Patents

Literature

46results about How to "Guaranteed fatigue performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat treatment method for improving high-temperature endurance property of GH2132 bolt

InactiveCN105734241ASmall sizeImprove diffusivityFurnace typesHeat treatment furnacesThermodynamicsEngineering

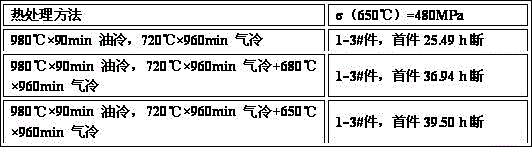

The invention discloses a heat treatment method for improving the high-temperature endurance property of a GH2132 bolt. The bolt is subjected to head forming and heading first and then subjected to solid solution treatment process; and afterwards, the processed bolt is subjected to two aging processes and finally processed to a finished product. The high-temperature endurance property of the bolt is improved sharply, and the fatigue life of the bolt can be guaranteed. According to the heat treatment method, the solid solution process and the two aging processes are adopted, so that the high-temperature endurance property of the GH2132 bolt is improved by a large margin, and the fatigue property and application security are ensured. The technical problem that grain size and high-temperature endurance cannot be guaranteed at the same time in conventional heat treatment production is accordingly solved successfully and therefore the heat treatment method can be popularized in the field of aero-engine GH2132 bolts.

Owner:GUIZHOU AEROSPACE PRECISION PRODS

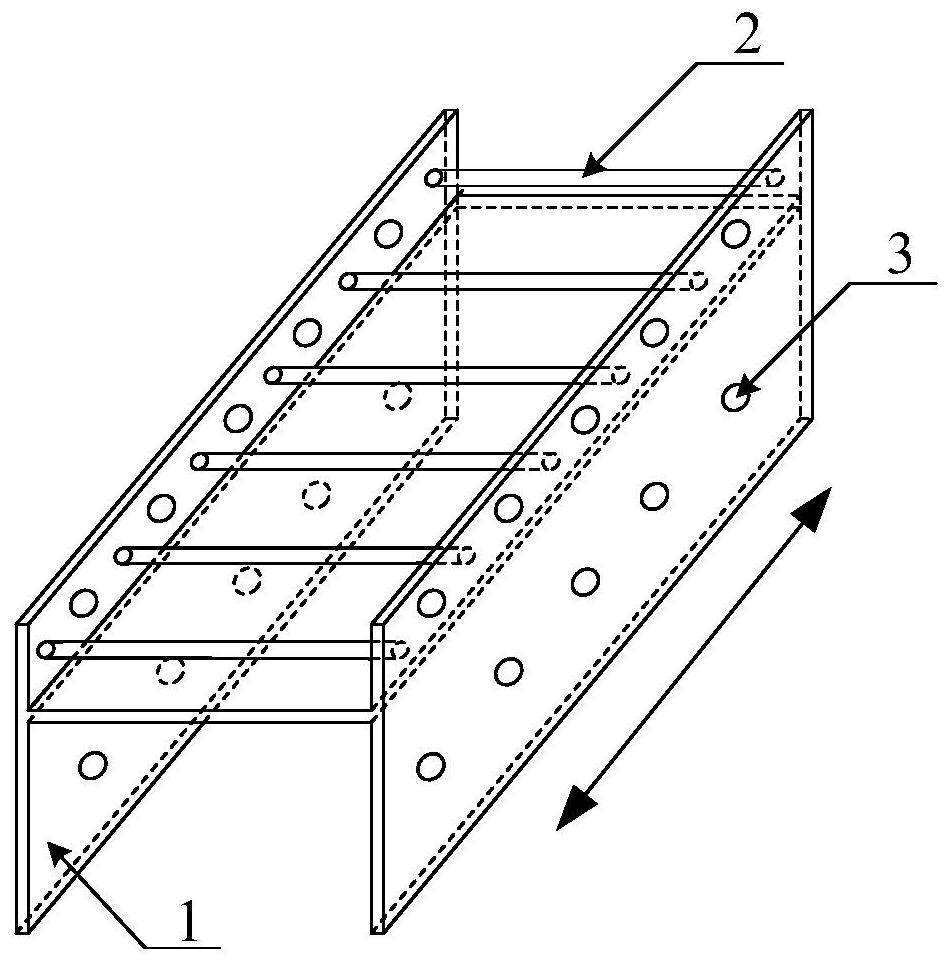

Entire grid beam optimum design method

ActiveCN106599485AAccurate analysisGuaranteed fatigue performanceGeometric CADDesign optimisation/simulationSize parameterEngineering

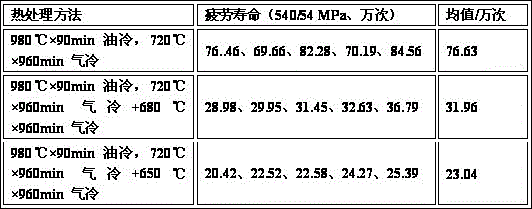

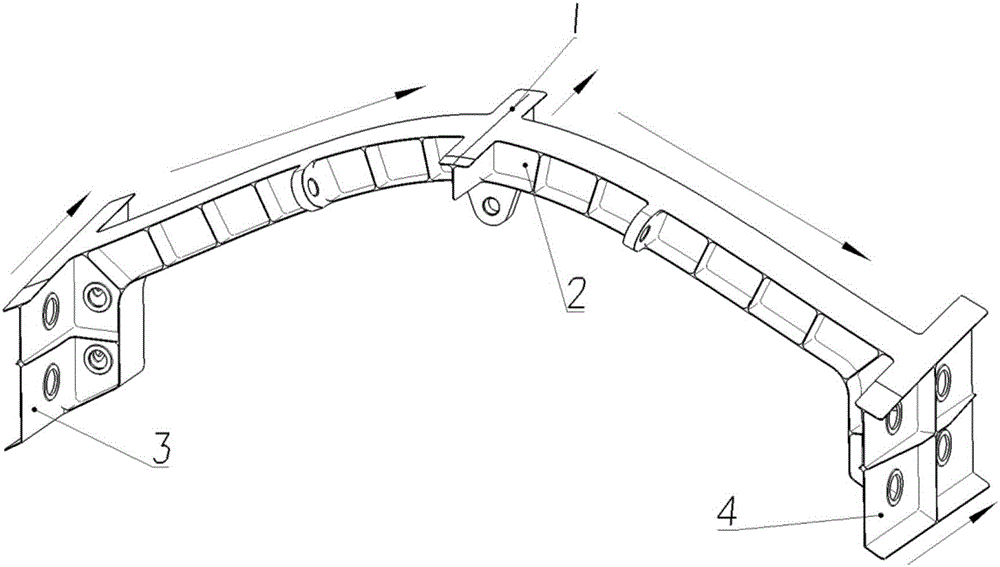

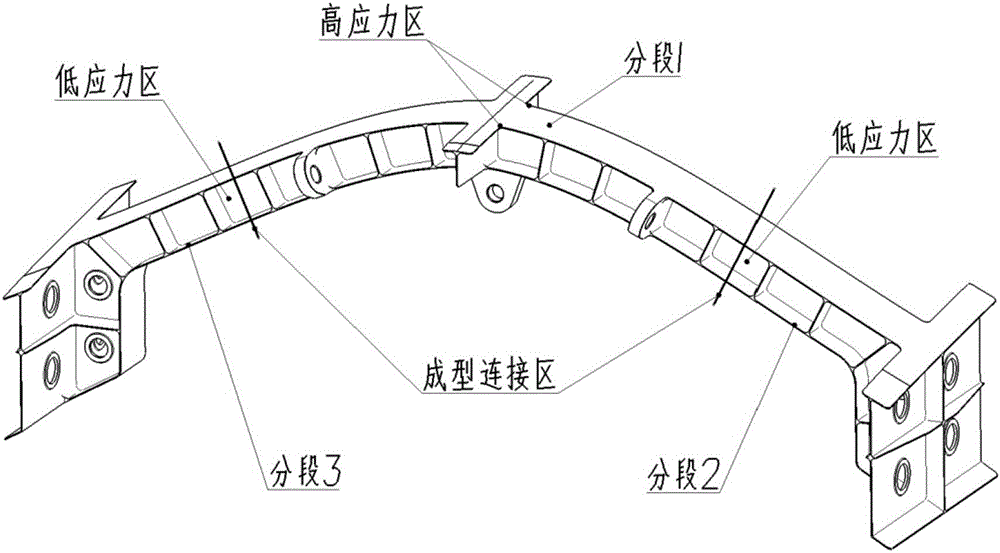

The invention relates to an optimum design method of an entire grid beam. By use of the electron beam fuse deposition molding technology, the method specifically comprises the following steps: step one, optimizing a structure size of a component according to a grid beam structure design allowable value given by design input to obtain an optimized size parameter; step two, determining force directions of different sections according to the size parameter, and designing that a fiber placement path of each section of the component is consistent with the force direction in combination with the mechanics optimum of a fiber placement direction; step three, lowering stress concentration of a stress region higher than the design allowable value according to the design allowable value; step four, if the entire grid beam is the component with high length ratio and stiffness mutation, first dividing the entire grid beam into a plurality of sections to be synchronously molded, and then performing the centralized molding connection. By use of the optimum design method of the entire grid beam disclosed by the invention, the process feasibility of the entire grid beam based on the electron beam fuse deposition molding technology can be guaranteed, and the strength, rigidity, the life and other design requirements can be satisfied at the same time.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

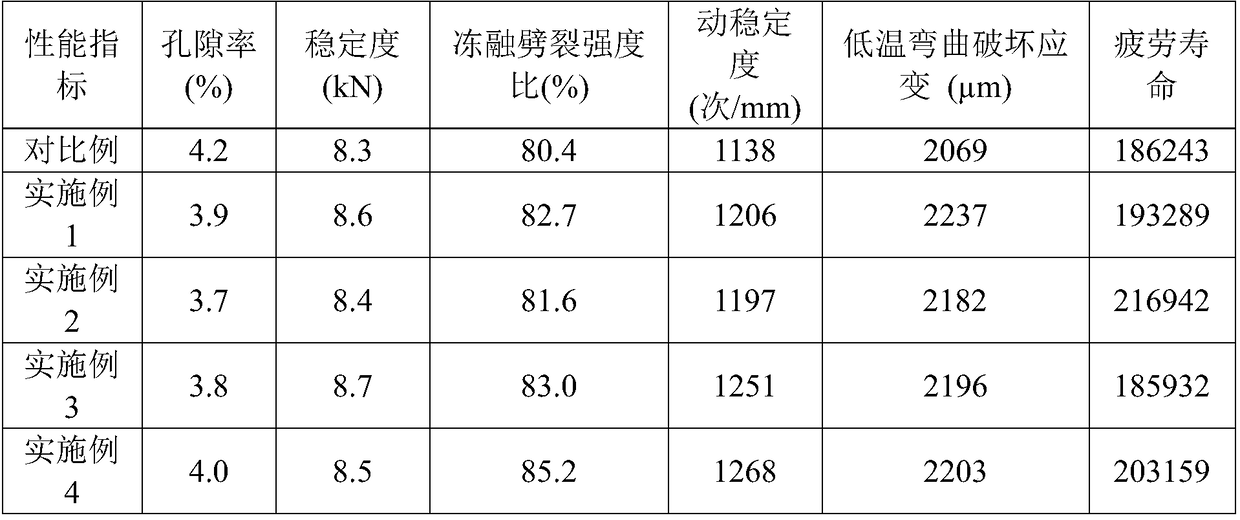

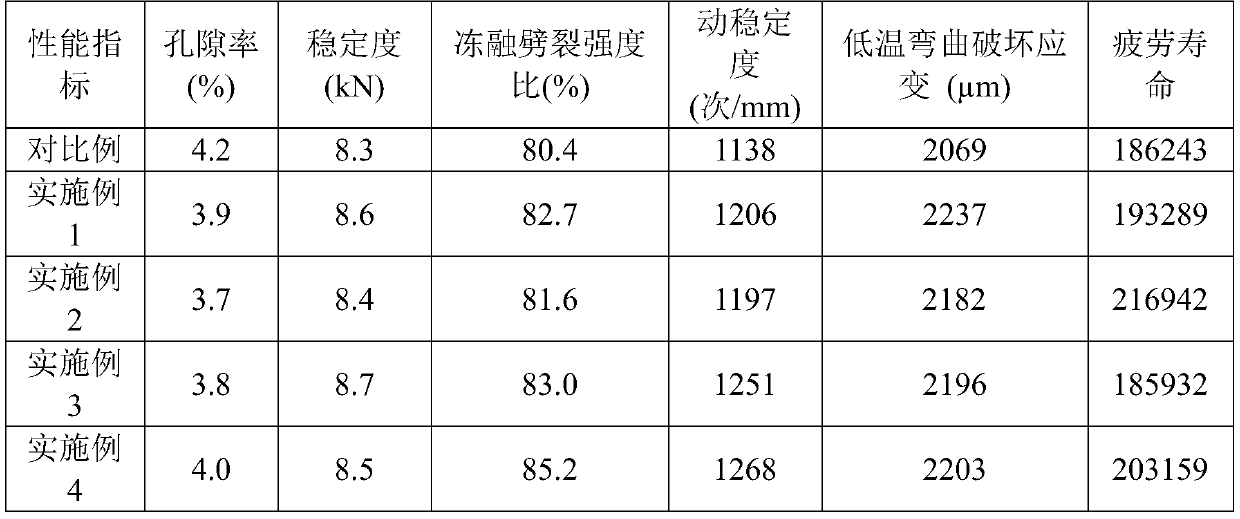

Red mud-based asphalt mixture warm-mixing agent and preparation method thereof

ActiveCN109336456AReduce the temperatureLow molding temperatureCement productionActive agentGeopolymer

The invention relates to a red mud-based asphalt mixture warm-mixing agent and a preparation method thereof, and belongs to the technical field of asphalt warm-mixing agents. The preparation method comprises the following steps: step 1) calcining red mud powder and then mixing with an active aluminum silicon source in proportion, and allocating the molar ratio of SiO2 / Al2O3 to obtain a geopolymerprecursor; step 2) adding the geopolymer precursor obtained in the step 1) into an alkaline activator solution, and stirring to obtain geopolymer mud; step 3) curing the geopolymer mud obtained in thestep 2) to obtain a geopolymer block, and preparing the geopolymer block into powder; and step 4) adding the geopolymer powder obtained in the step 3) into a surfactant solution, stirring uniformly,and then suction-filtering and drying the obtained slurry to obtain the red mud-based asphalt mixture warm-mixing agent. According to the invention, the asphalt mixture warm-mixing agent is prepared by surface modification of red mud-based geopolymer powder, thereby effectively ensuring mechanical properties of an asphalt mixture while significantly reducing a mixing temperature and a molding temperature of the asphalt mixture.

Owner:SHANDONG UNIV

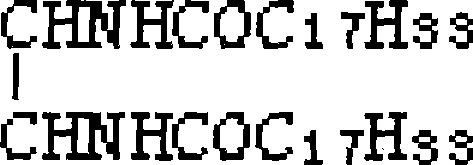

Preparation of rubber asphalt mixture

InactiveCN101462849AImproved adhesion and high temperature performanceGuaranteed Low Temperature PerformanceSolid waste managementRubberized asphaltPetroleum

The invention discloses a method for preparing a rubber asphalt mixture. The method comprises the following steps: adding tyre rubber powder into the road petroleum asphalt, and carrying out the stirring and reaction for 45 to 120 minutes to prepare the rubber asphalt; and adding N,N'-ethidence dioleamide into the heated stone material in the mineral aggregate, stirring the mineral aggregate evenly, then adding the rubber asphalt into the mineral aggregate, and stirring the mixture evenly to obtain the composite modified rubber asphalt mixture finished product. The obtained rubber asphalt mixture can simultaneously improve the high temperature performance and bonding performance of the rubber asphalt mixture.

