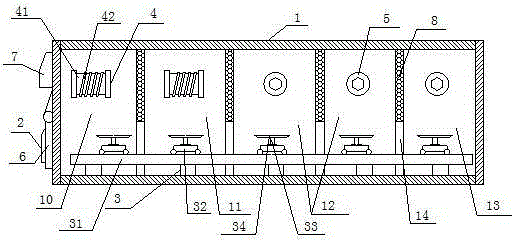

Rail-type continuous cycle multiple-temperature zone testing box and method

A multi-temperature zone, track-type technology, applied in the direction of environmental/reliability testing, measuring devices, instruments, etc., can solve the difficulty of reading test equipment data, low efficiency of product testing work, and narrow temperature adjustment range To achieve the effect of improving the scope of application and equipment utilization, improving the efficiency and accuracy of the test, and stabilizing the driving force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, wherein detection material is divided into 4 parts altogether, then

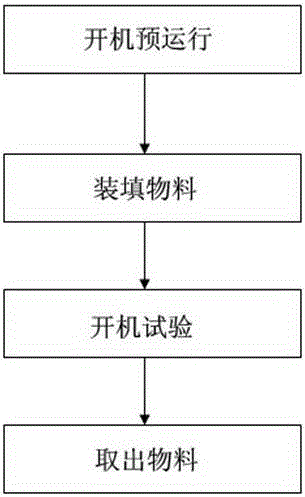

[0025] Such as figure 2 Shown, a kind of test method of track-type continuous circulation multi-temperature zone test chamber is characterized in that: the test method of described Muscovy duck raising steel cable shed comprises the steps:

[0026] The first step is to start the pre-operation. First, turn on the power of the equipment, and drive the transmission device, heating device, and cooling device to start running at the same time, and then open the automatic door to stand by;

[0027] The second step is to load the material. The material is installed on the tray of the transmission device in the test chamber through the automatic door and positioned, and only one piece of material is installed on each tray. A total of 4 trays are used, and each tray passes through the transmission device in turn. Material loading through automatic doors;

[0028] The third step is to start the...

Embodiment 2

[0030] Embodiment 2, wherein detection material is divided into 10 parts altogether, then

[0031] Such as figure 2 Shown, a kind of test method of track-type continuous circulation multi-temperature zone test chamber is characterized in that: the test method of described Muscovy duck raising steel cable shed comprises the steps:

[0032] The first step is to start the pre-operation. First, turn on the power of the equipment, and drive the transmission device, heating device, and cooling device to start running at the same time, and then open the automatic door to stand by;

[0033] The second step is to load the material. The material is installed on the tray of the transmission device in the test chamber through the automatic door and positioned, and only one piece of material is installed on each tray. A total of 10 trays are used, and each tray passes through the transmission device in turn. Material loading through automatic doors;

[0034] The third step is to start t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com