Patents

Literature

84results about How to "Improve dispensing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

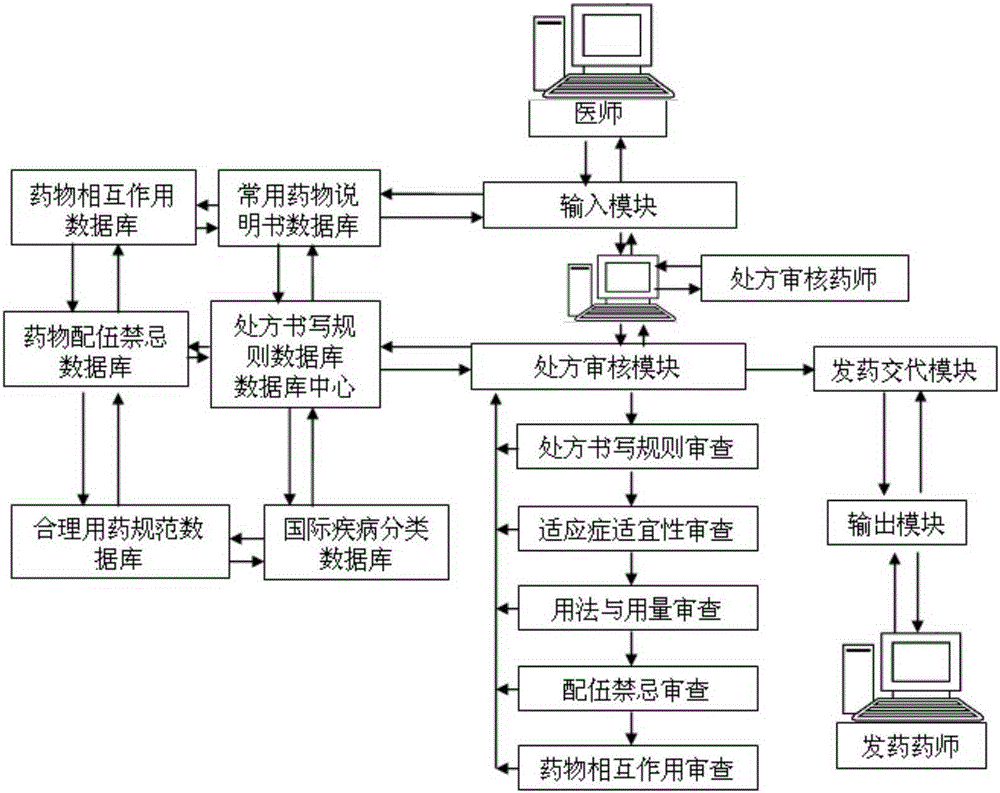

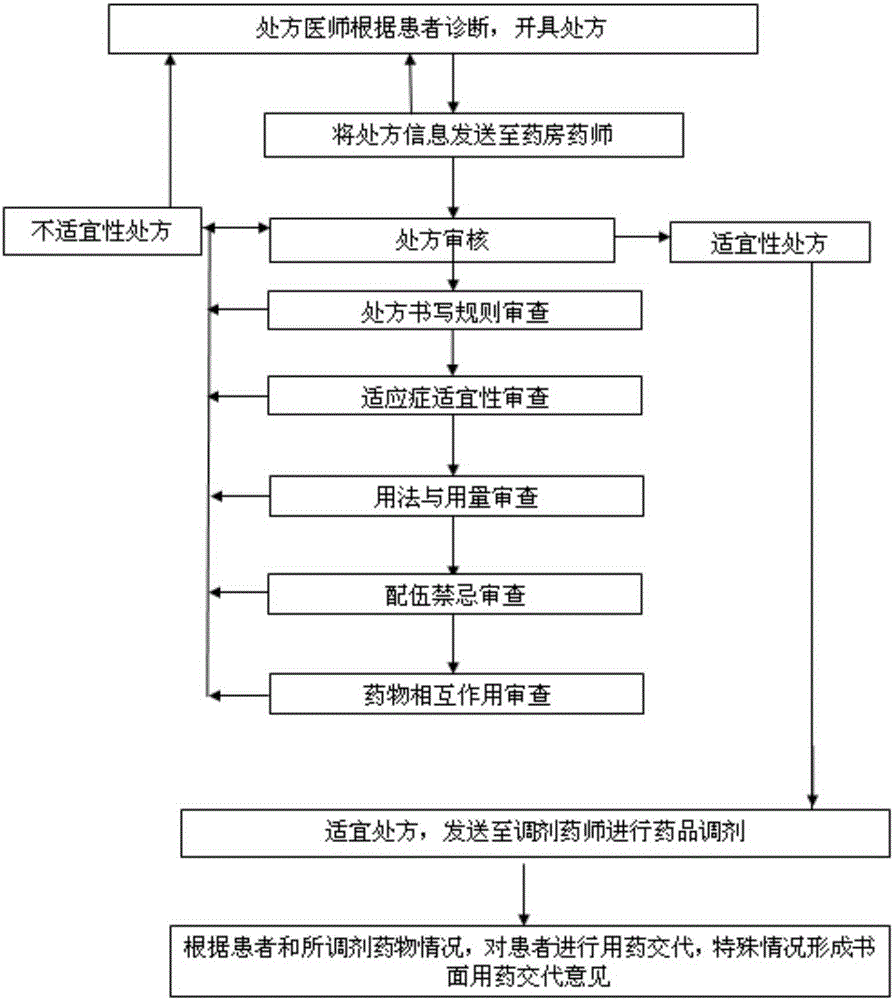

Intelligent prescription auditing system and method

InactiveCN105224794ARegulate Prescribing BehaviorNormative behaviorSpecial data processing applicationsDrug interactionControl system

The invention provides an intelligent prescription auditing system and an intelligent prescription auditing method. The system is provided with an input module, various databases, a prescription auditing module, a dispensing explaining module, and an output module. The method is implemented as follows: a doctor refines a prescription through the input module and then sends the prescription to the prescription auditing module; after receiving the prescription, the pharmacist reviews writing rules, indications, dosage, incompatibility and drug interactions of the prescription according to various databases; the doctor returns checking comments of the disqualified prescription to the prescription input module so as to modify or re-issue the prescription or give suggestions, and sends the qualified prescription to the dispensing explaining module; after receiving the prescription, an allocation doctor allocates medicines; after receiving the prescription, a dispensing doctor generates prescription information, a medication explaining matter and the like of dispensing explaining, which are printed by the output module and then explained to a patient. The invention provides a medicine dispensing control system and a medicine dispensing control method which are capable of effectively avoiding great prescription, irregular prescription, unsuitable medication for the prescription and unconventional prescription.

Owner:石庆平

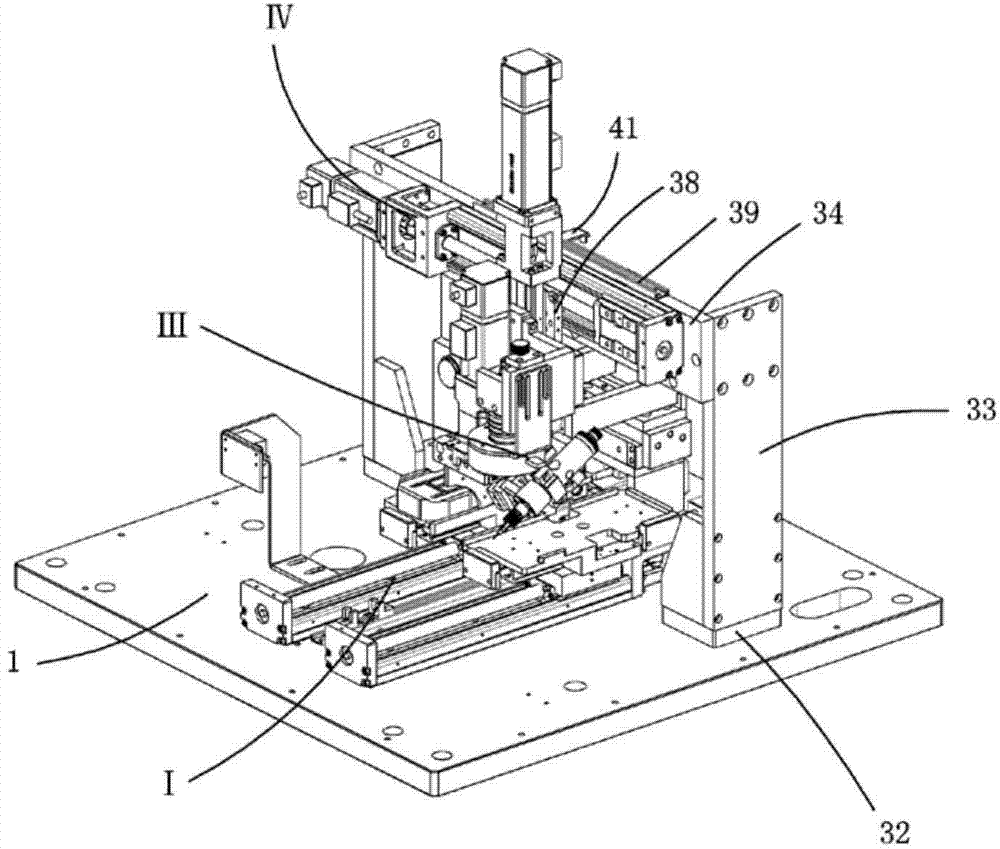

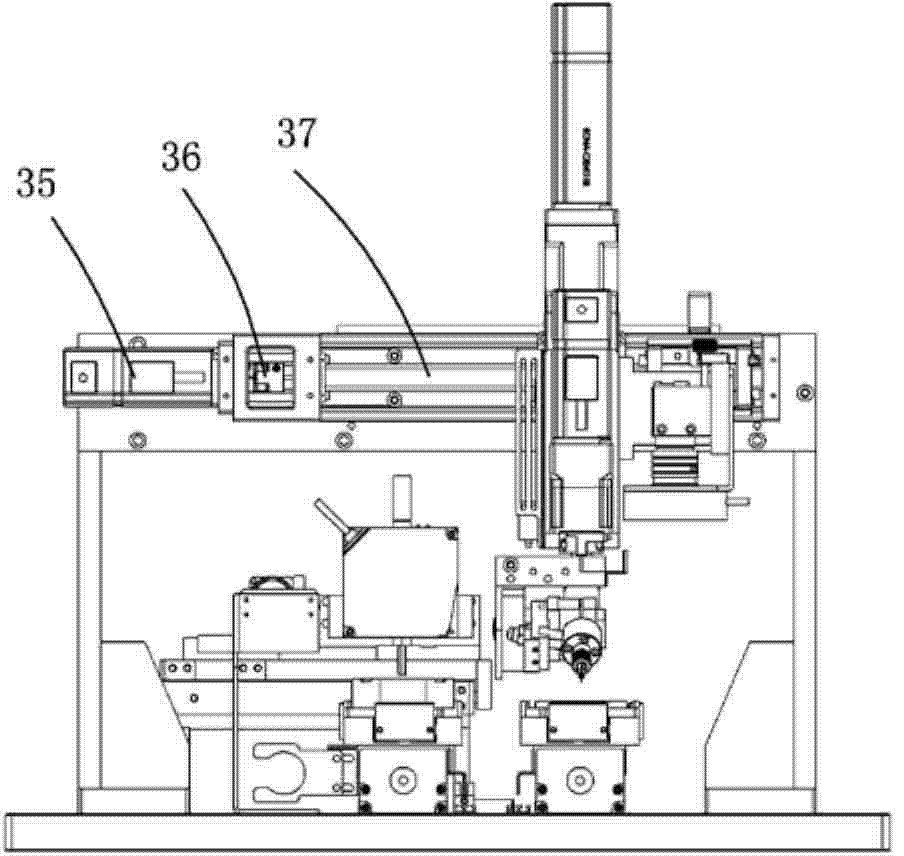

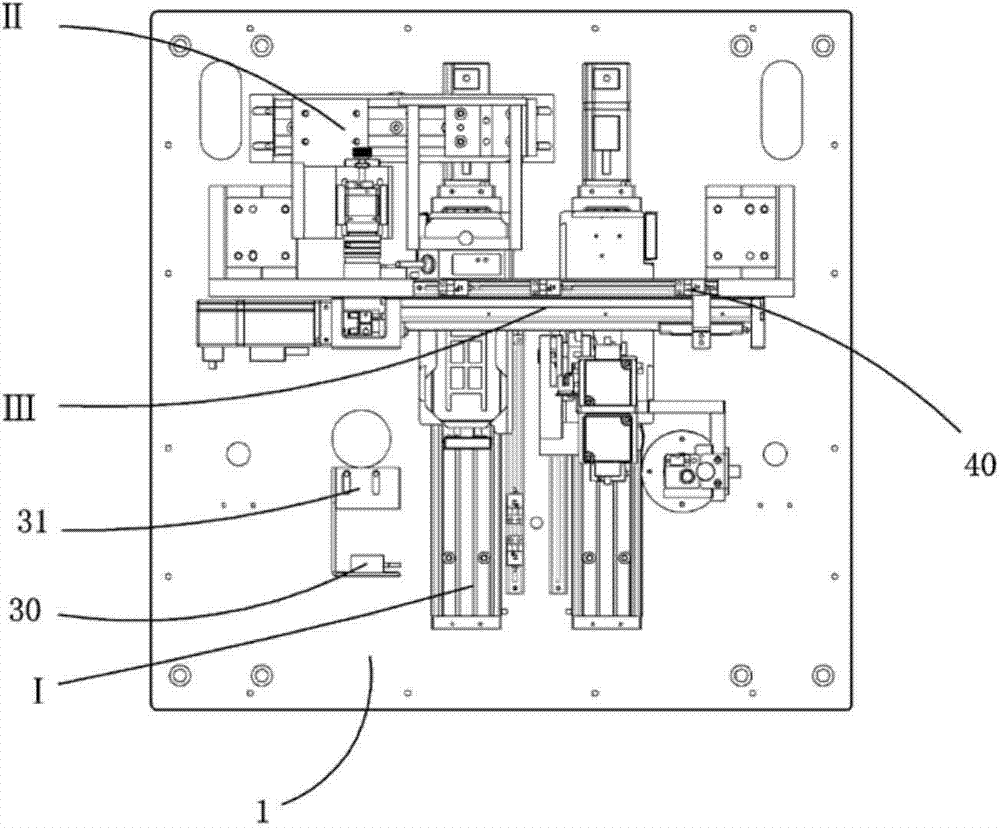

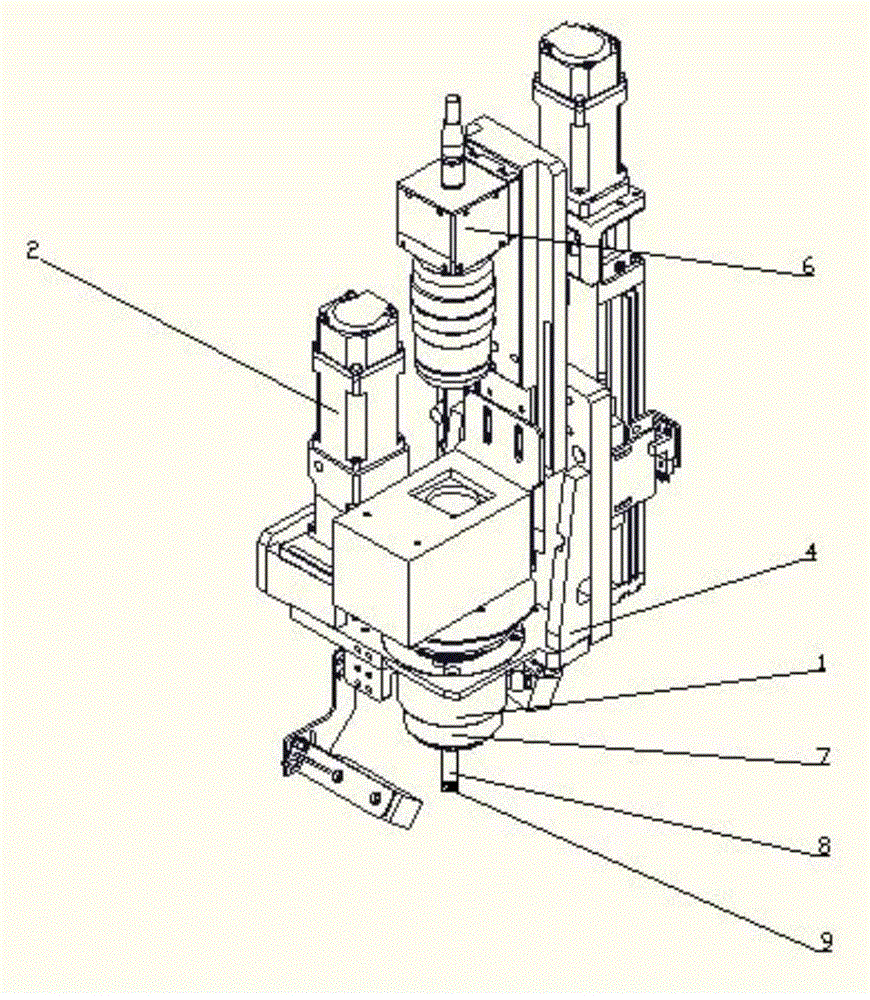

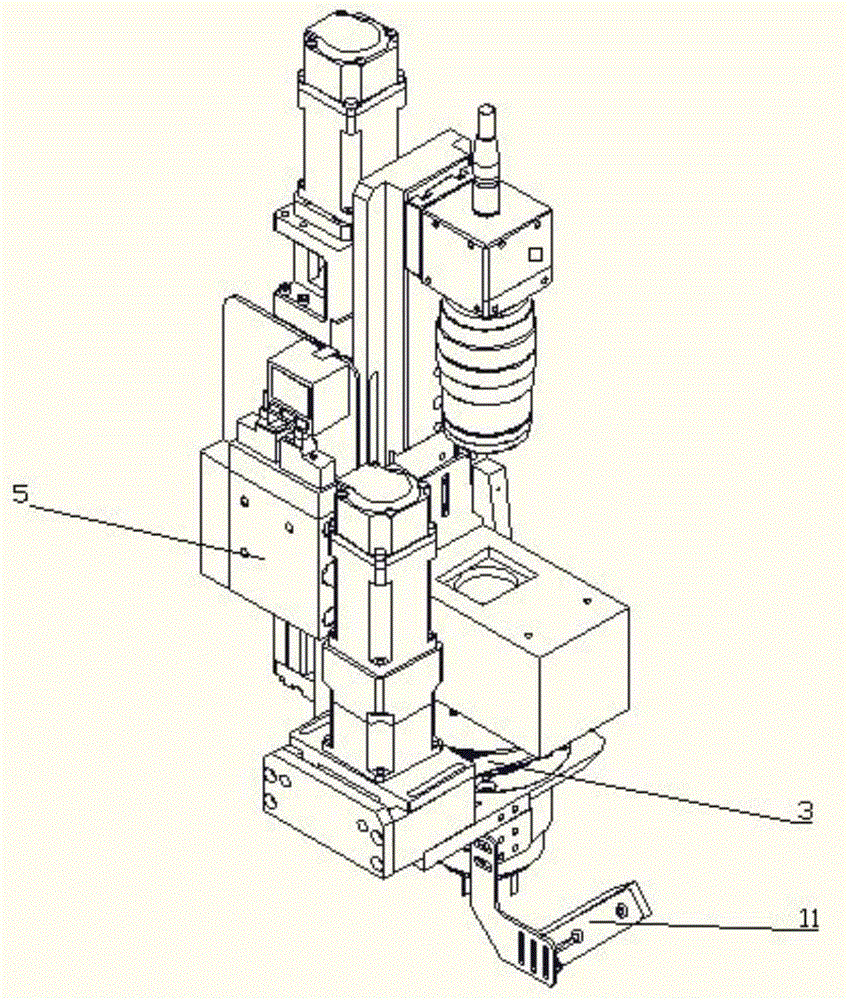

Automatic dispensing machine

ActiveCN103785579AImplement pushAchieve exitPretreated surfacesCoatingsHeight differenceCharge couple device

The invention relates to an automatic dispensing machine. Two groups of carrier transportation mechanisms are respectively arranged on a base plate; a calibration mechanism and a dispensing mechanism are respectively arranged on the base plate; the calibration mechanism is positioned below the dispensing mechanism; a product is arranged at the front end of a carrier; a part is arranged on the rear part of the carrier; under the action of a motor, the carrier is pushed inwards, a height difference between the mounting position of the part and the mounting position of the product is acquired in a laser manner, and the glue outlet amount is calculated; then the carrier is pulled out; a worker takes out the carrier, puts the carrier onto another carrier transportation device and inwards pushes the carrier; before dispensing, a Z-axis mechanism on the dispensing mechanism drives an R-axis mechanism to move to be in front of the calibration mechanism according to acquired data; the position of a dispensing valve is adjusted according to a requirement; after being calibrated, the dispensing valve is transported to a position required to be dispensed of the product; the CCD (charge coupled device) calibration mechanism is used for calibrating a dispensing position, so that the dispensing position is precise; then dispensing is executed; finally a UV (ultraviolet) lamp is moved to be aligned with the dispensing position so as to implement solidification. The automatic dispensing machine is used for performing dispensing and solidifying in the process of adhering small-size parts to an electronic product.