Owner:TONGJI UNIV

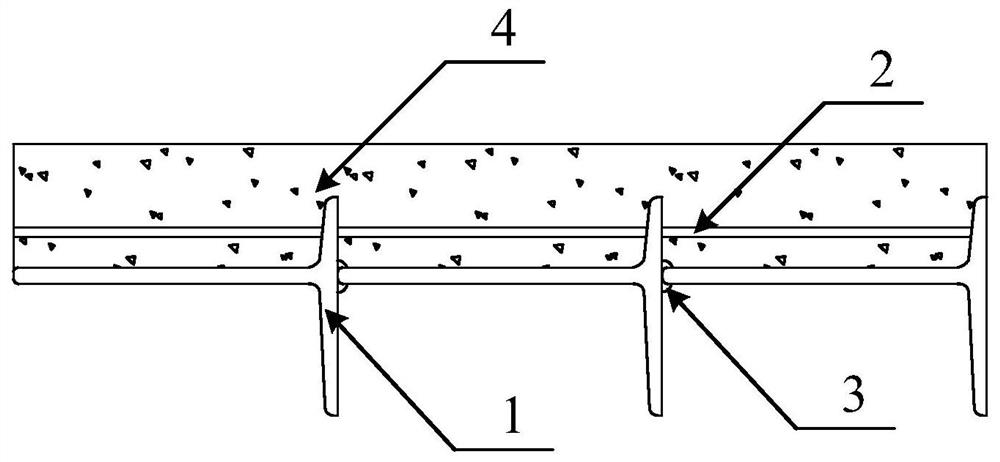

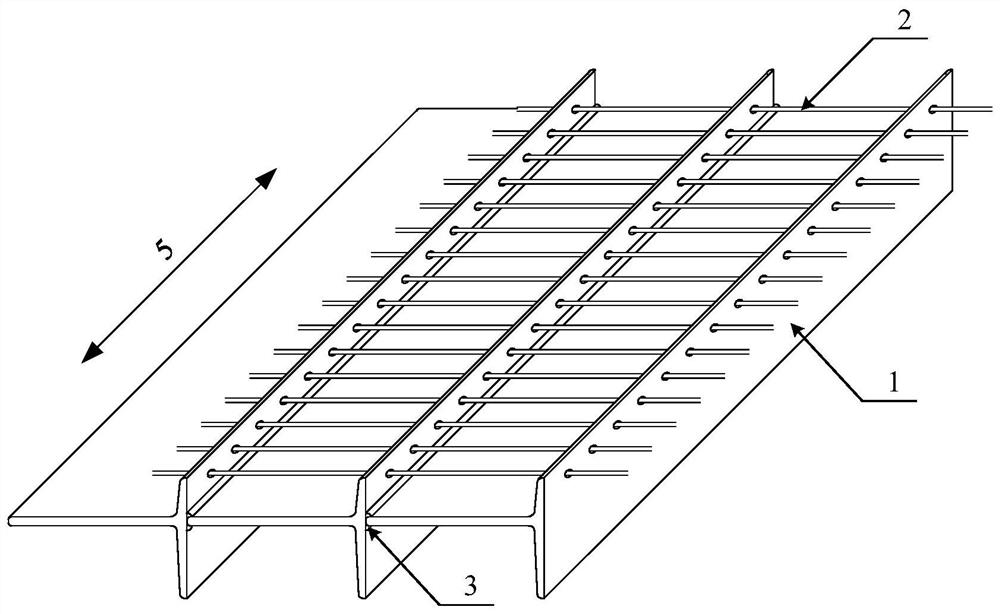

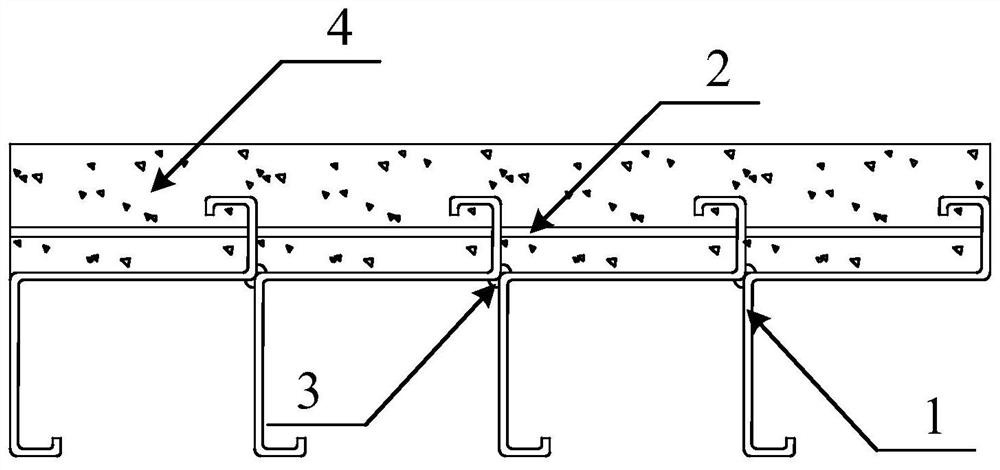

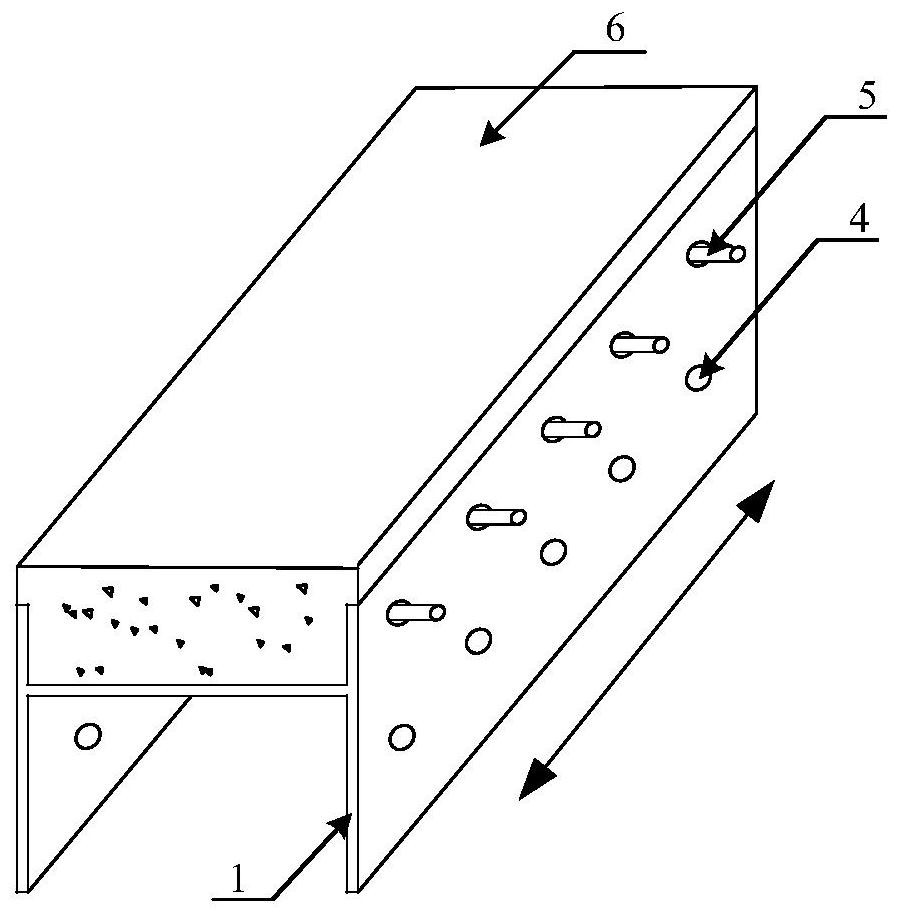

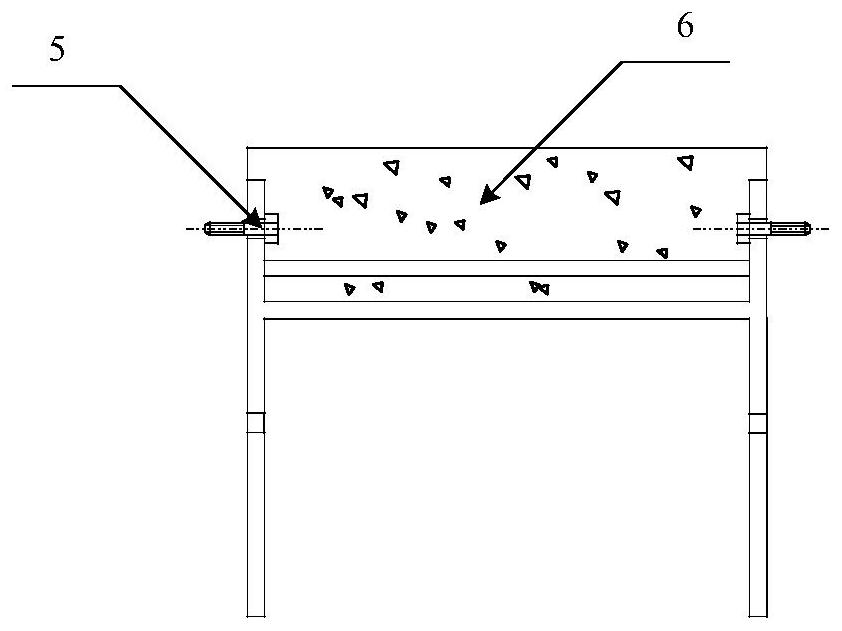

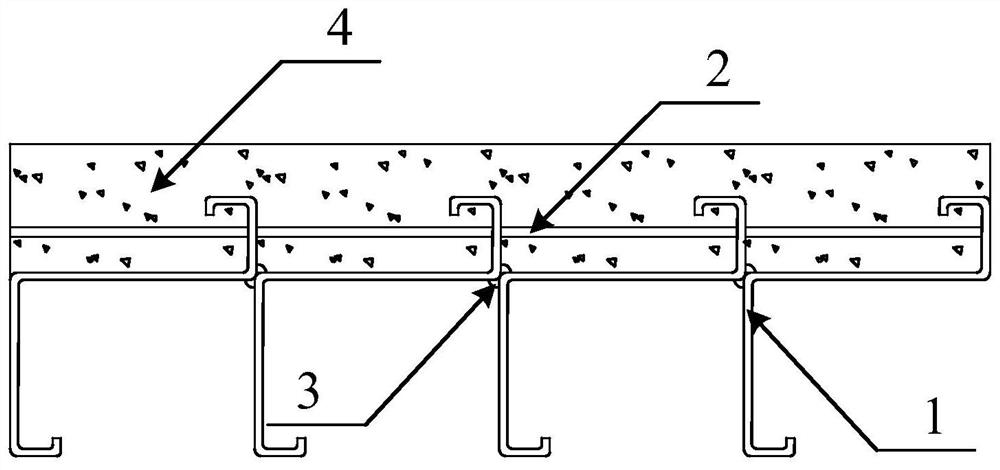

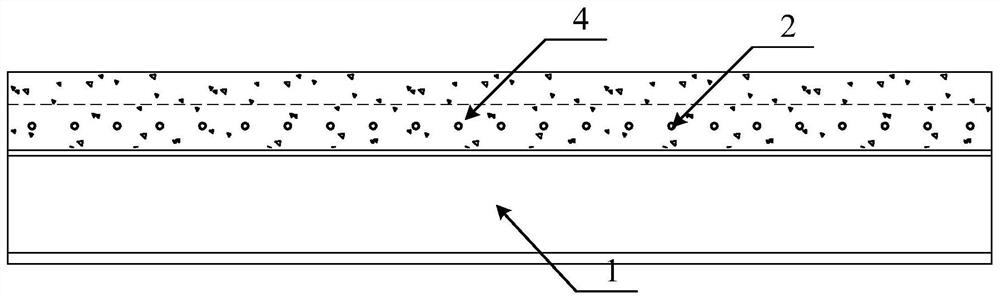

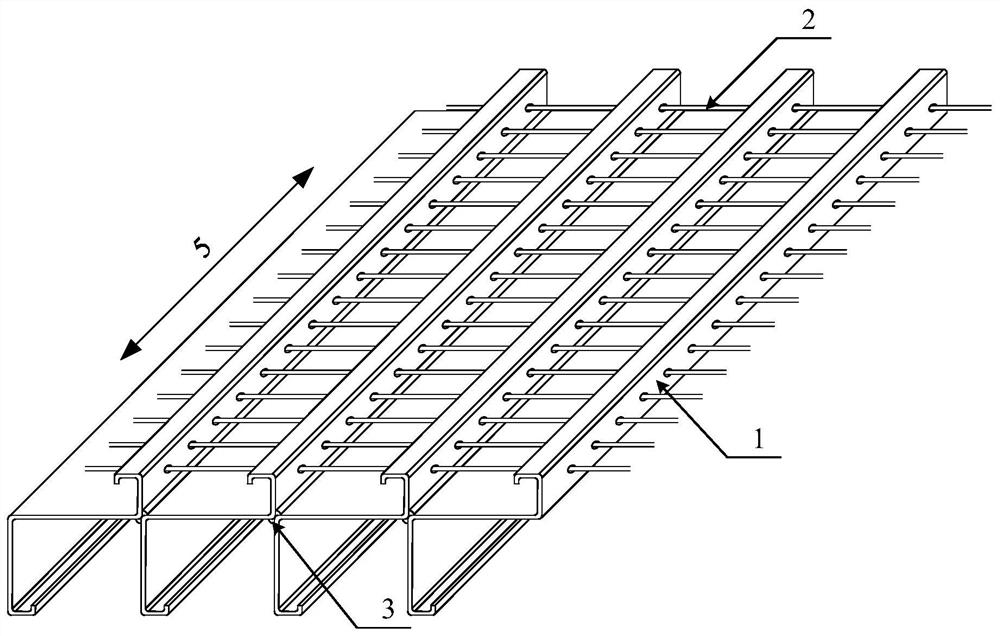

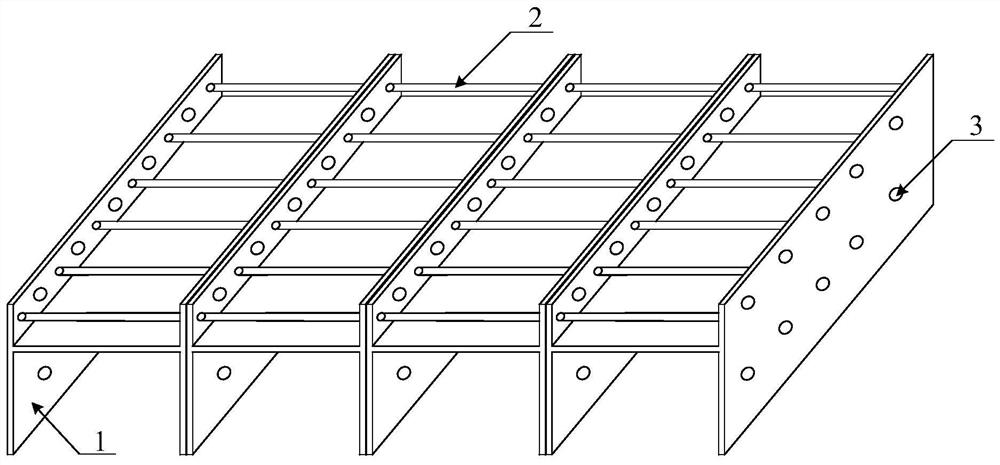

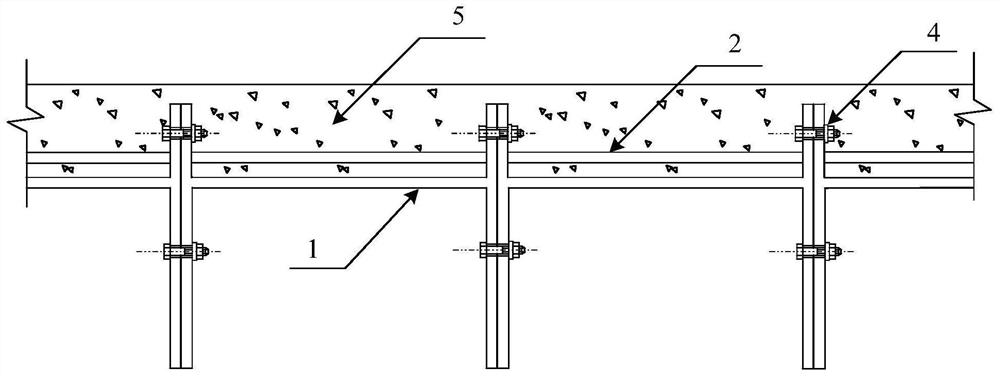

Tough combined bridge deck slab composed of T-shaped steel

ActiveCN112195778APrevent rustImprove toughnessSolid waste managementBridge structural detailsFillet weldBridge deck

The invention discloses a tough combined bridge deck slab system composed of T-shaped steel. The tough combined bridge deck slab system comprises hot-rolled T-shaped steel, transverse steel bars and ultrahigh-toughness concrete. The T-shaped steel is transversely and continuously placed side by side along a bridge deck, and adjacent steel is welded through two fillet welds to form a bridge deck steel framework. The lower side flange of the T-shaped steel is long and plays a role in reinforcing the outer side of the slab surface; the upper side flange of the hot-rolled T-shaped steel is short and is provided with a row of circular holes, and the transverse steel bars penetrate through the flanges of the T-shaped steel through the circular holes. The ultrahigh-toughness concrete is poured onthe bridge deck steel framework to play a role in protecting the bridge deck steel framework. In the combined bridge deck slab system provided by the invention, the ultra-high toughness concrete canensure that tiny cracks of 100 microns or below are not generated or only tiny cracks of 100 microns or below are generated, and the toughness and durability of the structure are improved; the T-shaped steel and the transverse steel bars are combined to replace the anti-shearing and anti-pulling effects of studs, so that the out-of-plane stability of the bridge deck slab is improved, the materialcost and the construction complexity are remarkably reduced, and the fatigue performance is excellent.

