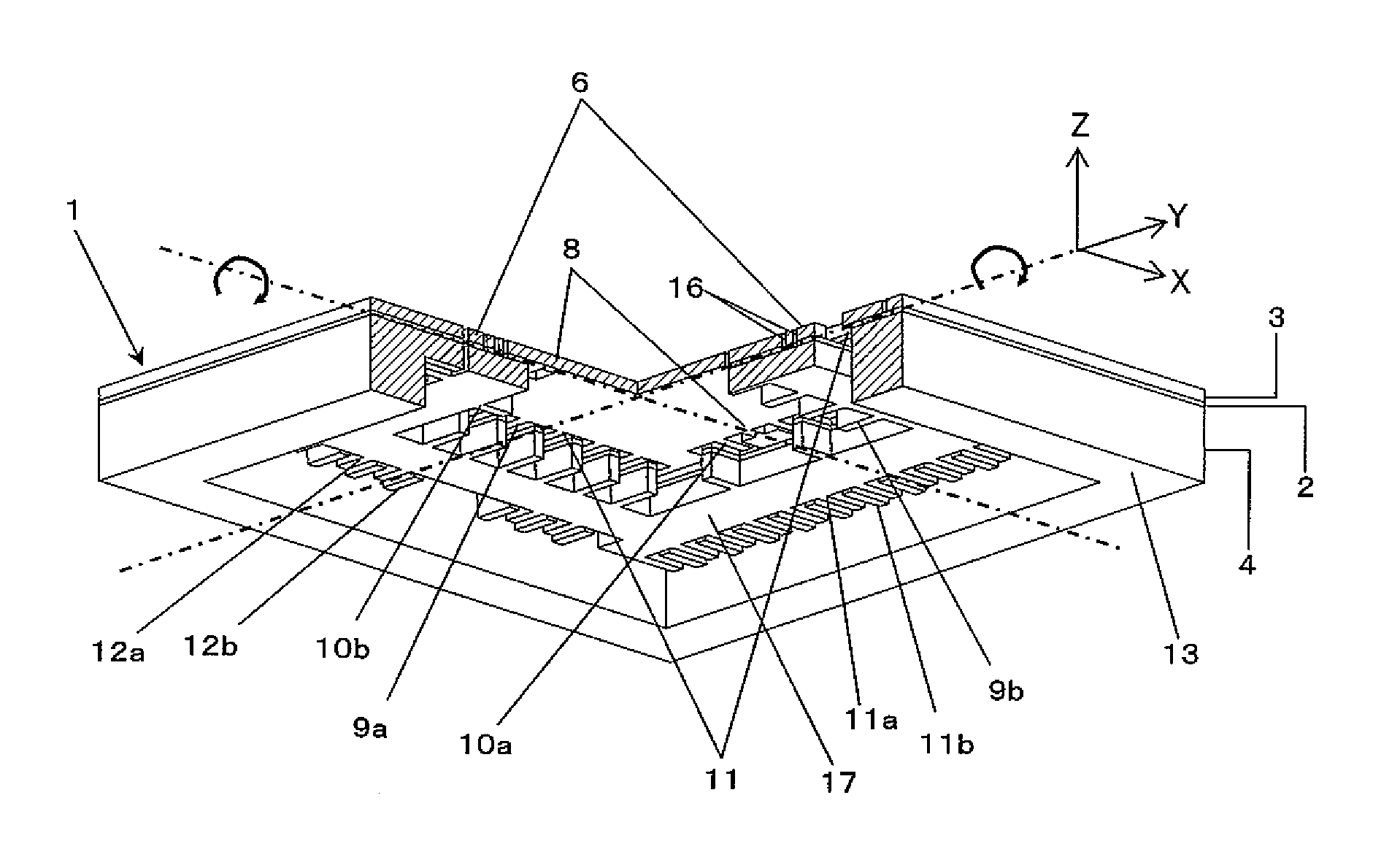

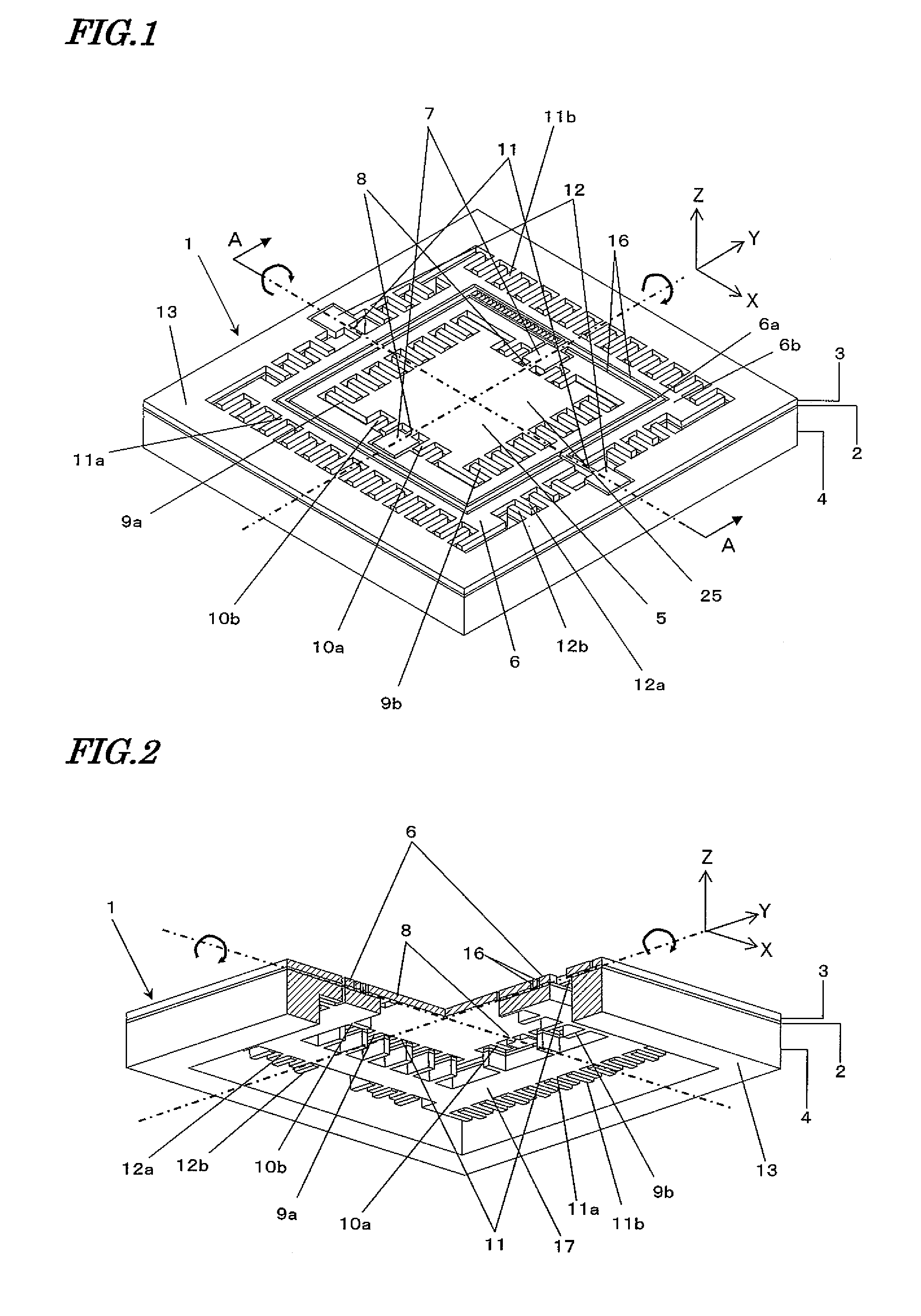

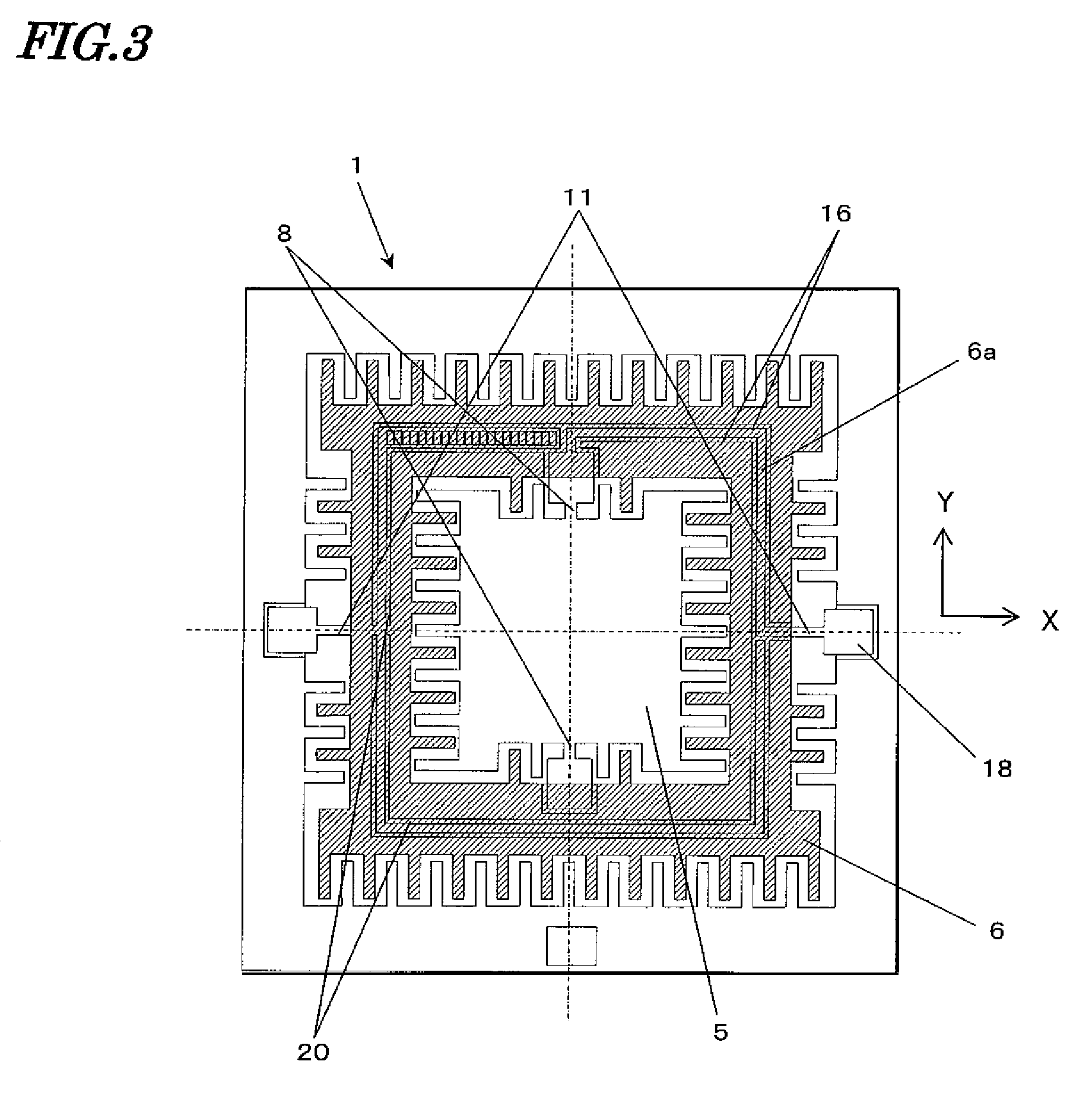

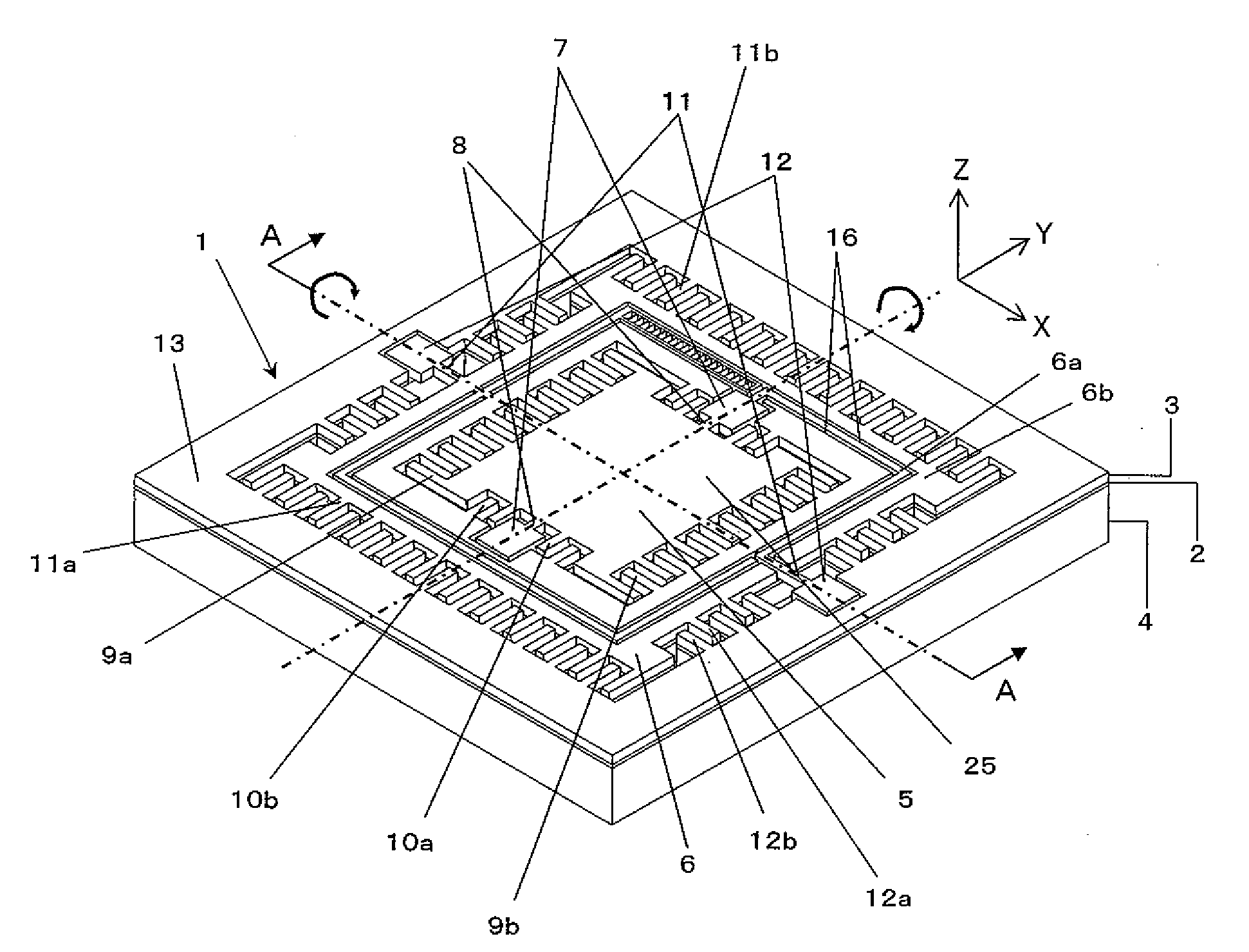

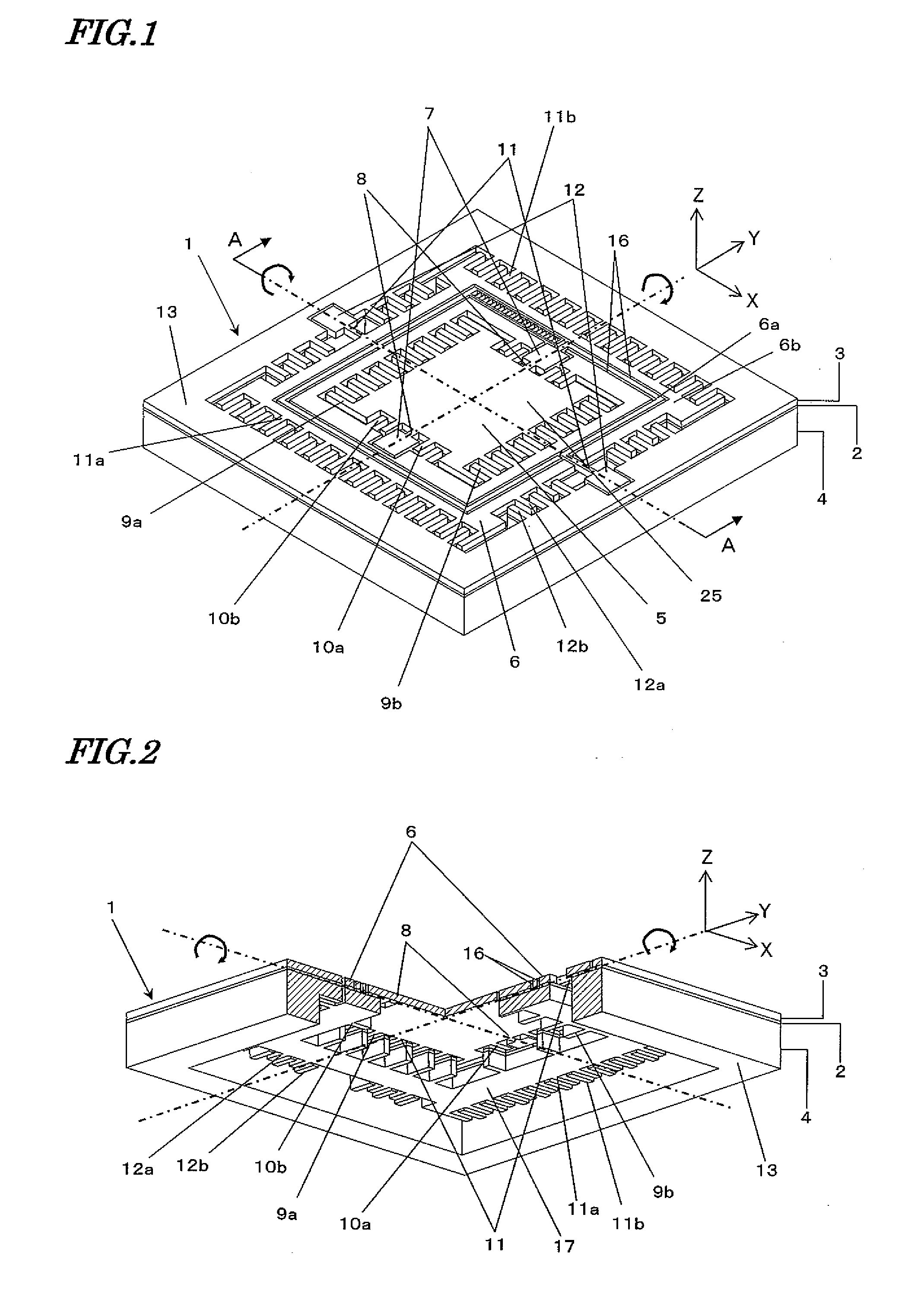

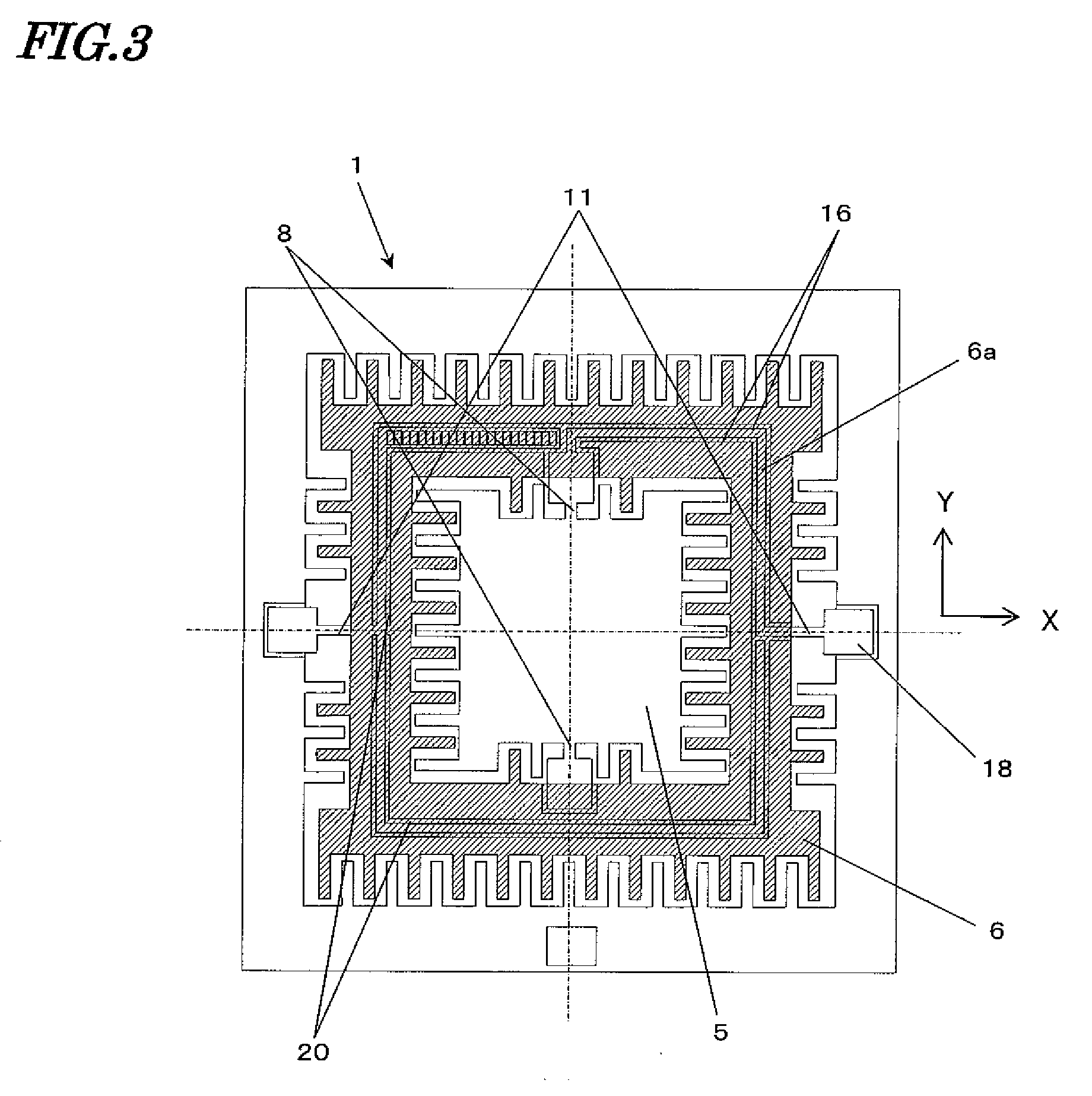

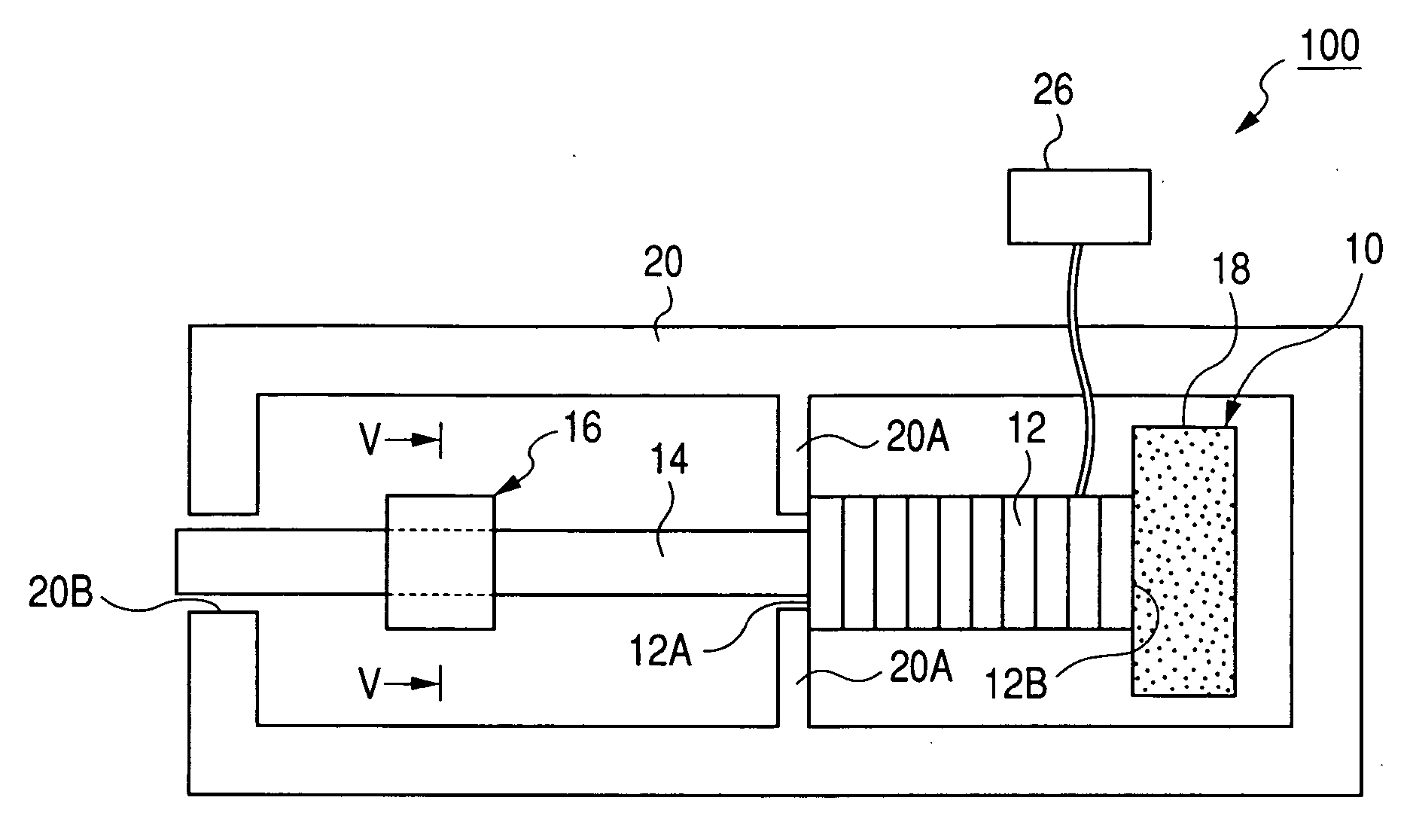

Actuator, image projection apparatus and production method for actuator

InactiveUS7923894B2Surely stabilizedSimplify production stepsElectrostatic motorsFlexible microstructural devicesElectricityActuator

The present invention is directed to a bi-axial pivoting type actuator having a first movable section, a second movable section supporting the first movable section, and backlining. A first conductive portion and a second conductive portion for independently applying a driving voltage to each of the first movable section and the second movable section are provided on the second movable section, in a state of being split by isolation trenches and being stabilized by the backlining provided under the second movable section. By providing such backlining, mutual stabilization of the first conductive portion and the second conductive portion in an electrically isolated state, and simplification of the production steps for the actuator are realized. By providing a mirror on the first conductive portion of the actuator of the present invention as such, it becomes possible to provide a bi-axial pivoting type mirror device through a simple production process.

