Bulging die for titanium-alloy thin-walled complicated irregular annular workpieces

A technology for annular workpieces and titanium alloys is applied in the field of bulging molds for titanium alloy thin-walled complex and special-shaped annular workpieces. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

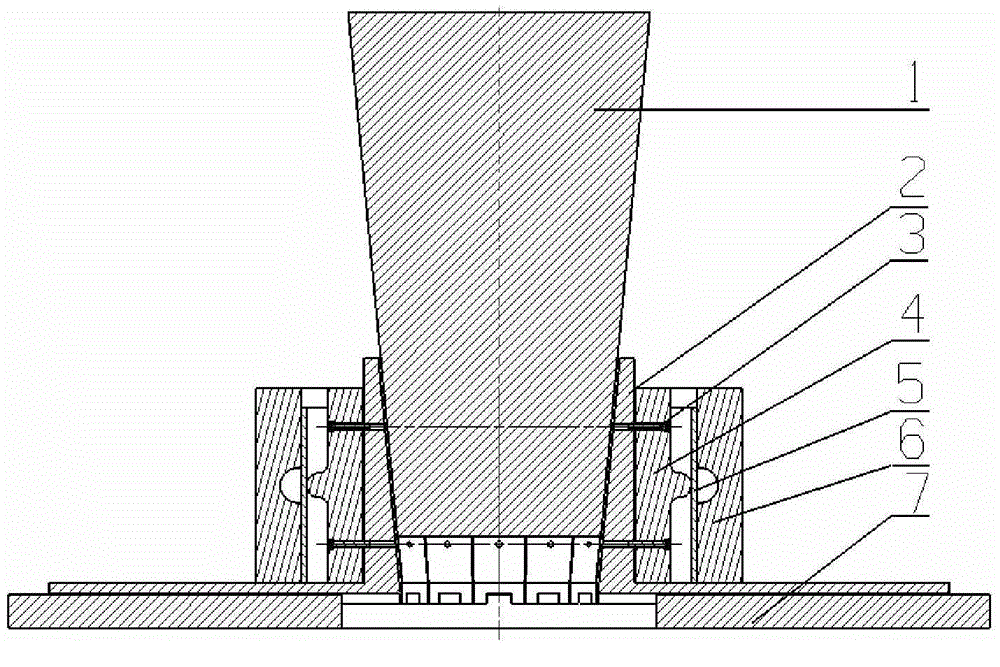

[0037] This example is a bulging die for forming a titanium alloy thin-walled complex special-shaped annular workpiece. In this example, the shape of the ring workpiece is as follows Figure 11 As shown, the wall thickness of the annular workpiece is b=15, the outer diameter of the annular workpiece is D=1000mm, and the length of the straight side of the upper end of the annular workpiece is h 1 , the length of the lower straight side is h 2 , and h 1 = h 2 =130mm; the middle part of the annular workpiece is an arc-shaped special-shaped area, and the outer radius R of the special-shaped area 2 = 50mm; the two ends of the special-shaped area and the upper straight edge and the lower straight edge of the annular workpiece are arc transitions respectively; the transition arc R 1 = 10 mm. The ring workpiece material is TA15 titanium alloy. H13 hot work die steel is used to make the punch and die, and the rest of the parts are made of 45 steel.

[0038]This example includes ...

