An electric blast drying oven for raw material processing in the ore detection process

A technology of electric blast drying and raw material treatment, which is applied in the direction of dryers for static materials, drying chambers/containers, and drying solid materials, etc. It can solve problems such as limited raw material specifications, poor applicability, and inability to put ore materials in. Achieve the effect of avoiding placement space, flexible and convenient adjustment, and maximizing the number of placed raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

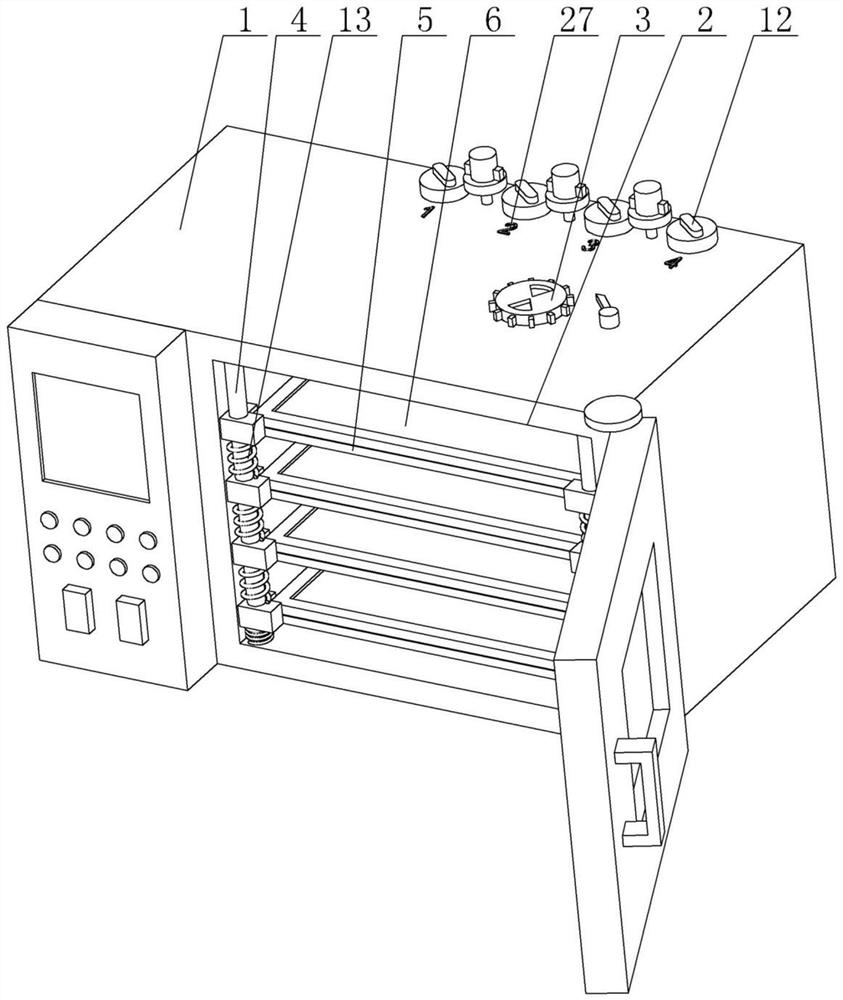

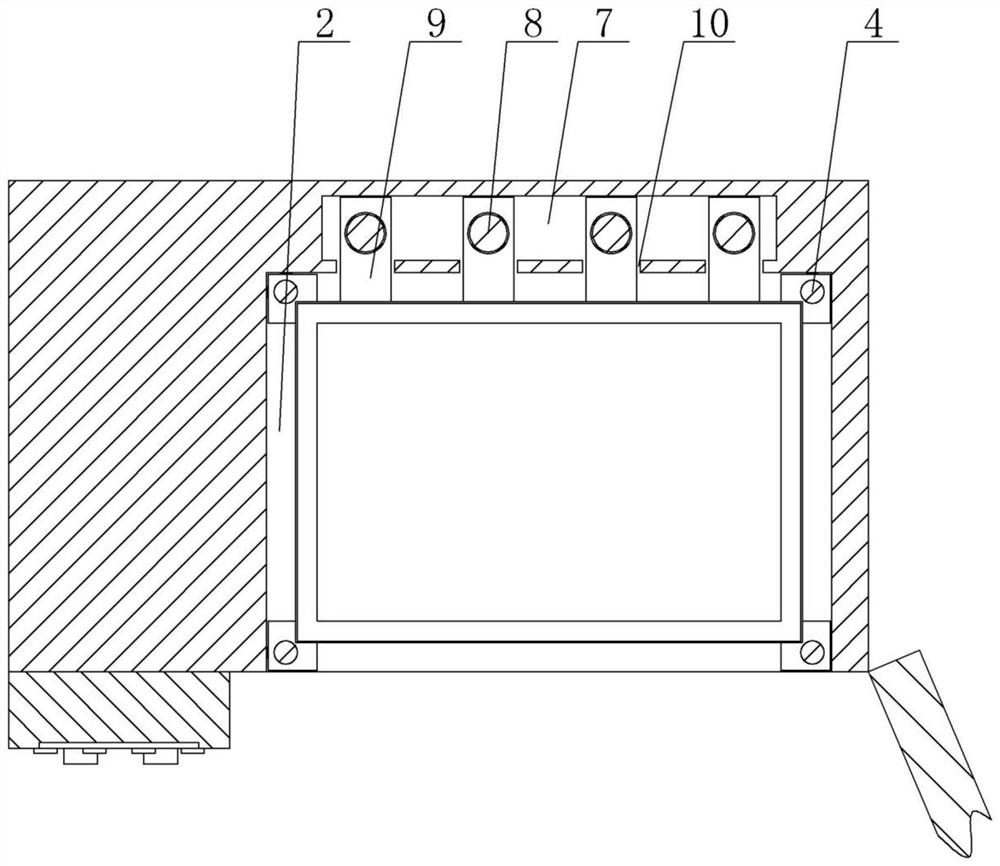

[0037] Embodiment 1: An electric blast drying box for raw material processing in the ore detection process, including a device main body 1, a working chamber 2 is provided inside the device main body 1, a vent cap 3 is provided on the device main body 1, and the The ventilation cap 3 includes a fixed block 21 installed on the top of the device main body 1, the fixed block 21 is provided with a first heat dissipation hole 22 penetrating through the device main body 1, and the outer rotation of the fixed block 21 is covered with a cap 23, the cap 23 The second heat dissipation hole 24 is provided on the top, and the coincidence exposure and dislocation shielding of the first heat dissipation hole 22 can be