Owner:ZHEJIANG UNIV

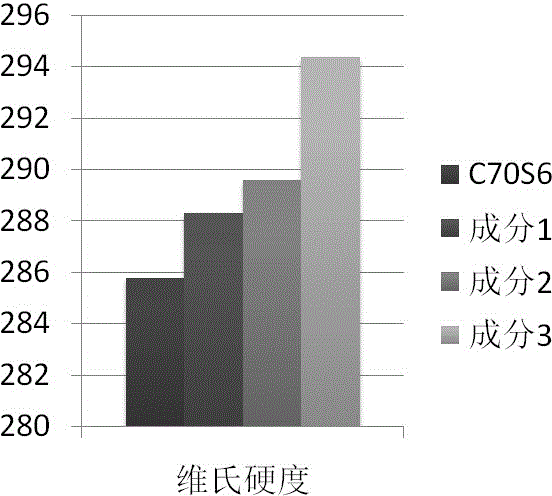

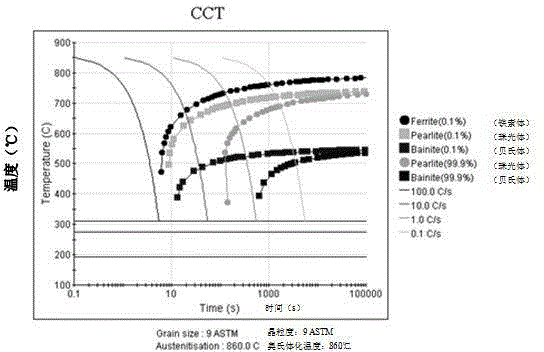

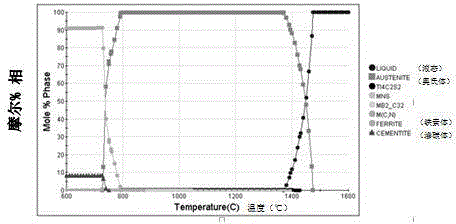

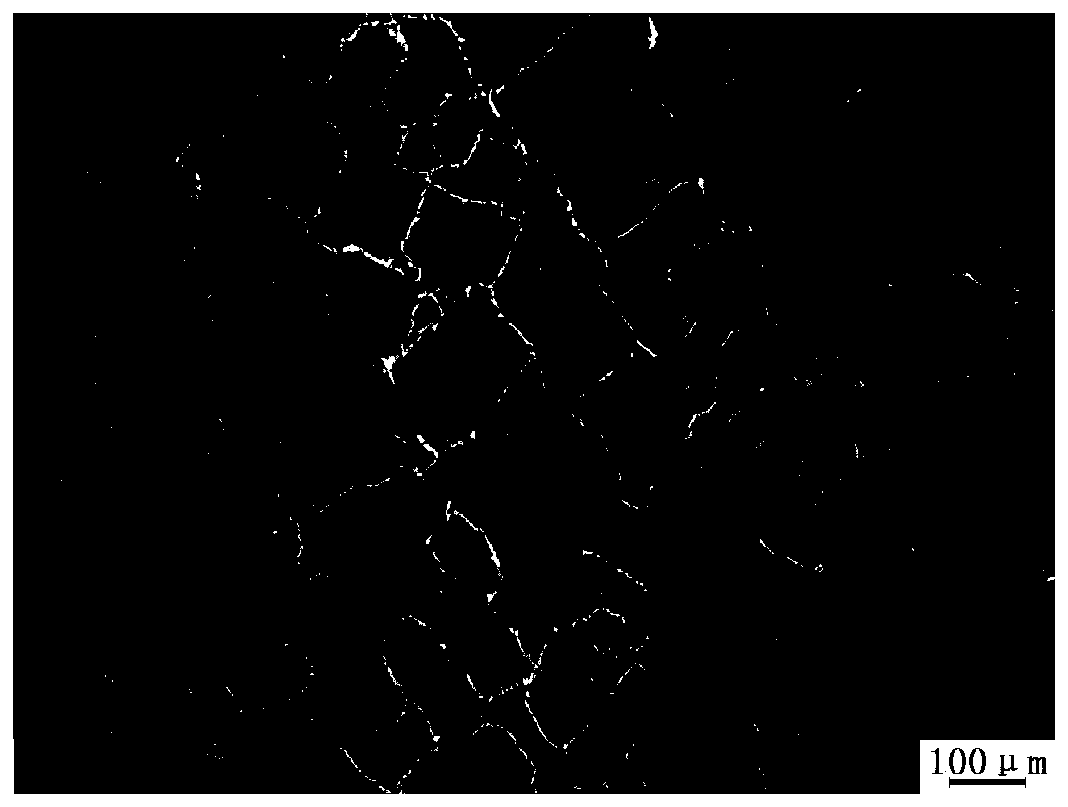

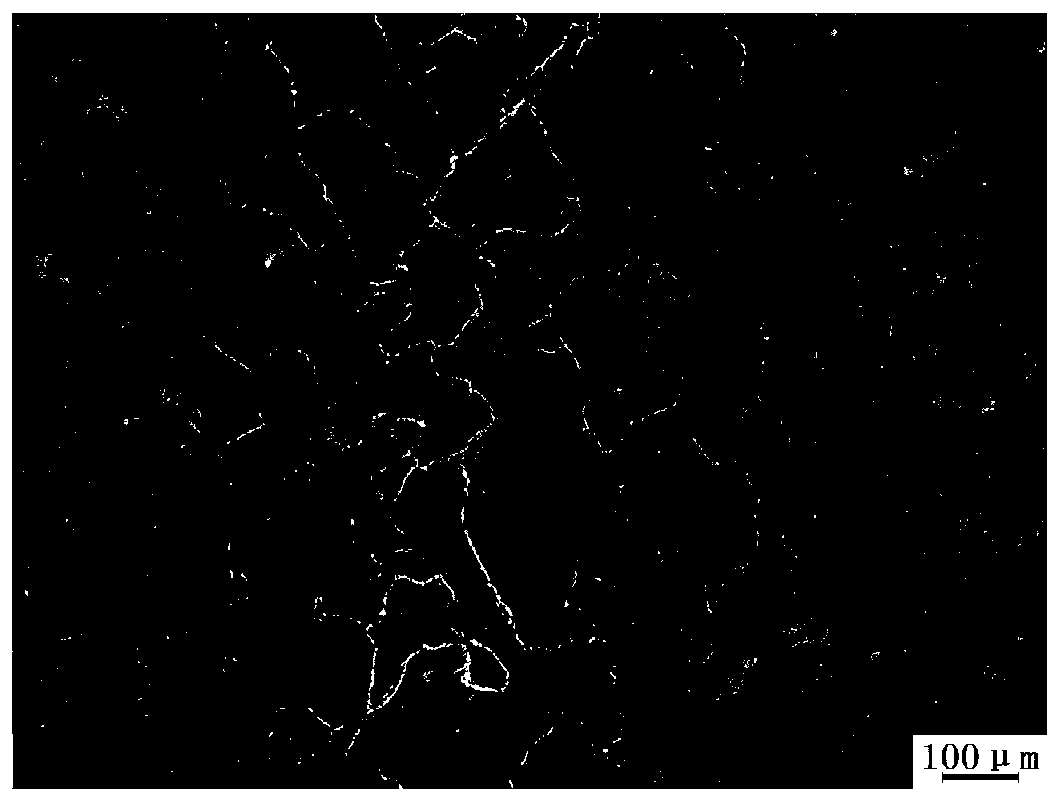

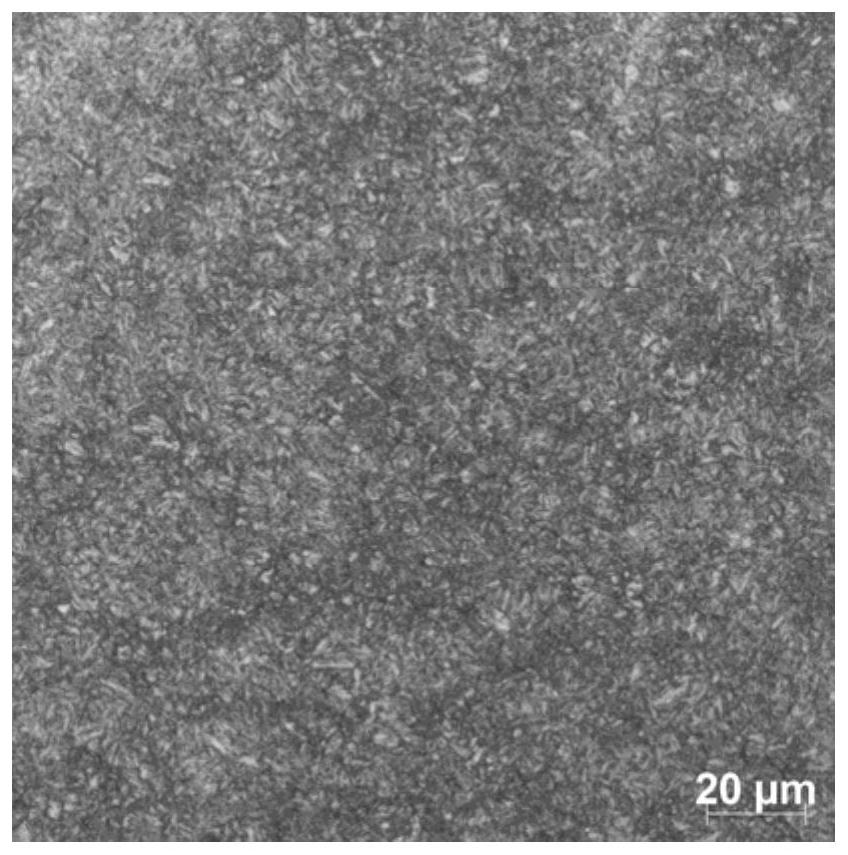

Fine crystal non-quenched and tempered steel for connecting rod

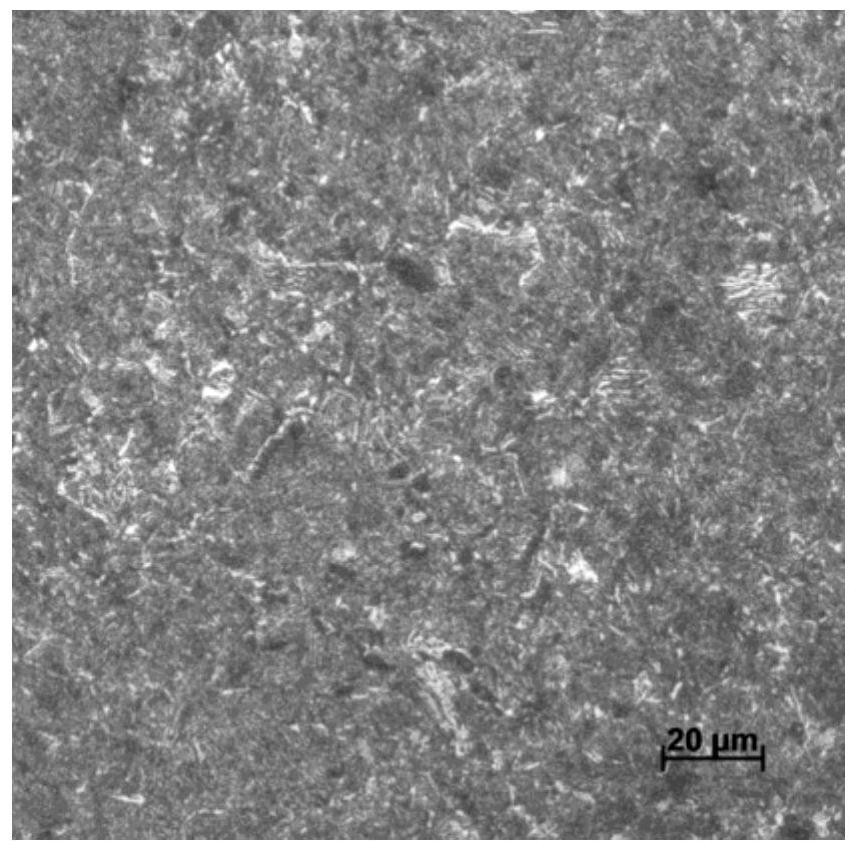

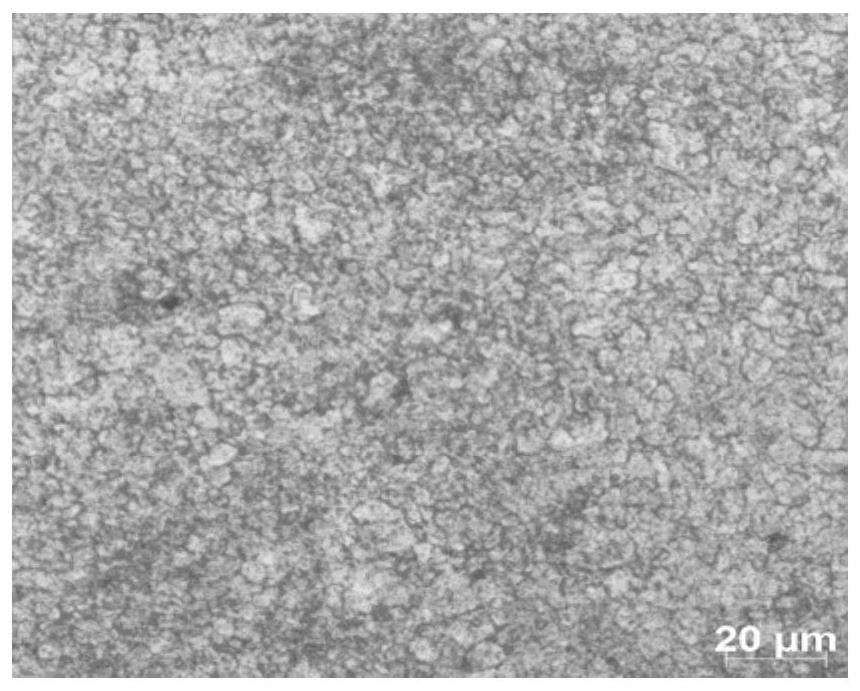

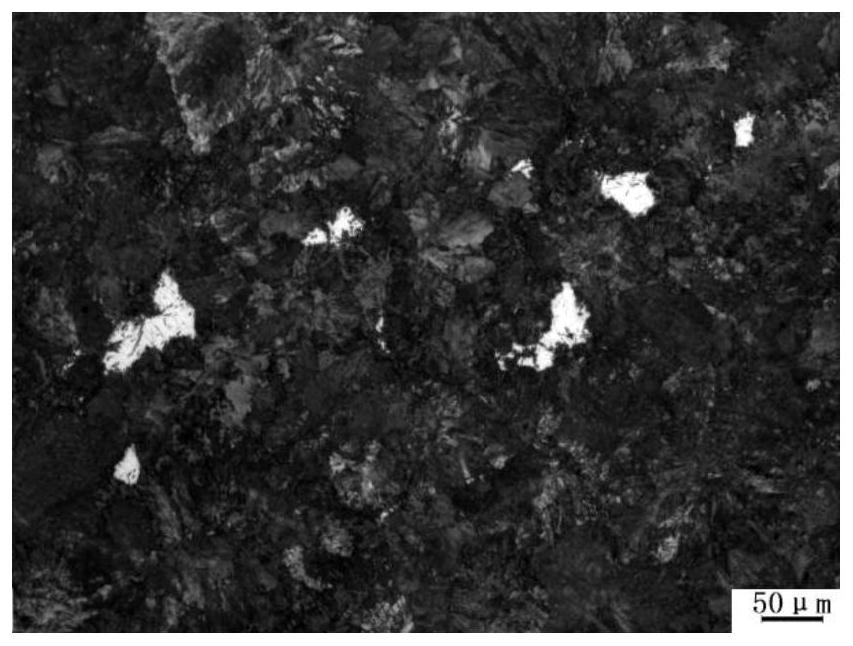

The invention discloses fine crystal non-quenched and tempered steel for a connecting rod and belongs to the technical field of special alloy steel. The fine crystal non-quenched and tempered steel is characterized by being prepared from the following elements in percentage by weight: 0.10-0.20% of (Ti+Nb), 0.35-0.45% of C, 0.60-0.70% of Si, 0.75-0.9% of Mn, 0.08-0.10% of P, 0.05-0.07% of S, 0.10-0.20% of Cr, 0.05-0.25% of V, 0.0005-0.001% of B and the balance of Fe. The metallographic structure of the alloy steel is upper bainite. On the premise that the expansion fatigue property of the connecting rod is ensured, the alloy steel is good in cutting processing property and expansion property.

