Patents

Literature

137 results about "Fixed Bridges" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

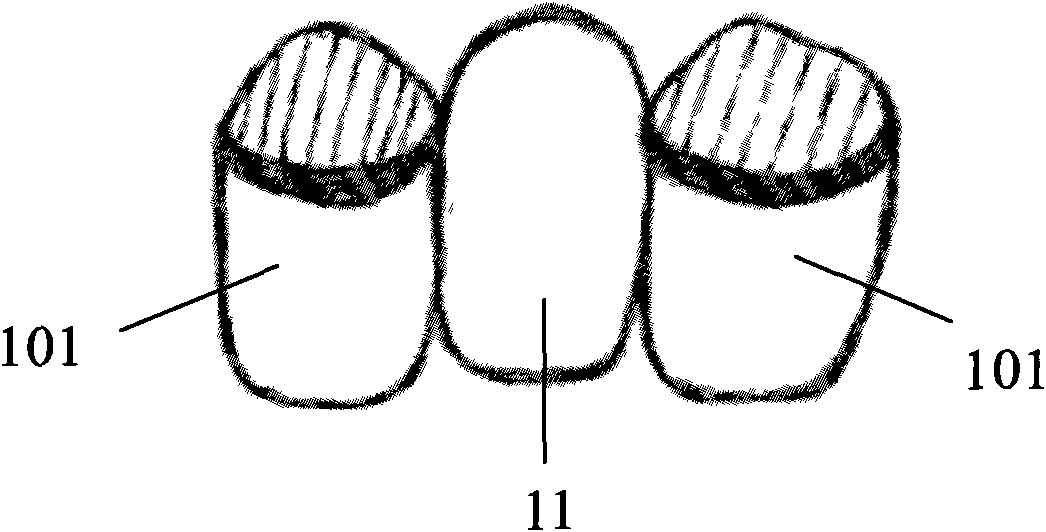

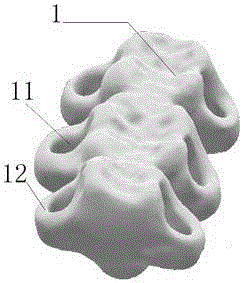

Zirconium dioxide full porcelain tooth and preparation method thereof

InactiveCN101647730AGood biocompatibilityImprove toughnessArtificial teethFixed BridgesUltimate tensile strength

The invention relates to a zirconium dioxide full porcelain tooth which comprises a false tooth fixing bridge structure and a glaze porcelain layer which covers the outer surface of the false tooth fixing bridge structure, wherein the false tooth fixing bridge structure is made of a zirconium dioxide material and comprises a plurality of inner false tooth crowns which are mutually bonded and supporting bodies which can be sleeved and bonded onto a tooth. The interiors of the supporting bodies are hollow and are respectively connected to both sides of each inner false tooth crown, and the glazeporcelain layer is made of a porcelain material. The invention also provides a manufacturing method of the zirconium dioxide full porcelain tooth. The method comprises the following steps of collecting data, cutting and grinding the false tooth fixing bridge structure, firing and coating porcelain for decoration. The zirconium dioxide full porcelain tooth has no off-smell and no toxicity to humanbodies, cannot change the color of the gingival, has high strength and is suitable for manufacturing false teeth with large-span fixing bridge structures.

Owner:SHANGHAI I DENTAL TECH CO LTD

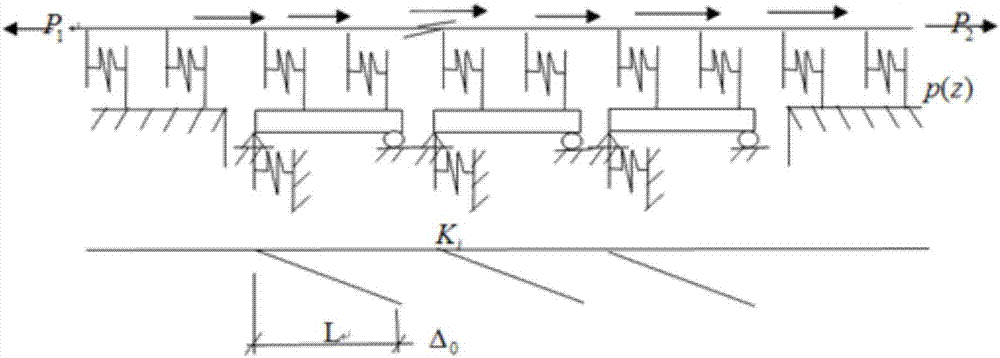

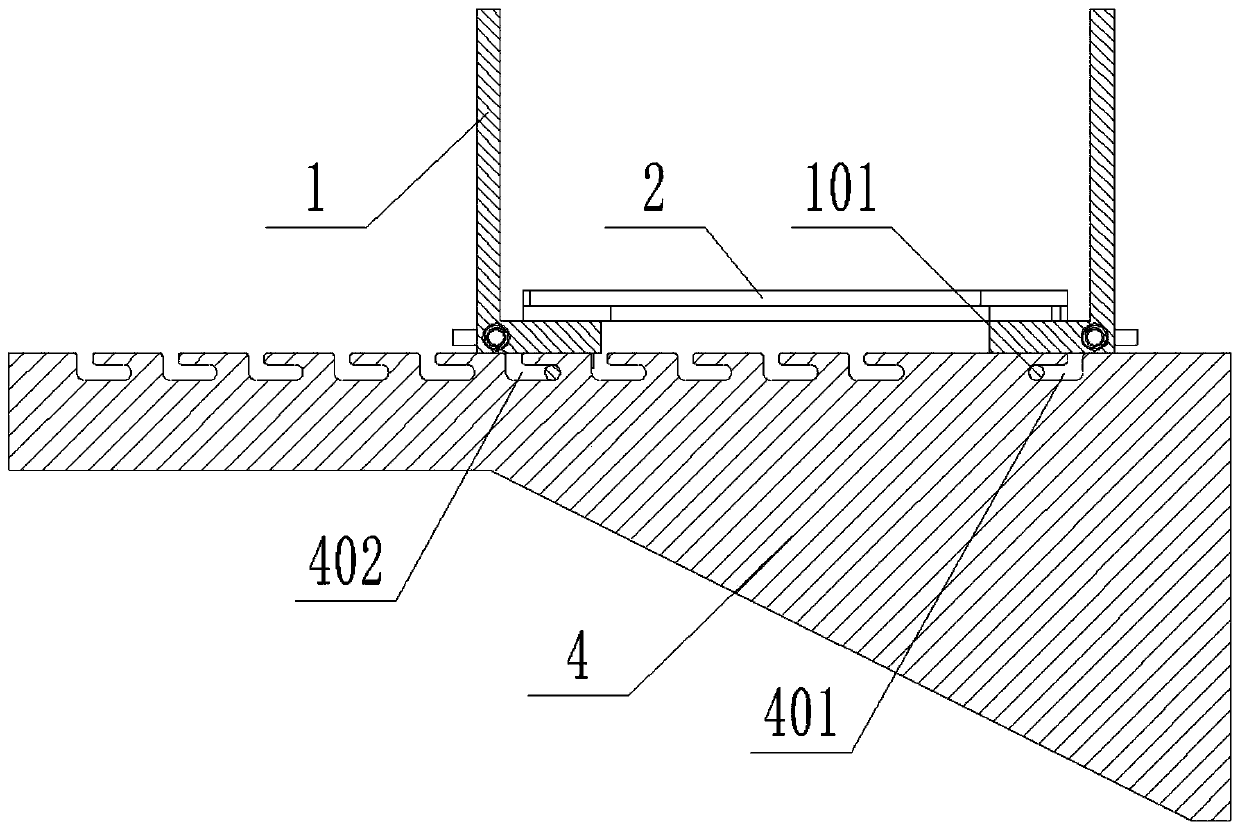

Method for longitudinal stiffness control over high-pier large-span concrete continuous girder bridge and bridge

ActiveCN107201716AMeet vertical and horizontal control standardsProcess stabilityBridge structural detailsEngineeringFixed Bridges

The invention relates to the technical field of high-pier large-span concrete bridges, in particular to a method for longitudinal stiffness control over a high-pier large-span concrete continuous girder bridge and a bridge. The method for longitudinal stiffness control comprises a step a) of establishing a linear bridge pier integrated calculation model; a step b) of applying an analog load; a step c) of analyzing beam track acting force and jointless track stress deformation laws; and a step d) of determining longitudinal rigidity limits of a fixed bridge pier and track treatment measures. Therefore, beam shape arrangement and fixed pier rigidity are determined, a problem that in the prior art, it is difficult to control longitudinal stiffness of the high-pier large-span continuous girder bridge is solved, and the blank of the high-pier large-span girder bridge in the field of longitudinal stiffness control is filled. Meanwhile, normative standards of longitudinal linear stiffness limits of the high-pier large-span concrete continuous girder bridge are established, a reference and a basis are provided for bridge design and construction, so the design cost is reduced, and the actually built bridge meets specific usage environments.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

