Adhesive dispensing machine and adhesive dispensing method thereof

A glue dispensing machine and glue dispensing technology, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems affecting the production efficiency of the whole line, increase the labor cost, increase the equipment cost, etc., to reduce the floor space and The effect of equipment procurement cost, improving dispensing quality, and saving work cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Embodiments of the present invention are described in detail below:

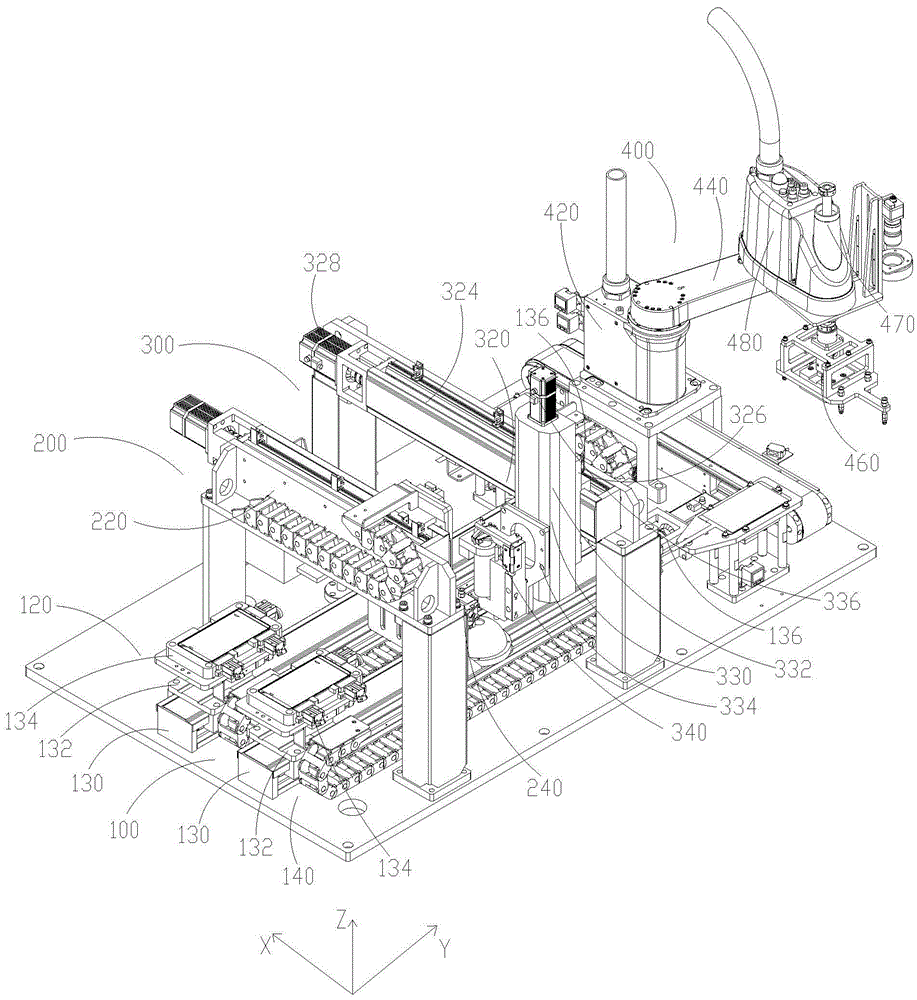

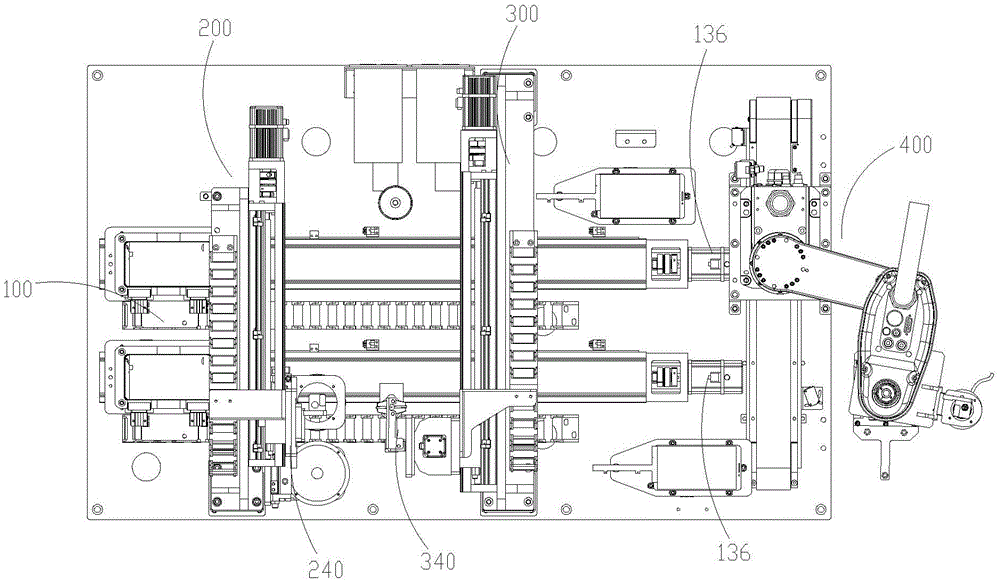

[0034] Such as figure 1 , image 3 As shown, a glue dispensing machine includes a control system, a feeding system 100, and a visual inspection system 200 and a dispensing system 300 that are all located above the feeding system;