Owner:SHANGHAI UNIV

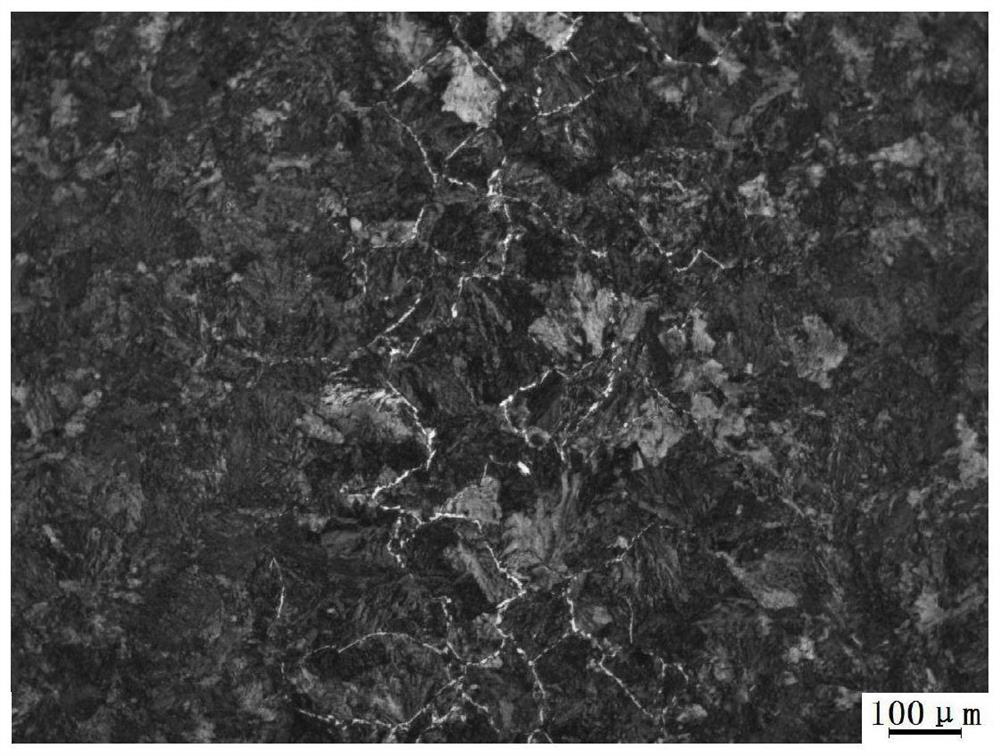

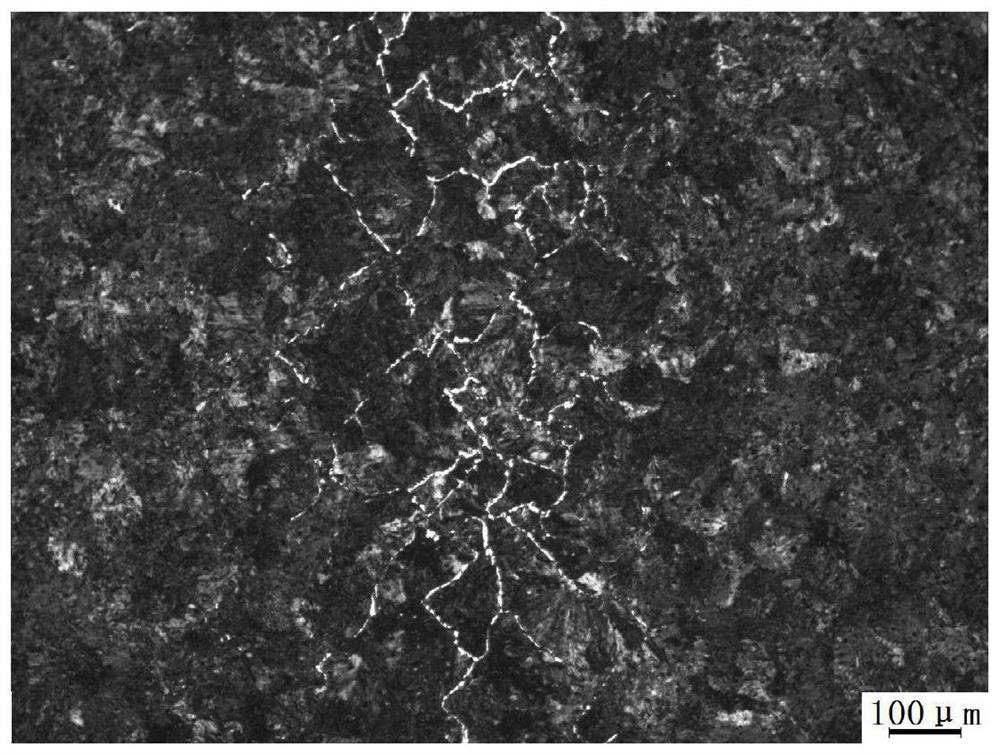

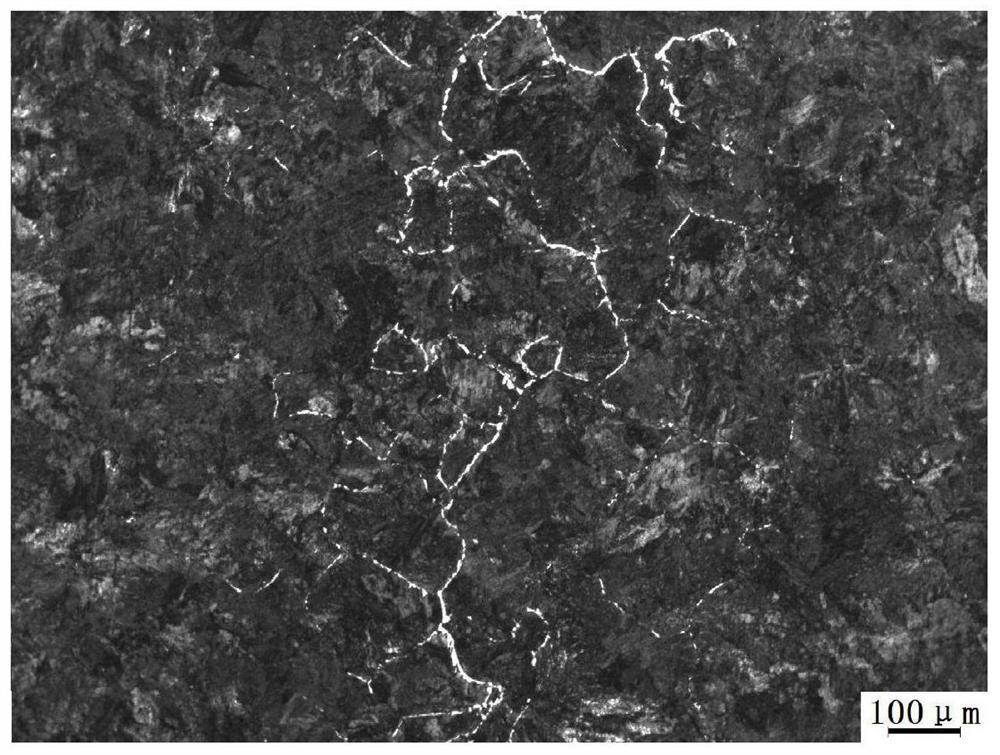

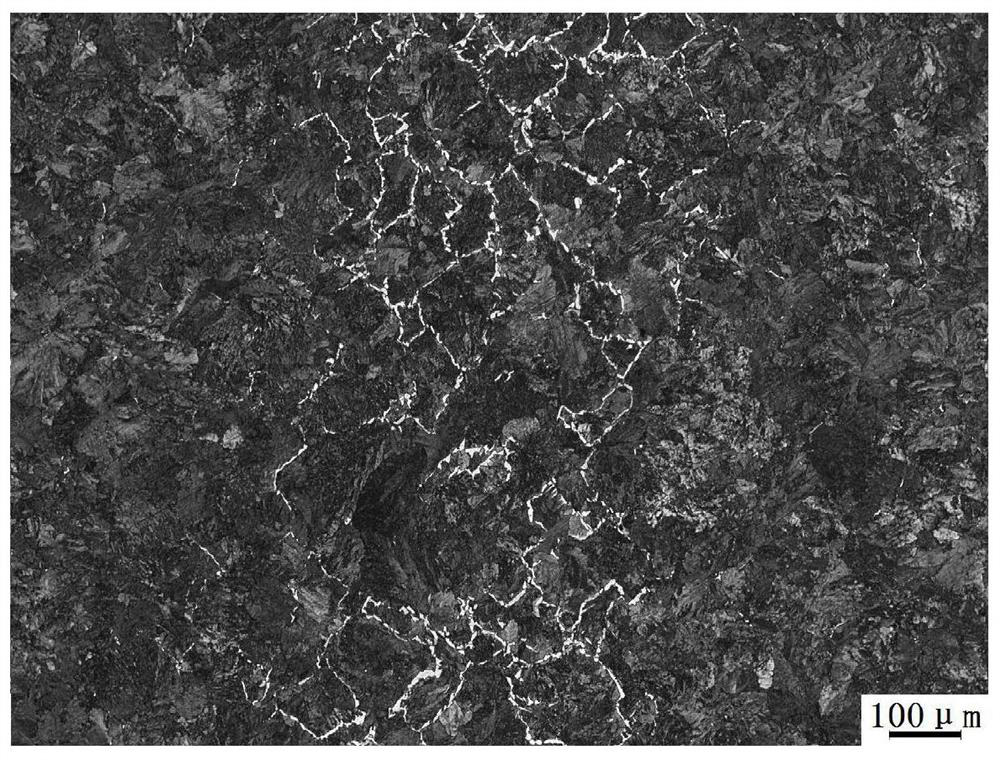

Process for controlling extreme upper-limit Mn content R350HT steel rail flash welding joint structure

ActiveCN110480138AGuaranteed hardnessGuaranteed static bendingResistance welding apparatusChemical compositionRoom temperature

The invention discloses a process for controlling an extreme upper-limit Mn content R350HT steel rail flash welding joint structure, and belongs to the technical field of steel rail flash welding. According to the process for controlling the extreme upper-limit Mn content R350HT steel rail flash welding joint structure, the technical problem that a martensitic structure is prone to being caused inan R350HT steel rail flash welding joint in the prior art is solved. The process comprises a welding process and post-welding treatment; in the welding process, the welding heat input is controlled to be 8.5-9.5 MJ pulsation or preheating flash welding, wherein the welding upsetting amount is 15.5-16.0 mm; and in the post-welding treatment, the joint is naturally cooled to 575-585 DEG C, then heat preservation is carried out and the joint is cooled to be less than or equal to 250 DEG C, and finally, the joint is naturally cooled to the room temperature. By comprehensively controlling the chemical components, a hot rolling process, the welding process and the post-welding cooling of a steel rail, abnormal structures, such as the martensitic structure, cannot exist in the steel rail flash welding joint, and the mechanical property of the joint is ensured at the same time.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

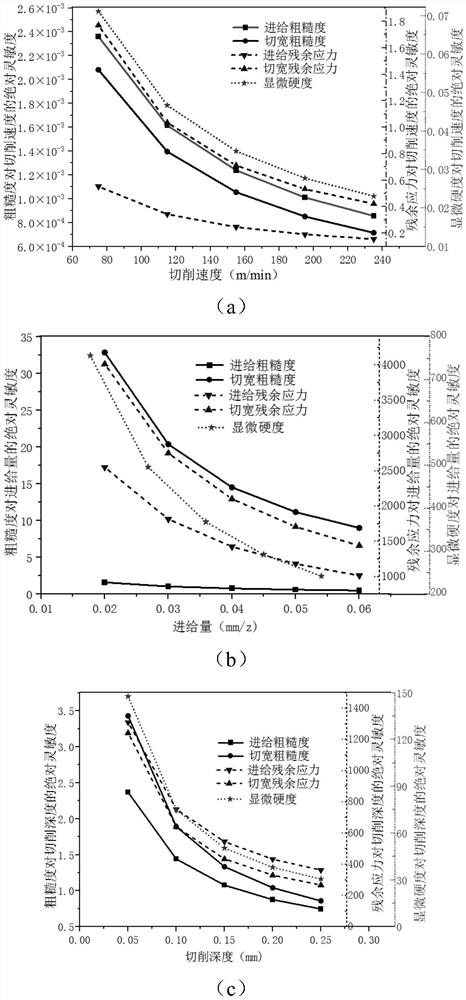

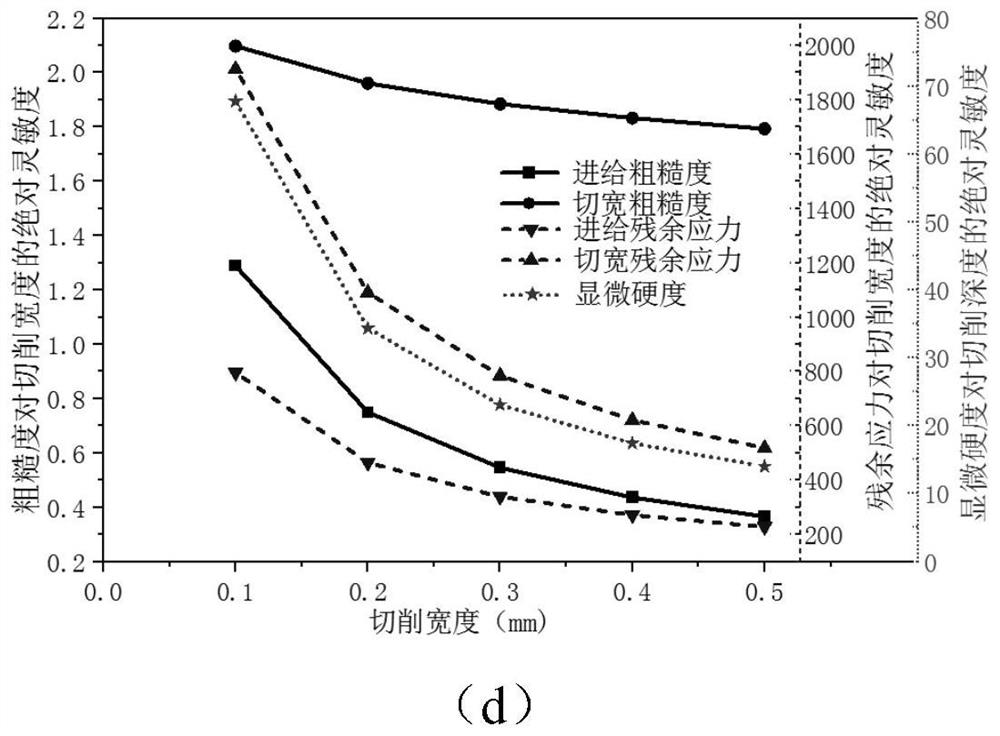

Titanium alloy thin-wall structure precision milling surface state robustness process control method

ActiveCN113894333AImprove dimensional and geometric accuracyHigh dimensional accuracyAutomatic control devicesFeeding apparatusThin walledTitanium alloy

Owner:NORTHWESTERN POLYTECHNICAL UNIV

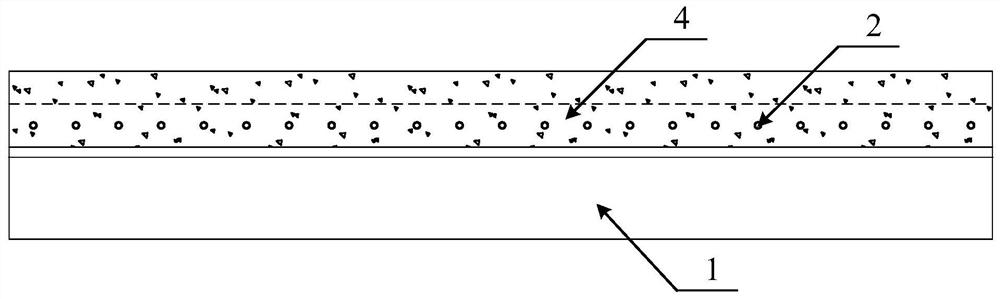

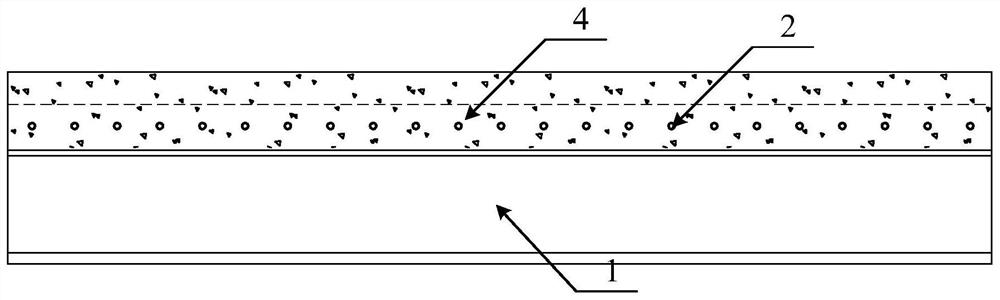

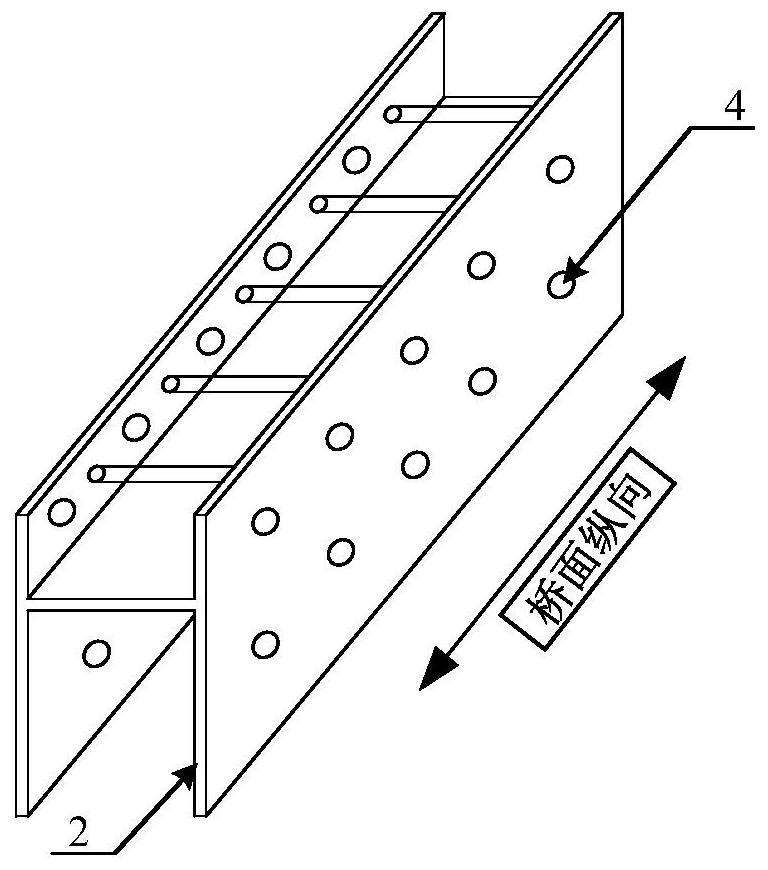

Tough combined bridge deck composed of cold-bent Z-shaped steel

ActiveCN112227199AImprove toughnessIncreased durabilityBridge structural detailsBridge materialsFillet weldBridge deck

The invention discloses a tough combined bridge deck composed of cold-bent Z-shaped steel. The tough combined bridge deck comprises cold-bent curled Z-shaped steel, transverse reinforcing steel bars and ultrahigh-toughness concrete. And the cold-bent Z-shaped steel is transversely and continuously placed along the bridge deck and forms bridge deck steel framework through fillet weld welding. The lower side flange of the cold-bent Z-shaped steel is long and plays a role in reinforcing the outer side of the plate surface; the upper side flange is short and is provided with a row of circular holes, and the transverse reinforcing steel bars penetrate through the cold-bent Z-shaped steel flanges through the circular holes. And the ultrahigh-toughness concrete is poured on the bridge deck steelskeleton to play a role in protecting the bridge deck steel skeleton. In the combined bridge deck slab system provided by the invention, the ultra-high toughness concrete can ensure that tiny cracks of below 100 microns are not generated or only generated, and the toughness and durability of the structure are improved; the construction mode of combining the cold-bent Z-shaped steel and the transverse reinforcing steel bars replaces the anti-shearing and anti-pulling effects of studs, meanwhile, the out-of-plane stability of the bridge deck slab is improved, the material cost and the construction complexity are remarkably reduced, and the fatigue performance is excellent.