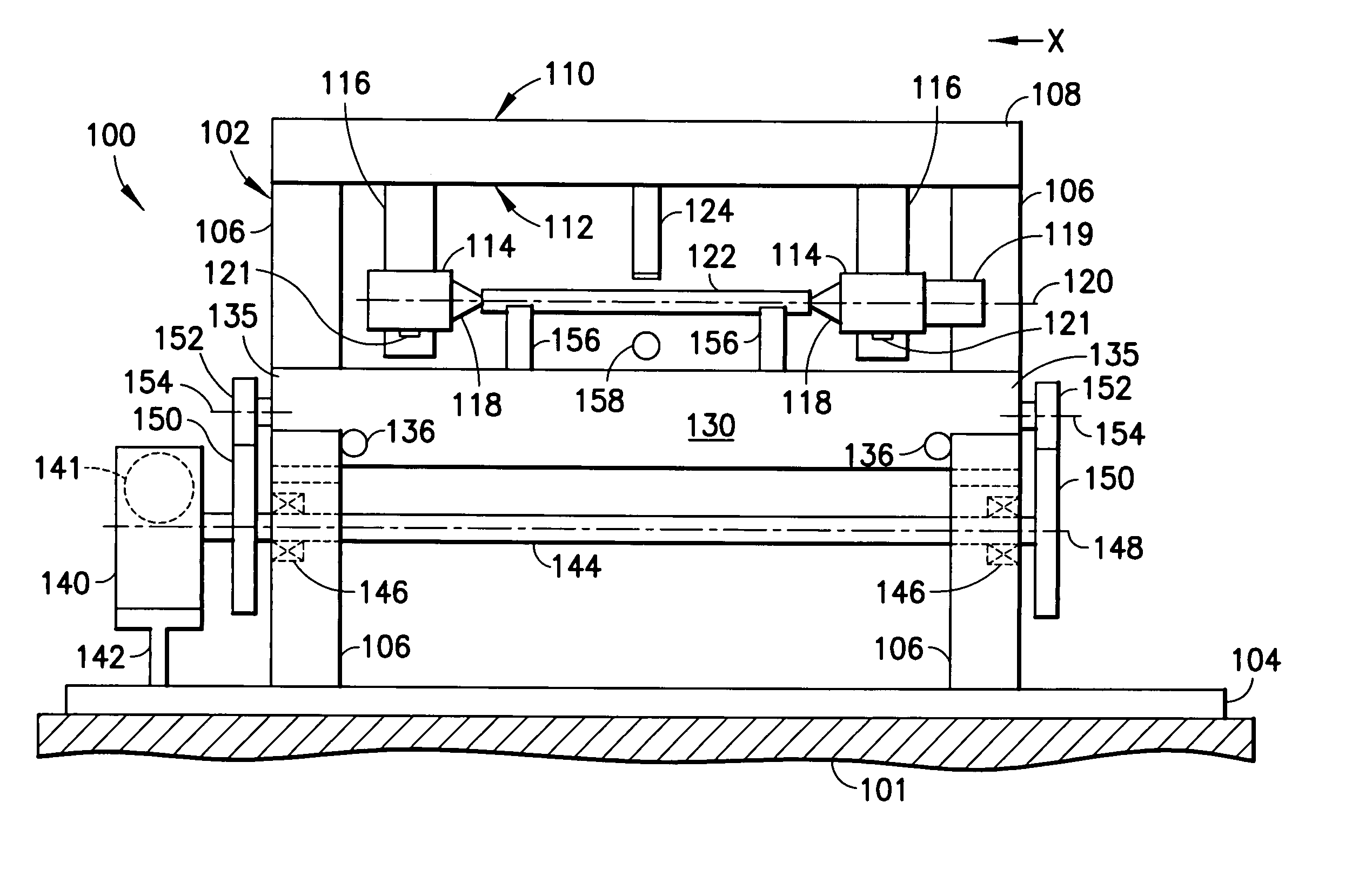

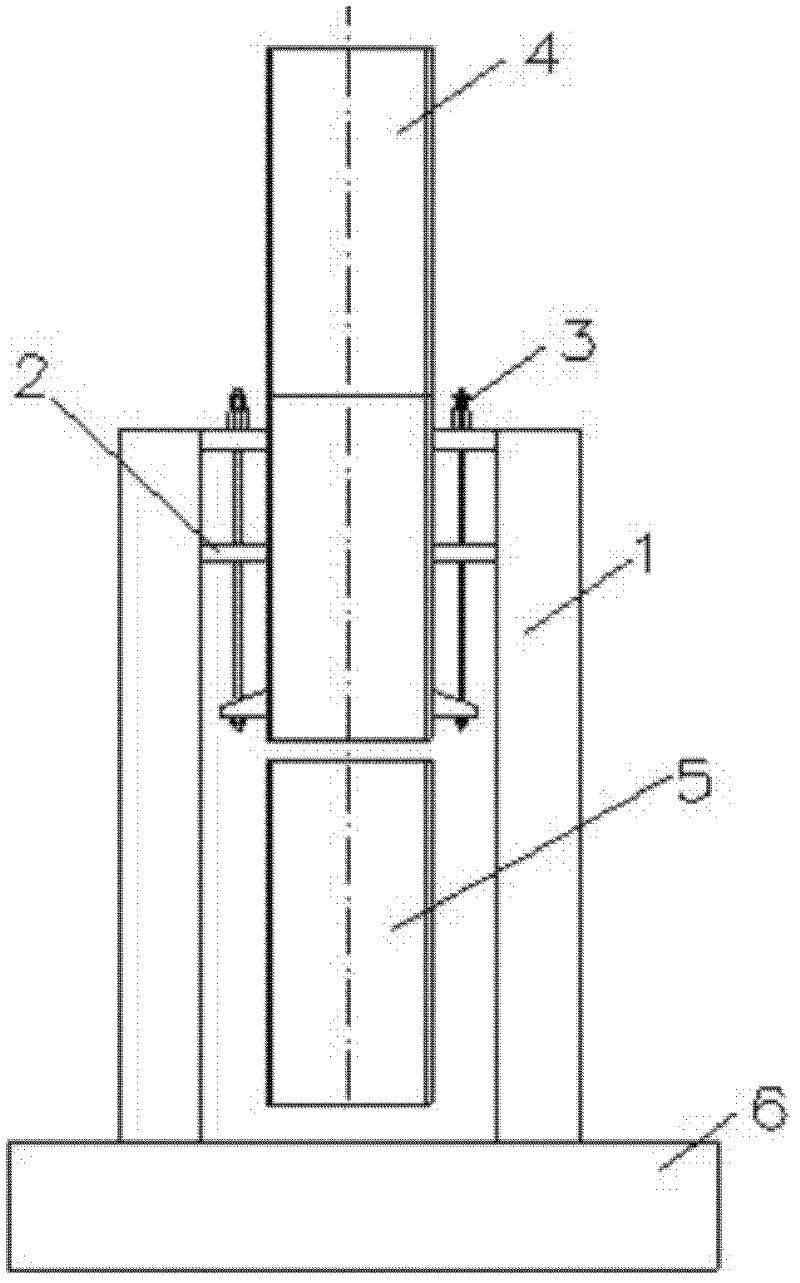

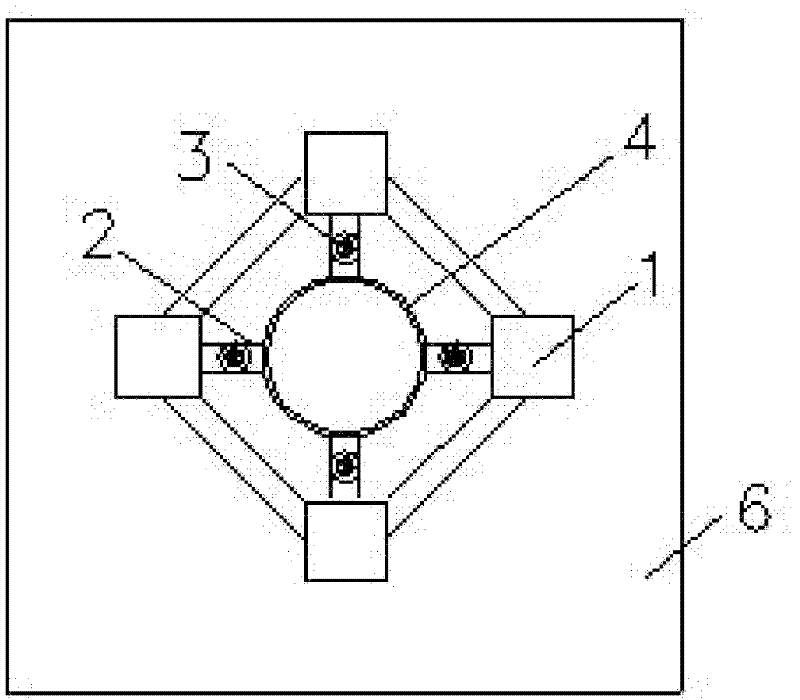

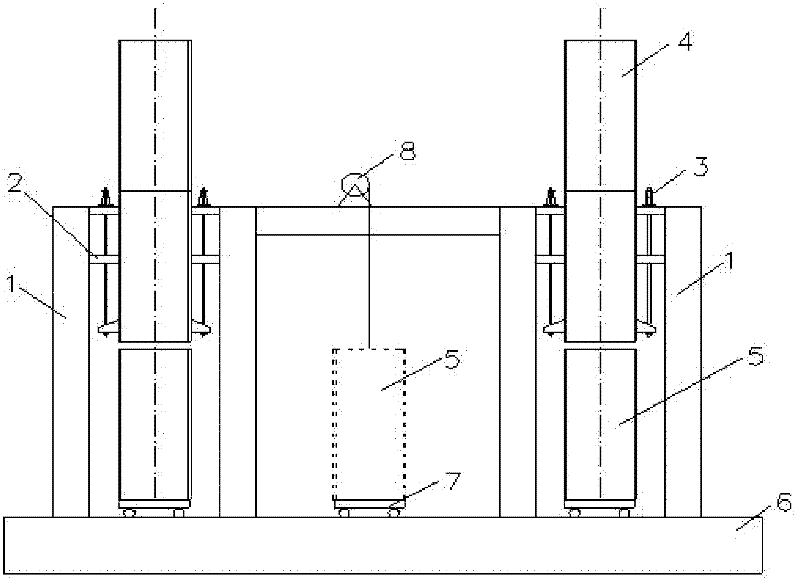

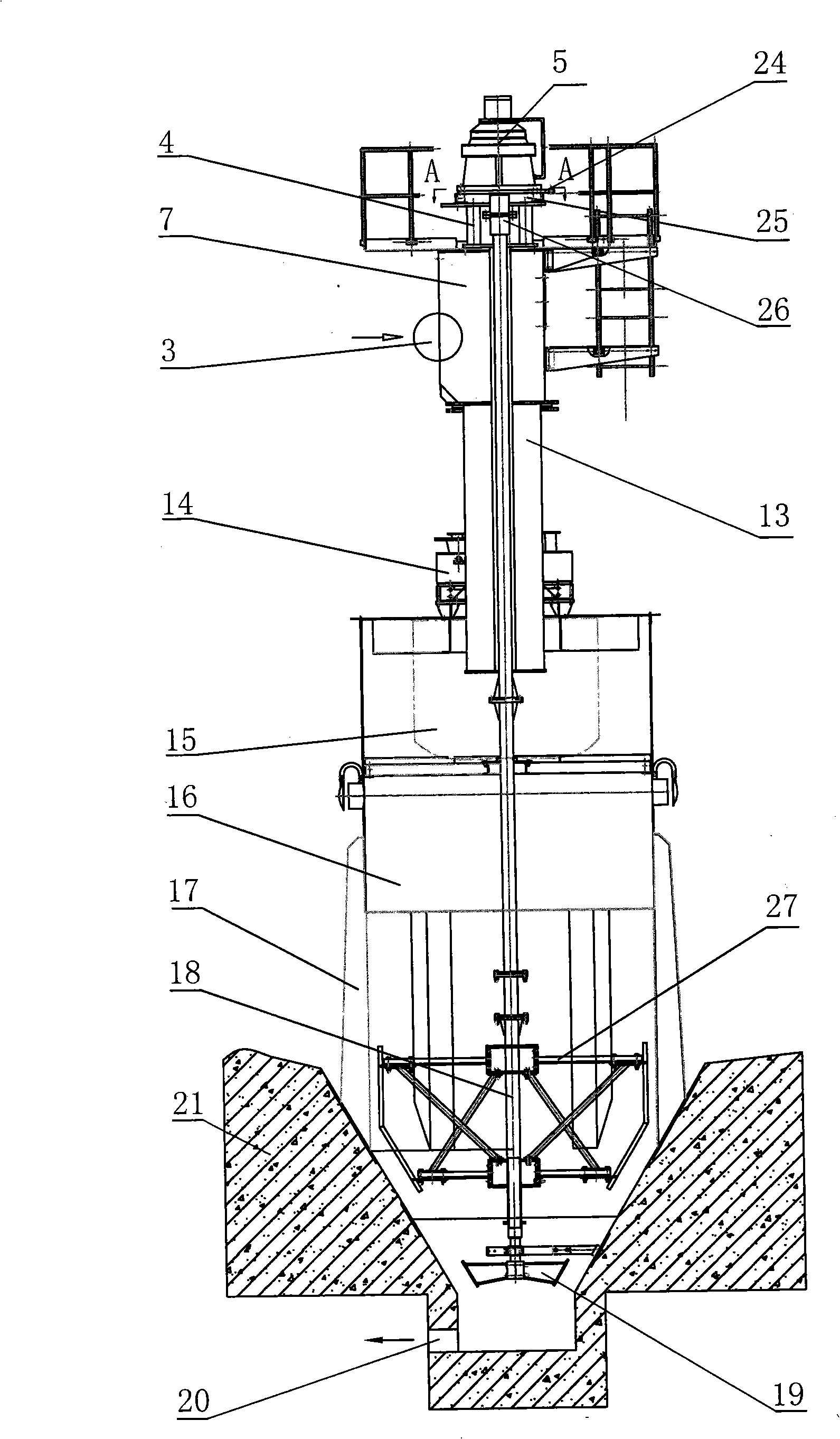

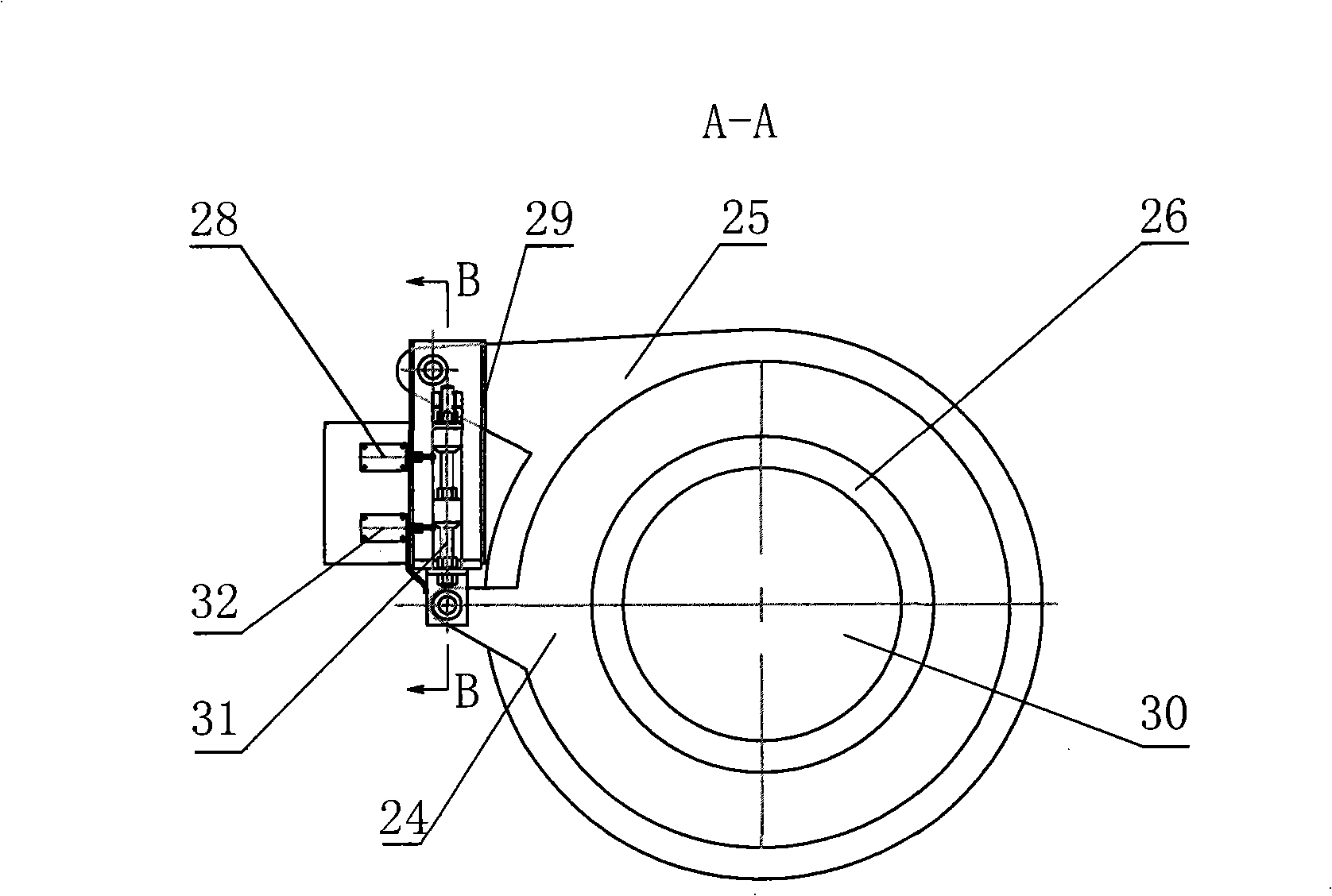

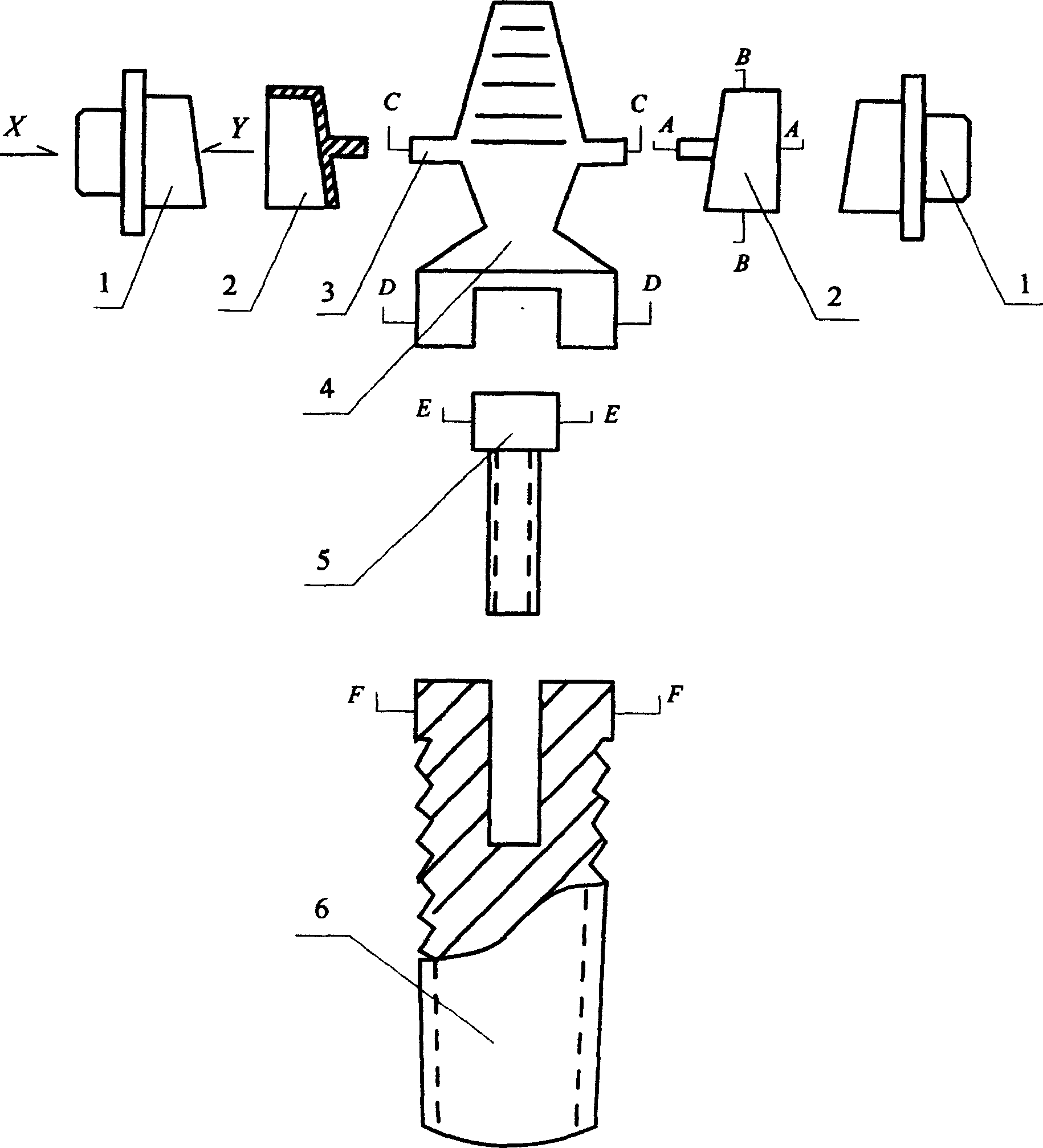

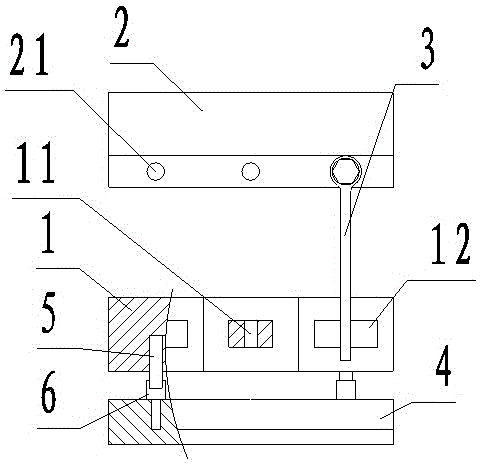

Bend-straightening machine with vertically movable table

A bend-straightening machine with a vertically movable table for straightening long workpieces is provided. The bend-straightening machine of the present disclosure includes straightening supports for supporting a workpiece mounted on a movable table which moves in a vertical plane driven by a driving mechanism. The machine is constructed as a rigid frame including a base for supporting at least one upright column. A fixed bridge is joined to an upper portion of the upright column and supplies a stationary surface for mounting at least two workpiece holding fixtures, which grip the ends of the workpiece, allowing the workpiece to be rotated. Also, mounted to the bridge is at least one straightening punch which remains stationary during straightening. The moving table and straightening supports act vertically upward on the workpiece causing the workpiece to bend, i.e., straighten, when it contacts the straightening punch.

Owner:MAE EITEL

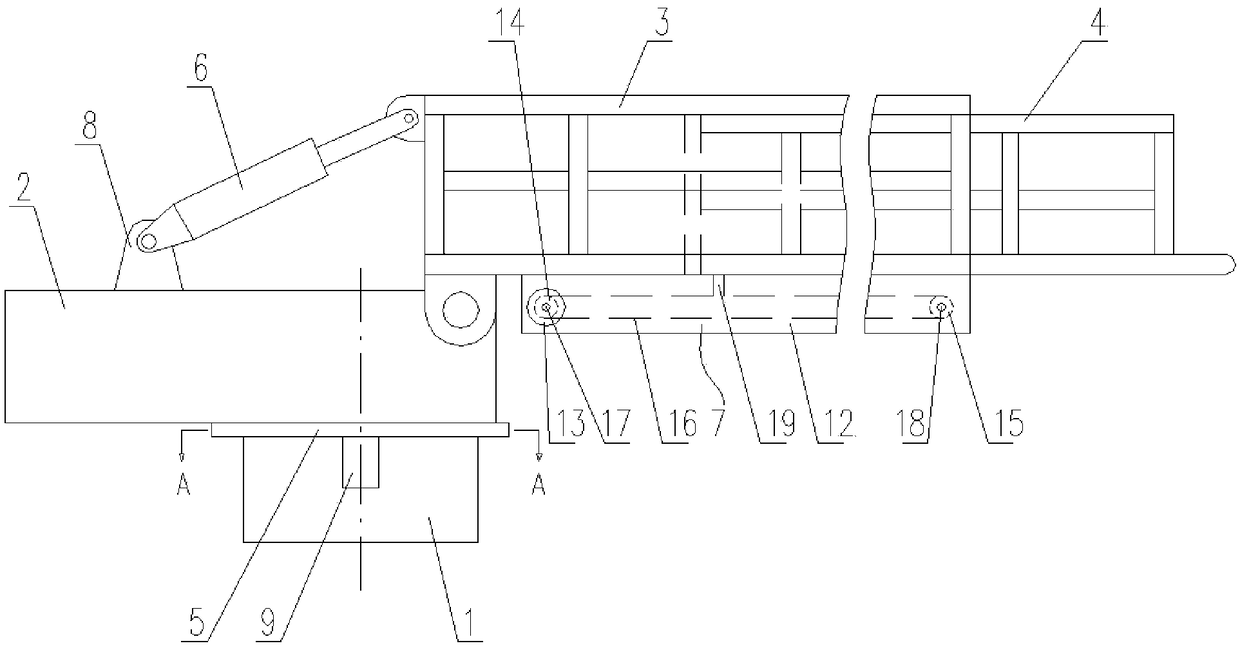

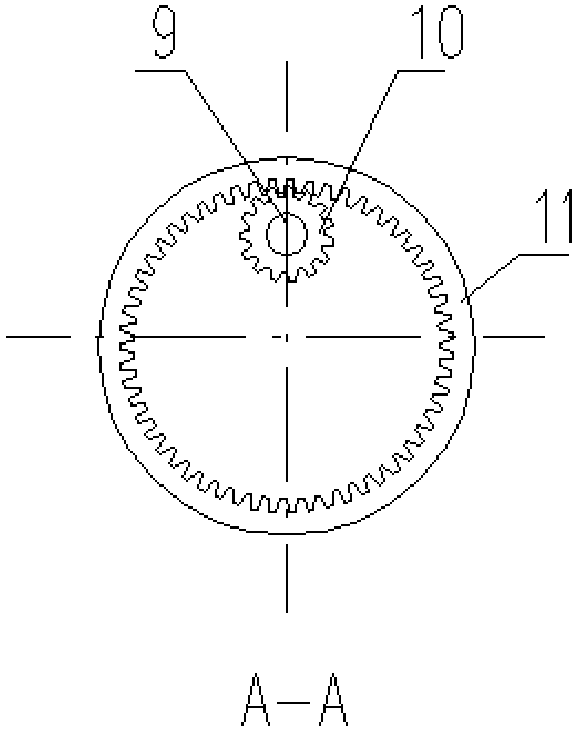

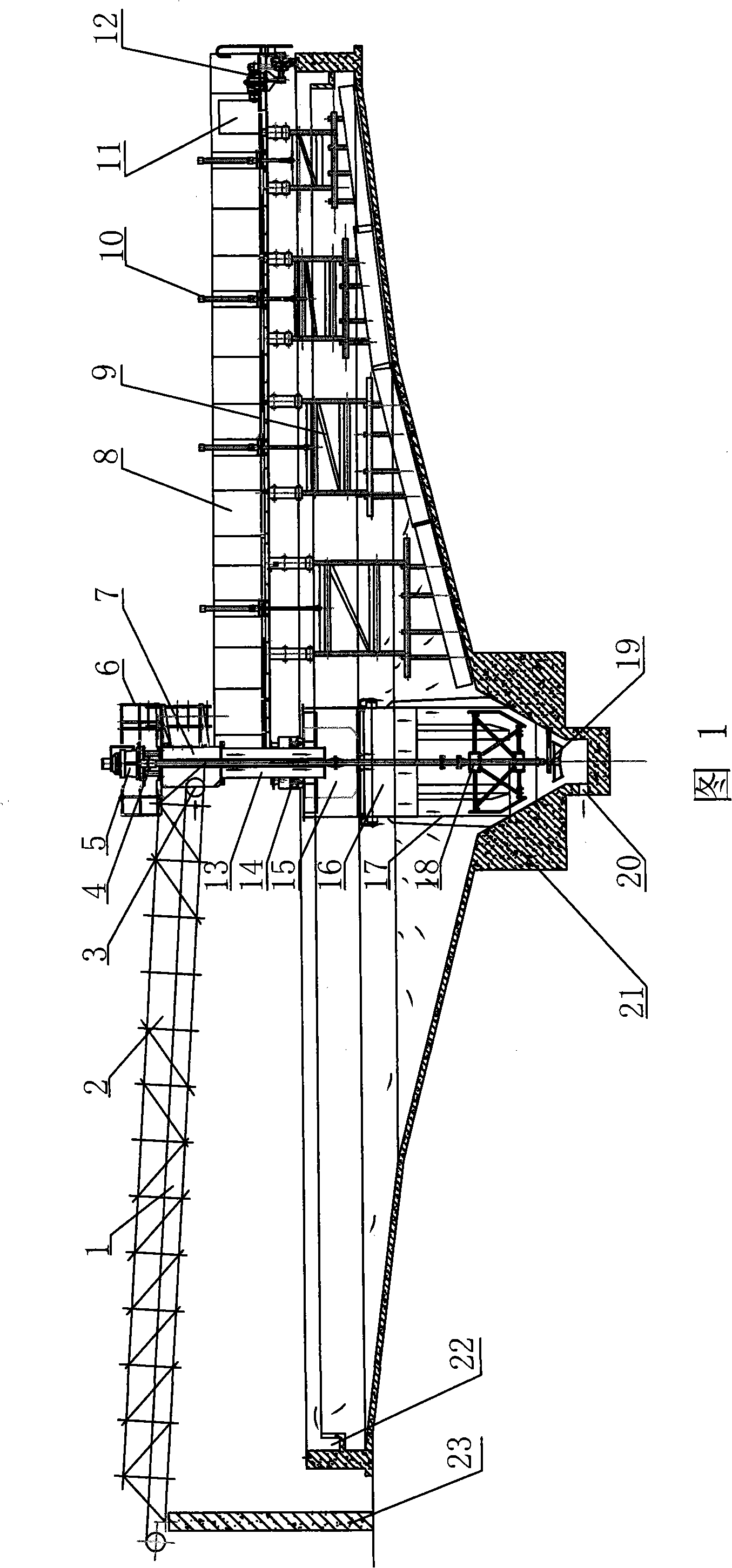

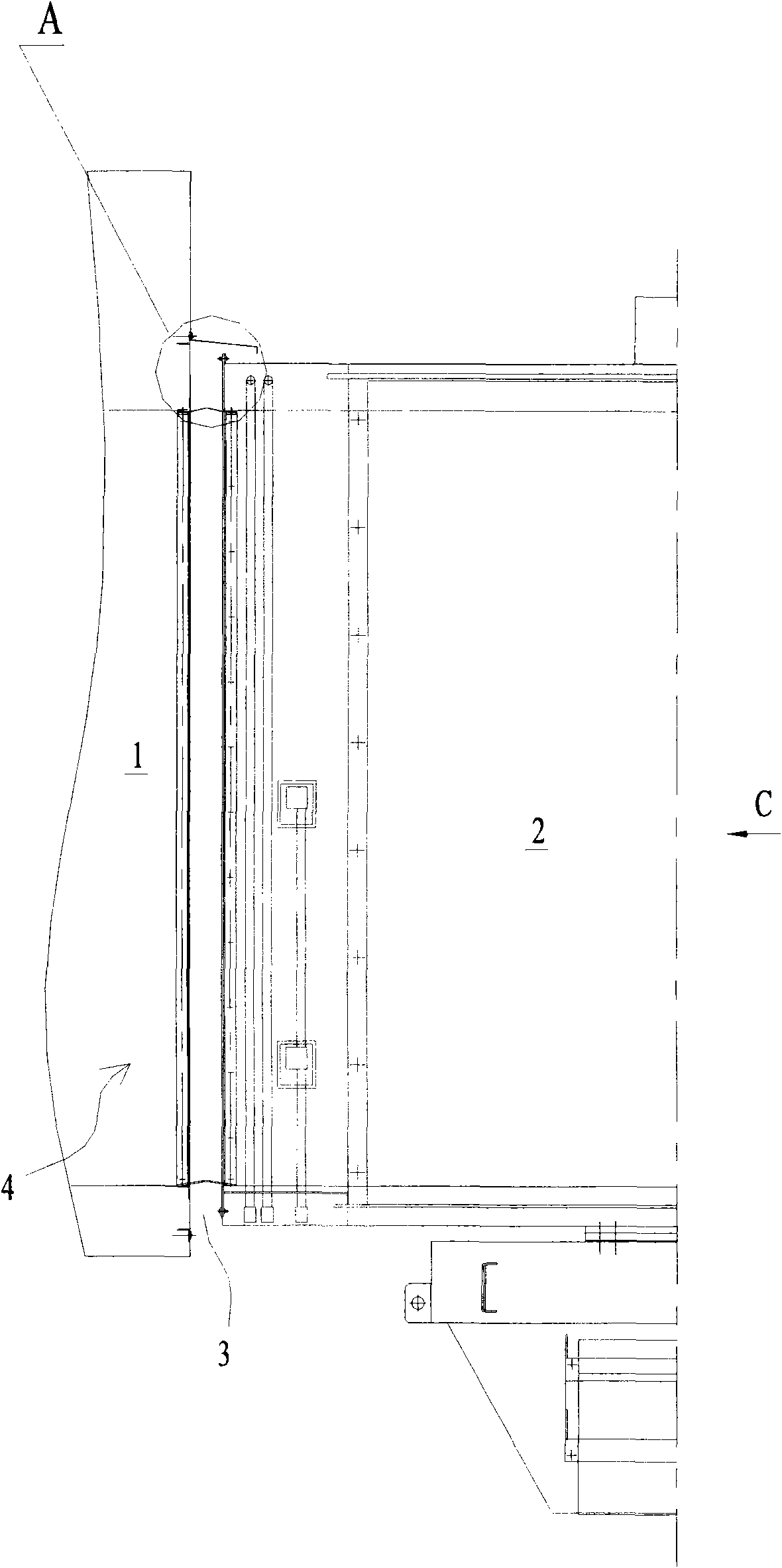

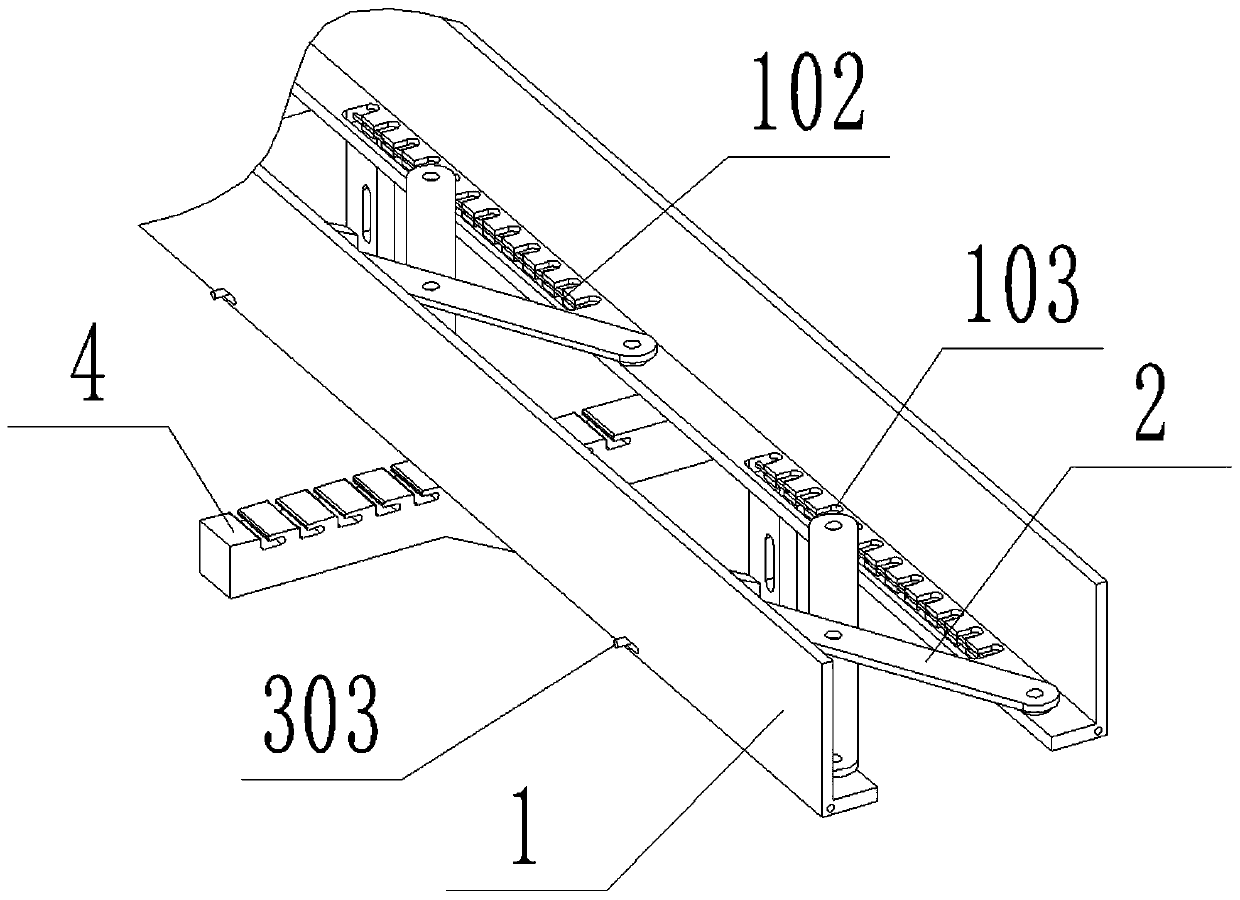

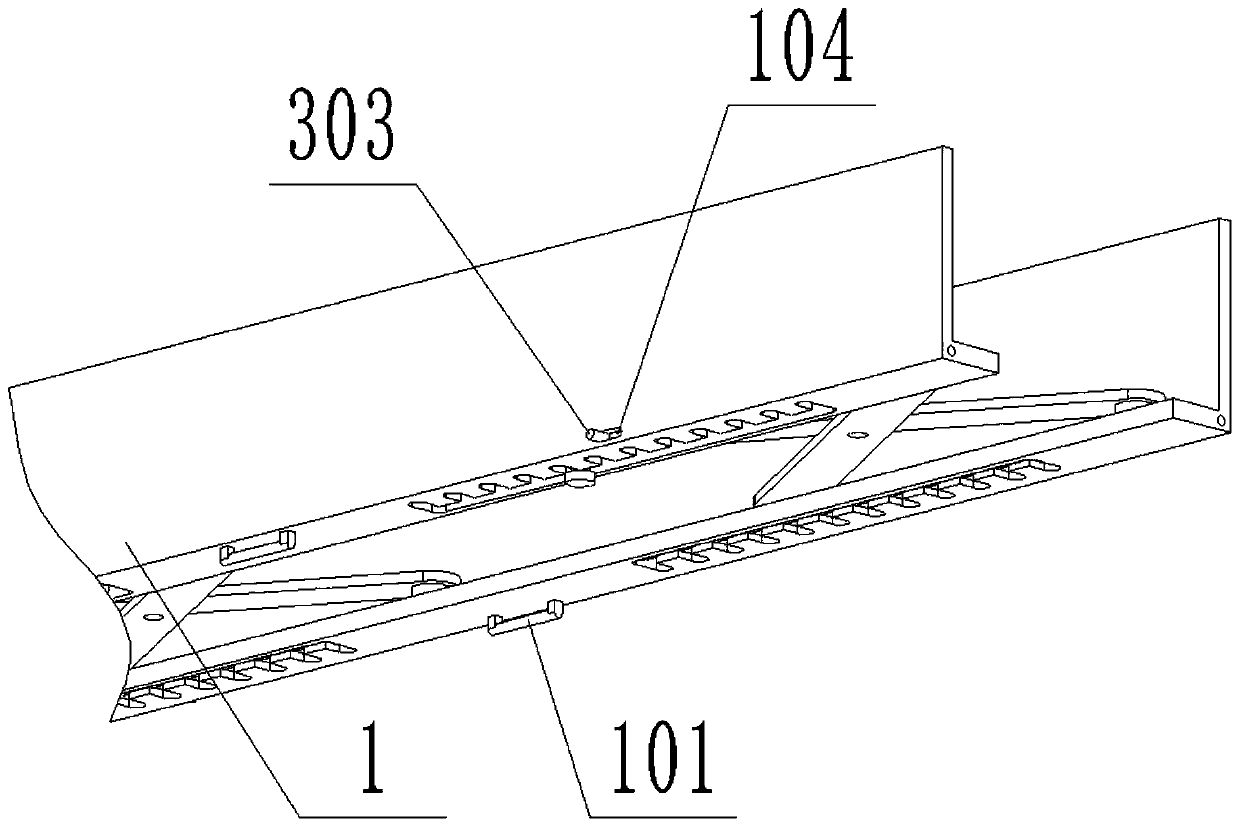

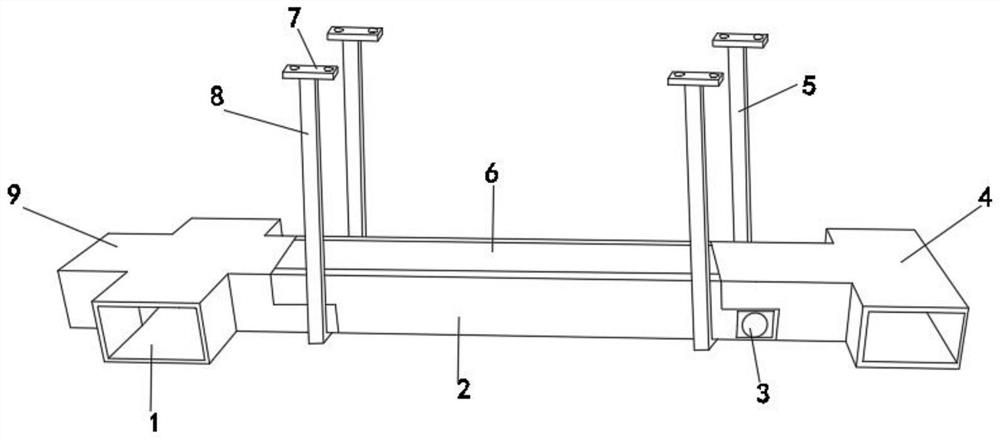

Gangway bridge with rotating, pitching and extending-retracting functions

InactiveCN108407982AEffective carryingTransportation safetyCargo handling apparatusPassenger handling apparatusThree degrees of freedomStructural engineering

The invention discloses a gangway bridge with rotating, pitching and extending-retracting functions, and belongs to the field of marine engineering. The problem that maintenance personnel of a marinefixed structure and materials needed for maintenance cannot be stably conveyed and transferred to a structure platform from an operation and maintenance ship is solved. The gangway bridge comprises arotating seat, a gangway bridge base, a fixed bridge ladder and a sliding bridge ladder; a rotating mechanism is mounted on the rotating seat; the gangway bridge base makes 360-degree rotating movement under the effect of the rotating mechanism; a pitching hydraulic oil cylinder is mounted on the upper end face of the gangway bridge base; the fixed bridge ladder is hinged to the gangway bridge base and connected with the pitching hydraulic oil cylinder, and the fixed bridge ladder makes vertical pitching movement under the effect of the pitching hydraulic oil cylinder; a gangway bridge telescopic transmission device is mounted at the bottom of the fixed bridge ladder; the sliding bridge ladder is sleeved with the fixed bridge ladder; and the sliding bridge ladder makes telescopic movementunder the effect of the gangway bridge telescopic transmission device. According to the gangway bridge, under the effect of the three degrees of freedom, the gangway bridge can be effectively overlapped to the marine structure, and thus the operation and maintenance personnel and the materials are safely and quickly conveyed.

Owner:重庆海士智能科技研究院有限公司 +3

Jacking bracket system for segmented mounting of bridge tower and construction process thereof

ActiveCN102251486ARealize segmented installationSave auxiliary materialsBridge erection/assemblyBridge engineeringTower

The invention relates to a jacking bracket system for segmented mounting of a bridge tower and a construction process thereof, belonging to the field of bridge engineering. The segmented-mounted jacking bracket system is formed by matching fixed brackets, limiting devices and jacking devices. The construction process is characterized in that the brackets are fixed on the circumference of the design position of the bridge tower; a top section for mounting the bridge tower is arranged in the brackets and is lifted to a certain height by using the jacking devices; the height is lower than the height of the brackets and higher than the height of the section of the bridge tower; the circumference of the bridge tower is fixed by using the limiting devices on the bracket, so that the bridge tower is erected in a suspended state; a second section is spliced at the lower end of the top section; two spliced sections are jacked to a certain height by using the jacking devices; a third section isspliced below the spliced two sections; all sections are sequentially spliced; and finally, a bottom section of the bridge tower is connected with a foundation to finish mounting of the bridge tower.The jacking bracket system and the construction process thereof can be used for saving an auxiliary material for mounting the bridge tower; meanwhile, the mounting operation height is reduced and theconstruction safety is improved.