Owner:PANASONIC CORP

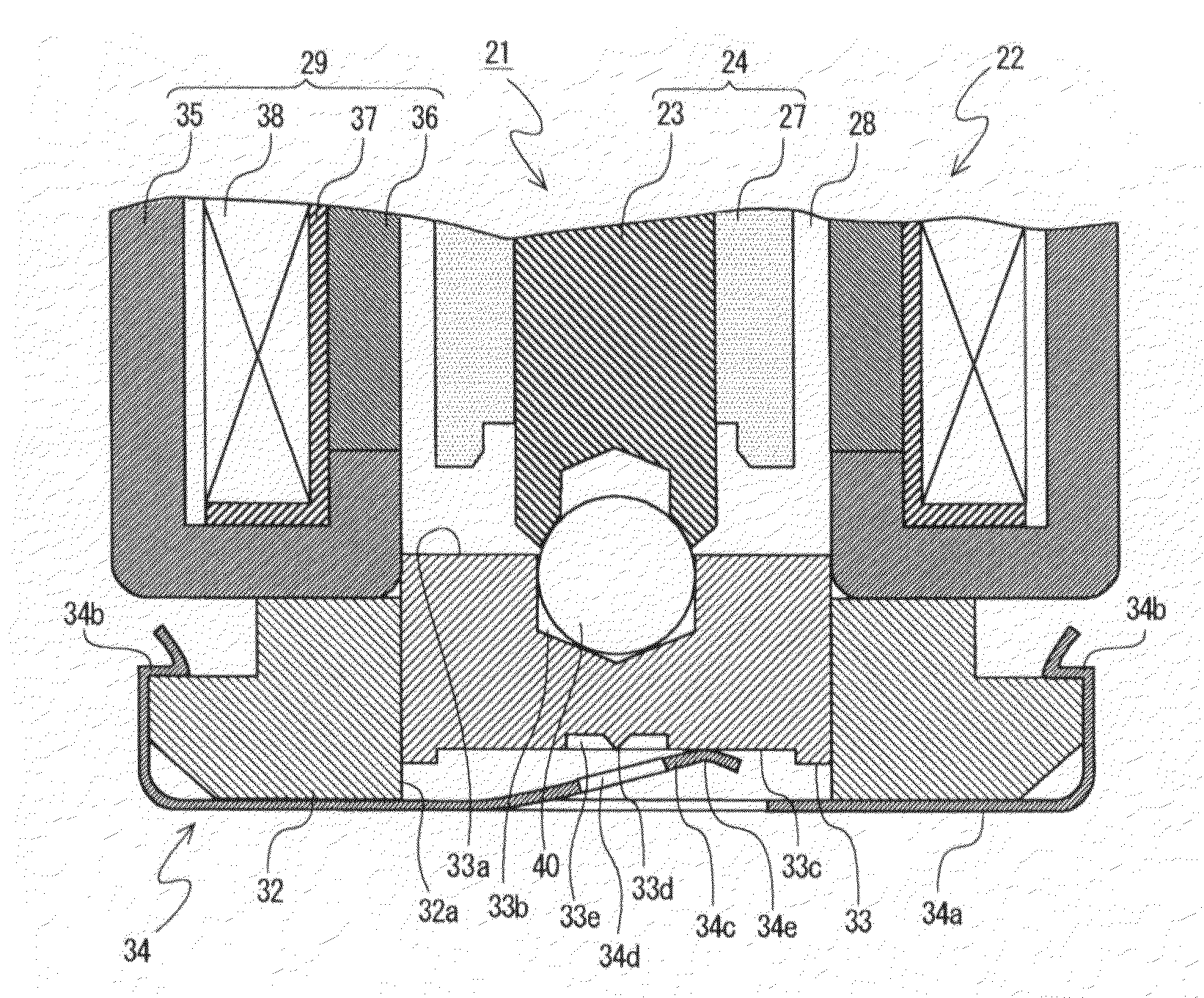

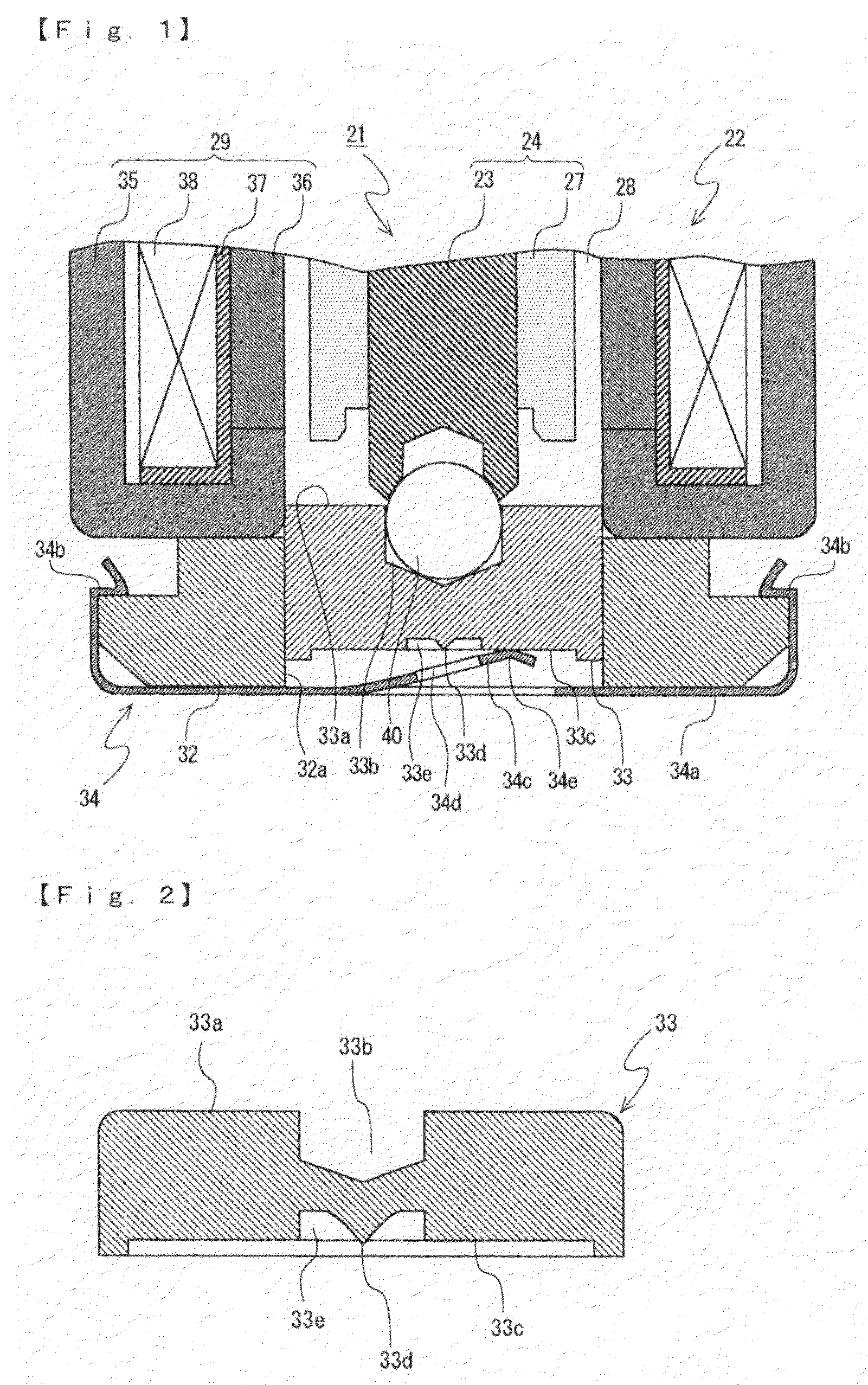

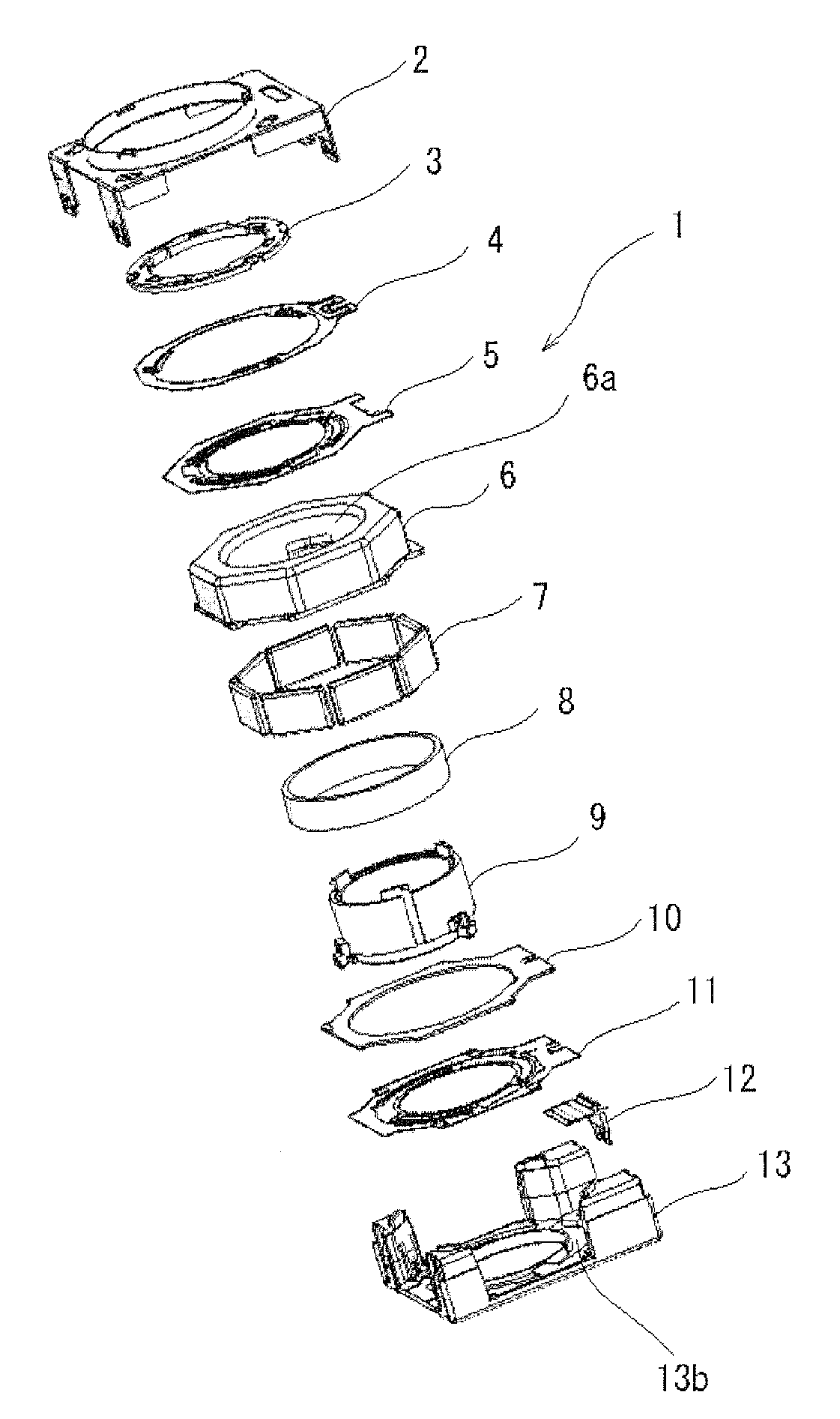

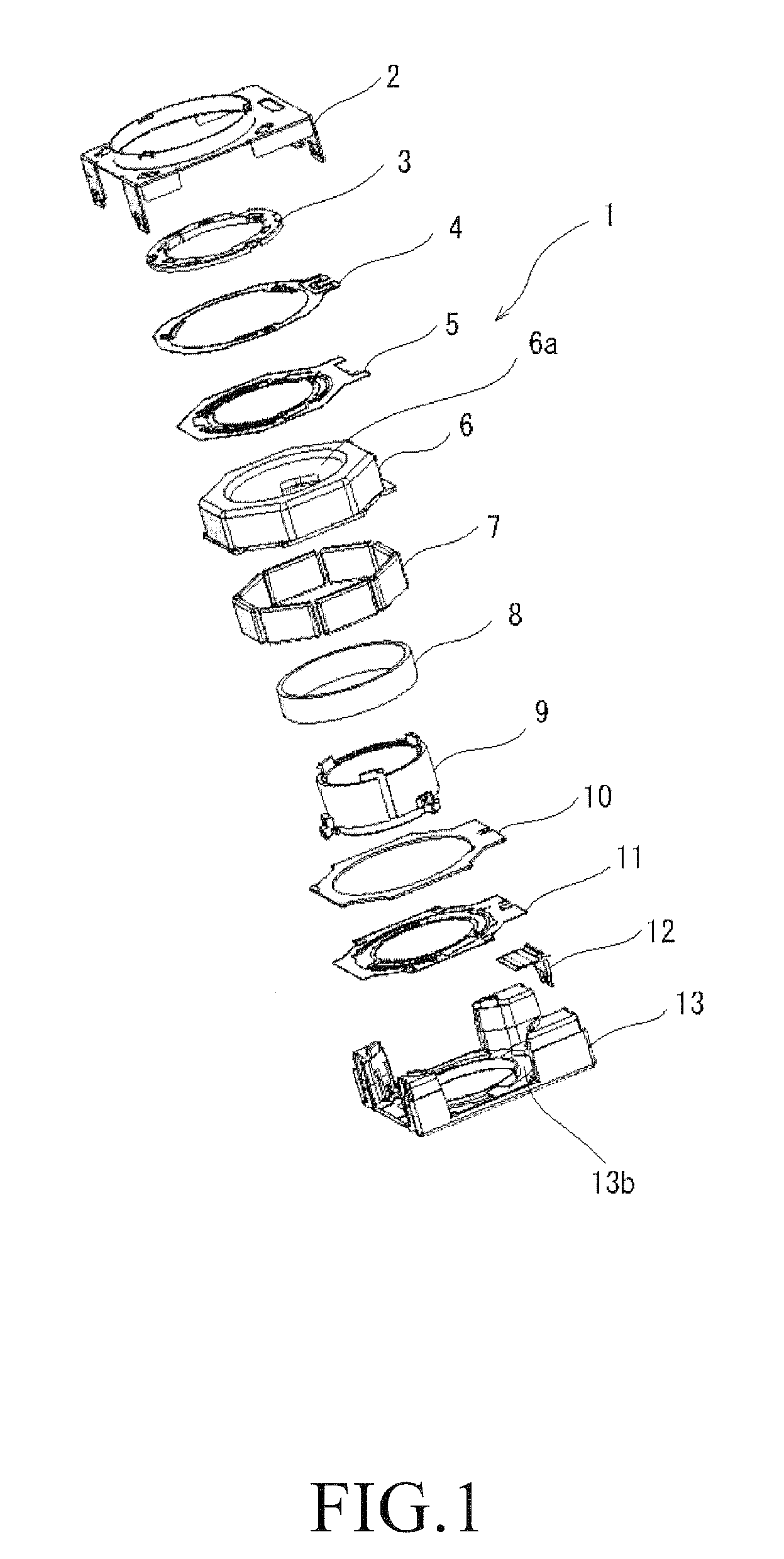

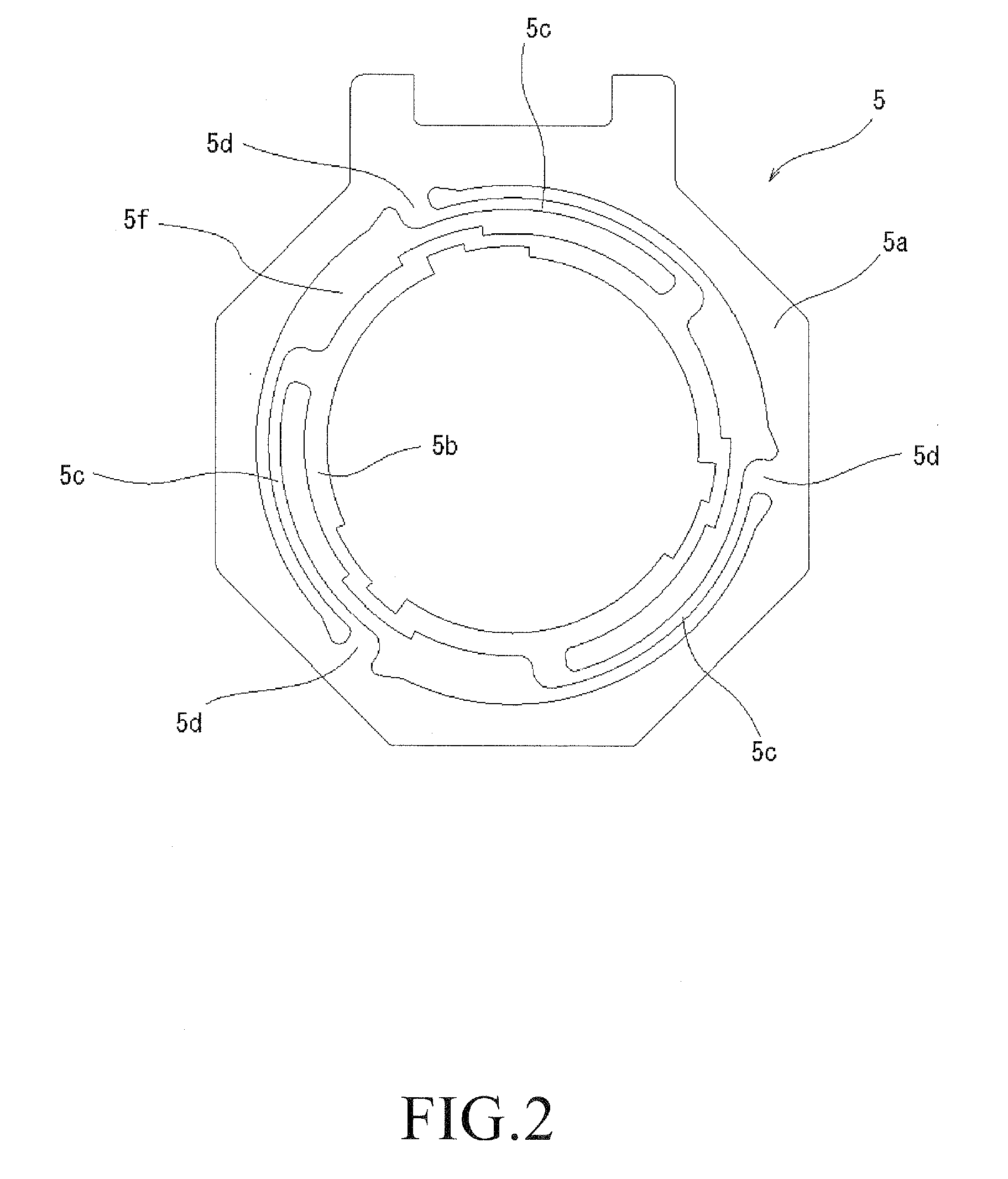

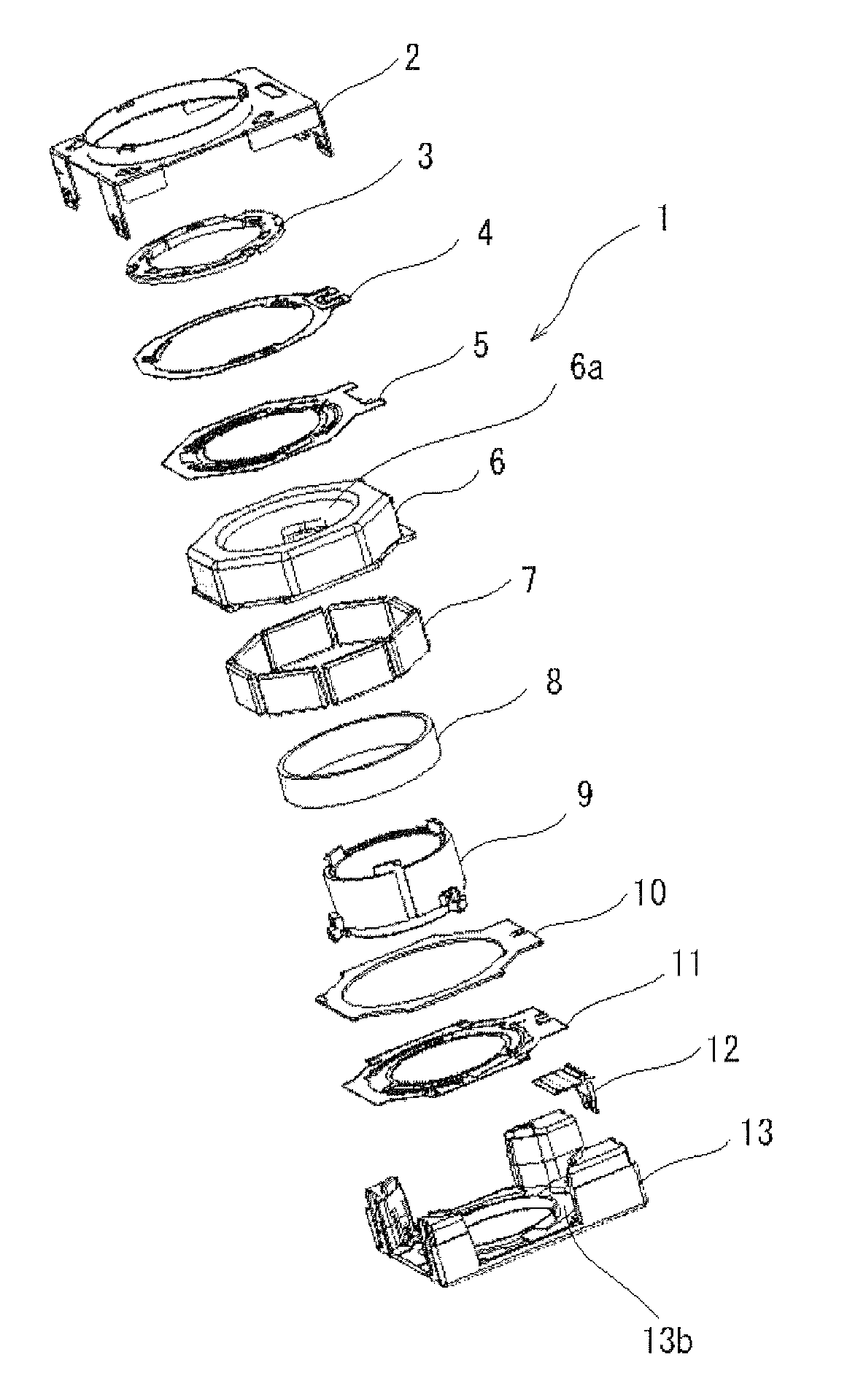

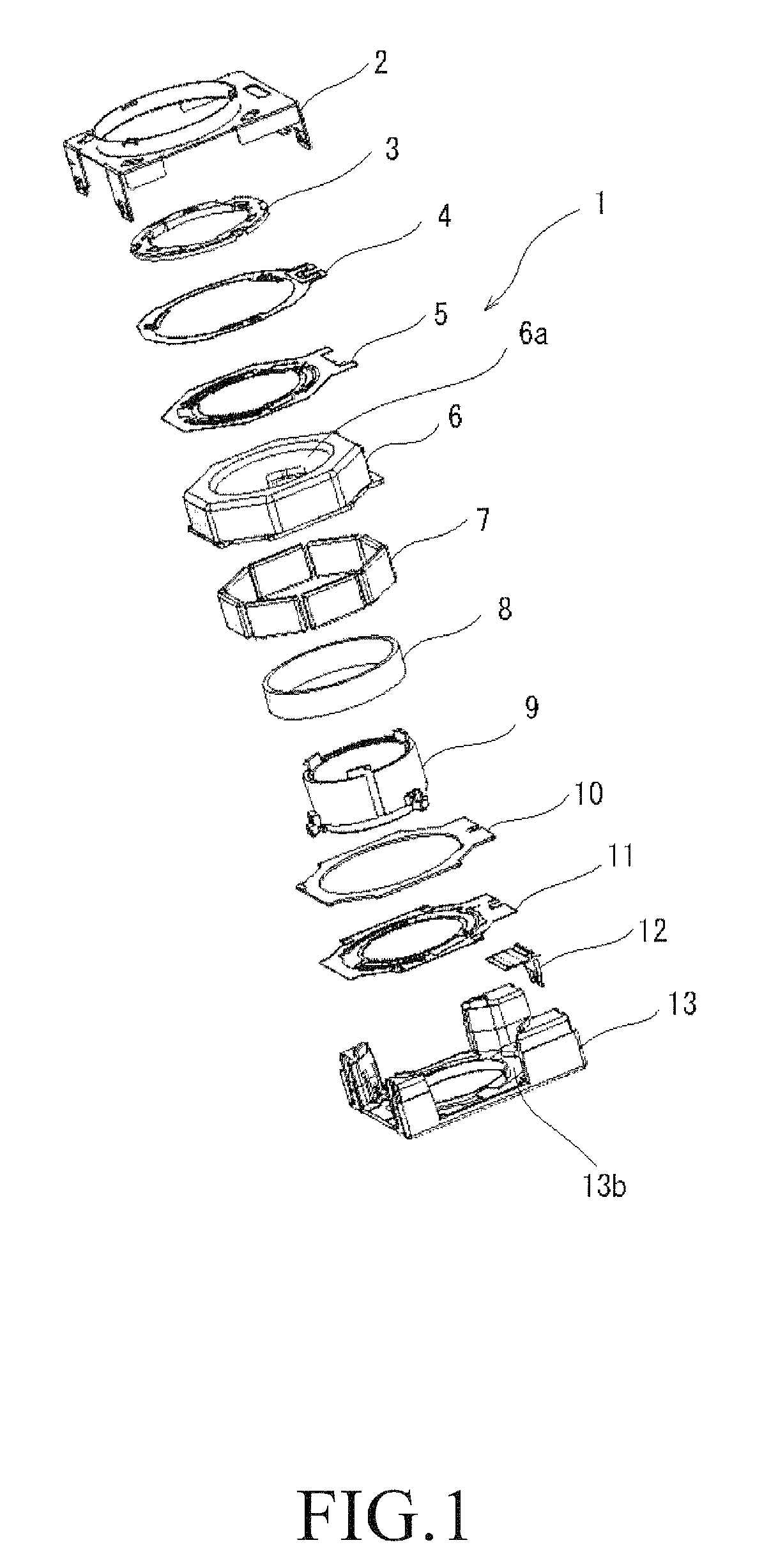

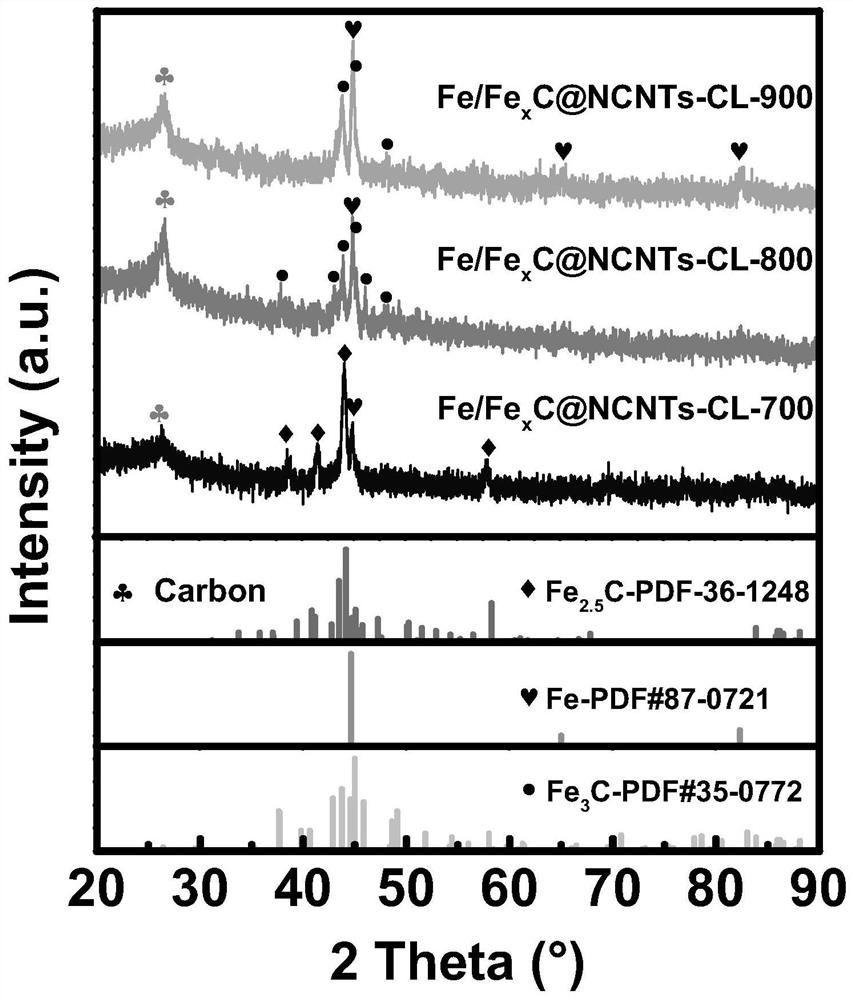

Camera module

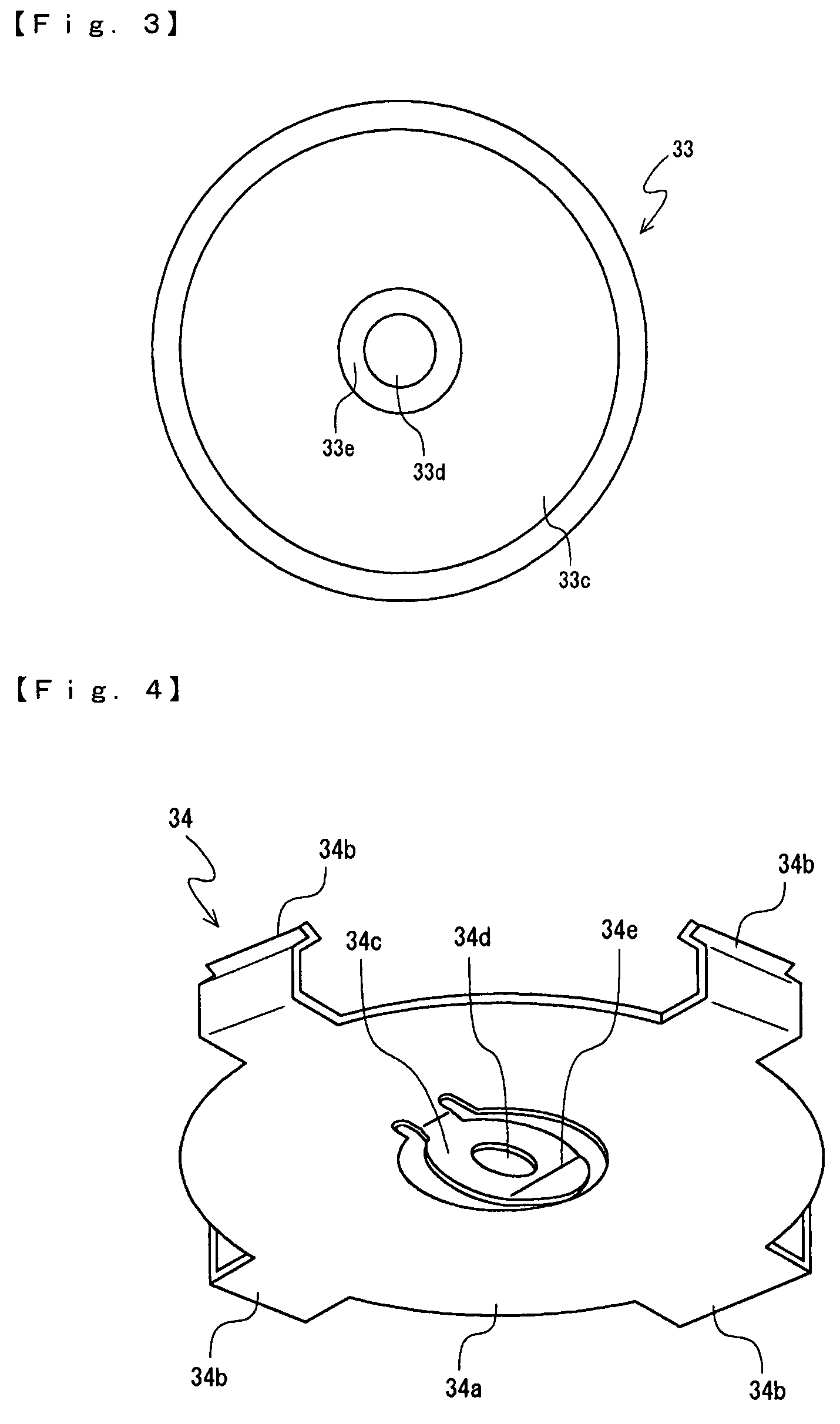

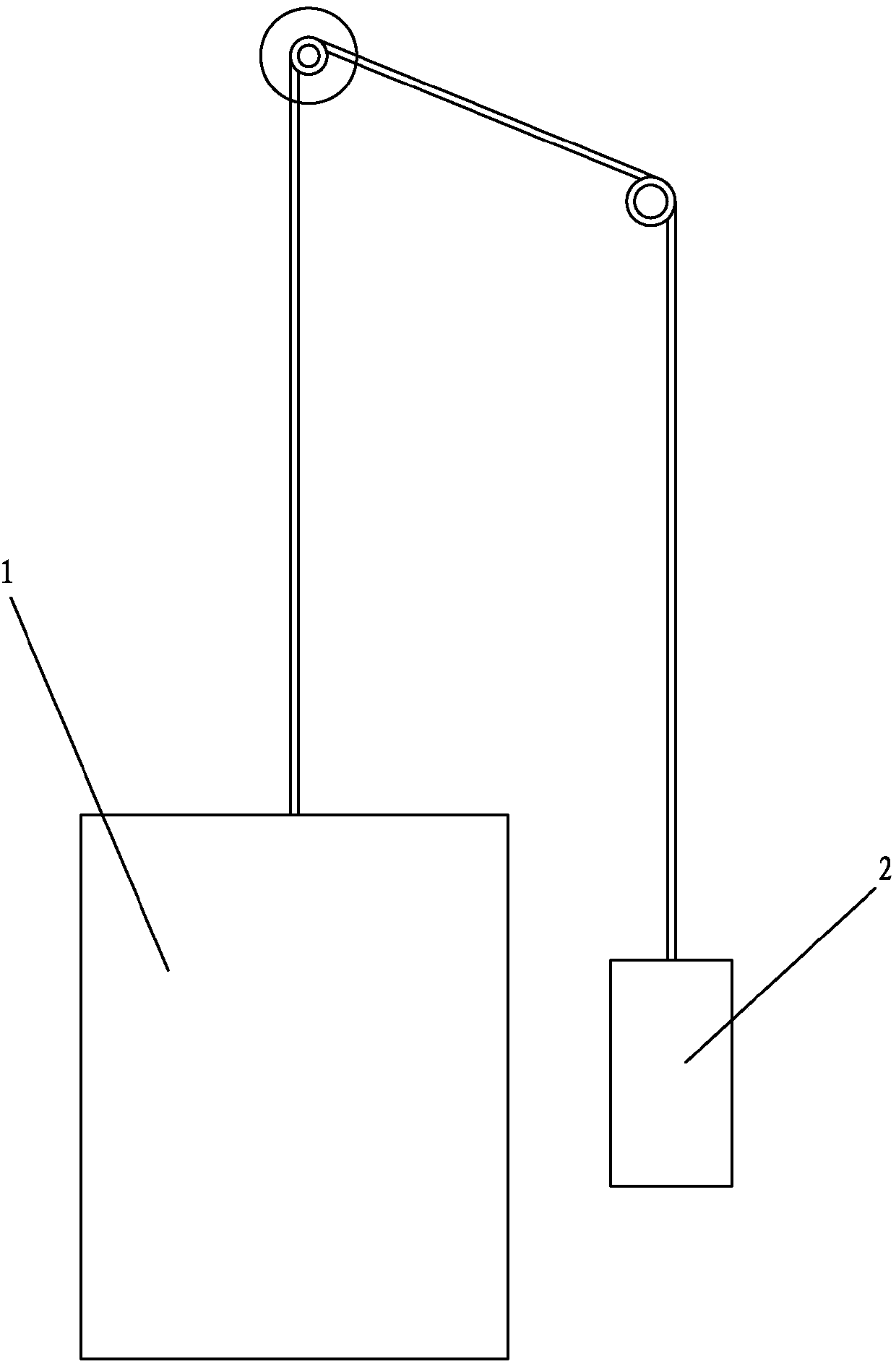

ActiveUS20080266682A1Easily adjust resiliencyPrevent leakageMountingsFocusing aidsCamera moduleEngineering

A camera module includes upper and lower leaf springs having a stable load characteristic and a holder displaceably held by the leaf springs so that the holder can be stably displaced within a magnetic circuit. The upper spring 5 has an outer annular portion 5a, an inner annular portion 5b provided inside the outer annular portion 5a so as to be displaceable with respect to the outer annular portion 5a and attached to the holder 9, and a plurality of bridge portions 5c coupled between the outer annular portion 5a and the inner annular portion 5b. The camera module further includes a bridge portion supporting member 4 for supporting a part of at least one of the plurality of bridge portions so that a load characteristic of the leaf spring can be changed. By rotating the bridge portion supporting member 4 in a clockwise direction, an overlapping part between the extending part 4c and the bridge portion 5c is increased according to the amount of the rotation so that a spring constant of the upper leaf spring 5 is apparently increased.

