Patents

Literature

1031 results about "Surface fitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

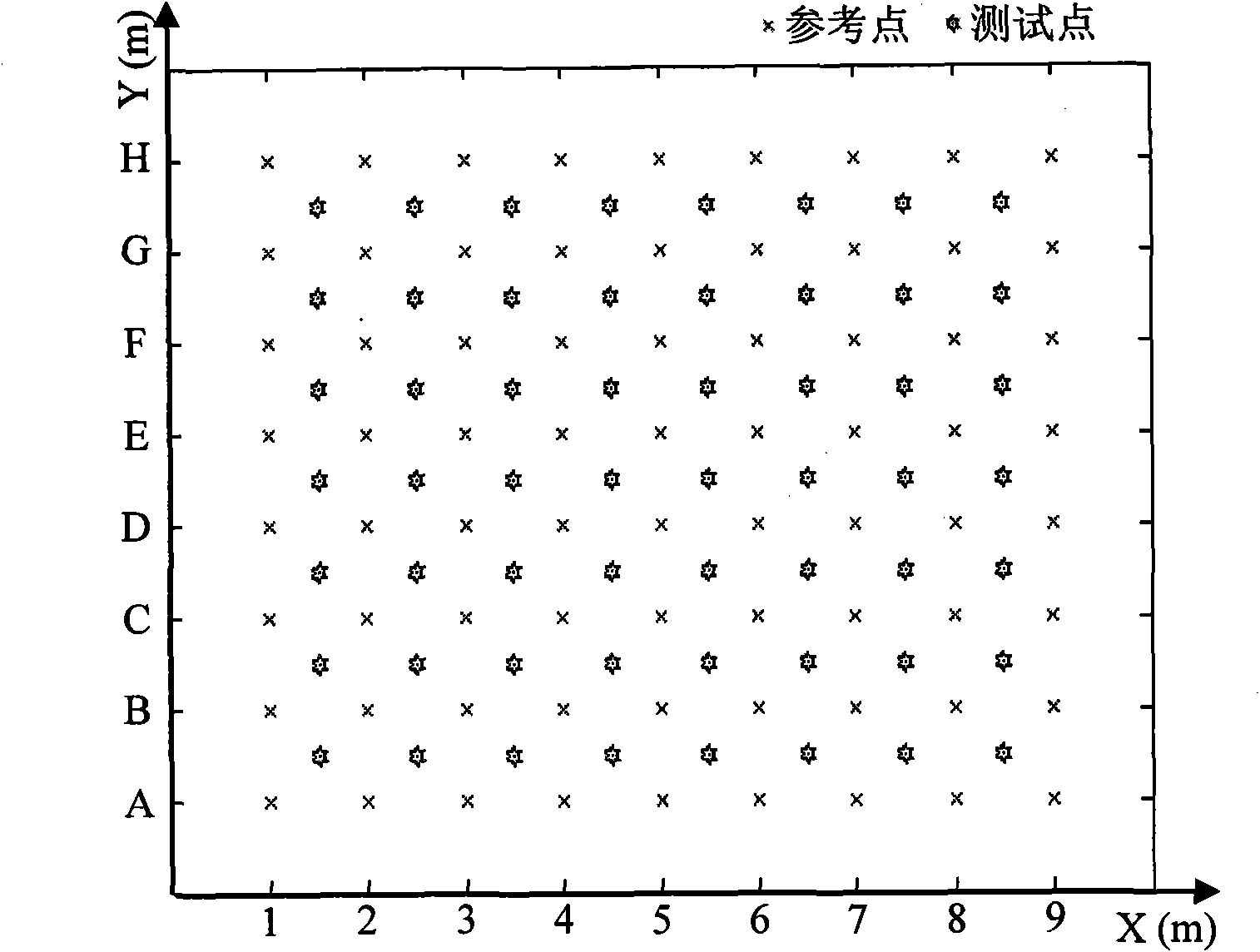

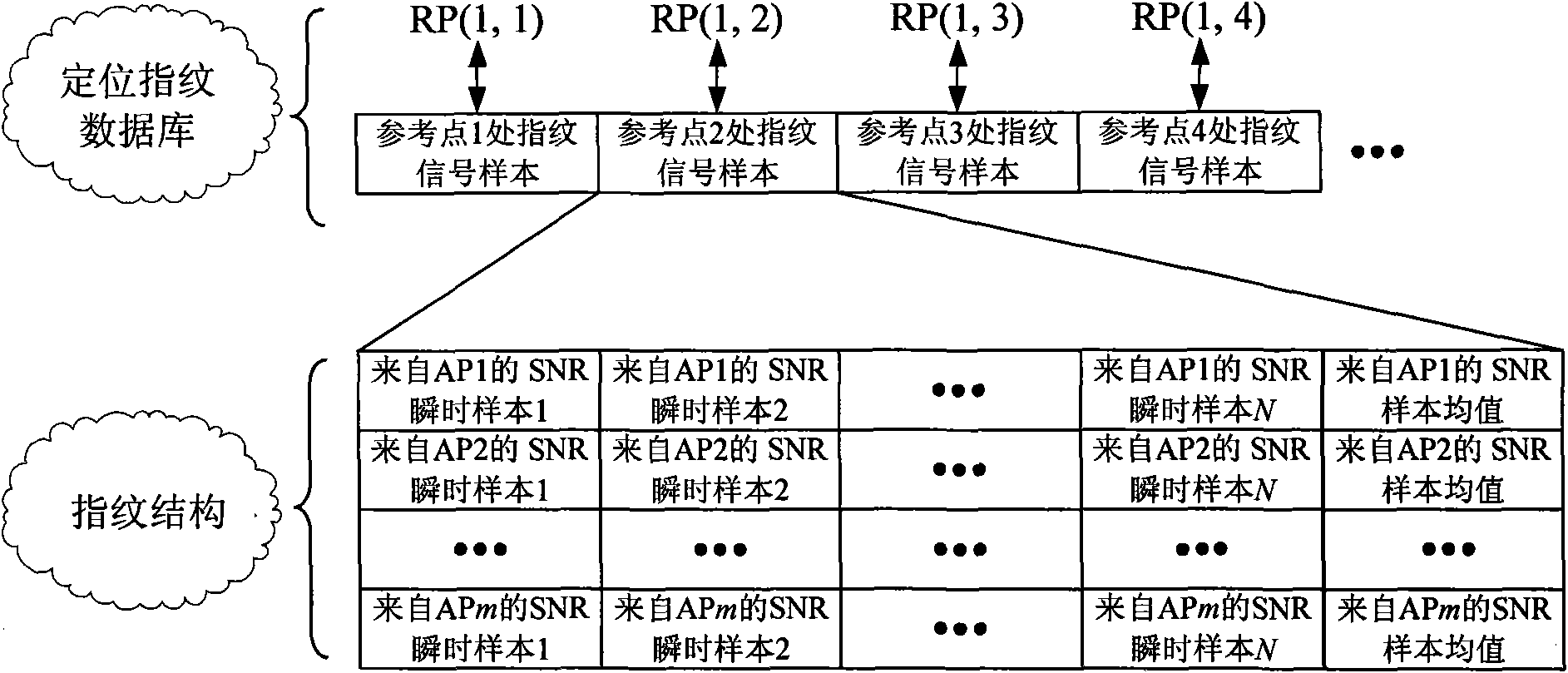

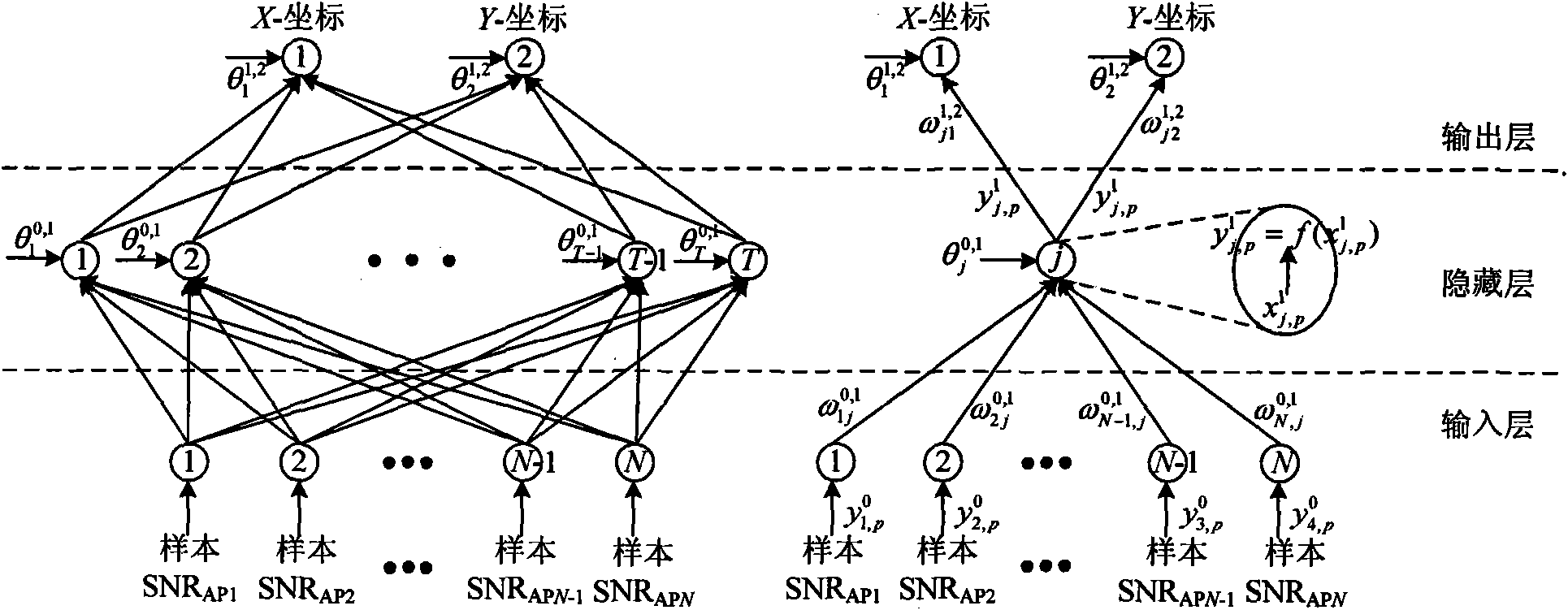

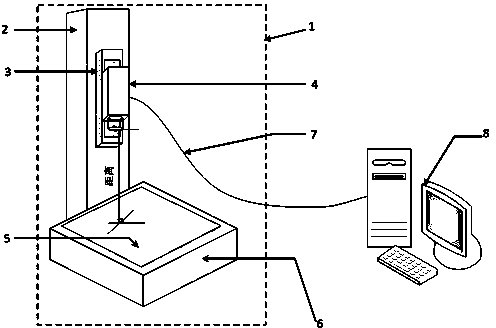

Method for optimizing WLAN (Wireless Local Area Network) indoor ANN (Artificial Neural Network) positioning based on FCM (fuzzy C-mean) and least-squares curve surface fitting methods

InactiveCN101778399ARealize terminal location positioningHigh positioning accuracyNetwork topologiesPhysical realisationAlgorithmEuclidean distance

The invention discloses a method for optimizing WLAN (Wireless Local Area Network) indoor ANN (Artificial Neural Network) positioning based on FCM (fuzzy C-means) and least-squares curve surface fitting methods, relating to an indoor positioning method used for indoor positioning and aiming to solve generalization capability reduction of an ANN system caused by singular reference points existing in a training sample space. The method comprises the following steps of carrying out clustering on pre-labeled reference points based on the FCM method to confirm corresponding clustering centers and membership degree of different reference points to clustering centers thereof; obtaining the space position of the singular reference points in a target positioning area on the basis of carrying out quantitative processing and similarity calculation on the membership degree of the reference points; updating positioning fingerprint database by utilizing the least-squares curve surface fitting method to reject abrupt change points in an intensity distribution chart; estimating the cluster of a terminal on the basis of calculating the Euclidean distance between signal intensity samples collected online and different clustering centers; and finally accurately estimating the terminal by utilizing corresponding ANN subsystems.

Owner:HARBIN INST OF TECH

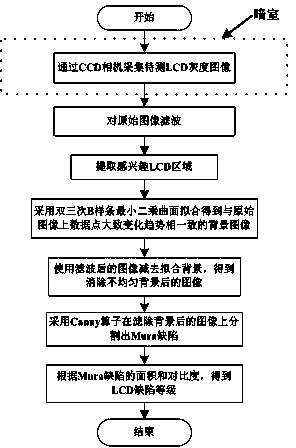

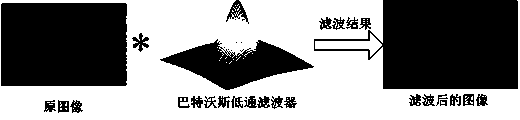

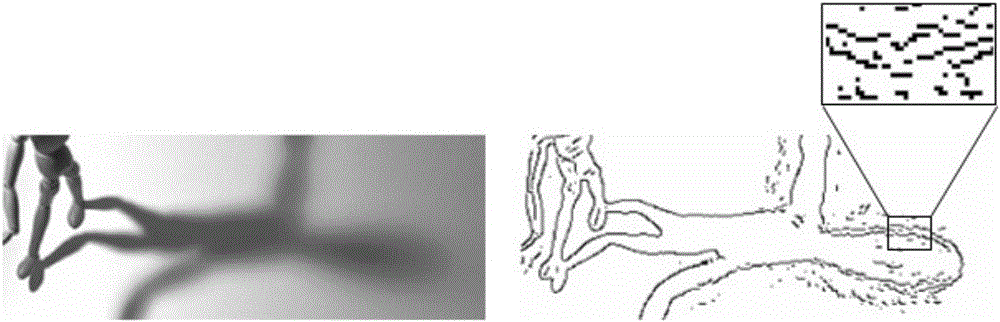

TFT-LCD Mura defect machine vision detecting method based on B spline surface fitting

InactiveCN103792699ASimplify the build processEasy to operateOptically investigating flaws/contaminationNon-linear opticsMachine visionCcd camera

The invention discloses a TFT-LCD Mura defect machine vision detecting method based on B spline surface fitting and belongs to the field of LCD display defect detecting. The method includes: using a CCD camera to collect the grayscale image of a lighted to-be-detected LCD; filtering the original image; extracting an interested area; using double three-time B spline surface fitting to fit an image background; using the original image to subtract the background image so as to obtain the image with the background, with uneven brightness, being removed; using a Canny operator to detects Mura defects; determining defect level. The method has the advantages that the method is reliable, high in accuracy and time saving in calculation.

Owner:SICHUAN ENTRY EXIT INSPECTION & QUARANTINE BUREAU OF THE PEOPLES REPUBLIC OF CHINA

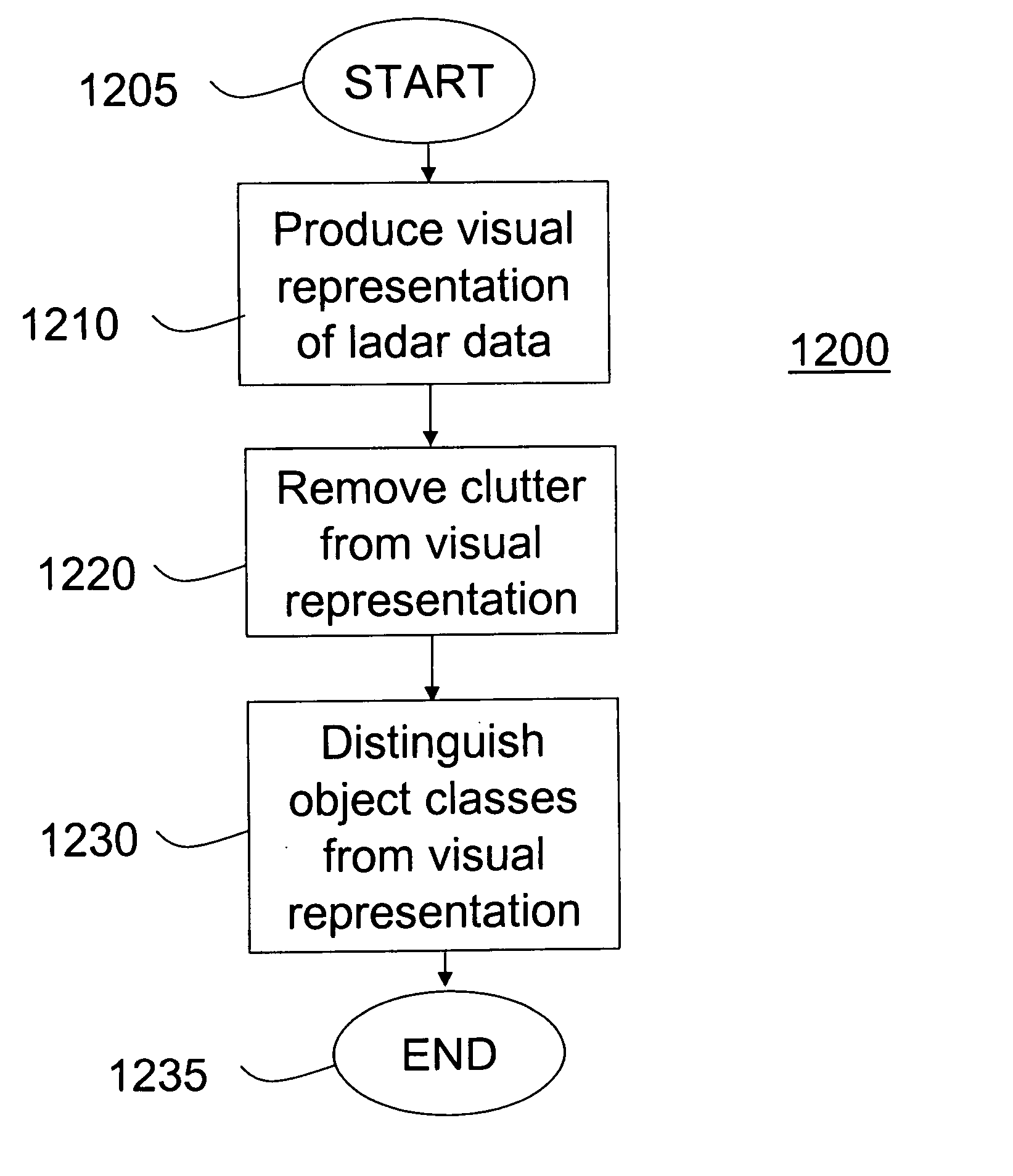

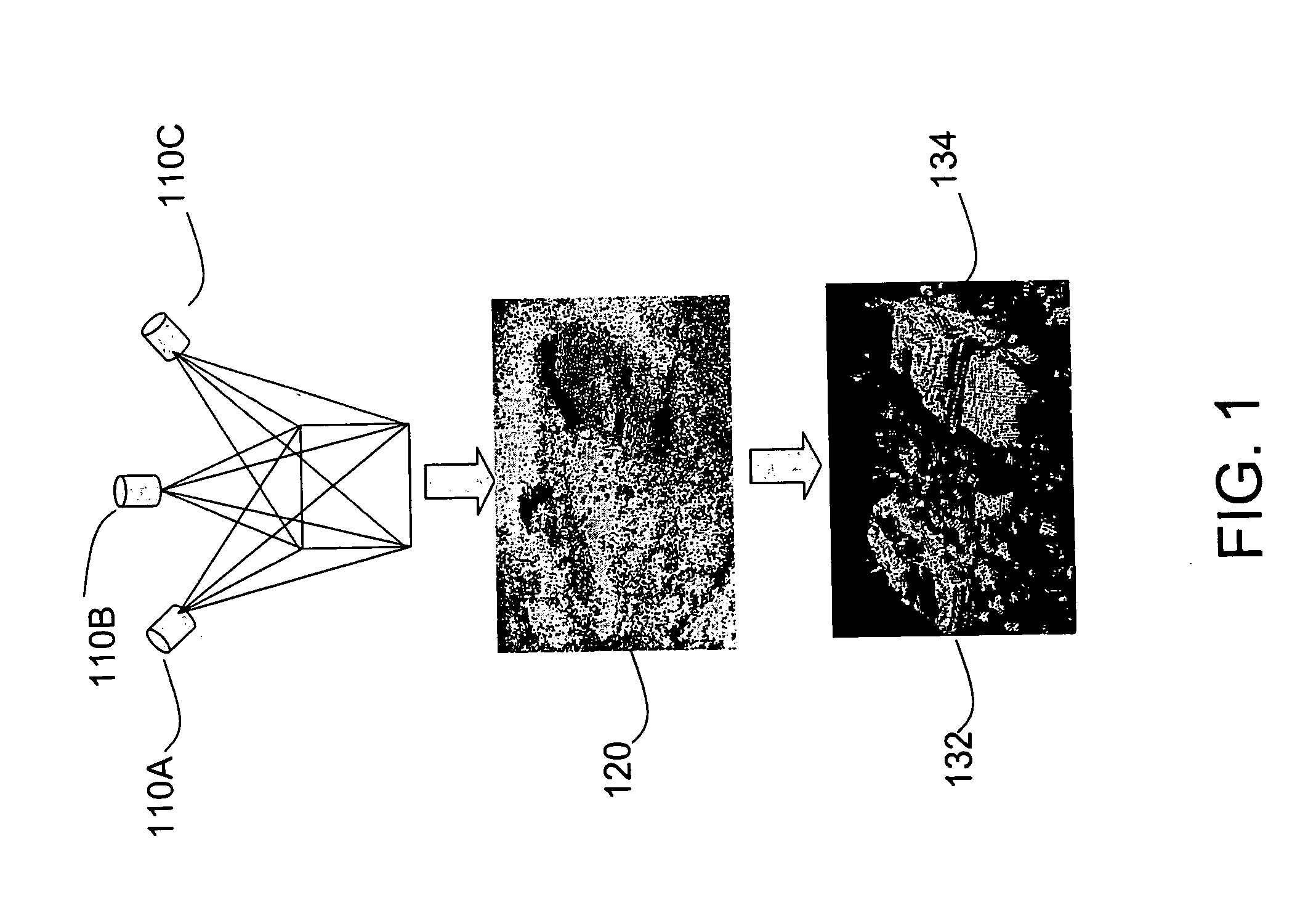

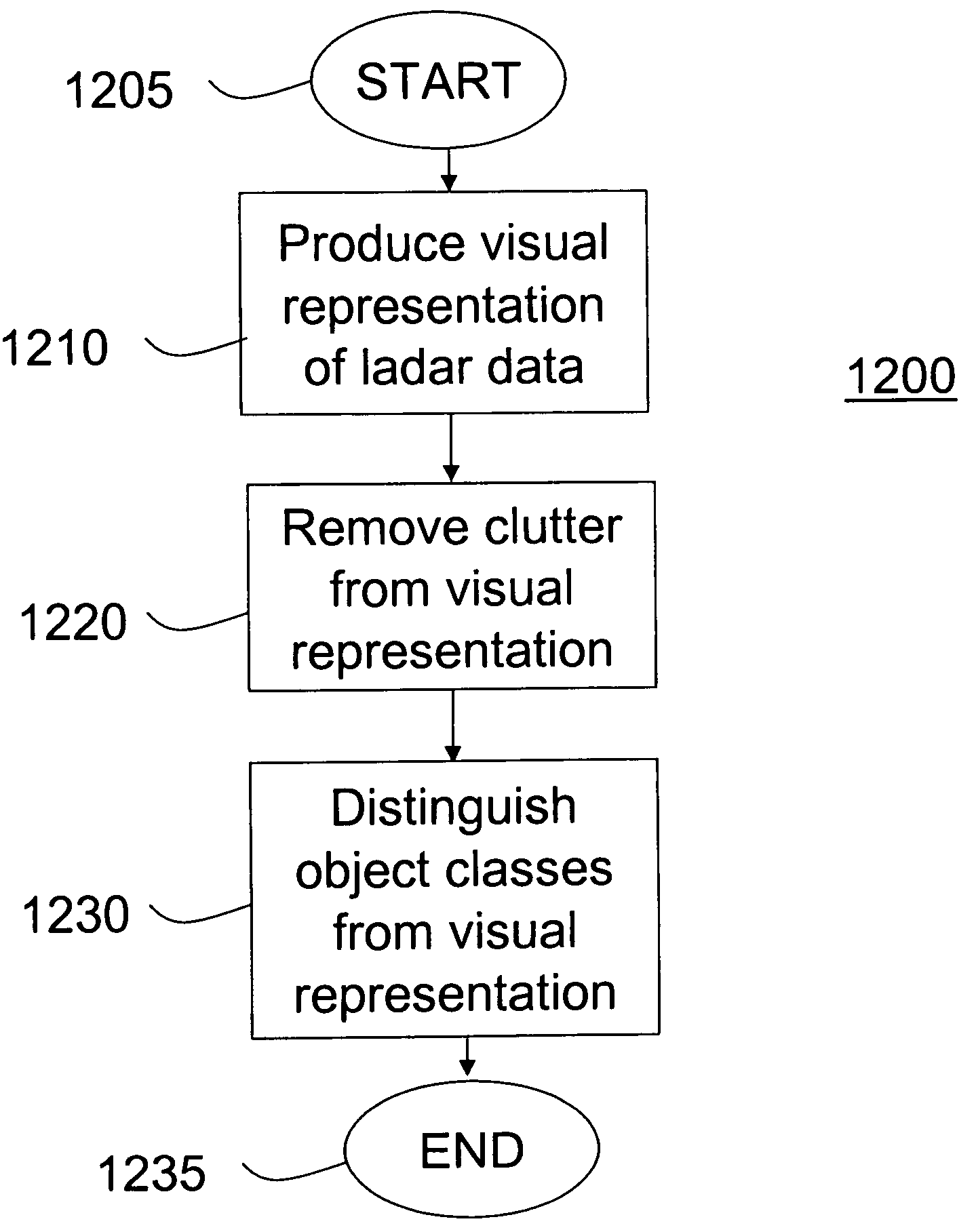

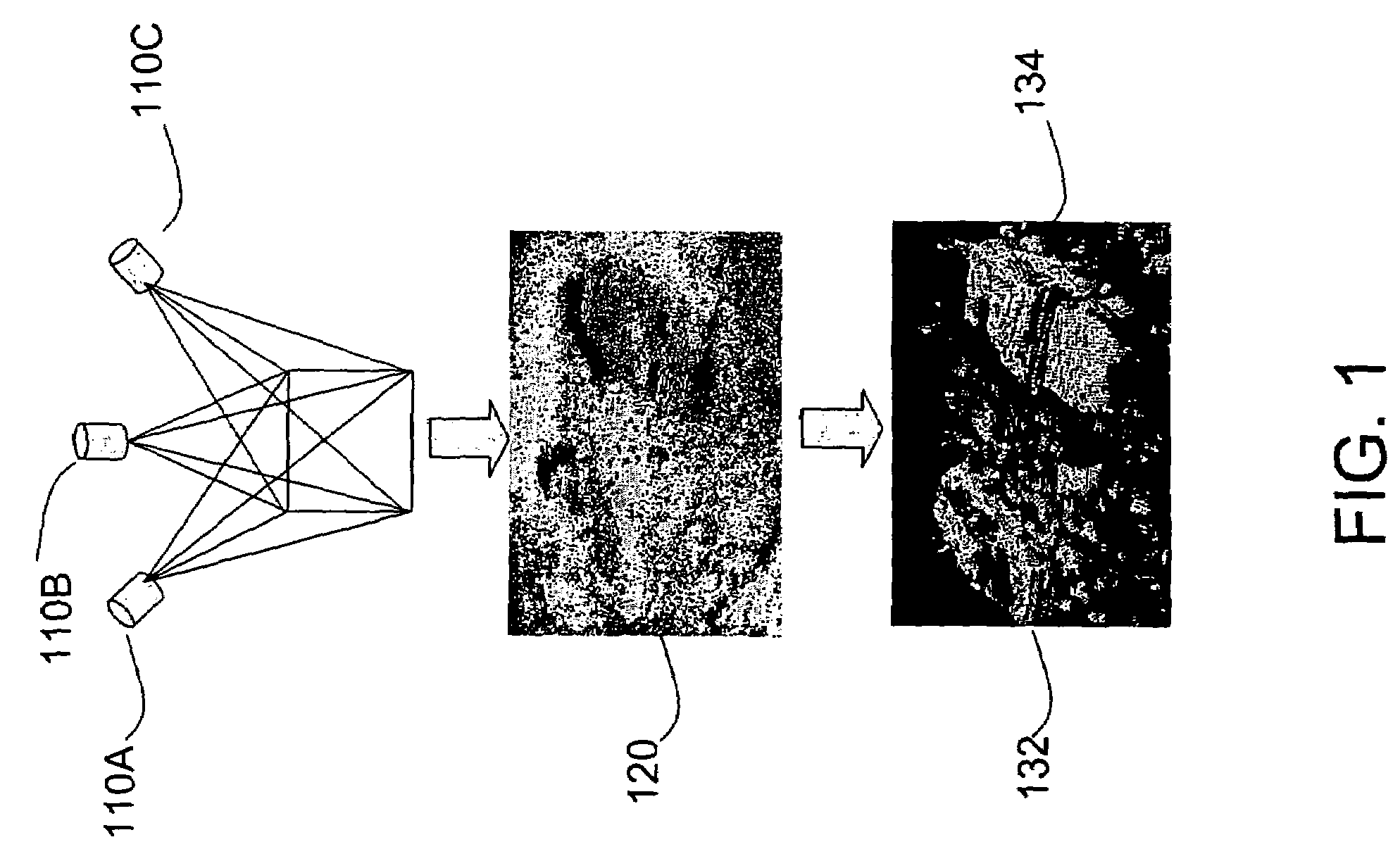

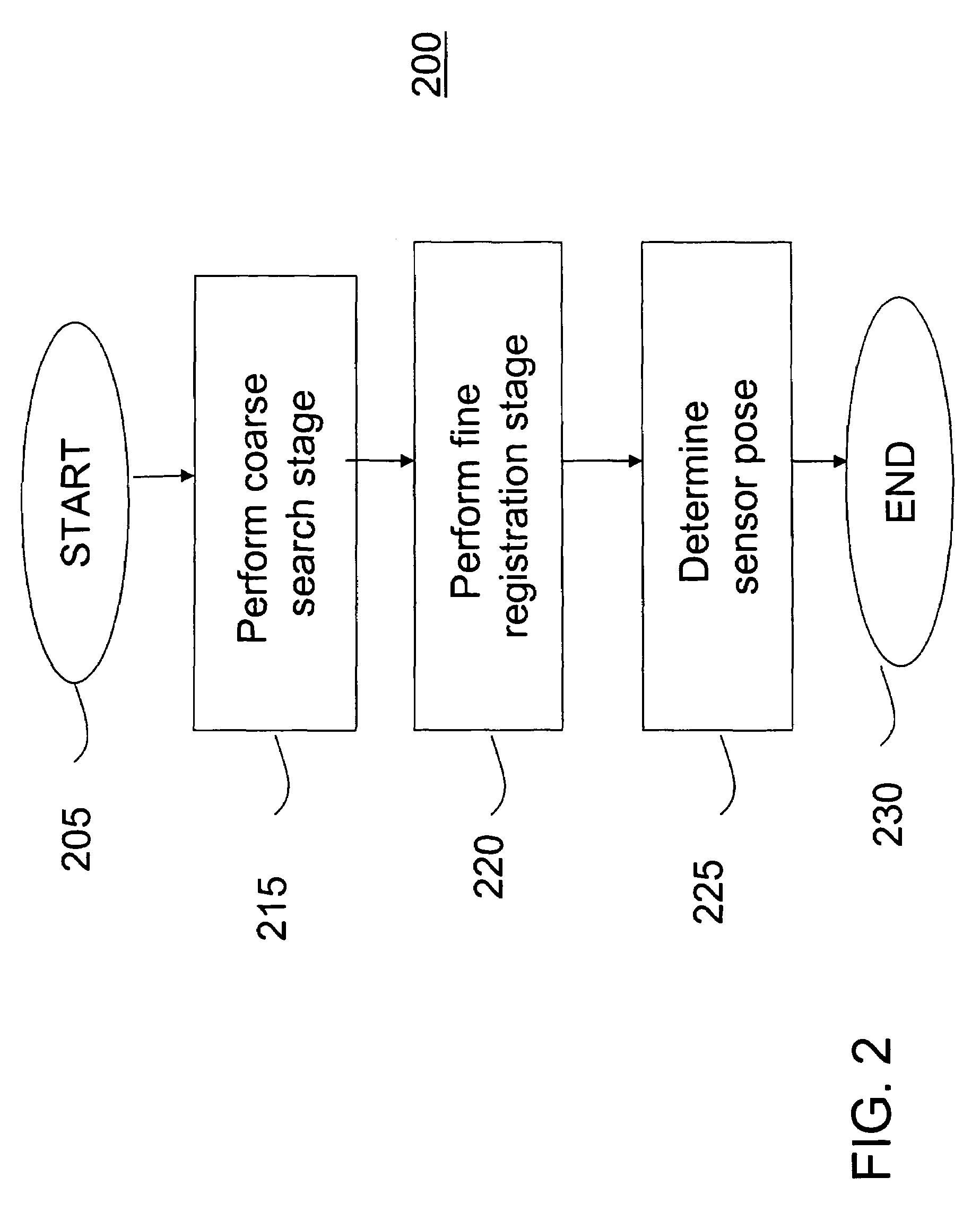

Method and apparatus for automatic registration and visualization of occluded targets using ladar data

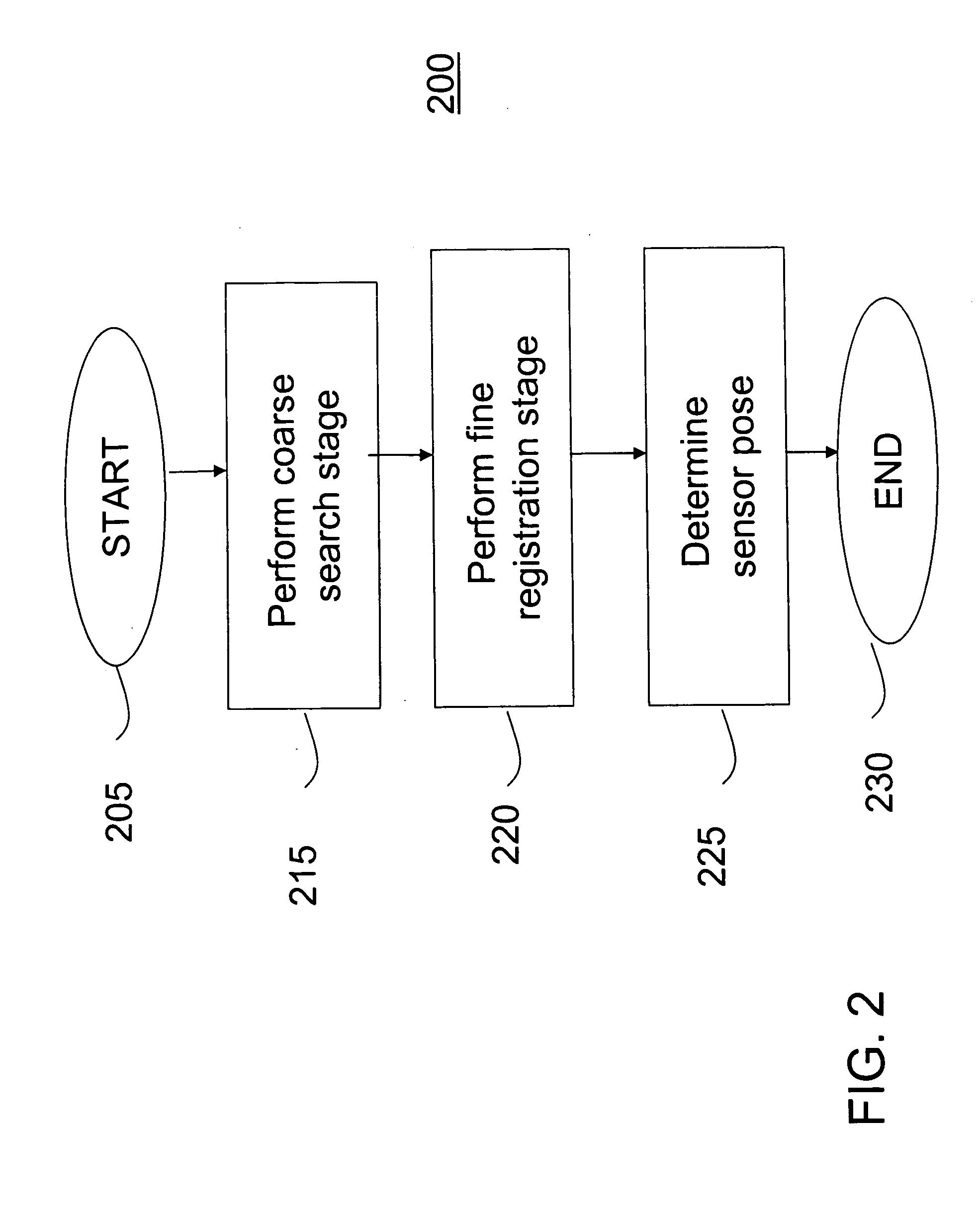

ActiveUS20050243323A1Enhancing visual exploitationImage enhancementRadiation pyrometryClosest pointPoint cloud

A method and apparatus for high-resolution 3D imaging ladar system which can penetrate foliage and camouflage to sample fragments of concealed surfaces of interest is disclosed. Samples collected while the ladar moves can be integrated into a coherent object shape. In one embodiment, a system and method for automatic data-driven registration of ladar frames, comprises a coarse search stage, a pairwise fine registration stage using an iterated closest points algorithm, and a multi-view registration strategy. After alignment and aggregation, it is often difficult for human observers to find, assess and recognize objects from a point cloud display. Basic display manipulations, surface fitting techniques, and clutter suppression to enhance visual exploitation of 3D imaging ladar data may be utilized.