Owner:ZHEJIANG UNIV

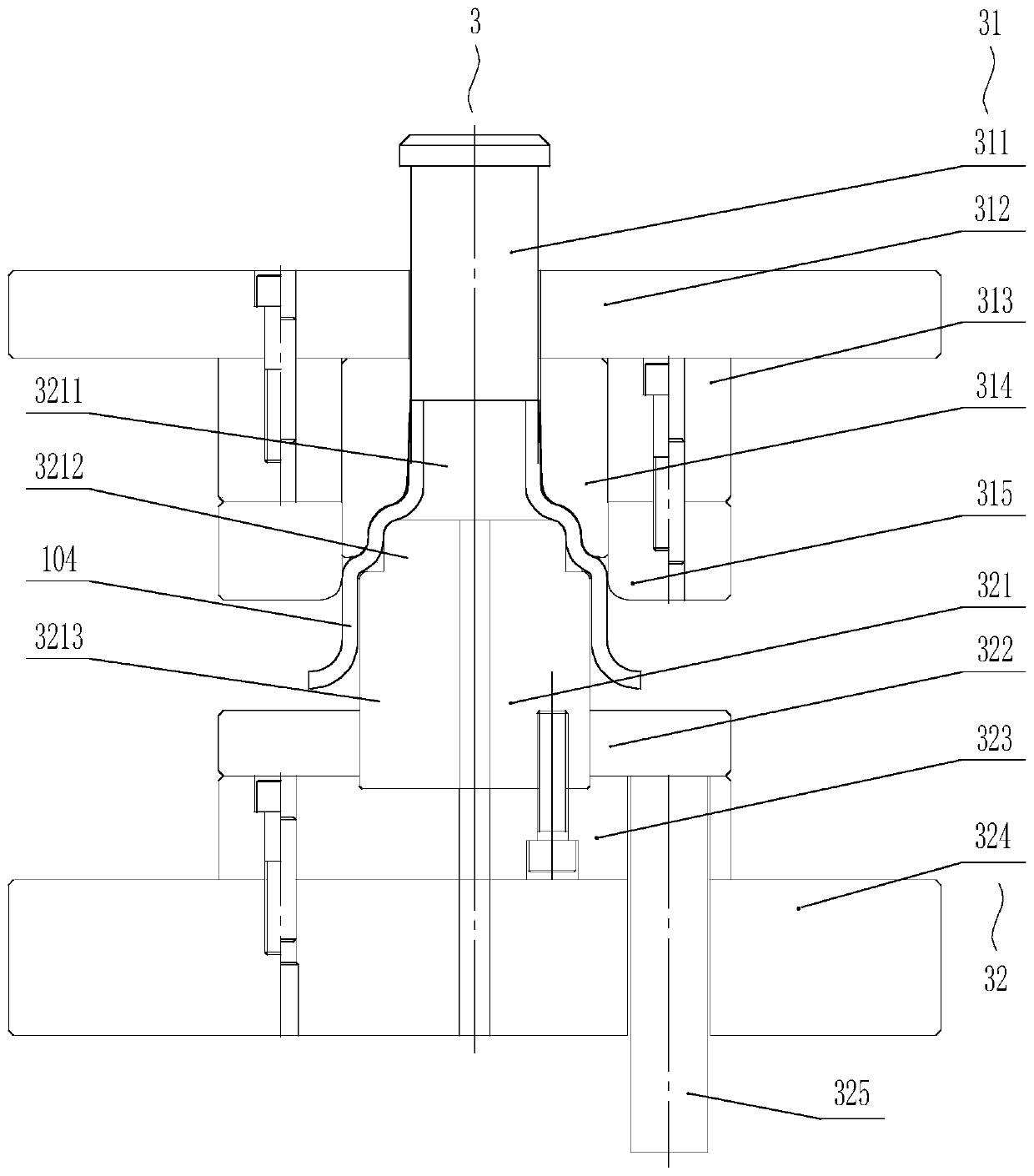

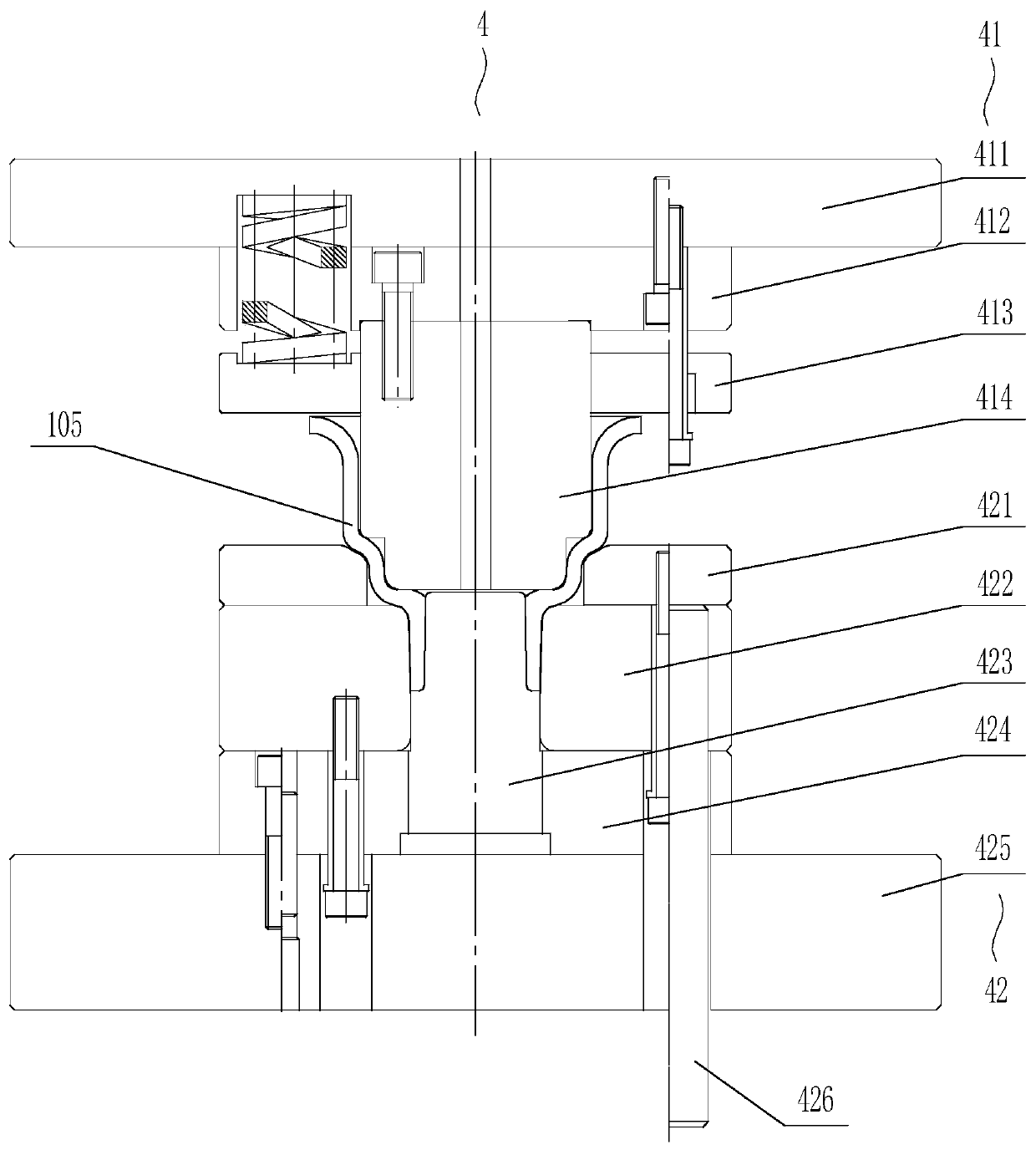

Multi-station forming technology for driven pulley piston of CVT

ActiveCN110038995AMeet strength requirementsGuaranteed liquidityMetal-working apparatusPistonsSheet steelHigh intensity

The invention relates to a multi-station forming technology for a driven pulley piston of a CVT (Continuously Variable Transmission). The multi-station forming technology comprises the steps of S1, shearing a plate, S2, falling, S3, drawing, S4, upsetting and S5, shaping; in the step S1, a high-strength steel plate with a thickness of 5.5-6.5 mm is used as a raw material and subjected to spheroidizing annealing treatment; in the step S3, the drawing coefficient is 0.65-0.85; the step S3 comprises the following steps of S31, inner hole drawing, S32, outer circle drawing, and S33, step drawing;in the S31, a falling blank is subjected to inner hole drawing for many times to form a cap-shaped blank with a center hole; in the S32, the cap-shaped blank with the center hole is subjected to the outer circle drawing to obtain a first-stage stepped inverted cup-shaped blank; and in the S33, the outer circle of the top of a large-end barrel of the first-stage stepped inverted cup-shaped blank isdrawn to form a transition step to obtain a second-stage stepped inverted cup-shaped blank. The multi-station forming technology is suitable for the forming of the driven pulley piston of the CVT, has the characteristics of low material loss, simplicity in machining, reliable quality and light weight, and is easy to popularize and use.

Owner:柳州市龙杰汽车配件有限责任公司

Process for controlling medium and lower limit Mn content R350HT steel rail flash welding joint structure

ActiveCN110480141AGuaranteed hardnessGuaranteed fatigue performanceResistance welding apparatusLower limitChemical composition

The invention discloses a process for controlling a medium and lower limit Mn content R350HT steel rail flash welding joint structure, and belongs to the technical field of steel rail flash welding. According to the process for controlling the medium and lower limit Mn content R350HT steel rail flash welding joint structure, the technical problem of a martensitic structure easily caused by a R350HT steel rail flash welding joint in the prior art is solved. The process comprises a welding process and post-welding treatment; in the welding process, the welding heat input is controlled to be 5.0-7.0 MJ pulsation or preheating flash welding, and the welding upsetting amount is 12.0-14.5 mm; and in the post-welding treatment, the joint is naturally cooled to the room temperature in air. By comprehensively controlling the chemical components, a hot rolling process, the welding process and the post-welding cooling of a steel rail, abnormal structures, such as the martensitic structure, cannotexist in the steel rail flash welding joint, and the mechanical property of the joint is ensured at the same time.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

Process for flash welding medium control limit Mn content R350 HT steel rail with joint structure

ActiveCN110480144AGuaranteed hardnessGuaranteed static bendingResistance welding apparatusMedia controlsChemical composition

The invention discloses a process for flash welding a medium control limit Mn content R350 HT steel rail with a joint structure, and belongs to the technical field of steel rail flash welding. By means of the process, the technical problem that a process in the prior art easily results in a martensite structure on an R350HT steel rail flash welding joint is solved. The process comprises a weldingprocess and post-welding treatment; in the welding process, the welding heat input is controlled to be 6.5-8.0 MJ pulsation or preheating flash welding, and the welding upset forging amount is 14.0-15.0 mm; and in the process of post-welding treatment, the joint is naturally cooled to 515-545 DEG C, is subjected to heat preservation, then cooled to less than or equal to 250 DEG C, and finally naturally cooled to room temperature. By comprehensively controlling the chemical components, the hot rolling process, the welding process and the post-welding cooling of the steel rail, no abnormal structures such as the martensite structures in the steel rail flash welding joint are guaranteed, and the mechanical property of the joint is ensured at the same time.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Vertical vibration isolation spherical steel support with lever assemblies

ActiveCN108774949AReduce vertical stiffnessAchieve vertical vibration isolation functionBridge structural detailsVertical vibrationStructural engineering

Disclosed is a vertical vibration isolation spherical steel support with lever assemblies. A lower support plate and a bottom support plate of the spherical steel support are arranged in the verticaldirection; retaining blocks are separately arranged on two sides of the bottom support plate; the side surfaces of the two retaining blocks are separately in contact with two sides of the lower support plate; the upper surface of a bottom plate of the bottom support plate is provided with lever fulcrum curved surfaces which are symmetric about an axis center line of the spherical steel support; the center of the bottom surface of the lower support plate is provided with two embedded curved surfaces which are symmetric about the axis center line of the spherical steel support; the two sets of lever assemblies are arranged in the space enclosed by the lower support plate and the bottom support plate; the two sets of lever assemblies are symmetrically arranged on two sides of the axis centerline of the spherical steel support; and each of the lever assemblies comprises a rotating block, a lever and an elastic body. By virtue of the lever principle, the levers and the elastic bodies, thevertical stiffness of the support is split into the compression stiffness of the elastic bodies through the levers so as to appropriately reduce the overall vertical stiffness of the support. The vertical fundamental frequency is far from the main frequency of the vibration of an upper structure of the support so as to realize the vertical vibration isolation function.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

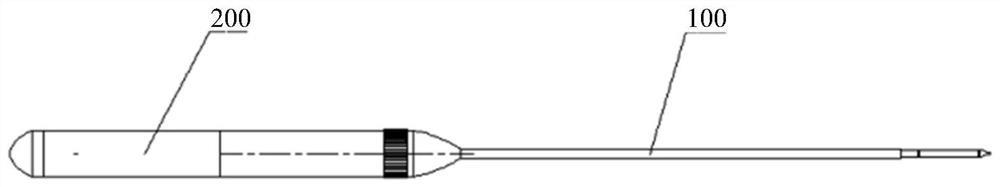

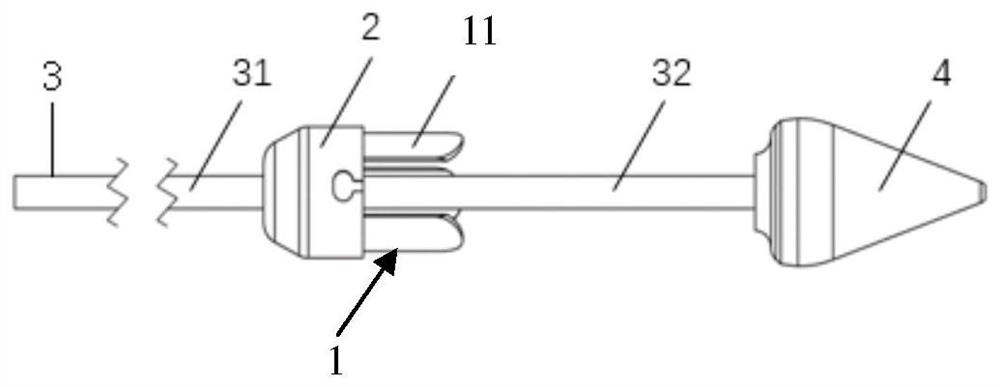

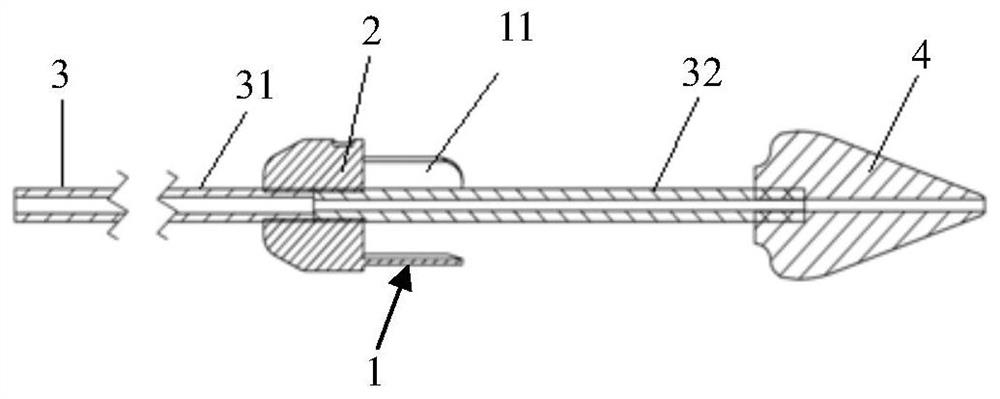

Implant conveying device and inner tube assembly and catheter thereof

The invention discloses an implant conveying device and an inner tube assembly and a catheter thereof, the inner tube assembly comprises an implant protection part, an inner tube and a fixing head connected with the inner tube, and the implant protection part is connected with the inner tube or / and the fixing head. The implant protection part is used for being in contact with an implant so as to support the implant; and a protection body is in a circular ring sheet shape or an arc sheet shape. According to the implant conveying device provided by the invention, the implant protection part is arranged, so that a non-anchoring rod with relatively weak circumferential supporting force of a valve stent can be supported, and inclination and damage of the valve stent in a loading process and distortion and inward sinking of the valve stent in a releasing process are avoided.