[0035] The feeding system 100 at least includes at least two feeding devices arranged side by side, and the feeding devices are connected in communication with the control system;

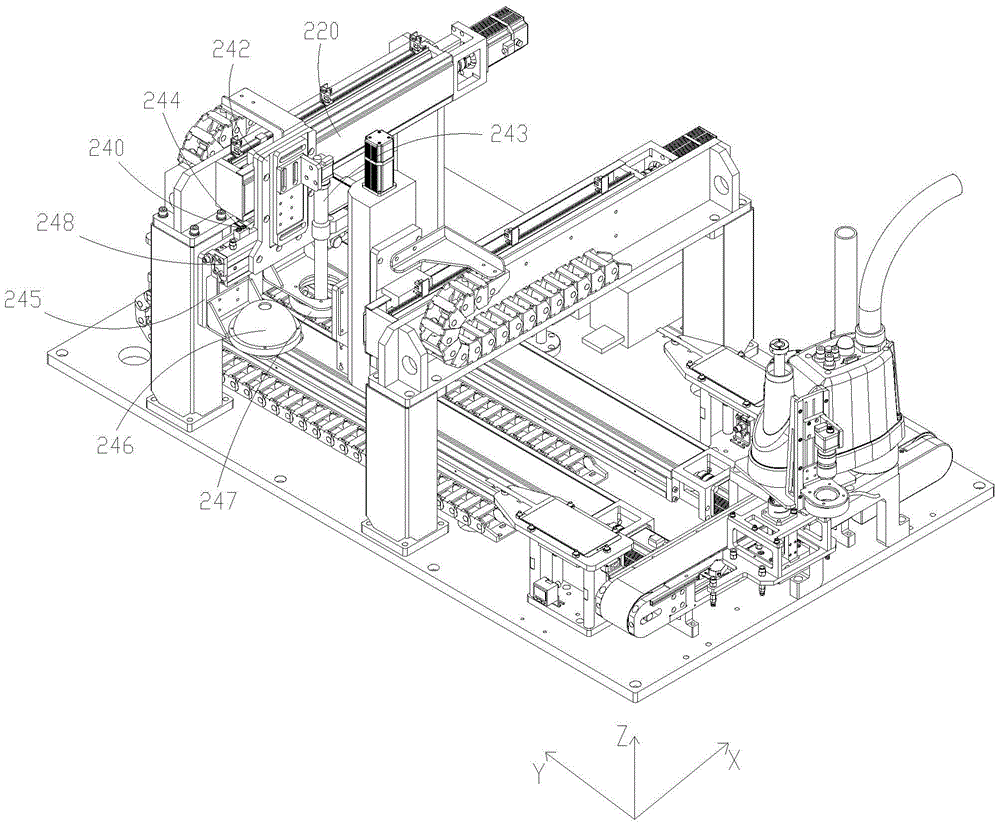

[0036] The visual inspection system 200 includes a detection track 220 horizontally erected above the feeding device, and a visual detection device 240 slidably fixed on the detection track 220;

[0037] The dispensing system 300 includes an X-axis dispensing guide rail 324 horizontally erected above the feeding device, and a dispensing device 320 slidably fixed on the X-axis dispensing guide rail 324 .

[0038]Wherein, the feeding system 100 adopts the dual feeding module of the first feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com