Owner:SRI INTERNATIONAL

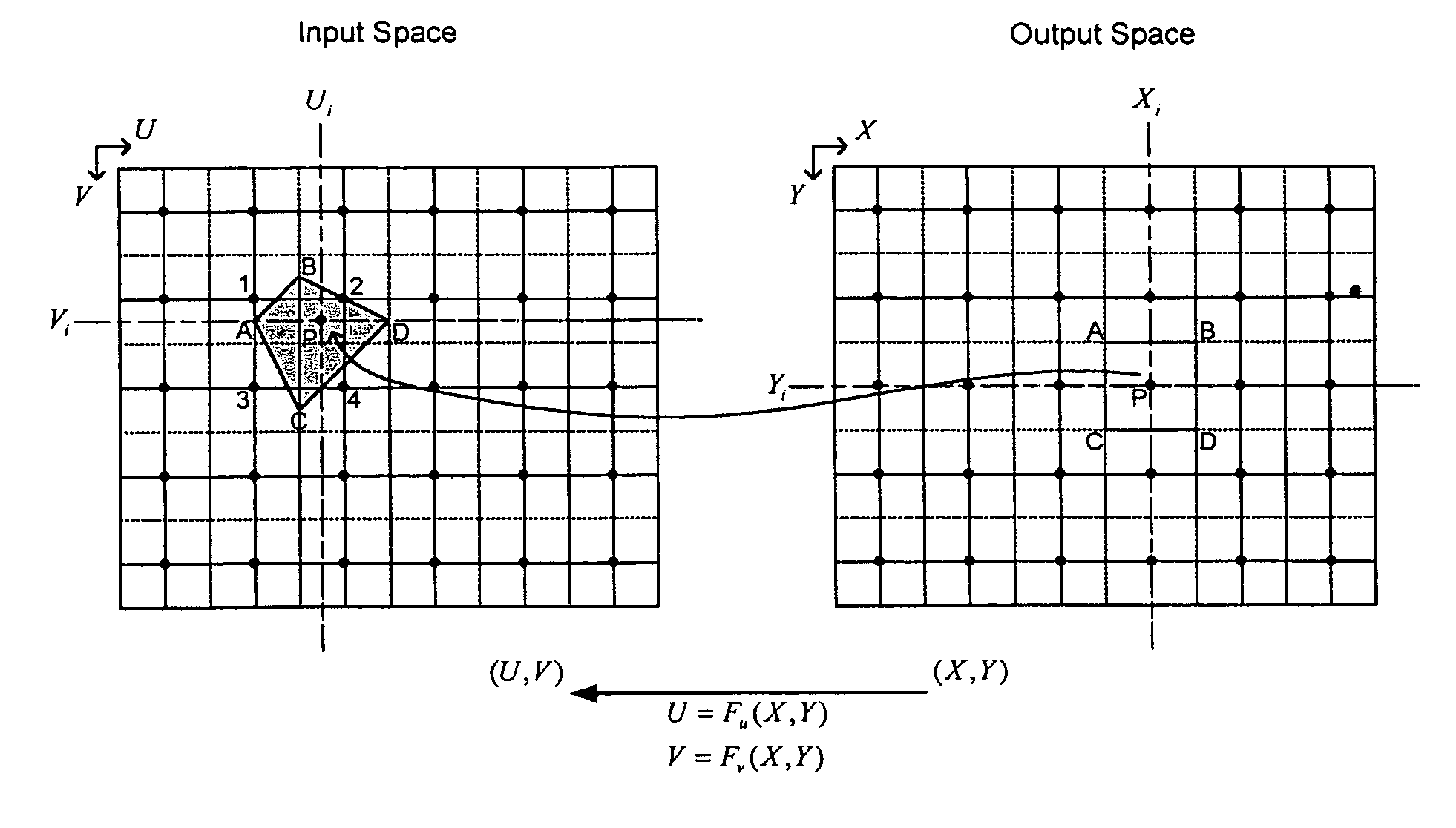

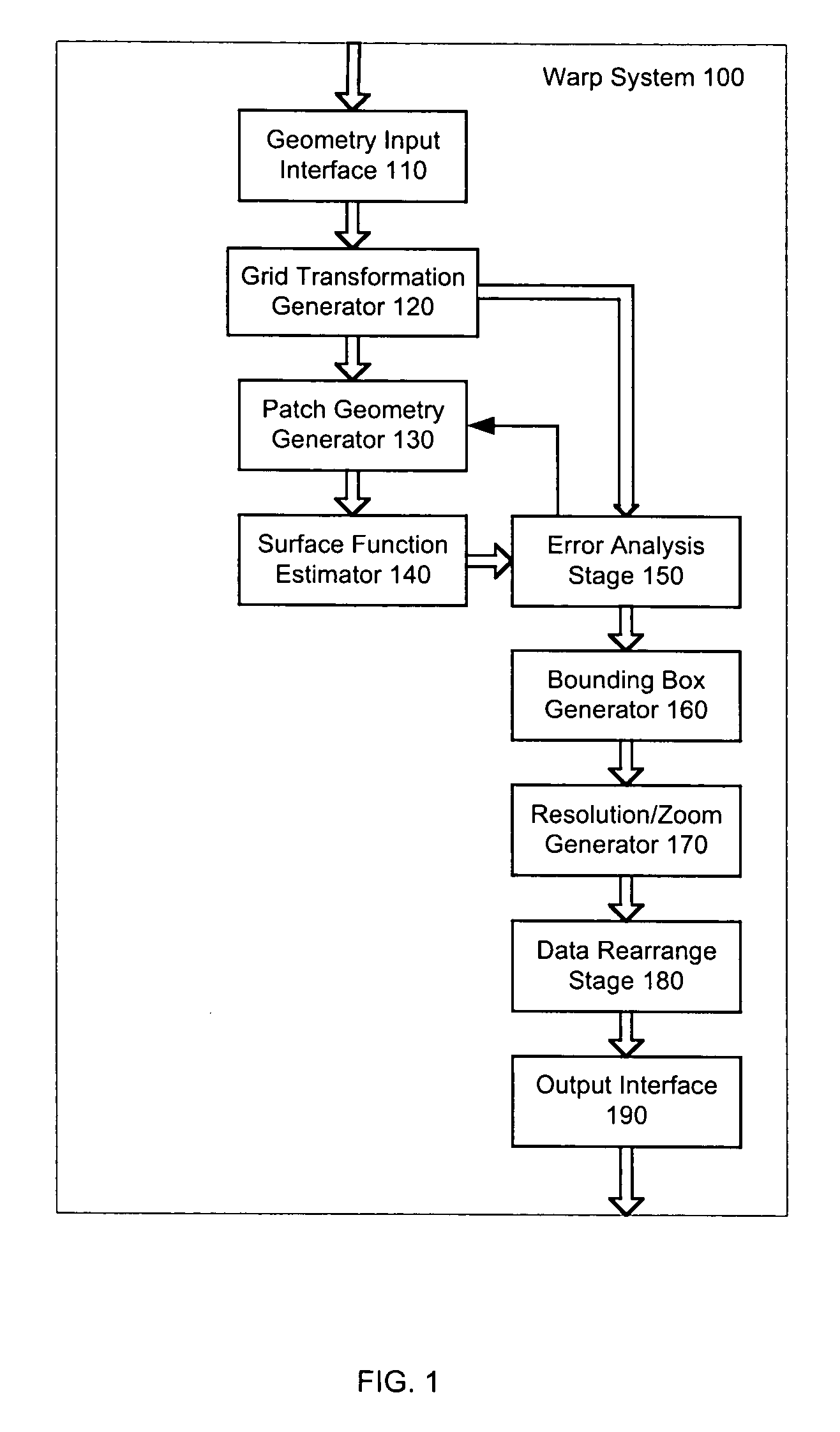

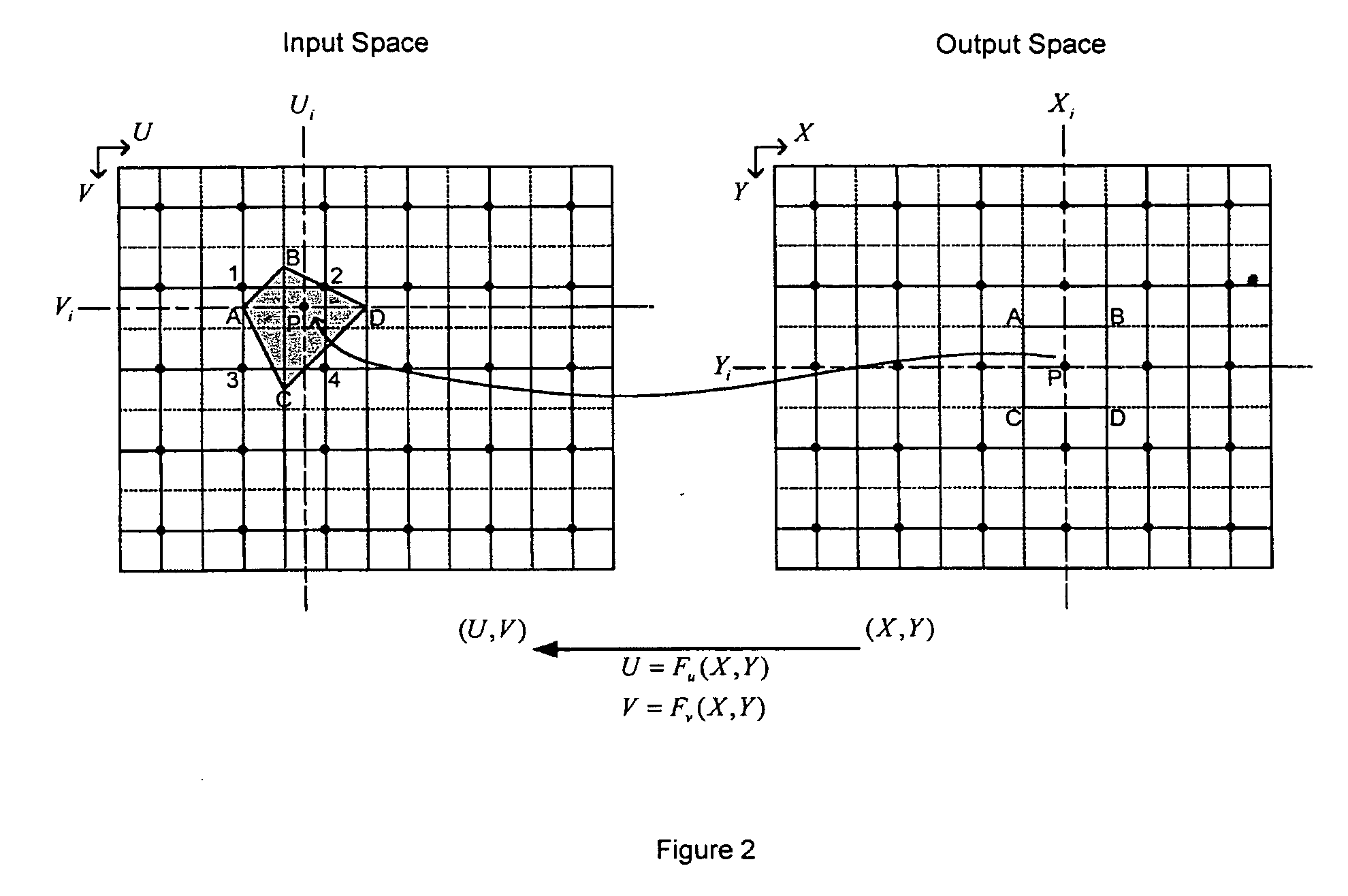

System and method for representing a general two dimensional spatial transformation

ActiveUS20060050074A1Geometric image transformationCharacter and pattern recognitionData setImage resolution

A system and method for representing a two-dimensional spatial transformation that describes the transformation by an inverse mapped grid data set. The grid data for each coordinate is surface fitted on an array of rectangular patches defined in the output space using numerical techniques. Error analysis determines whether a finer mesh resolution is required for surface fitting. The spatial transformation is then defined by the array of rectangular surface patches and the set of surface coefficients such that the spatial transformation can be executed through evaluation of the surface polynomials. The two-dimensional surface polynomial representation allows the transformation to be easily adjusted for scale changes and zooming and panning effects.

Owner:GEO SEMICONDUCTOR INC

Method and apparatus for automatic registration and visualization of occluded targets using ladar data

A method and apparatus for high-resolution 3D imaging ladar system which can penetrate foliage and camouflage to sample fragments of concealed surfaces of interest is disclosed. Samples collected while the ladar moves can be integrated into a coherent object shape. In one embodiment, a system and method for automatic data-driven registration of ladar frames, comprises a coarse search stage, a pairwise fine registration stage using an iterated closest points algorithm, and a multi-view registration strategy. After alignment and aggregation, it is often difficult for human observers to find, assess and recognize objects from a point cloud display. Basic display manipulations, surface fitting techniques, and clutter suppression to enhance visual exploitation of 3D imaging ladar data may be utilized.

Owner:SRI INTERNATIONAL

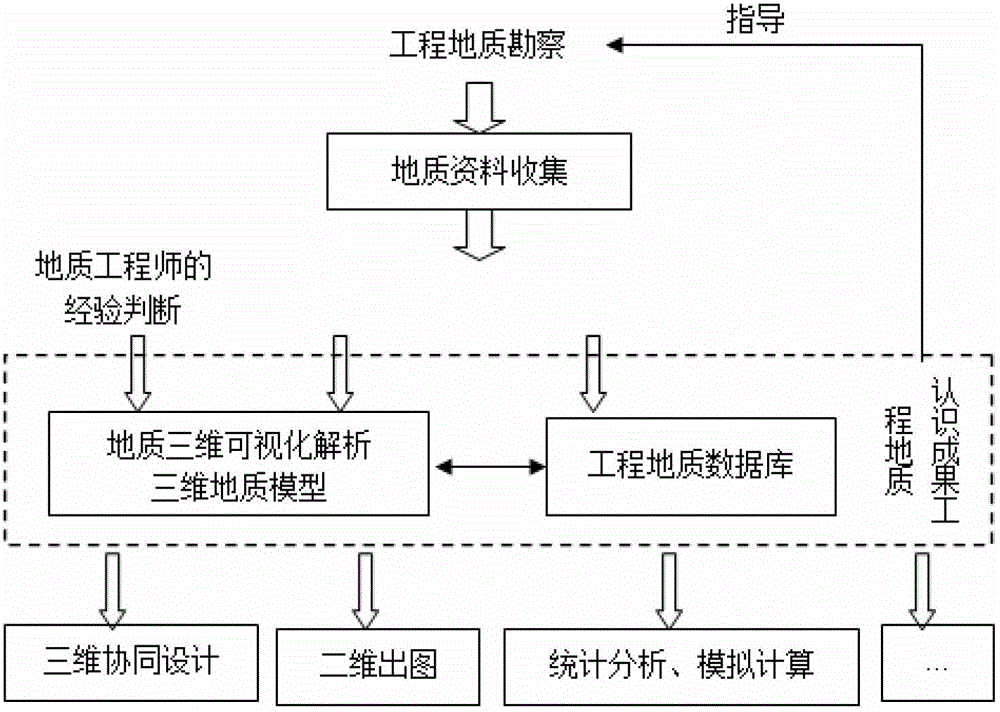

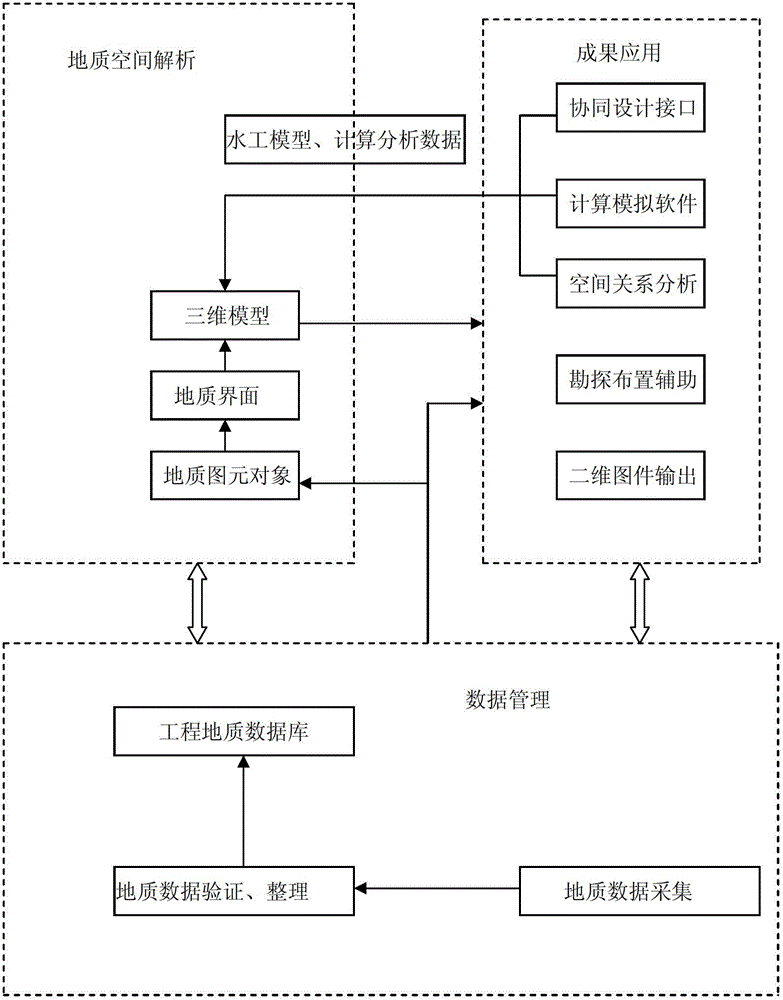

Construction method of three-dimensional geologic model

ActiveCN102750739AEnables direct 3D interpretation analysisQuick response3D modellingSurface fittingWorkload

Owner:POWERCHINA CHENGDU ENG

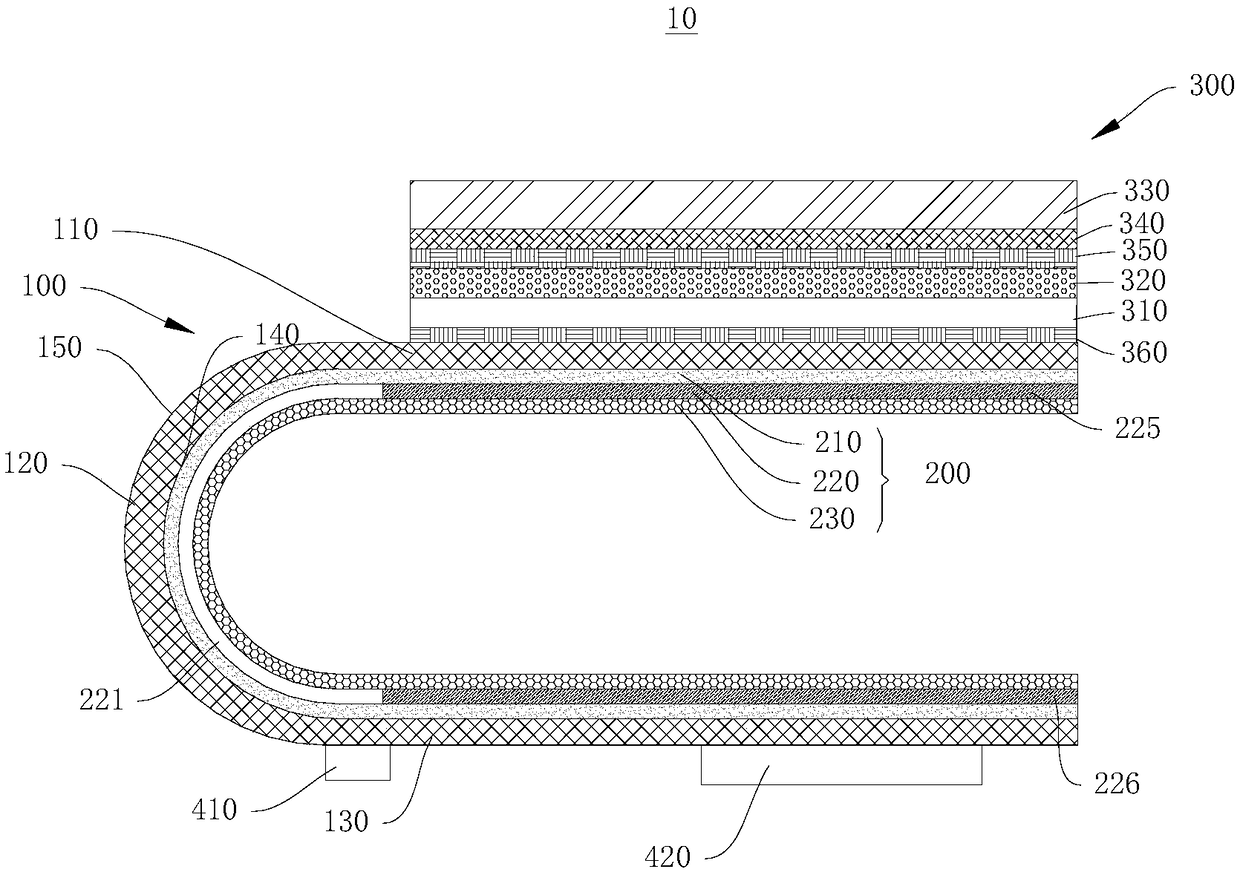

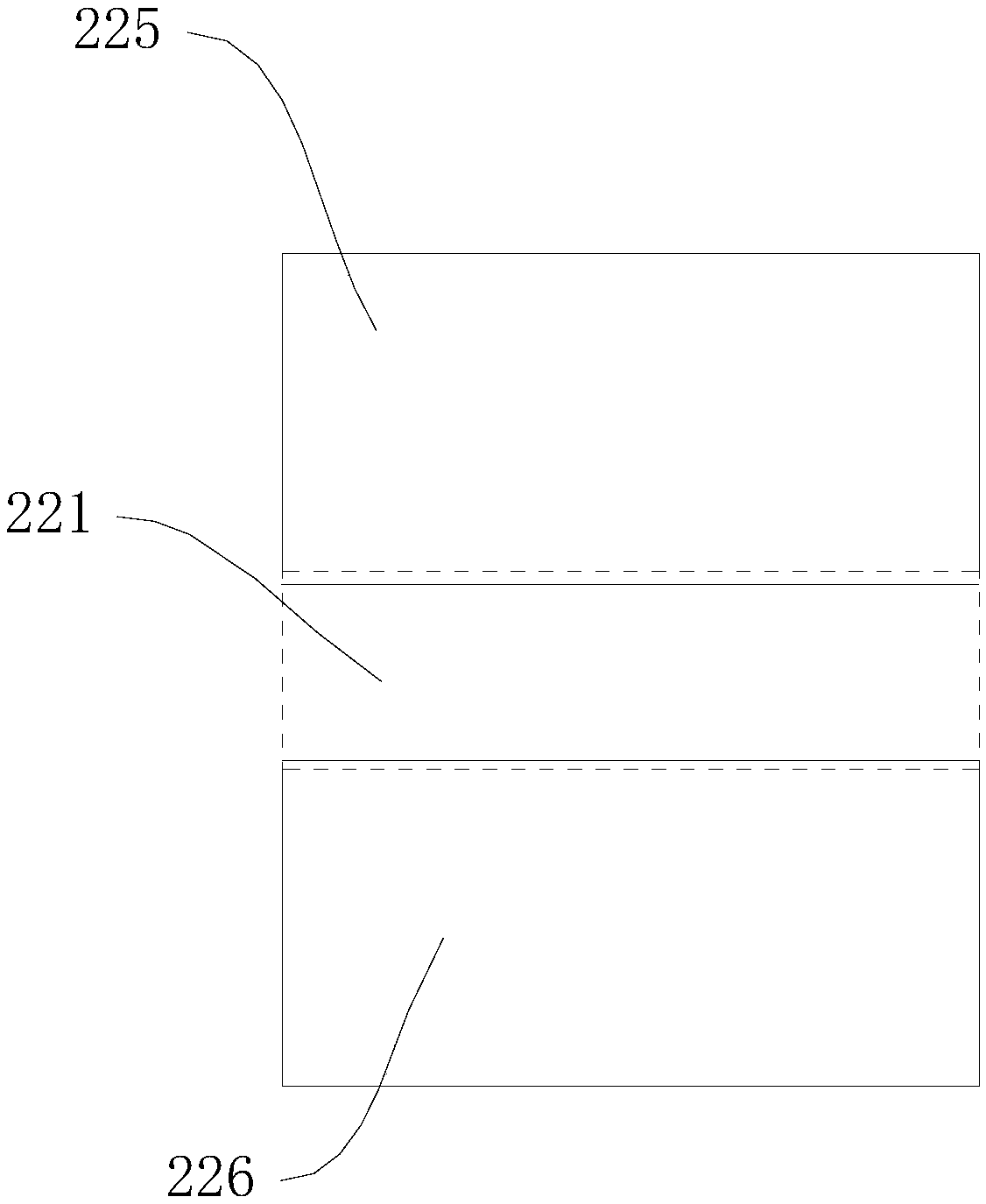

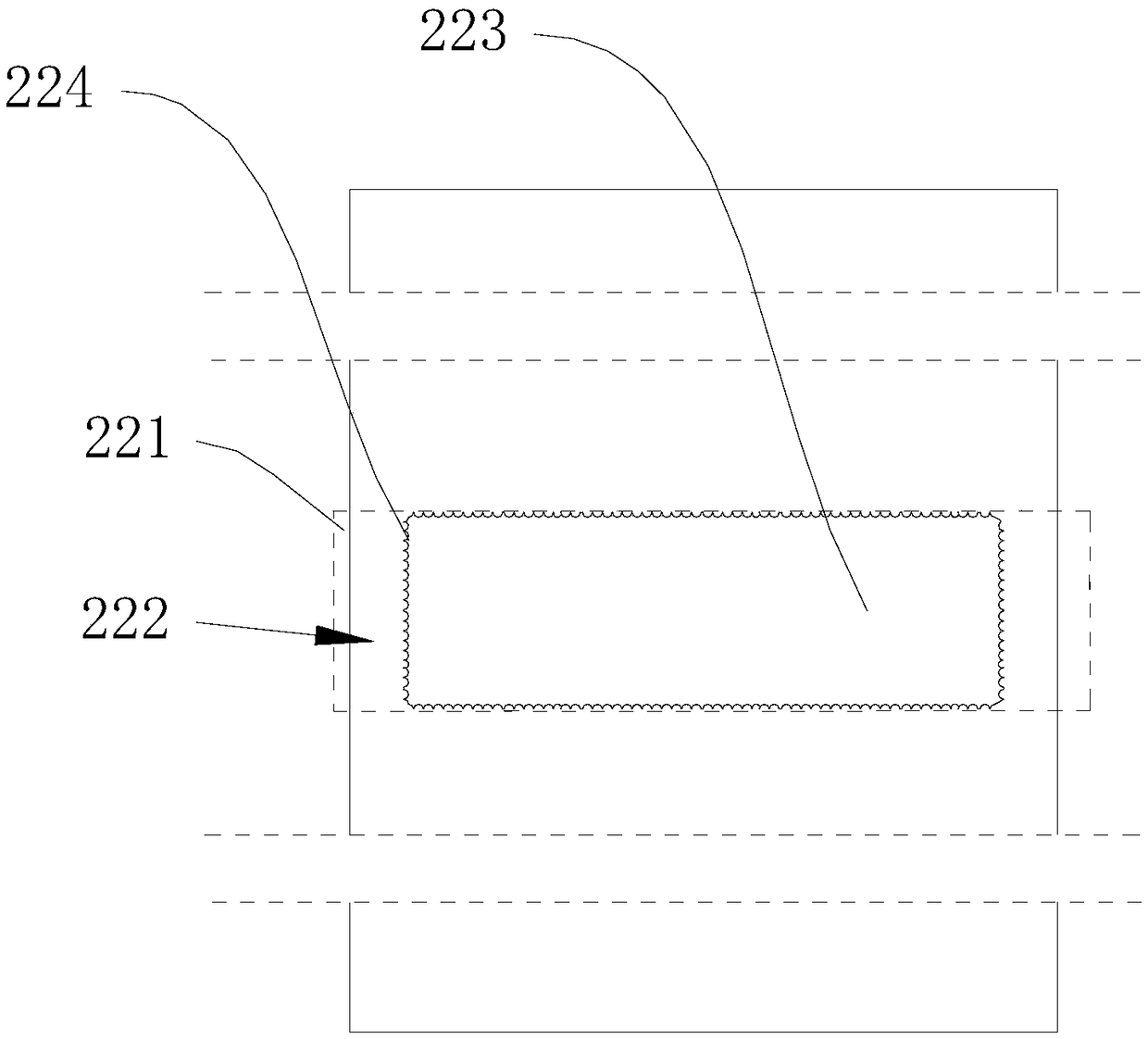

Display panel and manufacturing method of display panel

The invention relates to a display panel and a manufacturing method of the display panel. The display panel comprises a flexible screen body and a supporting layer, wherein the flexible screen body comprises a display area, a bending area and an extending area which are arranged in sequence; the flexible screen body also comprises a first surface and a second surface which are arranged oppositely;the flexible screen body is bent towards the first surface from the second surface; the display area and the extending area are arranged in parallel; the supporting layer is laminated to the first surface; the supporting layer comprises a bottom supporting film, at least one middle supporting film and a top supporting film which are laminated to the first surface in sequence, each middle supporting film comprises a stress relief area for reducing deformation stress, and the stress relief area is opposite to the bending area. The stress relief area can reduce the bending stress generated by the supporting layer in the bending area, so that the supporting layer is prevented from being damaged due to the generated greater bending stress.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

