Double-free-form-surface lens for laser beam shaping and design method thereof

A technology of laser beams and curved lenses, applied in the direction of lenses, optics, optical components, etc., can solve the problems that the phase cannot be adjusted at the same time, it is difficult to process, and the integrability conditions are not satisfied.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

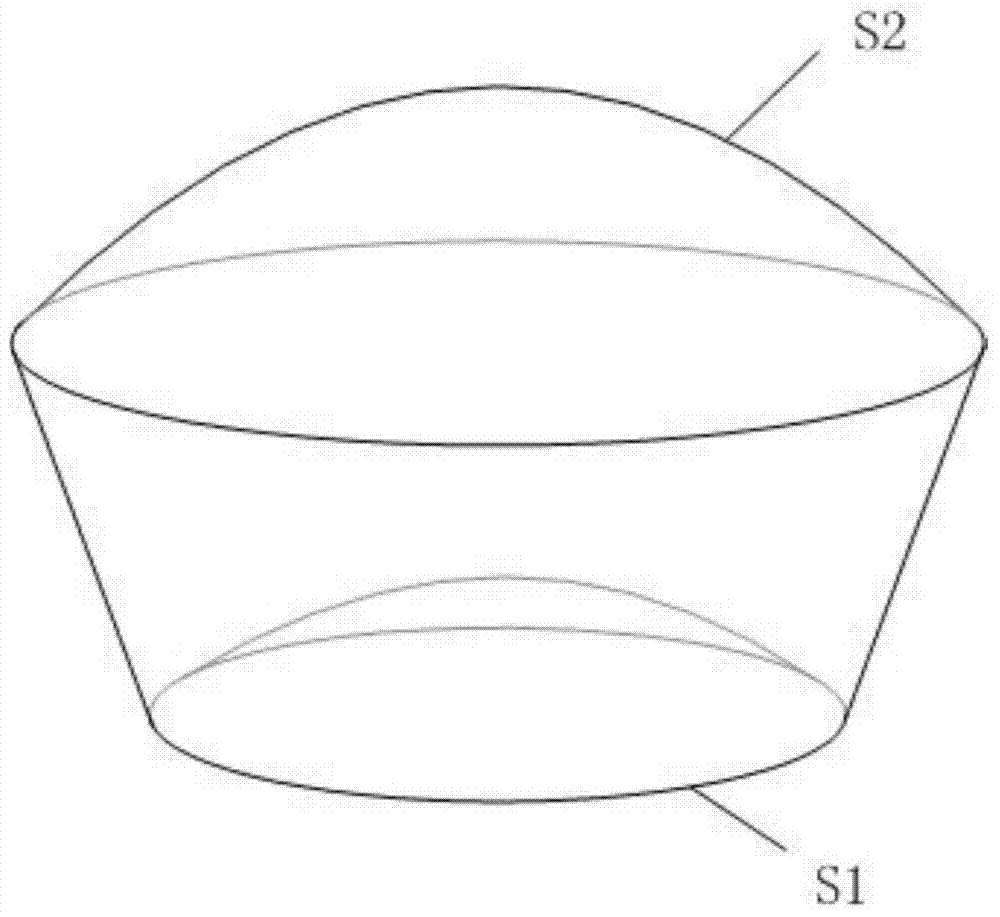

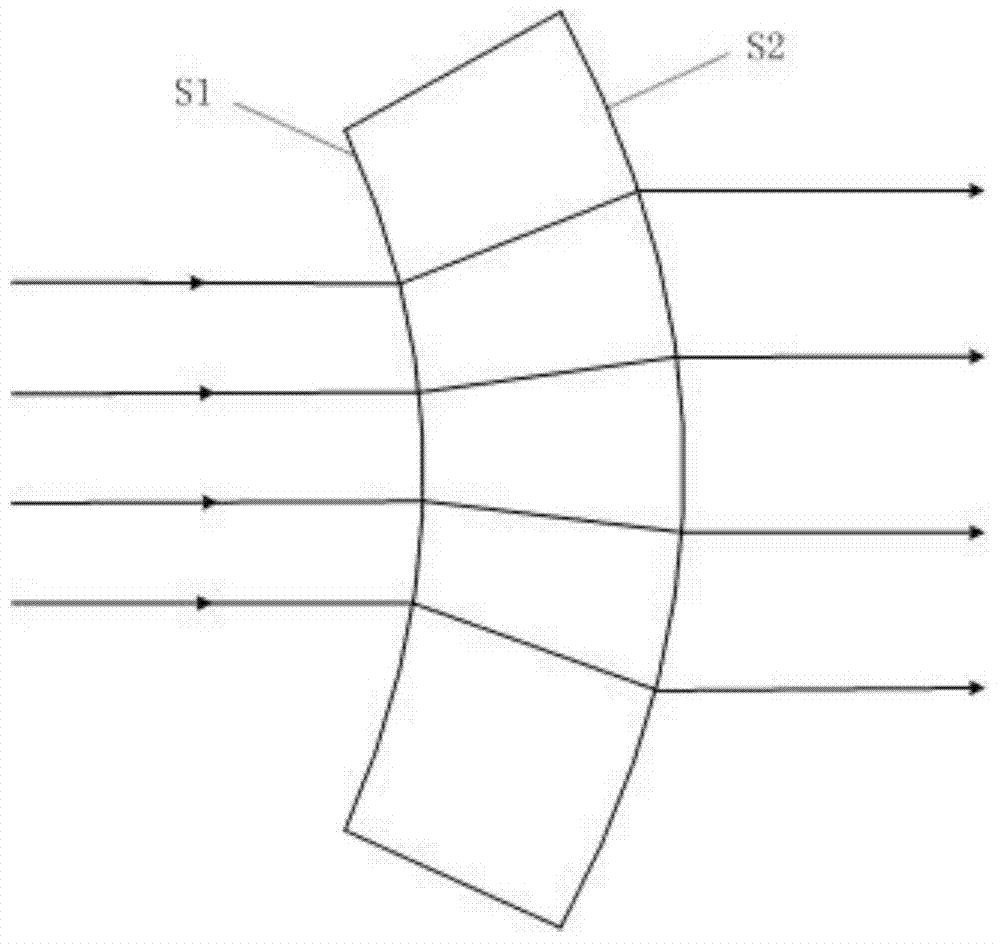

[0086] The double free-form surface lens is proposed to be used as attached figure 1 For the type of structure shown, the front and rear surfaces are freeform. It is assumed that the goal to be achieved by using a double free-form surface lens is: the parallel incident laser beam has a circular