realized by rotating the cap 23. A plurality of dials 25 are arranged on the outside of the cap 23, and the main body of the device 1 passes through a Rotating lever is provided with driving lever 26, and described driving lever 26 is positioned at ventilation cap 3 one side, a...

Embodiment 2

[0040] Embodiment 2: An electric blast drying box for raw material processing in the ore detection process, including a device main body 1, a working chamber 2 is provided inside the device main body 1, and a ventilation cap 3 is provided on the device main body 1,

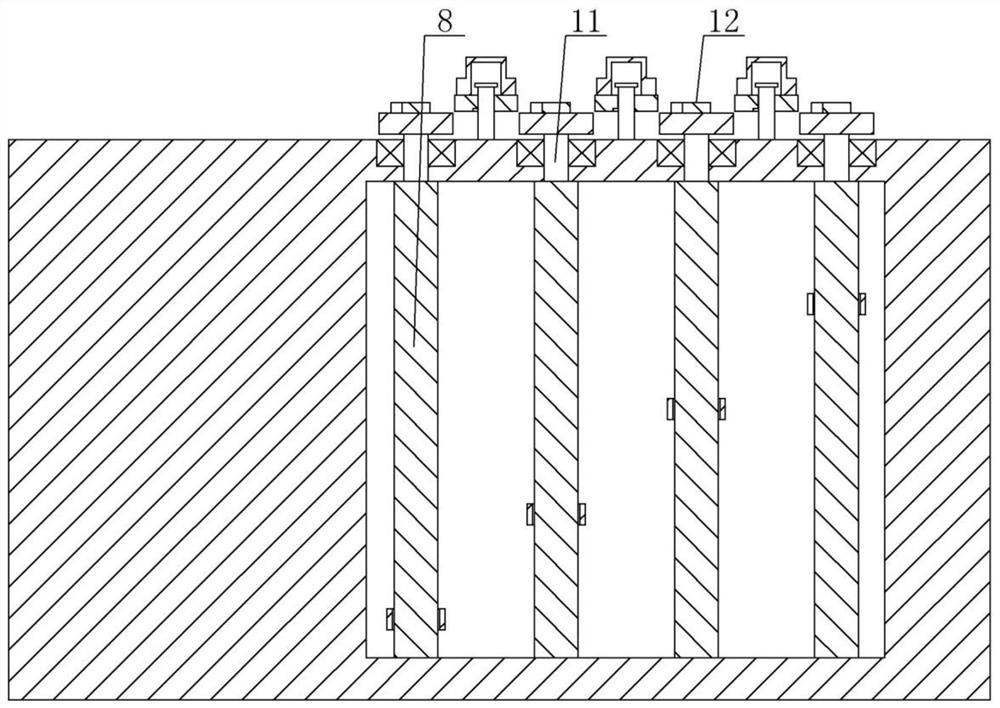

[0041] The working cavity 2 is provided with 4 stop rods 4, and 5 support frames 5 are slidably arranged on the stop rod 4, and a storage plate 6 is arranged on the support frame 5, and the support frame 5 includes a right-angle block 28 and a rectangular frame plate 29, the four corners of the rectangular frame plate 29 are respectively arranged in the corners of the right-angle block 28, the thickness of the rectangular frame plate 29 is less than the thickness of the right-angle block 28, and the bottom surface of the rectangular frame plate 29 is in contact with the The bottom surfaces of the right-angle blocks 28 are coplanar, and the rectangular frame plate 29 is provided with a storage board 6, and the four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com