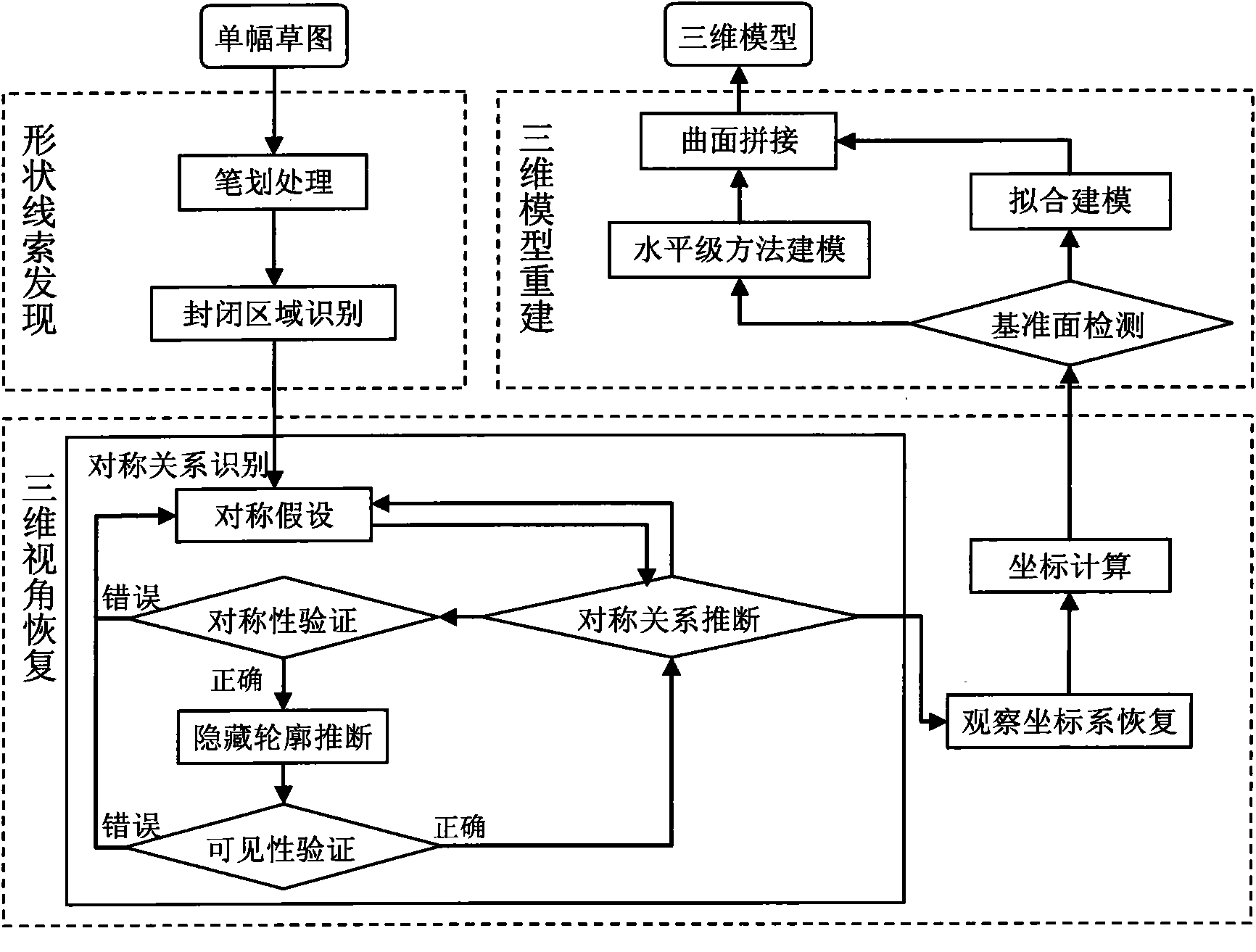

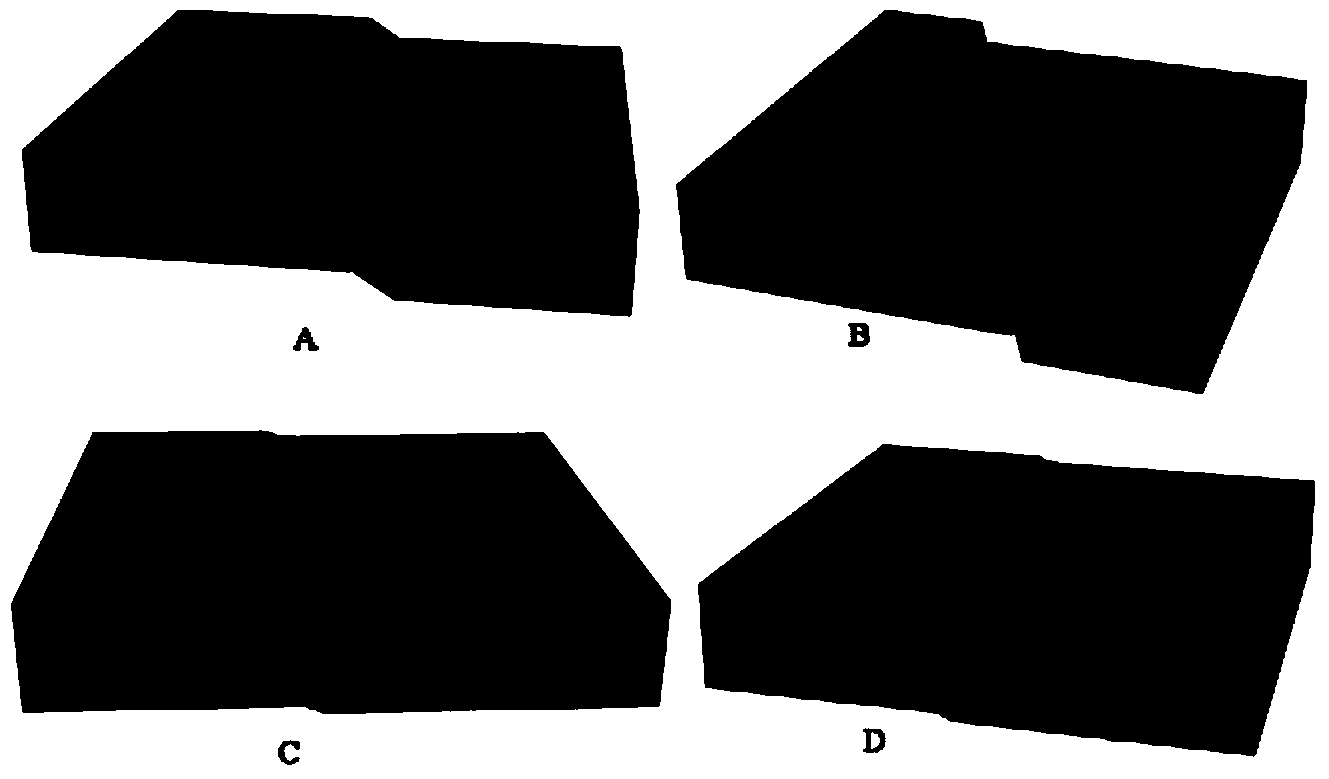

Method for creating three-dimensional surface model by using perspective sketch

The invention discloses a method for creating a three-dimensional surface model by using a perspective sketch. The method comprises the following steps of: identifying and processing a hand-drawn sketch into a vertex-edge graph consisting of contour sides and articulation points, and identifying closed areas; identifying the symmetric relation of the three-dimensional surface model, and completing hidden contours for the contours according to symmetry and visibility; establishing an object coordinate system of the surface model according to a symmetrical relation, calculating three-dimensional coordinates of the contour sides and the articulation points of the surface model, and recovering the coordinates of three-dimensional space curves among the articulation points according to curve projection between the three-dimensional coordinates of the articulation points and the articulation points; categorizing the three-dimensional closed areas of the model into different closed area pieces according to the characteristics of a level modeling method and a B-spline surface fitting method; and modeling the closed area pieces into sub-surfaces according to the characteristics of the closed area pieces by the level modeling method or the B-spline surface fitting method and jointing the sub-surfaces into a three-dimensional model through dispersing, blending and splicing.

Owner:NANJING UNIV

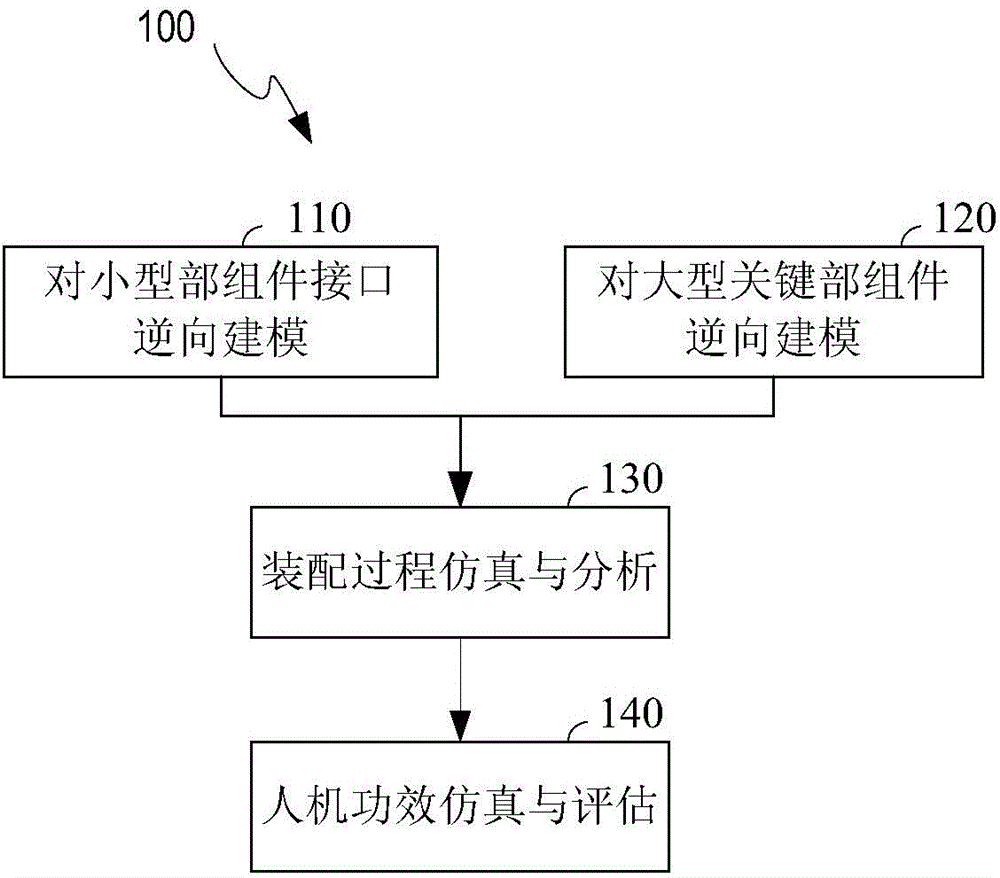

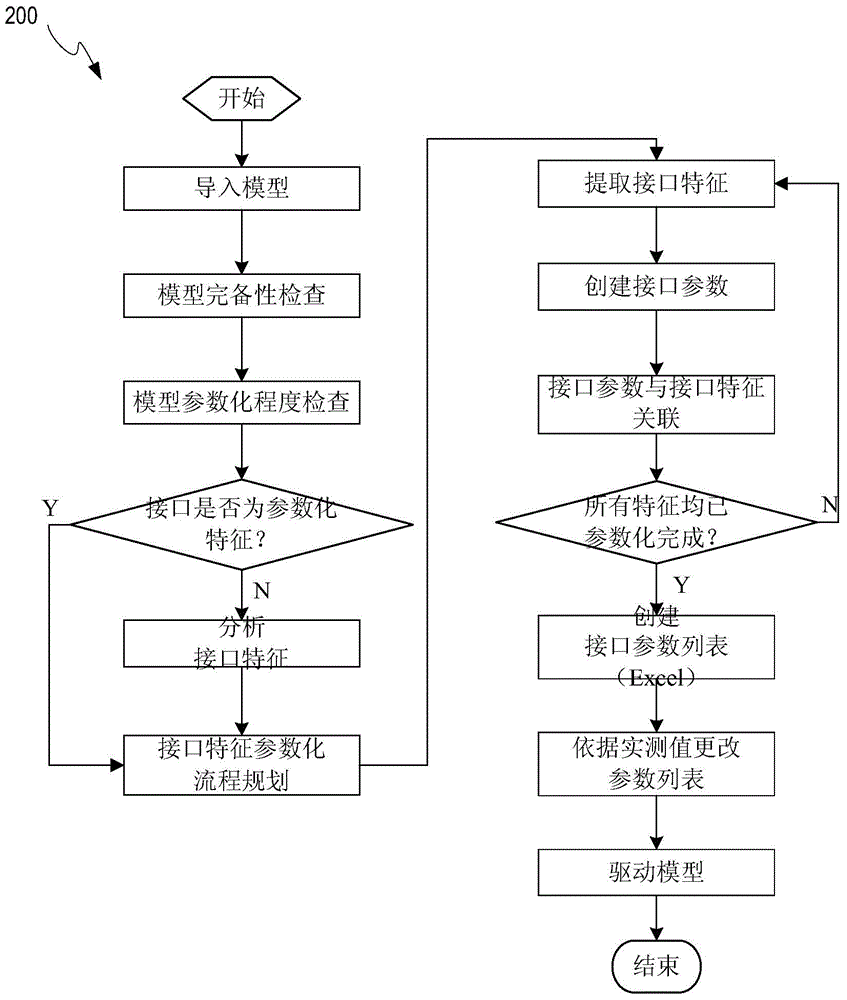

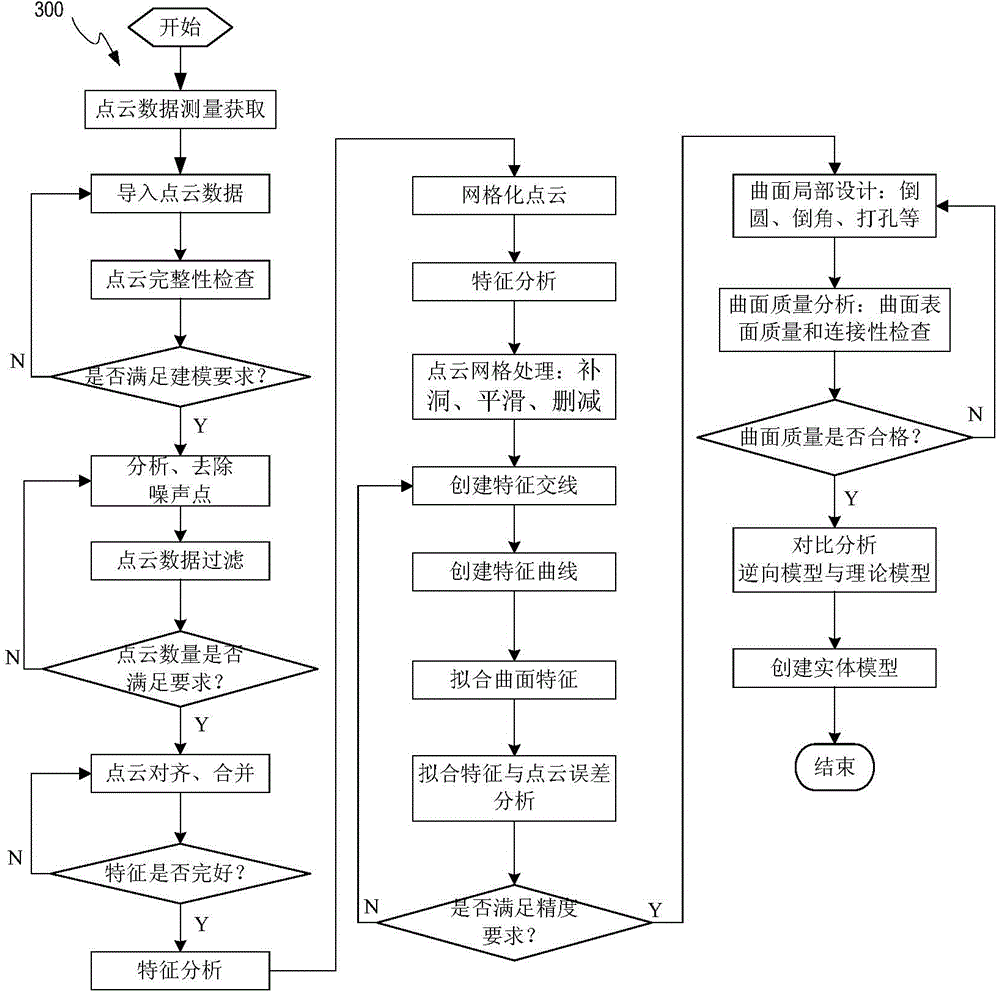

Actually measured data-based spacecraft component assembly simulation method

ActiveCN104598675AImprove reliabilityImprove efficiencySpecial data processing applicationsSimulationThree dimensionality

The invention discloses an actually measured data-based spacecraft component assembly simulation method. The assembly simulation method includes the following steps that a parametrized three-dimensional rapid modeling method is utilized to generate actually measured dimension-based three-dimensional small component models after final assembly inspection personnel actually measure and input the dimensions of key small component interfaces into a corresponding parametrized three-dimensional modeling system; a reverse point cloud curved surface fitting method is utilized to convert the surface shapes of real objects of large key components into discrete geometric coordinate points, and on the basis, the modeling of complex curved surfaces is carried out, so that reverse three-dimensional digitalized models of the large key components are formed; the assembly process is simulated and analyzed; ergonomics is simulated and evaluated. By combining a virtual reality scene with reverse real object modeling, the actually measured data-based spacecraft component assembly simulation method disclosed by the invention detects interference points and risk sources in advance to find out assembly incoordination and other problems, thus increasing the reliability of the final spacecraft assembly process and the efficiency of final assembly.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

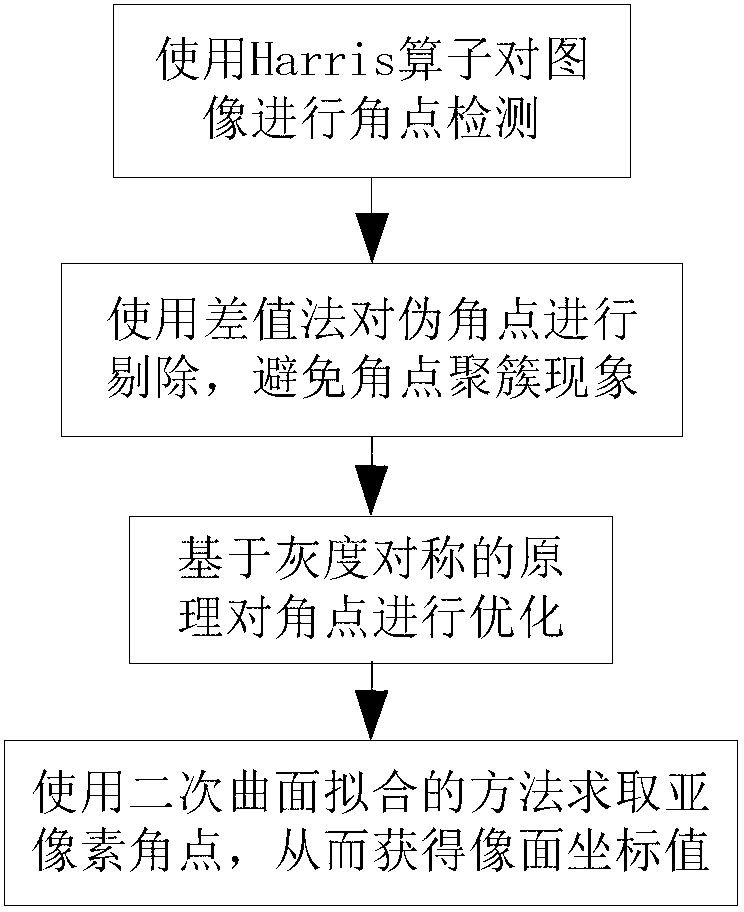

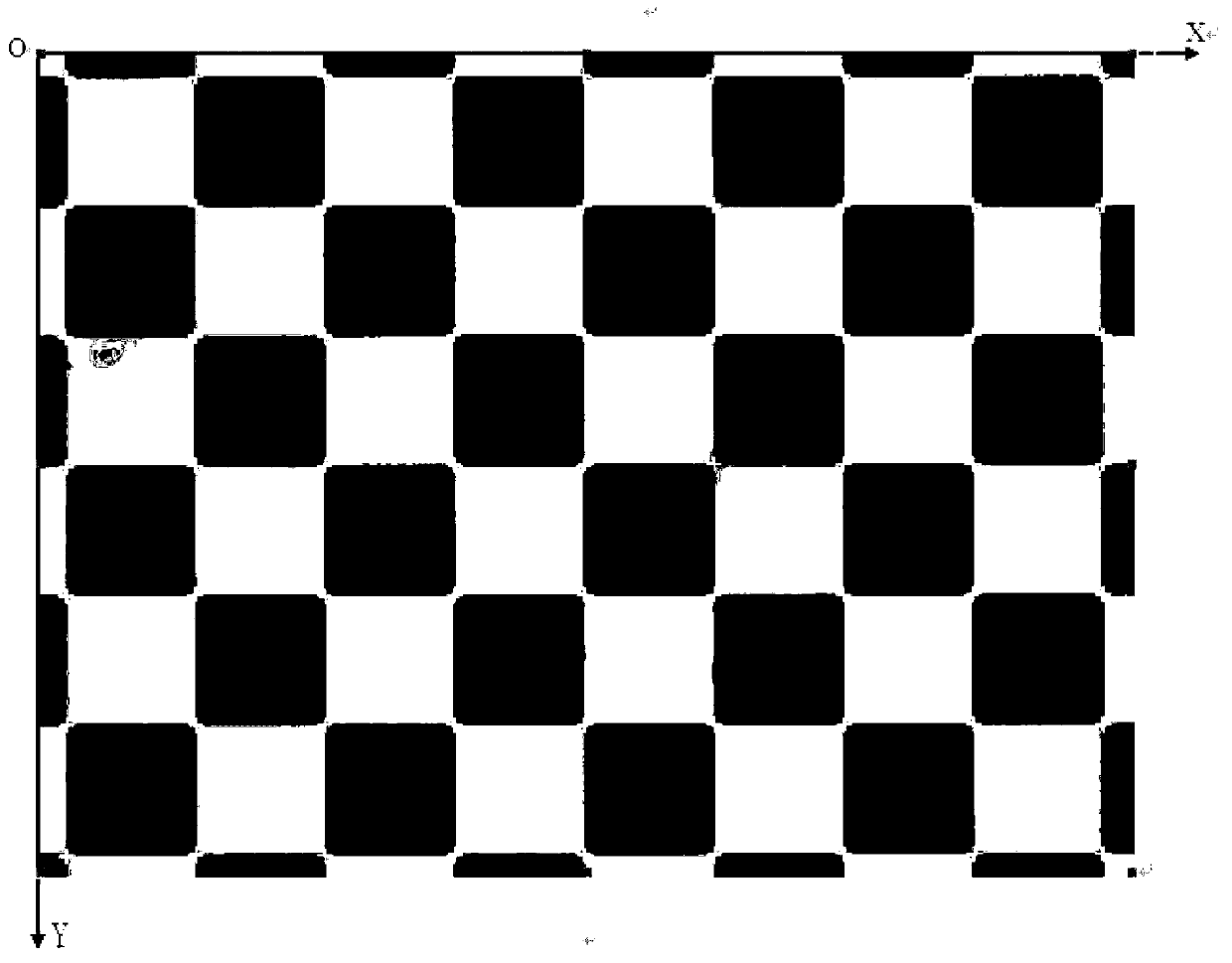

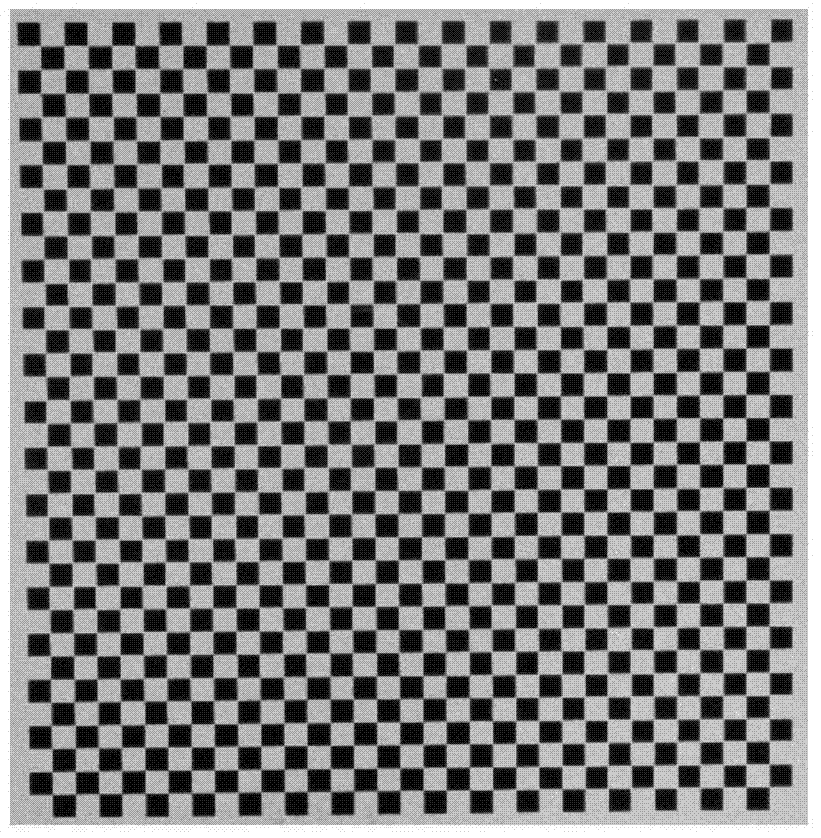

Chessboard angular point sub-pixel extraction method based on Harris operator

The invention relates to a chessboard angular point sub-pixel extraction method based on the Harris operator, and belongs to the technical field of micro-machine assembling and micro-vision detecting. The chessboard angular point sub-pixel extraction method comprises the steps that the Harris operator is used for conducing angular point detection on a chessboard; a processing result of the Harris operator is optimized and cluster points in angular points detected in the prior step are eliminated; noise points are eliminated by the utilization of the symmetric method, angular point secondary optimization is conducted in order to find out pixel-level angular points; based on secondary surface fitting, the precision of the pixel-level angular points is improved to be at the sub-pixel level. By means of the chessboard angular point sub-pixel extraction method, the angular points of the black and white chessboard can be detected precisely, fake angular points appearing in an existing algorithm cannot appear, and detecting precision reaches 0.1 pixel.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

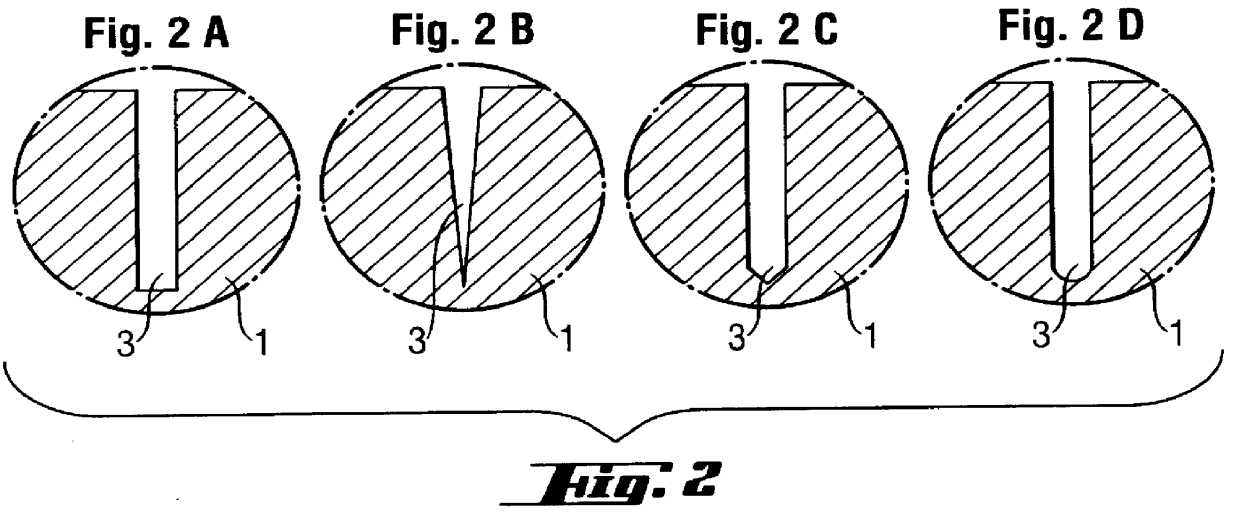

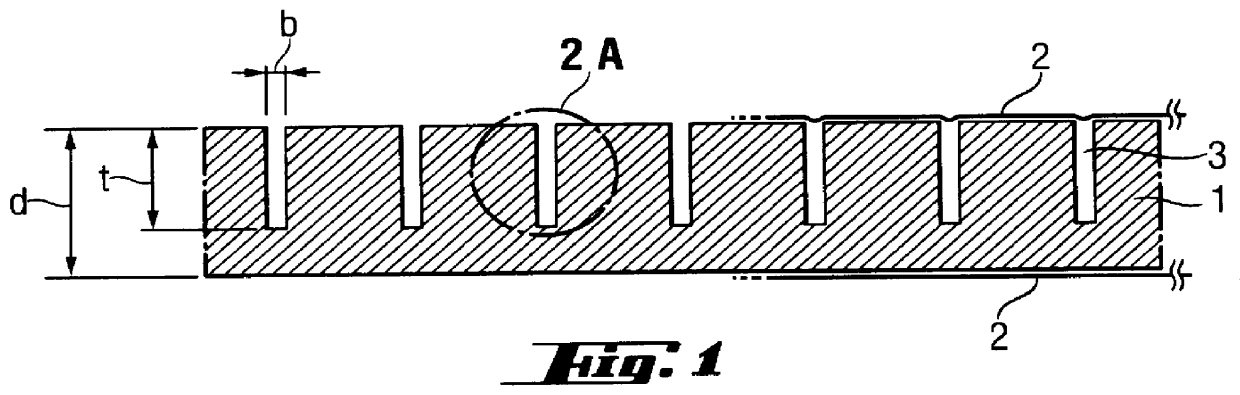

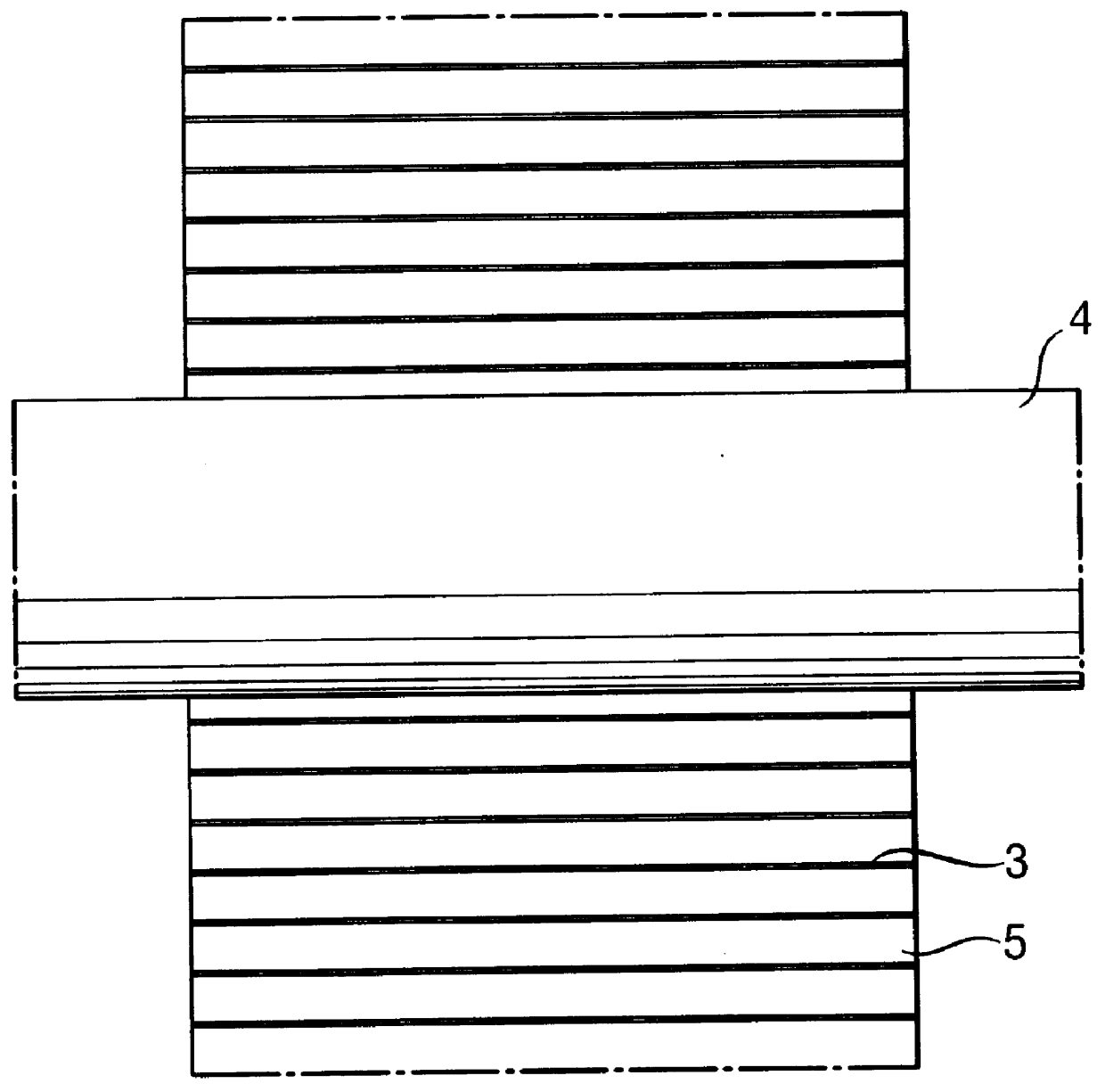

Panel-shaped, evacuated molded element, method of thermal insulation and use of the molded element

InactiveUS6110310AIncrease volumeReduce heat lossThermal insulationLayered productsShell moldingThermal insulation

The invention relates to a panel-shaped, evacuated and thermally insulating molded element which contains pressed and optionally hardened, microporous insulating material, wherein the insulating material is in one or more sheathed and evacuated layers, and the molded element has a surface with a lamellar structure, the lamellae being produced by elongate incisions into the surface and having a depth of 40 to 95% of the thickness of the molded element. The invention also relates to a method of insulation for curved surfaces with thermally insulating material, wherein the molded element is made to fit with the surface with a lamellar structure snugly against the curved surface, is fixed in position, and the vacuum is destroyed in at least one layer.