Owner:CHINA FIRST HIGHWAY ENG

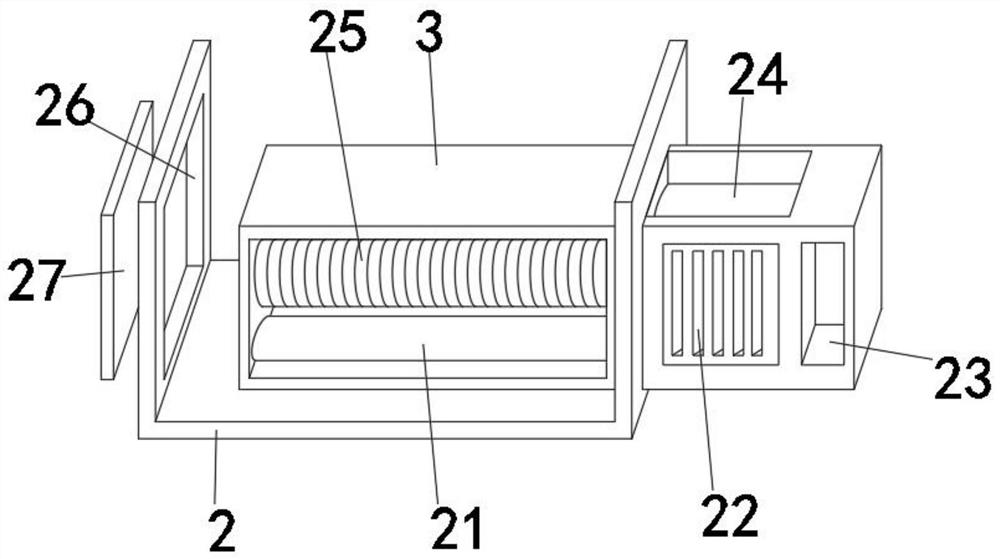

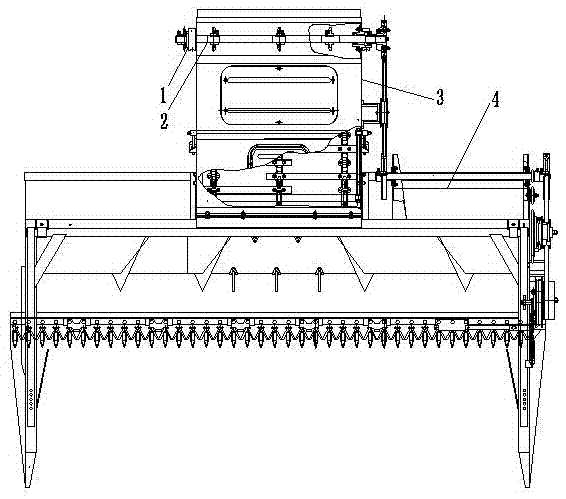

Automatic rake-lifting concentrator

ActiveCN101259337AStrong adaptability to dehydrationAdaptableSedimentation settling tanksEngineeringWater level

An automatic rake lifting thickener consists of a main axis, a bridge, a mud scraping rake, a chute, a feed port, a flow distributing barrel, a flow stabilizing barrel, a material room and a main axis driving device. The technical requirements are as follows: the main axis is arranged at the center of the cell body, and is provided with a central stirring device and failure pre-remover; the bridge consists of a fixed bridge which feeds materials and a rotary bridge which can drive a plurality of adjustable mud-scraping rakes to rotate. In the segmented hydraulic automatic lifting rake of the invention, the rake frames can be separately or collectively lifted according to the resistance, which is reliable; the height of the rakes lifting can be randomly adjusted according to the need, and the mud scraping board can be lifted from the lowest working position to above the water level, thus facilitating maintenance; a traveling gear and the main axis driving device can respectively drive the continuous variable rotation of the bridges and the central stirring device, and has the advantage of strong adaptability to the dehydration operation of different pulps. The thickener has the advantages of high automation, labor force saving, good gas-liquid separation effect, wide sphere of application, reliability and security, stable operation and high work efficiency, etc.

Owner:DALIAN DEETOP HEAVY IND

Split-bridge stent design

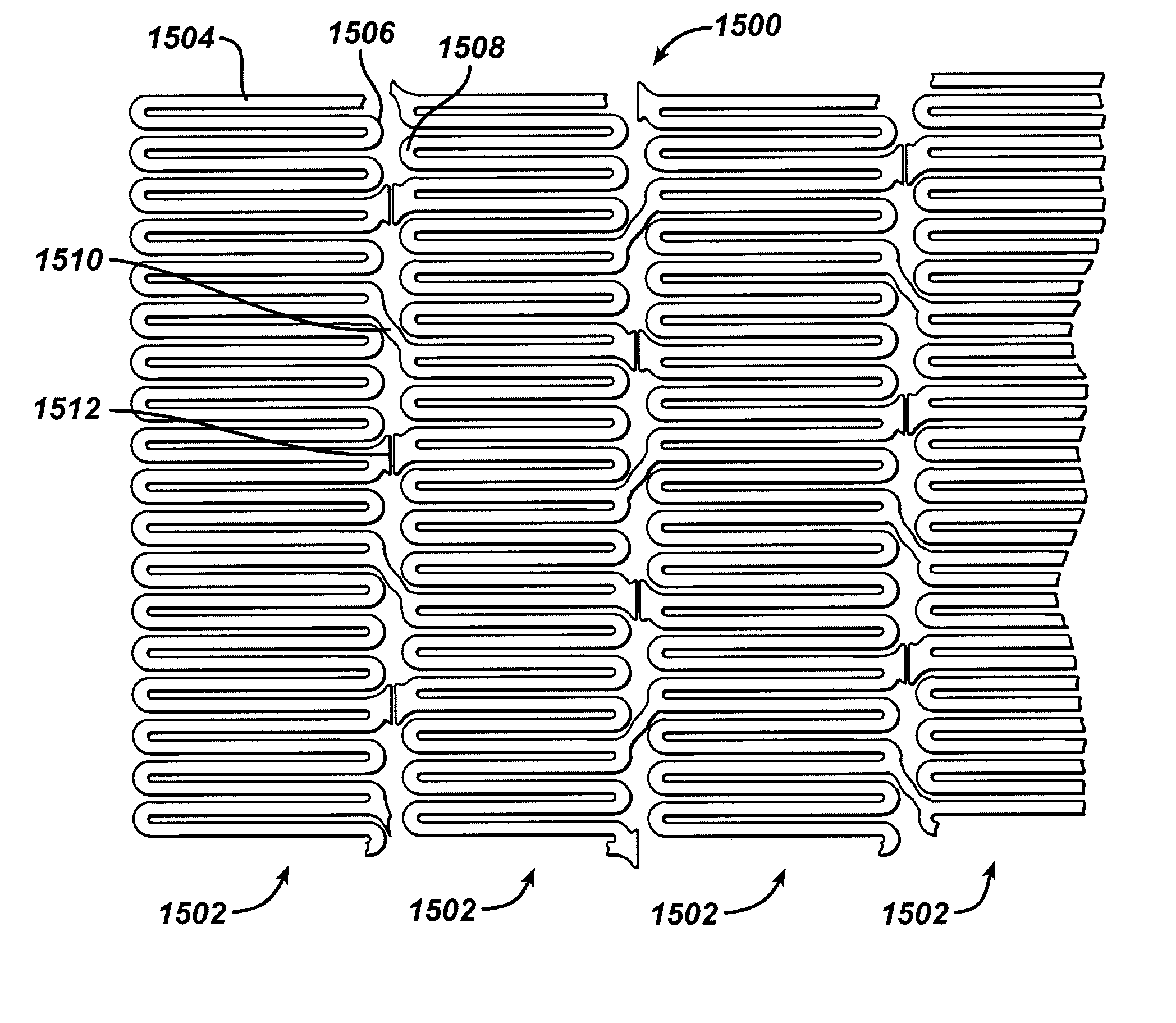

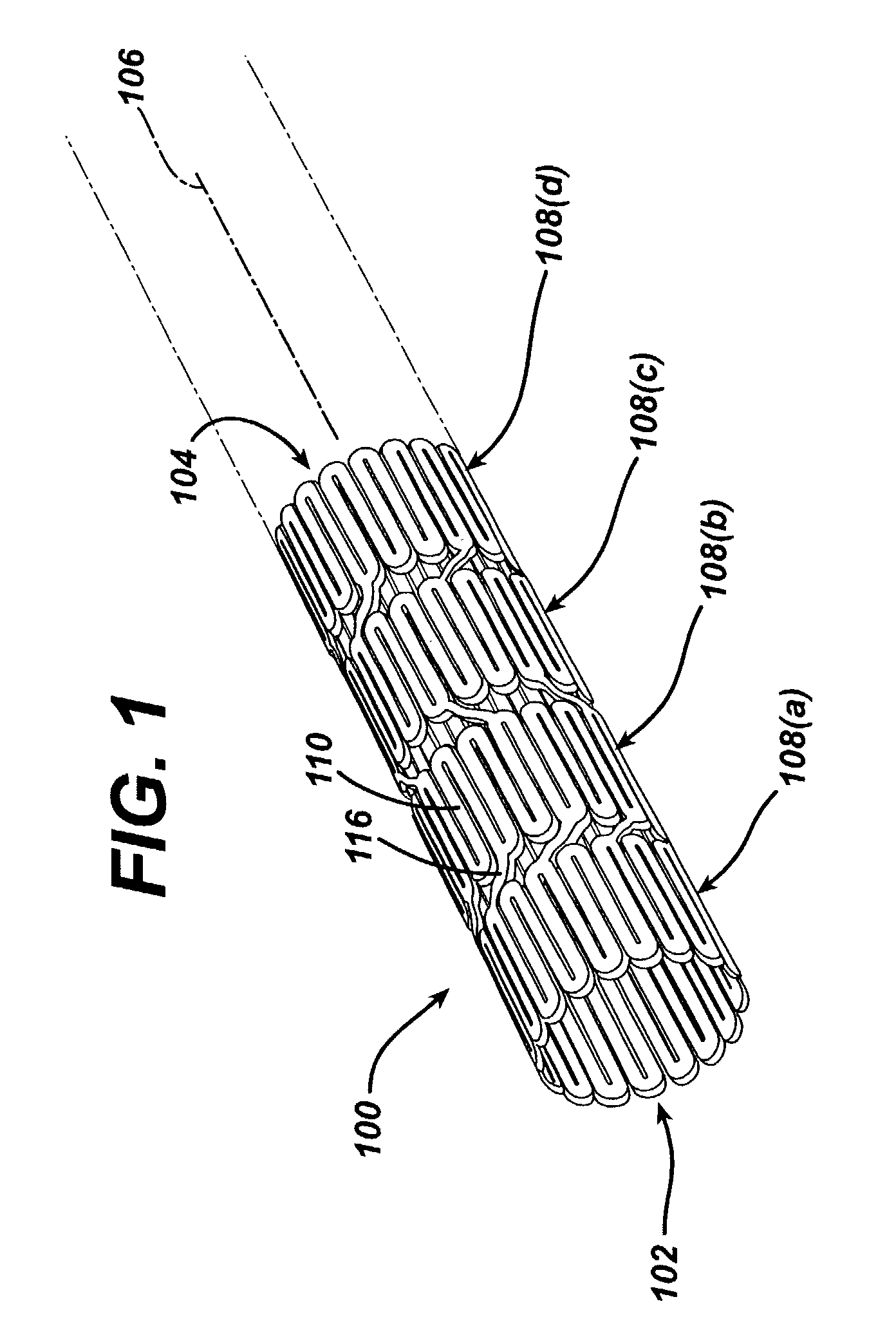

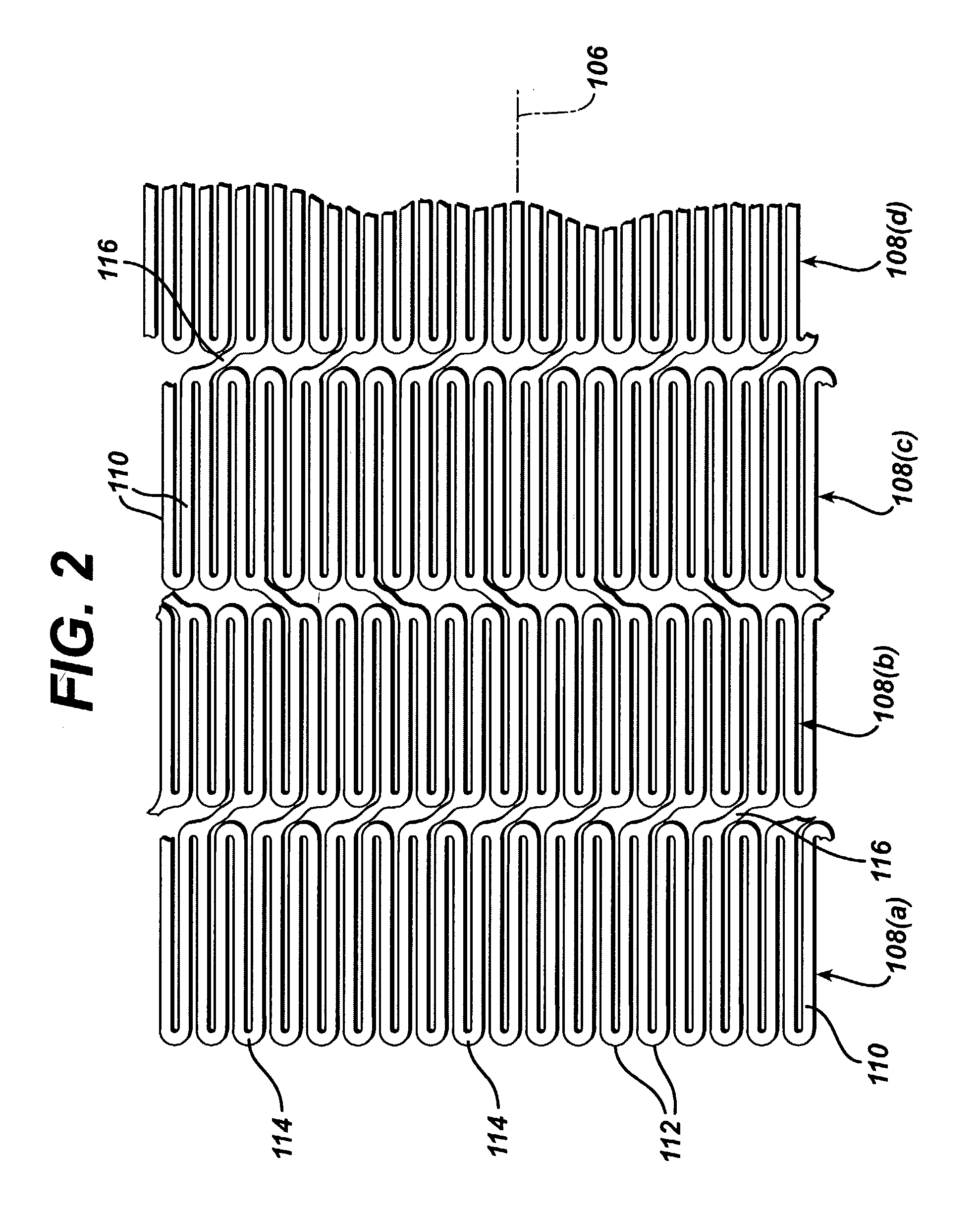

InactiveUS7214240B2Increase flexibilityLess-flexible stentStentsBlood vesselsPower flowFixed Bridges

A stent or other intraluminal medical device may be constructed utilizing a series of split-bridges interposed between a series of fixed bridges to reduce the likelihood of deformation during stent loading and stent deployment without sacrificing overall stent flexibility. The stent comprises a plurality of hoops interconnected by a plurality of fixed bridges. The stent also comprises a plurality of split-bridges, which only make contact when the stent is subjected to compressive axial loading. The stent may also comprise markers formed from housings integral with the stent and marker inserts having a higher radiopacity than the stent. This design provides for more precise placement and post-procedural visualization in a vessel, by increasing the radiopacity of the stent under X-ray fluoroscopy. The housings are formed integral to the stent and the marker inserts are made from a material close in the galvanic series to the stent material and sized to substantially minimize the effect of galvanic corrosion. The housings are also shaped to minimize their impact on the overall profile of the stent.

Owner:CARDINAL HEALTH SWITZERLAND 515 GMBH

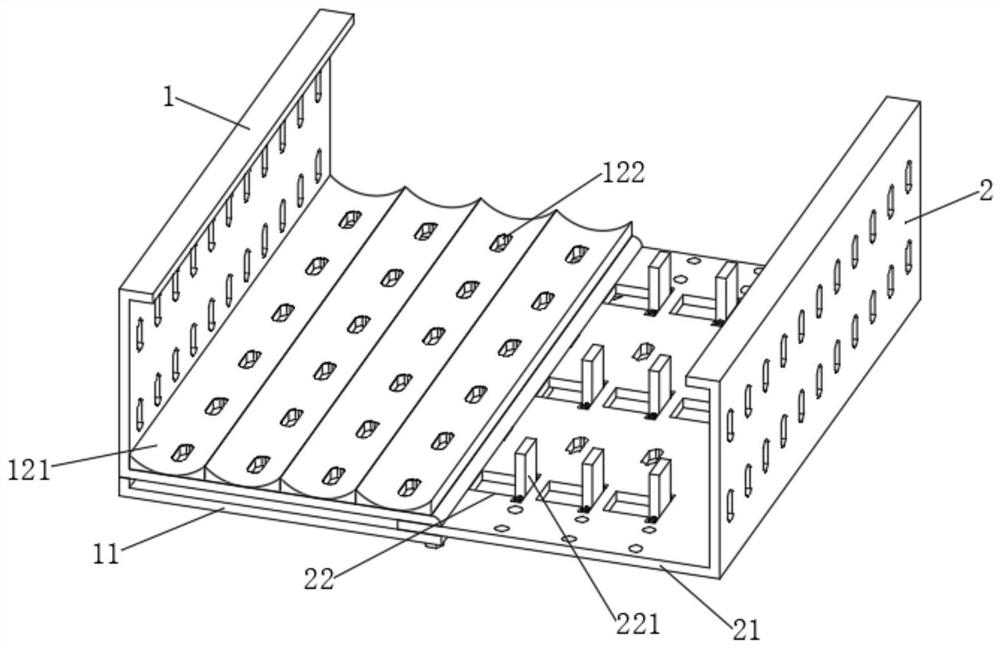

Cable bridge stand

InactiveCN108258626AEasy to installIncrease the installation areaElectrical apparatusEngineeringFixed Bridges

Owner:青岛鹏渤钢结构有限公司

Point-contact-typed explosion-proof capacitor for conductive column

InactiveCN104143436ASimplify the assembly processSimple structureFixed capacitor housing/encapsulationFixed capacitor terminalsCapacitanceEngineering

The invention discloses a point-contact-typed explosion-proof capacitor for a conductive column, and relates to the capacitor which comprises an aluminum shell and a capacitor body encapsulated in the aluminum shell. The upper end of the capacitor body and the lower end of the capacitor body are connected with first copper foil, the upper end of the aluminum shell is provided with an explosion-proof end cover, the inner side of the explosion-proof end cover is provided with a bridging-typed explosion-proof piece, and a fixed bridge is arranged between the bridging-typed explosion-proof piece and the explosion-proof end cover. The lower side of the bridging-typed explosion-proof piece is provided with second copper foil, a solid rivet is arranged in the bridging-typed explosion-proof piece, the bottom inside the aluminum shell is provided with a lower positioning sleeve, the capacitor body is inserted into the positioning sleeve, and the lower end of the bridging-typed explosion-proof piece is provided with an elongated baffle which abuts against the upper portion of the capacitor body. The point-contact-typed explosion-proof capacitor is simple in structure and easy to implement, the assembling procedures of the capacitor are simplified for a refrigerator with the capacitor, production efficiency is improved, internal heat dissipation is enhanced as well, and explosion-proof performance is enhanced.

Owner:ANHUI XINYANG ELECTRON

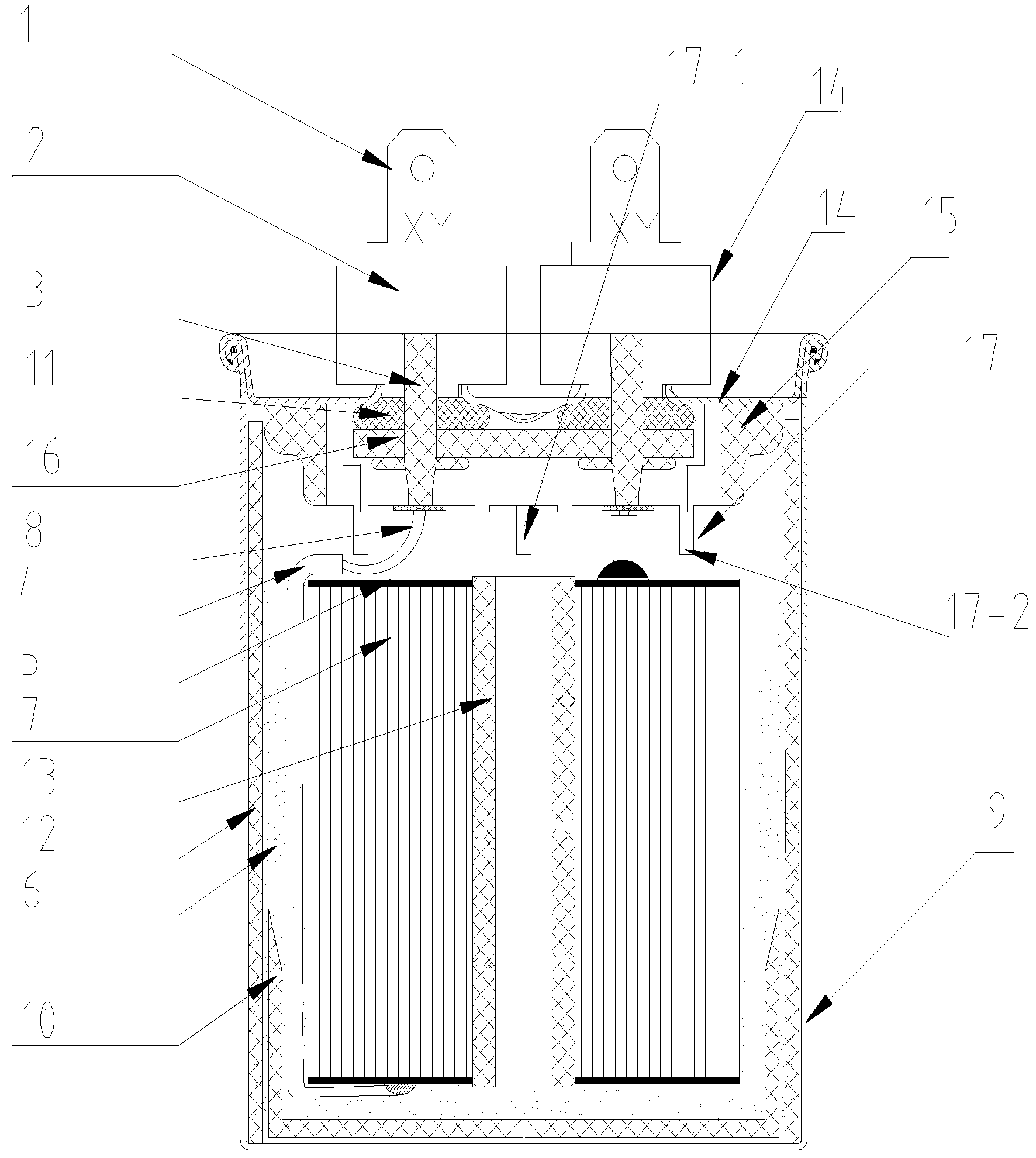

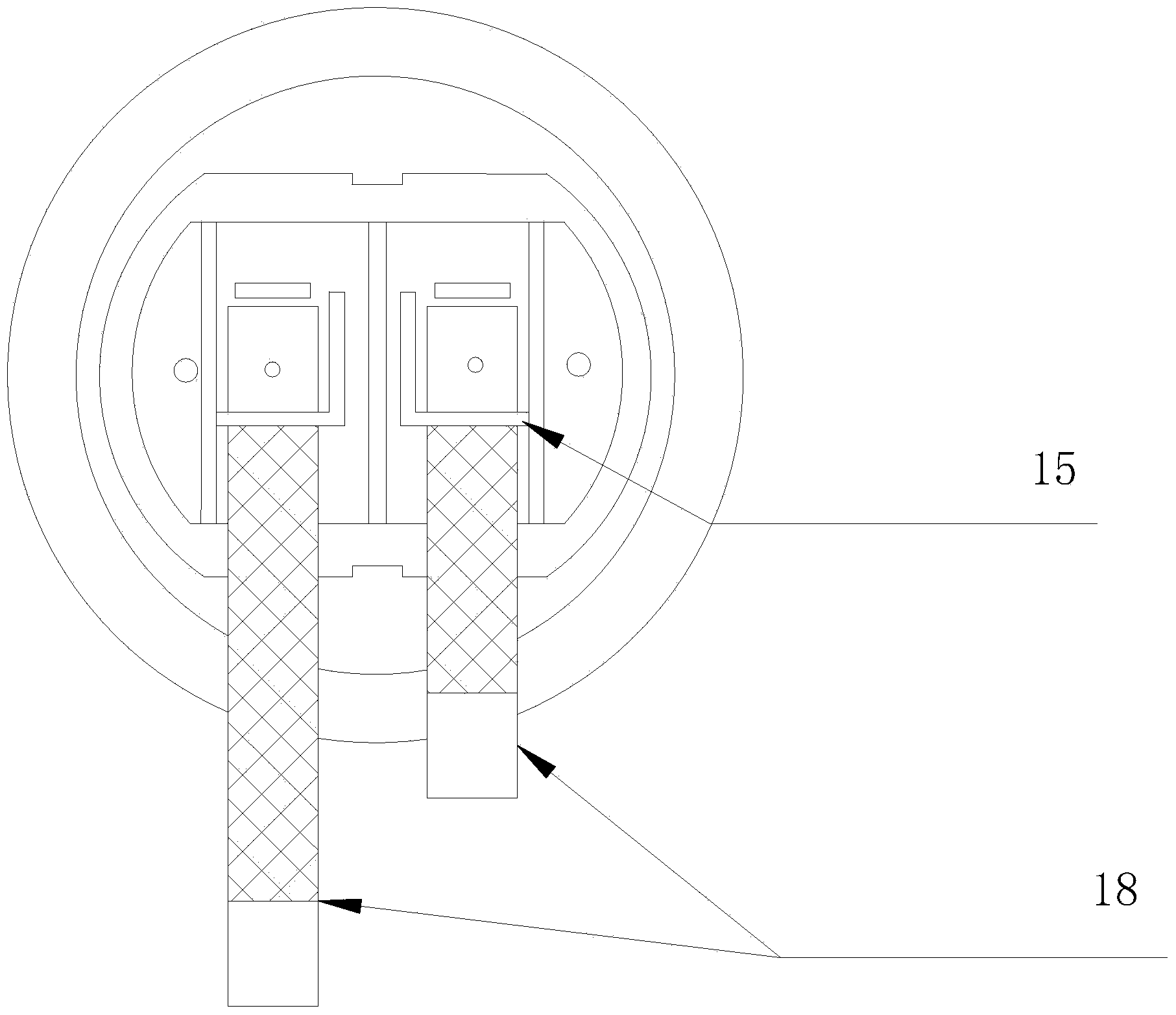

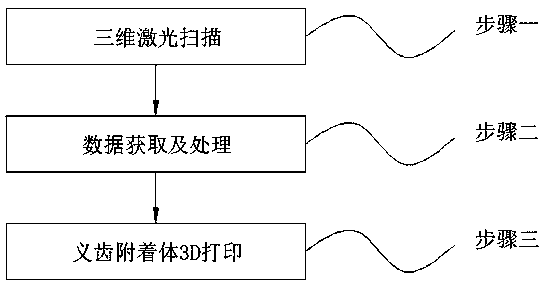

Digital integrated forming method of false tooth attachment

The invention discloses a digital integrated forming method of a false tooth attachment. The digital integrated forming method includes the following steps of 1, three-dimensional laser scanning; 2, data acquisition and processing; 3, 3D printing forming of the false tooth attachment. In the first step, according to an anterior tooth region implant fixing bridge, an extracoronal elastic attachmentfemale part, a posterior tooth region removable denture and an extracoronal elastic attachment male part which are made by an edentulous jaw model, a plaster model is prepared, white developing powder is sprayed to the metal portion of the model, a fixing bridge model is put on a laser scanner rotary table, a non-contact type three-dimensional analog converter is switched on, a horizontal laser beam is emitted to scan the plaster model, the scanning range is determined, after one face is scanned, the rotary table rotates by 90 degrees, and the other regions are scanned. After reconstruction is completed, images are clear, nest ditch pits and the attachment are accurate in structure, no obvious scanning blind region exists, convenience and rapidness are achieved, the false tooth attachmentis rapidly formed, and high efficiency is achieved.

