Multi-station forming technology for driven pulley piston of CVT

A forming process and multi-station technology, applied to pistons, metal processing equipment, etc., to achieve the effect of ensuring fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] A multi-station forming process for a driven pulley piston of a CVT transmission, comprising the steps of S1. shearing, S2. blanking, S3. deep drawing, S4. upsetting, and S5. shaping, wherein:

[0082] S1. Shearing plate: The raw material of the shearing plate is high-strength steel plate with a thickness of 5.5mm. The material is high-strength automotive structural steel, such as SPFH590. Deep drawing can be completed without annealing.

[0083] S2. Blanking;

[0084] S3. Deep drawing: the drawing coefficient is 0.65; this step S3. Deep drawing includes the following procedures:

[0085] S31. Drawing inner hole:

[0086] Deepen the inner hole of the blanking blank 101 multiple times to form a hat-shaped blank 102 with a central hole, and the height of the central hole is H1=47mm;

[0087] S32. Deep drawing outer circle:

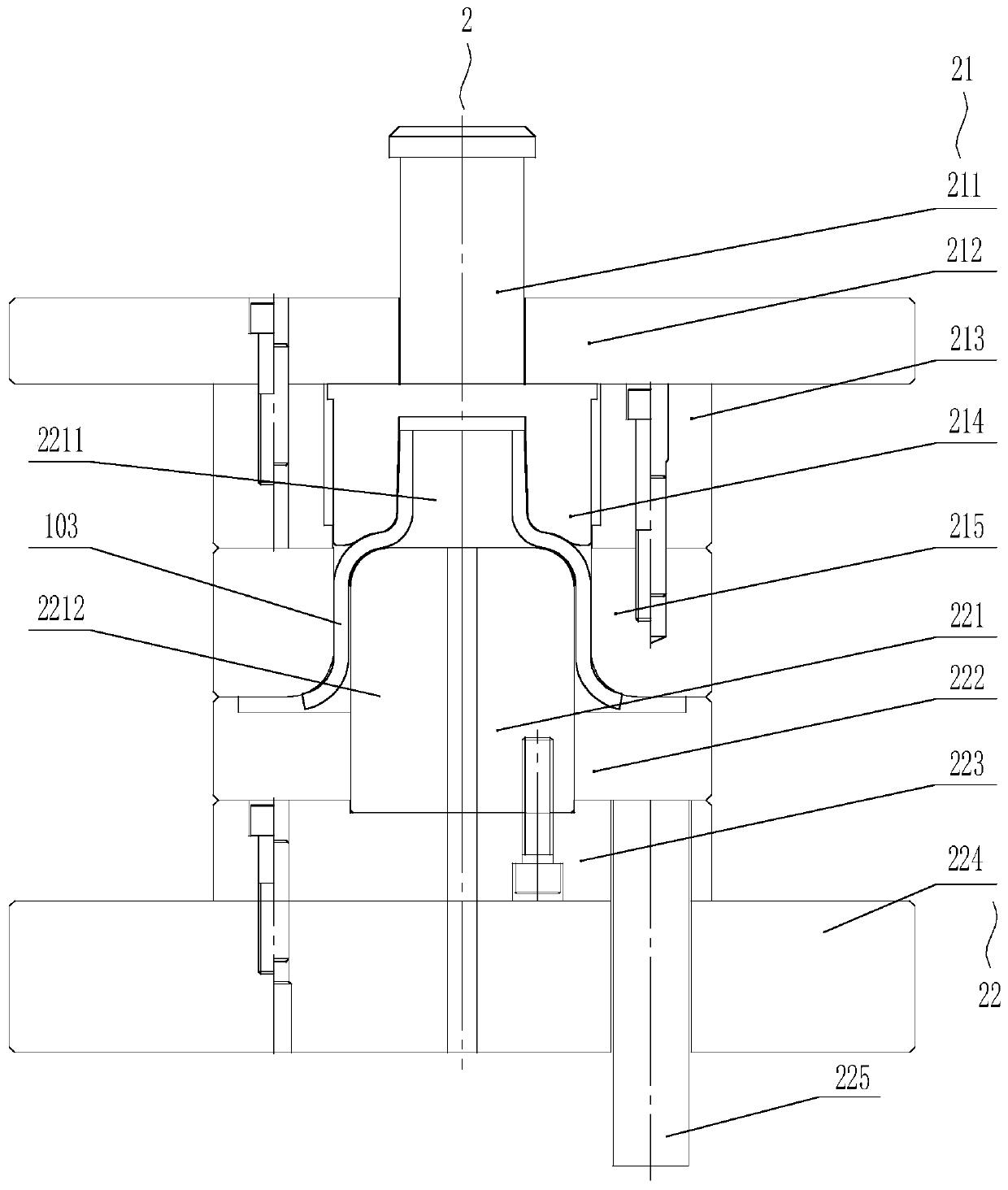

[0088] The cap-shaped blank 102 with a central hole is subjected to external circular drawing to obtain a one-stage inverted cup-shaped blank 103 ...