Owner:BOZHON PRECISION IND TECH CO LTD

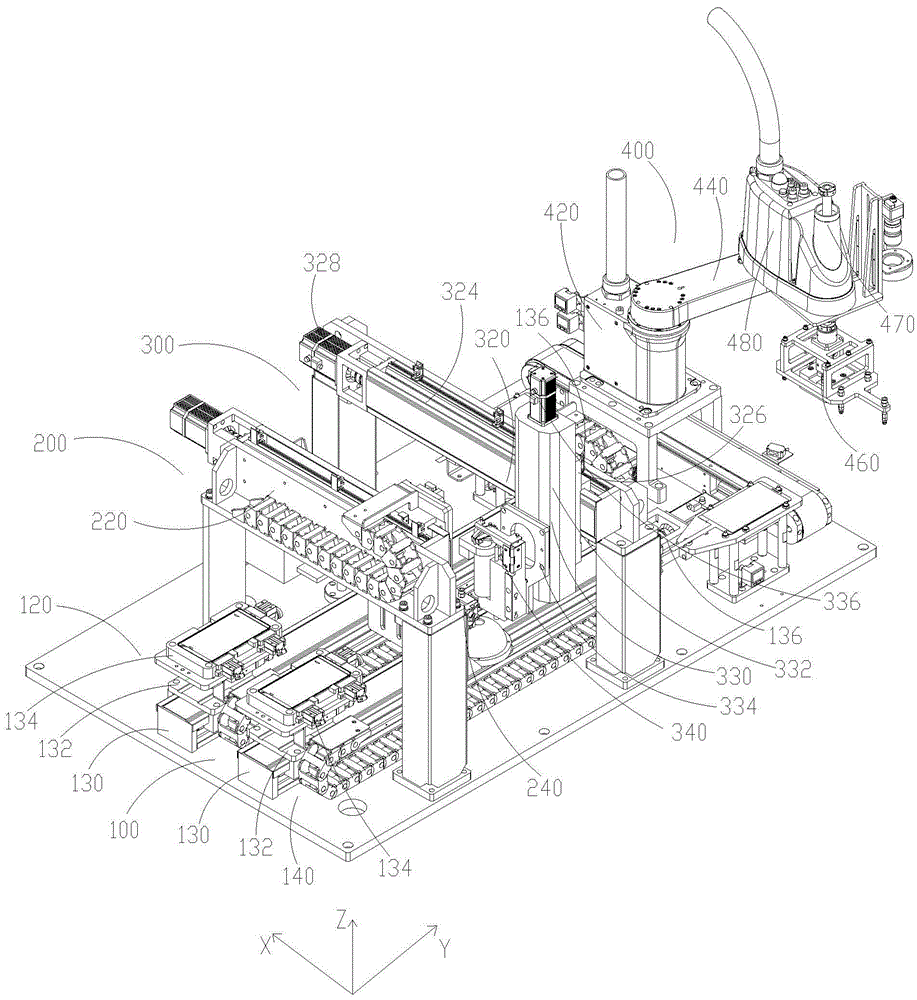

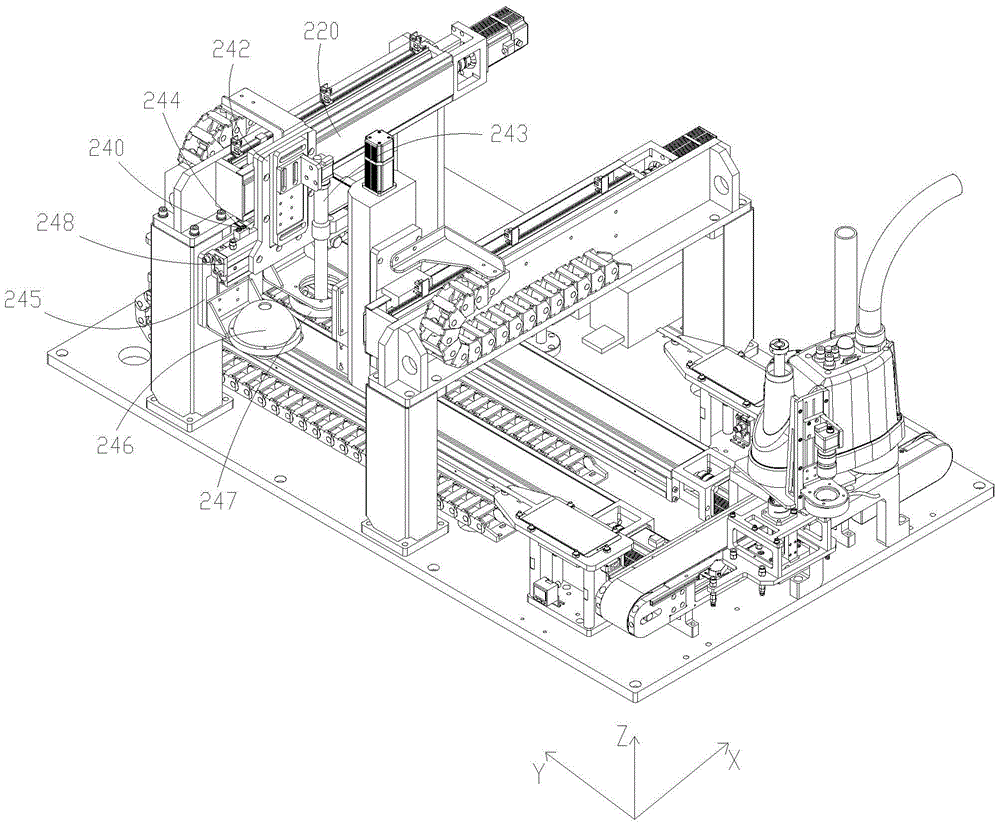

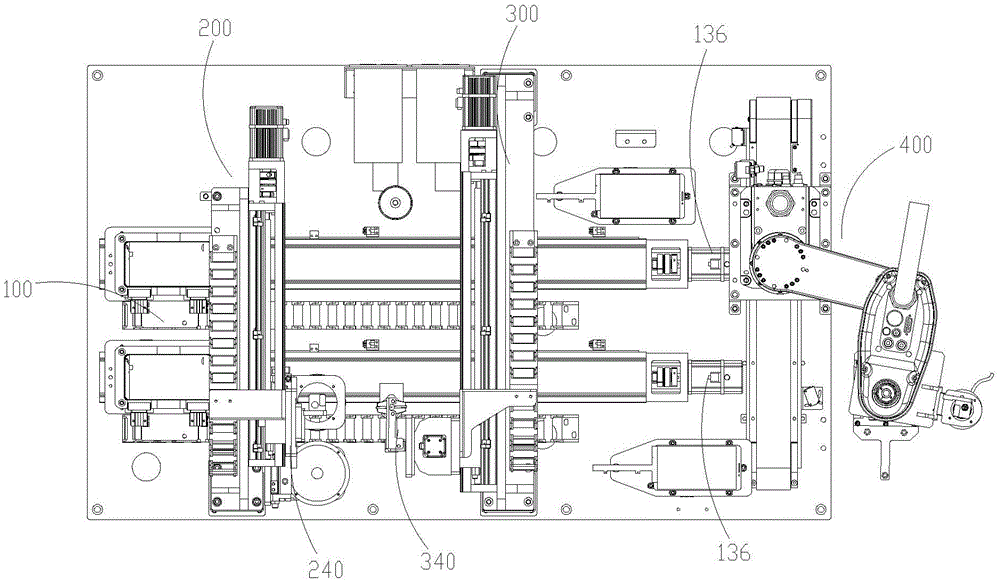

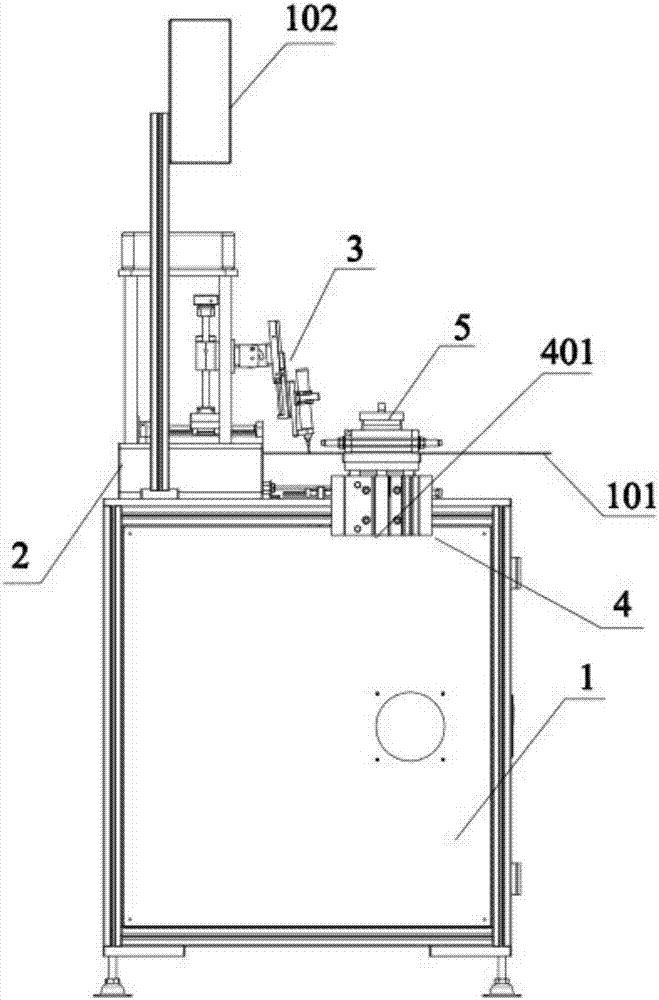

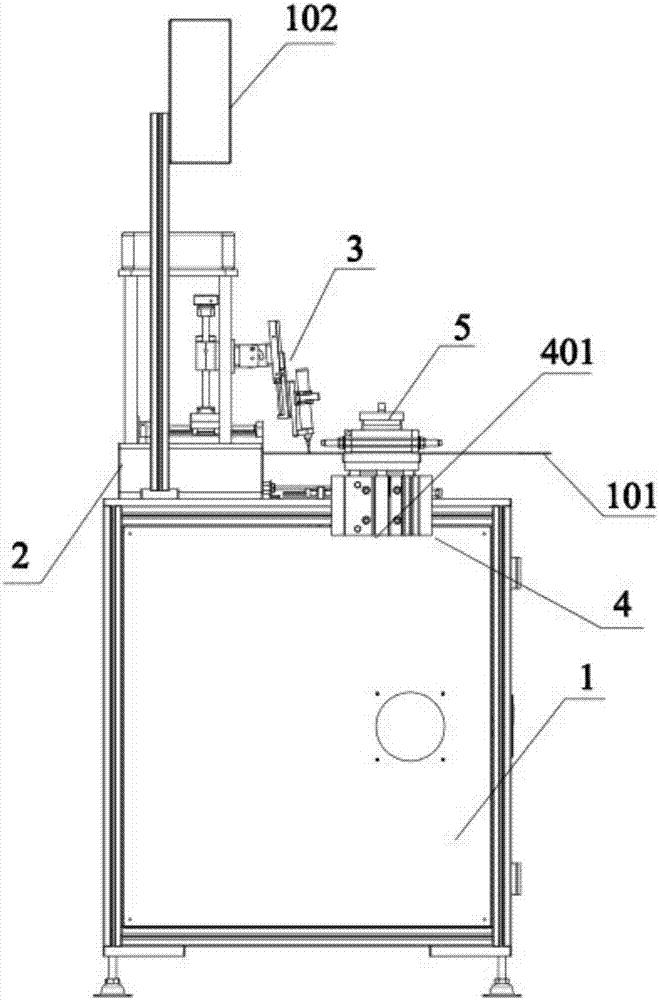

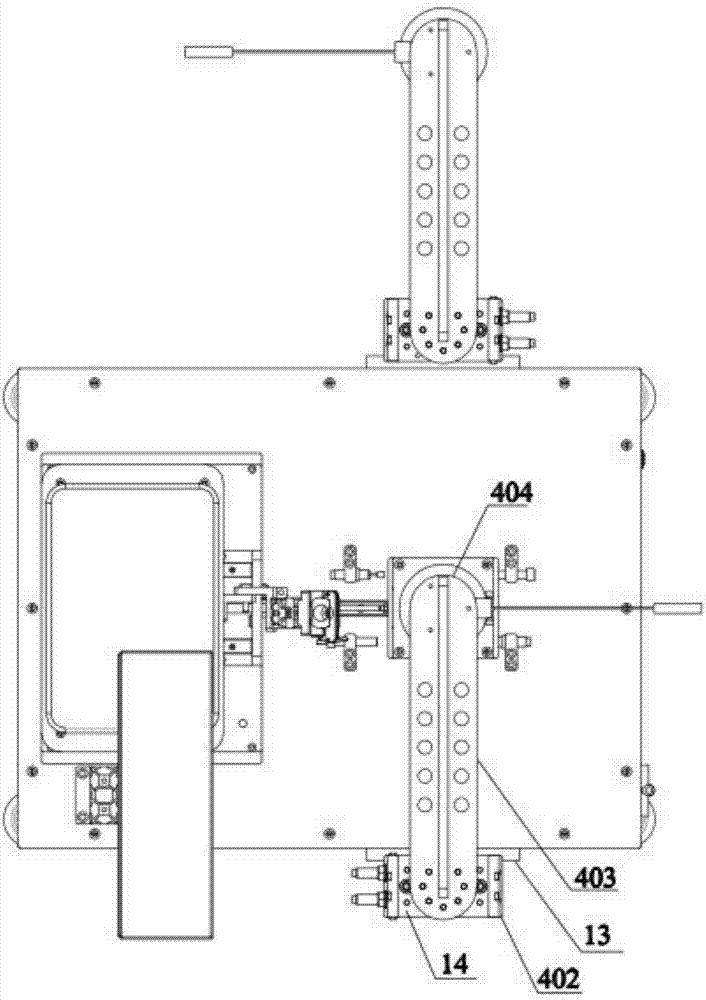

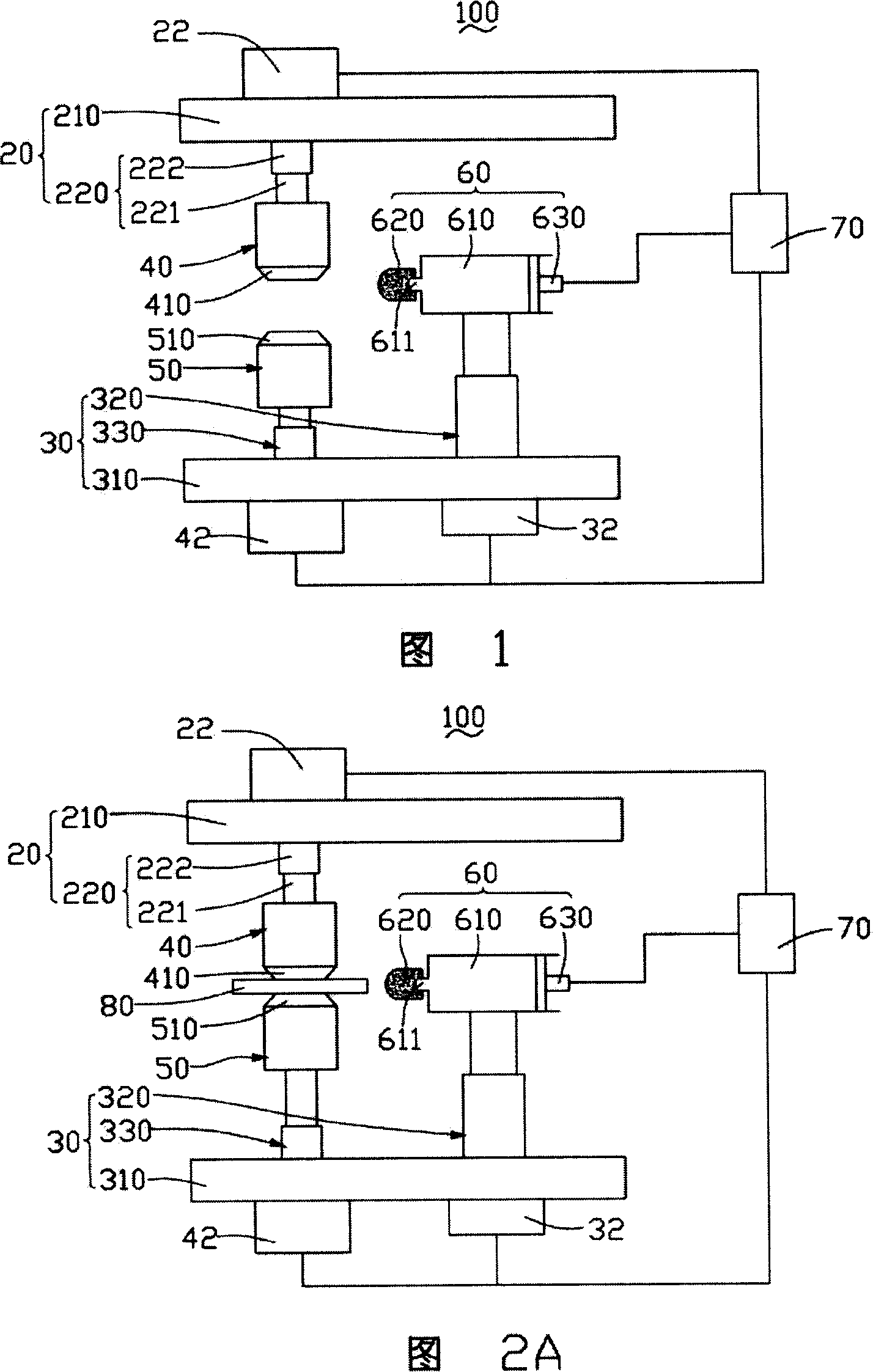

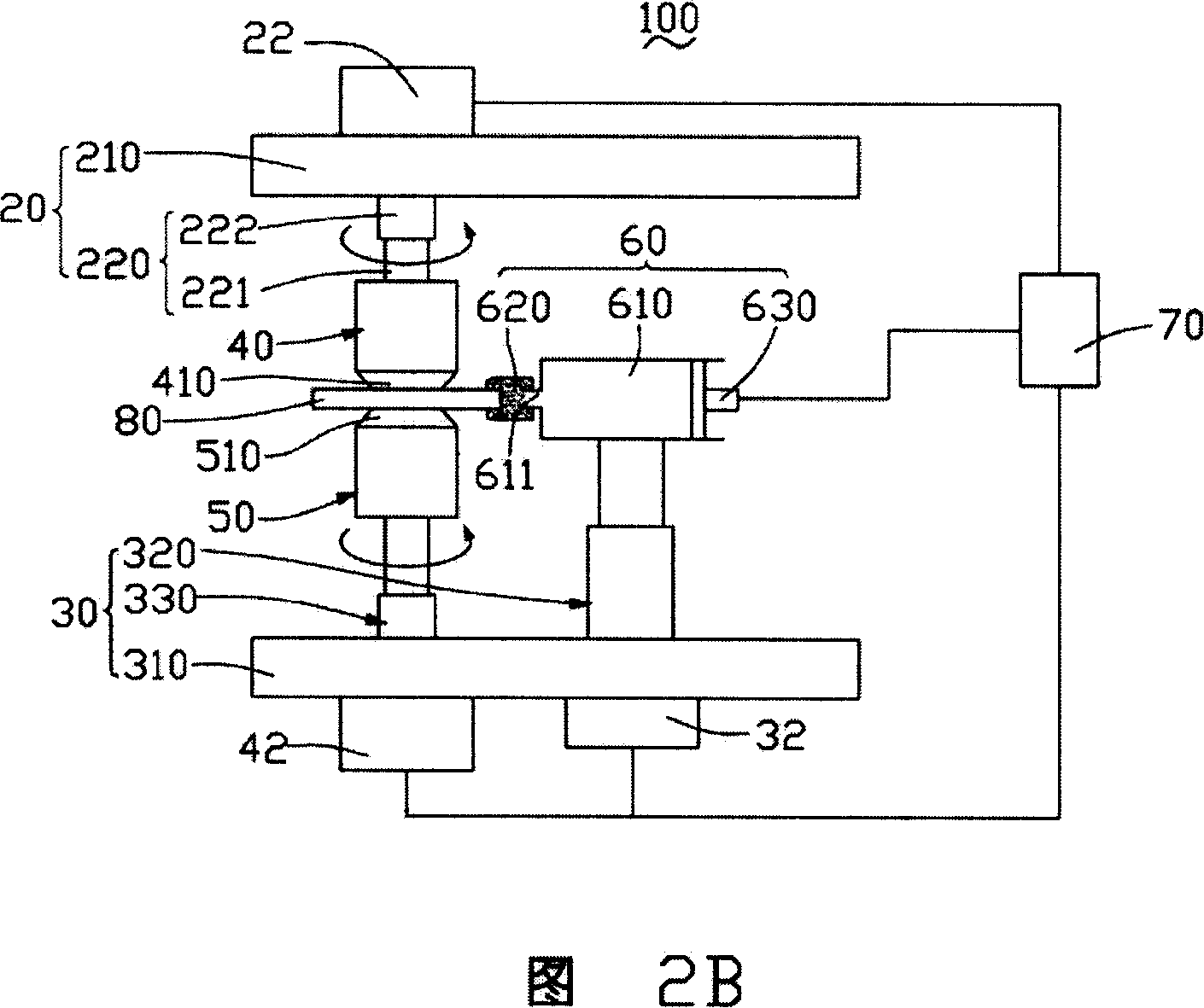

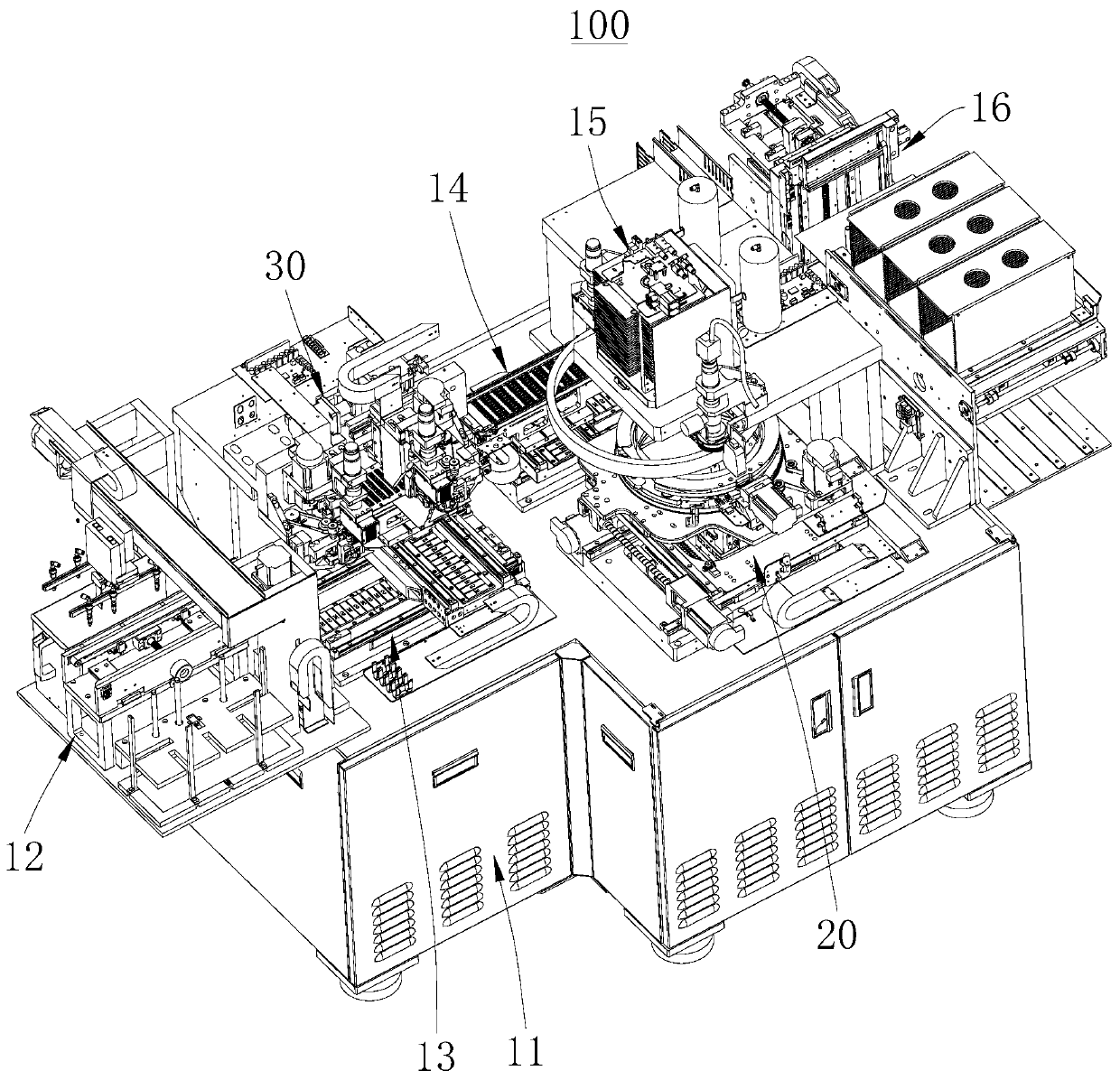

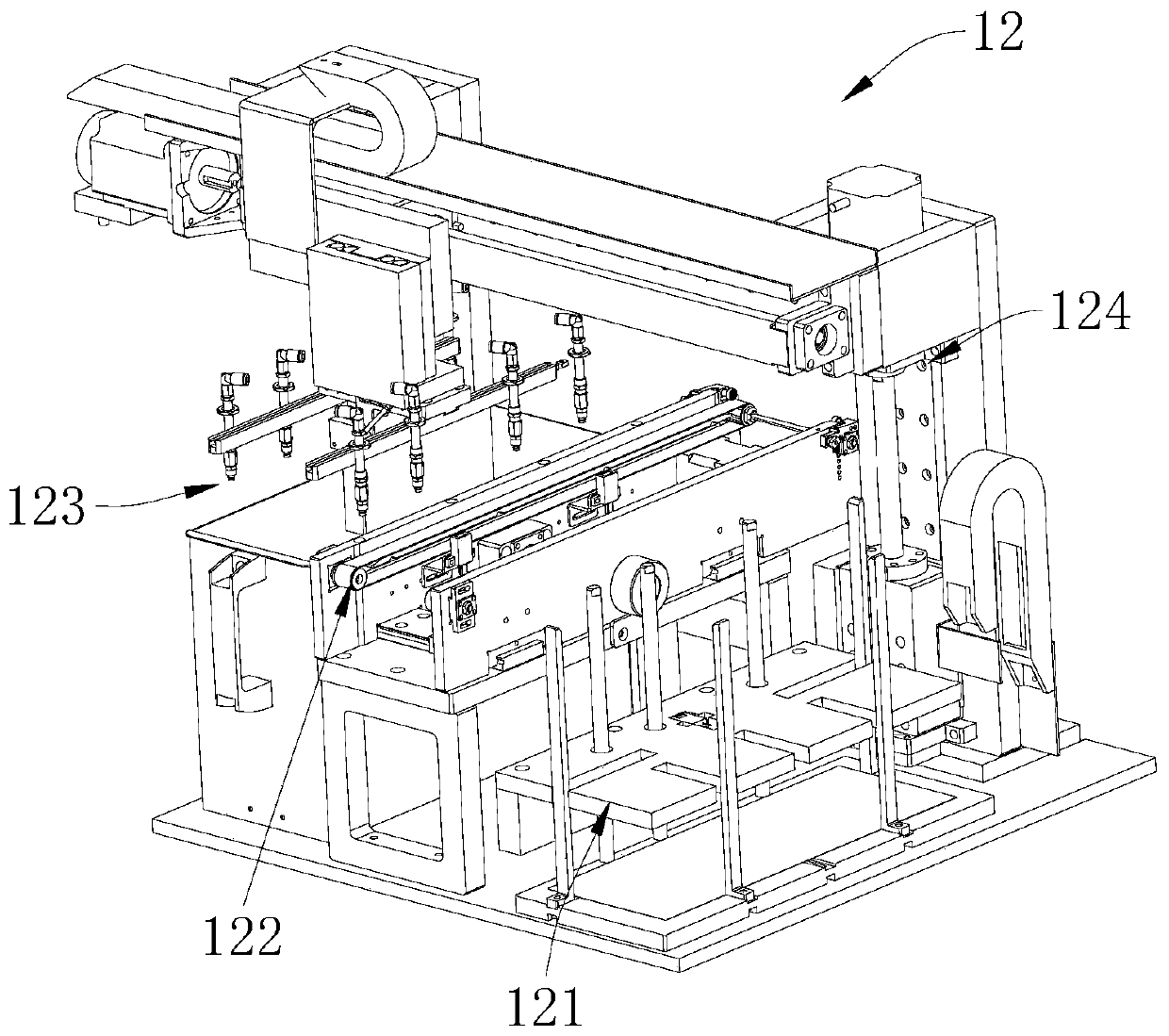

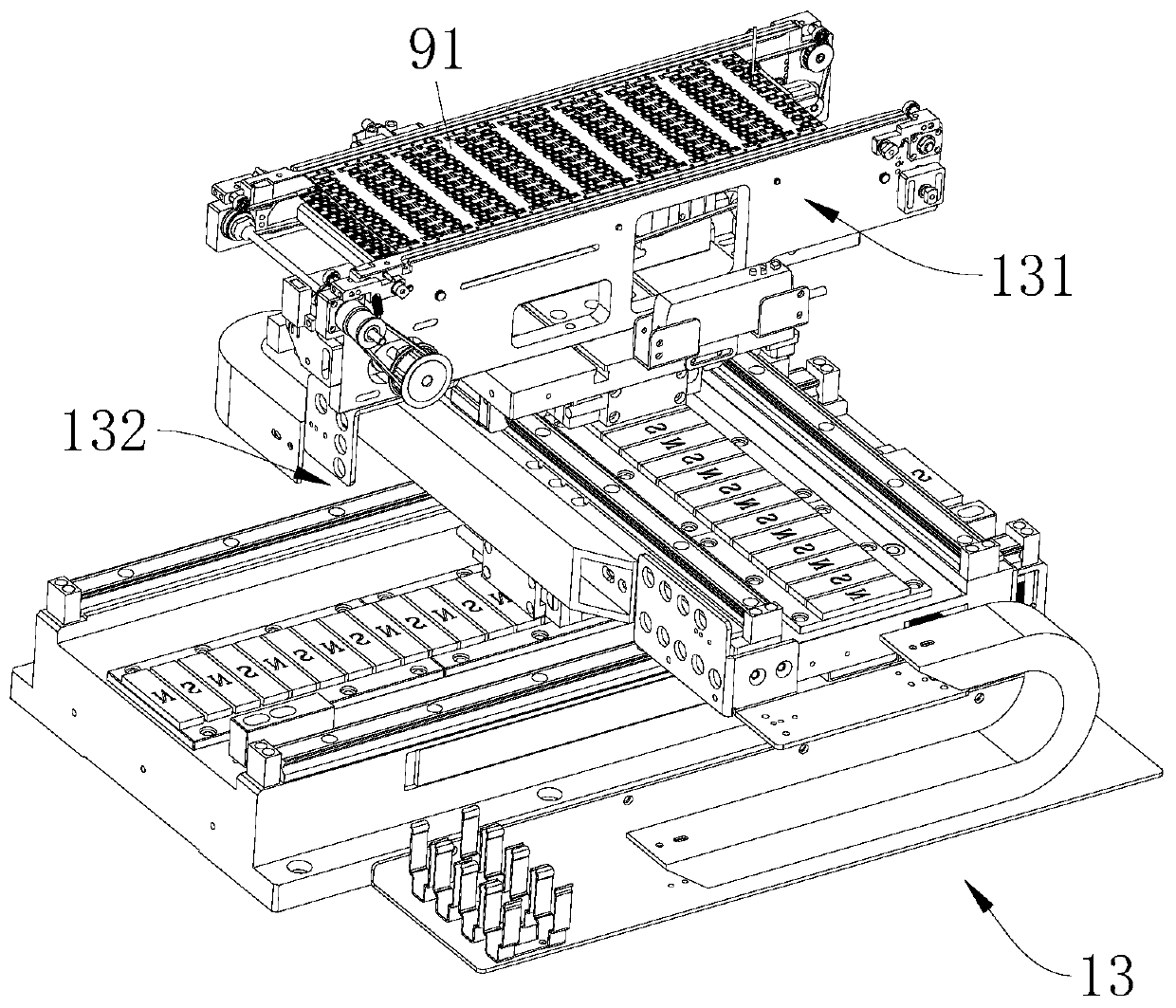

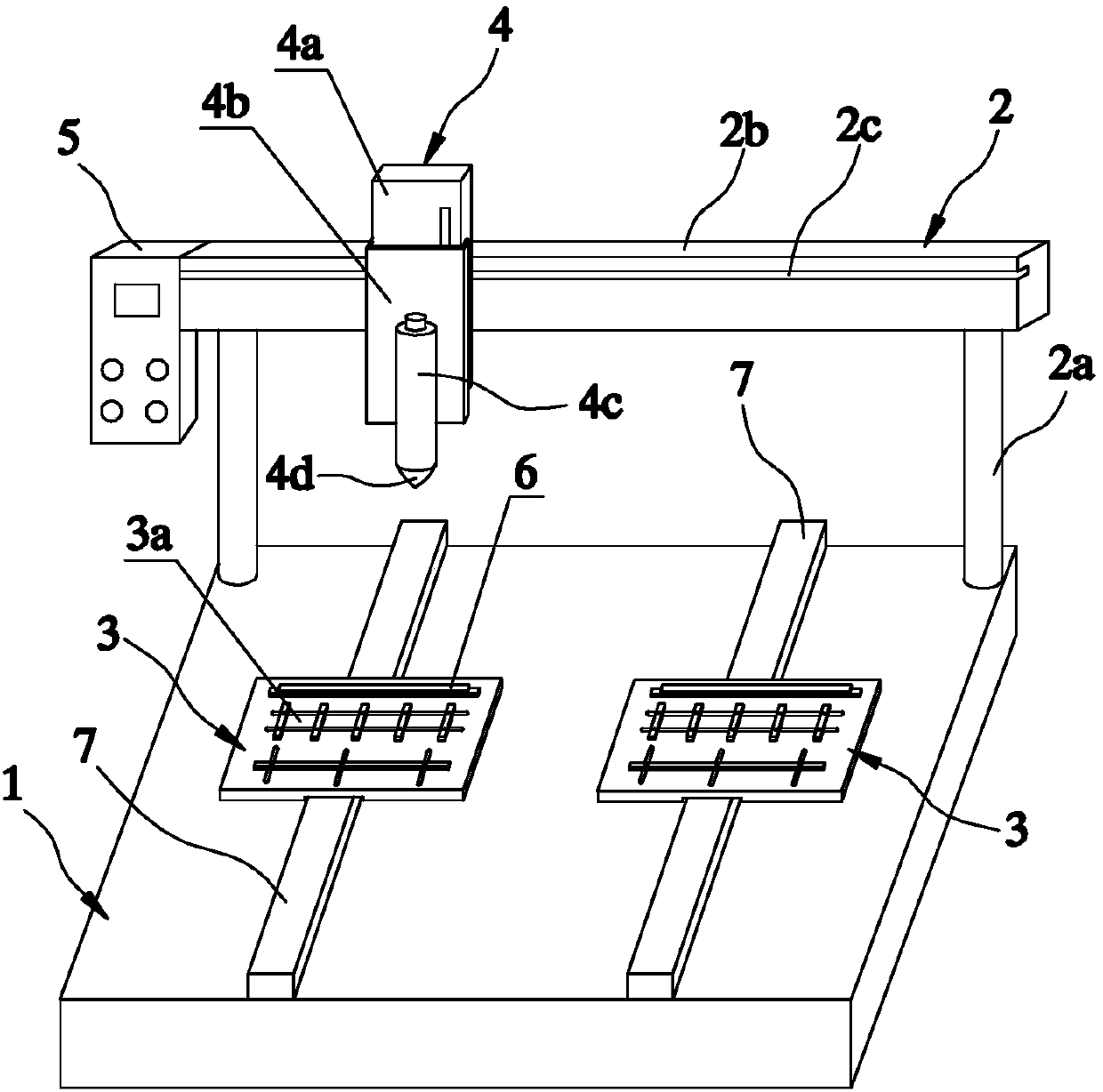

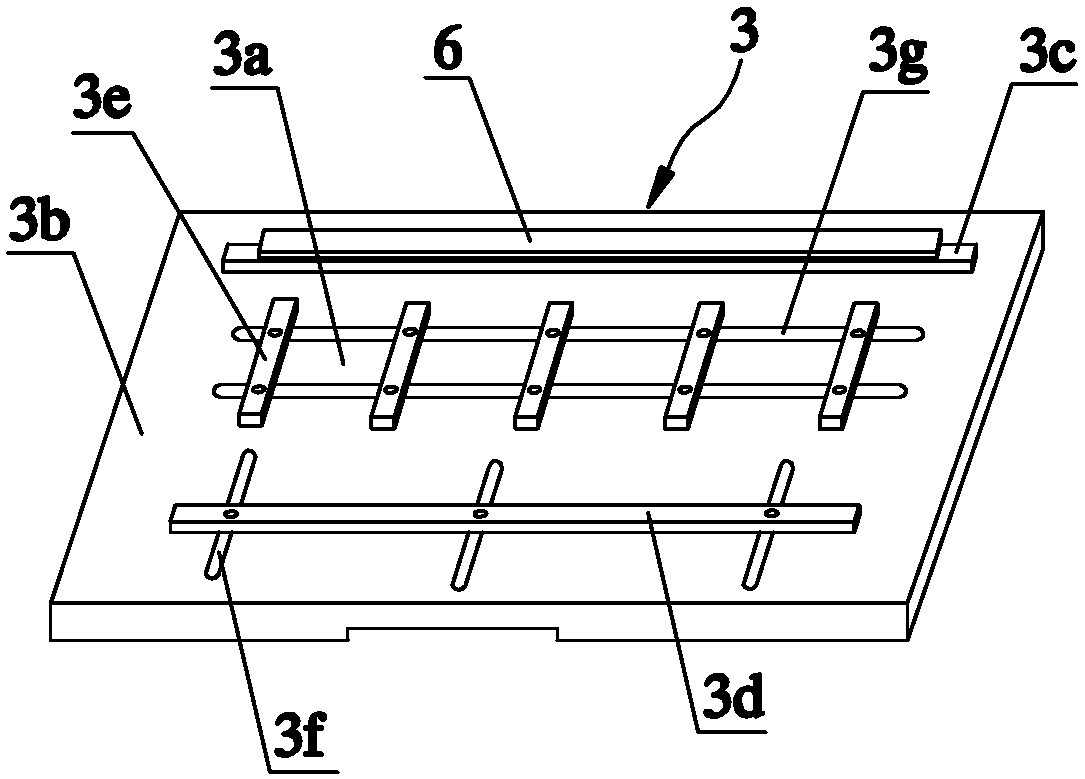

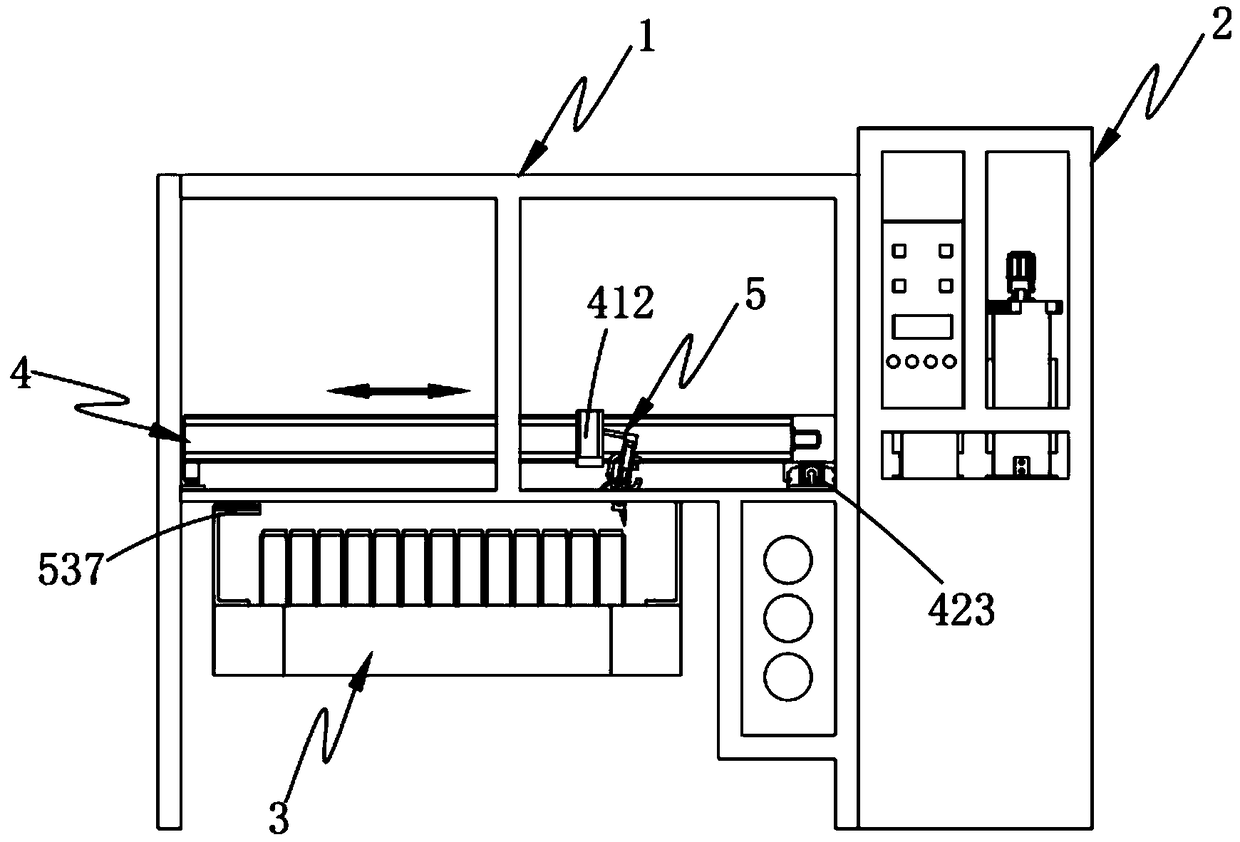

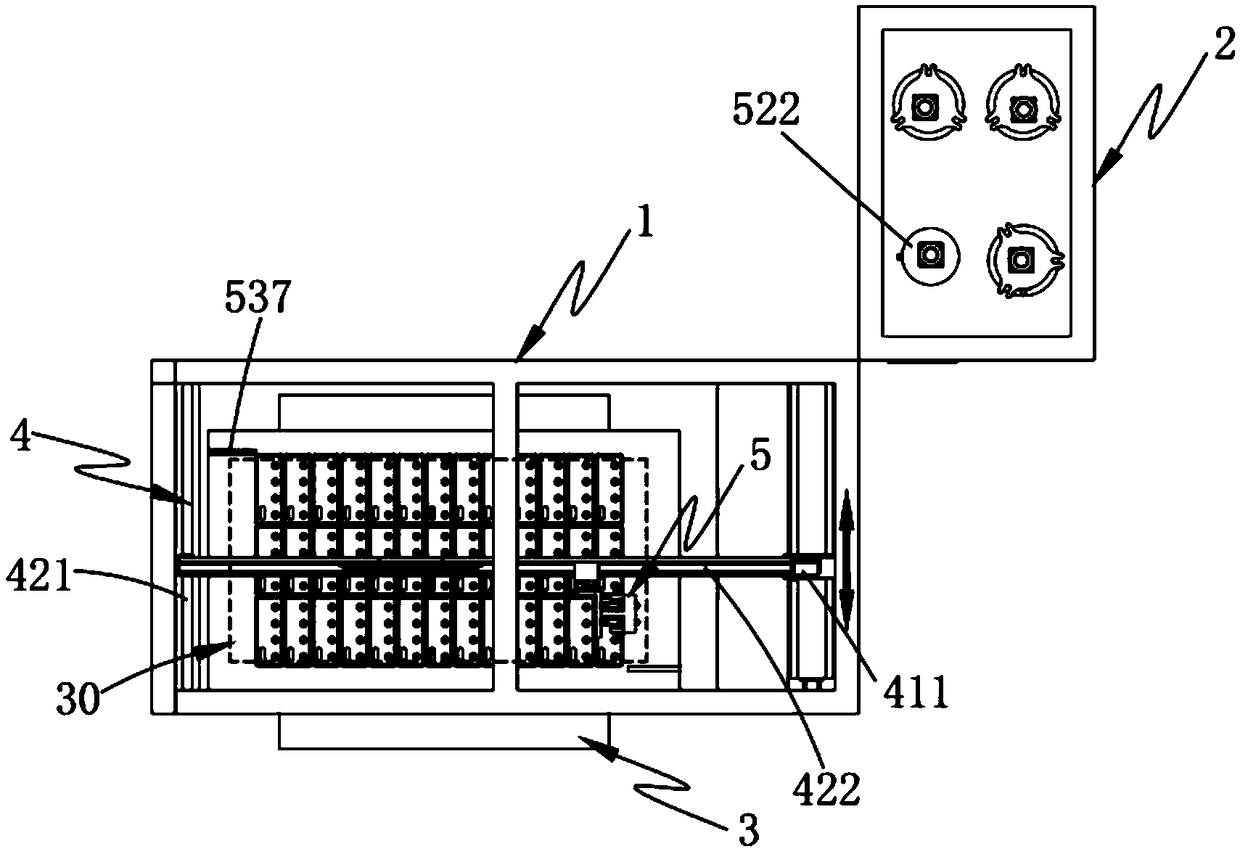

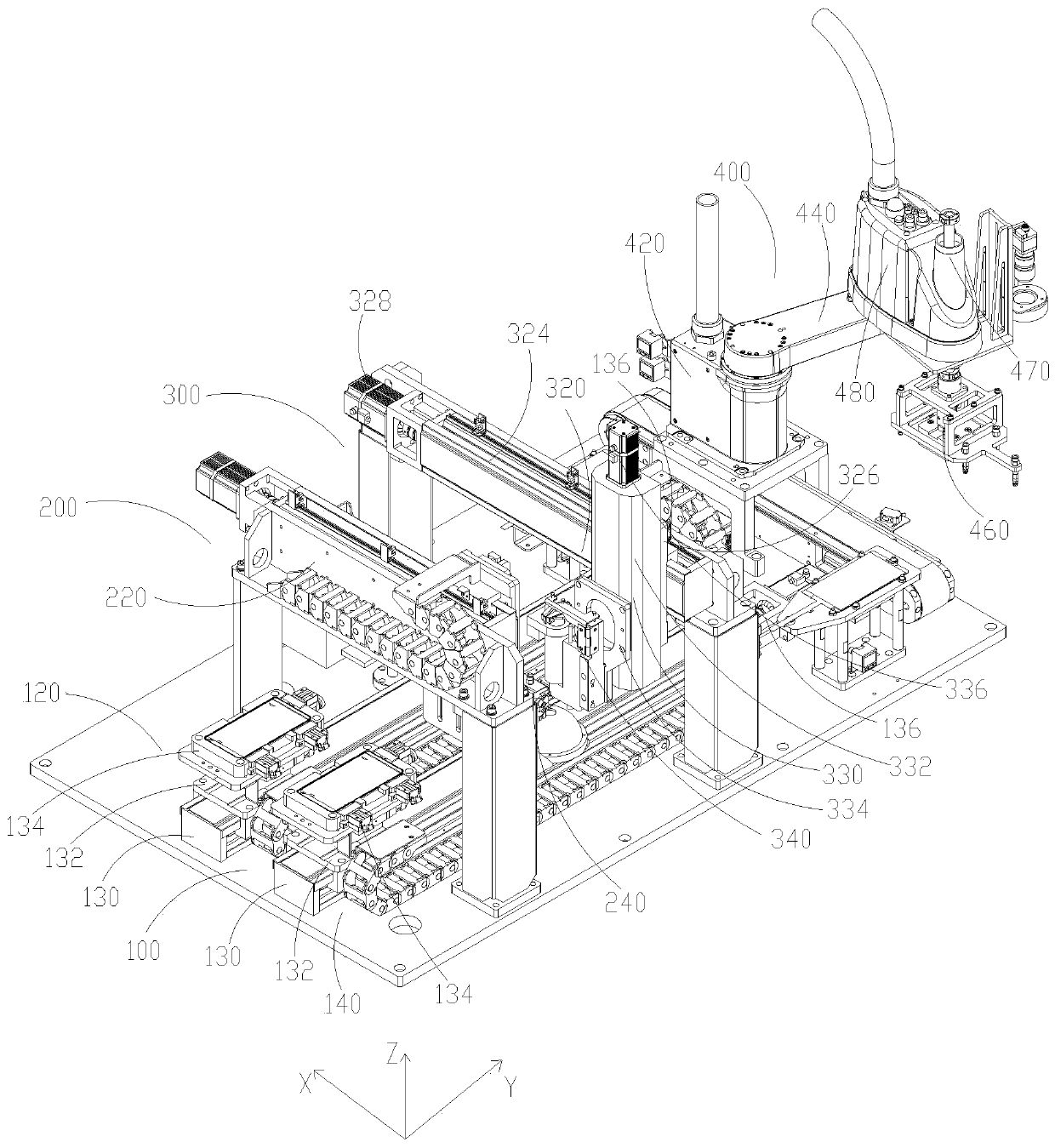

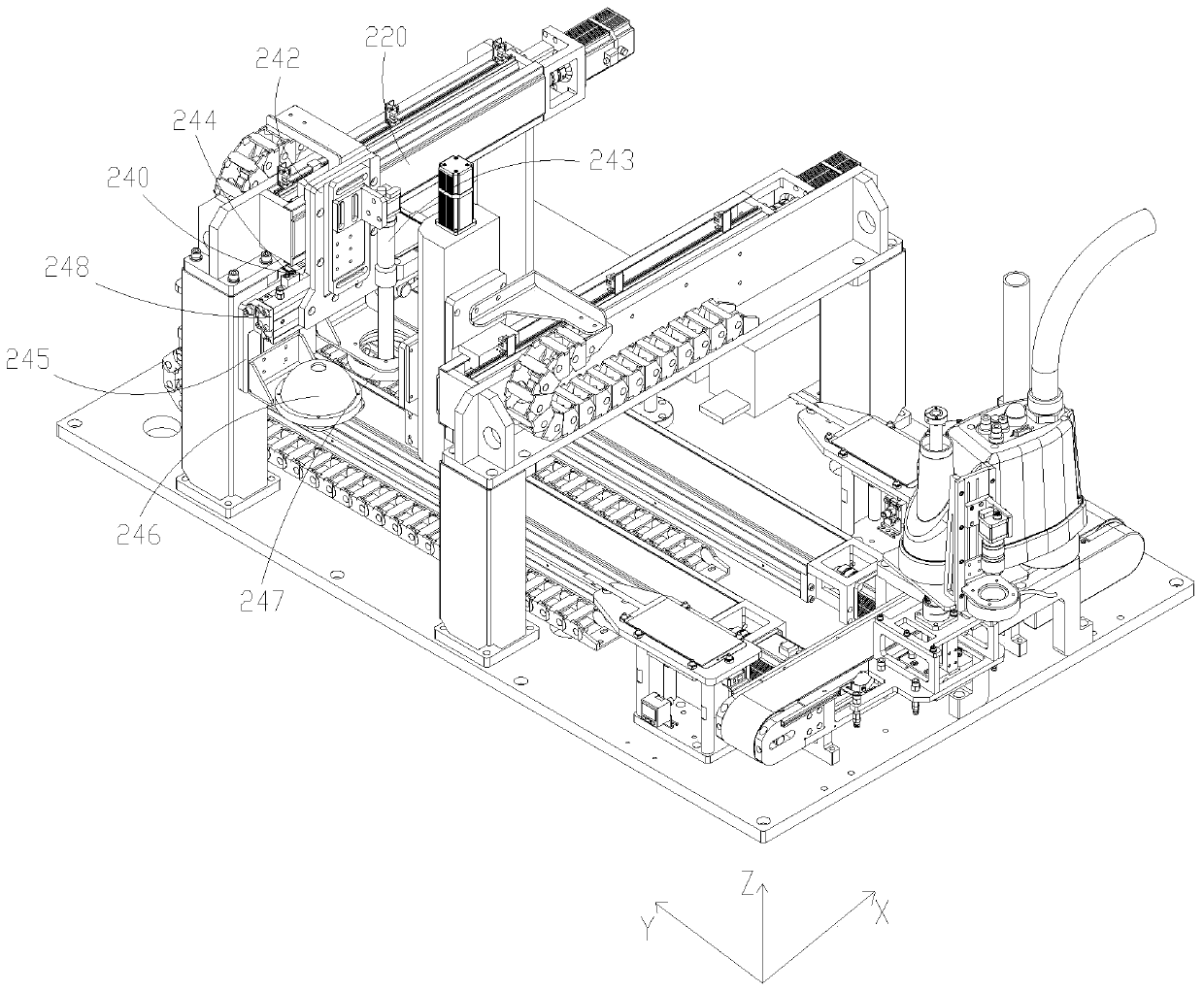

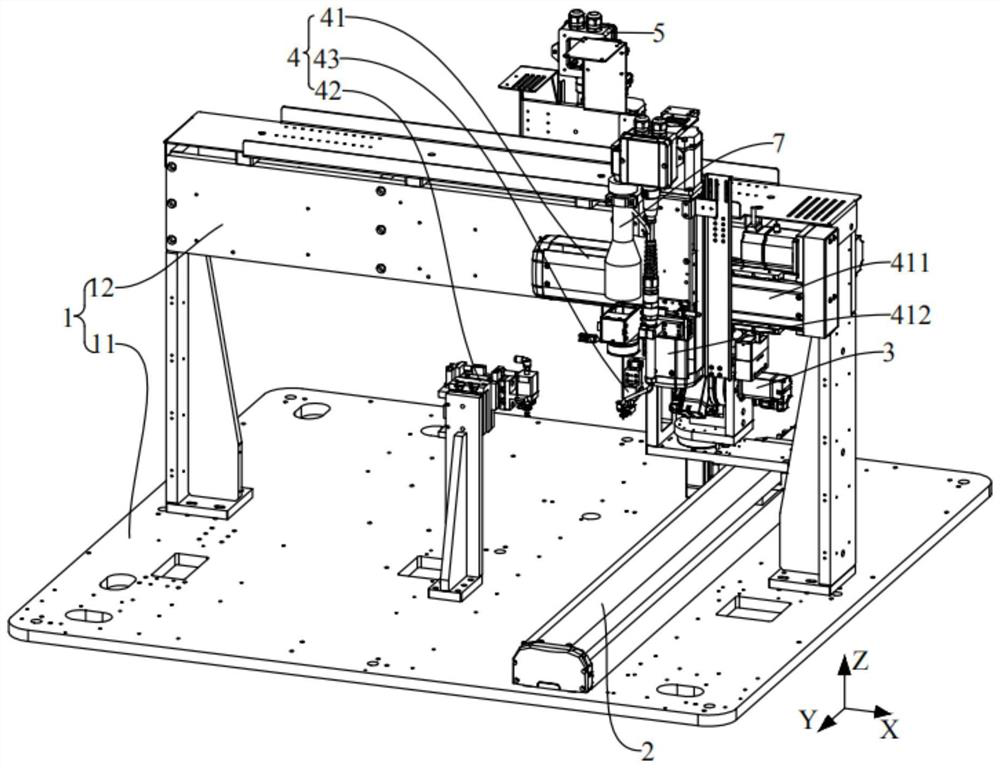

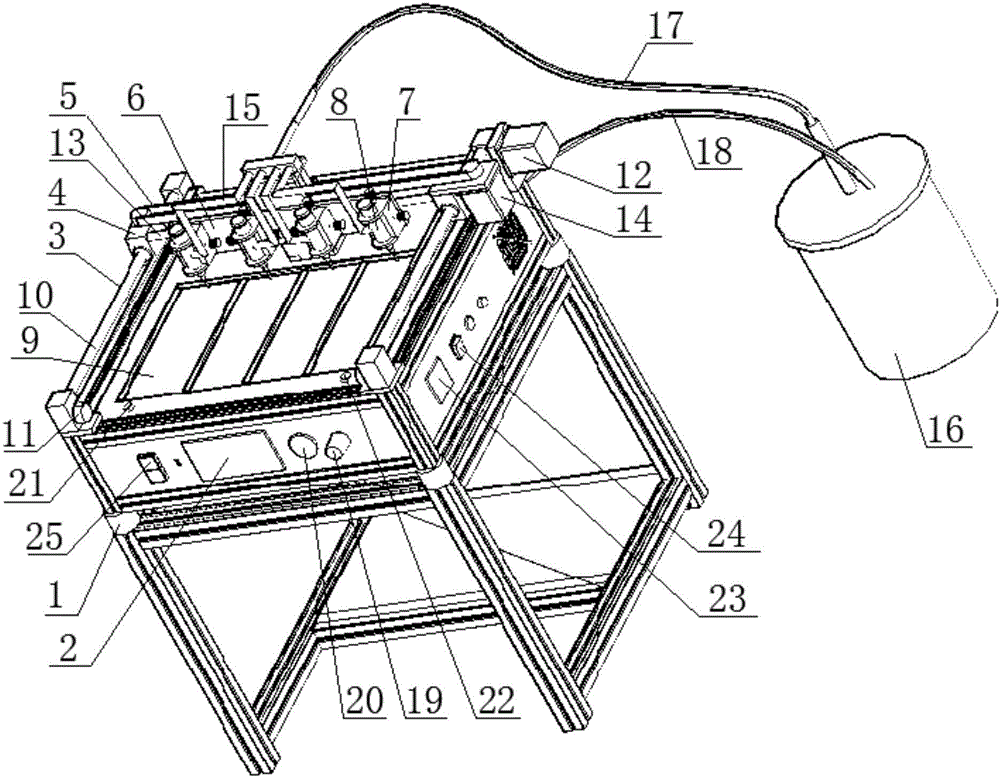

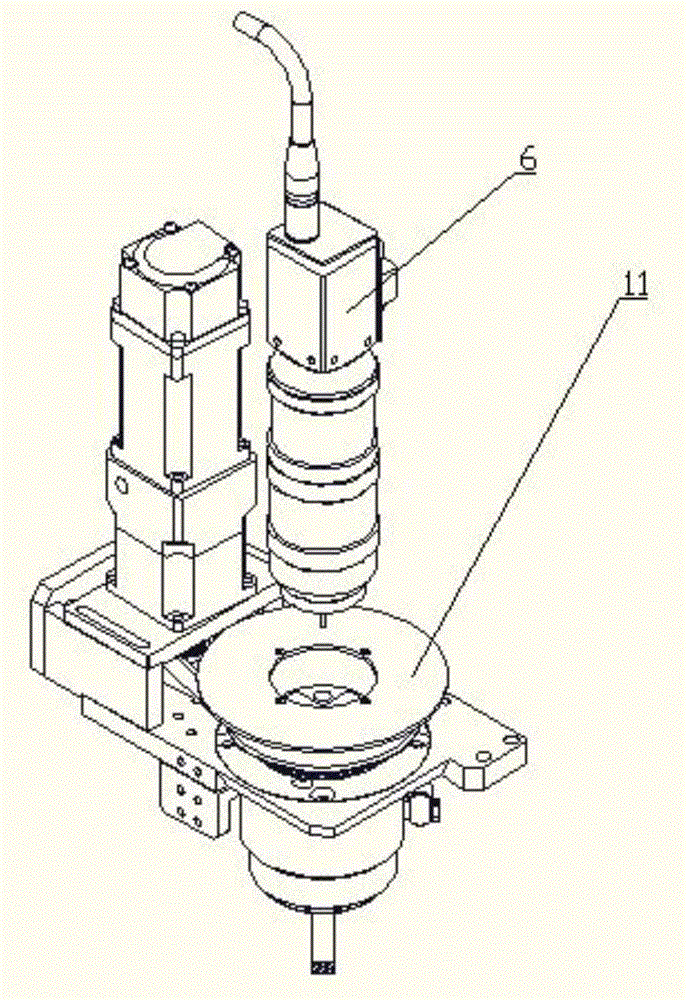

Adhesive dispensing machine and adhesive dispensing method thereof

ActiveCN105457840AShorten the working cycleIncrease productivityLiquid surface applicatorsCoatingsAdhesiveControl system

The invention discloses an adhesive dispensing machine and an adhesive dispensing method thereof. The adhesive dispensing machine comprises a control system, a charge system, and a visual inspection system and an adhesive dispensing system which are both located above the charge system. The charge system adopts a double-charge module comprising a first charge device and a second charge device, and matches with the visual inspection system and the adhesive dispensing system, thus the work of adhesive path planning, adhesive dispensing and adhesive path recheck carried out on production for products which are sequentially loaded and charged by the charge system, is realized; the adhesive path planning is carried out on products on the second charge device by virtue of time for adhesive dispensing for products on the first charge device, the work of adhesive dispensing is carried out on the products on the second charge device while recheck is carried out on the products on the first charge device, and the operation is circulated, thus the work cycle of the whole machine can be greatly saved, and the production efficiency of the whole machine is increased; and meanwhile, the labor cost can also be greatly reduced, and the adhesive dispensing quality is improved.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