Owner:SHANGHAI MICROPORT CARDIOFLOW MEDTECH CO LTD

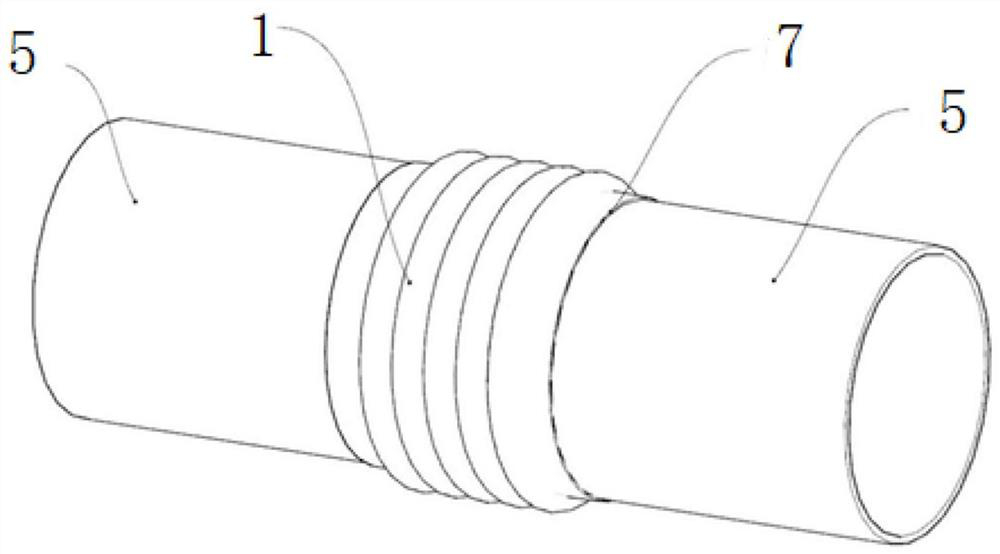

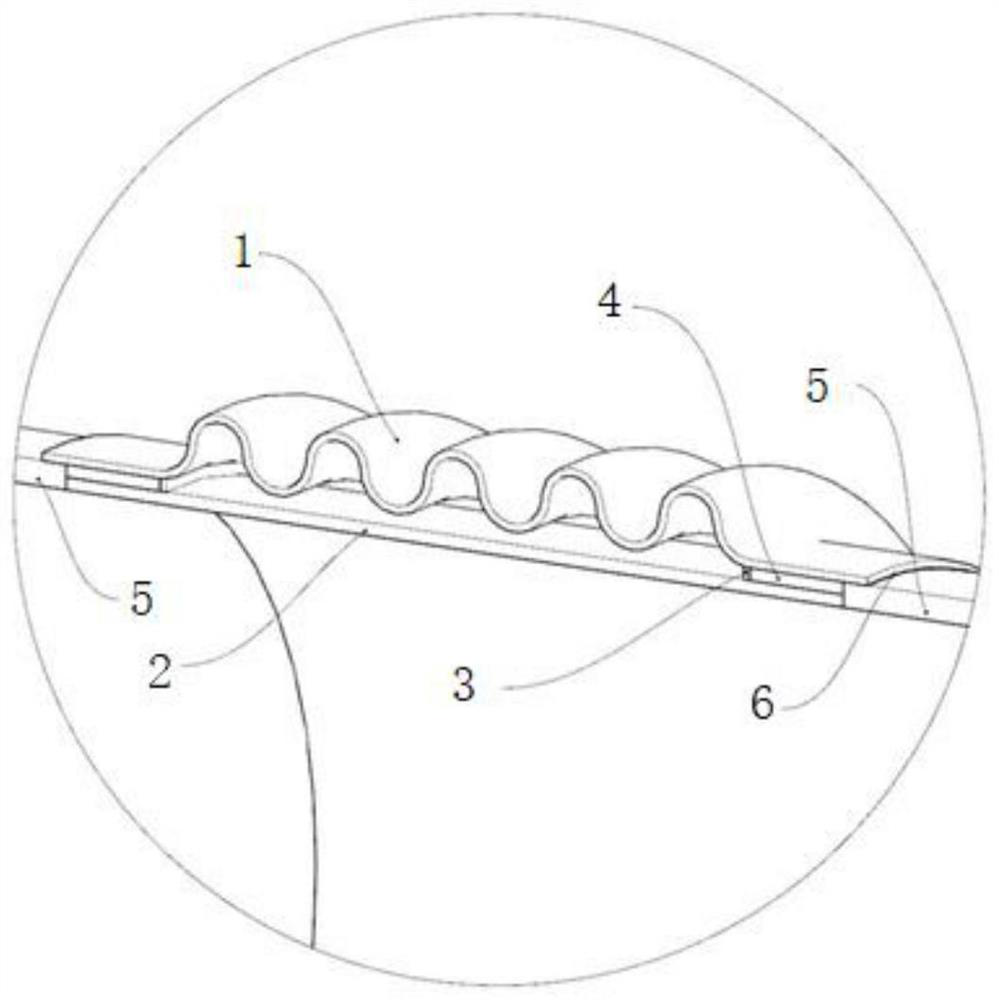

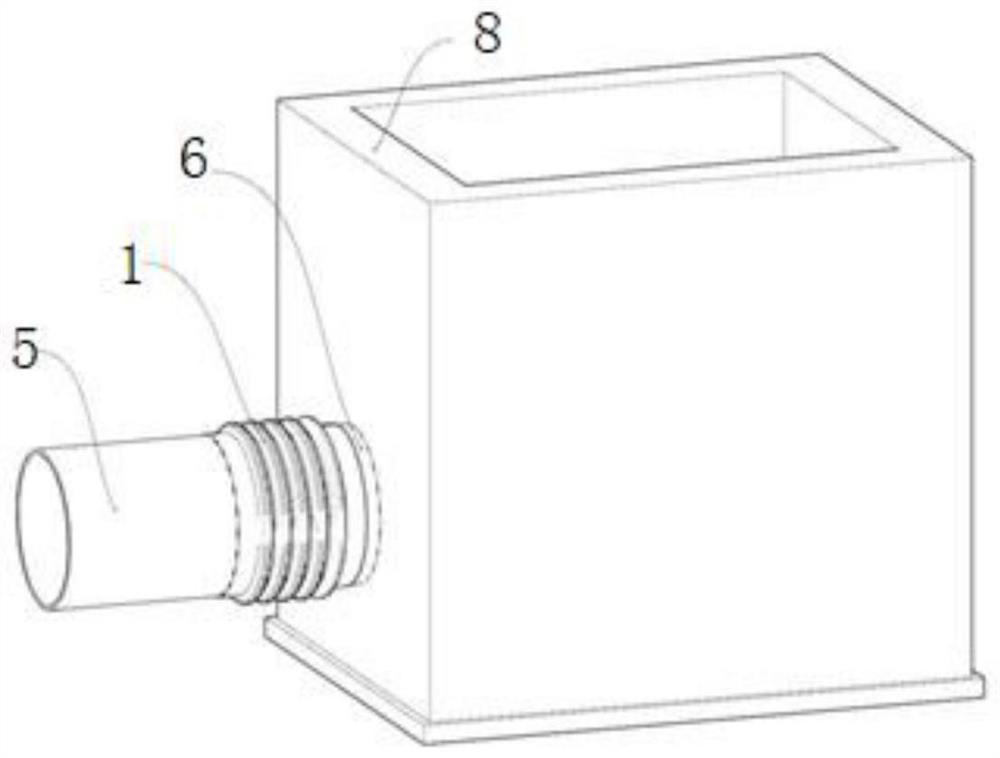

Steel pipe connecting structure for compensating differential settlement and construction method

InactiveCN112344122AFirmly connectedAvoid deformationPipeline expansion-compensationPipe protection against damage/wearArchitectural engineeringWater flow

The invention discloses a steel pipe connecting structure for compensating differential settlement and a construction method. The steel pipe connecting structure for compensating differential settlement comprises a steel pipe and other pipes connected with the steel pipe, wherein a steel corrugated pipe is arranged between the steel pipe and the other pipes, a lining pipe is arranged in the steelcorrugated pipe and is a flexible lining, and the end of the lining pipe is bonded with the steel corrugated pipe through high-strength metal glue. The steel corrugated pipe compensator and the flexible lining are bonded through the high-strength metal glue, the problem of defects or leakage at the steel pipe connecting position caused by differential settlement of a foundation is solved through good axial strain and three-dimensional rotation micro-deformation of the steel corrugated pipe, the flexible lining is used, water flow resistance can be reduced, corrosion damage caused by contact ofthe steel corrugated pipe and sewage is isolated, and the situation that waste blocks the pipes is avoided.

Owner:CHINA FIRST METALLURGICAL GROUP

Preparation of rubber asphalt mixture

InactiveCN101462849BGuaranteed Low Temperature PerformanceGuaranteed fatigue performanceSolid waste managementPolymer sciencePetroleum

The invention discloses a method for preparing a rubber asphalt mixture. The method comprises the following steps: adding tyre rubber powder into the road petroleum asphalt, and carrying out the stirring and reaction for 45 to 120 minutes to prepare the rubber asphalt; and adding N,N'-ethidence dioleamide into the heated stone material in the mineral aggregate, stirring the mineral aggregate evenly, then adding the rubber asphalt into the mineral aggregate, and stirring the mixture evenly to obtain the composite modified rubber asphalt mixture finished product. The obtained rubber asphalt mixture can simultaneously improve the high temperature performance and bonding performance of the rubber asphalt mixture.

Owner:TONGJI UNIV

A warm mixing agent for red mud-based asphalt mixture and its preparation method

ActiveCN109336456BReduce the temperatureLow molding temperatureCement productionPolymer scienceActive agent

The invention relates to a red mud-based asphalt mixture warm mix agent and a preparation method thereof, belonging to the technical field of asphalt warm mix agents. The method comprises: 1) calcining the red mud powder and mixing it with an active aluminum silicon source in proportion, and preparing SiO 2 / Al 2 o 3 mol ratio to obtain the geopolymer precursor; 2) the geopolymer precursor obtained in step 1) is added to the alkaline activator solution, and the geopolymer slurry is obtained after stirring; 3) the geopolymer slurry obtained in step 2) is Solidify the material slurry to obtain a geopolymer block, and then make the geopolymer block into powder; 4) add the geopolymer powder obtained in step 3) into the surfactant solution, stir the obtained slurry Suction filtration, drying, that is. The invention prepares the asphalt mixture warm mix agent by modifying the surface of the red mud base polymer powder, which effectively ensures the mechanical properties of the asphalt mixture while significantly reducing the mixing temperature and molding temperature of the asphalt mixture.

Owner:SHANDONG UNIV

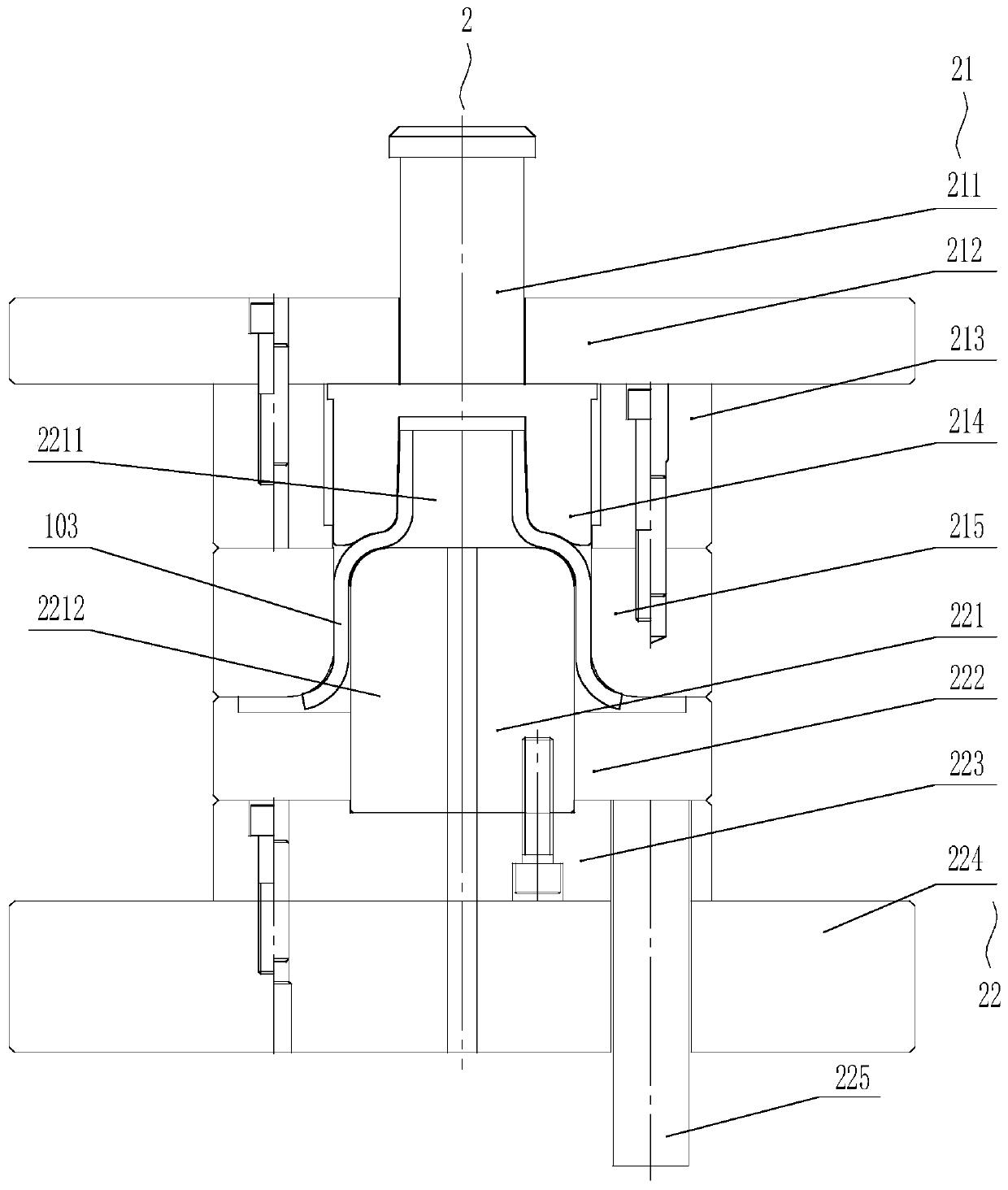

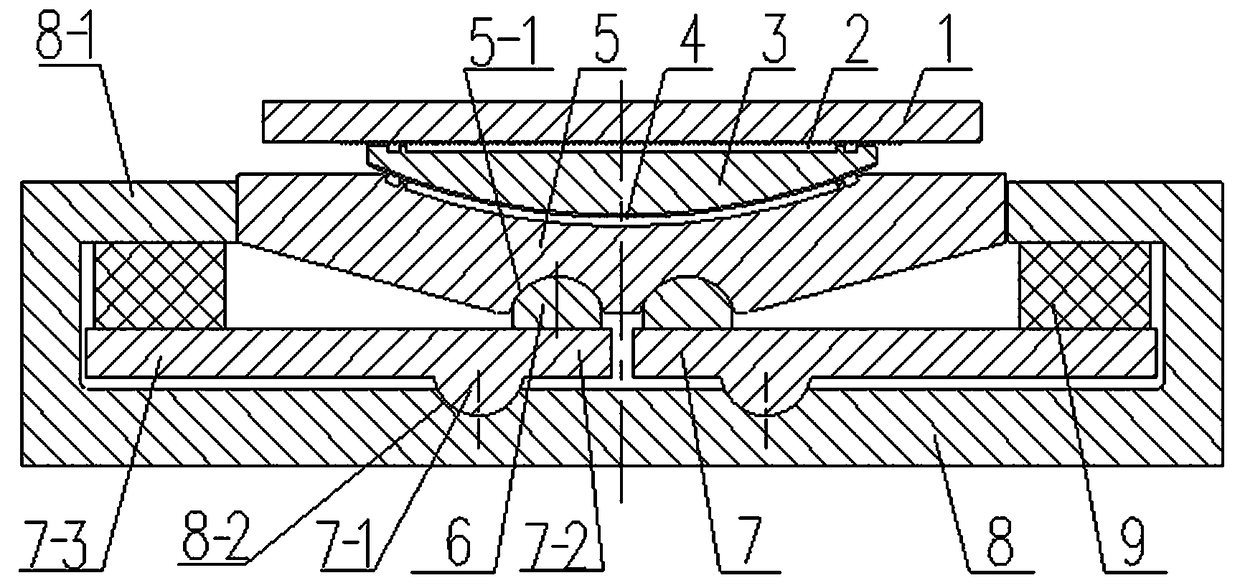

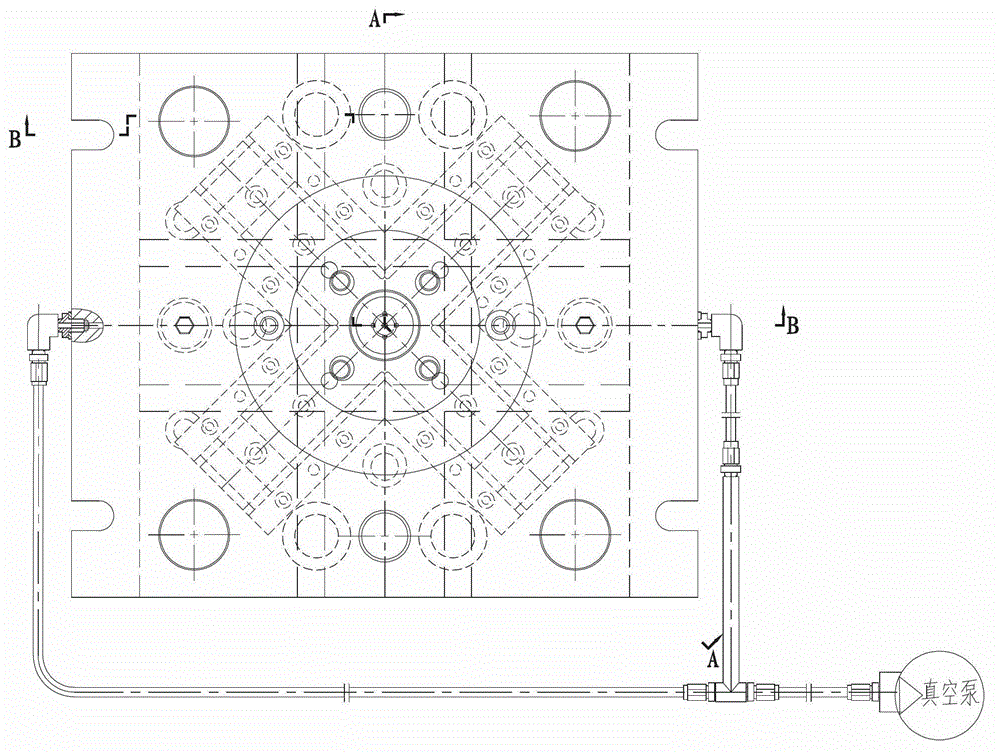

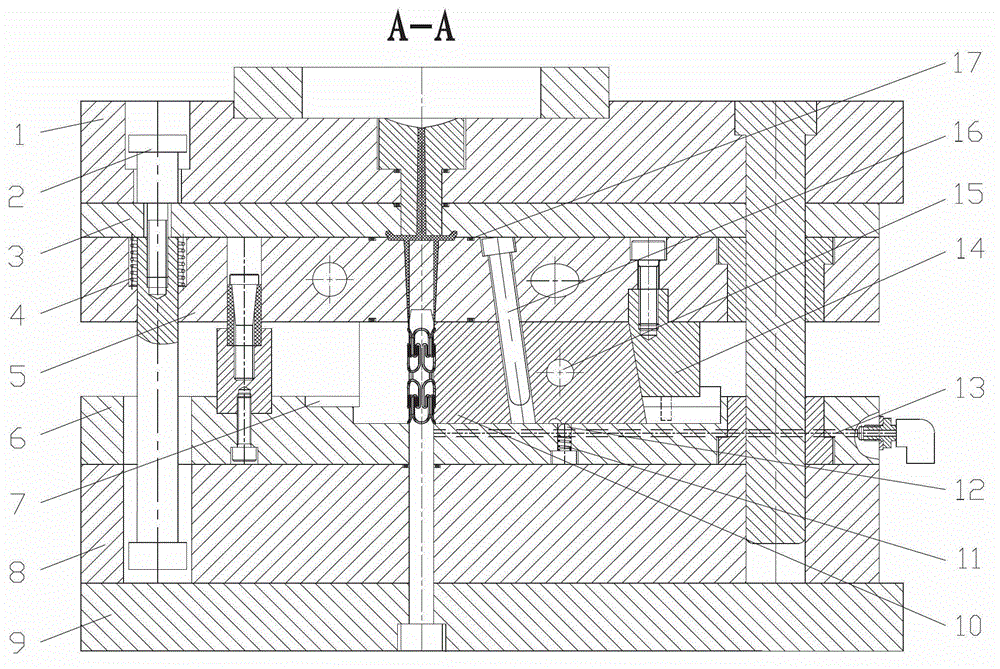

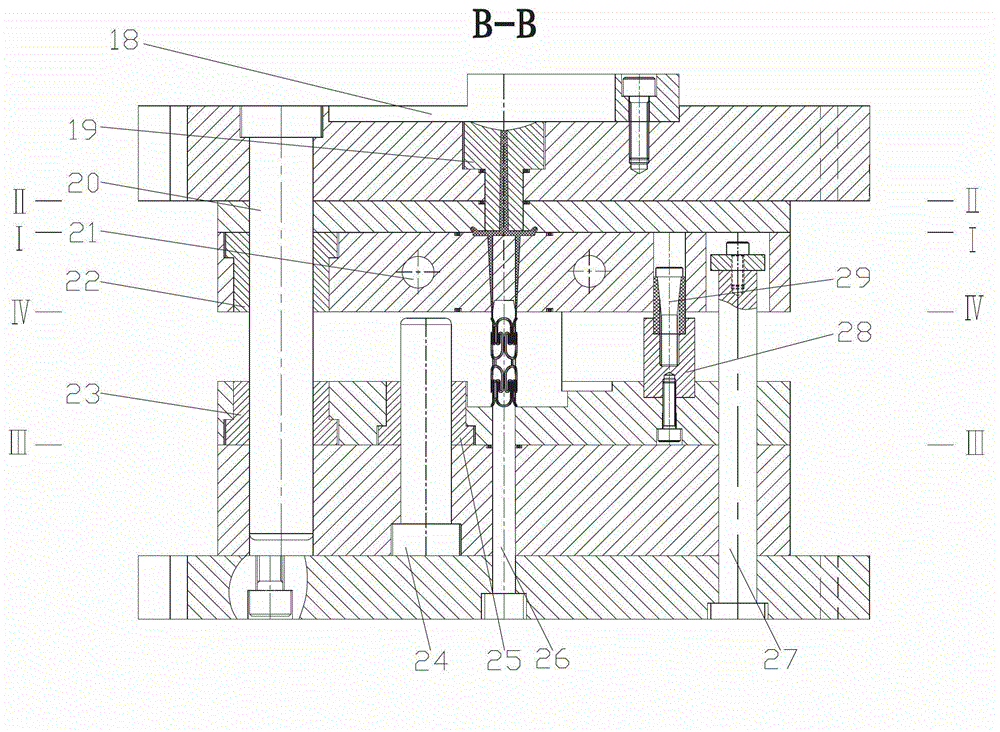

A micro-injection mold for biodegradable vascular stent

InactiveCN102873821BReduce manufacturing costGuaranteed dimensional accuracyTemperature controlHeating oil