Owner:AI JIA DENTAL LAB

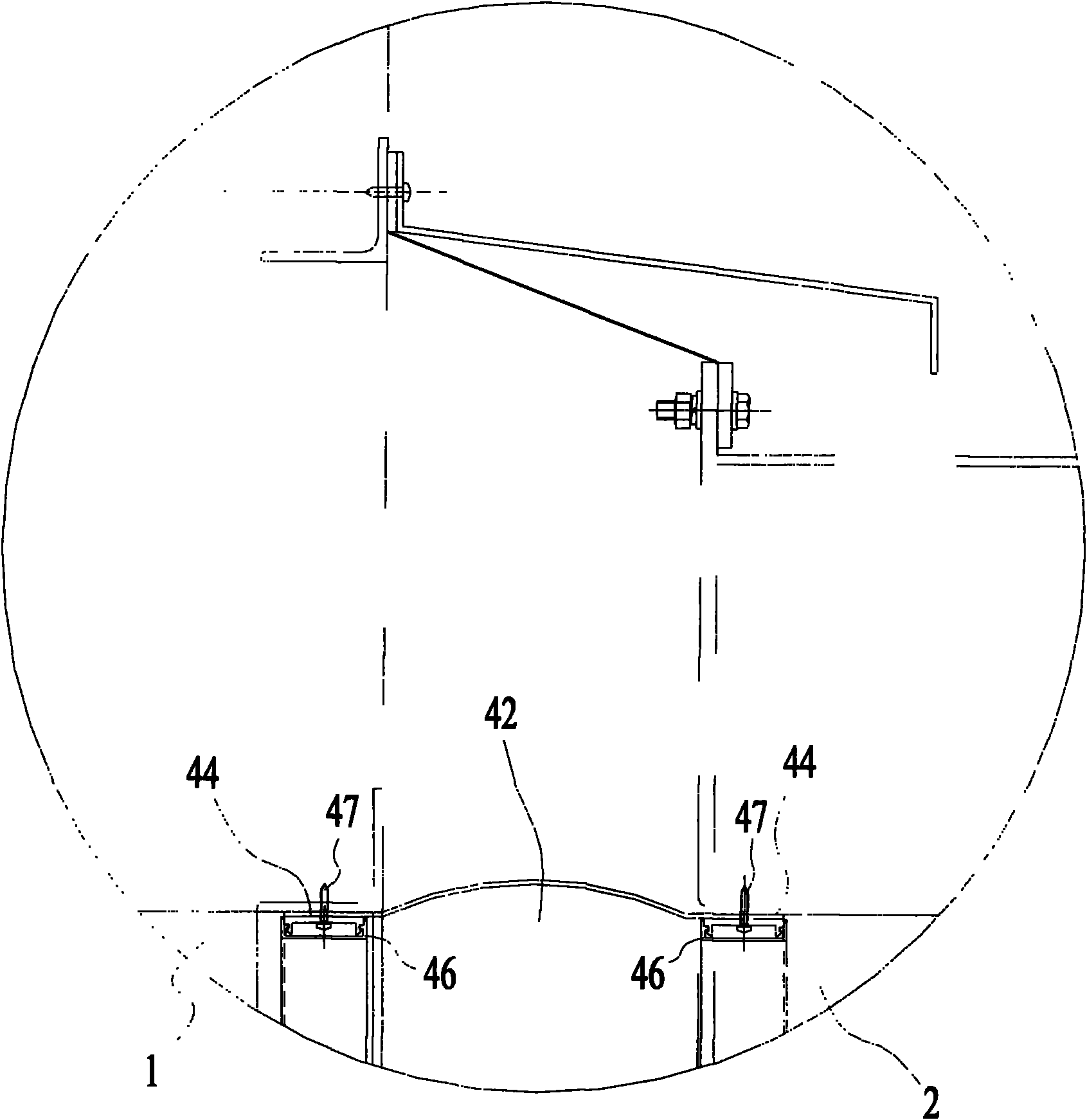

Boarding bridge flexible connection device

Owner:SHENZHEN CIMC TIANDA AIRPORT SUPPORT +1

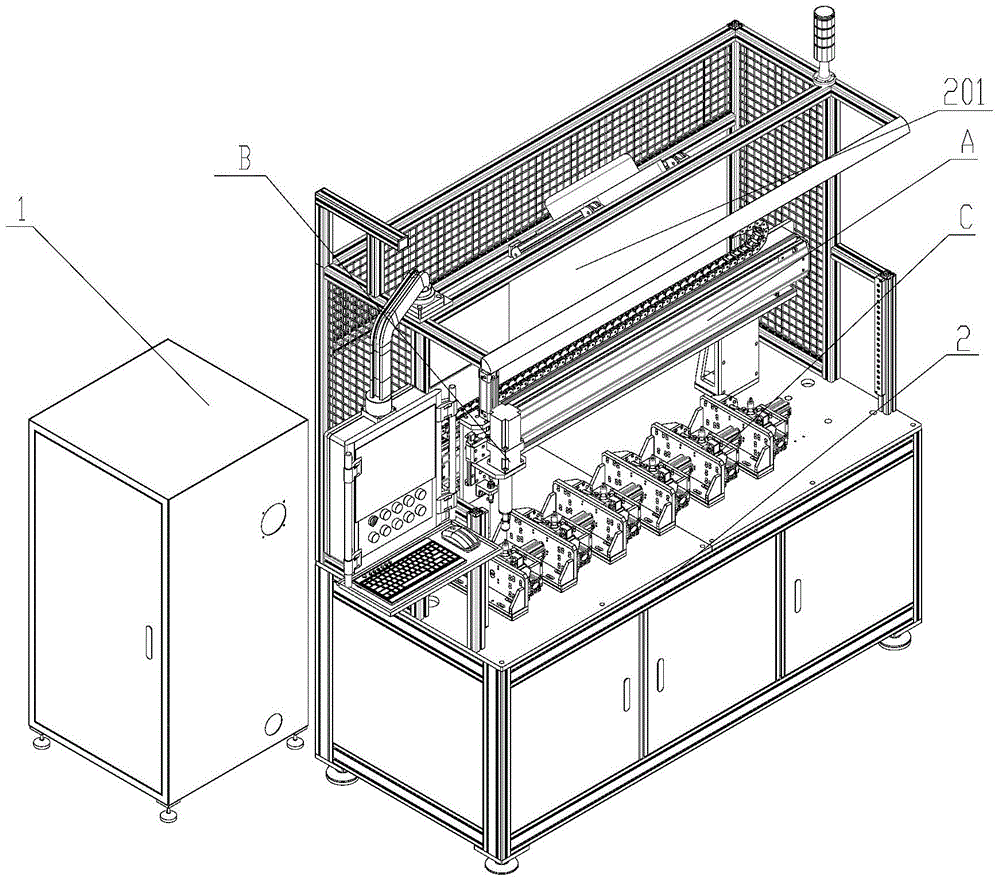

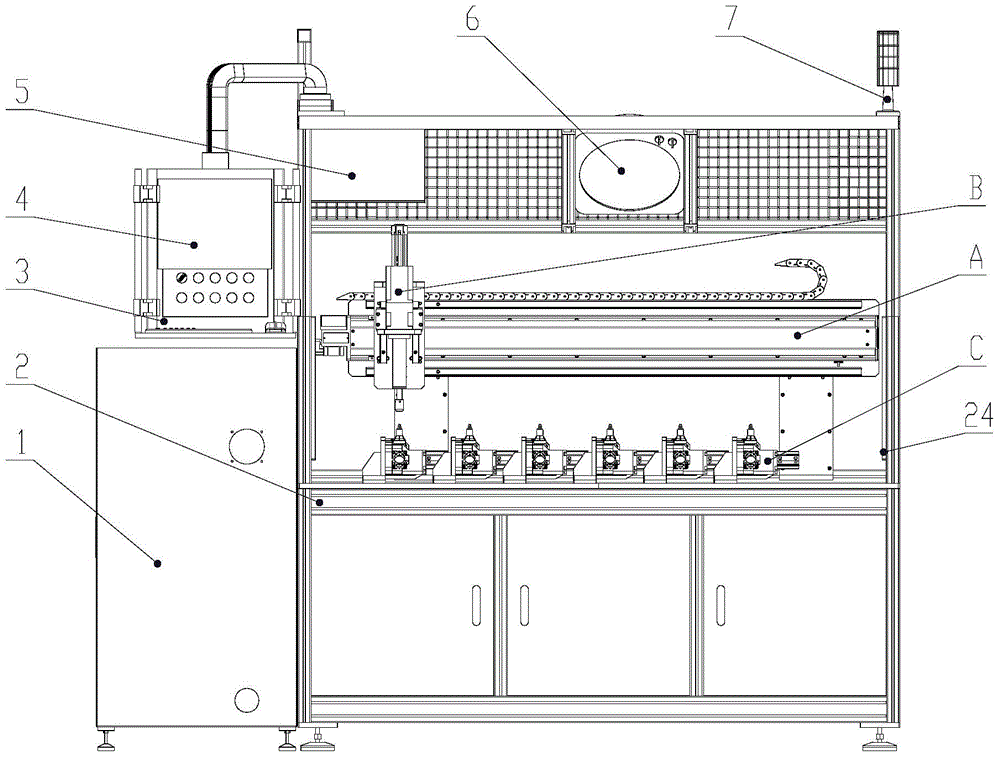

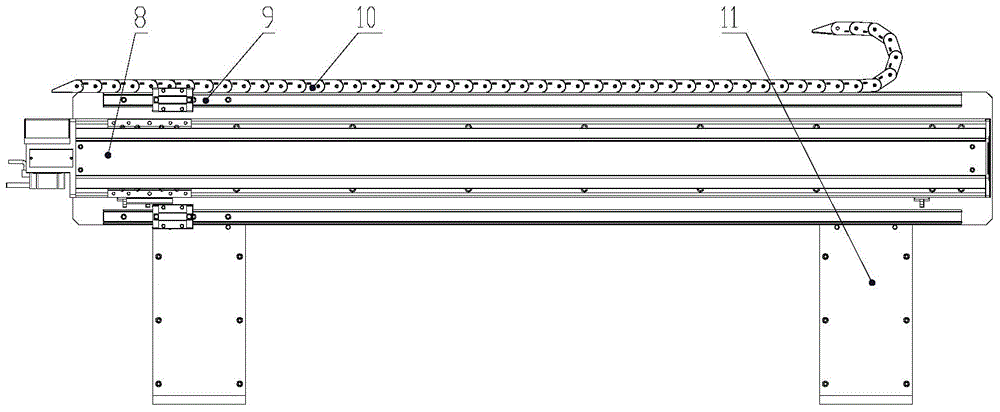

Pressure regulation and leakage detection device of automobile air filtration regulator

ActiveCN104089746AFast and accurate fixationCompact structureMeasurement of fluid loss/gain rateAir filtrationAssembly line

The invention discloses a pressure regulation and leakage detection device of an automobile air filtration regulator. The pressure regulation and leakage detection device comprises an electronic control cabinet, a test rack, a fixed bridge, a regulation tool and a positioning clamp, wherein the fixed bridge, the regulation tool and the positioning clamp are arranged on the test rack. The test rack comprises a test board panel and a rack cavity. The test board panel serves as the framework of the test rack. The space defined by the test board panel serves as the rack cavity. The fixed bridge comprises a servo sliding table, a slide rail, a drag chain and an installation frame. The regulation tool comprises a cylinder, a motor, an installation metal plate, a speed reducer, a slide rail, a screwing mechanism and an oil buffer. The positioning clamp comprises a metal plate, a cylinder, a plug, a clamping block and a positioning block. By means of the pressure regulation and leakage detection device, the leakage detection procedure and the pressure regulation procedure are fused together, the pressure regulation and leakage detection device is tightly connected with a product assembly line, the manual carrying process is omitted, management is convenient, leakage detection and pressure regulation can be conducted on six products at the same time, cost is reduced, space is saved, and efficiency is improved.

Owner:HANGZHOU WOLEI INTELLIGENT TECH

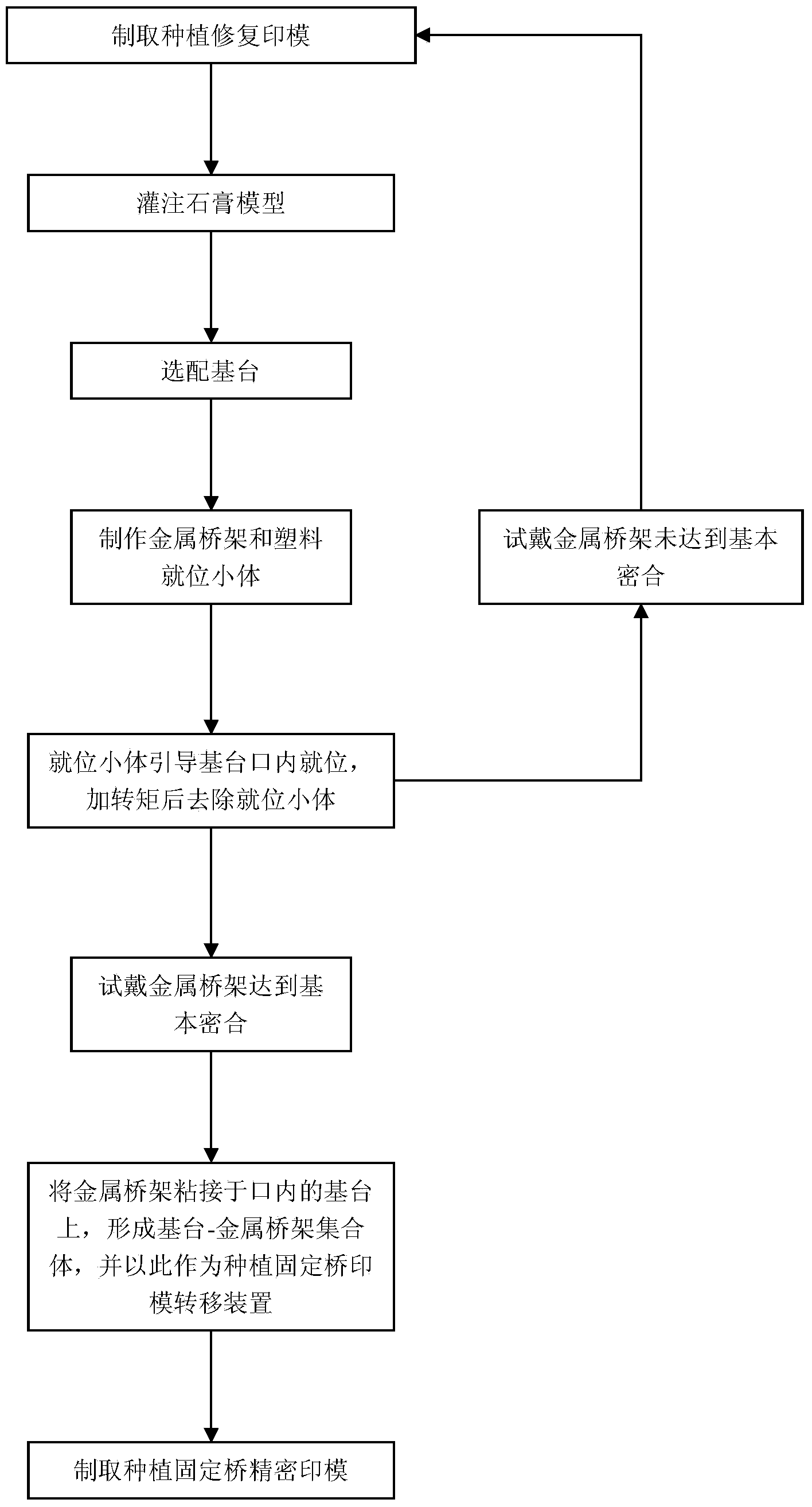

Method for preparing precise impression of implant fixed bridge

The invention discloses a method for preparing a precise impression of an implant fixed bridge. The method comprises the following steps: preparing an implant restoration impression; filling a plaster model; selecting an abutment; making a metal bridge and a plastic in-position small body; guiding the abutment to be in a mouth by the in-position small body, applying a torque, and removing the in-position small body; enabling the try-in metal bridge to reach the abutment and closely contact the abutment; bonding the metal bridge onto the abutment in the mouth to form an abutment-metal bridge combination body, and taking the combination body as a transfer device; preparing the precise impression of the implant fixed bridge. The method can be used for improving the accuracy of the impression of the implant fixed bridge. According to the method, rigid connection between abutments is realized, the bending strength of the transfer device is improved, the influence caused by deformation of an impression material can be eliminated, the deformation of model plaster can be resisted, and loosening and shifting between connection devices are avoided, thereby improving the accuracy of the impression during implant fixed bridge repairing.

Owner:赤峰学院附属医院

Width-adjustable tray type cable bridge

Owner:江苏万奇电器集团(盱眙)有限公司

Fixed bridge type planted tooth without corona sheath and its production method

The bridge-fixed implanted tooth without crown sleeve includes one body part and one connected pile and features that the pile has two wings connected to a fixing unit via a connecting cap or to the wing in other pile. The making process of the bridge-fixed planted tooth includes making female oral cavity mold with the position of adjacent teeth; making male oral cavity mold with fixing unit connecting cap, fixing planted unit and pile connecting core; setting implant pile and welding the two wings with connecting cap; and making the upper structure of the implanted artificial tooth. The present invention makes adjacent teeth share partial pressure and reduces the pressure of the implant tooth to alveolar bone to prolong the service life of the implanted tooth. Separating the implant into two, one outer and one inside, parts facilitates the clinical operation.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

Oral implant fixed bridge device for fatigue and tensile test and manufacturing method thereof

ActiveCN106236300AEven by forceGuaranteed In Vitro Fatigue TestDental implantsMaterial strength using tensile/compressive forcesFatigue loadingAdhesive

The invention relates to an oral implant fixed bridge device for a fatigue and tensile test. The oral implant fixed bridge device comprises a rigid fixed bridge, a base, a base station and an alternative body. The rigid fixed bridge and the base station are adhered and fixed through an adhesive; the base station is connected with the alternative body; the base and the alternative body are fixed into a whole. A retention hole boss is designed on each dental crown cheek and on the side edge of a tongue of the rigid fixed bridge; a retention hole is processed on each retention hole boss; a tensioning and fixing device and drag hooks are designed; hook ends of the drag hooks are matched with the retention holes and can penetrate through the retention holes; the upper ends of the drag hooks are fixed onto the tensioning and fixing device. The oral implant fixed bridge device provided by the invention has the advantages that the whole stressing is uniform, the oral implant fixed bridge device can be used for the comprehensive fatigue and tensile test, the fixed bridge is enabled to conduct an external fatigue test, a thermal-cooling cycling test and the like, a running-in test can be directly conducted to simulate chewing movement in a mouth, an oral environment is simulated to an extreme, the tested fixed bridge can be used for conducting the tensile test so as to detect the change of an adhesive property of the adhesive after a prosthesis is subjected to a certain fatigue loading test, and an experimental basis is provided for selecting the adhesive clinically.

Owner:福建医科大学附属口腔医院

Integrated adjustable bridge structure for high-voltage cable construction

ActiveCN110752563AAdjustable widthSmall footprintElectrical apparatusArchitectural engineeringStructural engineering

The invention provides an integrated adjustable bridge structure for high-voltage cable construction. The integrated adjustable bridge structure comprises side plates, a fixed clamping shaft and a movable end clamping groove; the bottoms of two groups of the side plates are connected through multiple groups of bottom surface connecting rods; a group of lock pins are slidably connected to the innersides of the bottoms of each group of side plates; and multiple groups of bridge support arms are plugged together at the bottoms of the two groups of the side plates. According to the integrated adjustable bridge structure for the high-voltage cable construction provided by the invention, the two groups of the side plates are connected together and a bottom surface is formed by adopting a shears-fork mechanism; the distance between the two groups of side plates can be arbitrarily adjusted during use, and the bridge width can be conveniently adjusted; at the same time, a roller is fixed on the clamping groove by a clamping tooth when the clamping tooth is released by hands, so that the shears-fork mechanism cannot be changed, so that the bridge width can be fixed, and different numbers ofcables can be applied; and when cables in the bridge are increased, the width of the bridge can be adjusted without re-adding or replacing the bridge, thereby reducing the installation operations, increasing the construction speed and reducing the cost.