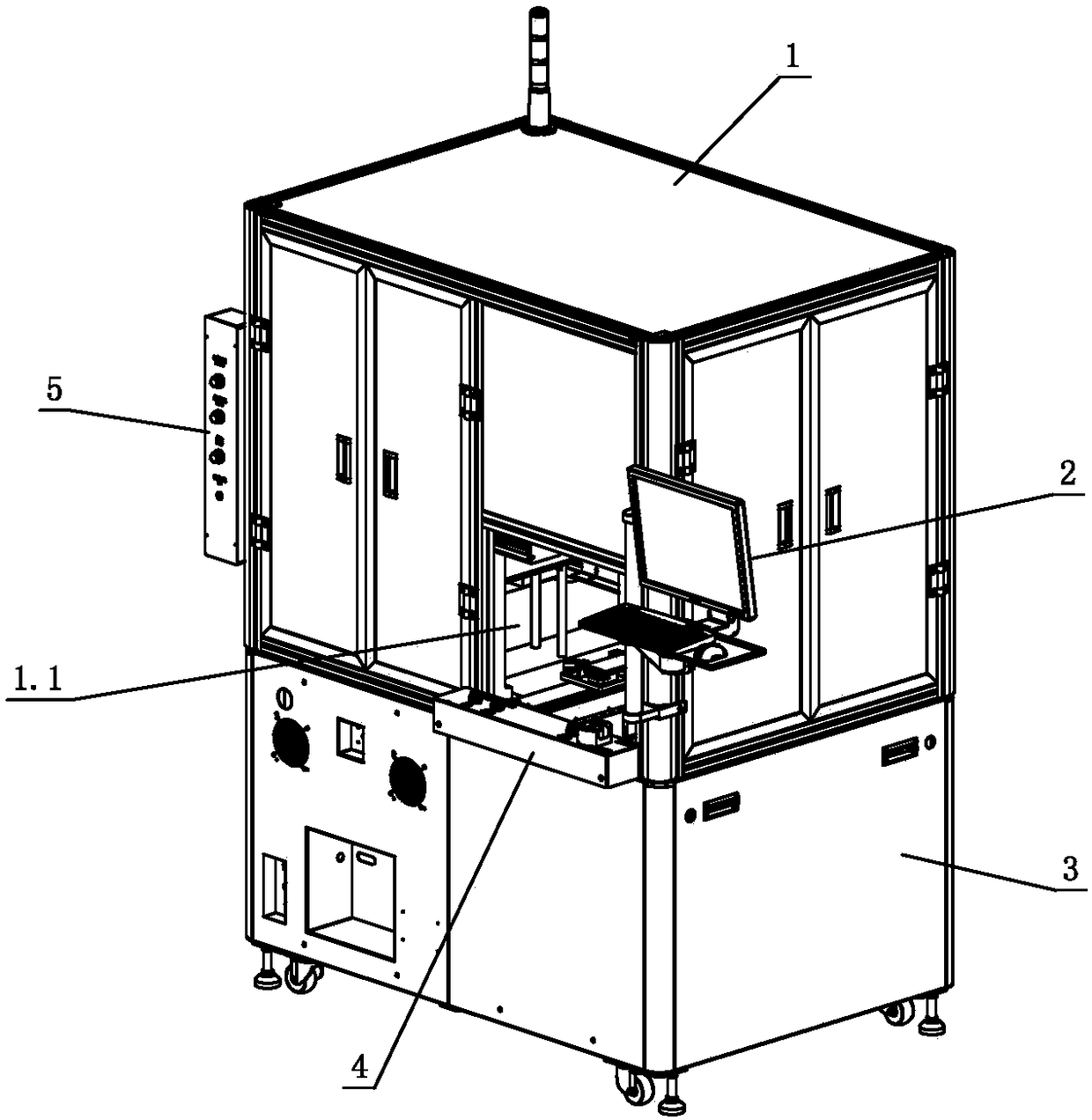

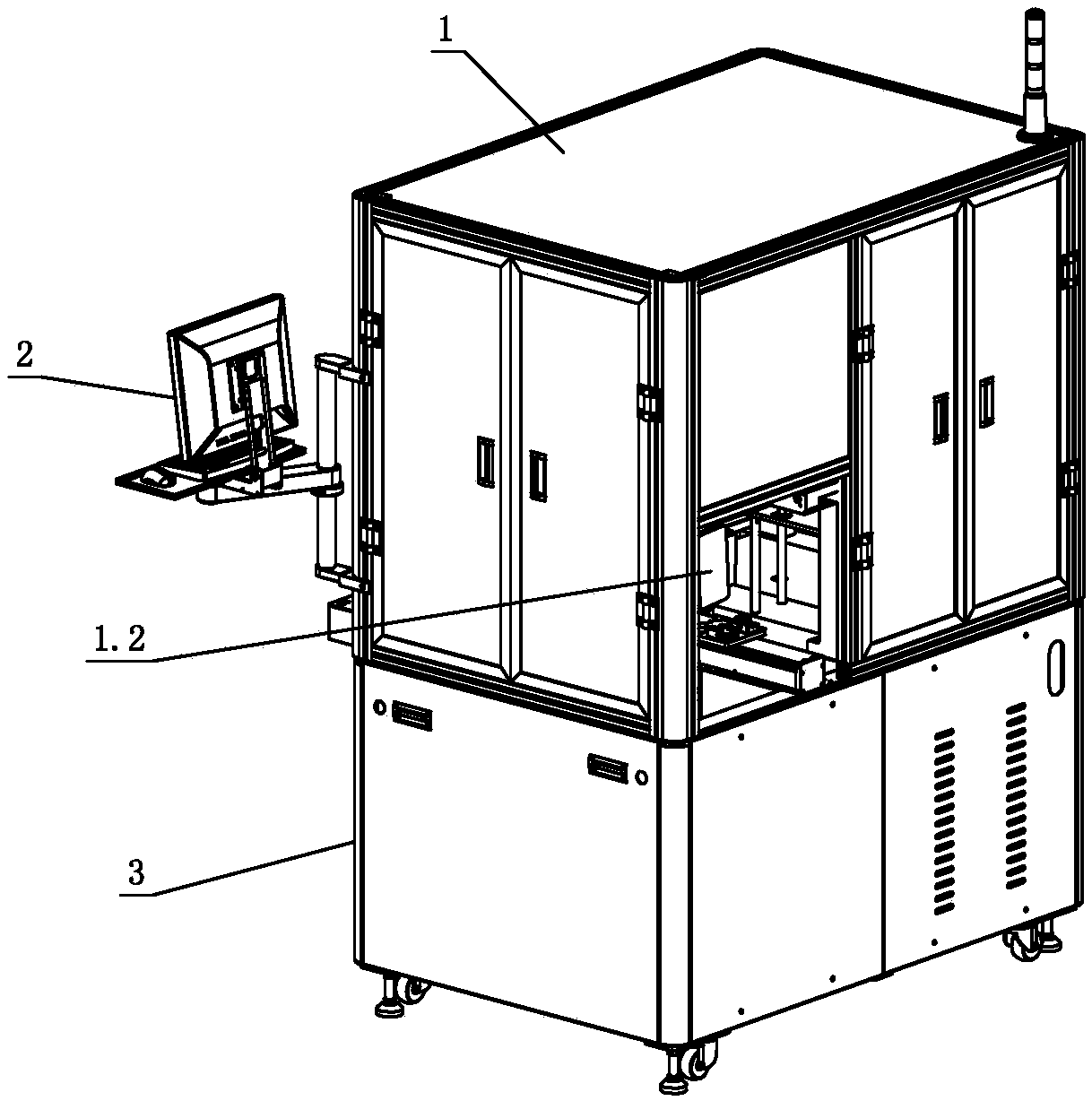

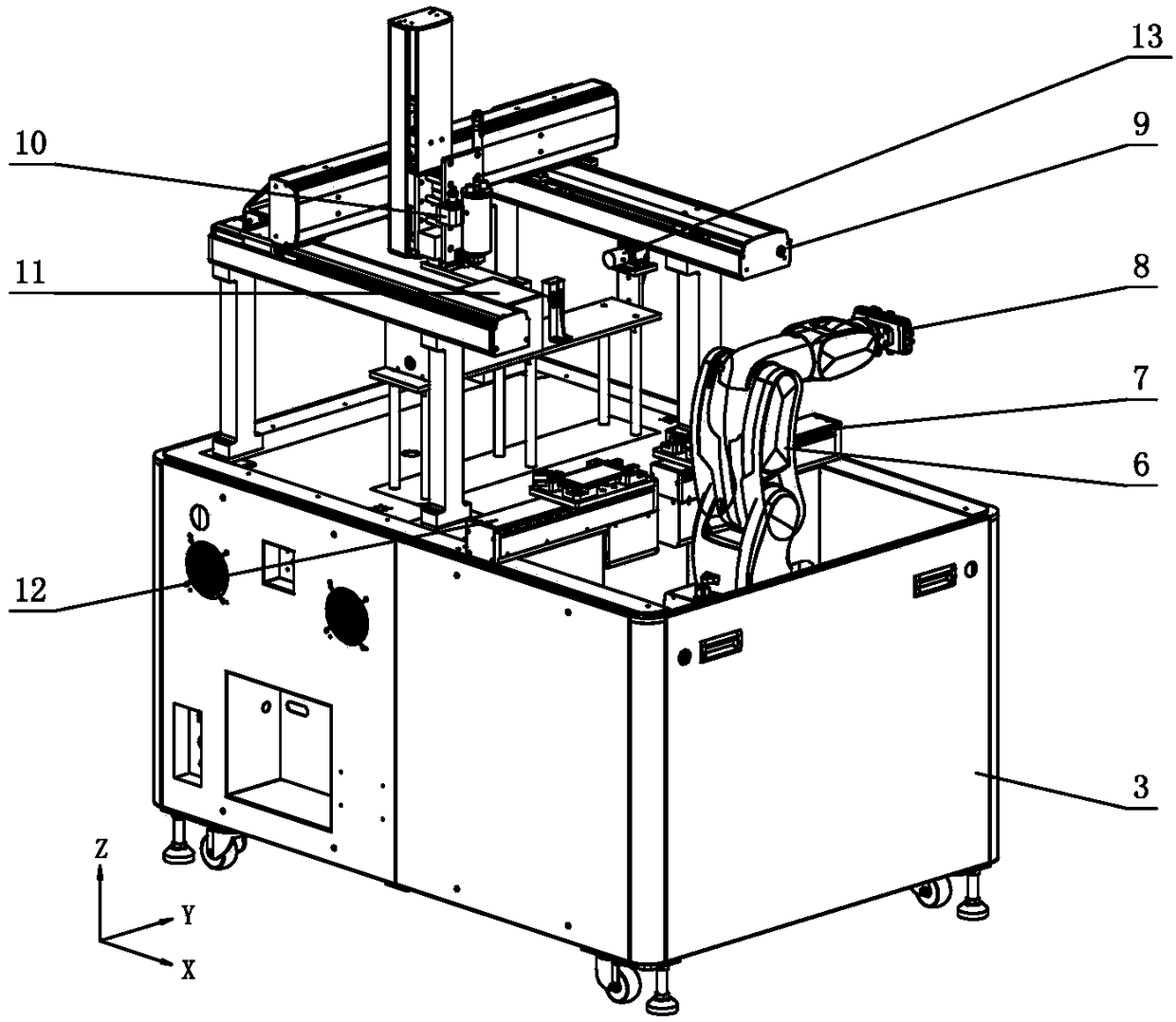

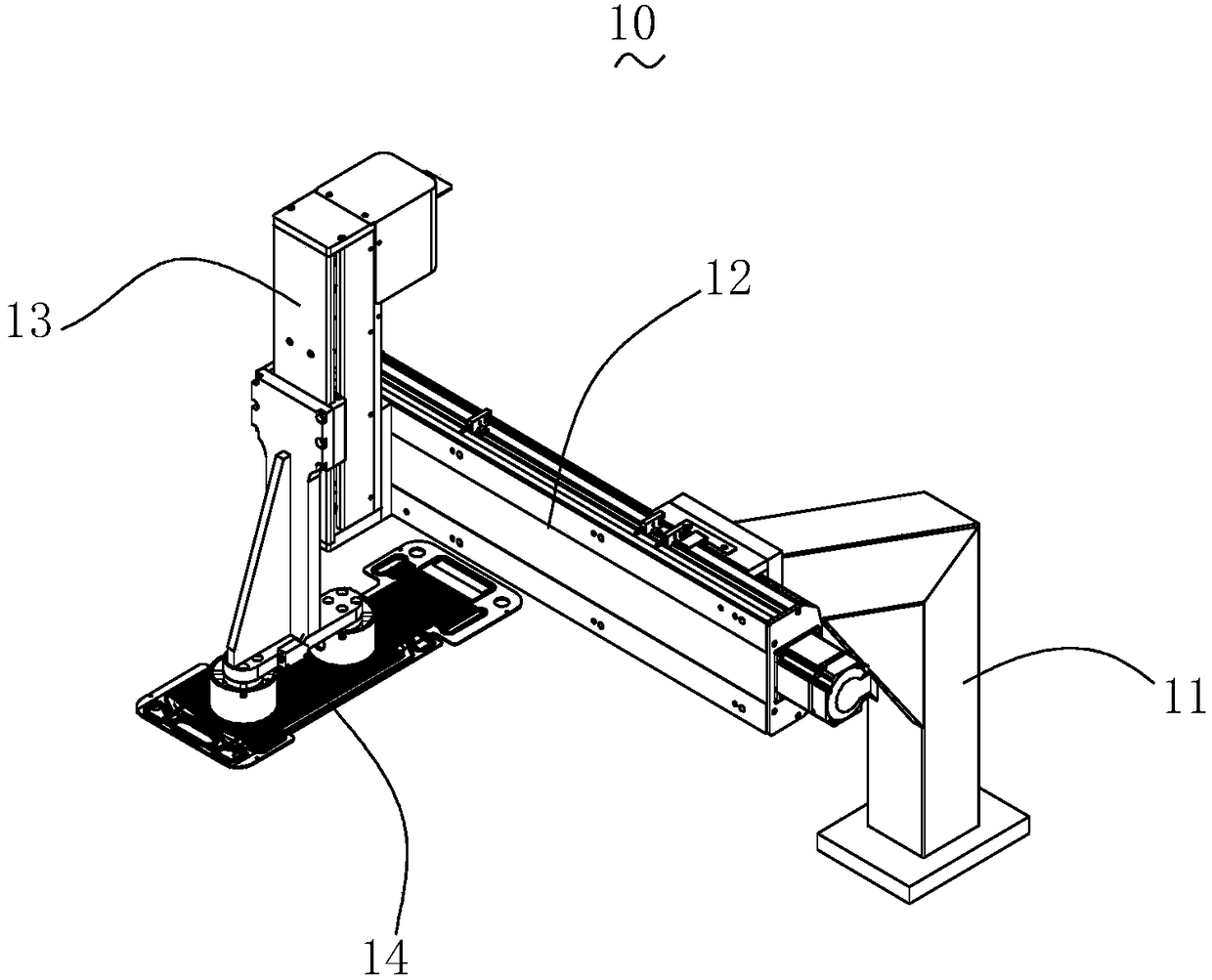

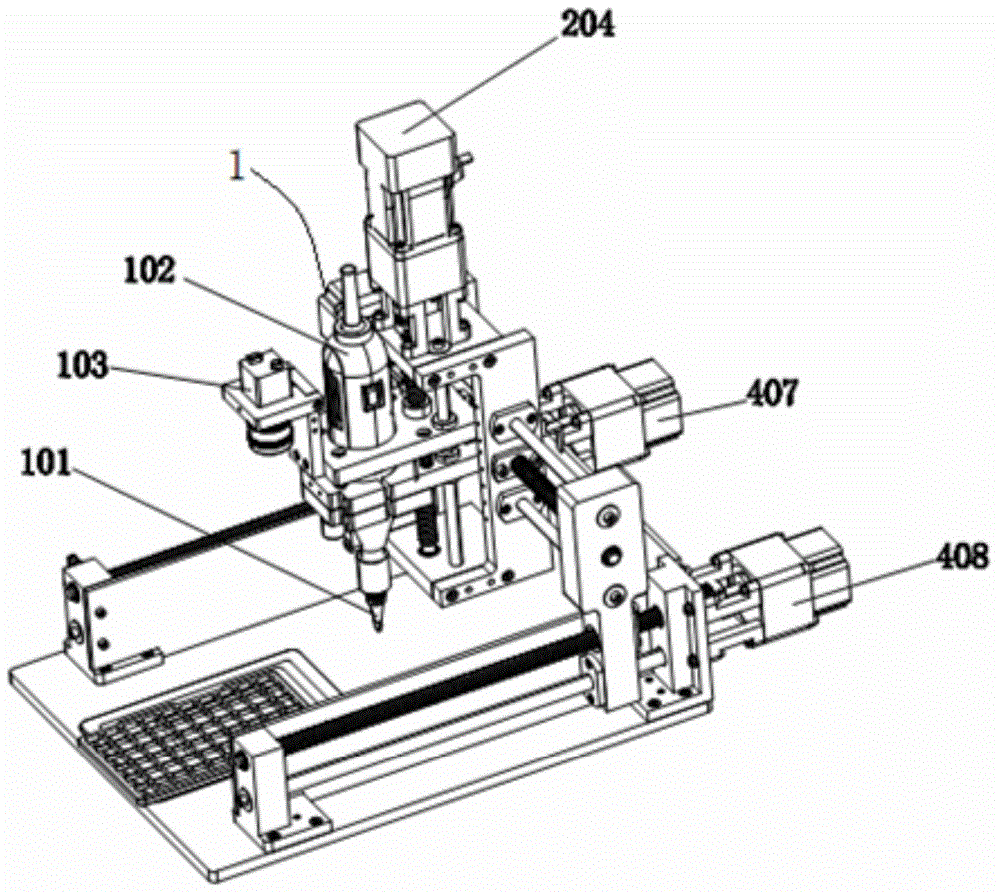

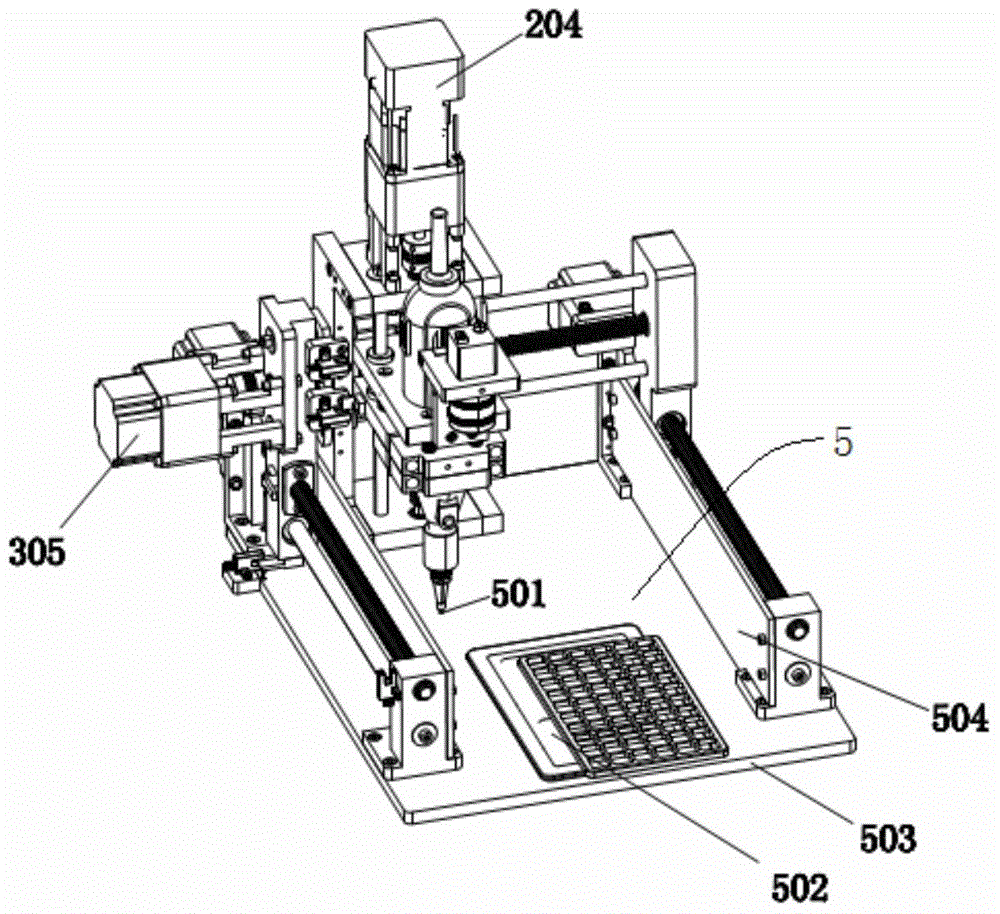

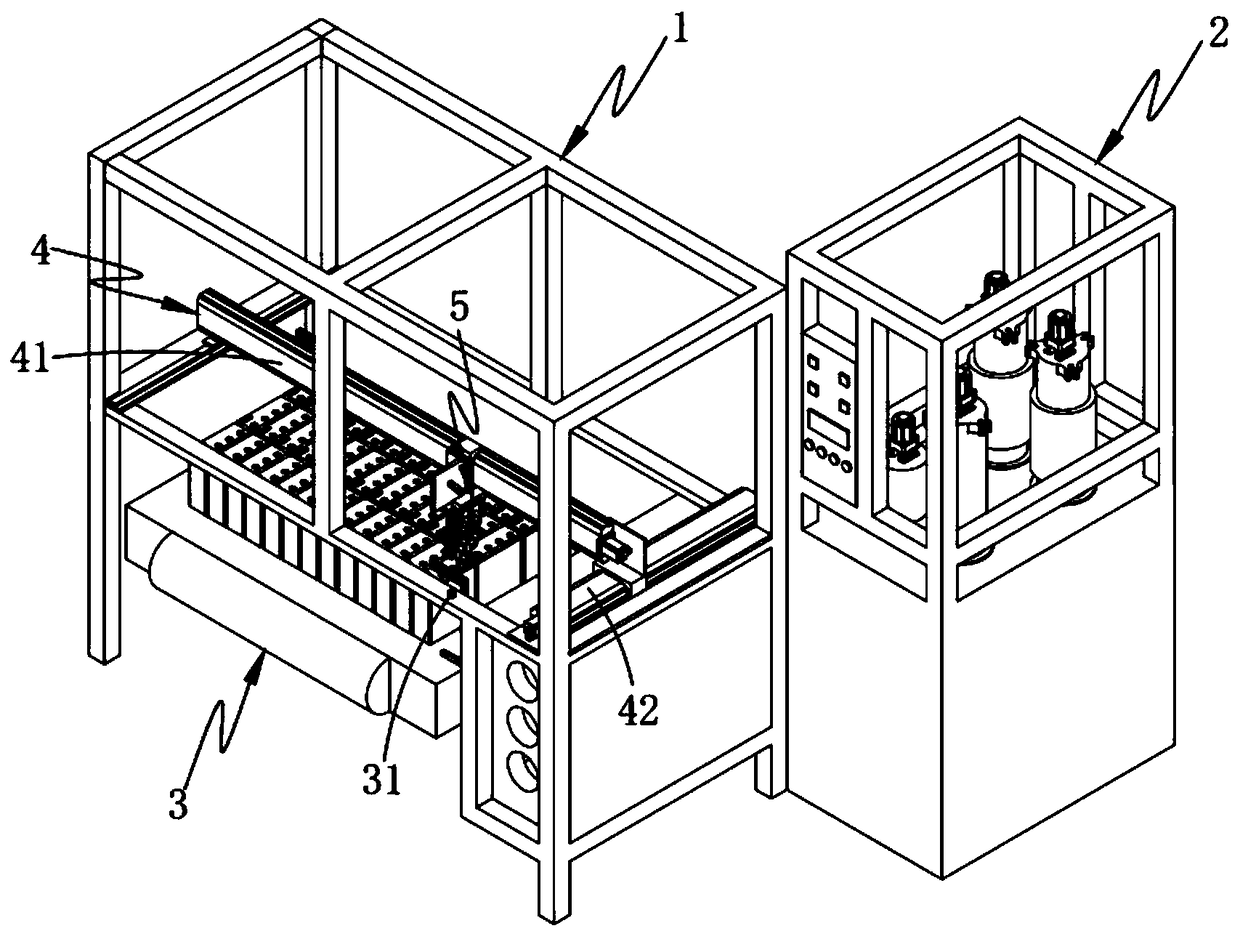

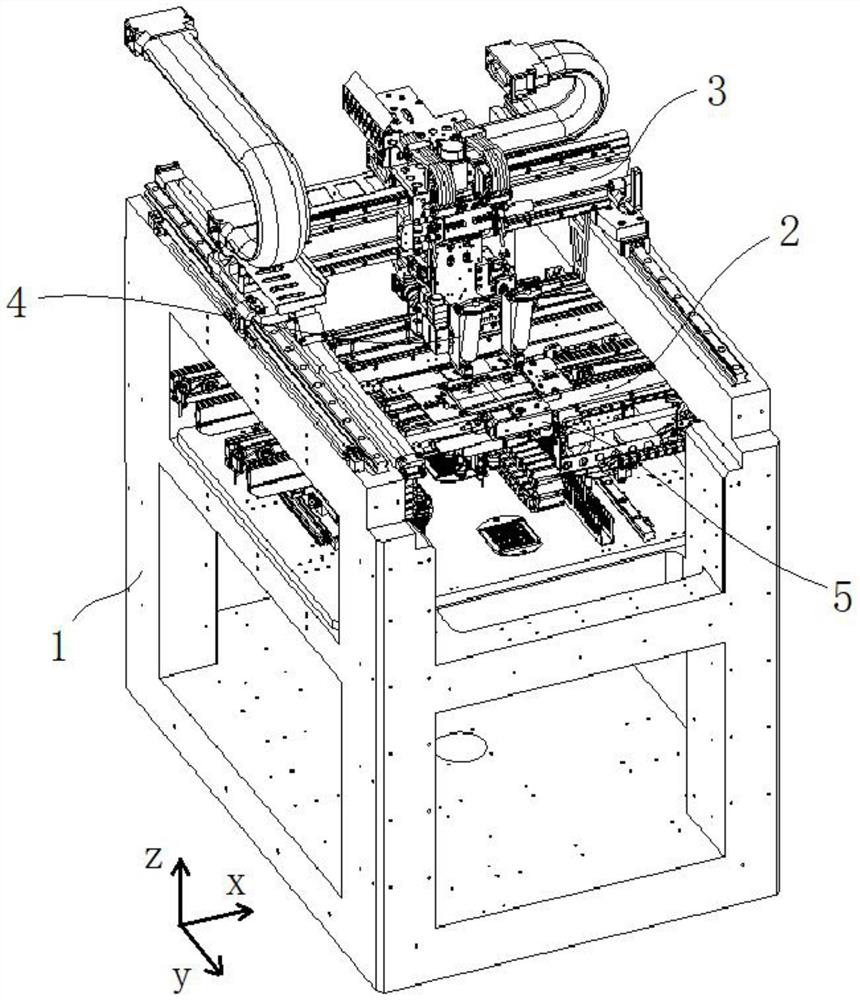

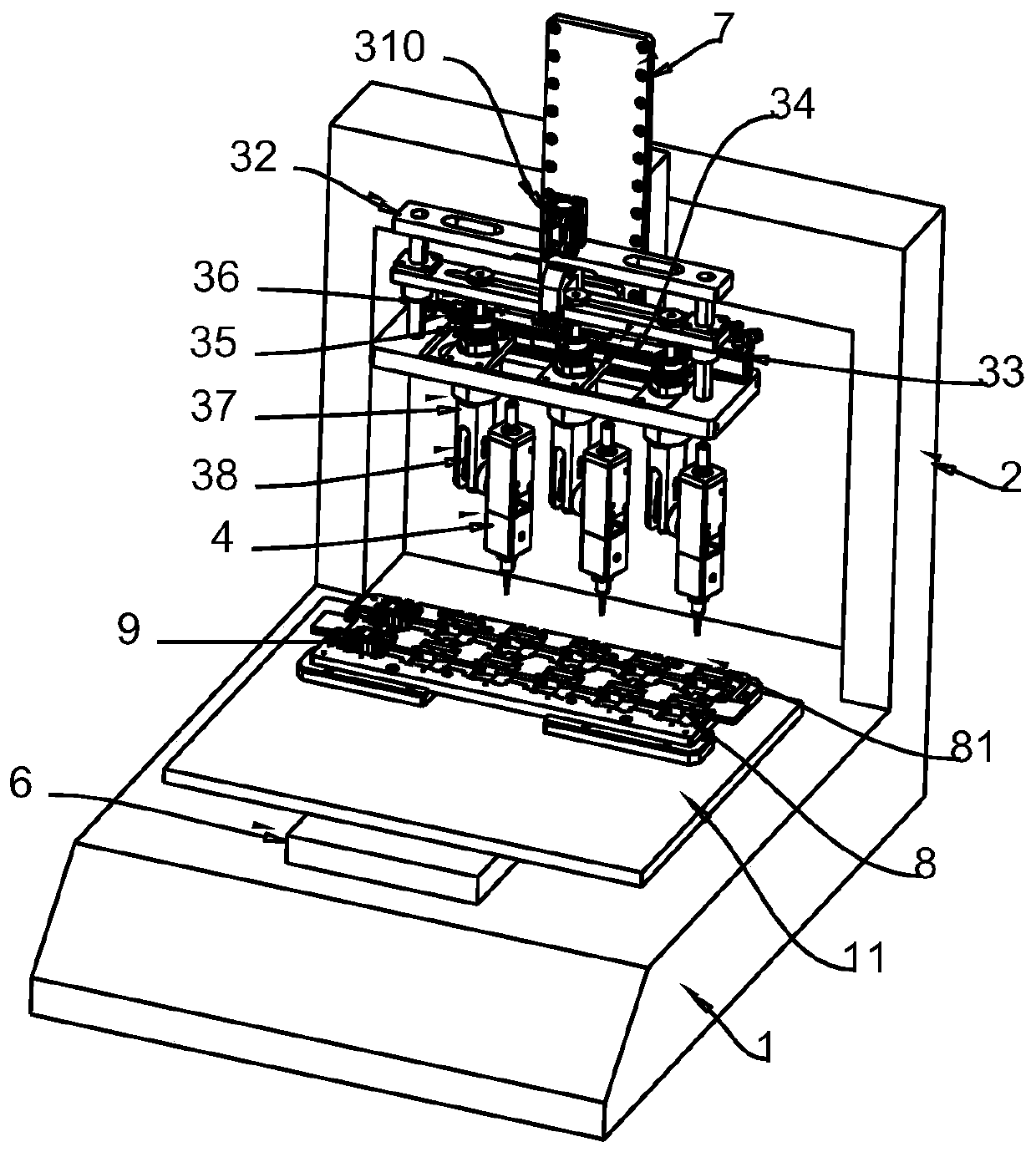

Automatic dispensing equipment

ActiveCN108284044AImprove heating efficiency and heating uniformityImprove dispensing qualityLiquid surface applicatorsCoatingsWorking rangeHot-melt adhesive

The invention provides automatic dispensing equipment. The automatic dispensing equipment comprises an equipment console, wherein a dispensing mechanism, a triaxial correcting mechanism, a feeding mechanism, a discharging mechanism and a transferring robot are arranged on the equipment console; the conveying starting end of the feeding mechanism is located in the material swinging area, and the conveying tail end of the feeding mechanism is located in the feeding area; the conveying starting end of the discharging mechanism is located in the feeding area, and the conveying tail end of the discharging mechanism is located in the material taking area; and the dispensing and transferring track of the transferring robot is programmed by an off-line programming software, and the working range of the feeding area at least covers the feeding area and the discharging area. The dispensing mechanism, the feeding mechanism and the discharging mechanism are integrated on the same device, and a six-axis transfer robot is adopted for grabbing products to carry out dispensing operation, so that the dispensing quality and efficiency can be improved, and the automatic dispensing equipment can be applied to dispensing of a space curve track, such as coating hot melt adhesive between a mobile phone screen and a middle frame gap, so that the protection level of a mobile phone can be improved, andabattery back cover of a hyperboloid screen phone can be subjected to hot melt adhesive operation and the like.

