Three-dimensional measurement method and device based on linear structured light

A three-dimensional measurement, line structured light technology, applied in measurement devices, optical devices, image data processing, etc., can solve problems such as high price and achieve good noise immunity and high calibration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

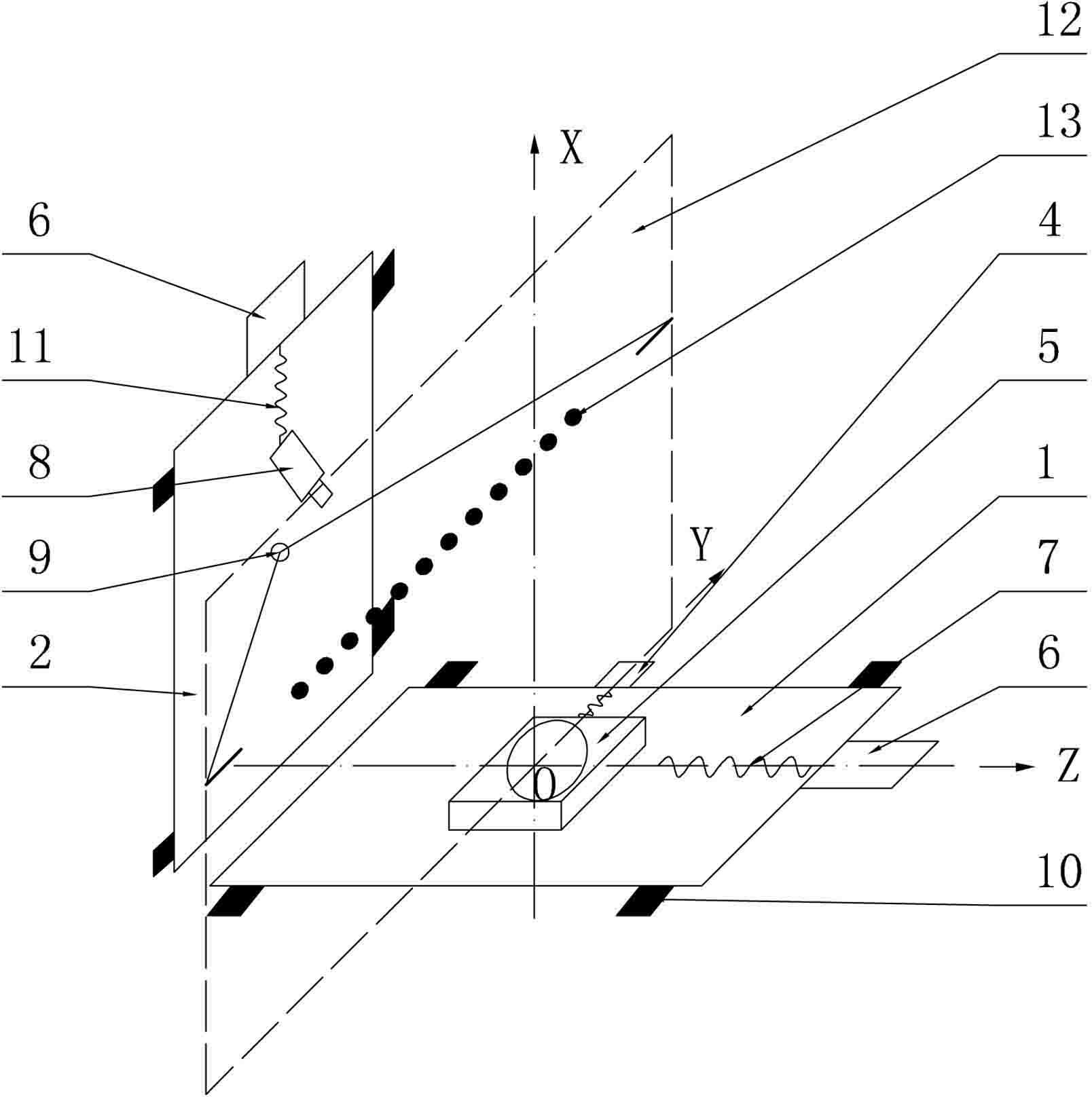

[0024] The specific device of the present invention is as figure 1 As shown, the horizontal platform 1 and the vertical platform 2 are arranged vertically, a turntable 5 is arranged on the horizontal platform 1, a camera 8 and a laser 9 are arranged on the vertical platform 2, and the camera 8 forms an angle of 45° with the vertical platform 2. 1 and the vertical table 2 are respectively provided with servo motors 6, and the central axes of the two servo servo motors 6 are vertical; The motor 4 is connected to the turntable 5, and the axis of the stepper motor 4 is perpendicular to the axis of the servo motor 6 on the horizontal platform 1; Limit switches 10 are arranged on the sides of both ends.