Owner:JIANGSU ELECTRIC POWER CO

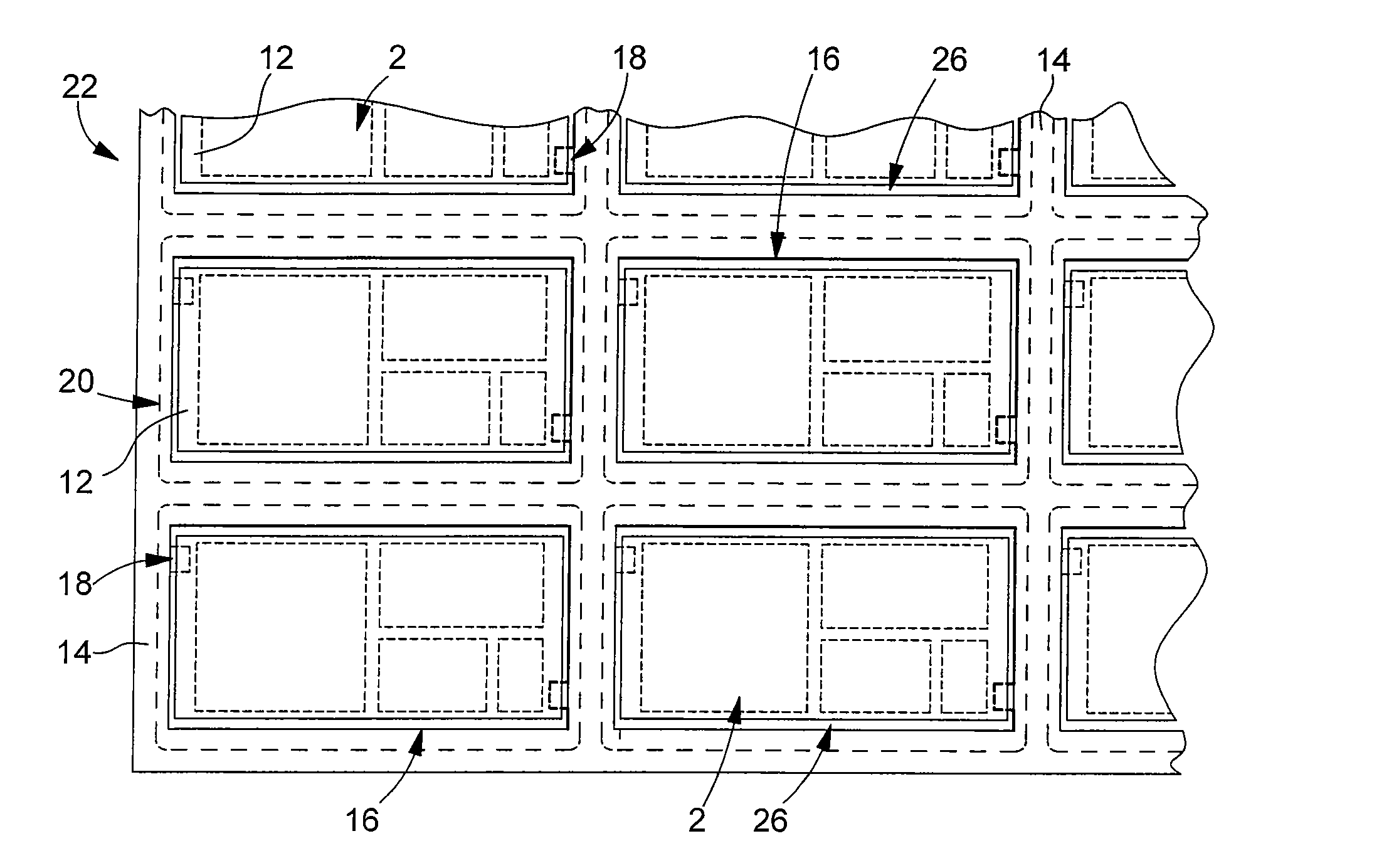

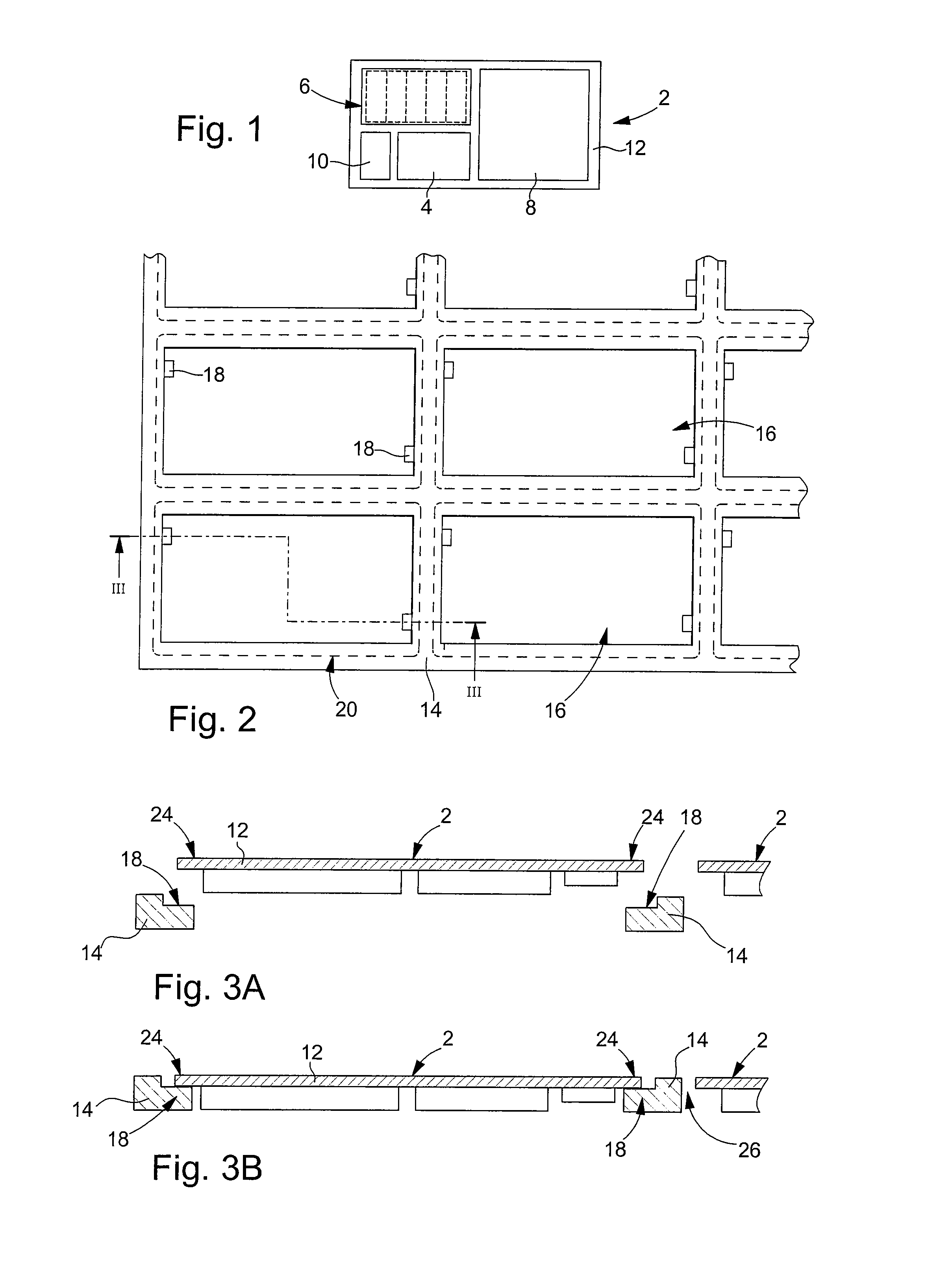

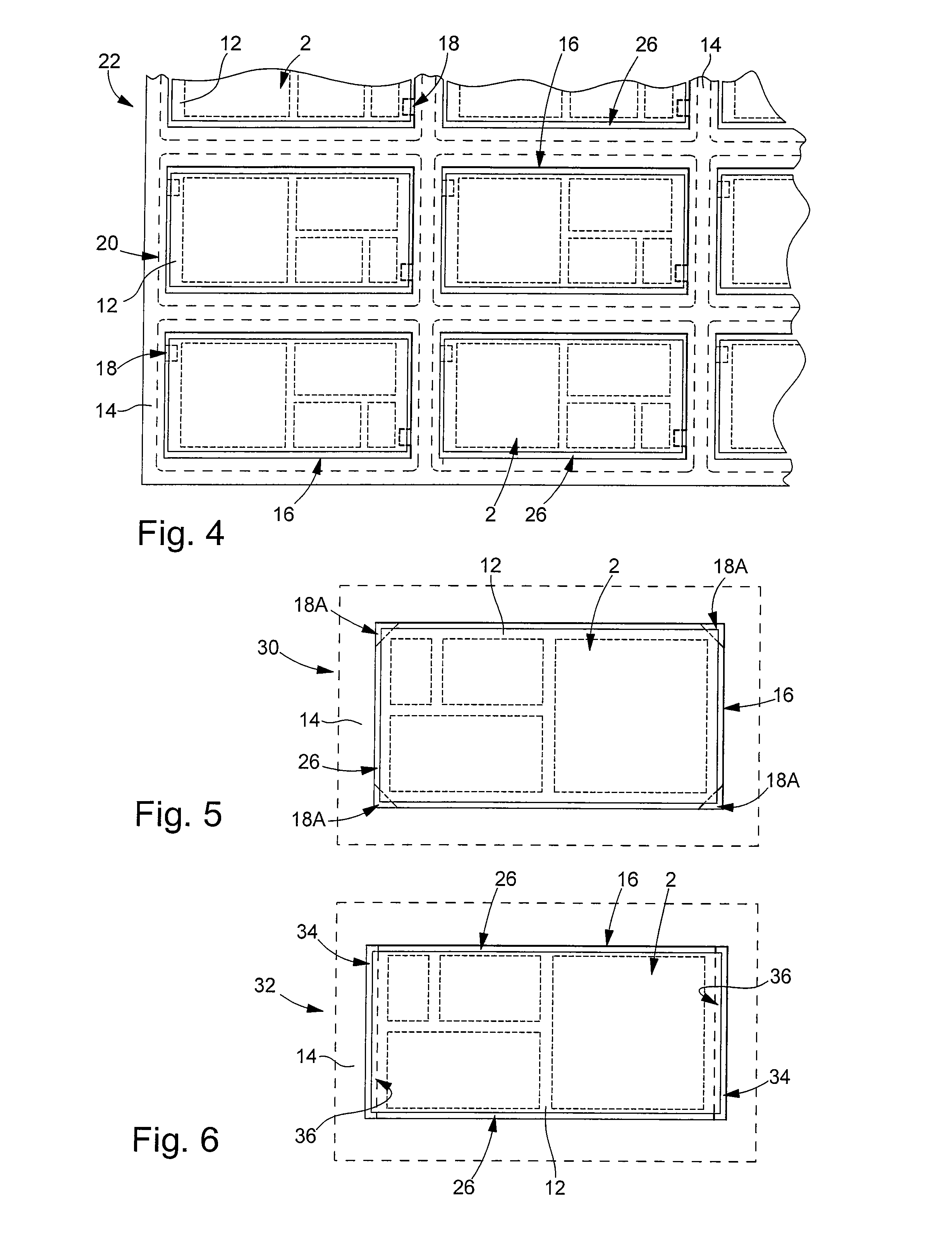

Method of manufacturing cards comprising at least one electronic module, assembly produced during this method and intermediate products

ActiveUS20100090009A1Synthetic resin layered productsSolid-state devicesFilling materialsComputer module

The assembly (22) involved in the fabrication of electronic cards comprises a plate (14) exhibiting a plurality of apertures (16) in which are respectively housed a plurality of electronic modules (2). These electronic modules are assembled to the plate 14 by fixing means, in particular by fixing bridges leaving a slot (26) over the major part of the surround of the electronic module. For example the fixing means are formed by projecting parts (18) at the periphery of the apertures (16), these projecting parts exhibiting a smaller thickness than the thickness of the plate (14) and serving as supports for the electronic modules, in particular for a substrate (12) of these modules. Fixing is performed for example by welding or adhesive bonding. The invention also relates to an intermediate product formed by such an assembly and a filing material that fills at least the major part of the remaining space in the apertures (16). The invention also relates to a method of fabricating cards in which the assembly according to the invention is finally coated in a resin to form substantially plane cards.

Owner:NAGRAVISION SA

Cable bridge based on hot galvanizing bimetallic epoxy resin anticorrosive coating

The invention discloses a cable bridge based on a hot galvanizing bimetallic epoxy resin anticorrosive coating. The cable bridge comprises a fixed bridge frame, a first fixing frame, a second fixing frame and a splicing clamping piece, the first fixing frame is fixedly mounted on the outer surface of the fixed bridge frame, the second fixing frame is fixedly installed on the side, close to the first fixing frame, of the outer surface of the fixed bridge frame, connecting bolt plates are fixedly mounted on the outer surfaces of the top ends of the second fixing frame and the first fixing frame,lifting sleeve plates are movably connected to the inner surfaces of the side edges of the second fixing frame and the first fixing frame in a sleeving mode, the splicing clamping piece is fixedly connected to the inner side of one end of the fixed bridge frame in a sleeving mode, and the middle positions of the inner sides of the bottoms of the second fixing frame and the first fixing frame aremovably connected with middle sleeve plates in a sleeving mode. According to the cable bridge based on the hot galvanizing bimetallic epoxy resin anticorrosive coating, double adjustment operation canbe carried out, so the use flexibility of the cable bridge is improved; and the cable bridge has an auxiliary fixing structure, so the safety of the cable bridge is improved.

Owner:安徽精工电缆桥架有限公司

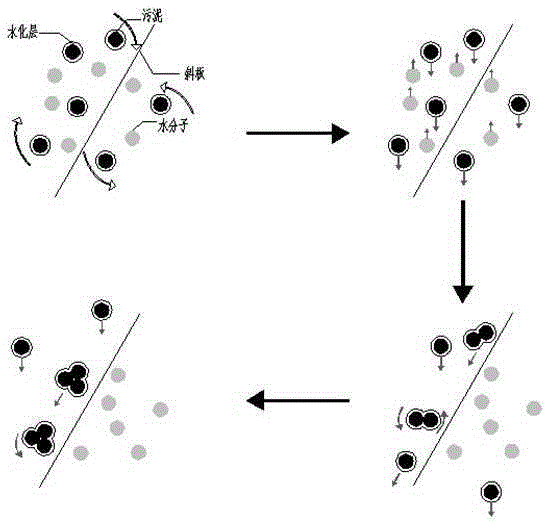

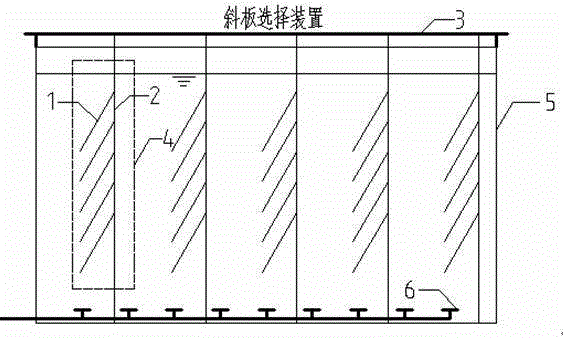

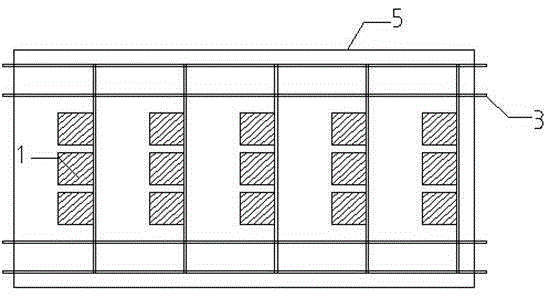

Inclined plate selective culture method and device for aerobic granular sludge

InactiveCN105293866AGuaranteed stabilityCompact structureSludge treatment by de-watering/drying/thickeningSludgeWastewater

The invention discloses an inclined plate selective culture method and device for aerobic granular sludge, and belongs to the field of environmental engineering wastewater treatment. According to the method, a plurality of inclined plate groups are mounted in a whole aerobic reactor or partial regions of the aerobic reactor; each inclined plate group comprises a plurality of inclined plates and a supporting rod; the corresponding inclined plates are uniformly arranged on each inclined plate group; sludge slides down or rolls down on the inclined plate, so that the possibility of sludge collision is increased, sludge aggregation is promoted, and then forming of the aerobic granular sludge is accelerated. The device is used for implementing the method, and mainly comprises the inclined plate groups and a fixing bridge, wherein each inclined plate group is formed by uniformly fixing a plurality of corresponding inclined plates on one corresponding supporting rod; the fixing bridge is used for fixing the inclined plate groups in the aerobic reactor. The method and the device have the benefits that sludge granulation can be continuously and stably promoted.

Owner:CHINA UNIV OF MINING & TECH

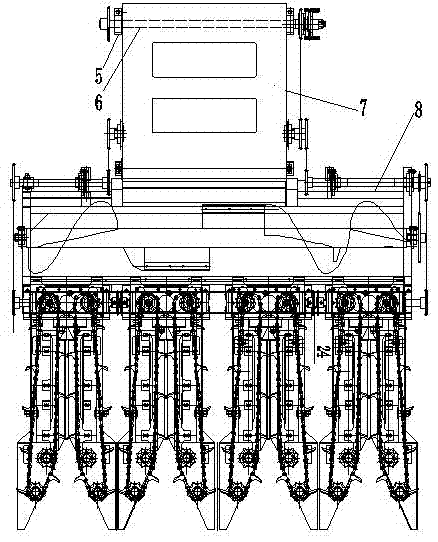

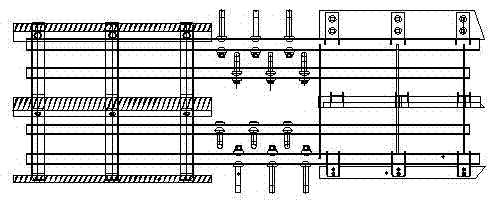

Corn combine harvester

PendingCN107231884AReduce procurement costsIncrease frequency of useMowersDrive shaftAgricultural engineering

The invention discloses a corn combine harvester. The harvester consists of a rack, a header, a gap bridge, a threshing device and a grading device. The header is connected to a threshing chamber through the gap bridge. The threshing chamber is fixed on the rack. The gap bridge is hinge jointed to the rack through a bearing block of a driving shaft. The threshing device consists of a threshing chamber, and a threshing cylinder installed in the threshing chamber. The threshing chamber consists of an upper cover and a concave grate. The grading device consists of a grading sieve. The header is a header for harvesting wheat. The gap bridge is a gap bridge for harvesting wheat. The concave grate is a grid concave grate. The grading sieve is a fish scale grading sieve. The corn combine harvester can efficiently reduce the purchase cost of corn harvesters, increase the usage frequency of corn combine harvesters, and reduce the production cost of users.