Owner:GUANGDONG LXD ROBOTICS CO LTD

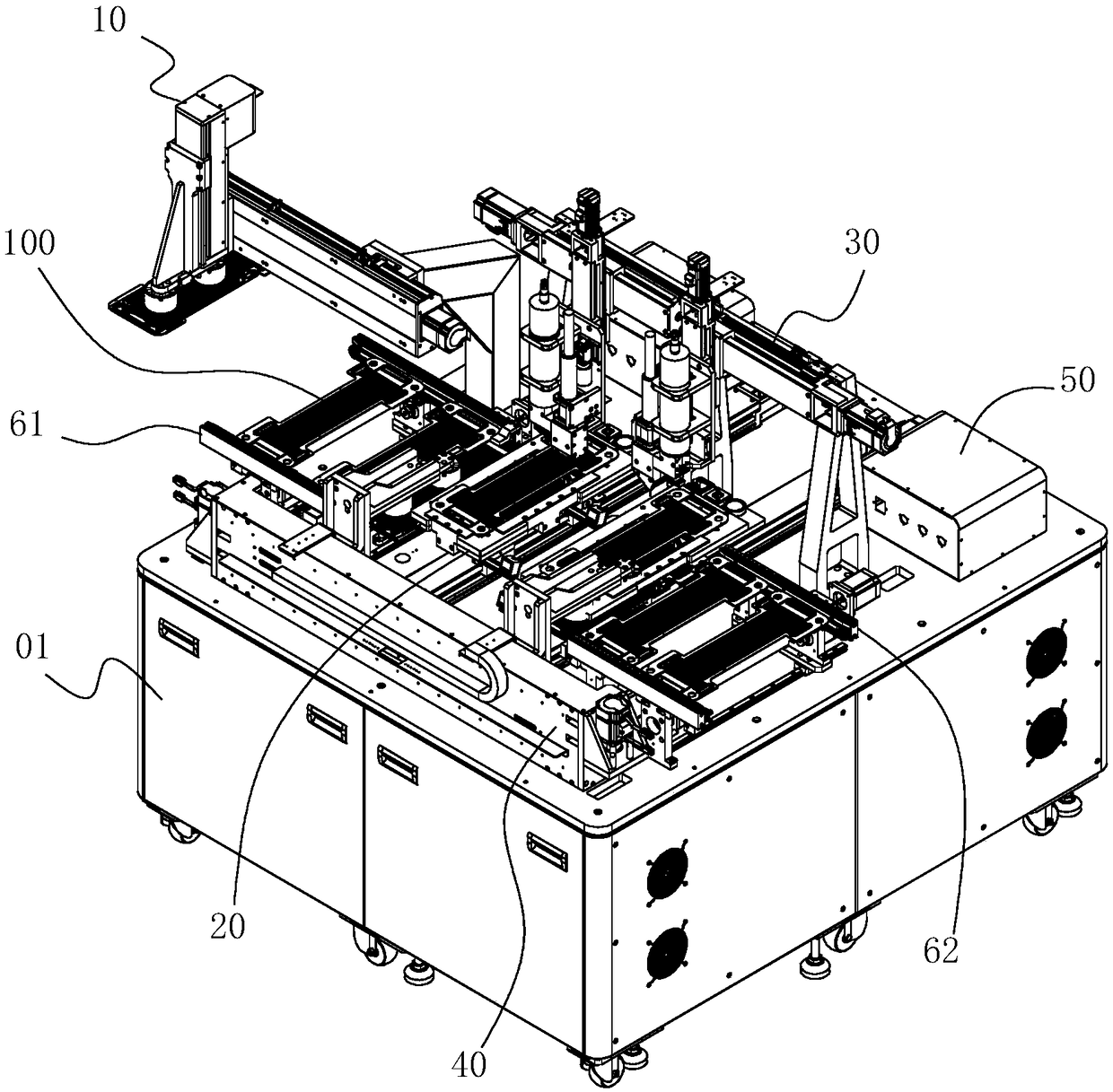

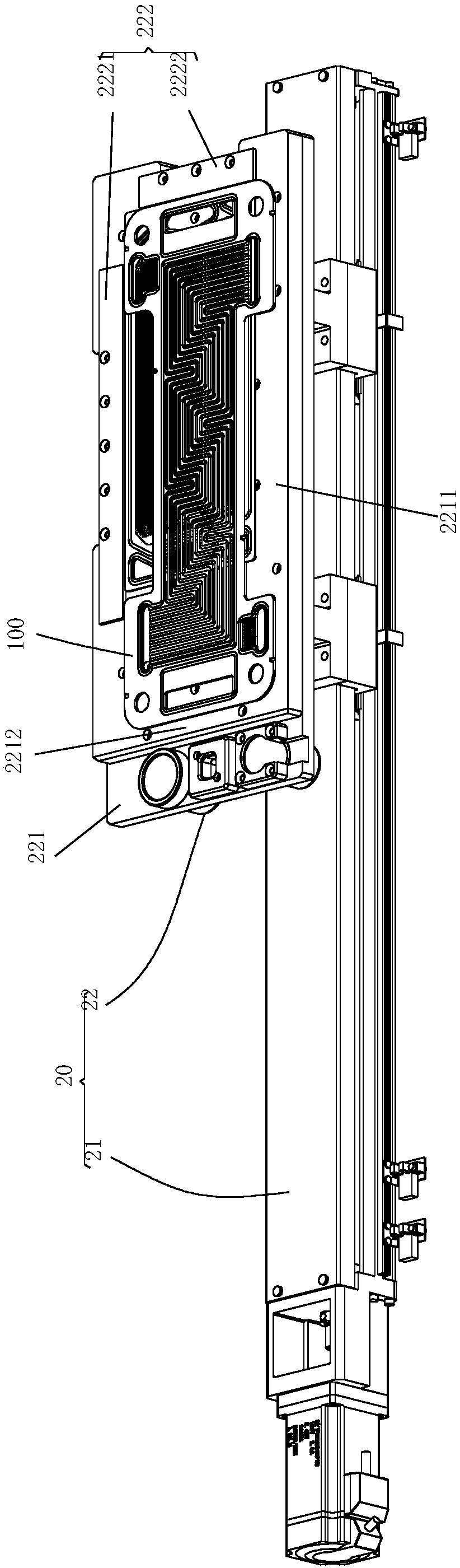

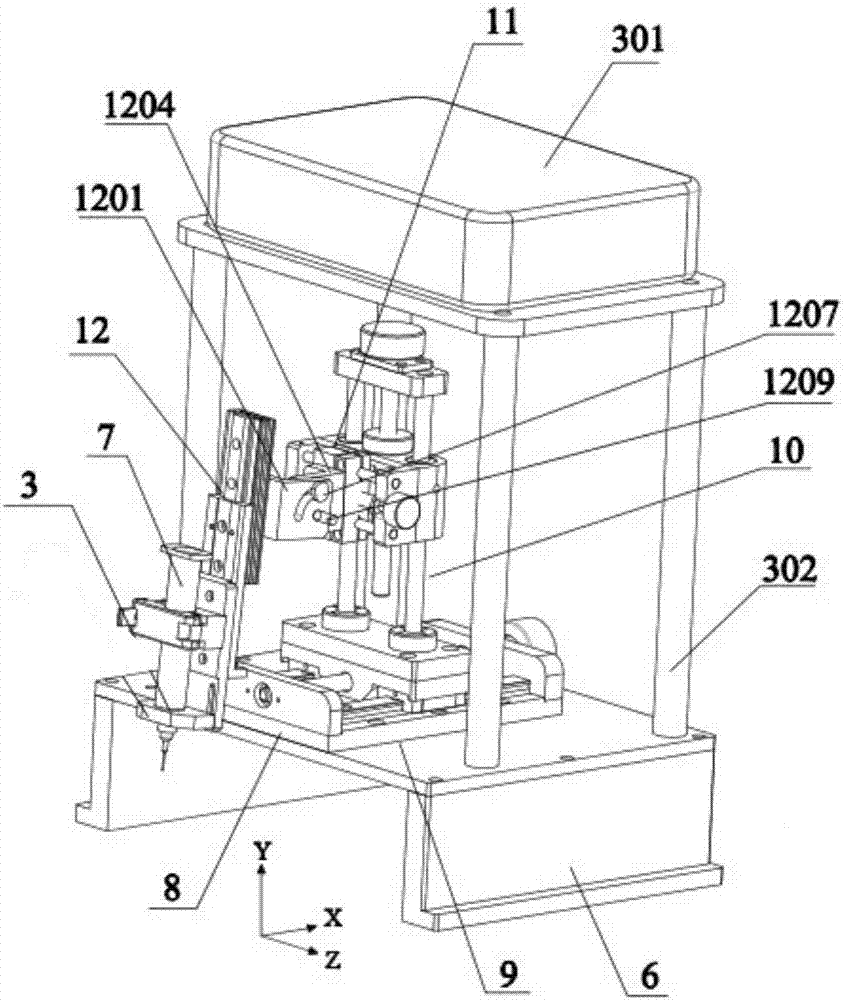

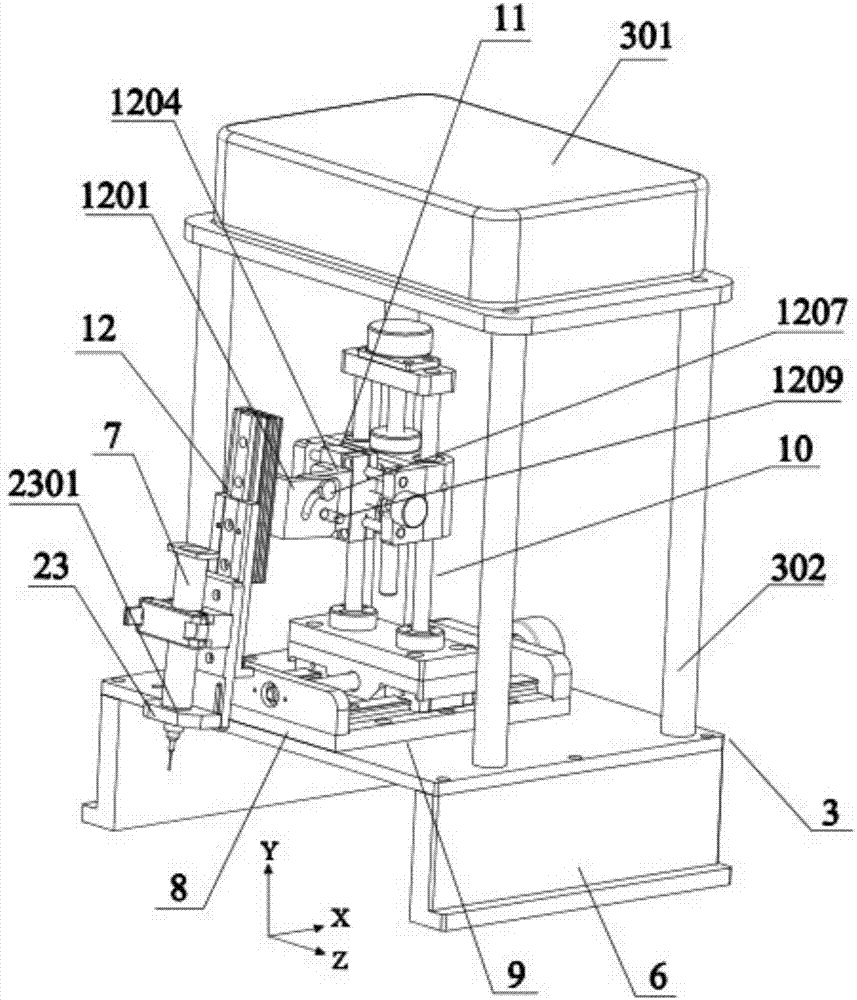

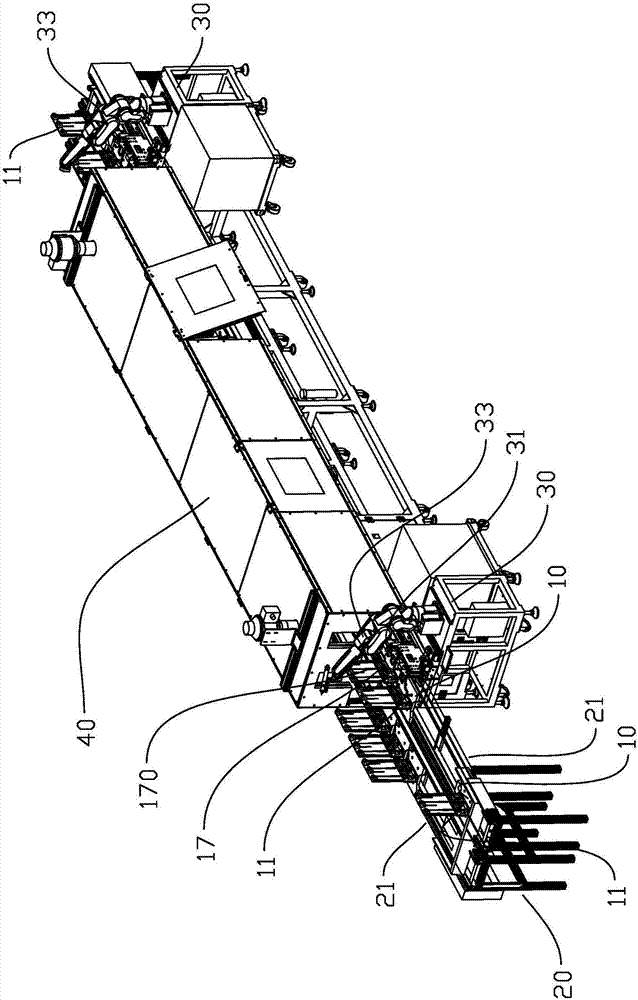

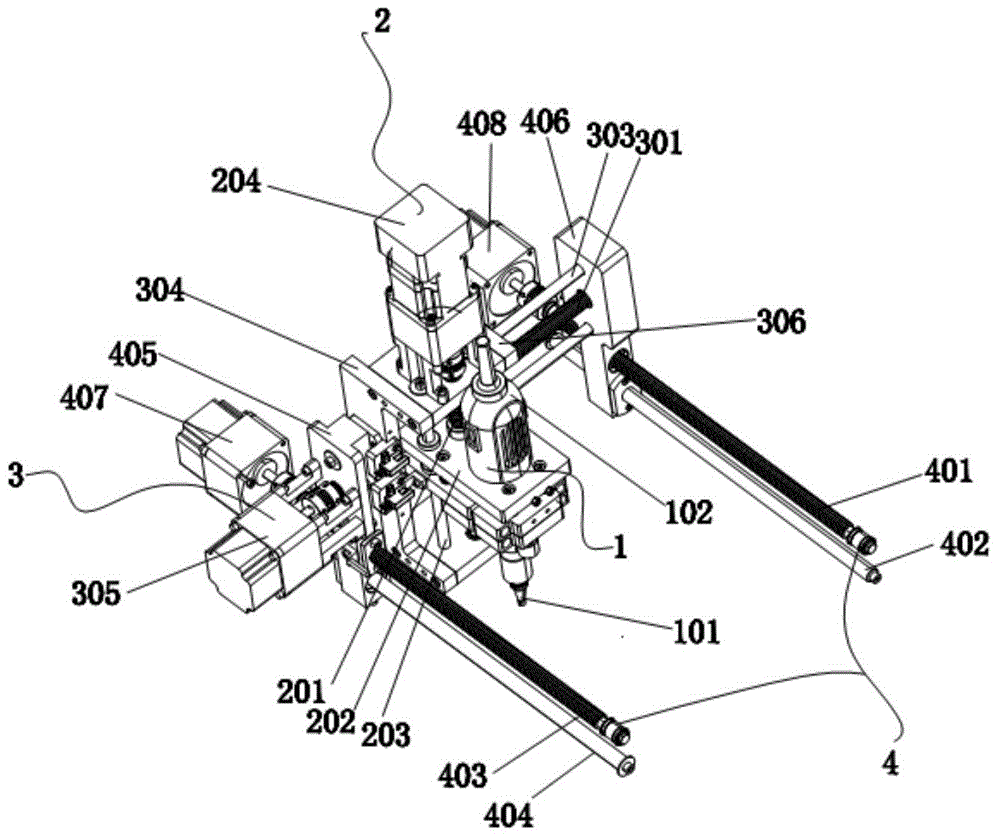

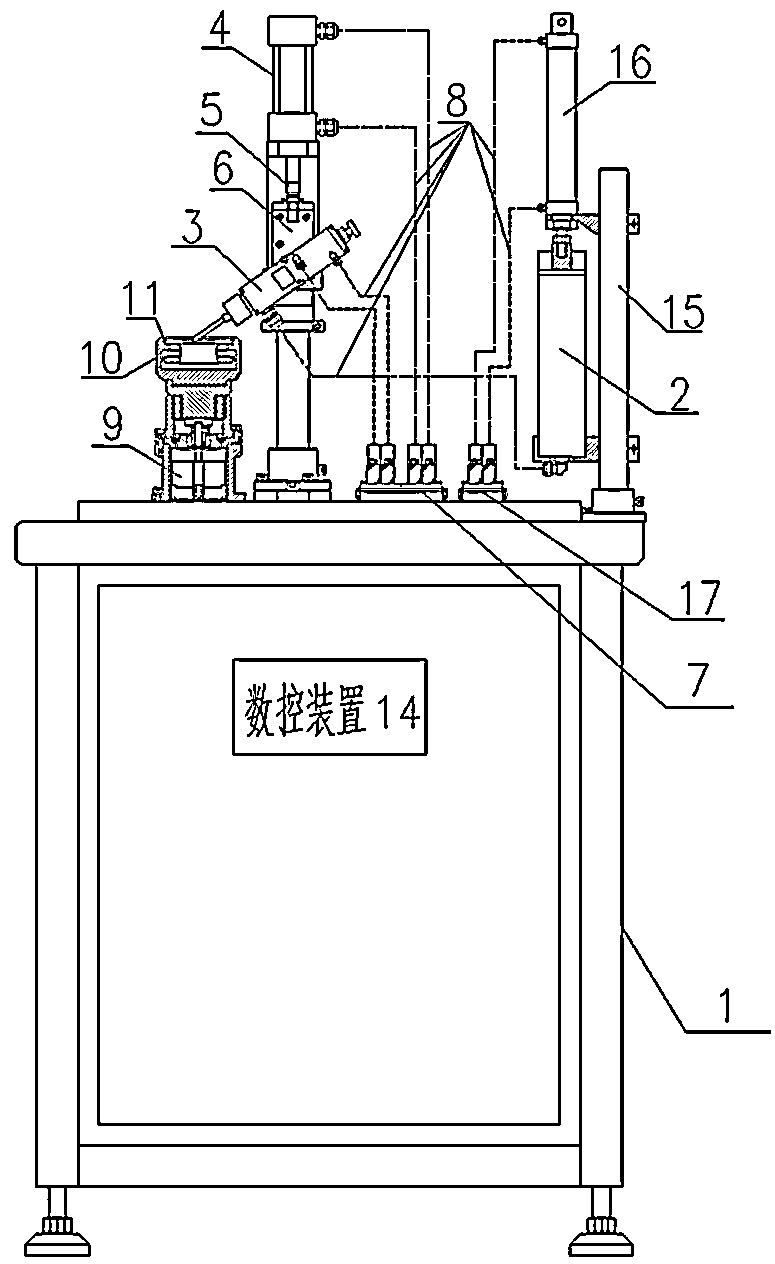

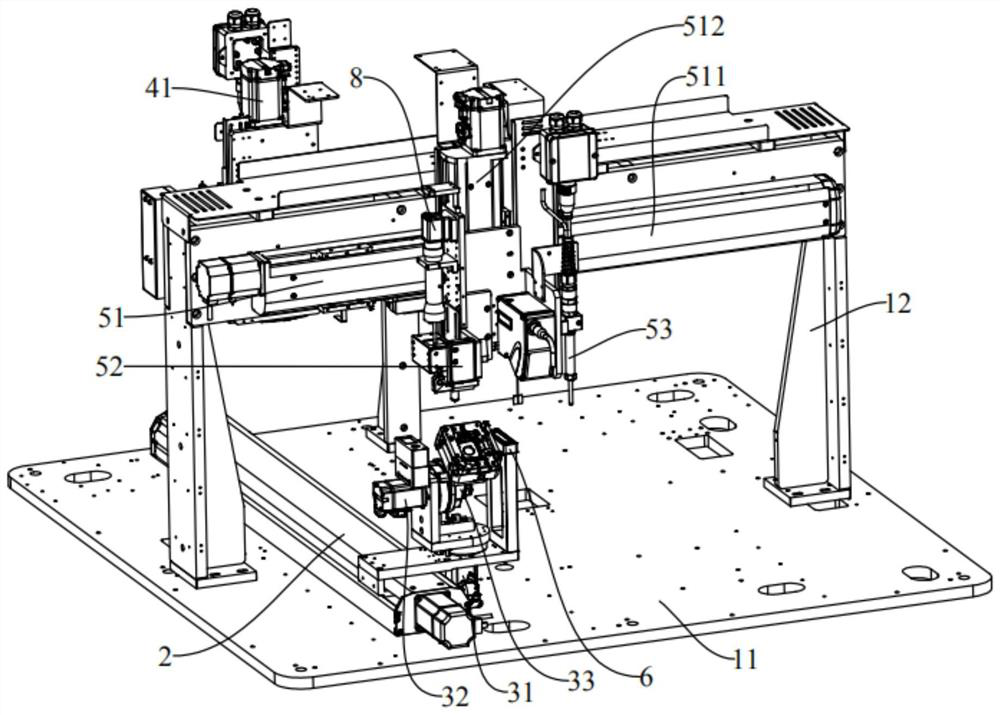

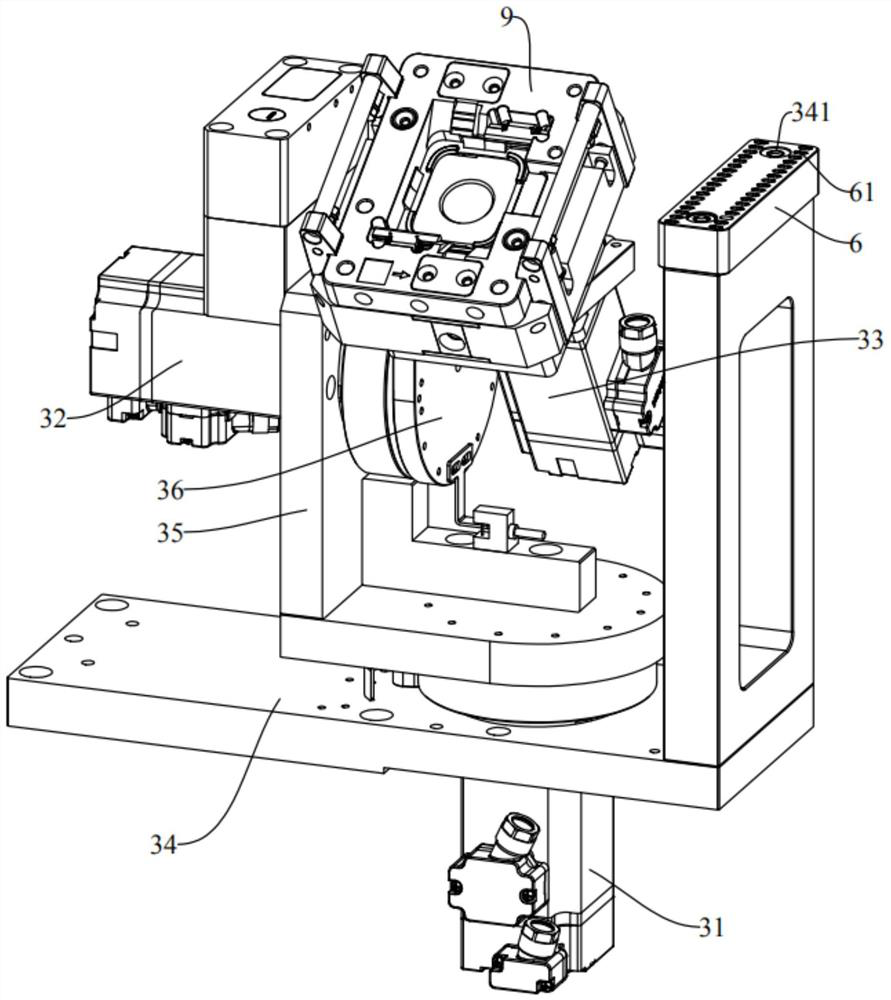

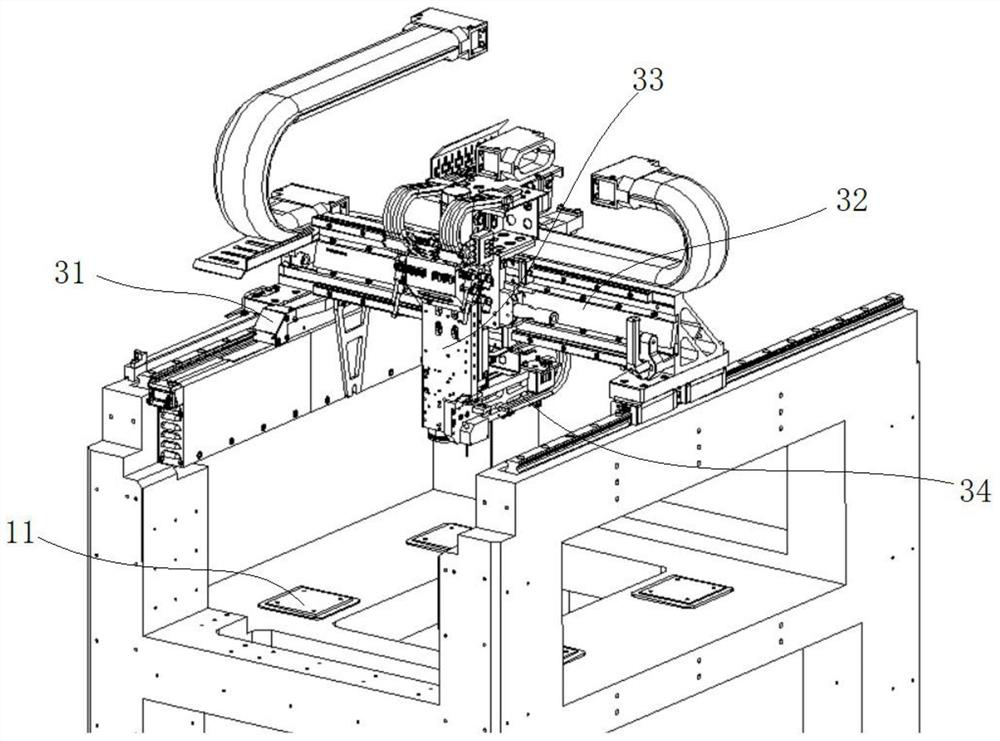

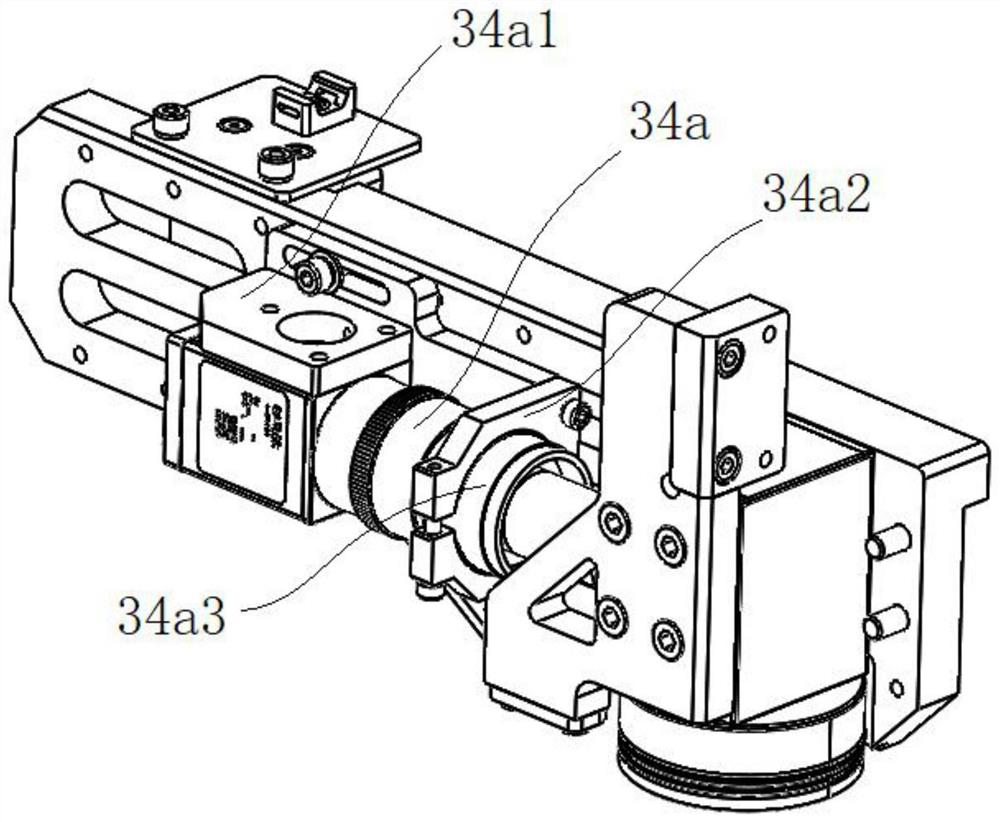

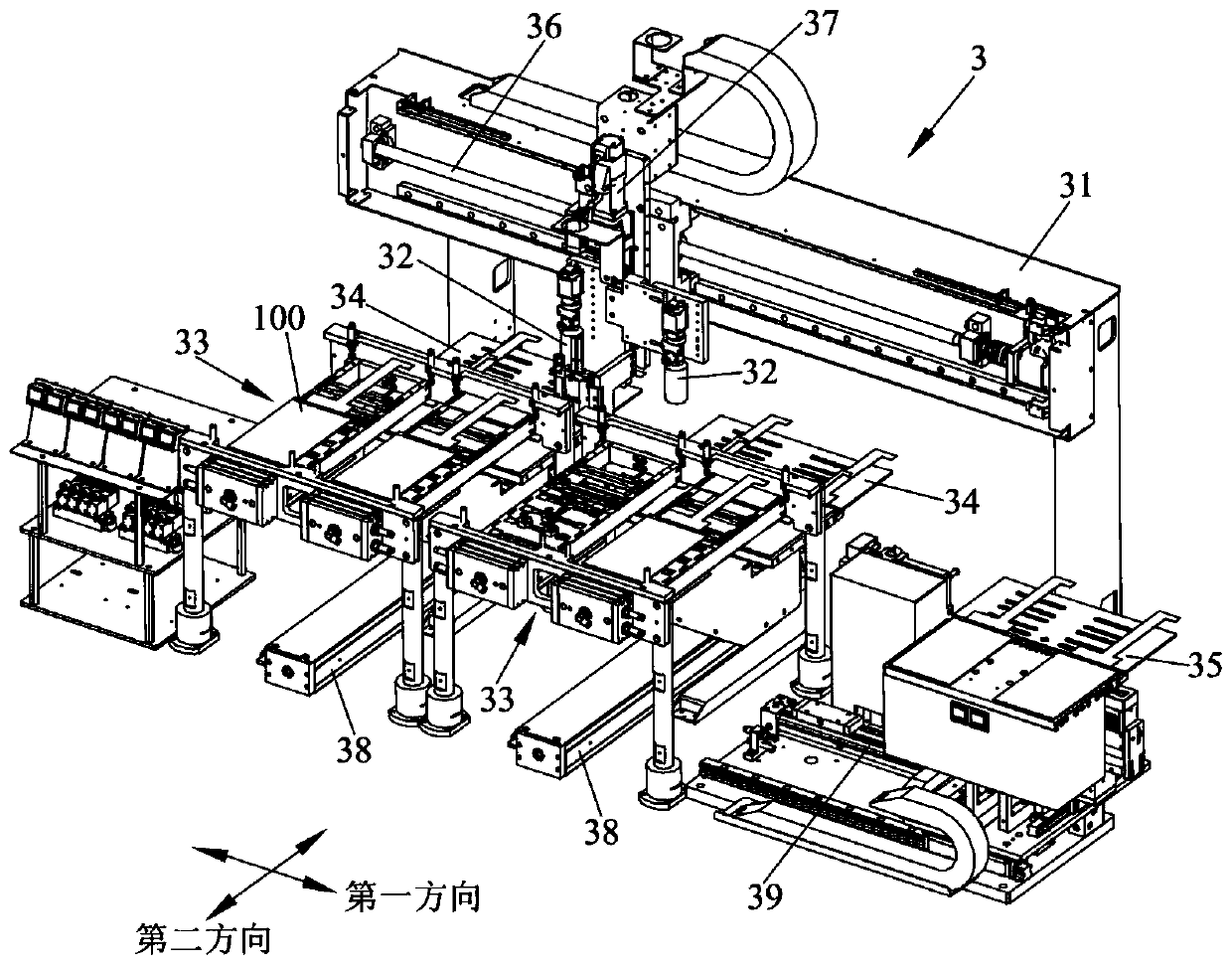

Dispensing machine of fuel cell bipolar plate and automatic production line

PendingCN108311341AImprove dispensing qualityEliminate processing effectsLiquid surface applicatorsCoatingsProduction lineFuel cells

The invention provides a dispensing machine of a fuel cell bipolar plate and an automatic production line. The dispensing machine comprises a feeding mechanical arm, a dispensing station assembly, a dispensing operation assembly, a discharging mechanical arm and a control server, wherein the feeding mechanical arm is mounted on a joint adhesive dispensing device mounting platform; the dispensing station assembly comprises a longitudinal linear driver and a polar plate clamping structure; the dispensing operation assembly comprises a mounting bracket, a transverse linear driver and a dispensingstructure; movement directions of movement parts of the transverse linear driver and the longitudinal linear driver are parallel to the horizontal plane, and the movement directions of the two drivers are mutually vertical; the dispensing structure is connected onto the movement part of the transverse linear driver; the discharging mechanical arm is mounted on the joint adhesive dispensing devicemounting platform; the control server is electrically connected with the feeding mechanical arm, the longitudinal linear driver, the polar plate clamping structure, the transverse linear driver, thedispensing structure and the discharging mechanical arm respectively. By adopting the dispensing machine provided by the invention, the problems in the prior art that the dispensing processing and production working efficiency is low and the consistency of product quality of each fuel cell polar plate is poor can be solved.

Owner:SHENZHEN SECOND INTELLIGENT EQUIP CO LTD

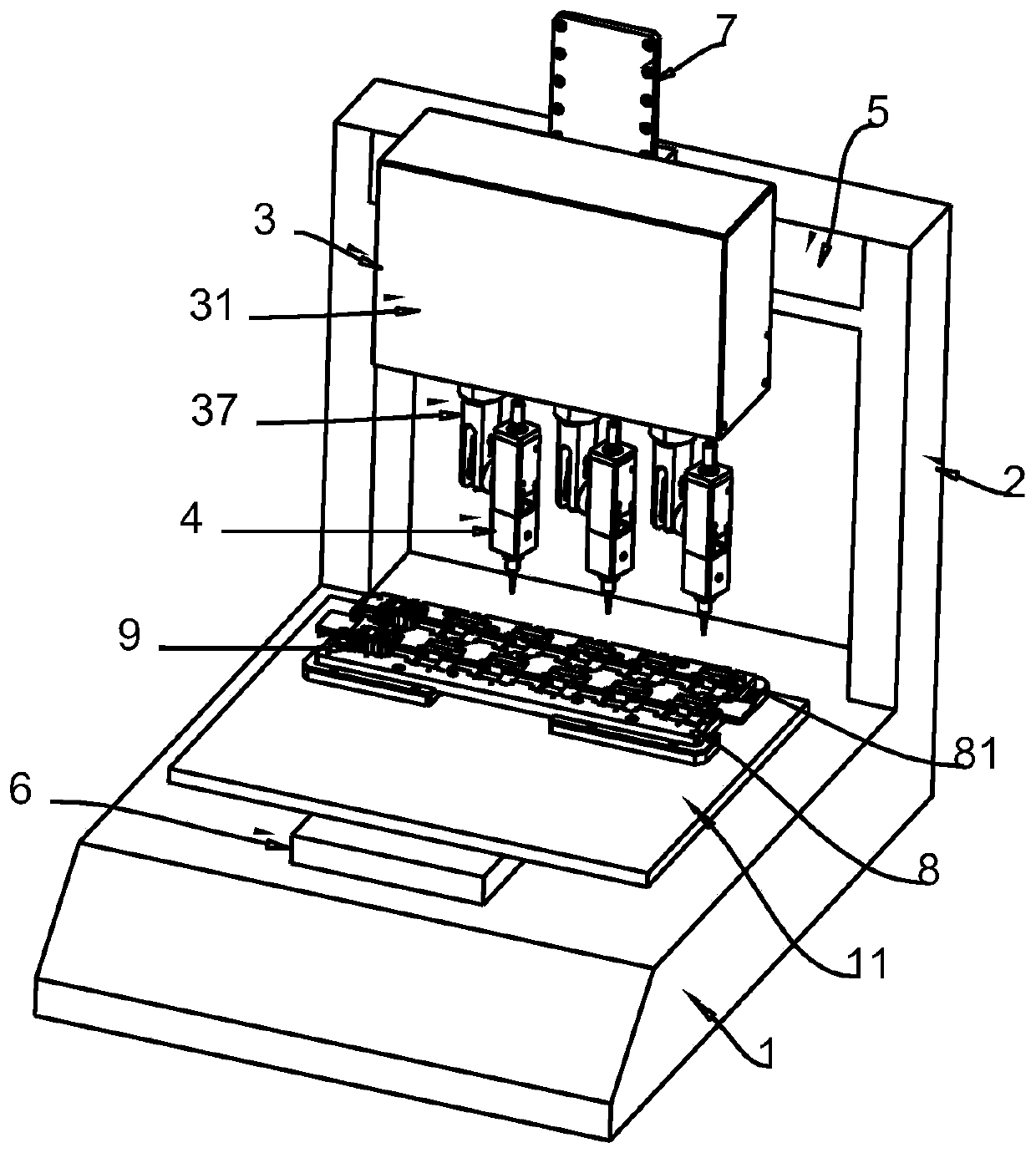

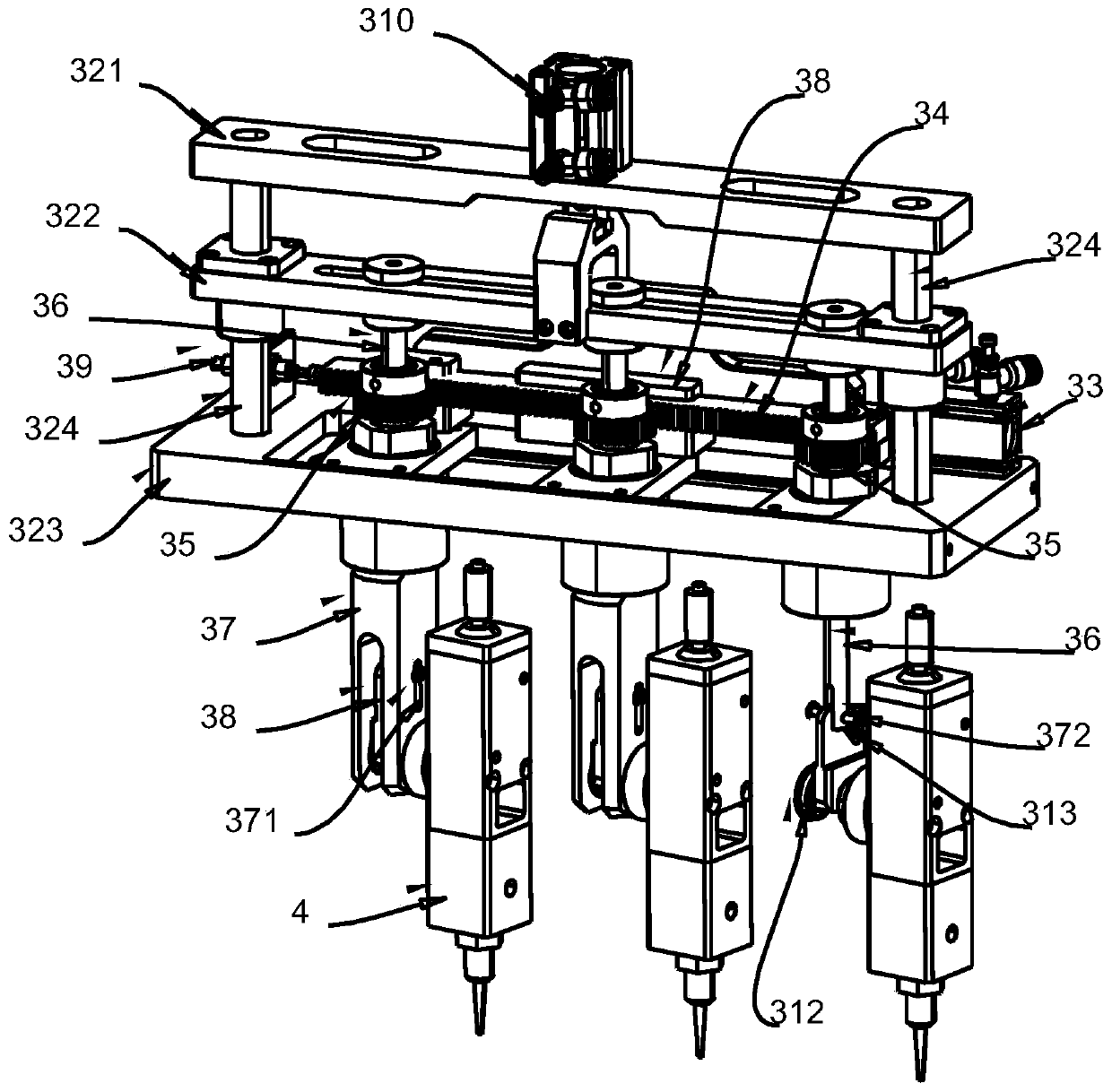

Dispensing machine with dispensing head assembly

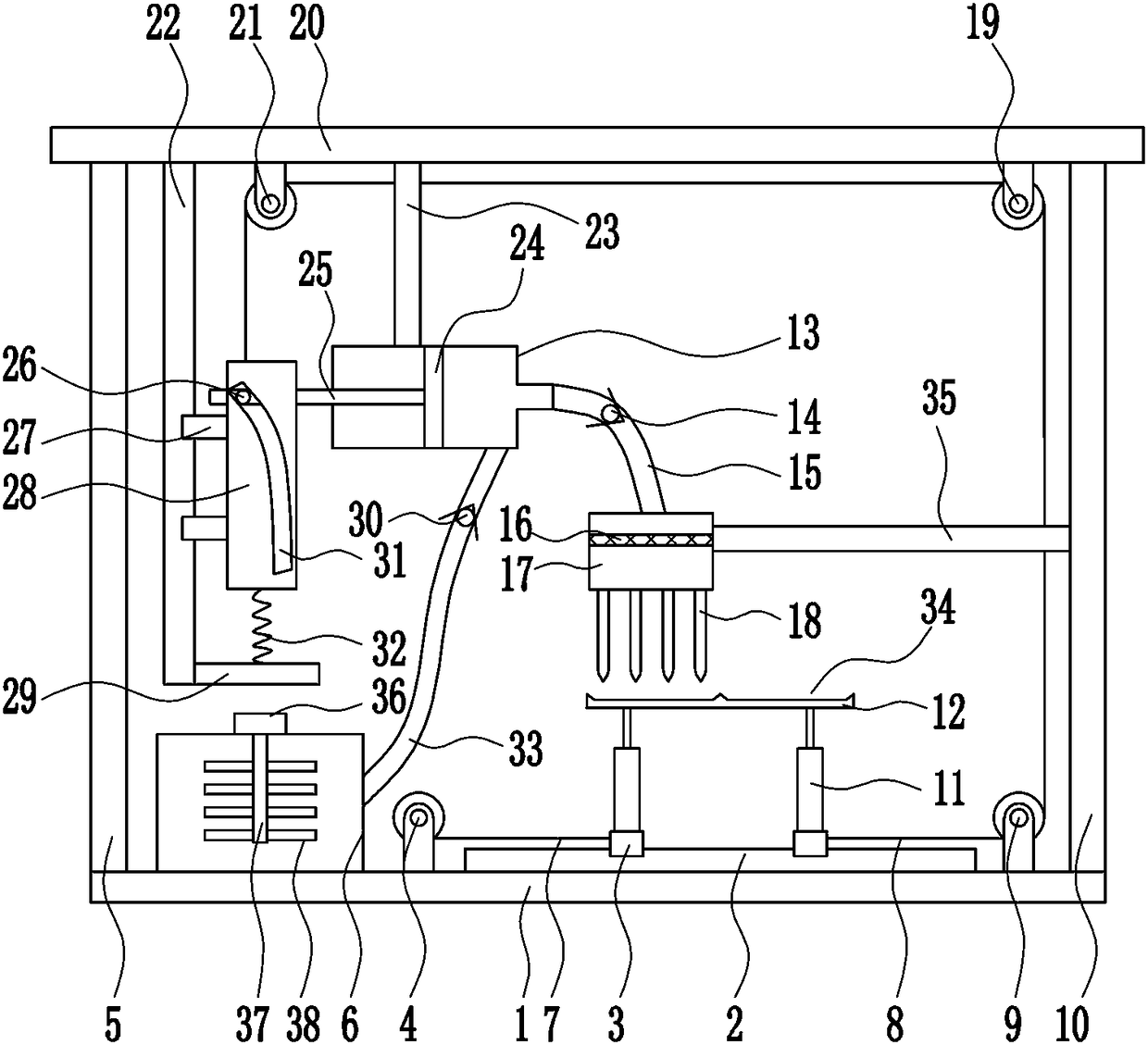

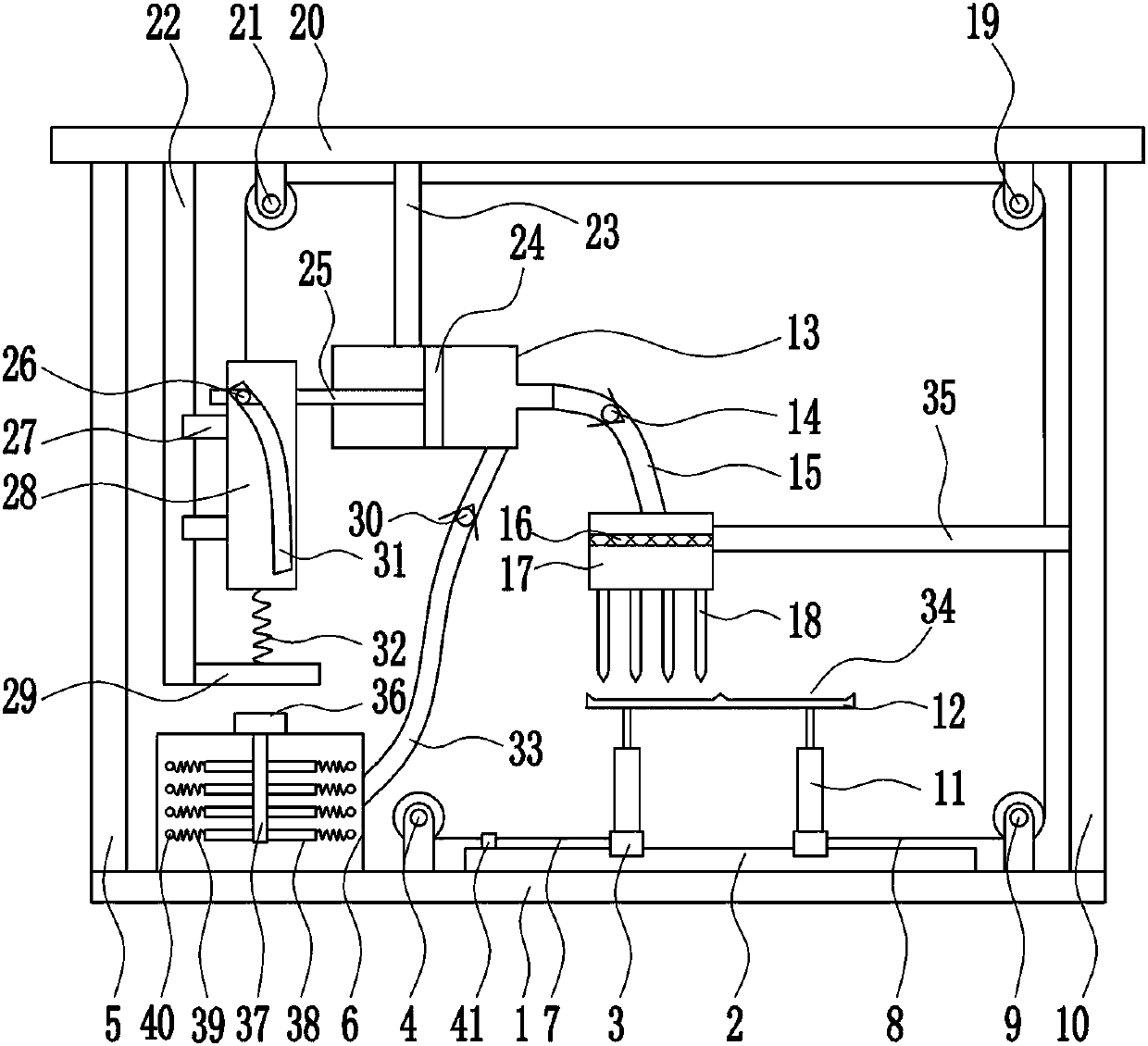

InactiveCN107537733AFlexible moving processImprove dispensing qualityLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The present invention provides a dispensing machine with a dispensing head assembly, which includes a control cabinet and a dispensing unit located on the control cabinet, the control cabinet includes a working table and a control mechanism, and the dispensing unit includes the The dispensing head assembly electrically connected to the control mechanism, the transmission device, the positioning device for limiting the positioning of the product to be dispensed, and the driving dispensing head assembly can move the dispensing tube along the X-axis, Y-axis, and Z-axis respectively Drive mechanism; in this way, through the cooperation of the first drive mechanism, the second drive mechanism and the third drive mechanism, the flexible movement of the dispensing head assembly in the three-axis direction can be realized. By setting the fourth drive mechanism, the dispensing head assembly can be controlled. Rotating, it can effectively dispensing work on the parts that are difficult to dispensing, such as the corners of the dispensing product. Reliable and improve the quality of the product.