Owner:MITSUMI ELECTRIC CO LTD

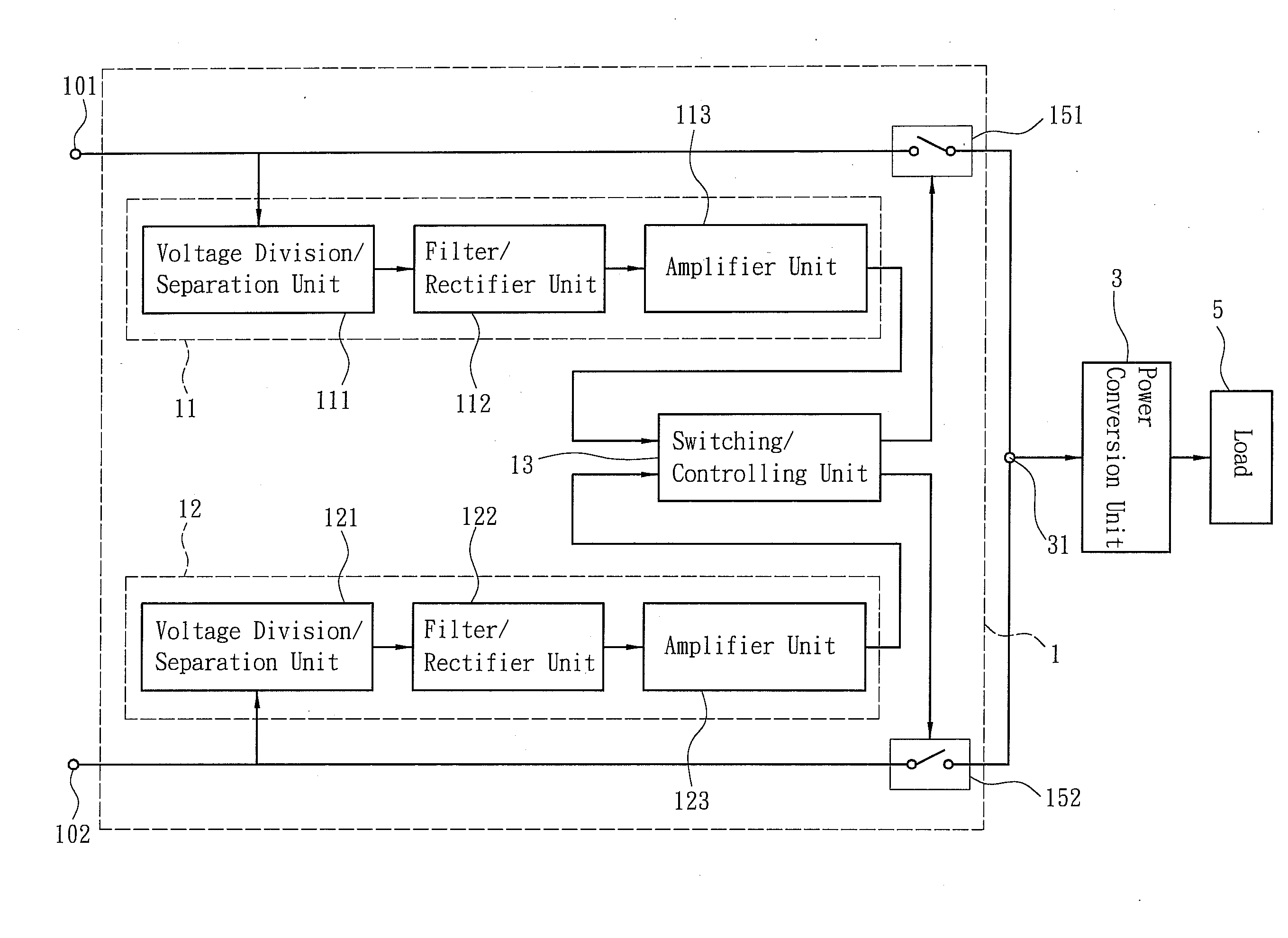

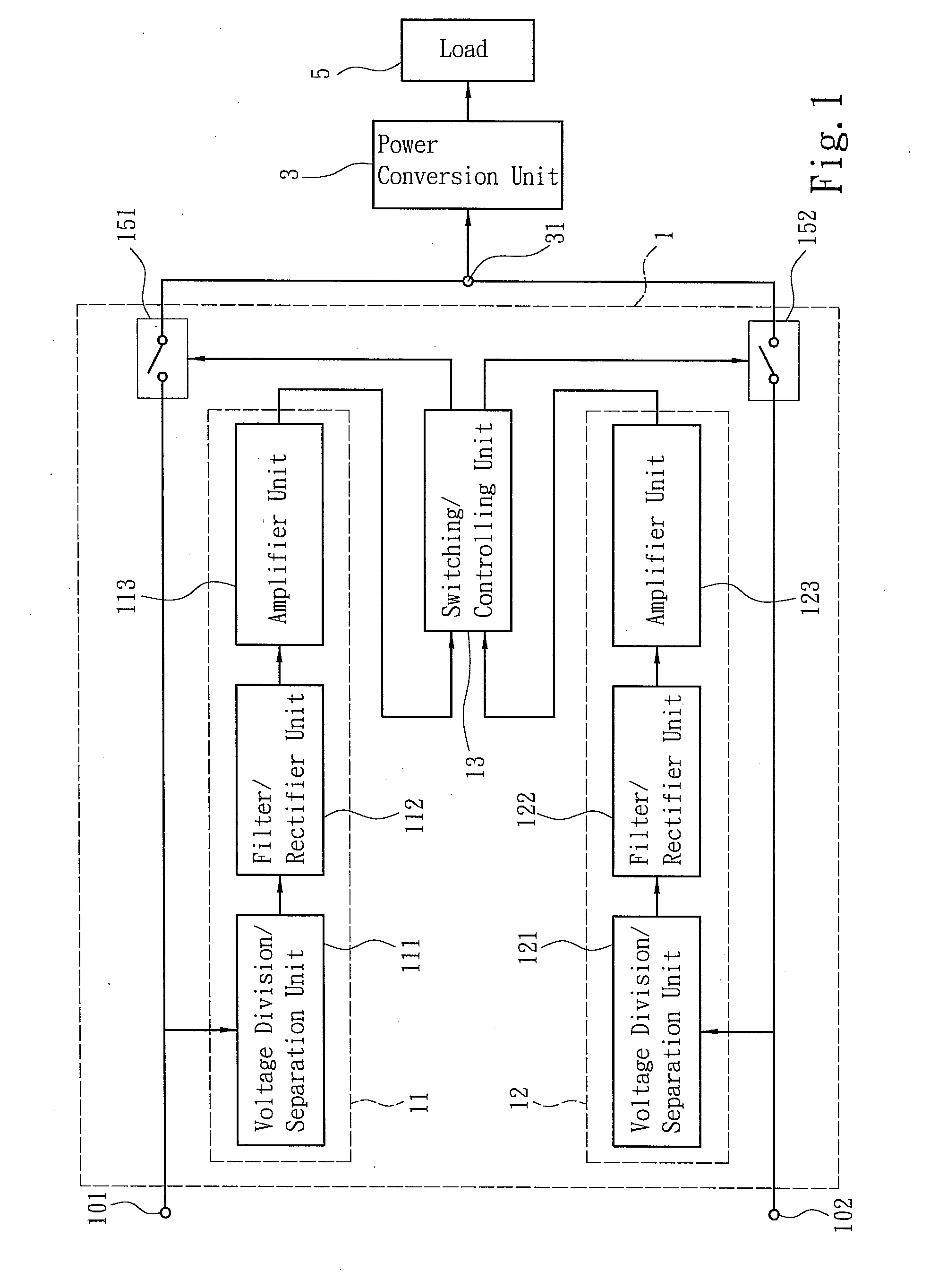

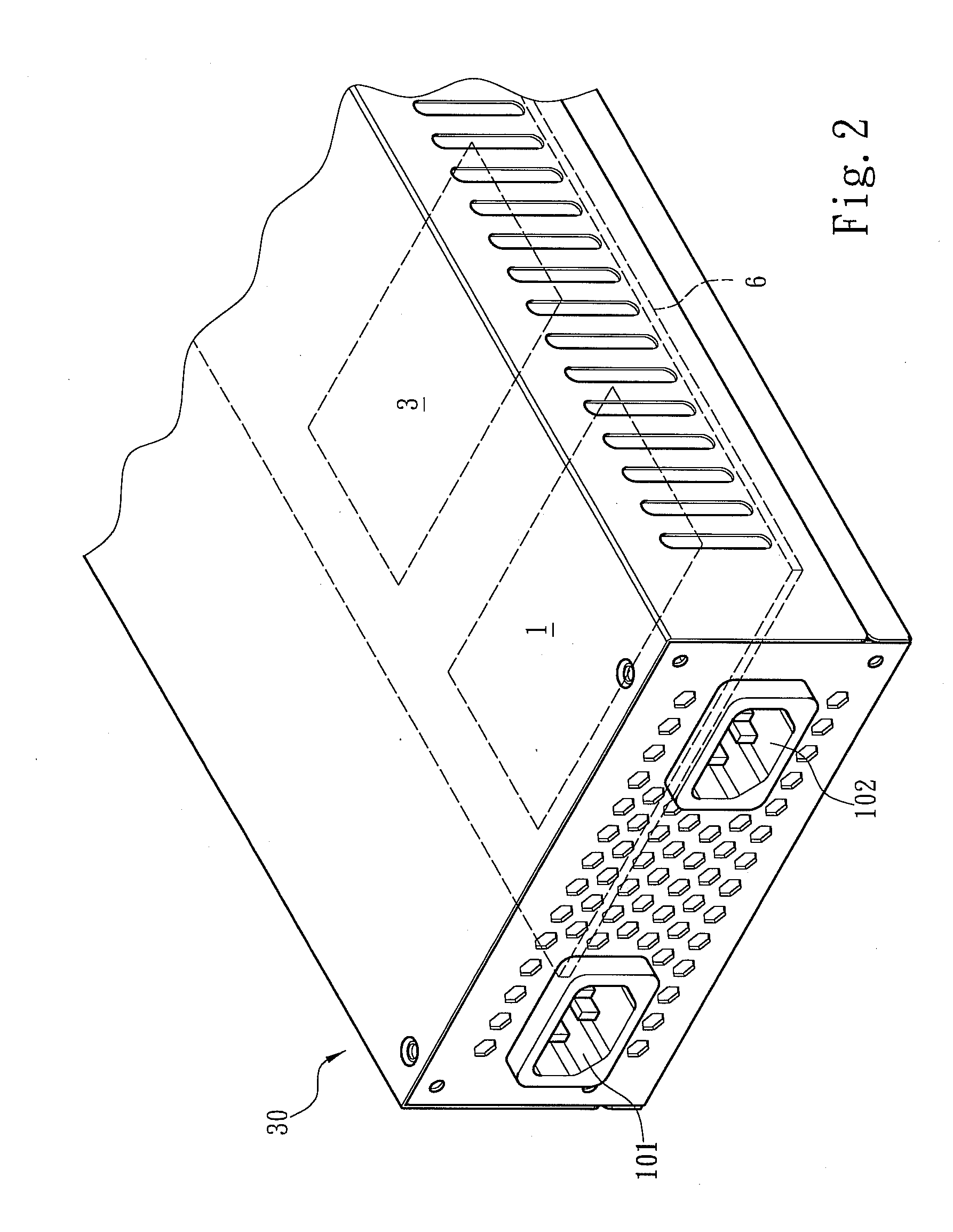

Multi-input power-switching circuit

InactiveUS20090284077A1Driving force is stableEasy to operateDc network circuit arrangementsSelective ac load connection arrangementsMulti inputPower switching

The present invention discloses a multi-input power-switching circuit, which comprises: more than one power input terminal, more than one detection / evaluation circuit, and a switching / controlling unit. A switch is arranged in the path via which the input power is received by the power input terminal and then transferred to the power conversion unit. Each detection / evaluation circuit receives a partial voltage signal from one input power and generates a detection signal according to the partial voltage signal. The switching / controlling unit receives the detection signals from the detection / evaluation circuits, determines which power input terminal has a higher voltage level according to the detection signals, and generates a turn-on signal to turn on the switch connected with the power input terminal having a higher voltage level. Thereby, the power conversion unit can acquire a higher voltage input power and provide a stable driving power for a load.

