Double-face polishing arm device for polishing propeller of large-sized ship

A marine propeller, double-sided technology, applied in the direction of grinding drive device, grinding machine parts, grinding machine, etc., can solve the problems of simple device structure, increase system response time, prolong device working cycle, etc., to improve efficiency, reduce duty cycle, the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

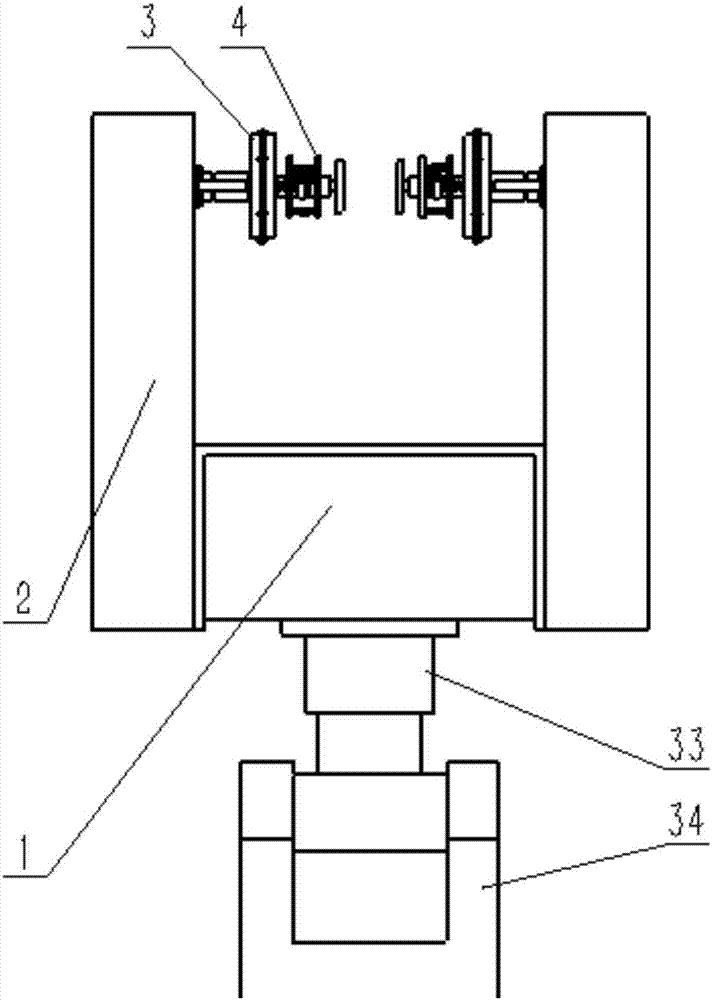

[0022] A double-sided sanding arm unit for sanding large marine propellers, comprising:

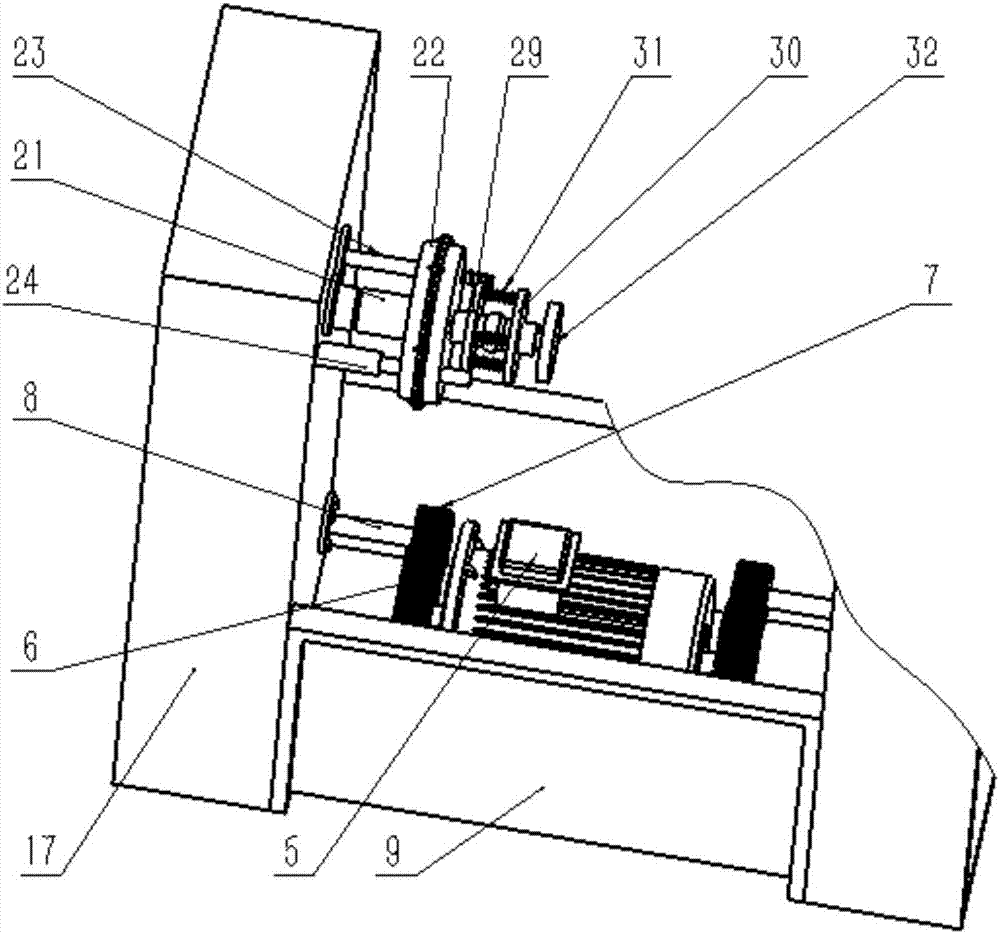

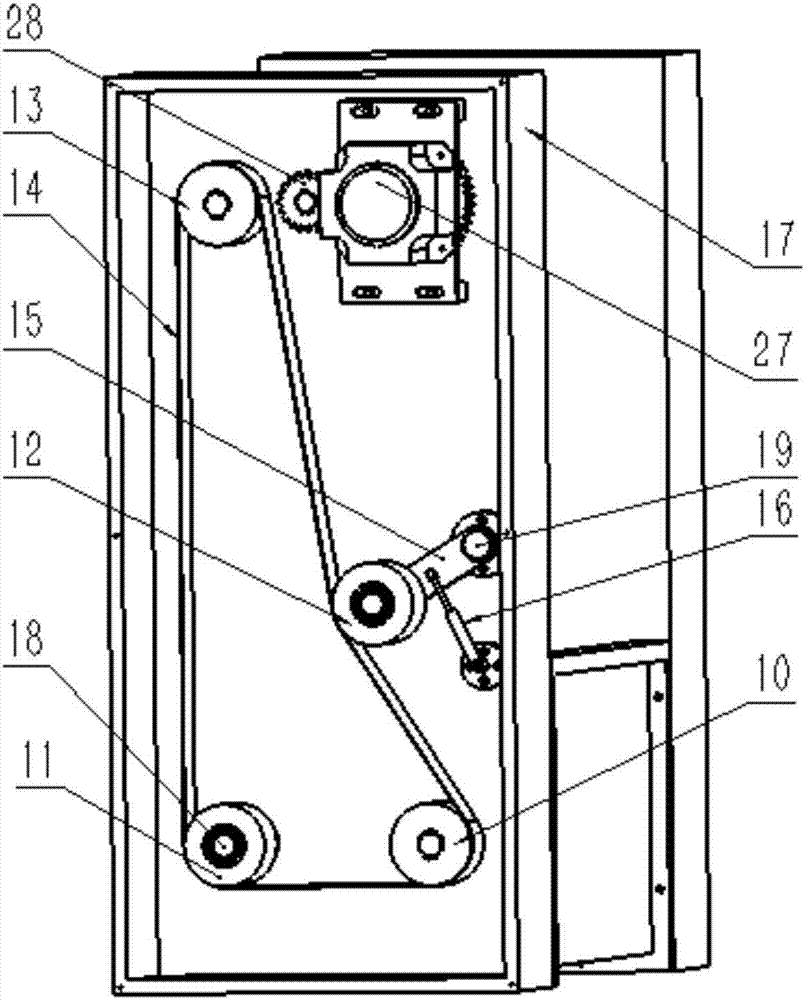

[0023] Power module 1: The power module 1 includes a double-shaft extension motor 5, a speed-up gear 6, a speed-up pinion 7, a belt transmission input shaft 8, and a motor installation shell 9; the double-shaft extension motor 5 is fixed on the motor installation shell 9 On the top, the extension shaft of the double-shaft extension motor 5 is directly connected and fixed with the speed-up gear 6; the input end of the belt drive input shaft 8 is connected and fixed with the speed-up pinion 7; the speed-up big gear 6 and the speed-up pinion 7 The two-axis extension motor 5 drives the speed-up gear 6 to rotate, thereby driving the speed-up pinion 7 and the belt drive input shaft 8 to rotate, and realizes speed-up, and transmits the power to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com