Owner:河南沃德机械制造有限公司

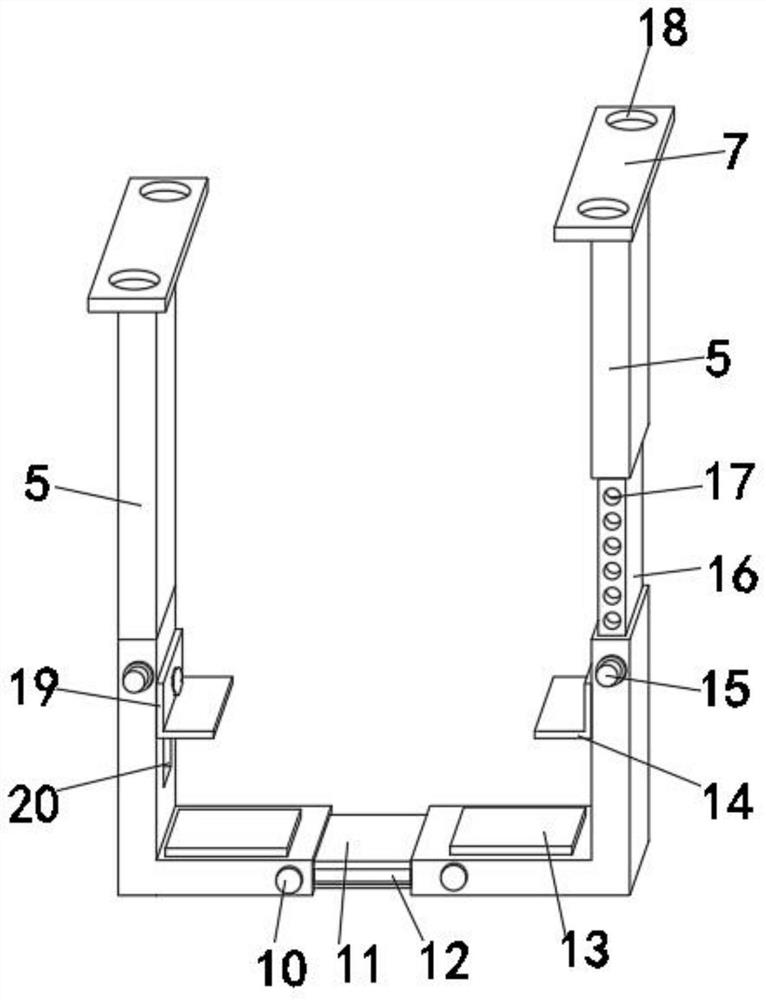

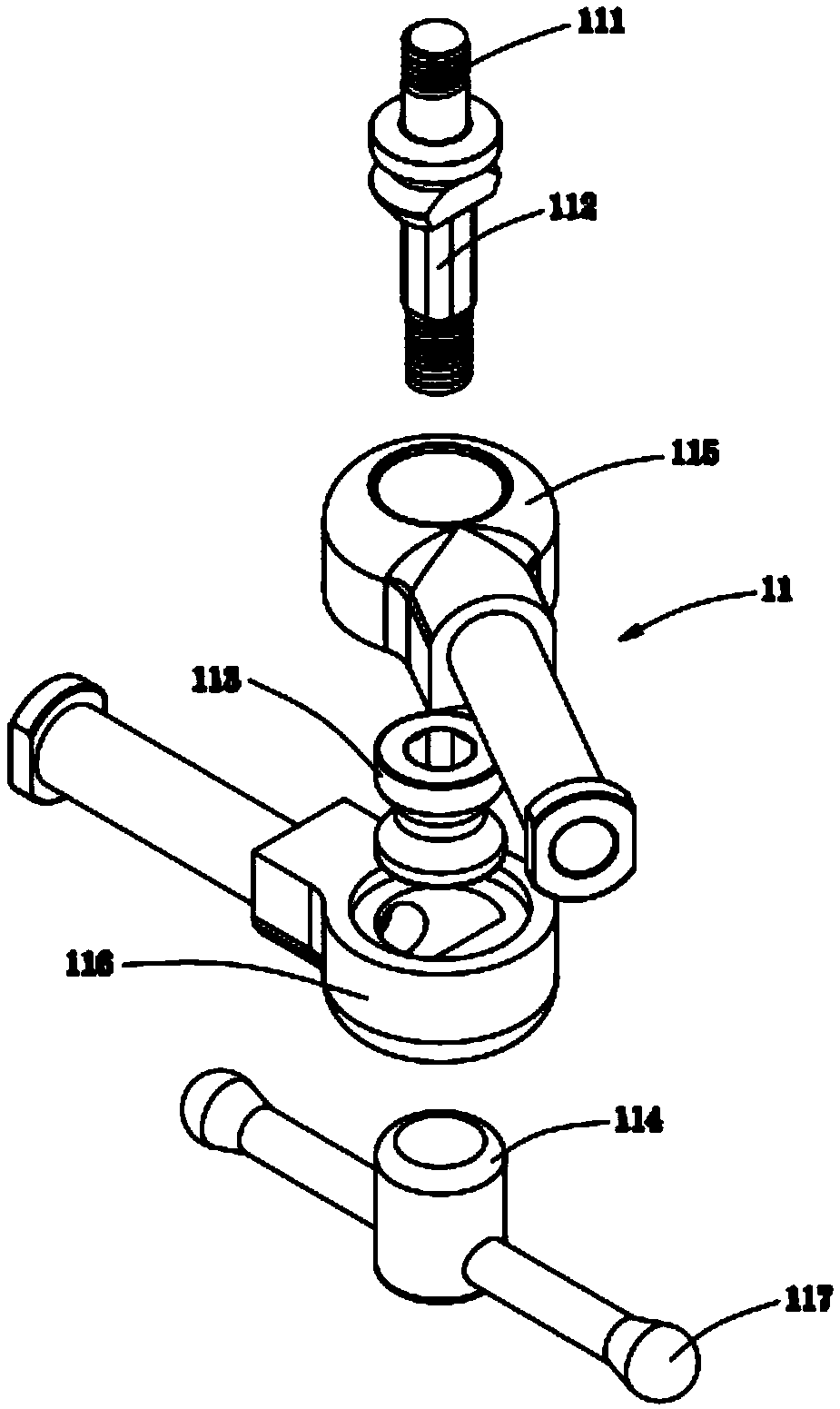

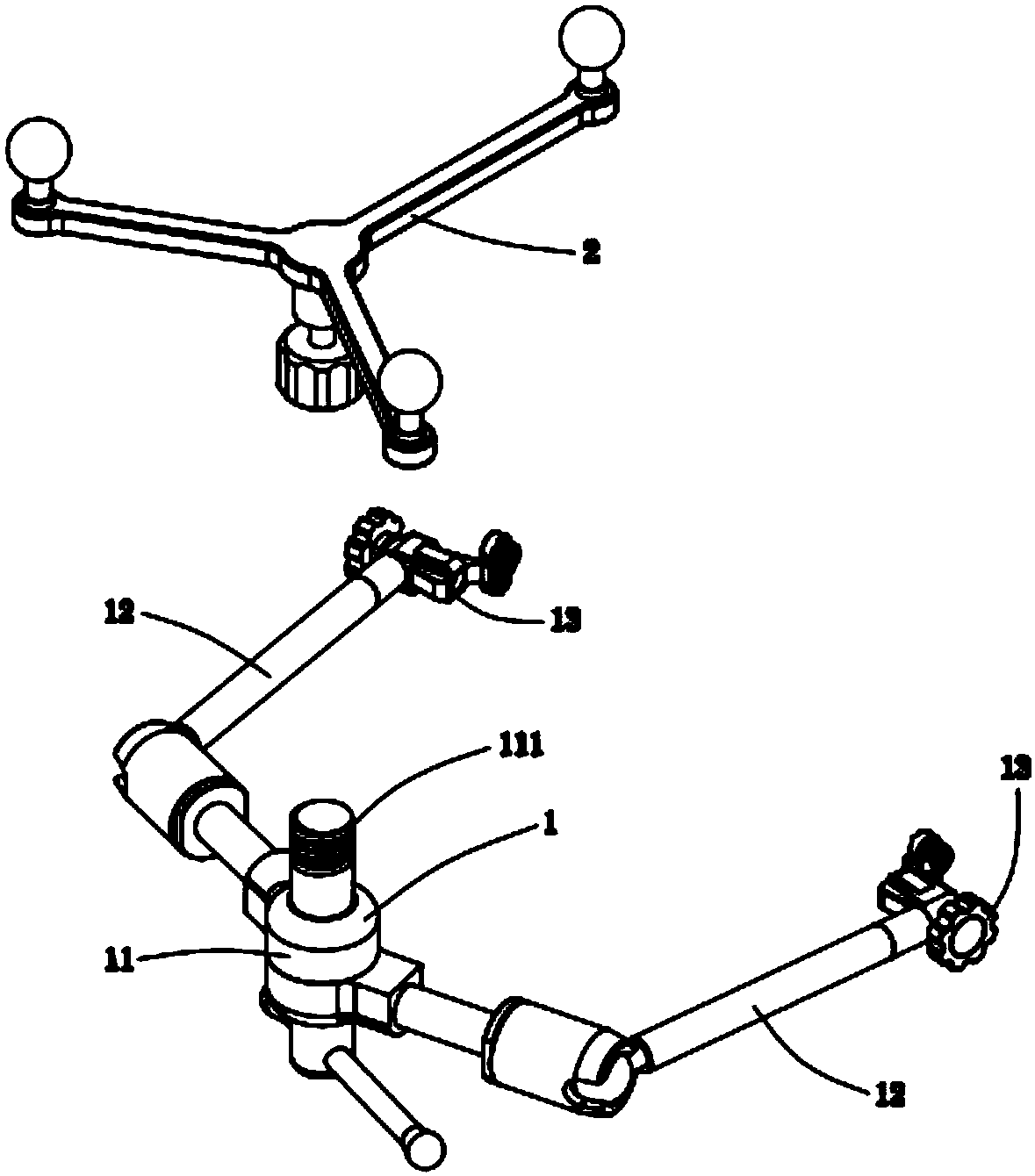

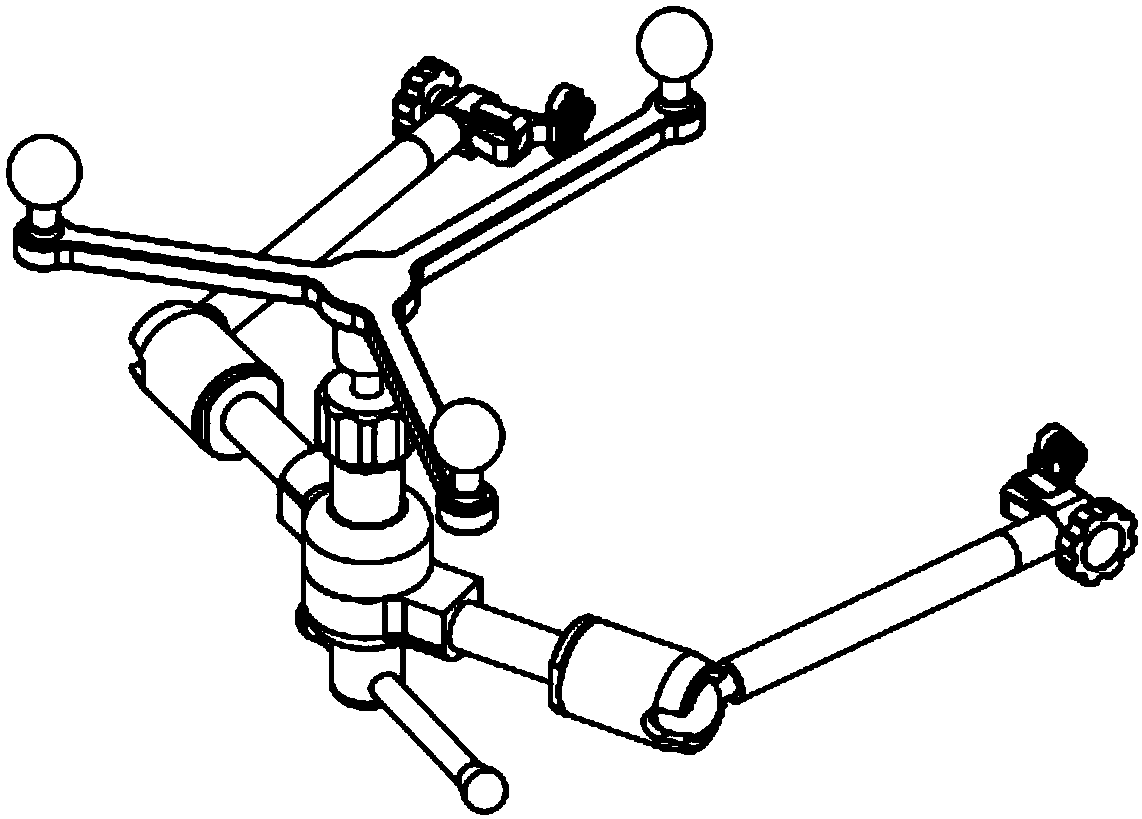

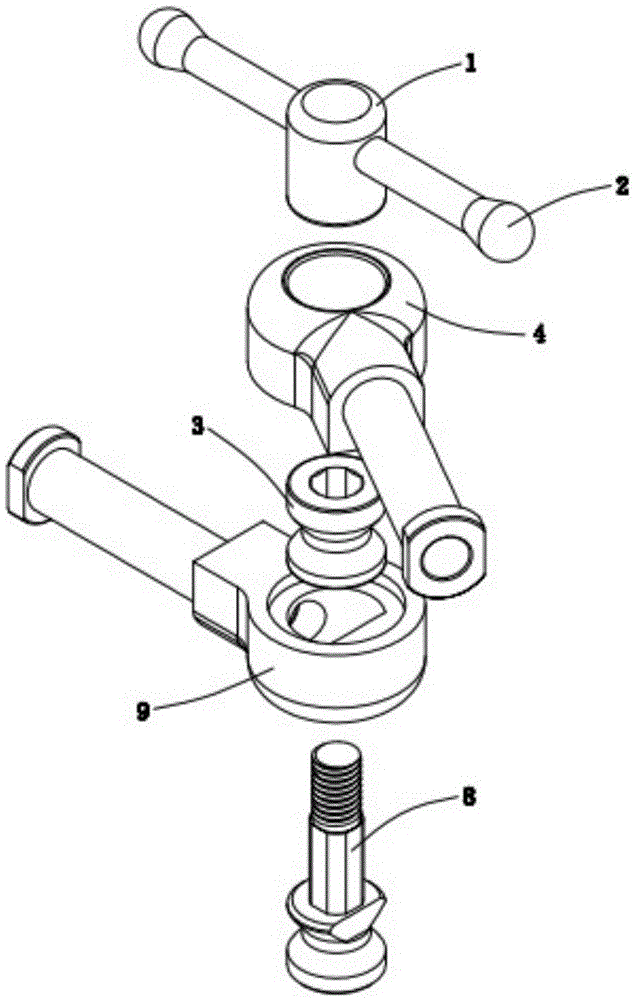

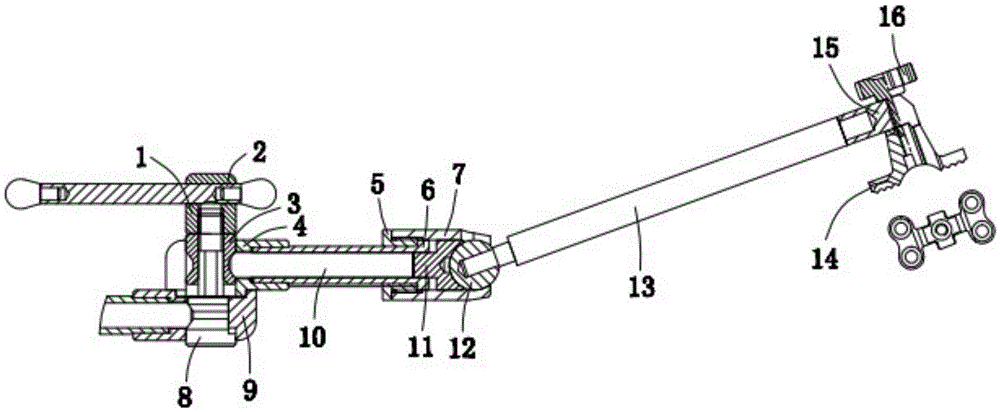

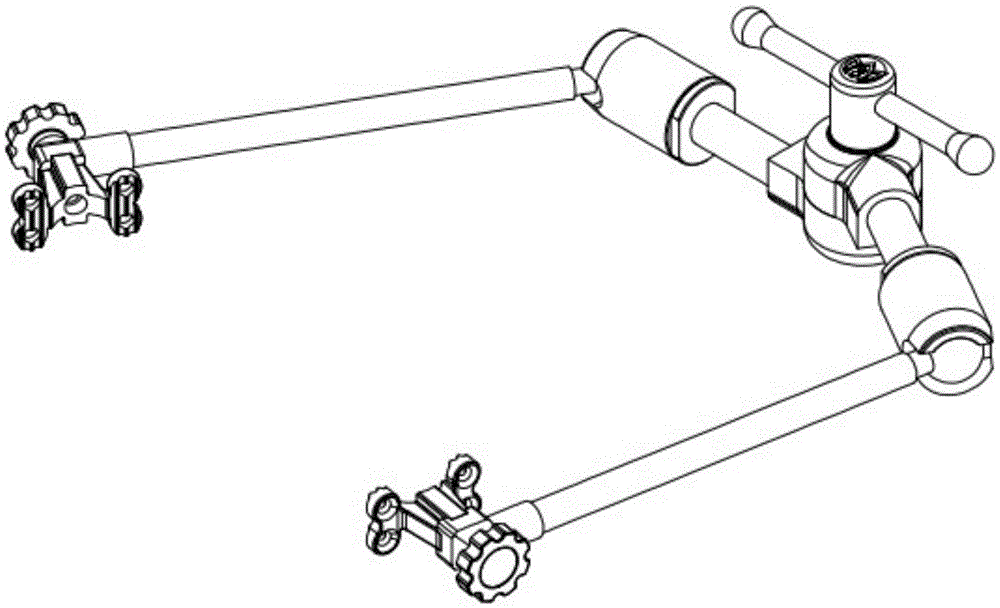

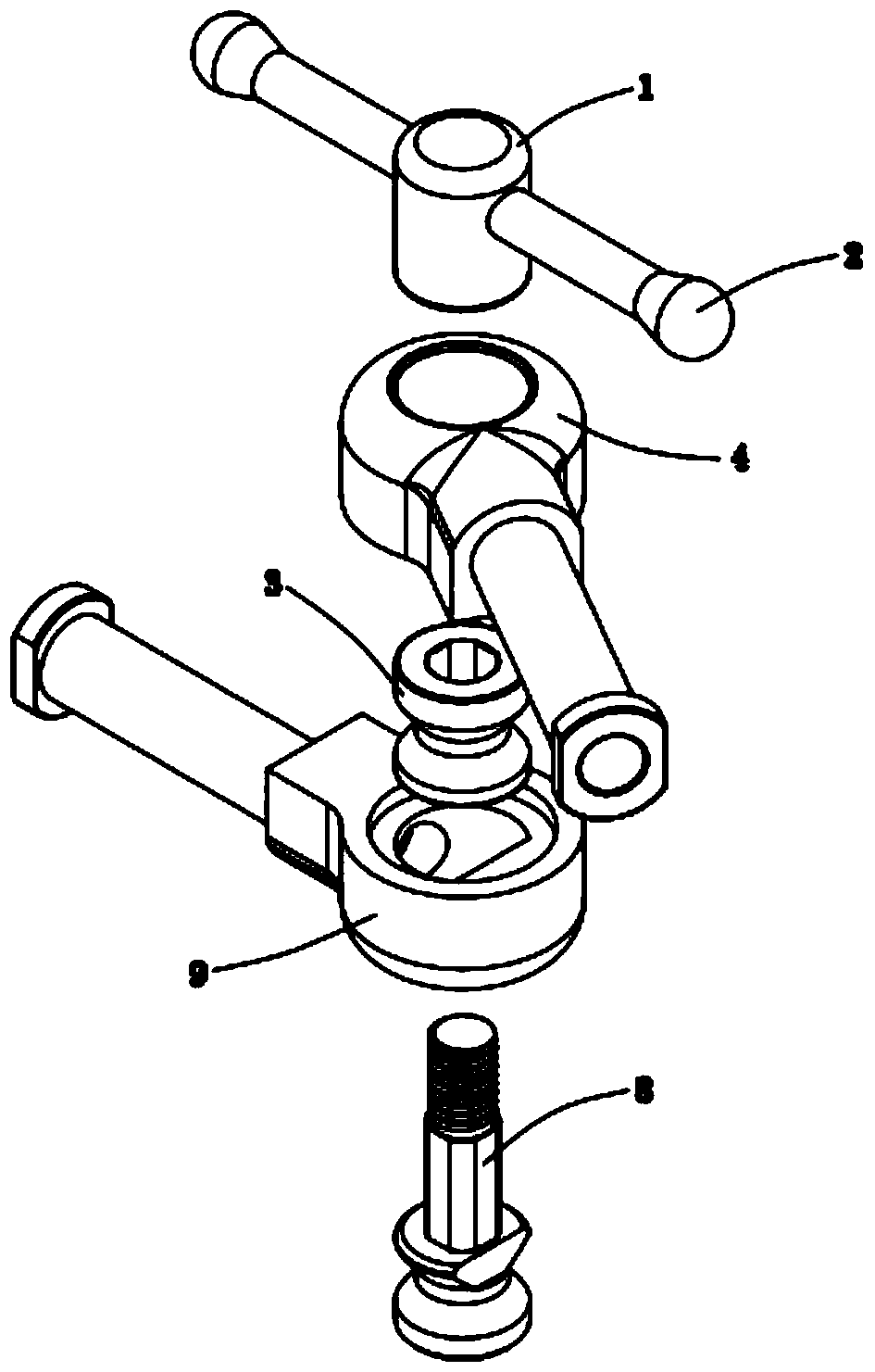

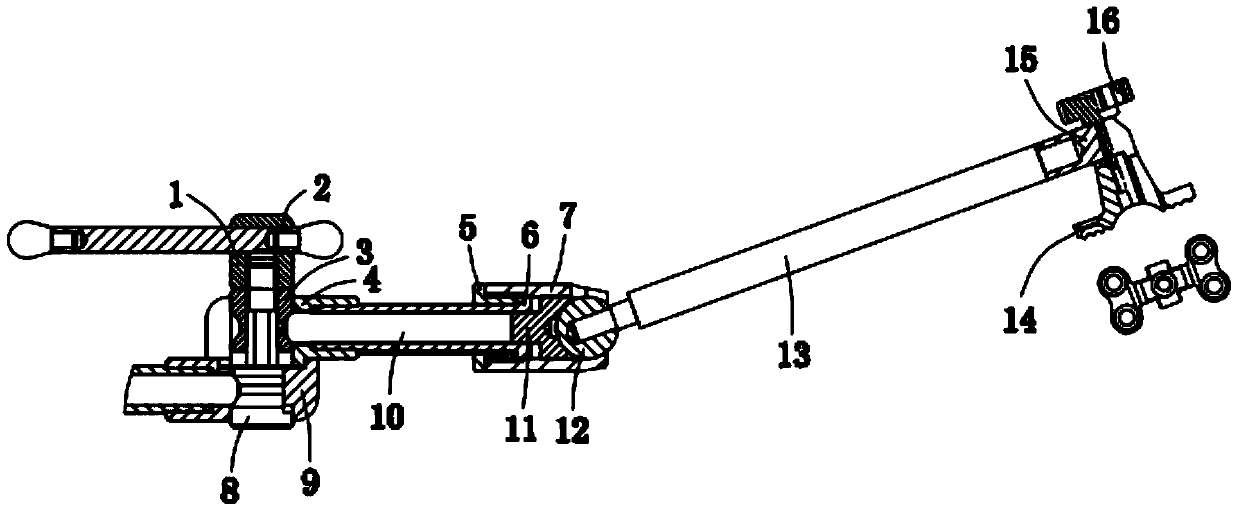

Mandible external fixation device with navigation

PendingCN110960303AImprove registration positioning accuracySimplify the reconstructive surgery processSurgical navigation systemsExternal osteosynthesisPhysical medicine and rehabilitationAnatomy

The invention provides a mandible external fixation device with navigation. The mandible external fixation device with navigation includes a mandible external fixation bridge and a navigation reference frame; and the mandible external fixation bridge includes a central locking mechanism, position fixing arms at two sides and alveolar position fixing legs at two sides, and a connection device connected with the navigation reference frame is arranged on the central locking mechanism. The mandible external fixation device with navigation has the advantages that the mandible external fixation bridge and the navigation reference frame are combined, and the reference frame is located at the middle of a mandible so that registration positioning accuracy of the mandible during mandible remodelingcan be significantly improved. An original position of the mandible is fixed and recorded, meanwhile, the mandible is registered and positioned noninvasively and directly, therefore, a mandible remodeling operation process is simplified, and the accuracy of mandible remodeling is improved.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE +1

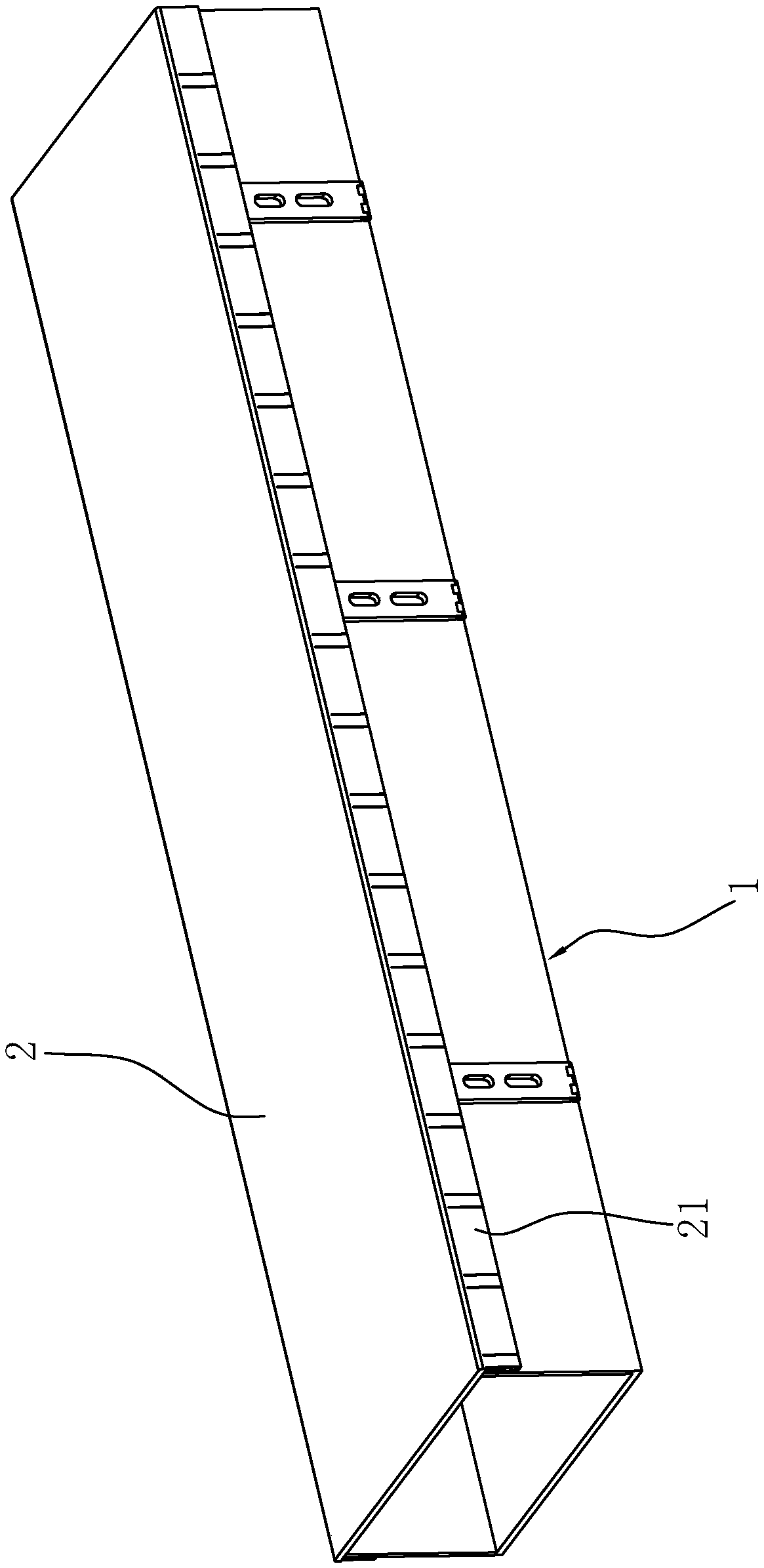

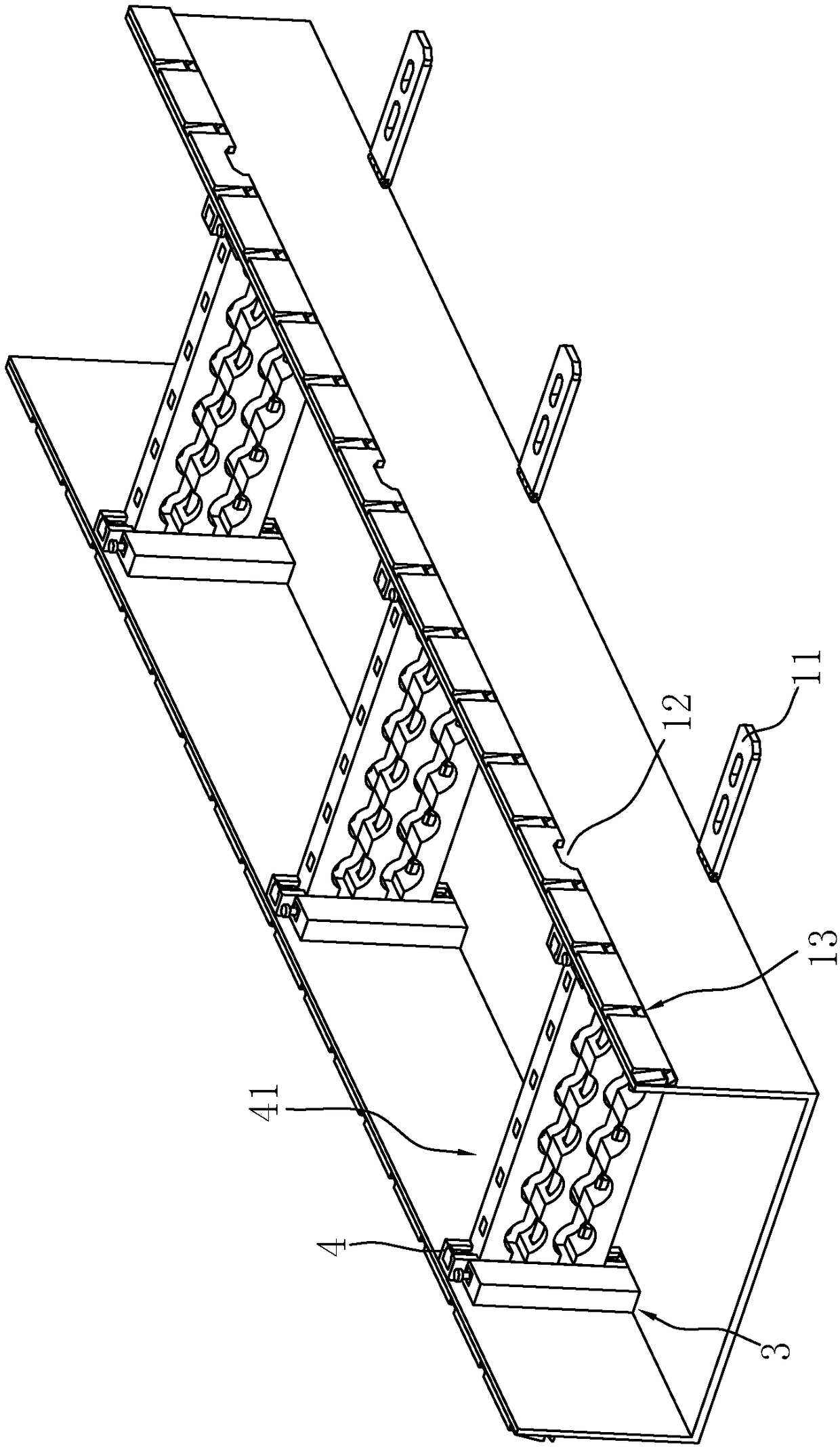

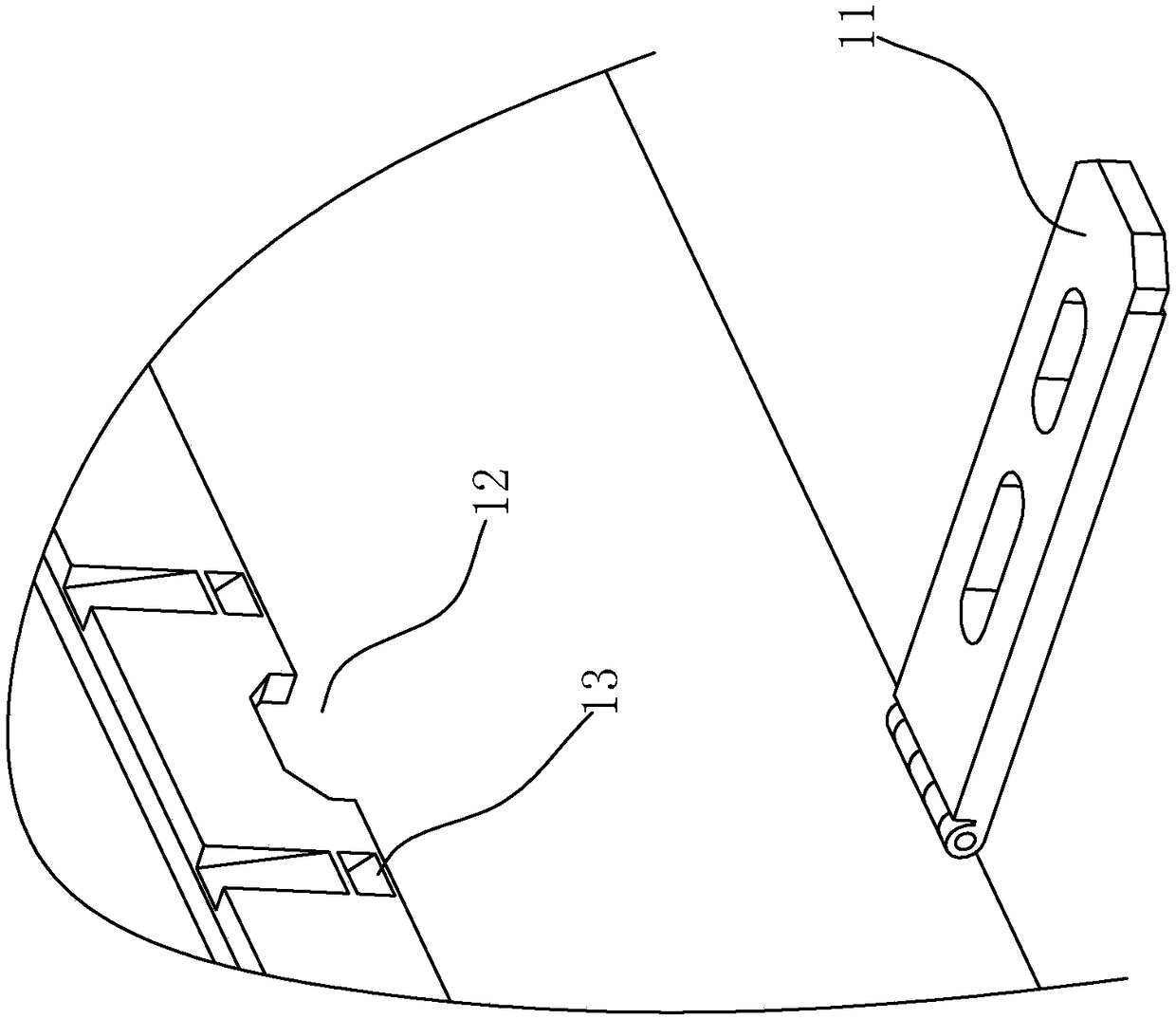

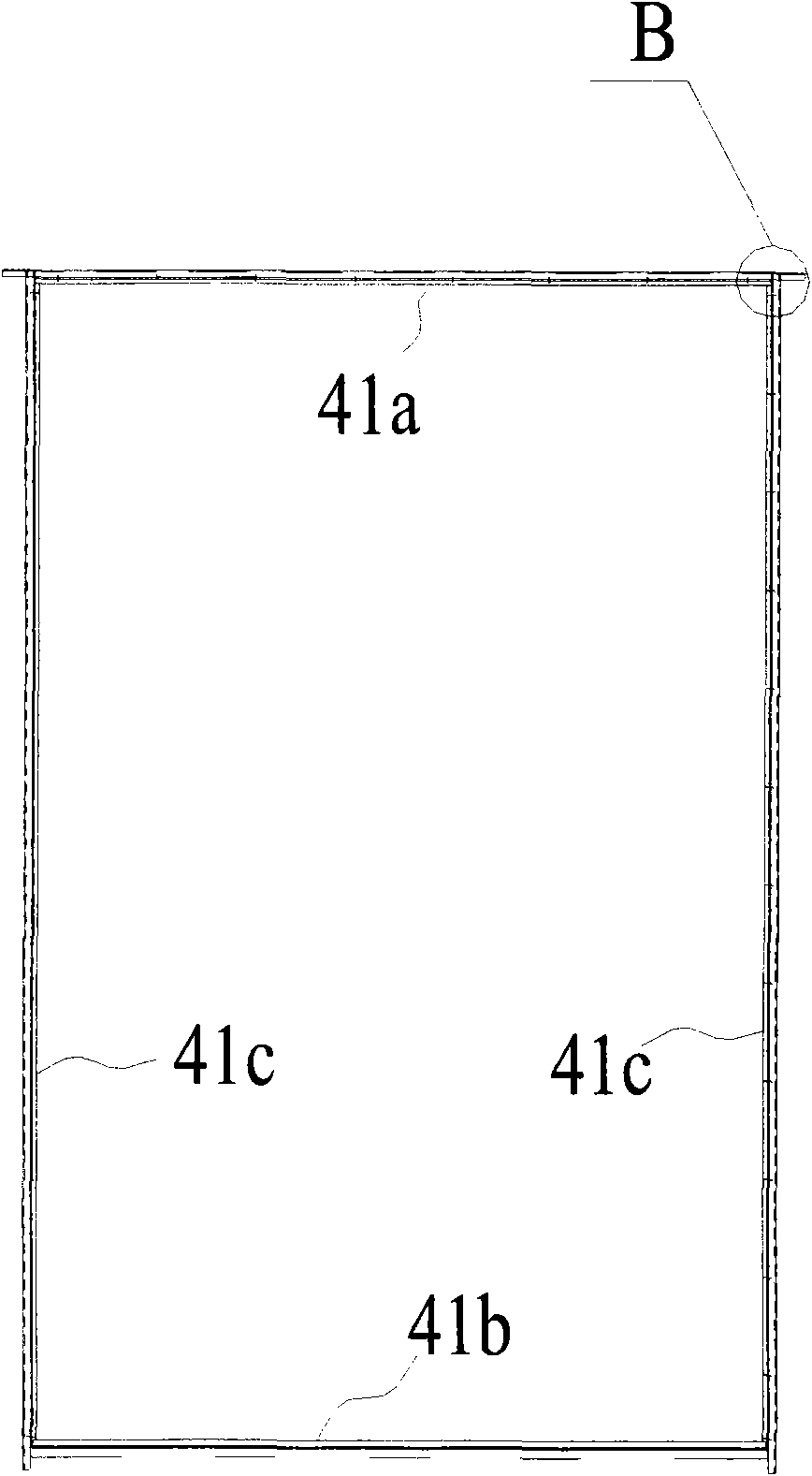

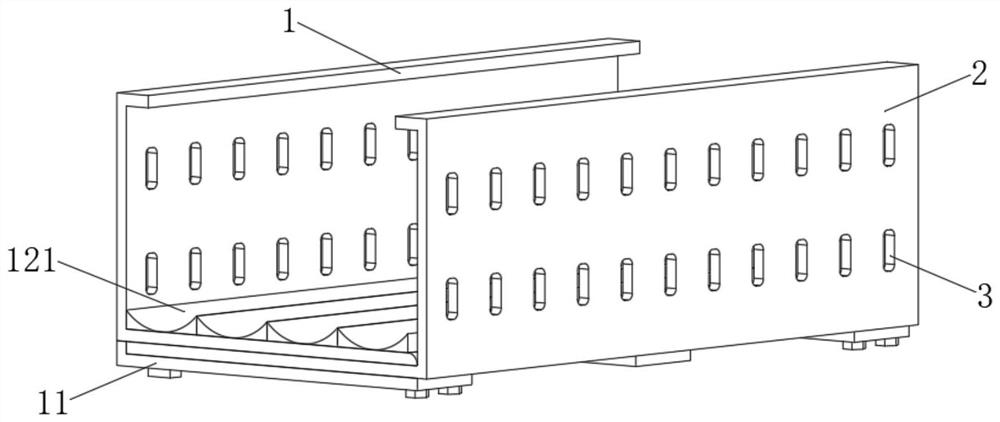

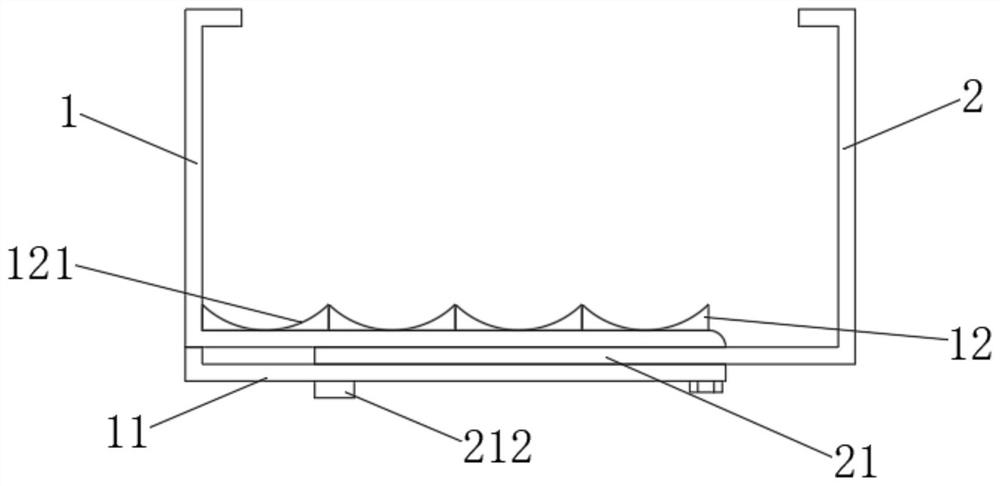

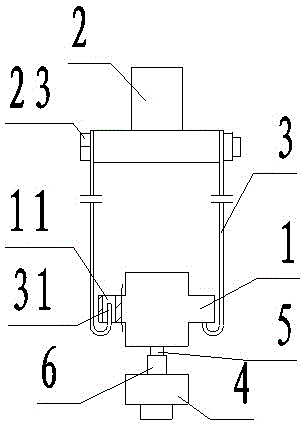

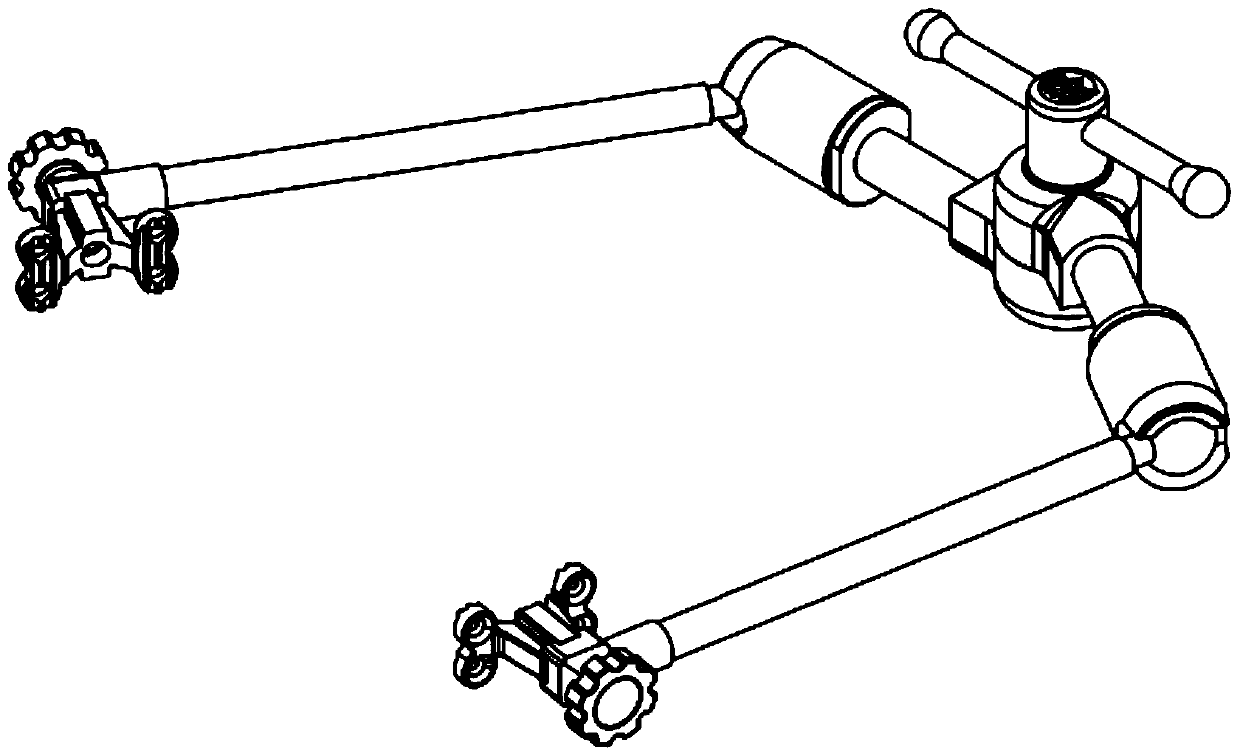

Outer mandible fixing bridge

ActiveCN105476703ASimplify the rebuild processThe effect of accurate reconstructionExternal osteosynthesisBody of mandibleEngineering