Owner:ZIPPY TECH

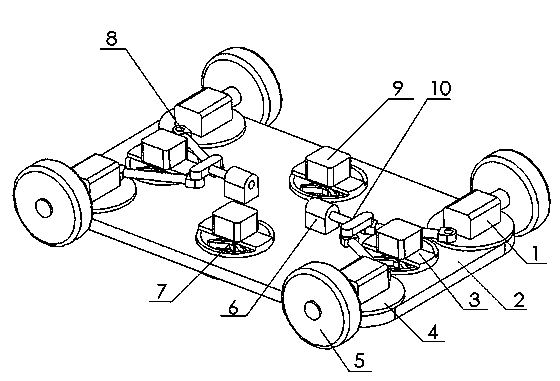

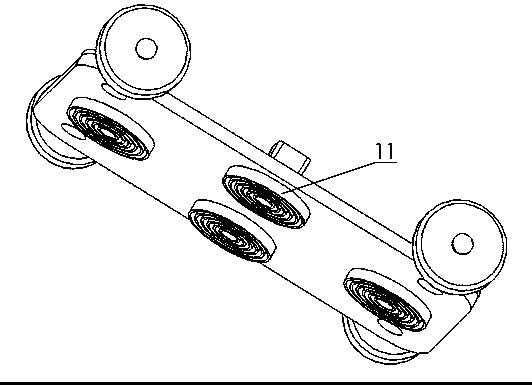

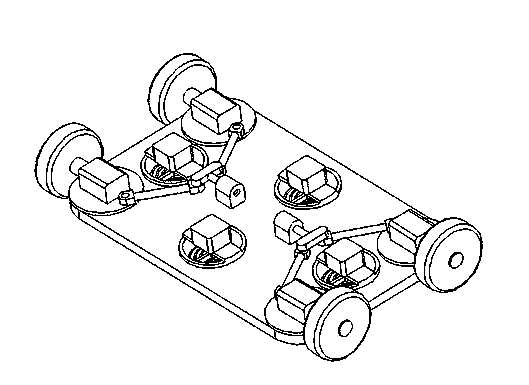

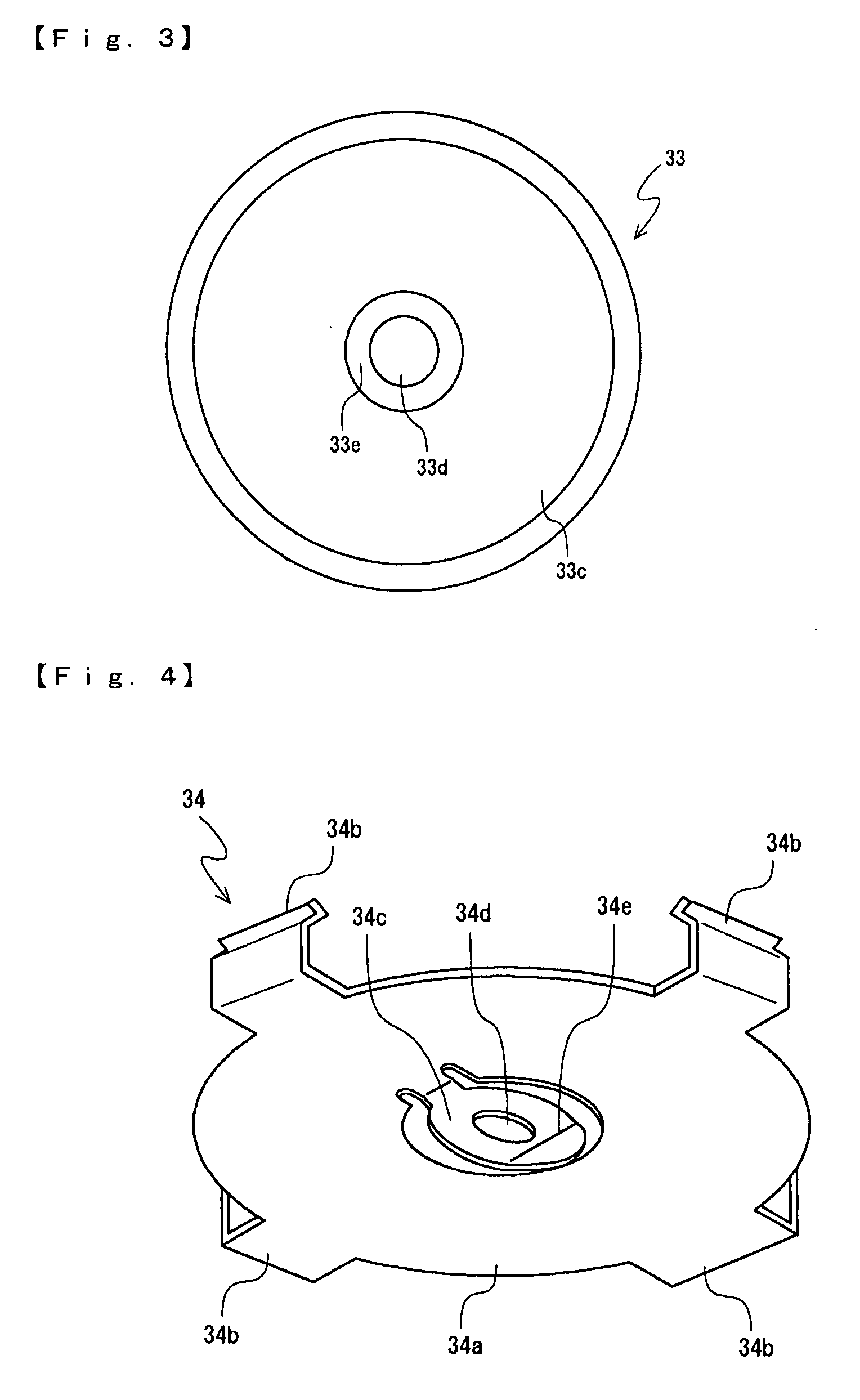

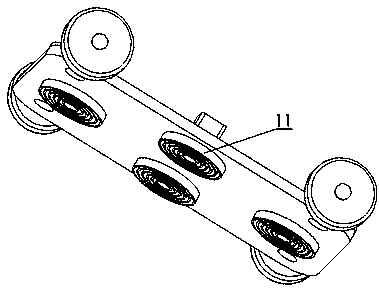

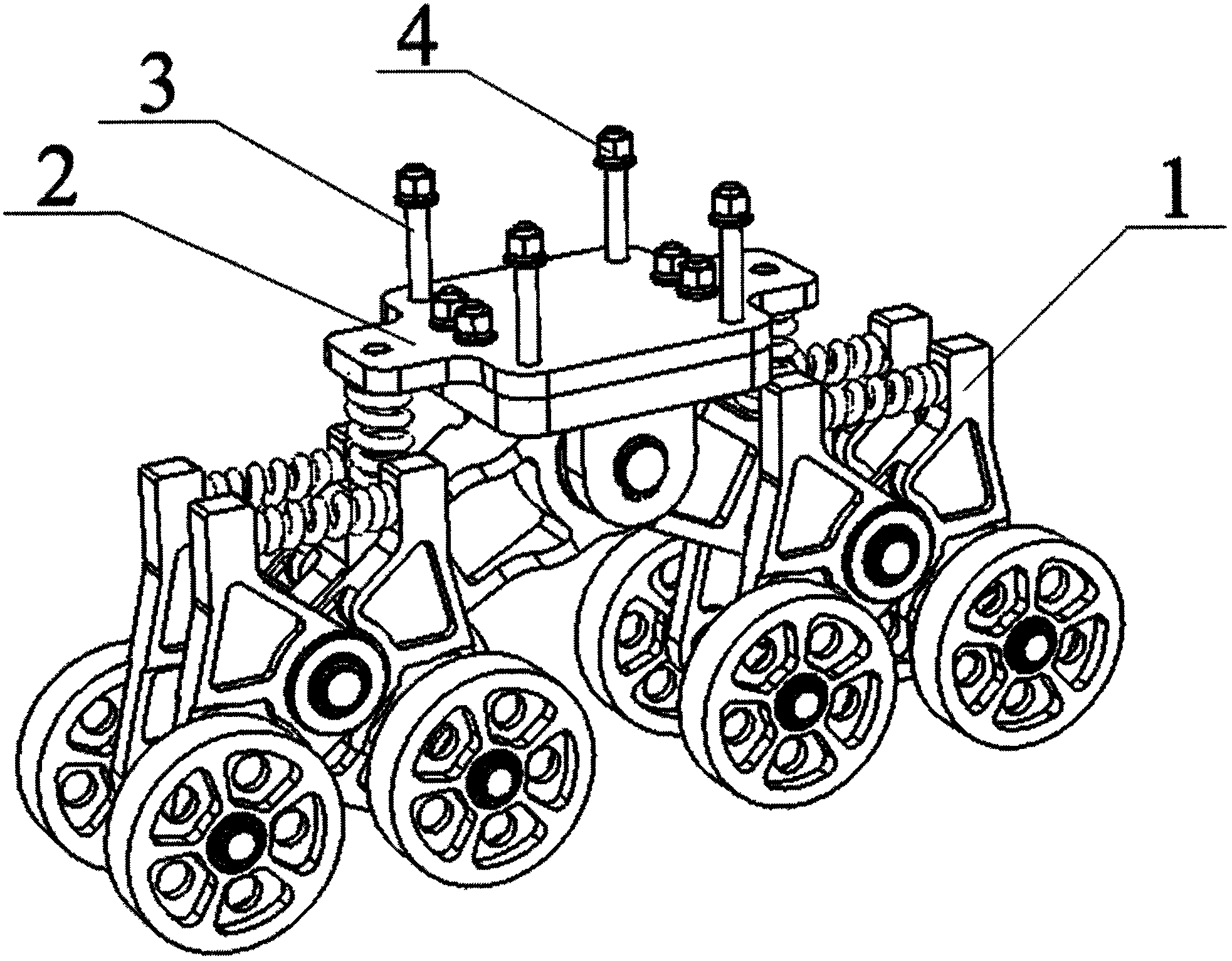

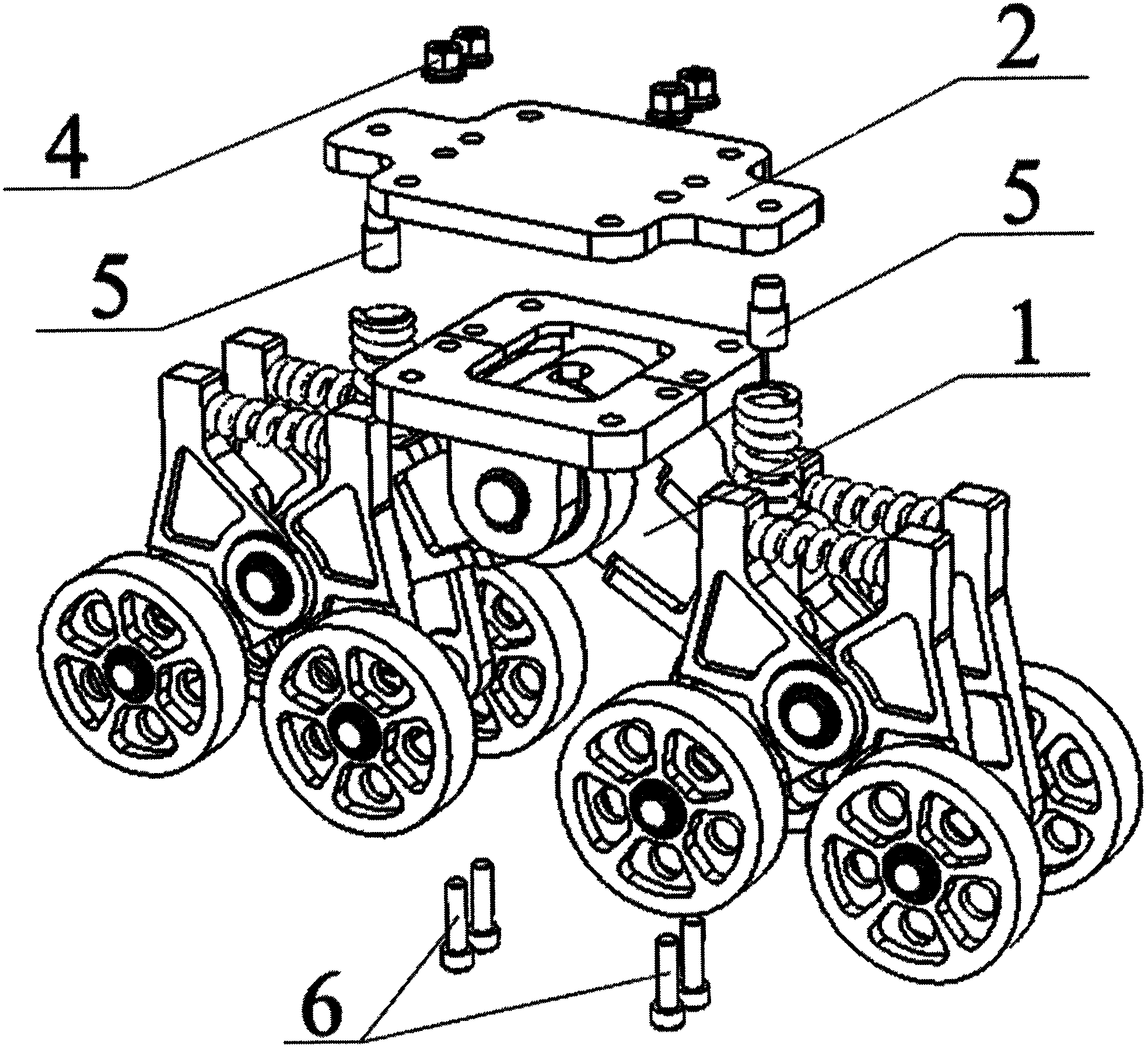

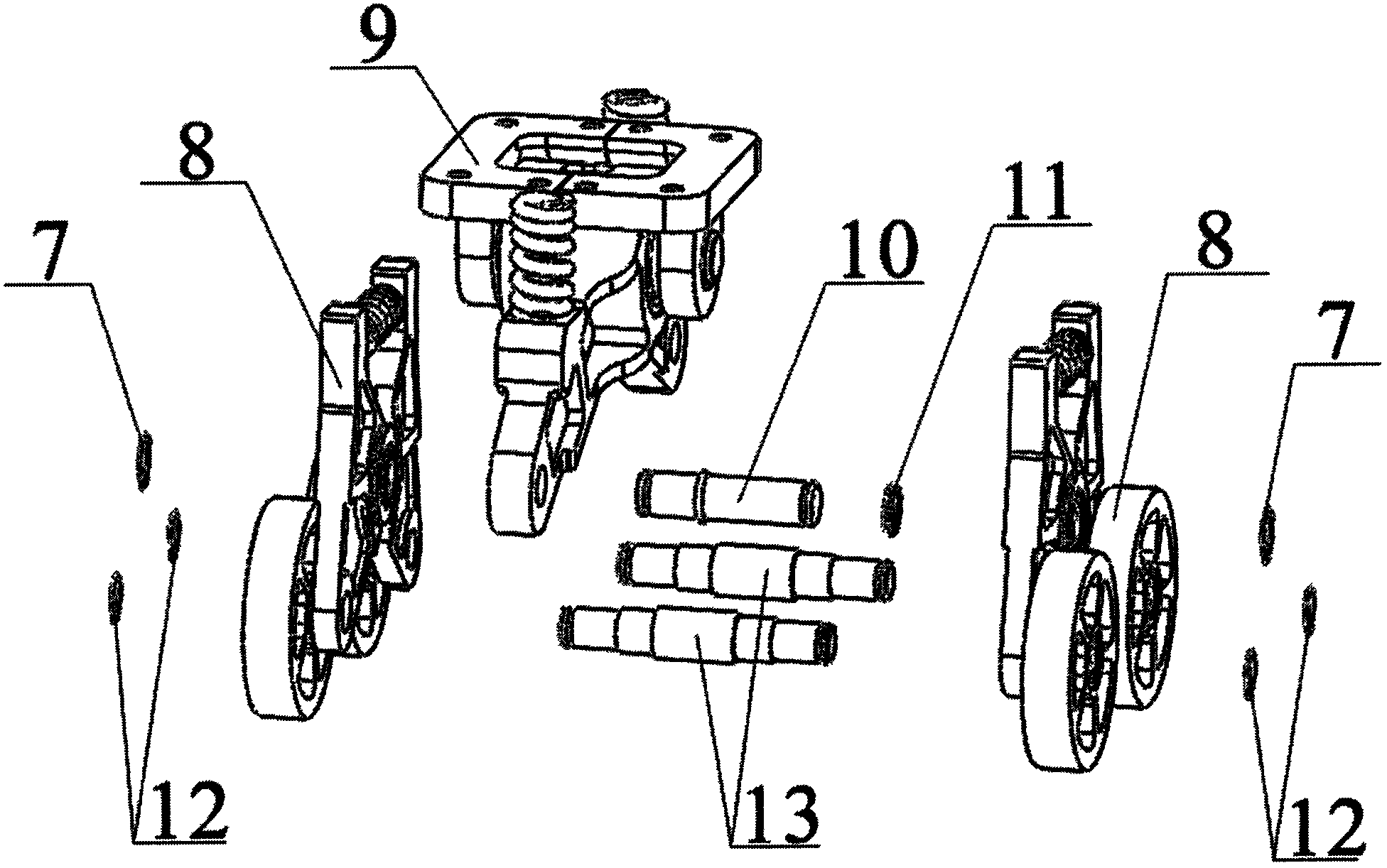

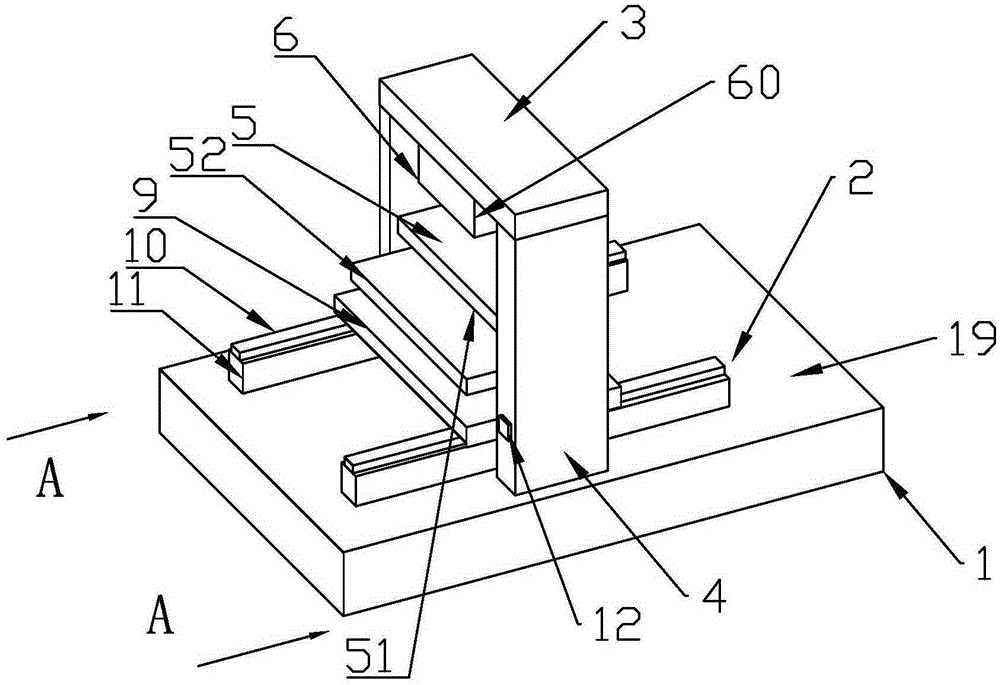

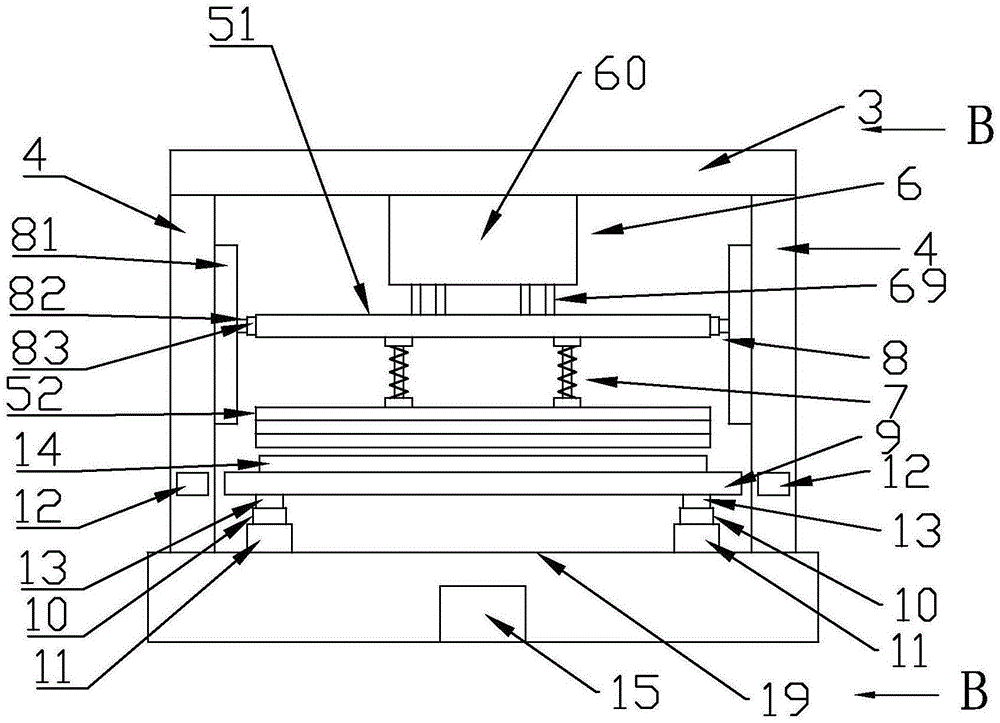

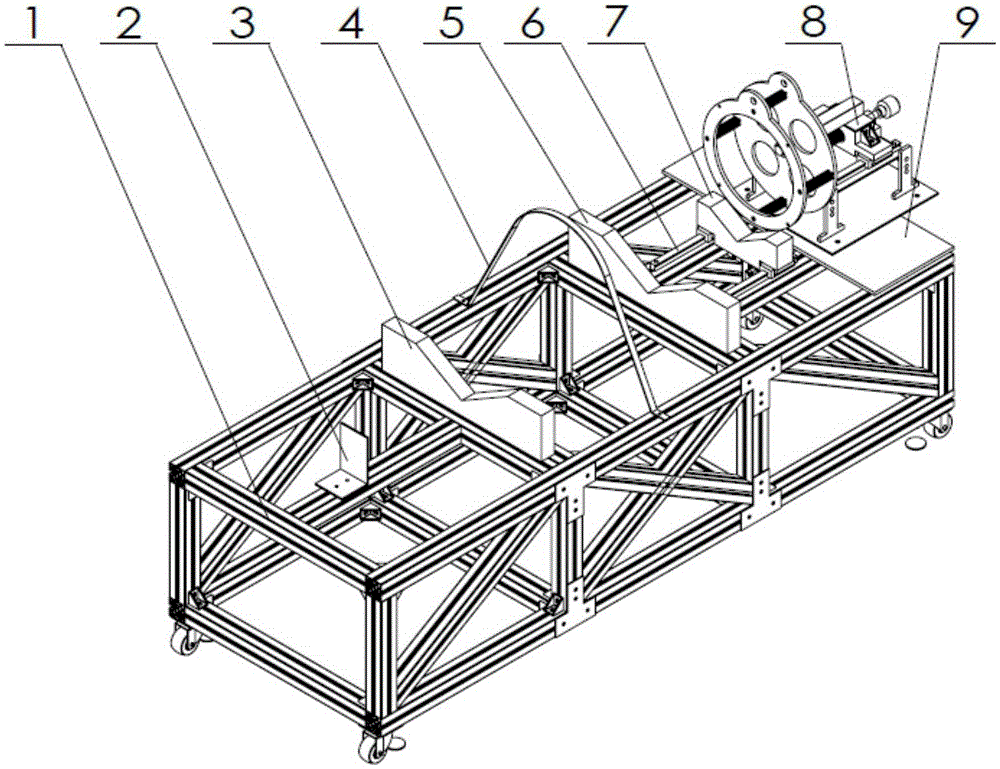

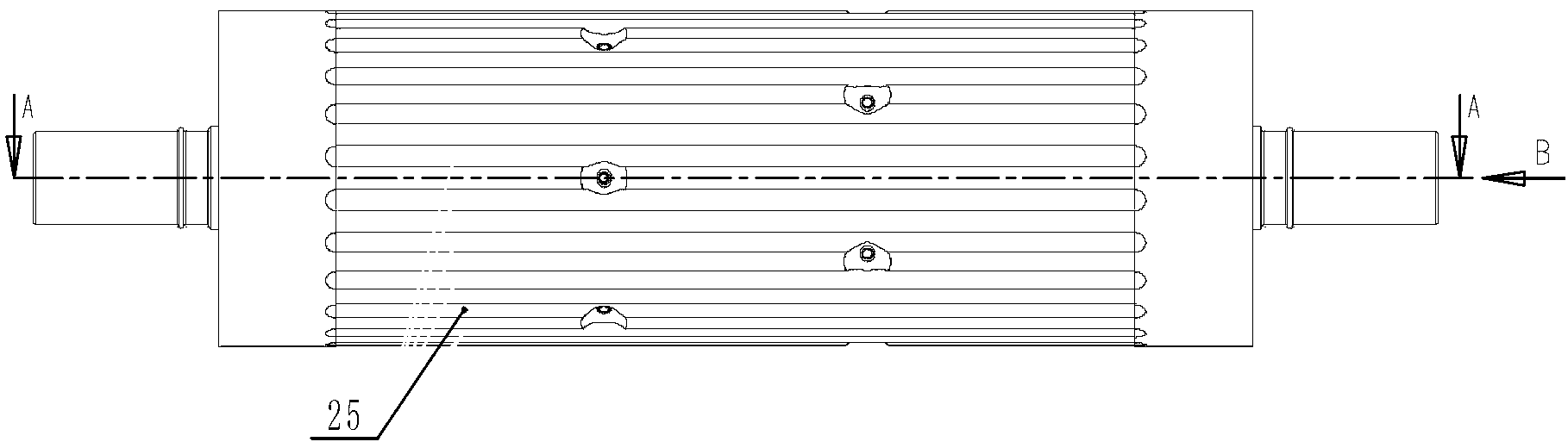

Bearing and damping device for crawler-type locomotive platform

InactiveCN102700640AImprove obstacle performanceImprove motion stabilityEndless track vehiclesSmall amplitudeEngineering

The invention relates to a bearing and damping device for a crawler-type mobile platform, which is a mechanical type suspension system which is suitable for a small and medium size crawler-type locomotive platform and has the advantages of strong bearing capacity, good damping effect and high cost performance. The bearing and damping device comprises four X swing arm components, a V swing arm component, springs and other parts. A bearing function of the bearing and damping device is realized through spring systems arranged on the X swing arms and the V swing arm, the elastic force of the springs horizontally placed on the swing arms is amplified in multiples through a force boosting lever principle so as to improve the main body bearing capacity and the part damping capacity; multiple damping can be realized through the deformation of the springs and the swinging of the X swing arms and the V swing arm; small-amplitude high-frequency turbulence vibration in the vertical direction is converted to the horizontal direction by utilizing the X swing arms and absorbed by the horizontally and oppositely arranged springs; large-amplitude low-frequency vibration is buffered and absorbed by utilizing the structural characteristic of the V swing arm, so that a quite obvious damping effect is applied on the platform; and mechanical limit is taken into account in the part design, so that the stability and the reliability of the bearing and damping device can be guaranteed.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

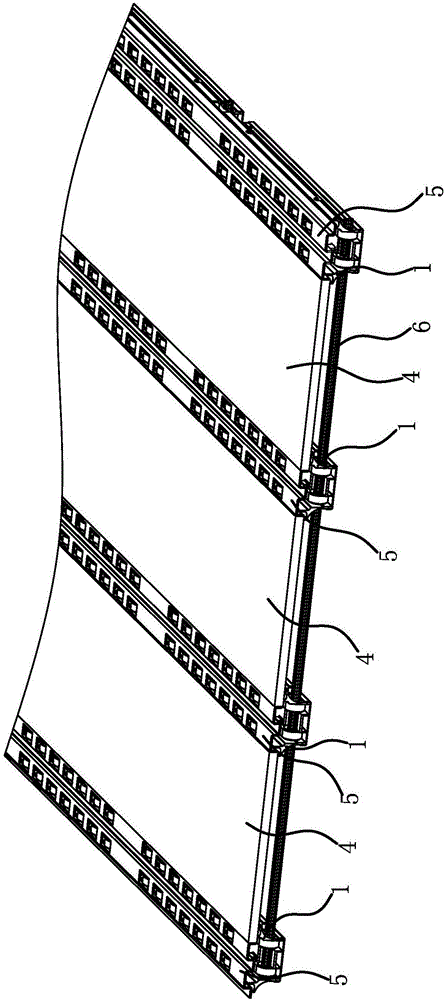

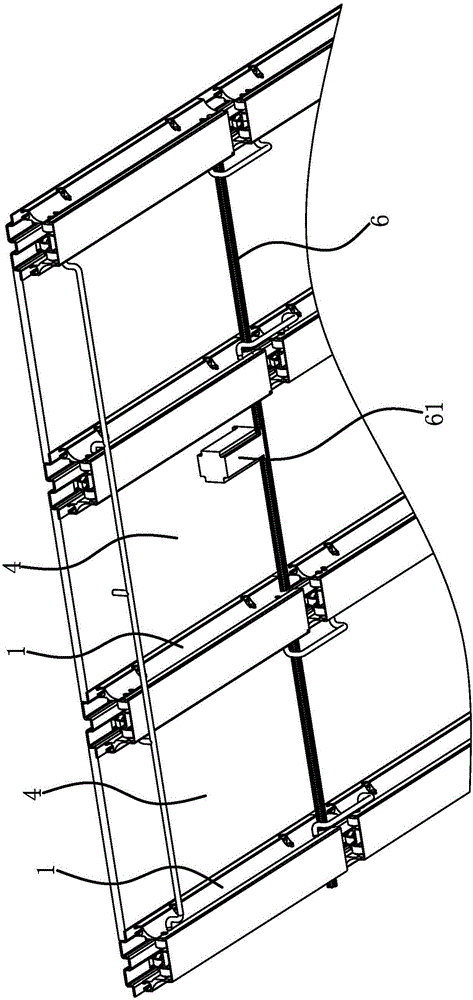

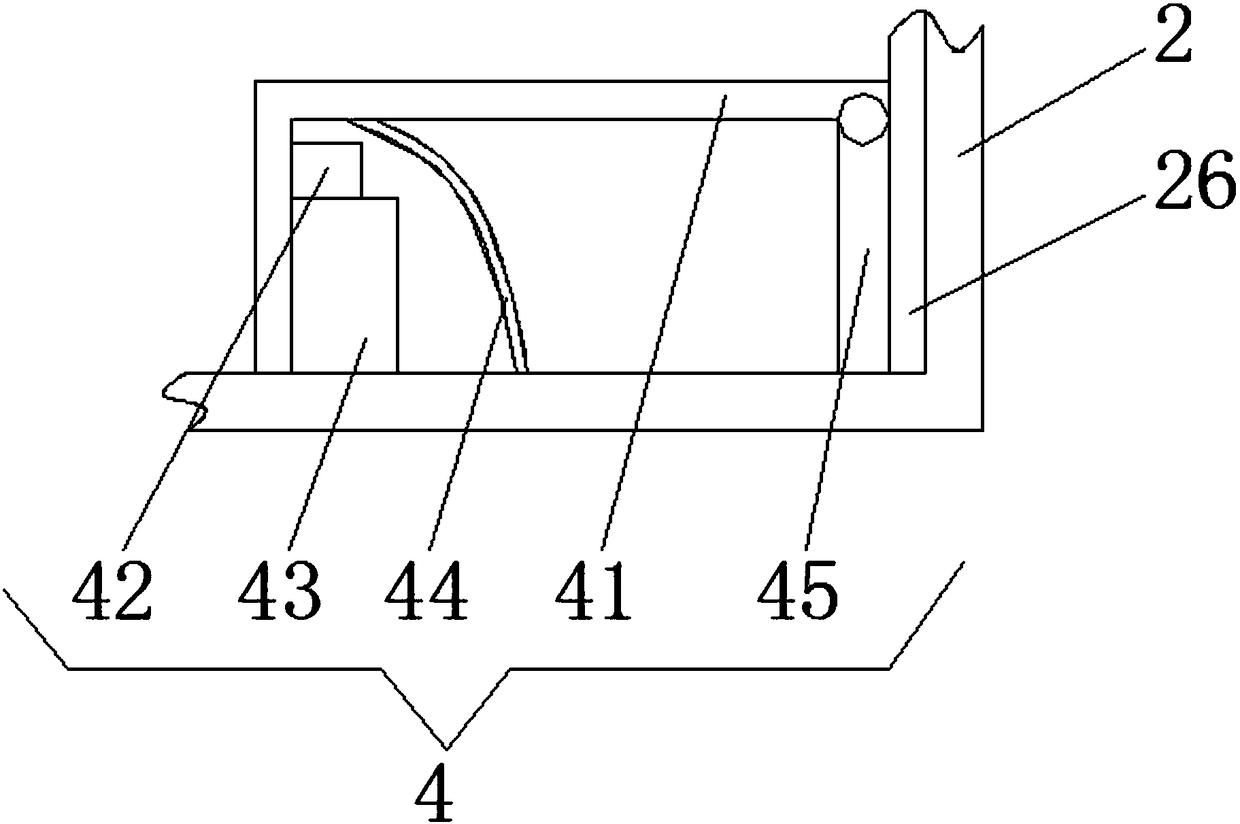

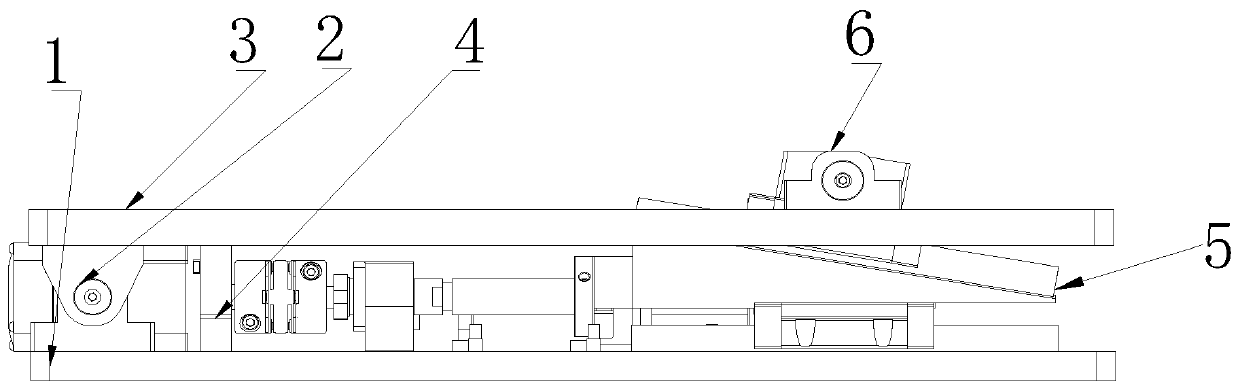

Conveying mechanism for goods in carriage

The invention provides a conveying mechanism for goods in a carriage, and belongs to the technical field of lorry auxiliary equipment. The problem that an existing conveying device is arduous is solved. The conveying mechanism for the goods in the carriage comprises supporting frames, an air bag and a lifting frame are arranged in each supporting frame, and multiple rolling wheels are rotationally connected in each lifting frame; a driving belt wheel is rotationally connected to one end of each supporting frame, wherein a driven belt wheel is rotationally connected to the other end of the supporting frame, a transmission belt is arranged between the driving belt wheel and the driven belt wheel in a sleeving mode, and the upper half part of the transmission belt penetrates through the lifting frame and is attached to the wheel faces of the lower portions of the rolling wheels. By means of the conveying mechanism for the goods in the carriage, the goods are moved in the carriage more conveniently with less effort.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

Bionic multi-degree of freedom precise piezoelectric driving device

InactiveCN104320015AIncrease freedomCompact structurePiezoelectric/electrostriction/magnetostriction machinesDrive by wireMachine

