Corn combine harvester

A combine harvester and corn technology, applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problem of reducing the frequency of use of combine harvesters, increasing user costs, and the incompatibility of wheat combine harvesters and corn combine harvesters And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

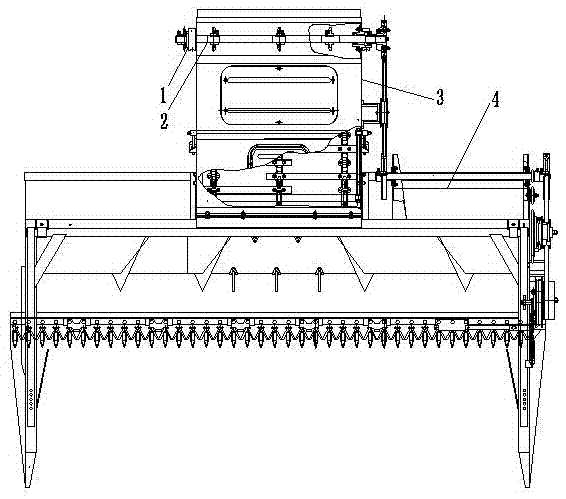

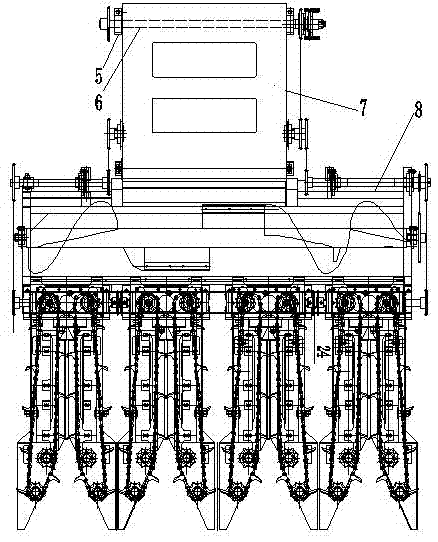

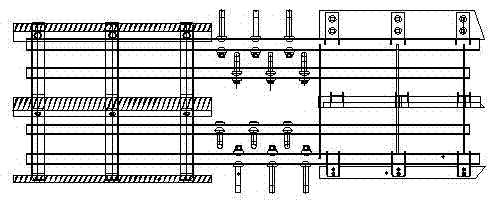

[0016] The present invention will be described in further detail in conjunction with the accompanying drawings. A corn combine harvester, comprising a frame, a header, a bridge, a threshing device, and a cleaning device, the header communicates with a threshing chamber fixed on the frame through the bridge, and the bridge passes through the drive shaft bearing 1 is hinged with the frame; the power of the header for harvesting corn comes from the drive shaft 2; the threshing device includes a threshing chamber, a threshing drum located in the threshing chamber, and the threshing chamber includes a loam cake, a grid concave screen, The cleaning device includes a fish scale cleaning screen, the header is a header 4 for harvesting wheat, and the bridge is a bridge 3 for harvesting wheat. figure 1 The serial number 5 shown in is the bearing seat of the driving shaft for harvesting corn, the serial number 6 is the driving shaft, the serial number 7 is used to cross the bridge for ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com