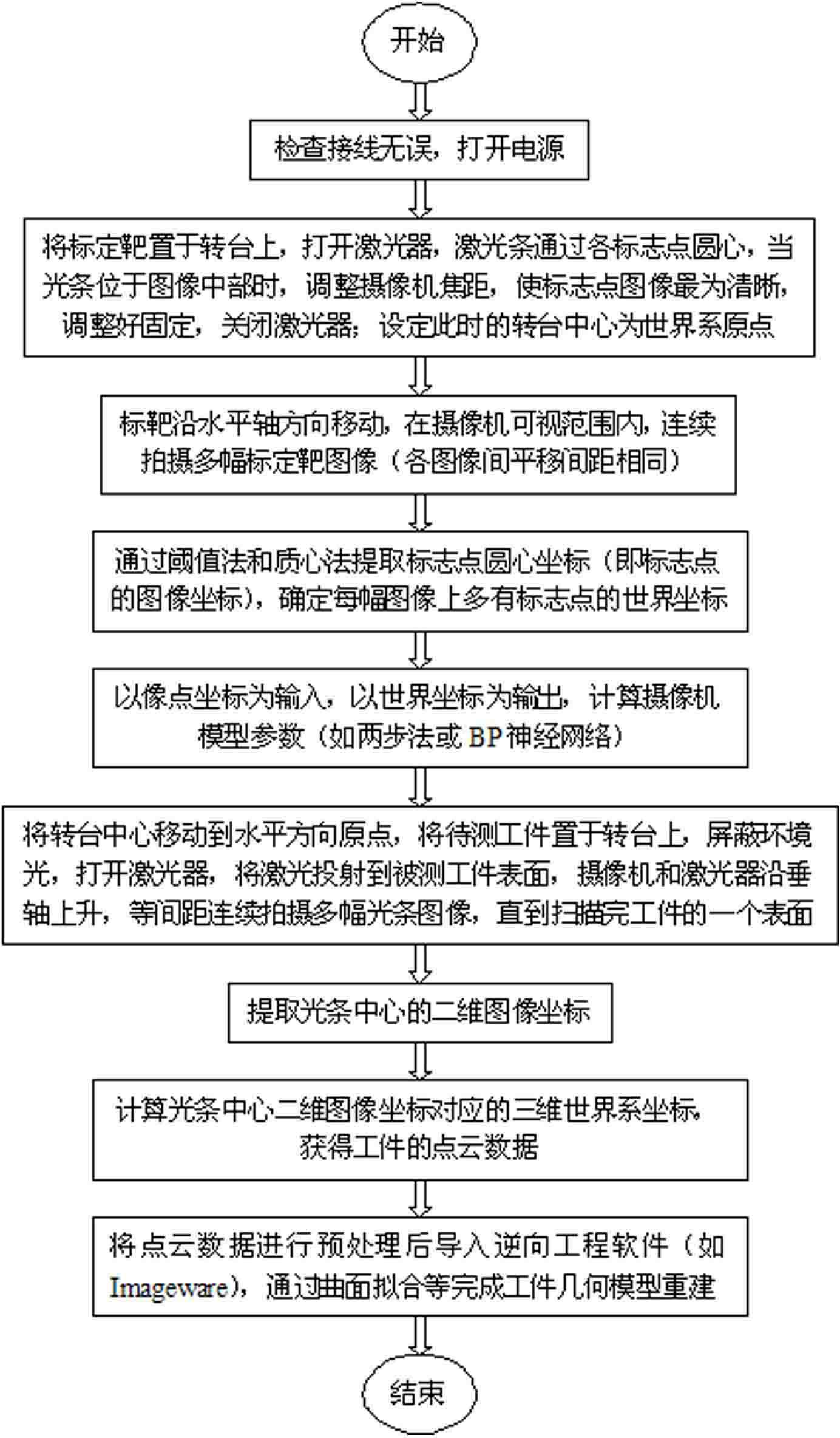

[0025] Such as figure 2 As shown, using the device of the present invention to perform three-dimensional measurement based on line structured light, the steps are as follows:

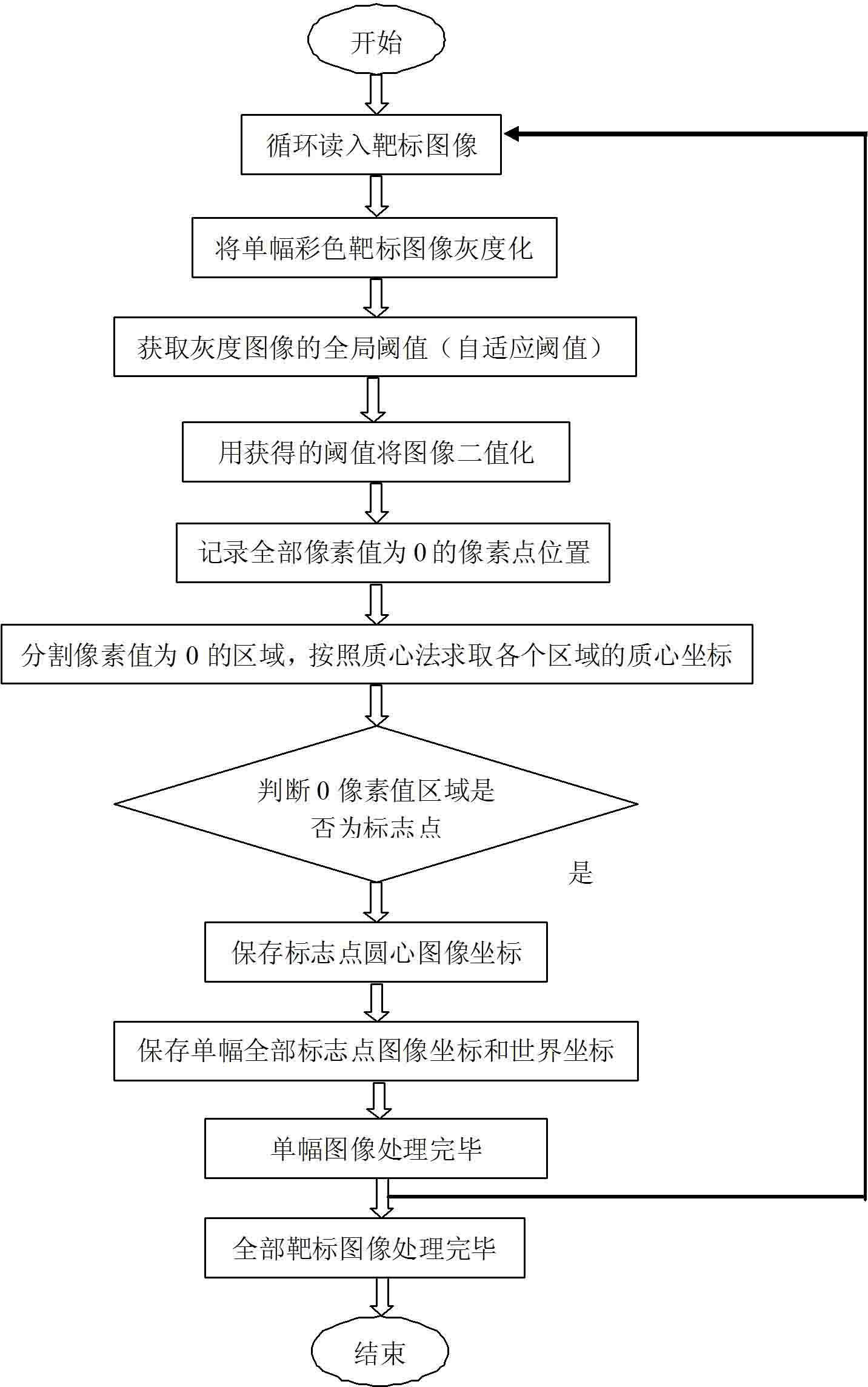

[0026] 1) Set a plane as the target 12, the center of the target 12 is provided with a mark point 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com