The invention relates to a bionic multi-degree of freedom precise piezoelectric driving device and belongs to the precise machining field. The multi-degree of freedom precise piezoelectric driving device is formed by a rotor and a stator; the stator comprises a first layer, a second layer and a third layer which form into an integral structure through flexible hinges; a thin wall flexible hinge, a rotation driving mechanism and a straight line driving mechanism are packed inside the stator. According to the multi-degree of freedom precise piezoelectric driving device, stepping forward and reverse 360-degree continuous rotational motion and straight line motion of the rotor are achieved based on a loopworm movement principle through the forward reasoning function of piezoelectric stack, the reverse elastic function of the flexible hinges and the clamping function of the flexible hinges. The multi-degree of freedom precise piezoelectric driving device has the advantages of being compact in structure, compact, high in displacement control accuracy, rapid in response, low in driving power, wide in working frequency and high in benefit, applied to fields such as ultraprecise machine tools, micro electro mechanical systems, precision optics, aerospace and robots and wide in development prospect and application values.

Owner:JILIN UNIV

Automatic stamping machine applied to garment production

ActiveCN105200750ASimple structureStrong targetingIroning apparatusTextiles and paperEngineeringAutomation

The invention discloses an automatic stamping machine applied to garment production. The automatic stamping machine comprises a machine frame and a machine frame table top, wherein a conveying device and a stamping device are arranged on the machine frame table top; the conveying device transversely passes through the whole machine frame table top and comprises a conveying table; a stamping support plate is arranged on the conveying table; the stamping device is positioned in the middle of the machine frame table top, and comprises a stamping frame and a stamping mechanism; the stamping frame comprises a stamping transverse frame and a stamping vertical frame; the stamping vertical frame is fixedly arranged on the machine frame table top; the stamping transverse frame is connected with the stamping vertical frame; the stamping mechanism is arranged on the stamping vertical frame, and comprises a stamping assembly and a stamping seat; a buffer mechanism is arranged between the stamping assembly and the stamping seat; the upper end of the stamping seat is provided with a sliding mechanism and a stamping transmission mechanism; the sliding mechanism is positioned on the stamping vertical frame; the stamping transmission mechanism is positioned on the stamping transverse frame. The automatic stamping machine has the advantages that the structure is simple; scientificity and convenience are realized; the pertinency is high; the automation degree is high; the cloth stamping problem is well solved.

Owner:浙江新月朗服饰股份有限公司

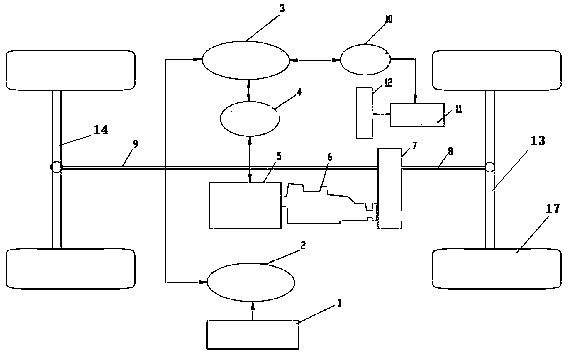

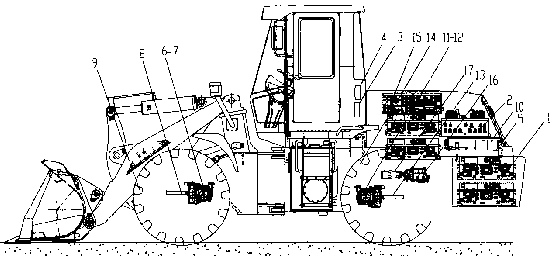

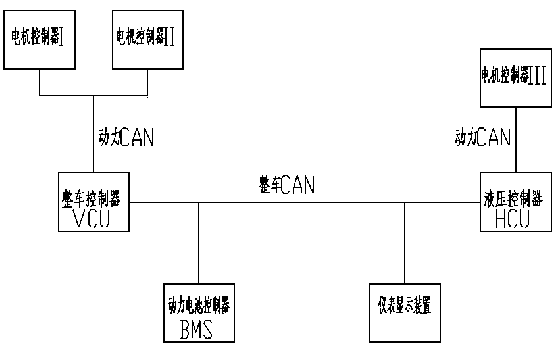

Three-motor novel pure electric loader drive control system

PendingCN110816296ADriving force is stableEfficient driving forceSpeed controllerFluid steeringHydraulic pumpControl theory

The invention discloses a pure electric loader, and belongs to the shoveling and conveying engineering machine vehicle technology. A whole vehicle controller VCU is electrically connected with a motorcontroller I, a motor controller II, a hydraulic controller HCU and a power battery controller BMS. The motor controller I is connected with a walking motor I, the walking motor I drives a front transmission shaft through an AMT speed changing box I, and the front transmission shaft drives a front wheel. The motor controller II is connected with a walking motor II, the walking motor II drives a rear transmission shaft through an AMT speed changing box II, and the rear transmission shaft drives a rear wheel. The hydraulic controller HCU is connected with a motor controller III, the motor controller III is connected with a hydraulic motor, the hydraulic motor drives a hydraulic pump, and the hydraulic pump provides power for a hydraulic system. The power battery controller BMS is connectedwith a power battery set. The pure electric loader is low in noise and free of pollution, an independent electric drive walking system and an electric drive hydraulic system are adopted so that stepless speed changing and easy gear shifting can be achieved, the power is strong, and the hydraulic system can provide stable and efficient powerful drive force.