Embodiment 2

[0102] A multi-station forming process for a driven pulley piston of a CVT transmission, comprising the steps of S1. shearing, S2. blanking, S3. deep drawing, S4. upsetting, and S5. shaping, wherein:

[0103] S1. Shearing plate: The raw material of the shearing plate is high-strength steel plate with a thickness of 6.5mm. The material is high-strength automotive structural steel, such as SPFH780. Deep drawing can be completed without annealing.

[0104] S2. Blanking;

[0105] S3. Deep drawing: the drawing coefficient is 0.85; this step S3. Deep drawing includes the following procedures:

[0106] S31. Drawing inner hole:

[0107] Deepen the inner hole of the blanking blank 101 multiple times to form a hat-shaped blank 102 with a central hole, and the height of the central hole is H1=49mm;

[0108] S32. Deep drawing outer circle:

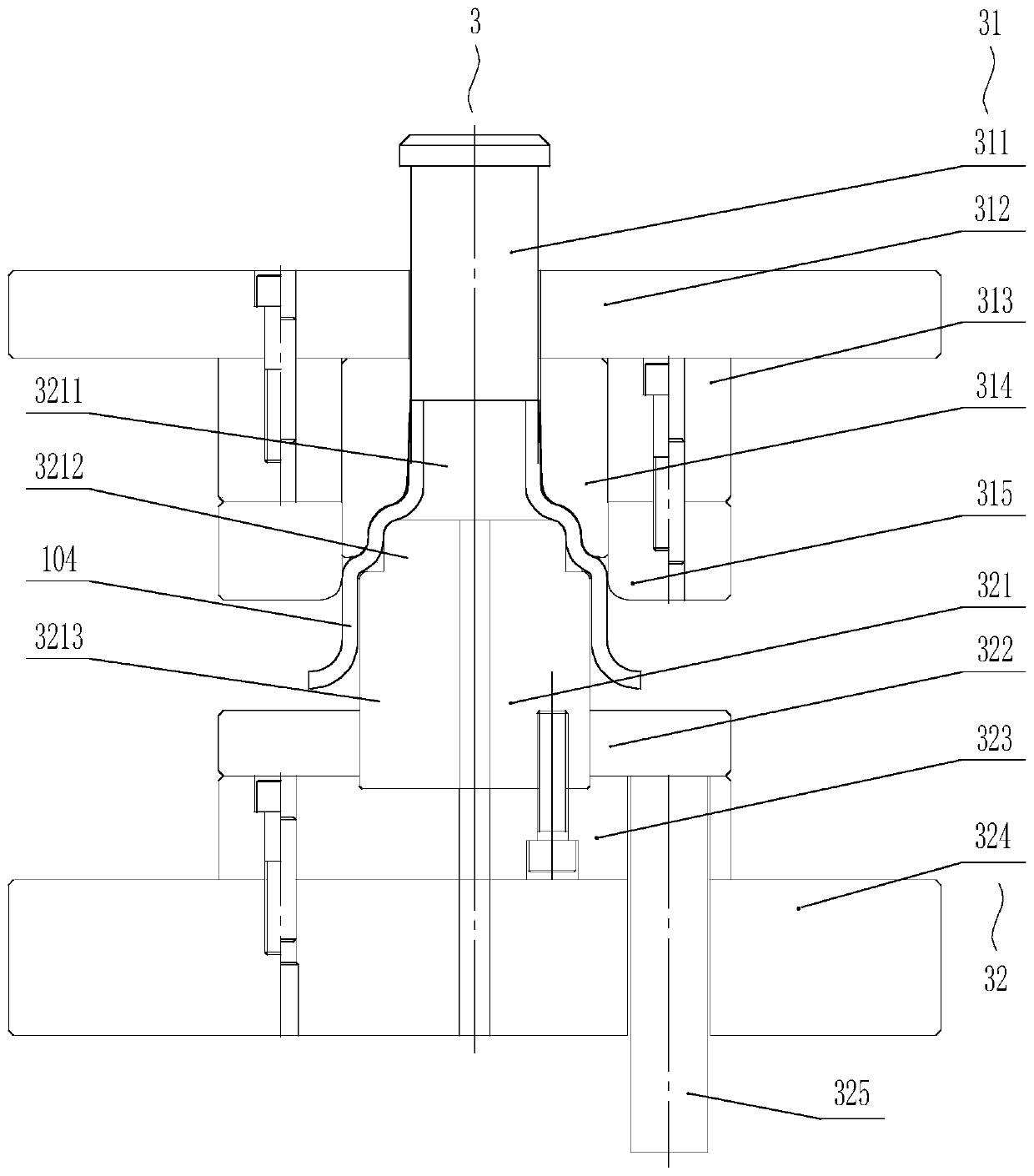

[0109] The cap-shaped blank 102 with a central hole is subjected to external circular drawing to obtain a one-stage inverted cup-shaped blank 103 ...