The invention discloses an outer mandible fixing bridge which is composed of a central locking structure, a universal retention arm and a phatnoma retention foot. Retention is conducted on the residual end of the mandible at any angle through the central locking structure and the universal retention arm. The central locking structure fixes the position of the retention arm through a locking device, is controlled in a single-joint mode, is good in operability and more flexible and accordingly facilitates intra-operative operation. The universal retention arm can be applicable to fixing of the residual end of the bilateral mandible at any position and is convenient to use. The universal retention arm is also provided with a locking structure so that the retention arm can be locked at any angle to stabilize the relative position of the residual end of the mandible. Accordingly, the mandible remodeling process is simplified, and the accurate mandible remodeling effect is achieved. A phatnoma retention block can be separated from a fixing bridge body, the phatnoma retention foot is fixed to the residual end of the mandible through four holes to facilitate the intra-operative operation performed by a surgeon, and the face, in contact with the phatnoma, of the phatnoma retention block is zigzag so that the stability of the phatnoma retention block can be stabilized.

Owner:SHANGHAI JINGTANG MEDICAL APP & INSTR LTD +1

Mandibular External Fixation Bridge

ActiveCN105476703BSimplify the rebuild processThe effect of accurate reconstructionExternal osteosynthesisBody of mandibleEngineering

The invention discloses an outer mandible fixing bridge which is composed of a central locking structure, a universal retention arm and a phatnoma retention foot. Retention is conducted on the residual end of the mandible at any angle through the central locking structure and the universal retention arm. The central locking structure fixes the position of the retention arm through a locking device, is controlled in a single-joint mode, is good in operability and more flexible and accordingly facilitates intra-operative operation. The universal retention arm can be applicable to fixing of the residual end of the bilateral mandible at any position and is convenient to use. The universal retention arm is also provided with a locking structure so that the retention arm can be locked at any angle to stabilize the relative position of the residual end of the mandible. Accordingly, the mandible remodeling process is simplified, and the accurate mandible remodeling effect is achieved. A phatnoma retention block can be separated from a fixing bridge body, the phatnoma retention foot is fixed to the residual end of the mandible through four holes to facilitate the intra-operative operation performed by a surgeon, and the face, in contact with the phatnoma, of the phatnoma retention block is zigzag so that the stability of the phatnoma retention block can be stabilized.

Owner:SHANGHAI JINGTANG MEDICAL APP & INSTR LTD +1

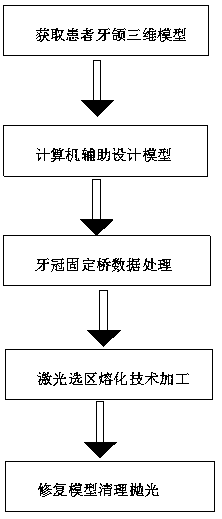

Preparation method of implant fixed bridge repair model

PendingCN111568580AIncrease profitShort processing cycleDental prostheticsComputer Aided DesignSelective laser melting

The invention relates to a preparation method of an implant fixed bridge repair model. The preparation method comprises the following steps of acquiring a three-dimensional model of the dental jaw ofa patient, performing computer aided design on the model, performing data processing on a dental crown fixed bridge, performing processing by a selective laser melting technology, and cleaning and polishing the repair model. The preparation method of the model has the advantages that complex parts are formed at a time, the machining period is short, the material utilization rate is high, the mechanical property of workpieces is good, and the individuation degree is high.

Owner:赤峰学院附属医院

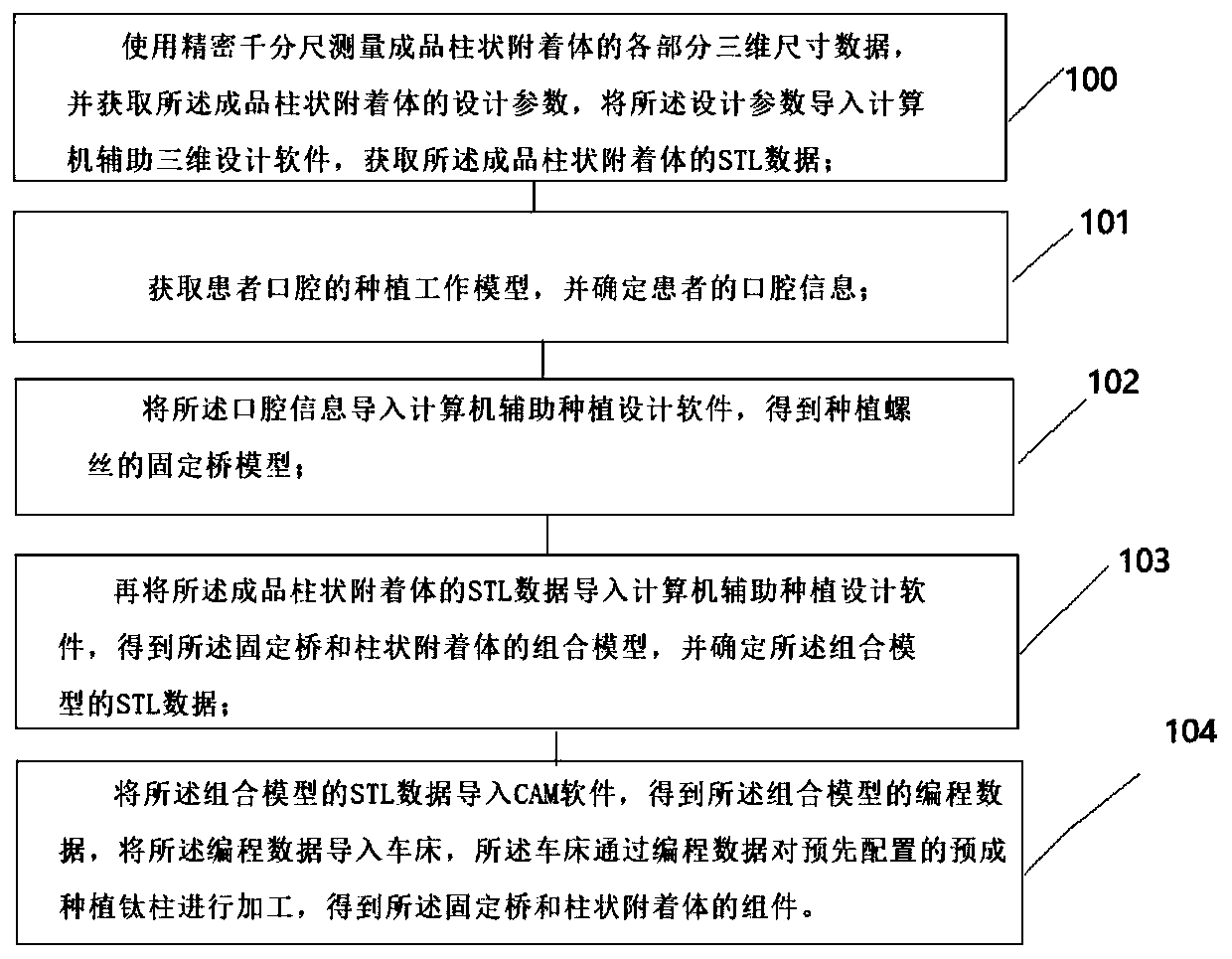

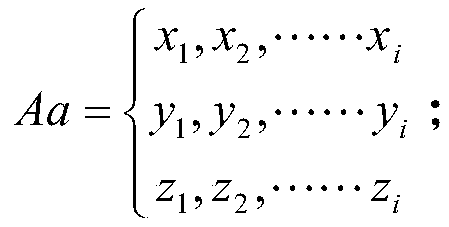

Manufacturing method of assembly of fixed bridge and columnar attachment of implantation screw

ActiveCN111529099ASimplify the design processEasy to installGeometric CADDental implantsData ingestion3d design

The invention provides a manufacturing method of an assembly of a fixed bridge and a columnar attachment of an implantation screw. A precise micrometer is used to measure 3D size data of each part ofthe finished columnar attachment and acquire design parameters of the finished columnar attachment, the design parameters are imported into computer assisted 3D design software, and STL data of the finished columnar attachment are acquired; programming data of a combined model are acquired and imported in a lathe, and the lathe machines a pre-configured preformed implantation titanium column through the programming data to obtain the assembly of the fixed bridge and the columnar attachment. The manufacturing method has the beneficial effects as follows: firstly, parameters of finished columnarattachment serve as one part of parameters of the invention, so that the design program of the columnar attachment is simplified, a massive data extraction design in the early period is not required,and mass assembly production can be realized by fine adjustment under the condition of determining the fixed bridge.

Owner:北京联袂义齿技术有限公司

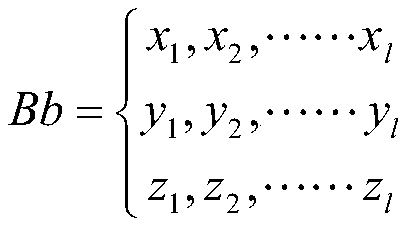

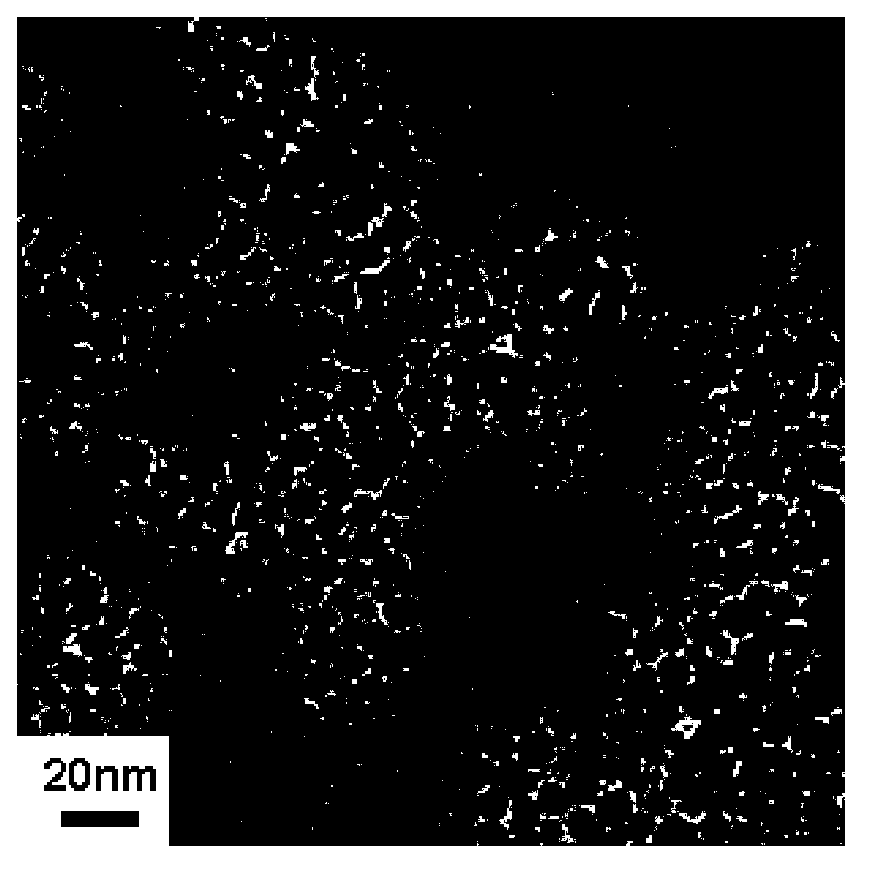

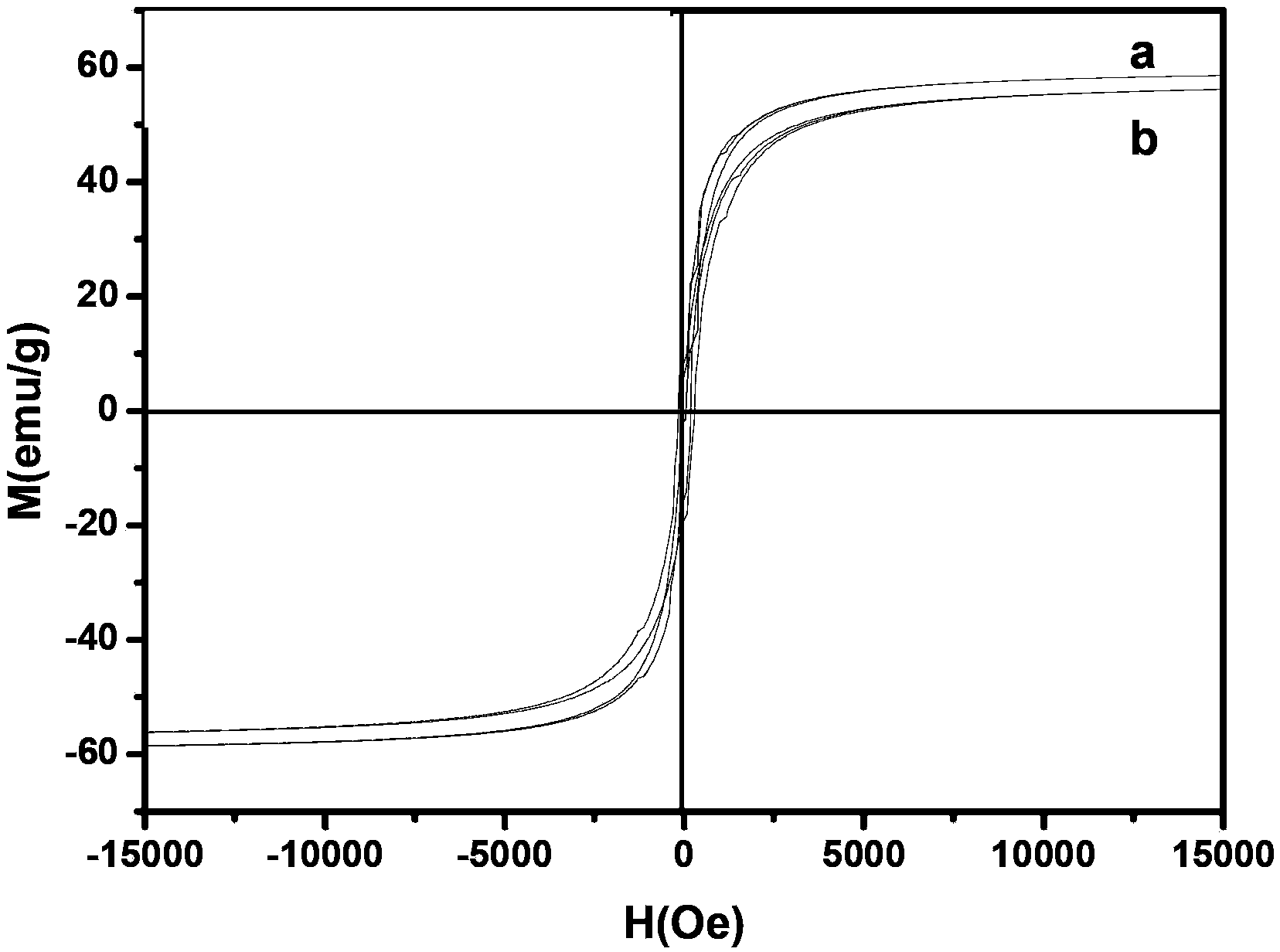

Preparation method for water-soluble magnetic nanometer particles

ActiveCN104064305AGood biocompatibilitySimple methodInorganic material magnetismFerroso-ferric oxidesDispersitySolubility

The invention provides a preparation method for water-soluble magnetic nanometer particles. According to the preparation method, polyethylene glycol diacid is selected and used as ligand replacement molecules; through simple replacement reaction, the water-soluble magnetic nanometer particles can be prepared. According to the water-soluble magnetic nanometer particles prepared by the preparation method, the advantages of good dispersity and superparamagnetism of oil-soluble nanometer particles are reserved and the water solubility is achieved; moreover, as a functional group, namely carboxyl, is introduced to serve as a fixing bridge on the surfaces of nanometer particles of bio-molecules, the requirement of biochemical reaction is satisfied. The water-soluble magnetic nanometer particles can be widely applied in the biological medicine field such as nuclear magnetism imaging, targeted drugs and immobilized enzyme.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