Owner:XCMG CONSTR MACHINERY

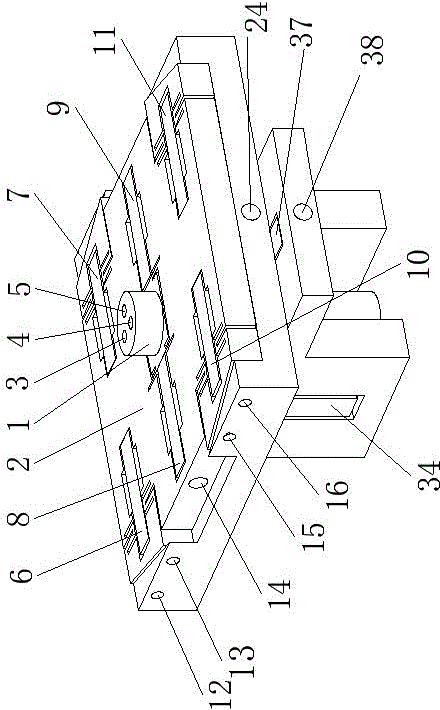

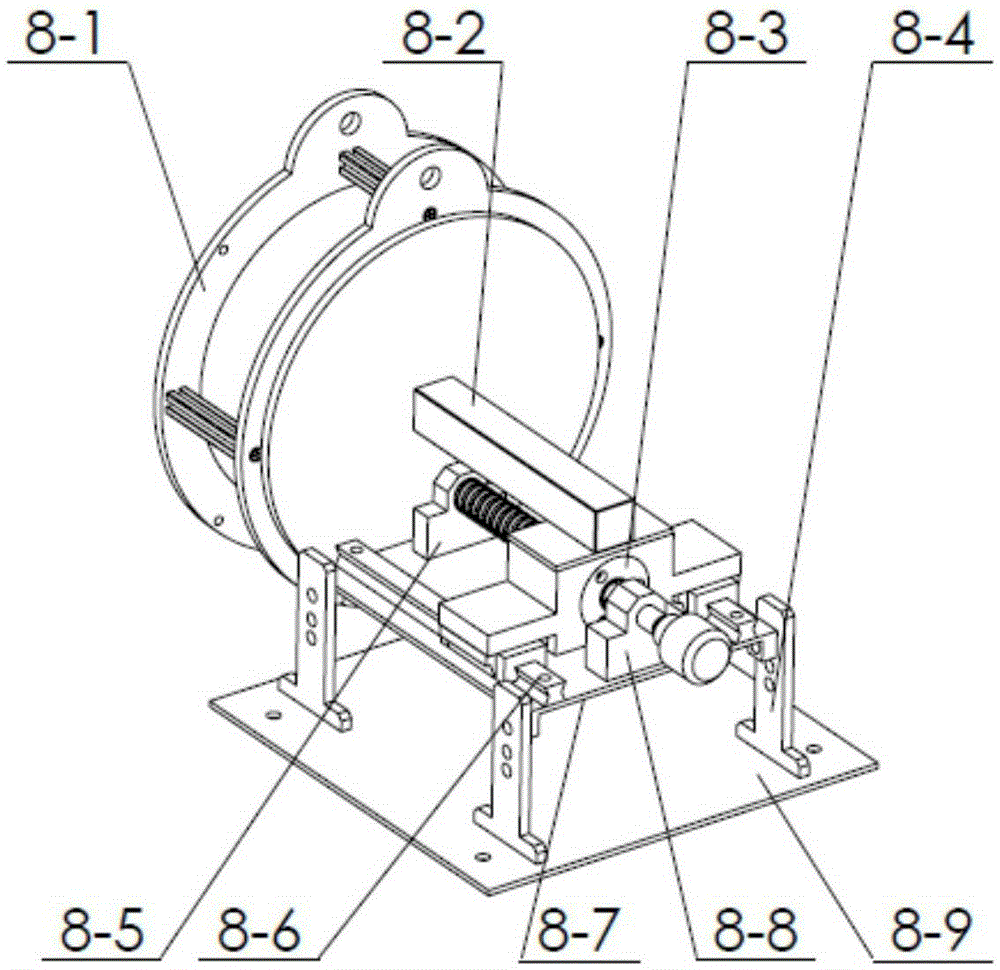

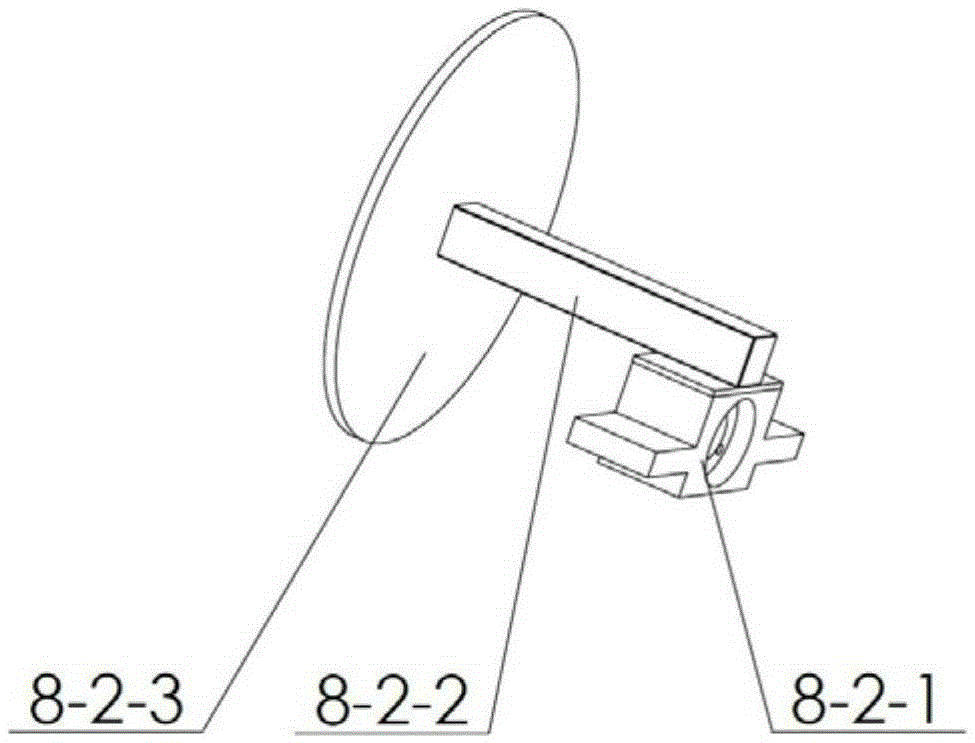

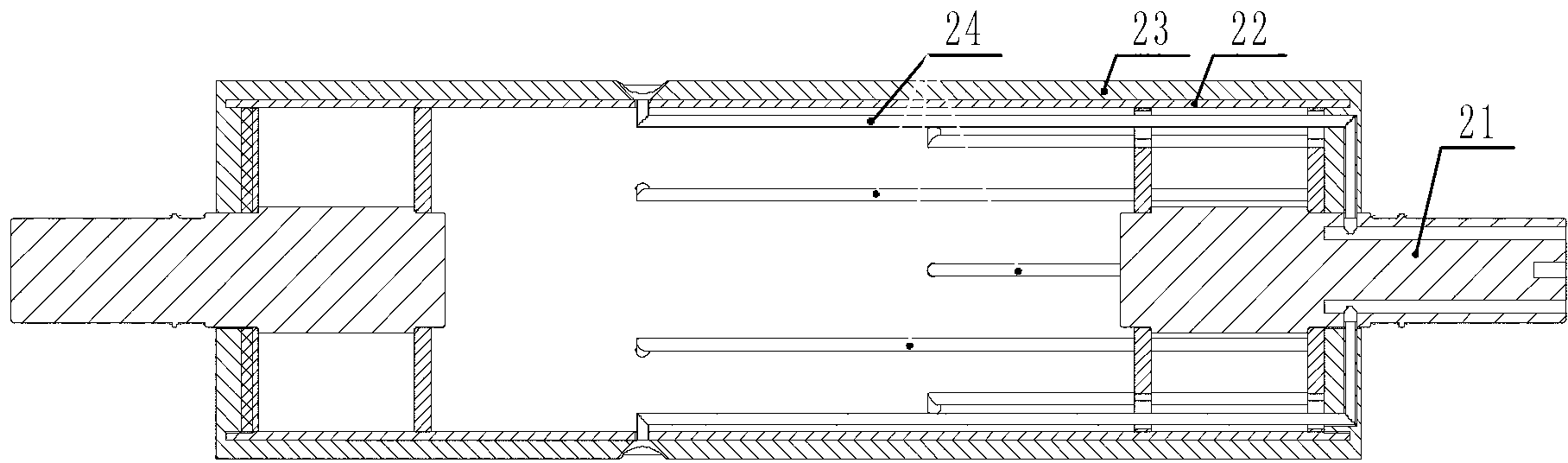

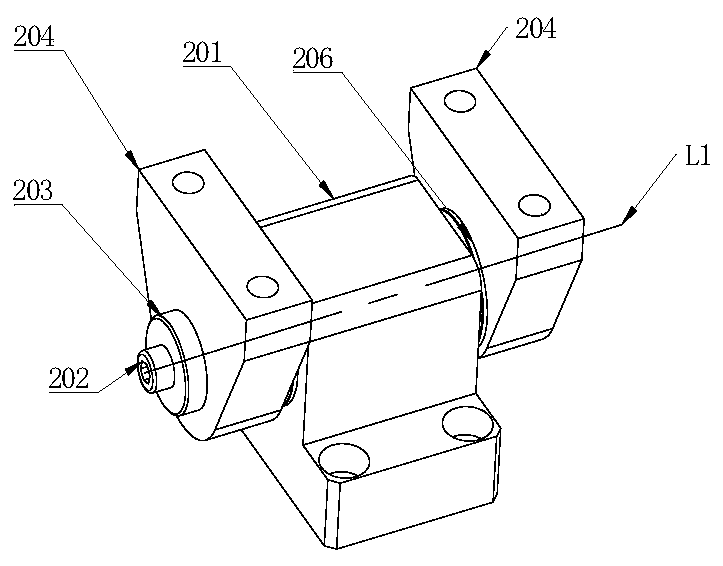

Auxiliary disassembly-assembly device for deep-sea airtight cabin

InactiveCN105196029APrecise positioningAvoid displacementWork holdersMetal working apparatusBall screw driveMechanical engineering

The invention discloses an auxiliary disassembly-assembly device for a deep-sea airtight cabin. The auxiliary disassembly-assembly device for the deep-sea airtight cabin comprises a supporting seat, an L-shaped stop block, three V-shaped plates, a fixing clamp, two pairs of linear guide rails, a supporting bottom plate, a location disk, a movement platform, a ball screw pair, four supports, a front bearing pedestal, a supporting plate and a back bearing pedestal. By using the device provided by the invention, a deep-sea airtight cabin body and an end cover can be placed on the different V-shaped plates for location respectively, are fixedly arranged by utilizing the L-shaped stop block and the fixing clamp; the location disk is fixedly connected with the end cover of the deep-sea airtight cabin body; the movement platform is driven by rotating a ball screw to drive the location disk and the end cover to move towards or away from the deep-sea airtight cabin body; the disassembly and the assembly of the end cover of the deep-sea airtight cabin are completed in an auxiliary manner. The auxiliary disassembly-assembly device for the deep-sea airtight cabin is simple in structure; the disassembly and the assembly of the end cover of the deep-sea airtight cabin can be conveniently and quickly completed in the condition that the mounting precision is guaranteed; the labor power is saved.

Owner:ZHEJIANG UNIV

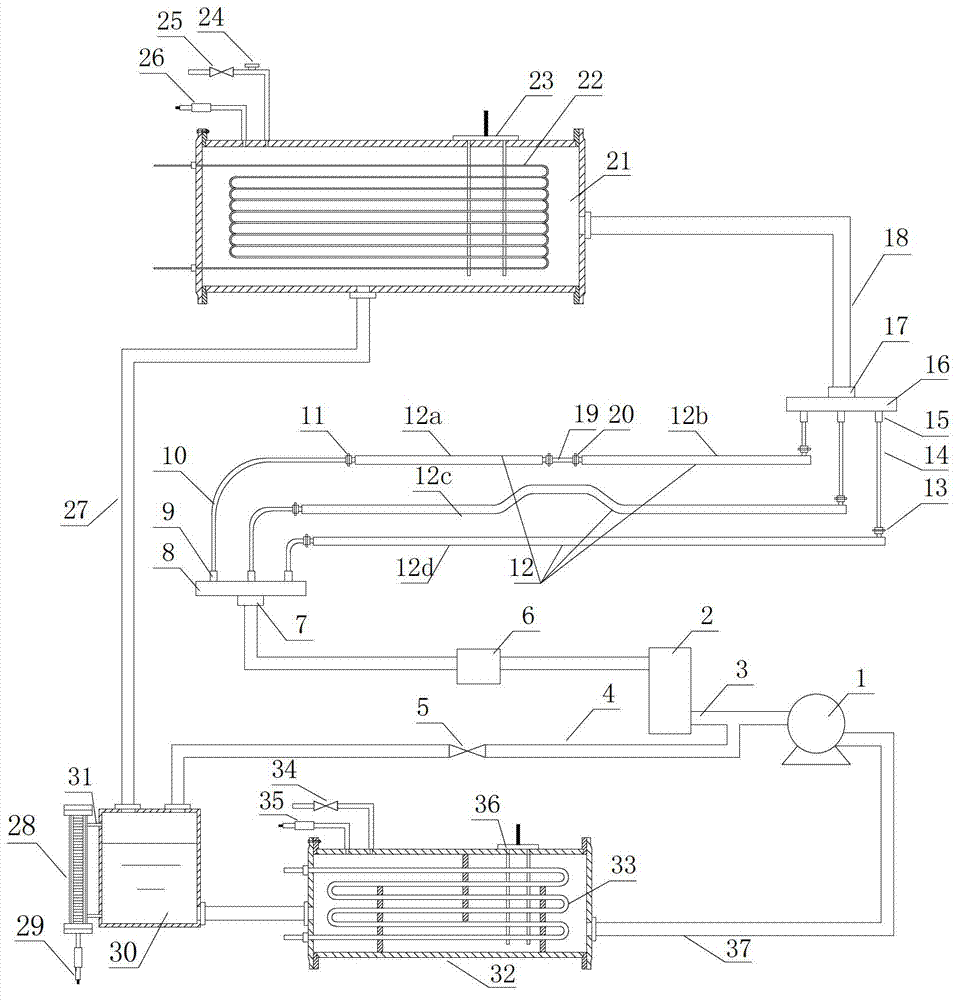

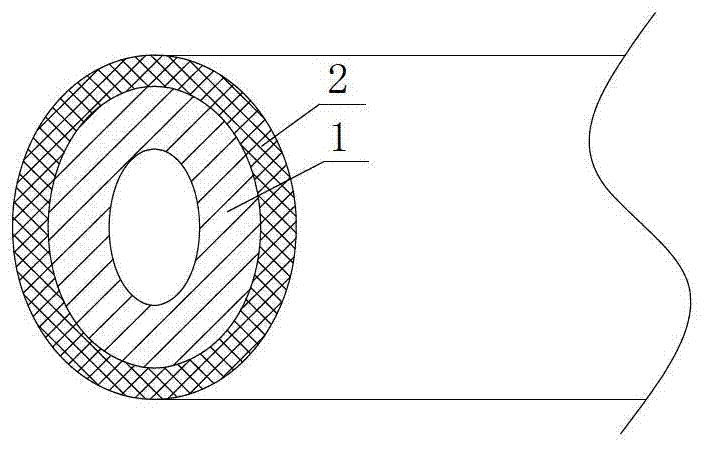

Forced circulation evaporation cooling device of hydro-generator stator busbar

ActiveCN102969838AAvoid short circuit accidentsImprove securityCooling/ventillation arrangementBusbarEvaporation

Provided is a forced circulation evaporation cooling device of a hydro-generator stator busbar. The stator busbar (12), a condenser (21), a liquid storage tank (30), a cooling device (32), a pump (1), a pressure stabilizing tank (2), a flowmeter (6), a liquid dividing pipe (8), a gas collecting pipe (16), a liquid supply main pipe (3), a gas outlet pipe (18), a liquid return main pipe (27), a total liquid return main pipe (37), a by-pass pipe (4) and an electro-liquid separation joint are connected to form an evaporative cooling circulation loop. An evaporative cooling medium in the loop is driven by a pump. The stator busbar includes one or a plurality of busbar branches, an inlet and an outlet of each busbar branch are respectively connected with the liquid dividing pipe and the gas collecting pipe through the electro-liquid separation joint and an insulation guide pipe, the busbar branches are connected in parallel, and the stator busbar is connected with the pump, the condenser, the cooling device and the like to form the independent evaporative cooling circulation loop. The forced circulation evaporation cooling device enables a plurality of busbars to be combined to form a unified parallel-connection pipeline and builds the independent evaporative cooling circulation loop.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Multistage drying equipment for traditional Chinese medicine processing

InactiveCN108151495AStable physical structureWill not destroy the medicinal propertiesDrying solid materials with heatDrying gas arrangementsEngineeringPhysical structure

The invention discloses multistage drying equipment for traditional Chinese medicine processing and relates to the technical field of medicine processing. The multistage drying equipment comprises a main body shell. The top of the inner wall of the main body shell is fixedly connected with a fixed support; the bottom of the right side of the fixed support is fixedly connected with an electric heating pipe, and the position, located on the right side of the fixed support, of the top of the inner wall of the main body shell is fixedly connected with an electrified support; the bottom of the electrified support is fixedly connected with the surface of the right end of the electric heating pipe; and the left side of the bottom of the fixed support is rotatably connected with a clamp through arotating shaft, the top of the clamp is fixedly connected with a buckle, and the inner wall of the clamp is movably connected with a first rotating rod. According to the multistage drying equipment for traditional Chinese medicine processing, a motor achieves autonomous turning-over of traditional Chinese medicines through the gravity, the uniform thermal drying purpose is achieved through cooperation of the electric heating pipe, no redundant mixing structure is arranged inside a drying bin, the stable physical structure of the traditional Chinese medicines is protected while drying is conducted, and thus the medicinal property of the traditional Chinese medicines is not damaged.

Owner:ZHONGSHAN DEGAOXING INTPROP CENT LLP

Camera module

A camera module includes upper and lower leaf springs having a stable load characteristic and a holder displaceably held by the leaf springs so that the holder can be stably displaced within a magnetic circuit. The upper spring has an outer annular portion, an inner annular portion provided inside the outer annular portion so as to be displaceable with respect to the outer annular portion and attached to the holder, and a plurality of bridge portions coupled between the outer annular portion and the inner annular portion. The camera module further includes a bridge portion supporting member for supporting a part of at least one of the plurality of bridge portions so that a load characteristic of the leaf spring can be changed.

Owner:MITSUMI ELECTRIC CO LTD

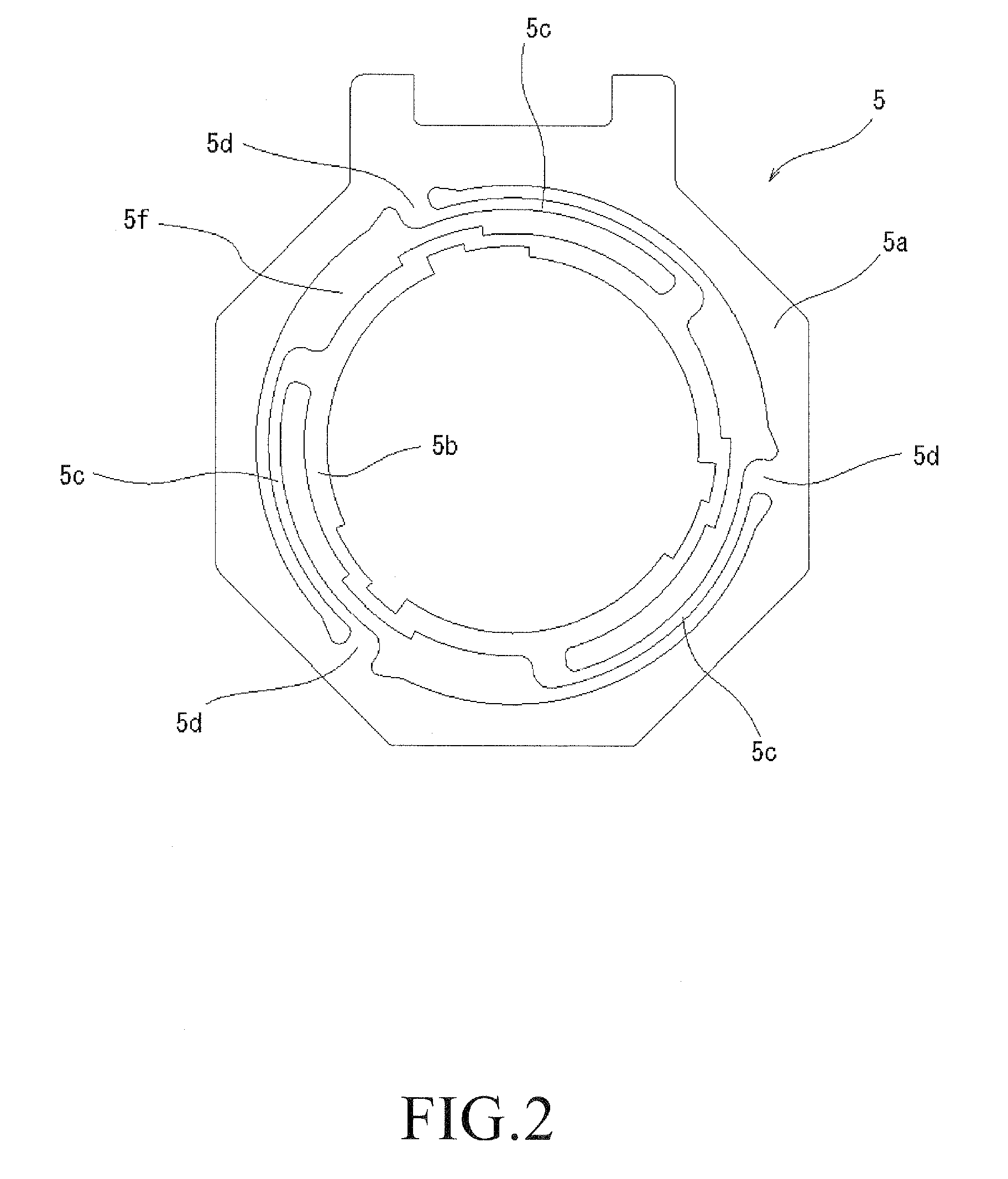

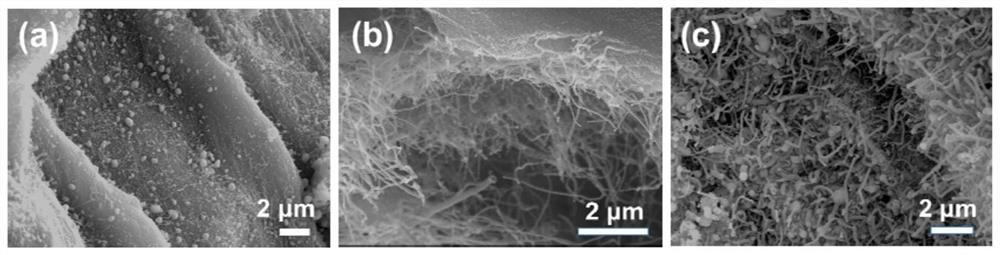

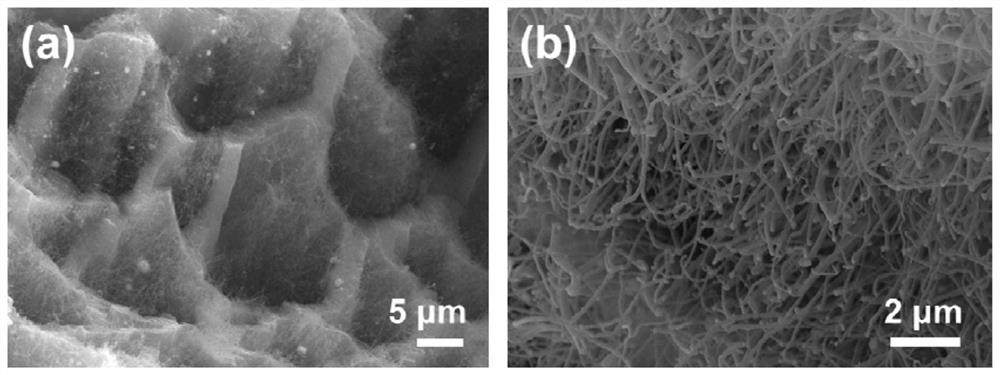

Preparation method and application of loofah sponge biomorphic supported nitrogen-doped carbon nanotube coated iron nanoparticle Fenton-like catalyst

ActiveCN112121843AUnique porous vascular bundle structureGood dispersionPhysical/chemical process catalystsWater treatment compoundsPtru catalystTetracycline Hydrochloride

The invention discloses a preparation method and application of a loofah sponge biomorphic supported nitrogen-doped carbon nanotube coated iron nanoparticle Fenton-like catalyst, relates to a preparation method and application of a Fenton-like catalyst, and aims to solve the problems of easy agglomeration of active components, ion leaching, slow Fe < 3 + > / Fe < 2 + > conversion under a neutral condition and poor cycling stability of the existing Fenton-like catalyst. The method comprises the following steps: 1, preparing dried loofah sponge with the particle size of 8-10mm; 2, alkalization treatment; 3, precipitating Fe < 3 + > on the surface of the loofah sponge; 4, doping a nitrogen source; 5, carrying out pyrolysis; 6, cleaning and drying. The loofah sponge biomorphic supported nitrogen-doped carbon nanotube coated iron nanoparticle Fenton-like catalyst is used for degrading tetracycline hydrochloride in sewage. The method is suitable for degrading antibiotics.

Owner:HARBIN INST OF TECH

Walking chassis device for wall-climbing magnetic adsorption robot

The invention discloses a walking chassis device for a wall-climbing magnetic adsorption robot, comprising two sets of magnetic adsorption driving wheels, an image acquisition device, a frame and a universal wheel, wherein the two magnetic adsorption driving wheels are connected with two sides of the rear end of the frame, the front end of the frame is connected with the universal wheel, and the image acquisition device is fixedly arranged at the upper end of the frame. The walking chassis device for the wall-climbing magnetic adsorption robot has a simple structure; a mobile vehicle body is based on the idea of modularized design and adopts detachable modules in three-wheel structure layout, so that quick disassembly and recombination can be realized when the robot passes through a non-continuous narrow limited operation space and the like; an absorption unit adopts sandwiched permanent magnetic adsorption which has higher adsorption efficiency and lighter weight compared with the traditional adsorption mode; the moving mode is as follows: one universal wheel is adopted, and the other two wheels are adopted for driving to move; and the two driving wheels provide stable driving force for the wall-climbing robot.

