TFT-LCD Mura defect machine vision detecting method based on B spline surface fitting

A technology of machine vision inspection and spline surface, which is applied in the direction of optical testing flaws/defects, instruments, optics, etc. It can solve the problems that Mura defects cannot be accurately segmented and the brightness of the image background is uneven, so as to solve the problems of poor real-time performance, The effect of overcoming the inaccurate segmentation of Mura defects and the standardization of grade division

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

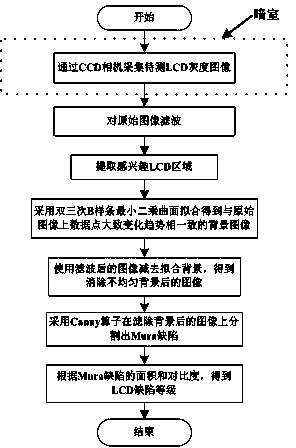

[0037] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

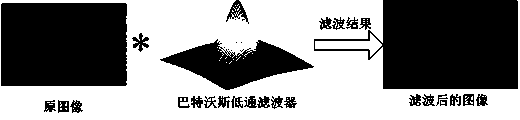

[0038] The idea of the present invention is to use the B-spline surface fitting method to fit a background image, which can represent the image to the greatest extent through most of the points on the preprocessed TFT-LCD image. Grayscale change trend, and then subtract the background image from the preprocessed TFT-LCD image, so as to obtain an image without a background with uneven brightness, and then accurately detect Mura defects. The hardware system and the specific implementation method of the method will be introduced in detail below.

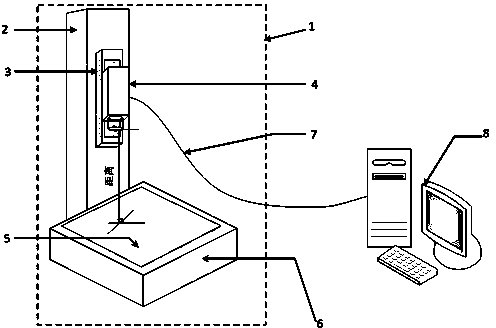

[0039] according to figure 1 as well as figure 1In the digital part, the hardware part of the Mura defect detection system mainly includes the following parts. 1 represents the dark room, which is used to control the ambient light to filter out the impact of external light on image acquisition. In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com