Owner:WACKER CHEM GMBH

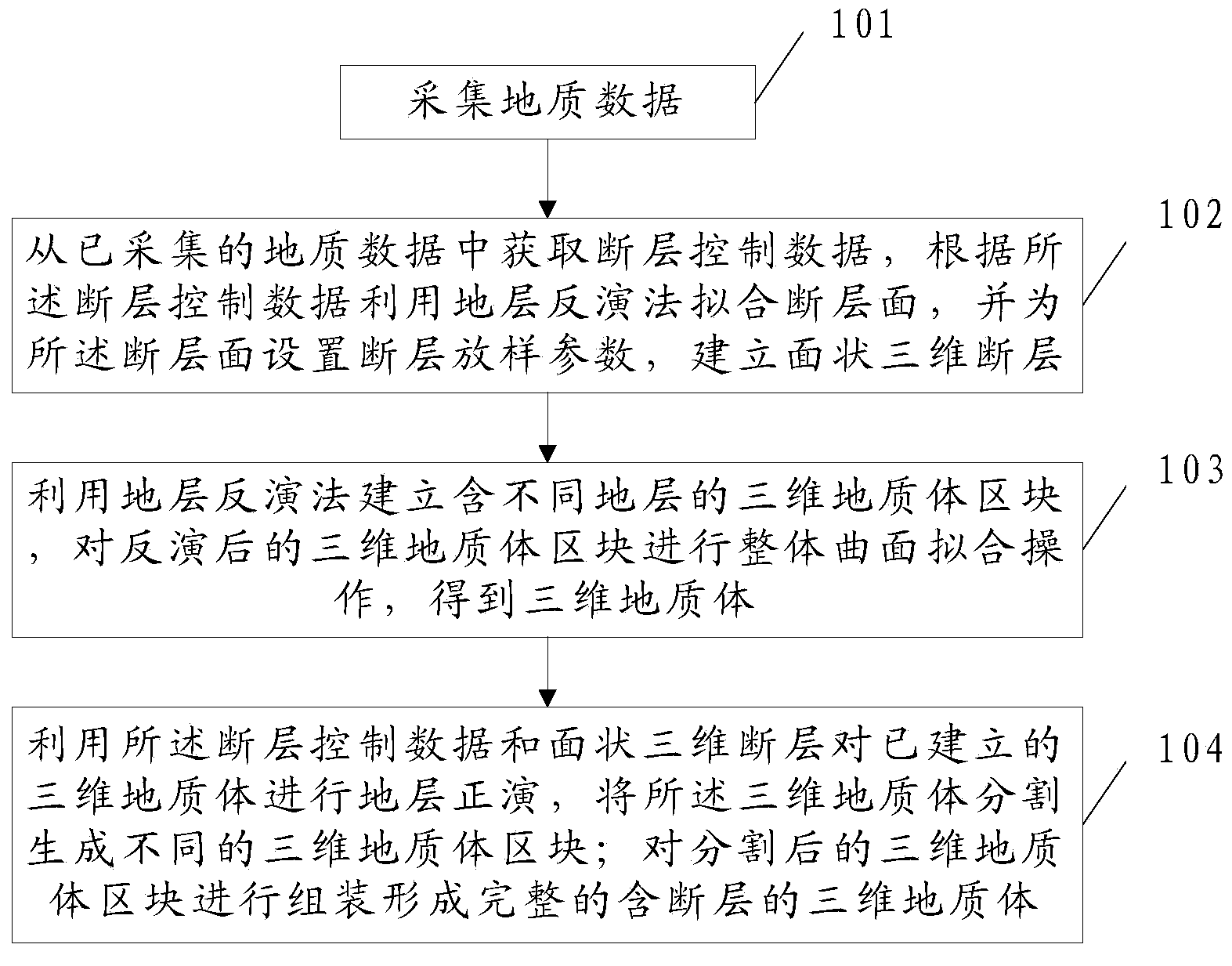

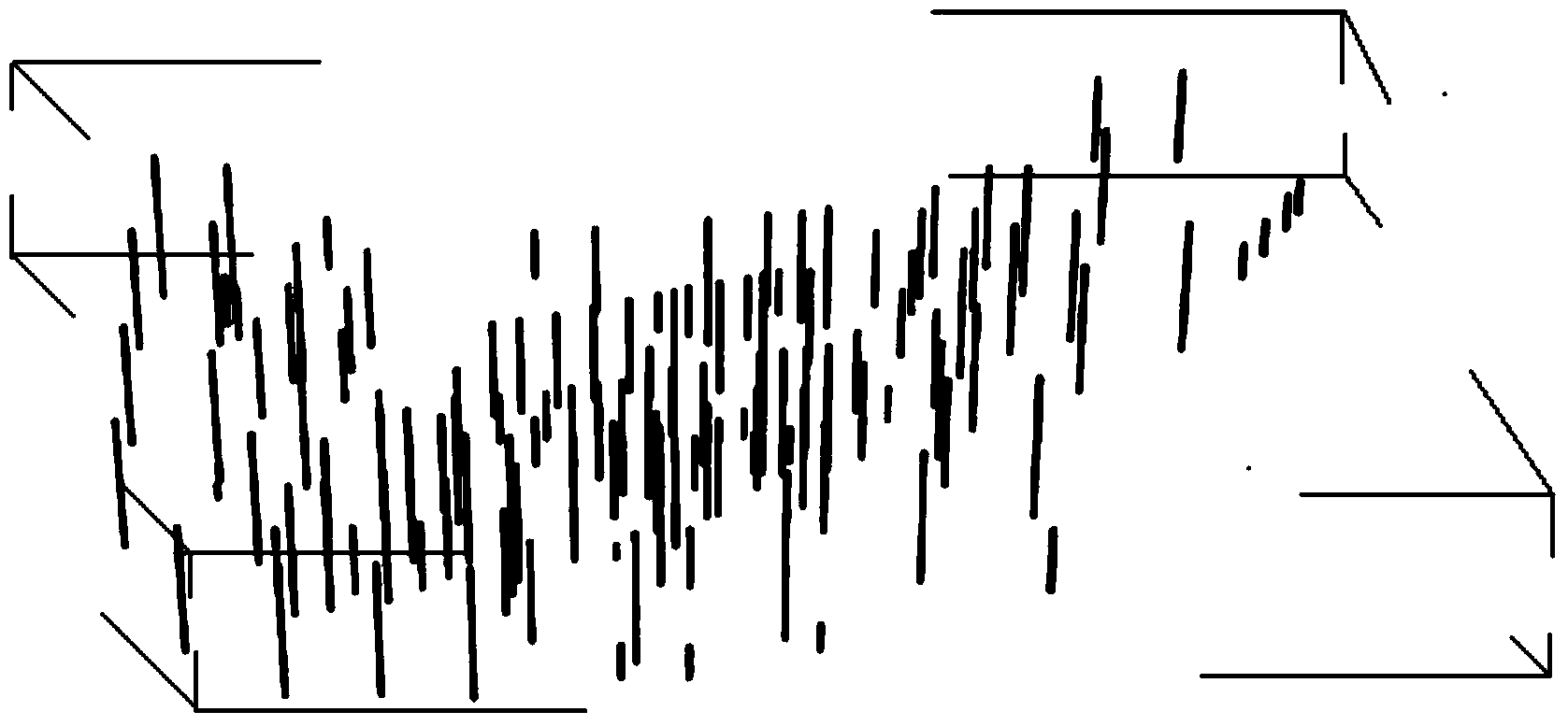

Three-dimensional geological modeling method and device

The invention discloses a three-dimensional geological modeling method and device, relates to the field of geological modeling, overcomes primary shortcomings of an existing integral approach, combines advantages of a local method and can quickly establish a multilayer complex geological body through the utilization of geological original data. The three-dimensional geological modeling method mainly comprises obtaining fault control data from collected geological data, utilizing a stratum inversion method to fit a fault surface, setting fault lofting parameters for the fault surface, and establishing a planar three-dimensional fault; utilizing the stratum inversion method to establish three-dimensional geological body blocks containing different strata, and performing overall surface fitting operation on the post-inversion three-dimensional geological body blocks to obtain a three-dimensional geological body; performing stratum forward modeling on the established three-dimensional geological body by utilizing the fault control data and the planar three-dimensional fault and dividing the three-dimensional geological body into different three-dimensional geological body blocks; assembling the divided three-dimensional geological body blocks to form an integrated fault-contained three-dimensional geological body. The three-dimensional geological modeling method and device is mainly applicable to three-dimensional modeling of fault display.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

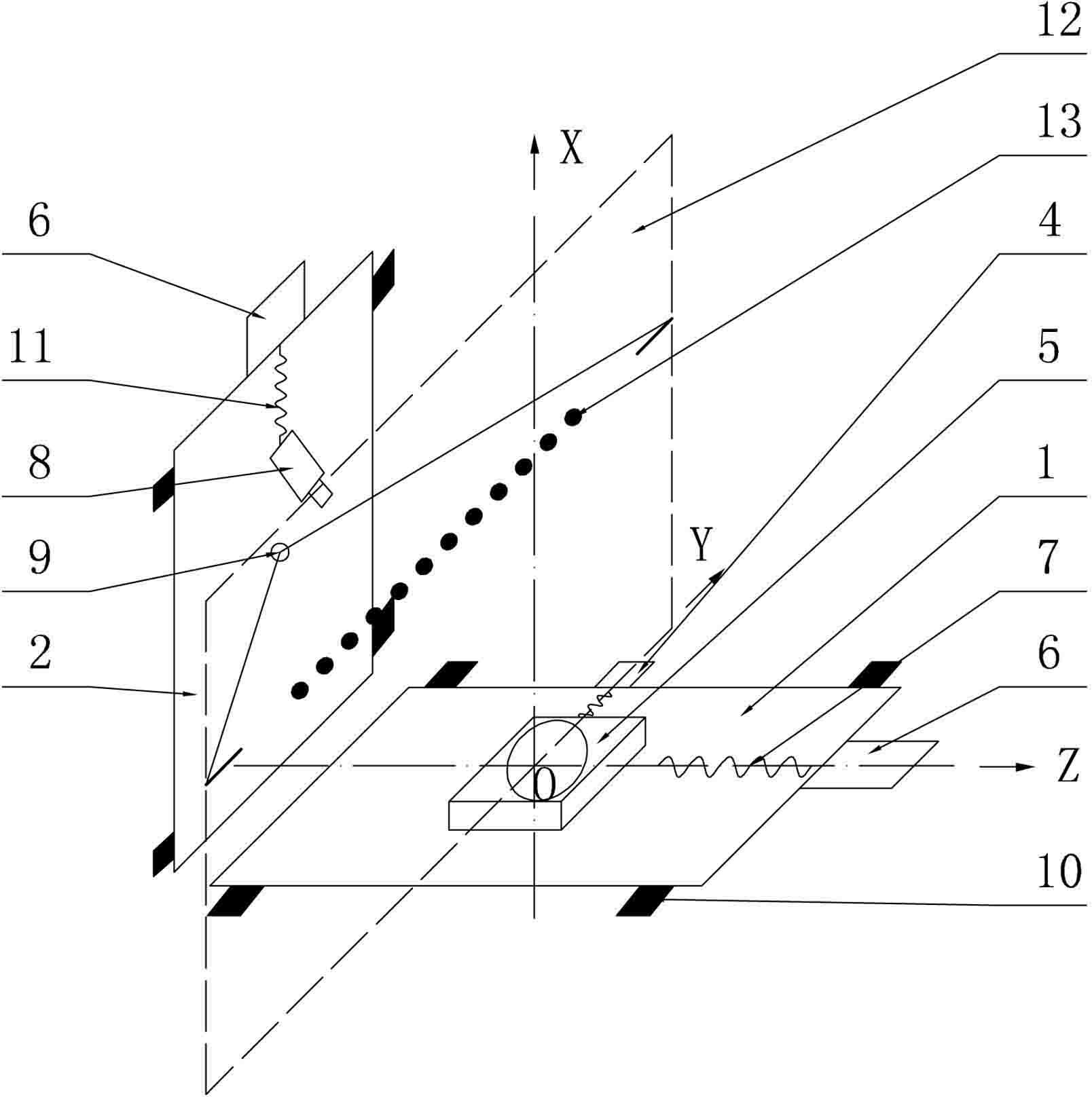

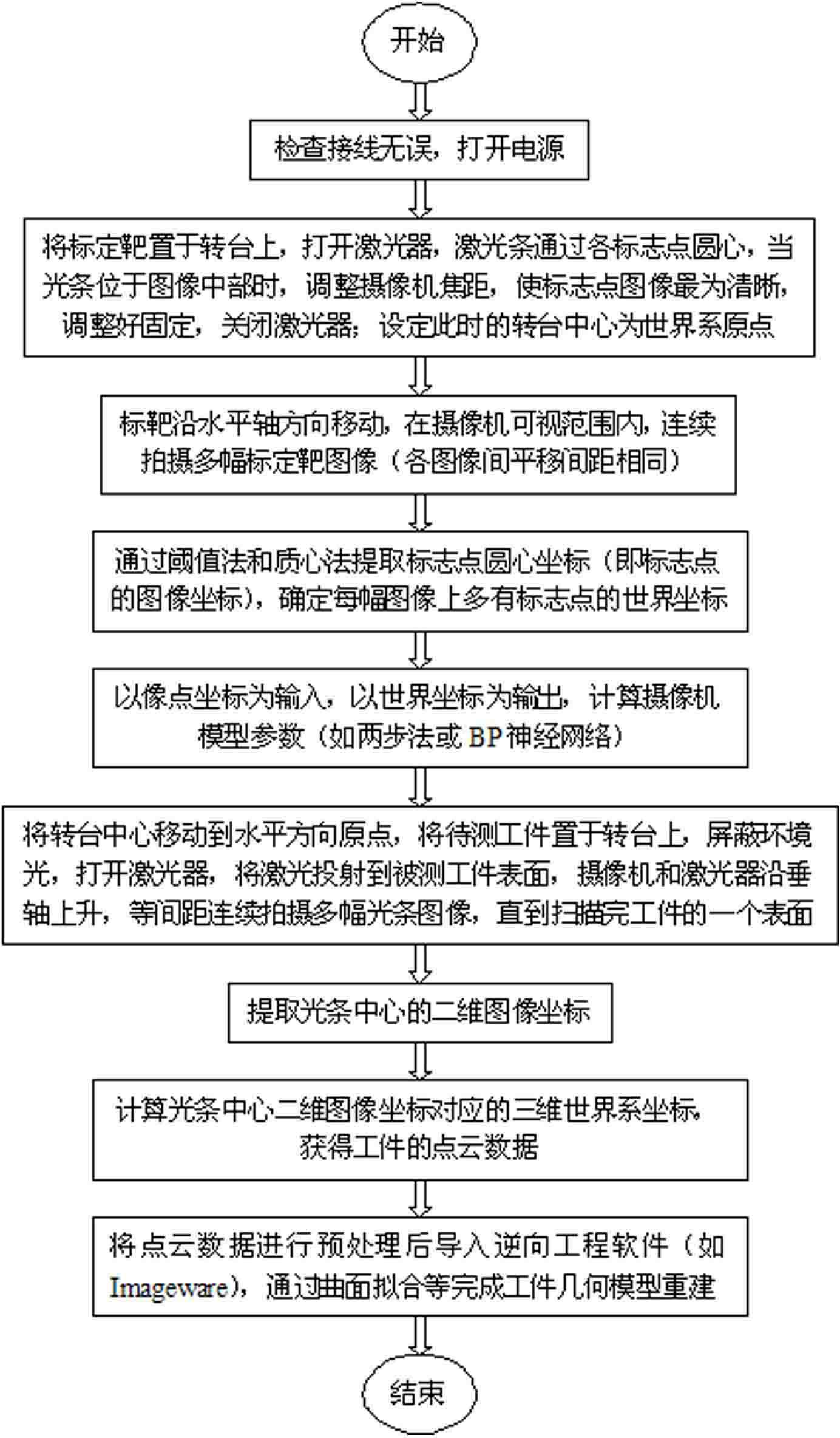

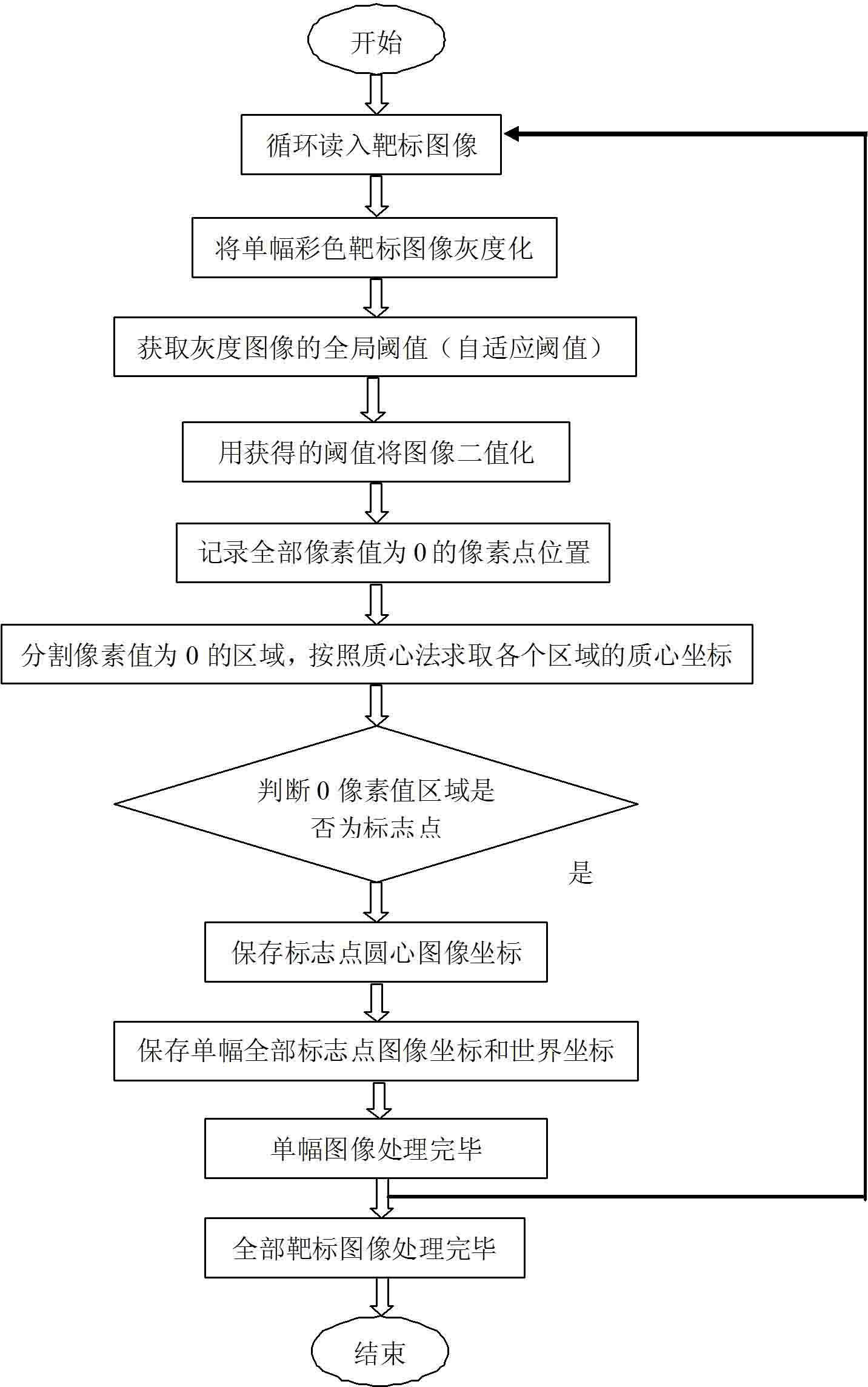

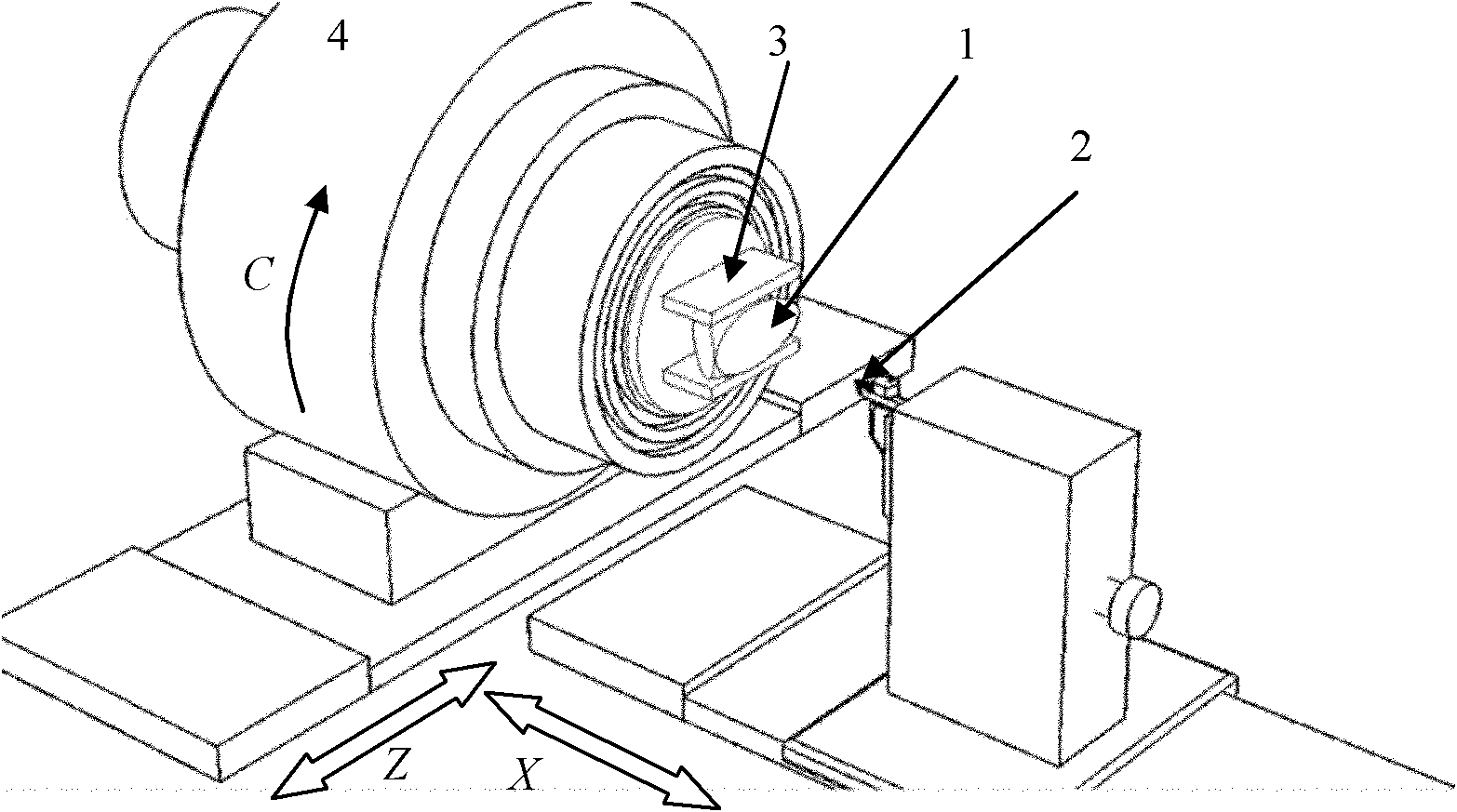

Three-dimensional measurement method and device based on linear structured light

InactiveCN102183216ASolving Nonlinear Solving ProblemsAccurate detectionImage analysisUsing optical meansPoint cloudThree dimensional measurement

The invention relates to a three-dimensional measurement method based on linear structured light. The three-dimensional measurement method comprises the following steps of: 1, arranging a plane with marking points and marking lines as a target, and vertically placing the plane on a turntable; 2, regulating a laser and a camera, and setting the center of the turntable as an original point of a world coordinate system; 3, continuously shooting the marking points; 4, determining a world coordinate and an image coordinate of each marking point; 5, determining a camera model; 6, scanning a workpiece to be measured; 7, obtaining a two-dimensional image coordinate of a central point of a scanning light bar; 8, calculating a corresponding three-dimensional world system coordinate by using the two-dimensional image coordinate of the central point of the scanning light bar according to the determined camera model, and acquiring point cloud data of the workpiece; and 9, preprocessing the point cloud data and introducing the point cloud data into reverse engineering software, and finishing reestablishment of a workpiece geometric model by curved surface fitting. By the method, the precision requirement on the camera is low; the method is simple; the requirement on camera calibration can be met well; and the method is higher in precision.

Owner:SHENYANG AIRCRAFT CORP +1

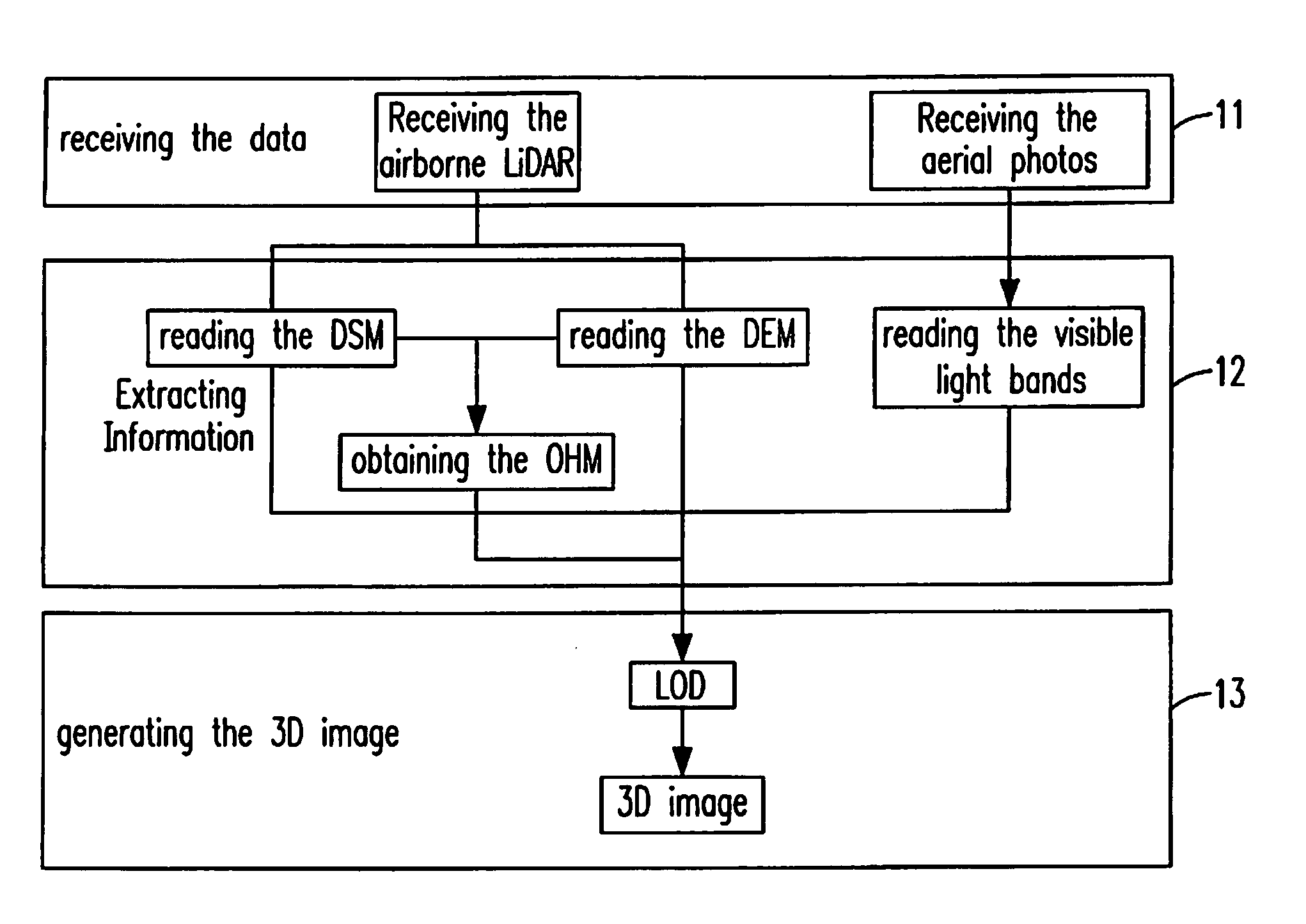

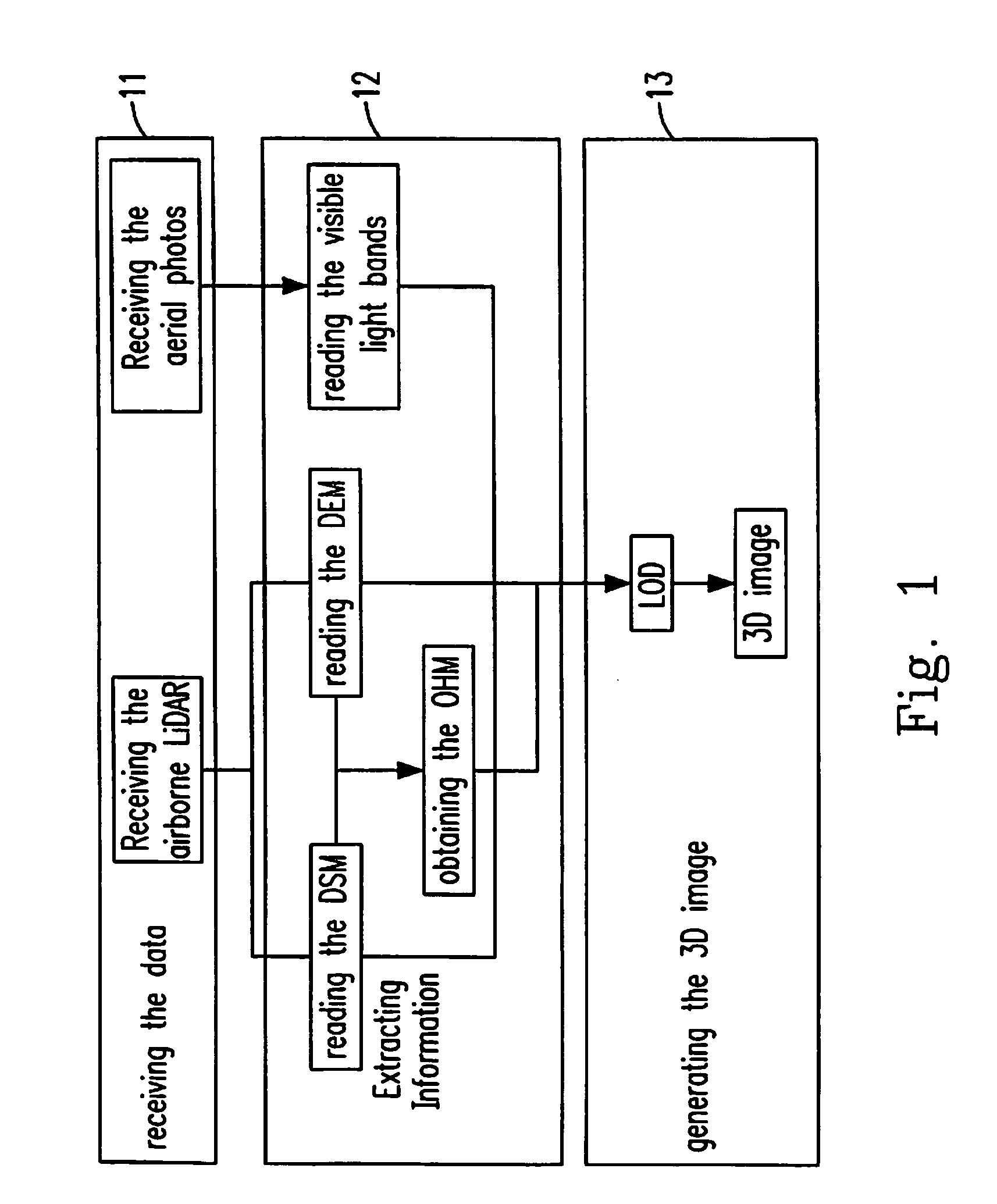

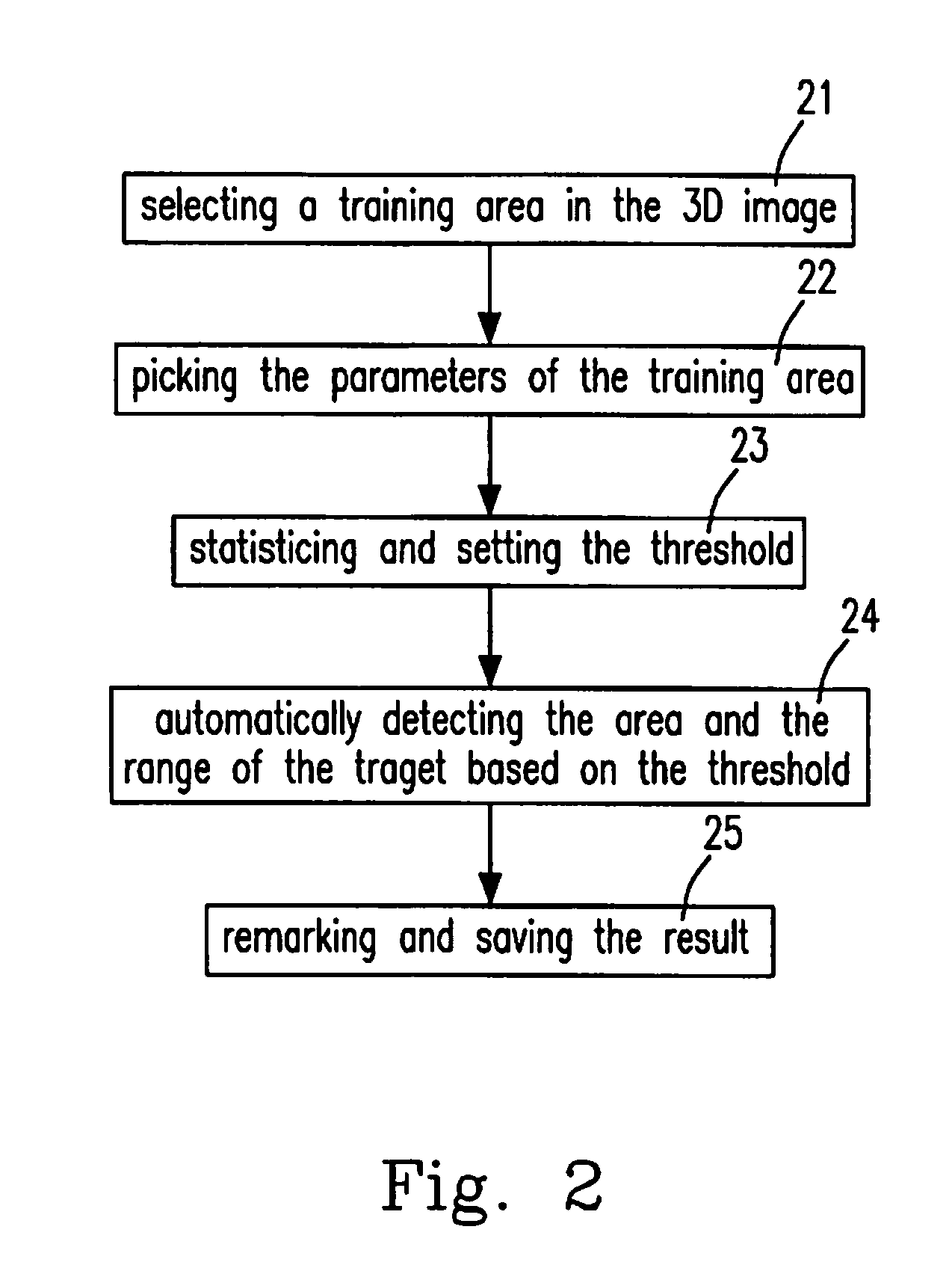

Target detecting, editing and rebuilding method and system by 3D image

InactiveUS20090161944A1Optical rangefindersCharacter and pattern recognitionComputer graphics (images)3d image

A method and system for target detecting, editing and rebuilding by 3D image is provided, which comprises an inputting and picking unit, a training and detecting unit, a displaying and editing unit and a rebuilding unit. The inputting and picking unit receives a digital image and a LiDAR data and picks up a first parameter to form a 3D image. The training and detecting unit selects a target, picks up a second parameter therefrom, calculates the second parameter to generate a threshold and detects the target areas in the 3D image according to the threshold. The displaying and editing unit sets a quick selecting tool according to the threshold and edits the detecting result. The rebuilding unit sets a buffer area surrounding the target, picks up a third parameter therefrom and calculates the original shape of the target by the Surface Fitting method according to the third parameter.