Owner:LUOYANG SHENGRUI INTELLIGENT ROBOT

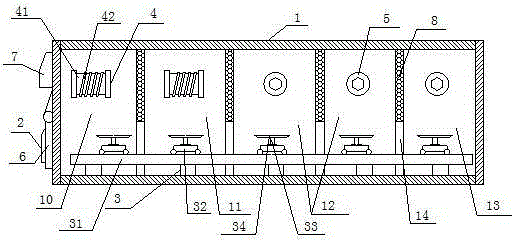

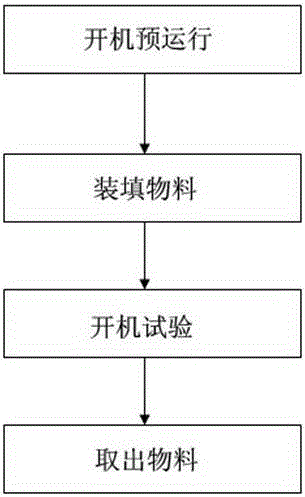

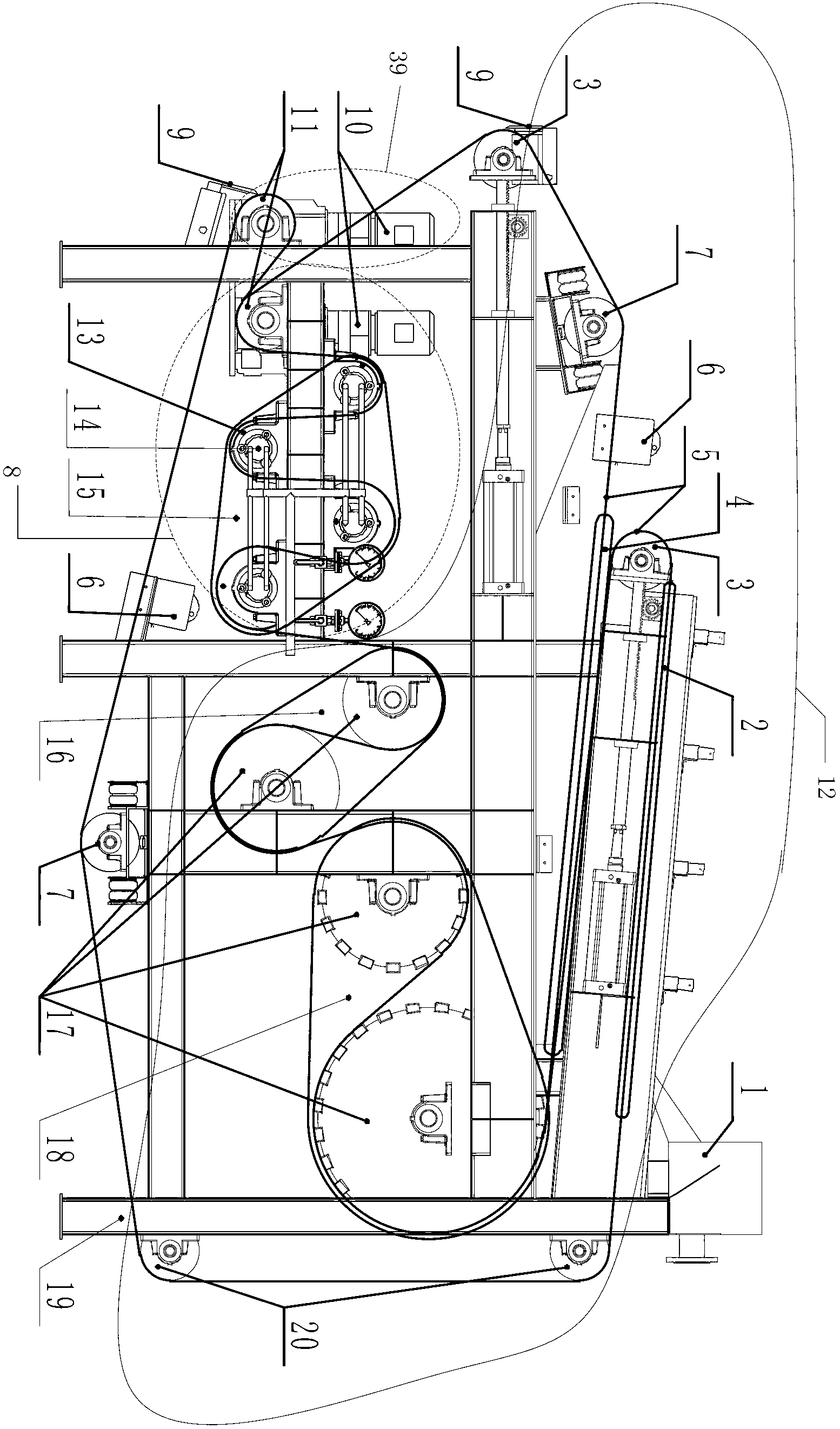

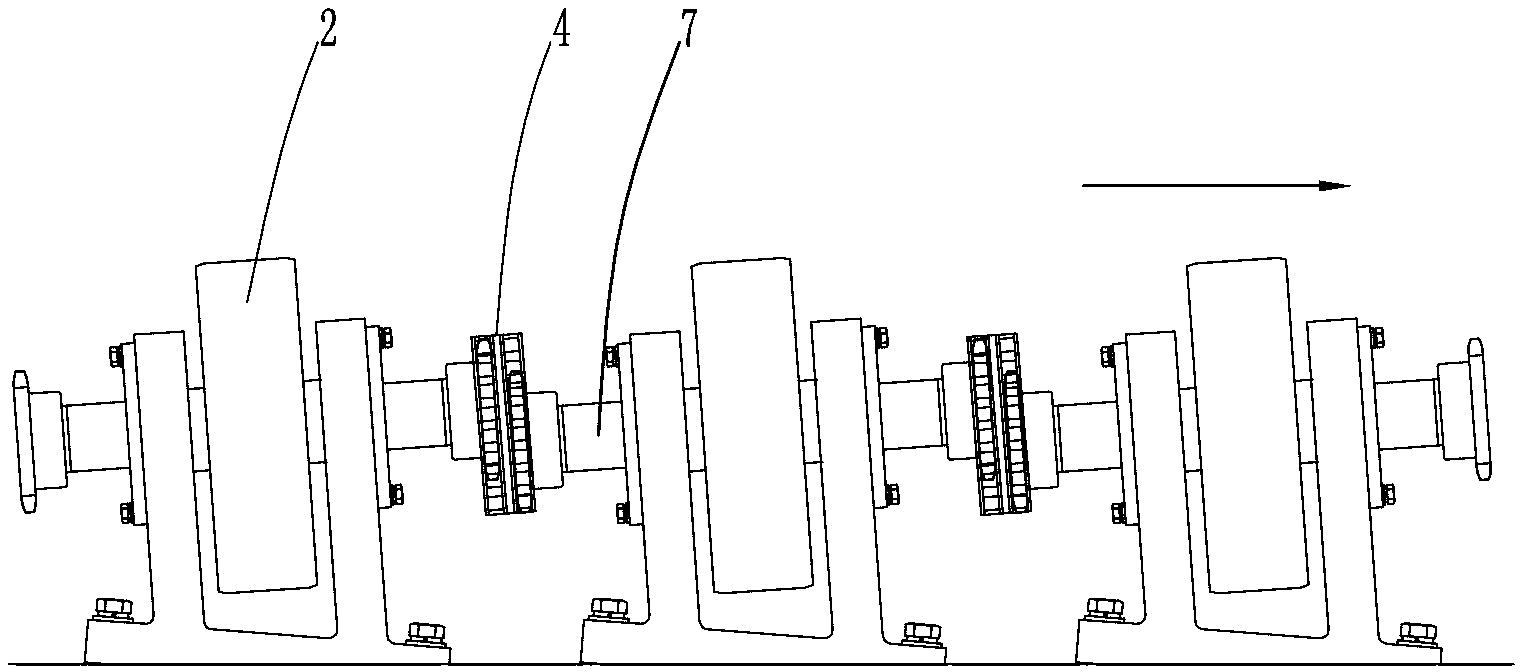

Rail-type continuous cycle multiple-temperature zone testing box and method

InactiveCN105352536AFlexible and convenient to move and adjustIncreased flexibility of useEnvironmental/reliability testsMaterial analysisTest articleControl system

The invention discloses a rail-type continuous cycle multiple-temperature zone testing box, and the box comprises a thermal insulation housing, a transmission device, heating devices, cooling devices, an automatic door, and a control system. A side surface of the thermal insulation housing is provided with the automatic door, and the interior of the thermal insulation housing is provided with at least four thermal baffles, thereby enabling the interior of the thermal insulation housing to be divided into a high-temperature region, a medium-temperature region, a low-temperature region, and an ultralow-temperature region. The transmission device comprises a conveying rail and a material conveying vehicle. The heating devices are located in the high-temperature region and the medium-temperature region. The cooling devices are located in the low-temperature region and the ultralow-temperature region. The control system is embedded on the external surface of the thermal insulation housing. The testing method comprises four steps: starting pre-operation, material filling, starting test, and material taking. The box can effectively improve the use flexibility and reliability of testing equipment, is high in automation degree of a testing process, is flexible and convenient for the moving and adjusting of testing temperature and a test article, is stable in driving force, and greatly improves the testing efficiency and precision.

Owner:杜光明

Vacuum presser

ActiveCN103285647AEasy to handleWide range of applicationsMoving filtering element filtersClosed loopDistributor

The invention relates to a vacuum presser which comprises a distributor, a pressing system, an unloading device, a vacuum system, a driving system, two pieces of filter cloth and a frame, wherein the pressing system is arranged on the top and the middle lower part on the right side of the frame; the distributor is arranged at one end of the top of the pressing system; the unloading device is arranged on one side, which is opposite to the distributor, of the pressing system; the vacuum system is arranged on the left lower part of the frame; the driving system is arranged on the frame below the unloading device; the two pieces of filter cloth are respectively wound into two closed loops; the two pieces of filter cloth are meshed in the right middle part of the pressing system. The traditional pressing dehydration and vacuum negative pressure dehydration are perfectly combined together, and materials can be well treated, so that the equipment is wide in application range, and the dehydration efficiency in unit time is greatly improved.

Owner:YANTAI SUNNY HEXING ENVIRONMENT PROTECTION EQUIP

Actuator

InactiveUS20100067078A1Surely stabilizeSimplify production stepSemiconductor/solid-state device manufacturingElectrostatic motorsEngineeringVoltage

The present invention is directed to a bi-axial pivoting type actuator having a first movable section, a second movable section supporting the first movable section, and backlining. A first conductive portion and a second conductive portion for independently applying a driving voltage to each of the first movable section and the second movable section are provided on the second movable section, in a state of being split by isolation trenches and being stabilized by the backlining provided under the second movable section. By providing such backlining, mutual stabilization of the first conductive portion and the second conductive portion in an electrically isolated state, and simplification of the production steps for the actuator are realized. By providing a mirror on the first conductive portion of the actuator of the present invention as such, it becomes possible to provide a bi-axial pivoting type mirror device through a simple production process.

Owner:PANASONIC CORP

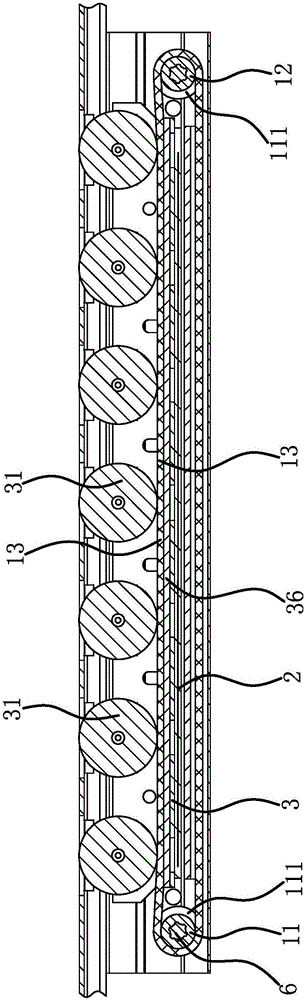

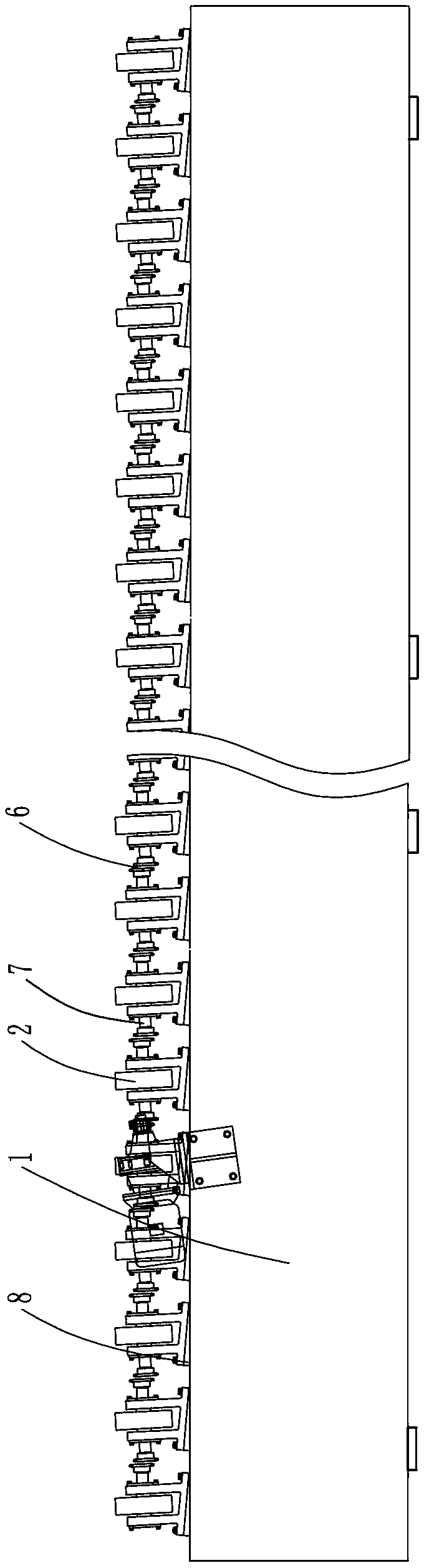

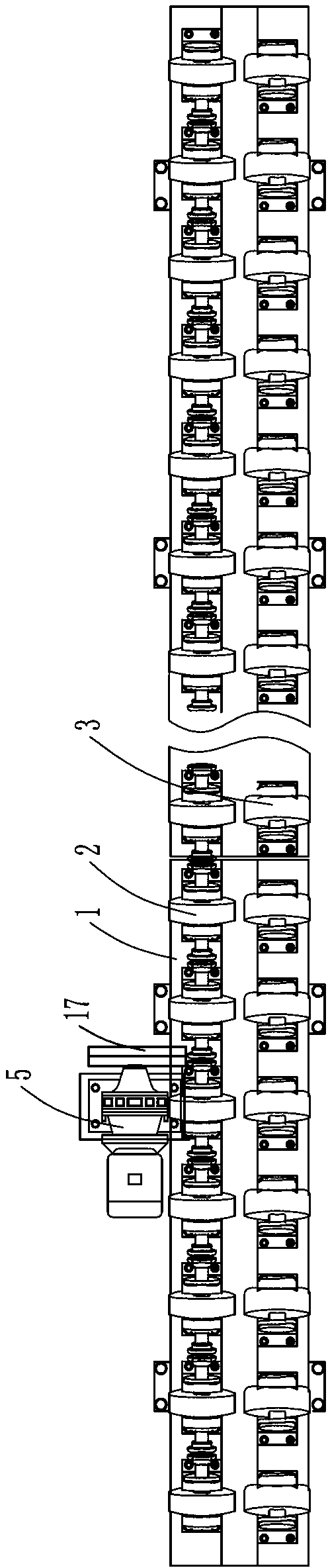

Riding wheel transmission mechanism

InactiveCN103223639AAccurate transmission ratioHigh transmission powerGrinding drivesSprocketControl theory

The invention discloses a riding wheel transmission mechanism which comprises a frame (1), wherein two rows of riding wheels are arranged at the upper part of the frame (1) in parallel; one row is drive riding wheels (2), and the other row is follow-up riding wheels (3); the drive riding wheels (2) are sleeved on a principal shaft (7); chain wheels (6) are correspondingly sleeved at the front and the back end of the principal shaft (7); a double-row gear (17) of a motor (5) is directly meshed with two chain wheels (6) between two adjacent drive riding wheels (2); and two chain wheels (6) between two adjacent drive riding wheels (2) in other positions are connected through double-chains (4). Through the adoption of the structure that the double-row gear of the motor is directly meshed with the corresponding chain wheels; and the two chain wheels between two adjacent drive riding wheels (2) in other positions are connected through the double-chains, the riding wheel transmission mechanism has the advantages that the equable transmission of the workpiece with small draw ratio and high quality is realized; and production efficiency can be adjusted and optimized by arranging a gradient adjusting device between a riding wheel base and the frame.

Owner:CHONGQING HENGSHAN MACHINERY +1

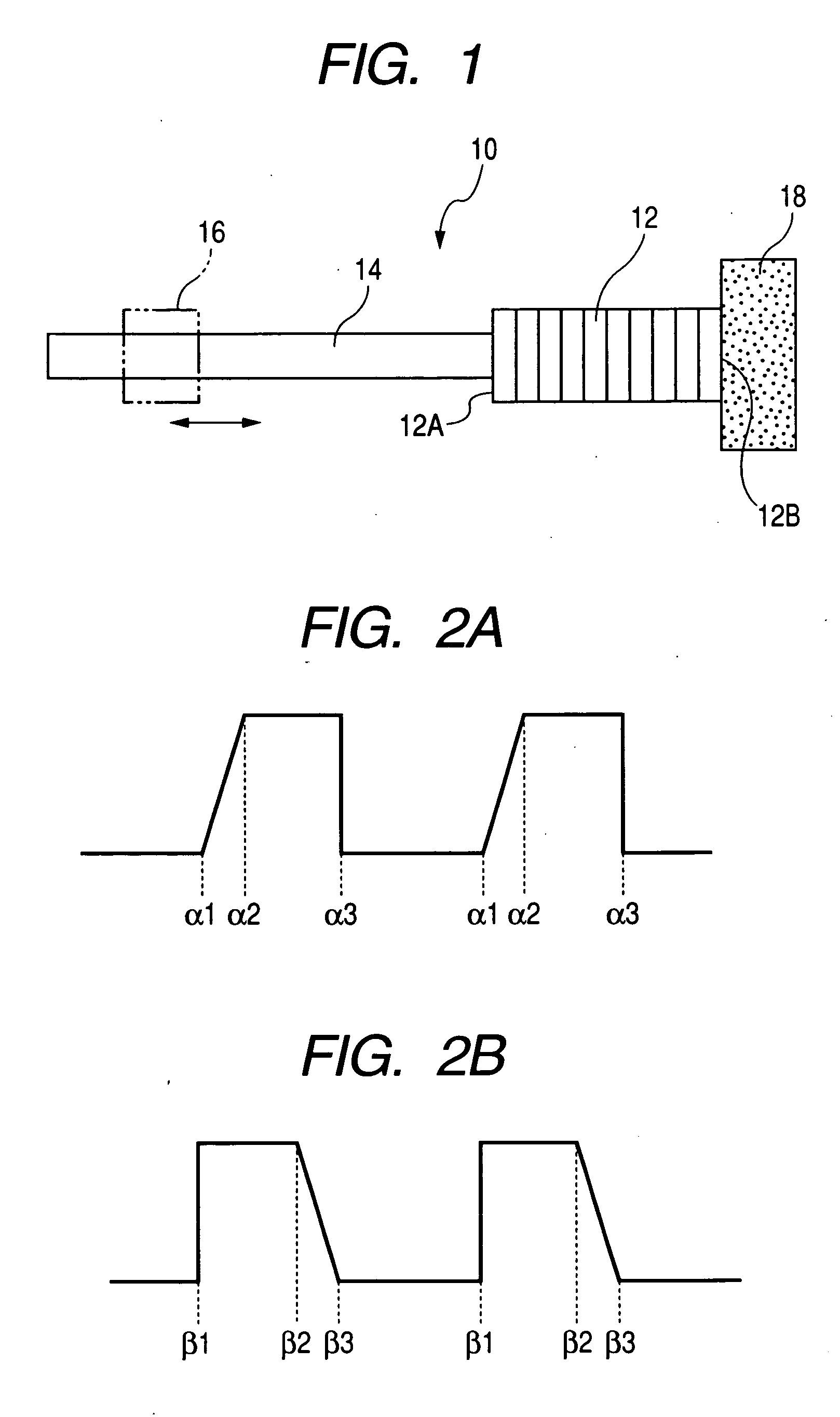

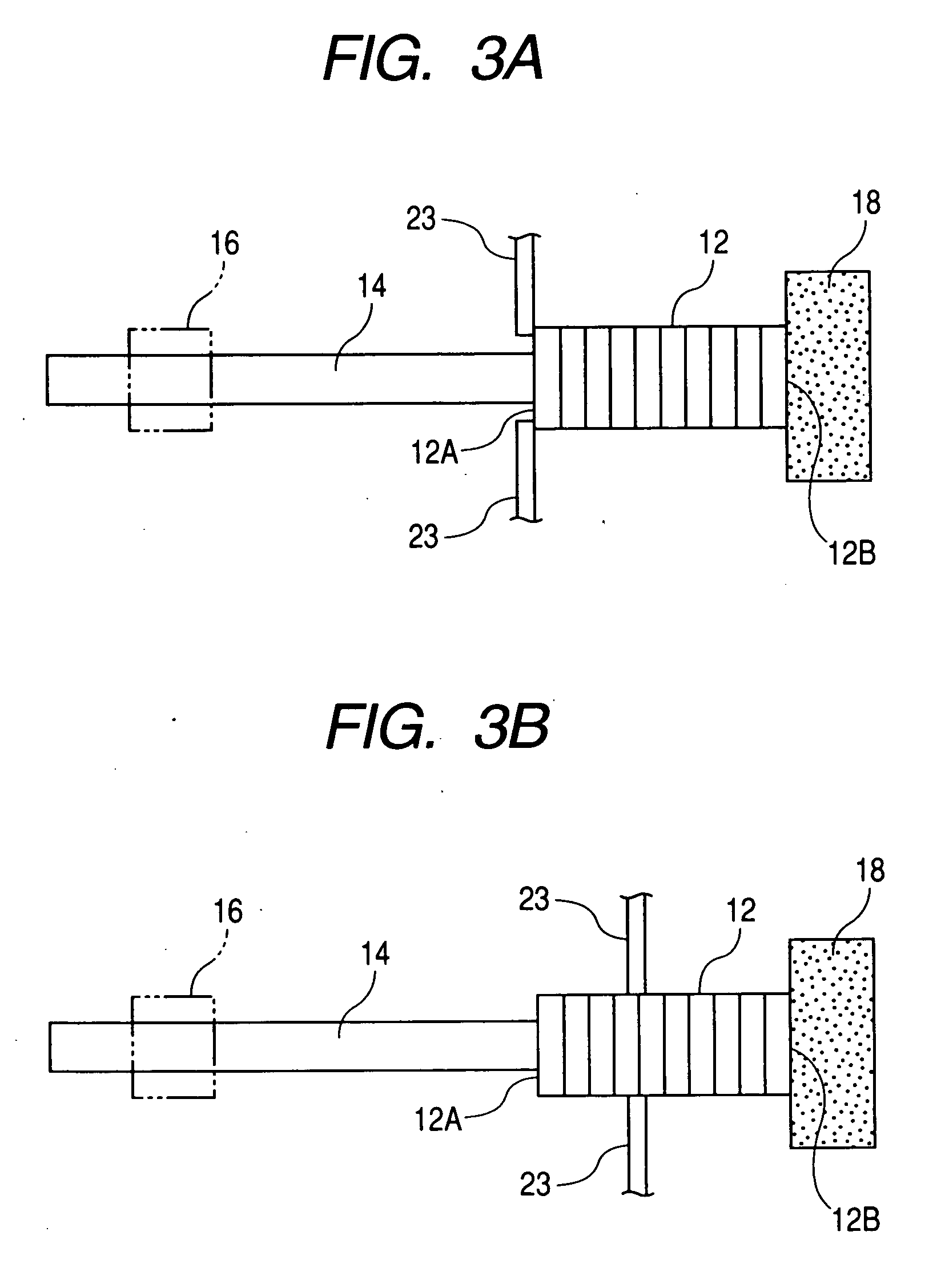

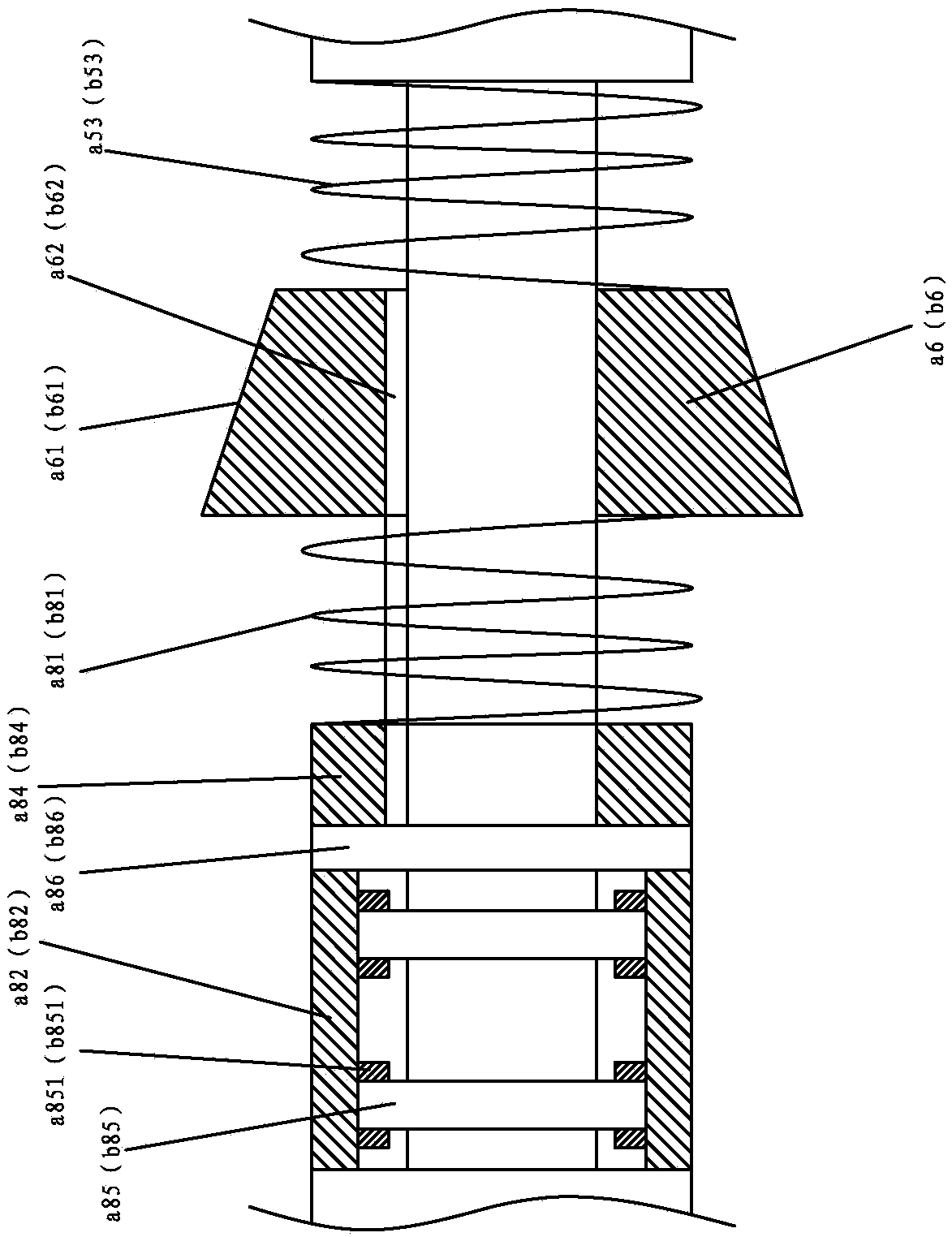

Driving mechanism, photographic mechanism and cellular phone

ActiveUS20060232169A1Driving and controlling driven accurately and stablyDriving force is stablePiezoelectric/electrostriction/magnetostriction machinesProjector focusing arrangementResonanceEngineering

A driving mechanism comprises: (i) an actuator comprising: an electro-mechanical conversion element; a driving member which is connected to one end of the electro-mechanical conversion element and moves in accordance with elongation or contraction of the electro-mechanical conversion element; and a weight member provided on the other end of the electro-mechanical conversion element; and (ii) a driven member frictionally engaged with the driving member, wherein the actuator allows the driven member to move along the driving member, and the weight member comprises a member which reduces a resonance frequency of the actuator.