Owner:柏跃龙

Full-automatic glue dispenser

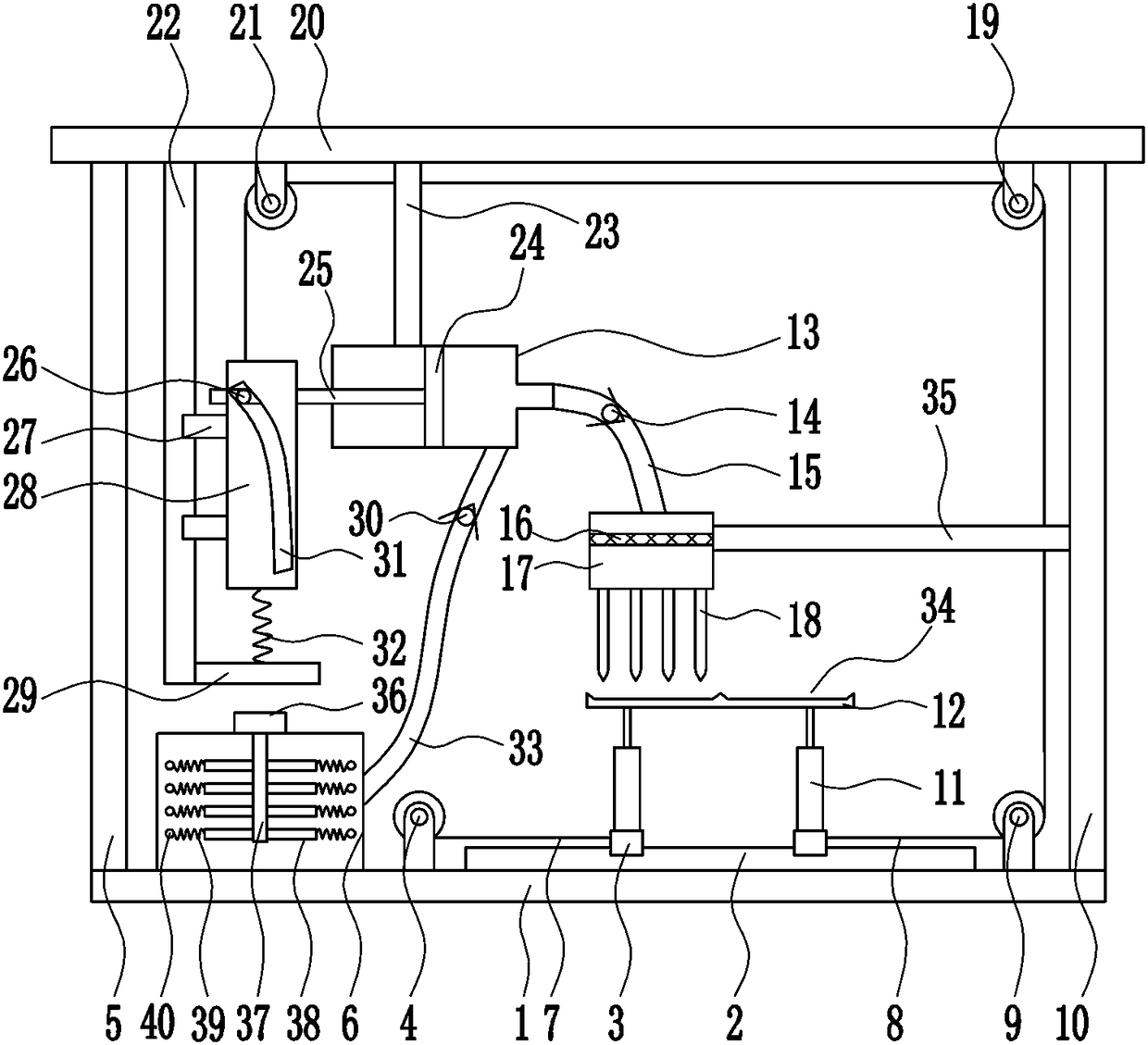

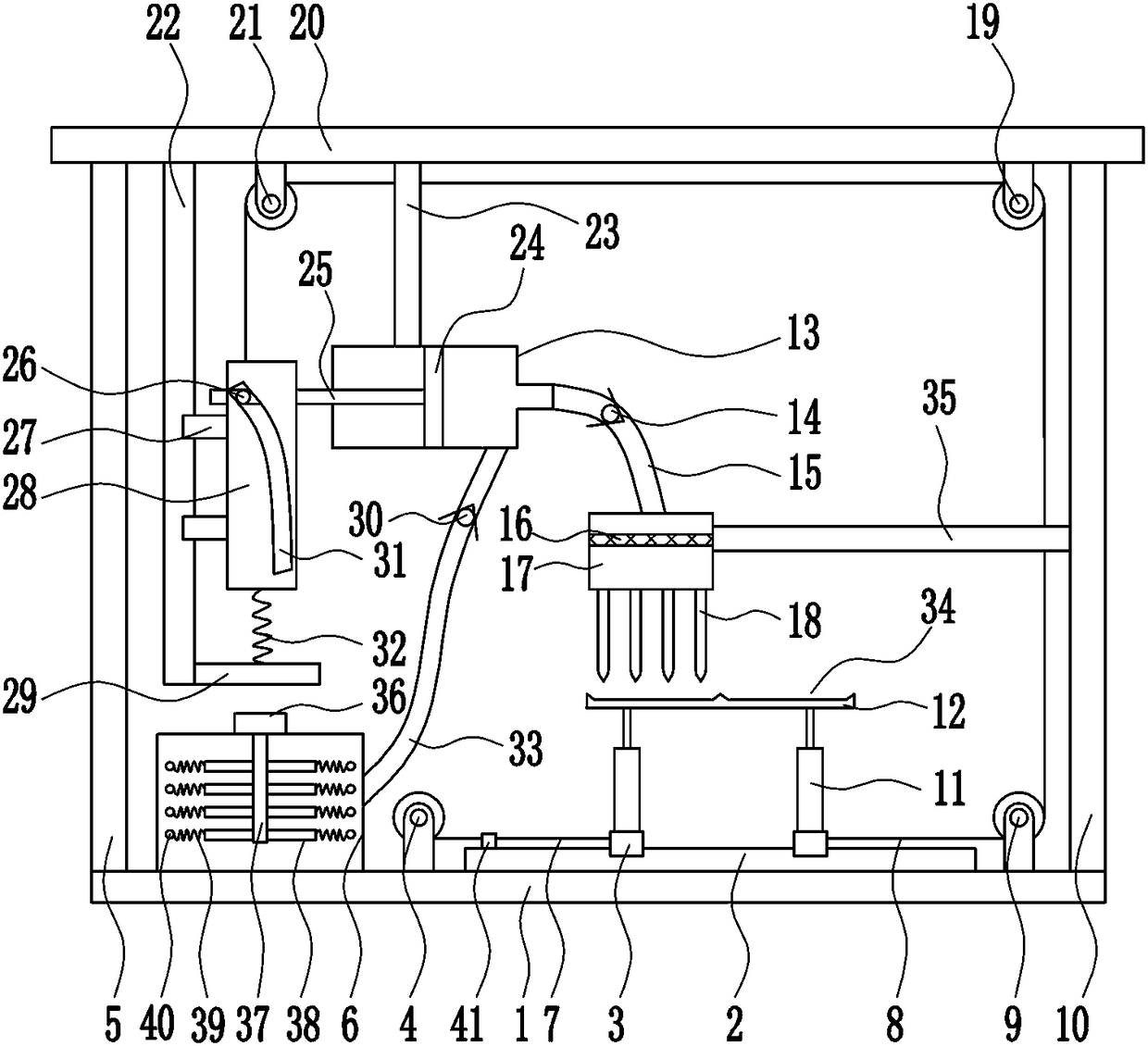

InactiveCN107398398AImprove dispensing qualityEffective dispensingLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention provides a fully automatic dispensing machine, which includes a control cabinet and a dispensing unit, the control cabinet includes a working table and a control mechanism, and the dispensing unit includes a dispensing device, a transmission device and a positioning device electrically connected to the control mechanism; dispensing The device includes a fixed base, a dispensing tube and a dispensing tube driving mechanism. The dispensing tube driving mechanism includes a first driving mechanism for controlling the movement of the dispensing tube along the X-axis direction, a second driving mechanism for controlling the movement of the dispensing tube along the Y-axis direction, The third driving mechanism that moves in the Z-axis direction and the fourth driving mechanism that controls the rotation of the dispensing hose; the transmission device includes a lifting cylinder, a rotating cylinder, a rotating arm and a grabbing mechanism, and the positioning device includes a stopper and is connected with the stopper the first axis of rotation. The invention aims to solve the problems that the dispensing tube of the existing dispensing machine is difficult to be accurately aligned and cannot be flexibly controlled during three-axis movement.

Owner:柏跃龙

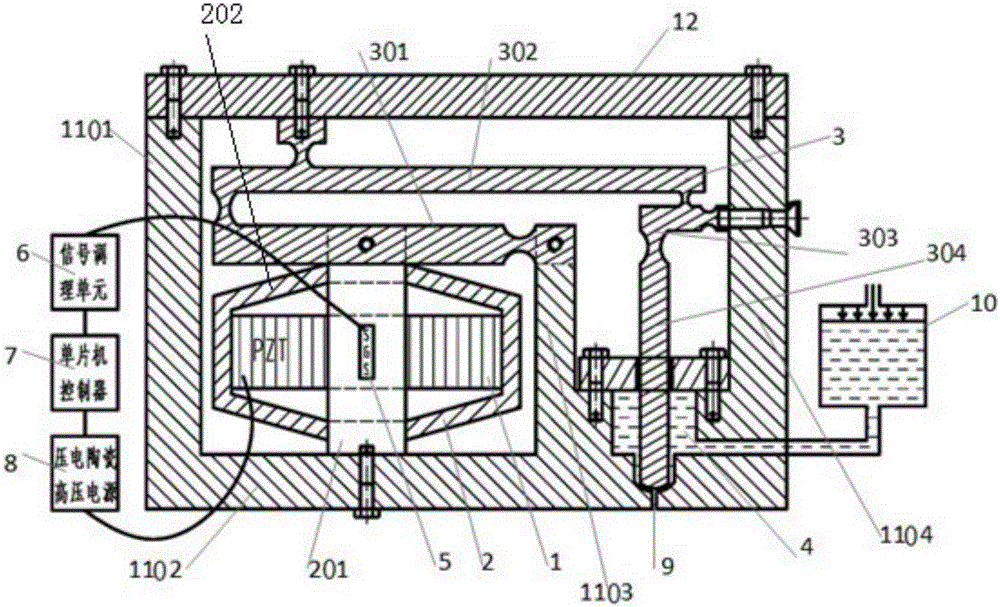

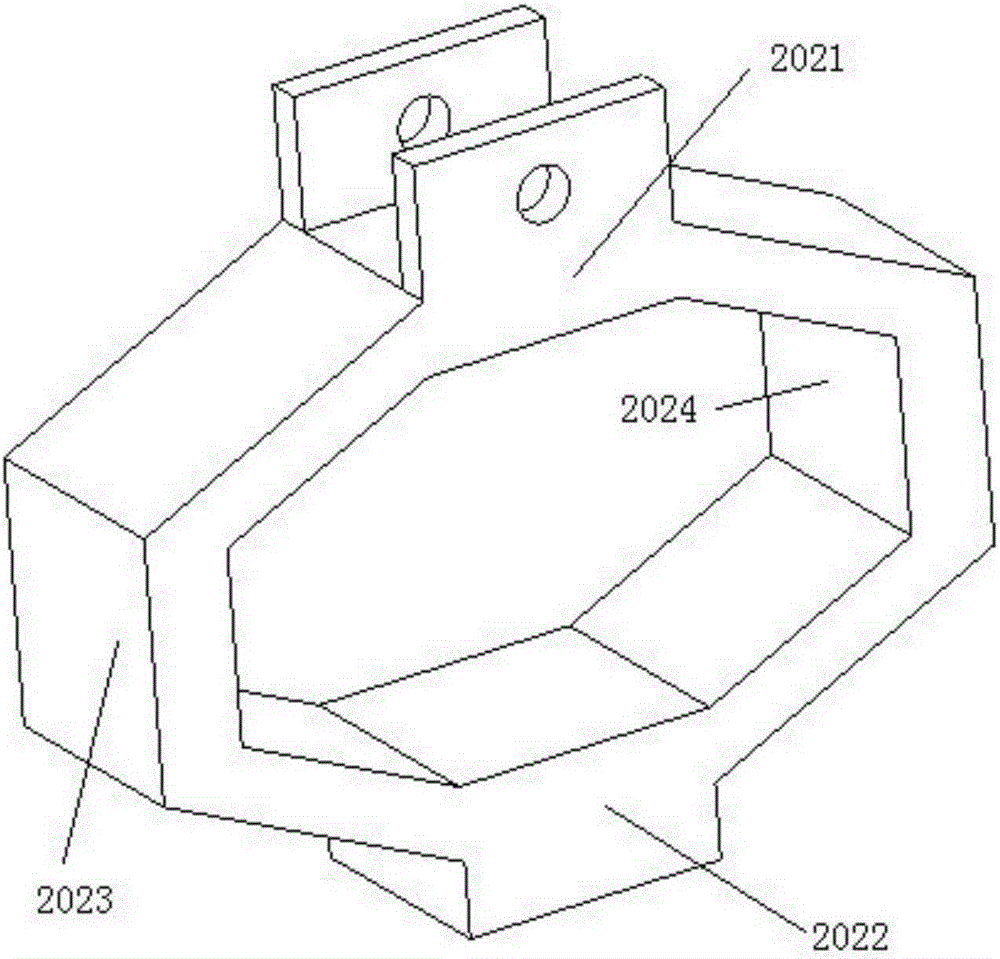

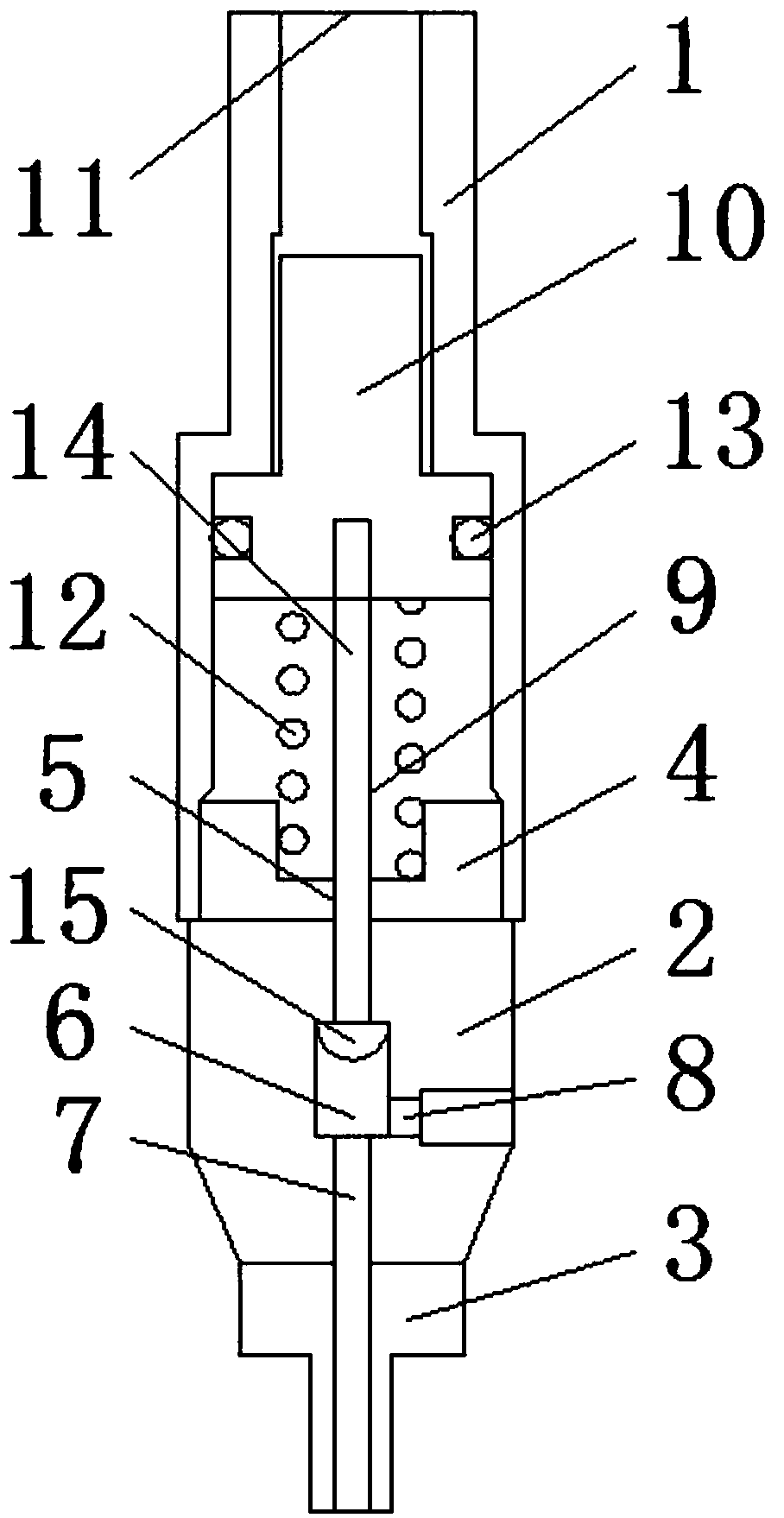

Piezoelectric injection type precise quantification dispensing device and dispensing method thereof

InactiveCN105289934AAccurate and controllable displacementImprove dispensing accuracyLiquid surface applicatorsCoatingsElectricityInterference fit

The invention relates to the field of electronic packaging, and particularly relates to a piezoelectric injection type precise quantification dispensing device and a dispensing method thereof. A piezoelectric stack PZT driver is inlaid in a primary amplifying mechanism in interference fit; the piezoelectric stack PZT driver is connected with a piezoelectric ceramic high voltage power supply; sheet metal is adhered to the primary amplifying mechanism, and an SGS strain gage is adhered on the sheet metal; the SGS strain gage is connected with a signal conditioning unit; a thrice-amplifying mechanism is arranged above the primary amplifying mechanism and comprises a lower plate, an upper plate, a connecting rod and a firing pin; the same ends of the upper plate and the lower plate are flexibly connected, and the lower plate is also connected with the upper part of the body of an elastic amplifying mechanism; the firing pin is inserted into a hole in a cover plate above a cavity of a machine base, a sealing ring is arranged in the hole, and the firing pin extrudes a glue solution in the cavity to be ejected from a nozzle. The device realizes quartic amplification of slight elongation produced by the piezoelectric stack PZT driver, the piezoelectric stack PZT driver is used as a power to achieve injection type non-contact dispensing, and the dispensing quality is improved.

Owner:HENAN POLYTECHNIC UNIV

Glue dispensing device and method thereof

InactiveCN101152643AIncrease the areaReduce the chance of failureLiquid surface applicatorsSpraying apparatusAdhesiveEngineering

The invention relates to a dispensing device, which comprises a rotary first vacuum absorption device, a second vacuum absorption device synchronously rotating along the first vacuum absorption device as well as a dispenser. The first vacuum absorption device comprises a first vacuum suction nozzle, the second vacuum absorption device comprises a second vacuum suction nozzle, the first vacuum suction nozzle is arranged relative to the second vacuum suction nozzle and then is used for fixing an awaiting dispersing optical element after coordinating with each other, and the dispenser comprises a soft coating head and is used for being abut with the edge of the fixed awaiting dispersing optical element for dispersing. The invention also relates to a dispersing method of the dispersing device, the first vacuum absorption device and the second vacuum absorption device of the dispersing device are used for fixing and rotating the awaiting dispersing optical element, meanwhile, the dispenser with the coating head is adopted to carry on dispersing, thus not only increasing coating area of bonding adhesive on the awaiting dispersing element, but also realizing uniform and stable coating of bonding adhesive on the awaiting dispersing optical element.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Die bonder

ActiveCN111370350AGuaranteed dispensing accuracyEnsure dispensing qualitySemiconductor/solid-state device manufacturingWaferingElectric machinery

The invention provides a die bonder. The die bonder comprises a rack; a dispensing device; a dispensing shifting mechanism; a feeding mechanism; a die bonding swing arm device; a crystal supply platform; a die bonding displacement mechanism; and a material receiving mechanism. The die bonding swing arm device comprises a rotating frame, a plurality of die bonding swing arms, a lifter and a die bonding motor, and each die bonding swing arm is provided with a suction nozzle; the dispensing device comprises a plurality of dispensing modules. The invention provides a die bonder. According to the invention, the plurality of dispensing modules are combined with the plurality of die bonding swing arms, so that the operation speeds of the plurality of dispensing modules can be adjusted to be matched with the operation speeds of the plurality of die bonding swing arms on the premise of ensuring the dispensing precision and quality and ensuring the wafer taking and placing precision, the idle time of each dispensing module and each die bonding swing arm is reduced, and the die bonding efficiency is greatly improved.

Owner:SHENZHEN XINYICHANG TECH CO LTD

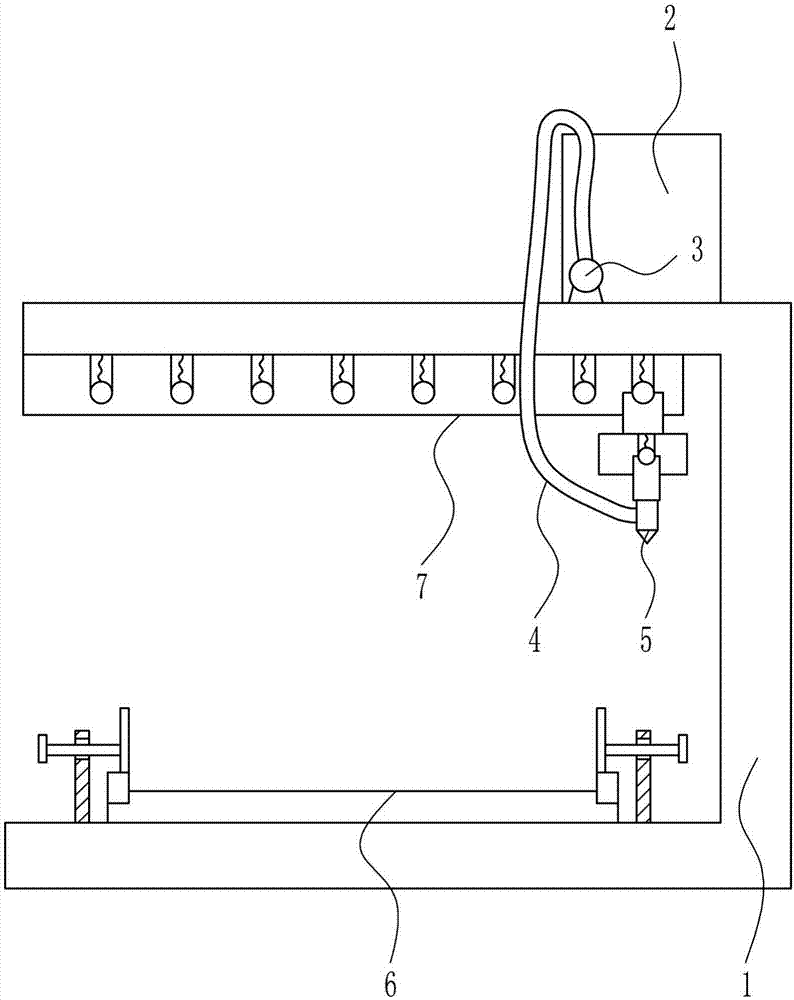

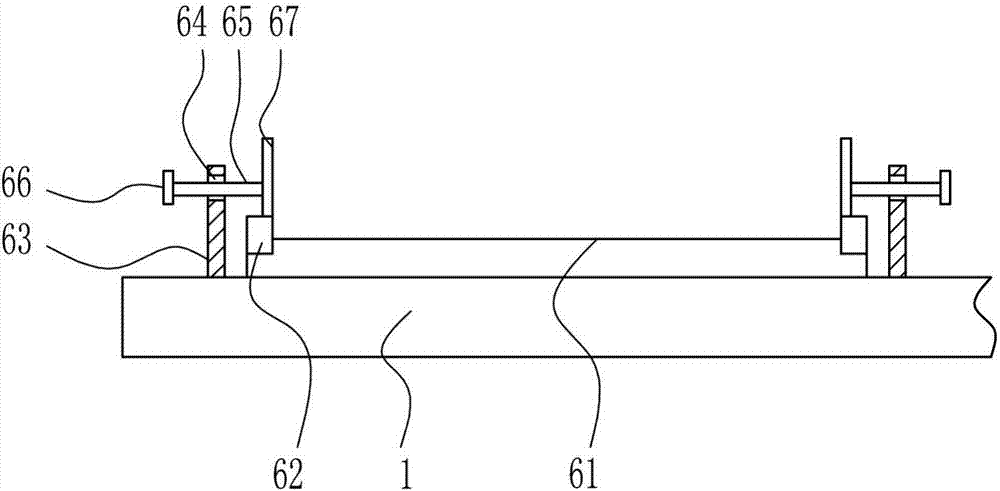

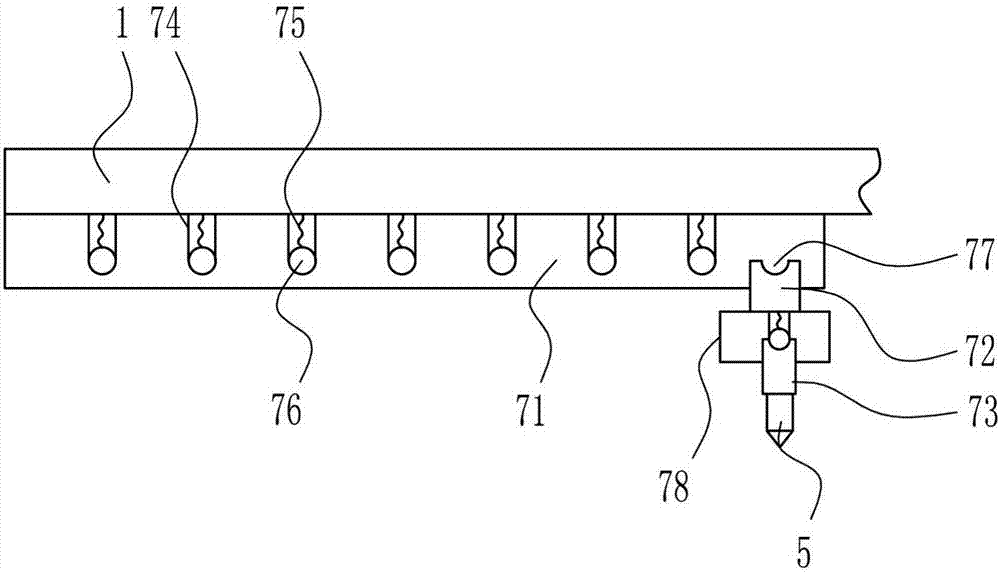

Wire dispensing production line

ActiveCN107511298AImprove dispensing qualityImprove dispensing efficiencyPretreated surfacesCoatingsProduction lineEngineering

The invention discloses a wire dispensing production line. The wire dispensing production line comprises a tool mechanism, a conveying device used for driving the tool mechanism to move, more than one dispensing device and a curing oven, wherein the conveying device conveys the tool mechanism to the dispensing device for dispensing, and the conveying device conveys the tool mechanism into the curing oven for curing. A user puts a to-be-dispensed workpiece onto the tool mechanism, the conveying device conveys the tool mechanism to the dispensing device, the dispensing device dispenses the to-be-dispensed workpiece on the tool mechanism, then the conveying device conveys the tool mechanism and the workpiece into the curing oven for curing, the traditional modes of manual dispensing for wire harnesses and sheaths are abandoned, the dispensing quality is improved, the dispensing efficiency is improved, and the social competitiveness of an enterprise is enhanced.