symmetric Gaussian distribution, and after being deflected by the double free-form surface lens, a uniform circular illumination with the same direction and parallel to the incident light is produced.

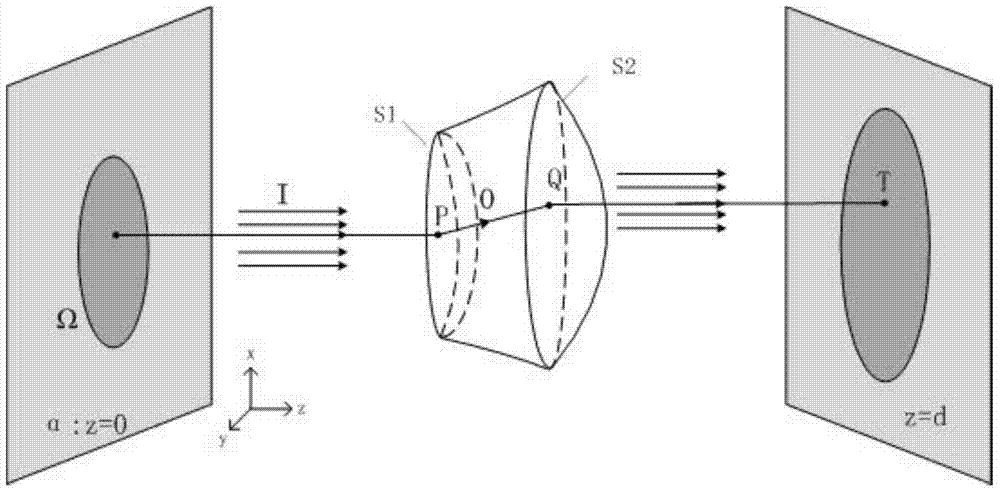

[0087] as attached figure 2 As shown, a rectangular coordinate system is established with a cross-section α of the incident laser beam as the coordinate plane xoy, the direction of the laser beam is parallel to the z-axis, the target plane is parallel to the cross-section α, and the distance from the plane xoy is d=80mm. The laser light source is Gaussian distributed, the beam waist after beam expansion is 40mm, and the radius of the circular cross section is 10mm. The radius of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com