Embodiment 3

[0123] A multi-station forming process for a driven pulley piston of a CVT transmission, comprising the steps of S1. shearing, S2. blanking, S3. deep drawing, S4. upsetting, and S5. shaping, wherein:

[0124] S1. Shearing plate: the raw material of the shearing plate is high-strength steel plate with a thickness of 5.5-6.5mm, and the raw material is Cr alloy structural steel plate, such as 40Cr alloy structural steel plate, etc. For Cr alloy structural steel plate with higher yield strength requirements, spheroidizing annealing is required treatment to make the spherical pearlite structure of the steel plate reach more than 85%.

[0125] S2. Blanking;

[0126] S3. Deep drawing: the drawing coefficient is 0.75; this step S3. Deep drawing includes the following procedures:

[0127] S31. Drawing inner hole:

[0128] Deepen the inner hole of the blanking blank 101 multiple times to form a hat-shaped blank 102 with a central hole, and the height of the central hole is H1=48mm;

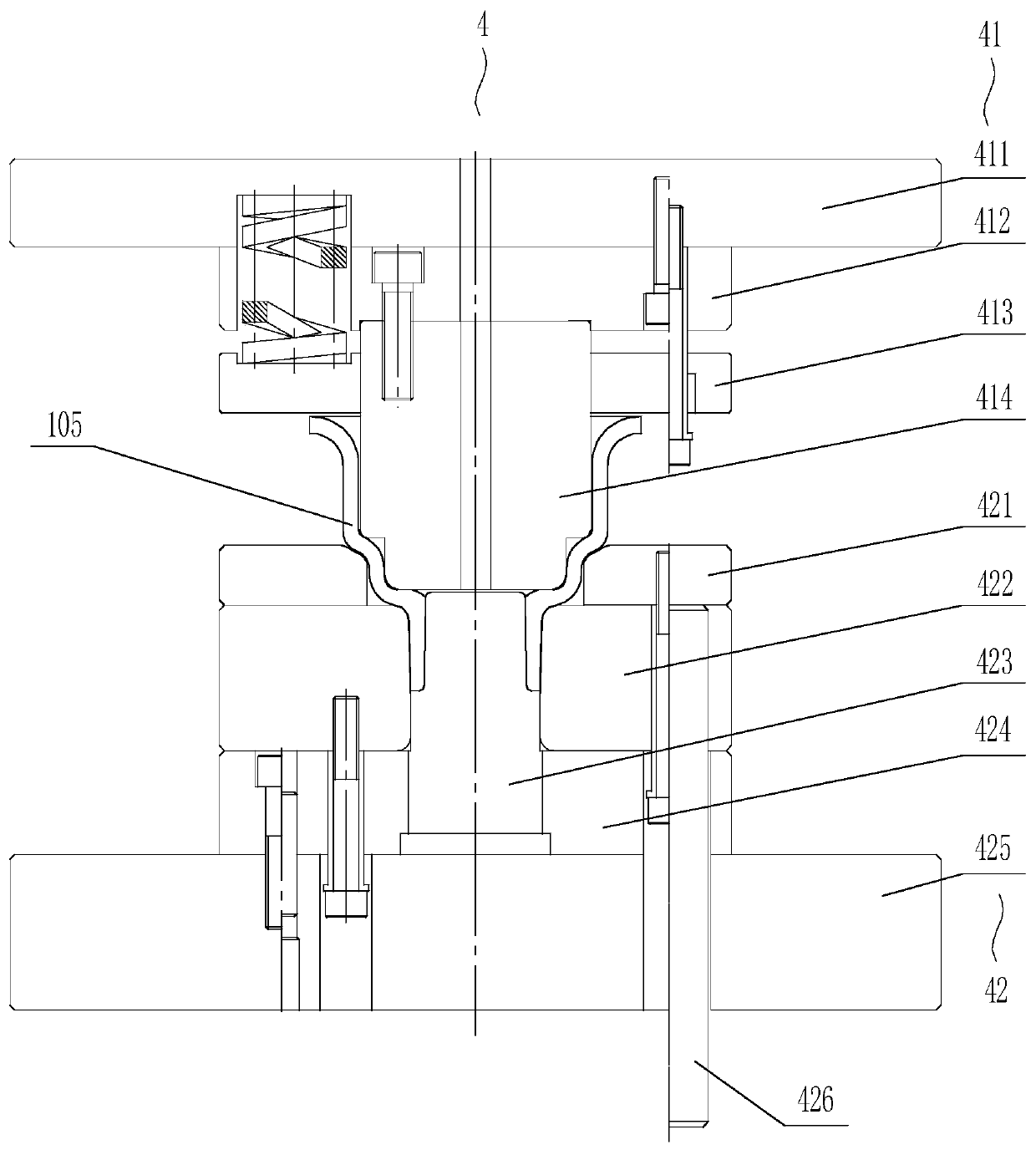

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com