Owner:GUANGDONG JINHONGDA AUTOMATION TECH CO LTD

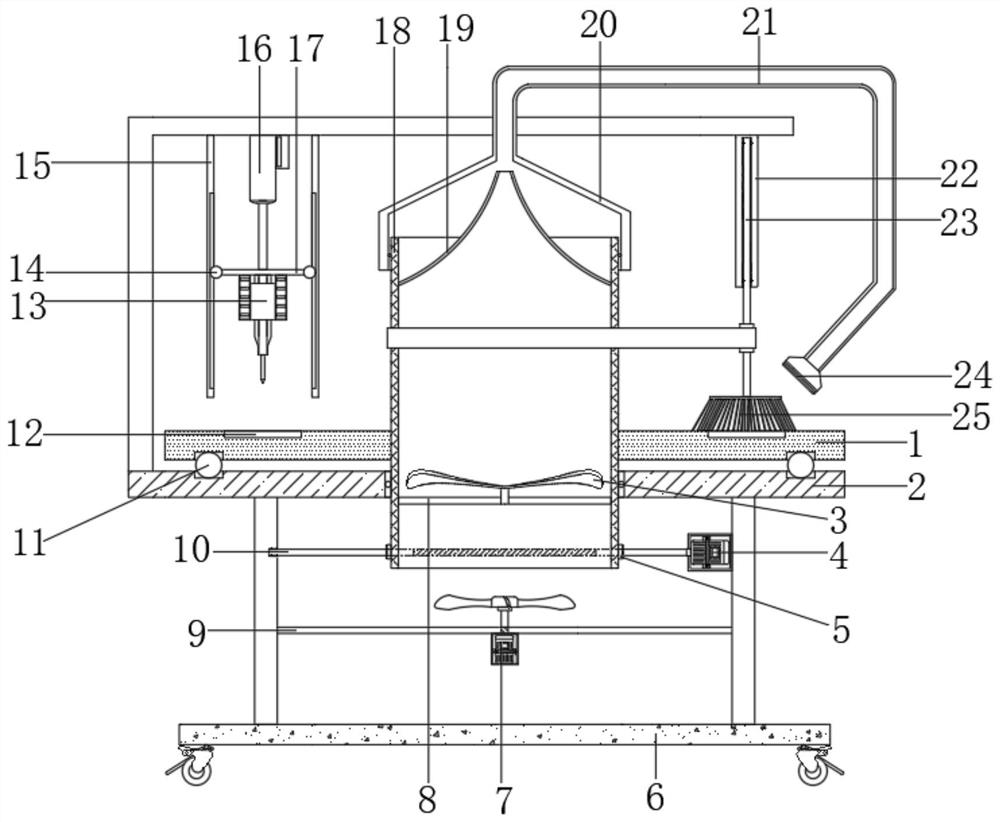

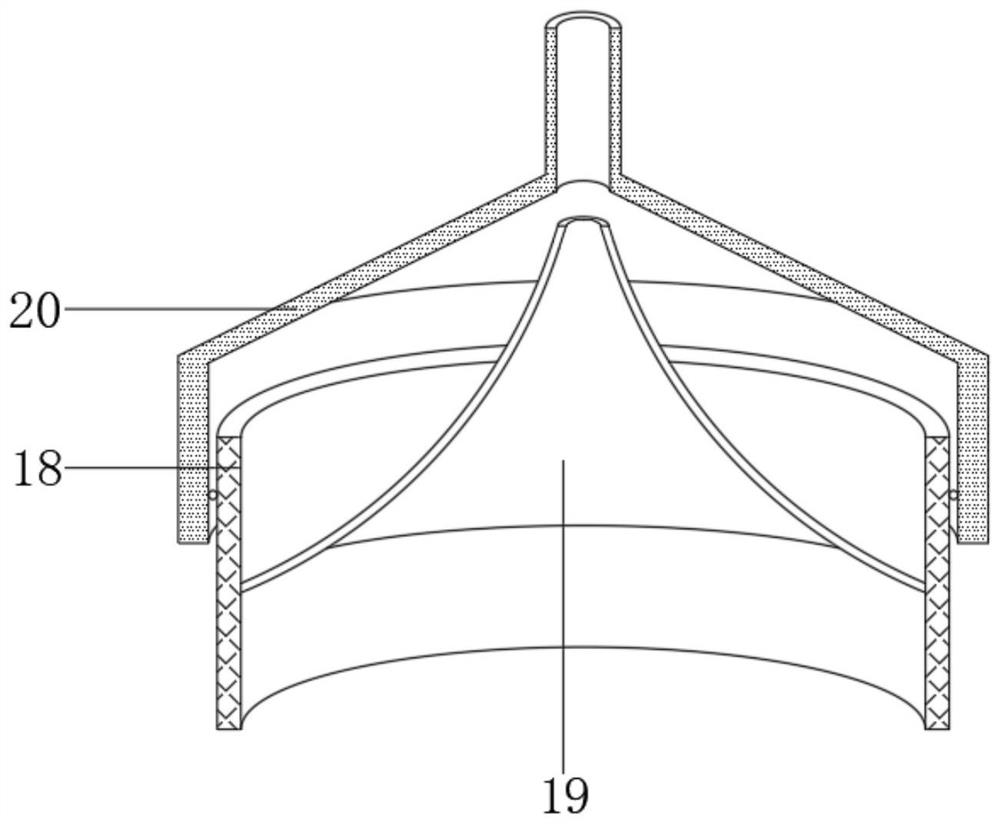

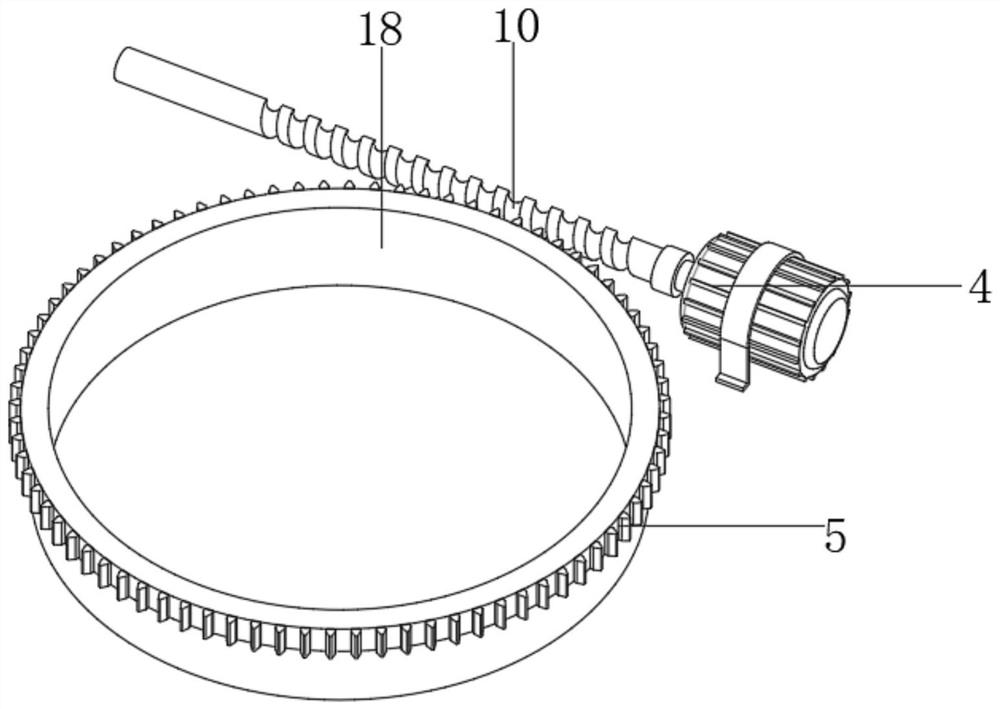

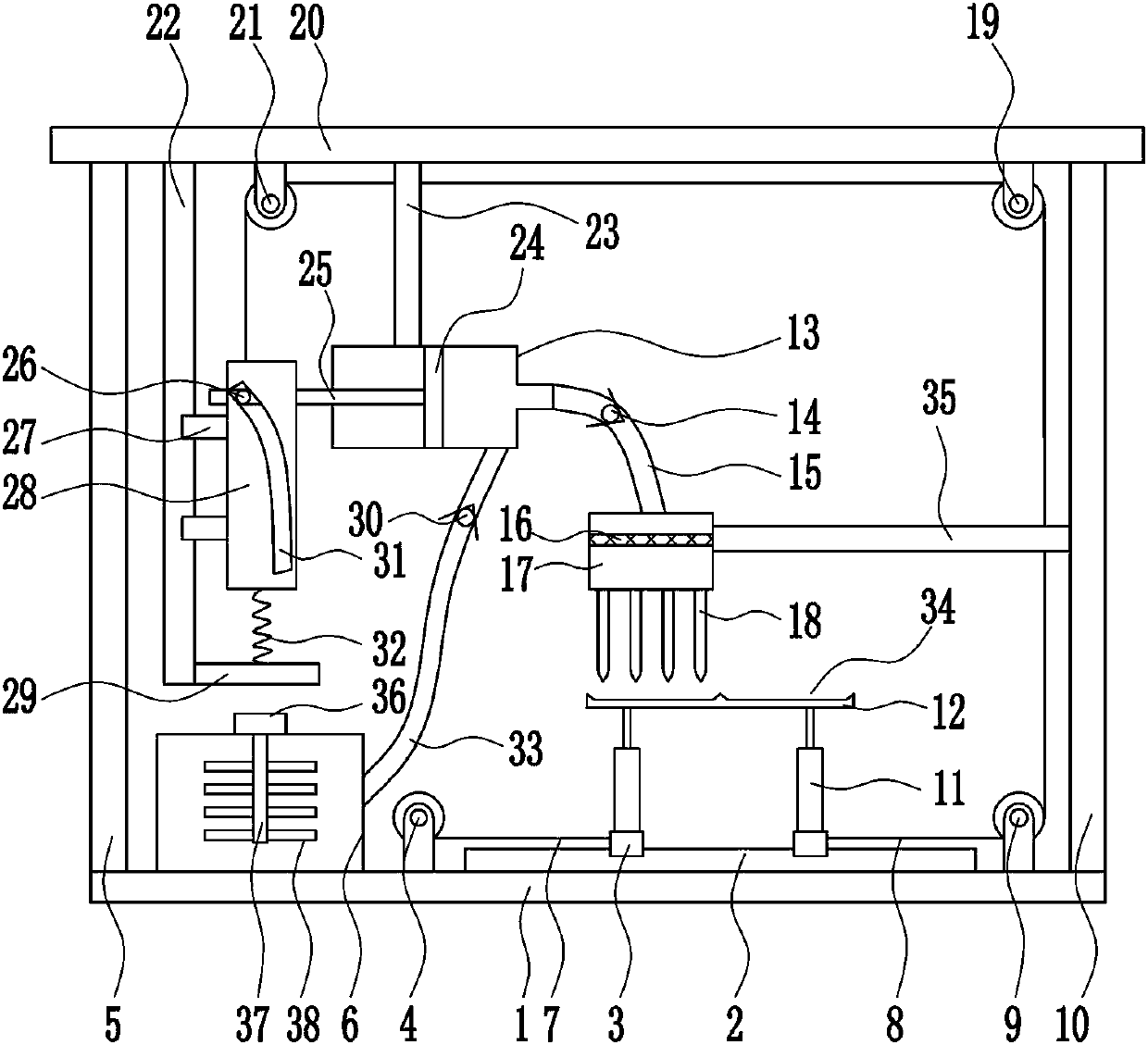

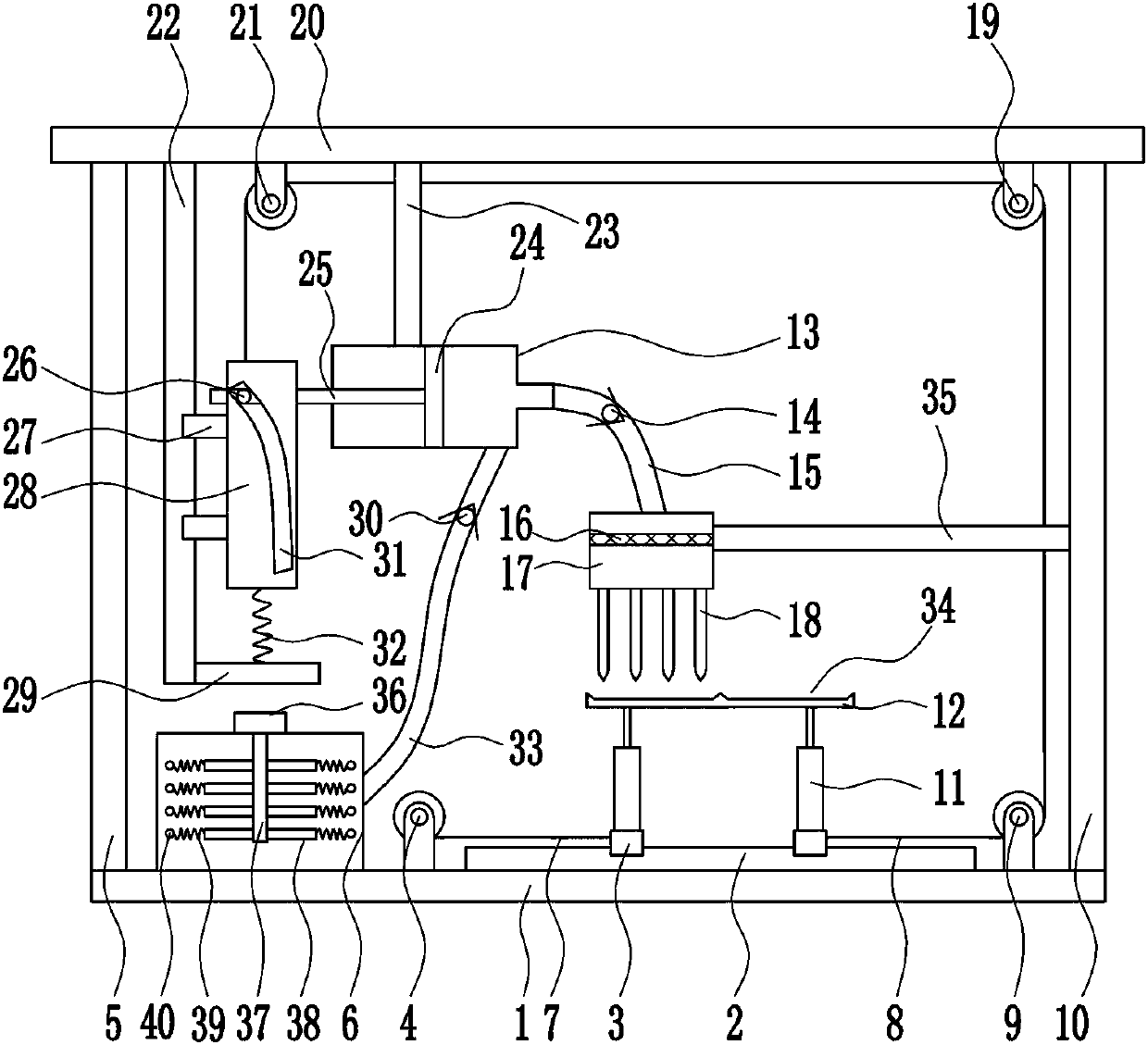

Dispensing equipment for floodlight production

InactiveCN107088501AGuaranteed resetImprove deformationLiquid surface applicatorsCoatingsBiomedical engineeringStorage tank

The invention relates to a glue dispensing device, in particular to a glue dispensing device for lighting lamp production. The technical problem to be solved by the present invention is to provide a kind of dispensing equipment for lighting production which can effectively control the dispensing amount and dispensing position. In order to solve the above technical problems, the present invention provides such a dispensing equipment for lighting production, including a mounting frame, etc.; a fixing device is provided at the bottom of the mounting frame; There is a booster pump on the left side of the inner bottom, and a hose is connected to the booster pump. A position adjustment device is installed on the top of the installation frame, and a dispensing head is installed at the bottom of the position adjustment device. The hose passes through the storage box and the dispensing head. connect. The present invention can dispens glue at different positions through the position adjustment device, and the arrangement of the first spring and the steel ball cooperates with the first arc-shaped groove, so that the second slider and the third slider each reach a hollow column.

Owner:GRACE(NINGBO) LIGHTING CO LTD

Three-axis integrative linkage-type automatic dispenser

ActiveCN105983515AFlexible replacementWiden the working surface widthLiquid surface applicatorsCoatingsIndependent motionMachined surface

The invention relates to a three-axis integrative linkage-type automatic dispenser, which is formed by a dispensing device, an X-direction movement mechanism, a Y-direction movement mechanism, a Z-direction movement mechanism and structural parts. The three-axis integrative linkage-type automatic dispenser has the advantages that while in use, a dispensing head enables independent movement and does not depend on the relative motion of the workpieces, the positioning precision of the different sizes of the workpieces are not influenced by the different workpieces, according to the different dispensing requirement of the different workpieces, and the dispensing head can be replace with a flexible mode for satisfying the dispensing requirements. According to the invention, machined surface by single machine dispensing is widened, automatic operation is reduced, dispensing position is accurate, dispensing quality is high, product quality is ensured, labour force is saved, production efficiency is increased, and usage is convenient.

Owner:宁波奥可智能科技发展有限公司

Dispensing device for semiconductor chip packaging

InactiveCN111617928AQuality improvementQuick dust removalLiquid surface applicatorsCleaning using toolsAir filterSemiconductor chip

The invention belongs to the technical field of chip processing, in particular to a dispensing device for semiconductor chip packaging. In view of the problem that most of the traditional chip processing dispensers are relatively simple in structure and dust attached to the chip affects the dispensing effect easily, the following scheme is proposed. The dispensing device comprises a dispensing platform and a fixed support platform, an installation groove and a transferring opening are respectively formed in the centers of the dispensing platform and the fixed support platform, a transmission cylinder which is rotationally connected with the transferring opening by a bearing is welded on the inner wall of the installation groove, and side support plates are vertically welded at the two sides of the outer wall of the bottom of the fixed support platform. According to the invention, clean air is blown to a chip in a placing groove for dust blowing effect through the action of the transmission cylinder, a fixed cover end and an air pipe and an air filter element; a drive mechanism can drive the transmission cylinder to rotate, a rotating rod and a brush head are driven to rotate by theaction of a belt so as to brush the chip, the effect of removing dust quickly is achieved, and the dispensing quality is improved.

Owner:顾骏

Automatic glue dispenser

InactiveCN104338651AGood liquidityImprove dispensing qualityLiquid surface applicatorsCoatingsEngineeringMechanical engineering

Owner:ANHUI AOFO MEDICAL EQUIP TECH

Novel glue dispenser

PendingCN107670909AHigh degree of automationImprove dispensing efficiencyLiquid surface applicatorsCoatingsEngineeringWork space

The invention discloses a novel dispensing machine, which comprises a processing platform, a frame, at least one dispensing fixture, a novel dispensing mechanism and a controller. The frame is installed at the back end of the processing platform, and the dispensing fixture can be installed on the processing platform movable back and forth. There are multiple clamping stations with adjustable positions on the dispensing fixture, and the rear of the clamping station The ends are removable with foam blocks. A new dispensing mechanism can be installed on the frame up and down, left and right, and a controller is installed on the frame and is used to control the forward and backward movement of the dispensing fixture and the up and down, left and right movement of the new dispensing mechanism. The invention controls the forward and backward movement of the dispensing fixture and the up, down, left and right movement of a new type of dispensing mechanism through the controller, thereby realizing the automatic dispensing of different positions of the mobile phone, improving the dispensing efficiency, and the rear end of the clamping station can be The disassembled one is equipped with a foam block, which can rub the residual glue on the foam block to prevent it from affecting the dispensing of subsequent products and improve the dispensing quality of the product.

Owner:重庆市量劲科技有限公司

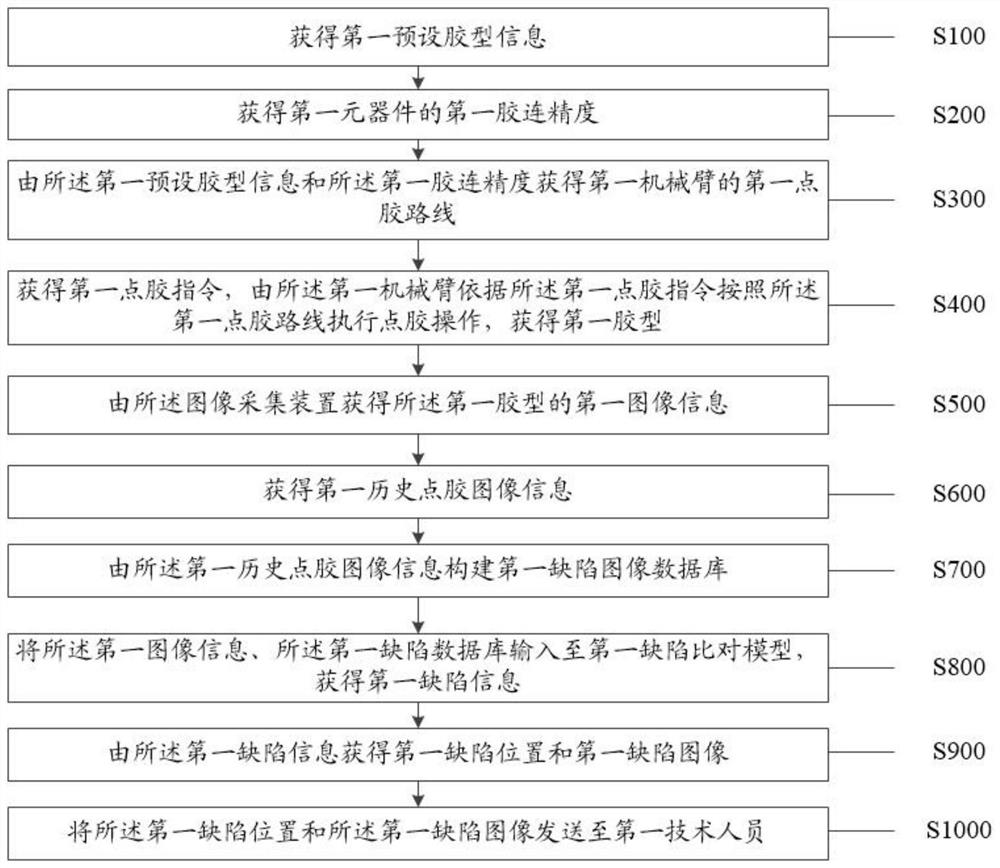

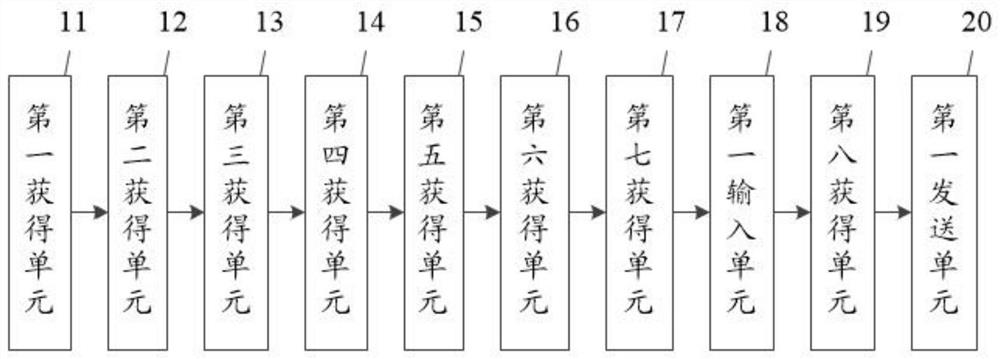

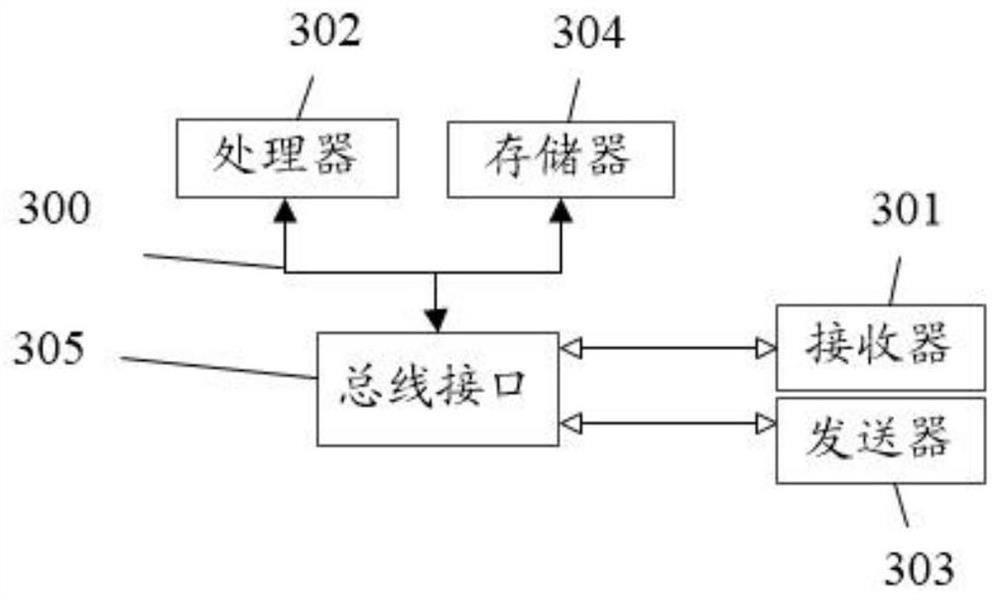

Precise dispensing information processing method and system

ActiveCN112950604ARealize visual inspectionImprove dispensing qualityLiquid surface applicatorsImage analysisInformation processingEngineering

The invention discloses an information processing method and system for precise dispensing, and the method comprises the steps: obtaining first preset glue type information; obtaining the first glue connection precision of the first component; obtaining a first dispensing route of a first mechanical arm according to the first preset glue type information and the first glue connection precision; the first mechanical arm executing dispensing operation according to the first dispensing route, and a first glue type being obtained; obtaining first image information of the first glue type; constructing a first defect image database according to the historical dispensing image information; inputting the first image information and the first defect database into a first defect comparison model to obtain first defect information; and obtaining a first defect position and a first defect image according to the first defect information, and sending the first defect position and the first defect image to a first technician. The technical problems that in the prior art, the intelligent control degree of the dispensing precision is not enough, and defect analysis cannot be conducted in real time are solved.

Owner:SHENZHEN XINLUYUAN ELECTRONICS EQUIP CO LTD

Efficient automatic dispenser

InactiveCN109127290AAchieve recyclingAvoid cloggingLiquid surface applicatorsSpraying apparatusEngineeringMechanical engineering

The invention provides an efficient automatic dispenser. The efficient automatic dispenser comprises a rack, a glue heating mechanism, a bearing workbench, a traveling mechanism and a dispensing mechanism, wherein the traveling mechanism is arranged on the rack and comprises a transverse traveling assembly and a longitudinal traveling assembly; a dispensing reciprocation area is formed above the bearing workbench and the traveling mechanism acts in the dispensing reciprocation area in a reciprocation manner; the dispensing mechanism comprises a glue outlet assembly, a glue solidification prevention assembly, a rotation switching assembly and a cycle assembly; and a dispensing head is arranged on the rotation switching assembly. According to the efficient automatic dispenser, the dispensingmechanism is arranged above the bearing workbench, the traveling mechanism is matched to dispense workpieces on the bearing workbench in the reciprocating movement process, in the dispensing process,the dispensing head is located in a connected state all the time through the switching of the rotation switching assembly, and recycle of the glue is realized through the cycle assembly, so that thetechnical problem that dispensing guns are easy to adhere residual glue and difficult to clean in the prior art is solved.

Owner:CHANGXING BEST MASCH CO LTD

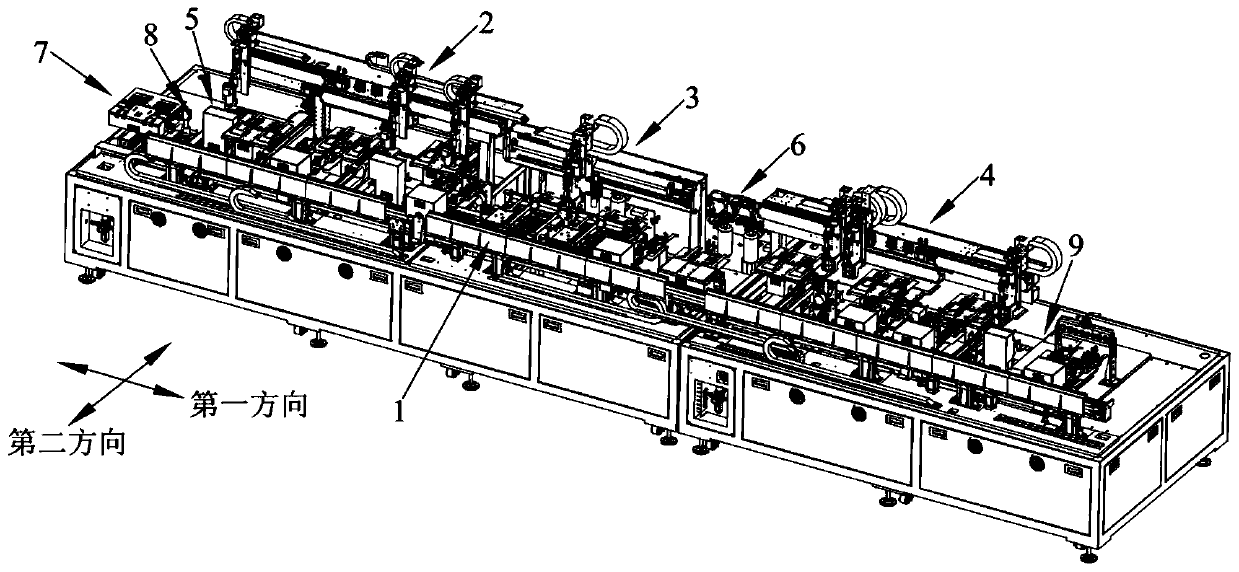

Dispensing machine and its dispensing method

ActiveCN105457840BShorten the working cycleIncrease productivityLiquid surface applicatorsCoatingsControl systemAdhesive

The invention discloses an adhesive dispensing machine and an adhesive dispensing method thereof. The adhesive dispensing machine comprises a control system, a charge system, and a visual inspection system and an adhesive dispensing system which are both located above the charge system. The charge system adopts a double-charge module comprising a first charge device and a second charge device, and matches with the visual inspection system and the adhesive dispensing system, thus the work of adhesive path planning, adhesive dispensing and adhesive path recheck carried out on production for products which are sequentially loaded and charged by the charge system, is realized; the adhesive path planning is carried out on products on the second charge device by virtue of time for adhesive dispensing for products on the first charge device, the work of adhesive dispensing is carried out on the products on the second charge device while recheck is carried out on the products on the first charge device, and the operation is circulated, thus the work cycle of the whole machine can be greatly saved, and the production efficiency of the whole machine is increased; and meanwhile, the labor cost can also be greatly reduced, and the adhesive dispensing quality is improved.

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

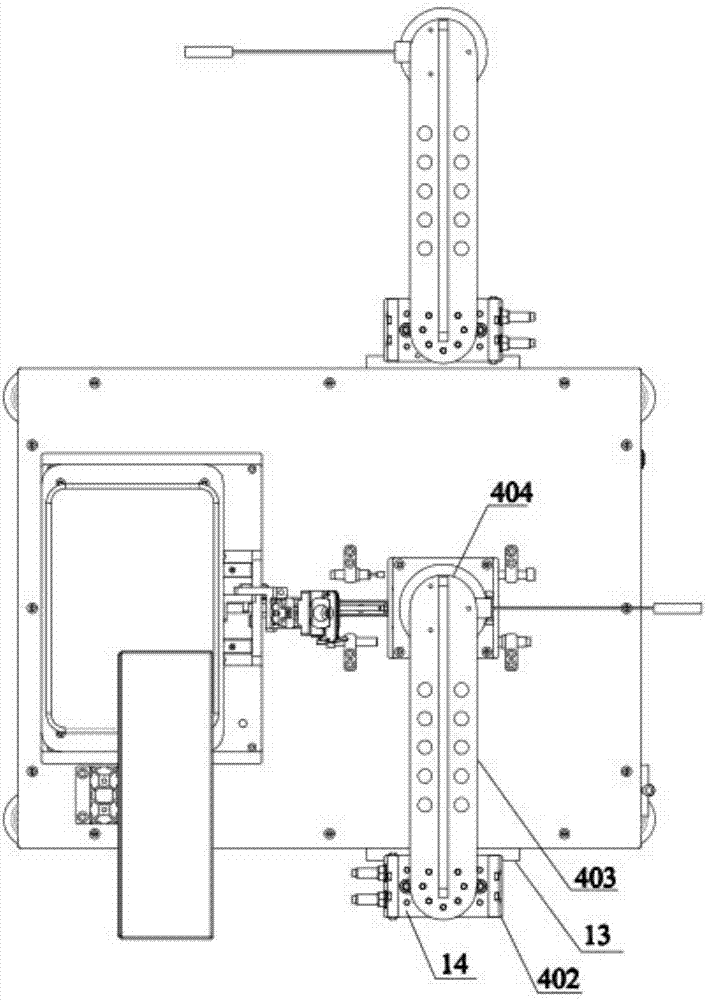

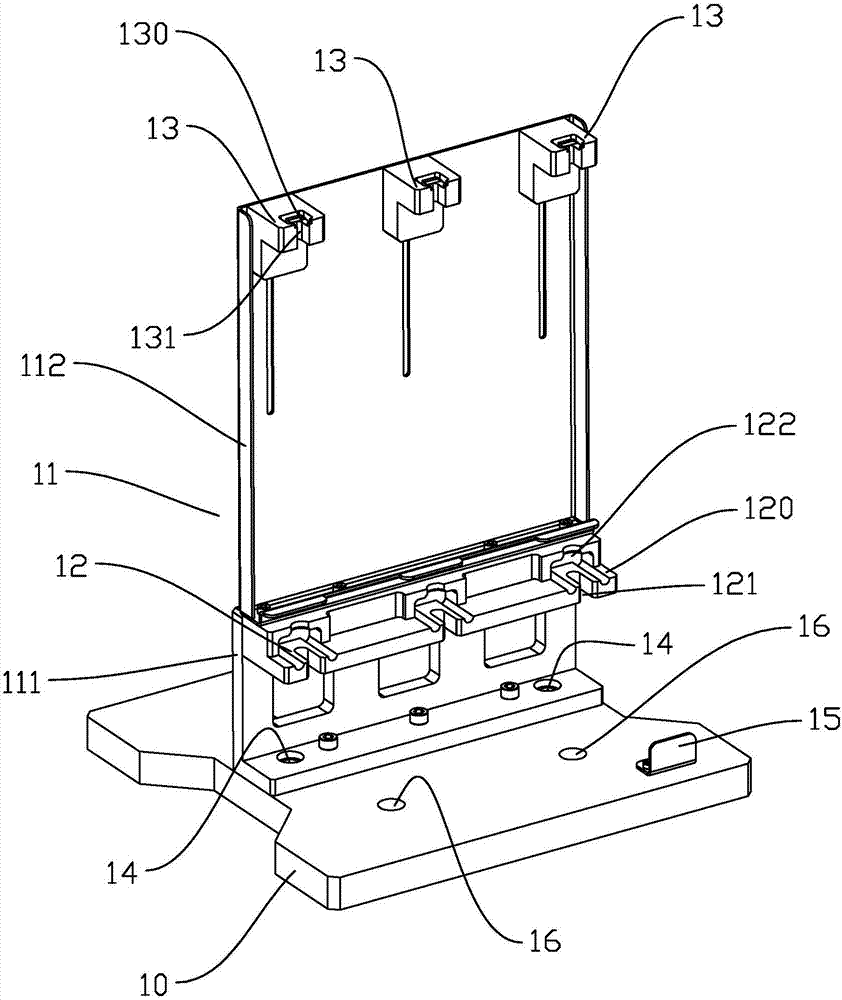

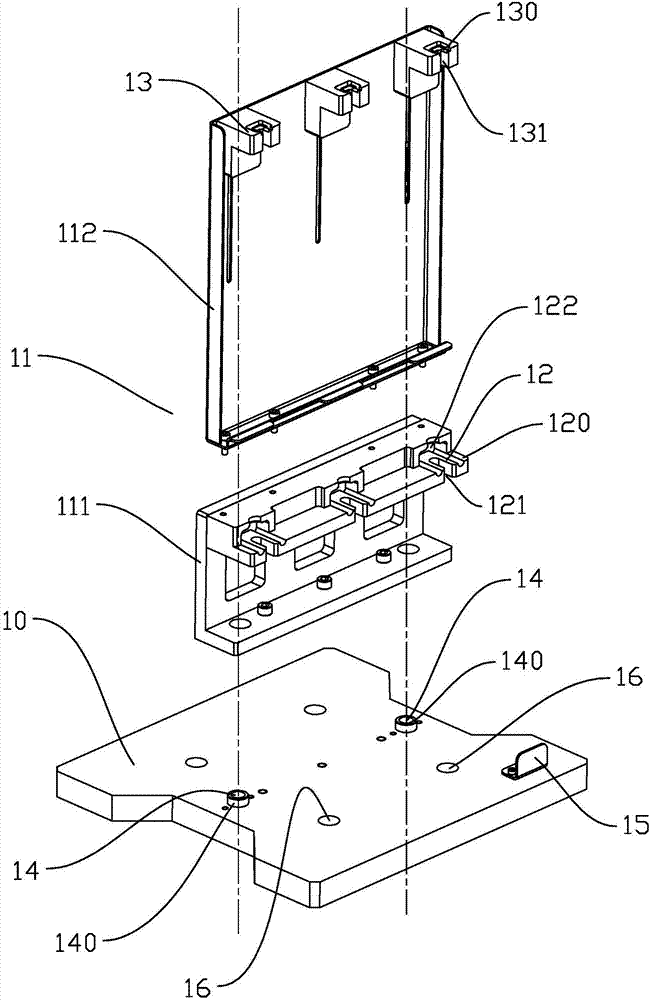

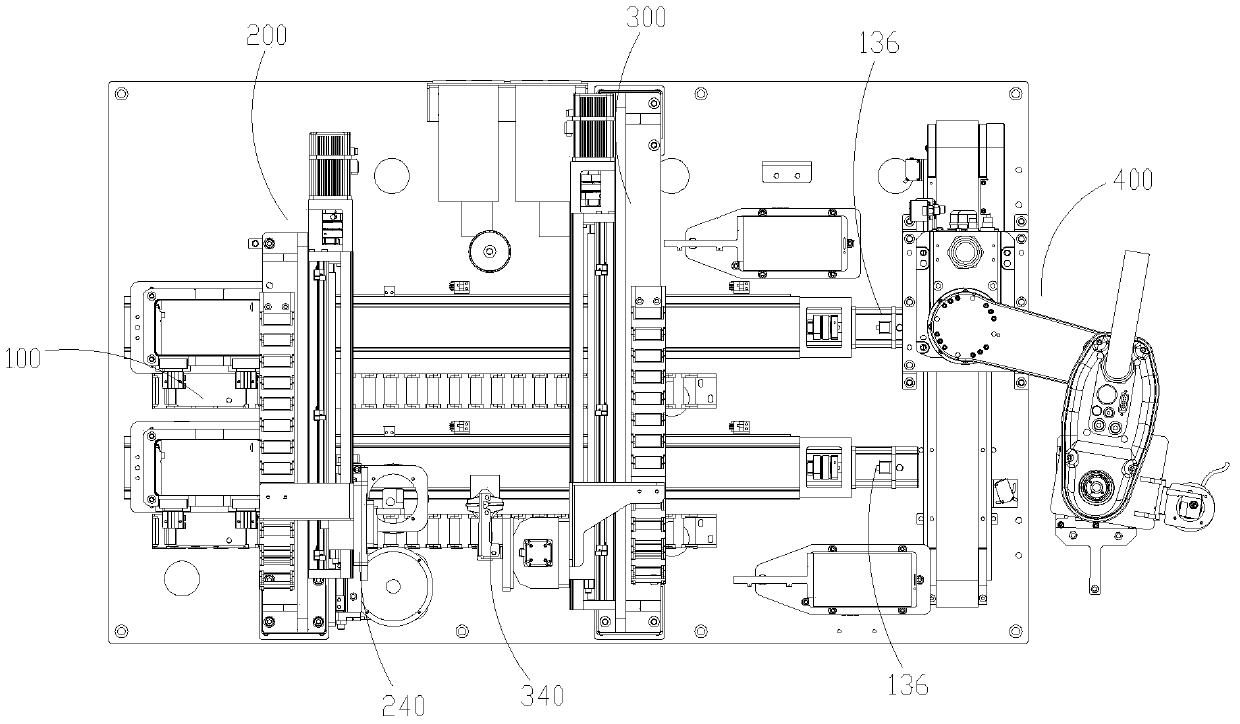

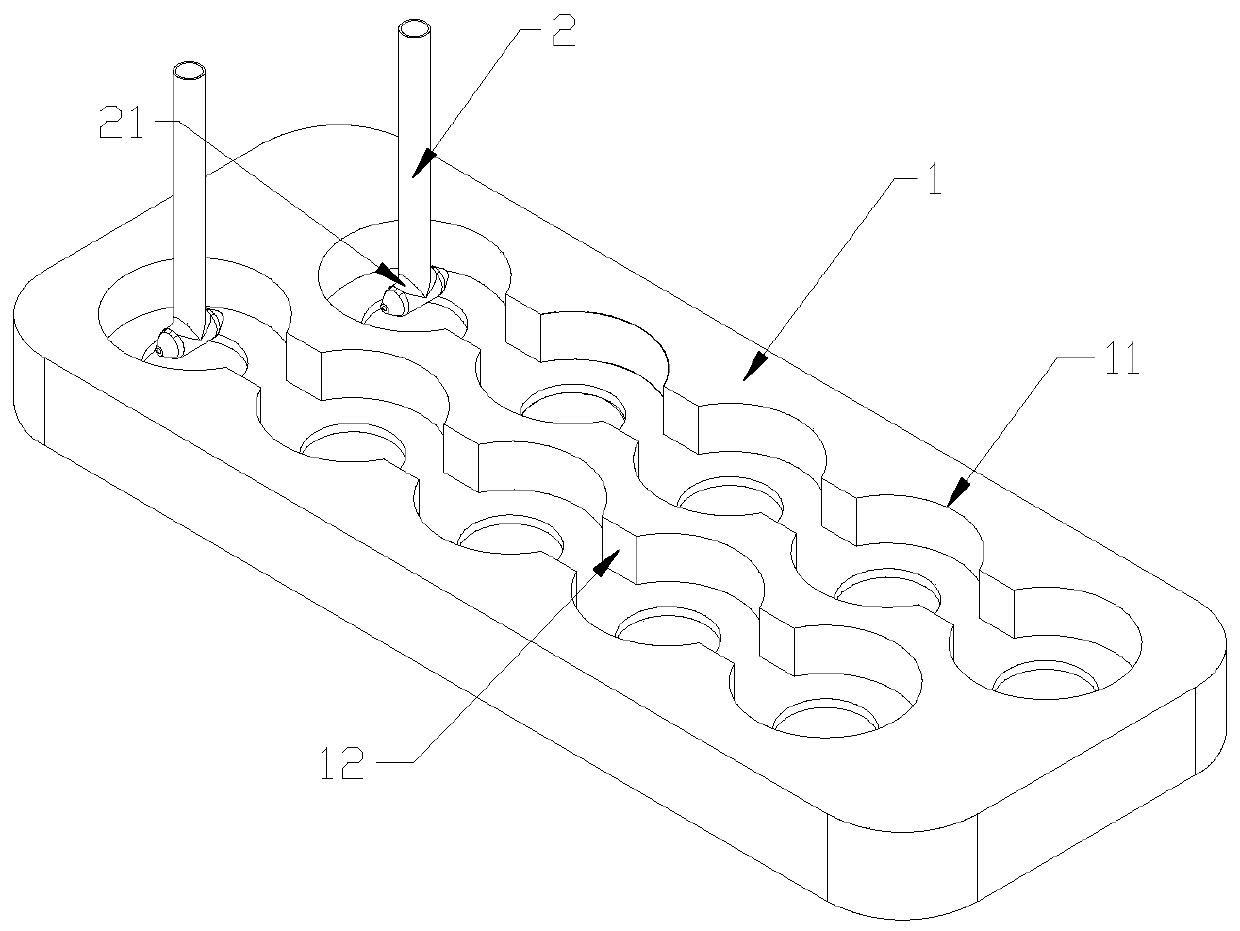

Assembling and glue dispensing device

ActiveCN112439644AImprove installation qualityImprove dispensing qualityLiquid surface applicatorsMaterial gluingEngineeringMachining

The invention discloses an assembling and glue dispensing device, and belongs to the technical field of electronic product machining equipment. The assembling and glue dispensing device comprises a rack, a Y-axis driving mechanism, an adjusting mechanism, an assembling mechanism and a glue dispensing mechanism, wherein the Y-axis driving mechanism is connected to the rack. The adjusting mechanismis connected to the output end of the Y-axis driving mechanism and can fix and adjust the position of a jig. The assembling mechanism comprises a first driving assembly, a first suction nozzle assembly and a second suction nozzle assembly, and the first driving assembly is arranged above the Y-axis driving mechanism. The first suction nozzle assembly is arranged at one side of the Y-axis driving mechanism, the second suction nozzle assembly is connected to the output end of the first driving assembly, and the first suction nozzle assembly installs parts on a product in the adjusting mechanismthrough the second suction nozzle assembly. The glue dispensing mechanism comprises a second driving assembly and a glue dispensing assembly, and the second driving assembly is connected to the rack.The glue dispensing assembly is connected to the output end of the second driving assembly. According to the invention, the machining quality and the production efficiency for product are improved.

