Titanium alloy thin-wall structure precision milling surface state robustness process control method

A thin-walled structure and surface state technology, applied in metal processing, metal processing equipment, automatic control devices, etc., can solve the problem of poor stability in the processing process, difficulty in meeting the design requirements for the size and shape accuracy of thin-walled parts, and tissue damage. and other issues to achieve the effect of improving the size and shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0034] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

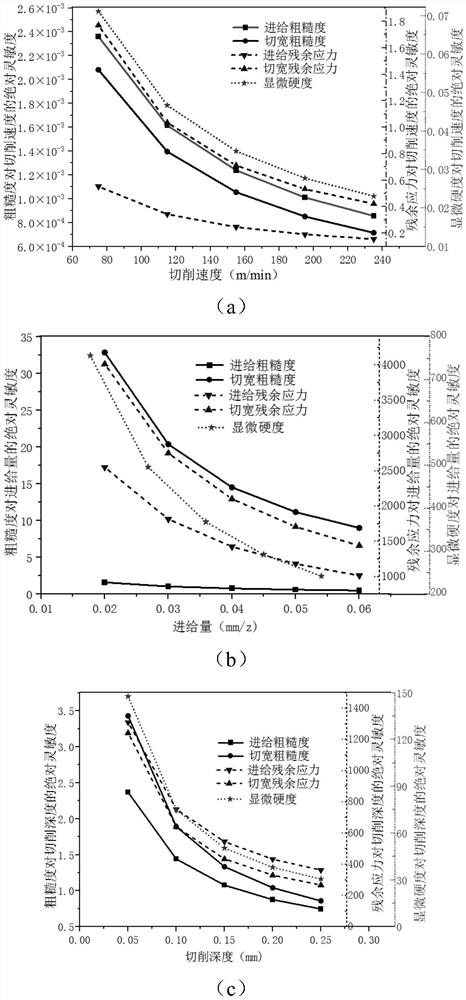

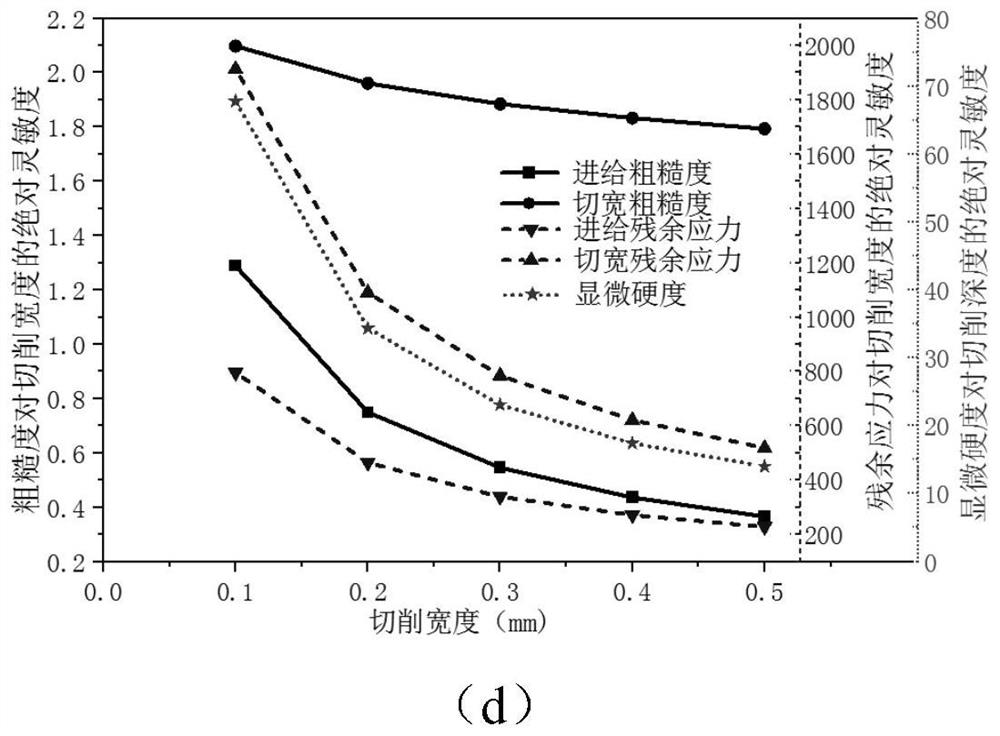

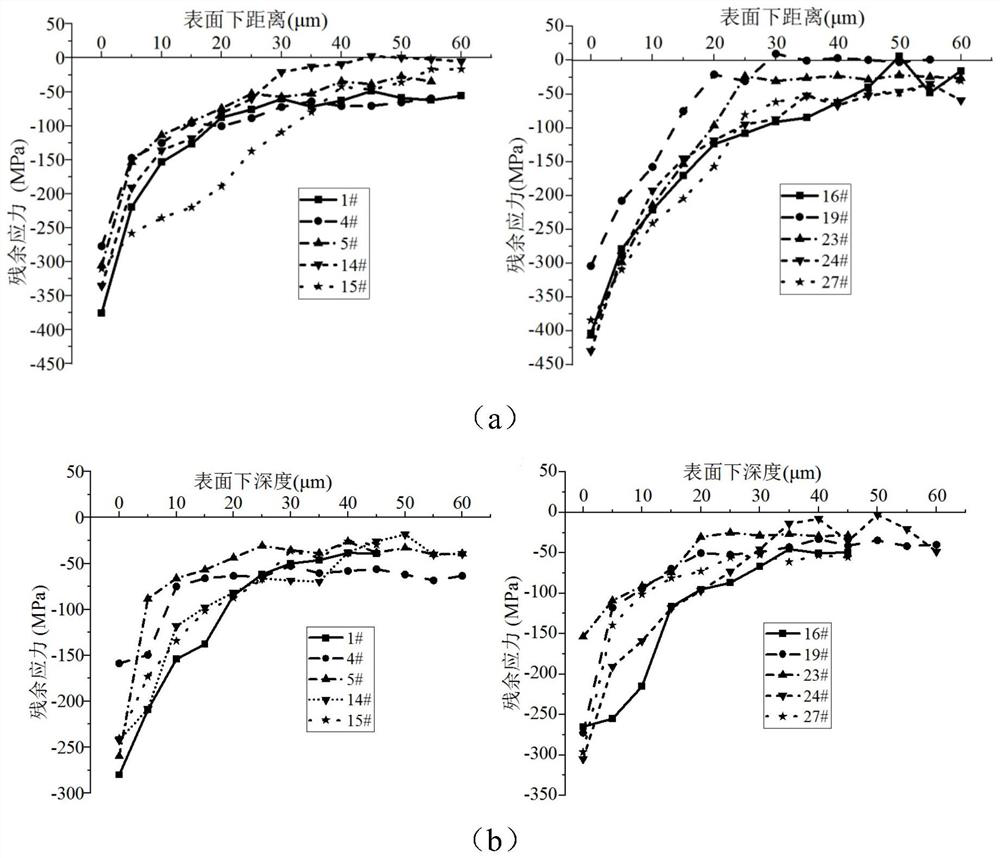

[0035] The problem of surface integrity of titanium alloy thin-walled structural parts is caused by improper control of cutting process parameters, resulting in severe thermal and mechanical coupling. Therefore, the surface integrity of thin-walled structural parts is not only affected by controllable process parameters such as milling speed and feed per tooth, but also by process variables such as workpiece and tool contact state, tool vibration, and workpiece deformation.

[0036] When the input variables such as cutting speed and feed rate are fixed, the fluctuation of workpiece state, tool state, interface state such as cutting force and cutting temperature, and machining vibration over time will cause surface roughness, residual stress, microhardness, etc. The output fluctuates. In actual production, the output is generally controlled to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com