Owner:IND TECH RES INST

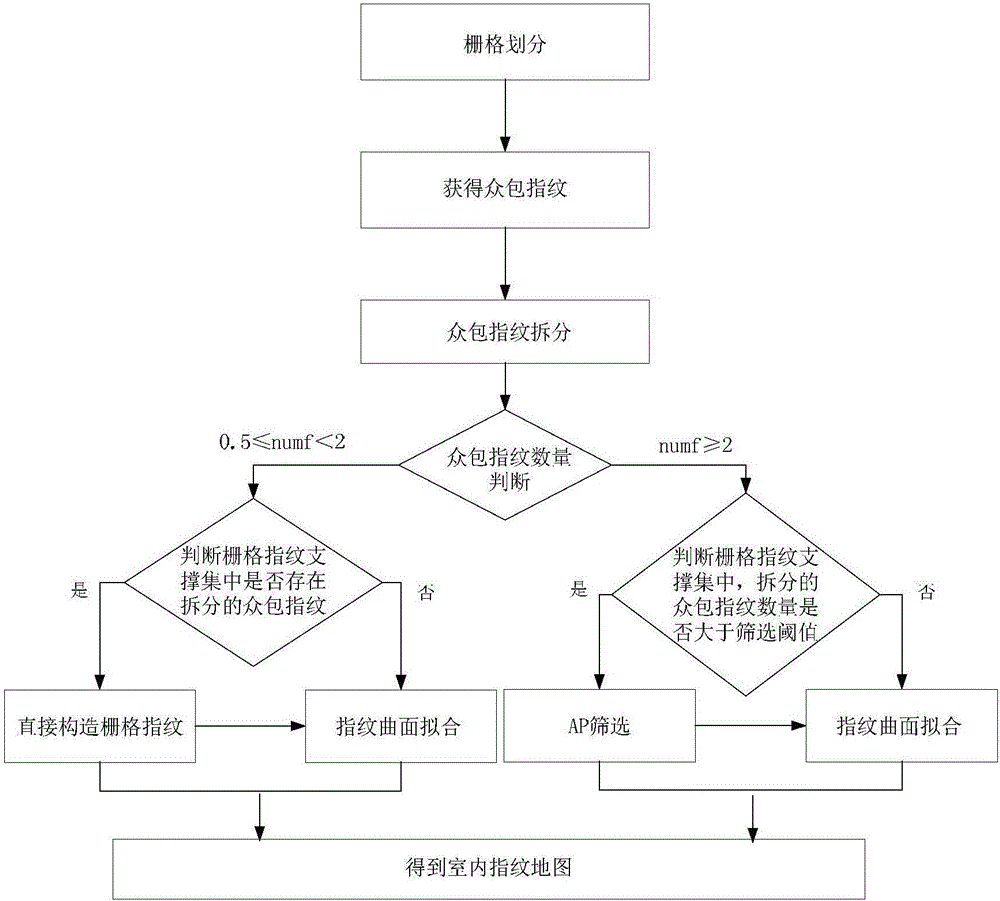

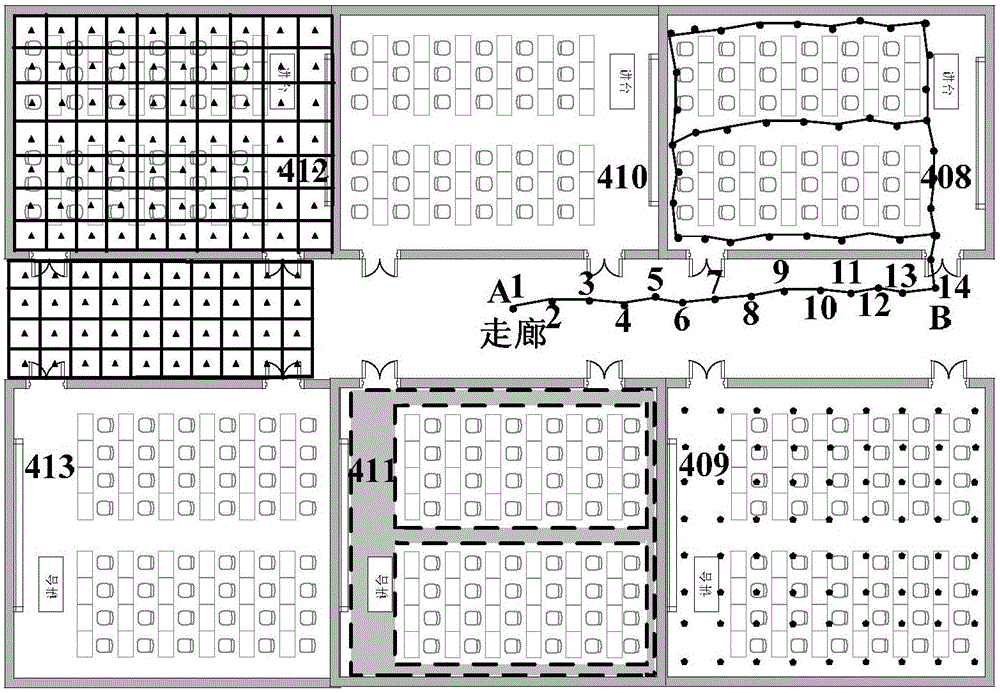

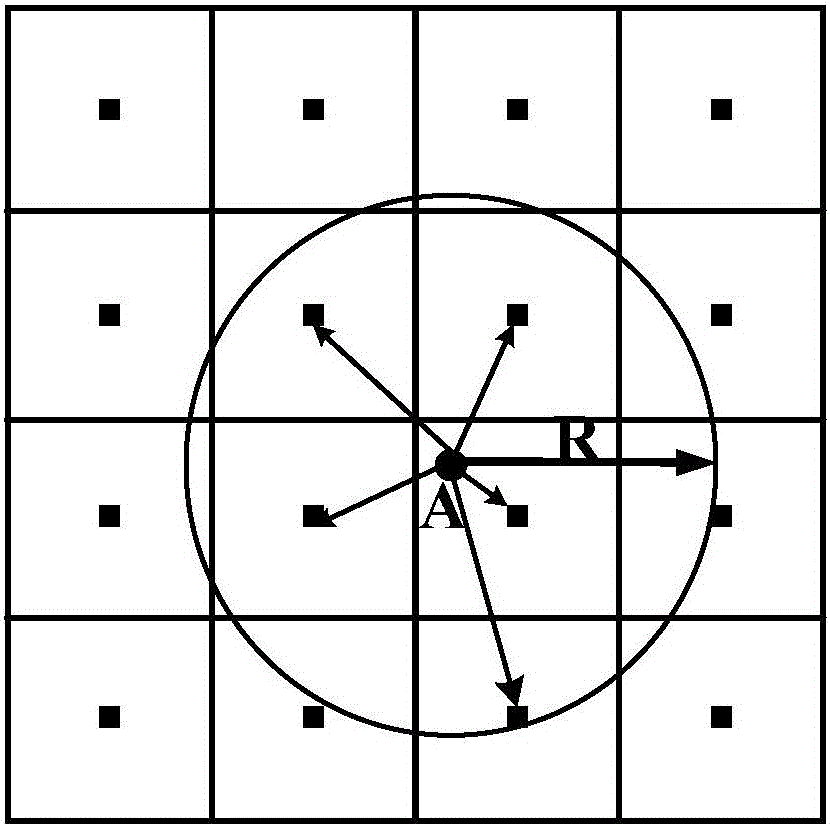

Indoor fingerprint map constructing method based on crowdsourcing fingerprint

ActiveCN106792465AReduce collection workloadIncrease the number of fingerprintsWireless commuication servicesLocation information based serviceWorkloadData mining

The invention discloses an indoor fingerprint map constructing method based on crowdsourcing fingerprint, and belongs to the indoor positioning technology based on the fingerprint. The method is capable of solving the existent problems of constructing the indoor fingerprint map based on the crowdsourcing fingerprint that the positioning accuracy is not high and the calculated amount is larger because the crowdsourcing fingerprint position marking is not accurate, the dimensions are different and the distribution is not uniform, and is used for the technical field of the communication and wireless network. The method comprises a step of grid division, a step of crowdsourcing fingerprint acquisition, a step of crowdsourcing fingerprint resolution, a step of crowdsourcing fingerprint number judgment, a step of AP screening, a step of directly constructing grid fingerprint and a step of fingerprint surface fitting. The method is capable of reducing the workload of the fingerprint acquisition, improving the positioning accuracy, and reducing the workload of the fingerprint comparison.

Owner:HUAZHONG UNIV OF SCI & TECH

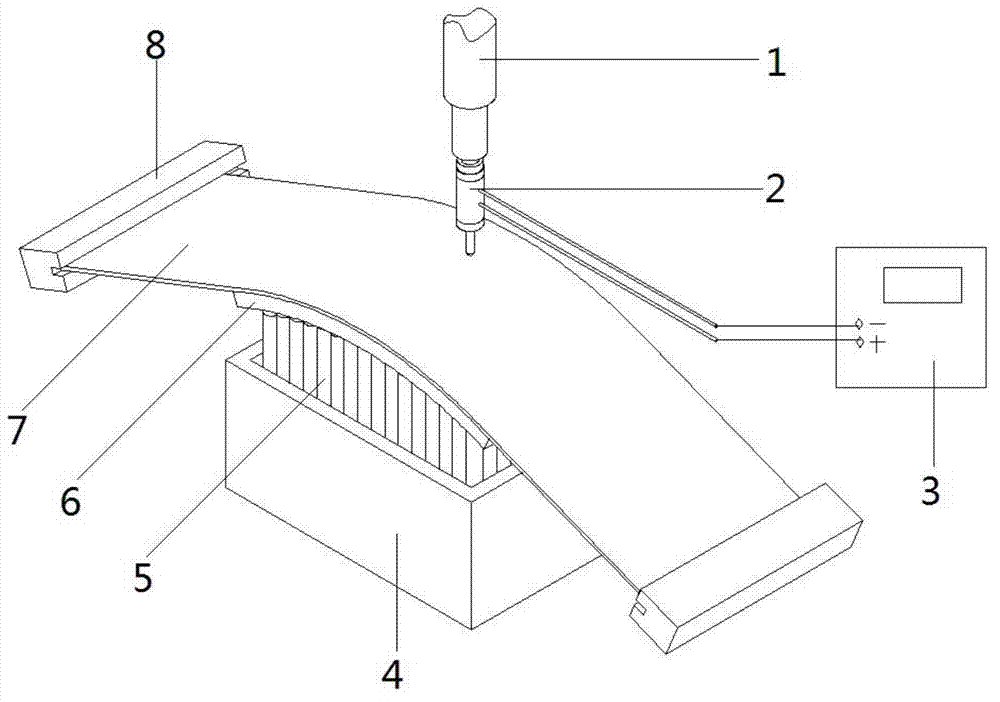

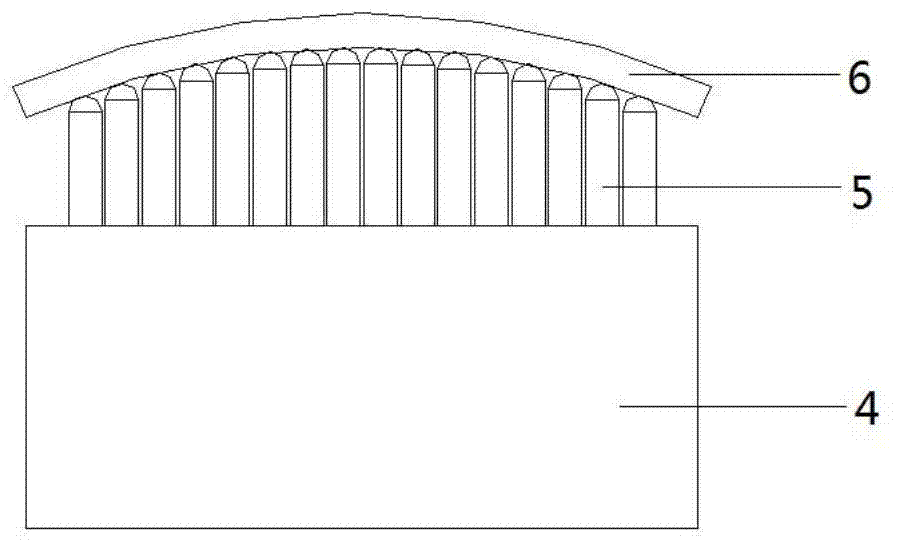

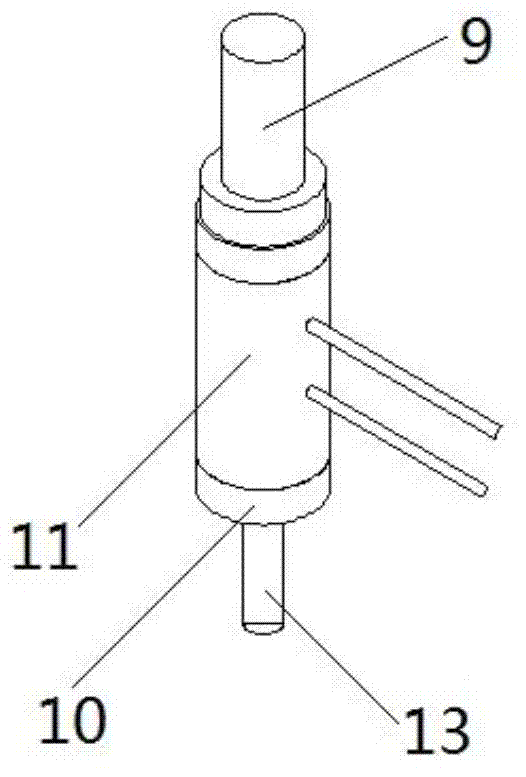

Flexible stretch-forming device and method for carrying out stretch-forming on plate by utilizing same

InactiveCN103480713AReduce deformation resistanceHigh forming precisionShaping toolsIndustrial machineIndustrial manipulator

The invention discloses a flexible stretch-forming device and a method for carrying out stretch-forming on a plate by utilizing the flexible stretch-forming device and solves the technical problem that the stretch-forming accuracy of a flexible stretch-forming device for the molded surface of a reconfigurable unidirectional continuous die is low. The technical scheme includes that the flexible stretch-forming device comprises an industrial manipulator, a heating forming head, a power supply, a multipoint die, a nail post and a polyurethane elastic cushion. The nail post is mounted on the base of the multipoint die, the polyurethane elastic cushion is positioned above the nail post, the lower surface of the polyurethane elastic cushion is attached to the discrete surface formed by the nail head of the nail post, the plate is positioned above the polyurethane elastic cushion, the lower surface of the plate is attached to the upper surface of the polyurethane elastic cushion, the heating forming head is positioned above the plate, and the spherical head surface of the heating forming head is contacted with the upper surface of the plate. According to the flexible stretch-forming device and the method for carrying out stretch-forming on the plate by utilizing the flexible stretch-forming device, the electromagnetic induction heating forming head is adopted to locally heat the plate in the stretch-forming process, the local heat effect of the region can reduce the deformation resistance of the plate, the plasticity is improved, the resilience value is reduced, and the forming accuracy of the plate is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

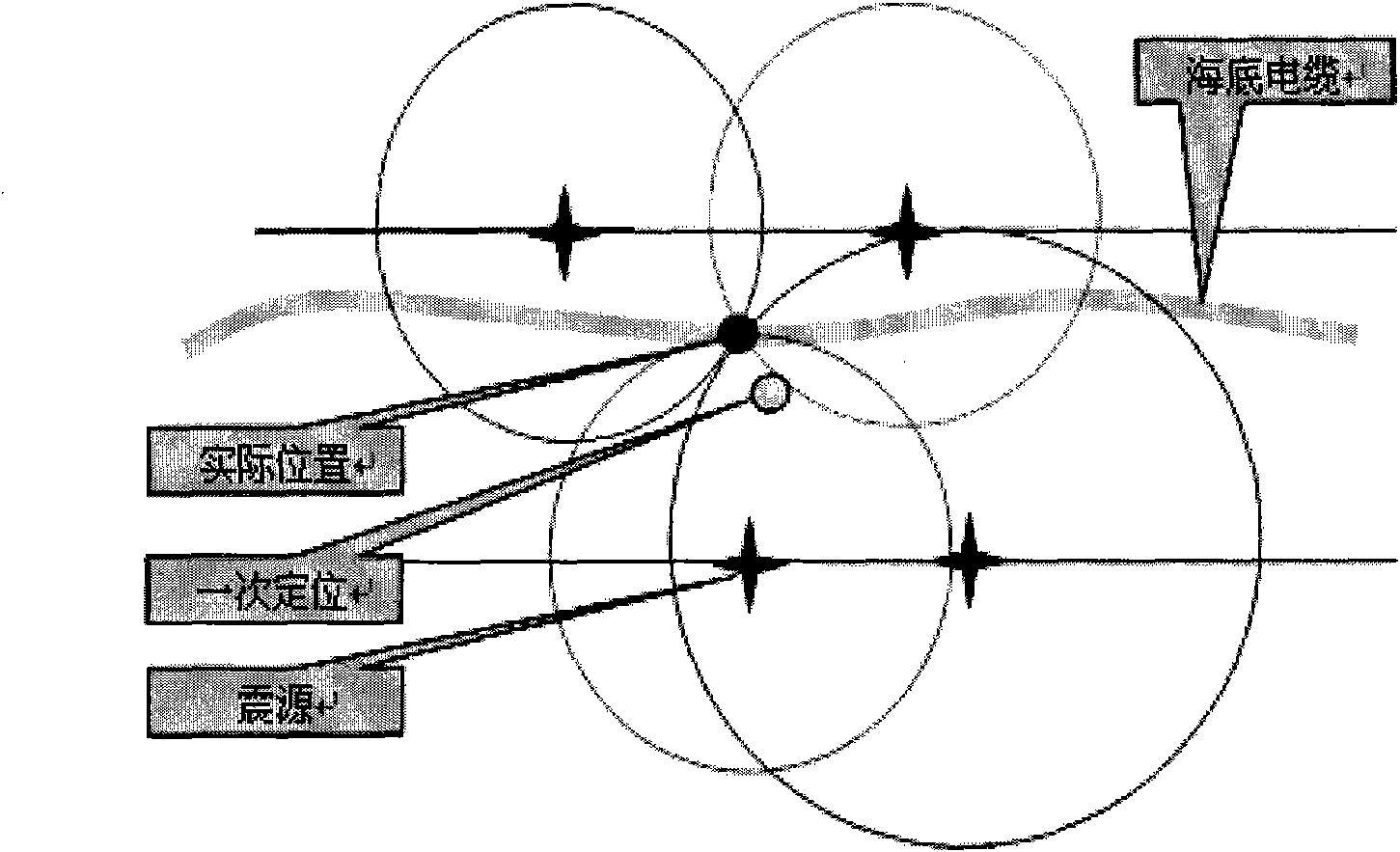

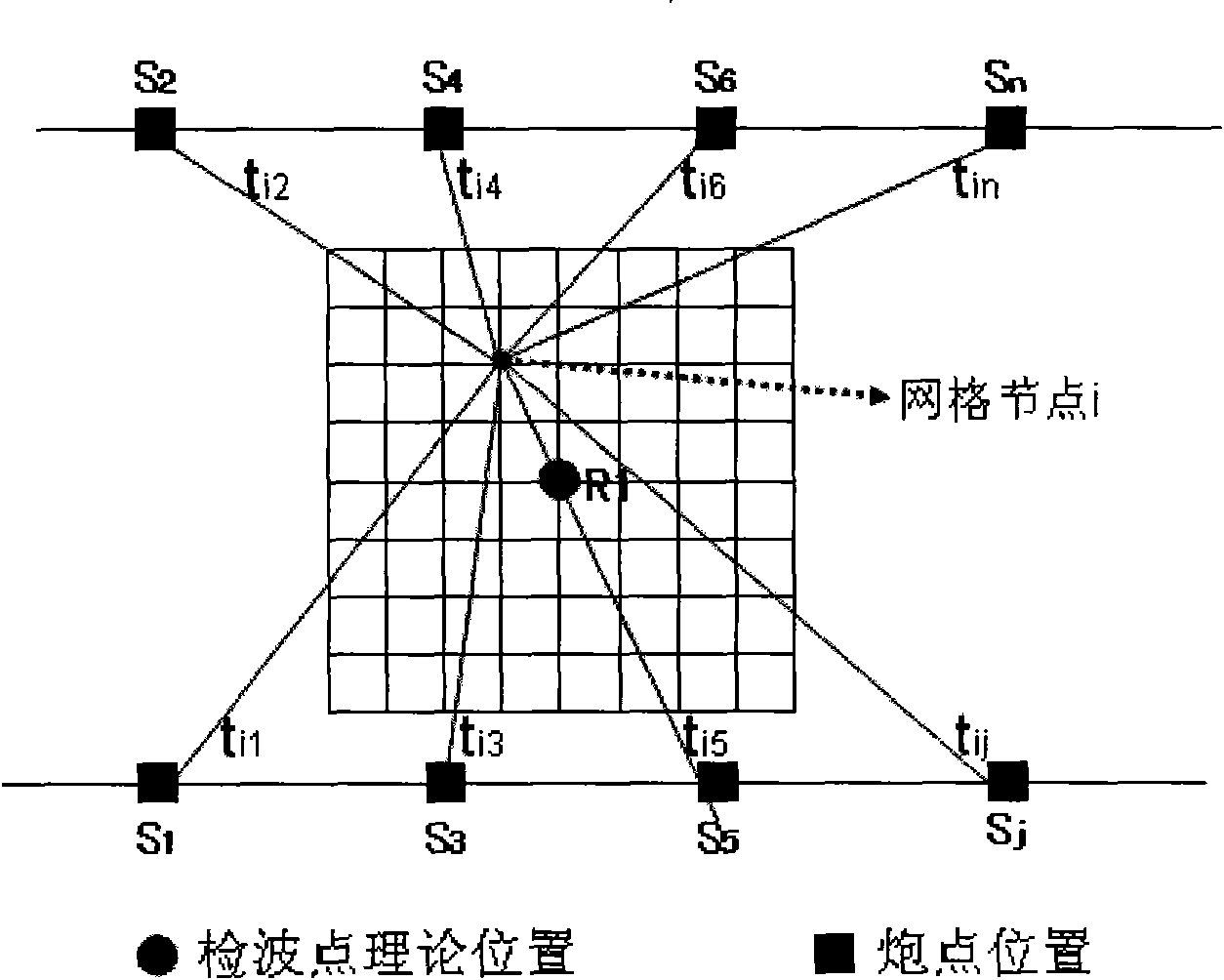

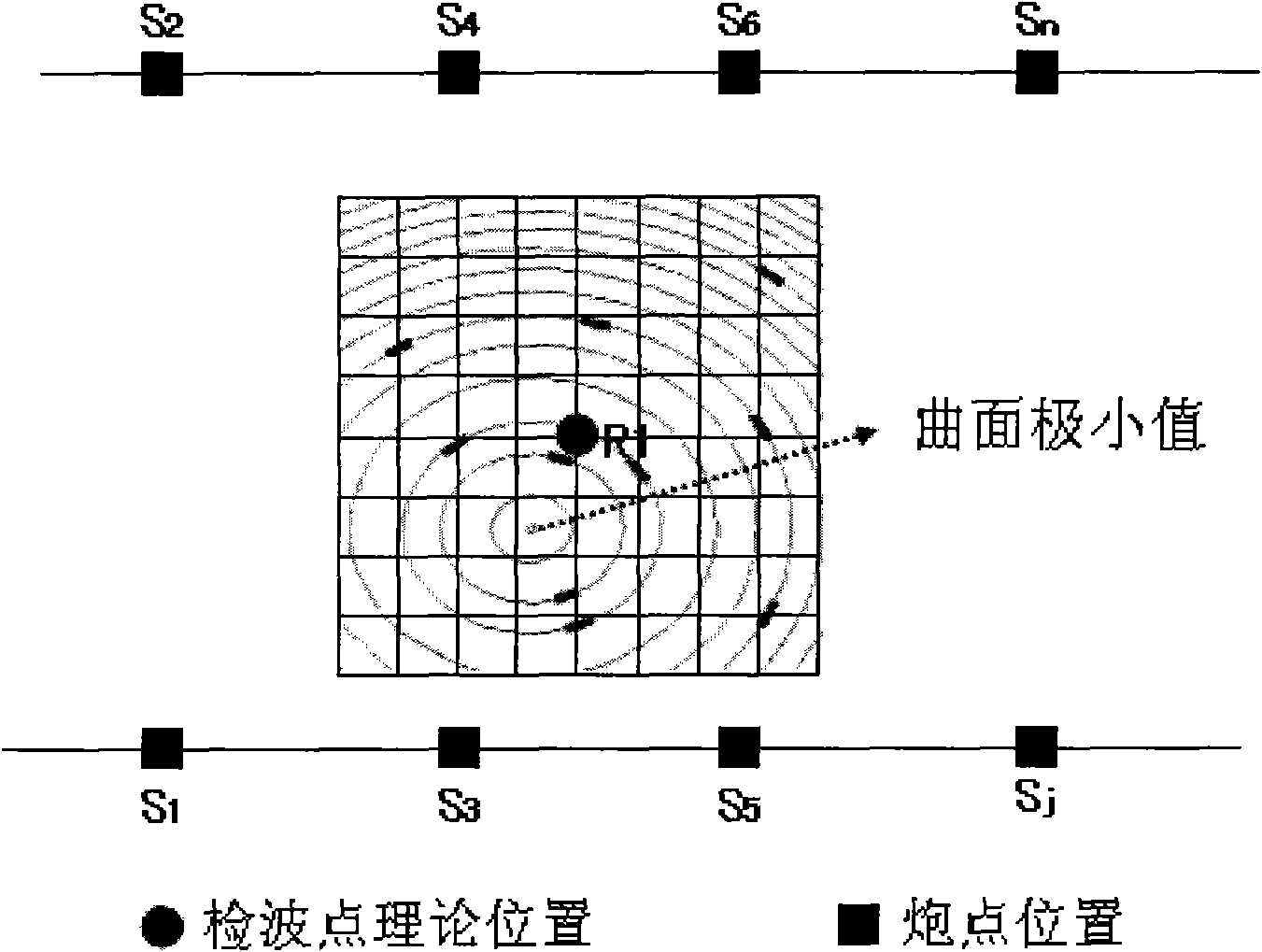

Secondary positioning method for submarine cable based on surface fitting

ActiveCN101930080ATake advantage ofHigh positioning accuracySeismic signal processingGeophoneSurface fitting

The invention relates to a data processing technology of petroleum geophysical prospecting, in particular to a secondary positioning method for a submarine cable based on surface fitting, which comprises the following steps: obtaining a practical first arrival time by using a picking method, calculating the theoretical shot-geophone distance from an acceptance point to each shot point, carrying out surface fitting, calculating the shot-geophone distance by using geophone positions as midpoints to carry out meshing, calculating the theoretical time from a grid node to the shot point, calculating the sum of squares of the difference between the time from a grid node to the shot point and the corresponding first arrival time to serve as the error value of the grid node, composing coordinates of all the grid nodes and corresponding node error values into a cubic polynomial for space splattering so as to fit a cubic surface, and calculating the point-coordinate position of the minimum value on the surface. Under the premise of improving the positioning accuracy, the calculation efficiency is greatly increased by almost 1.6 times compared with the grid scanning algorithm and by almost 8 times compared with the first-arrival circular positioning efficiency.