Owner:BOZHON PRECISION IND TECH CO LTD

Electronic element guide rail type adhesive dispensing device for LED lamp production

InactiveCN108067399APrevent solidificationQuality assuranceLiquid surface applicatorsCoatingsAdhesiveSteel ball

The invention belongs to the technical field of LED lamp production, and particularly relates to an electronic element guide rail type adhesive dispensing device for LED lamp production. According tothe main technical purposes of the electronic element guide rail type adhesive dispensing device for LED lamp production, operation is easy, the adhesive dispensing effect is good, and the adhesive dispensing speed is high. In order to achieve the technical purposes, the electronic element guide rail type adhesive dispensing device for LED lamp production comprises a bottom plate, a first slide rail, a first slider, an electric wire winding wheel, a left frame, a material storing tank, a first pulling wire, a second pulling wire, a first fixed pulley, a right frame, an electric pushing rod, asecond hose and a second connection rod and the like; and the left frame is welded to the left side of the bottom plate. According to the electronic element guide rail type adhesive dispensing devicefor LED lamp production, the effects of the electric wire winding wheel and the first spring are given full play to, the electric wire winding wheel and the first spring are mutually matched and converted, and further due to the ingenious application of a net plate and steel balls, and the work effect of the device is further improved.

Owner:HUIZHOU HUITUO LIGHTING TECH CO LTD

Full-automatic COB glue sealing machine

ActiveCN106179883APrecisely control the glue out timeControl the amount of glueLiquid surface applicatorsCoatingsMotion controllerEngineering

The invention relates to a full-automatic COB glue sealing machine. The full-automatic COB glue sealing machine comprises a machine table, a motion controller, a longitudinal motion mechanism, a movement truss, a transverse motion mechanism, a supporting frame, a vertical rising and falling air cylinder and four dispensing valves. The motion controller is fixedly embedded on the machine table; the longitudinal motion mechanism and the transverse motion mechanism are both connected with the motion controller through lines; the longitudinal motion mechanism is arranged at the upper end of the machine table longitudinally, the movement truss is transversely arranged at the upper end of the longitudinal motion mechanism, and the longitudinal motion mechanism drives the movement truss to longitudinally move; the transverse motion mechanism is transversely arranged at the upper end of the movement truss and driven by the movement truss to move longitudinally, and the supporting frame is arranged at the upper end of the transverse motion mechanism and transversely moves along with the transverse motion mechanism; the vertical rising and falling air cylinder is arranged between the movement truss and the supporting frame; the supporting frame is provided with a three-shaft adjusting frame which is provided with the dispensing valves; and the machine table is provided with a heating platform. By means of the full-automatic COB glue sealing machine, full-automatic running can be achieved, the running stability is improved, and the product quality is improved.

Owner:深圳市拓普微科技开发有限公司

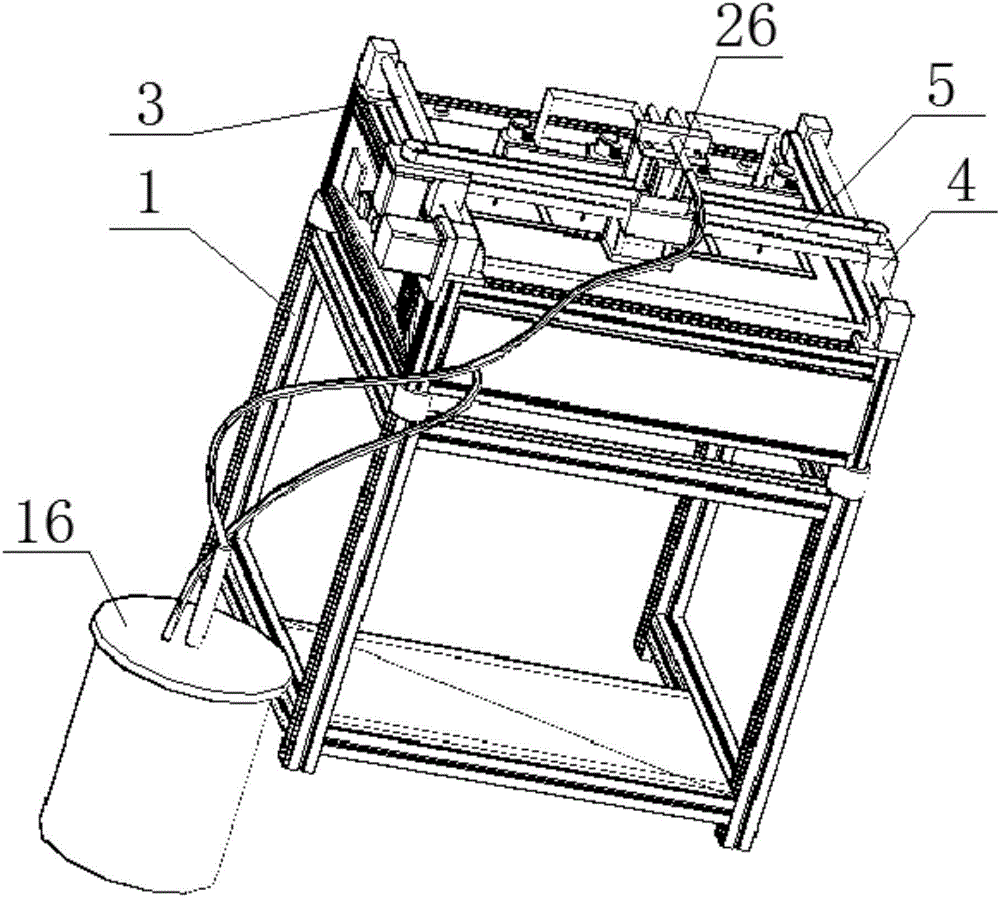

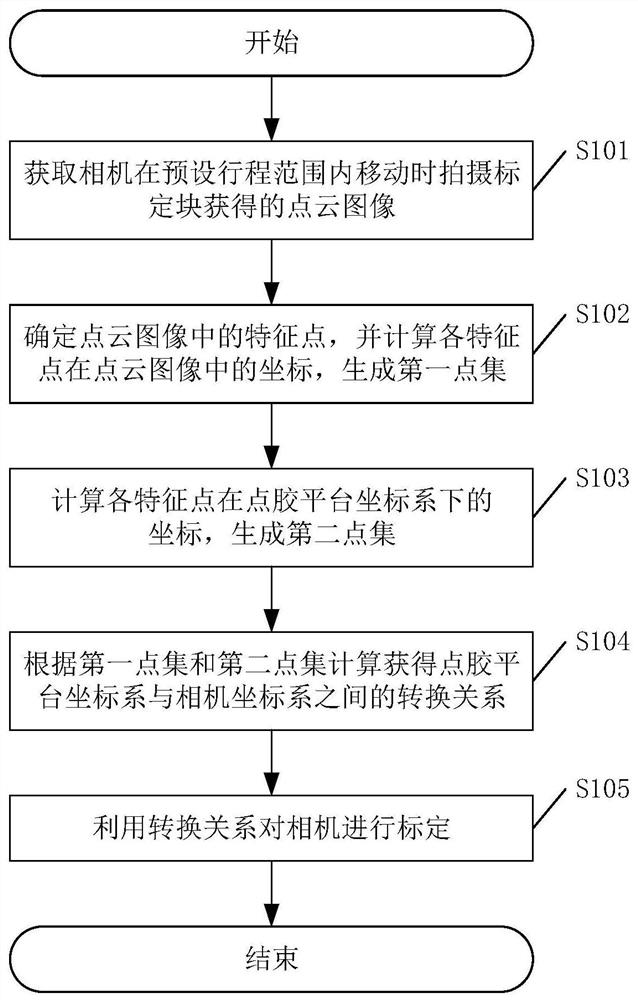

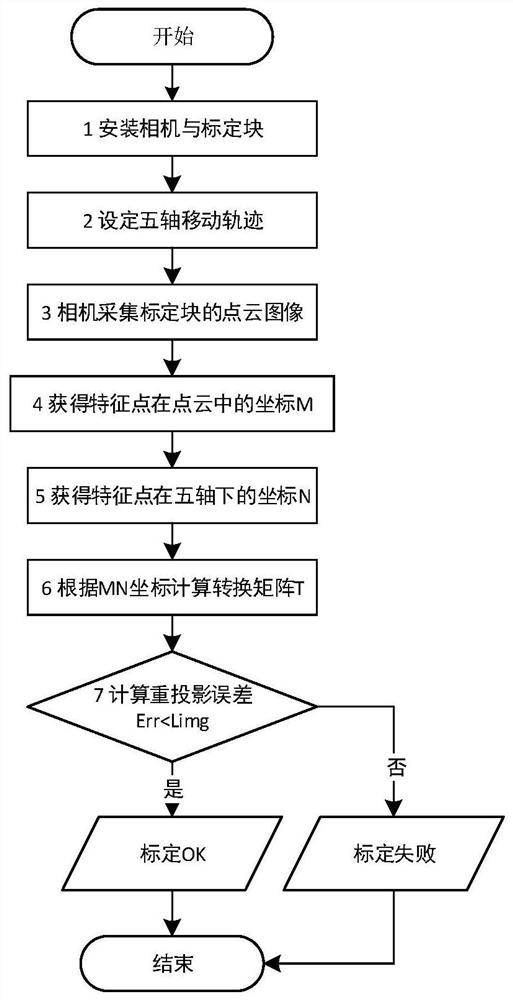

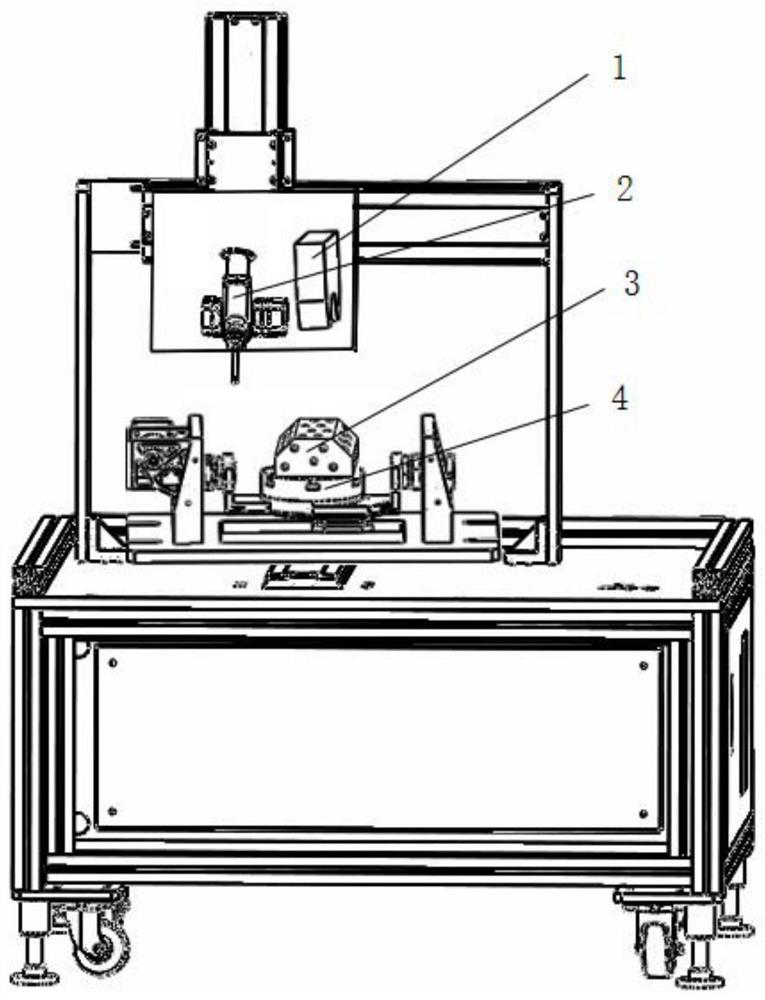

Camera calibration method and device for dispensing platform and related equipment

ActiveCN112907683AAchieve precise calibrationImprove dispensing qualityImage analysisPoint cloudComputer graphics (images)

The invention discloses a camera calibration method for a dispensing platform. The camera calibration method comprises the following steps: acquiring a point cloud image obtained by shooting a calibration block when a camera moves within a preset travel range; determining feature points in the point cloud image, and calculating coordinates of each feature point in the point cloud image to generate a first point set; calculating the coordinate of each feature point under the coordinate system of the dispensing platform to generate a second point set; calculating according to the first point set and the second point set to obtain a conversion relation between the dispensing platform coordinate system and a camera coordinate system; calibrating the camera by using the conversion relation. According to the camera calibration method of the dispensing platform, accurate calibration of the camera in the dispensing platform can be realized, so that the dispensing quality of a product is effectively ensured. The invention further discloses a camera calibration device and equipment for the dispensing platform and a computer readable storage medium which all have the above beneficial effects.

Owner:GEER TECH CO LTD +2

Double-fluid distribution operation device and operation method thereof

PendingCN112791911APrevent movementImprove dispensing qualityLiquid surface applicatorsSpraying apparatusAdhesiveMechanical engineering

The invention discloses a double-fluid distribution operation device and an operation method thereof. The double-fluid distribution operation device comprises a workpiece carrying, locating and clamping device, an xyz-direction driving device and a double-fluid distribution operation xyz fine adjustment device, wherein workpieces are borne on the workpiece carrying, locating and clamping device; one part of the workpiece carrying, locating and clamping device drives the workpieces to move along an x-axis, and the other part of the workpiece carrying, locating and clamping device can move towards the workpieces in the y-axis direction and the z-axis direction so as to locate and press the workpieces; the xyz-direction driving device is located above the workpiece carrying, locating and clamping device and can move in the x-axis direction, the y-axis direction and the z-axis direction; and the double-fluid distribution operation xyz fine adjustment device is arranged on the xyz-direction driving device and is used for simultaneously dispensing adhesives on two workpieces at different positions by finely adjusting the relative positions of a first fluid distributor and a second fluid distributor. The double-fluid distribution operation device has the advantages of high adhesive dispensing precision and high adhesive dispensing efficiency.

Owner:CHANGZHOU MINGSEAL ROBOT TECH CO LTD

Efficient spraying type dispensing method

InactiveCN111420852ASimplify the dispensing processShorten production timePrimary cell to battery groupingLiquid surface applicatorsElectrical batteryMechanical engineering

The invention discloses an efficient spraying type dispensing method. The efficient spraying type dispensing method comprises the following steps that a battery module cover plate is prepared, and isfixed to the position below a glue spraying machine, a glue spraying machine glue spraying pipe is aligned with a first battery mounting hole, at least one glue spraying pipe nozzle is mounted, rightfaces two sides in the battery mounting hole and is parallel to the slotting end face, the glue spraying pipe nozzle completely extends into the battery mounting hole, the glue spraying machine is started, two glue spraying pipe nozzles carry out glue spraying at the same time, after glue spraying is finished, the battery module cover plate is fixed, the glue spraying machine glue spraying pipe ismoved, through slotting, the glue spraying pipe nozzles move into the next battery mounting hole, and the two glue spraying pipe nozzles carry out glue spraying at the same time. According to the method, the action track of a dispensing machine is changed, original action is directly simplified into a linear motion of a glue nozzle, the dispensing procedure is simplified, the production time is saved, production efficiency is improved, glue position tail pulling generated by a traditional method can be removed, the dispensing environment is improved, the dispensing quality is improved, and the method is easy and convenient, and efficient and precise.

Owner:安徽江淮华霆电池系统有限公司

A suction device

Owner:SUZHOU RS TECH

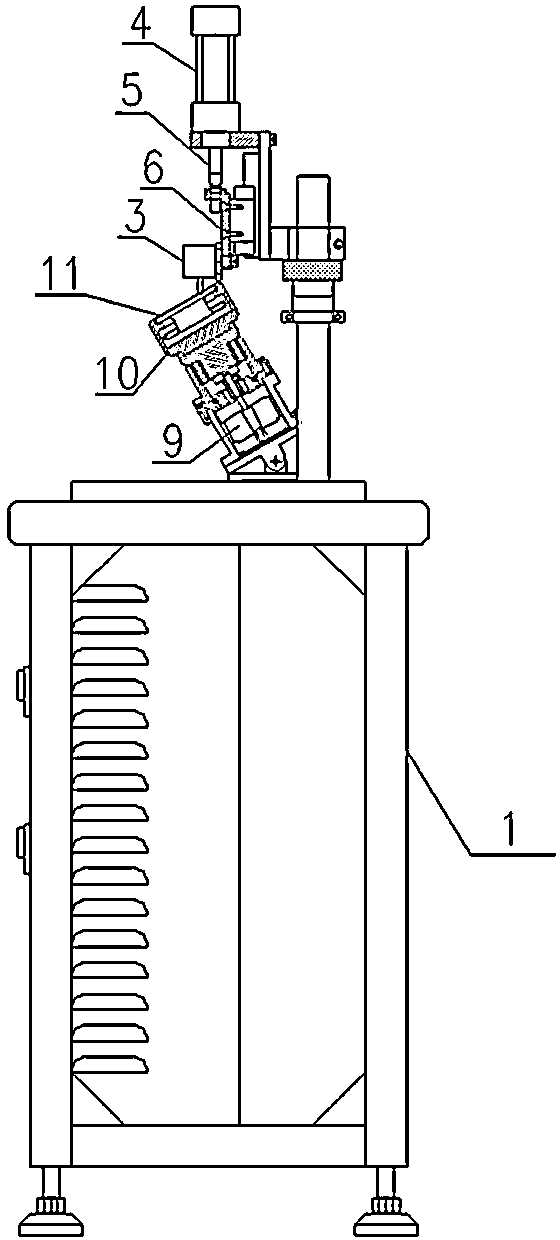

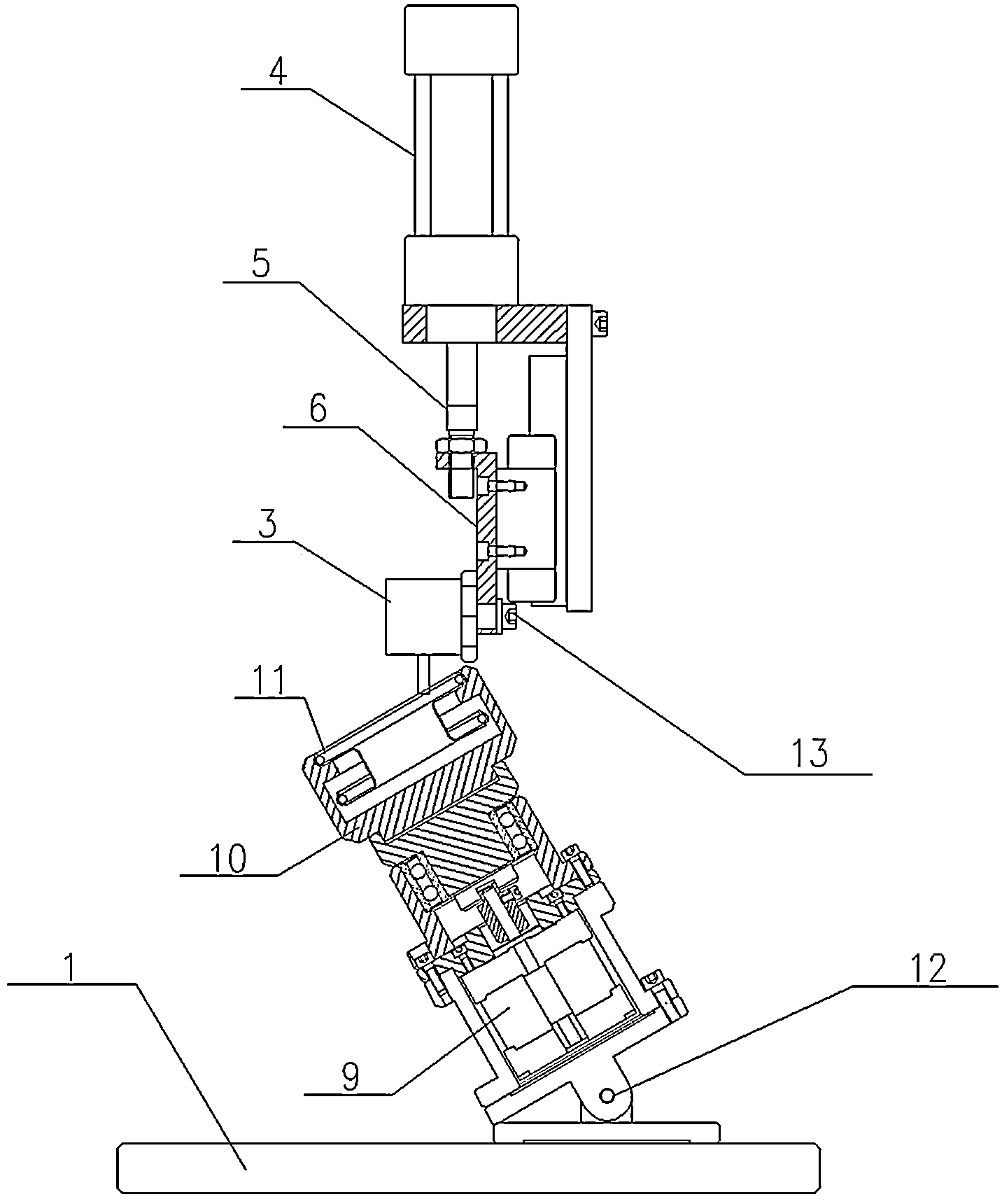

Gluing device for performing multi-angle gluing on PCBA board

PendingCN111318421AImprove dispensing efficiency and dispensing qualitySave manpower and costLiquid surface applicatorsPrinted circuit manufactureManufacturing engineeringElectrical and Electronics engineering

The invention discloses a gluing device for performing multi-angle gluing on a PCBA board. The device comprises an electric control cabinet, a rotating mechanism, a moving mechanism, a gluing mechanism and a gluing jig, wherein the moving mechanism, the rotating mechanism, the gluing mechanism and the gluing jig are all connected with the electric control cabinet, the electric control cabinet is configured to control the operation of the whole device, the rotating mechanism is connected with the gluing mechanism, the rotating mechanism can drive the gluing mechanism to rotate, the moving mechanism is connected with the gluing mechanism or / and the gluing jig, and the moving mechanism can drive the gluing mechanism or / and the gluing jig to move. According to the device, vertical gluing can be carried out on a product, and multi-angle and multi-position gluing can be carried out on the product in inclined directions, so that the gluing efficiency and the gluing quality are greatly improved; and gluing can be completed through one device, so that the manpower and cost are saved.

Owner:赛尔康(贵港)有限公司

Electronic element guide rail type glue dispensing equipment for LED lamp production

InactiveCN109926268APrevent solidificationQuality assuranceLiquid surface applicatorsCoatingsMutual transformationSteel ball

The invention belongs to the technical field of LED lamp production, and particularly relates to electronic element guide rail type glue dispensing equipment for LED lamp production. The electronic element guide rail type glue dispensing equipment for LED lamp production aims to achieve the technical effects that the operation is simple, the glue dispensing effect is good, and the glue dispensingspeed is high. In order to achieve the technical effects, the provided electronic element guide rail type glue dispensing equipment for LED lamp production comprises a bottom plate, a first sliding rail, a first sliding block, an electric wire winding wheel, a left frame, a storage tank, a first pull wire, a second pull wire, a first fixed pulley, a right frame, an electric push rod and the like,a second hose and a second connecting rod are involved, and the left frame is welded to the left side of the bottom plate. According to the electronic element guide rail type glue dispensing equipment, the functions of the electric wire winding wheel and the first spring are fully exerted, mutual cooperation and mutual transformation between the electric wire winding wheel and the first spring areachieved, in addition, through ingenious application of a mesh plate and a steel ball, the working effect of the equipment is further improved.

Owner:杨路娣

Novel striker dispensing valve

InactiveCN108202010ALight in massReduce resistanceLiquid surface applicatorsCoatingsAdhesiveEngineering

The invention discloses a novel striker dispensing valve. The novel striker dispensing valve comprises a valve body, an adhesive feeder and an adhesive discharger; a stop block is fixedly arranged atthe junction of the valve body and the adhesive feeder; an adhesive feeding chamber is arranged in the adhesive feeder and communicates with an adhesive inlet and an adhesive outlet of the adhesive feeder; a striker bar is arranged in the valve body; the top end of the striker bar is fixedly connected with a piston; an air inlet is formed in the position, on the upper portion of the piston, of thevalve body; the bottom end of the striker bar penetrates through a through hole in the middle of the stop block and is inserted into the adhesive feeding chamber; and the portion, between the stop bloc, and the piston, of the striker bar is sleeved with a spring. High-pressure gas is injected via the air inlet, the piston is pressed to dispense adhesives, the spring jacks up the piston to injectthe adhesives, the pressure intensity of high-pressure gas injected via the air inlet is controlled to be coincident, accordingly the consistency of the adhesive discharging volume each time is ensured, and the dispensing quality is improved.

Owner:SUZHOU RSHTEK ELECTRICAL EQUIP CO LTD

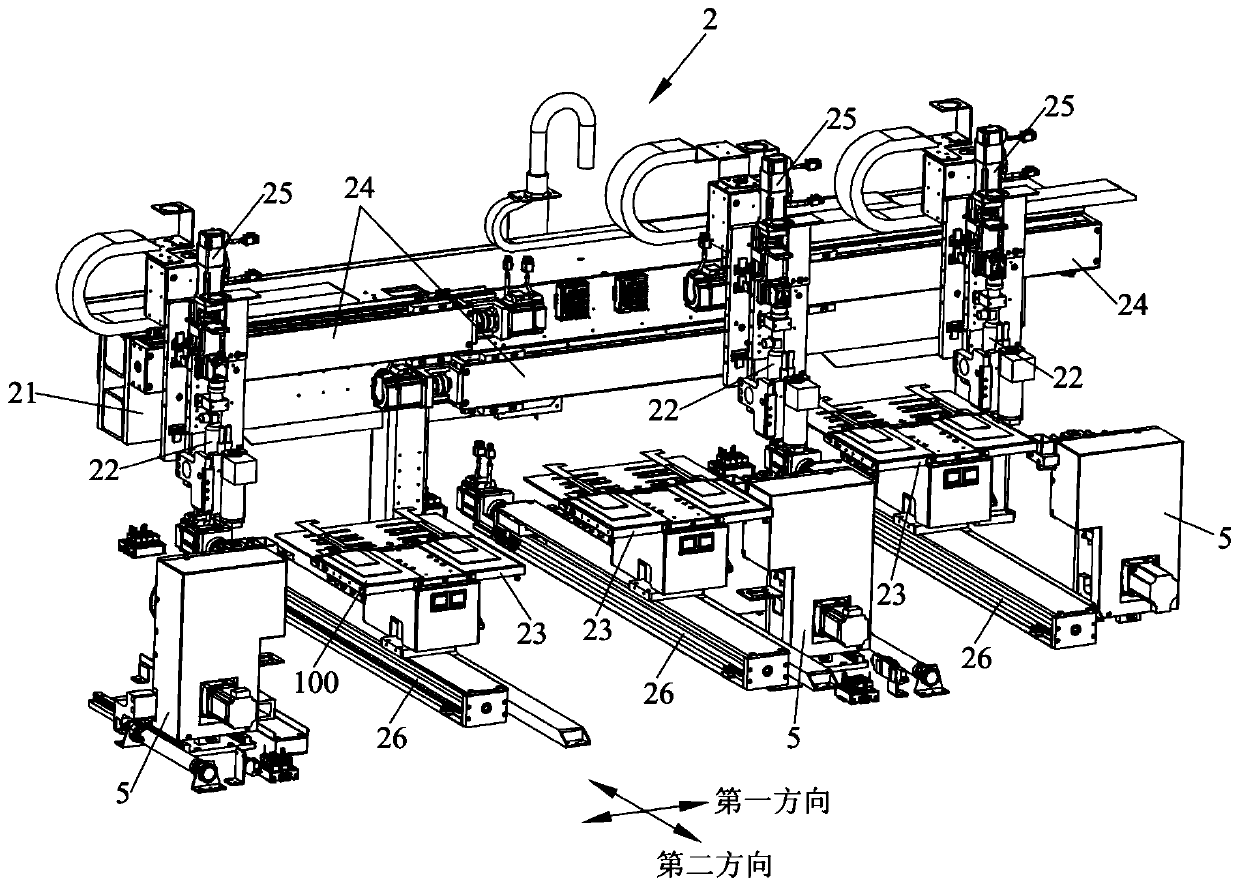

Dispensing production line

PendingCN111346788AExtended service lifeAvoid cloggingLiquid surface applicatorsSpraying apparatusAdhesive glueSilver colloid

The invention relates to the technical field of automatic dispensing equipment and discloses a dispensing production line. A carrying mechanism is arranged on a workbench in the first direction. A silver colloid mechanism, a back dispensing mechanism and a front dispensing mechanism are sequentially arranged in the first direction. The carrying mechanism can carry products to the silver colloid mechanism. The silver colloid mechanism can carry out silver colloid dispensing on the front surfaces of the products. After the silver colloid dispensing is completed, the carrying mechanism can carrythe products to the back dispensing mechanism, the back dispensing mechanism can turn the products so that the back faces of the products can be upward and subjected to back dispensing, and after theback dispensing is completed, the back dispensing mechanism can turn the products again so that the front faces of the products can return upwards. After the front faces of the products return upwards, the carrying mechanism can carry the products to the front dispensing mechanism, and the front dispensing mechanism can carry out dispensing on the front faces of the products. After any one of thesilver colloid mechanism, the back dispensing mechanism and the front dispensing mechanism completes dispensing once, a glue wiping mechanism can wipe off the colloid remaining on any one of the silver colloid mechanism, the back dispensing mechanism and the front dispensing mechanism. The dispensing production line is high in production efficiency and good in dispensing quality.

Owner:KUNSHAN SAMON AUTOMATION TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com