The invention discloses a micro injection mould for a biodegradable vascular stent and belongs to the technical field of polymer injection moulds. The micro injection mould for the biodegradable vascular stent is characterized by adopting a single-cavity injection mould with a split type mould cavity structure, four-time parting, multi-point sprue feeding and multiway sequential core pulling of an inclined sliding block, wherein the single-cavity injection mould comprises a mould frame part, a side parting part, a mould temperature control part and a vacuumizing part; and the micro injection mould for the biodegradable vascular stent mainly comprises a positioning ring, a sprue sleeve, a fixed mould fixed plate, a demoulding runner plate, a fixed template, a moveable template, a pad plate, a moveable mould fixed plate, a sliding block, a sliding block pressing plate, a limited steel ball, a wedge block, an inclined guide column, a mould core, a heating oil channel, a cooling water channel, a sealing ring, a limited rod, a spring, a guide column, a guide sleeve, a nylon sleeve fixed block and a nylon sleeve. The micro injection mould for the biodegradable vascular stent has the beneficial effects of forming the vascular stent at one step, guaranteeing the size precision, the surface quality, the integral strength and the fatigue performance required by the stent, realizing automatic production, improving the production efficiency and reducing the manufacturing cost of the vascular stent.

Owner:DALIAN UNIV OF TECH

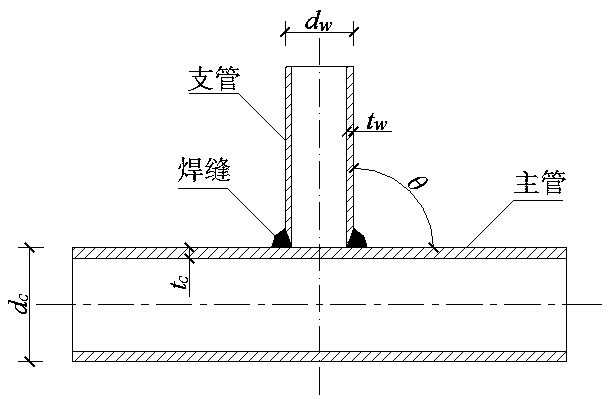

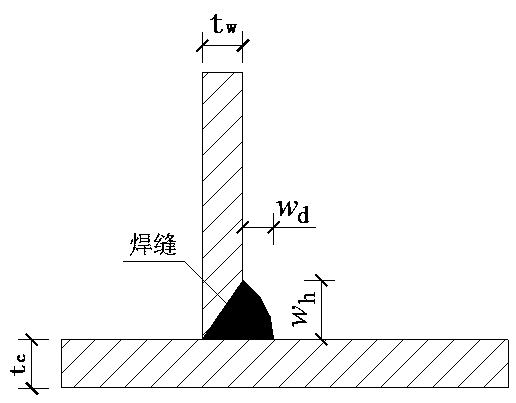

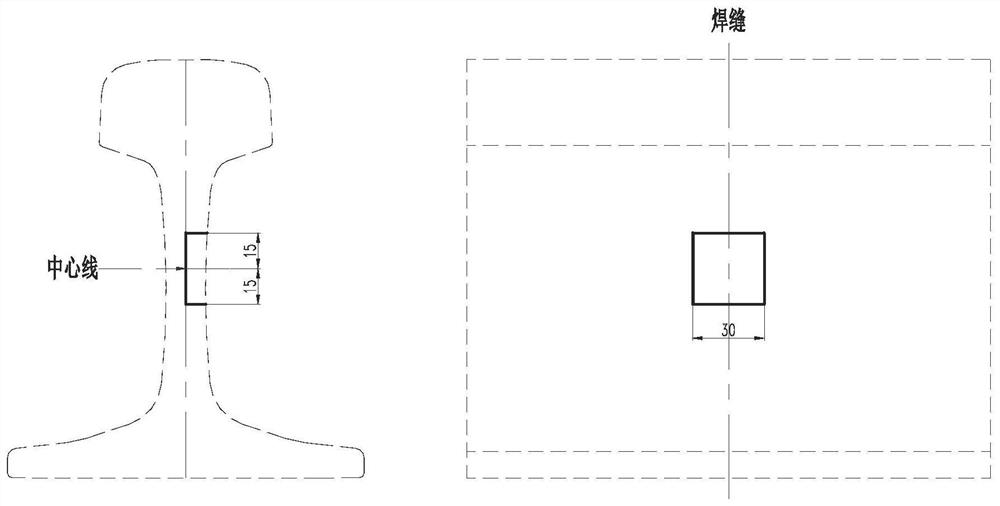

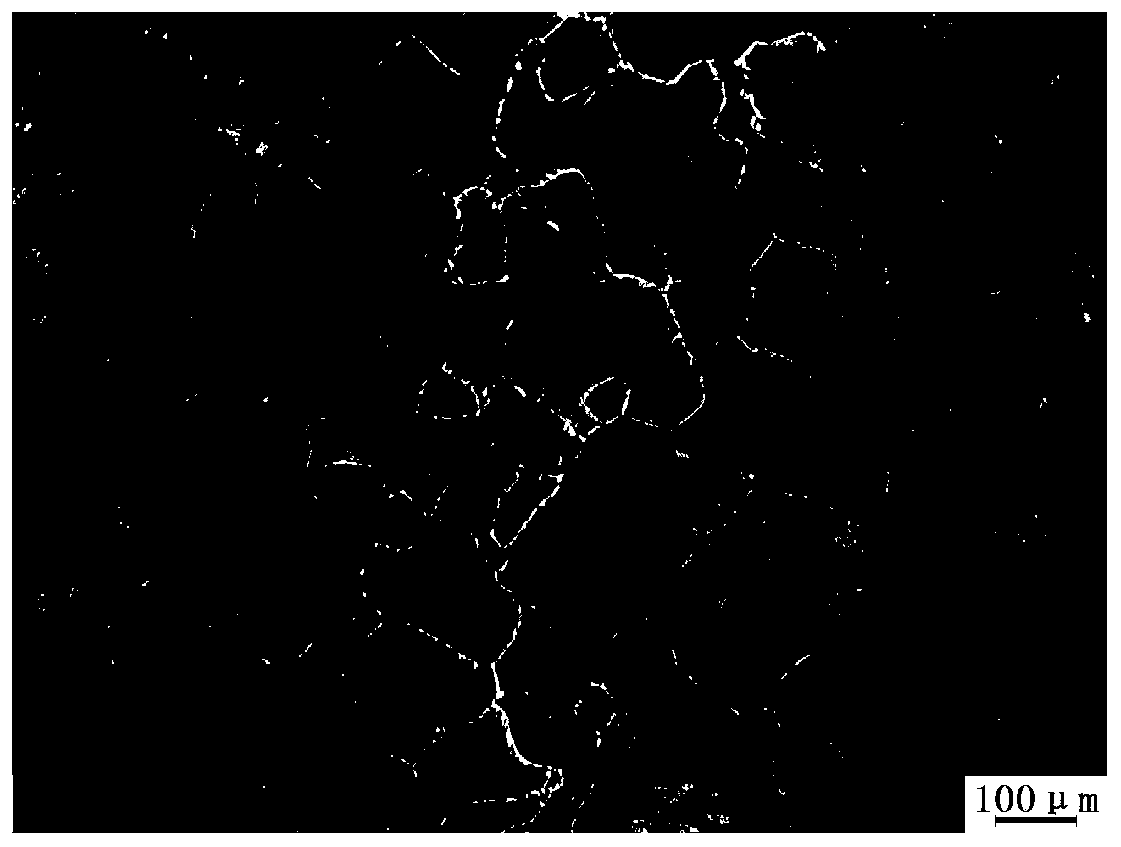

An evaluation method for fatigue performance of steel pipe welded intersecting joints

ActiveCN106735997BGuaranteed fatigue performanceReduce defectsWelding apparatusMaterial analysisEngineeringPipe welding

Owner:FUZHOU UNIV

High-speed rail axle with long fatigue life and speed of not less than 400 kilometers per hour, and laser quenching method of high-speed rail axle

ActiveCN112176152ACools well and evenlyGuaranteed fatigue performanceFurnace typesAxle unitsTemperingLaser quenching

The invention provides a high-speed rail axle with a long fatigue life and a speed of not less than 400 kilometers per hour, and a laser quenching method of the high-speed rail axle. The method comprises the following steps: a quenching machine tool is vertical, the axle is vertically placed, a laser device is axially vertical to the axle, and the spot size is kept stable in a laser quenching process; a plurality of rows of gas nozzles are formed at different angles to ensure good and uniform cooling at an R-angle transition part of the axle; the depth H of a hardening layer is selected to be1.0-2.0mm, the laser output power P is 2000-8000W, the laser scanning speed is 500-1300mm / min, and the laser overlapping rate is controlled between 30% and 40%. Compared with the prior art, after theaxle is subjected to the heat treatment of normalizing, quenching and high-temperature tempering, laser quenching is carried out on the whole length of the axle, and after the laser quenching, the surface hardness is not less than 630 HV, the surface residual compressive stress exceeds -800 MPa, and the fatigue strength exceeds 690 MPa.

Owner:MAANSHAN IRON & STEEL CO LTD

Process of controlling the microstructure of flash welded joints of r350ht rail with the upper limit of mn content

ActiveCN110480138BGuaranteed hardnessGuaranteed fatigue performanceResistance welding apparatusChemical compositionFlash welding

The invention discloses a process for controlling the microstructure of a rail flash welding joint of R350HT rail with an extremely upper limit Mn content, belonging to the technical field of rail flash welding. In order to solve the technical problem in the prior art that the flash-welded joint of the R350HT rail is easily caused to appear martensite, the invention provides a process for controlling the microstructure of the flash-welded joint of the R350HT rail with the upper limit Mn content, including the welding process and the post-weld treatment; In the welding process, the welding heat input is controlled to be 8.5-9.5MJ for pulsation or preheating flash welding, and the welding upsetting amount is 15.5-16.0mm; in the post-weld treatment, the joint is naturally cooled to 575-585 ℃, and then cooled to ≤250℃, and finally cooled to room temperature naturally. Through the comprehensive control of the chemical composition of the rail, the hot rolling process, the welding process, and the cooling after welding, it is ensured that there is no abnormal structure such as martensite in the rail flash welded joint, and the mechanical properties of the joint are also guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Process for controlling upper limit mn content r350ht rail flash welded joint microstructure

ActiveCN110480140BGuaranteed hardnessGuaranteed fatigue performanceResistance welding apparatusChemical compositionFlash welding

The invention discloses a technique for controlling the upper limit Mn content of R350HT rail flash welding joint structure, and belongs to the technical field of rail flash welding. In order to solve the technical problem in the prior art that easily leads to martensitic structure in the R350HT rail flash welding joint, the present invention provides a process for controlling the upper limit Mn content of the R350HT rail flash welding joint structure, including welding process and post-weld treatment; welding In the process, the welding heat input is controlled to be 8.0-9.0MJ pulsation or preheating flash welding, and the welding upsetting amount is 15.0-15.8mm; in the post-welding treatment, the joint is naturally cooled to 550-580°C, and then heat-preserved and cooled to ≤ 250°C, and finally cooled to room temperature naturally. Through the comprehensive control of the chemical composition of the rail, hot rolling process, welding process, and post-weld cooling, it is ensured that there is no abnormal structure such as martensite in the rail flash welded joint, and at the same time, the mechanical properties of the joint are guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Process for controlling microstructure of flash welded joints of r350ht rail with lower limit of mn content

ActiveCN110480143BGuaranteed hardnessGuaranteed fatigue performanceResistance welding apparatusChemical compositionEngineering

The invention discloses a technique for controlling the joint structure of flash welding joints of R350HT rail with lower limit Mn content, and belongs to the technical field of rail flash welding. In order to solve the technical problem in the prior art that easily leads to martensitic structure in the flash welded joint of R350HT rail, the present invention provides a process for controlling the microstructure of the flash welded joint of R350HT rail with a lower limit of Mn content, including welding process and post-weld treatment; In the welding process, the welding heat input is controlled to be 3.5-4.5MJ pulsation or preheating flash welding, and the welding upsetting amount is 10.0-11.5mm; in the post-welding treatment, the joint is naturally cooled to room temperature in the air. Through the comprehensive control of the chemical composition of the rail, hot rolling process, welding process, and post-weld cooling, it is ensured that there is no abnormal structure such as martensite in the rail flash welded joint, and at the same time, the mechanical properties of the joint are guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Process for Controlling Microstructure of Flash Welded Joints in R350ht Rails with Medium and Upper Mn Contents

ActiveCN110480142BGuaranteed hardnessGuaranteed fatigue performanceResistance welding apparatusChemical compositionFlash welding

The invention discloses a technology for controlling the flash welding joint structure of R350HT rail with upper and lower Mn content, and belongs to the technical field of rail flash welding. In order to solve the technical problem in the prior art that easily leads to the martensite structure of the R350HT rail flash welding joint, the present invention provides a process for controlling the upper limit Mn content of the R350HT rail flash welding joint structure, including the welding process and post-weld treatment; In the welding process, the welding heat input is controlled to be 7.0-8.5MJ pulsation or preheating flash welding, and the welding upsetting amount is 14.5-15.5mm; in the post-welding treatment, the joint is naturally cooled to 525-560°C, and then heat-preserved and cooled to ≤250°C, and finally cool down to room temperature naturally. Through the comprehensive control of the chemical composition of the rail, hot rolling process, welding process, and post-weld cooling, it is ensured that there is no abnormal structure such as martensite in the rail flash welded joint, and at the same time, the mechanical properties of the joint are guaranteed.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

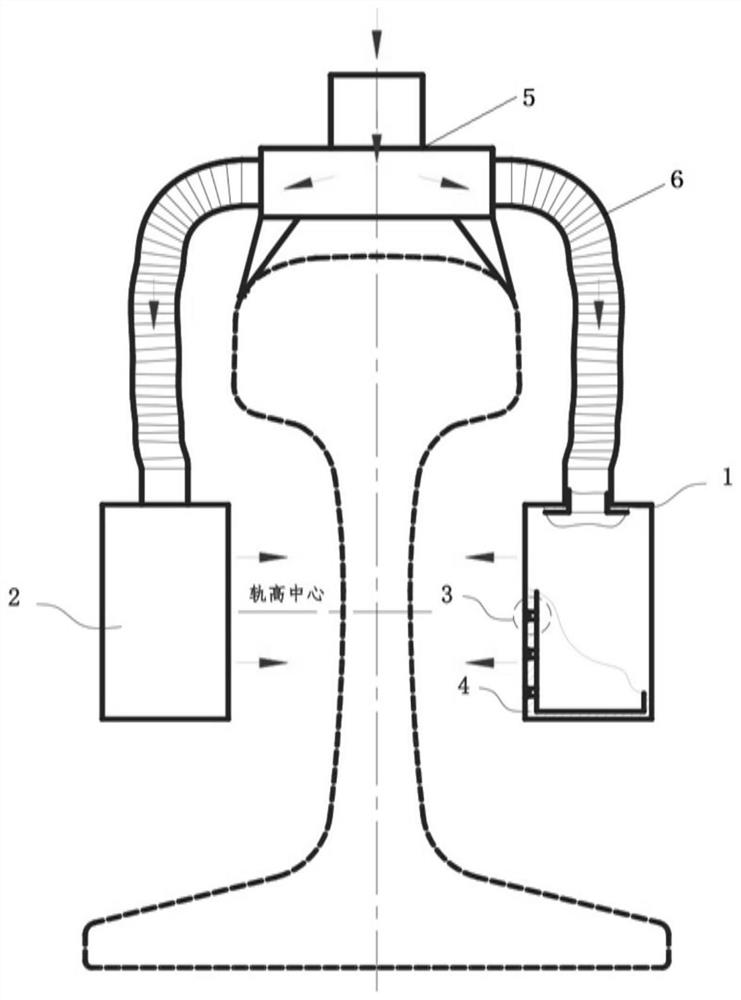

Method for regulating and controlling microscopic structure of steel rail welding joint