Owner:BGP OF CHINA NAT GASOLINEEUM CORP

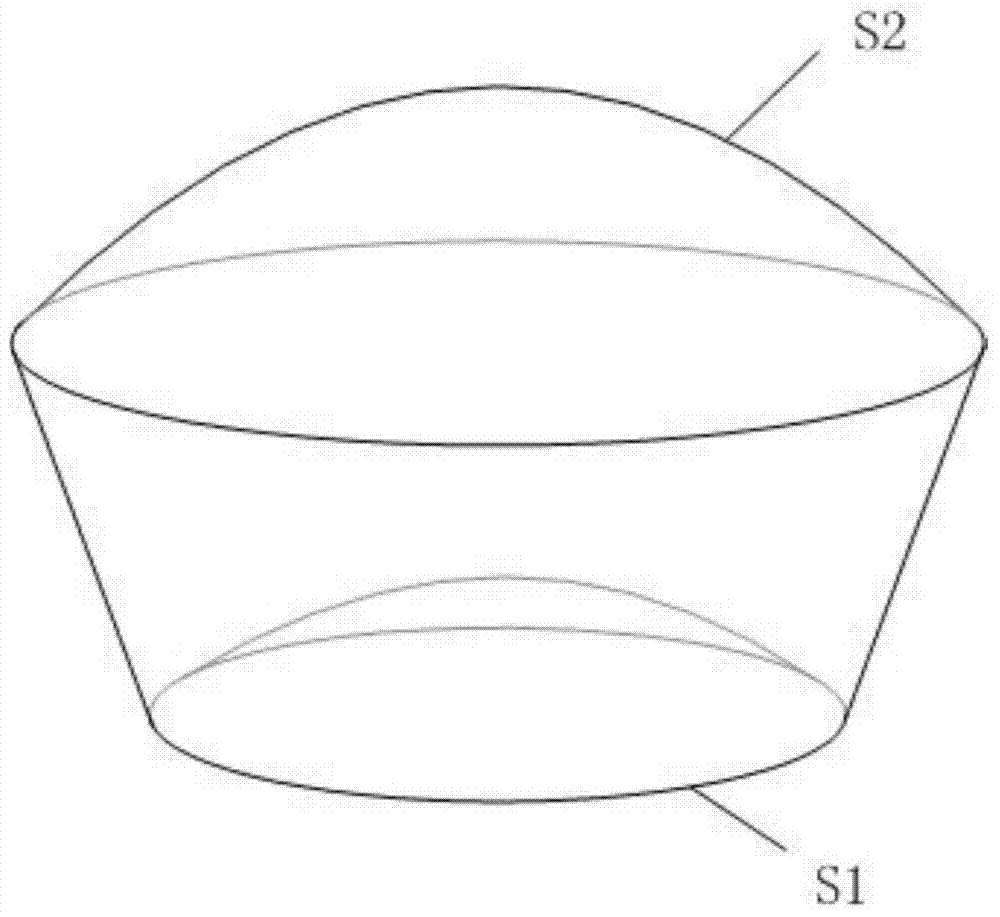

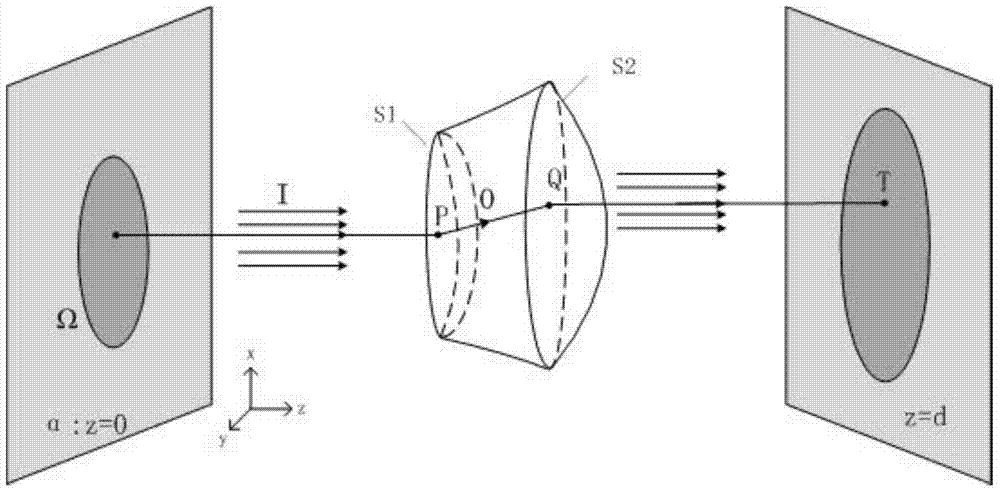

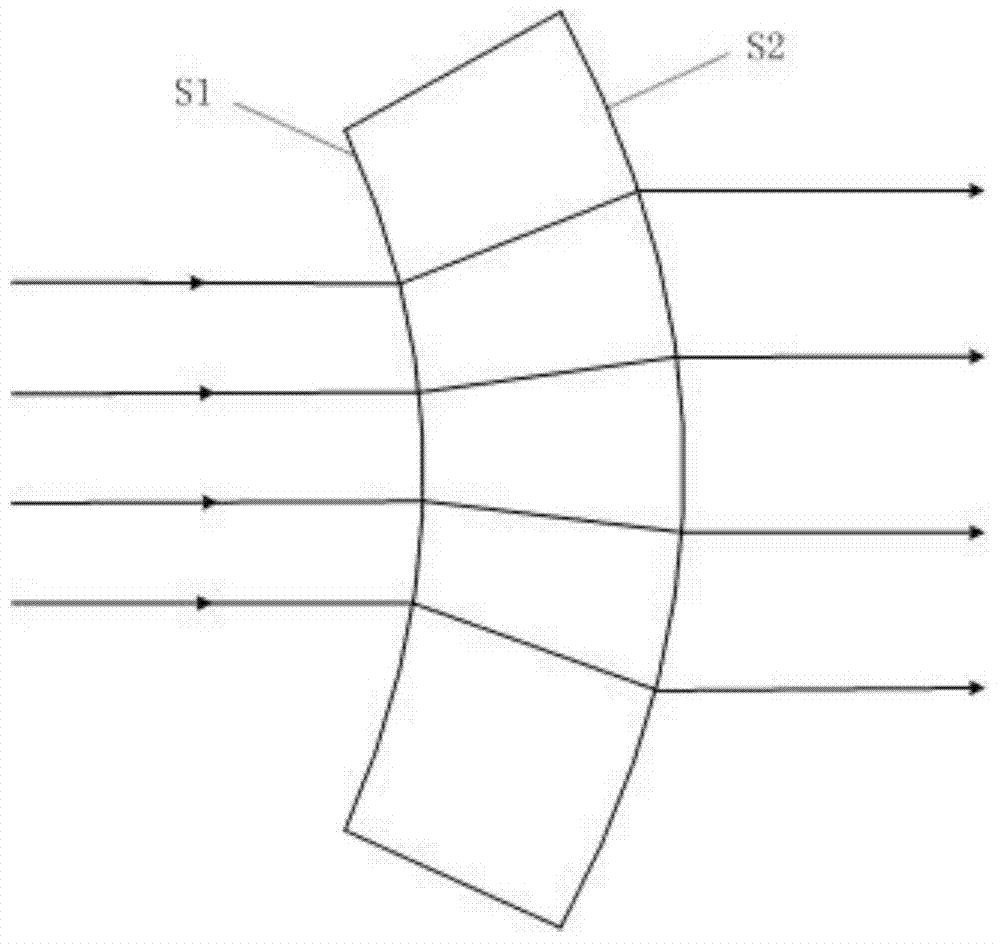

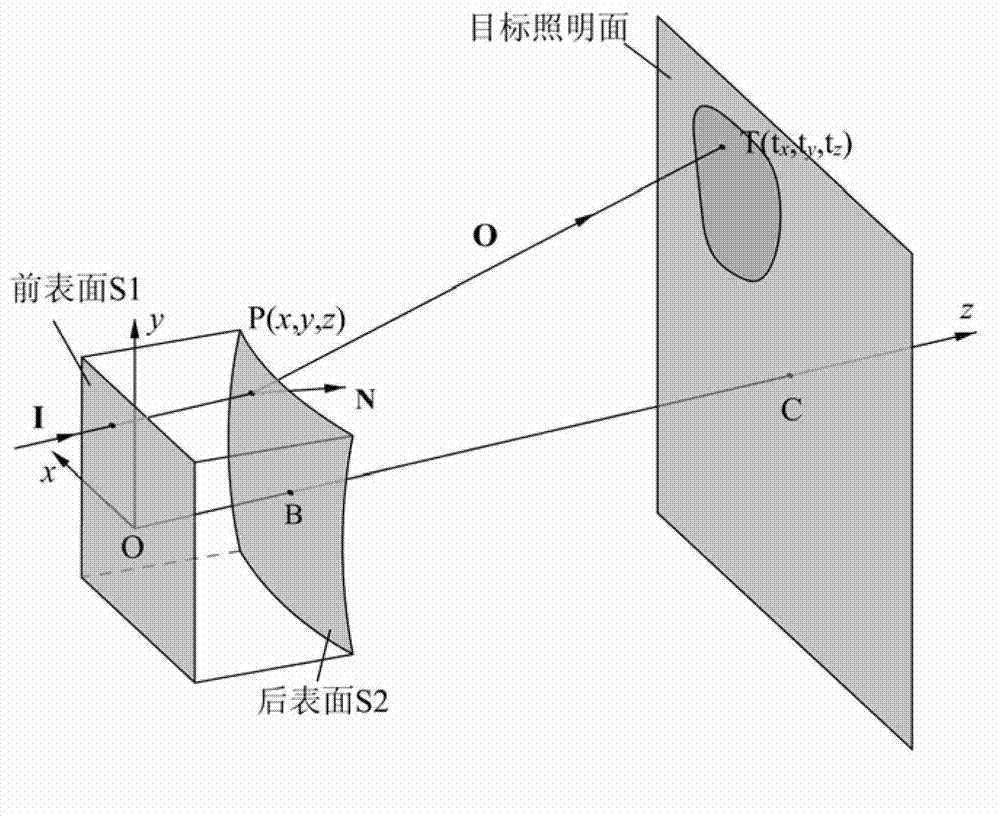

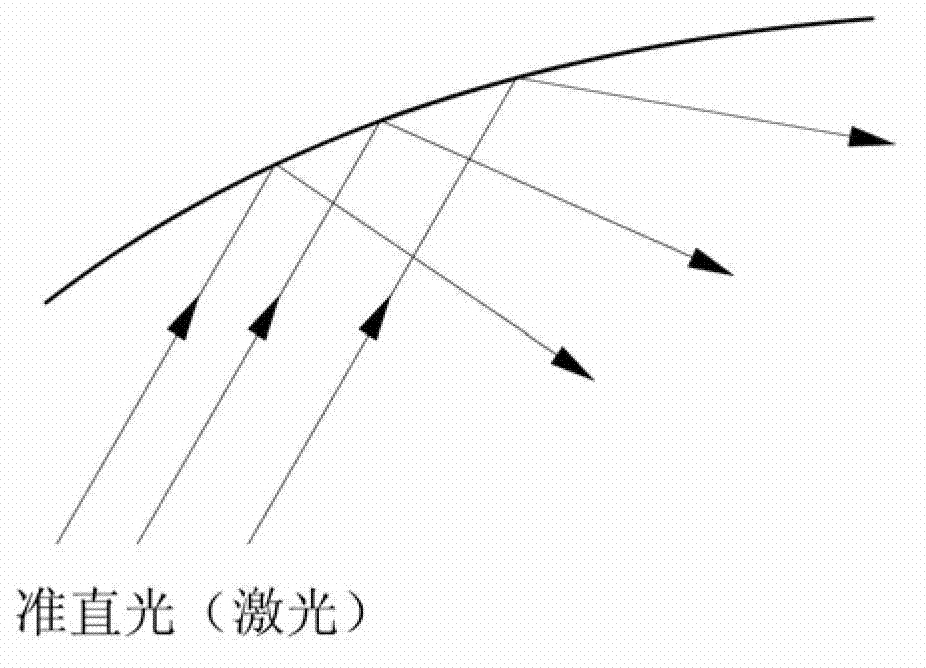

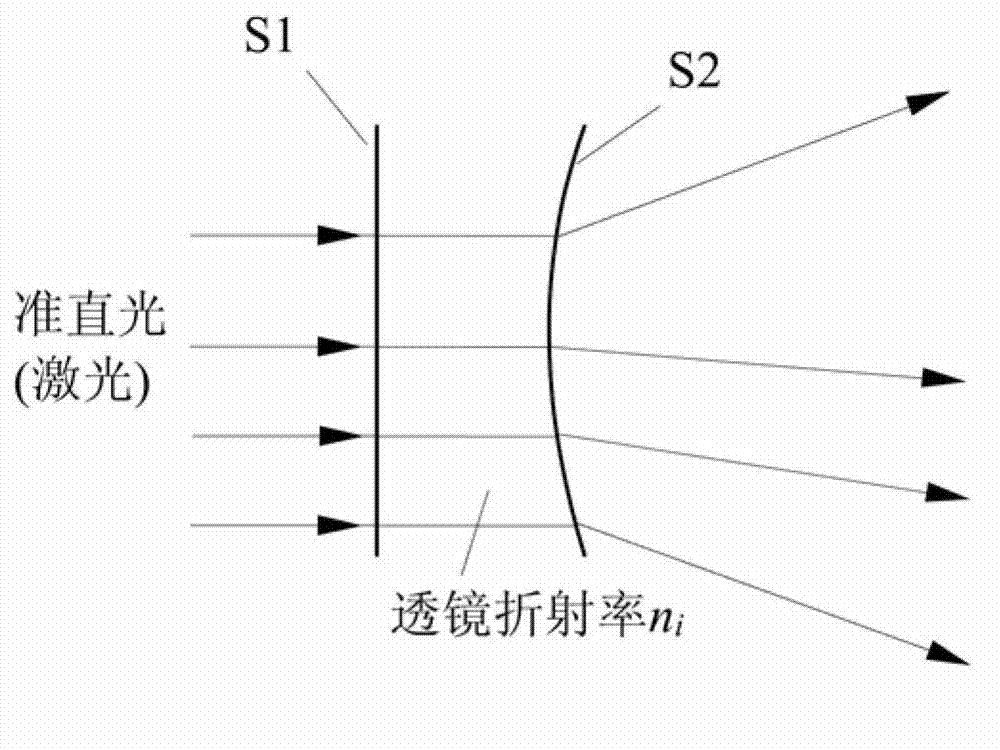

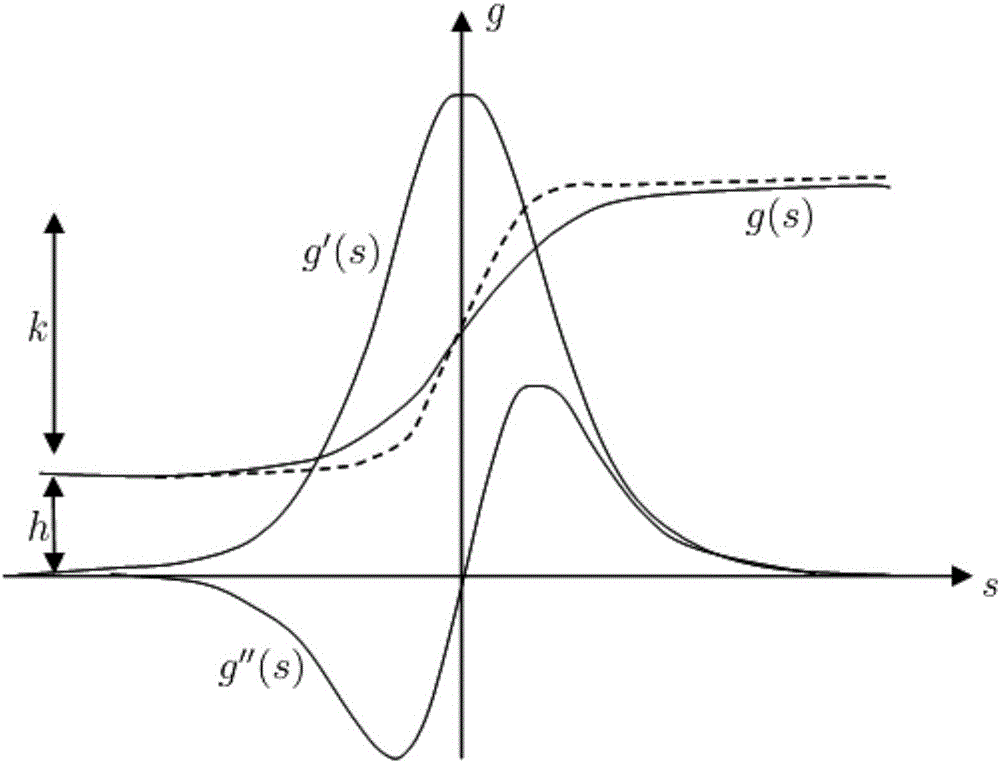

Double-free-form-surface lens for laser beam shaping and design method thereof

The invention discloses a design method of a double-free-form-surface lens for laser beam shaping and belongs to the technical field of non-imaging optics and laser beam shaping. An initial structure of the double-free-form-surface lens is set according to design requirements, the double-free-form-surface lens meeting lighting requirements is designed according to the relation of energy conservation, the refraction law and the optical path and with the assistance of a computer, and therefore after incident laser beams pass through the lens and are deflected, preset strength distribution and preset phase distribution are generated. The double-free-form-surface lens comprises double free-form surfaces, namely the front surface and the rear surface, and in addition, the front free-form surface and the rear free-form surface are obtained through surface fitting discrete data points. The invention further discloses the double-free-form-surface lens for laser beam shaping based on the method. A continuous free-form-surface form is obtained, the surfaces can be processed, regulating of strength distribution and phase distribution of the laser beams can be achieved at the same time, the control capability is strong, and the design efficiency is high.

Owner:ZHEJIANG UNIV

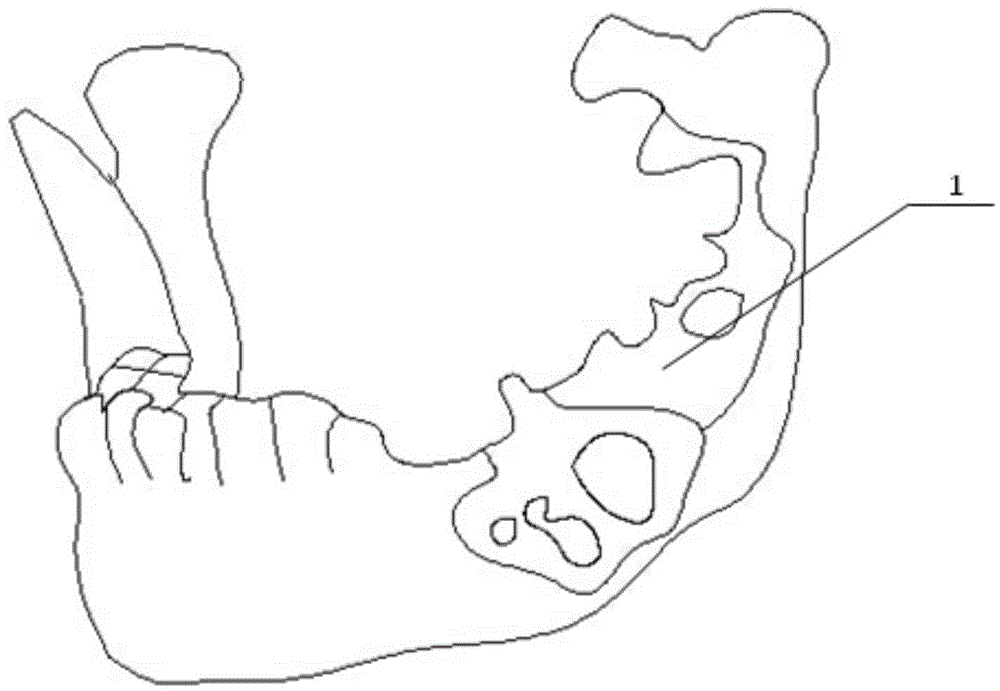

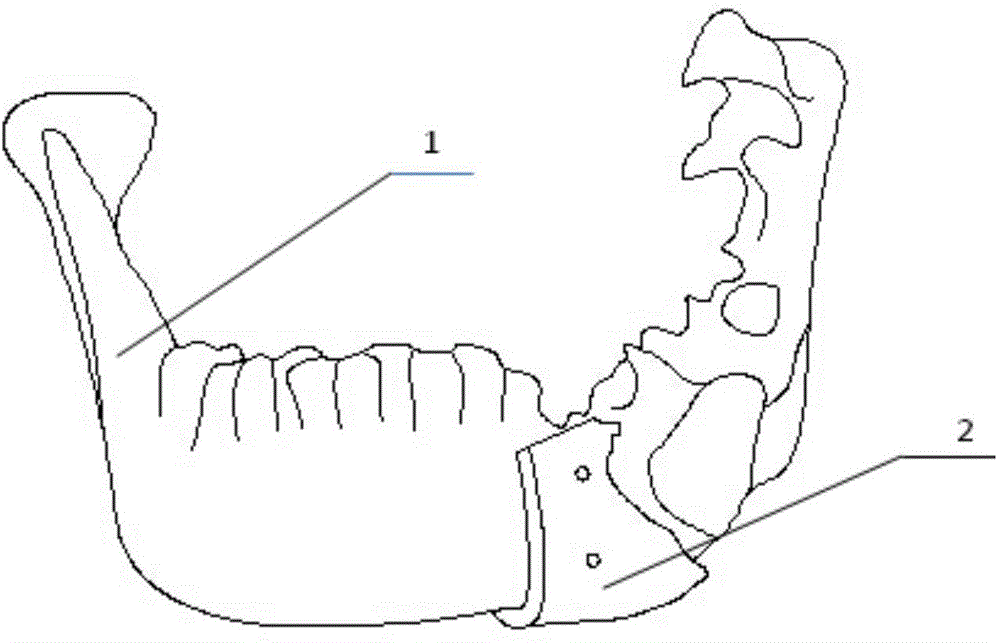

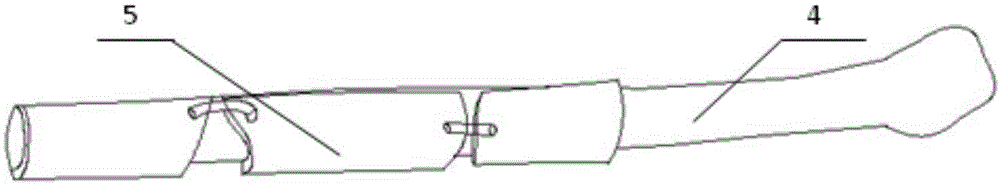

Fibular flap repairing mandible defect operation guiding template and manufacturing method

InactiveCN104825235AImprove accuracyImprove efficiencyDiagnosticsSurgeryThree dimensional modelSurface fitting

The invention discloses a manufacturing method for a fibular flap repairing mandible defect operation guiding template. The manufacturing method for the fibular flap repairing mandible defect operation guiding template comprises the steps that a mandible three-dimensional model and a fibula three-dimensional model are rebuilt, a lesion area is determined, and the target fibula is determined; the lesion area is excised, and a jaw non-lesion area model and a lesion area model are saved; the inner surface of a jaw cutting locating guiding template is attached to the outer surface of the lesion area model; the area where the fibula three-dimensional model and fibula subsection models are placed is partitioned to form a fibula repairing area; the inner surface of a fibula molding guiding template is entirely attached to the cheek side surface of the fibula repairing area; the inner surface of a fibula cutting locating guiding template is entirely attached to the outer surface of the corresponding fibula subsection model; the jaw cutting locating guiding template, the fibula molding guiding template and the fibula cutting locating guiding template are molded. The fibular flap repairing mandible defect operation guiding template and the manufacturing method have the advantages that the bone cutting scheme of the fibula and the molding position of each section of the fibula can be accurately controlled, the precise implement of a fibular flap transplanting repairing mandible defect operation is guaranteed, the operation time is shortened for the fibular flap repairing mandible defect operation.

Owner:6D DENTAL TECH

Method for free curved surface optical component for collimating light shaping

The invention discloses a method for designing a free curved surface optical component for collimating light shaping and belongs to the technical field of non-imaging optics. The specific structure of the free curved surface optical component is set according to the design requirement, and the free curved surface which meets the preset illumination requirement can be designed according to the refraction law and the energy conversion law under the assistance of a computer, so that emergent light of a light source is deflected by the free curved surface to generate illumination light spots such as the square illumination light spots with the smile face patterns and the rectangular illumination light spots with the characters 'mao' in a target illumination area. A certain surface of the free curved surface optical component is the free curved surface which is obtained by curved surface fitting discrete data. The method is high in design efficiency; the complex illumination step can be realized; the continuous free curved surface can be obtained; and the curved surface can be processed. Refraction and reflection free curved surface optical components can be obtained by a compression molding technology by optical glass.

Owner:ZHEJIANG UNIV

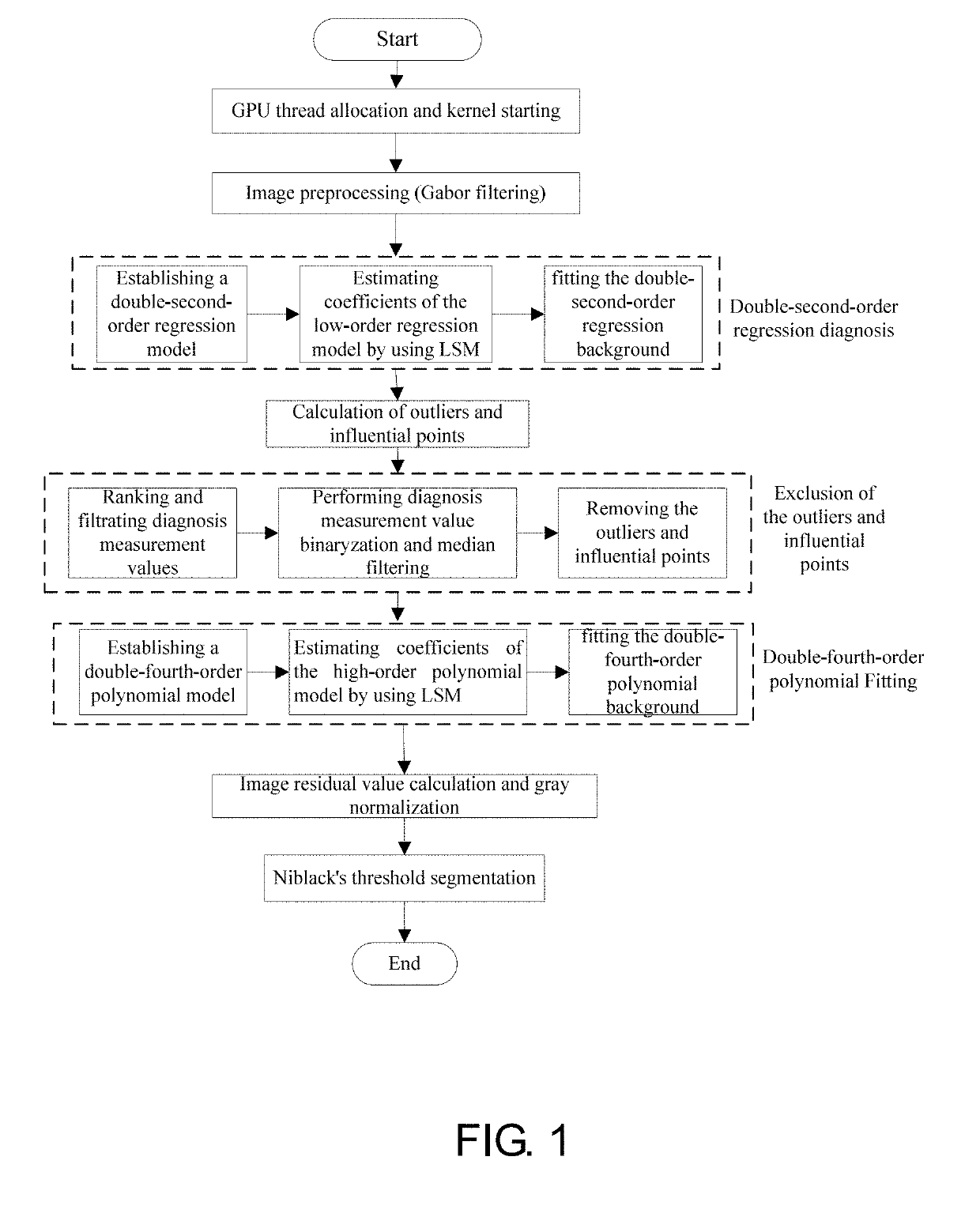

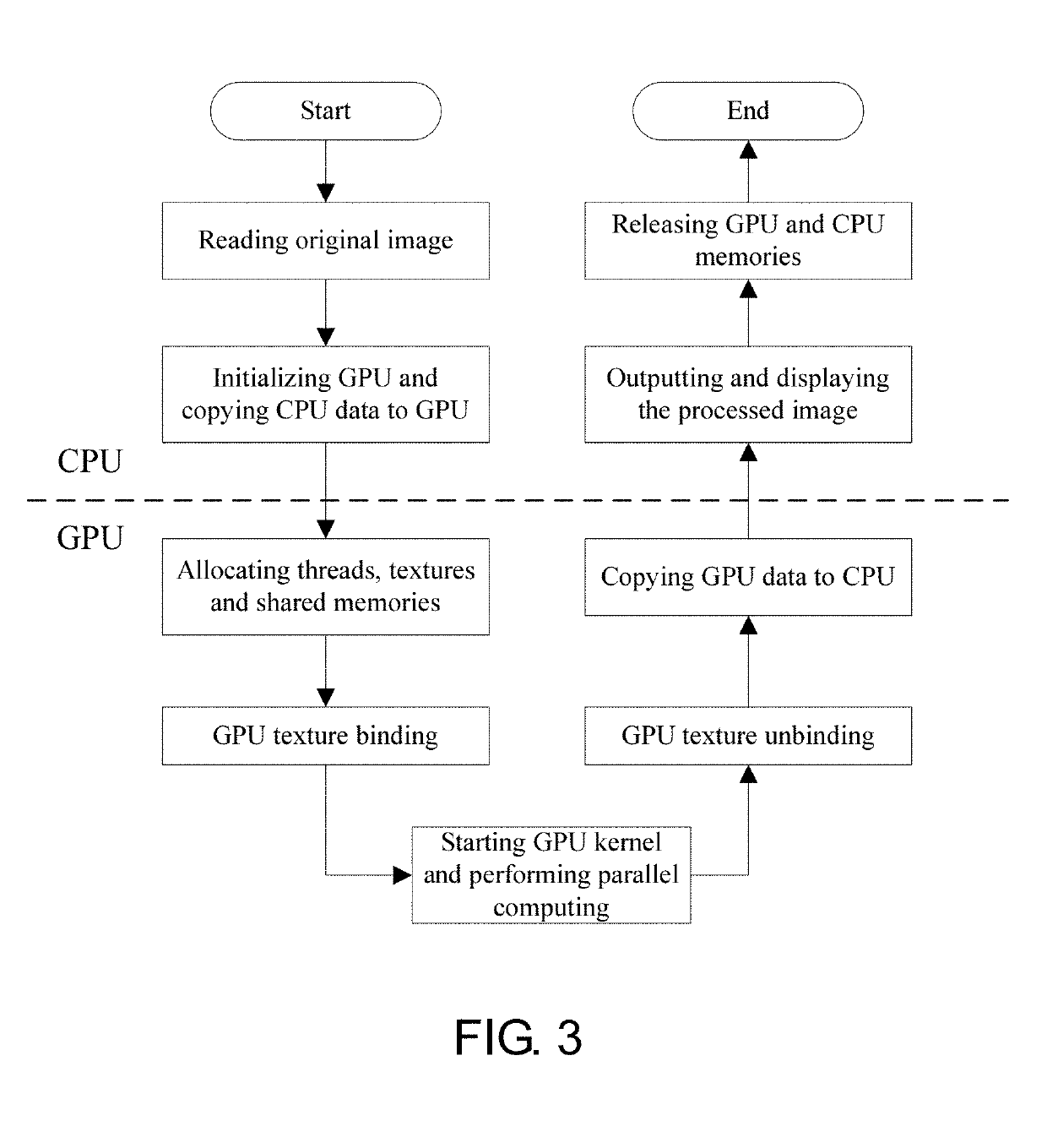

Gpu-based tft-lcd mura defect detection method

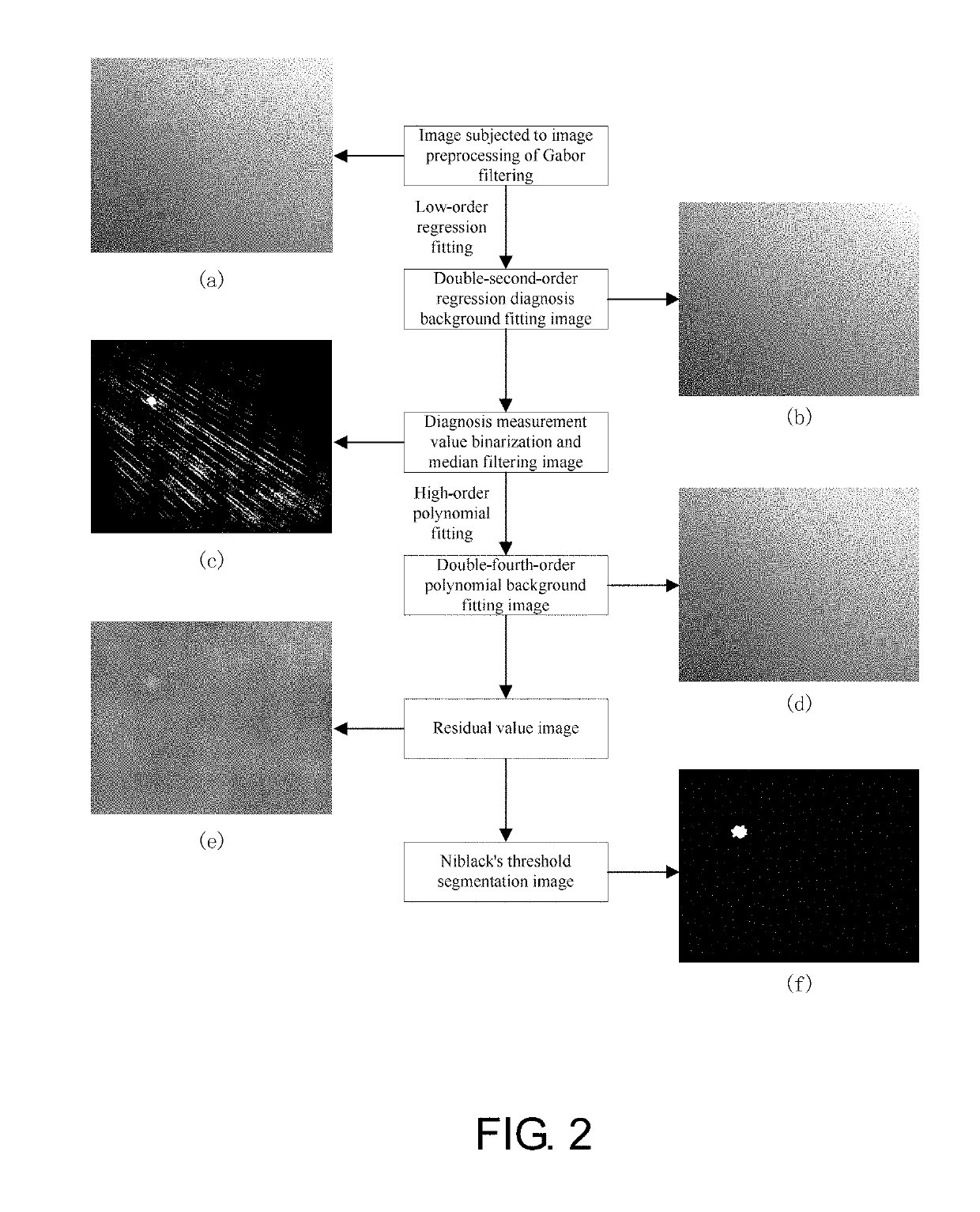

ActiveUS20190197678A1Eliminate the effects ofArea as unevennessImage enhancementImage analysisStudentized residualOutlier