Owner:FUJI PHOTO OPTICAL CO LTD

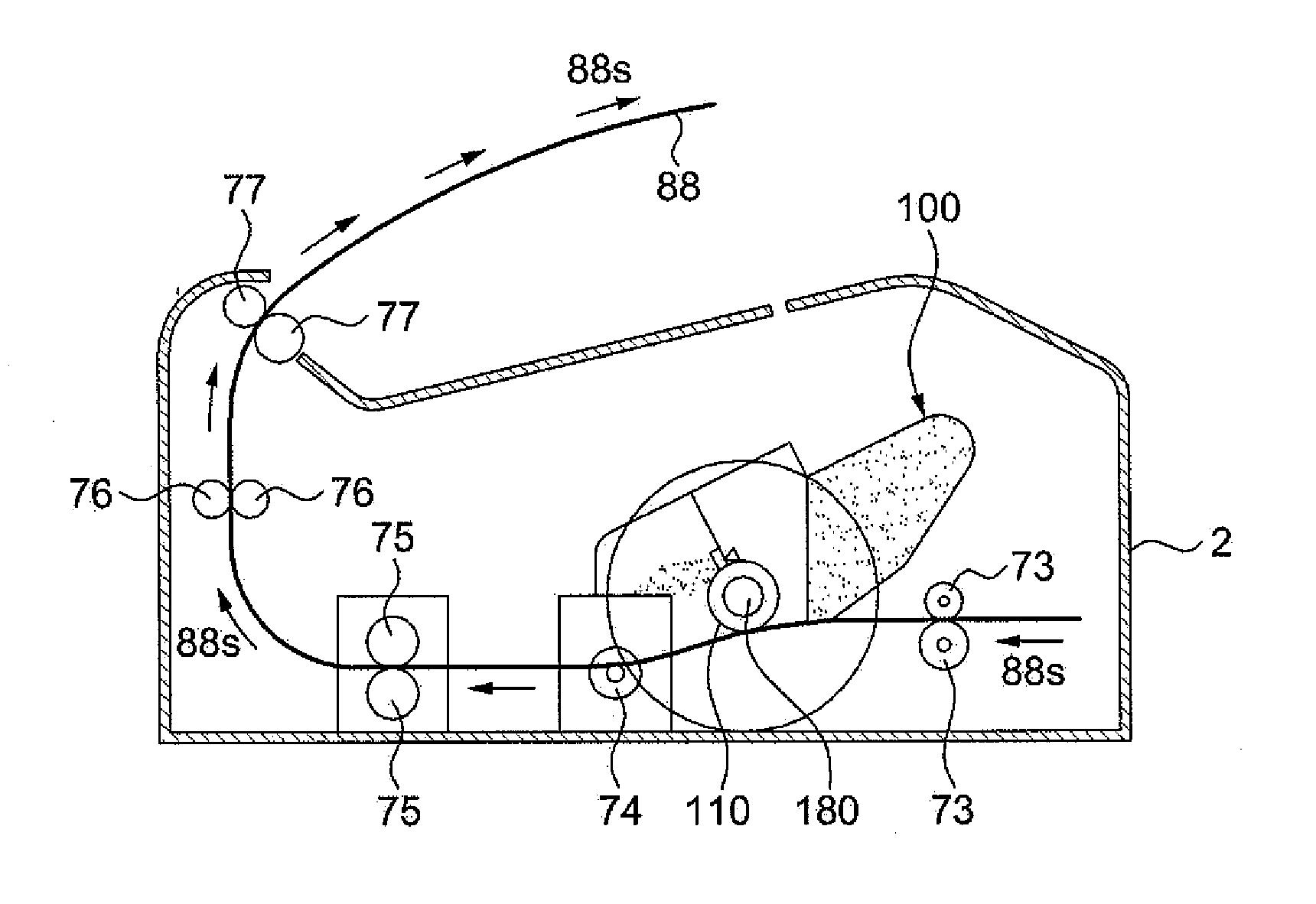

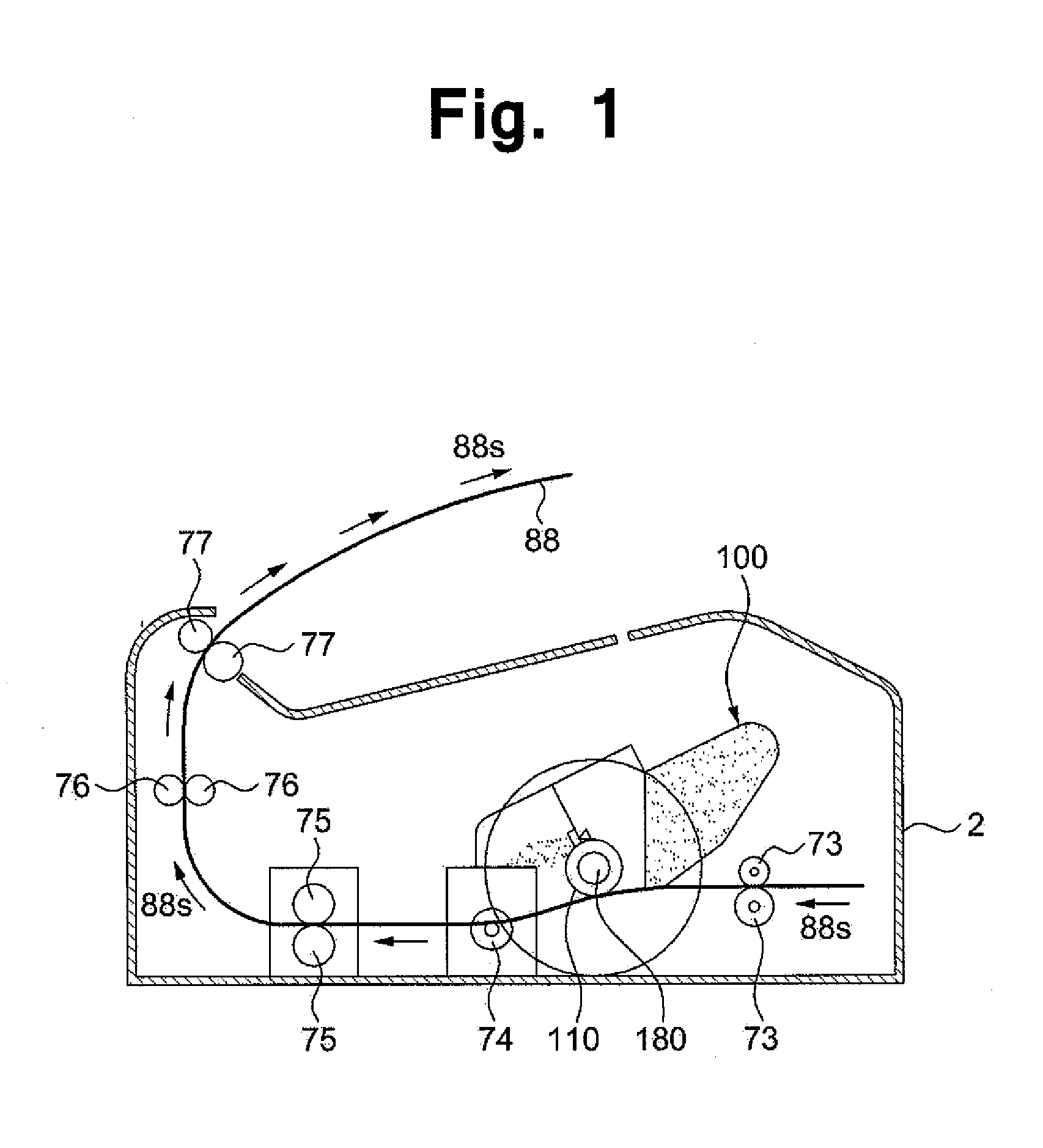

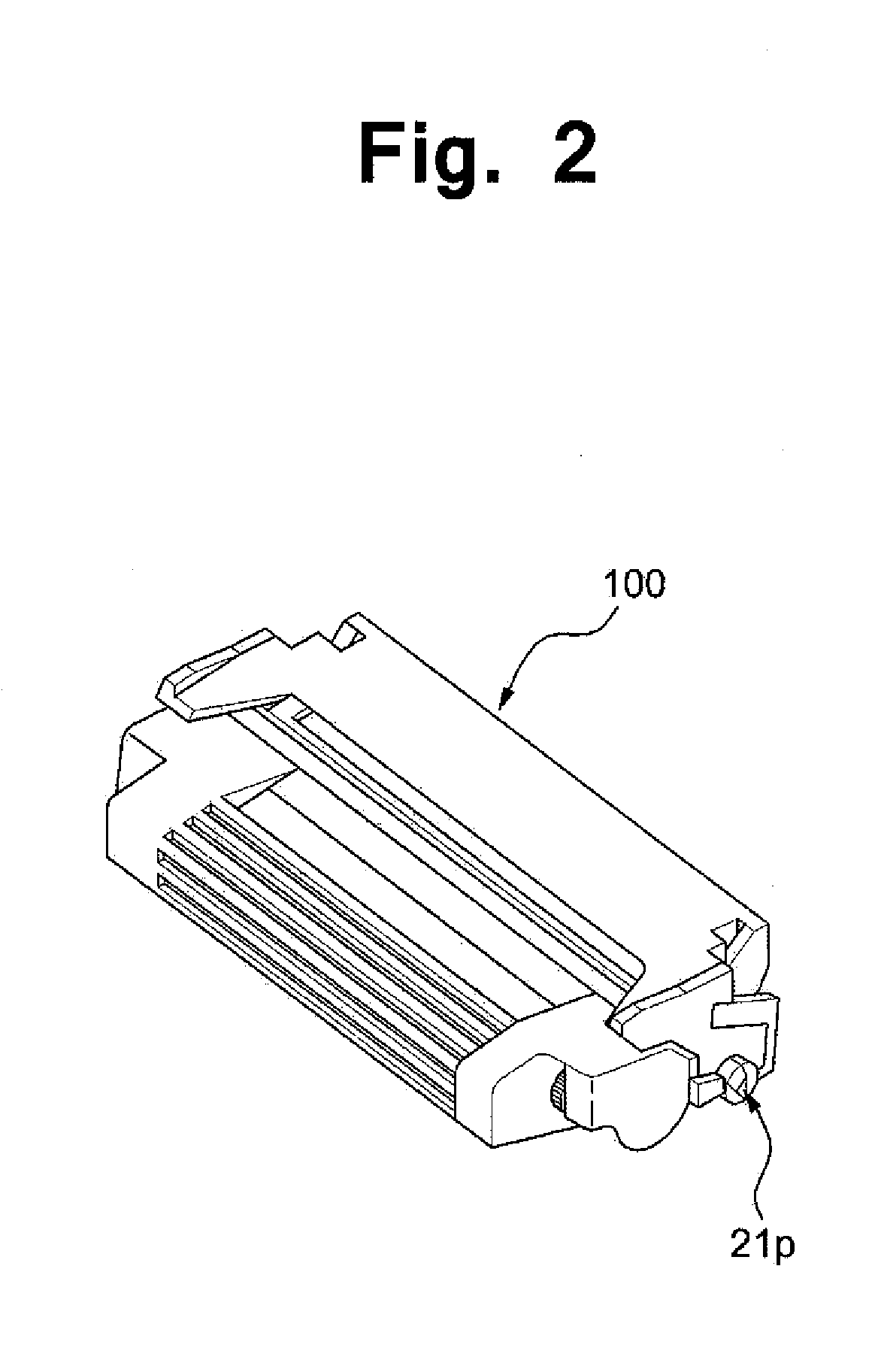

Driving assembly for photosensitive drum, photosensitive drum assembly, process cartridge, and image forming apparatus

InactiveUS20130058681A1Easily abradedNot easy to damageElectrographic process apparatusDrive shaftImage formation

Provided is a photosensitive drum driving assembly, a photosensitive drum assembly, a process cartridge, and an image forming apparatus. The driving assembly including a supporting body and an engaging protrusion is connected to a drive shaft having a triangular twisted hole to transfer a rotary driving force from an image forming apparatus. The engaging protrusion twistedly protrudes to be inserted into the twisted hole, and includes three or more line contact portions on its cross-section perpendicular to the protrusion direction. The line contact portions are in line-contact with the surface of the twisted hole, and at least one portion of a surface formed by continuously joining the line-contact portions along the protrusion direction is a twisted contact-surface to receive the rotary driving force transferred by the drive shaft.

Owner:BAIKSAN OPC +1

Motor

InactiveUS7635935B2Simple moldingLarge abuttingShaftsMagnetic circuit stationary partsEngineeringMetal

A motor may include a bearing made of resin for rotatably supporting one end part of the rotor shaft, and an urging member attached to a bearing holder and abutted with a pressurization face of the bearing to urge the bearing toward a side of the rotor shaft. A molding material injection gate trace (projection) which has been used when the bearing is resin-molded is positioned at a center portion of the pressurization face. The molding material injection gate trace may be positioned in a recessed part which is formed at a roughly center portion of the pressurization face of the bearing. Further, the urging member may include an urging piece which is formed by cutting a center portion of a metal plate in a ring shape and an opening part is formed in the urging piece.

Owner:SANKYO SEIKI MFG CO LTD

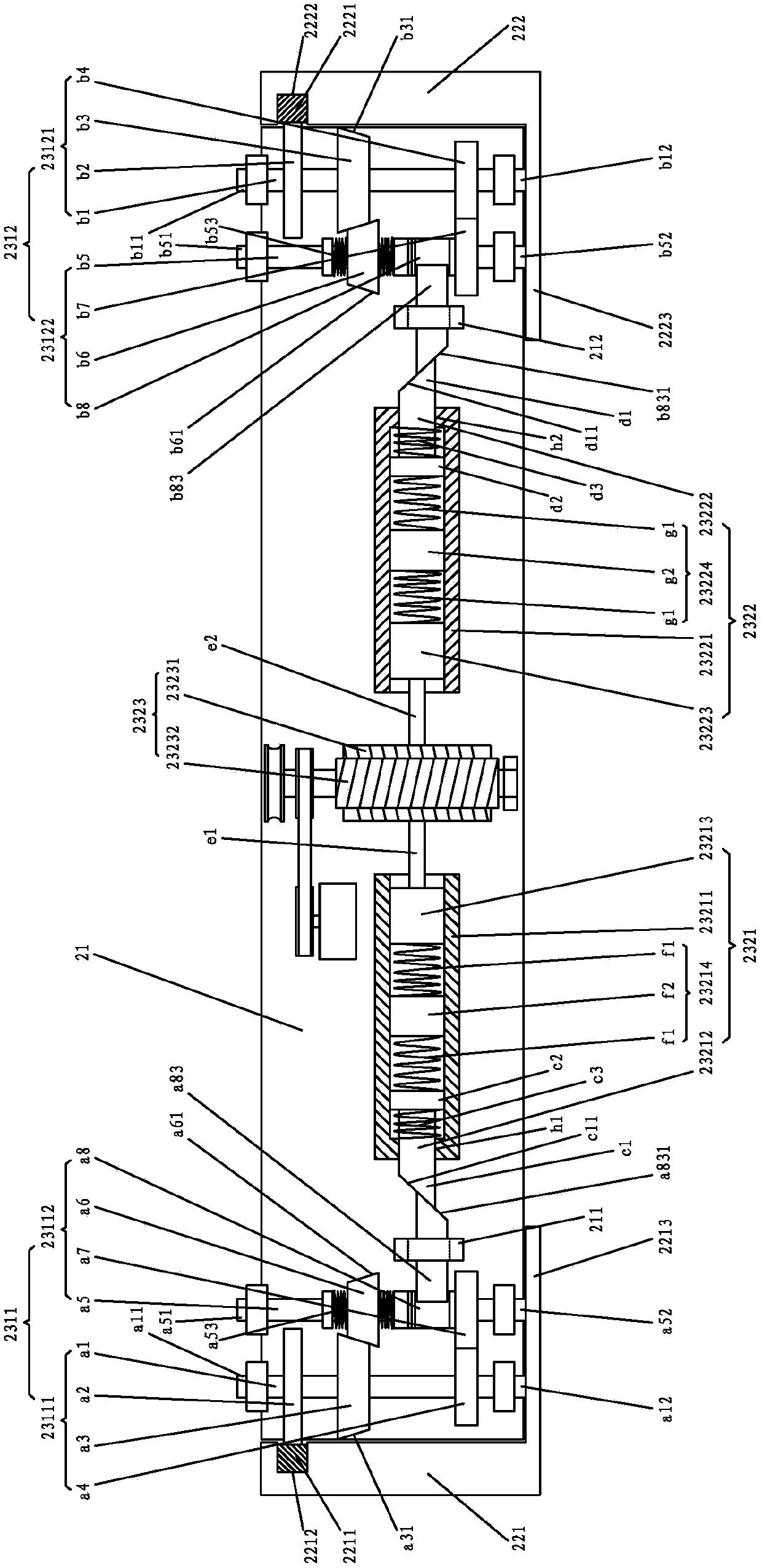

Energy-saving anti-falling vertical elevator

ActiveCN107720508AReduce twisting forceNot easy to break and other damageElevatorsBuilding liftsStress concentrationEnergy loss

The invention provides an energy-saving anti-falling vertical elevator. A sensor detects the weight of a borne object in an elevator car and transmits a weight sensor to a controller, the controller controls a sliding power device to drive a first adjusting driving single body and a second adjusting driving single body, so that the first adjusting driving single body and the second adjusting driving single body drive a first balance adjusting executing single body and a second balance adjusting executing single body respectively to perform balance adjustment, a balance weight device and the elevator car achieve balance, an elevator car lifting driving motor can lift the elevator car by only providing a small traction force, a traction rope winding twisting force of the elevator car liftingdriving motor can further be greatly alleviated while the energy consumption of the elevator car lifting driving motor is reduced, a traction rope is not subjected to stress concentration and thus does not undergo damage such as breakage, the service life of the traction rope is greatly prolonged, and the elevator car does not drop easily.

Owner:福建科大高科发展有限公司

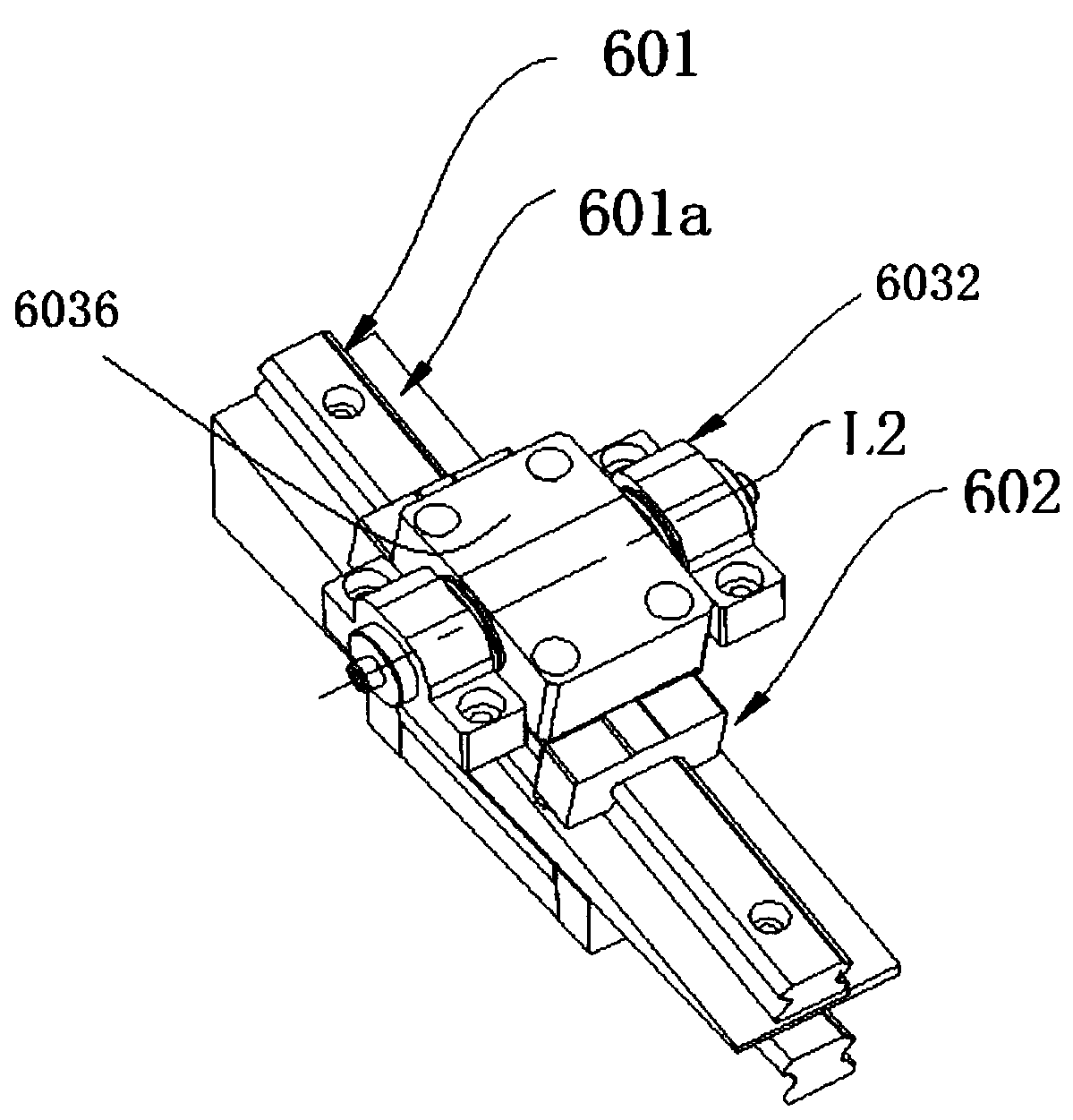

Inclination adjusting device and carrying robot

ActiveCN110294055AAchieve reliabilityAchieve fluencyManipulatorVehiclesDegrees of freedomMechanical engineering

The invention discloses an inclination adjusting device. Through the setting of a sliding block mechanism and an articulated mechanism of the inclination adjusting device, a robot bearing platform hasa reliable and stable degree of freedom in the vertical driving direction, thereby achieving the effect that the inclination adjusting device is high in reliability, good in rigidity and smooth in movement.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com