InactiveCN112280966AGuaranteed hardnessGuaranteed static bendingFurnace typesHeat treatment process controlWeld seamPearlite

The invention relates to the field of steel rail welding, and discloses a method for regulating and controlling a microscopic structure of a steel rail welding joint. The method comprises the following steps that 1, an accelerated cooling device is used, water mist is adopted as a cooling medium, a to-be-cooled joint rail waist part obtained through flash welding is subjected to first-stage accelerated cooling, and meanwhile, the temperature of the center position of a welding seam of the joint rail waist is measured and monitored; 2, when the temperature is reduced to a first preset temperature, compressed air is adopted as a cooling medium to carry out second-stage accelerated cooling on the joint rail waist part, and meanwhile, the temperature of the center position of the welding seamof the joint rail waist is measured and continuously monitored; and 3, when the temperature is reduced to a second preset temperature, accelerated cooling is stopped, and then the joint is placed in air to be naturally cooled to the room temperature. According to the method, waste heat of the steel rail welding joint is utilized, so that abnormal structures such as intergranular cementite in a pearlite steel rail flash welding joint can be effectively ensured to be normal, and meanwhile, the hardness, the static bending performance and the like of the joint can be ensured to meet the use requirements.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Process of controlling lower-limit Mn content of R350HT steel rail flash welded joint structure

ActiveCN110480143AGuaranteed hardnessGuaranteed fatigue performanceResistance welding apparatusLower limitFree cooling

The invention belongs to the technical field of steel rail flash welding and discloses a process of controlling the lower-limit Mn content of an R350HT steel rail flash welded joint structure in orderto solve the technical problem that an R350HT steel rail flash welded joint is likely to have the martensitic structure in the prior art. The process of controlling the lower-limit Mn content of theR350HT steel rail flash welded joint structure, provided by the invention, comprises the steps of welding and postweld treatment, wherein in the welding process, pulsation or preheating flash weldingis conducted by controlling the welding heat input to be 3.5-4.5 MJ, and the welding upset forging amount is 10.0-11.5 mm; and in the postweld treatment process, the joint is naturally cooled to the indoor temperature in the air. According to the process, no abnormal structures such as the martensitic structure existing in the steel rail flash welding joint are ensured through comprehensive control over chemical components of a steel rail, the hot rolling process, the welding process and postweld cooling, and meanwhile, the mechanical performance of the joint is ensured.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

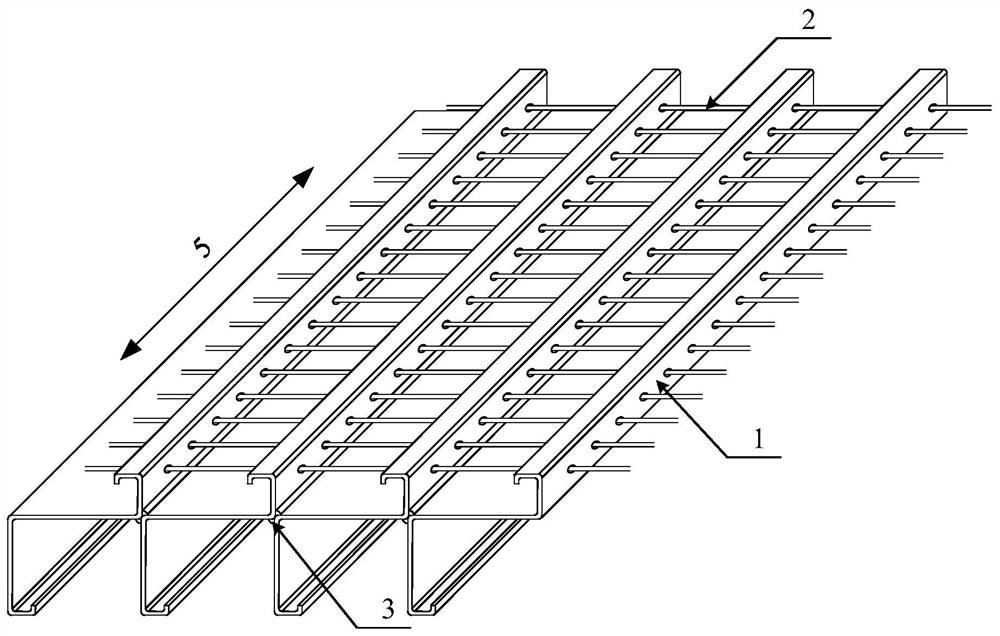

Prefabricated assembly type toughness combined bridge deck slab with cast-in-place wet joints and manufacturing method

ActiveCN113062216APrevent rustImprove toughnessBridge structural detailsBridge erection/assemblyStructural fatigueBridge deck

The invention discloses a prefabricated assembly type toughness combined bridge deck slab with cast-in-place wet joints and a manufacturing method. The combined bridge deck slab is composed of profile steel combined prefabricated parts, prefabricated connecting parts, high-strength bolts and cast-in-place ultrahigh toughness concrete. In the section steel combined prefabricated parts, a bolt hole is formed in a flange of wide hot-rolled H-shaped steel, a transverse round steel bar is welded to a flange plate on the wide hot-rolled H-shaped steel, and ultrahigh-toughness concrete is poured after the high-strength bolts and screws are pre-embedded. In the prefabricated connecting parts, a bolt hole is formed in a flange of narrow hot-rolled H-shaped steel, and a transverse round steel bar is welded on a flange plate on the upper side of the narrow hot-rolled H-shaped steel. In the construction process, the section steel combined prefabricated parts and the prefabricated connecting parts are arranged side by side at intervals, the prefabricated parts are connected into a whole through the high-strength bolts, and the ultrahigh-toughness concrete is cast in situ on the upper portions of the prefabricated connecting parts, so that the cast-in-situ wet joints are formed. The system provided by the invention has the advantages of high toughness, high prefabrication degree, no need of arrangement of studs, no need of field welding, low cast-in-place concrete proportion, convenience in construction and remarkable improvement of structural fatigue performance.

Owner:ZHEJIANG UNIV

A ductile composite bridge deck composed of cold-formed z-shaped steel

ActiveCN112227199BPrevent rustImprove toughnessBridge structural detailsBridge materialsFillet weldBridge deck

The invention discloses a ductile composite bridge deck composed of cold-formed Z-shaped steel, which comprises cold-formed and curled Z-shaped steel, transverse steel bars and ultra-high toughness concrete. The cold-formed Z-shaped steel is continuously placed laterally along the bridge deck and welded by fillet welds to form the steel skeleton of the bridge deck. The lower flange of the cold-formed Z-shaped steel is longer, which plays the role of external reinforcement of the plate surface; the upper flange is shorter and has a row of round holes on it, and the transverse steel bars pass through each cold-formed Z-shaped steel flange through the round holes. The ultra-high toughness concrete is poured on the steel skeleton of the bridge deck to protect the steel skeleton of the bridge deck. In the composite bridge deck system proposed by the present invention, the ultra-high toughness concrete can ensure that no or only tiny cracks below 100 microns will be generated, and the toughness and durability of the structure will be improved; The anti-shear and pull-out effects of the studs are improved, and the out-of-plane stability of the bridge deck is improved, the material cost and construction complexity are significantly reduced, and the fatigue performance is superior.

Owner:ZHEJIANG UNIV

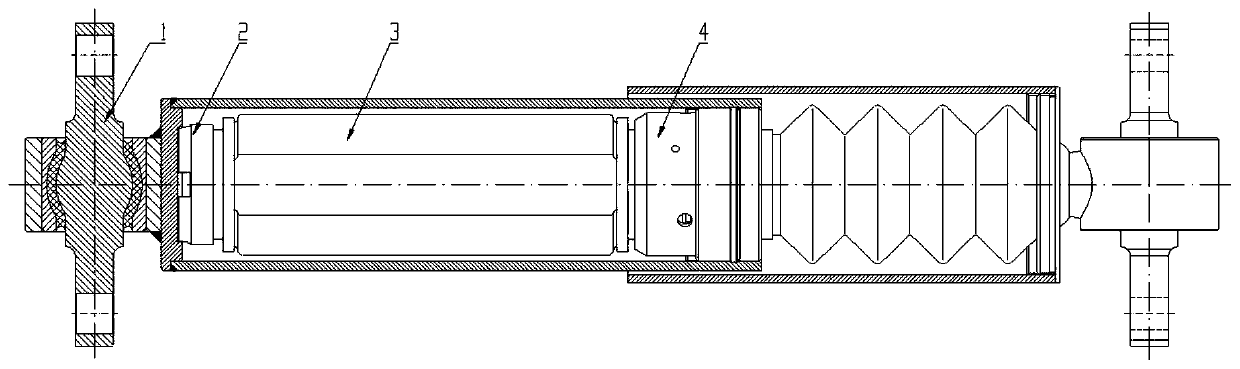

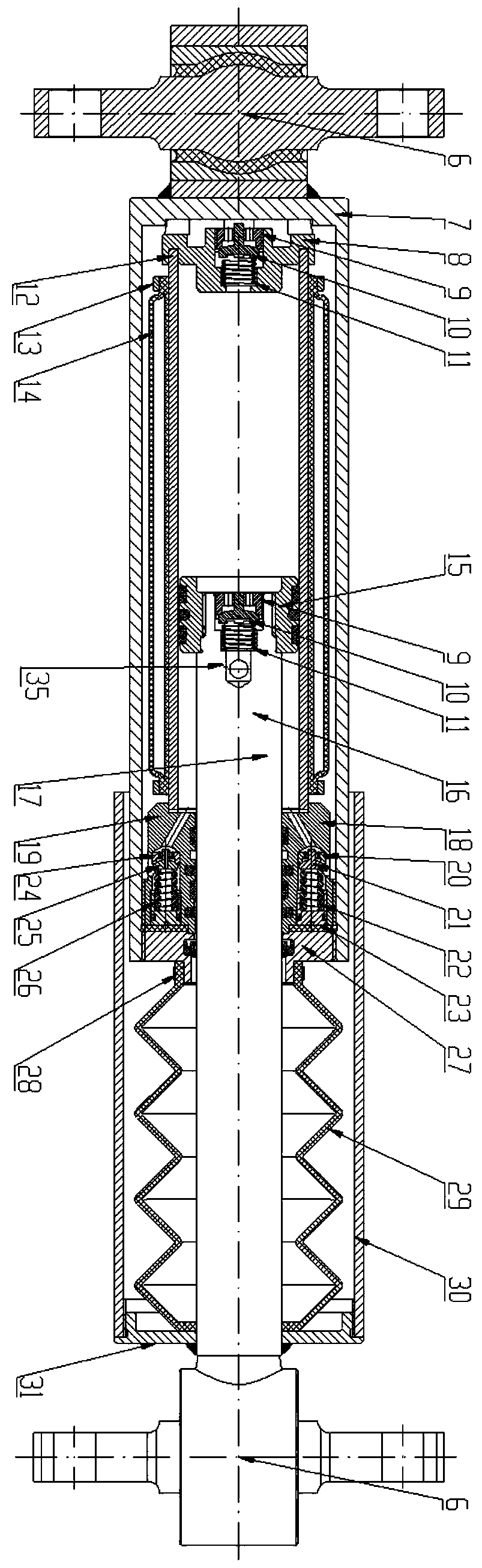

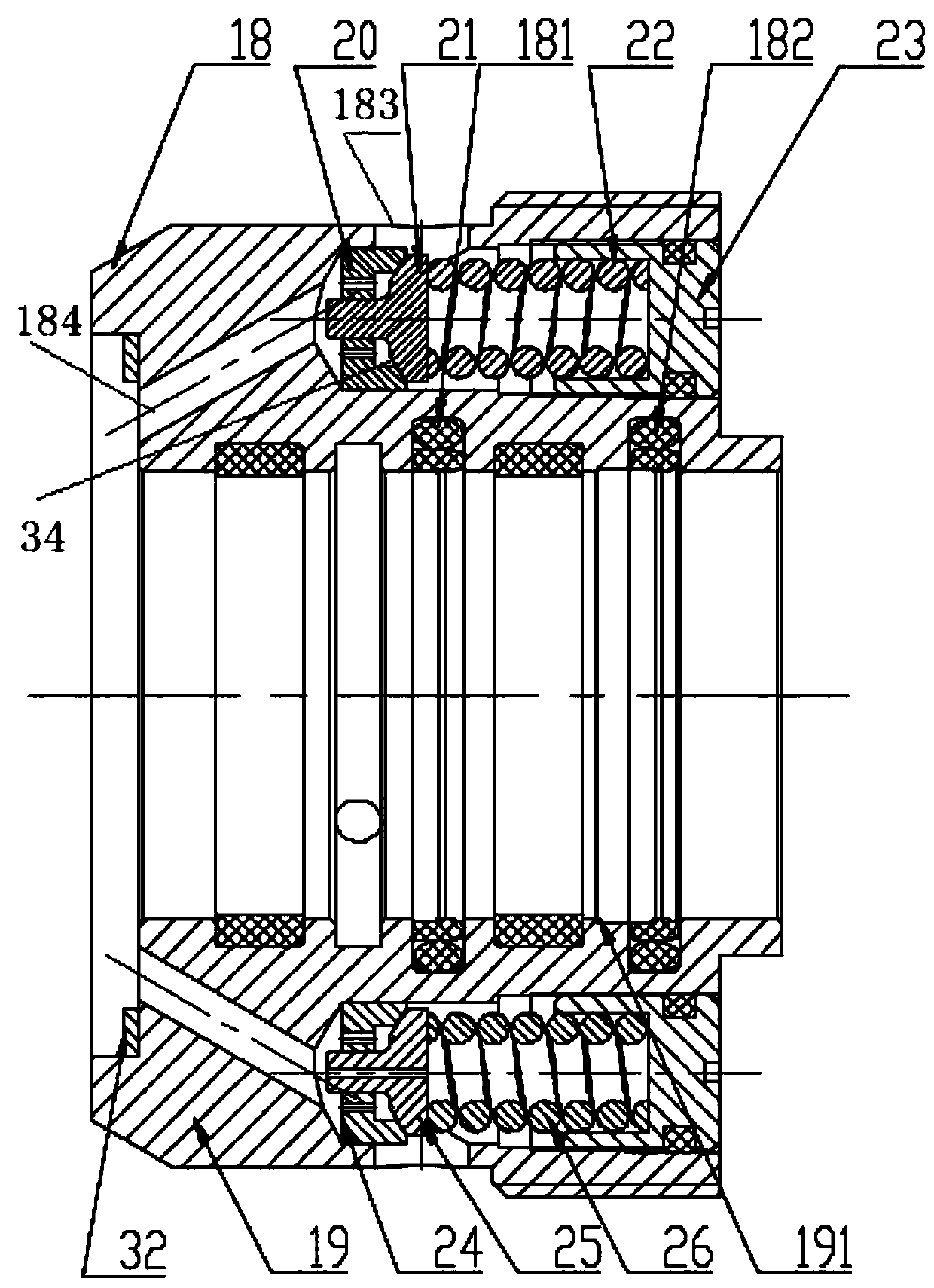

Hydraulic shock absorber

PendingCN110822006AAchieve circulationSave spaceSpringsSprings/dampers design characteristicsEngineeringMechanical engineering

The invention discloses a hydraulic shock absorber. The hydraulic shock absorber comprises a lower connecting assembly, a bottom valve assembly, an inner oil cylinder assembly and an upper connectingassembly; the lower connecting assembly is formed by welding a ball corner connecting shaft assembly and an outer oil cylinder; the bottom valve assembly is arranged on the inner side of the bottom ofthe outer oil cylinder, and an inner oil cylinder is arranged on the bottom valve; the upper connecting assembly comprises a guide sleeve assembly and an upper connecting assembly, the guide sleeve assembly comprises a guide sleeve and a gland, and the guide sleeve and the gland are screwed into the upper inner wall of the outer oil cylinder through threads and are in contact with the top surfaceof the inner oil cylinder; the upper connecting assembly comprises a piston, a piston rod and the ball corner connecting shaft assembly, the piston is arranged in the inner oil cylinder, the piston rod penetrates through the guide sleeve, one end of the piston rod is connected with the piston, the other end of the piston rod is welded to the ball corner connecting shaft assembly, and a sealing structure is arranged between the piston rod and the guide sleeve; and the bottom valve comprises a bottom valve, a first fixed throttling hole and a first one-way valve on the bottom valve; and a second fixed throttling hole and a second one-way valve are arranged on the piston. The device is simple in structure, stable in vibration reduction performance, good in sealing performance, easy to process a workpiece, free of cavitation and long in service life.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

Fabricated steel-ultrahigh toughness concrete combined bridge deck

PendingCN112878192APrevent rustImprove toughnessBridge structural detailsBridge materialsStructural fatigueArchitectural engineering

The invention discloses a fabricated steel-ultrahigh-toughness concrete combined bridge deck which comprises hot-rolled H-shaped steel, round steel bars, high-strength bolts and ultrahigh-toughness concrete. Bolt holes are formed in flanges of the hot-rolled H-shaped steel, and transverse round steel bars are welded to flange plates on the flanges, so that the section steel prefabricated part units are formed. The high-strength bolts penetrate through the bolt holes and are connected with the adjacent hot-rolled H-shaped steel to form a bridge deck steel framework. The ultrahigh-toughness concrete is poured on the bridge deck steel framework to play a role in protecting the bridge deck steel framework. In the combined bridge deck slab system, the ultra-high toughness concrete can ensure that micro cracks of 100 microns or below are not generated or only generated, and the toughness and durability of the structure are improved; the bridge deck steel framework is formed by connecting factory prefabricated parts through the high-strength bolts, the prefabrication and assembly degree is high, and the construction precision and quality are guaranteed; and no stud needs to be arranged, so that the construction complexity is reduced, and the structural fatigue performance is ensured.

Owner:SHANDONG TRAFFIC PLANNING DESIGN INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com