The present disclosure discloses a GPU-based TFT-LCD Mura defect detection method, comprising: (1) establishing a studentized residual based double-second-order regression diagnosis model based original image data to obtain double-second-order regression background data; (2) obtaining influence quantities of respective data points on fitted values according to the original image data and the double-second-order regression background image data; (3) excluding outliers and influential points in the original image data according to the influence quantities to obtain a new pixel point set; (4) establishing a double-N-order polynomial surface fitting model according to the new pixel point set to obtain double-N-order background image data; (5) obtaining a residual image R according to the double-N-order background image data and the original image data, and performing threshold segmentation on the residual image to obtain a threshold segmentation image; and (6) performing morphological processing on the threshold segmentation image to obtain an eroded and dilated image, thereby achieving effective segmentation of Mura defects with uneven brightness distribution.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

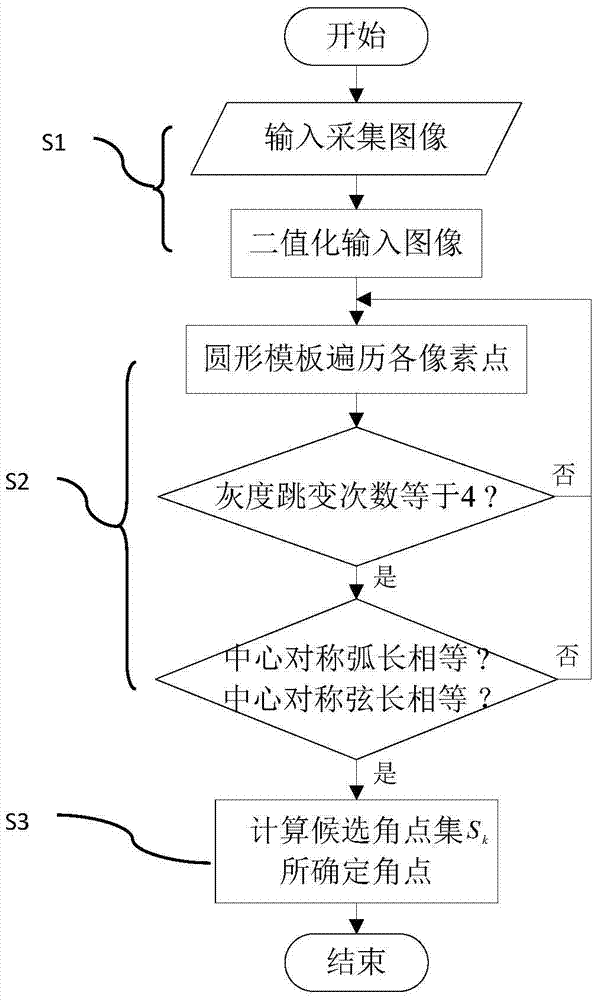

Detection method of checkboard grid image angular point sub pixel

The invention provides a detection method of a checkboard grid image angular point sub pixel. The detection method of the checkboard grid image angular point sub pixel comprises the steps that 1, a checkboard grid calibration template is filmed trough a camera, a template image of the checkboard grid calibration template is obtained, and binaryzation is conducted on the template image to obtain a binaryzation image; 2, traversal is conducted on the binaryzation image through a circular template, and screening is conducted on all the tested pixel points of the binaryzation image to screen out candidate angular points; 3, according to the character of the candidate angular points that the candidate angular points are symmetrically arranged near a true angular point which is determined by an angular point set, the abscissa average value and the ordinate average value of the pixel positions of the candidate angular points are calculated, and the abscissa average value and the ordinate average value serve as the sub pixel coordinates of the true angular point. According to the detection method of the checkboard grid image angular point sub pixel, only simple arithmetic is needed, and operations of differential, interpolation, surface fitting and the like are not needed, so that the detection process is simple and easy to realize, sub pixel level precision can be directly obtained, and good detection precision and real-time are obtained.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

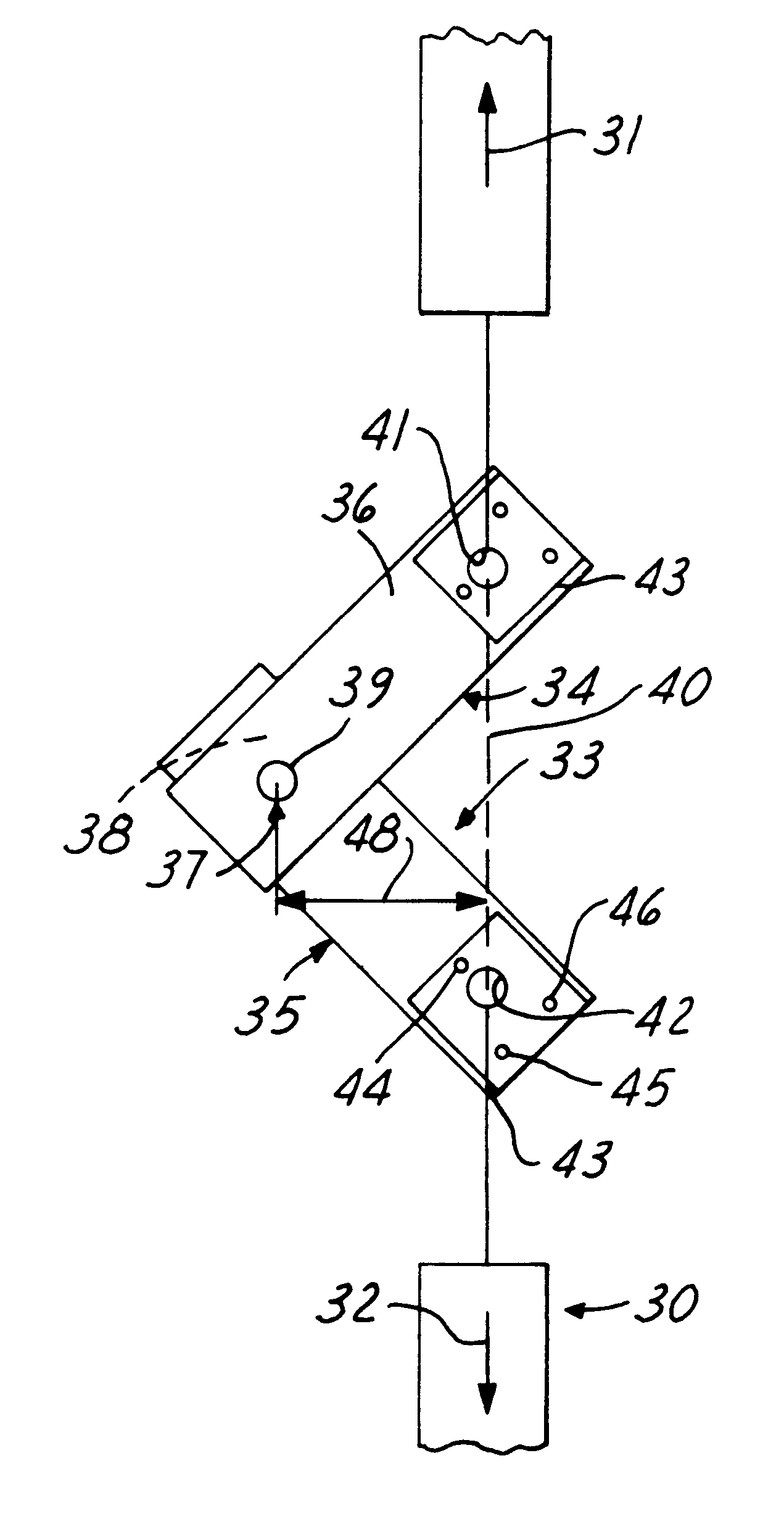

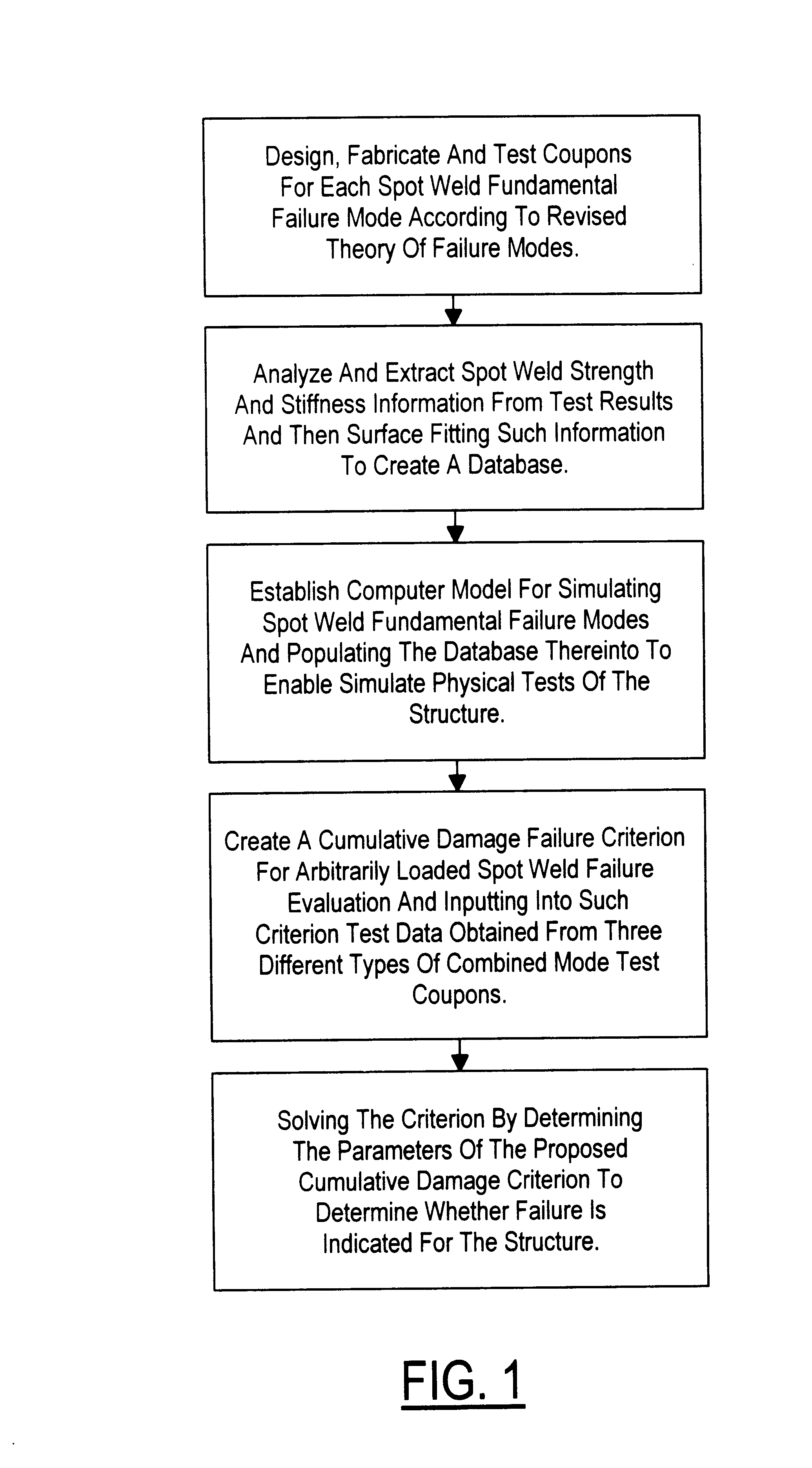

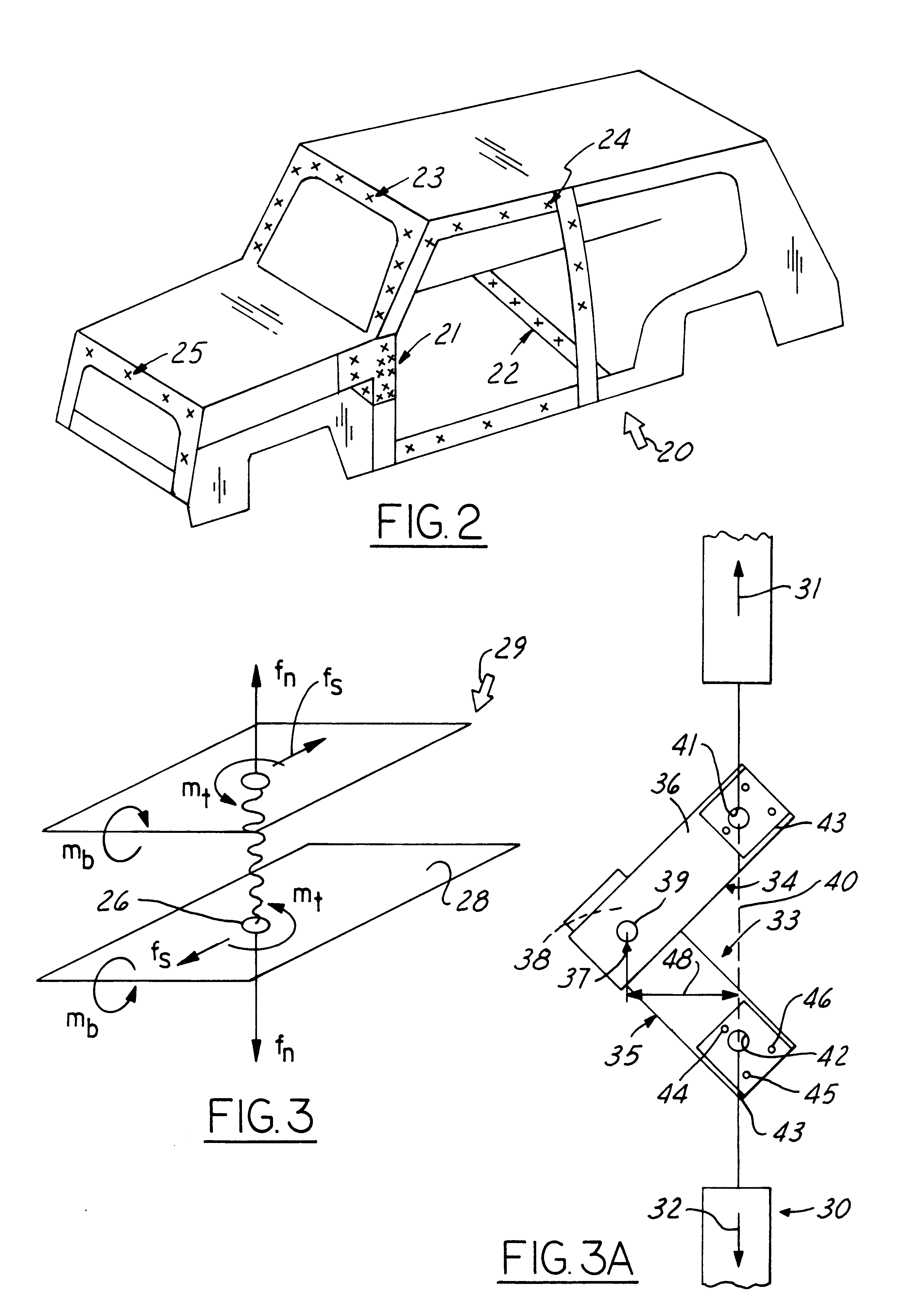

Method of analyzing spot welded structures

InactiveUS6186011B1Improve accuracyMaterial strength using steady bending forcesResistance welding apparatusIn planeMathematical model

Method of analyzing spot welded sheet metal structures subjected to forces that promote one or more basic failure modes of either shear tension, in-plane rotation, coach peel, normal tension, or any combination of such basic modes, the method comprising: (i) providing spot welded sheet metal test coupons for analysis of the selected failure mode for the structure to be analyzed and subjecting such test coupons to progressively increasing forces that eventually achieve failure in the selected failure mode to thereby generate measured load and displacement test data; (ii) analyzing the data from the basic modes to derive and extract spot weld strength and stiffness information and then surface fitting such extracted data to create a database; (iii) establishing a computer math model for simulating the spot weld failure modes of the structure and populating the database thereinto to enable simulated physical tests of the structure; (iv) creating a cumulative-damage failure criterion for the spot welded structure that ratios (a) the resultant strength information from the populated math model for selected combinations of load and selected combinations of time and structure thickness, and (b) the measured strength information derived for such combinations of load derived from the test data; and (v) solving the criterion to determine whether it indicates failure for the combination of resultant strength and other values selected.

Owner:FORD GLOBAL TECH LLC

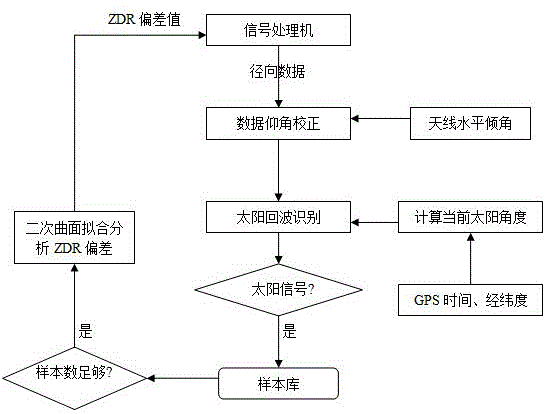

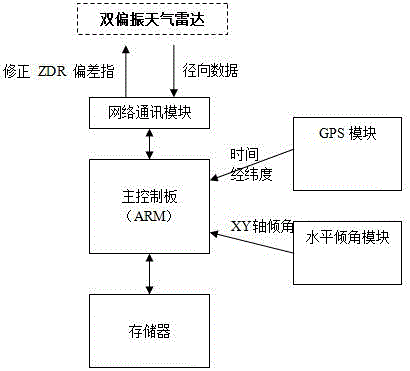

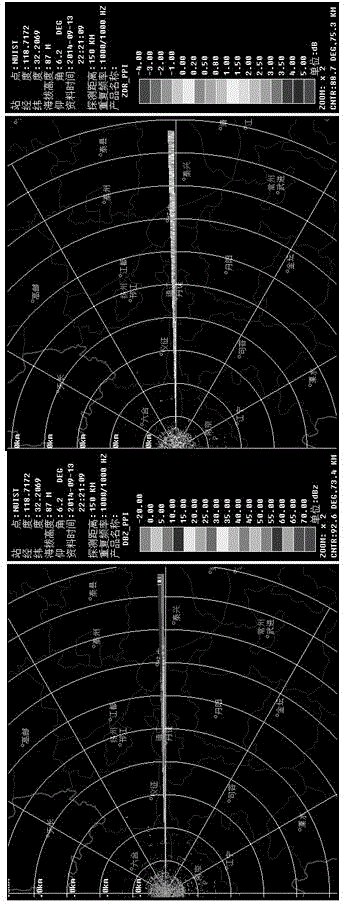

ZDR on-line calibration method of dual-polarization weather radar and apparatus thereof

ActiveCN105137407AGuaranteed continuityHigh precisionWave based measurement systemsWeather radarAtmospheric sciences

The invention discloses a ZDR on-line calibration method of a dual-polarization weather radar and an apparatus thereof. The on-line calibration method comprises the following steps: (1), receiving radial data outputted by a signal processor of a dual-polarization weather radar; (2), identifying a solar echo signal in the radial data received by the step (1); and (3), carrying out quadric surface fitting on the solar echo signal identified by the step (2) and calculating a ZDR deviation to carry out ZDR calibration. With the method and apparatus, real-time on-line calibration is carried out effectively without manual intervention; completion is realized automatically; and normal observation of the radar does not need to be interrupted.

Owner:南京信大气象科学技术研究院有限公司

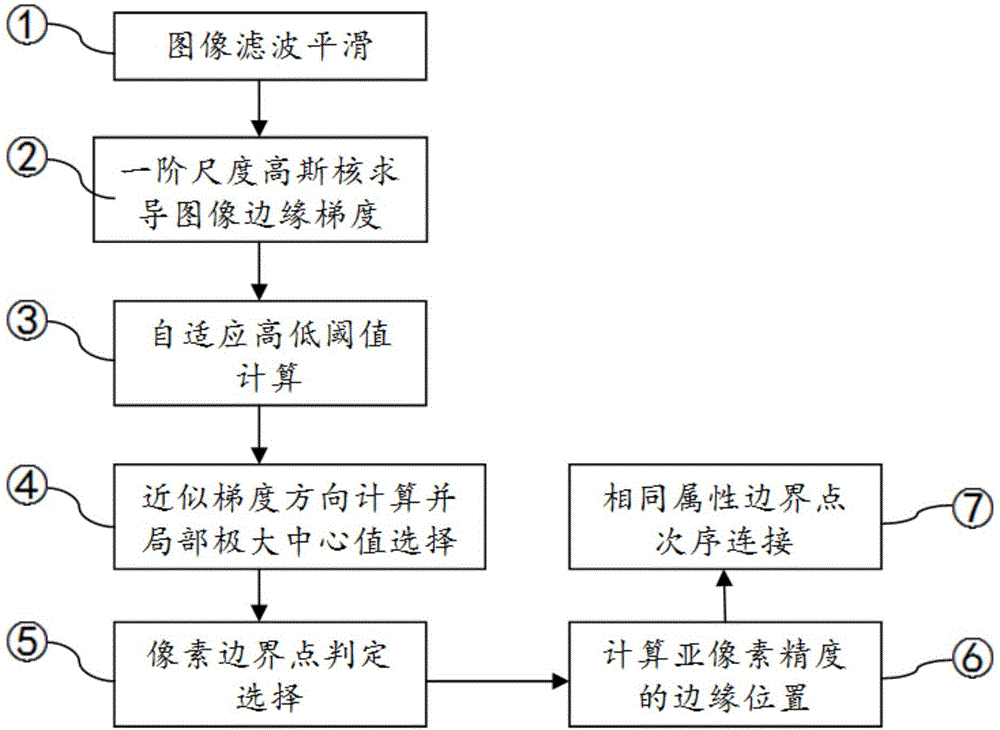

Image sub-pixel edge extraction method having extensive adaptability

The invention discloses an image sub-pixel edge extraction method having extensive adaptability, comprising steps of adopting an adaptive high-low threshold value calculation method, executing a local maximum central value choosing operation on a gradient image by combining with gradient direction information of a pixel point after obtaining a gradient image, establishing a relative coordinate with a random pixel point as an origin point, taking eight-neighborhood pixels around the origin point as local maximum central value choosing data samples, obtaining a comparison result between the adjacent neighborhoods according to a gradient direction, determining whether the current pixel position is a boundary point candidate position, adopting a Hessian matrix method based on a Steger surface fitting method to solve a sub-pixel position of the boundary point and connecting boundary points for forming a line to constitute a set of directed continuity points. Determination whether an extreme value of a local gradient magnitude is a boundary point can be made by combining with a specific threshold value; if the local extreme value is greater than a given threshold value, the local extreme value is marked as a boundary point, and if the local extreme value is smaller than a given threshold value, the local extreme value is a noise point or a background point The invention has great instantaneity.

Owner:BOZHON PRECISION IND TECH CO LTD

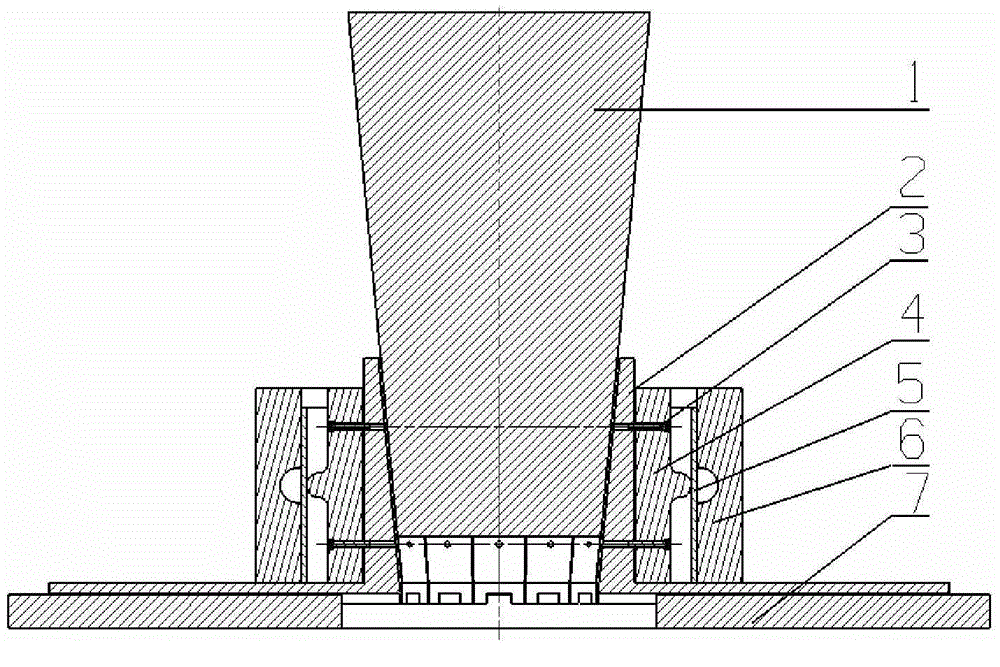

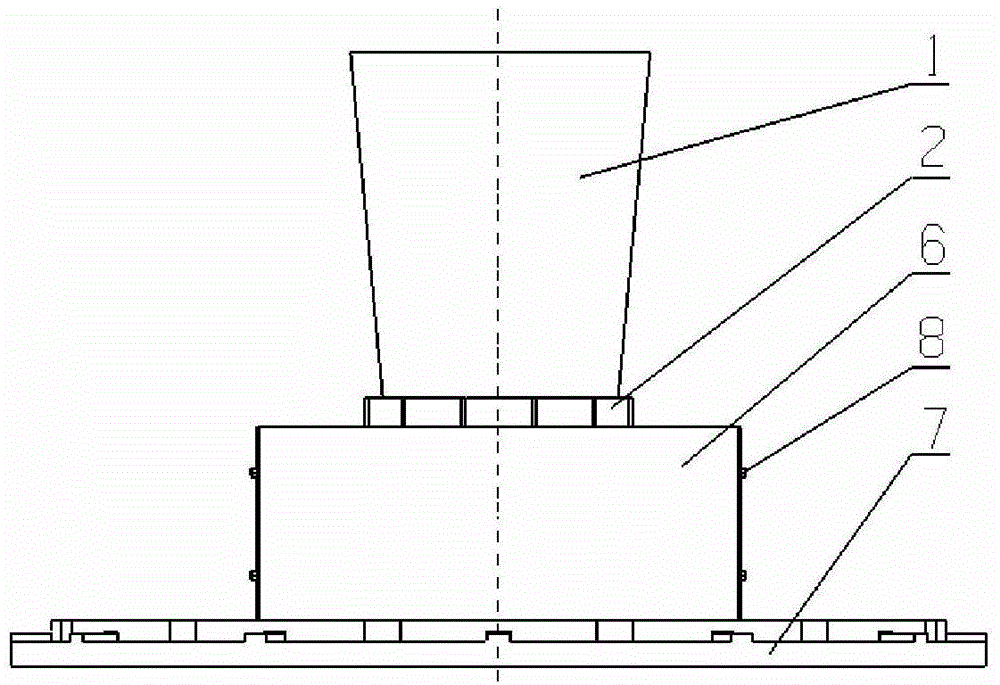

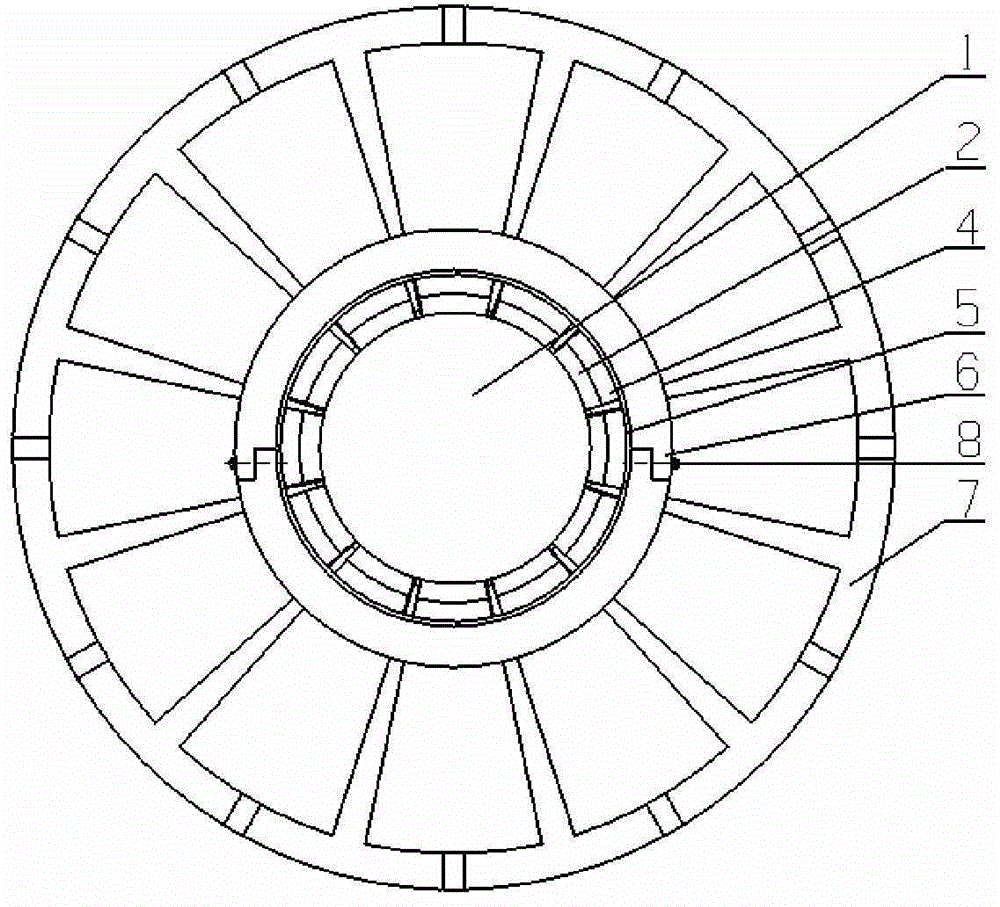

Bulging die for titanium-alloy thin-walled complicated irregular annular workpieces

ActiveCN104801598AImprove shape and position accuracyHigh precisionShaping toolsForming faceEngineering

The invention relates to a bulging die for titanium-alloy thin-walled complicated irregular annular workpieces. The bulging die comprises a core shaft, n brackets, n male dies, female dies and a base, wherein n sliding rails are uniformly distributed on the upper surface of the base, and all brackets are respectively embedded in all the sliding rails so as to form a circular assembly; the small-diameter end of the core shaft is located in the assembly and is fit with the internal surfaces of all the brackets; the n male dies are fixedly arranged on all the brackets respectively; each circular female die is formed through folding corresponding two semicircular female die clacks and sleeves the external surface of the corresponding male die; the internal surfaces of the female dies and the external surfaces of the male dies are workpiece forming faces. According to the bulging die, the forming of the irregular annular workpieces mainly relies on the plastic forming of a material, so that the surface wear resistance of parts is improved, the service lives of the parts are prolonged, and the material is saved; the accuracy of the annular workpieces can be corrected; during continuous repeated machining, the consistency of size and accuracy of the parts can be guaranteed.