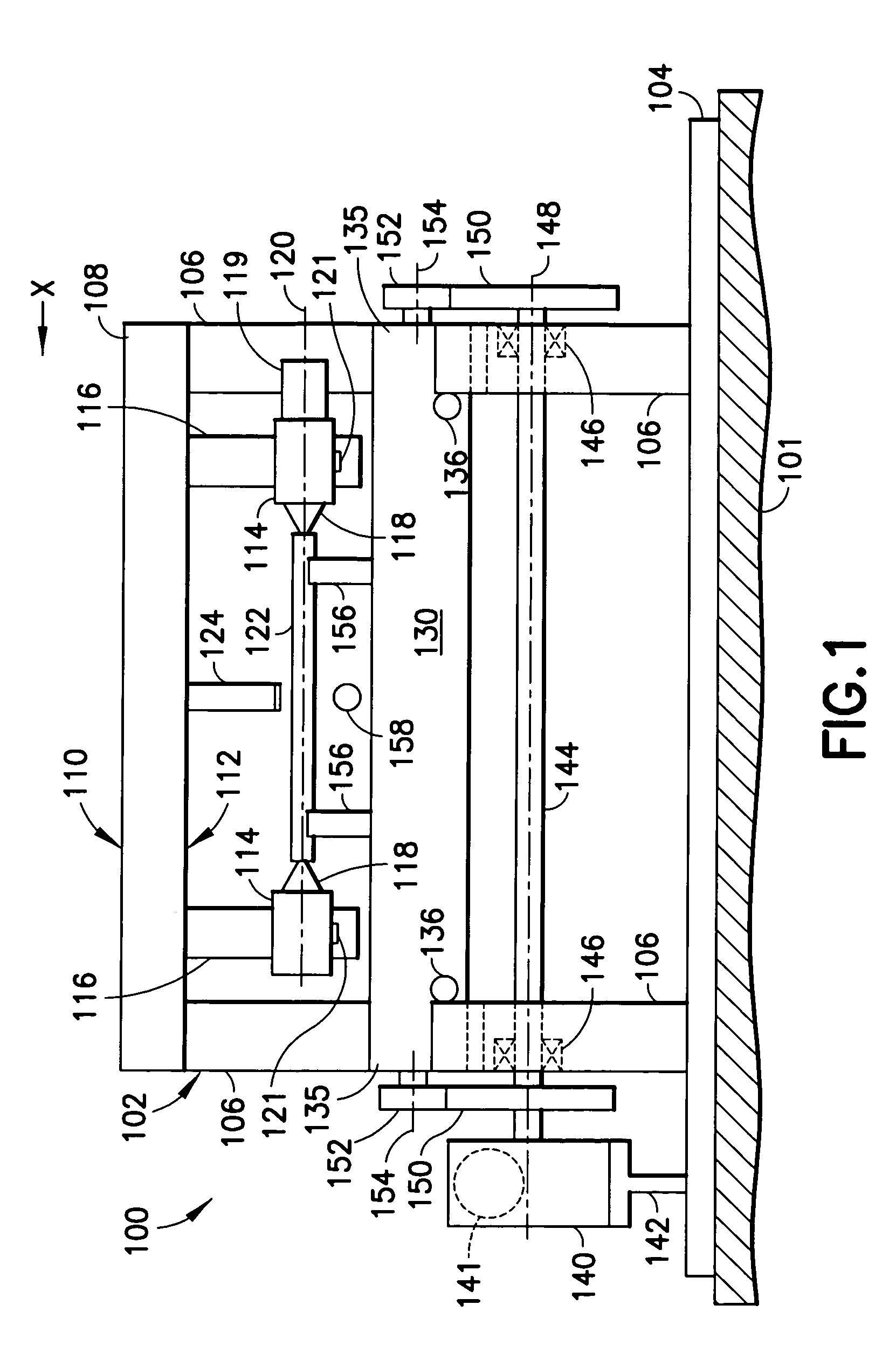

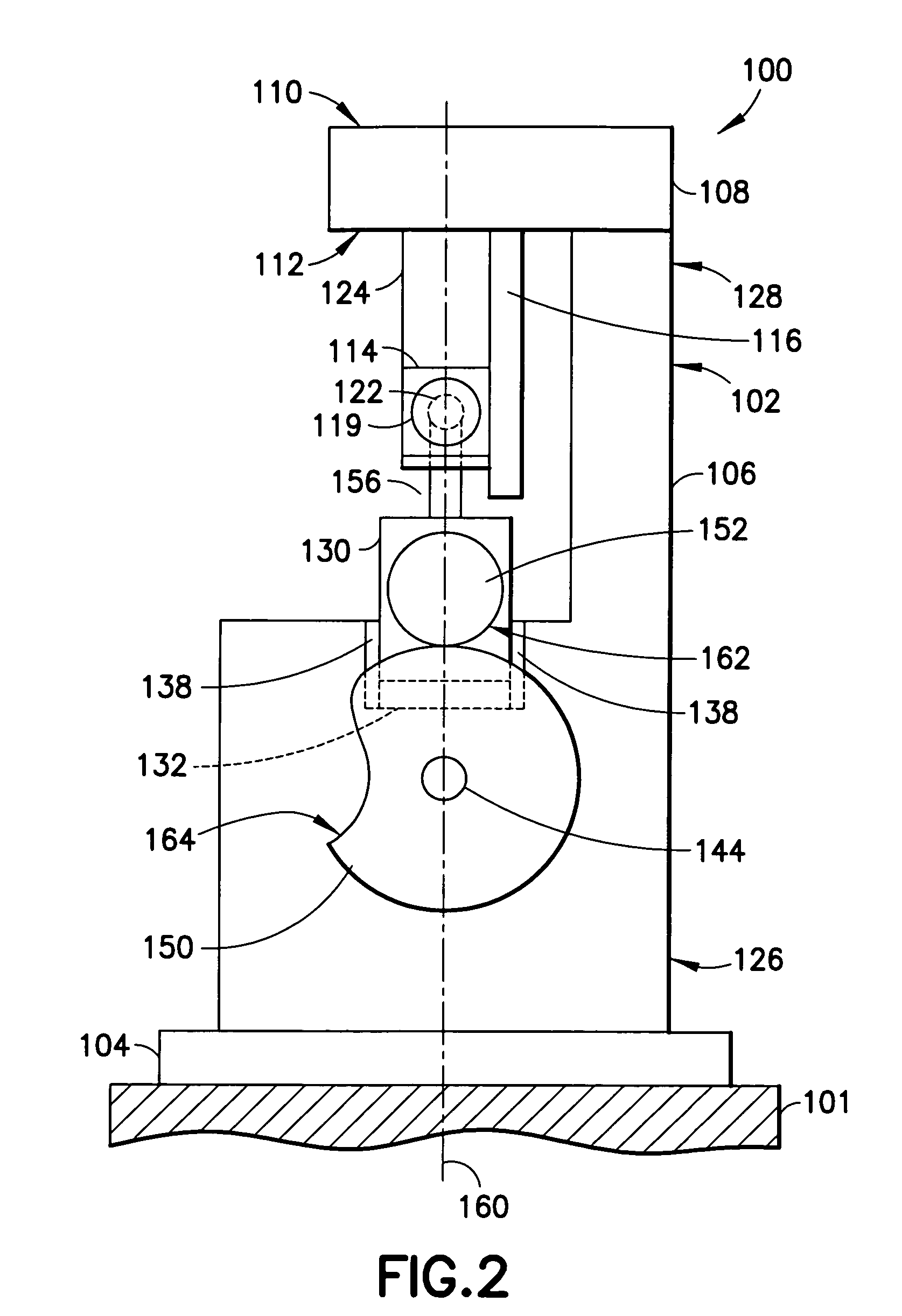

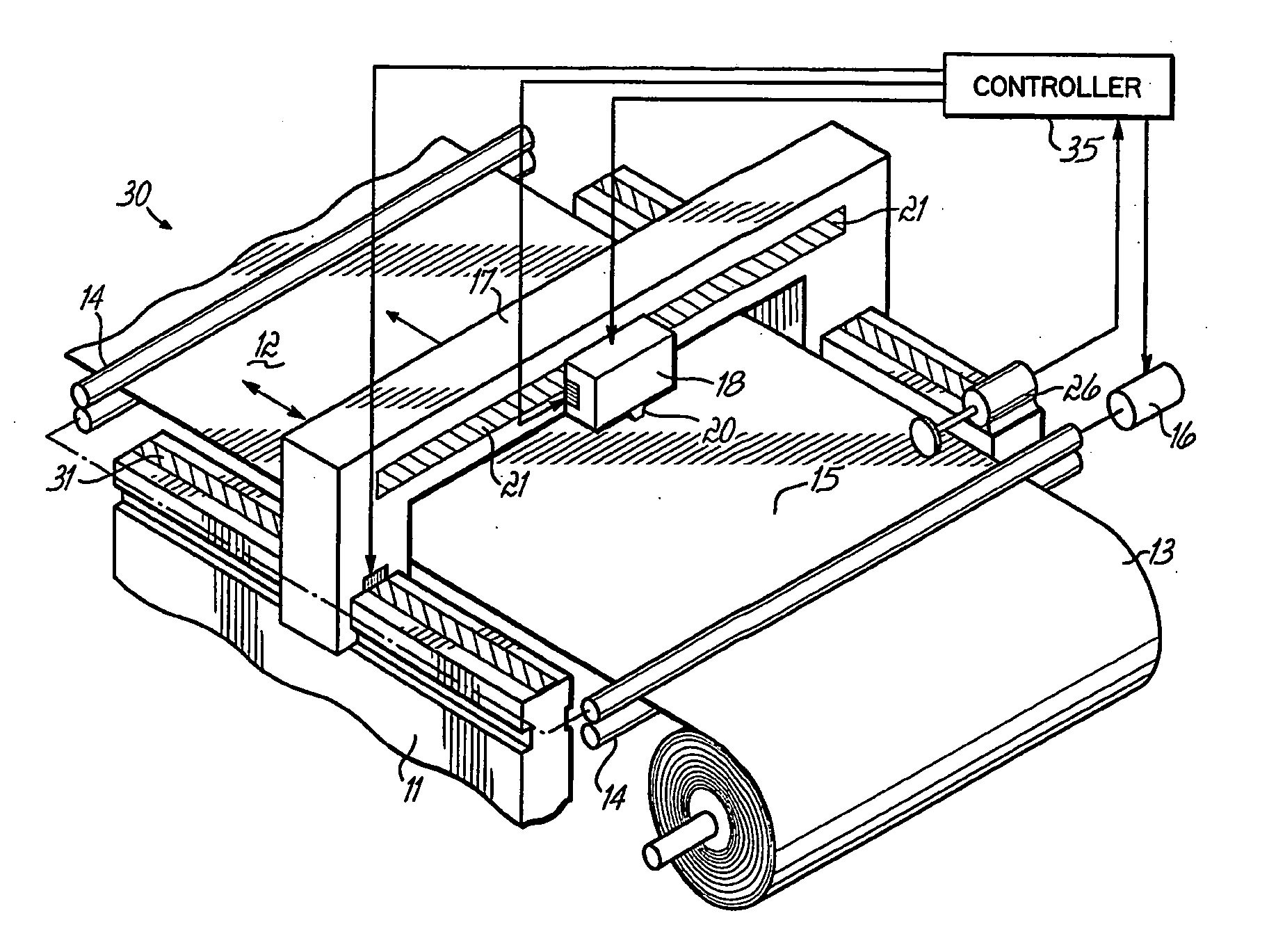

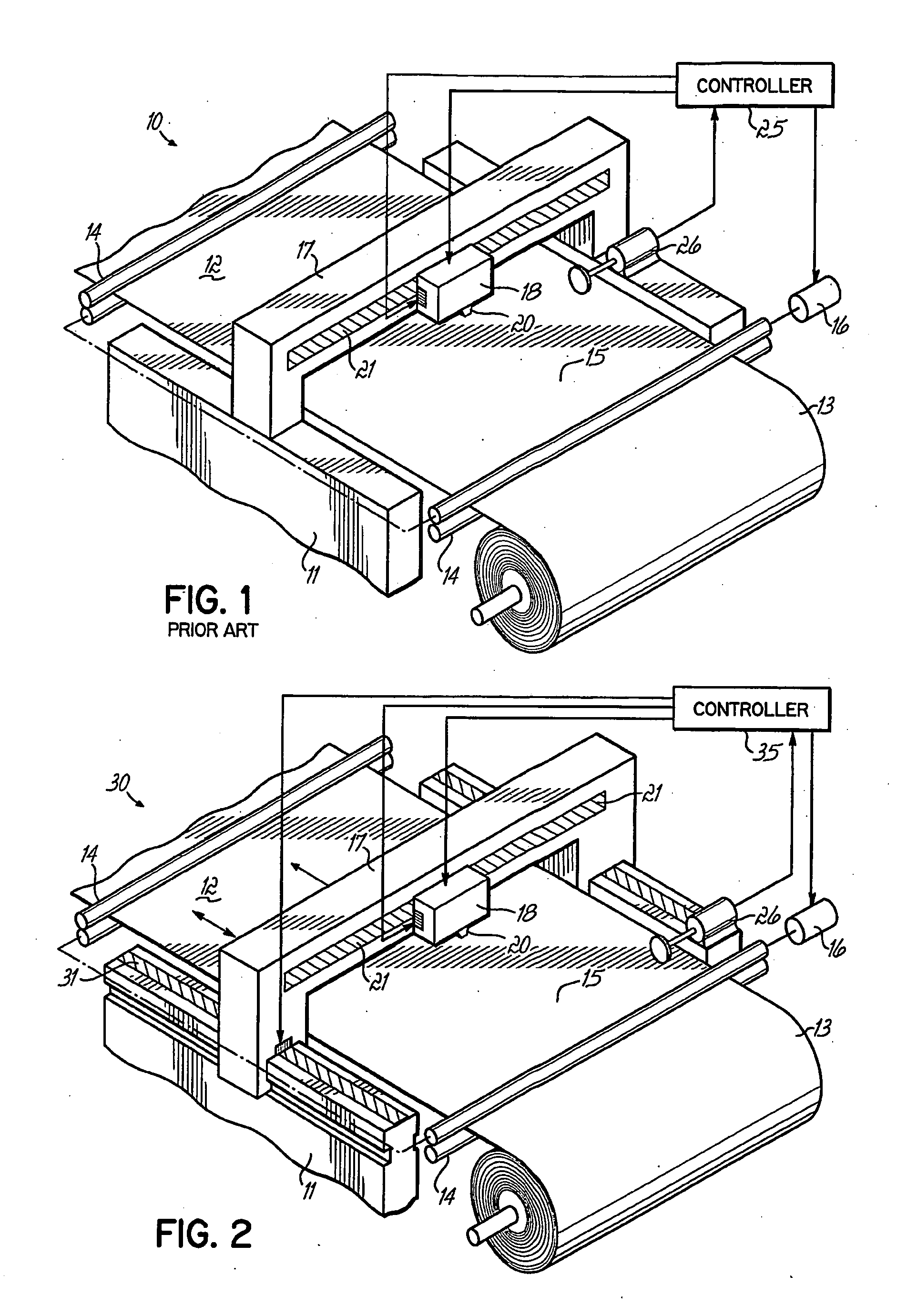

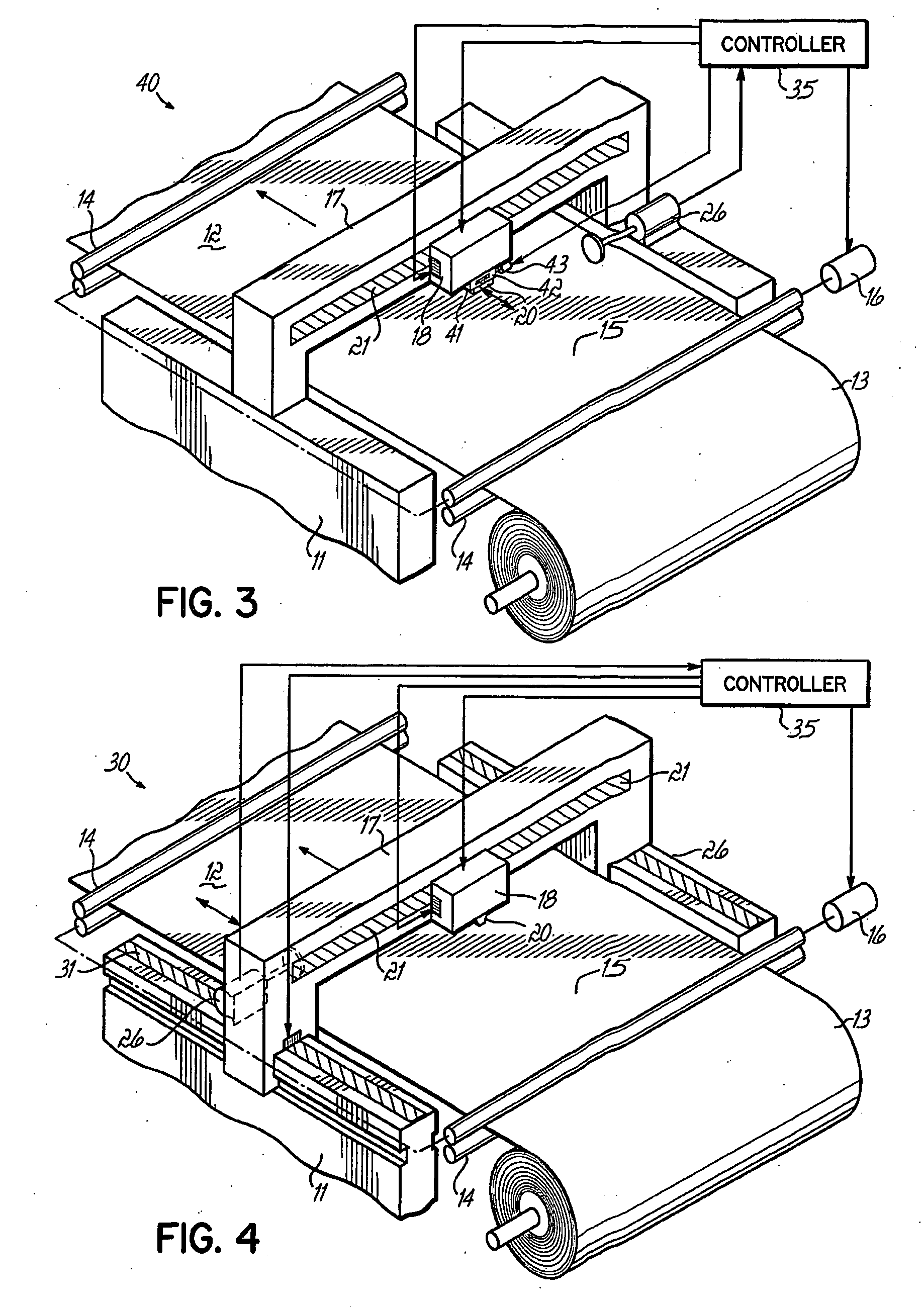

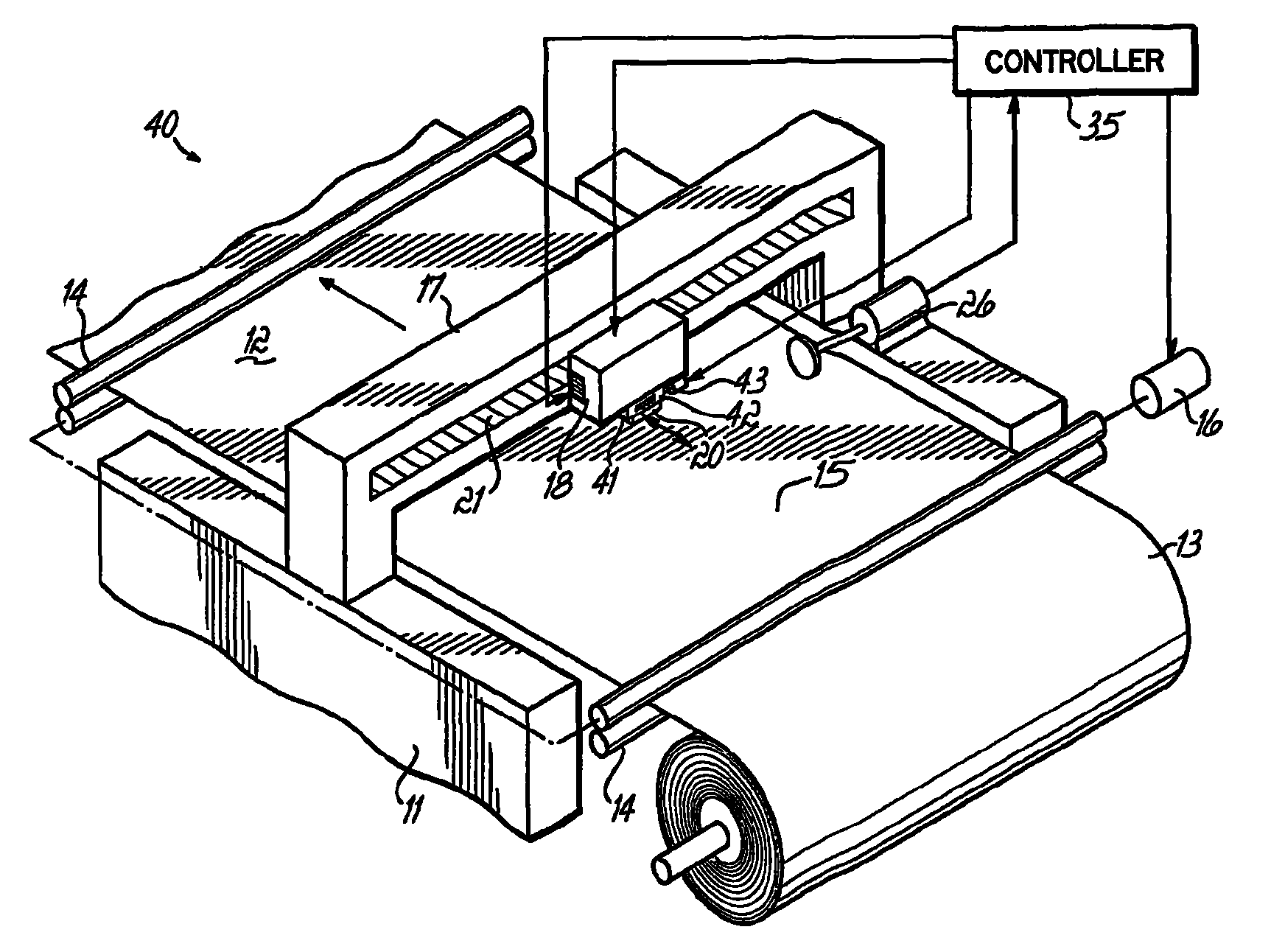

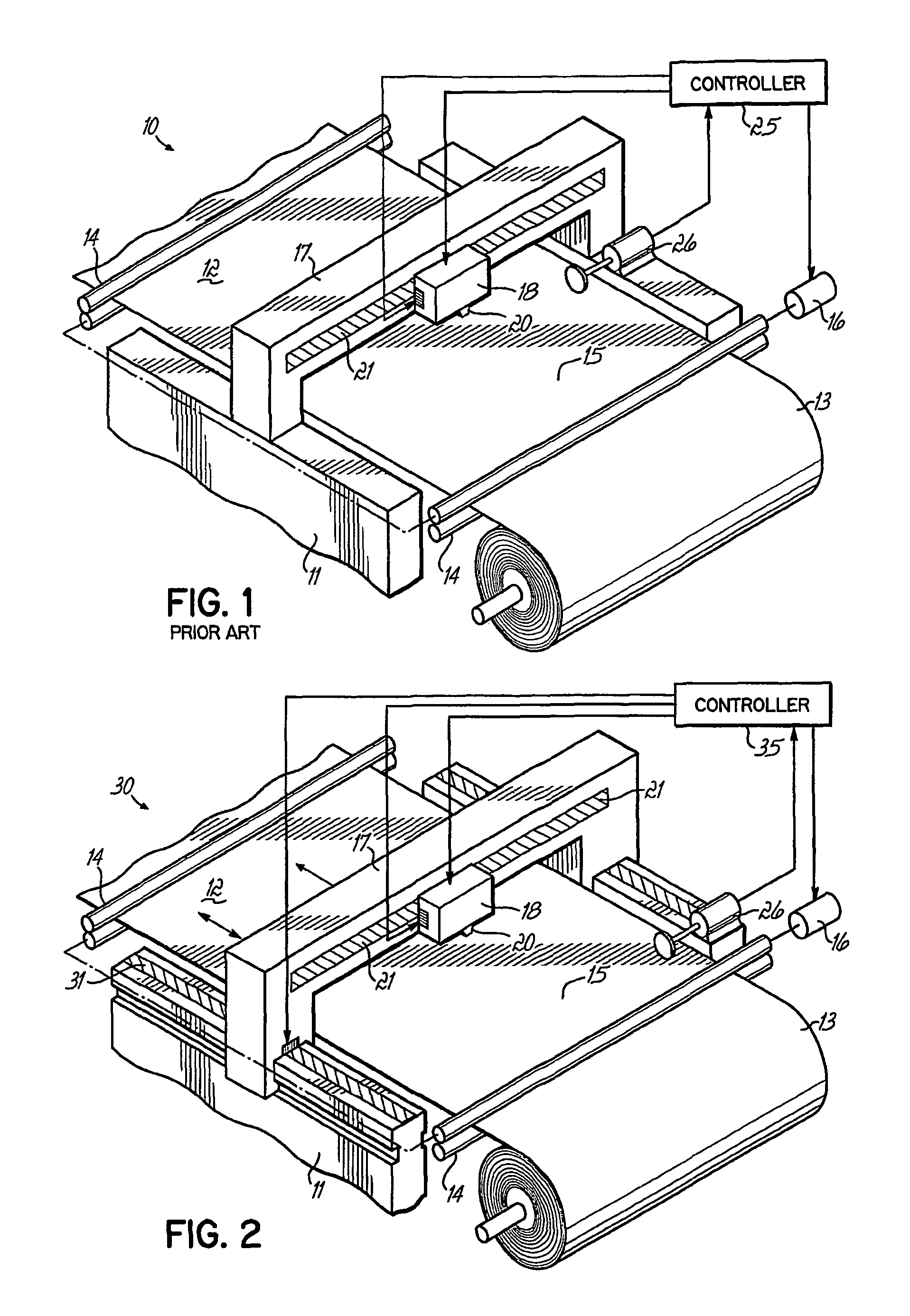

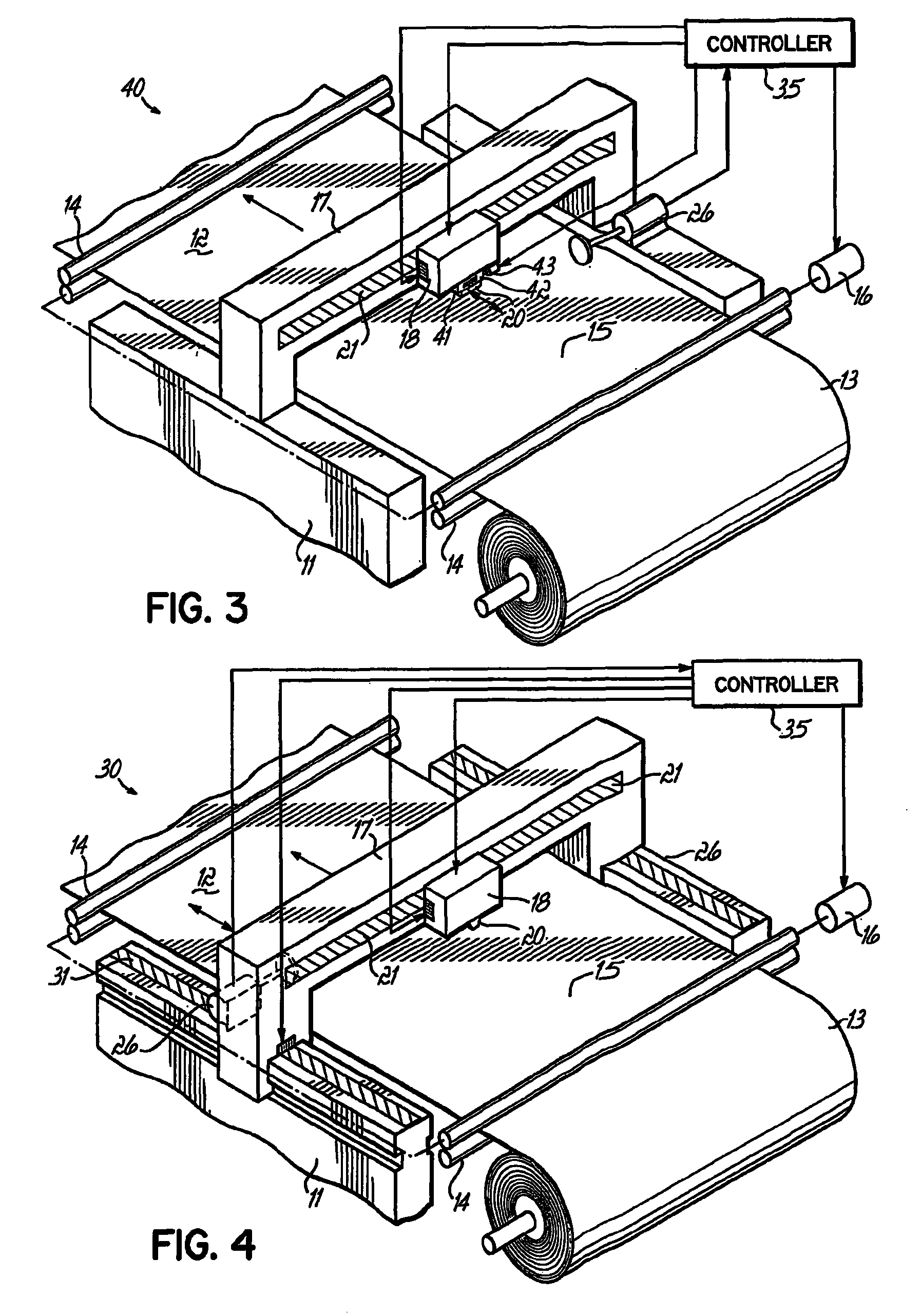

High Precision Feed Particularly Useful for UV Ink Jet Printing on Vinyl

InactiveUS20080297559A1High precisionTypewritersOther printing apparatusMeasurement deviceFixed Bridges

An apparatus (30, 40, 50) and a method of ink jet printing arc disclosed that use a system for feeding a substrate longitudinally relative to a support area and a system for moving a printhead parallel to the direction of substrate feed. Indexing between transverse scan rows of a printhead (20) is carried out initially by the substrate feed system (16) and the actual feed distance is measured using an encoder or other substrate position measurement device (26). A controller (25) determines the amount of any error that occurs between the actual and the desired feed distances. The controller (25) then sends signals to move the printhead (20) to compensate for any error in the feed system feed. Compensating adjustments are then made to the next subsequent substrate indexing step so that the printhead tends to move back toward its home or zeroed position with its next correction and does not walk away from this home position as a result of cumulative movements. For printers that have bridges (17) moveable relative to the machine frame (11) on which the printhead (20) is carried, printhead motion is achieved by moving the bridge, for example, by actuating a linear servo bridge motion system (31). For fixed bridge roll-to-roll printers, the printhead (20) can be caused to shift longitudinally on the bridge (17) to make the correcting movements.

Owner:POLYTYPEAG

High precision feed particularly useful for UV ink jet printing on vinyl

An apparatus (30, 40, 50) and a method of ink jet printing are disclosed that use a system for feeding a substrate longitudinally relative to a support area and a system for moving a printhead parallel to the direction of substrate feed. Indexing between transverse scan rows of a printhead (20) is carried out initially by the substrate feed system (16) and the actual feed distance is measured using an encoder or other substrate position measurement device (26). A controller (25) determines the amount of any error that occurs between the actual and the desired feed distances. The controller (25) then sends signals to move the printhead (20) to compensate for any error in the feed system feed. Compensating adjustments are then made to the next subsequent substrate indexing step so that the printhead tends to move back toward its home or zeroed position with its next correction and does not walk away from this home position as a result of cumulative movements. For printers that have bridges (17) moveable relative to the machine frame (11) on which the printhead (20) is carried, printhead motion is achieved by moving the bridge, for example, by actuating a linear servo bridge motion system (31). For fixed bridge roll-to-roll printers, the printhead (20) can be caused to shift longitudinally on the bridge (17) to make the correcting movements.

Owner:POLYTYPEAG

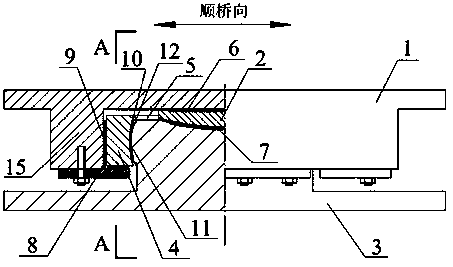

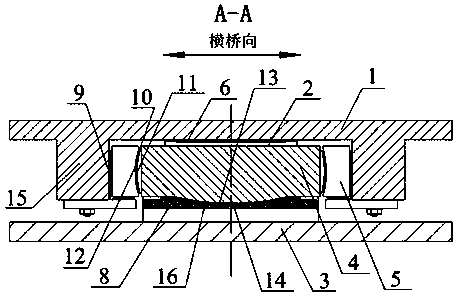

Multi-directional coordinated rotating fixed bridge support

PendingCN108570926AExtended service lifeExtend your lifeBridge structural detailsEngineeringFixed Bridges

The invention discloses a multi-directional coordinated rotating fixed bridge support, comprising an upper support plate, a spherical crown lining plate and a lower support plate, wherein a bridge forward-direction rotating block and a bridge cross-direction rotating block are arranged between the inner side wall of a check block of the upper support plate and the outer edge periphery of the top of the lower support plate; the outer side faces of the bridge forward-direction rotating block and the bridge cross-direction rotating block are separately connected with the plane of the check blockof the upper support plate in a sliding way, the inner side faces of the bridge forward-direction rotating block and the bridge cross-direction rotating block are separately and rotatably connected with the spherical surface of the outer edge of the upper end of the lower support plate, the bottom surfaces of the bridge forward-direction rotating block and the bridge cross-direction rotating blockare separately and rotatably connected with the spherical surface of a horizontal rotary check block fixedly connected with the bottom of the check block of the upper support plate, and adjustable gaps are reserved between the rabbet inner wall of the check block of the upper support plate and the top surfaces of the bridge forward-direction rotating block and the bridge cross-direction rotatingblock, so that multi-directional coordinated rotation of the support is realized. The multi-directional coordinated rotating fixed bridge support is simple in structure, low in manufacturing cost, andconvenient and fast to install; by means of multi-azimuth spherical rotational connection, all the components are in a surface contact stress state during work of the support, so that the service life of the support is significantly prolonged; therefore, the support has good economical practicability and popularization prospect.

Owner:GUIZHOU TRANSPORTATION PLANNING SURVEY & DESIGN ACADEME

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com