Embodiment 2

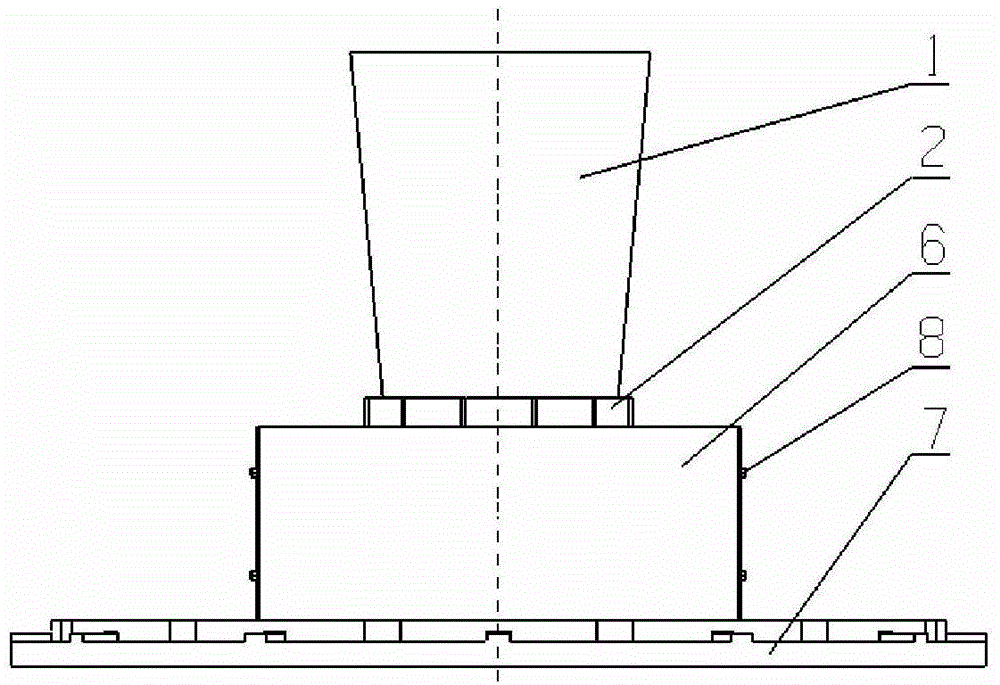

[0057] This example is a bulging die for forming a titanium alloy thin-walled complex special-shaped annular workpiece. In this example, the shape of the ring workpiece is as follows Figure 12 As shown, the wall thickness of the annular workpiece is b=15, and the outer diameter of the small end of the annular workpiece is D 1 =1000mm, the outer diameter of the large end of the annular workpiece D 2 =1100mm, the height of the annular workpiece h=350mm. The ring workpiece material is TA15 titanium alloy. H13 hot work die steel is used to make the punch and die, and the rest of the parts are made of 45 steel.

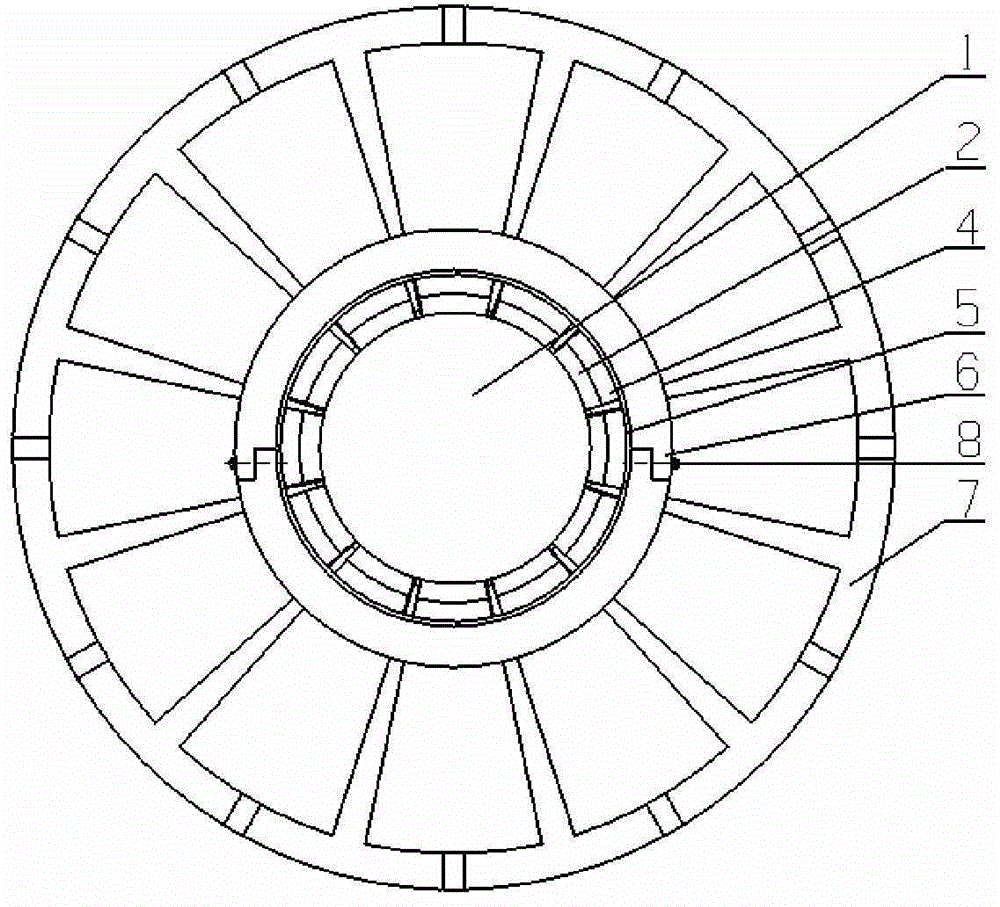

[0058] This example includes a mandrel 1, 12 supports 2, a punch 4, a die 6, and a base 7. Described each support is positioned at the upper surface of base 7, and the chute of each support lower surface is fitted with each slide rail that is distributed on base 7 upper surface respectively, makes each support can make diameter on the upper surface of described base a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com