Owner:丹东丰能工业股份有限公司

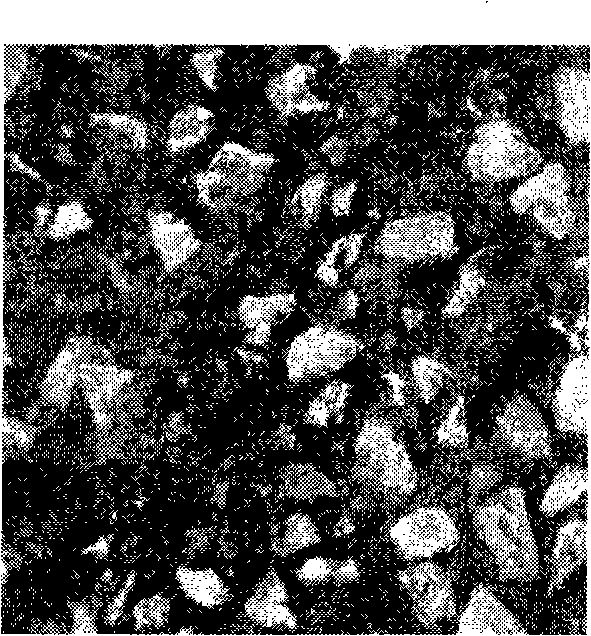

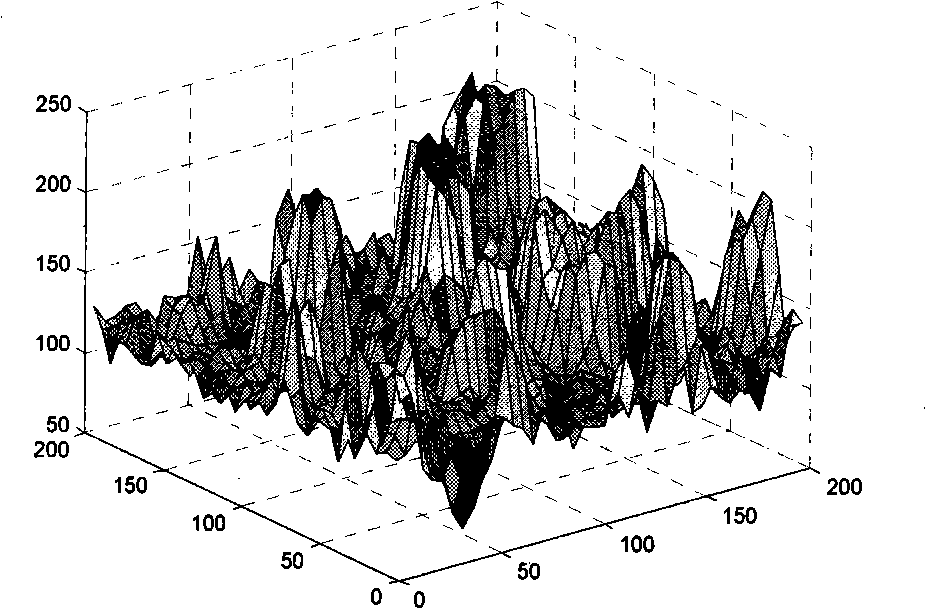

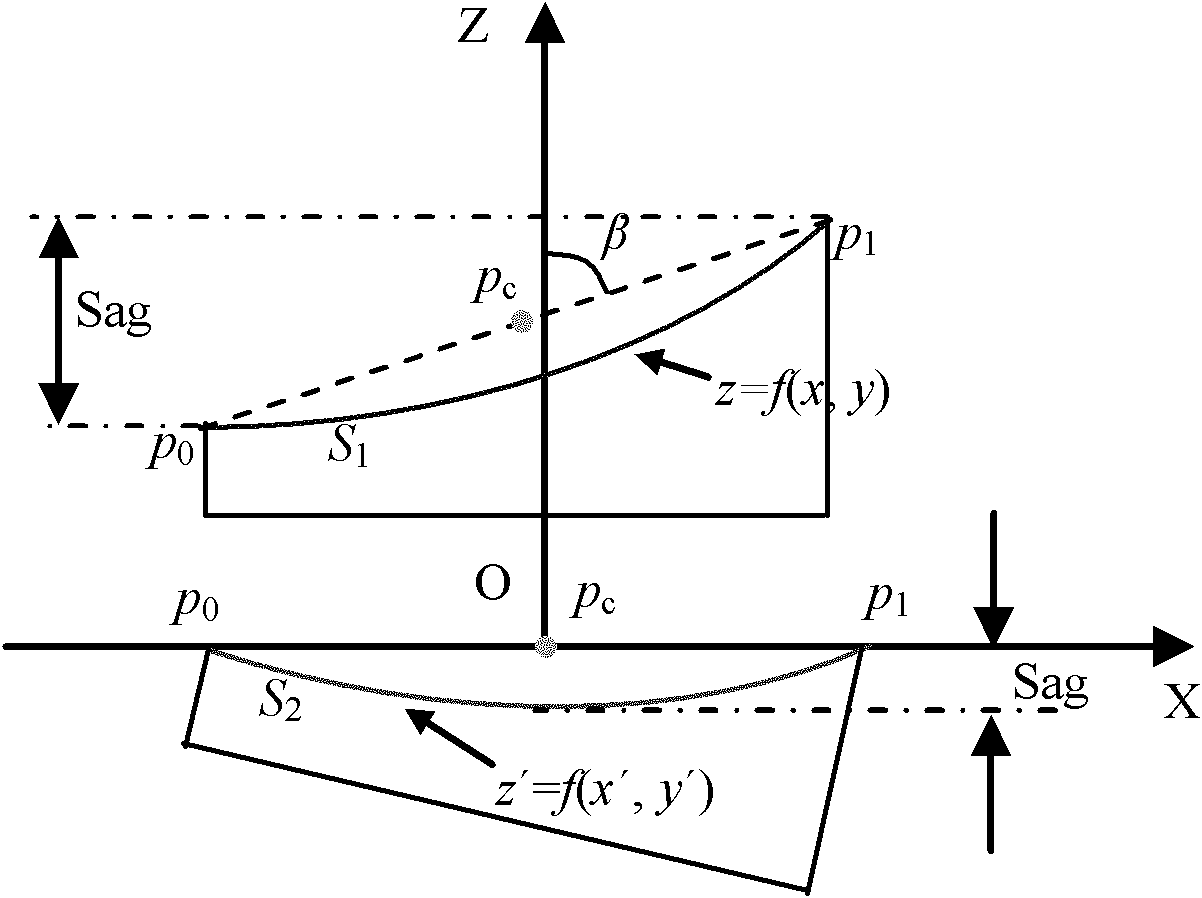

Method for determine surface structure depth of exposed aggregate concrete by curved surface fitting

The present invention discloses a method adopting a surface fitting method to determine the depth of the surface structure of the exposed concrete, and adopts the steps: 1) a digital image of the measured road is shot; 2)the digital image is dealt with the decoloration treatment to be converted into a gray level image; 3)two-dimensional array data of the pixel matrix corresponding to the gray level image is extracted; 4)according to the extracted two-dimensional array data, the curved-surface model of the measured road is obtained with the surface fitting method; 5)the depth of the surface structure of the measured road is calculated according to the curved-surface model; the present invention has the advantages of simple and convenient operation, low expense, wide application range and high measurement precision.

Owner:CHONGQING JIAOTONG UNIVERSITY

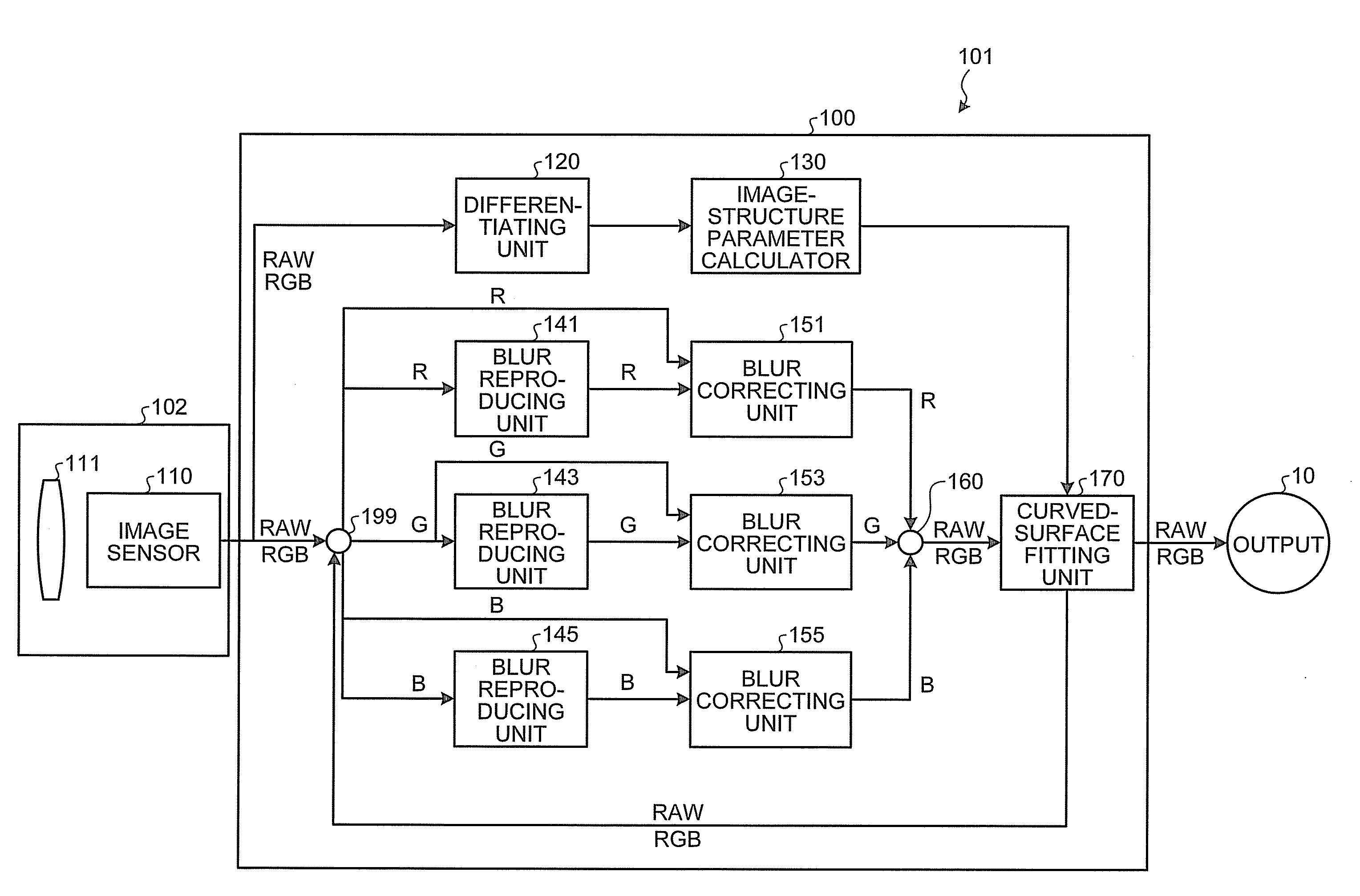

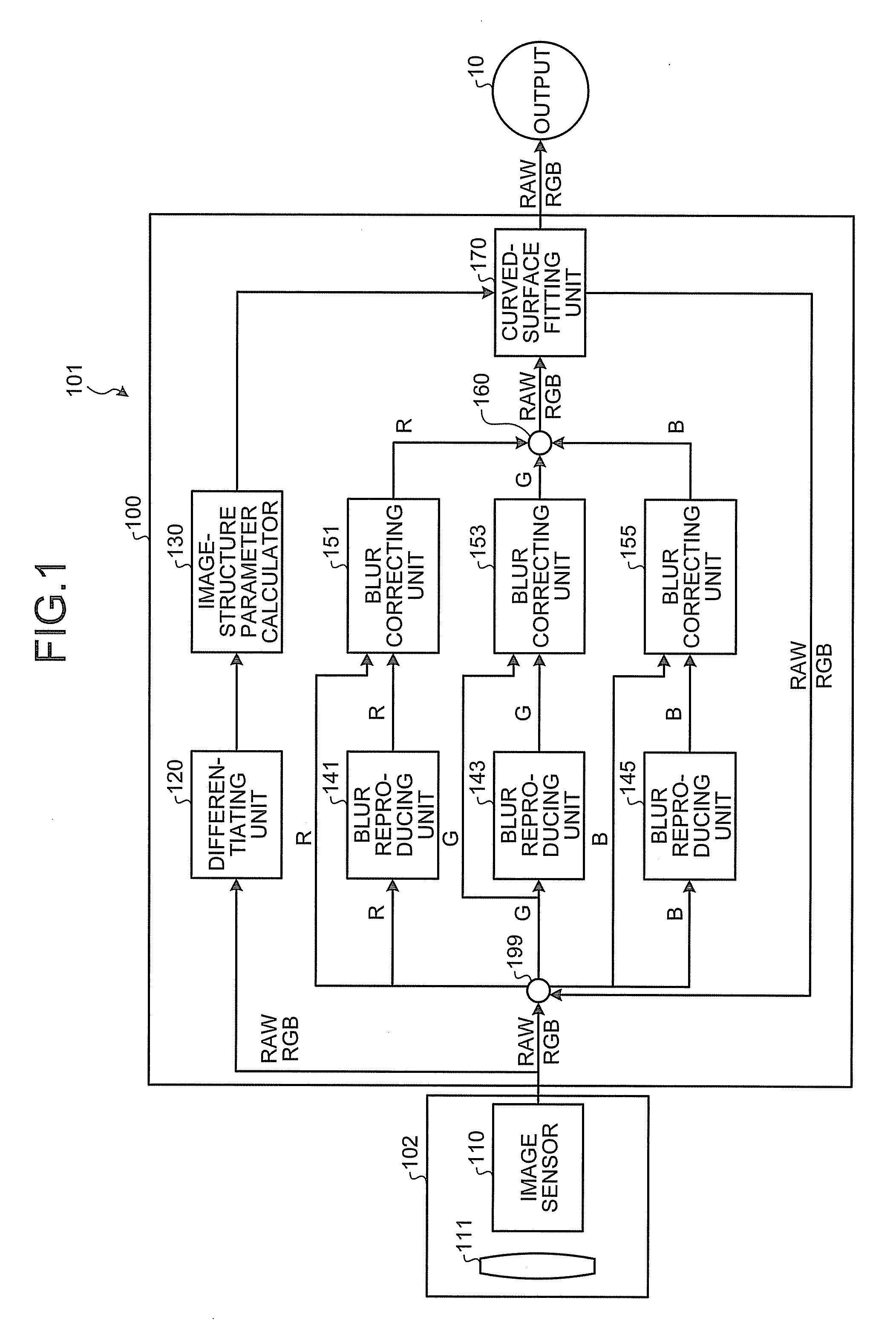

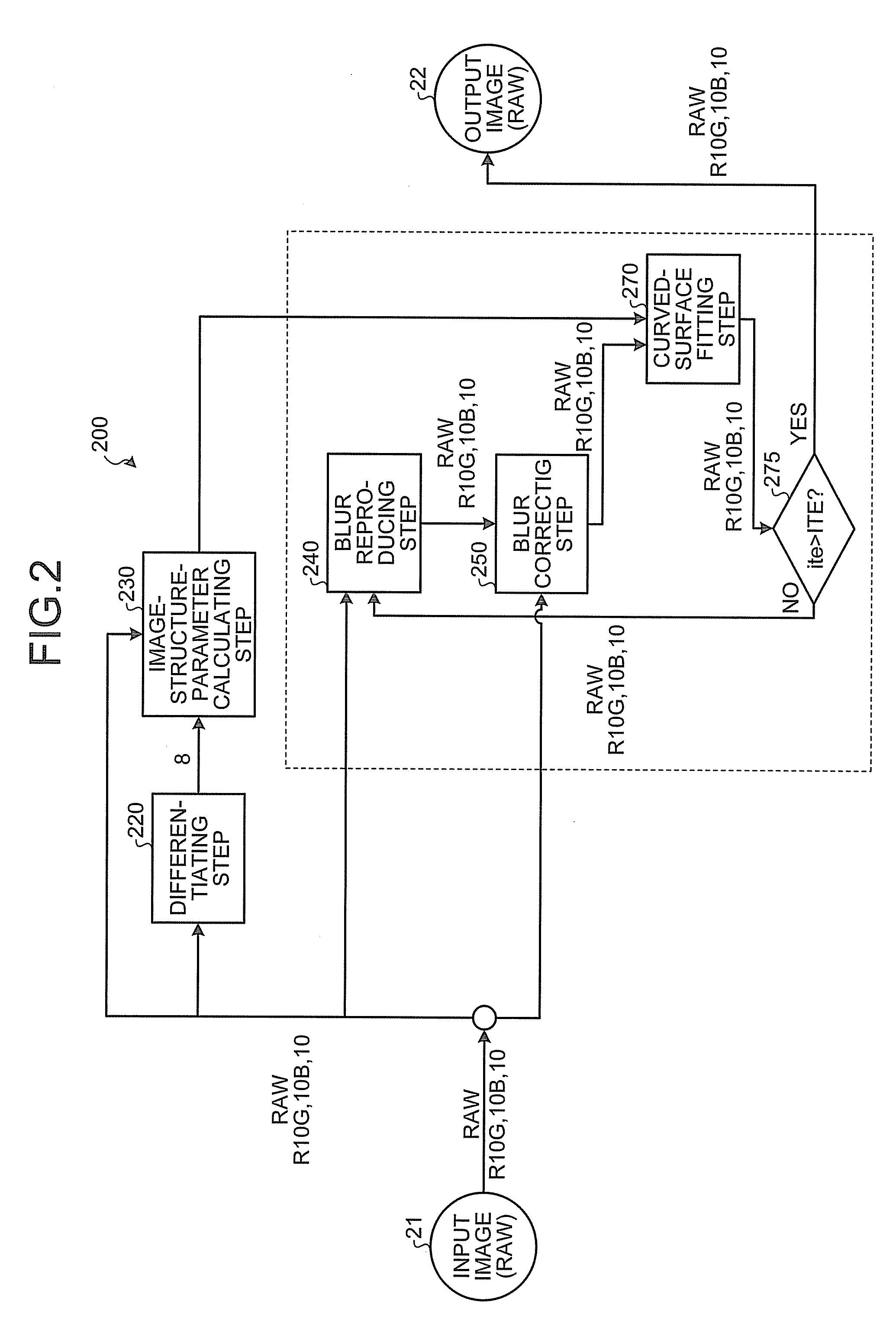

Image processing apparatus, imaging device, image processing method, and computer program product

InactiveUS20100079630A1Relatively small errorImage enhancementImage analysisCamera lensImaging processing

An image processing apparatus includes a blur reproducing unit that generates blur-reproduced image data by reproducing a predetermined blur of a lens, with respect to blur-corrected image data of which an initial data is input image data inputted from an image sensor; a blur correcting unit that corrects the blur-corrected image data so that an error between the blur-reproduced image data and the input image data becomes smaller; and a curved-surface fitting unit that obtains curve surface parameters of each functions approximating distribution of pixel values of each of color components of the blur-corrected image data so that curved-surface shapes of the functions become the same among the color components, and updates the pixel values of the blur-corrected image data by using the curve surface parameters.

Owner:KK TOSHIBA

Ultraprecise turning method of optical lens with incline

The invention belongs to the technical field of manufacture and ultraprecise processing of optical elements, and relates to an ultraprecise turning method of an optical lens with an incline, which comprises the steps of: taking two datum points on the incline, determining a workpiece initial plane, roughly processing on the incline to be processed; making a fixture and assembling the workpiece on the end face of a processing lathe, regulating the workpiece initial plane to be vertical to the z axis, regulating a workpiece center to be coincide with a main shaft center; and carrying out coordinate conversion to obtain a connecting line of two end points to be coincide with the x axis, calculating a normal angle of the whole curved surface with center coordinates of the two datum points as a new curved surface of the original point, determining a diamond tool rear angle required by processing the curved surface, selecting a proper tool to be assembled on the lathe, carrying out NURBS (Non-Uniform Rational B-Spline) curved surface fitting on the curved surface subjected to the coordinate conversion, and determining the processing path according to a spiral drive line method. The lens surface is leveled by the coordinate conversion, and the tool rear angle required by processing the curved surface is reduced, thus the processing efficiency and the size of the processing workpiece can be increased, and the method is suitable for processing the large-incline optical lens with any gradient and Sag value.

Owner:TIANJIN UNIV

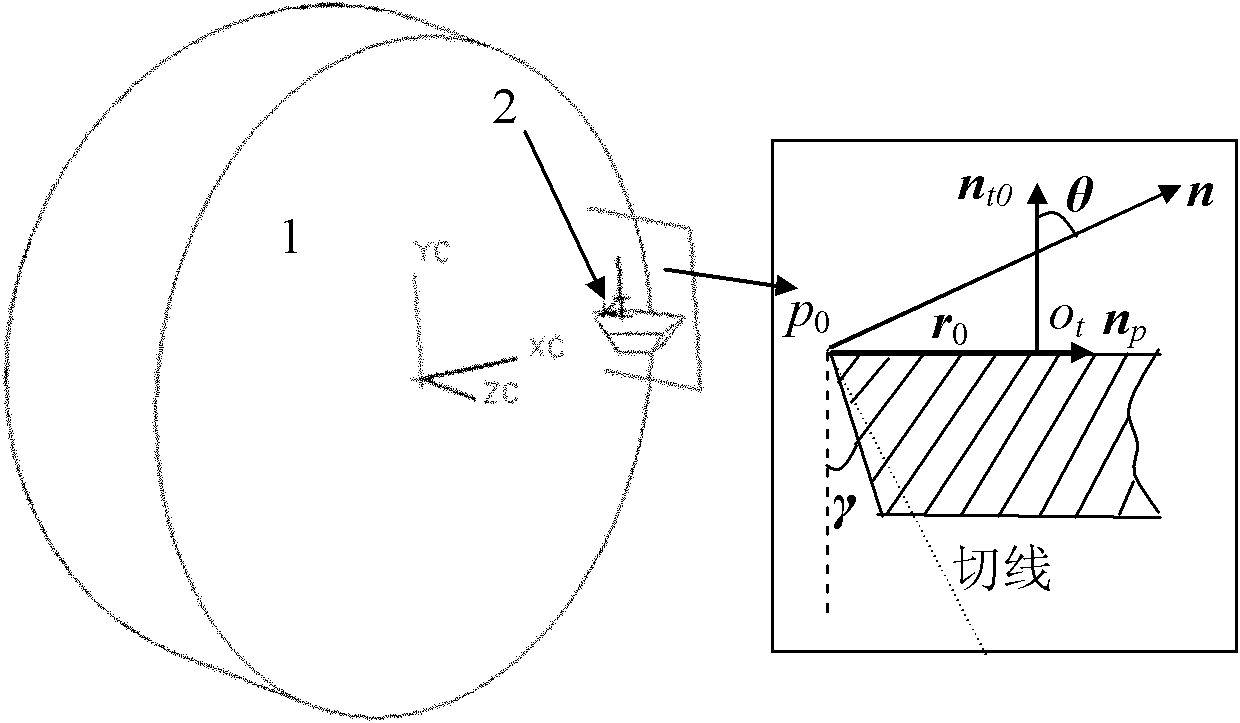

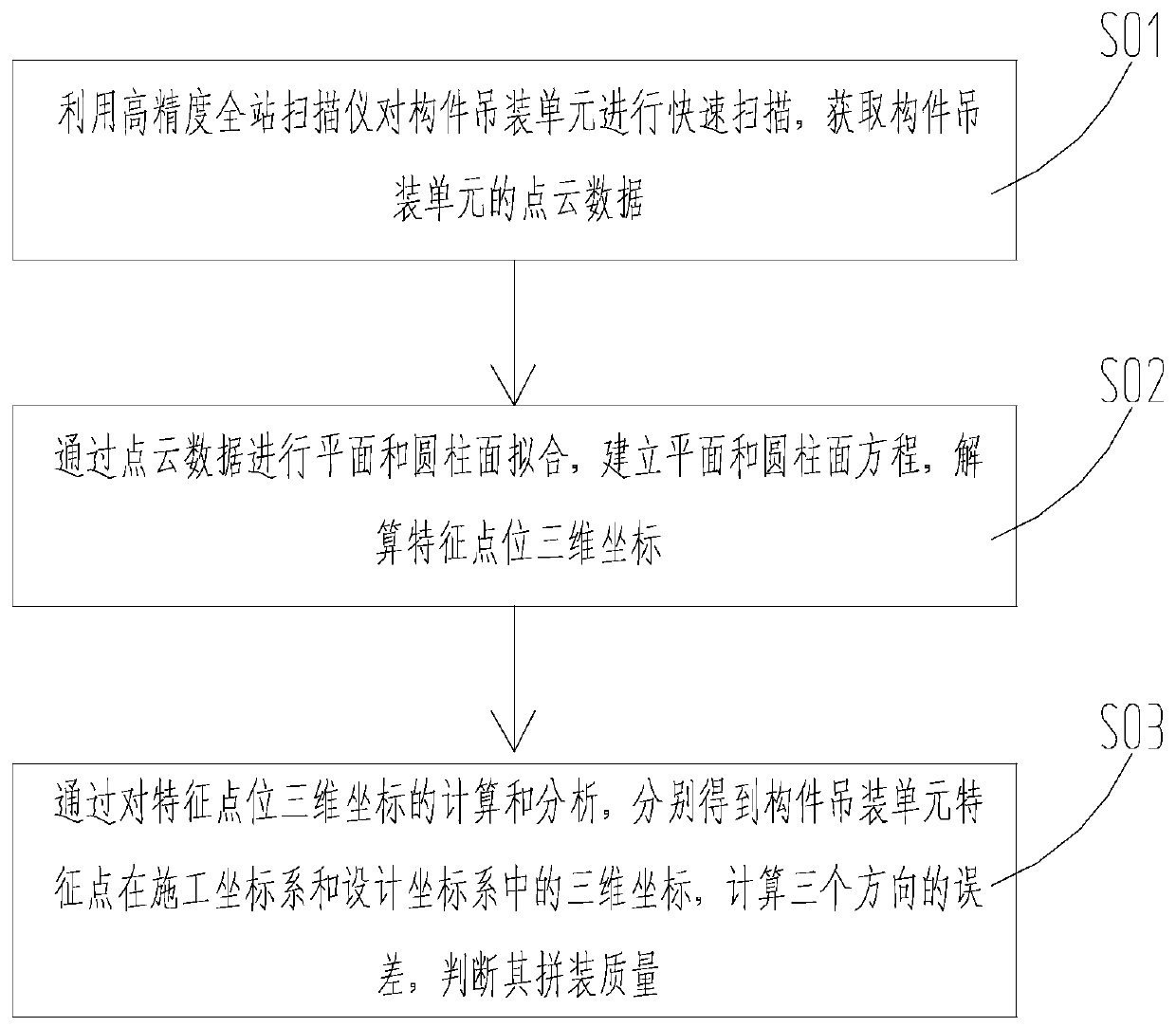

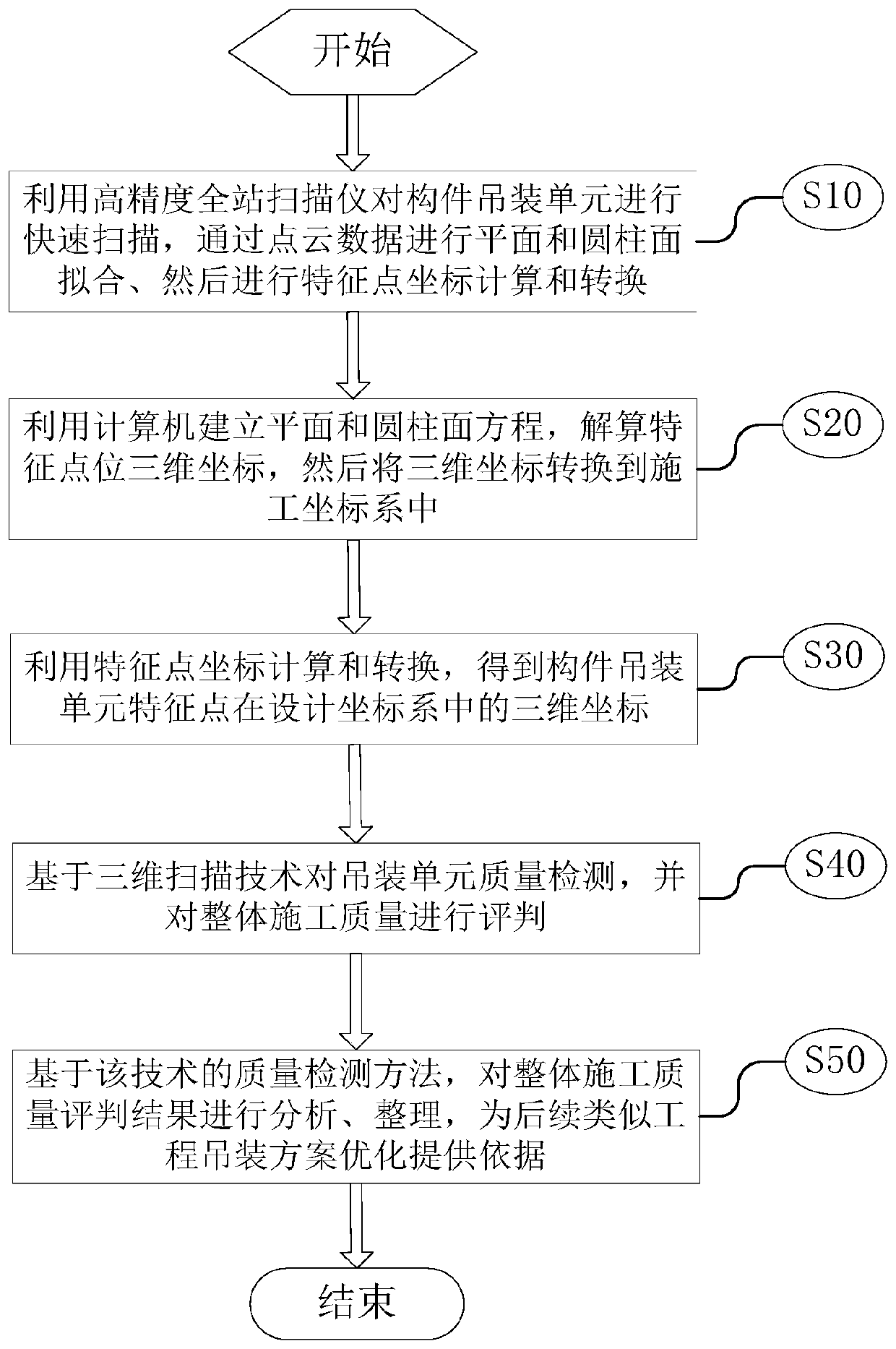

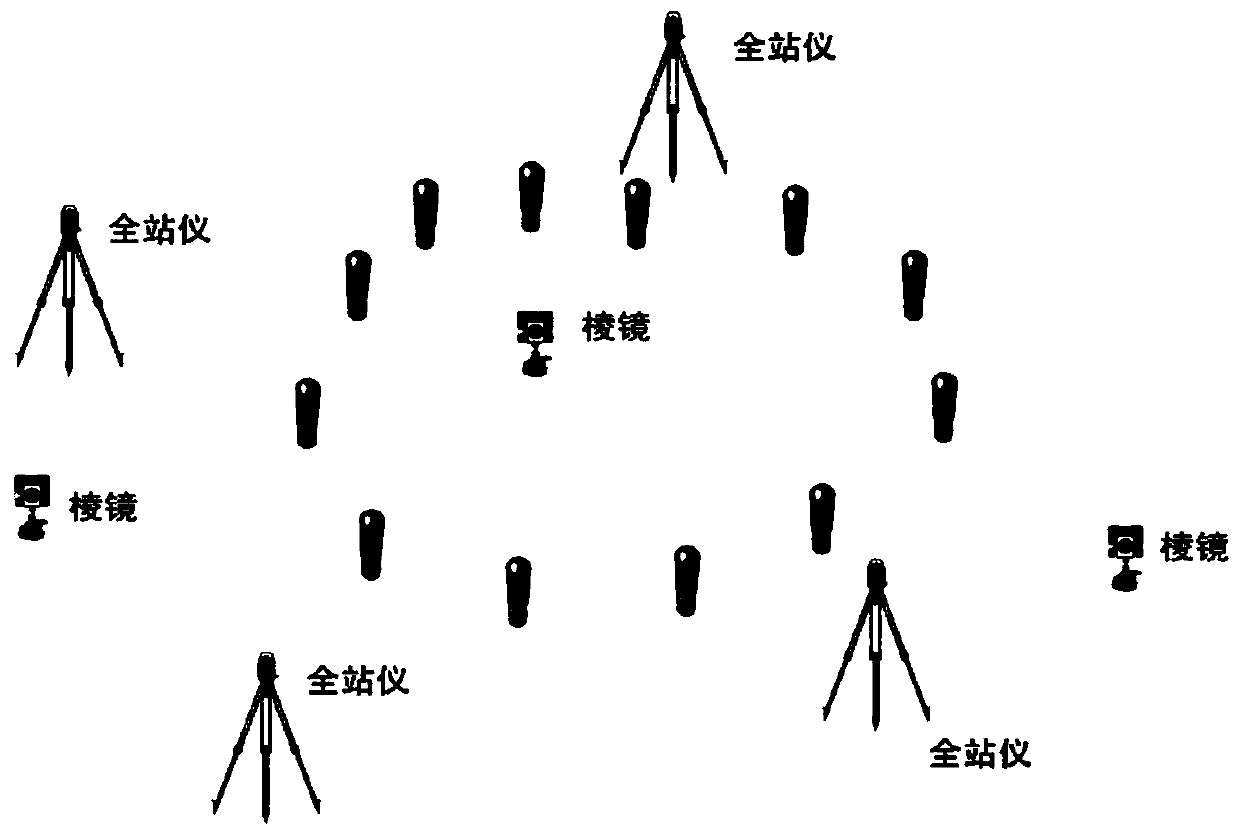

Rapid quality inspection method for steel structure based on three-dimensional scanning technology

The invention, which belongs to the technical field of building construction, discloses a rapid quality inspection method for the steel structure based on a three-dimensional scanning technology. Themethod comprises the following steps: step one, performing rapid scanning; to be specific, scanning a component lifting unit rapidly by using a high-precision full-station scanner to obtain point cloud data of the component lifting unit; step two, performing feature point coordinate calculation; to be specific, carrying out plane and cylindrical surface fitting by the point cloud data, establishing plane and cylindrical surface equations, and calculating three-dimensional coordinates of feature point locations; and step three, performing the quality analysis; to be specific, calculating and analyzing the three-dimensional coordinates of feature point locations to obtain three-dimensional coordinates of feature points of the component lifting unit in a construction coordinate system and a design coordinate system, calculating errors of three directions, and determining the splicing quality. According to the invention, plane and cylinder fitting, three-dimensional coordinate calculationof key point locations, and three-dimensional coordinate transformation are carried out to obtain the three-dimensional coordinates of rod nodes of the lifting unit in the design coordinate system; and the component quality of the lifting unit is evaluated based on the coordinate difference of three directions.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com